Patents

Literature

176results about How to "Manufactured using" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

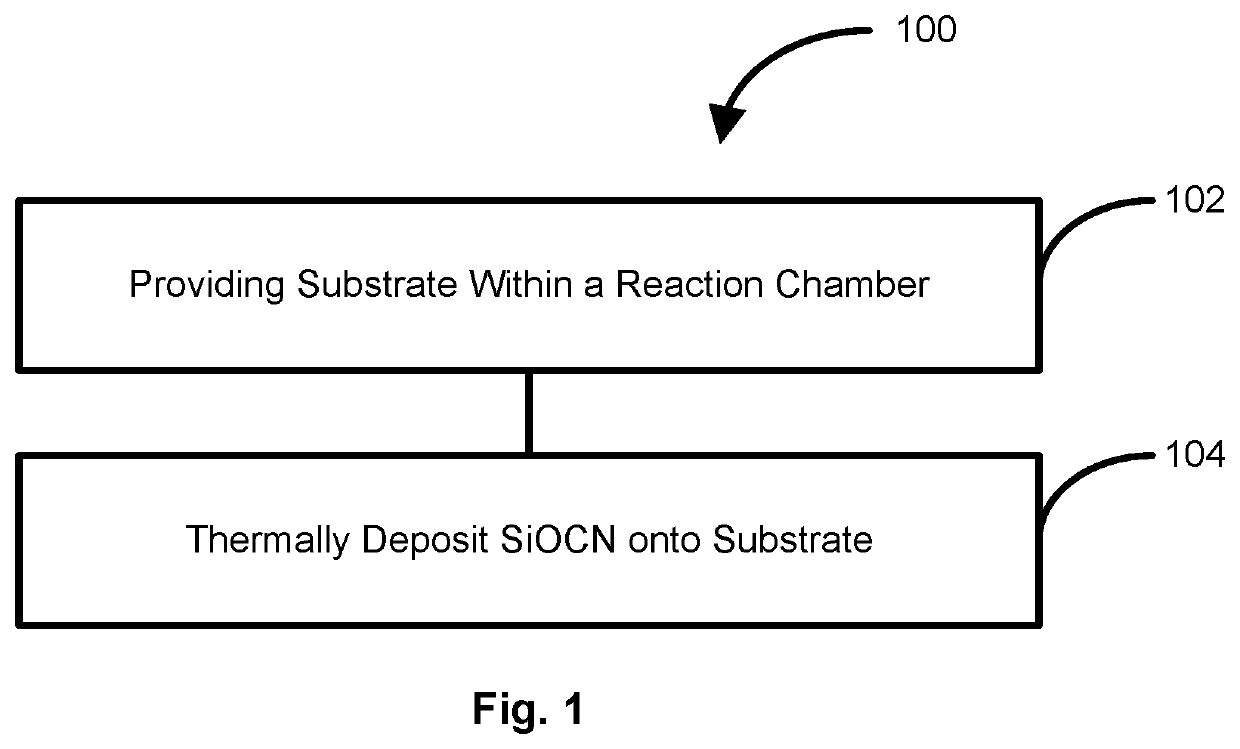

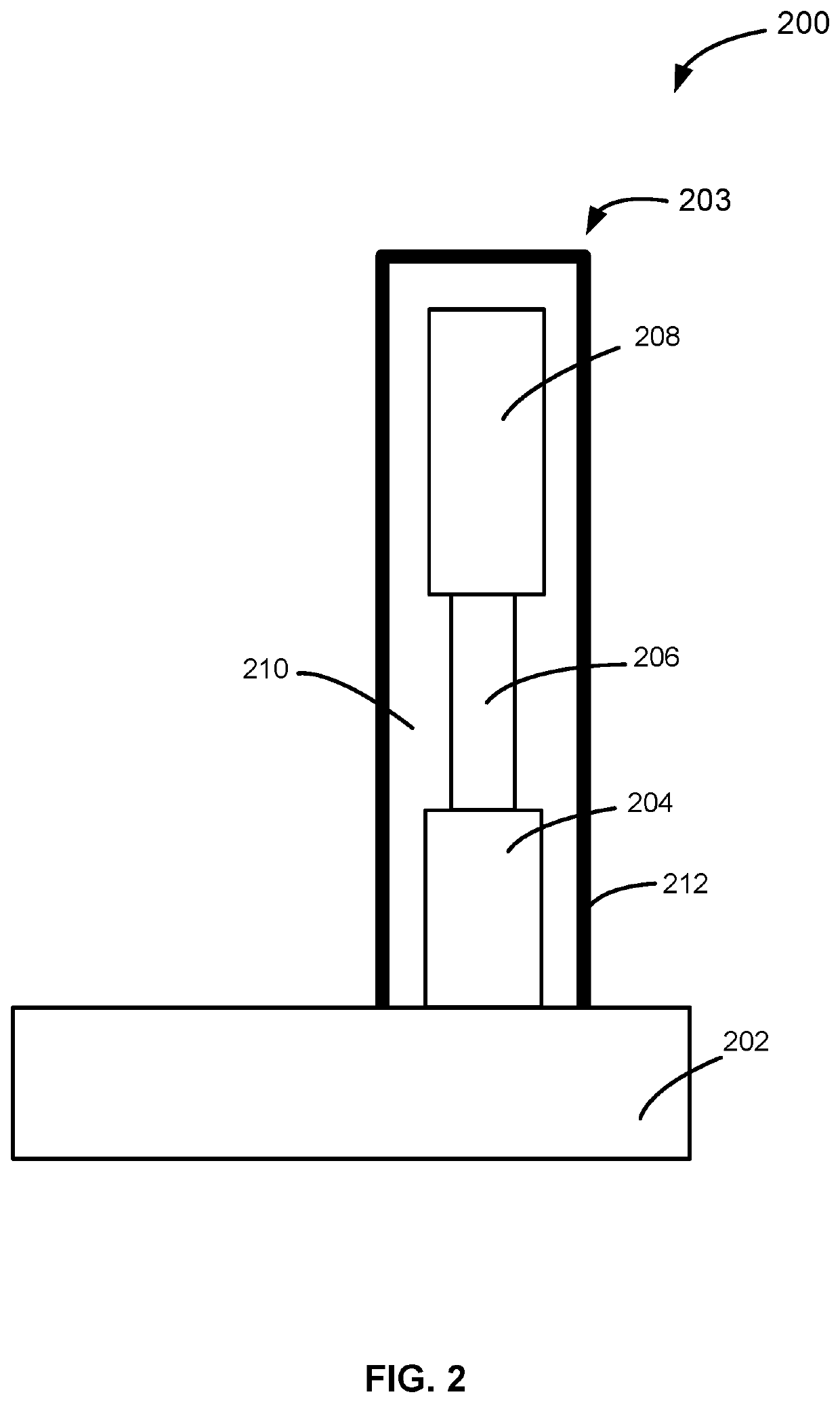

STRUCTURE INCLUDING SiOCN LAYER AND METHOD OF FORMING SAME

ActiveUS20200283893A1Manufactured usingDesired propertySemiconductor/solid-state device manufacturingChemical vapor deposition coatingThermal depositionEngineering

A method for forming a layer comprising SiOCN on a substrate is disclosed. An exemplary method includes thermally depositing the layer comprising SiOCN on a surface of the substrate. The layer comprising SiOCN can be used for various applications, including spacers, etch stop layers, and etch resistant layers.

Owner:ASM IP HLDG BV

Lightweight proppant and method of making same

InactiveUS20060016598A1Manufactured usingSuitable viscosityFluid removalDrilling compositionPrillHigh intensity

A lightweight, high-strength proppant is disclosed, comprising the formation of finely dispersed ceramic precursors and sintering at low temperatures, causing the formation and retention of mesopores and micropores in pelletized ceramic. A method of manufacturing such a proppant is also disclosed, comprising the steps of manufacturing finely divided ceramic precursors and additives using grinding, milling, and preferably sol-gel processes, and dispersing the finely divided ceramic precursors and additives in a liquid, preferably water. The dispersion has a viscosity profile, which permits the shaping of spheres using conventional pelletizing techniques. Drying of the pellets and sintering at temperatures below 1,400.degrees. C. forms and retains mesopores and micropores in the ceramic. Preferred total pore volumes range from 0.05 to 0.7 cm.sup.3 / g. The pelletized and porous ceramic is useful as lightweight and high-strength proppants.

Owner:URBANEK THOMAS WILHELM

Lightweight proppant and method of making same

InactiveUS20060162929A1Manufactured usingImprove stabilityFluid removalDrilling compositionMetallurgyMicrosphere

A method of forming lightweight, high-strength proppants is disclosed, comprising the steps of: homogeneously blending at least one ceramic precursor and at least one pore former; pelletizing the blend to form microspheres; heating the microspheres to less than sintering temperatures, to evaporate volatile components and pyrolyze fugitive components; further heating the microspheres to temperatures sufficient to sinter the continuous phase of the ceramic precursor, to form sintered particles; and then forming the sintered particles into generally spheroid proppants. The generally spheroid proppants, which have preferably been sintered to near theoretical density, may then be coated. Heating of the microspheres may comprise a series of heating stages.

Owner:GLOBAL SYNFRAC

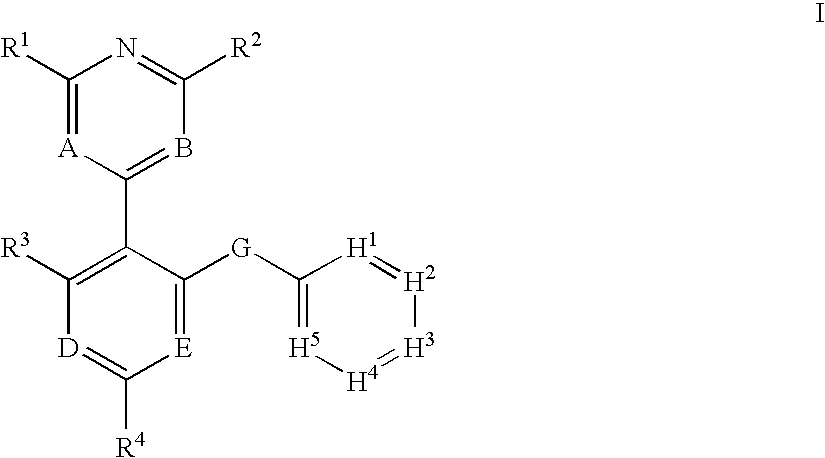

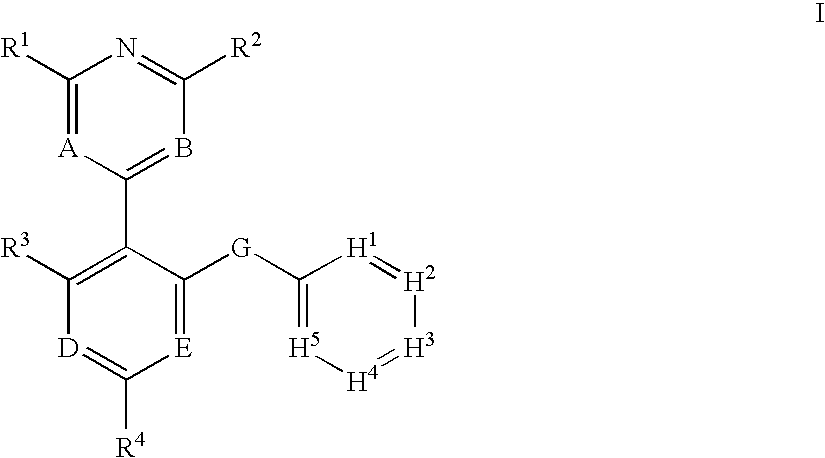

Protein kinase modulators and method of use

ActiveUS20060009453A1Attenuate and prevent disorderManufactured usingBiocideSenses disorderMolecular biologyProtein kinase modulator

The present invention relates to chemical compounds having a general formula I wherein A, B, D, E, G, H1-5 and R1-4 are defined herein, and synthetic intermediates, which are capable of modulating various protein kinase receptor enzymes and, thereby, influencing various disease states and conditions related to the activities of these kinases. For example, the compounds are capable of modulating kinase enzymes thereby influencing the process of angiogenesis and treating angiogenesis-related diseases and other poliferative disorders, including cancer and inflammation. The invention also includes pharmaceutical compositions, including the compounds, and methods of treating disease states related to the activity of protein kinases.

Owner:AMGEN INC

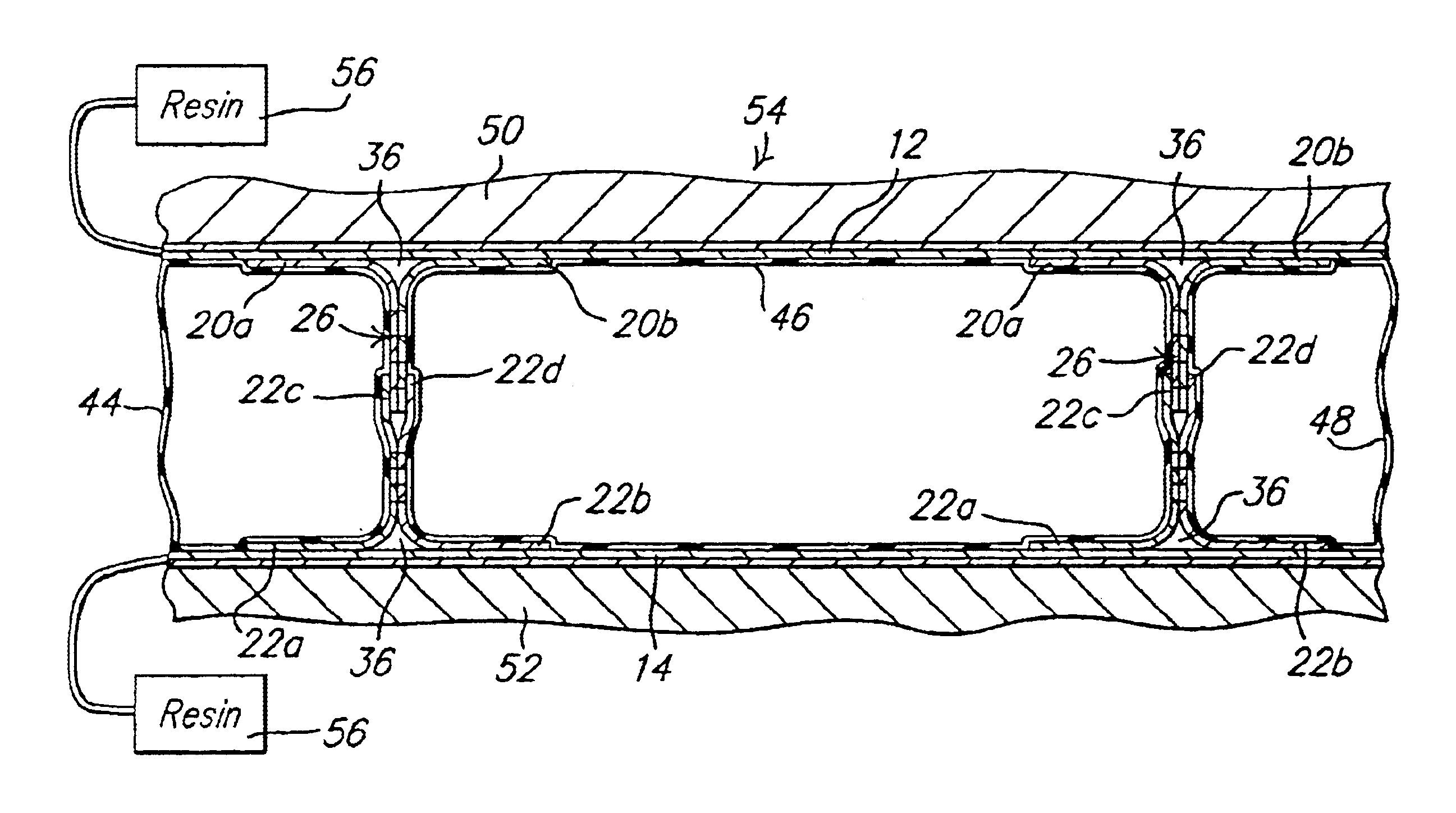

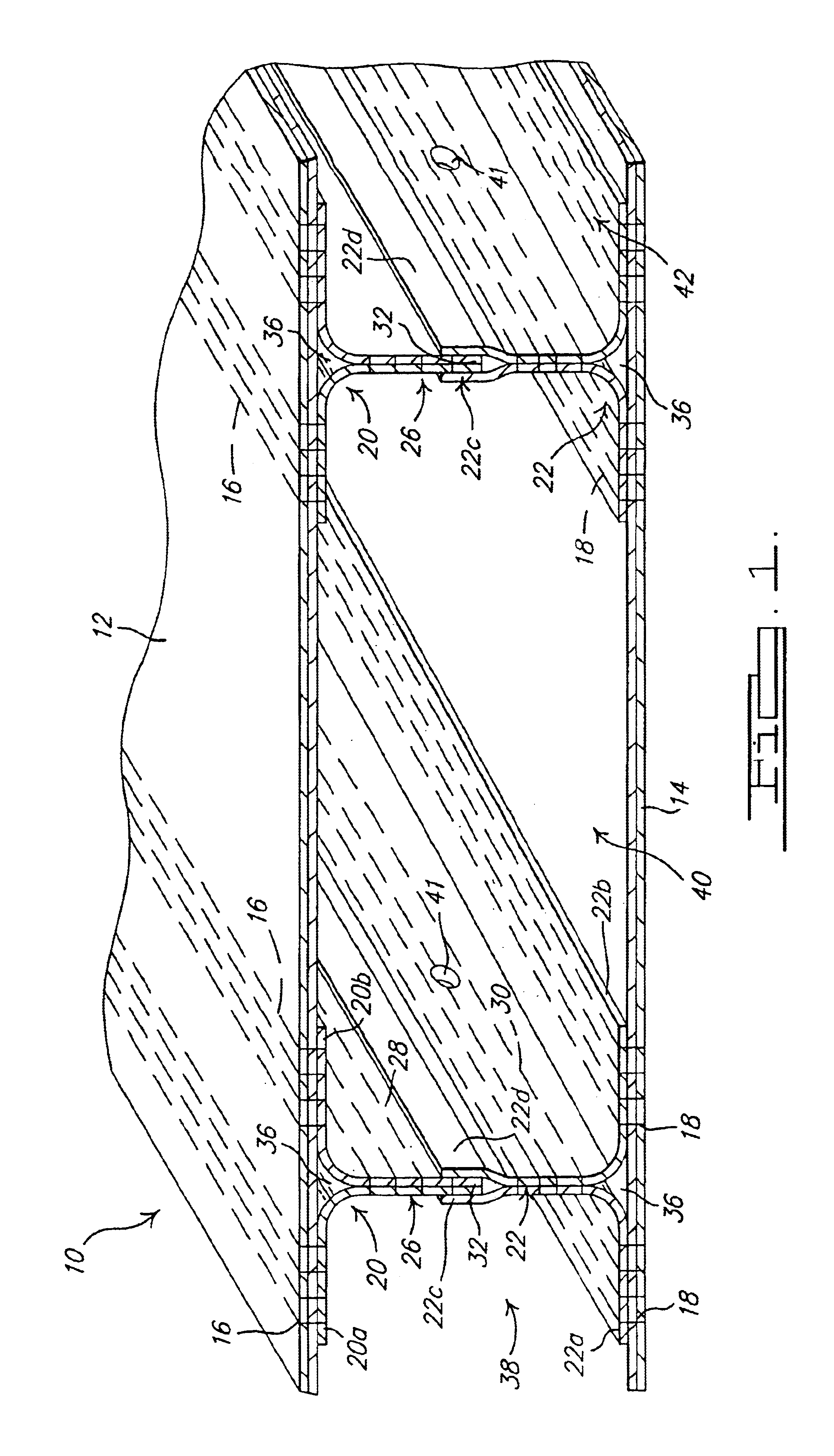

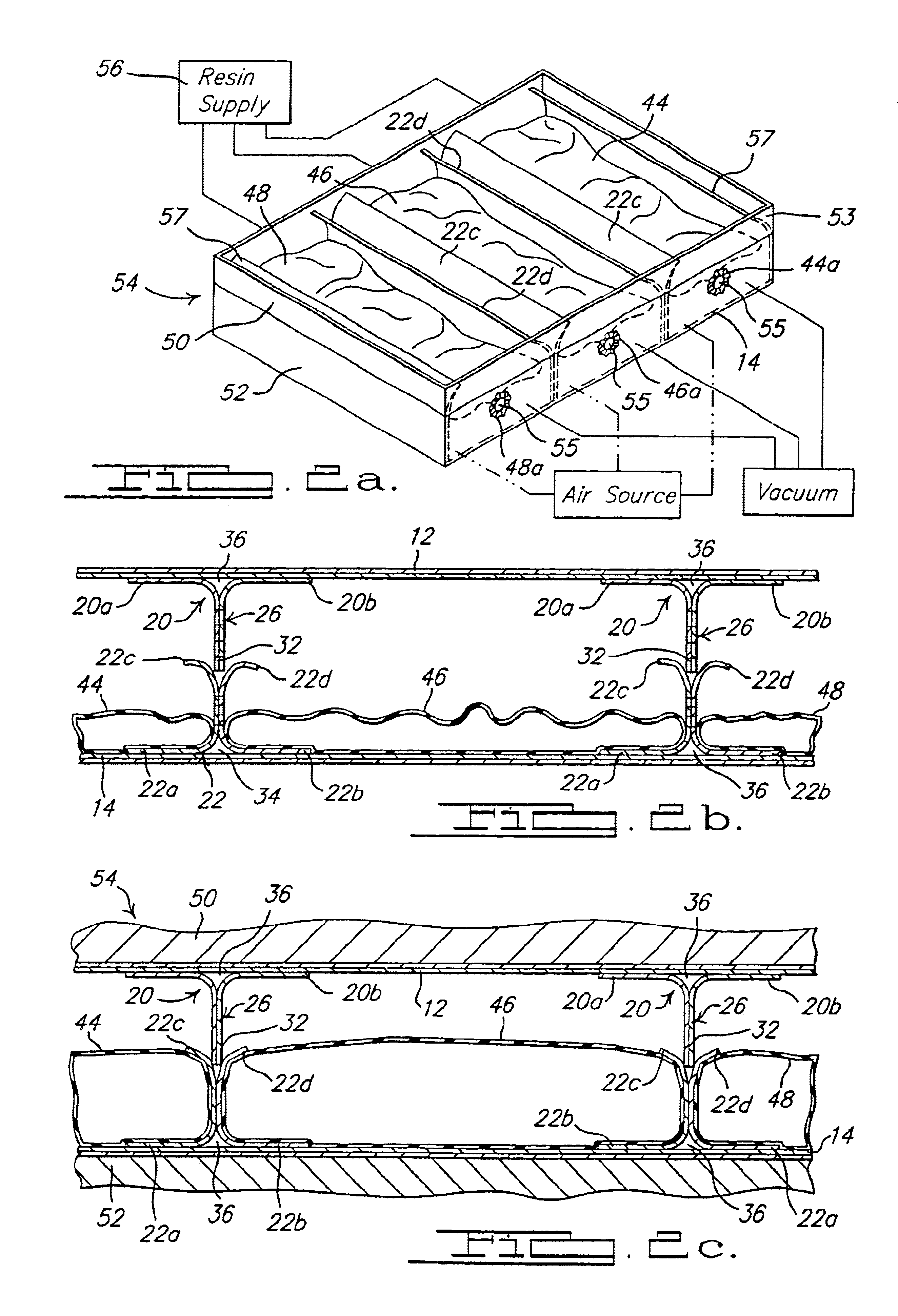

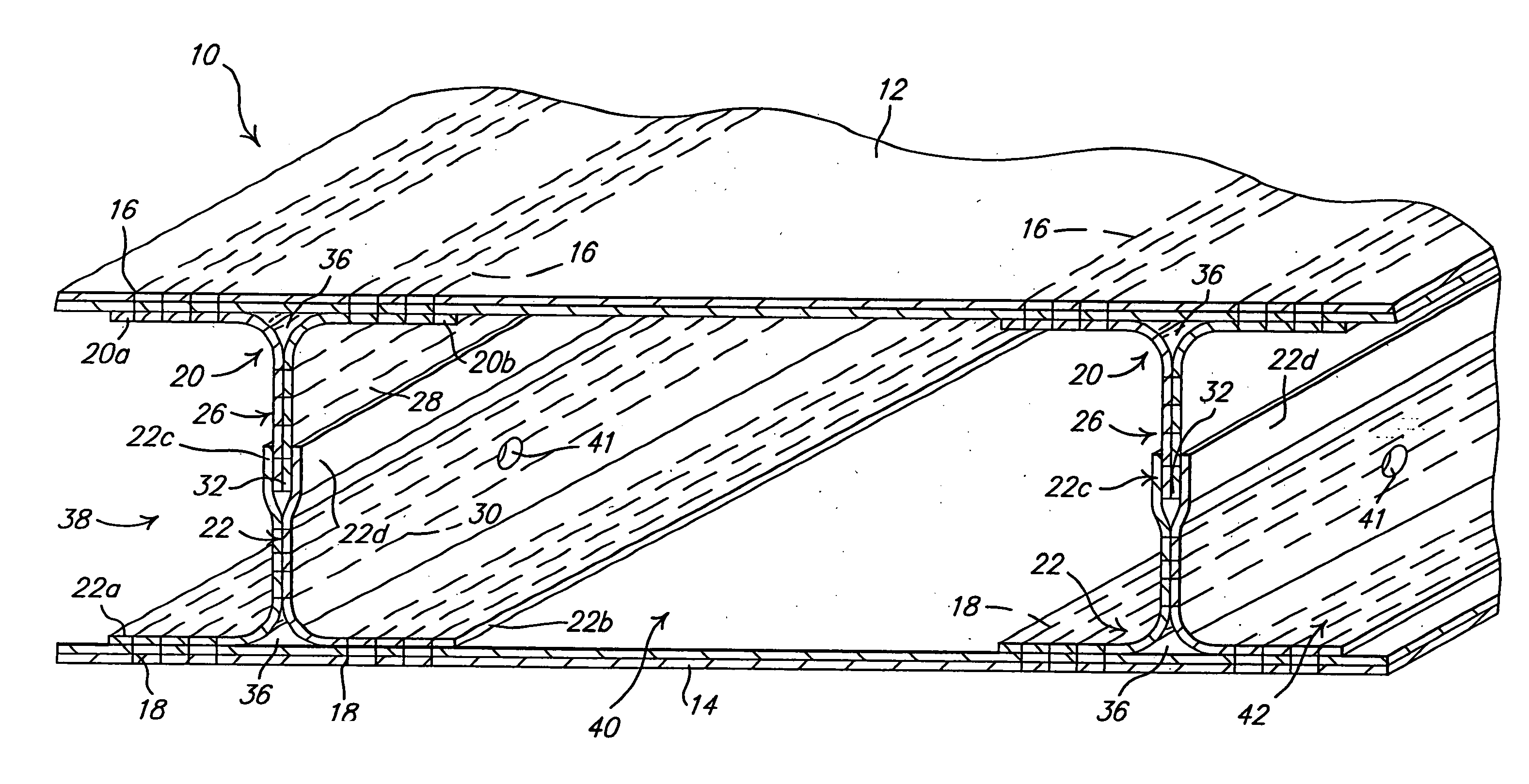

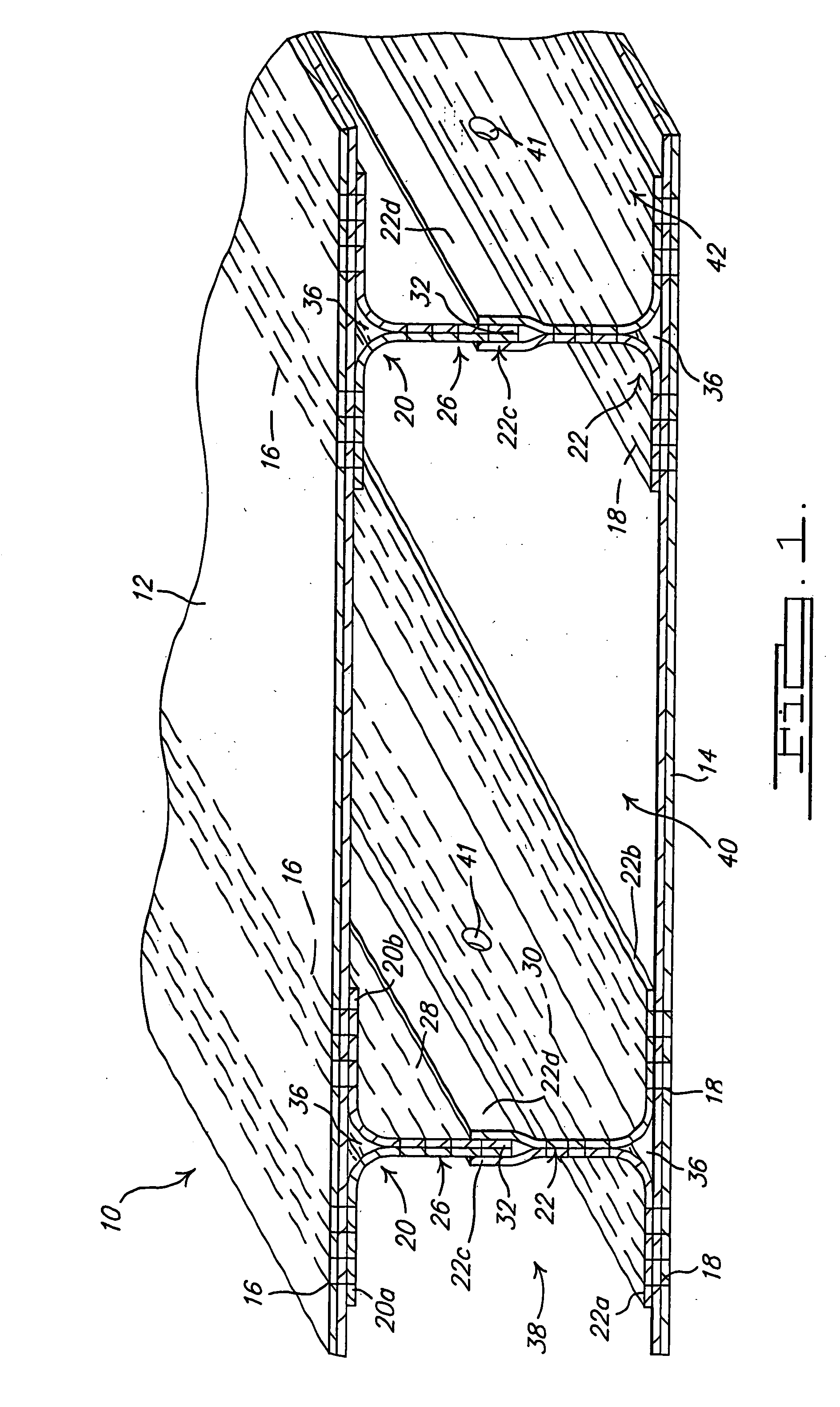

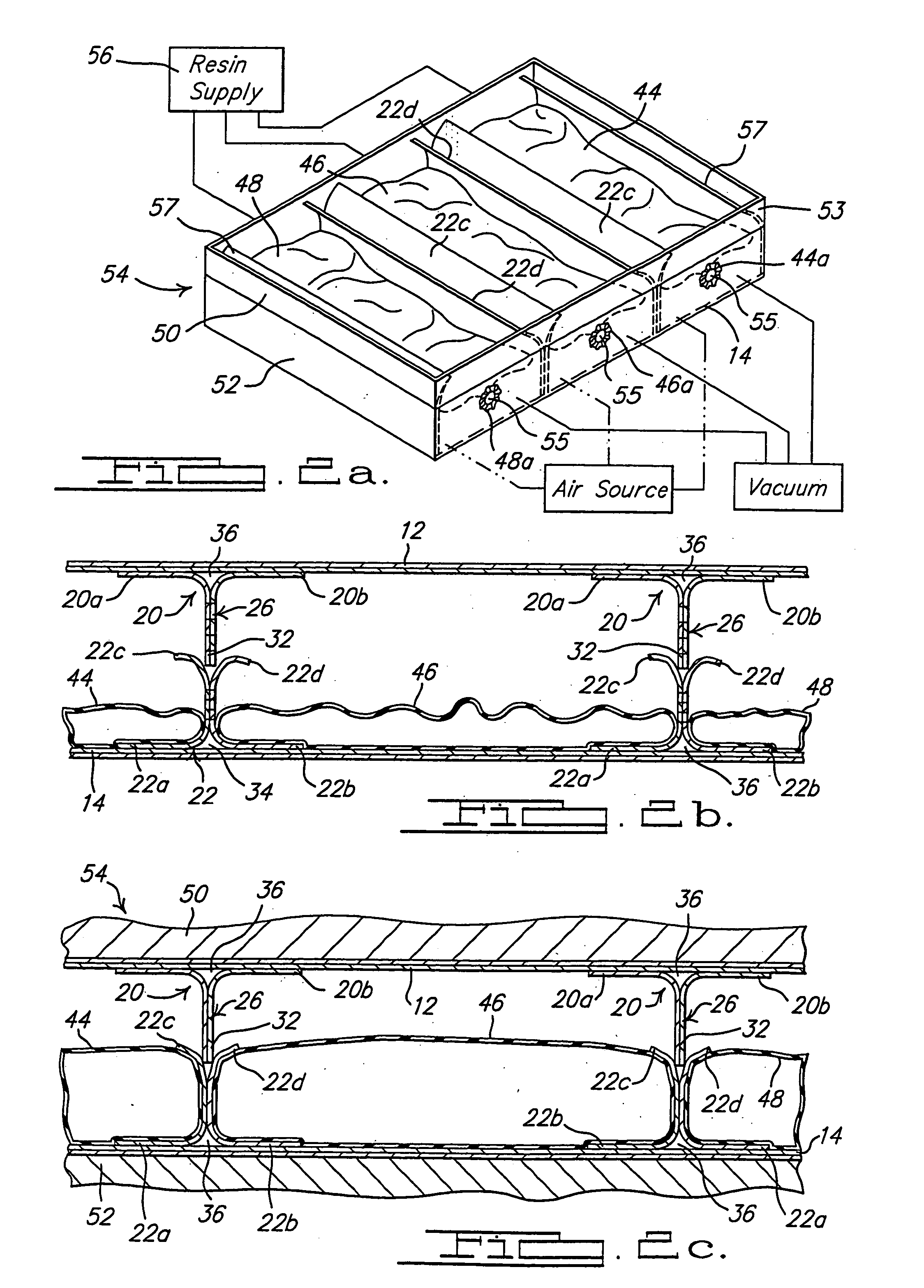

Molding process and apparatus for producing unified composite structures

InactiveUS6896841B2Stable structureManufactured usingLaminationWood working apparatusShell moldingEngineering

A method of forming a unitary, composite structural member, and a member formed in accordance with the process. The process involves stitching a plurality of warp knit panel sections together to generally form a plurality of independent panel sections. The sections are placed within the dies of a molding tool such that a rib portion of each section aligns. Inflatable bladders are then slipped into voids formed in between the various panel sections of the assembly. The bladders are inflated to hold with one another. Resin is then infused into the panels that make up the assembly. The assembly is then cured. When the panels are removed from the molding tool a unitary, complexly shaped, composite structural member is formed.

Owner:THE BOEING CO

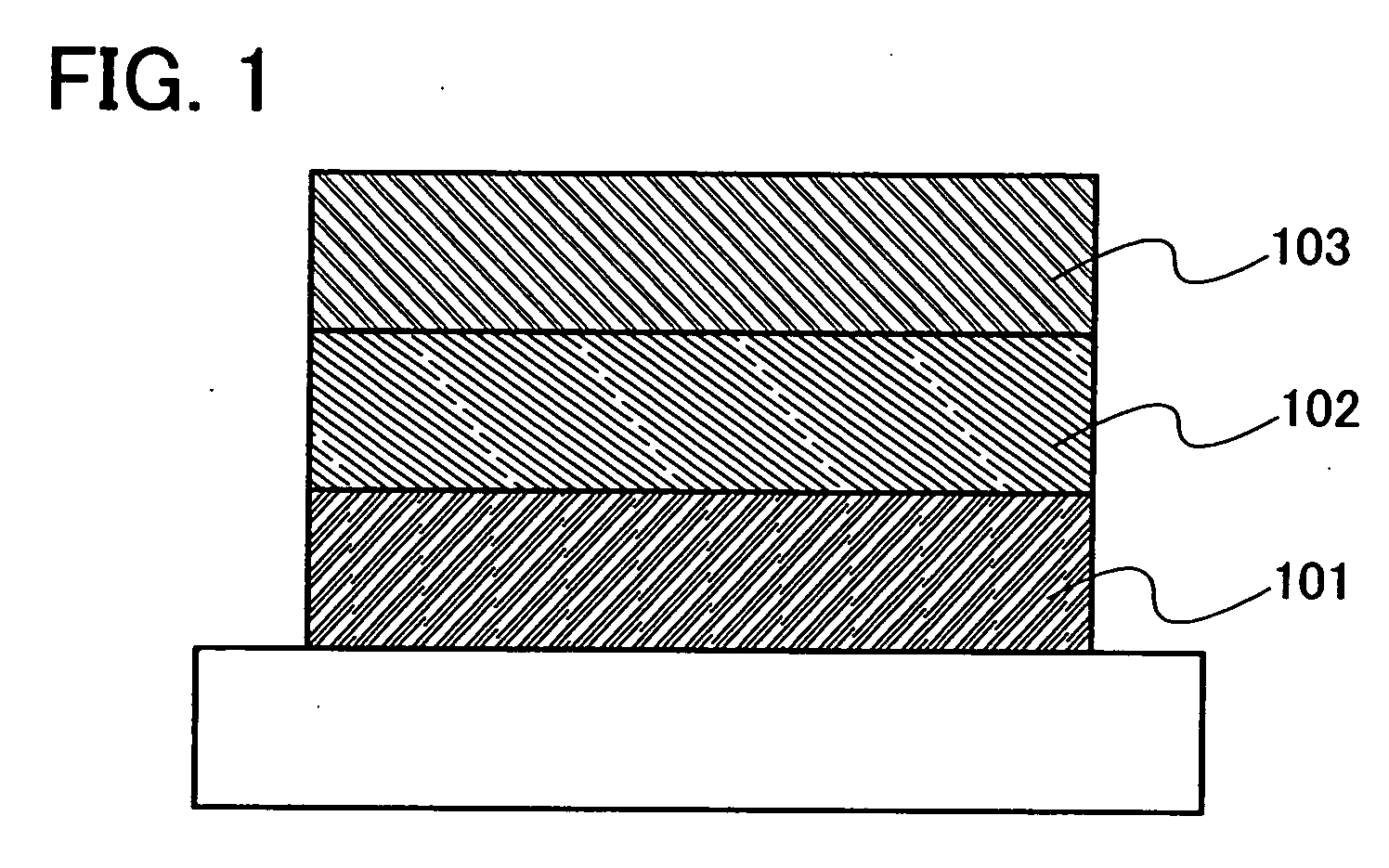

Carbazole derivative, material for light emitting element, light emitting element, light emitting device, and electronic device

InactiveUS20070049760A1Increase resistanceImprove compound stabilityOrganic chemistryDischarge tube luminescnet screensArylHydrogen

An object of the present invention is to provide a carbazole derivative which is useful in manufacturing a substance having resistance to oxidation. Another object is to provide a carbazole derivative which is useful in manufacturing a novel material with high reliability. Still another object is to provide a material for a light emitting element with high reliability. The present invention is a carbazole derivative represented by the following general formula (1) (where each of Ar1 and Ar2 represents an aryl group having 6 to 14 carbon atoms which may include a substitute, Ar1 and Ar2 may be either the same or different, and R in the formula represents hydrogen or an alkyl group having 1 to 4 carbon atoms). In addition, the present invention is a material for a light emitting element which includes a carbazole derivative represented by the following general formula (1) as a substituent.

Owner:SEMICON ENERGY LAB CO LTD

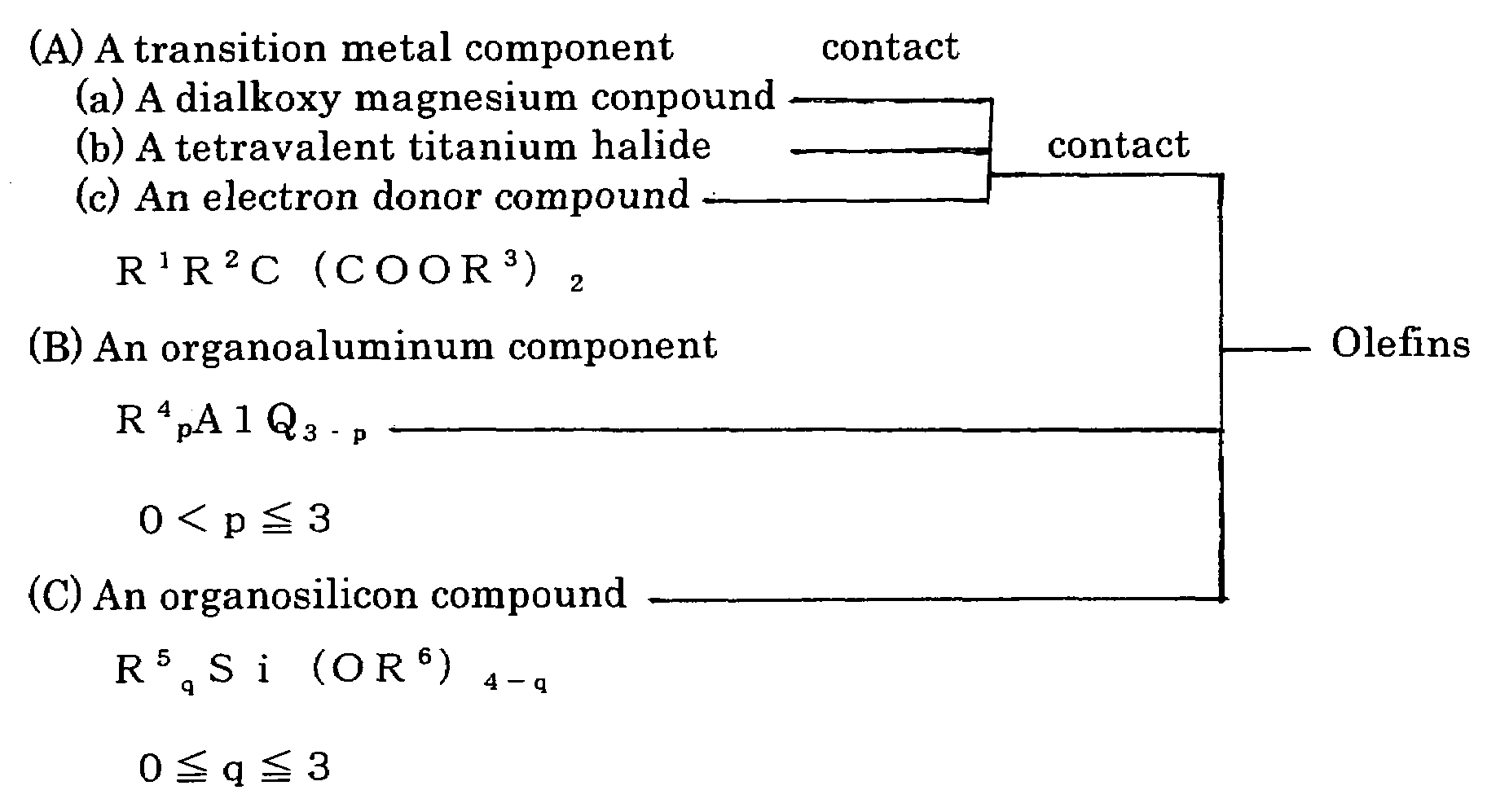

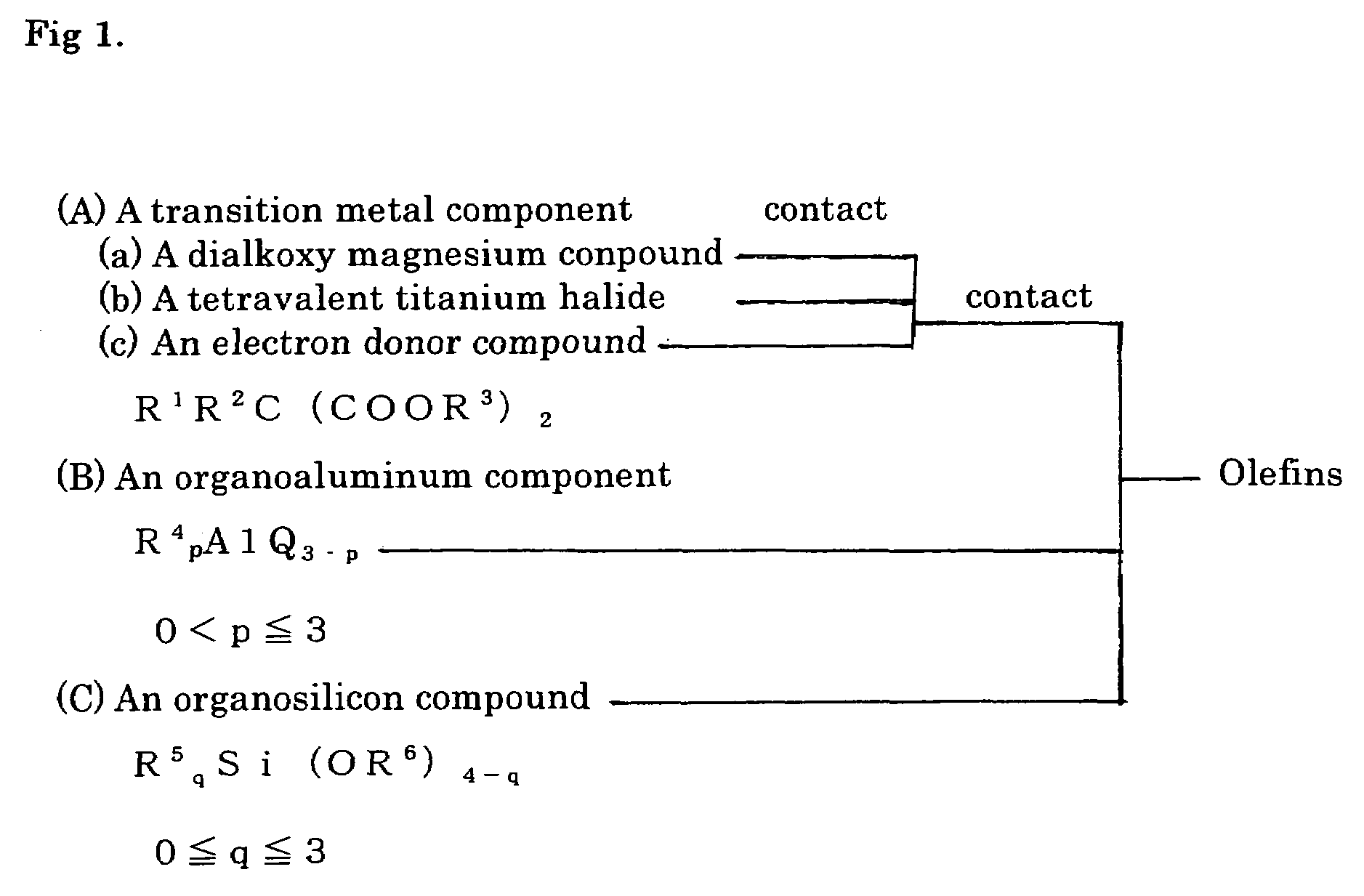

Solid catalyst component for olefin polymerization and catalyst

InactiveUS7208435B2Efficient processHigh catalytic activityOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationHydrogenElectron donor

A solid catalyst component for polymerization of olefins prepared by contacting (a) a dialkoxy magnesium compound, (b) a tetra-valent titanium halide, and (c) an electron donor compound of the formula R1R2C(COOR3)2 suspended in (d) an aromatic hydrocarbon having a boiling point in the range of 50–150° C. The catalyst containing the catalyst component is excellent in the olefin polymerization catalyst activity to hydrogen and can produce a polymer with a high stereoregularity in a high yield.

Owner:TOHO TITANIUM CO LTD

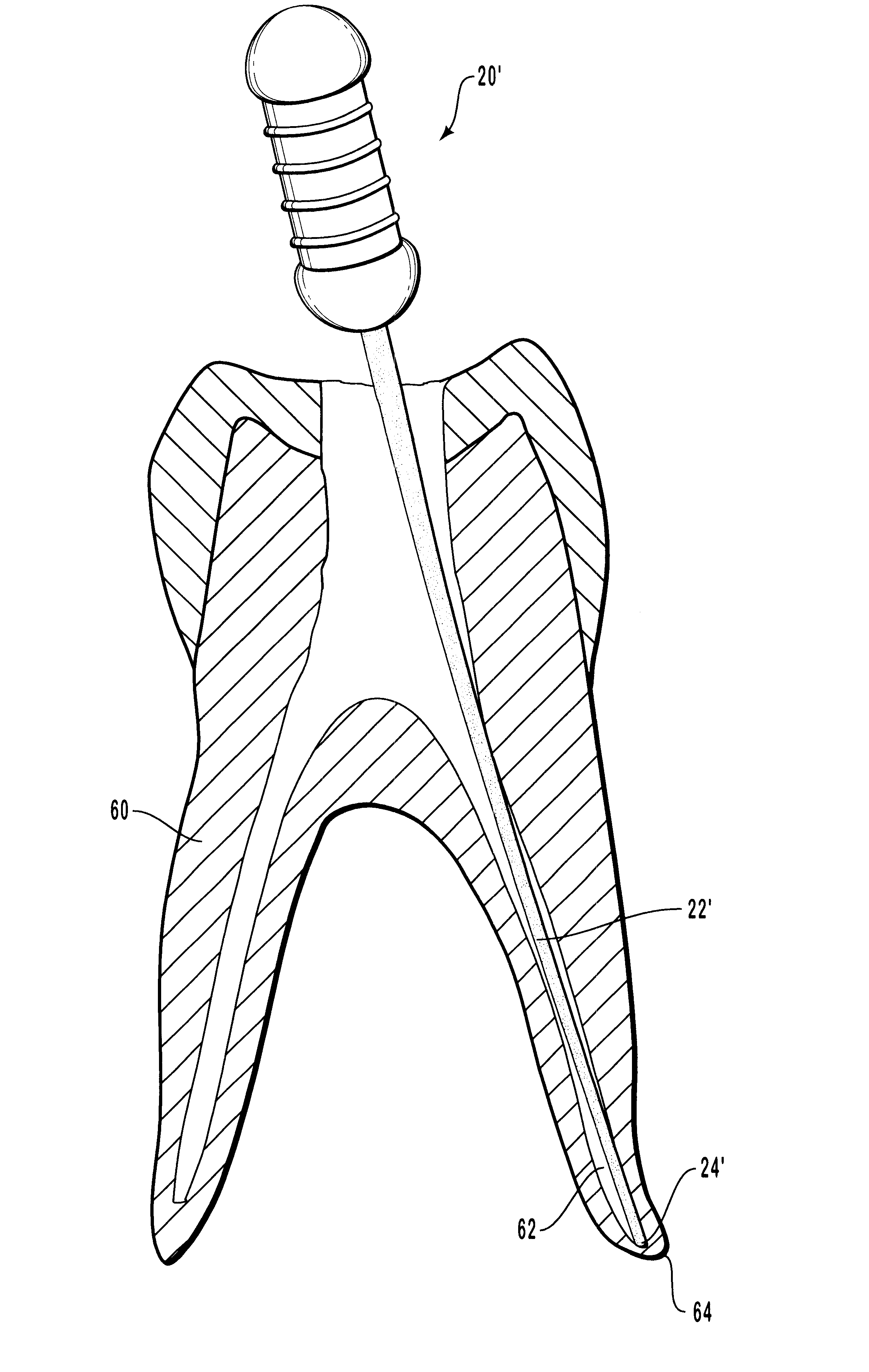

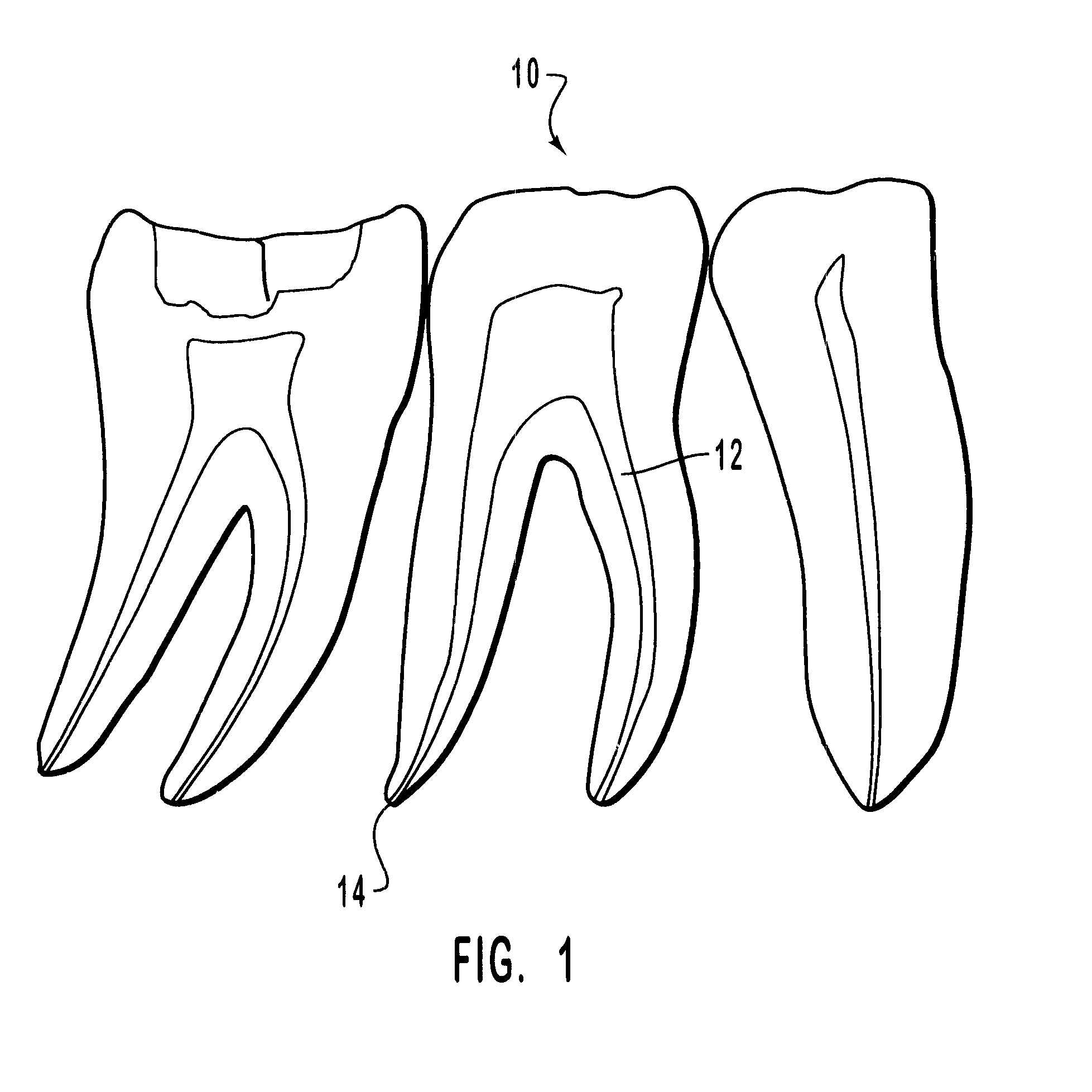

Abrasive radiopaque endodontic marking tools and related methods

InactiveUS6468079B1Low costReduce in quantityTeeth cappingTeeth nerve/root treatment implementsPlatinumContrast level

Enhanced radiographic detection is provided by an endodontic marking instrument having a highly radiopaque elongate member, thereby enabling a dentist to better identify the location of the instrument in a root canal and the length of the root canal. The highly radiopaque, high contrast material of the elongate member is a non-toxic, material such as gold, platinum, palladium, silver, tungsten, and the like. The endodontic marking tools of the present invention are distinctly visible on radiographic images in light of the substantial contrast between the highly radiopaque material and the tooth of the patient.

Owner:ULTRADENT PROD INC

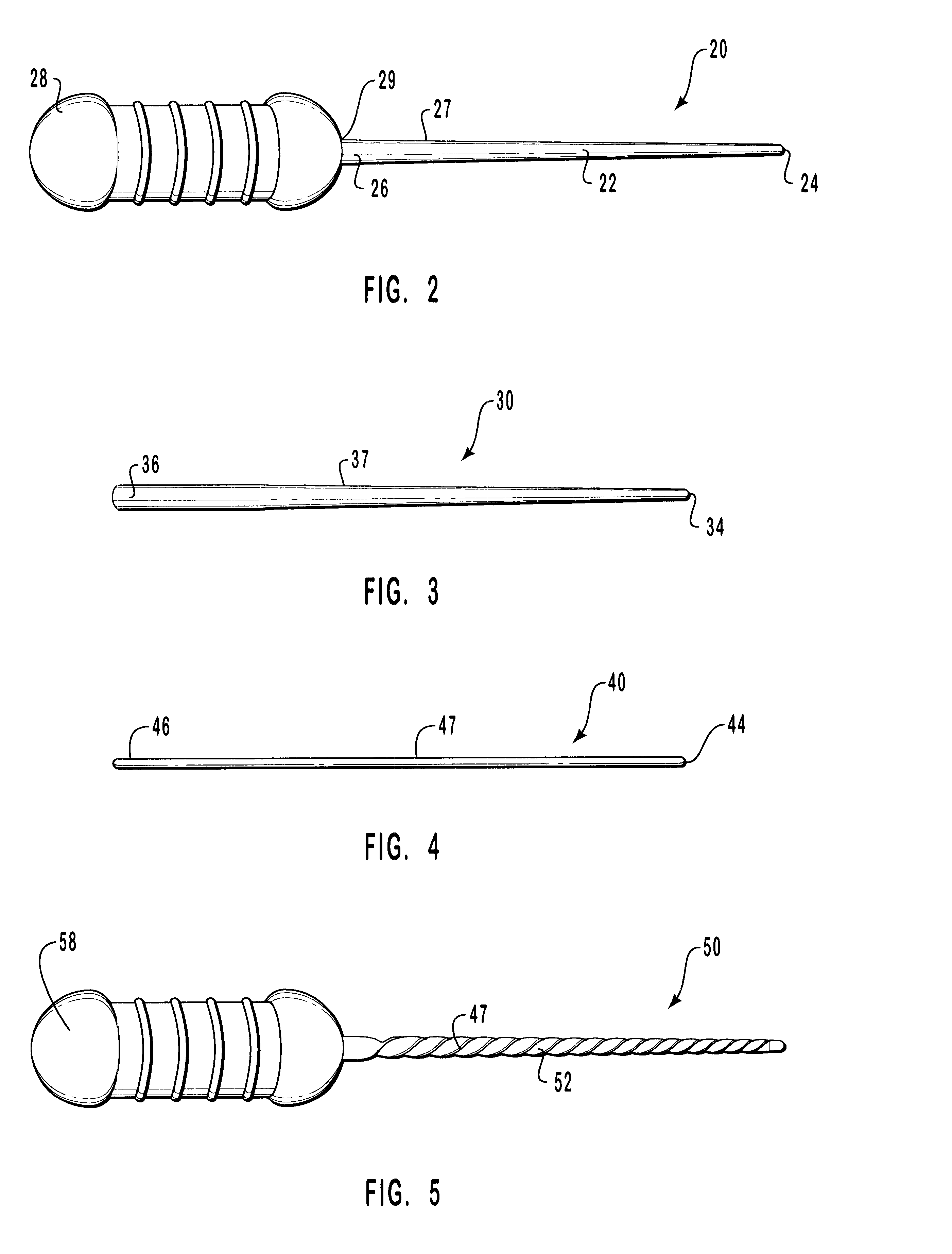

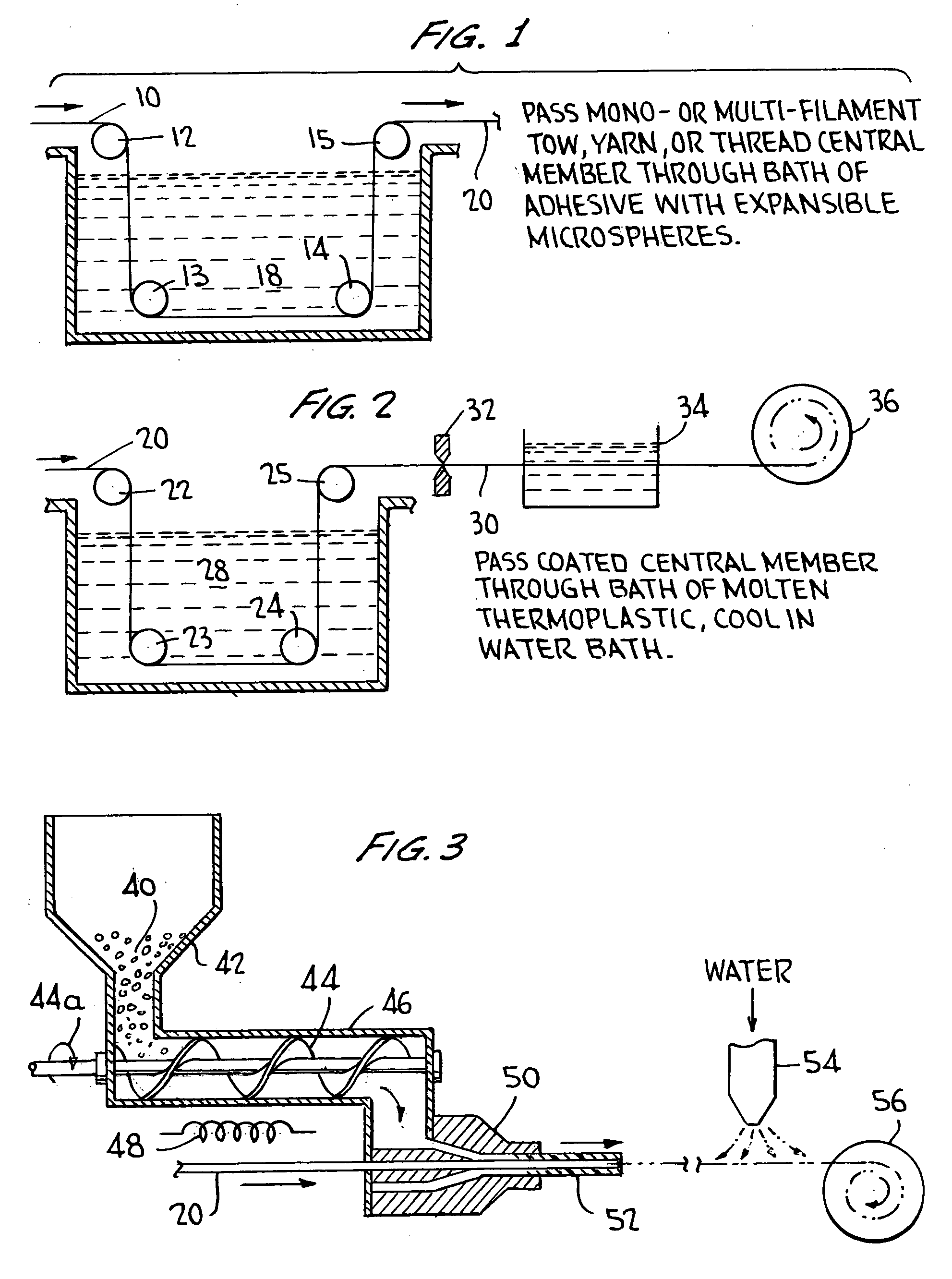

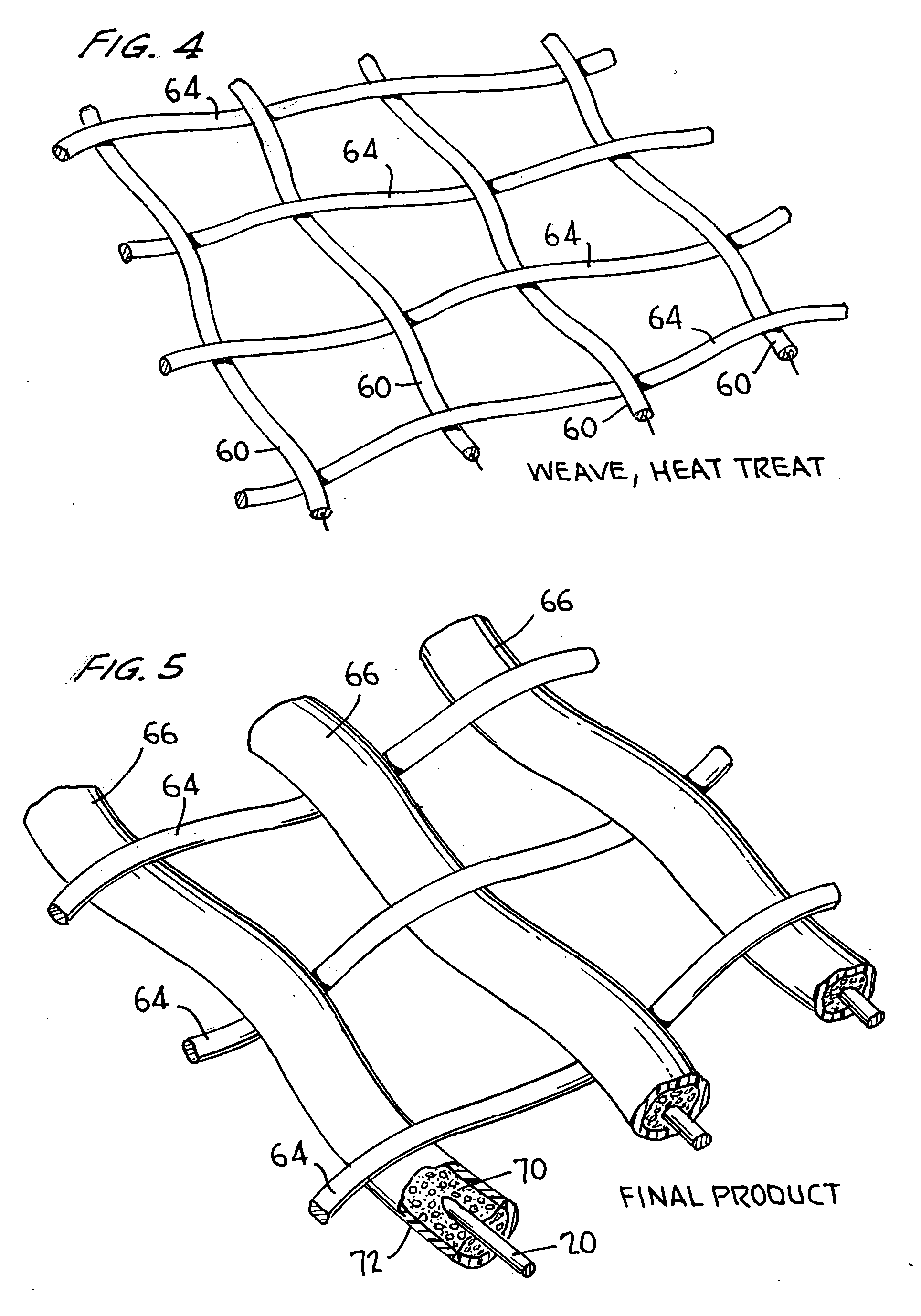

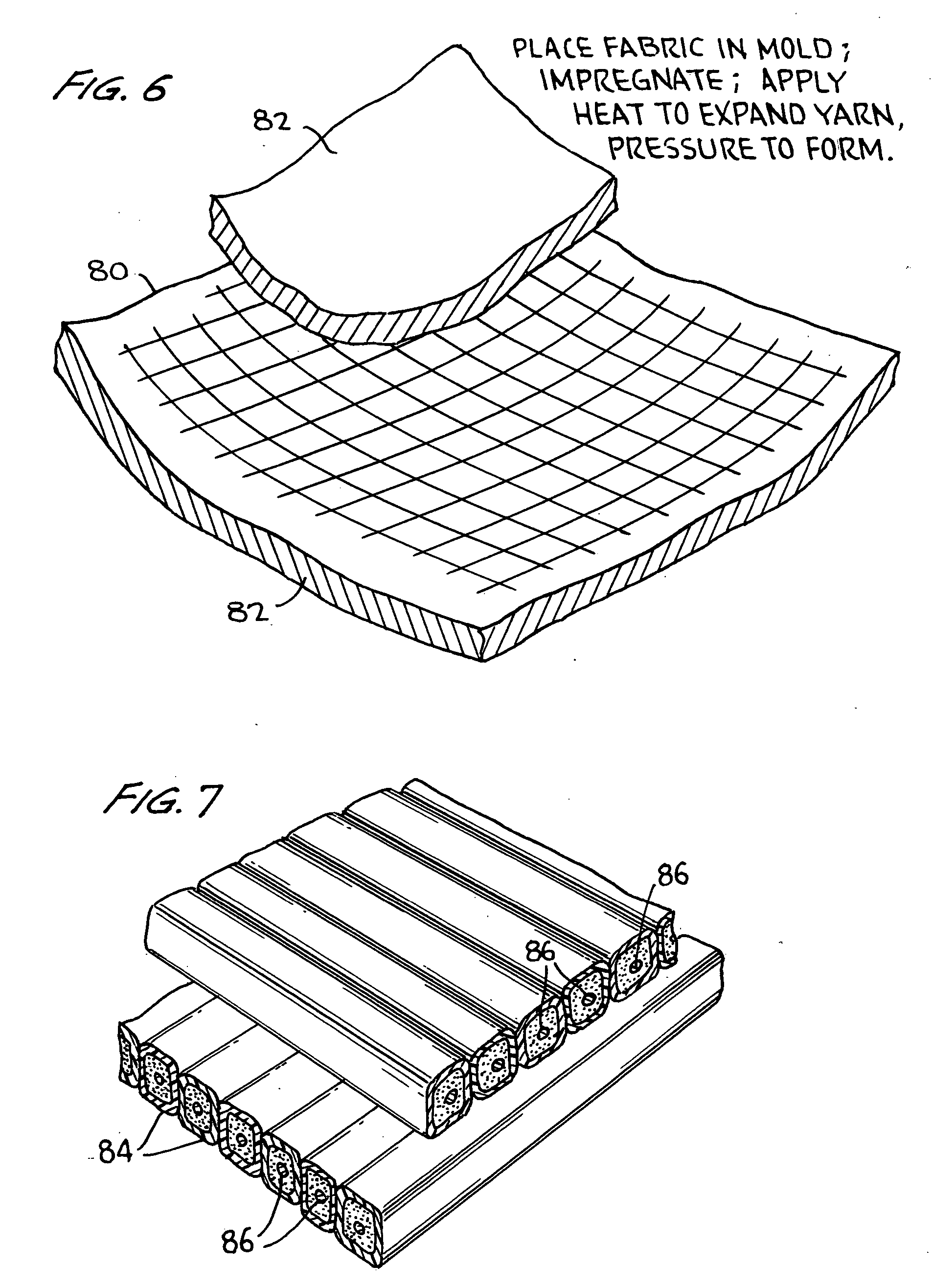

Expansible yarns and threads, and products made using them

A precursor yarn or thread is made by passing a central element, e.g., a filament, a tow, or a flat member, through a bath of a binder, such as a low-temperature hot-melt adhesive, and aqueous urethane, or an acrylic material, with which is mixed a quantity of hard-shelled microspheres which expand when heated to a higher temperature. This is then covered by a sheath, e.g, of PVC, polyurethane, polyester, acrylic resin, polycarbonate, polypropylene, or polyethylene in a second bath. When this product is heated to a transition temperature which is characteristic of the microspheres chosen, the microspheres expand, swelling the sheath. Such a precursor could be woven into a fabric and then heated, so that as the yarn expands the fabric mesh becomes tighter, reducing its porosity. This would be useful as a yarn in making papermaker's felts. Heat-expansible threads made similarly would be useful in manufacture of shoes, sails, tents, clothing and other items where porosity is undesirable; that is, the product could be sewn together using the thread of the invention and then heat-treated, causing the thread to expand, sealing the holes made in sewing. Such threads would also be useful for decorative purposes, e.g., as embroidery yarns, and likely for other purposes. The yarns of the invention can also be disposed in a desired position and infused with a hardening resin while heat is applied to cause the microspheres to expand, forming a lightweight and stiff composite structure.

Owner:PASCALE INDS

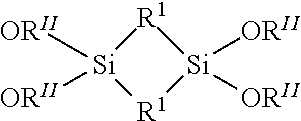

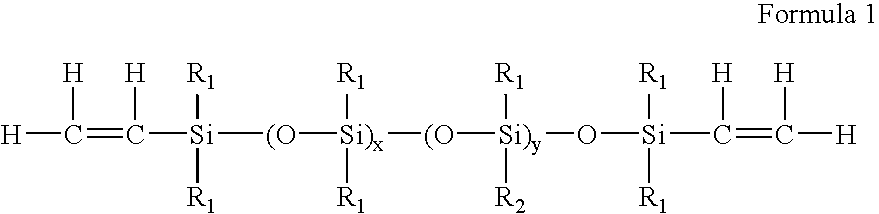

High refractive index polysiloxane prepolymers

InactiveUS6956087B2Quality improvementImprove reliabilityOptical articlesSkin careCorneal inlayHigh-refractive-index polymer

A process for producing polysiloxane prepolymers of improved homogeneity for use in the production of relatively high refractive index polymeric compositions is described herein. Polymeric compositions so produced are useful in the production of ophthalmic devices such as for example intraocular lenses and corneal inlays.

Owner:BAUSCH & LOMB INC

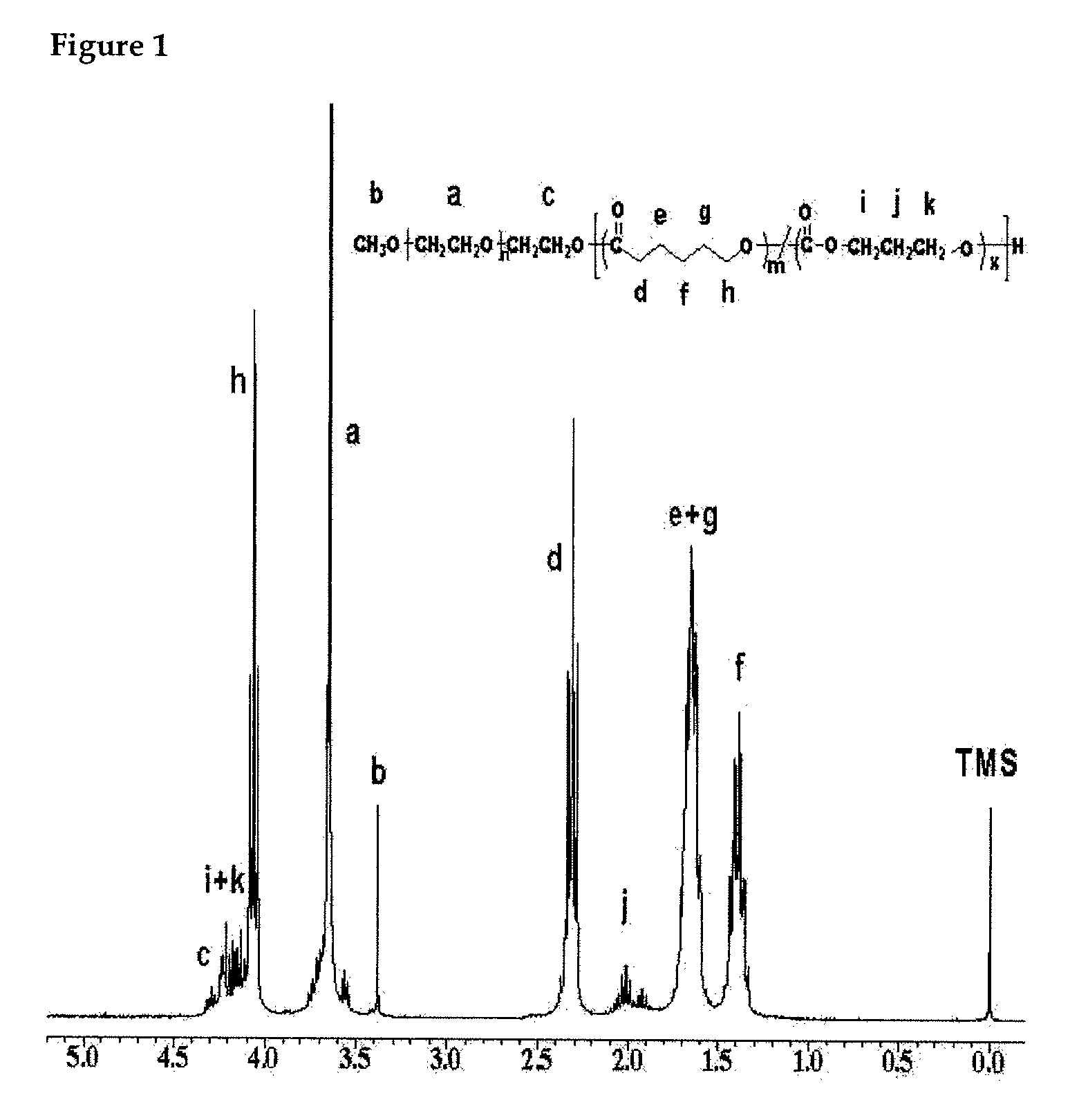

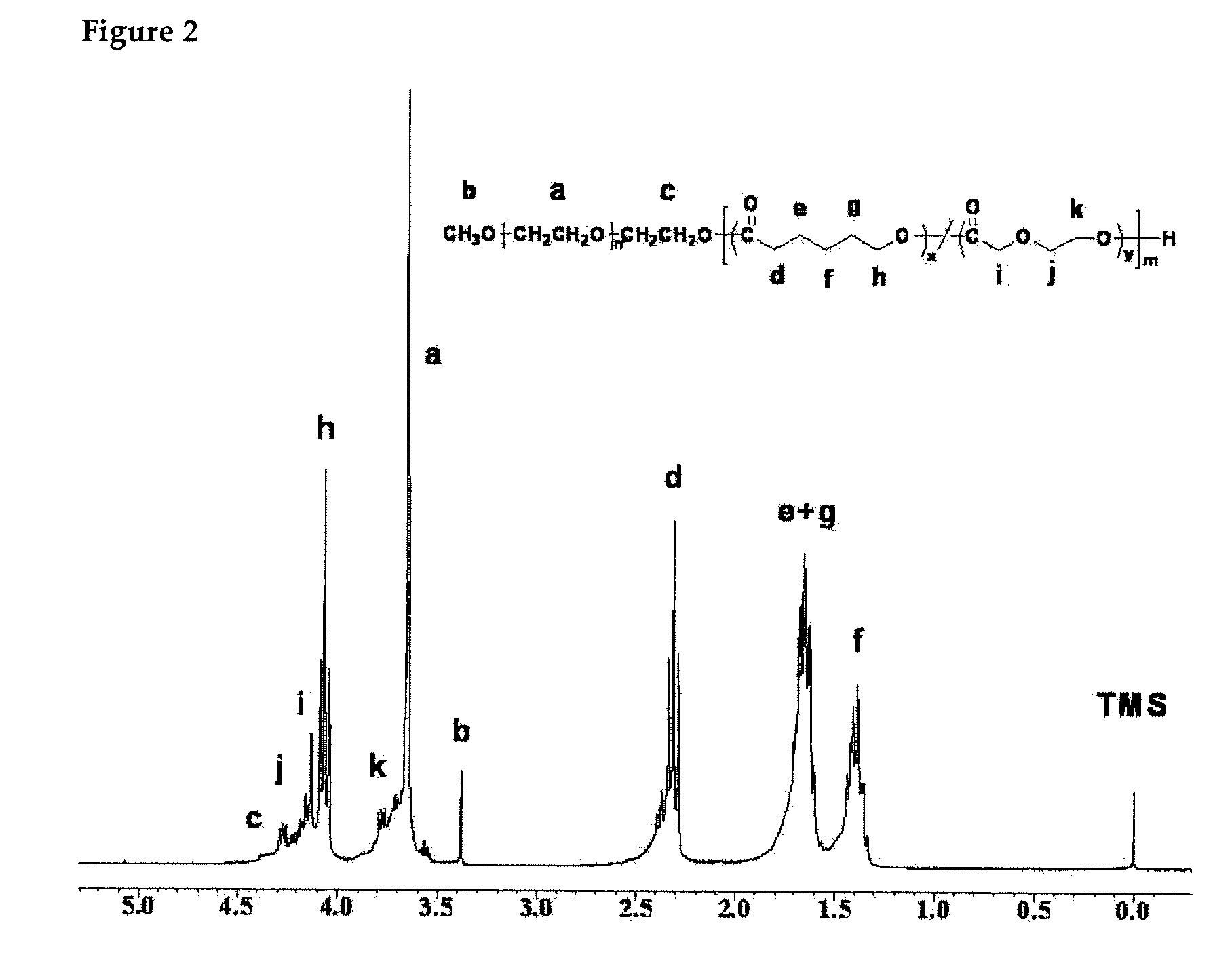

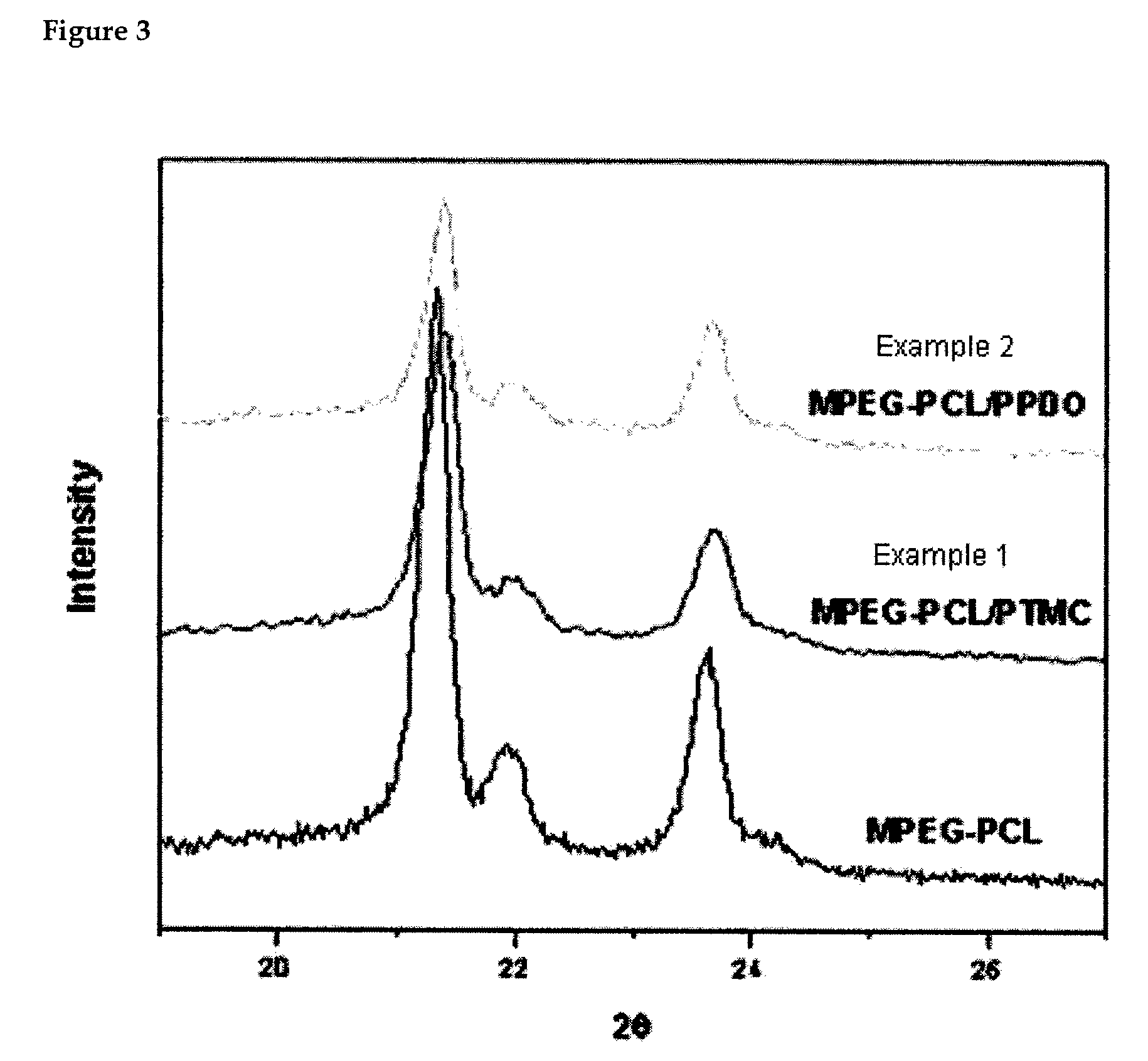

Preparation and characterization of polyethyleneglycol/polyesters as biocompatible thermo-sensitive materials

InactiveUS20070218099A1Reduce molecular weightWell formedPharmaceutical non-active ingredientsProsthesisPolyesterPolymer science

The present invention relates to a biocompatible and thermosensitive poly(ethylene glycol) / polyester block copolymer and a method of its preparation thereof, and particularly to a multi-functional intelligent hydrogel polymer comprising a hydrophilic part of a poly(ethylene glycol) (PEG) having a low molecular weight and a hydrophobic part comprising an ester-based caprolactone (CL) segment as an essential ingredient and further comprising a para-dioxanone (PDO) segment, a trimethylene carbonate (TMC) segment or a PDO / TMC copolymer containing the PDO and the TMC segments in a predetermined ratio, which easily forms a desired-shaped gel and decomposes or disperses without necessitating the operation process for removing the gel due to the temperature-dependent phase transition caused by the coagulation and the expansion of polymer micelles comprising a hydrophilic part and a hydrophobic part, thus being applicable to a drug delivery system or a porous support for tissue engineering purpose.

Owner:KOREA RES INST OF CHEM TECH

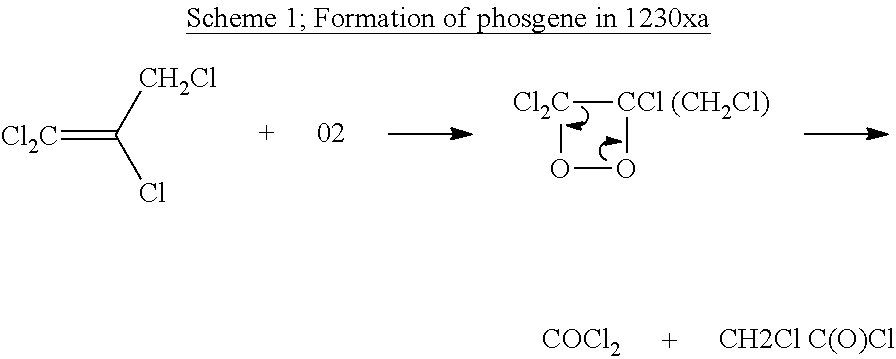

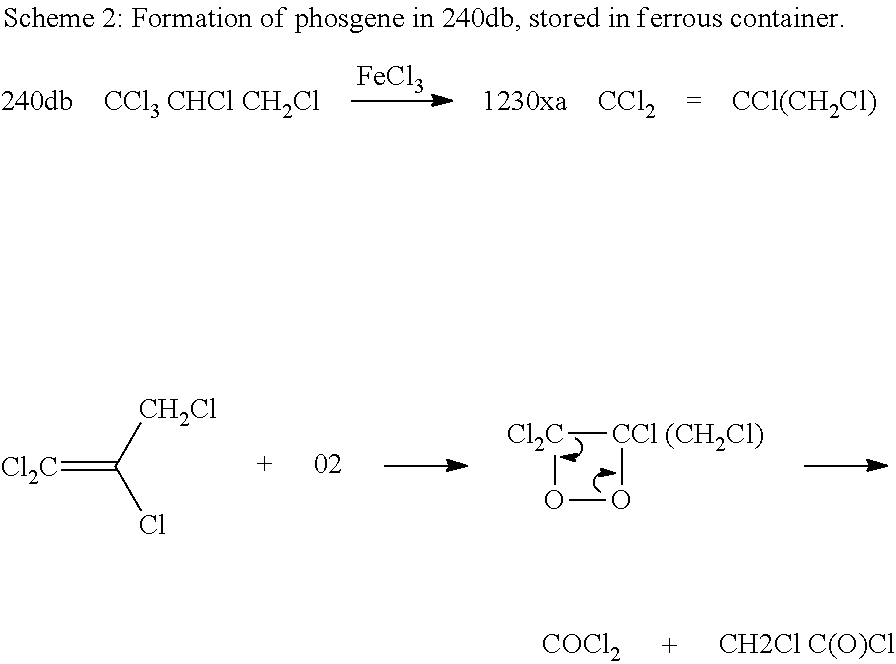

Method to purify and stabilize chloroolefins

ActiveUS20120226081A1Manufactured usingHalogenated hydrocarbon separation/purificationDecompositionChemistry

The present invention is directed towards a method of purification of chloroolefins having 3 carbons and to a method to provide stable compositions of chloroolefins having 3 carbons. The chloroolefins are purified via the use of a solid absorbents for the removal of decomposition product such as phosgene and / or phosgene precursory from the reaction of the chloroolefins with oxygen. The chloroolefins stabilized against an increase of the phosgene level via the addition of inhibitors to the chloroolefins.

Owner:ARKEMA INC

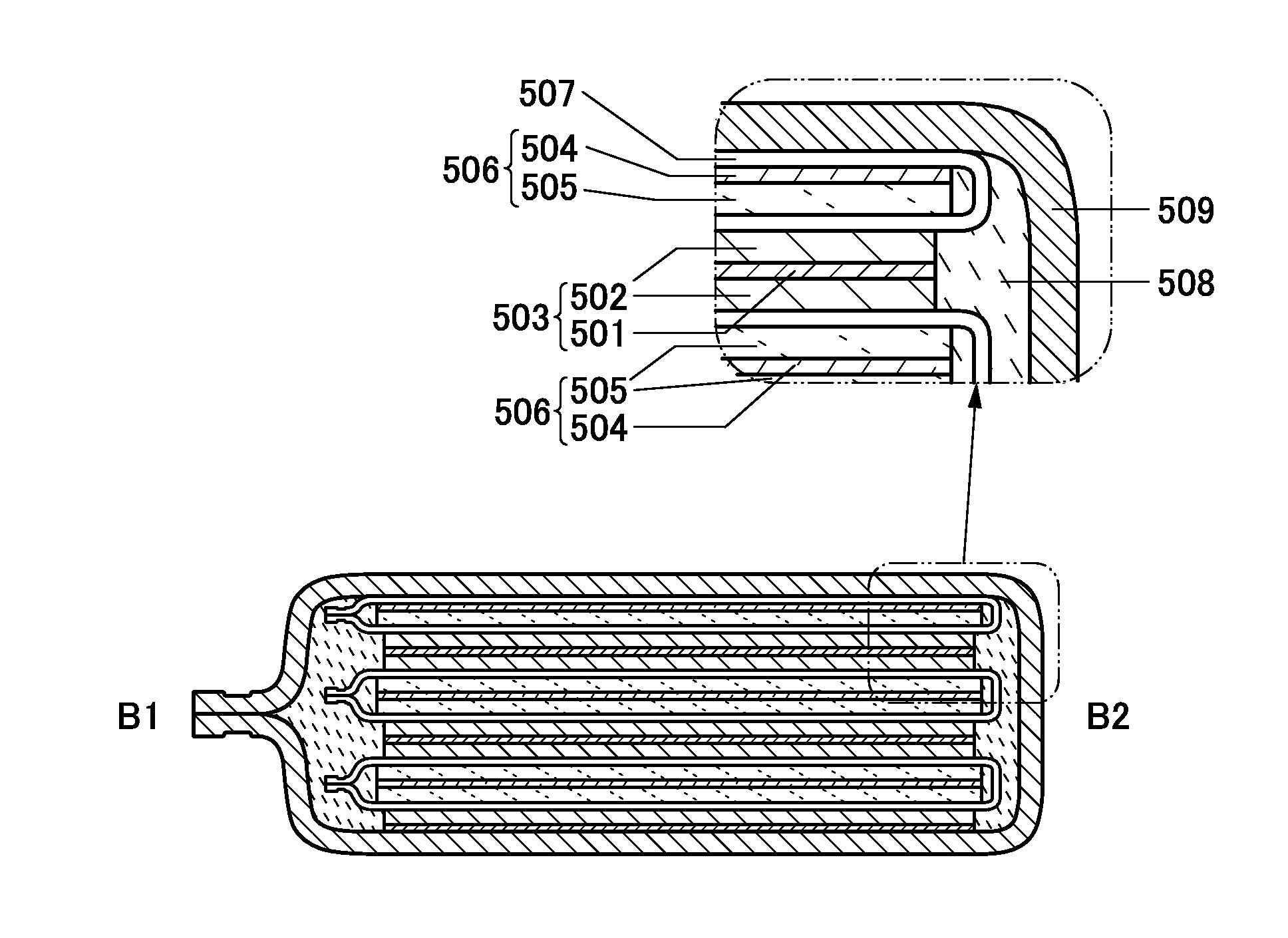

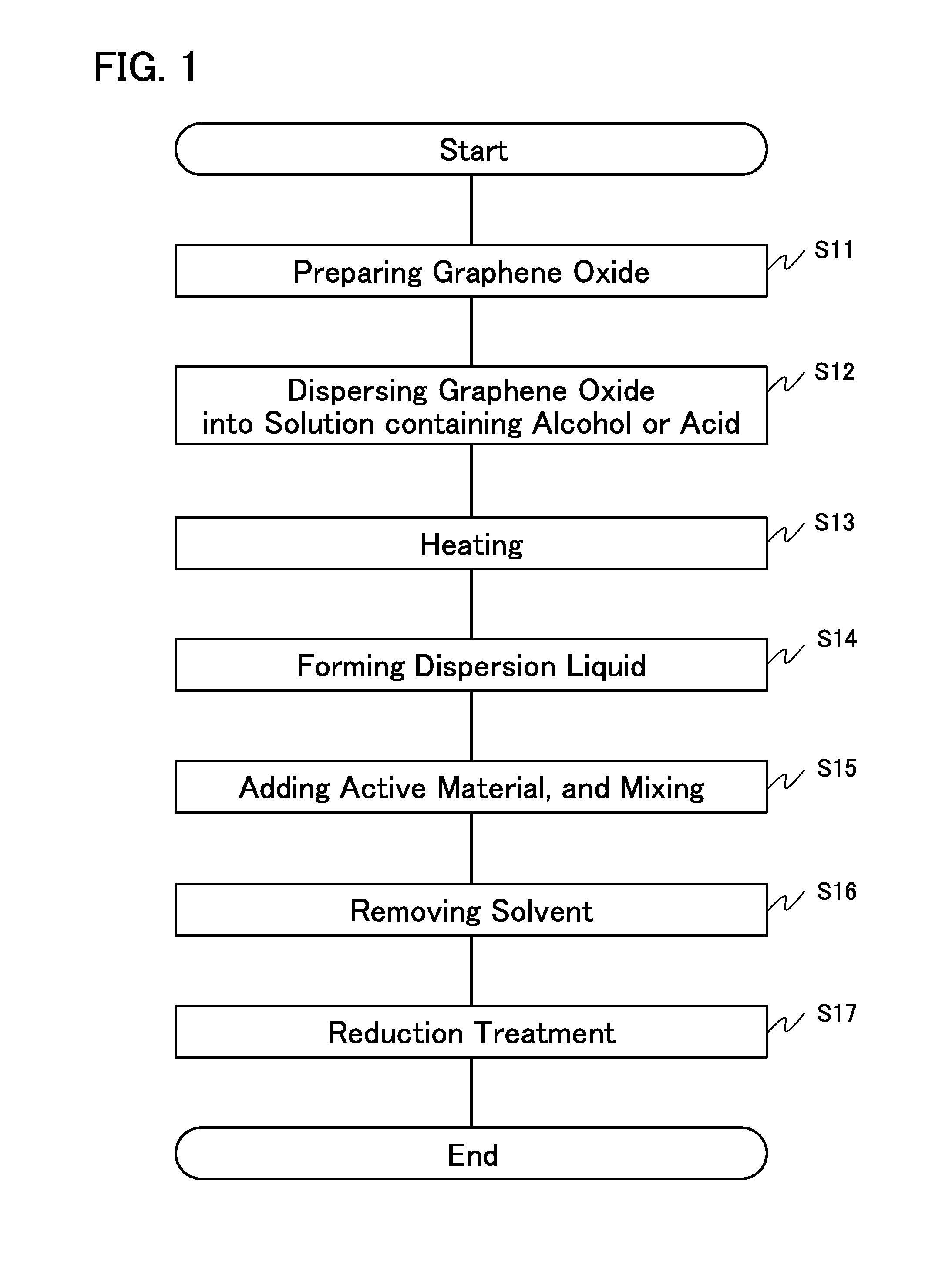

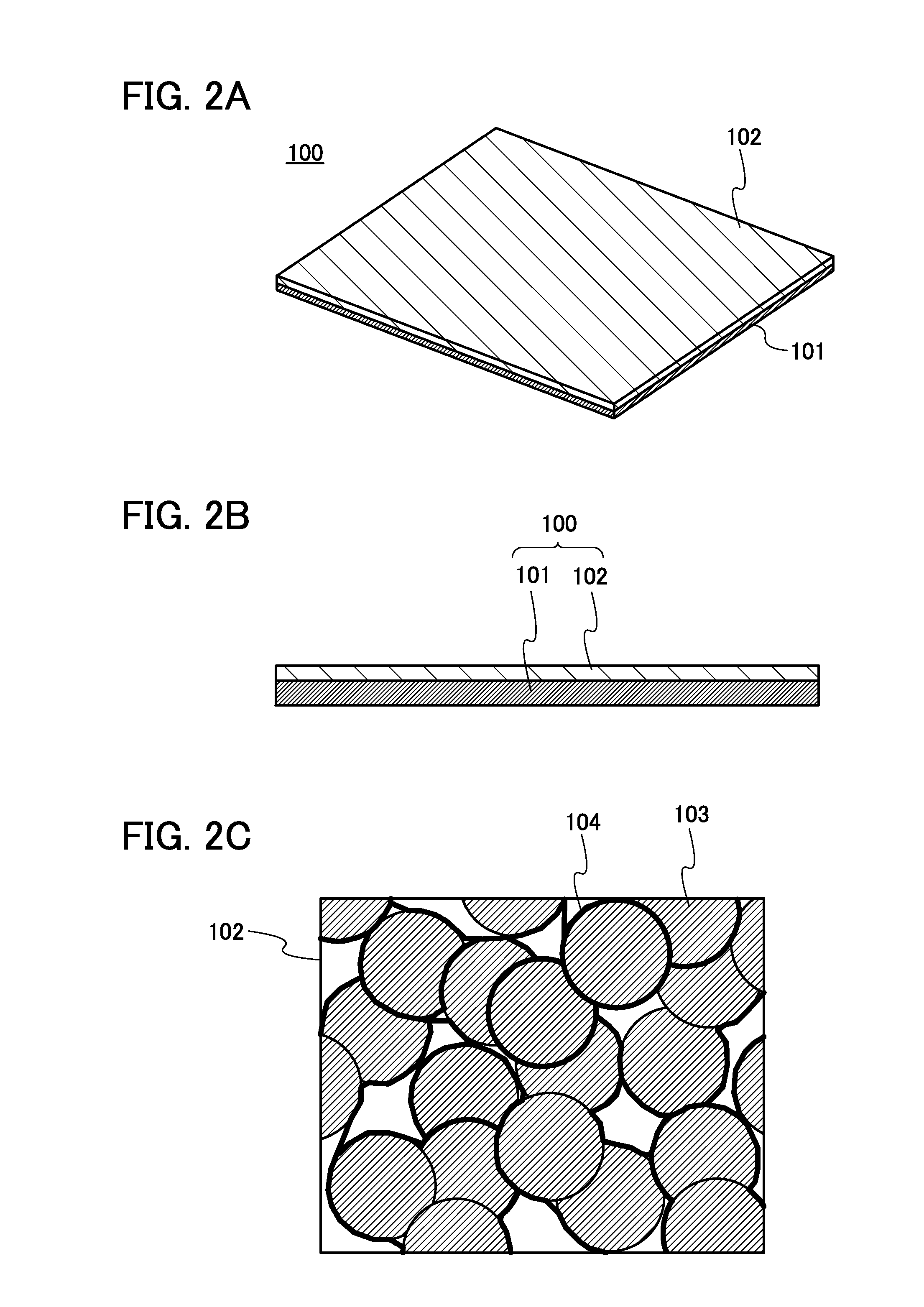

Storage battery electrode, manufacturing method thereof, storage battery, electronic device, and graphene

ActiveUS20160064726A1Good dispersionImprove electronic conductivityOrganic chemistryElectrode thermal treatmentAlcoholHigh electron

To provide graphene oxide that has high dispersibility and is easily reduced. To provide graphene with high electron conductivity. To provide a storage battery electrode including an active material layer with high electric conductivity and a manufacturing method thereof. To provide a storage battery with increased discharge capacity. A method for manufacturing a storage battery electrode that is to be provided includes a step of dispersing graphene oxide into a solution containing alcohol or acid, a step of heating the graphene oxide dispersed into the solution, and a step or reducing the graphene oxide.

Owner:SEMICON ENERGY LAB CO LTD

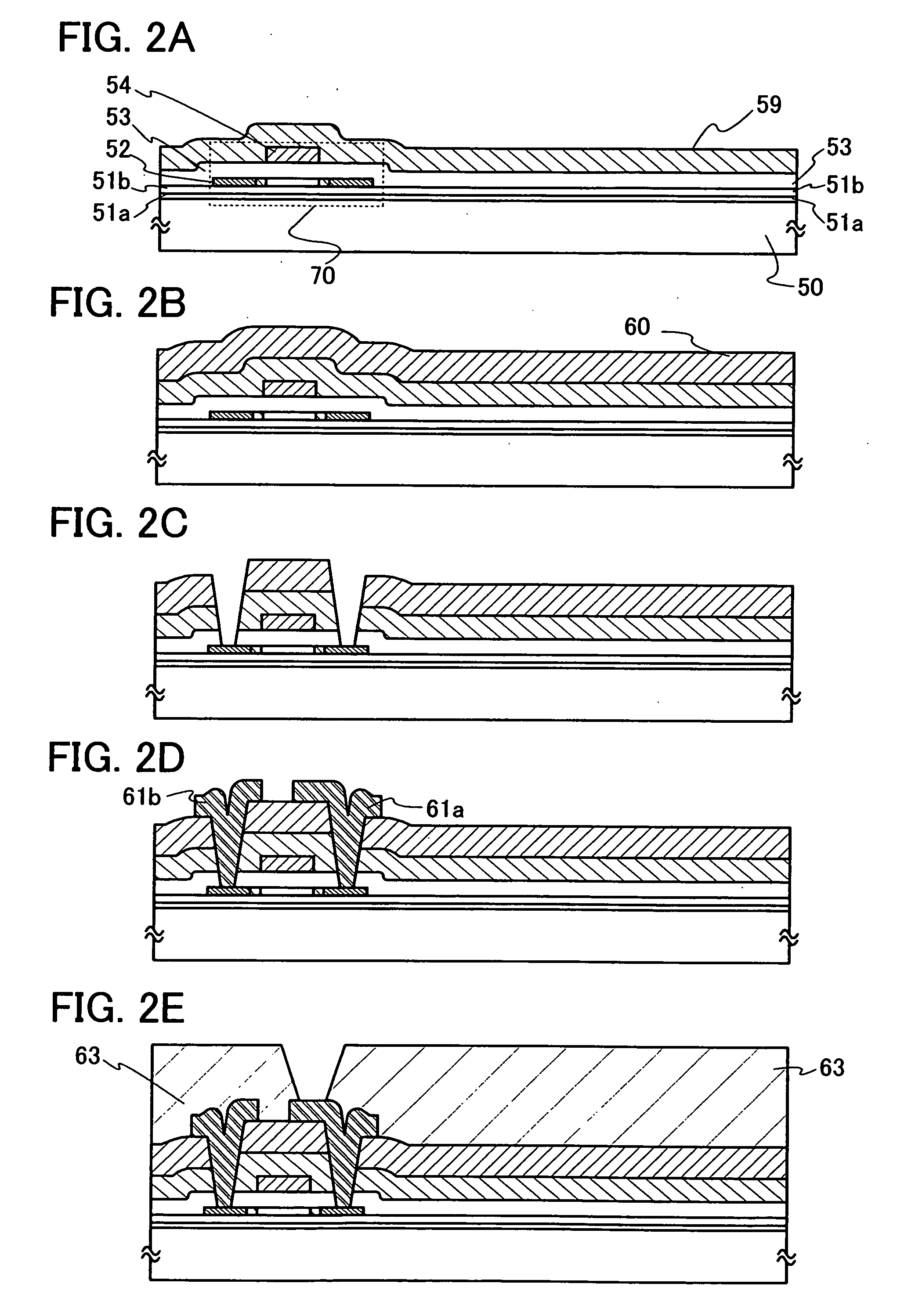

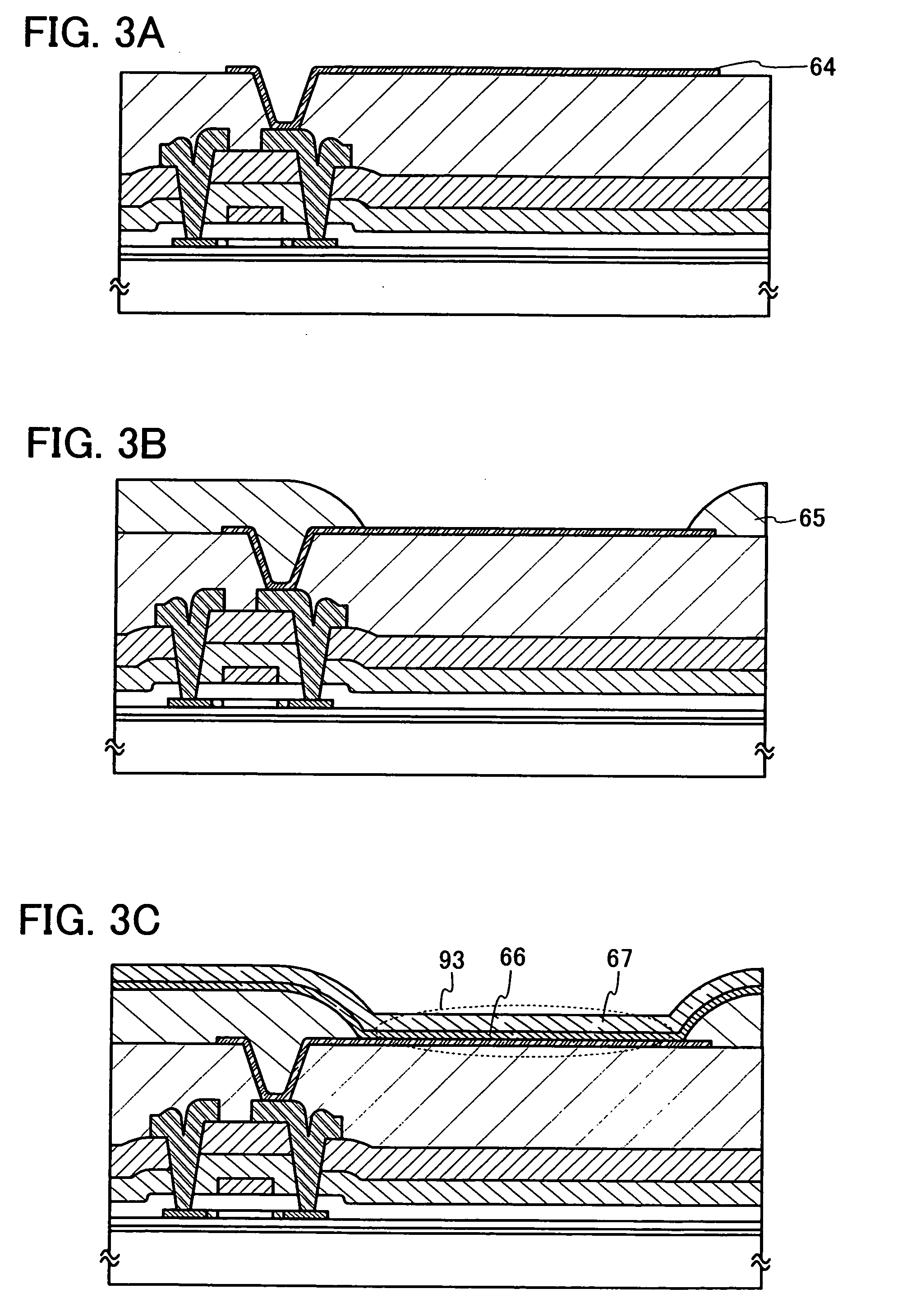

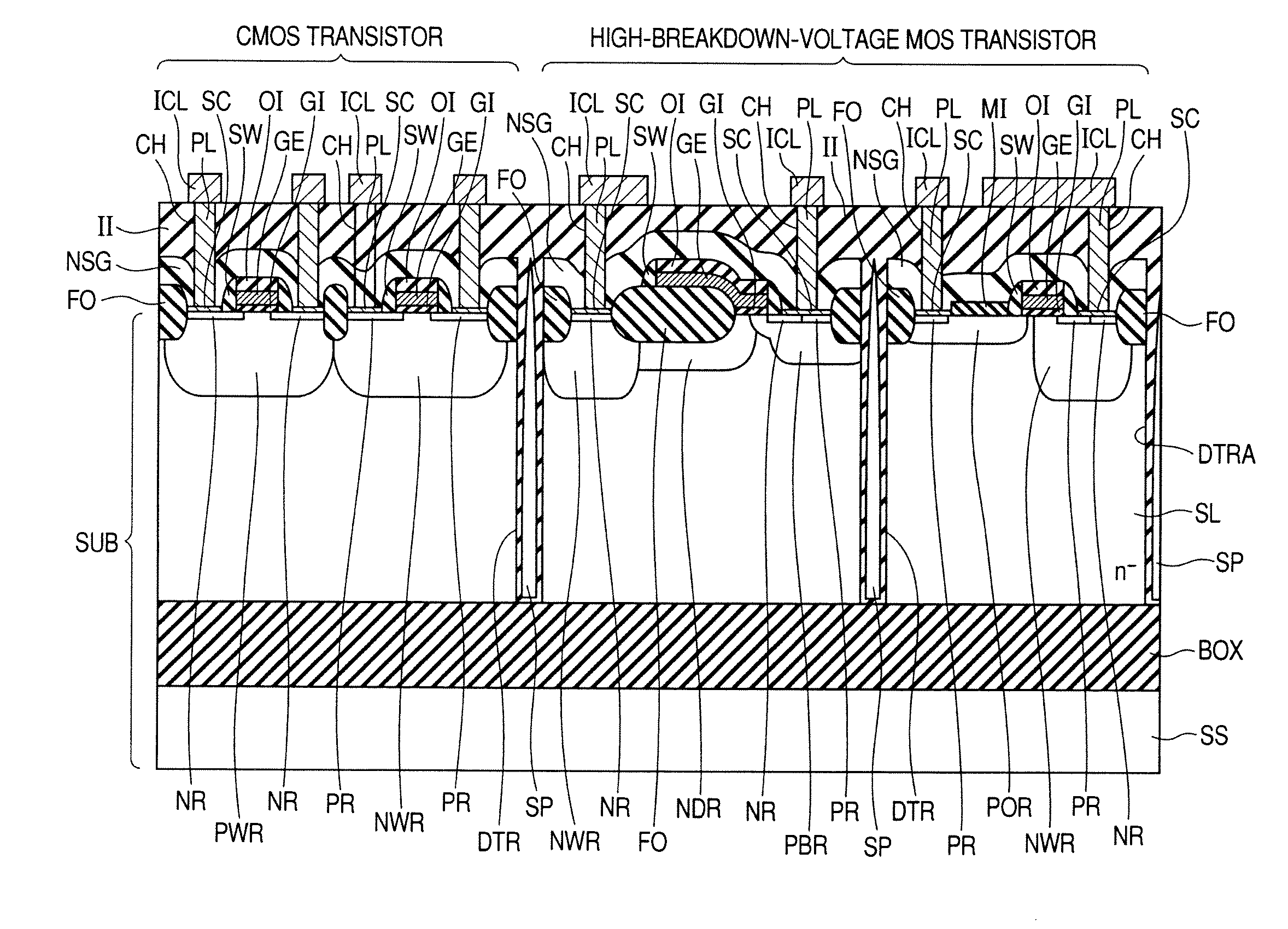

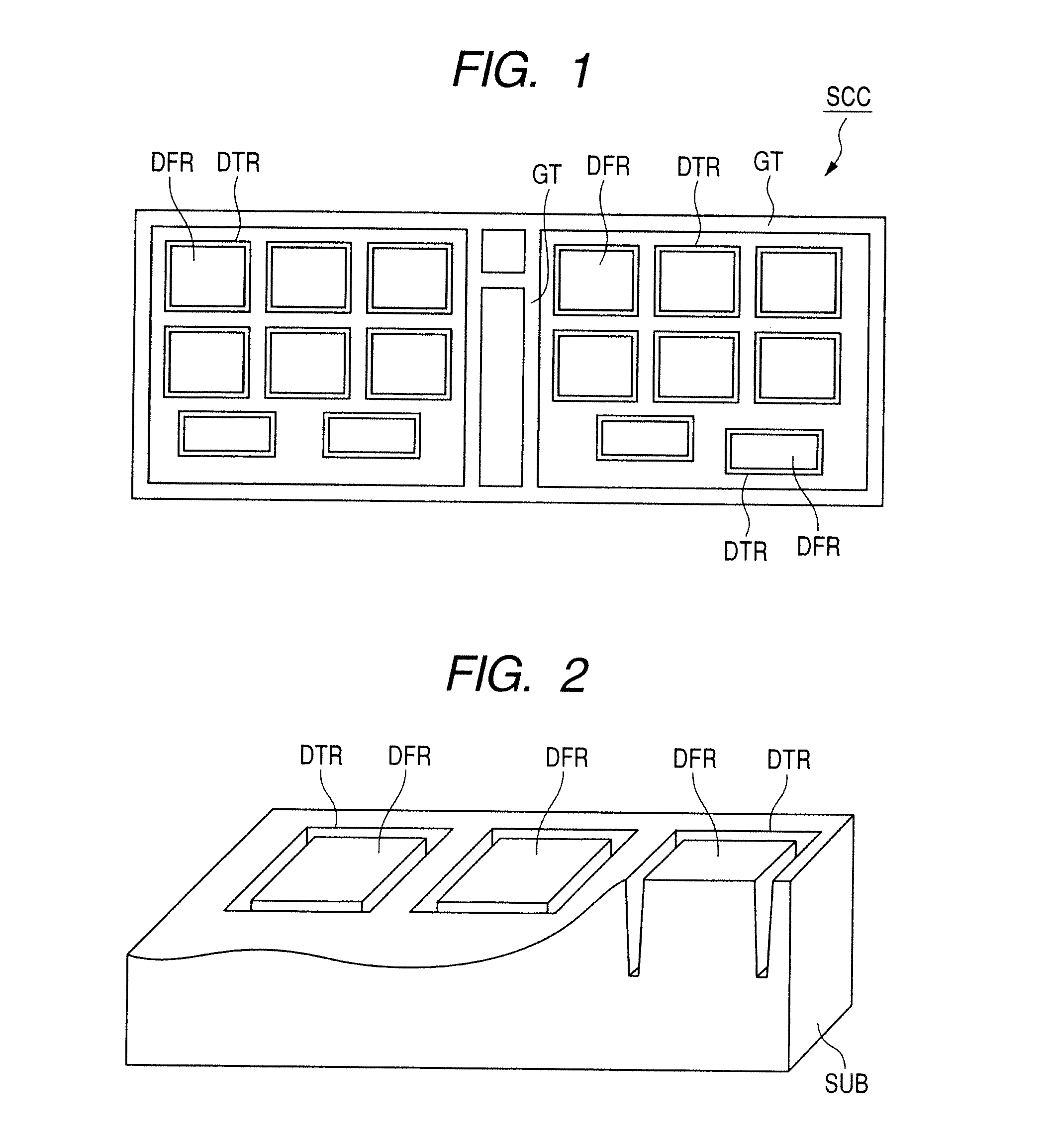

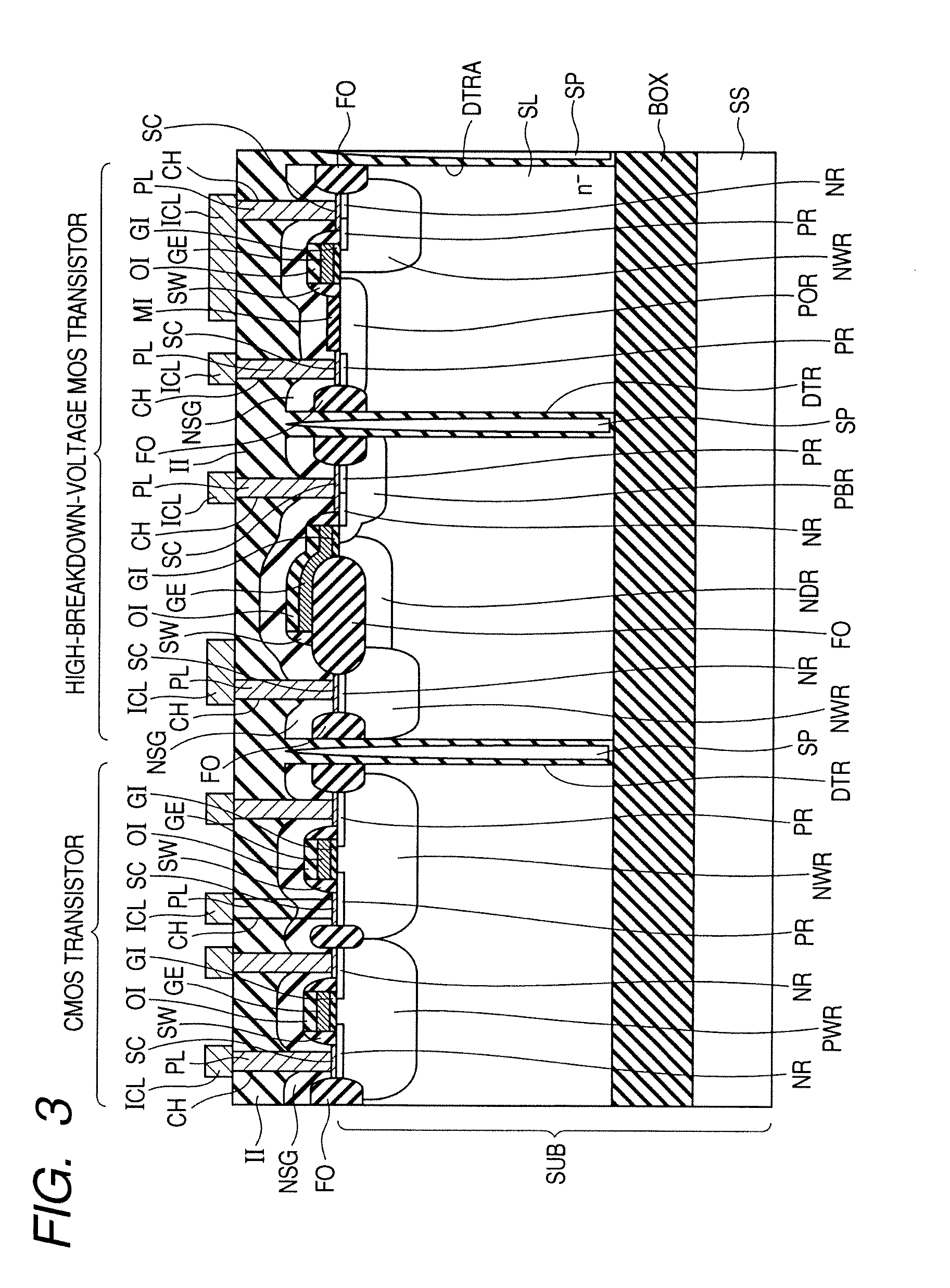

Semiconductor device and manufacturing method thereof

ActiveUS20110175205A1Simple processHigh burying propertySemiconductor/solid-state device testing/measurementSolid-state devicesEngineeringSemiconductor

To provide a semiconductor device that can be manufactured using a simple process without ensuring a high embedding property; and a manufacturing method of the device. In the manufacturing method of the semiconductor device according to the invention, a semiconductor substrate having a configuration obtained by stacking a support substrate, a buried insulating film, and a semiconductor layer in order of mention is prepared first. Then, an element having a conductive portion is completed over the main surface of the semiconductor layer. A trench encompassing the element in a planar view and reaching the buried insulating film from the main surface of the semiconductor layer is formed. A first insulating film (interlayer insulating film) is formed over the element and in the trench to cover the element and form an air gap in the trench, respectively. Then, a contact hole reaching the conductive portion of the element is formed in the first insulating film.

Owner:RENESAS ELECTRONICS CORP

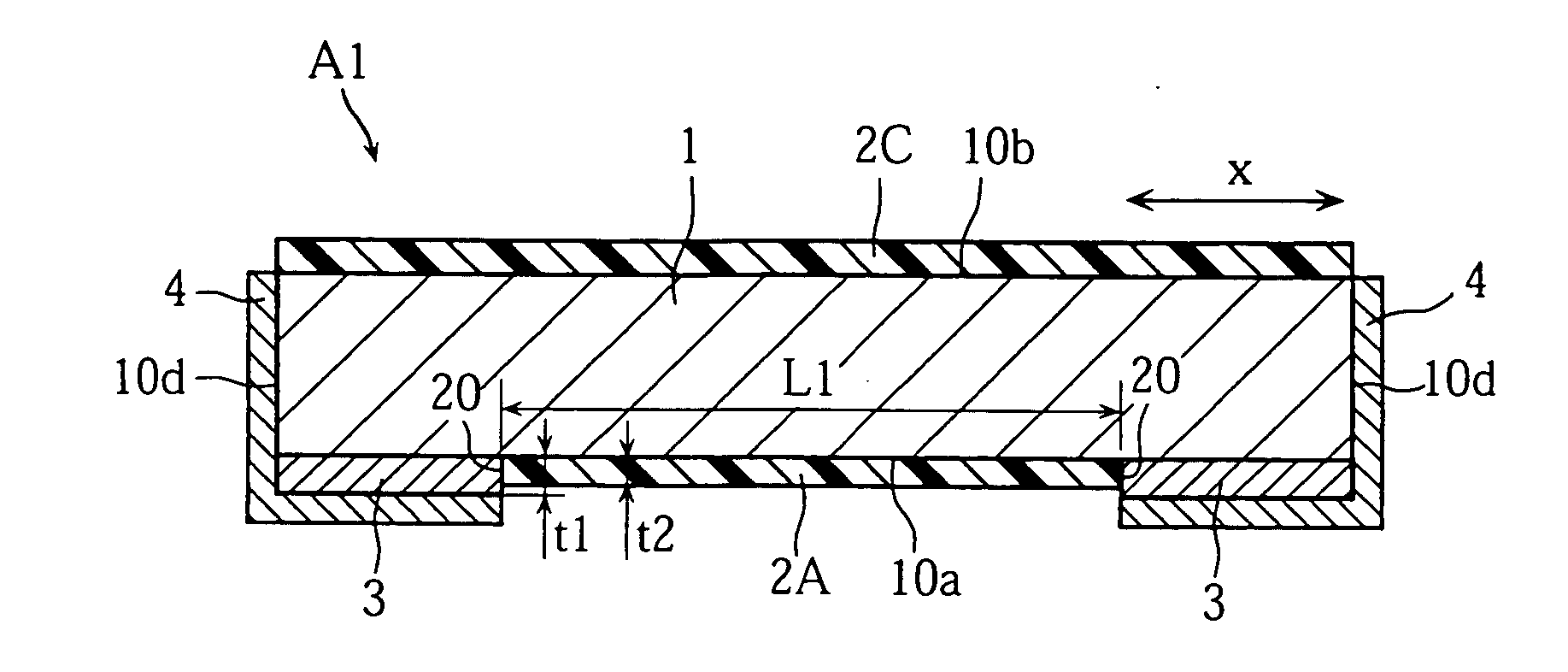

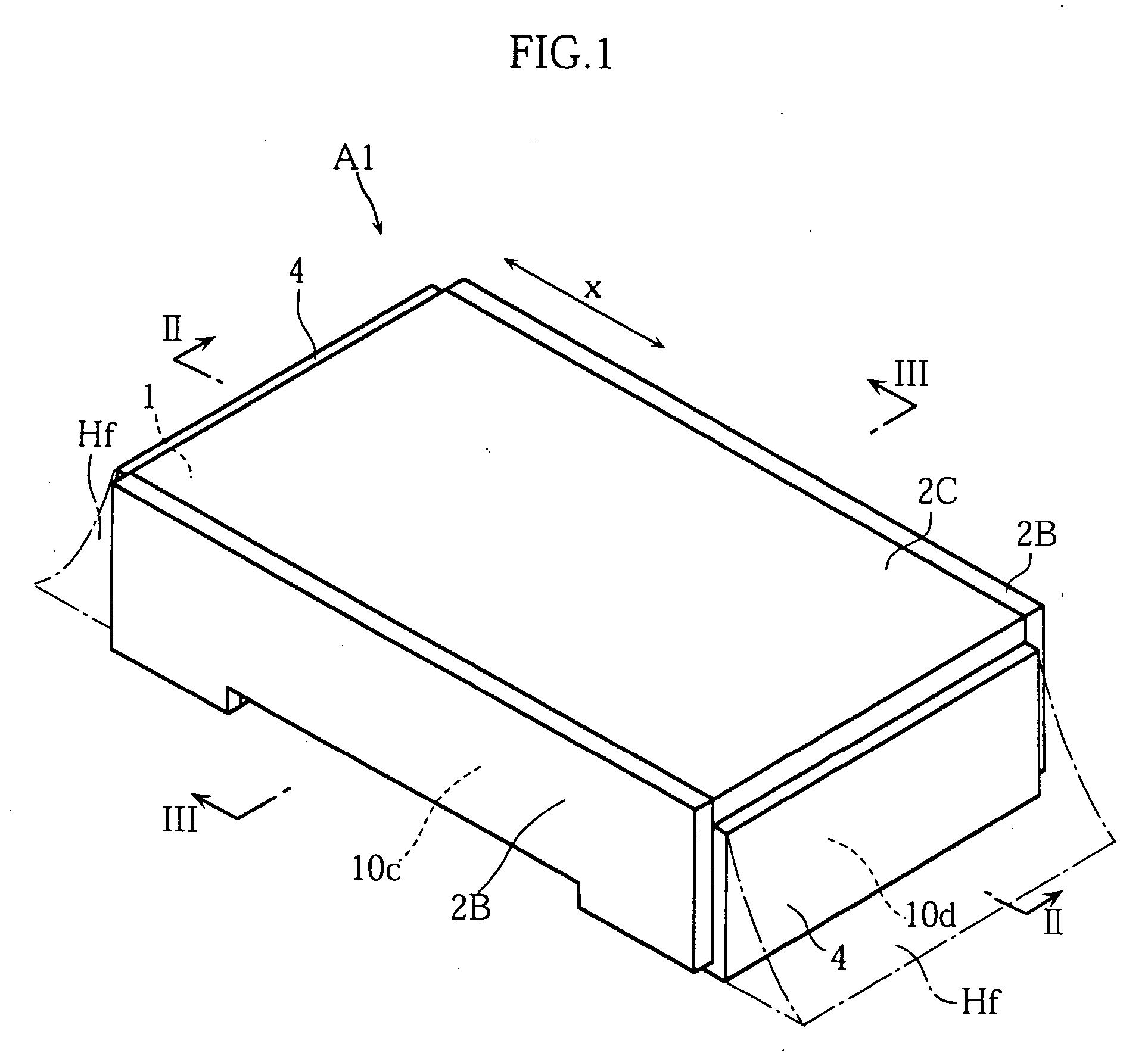

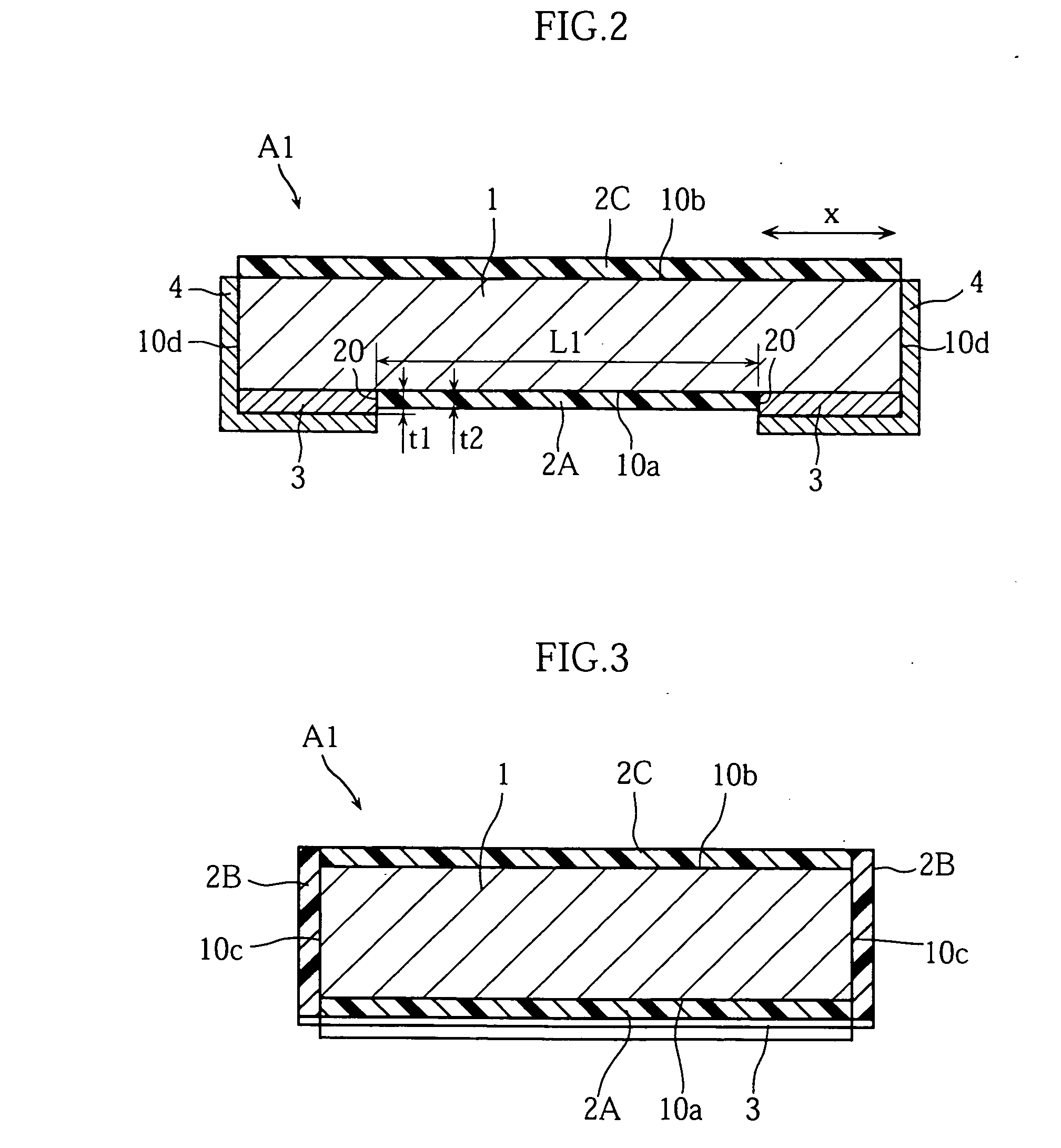

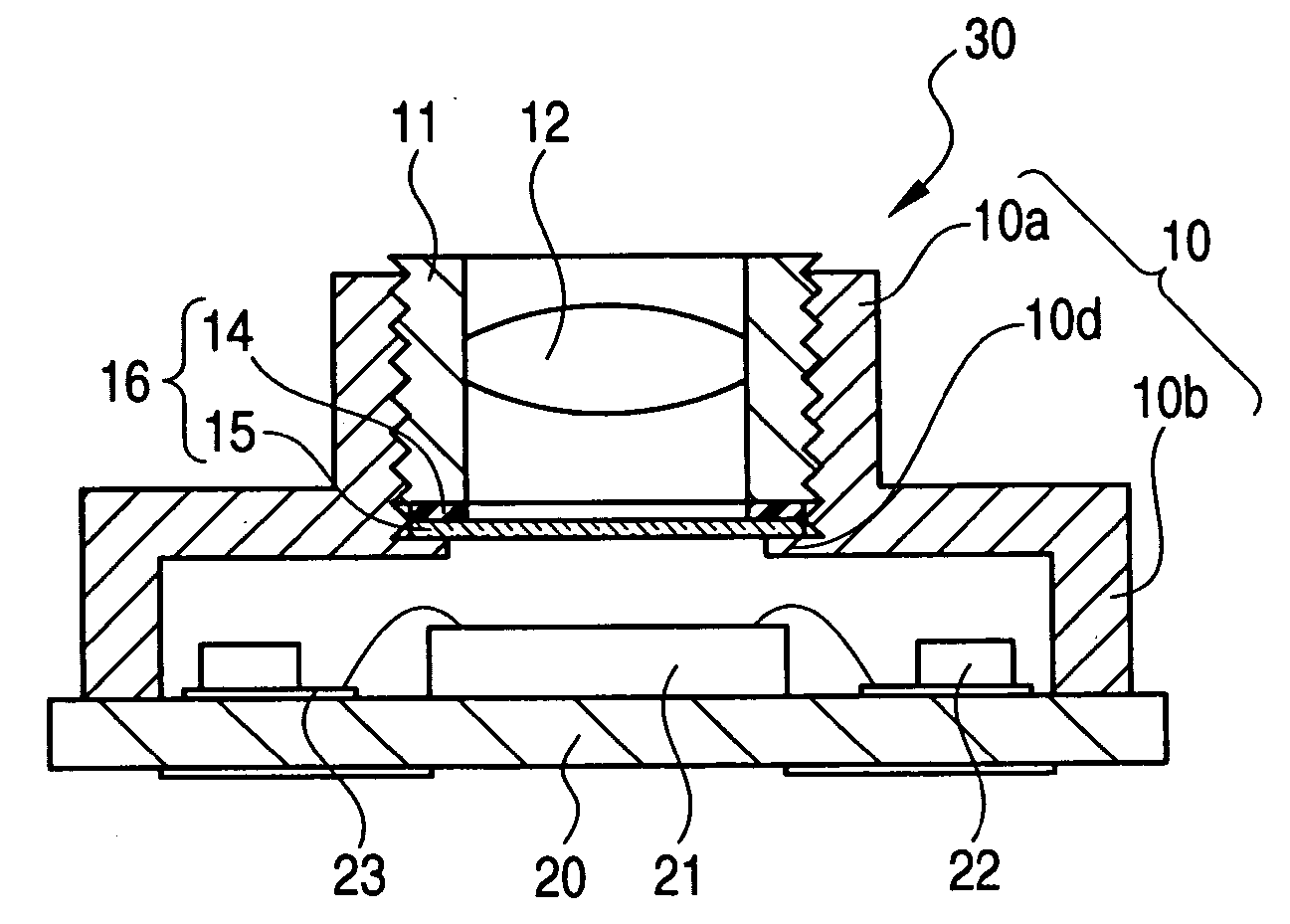

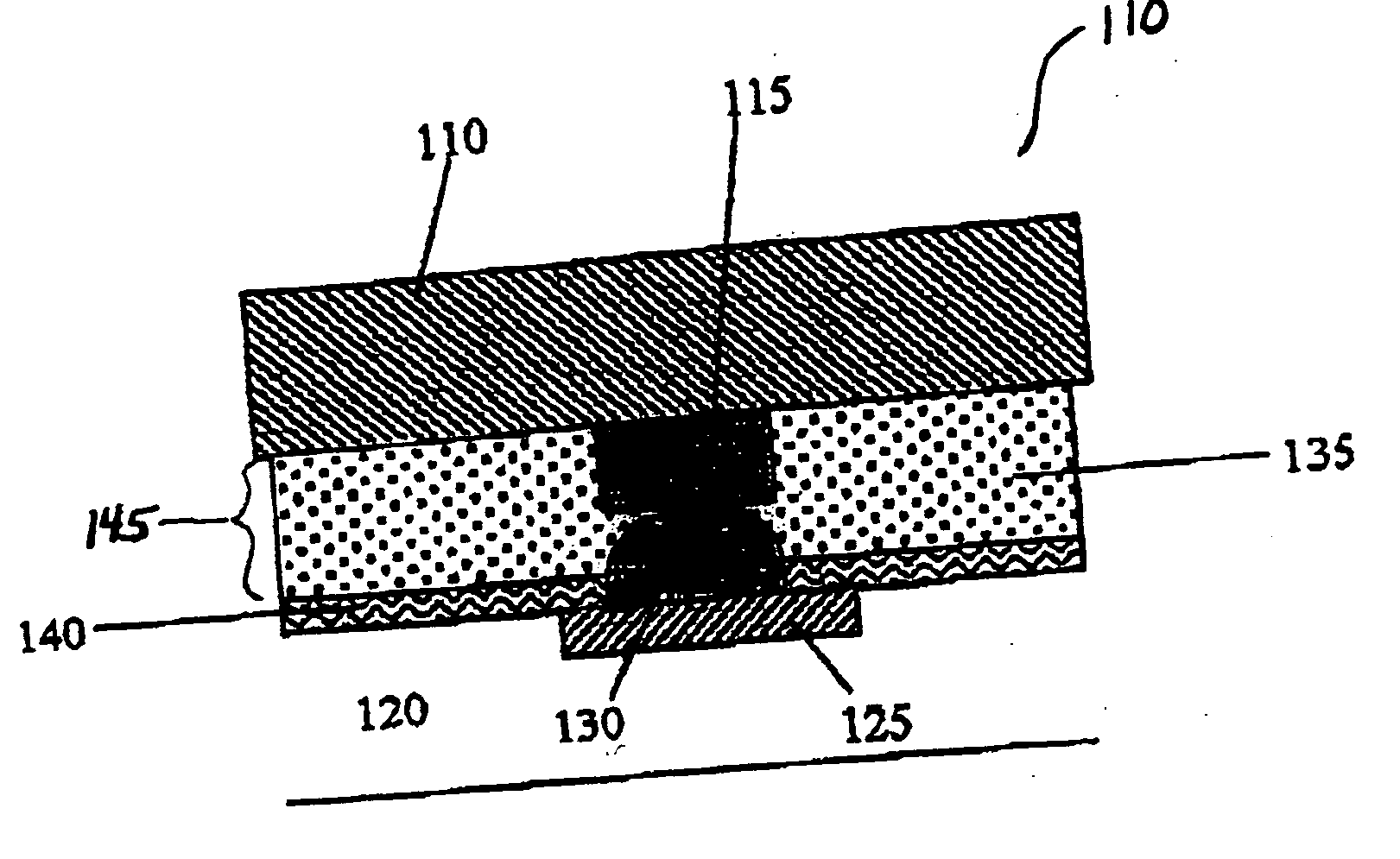

Chip resistor, process for producing the same, and frame for use therein

ActiveUS20060097340A1Manufactured usingPrinted circuit assemblingSemiconductor/solid-state device manufacturingInsulation layerElectrical and Electronics engineering

A chip resistor (A1) comprises a first insulation layer (2A) covering the regions between a plurality of electrodes (3) on a rear surface (10a) of a resistor (1), and a second insulation layer covering a pair of side faces of the resistor (1). Inadvertent adhesion of solder to an improper part of the resistor (1) can thereby be eliminated. A solder layer (4) is preferably formed on a pair of end faces (10d) of the resistor (1). In so doing, a solder fillet can be formed appropriately.

Owner:ROHM CO LTD

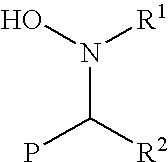

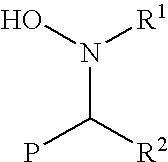

Functionalization of living rubbery polymers with nitrones

This invention discloses a low cost process that can be used to functionalize living rubbery polymers with terminal nitroxide end-groups to promote interaction between the polymer end-groups and surface functionalities commonly found on carbon black and silica fillers. Such functionalization makes the rubbery polymer more desirable for used in tire tread compositions and other rubber products. This technique more specifically involves reacting a metal terminated living polydiene rubber with a nitrone. The metal will typically be lithium and the polydiene rubber will typically be a polybutadiene rubber, a polyisoprene rubber, a styrene-butadiene rubber, a styrene-isoprene-butadiene rubber, an isoprene-butadiene rubber, or a styrene-isoprene rubber.

Owner:THE GOODYEAR TIRE & RUBBER CO

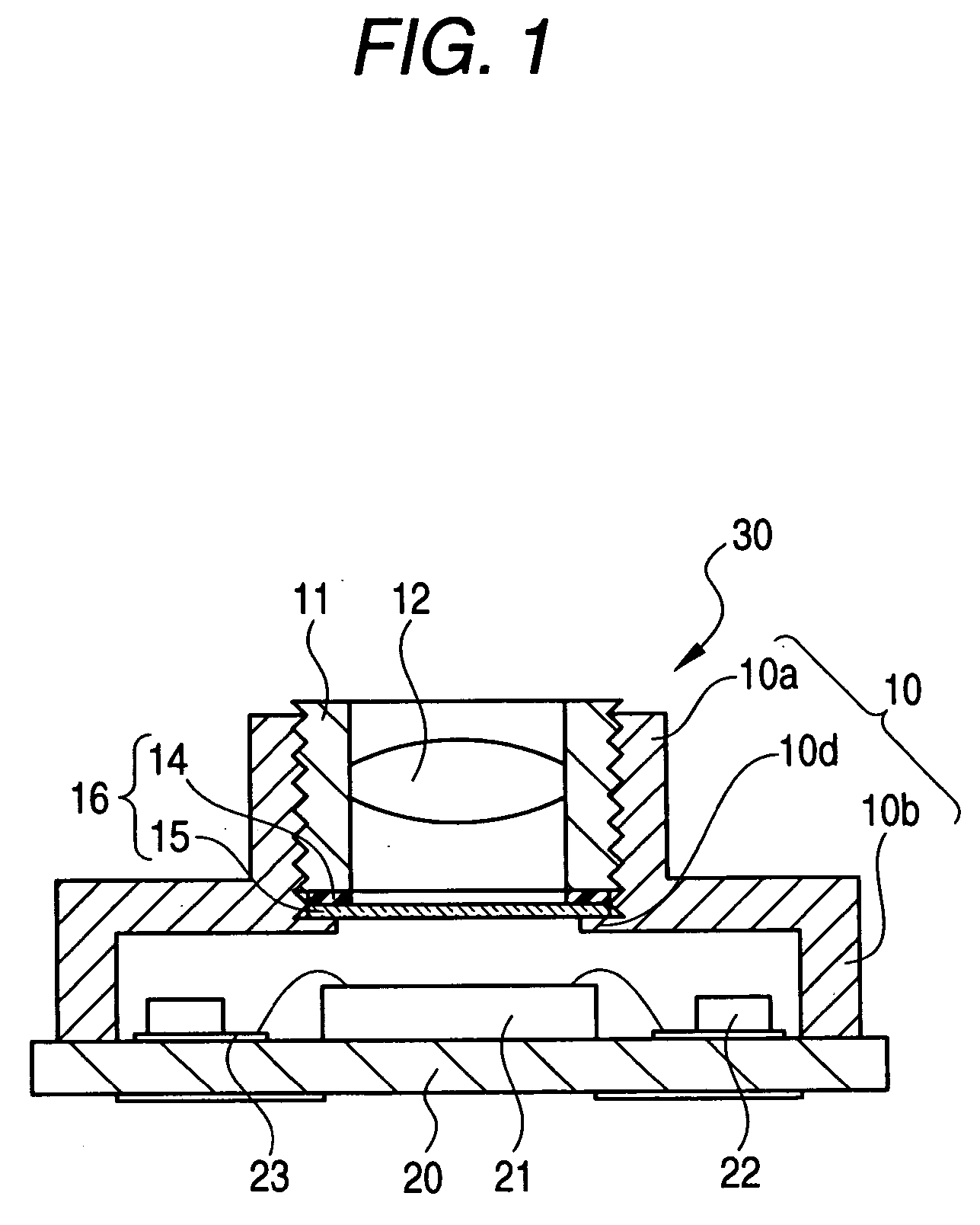

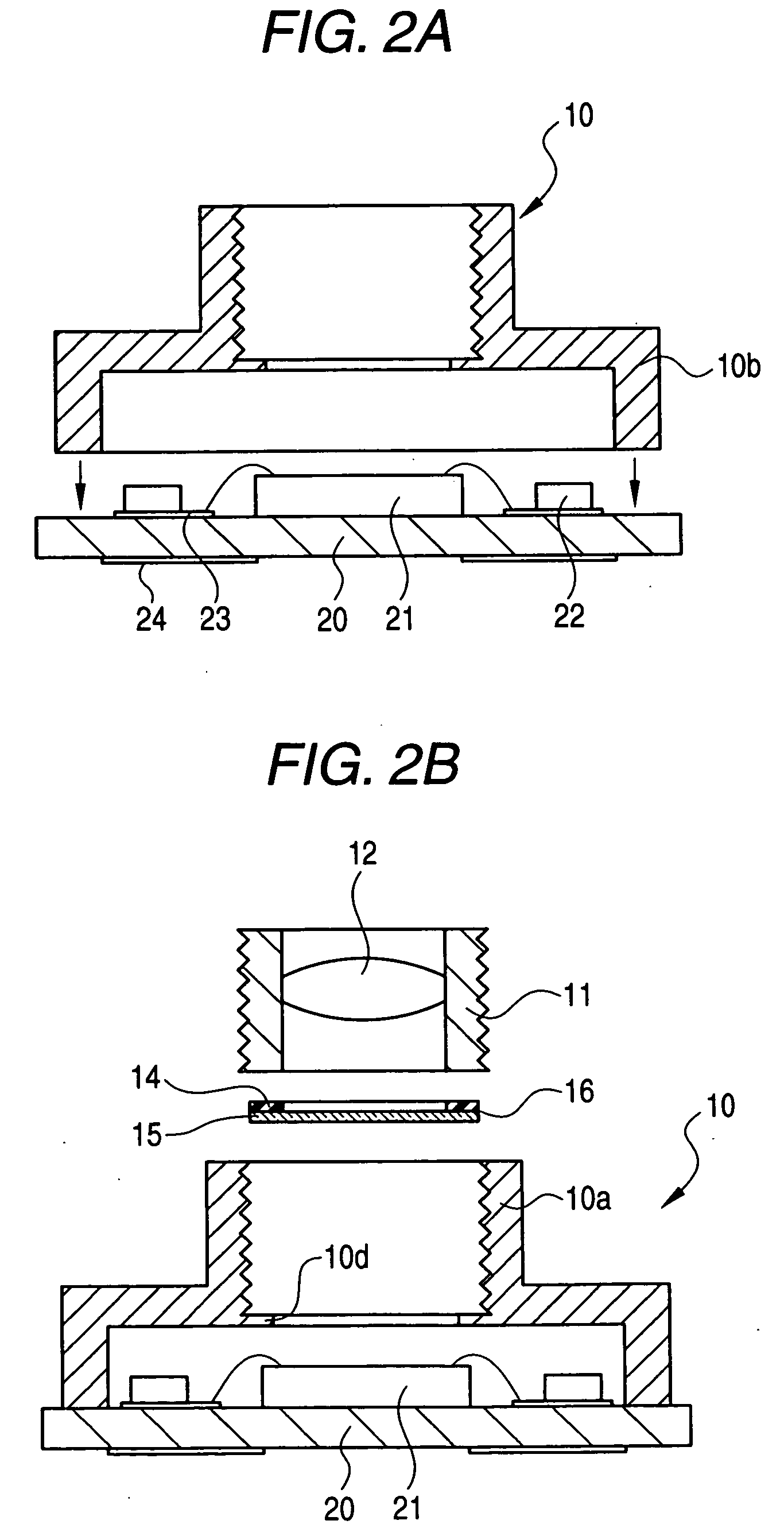

Image pickup module, method of manufacturing the same, and spacer with infrared ray cut film

InactiveUS20060126194A1Increase productivitySimple manufacturing processTelevision system detailsSolid-state devicesInfraredEngineering

An image pickup module comprises a substrate mounting an image pickup element thereon, a holder mounted on the substrate so as to cover the image pickup element, the holder including a barrel portion for supporting a light receiving lens, the barrel portion having a stopper portion at its inner circumferential surface, a lens holder holding the light receiving lens, the lens holder being screwed and fixed into the barrel portion of the holder, and a spacer interposed between the stopper portion of the holder and the lens holder, the spacer being integrally formed with a sheet-like infrared ray cut film.

Owner:SHINKO ELECTRIC IND CO LTD

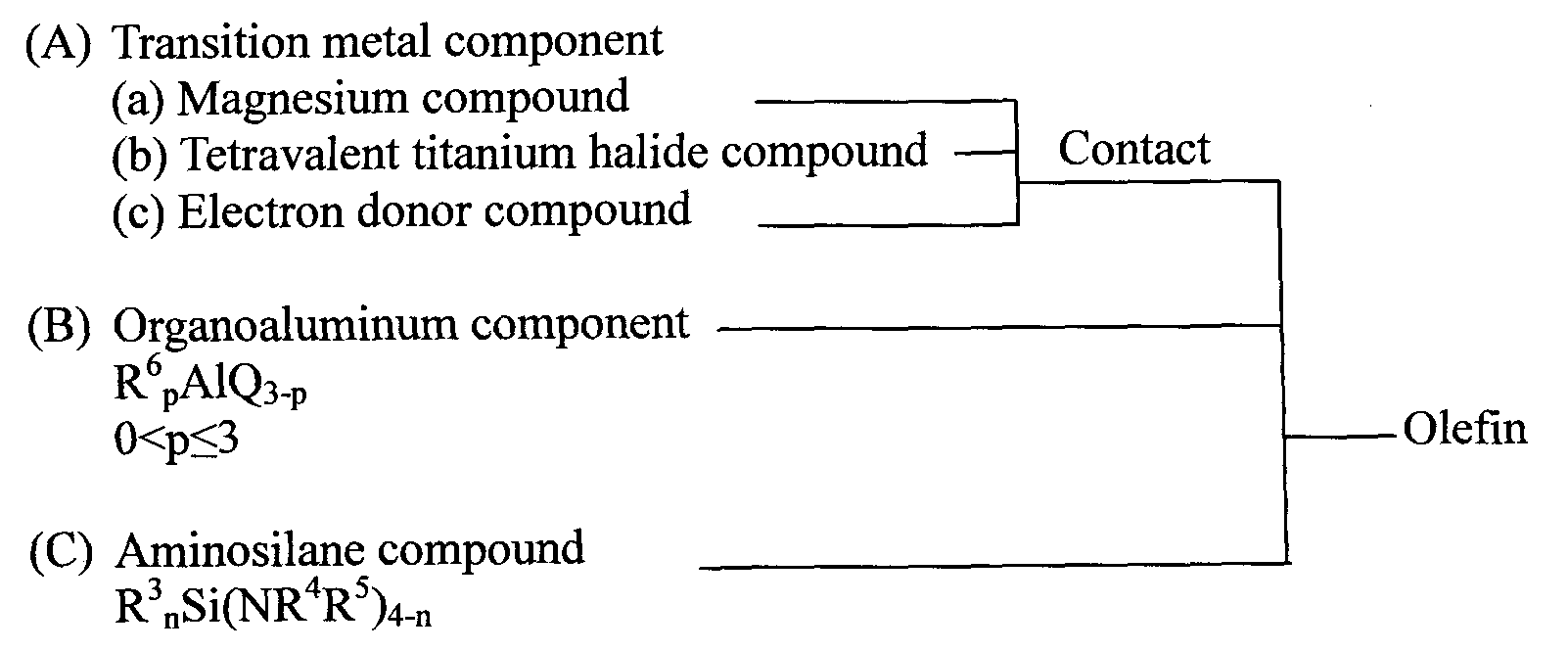

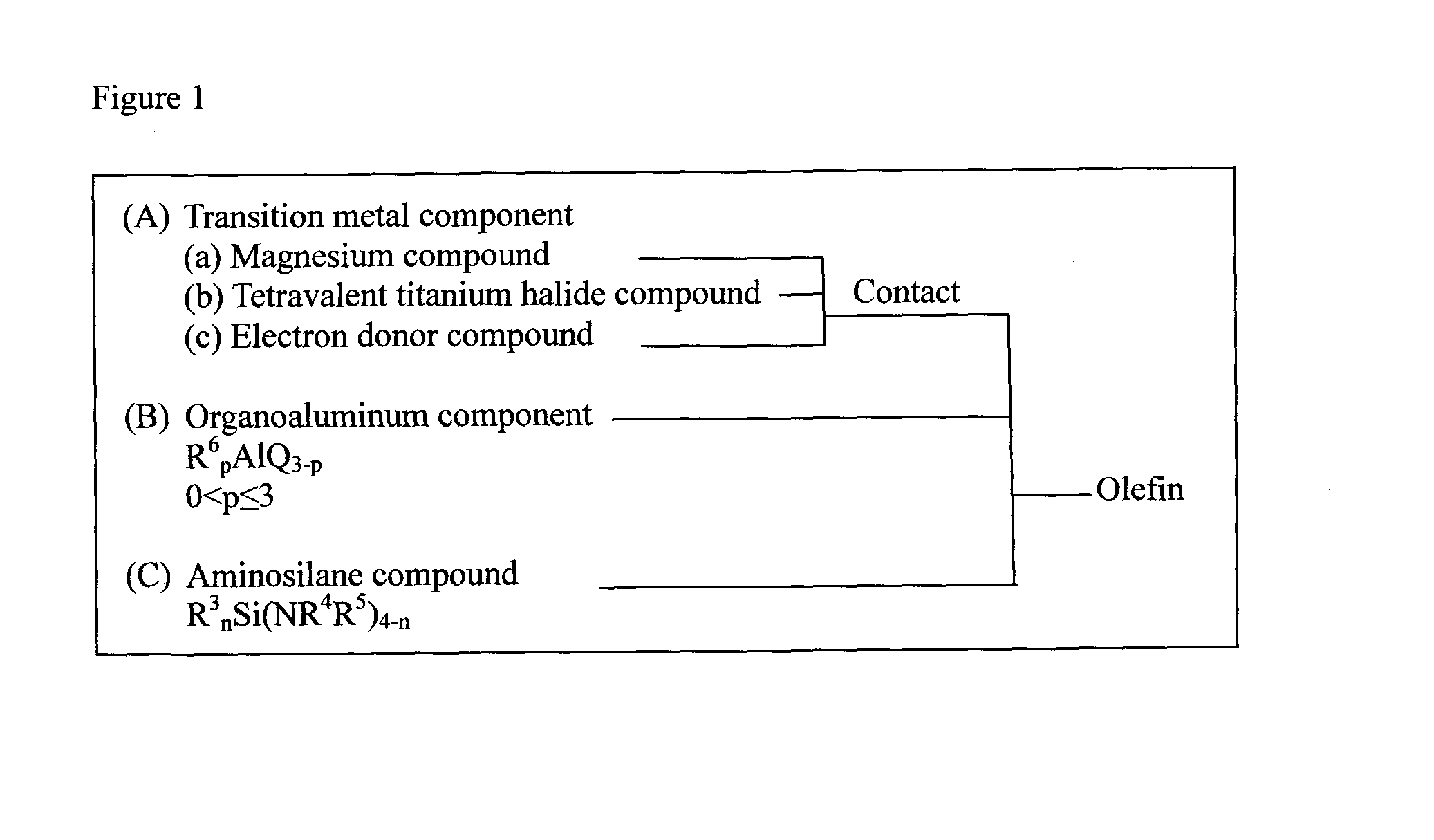

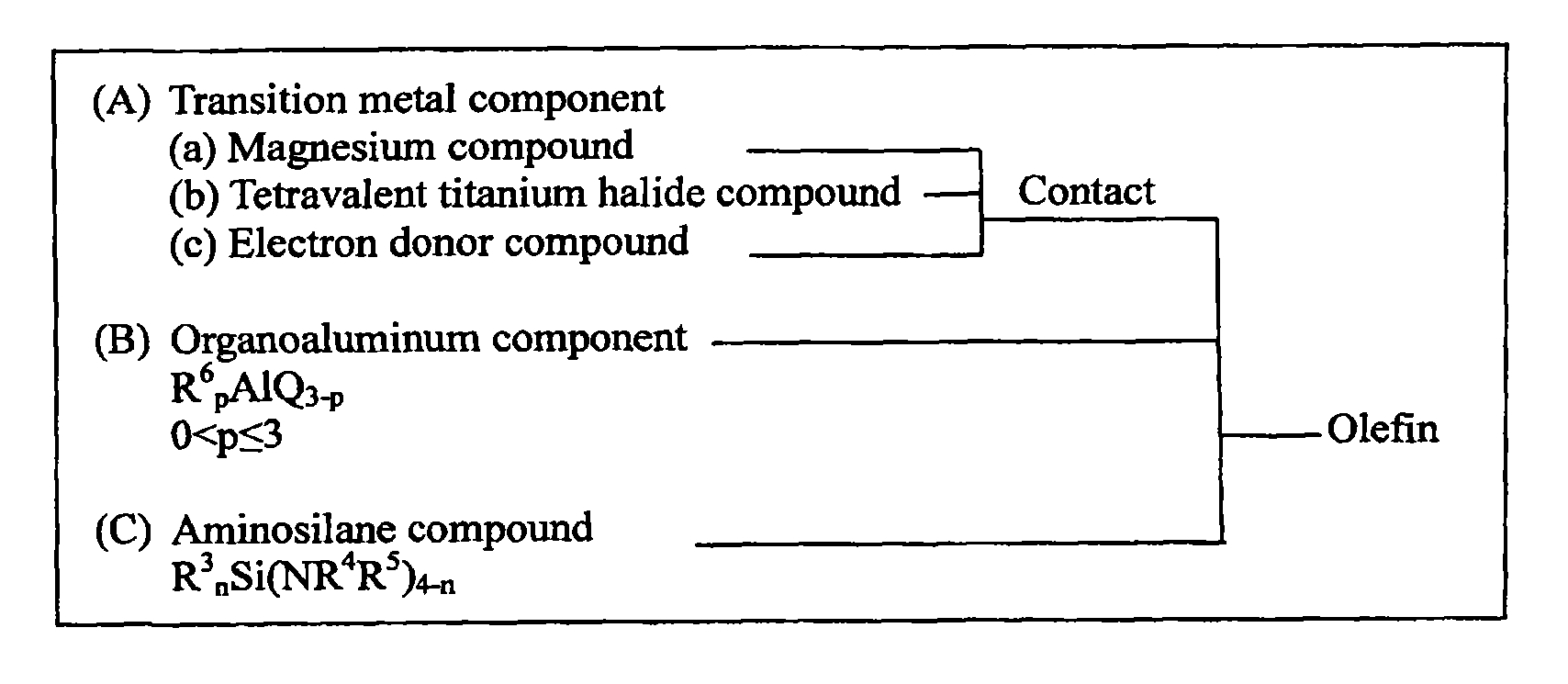

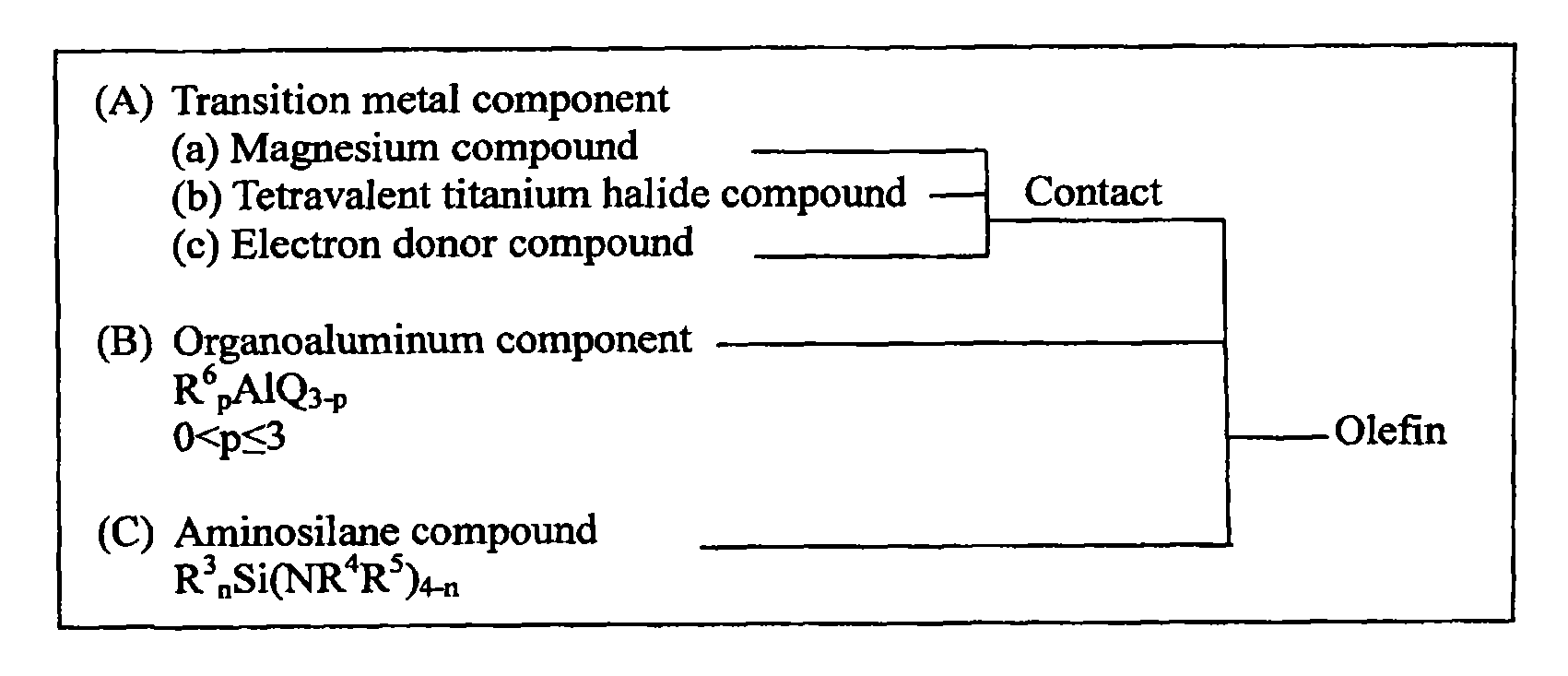

Aminosilane compounds, catalyst components and catalysts for olefin polymerization, and process for production of olefin polymers with the same

InactiveUS20100190942A1High stereoregularity and yieldLow costSilicon organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsPolymer sciencePtru catalyst

A catalyst for polymerization of olefins formed from (A) a solid catalyst component containing magnesium, titanium, halogen, and an electron donor compound, (B) an organoaluminum compound shown by the formula, R6pAlQ3-p, and (C) an aminosilane compound shown by the formula, R3nSi(NR4R5)4-n; and a process for producing a catalyst for polymerization of olefins in the presence of the catalyst are provided. A novel aminosilane compound, a catalyst component for polymerization of olefins having a high catalytic activity, capable of producing polymers with high stereoregularity in a high yield, and exhibiting an excellent hydrogen response, a catalyst, and a process for producing olefin polymers using the catalyst are provided.

Owner:TOHO TITANIUM CO LTD

Use of Sucralose as a Granulating Agent

InactiveUS20100034894A1Large particle sizeHigh bonding strengthBiocideOrganic active ingredientsActive agentSolvent

A method of making a granulation comprising the steps of (a) combining sucralose, a polar solvent, a wettable material and an active agent, thereby forming a mixture; and (b) drying the mixture, thereby forming the granulation.

Owner:JOHNSON & JOHNSON CONSUMER COPANIES

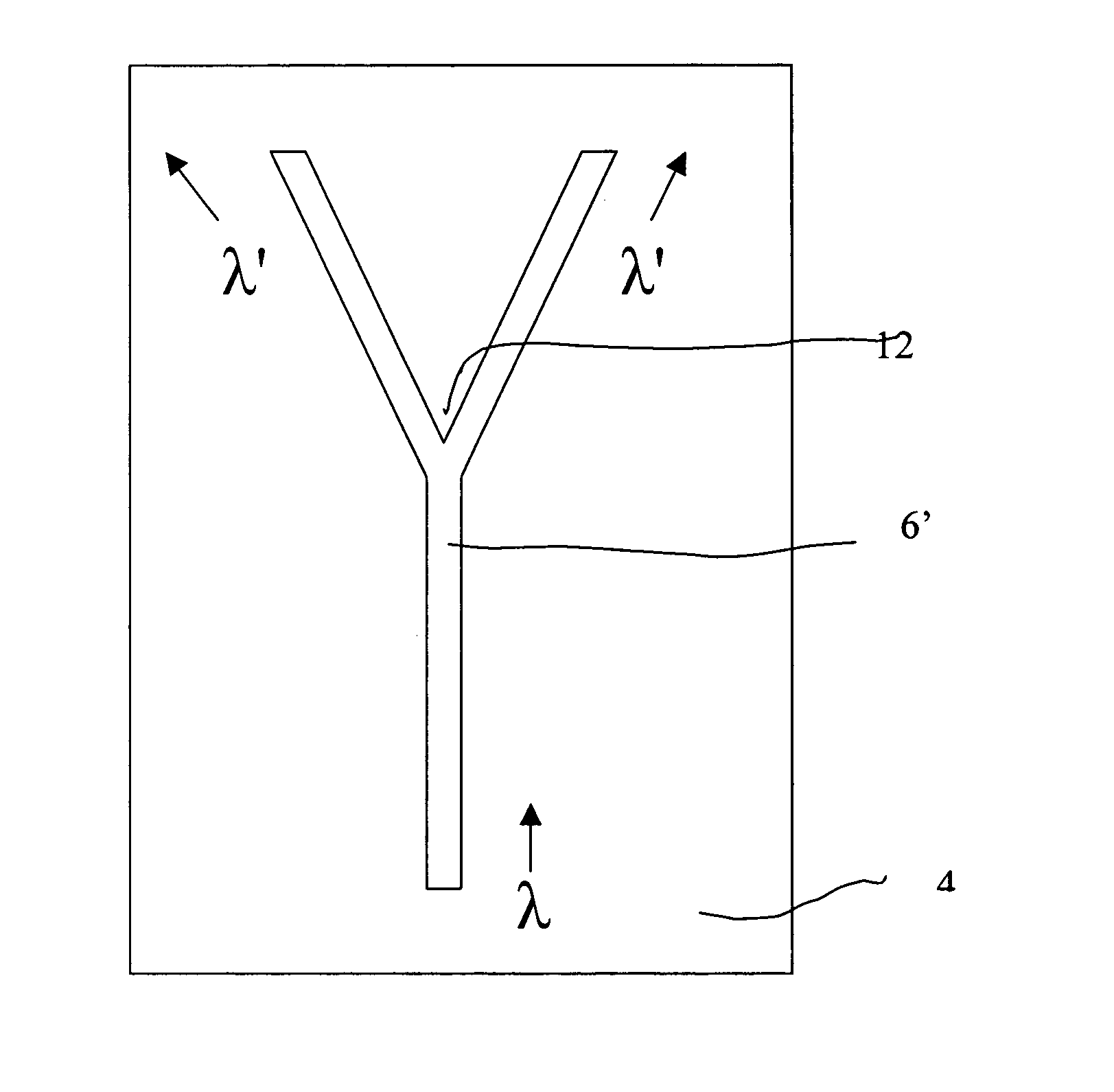

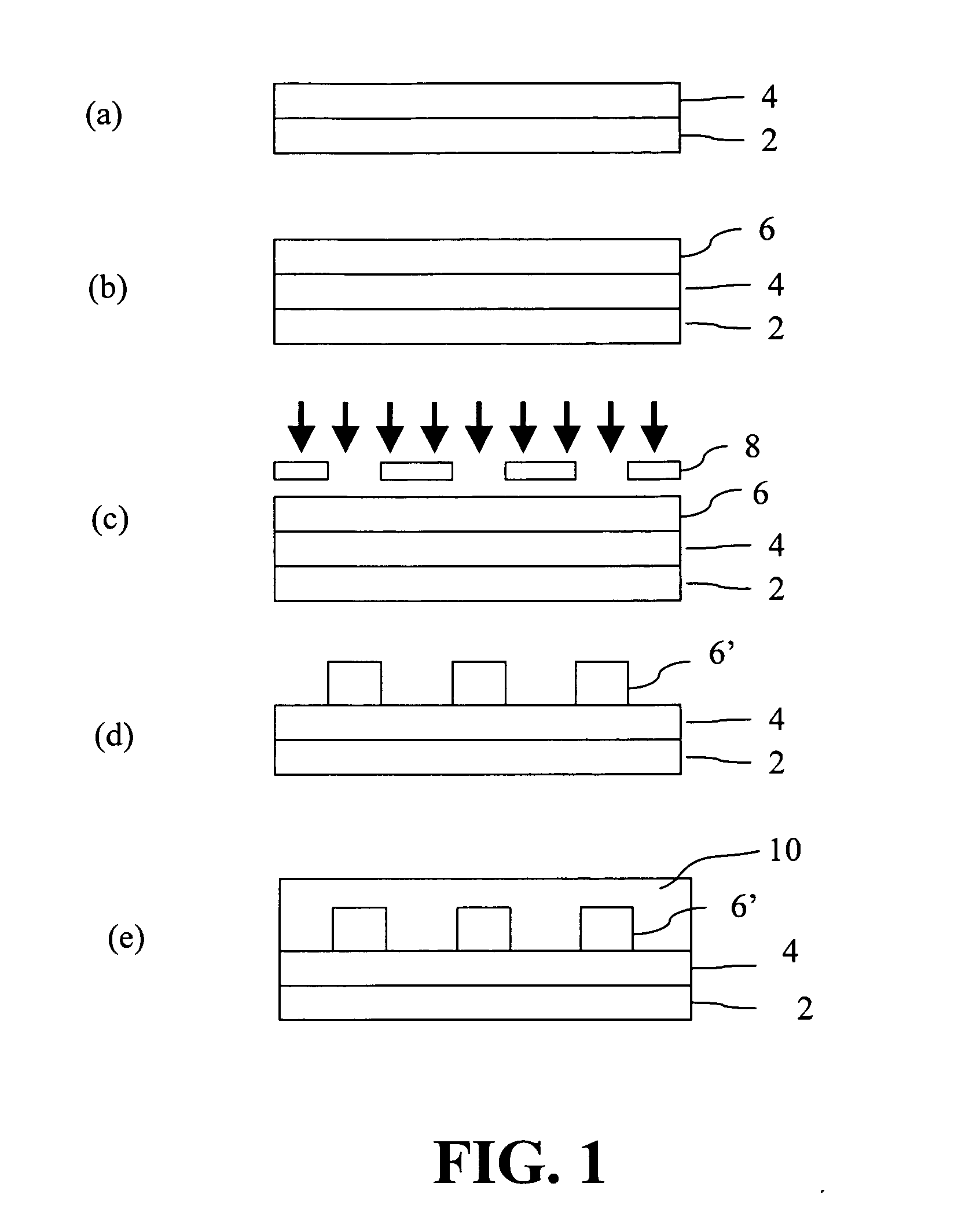

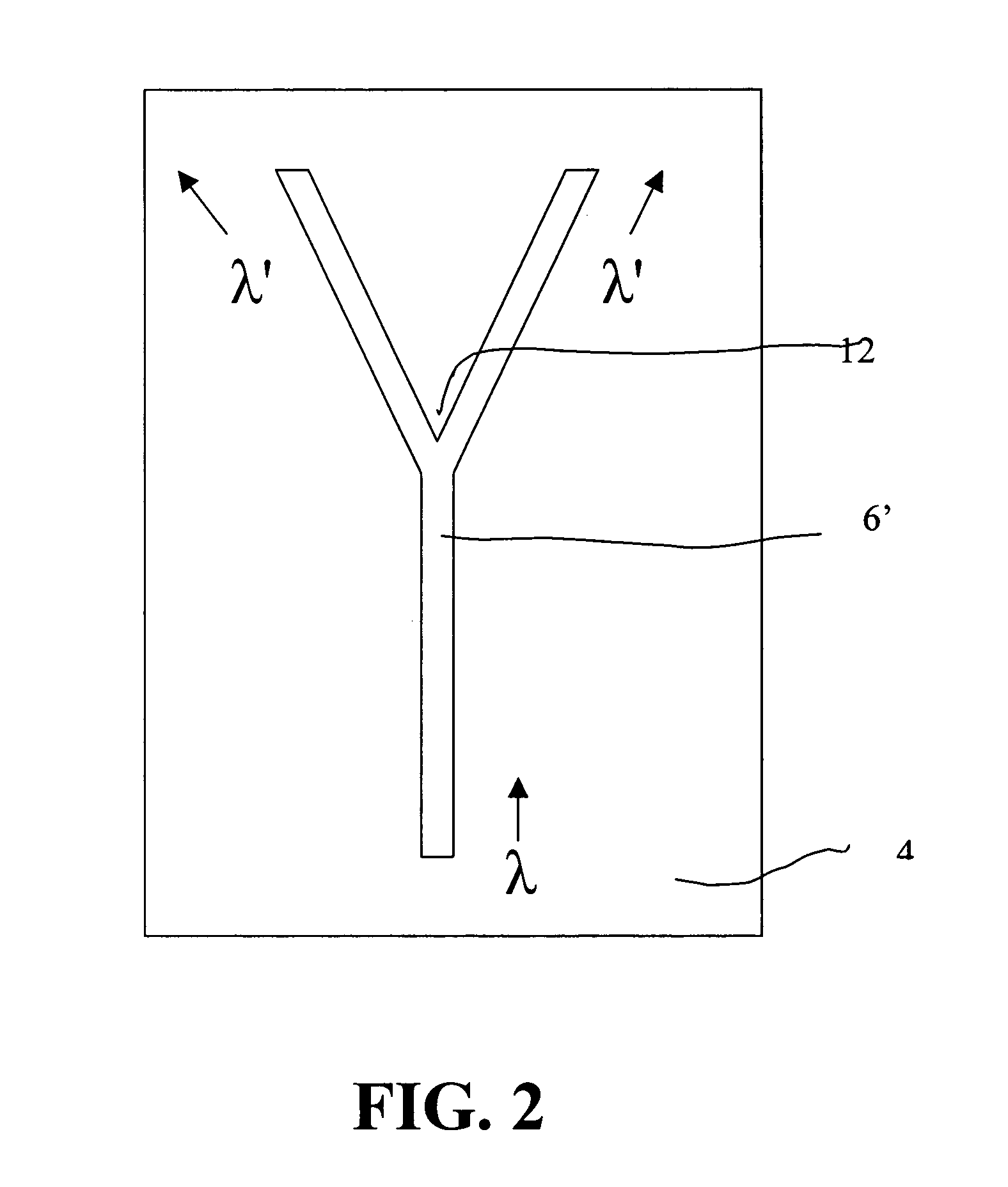

Waveguide compositions and waveguides formed therefrom

ActiveUS20050141839A1Altered solubilityIncrease flexibilityOptical fibre with graded refractive index core/claddingPhotosensitive materialsSolubilityThiol

Provided are compositions suitable for use in forming a flexible optical waveguide. The compositions include a polymer, having units of the formula (RSiO1.5), wherein R is a substituted or unsubstituted organic group, and a plurality of functional end groups. A first component is provided for altering the solubility of the composition in a dried state upon activation. A second component contains a plurality of functional groups chosen from hydroxy, amino, thiol, sulphonate ester, carboxylate ester, silyl ester, anhydride, aziridine, methylolmethyl, silyl ether, and combinations thereof. The second component is present in an effective amount to improve flexibility of the composition in a dried state before and after activation. Also provided are flexible optical waveguides, methods of forming flexible optical waveguides and electronic devices that include a flexible optical waveguide.

Owner:ROHM & HAAS ELECTRONICS MATERIALS LLC

Biodegradable polymer compositions, methods for making same and articles therefrom

InactiveUS6362256B2Manufactured usingEasy to prepareSuture equipmentsCosmetic preparationsPolyesterFunctional polymers

A polymer composition includes a first component being a hydroxy-functional polymer, a second component being a natural polymer and a third component being a thermoplastic polyester. The first component, second component and third component are compounded to form a polymer composition.

Owner:US SEC AGRI +1

Printed circuits on shrink film

InactiveUS7033667B2Quick and inexpensiveManufactured usingShrinkable dielectricsPrinted circuit secondary treatmentEngineeringPolymer

Methods of creating fine featured circuits by printing a circuit trace onto polymer shrink films or other biaxially-oriented polymer films are disclosed. The shrink films are heated and shrunk after printing, annealing the circuit trace to form conductive features. Compositions suitable for printing onto the films and articles made using the method and composition are also disclosed.

Owner:3M INNOVATIVE PROPERTIES CO

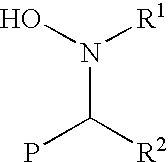

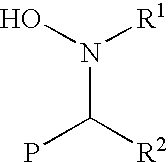

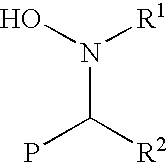

Functionalization of living rubbery polymers with nitrones

InactiveUS20070004869A1High affinityLow costSpecial tyresPneumatic tyre reinforcementsArylHydroxylamine

This invention relates to a tire which is comprised of a generally toroidal-shaped carcass with an outer circumferential tread, two spaced beads, at least one ply extending from bead to bead and sidewalls extending radially from and connecting said tread to said beads, wherein said tread is adapted to be ground-contacting, and wherein said tread is a cured the rubber formulation which is comprised of (1) hydroxylamine end-group functionalized rubbery polymer of the structural formula: wherein P represents polymer chains of the rubbery polymer, and wherein (i) R1 and R2 are independently selected from the group consisting of substituted or unsubstituted straight, branched, or cyclic alkylgroups, alkenyl groups, alkynyl groups, aryl groups, heteroaryl groups, alkaryl groups, alkoxyl groups, halo-alkyl groups, and combinations thereof; or (ii) R1 and R2 taken together with the carbon and nitrogen to which they are attached form a 5 to 8 membered ring; and (2) a filler selected from the group consisting of carbon black and silica.

Owner:THE GOODYEAR TIRE & RUBBER CO

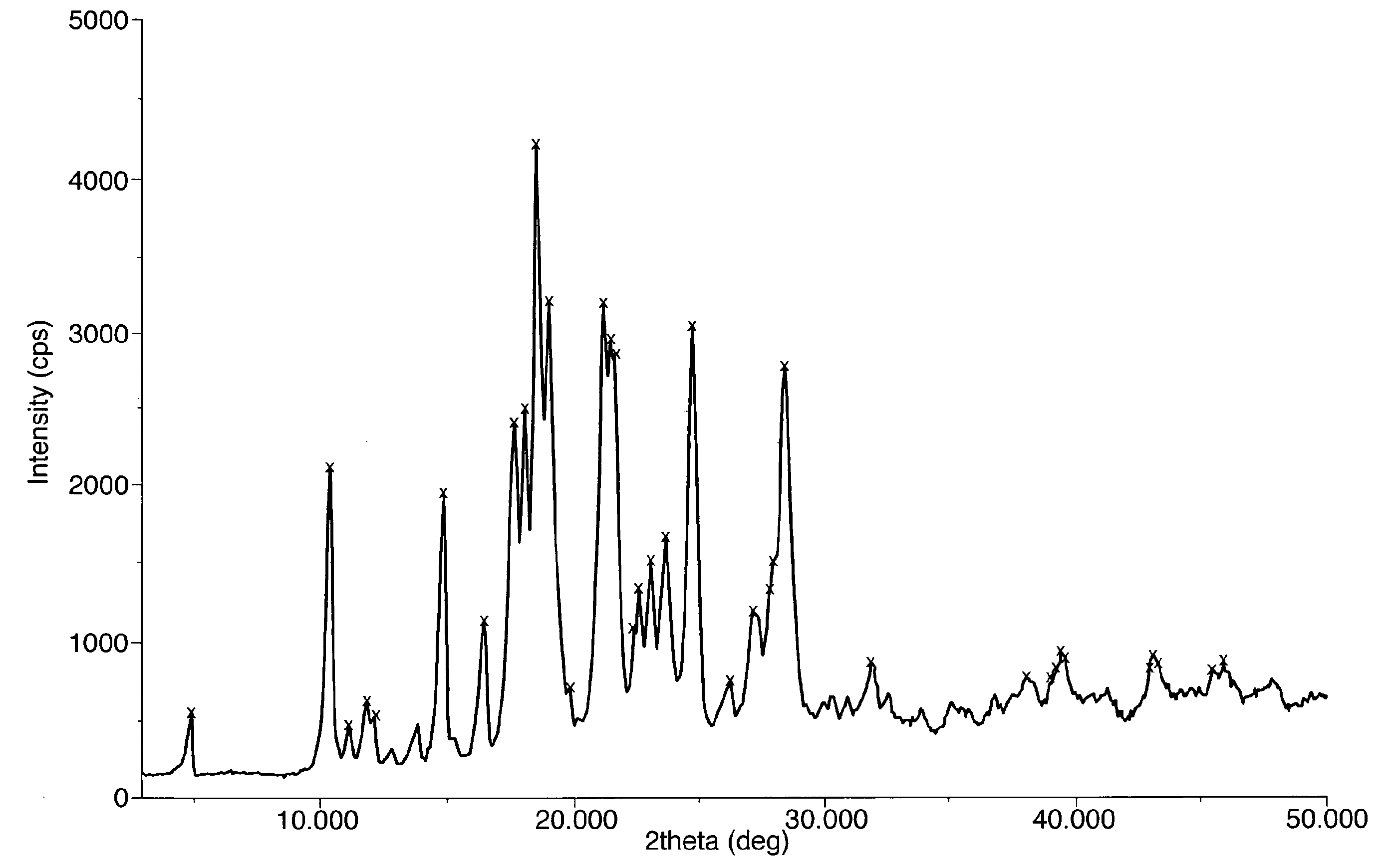

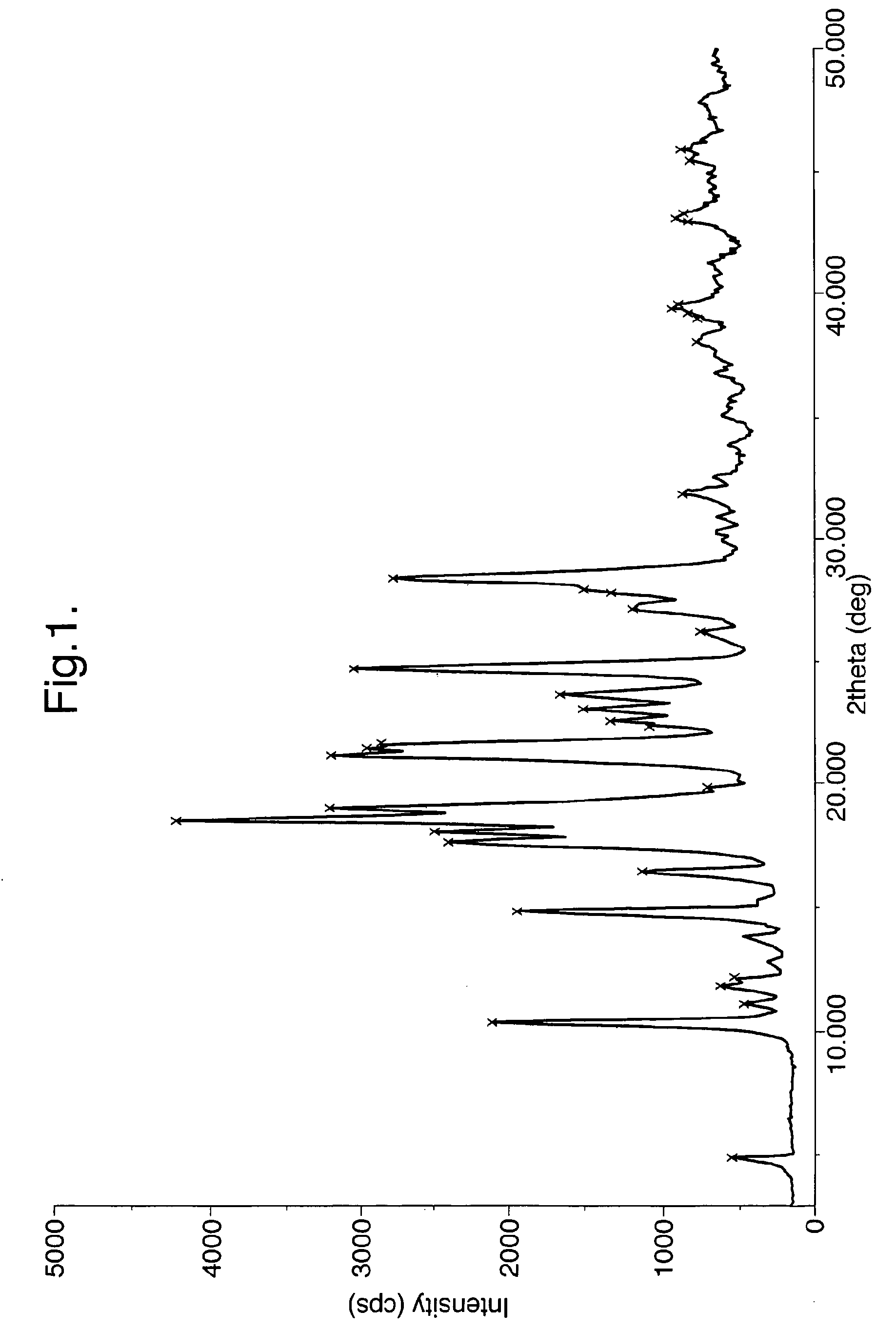

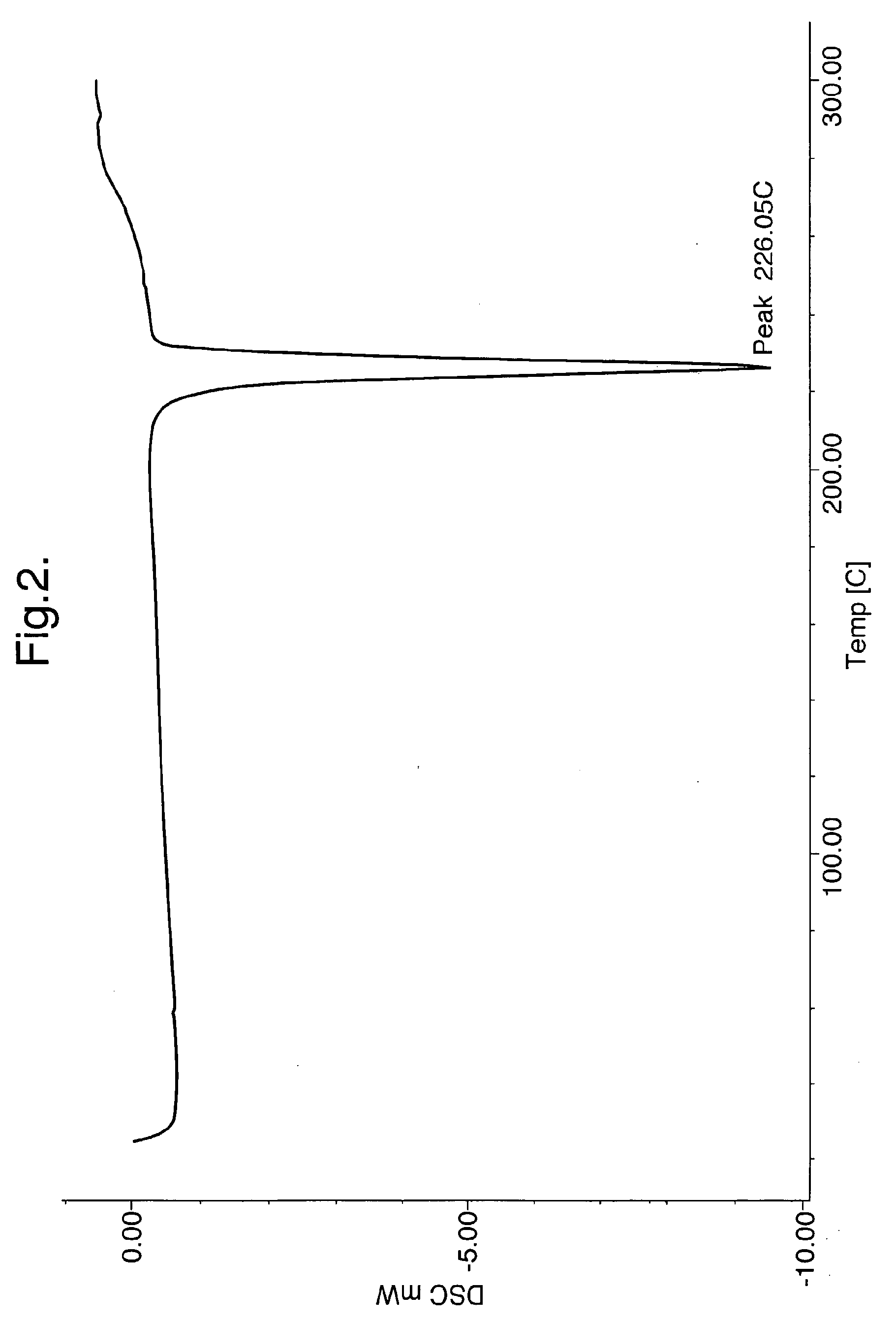

Stable Crystal Form of Imatinib Mesylate and Process for the Preparation Thereof

InactiveUS20070265288A1Stable and non-hygroscopicUseful in therapyOrganic active ingredientsBiocideMethane sulfonic acidPyridine

The invention relates to a stable, non hygroscopic alpha crystalline form of methane sulfonic acid addition salt of 4-(4-methyl piperazin-1yl methyl)-N-[4-methyl-3-(4-pyridin-3-yl) pyrimidin-2-yl amino)phenyl]-benzamide (imatinib mesylate). A process for the preparation of the crystalline form is also described.

Owner:CIPLA LTD

Aminosilane compounds, catalyst components and catalysts for olefin polymerization, and process for production of olefin polymers with the same

ActiveUS8648001B2High stereoregularity and yieldLow costGroup 4/14 element organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsPolymer sciencePtru catalyst

A catalyst for polymerization of olefins formed from (A) a solid catalyst component containing magnesium, titanium, halogen, and an electron donor compound, (B) an organoaluminum compound shown by the formula, R6pAlQ3-p, and (C) an aminosilane compound shown by the formula, R3nSi(NR4R5)4-n; and a process for producing a catalyst for polymerization of olefins in the presence of the catalyst are provided. A novel aminosilane compound, a catalyst component for polymerization of olefins having a high catalytic activity, capable of producing polymers with high stereoregularity in a high yield, and exhibiting an excellent hydrogen response, a catalyst, and a process for producing olefin polymers using the catalyst are provided.

Owner:TOHO TITANIUM CO LTD

Molding process and apparatus for producing unified composite structures

InactiveUS20050163965A1Stable structureManufactured usingLayered productsEfficient propulsion technologiesEngineeringFace sheet

A method of forming a unitary, composite structural member, and a member formed in accordance with the process. The process involves stitching a plurality of warp knit panel sections together to generally form a plurality of independent panel sections. The sections are placed within the dies of a molding tool such that a rib portion of each section aligns. Inflatable bladders are then slipped into voids formed in between the various panel sections of the assembly. The bladders are inflated to hold the panel sections in the shape of the final product and to hold the rib portions in contact with one another. Resin is then infused into the panels that make up the assembly. The assembly is then cured. When the panels are removed from the molding tool a unitary, complexly shaped, composite structural member is formed.

Owner:VELICKI ALEXANDER +3

Water based adhesive composition with release properties

InactiveUS6838187B2Good release propertyManufacture useAdhesive processesNon-macromolecular adhesive additivesTapioca starchNuclear chemistry

Owner:HENKEL KGAA

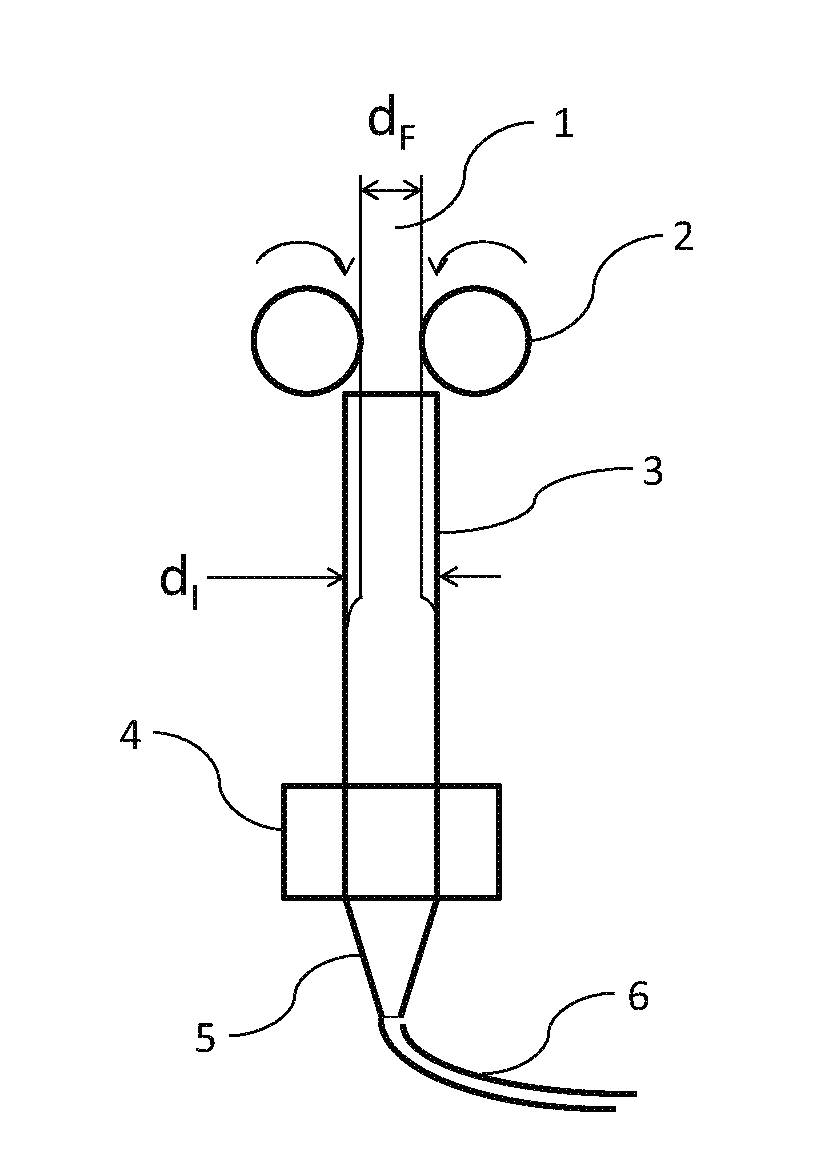

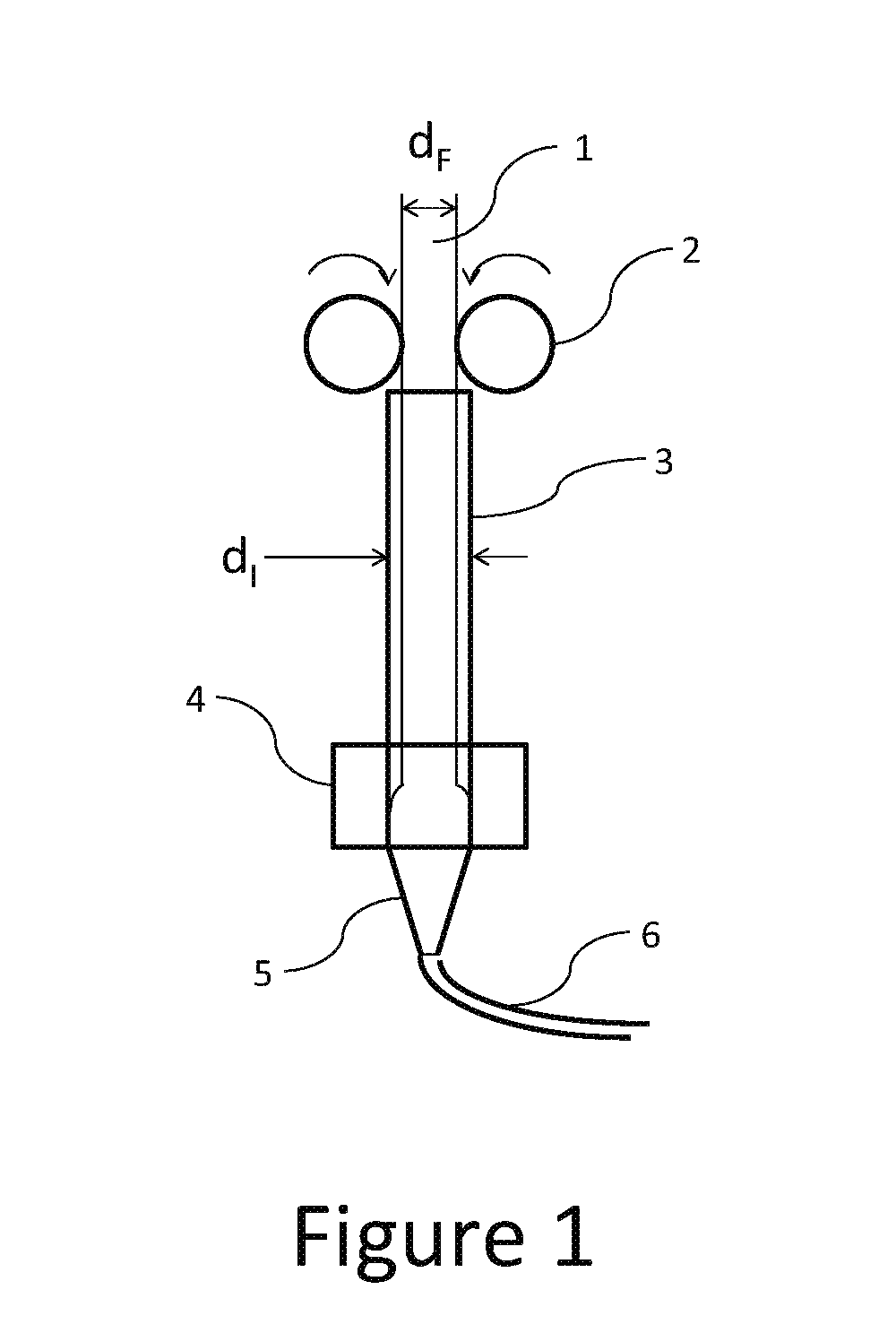

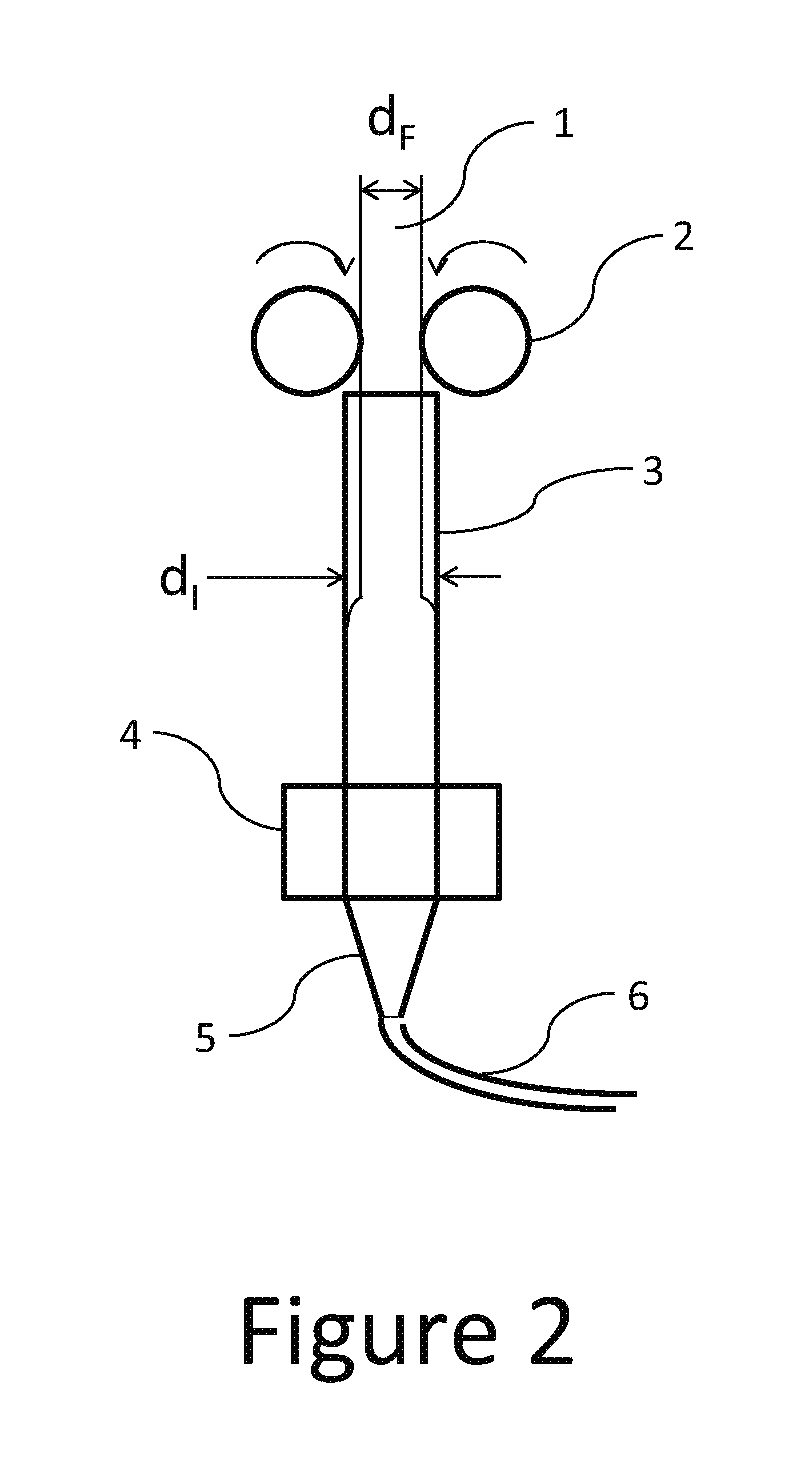

High crystalline poly(lactic acid) filaments for material-extrusion based additive manufacturing

PendingUS20170066188A1Improve the immunityWithout compromising qualityAdditive manufacturing apparatusArtificial filament physical treatmentPoly l lactic acidPoor quality

Provided is a new and better solution to the problems associated with the premature softening of PLA filaments in the additive manufacturing of three dimensional articles. It is based upon the finding that poly (lactic acid) filaments with high crystallinity offer much better resistance to heat-induced softening. The crystalline poly (lactic acid) filament can accordingly be used in the additive manufacturing of three dimensional articles without encountering the problems associated with premature softening, such as poor quality and printer jamming. The crystalline poly (lactic acid) filaments can also be used in additive manufacturing of three dimensional articles without compromising the quality of the ultimate product, reducing printing speed, increasing cost, or leading to increased printer complexity. It more specifically discloses a filament for use in three-dimensional printing which is comprised of crystalized poly (lactic acid), wherein said filament has a diameter which is within the range of 1.65 mm to 1.85 mm.

Owner:JF POLYMERS (SUZHOU) CO LTD

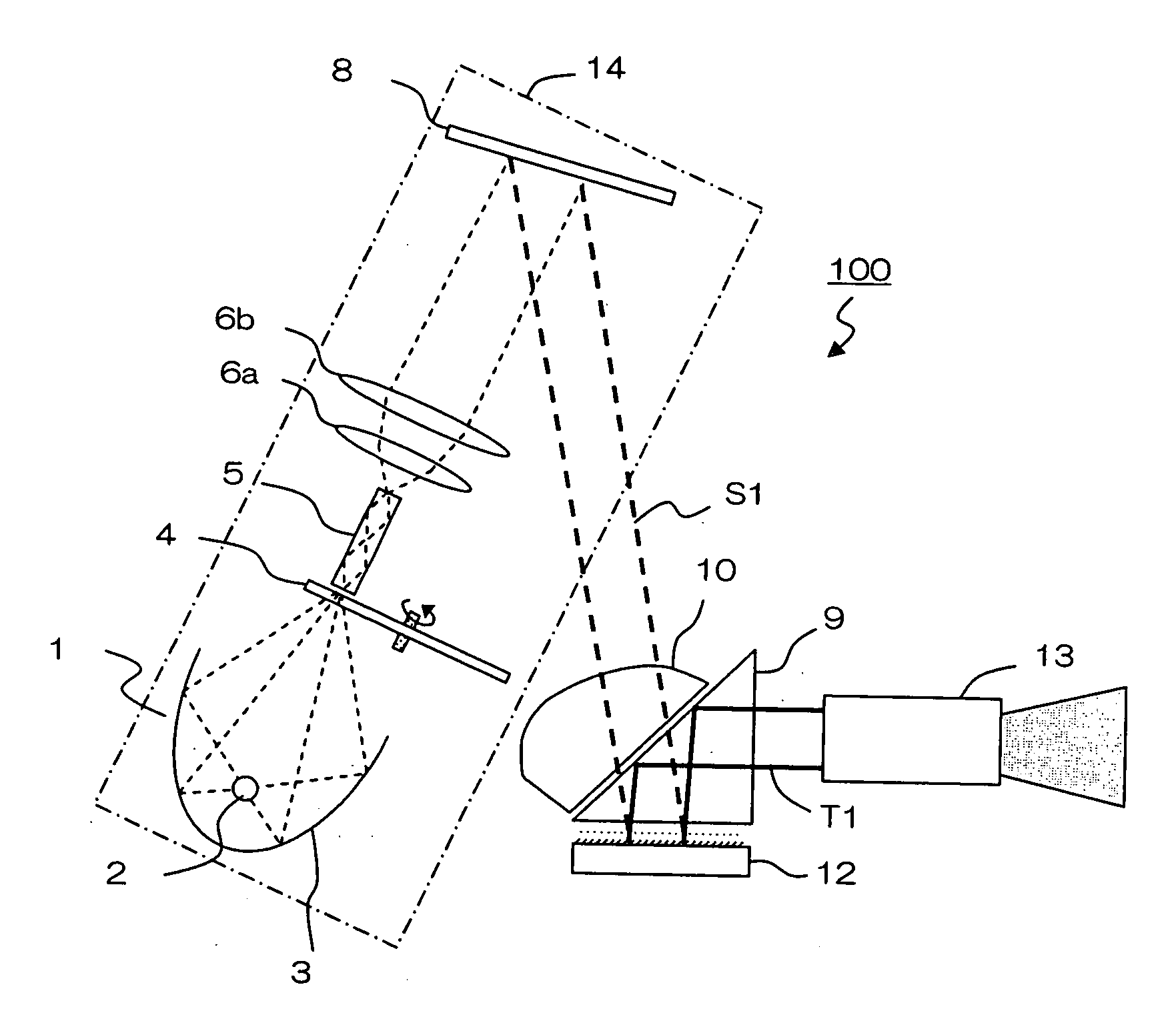

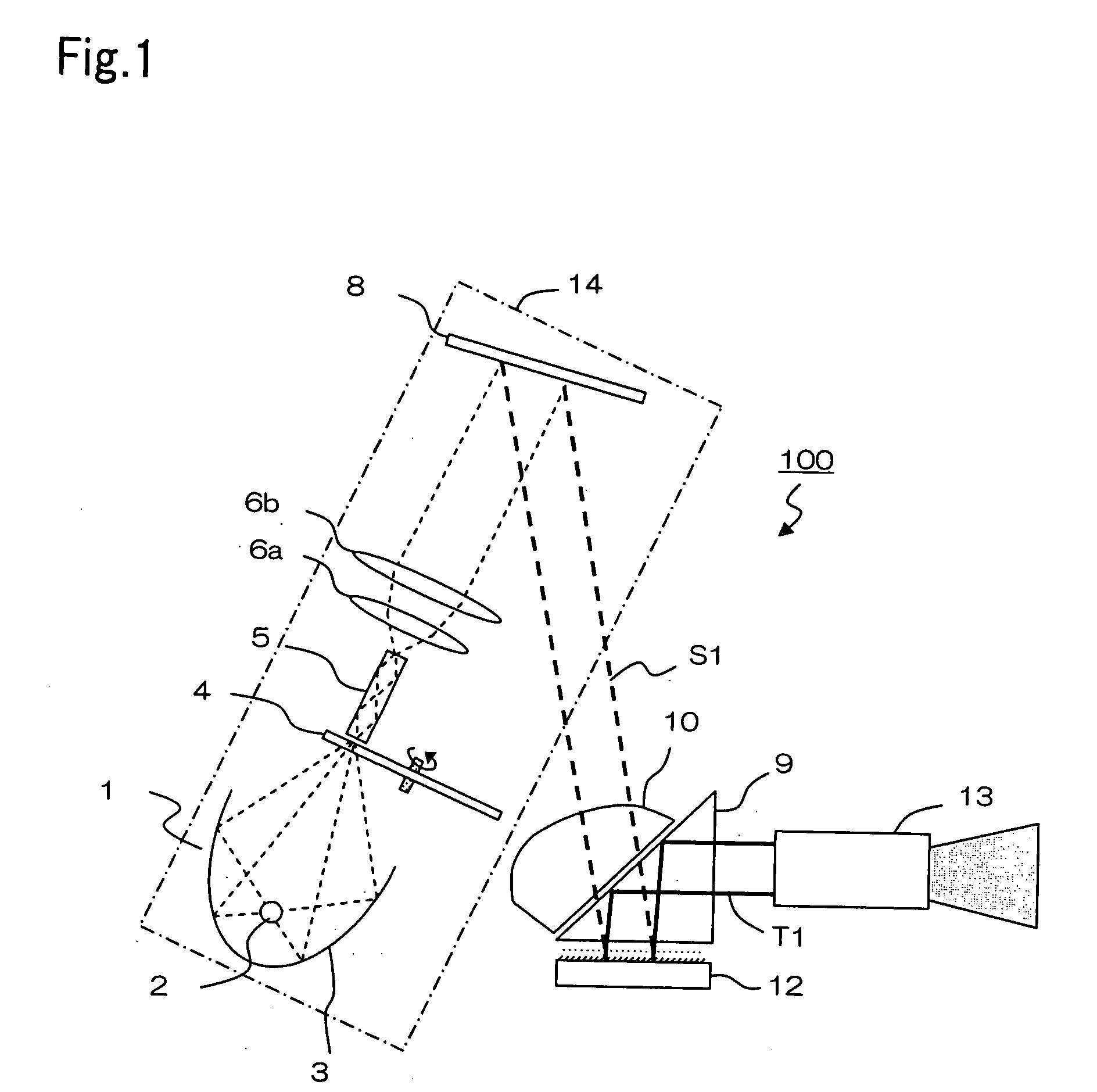

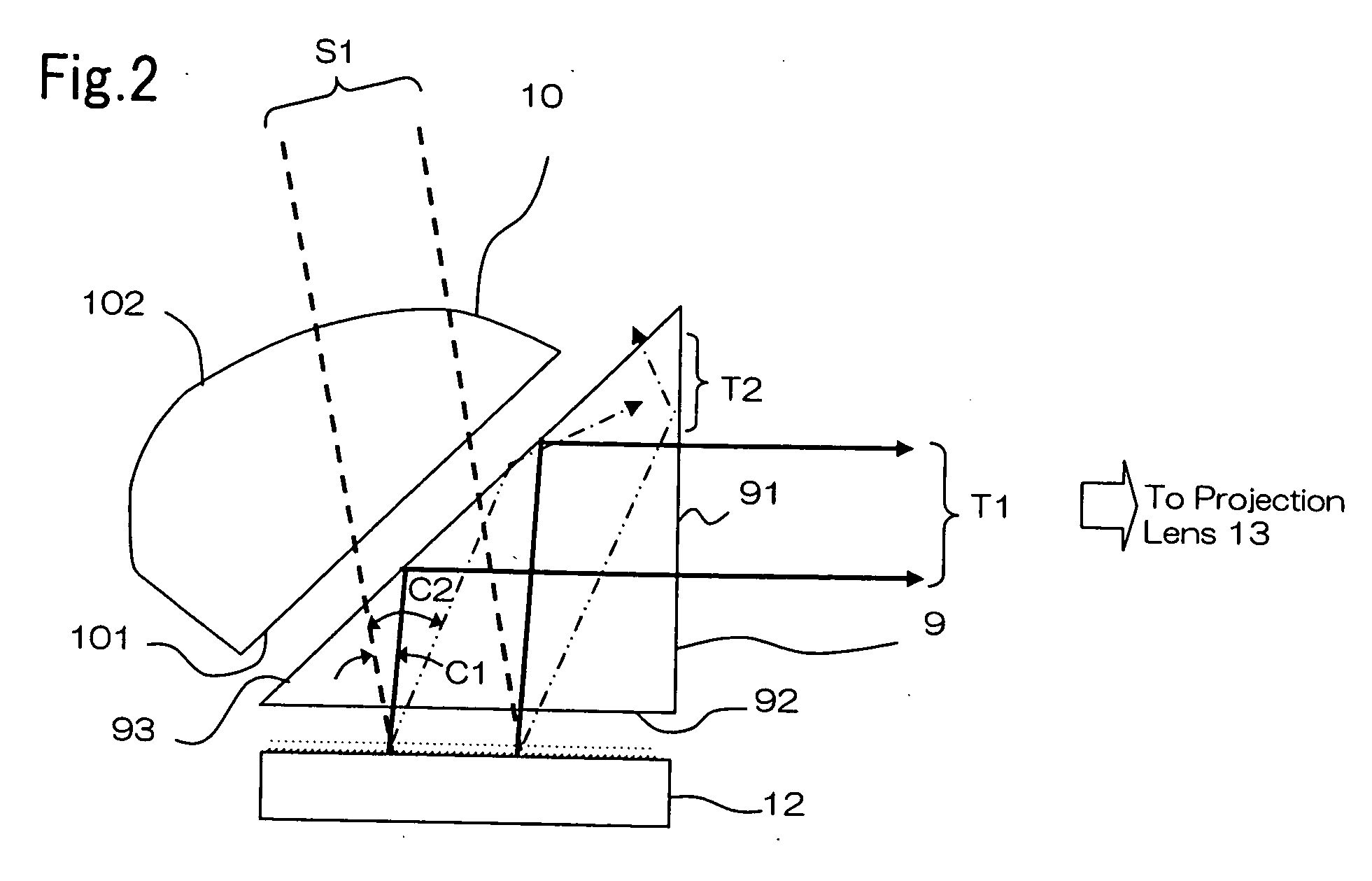

TIR PRISM for a projection display apparatus having a partially masked surface

InactiveUS20070019165A1Avoid stray lightIncrease contrastTelevision system detailsPrismsLight beamOptoelectronics

A projection display apparatus has: a TIR prism having a first prism surface, a second prism surface, and a third prism surface; a projection lens which is disposed opposite to the first prism surface; and an image display device which is disposed opposite to the second prism surface. The image display device reflects incident light in a first direction or in a second direction in accordance with an image signal. The first, second, and third prism surfaces are formed so as to define a modulated light path, wherein the light is reflected in the first direction, then is incident on the second prism surface, then is totally reflected internally on the third prism surface, then exits from the first prism surface, and then is incident on the projection lens along the modulated light path. The first prism surface includes a first effective light beam area and a first shield area for shielding the light, wherein the modulated light path passes through the first effective light beam area, and wherein the first shield area is formed on at least a part of the first prism surface except for the first effective light beam area.

Owner:NEC DISPLAY SOLUTIONS LTD

Curable composition having low coefficient of thermal expansion, method of making an integrated circuit, and an integrated circuit made there from

ActiveUS20060197236A1Low coefficientManufactured usingSemiconductor/solid-state device detailsSolid-state devicesIntegrated circuitEmpirical formula

Disclosed is a curable composition having a low CTE. In one embodiment, a curable composition is disclosed that comprises (i) a binder comprising at least one epoxy compound of the structure: X—((CH2)m—(N)—((CH2)n-(Z))2)p wherein X is an aromatic ring or a six membered cycloaliphatic ring, m is from about 0 to about 2, n is from about 1 to about 3, Z is an epoxy group of empirical formula: C2H3O, p is a number from about 2 to about 3, and (ii) a cross-linking agent comprising at least one polyamine. This curable composition is characterized by a CTE of no more than 60 ppm / ° C. when cured for a time of from about 20 to about 60 minutes at temperature of from about 100 to 240° C. Also disclosed are methods of making integrated circuits and integrated circuits made there from, especially flip chips.

Owner:INTEL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com