Patents

Literature

56 results about "Large ribs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

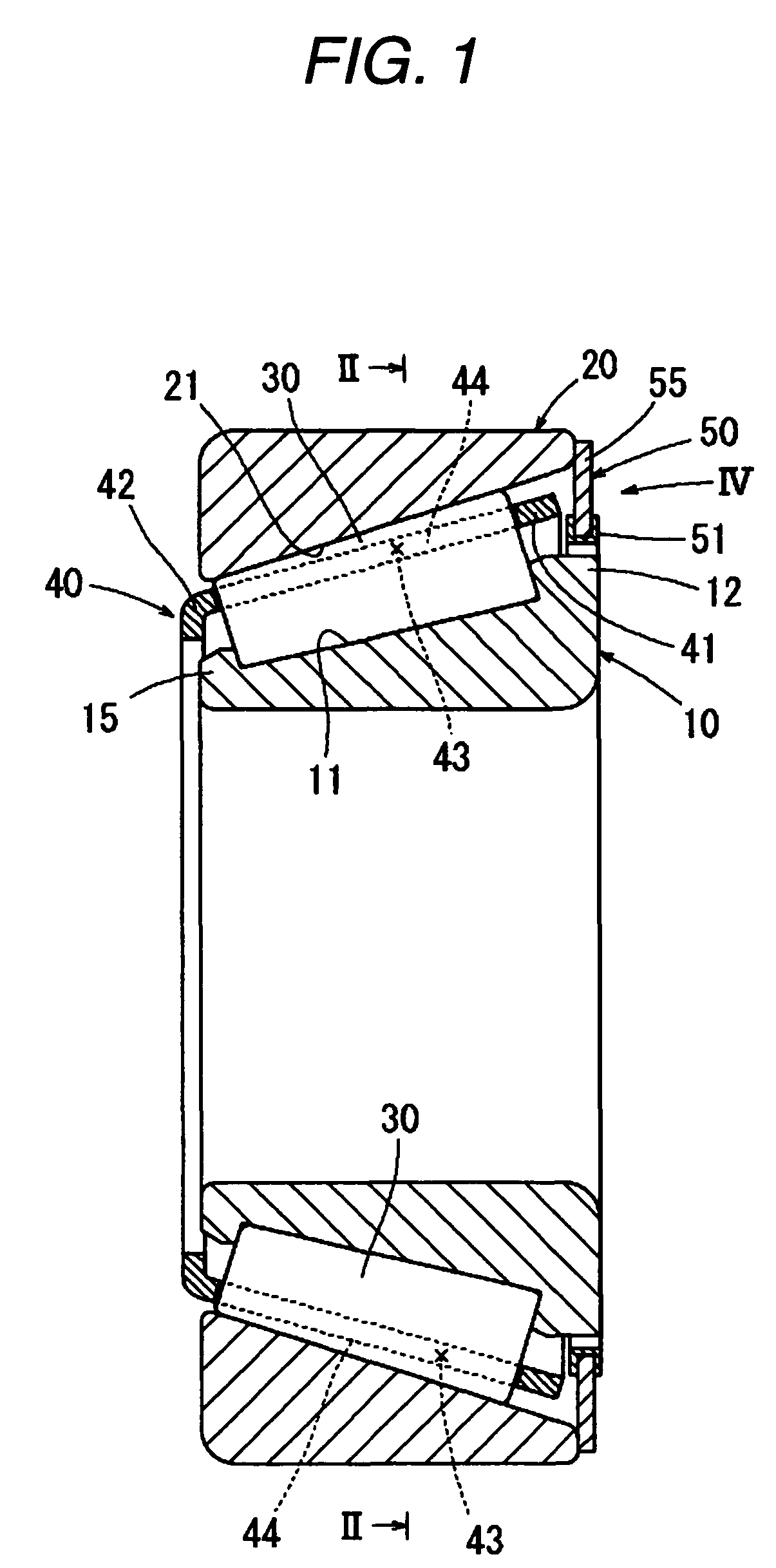

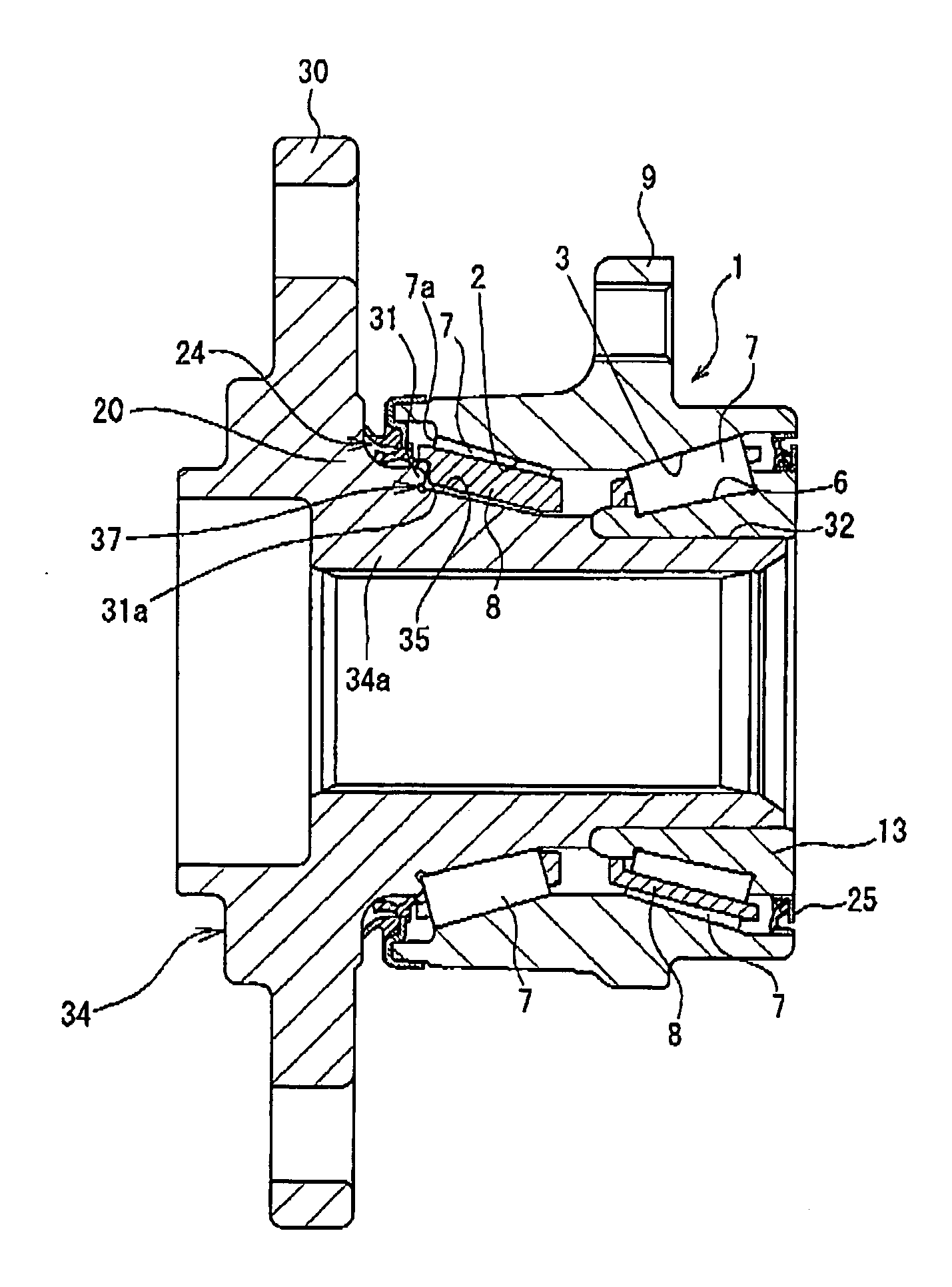

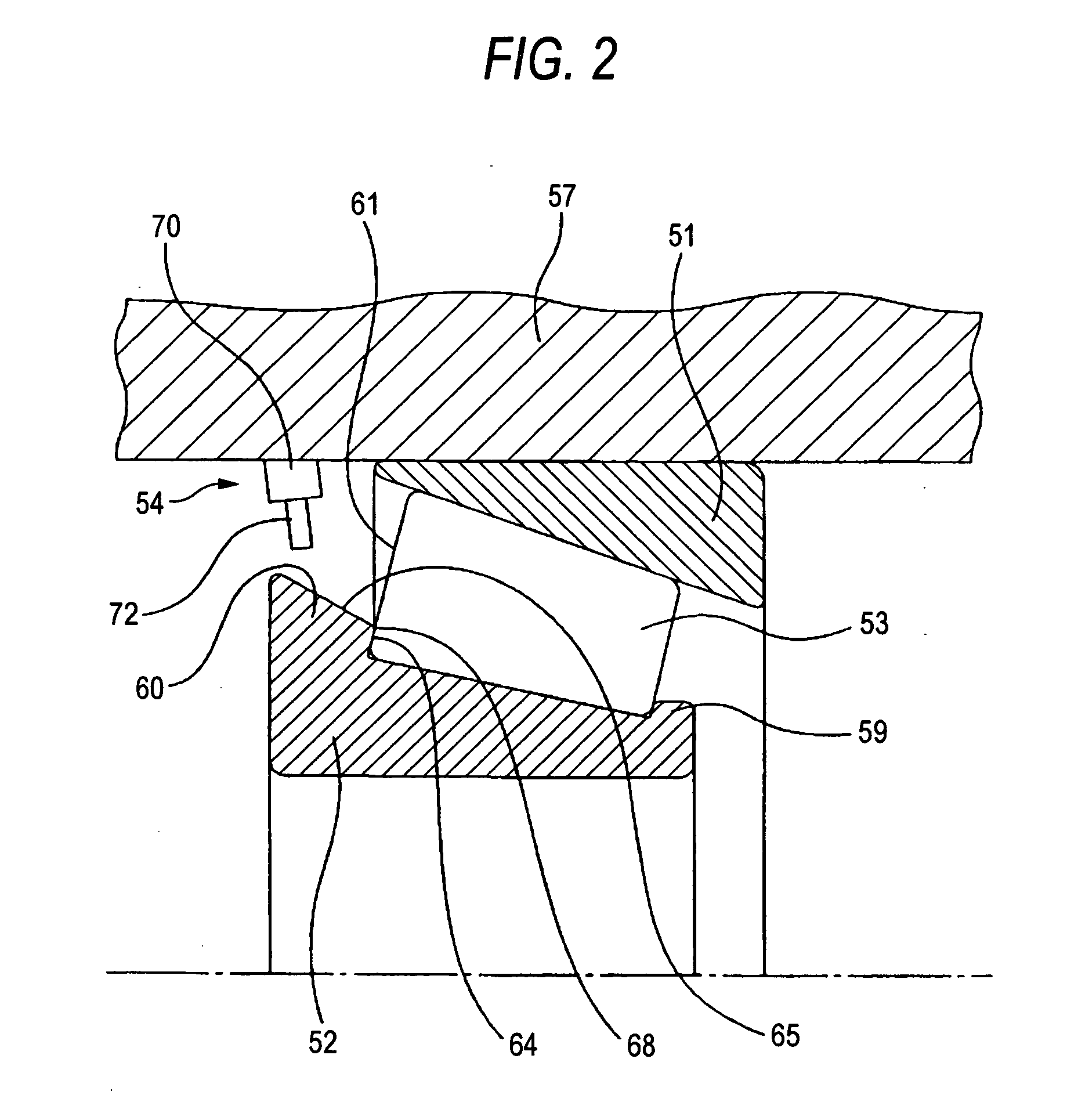

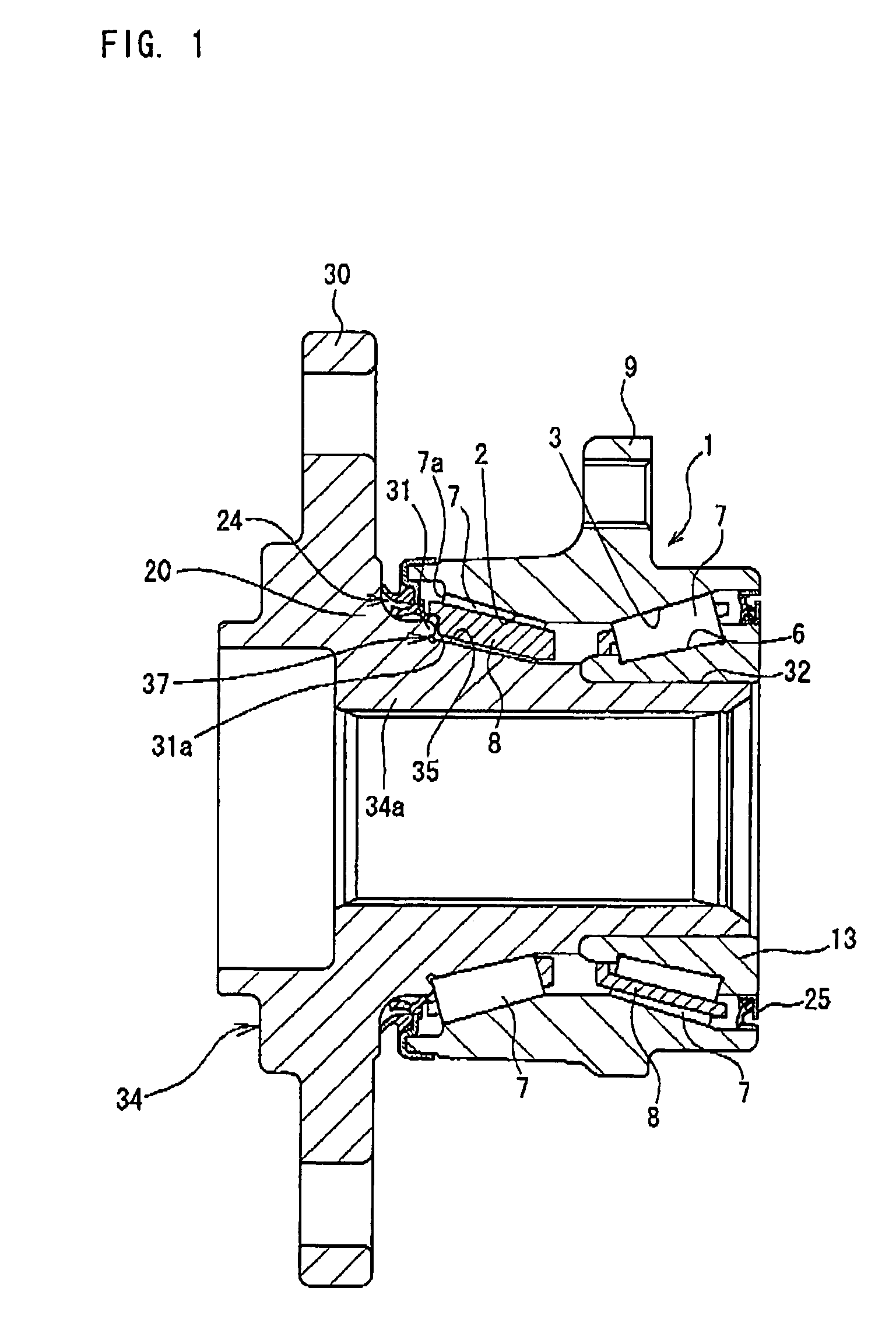

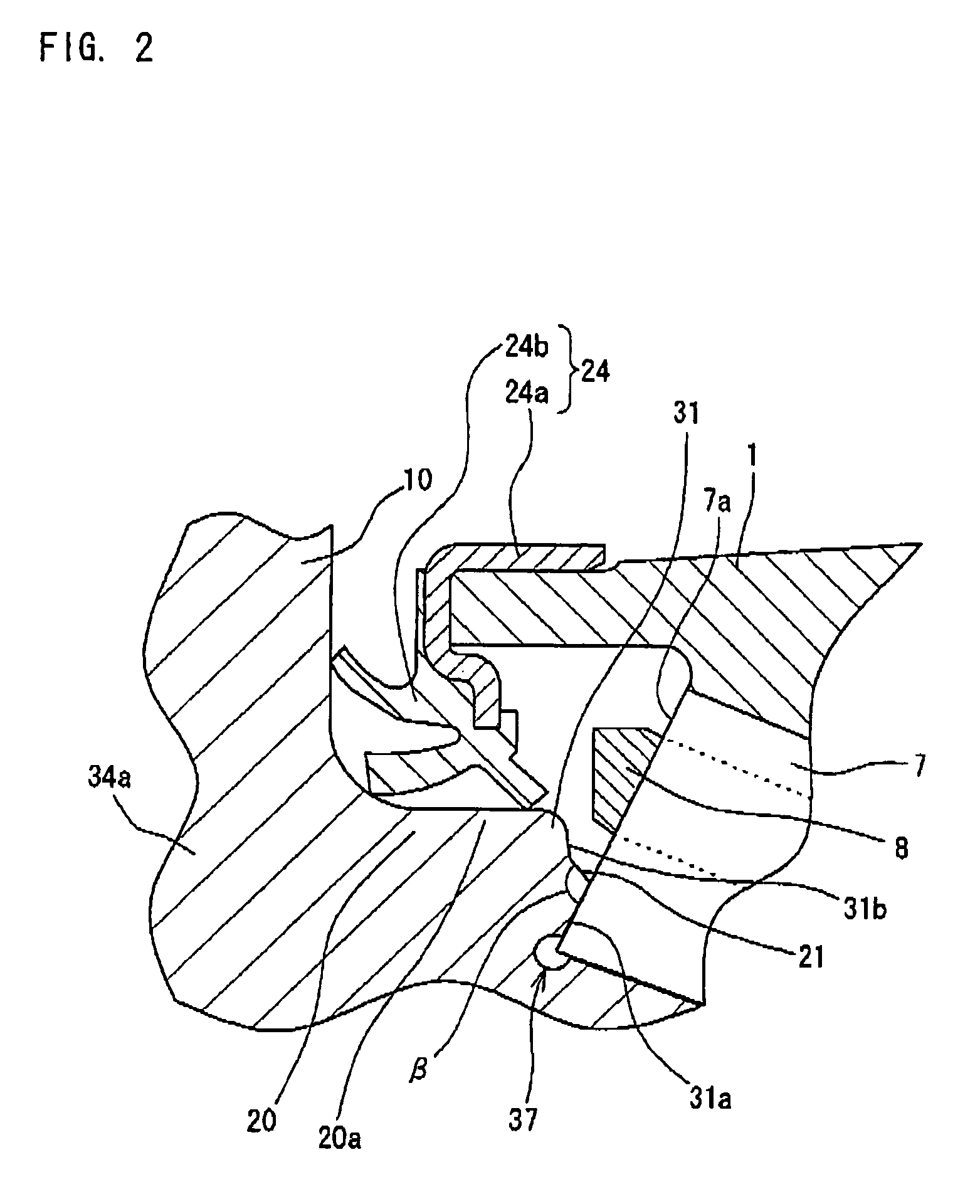

Tapered roller bearing and differential gear apparatus

InactiveUS20080096715A1Reduce fuel consumptionIncreased durabilityRoller bearingsGearboxesEngineeringLarge ribs

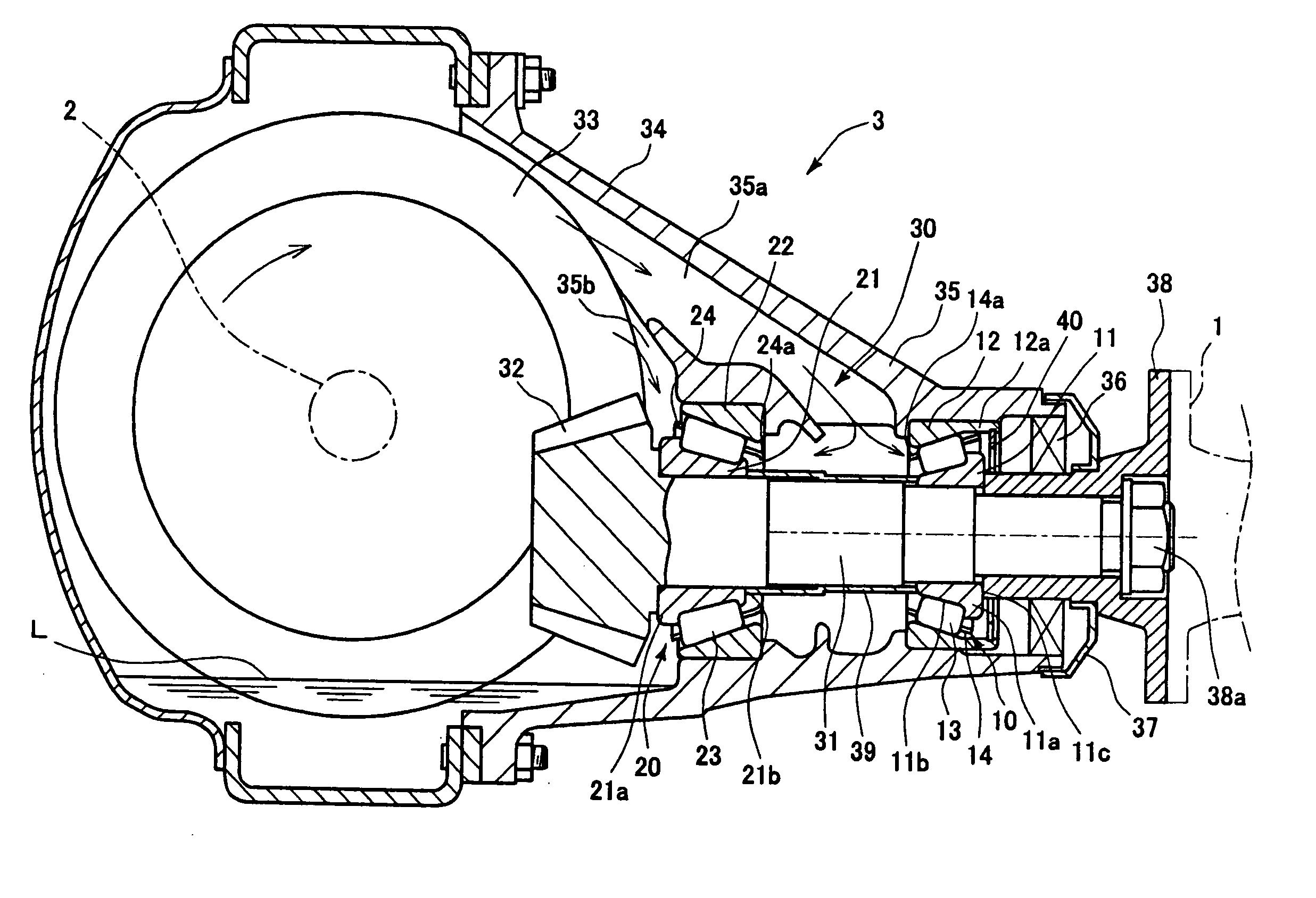

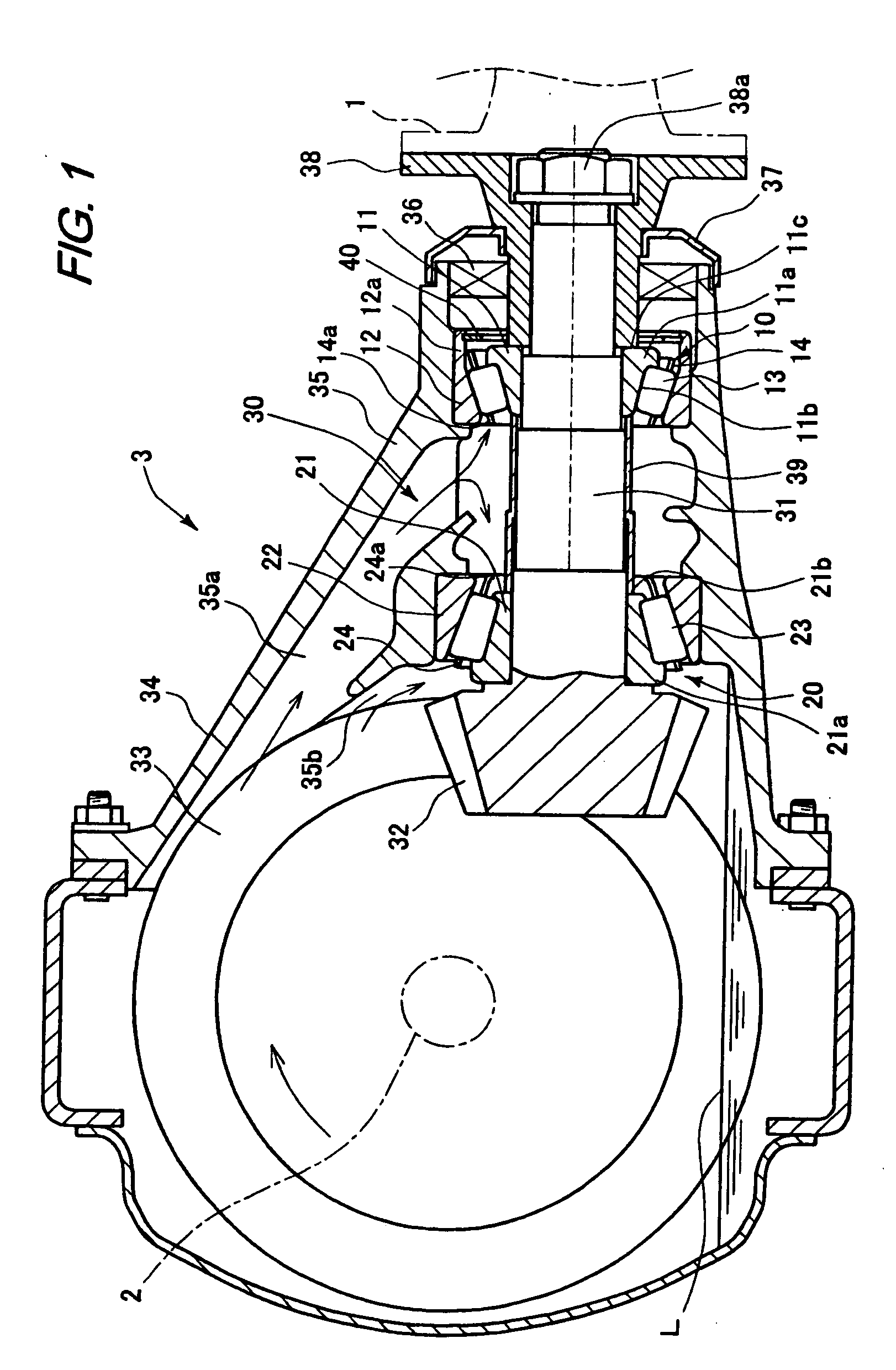

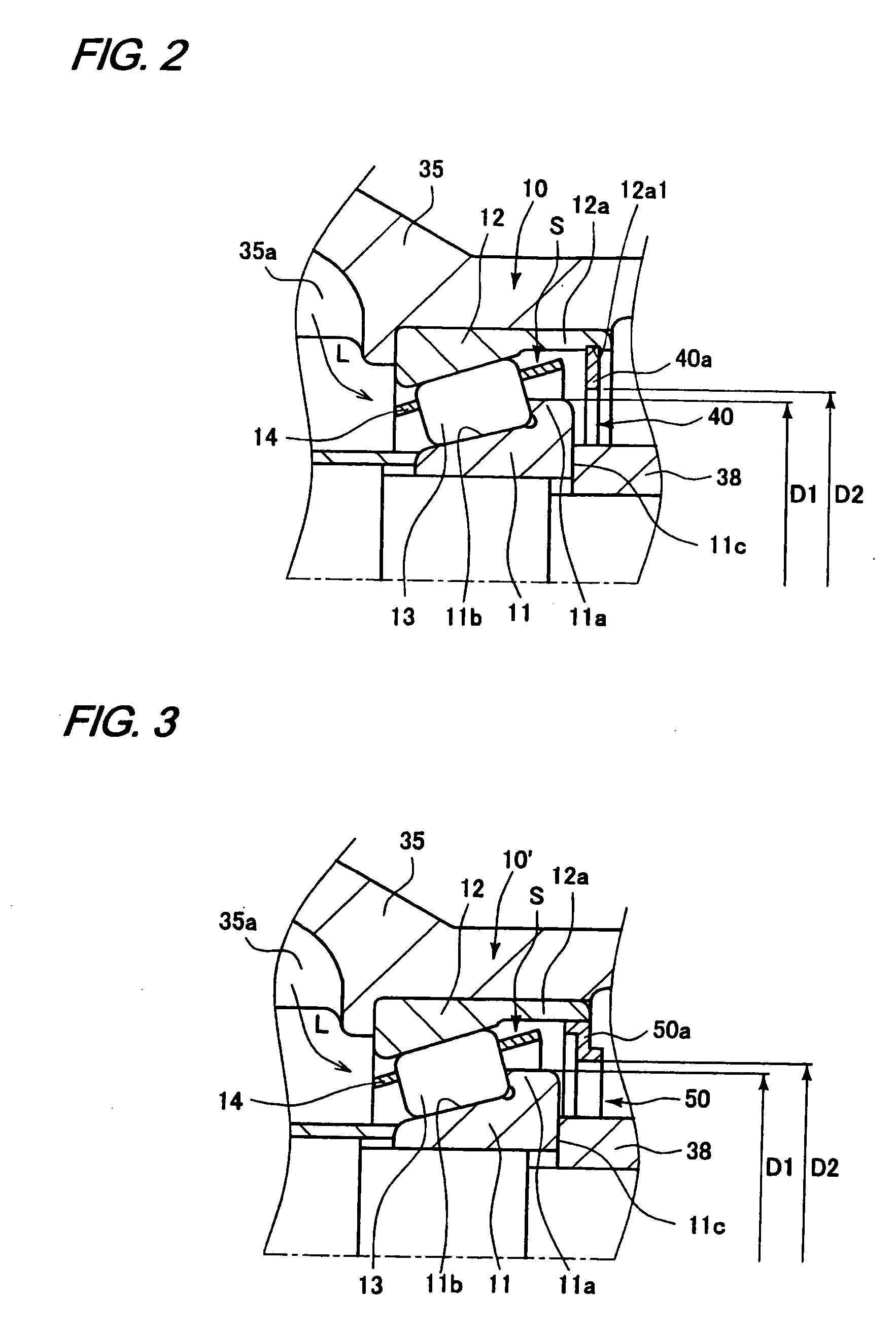

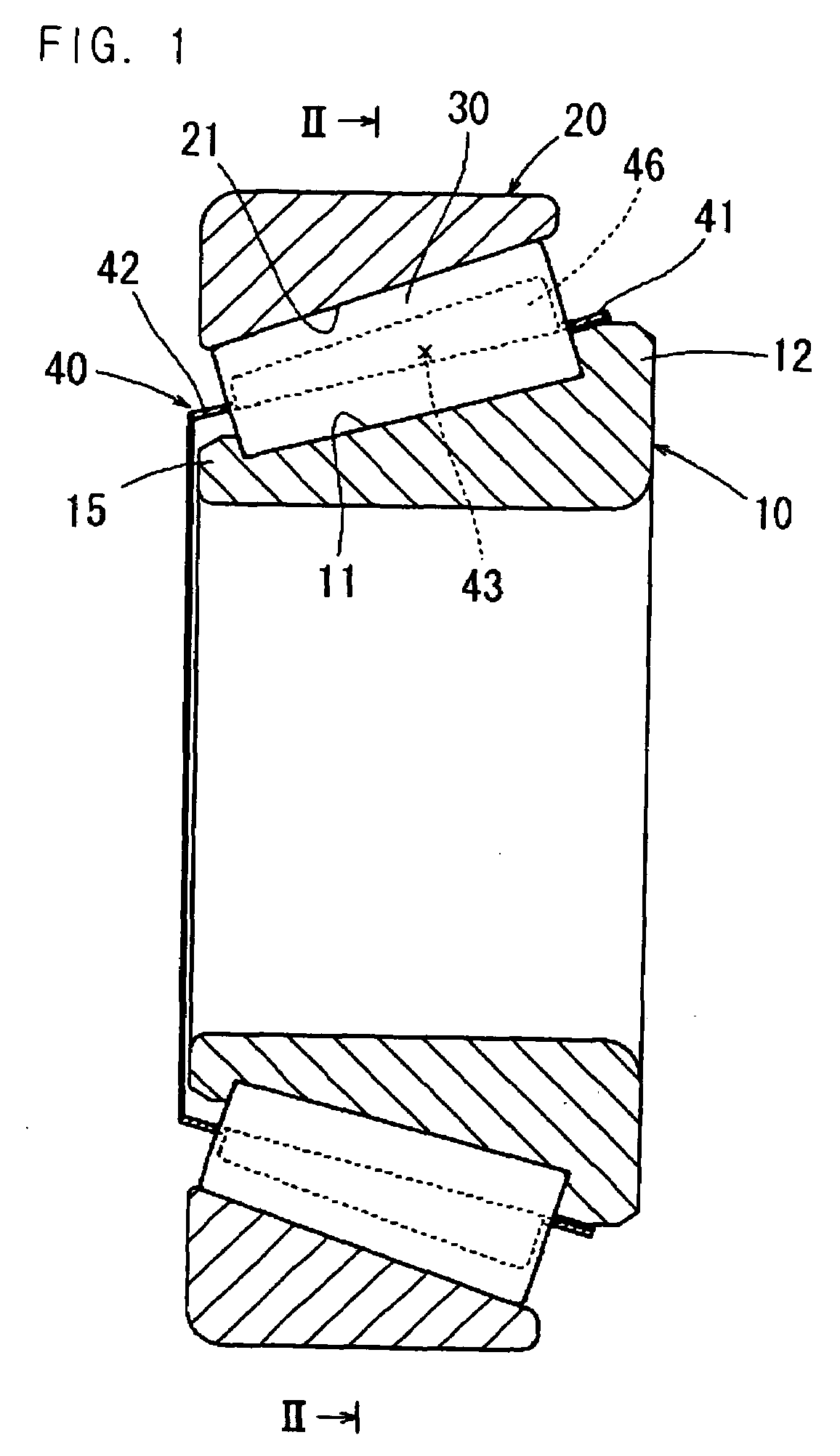

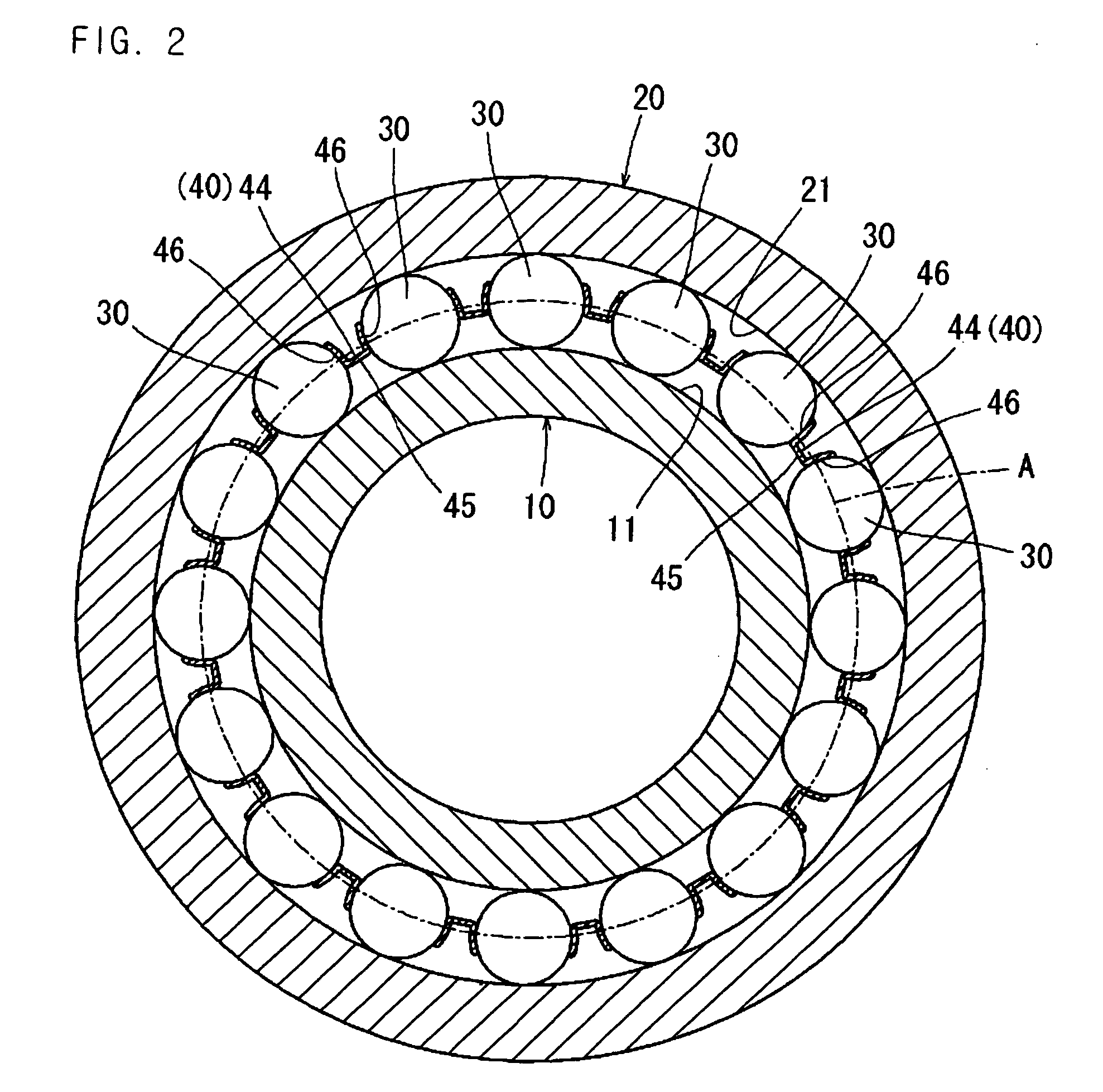

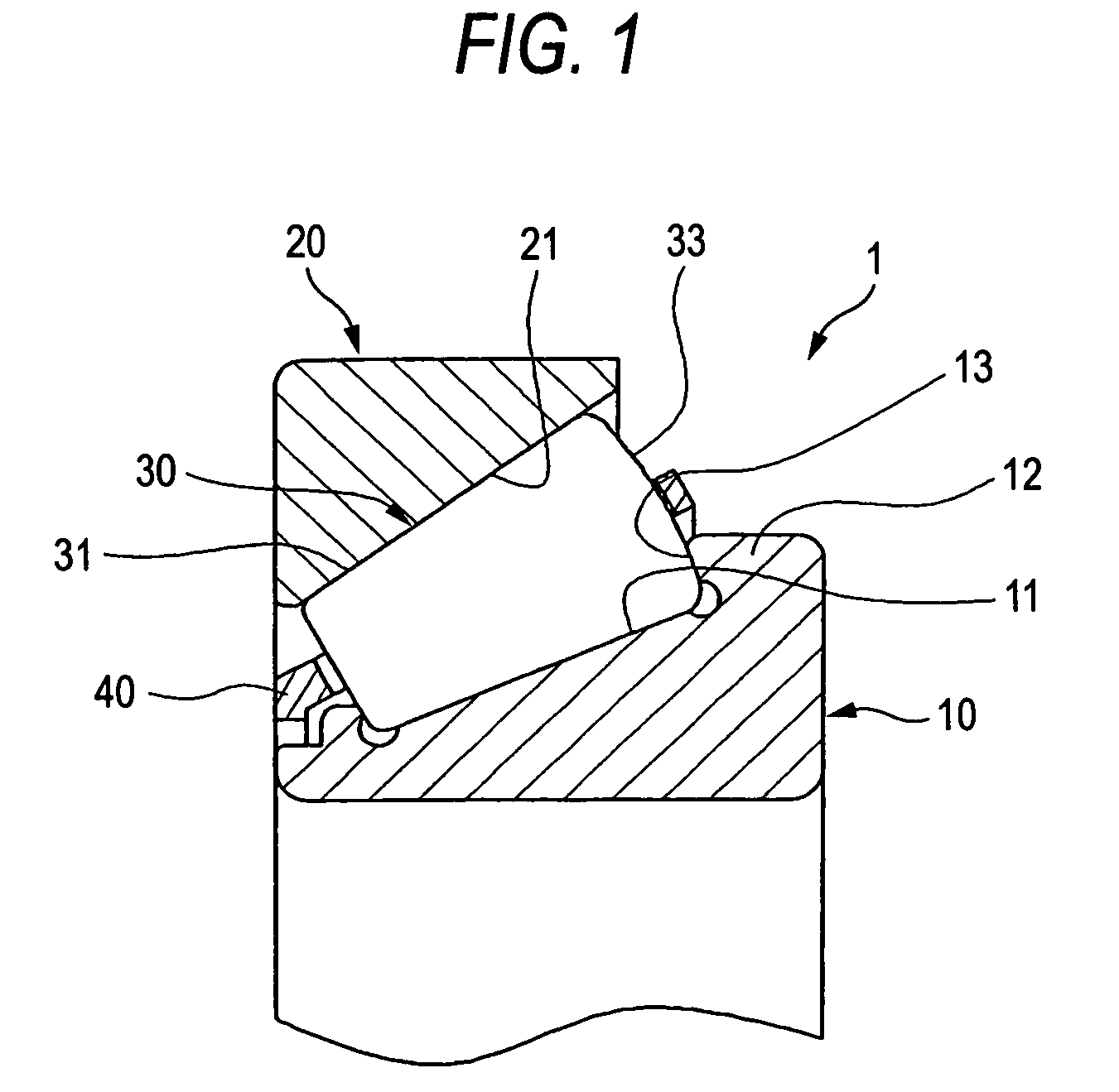

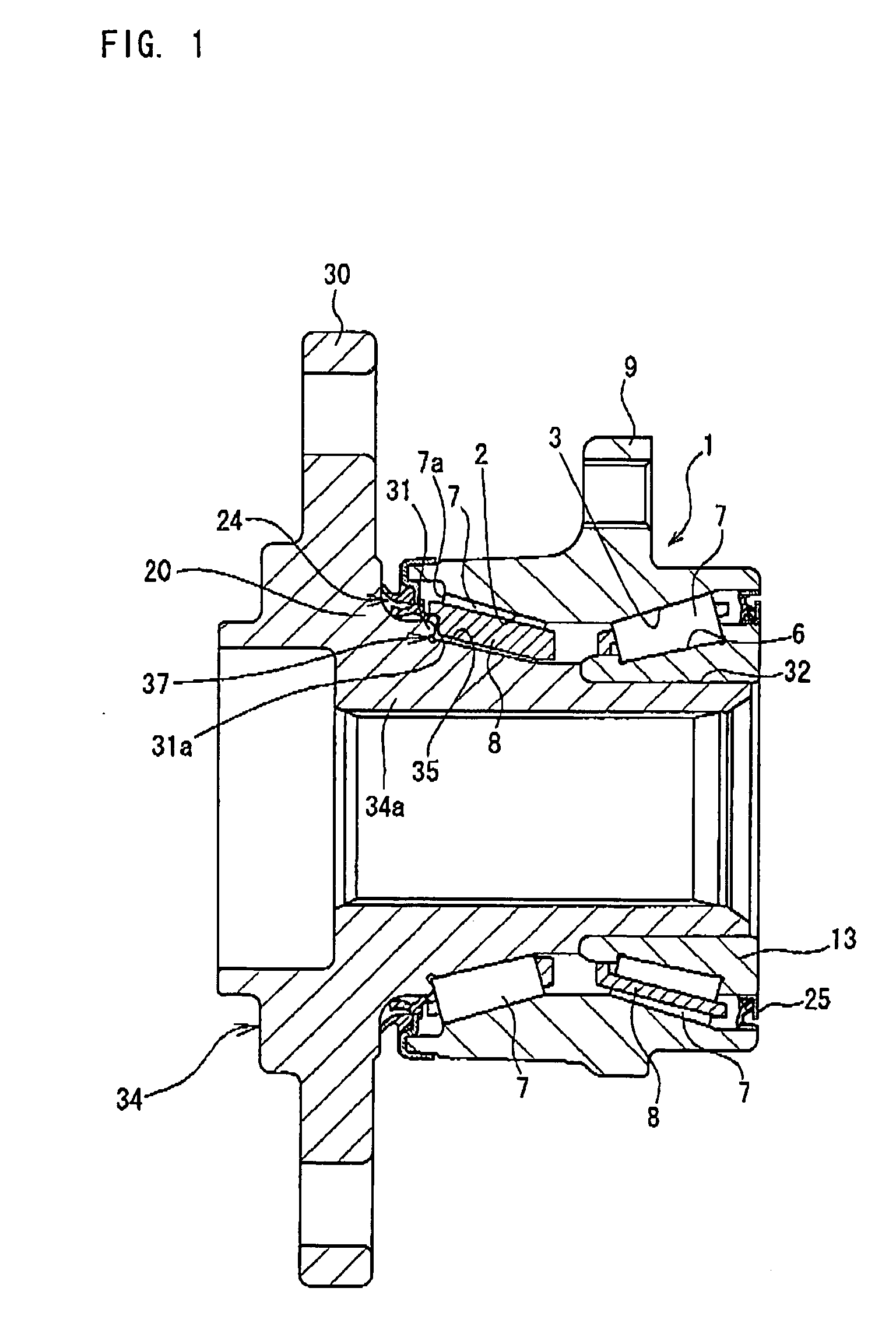

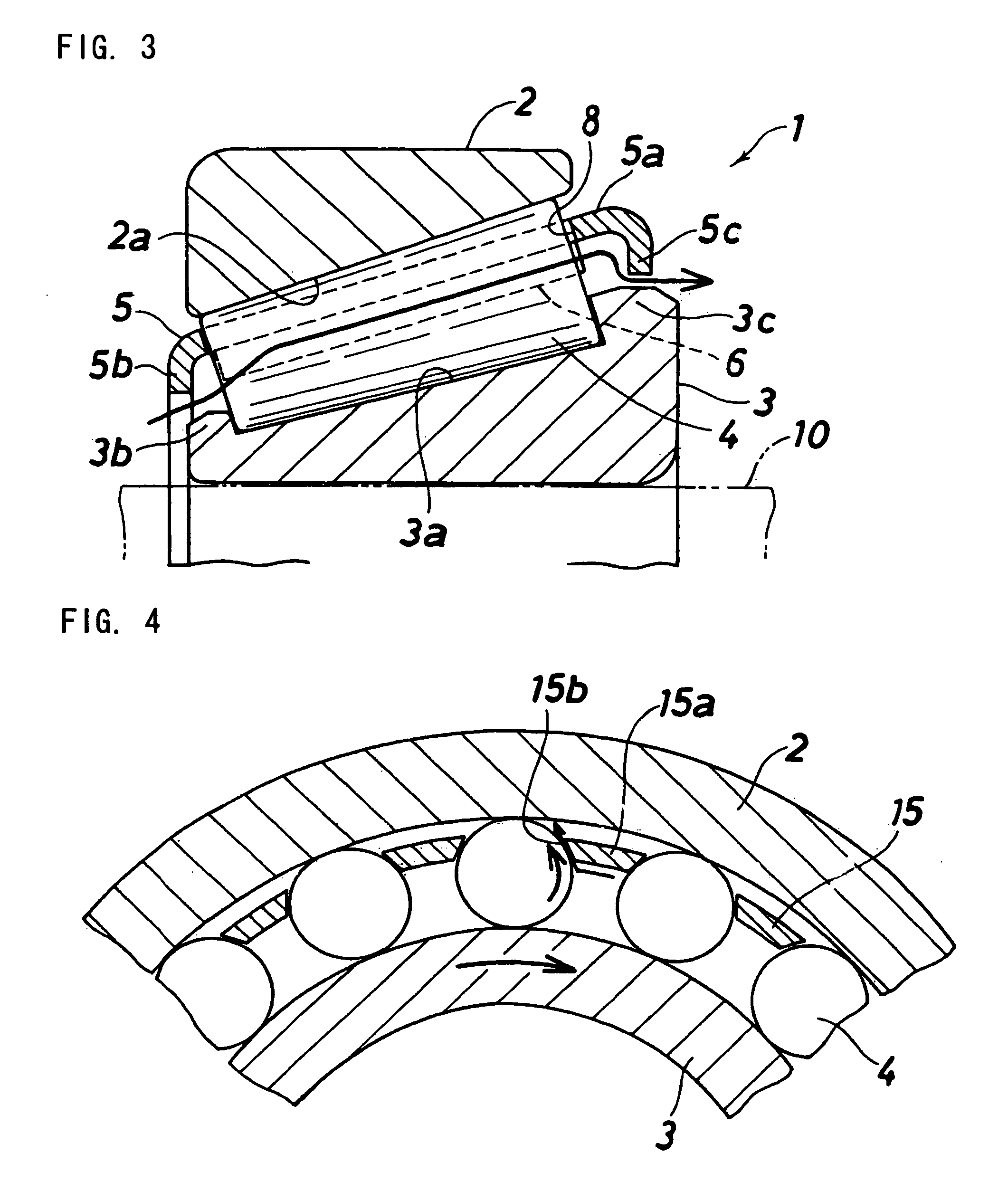

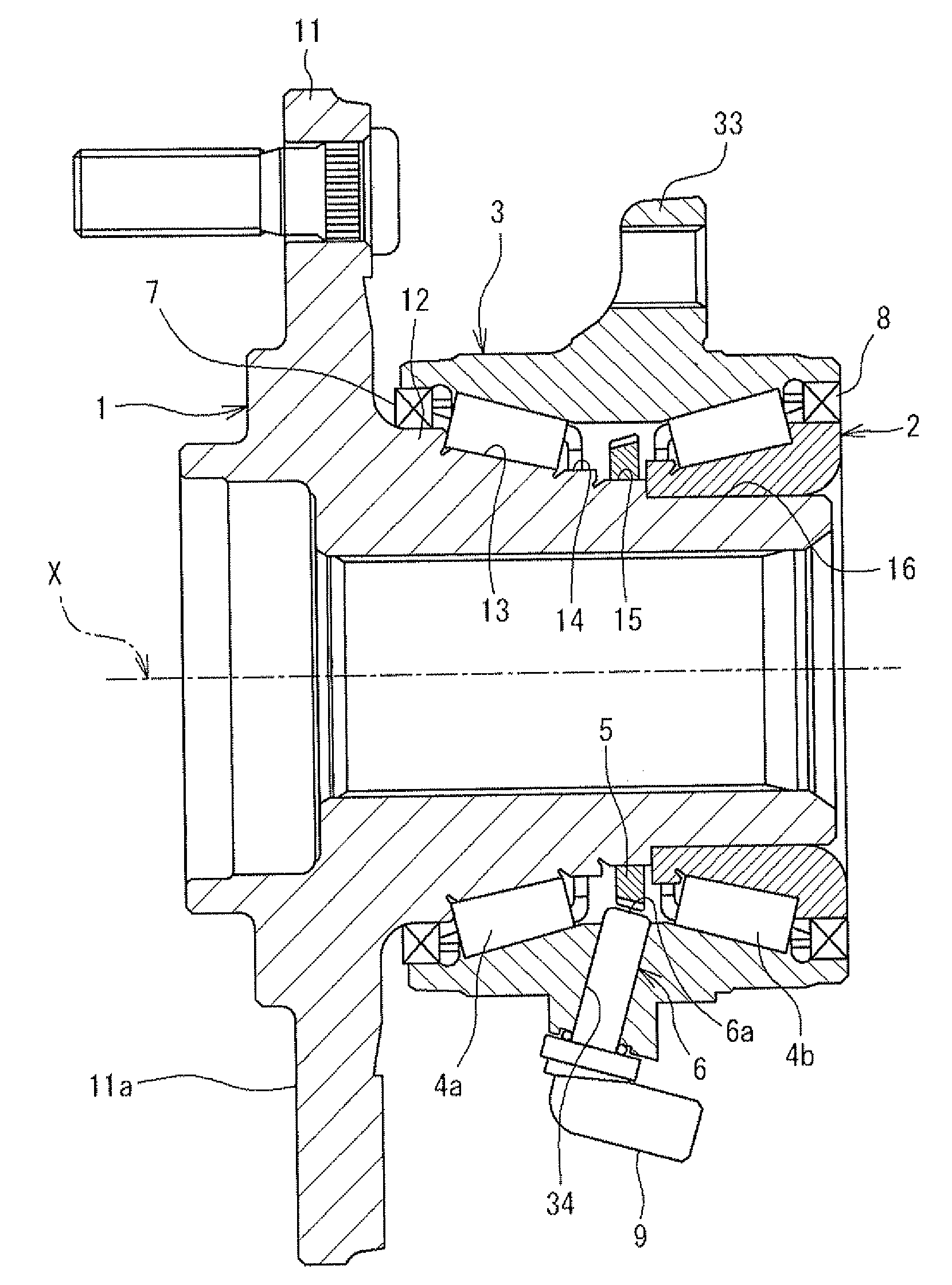

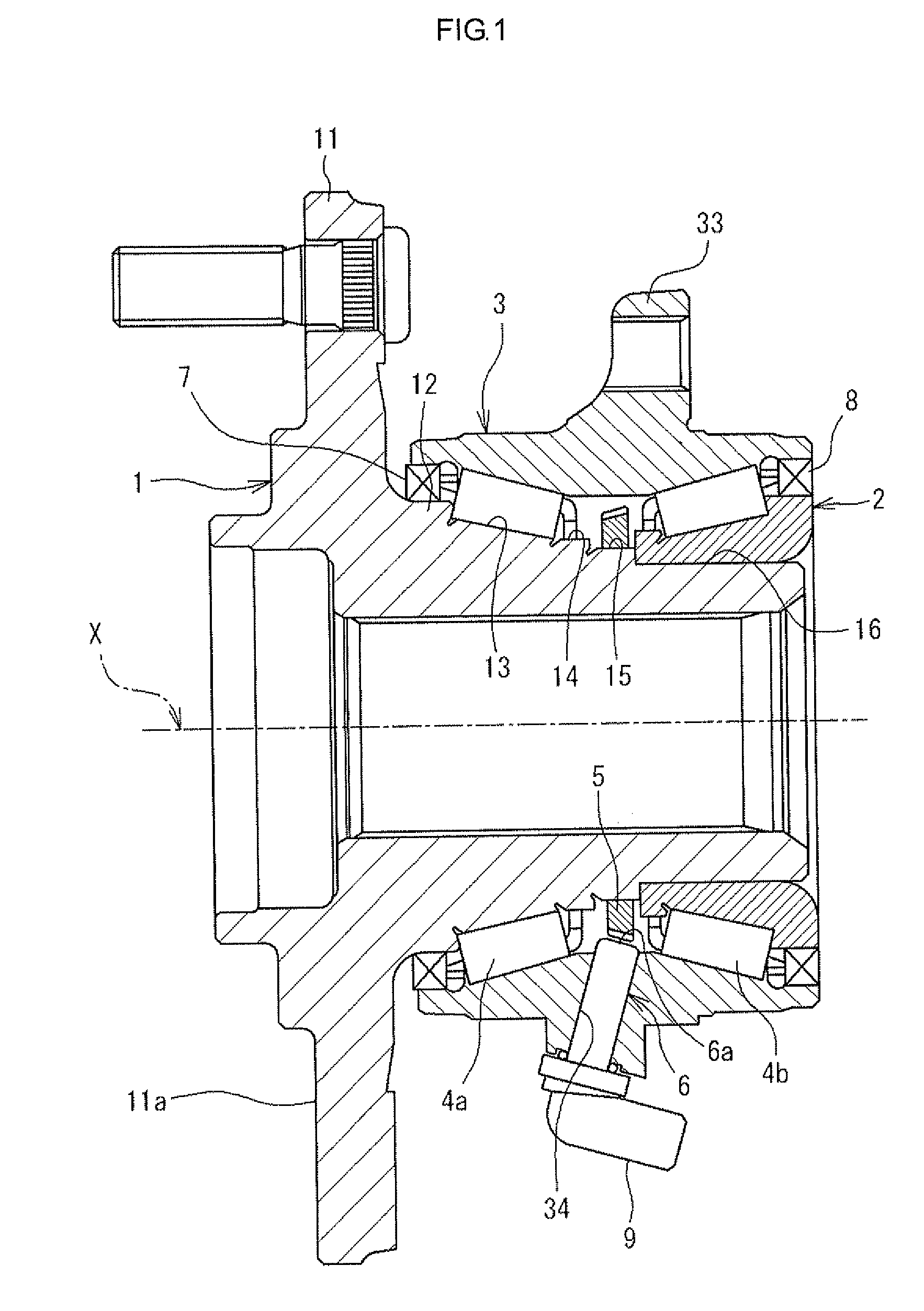

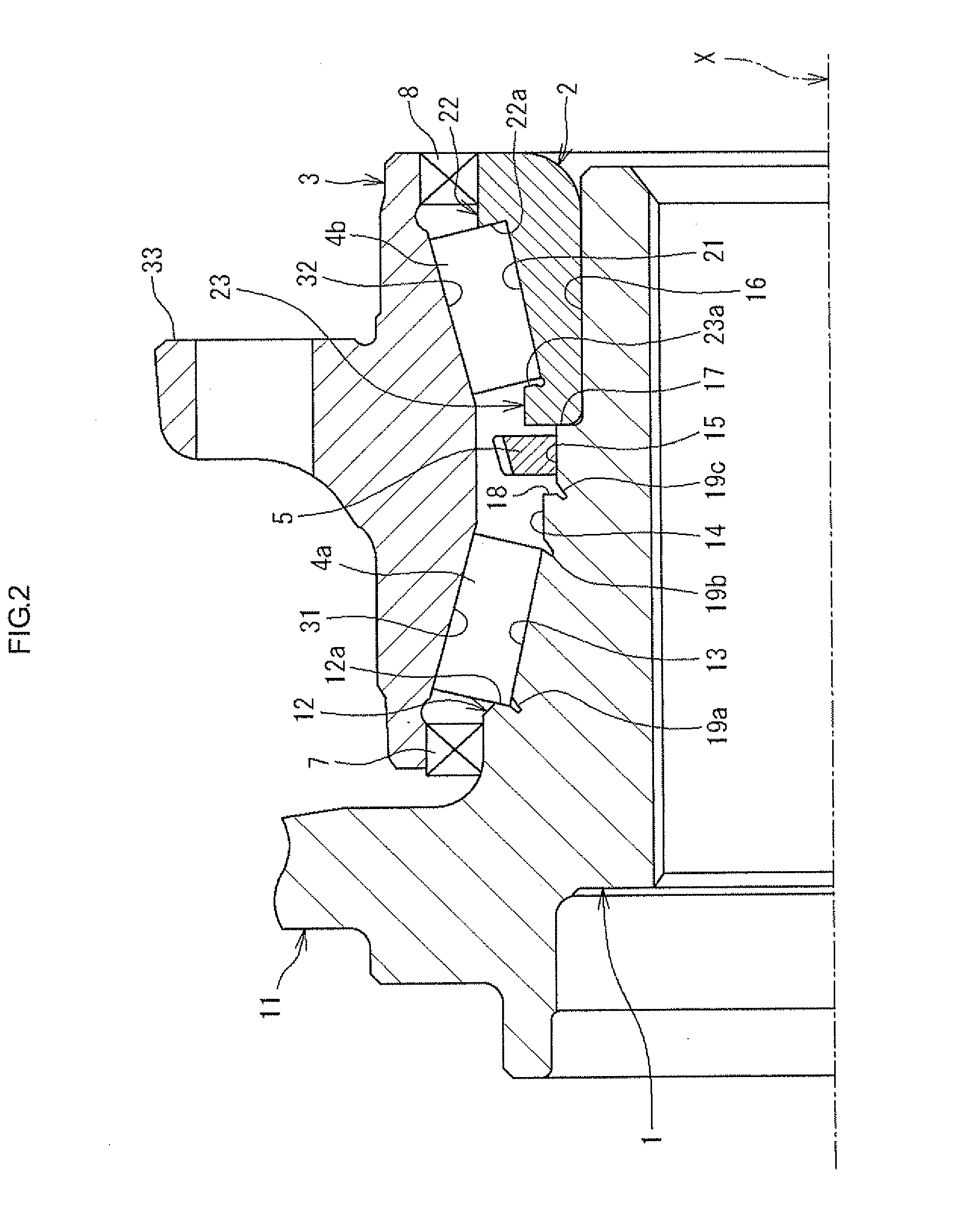

An outer peripheral surface of an inner ring extends straight along outer peripheral surfaces of tapered rollers, and is open at a front side of a tapered roller bearing which is a lubricating oil supply side. A smaller-diameter end portion of a cage is cut in a radial direction to be open. A hole retaining ring is disposed at aback face side of the inner ring which is a lubricating oil discharge side, and is fixed at its outer peripheral portion to an inner peripheral portion of an extension portion of an outer ring. An inner diameter of the hole retaining ring is larger than an outer diameter of a larger rib portion of the inner ring.

Owner:JTEKT CORP

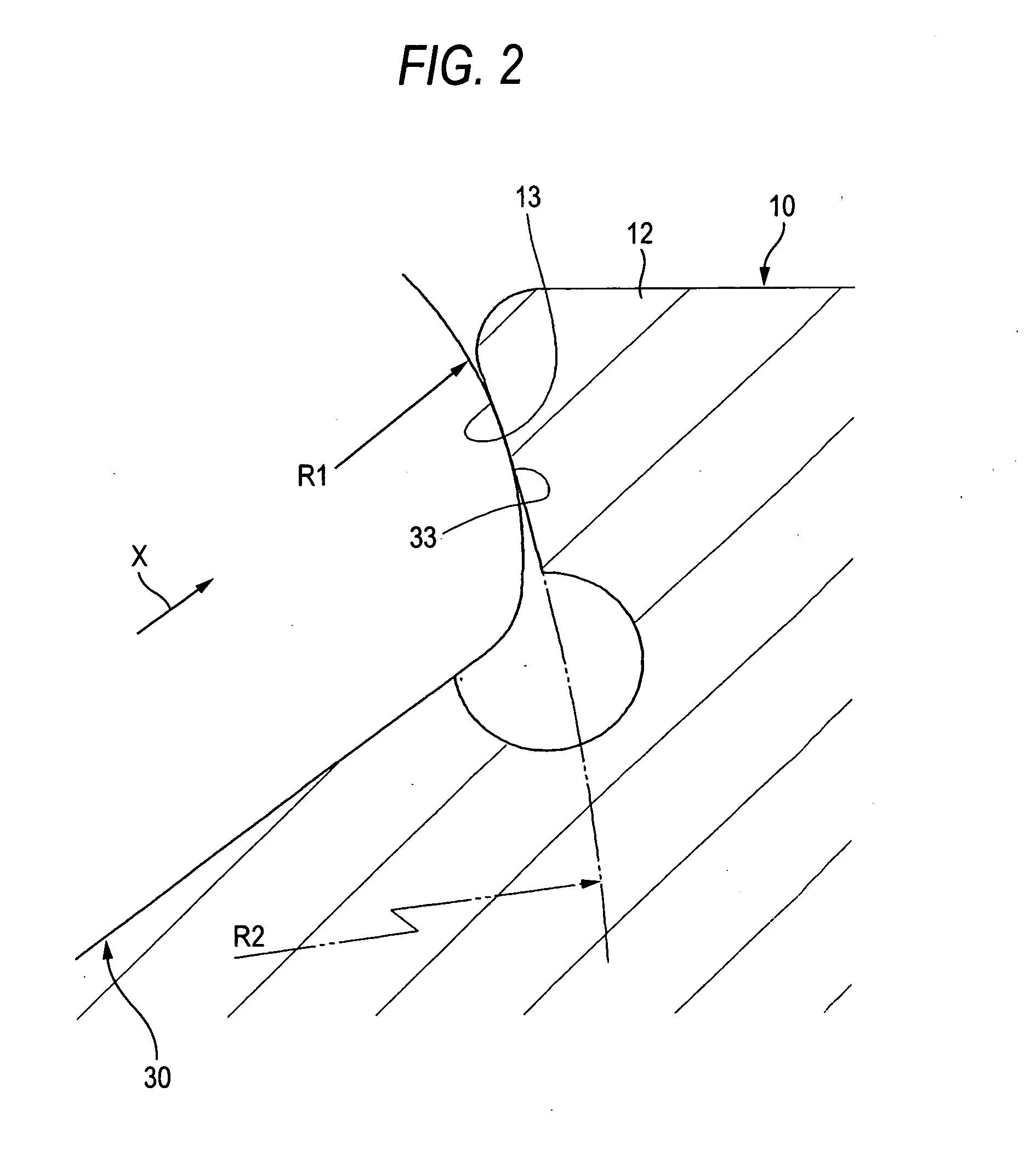

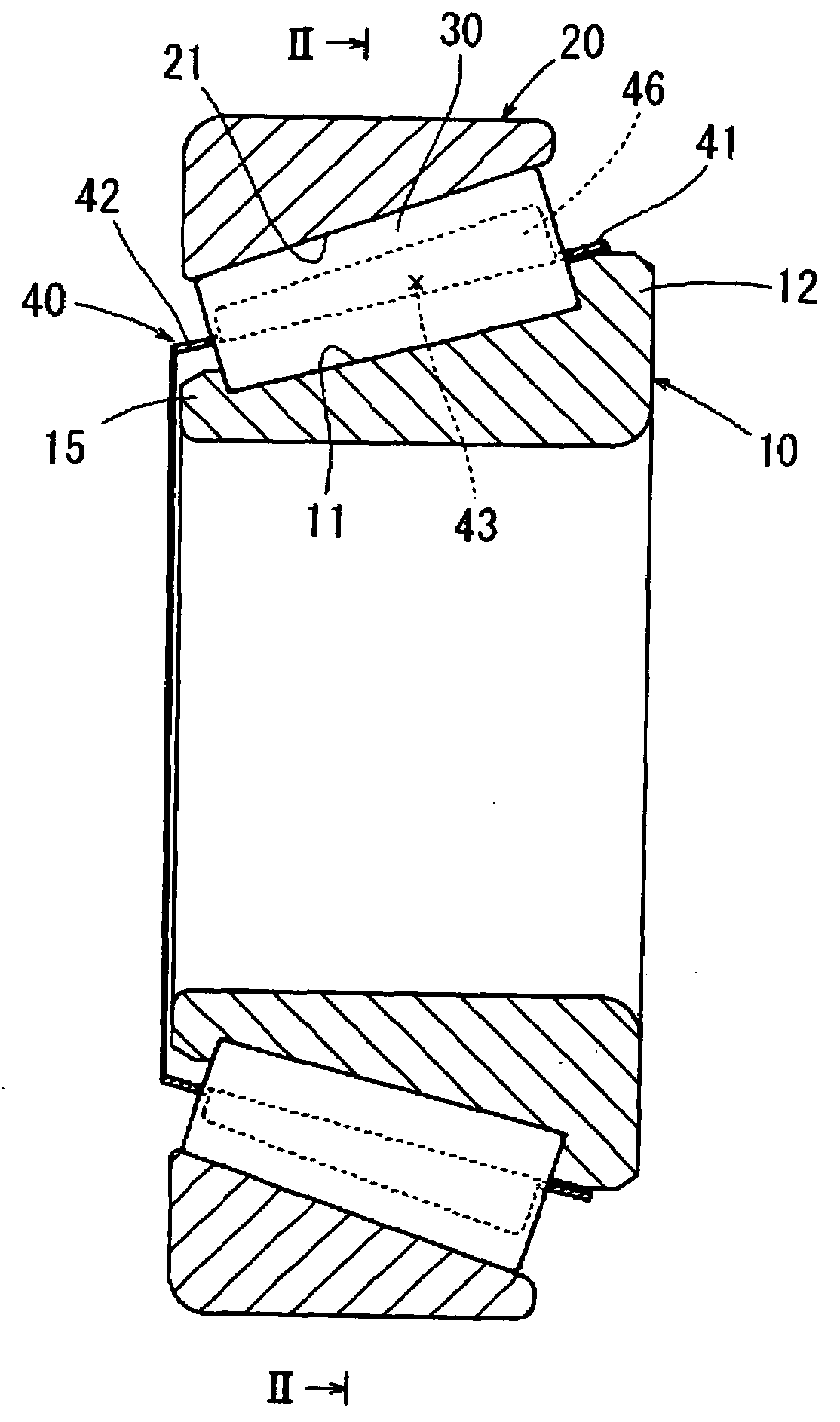

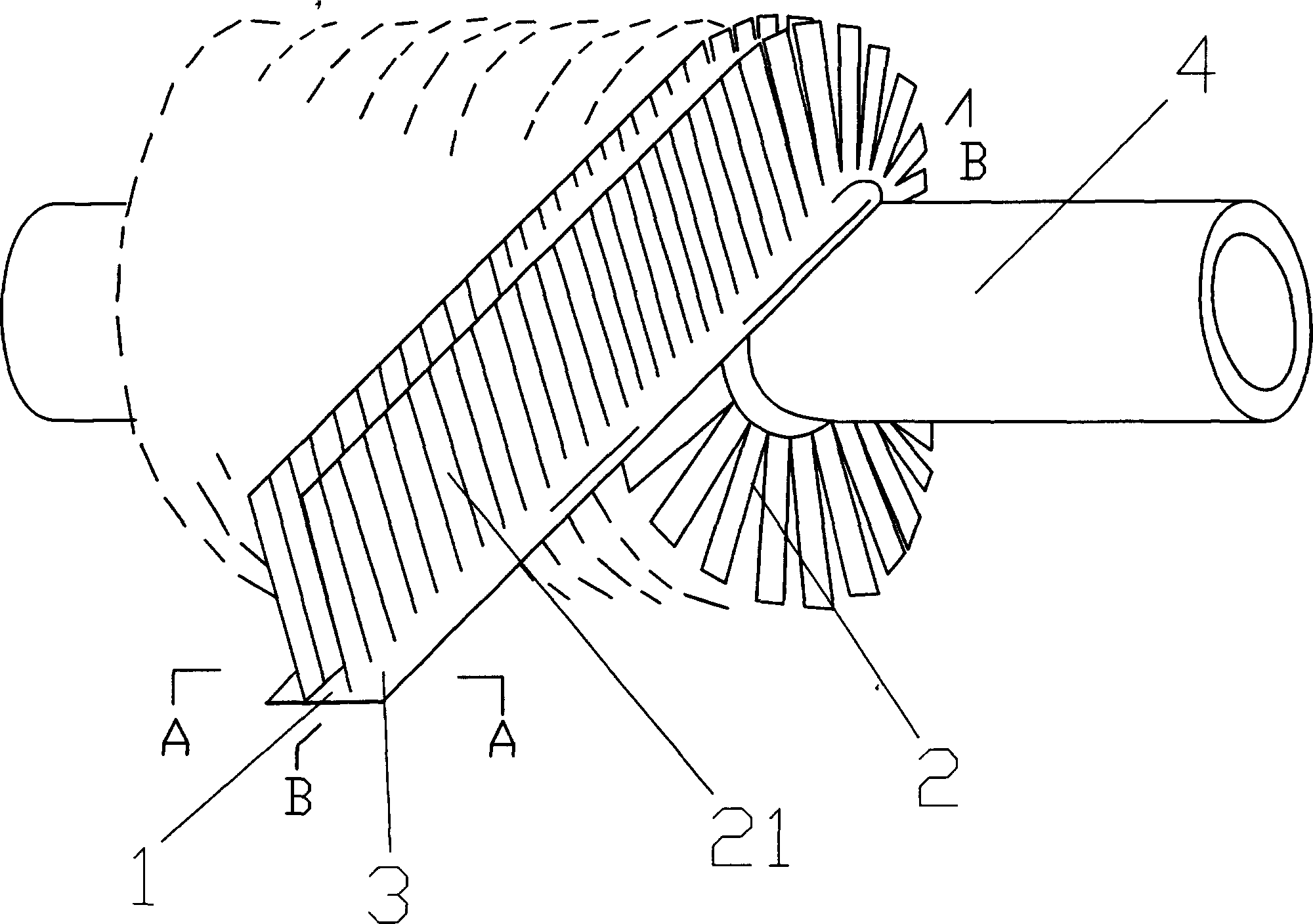

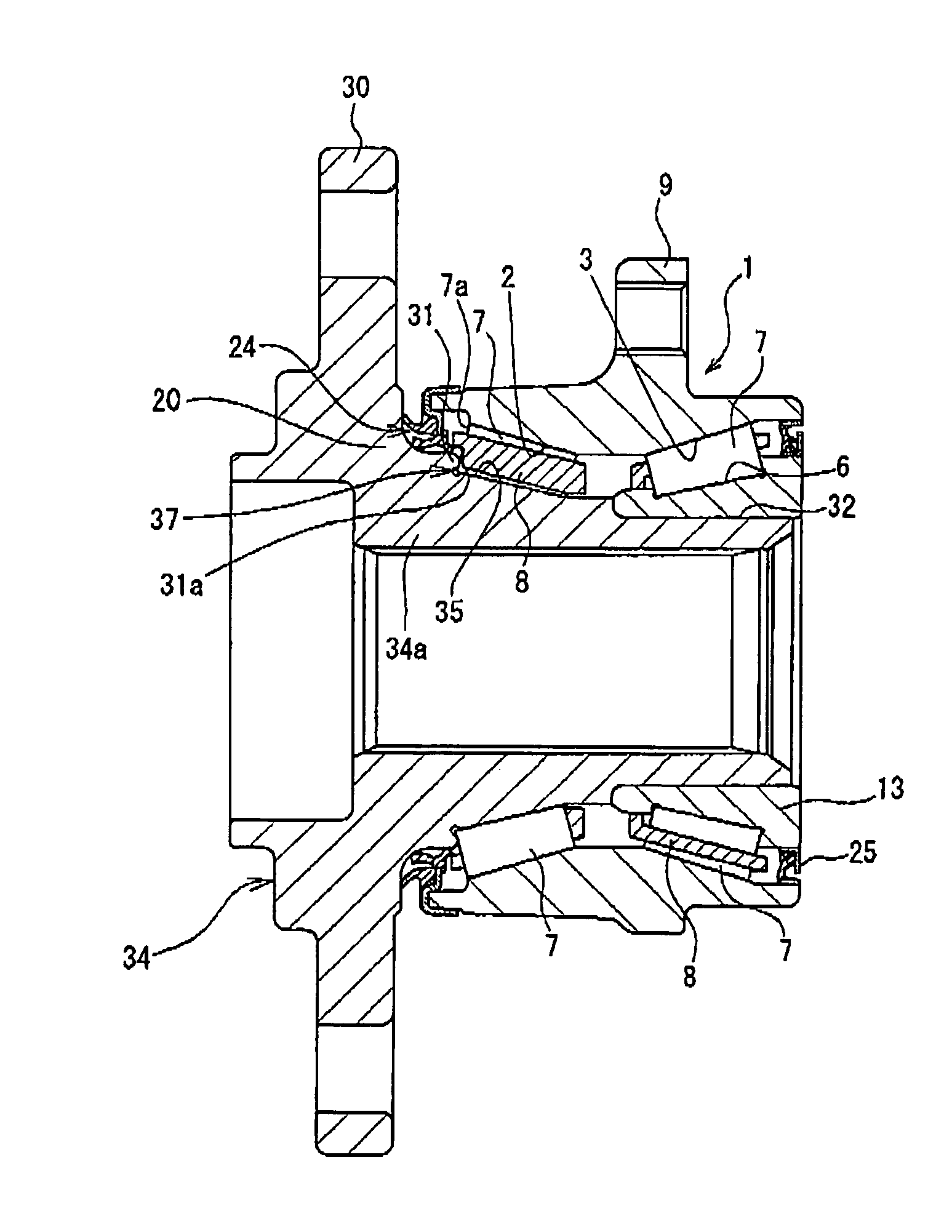

Tapered roller bearing and transmission bearing apparatus

InactiveUS20070041678A1Reduce rotation lossAvoid it happening againRoller bearingsShaftsConvex sideEngineering

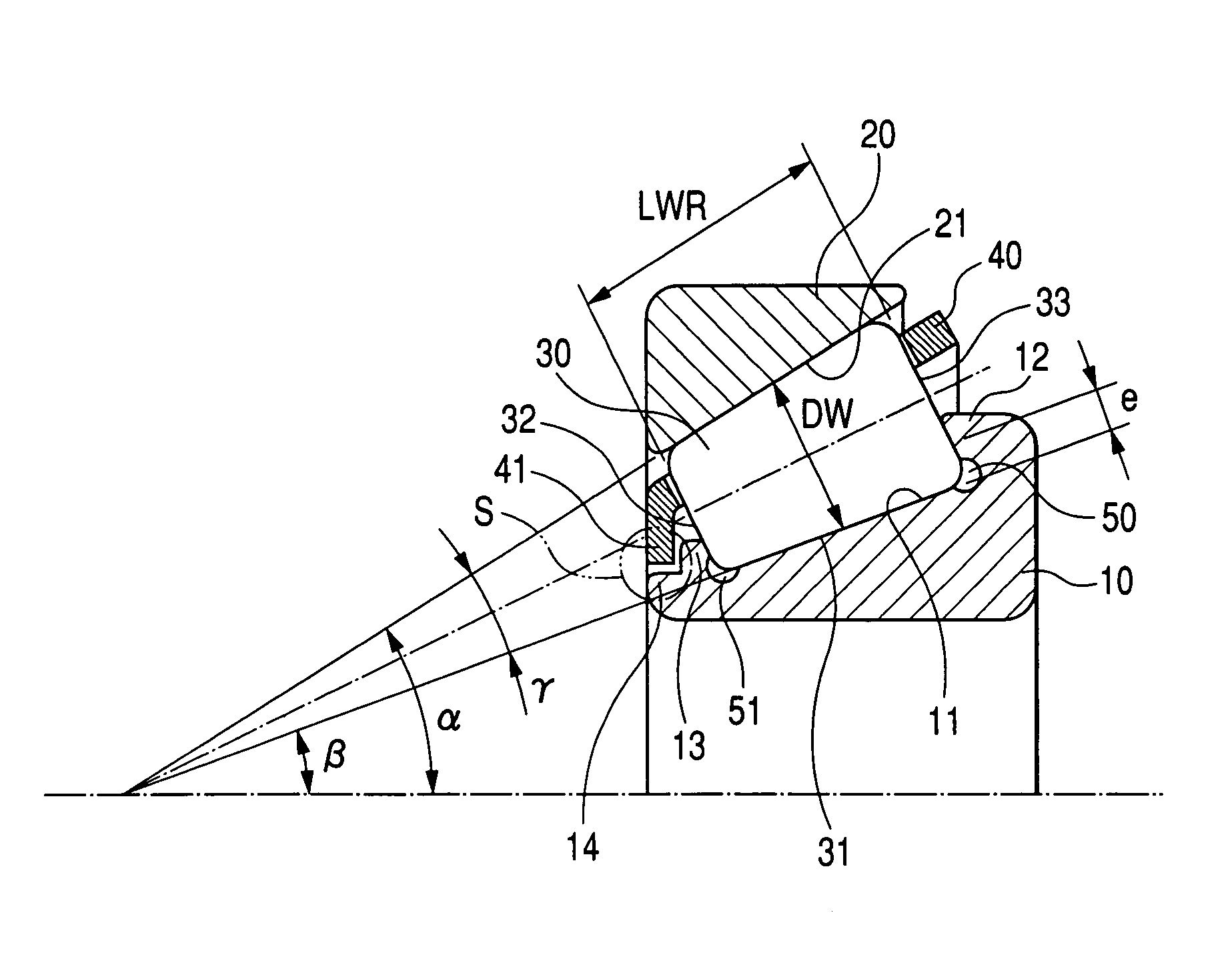

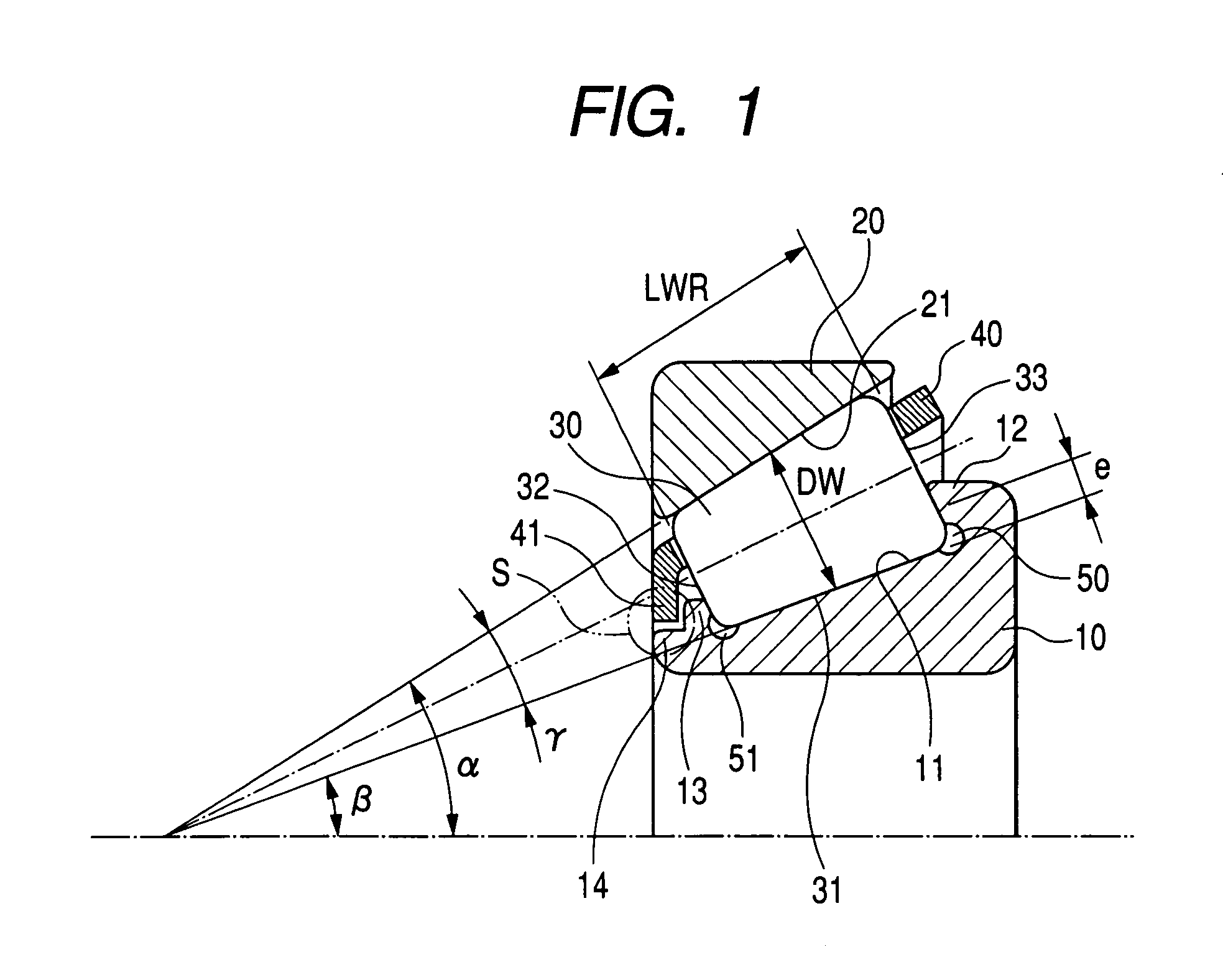

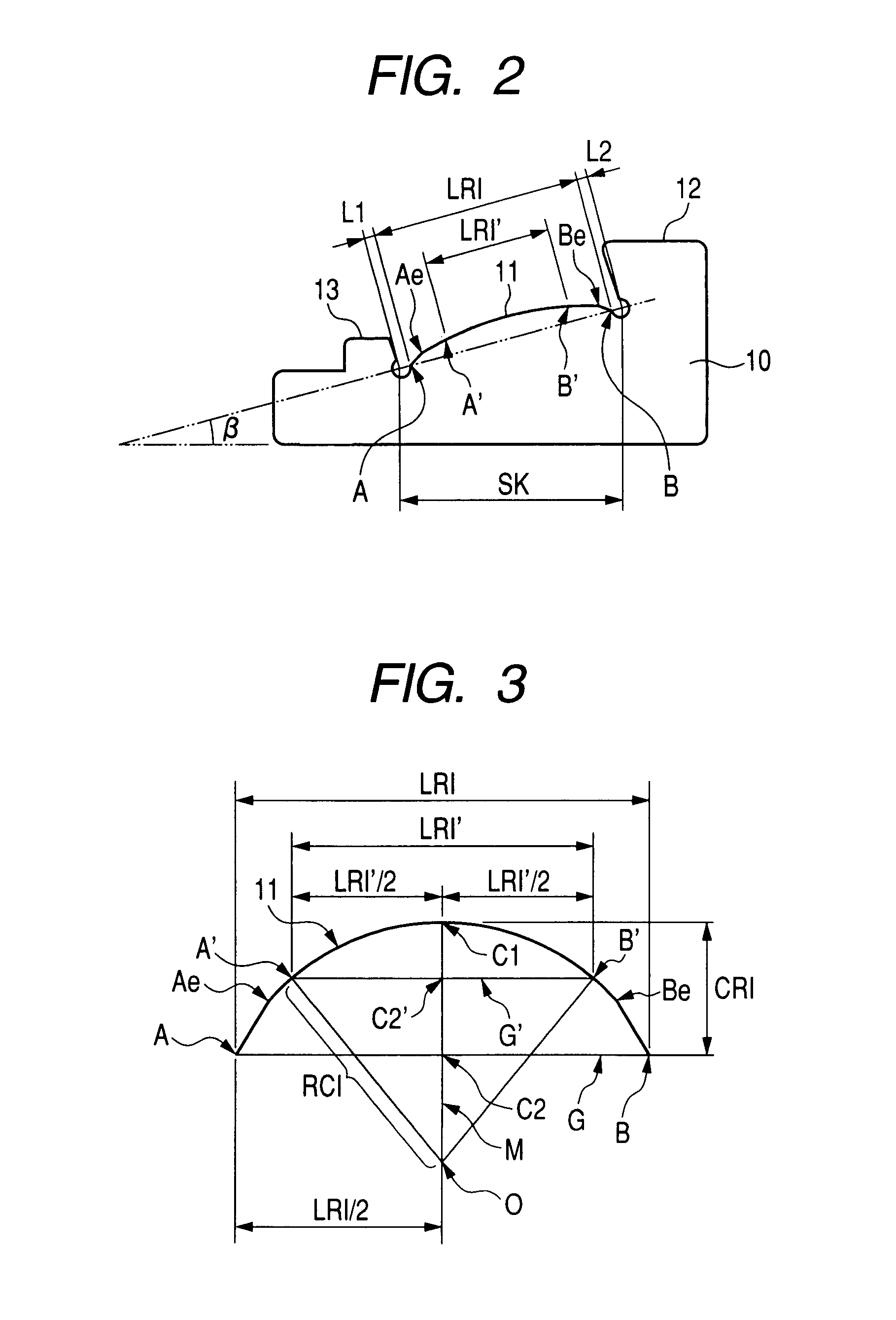

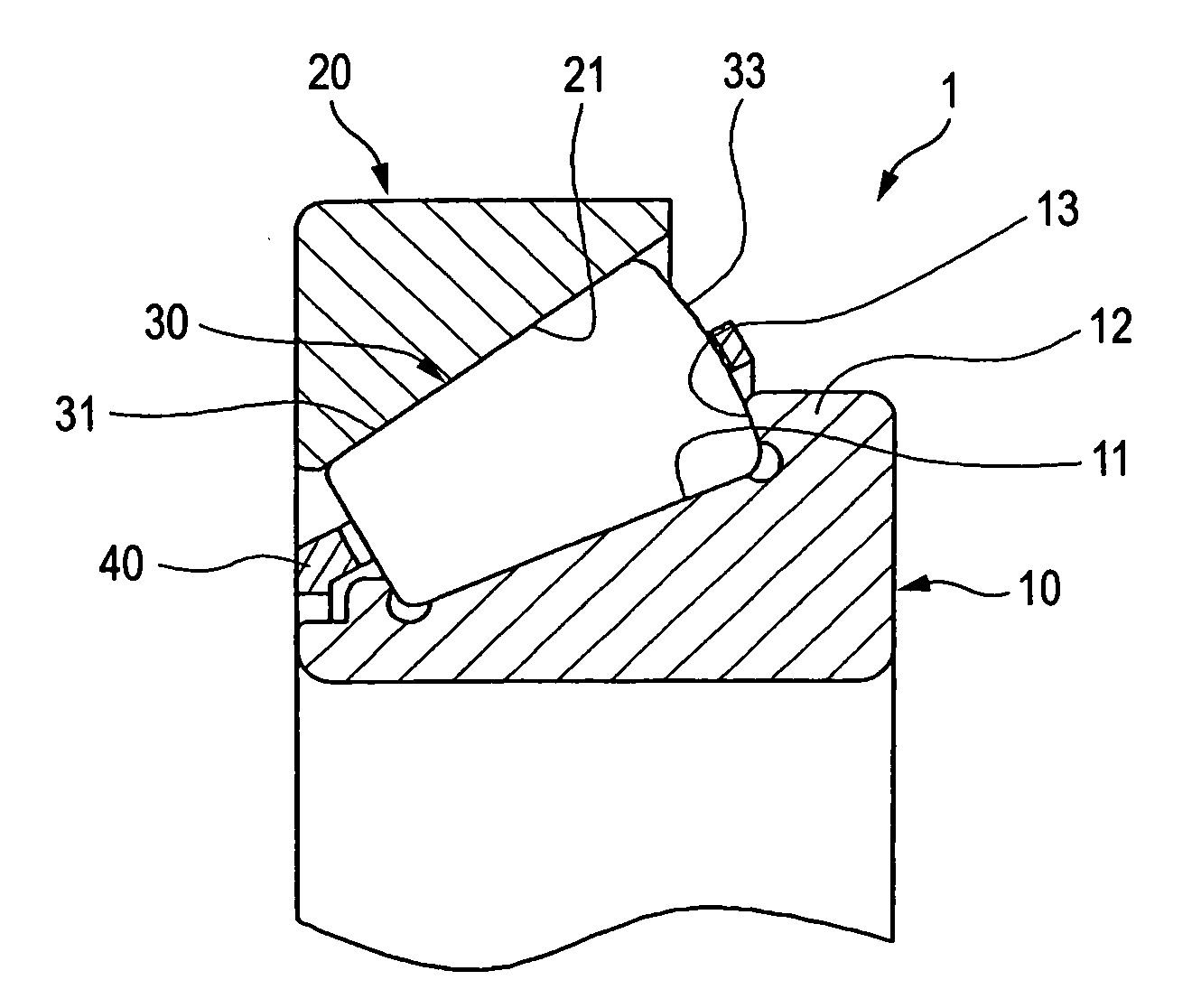

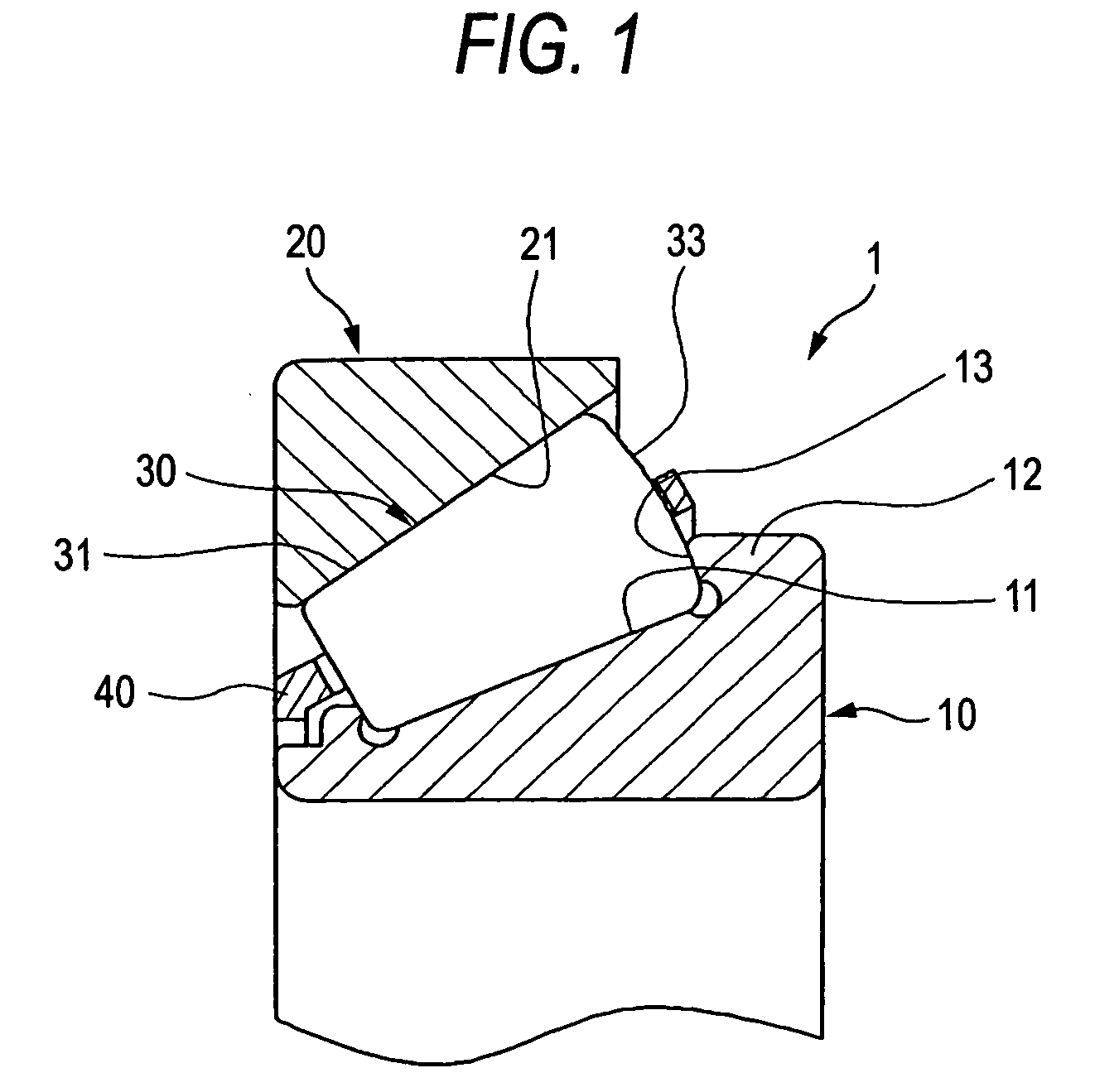

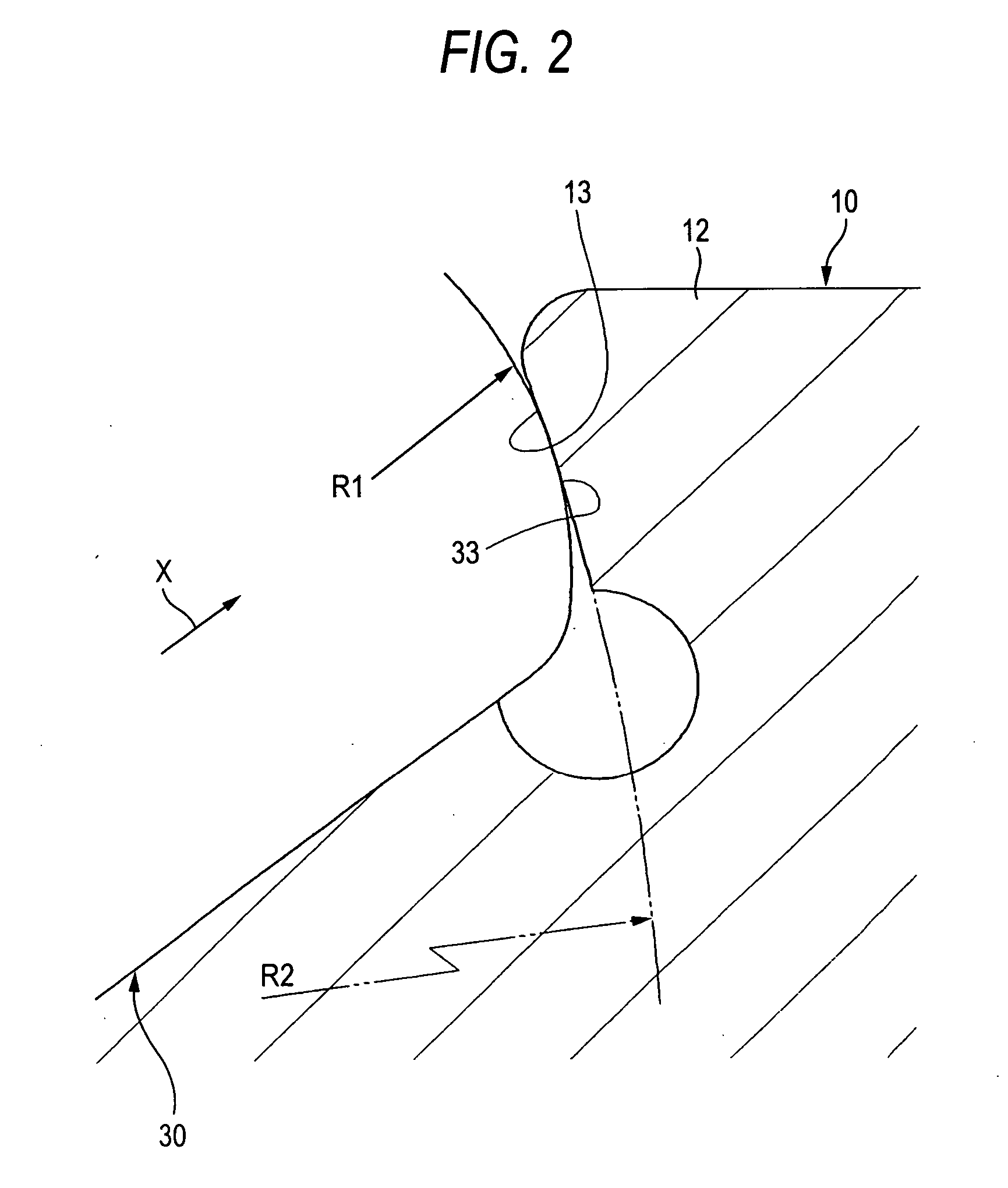

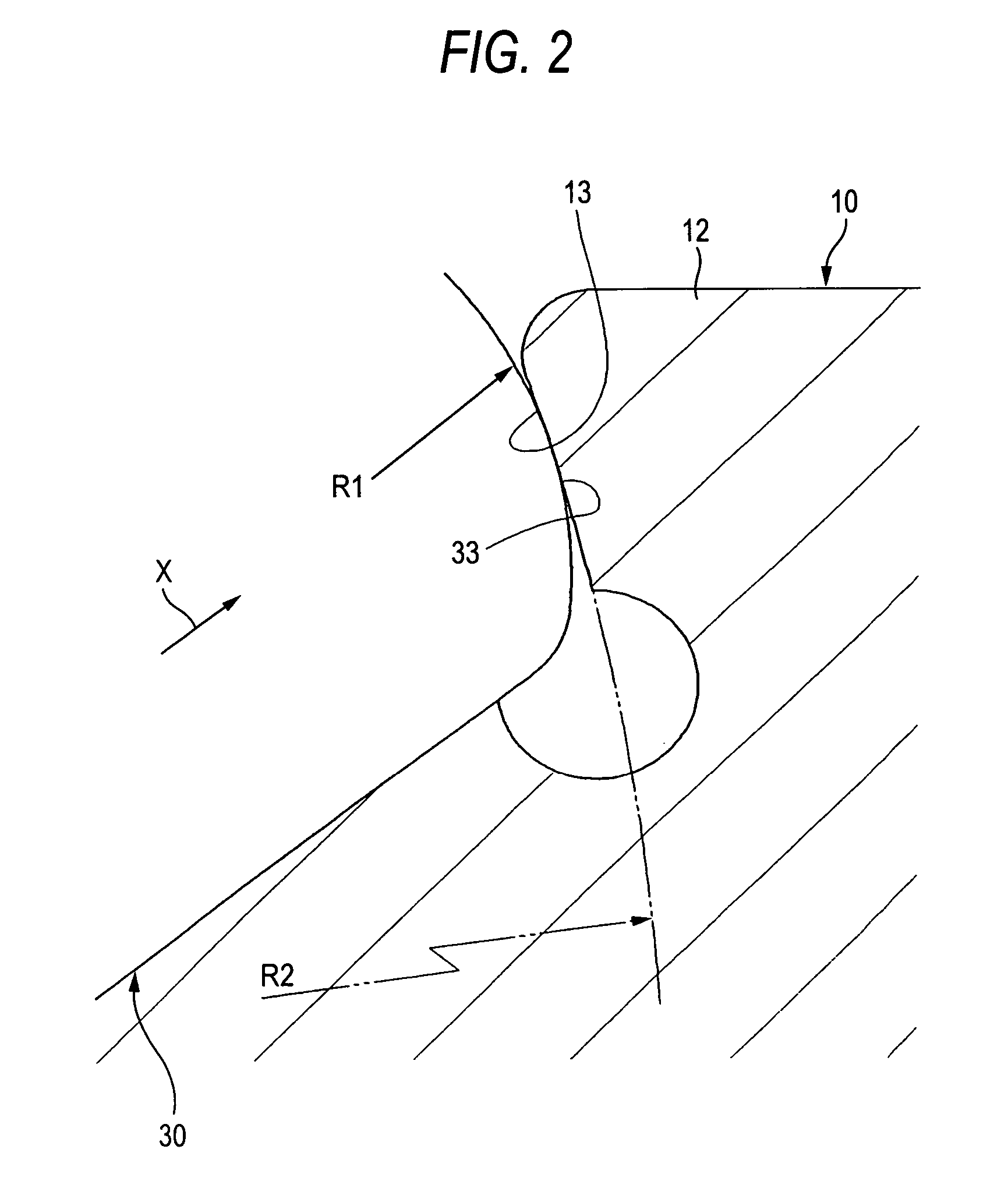

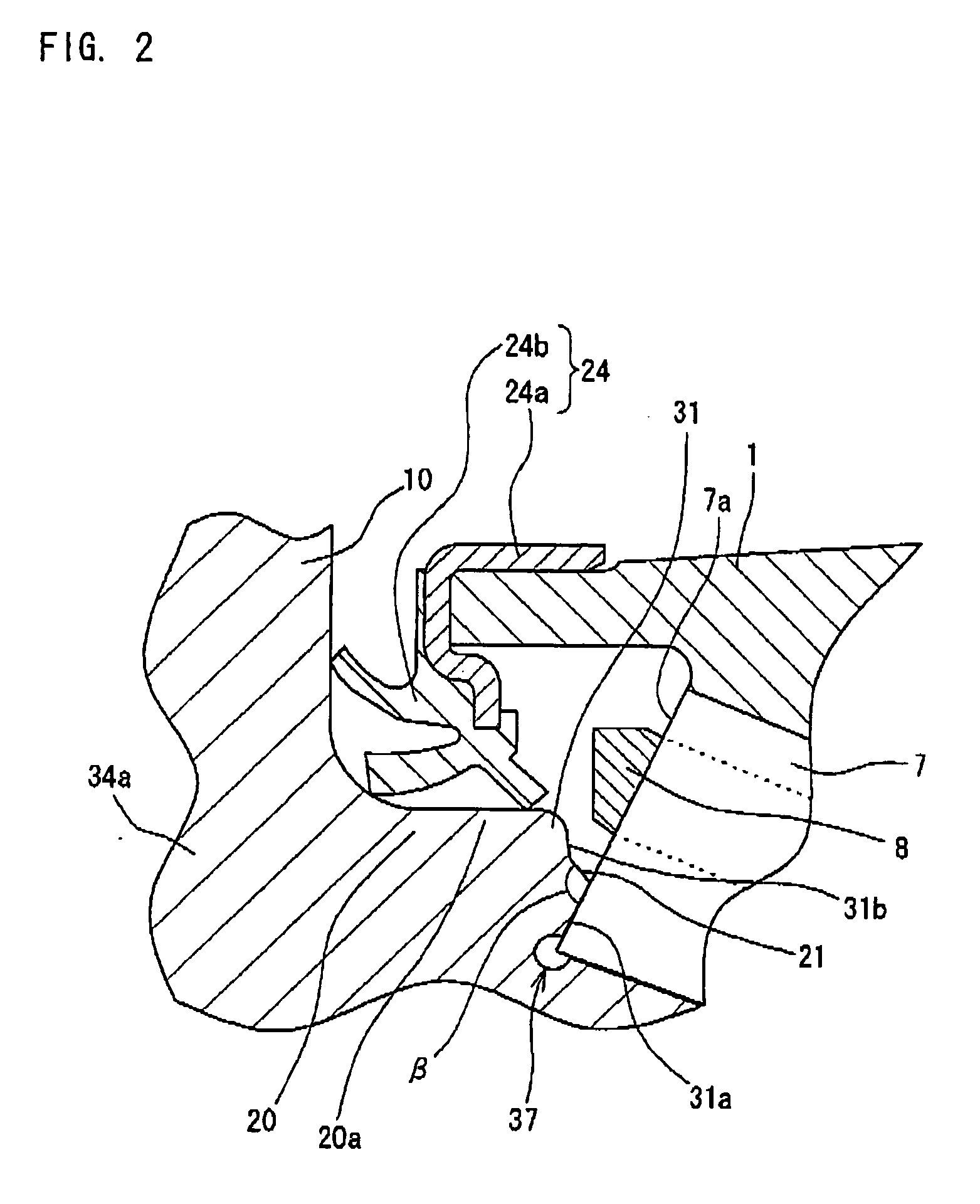

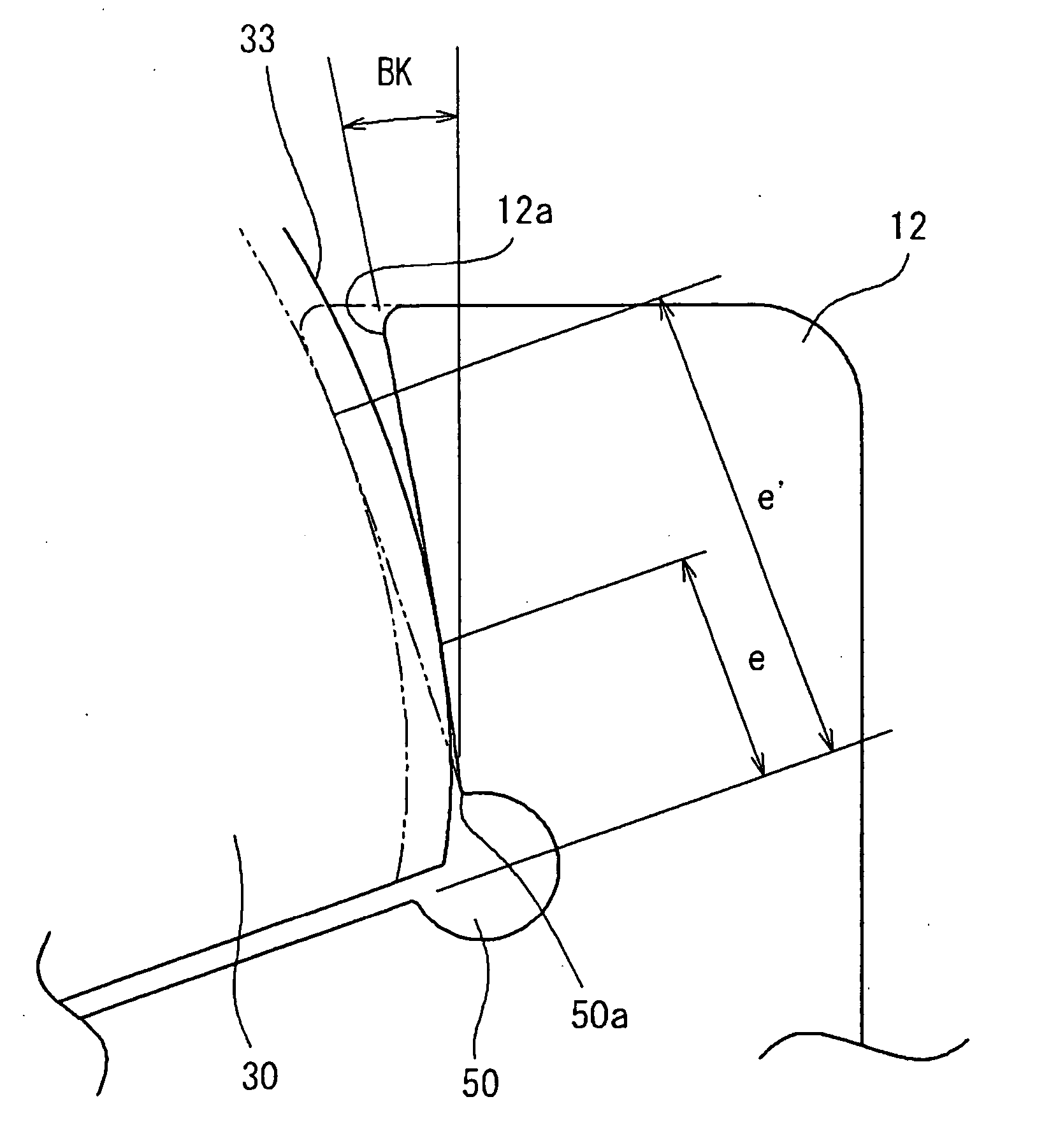

A tapered roller bearing includes an outer ring, an inner ring including a large rib surface formed into a concavely curved surfaced recessed in an axial direction, and a plurality of tapered rollers. R1 / R2 is in the range of 0.07 to 0.8 where R1 represents radius of curvature of a large end face of the tapered roller and R2 represents a radius of curvature of the concavely curved surface. An arithmetical mean roughness the large end face is in the range of 0.01 to 0.03 μm. A total crowning amount is 50 μm or larger, an outer ring crowning rate, which is a rate of the outer ring crowning amount on the total crowning amount, is 40% or larger, and a roller crowning rate, which is a rate of two times of the roller crowning amount on the total crowning amount is 20% or smaller.

Owner:JTEKT CORP

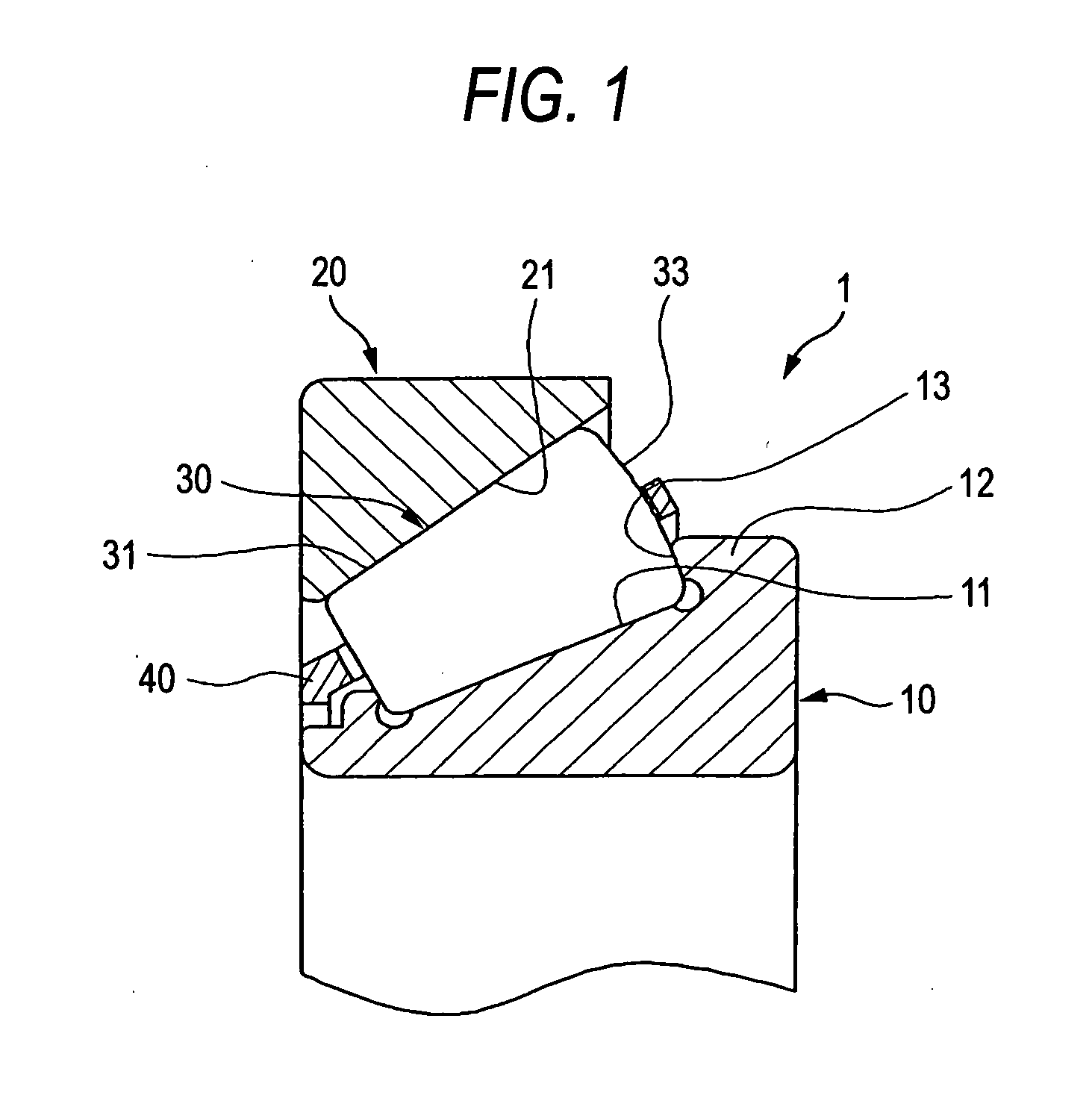

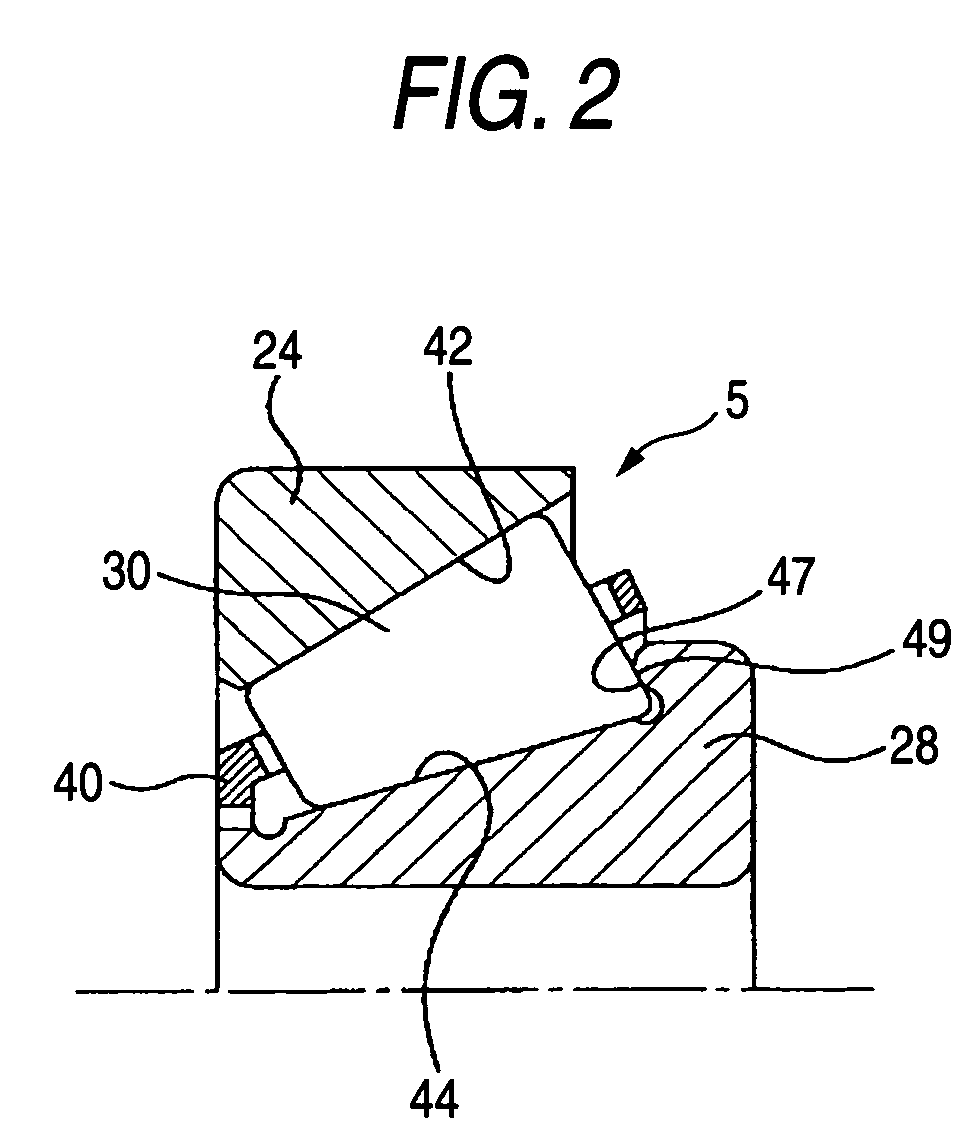

Tapered roller bearing

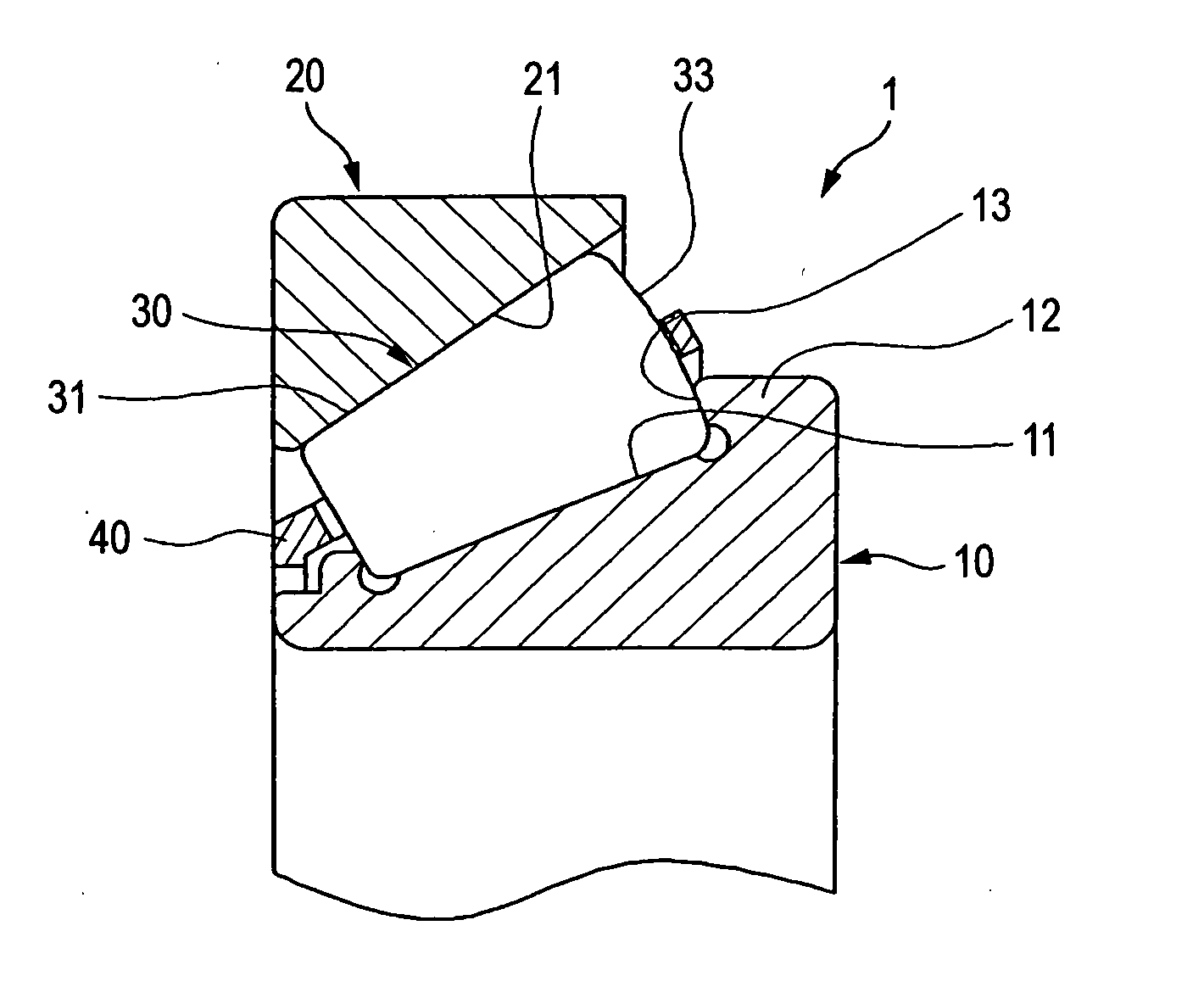

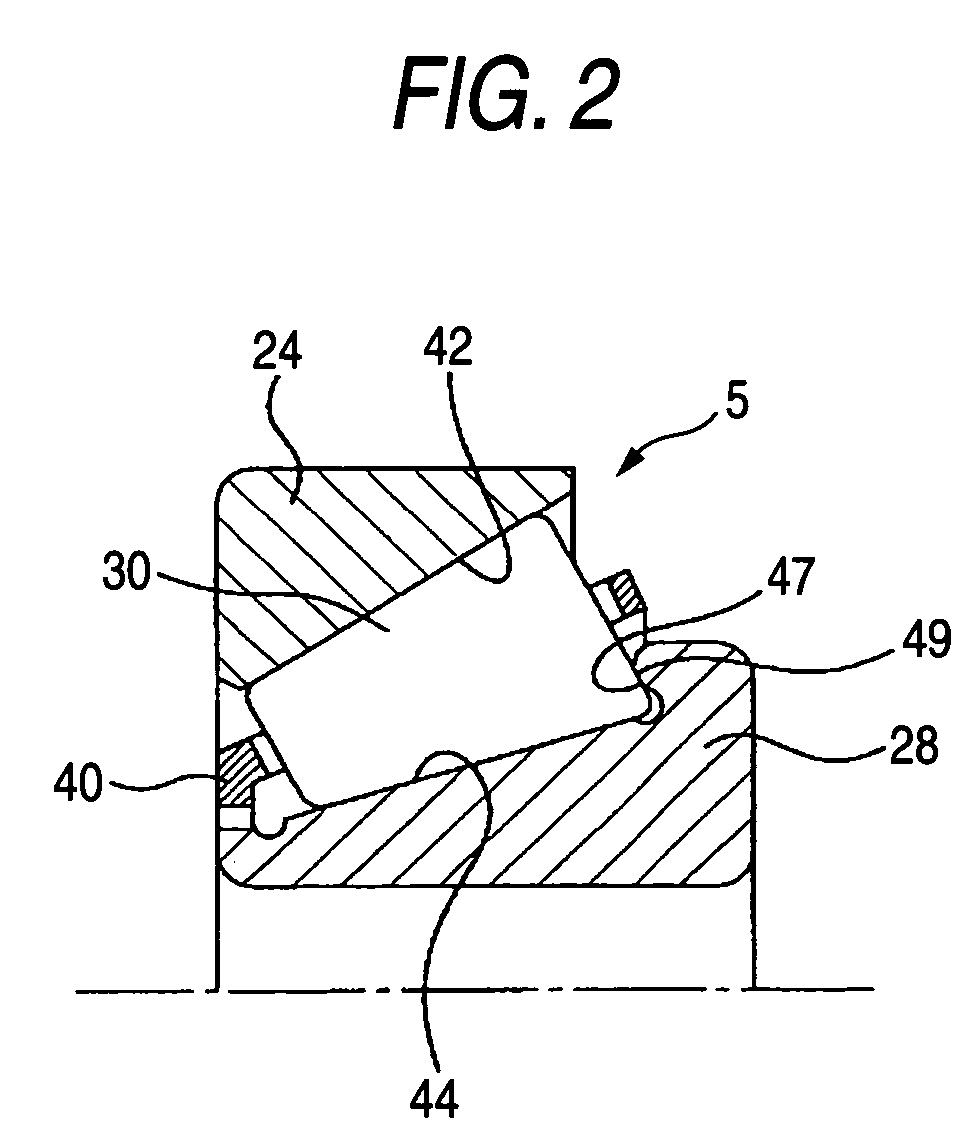

A tapered roller bearing includes: an oil guide member that opens and closes an annular opening between an outer peripheral surface of a large rib of an inner ring and an outer ring and is mounted on the large rib; and a discharge port that discharges, along the outer peripheral surface of the large rib, lubricating oil and is formed through an inner peripheral portion of the oil guide member. The oil guide member includes a closing portion for closing the annular opening. When a fluid pressure of the lubricating oil which flows through pockets of a cage toward an inner peripheral surface of the outer ring is below a predetermined values, the closing portion closes the annular opening and guides the lubricating oil toward the discharge port. When the fluid pressure exceeds the predetermined value, the closing portion opens the annular opening.

Owner:JTEKT CORP

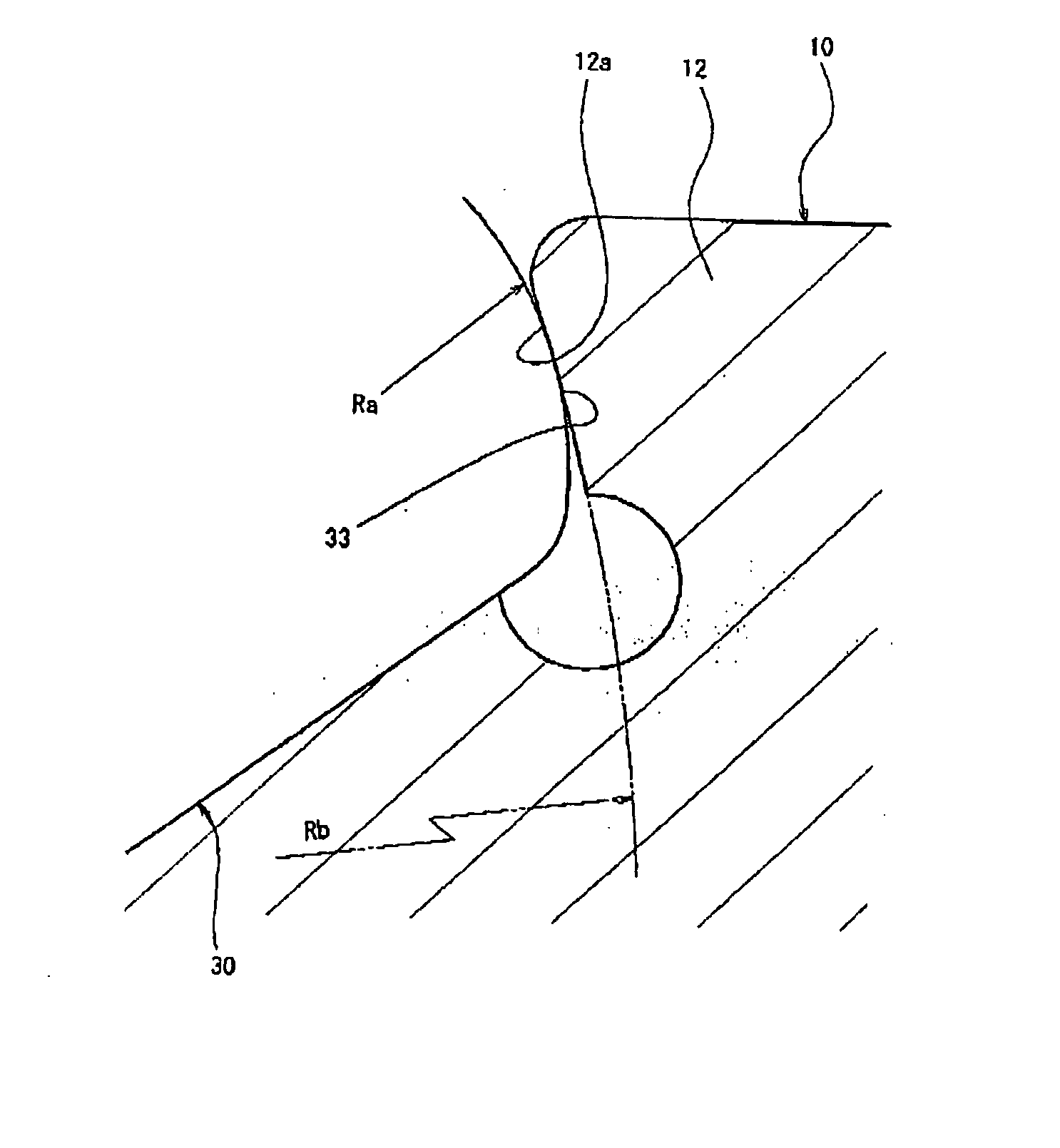

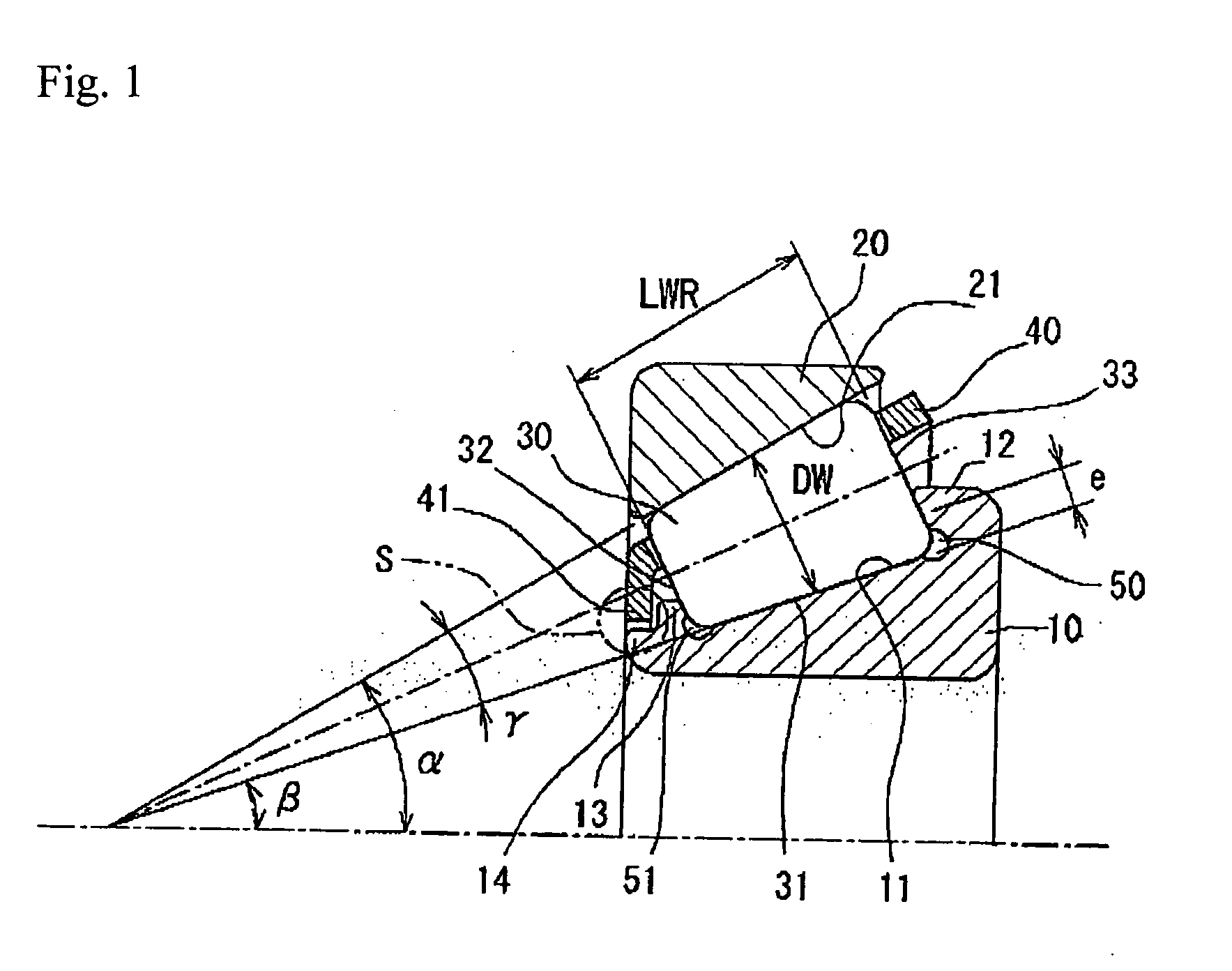

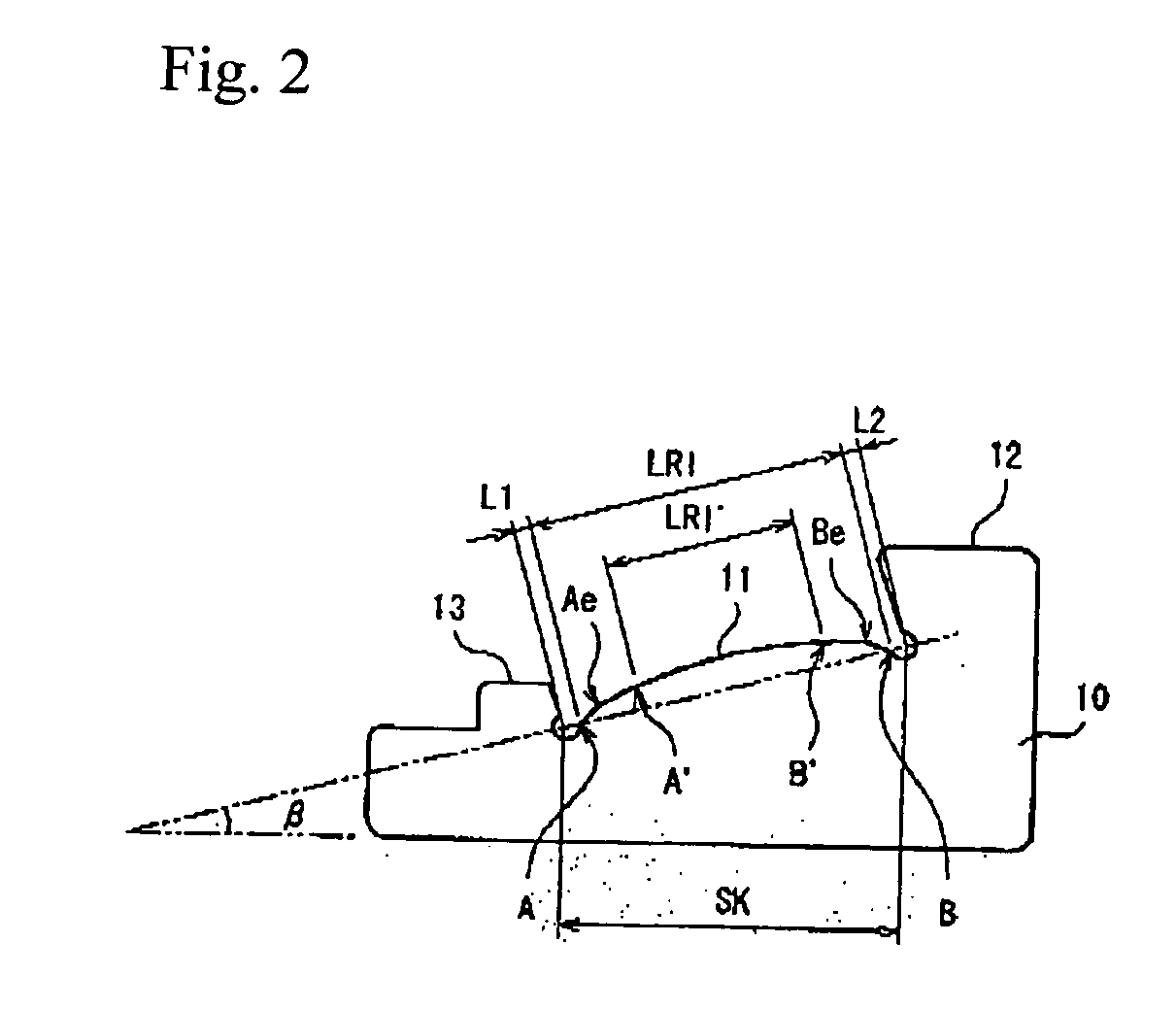

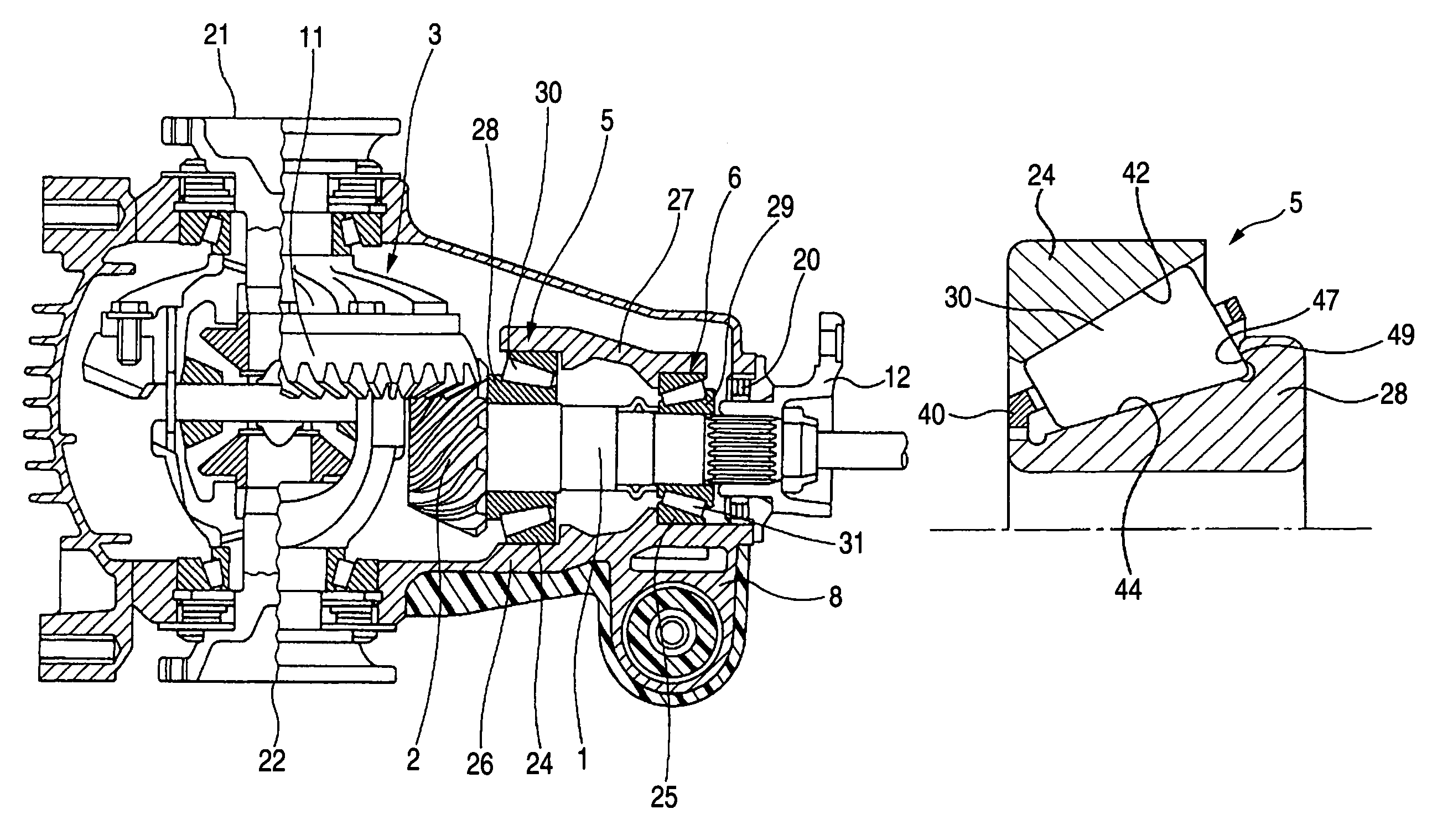

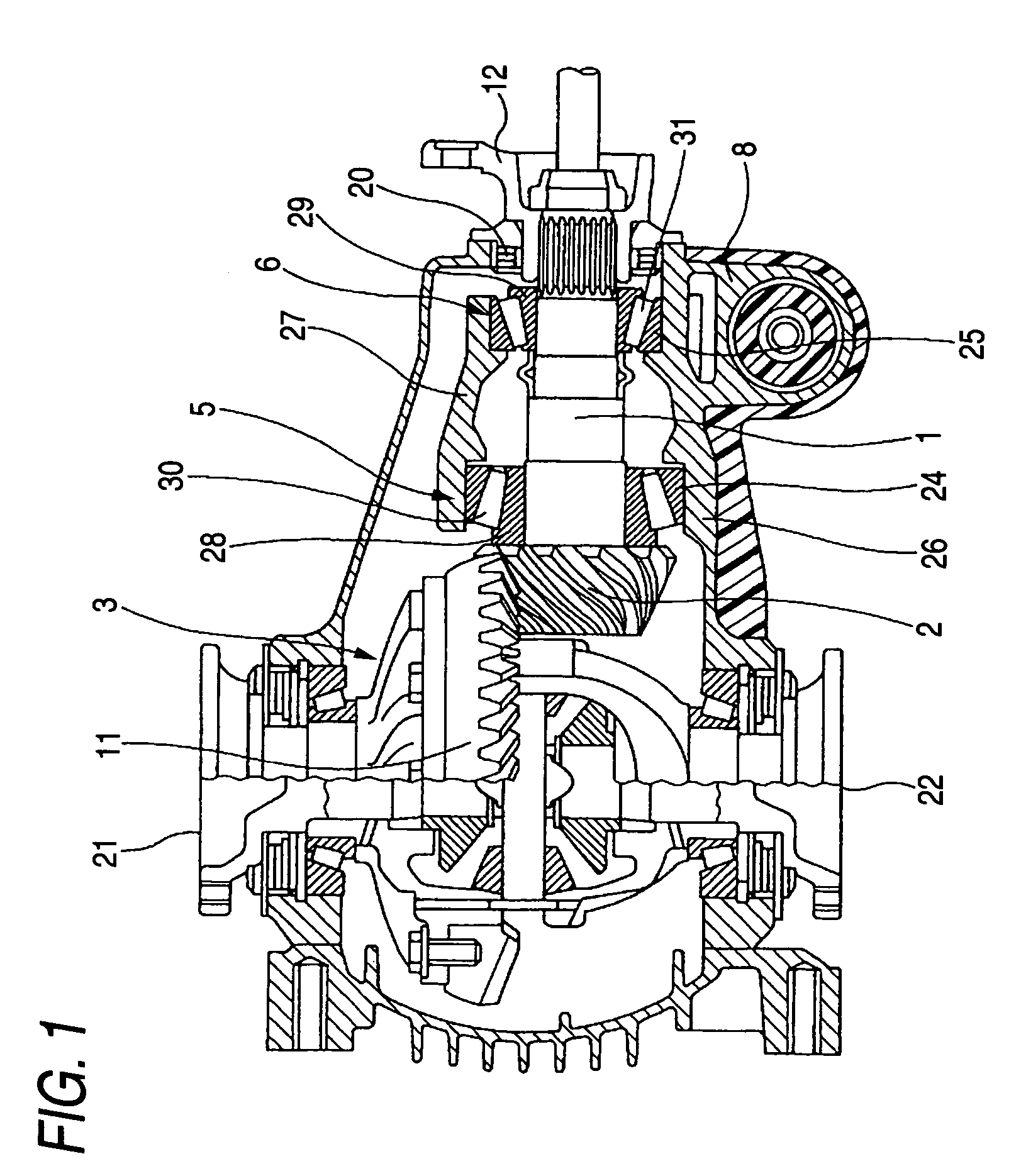

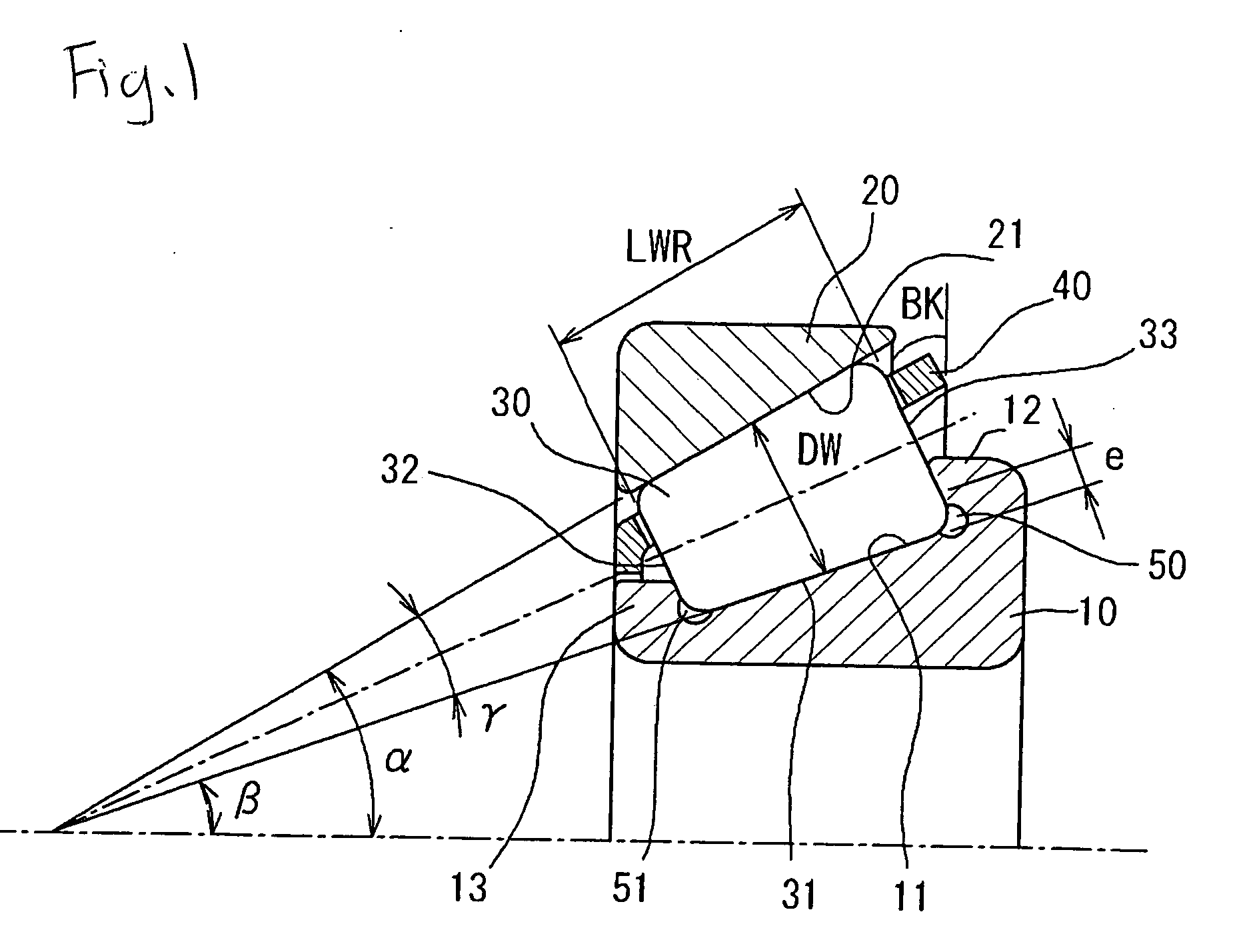

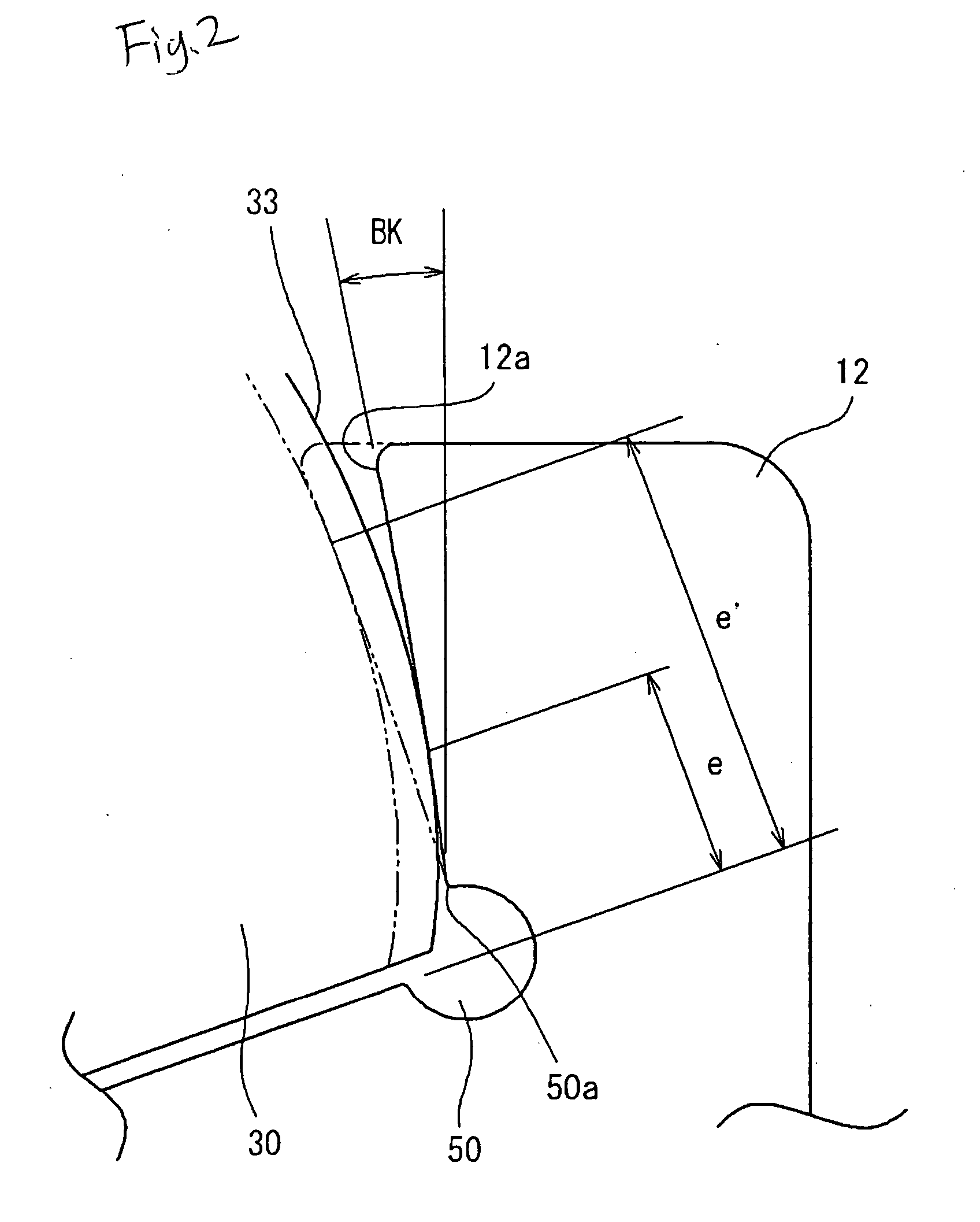

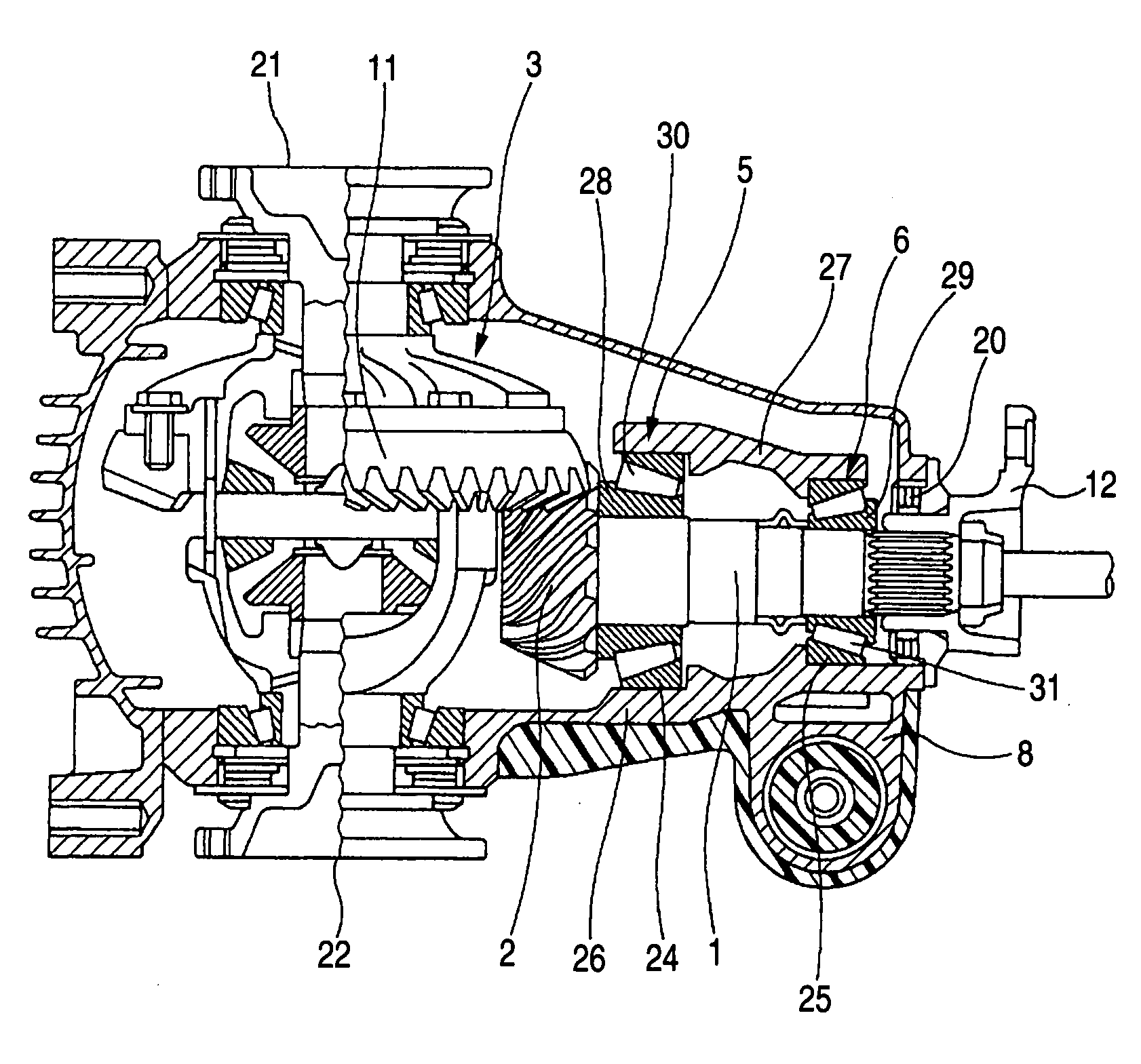

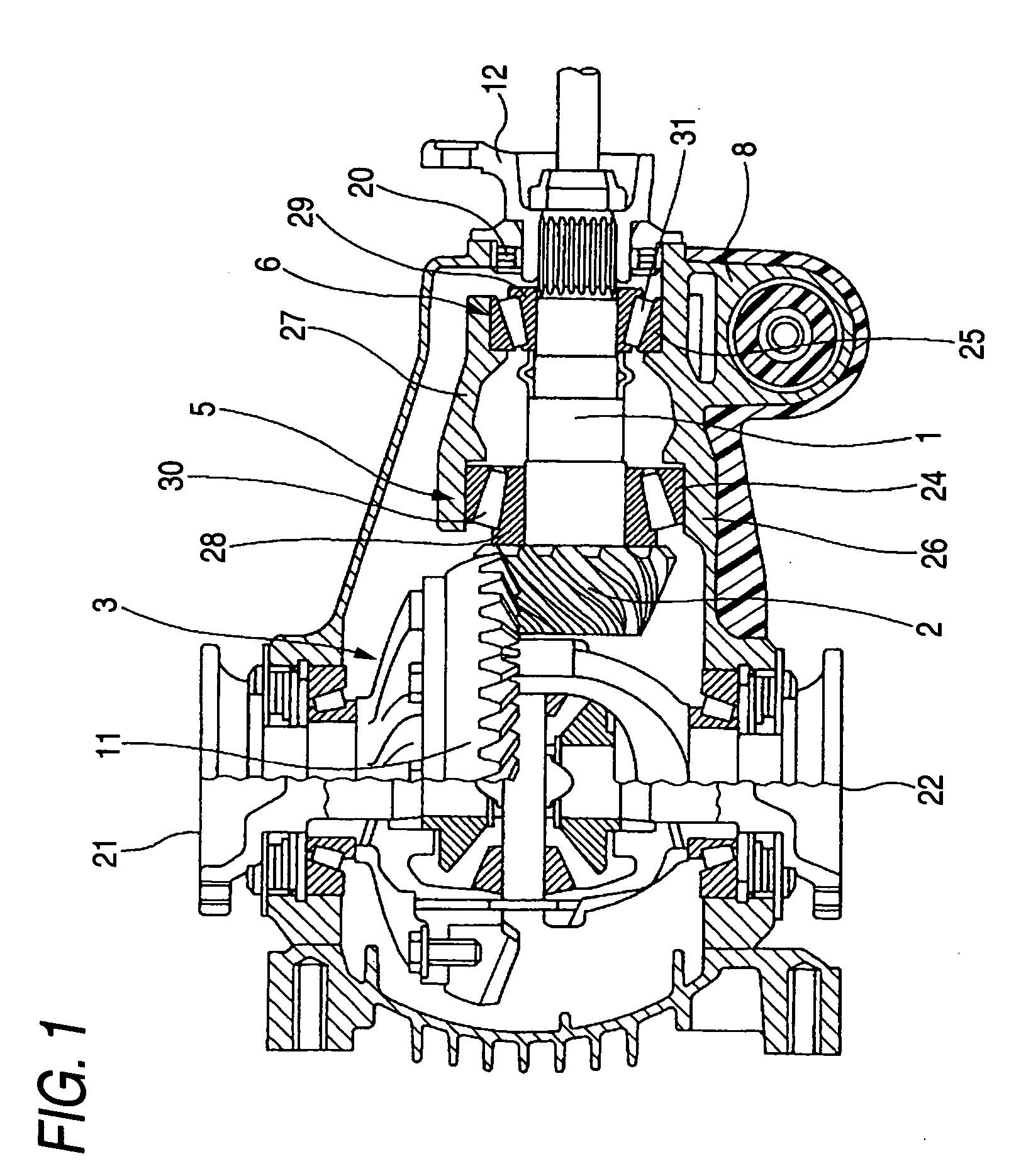

Tapered roller bearing, tapered roller bearing apparatus, and automotive pinion shaft supporting apparatus utilizing same tapered roller bearing apparatus

A tapered roller bearing includes an outer ring, an inner ring, a plurality of tapered rollers interposed between the outer ring and the inner ring, and a cage for the tapered rollers. Ra is smaller than Rb where Ra represents a radius of curvature of a large end face of the tapered roller and Rb represents a radius of curvature of an end face of a large rib portion of the inner ring.

Owner:JTEKT CORP

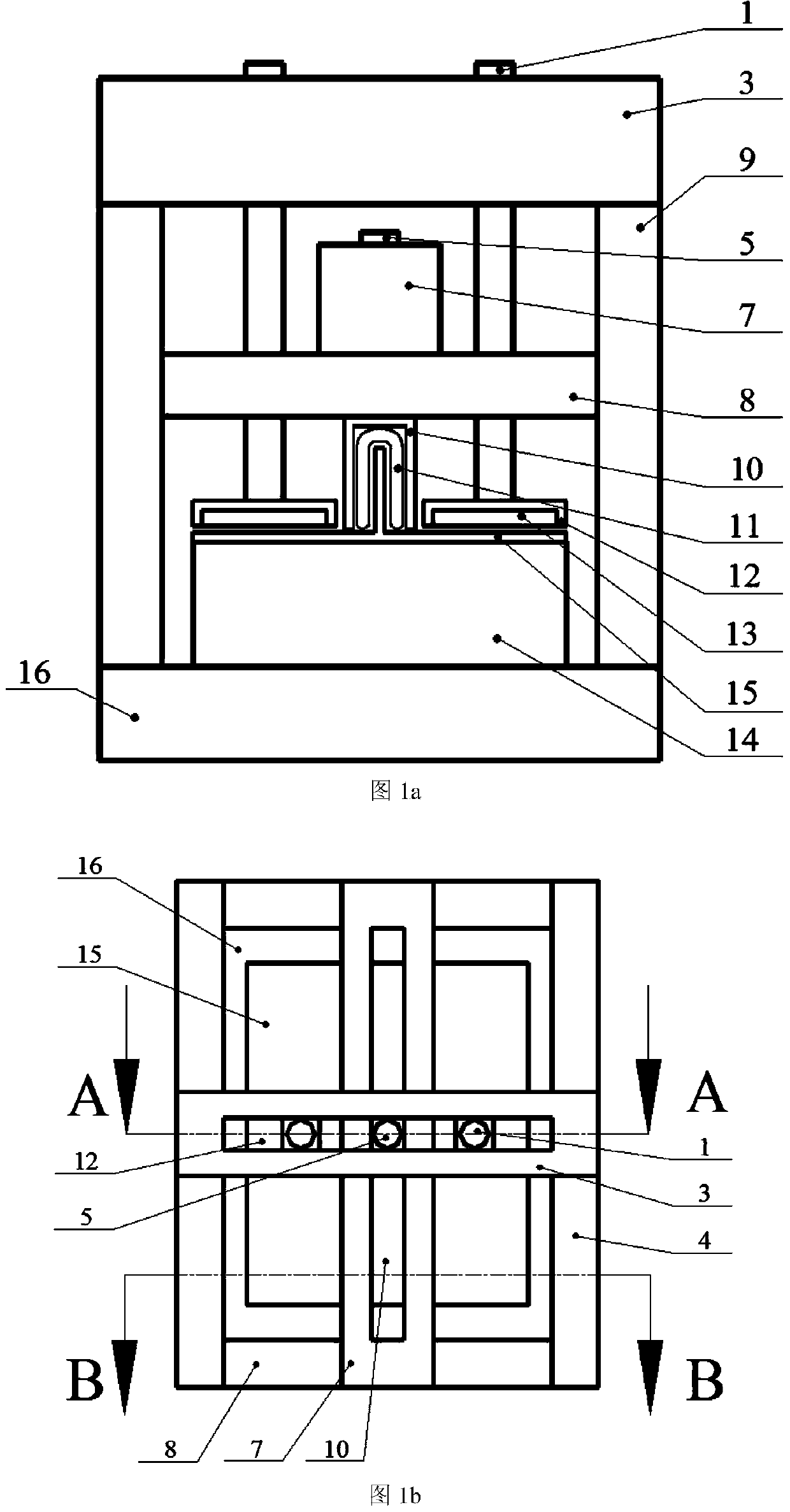

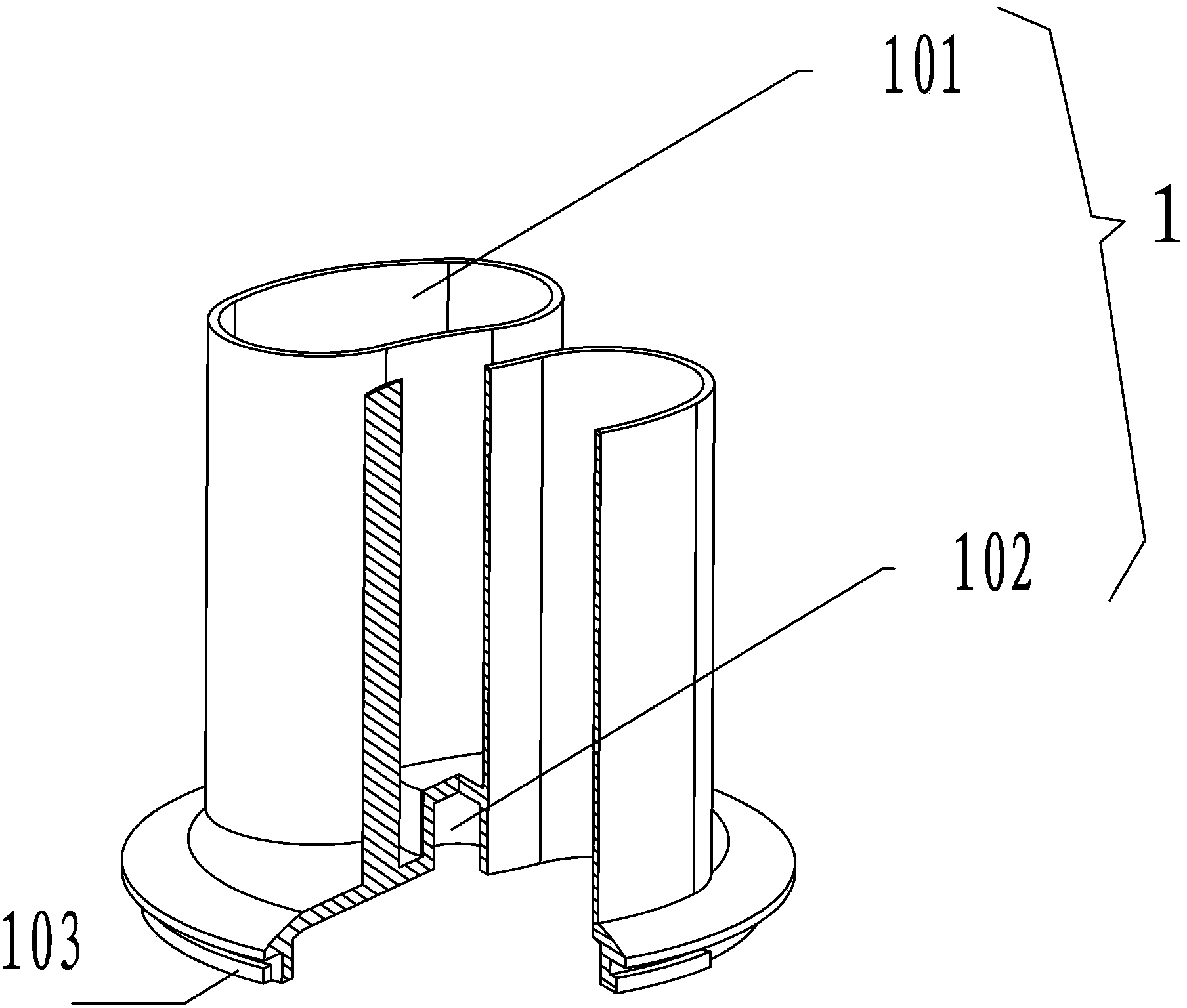

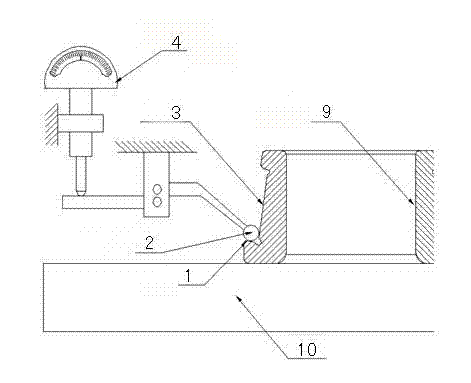

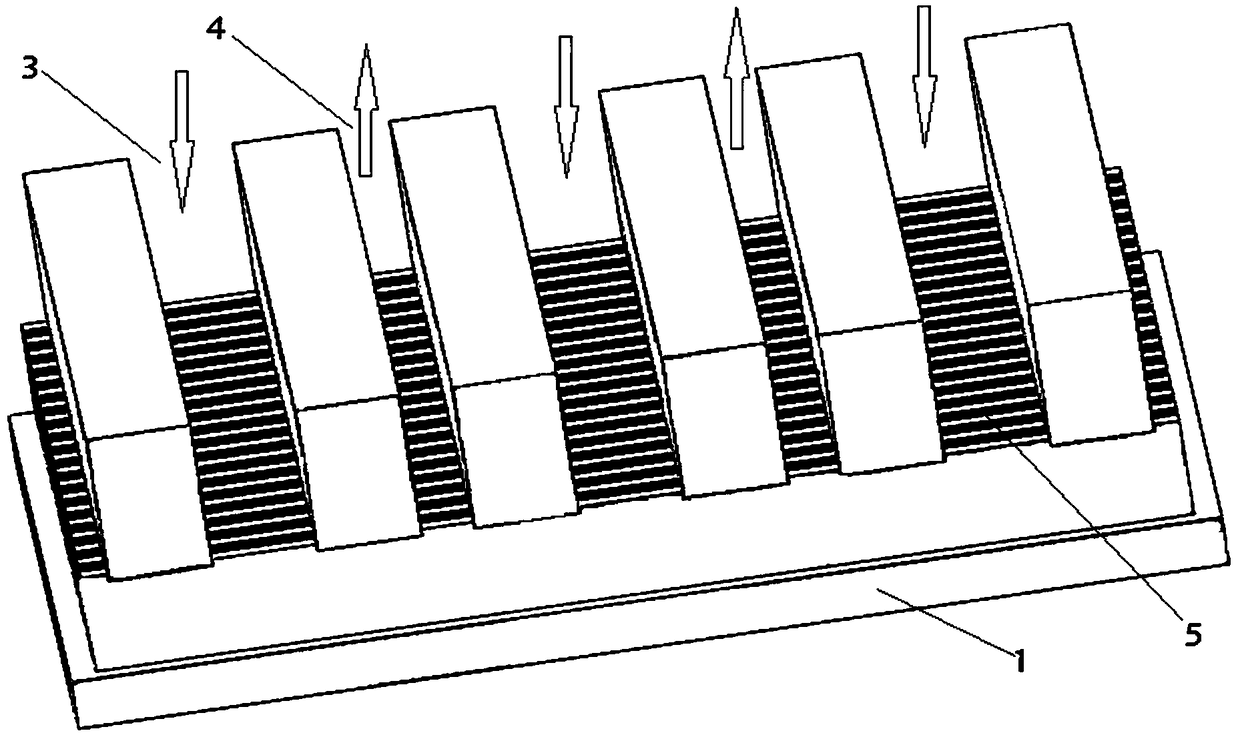

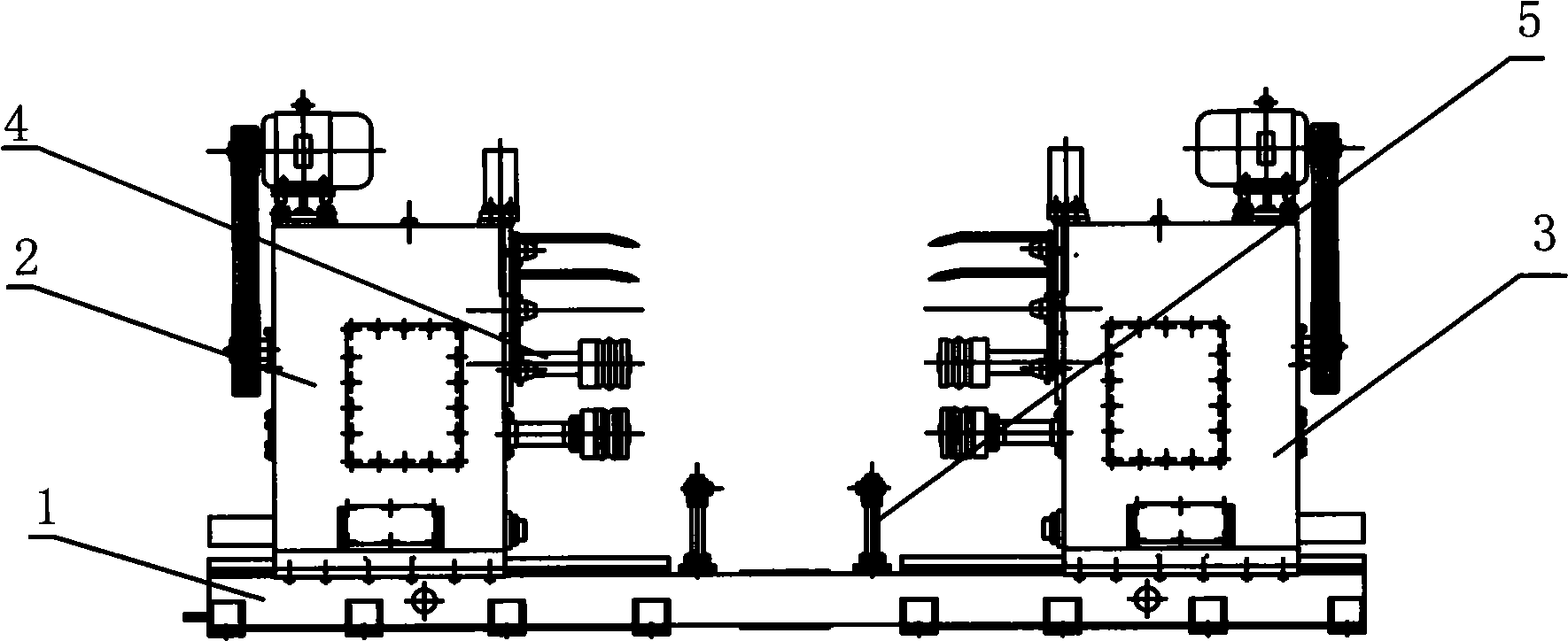

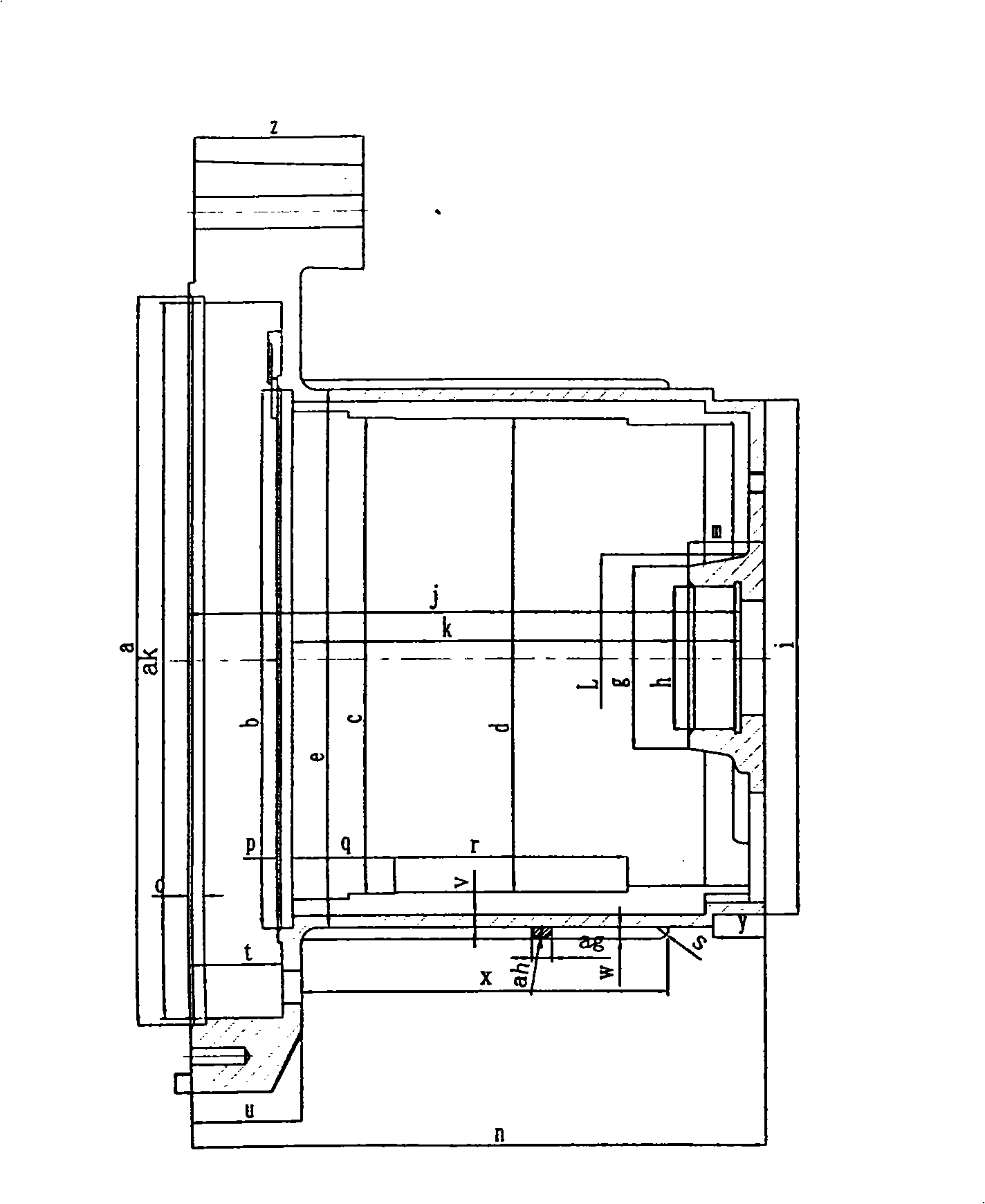

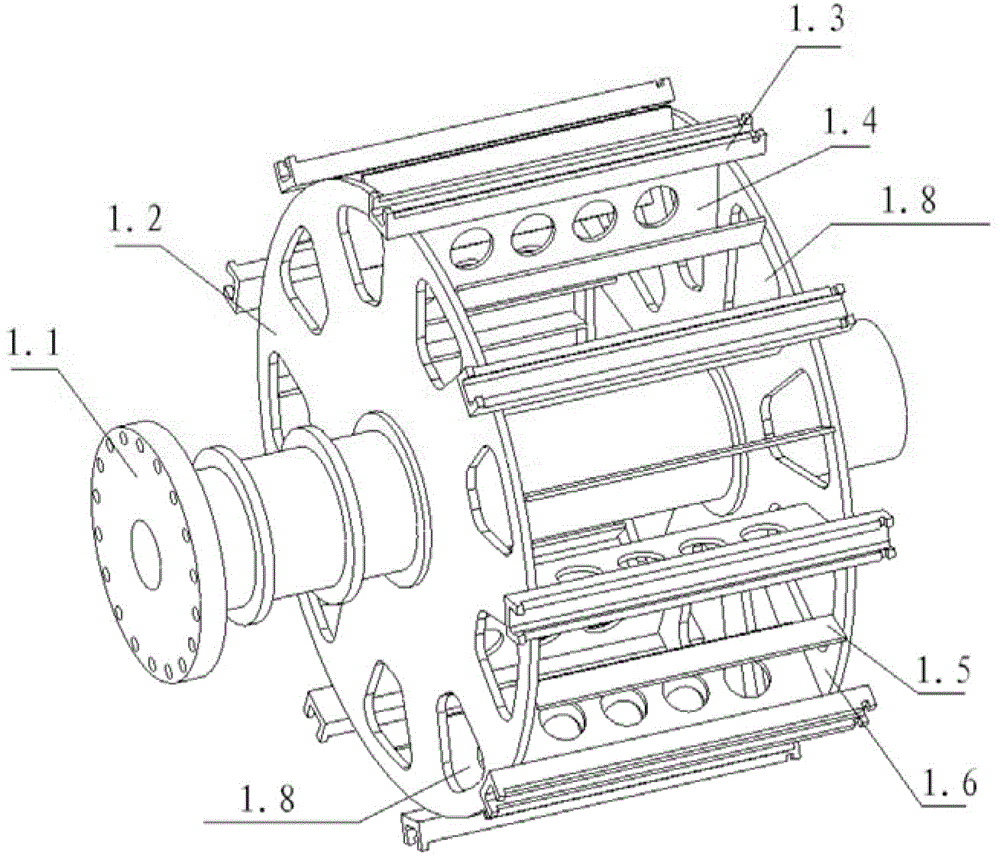

Electromagnetic forming device and forming method for aluminum alloy rib plate

The invention discloses an electromagnetic forming device and a forming method for an aluminum alloy rib plate. The electromagnetic forming device is characterized in that a forming coil comprises two web coils and a rib coil, the web coils are used for forming webs of the rib plate, and the rib coil is used for forming ribs of the rib plate. The rib coil is fixedly sealed in a rib coil shell and then is serially connected into a rib coil discharge circuit. The two web coils are respectively used for forming the corresponding webs on two sides of each rib; the web coils and web coil shells are respectively fixedly and integrally sealed with one another, and the two web coils are connected into web coil discharge circuits in parallel. The forming coil is positioned above the rib plate. The forming method includes that interactive magnetic field force is generated among the coils in the pulse discharge circuits and the rib plate to be machined; the web coils continuously move in horizontal planes along certain tracks, and the rib plate can be incrementally machined by the aid of the magnetic field force generated by the two types of coils, finally is laminated on a mold and is formed accumulatively. The electromagnetic forming device and the forming method have the advantages of high forming speed, good mold lamination property of the rib plate and surface quality of a formed part, low forming rebounding and the like, and are applicable to machining large rib plates.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

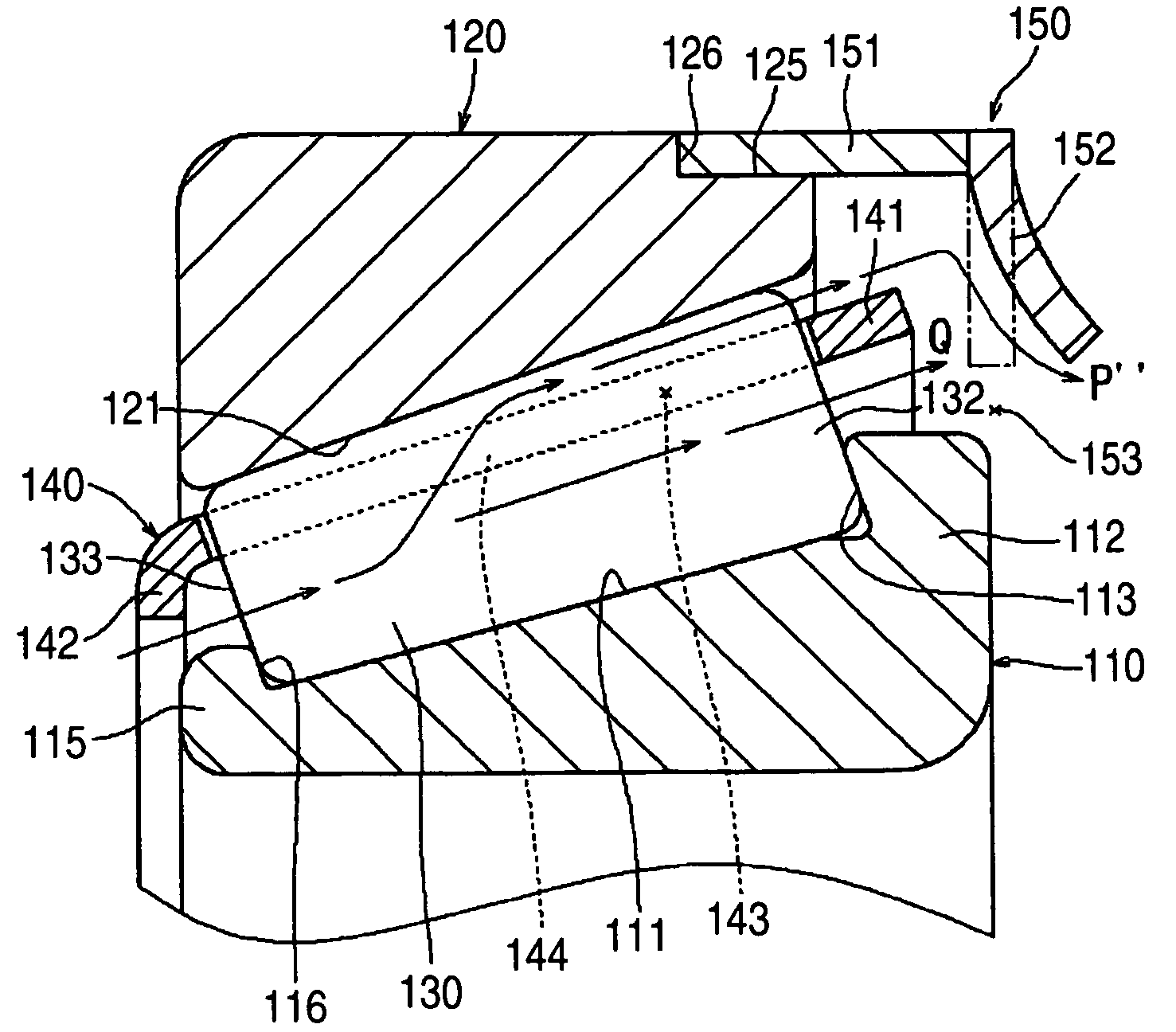

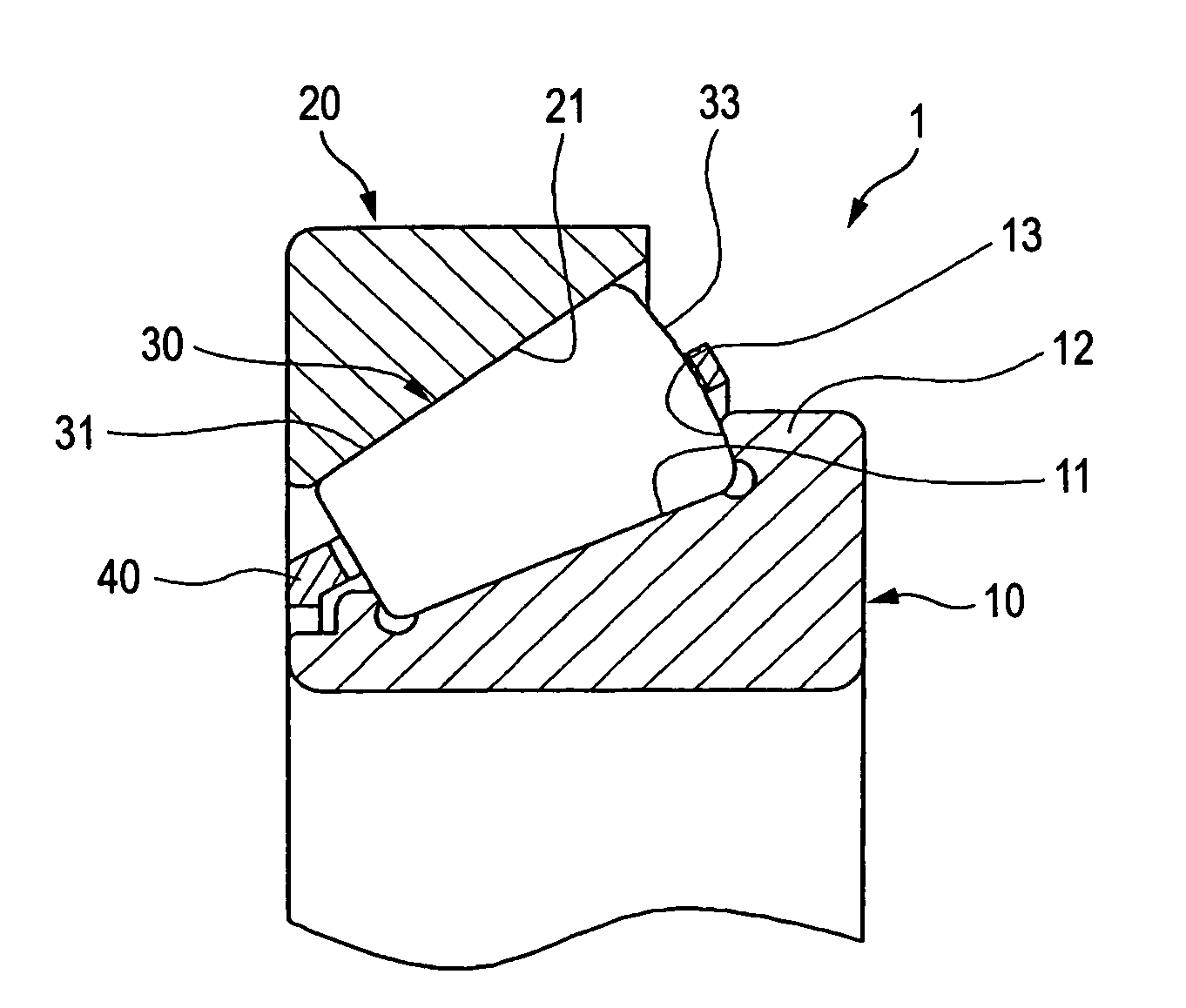

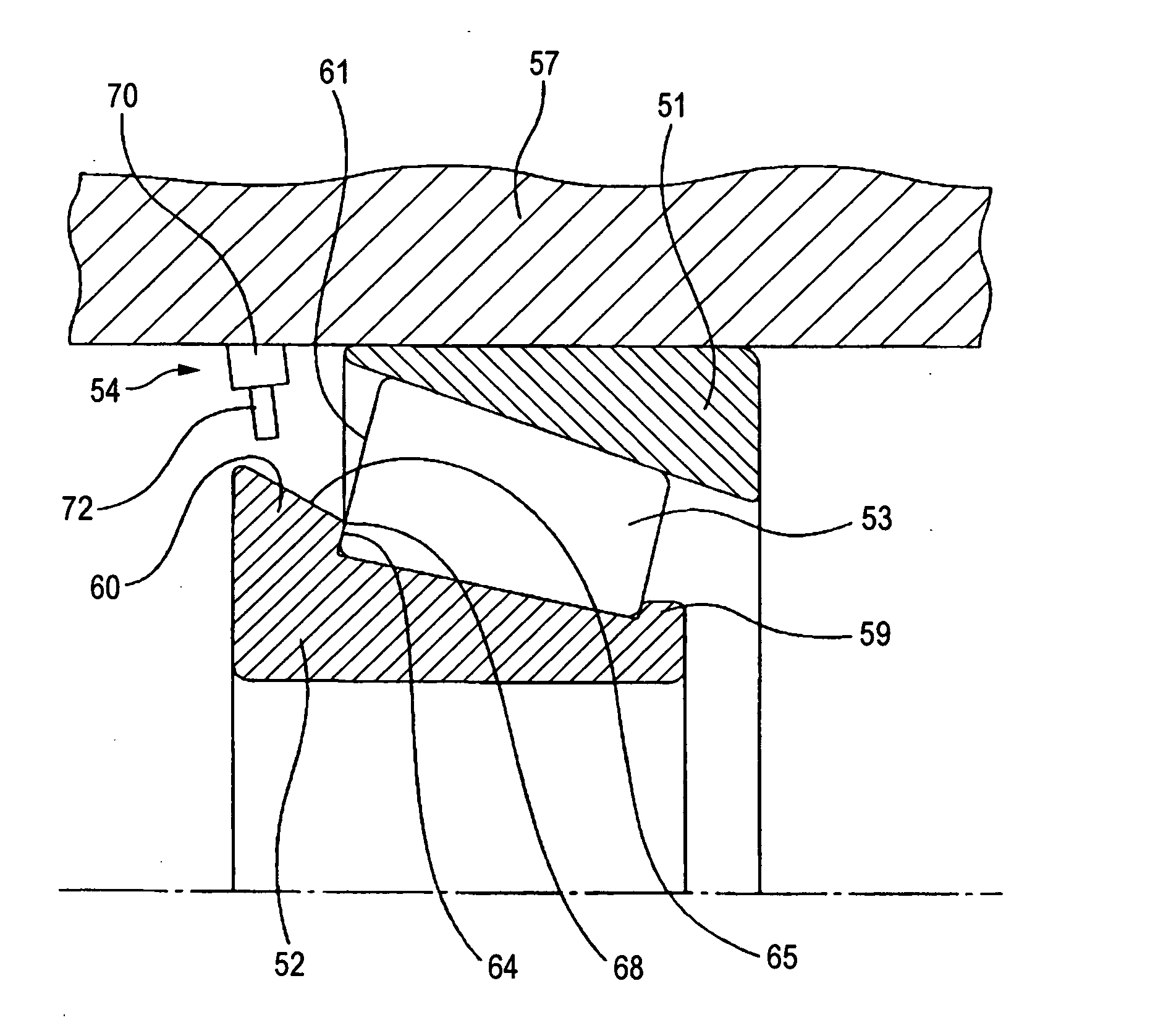

Tapered roller bearing

InactiveUS20080205813A1Decrease torque lossImproved seizure resistanceRolling contact bearingsShaftsCircular coneEngineering

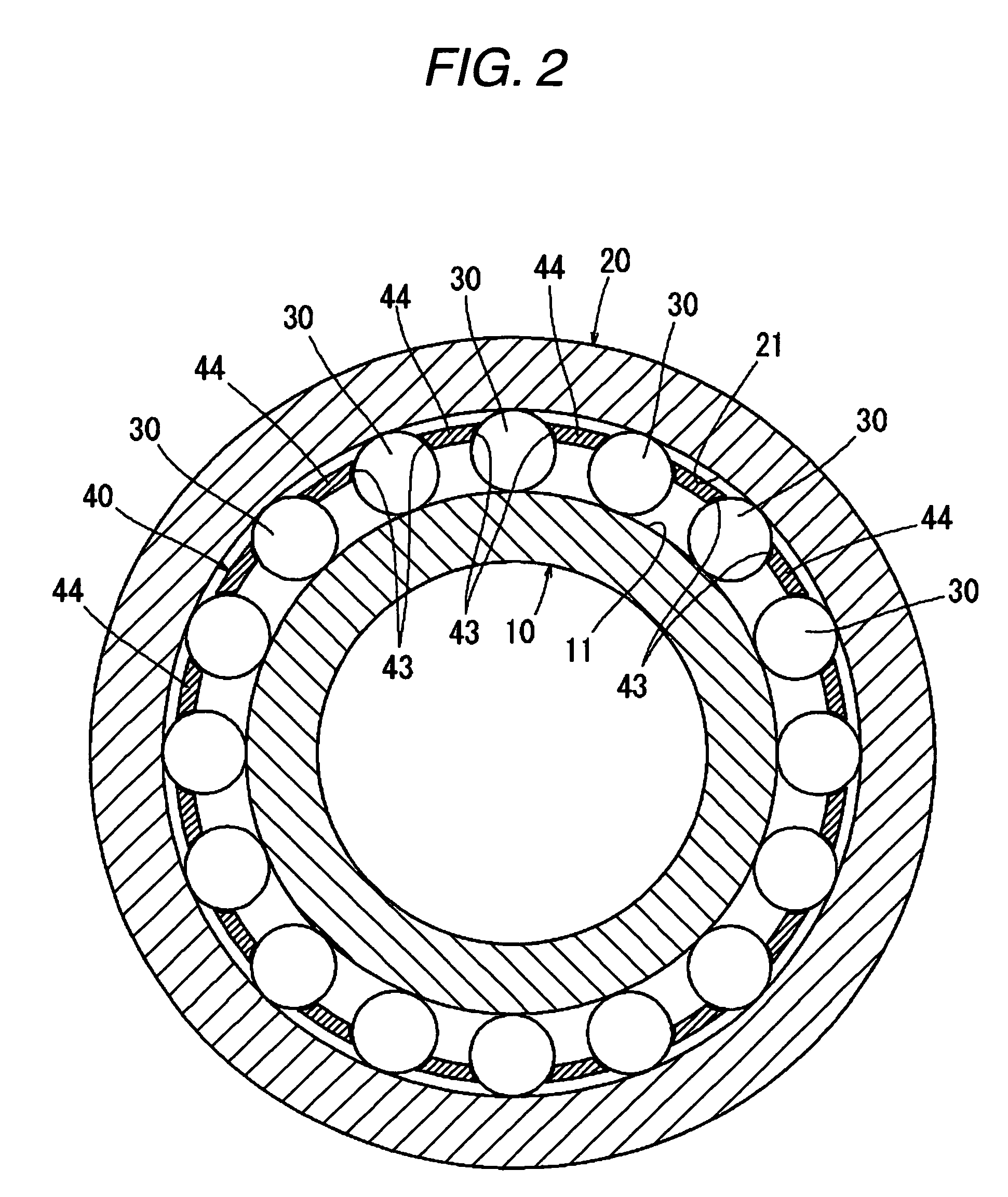

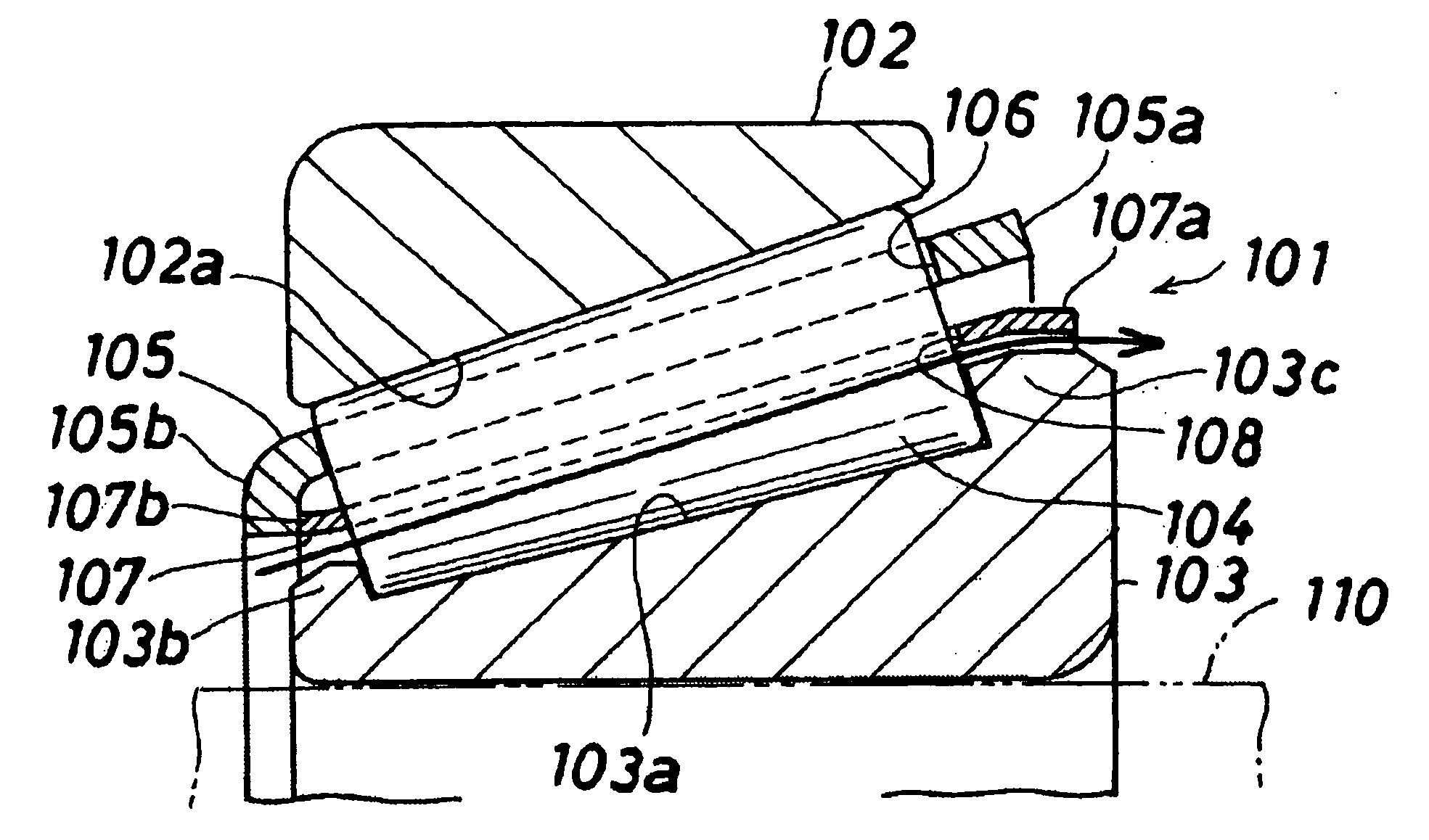

A tapered roller bearing includes an inner ring, an outer ring, a plurality of tapered rollers, and a cage. The cage includes a large diameter-side annular section, a small diameter-side annular section, and pillar sections connecting the large diameter-side annular section and the small diameter-side annular section and forming pockets retaining the tapered rollers. The radially inner surfaces of the pillar sections are disposed closer to the center than a pitch circle of the tapered rollers and are inclined from the small diameter-side annular section toward the large diameter-side annular section, thereby forming guide surfaces that guide lubricating oil toward the large rib. Roller holding portions are formed on side portions of the pillar sections so as to protrude along the outer peripheral surfaces of the tapered rollers to a position located at the outer side in the radial direction than the pitch circle.

Owner:JTEKT CORP

Tapered roller bearing and automotive pinion shaft supporting apparatus utilizing same tapered roller bearing

ActiveUS20070098317A1Reduce rotation lossReduce gear noiseRolling contact bearingsShaftsSurface roughnessEngineering

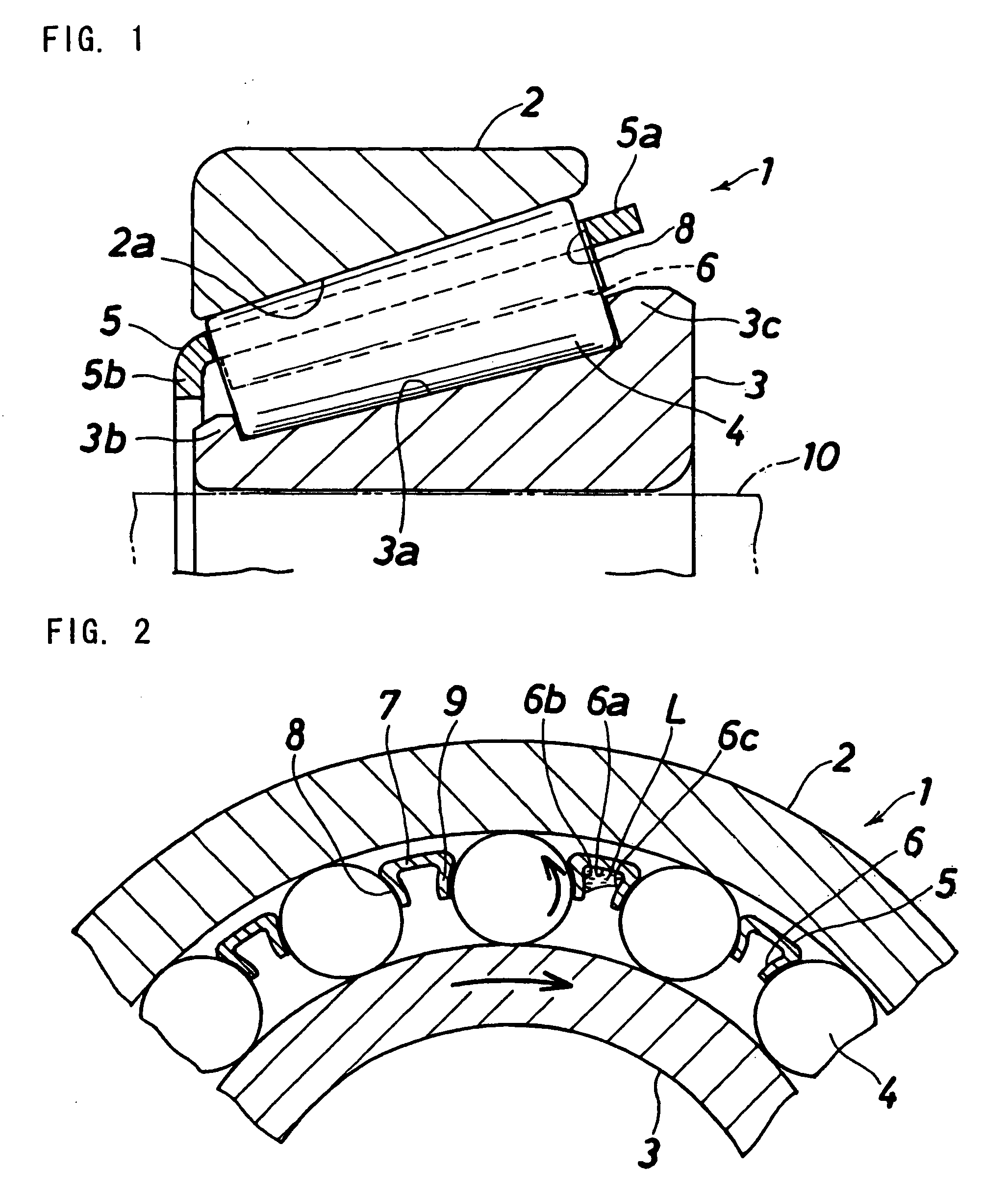

A tapered roller bearing according to the invention is such that when an arithmetical mean roughness as a surface roughness of a large end face of a tapered roller is σ1 and an arithmetical mean roughness as a surface roughness of a large rib surface of an inner ring is σ2, σ1 is 0.04 μm or larger, and a composite roughness that is expressed by a square root of a sum of a squared value of σ1 and a squared value of σ2 is 0.17 μm or smaller. Raceway surfaces of an outer ring and the inner ring and a rolling contact surface of the tapered roller are crowned, and a total crowning amount is set to 50 μm or larger, an outer ring crowning rate is set to 40% or larger, and a roller crowning rate is set to 20% or smaller.

Owner:JTEKT CORP

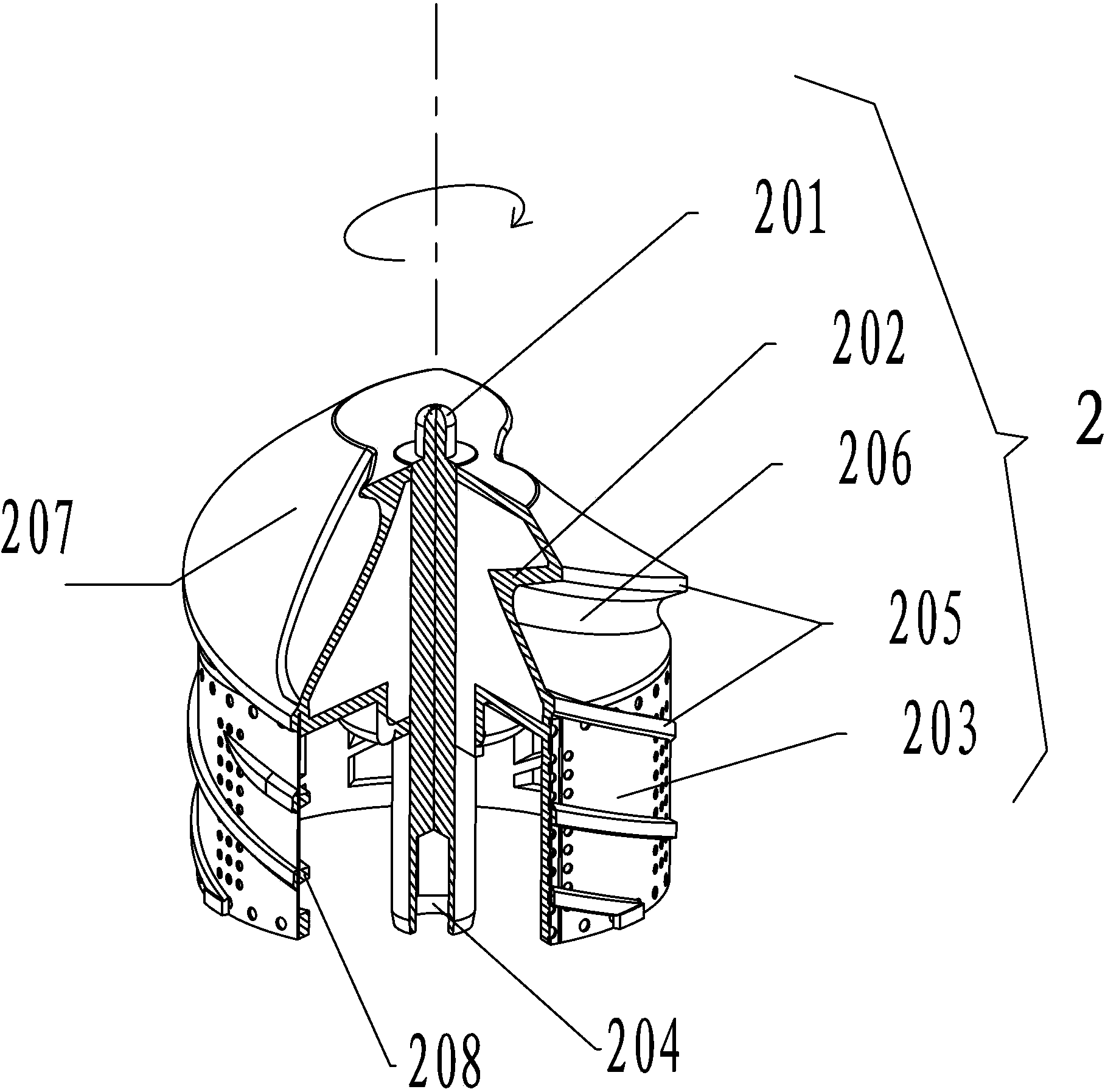

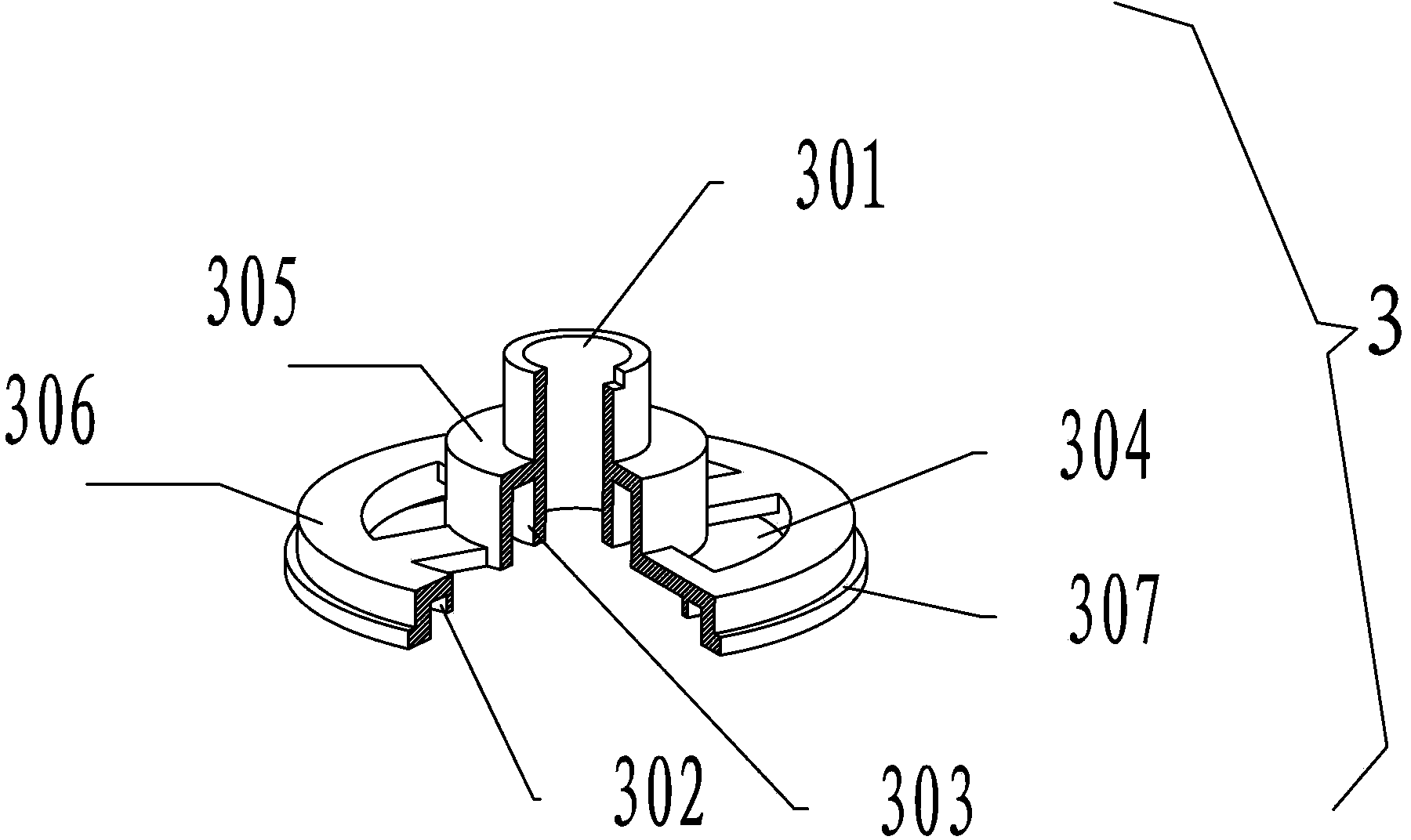

Juice and residue separation mechanism and low-speed juice extractor including same

The invention relates to a juice and residue separation mechanism and a low-speed juice extractor including the same. The juice and residue separation mechanism comprises a juicing cup. A hollow cover suitable for rotating is arranged in the juicing cup in a running fit mode, a filter screen is arranged on the side wall of a hollow cover, spiral ribs used for squeezing materials downwards when the hollow cover rotates are further arranged on the outer side face of the hollow cover, multiple vertical ribs are arranged on the inner side face of the juicing cup, a juice collection tank arranged inside the hollow cover in a matched mode is arranged on the bottom surface of the inner side of the juicing cup, and a residue collection tank arranged outside the hollow cover in a matched mode is arranged on the bottom surface of the inner side of the juicing cup. When the hollow cover rotates, gaps always exist between the vertical ribs and the spiral ribs. The spiral ribs in the juice and residue separation mechanism do not conduct direct contact friction against large ribs or small ribs; meanwhile, the situations that a screw rubs against the filter screen and the filter screen rubs against the inner wall of the juicing cup do not exist; thus, metal powder cannot be generated in the juicing process. Fruit juice is directly separated from fruit residues when fruits are ground.

Owner:JIANGSU SHUNFA ELECTRIC APPLIANCE

Tapered roller bearing, tapered roller bearing apparatus, and automotive pinion shaft supporting apparatus utilizing same tapered roller bearing apparatus

ActiveUS20070041677A1Reduce operating torqueImprove the lubrication effectRoller bearingsShaftsEngineeringPinion

A tapered roller bearing includes an outer ring, an inner ring, a plurality of tapered rollers interposed between the outer ring and the inner ring, and a cage for the tapered rollers. Ra is smaller than Rb where Ra represents a radius of curvature of a large end face of the tapered roller and Rb represents a radius of curvature of an end face of a large rib portion of the inner ring.

Owner:JTEKT CORP

Tapered roller bearing and automotive pinion shaft supporting apparatus utilizing same tapered roller bearing

ActiveUS7874737B2Reduce operating torqueRolling viscous resistanceRolling contact bearingsShaftsSurface roughnessEngineering

A tapered roller bearing according to the invention is such that when an arithmetical mean roughness as a surface roughness of a large end face of a tapered roller is σ1 and an arithmetical mean roughness as a surface roughness of a large rib surface of an inner ring is σ2, σ1 is 0.04 μm or larger, anda composite roughness that is expressed by a square root of a sum of a squared value of σ1 and a squared value of σ2 is 0.17 μm or smaller. Raceway surfaces of an outer ring and the inner ring and a rolling contact surface of the tapered roller are crowned, and a total crowning amount is set to 50 μm or larger, an outer ring crowning rate is set to 40% or larger, and a roller crowning rate is set to 20% or smaller.

Owner:JTEKT CORP

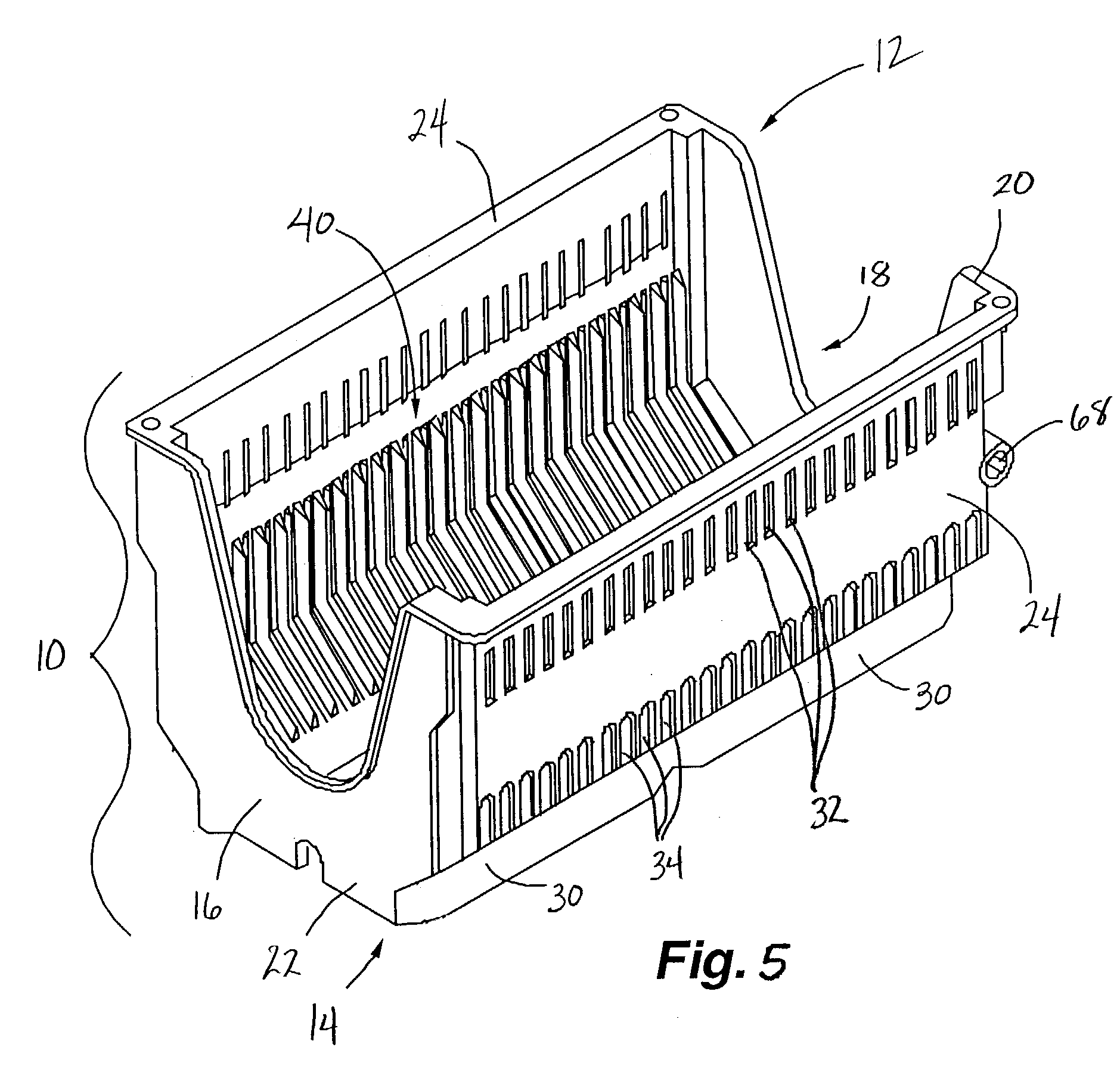

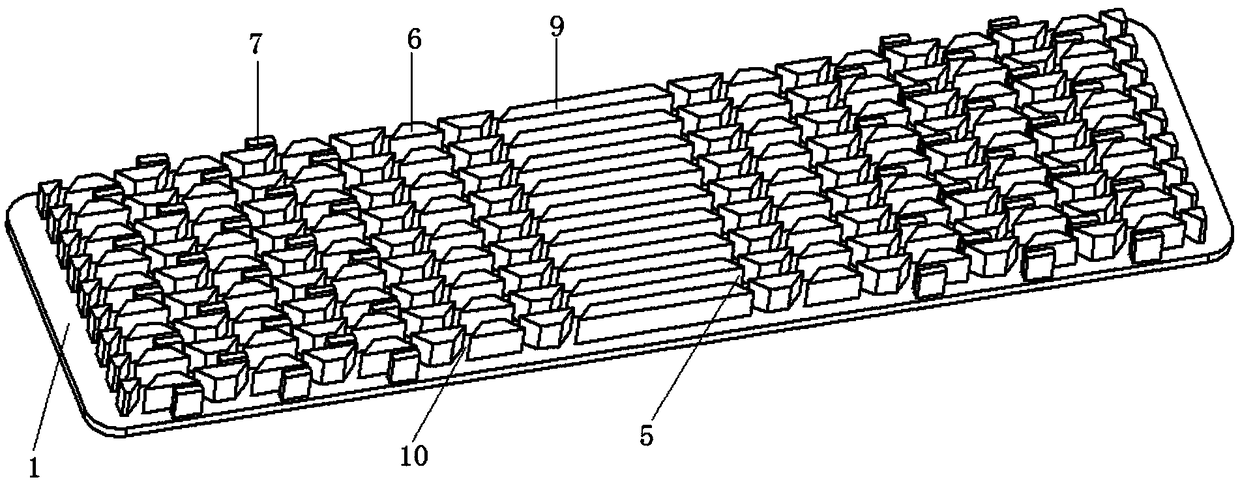

Method for manufacturing single-sided hard memory disks

InactiveUS7168153B2Increase productionReconditioning/cleaning record carriersLayered productsEngineeringMechanical engineering

Various apparatus and methods are provided for positioning and handling single-sided hard memory disks. A disk carrier is provided with ribs formed on the inside surface of opposing side walls. The ribs form disk receiving grooves or channels. The ribs further comprise an alternating pattern of large and small ribs. The large ribs separate pairs of disks from other pairs, the small ribs separate and maintain spacing of the two disks comprising each pair of disks.

Owner:MAXTOR

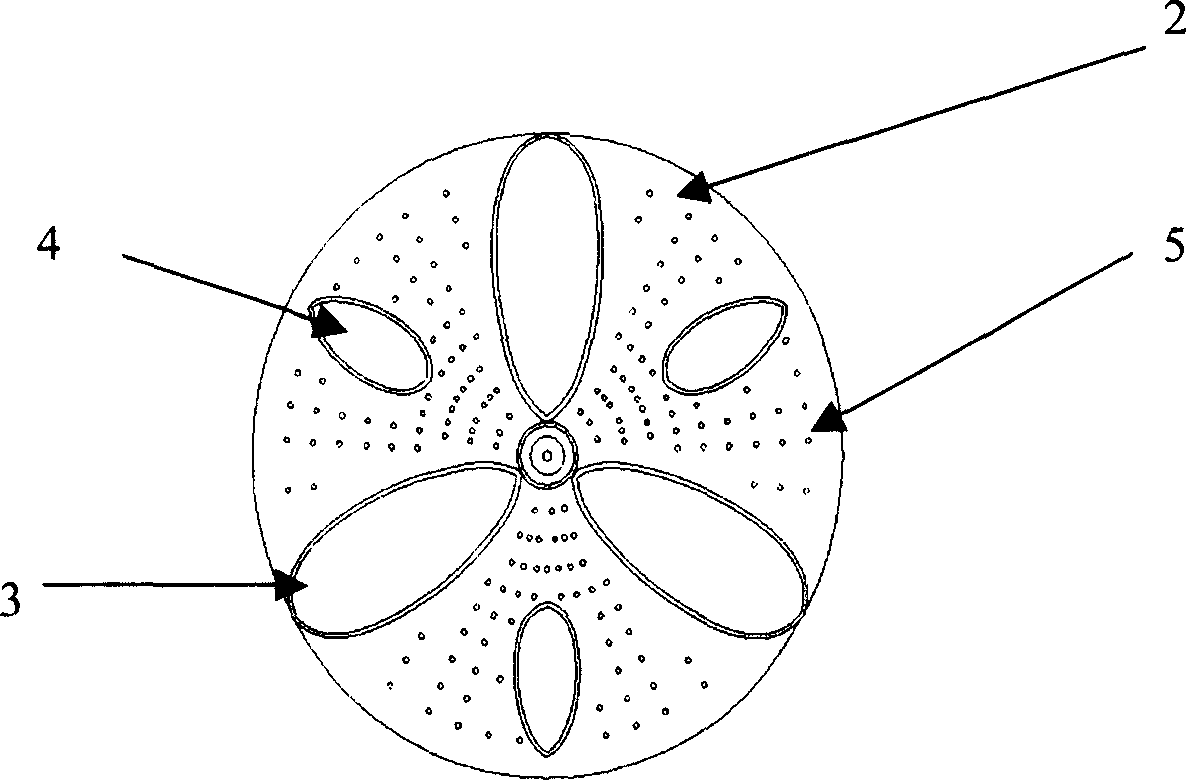

Modified washing machine impeller structure

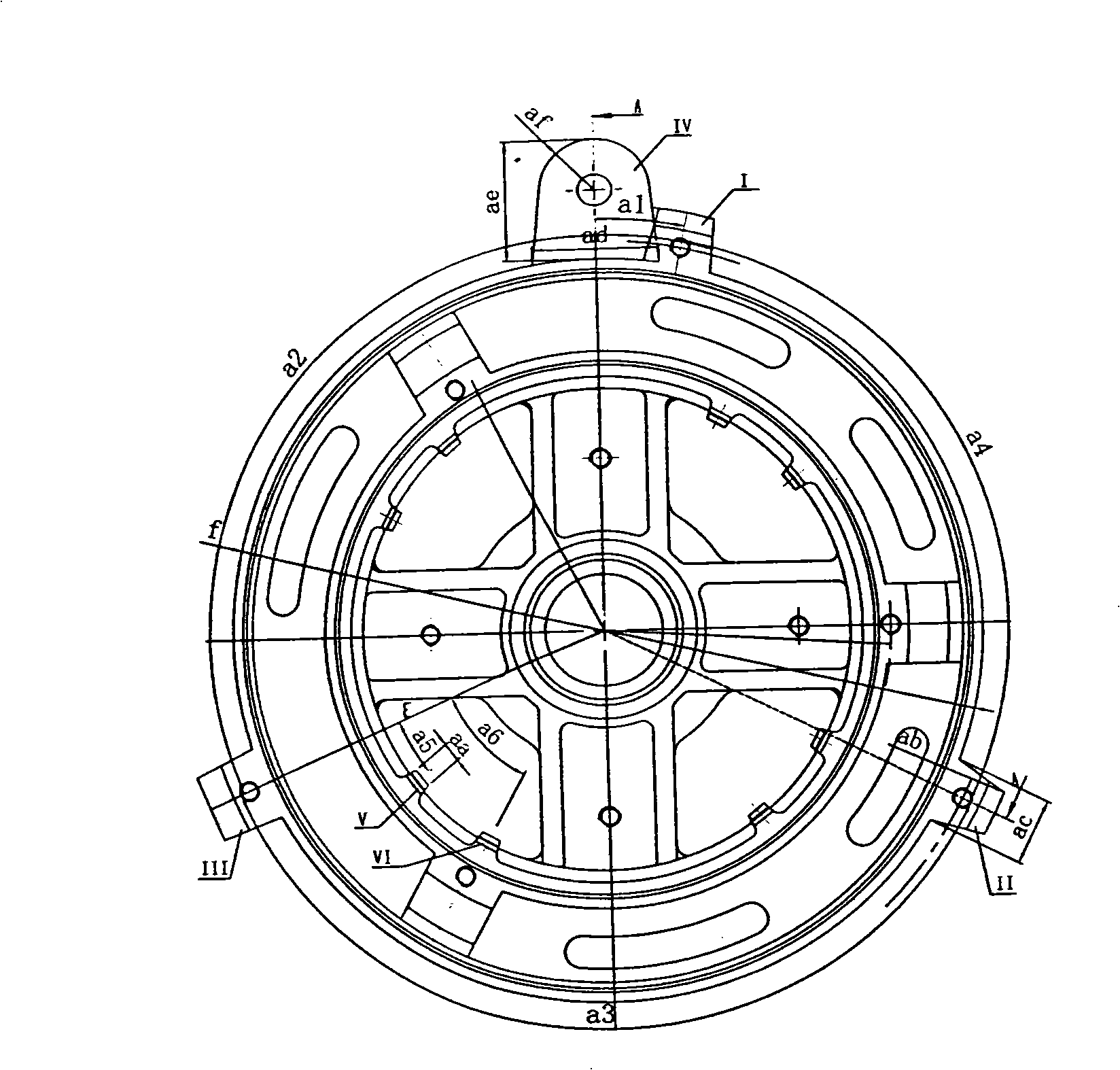

InactiveCN101210367AEasy to shapeHigh densityWashing machine with receptaclesTextiles and paperImpellerWater discharge

An improved wave wheel structure of a washing machine comprises a wave wheel disk surface, and ribs arranged on the wave wheel disk surface and including three relatively larger ribs and three relatively smaller ribs arranged at intervals. Further, water discharge holes are arranged on the wave wheel disk surface. The surface of the relatively larger rib forms an angle of 40 to 50 DEG with the wave wheel disk surface, which is an arc surface forming an angle of 3 to 9 DEG with the horizontal surface. The height of the relatively larger rib is 2 to 3 cm with respect to the wave wheel disk surface. The three relatively larger ribs are uniformly arranged on the wave wheel disk surface radially, and the three relatively smaller ribs are uniformly arranged on the wave wheel disk surface radially. The invention has the advantages of improved wave wheel shape, in particular to the shape of the rib on the wave wheel, to form 3D and optional water flow in the washing process; and improved density of the water discharge holes to prevent clothes from twisting, thus facilitating the improvement in washing effect of the washing machine.

Owner:SUZHOU SAMSUNG ELECTRONICS CO LTD

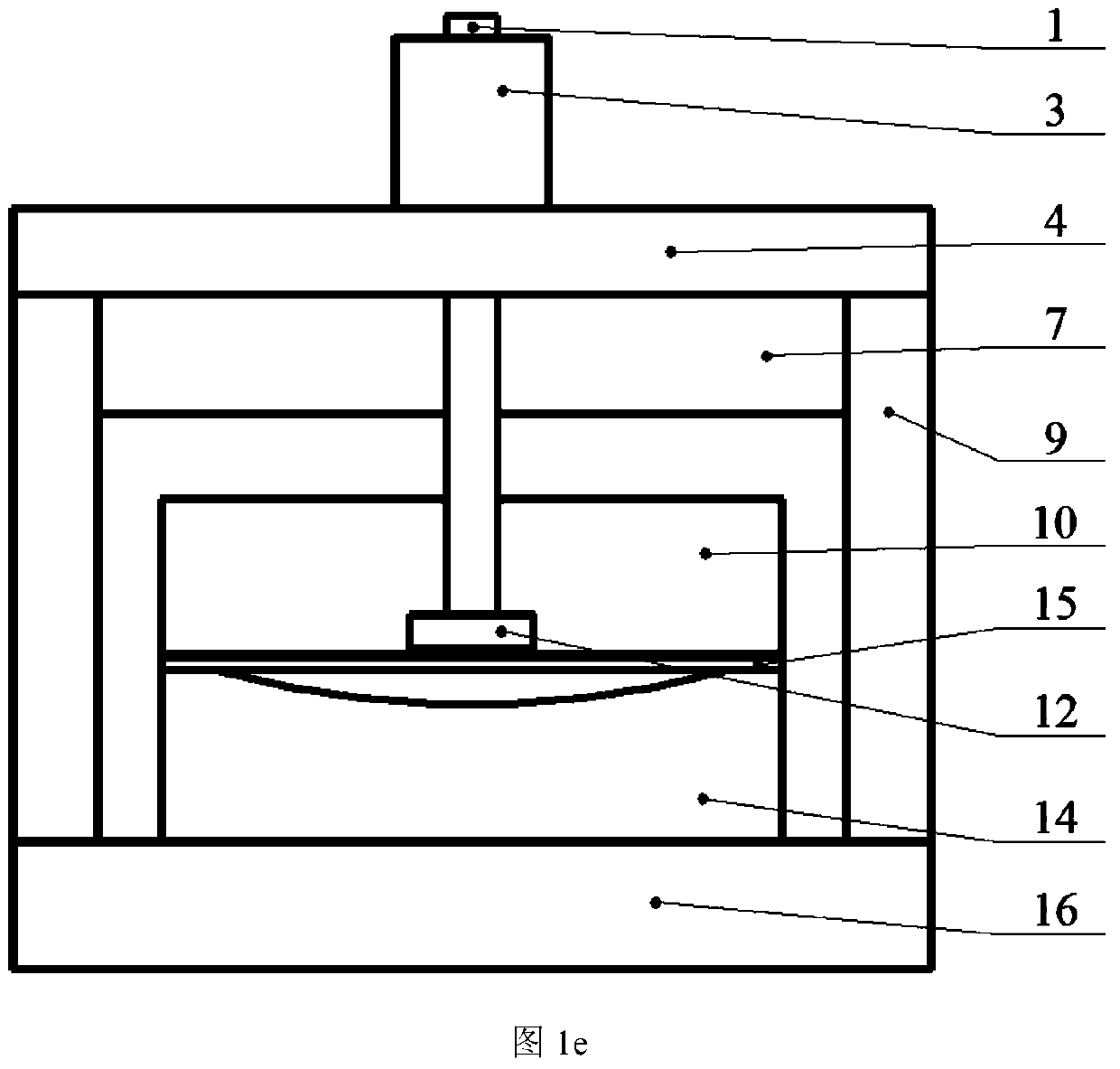

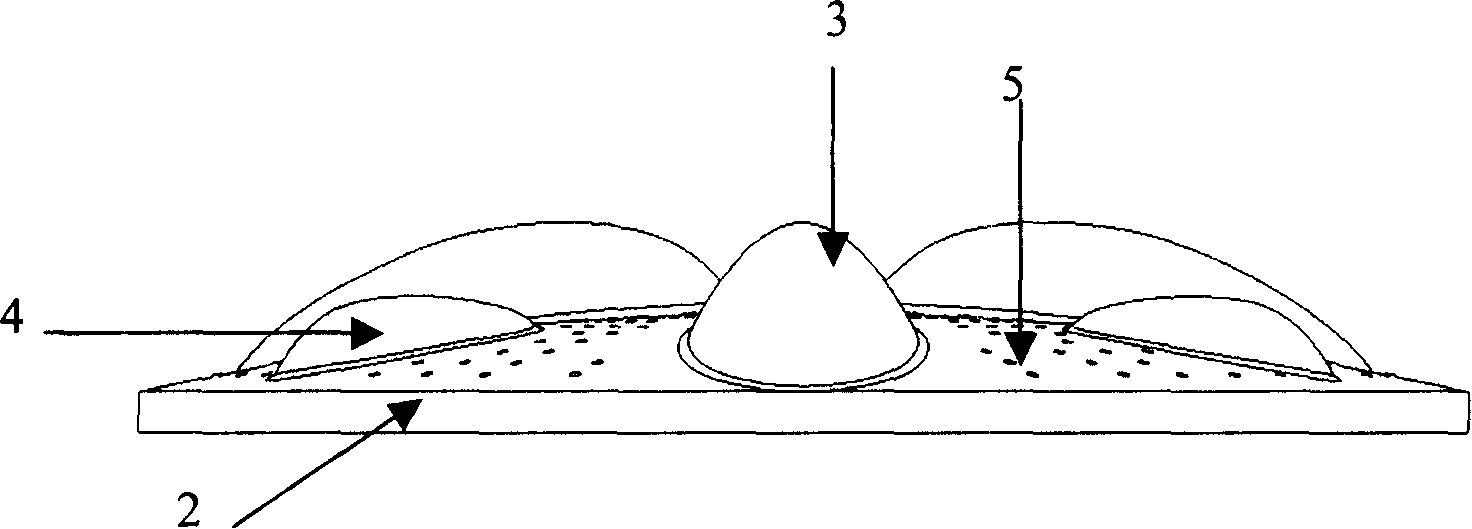

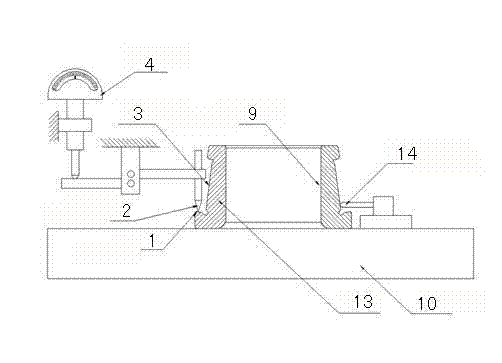

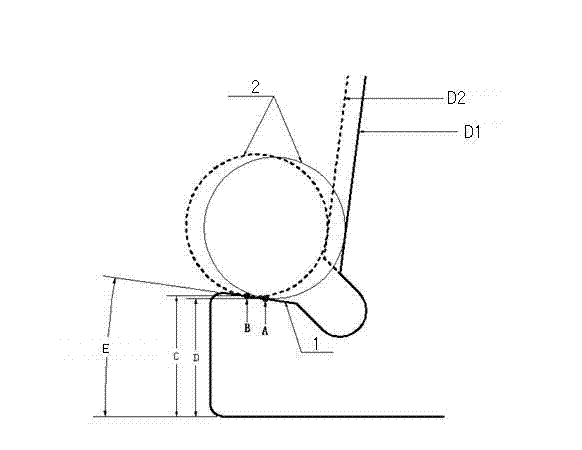

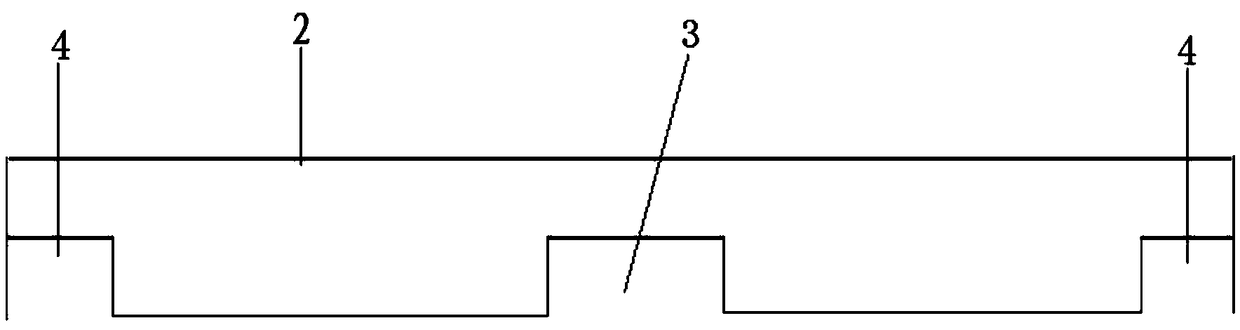

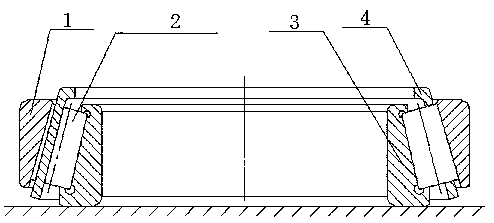

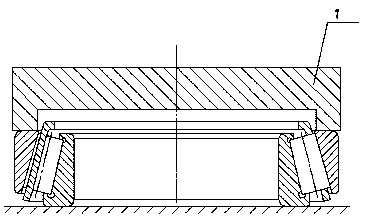

A method and device for measuring the height of the large rib of the inner ring of a tapered roller bearing

ActiveCN102297671AMeasurement advantagesRealize zero error in positioningMeasurement devicesCircular coneEngineering

The invention discloses a method and a device for measuring the height of a large rib of an inner ring of a tapered roller bearing. The invention aims at providing a method and device for measuring the height of a large rib of an inner ring of a tapered roller bearing without measurement and location error of the rib caused by diameter change of a rolling way. In the technical scheme of the measurement method disclosed by the invention, circle centre positioning is adopted for measuring the height of the large rib of the inner ring of the tapered roller bearing. By adopting the circle centre positioning, the measurement and location error of the rib caused by the diameter change of the rolling way can be avoided; the location zero error of the height measurement of the large rib of the tapered bearing is realized; and the measurement precision is increased.

Owner:JM BEARING GRP

A microchannel heat sink with hybrid structure

ActiveCN109149325AEnhanced blendingImprove temperature uniformitySemiconductor lasersLaser cooling arrangementsEngineeringHeat sink

A microchannel heat sink with hybrid structure comprises a heat sink module and a cover plate which are sealingly connected, the cover plate is located above the heat sink module, the cover plate is provided with a plurality of spaced inlets and outlets, A heat sink module includes a substrate and a microchannel heat dissipation structure obtained on the substrate by etching or machining, The micro-channel heat dissipation structure comprises a plurality of fins arranged in parallel, wherein the fins form a micro-channel, the micro-channel is arranged vertically with an inlet and an outlet, asecondary flow channel is arranged on the fins, and a rectangular fin is arranged between the inlet and the outlet; A large rib corresponding to the inlet is arranged on the base below the inlet, andthe length of the large rib is equal to the width of the inlet. The mixed structure heat sink composed of the manifold type, the secondary flow channel and the rectangular fin shortens the flow distance of the coolant in the microchannel, increases the flow space, and enhances the disturbance in the flow process, thereby simultaneously enhancing heat exchange and reducing pressure loss, and further improving the uniformity of the chip temperature.

Owner:TSINGHUA UNIV

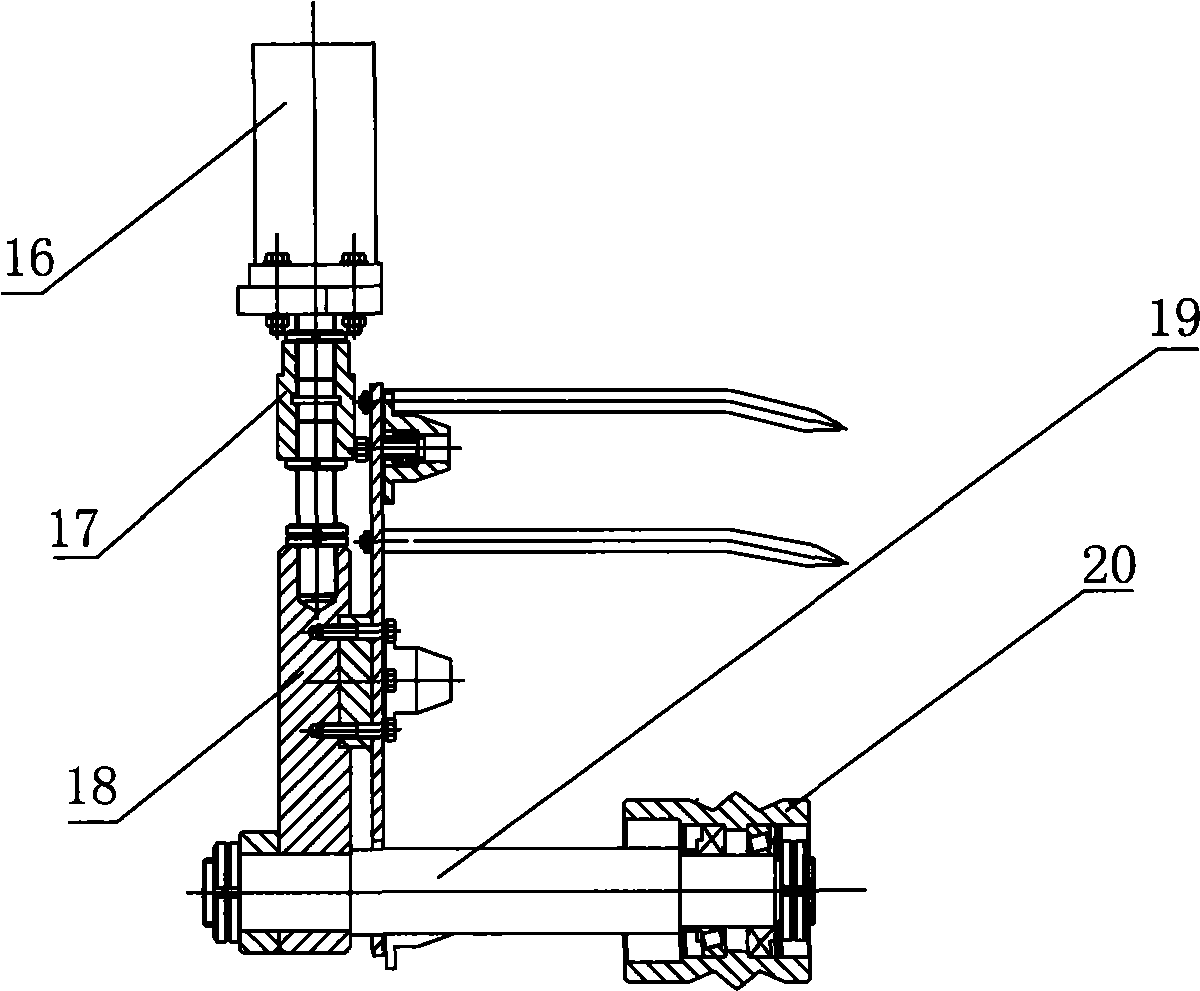

Flexible processing method of ribbed thin-wall large-sized aluminum alloy cylinder

InactiveCN107443023AImplementation of flexible processing methodsConstructions elementsManufacturing cost reductionLarge ribs

The invention provides a flexible processing method of a ribbed thin-wall large-sized aluminum alloy cylinder. According to the method and through the technical processes of punching cylindrical aluminum alloy billets, performing ring rolling, performing axial extrusion, dividing a unit body, performing welding integration and the like, flexible batched production of a series of ribbed thin-wall large-sized aluminum alloy cylinder structural pieces with different diameter can be realized. According to the method, the process, with large rib part machining quanity and long processing cycle, of the thin-wall large-sized aluminum alloy cylinder structural piece in the past is changed, the production efficiency and the stability of the cylindrical pieces are greatly improved, and the manufacturing cost and the development cycle are reduced.

Owner:WUHAN UNIV OF TECH

Vehicle pinion shaft support system

InactiveUS7435008B2Reduce torque valueReduce runningRoller bearingsShaftsSupporting systemSurface layer

There are provided tapered roller bearings which support a pinion shaft. Inner races have large rib faces each having a recessed surface shape on which large-diameter end faces of tapered rollers slide. The surface roughness of the large-diameter end face is σ1 [μmRa] is 0.025 or more. In addition, assuming the surface roughness of the large rib face is σ2 [μmRa], (σ12+σ22)1 / 2 is 0.17 [μmRa] or less. The sliding portion of the large-diameter end face and the sliding portion of the large rib face are made of a carburized steel, and the carbon content in a matrix phase in a surface layer portion of each of the sliding portions to a depth of 50 μm from a surface is 0.8 wt % or more, the surface hardness thereof is in the range of Rockwell C63 to 67, and a surface retained austenite amount is set to be 20% or more and 25% or less.

Owner:JTEKT CORP

Heat exchanger

InactiveCN1776343ANovel and reasonable structureIngenious designTubular elementsEngineeringLarge ribs

The heat exchanger includes pipes of heat exchanger and fins on pipes. Fins on bars arranged in helical shape are setup on excircle surface of pipe. Bar shaped fins includes basal pieces and fins. Fins are vertically installed on basal pieces. Basal pieces enwinds on pipes of heat exchanger in helical shape. Features are: large heat transfer surface area, large rib coefficient and good performance of heat exchange. Features are: smart design, new and reasonable structure

Owner:GUANGDONG MIDEA ELECTRIC APPLIANCES CO LTD

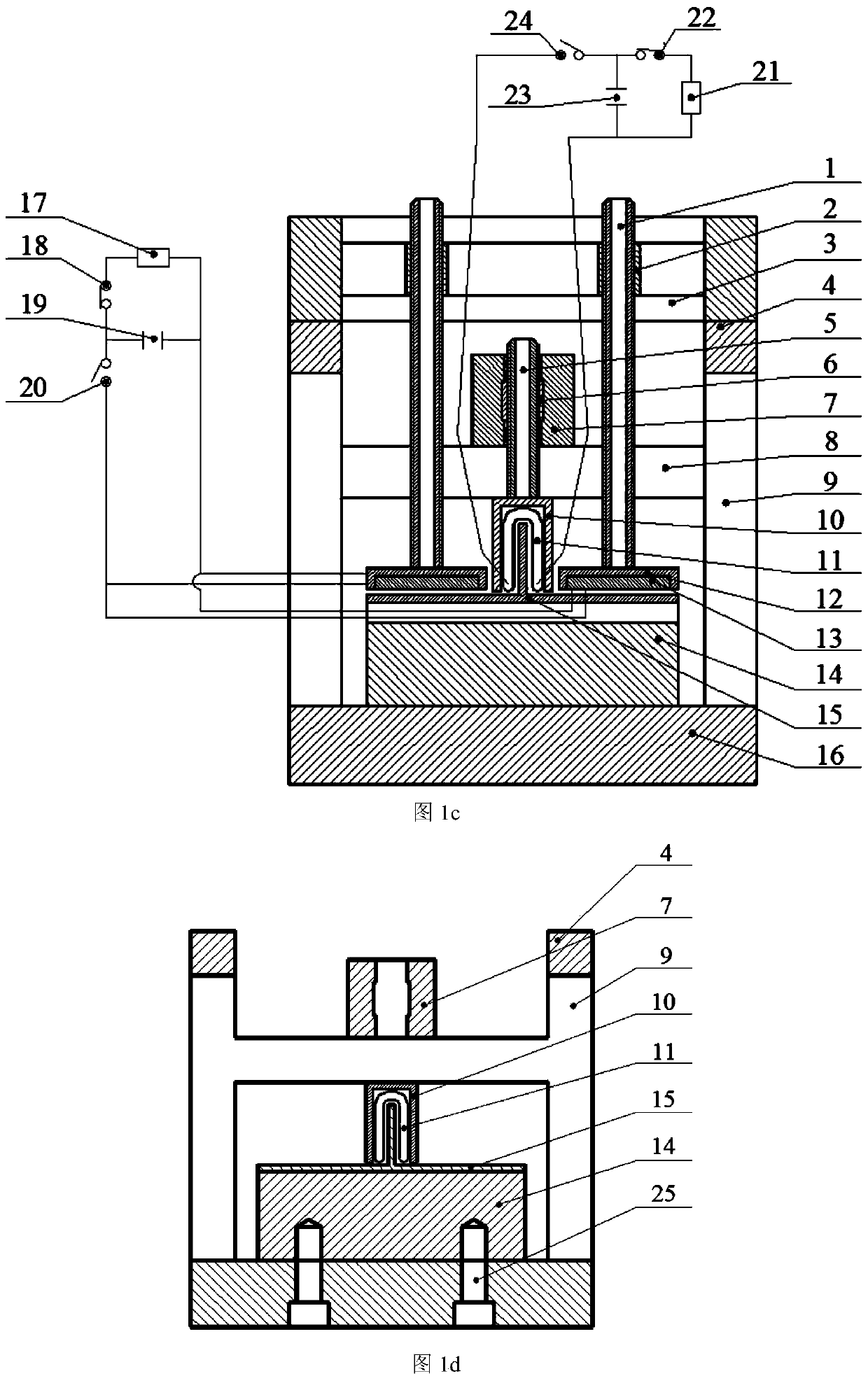

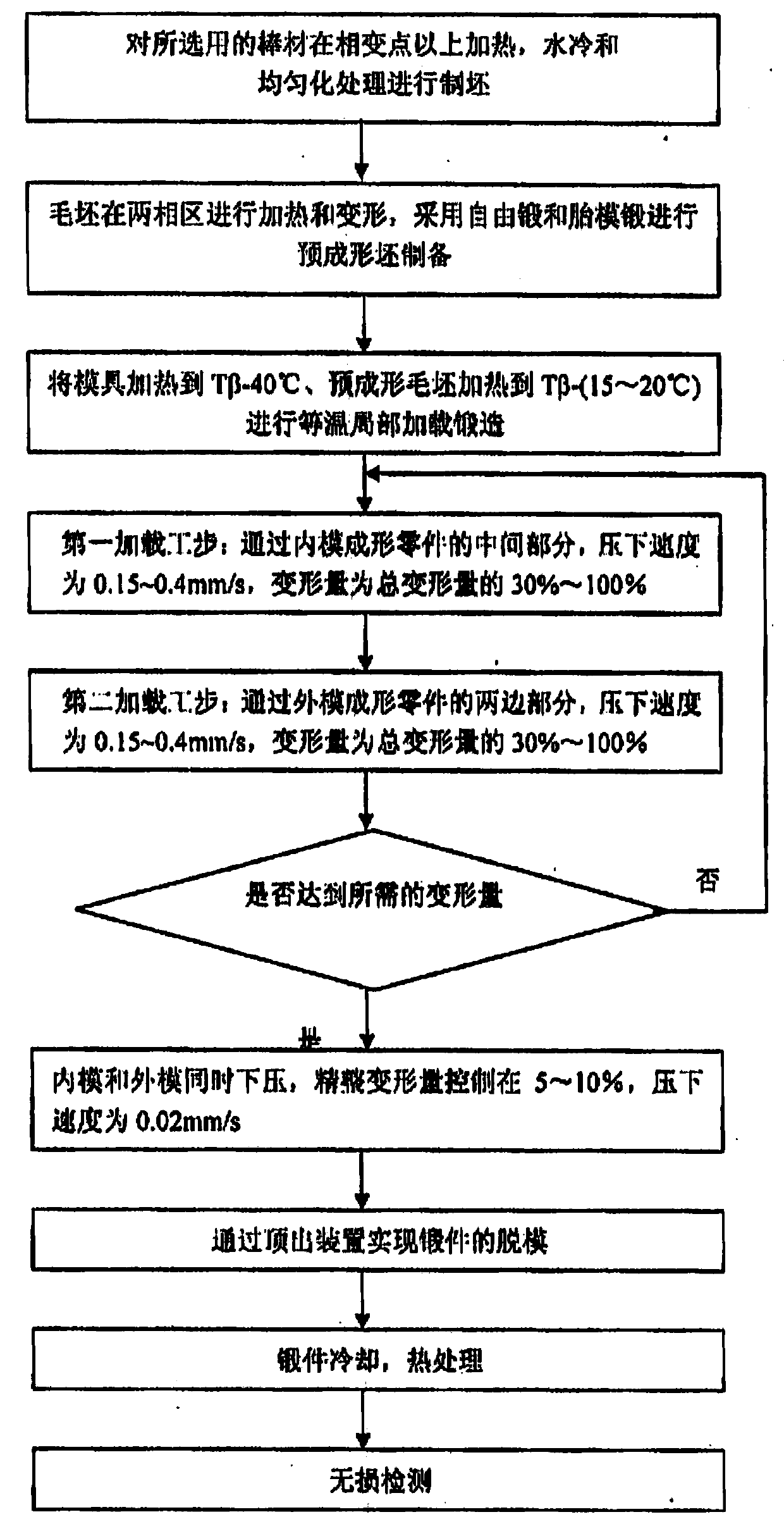

Isothermal Local Loading Forming Method for Complex Integral Members of Titanium Alloy Large Ribbed Plates

InactiveCN106134317BImprove reliabilityIncrease profitMetal-working apparatusComputer moduleTitanium

The invention relates to an isothermal local loading forming method for complex integral components such as large-scale ribbed plates of titanium alloys. An isothermal local loading mold consisting of an inner mold and an outer mold as an upper mold is adopted, and the local loading forming of forgings is realized by controlling the movement of the outer mold and the inner mold. During the loading and forming process, the workpiece can be divided into deformed area and undeformed area in each loading pass, and the tonnage required for the deformation of each partition does not exceed the maximum tonnage of the press used, and the weight of each module is also in the casting within tonnage. In each loading pass, local loading is carried out sequentially on different regions until the total deformation is reached. The invention realizes the overall forming of large and complex titanium alloy components, eliminates welds, improves the reliability of the components, and the metal filling performance and mechanical properties of the formed workpiece are good, avoiding the problems that the large superalloy mold cannot be cast at one time and the quality cannot be guaranteed , Partially loaded sub-modules are separated on the ribs, which reduces defects in the transition zone and leaves burrs on the ribs for subsequent cleaning.

Owner:NORTHWESTERN POLYTECHNICAL UNIV +4

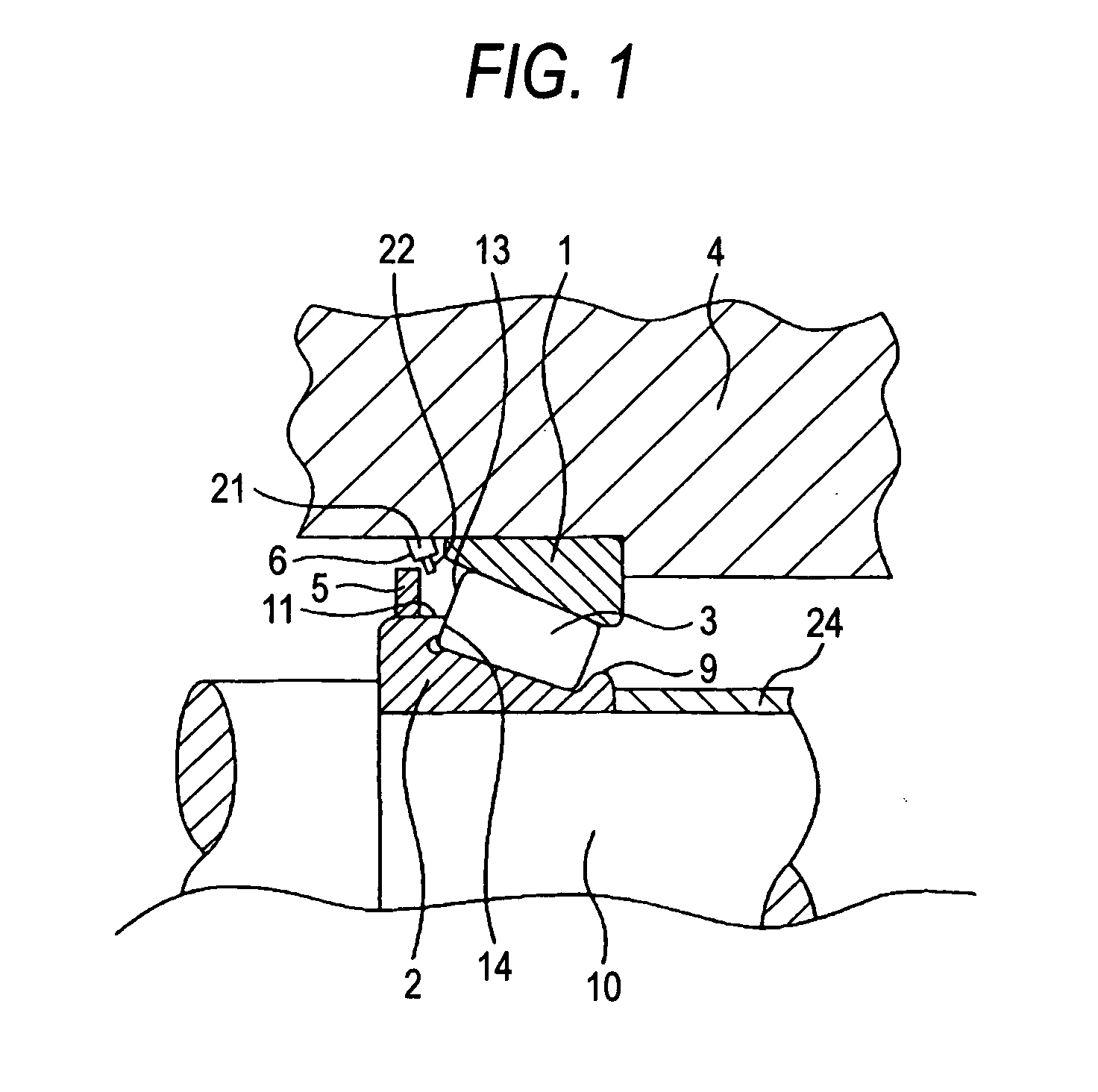

Tapered roller bearing apparatus and hub unit

ActiveUS20090252445A1Ensure sealing performanceAvoid interferenceRolling contact bearingsHubsEngineeringMechanical engineering

A tapered roller bearing apparatus includes: an outer ring that includes an outer-ring raceway formed in an inner circumferential surface thereof; an inner ring which includes a large-diameter portion having a cylindrical portion with a substantially uniform outer diameter, a large rib portion having an outer circumferential surface and a guide surface continued to the outer circumferential surface, an inner-ring raceway, and a small-diameter cylindrical portion which are sequentially formed from one end to the other end, and are subjected to a heat treatment to have a surface-hardened layer; and a plurality of tapered rollers which are rollably disposed between the inner-ring raceway and the outer-ring raceway, a large-diameter end surface of the tapered roller being guided by the guide surface. An angle formed between the guide surface and the outer circumferential surface is obtuse.

Owner:JTEKT CORP

Tapered roller bearing

InactiveUS20090028486A1Low-torque designReduce the amount requiredRolling contact bearingsBearing componentsEngineeringMechanical engineering

Owner:JTEKT CORP

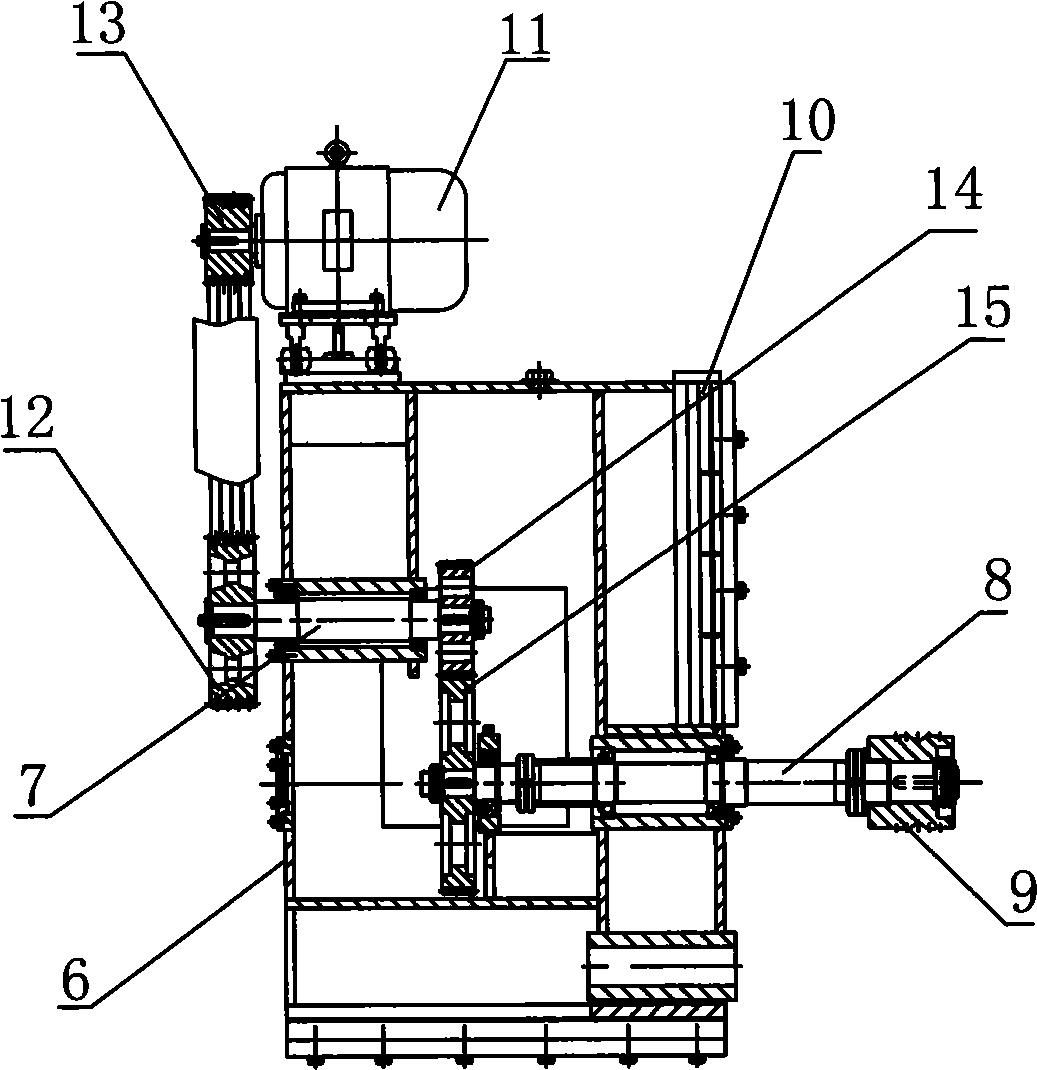

Steel drum W-shaped beading machine

InactiveCN101497091AReduce capacityReduce the maximum outer diameterMetal-working feeding devicesPositioning devicesEngineeringUltimate tensile strength

The invention provides a steel drum W-shaped rib roller with high strength, reasonable structure and convenient transportation. The steel drum W-shaped rib roller comprises a base, a left box body, a right box body, an upper press roll mechanism, an entrust material mechanism, a pneumatic system, a hydraulic system and an electrical system; the base is provided with a guide rail and a lower oil cylinder; the left box body and the right box body comprise box bodies, input shafts, output shafts, lower press rolls, sliding seats and motors; the upper press roll mechanism comprises an upper oil cylinder, an adjusting thread bush, a sliding block, a shaft and an upper press roll; and the entrust material mechanism comprises a rubber roller, a supporting bracket, a supporting seat, a cylinder seat and a cylinder. The steel drum W-shaped rib roller has the advantages that the steel drum W-shaped rib roller has reasonable structure, two W-shaped ring ribs are processed in the middle of a drum body to replace two prior large ribs, and the steel drum W-shaped rib roller reduces the largest outside diameter of a steel drum on the premises of not reducing the strength of the steel drum and reducing the capacity, and greatly facilitates the transportation.

Owner:高邮华兴石油装备有限公司

Vehicle bearing device

InactiveUS20120243818A1Well formedRolling contact bearingsBearing assemblyEngineeringMechanical engineering

In a vehicle bearing device hub spindle, annular first to third grinding undercut portions, each being a recess in sectional view, are formed in the same shape, through turning, at a large-rib-surface-side end portion of an inner raceway surface, a large-diameter-portion-side end portion of the inner raceway surface, and a large-diameter-portion-side end portion of an outer peripheral surface of an intermediate-diameter portion.

Owner:JTEKT CORP

Tapered roller bearing, tapered roller bearing apparatus, and automotive pinion shaft supporting apparatus utilizing same tapered roller bearing apparatus

ActiveUS20070041676A1Reduce operating torqueRolling contact bearingsShaftsMean diameterEffective length

Owner:JTEKT CORP

Tapered roller bearing device

InactiveUS20080089632A1Sliding surface can be decreasedAvoid seizuresRoller bearingsBearing componentsEngineeringMechanical engineering

Owner:JTEKT CORP

Method for detecting surface contact area between inner ring of tapered roller bearing and roller ball base

ActiveCN110231172AAccurate detectionAccurate judgmentMachine bearings testingNeedle roller bearingWear resistant

The invention proposes a method for detecting a surface contact area between an inner ring of a tapered roller bearing and a roller ball base. The method comprises the following steps of using high-strength wear-resistant cloth coated with milled micro powder as abrasive cloth; selecting three standard tapered rollers and rotating ball bases of the three standard tapered rollers on the abrasive cloth for 1 to 2 cycles; placing the small end face of a holding frame on a workbench downwards, uniformly distributing big end faces of the three standard tapered rollers bonded with the milled micro powder in a window hole of the holding frame upwards, placing the small end face of the inner ring of the tapered roller bearing in the holding frame downwards, forming an inner component having only three tapered rollers, then reversing the inner component, pressing the outer ring of the tapered roller on the rollers, and rotating the outer ring for milling; and enabling the three standard taperedrollers bonded with the milled micro powder to rub against the inner ring. The method provided by the invention solves the measurement problem that the large rib of the inner ring of the tapered roller bearing contacts with the roller ball base in an inner ring large rib contact area.

Owner:LUOYANG LYC BEARING +1

Vehicle pinion shaft support system

InactiveUS20060133710A1Reduce torque valueReduce runningRoller bearingsShaftsSupporting systemSurface layer

There are provided tapered roller bearings which support a pinion shaft. Inner races have large rib faces each having a recessed surface shape on which large-diameter end faces of tapered rollers slide. The surface roughness of the large-diameter end face is σ1 [μmRa] is 0.025 or more. In addition, assuming the surface roughness of the large rib face is σ2 [μmRa], (σ12+σ22)1 / 2 is 0.17 [μmRa] or less. The sliding portion of the large-diameter end face and the sliding portion of the large rib face are made of a carburized steel, and the carbon content in a matrix phase in a surface layer portion of each of the sliding portions to a depth of 50 μm from a surface is 0.8 wt % or more, the surface hardness thereof is in the range of Rockwell C63 to 67, and a surface retained austenite amount is set to be 20% or more and 25% or less.

Owner:JTEKT CORP

Industrial sartorius electromotor shell

ActiveCN101267135AReduce weightSmall fuselage structureSupports/enclosures/casingsHollow cylinderLarge ribs

The present invention provides a motor casing of an industrial sewing machine, the whole structure of the motor casing is directly casting forming, being two hollow cylinders, one segment is a larger cylinder, the other segment is a small cylinder, the outer surface of the small cylinder is distributed with a plurality of small ribs, the inner wall is distributed with a plurality of large ribs, one end of the small cylinder is a base, forming cross close, the center of the base has a circular cone which is protruding inwards. The advantages of the invention is smaller body, adopting 6202 bearing, not only saving raw material, but also achieving output power of the same motor, further easing the weight of the motor, reducing the cost at the same time.

Owner:麦德添

Tapered roller bearing apparatus and hub unit

ActiveUS9051964B2Avoid crackingEnsure sealing performanceRoller bearingsHubsEngineeringMechanical engineering

A tapered roller bearing apparatus includes: an outer ring that includes an outer-ring raceway formed in an inner circumferential surface thereof; an inner ring which includes a large-diameter portion having a cylindrical portion with a substantially uniform outer diameter, a large rib portion having an outer circumferential surface and a guide surface continued to the outer circumferential surface, an inner-ring raceway, and a small-diameter cylindrical portion which are sequentially formed from one end to the other end, and are subjected to a heat treatment to have a surface-hardened layer; and a plurality of tapered rollers which are rollably disposed between the inner-ring raceway and the outer-ring raceway, a large-diameter end surface of the tapered roller being guided by the guide surface. An angle formed between the guide surface and the outer circumferential surface is obtuse.

Owner:JTEKT CORP

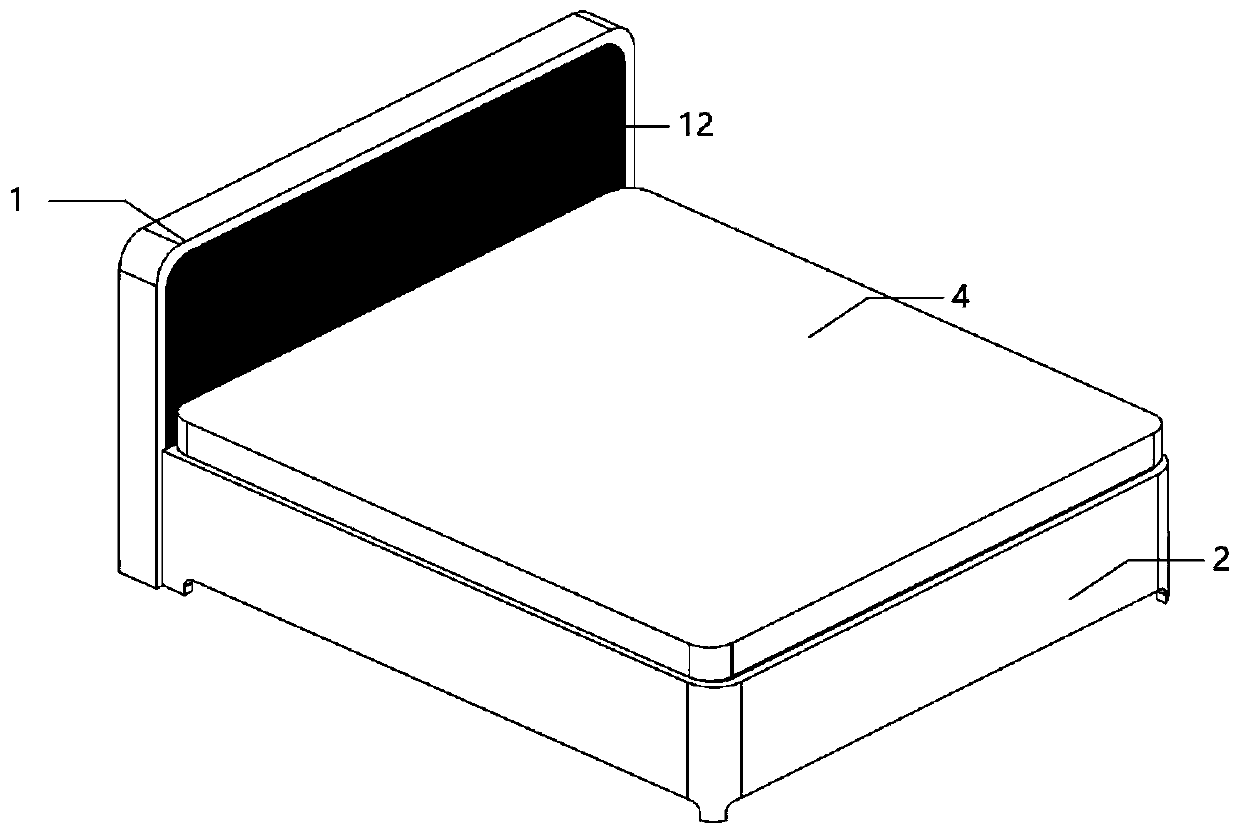

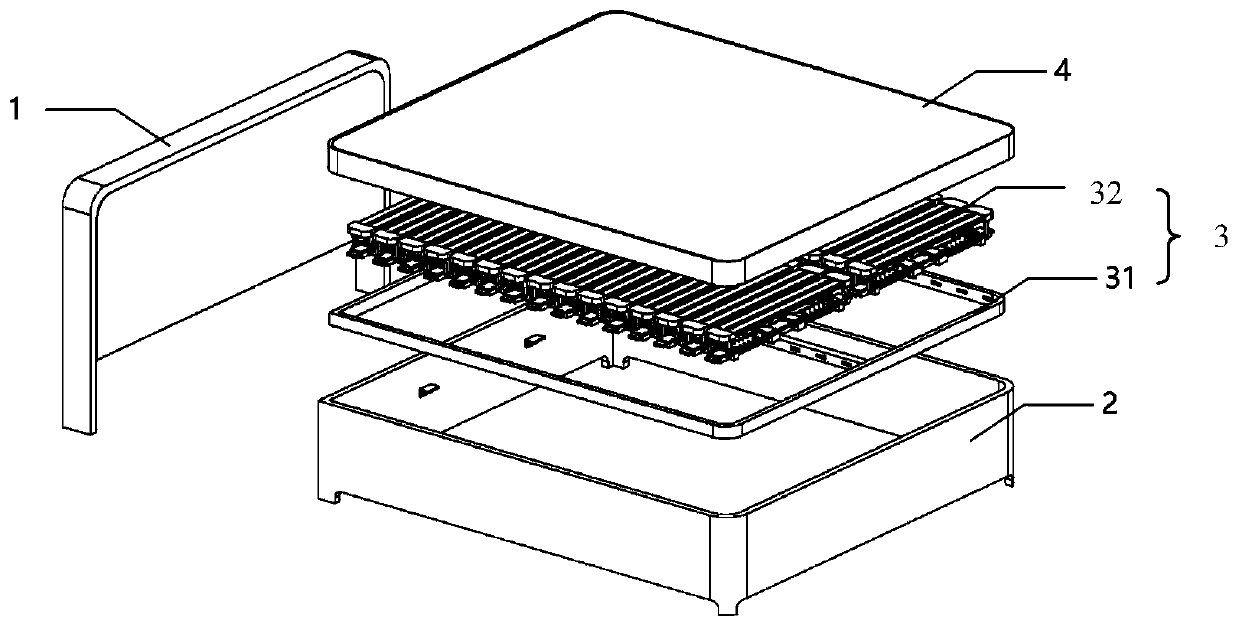

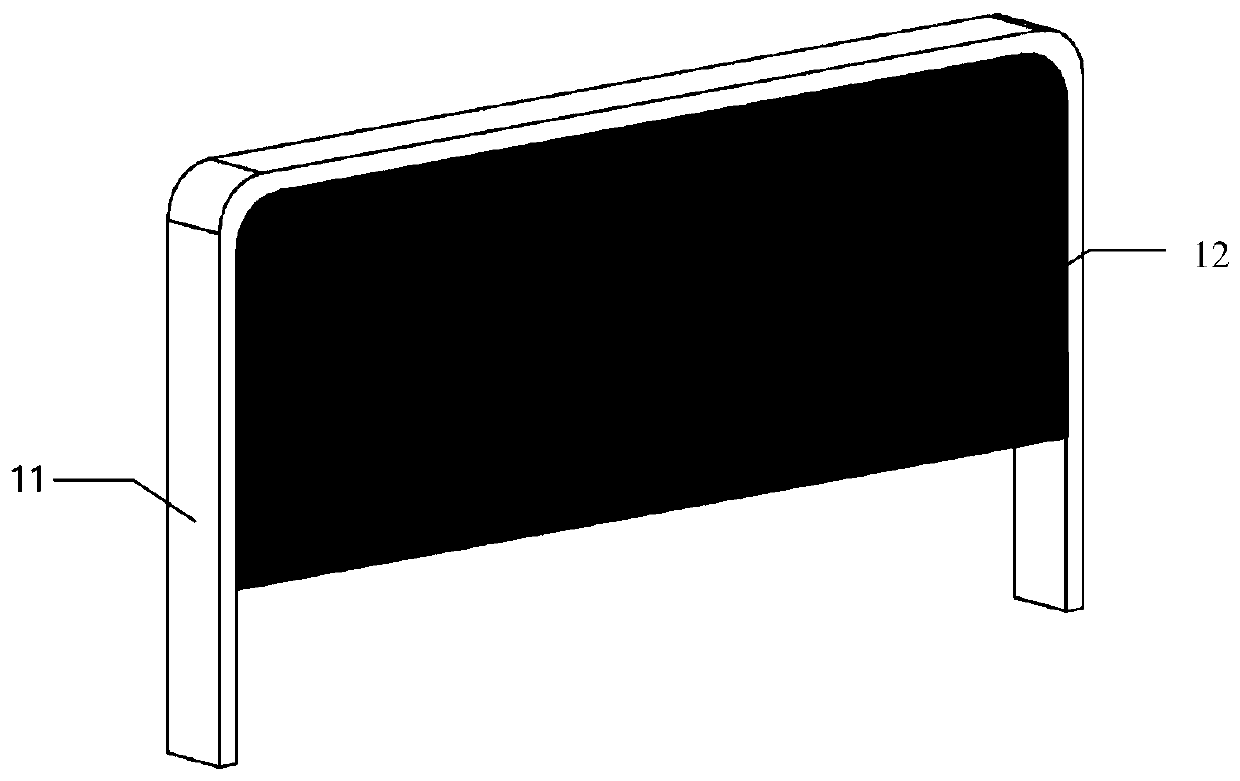

Full-bamboo functional bed capable of adjusting hardness

PendingCN110664161AAdjust softnessOvercome limitationsStuffed mattressesSpring mattressesLarge ribsBody frame

The invention discloses a full-bamboo functional bed capable of adjusting hardness, a bed screen is fixed at one end of a bed frame, and a main body frame structure of the bed frame and the bed screenis made of bamboo; the bed frame is cooperatively provided with a rib frame and a mattress in sequence from bottom to top; the rib frame comprises a support frame and a plurality of rib strips mounted in the support frame; each rib strip comprises two or three layers of bamboo shrapnel, two metal sleeves sleeved at the two ends of the two or three layers of bamboo shrapnel and a hardness adjusting device connected to the bottoms of the two metal sleeves, and the hardness adjusting device is used for pressure regulation when the surfaces of the two or three layers of bamboo shrapnel are stressed. According to the full-bamboo functional bed capable of adjusting the hardness in the invention, a metal scale ruler is arranged on a rib frame base, as a scale for quantitative adjustment of the hardness of the rib frame, the more sliding blocks are adjusted to the two sides, the larger the scale is, and the larger the hardness of the rib frame is; and the hardness of each area of the bed surface can be adjusted and controlled in a quantitative manner, and the requirements for supporting various parts of crowds in different body types and weight are met.

Owner:ANHUI AGRICULTURAL UNIVERSITY

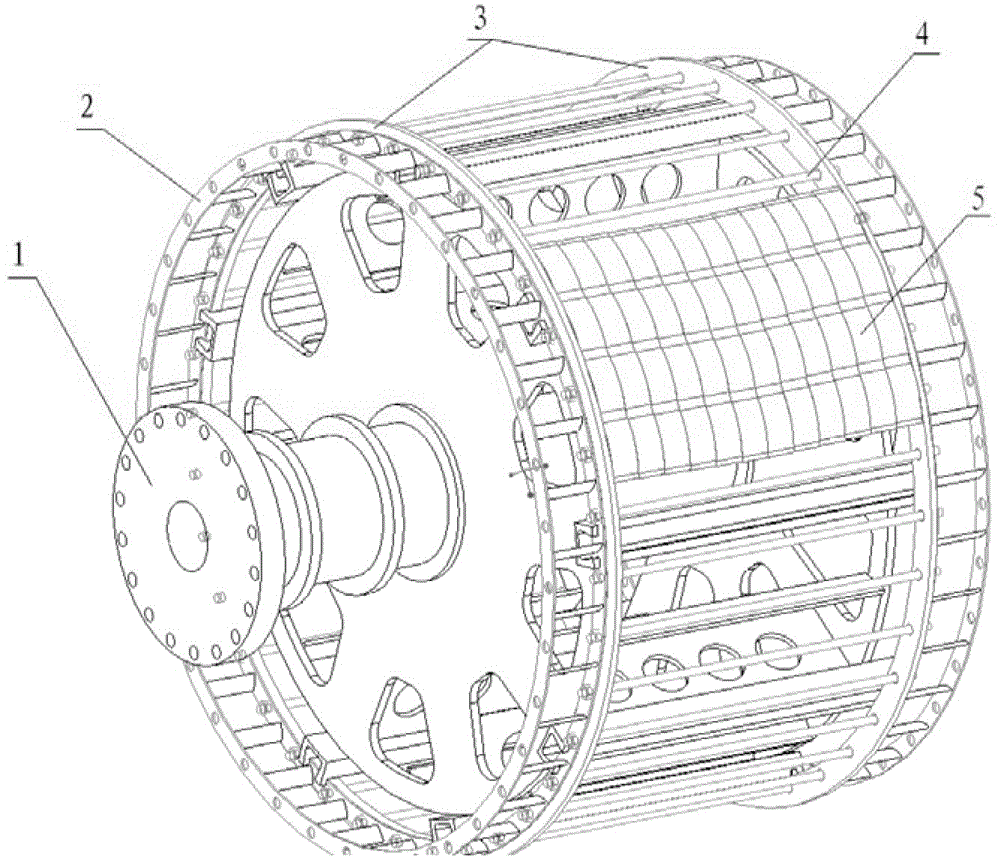

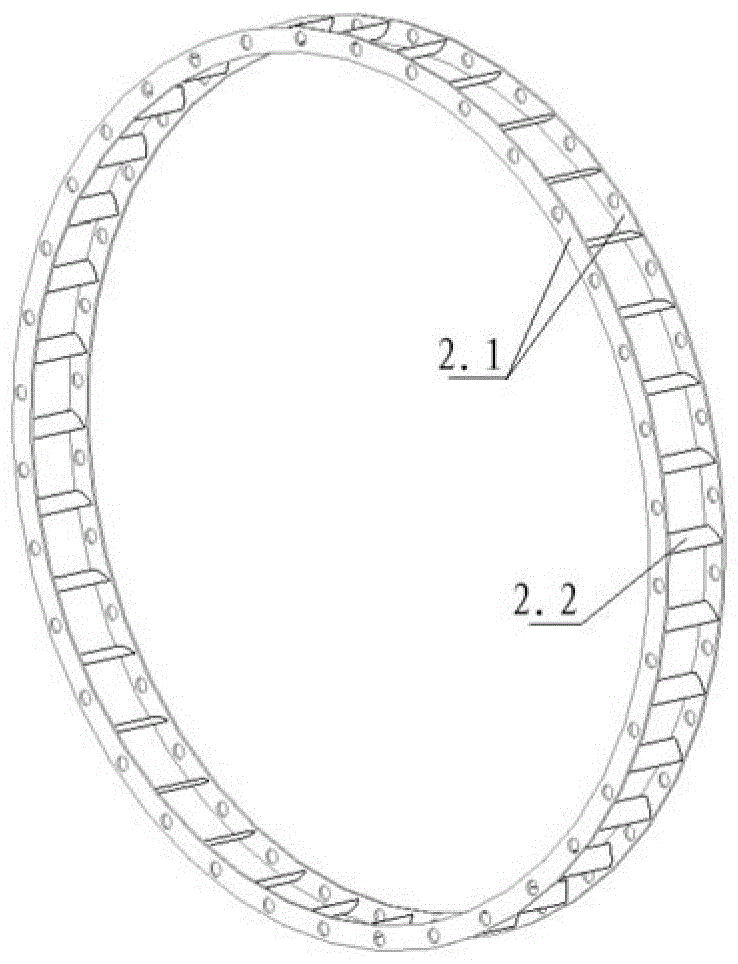

Novel marine propulsion motor

ActiveCN106160312AIncreased torque densityLarge ribs and low torque densitySupports/enclosures/casingsMarine propulsionTorque density

The invention discloses a novel marine propulsion motor. The novel marine propulsion motor comprises a stator and a rotor. The rotor comprises a rotating shaft support and a rotor iron core; the rotating shaft support comprises a hollow core shaft, a driving-end ring plate and a non-driving-end ring plate, wherein the driving-end ring plate and the non-driving-end ring plate are arranged on the external circumference of the core shaft, a plurality of iron-core bench supports are arranged on the external circumference of the driving-end ring plate and the external circumference of the non-driving-end ring plate, large rib plates are arranged between the core shaft and the iron core bench supports, a plurality of small rib plates are arranged between the inner side of the external circumference of the driving-end ring plate and the inner side of the external circumference of the non-driving-end ring plate, rotor iron core pressing rings are arranged at the two ends of the iron core bench supports respectively, and the rotor iron core is fixed between the two rotor iron core pressing rings. According to the novel marine propulsion motor, technology manufacturing of the rotating shaft is simple, the production cost is reduced, and the manufacturing period is shortened; meanwhile, the quality and the rotational inertia of the motor are reduced, and the torque density of the motor is increased.

Owner:中国船舶重工集团公司第七一二研究所

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com