Optical unit direct leading-down structure of OPPC (Optical Phase Conductor) and construction method of optical unit direct leading-down structure

A technology of optical unit and optical cable, which is applied in the direct lead-down structure of optical unit and its construction field, which can solve the problems of difficulty and unfavorable remaining cables in the coil, and achieve the effect of simple and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Such as Figure 1-1 to Figure 4 As shown, the optical unit of the OPPC optical cable according to Embodiment 1 of the present invention directly leads down the structure, and is provided with an OPPC optical cable 1, an optical unit outlet joint 2, a pre-twisted wire assembly 3, a first connecting fitting 4, a remaining cable rack 5, a second Connect fittings 6, insulator strings 7 and electrical connection jumpers 8, wherein the remaining cable rack 5 is composed of a horizontal pull rod 51 and a vertical pull rod 52 whose upper end is fixed in the middle of the horizontal pull rod 51, and wire lugs are installed on the horizontal pull rod 51 and the vertical pull rod 52 53.

[0053] The above-mentioned pre-twisted wire assembly 3 is installed on the OPPC optical cable 1, and the pre-twisted wire assembly 3 is connected to one end of the insulator string 7 through the first connecting fitting 4, the horizontal pull rod 51 of the remaining cable rack 5 and the second co...

Embodiment 2

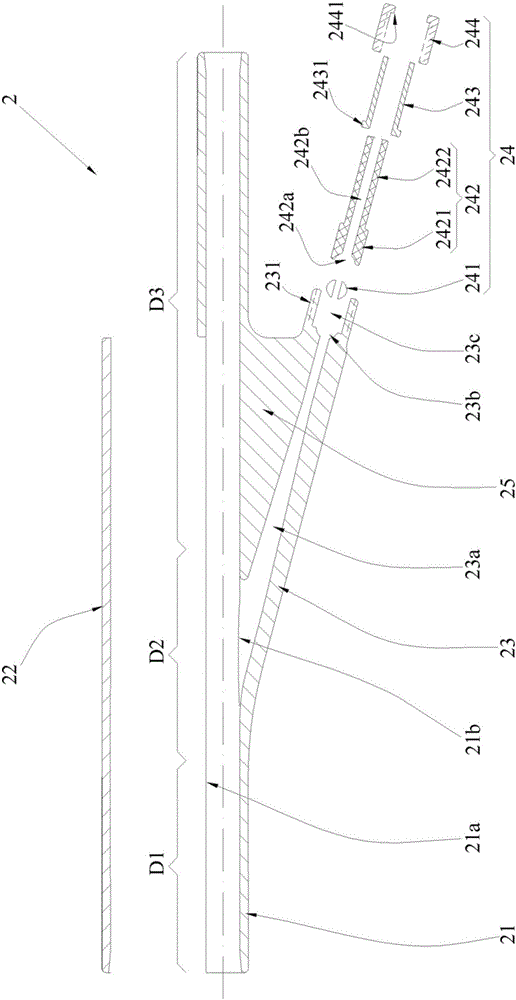

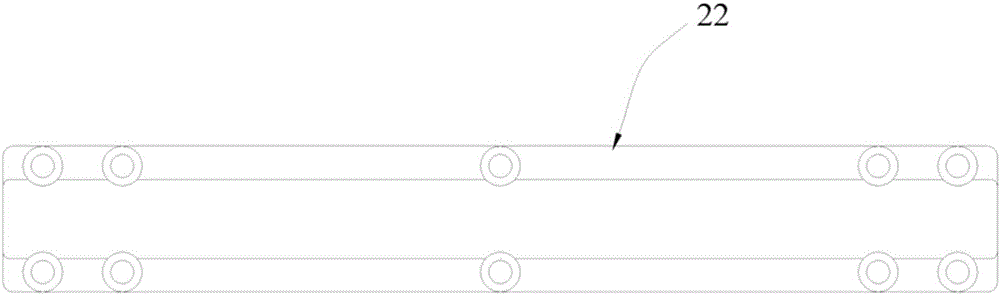

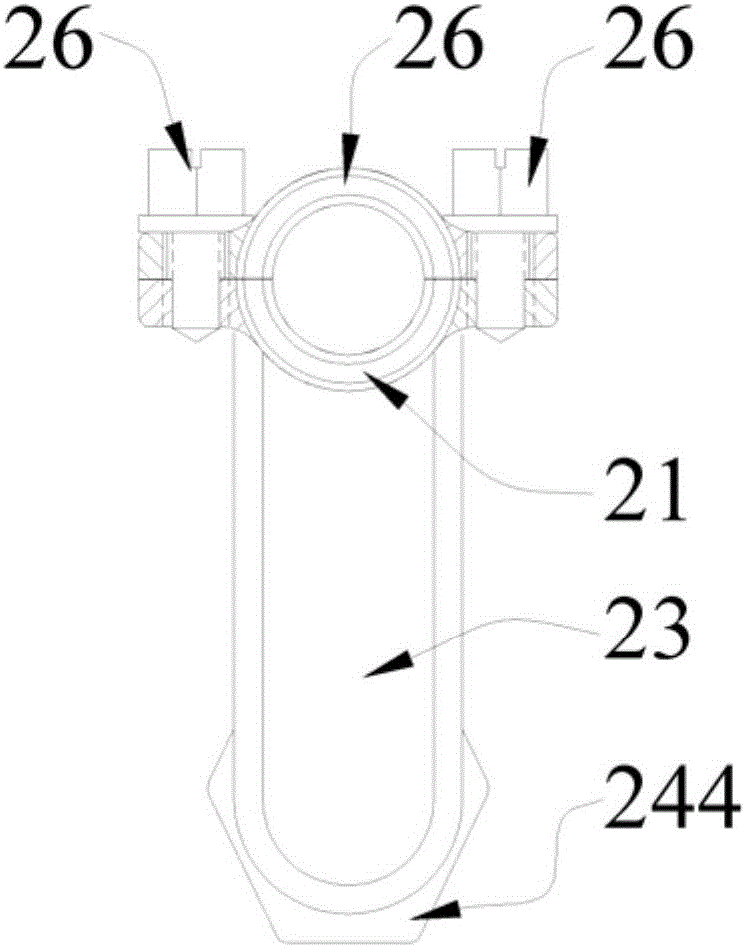

[0069] like Figure 5-1 to Figure 6 As shown, the structure of the direct down-leading of the optical unit in the second embodiment of the present invention is basically the same as that in the first embodiment. Assemblies 24, the upper cover 22 is provided with an upper cover lead-out hole 22a, and the upper cover lead-out hole 22a is located in the composite section D1 when the upper cover 22 is closed on the cover opening 21a of the base 21; the first lead-out pipe 23 is connected to the base 21, so that the first lumen 23a of the first lead-out tube 23 communicates with the lumen of the base 21 through the lead-out hole 21b, and the second lead-out tube 23 is connected with the outer wall of the upper cover 22, so that the second lead-out tube 23 The first lumen 23a of the upper cover communicates with the lumen of the base 21 through the outlet hole 22a of the upper cover. Moreover, the OPPC optical cable 1 is provided with two plastic tube optical units 11; the two plas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com