Patents

Literature

242results about How to "Enhanced blending" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

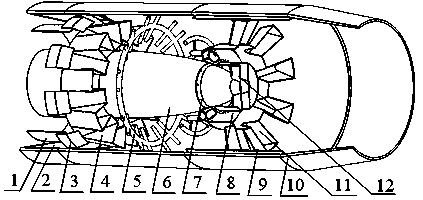

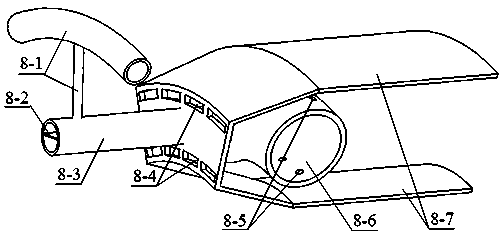

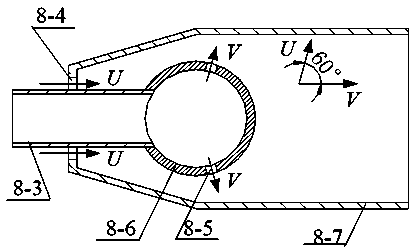

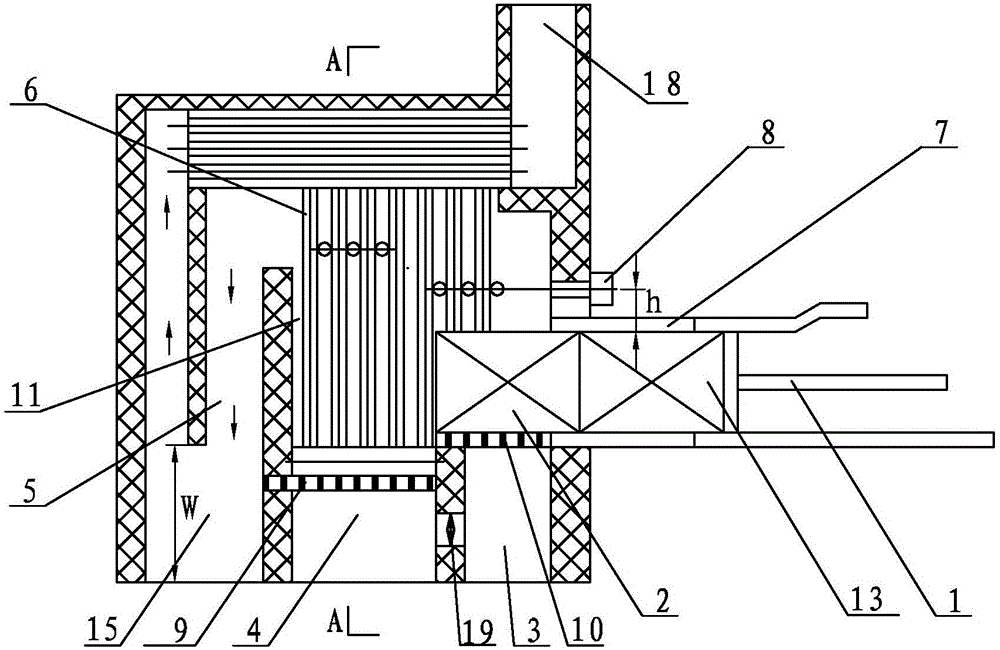

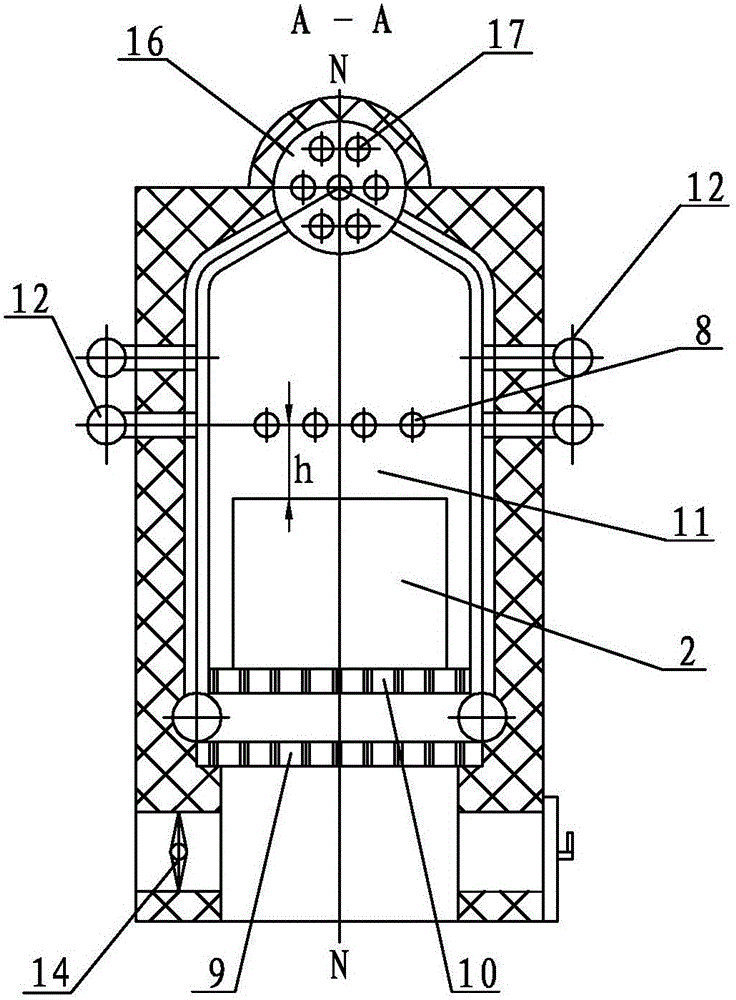

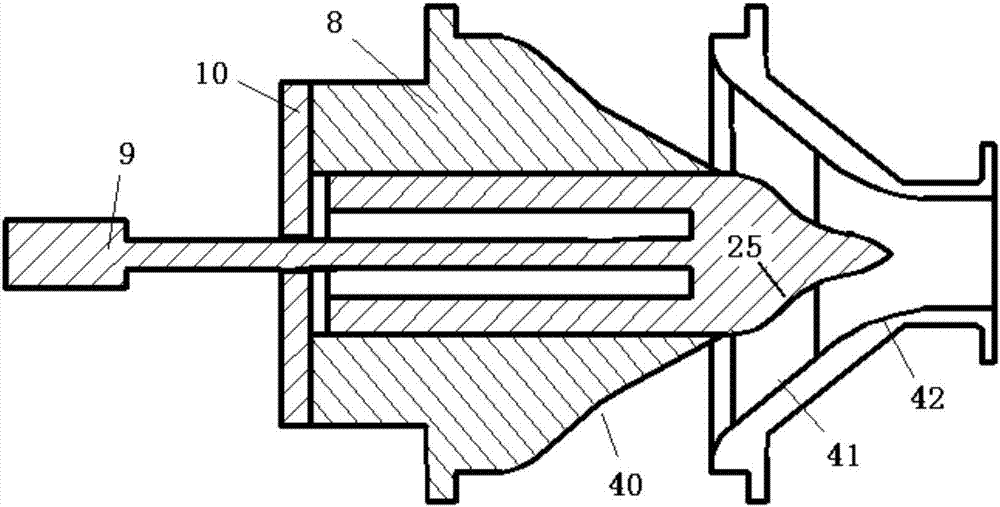

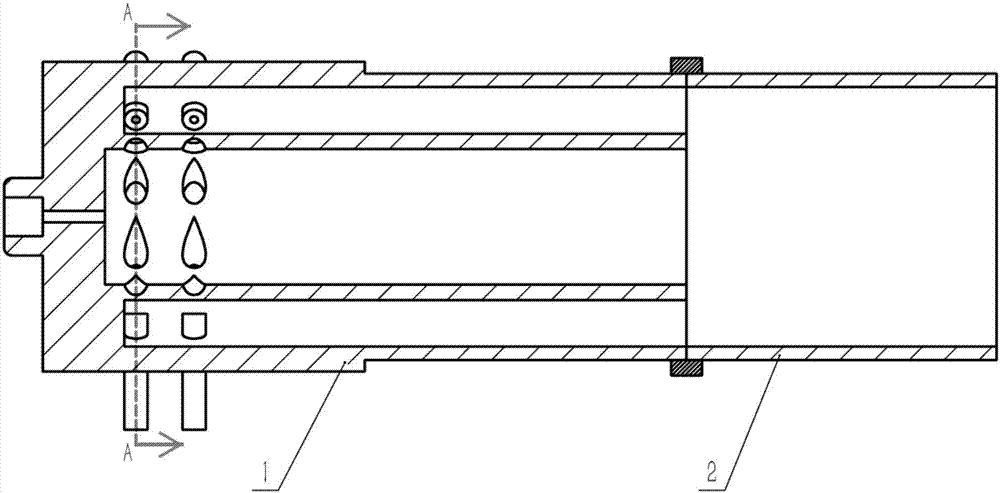

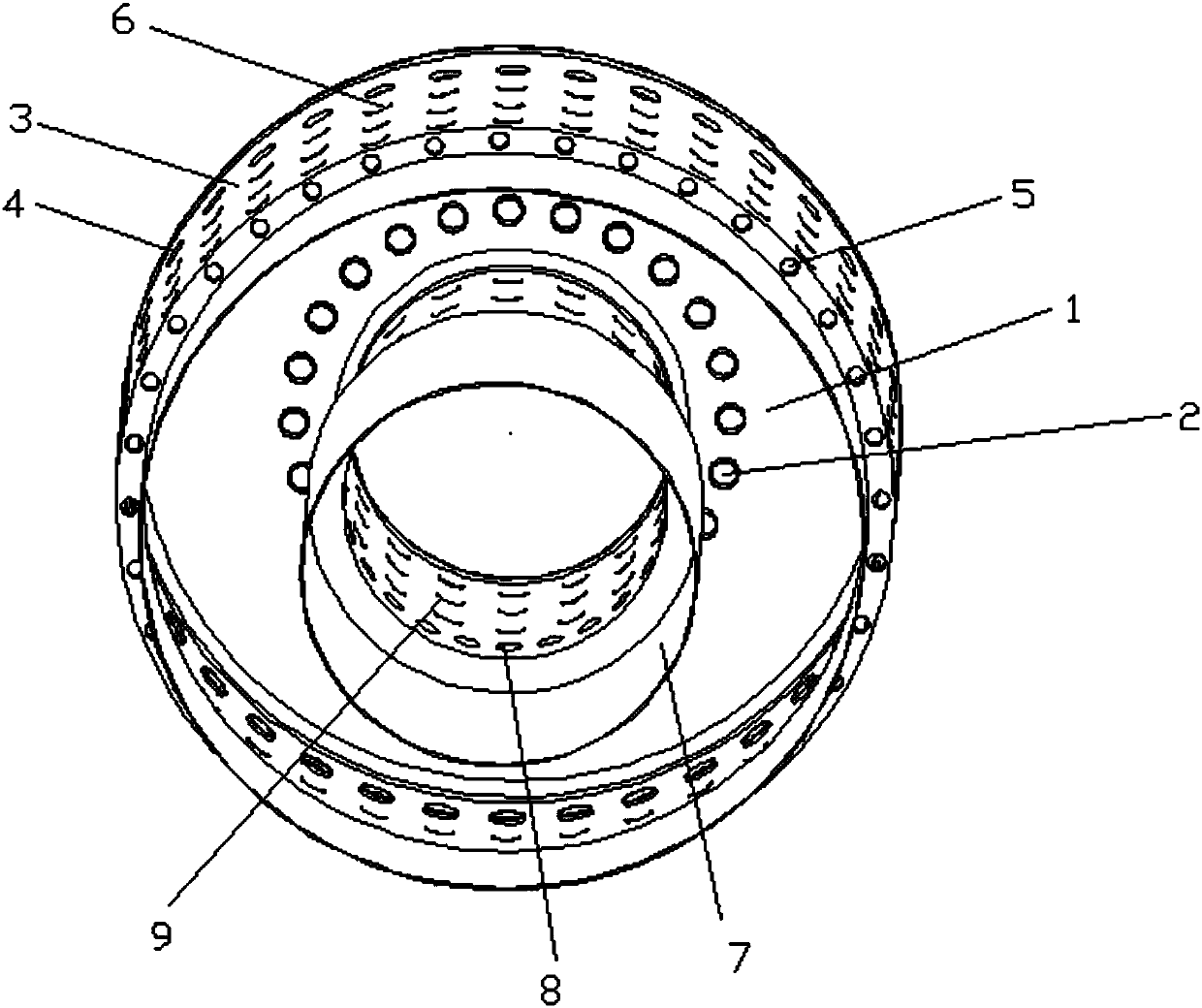

Turbine-based combined cycle engine super-combustion chamber

InactiveCN104019465ASatisfy Advancement RequirementsSolve key technical difficultiesContinuous combustion chamberRamjetGroove width

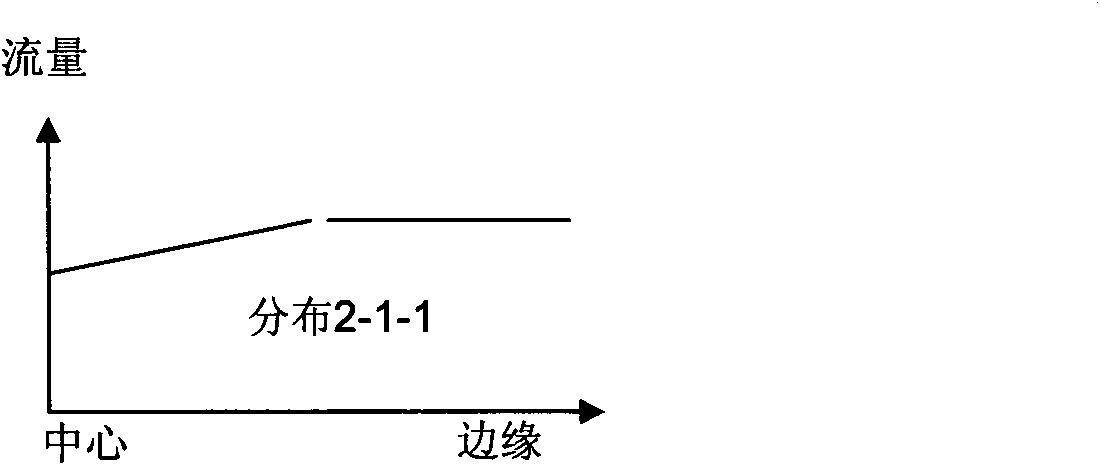

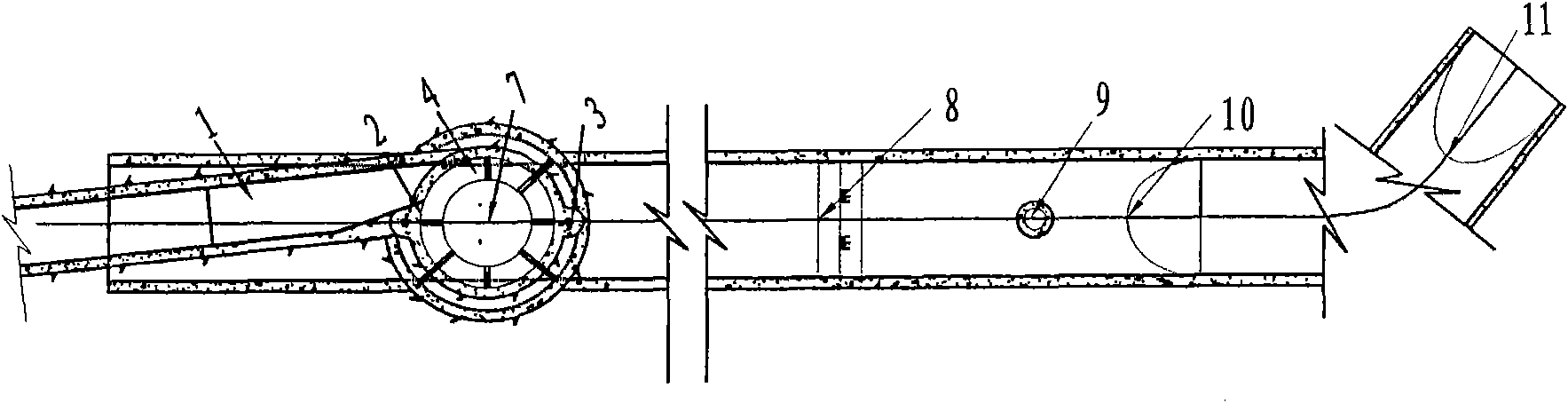

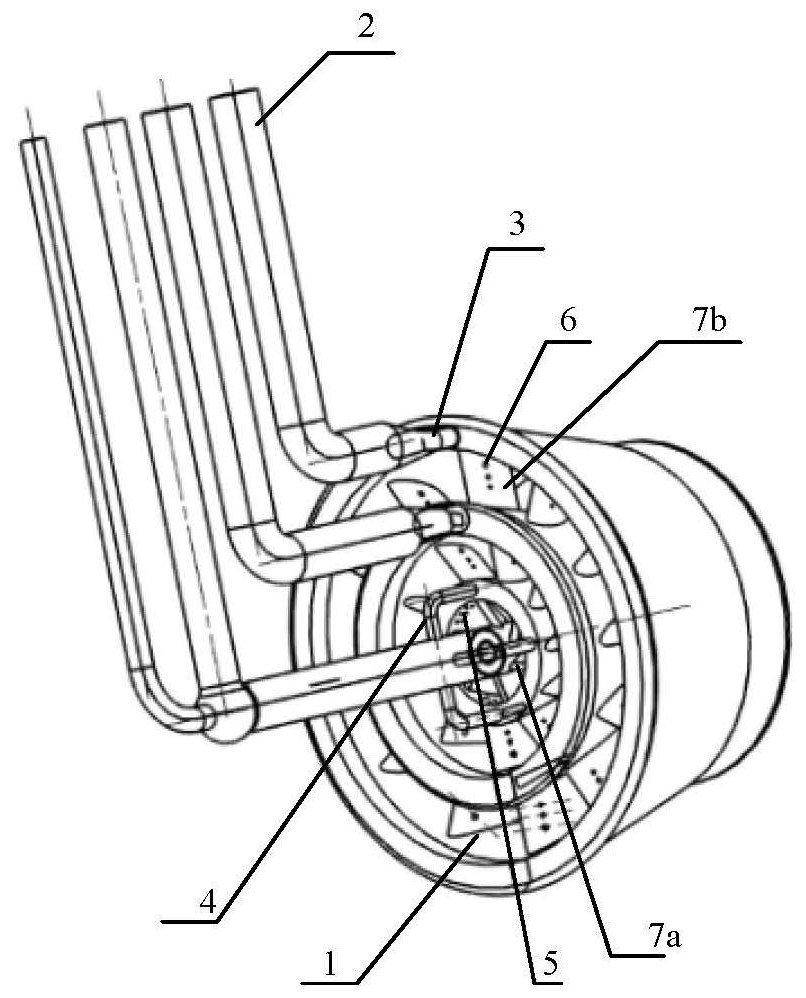

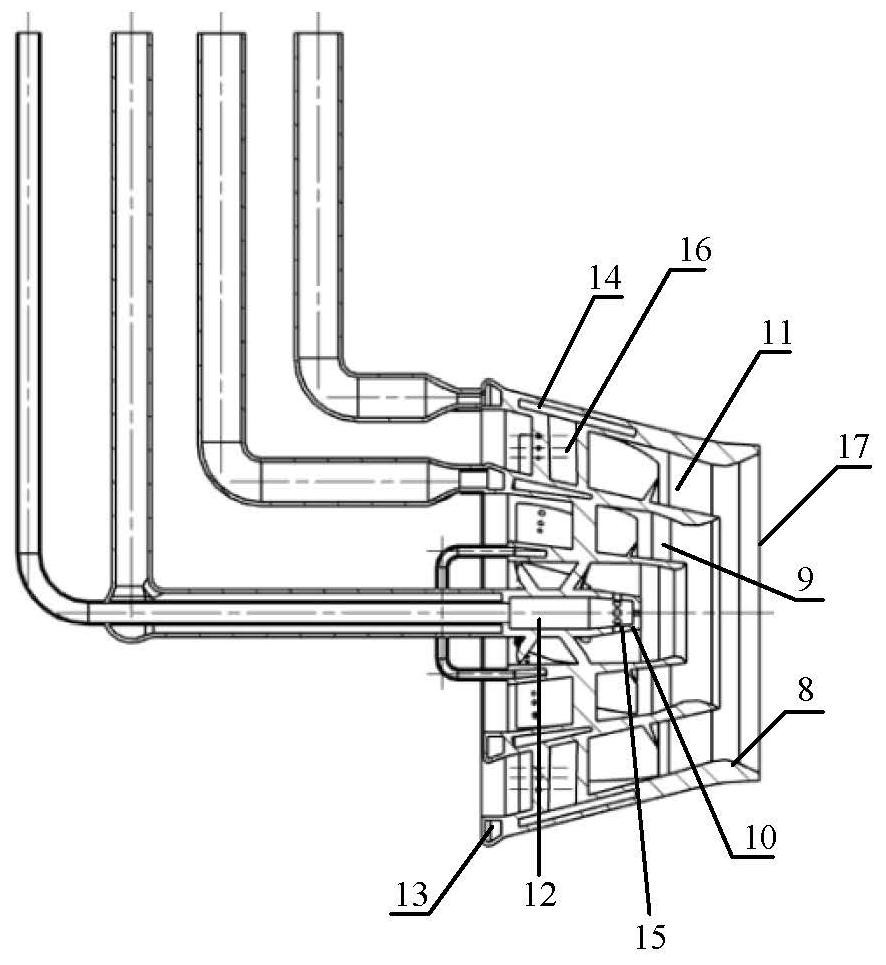

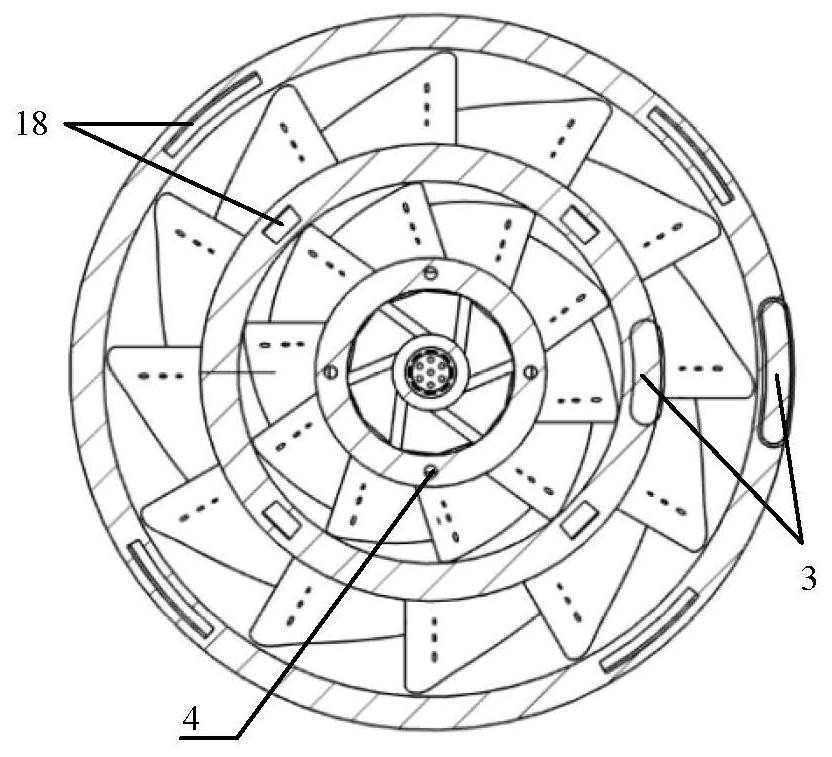

The invention discloses turbine-based combined cycle engine super-combustion chamber. Key parts of the super-combustion chamber comprise a shunt ring, a rear area-variable deflation valve, a flow guide tongue piece, a square lobe mixer, a first area fuel ejector, a center cone, a second area fuel injection ring, an evaporation tube flame stabilizer, a heat-isolating screen, a super-combustion chamber cylinder, an outer extending groove-width-variable radial flame stabilizer and an inner extending radial flame stabilizer. An internal flow field of the super-combustion chamber is reasonably distributed, the phenomenon of backflow from a punching duct to a turbofan duct can not occur, flow separation can not occur in the square lobe mixer, and the evaporation tube flame stabilizer can achieve soft ignition of the super-combustion chamber. The whole super-combustion chamber is high in mixing efficiency, little in cold flow resistance, high in combustion efficiency, reasonable in temperature distribution, and capable of meeting use requirements in a whole flight envelope of the super-combustion chamber in each work state and the requirement for boost of an turbofan ramjet.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

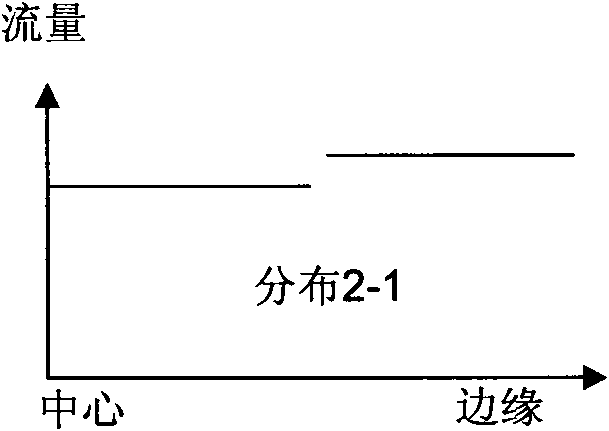

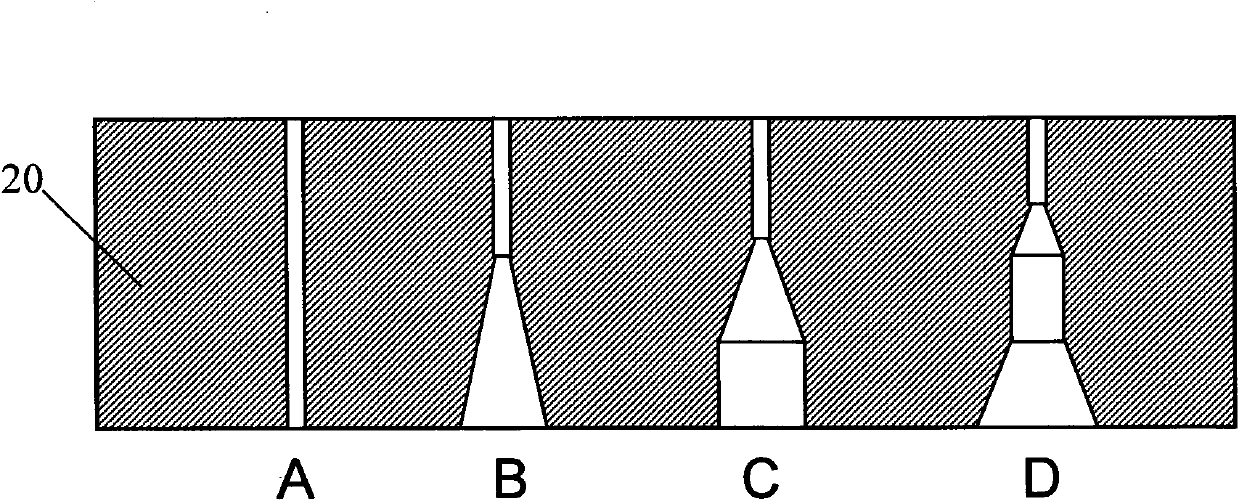

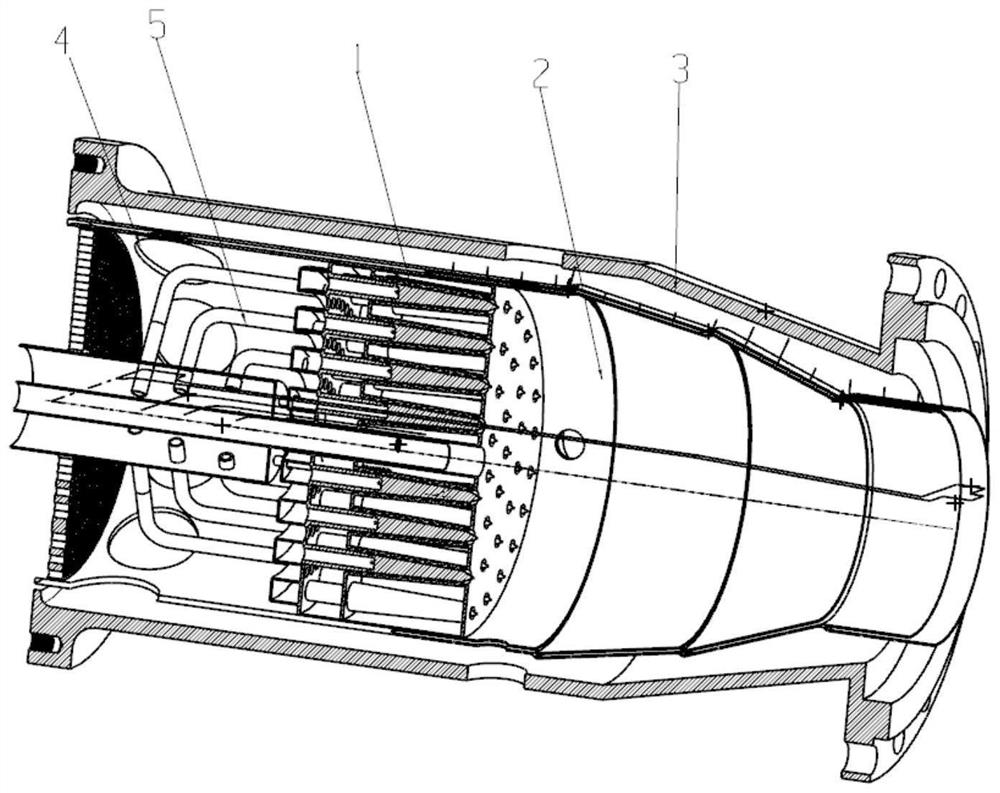

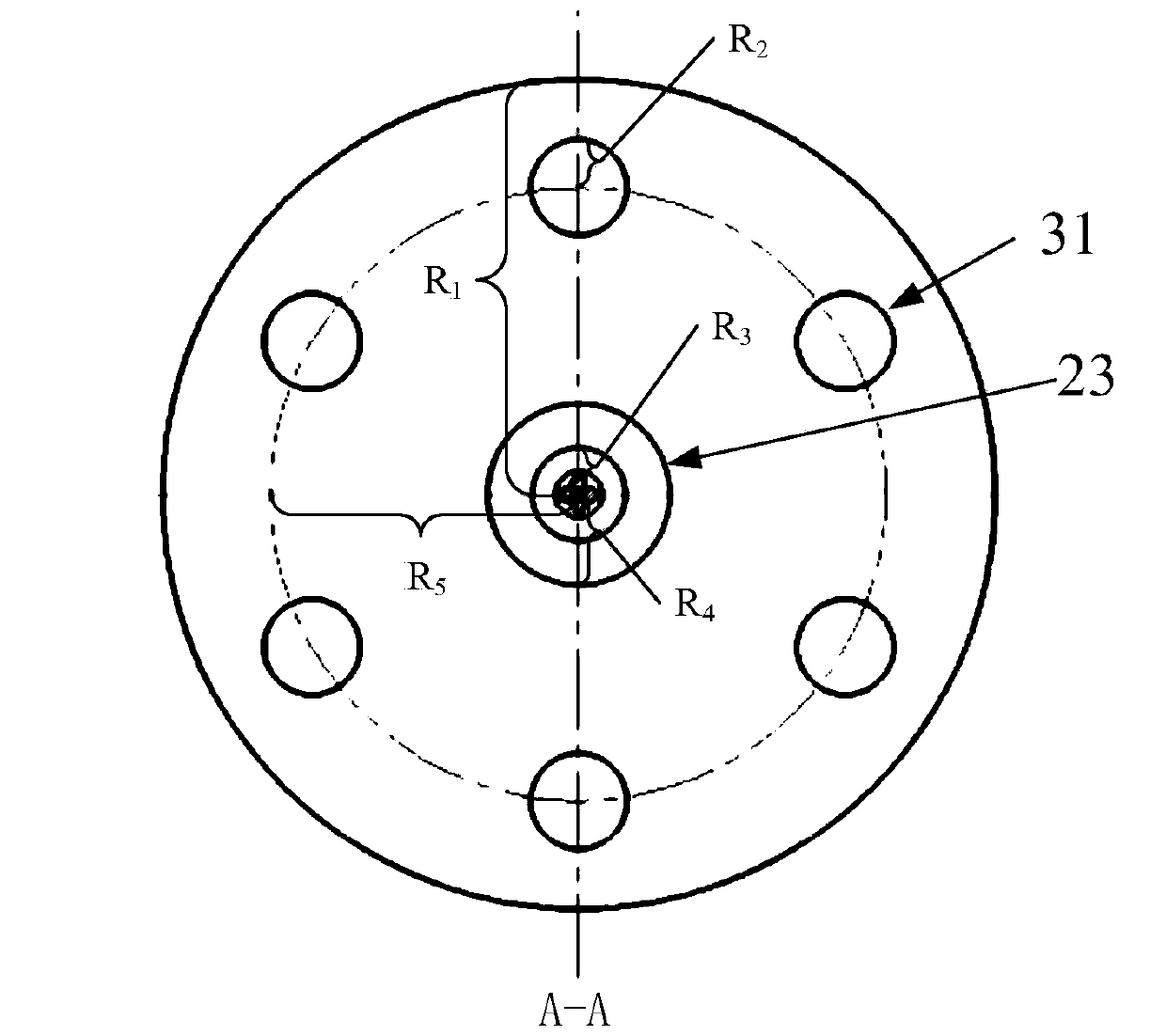

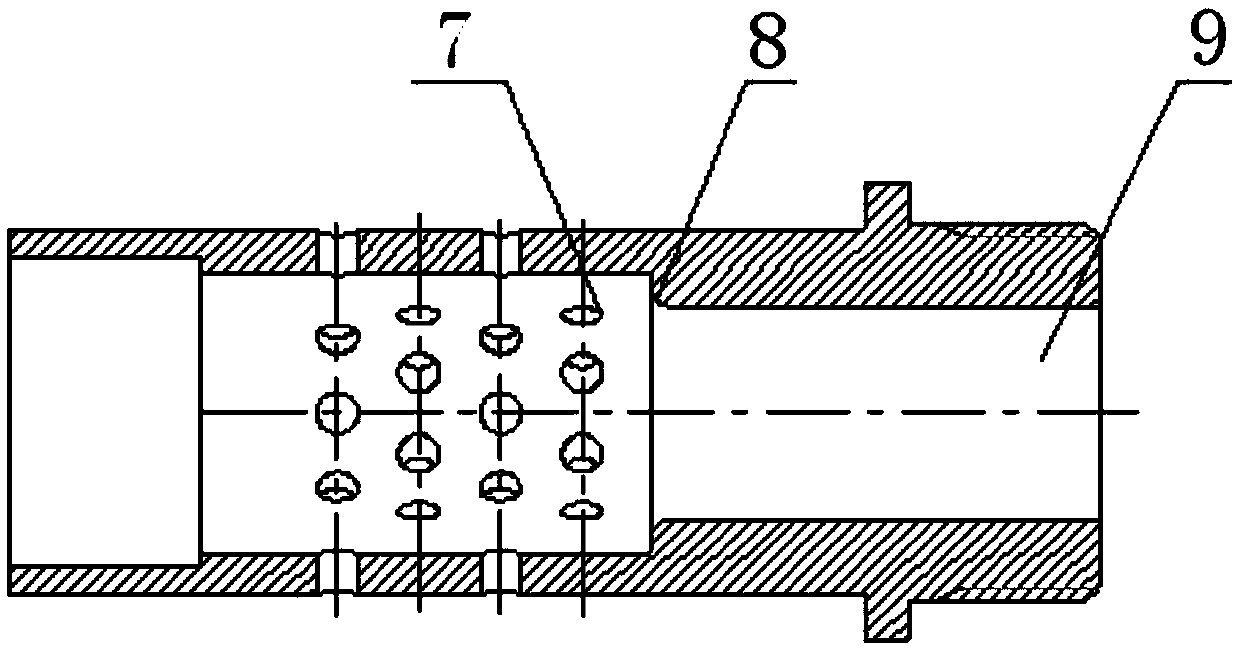

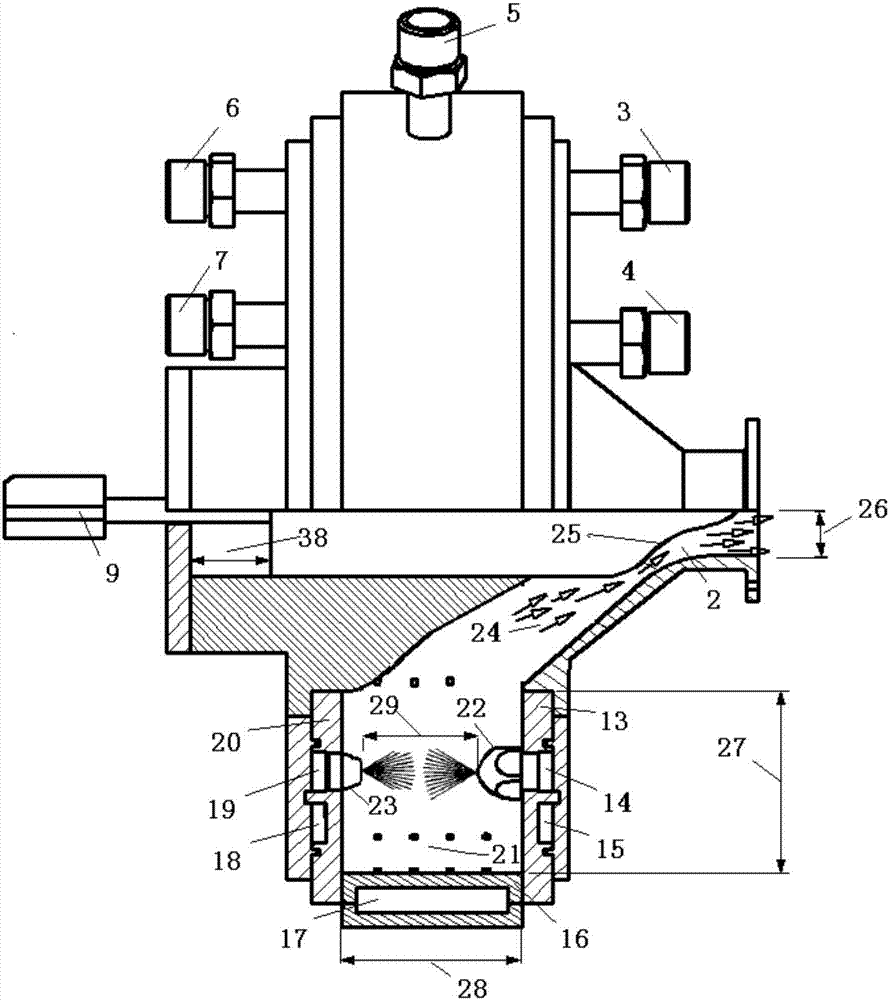

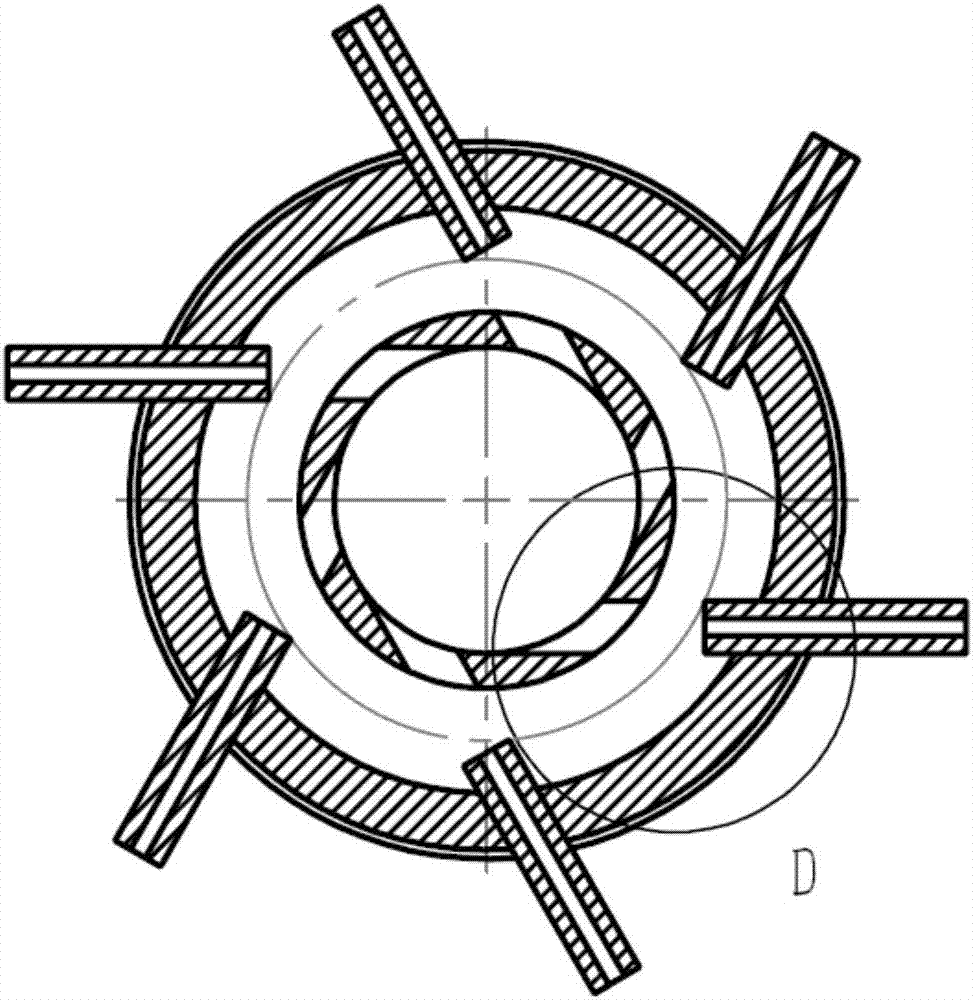

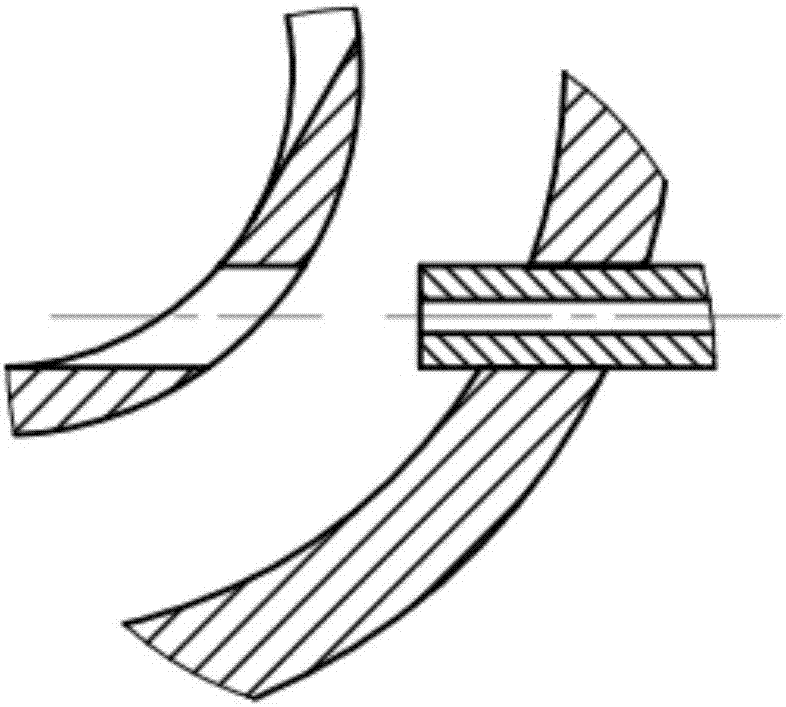

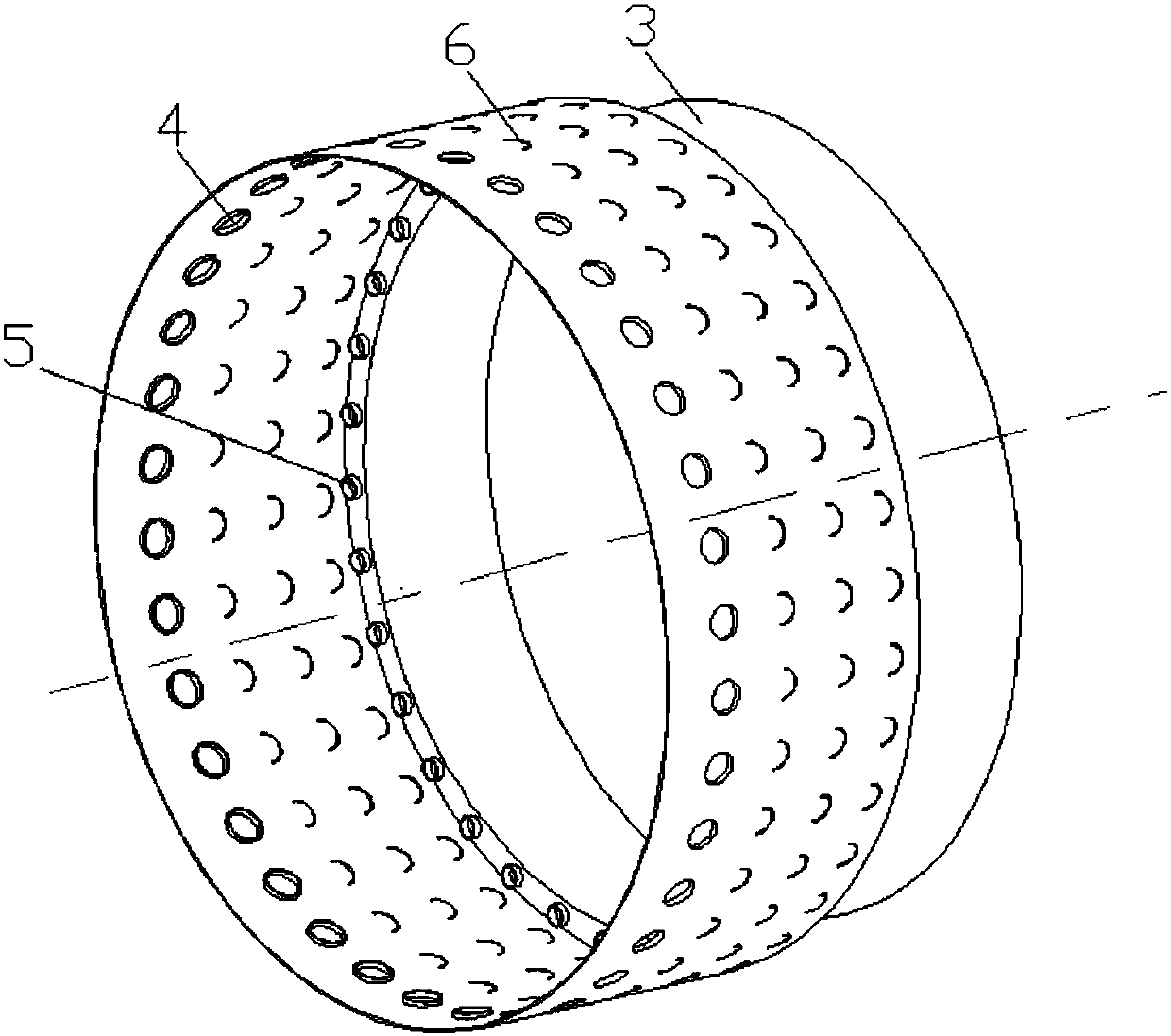

Device for controlling delivery and uniform distribution of reaction gases in MOCVD reaction chamber

ActiveCN101914761AReduce manufacturing costControl consumptionChemical vapor deposition coatingSystem capacityEngineering

The invention discloses a device for controlling the delivery and the uniform distribution of reaction gas in a MOCVD reaction chamber. By respectively controlling the flow of gas passages non-uniformly distributed radially on a front gas homogenizing plate and input passages at different positions, at least two reaction gases are respectively introduced into two paths which are radially and axially crossed on a spray header, and can be secondarily distributed by nozzles in different shapes, so the uniformly distributed boundary layer concentration, speed and temperature required are achieved on the surface of a rotary epitaxial wafer, the quality of massively produced epitaxial films and the finished product ratio of massively produced epitaxial wafers are improved, the consumption of expensive reaction gases can be effectively controlled and the epitaxial production cost is reduced. By properly increasing the distance between the surface of the spray header and the epitaxial wafer, deposits generated on the surface of the spray header and the nozzles in the epitaxial growth are reduced, the cleaning period is prolonged, and the production efficiency and system capacity are improved. The device also can reduce the processing difficulty and manufacturing cost of the nozzles of the spray header and cooling medium passages.

Owner:JIANGSU ZHONGSHENG SEMICON EQUIP

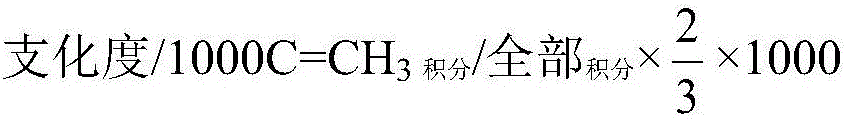

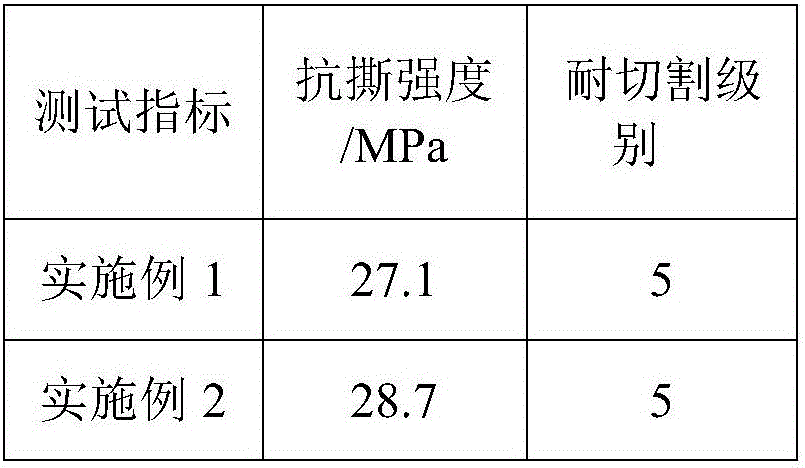

UHMWPE composition and high-wear-resistant and high-cutting-resistance fiber prepared from same

ActiveCN106222781AIncrease repulsionAlleviate the problem of inhomogeneous blendingMonocomponent polyolefin artificial filamentArtifical filament manufactureWear resistantUltra-high-molecular-weight polyethylene

The invention provides an ultra-high molecular weight polyethylene composition. The ultra-high molecular weight polyethylene composition comprises silicon carbide, modified graphene and ultra-high molecular weight polyethylene, wherein the modified graphene is hyperbranched polyethylene grafted graphene. The material prepared from the composition simultaneously has relatively high cutting resistance and very strong tensile strength.

Owner:JIANGSU JONNYMA NEW MATERIALS CO TLD

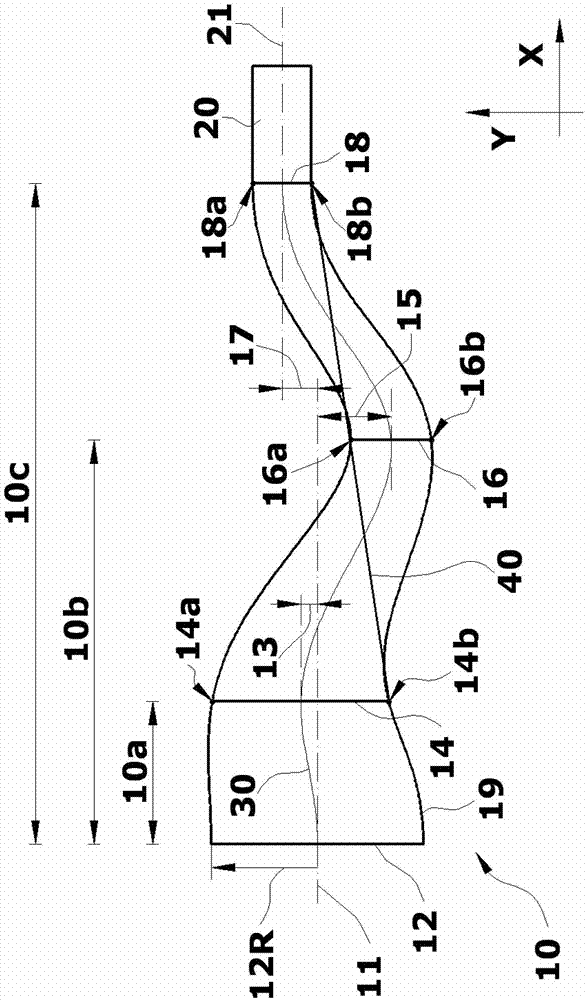

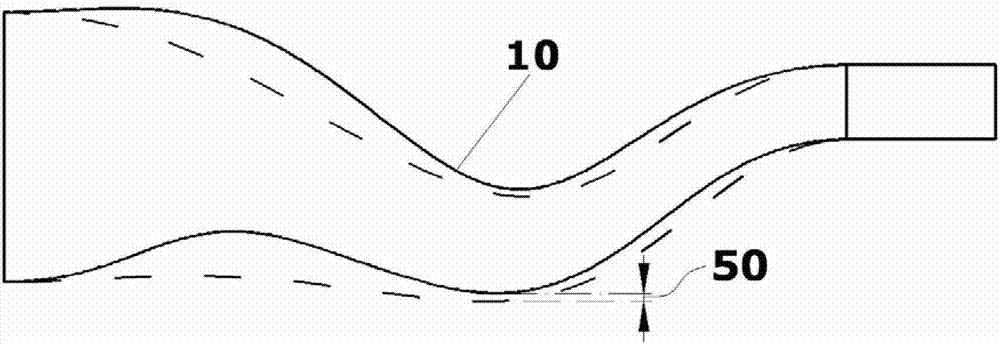

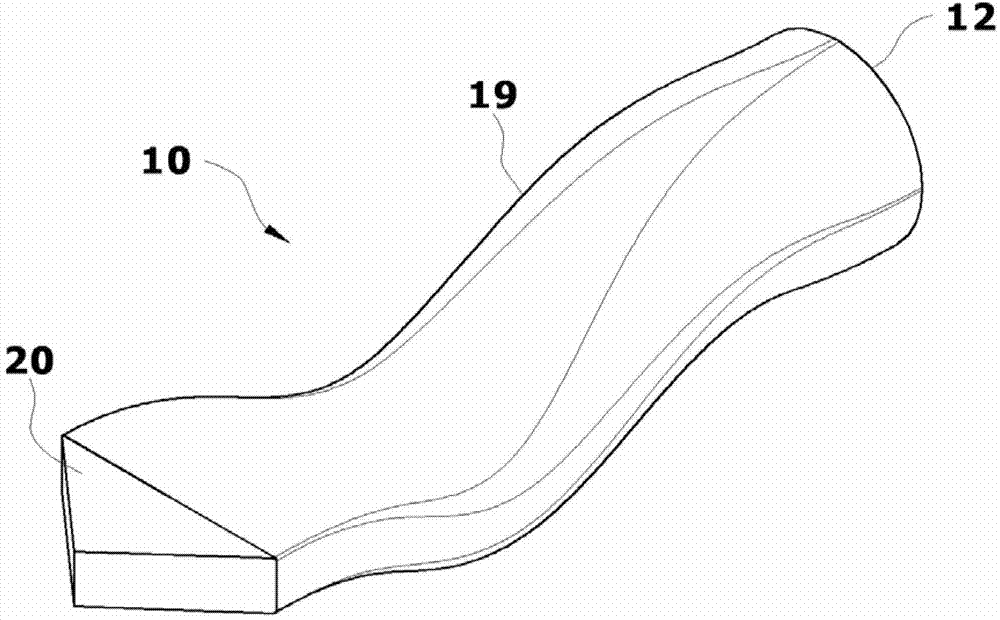

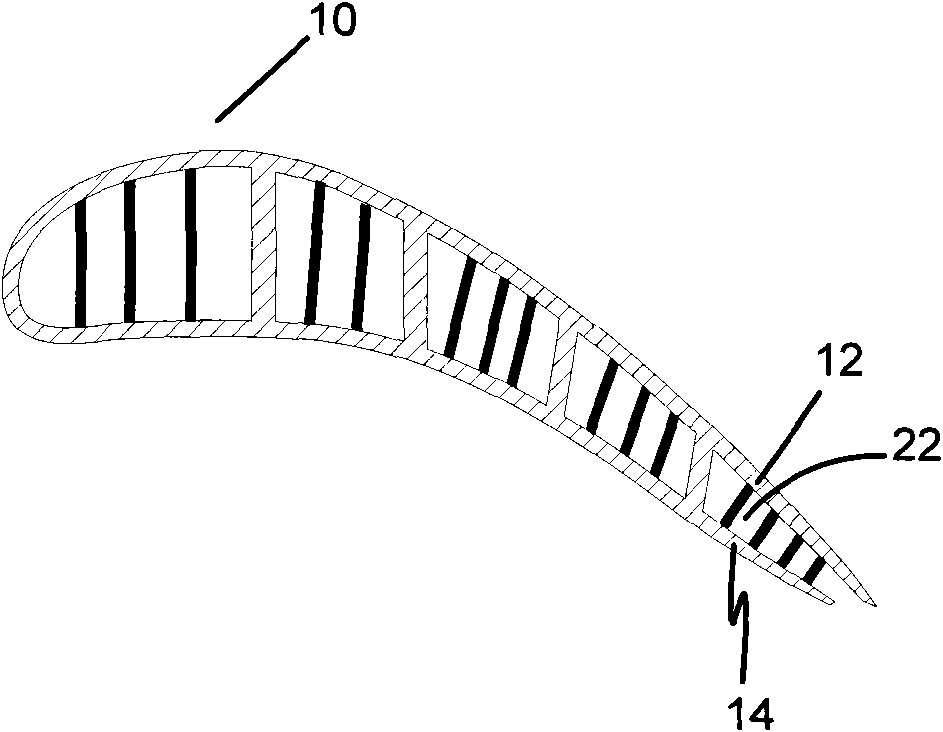

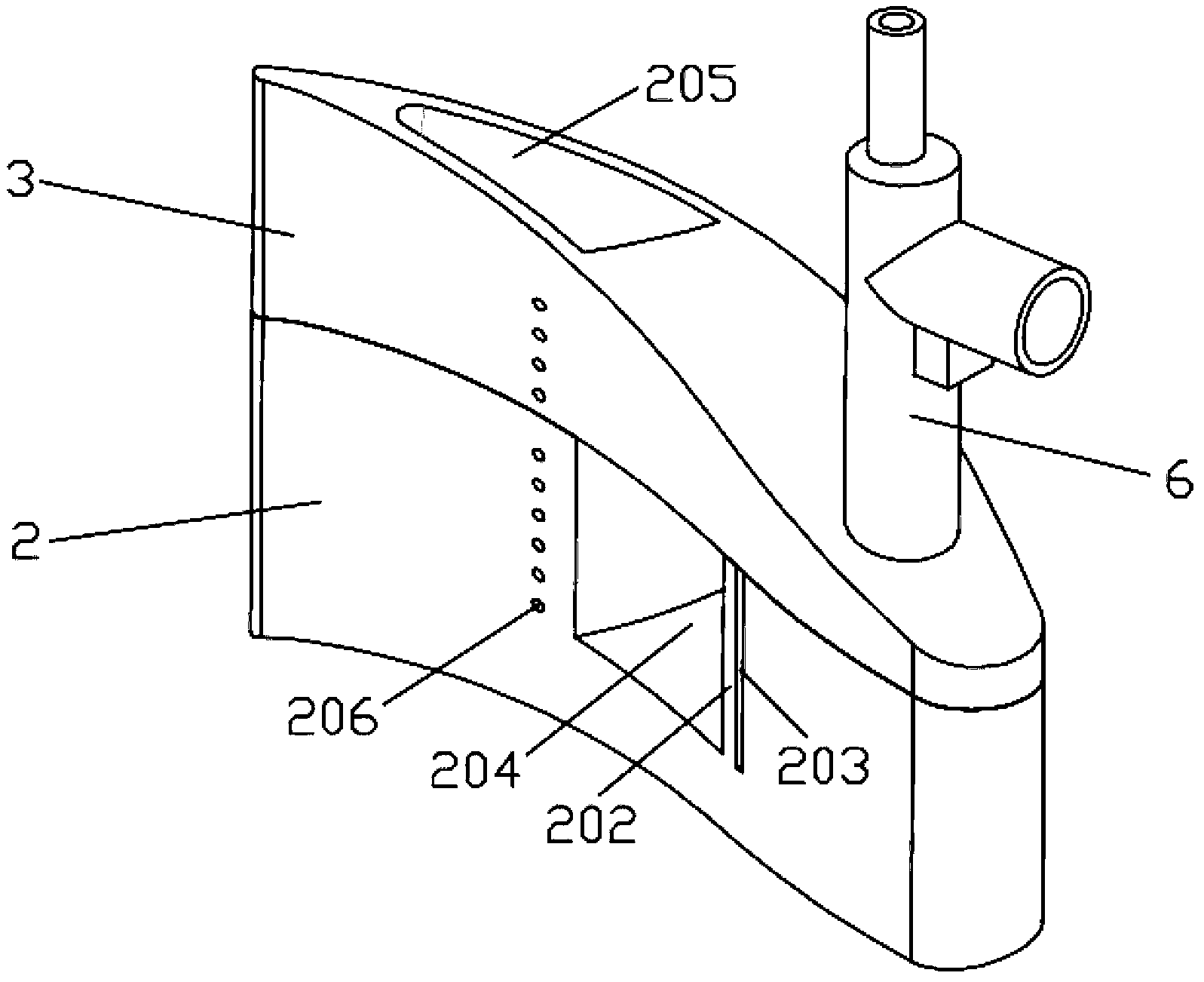

Stealth exhaust system

ActiveCN102926888AImprove adaptabilityImprove infrared stealth performancePower plant exhaust arrangementsJet propulsion plantsThroatRadar

The invention relates to an exhaust system applied to an air vehicle, in particular to a stealth exhaust system. A cross-section shape of a throat of a spray pipe is designed to a non-round shape with an aspect ratio greater than 1, so that mixing of high-temperature exhaust airflow of an engine and ambient air is strengthened, the exhaust temperature is reduced, and an infrared stealth property of the exhaust system is improved. Central lines of the stealth exhaust system are three longitudinal S-bent curves, and the bent central lines can enable sidewalls of the spray pipe to shield high-temperature components of the engine, therefore, the infrared stealth property of the exhaust system can be improved; and simultaneously, the bent central lines can also cause radar waves going into the stealth exhaust system from the rear to difficultly generate backward waves, therefore, a radar stealth property of the exhaust system can be improved. Properties of the exhaust system are considered while the stealth properties are ensured, so that a requirement of the stealth exhaust system on the layout space is reduced, and adaptability of the stealth exhaust system is strengthened.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

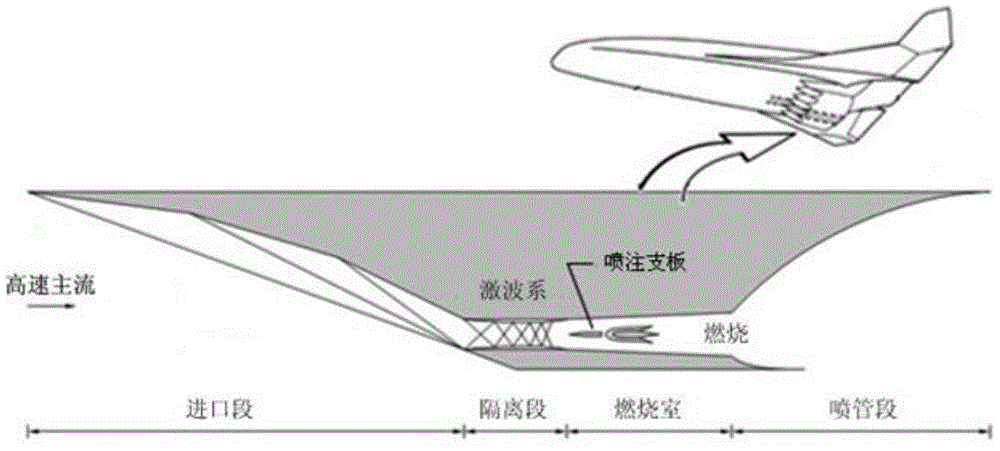

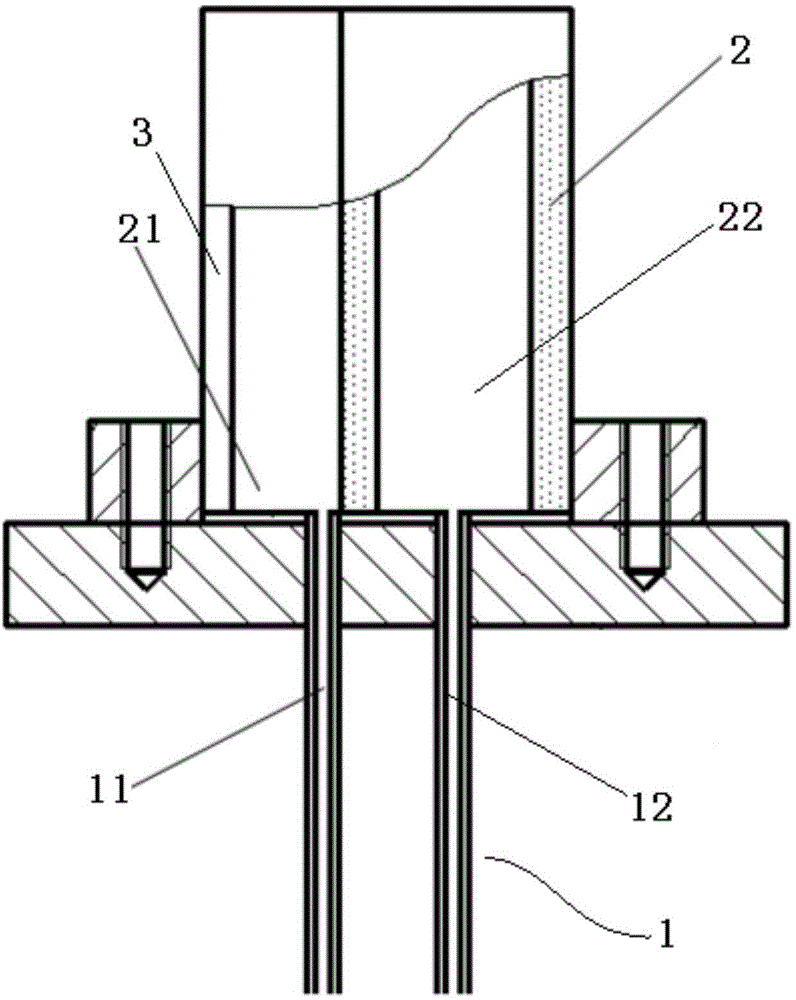

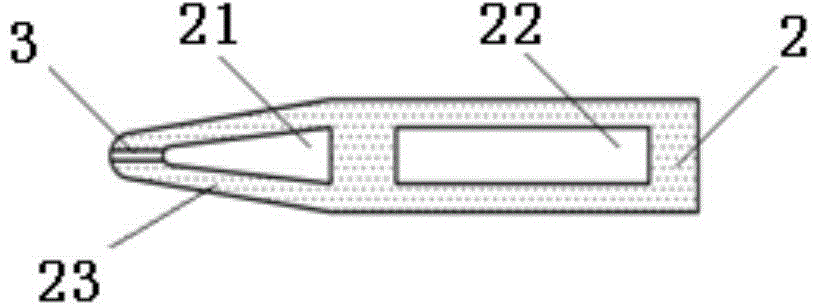

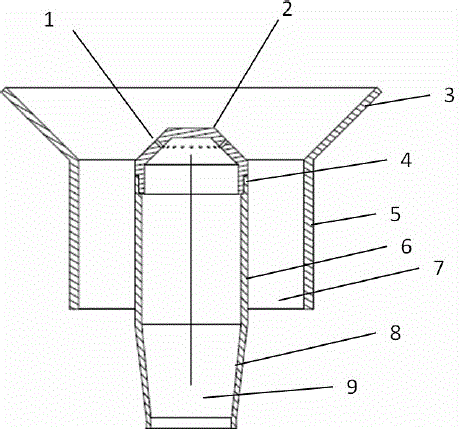

Thermal protection method of porous medium jetting support plate leading edge nose cone

InactiveCN104633709AEffective heat protectionReduce the temperatureContinuous combustion chamberLeading edgeShock wave

The invention relates to a thermal protection method of a porous medium jetting support plate leading edge nose cone. The thermal protection method comprises the following steps that firstly, a narrow seam is formed in the jetting support plate leading edge nose cone, a front cavity of a jetting support plate is communicated with one fuel pipe, and a back cavity of the jetting support plate is communicated with the other fuel pipe; secondly, most of low-temperature fuel is quickly sprayed out of the narrow seam through the fuel pipe arranged at the front cavity, and the rest part of fuel permeates to the surface of the front cavity in a sweating mode; thirdly, the fuel sprayed to the leading edge is collected through the narrow seam, and produced detached shock waves are pushed away from the leading edge nose cone; fourthly, a thick protection air film is formed at the leading edge nose cone through the fuel sprayed out of the narrow seam and under the action of high-speed main stream, the thick protection air film is fused with a compact air film formed on the surface of the jetting support plate in a sweating and cooling mode, and thermal protection for the jetting support plate is enhanced. According to the thermal protection method, due to the fact that the fuel is sprayed to the high-speed main stream through the narrow seam at the leading edge nose cone, the low-temperature fuel serves as coolant for reducing the temperature of the leading edge nose cone when sprayed out of the narrow seam, meanwhile the sprayed fuel can form the protection air film on the surface of the jetting support plate, and the protection air film can conduct effective thermal protection on the jetting support plate.

Owner:TSINGHUA UNIV

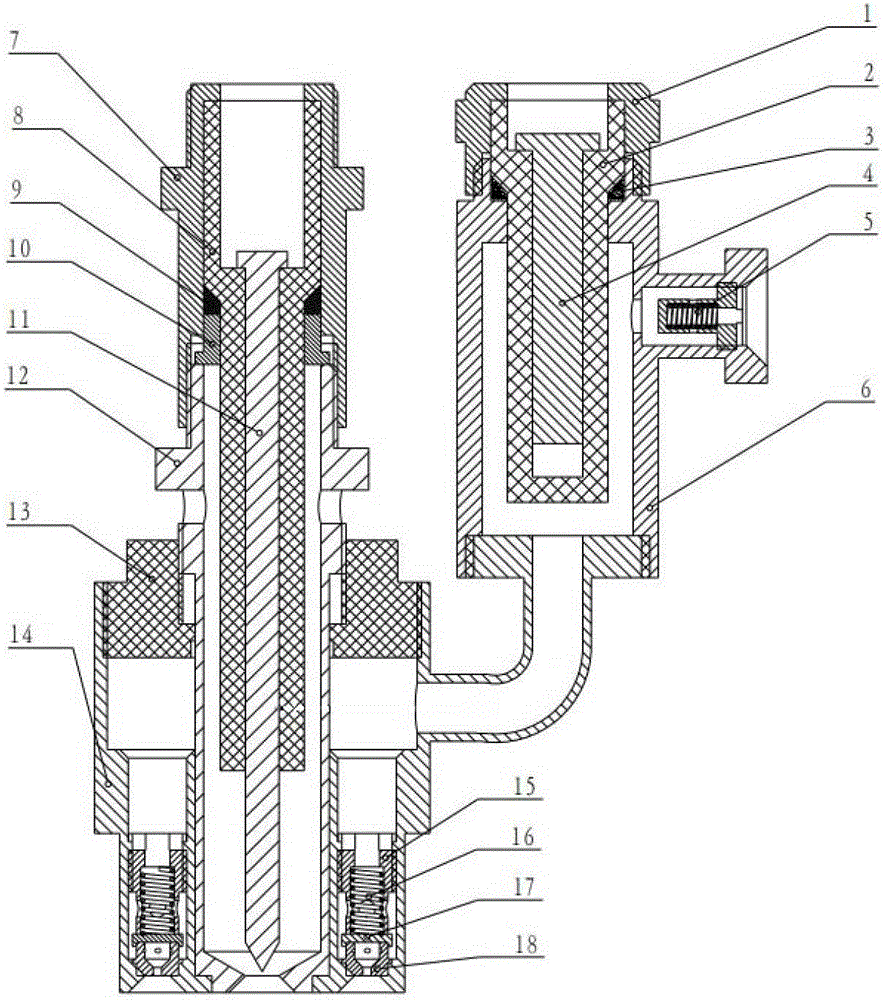

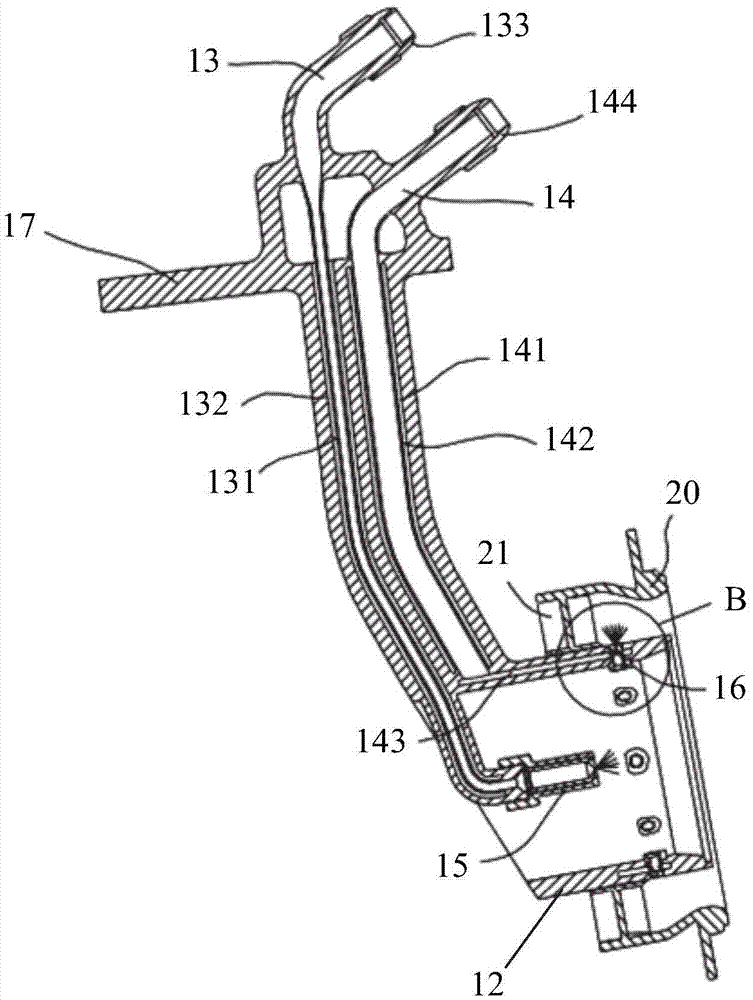

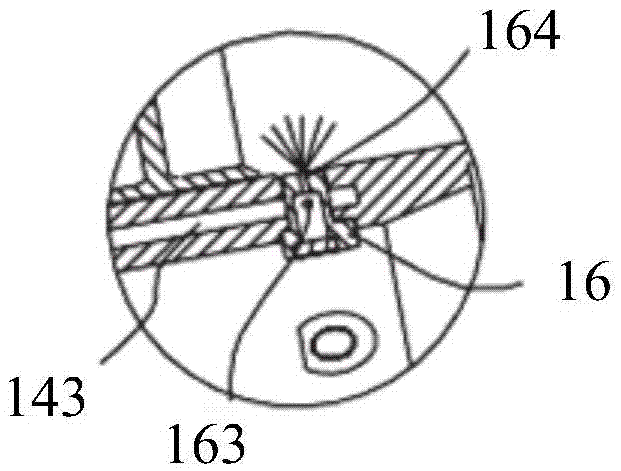

Plasma catalysis ignition integrated nozzle

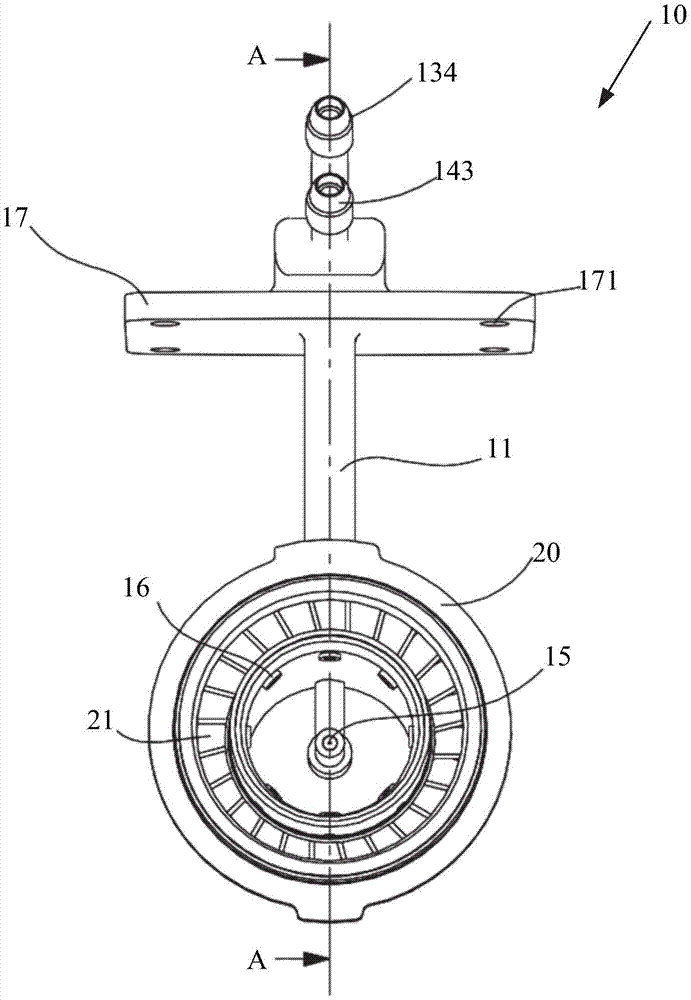

InactiveCN102980209AGood drop spectrumLower activation energyContinuous combustion chamberPlasma jetCombustion chamber

The invention provides a plasma catalysis ignition integrated nozzle which is a plasma assisted atomization and plasma ignition integrated nozzle formed by a low-temperature plasma discharge assembly, a fuel pressure atomization nozzle assembly and a high-energy plasma ignition assembly. A barrier medium uniformly discharges to ensure that a liquid fuel partially pyrolyzes to generate a large quantity of gas activated components, so that a gas-liquid coexisting plasma microcell is formed, fuel activation energy and ignition energy are reduced, physical conditions of gas assisted atomization are formed, and atomization effect is improved. A plasma ignitor is arranged on the middle of a multi-point nozzle and is positioned in a combustion chamber low-pressure region, plasma and fuel atomized particles are well mixed to generate a chemical reaction, and a stable high-temperature ignition core is easily formed. Ignition is directly carried out by adopting a plasma jet, and because the plasma jet has special discharge characteristics and larger discharge energy and is highly concentrated in energy, the ignition reliability and the ignition concentration limit of a gas turbine are greatly improved. The plasma catalysis ignition integrated nozzle can be applied to a combustion chamber of the gas turbine.

Owner:三亚哈尔滨工程大学南海创新发展基地

Gas circuit axial grading type dual-fuel nozzle

InactiveCN103175223AIncrease the circulation areaReduce radial sizeContinuous combustion chamberWater vaporEngineering

The invention aims to provide a gas circuit axial grading type dual-fuel nozzle which comprises a gas circuit outer wall and a main oil circuit wall arranged inside the gas circuit outer wall. An auxiliary oil circuit wall is arranged inside the main oil circuit wall. A main oil circuit channel is formed between the main oil circuit wall and the auxiliary oil circuit wall. An auxiliary oil circuit channel is formed inside the auxiliary oil circuit wall. A gas circuit is formed between the gas circuit outer wall and the main oil circuit wall. The gas circuit comprises a gas circuit front cavity, a gas circuit laryngeal and a gas circuit rear cavity in sequential communication. A first level gas circuit gas ejection hole is formed in a position, arranged on the gas circuit front cavity, of the gas circuit outer wall. A laryngeal gas ejection hole is formed in the gas circuit laryngeal. A second level gas circuit gas ejection hole is formed in the gas circuit rear cavity. Due to the fact that a gas circuit axial grading type structure is adopted, the gas circuit axial grading type dual-fuel nozzle has the advantages of reducing the radial size of the nozzle, simultaneously increasing gas circuit flow area, enhancing mixing of fuel and air, strengthening burning, shortening flame, and simultaneously not burning the wall surface of a flame tube. When liquid fuel is burned, water vapor reinjection is conducted by the gas circuit.

Owner:HARBIN ENG UNIV

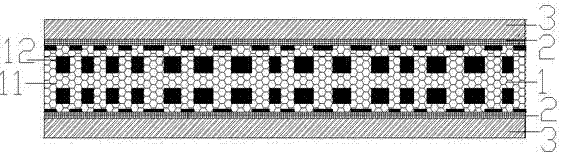

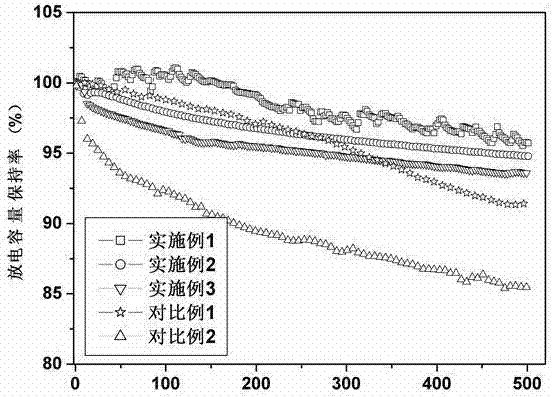

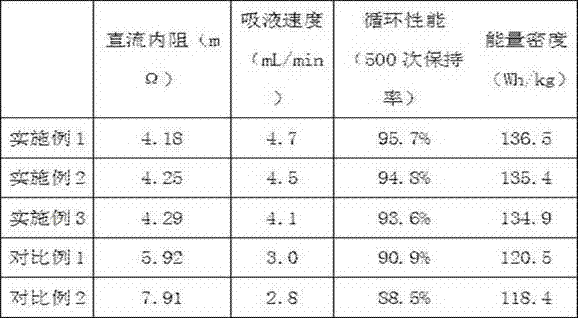

Lithium ion battery with high energy density

PendingCN106960949AImprove compactnessEasy to controlSecondary cellsManufacture by sprayingCarbon compositesElectrical battery

The invention belongs to the field of preparation of a lithium ion battery, and particularly relates to a lithium ion battery with high energy density. The lithium ion battery comprises a ternary positive electrode material, a hard carbon composite negative pole plate, a ceramic separator and a functional electrolyte, wherein the preparation method of the hard carbon composite negative pole plate comprises the steps of depositing a lithium salt on a surface of a hard carbon electrode, preparing a hard carbon / lithium salt composite pole plate, coating a surface of the hard carbon / lithium salt composite pole plate with an organic polymer, and preparing a hard carbon composite pole plate containing the lithium salt and the polymer coating layer. Lithium supplementary is performed on the surface of the hard carbon pole plate by an electrochemical method, the initial efficiency of hard carbon can be substantially improved, the transmission quantity of lithium ions during the charge-discharge process is increased, and the rate performance of the lithium ion battery is improved; and meanwhile, a shell is coated with a special polymer material, the lithium salt on a surface of the material is prevented from being in contact with outside air, and the processability and the safety of the material are improved.

Owner:江苏元景锂粉工业有限公司

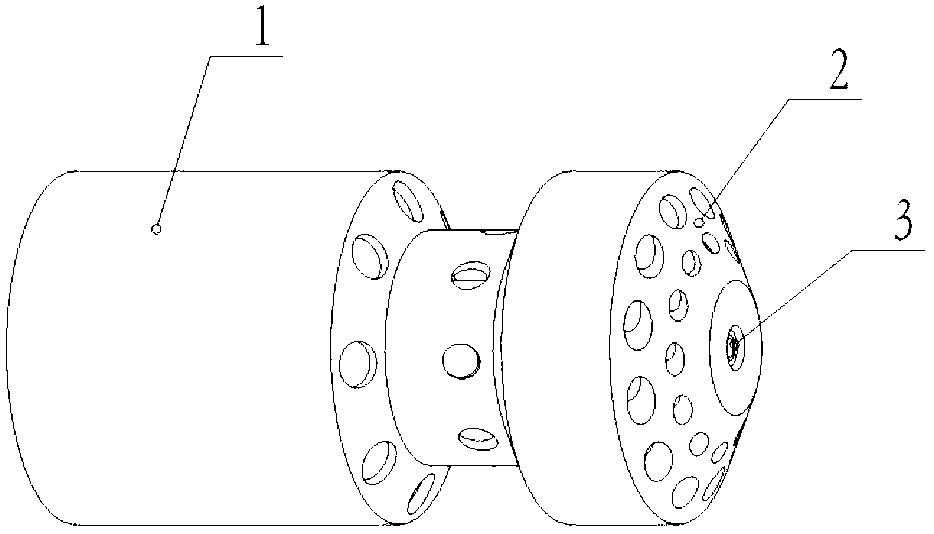

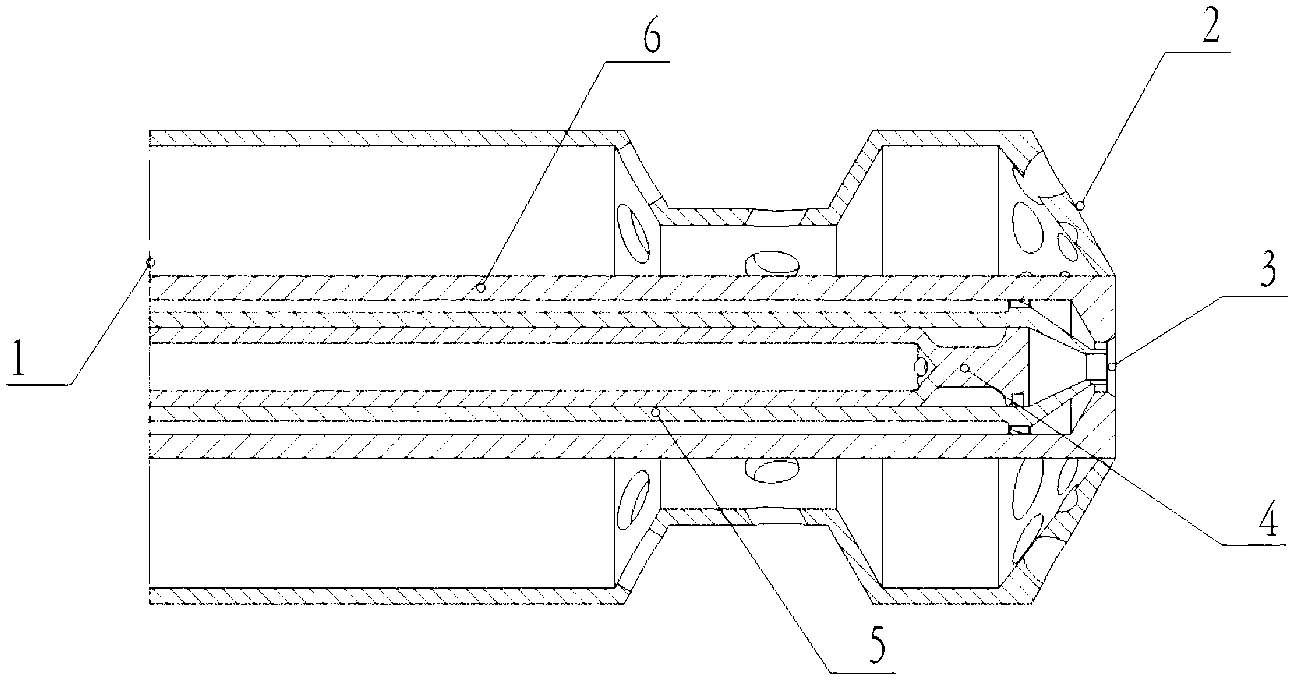

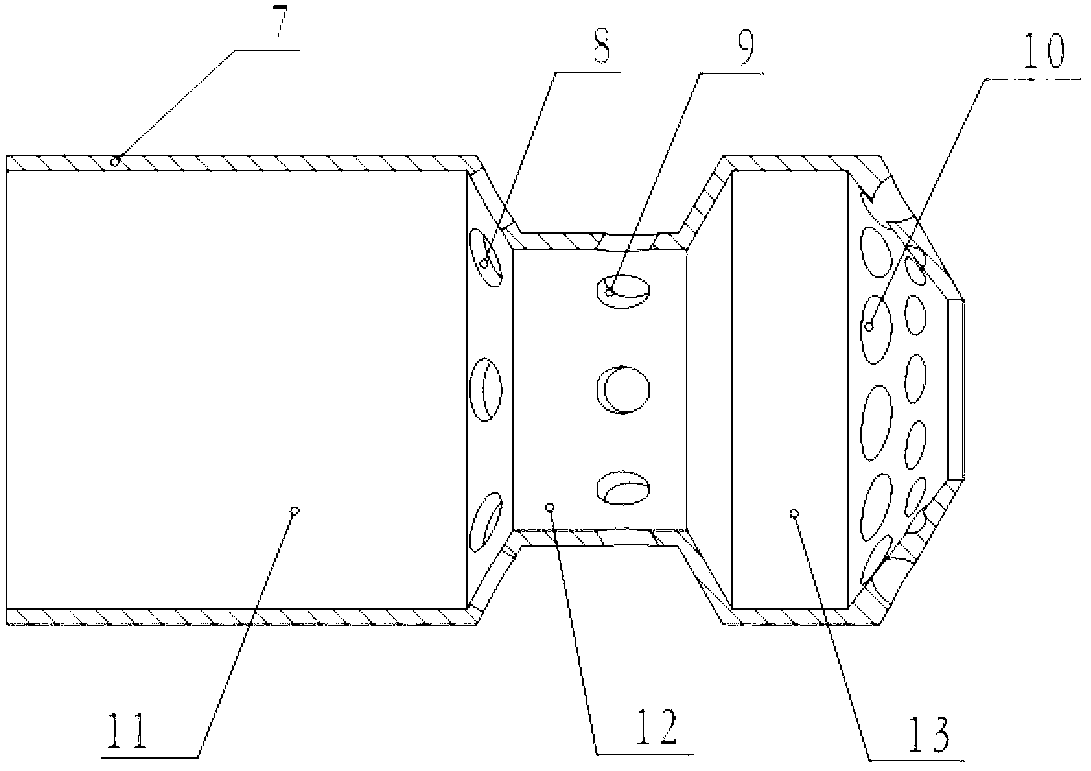

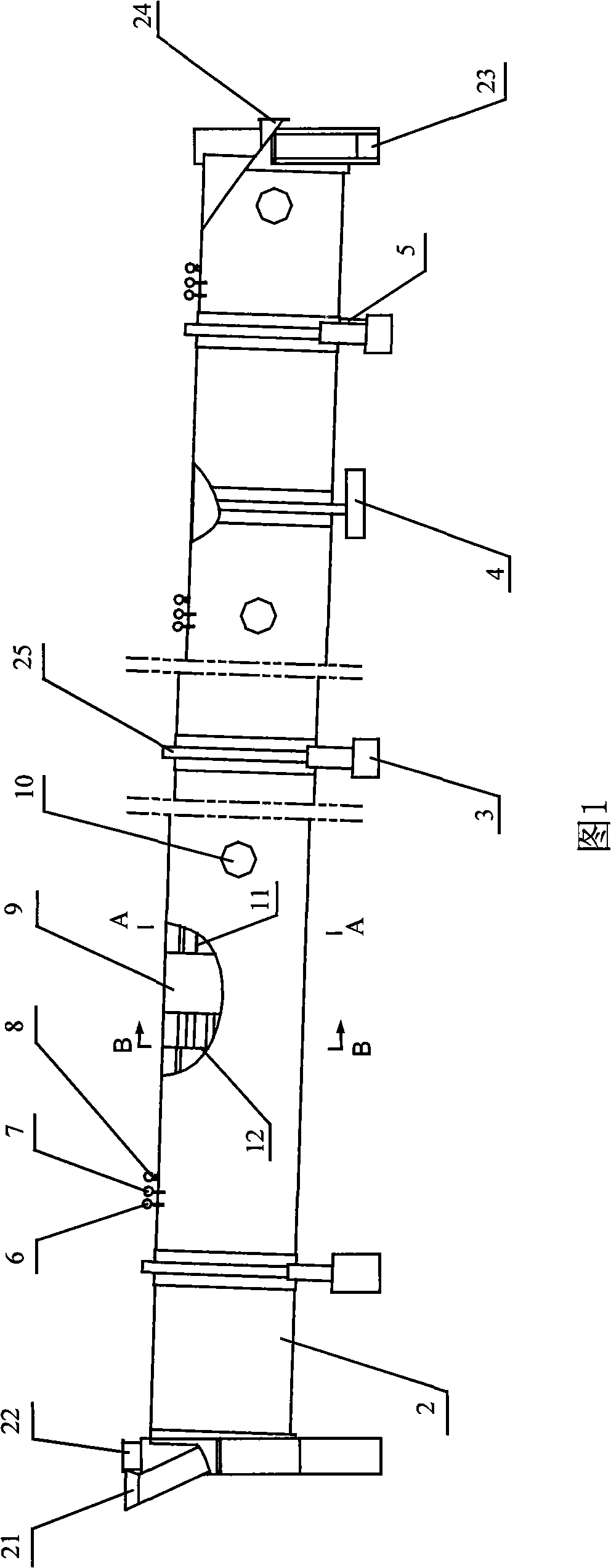

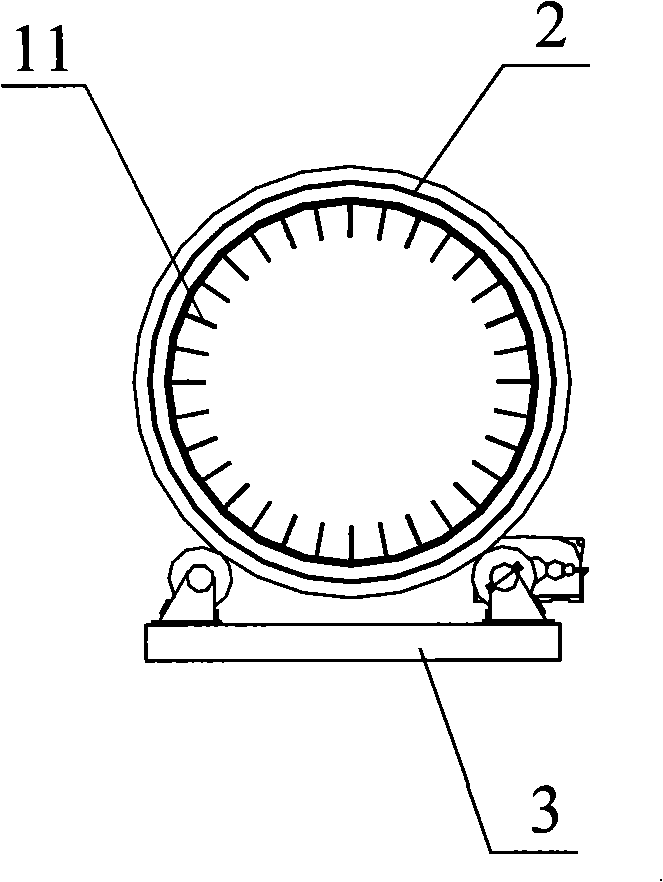

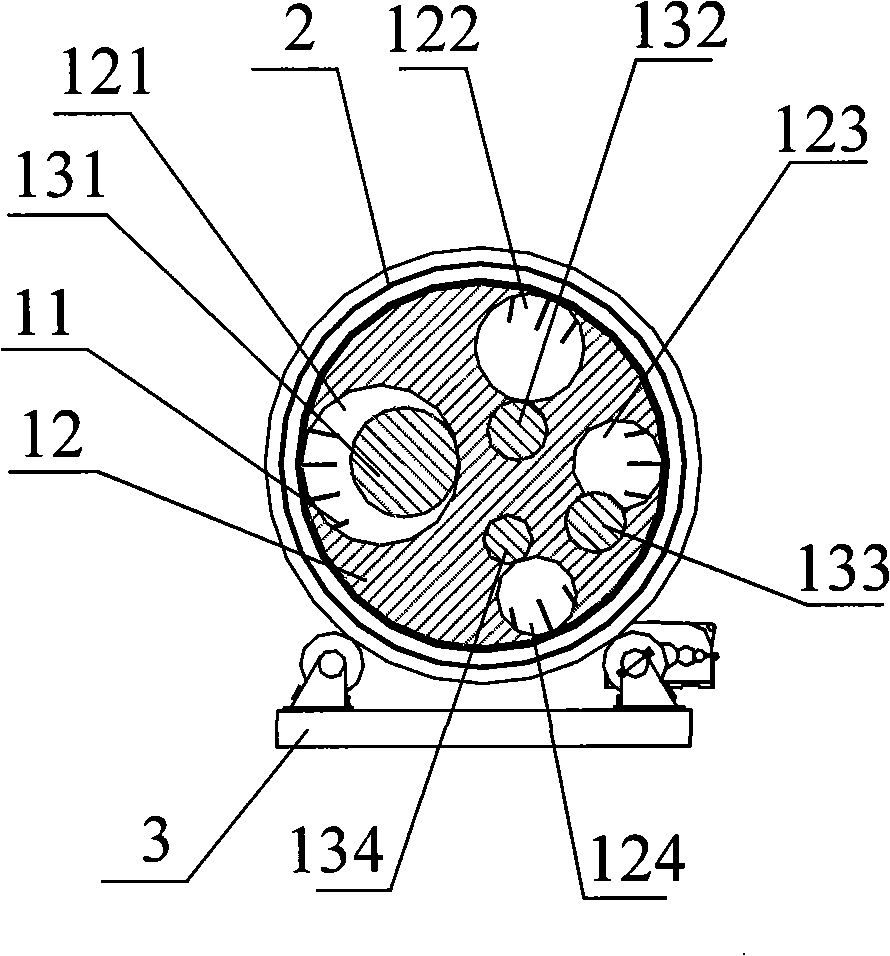

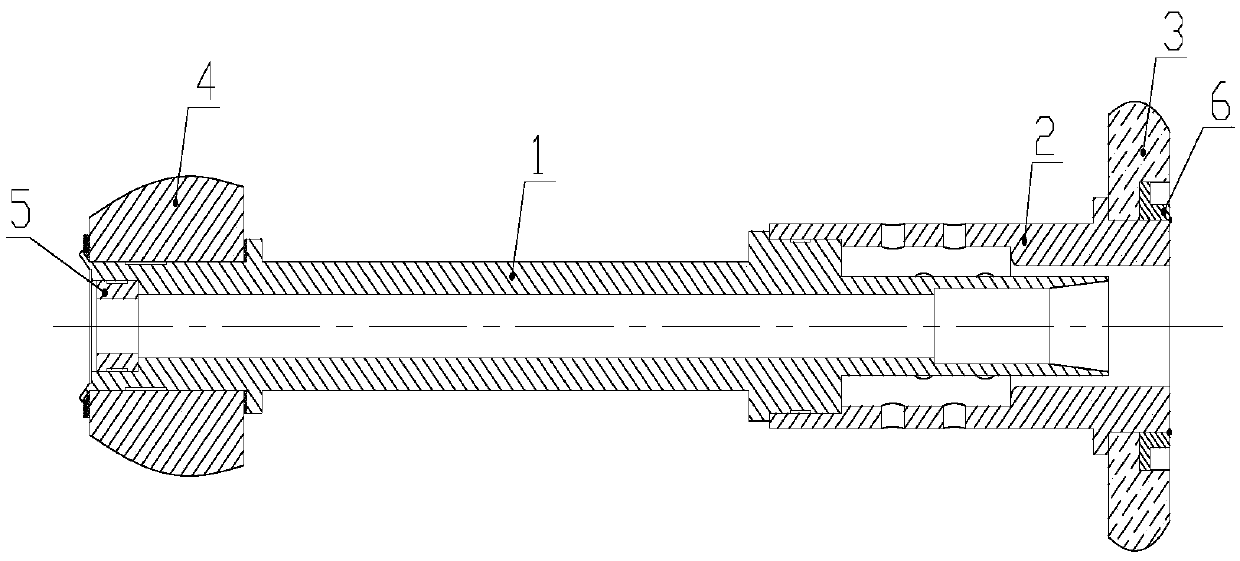

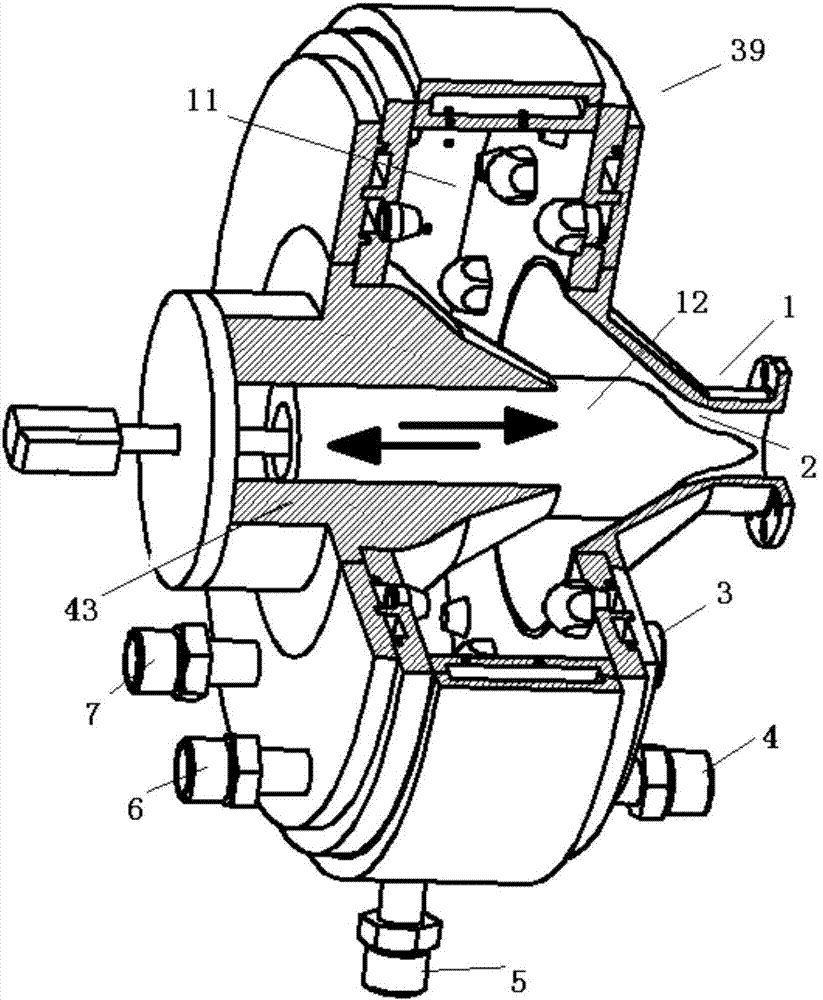

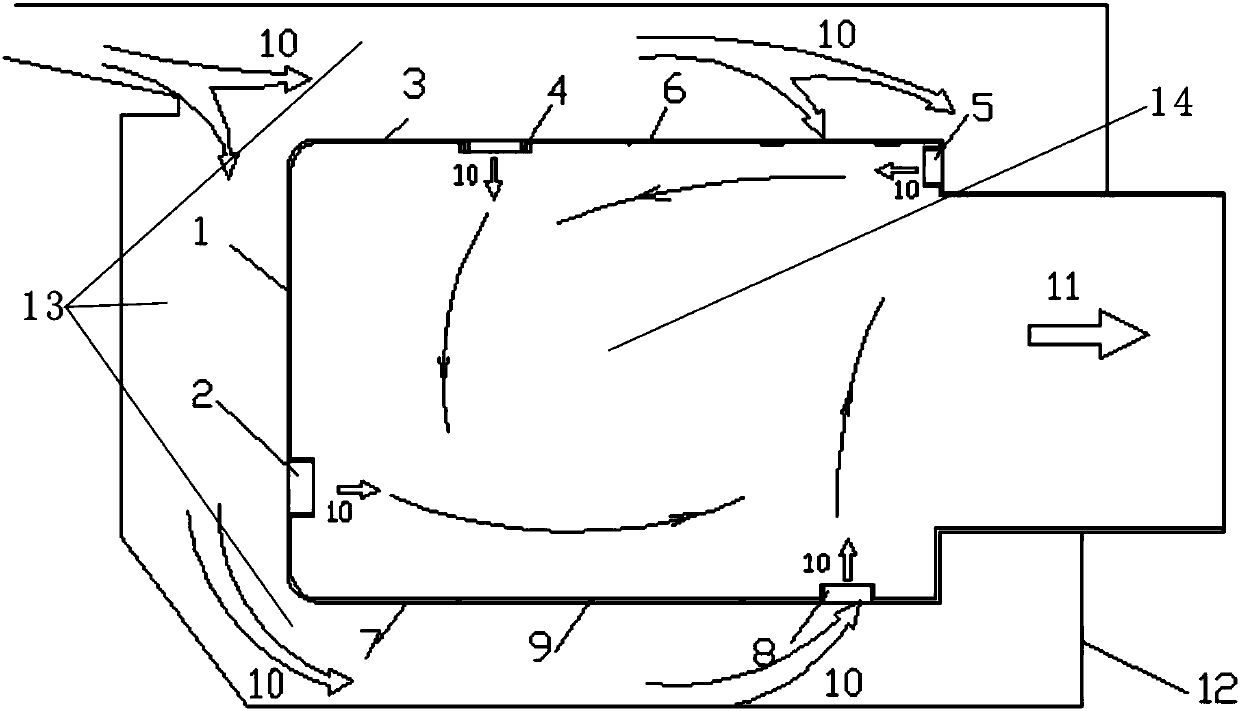

Special equipment for rubbish fermentation and rubbish fermentation method

InactiveCN101289337AVersatileEnhanced blendingClimate change adaptationOrganic fertilisersEngineeringLitter

The invention discloses a special device for waste fermentation, which comprises a fermentation cylinder (2) connected with a driving mechanism (4); wherein, the fermentation cylinder (2) is rotationally connected with a riding wheel frame component (3); the fermentation cylinder (2) is respectively provided with a feed inlet (21), a discharging hole (23), an air inlet (24) and an air outlet (22); a copy board (11) and a baffle (12) are arranged in the fermentation cylinder (2), and the baffle (12) is provided with at least one via hole aperture of which can be adjusted the. A waste fermentation method by utilizing the device is also provided by the invention, the fermentation cylinder (2) with an inner cavity which is 32 meters in length and 3.2 meters in diameter is selected, the rotational speed of the fermentation cylinder (2) is controlled to be 2r / min, and the angle between the central axis of the fermentation cylinder (2) and the horizontal plane of the fermentation cylinder (2) is 2 degrees; heated air is input from the air inlet (24) and the ventilation rate is 10000m<3> / h. Treating wastes by the device of the invention ensures that the waste fermentation period is shorter and the fermentation is more full.

Owner:ZHEJIANG UNIV

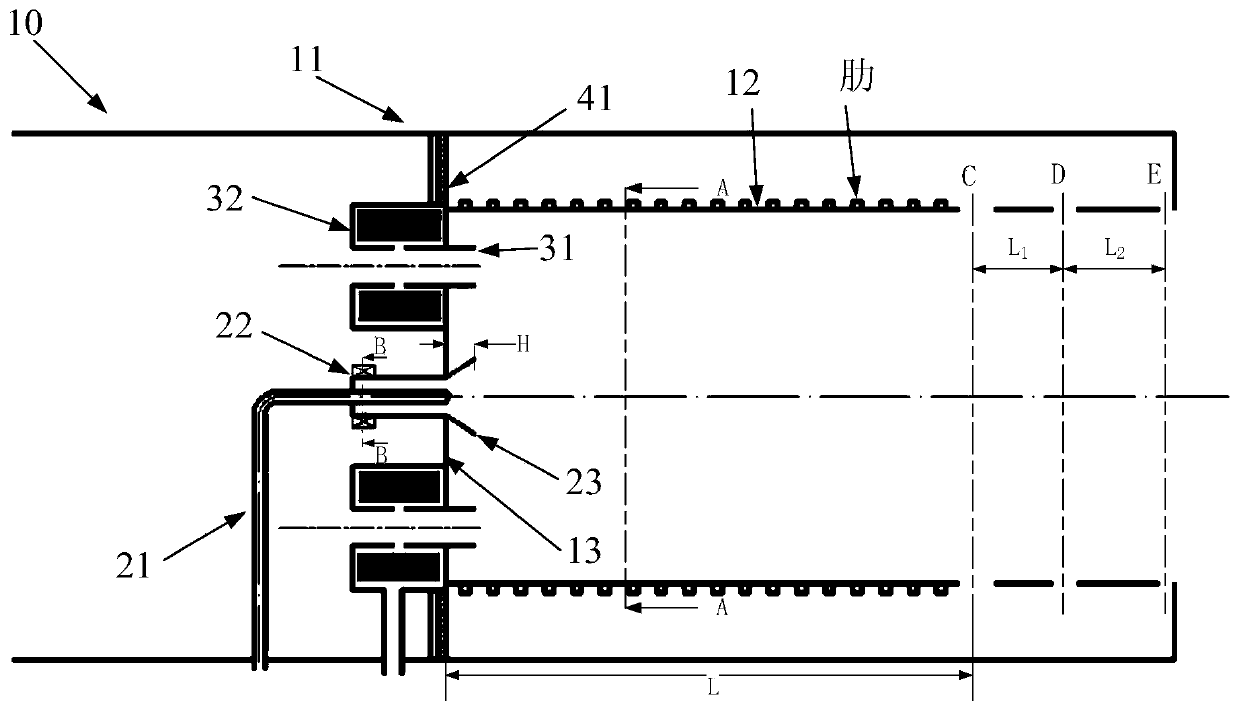

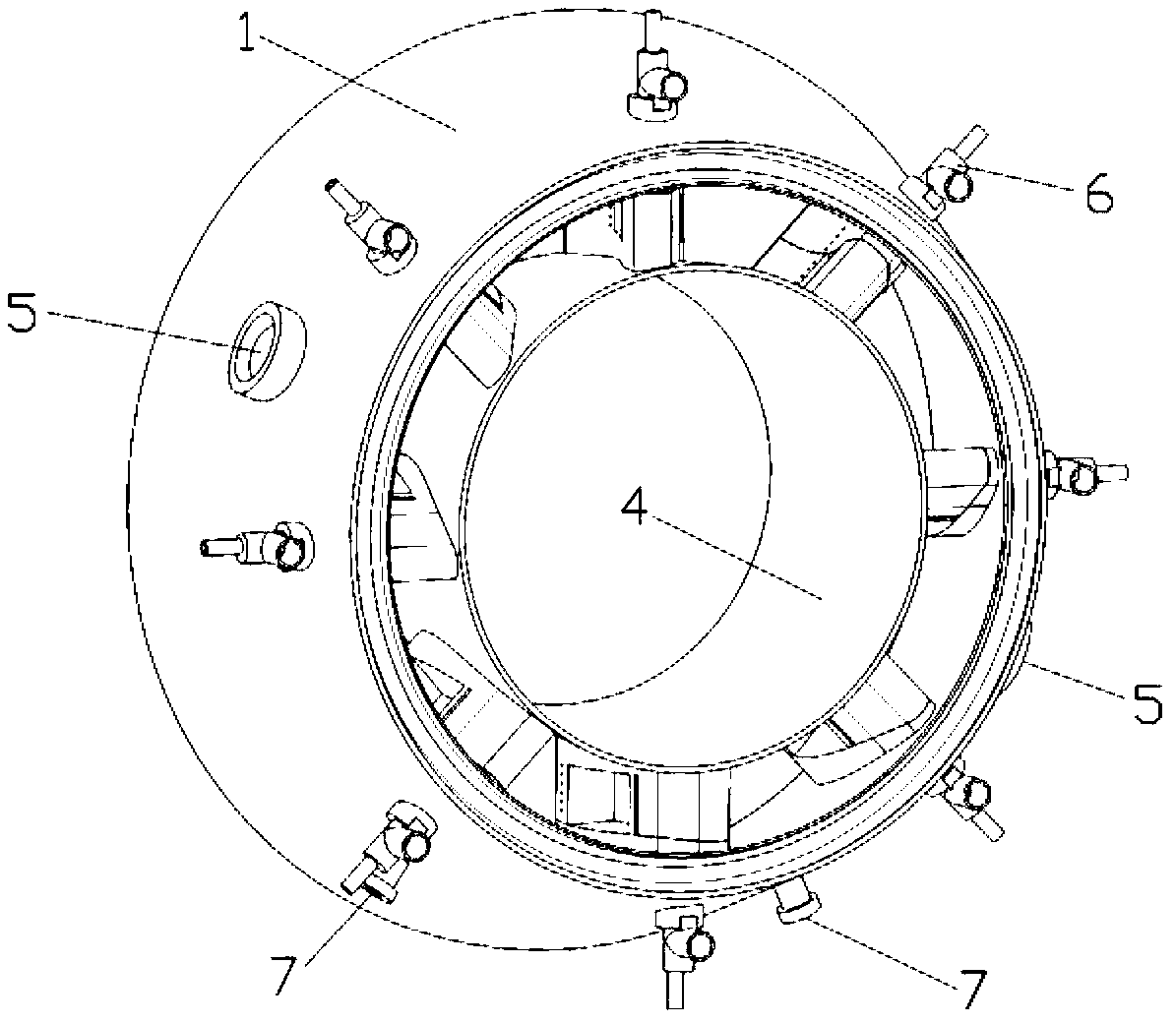

High-efficiency low-emission combustion chamber head capable of premixing hydrogen

InactiveCN114183772AImprove uniformityGuaranteed uniformityContinuous combustion chamberCombustion chamberEngineering

According to the hydrogen premixing efficient low-emission combustion chamber head, the characteristic that hydrogen premixing flames are high in propagation speed and the advantage that the hydrogen flames are thin are combined, the low-emission combustion chamber stable-combustion head structure is designed, the structural design that the multiple stages of fuel annular cavities are connected with the annular cavities is adopted, and the combustion efficiency is improved; the multi-stage premixing flow channel is arranged in the combustor head, the uniformity of fuel entering the combustor head can be greatly improved, the multi-stage premixing flow channel is gradually shrunk, the spiral grooves are formed in the premixing flow channel, mixing of the fuel and air is enhanced, the combustion temperature field is improved, reliable and stable combustion of hydrogen under the premixing condition is achieved, and therefore emission of nitric oxide in the hydrogen combustion process is reduced, and the combustion efficiency is improved. And clean and efficient hydrogen combustion is realized. The scheme has the advantages of light and handy structure, high space utilization rate, high volume heat intensity, low pollutant emission, uniform outlet temperature, good universality, simplicity in processing and maintenance and the like.

Owner:HARBIN ENG UNIV

Fixed grate boiler allowing square bundle of stalks to be combusted

ActiveCN105889901AImprove efficiencyAvoid contaminationSolid fuel combustionAir/fuel supply for combustionAir volumeCombustion chamber

The invention relates to a fixed grate boiler allowing a square bundle of stalks to be combusted, and in order to solve the problems that conventional boiler allowing a bundle of stalks to be combusted cannot guarantee that the stalks are sufficiently combusted, slag bonding is easy to occur, discharged pollution is high, and the efficiency of the boiler is low. Square water-cooled jackets are arranged all around a pre-combustion chamber, and a part in front of the pre-combustion chamber communicates with a feed opening; an outlet of the pre-combustion chamber communicates with a step combustion chamber which is divided into two-stage combustion chambers, wherein fixed grates are arranged at the lower part of a first-stage combustion chamber; turnover grates are arranged at the lower part of a second-stage combustion chamber; a first-stage primary air chamber is arranged under the fixed grates, a second-stage primary air chamber is arranged under the turnover grates; the total amount of primary air is adjusted through an air inlet regulating baffle, and the first-stage primary air amount and the second-stage primary air amount are distributed through a middle adjusting baffle; secondary air filling nozzles are arranged on two side walls of the step combustion chamber; secondary air reinforcing nozzles are arranged on the front wall of the step combustion chamber, and an inlet of an after-combustion chamber communicates with an outlet of the step combustion chamber. The fixed grate boiler disclosed by the invention is used for heating by peasant households away from heating sources in winter and is used as heat supply heating sources of agricultural greenhouses.

Owner:哈尔滨哈东新春锅炉有限公司

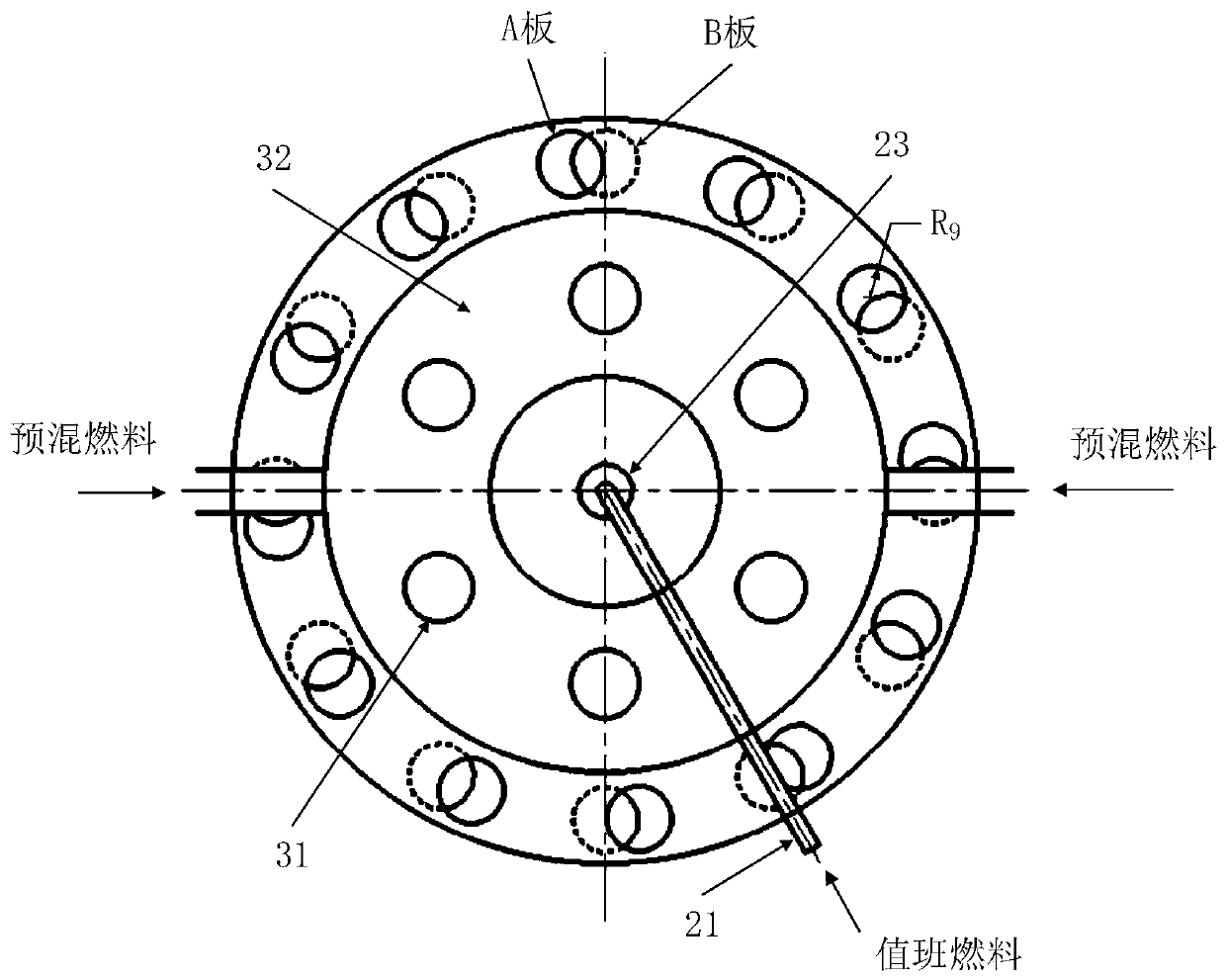

High-temperature smoke generator and control method thereof

ActiveCN110836383AReduce oxygen concentrationReduce the temperatureContinuous combustion chamberCombustion chamberNitrogen oxides

The invention provides a high-temperature smoke generator and a control method thereof. A duty nozzle assembly is arranged at the center of a combustion chamber head baffle, and a premixing nozzle assembly is uniformly distributed on the combustion chamber head baffle in the circumferential direction. An annular air channel is formed between the outer wall of a combustion chamber and a combustionchamber flame tube, and an airflow rate distributing adjusting valve is arranged at an annular channel inlet. High-speed jet flow of premising nozzles forms entrainment backflow in the middle of the combustion chamber, and through a smoke internal circulation mechanism, the forming amount of nitrogen oxide in the combustion chamber is decreased. The outer wall surface of the combustion chamber flame tube is provided with a fin structure to enhance cooling of air in the annular channel to the flame tube. The tail of the combustion chamber flame tube is provided with a plurality of rows of mixing holes, by reasonably distributing the hole diameter and the position of the mixing holes, smoke and mixed air are sufficiently mixed, and accordingly, the uniformity of the outlet smoke temperatureand component distribution is ensured. The high-temperature smoke generator cooperates with the airflow rate adjusting valve, so that effective adjusting of the outlet smoke temperature is achieved.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

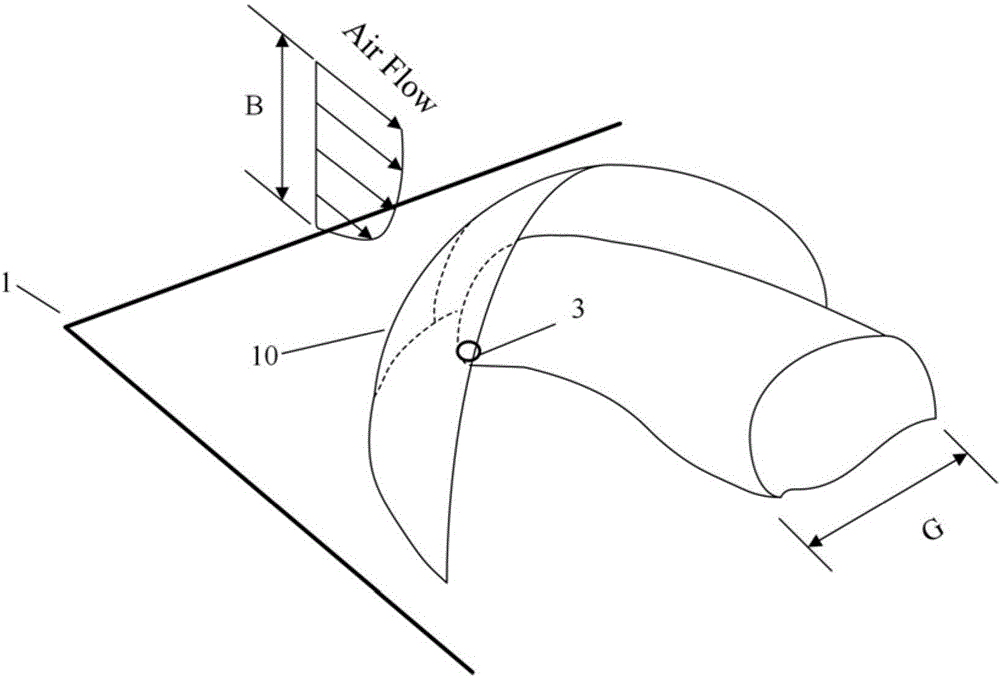

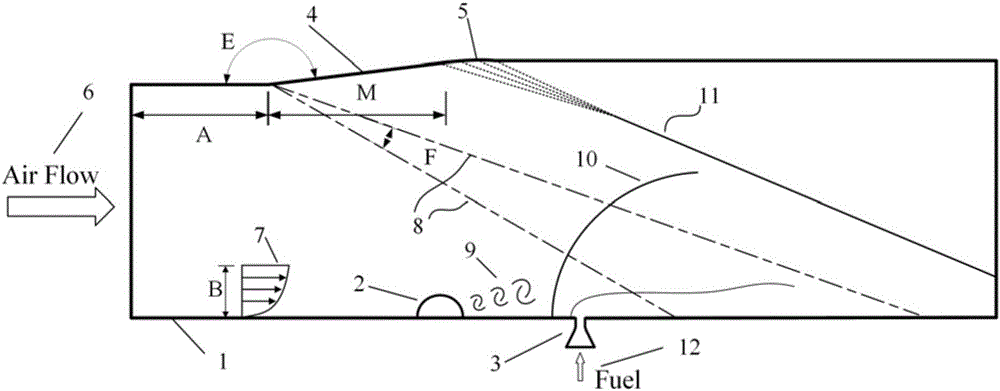

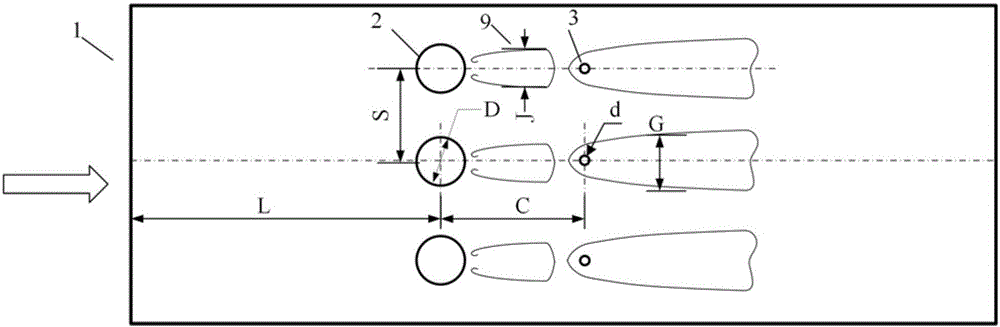

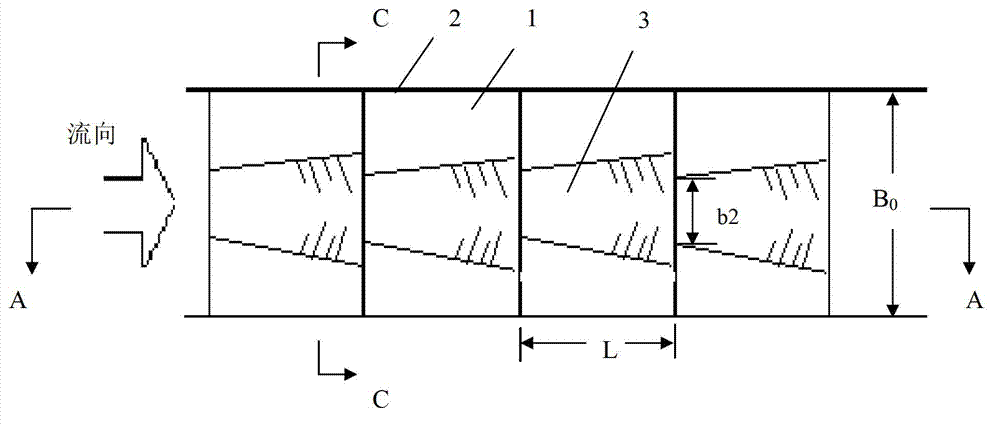

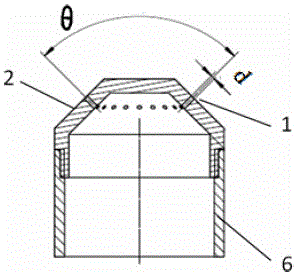

Design method for improving fuel injecting and mixing in super-combustion combustion room

ActiveCN105716115AEnhanced blendingImprove work efficiencyContinuous combustion chamberRamjetCombustion chamber

The invention discloses a design method for improving fuel injecting and mixing in a super-combustion combustion room and relates to scramjet engines. The design method includes the steps that firstly, the diameter and the number of round fuel nozzles are determined according to the total flow of needed fuel, numerical calculation is conducted on a calculating example only with the single round fuel nozzle, and the diffusion diameter and the wall face boundary layer development rule of the fuel are obtained; secondly, the diameters and the positions of semispherical vortex generators are determined; thirdly, the positions of the round fuel nozzles are determined; fourthly, the center distance between every two adjacent semispherical vortex generators is determined; fifthly, the turning angle, the length and the position of an expansion section are determined; and finally, an isentropic compression section is used for transition connection of the expansion section and the upper wall face of the super-combustion combustion room, and therefore design of an injection system of the whole super-combustion combustion room is completed. The working efficiency of the super-combustion combustion room is improved, the size of the super-combustion combustion room is reduced, the weight of the super-combustion combustion room is reduced, engine thrust is increased, and fuel tissue can be better stably combusted; and total pressure losses are low, thermal loads are low, and the thermal protection difficulty of the structure in the super-combustion combustion room is lowered.

Owner:XIAMEN UNIV

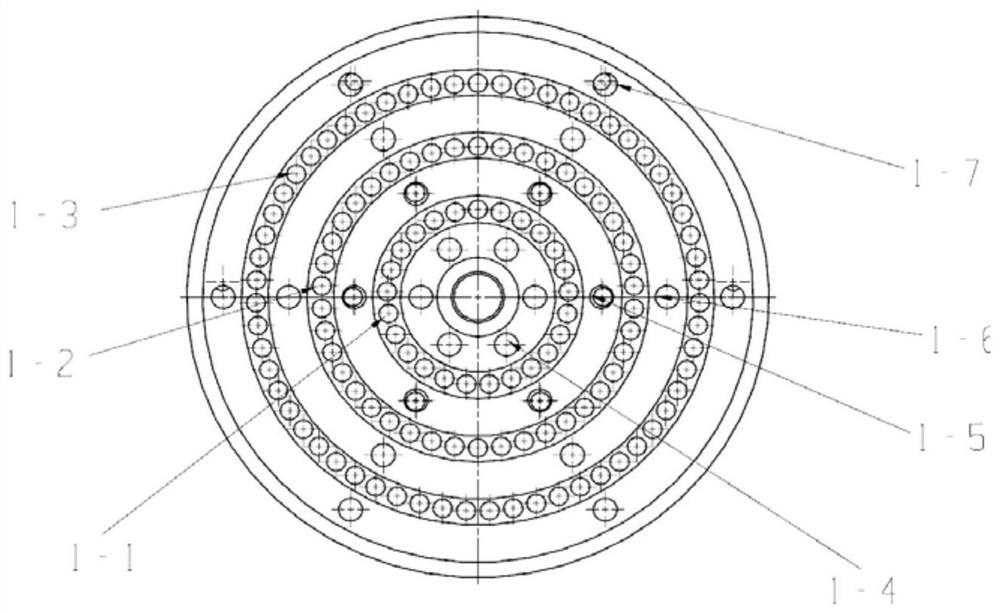

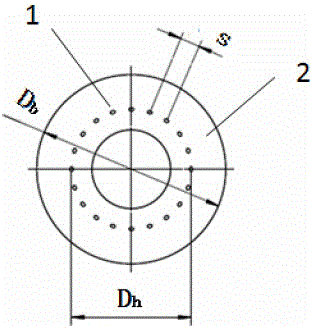

Device for improving jetting uniformity of nozzles

InactiveCN105508111AImprove injection uniformityImprove combustion efficiencyFuel injection apparatusMachines/enginesThrust chamberEngineering

The invention provides a device for improving jetting uniformity of nozzles. The device comprises an oxidizing agent nozzle and a fuel nozzle which are connected with each other and constitute a two-component jetting unit, wherein an oxidizing agent nozzle inlet throttling hole is embedded in an inlet of the oxidizing agent nozzle, and an outlet of the oxidizing agent nozzle is formed in the fuel nozzle; multiple rows of radial inlet holes are radially formed in the fuel nozzle, multiple rows of small holes are further axially formed in the fuel nozzle, and an annular cavity is formed in the lower end of the fuel nozzle; during working, an oxidizing agent enters the oxidizing agent nozzle inlet throttling hole via the inlet of the oxidizing agent nozzle, fuel enters the radial inlet holes of the fuel nozzle, is subjected to primary flow equalization, is subjected to secondary flow equalization by the aid of the annular cavity and is sprayed out via an outlet of the fuel nozzle finally, and uniform distribution along the circumferential height can be obtained. With the adoption of the device, the jetting uniformity of the fuel is improved, mixing and burning effects of the fuel and the oxidizing agent are enhanced, and then the burning efficiency of a thrust chamber is improved.

Owner:BEIJING AEROSPACE PROPULSION INST

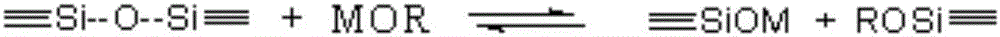

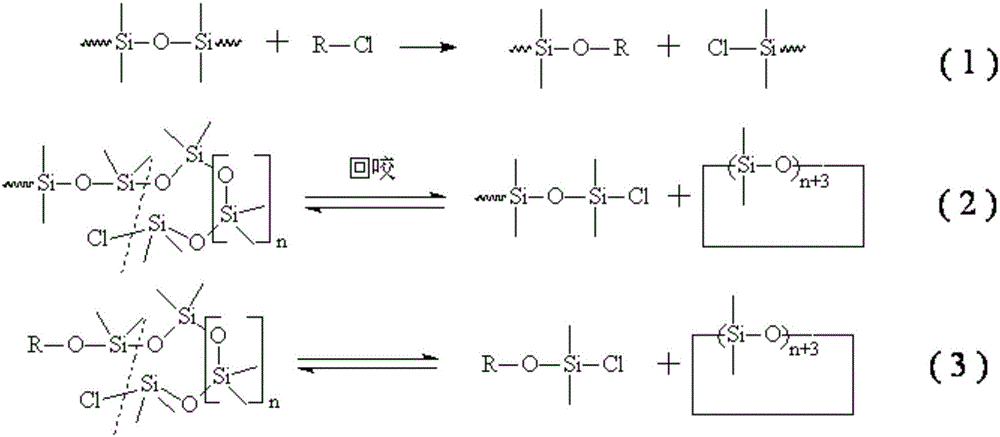

Method for recovering organosilicon micro-molecules and organosilicon cyclic compounds through cracking silicone rubber serial substances

The invention relates to a method for recovering organosilicon micro-molecules and organosilicon cyclic compounds through cracking silicone rubber serial substances. The method comprises the following steps: a chemical reaction of an organosilicon halogenation agent and a polysiloxane main chain in silicone rubber is carried out to break the polysiloxane main chain into polysiloxanes with silicon-chlorine bonds, and the polysiloxanes with silicon-chlorine bonds undergo a series of back-biting reactions and are degraded into an organosilicon micro-molecule and organosilicon cyclic compound mixture; and organosilicon micro-molecules and organosilicon cyclic compounds obtained after cracking undergo a rearrangement reaction to obtain highly pure D4 used for synthesizing various organosilicon polymers and materials as a basic raw material.

Owner:SHANDONG UNIV

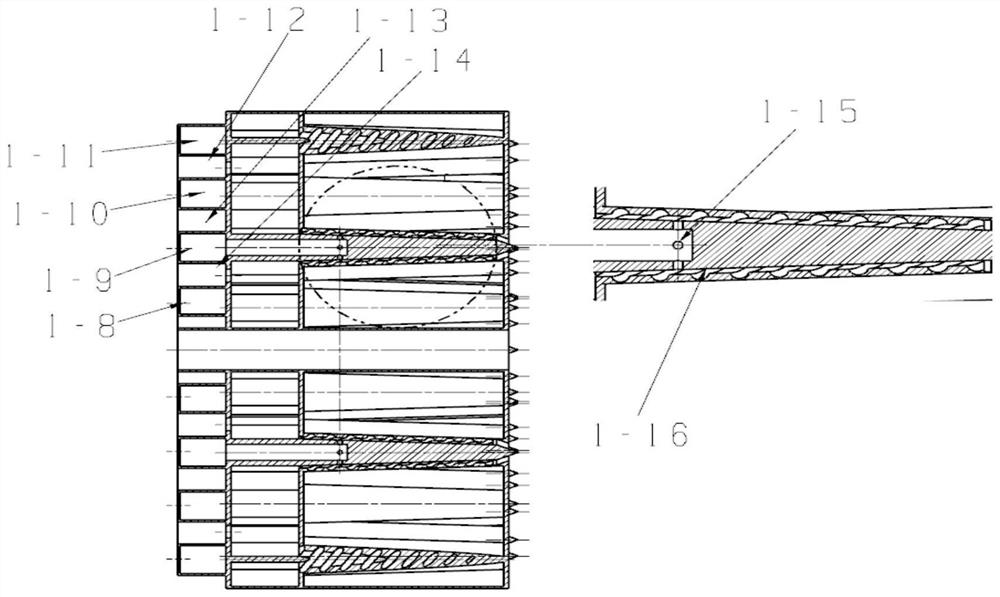

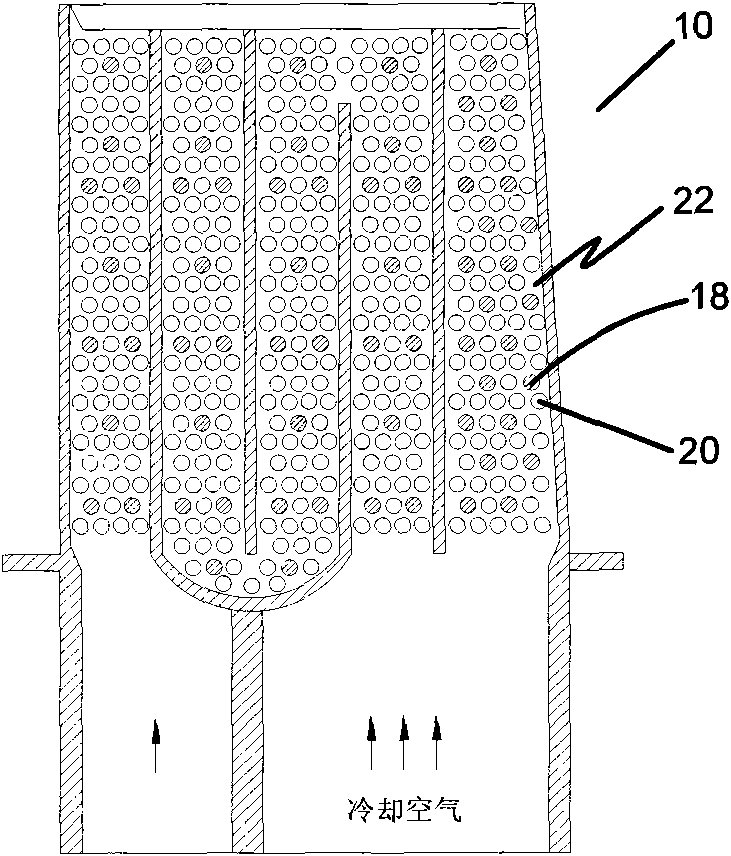

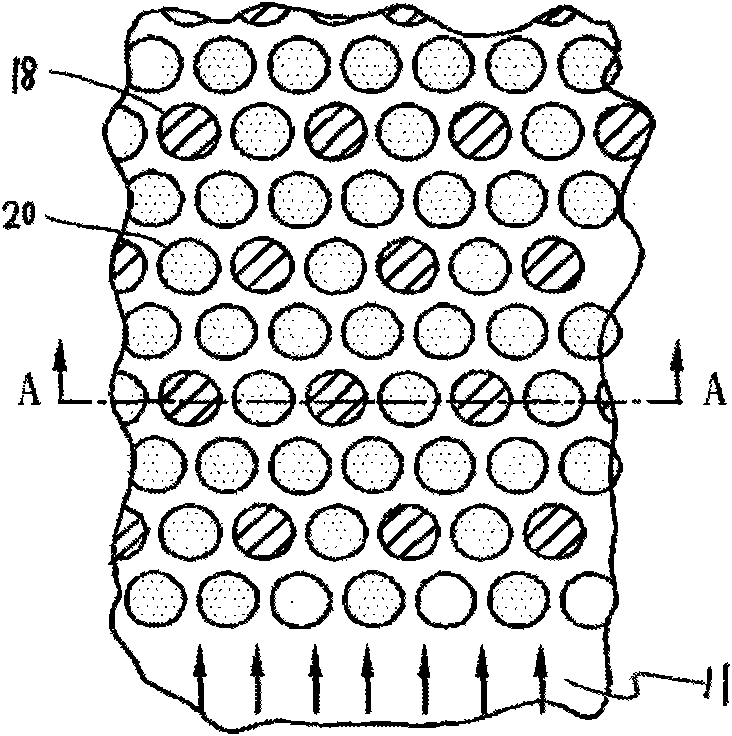

Turbine blade compound cooling structure with sunken internal pin

InactiveCN101581235AImprove heat transfer effectEnhanced blendingBlade accessoriesMachines/enginesTurbine bladeCooling fluid

The invention relates to a turbine blade compound cooling structure with sunken internal pins, comprising a blade passage and a pin; the cooling structure is characterized by further comprising a sunken part, pins are arranged in the blade passage, the blade passage has at least one internal wall surface provided with sunken parts; the sunken parts are arranged in the blade passage in a dislocation way; the sunken parts are of semisphere or part of the semisphere or cone with top part cut off. In the invention, the pins are respectively connected with two wall surfaces in the blade passage, thus on one hand increasing heat exchange area of cooling fluid and on the other hand consolidating the passage; the sunken parts cause the flowing through to generate vortex, thus improving convection and heat exchange effect between the air stream and wall surface of the blade passage and pin surface; meanwhile, when the air stream flows through the sunken parts, direct impact on the pins by the lower reaches of the fluid body is reduced, thus avoiding increase of flow losses while increasing heat exchange area.

Owner:SHANGHAI JIAO TONG UNIV

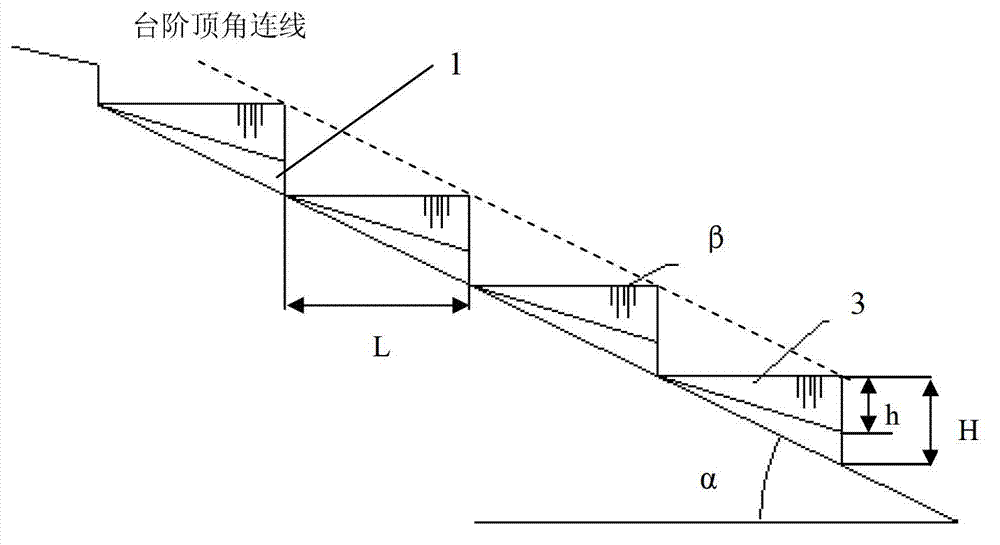

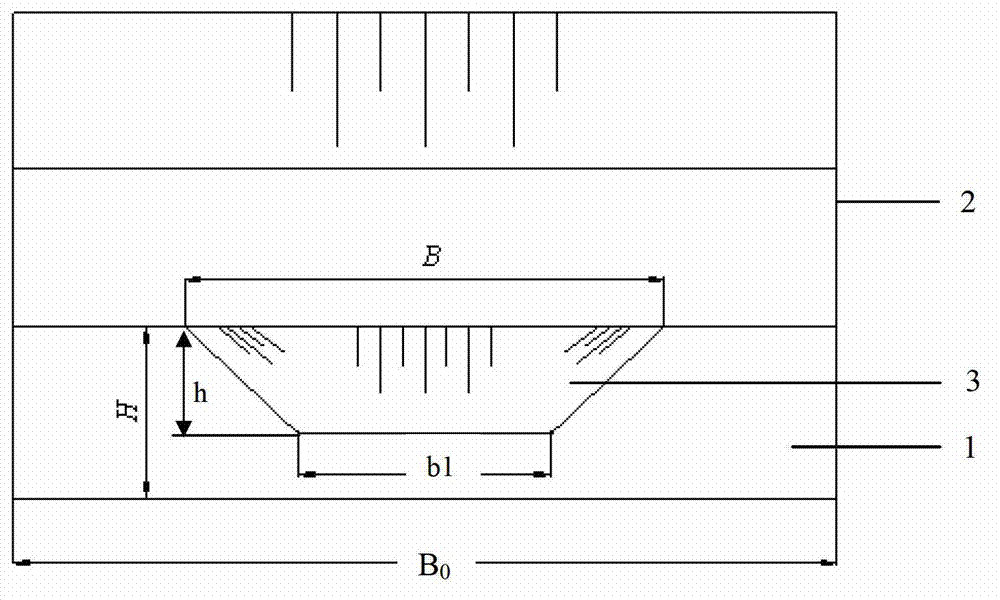

Debris-flow drainage canal with energy dissipation and drainage functions and application thereof

The invention discloses a debris-flow drainage canal with energy dissipation and drainage functions and an application of the debris-flow drainage canal with energy dissipation and drainage functions. The drainage canal comprises a fully-lining drainage canal bottom plate and drainage canal side walls on two sides of the drainage canal bottom plate; the drainage canal bottom plate is in the shape of continuously-connected multiple-stage steps, the steps are provided with grooves; the width of the grooves on the top surfaces of the steps increases gradually along the flow direction of the debris flow, and the width of the grooves on the vertical surfaces of the steps decreases gradually; and the maximum width of the grooves on the top surfaces of the steps coincide with the maximum width B on the vertical surfaces of the steps. Compared wit the prior art, the step shape design is adopted to dissipate the energy of the debris flow all the way and the groove design is adopted to drain the debris flow, so the debris-flow drainage canal disclosed by the invention has high efficiency and good drainage capacity. By adjusting the height and the length of the steps and the size and the shape of grooves, the debris-flow drainagedrainage canal can be used for preventing the debris flow with any gradient and any nature.

Owner:INST OF MOUNTAIN HAZARDS & ENVIRONMENT CHINESE ACADEMY OF SCI

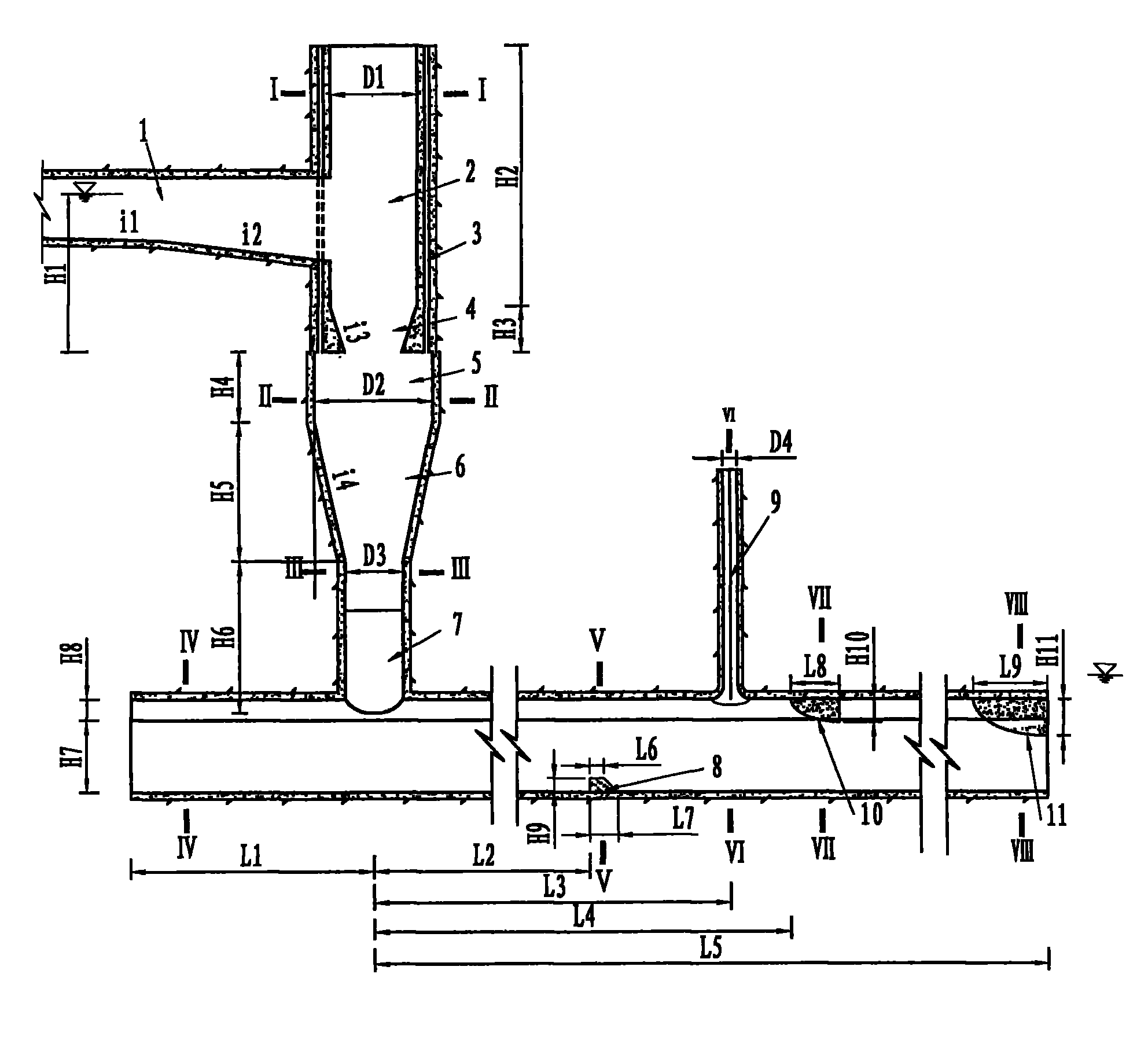

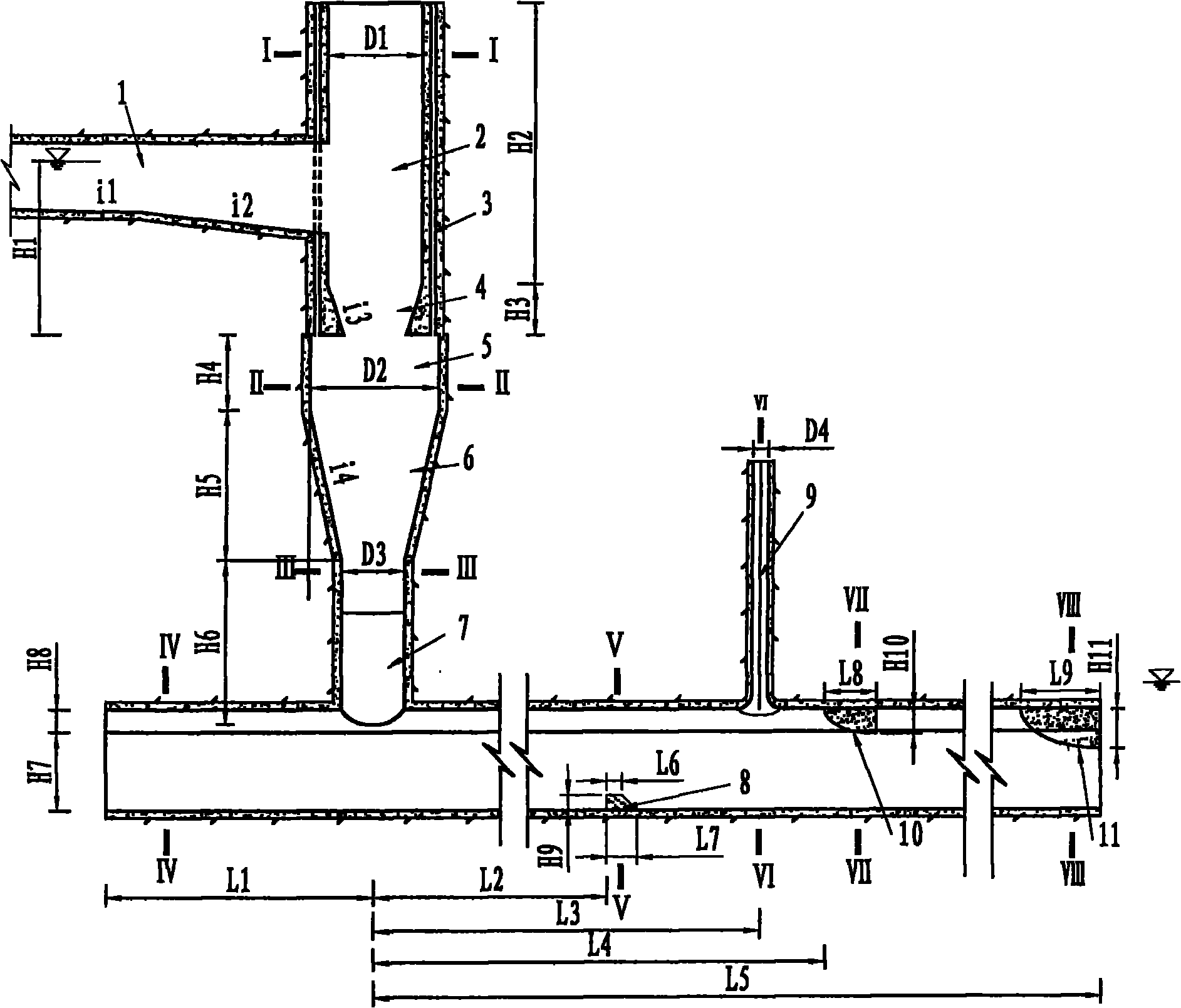

Submerged cyclone shaft sluice tunnel

InactiveCN101812832AImprove fluidityGood exhaust conditionBarrages/weirsCyclonePulp and paper industry

A submerged cyclone shaft sluice tunnel comprises a sluice tunnel and an aerated cyclone shaft with double volute chambers installed at the closed end of the sluice tunnel and communicated with the sluice tunnel; the sluice tunnel is internally provided with a stop part and a middle part slope; the top of the sluice tunnel is provided with an air exit hole; the aerated cyclone shaft with double volute chambers is positioned at the top of the sluice tunnel, and the central line thereof is vertical to the central line of the sluice tunnel; the stop part is installed on the bottom plate of the sluice tunnel; the distance L2 between the beginning end of the stop part and the central line of the aerated cyclone shaft with double volute chambers is equal to 5H7 to 10H7; the air exit hole is positioned in the middle of the stop part and the middle part slope; the distance L3 between the central line of the air exit hole and the central line of the aerated cyclone shaft with double volute chambers is equal to 7H7 to 15H7; the middle part slope is installed at the top of the sluice tunnel; the distance L4 between the beginning end of the middle part slope and the central line of the aerated cyclone shaft with double volute chambers is equal to 8H7 to 15H7; and the H7 in each formula is the height of the upright wall of the gate-shaped sluice tunnel.

Owner:SICHUAN UNIV

Active control type fully-immersed liquid-cooled power battery thermal management system

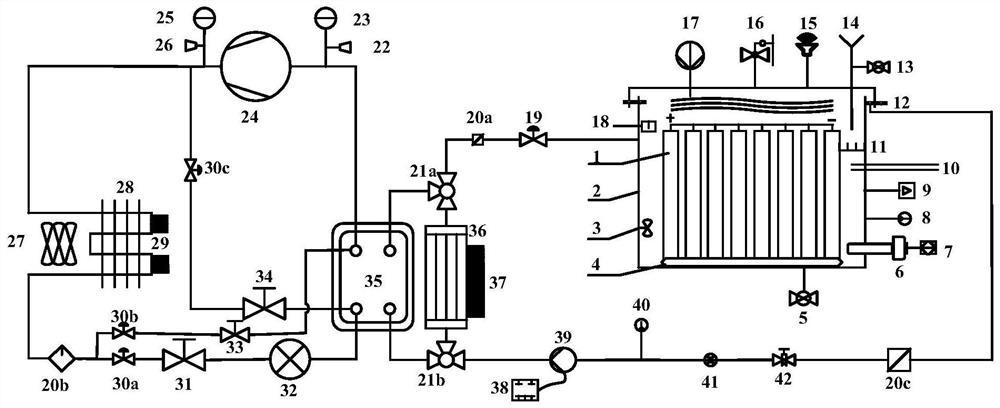

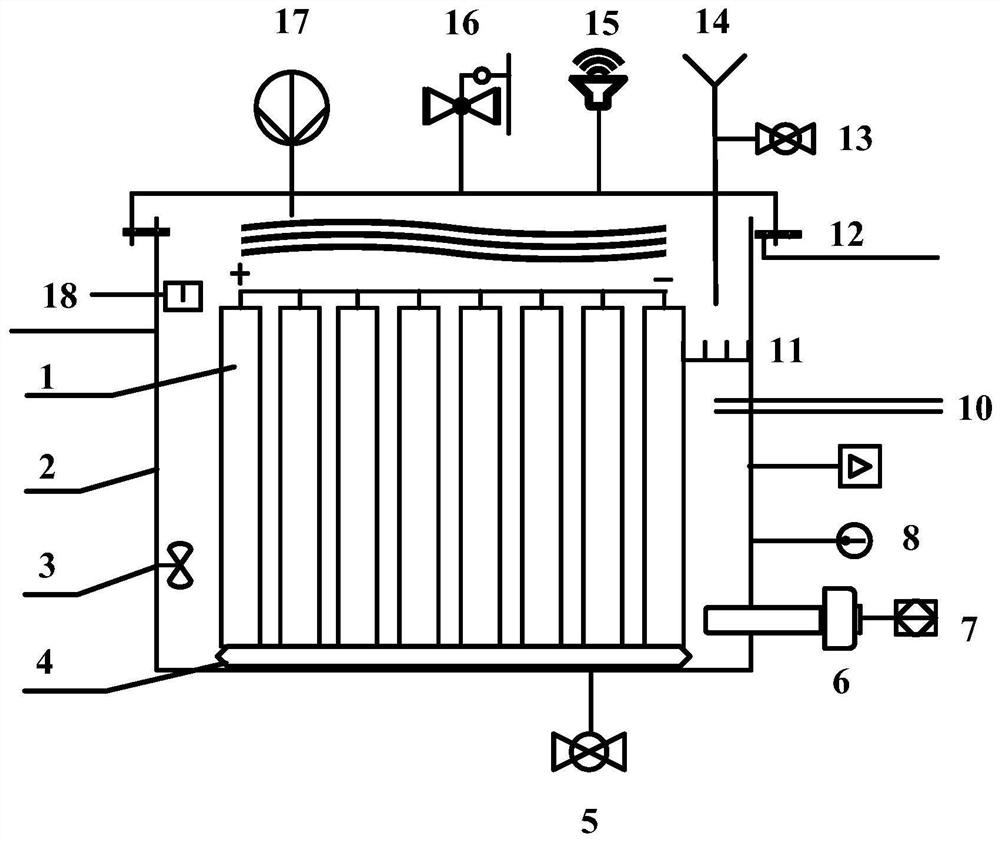

InactiveCN112886093AReduce lossesImprove heat transfer efficiencyCell temperature controlCirculator pumpEngineering

The invention aims to provide an active control type fully-immersed liquid-cooled power battery thermal management system. A compressor, a condenser, a refrigeration electromagnetic valve, an expansion valve and an evaporator are connected in series to form a compressor unit main refrigeration unit; a manual valve and a liquid spraying electromagnetic valve are led out from a pipeline in front of the refrigeration electromagnetic valve to form a spraying branch; a thermal manual valve and a thermal electromagnetic valve are led out from a pipeline between the compressor and the condenser to the evaporator to form a thermal bypass branch; and a first three-way reversing valve and a second three-way reversing valve are connected with a plate heat exchanger and the evaporator and are connected in parallel to form a plate heat exchanger auxiliary cooling unit, the first three-way reversing valve is connected with a drying filter and the manual valve to a cooling liquid tank, and the second three-way reversing valve is connected with an electronic circulating pump, a temperature sensor and a flow sensor to the cooling liquid tank. The direct contact type fully-immersed liquid-cooled mode is adopted, the heat loss in the heat exchange process of the whole heat management system can be greatly reduced and improved, the heat exchange resistance of the system is reduced, and the heat exchange efficiency is improved.

Owner:HARBIN ENG UNIV

Combustion chamber fuel nozzle device

ActiveCN107013941AStructural innovationCompact structureContinuous combustion chamberCombustion chamberFuel oil

The invention provides a combustion chamber fuel nozzle device. The combustion chamber fuel nozzle device comprises a nozzle rod part and a fuel nozzle shell; a main combustion level oil line and a pre-combustion level oil line are arranged in the nozzle rod part; one end of the pre-combustion level oil line is connected into the fuel nozzle shell and provided with a pre-combustion level nozzle; one end of the main combustion level oil line is annularly distributed on the periphery of the fuel nozzle shell and provided with a plurality of main combustion level nozzles which are machined independently so that fuel oil in the main combustion level oil line can be ejected rotationally; and the fuel nozzle shell is connected with a main swirler and located at the outlet ends of the main combustion level nozzles and the outlet end of the pre-combustion level nozzle. According to the combustion chamber fuel nozzle device, the main combustion level nozzles are machined independently and then welded to the fuel nozzle shell, the oil injection mode of the main combustion level nozzles is adjusted, thus, the oil injection mode of the main combustion level nozzles is converted from the direct-injection mode into the centrifugal mode, the atomization effect is strengthened, mixing of fuel oil and air in a main combustion zone is facilitated, and finally, pollutant discharge of a combustion chamber is reduced.

Owner:AECC COMML AIRCRAFT ENGINE CO LTD

Online adjustable fuel gas generator adopting jet flow collision combustion manner

InactiveCN107013943APromote fragmentationPromote atomizationContinuous combustion chamberPilot systemCombustion chamber

The invention provides an online adjustable fuel gas generator adopting a jet flow collision combustion manner. The online adjustable fuel gas generator is composed of an annular slot combustion chamber, a convergence segment and an adjustment plug cone, and the adjustment plug cone is located at the head of the combustion chamber; the combustion chamber is of an annular-slot-shaped structure and is composed of a front jet panel, a rear jet panel and a side body portion cooling panel; a plurality of sets of rotational flow type air feeding holes of different rotation directions are formed in the side body portion cooling panel of the combustion chamber to provide liquid film type regeneration cooling for the combustion chamber body portion and enhance mixing of fuel gas; and the adjustment plug cone molded surface and the convergence segment molded surface are designed in a matched manner, the adjustment plug cone can move front and back, the relative position is manually set, or the size of the outlet throat portion is subjected to online self-adaption adjustment based on combustion chamber pressure. The online adjustable fuel gas generator is compact in structure, the length of the combustion chamber is small, the structural size and cooling area requirements of the combustion chamber are greatly lowered, the online adjustable fuel gas generator can be adapted to online adjustment of fuel gas generators of ground test systems in the aerospace field in various combustion working conditions and has excellent flame stability and fuel gas mixing capacity, and an outlet flow field is uniform.

Owner:PLA PEOPLES LIBERATION ARMY OF CHINA STRATEGIC SUPPORT FORCE AEROSPACE ENG UNIV

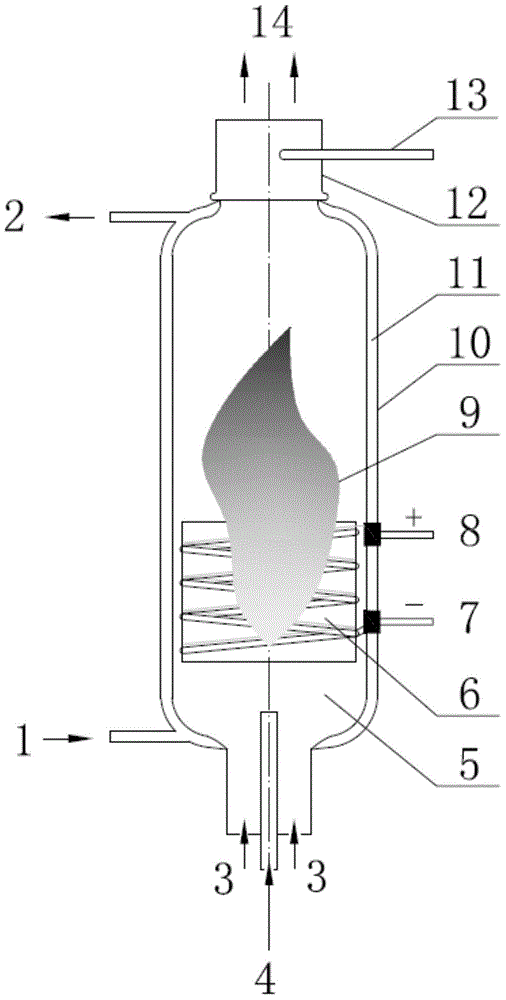

Directional spinning plasma combustion-supporting system

ActiveCN103953474AIncrease momentumEnhanced blendingContinuous combustion chamberInternal combustion piston enginesSupporting systemBusiness efficiency

The invention relates to a directional spinning plasma combustion-supporting system, which comprises a hollow shell, a nanosecond pulse plasma power source and a plasma actuator which is connected to the nanosecond pulse plasma power source, wherein a gas collection device and a gas inlet are respectively arranged at the top end and the lower end of the hollow shell; a combustion zone and a premixing zone are formed in the hollow shell from top to bottom; the plasma actuator and the nanosecond pulse plasma power source are respectively arranged inside and outside the hollow shell; the gas inlet is communicated with the gas collection device by sequentially passing the premixing zone and the combustion zone. The invention provides the directional spinning plasma combustion-supporting system which is capable of improving the combustion-supporting performance and the energy efficiency ratio.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

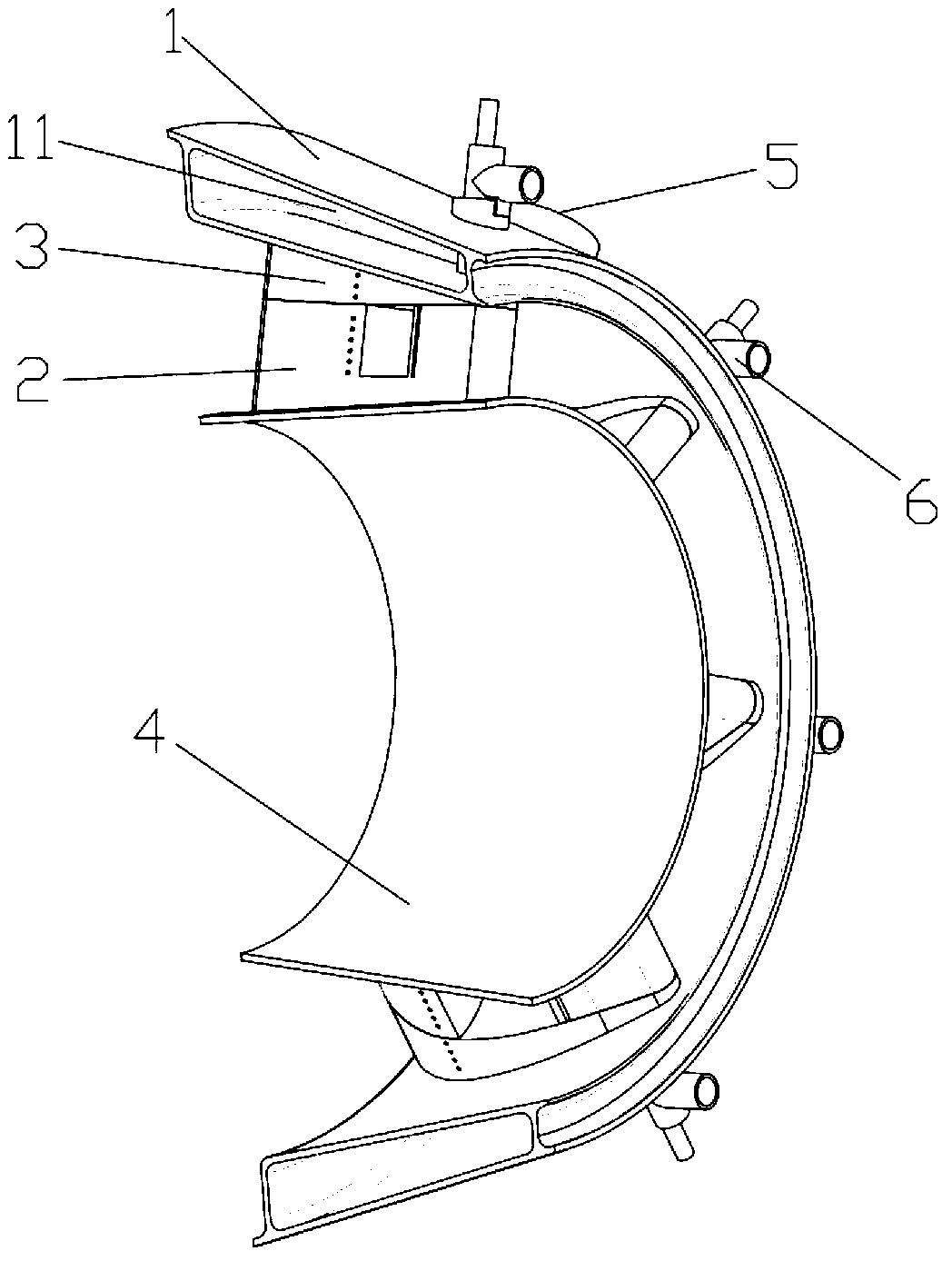

Turbine stator blade with interstage combustor

InactiveCN103266922AIncrease motivationLower blocking ratioContinuous combustion chamberGas turbine plantsCombustion chamberCombustor

The invention discloses a turbine stator blade with an interstage combustor, and relates to turbine stator blades of aero-engines or gas turbines. The turbine stator blade comprises an inner ring, an outer ring and multiple guide blades, wherein the guide blades are provided with a guide blade main body and a guide blade cover; the guide blade cover is arranged on the upper end of the guide blade main body, and the guide blade main body is provided with a front oil injection cavity, a middle backflow cavity and a rear cooling cavity; another cooling cavity is formed at the rear of the guide blade cover, and the oil injection cavity is internally provided with a spraying rod slot; the cooling cavity of the guide blade main body and the cooling cavity of the guide blade cover respectively have cooling holes; the turbine stator blade is also provided with ignition devices and multiple spraying rod devices, and the ignition devices are provided with ignition bases and ignition electric nozzles; the spraying rod devices are arranged on the guide blades, the outer ends of the spraying rod devices pass through and are exposed of the outer ring, and the inner ends of the spraying rod devices stretch into oil injection cavities of the guide blades; and the spraying rod devices are provided with oil pipes, gas pipes and nozzles, oil spraying ports and multiple gas spraying ports are formed in the nozzles, and the oil pipes and the air pipes are respectively connected with an oil supplying pipe and a gas supplying pipe.

Owner:XIAMEN UNIV

Multi-hole fuel gas jet flow burner

The invention discloses a multi-hole fuel gas jet flow burner. The burner comprises a gas pipeline, a gas nozzle, an air pipeline and an air pipeline outlet, wherein the gas pipeline is a gas flow passageway, a hollow cavity between the air pipeline and the gas pipeline is an air flow passageway, a round of fire holes are evenly formed in the wall of the gas nozzle, an axial centre line of the gas nozzle serves as a circle center of an annular ring formed by the fire holes, and the following formulas: Dh / D b = 0.4-0.8, d / s =1.5-4, theta= 20 degrees-150 degrees are satisfied; the fire holes and intervals are arranged reasonably, and fully co-firing of gas and air can be achieved; multi-hole fuel gas jet flow is injected into incoming flow air in the direction of an included angle formed by an axis of the nozzle and the multi-hole fuel gas jet flow, expansion type flow is adopted to form a negative pressure in a rear side of the gas nozzle, backflow of high temperature smoke is achieved, and flame blowoff and flameout are avoided; air flow can increase negative pressure in the rear side of the gas nozzle, the backflow of the high temperature smoke is facilitated, and flame stabilization is further facilitated; fuel gas jet flow injects into shear layer outside a backflow area, and mixing of the air and flue is facilitated.

Owner:东方电气洁能科技成都有限公司

Coaxial staged combustor for low-pollution combustion chamber of gas fuel gas turbine

ActiveCN113310071ASimple structureReduce Pollutant EmissionsContinuous combustion chamberEngineeringStaged combustion

Owner:HARBIN ENG UNIV

Process for preparation of a dry instant porridge

InactiveUS20140314907A1Enhanced mixing processLow viscosityMilk preparationDough treatmentEnzymatic hydrolysisMoisture

The present invention relates to a process for the preparation of a dry instant porridge comprising the enzymatic hydrolysis of a milled carbohydrate-rich food blend by at least one amylase enzyme in an extruder and at low moisture content. The present invention also refers to a dry instant porridge or a fortified dry instant porridge obtainable by the above mentioned process.

Owner:DSM IP ASSETS BV

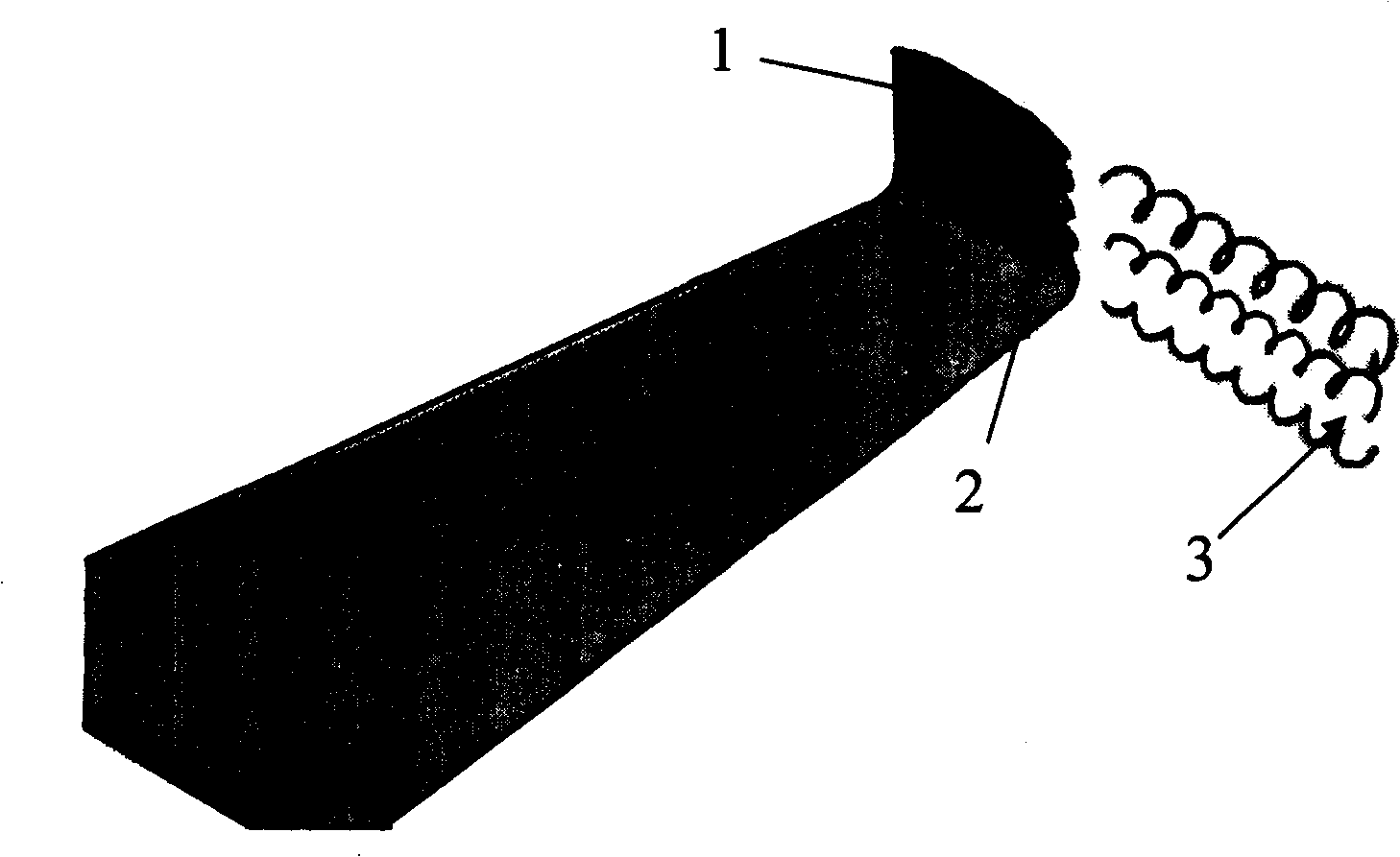

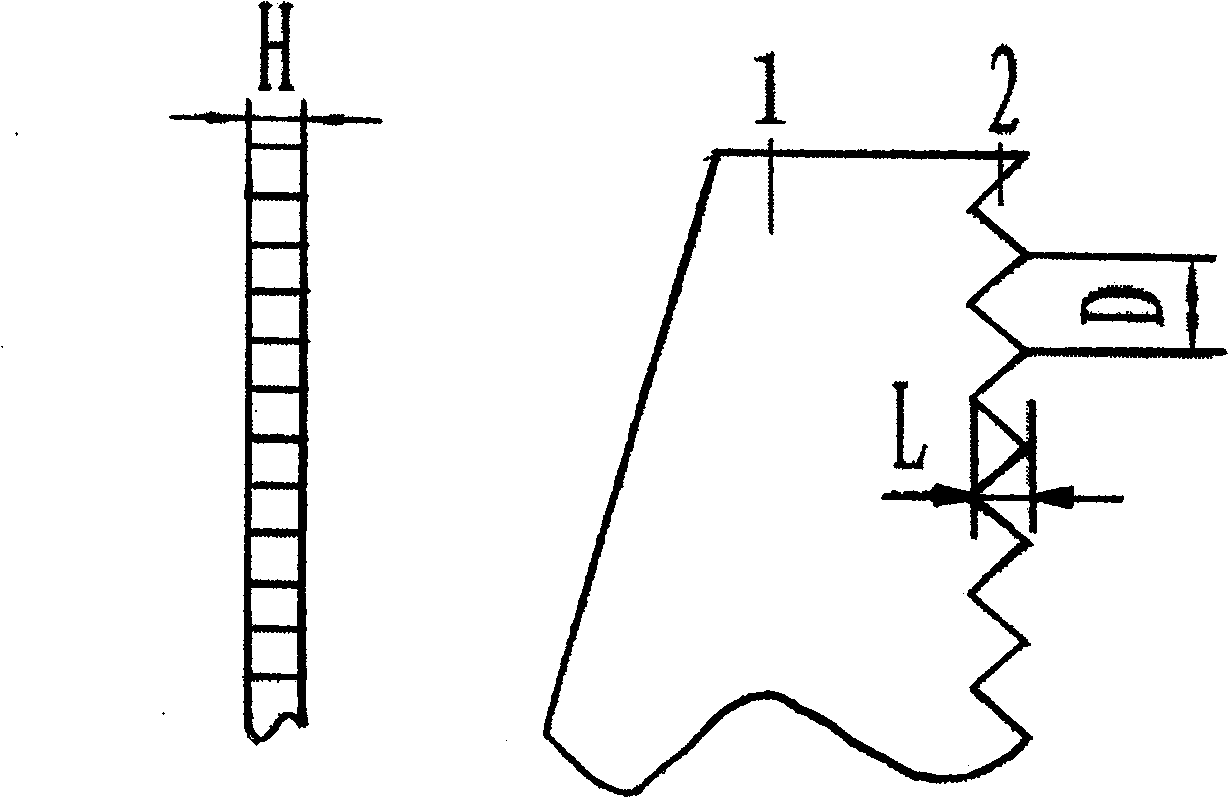

Quick wing tip vortex weakening apparatus

The invention relates to a wingtip vortex fast weakening device which designs the back edge of an alula at the wingtip of an airfoil into a sawtooth structure and leads the sawtooth structure to be parallel with the back edge of the alula at the wingtip. The structure of the invention is simple and is improved based on the original alula structure at the wingtip, which can not bring any additional quantity to an airplane. Simultaneously, the invention runs stably, does not need to be provided with power when running and is convenient for being maintained. The wingtip vortex fast weakening device of the alula at the wingtip in the sawtooth shape of the back edge designed by the invention has physical characteristic scales of the wingtip vortex, can speed up and induce the mixing between a high speed air flow and a low speed air flow generated by the wingtip vortex and can lead the wingtip vortex to fast break into a vortex with a small scale, thus achieving the effect of speeding up the dissipation of the wingtip vortex and fast weakening the wingtip vortex.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

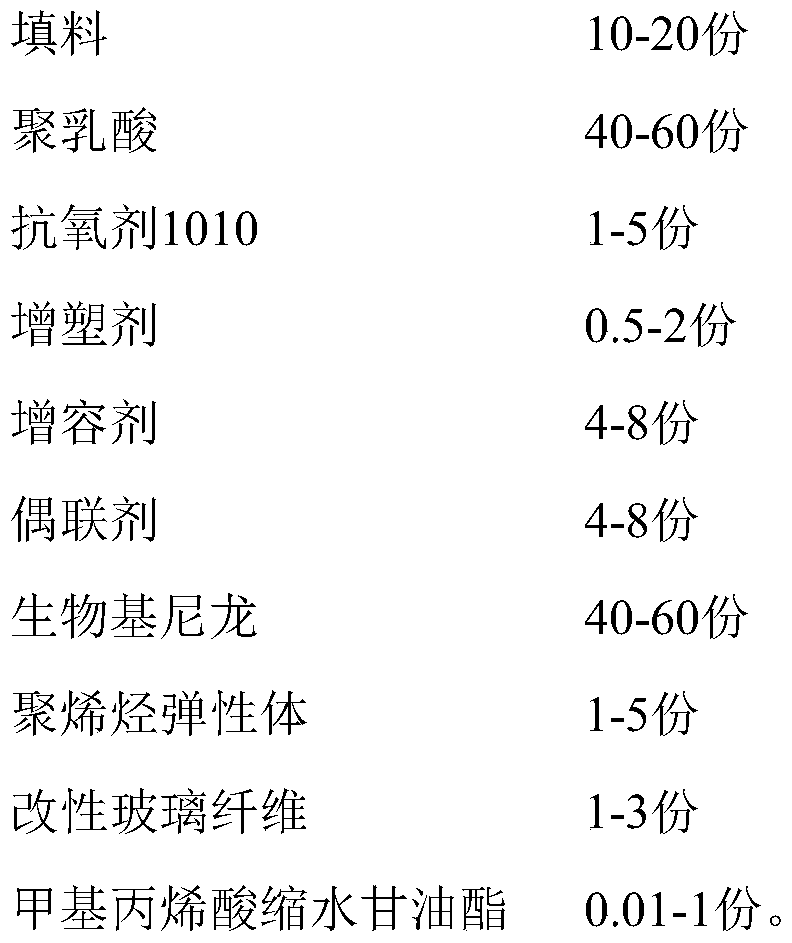

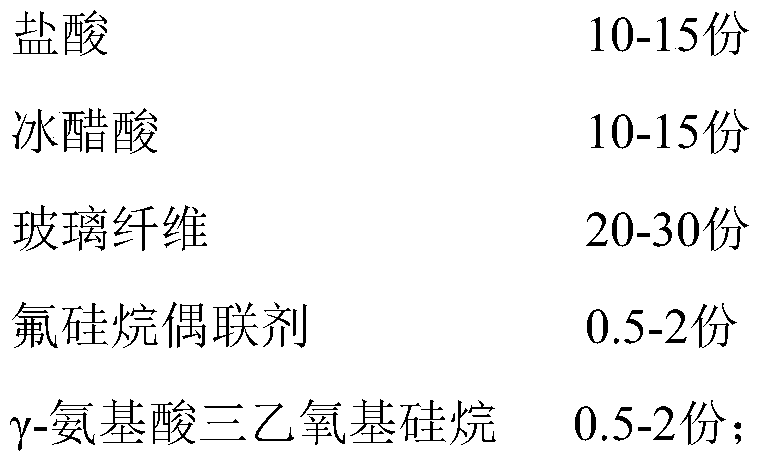

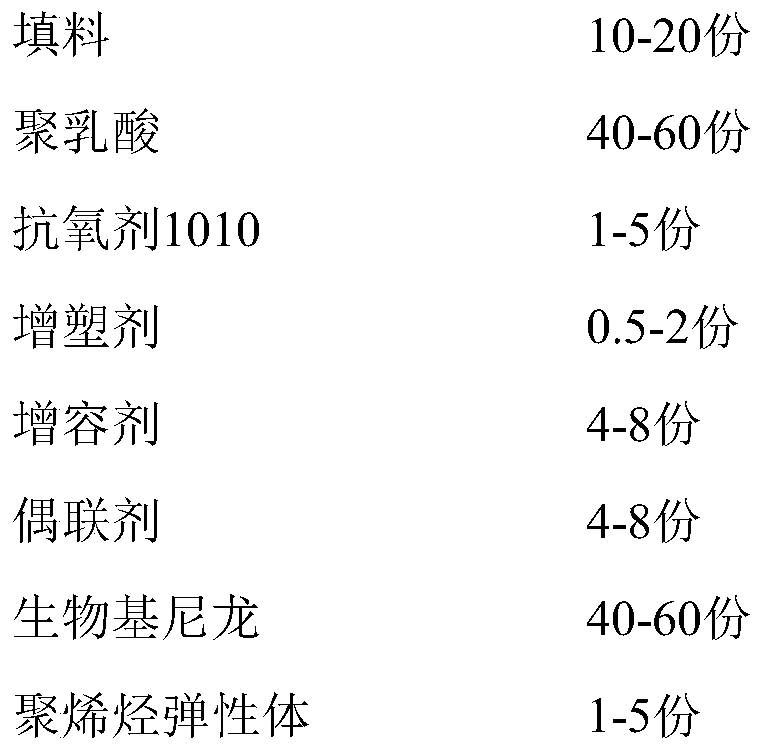

Bio-based nylon composite PLA material and preparation method thereof

ActiveCN110467804AProtects against thermo-oxidative degradationHigh mechanical strengthElastomerGlycidyl methacrylate

The invention relates to the technical field of biomaterials, particularly to a bio-based nylon composite PLA material and a preparation method thereof, wherein the raw materials comprise, by weight,10-20 parts of a filler, 40-60 parts of polylactic acid, 1-5 parts of an antioxidant1010, 0.5-2 parts of a plasticizer, 4-8 parts of a compatibilizer, 4-8 parts of a coupling agent, 40-60 parts of a bio-based nylon, 1-5 parts of a polyolefin elastomer, 1-3 parts of modified glass fiber, and 0.01-1 part of glycidyl methacrylate. According to the present invention, the mechanical strength and the size stability of the PLA material are improved by filling the modified glass fiber with the bio-based nylon and the polylactic acid while the bio-based nylon and polylactic acid compounding process isfilled and grafted by using the filler and the high-toughness grafting agent glycidyl methacrylate, such that the bio-based nylon composite PLA material meets the performance requirements of engineering plastics and has good degradability.

Owner:DONGGUAN ZHONGYI NEW MATERIAL TECH CO LTD

Self-circulation low nitrogen oxide swirling burner

The invention discloses a self-circulation low nitrogen oxide swirling burner and belongs to the field of burning. The self-circulation low nitrogen oxide swirling burner comprises a burner body and a connecting pipe, wherein the burner body is of a dual-layer ring sleeve structure. A guide pipe is connected with a gas cylinder or an air compressor through a pressure relief valve. Air flows into an outer hole via the guide pipe, is sprayed into a ring cavity via the outer hole and forms a low-pressure area in the ring cavity, then an tangential jet air flow enters the cavity and generates a swirling flow by rotating along an arc wall continuously, and a uniform stable swirling flow flame is formed after ignition; and when the air flow reaches an outlet of a combustor body, the main component of the air flow is burnt fuel gas, due to the mobility characteristic of the swirling flow and the low-pressure area, part of gas at the outlet of the burner body flows back to an inlet from the ring cavity and enters the combustor body again, and operations are repeatedly conducted so that the purpose of circulation of the flue gas can be achieved. The self-circulation low nitrogen oxide swirling burner achieves the technical effects of reducing emission of harmful gas generated during burning, improving the burning efficiency of liquid fuel and solid fuel, preventing the liquid fuel and the solid fuel from adhering to walls, and prolonging the service life.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Trapped vortex type micro-turbine engine combustion chamber

ActiveCN107906560AExtended stayEnhanced blendingContinuous combustion chamberCombustion chamberEngineering

The invention discloses a trapped vortex type micro-turbine engine combustion chamber comprising a flame tube and an engine casing. The flame tube comprises a flame tube outer wall, a flame tube frontwall and a flame tube inner wall, wherein the flame tube outer wall, the flame tube front wall and the flame tube inner wall are sealed to form a flame tube airflow cavity A, and an annular cavity Bis formed between the flame tube and the engine casing. The flame tube outer wall is provided with a second jet flow hole. The end, far away from the flame tube front wall, of the flame tube outer wall is provided with a third jet flow hole. The flame tube front wall is provided with a first jet flow hole. A fourth jet flow hole is formed in the flame tube inner wall. A first group of cooling holes are formed in the flame tube outer wall. The flame tube inner wall is provided with a second group of cooling holes. By the adoption of the trapped vortex type micro-turbine engine combustion chamber, a center strong backflow region enables the staying time of air flow in the combustion chamber to be prolonged, the peripheral low-speed-zone area of the backflow region is widened, so that spreading of flame is facilitated, and therefore the combustion in the head region is stable.

Owner:SICHUAN AEROSPACE ZHONGTIAN POWER EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com