Patents

Literature

912 results about "Gel permeation chromatography" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gel permeation chromatography (GPC) is a type of size exclusion chromatography (SEC), that separates analytes on the basis of size. The technique is often used for the analysis of polymers. As a technique, SEC was first developed in 1955 by Lathe and Ruthven. The term gel permeation chromatography can be traced back to J.C. Moore of the Dow Chemical Company who investigated the technique in 1964 and the proprietary column technology was licensed to Waters Corporation, who subsequently commercialized this technology in 1964. GPC systems and consumables are now also available from a number of manufacturers. It is often necessary to separate polymers, both to analyze them as well as to purify the desired product.

Cement dispersant, method for production thereof, and cement composition using the dispersant

InactiveUS6376581B1Delayed slump lossLowering of unit water contentPolymer sciencePolyethylene glycol

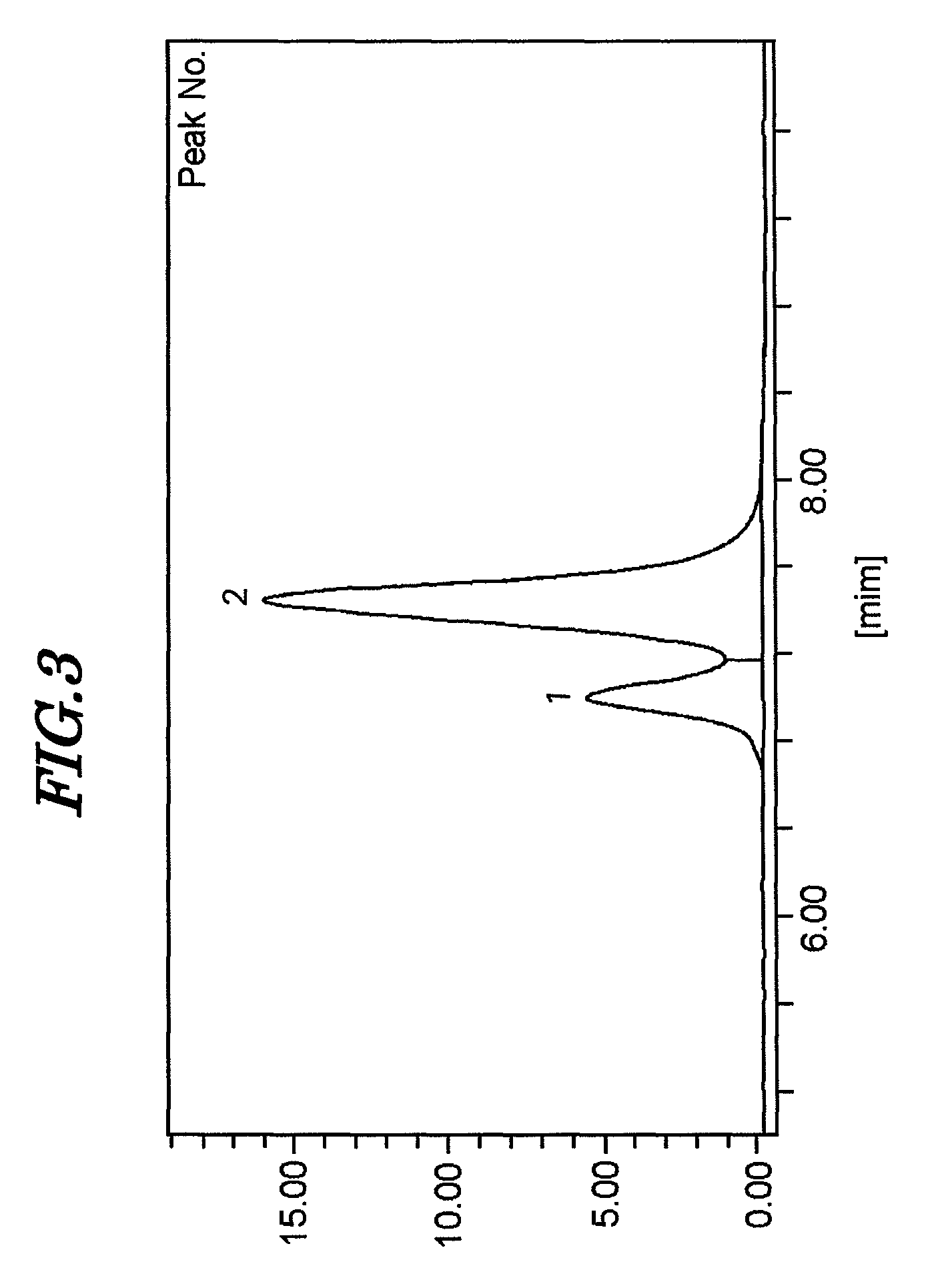

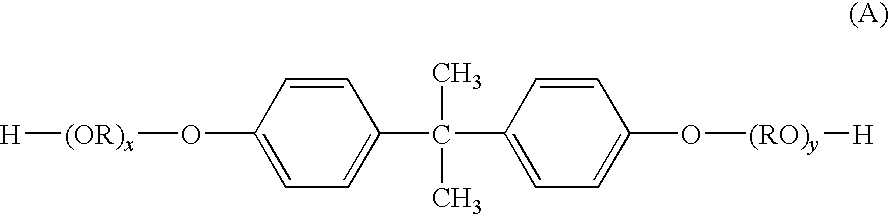

A cement dispersant having excellent ability to prevent slump loss and high water-reducing property which comprises a polycarboxylic acid type polymer having a specific molecular weight distribution, a method for the production thereof, and a cement composition using the dispersant are provided. The cement dispersant comprises as a main component thereof a polycarboxylic acid type polymer (A), having a weight average molecular weight in the range of 10,000 to 500,000 in terms of polyethylene glycol determined by gel permeation chromatography, and having a value determined by subtracting the peak top molecular weight from the weight average molecular weight in the range of 0 to 8,000.

Owner:MBT HLDG

Chondroitinase, process for preparing the same, and pharmaceutical composition comprising the same

InactiveUS6184023B1Avoid stickingInhibit productionBacteriaHydrolasesChondroitinase ABCConcentration gradient

A crystallizable, purified chondroitinase ABC having a molecular weight of about 100,000 dalton by the measurement of the SDS-polyacrylamide gel electrophoresis (SDS-PAGE) and the measurement by the gel permeation chromatography method, having alanine as the N-terminal amino acid and proline as the C-terminal amino acid. A process for the purification of the crystallizable purified chondroitinase ABC comprising removing nucleic acid from an surfactant solution extract obtained from cells of chondroitinase ABC-producing microorganisms and chromatographically treating by concentration gradient elution using a weak cation exchange resin or a strong cation exchange resin. A composition comprising a chondroitinase and serum albumin, gelatin, or a nonionic surfactant.

Owner:SEIKAGAKU KOGYO CO LTD

Aqueous ink composition and method of manufacturing the same

InactiveUS20050004261A1Improve printing qualityReduce blurDuplicating/marking methodsInksMethacrylatePolymer science

An aqueous ink composition comprising: a pigment, having a particle diameter as determined by the light scattering method of no less than 20 nm and no more than 200 nm; and a water dispersible polymer, having a styrene-equivalent number average molecular weight of as determined by gel permeation chromatography no less than 5000 and no more than 200000, having a surface tension of no less than 20 mN / m and no more than 40 mN / m, and wherein the abovementioned pigment is a polymer-coated pigment that is coated with the abovementioned water dispersible polymer, is provided. The water-dispersible polymer may be a copolymer of monomers, mainly comprising acrylic acid and / or methacrylic acid and an acrylate and / or methacrylate. With this ink composition, the printing quality can be improved.

Owner:SEIKO EPSON CORP

Polypropylene resin composition and use thereof

A polypropylene resin composition exibiting a high melt tension and superior moldability, which can be molded efficiently by a high-speed molding into scarcely deformable larger molded articles of better appearance with high stiffness and which comprises polypropylene as a main component and has the following characteristic features 1) to 4), namely,1) that a melt flow rate (MFR, determined at 230° C. under a load of 2.16 kg) is in the range of 0.01 to 5 g / 10 min.,2) that a content of a high molecular weight polypropylene exhibiting an intrinsic viscosity [eta], determined at 135° C. in decalin, of 8-13 dl / g is in the range of 15 to 50% by weight,3) that a gel areal density in number is 3,000 / 450 cm2 or less and4) that a molecular weight distribution determined by gel permeation chromatography (GPC) is 6-20, as expressed by Mw / Mn, and is 3.5 or higher, as expressed by Mz / Mw.

Owner:PRIME POLYMER CO LTD

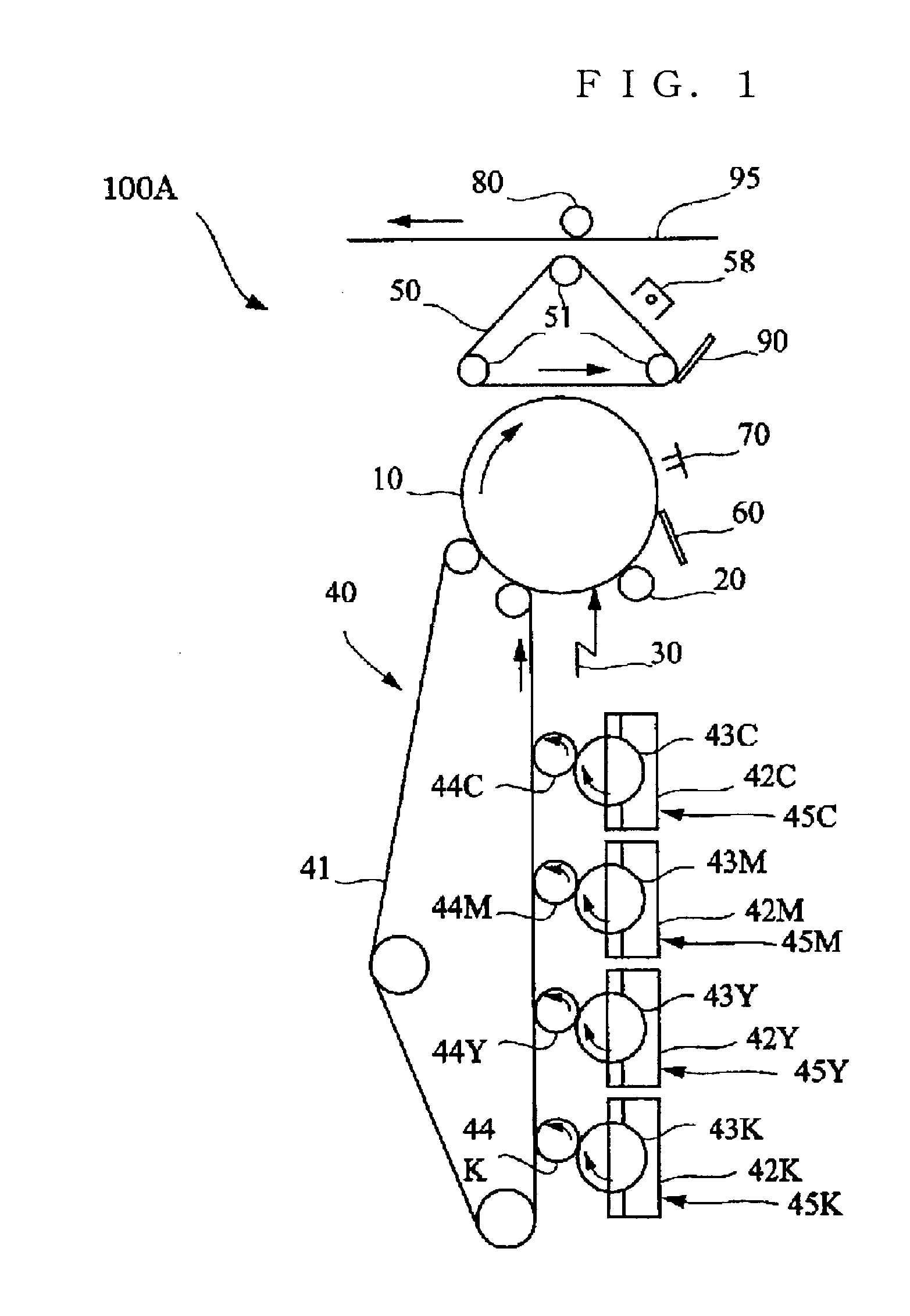

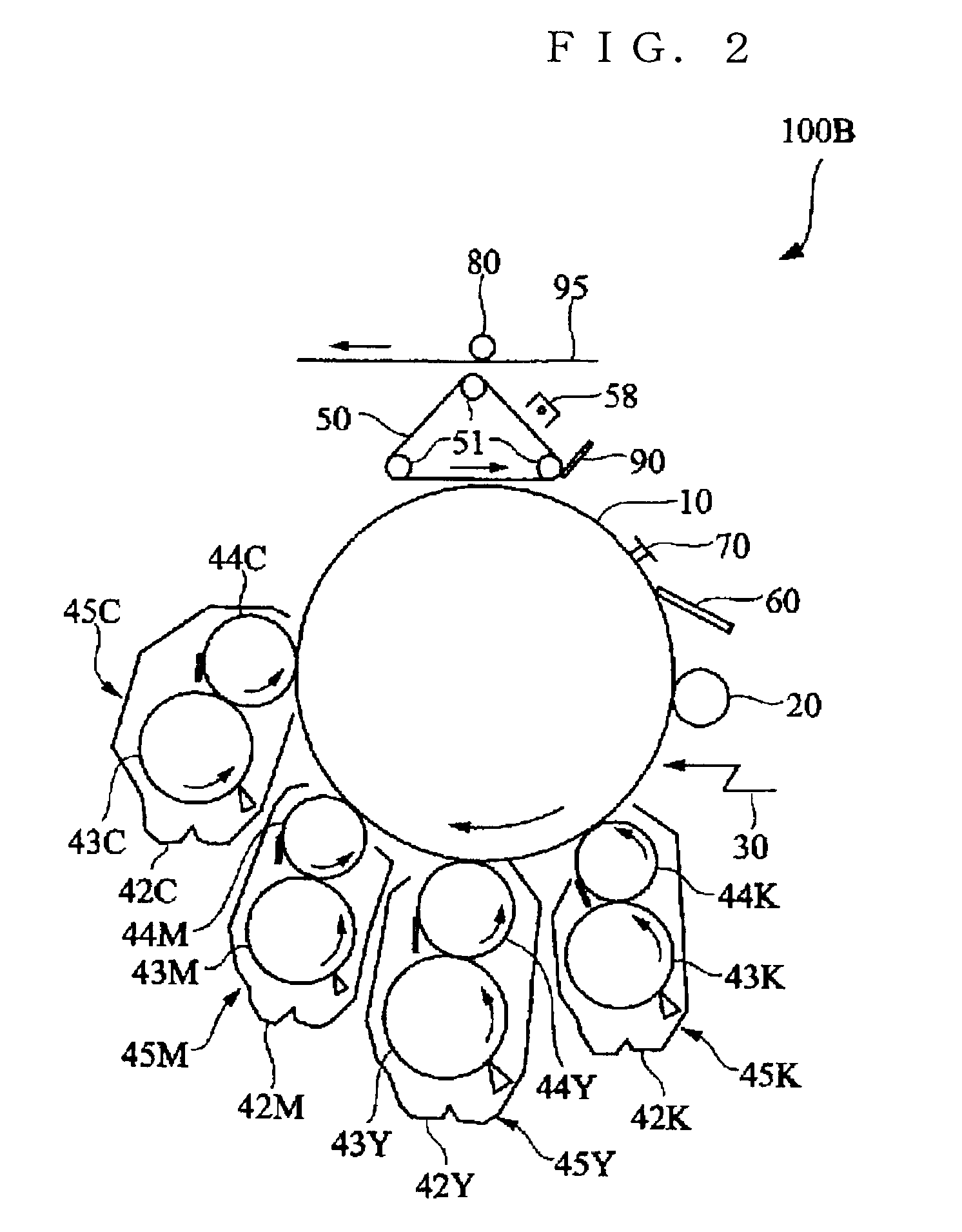

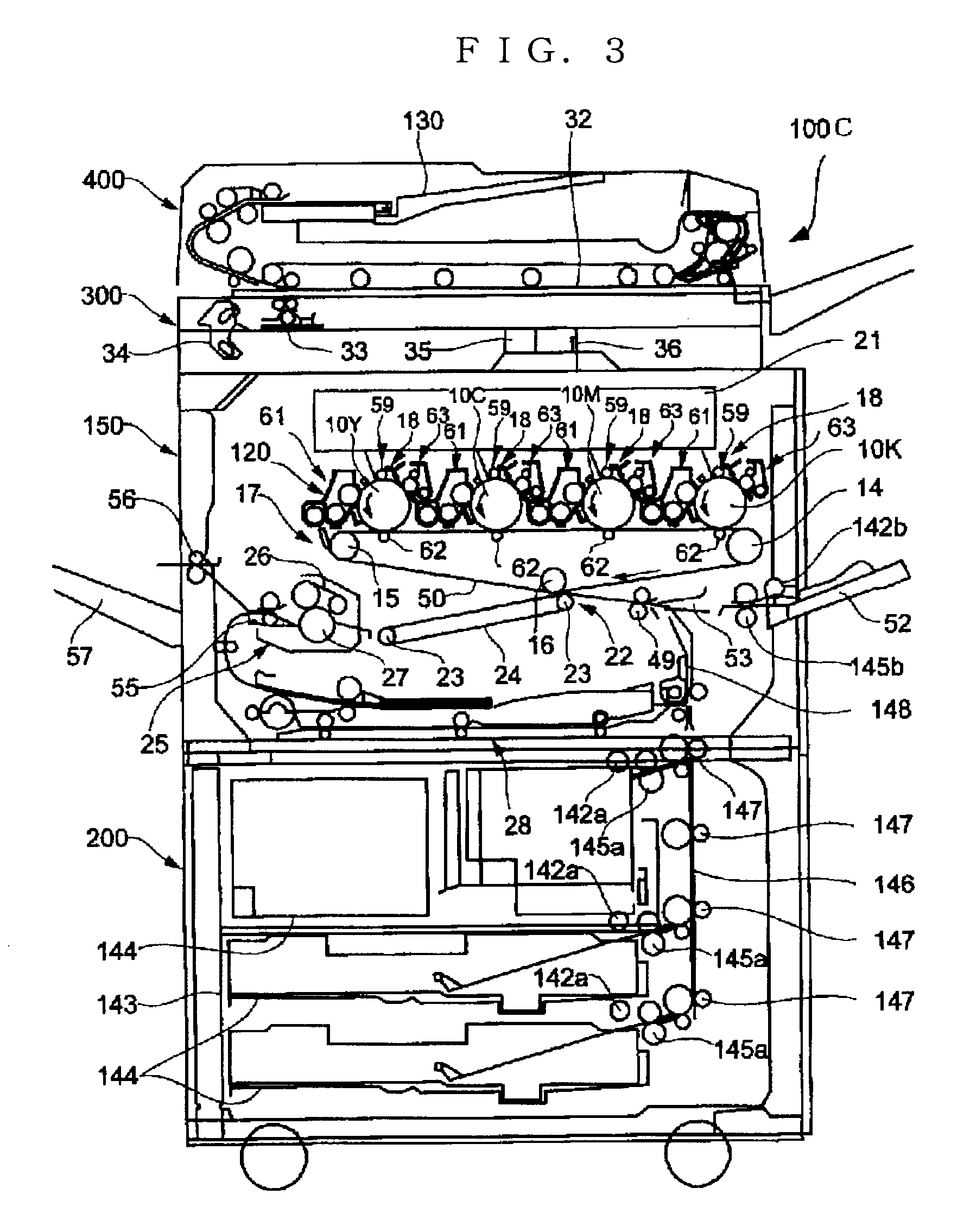

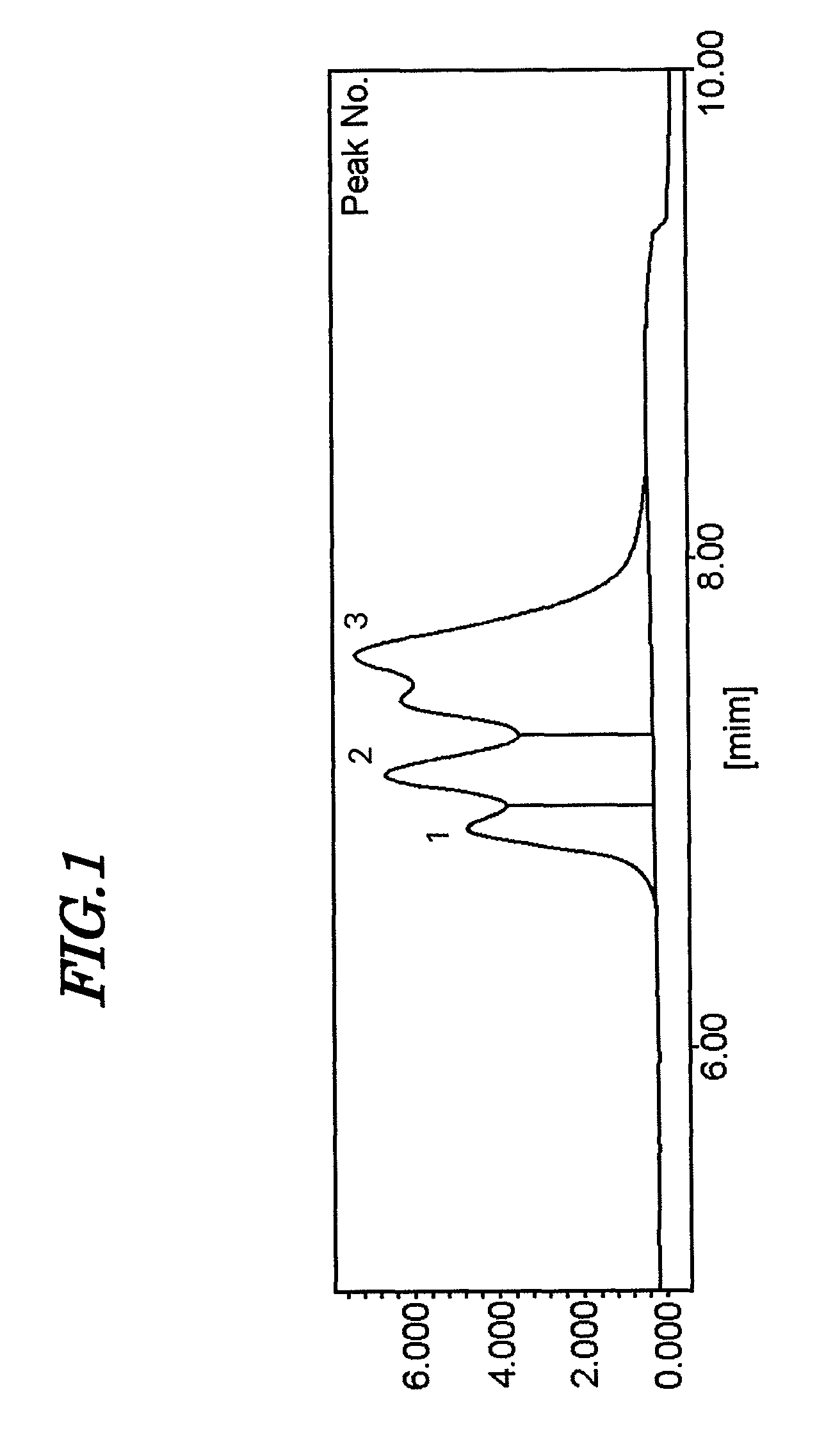

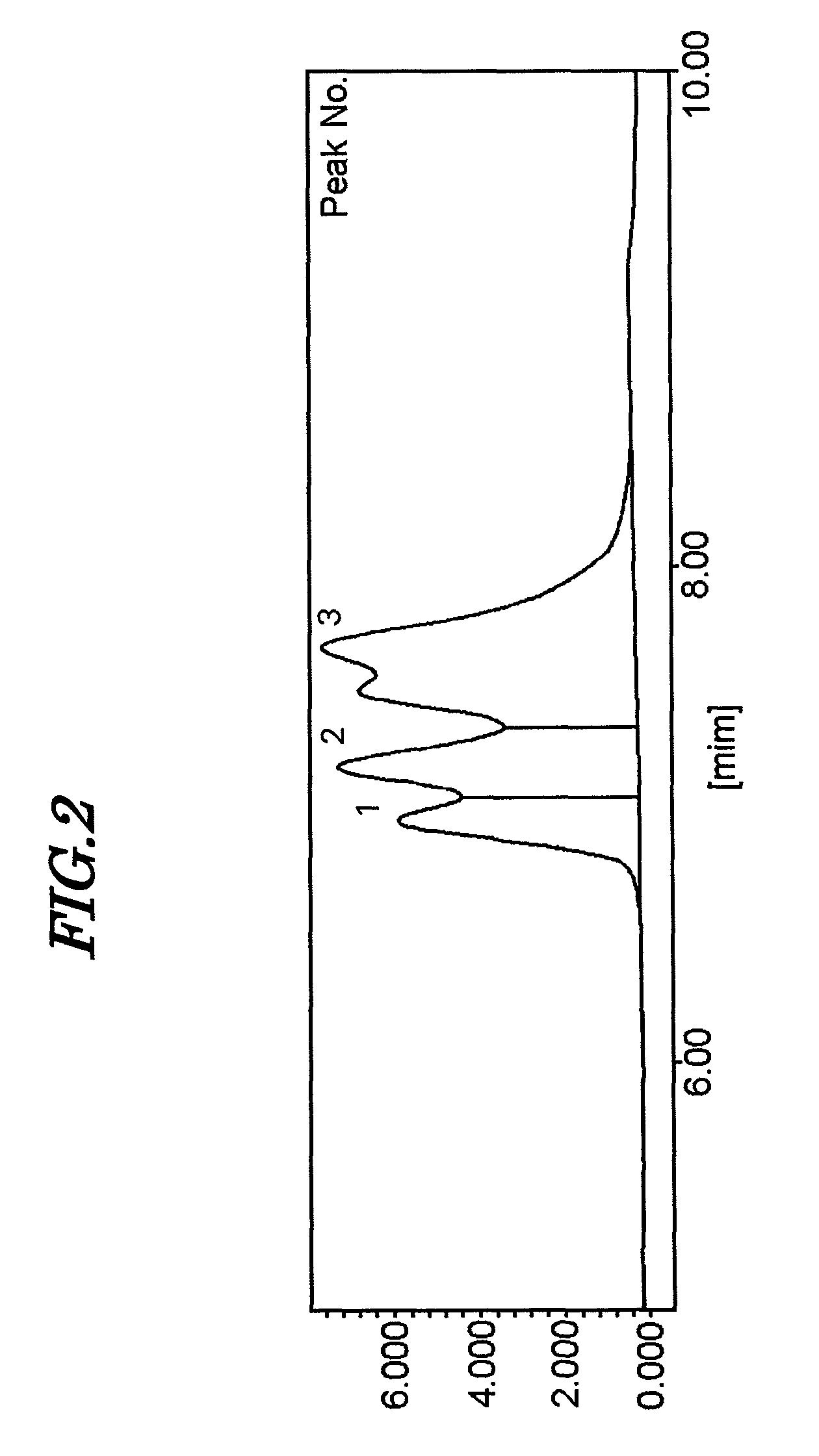

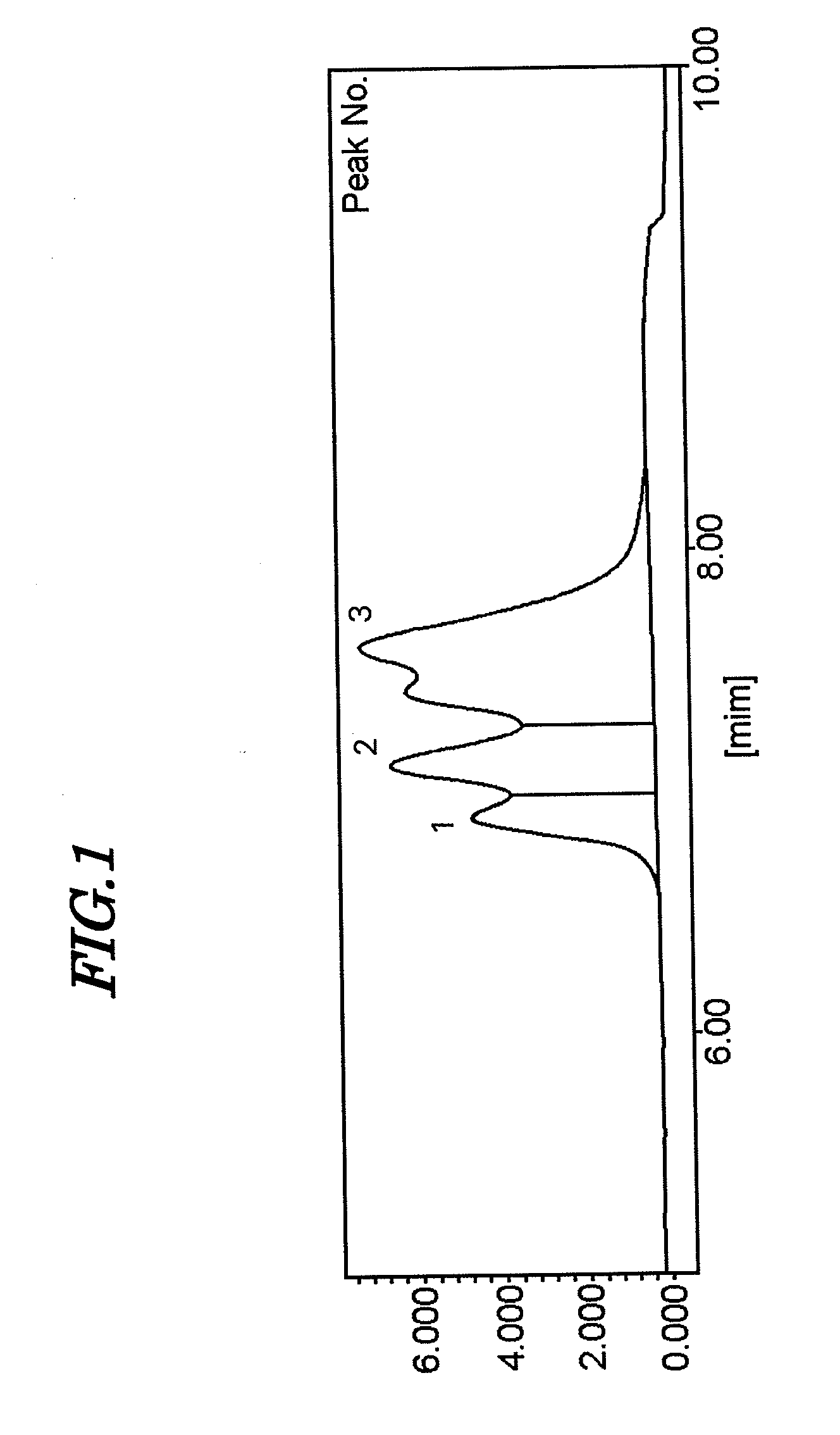

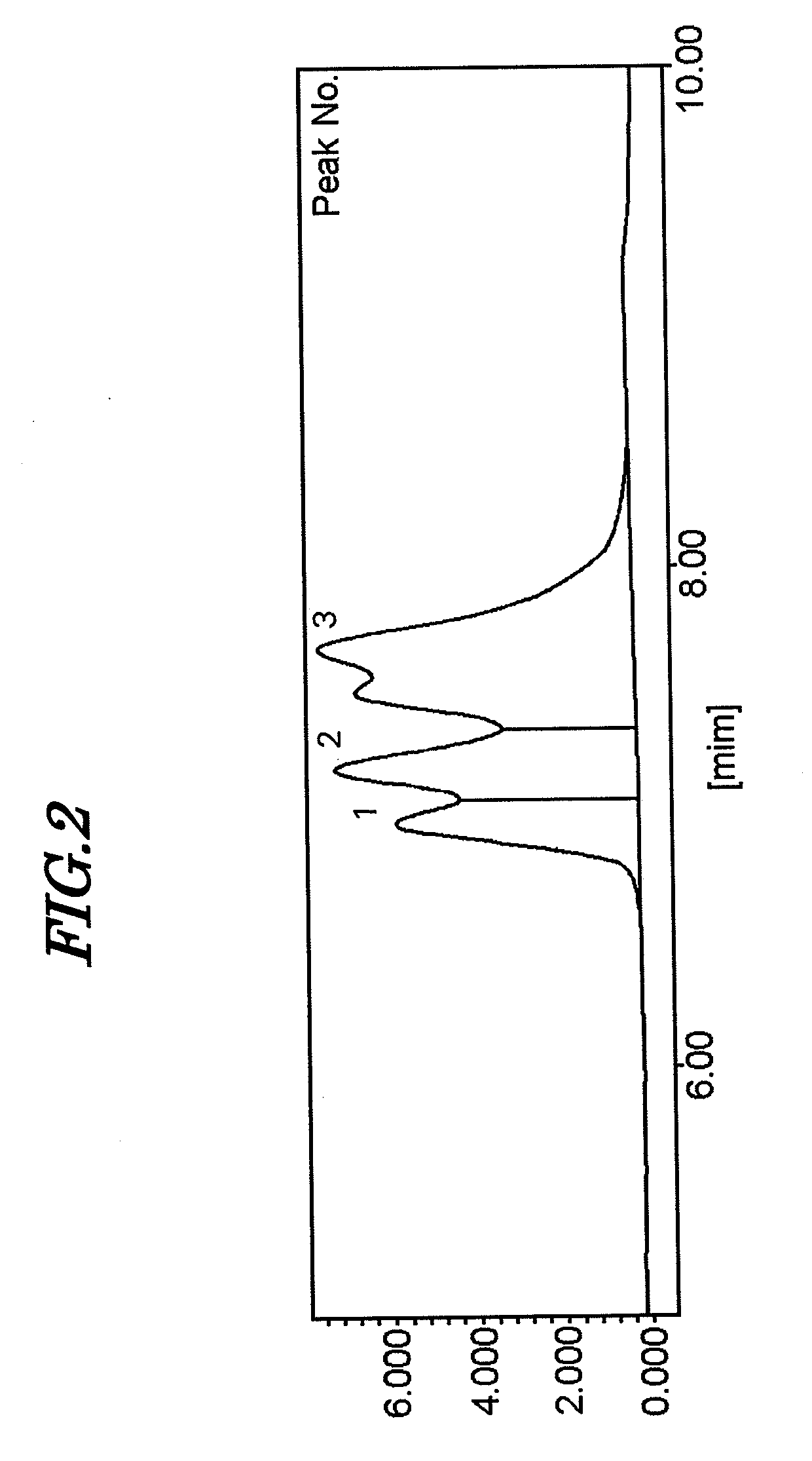

Electrophotographic toner, method for producing the same, electrophotographic developer, method for producing the developer, and image forming method

ActiveUS20060292477A1Preferable low-temperature fixing efficiencyHigh-strength and high-glossinessDevelopersElectrographic processes using charge patternForming processesColoring agents

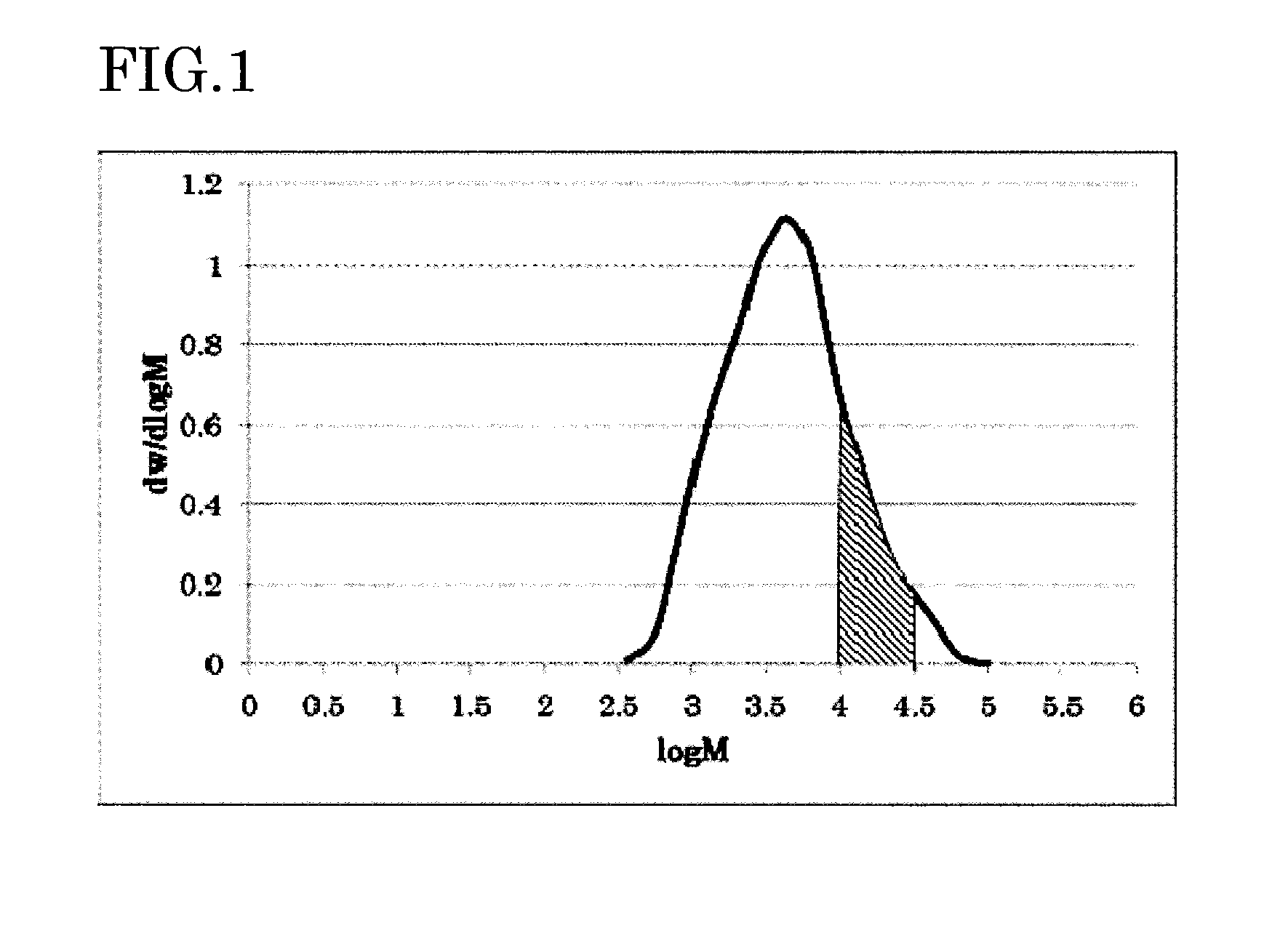

Provided are an electrophotographic toner, comprising a binder resin containing a coloring agent, a crystalline resin and an amorphous resin, wherein the crystalline resin has two or more peaks in weight-average molecular weight as determined by gel permeation chromatography, one of the peaks has a weight-average molecular weight in the range of 15,000 to 40,000, and another peak has a weight-average molecular weight in the range of 2,000 to 10,000 and a production method thereof, and an electrophotographic developer and an image-forming process using the electrophotographic toner.

Owner:FUJIFILM BUSINESS INNOVATION CORP

Polypropylene resin composition and injection-molded article thereof

A polypropylene resin composition, which is light weighing, has very high values for the stiffness and heat resistance and is superior in the scratch-proof property with better moldability upon molding and which can be injection-molded into formed articles without occurrence of cracking, comprising 5-25% by weight of a higher molecular weight polypropylene (A) having an intrinsic viscosity [eta], determined in decalin at 135° C., in the range from 6 to 11 dl / g and 95-75% by weight of a lower molecular weight polypropylene (B) having an intrinsic viscosity [eta], determined in decalin at 135° C., in the range from 0.6 to 1.6 dl / g, wherein the said resin composition has the following charactristic features <<1>> and <<2>>, namely,<<1>> an isotactic pentad fraction (mmmm-fraction), determined by 13C-NMR, of at least 96.5% and<<2>> a molecular weight distribution value expressed by Mw / Mn (weight-average molecular weight / number-average molecular weight), determined by gel permeation chromatography (GPC), of at least 8.

Owner:PRIME POLYMER CO LTD

Polyacrylonitrile polymer, method of producing the same, method of producing precursor fiber used for producing carbon fiber, carbon fiber and method of producing the same

ActiveUS20100003515A1Stable productionModulus improvementLayered productsMonocomponent synthetic polymer artificial filamentCarbon fibersPolymer science

A polyacrylonitrile-based polymer, containing a polymer of which main component is acrylonitrile, which satisfies at least one kind requirement selected from the following [a] to [d].[a] Z-average molecular weight (Mz) determined by gel-permeation chromatograph is 800,000 to 6,000,000 and degree of polydispersity (Mz / Mw) (Mw denotes weight average molecular weight) is 3.0 to 10.0.[b] Z+1-average molecular weight (Mz+1) determined by GPC method is 3,000,000 to 10,000,000 and degree of polydispersity (Mz+1 / Mw) is 6.0 to 25.0.[c] Mzm determined by gel-permeation chromatograph multi-angle laserlight scattering photometry is 400,000 to 1,000,000 and degree of polydispersity (Mzm / Mwm) is 3.0 to 10.0.[d] Z-average radius of gyration (Rz) determined by gel-permeation chromatograph multi-angle laserlight scattering photometry is 25 to 45 nm and its ratio to weight average radius of gyration (Rz / Rw) is 1.3 to 2.5.

Owner:TORAY IND INC

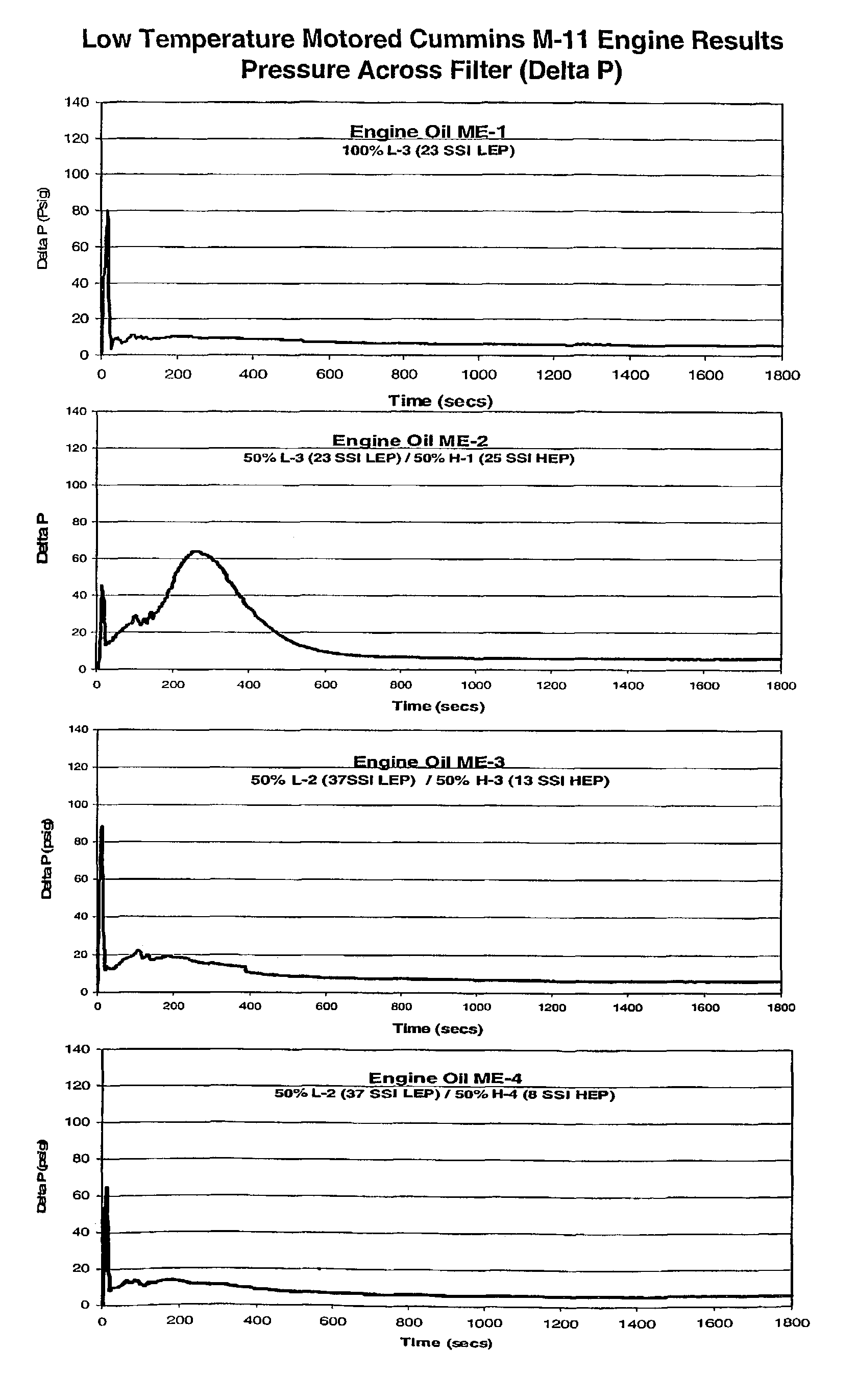

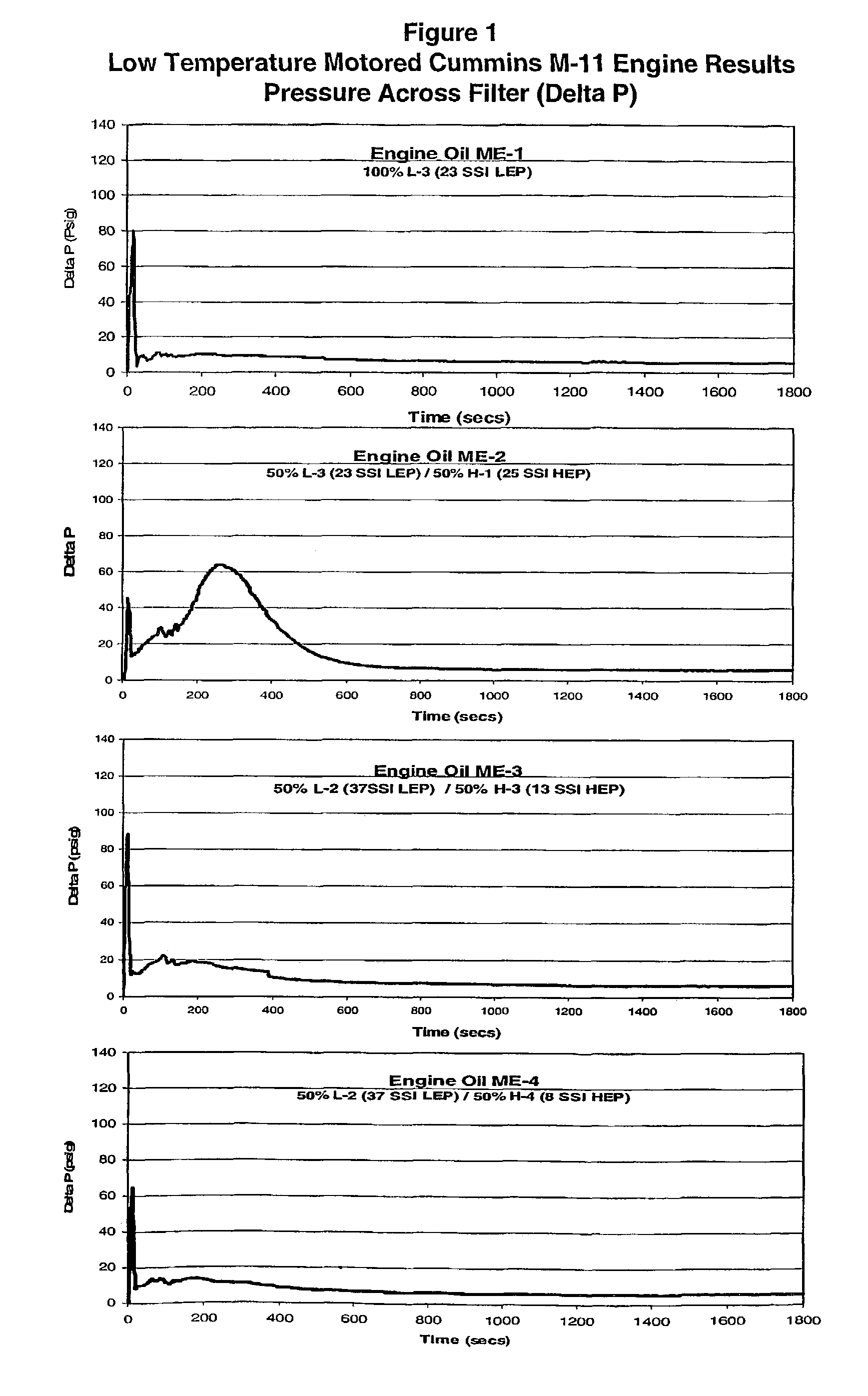

Viscosity improver compositions providing improved low temperature characteristics to lubricating oils

InactiveUS7402235B2Improved viscosity propertiesPolymeric viscosity improver compositionOrganic detergent compounding agentsOrganic chemistryPolymer sciencePolystyrene

A mixture comprising A) a copolymer comprising from about 70 to about 79% by weight of units derived from ethylene, and having (a) Mw measured by gel permeation chromatography employing polystyrene standard ranging from about 50,000 up to less than 130,000 and / or (f) SSI≦18; (b) density (D) ranging from about 845 to about 895 kg / m3; (c) Mw / Mn less than 3; (d) melting point (Tm) measured by differential scanning calorimeter ranging from about 15° C. to about 60° C.; and (e) degree of crystallinity≧15%, and B) an amorphous polymer having Mw ranging from about 130,000 to about 1,000,000 having degree of crystallinity≦5%. In one embodiment the density and the melting point of the copolymer A) fulfill the expression Tm≦1.247 D−1037. In another embodiment, the percentage content (E: % by weight) of repeating units derived from ethylene and melting point (Tm: ° C.) of the copolymer A) fulfill the expression 3.44E−206≧Tm. Also, additive concentrates and lubricating compositions comprising the components making up the mixture.

Owner:THE LUBRIZOL CORP

Rubber composition for tire and tire made therefrom

A rubber composition for tires which comprises 100 parts by mass of (A) copolymer (a) which is a styrene-butadiene copolymer having a weight-average molecular weight of 4.0×105 to 3.0×106; as obtained in accordance with gel permeation chromatography and expressed as the value of corresponding polystyrene, a content of the bound styrene St(a) of 10 to 50% by mass and a content of the vinyl unit in the butadiene portion of 20 to 70%; 10 to 200 parts by mass of (B) copolymer (b) which is a hydrogenated styrene-butadiene copolymer having a weight-average molecular weight of 5.0×103 to 2.0×105, as obtained in accordance with gel permeation chromatography and expressed as the value of corresponding polystyrene, a content of the bound styrene St(b) which is in the range of 25 to 70% by mass and satisfies a relation expressed by equation (I) and a fraction of hydrogenated double bond in the butadiene portion of 60% or greater and (C) at least one substance selected from resins providing tackiness to the rubber composition and liquid polymers having a weight-average molecular weight of 1,000 to 50,000. St(b)≧St(a)+10 (I)

Owner:BRIDGESTONE CORP

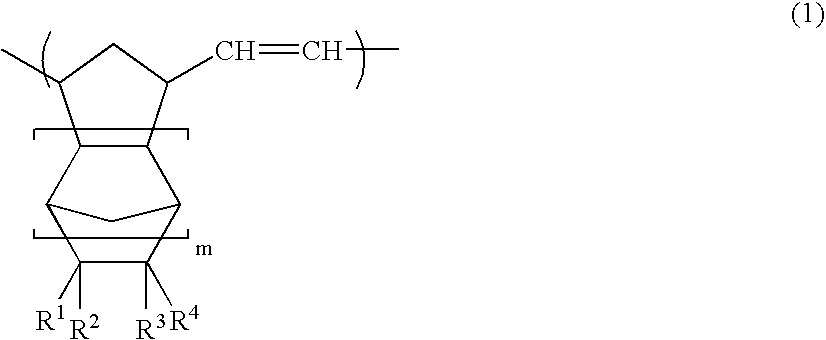

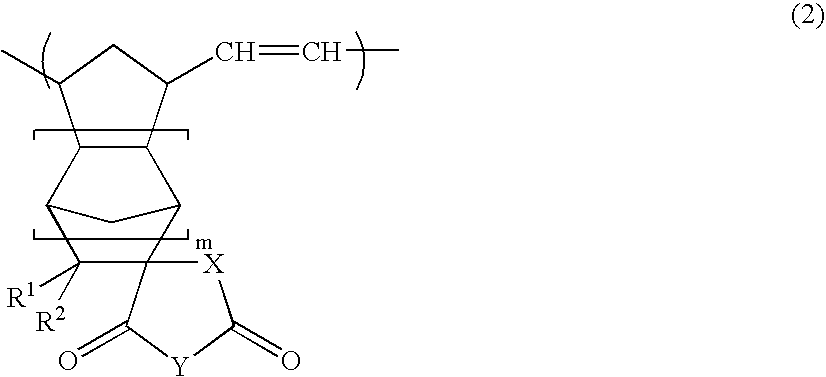

Norbornene-based ring-opening polymerization polymer, product of hydrogenation of norbornene-based ring-opening polymerization polymer, and processes for producing these

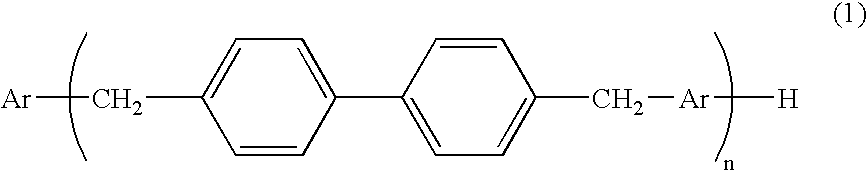

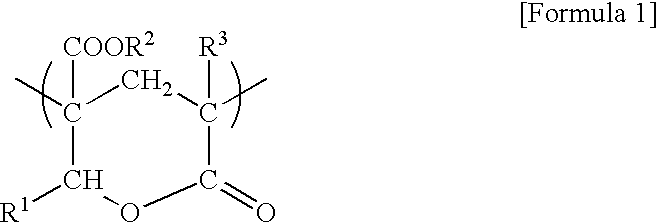

A norbornene ring-opened polymer which in the molecule has repeating units represented by the formula (1): wherein R1 represents Q, R2 represents Q or C(═O)R5, R3 represents Q or C(═O)R6, and R4 represents Q or X—C(═O)R7 (wherein Q represents hydrogen, a C1-10 hydrocarbon group, etc.; R5, R6 and R7 each represents hydroxyl, C1-10 alkoxyl, etc., provided that R6 and R7 may be bonded to each other to constitute oxygen, NH, etc.; X represents methylene, etc., provided that when R2 is Q, then R3 is C(═O)R6 and R4 is X—C(═O)R7 and that when R4 is Q, then R2 is C(═O)R5, R3 is C(═O)R6, and the configuration of R2 and R3 is trans, and m is 0 or 1), the polymer having a weight-average molecular weight as determined by gel permeation chromatography of 1,000 to 1,000,000. Also provided is a hydrogenation product of the norbornene ring-opened polymer. The norbornene ring-opened polymer and the hydrogenation product are excellent in heat resistance, electrical properties, etc.

Owner:ZEON CORP

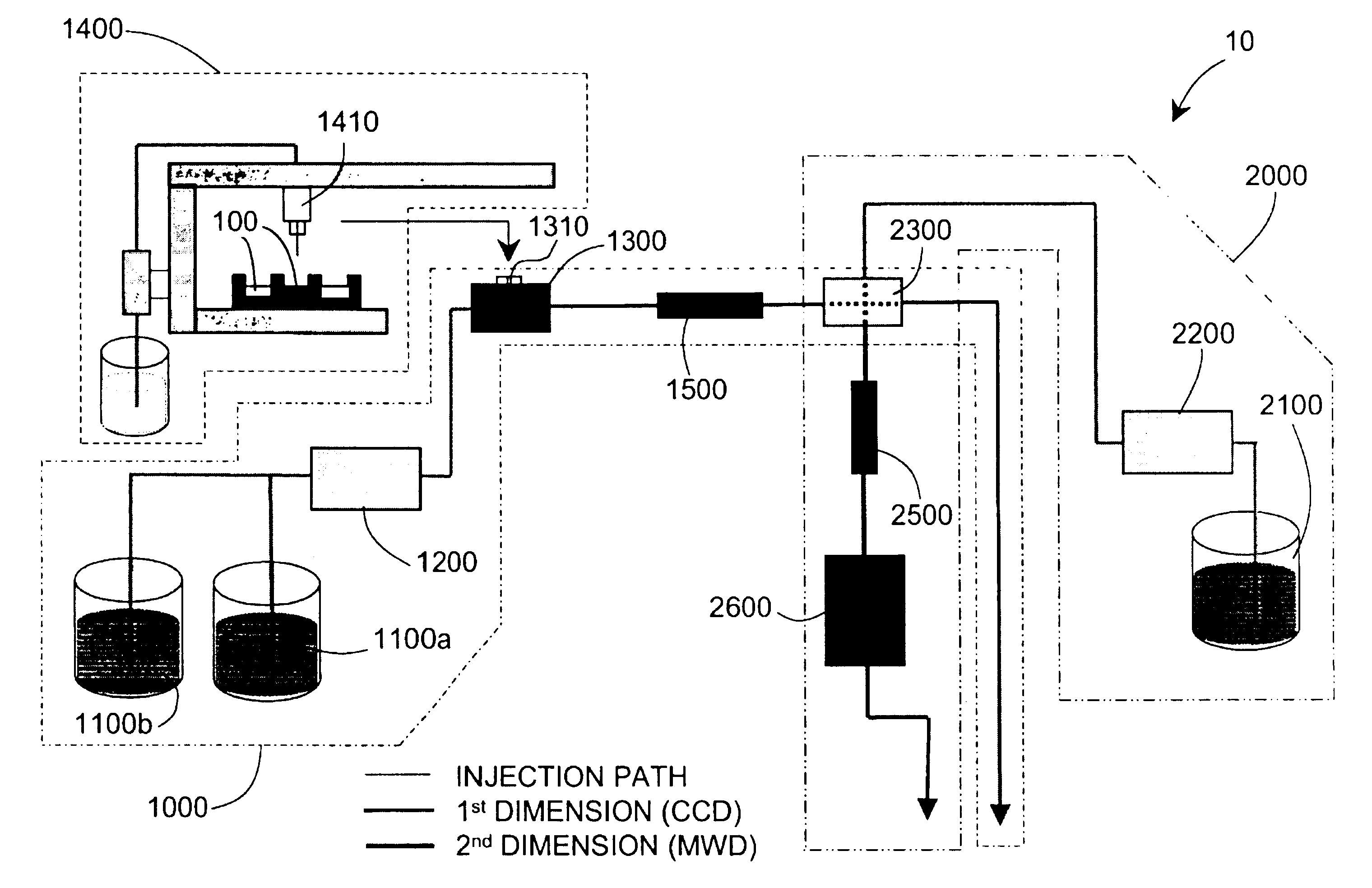

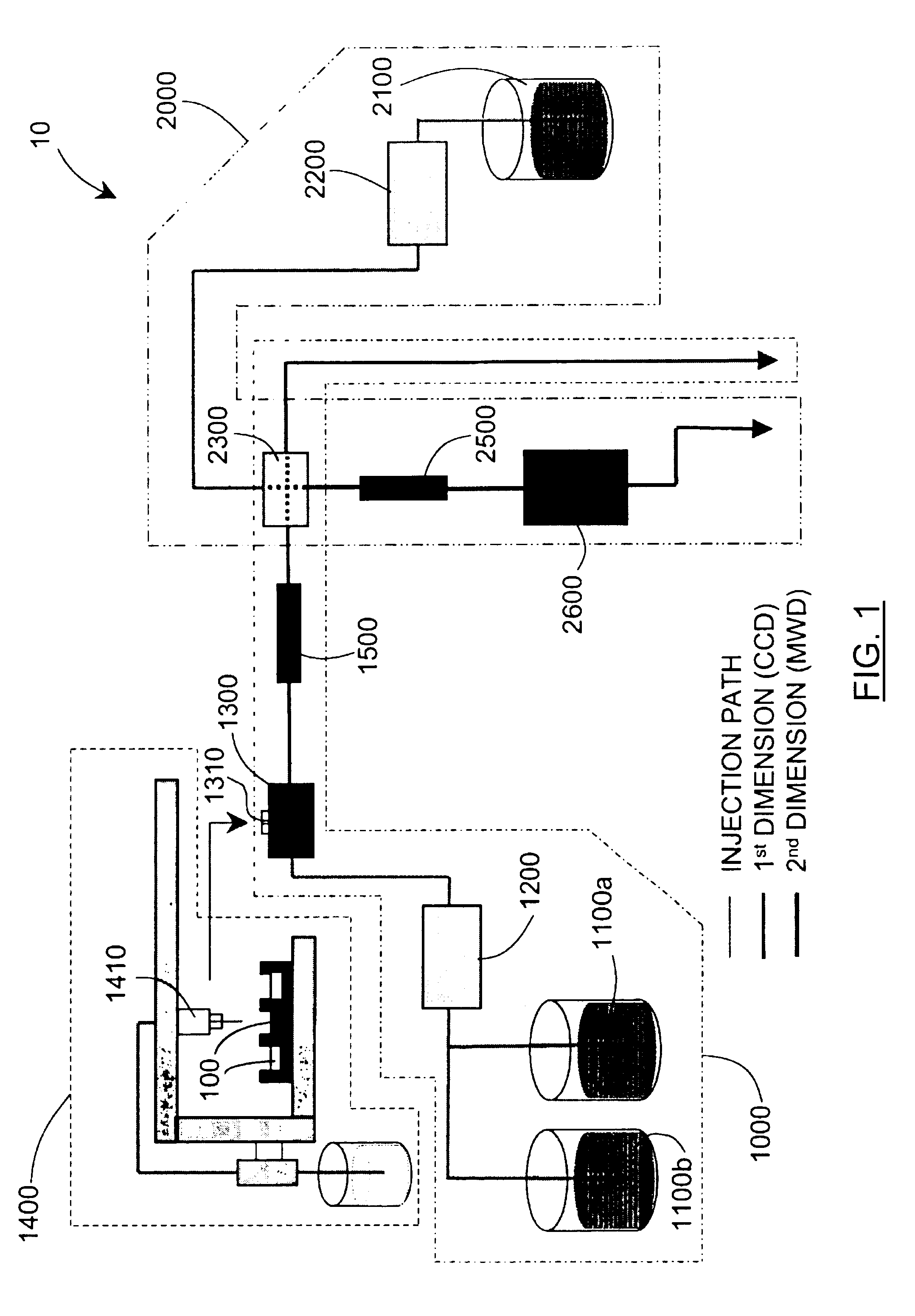

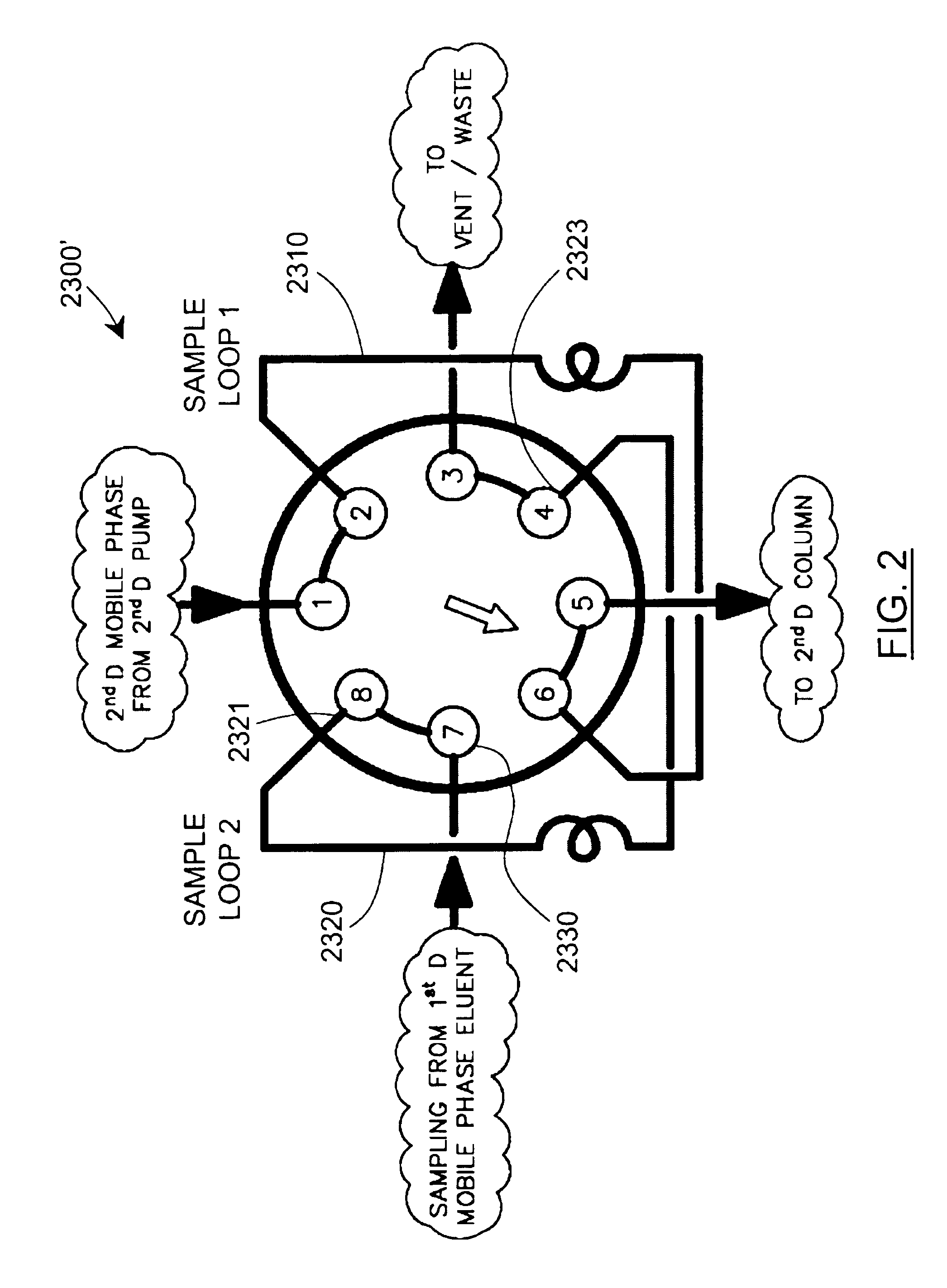

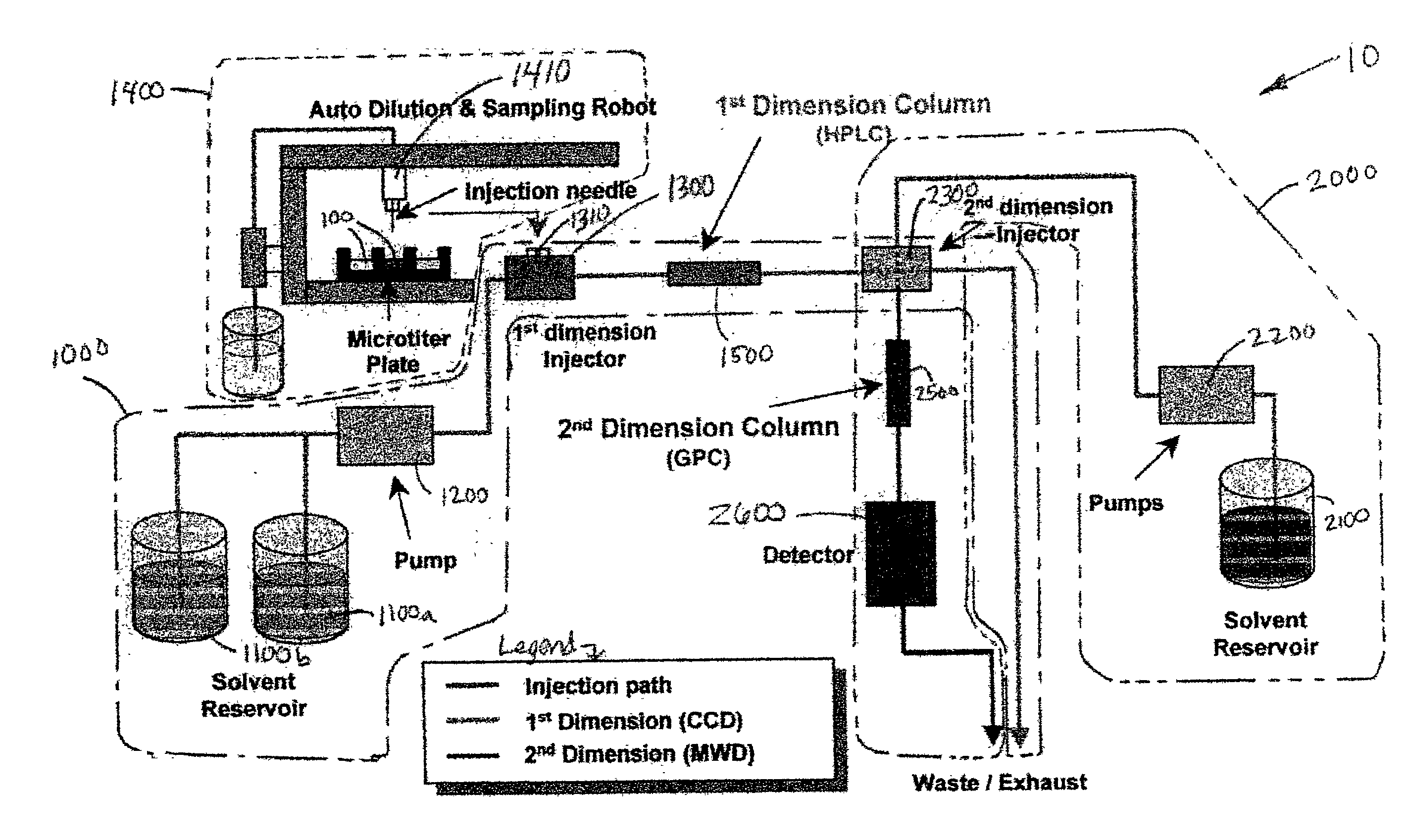

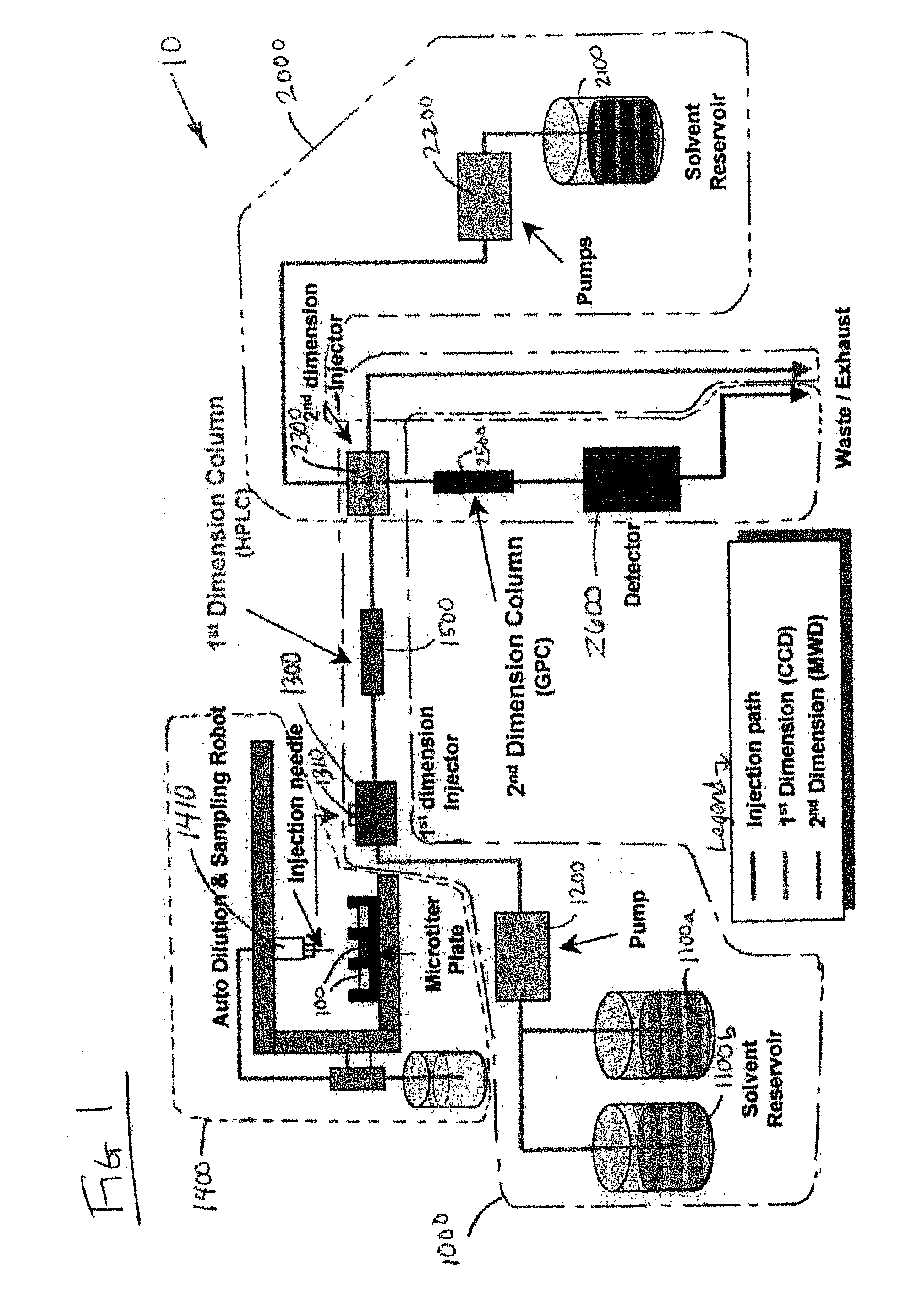

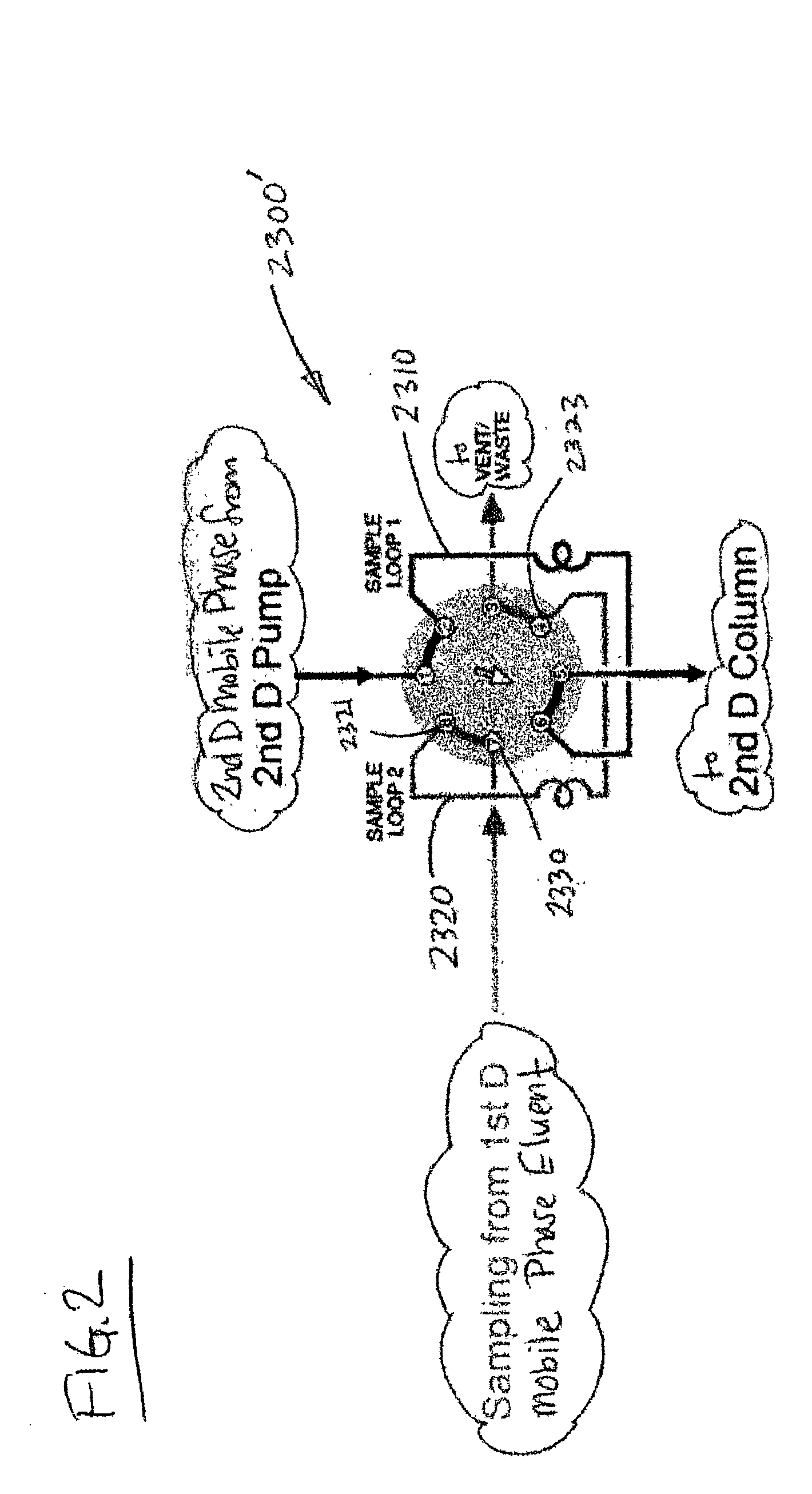

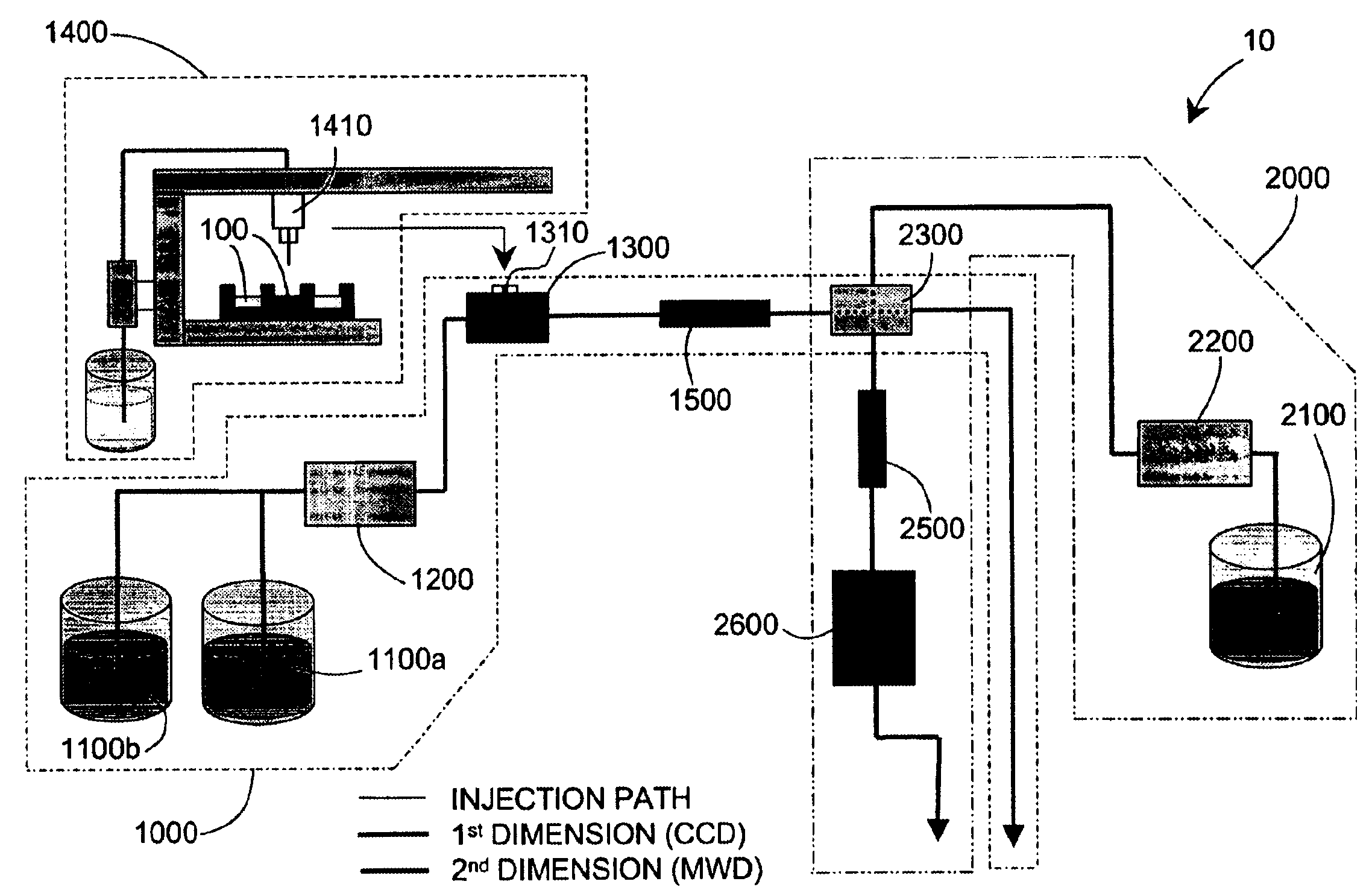

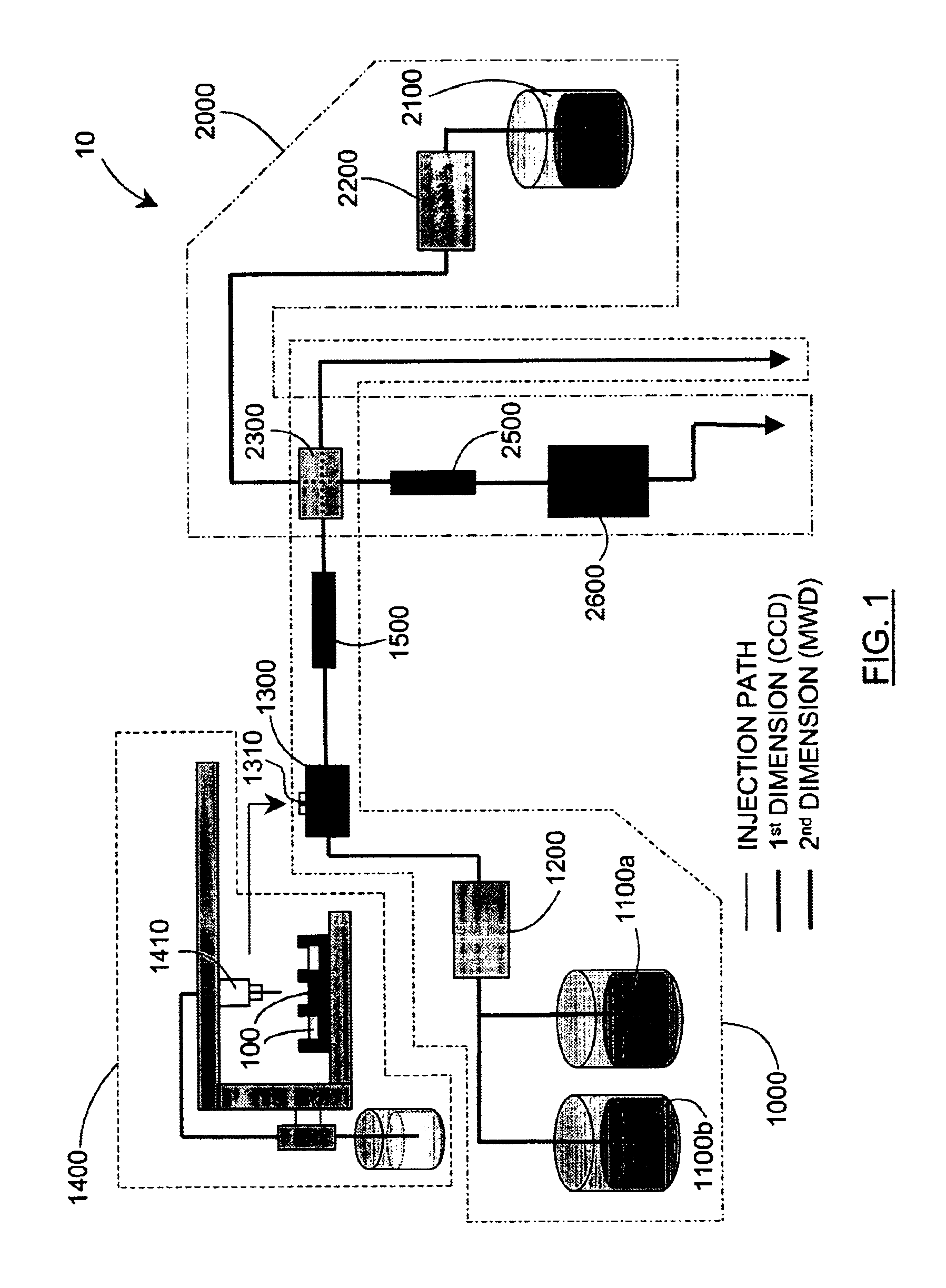

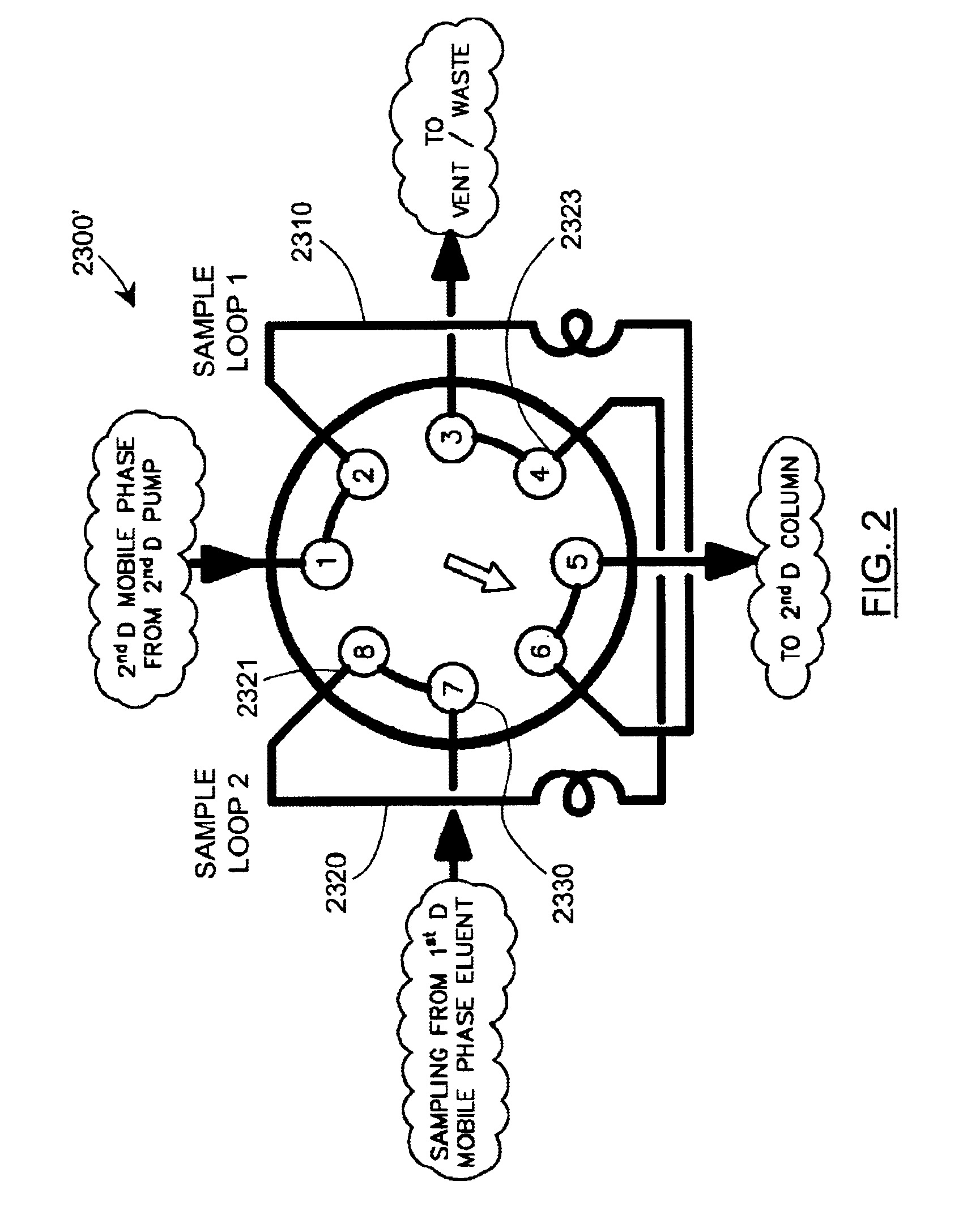

Methods and apparatus for characterization of polymers using multi-dimensional liquid chromatography with regular second-dimension sampling

InactiveUS6730228B2Less complicatedUniversal applicabilityIon-exchange process apparatusSequential/parallel process reactionsGradient elutionPhase gradient

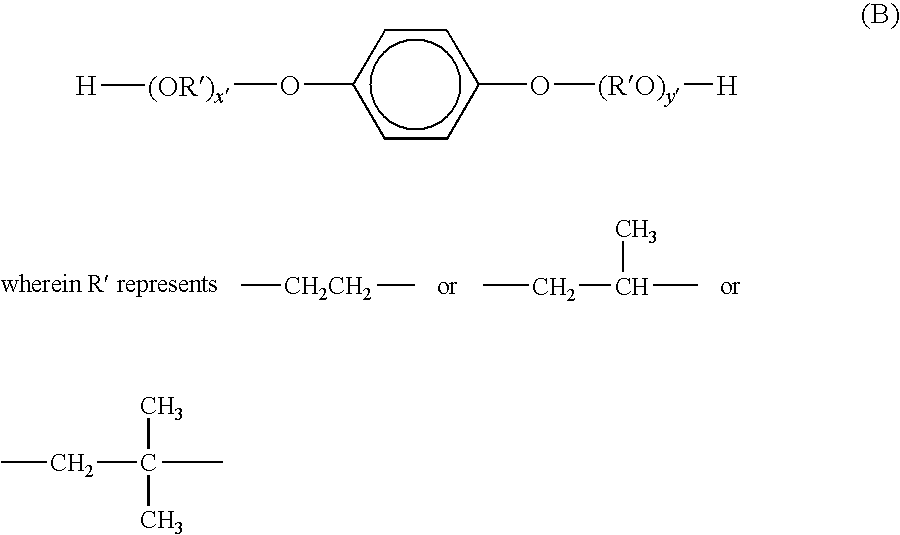

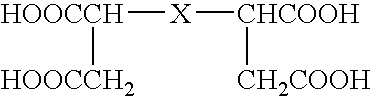

Methods and apparatus for characterizing a polymer sample and in preferred embodiments, libraries of polymer samples, in a comprehensive, directly-coupled multi-dimensional liquid chromatography system are disclosed. The first and second dimensions are preferably high-performance liquid chromatography dimensions, such as for example, a first dimension adapted for determining composition (e.g. adapted for mobile-phase gradient elution chromatography, including reverse phase chromatography, adsorption chromatography and the like), and a second dimension adapted for determining molecular weight or particle size (e.g., adapted for size exclusion chromatography, including gel permeation chromatography).

Owner:FREESLATE

Methods and apparatus for characterization of polymers using multi-dimensional liquid chromatography with parallel second-dimension sampling

InactiveUS20030089663A1Less complicatedUniversal applicabilityIon-exchange process apparatusSamplingGradient elutionPhase gradient

Methods and apparatus for characterizing a polymer sample and in preferred embodiments, libraries of polymer samples, in a comprehensive, directly-coupled multi-dimensional liquid chromatography system are disclosed. The first and second dimensions are preferably high-performance liquid chromatography dimensions, such as for example, a first dimension adapted for determining composition (e.g. adapted for mobile-phase gradient elution chromatography, including reverse phase chromatography, adsorption chromatography and the like), and a second dimension adapted for determining molecular weight or particle size (e.g., adapted for size exclusion chromatography, including gel permeation chromatography).

Owner:FREESLATE

Aliphatic diol-based polycarbonates, method of making, and articles formed therefrom

Owner:SABIC INNOVATIVE PLASTICS IPBV

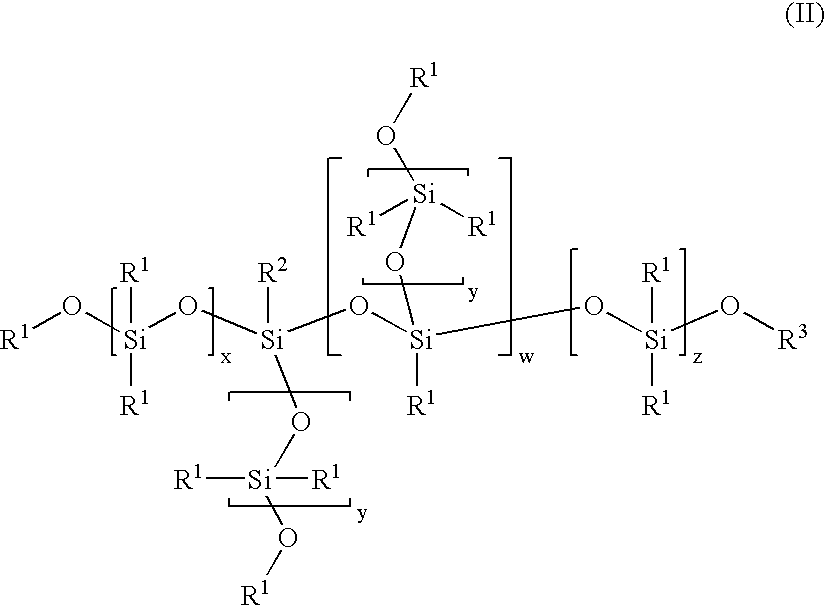

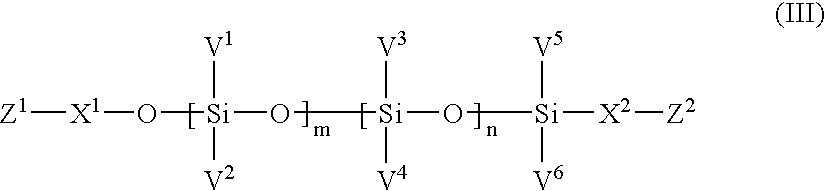

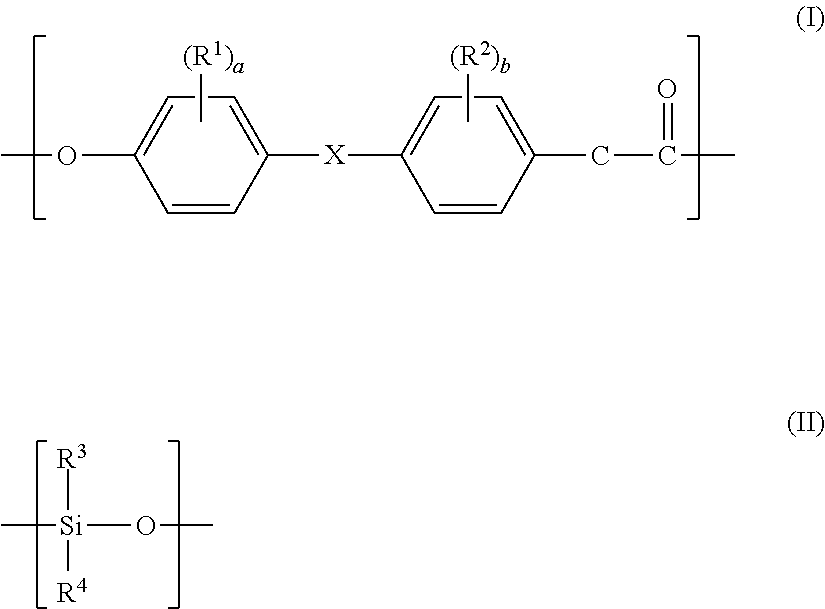

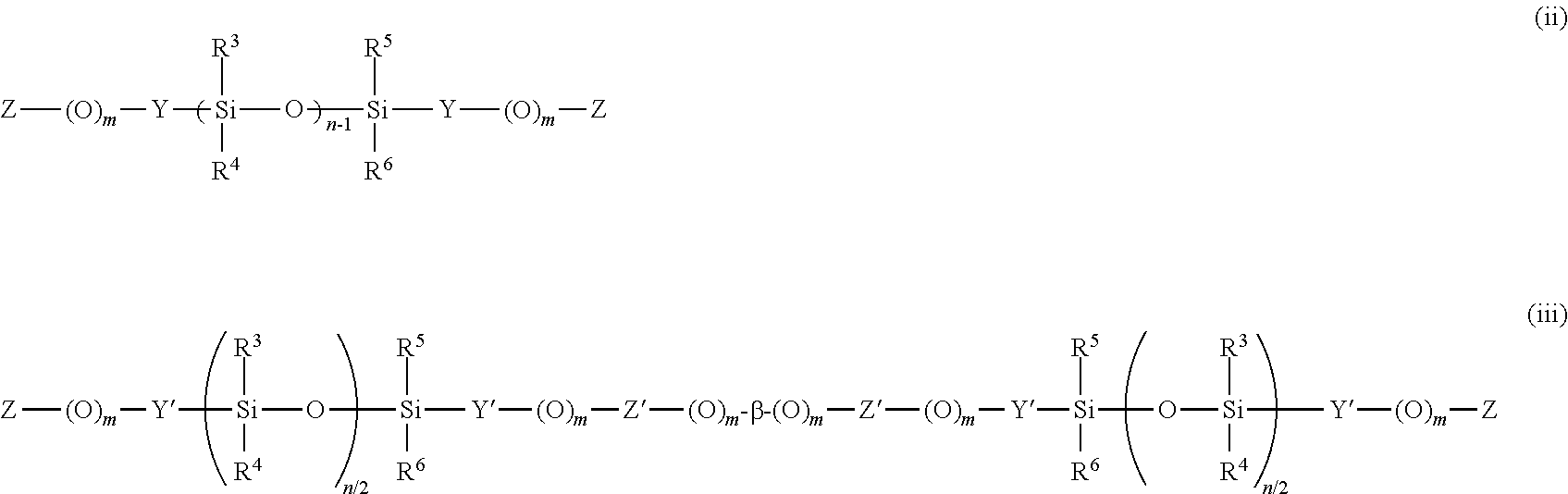

Curable Silicone Composition

A curable silicone composition comprising at least the following components: (A) a diorganopolysiloxane having in one molecule at least two alkenyl groups; (B) at least two resin-like organopolysiloxanes that have different mass-average molecular weights as reduced into standard polystyrene measured gel permeation chromatography and that are composed of SiO4 / 2 units, R12R2SiO1 / 2 units, and R13SiO1 / 2 units, wherein R1 is an optionally substituted univalent hydrocarbon group that is free of aliphatic unsaturated bonds and R2 is an alkenyl group; (C) an organopolysiloxane that contains in one molecule at least two silicon-bonded hydrogen atoms; and (D) a hydrosilylation catalyst; possesses excellent flowability and filling ability and that can be prepared without extreme viscosity even if the composition contains resin-like organopolysiloxanes required to form a cured silicone body of appropriate strength and hardness.

Owner:DOW CORNING TORAY CO LTD

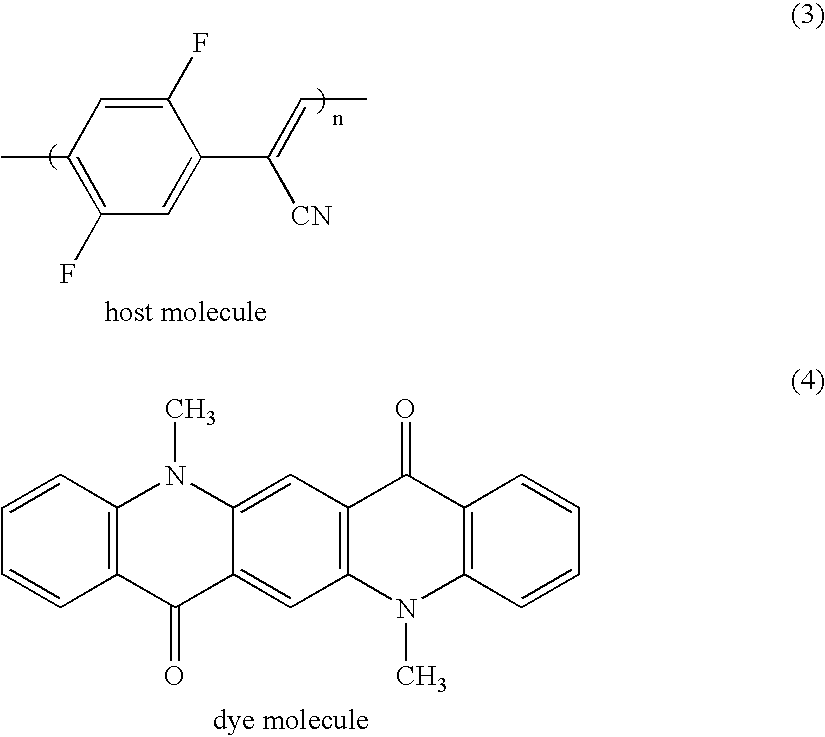

Coloring composition, colored pattern, color filter and method of producing the same, pattern forming method, solid-state imaging device, and image display device

ActiveUS9519079B2Avoid it happening againExcellent color separation propertyLiquid crystal compositionsOptical filtersMaterials scienceAnalytical chemistry

A coloring composition is provided which is less likely to remain on a pattern of other colors as residues and can inhibit occurrence of coating defects. Also provided are a colored pattern, a color filter, a method of producing a color filter, a pattern forming method, a solid-state imaging device, and an image display device, each using the coloring composition. The coloring composition contains a resin (A) having a dye structure, in which in the peak area of the total molecular weight distribution of the resin (A) as measured by gel permeation chromotography, the proportion of the peak area of a component having a molecular weight of 20,000 or more is 10% or less.

Owner:FUJIFILM CORP

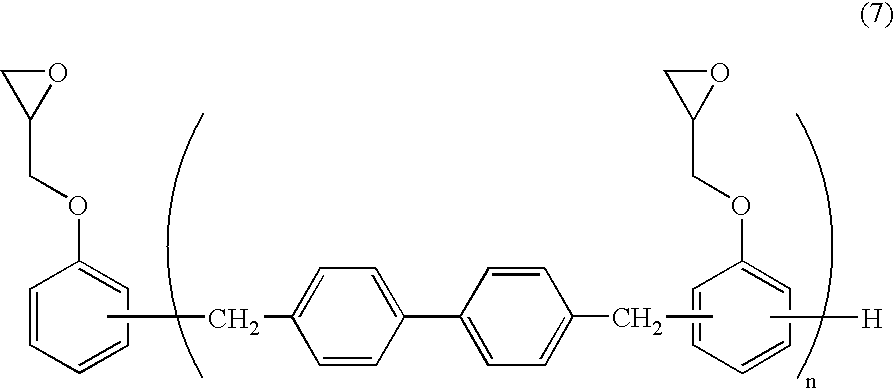

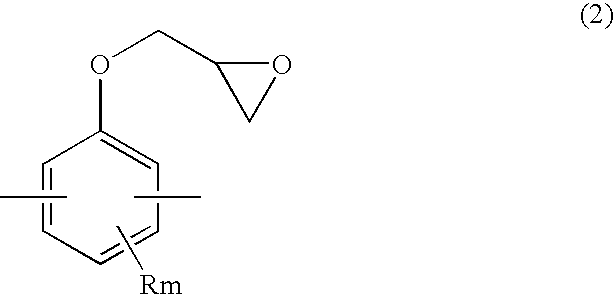

Epoxy Resin, Hardenable Resin Composition Containing the Same and Use Thereof

It is an object of the present invention, with respect to a phenol aralkyl type epoxy resin, to suppress any crystal precipitation, improve the quality manageability and operation efficiency at composition production and enhance the properties, including heat resistance, thereof. It is also intended to provide a resin composition that even when stored in the form of a varnish for a prolonged period of time, is resistant to crystal precipitation, excelling in storage stability and operation efficiency, and that gives a hardening product of low dielectric constant and low dielectric tangent excelling in heat resistance, water resistance and flame retardance.There is provided an epoxy resin characterized by comprising a phenol aralkyl type epoxy resin in which a content (an area % measured by gel permeation chromatography) of a bifunctional compound is 20% or less, and provided a resin composition obtained therefrom.

Owner:NIPPON KAYAKU CO LTD

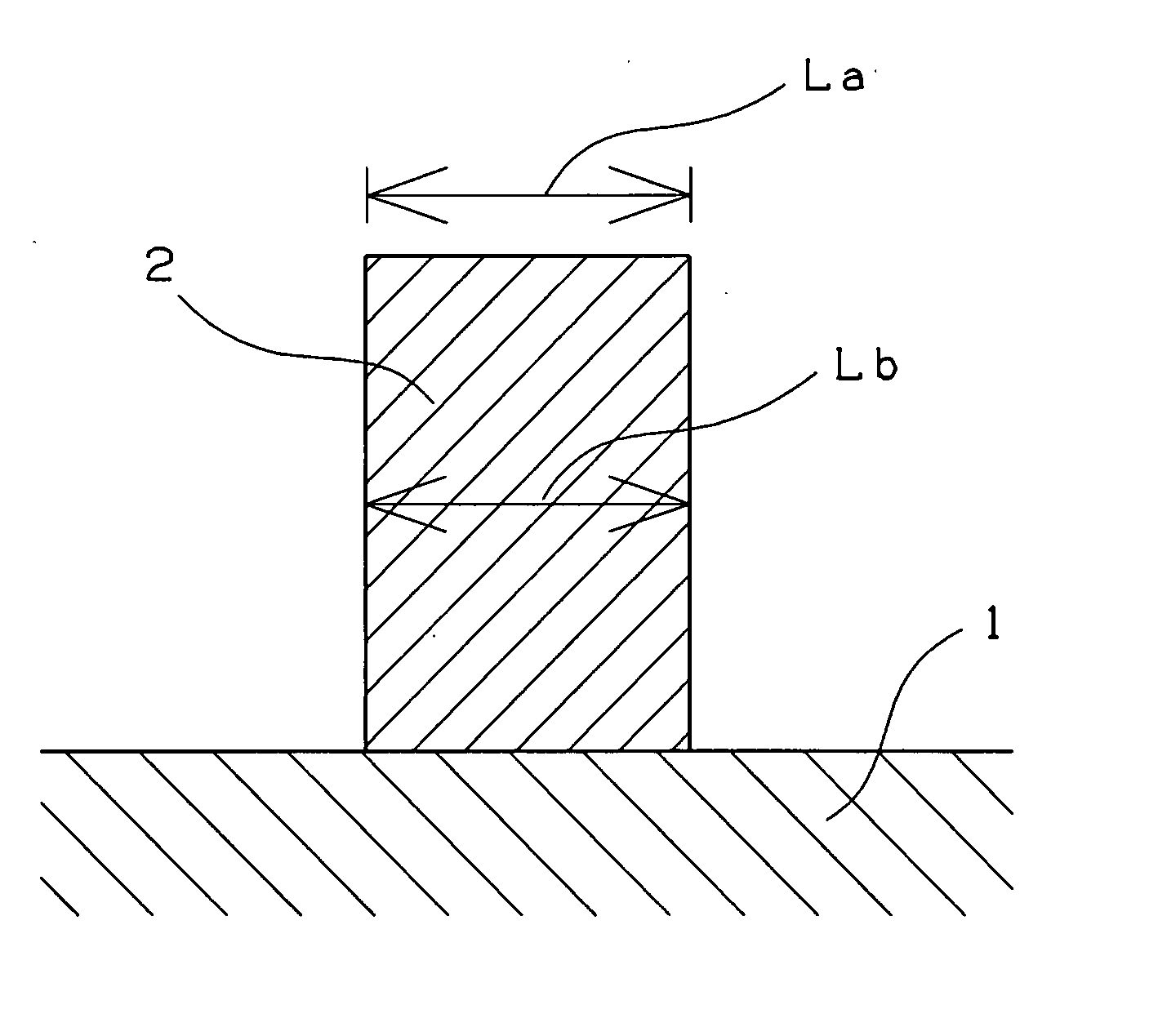

Toner, method for producing the toner and image forming apparatus

InactiveUS20070218381A1Improve abilitiesFine dot reproducibilityDevelopersWater basedImage formation

It is an object to provide toner excellent in charge stability, fixing property at low temperature, durability, microdot reproducibility and cleaning ability. An excellent image forming apparatus using the toner is provided. Said toner has at least a plurality of resins, a colorant and a layered inorganic material in which at least a part of ions in the layered inorganic material has been exchanged with organic ions in the toner prepared by dispersing and / or emulsifying an oil phase comprising at least a toner composition and / or a toner composition precursor in a water-based medium to granulate, and wherein a first resin in said a plurality of resins has a weight average molecular weight of 3,000 to 10,000 in a molecular weight distribution obtained by gel permeation chromatography (GPC).

Owner:RICOH KK

Copolymer and Top Coating Composition

ActiveUS20080038661A1Efficient use ofManufactured usingPhotosensitive materialsCoatingsPhotoresistFilm-coated tablet

Owner:JSR CORPORATIOON

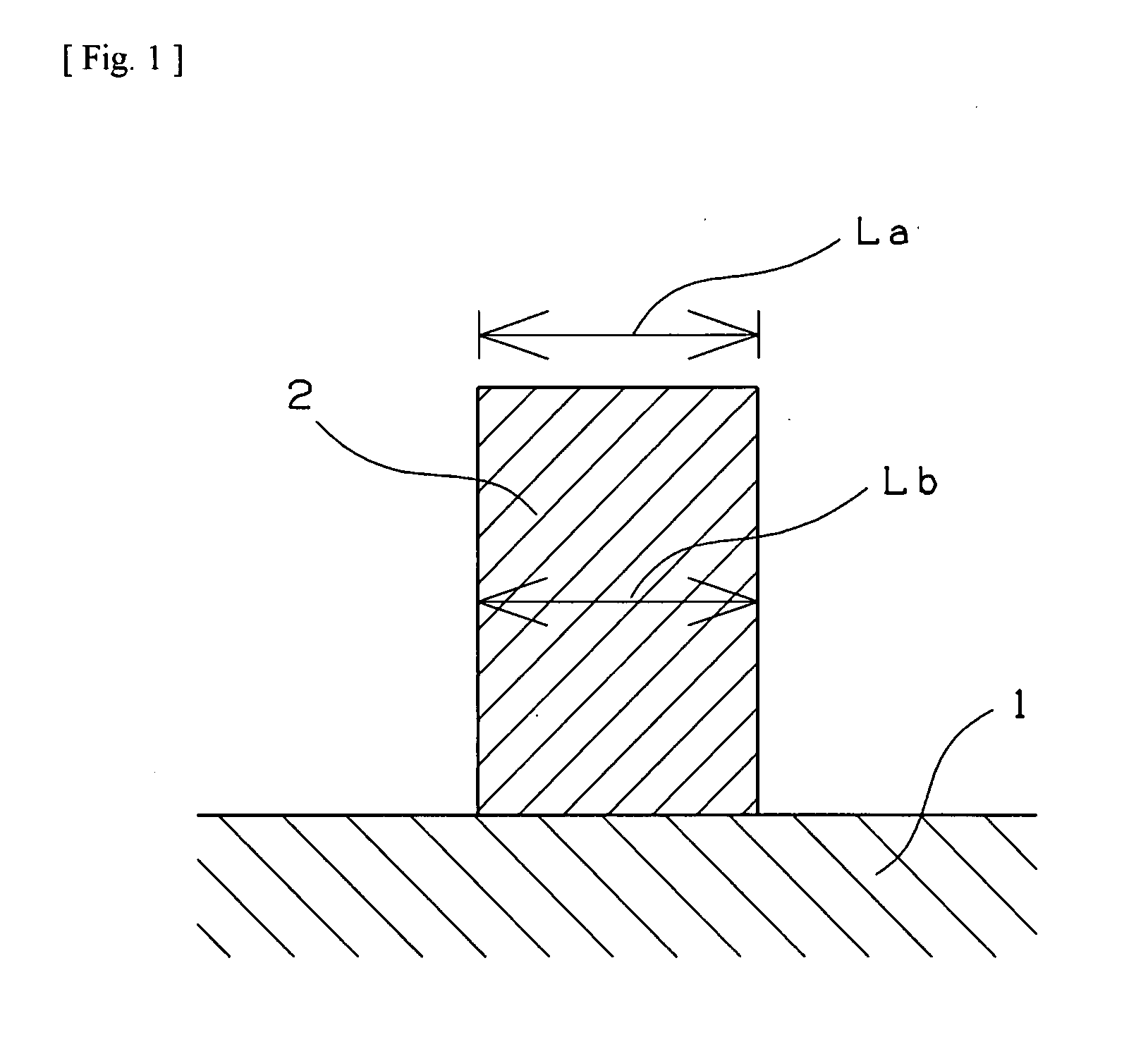

Aqueous ink composition

InactiveUS7294659B2Improve printing qualityGood colorDuplicating/marking methodsInksMethacrylateWater dispersible

Owner:SEIKO EPSON CORP

Method of preparing toner and the toner, and developer and image forming method using the toner

ActiveUS20090117486A1Excellent offset resistanceGood monodispersityElectrographic process apparatusDevelopersOrganic solventGas phase

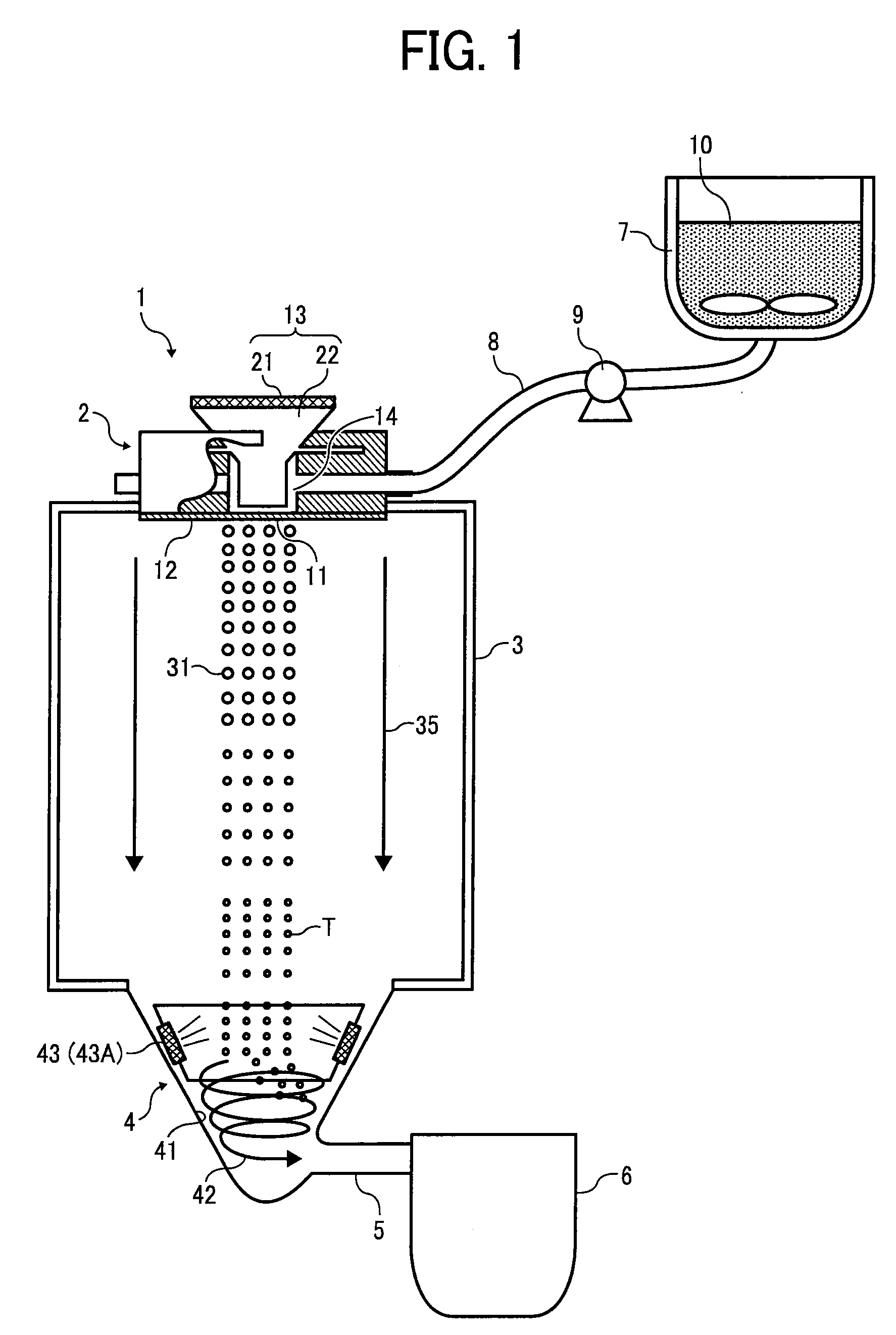

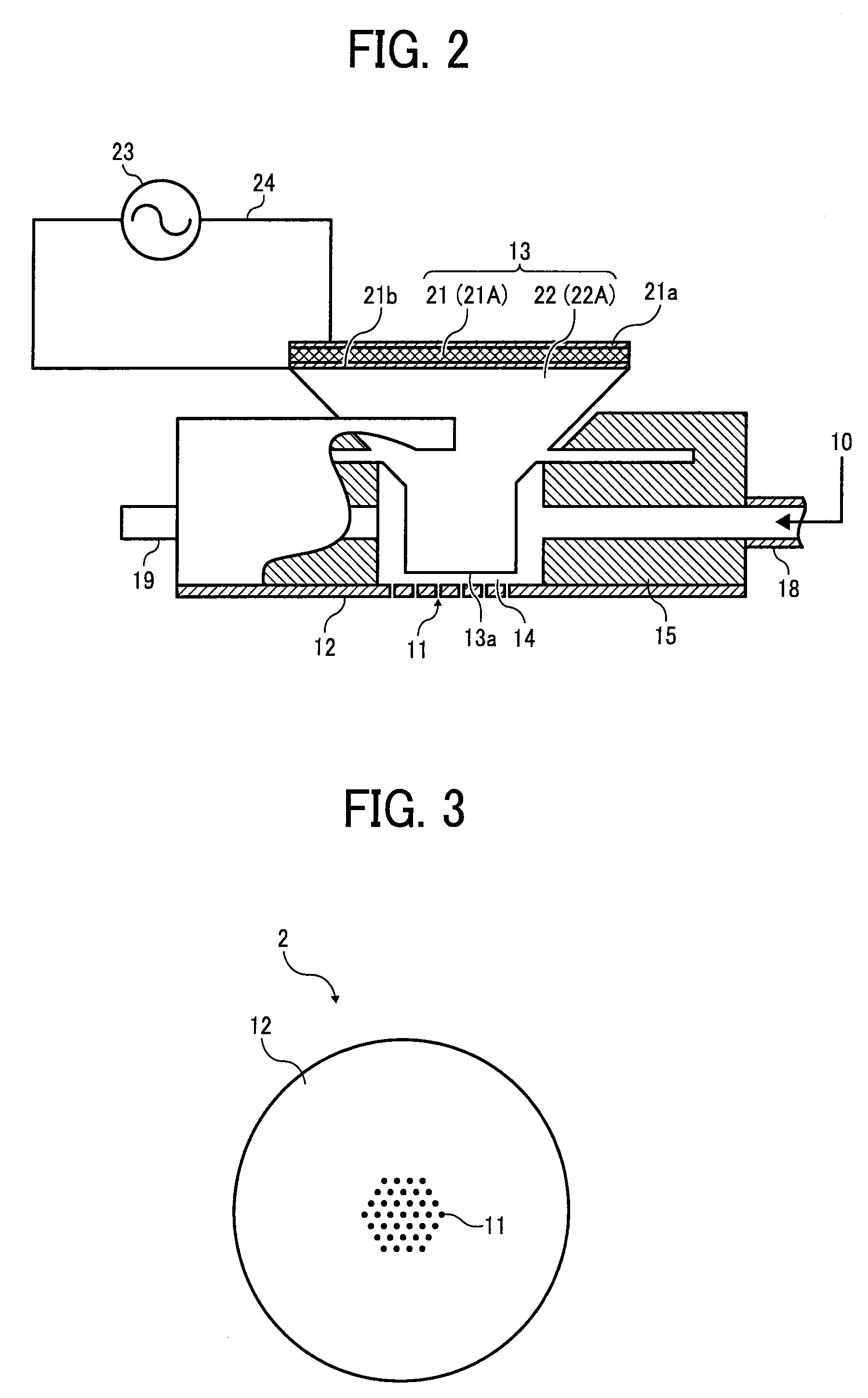

A method of preparing a toner, including periodically discharging a toner constituent liquid from plural nozzles having the same aperture diameter with a mechanical oscillator, wherein the toner constituent liquid includes:a binder resin,a colorant, andan organic solvent,wherein the binder resin and the colorant are dissolved or dispersed in the organic solvent; forming a droplet of the toner constituent liquid in a gas phase; and solidifying the droplet, wherein the aperture diameter is from 3 to 30 μm, and the binder resin has a ratio (Mw / Mn) of a weight-average molecular weight (Mw) to a number-average molecular weight (Mn) of THF (tetrahydrofuran)-soluble components therein of from 1.5 to 15 in a molecular weight distribution measured by GPC (gel permeation chromatography), and a ½ flow temperature (Tm) of from 114 to 149° C.

Owner:RICOH KK

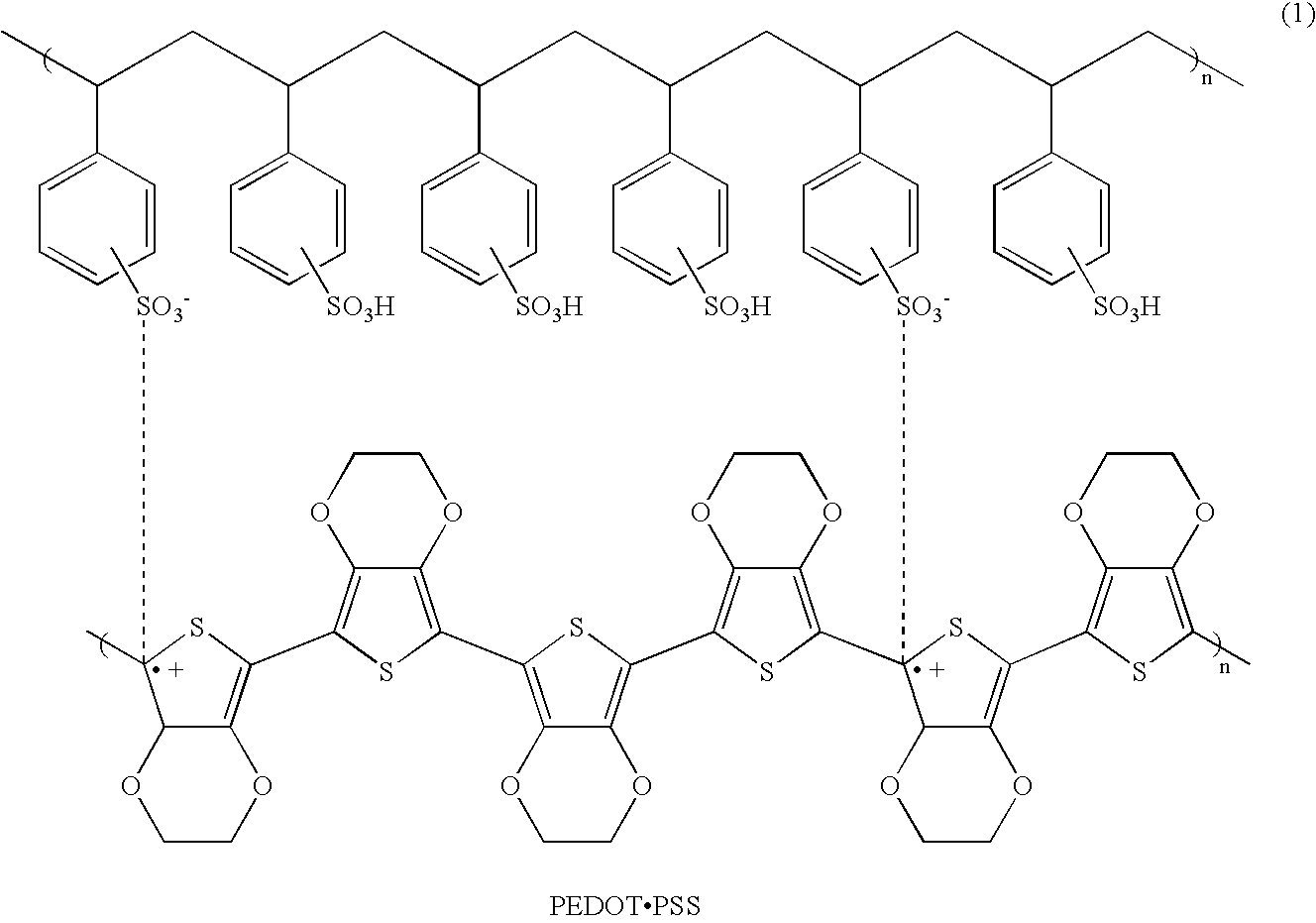

Ink for forming a hole injection layer of organic EL display devices and manufacturing method thereof, organic EL display devices, and manufacturing method of the same

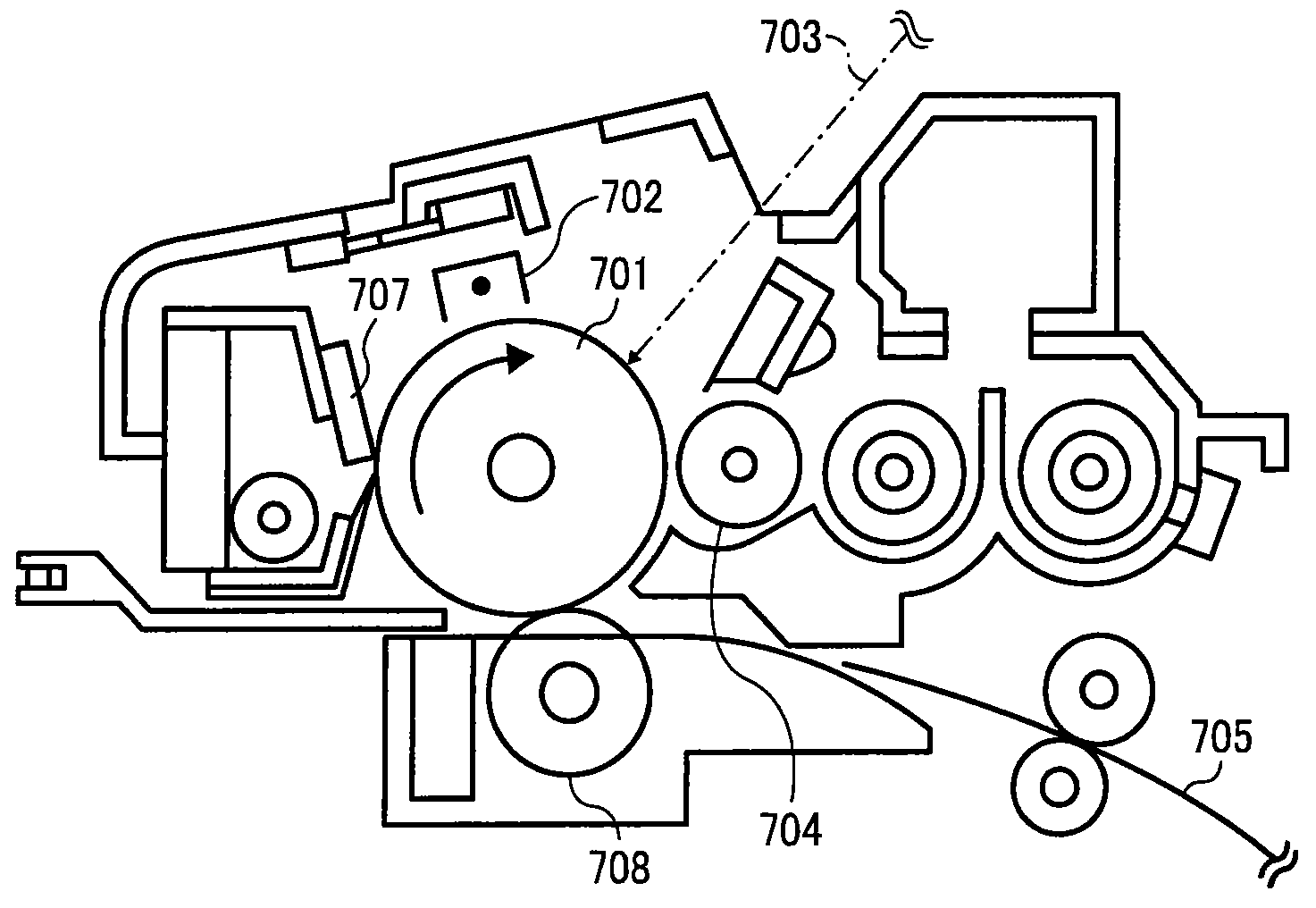

There is disclosed an organic electro luminescence display device comprising a two-dimensional array of pixels comprising organic electro luminescence elements capable of emitting a of color or different plural colors, each of the organic electro luminescence elements being provided with an anode, a cathode, a polymeric luminescence layer located between the anode and the cathode, and a hole injection layer. The hole injection layer is constituted by solid matters containing a donor molecule comprising polythiophene and / or a derivative thereof, and an acceptor molecule comprising polystyrenesulfonic acid and / or a derivative thereof, a concentration of sulfate ion in the hole injection layer is 125 ppm or less, and components having a molecular weight of 110,000 or less is 35% or less based on an entire solid matters, the molecular weight being converted as sodium polystyrenesulfonate in an aqueous gel permeation chromatography measured by using UV of 254 nm in wavelength.

Owner:KK TOSHIBA

Conjugated diene polymer, method for producing conjugated diene polymer, and conjugated diene polymer composition

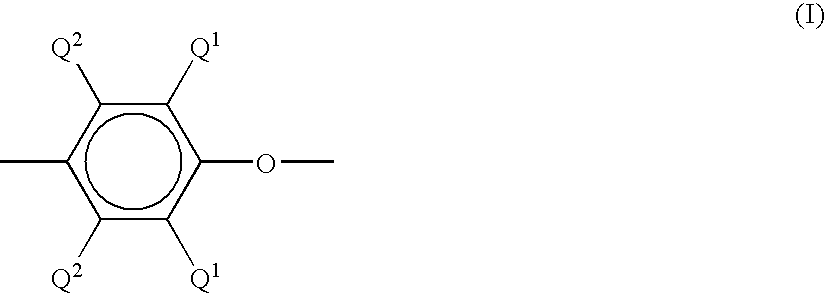

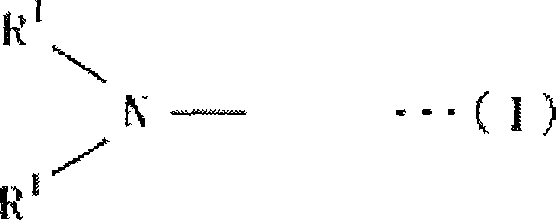

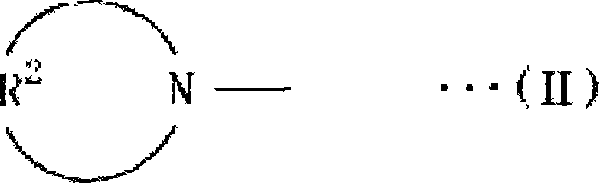

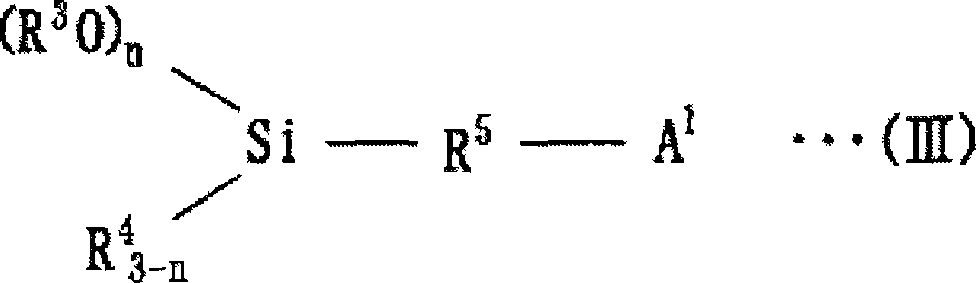

A conjugated diene polymer is provided that contains a conjugated diene-based monomer unit and a group represented by Formula (I) below, at least peaks H, M, and L below being present in a molecular weight distribution curve obtained by gel permeation chromatography measurement, and when the total area of the molecular weight distribution curve is 100%, the total peak area of peak H is 3% to 30%, the total peak area of peak M is 5% to 45%, and the total peak area of peak L is 40% to 80%(in Formula (I), R1 and R2 independently denote a hydrocarbon group having 1 to 4 carbon atoms, a hydrocarbonoxy group having 1 to 4 carbon atoms, a hydroxy group, or a polymer chain containing a conjugated diene-based monomer unit, m denotes an integer of 0 to 10, and A1 denotes a polar functional group that does not have an active hydrogen)Peak H: a peak for which the molecular weight at the peak top is higher than the molecular weight at the peak top of peak MPeak M: a peak for which, when the molecular weight at the peak top of peak H is MH, the molecular weight at the peak top is 0.6×MH to 0.8×MHPeak L: a peak for which, when the molecular weight at the peak top of peak H is MH, the molecular weight at the peak top is 0.2×MH to 0.4×MH.

Owner:SUMITOMO CHEM CO LTD

Poly(arylene ether)/polyamide composition

Disclosed herein is a polymer composition comprising a poly (arylene ether) resin; a polyamide resin having a weight average molecular weight greater than or equal to about 75,000 as determined by gel permeation chromatography using polystyrene standards; an impact modifier; and a flame retardant.

Owner:SABIC GLOBAL TECH BV

Rubber composition and tire using same

This invention relates to a rubber composition having excellent workability, fracture characteristics and wear resistance and a low heat buildup and a high storage modulus (G'), and more particularly to a rubber composition comprising not less than 20 parts by mass of a reinforcing filler (B) and 5 to 60 parts by mass of a low-molecular weight aromatic vinyl compound-conjugated diene compound copolymer (C) having an aromatic vinyl compound content of 5 to 80% by mass, a vinyl bond content in a conjugated diene compound portion of 10 to 80% by mass and a weight average molecular weight as measured with a gel permeation chromatography and converted to polystyrene of 5,000 to 300,000 based on 100 parts by mass of a rubber component (A) containing not less than 10% by mass of a modified conjugated diene-based polymer having at least one functional group.

Owner:BRIDGESTONE CORP

Pressure-sensitive adhesive composition for optical films, pressure-sensitive adhesive optical film and image display

InactiveUS20090208741A1Easy to processExcellent reworkabilitySynthetic resin layered productsPolarising elementsMeth-Display device

There is provided a pressure-sensitive adhesive composition for optical films. The composition can form a pressure-sensitive adhesive layer that can prevent light leakage caused by stress associated with dimensional change of a component such as an optical film, which include the pressure-sensitive adhesive layer that has reworkability such that it can be easily peeled from a component, and that has satisfactory processability such that it can be processed without pressure-sensitive adhesive stain or dropout, after it is formed on an optical film. A pressure-sensitive adhesive optical film produced using the composition is also provided. The pressure-sensitive adhesive composition includes a (meth)acrylic polymer including (a) 34 to 94% by weight of an alkyl(meth)acrylate monomer unit, (b) 5 to 35% by weight of an aromatic ring-containing (meth)acrylate monomer unit, and (c) 0.01 to 0.5% by weight of an amino group-containing (meth)acrylate monomer unit and further including (d) 0.05 to 3% by weight of a carboxyl group-containing (meth)acrylate monomer unit and / or (e) 0.05 to 2% by weight of a hydroxyl group-containing (meth)acrylate monomer unit and having a weight average molecular weight of 1,600,000 to 3,000,000 as determined by gel permeation chromatography; crosslinking agents including 0.01 to 5 parts by weight of an isocyanate crosslinking agent and 0.01 to 2 parts by weight of a silane coupling agent based on 100 parts by weight of the (meth)acrylic polymer.

Owner:NITTO DENKO CORP

Toner

To provide a toner which has superior low-temperature fixing performance, high-temperature anti-offsetting properties and developing performance and may cause neither melt sticking of toner to photosensitive member nor turn-up of cleaning blade. The toner contains at least a binder resin, a colorant and a wax, and the wax is characterized by i) being an oxidized hydrocarbon wax, ii) having a hydroxyl value of from 5 mgKOH / g or more to 150 mgKOH / g or less, and iii) having, in molecular weight distribution measured by gel permeation chromatography of tetrahydrofuran-soluble matter, a main peak within the range of molecular weight of from 200 or more to 600 or less, and a component with a molecular weight of 700 or more in a content of 3% by mass or less.

Owner:CANON KK

Methods for characterization of polymers using multi-dimensional liquid chromatography with parallel second-dimension sampling

InactiveUS6855258B2Less complicatedUniversal applicabilityIon-exchange process apparatusSamplingGradient elutionPhase gradient

Methods and apparatus for characterizing a polymer sample and in preferred embodiments, libraries of polymer samples, in a comprehensive, directly-coupled multi-dimensional liquid chromatography system are disclosed. The first and second dimensions are preferably high-performance liquid chromatography dimensions, such as for example, a first dimension adapted for determining composition (e.g. adapted for mobile-phase gradient elution chromatography, including reverse phase chromatography, adsorption chromatography and the like), and a second dimension adapted for determining molecular weight or particle size (e.g., adapted for size exclusion chromatography, including gel permeation chromatography).

Owner:FREESLATE

Conjugated diene polymer, method for producing conjugated diene polymer, and conjugated diene polymer composition

Owner:SUMITOMO CHEM CO LTD

Polycarbonate-polyorganosiloxane copolymer and method for producing same

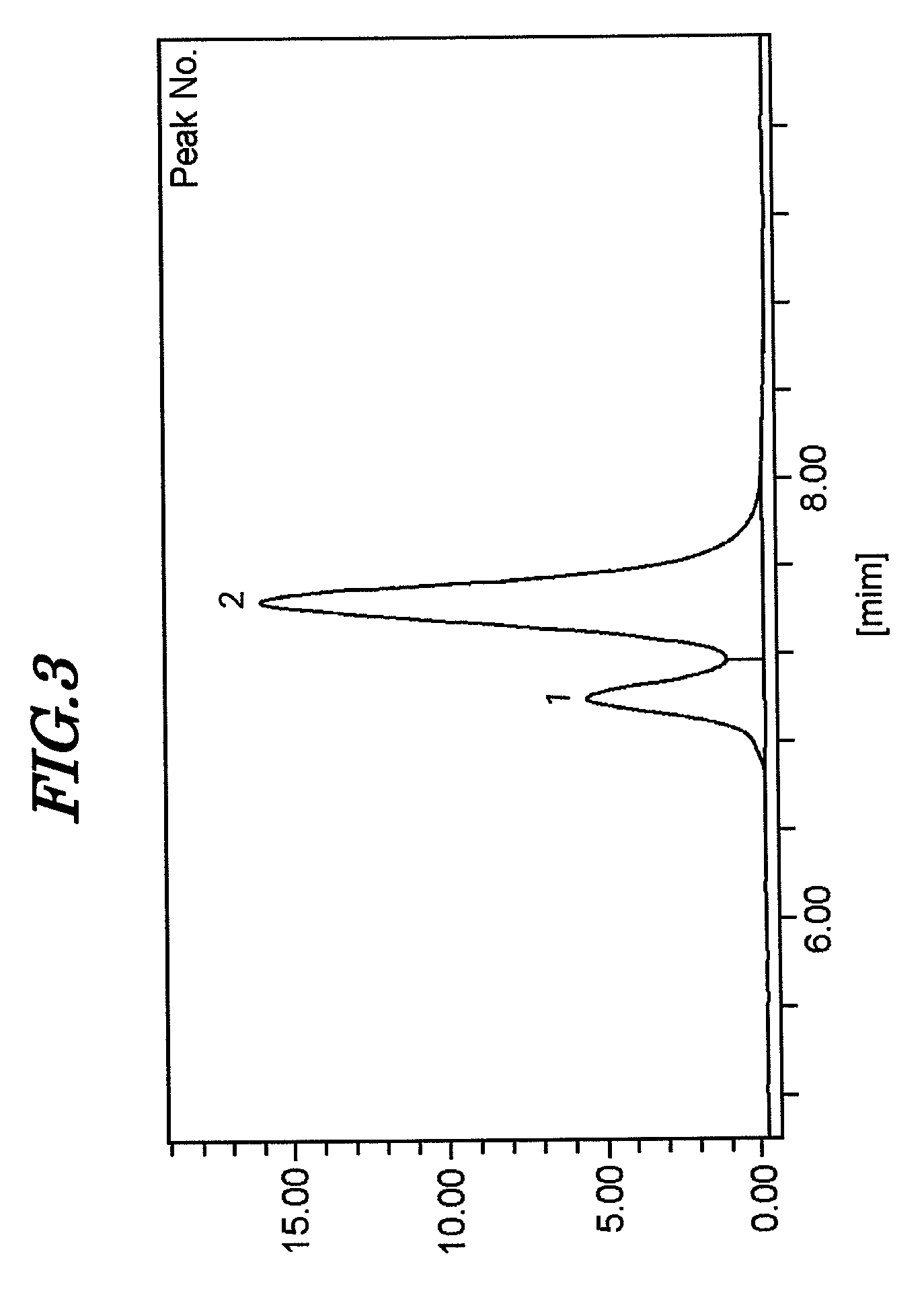

Provided is a polycarbonate-polyorganosiloxane copolymer, including a specific polycarbonate block unit (A) and a specific polyorganosiloxane block unit (B), in which in a differential molecular weight distribution curve obtained from measurement of the polyorganosiloxane block unit (B) by gel permeation chromatography using the polystyrene calibration curve, the curve having an axis of abscissa indicating a logarithmic value log(M) of a molecular weight M and an axis of ordinate indicating dw / d log(M) obtained by differentiating a concentration fraction w with respect to the logarithmic value log(M) of the molecular weight, (1) a dw / d log(M) value becomes maximum in a range of 3.4≦log(M)≦4.0, and (2) in the differential molecular weight distribution curve, a ratio of a value obtained by integrating the dw / d log(M) value over a range of 4.0≦Log(M)≦4.5 to a value obtained by integrating the dw / d log(M) value over the entire range of the log(M) is 6% or more and 40% or less.

Owner:IDEMITSU KOSAN CO LTD

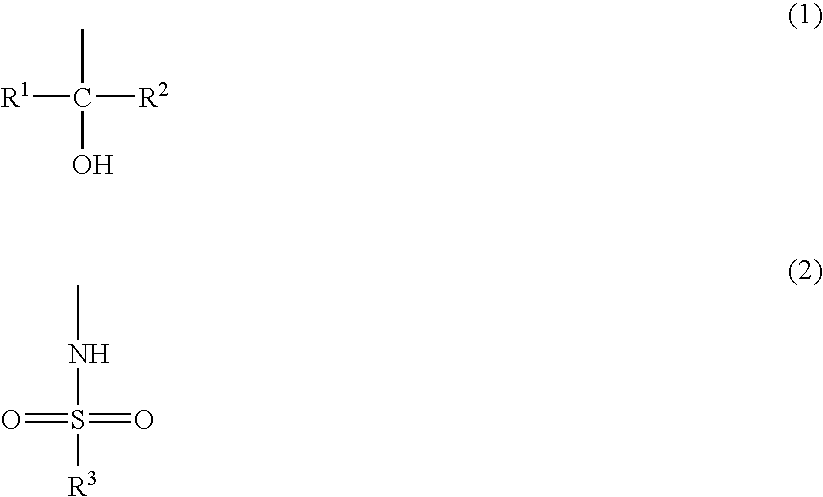

Polyalkylene glycol derivative and modified bio-related substance

ActiveUS20060073113A1Improve stabilityAvoid easy decompositionOrganic chemistryOrganic compound preparationHydrocarbonCarbon atom

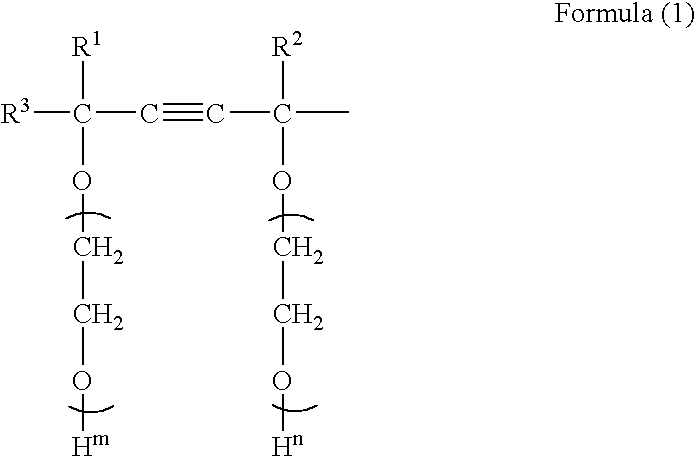

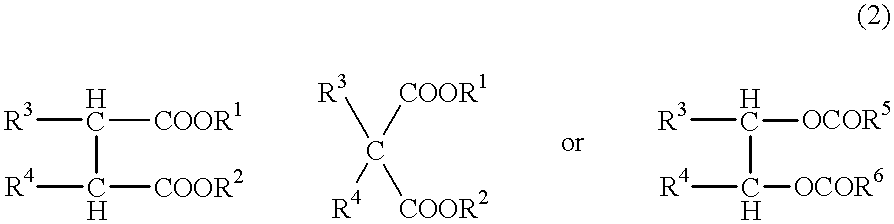

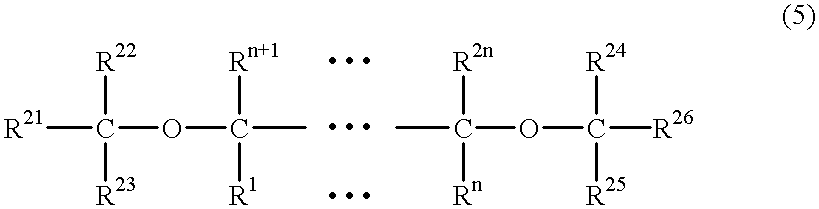

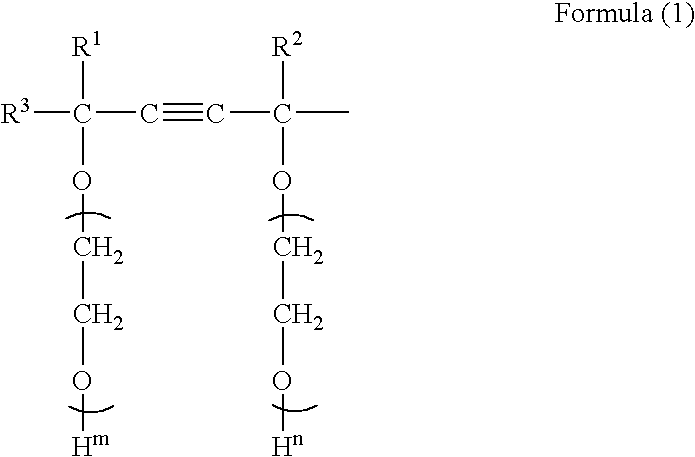

A polyalkylene glycol derivative containing a compound of the formula (1): wherein R is a hydrocarbon group having 1 to 24 carbon atoms, OA2 is an oxyalkylene group having 2 to 4 carbon atoms, the groups represented by R are the same or different from each other in one molecule, the groups represented by OA2 are the same or different from each other in one molecule, m is an average number of moles of the oxyalkylene group added, m represents 10 to 1000, and X represents a functional group capable of chemically reactive with a bio-related substance, polydispersity Mw / Mu of the above polyalkylene glycol derivative in gel permeation chromatography satisfying the following relationship: Mw / Mn≦1.07 wherein Mw represents a weight average molecular weight and Mn represents a number average molecular weight.

Owner:NOF CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com