Directional spinning plasma combustion-supporting system

A plasma and combustion-supporting system technology, which is applied in the charging system, combustion chamber, combustion method, etc., can solve the problems of low oxygen content, increase the difficulty of ignition, and provide high-pressure air in the combustion chamber, so as to promote mixing and enhance momentum. and energy exchange, increasing speed and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

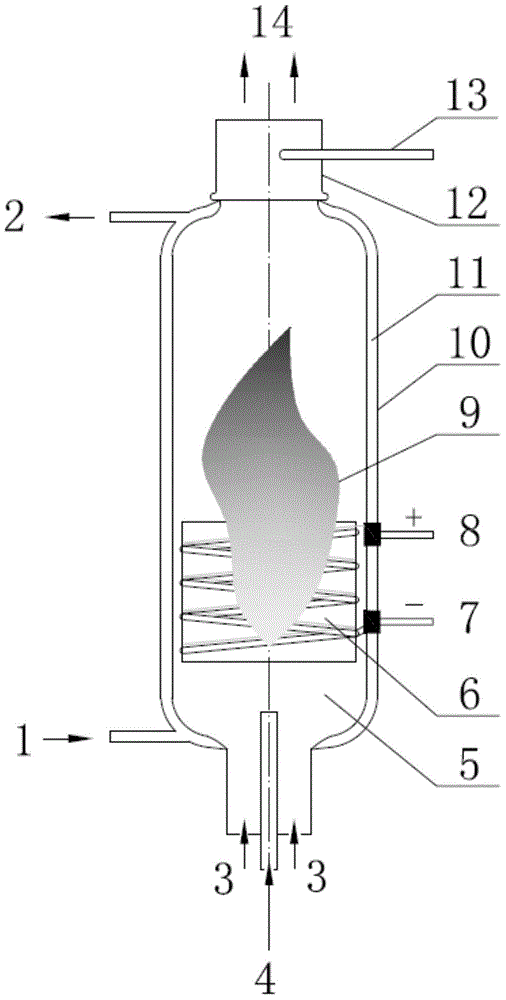

[0021] The invention provides a directional spin plasma combustion-supporting system, the directional spin plasma combustion-supporting system includes a hollow shell, a nanosecond pulse plasma power supply and a plasma exciter connected with the nanosecond pulse plasma power supply; The top and bottom of the hollow shell are respectively provided with a gas collection device and a gas inlet; the combustion zone and the premixing zone are formed from top to bottom inside the hollow shell; the plasma exciter and the nanosecond pulse plasma power supply are respectively set in the middle The inside and outside of the hollow shell; the gas inlet is connected through the premixing zone, the combustion zone and the gas collection device in sequence.

[0022] The plasma exciter includes a high-voltage electrode, a low-voltage electrode, and an insulating medium arranged between the high-voltage electrode and the low-voltage electrode. The electrodes are respectively connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com