UHMWPE composition and high-wear-resistant and high-cutting-resistance fiber prepared from same

A composition and ultra-high molecular weight technology, applied in the field of D01F, can solve the problems of high viscoelasticity and poor dispersion of inorganic fillers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

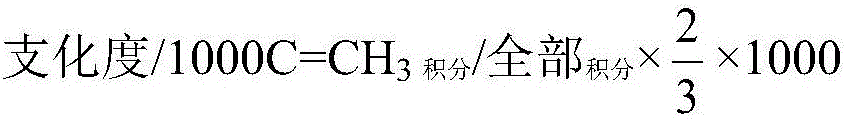

[0042] As an embodiment of the present invention, the weight average molecular weight of the ultra-high molecular weight polyethylene is 1 million to 4 million;

[0043] As a preferred mode of the present invention, the weight average molecular weight of the ultra-high molecular weight polyethylene is 2 million to 2.4 million.

[0044]The weight average molecular weight is a value obtained in terms of polystyrene based on gel permeation chromatography (hereinafter, abbreviated as "GPC") measurement. The determination condition of GPC adopts the conventional condition test in this field, for example, it can be tested in the following manner.

[0045] Column: The following columns were connected in series and used.

[0046] "TSKgelG5000" (7.8mmI.D.×30cm)×1

[0047] "TSKgelG4000" (7.8mmI.D.×30cm)×1

[0048] "TSKgelG3000" (7.8mmI.D.×30cm)×1

[0049] "TSKgelG2000" (7.8mmI.D.×30cm)×1

[0050] Detector: RI (differential refractometer); column temperature: 40°C; eluent: tetrahydr...

Embodiment approach 1

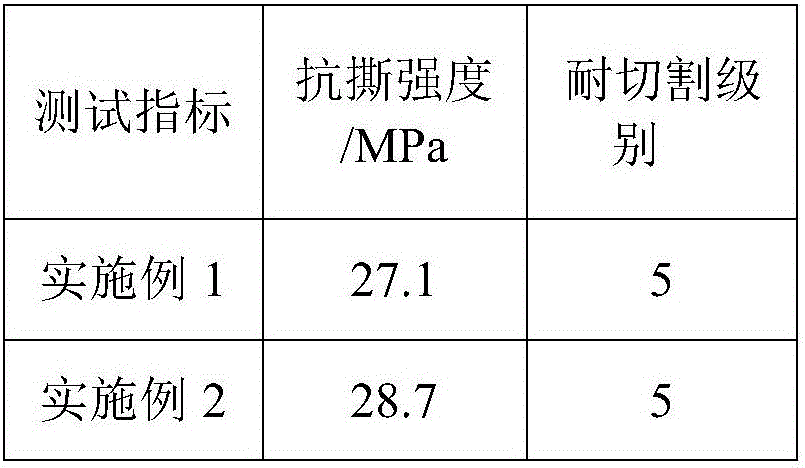

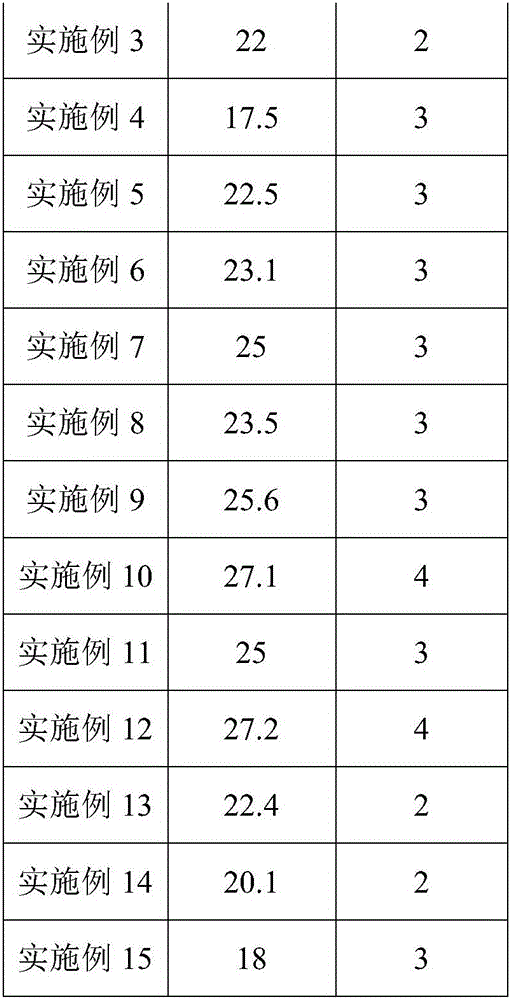

[0143] Embodiment 1: an ultra-high molecular weight polyethylene composition, which comprises: silicon carbide, modified graphene and ultra-high molecular weight polyethylene; wherein, the modified graphene is hyperbranched polyethylene grafted graphene.

Embodiment approach 2

[0144] Embodiment 2: same as Embodiment 1, except that the average particle diameter of the silicon carbide is 5-90 nm or 0.6-1 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Young's modulus | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com