Aminosilane compounds, catalyst components and catalysts for olefin polymerization, and process for production of olefin polymers with the same

a technology of olefin polymerization and aminosilane, which is applied in the direction of catalyst activation/preparation, chemical/physical processes, group 4/14 element organic compounds, etc., can solve the problem that the compound has not been known as useful, and achieve high melt flow rate, high stereoregularity and yield of the polymer, and reduce the amount of hydrogen used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

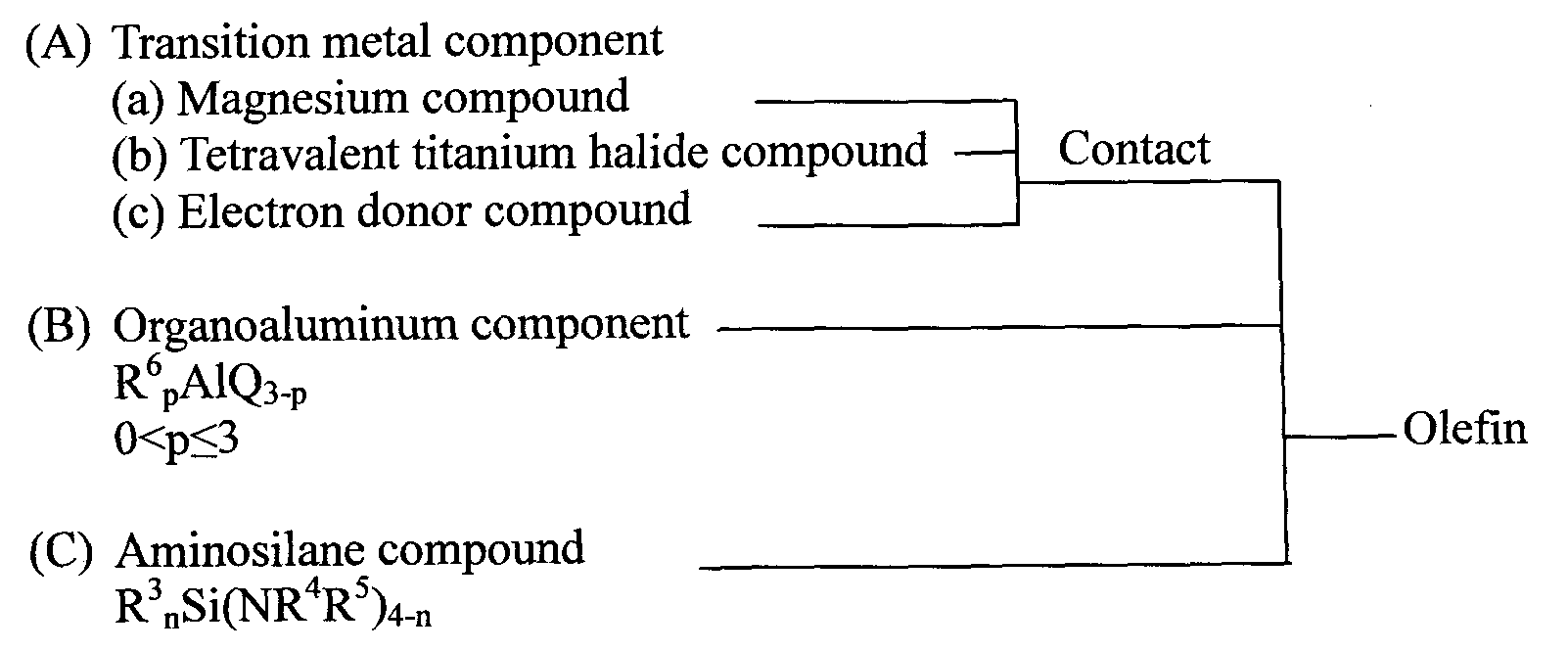

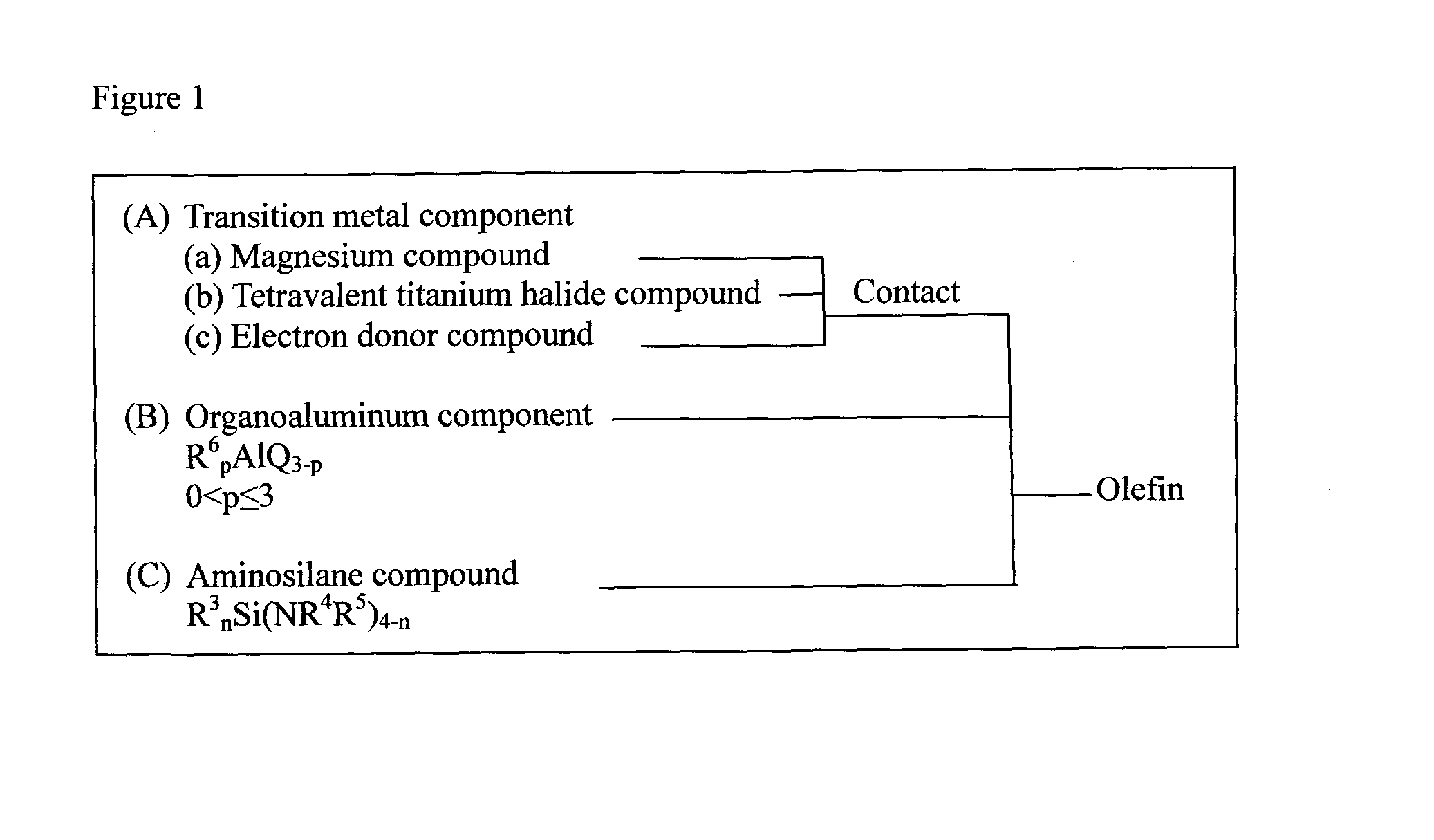

Method used

Image

Examples

example 1

Synthesis of Aminosilane Compound

[0065]A flask in which the internal atmosphere was sufficiently replaced with nitrogen gas was charged with a THF solution of ethylamine in a nitrogen stream. The solution was cooled to −10 to 0° C. and a hexane solution of commercially available butyl lithium, in an amount equimolar to ethylamine, was slowly added using a dripping funnel while stirring. After the addition, the temperature was gradually increased to 50° C. and the mixture was reacted for two hours to obtain a slurry of lithium salt of ethylamine. Another flask in which the internal atmosphere was sufficiently replaced with nitrogen gas was charged with a toluene solution of dicyclopentyldimethoxysilane (a commercially available product) which was cooled to −10 to 0° C., and the above slurry of lithium salt of ethylamine, in an amount 2.1 times mol of the dicyclopentyldimethoxysilane, was slowly added using an injector in a nitrogen stream. After the addition, the temperature was grad...

example 2

Synthesis of Aminosilane Compound

[0067]A three-necked flask in which the internal atmosphere was sufficiently replaced with nitrogen gas was charged with 60 ml of a THF solution containing 0.04 mol of ethylamine in a nitrogen stream. 30 ml of a hexane solution containing 0.04 mol of BuLi was slowly added to the ethylamine solution cooled to −10° C. using a dripping funnel. After the addition, the mixture was gradually heated and reacted at 50° C. for two hours. Another container of which the internal atmosphere was purged with nitrogen was charged with 60 ml of a toluene solution containing 0.02 mol of t-butylethyldimethoxysilane and cooled to −10° C. The above slurry of Li salt of methylamine was slowly added dropwise to the cooled solution under nitrogen seal. After the addition, the mixture was reacted at 50° C. for three hours. The reaction mixture was separated into a solid and a solution by centrifugation. The solid was washed with 20 ml of toluene and added to the solution. T...

example 3

Synthesis of Aminosilane Compound

[0068]A flask in which the internal atmosphere was sufficiently replaced with nitrogen gas was charged with a THF solution of ethylamine. The solution was cooled to −10 to 0° C. and a hexane solution of commercially available butyl lithium, in an amount equimolar to ethylamine, was slowly added using a dripping funnel while stirring. After the addition, the temperature was gradually increased to 50° C. and the mixture was reacted for two hours to obtain a slurry of lithium salt of ethylamine. Another flask in which the internal atmosphere was sufficiently replaced with highly pure nitrogen gas was charged with a toluene solution of bis(methoxy)diisopropylsilane (a commercially available product) which was cooled to −10 to 0° C., and the above slurry of lithium salt of ethylamine, in an amount 2.1 times mol of the bis(methoxy)diisopropylsilane, was slowly added using an injector in a nitrogen stream. After the addition, the temperature was gradually i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| durability | aaaaa | aaaaa |

| fluidity | aaaaa | aaaaa |

| melt flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com