Patents

Literature

215 results about "Central element" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A central element is the bundling of production processes for vulcanization accelerators, which are used primarily in the tire industry.

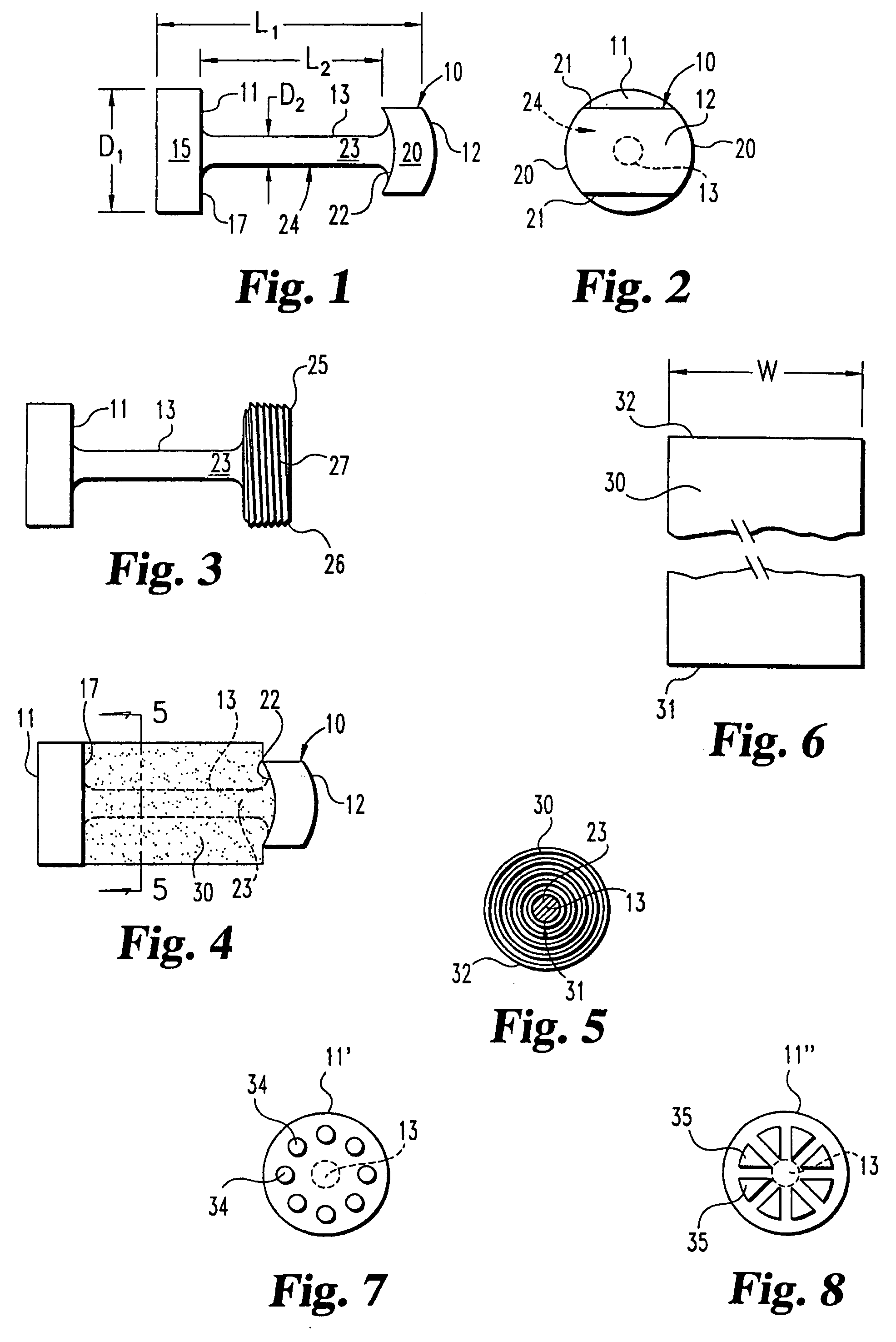

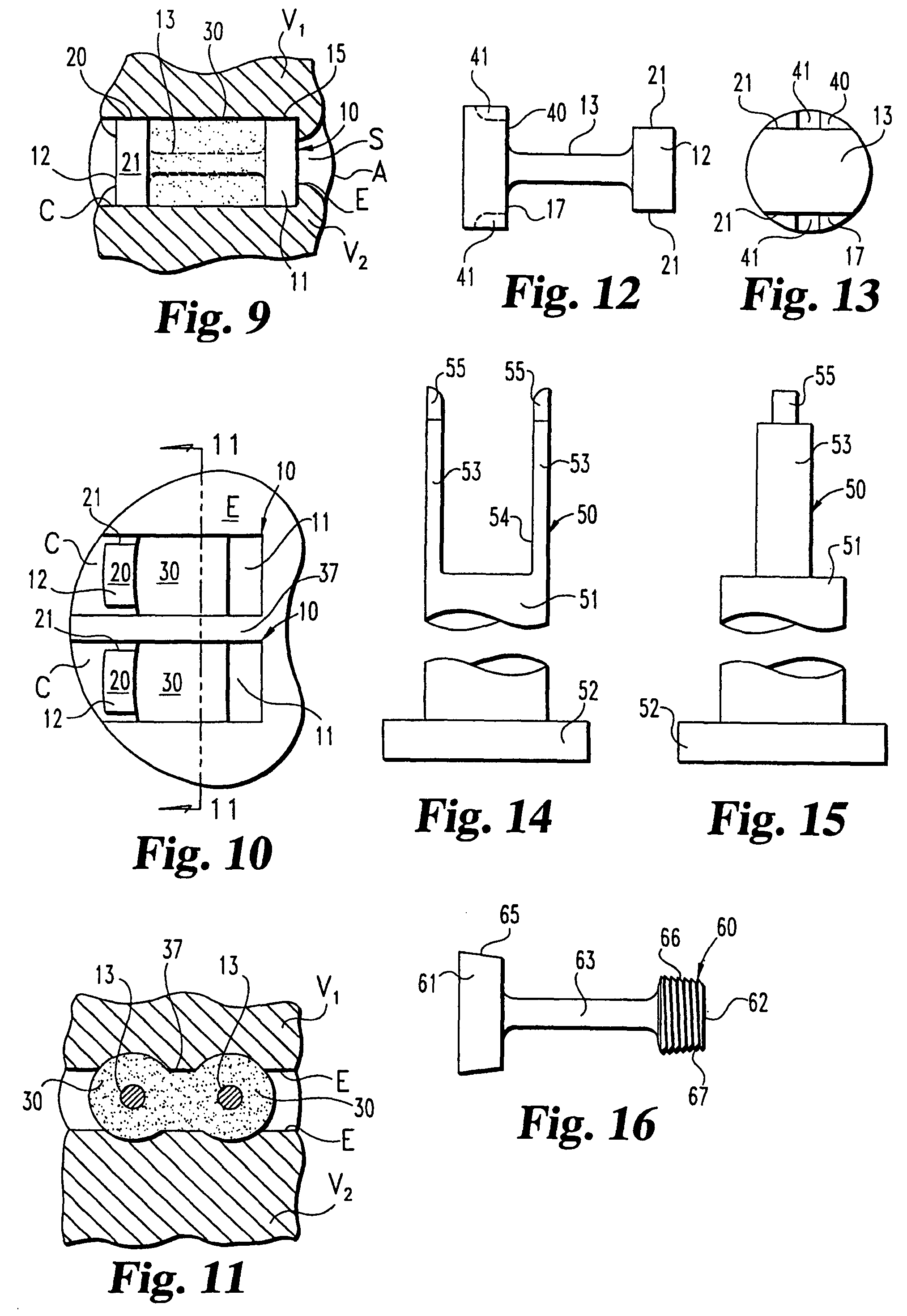

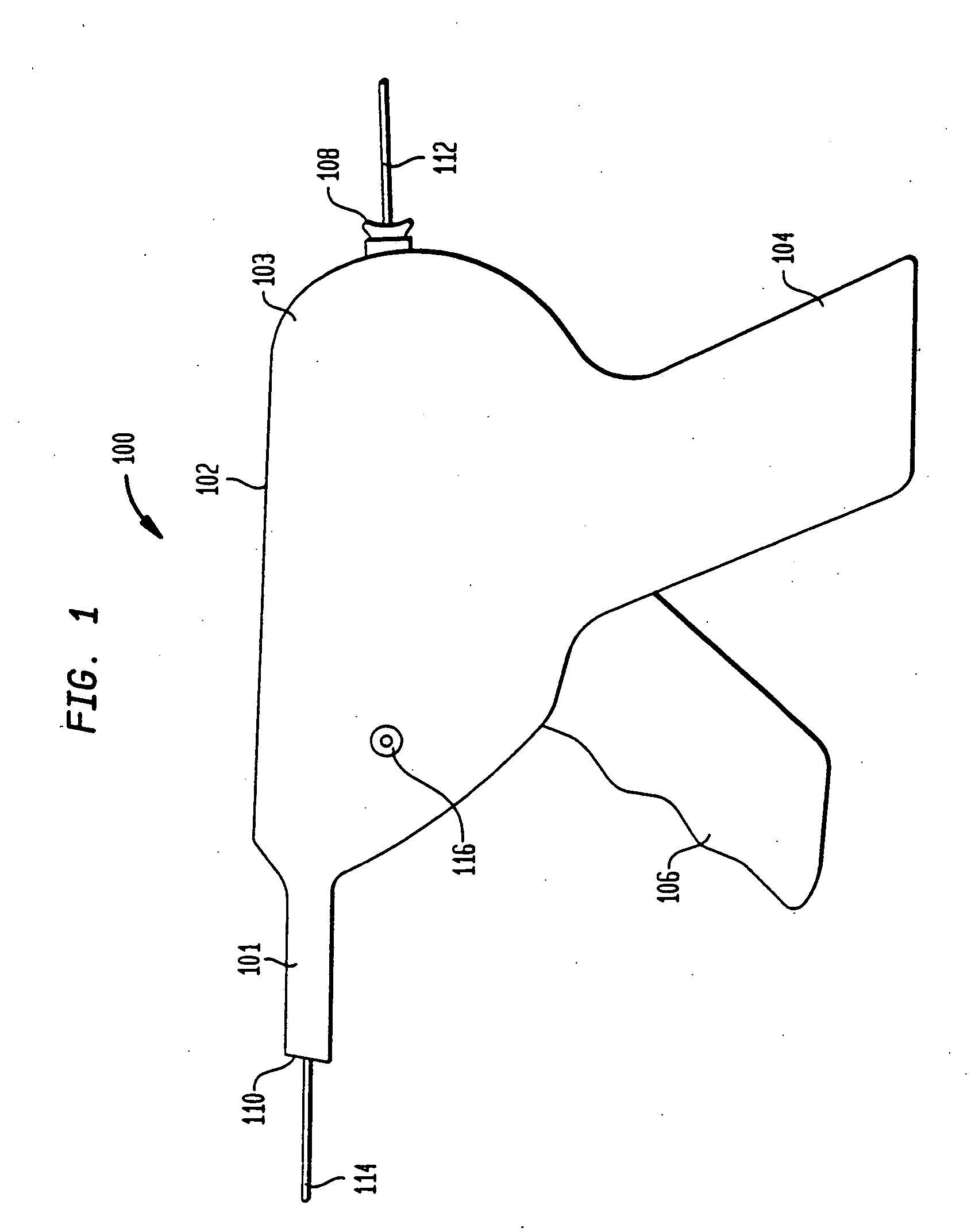

Osteogenic fusion device

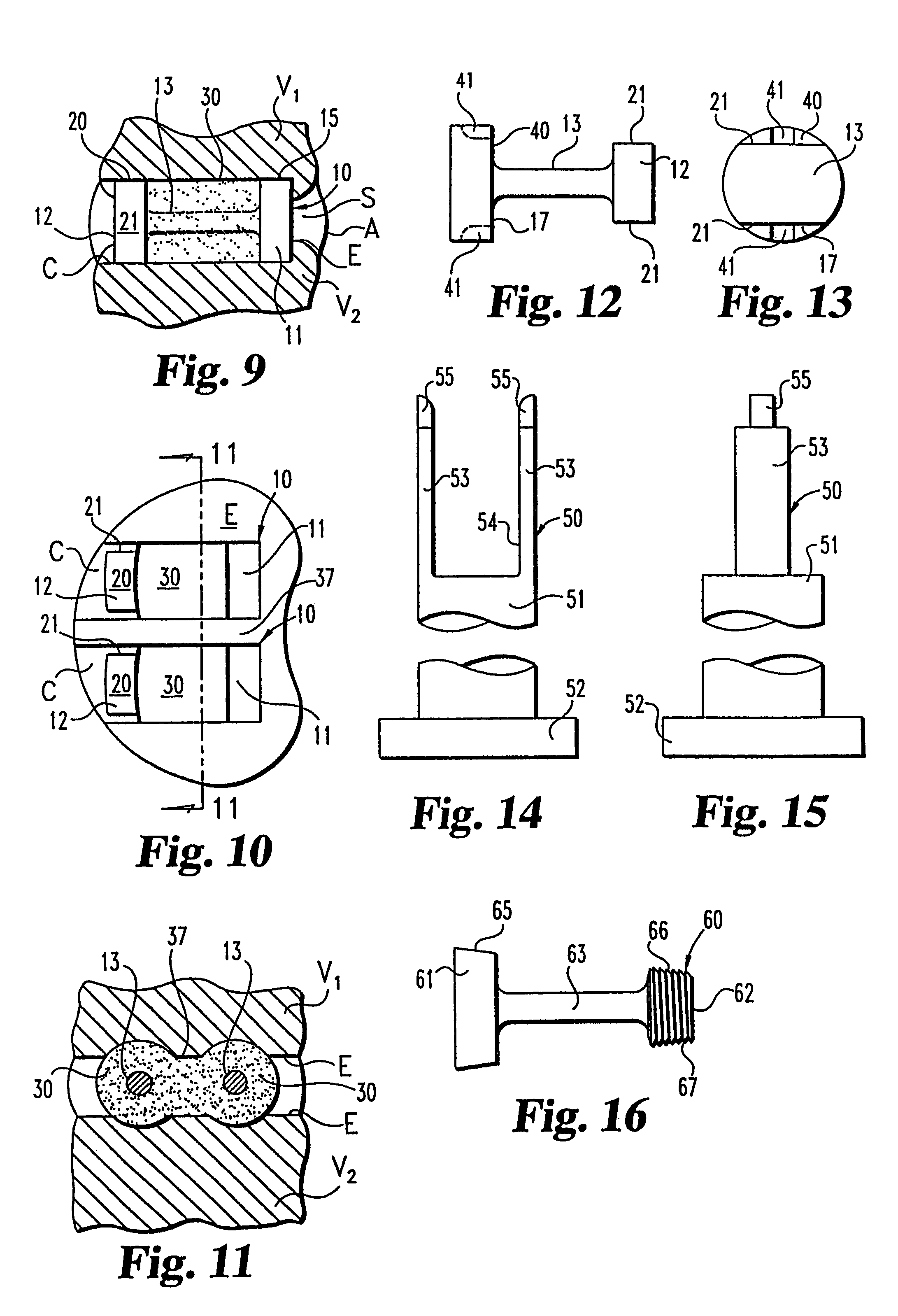

InactiveUS7179293B2Support of loadMinimize radiopacityBone implantJoint implantsDevice formBone growth

An interbody osteogenic fusion device is provided that includes opposite end pieces with an integral central element. The end pieces are sized to maintain the height of an intervertebral disc space. The central element has a much smaller diameter so that the osteogenic fusion device forms an annular pocke around the central element. An osteogenic material is disposed within the annular pocket between the opposite end pieces. In one embodiment,the osteogenic material constitutes a collagen sheet soaked in asolution containing a bone morphogenetic protein. The osteogenic fusion device is configured so that the osteogenic material is in direct contact with the adjacent vertebral bone. In addition to the enhanced area of contact between the vertebral bone and the fusion material, the inventive osteogenic fusion device reduces stress-shielding and minimizes the radiopacity of the implant so that growth of the fusion mass can be continuously assessed. In yet another embodiment, the osteogenic fusion device includes at least one end piece with a truncated surface. The osteogenic fusion devices of the present invention may be combined with other fusion devices to form an implant system. The implant system includes at least one load bearing member having a truncated surface configured to nest within another load bearing member, preferably the load bearing, osteogenic fusion device of the present invention. The invention also provides implant systems comprising adjacent load bearing members connected to one another to resist lateral separation. Methods of promoting fusion bone growth in the space between adjacent vertebrae utilizing devices and systems of the invention are also described.

Owner:WARSAW ORTHOPEDIC INC

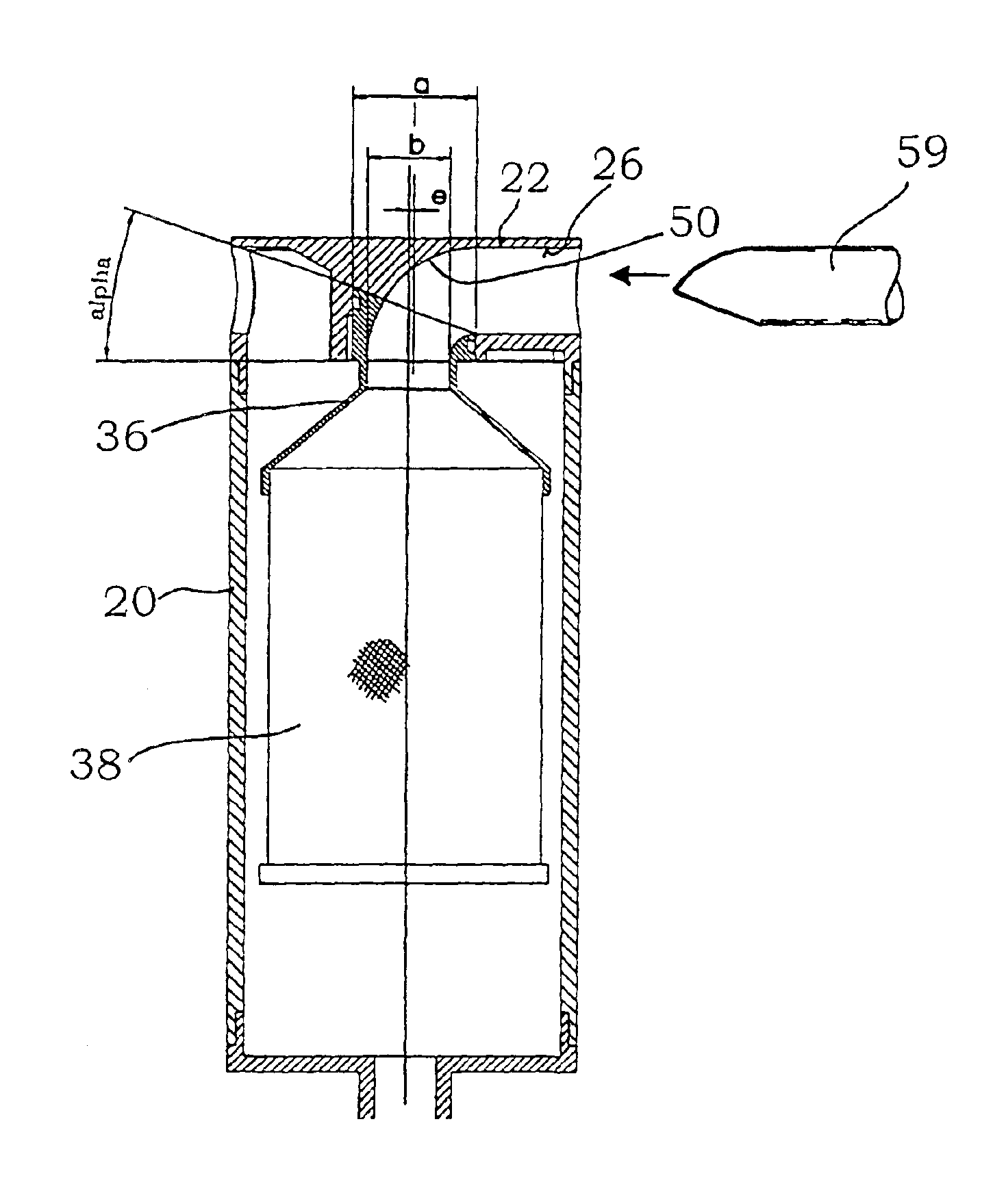

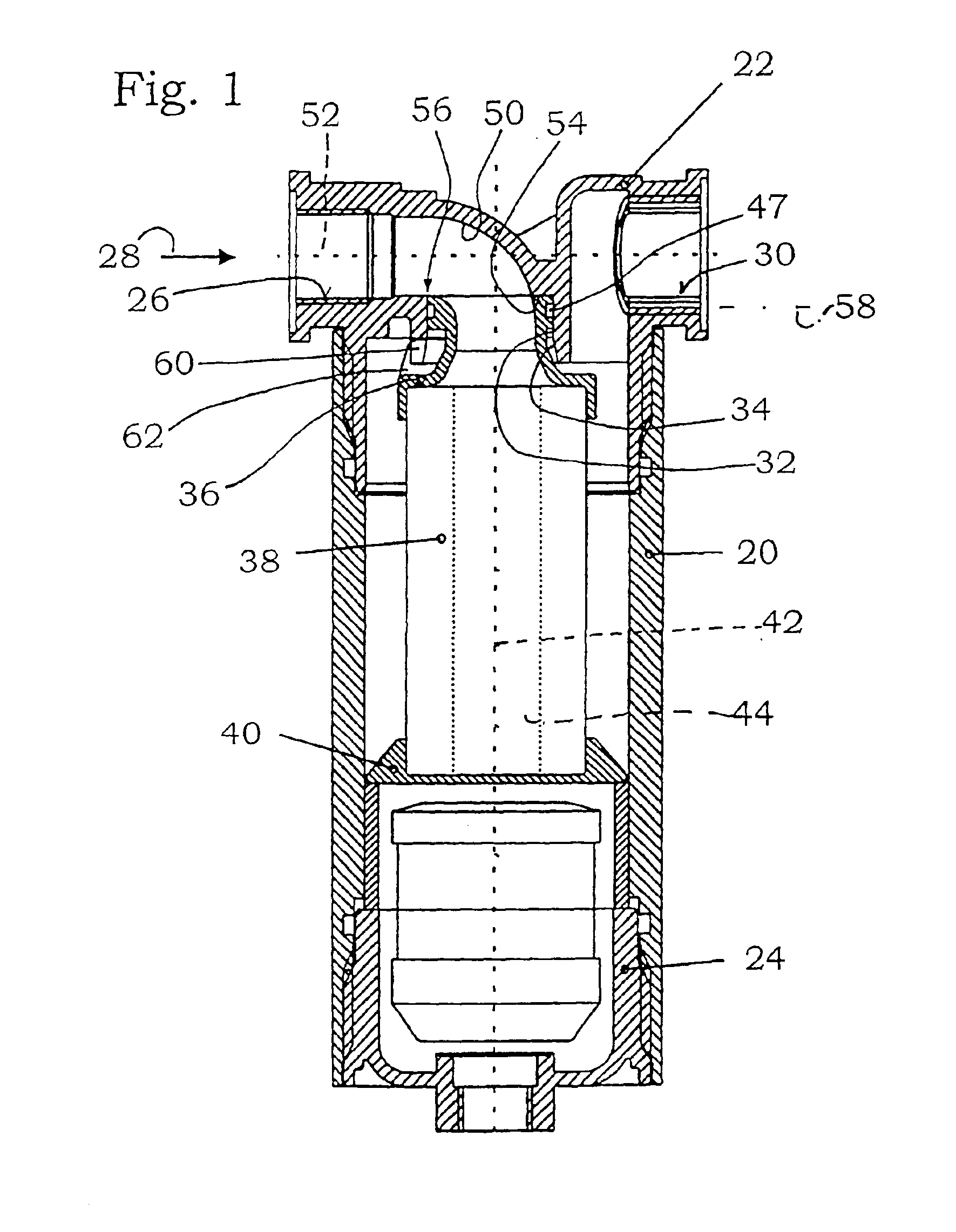

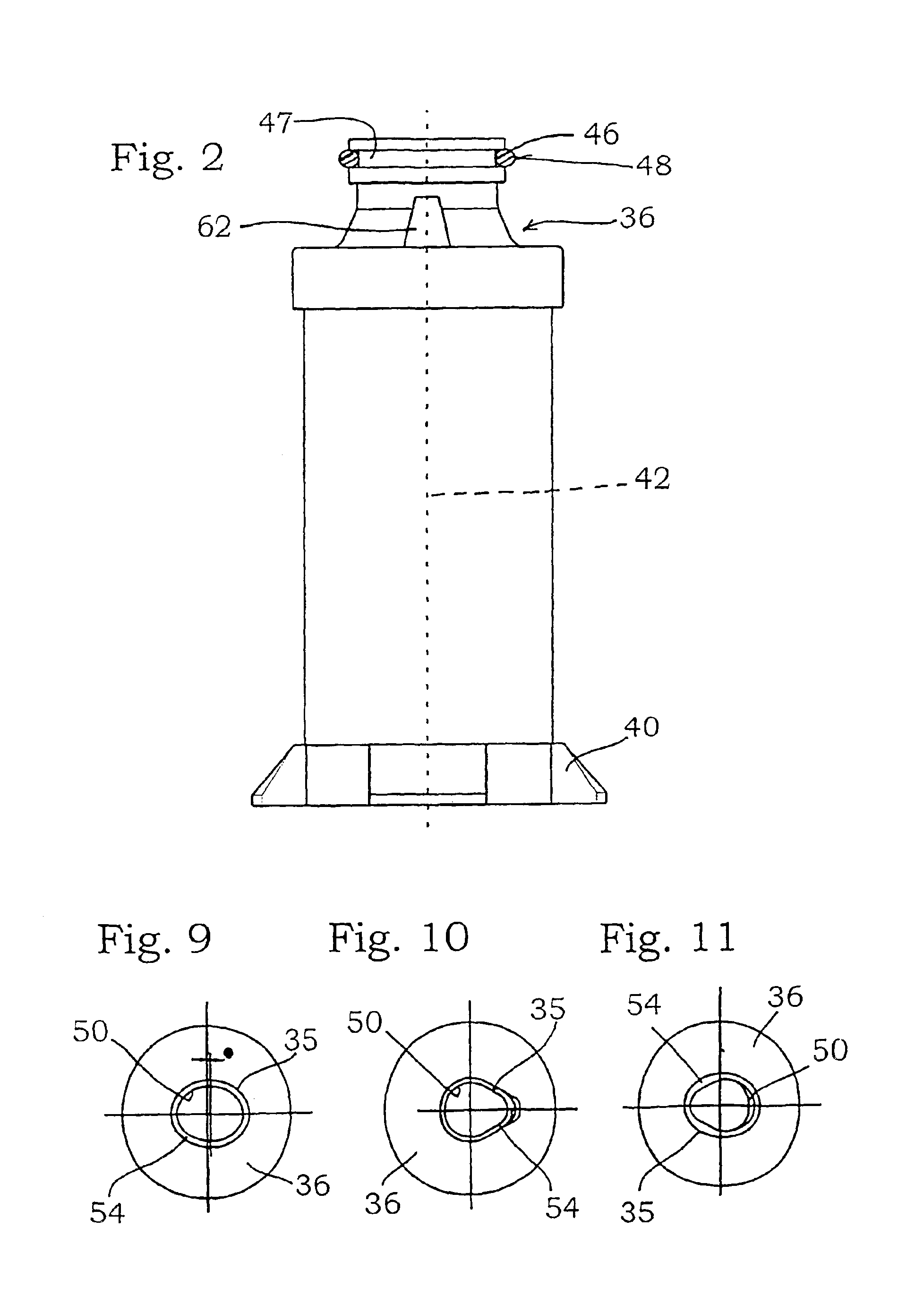

Filter for the separation of contaminants from gas stream

InactiveUS6936084B2Easy to manufactureEasy to useCombination devicesDispersed particle filtrationEngineeringCentral element

A filter for separating contaminants from a gas stream, including (a) a housing having a housing body and a housing head, the housing head having an inlet for the gas stream to be purified, an outlet and a first sealing surface, and (b) a filter element accommodated in the housing, having an element head and an element body having a central element axis and an element interior. The element head has a second sealing surface which cooperates with the first sealing surface. A curved inlet manifold is formed between the inlet and the element interior. The inlet manifold is embodied partly in the housing head and partly in the element head such that the first and second sealing surfaces contact in a sealing plane at a 90° to 60° angle to the element axis. A radially arranged seal is provided on the sealing plane, forming one of the sealing surfaces.

Owner:BEKO TECHNOLOGIES GMBH

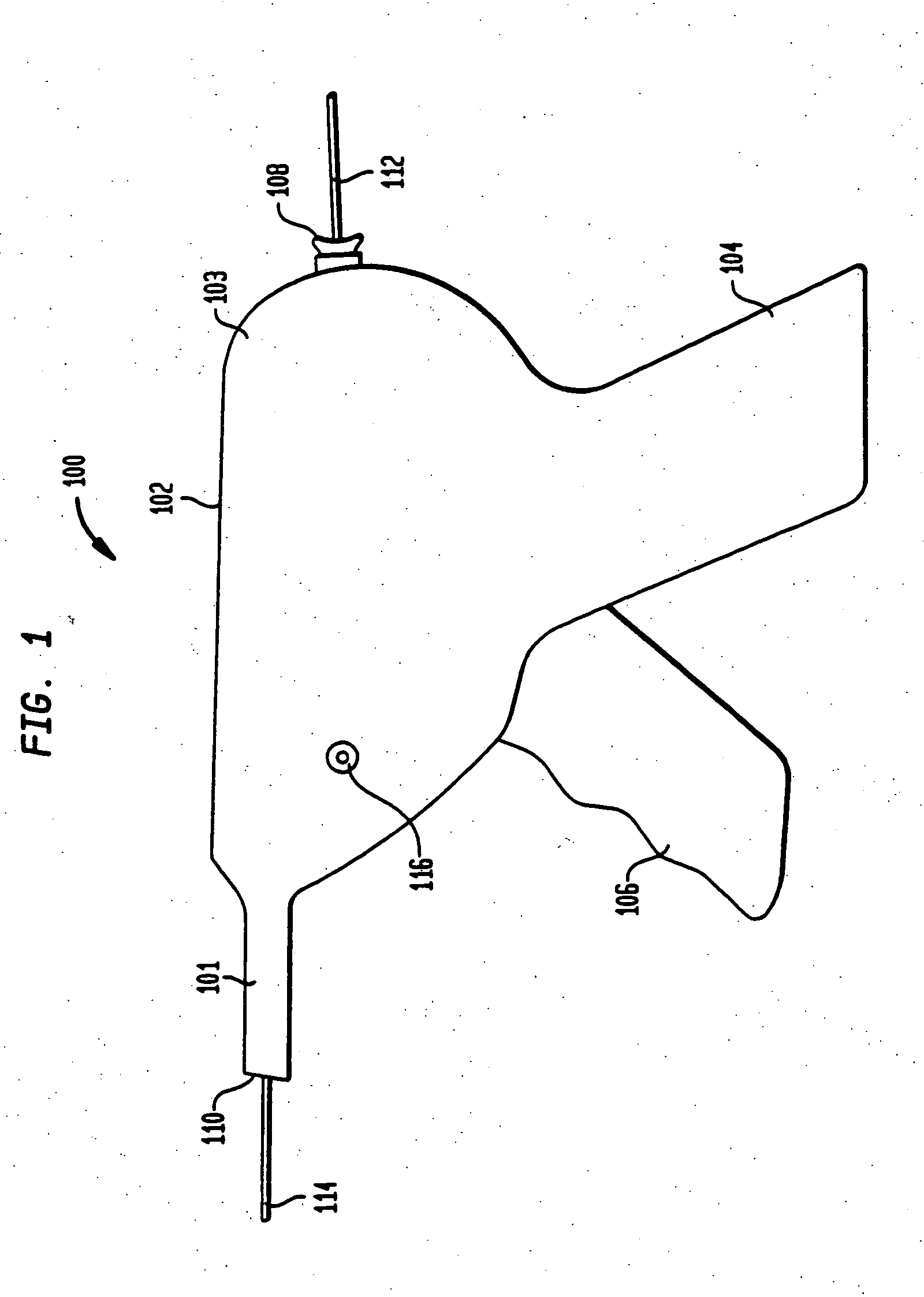

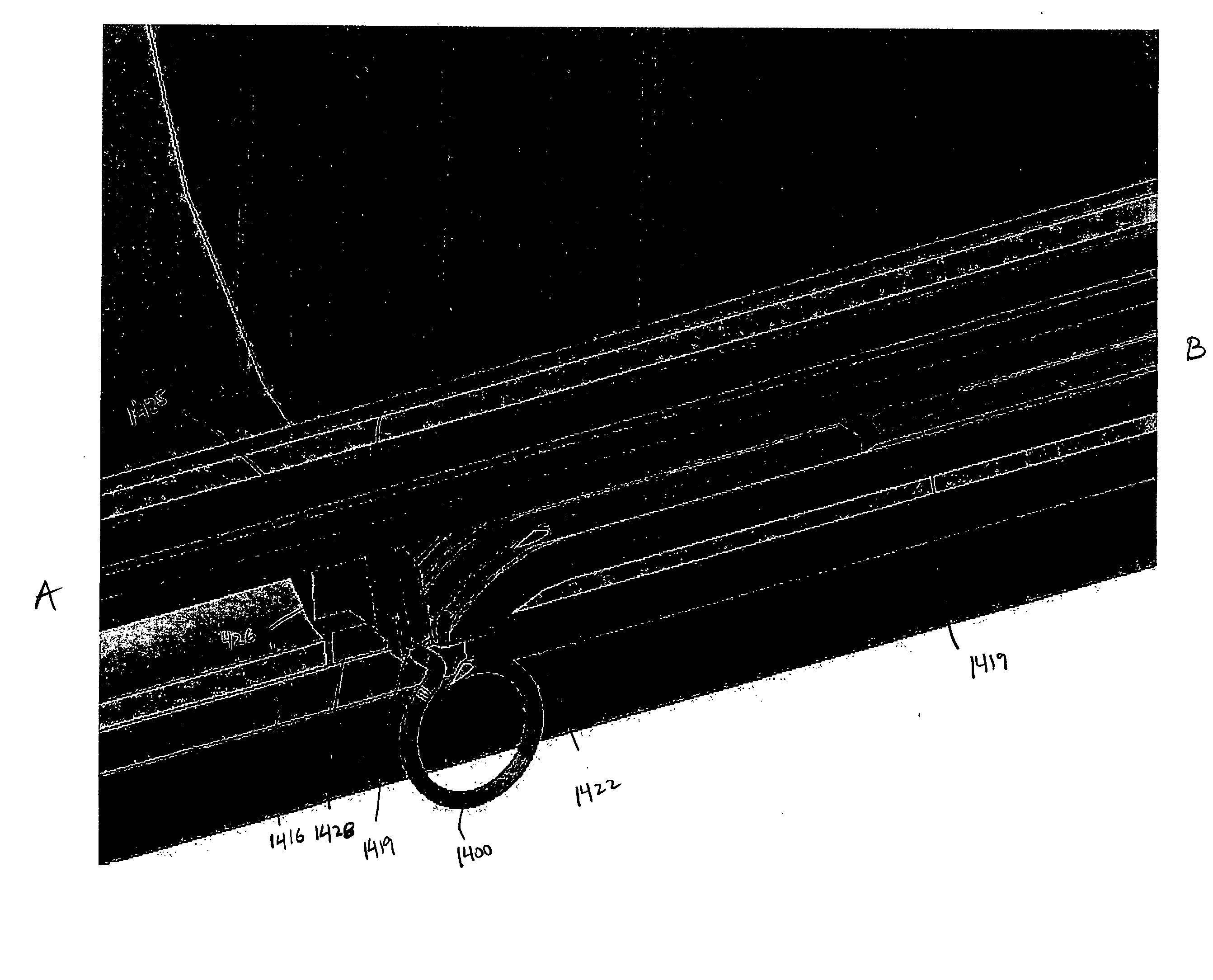

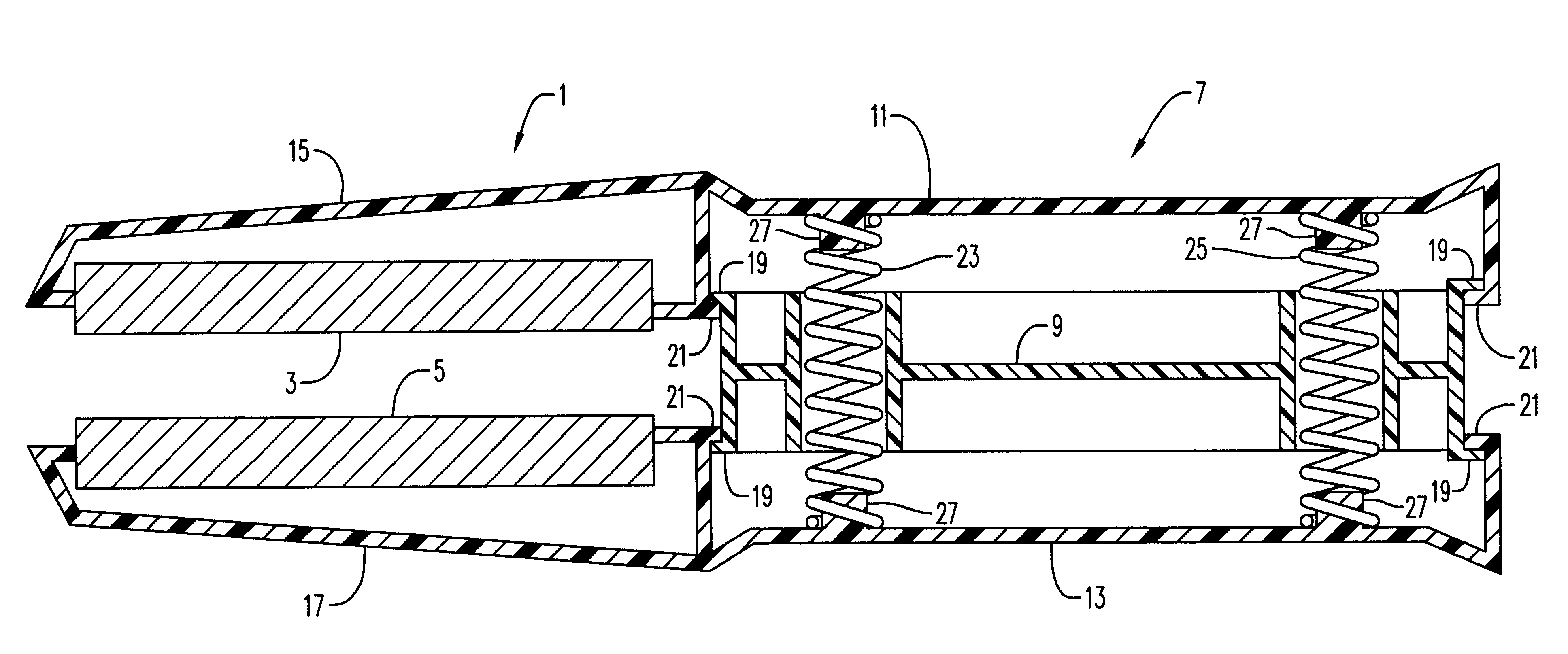

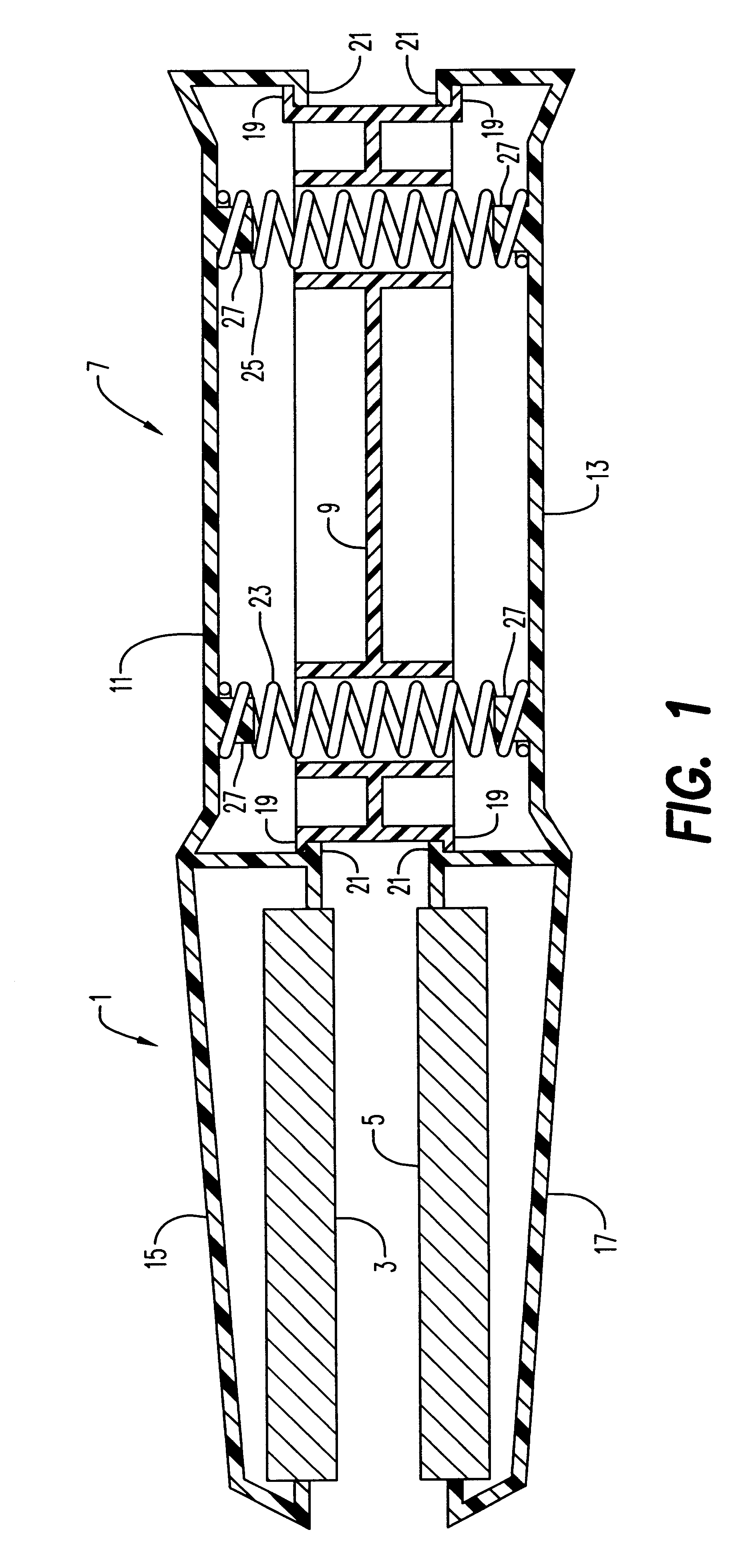

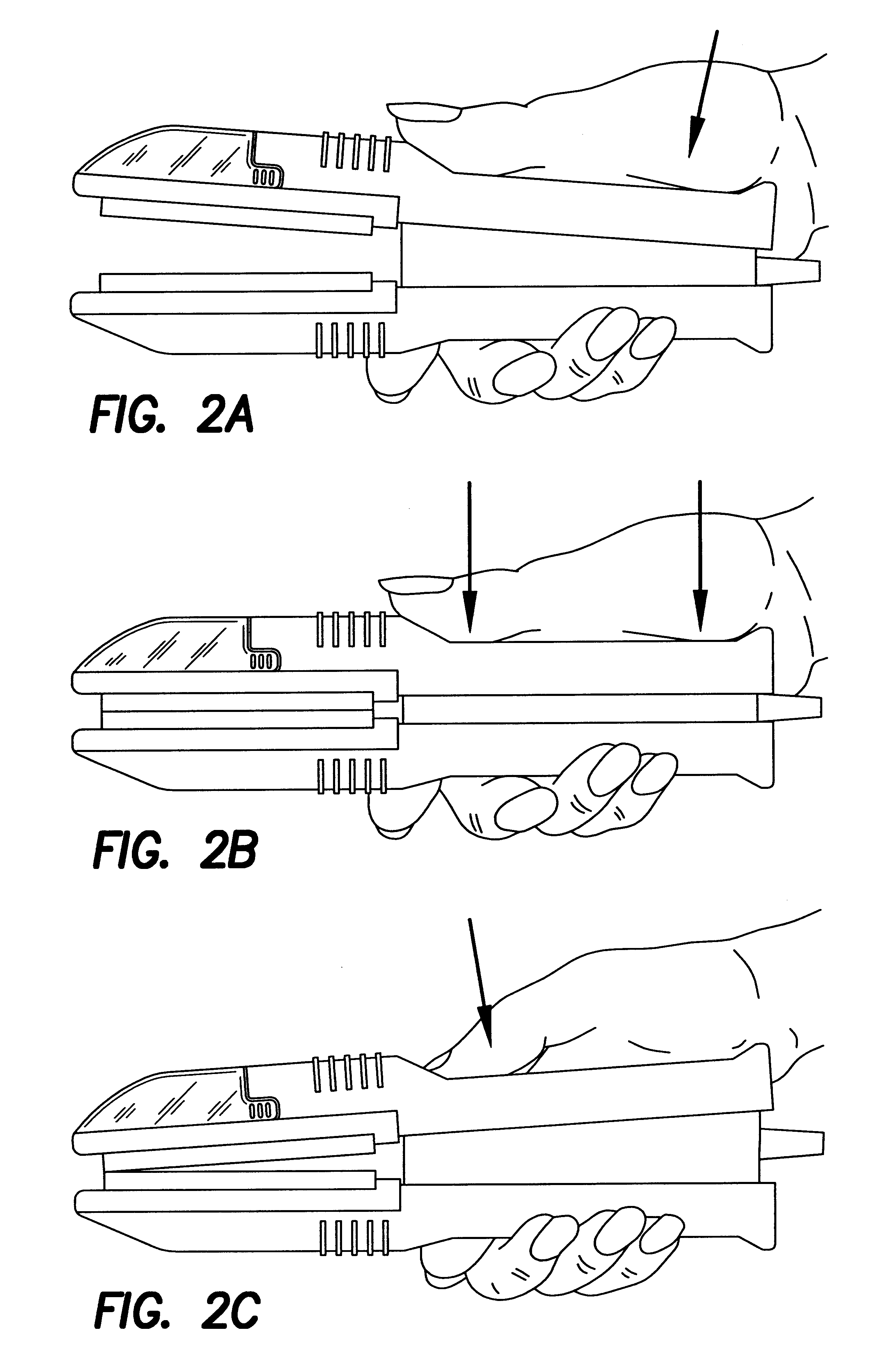

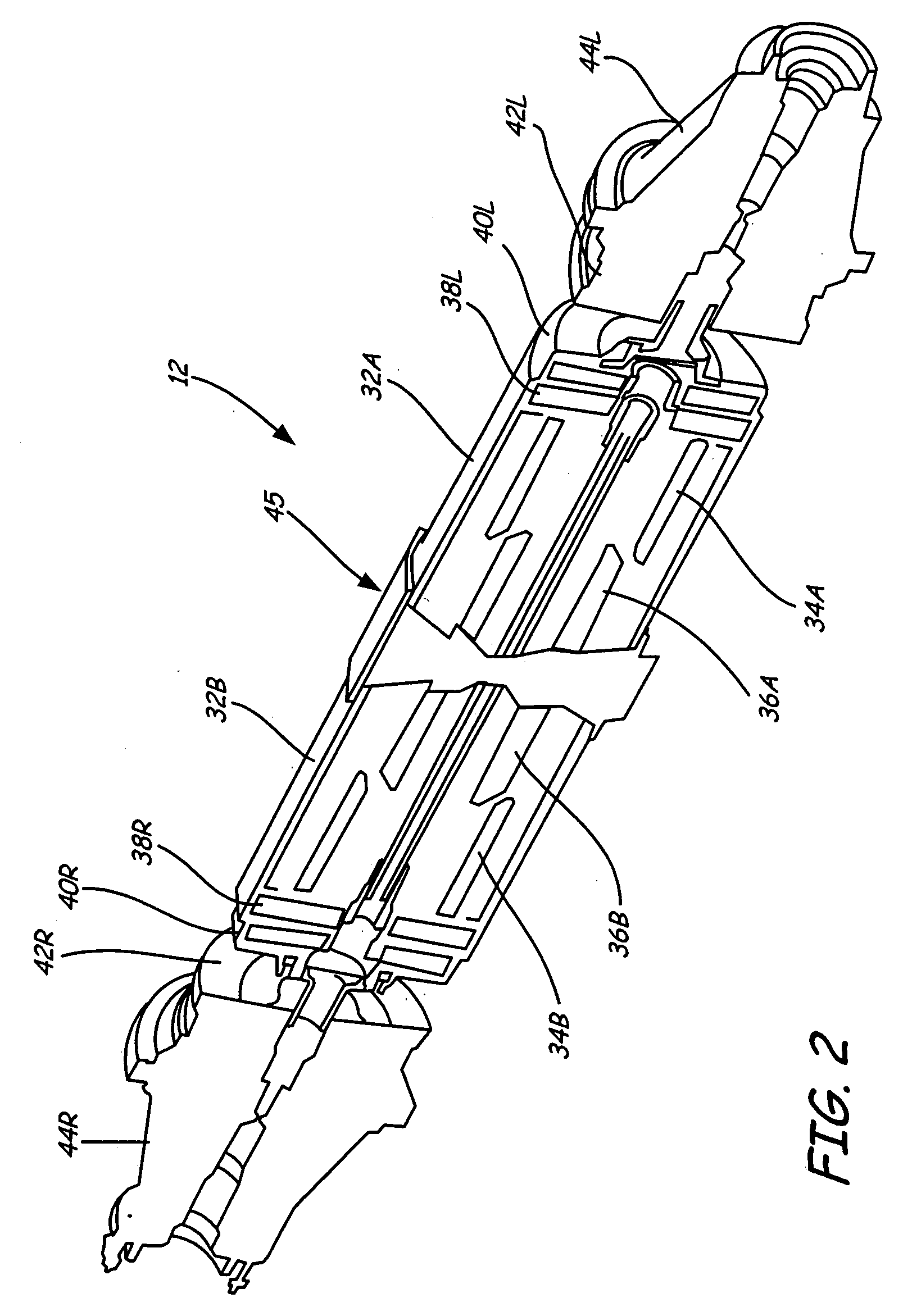

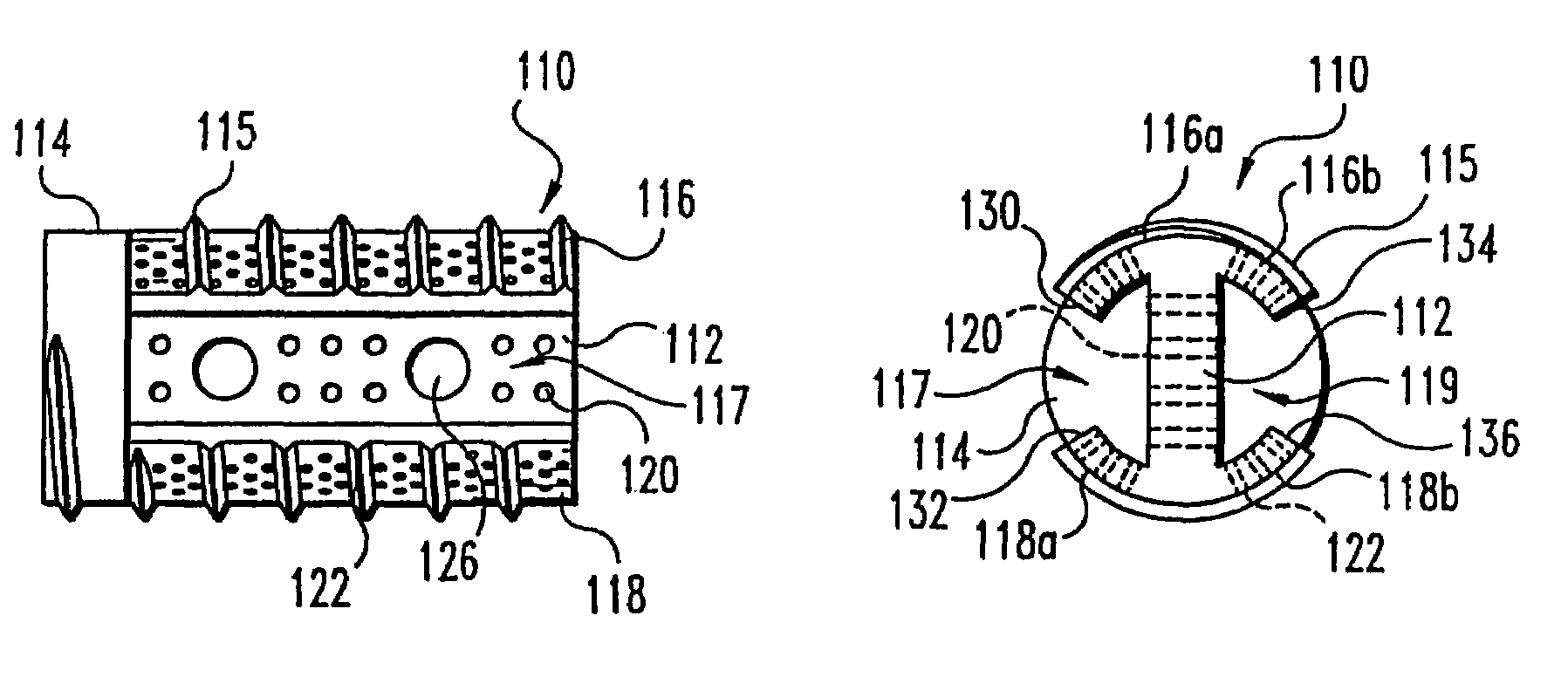

Endovascular stapler

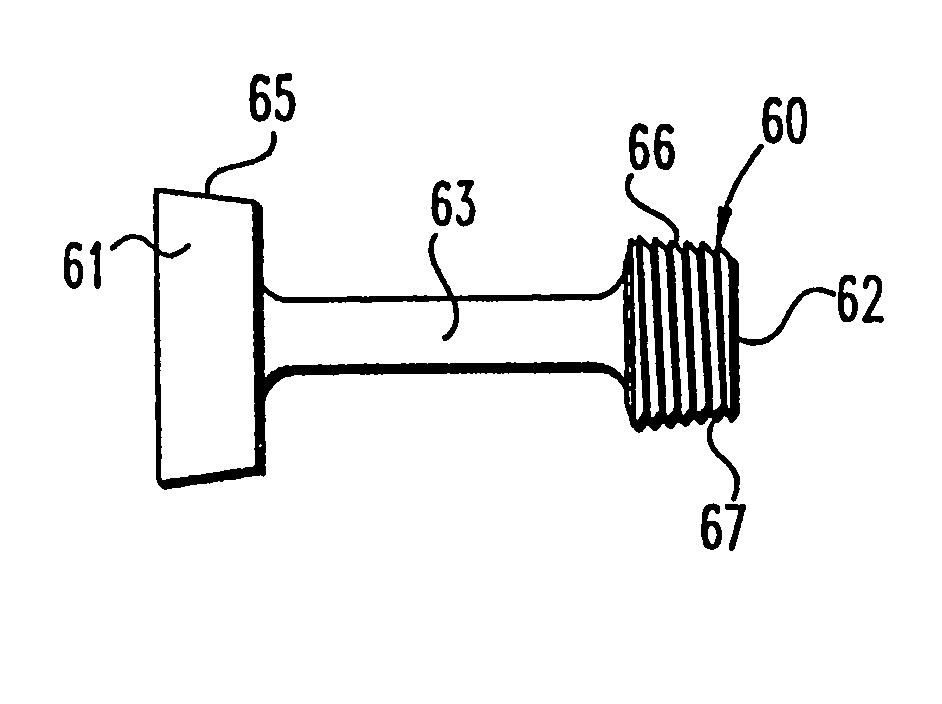

An endovascular stapler for securing an endograft to a vessel is disclosed. The stapler includes a staple housing adapted for storing at least one staple therein, the staple housing having an exit area for discharge of the at least one staple therethrough, an actuating assembly adapted for discharging the at least one staple through the exit area, and a displacement mechanism in operative association with the staple housing near the exit area. The displacement member is operative for pushing the exit area against the endograft when discharging the at least one staple therethrough. The discharged staple forms a plurality of opposed loops connected by a central element upon discharge. Also disclosed are staples and displacement mechanisms adapted for use with surgical instruments such as the present endovascular staplers. The staples may be formed from memory metal or other metal. The displacement mechanisms disclosed include balloons and rigid offsetting devices.

Owner:EDRICH HEALTH TECH

Endovascular stapler

An endovascular stapler for securing an endograft to a vessel is disclosed. The stapler includes a staple housing adapted for storing at least one staple therein, the staple housing having an exit area for discharge of the at least one staple therethrough, an actuating assembly adapted for discharging the at least one staple through the exit area, and a displacement mechanism in operative association with the staple housing near the exit area. The displacement member is operative for pushing the exit area against the endograft when discharging the at least one staple therethrough. The discharged staple forms a plurality of opposed loops connected by a central element upon discharge. Also disclosed are staples and displacement mechanisms adapted for use with surgical instruments such as the present endovascular staplers. The staples may be formed from memory metal or other metal. The displacement mechanisms disclosed include balloons and rigid offsetting devices.

Owner:VESTECK INC

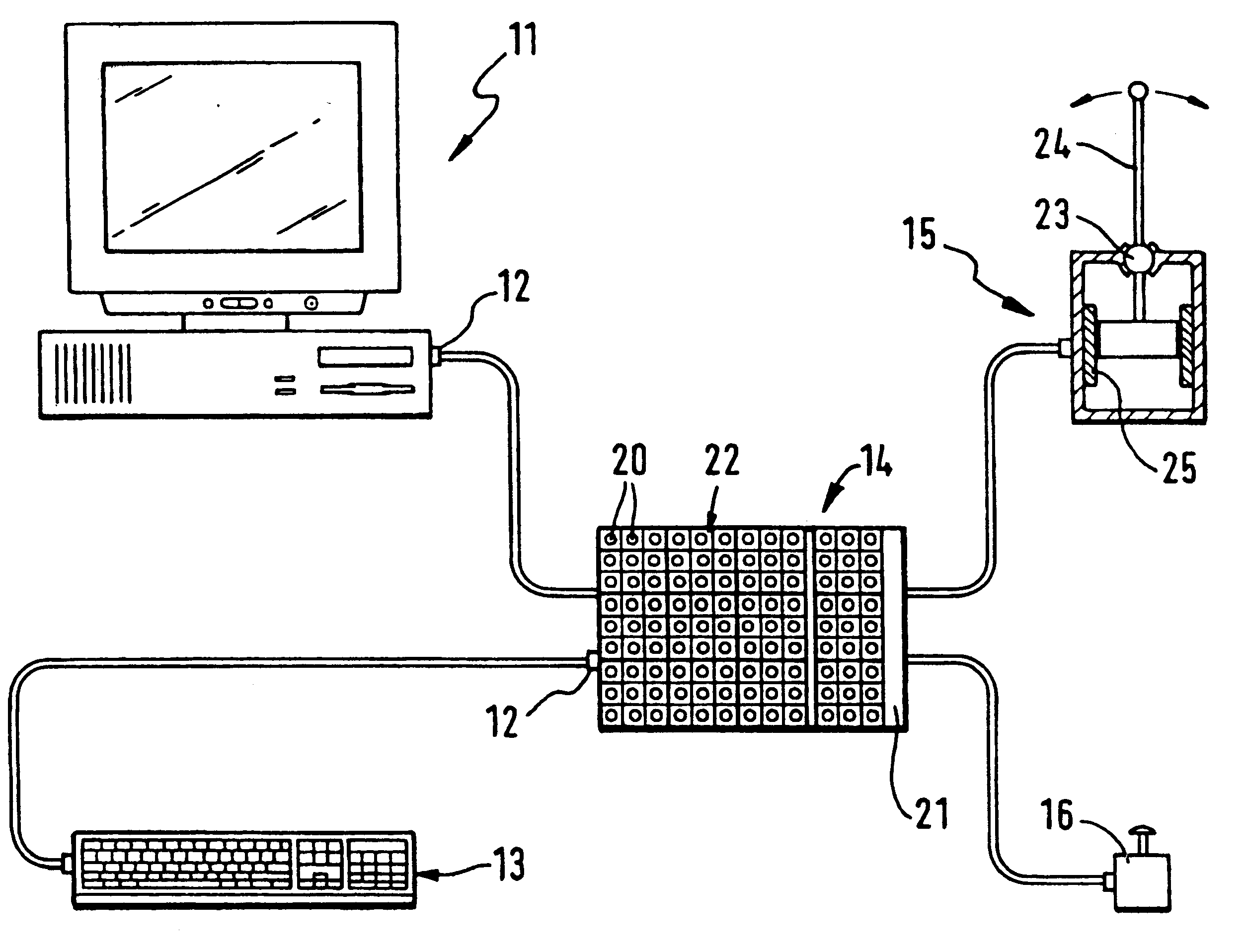

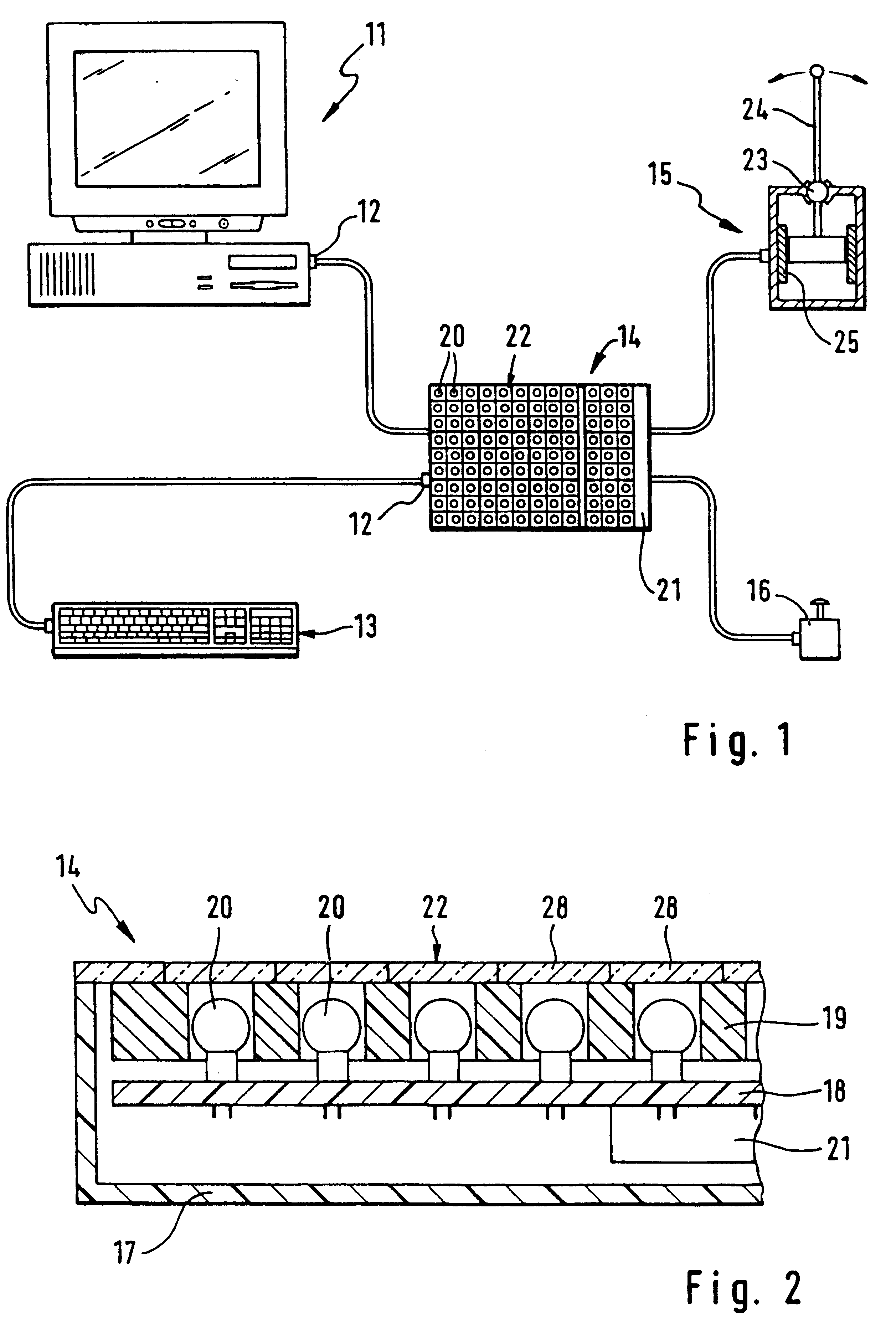

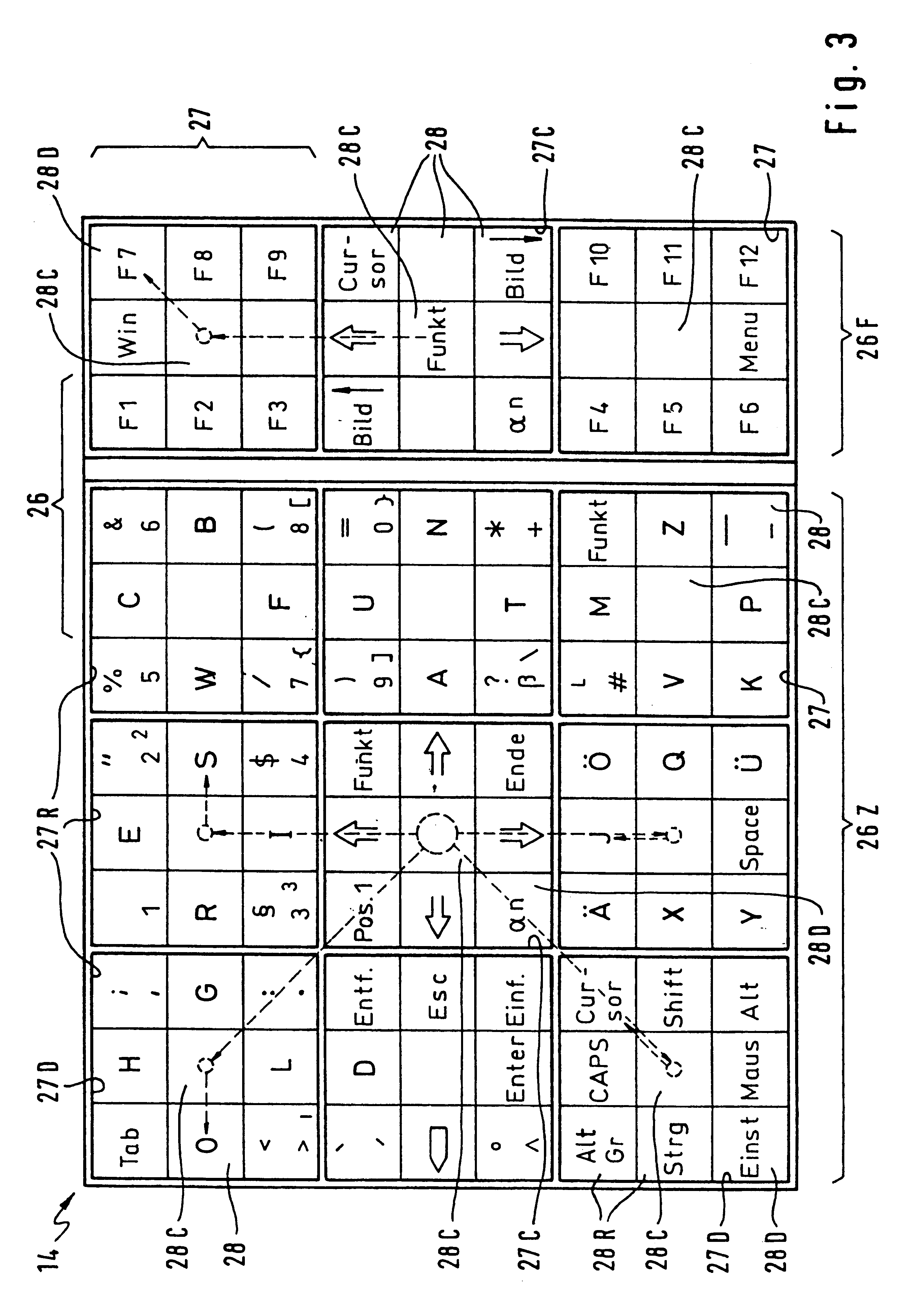

Method for transferring characters especially to a computer and an input device which functions according to this method

InactiveUS6580414B1Easy to operateAddressing slow performanceInput/output for user-computer interactionElectronic switchingJoystickPersonal computer

A personal computer for a handicapped person includes an input panel that is subdivided into a group of fields, with one of the fields designated as a central field for the group. Each field is, in turn, subdivided into nine elements (spaces) comprised of a neutral central element surrounded by eight output elements. Each of those eight output elements has an output character representing a respective output signal. A mark (cursor) is moved across the panel by a control stick that is manipulated by a user. The cursor is always initially located at the center element of the central field. In order to move the cursor to a desired output element, the user: (a) identifies the field in which the desired output character is located, (b) moves the cursor in a first direction to the central element of that identified field, and (c) moves the cursor by one space directly to the desired output element in a second direction oriented either orthogonally or diagonally to the first direction.

Owner:WERGEN GERHARD +1

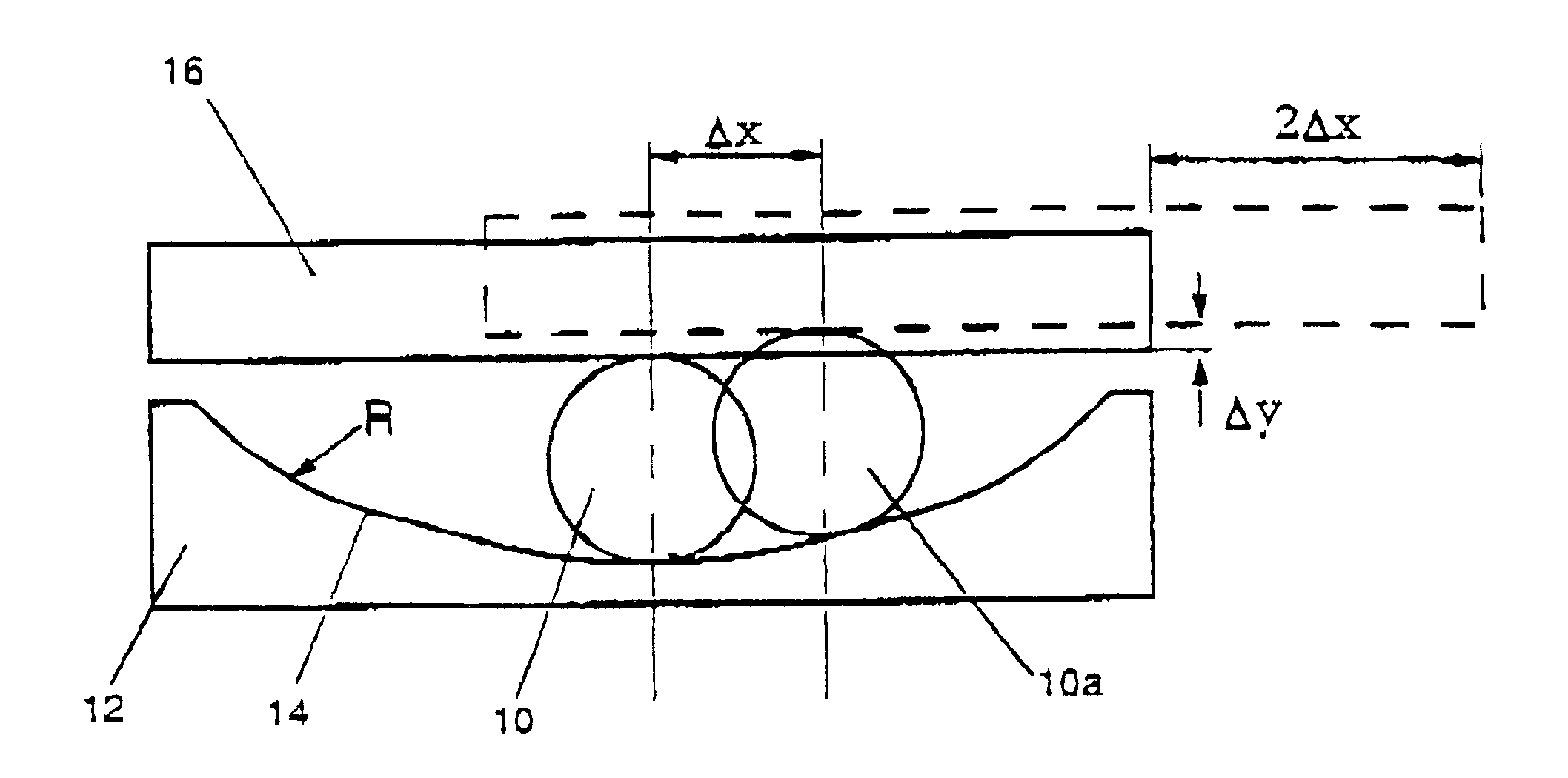

Energy absorber

InactiveUS6321492B1Increase coefficient of frictionNon-rotating vibration suppressionProtective foundationRelative motionEngineering

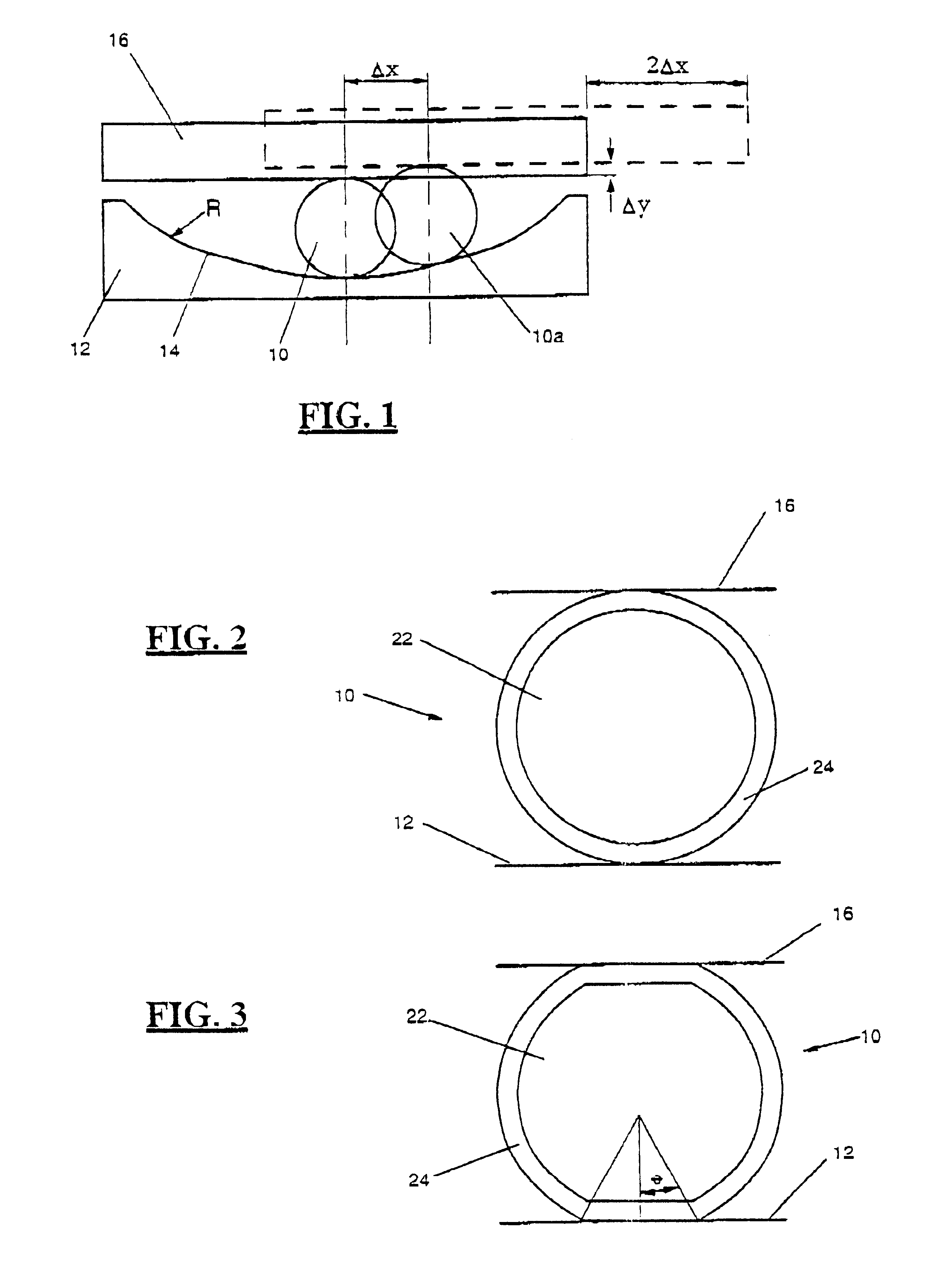

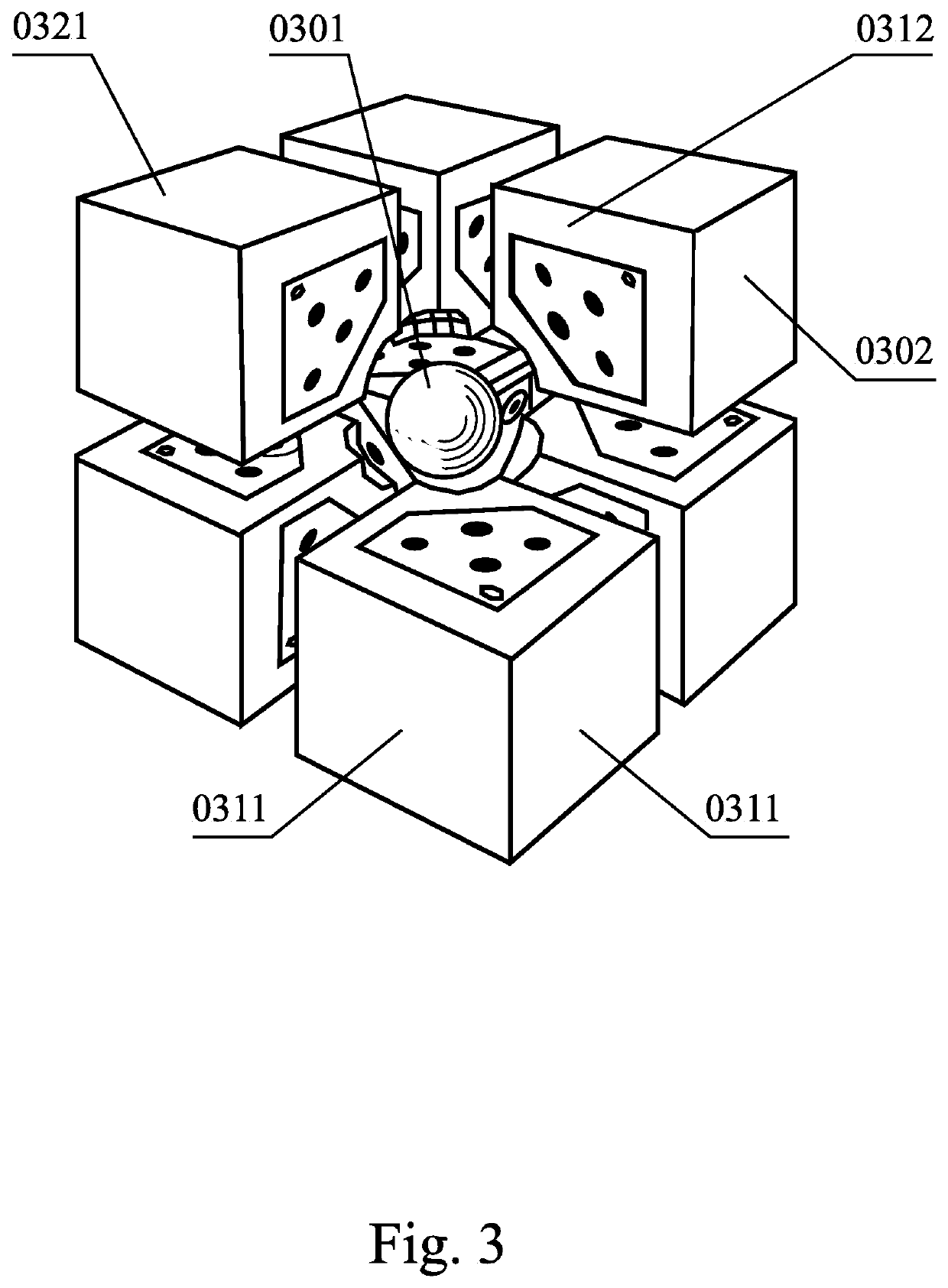

The invention described is a system for seismic isolation or vibration of structures which is simple, relatively inexpensive and readily used for smaller structures. It involves use of bearings comprising a ball (10) and ball seats (12, 18) interposed between the structure and its foundation. Either the ball itself (24) or the seat surface (15) on which it rolls is compressible, the resistance to that compression providing a frictional braking force resisting rolling of the ball. This serves to dampen relative movement between the structure and its foundation. There are described several alternative constructions of the friction ball which is the preferred central element in the bearing device. There may be a plurality of balls (44, 47) in each combination of balls and seats.

Owner:ROBINSON SEISMIC

Hair styling tongs with biased handles

Hairdressing tongs have a pair of arms extending from handles. Each arm has a heating pad affixed thereto. The handles have opposed openings. A central element is positioned between the handles and fitted within the openings such that the central element is slidable toward the handles. The central element has guide openings. Springs are positioned in the guide openings for biasing apart the handles. The springs enable hand pressure to move the handles and arms together from a completely open position to a completely closed position and, in absence of the hand pressure, to maintain the handles and arms in relatively parallel configuration, biased against stops of the central element.

Owner:CONAIR CORP

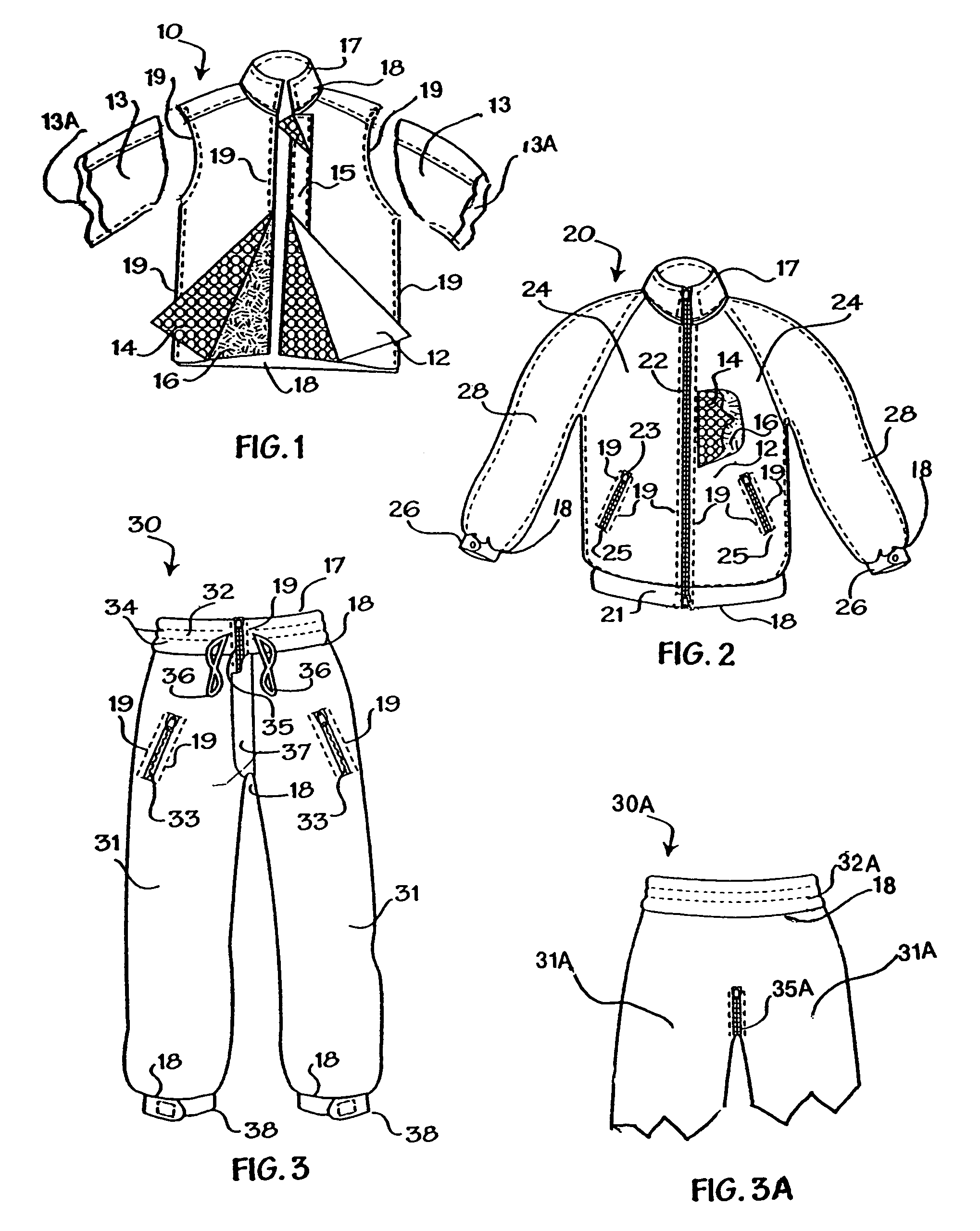

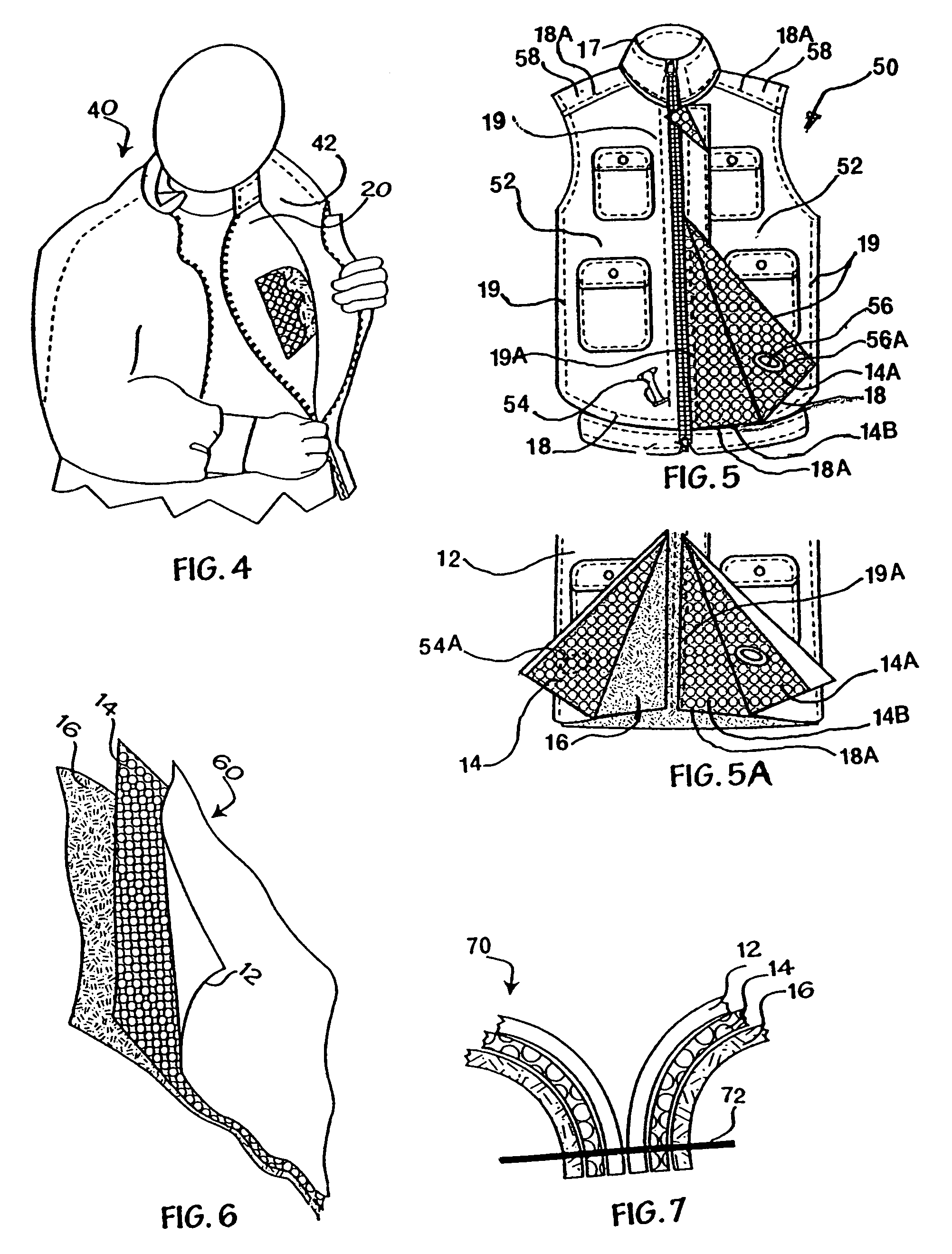

Liner and garment ensemble for thermal wear and anti-exposure suits

ActiveUS7013489B1Performance requirementSatisfies needLife-buoysBody suitsEngineeringCentral element

A multi-layer liner light weight garment ensemble that offers low bulk, water impermeability, wind resistance, thermal protection, and buoyancy. The core element and essential component of the invention is the light weight sealed air polymer cellular thermal layer, interposed between the inner and outer layers. This central element can be water impermeable and offers both thermal protection and buoyancy effects. The garment ensemble can be used as a light weight thermal winter garment as well as survival apparel for those who work and play in and around water.

Owner:MCGRATH DIVERSE PRODS

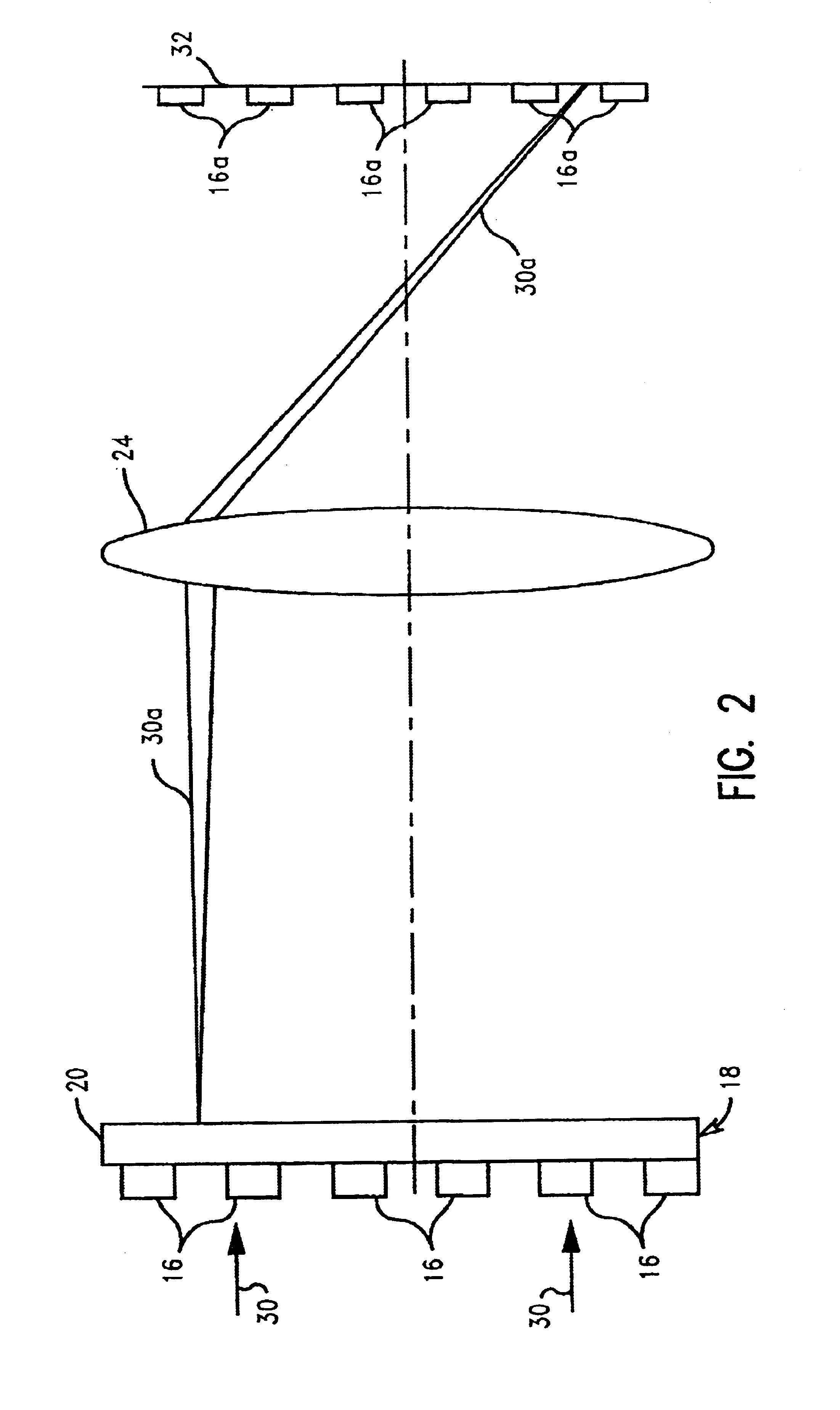

Cellular reflectarray antenna and method of making same

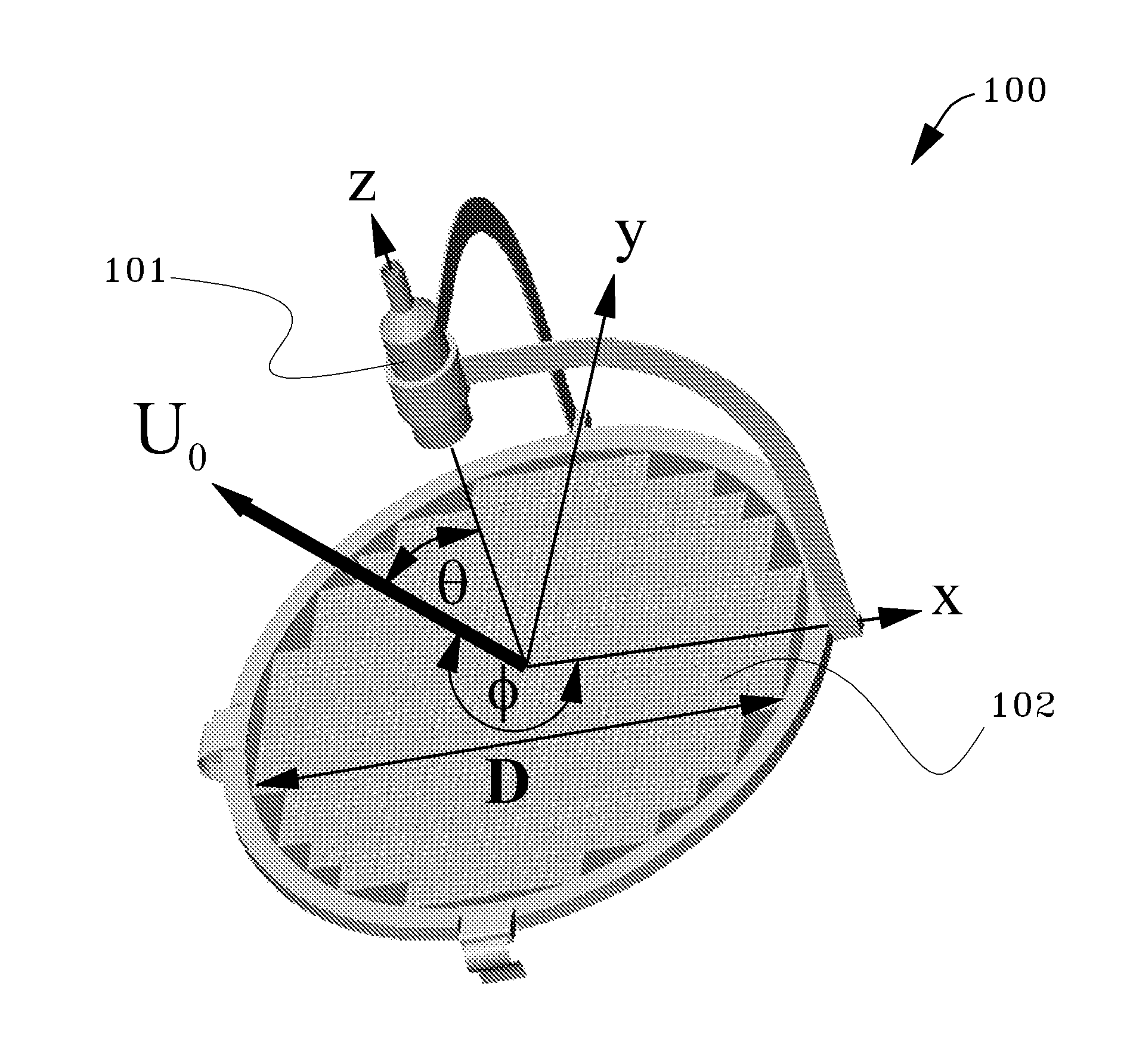

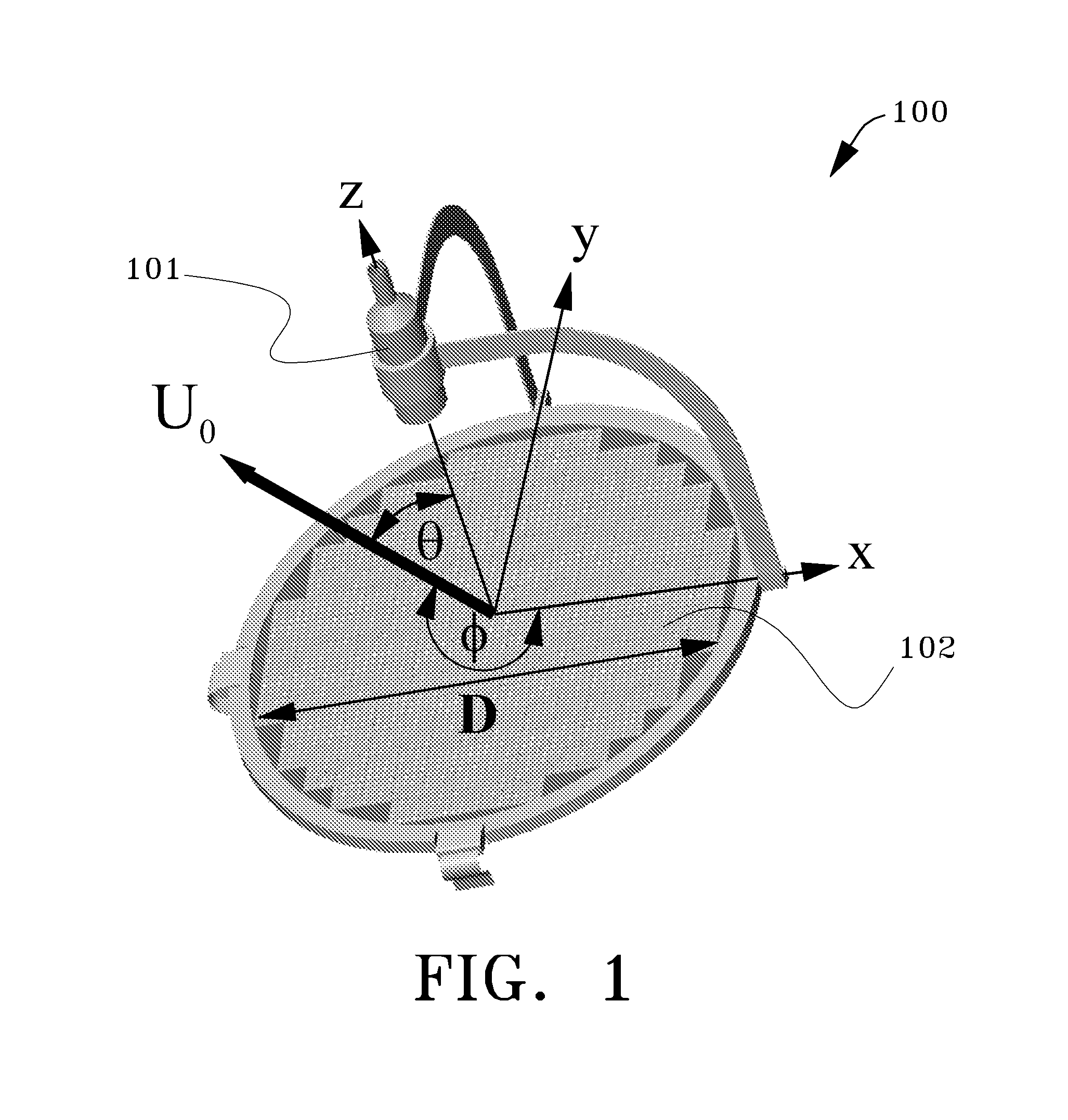

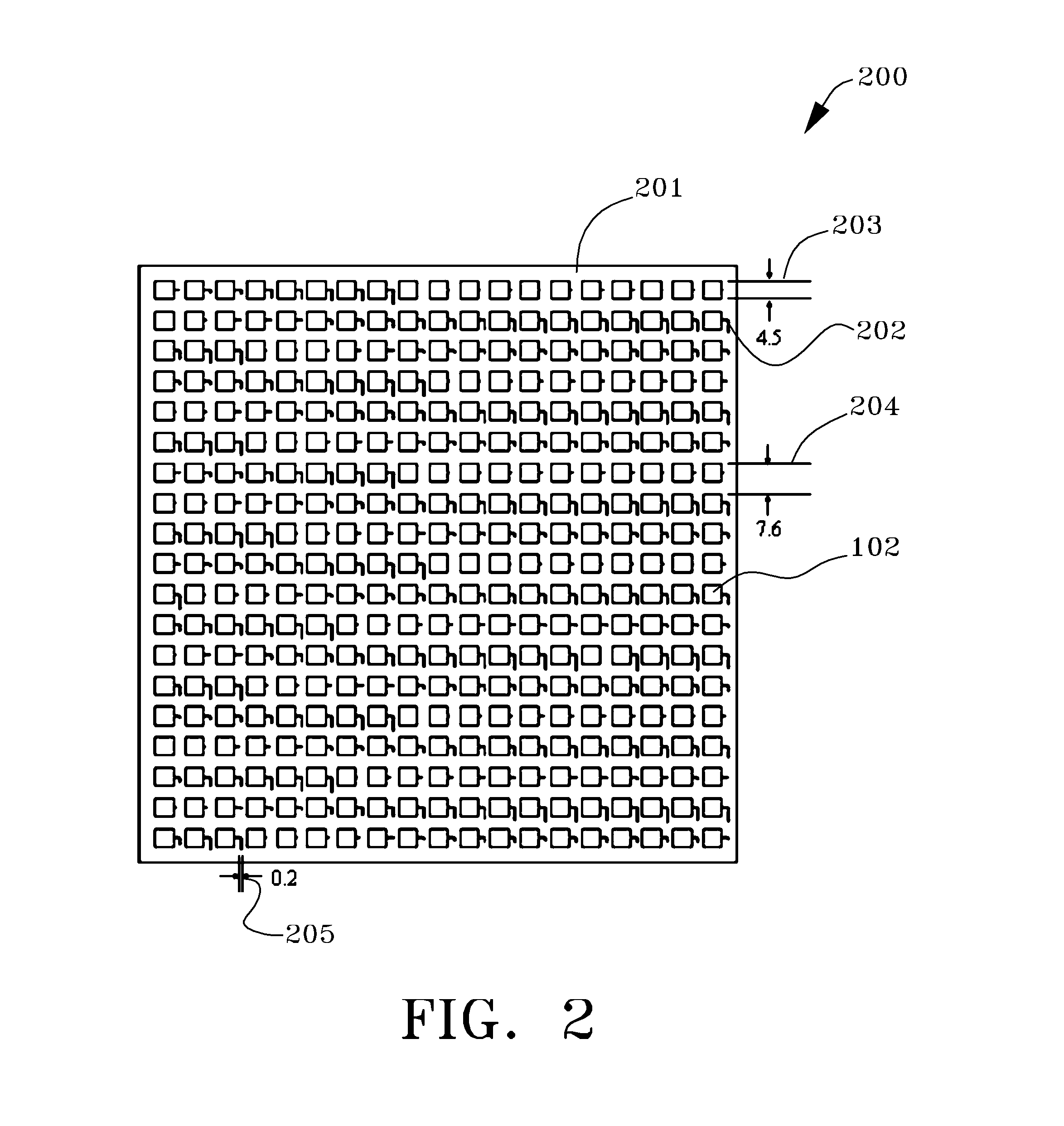

InactiveUS7791552B1Quick installationSimultaneous aerial operationsRadiating elements structural formsLongitudeLength wave

A method of manufacturing a cellular reflectarray antenna arranged in an m by n matrix of radiating elements for communication with a satellite includes steps of determining a delay φm,n for each of said m by n matrix of elements of said cellular reflectarray antenna using sub-steps of: determining the longitude and latitude of operation, determining elevation and azimuth angles of the reflectarray with respect to the satellite and converting theta0 (θ0) and phi0 (φ0), determining Δβm,n, the pointing vector correction, for a given inter-element spacing and wavelength, determining Δφm,n, the spherical wave front correction factor, for a given radius from the central element and / or from measured data from the feed horn; and, determining a delay φm,n for each of said m by n matrix of elements as a function of Δβm,n and Δφm,n..

Owner:NASA

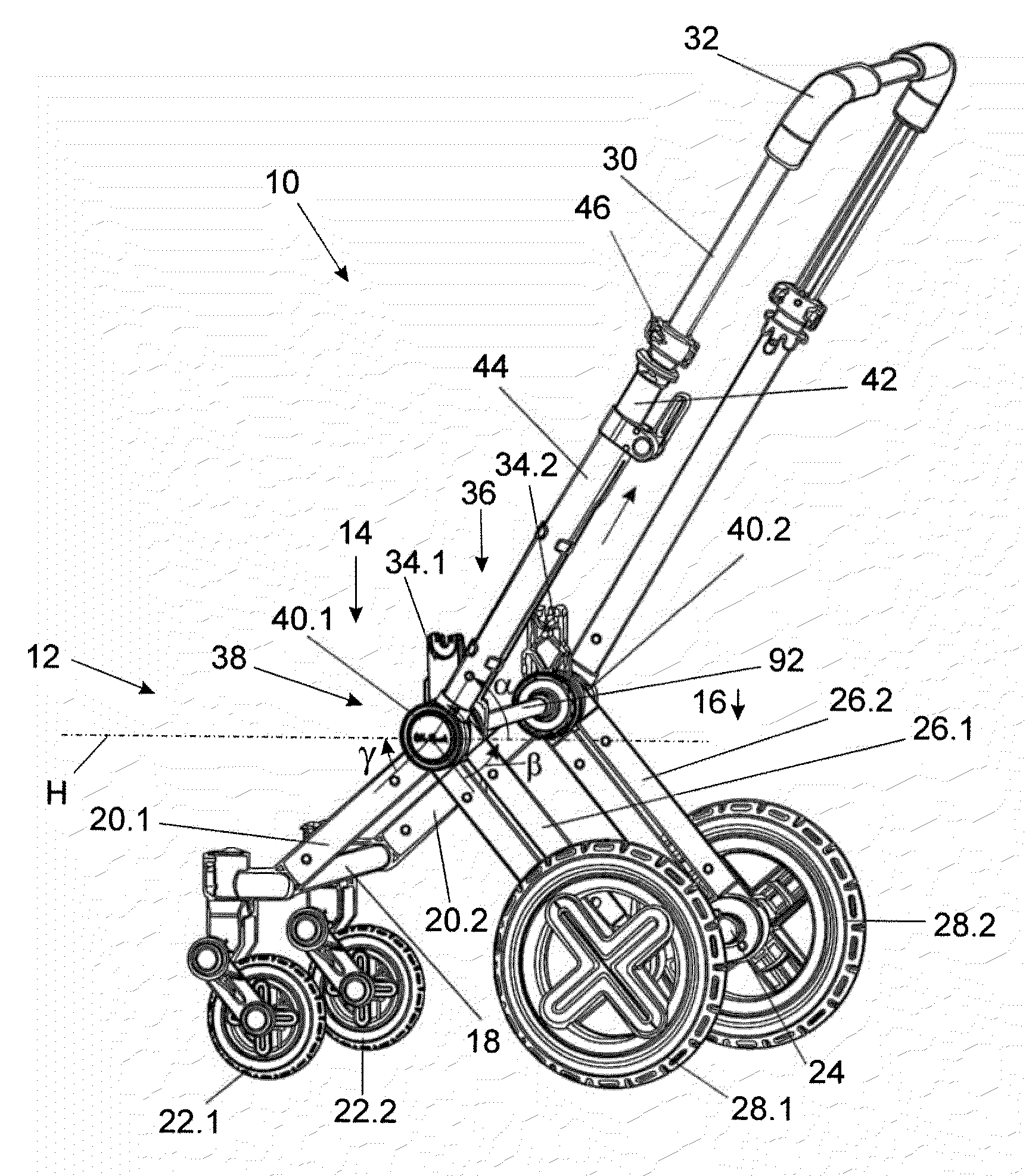

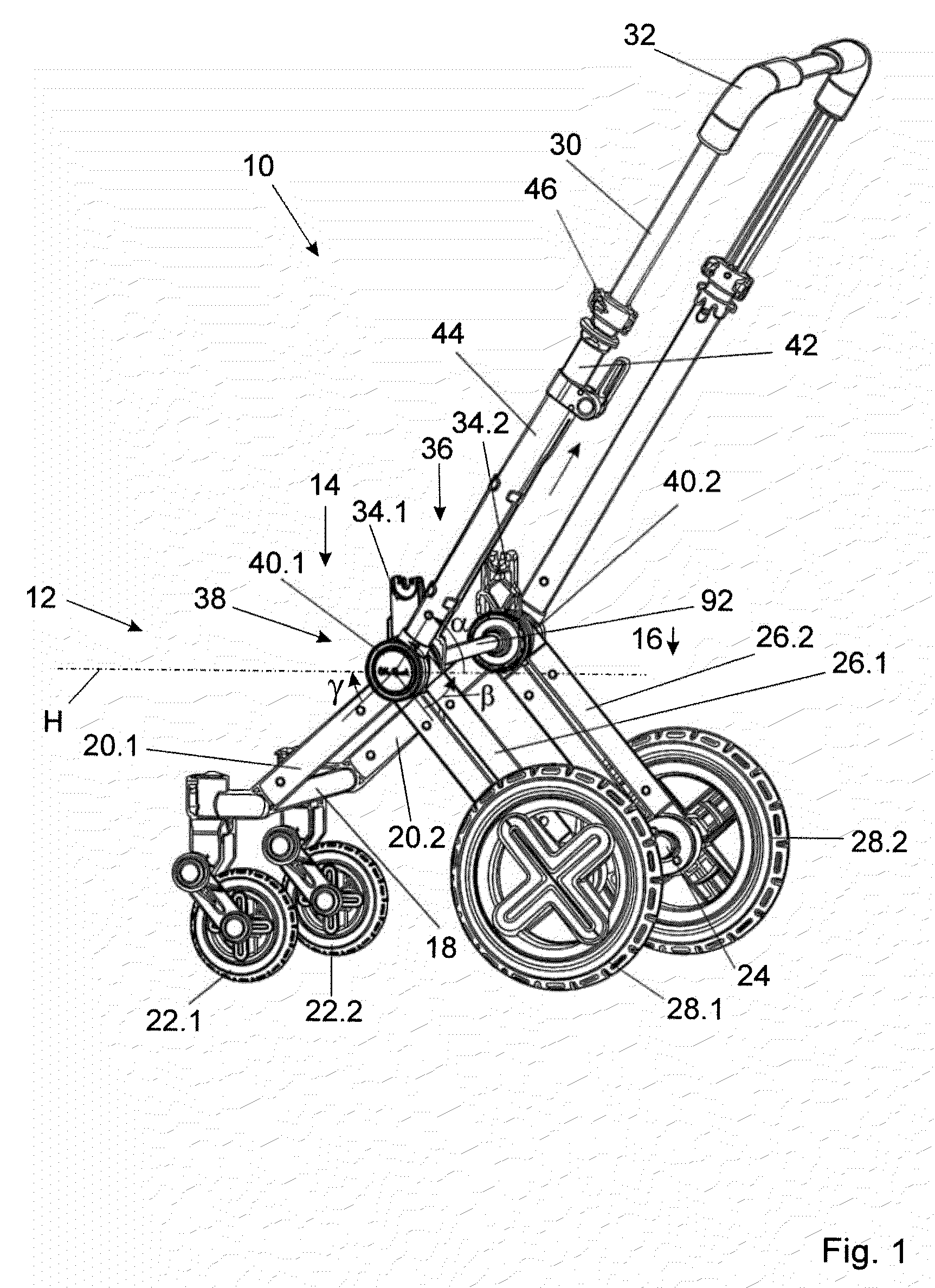

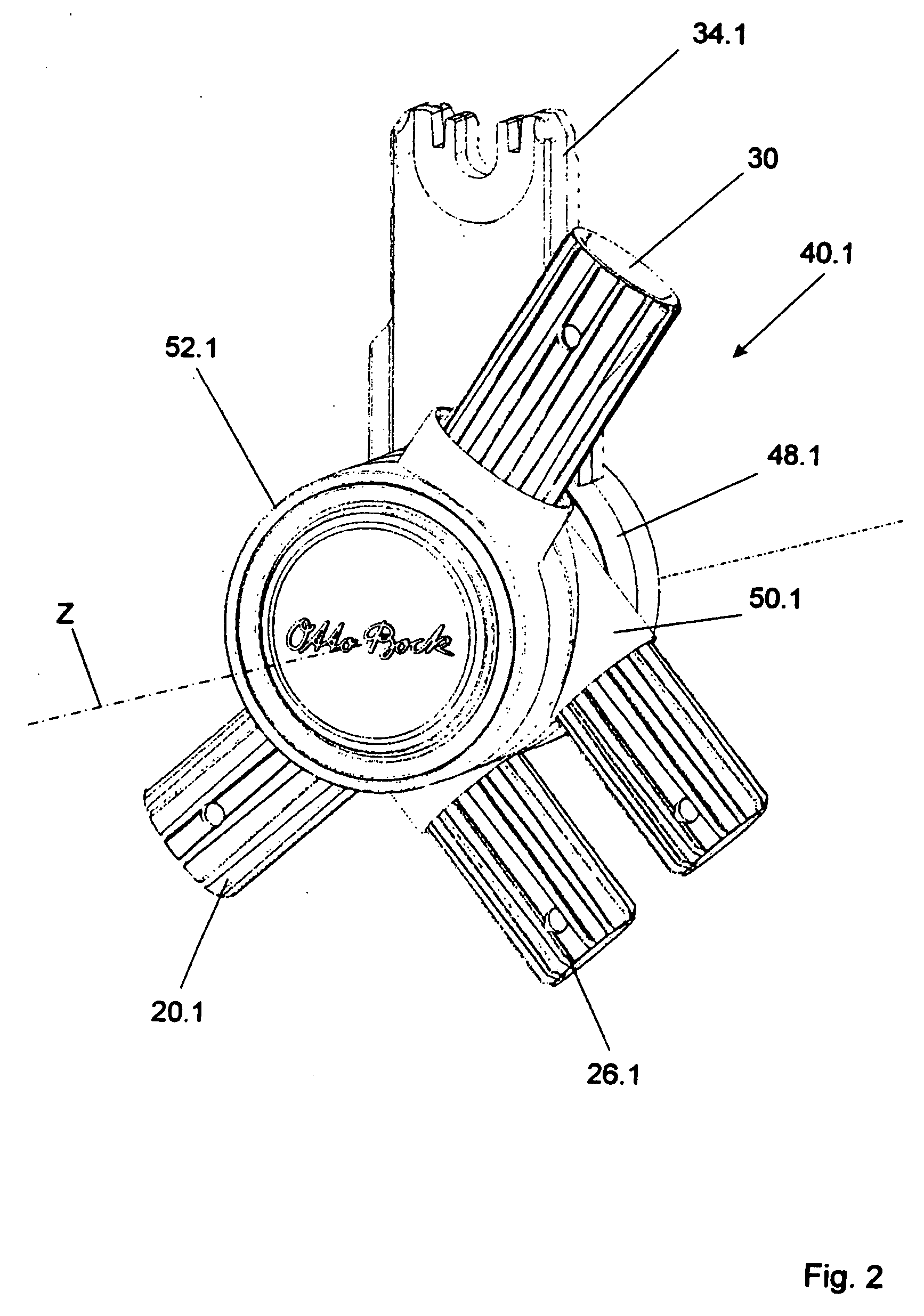

Jogger

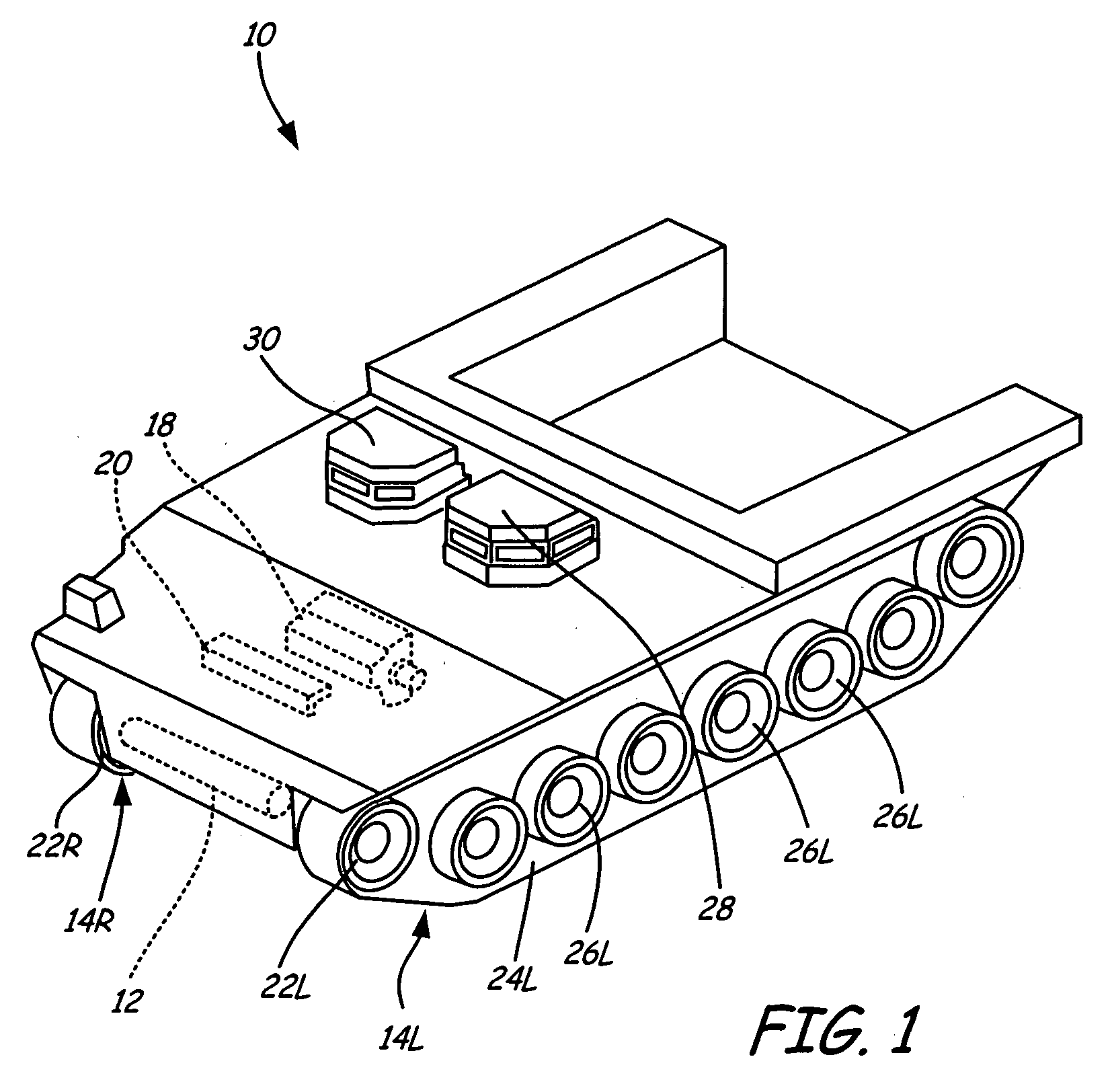

InactiveUS20090121455A1Easy to manufactureCarriage/perambulator accessoriesSledgesEngineeringCentral element

The invention relates to a jogger, in particular a child's rehabilitation jogger, with a framework (12) which comprises a front frame (14) with at least one front wheel (22) and a rear frame (16) with at least one rear wheel (28), a push rod (30) for pushing or pulling the jogger (10), a seat retainer (36) for accommodating a seat and a central element (38) which connects the front frame (14), the rear frame (16) and the push rod (30) locked and pivotably to one another, an actuating element (42) for releasing the central element (38) and a slider sleeve (56) which has a lock position, in which the front frame (14) is connected torque-proof to the rear frame (16) and a folding position, in which the front frame (14) can be pivoted relative to the rear frame (16). According to the invention it is provided for the central element (38) to have at least one slide element (82, 83) and the slider sleeve (56) to have a guide track (88) designed to slide away on the slide element (82, 83) such that rotating the slide elements (82) relative to the slider sleeve (56) about a central shaft (92) causes an axial shift of the slider sleeve (56) from the lock position to the folding position.

Owner:OTTO BOCK HEALTHCARE IP GMBH & CO KG

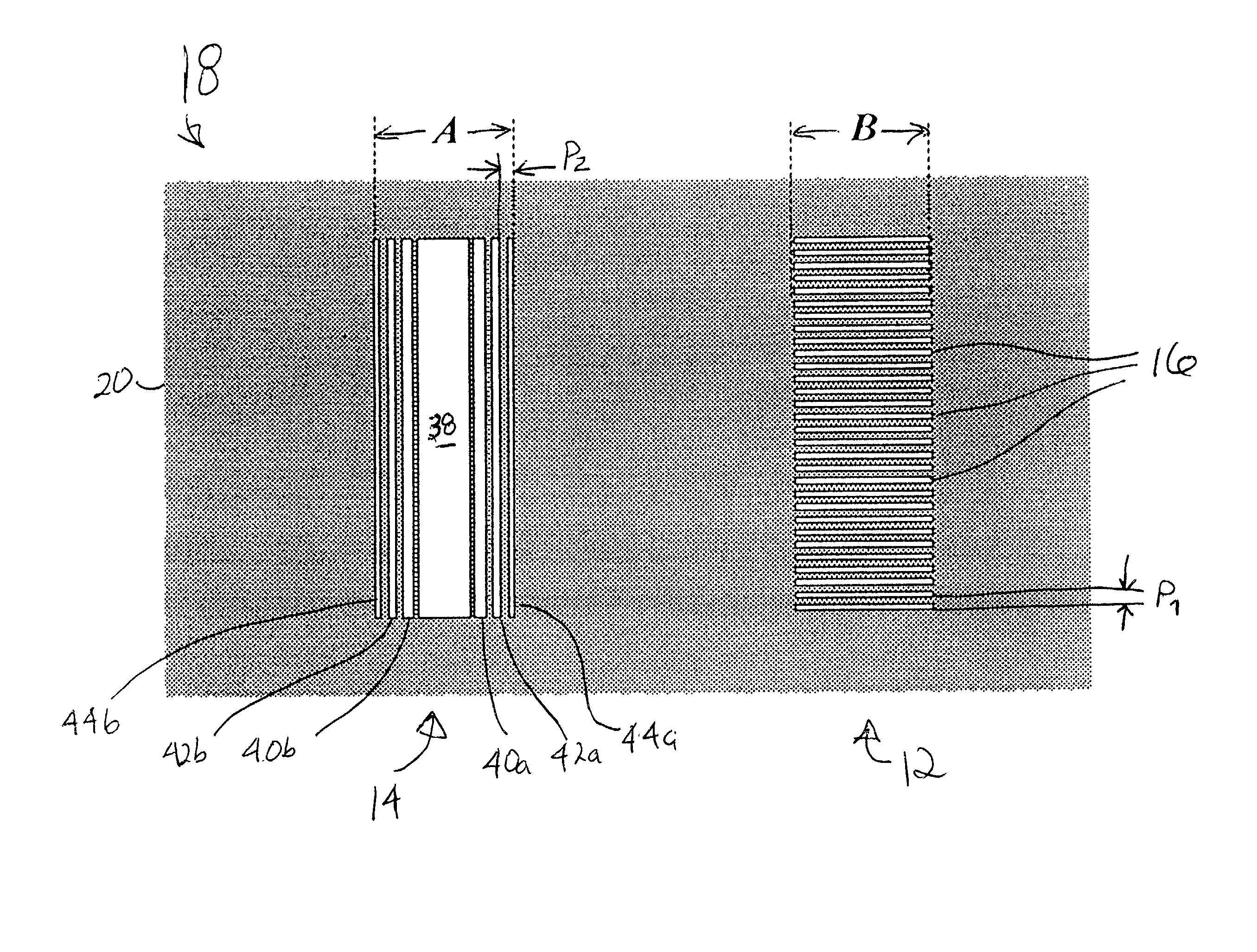

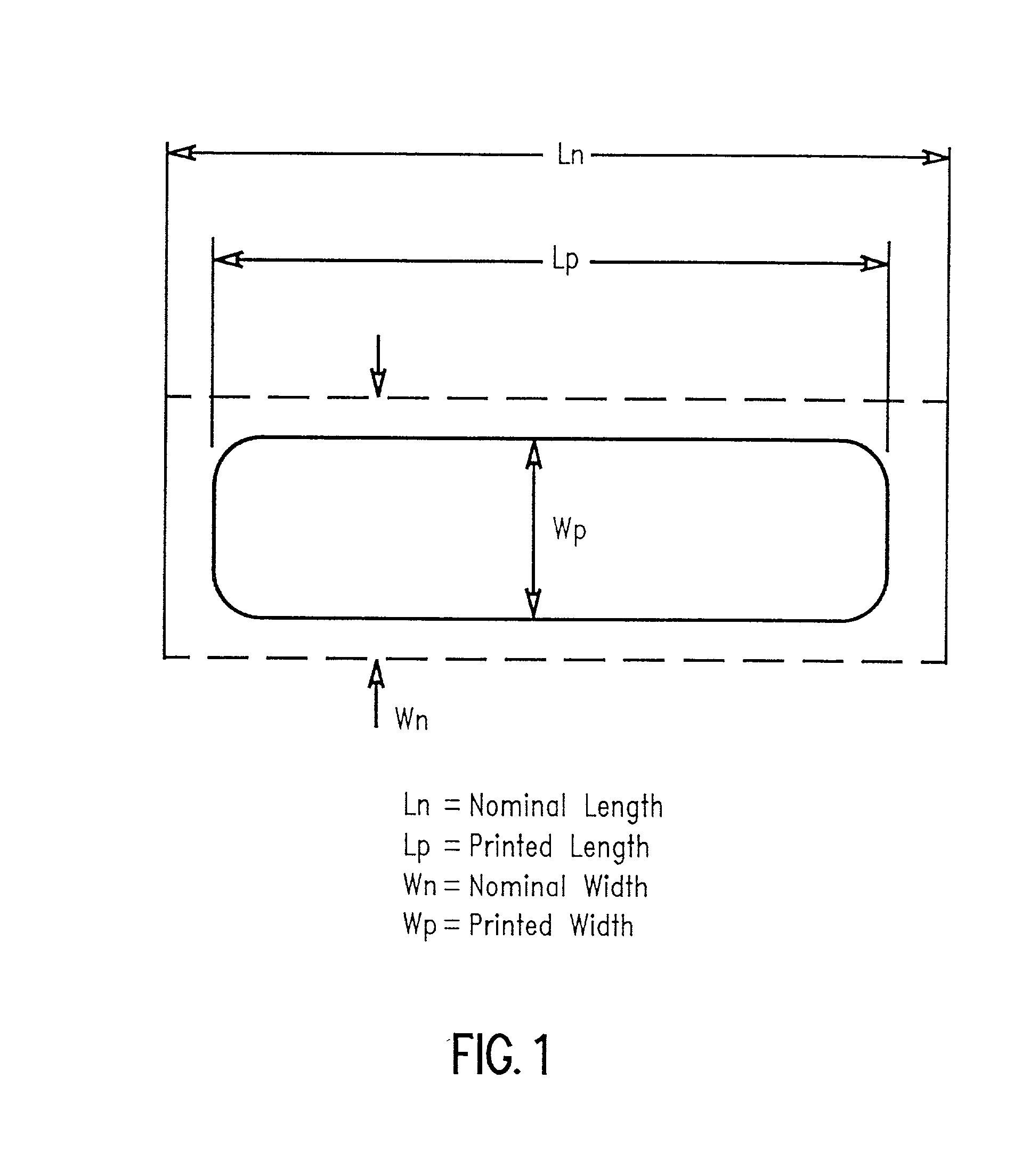

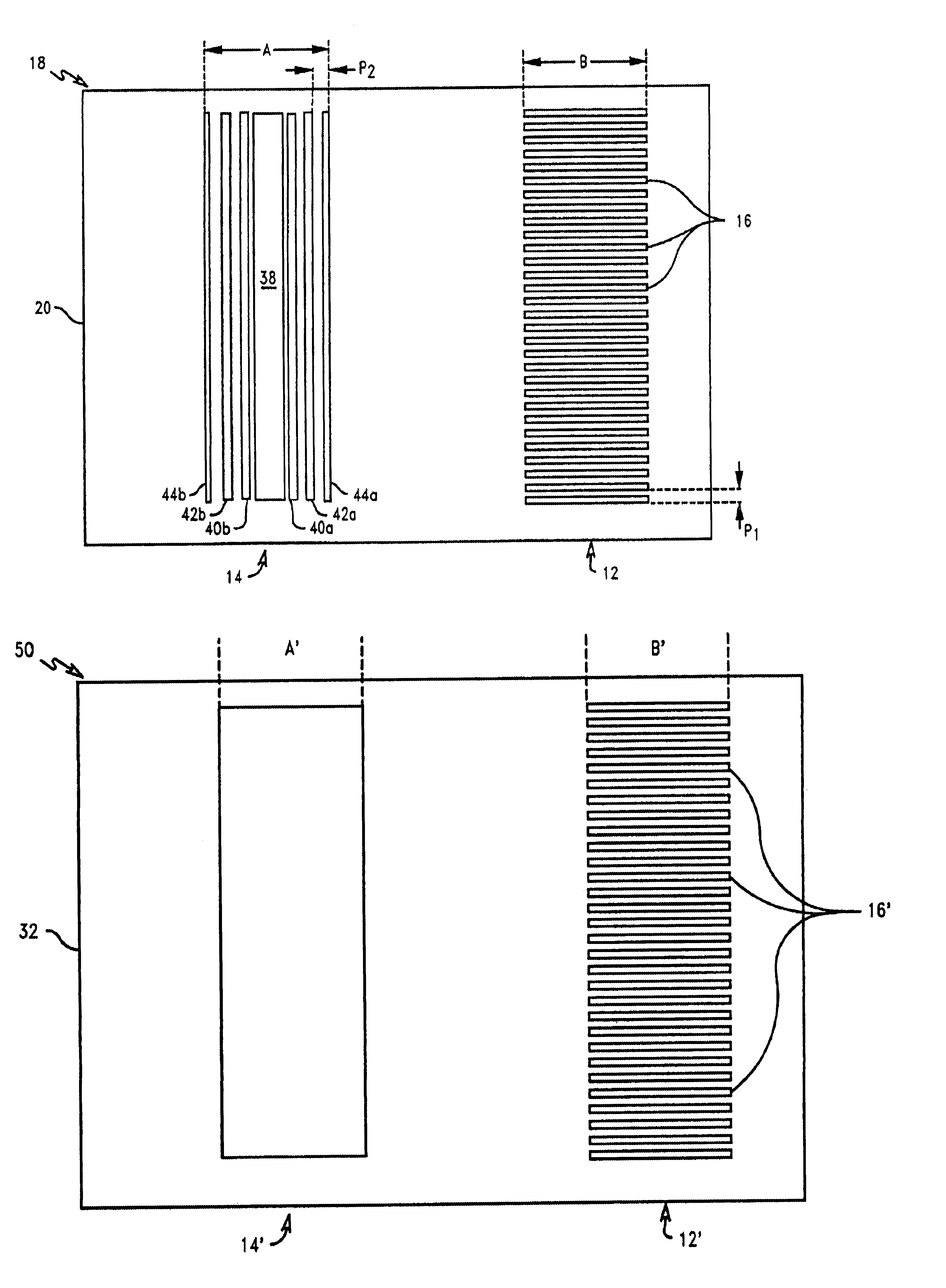

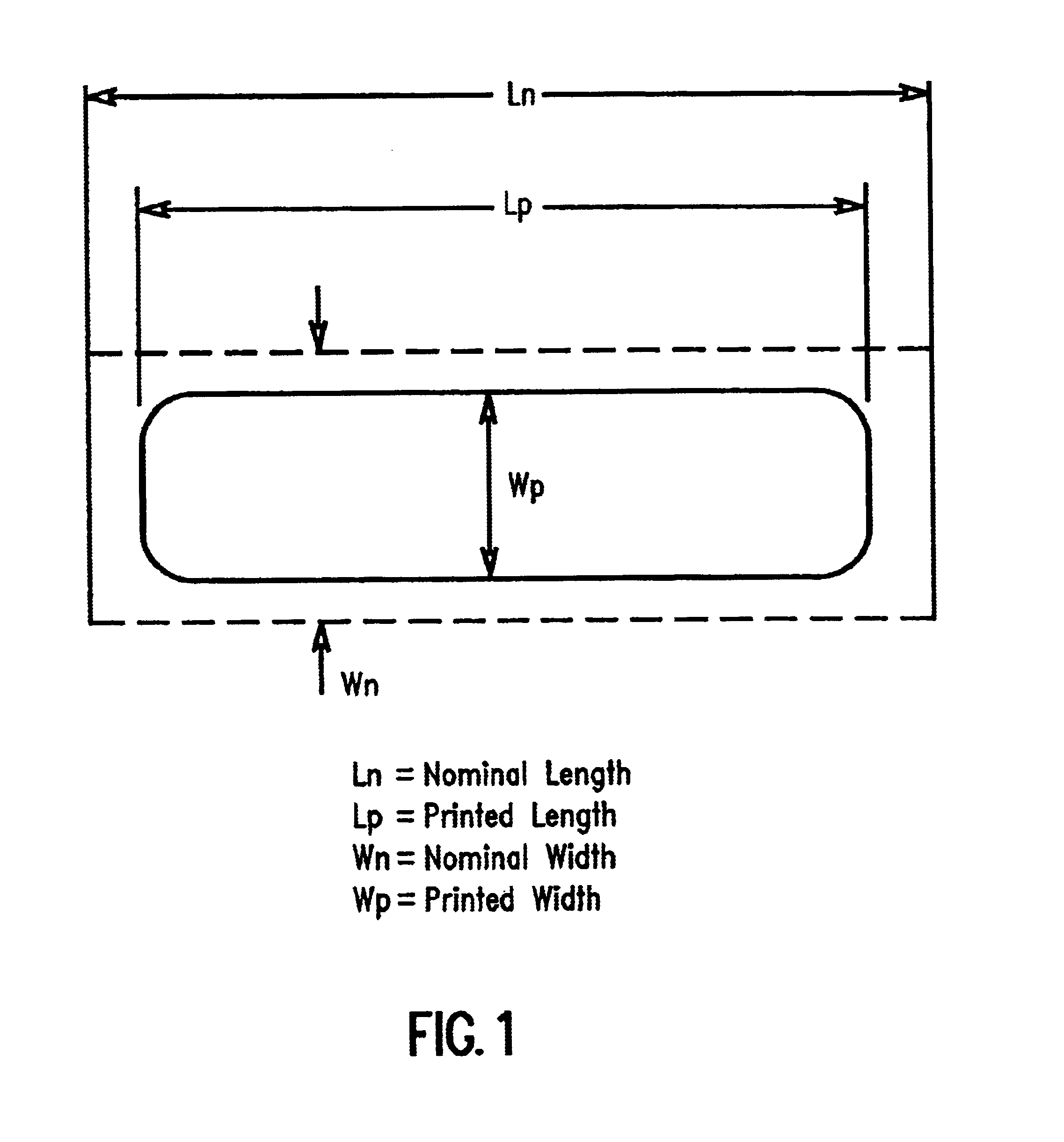

Single tone process window metrology target and method for lithographic processing

InactiveUS20020097399A1Using optical meansPhotomechanical exposure apparatusMetrologyCentral element

A metrology target mask for determining proper lithographic exposure dose and / or focus in a pattern formed in a layer on a semiconductor substrate by lithographic processing. The target mask comprises a mask substrate and a first, dose and focus sensitive mask portion on the mask substrate having a first array of elements comprising a plurality of spaced, substantially parallel elements having essentially the same length and width. Ends of the individual elements are aligned to form first and second opposing array edges, with the lengths of and spaces between the elements being sensitive to both dose and focus of an energy beam when lithographically printed in a layer on a semiconductor substrate. The target mask also includes a second, dose sensitive mask portion on the mask substrate having a second array of elements comprising a central element having a length and a width, and a plurality of spaced, substantially parallel outer elements having a length and a width. The width of the outer elements is less than the width of the central element, with edges of outer elements on each side of and farthest from the central element forming opposing array edges. The pitch of the outer elements is selected such that the outer elements are not resolvable after lithographic printing in a layer on a semiconductor substrate. The resulting printed second target portion width is sensitive to dose but not focus of the energy beam. Dose and / or focus of the energy beam during lithographic processing of the layer may be determined after projecting an energy beam through the mask and lithographically printing the mask portions in a layer on a semiconductor substrate and determining the widths of the first and second target portions in the layer by measuring distance between opposing array edges in each of the first and second portions.

Owner:IBM CORP

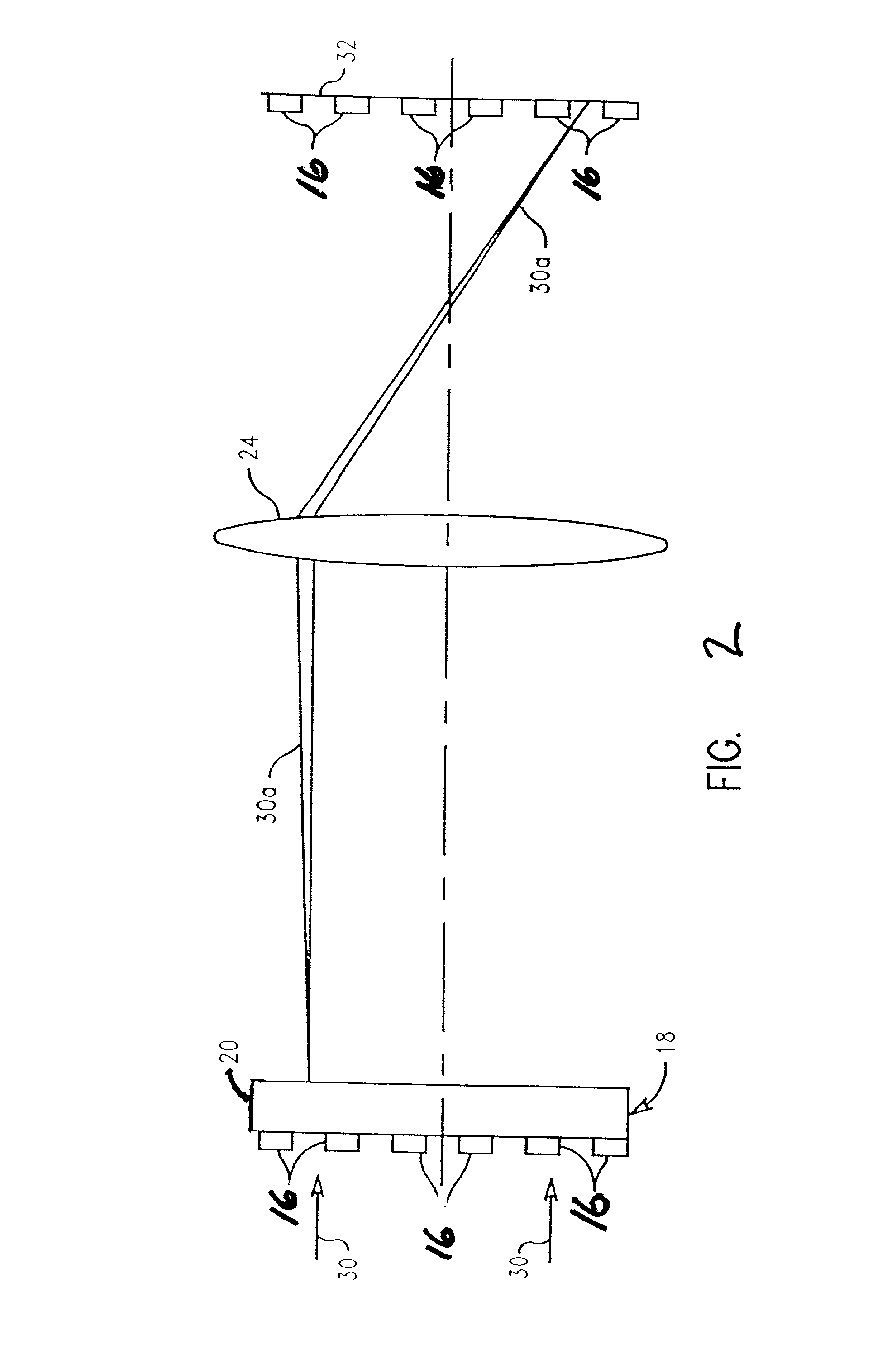

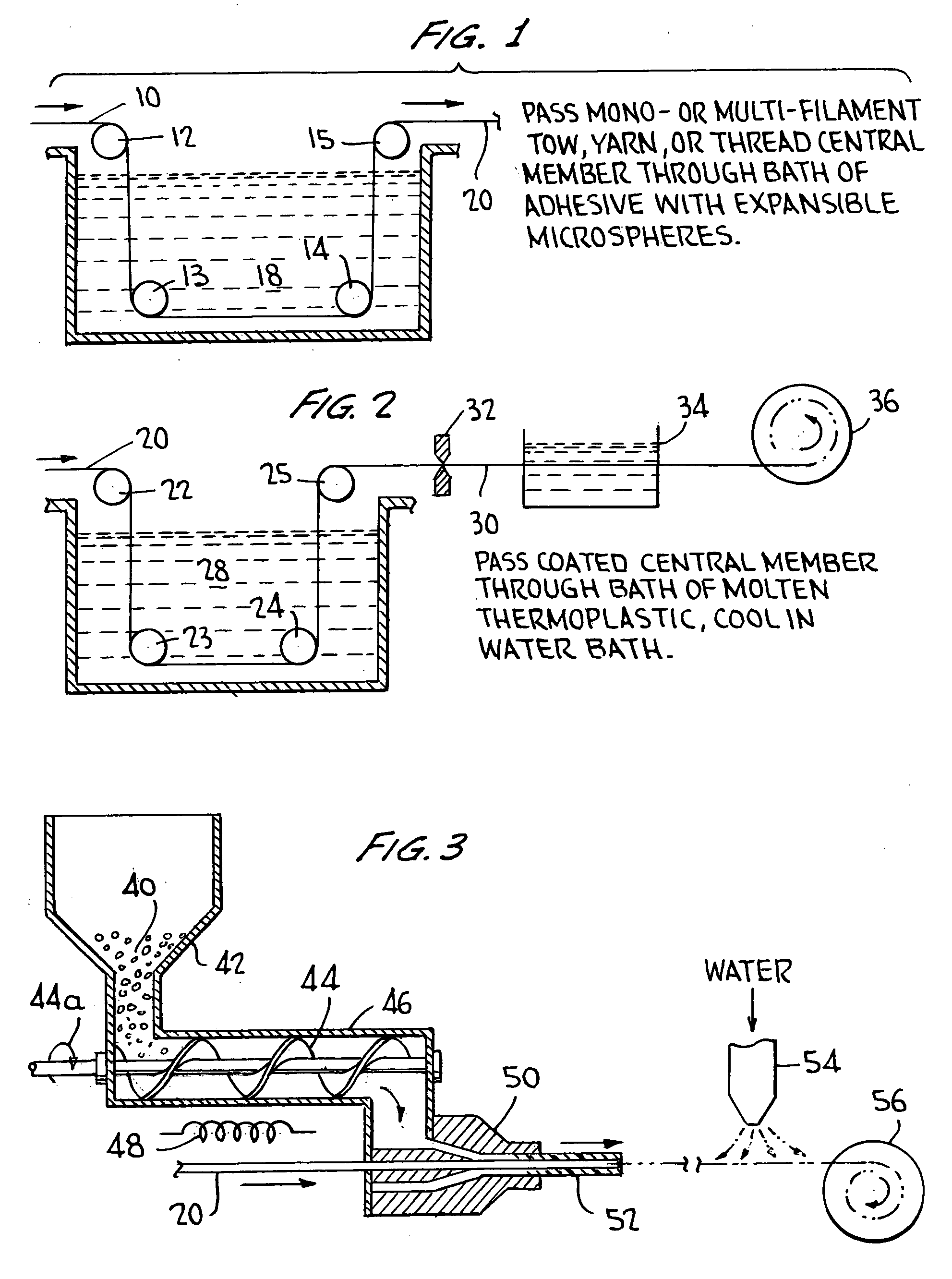

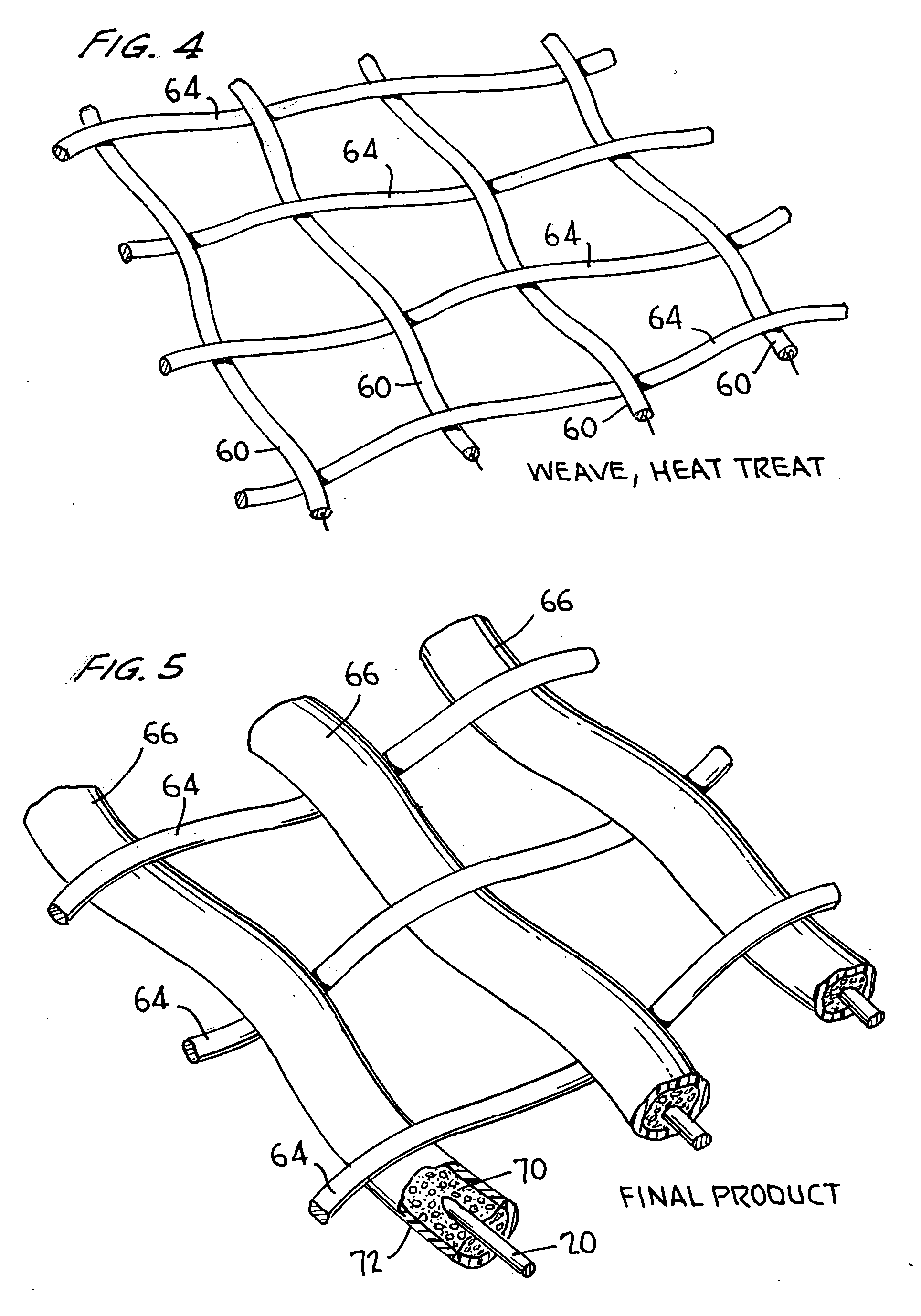

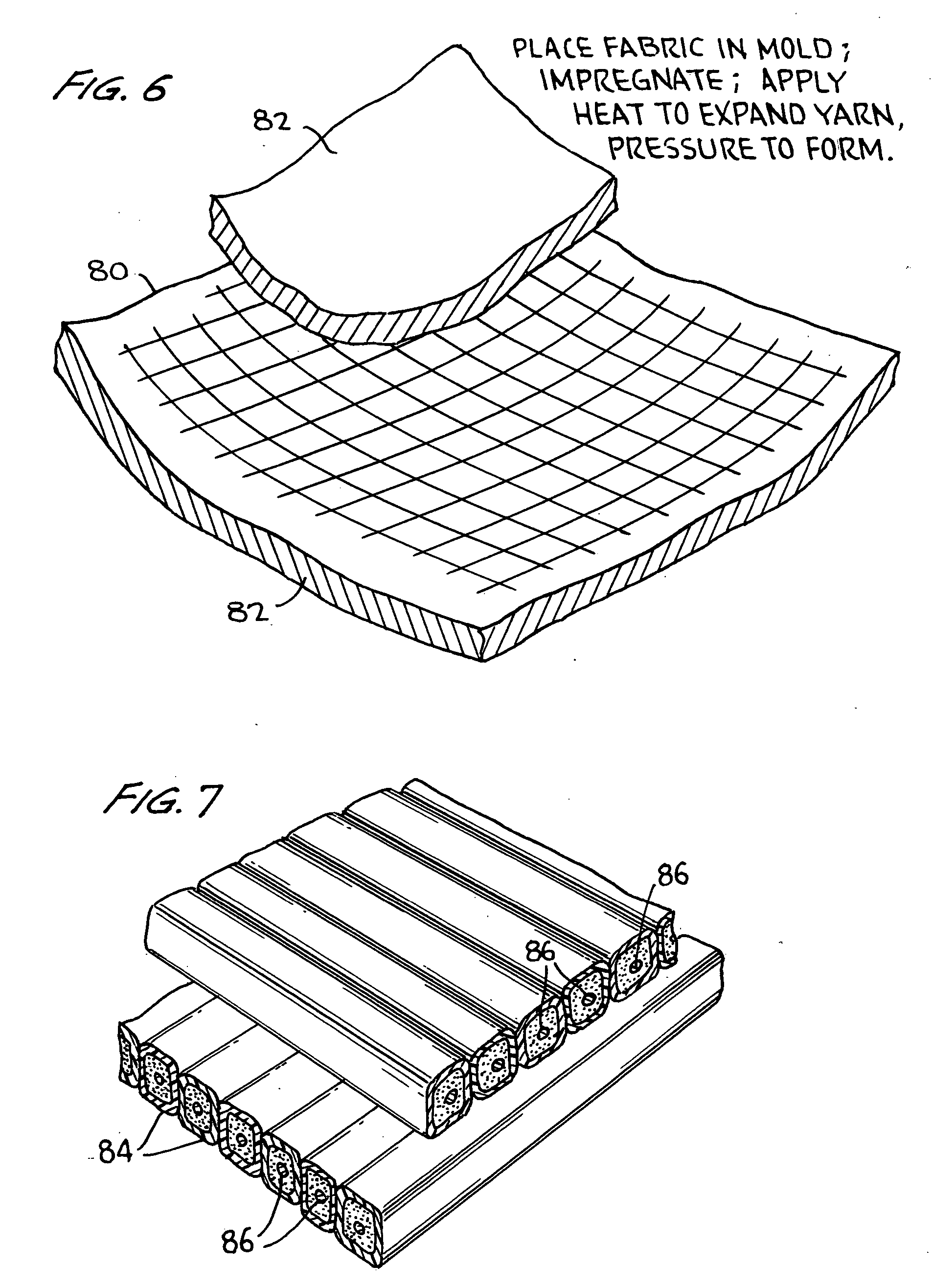

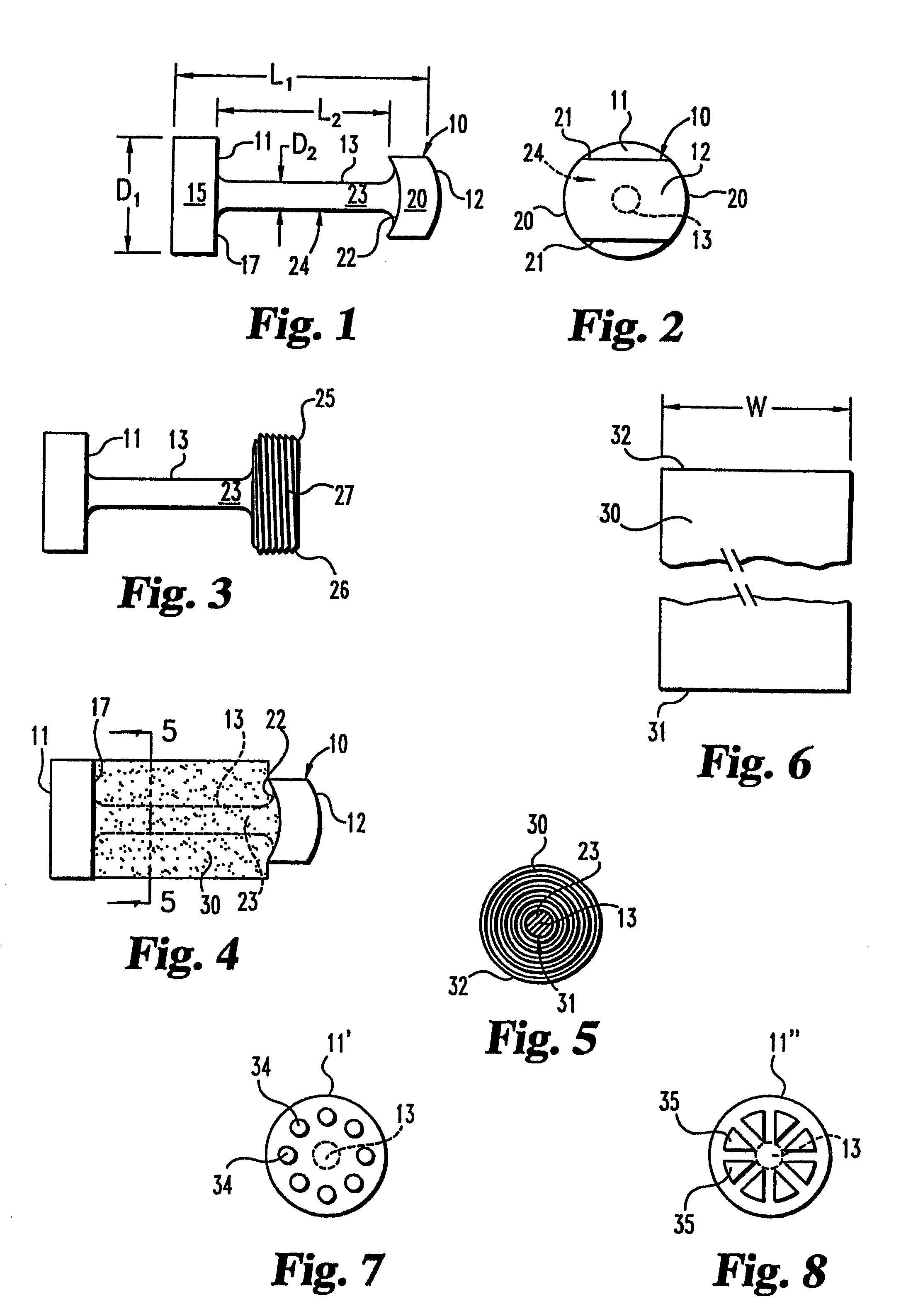

Expansible yarns and threads, and products made using them

A precursor yarn or thread is made by passing a central element, e.g., a filament, a tow, or a flat member, through a bath of a binder, such as a low-temperature hot-melt adhesive, and aqueous urethane, or an acrylic material, with which is mixed a quantity of hard-shelled microspheres which expand when heated to a higher temperature. This is then covered by a sheath, e.g, of PVC, polyurethane, polyester, acrylic resin, polycarbonate, polypropylene, or polyethylene in a second bath. When this product is heated to a transition temperature which is characteristic of the microspheres chosen, the microspheres expand, swelling the sheath. Such a precursor could be woven into a fabric and then heated, so that as the yarn expands the fabric mesh becomes tighter, reducing its porosity. This would be useful as a yarn in making papermaker's felts. Heat-expansible threads made similarly would be useful in manufacture of shoes, sails, tents, clothing and other items where porosity is undesirable; that is, the product could be sewn together using the thread of the invention and then heat-treated, causing the thread to expand, sealing the holes made in sewing. Such threads would also be useful for decorative purposes, e.g., as embroidery yarns, and likely for other purposes. The yarns of the invention can also be disposed in a desired position and infused with a hardening resin while heat is applied to cause the microspheres to expand, forming a lightweight and stiff composite structure.

Owner:PASCALE INDS

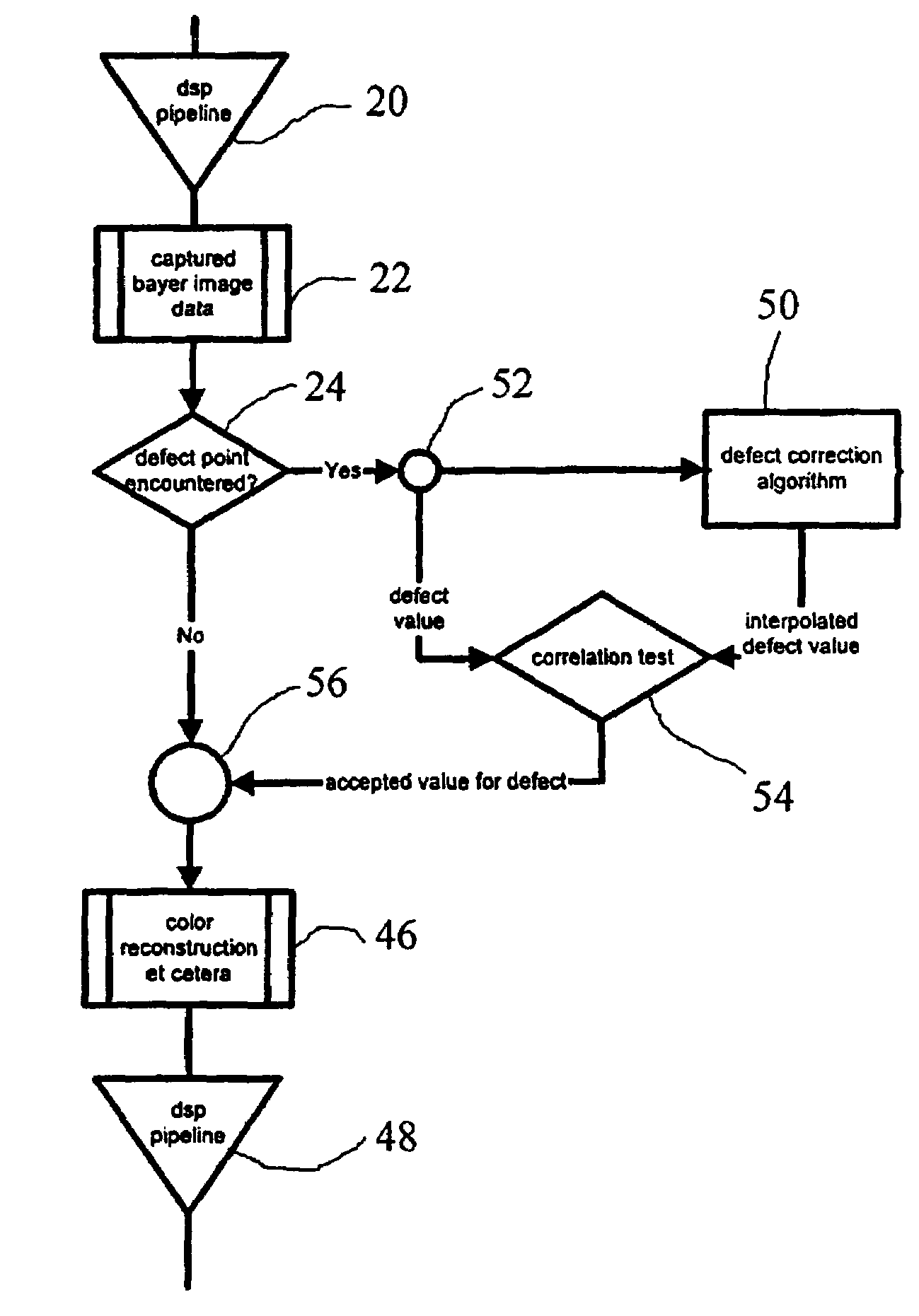

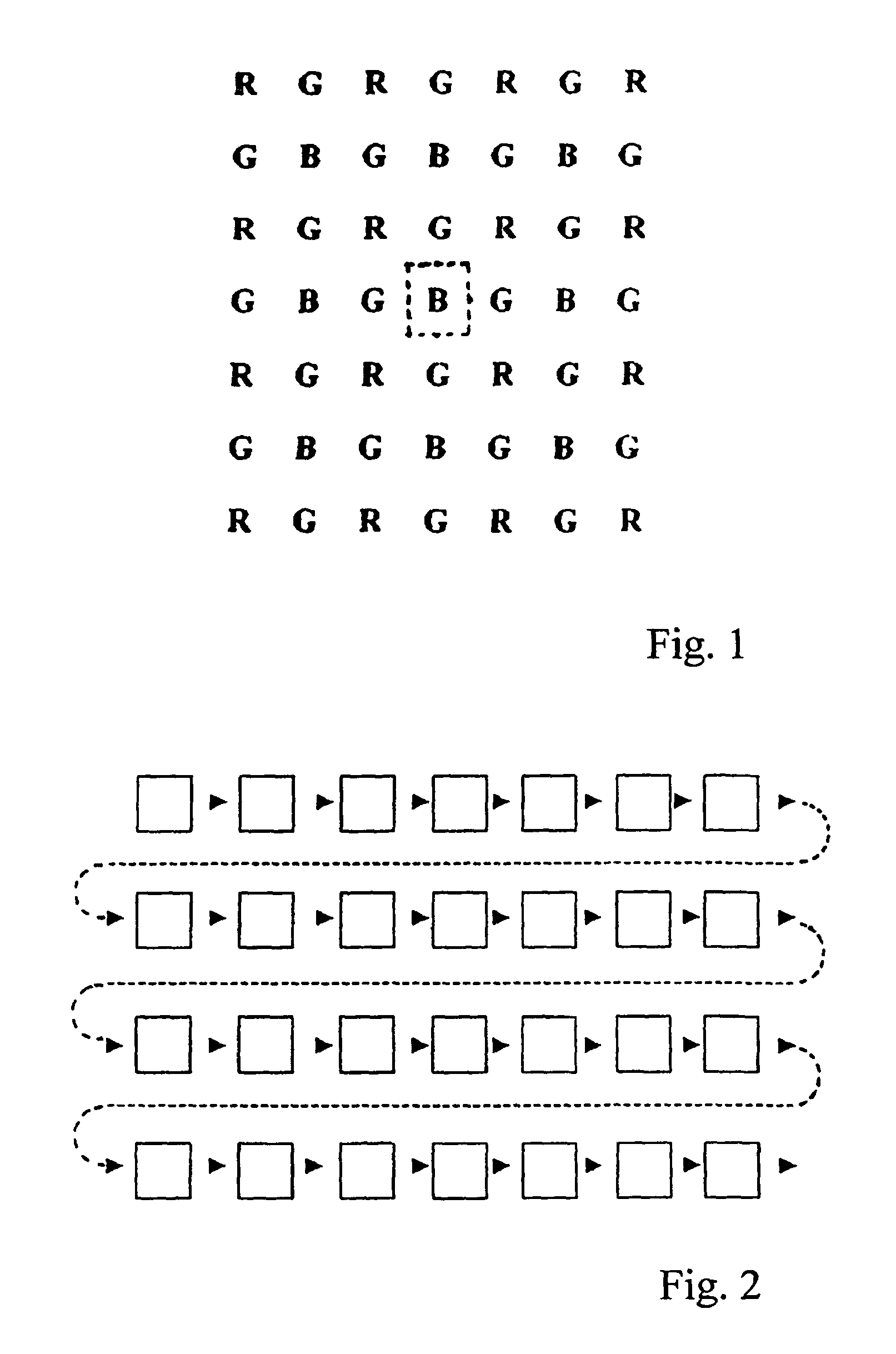

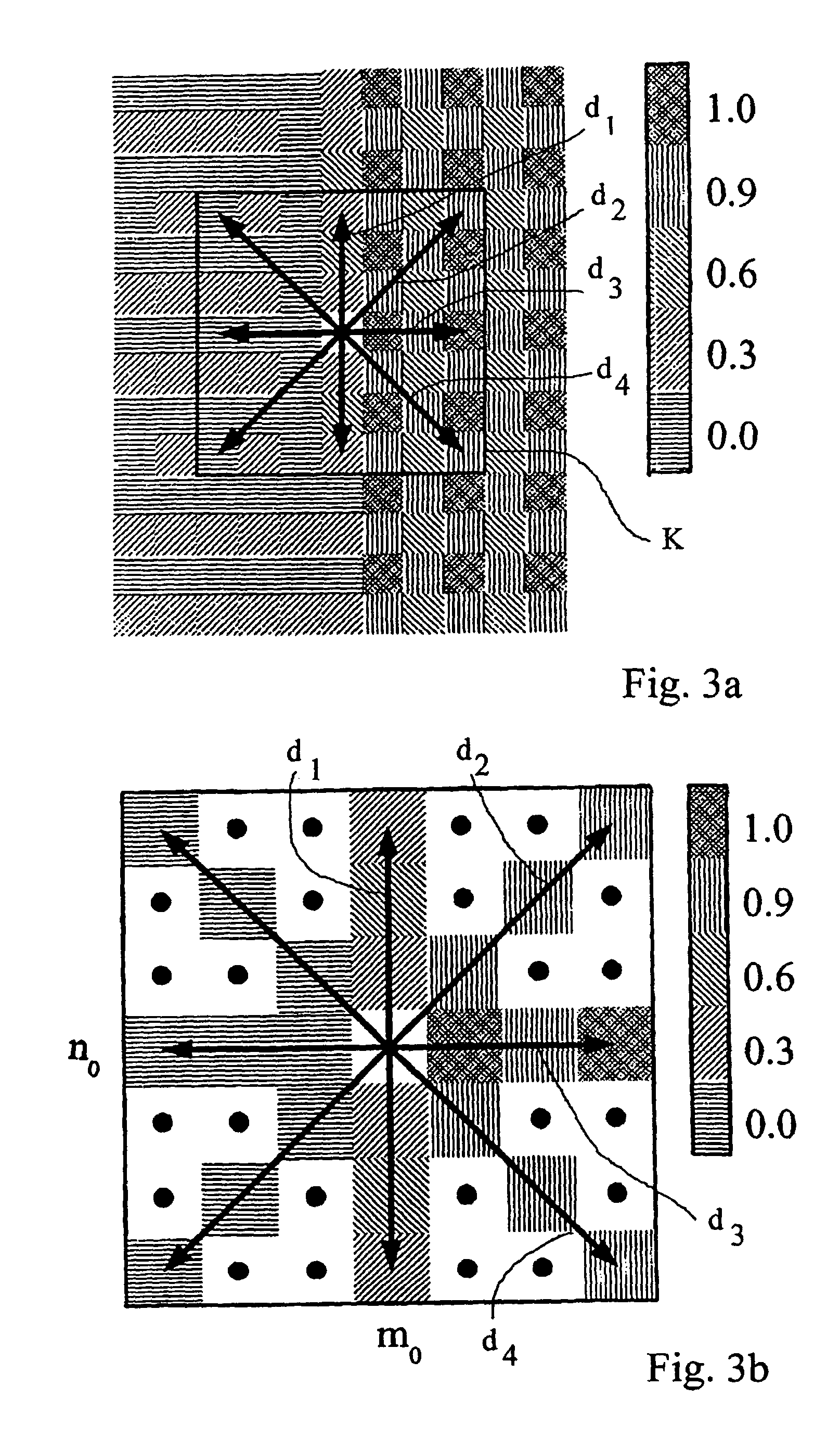

Method and apparatus for adaptive pixel correction of multi-color matrix

A method of adaptive pixel correction of a multi-color matrix from a sensor includes collecting pixel values, generating plural vectors, normalizing values and determining an estimated value. The collecting pixel values collects values of a two-dimensional multi-pixel kernel around a particular pixel from the multi-color matrix. The generating plural vectors generates vectors from the kernel where each vector has the particular pixel as a central element. The normalizing values normalizes values for nearest neighbor elements to the central element for each vector. The determining an estimated value determines the value based on the normalized values.

Owner:TELEDYNE DIGITAL IMAGING INC

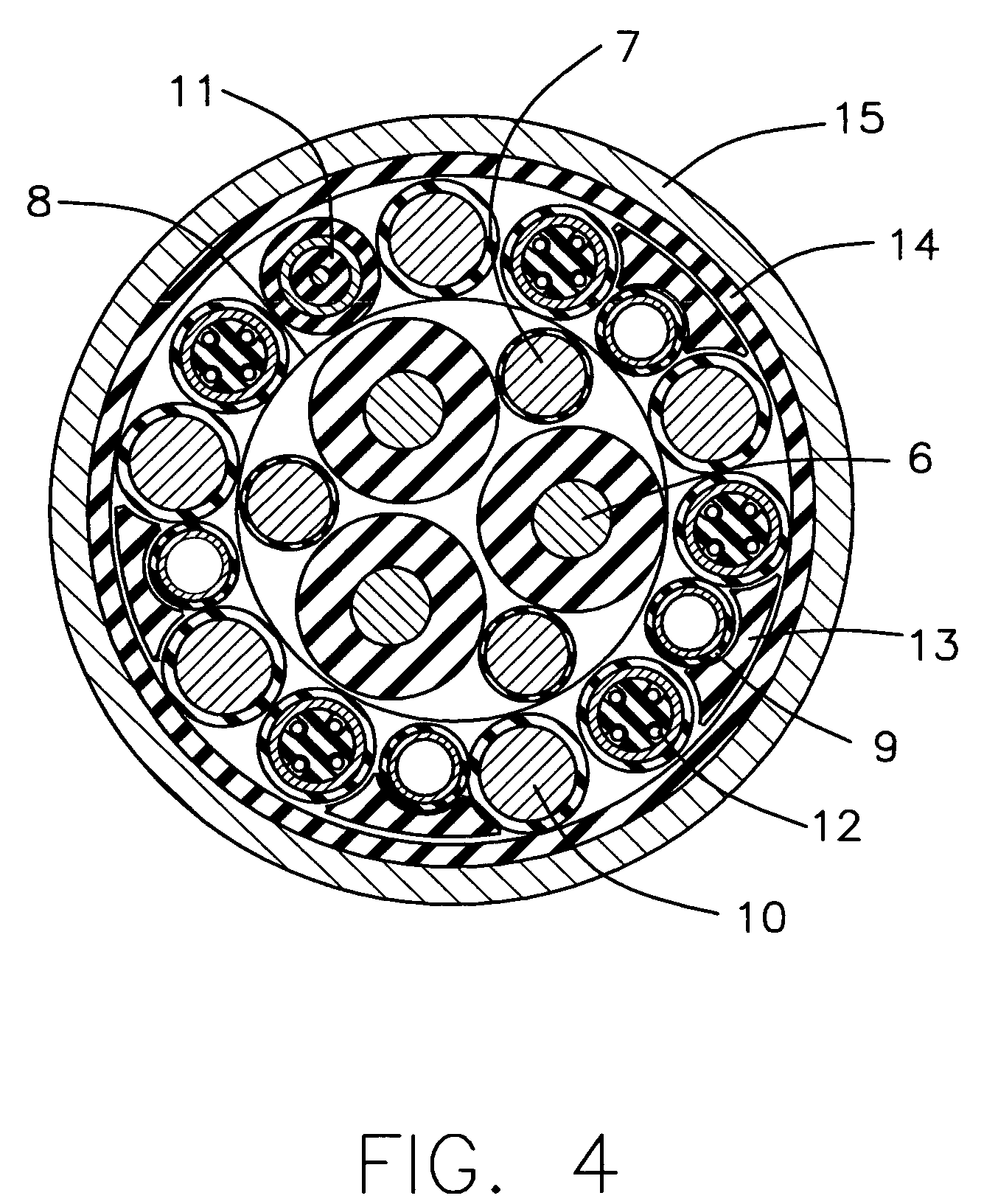

Nested variable field dynamoelectric machine

A dynamoelectric machine comprises a first rotor shaft, a second rotor shaft and a central element. The first rotor shaft rotates about a central axis of the machine and has a first magnetic drive element disposed about an outer circumference of the first rotor shaft. The second rotor shaft rotates about the first rotor shaft and has a second magnetic drive element disposed about an inner circumference of the second rotor shaft. The central element is disposed between the first rotor shaft and the second rotor shaft and is configurable to remain stationary while the first rotor shaft and the second rotor shaft rotate about the central axis. The central element also includes a third magnetic drive element for interacting with the first magnetic drive element, and a fourth magnetic drive element for interacting with the second magnetic drive element.

Owner:HAMILTON SUNDSTRAND CORP

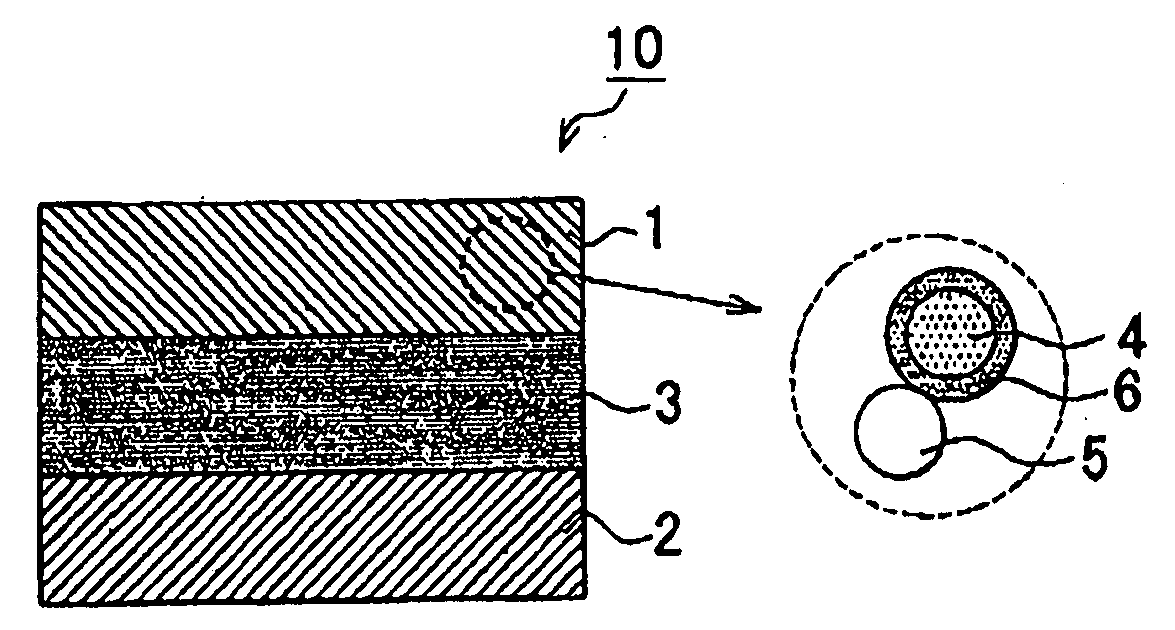

All-solid battery

InactiveUS20120052396A1Shorten the timeExtension of timeMaterial nanotechnologyNon-aqueous electrolyte accumulatorsChemical compoundEngineering

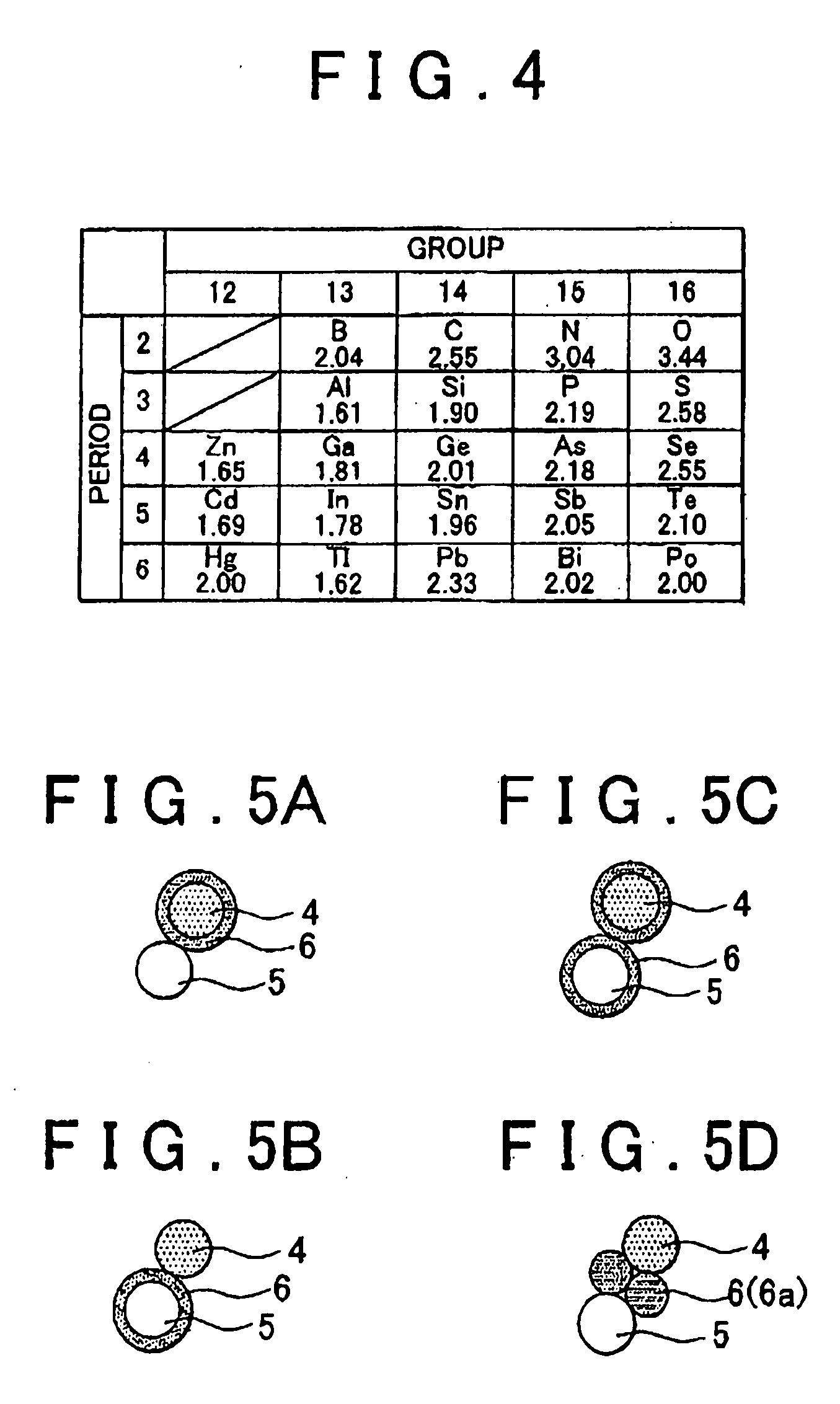

An all-solid battery includes: a positive electrode active material layer that includes a positive electrode active material; a negative electrode active material layer that includes a negative electrode active material; and a solid electrolyte layer that is formed between the positive electrode active material layer and the negative electrode active material layer. The positive electrode active material layer or the solid electrolyte layer further includes a solid electrolyte material. A reaction suppressing portion is formed at an interface between the positive electrode active material and the solid electrolyte material. The reaction suppressing portion is a chemical compound that includes a cation portion formed of a metal element and a polyanion portion formed of a central element that forms covalent bonds with a plurality of oxygen elements.

Owner:TOYOTA JIDOSHA KK +1

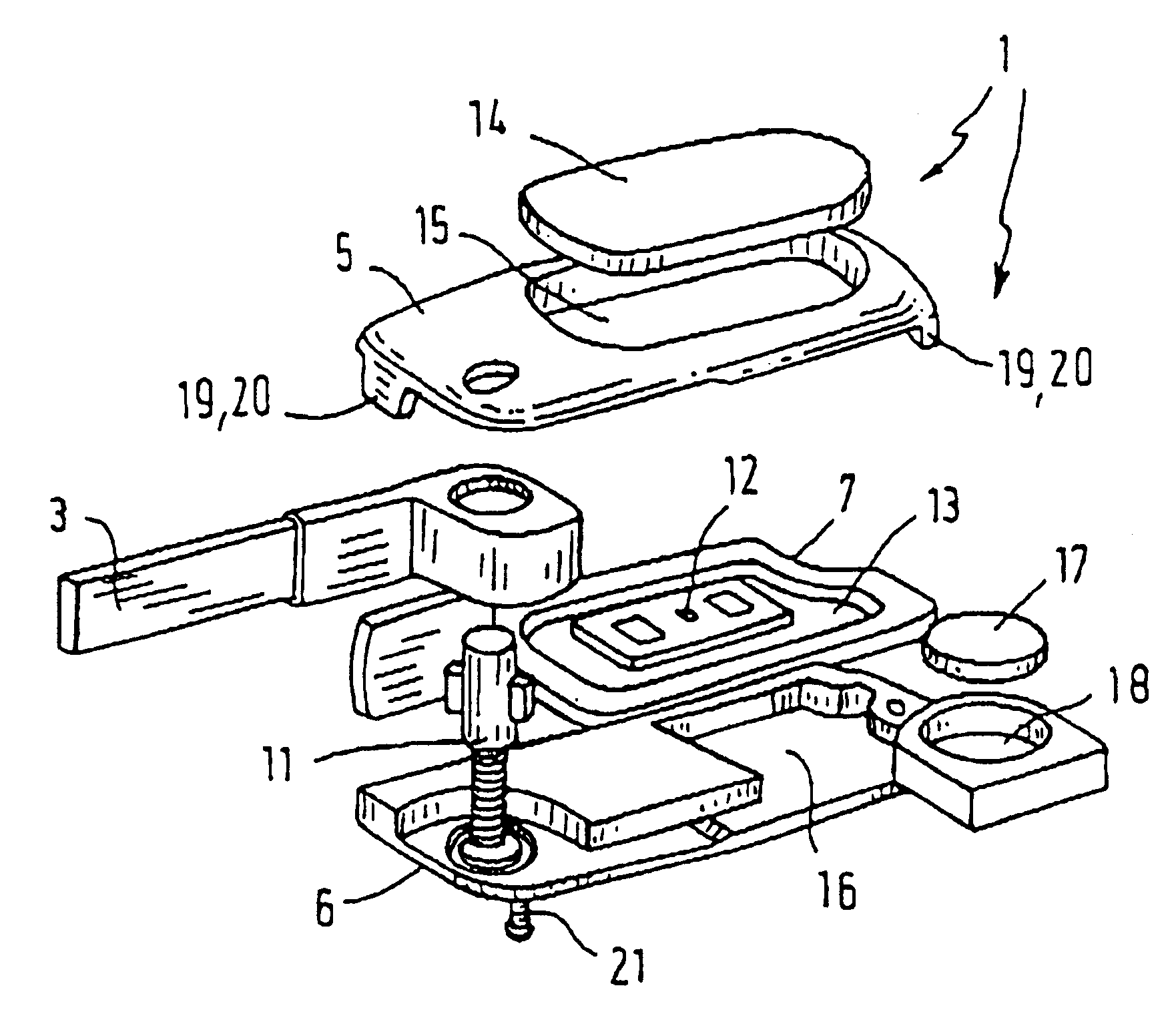

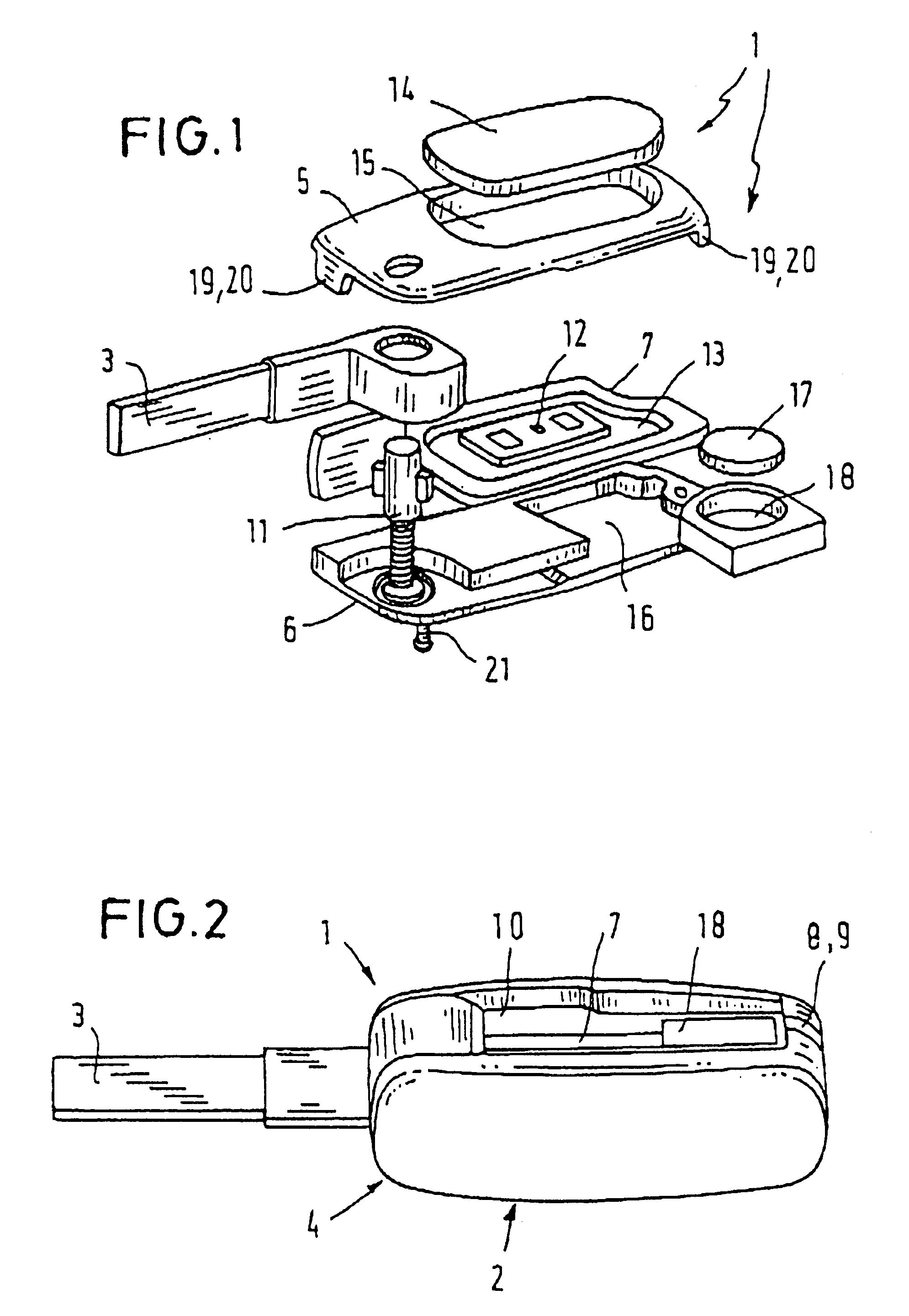

Electronic flat key

The invention relates to an electronic flat key having a grip element (2) and a key bit (3), the grip element (2) including a casing (4) in which are arranged an electronic switching device (12) for remote operation of a lock or locking system and a holder (16) for at least one battery (17) for supplying power to the switching device, the grip element casing (4) including two side elements (5, 6) constructed in the form of shells, and the key bit (3) being arranged on the grip element casing (4) in a manner enabling it to be swiveled from a retracted position, in which it is situated in a lateral well (10) in the grip element casing (4), into an extended position. In order for the grip element casing (4) to also consist of metallic side elements (5, 6) constructed in the form of shells, without this substantially affecting (electrically shadowing) the transmitting and / or receiving elements located in the casing (4) for remote operation or a lock or locking system, the invention proposes that between the two side elements (5,6) of the grip element casing (4), which are made of metal and are constructed in the form of shells, there is arranged a central element (7) of frame-like construction which is made of a material that does not conduct electricity, which extends peripherally at least in sub-portion (8) of the grip element casing (4) as far as the outer surface (9) of the casing (4) and is sufficient for conveying an adequate signal between the transmitting and / or receiving elements located in the grip element casing (4) and those located in the lock zone or locking system zone.

Owner:VALEO & SCHLIESSYST

Single tone process window metrology target and method for lithographic processing

Owner:INT BUSINESS MASCH CORP

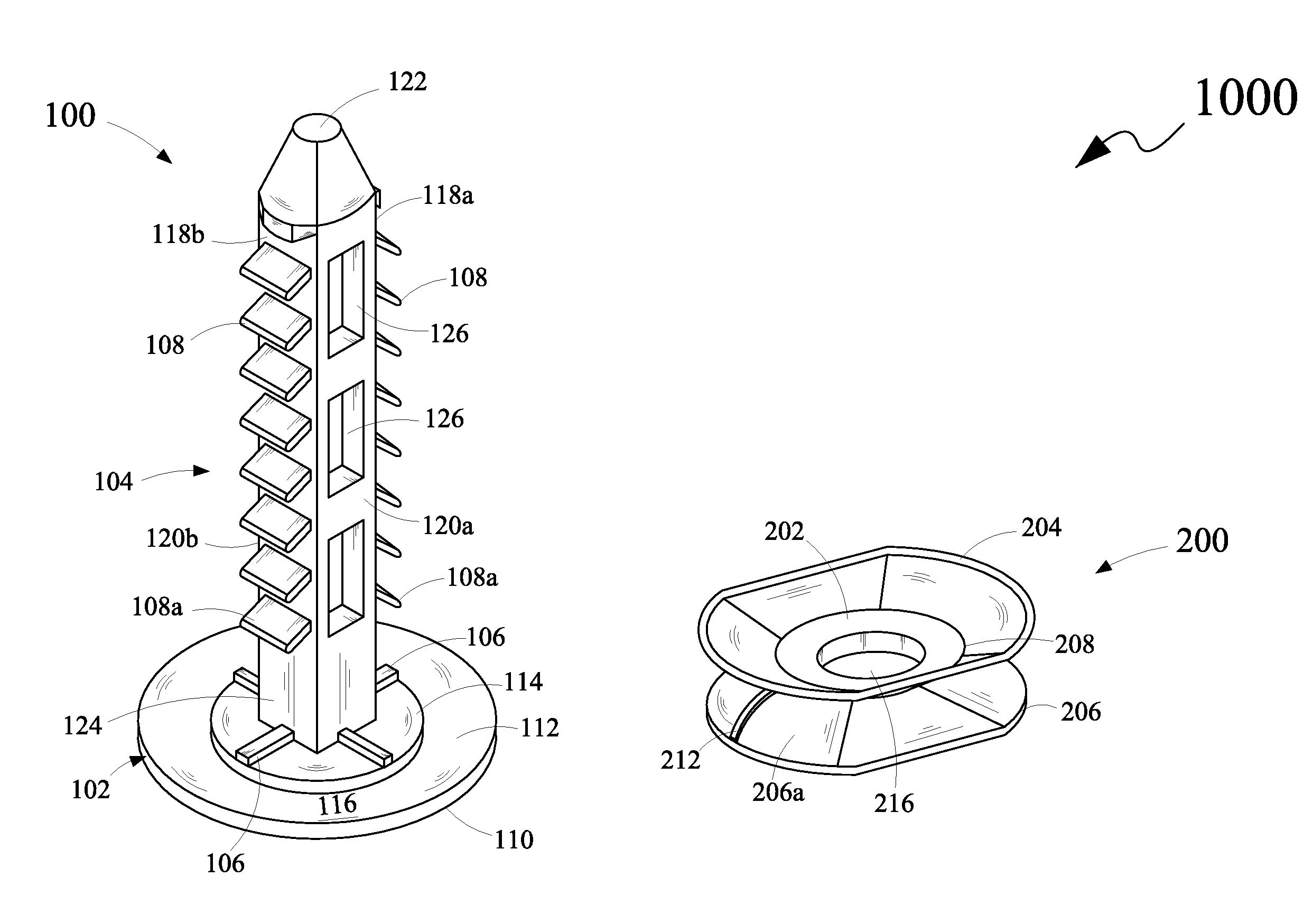

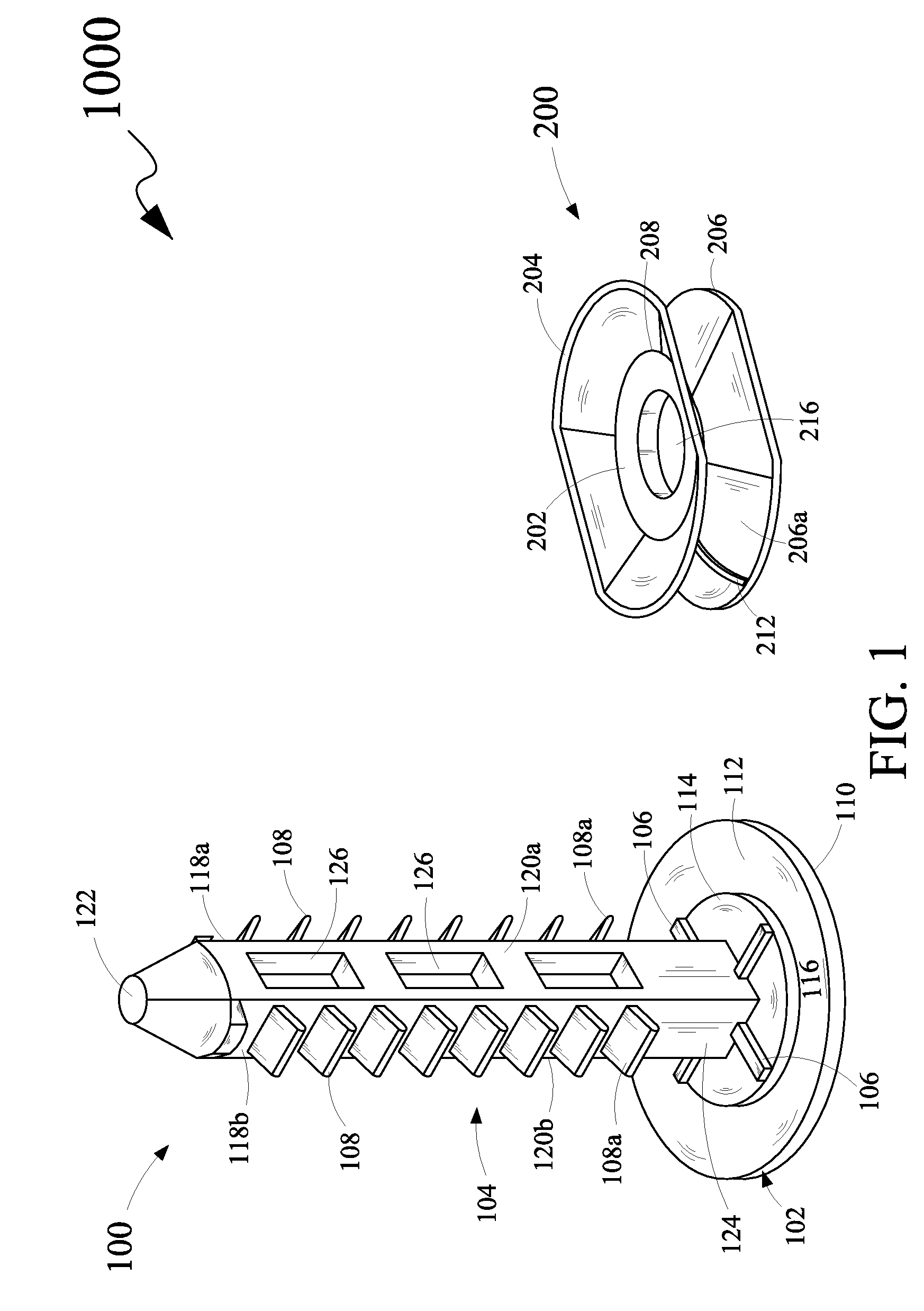

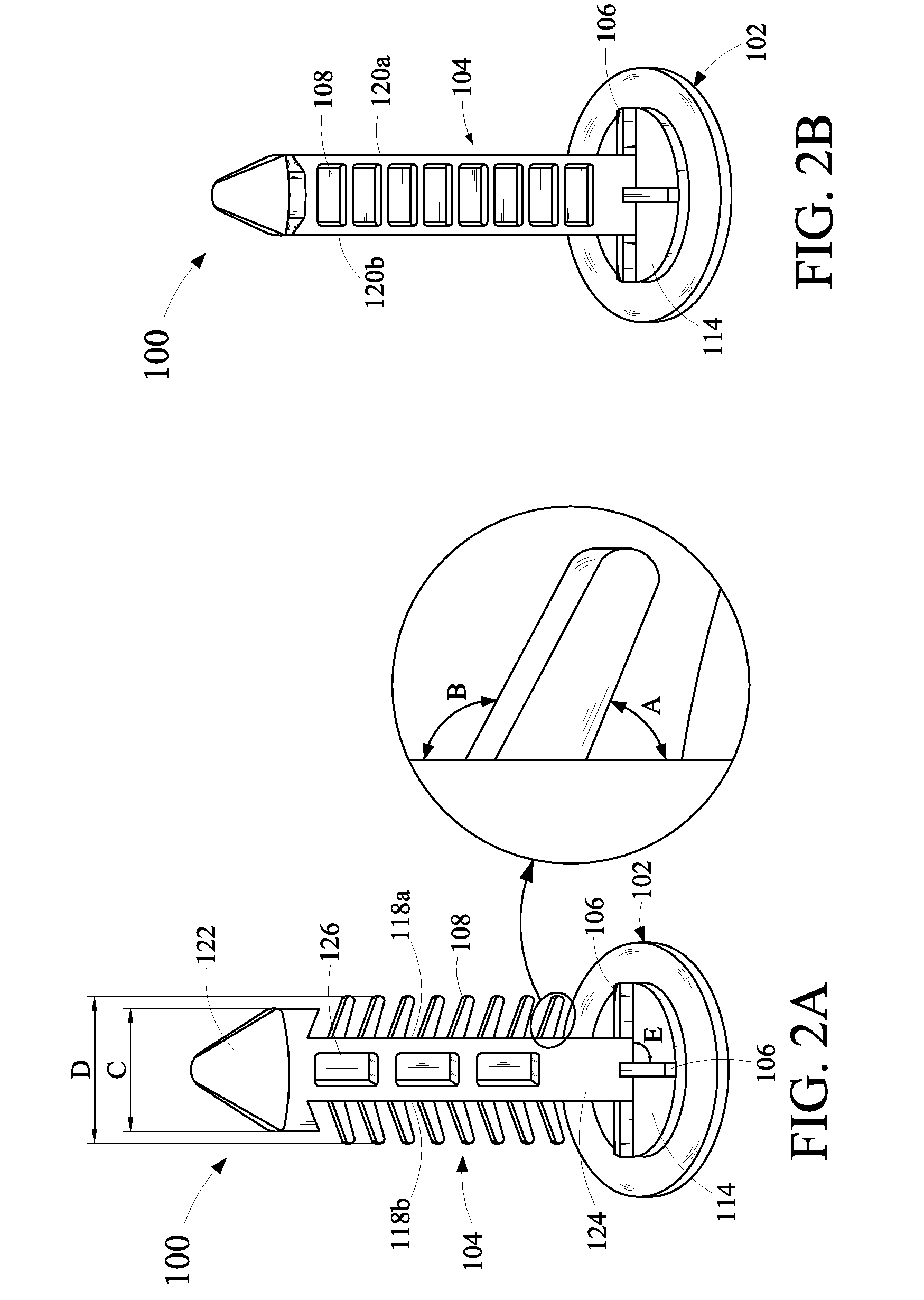

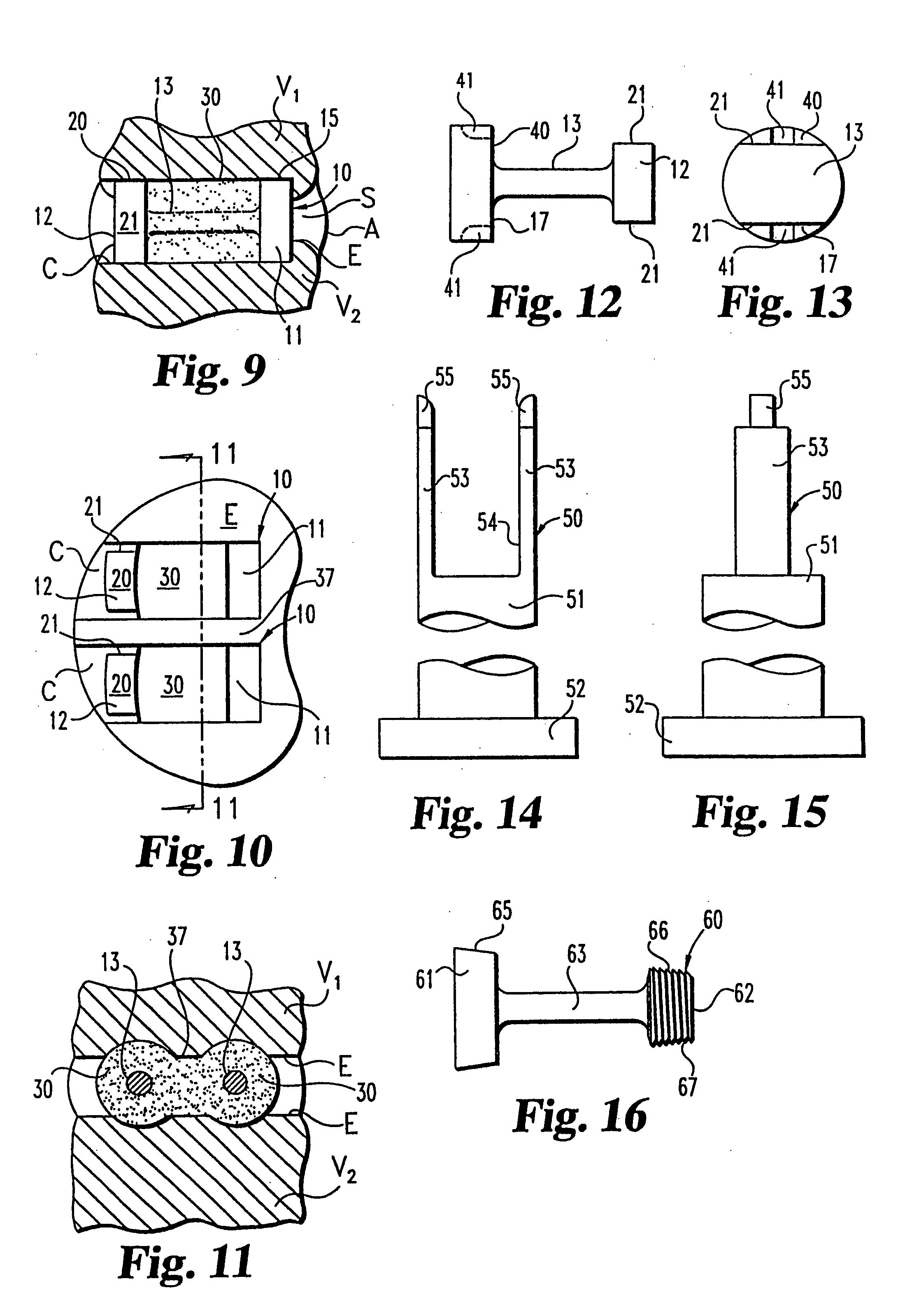

Two-piece Fastener

ActiveUS7896601B2Help positioningGuaranteed accurate fixationSnap fastenersScrewsEngineeringCentral element

Disclosed is a fastener that comprises a stud member and a nut member. The stud member includes a base portion, a stem, a plurality of locating features, and, a plurality of slanted ridges. The stem has a head portion and a body portion, where the body portion is positioned on the base portion for enabling the stem to extend vertically from the base portion. The plurality of locating features extends from the body portion, and is disposed on the base portion. The plurality of slanted ridges extends from the stem. The nut member includes a central element configured to have two projecting members extending opposite to each other from a periphery of the central element. The central element comprises an aperture therewithin for receiving the stem therethrough and for interlocking the nut member with the stud member to retain the stud member at a locked configuration.

Owner:MARIMBA AUTO

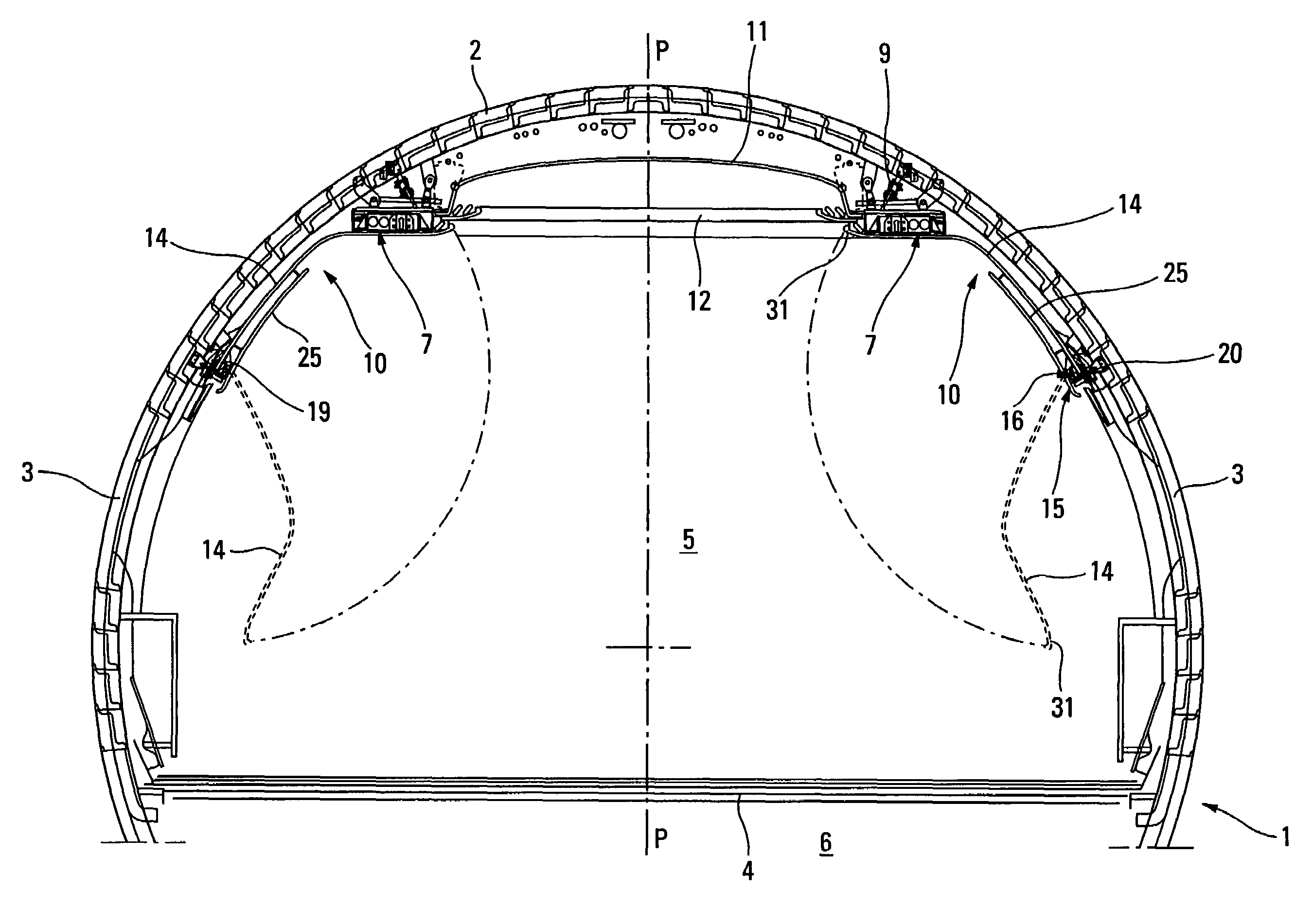

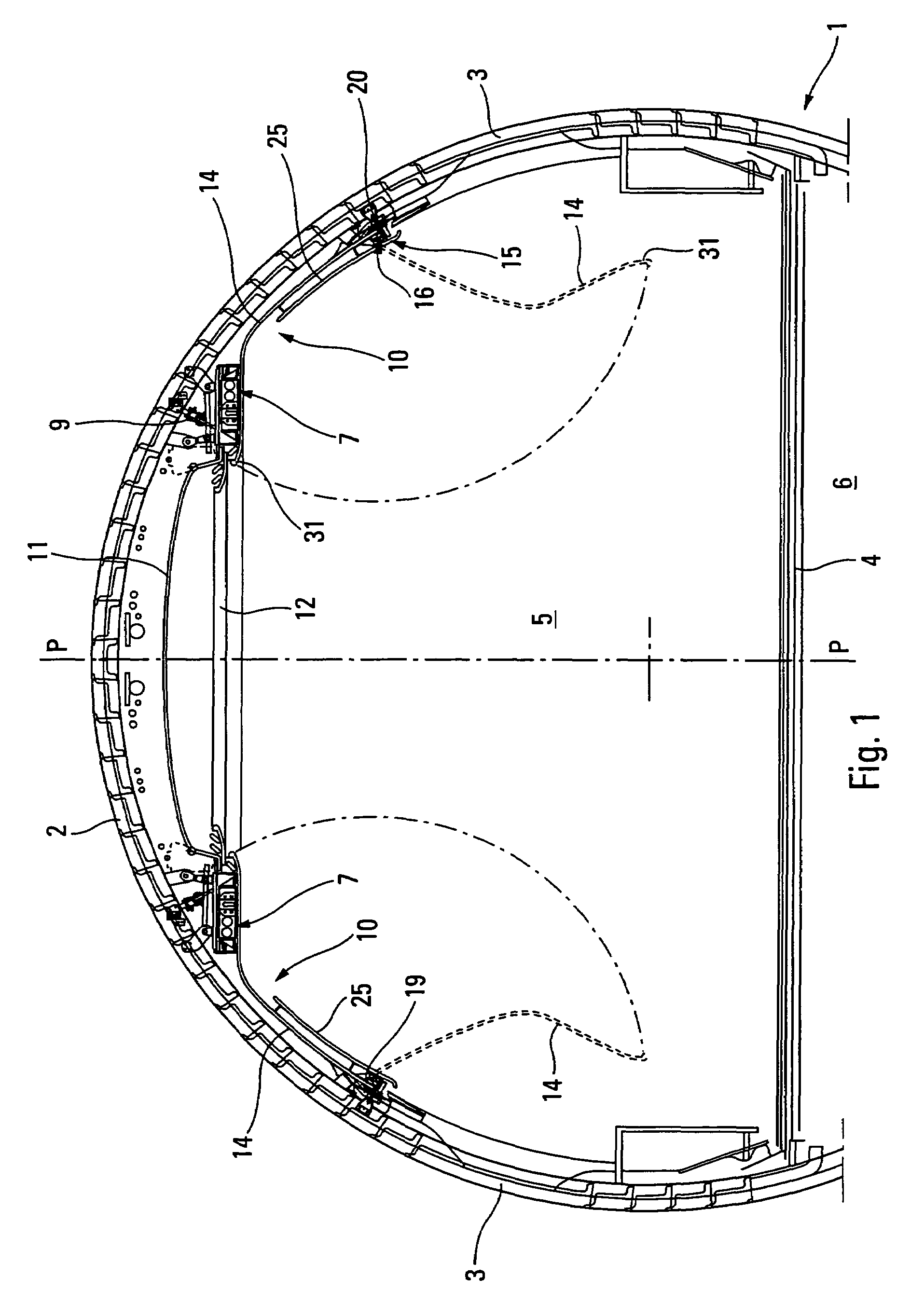

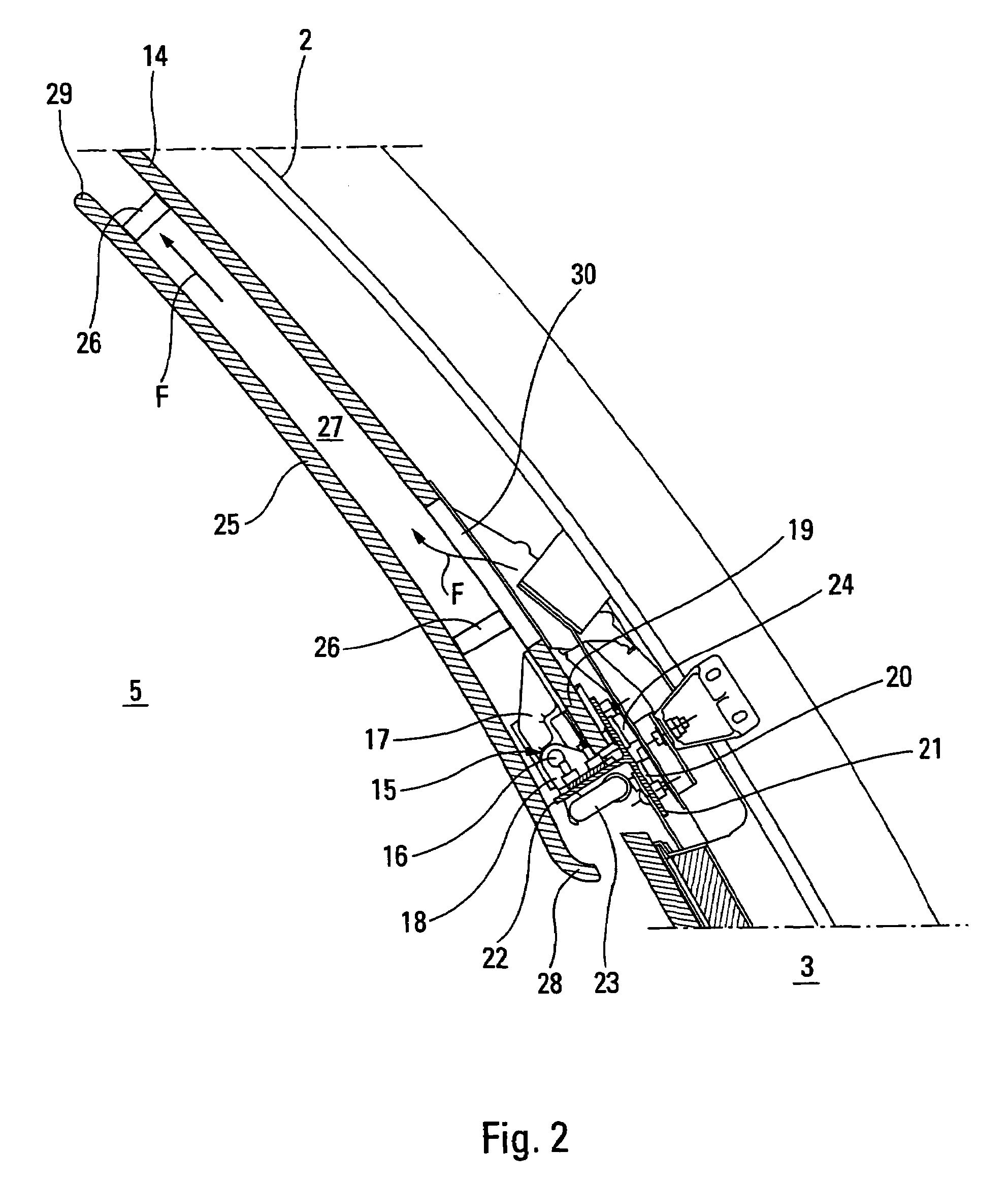

Internal arrangement of the walls of the fuselage of an aircraft

InactiveUS7461816B2Lower acoustic noise levelGood lookingFuselage framesAir-treatment apparatus arrangementsLongitudinal planeCentral element

An internal arrangement of aircraft fuselage walls supports two longitudinal auxiliary passage ducts at the upper part of the fuselage and on each side of its longitudinal plane of symmetry. The arrangement includes a longitudinal central element forming a dome connecting the structural ducts, an interior ceiling panel situated under the dome and facing toward the cabin, and two lateral cover panels. A lower edge of each lateral panel is articulated with respect to the fuselage so that it may occupy a raised position in which it is connected to a respective one of the structural ducts near an upper edge of the structural duct and a lowered position in which it is distant from the structural duct. Also, the upper edge of each lateral panel is extended, in the raised position, beyond the structural duct to cover the corresponding longitudinal edges of the dome and the ceiling panel.

Owner:EADS SOGERMA SERVICES

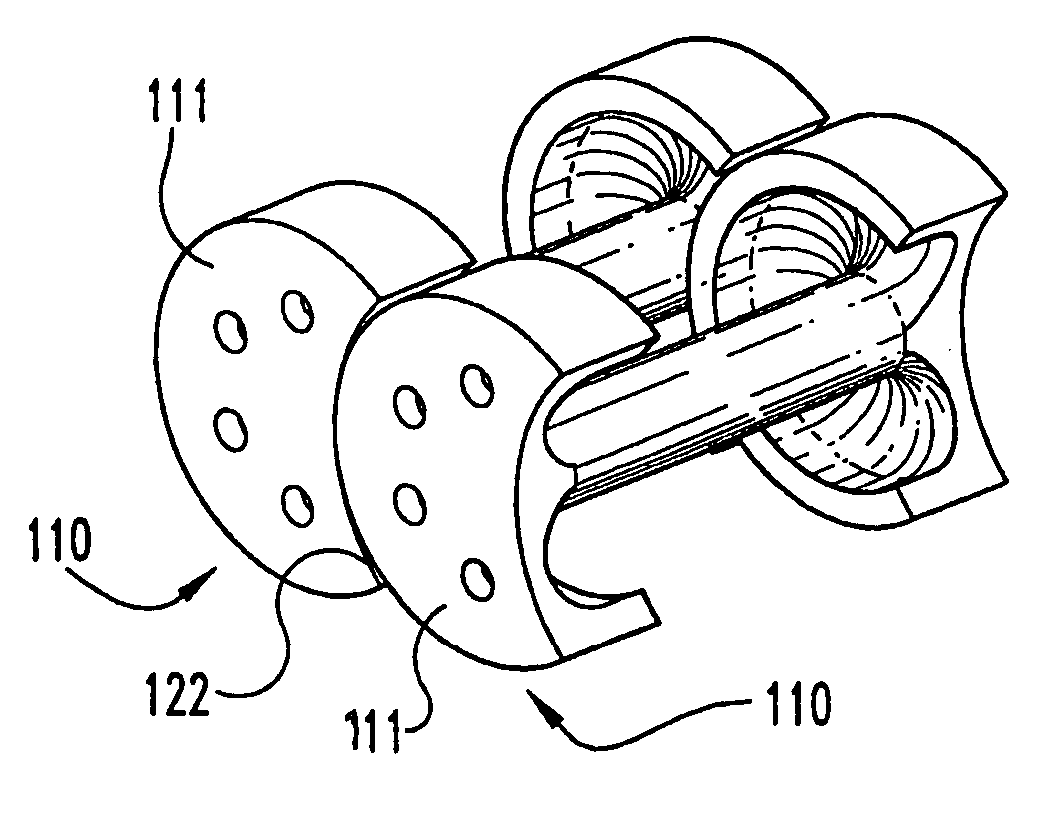

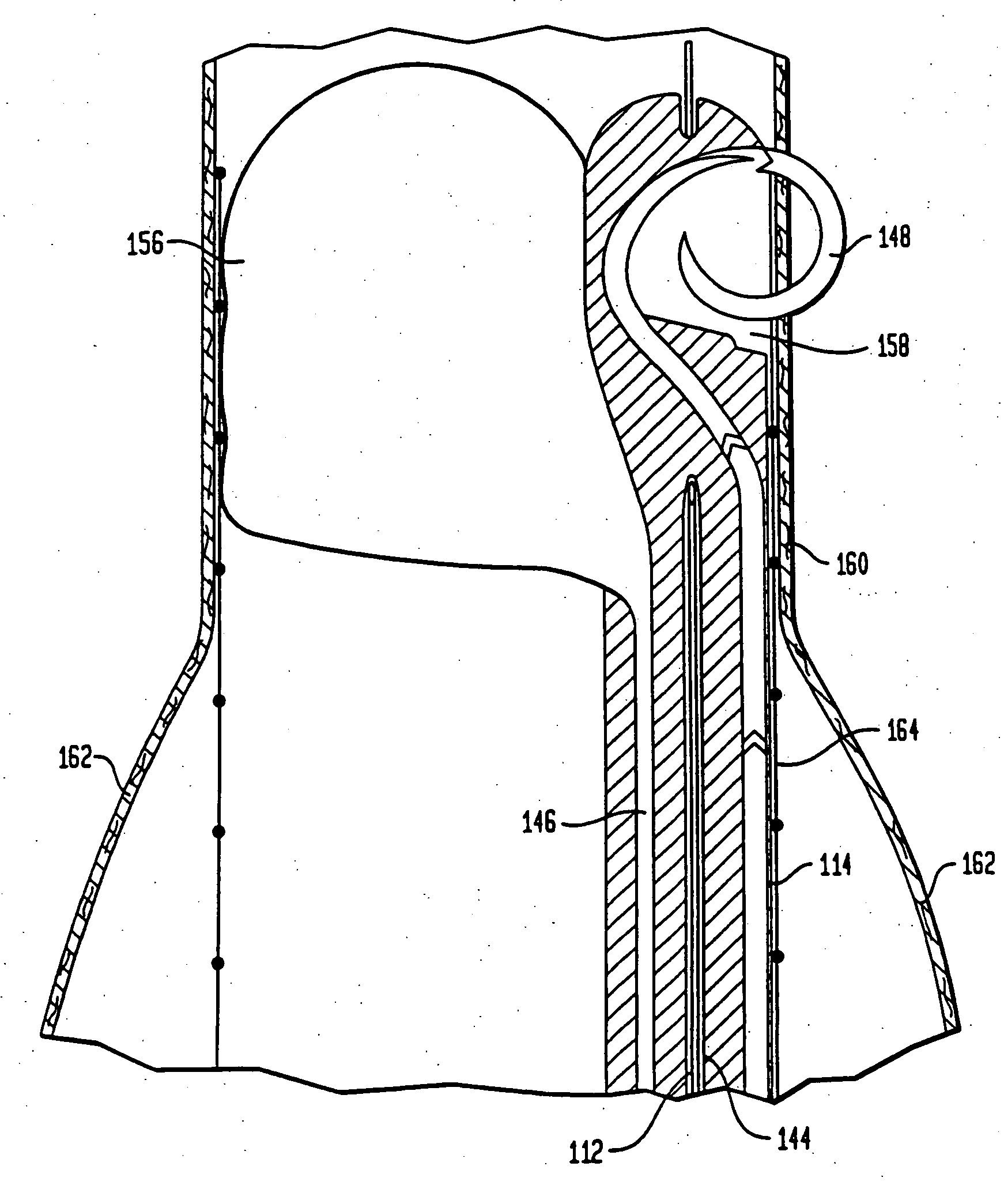

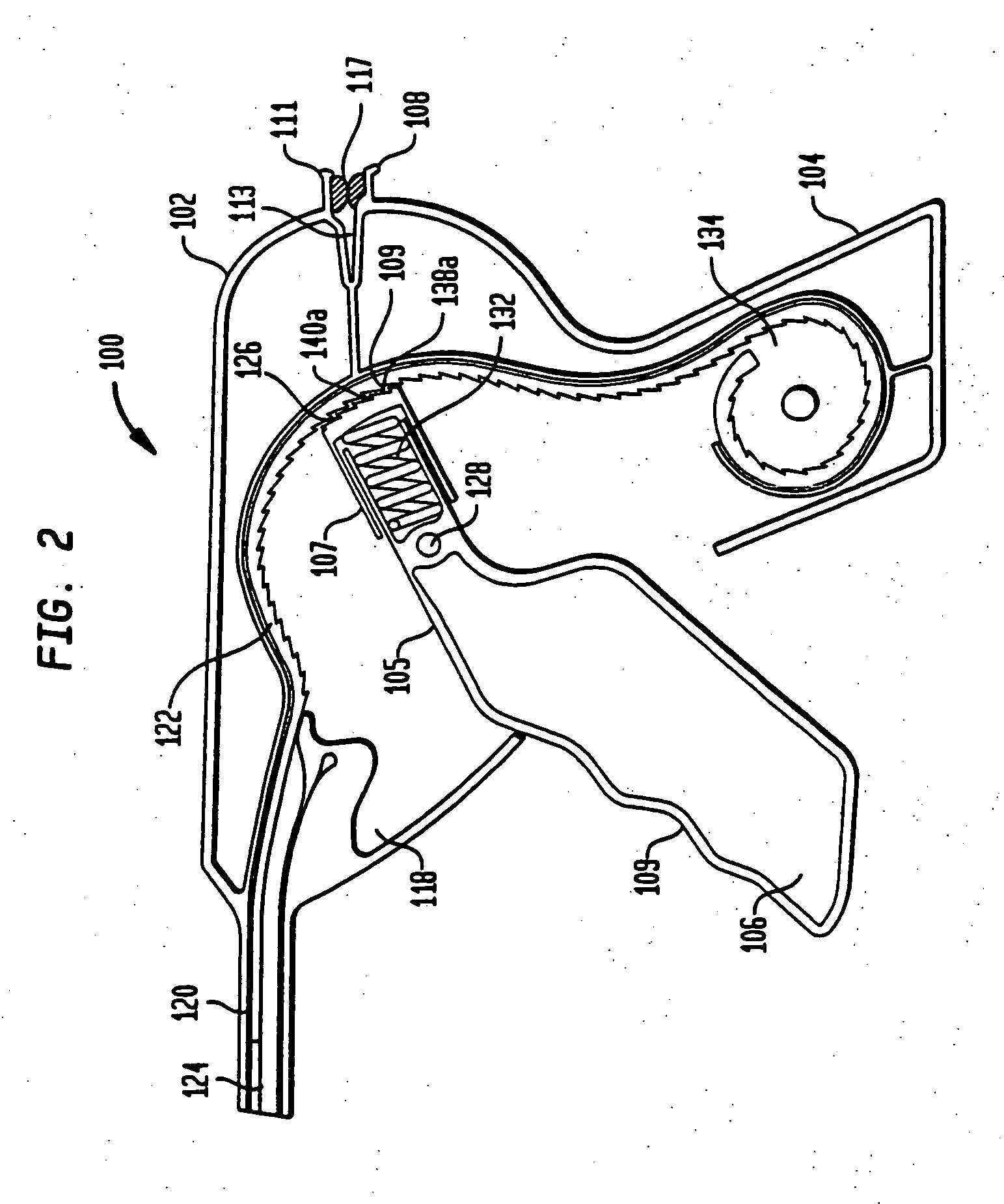

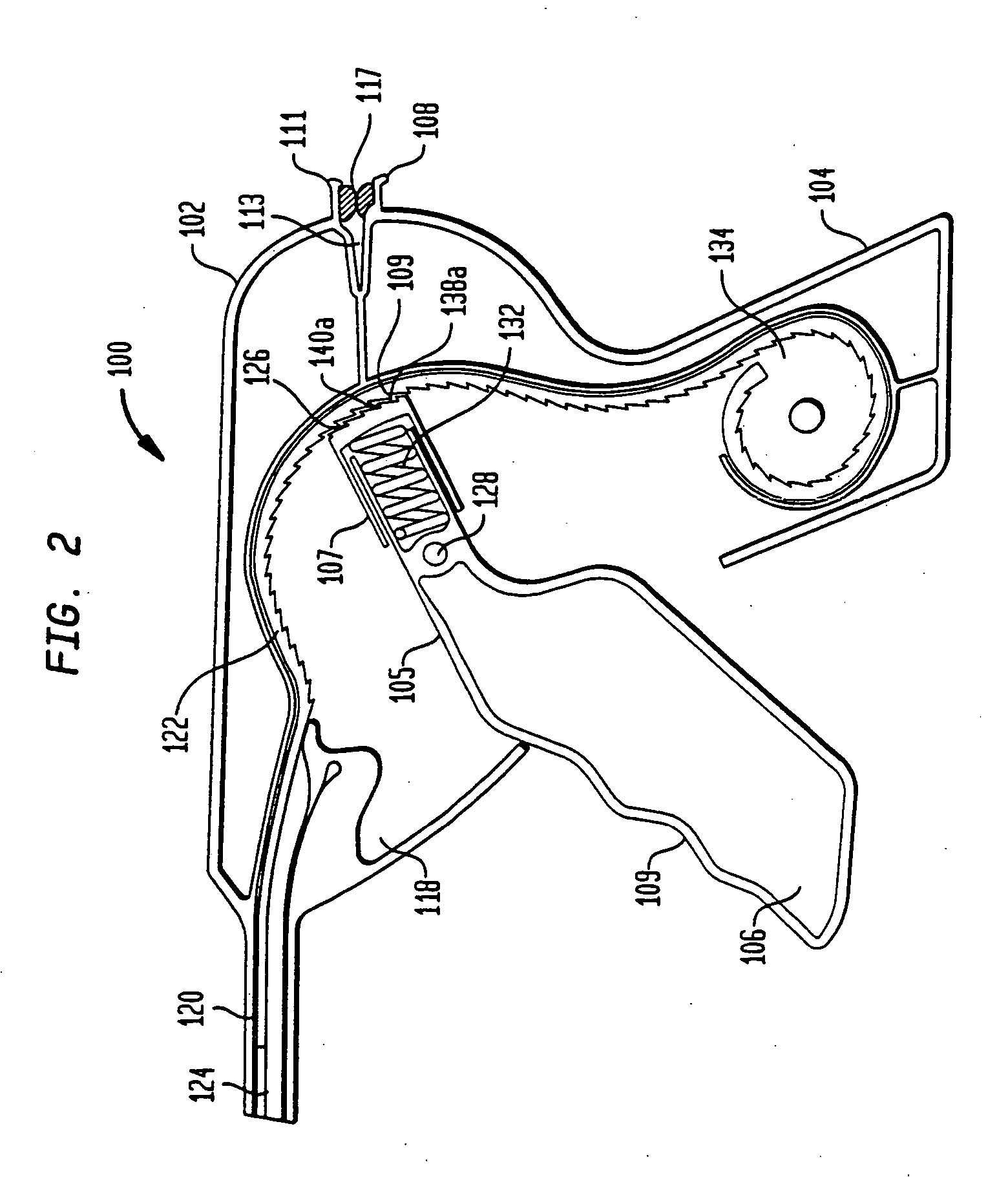

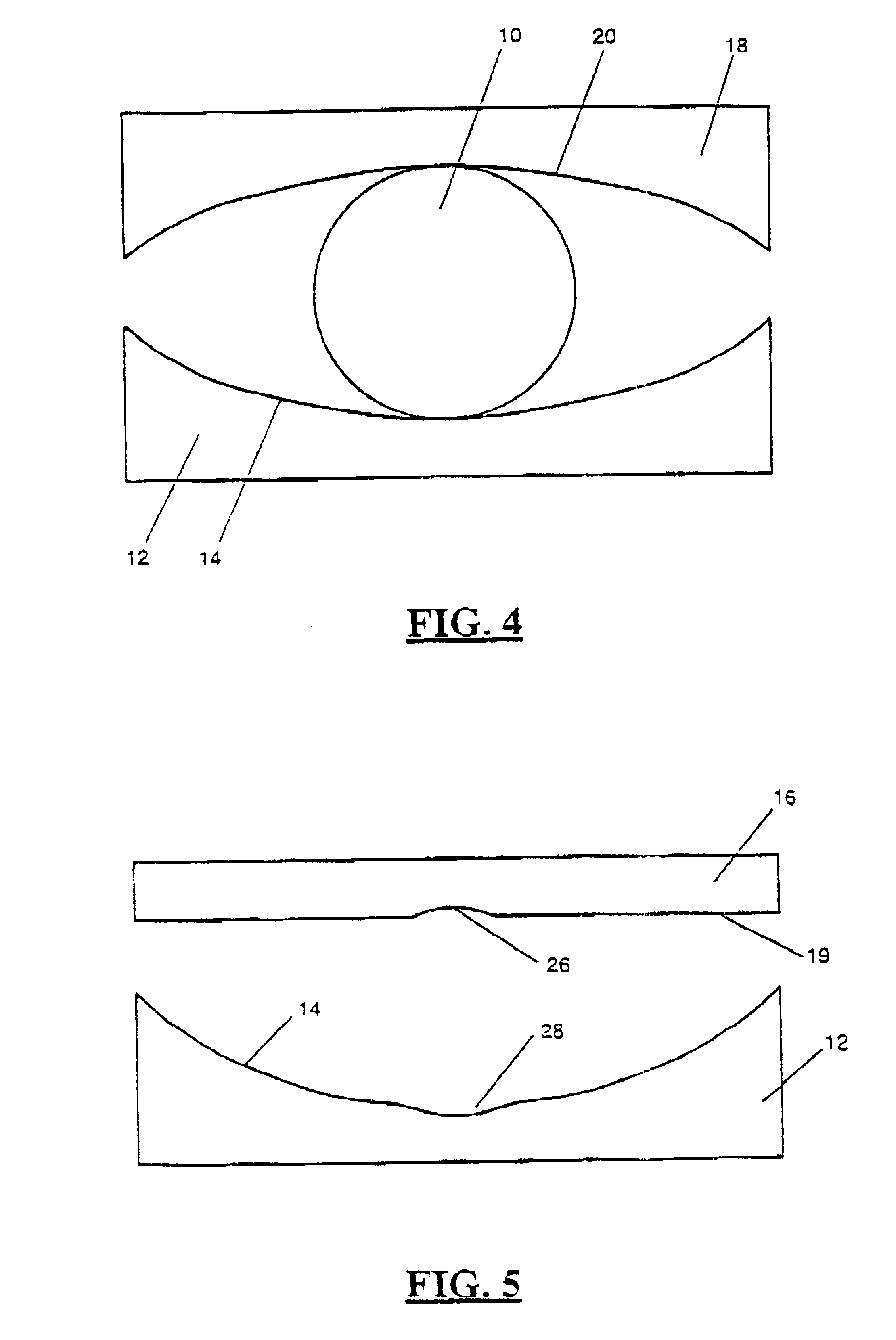

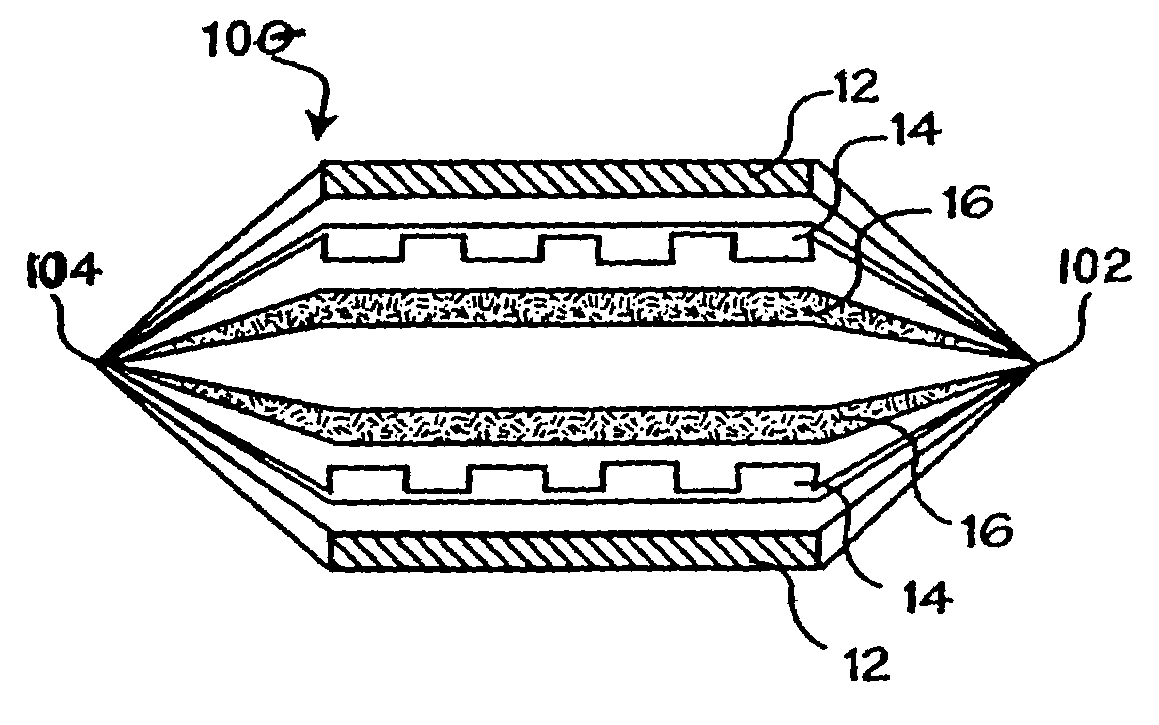

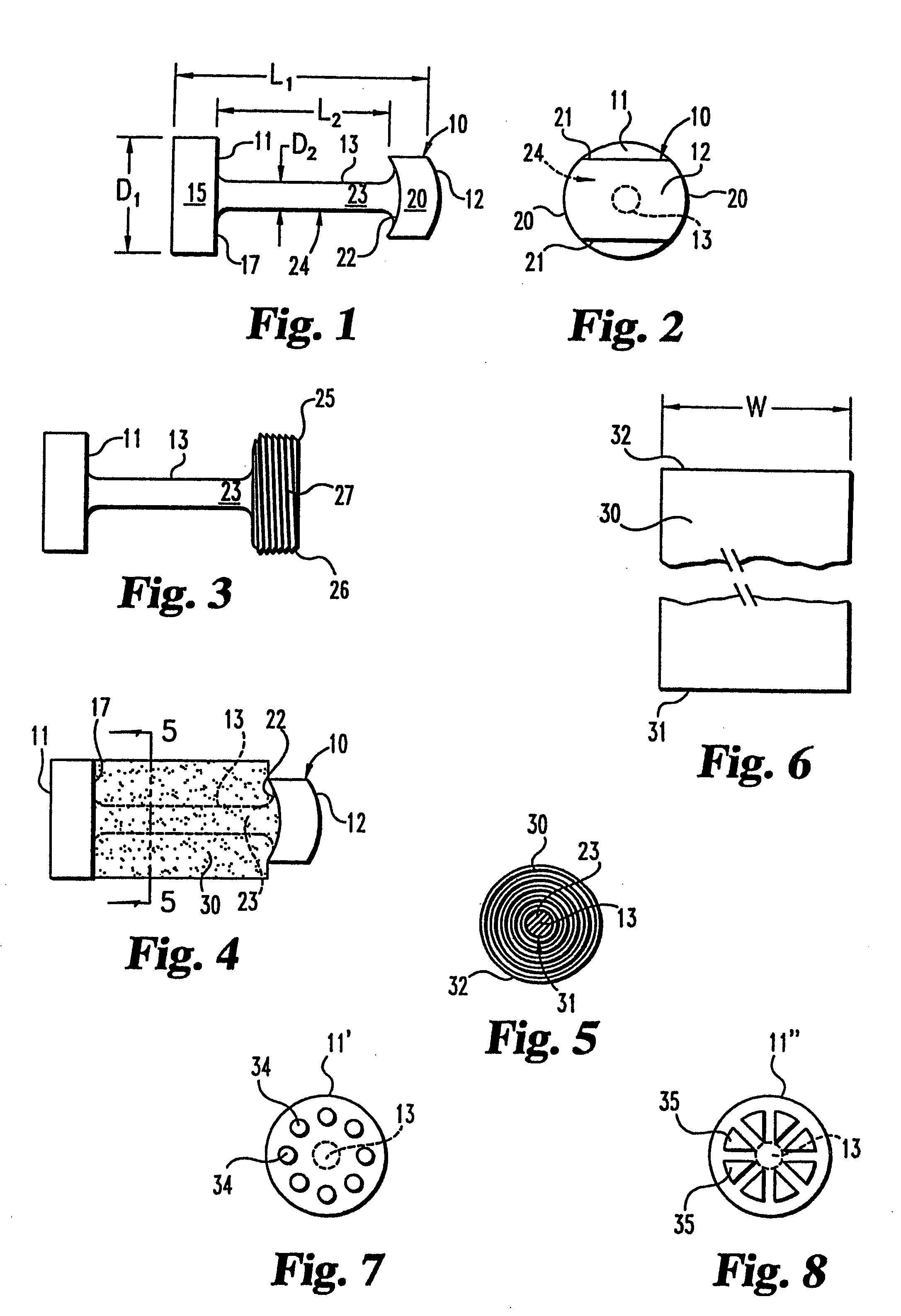

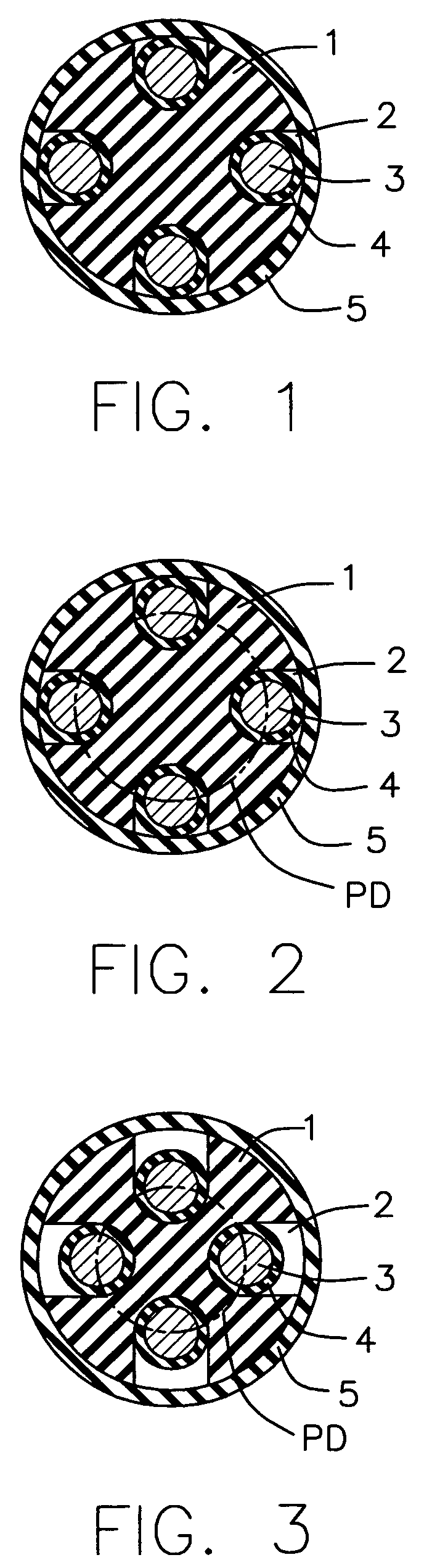

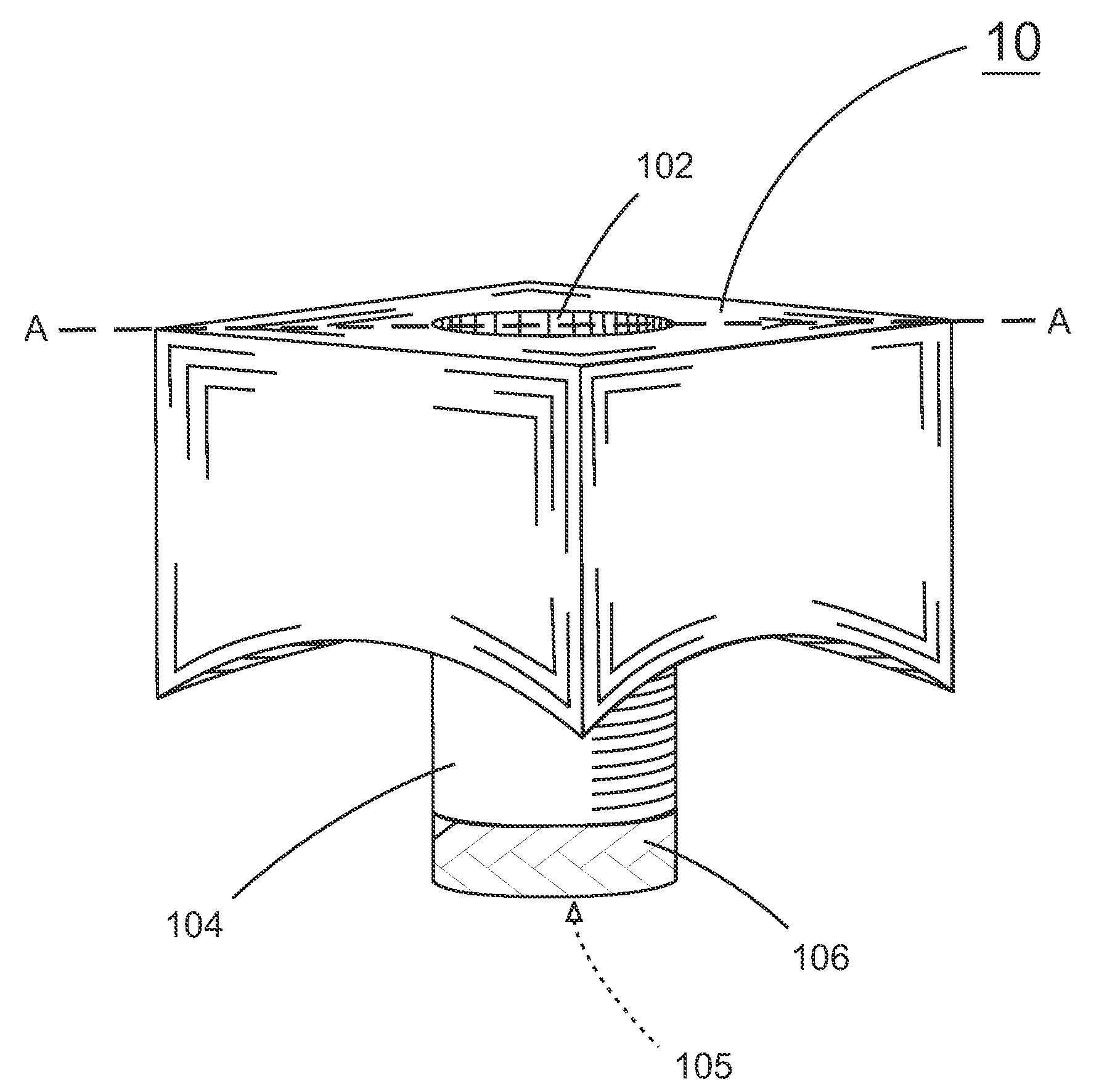

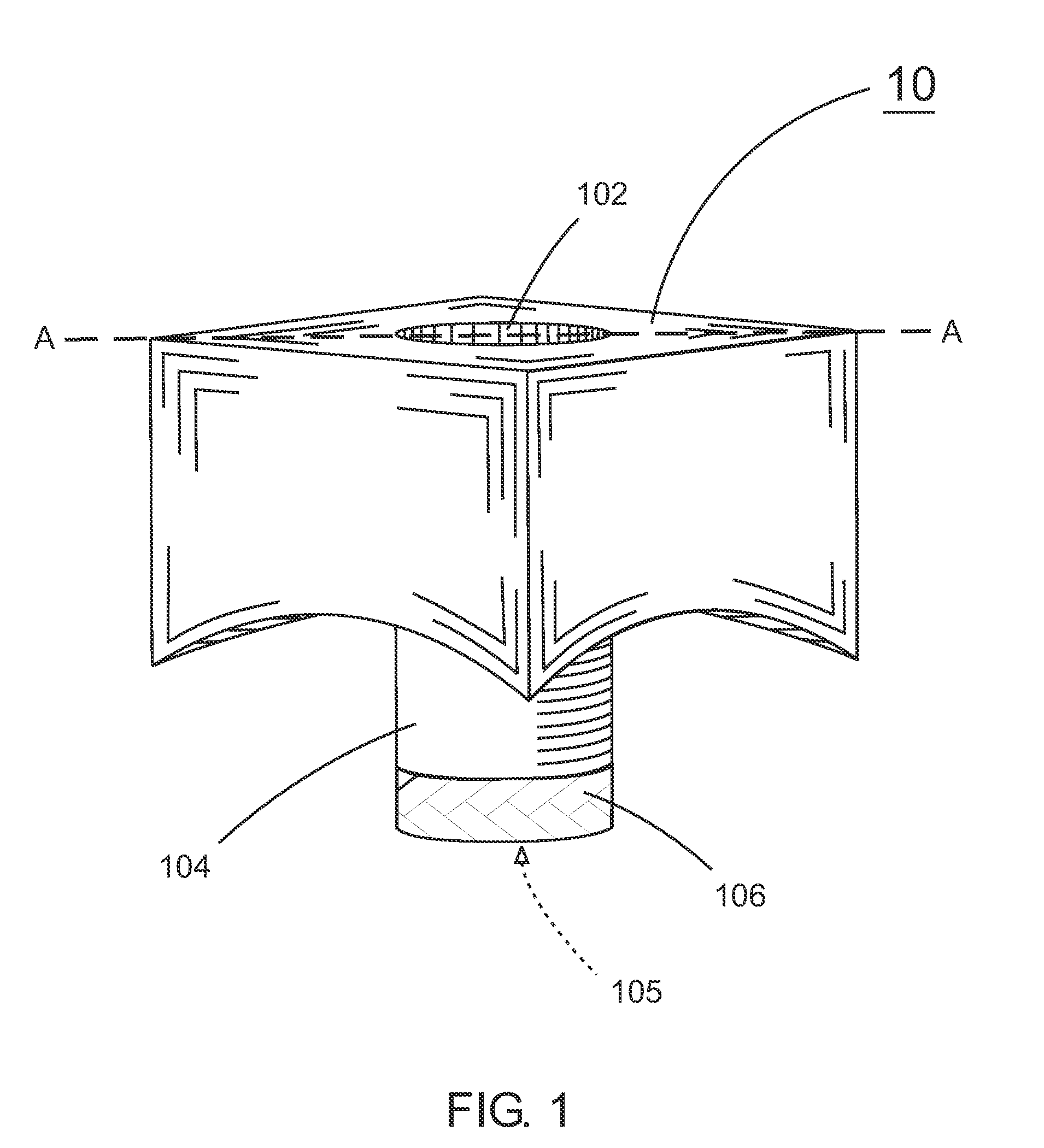

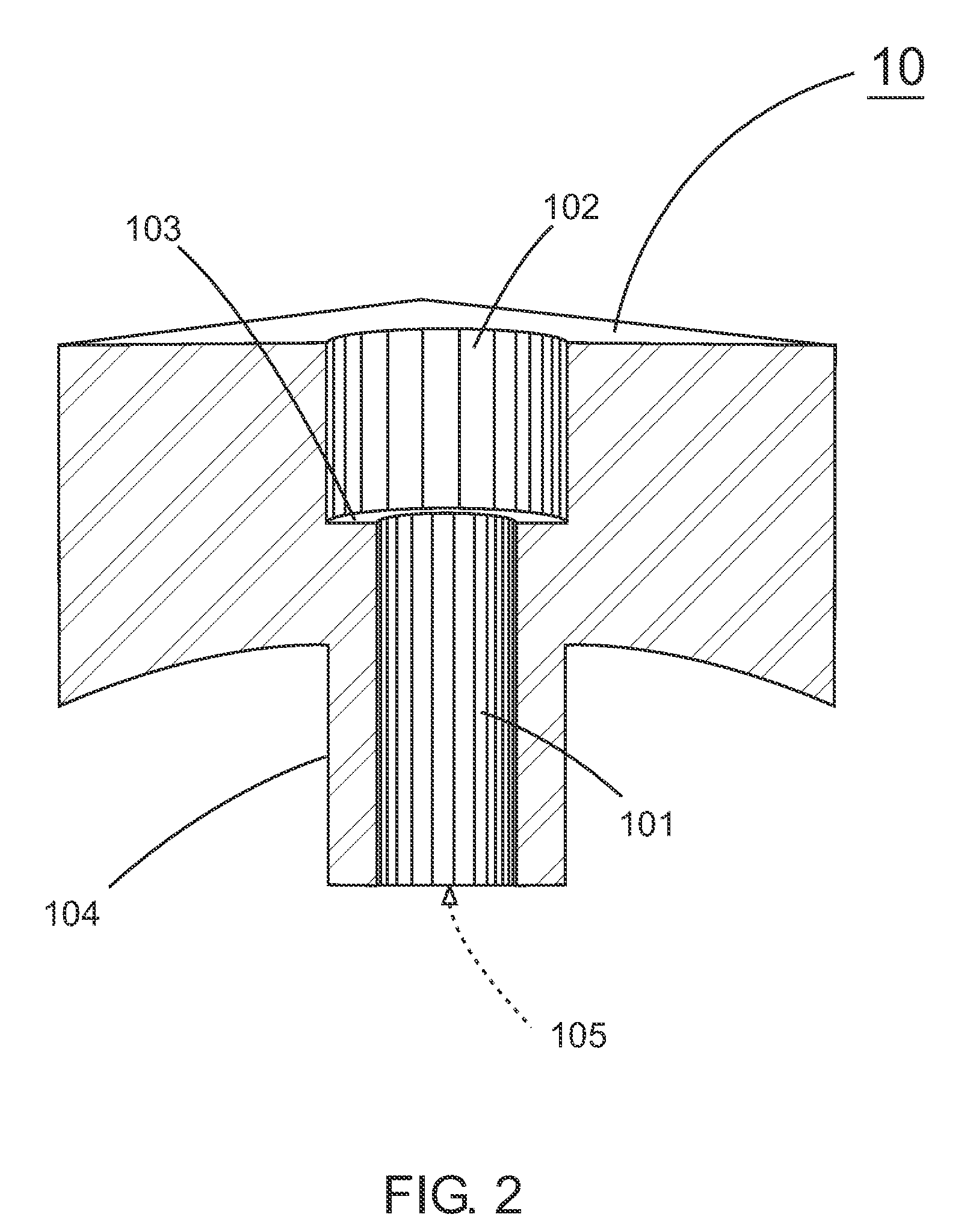

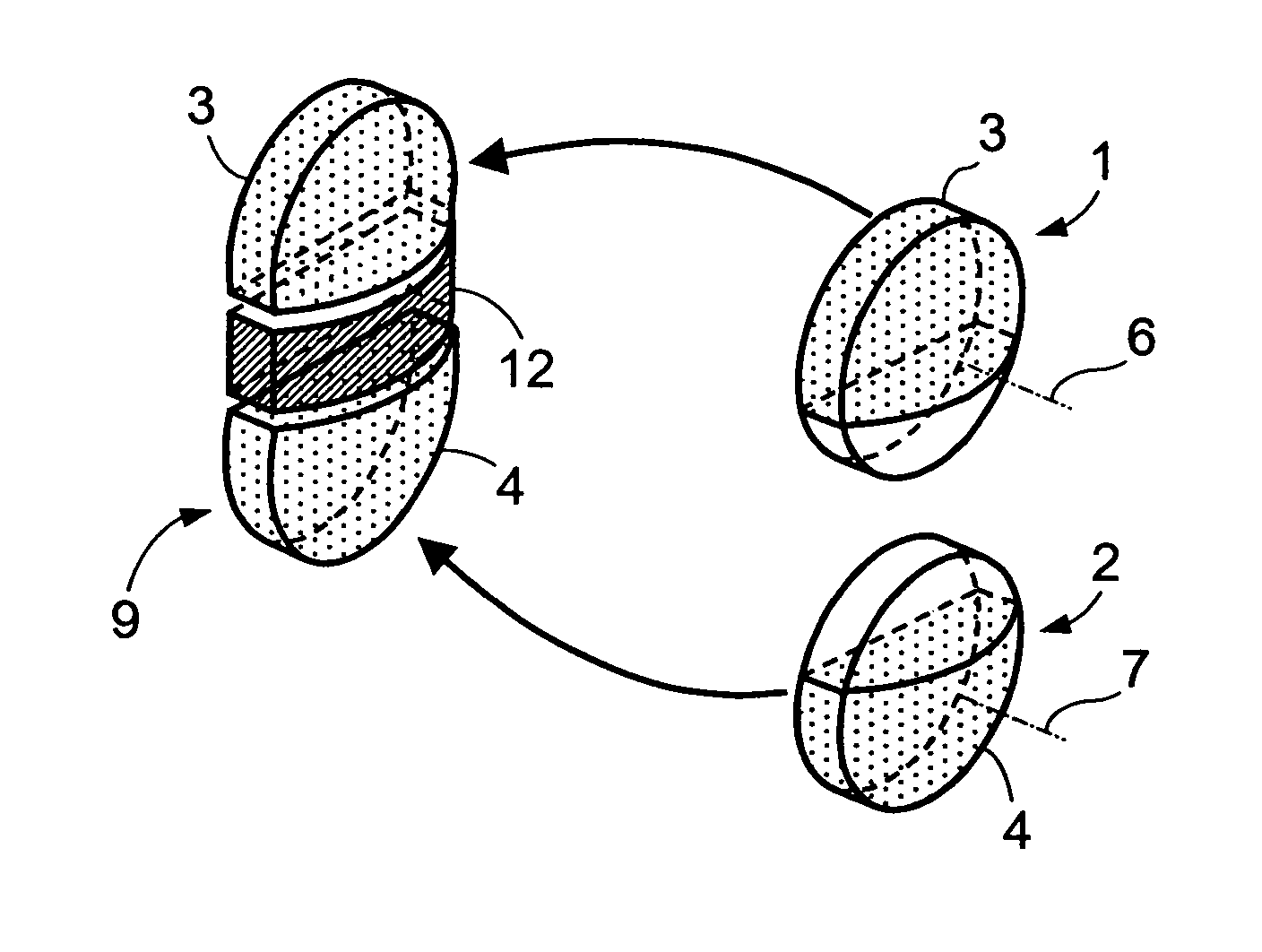

Osteogenic fusion device

InactiveUS20050187626A1The implementation process is simpleSupport of loadBone implantJoint implantsEngineeringCentral element

An interbody osteogenic fusion device is provided that includes a rigid elongated central element and a pair of opposing bone engaging members. The device promotes fusion bone growth in the space between adjacent vertebrae. In one aspect, a cylindrical end cap is coupled to one end of the central element. The opposing bone engaging members are configured to contact and support the adjacent vertebrae. The opposing bone engaging members are coupled at opposite sides of the central element and extend from the end cap to the other end of the central element. The central element, cylindrical end cap, and bone engaging members define opposite cavities for containing osteogenic material.

Owner:SDGI HLDG

Deep water signal cable

InactiveUS7485811B2Increase flexibilityFlexible cablesFlexible conductorsElectrical conductorCentral element

An electrical signal cable having, at least two insulated conductors, wherein each of the insulated conductors is arranged in a groove (2) of a longitudinal central element (1) made of an elastic material which allows the insulated conductors to move in radial direction when the electrical signal cable is exposed to longitudinal tensile stress.

Owner:NEXANS

Osteogenic fusion device

InactiveUS7285135B2The implementation process is simpleSupport of loadBone implantJoint implantsCentral elementBone growth

An interbody osteogenic fusion device is provided that includes a rigid elongated central element and a pair of opposing bone engaging members. The device promotes fusion bone growth in the space between adjacent vertebrae. In one aspect, a cylindrical end cap is coupled to one end of the central element. The opposing bone engaging members are configured to contact and support the adjacent vertebrae. The opposing bone engaging members are coupled at opposite sides of the central element and extend from the end cap to the other end of the central element. The central element, cylindrical end cap, and bone engaging members define opposite cavities for containing osteogenic material.

Owner:SDGI HLDG

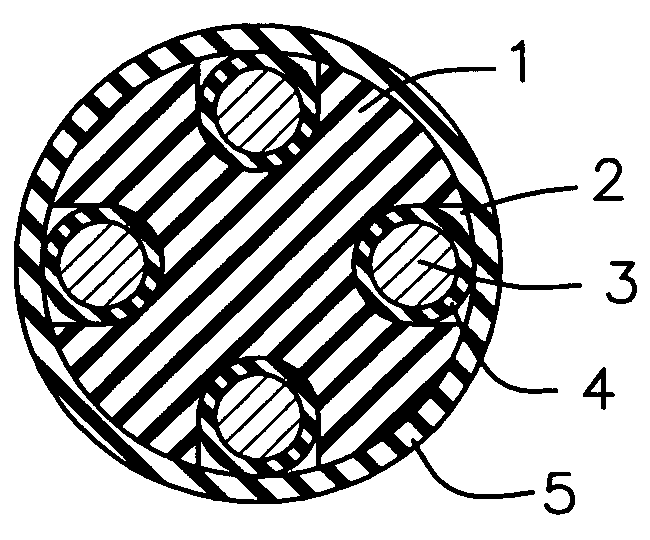

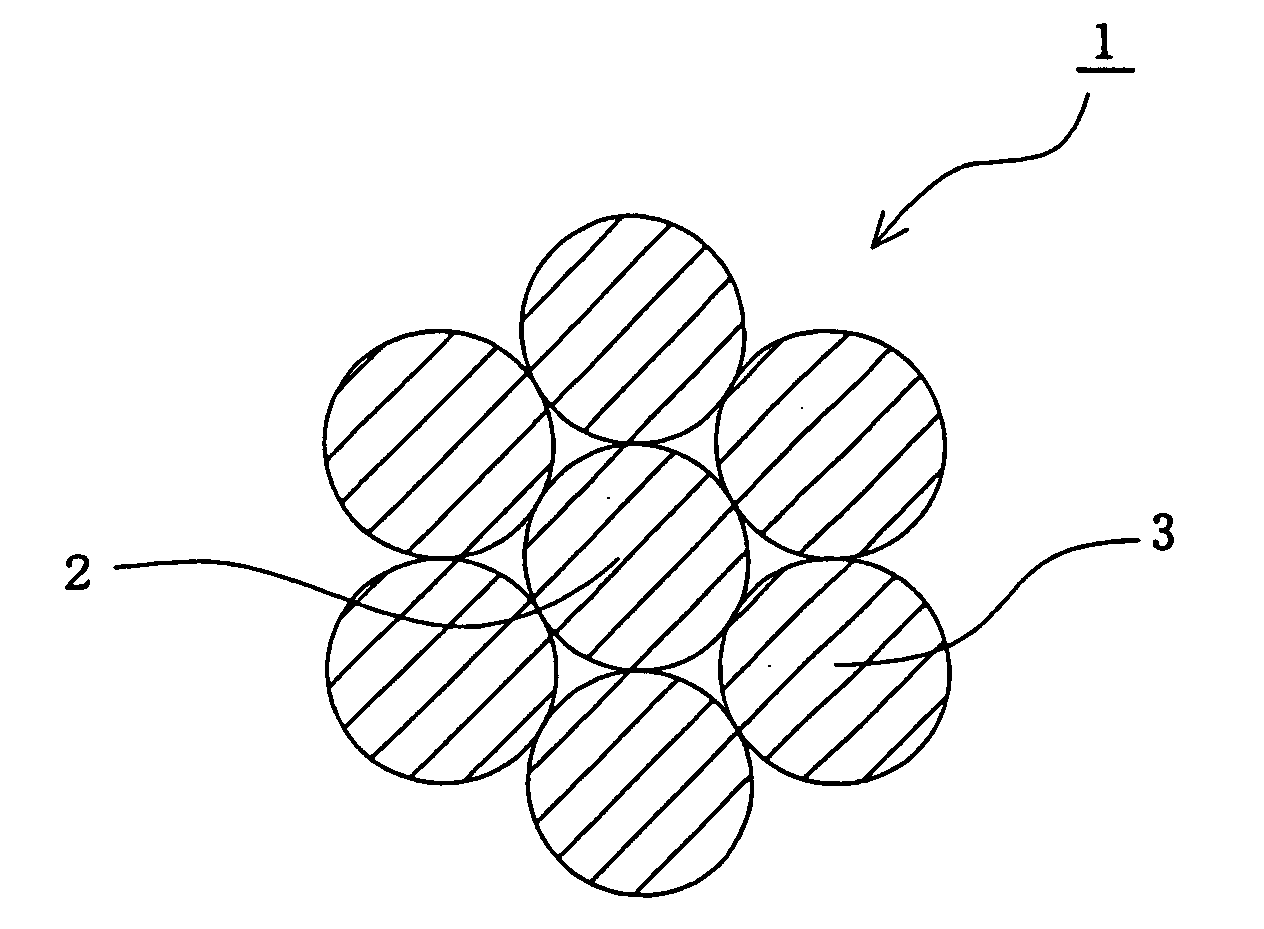

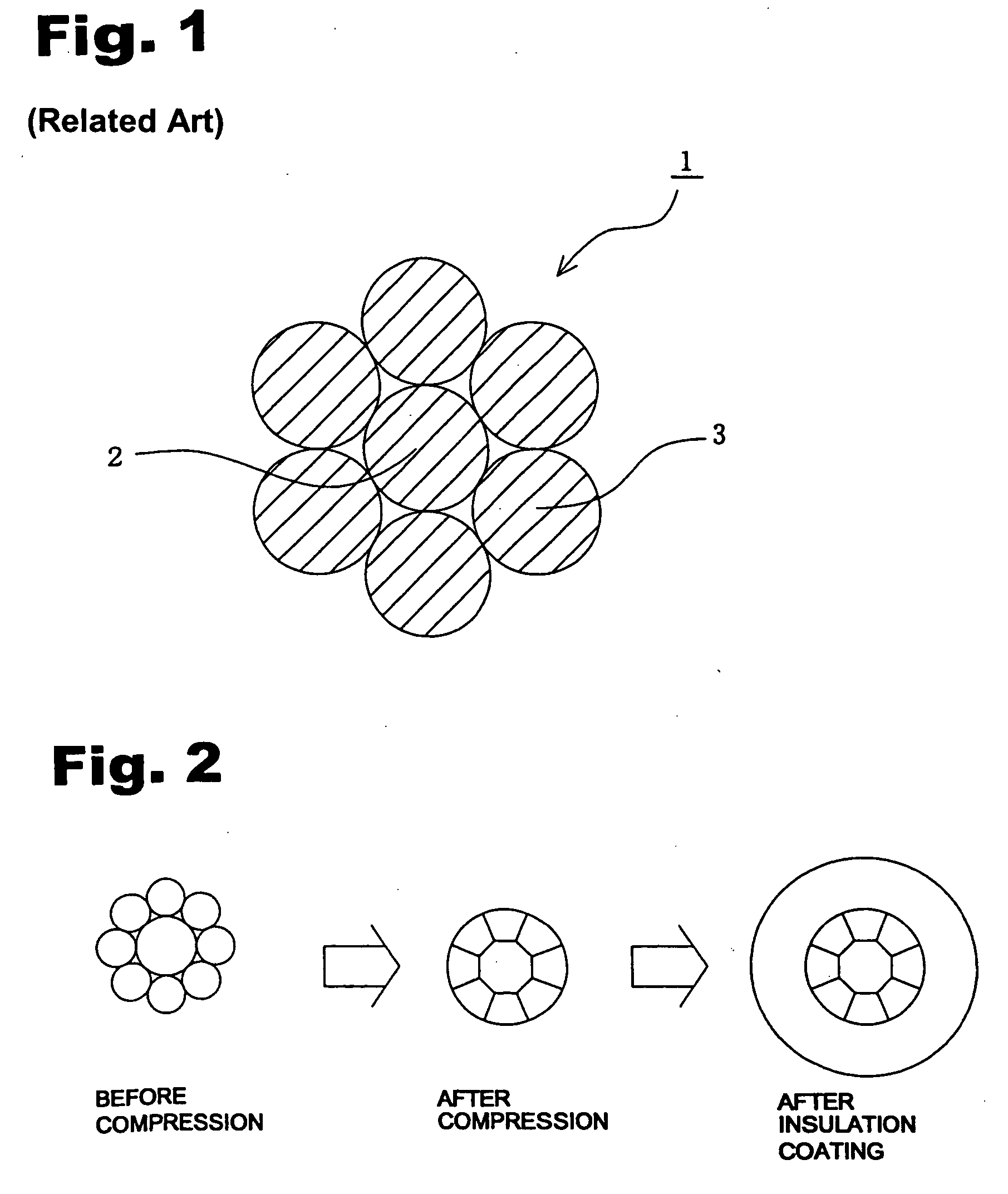

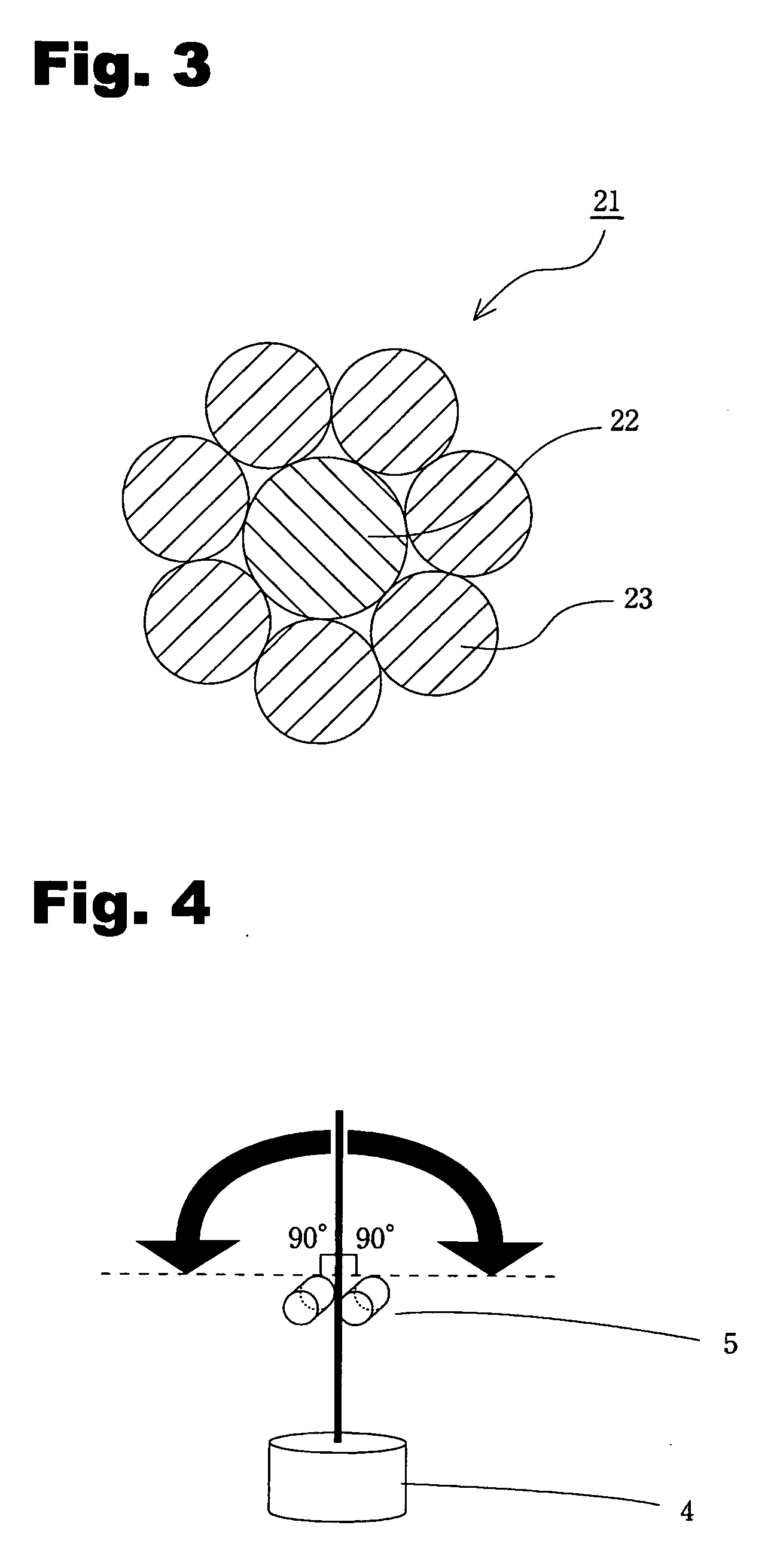

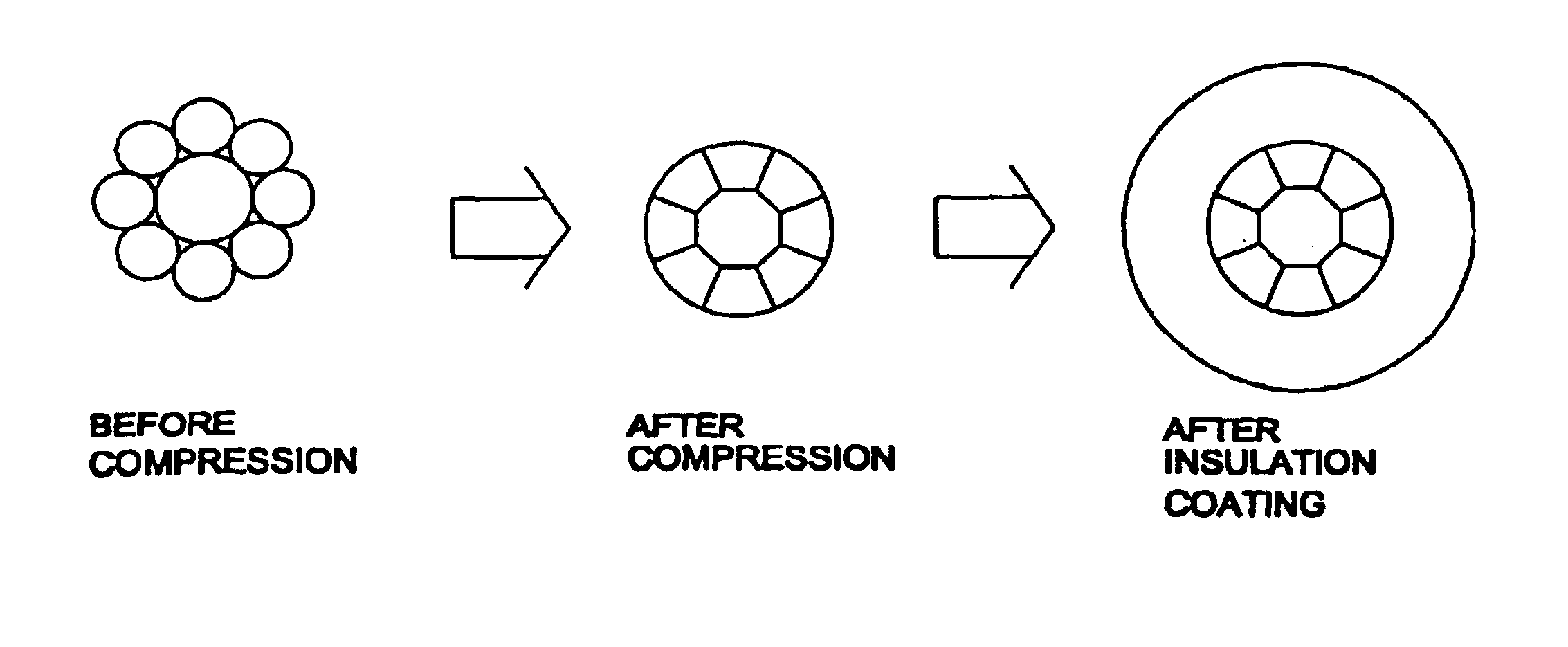

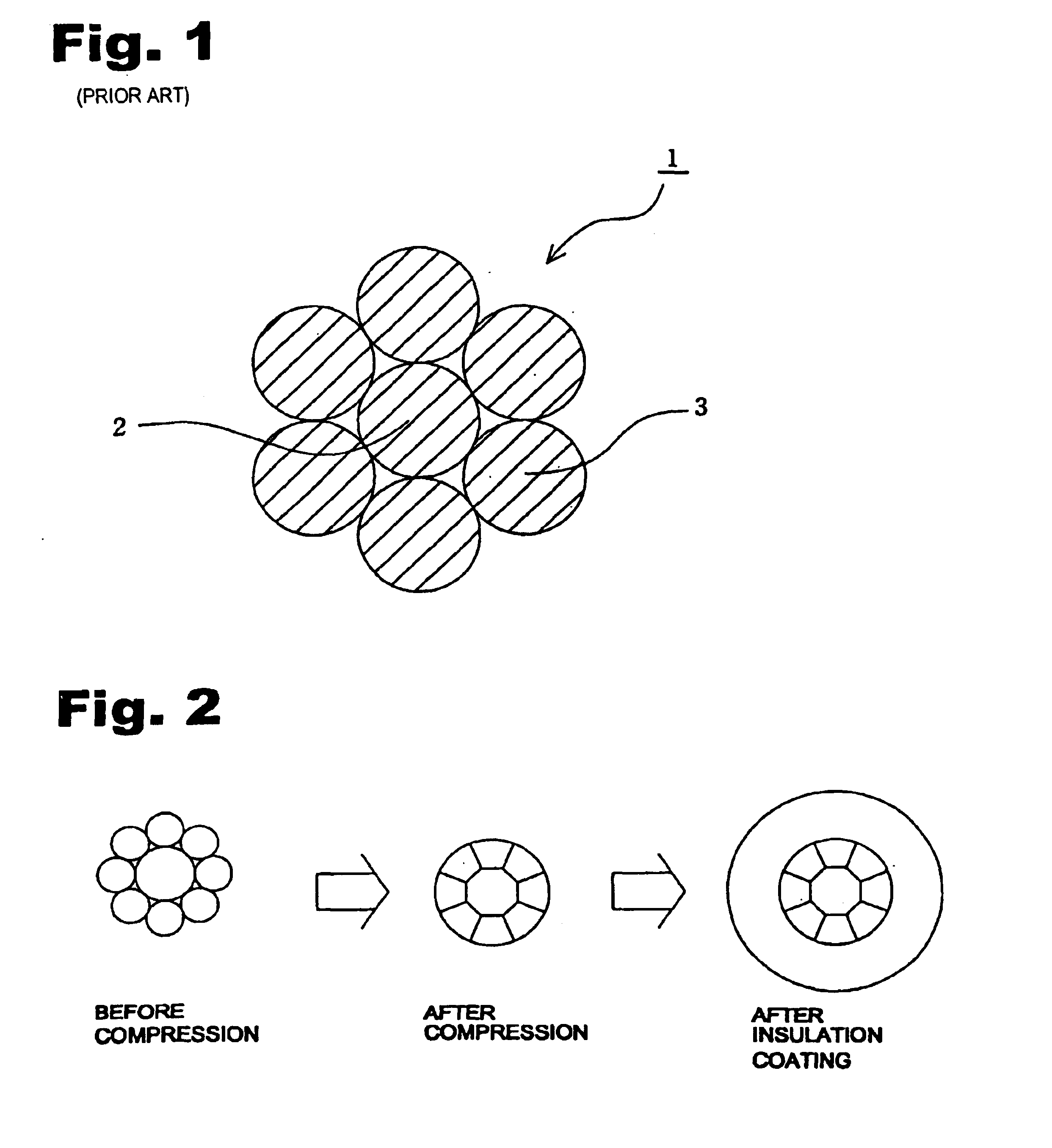

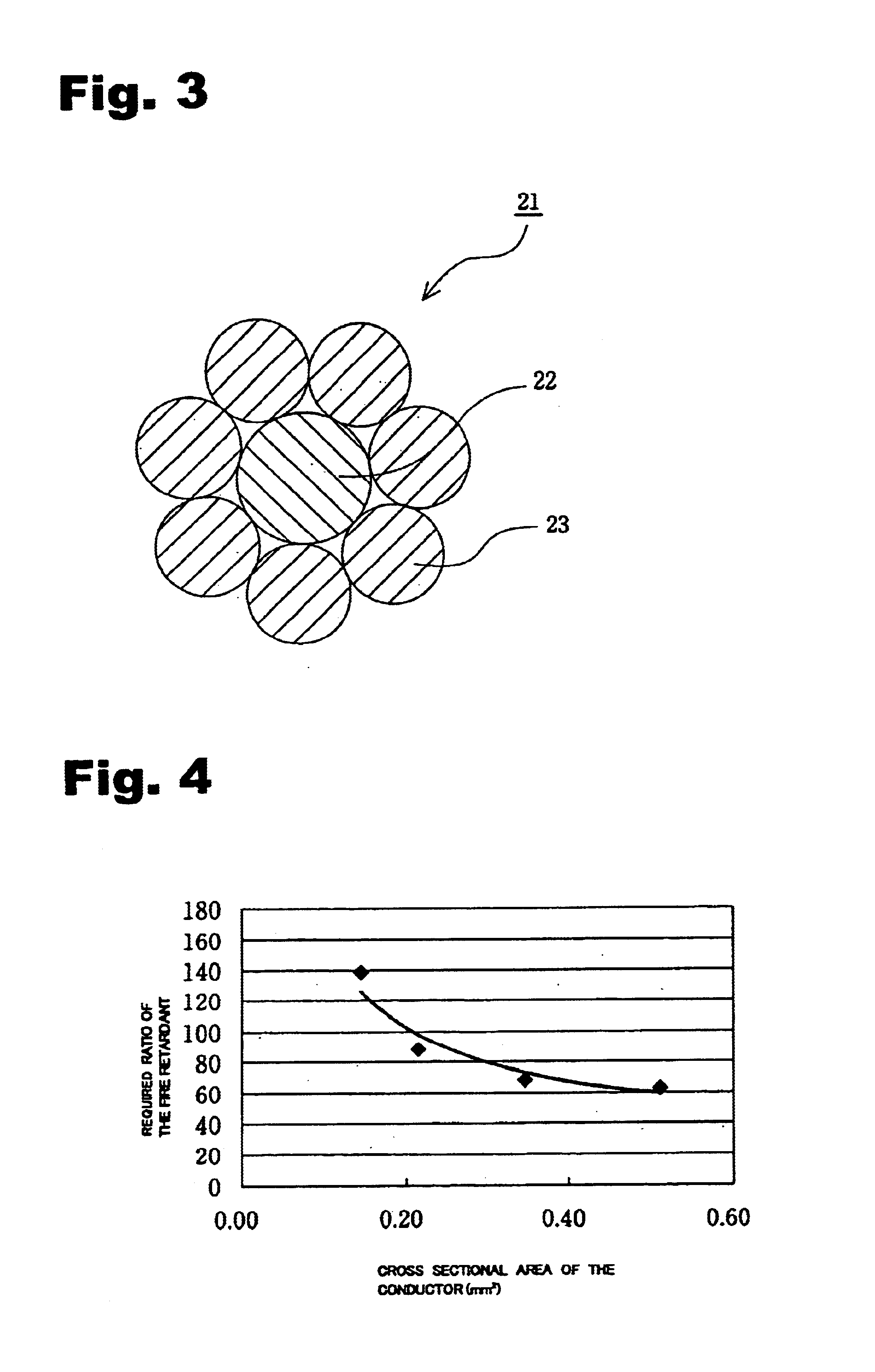

Electric wire for automobile

ActiveUS20060011378A1Non-insulated conductorsReduction of cables/conductors sizeElectrical conductorCentral element

An electric wire for automobile including a compressed conductor which is obtained by arranging, around a single central element wire of stainless steel, a plurality of peripheral element wires of copper or copper alloy in a single circle in tight adherence with each other, wherein the cross sectional area of the conductor is 0.10 through 0.30 mm2, and a ratio C of the cross sectional area of the central element wire to the cross sectional area of the conductor expressed by the formula below is 19.6 through 33.3%: the ratio C of the cross sectional area of the central element wire to the cross sectional area of the conductor being A / (A+B)}×100 [%], wherein the symbol A denotes the cross sectional area of the central element wire and the symbol B denotes the total cross sectional area of the peripheral element wires; or the diameter of the central element wire is larger than the diameters of the peripheral element wires, and the compression rate from the cross sectional area of the conductor before compression to the cross sectional area of the conductor after compression is 5 through 20%.

Owner:SUMITOMO WIRING SYST LTD

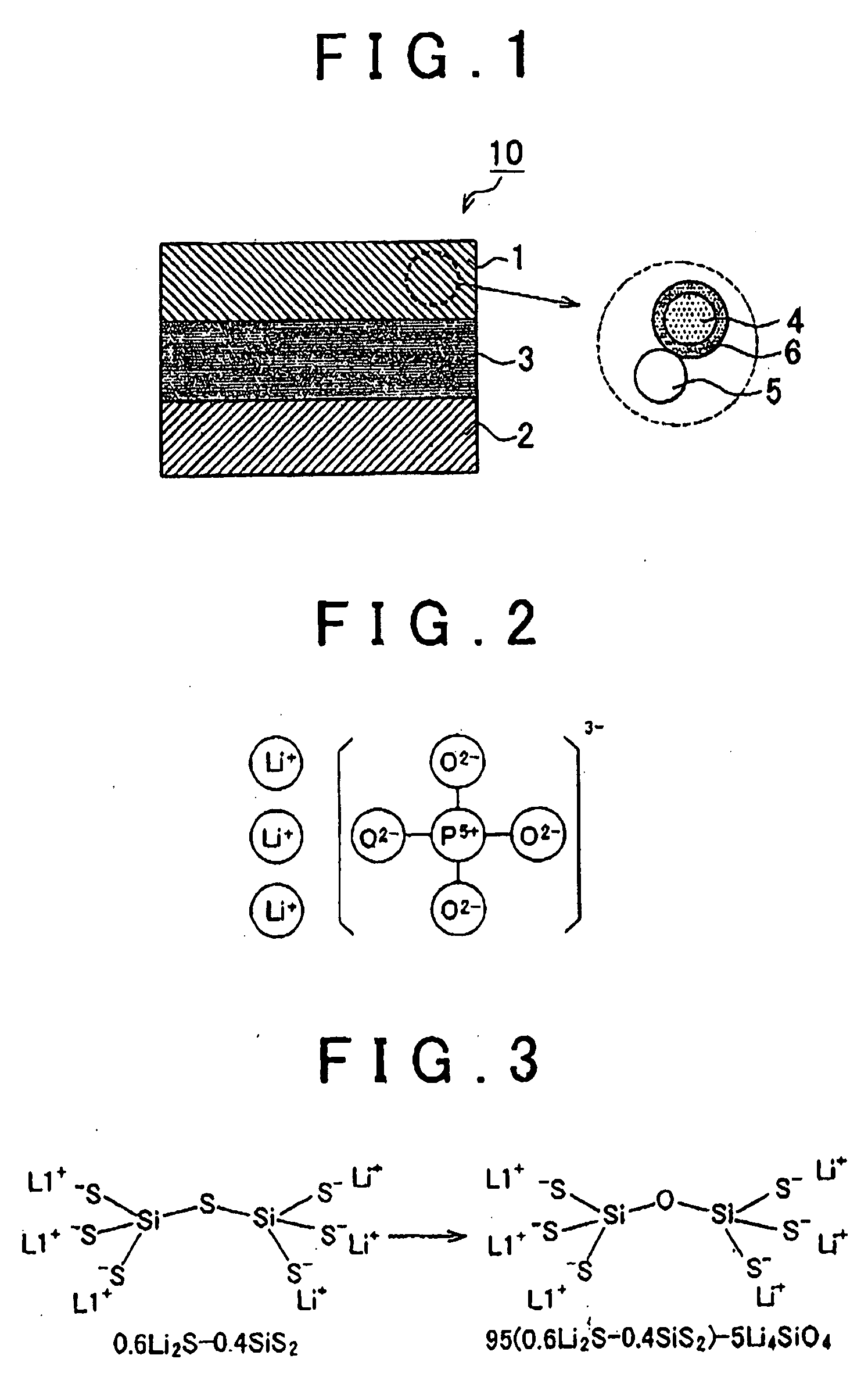

Aluminum cladding method of high-safety lithium ion battery anode material

InactiveCN102364723AImprove cycle performanceImprove securityCell electrodesHigh temperature storageElectrical battery

The invention relates to a manufacturing method of a lithium ion battery anode material, in particular to an aluminum cladding method of a high-safety lithium ion battery anode material. The method comprises the following steps of: a, manufacturing a non-cladded anode material by adopting a conventional method; b, preparing a cladding solution, wherein the cladding solution is aluminum salt sol formed by mutually dissolving an aluminum source and a cosolvent, and the weight concentration of the aluminum salt in the sol is 15-30 percent; c, performing a cladding process: adding the non-cladded anode material to cladding-phase methanol or ethanol or acetone, stirring and mixing, and then adding an aluminum salt sol cladding solution, wherein the molar ratio Al / M of the element Al to the central element M of the anode material is 0.002-0.05; and d, heating and drying for 1-6h at 70-100 DEG C under the vacuumizing condition to form a finished product. According to the aluminum cladding method disclosed by the invention, the high-temperature storage safety and the cycle stability of the lithium ion anode material under high charging cutoff voltage can be ensured.

Owner:JIANGSU KING LITHIUM CELL

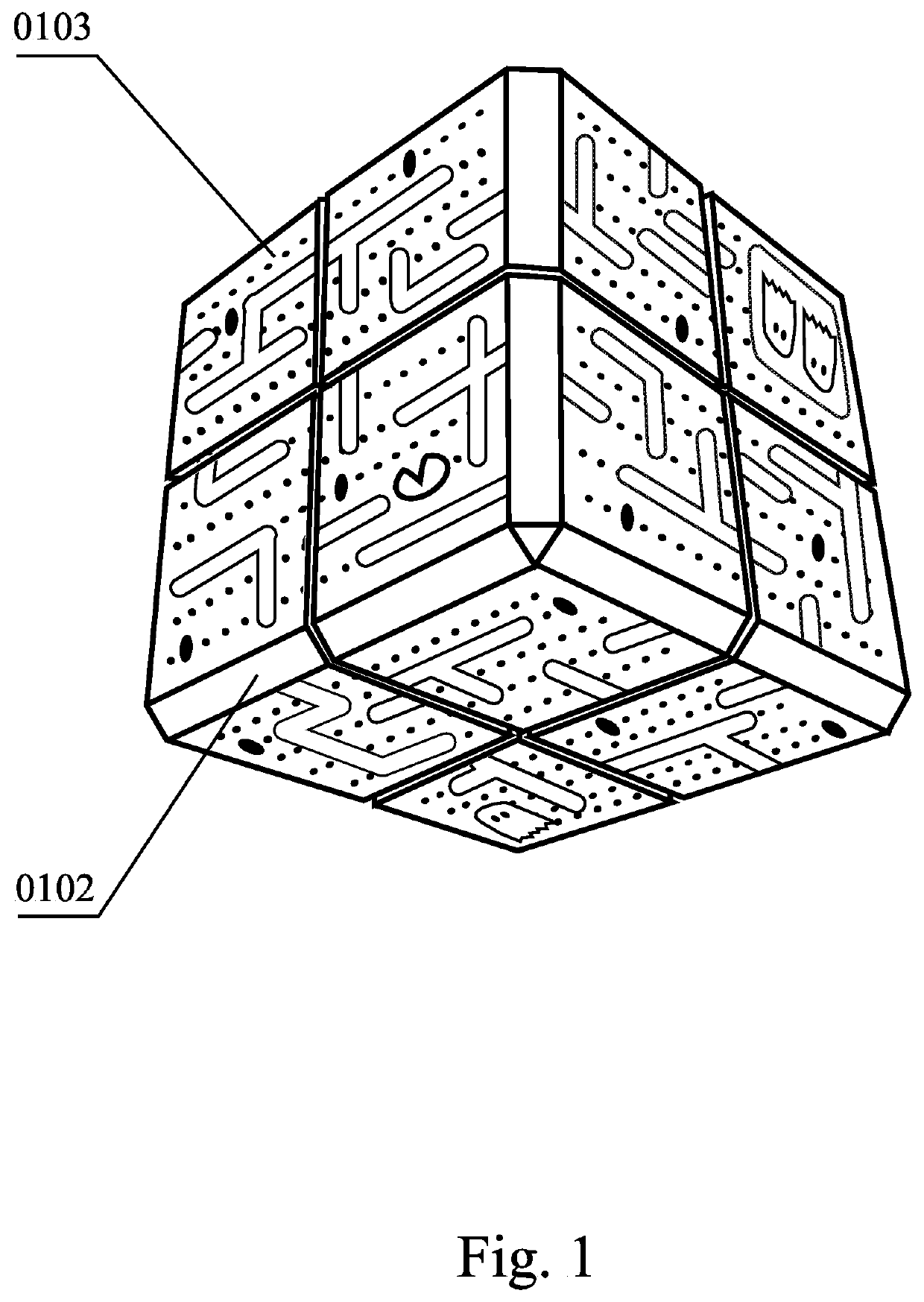

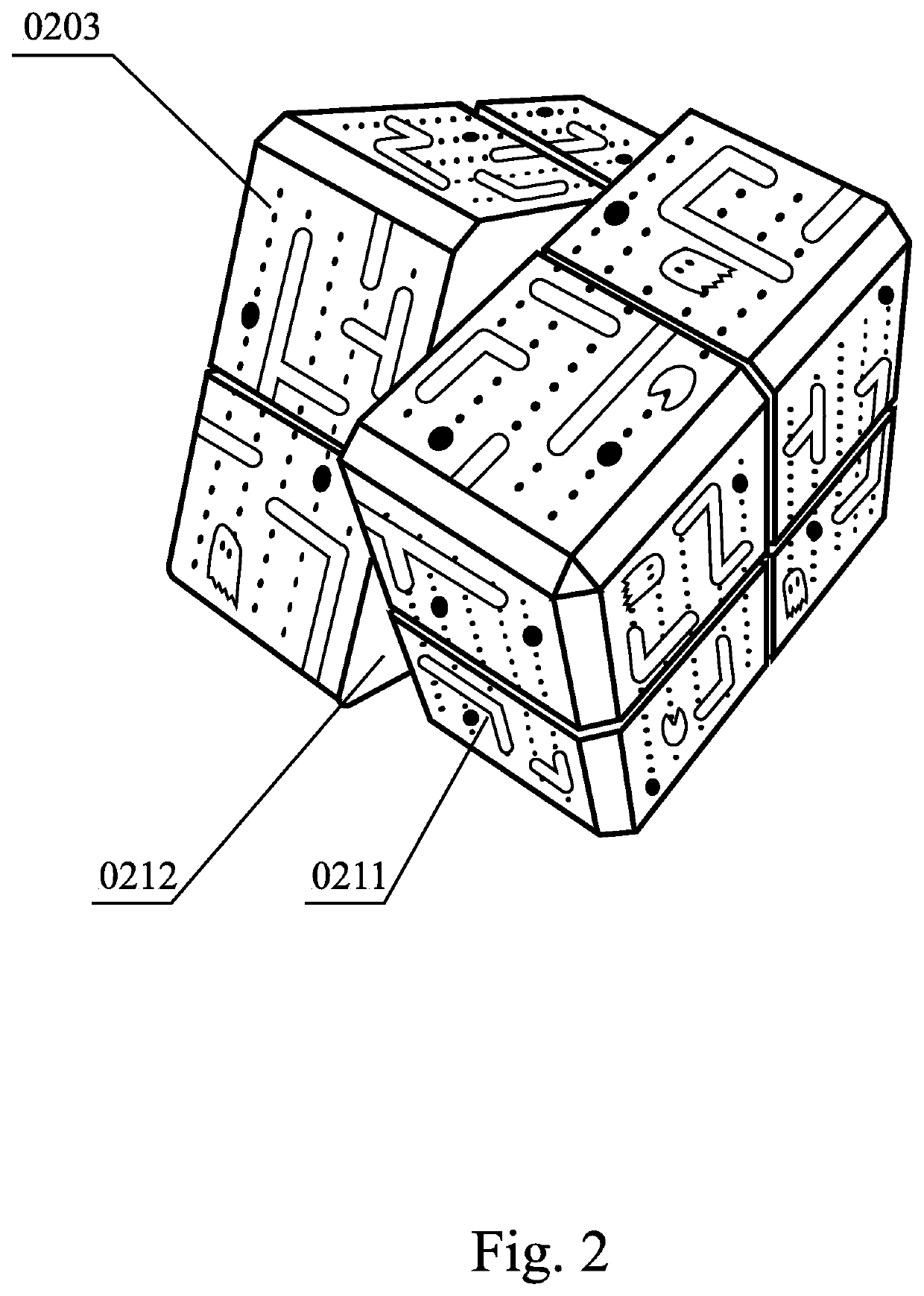

Shiftable cubic puzzle with superimposed slidable elements

A cubic puzzle improves on the Rubik's Cube by adding slidable elements to exterior surfaces of the cube. The improved cubic puzzle has a plurality of cubic elements connected to an interior central element, the cubic elements of each of the six surfaces of the cube being grouped into six rotatable groups of cubic elements that can be rotatably shifted relative to the central element about one of the three orthogonal axes of the cubic puzzle. The cubic puzzle further includes a plurality of slidable elements slidably disposed on exterior faces of the cubic elements.

Owner:PAQUETTE MAXIME

Electric wire for automobile

An electric wire for automobile including a compressed conductor which is obtained by arranging around a single central element wire of stainless steel, seven or more peripheral element wires of copper or copper alloy in a single circle in tight adherence with each other, and an insulation coating layer which covers the outer circumference of the conductor, wherein the diameter of the central element wire is larger than the diameters of the peripheral element wires, the cross sectional area of the conductor is 0.13 through 0.16 mm2, and the insulation coating layer contains a fire retardant in the amount of 160 weight parts or more relative to 100 weights parts of insulation polymer.

Owner:SUMITOMO WIRING SYST LTD

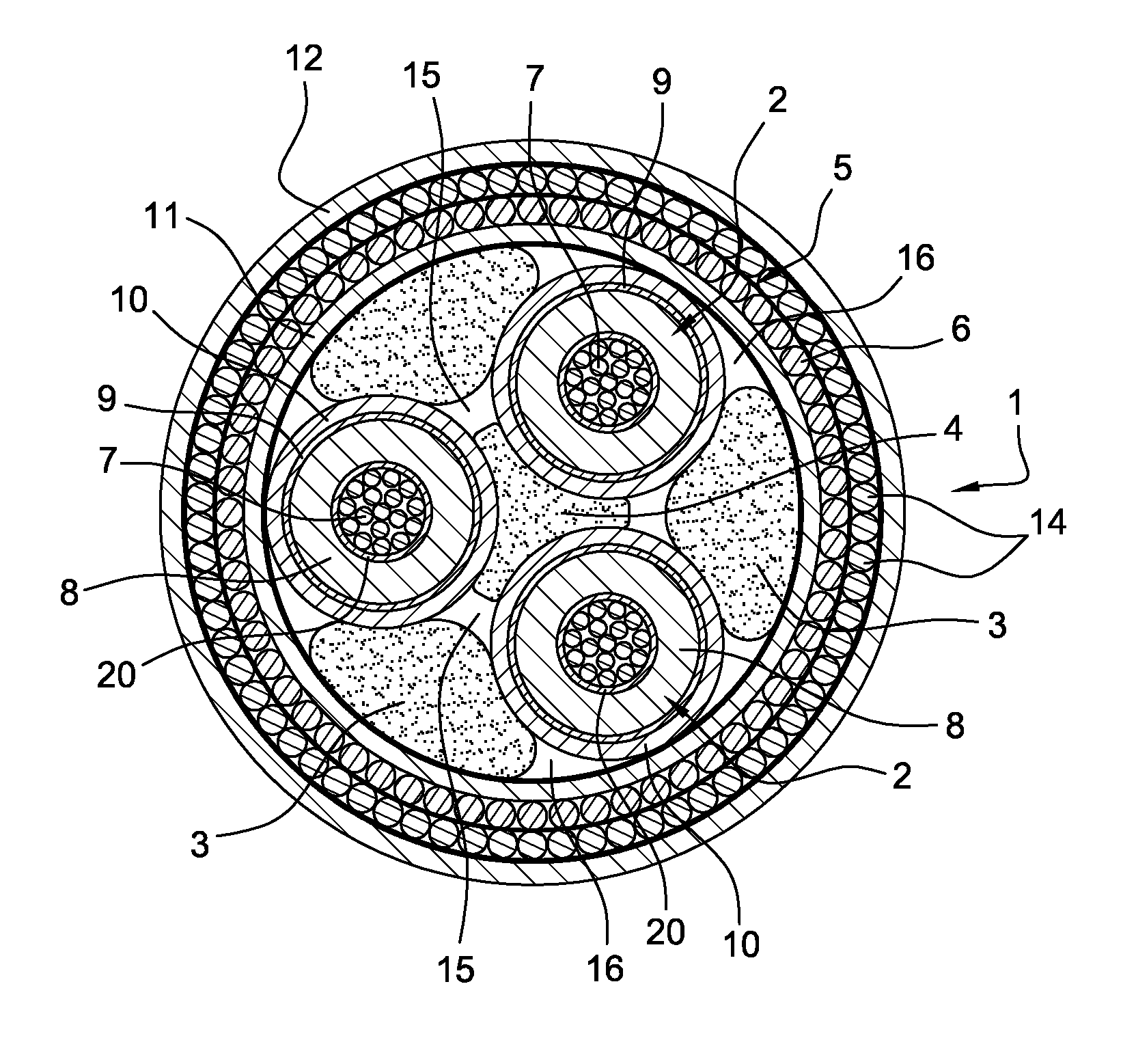

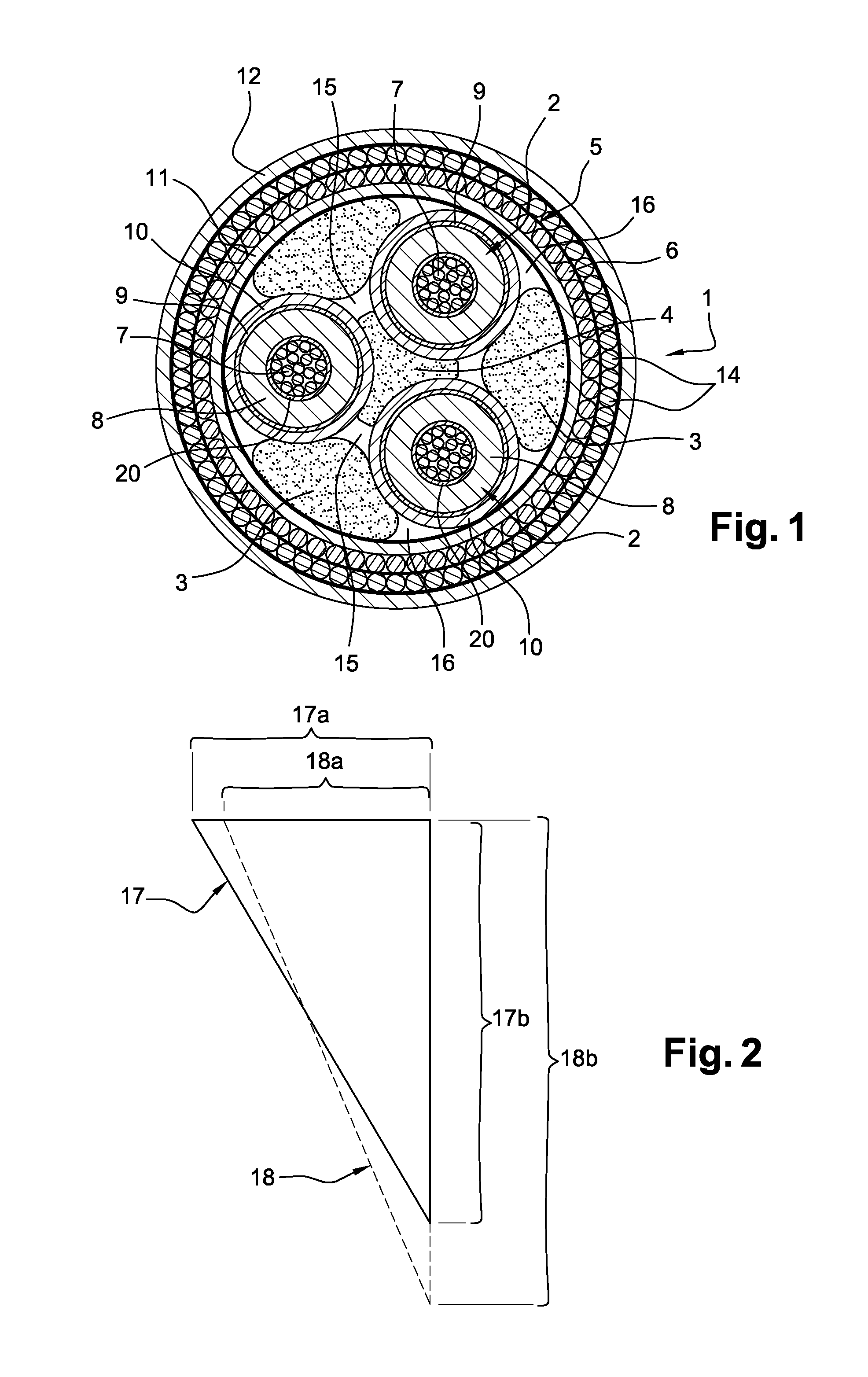

High voltage power cable for ultra deep waters applications

ActiveUS20120279750A1Simple processEasy to implementPower cables with screens/conductive layersInsulated cablesElectrical conductorPower cable

A high voltage power cable (1) includes at least two insulated conductors (2) and an armour package (6) surrounding the conductors (2). The cable (1) has a longitudinal central element (4) of an elastic material, and longitudinal elements (3) of polymer material placed between the said insulated conductors (2).

Owner:NEXANS

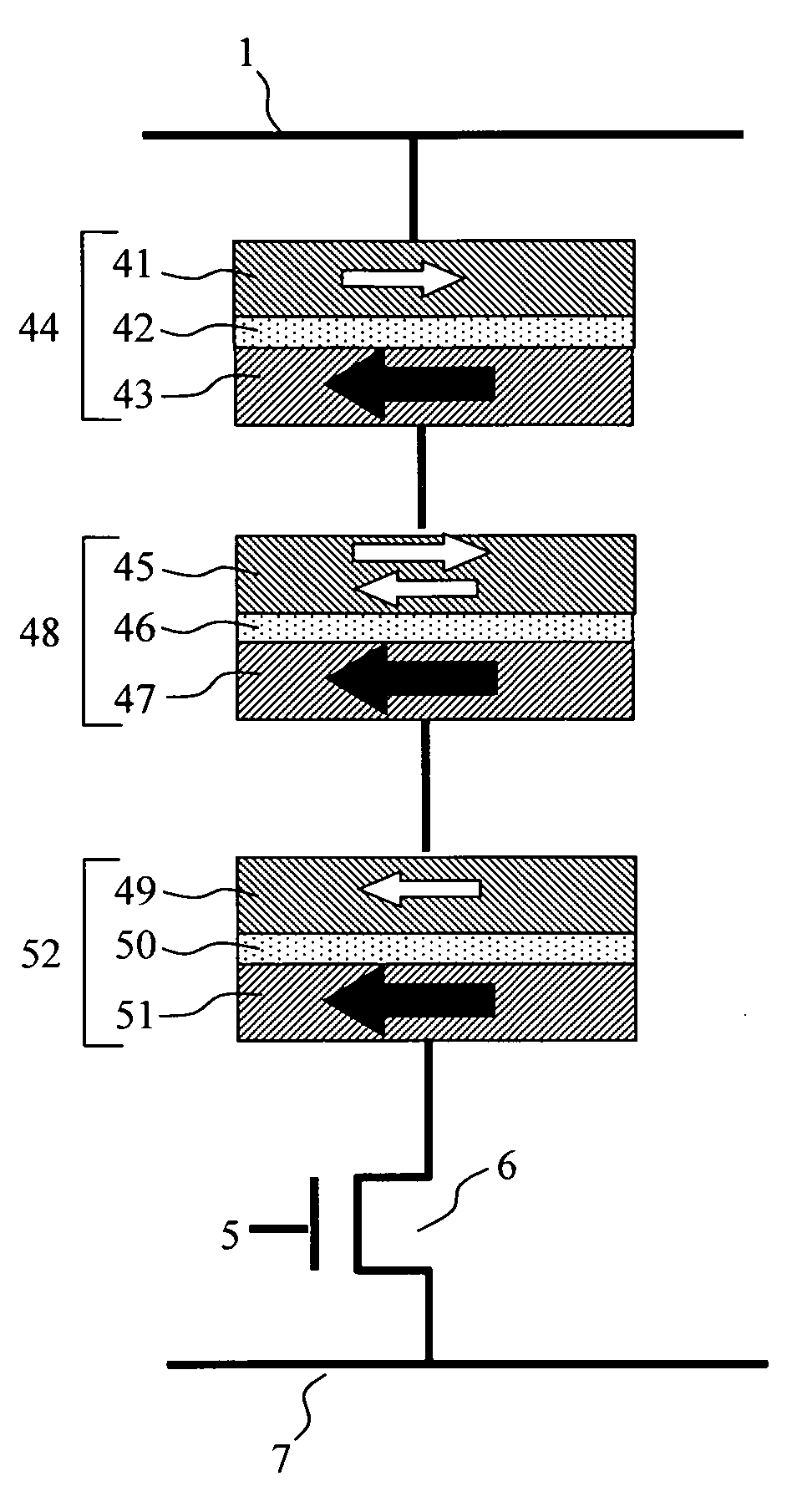

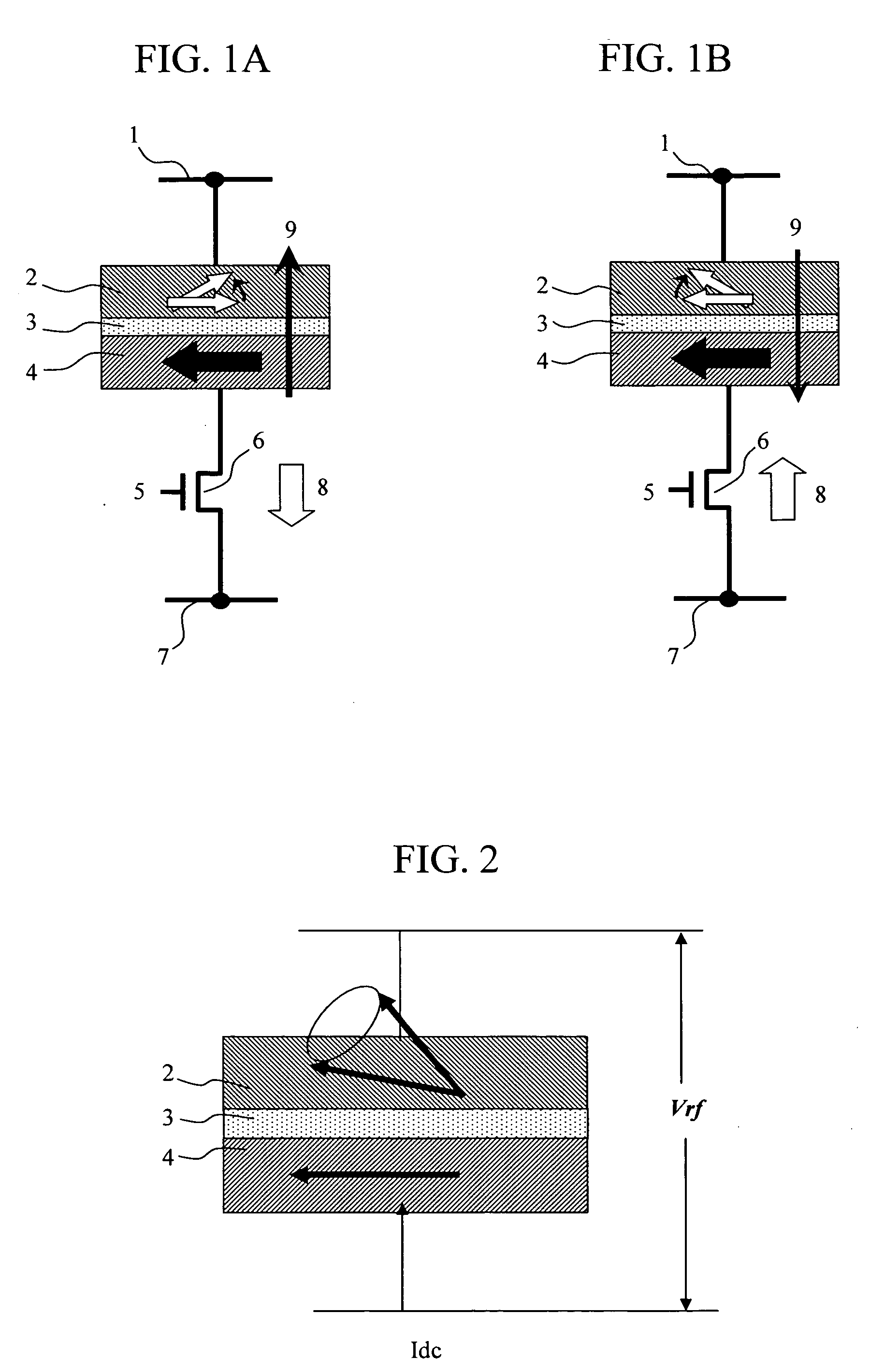

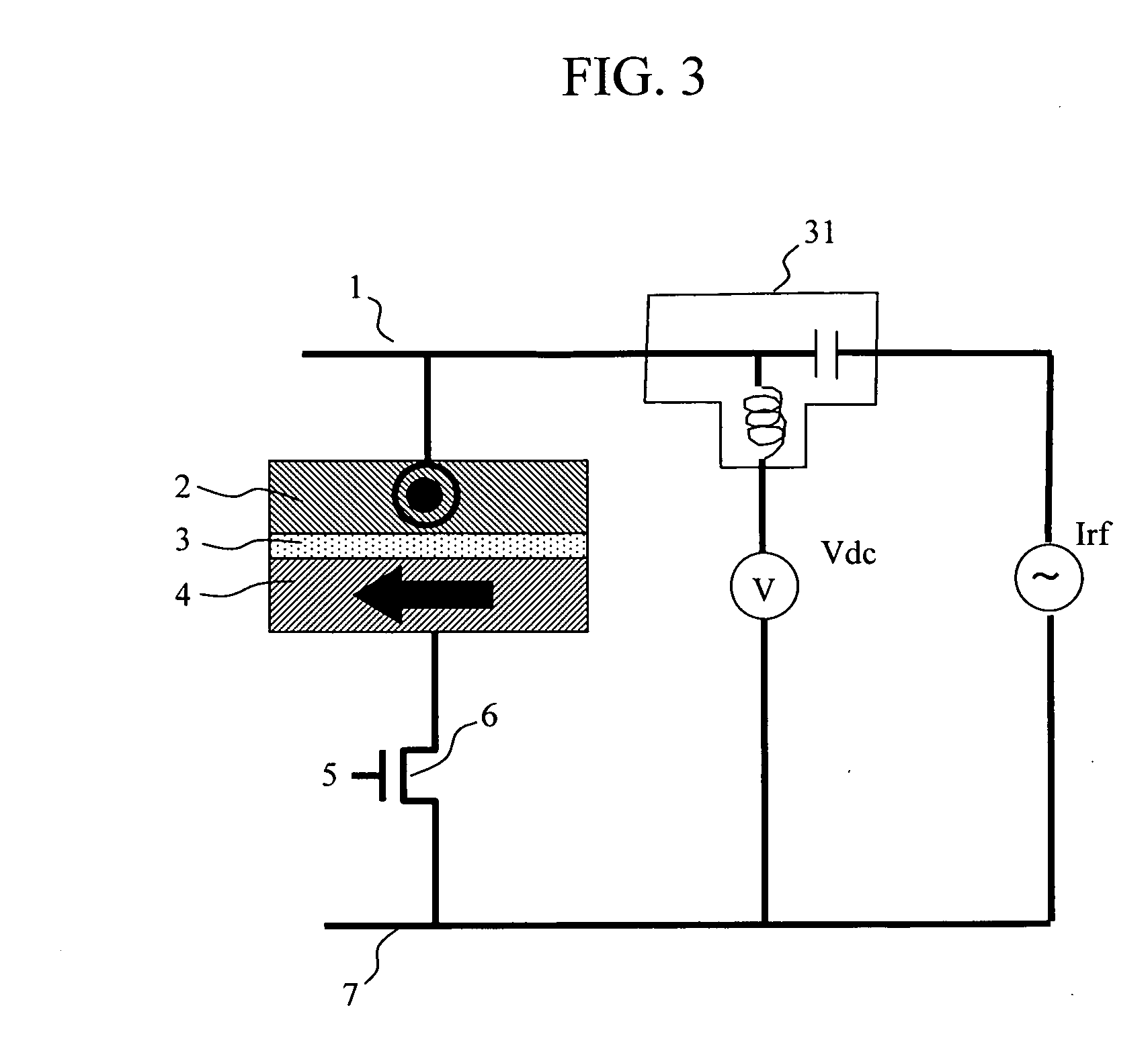

Magnetic memory and method for writing to magnetic memory

InactiveUS20090168501A1Reduce power consumptionSmall currentDigital storageRandom access memoryMagnetic memory

Provided is a magnetic random access memory employing spin torque magnetization reversal having a small write current value is applied. The memory includes: a switching element the conduction of which is controlled by a gate electrode, and three magnetoresistance effect elements connected to the switching element in series. Each magnetoresistance effect element may be a TMR element or a GMR element that includes a multilayered film composed of a fixed layer, a non-magnetic layer and a free layer. The central element serves as a storage element. The magnetoresistance effect elements are manufactured such that an absolute value of current necessary for changing a magnetization direction of at least one of the magnetoresistance effect elements located at both ends is larger than an absolute value of current necessary for changing a magnetization direction of the central magnetoresistance effect element.

Owner:HITACHI LTD

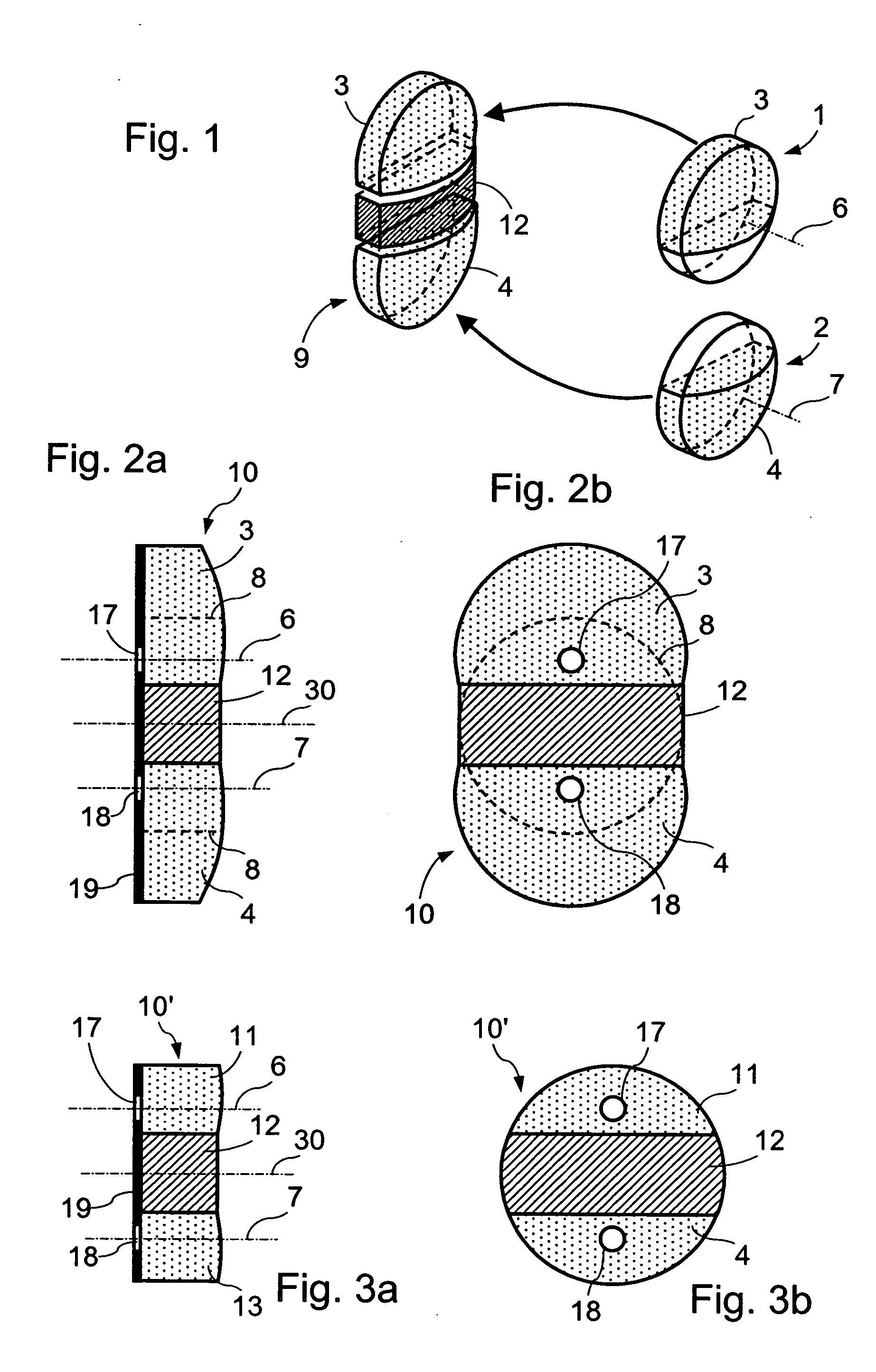

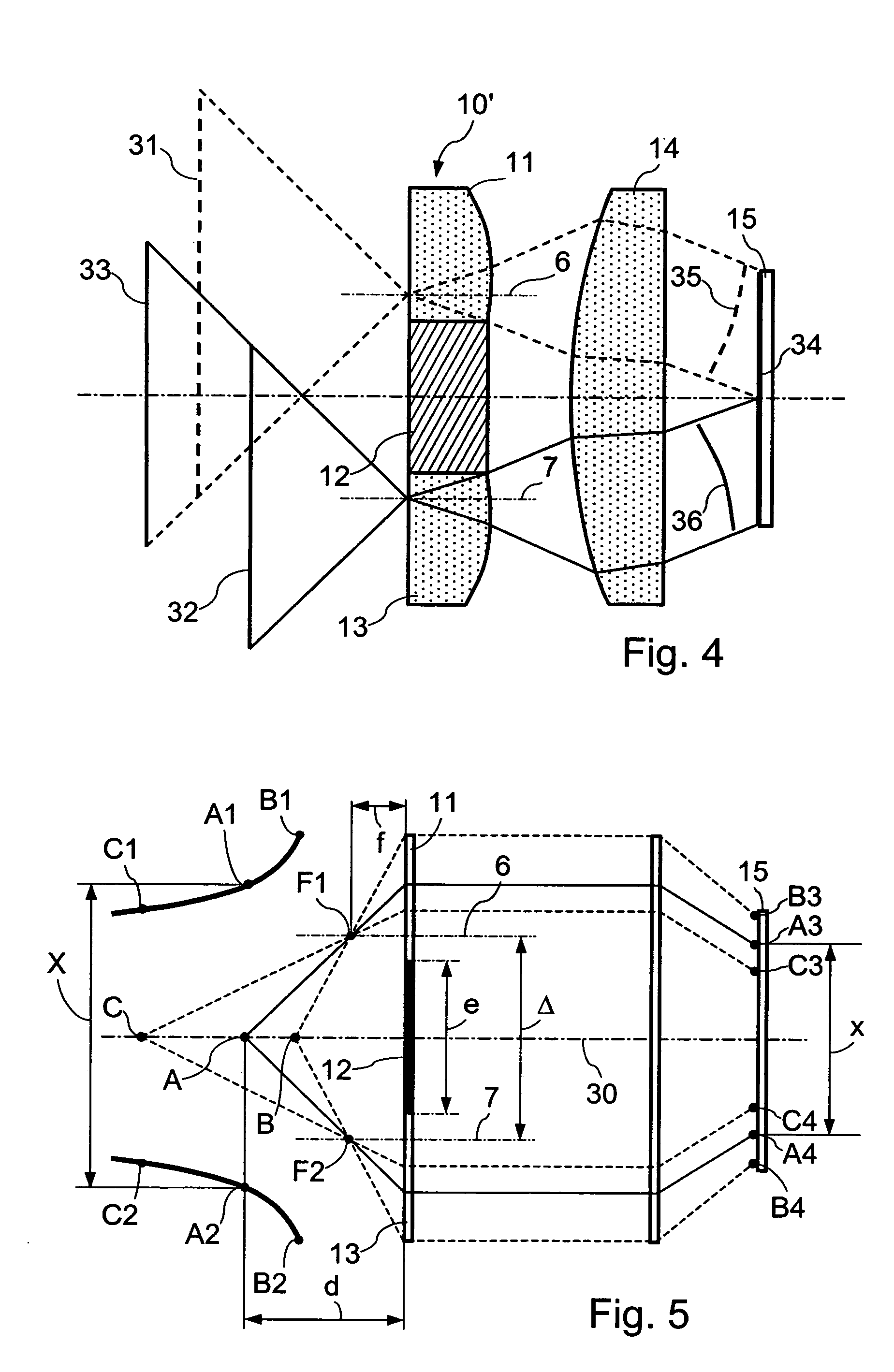

Metrology device for videoendoscopic probe

Image splitting device for videoendoscope, comprising an image splitting optical component to form on the sensitive surface of a video sensor housed in the distal end part of a videoendoscope a single composite image formed from two images of an observed target, viewed from two different angles; the image splitting optical component comprises two sections of identical convergent lenses, integrated into an opaque central element, maintaining the space between the two section of lenses, each of the two sections of lenses are at least equal to a half-moon so that it is crossed by the optical axis of the lens

Owner:TOKENDO

Electronic device with a three-dimensional transformable display

Electronic devices with bulk transformable display include a plurality of peripheral elements with planar faces adapted to the movement and rotation around the central element. Each of the peripheral elements has at least one display on its outer face, a contact element group, a microprocessor and a power source. The contact group of said peripheral elements are formed by magnets, adapted to connect adjacent peripheral elements to each other and simultaneously transmitting electrical signals therebetween. The magnets can rotate freely inside the sockets, enabling stable and reliable connection between the peripheral elements.

Owner:CUBIOS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com