Patents

Literature

362results about "Reduction of cables/conductors size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

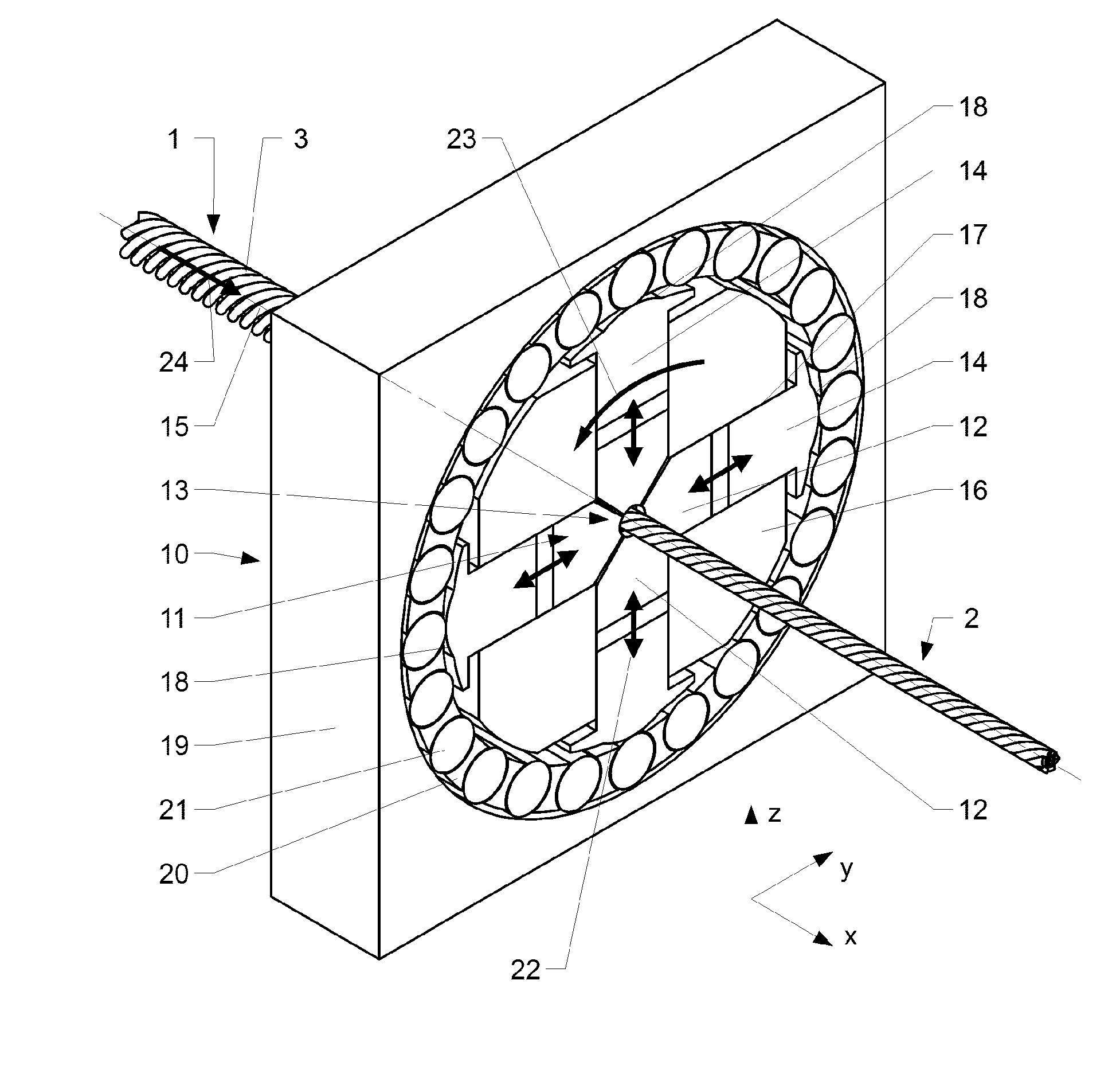

Load-Resistant Coaxial Transmission Line

ActiveUS20050067159A1Improve conductivityLow constantDrilling rodsCable insulation constructionDielectricElectricity

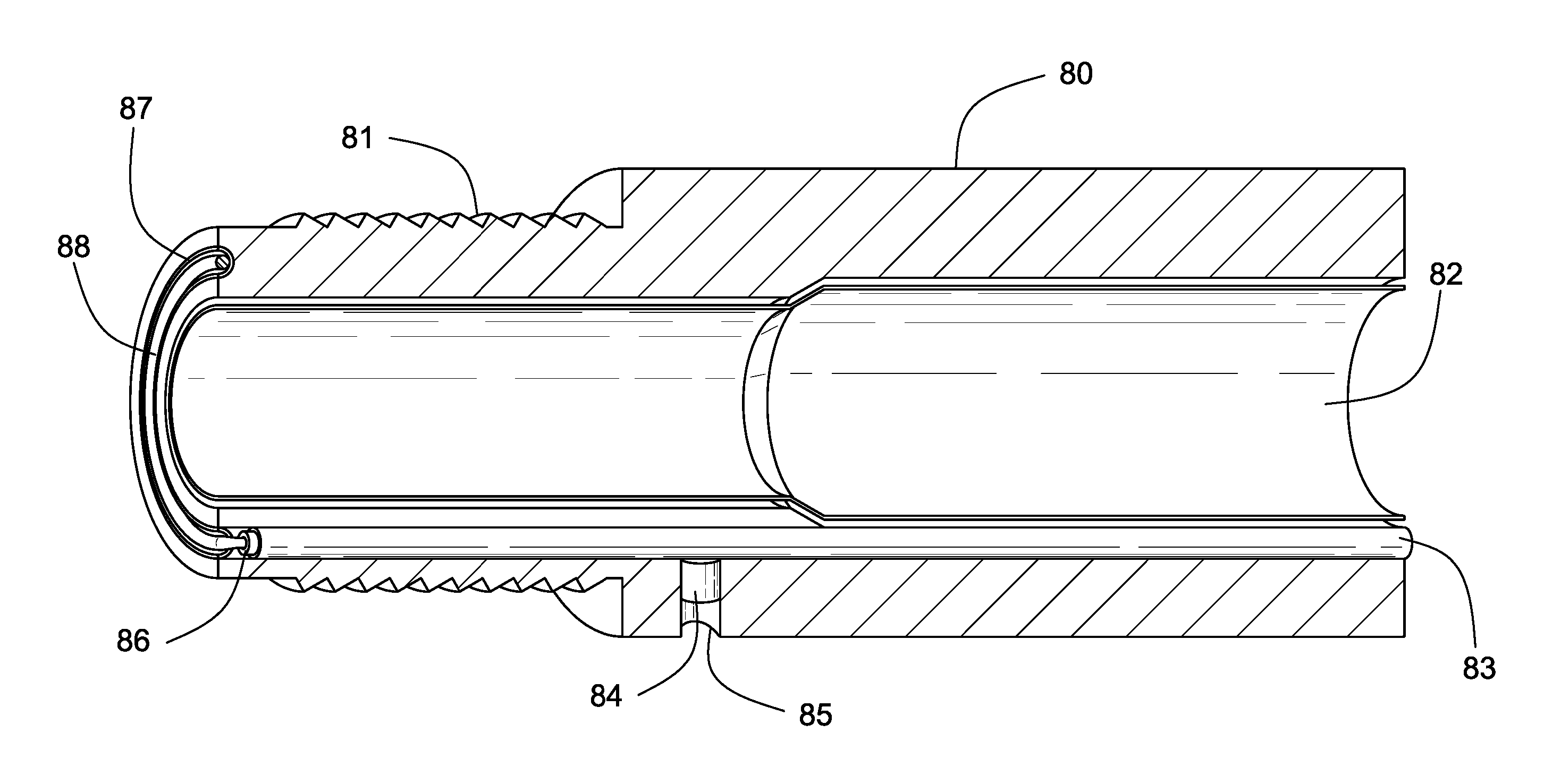

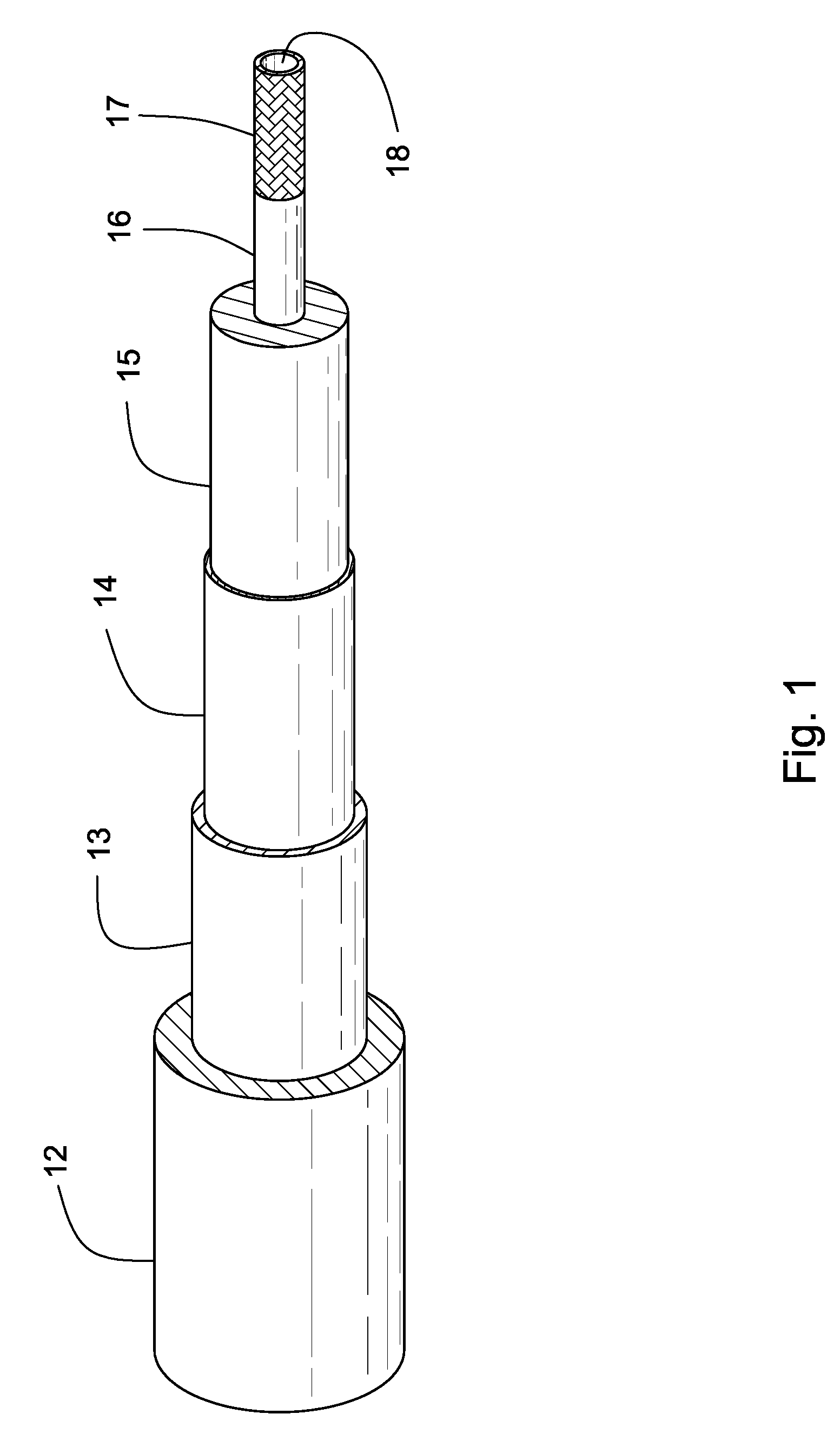

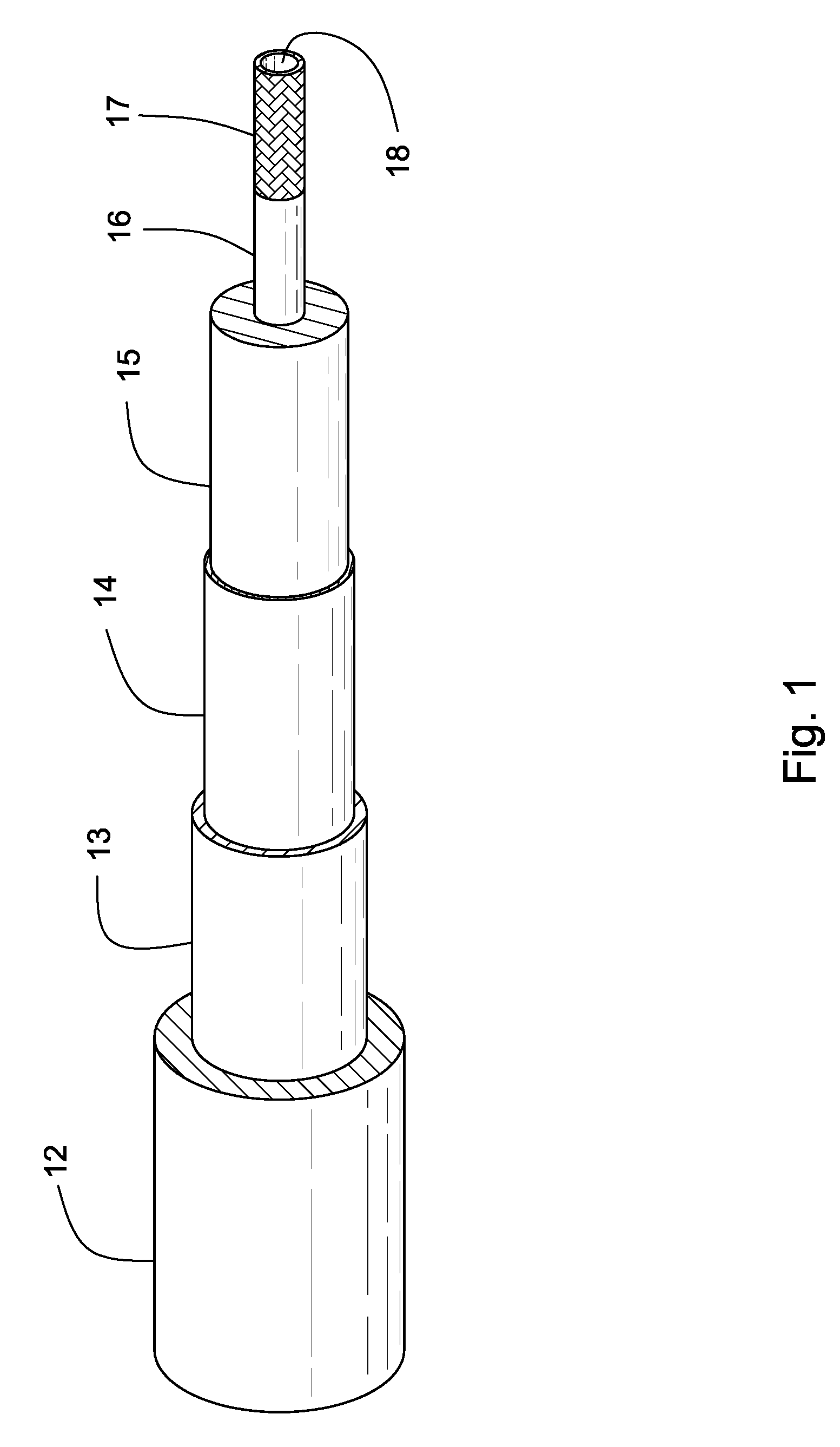

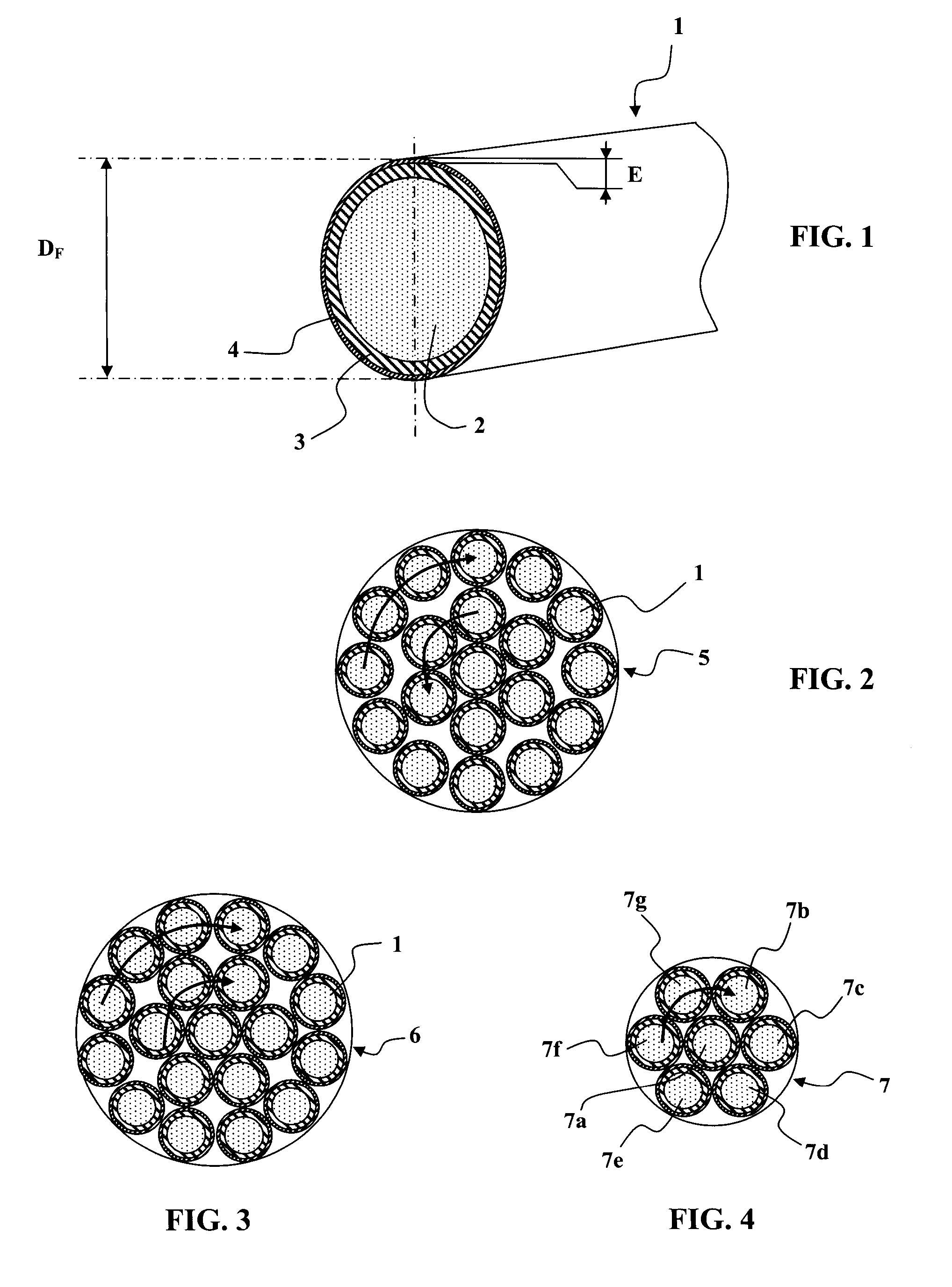

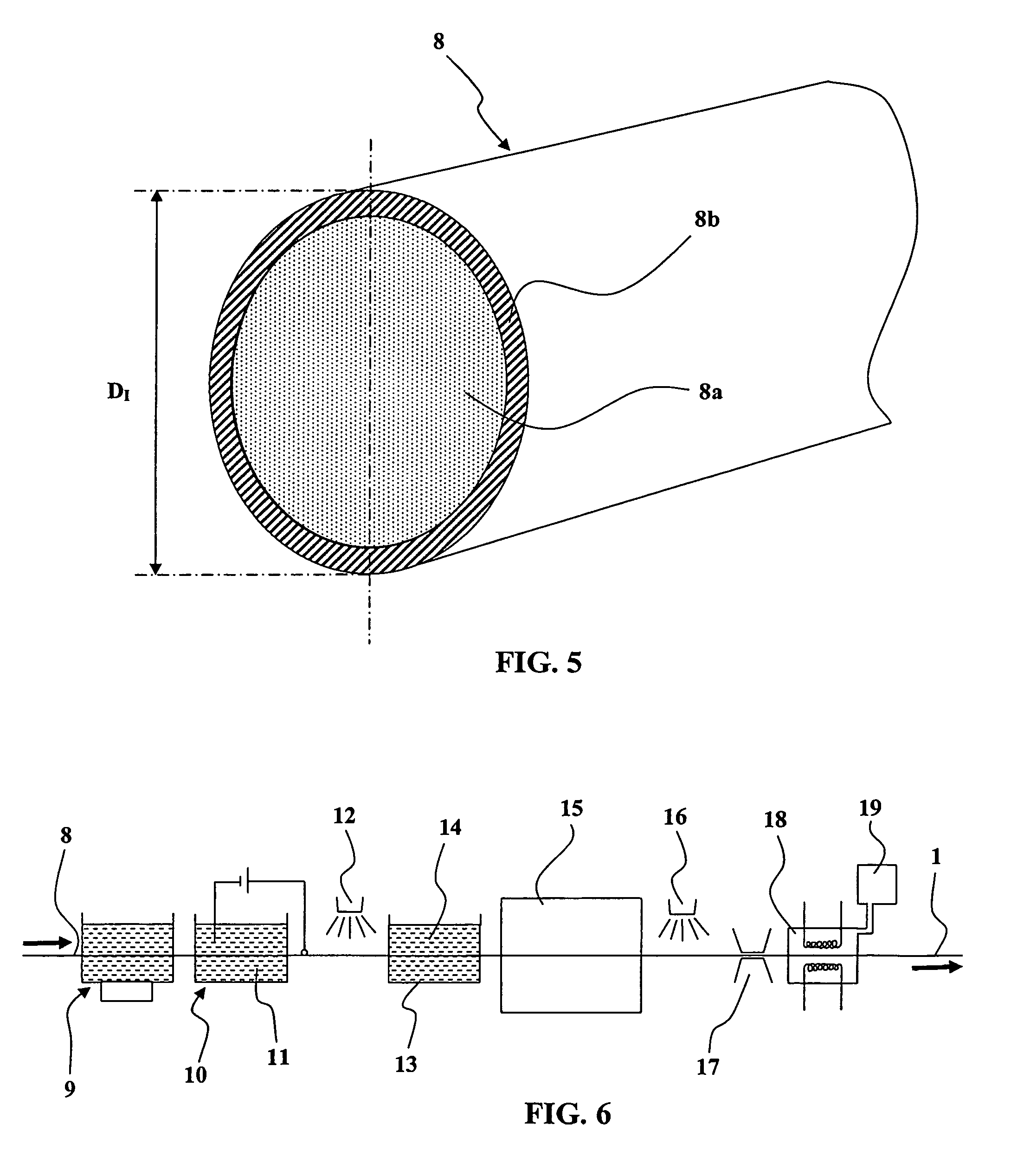

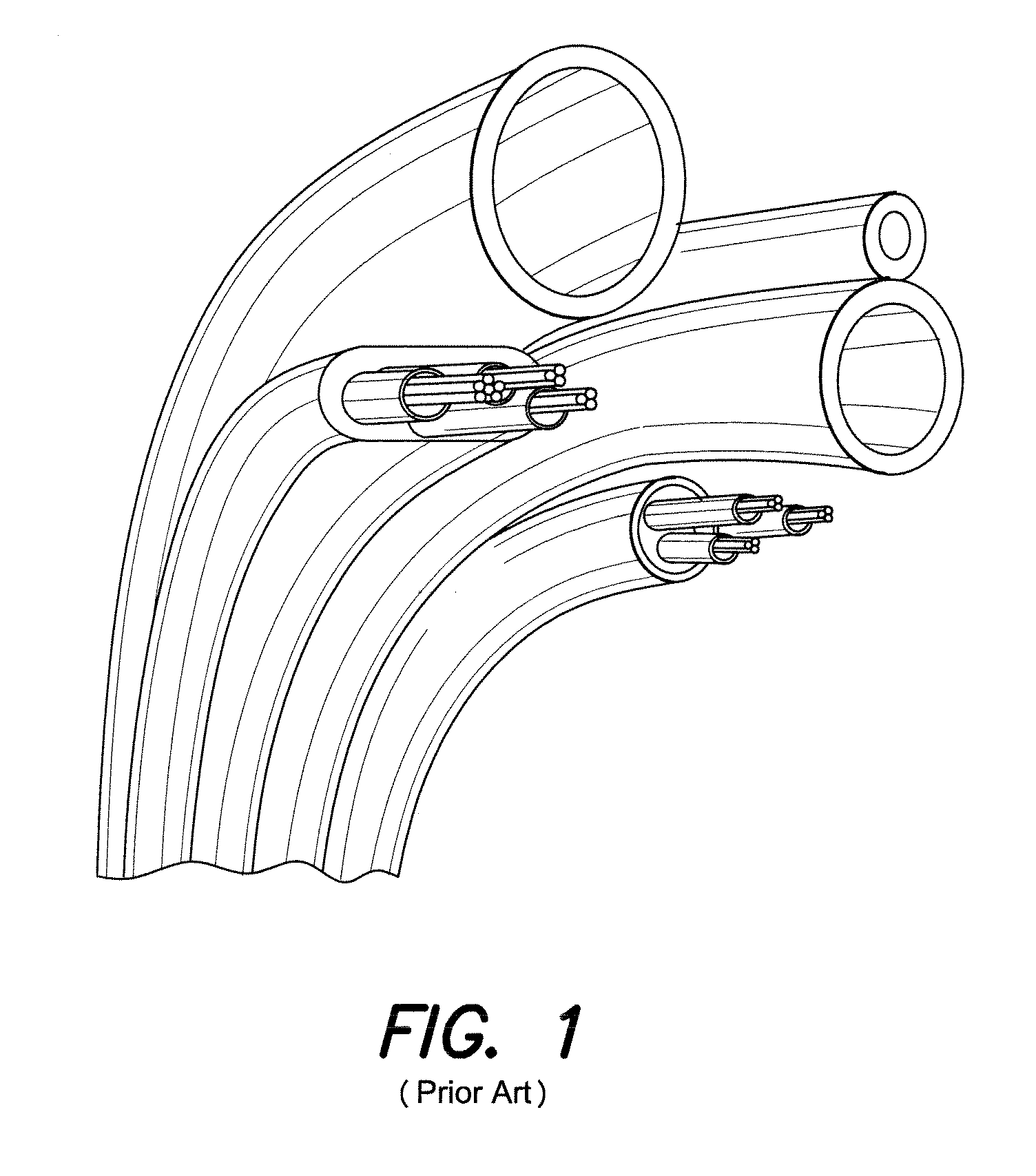

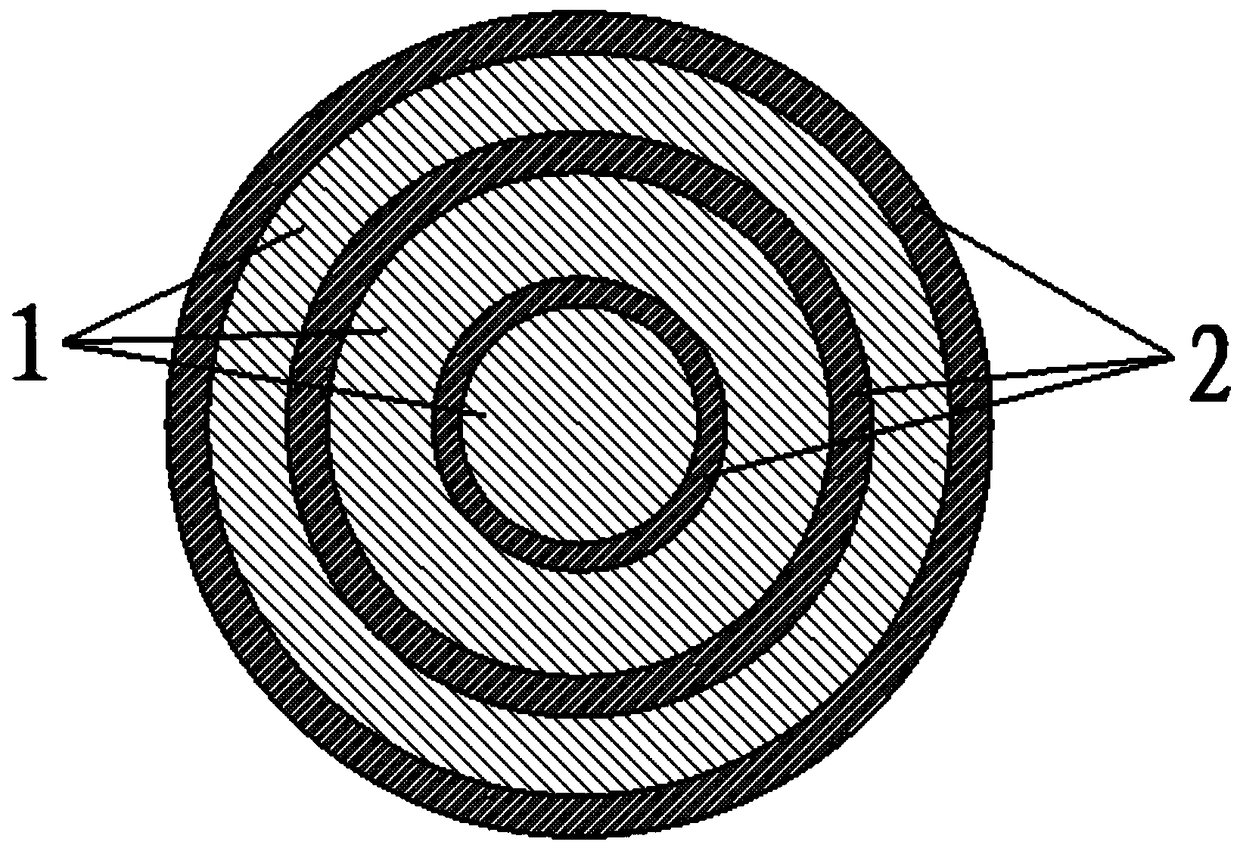

A transmission line for downhole tools that make up all or part of a tool string for drilling and production of oil, gas, and geothermal wells that can withstand the dynamic gravitational forces and other accelerations associated with downhole excavations. The transmission line comprises a metal tube, or outer conductor, that houses a coaxial wire inner conductor. A non-metallic dielectric material is interposed between the inner and outer conductors. The outer and inner conductors and the dielectric are sufficiently compressed together so that independent motion between them is abated. Compression of the components of the transmission line may be achieved by drawing the transmission through one or more dies in order to draw down the outer conductor onto the dielectric, or by expanding the inner conductor against the dielectric using a mandrel or hydraulic pressure. Non-metallic bead segments may be used in aid of the compression necessary to resist the dynamic forces and accelerations of drilling.

Owner:INTELLISERV

Load-resistant coaxial transmission line

A transmission line for downhole tools that make up all or part of a tool string for drilling and production of oil, gas, and geothermal wells that can withstand the dynamic gravitational forces and other accelerations associated with downhole excavations. The transmission line has a metal tube, or outer conductor, that houses a coaxial wire inner conductor. A non-metallic dielectric material is interposed between the inner and outer conductors. The outer and inner conductors and the dielectric are sufficiently compressed together so that independent motion between them is abated. Compression of the components of the transmission line may be achieved by drawing the transmission through one or more dies in order to draw down the outer conductor onto the dielectric, or by expanding the inner conductor against the dielectric using a mandrel or hydraulic pressure. Non-metallic bead segments may be used in aid of the compression necessary to resist the dynamic forces and accelerations of drilling.

Owner:INTELLISERV LLC

Steel core for an electric transmission cable and method of fabricating it

Owner:NV BEKAERT SA

Copper-iron alloy material electromagnetic shielding wire and preparation method thereof

ActiveCN110229972AIncrease profitRealize continuous productionApparatus for heat treatmentConductive materialWire rodElectromagnetic shielding

The invention provides a copper-iron alloy material electromagnetic shielding wire and a preparation method thereof, and belongs to the technical field of electromagnetic shielding wire material. Thecopper-iron alloy material comprises the following chemical components of, in percentage by weight, 5%-20% of Fe, less than or equal to 0.2% of Ni, less than or equal to 0.2% of Mn, less than or equalto 0.1% of Pb and the balance of Cu. The preparation method comprises the following steps of S1, preparing material; S2, smelting, and up leading continuously casting to obtain a phi 10 mm-20 mm copper rod blank; step 3, drawing, and repeatedly carrying out high-temperature annealing during drawing to obtain a phi 1 mm-2 mm copper-iron alloy wire rod; S4, carrying out heat preservation; S5, carrying out multi-pass drawing again to obtain an electromagnetic shielding wire with the diameter of phi 0. 05 mm-0.5 mm; and S6, weaving to obtain a net wire with electromagnetic shielding. According tothe method, the performance, the structure, the material utilization rate, the industrialization and other aspects of the prepared copper-iron alloy shielding wire are further improved, and a new path is provided for the application and the development of the copper-iron alloy shielding wire.

Owner:SHAANXI SIRUI ADVANCED MATERIALS CO LTD

Aluminum alloy conductor, alum1inum alloy stranded wire, sheathed wire, wire harness, and method for manufacturing aluminum alloy conductor

ActiveCN104781431AShock resistantImproved bending fatigue resistancePlastic/resin/waxes insulatorsSingle bars/rods/wires/strips conductorsHigh conductivityElectrical resistivity and conductivity

Owner:FURUKAWA ELECTRIC CO LTD +1

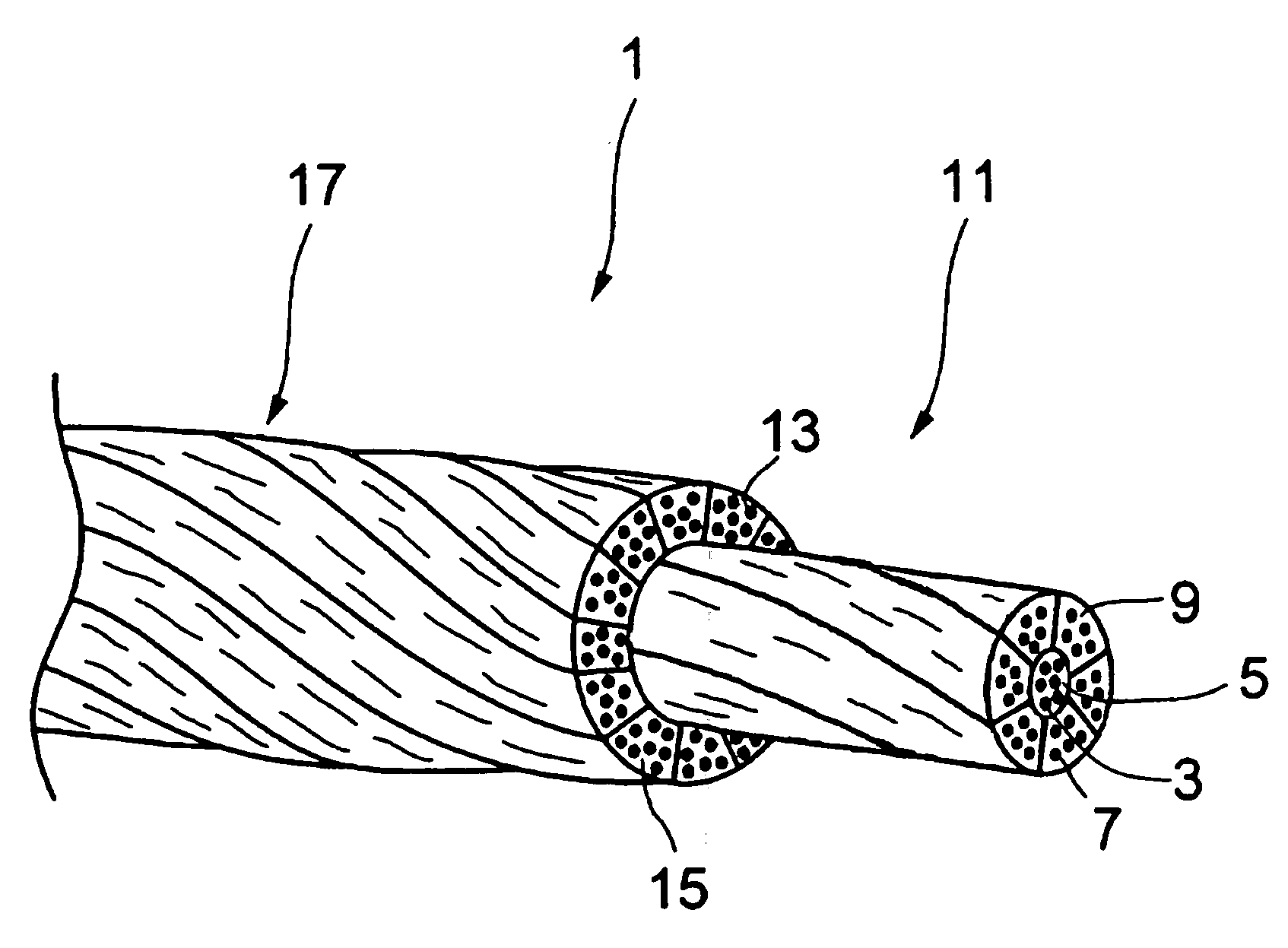

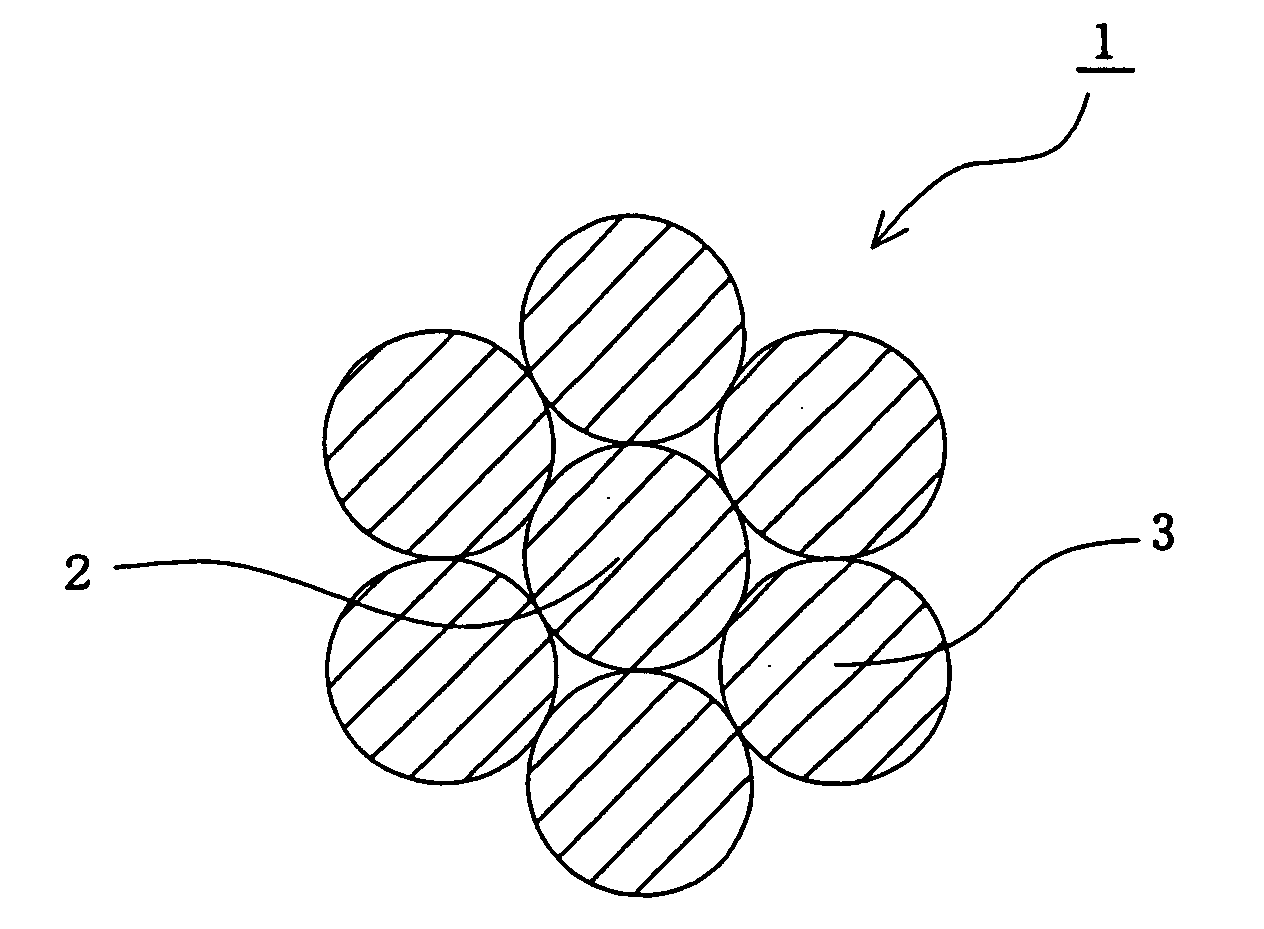

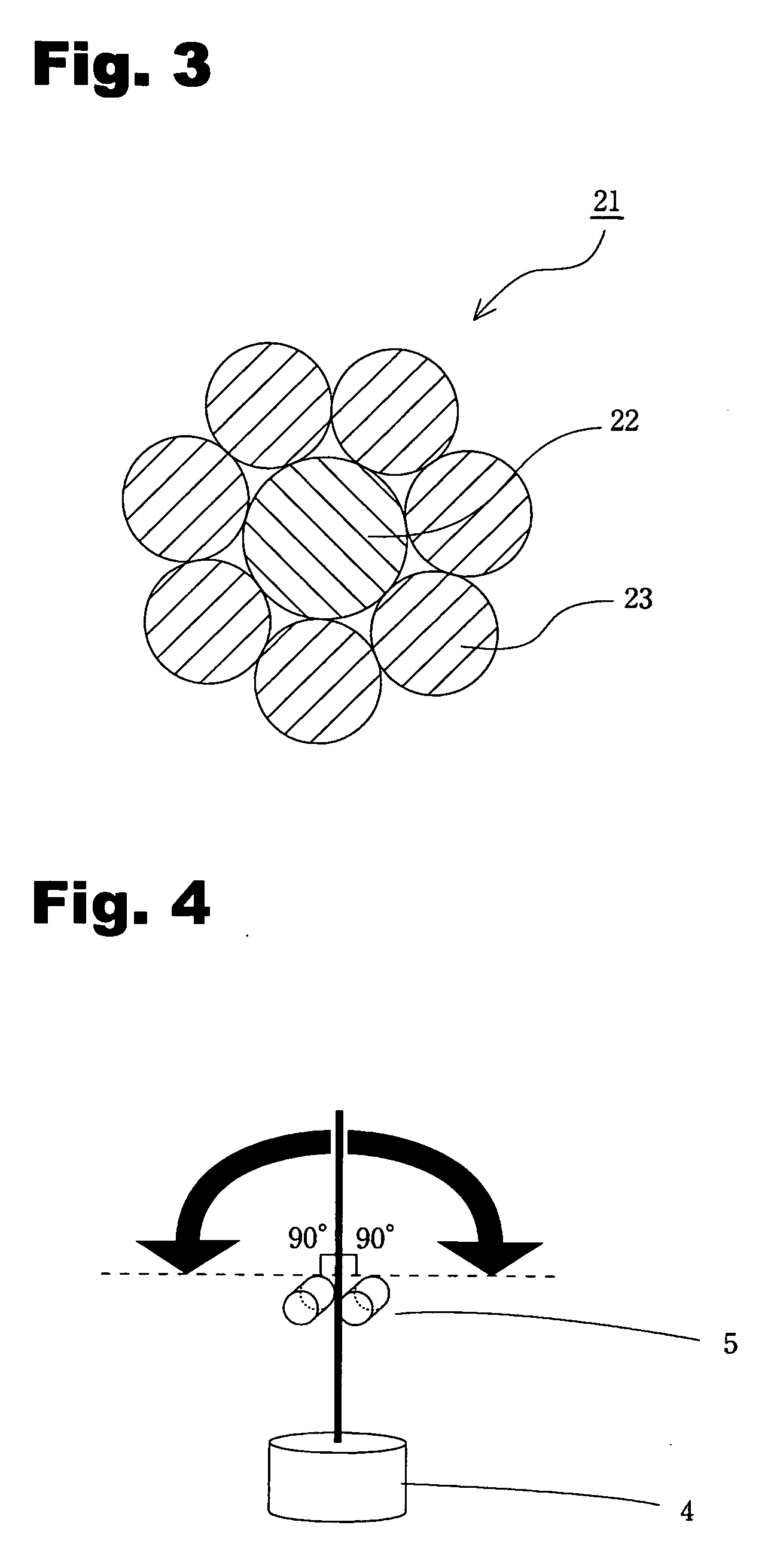

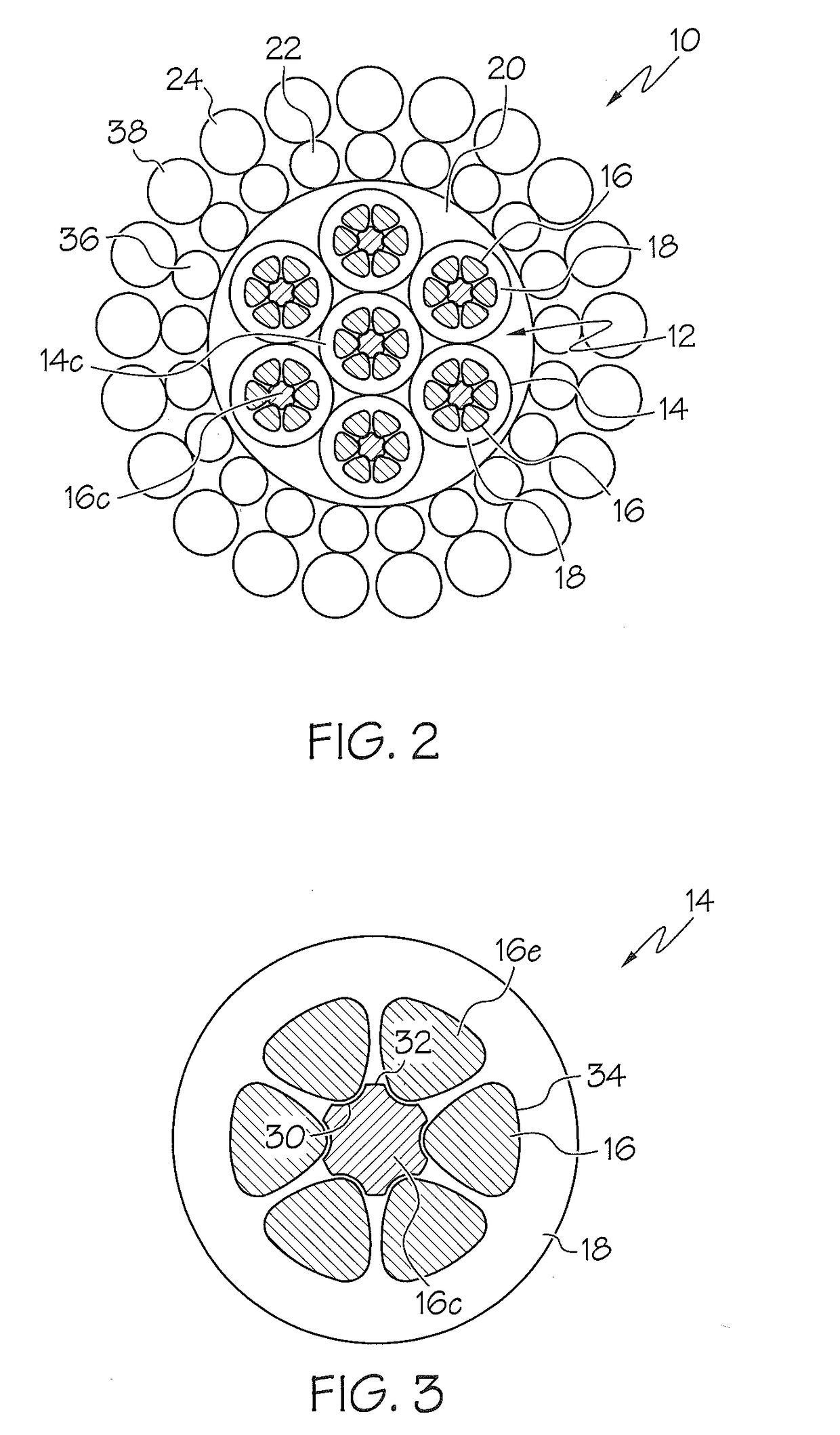

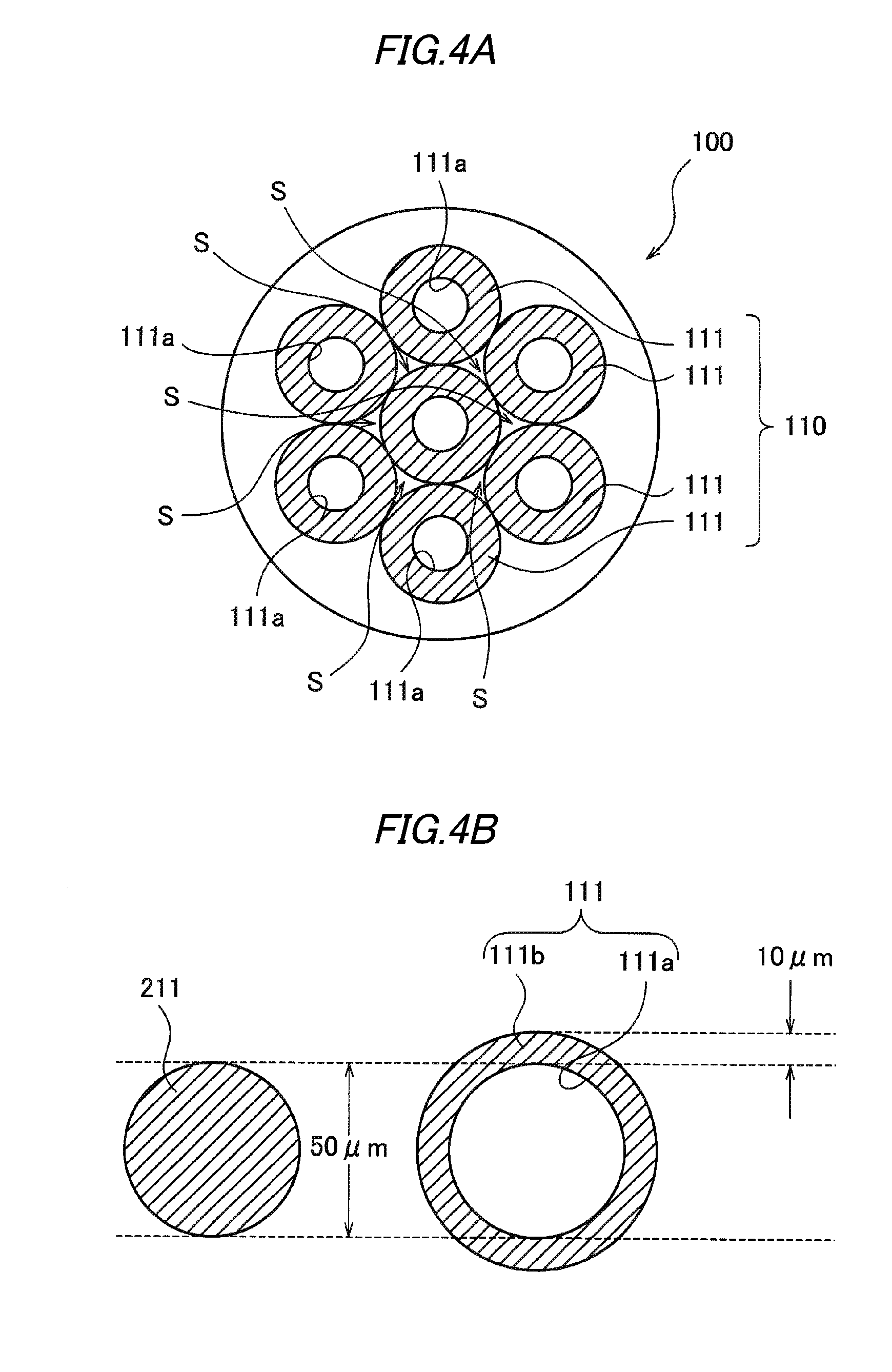

Concentric stranded conductor

ActiveUS20070251204A1Good flexibilityProportion of face contact between single wires is enhancedReduction of cables/conductors sizePower cablesElectrical conductorEngineering

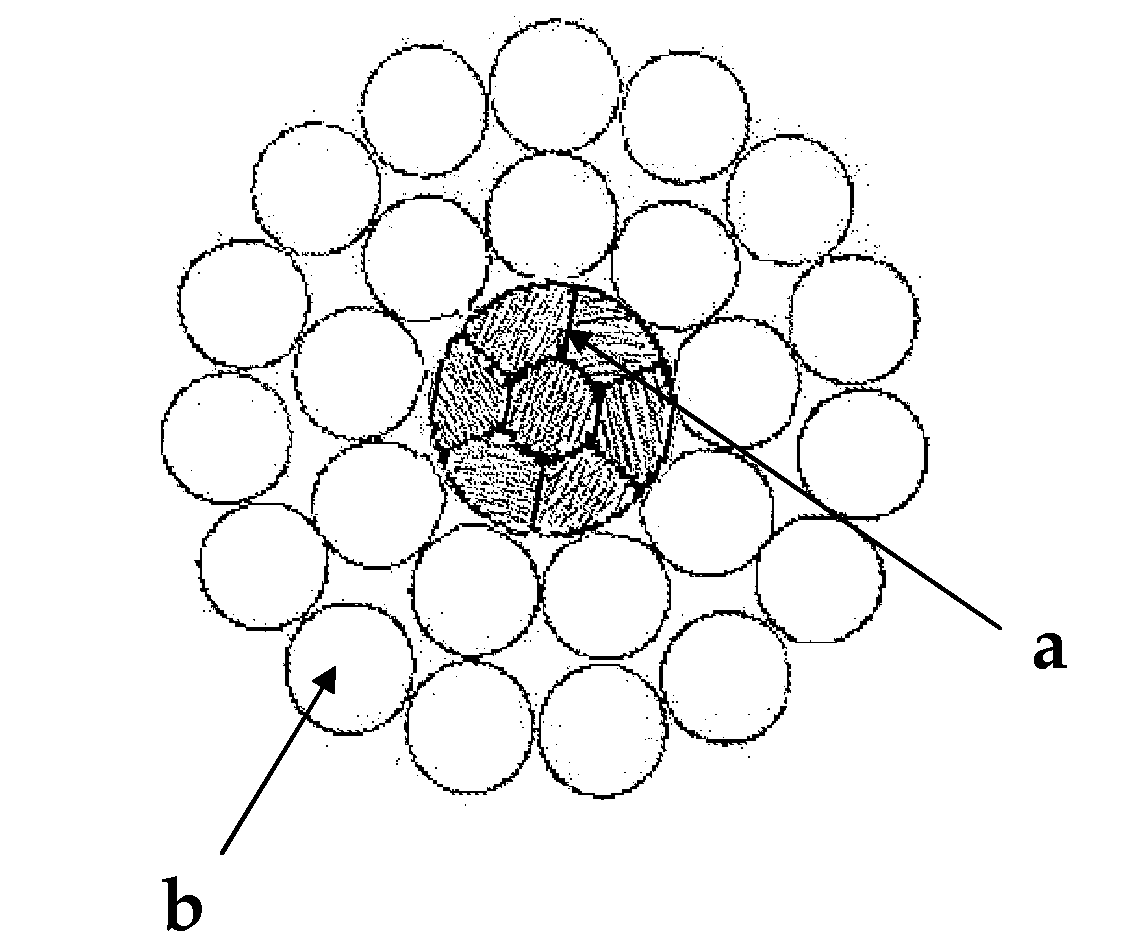

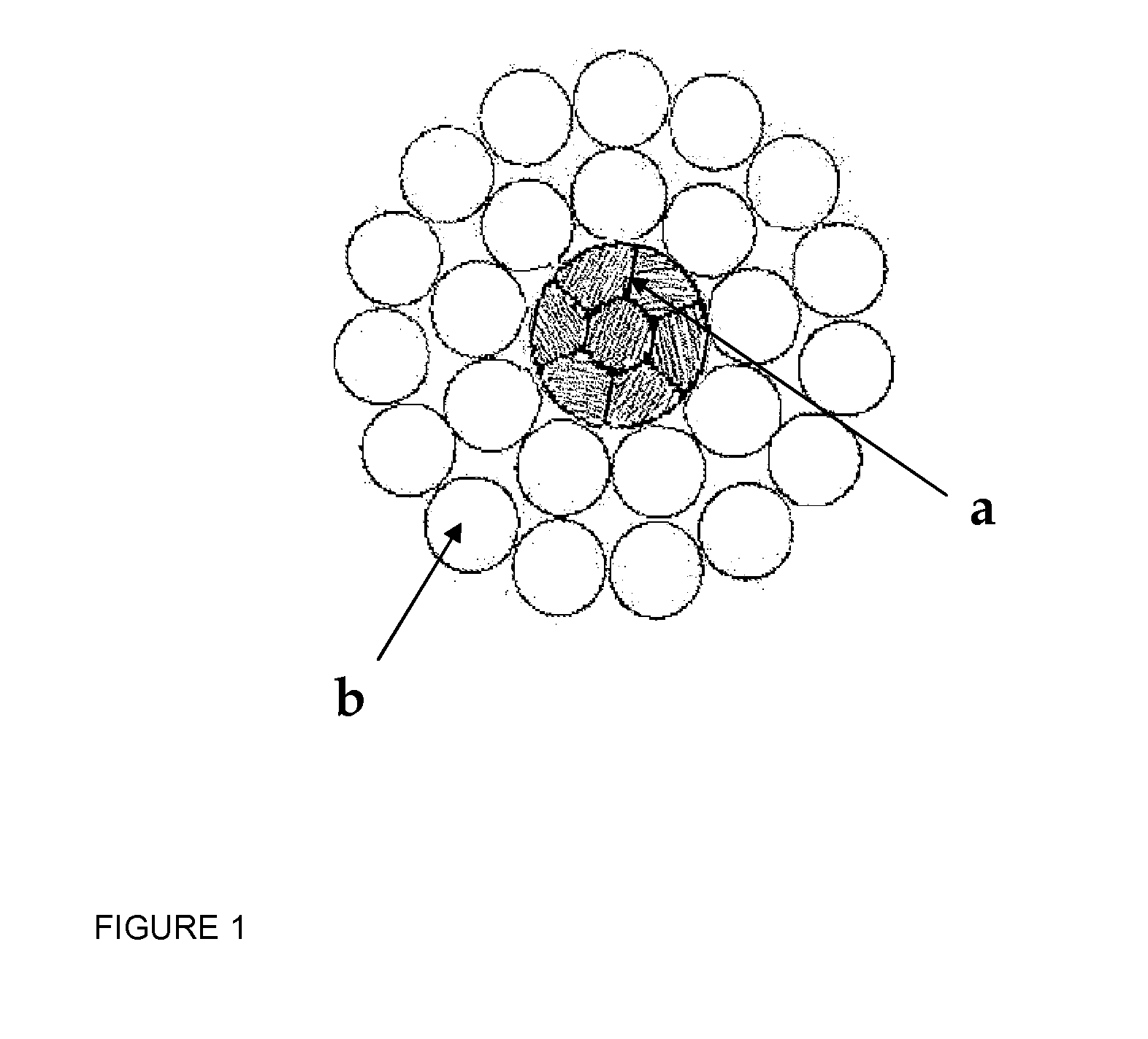

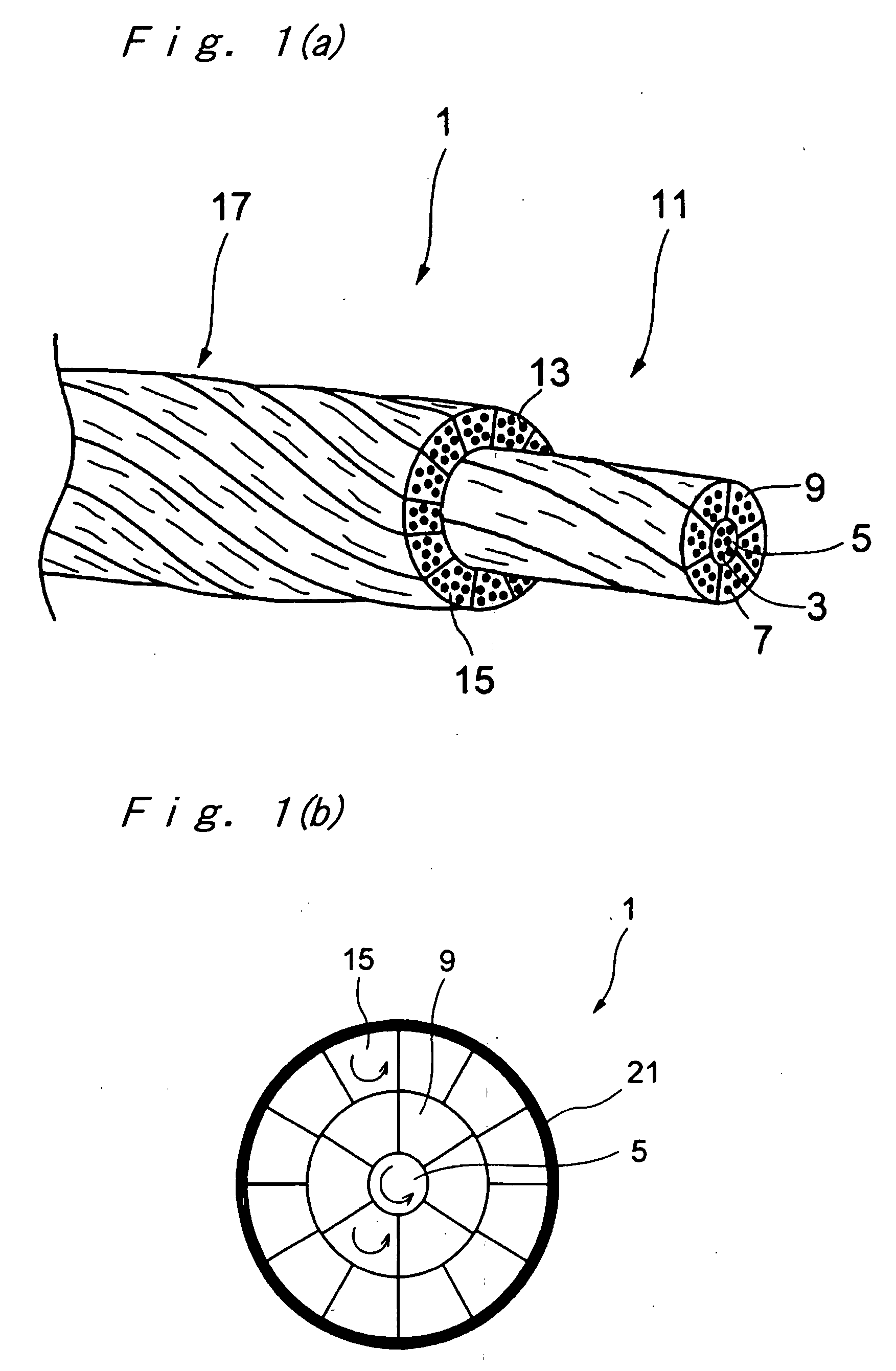

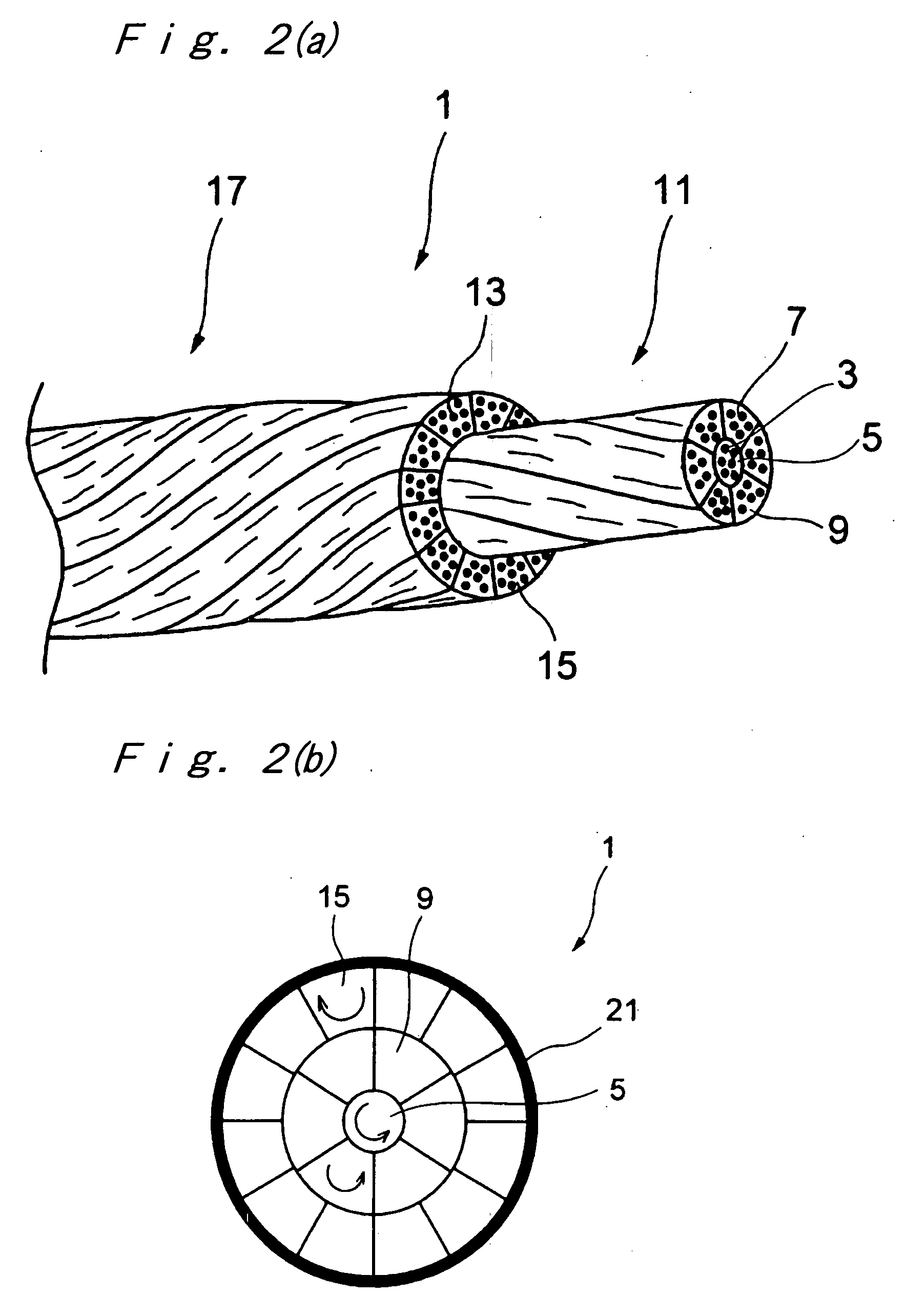

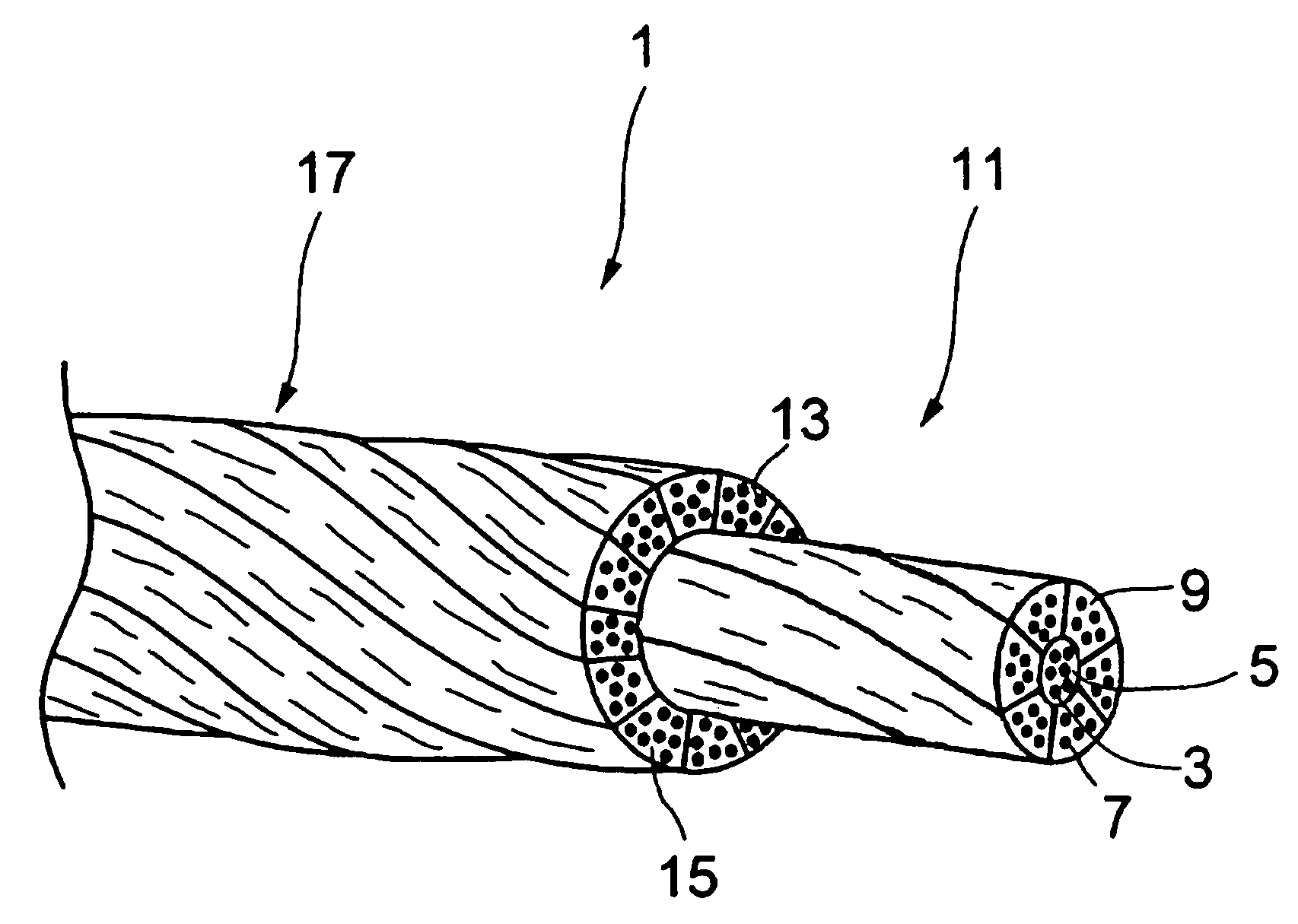

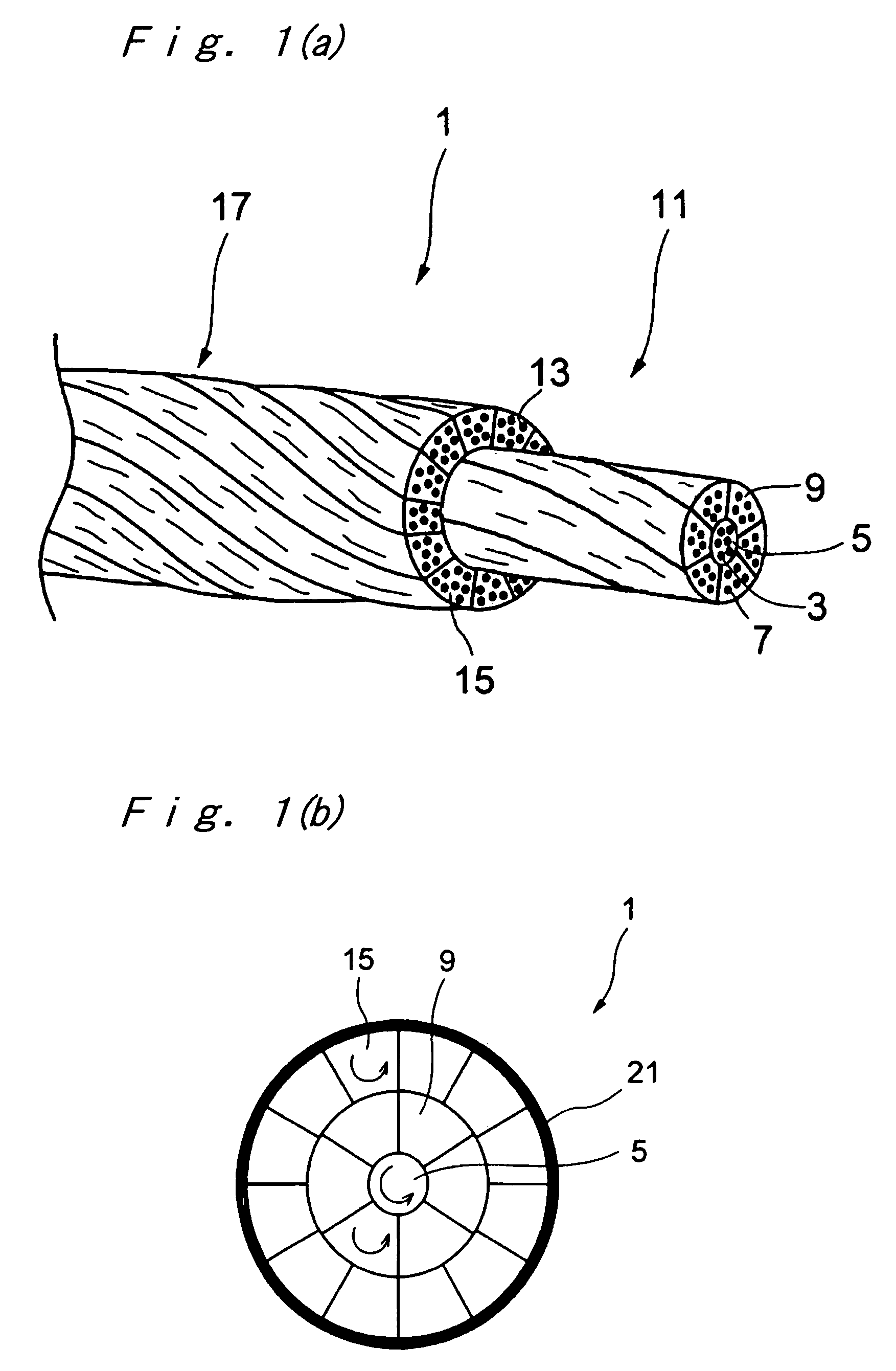

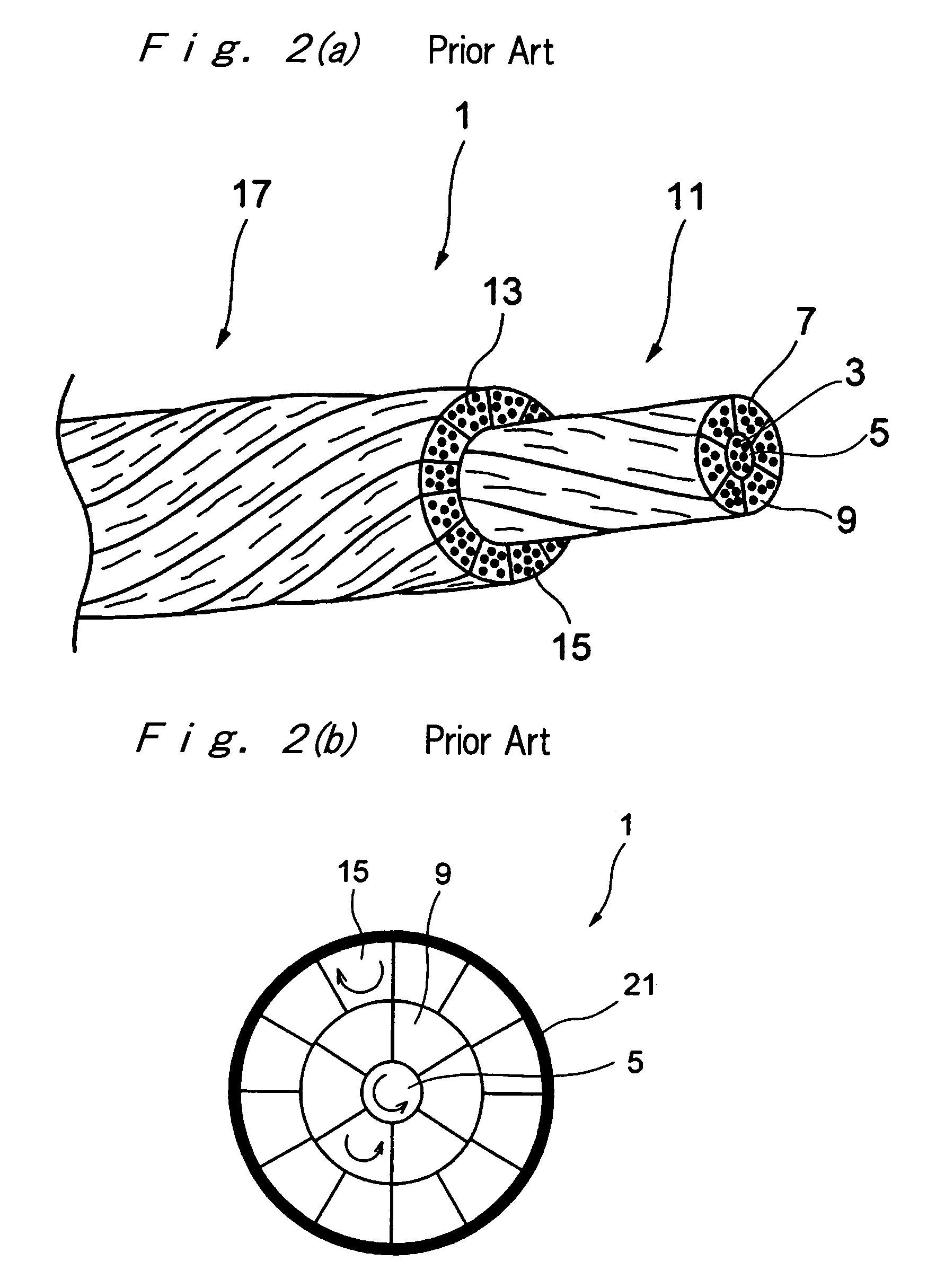

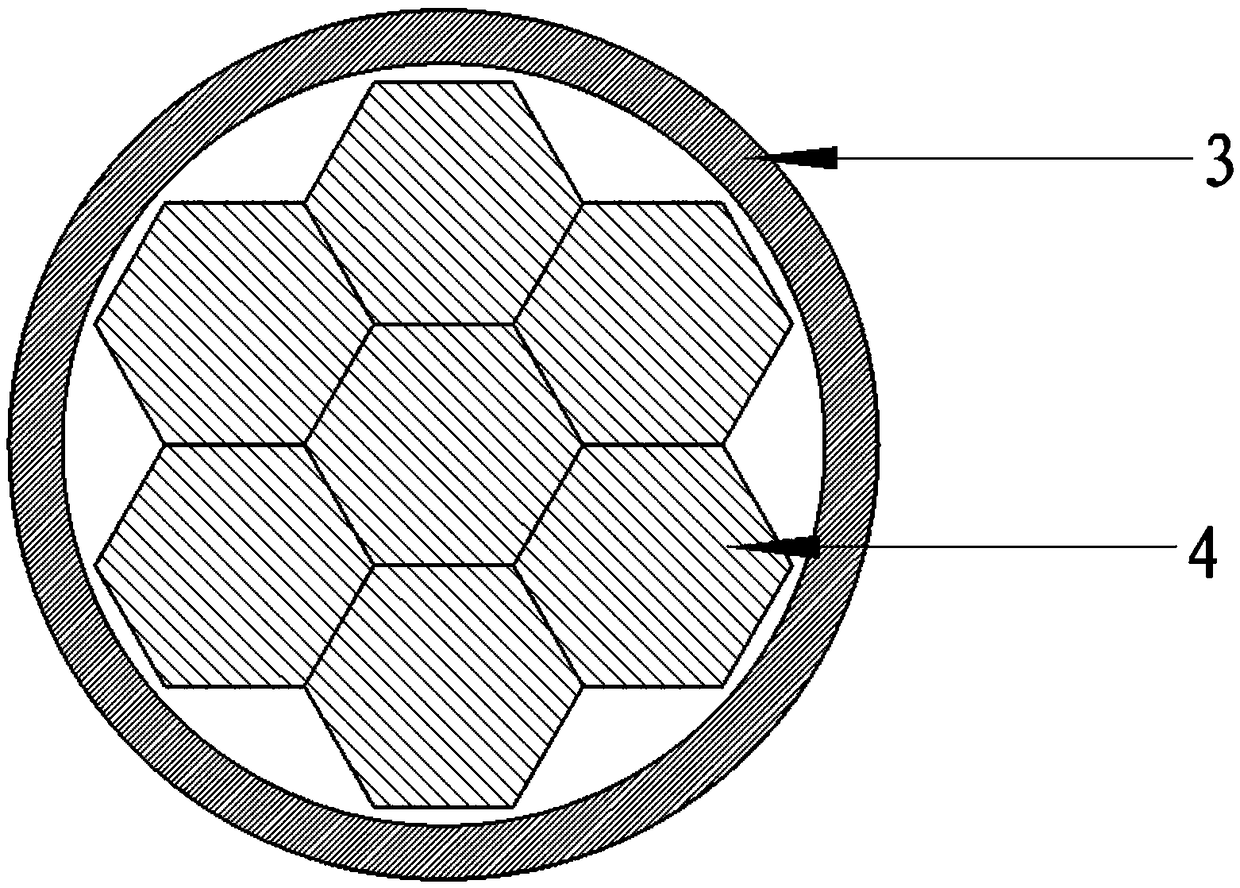

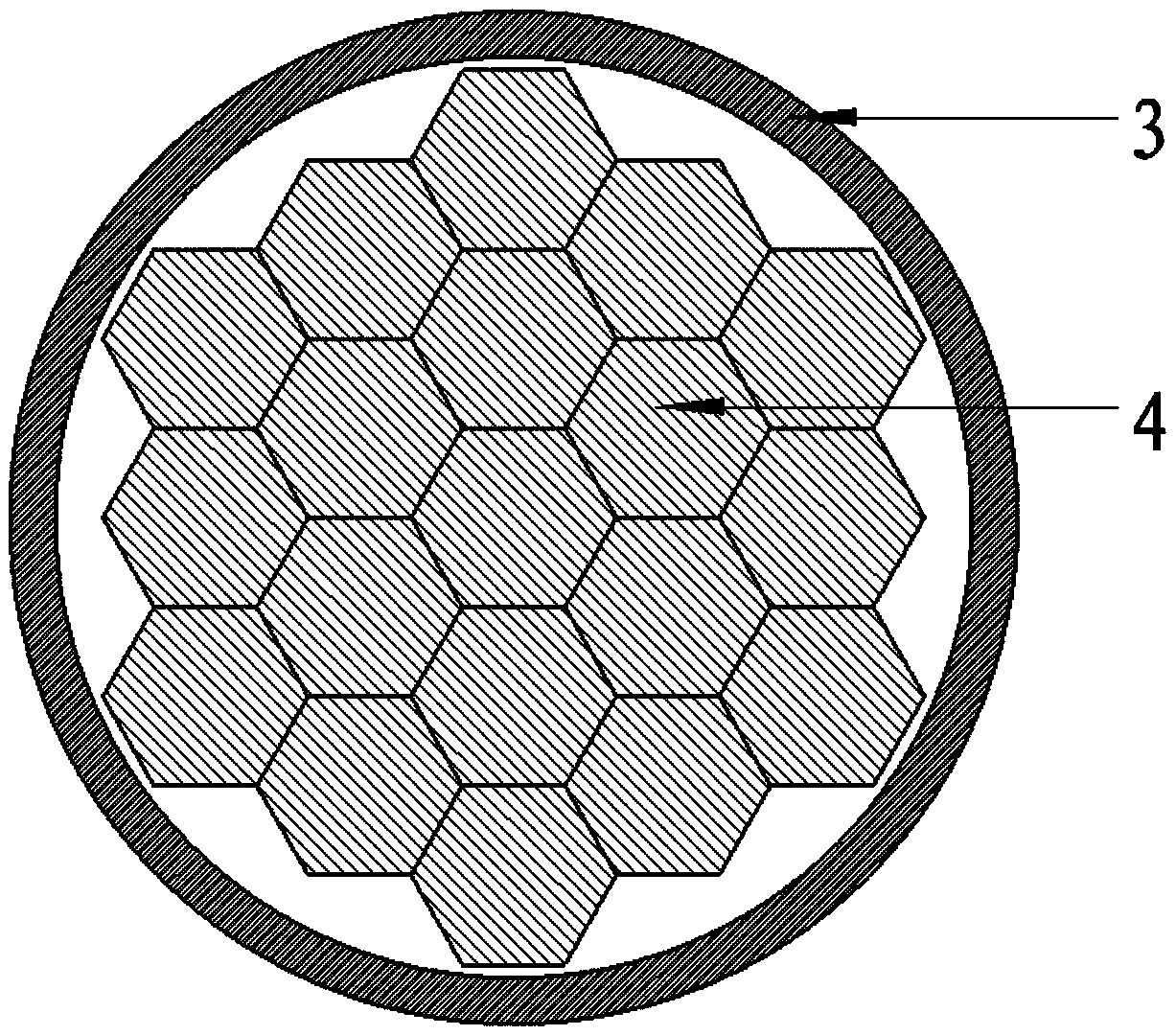

A concentric stranded conductor having a concentric strand having multiple bunched strands twisted together, in which each bunched strand has multiple single wires twisted together; wherein the concentric stranded conductor has a central core bunched strand (5) and a first-layer concentric strand (11) having multiple first-layer bunched strands (9) twisted together around the central core bunched strand (5); wherein a twist pitch of the central core bunched strand (5) is from 8 to 70 times an outer strands distance thereof, a twist pitch of the first-layer concentric strand (11) is from 8 to 30 times an outer strands distance thereof, a difference between a twist angle of the central core bunched strand (5) and a sum of twist angles of the first-layer bunched strands (9) and first-layer concentric strand (11) is 15 degrees or less, and each single wire is made of an aluminum or aluminum alloy, having elongation of 2% or more.

Owner:FURUKAWA ELECTRIC CO LTD

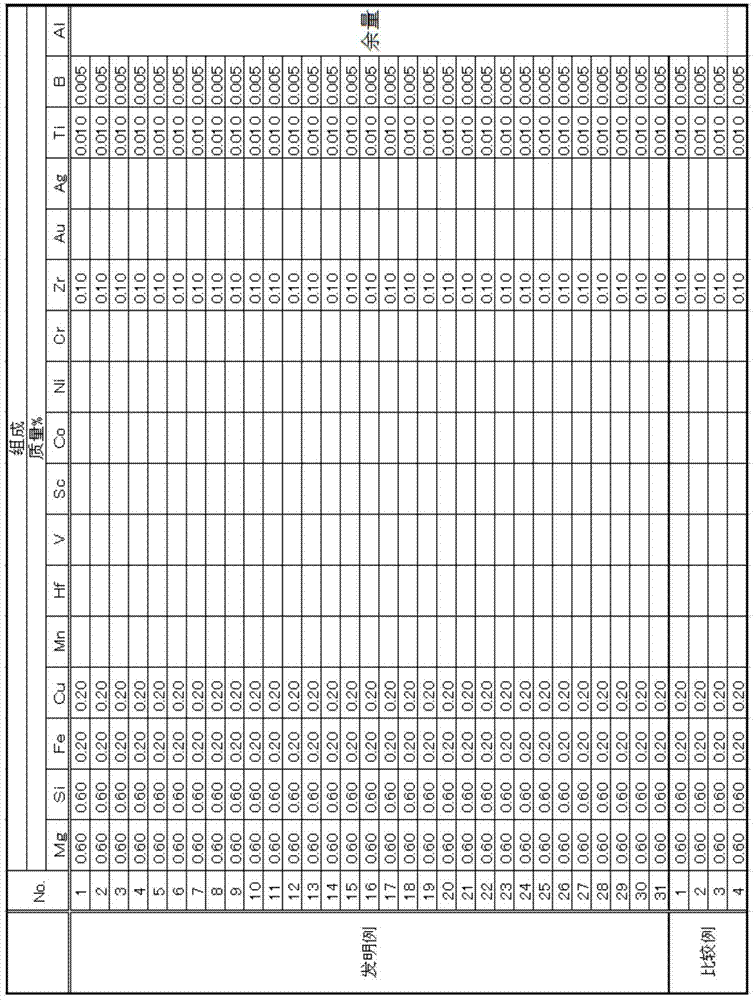

Copper alloy wire, copper alloy stranded wire, coated electric wire, wire harness and manufacturing method of copper alloy wire

InactiveCN105705665ASuppresses reduction in wire drawing workabilitySuppresses conductivity dropSingle bars/rods/wires/strips conductorsApparatus for heat treatmentElectrical conductorMetallurgy

The invention provides a copper alloy wire, a copper alloy stranded wire, a coated electric wire, a wire harness and a manufacturing method of the copper alloy wire. This copper alloy wire used as the conductor in a wire for use in vehicles contains 0.4-2.5 mass% Fe, 0.01-1.0 mass% Ti, and a total of 0.01-2.0 mass% of one or more species selected from Mg, Sn, Ag, Ni, In, Zn, Cr, Al and P, the remainder being Cu and unavoidable impurities. The O content is preferably 20ppm or less. The tensile strength is preferably 450MPa or greater. The element wire stretchability is preferably 5% or greater. The conductivity is preferably 62% IACS or greater.

Owner:AUTONETWORKS TECH LTD +2

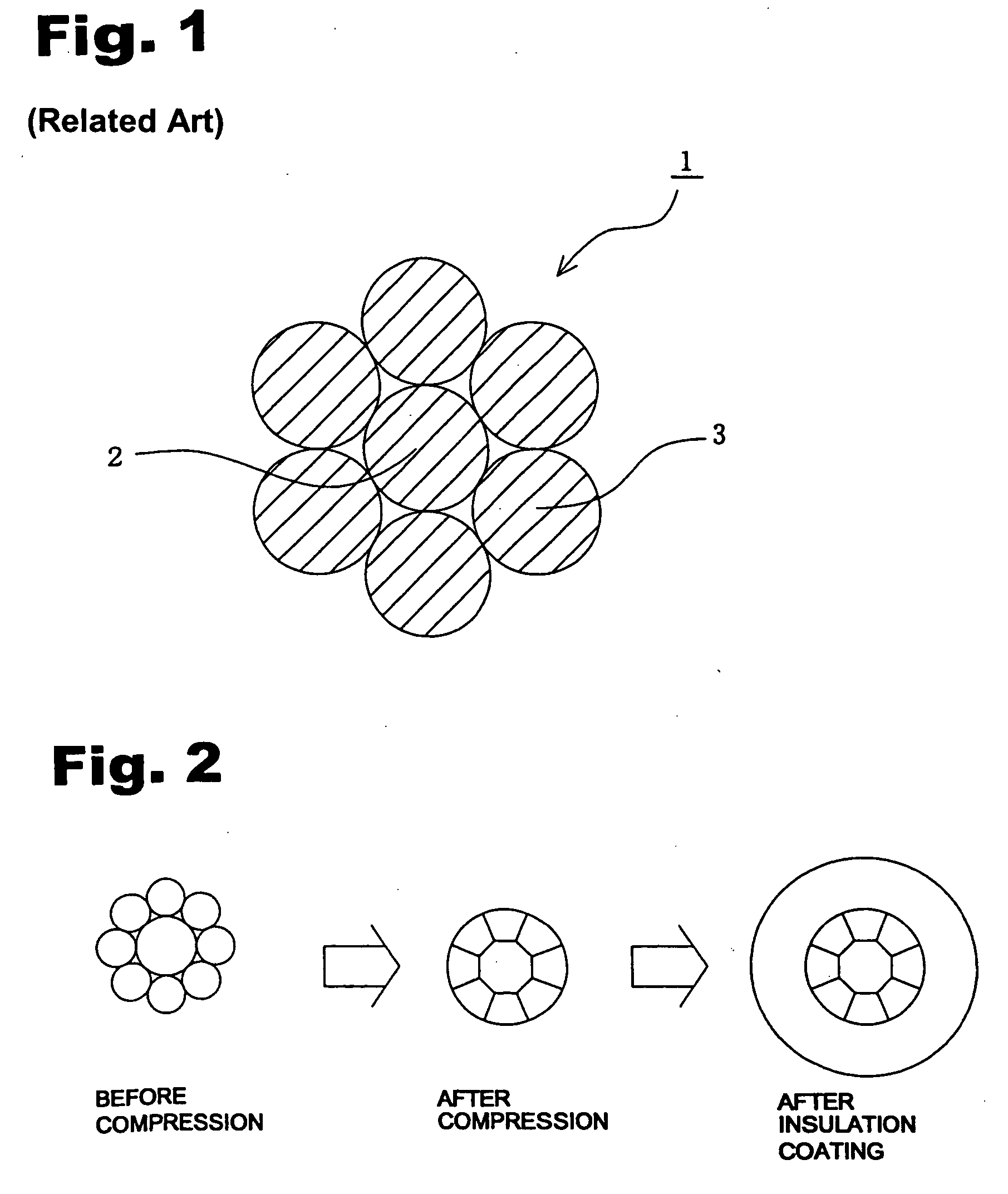

Electric wire for automobile

ActiveUS20060011378A1Non-insulated conductorsReduction of cables/conductors sizeElectrical conductorCentral element

An electric wire for automobile including a compressed conductor which is obtained by arranging, around a single central element wire of stainless steel, a plurality of peripheral element wires of copper or copper alloy in a single circle in tight adherence with each other, wherein the cross sectional area of the conductor is 0.10 through 0.30 mm2, and a ratio C of the cross sectional area of the central element wire to the cross sectional area of the conductor expressed by the formula below is 19.6 through 33.3%: the ratio C of the cross sectional area of the central element wire to the cross sectional area of the conductor being A / (A+B)}×100 [%], wherein the symbol A denotes the cross sectional area of the central element wire and the symbol B denotes the total cross sectional area of the peripheral element wires; or the diameter of the central element wire is larger than the diameters of the peripheral element wires, and the compression rate from the cross sectional area of the conductor before compression to the cross sectional area of the conductor after compression is 5 through 20%.

Owner:SUMITOMO WIRING SYST LTD

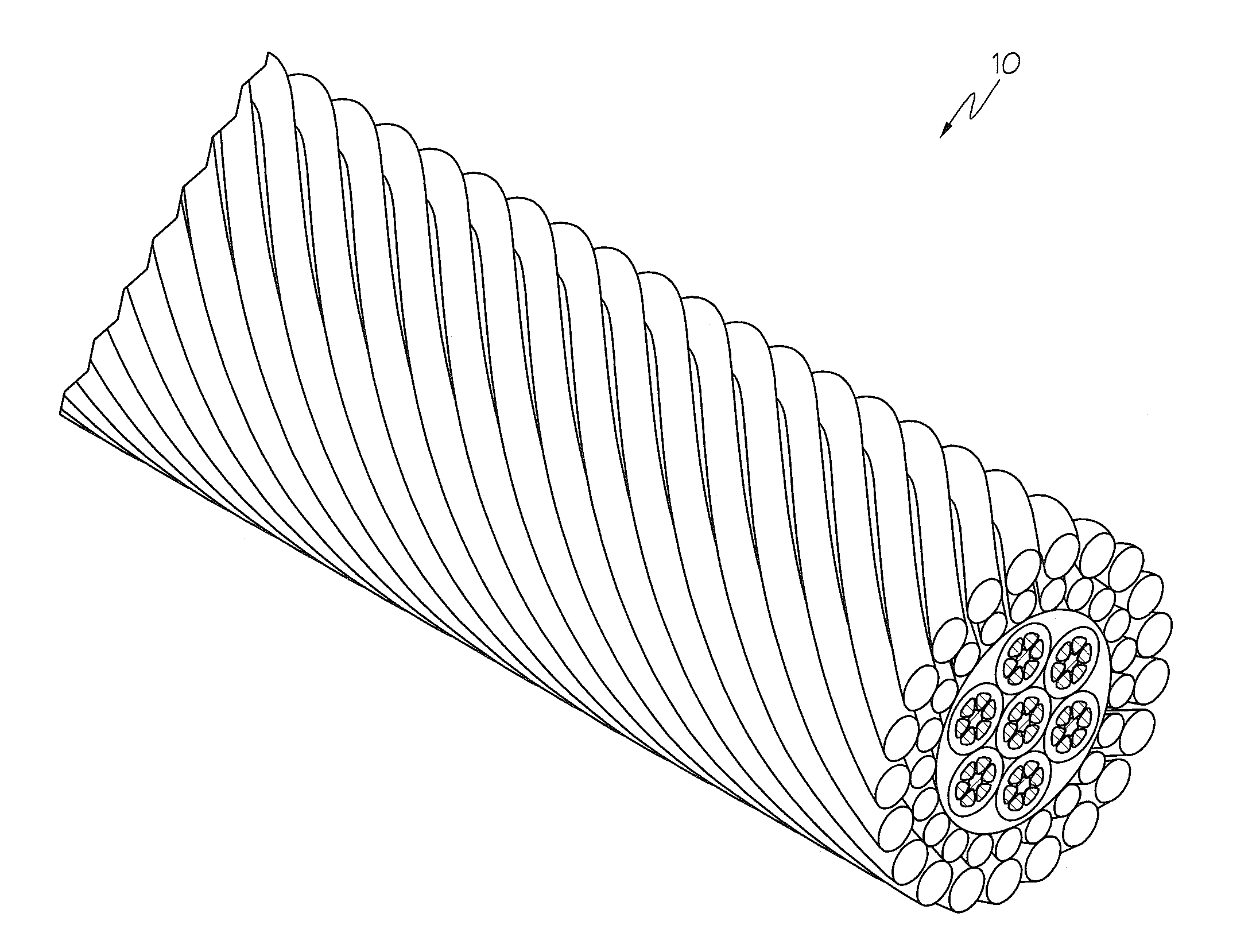

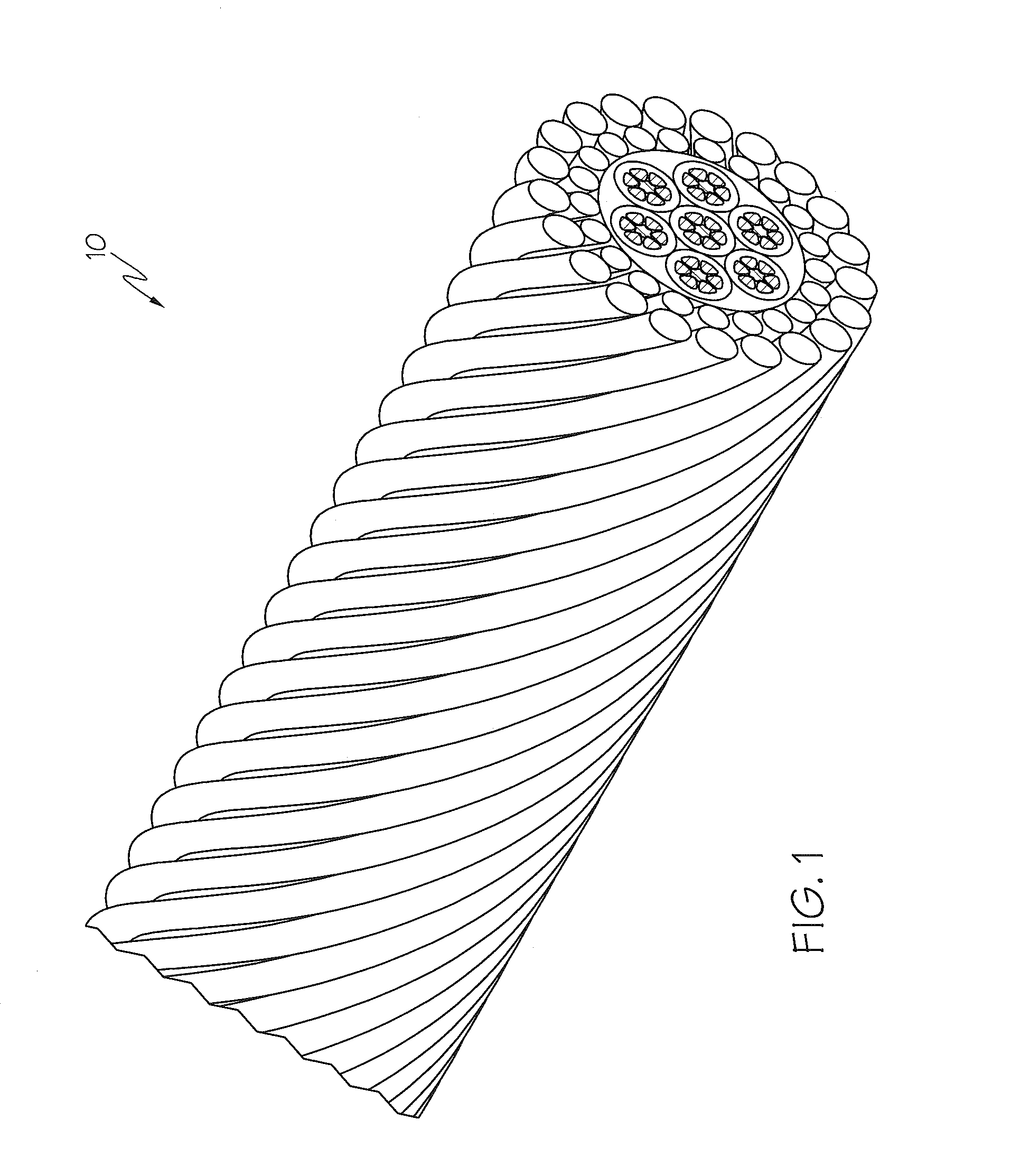

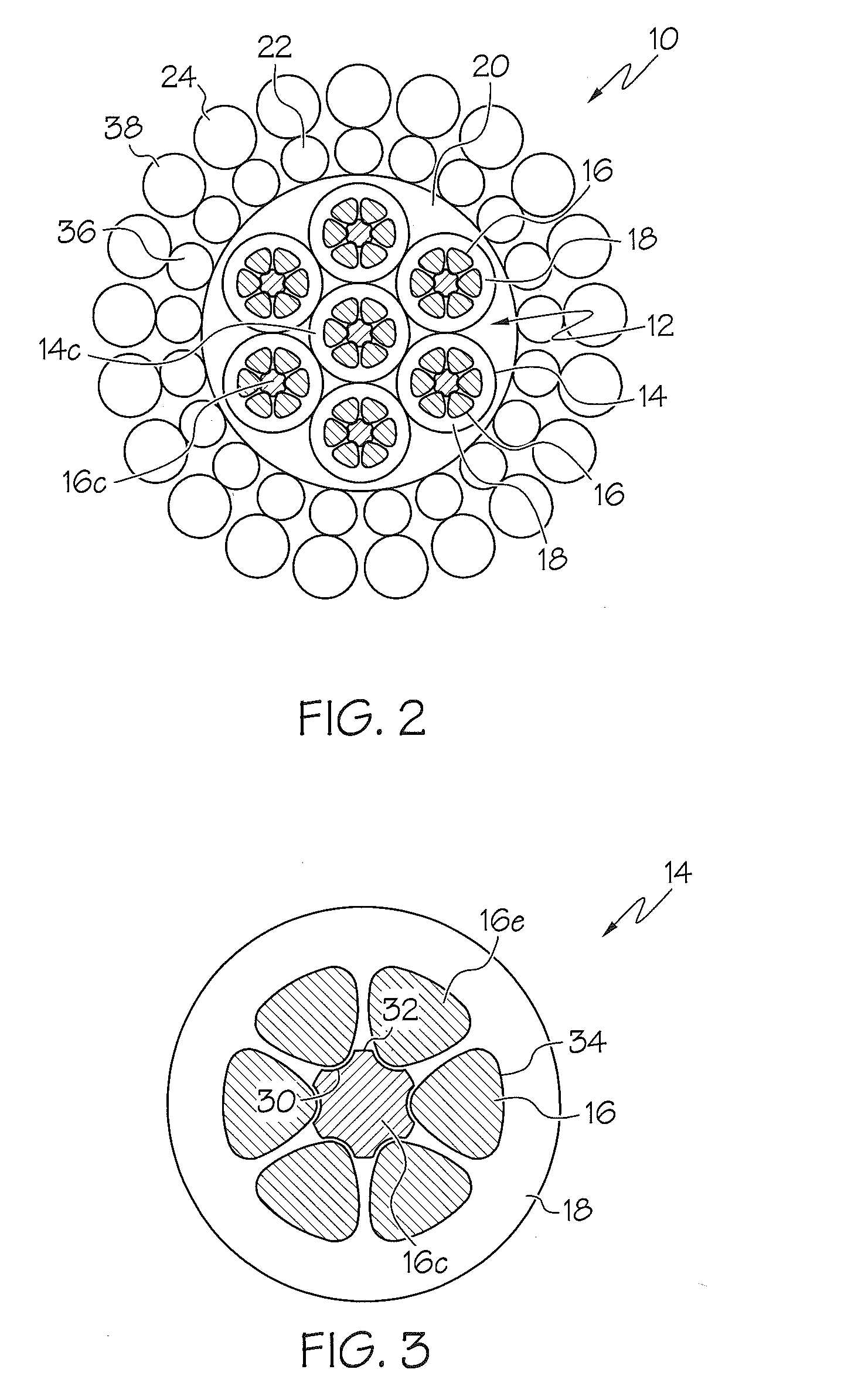

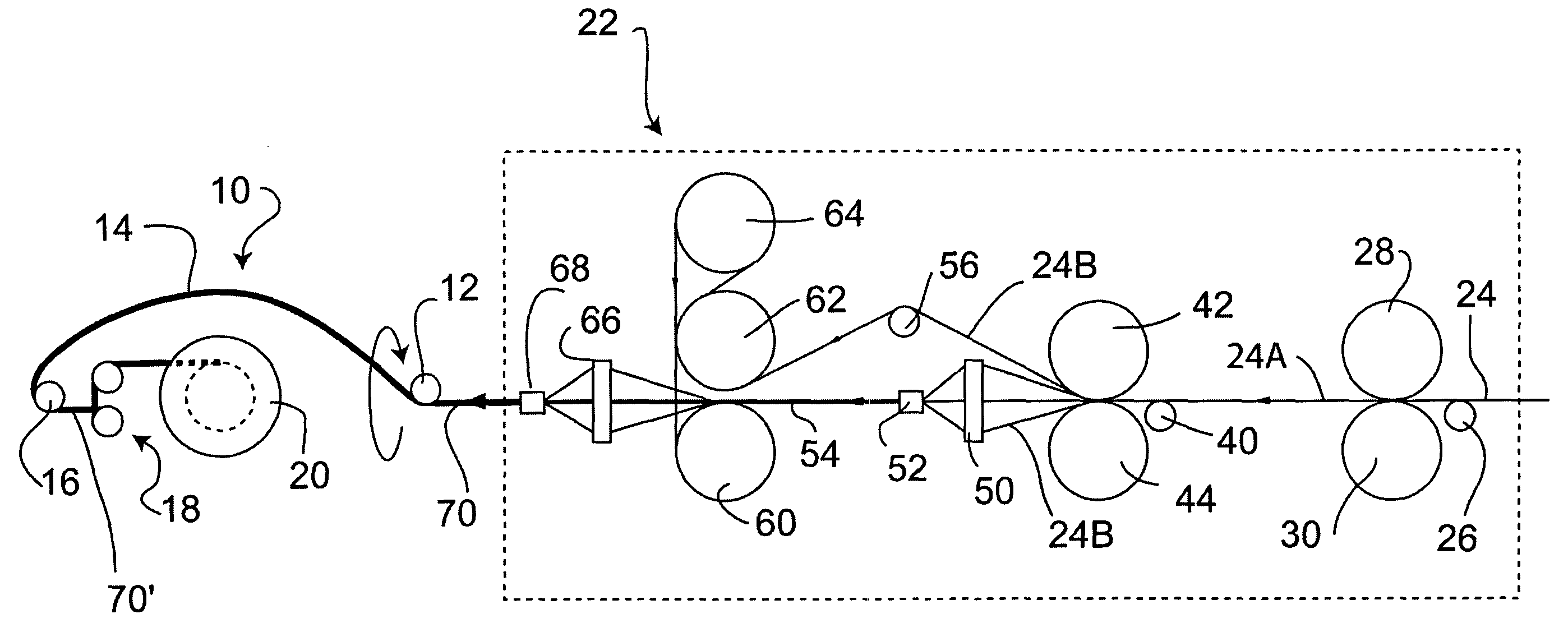

High-power low-resistance electromechanical cable

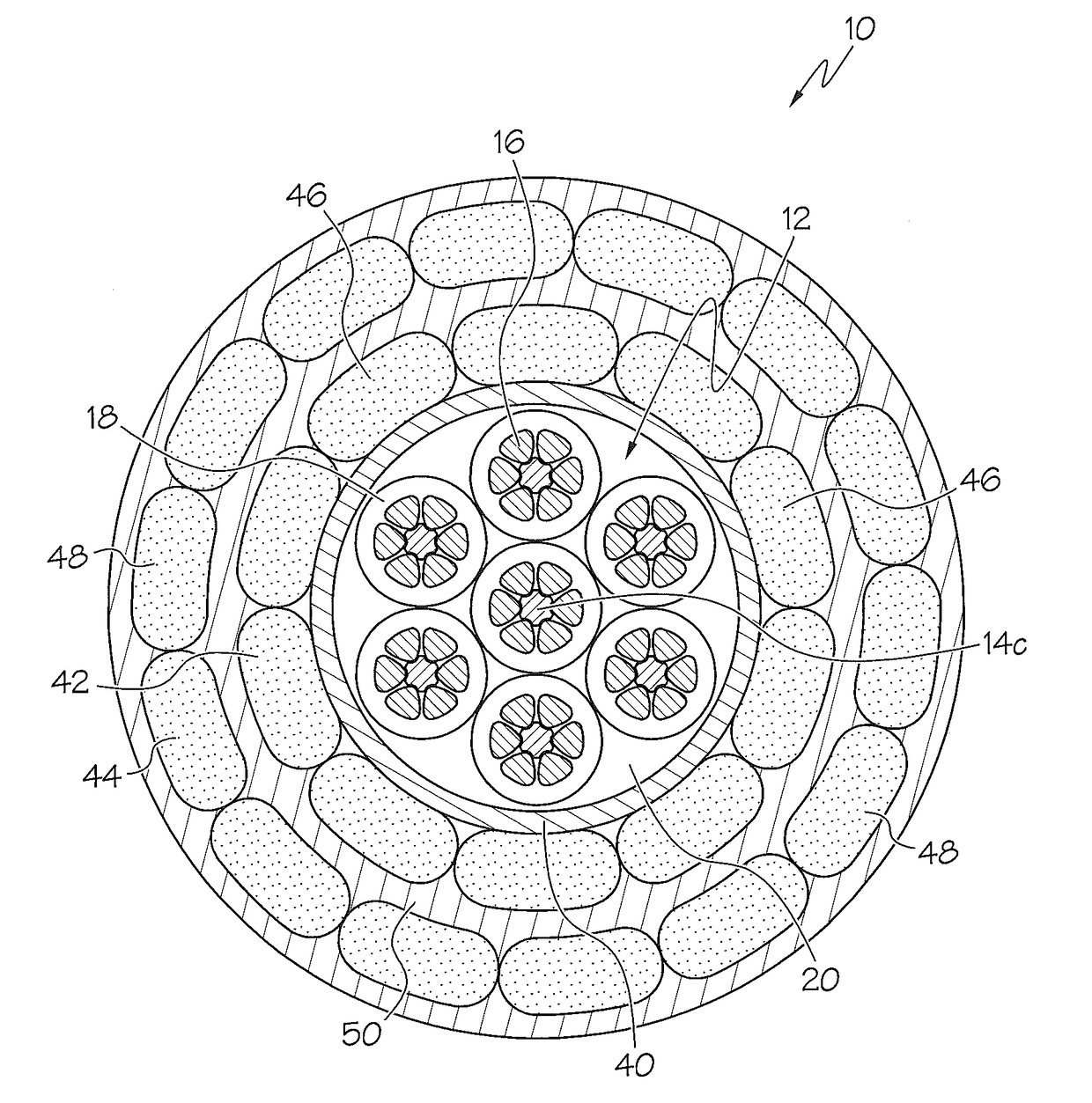

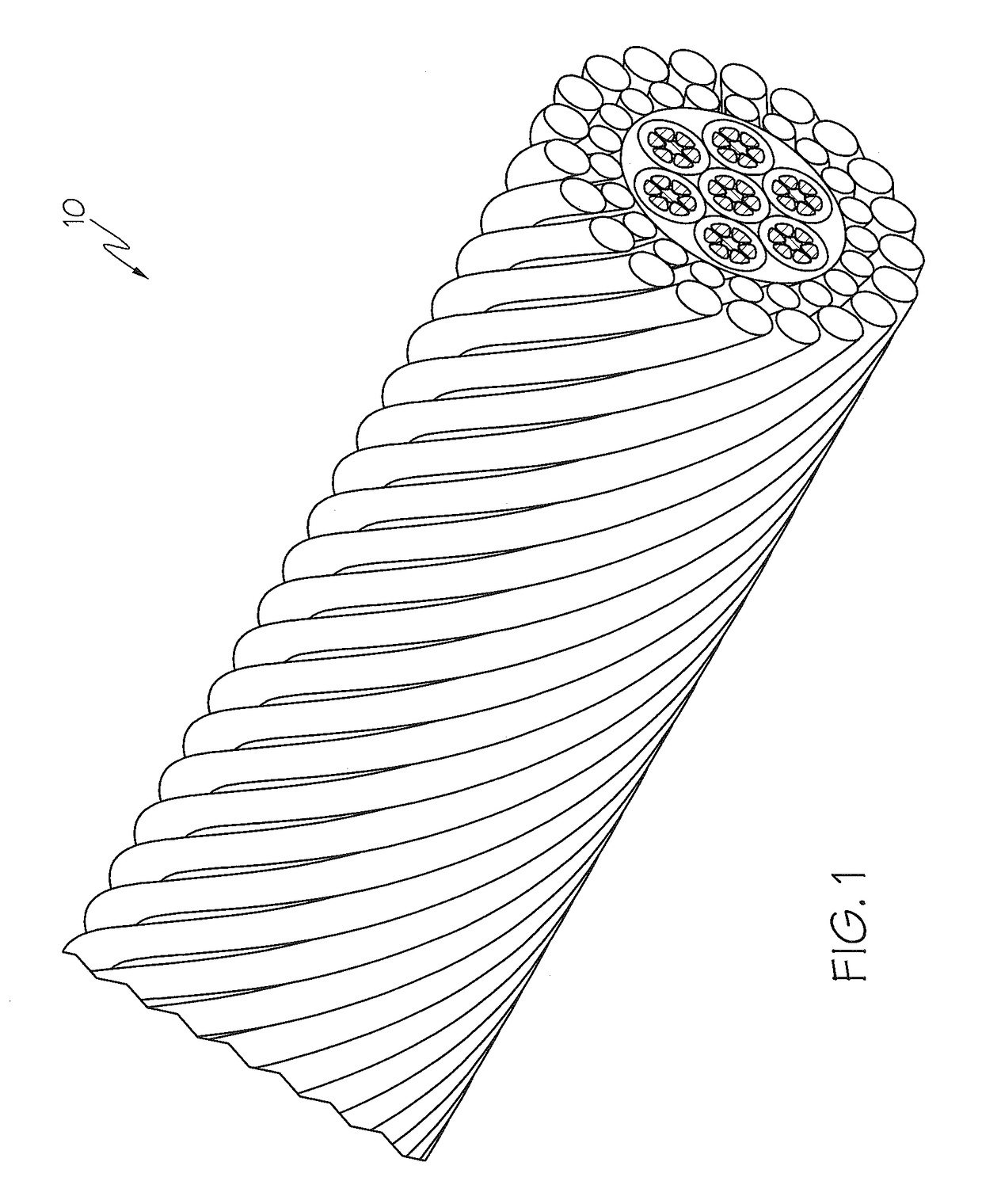

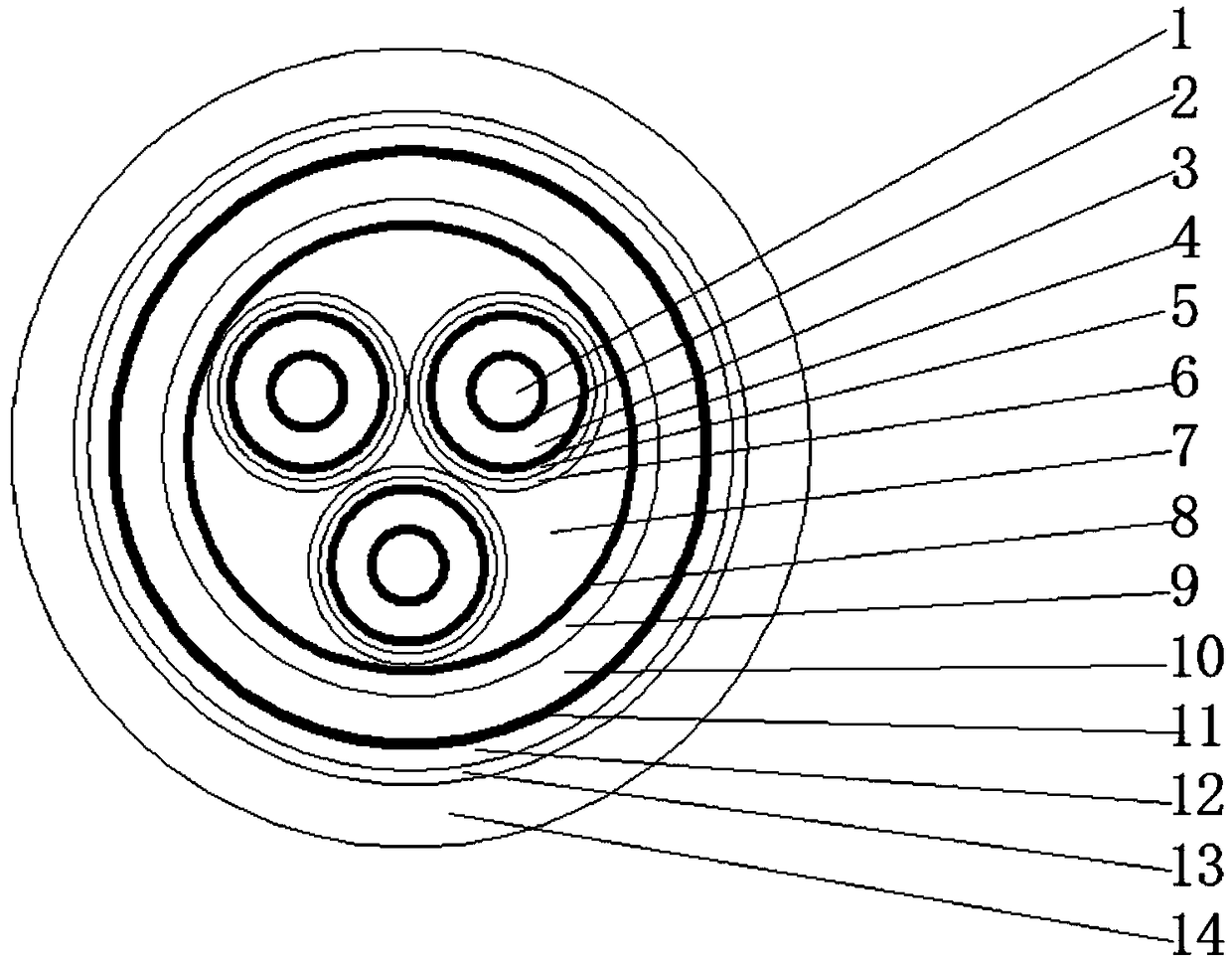

ActiveUS20140318858A1Power cables with screens/conductive layersInsulated cablesTetrafluoroethyleneElectrical conductor

A high-power low-resistance electromechanical cable constructed of a conductor core comprising a plurality of conductors surrounded by an outer insulating jacket and with each conductor having a plurality of wires that are surrounded by an insulating jacket. The wires can be copper or other conductive wires. The insulating jacket surrounding each set of wires or each conductor can be comprised of ethylene tetrafluoroethylene, polytetrafluoroethylene, polytetrafluoroethylene tape, perfluoroalkoxyalkane, fluorinated ethylene propylene or a combination of materials. A first layer of a plurality of strength members is wrapped around the outer insulating jacket. A second layer of a plurality of strength members may be wrapped around the first layer of a plurality of strength members. The first and / or second layer of strength members can be made of single wires, synthetic fiber strands multi-wire strands, or rope. If either or both layers are made up of synthetic fiber, then the synthetic fibers may be surrounding and encapsulated by an additional insulating and protective layer.

Owner:WIRECO WORLDGROUP INC

A production method of high-strength large-elongation aluminum-clad steel wire

InactiveCN108986989AChange heat treatment temperatureHigh tensile strengthSingle bars/rods/wires/strips conductorsApparatus for heat treatmentWire rodHigh carbon

The invention relates to a production method of high-strength large-elongation aluminum-clad steel wire, comprising the following steps: 1) hot-drawing high-carbon steel wire rod to different wire diameters through cold drawing; 2) carry out lead bath quenching treatment on that steel wire, and carry out on-line pickling and rinsing to obtain a pretreated steel wire; 3) uniformly cover an outer lay of that pretreated steel wire with a layer of aluminum to form a cladding blank; 4) that coat blank is drawn into a super-high-strength aluminum clad steel wire semi-finished product through multiple passes of a bimetal synchronous deformation wire draw machine; 5) age that semi-finished product of the high-strength aluminum-clad steel wire through a high-temperature box. The method of the invention changes the traditional lead bath heat treatment temperature, The tensile strength of Al-clad steel wire is increased by multi-pass synchronous deformation and drawing with small compression ratio, and the elongation of Al-clad steel wire is increased by high temperature aging treatment. The ultimate tensile strength >= 1700 MPa, elongation >= 3. 0%, and other indexes are in accordance with the requirements of Al-clad steel GB / T17937-2009 standard, thereby meeting the requirements of high strength and high elongation and meeting the application requirements.

Owner:HUBEI LONGSKY COMM TECH

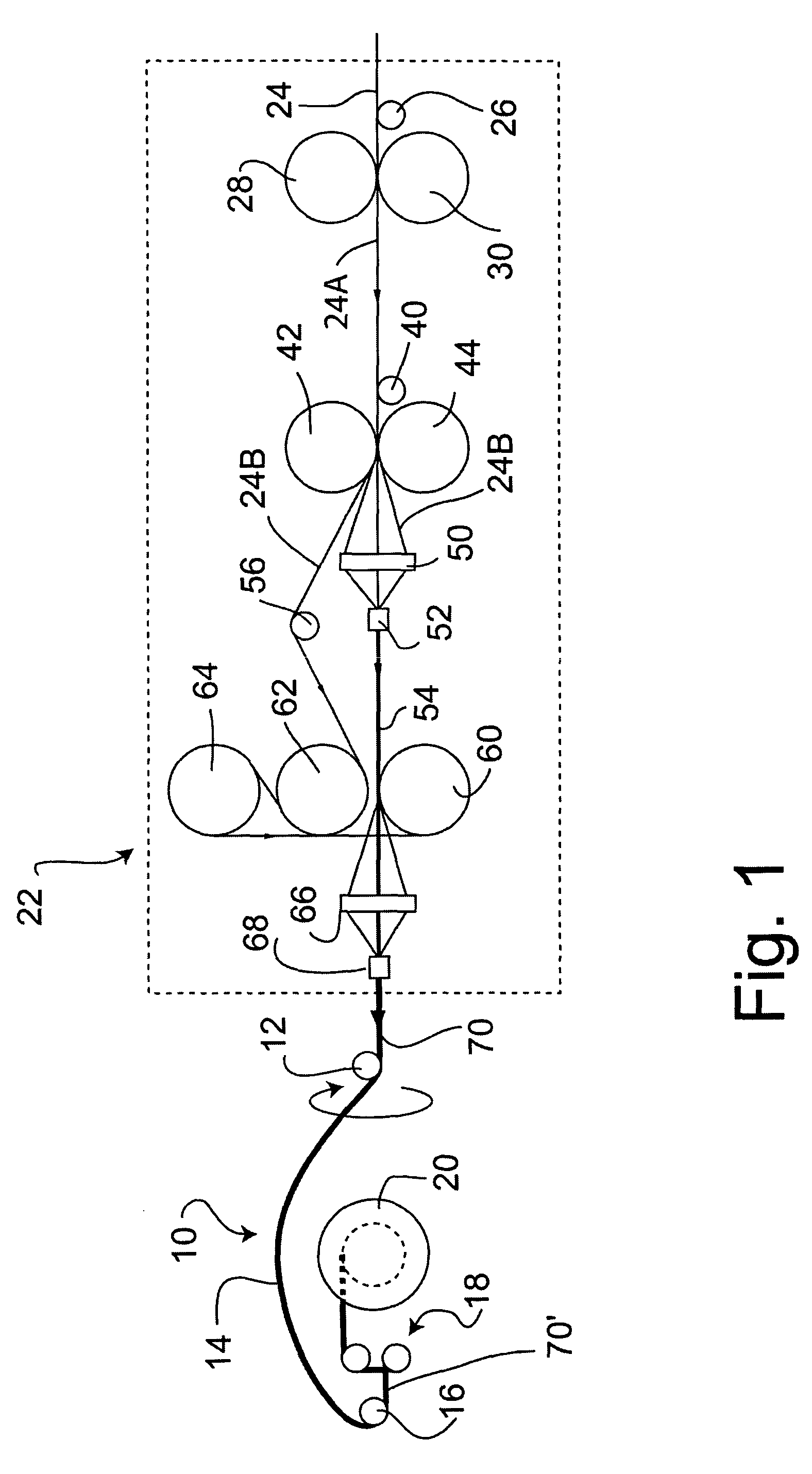

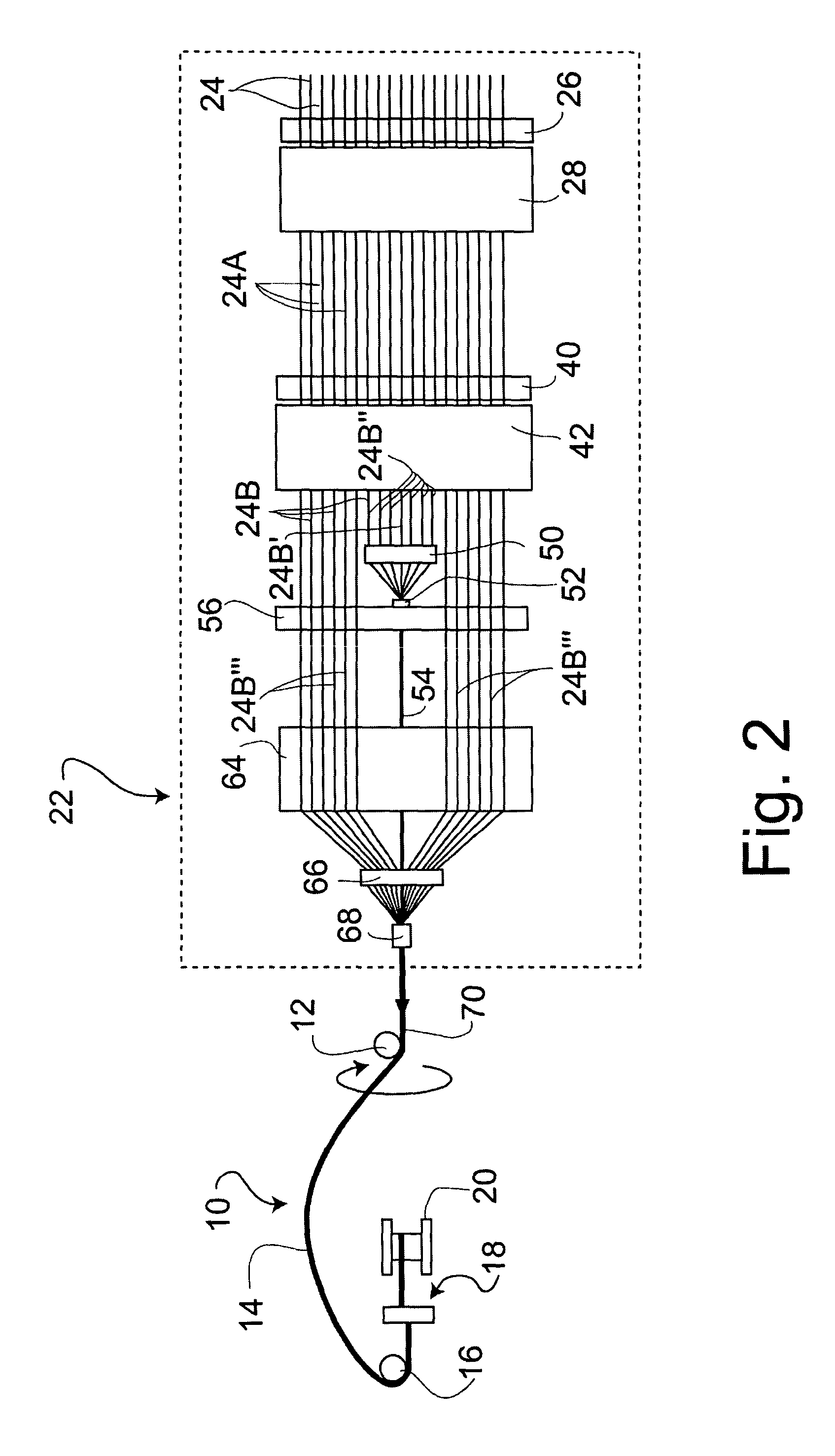

Method and apparatus for producing stranded aluminum cables

InactiveUS20050015978A1Reduce the cross-sectional areaLow costRope making machinesReduction of cables/conductors sizeWire rodEngineering

A method of producing a range of stranded aluminum cables of different gauge from aluminum wires all of the same cross-sectional area. The method involves assembling and stranding a first set of the wires to form a first cable and subsequently assembling and stranding other sets of the wires to form additional cables. Prior to the assembling of at least one set of the wires for the formation of at least one of the cables, the wires are reduced in cross-sectional area in at least two rolling steps, each rolling step causing a reduction in cross-sectional area less than an amount at which brittleness of the wires commences, preferably less than 40% reduction, preferably no more than 30% and ideally less than 25%. The invention also relates to an apparatus for carrying out the method.

Owner:ALCAN INT LTD

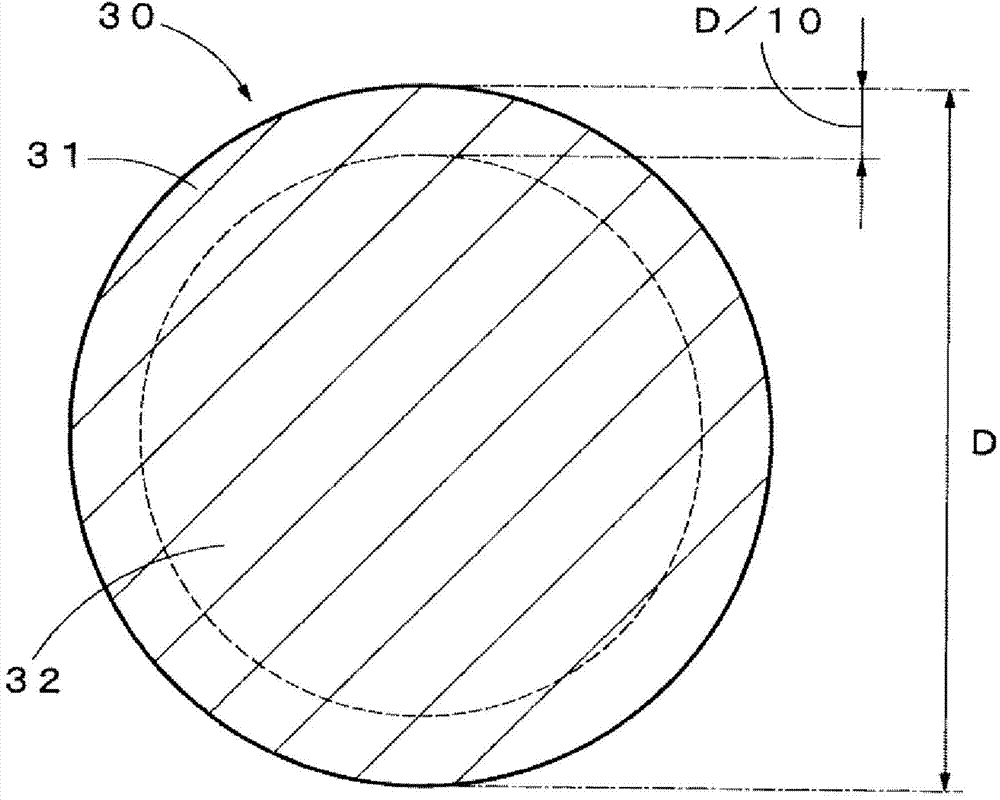

Aluminum alloy conductor and method of producing the same

InactiveUS20130126055A1High resistance to bending fatigueImprove machinabilityApparatus for heat treatmentConductive materialElectrical conductorTin

An aluminum alloy conductor, having a specific aluminum alloy composition of Al—Fe—Cu—Mg—Si—(TiN) or Al—Fe—(Cu / Mg / Si)—(TiN), in which, on a cross-section vertical to a wire-drawing direction, a grain size is 1 to 20 μm, and a distribution density of a second phase with a size of 10 to 200 nm is 1 to 102 particles / μm2; and a production method thereof.

Owner:FURUKAWA ELECTRIC CO LTD +1

Concentric stranded conductor

ActiveUS7409816B2Good flexibilityContact surfaceReduction of cables/conductors sizePower cablesElectrical conductorEngineering

Owner:FURUKAWA ELECTRIC CO LTD

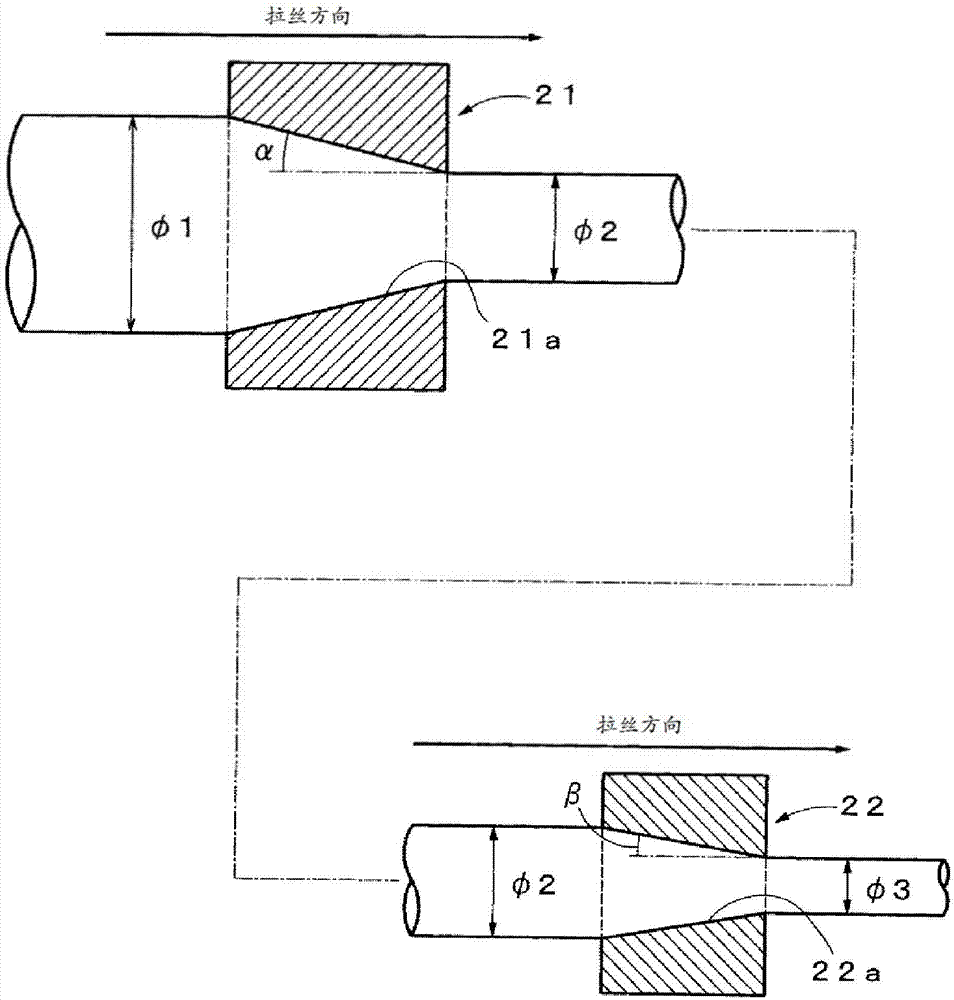

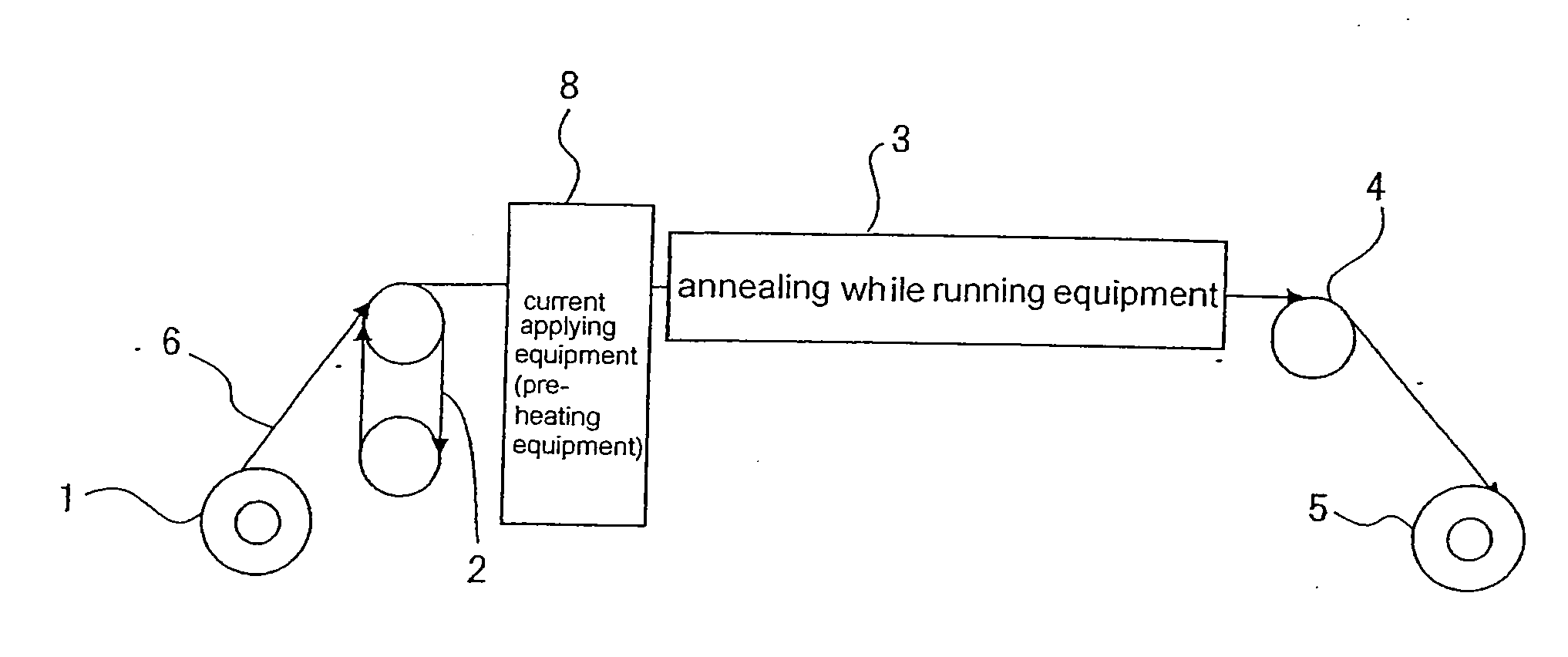

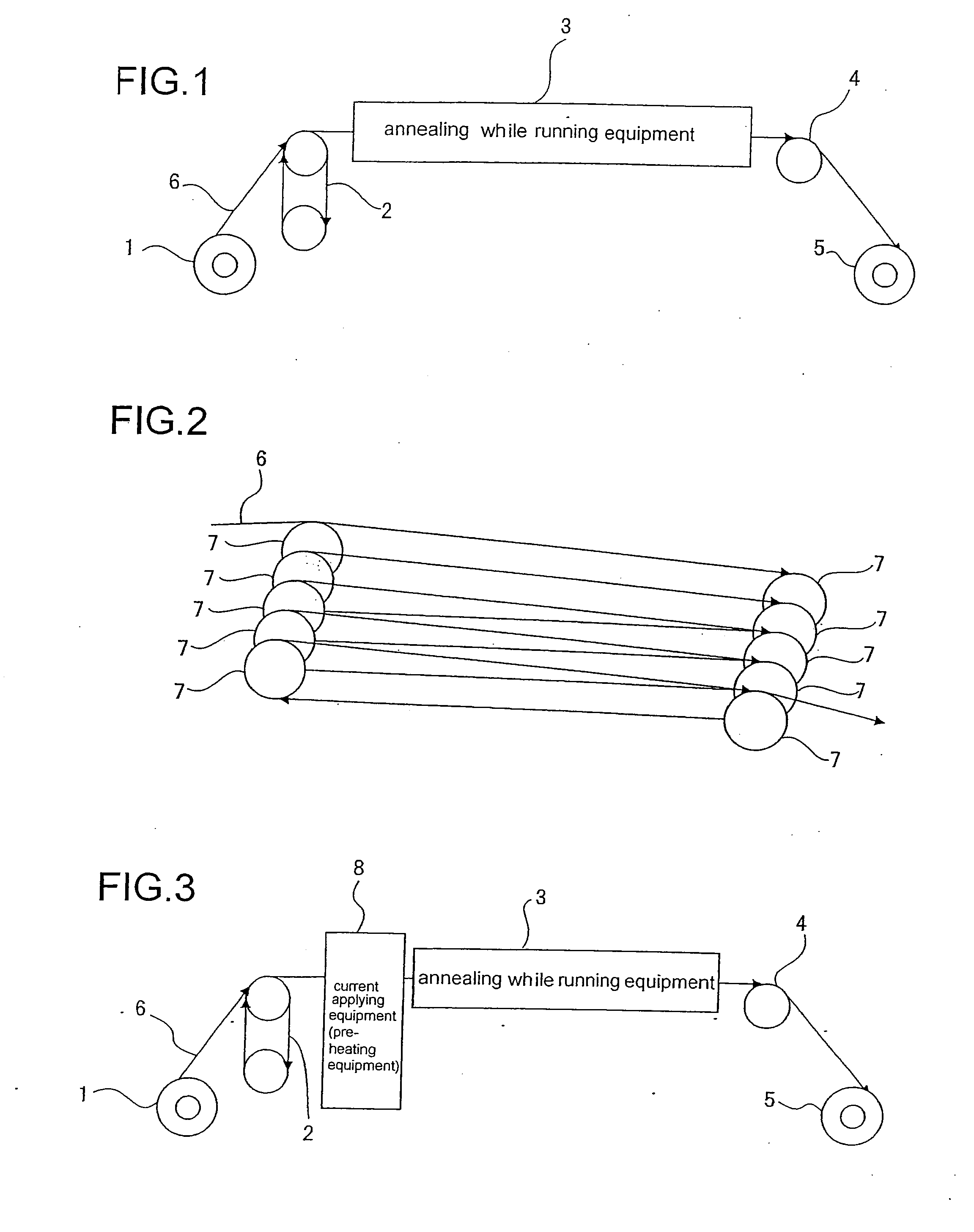

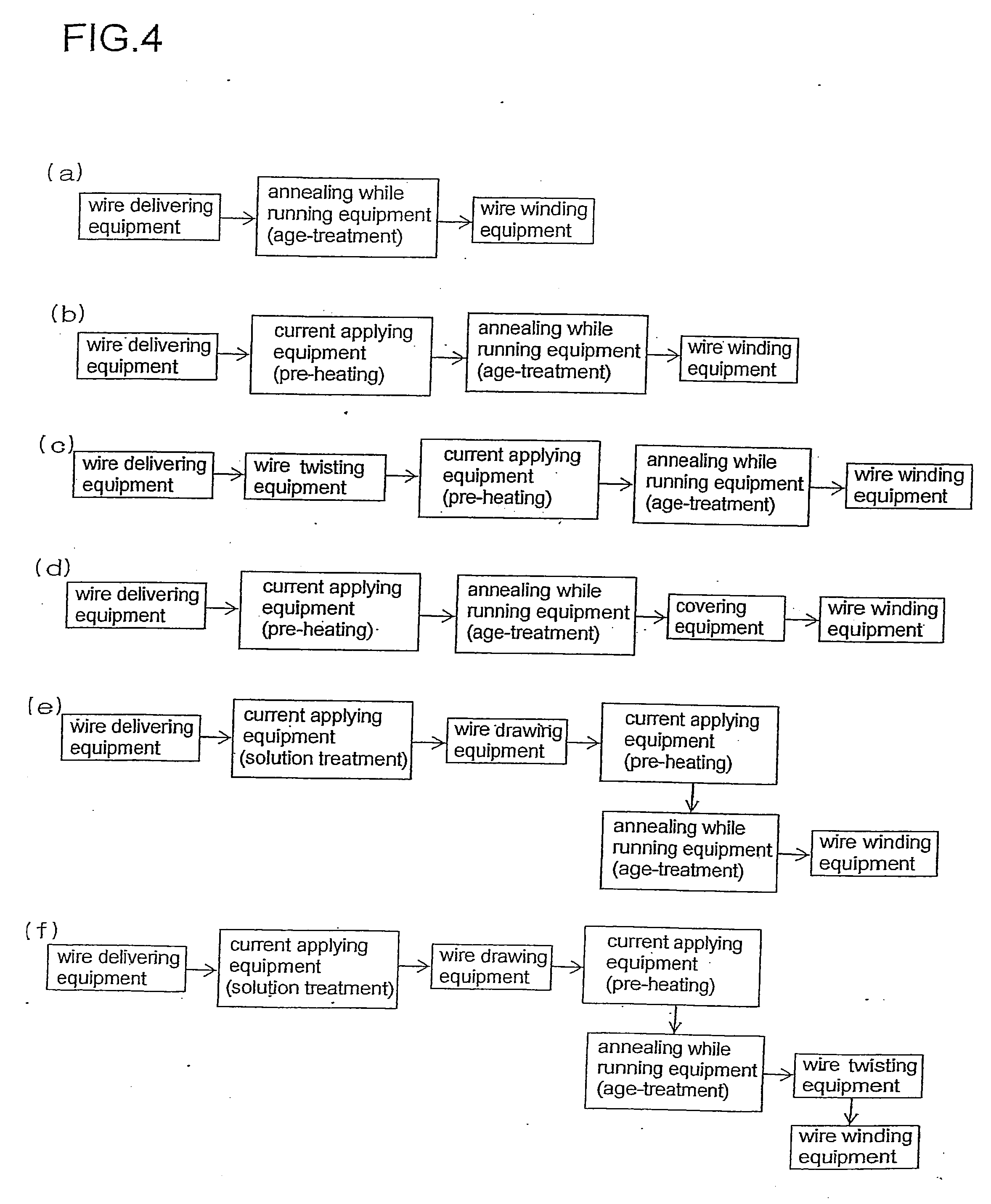

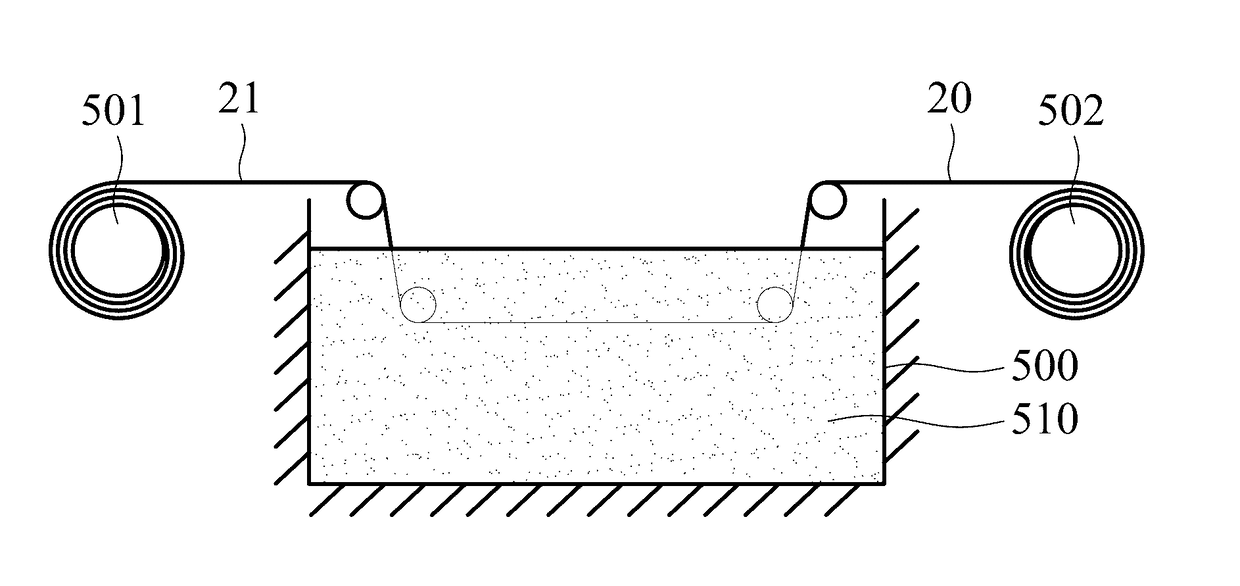

Method for manufacturing wire, apparatus for manufacturing wire, and copper alloy wire

InactiveUS20090229715A1Reduce the number of processesReduce in quantityApparatus for heat treatmentConductive materialWire rodSolution treatment

An apparatus for manufacturing wire comprising: a wire delivering equipment, a wire winding equipment, and an annealing while running equipment installed between the wire delivering equipment and the wire winding equipment, the age-precipitation copper alloy wire being passed in such manner that the wire turns around a plurality of times along a running route in the annealing while running equipment. The current applying equipment to raise a temperature of the age-precipitation copper alloy wire by generated Joule heat may be installed at upstream side of the annealing while running equipment. Another current applying equipment for solution treatment may be installed in tandem at upstream side of the annealing while running equipment. In place of the annealing while running equipment, a current applying equipment may be connected in tandem for age-treatment. By using those equipments, age-precipitation copper alloy wire having the diameter of from 0.03 mm to 3 mm may be obtained.

Owner:FURUKAWA ELECTRIC CO LTD

Stranded copper-plated aluminum cable, and method for its fabrication

ActiveUS7105740B2Low resistivityGood flexibilityConductive materialPower cables for overhead applicationElectricityCopper plating

Aluminum cable type electrical conductor having at least one stranded conductor based on conductive wires with an aluminum core coated with an intermediate layer of copper itself coated by a surface layer of nickel. The surface layer of nickel has a thickness from about 1.3 μm to about 3 μm, it has sufficient continuity to resist a polysulfide bath continuity test for at least 30 seconds without visible traces of attack of the copper appearing at ×1O magnification. This kind of conductor is particularly suitable in small diameters for conducting electricity in aircraft and motor vehicles.

Owner:F S P.-1

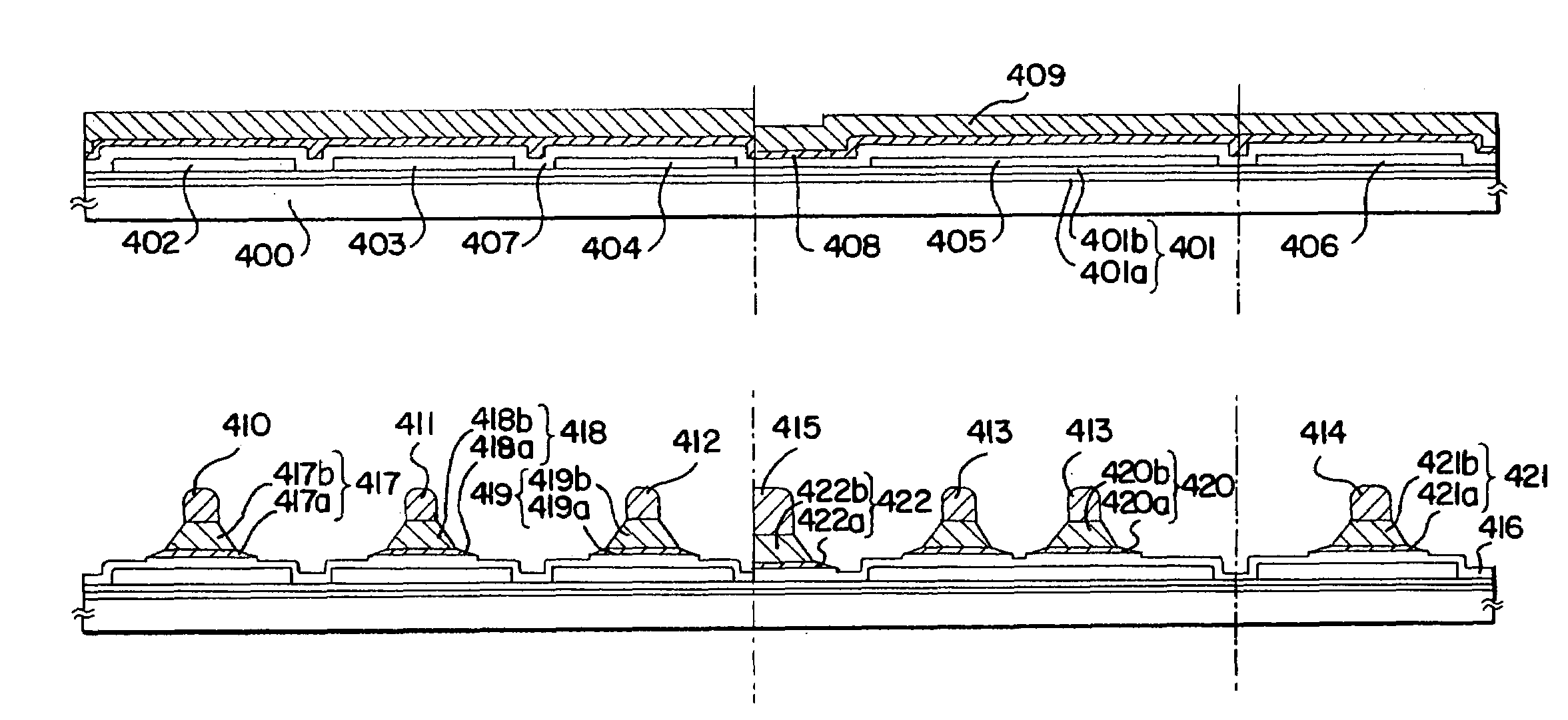

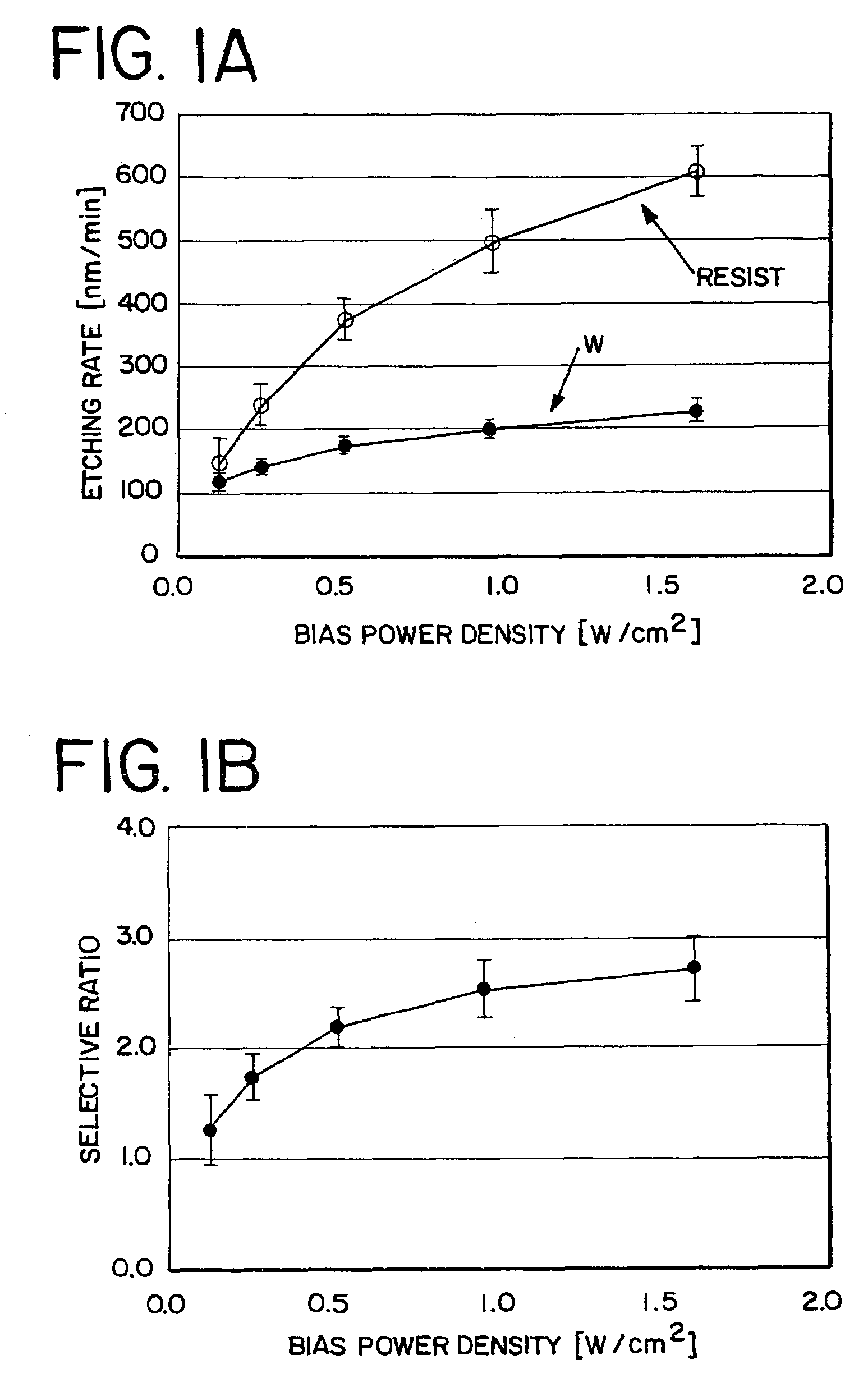

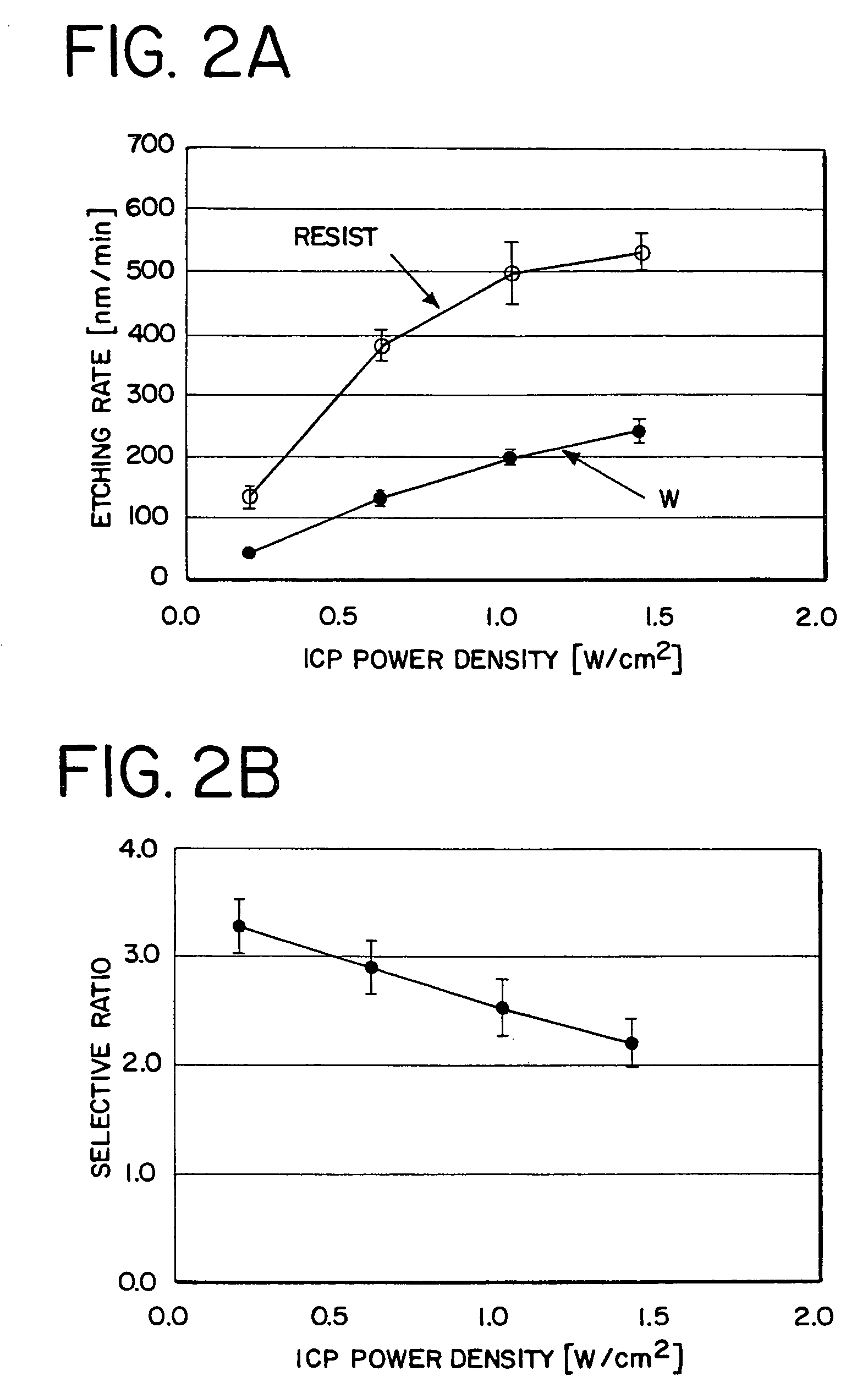

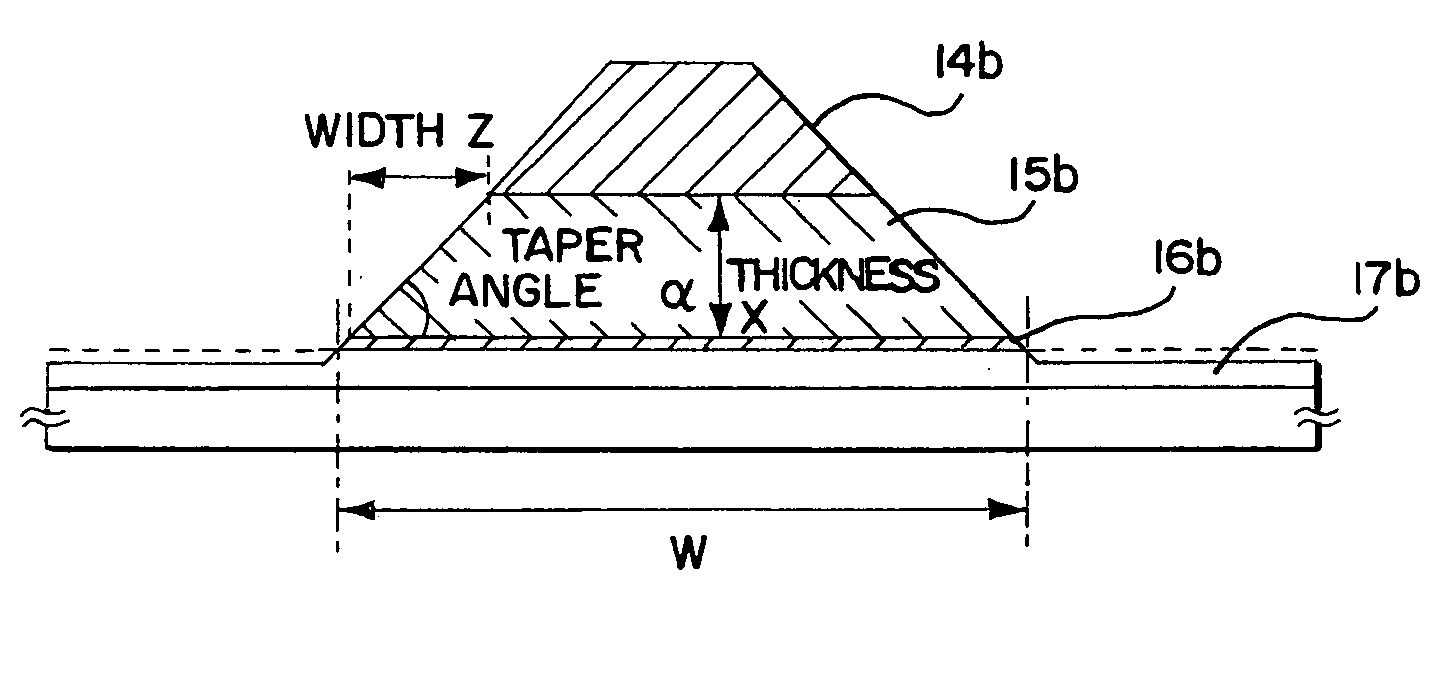

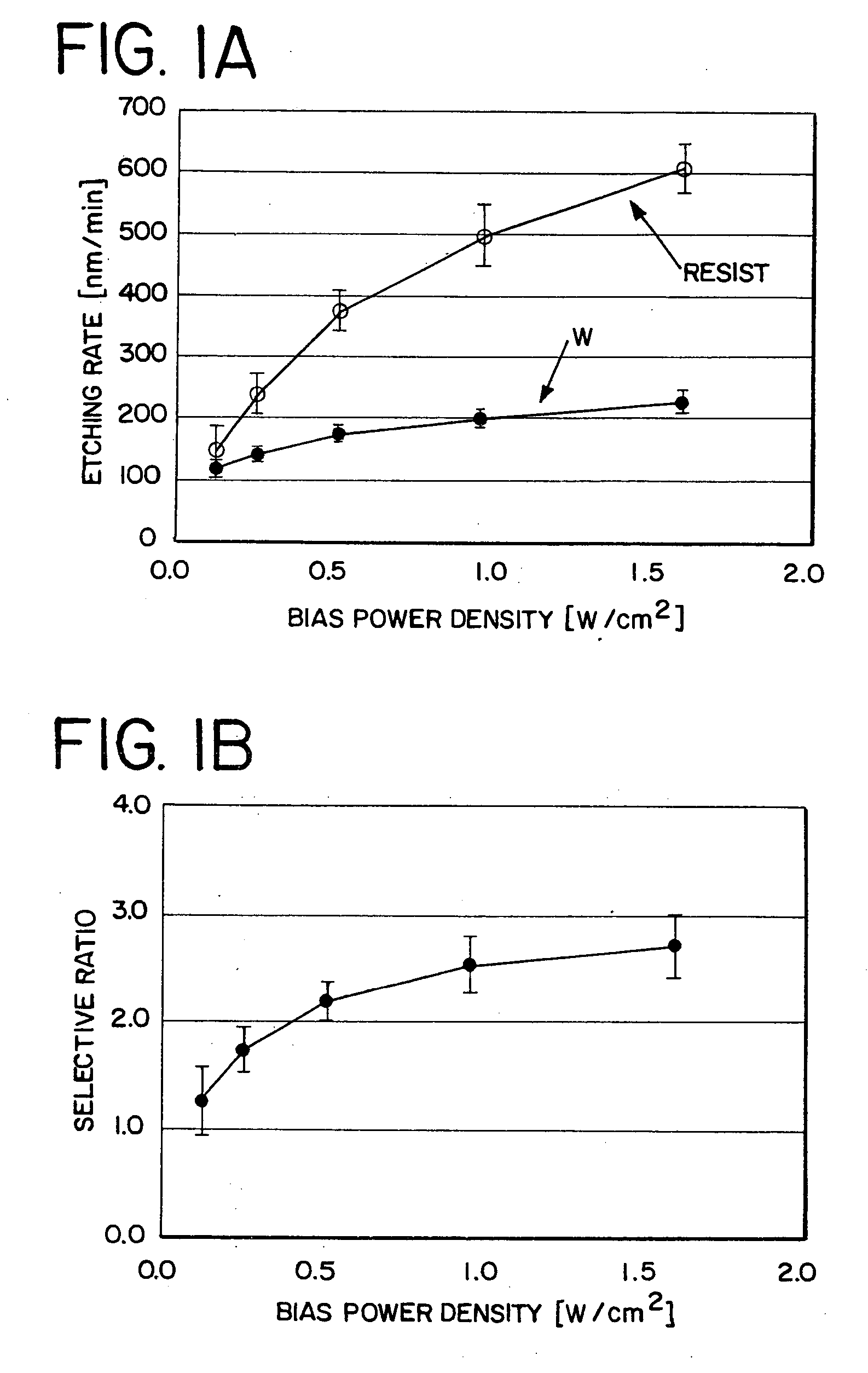

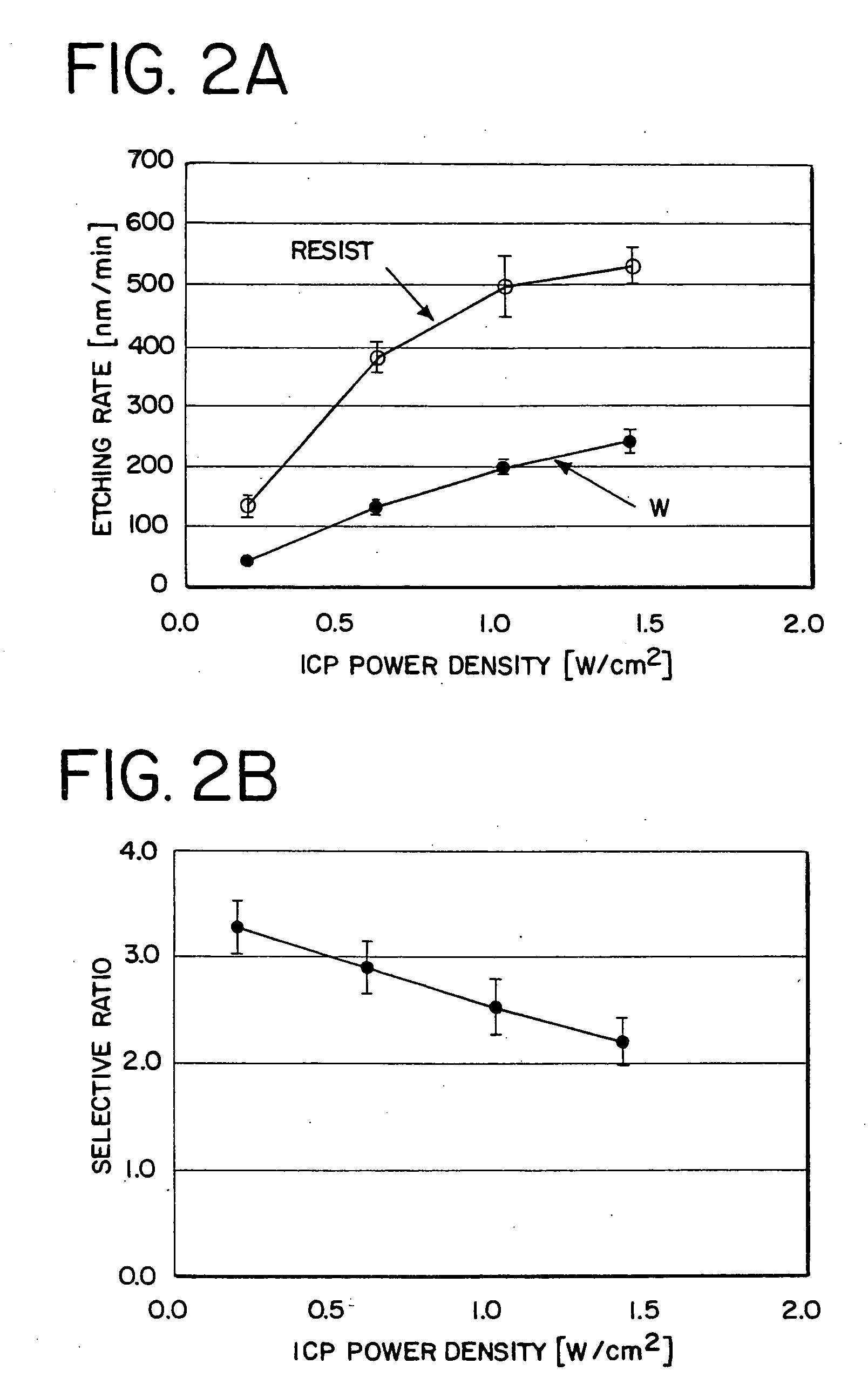

Metal wiring and method of manufacturing the same, and metal wiring substrate and method of manufacturing the same

A metal wiring suitable for a substrate of large size is provided. The present invention is characterized in that at least one layer of conductive film is formed on an insulating surface, a resist pattern is formed on the conductive film, and the conductive film having the resist pattern is etched to form a metal wiring while controlling its taper angle α in accordance with the bias power density, the ICP power density, the temperature of lower electrode, the pressure, the total flow rate of etching gas, or the ratio of oxygen or chlorine in etching gas. The thus formed metal wiring has less fluctuation in width or length and can satisfactorily deal with an increase in size of substrate.

Owner:SEMICON ENERGY LAB CO LTD

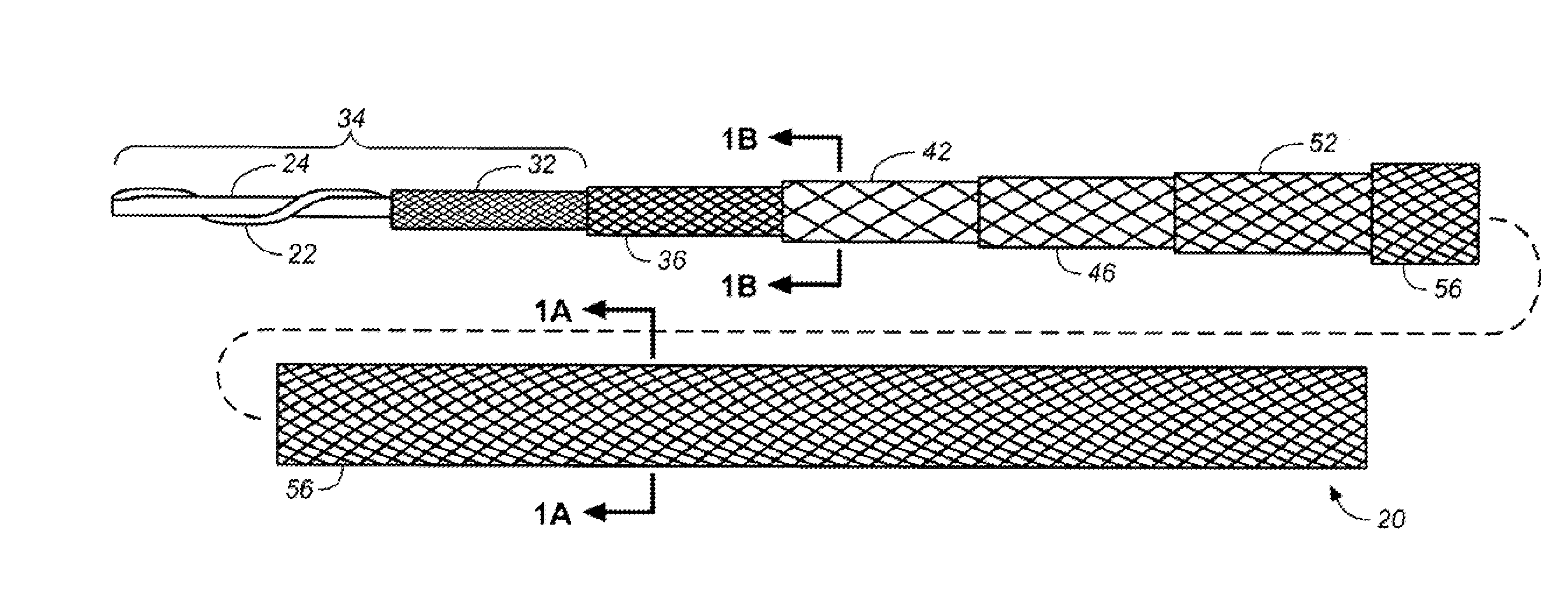

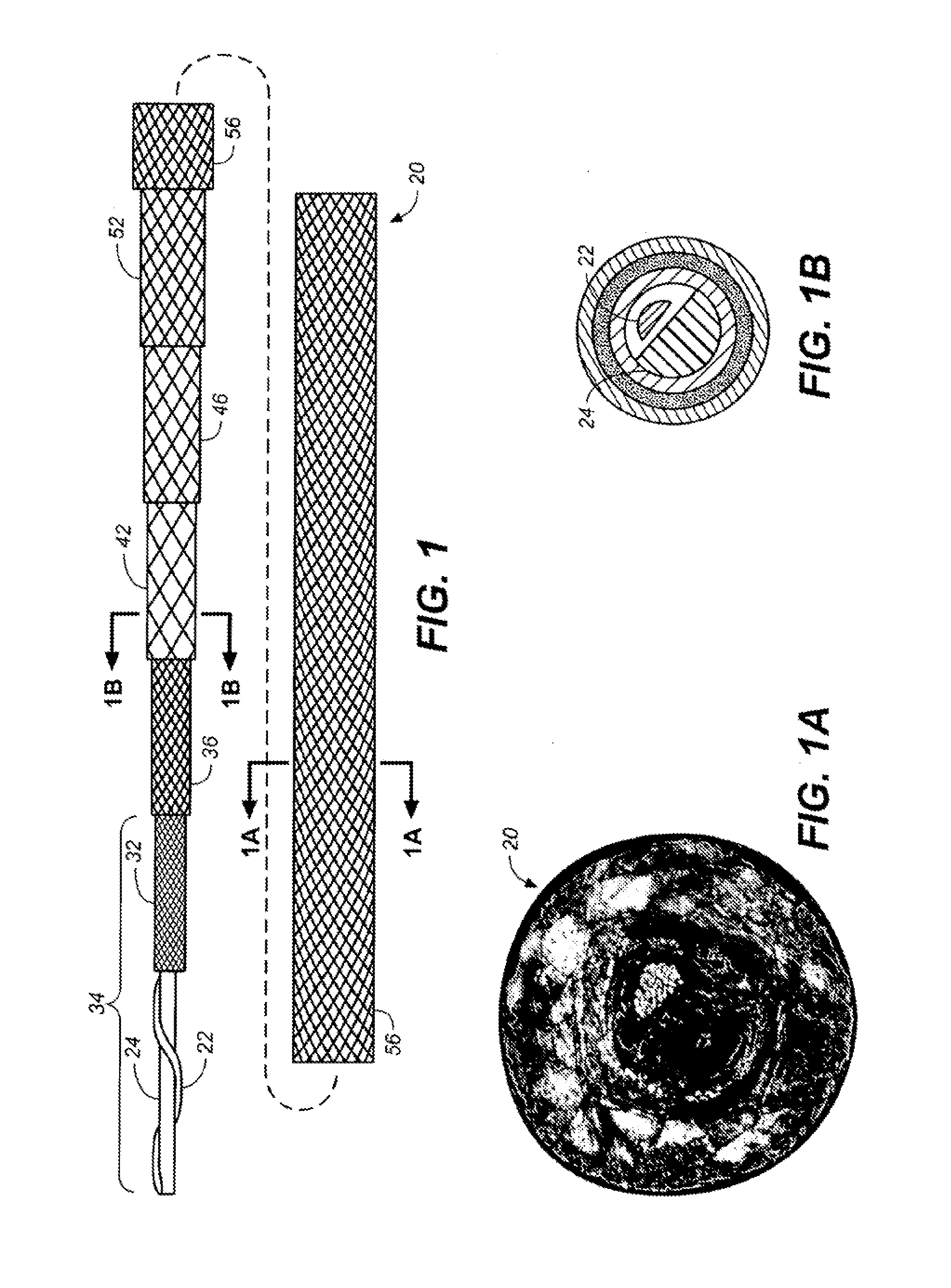

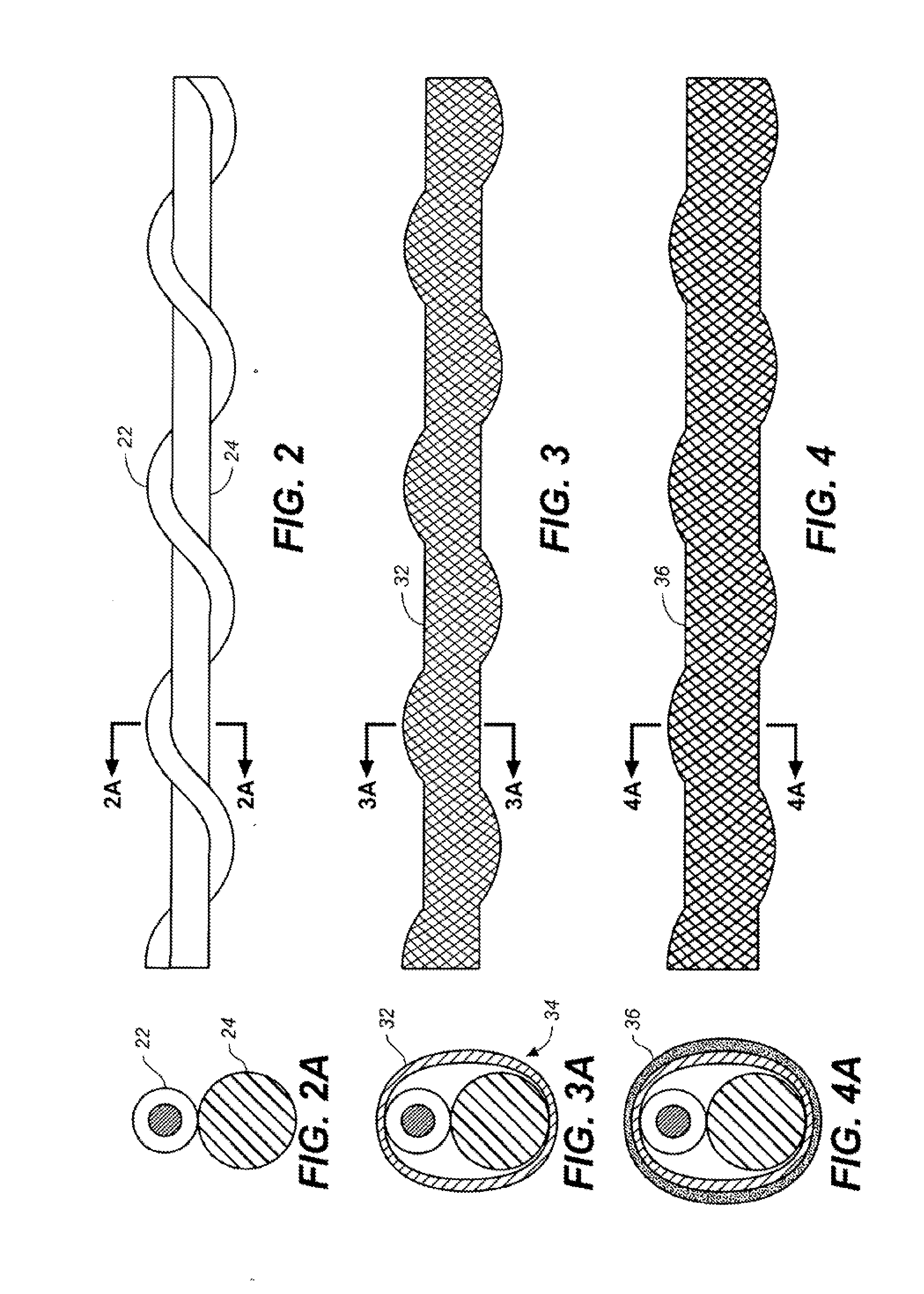

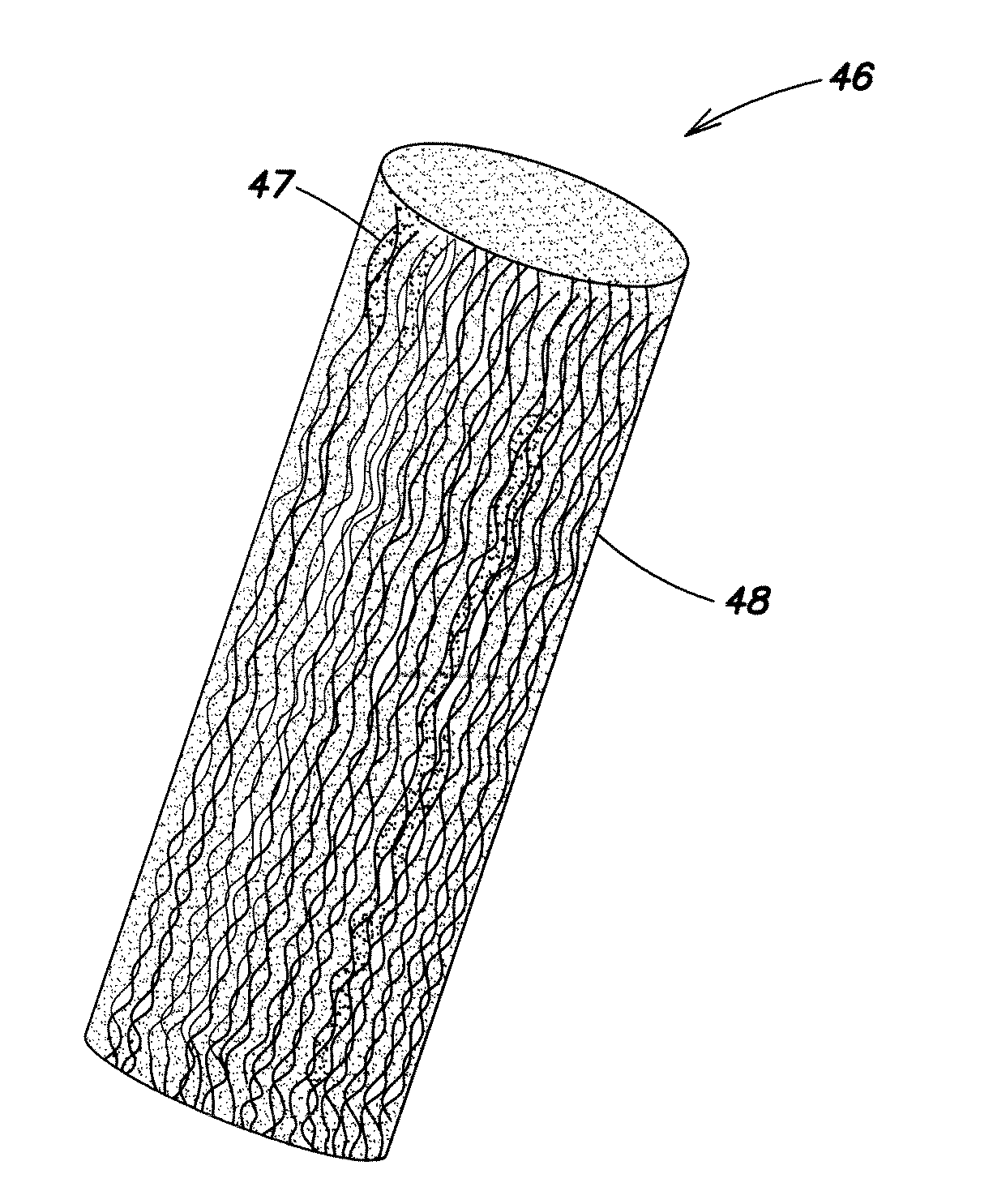

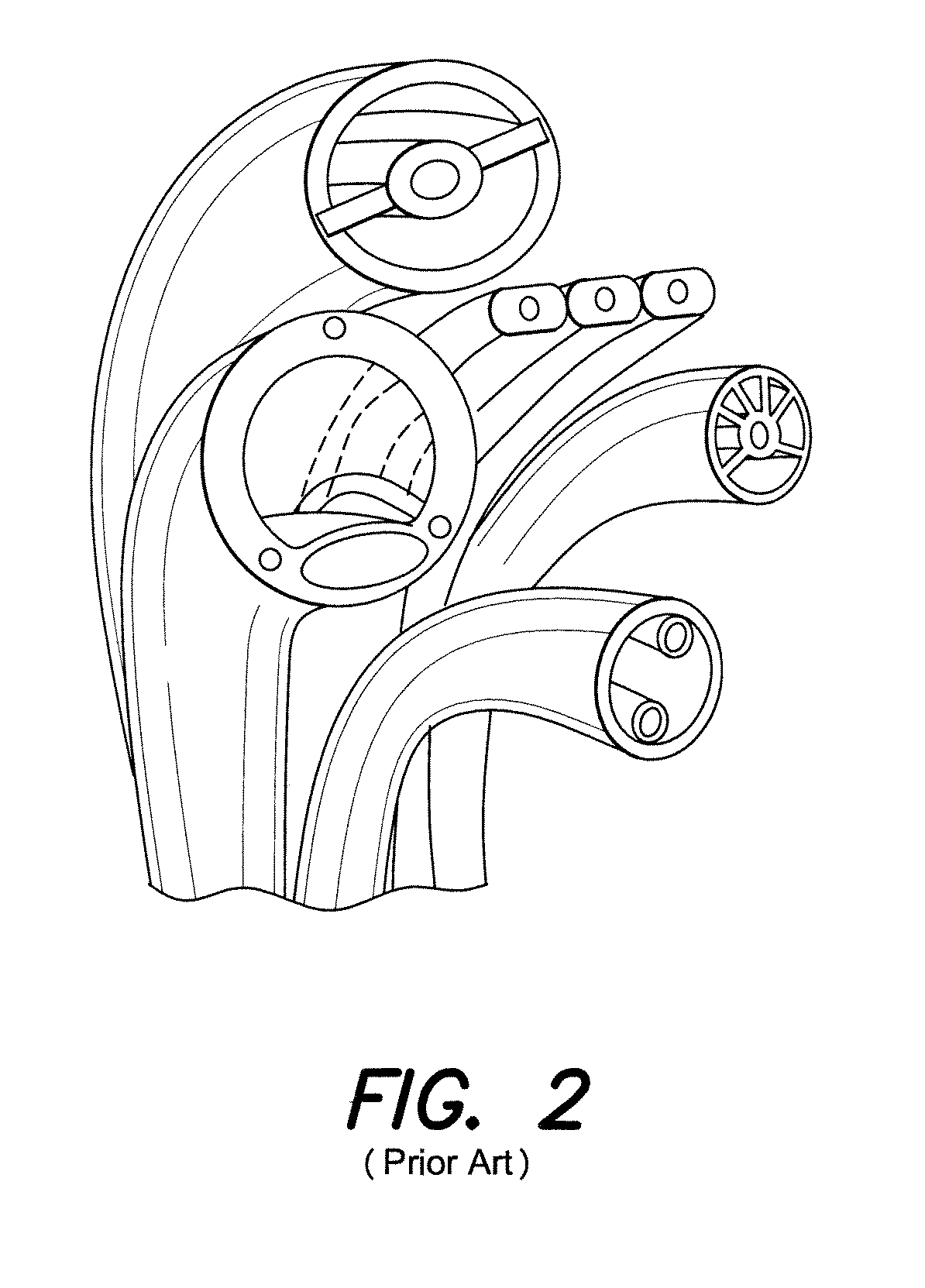

Headline sonar cable

ActiveUS20140216782A1Reduced Power RequirementsReduce heat fatigueLine/current collector detailsPlastic/resin/waxes insulatorsSonarBreaking strength

A production method for a headline sonar cable (20, 120) that exhibits a high breaking-strength and lighter weight than a conventional steel headline sonar cable. Producing the headline sonar cable (20, 120) is characterized by the steps of:a. providing an elongatable internally-located conductive structure (34, 134) that is adapted for data signal transmission; andb. braiding a strength-member jacket layer (52) of polymeric material around the structure (34, 134) while ensuring that the structure (34, 134) is slack when surrounded by the jacket layer (52).The structure (34, 134) of the cable (20, 120) retains conductivity upon stretching of the jacket layer (52) surrounding the structure (34, 134) that lengthens the cable (20, 120). For one embodiment of the method a conductor (20) wrapped around a rod (24) and enclosed within a sheath layer (32) forms the structure (34, 134). For another embodiment of the method a braided conductor (122) enclosed within a braided sheath (124) and a polymeric layer (132) forms the structure (34, 134).

Owner:HAMPIDJAN

High-power low-resistance electromechanical cable

ActiveUS9627100B2Communication cablesReduction of cables/conductors sizeElectrical conductorEngineering

A high-power low-resistance electromechanical cable constructed of a conductor core comprising a plurality of conductors surrounded by an outer insulating jacket and with each conductor having a plurality of wires that are surrounded by an insulating jacket. The wires can be copper or other conductive wires. The insulating jacket surrounding each set of wires or each conductor can be comprised of ethylene tetrafluoroethylene, polytetrafluoroethylene, polytetrafluoroethylene tape, perfluoroalkoxyalkane, fluorinated ethylene propylene or a combination of materials. A first layer of a plurality of strength members is wrapped around the outer insulating jacket. A second layer of a plurality of strength members may be wrapped around the first layer of a plurality of strength members. The first and / or second layer of strength members can be made of single wires, synthetic fiber strands multi-wire strands, or rope. If either or both layers are made up of synthetic fiber, then the synthetic fibers may be surrounding and encapsulated by an additional insulating and protective layer.

Owner:WIRECO WORLDGROUP INC

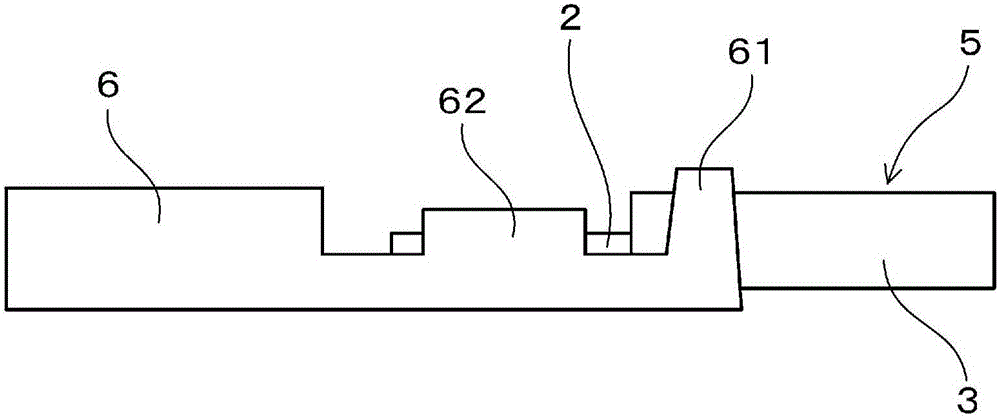

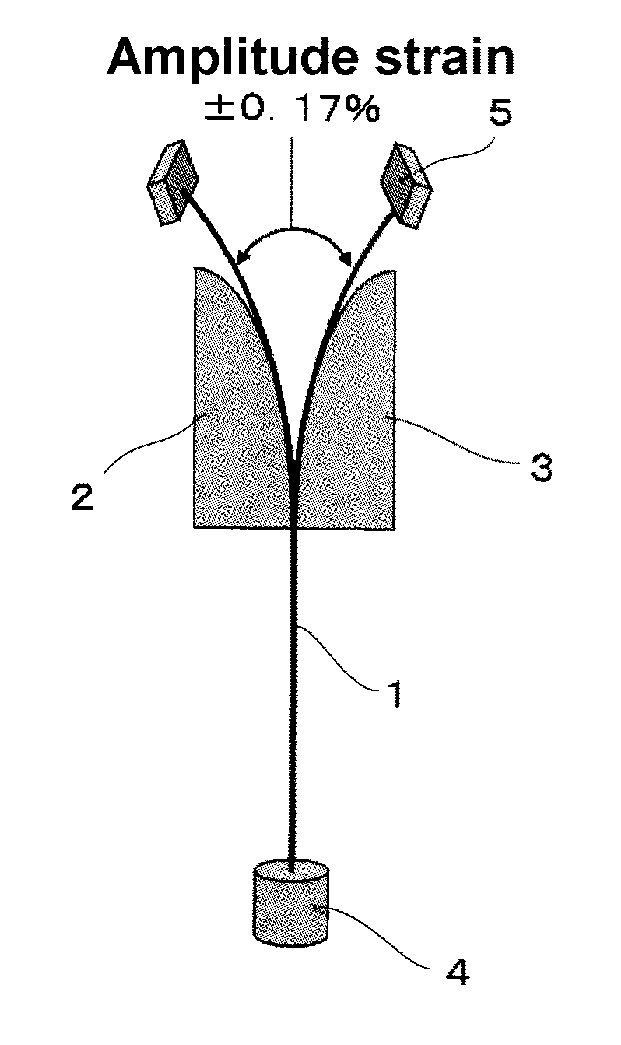

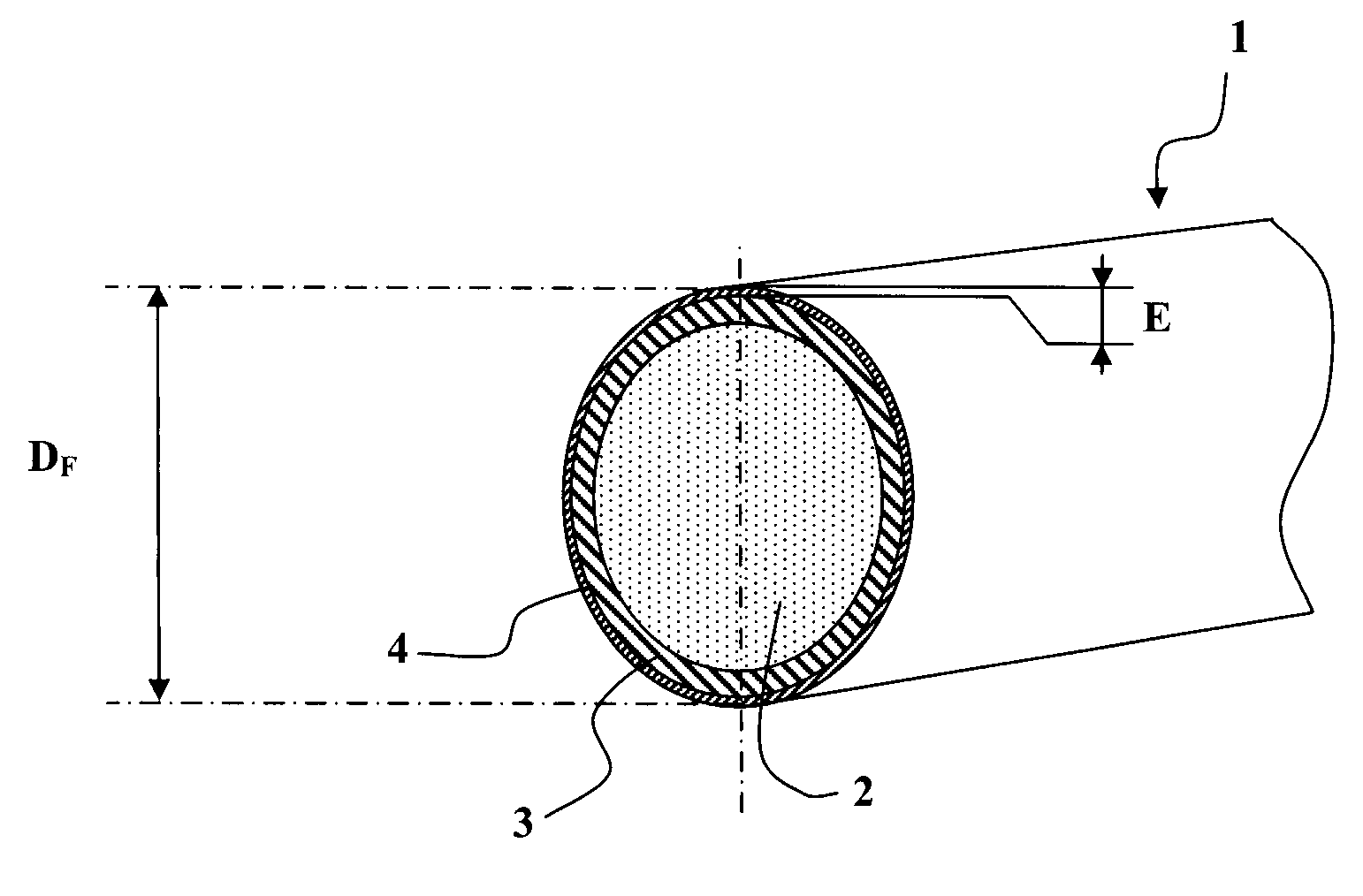

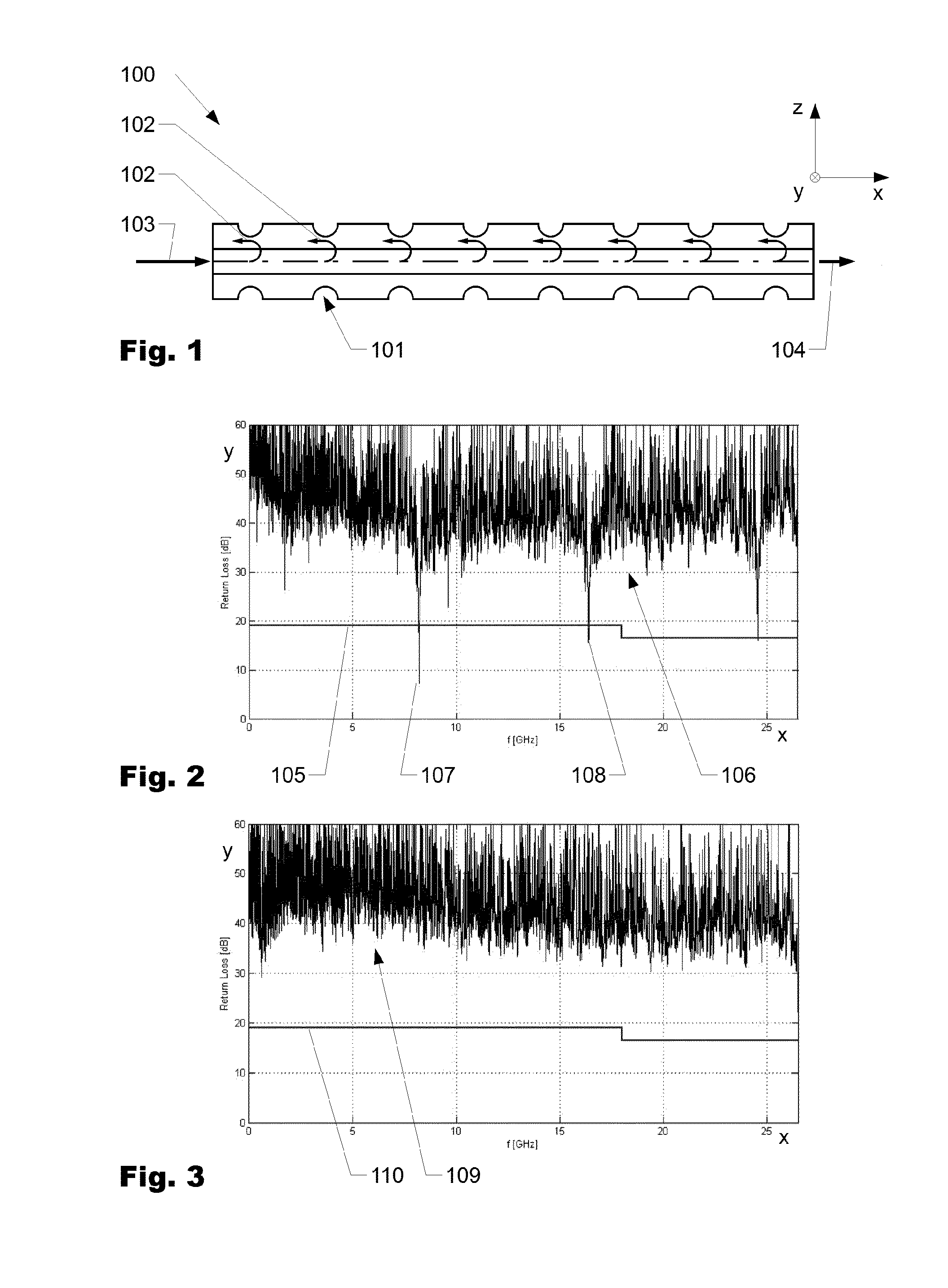

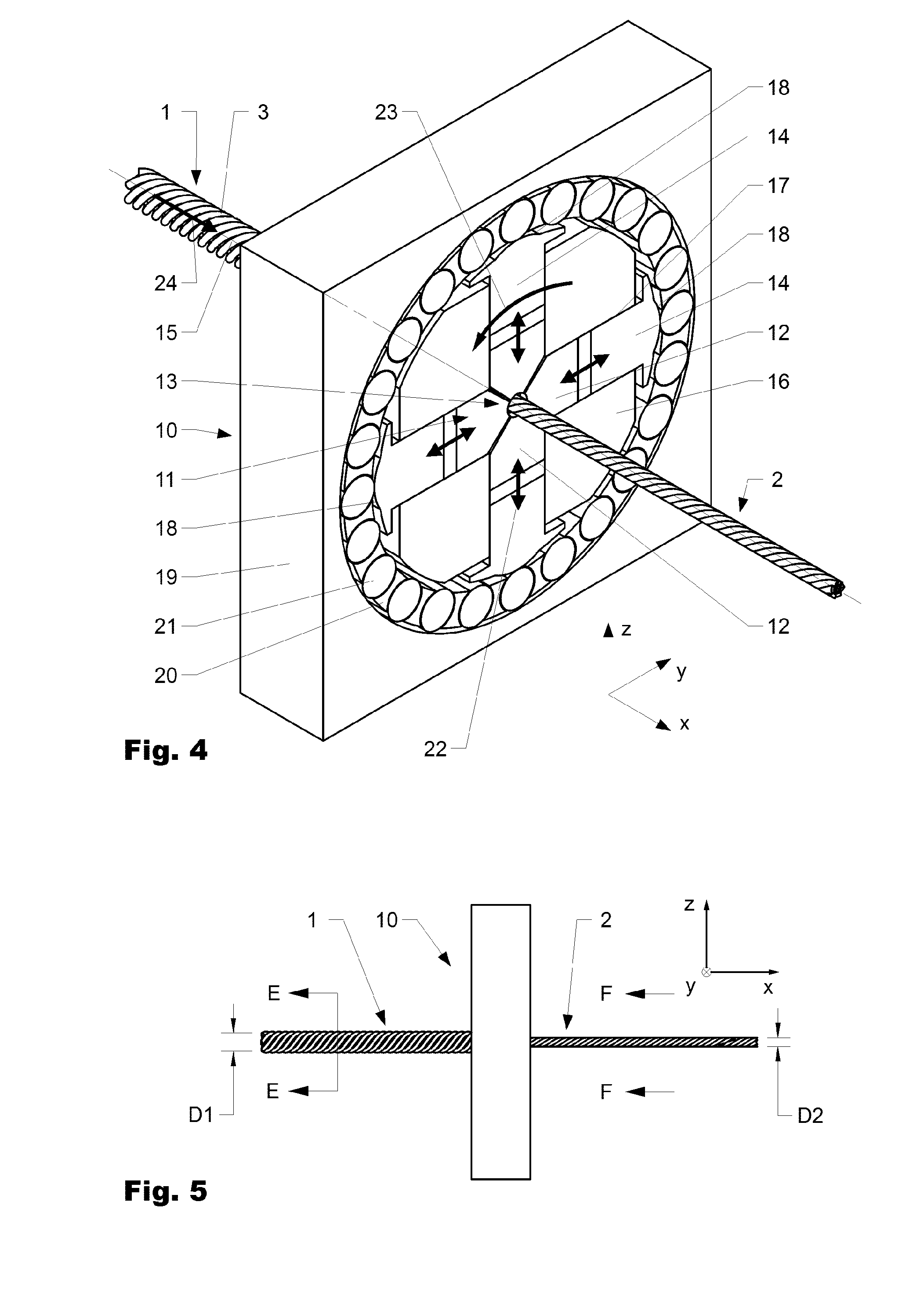

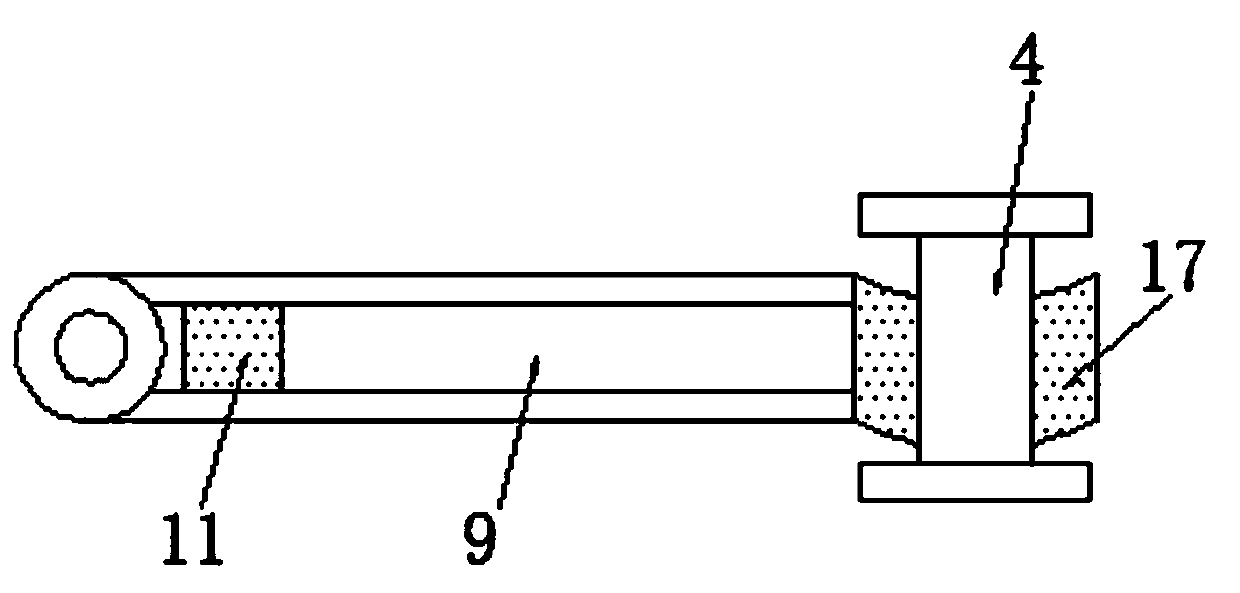

Method for producing a stranded inner conductor for coaxial cable, and coaxial cable

ActiveUS20150096781A1Avoid damageReduce lossCable conductor constructionPower cables with screens/conductive layersDielectricElectrical conductor

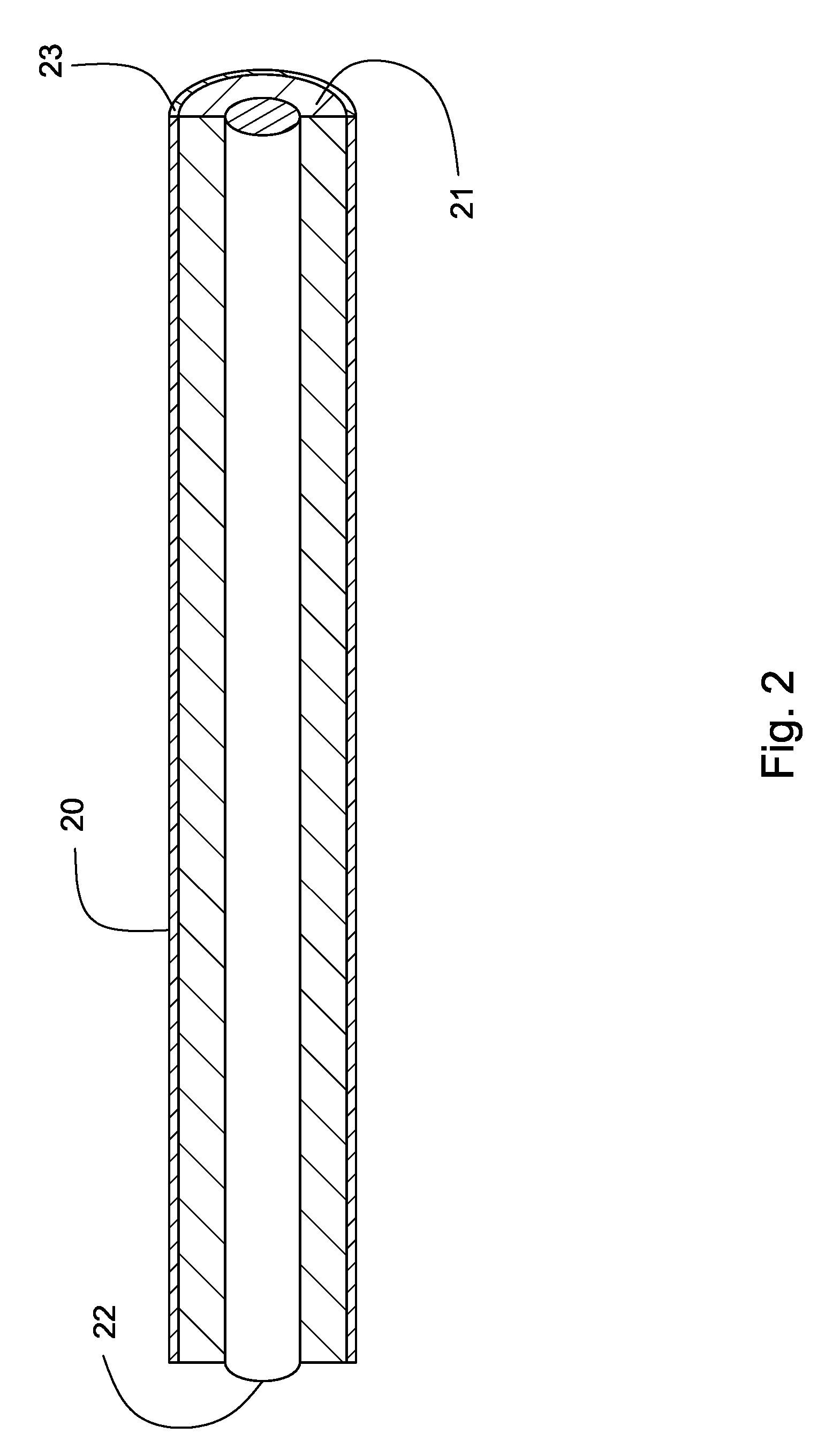

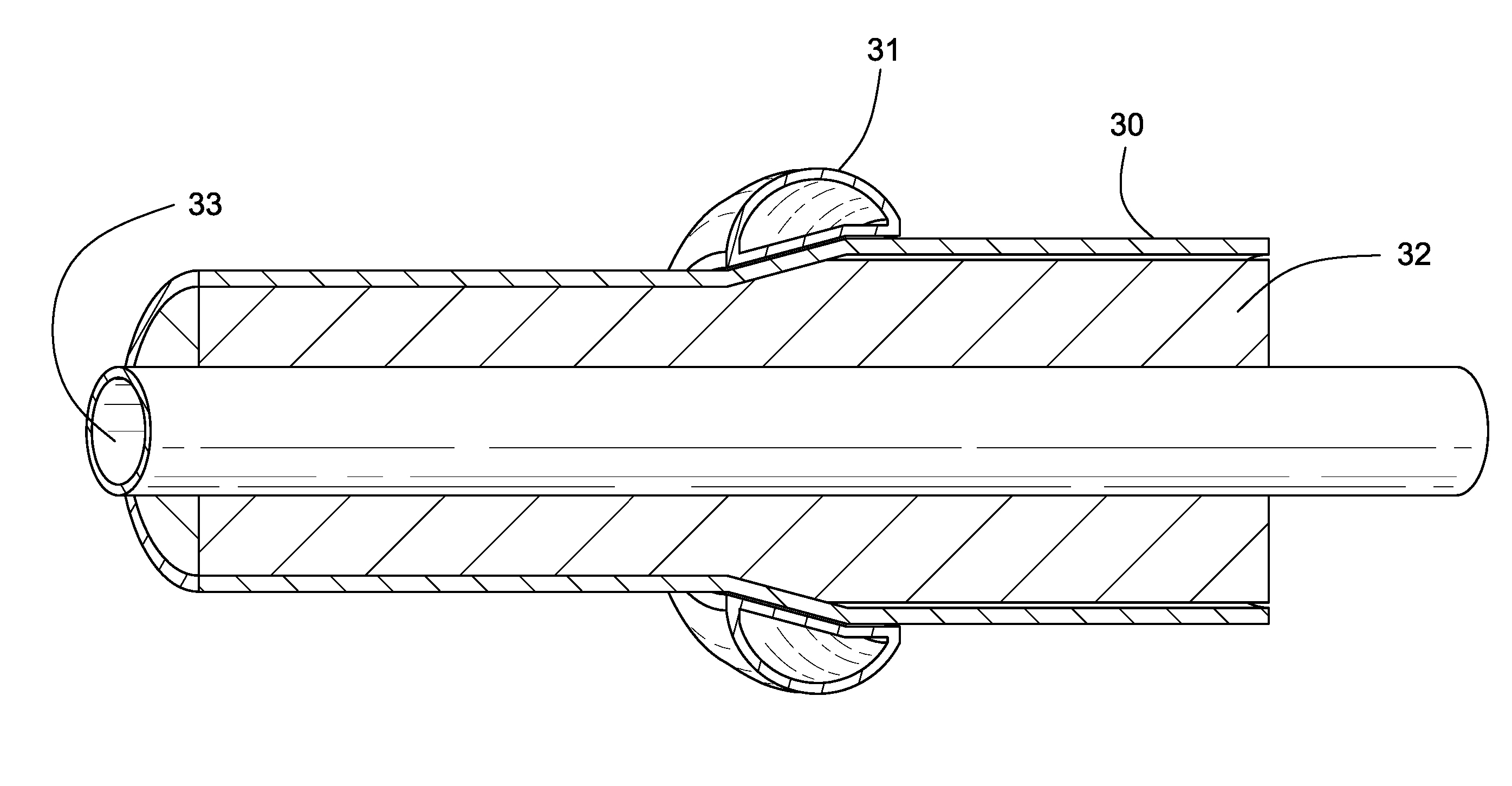

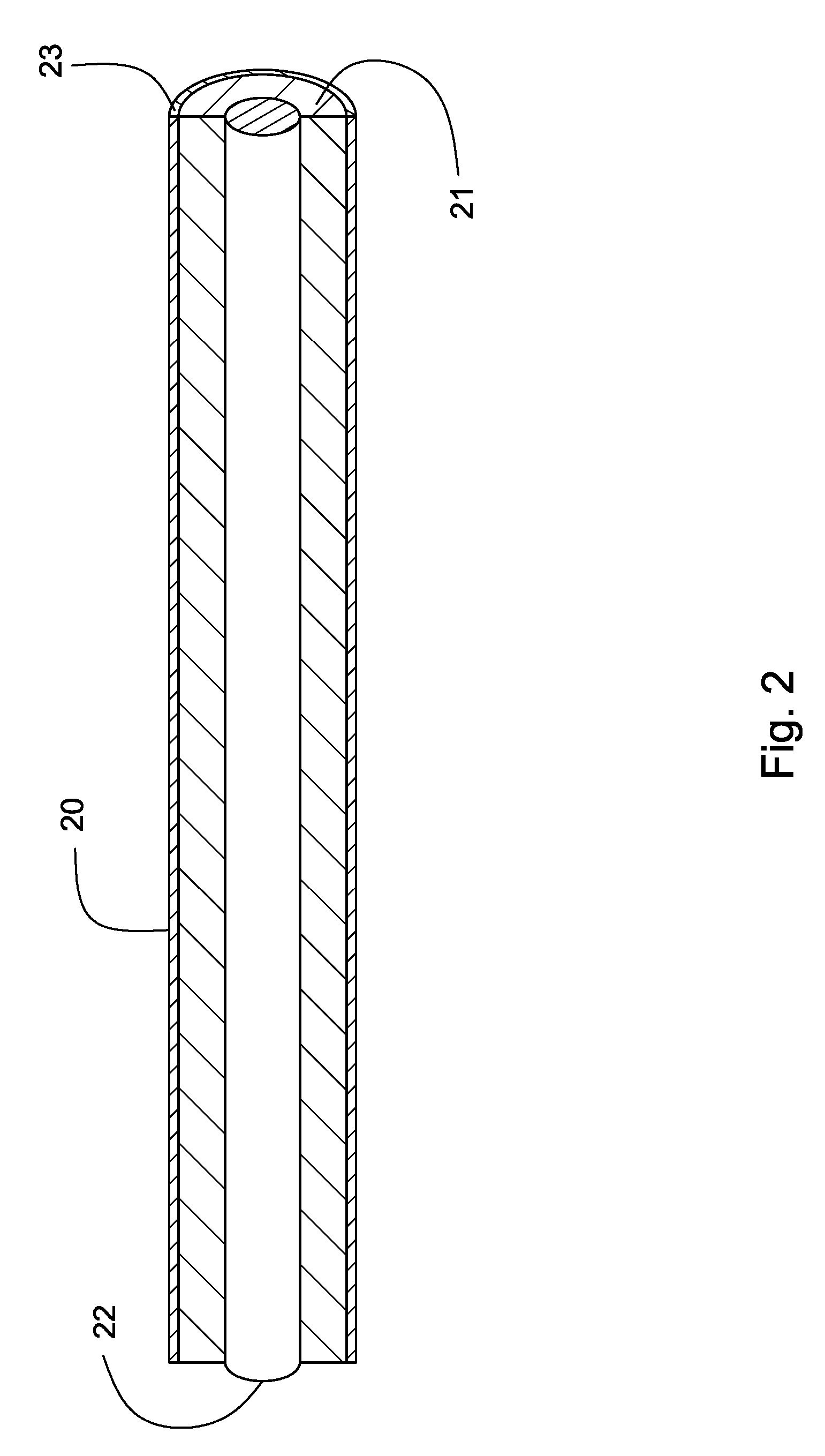

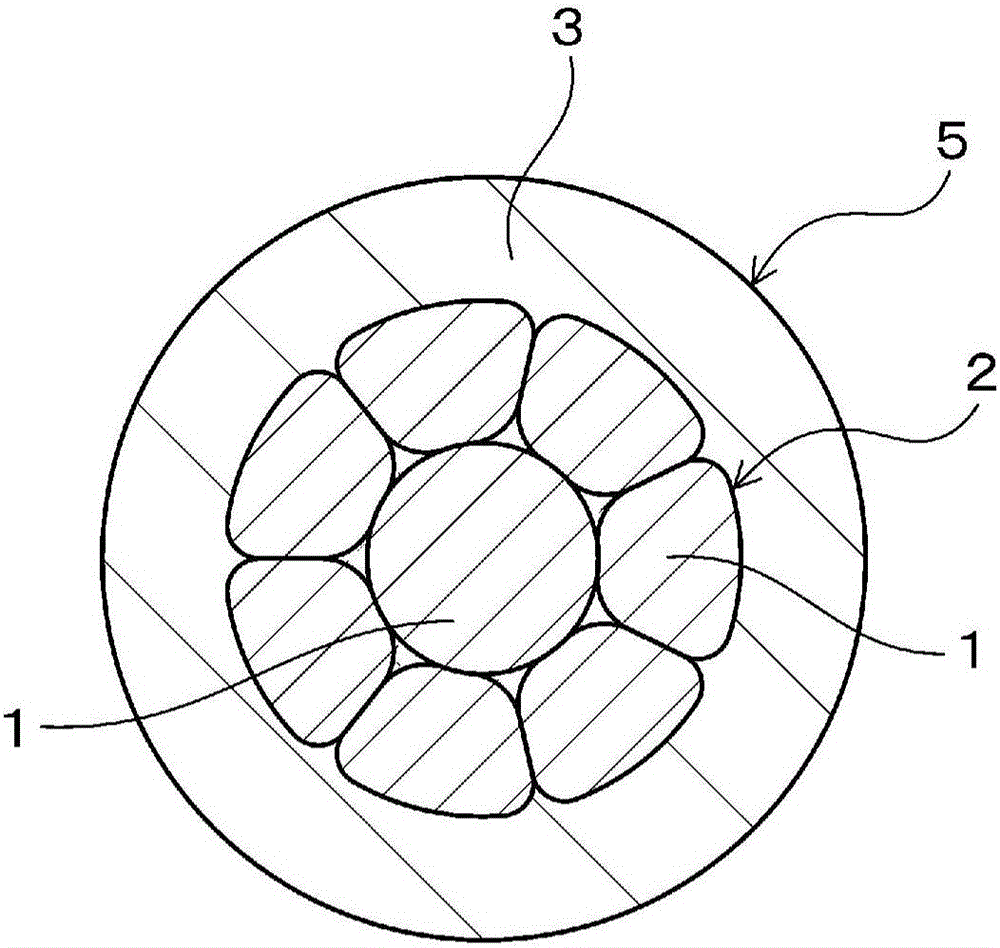

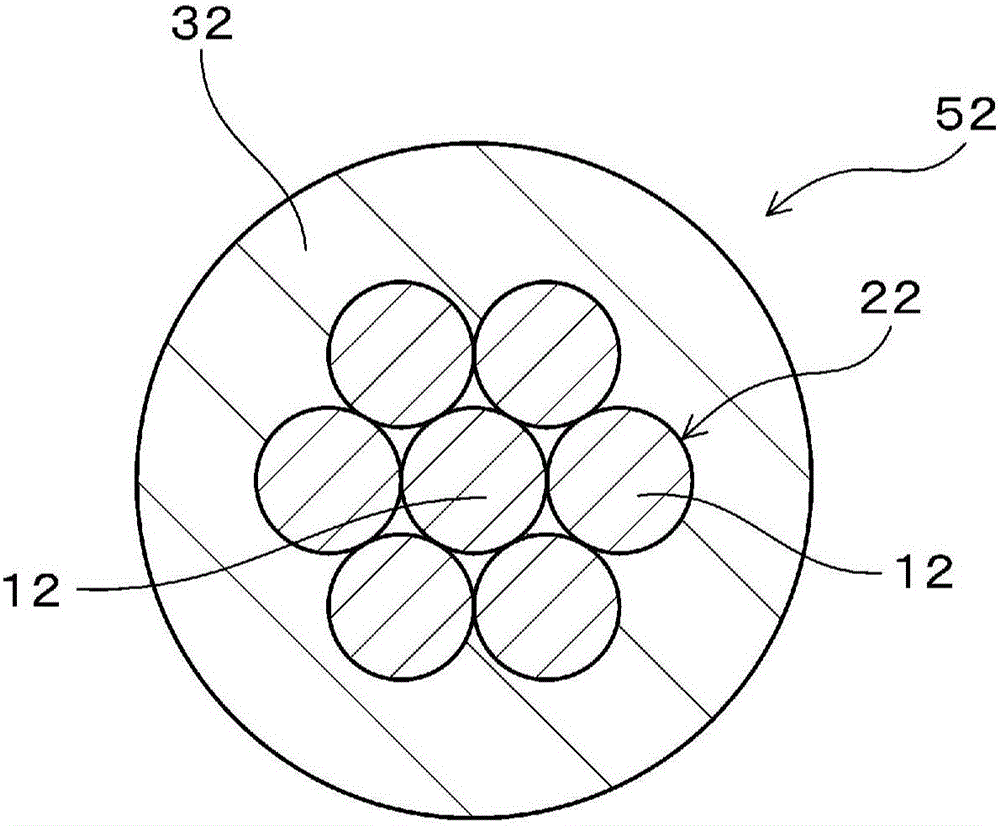

The invention relates to a method for producing a stranded inner conductor (1), and to a coaxial cable (9). In a first step, a stranded inner conductor (2) is provided, which consists of several wires (3) twisted together. Then the stranded inner conductor (1) is rotary swaged by means of a rotary swaging device (10). In a further step, the rotary swaged stranded inner conductor (3) is enclosed with a dielectric (4). In a further step, the dielectric (4) is enclosed with an outer conductor (5) and a cable sheath (6).

Owner:HUBERSUHNER AG

Method for manufacturing inorganic fireproof medium-high voltage cable

ActiveCN109448921AIntegrity guaranteedReduce stressPower cables with screens/conductive layersInsulated cablesElectricityElectric power system

The present invention discloses a method for manufacturing an inorganic fireproof medium-high voltage cable. The method comprises the following steps: A, performing wire drawing; B, performing conductor stranding; C, performing three-layer co-extrusion chemical crosslinking; D, wrapping a buffer layer; E, performing wrapping and phase separation on a metal shielding layer; F, performing cabling; G, extruding an oxygen barrier layer; H, performing inorganic fireproof layer wrapping; I, performing metal mounting; J, performing wrapping; K, extruding the outer sheath; and L, performing performance detection. According to the method provided by the present invention, the relationship between the electrical properties and the fire fireproof performance of the medium-high voltage cable is fullyconsidered, the balance between the two is solved, and instead of the traditional wrapped or extruded ceramized silicone rubber, the grouting inorganic fireproof layer is taken as the heat insulationlayer, so that the fireproof characteristics of the cable are greatly improved; and the medium-high voltage cable manufactured by using the method is laid on the building and has strong fireproof performance, so that the damage to the power system caused by sudden fires and the like can be greatly delayed.

Owner:SICHUAN MINGXING CABLE

Conductive tubing

Molded article for medical tubing and the like, and method of manufacture. The molded article is a coextruded tube having a tube wall of a non-conductive thermoplastic polymer and a central tubular bore. The tube further includes a coextruded conductive strip of conductive fibers in a thermoplastic polymer matrix, the conductive strip being disposed within a tubular passage in the tube wall extending the length of the tube, or within the central tubular bore. The strip is made from a pultruded fiber / polymer compound that can be co-extruded in strip form in the tube to provide an electrically conductive path along the tube length. Advantages include ease of manufacture, and one or more of improved handling (during use), reduced profile and reduced material costs.

Owner:TEKNI PLEX

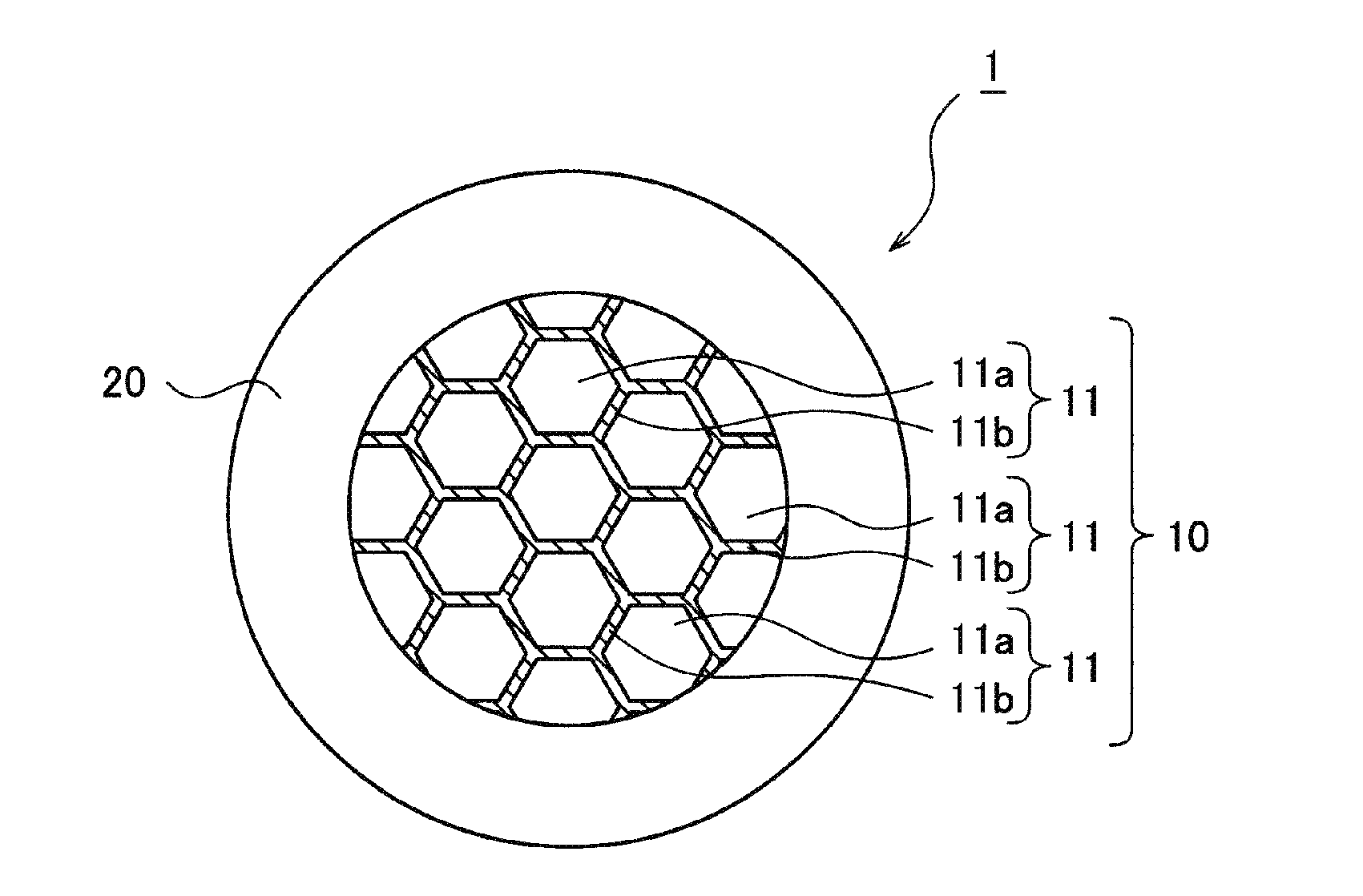

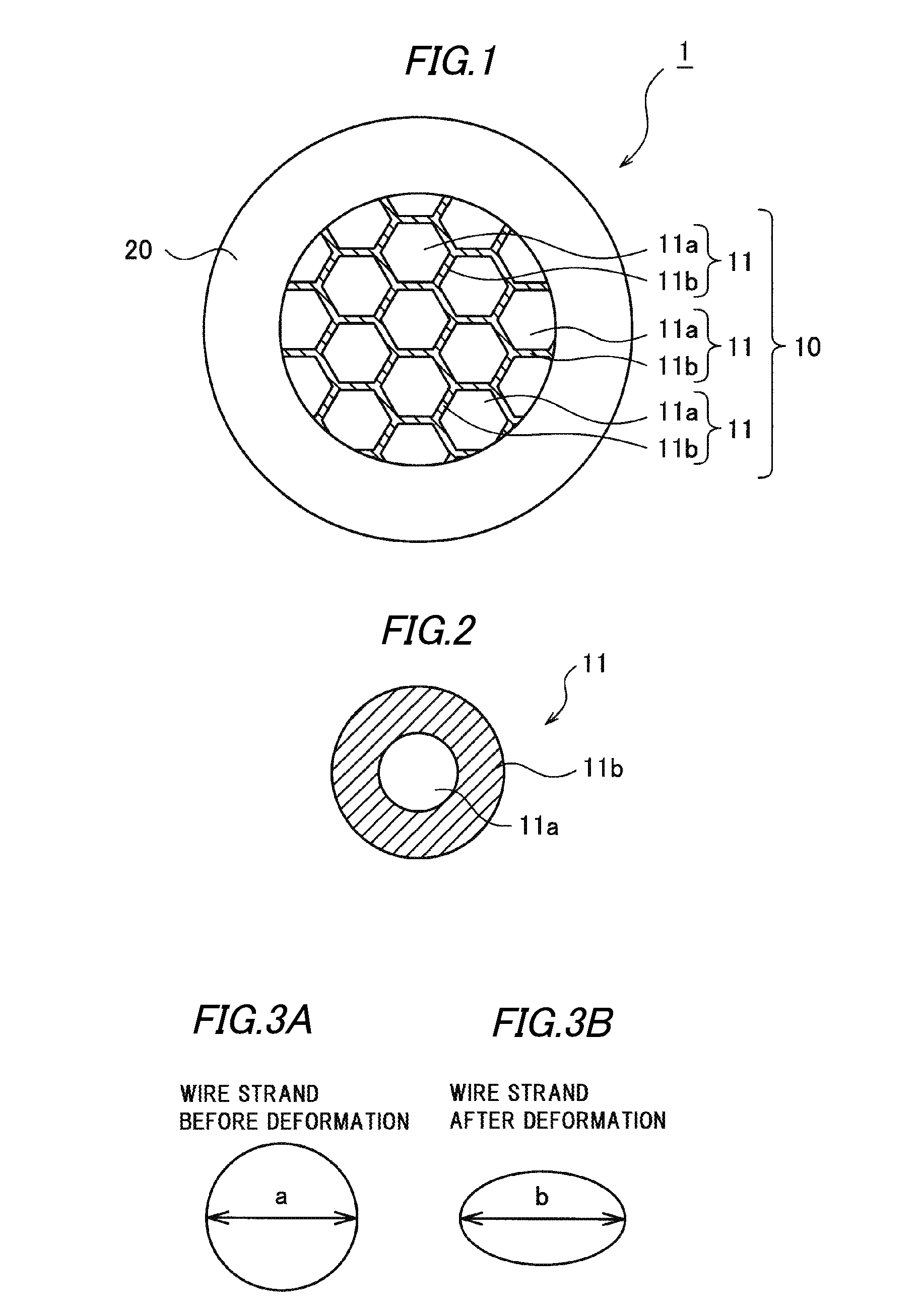

High-Frequency Electric Wire, Manufacturing Method Thereof, and Wire Harness

ActiveUS20160133356A1Reduce overall outer diameterImprove the immunityLine/current collector detailsPlastic/resin/waxes insulatorsWire rodElectrical conductor

A high-frequency electric wire is provided with a conductor which formed by compressing multiple wire strands, each of which is obtained by coating an outside of a wire rod made of insulating resin with a metal layer, and a sheath provided on the conductor. Each of the wire strands of the conductor is compressed in such a way that a deformation ratio of the wire strand exceeds 0% and is 20% or less. The compression is performed, for example, during bundling and sheathing of the multiple wire strands.

Owner:YAZAKI CORP

Cable production process

InactiveCN105390213AImprove toughnessSmall geometryReduction of cables/conductors sizeInsulating conductors/cablesProcess engineeringChemical corrosion

The invention discloses a cable production process, and relates to the field of machinery and equipment manufacturing. The cable production process comprises the nine steps of drawing, annealing, stranding, coating, brush coating of anti-corrosion materials, forming, filling, and wrapping. According to the cable production process, the mechanical strength, chemical corrosion resistance, humidity resistance, waterproof performance, flame retardancy and the like of the cable are improved.

Owner:季桂金

Metal wiring and method of manufacturing the same, and metal wiring substrate and method of manufacturing the same

InactiveUS20050230838A1Improve adhesionTransistorConductive layers on insulating-supportsResistVolumetric Mass Density

A metal wiring suitable for a substrate of large size is provided. The present invention is characterized in that at least one layer of conductive film is formed on an insulating surface, a resist pattern is formed on the conductive film, and the conductive film having the resist pattern is etched to form a metal wiring while controlling its taper angle a in accordance with the bias power density, the ICP power density, the temperature of lower electrode, the pressure, the total flow rate of etching gas, or the ratio of oxygen or chlorine in etching gas. The thus formed metal wiring has less fluctuation in width or length and can satisfactorily deal with an increase in size of substrate.

Owner:SEMICON ENERGY LAB CO LTD

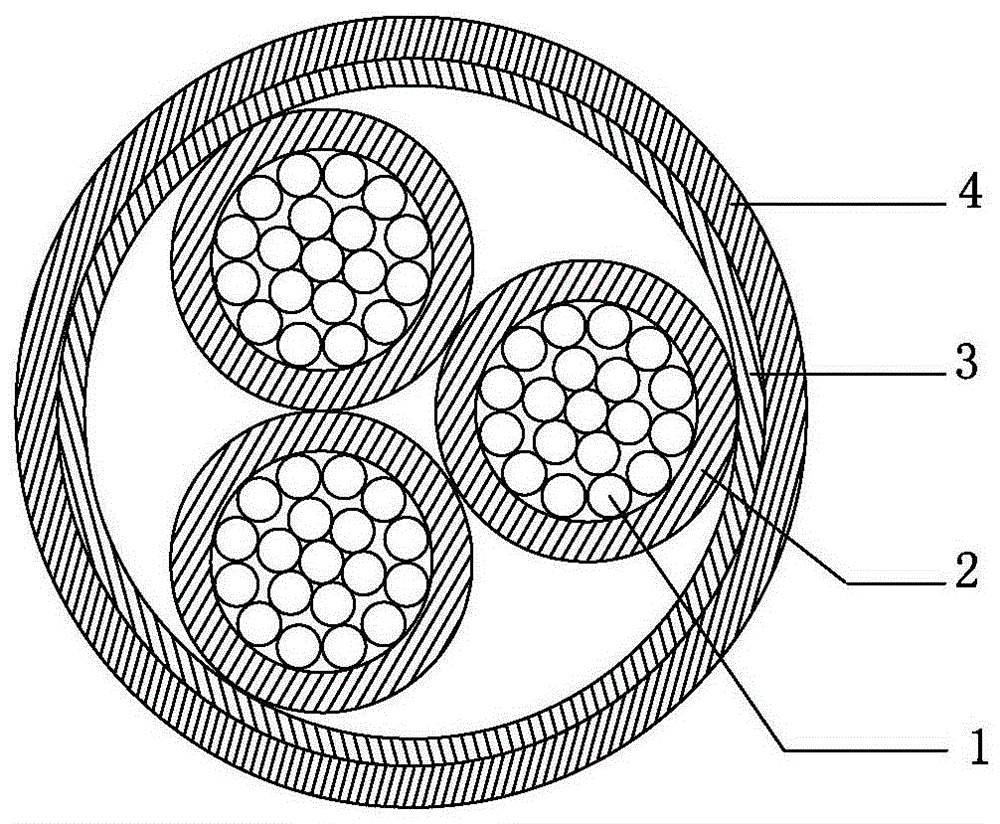

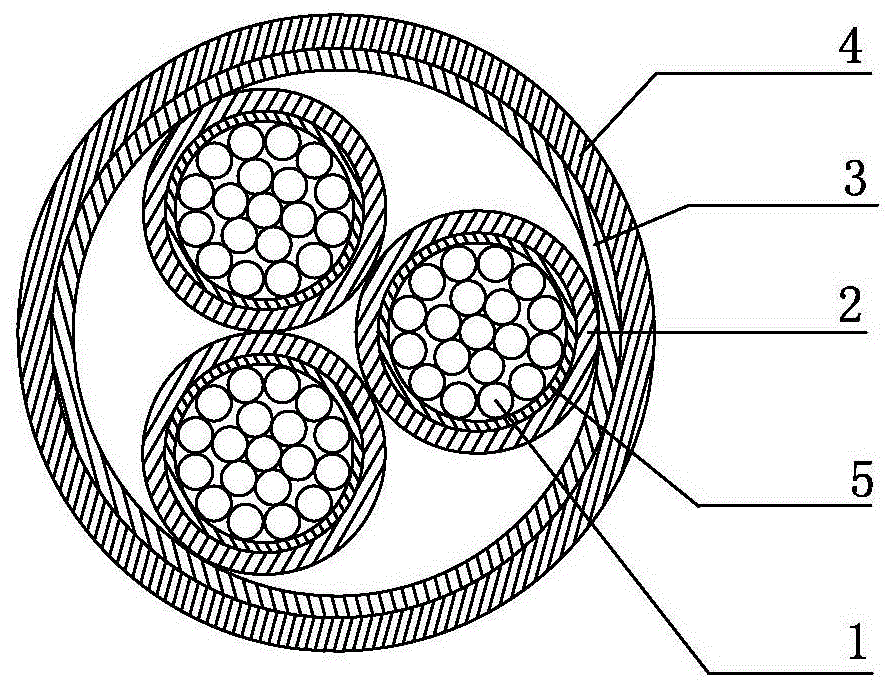

Nanographene low-voltage power cable and manufacturing method thereof

InactiveCN105741958AReduce your weightReduce conductor cross sectionNon-insulated conductorsReduction of cables/conductors sizePower cableCarrying capacity

The invention discloses a nanographene low-voltage power cable and a manufacturing method thereof. The nanographene low-voltage power cable comprises conductors, insulating layers and an outer sheath layer, wherein each conductor is formed by twisting a plurality of copper wires or aluminum wires along the length direction; the nanographene low-voltage power cable is characterized in that a nanographene layer coats the outside of each conductor; each insulating layer coats the outside of each nanographene layer to form an insulated wire core; 2-6 insulated wire cores are arranged; a wrapping layer is arranged at the outer sides of all insulated wire cores to form a cable core; and the outer sheath layer coats the outer side of the cable core. The manufacturing method comprises the following steps: drawing wires and twisting the conductors; carrying out electrostatic coating of the nanographene layers; manufacturing the insulating layers through extrusion; winding the wrapping layer to form the cable core; and extruding the outer sheath layer to obtain the nanographene low-voltage power cable. By the skin effect and the high conductivity of the nanographene, the sections of the cable conductors are reduced by 15%-30%; the carrying capacity can be improved by 5%; the production cost is greatly reduced; and the conductivity is improved.

Owner:SHANDONG KEHONG WIRE & CABLE TECH CO LTD

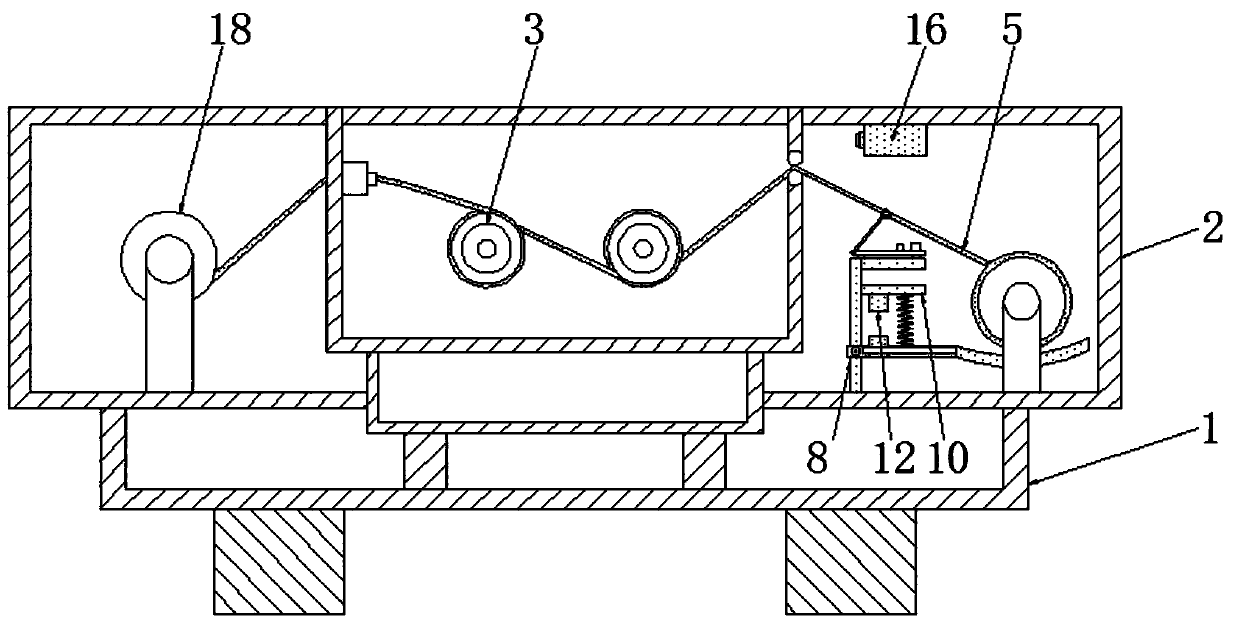

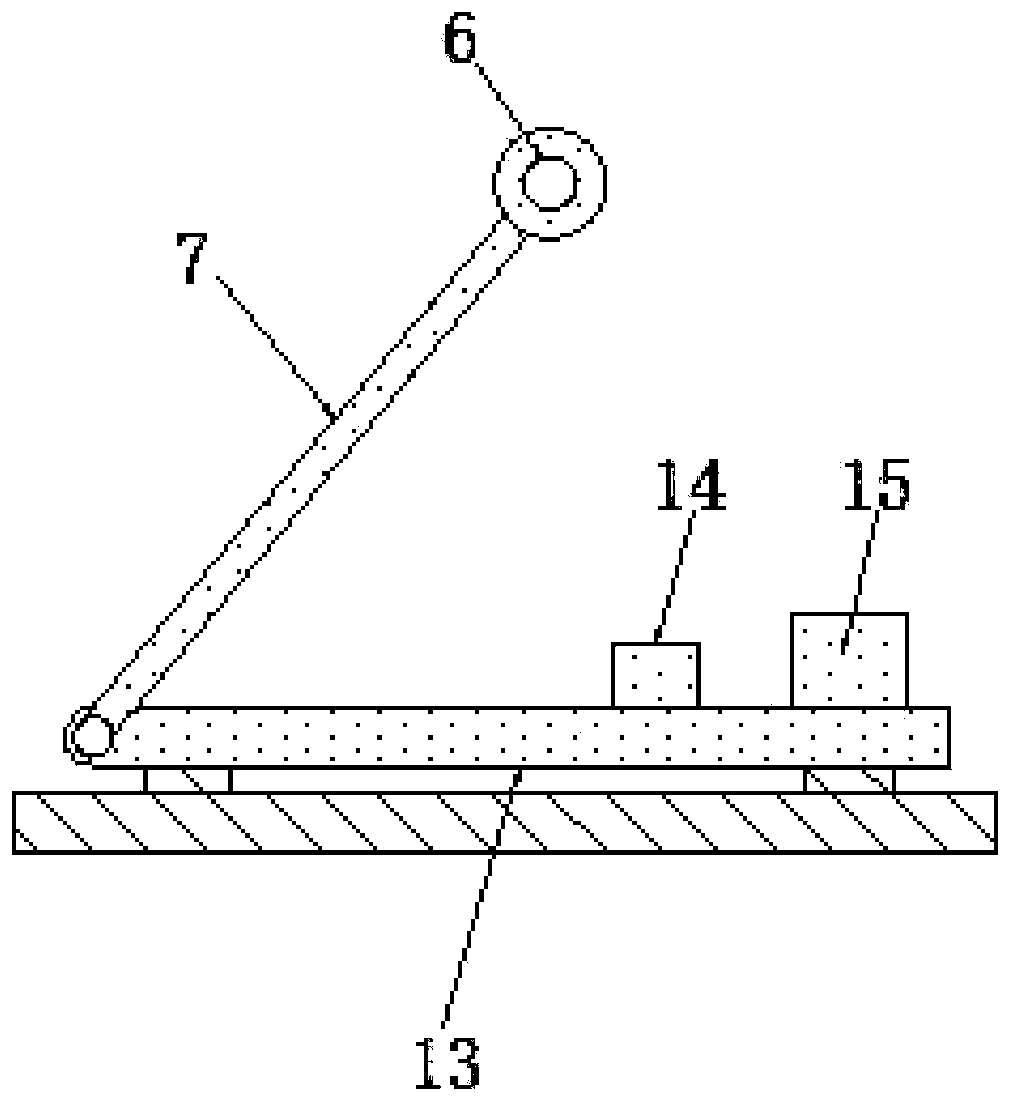

Cable wiredrawing wire breakage emergency braking device based on electromagnetism principle

ActiveCN110842041ARapid responseShort buffer timeReduction of cables/conductors sizePull forceElectric machine

The invention relates to the technical field of cables, and discloses a cable wiredrawing wire breakage emergency braking device based on the electromagnetism principle. The cable wiredrawing wire breakage emergency braking device comprises a base. The upper portion of the base is fixedly connected with a shell. Winding wheels are movably connected in the shell. By movably connecting an output shaft of a motor with the winding wheels, the winding wheels synchronously rotate, a metal wire sequentially passes through a wire outlet wheel and the two winding wheels, a take-up wheel rotates, wiredrawing is completed, the metal wire penetrates through a coil, and the coil bears tensile force of the metal wire and is kept upward; when the metal wire is broken, the tensile force borne by the coildisappears, the coil moves downwards due to the gravity of a connection rod itself and makes contact with a contact to form a closed circuit, a magnetic field is formed around a metal bar, the metal bar is attracted to a magnet, the attraction force of the magnet and the metal bar is larger than the elastic force of a spring, a connection plate tilts upwards with the left end as the fulcrum, a braking plate is made to tilt upwards and finally makes contact with the take-up wheel, rotation of the take-up wheel is blocked, emergency braking is generated, and rotation is stopped.

Owner:ELECTRIC POWER RES INST OF GUANGXI POWER GRID CO LTD +1

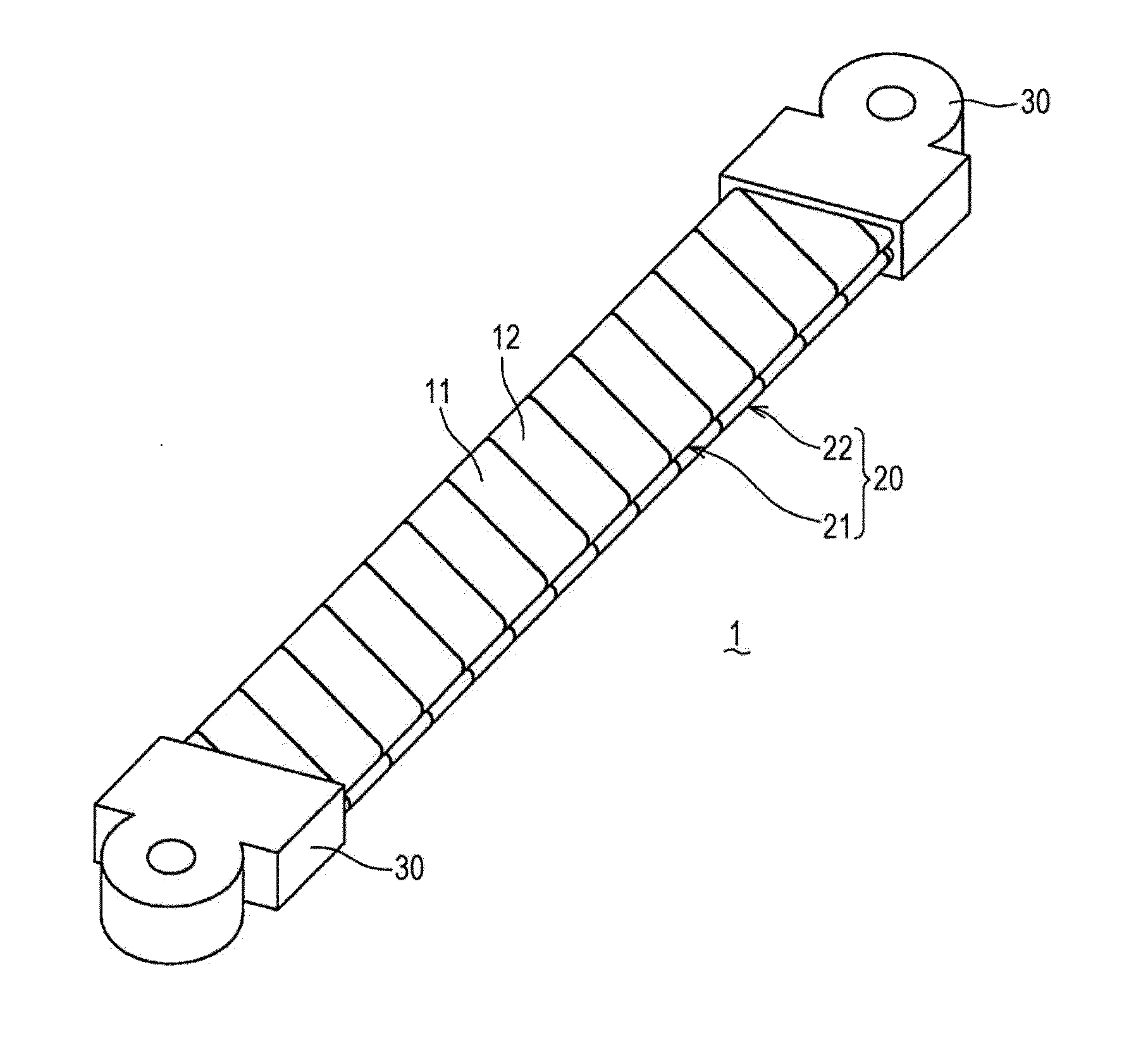

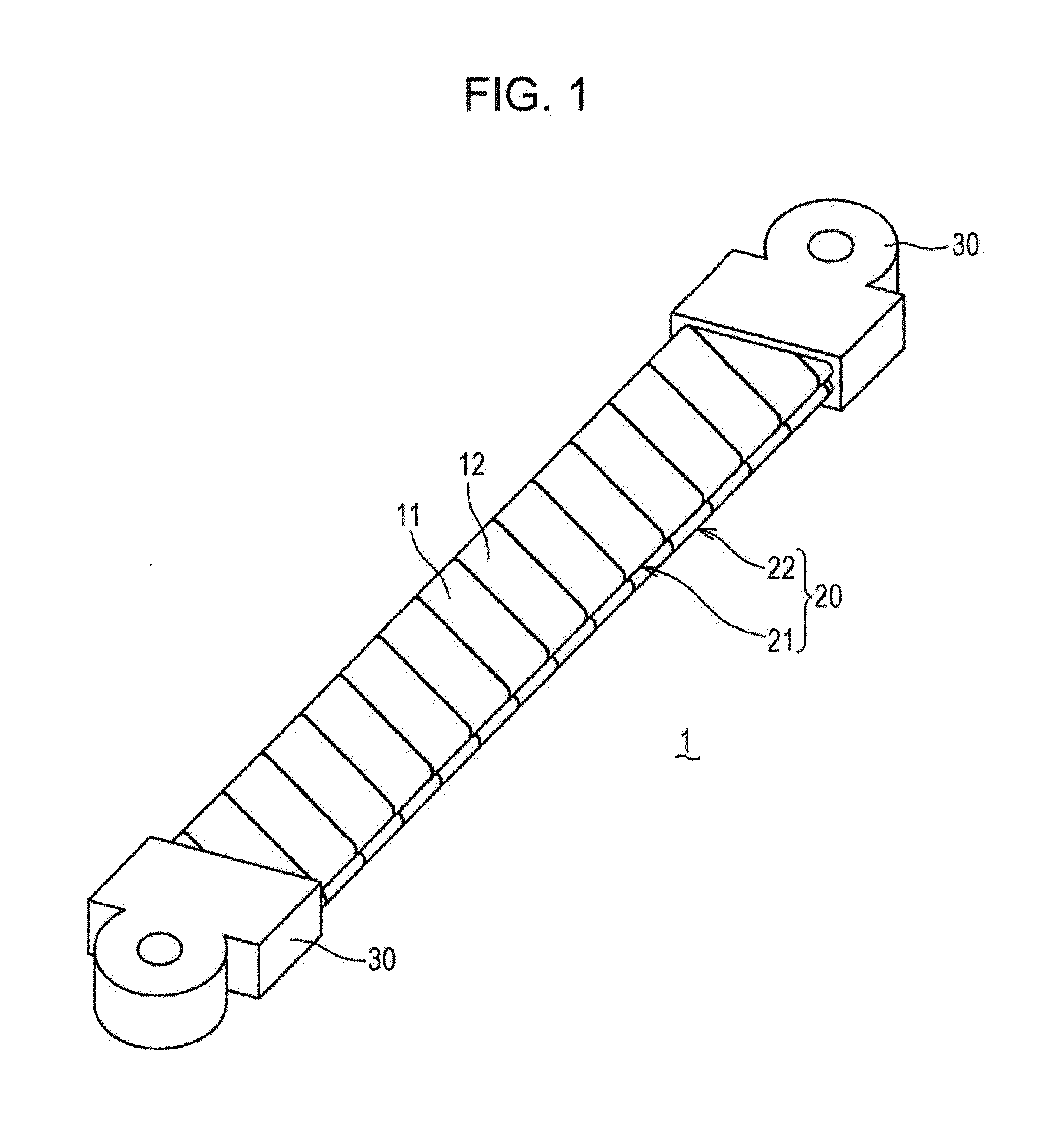

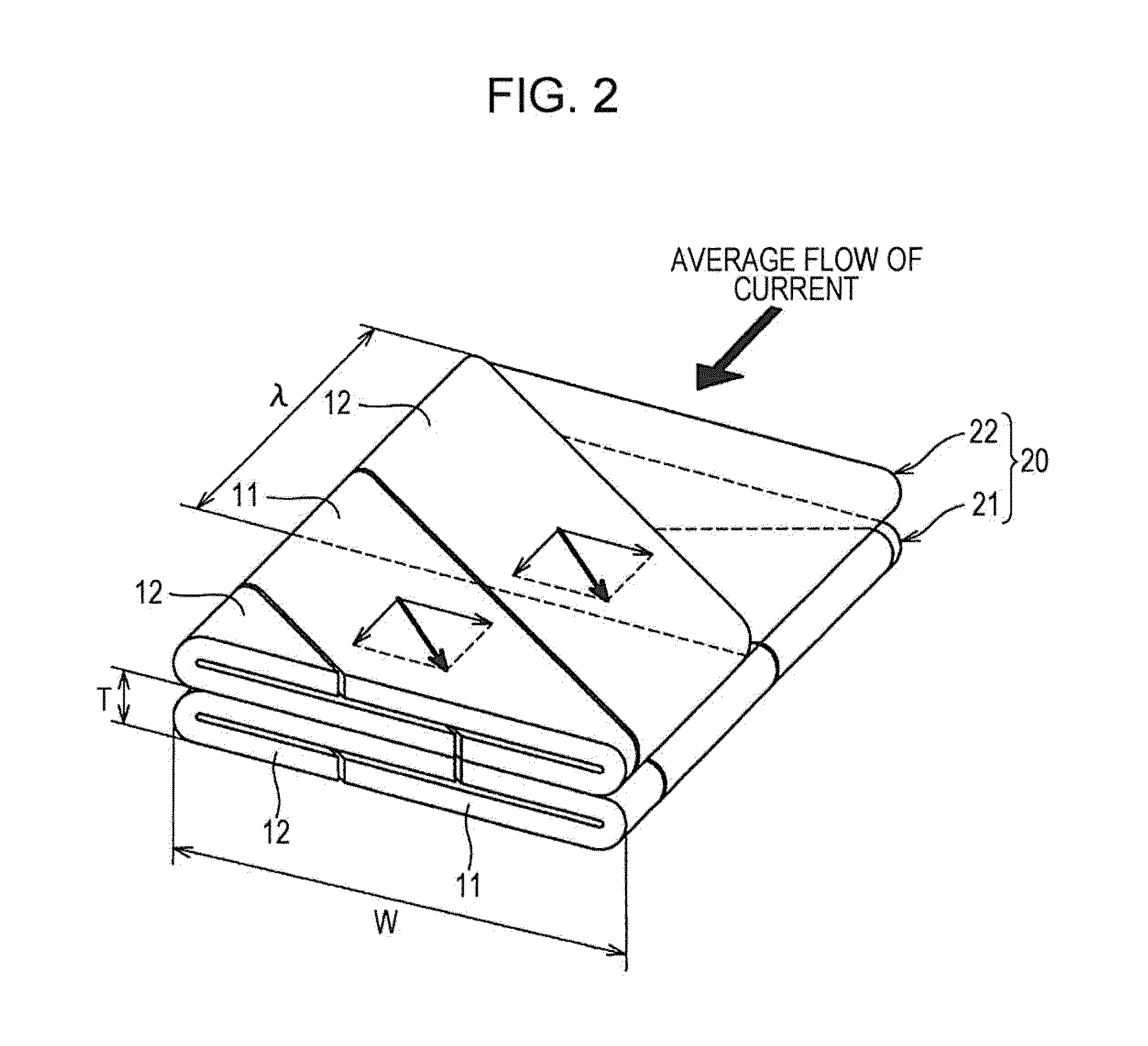

Bus bar, bus bar module, and method of manufacturing bus bar

ActiveUS20150255192A1Total current dropCurrent lossLine/current collector detailsElectrically conductive connectionsElectrical conductorEngineering

A bus bar (1) comprises: a laminated conductive wire (20) formed by arranging side by side in the longitudinal direction a first plate-shaped conductive wire (21) formed by spirally winding stripe conductors (11, 12) mutually adjacent in the width direction while bringing the opposing inner surfaces closer to each other, and a second plate-shaped conductive wire (22) formed by spirally winding the stripe conductors (11, 12) in the direction opposite the direction of the first conductive wire (21) while bringing the opposing inner surfaces closer to each other, and overlapping these wires (21, 22) so that the outer surfaces in the width direction face each other; and terminals (30) joined to the first conductive wire (21) and the second conductive wire (22) at both ends of the laminated conductive wire (20).

Owner:KOBE STEEL LTD

Preparation method of high-carrying current Bi-2223 multi-core superconduction strip

InactiveCN108597682AFirmly connectedImprove textureSuperconductors/hyperconductorsApparatus for heat treatmentManganeseAlloy

The invention discloses a preparation method of a high-carrying current Bi-2223 multi-core superconduction strip. The method comprises the steps of 1, performing high-temperature thermal treatment onBi-2223 powder to obtain tubing precursor powder; 2, loading the Bi-2212 tubing precursor powder in a gap of a silver sleeve to obtain a first tubing composite body; 3, placing the first tubing composite body after being drawn in a silver-manganese alloy tube to obtain a second tubing composite body; 4, obtaining a multi-core wire after drawing the second tubing composite body, performing plain rolling on the multi-core wire to obtain a multi-core strip; and 5, performing thermal treatment on the multi-core strip to obtain the high-carrying current Bi-2223 superconduction strip. According to the method, the silver sleeve formed by sleeving 2 or three silver tubes with coincided central lines in a lamination way is used as an encapsulation tube of the powder, and the superconduction current-carrying performance of the Bi-2212 multi-core superconduction strip is improved by expanding the area of a silver super interface in unit volume.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

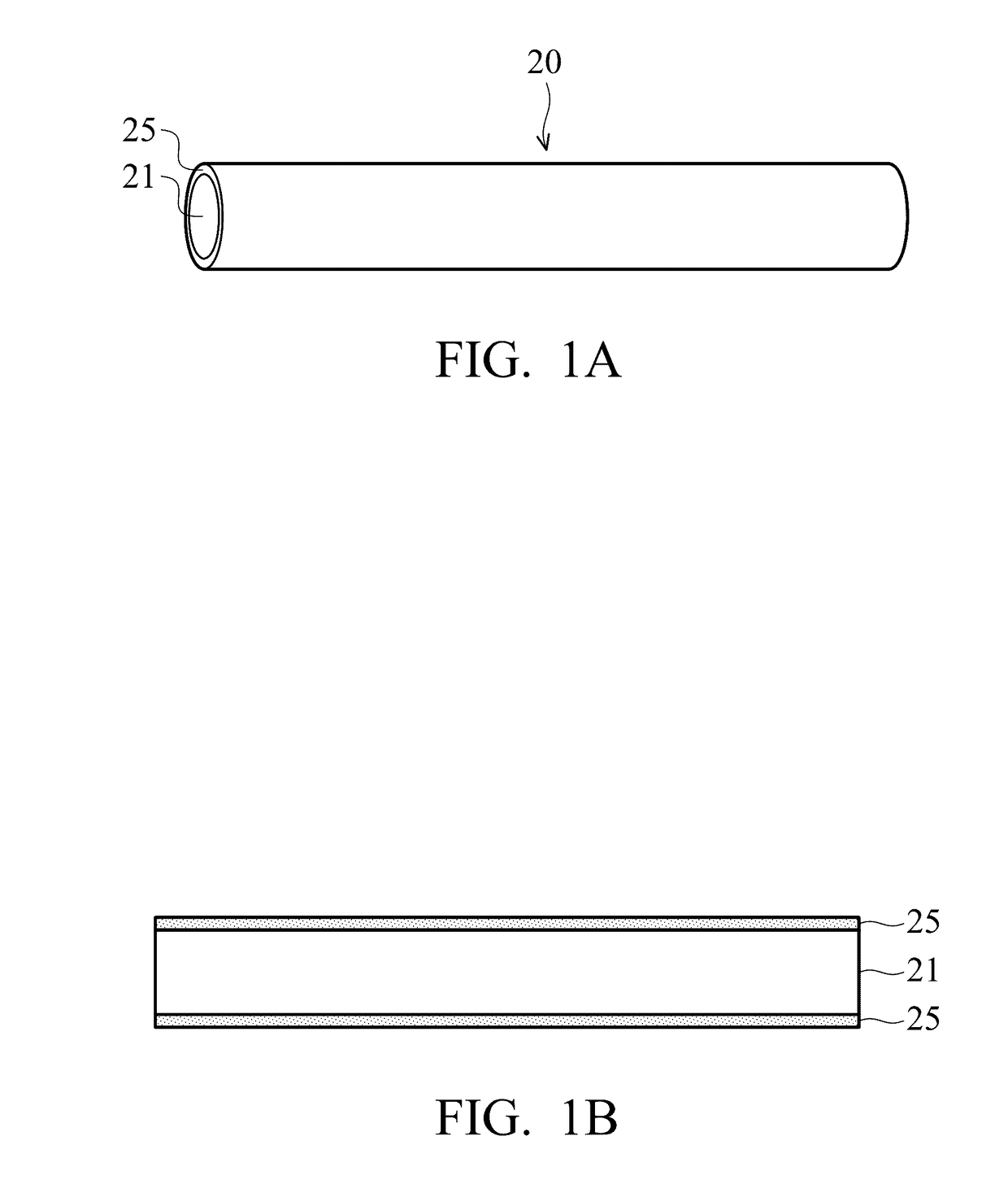

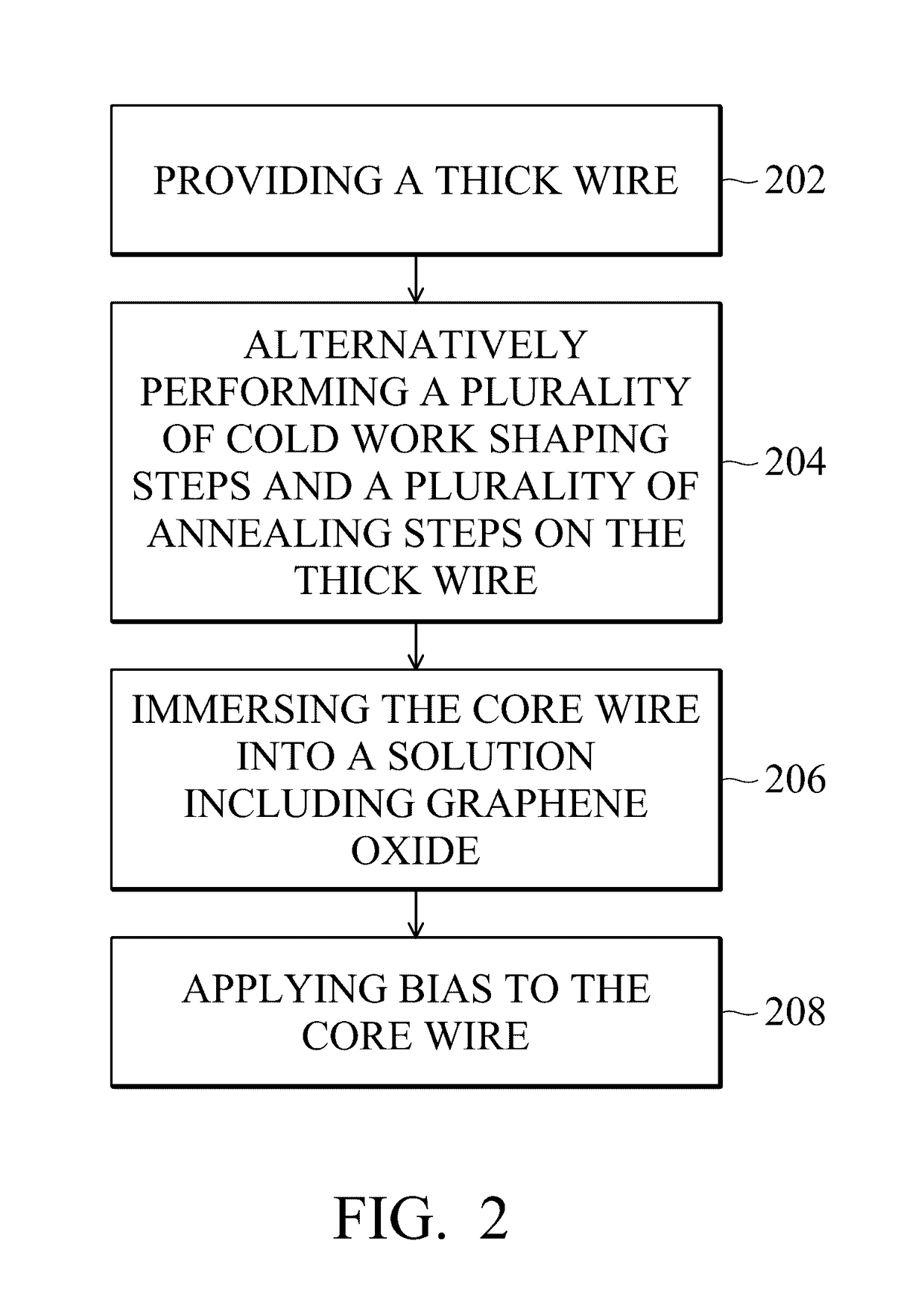

Graphene coated silver alloy wire and methods for manufacturing the same

A graphene coated silver alloy wire is provided. The composite wire includes a core wire and one to three layers of graphene covering surfaces of the core wire. The core wire is made of a silver-based alloy including 2 to 6 weight percent of palladium. The core wire may be optionally added with 0.01 to 10 weight percent of gold. The invention also includes a manufacturing method immersing the core wire into a solution including graphene oxide and applying bias to the core wire for manufacturing the graphene coated silver alloy wire.

Owner:WIRE TECH

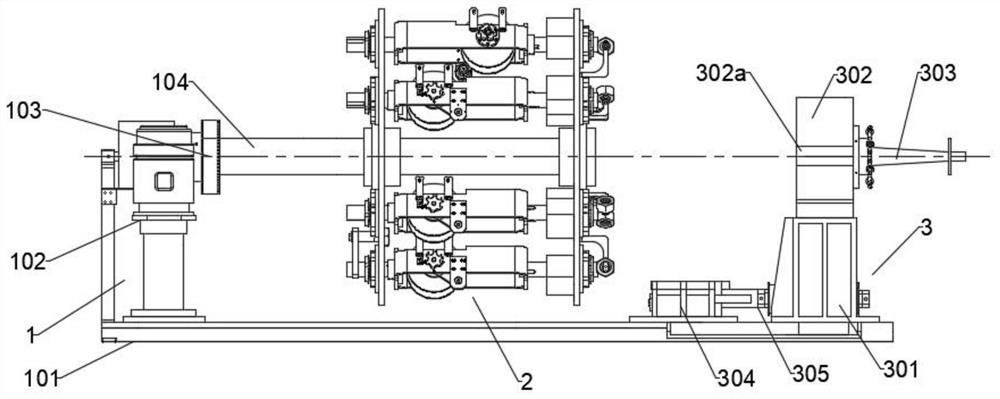

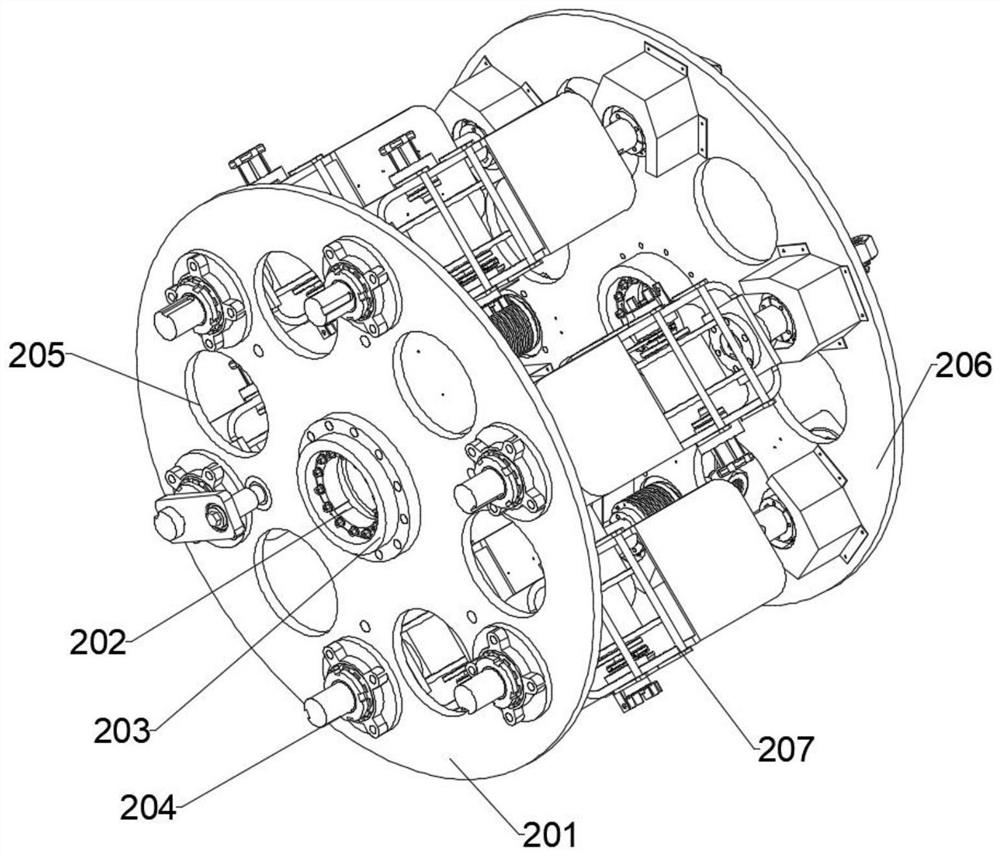

Cable twisting process and twisting device thereof

ActiveCN111768923APrevent slidingReduce tensionApparatus for heat treatmentReduction of cables/conductors sizeWire rodElectric machinery

The invention relates to the technical field of cable processing, in particular to a cable twisting process and a twisting device thereof. The twisting device comprises a driving assembly and a wire twisting assembly, and according to the movement direction of a cable, the driving assembly is located at the movement head end of the cable; the driving assembly comprises a supporting plate, a main driving motor and a main shaft, the main driving motor is fixedly installed at the front end of the supporting plate and connected with the front end of the main shaft, and the tail end of the main shaft is connected with the wire twisting assembly; the wire twisting assembly comprises a front winch, an untwisting unit, a rear winch and a twisting device, a first through connecting hole is formed in the middle of the front winch, a second through connecting hole is formed in the middle of the rear winch, the main shaft, the front winch and the rear winch are in synchronous transmission connection, and an untwisting unit is arranged between the front winch and the rear winch. The process and the device are used for solving the problems that in the prior art, a device is not suitable for themanufacturing of cable bundles with many winding wires, and the quality of stranded cables can be affected if the tension of a single wire is changed in the stranding process.

Owner:青海鑫邦线缆有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com