Patents

Literature

281results about "Power cables for overhead application" patented technology

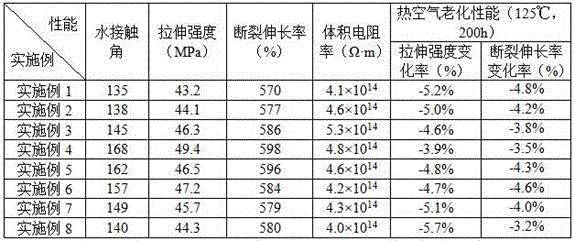

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

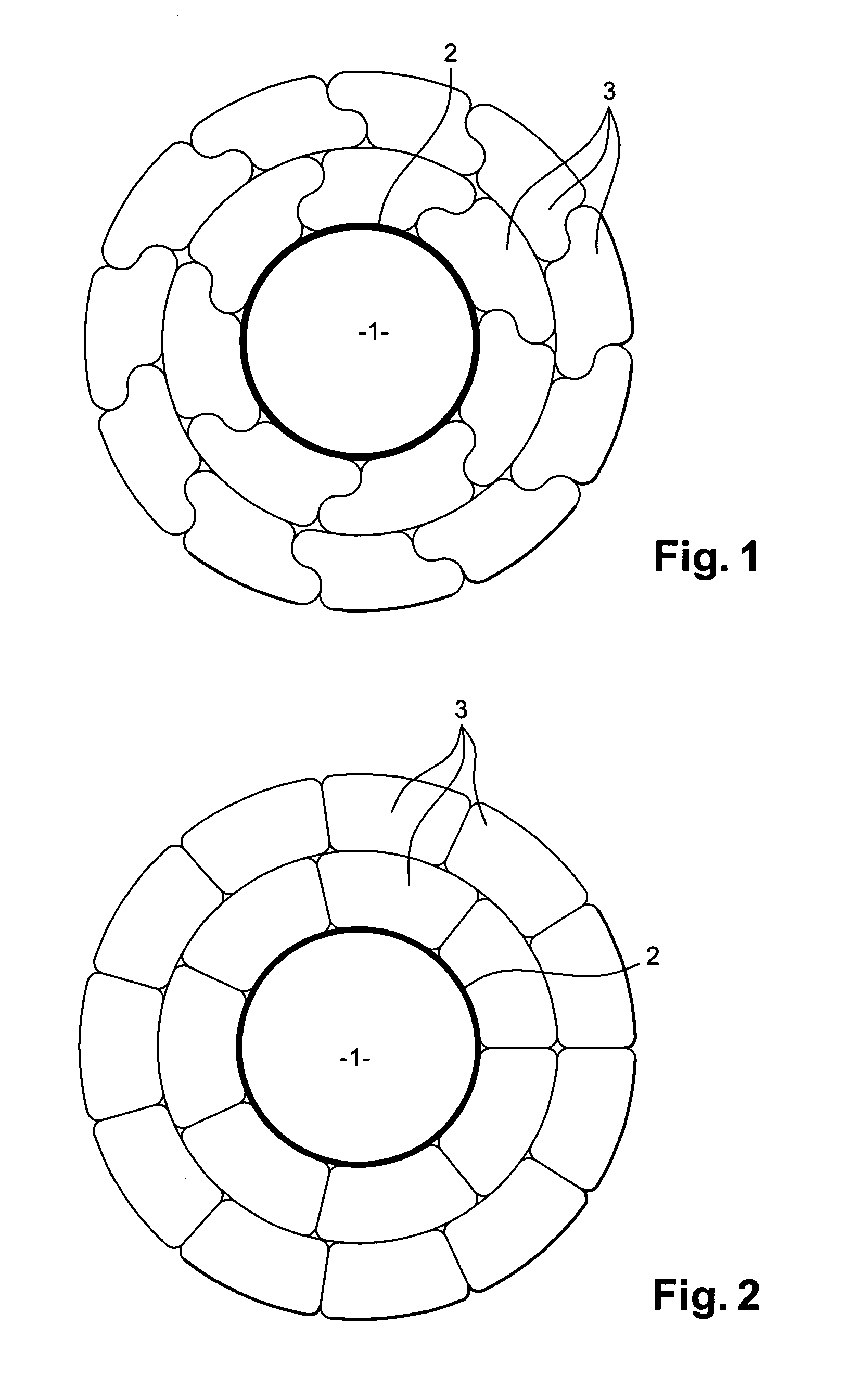

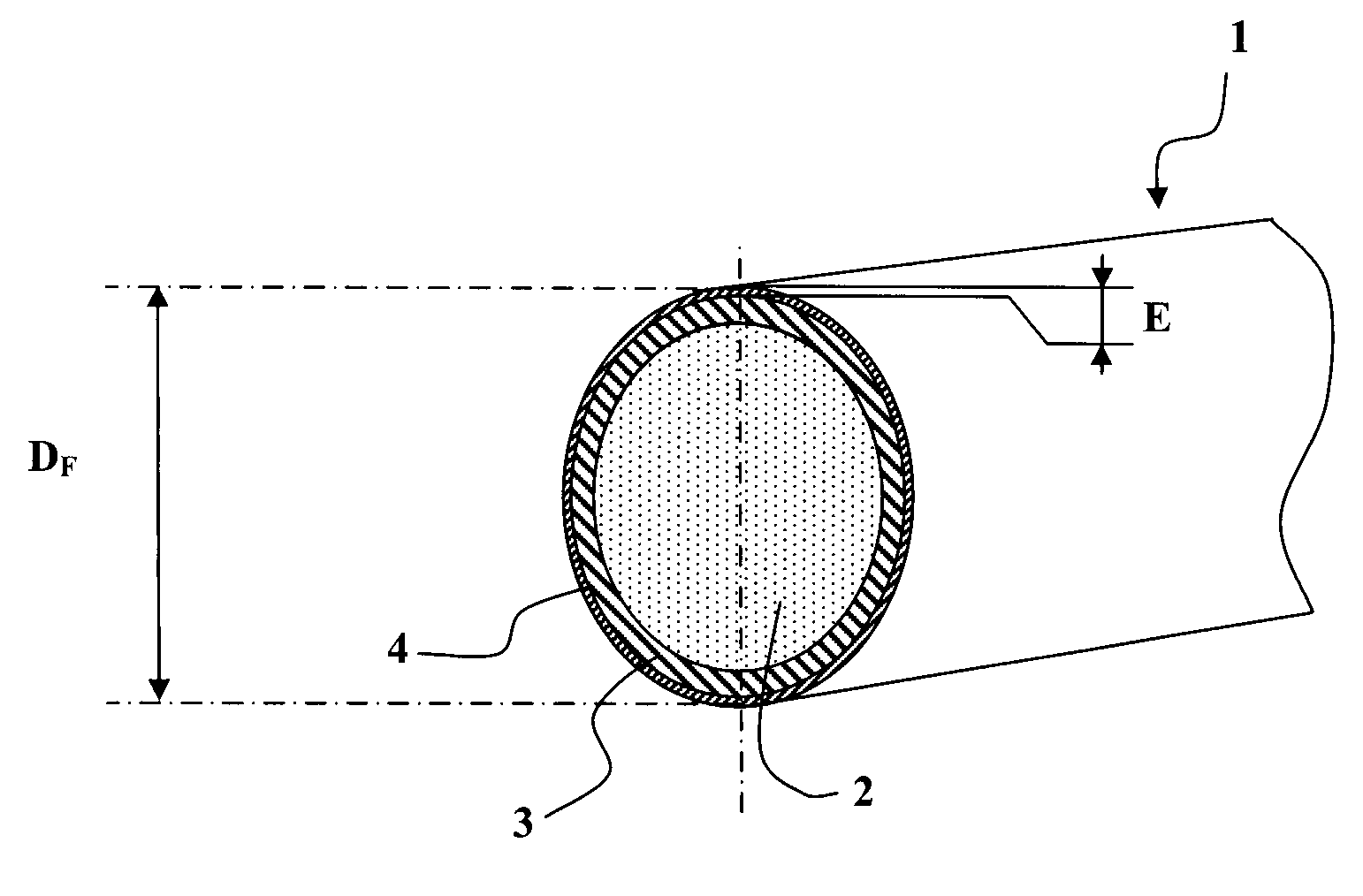

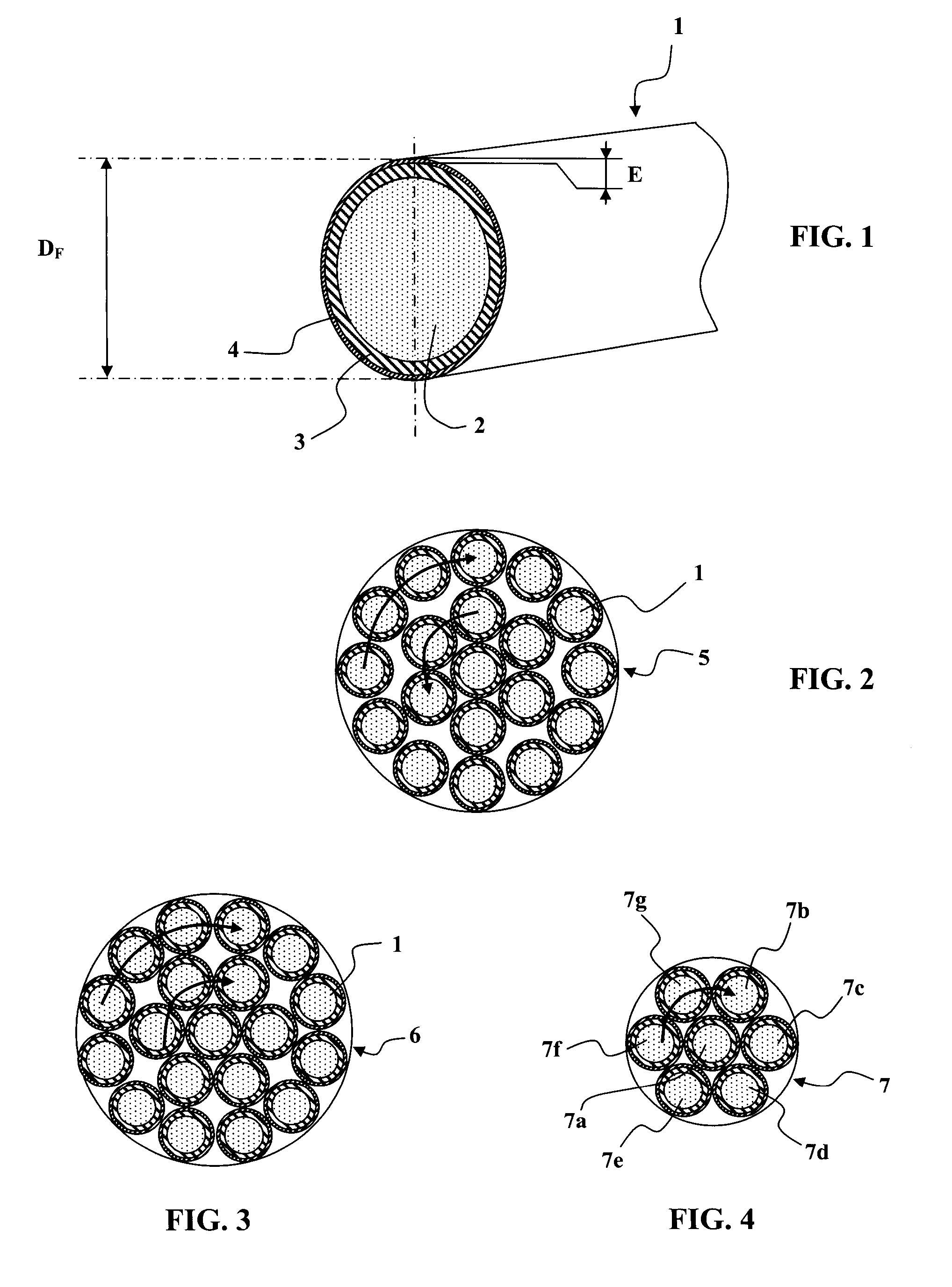

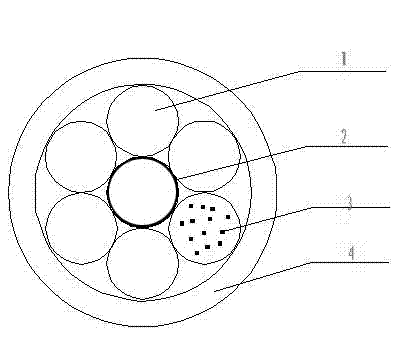

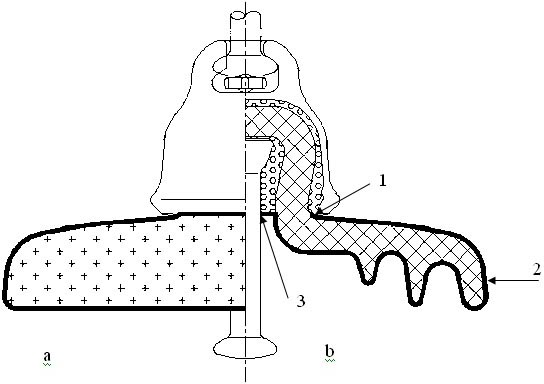

Electricity transport conductor for overhead lines

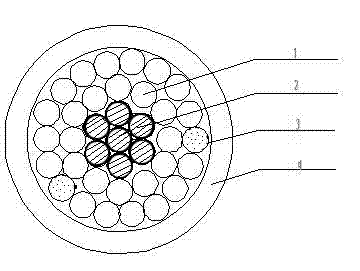

The invention relates to a method of fabricating an electricity transport conductor, in particular for overhead power lines, that are to operate at an operating temperature greater than or equal to 200° C., and comprising at least one composite central core 1 made of continuous fibers impregnated with an epoxy resin matrix, the core being covered in at least one layer of insulating material 2, and conductor wires 3 of aluminum or aluminum alloy being wound around the core. According to the invention, said insulating material is compatible with said operating temperature and is put into place on said core 1 without subsequent heating.

Owner:NEXANS

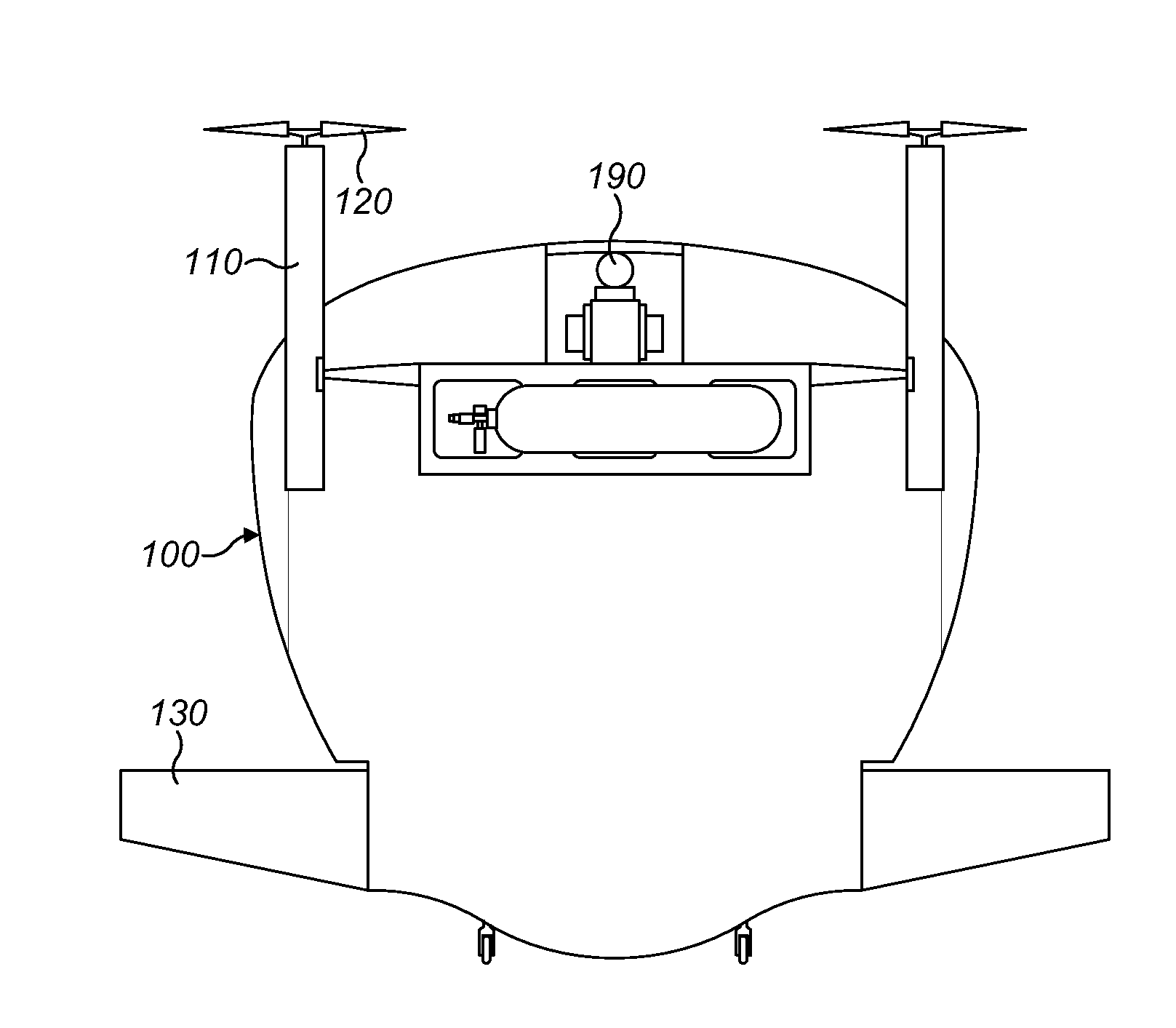

Unmanned Aerial Vehicle

ActiveUS20150210388A1Reduce noiseReduce vibrationDigital data processing detailsElectrical testingJet aeroplaneLarge distance

An unmanned aerial vehicle adapted for hover and short / vertical take-off and landing (S / VTOL) is disclosed. The vehicle comprises: a body having an aspect-ratio less than two and having therein a payload volume, at least one propeller located forward of the body, at least one rudder. The body may have an inverse Zimmerman planform which provides lift as air flows across the body in horizontal flight / fixed wing mode, and further adapted such that during hover and / or short / vertical take-off and landing (S / VTOL) the vehicle operates as a rotorcraft with the body oriented with the at least one propeller substantially above the body. The vehicle is suited to a method of inspection, such as power line inspection where large distances can be analysed efficiently by flying in fixed wing mode, but by transitioning to hover mode allows detailed inspection of selected areas.

Owner:THE BOEING CO

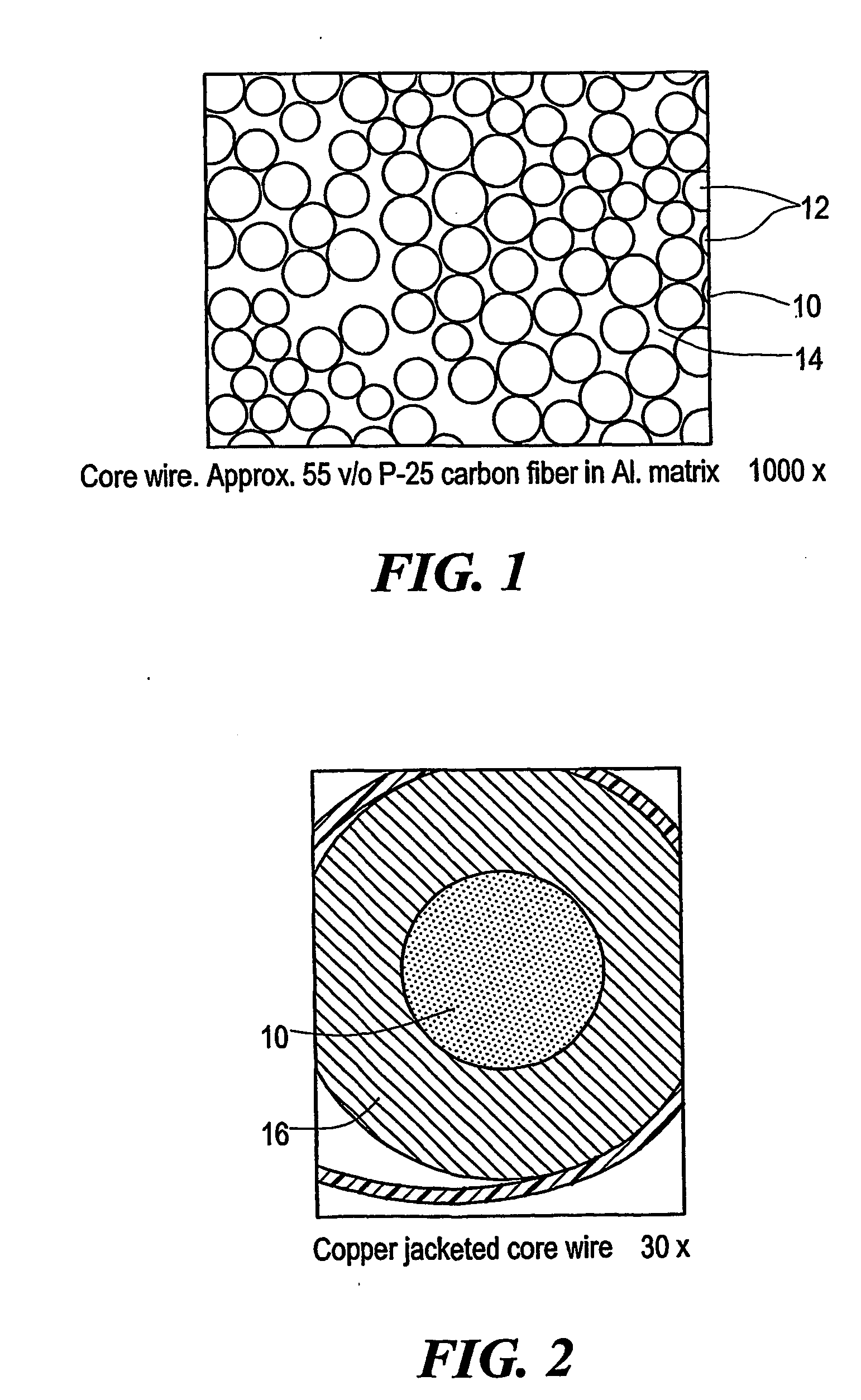

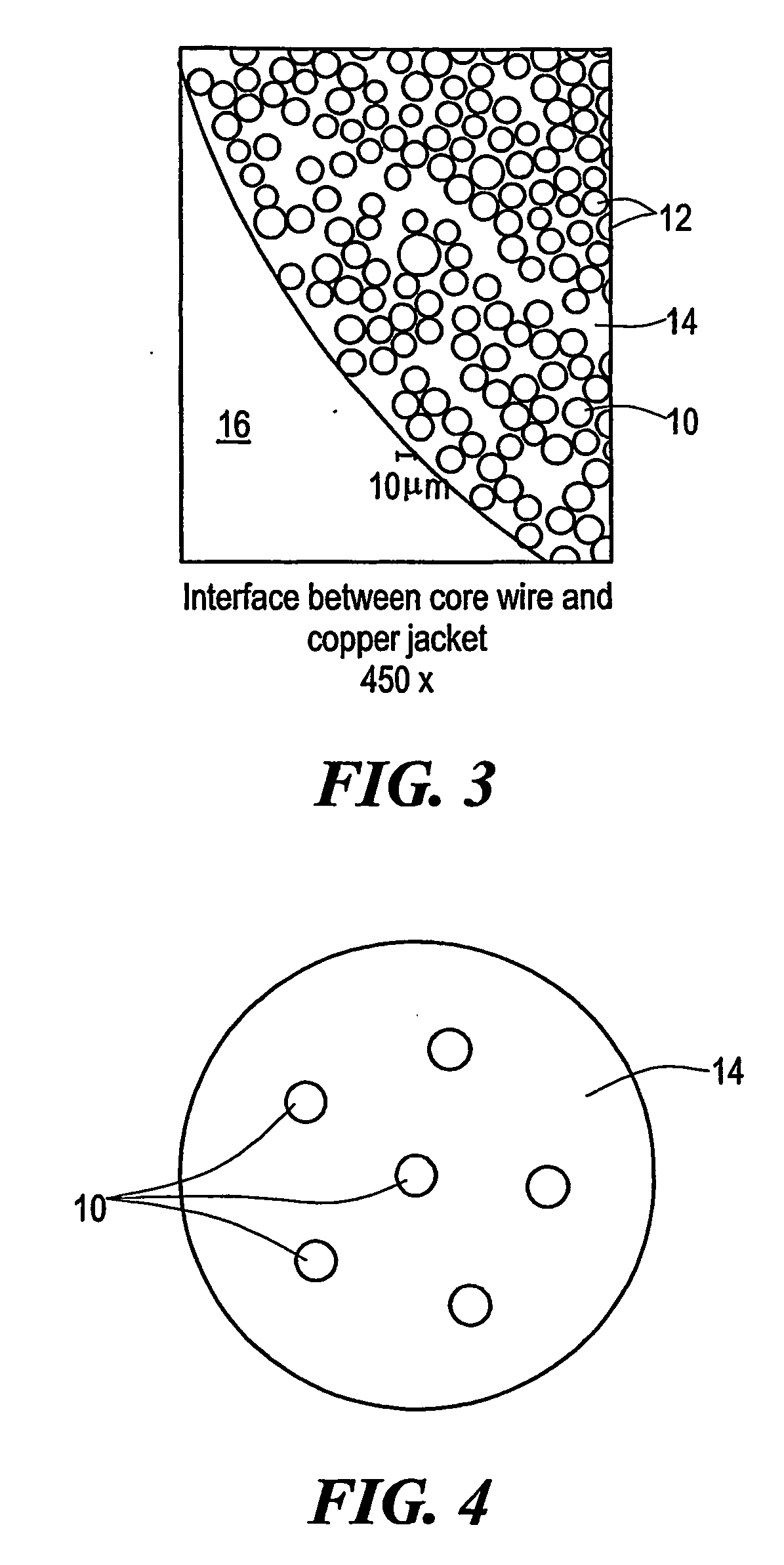

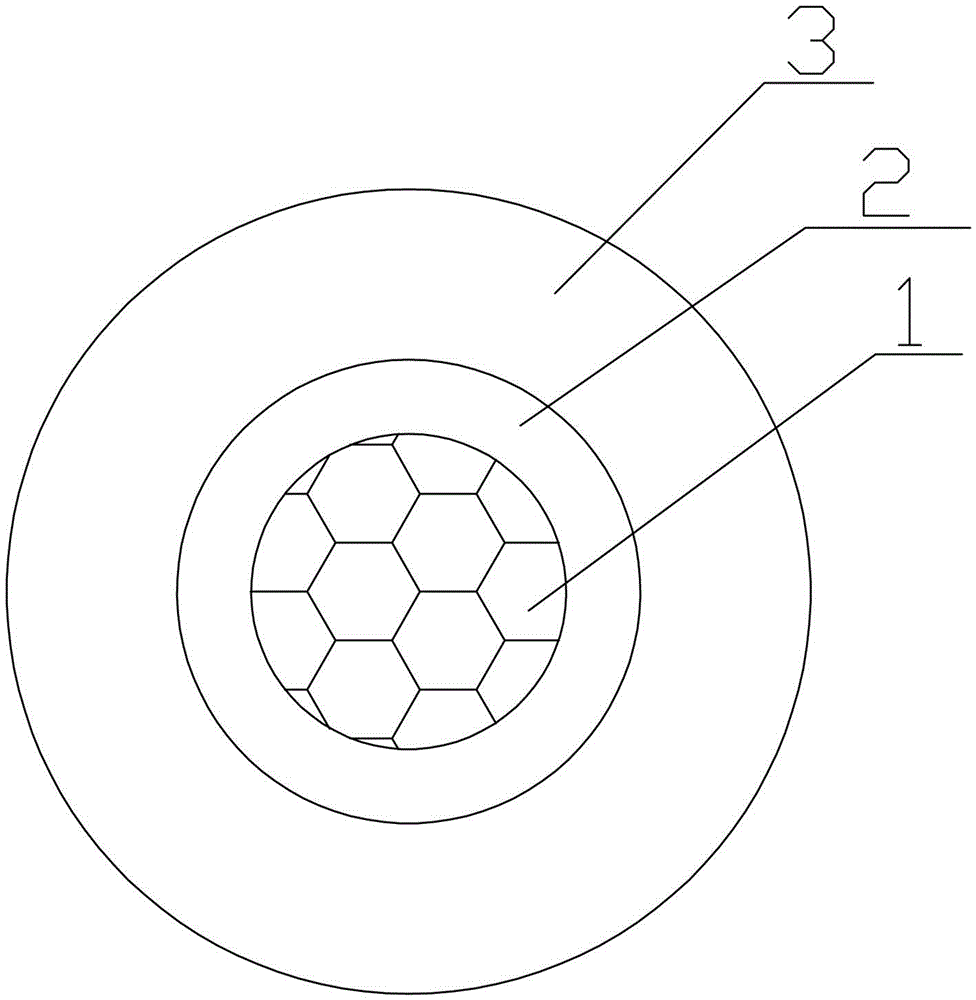

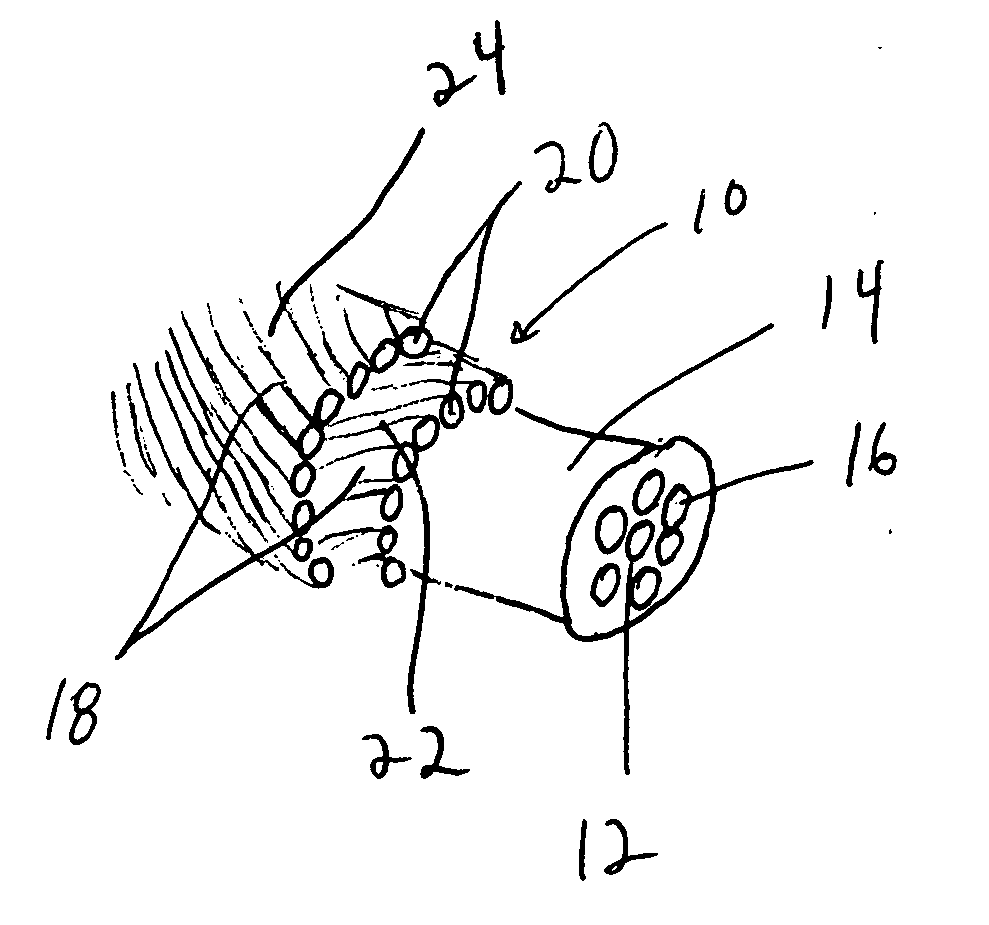

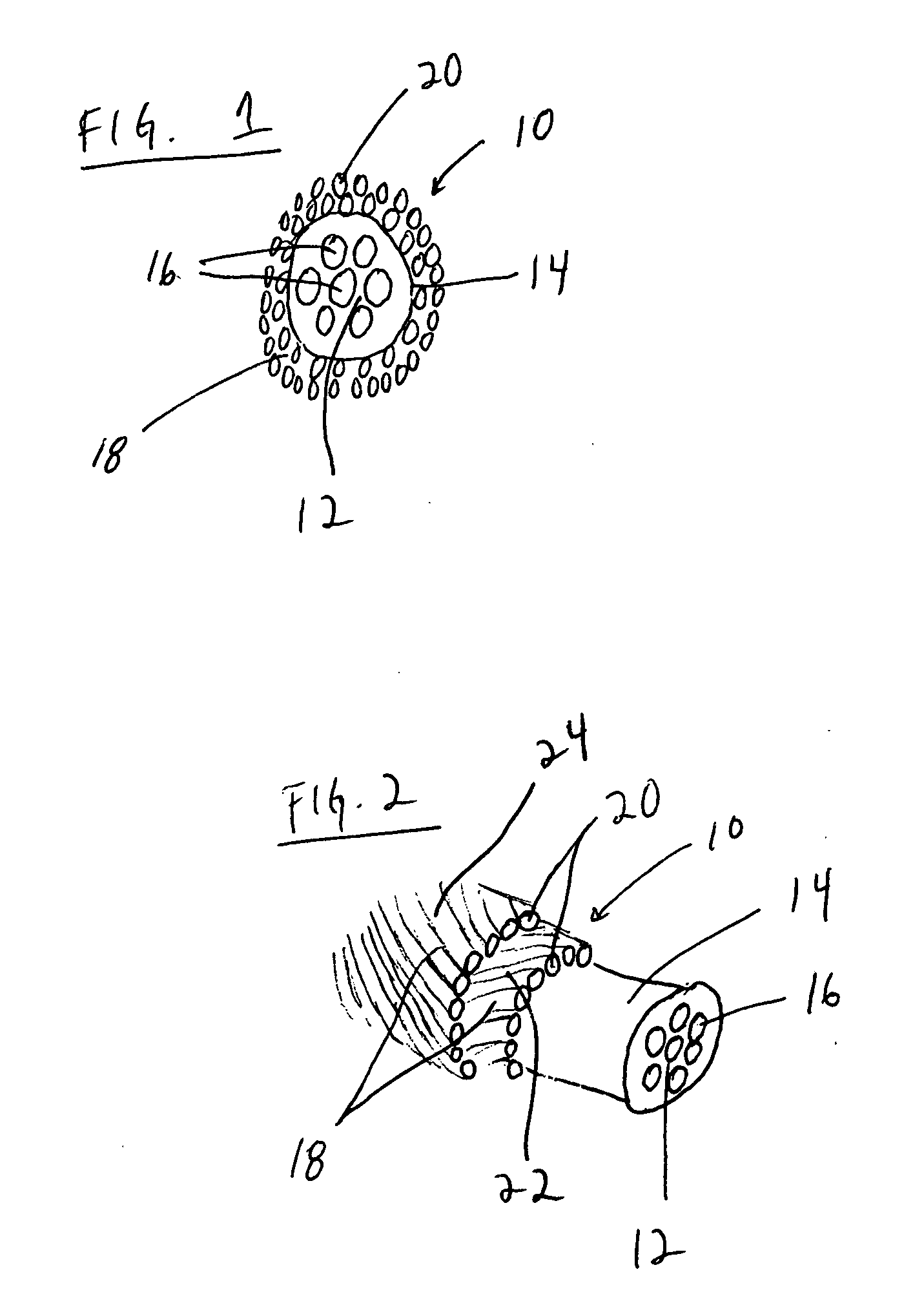

High voltage electrical power transmission cable having composite-composite wire with carbon or ceramic fiber reinforcement

InactiveUS20050061538A1Reduction factorIncrease powerNon-insulated conductorsPower cables for overhead applicationEpoxyElectric force

A high power electrical transmission cable having composite wires (10), wherein the wires have aligned reinforcing fibers (12) of carbon or ceramic embedded within a matrix material (14). A jacket of an electrically conductive material surrounds the core wire (10). The reinforcing fibers and the matrix material may be also electrically conducting materials. The matrix material may be aluminum, copper, a polymer, or an epoxy material.

Owner:NORTHEASTERN UNIV

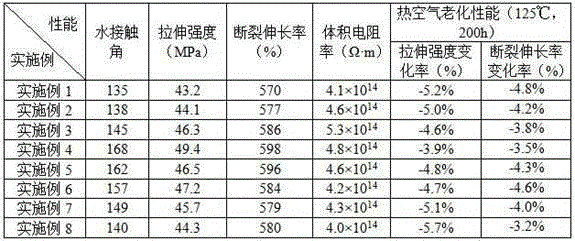

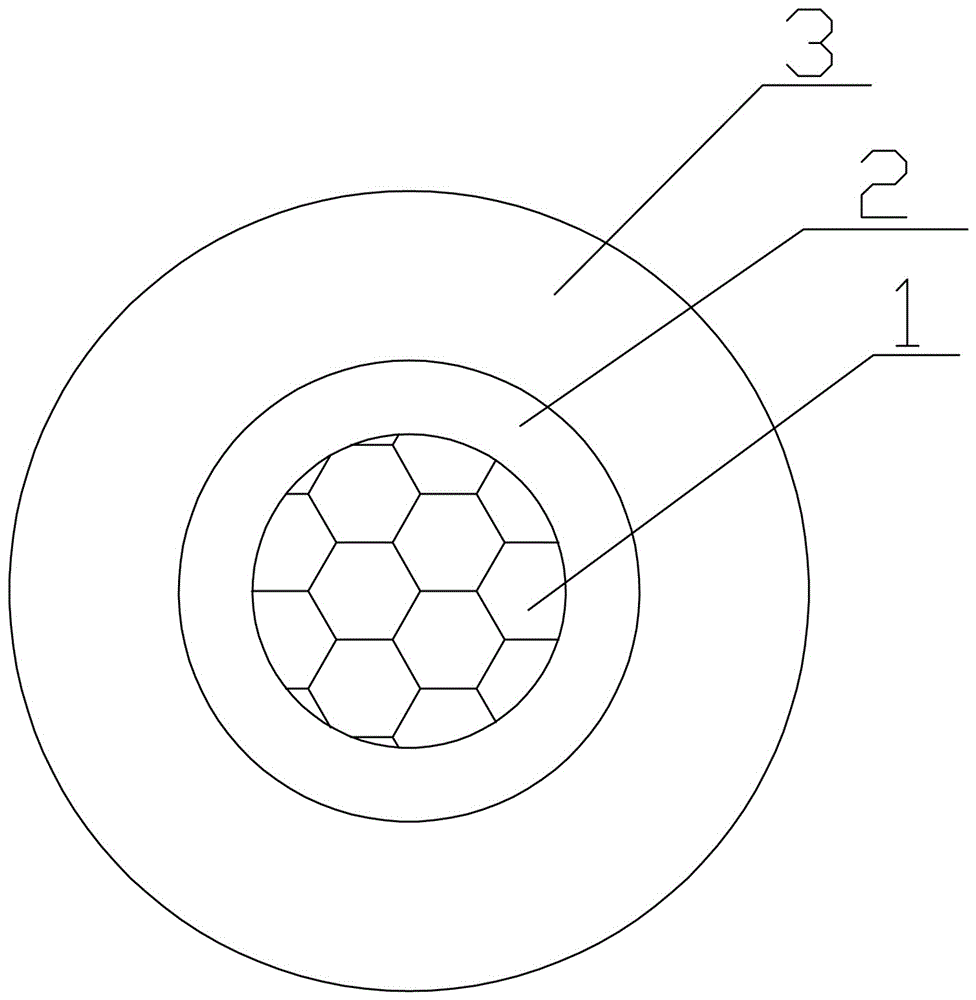

Anti-icing cable

ActiveCN105390189AAchieving Hydrophobic PropertiesAchieve strengthPower cables with screens/conductive layersInsulated cablesGlass fiberAntioxidant

The invention discloses an anti-icing cable. The cable comprises a core, a shielding layer and an anti-icing layer arranged in sequence from inside to outside, wherein the anti-icing layer comprises the following raw materials by weight: 60-75 parts of fluorosilicon resin, 20-30 parts of methyl vinyl silicone rubber, 10-15 parts of SiO2-glass fiber gel, 5-8 parts of polypropylene fiber powder, 3-5 parts of nano SiO2, 4-6 parts of nano TiO2, 0.5-1 part of a dispersing agent, 0.5-1.5 parts of a flame retardant, 1-2 parts of a silane coupling agent and 1-2 parts of an antioxidant. The anti-icing cable has excellent hydrophobic property and anti-icing performance, and is excellent in insulating performance, high in compressive strength, high in flexibility and anti-aging; and the anti-icing layer of the anti-icing cable can replace the insulating layer in the cable and a sheath outside the cable, so that the cable mass is lowered and the service life of the cable is prolonged.

Owner:STATE GRID HENAN DENGZHOU POWER SUPPLY CO

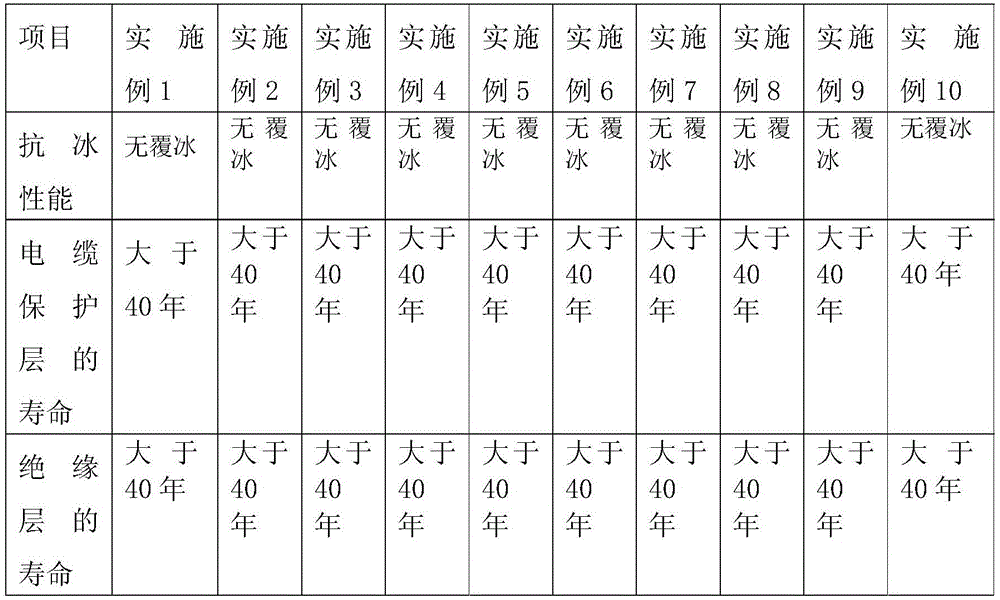

Power transmission cable with anti-icing function and preparation method of power transmission cable

ActiveCN106531335AReasonable structural designReduce escapePower cables with screens/conductive layersInsulated cablesSnow meltingCold weather

The invention relates to a power transmission cable with an anti-icing function. The power transmission cable sequentially comprises a power transmission cable inner core, an insulating layer sleeving the outside of the power transmission cable inner core, a cable shielding layer sleeving the outside of the insulating layer, and a cable sheath layer sleeving the outside of the cable shielding layer from inside to outside, wherein the power transmission cable is characterized in that an anti-icing function layer is also arranged in the middle of the insulating layer and the cable shielding layer and comprises an inner-layer high-temperature composite phase change material layer and an outer-layer low-temperature phase change material layer. The power transmission cable is reasonable in structure design and various parts are tightly combined and mutually isolated and insulated. In cold weather, the inner-layer high-temperature composite phase change material layer is capable of retarding heat escape and preventing overheat ageing of an outer-layer material; and the outer-layer low-temperature phase change material layer is capable of keeping the outer surface of the cable in a relatively low temperature state, preventing snow melting and icing, caused by heating of the inner core, of the outer surface of the power transmission cable, preventing cold shortness of the cable material and prolonging the life of the cable protection layer and the insulating layer.

Owner:FUJIAN REIDA PRECISION

A production method of high-strength large-elongation aluminum-clad steel wire

InactiveCN108986989AChange heat treatment temperatureHigh tensile strengthSingle bars/rods/wires/strips conductorsApparatus for heat treatmentWire rodHigh carbon

The invention relates to a production method of high-strength large-elongation aluminum-clad steel wire, comprising the following steps: 1) hot-drawing high-carbon steel wire rod to different wire diameters through cold drawing; 2) carry out lead bath quenching treatment on that steel wire, and carry out on-line pickling and rinsing to obtain a pretreated steel wire; 3) uniformly cover an outer lay of that pretreated steel wire with a layer of aluminum to form a cladding blank; 4) that coat blank is drawn into a super-high-strength aluminum clad steel wire semi-finished product through multiple passes of a bimetal synchronous deformation wire draw machine; 5) age that semi-finished product of the high-strength aluminum-clad steel wire through a high-temperature box. The method of the invention changes the traditional lead bath heat treatment temperature, The tensile strength of Al-clad steel wire is increased by multi-pass synchronous deformation and drawing with small compression ratio, and the elongation of Al-clad steel wire is increased by high temperature aging treatment. The ultimate tensile strength >= 1700 MPa, elongation >= 3. 0%, and other indexes are in accordance with the requirements of Al-clad steel GB / T17937-2009 standard, thereby meeting the requirements of high strength and high elongation and meeting the application requirements.

Owner:HUBEI LONGSKY COMM TECH

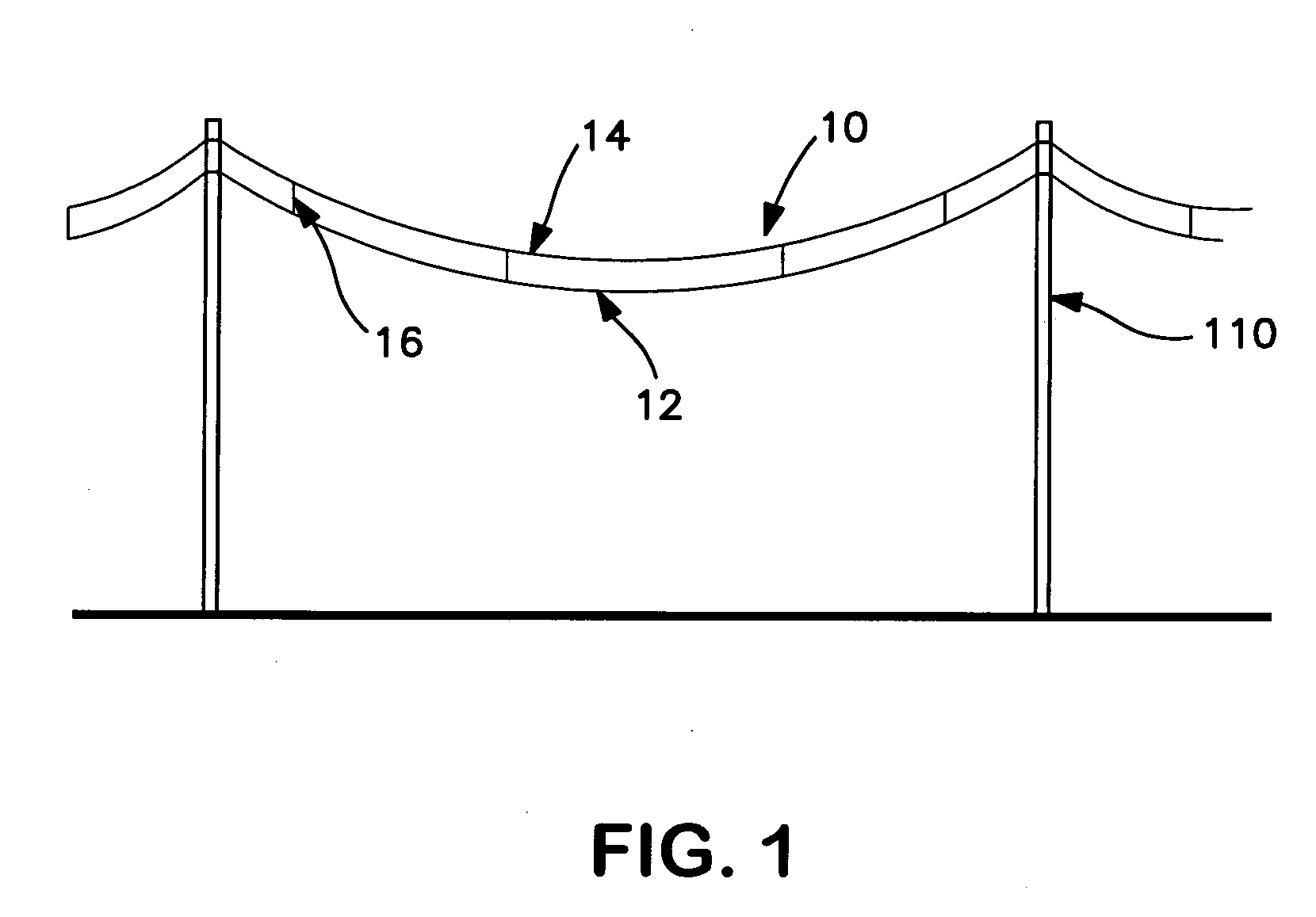

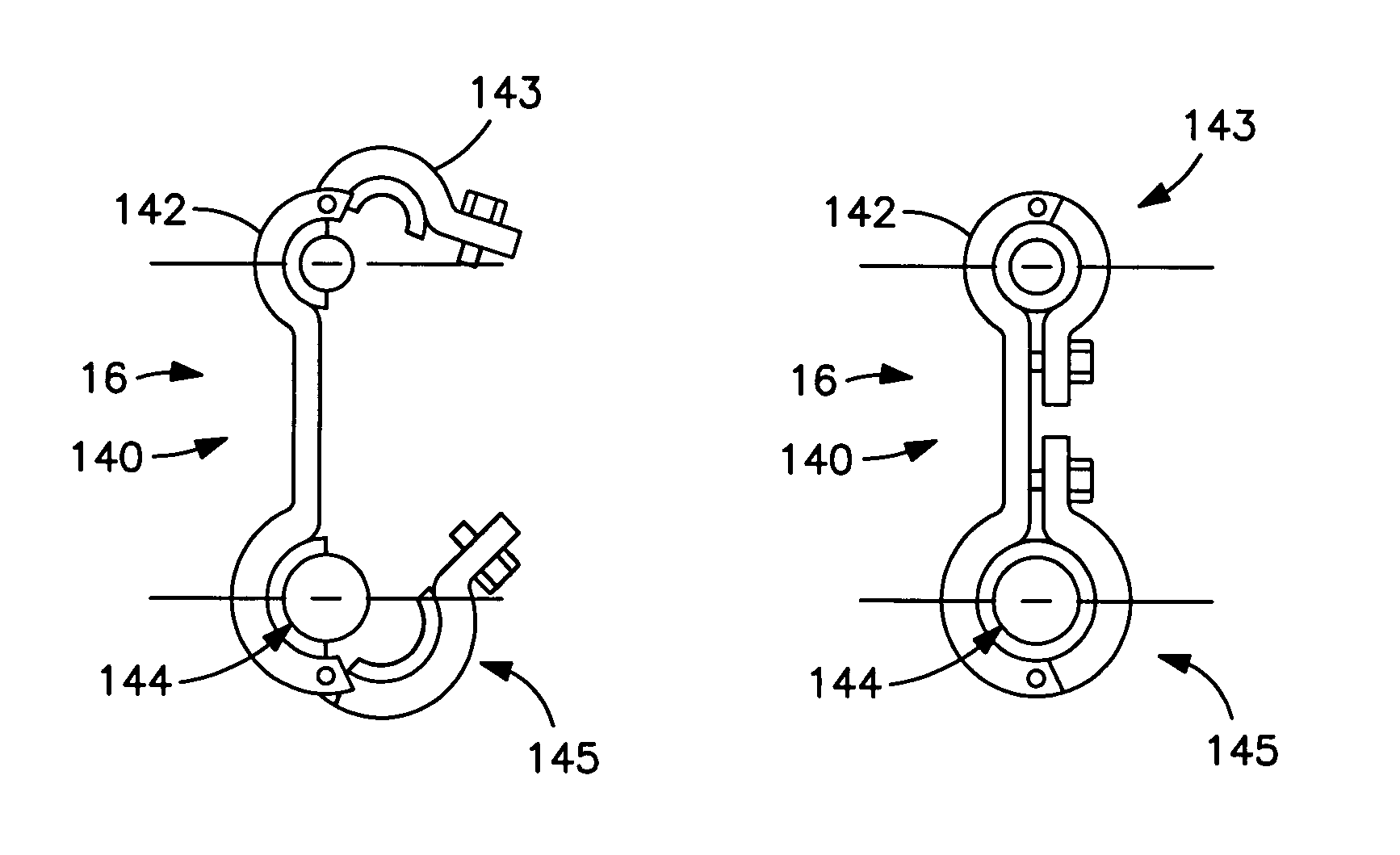

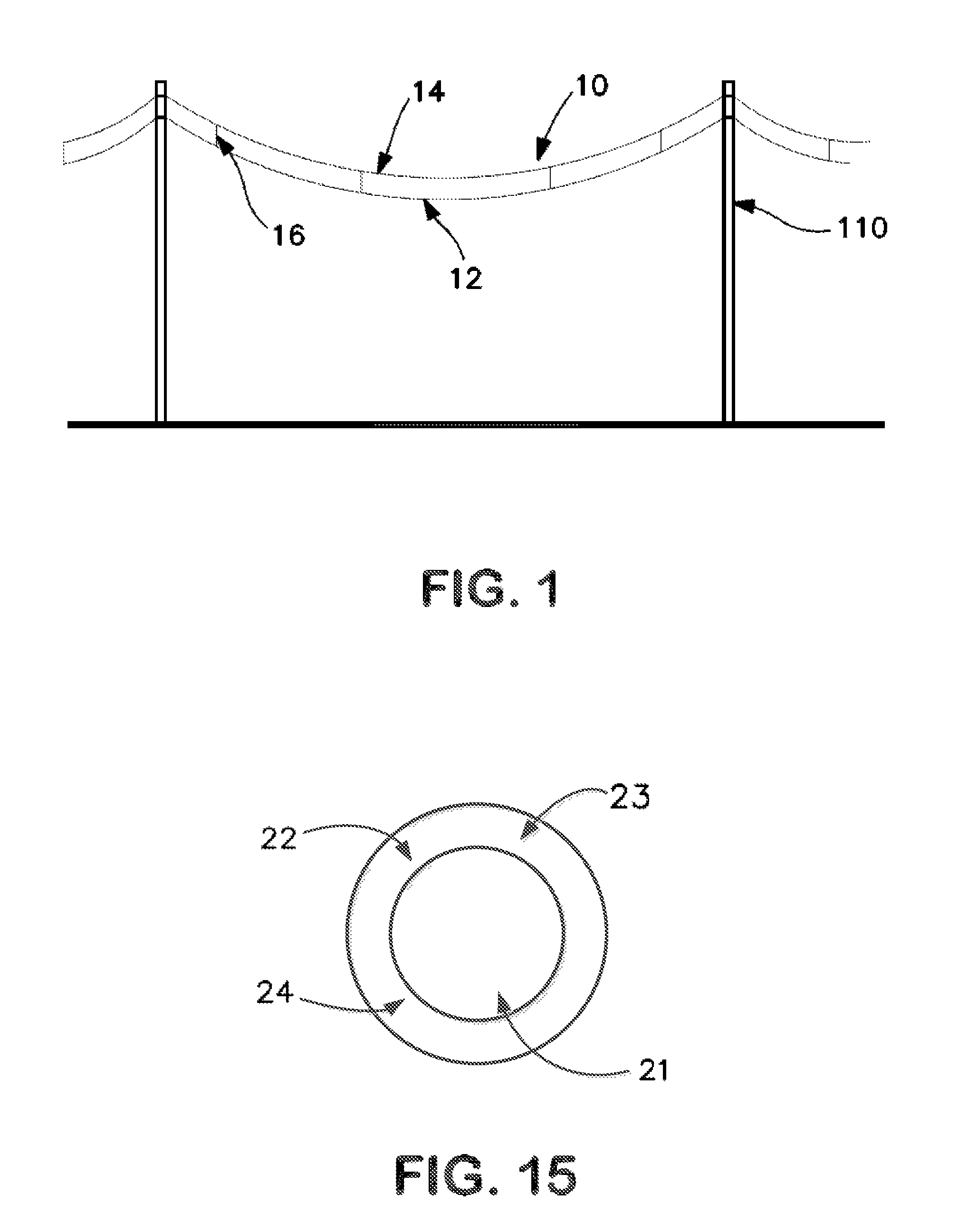

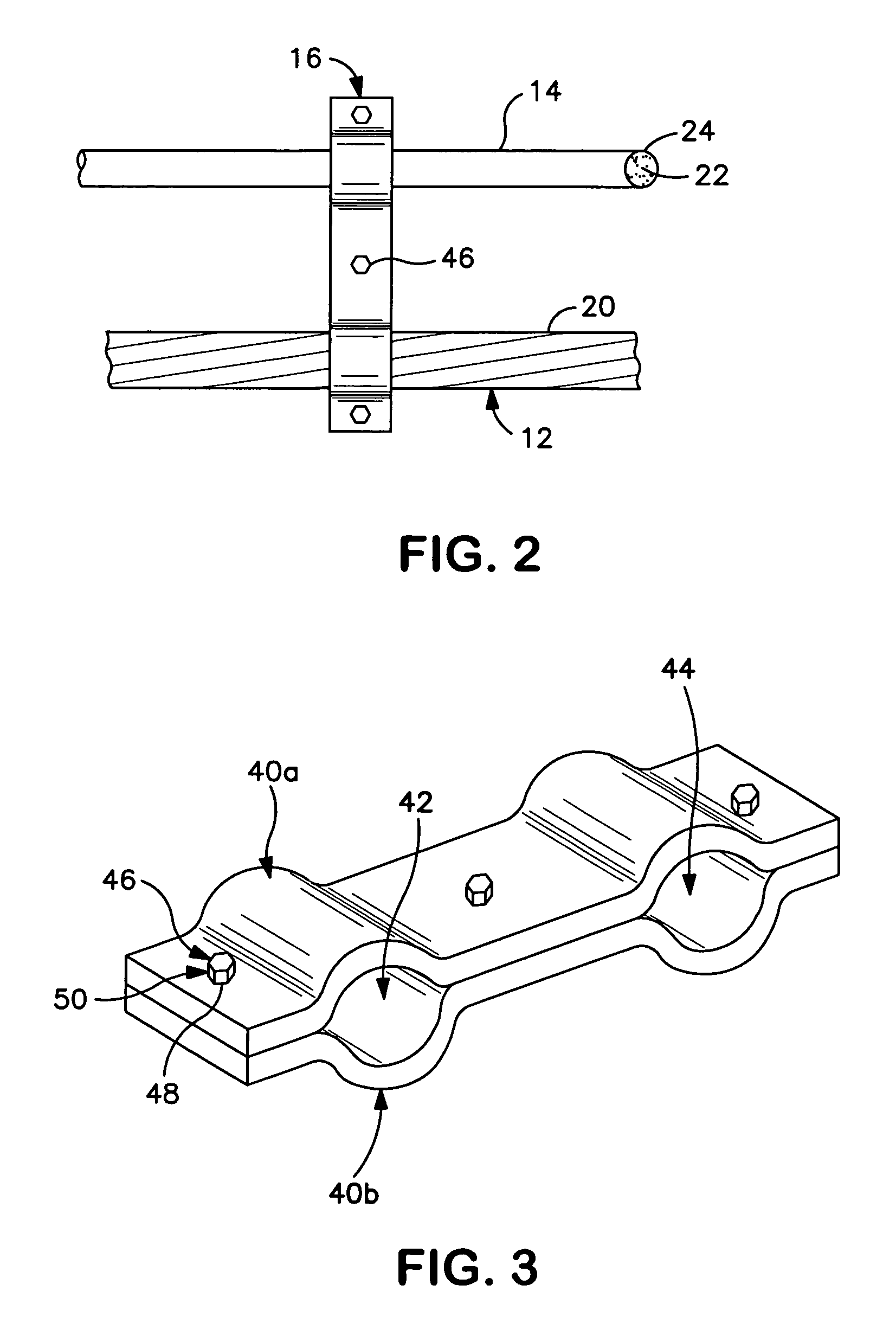

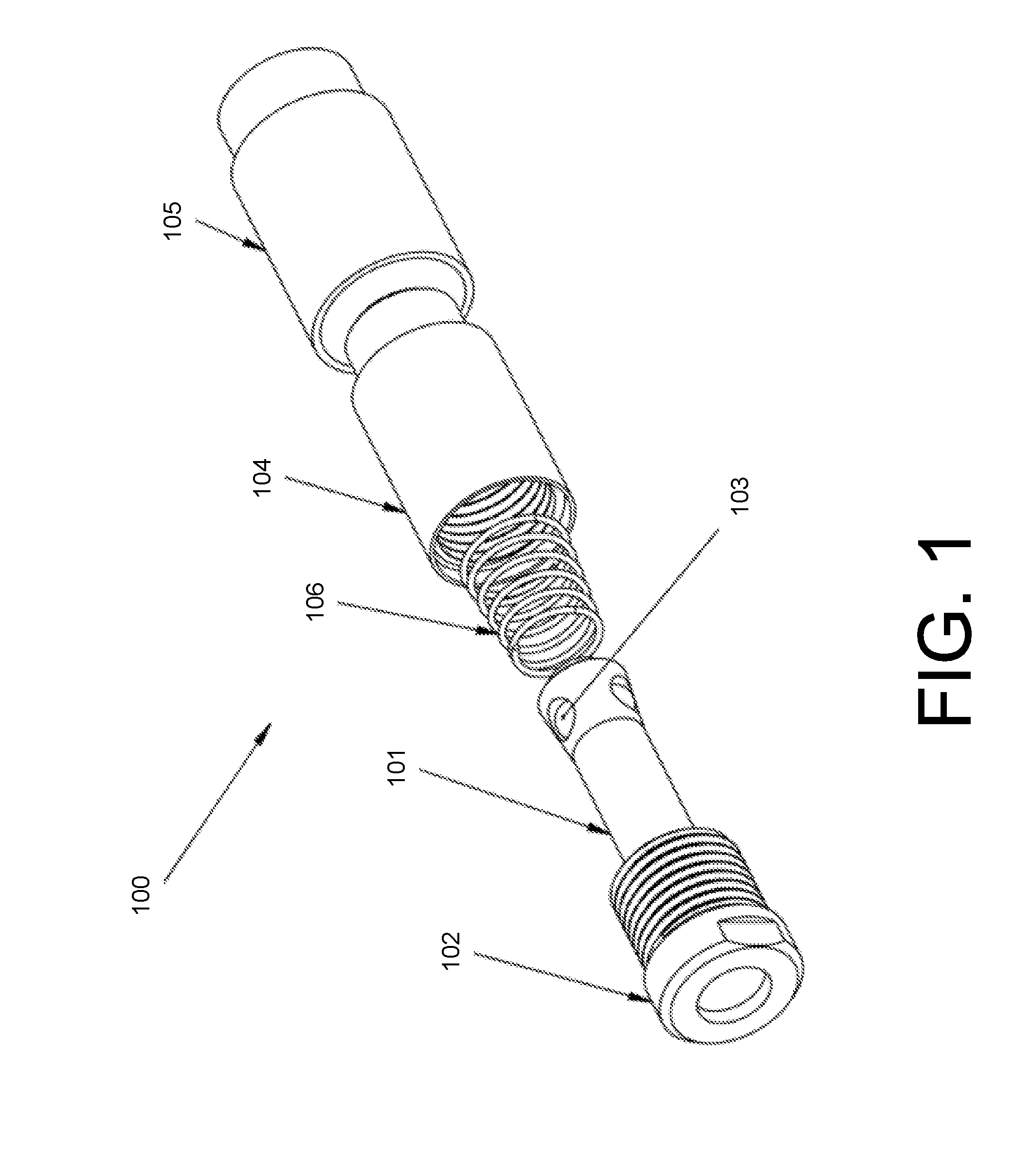

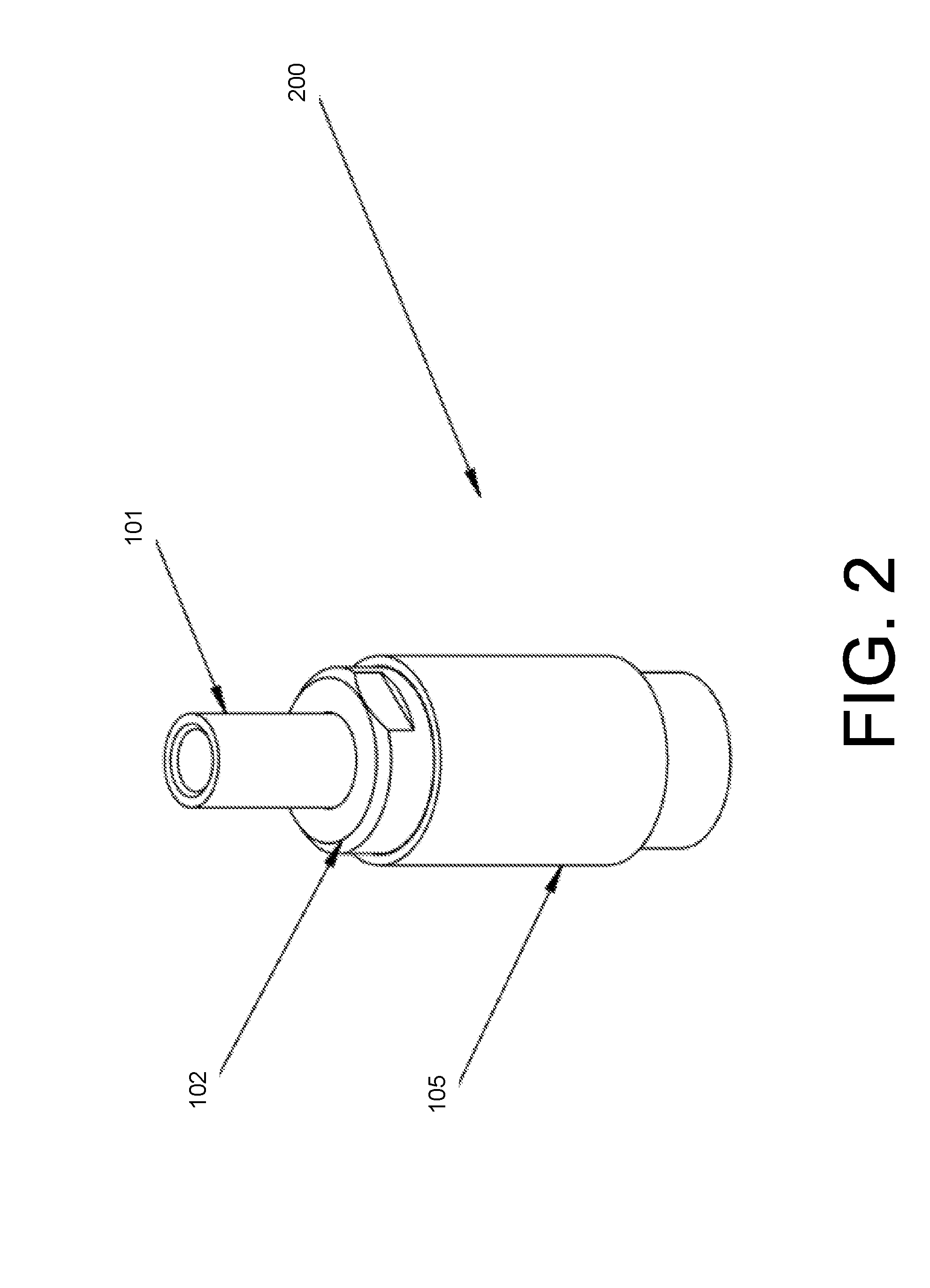

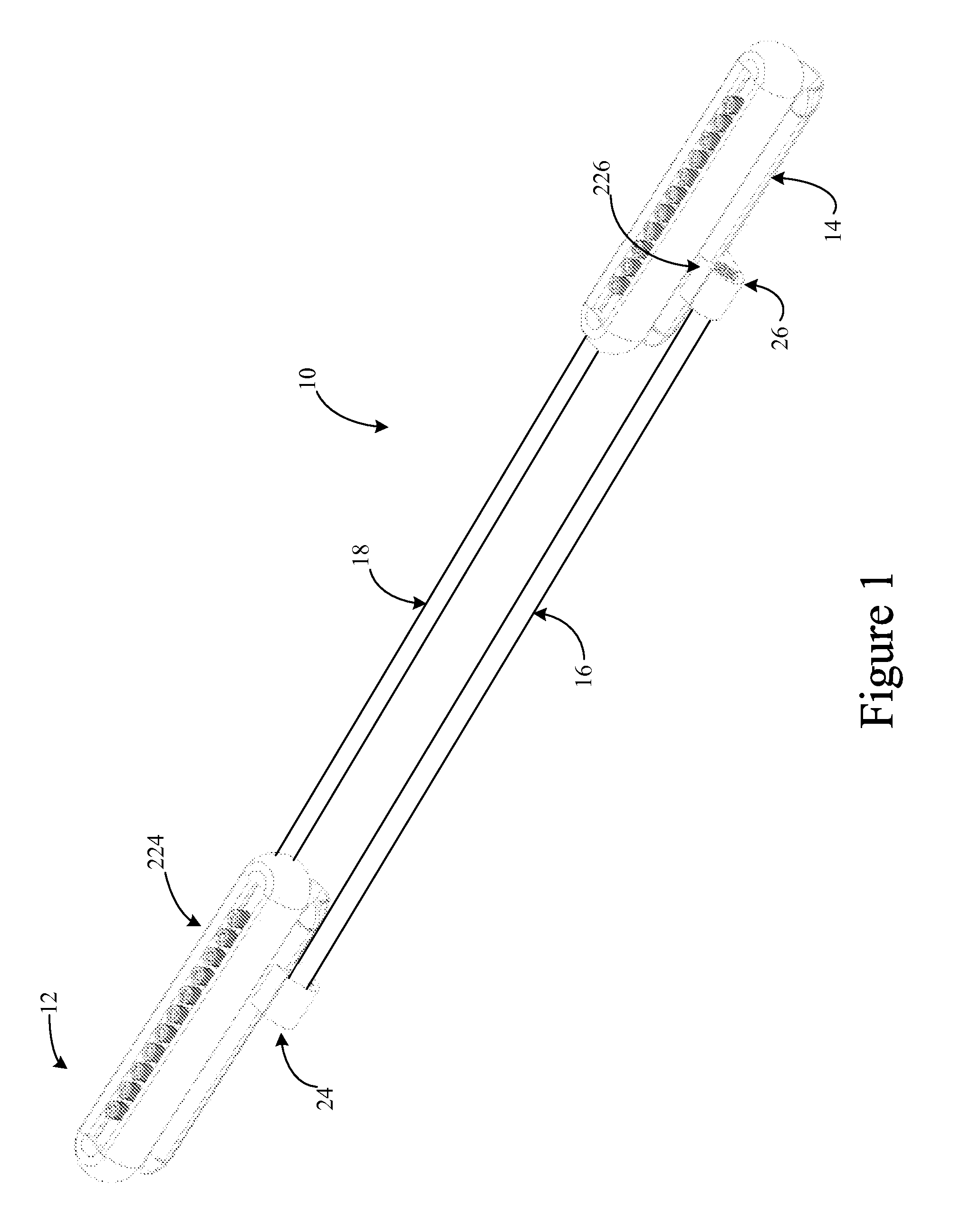

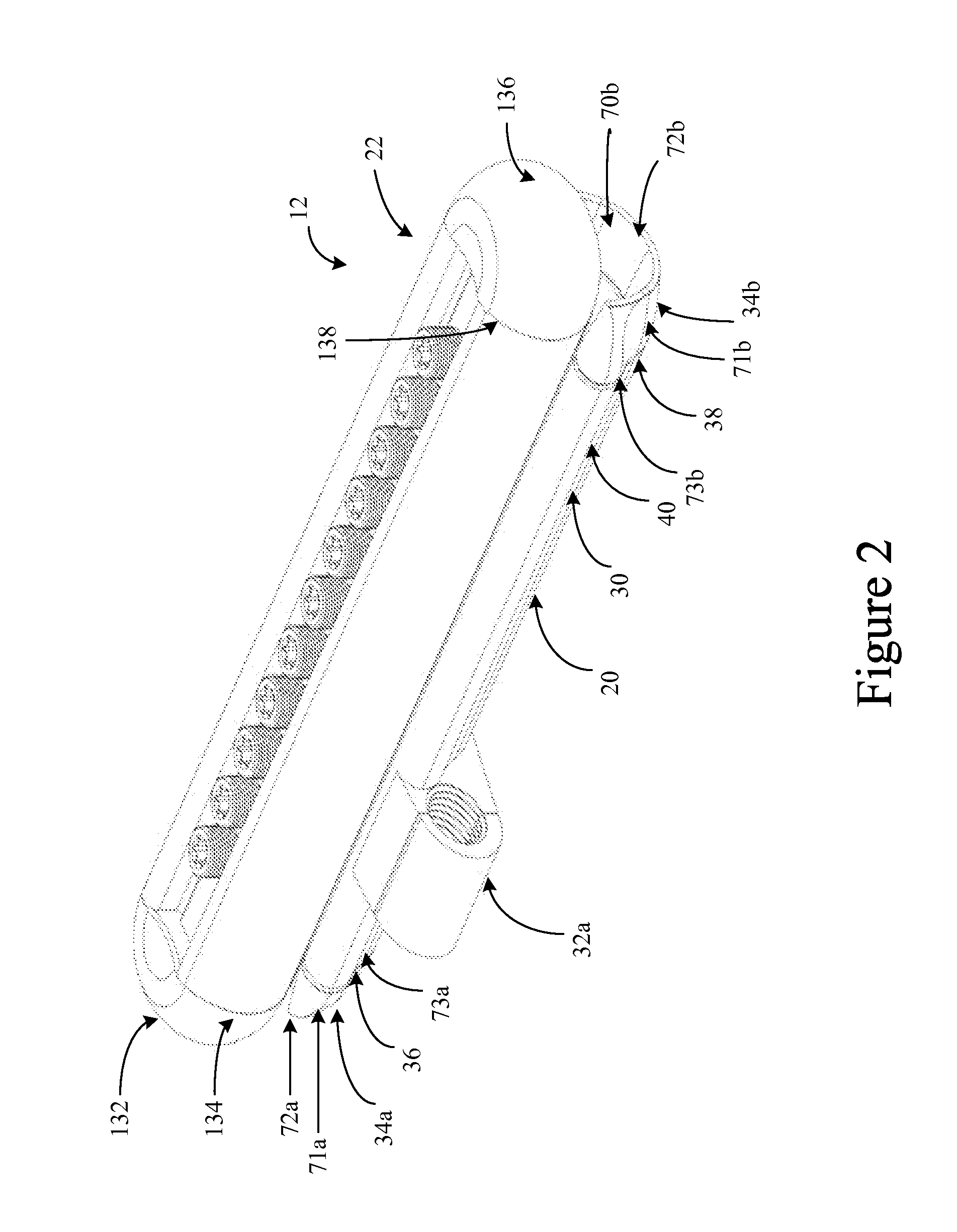

Messenger supported overhead cable for electrical transmission

ActiveUS20080099226A1Avoid damageFacilitates pivotable couplingMaintaining distance between parallel conductorsSuspension arrangements for electric cablesElectrical conductorCoupling

A transmission line assembly for transmission and distribution of high voltage power which comprises a conductor, a separate messenger member and coupling means. The conductor has a predetermined length. The separate messenger member has a predetermined length. The coupling means couples the messenger to the conductor to the messenger. The messenger member and the conductor remain structurally separate from each other and functionally independent.

Owner:ADVANCED TECH HLDG

Surface modified overhead conductor

ActiveUS20150235739A1Lower operating temperaturePlastic/resin/waxes insulatorsAuxillary non-insulated conductorsElectrical conductorSolar absorptivity

The present invention relates to a surface modified overhead conductor with a coating that allows the conductor to operate at lower temperatures. The coating is an inorganic, non-white coating having durable heat and wet aging characteristics. The coating preferably contains a heat radiating agent with desirable properties, and an appropriate binder / suspension agent. In a preferred embodiment, the coating has L* value of less than 80, a heat emissivity of greater than or equal to 0.5, and / or a solar absorptivity coefficient of greater than 0.3.

Owner:GENERAL CABLE TECH CORP

Stranded copper-plated aluminum cable, and method for its fabrication

ActiveUS7105740B2Low resistivityGood flexibilityConductive materialPower cables for overhead applicationElectricityCopper plating

Aluminum cable type electrical conductor having at least one stranded conductor based on conductive wires with an aluminum core coated with an intermediate layer of copper itself coated by a surface layer of nickel. The surface layer of nickel has a thickness from about 1.3 μm to about 3 μm, it has sufficient continuity to resist a polysulfide bath continuity test for at least 30 seconds without visible traces of attack of the copper appearing at ×1O magnification. This kind of conductor is particularly suitable in small diameters for conducting electricity in aircraft and motor vehicles.

Owner:F S P.-1

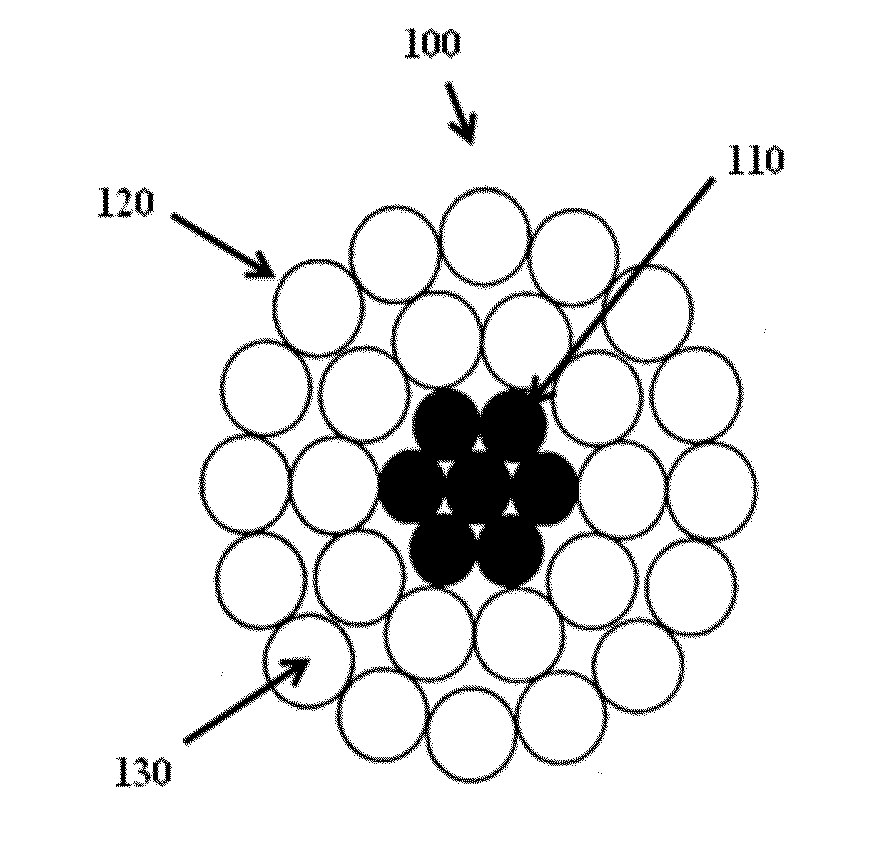

Electrical conductor cable and method for forming the same

InactiveUS20050205287A1Low costEasily substitutedNon-insulated conductorsPower cables with screens/conductive layersElectrical conductorEngineering

An electrical conductor cable for long distance transmission of electrical current is provided. The conductor cable includes a plurality of individual cylindrically shaped non-conductive components. The conductor cable further includes an electrically conductive member located on an exterior of the core. A method for forming such a conductor cable is also provided.

Owner:GIFT TECH LP

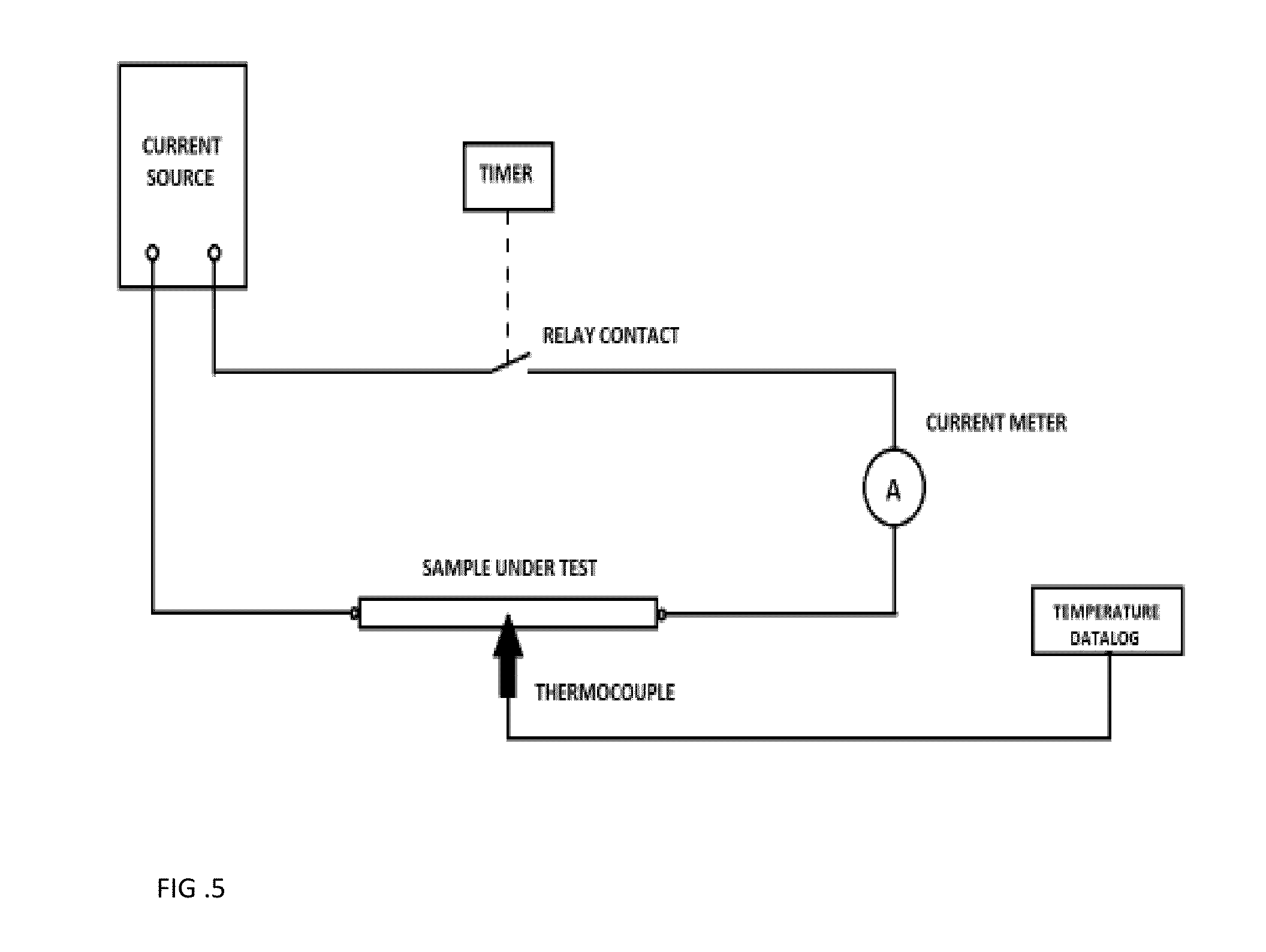

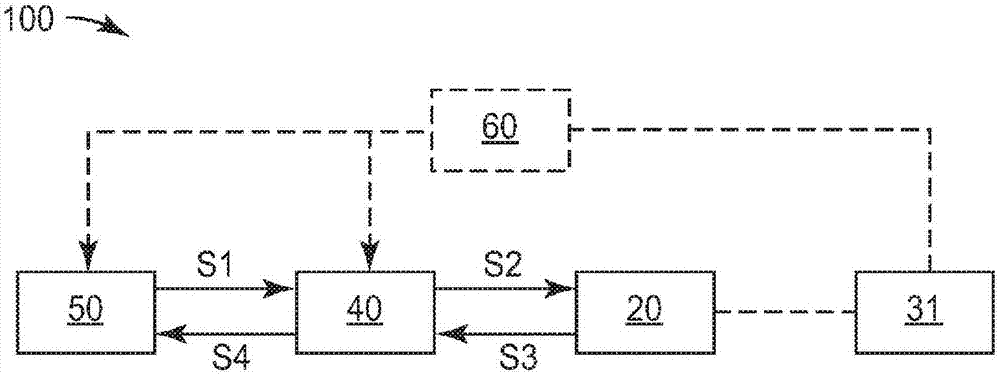

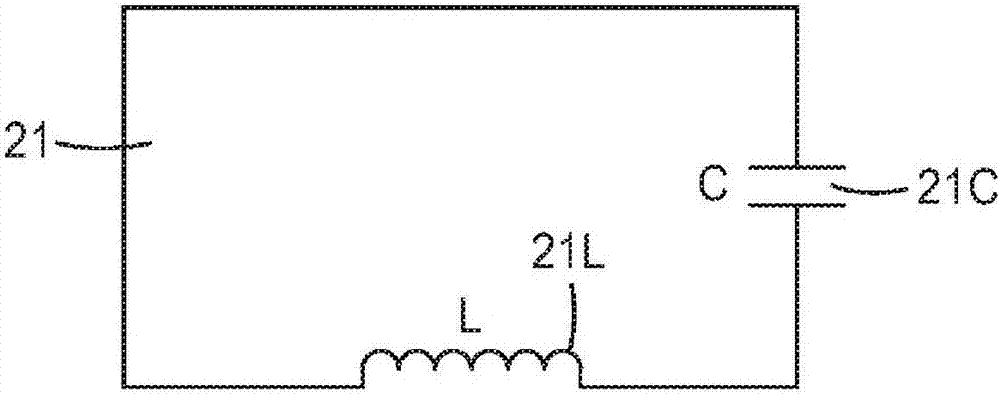

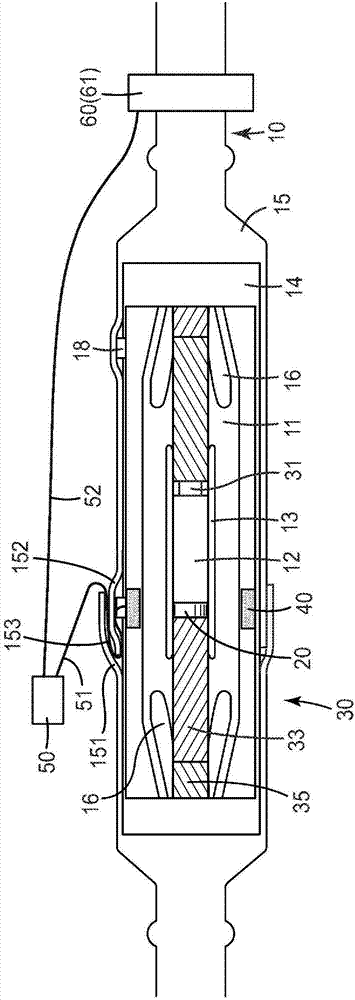

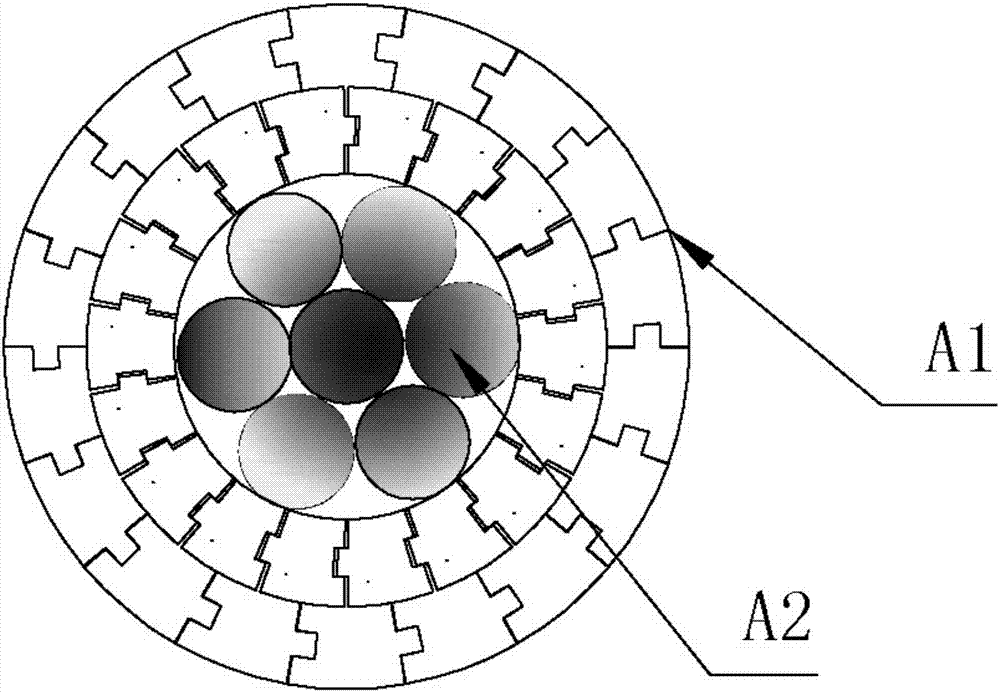

Capacitive temperature sensing for electrical conductor

ActiveCN107076621AThermometers using electric/magnetic elementsInsulated cablesCapacitanceElectrical conductor

Provided is a system for directly sensing, measuring, or monitoring the temperature of an electrical conductor (31) of a power cable (10). A temperature sensitive capacitor (21C) is disposed in direct thermal contact with the electrical conductor (31). The temperature sensitive capacitor (21C) includes a dielectric material that has a dielectric constant variable with the temperature of the electrical conductor (31). The temperature of the electrical conductor (31) can be sensed, measured, or monitored by measuring the capacitance of the temperature sensitive capacitor (21C).

Owner:3M INNOVATIVE PROPERTIES CO

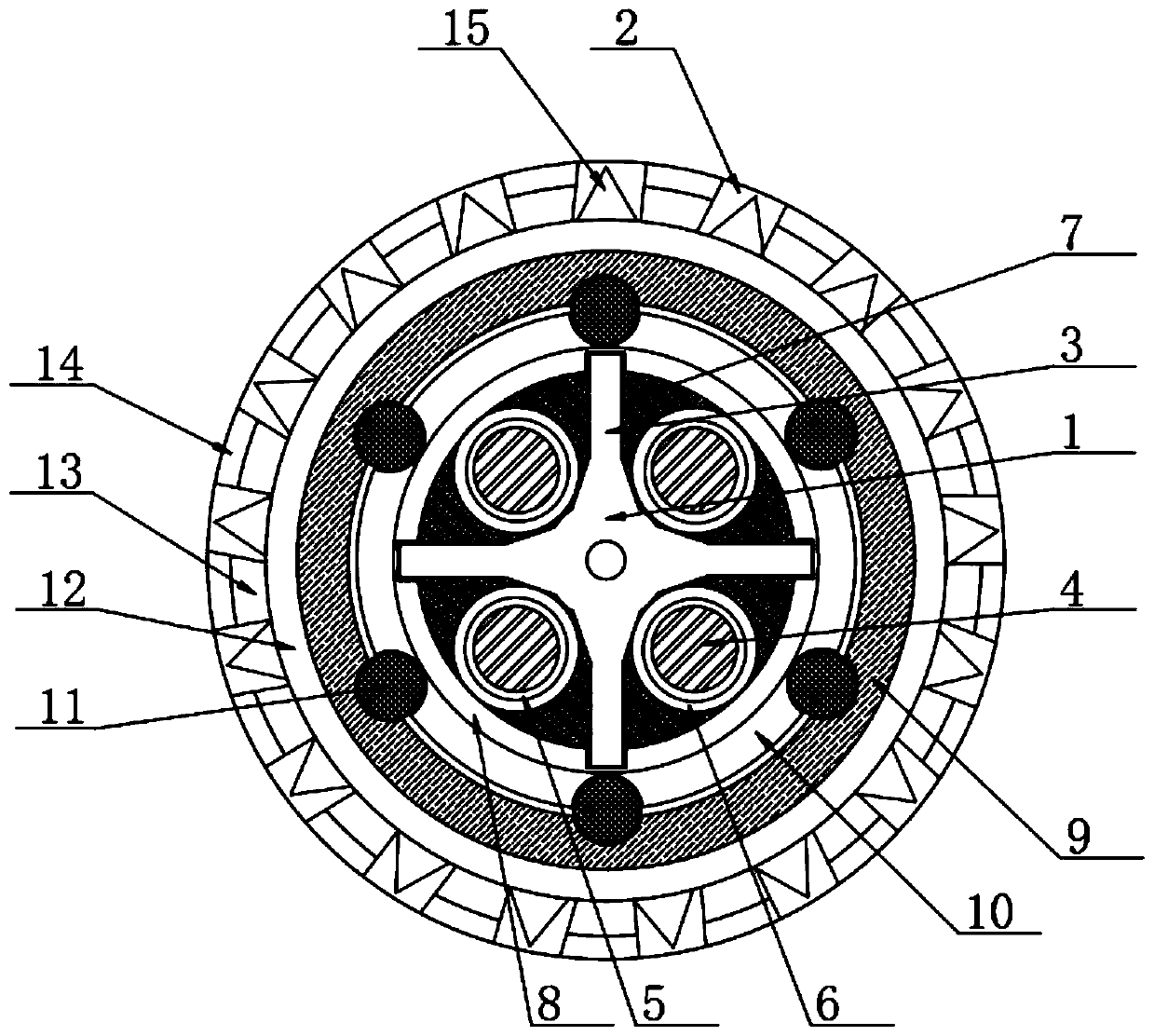

Reinforced high-temperature resistant optical fiber composite overhead insulating cable

InactiveCN102306522AIncrease operating temperatureImprove tensile propertiesPower cables with screens/conductive layersPower cables for overhead applicationElectrical conductorInformation feedback

The invention relates to a reinforced high-temperature resistant optical fiber composite overhead insulating cable, which comprises an electric flexible aluminum twisted wire serving as a conductor; a stainless steel tube optical unit and a carbon fiber composite reinforced core are arranged in the electric flexible aluminum twisted wire; and the outer side of the electric flexible aluminum twisted wire is coated with a high-temperature resistant insulating material. By the cable, a running temperature can be raised to above 180 DEG C and the tensile capability can be improved to 2,400MPa for a long time; and the cable has functions of communication, warning, information feedback and the like.

Owner:HENAN KOSEN CABLE

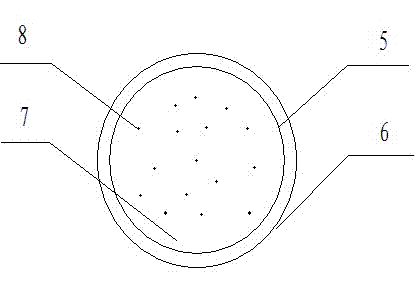

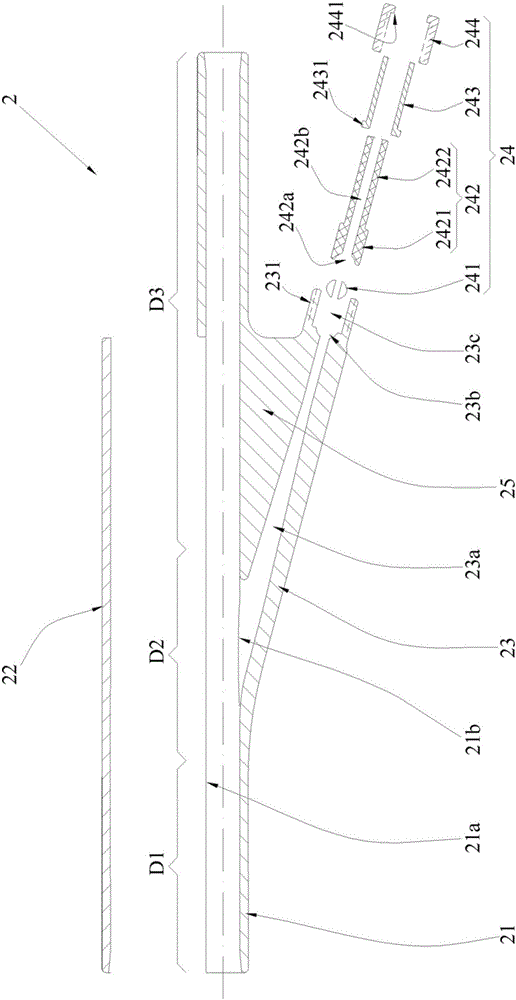

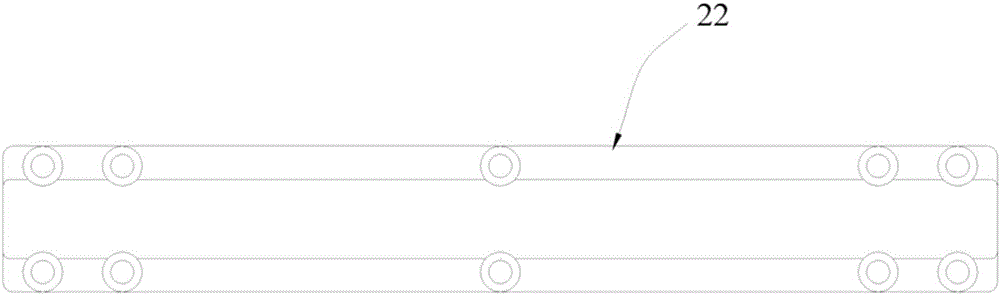

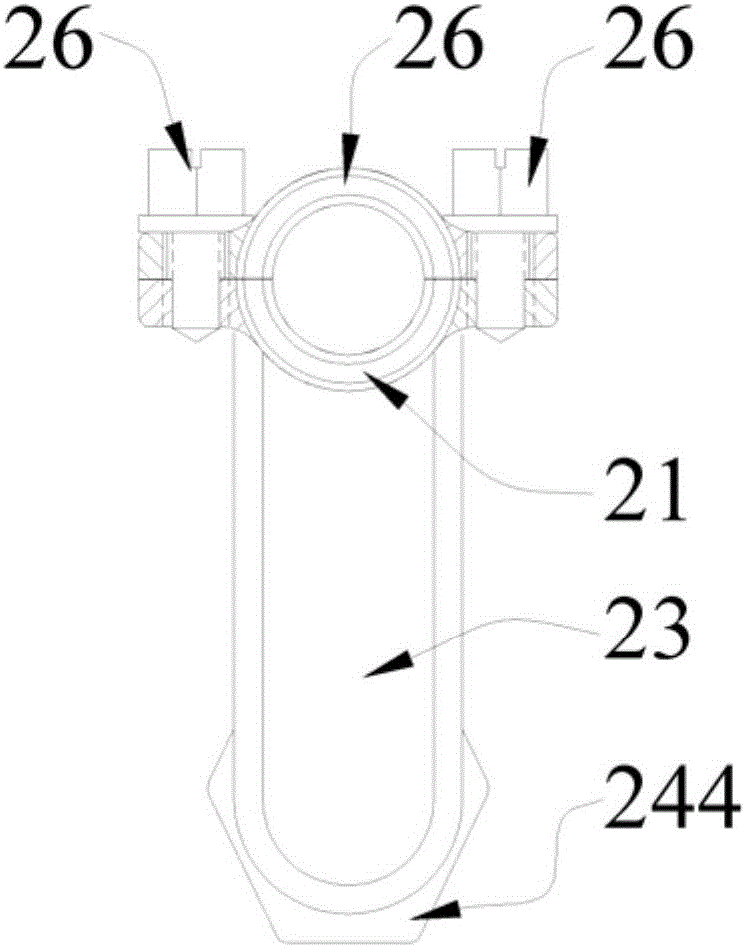

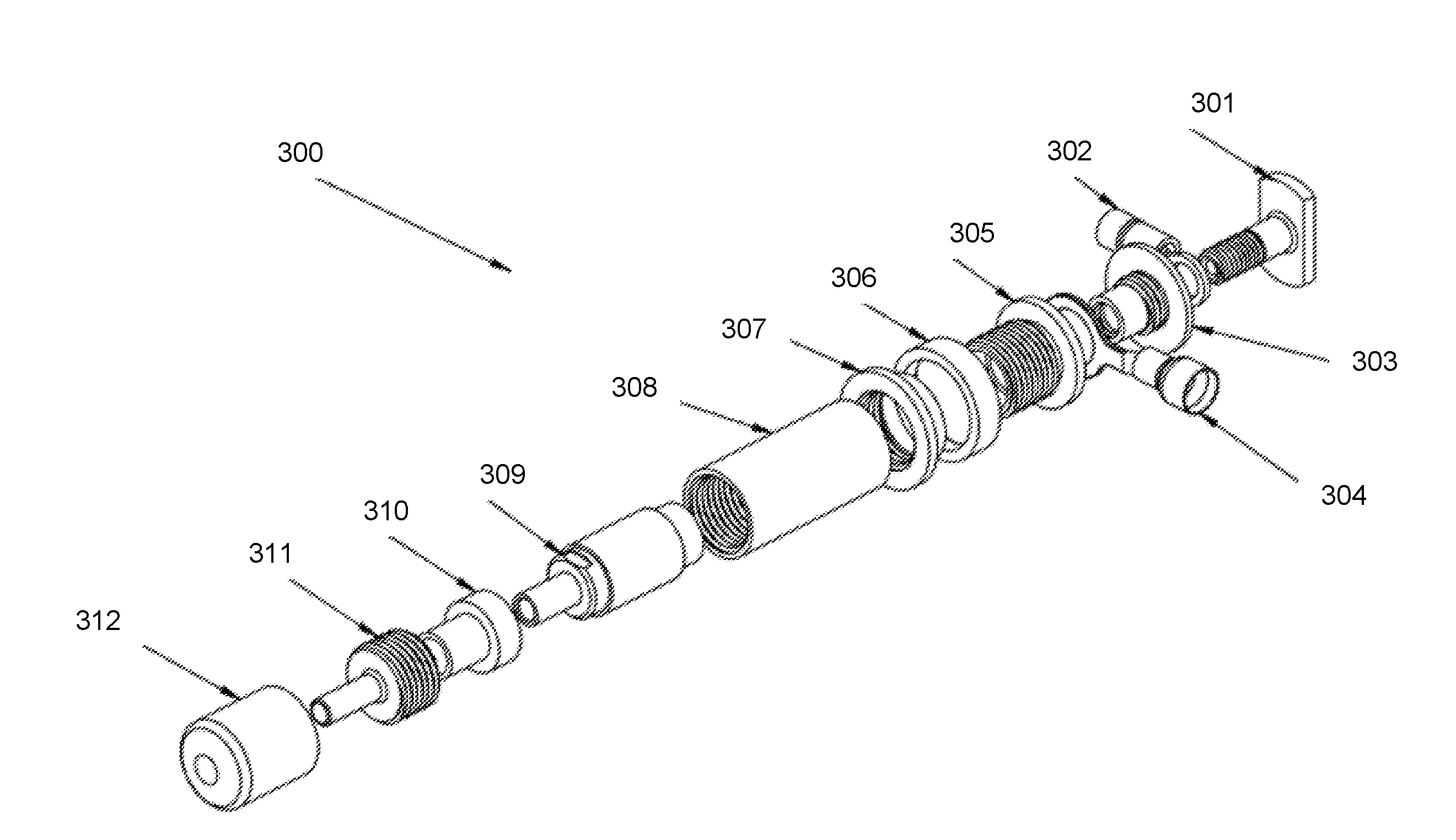

Optical unit direct leading-down structure of OPPC (Optical Phase Conductor) and construction method of optical unit direct leading-down structure

ActiveCN106300206AAvoid restrictionsAchieve separationPower cables for overhead applicationFibre mechanical structuresElectricityEngineering

The invention discloses an optical unit direct leading-down structure of an OPPC (Optical Phase Conductor) and a construction method of the optical unit direct leading-down structure. The optical unit direct leading-down structure is provided with an OPPC optical cable (1), a pre-twisted wire assembly (3), a first connection fitting (4), a second connection fitting (6), an insulator string (7) and an optical connection jumper (8) and is also provided with an optical unit leading-out connector (2). By the structure, a plastic pipe optical unit of the OPPC optical cable hung at a high altitude can be separated and directly lead down, and moreover, the structure is suitably used for the OPPC optical cable of which the plastic pipe optical unit is arranged at an arbitrary position in the OPPC optical cable. By the construction method, connection between the OPPC optical cable and the optical unit leading-out connector and connection and installation of the pre-twisted wire assembly, the first connection fitting, a remaining cable rack, the second connection fitting and the insulator string can be completed on the ground, the OPPC optical cable is pulled to a high altitude and then is connected to a cross arm of an iron tower or a telegraph pole after winding of a remaining cable segment, and finally, the plastic pipe optical unit is directly lead down. The construction method has the advantages of simplicity and convenience in construction.

Owner:林杨

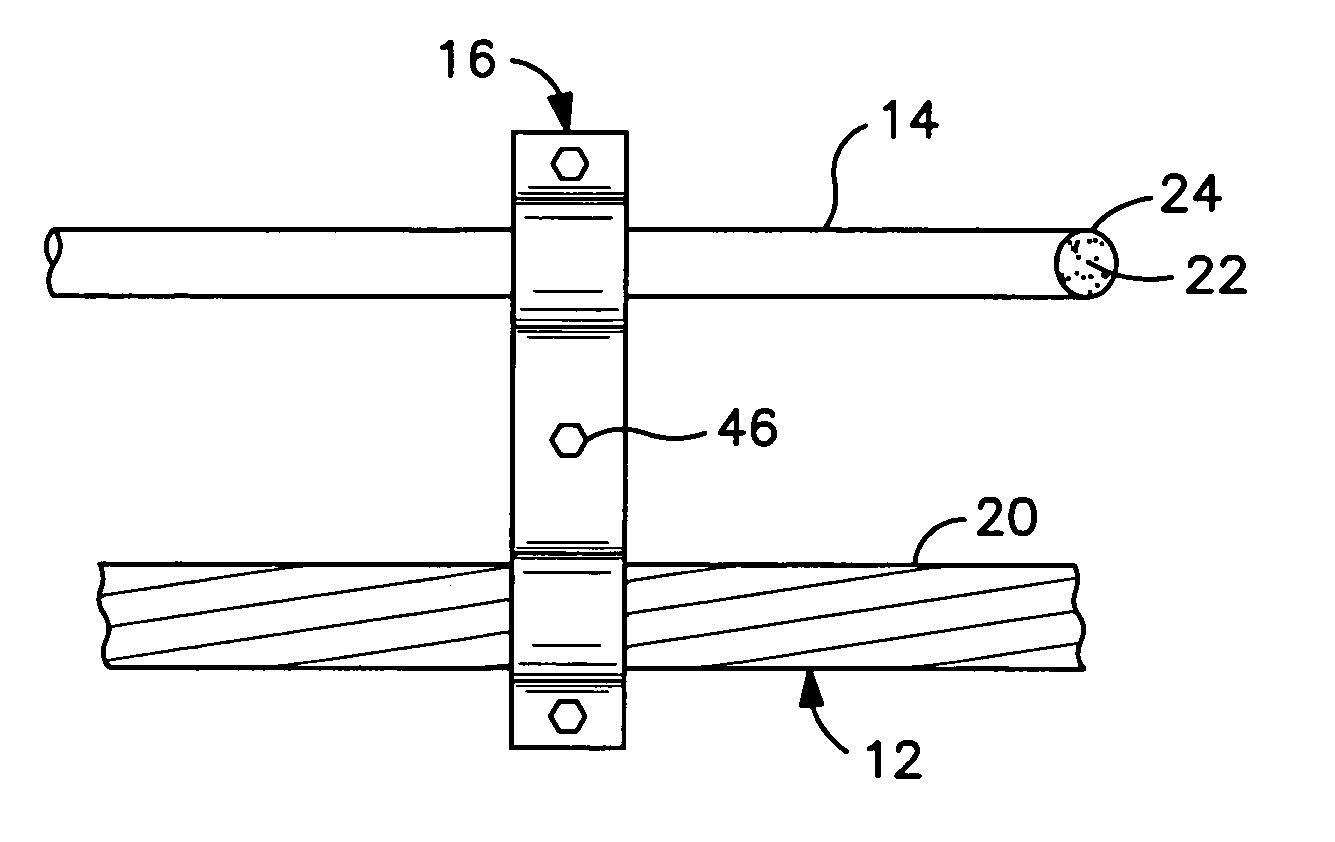

Messenger supported overhead cable for electrical transmission

ActiveUS8203074B2Easy maintenanceAvoid damageMaintaining distance between parallel conductorsSuspension arrangements for electric cablesElectrical conductorCoupling

A transmission line assembly for transmission and distribution of high voltage power which comprises a conductor, a separate messenger member and coupling means. The conductor has a predetermined length. The separate messenger member has a predetermined length. The coupling means couples the messenger to the conductor to the messenger. The messenger member and the conductor remain structurally separate from each other and functionally independent.

Owner:ADVANCED TECH HLDG

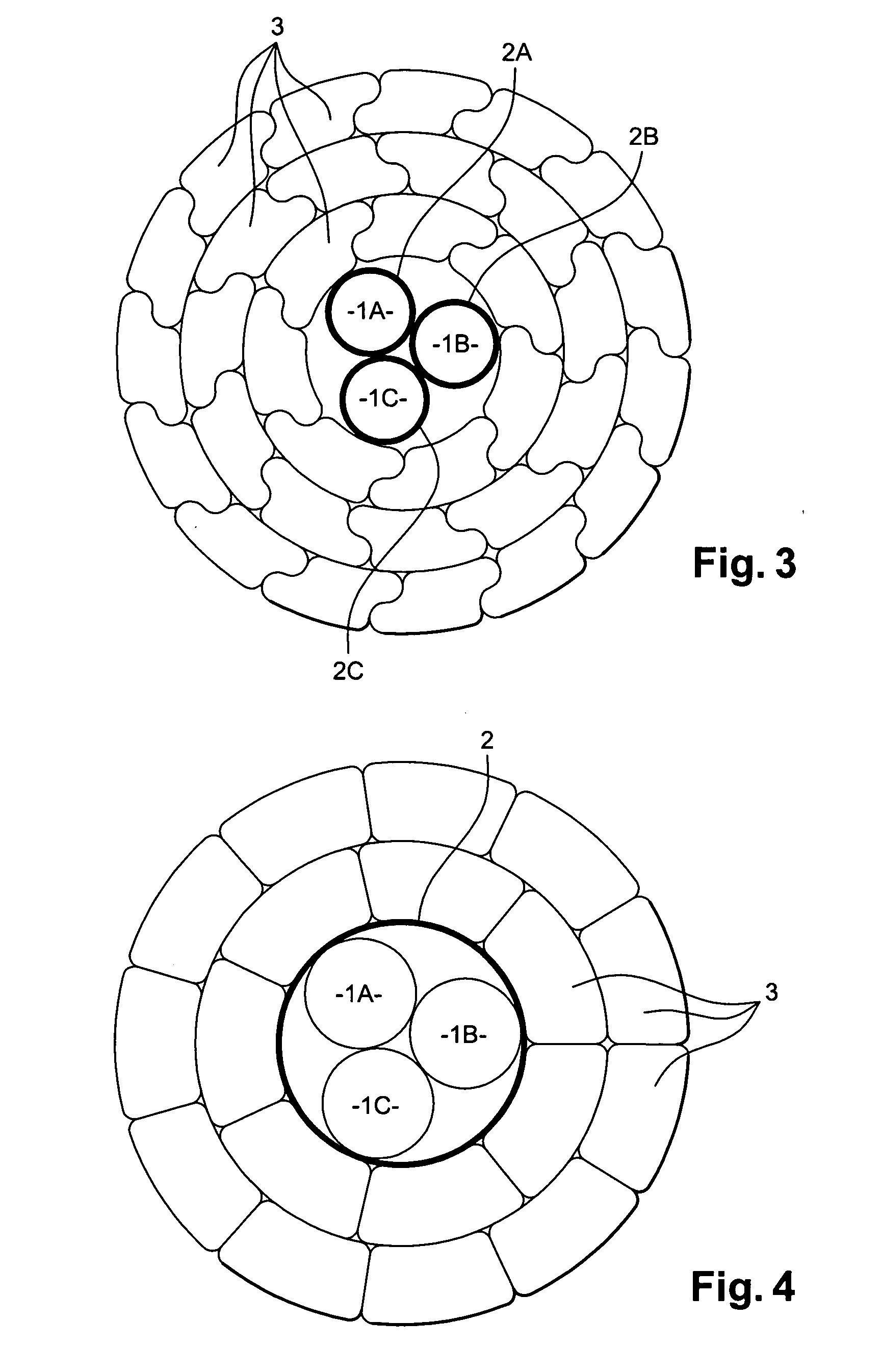

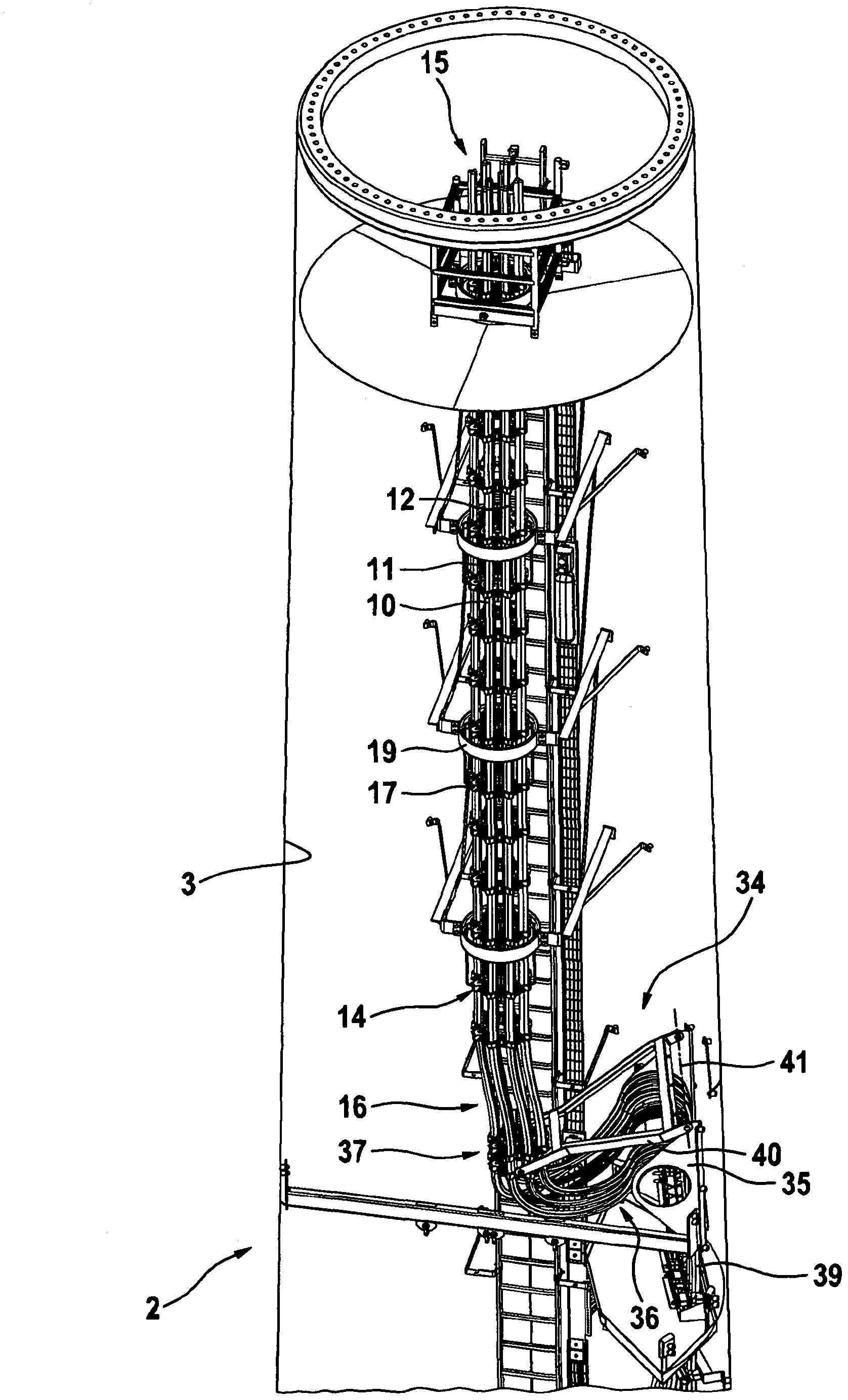

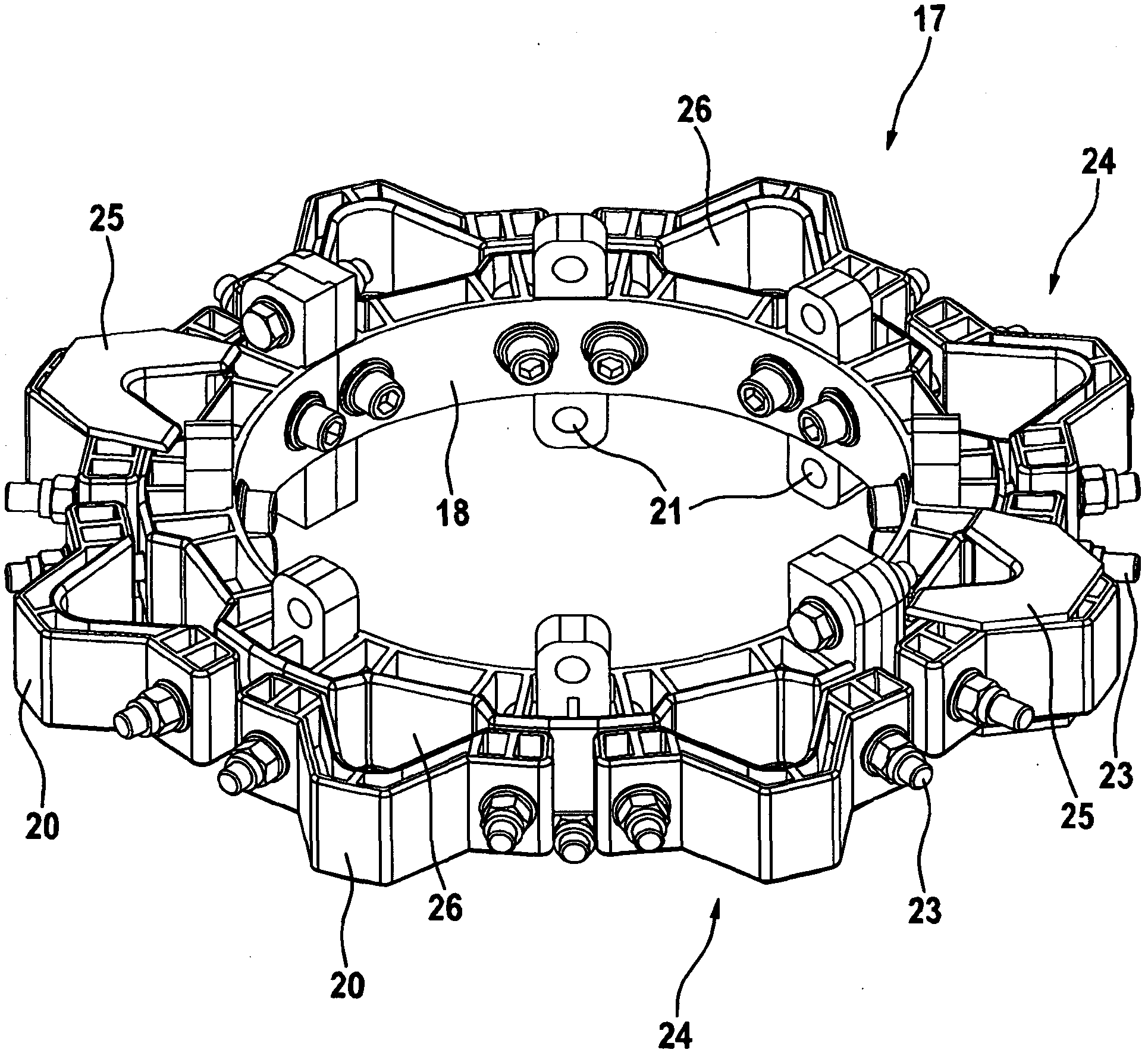

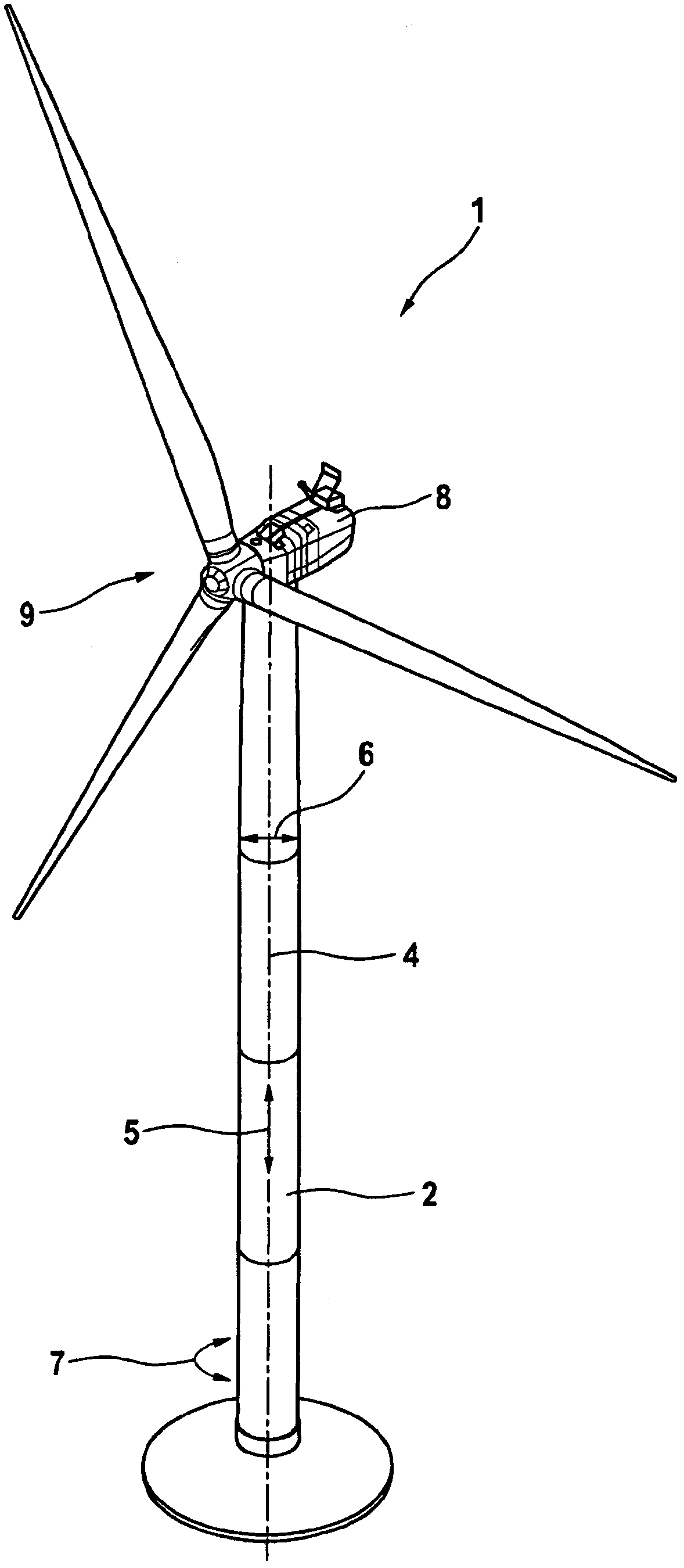

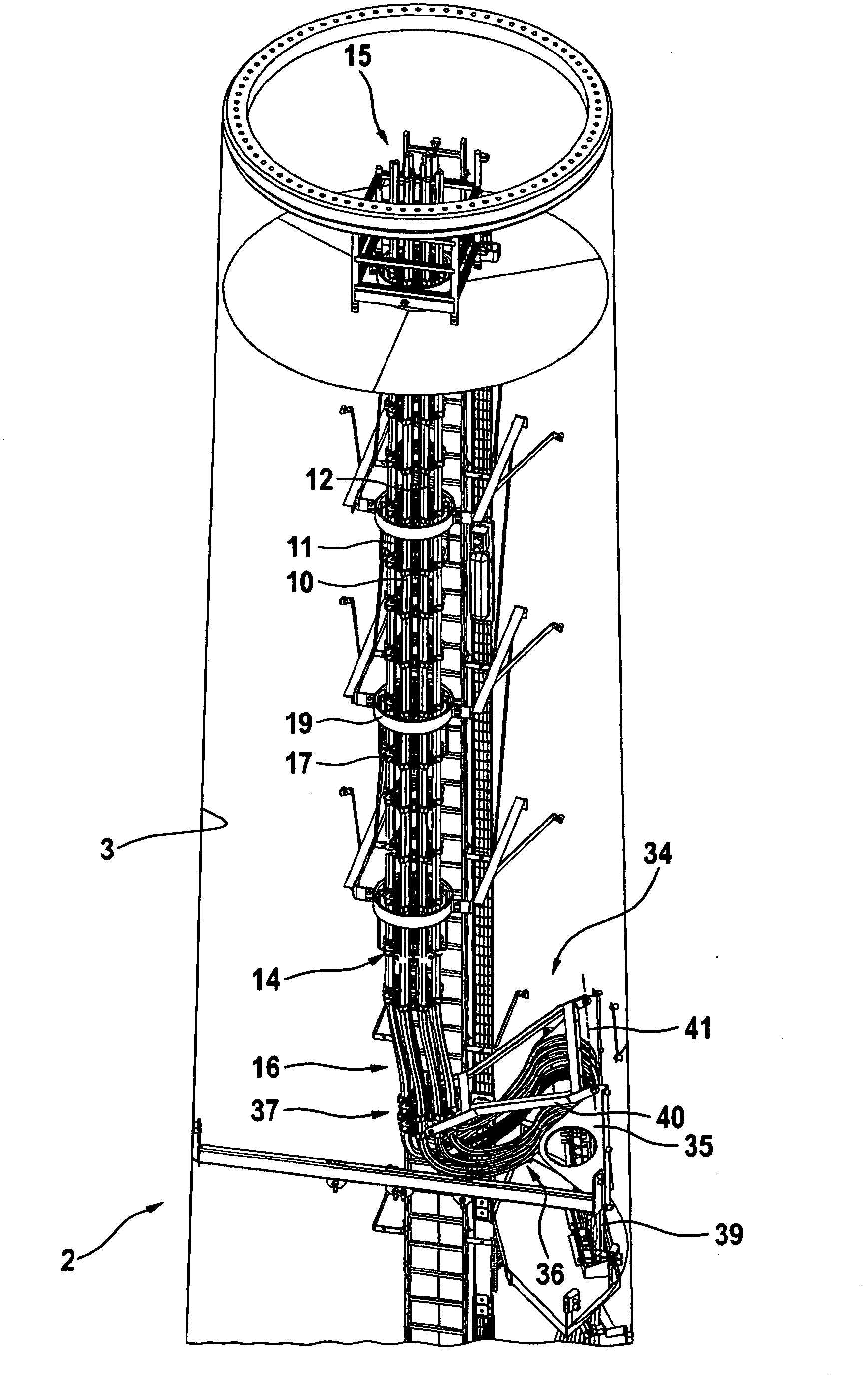

Tower for a wind turbine

InactiveCN102933845AGuaranteed current carrying capacityReduced current carrying capacityWind motor supports/mountsPower cables for overhead applicationWind forceThree-phase

The invention relates to a tower for a wind turbine and to a cable guide for a tower of a wind turbine, wherein a machine housing for the wind turbine is arranged on the tower such that it can rotate by means of the azimuth bearing about a vertical axis which runs in the longitudinal direction of the tower. Current-carrying cables, such as power cables, are routed in the tower of the wind turbine out of the machine housing from electrical components to the ground. These comprise a multiplicity of cables, for example a plurality of cables for electrically carrying individual phases of alternating current, in particular three-phase alternating current, cables for ground conductors and / or signal and control cables. One object of the invention is to specify improved routing of the cables which, inter alia, avoids the disadvantages of the prior art.; One particular aim is to ensure that the current load capacity of the cables is ensured, and / or that wear between the cables is reduced. According to the invention, the object is achieved by the features of the main claim 1, by arranging a guide apparatus effectively between the cable loom and the tower, in the tower, for at least partial fixing of the area of the cable loom to the tower, wherein the guide apparatus has means for supporting the lower area of the cable loom in a radial direction, and for support with respect to the tower in a circumferential direction. In this case, the guide apparatus is designed such that the lower area of the cable loom is mounted such that it can move in the axial direction with respect to the tower, but is essentially fixed with respect to the tower in the circumferential and radial directions.

Owner:SUZLON ENERGY LTD

Covers for electrical distribution lines and insulators and methods and systems including same

Owner:TYCO ELECTRONICS LOGISTICS AG (CH)

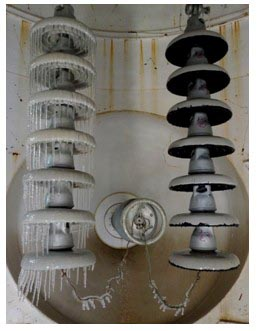

Insulator and transmission line

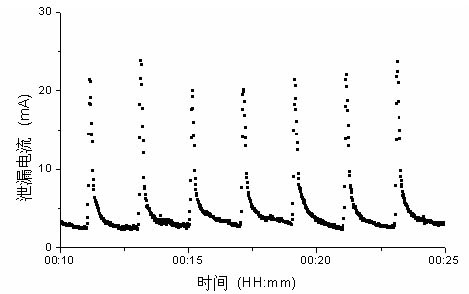

ActiveCN102511065AWith self-shutdown effectIncrease surface temperatureRubber insulatorsPower cables for overhead applicationConductive coatingEngineering

The present invention discloses an insulator comprising an insulation surface, wherein one part of the insulation surface is coated with conductive coating having special resistivity,the conducting coating area of the special resistivity and the uncondutive coating area are arranged in a discontinuous conduting channel between an upper armour clamp and a lower armour clamp of the insulator under a dry environment,and the conductive coating area of the special resistivity makes the leakage current value caused on the insulation surface reach to the temperature for preventing ice coating under ice coating weather conditions. The utility model also discloses a transmission device using the insulator. under the ice coating weather conditions, the conductive coating can improve the leakage current value of the surface of the insulator so as to prevent ice coating.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV +1

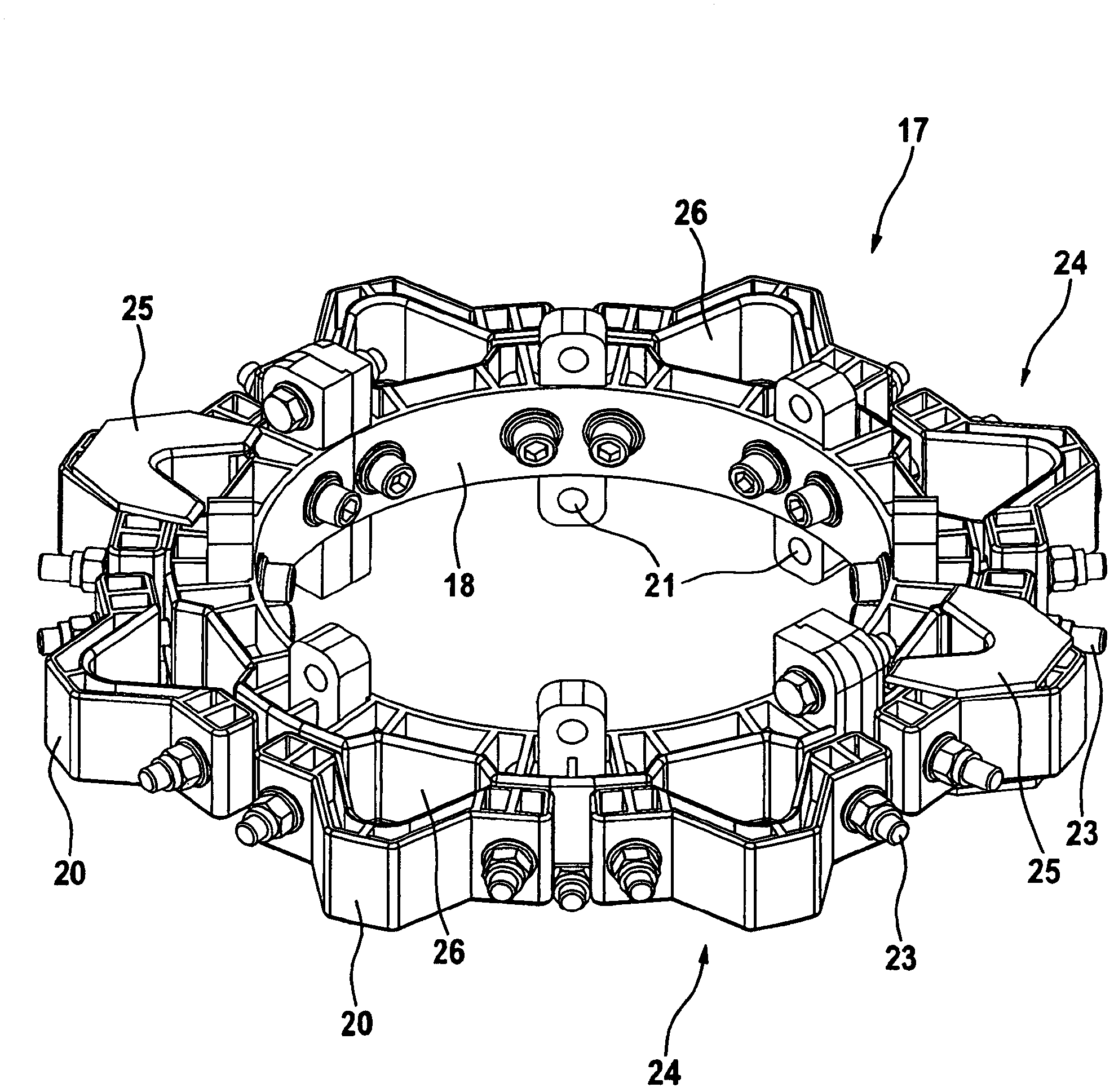

Tower for wind turbine

InactiveCN102939459AAvoid bendingWind motor supports/mountsPower cables for overhead applicationAlternating currentVertical axis

The invention relates to a tower for a wind turbine and to a cable guide for a tower of a wind turbine, wherein a machine housing for the wind turbine is arranged on the tower such that it can rotate by means of the azimuth bearing about a vertical axis which runs in the longitudinal direction of the tower. Current-carrying cables, such as power cables, are routed in the tower of the wind turbine out of the machine housing from electrical components to the ground. These comprise a multiplicity of cables, for example a plurality of cables for electrically carrying individual phases of alternating current, in particular three-phase alternating current, cables for ground conductors and / or signal and control cables. One object of the invention is to specify improved routing of the cables which, inter alia, avoids the disadvantages of the prior art.One particular aim is to ensure that the current load capacity of the cables is ensured, and / or that wear between the cables is reduced. According to the invention, the object is achieved by the features of the main claim 1, by the tower having at least two looming apparatuses, which are suitable for joining the individual cables which run longitudinally in the tower together to form a cable loom with the cables fixed with respect to one another. The looming apparatuses are attached to the cables between an upper and a lower area of the cable loom. In this case, geometric configuration of the looming apparatus ensures that a specific minimum separation at least between three cables is not undershot.

Owner:SUZLON ENERGY LTD

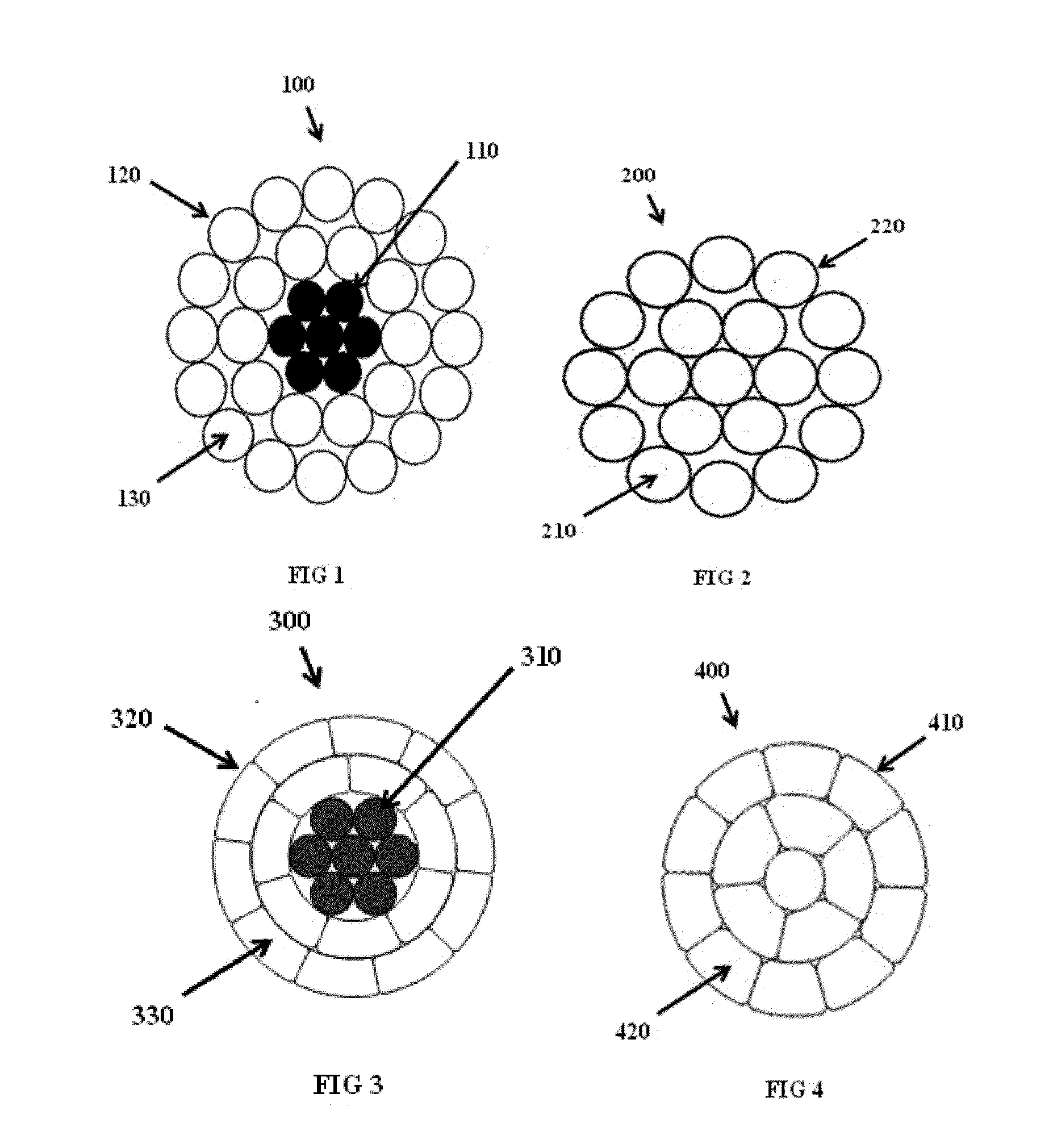

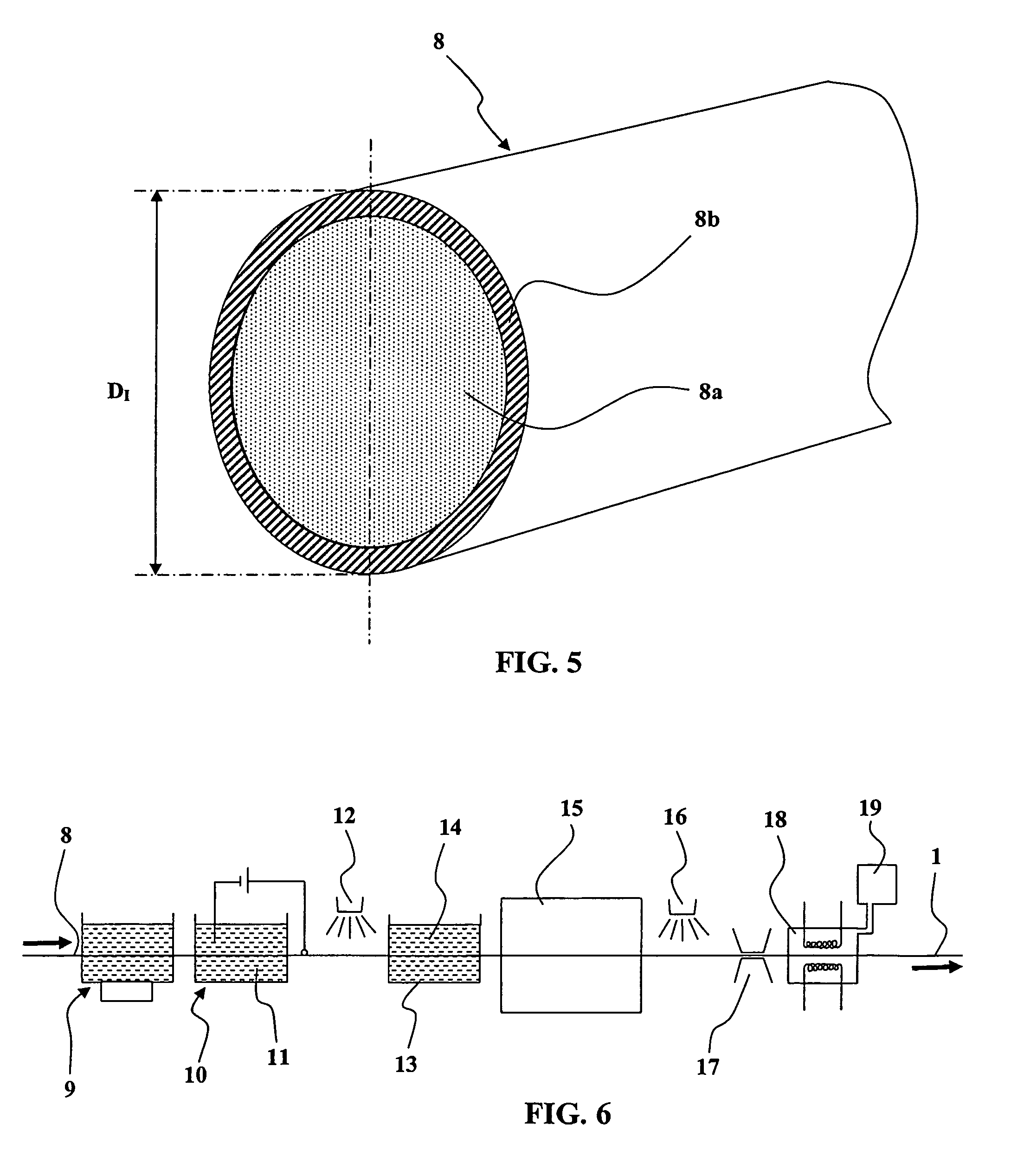

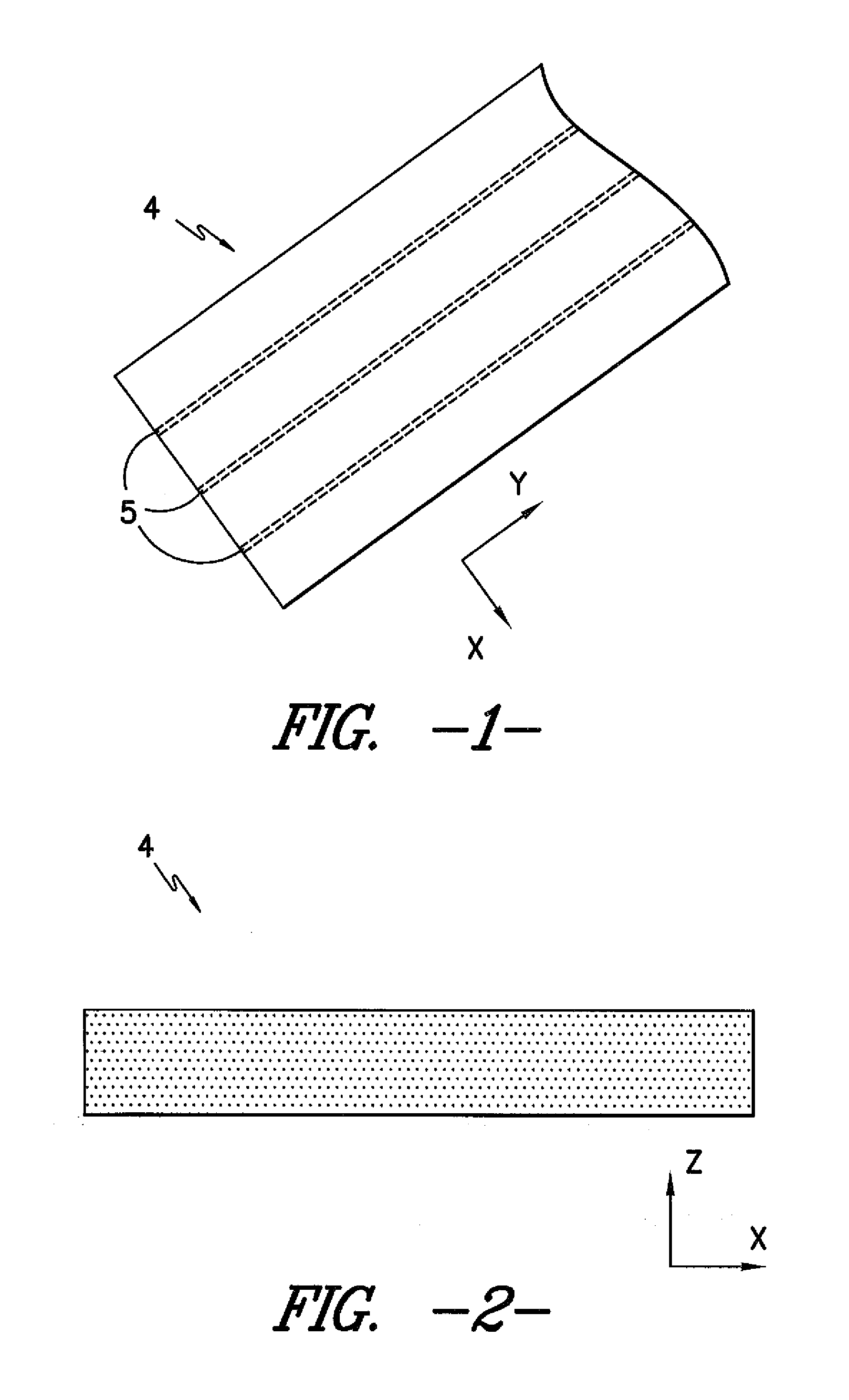

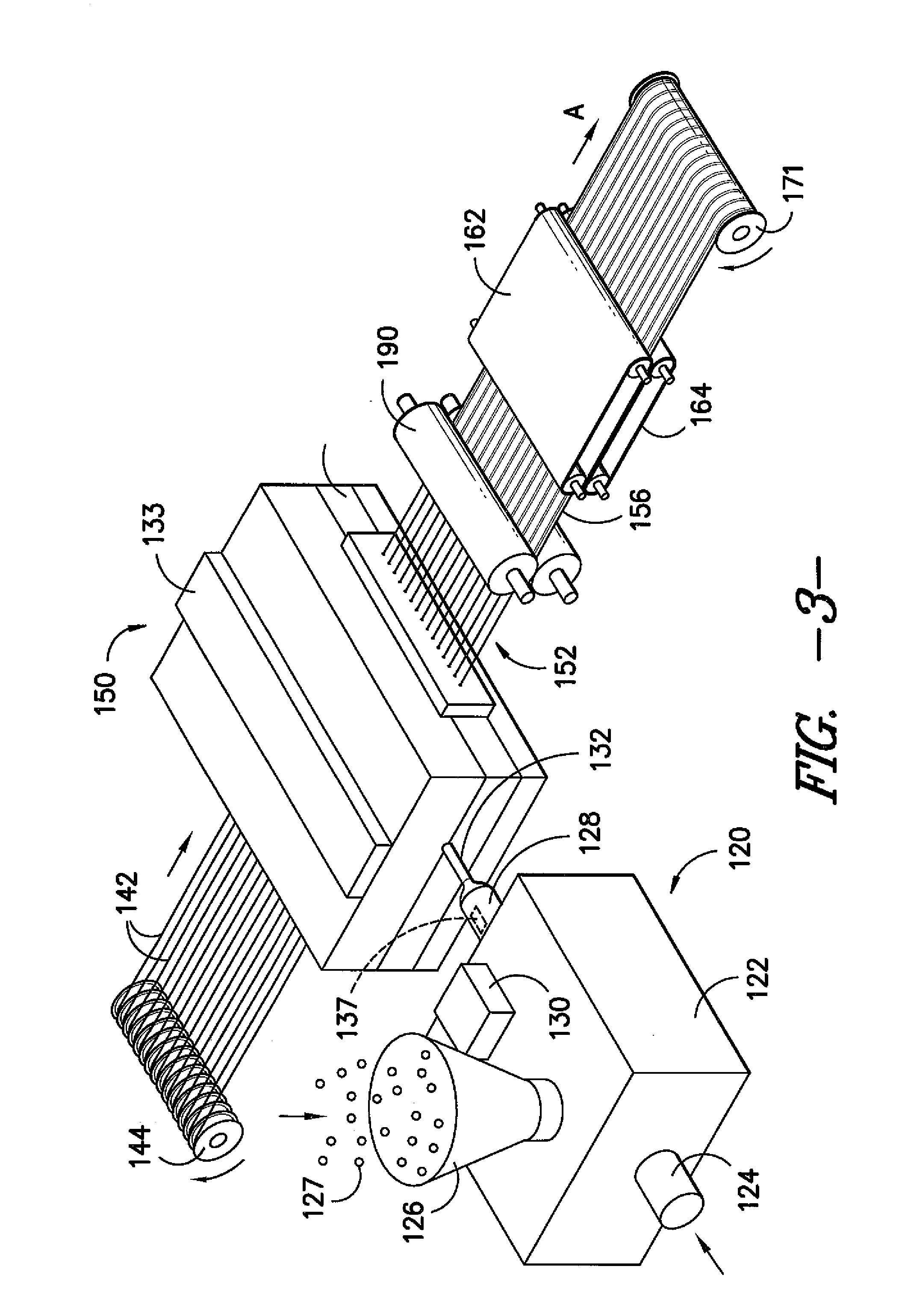

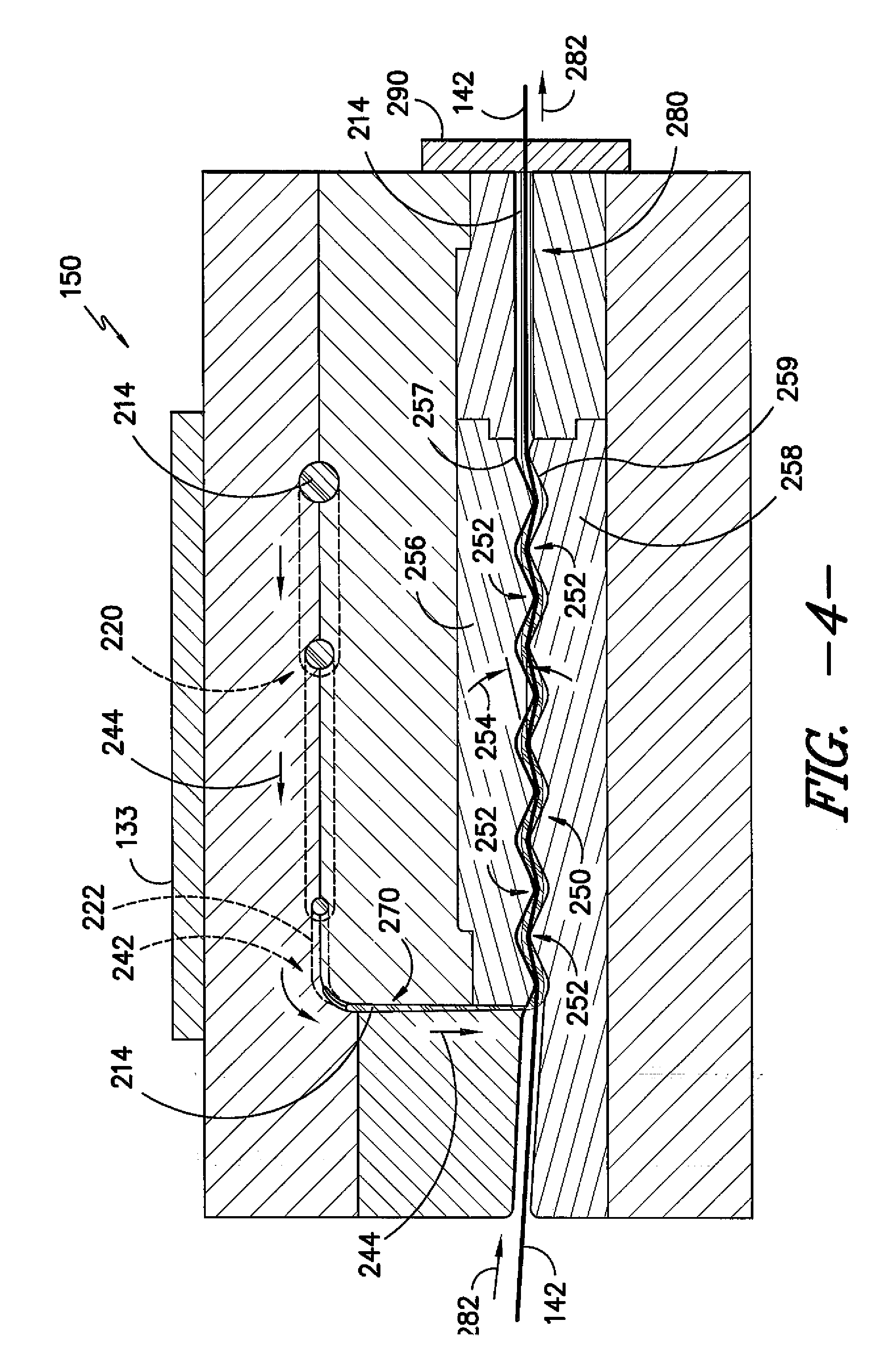

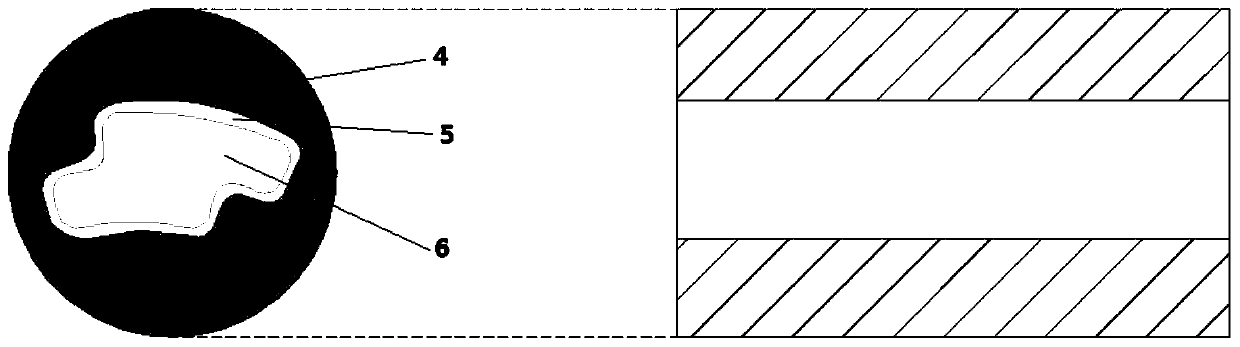

Composite Core for Electrical Transmission Cables

A composite core for use in electrical cables, such as high voltage transmission cables is provided. The composite core contains at least one rod that includes a continuous fiber component surrounded by a capping layer. The continuous fiber component is formed from a plurality of unidirectionally aligned fiber rovings embedded within a thermoplastic polymer matrix. The present inventors have discovered that the degree to which the rovings are impregnated with the thermoplastic polymer matrix can be significantly improved through selective control over the impregnation process, and also through control over the degree of compression imparted to the rovings during formation and shaping of the rod, as well as the calibration of the final rod geometry. Such a well impregnated rod has a very small void fraction, which leads to excellent strength properties. Notably, the desired strength properties may be achieved without the need for different fiber types in the rod.

Owner:TICONA LLC

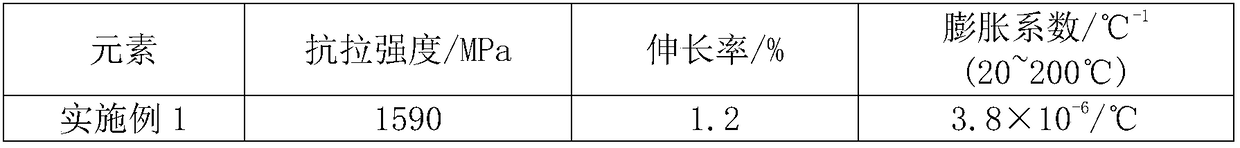

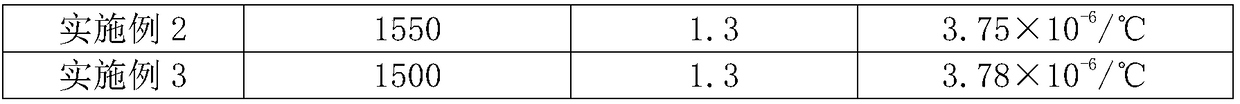

Alloy steel for overhead conductor, preparation method of alloy steel and overhead conductor

ActiveCN108588555AHigh strengthImprove toughnessPower cables for overhead applicationMetal/alloy conductorsUltimate tensile strengthImpurity

The invention discloses alloy steel for an overhead conductor, a preparation method of alloy steel and the overhead conductor. The alloy steel comprises the following components in percentage by weight: 0.1-0.25wt% of C, 0.08-0.15wt% of Si, 0.2-0.3wt% of of Mn, less than or equal to 0.03wt% of of P, less than or equal to 0.025wt% of S, 32-36wt% of Ni, 0.5-0.7wt% of Cr, 0.8-1.3wt% of V, 0.4-0.6wt%of Be and the balance of Fe and unavoidable trace impurities. According to the invention, through changing the material ratio of the alloy steel, the crystalline grain is refined, the strength and tenacity of the alloy steel are improved and the cost is lowered. The tensile strength of the alloy steel is equal to or greater than 1500 MPa, the elongation is equal to or greater than 1.2%, and the expansion coefficient is equal to or less than 3.8*10<-6> / DEGC at 20-200 DEG C.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +3

Dual-conductor suspension system for an electrical apparatus

ActiveUS20160201863A1Easy to adjustPoint-like light sourceLighting support devicesElectrical conductorElectrical devices

A system for suspending and powering an electrically-powered fixture, such as a luminaire, with a coaxial suspension cable, and for attaching the fixture to the cable and to a structure, such as a ceiling, using at least one cable gripping devices, such that the height of the fixture may be adjusted. The suspension cable may comprise an inner cable, which may include a plurality of strength strands wound around a conductive strand; and an outer conductor, such as a copper mesh, separated from the inner cable by an insulator layer. The system may include an assembly mounted to the structure and an assembly mounted to the fixture, each assembly configured to grip the inner cable at one end of the suspension cable and to allow a first conductive path to the inner cable and a second conductive path, insulated from the first conductive path, along the outer conductor.

Owner:GRIPLOCK SYST

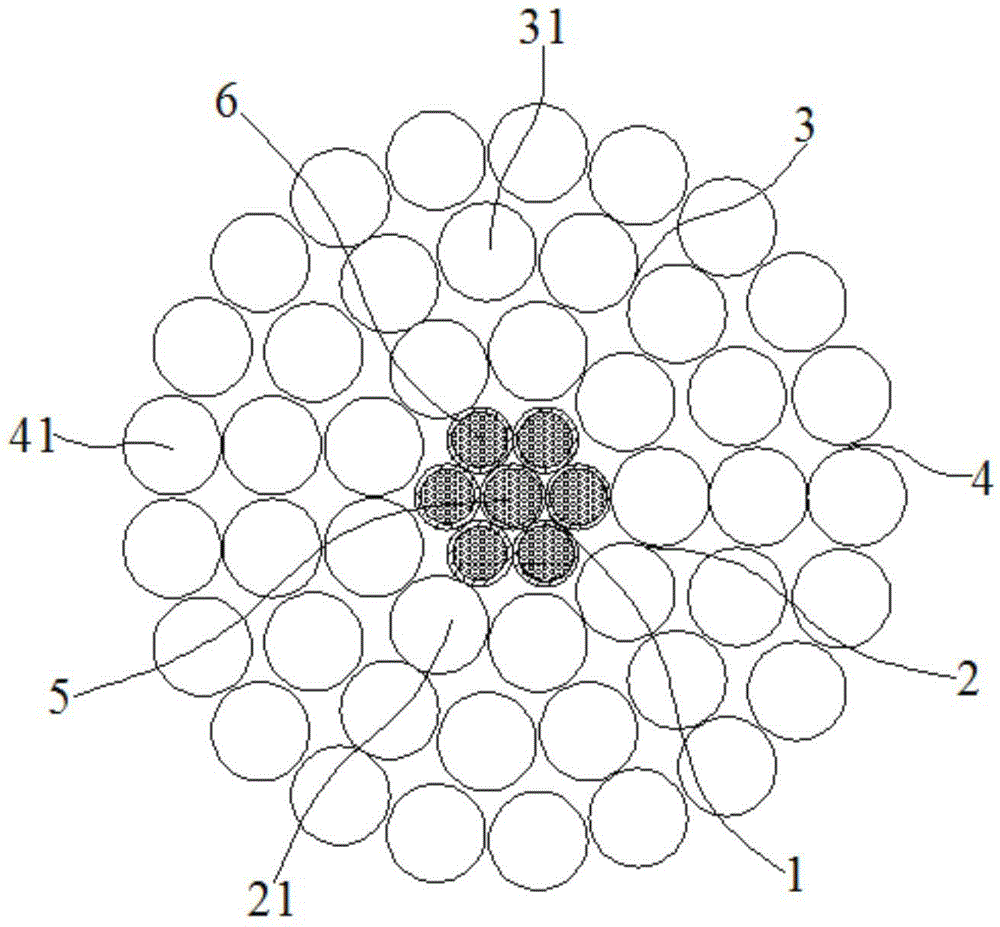

Aluminum twisted wire for overhead power transmission

ActiveCN104575825AGuaranteed to be roundAvoid damageNon-insulated conductorsNon-macromolecular adhesive additivesElectric power transmissionIsooctyl acrylate

The invention discloses an aluminum twisted wire for overhead power transmission. The aluminum twisted wire comprises a stressed unit positioned at the center, and a first aluminum conducting layer, a second aluminum conducting layer and a third aluminum conducting layer which are sequentially twisted with the outer surface of the stressed unit, wherein the stressed unit comprises a first carbon fiber single wire and 6 second carbon fiber single wires twisted with the outer surface of the first carbon fiber single wire; polyester adhesive filling parts are filled in an aluminum layer and positioned among a plurality of carbon fiber raw yarns; the polyester adhesive filling parts are formed by mixing a first component and a second component according to the mass ratio of 1:(2 to 4); the first component comprises the following raw materials in parts by weight: N-307 unsaturated polyester, butyl acrylate, iso-octyl acrylate, normal butanol, methylbenzene, talcum powder, aluminum powder, calcium carbonate and triethylene tetramine. The aluminum twisted wire not only guarantees the round of the carbon fiber raw yarns in the aluminum layer, but also avoids the aluminum layer damage during subsequent use, thereby guaranteeing the reliability of the electrical property, and the bending radius is reduced to 6 times the diameter of a cable.

Owner:JIANGSU HENGTONG ELECTRICAL SPECIAL WIRE CO LTD +1

Super strength aluminum alloy core overhead conductor and aluminum alloy core manufacturing method

ActiveCN107236882AIncrease effective currentIncreased pull-to-weight ratioNon-insulated conductorsPower cables for overhead applicationElectrical conductorPower flow

The invention relates to a super strength aluminum alloy core overhead conductor and an aluminum alloy core manufacturing method. Compared with the prior art, according to the super strength aluminum alloy core overhead conductor, multiple elements are adopted for alloying, and a super strength aluminum alloy core is manufactured; the super strength aluminum alloy core which is excellent in decay resistance, large in creep resistance and excellent in strength of extension and conductivity in the length direction is adopted for serving a reinforced core force bearing piece and an electric conductor at the same time; and a conductor is stranded to the outer layer of the super strength aluminum alloy core. According to the super strength aluminum alloy core overhead conductor in the embodiment, the tensile force weight ratio of the conductor is improved while the effective current of the conductor is improved, and the circuit carrying capacity is increased; the decay resistance of the super strength aluminum alloy core overhead conductor is excellent, the circuit service life can be prolonged, and the circuit safety performance can be improved; the construction cost of the super strength aluminum alloy core overhead conductor is low, and running is more economical; and in addition, environmental protection is better achieved during manufacturing.

Owner:BINZHOU YUYANG ALUMINUM IND

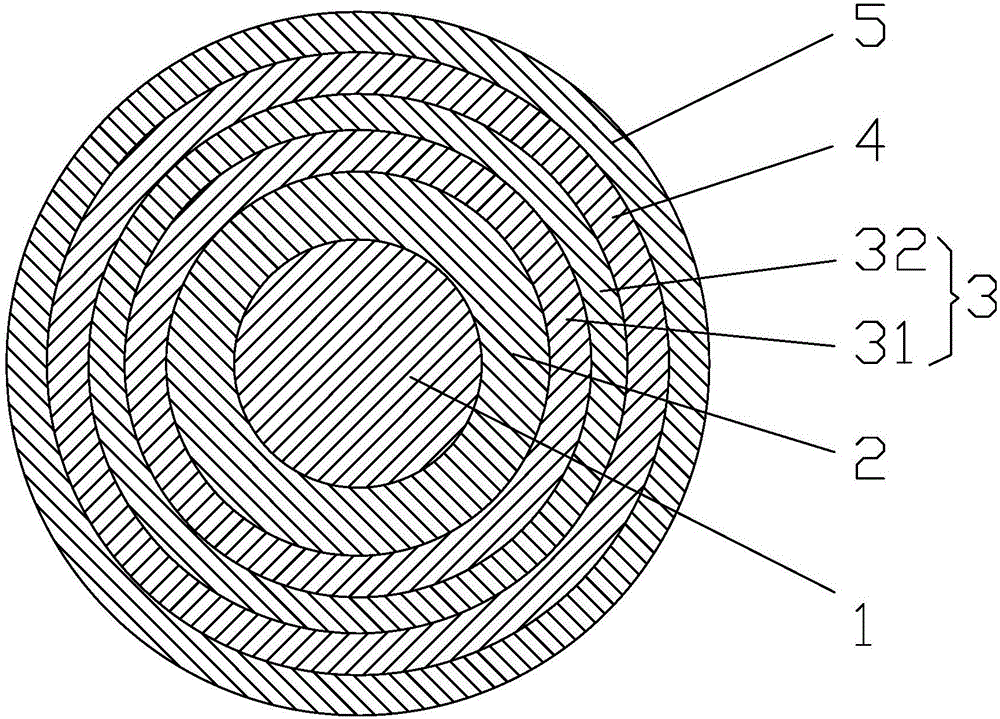

An anti-icing cable

ActiveCN105390189BImprove toughness and strengthHigh impact strengthPower cables with screens/conductive layersPower cables for overhead applicationGlass fiberAntioxidant

The invention discloses an anti-icing cable. The cable comprises a core, a shielding layer and an anti-icing layer arranged in sequence from inside to outside, wherein the anti-icing layer comprises the following raw materials by weight: 60-75 parts of fluorosilicon resin, 20-30 parts of methyl vinyl silicone rubber, 10-15 parts of SiO2-glass fiber gel, 5-8 parts of polypropylene fiber powder, 3-5 parts of nano SiO2, 4-6 parts of nano TiO2, 0.5-1 part of a dispersing agent, 0.5-1.5 parts of a flame retardant, 1-2 parts of a silane coupling agent and 1-2 parts of an antioxidant. The anti-icing cable has excellent hydrophobic property and anti-icing performance, and is excellent in insulating performance, high in compressive strength, high in flexibility and anti-aging; and the anti-icing layer of the anti-icing cable can replace the insulating layer in the cable and a sheath outside the cable, so that the cable mass is lowered and the service life of the cable is prolonged.

Owner:STATE GRID HENAN DENGZHOU POWER SUPPLY CO

Large-cross-section carbon-fiber-composite-core semi-hard aluminum lead

InactiveCN107358995AReduce in quantityPromote coordinated developmentNon-insulated conductorsPower cables for overhead applicationSocial benefitsGlass fiber

The invention relates to a large-cross-section carbon-fiber-composite-core semi-hard aluminum lead comprising a carbon-fiber composite core rod and a plurality of semi-hard aluminum wire layers twisted outside the carbon-fiber composite core rod. The carbon-fiber composite core rod includes a composite-material inner core and a glass-fiber composite material layer coating the composite-material inner core. The semi-hard aluminum lead has advantages of high carrying capacity, high strength, low sag, and low usage cost; and the tower number is reduced. The large-cross-section carbon-fiber-composite-core-included semi-hard aluminum lead applied to a large-cross-section carbon-fiber composite core widely is capable of creating great economic and social benefits to build the strong smart grid, realizing cleaning replacement, and promoting energy conservation and environment protection. With development of the ultra-high-voltage grid, the semi-hard aluminum lead has the great significance in stimulating the domestic demand and economic growth, leading the transformation and upgrading of the equipment manufacturing industry, promoting coordinated development between the western and eastern regions, increasing employment, and treating the atmospheric contamination.

Owner:ZHONGFU CARBON FIBER CORE CABLE TECH

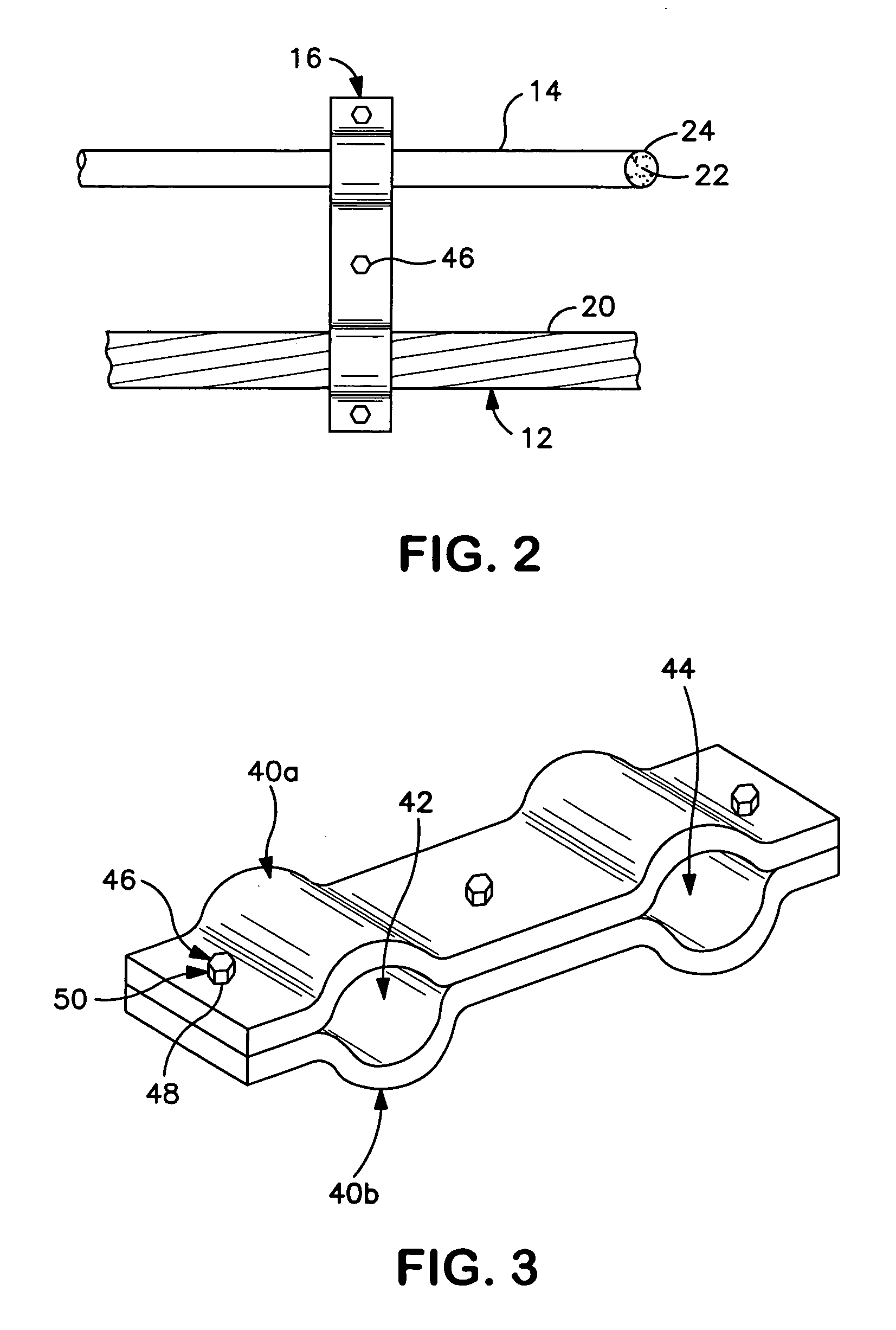

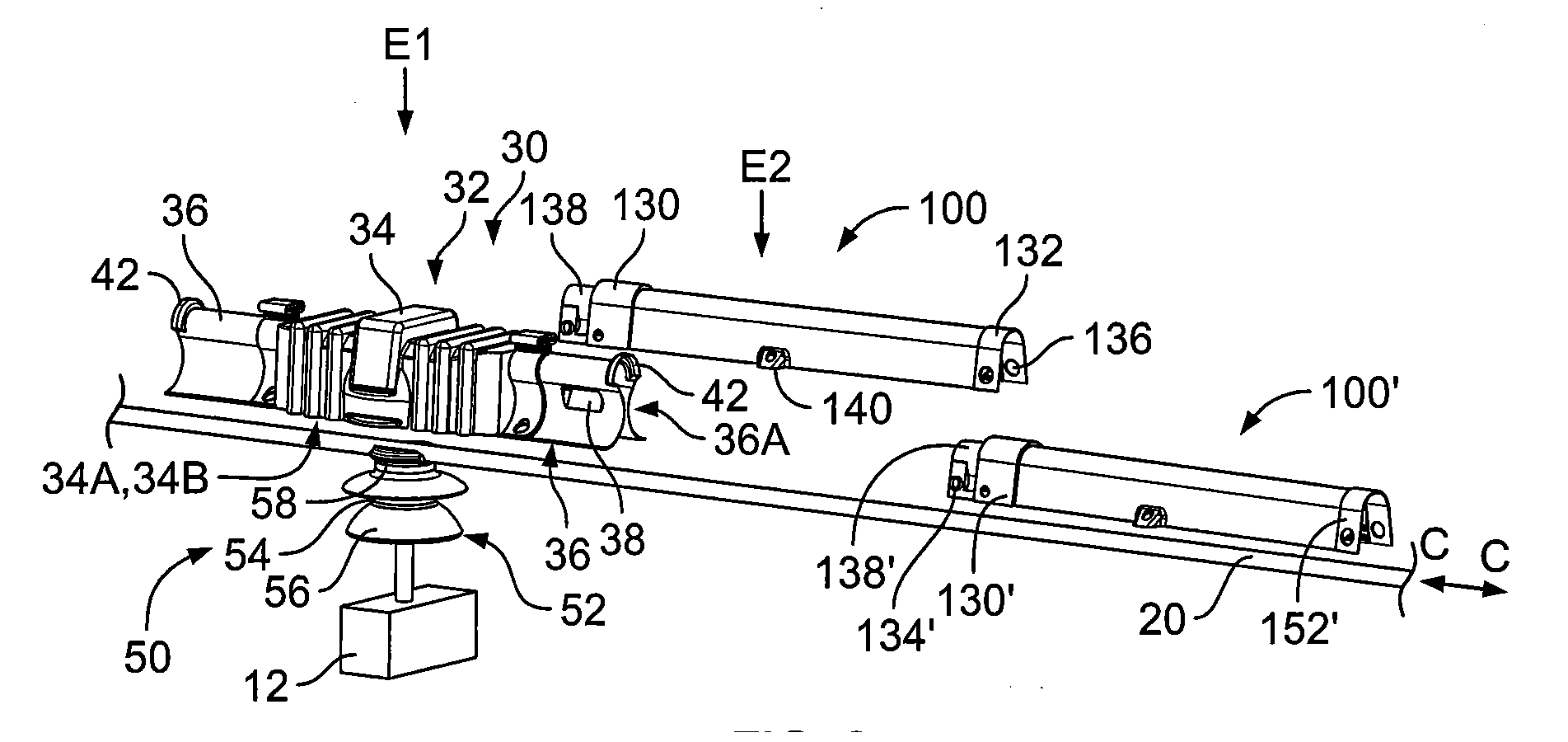

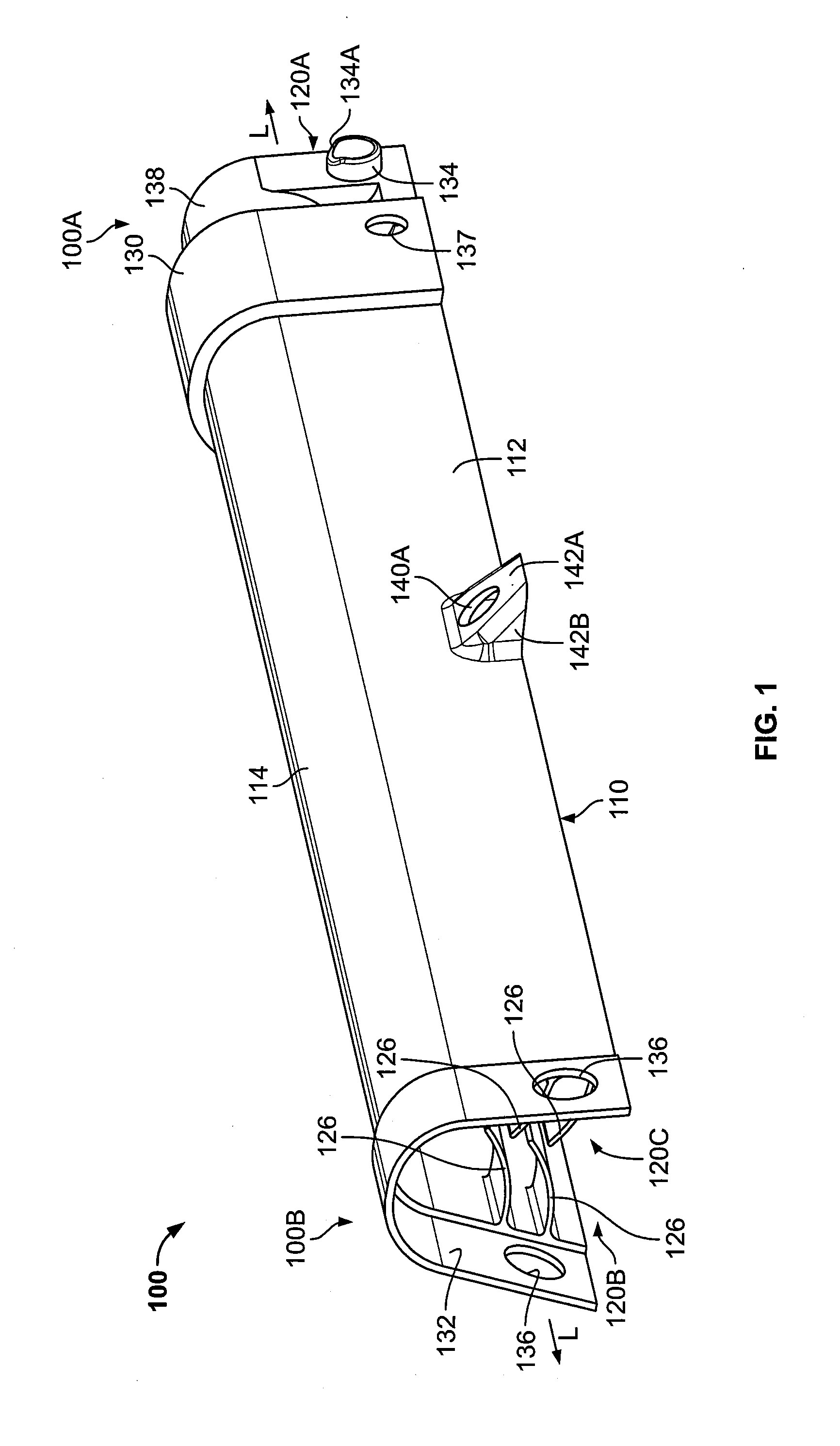

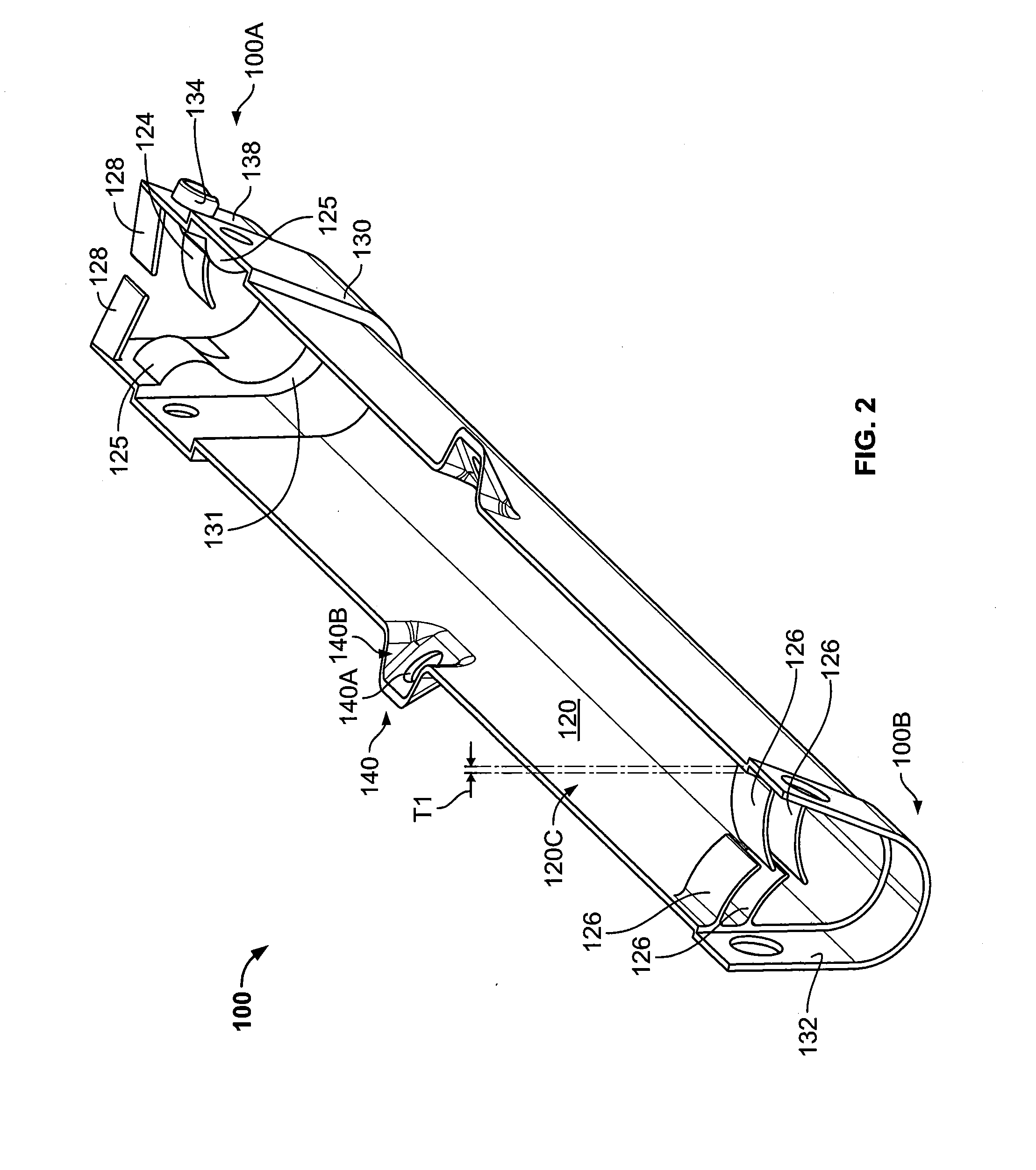

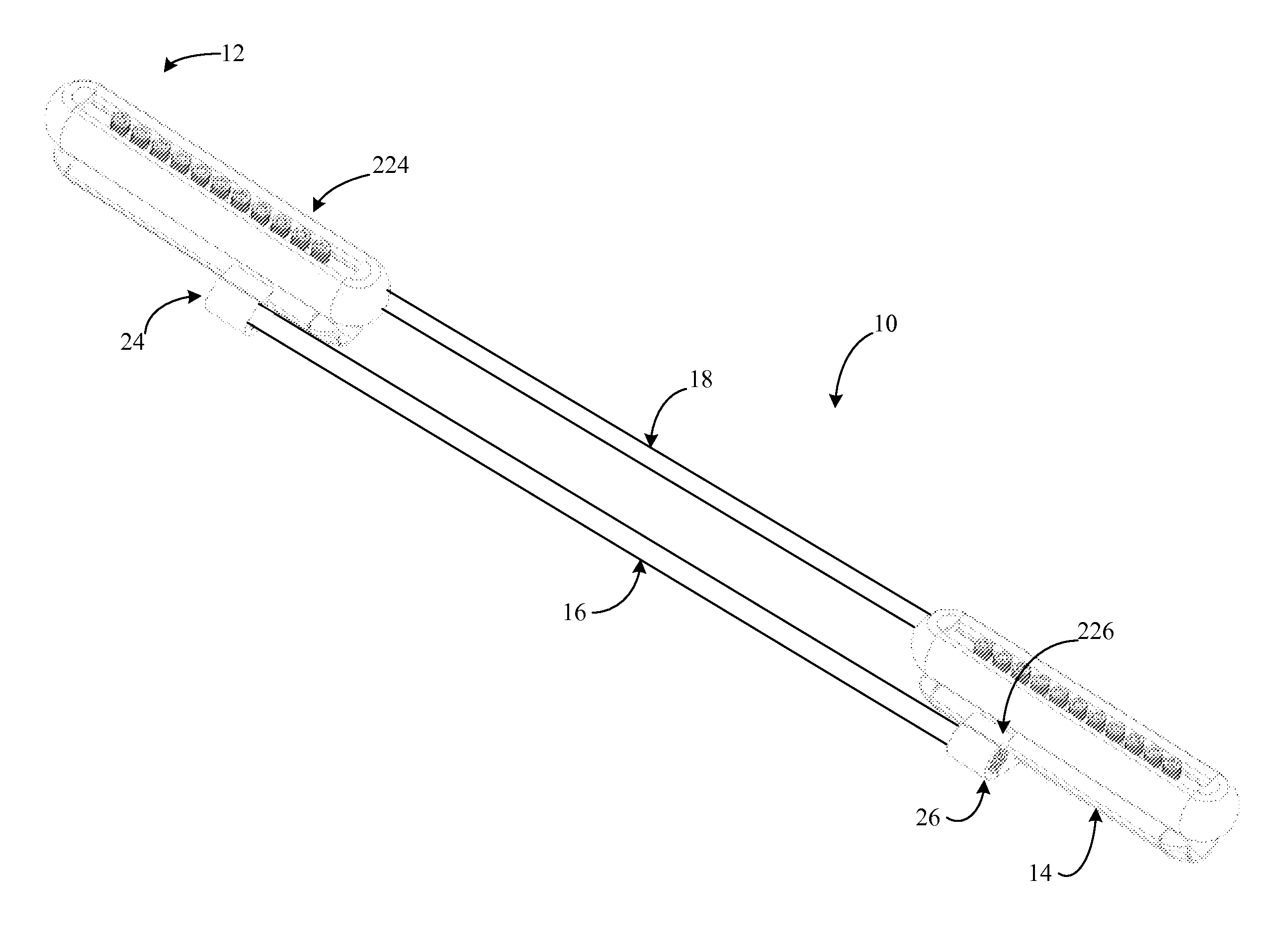

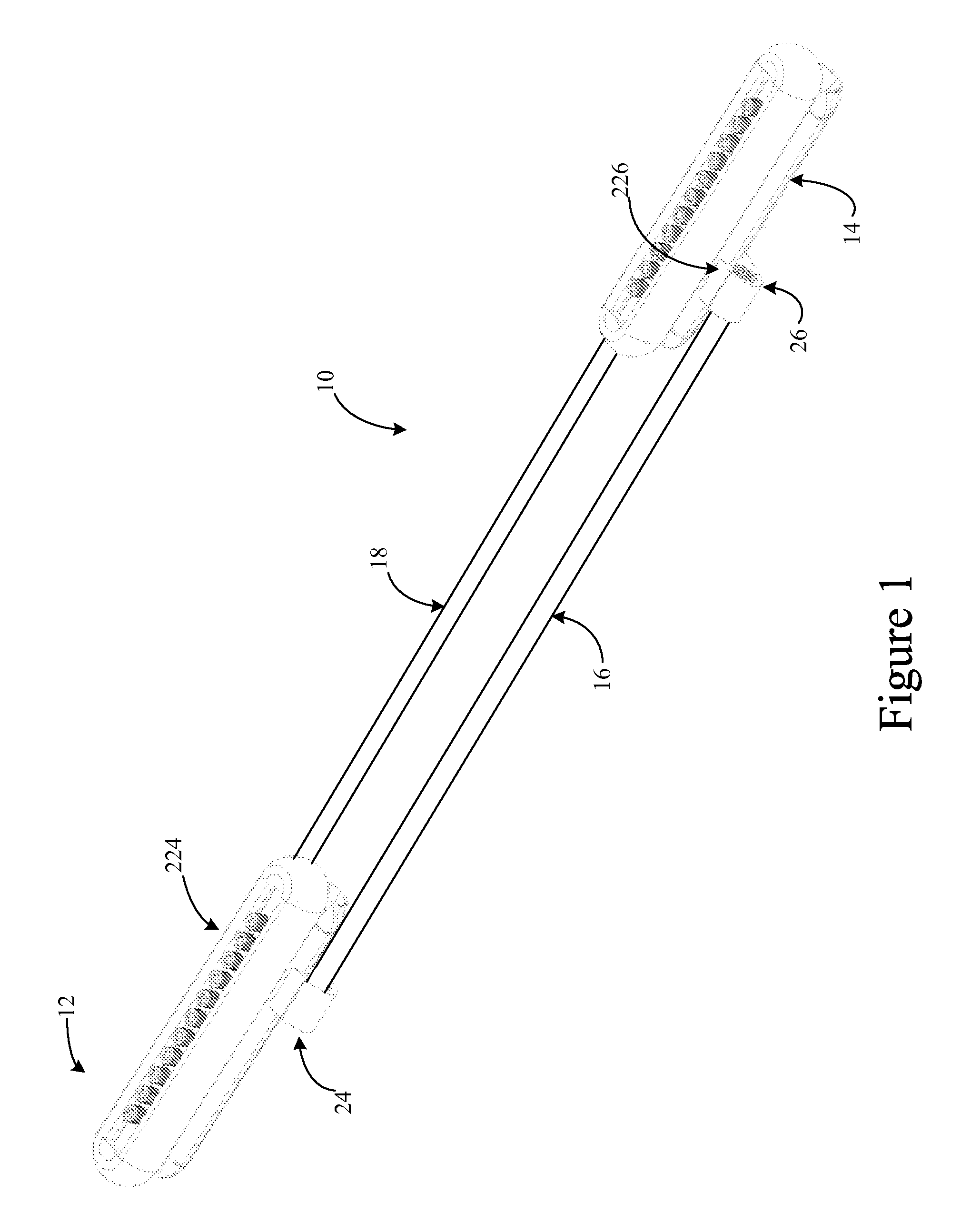

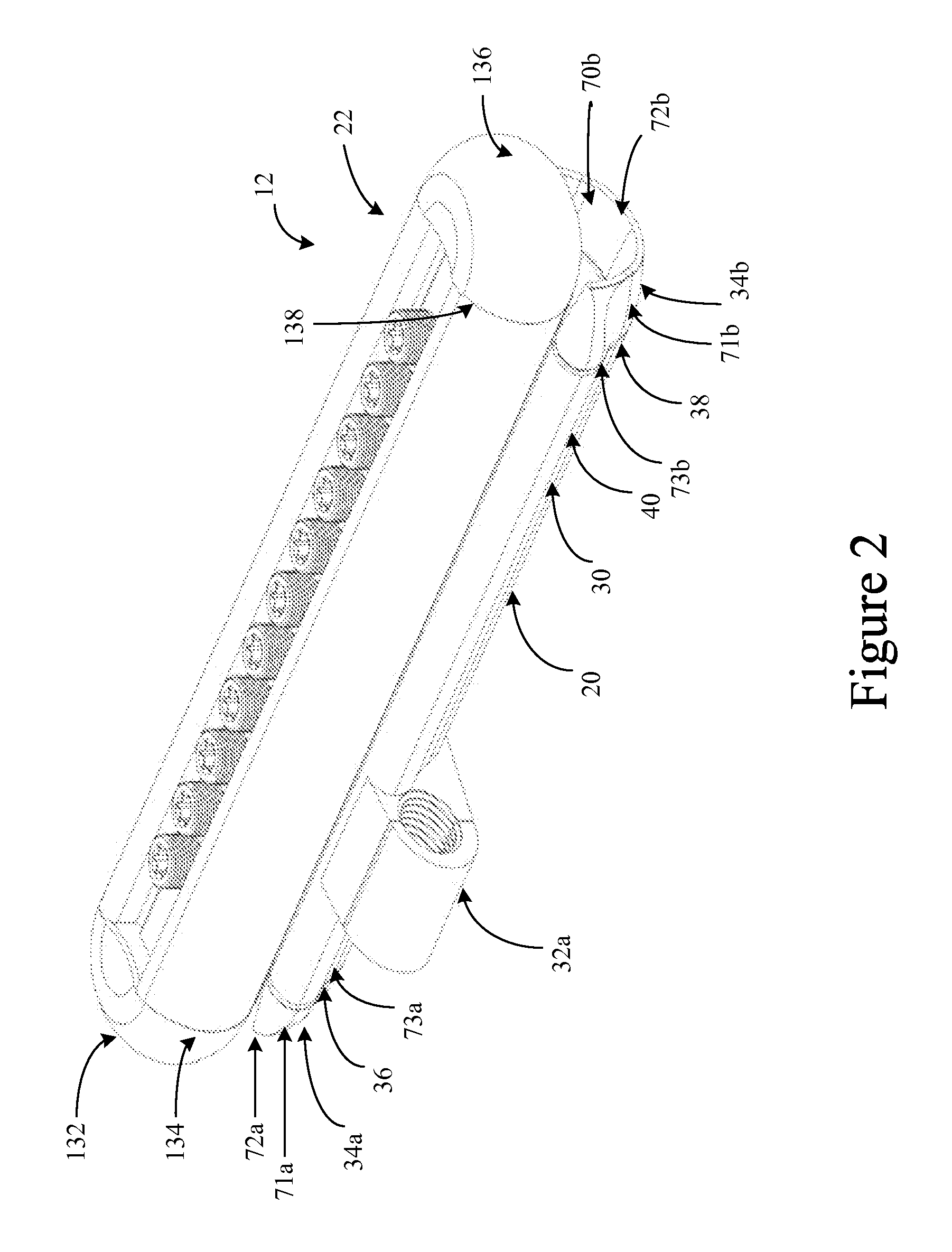

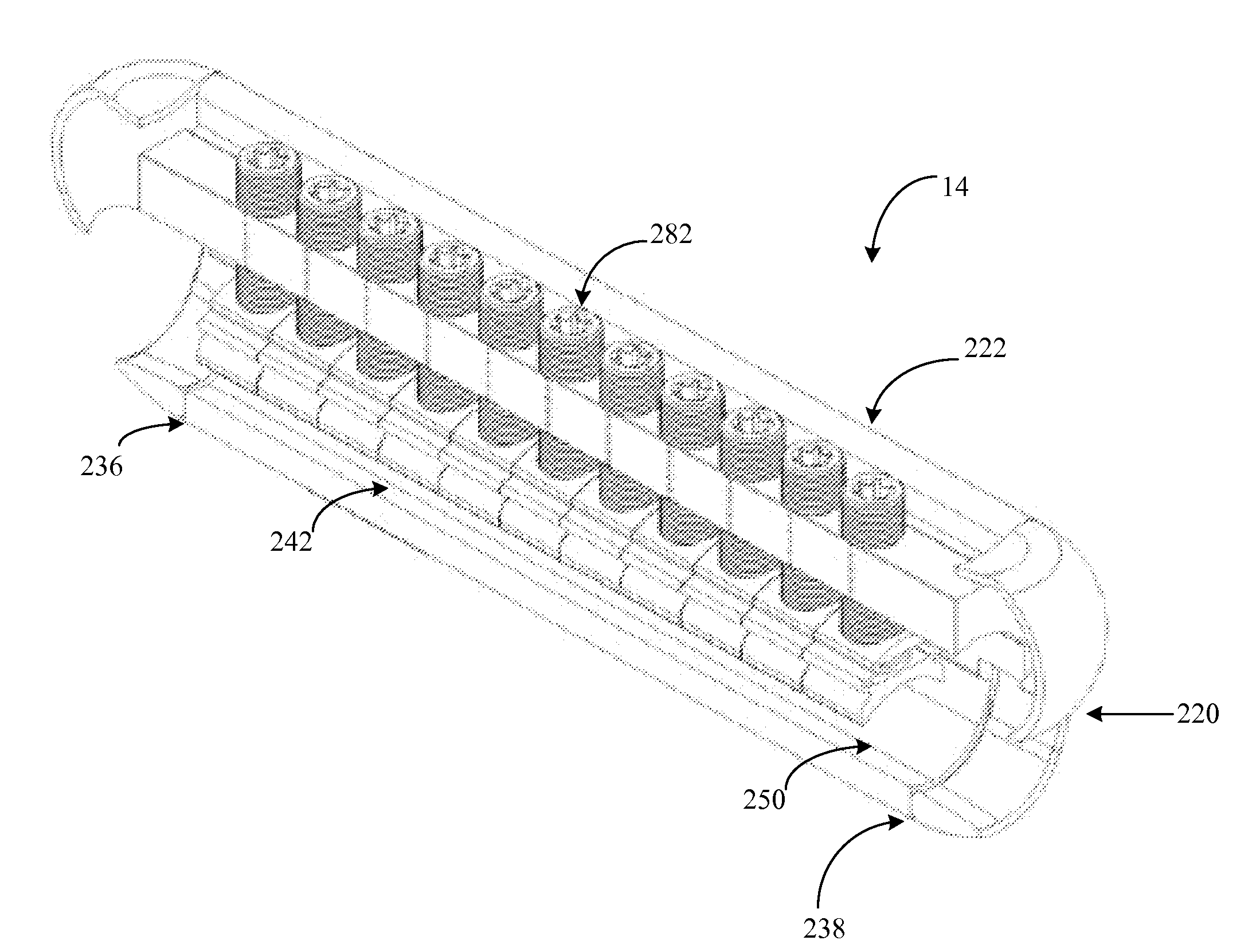

Electrical transmission line repair device

ActiveUS9577354B2Line connector maintainancePower cables for overhead applicationElectrical conductorEngineering

An electrical transmission line repair device including a first conductor clamp, a second conductor clamp and at least one tie rail extending between the first and second conductor clamps in a spaced apart orientation. The first conductor clamp including a lower assembly and an upper assembly. The lower assembly and the upper assembly are slidably engageable with each other so as to define a conductor cavity extending therealong. Clamping fasteners are configured to extend through openings in the upper assembly so as to be threadable toward and away from the conductor contact region of the lower assembly within the conductor cavity.

Owner:CLASSIC CONNECTORS

Electrical Transmission Line Repair Device

ActiveUS20160104954A1Line connector maintainancePower cables for overhead applicationElectric power transmissionElectrical conductor

An electrical transmission line repair device including a first conductor clamp, a second conductor clamp and at least one tie rail extending between the first and second conductor clamps in a spaced apart orientation. The first conductor clamp including a lower assembly and an upper assembly. The lower assembly and the upper assembly are slidably engageable with each other so as to define a conductor cavity extending therealong. Clamping fasteners are configured to extend through openings in the upper assembly so as to be threadable toward and away from the conductor contact region of the lower assembly within the conductor cavity.

Owner:CLASSIC CONNECTORS

High-insulativity aerial cable with double insulating layers

InactiveCN110491591AHigh tensile strengthImprove rigidityPower cables for overhead applicationInsulated cablesAerial cableEngineering

The invention discloses a high-insulativity aerial cable with double insulating layers in the technical field of cables. Including a central tensile member, reinforcing extending edges are arranged onthe outer wall of the center tensile piece in an annular array mode. A filling layer is arranged among the inner wall of the inner sheath, the central tensile member and the reinforcing extension edge. The outer wall of the inner sheath is provided with a waterproof layer. Tensile reinforcing strips are arranged on the outer wall of the waterproof layer in an annular array mode. Bird-proof protrusions are evenly arranged on the outer wall of a bird pecking prevention outer sheath. According to the invention, the central tensile piece and the reinforced extension edges are adopted to ensure the tensile property of the interior; the tensile reinforcing strips have the advantages of being high in tensile strength, good in rigidity and the like, the external tensile performance is guaranteed,the tensile performance and the torsion resistance of the cable are greatly improved, meanwhile, the cable is not prone to breaking and cracking due to the fact that the filling layer and the elasticlayer are arranged, and the service life of the cable is prolonged.

Owner:江苏瑞扬线缆有限公司

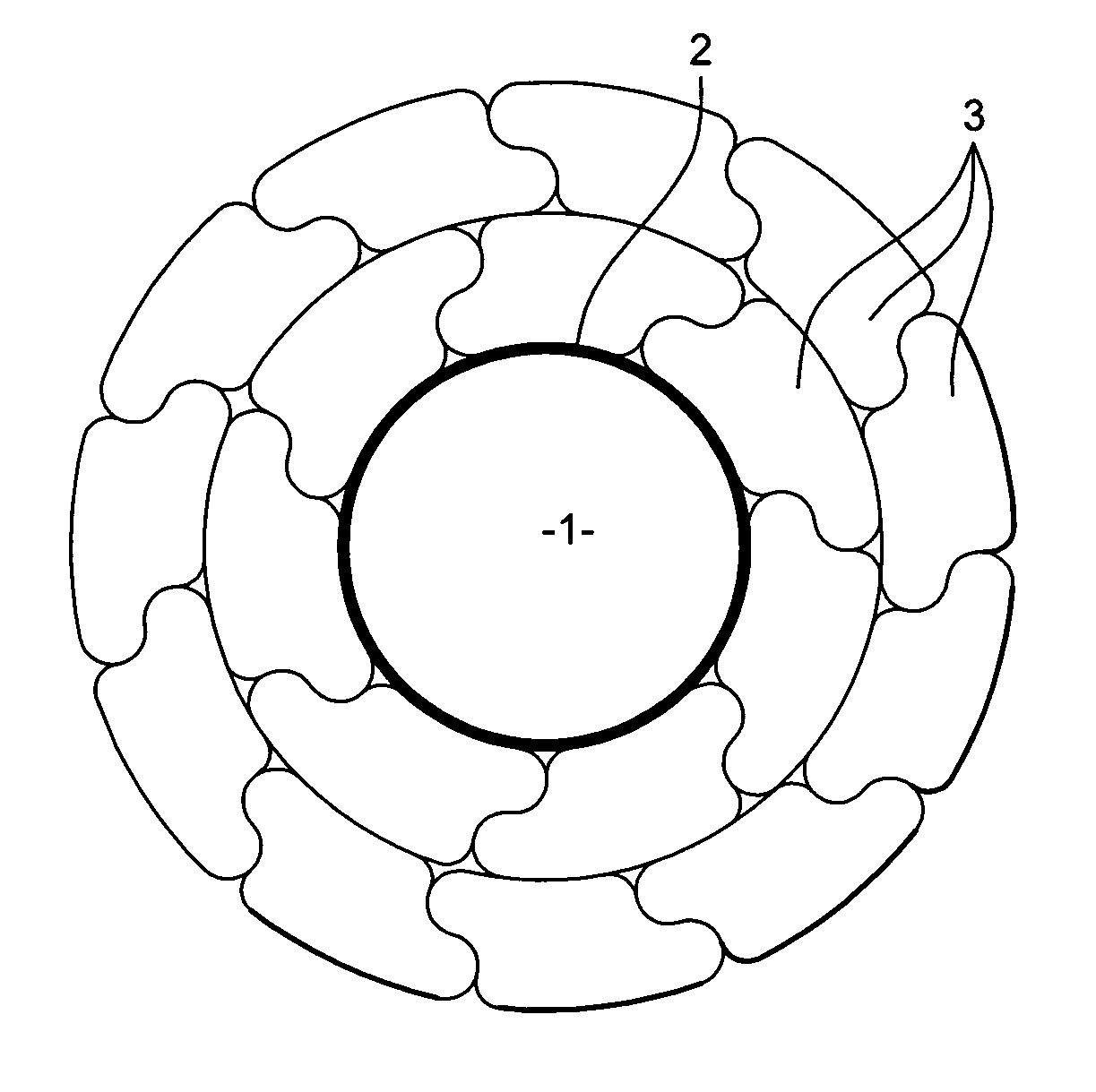

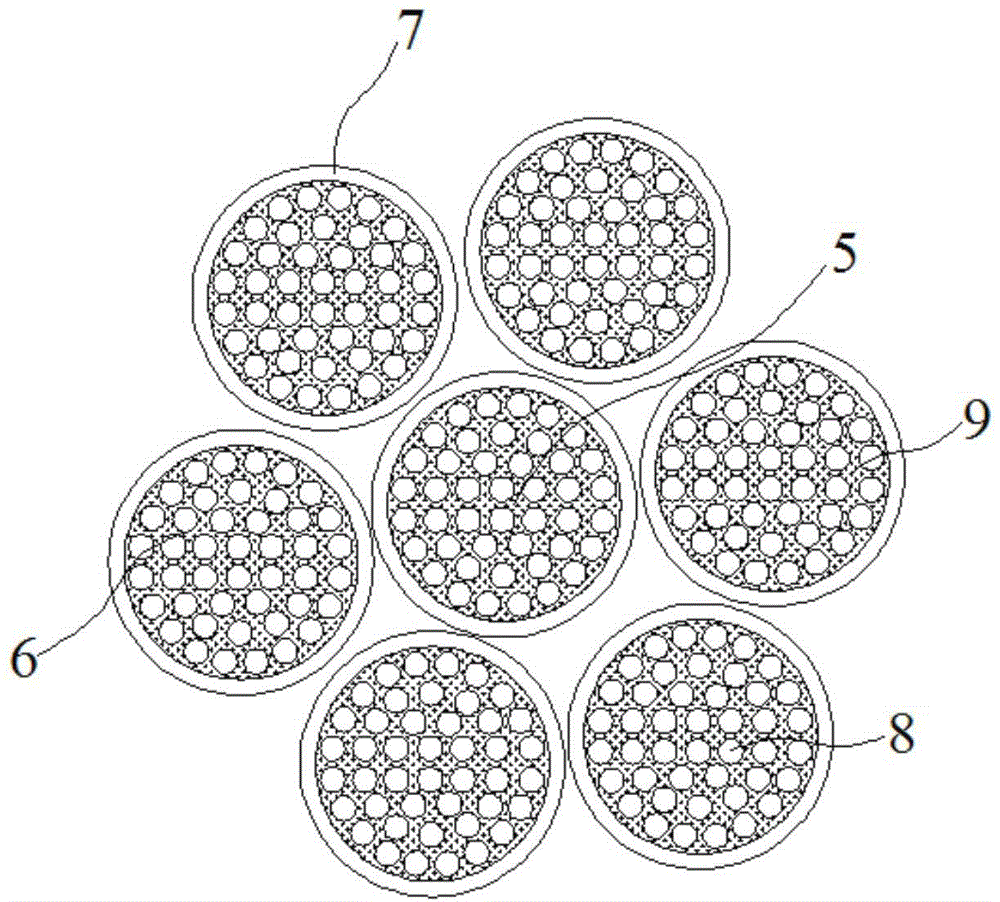

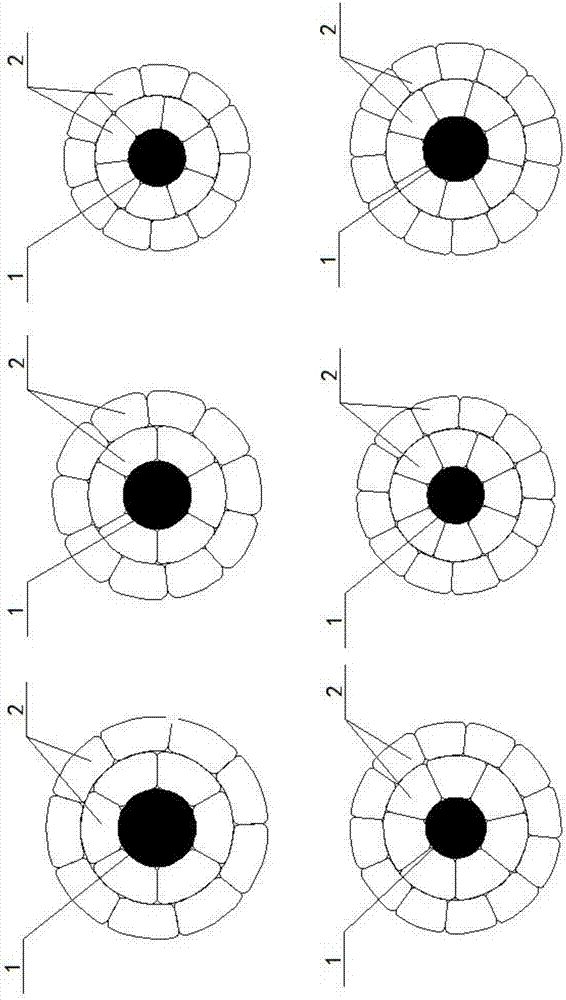

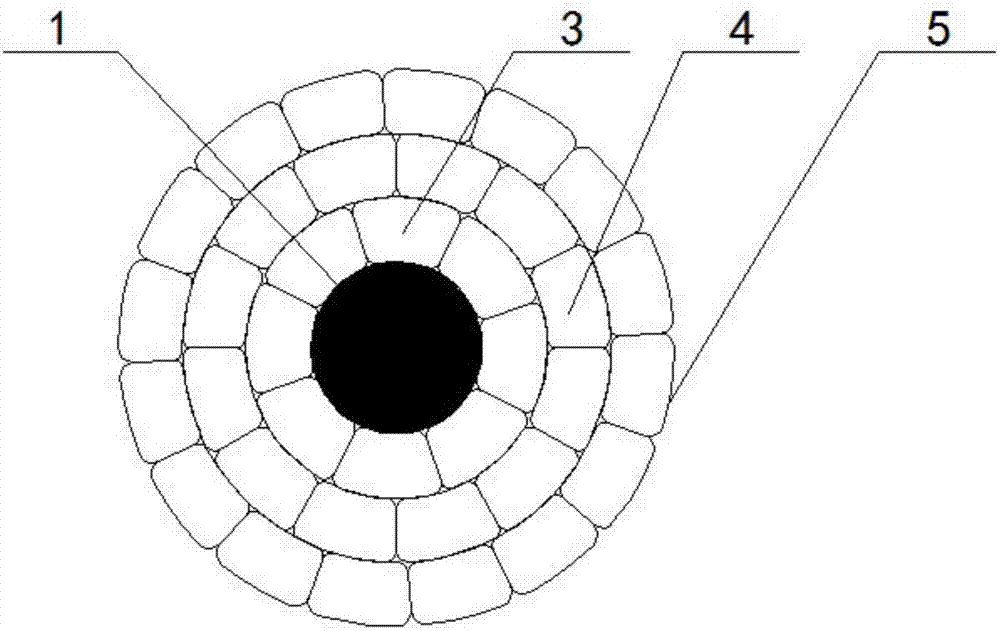

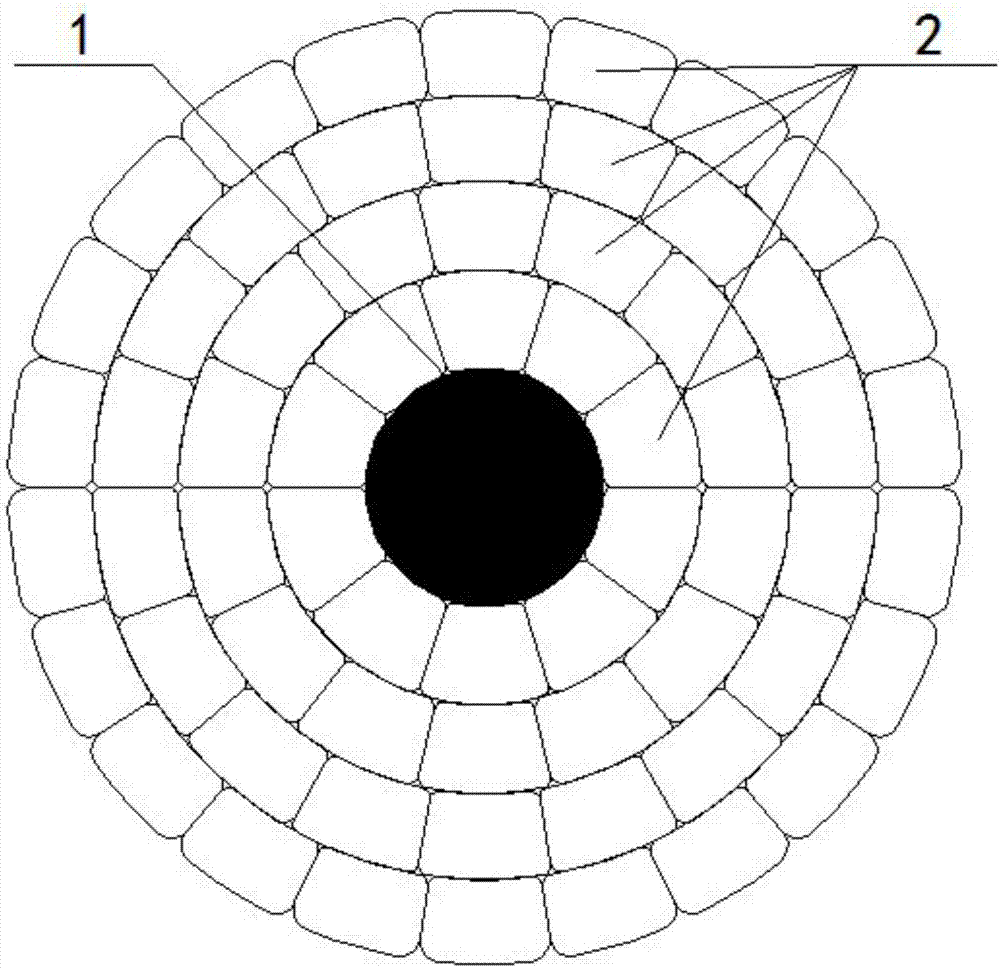

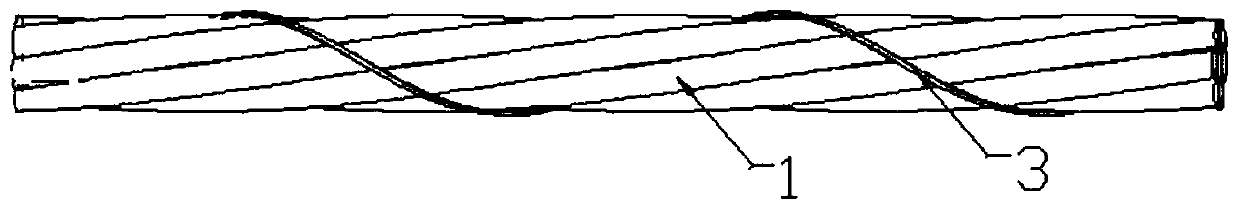

Multi-strand composite reinforcing core and preparation method thereof

PendingCN110197745AReasonable structural designImprove performancePower cables for overhead applicationInsulated cablesFiberAdhesive

The invention discloses a multi-strand composite reinforcing core and a preparation method thereof. The multi-strand composite reinforcing core is composed of seven or more single-wire rods (1). The single-core rods (1) are bonded by a base adhesive (2) and the outer layer of the entire rods is bonded by the base adhesive (2). The multi-strand composite reinforcing core is wrapped or not wrapped in a fiber (3). The multi-strand composite reinforcing core is applied to an overhead conductor, and has the advantages of good bending performance and safe line operation compared with a traditional single-core carbon fiber composite core conductor. The multi-strand composite reinforcing core has great advantages in the process of construction, is especially suitable for construction under harsh environments with large height differences and large corners.

Owner:ZHONGFU CARBON FIBER CORE CABLE TECH

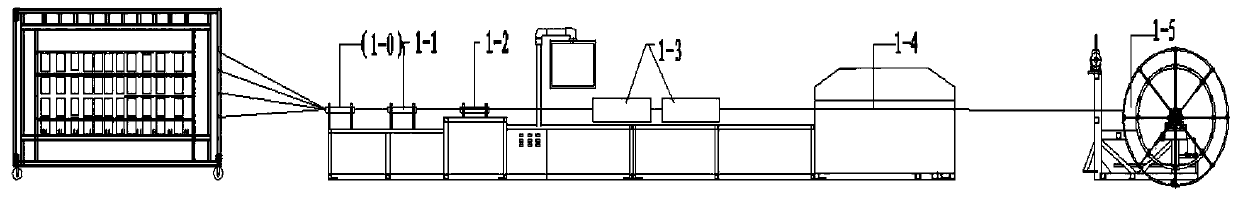

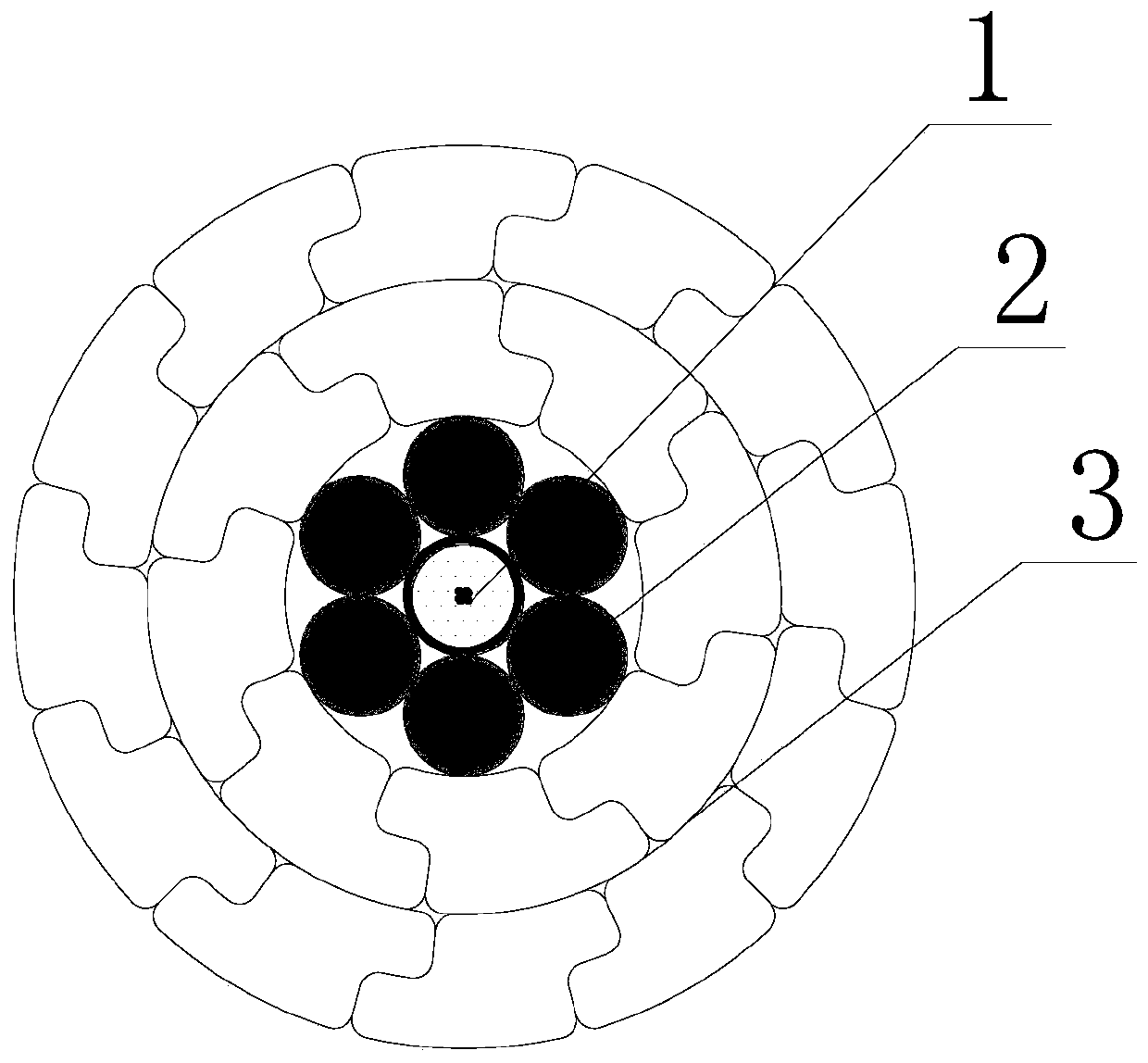

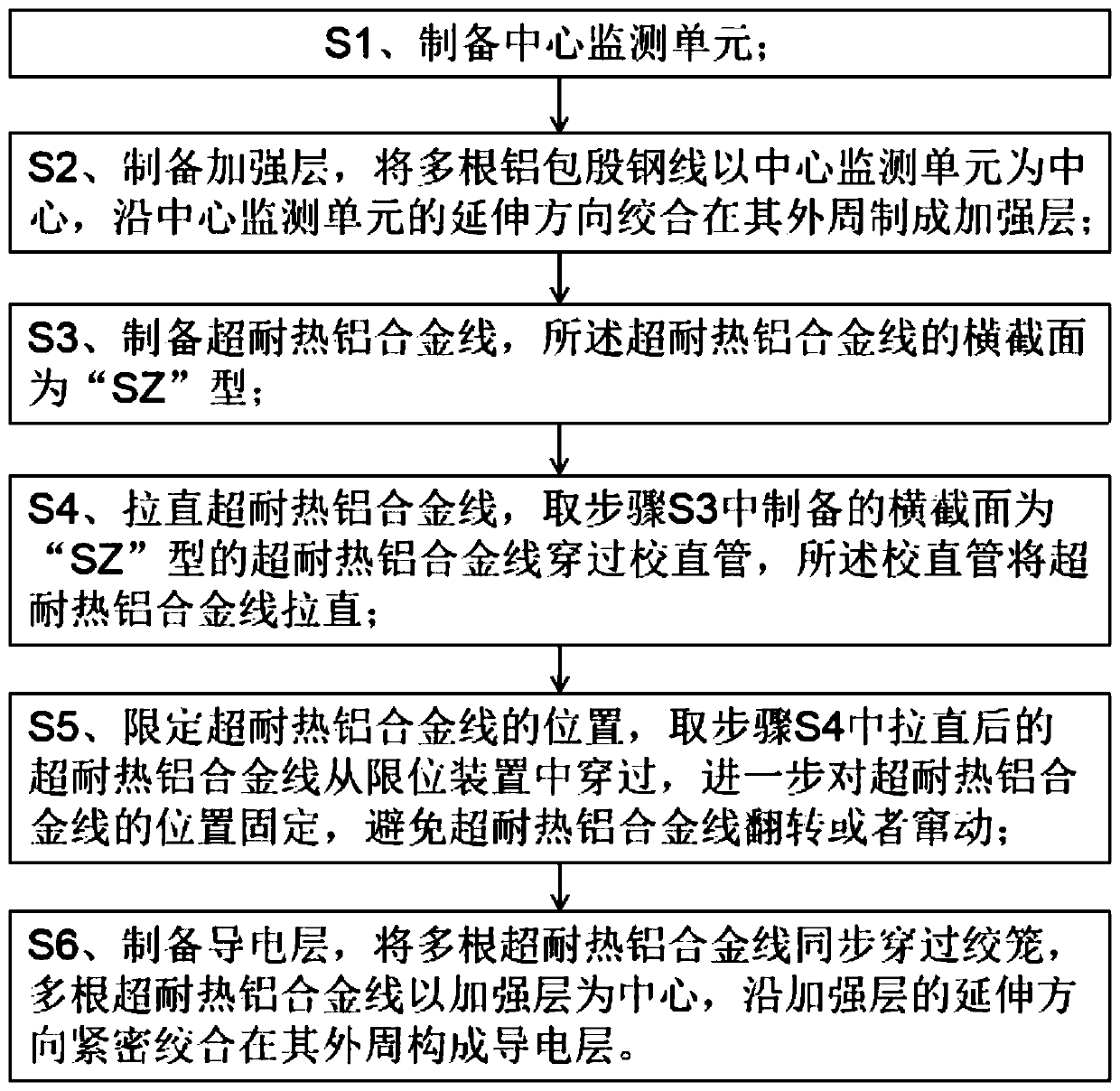

Manufacturing method of aluminum-clad invar steel core super-heat-resistant aluminum alloy wire

InactiveCN110033903AEliminate pay-off bendsStraight and stable directionNon-insulated conductorsPower cables for overhead applicationAluminium alloyHeat resistant

The invention discloses a manufacturing method of an aluminum-clad invar steel core super-heat-resistant aluminum alloy wire. The manufacturing method comprises the steps of S1, preparing a central monitoring unit; S2, twisting a plurality of aluminum-clad invar steel wires on the periphery of the central monitoring unit in the extension direction of the central monitoring unit by taking the central monitoring unit as a center to prepare a reinforcing layer; S3, preparing super-heat-resistant aluminum alloy wires, wherein the cross sections of the super-heat-resistant aluminum alloy wires arein an "SZ" shape; S4, enabling the super-heat-resistant aluminum alloy wires with the cross sections in the "SZ" shape to penetrate through a straightening pipe for straightening the super-heat-resistant aluminum alloy wires; S5, enabling the straightened super-heat-resistant aluminum alloy wires in the step S4 to penetrate through a limiting device for preventing the super-heat-resistant aluminumalloy wires from being turned over or moved; and S6, enabling the super-heat-resistant aluminum alloy wires to synchronously penetrate through a stranding cage, and tightly twisting the super-heat-resistant aluminum alloy wires on the periphery of the reinforcing layer in the extension direction of the reinforcing layer by taking the reinforcing layer as a center to form a conductive layer. According to the method, the aluminum alloy wires are flat and stable in the twisting process, so that the quality of a finished product is improved.

Owner:JIANGSU HENGTONG ELECTRICAL SPECIAL WIRE CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com