Patents

Literature

31results about How to "Avoid construction inconvenience" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

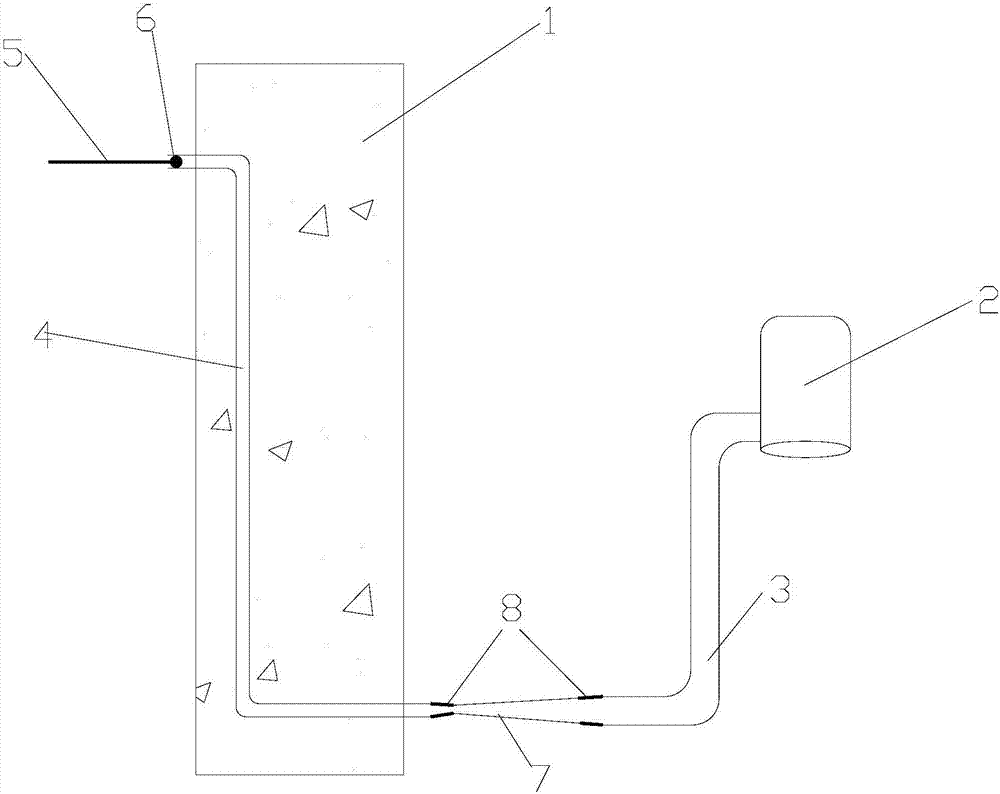

Optical unit direct leading-down structure of OPPC (Optical Phase Conductor) and construction method of optical unit direct leading-down structure

ActiveCN106300206AAvoid restrictionsAchieve separationPower cables for overhead applicationFibre mechanical structuresElectricityEngineering

The invention discloses an optical unit direct leading-down structure of an OPPC (Optical Phase Conductor) and a construction method of the optical unit direct leading-down structure. The optical unit direct leading-down structure is provided with an OPPC optical cable (1), a pre-twisted wire assembly (3), a first connection fitting (4), a second connection fitting (6), an insulator string (7) and an optical connection jumper (8) and is also provided with an optical unit leading-out connector (2). By the structure, a plastic pipe optical unit of the OPPC optical cable hung at a high altitude can be separated and directly lead down, and moreover, the structure is suitably used for the OPPC optical cable of which the plastic pipe optical unit is arranged at an arbitrary position in the OPPC optical cable. By the construction method, connection between the OPPC optical cable and the optical unit leading-out connector and connection and installation of the pre-twisted wire assembly, the first connection fitting, a remaining cable rack, the second connection fitting and the insulator string can be completed on the ground, the OPPC optical cable is pulled to a high altitude and then is connected to a cross arm of an iron tower or a telegraph pole after winding of a remaining cable segment, and finally, the plastic pipe optical unit is directly lead down. The construction method has the advantages of simplicity and convenience in construction.

Owner:林杨

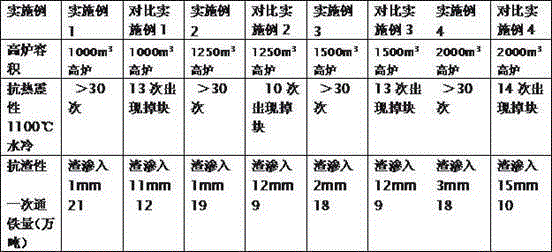

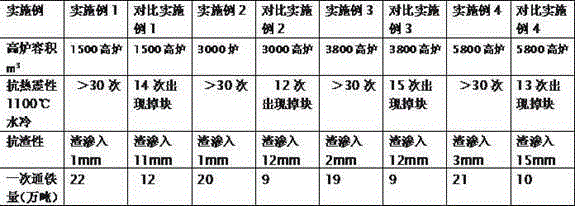

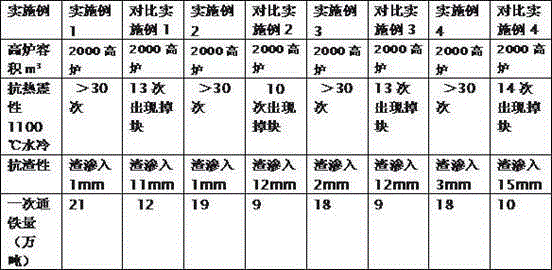

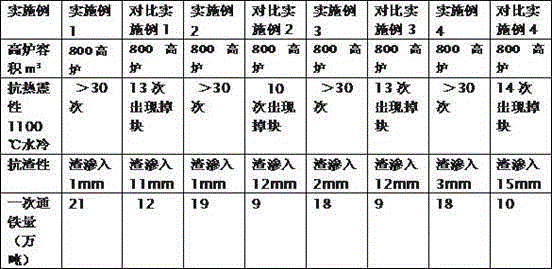

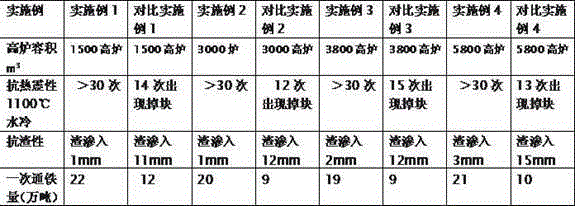

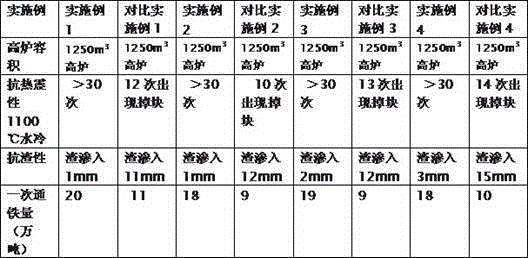

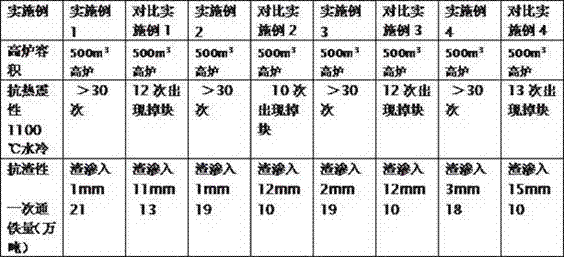

Large blast furnace main iron runner castable

InactiveCN105152669AImprove corrosion resistanceImprove thermal shock resistanceChromium nitrideThermal shock

The invention relates to a large blast furnace main iron runner castable, and belongs to the field of refractory castables. The large blast furnace main iron runner castable is prepared from, by weight, 5-8 parts of 8-5 mm chromium nitride, 15-20 parts of 5-3 mm chromium nitride, 10-15 parts of 3-1 mm sillimanite, 8-15 parts of 1-0 mm calcium chromate, 2-5 parts of partial clay powder, 3-7 parts of cobaltous oxide aluminum powder, 5-10 parts of cutting powder, 3-8 parts of amorphous graphite powder, 1-2 parts of composite charcoal powder, 0-3 parts of molybdenum trioxide powder, 3-5 parts of alumina micro powder, 1-5 parts of magnesium oxide iron powder, 1-3 parts of rho-aluminum oxide, 0-5 parts of electric smelting pure calcium aluminate cement and an addition agent, wherein the addition agent is prepared from, by weight, 0.1-0.2 part of calcium lignosulphonate, 0.01-0.05 part of nanometer potato powder, 0.01 part of malic acid and 0.1 part of C12H14N4O5S2. A blast furnace iron runner made of the castable has the advantages of being good in thermal shock resistance, high in corrosion resistance, large in iron exchanging amount and long in life.

Owner:张婷

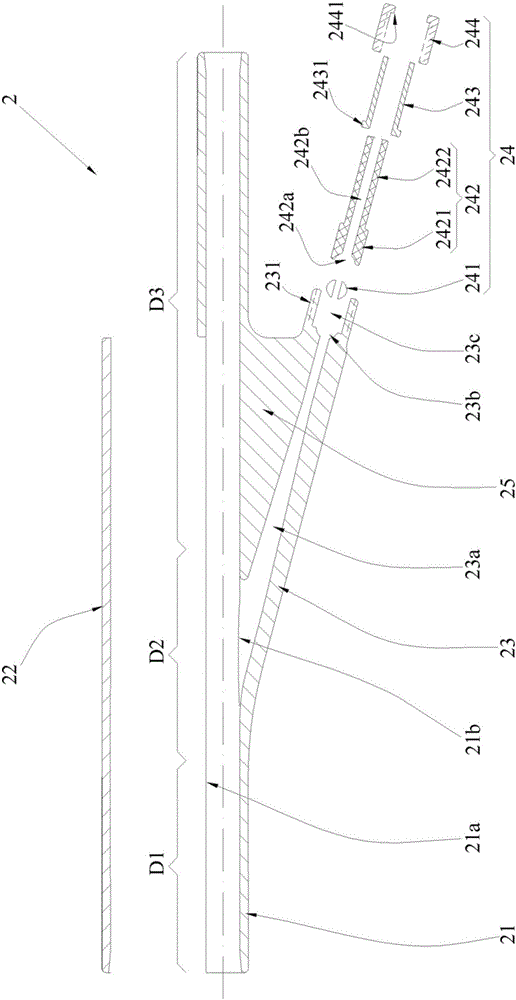

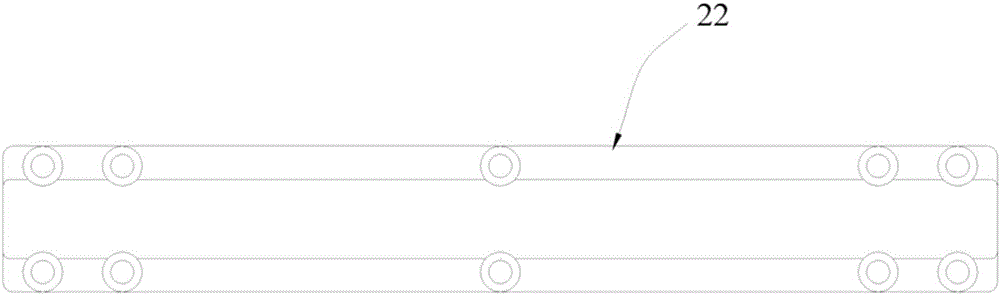

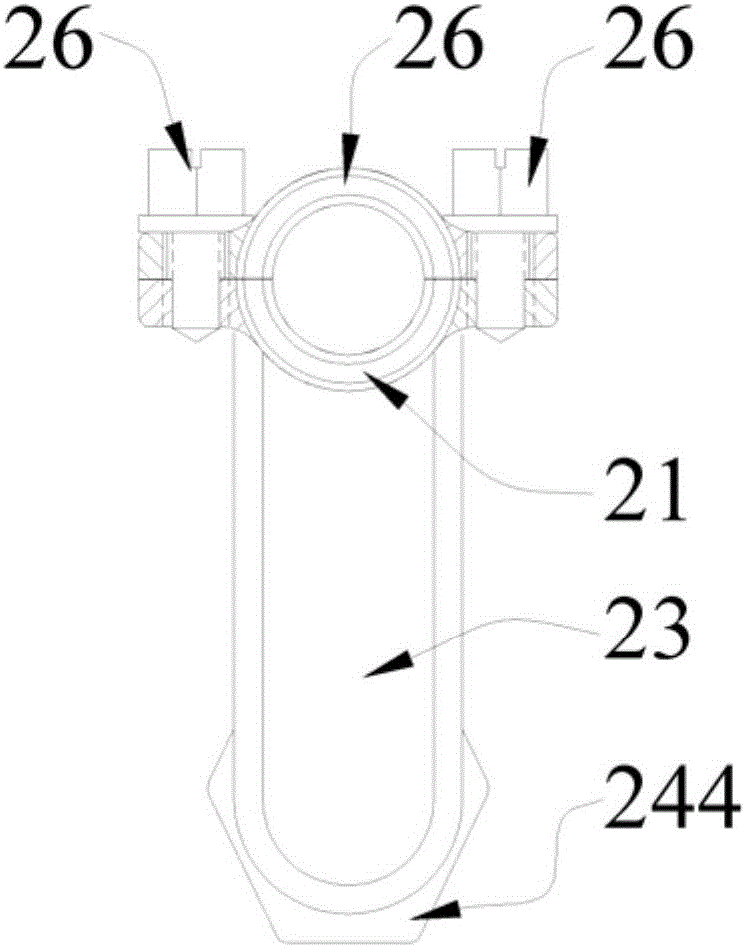

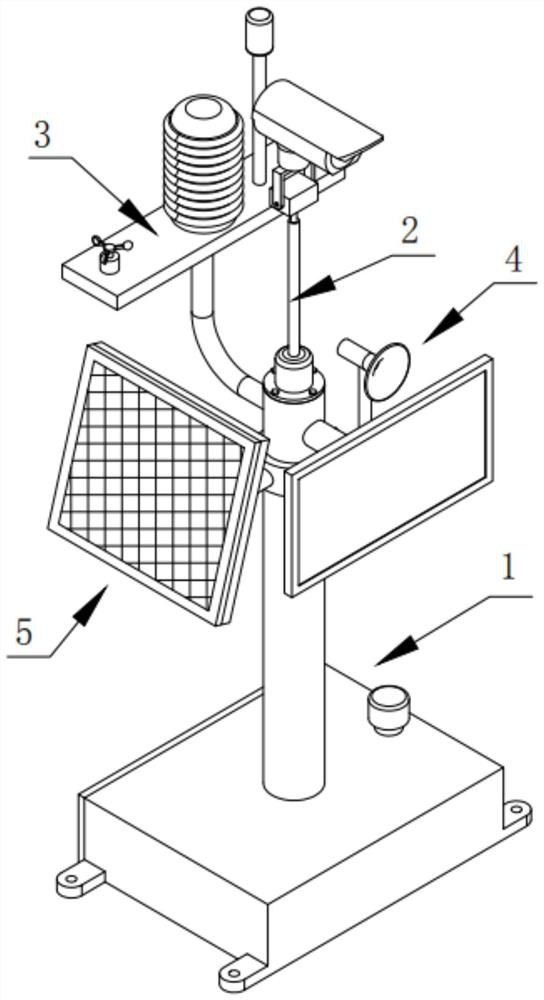

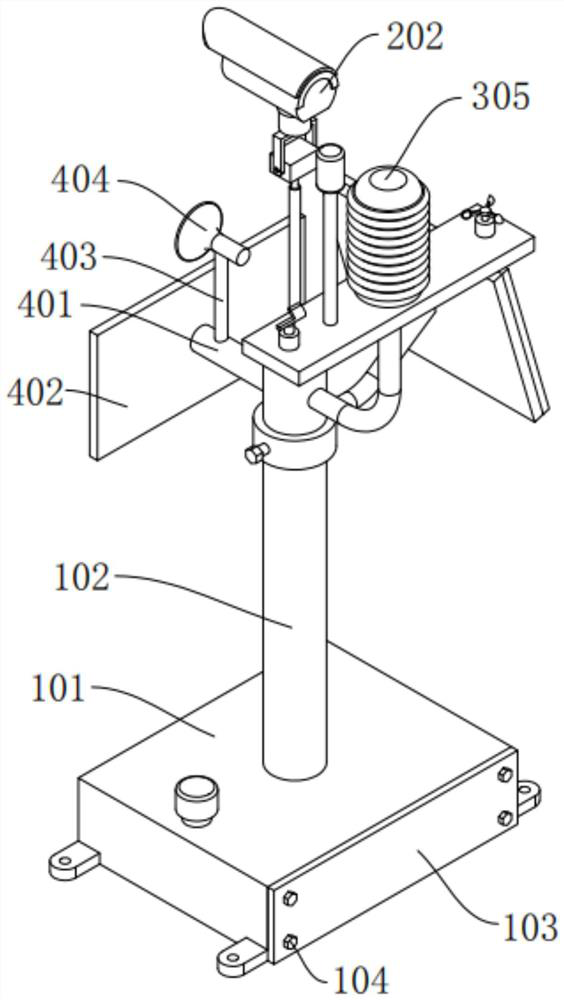

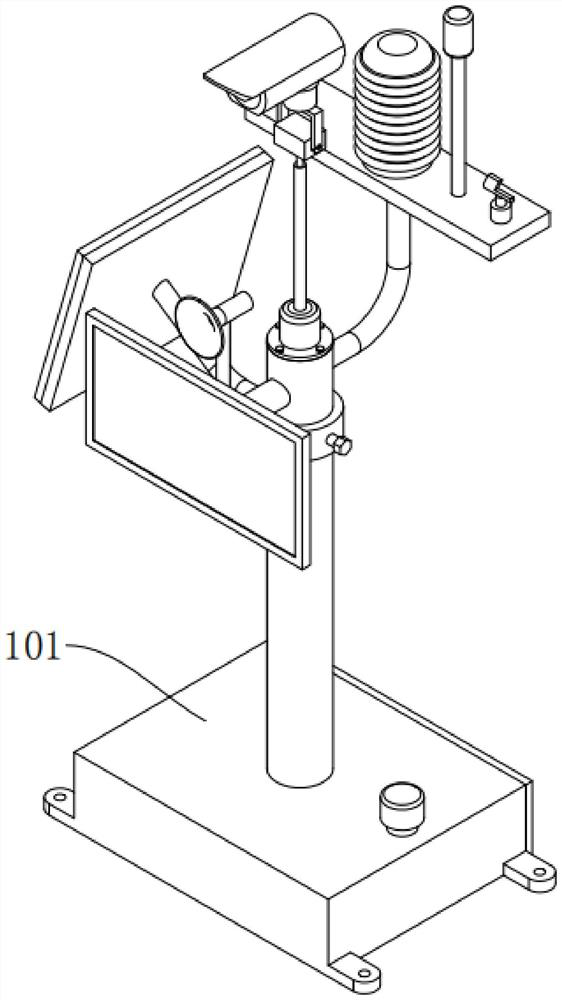

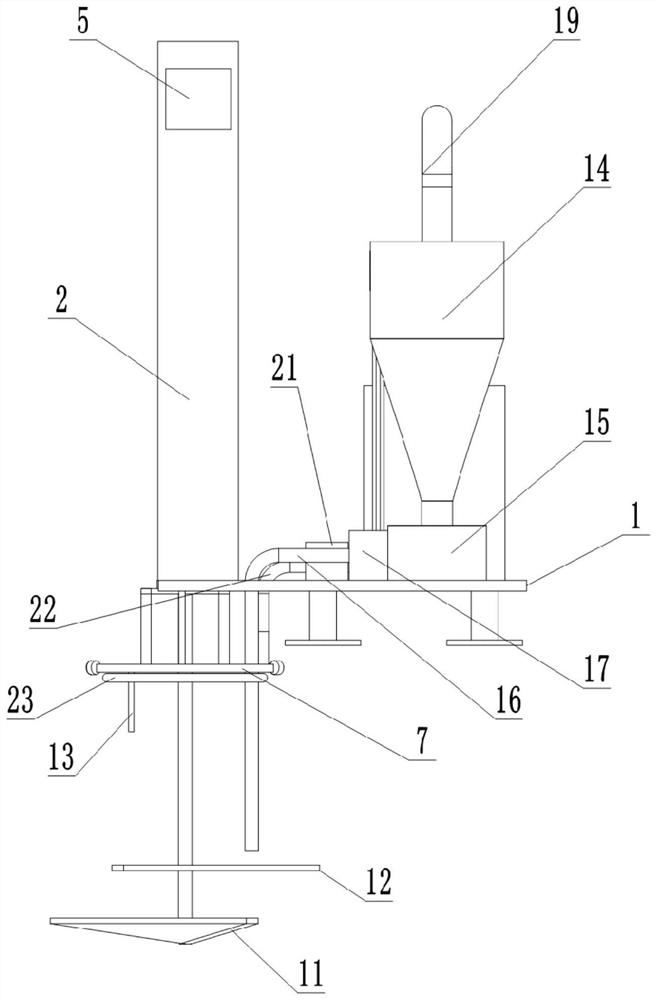

Intelligent safety supervision device for construction site

ActiveCN111935456AExpand the scope of supervisionComprehensive regulatory areaTelevision system detailsMeasurement devicesEnvironmental monitoringVideo monitoring

The invention discloses an intelligent safety supervision device for a construction site, and the device comprises a bottom supporting mechanism, a site video monitoring mechanism, an environment monitoring mechanism, a display mechanism, and a power generation mechanism, and the bottom supporting mechanism comprises a pedestal and a vertical column. According to the invention, all regions of a construction site can be monitored at 360 degrees without dead angles; supervision range is large, the supervision area is comprehensive, and environmental parameters can be comprehensively monitored; the service life of the sensor is long; the later maintenance cost can be effectively reduced; people who do not wear safety helmets on a construction site can be captured; responsibility and warning are carried out on people who do not wear safety helmets on a construction site; and therefore, safe construction is promoted, the occurrence rate of accidents on a construction site is reduced, solarenergy can be used for generating power to supply power to itself, natural resources are fully utilized, the environment-friendly value is good, meanwhile, inconvenience brought to construction due tocable pulling on the construction site can be avoided, and practicability is good.

Owner:厦门安科科技有限公司

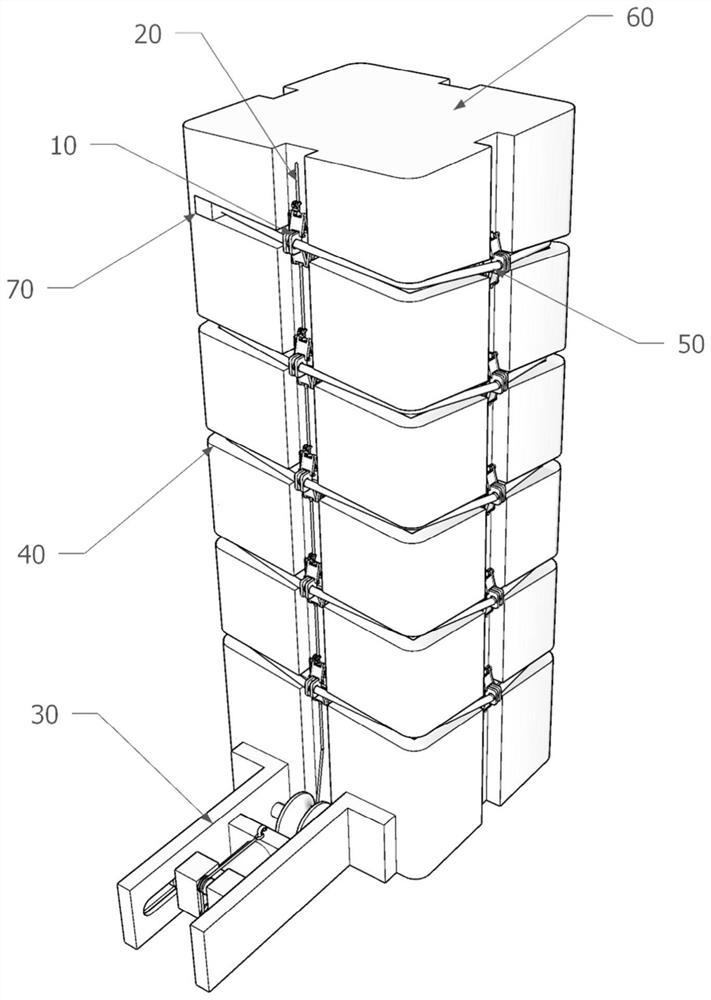

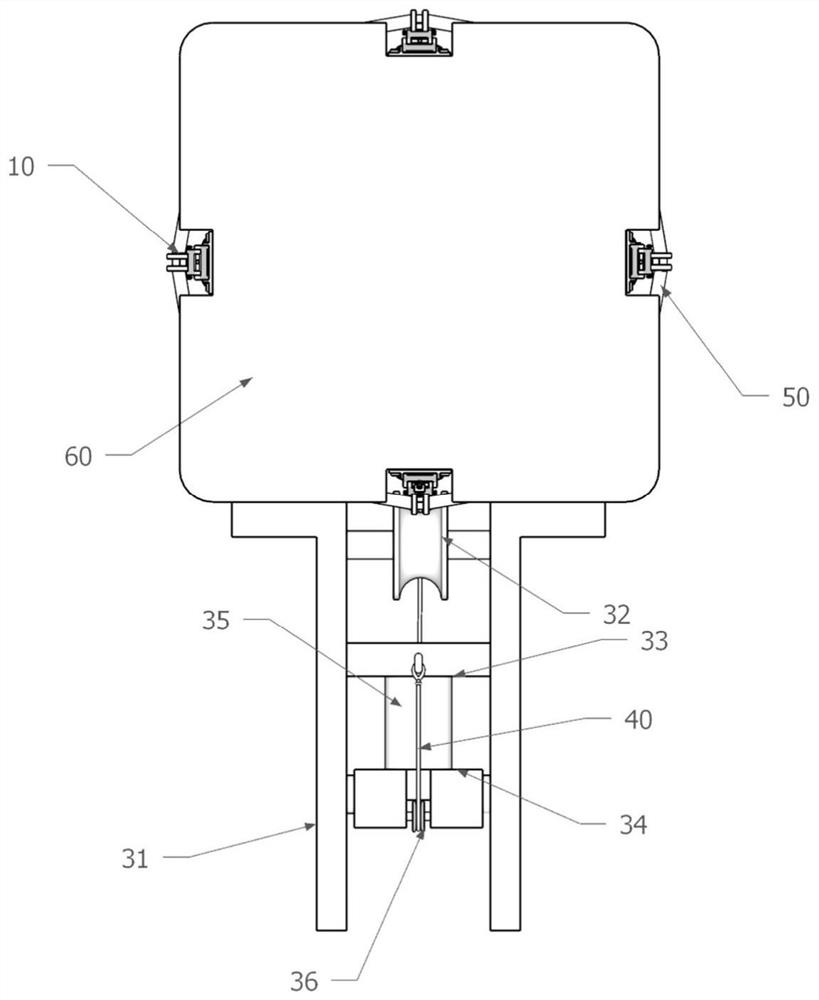

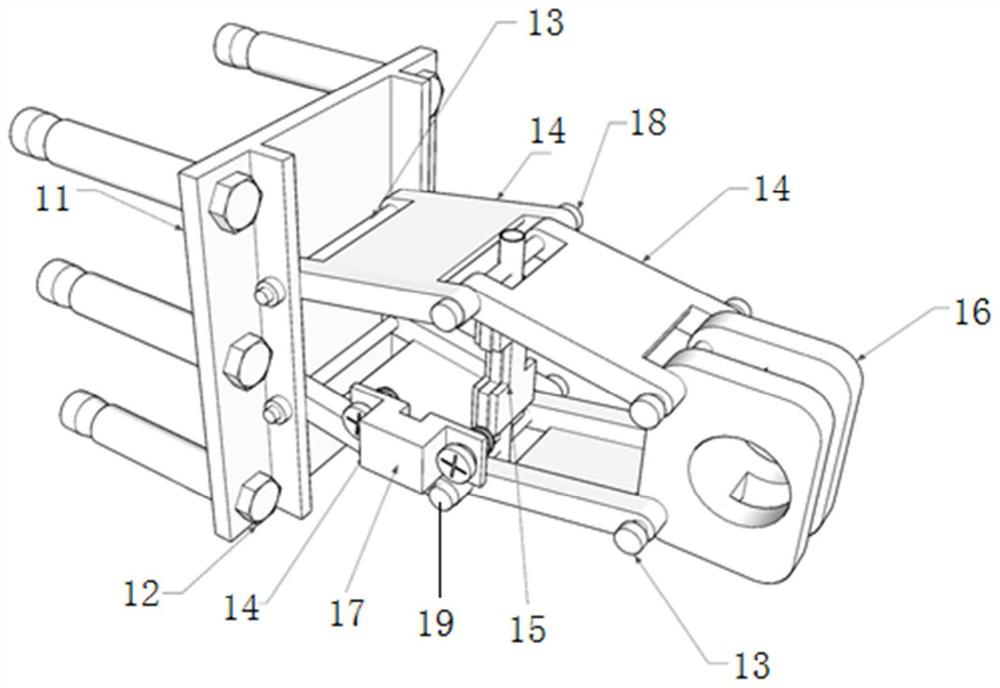

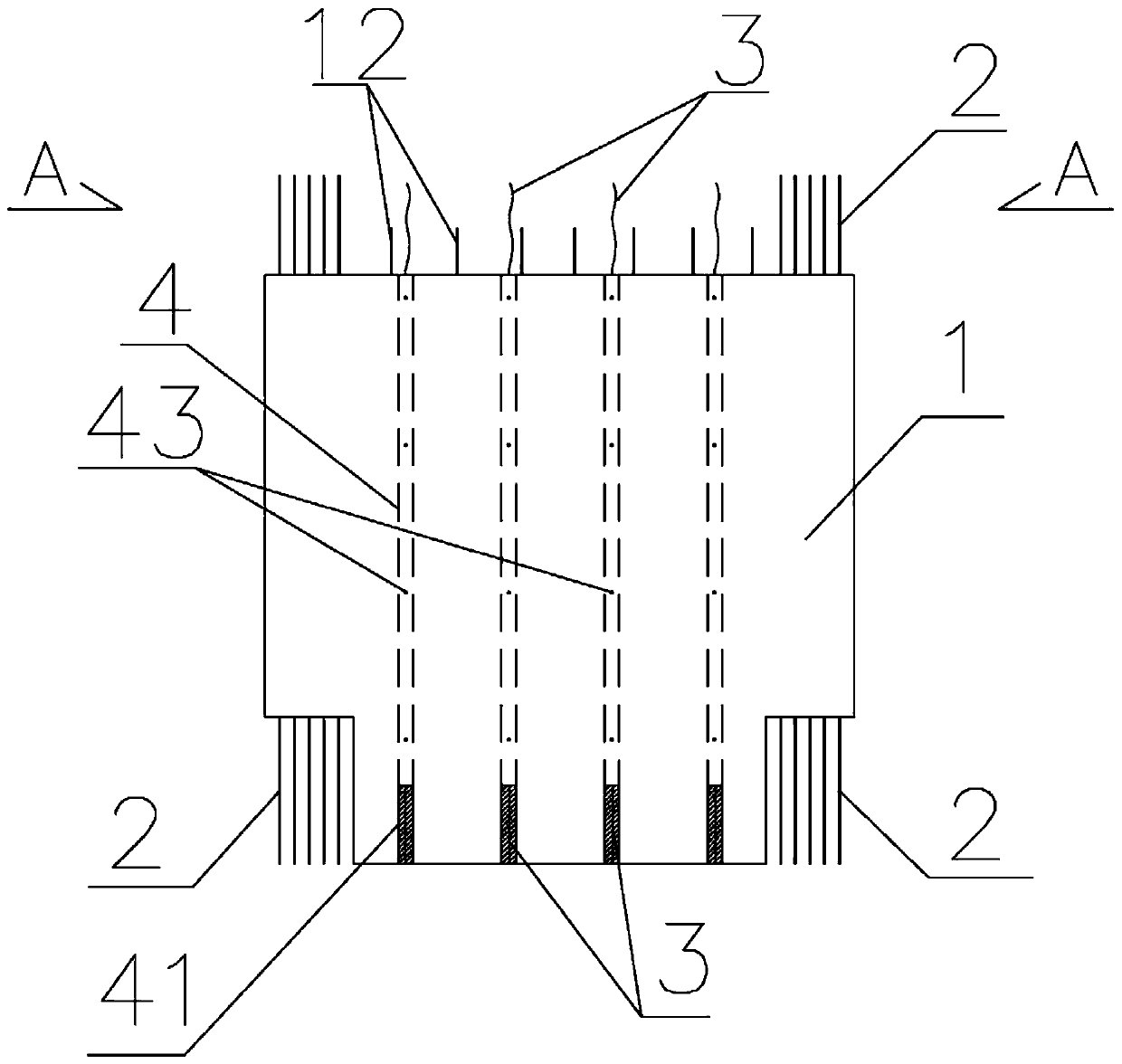

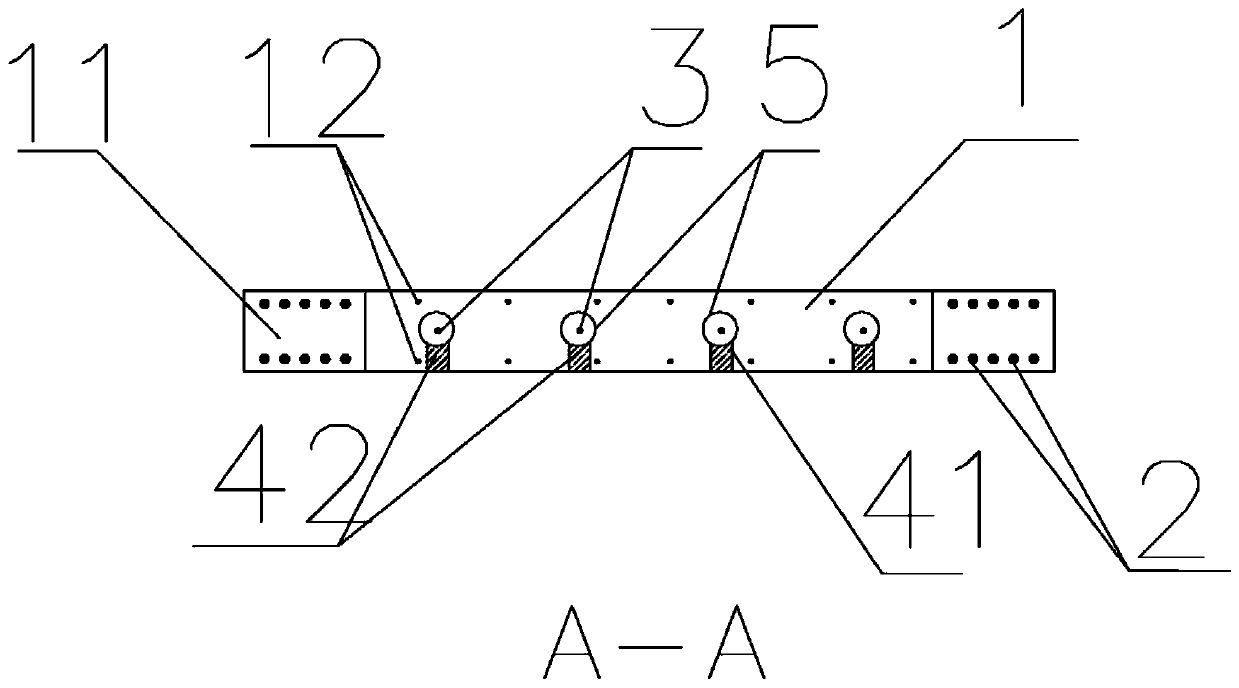

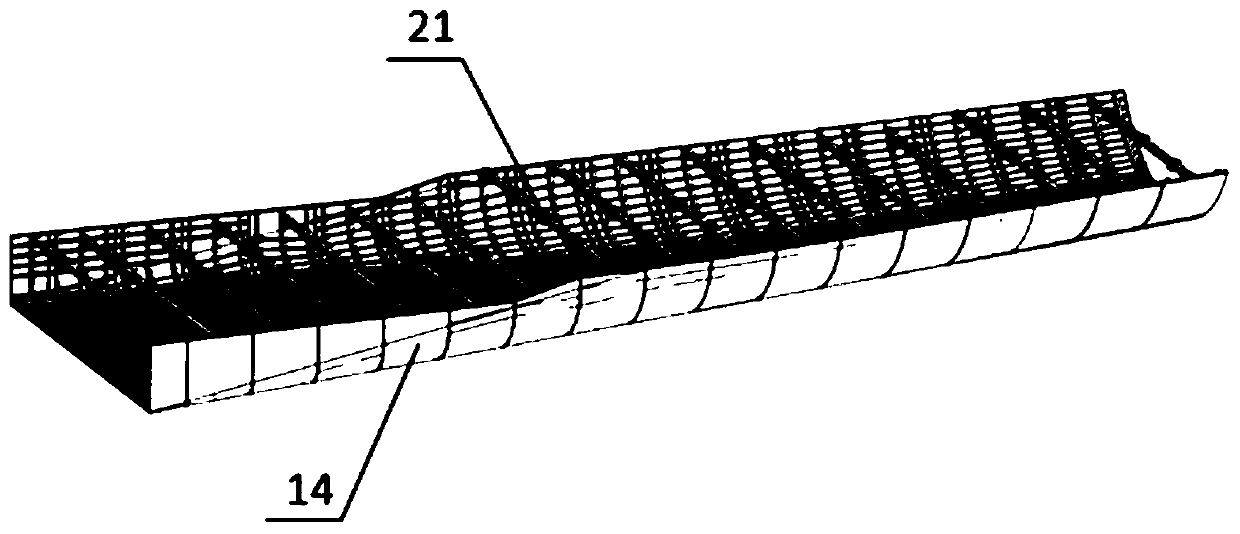

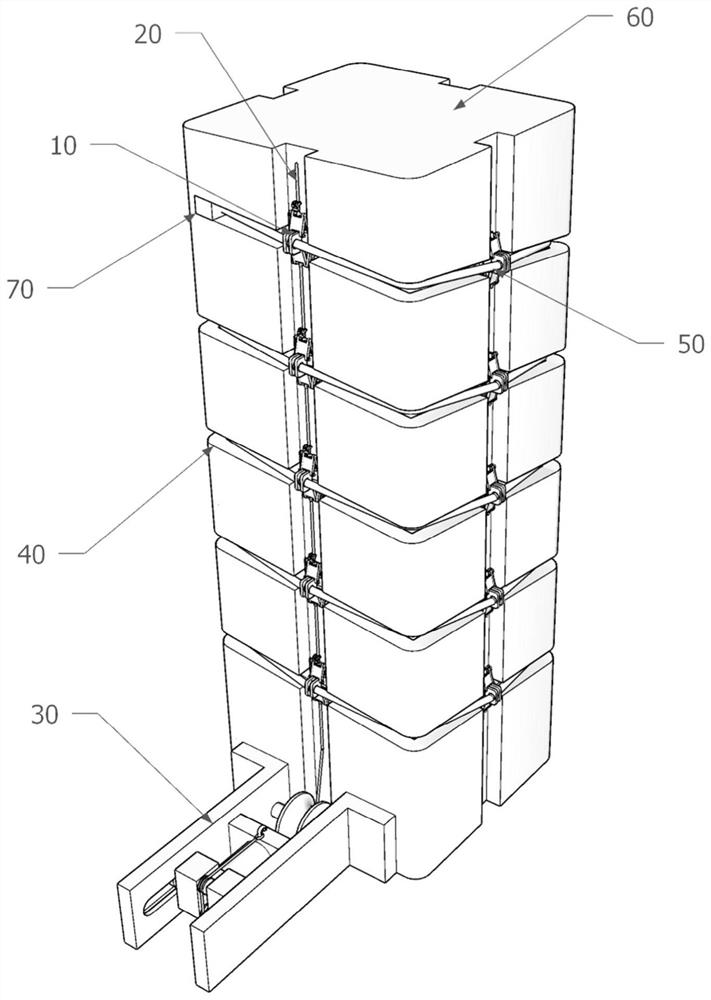

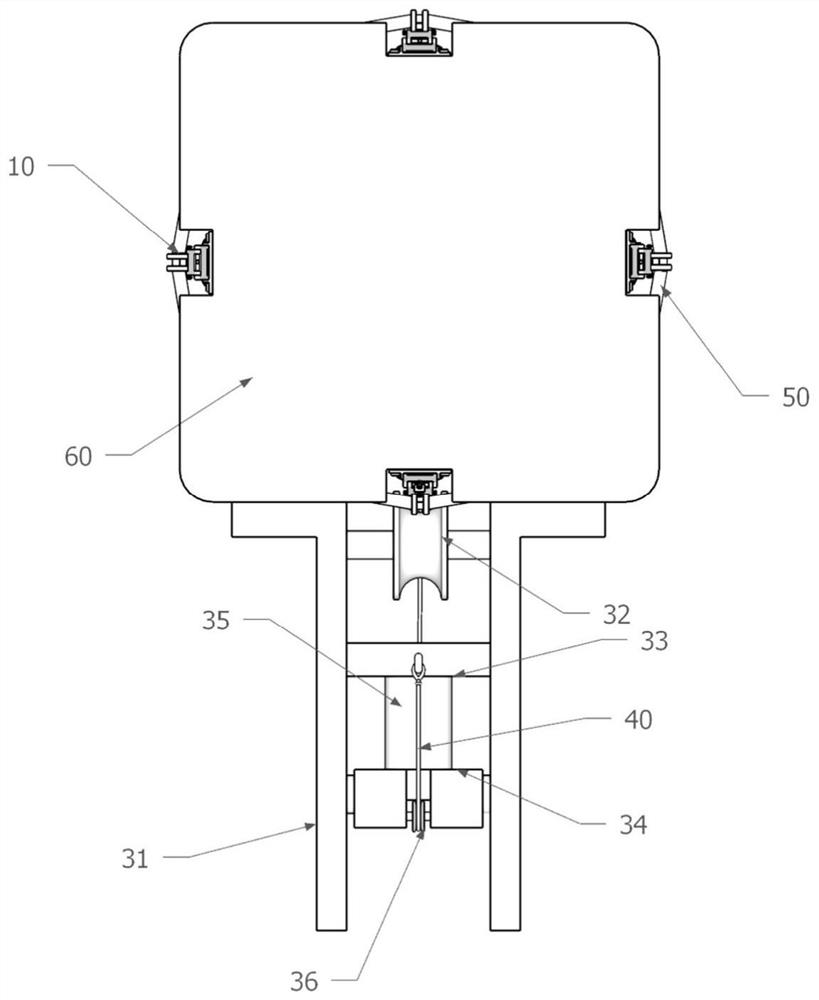

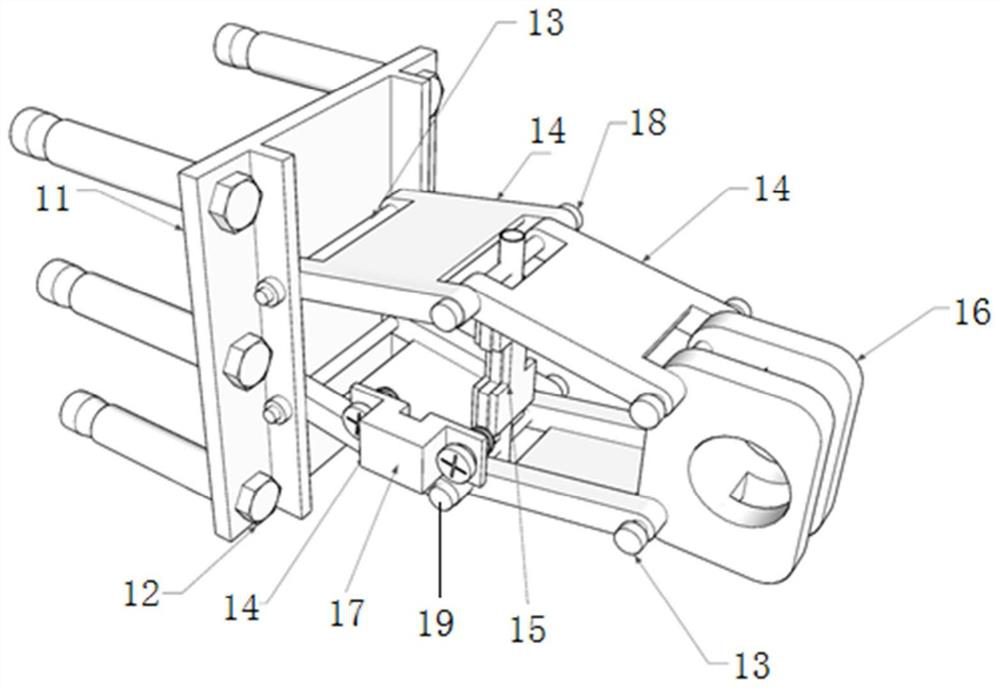

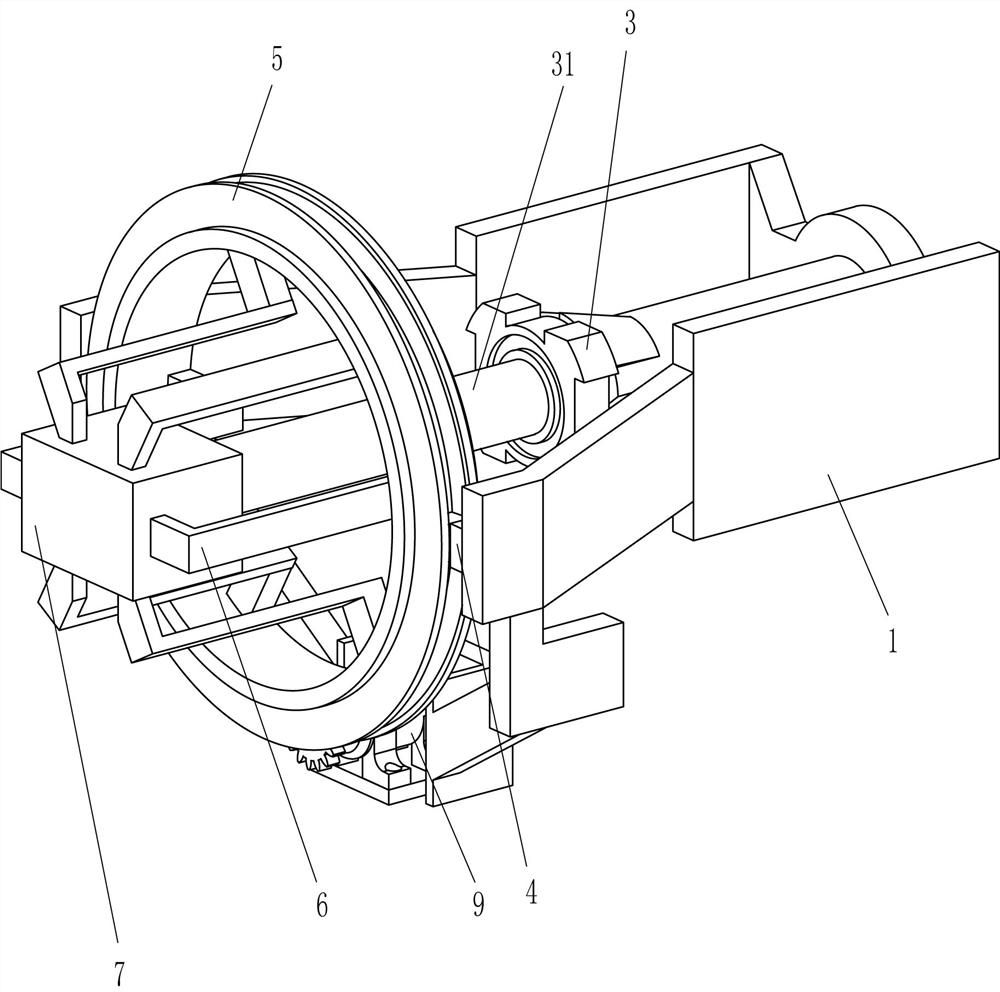

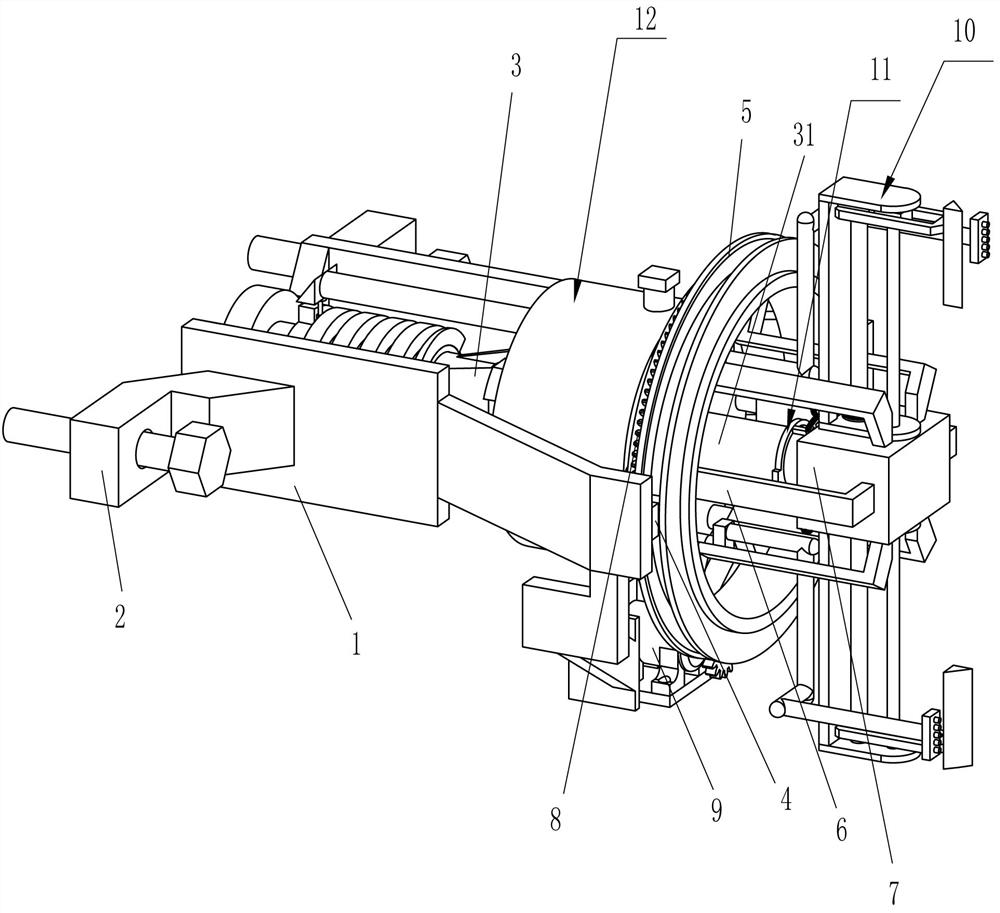

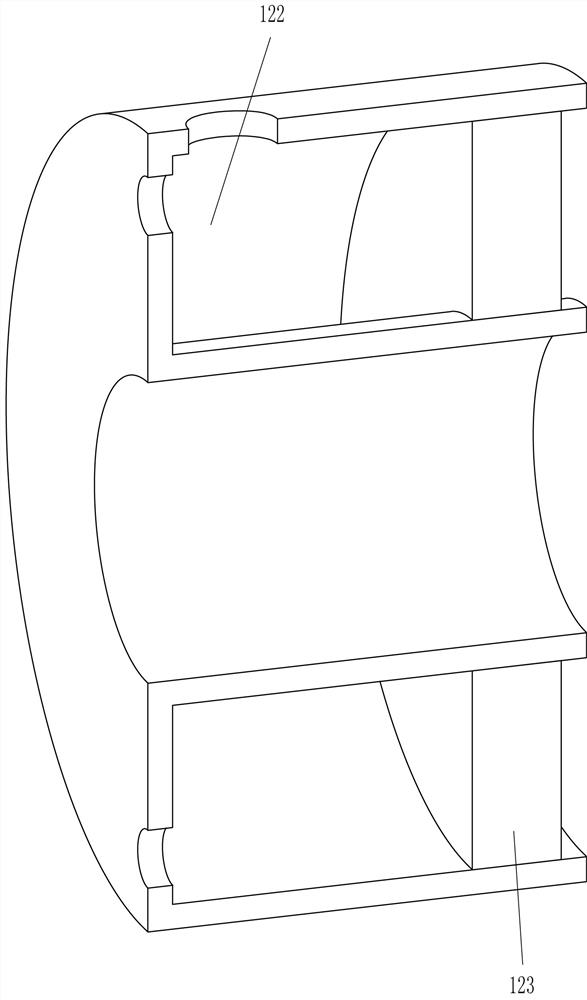

Embedded external prestress implementation system and reinforced RC column construction method thereof

ActiveCN112096108ARegulating excavationAdjust winding densityStrutsBuilding repairsPull forcePre stress

The invention discloses an embedded external prestress implementation system and a reinforced RC column construction method thereof. The embedded external prestress implementation system comprises steel strand arrangement grooves, prestress steel strands, end anchoring devices, prestress transverse tension devices, a traction line lifting device and a prestress applying device. The steel strand arrangement grooves which spirally ascend by m circles and n vertical grooves are formed in the surface of a reinforced concrete column to be reinforced. The prestress transverse tension devices are evenly distributed at the intersection points of the vertical grooves and the steel strand arrangement grooves. The traction line lifting device comprises a traction line and m traction line buckles. When the prestress applying device pulls the traction line downwards, the m traction line buckles extrude the m prestress transverse tension devices, so that m transverse tension assemblies transverselyextend, and then the prestress steel strands are transversely tensioned. By the adoption of the transverse tension mode, the expected tension effect can be achieved only by providing 1 / 5-1 / 7 of tension force during longitudinal tension. Meanwhile, anchoring is conducted firstly, then tension is conducted, end anchoring is convenient, and the anchoring difficulty is greatly lowered.

Owner:HOHAI UNIV

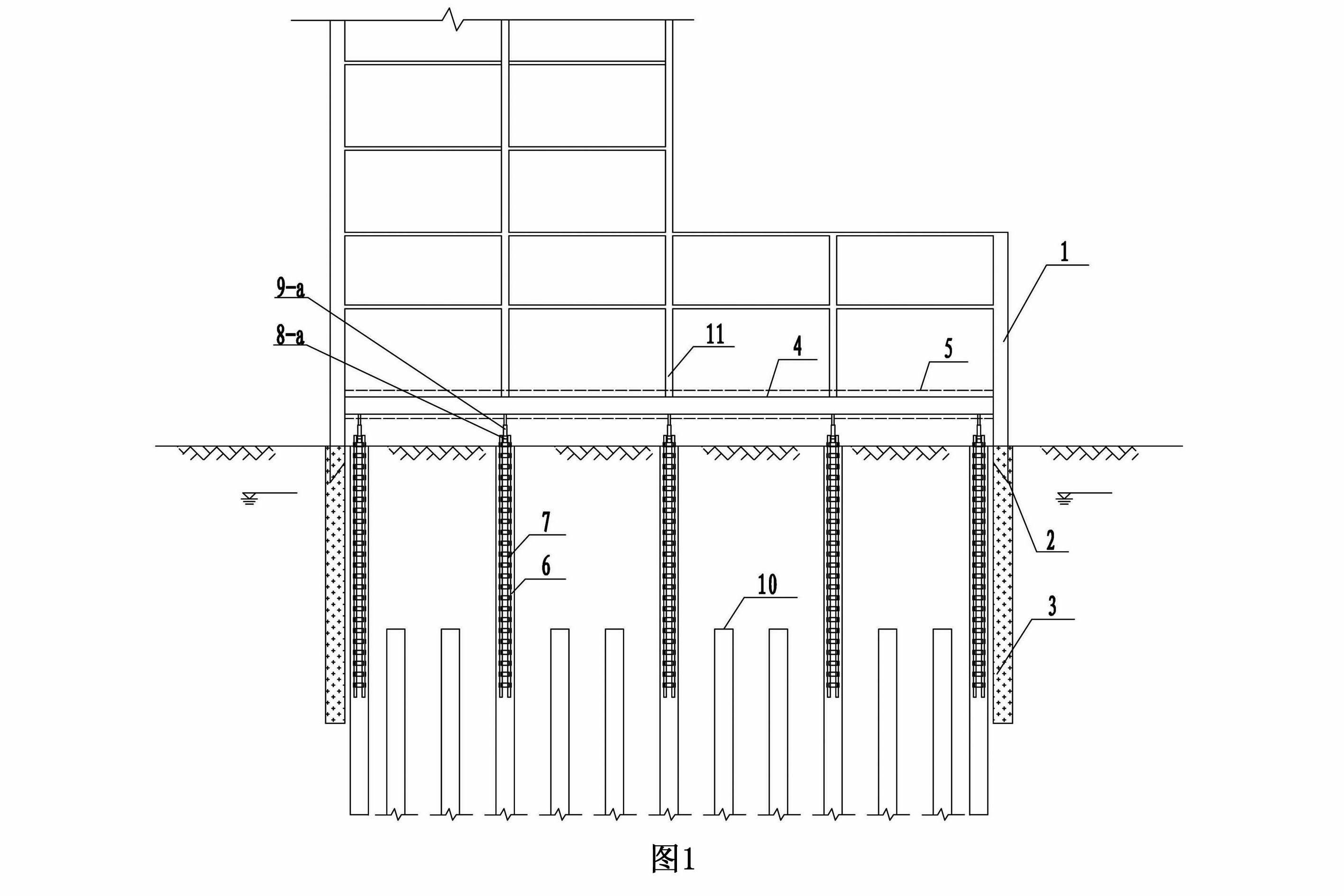

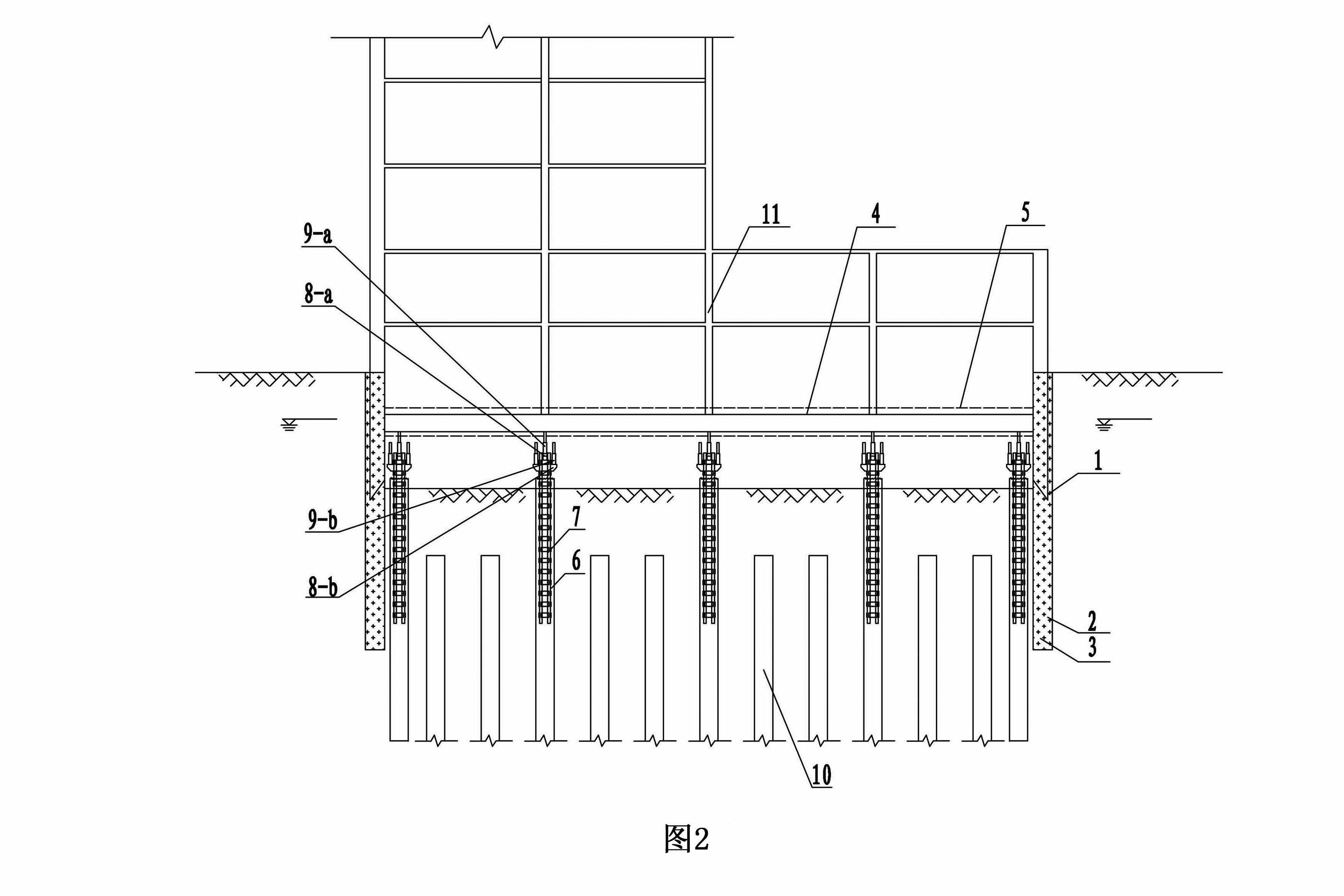

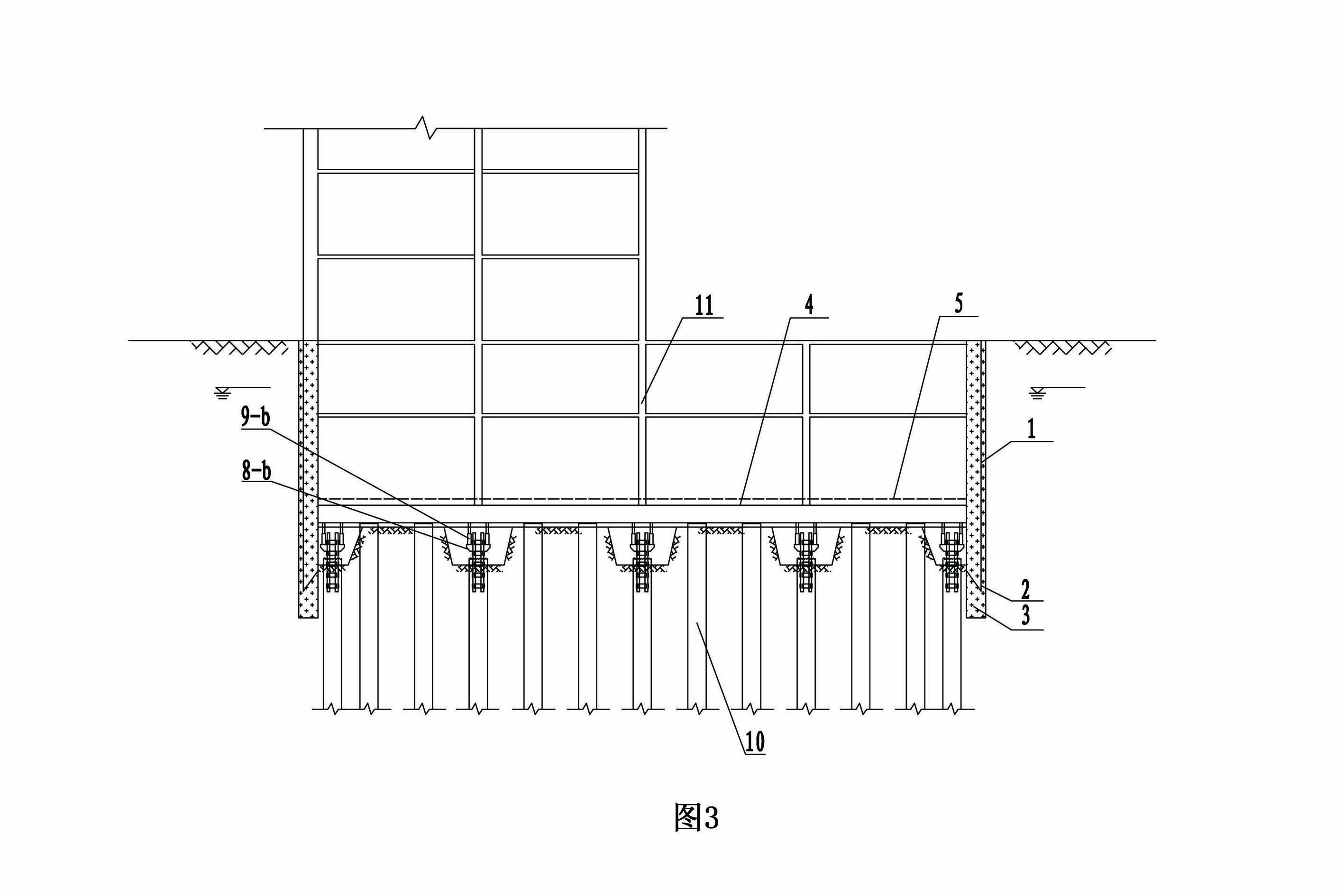

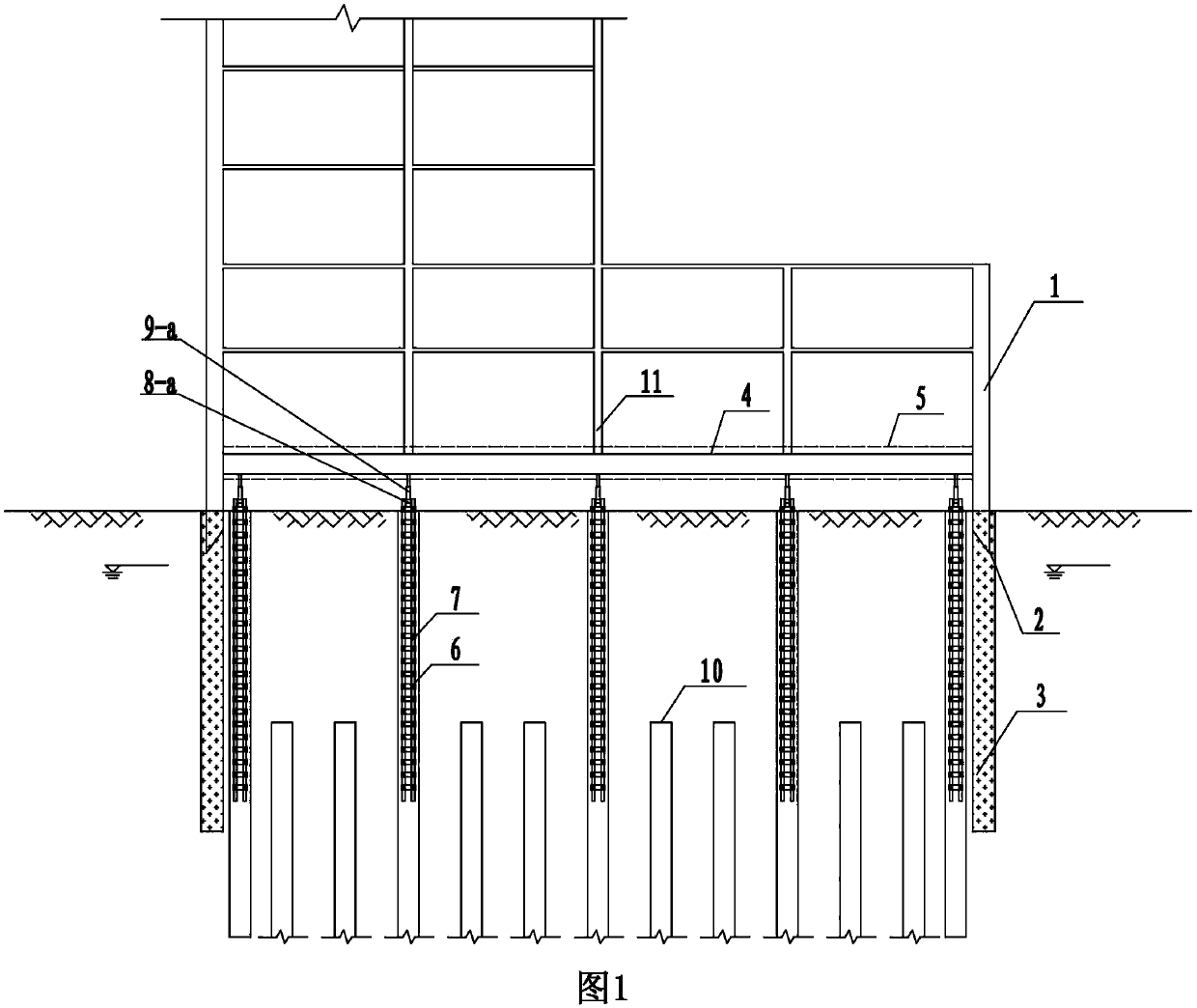

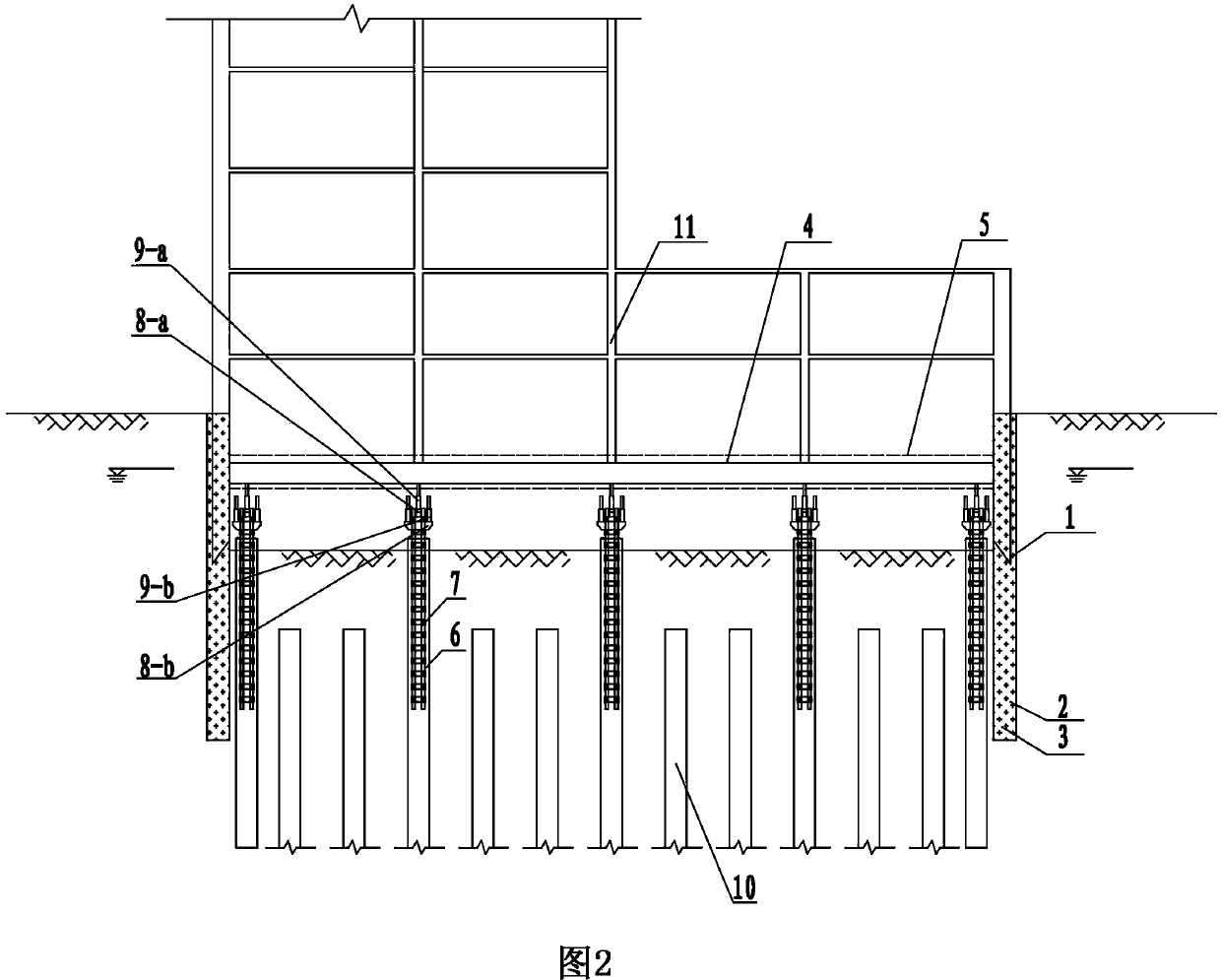

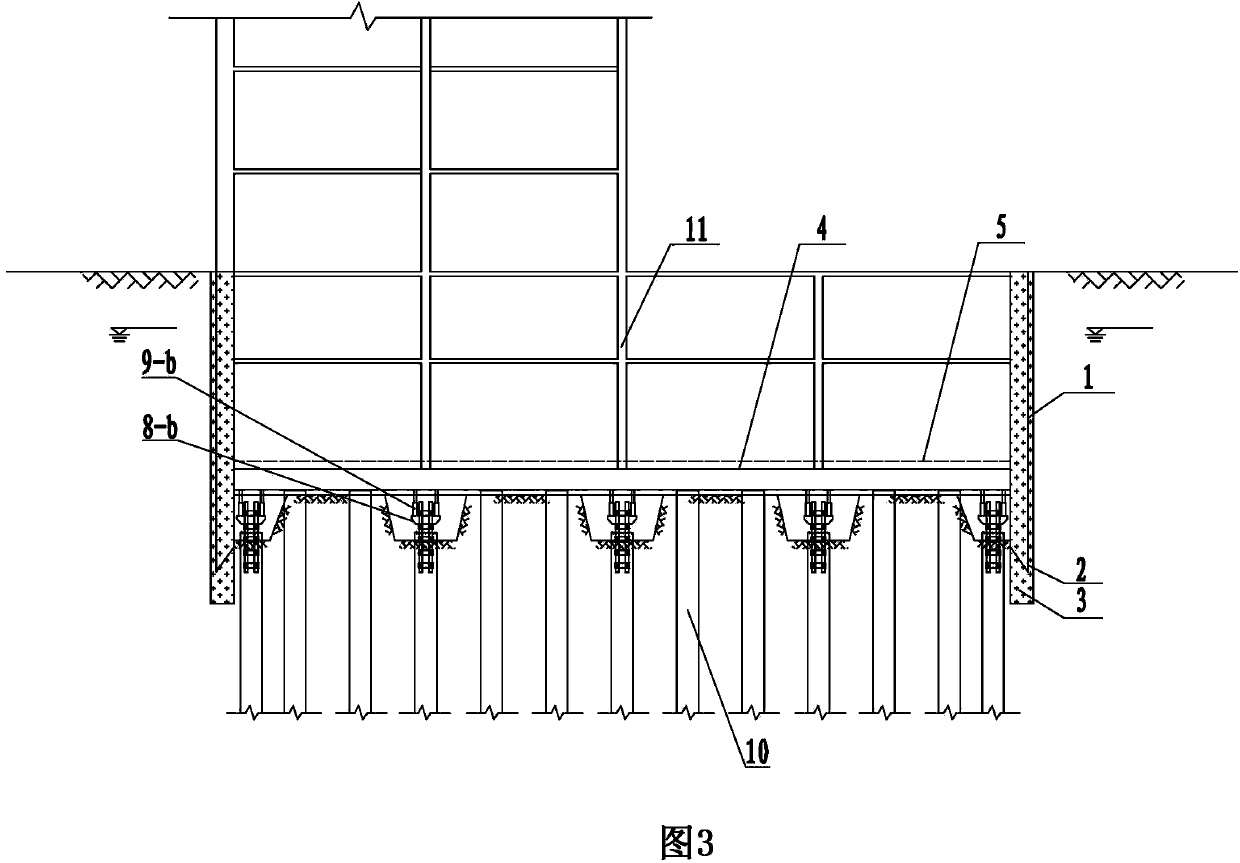

Construction method of pre-building supported and settled foundation on ground and fixing after pre-pressing for high-rise building with basement

ActiveCN102535535AReduce generationAvoid security risksFoundation engineeringBasementArchitectural engineering

The invention discloses a construction method of pre-building a supported and settled foundation on ground and fixing after pre-pressing for a high-rise building with a basement. The method comprises the following steps: constructing the whole building including the basement on the ground in advance; arranging a grid supporter at the position of a structural base plate, wherein the grid supporter is used to transfer a vertical load of the building and balance the lateral pressure of the soil around an outer wall; arranging supporting piles which extend to the ground; arranging alternate force-transferring devices capable of being lifted and temporarily fixed between the supporting piles and the grid supporter, thereby moving the building downwards completely and stably; arranging a flexible cut waterproof curtain at the position of the outer wall of the basement, thereby reducing the downward cutting resistance of the outer wall during the downward moving process of the building; when the building moves downwards to a preset position, pre-pressing the construction piles one by one by utilizing the dead load of the building and a special loading device to finish the set settling of single piles in advance; loading a non-pile supporting building in blocks and finishing the set settling in advance; after the dead load of the upper building reaches a preset value, completely descending the building to a designed height; and pouring the base plate and finishing the final fixing of the building.

Owner:CHINA CONSTR THIRD ENG BUREAU GRP CO LTD

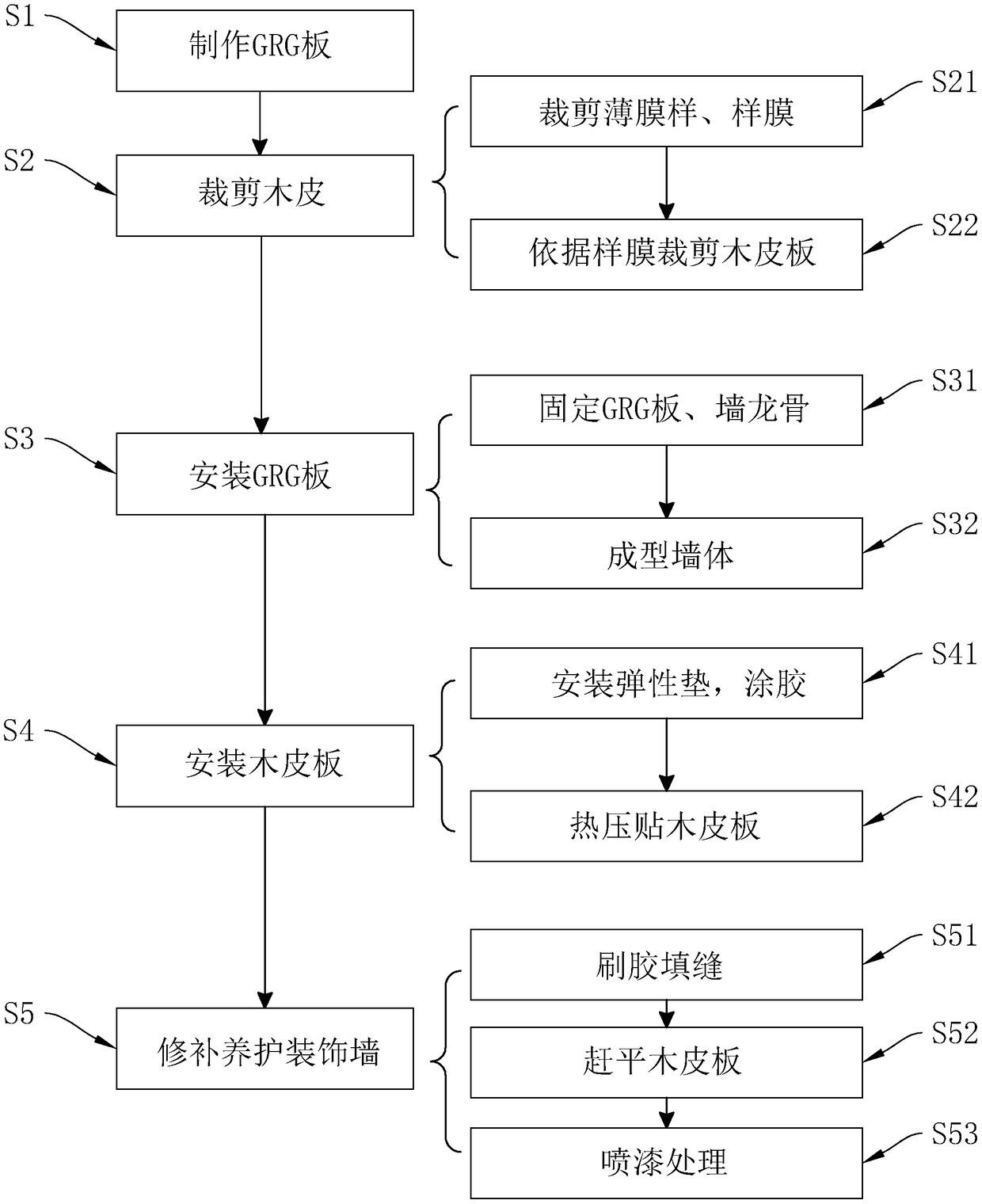

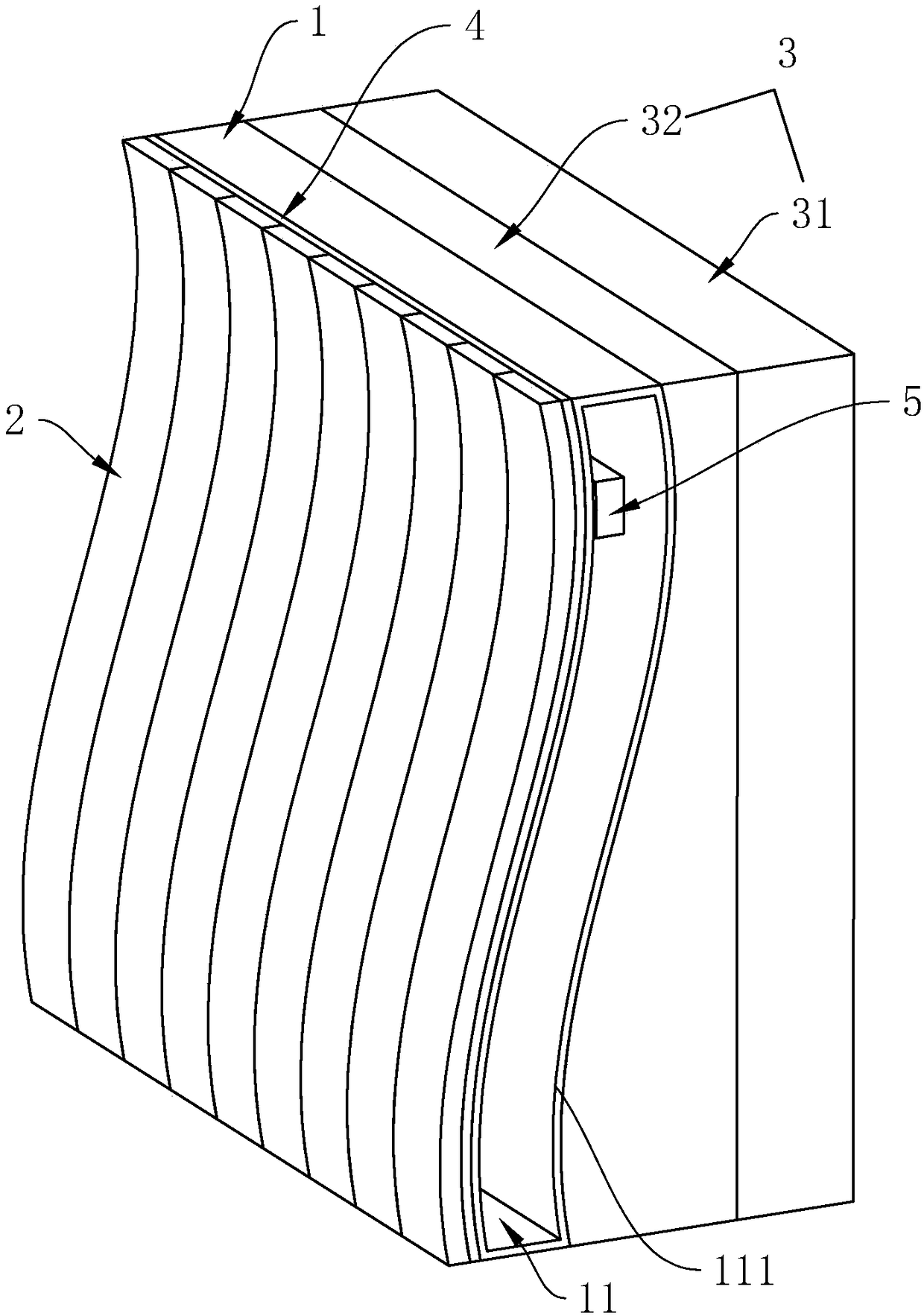

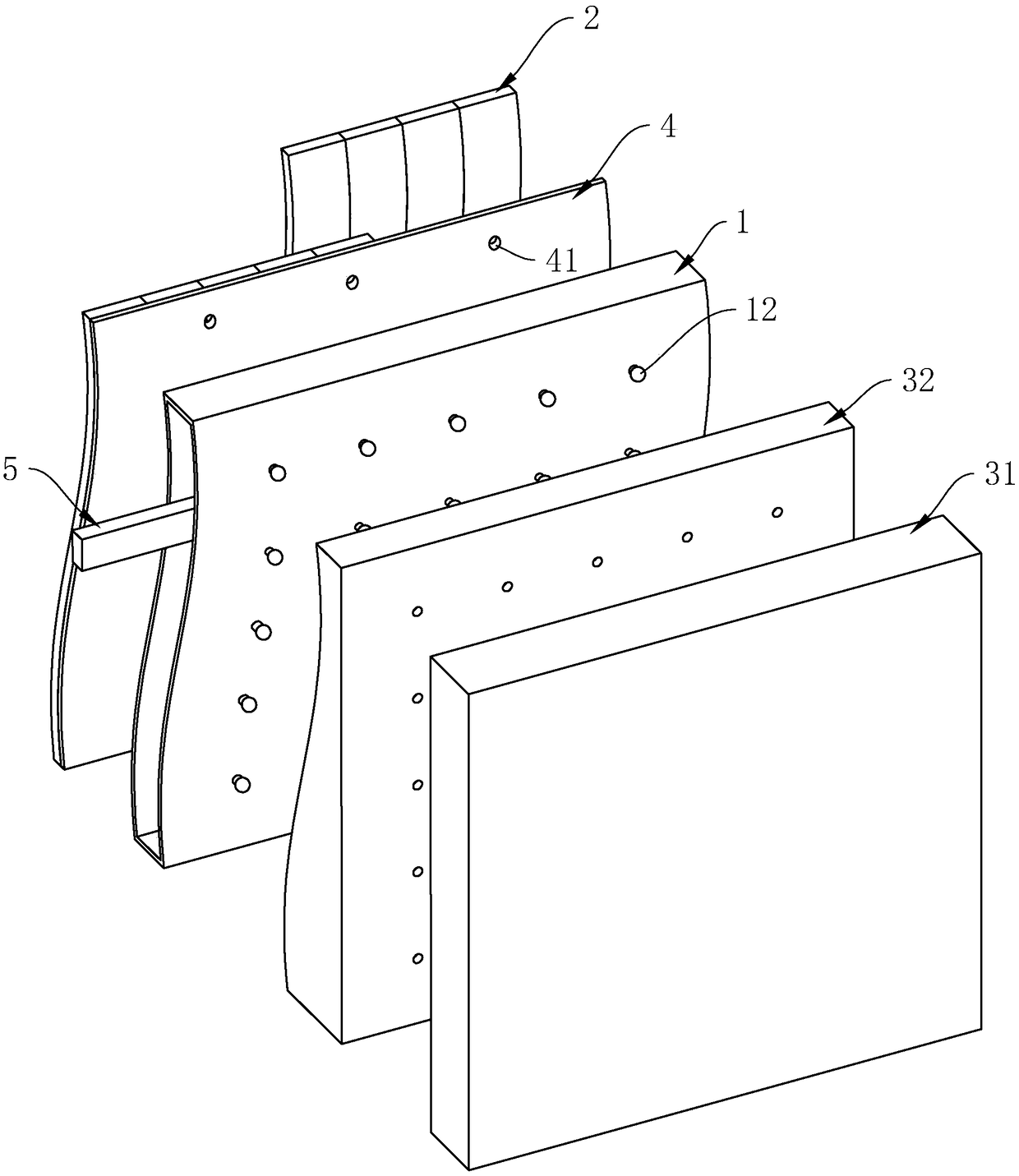

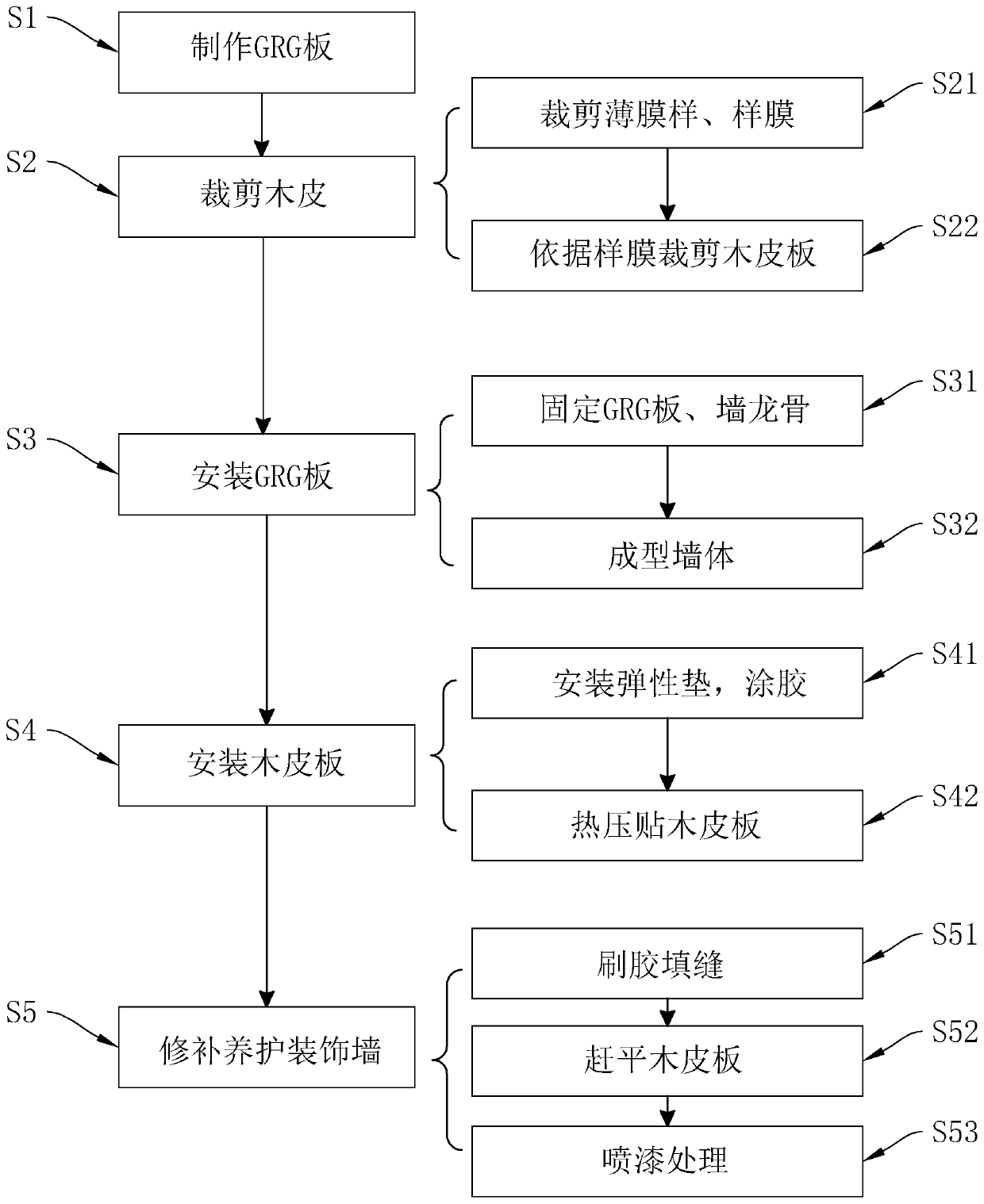

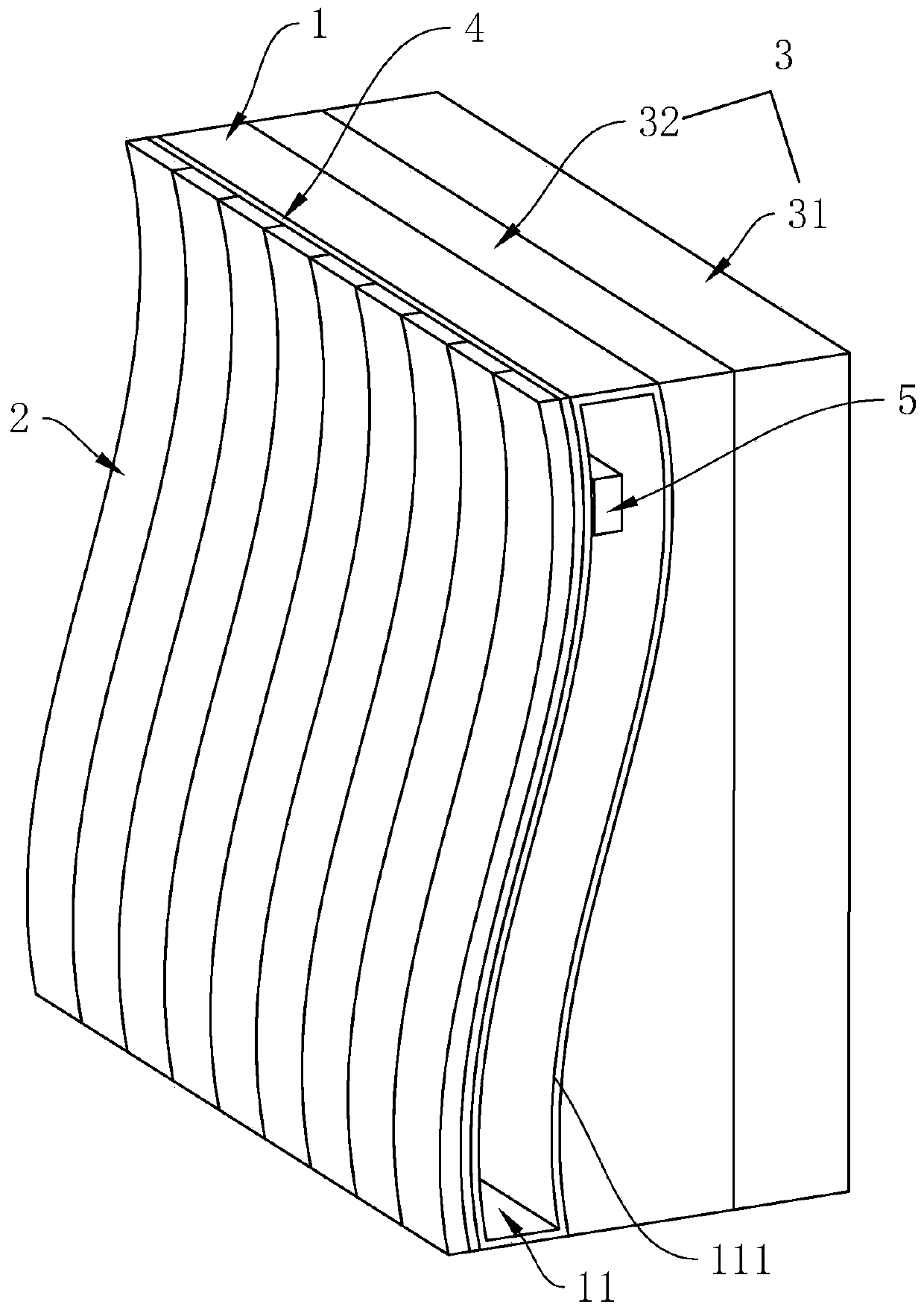

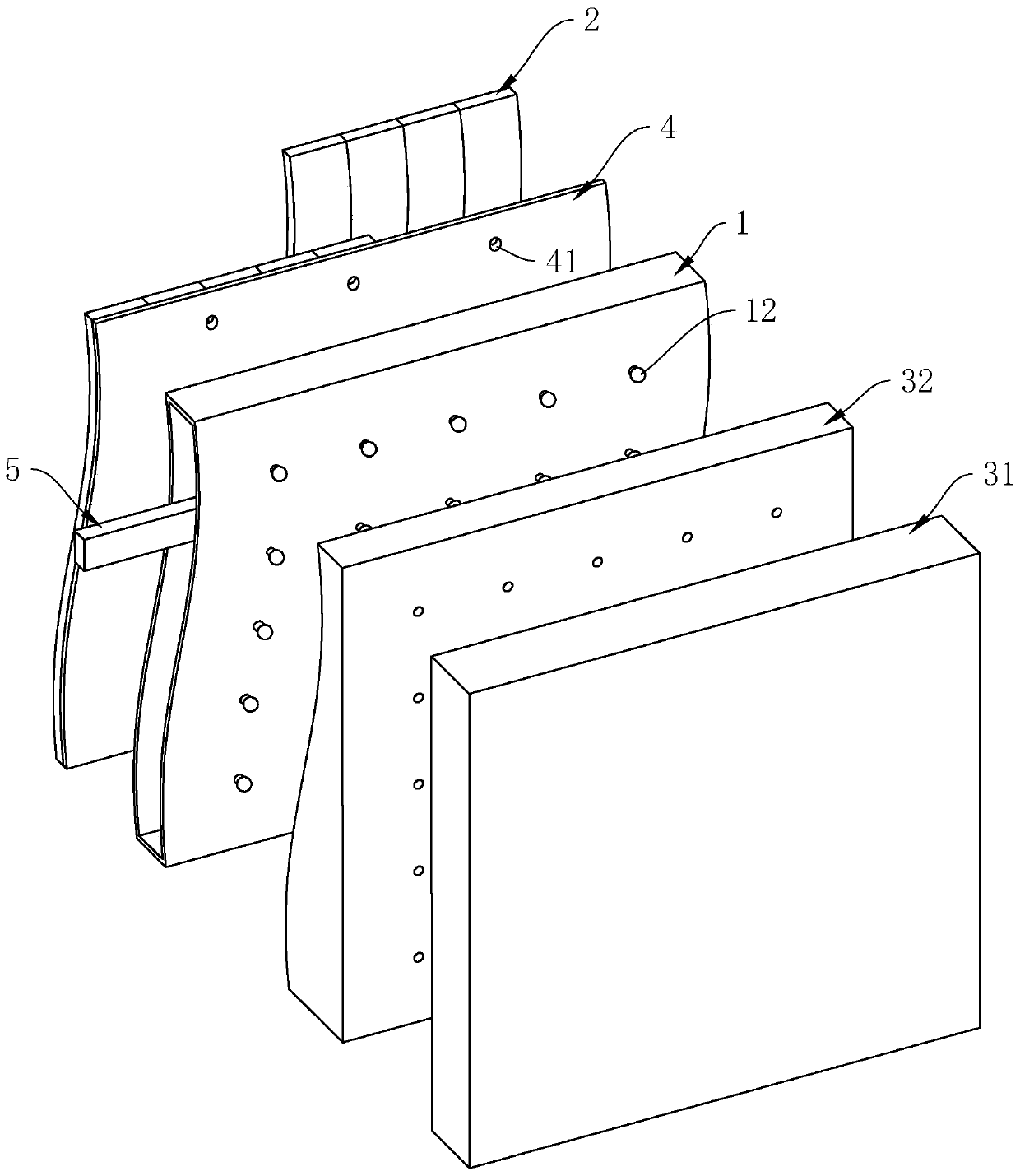

Theaterdecorative wall construction method

ActiveCN108979038AAvoid construction inconvenienceReduce gapCovering/liningsFlooringHot pressingBuilding construction

The invention discloses a theaterdecorative wall construction method, and relates to the technical field of wall construction. By adopting the theaterdecorative wall construction method, the problemsare solved that according to the prior art, it is not easy to attach veneer to a multi-curved surface, and after the veneer is mounted, the impression effect is poor. According to the technical scheme, the theaterdecorative wall construction method includes the steps that S1, a GRG plate is prepared; S2, the veneer is cut, wherein S21, a thin film sampleof which the area is equal to the area of the curved surface of the GRG plate is cut along the edge of the GRG plate, and S22, according to the thin film sample, veneer plates for being assembled are cut; S3, the GRG plate is mounted, wherein S31, a wall keel is mounted and the GRG plate is preliminarily fixed, and S32, concrete is poured at the wall keelto form a wall connected with the GRG plate; S4, the veneer plates are mounted, whereinS41, the GRG plate is uniformly glued, and S42, the veneer plates are subjected to hot pressing and flat attached to the GRG plate; S5, the decorative wall is repaired and maintained, wherein S51, glue brushing is conducted to repair seams after the veneer plates are assembled, S52, a rolling brush is handheld to flatten the surfaces of the veneer plates, and S53, paint spraying is conducted. Inthis way, the purposes are achieved that the veneer is conveniently attached to the multi-curved wall surface, and the impression quality of the veneer can be ensured.

Owner:浙江大丰建筑装饰工程有限公司

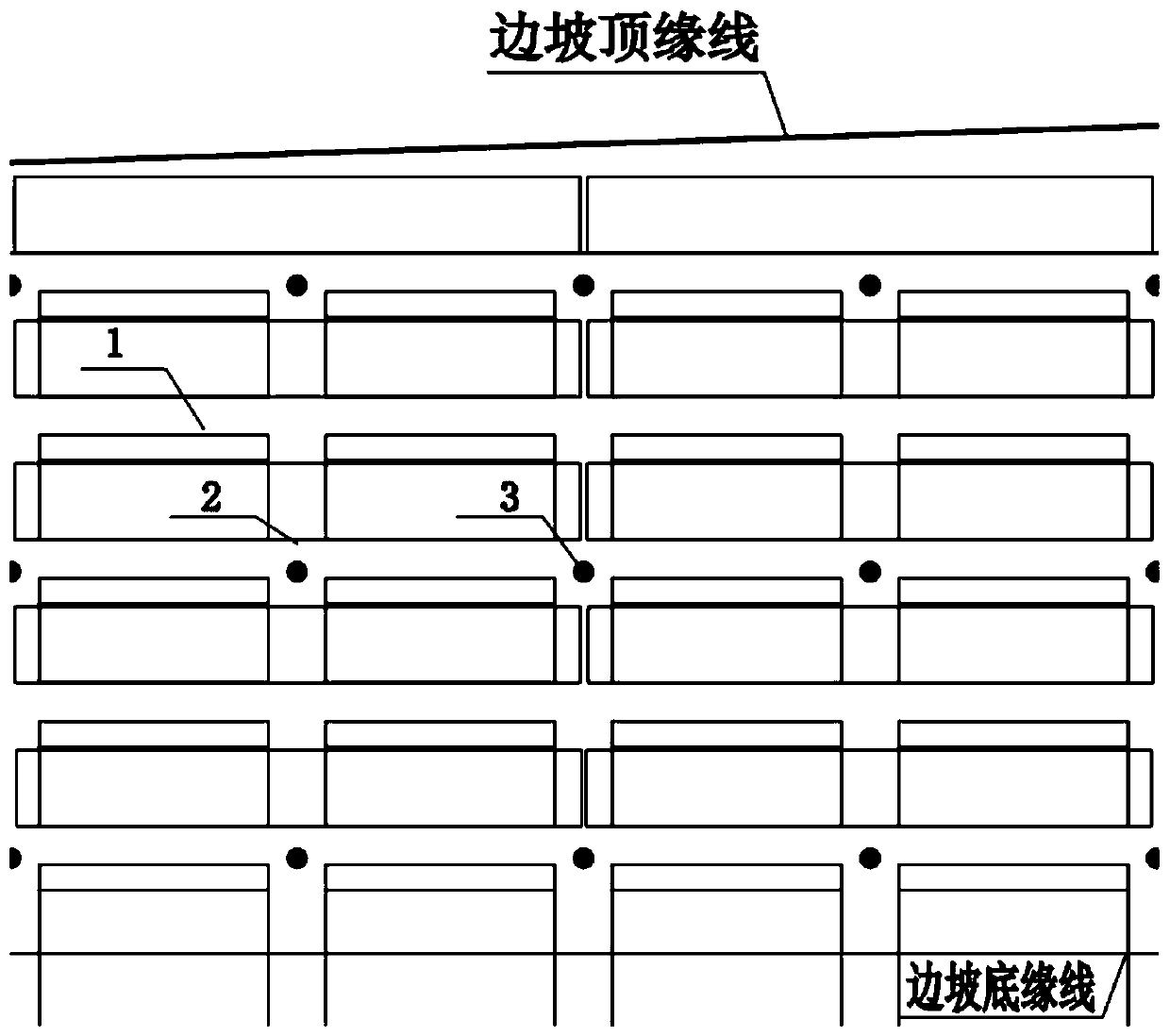

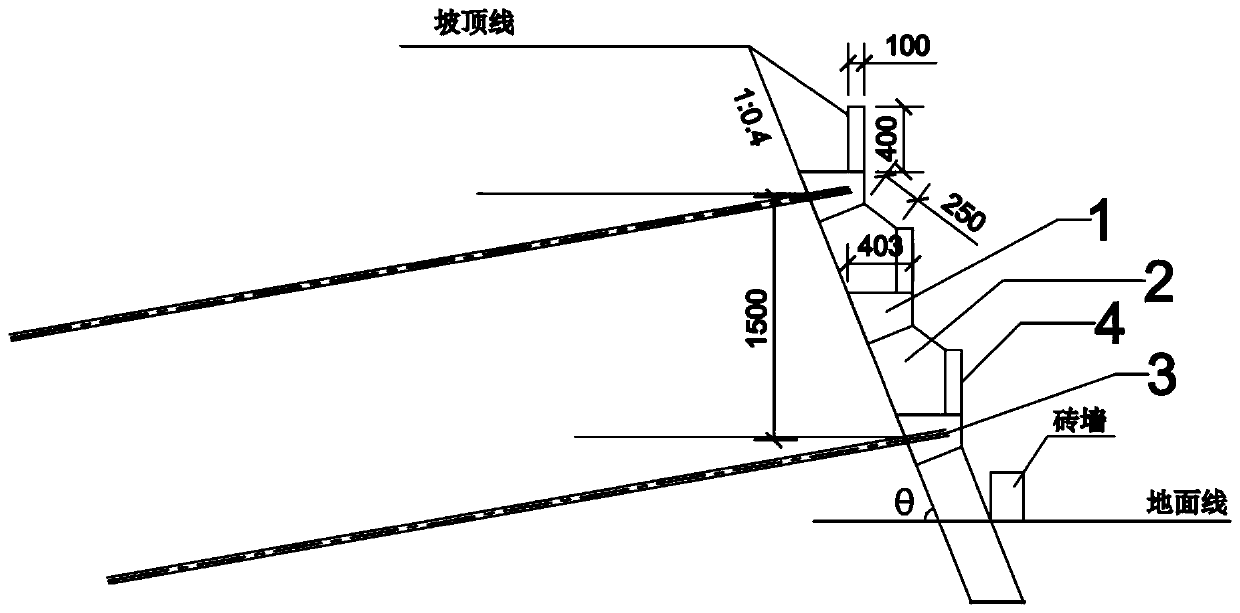

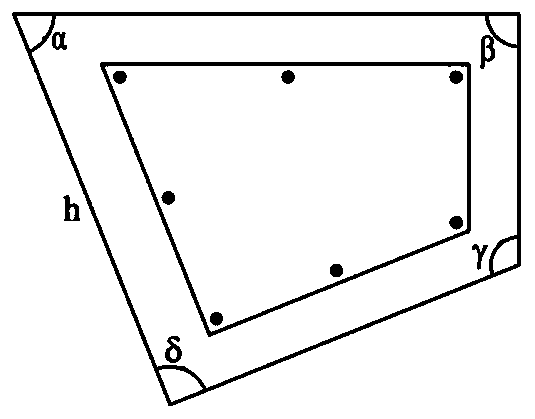

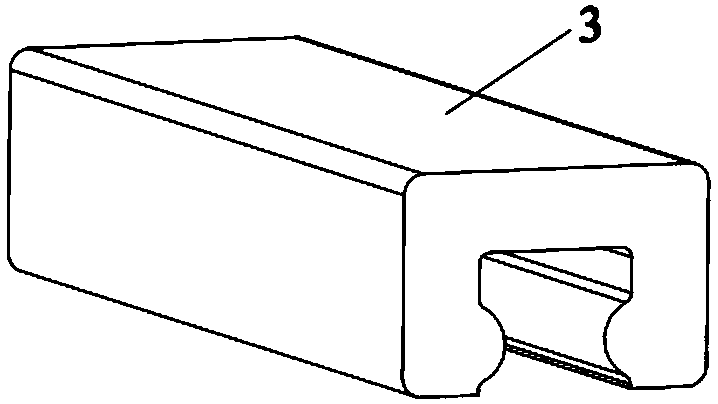

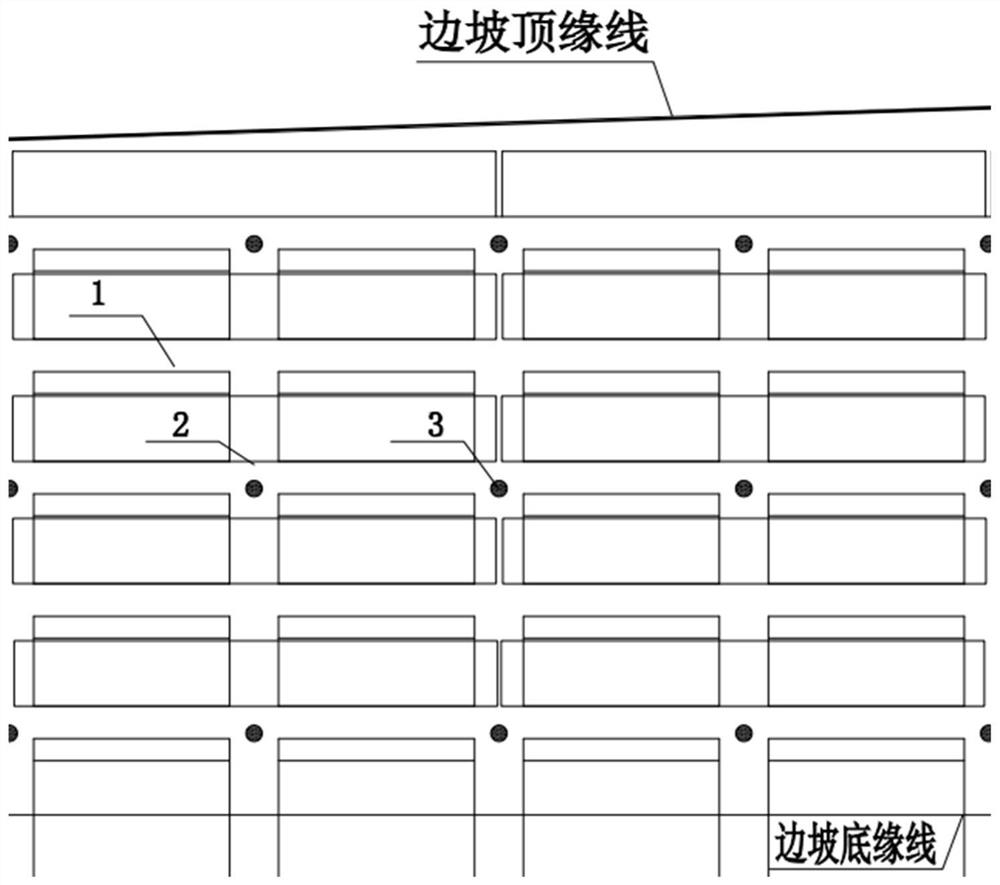

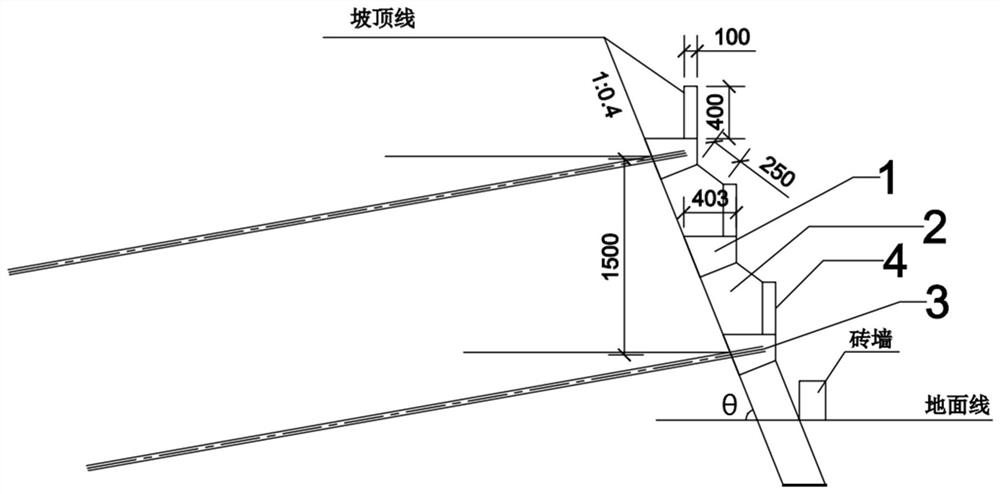

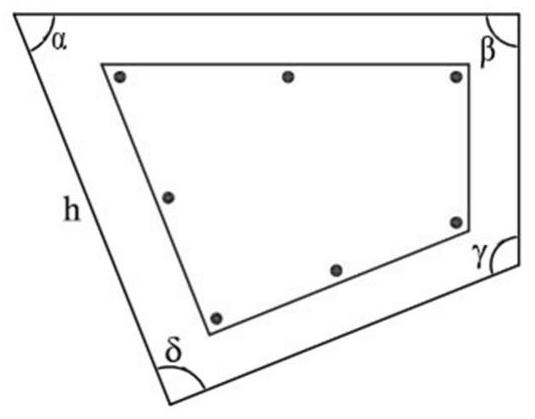

Assembled lattice frame beam

InactiveCN109811776AAvoid construction inconvenienceAvoid influenceGrowth substratesCulture mediaSlope stabilitySteep slope

Owner:JILIN UNIV

Prefabricated concrete shear wall panel connecting method employing prestressed steel strand for vertical connection

InactiveCN110230362AFirmly connectedEasy to check and acceptWallsProtective buildings/sheltersCement mortarPrecast concrete

The invention relates to a prefabricated concrete shear wall panel connecting method employing prestressed steel strand for vertical connection. The prefabricated concrete shear wall panel connectingmethod employing prestressed steel strand for vertical connection comprises the following steps that a layer of cement mortar for bonding is laid on the floor surface where a wall is about to be mounted, and then the wall is placed in the mounting position in position; a rope is used for being placed from the top of a full-length grouting hole, at an opening, the rope is connected to the end of the reserved steel strand; the steel strand is pulled out of the top of the full-length grouting hole, then the steel strand is enabled to penetrate through a hole in the middle of an anchor plate, a small tensioning jack is used for jacking the anchor plate, and the steel strand is stretched and drawn; after the design elongation is reached, the clamping piece is inserted into a gap between the anchor plate hole and the steel strand for anchoring steel strands, and then the opening in the bottom of the full-length grouting hole is closed, and the cement mortar is injected into the full-length grouting hole until the full-length grouting hole is filled with the cement mortar totally. The vertical connection problem of the prefabricated concrete shear wall panels can be effectively solved.

Owner:HUA HUI ENGINEERING DESIGN GROUP CO LTD +1

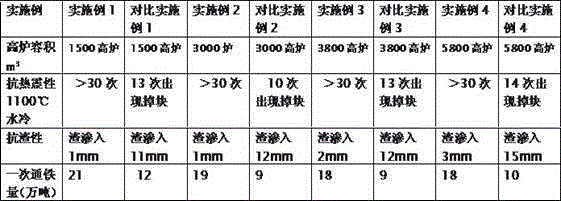

Castable for main trough of middle-sized blast furnace

InactiveCN105254316AImprove corrosion resistanceImprove thermal shock resistanceAl powderChromium nitride

The invention relates to a castable for a main trough of a middle-sized blast furnace and belongs to the field of refractory castables. The castable is prepared from the following components in parts by weight: 5 to 8 parts of 8-5mm tabular corundum, 15 to 20 parts of 5-3mm chromium nitride, 10 to 15 parts of 3-1mm sillimanite, 8 to 15 parts of 1-0mm calcium chromate, 2 to 5 parts of slightly viscous clay powder, 3 to 7 parts of cobaltous oxide aluminum powder, 5 to 10 parts of cutting powder, 3 to 8 parts of amorphous graphite powder, 1 to 2 parts of composite carbon powder, 0 to 3 parts of molybdenum trioxide powder, 3 to 5 parts of alumina micro powder, 1 to 5 parts of magnesium oxide iron powder, 1 to 3 parts of rho aluminium oxide and 0 to 5 parts of electric smelting pure calcium aluminate cement; it is assumed that the sum of the total weight parts of main ingredients is 100%, then additives comprise the following components in part by weight: 0.1 to 0.2 part of calcium lignosulphonate, 0.01 to 0.05 part of nanometer potato powder, 0.01 part of malic acid and 0.1 part of C12H14N4O5S2. The main trough of the blast furnace prepared with the castable has the advantages of good thermal shock resistance, strong erosion resistance, a big iron influx and a long service life.

Owner:张婷

Quick threading method by negative pressure

InactiveCN107240892AReduce homeworkEasy to get materialsApparatus for laying cablesSuction forceMechanical engineering

The invention provides a quick threading method by negative pressure. One end of a pre-wire-embedding pipe is connected with a diameter-variable pipe and an air channel in sequence; the cable end of a to-be-threaded cable is connected with a high-elastic and air-tight sponge sphere; one end with the sponge sphere of the cable is placed in the interior of one end, different from one end connected with the diameter-variable pipe, of the pre-wire-embedding pipe; a negative pressure source is started, and the sponge sphere and the cable connected therewith are inhaled to one end, connected with the diameter-variable pipe, of the pre-wire-embedding pipe through suction force, wherein the end plane at one end with a small diameter of the diameter-variable pipe props against the sponge sphere; and the diameter-variable pipe is separated from the pre-wire-embedding pipe, and the cable is drawn out. By creatively adopting the mechanical operation, the method is easy in material taking, simple in operation, quick and convenient, and capable of lowering construction workload; compared with the conventional method, the working efficiency is improved by at least three times; and steel wire traction is not adopted in the whole construction process, so that the operating process of steel wire threading is reduced, and inconvenience brought to construction caused by steel wire cracking can be avoided.

Owner:MCC TIANGONG GROUP

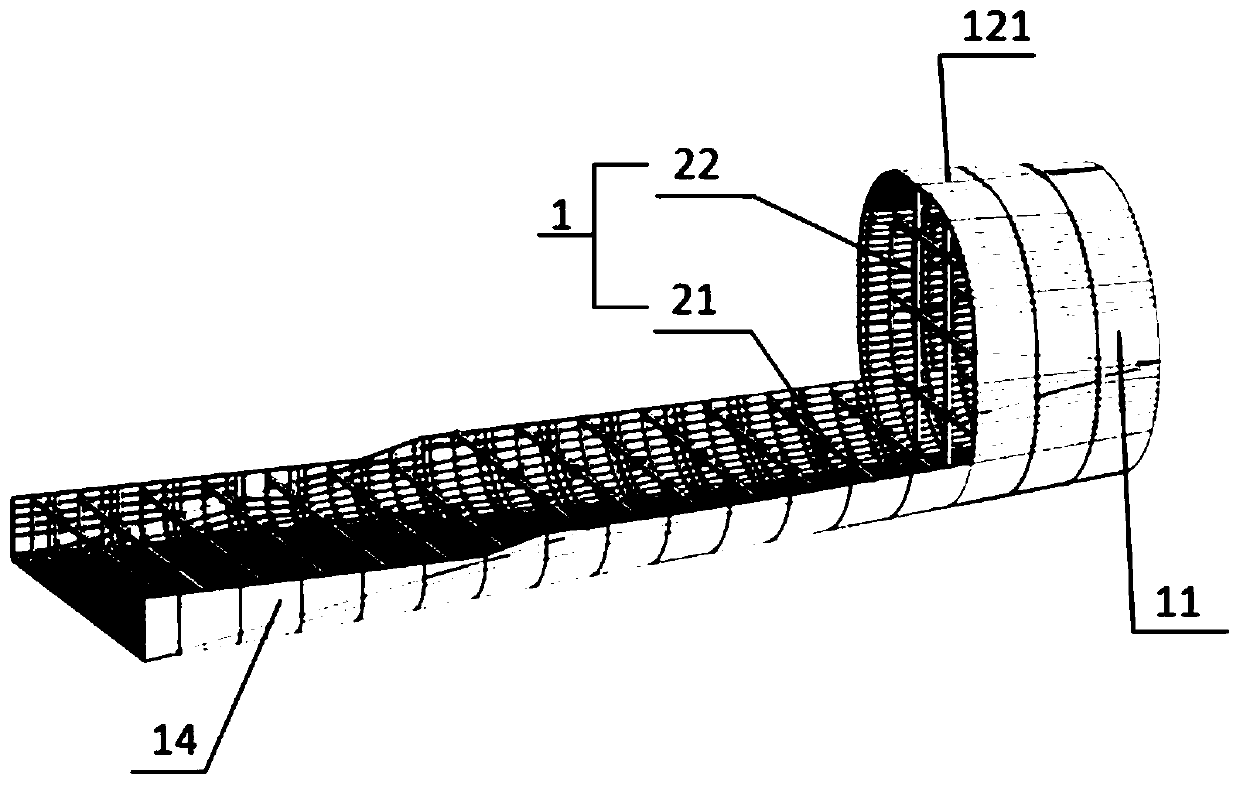

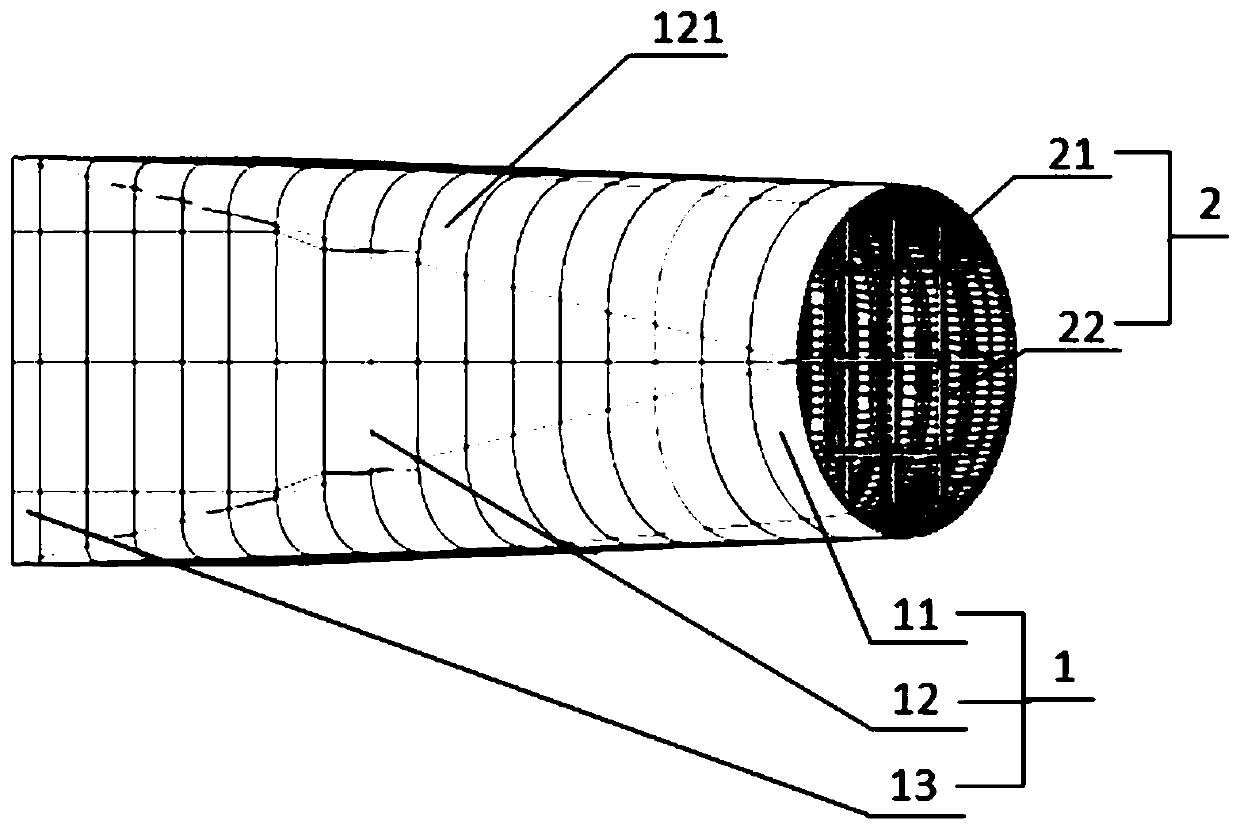

Construction method of inner mold support system for super large wind tunnel diffusion section

ActiveCN110284706AAvoid construction inconvenienceSimplify the construction processForms/shuttering/falseworksBuilding material handlingSteel cylinderMachining

The invention belongs to the technical field of wind tunnel construction methods, andparticularly relates to a construction method of an inner mold support system for a super large wind tunnel diffusion section.Theconstruction method of the inner mold support system for the super large wind tunnel diffusion sectioncomprises the following steps that A, an inner steel cylinder formwork and a profile steel structure support frameare structurally designed and subjected to consigned machining; B, the inner steel cylinder formwork and the profile steel structure support frame are machined, pass an examination, and are transported to a construction site, a project department organizes material acceptance, and data such as the size,flatness, curvature, and chord length of each formwork are rechecked one by one according to two-dimensional code data to ensure that the design requirements are met; C, on-site positioning and line dropping of each cross section of the inner steel cylinder formwork are conducted; and D, positioning and mounting of the inner steel cylinder formwork and the profile steel structure support frame are conducted.According to the construction method of the inner mold support system for the super large wind tunnel diffusion section, the construction problem of the super large wind tunnel circular-to-square diffusion section iseffectively solved,with the method, the internal mold support system which meets the construction accuracy requirements can be built, and smooth completion of the construction is ensured.

Owner:CONSTR DEV OF CHINA CONSTR SIXTH ENG DIV +1

Castable for main iron trough

InactiveCN105198467AImprove corrosion resistanceImprove thermal shock resistanceAl powderChromium nitride

The invention relates to a castable for a main iron trough. The castable comprises a main material and an additive, wherein the main material comprises components in parts by weight as follows: 5-8 parts of 10-5mm magnesium titanate, 15-20 parts of 5-3 mm chromium nitride, 10-15 parts of 3-1 mm sillimanite, 8-15 parts of 1-0 mm calcium chromite, 2-5 parts of clay powder, 3-7 parts of cobaltous oxide aluminum powder, 5-10 parts of cutting powder, 3-8 parts of amorphous graphite powder, 1-2 parts of composite carbon powder, 0-3 parts of molybdenum trioxide powder, 3-5 parts of alumina micropowder, 1-5 parts of magnesium oxide iron powder, 1-3 parts of rho aluminum oxide and 1-5 parts of fused calcium aluminate cement; the additive comprises, in parts by weight, 0.1-0.2 parts of calcium lignosulfonate, 0.01-0.05 parts of nano potato powder, 0.01 parts of malic acid and 0.1 parts of C12H14N4O5S2 on the basis that the parts of the main material by weight adds up to 100%. The blast furnace iron trough prepared with the castable has the characteristics of good thermal shock resistance, high corrosion resistance, large iron influx and long service life.

Owner:汤炼芳

Castable

InactiveCN105330311AImprove corrosion resistanceImprove thermal shock resistanceCobaltMolybdenum trioxide

The invention relates to castable. The castable is prepared from a main material and additives. The main material is prepared from, by weight, 5-8 parts of 8-5 mm barium aluminate, 15-20 parts of 5-3 mm chromium mononitride, 10-15 parts of 3-1 mm sillimanite, 8-15 parts of 1-0 mm calcium chromite, 2-5 parts of clay-like powder, 3-7 parts of cobalt aluminum oxide powder, 5-10 parts of cutting powder, 3-8 parts of amorphous graphite, 1-2 parts of composite powdered carbon, 0-3 parts of molybdenum trioxide powder, 3-5 parts of alumina micro powder, 1-5 parts of magnesium oxide iron powder, 1-3 parts of rho aluminum oxide and 0-5 parts of electric-smelted pure calcium aluminate cement. With the main material accounting for 100% by weight in total, the additives are prepared from, by weight, 0.1-0.2 part of calcium lignosulfonate, 0.01-0.05 part of nanometer dried potato powder, 0.01 part of malic acid and 0.01 part of C12H14N4O5S2. A blast furnace iron runner made of the castable has the advantages of being good in thermal shock resistance, high in corrosion resisting performance, large in iron exchanging amount and long in service life.

Owner:山国强

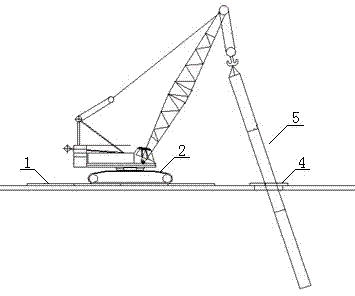

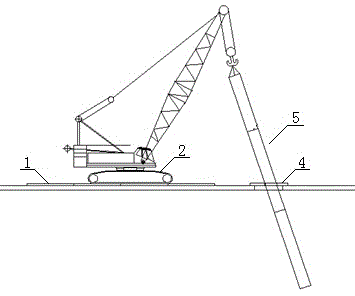

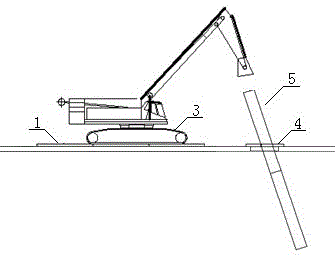

Pier piling method based on crawler type engineering machine

InactiveCN104711983AGuaranteed normal operationAvoid construction inconvenienceBulkheads/pilesSteel platesPier

The invention relates to a pier piling method based on a crawler type engineering machine. An existing pier ground serves as a supporting face, a crawler type hanging machine and a crawler type piling machine are sequentially arranged on a steel plate laid on the ground of a construction pier, pile bodies are hung, transported and constructed, and therefore the construction of the existing pier is reinforced; the whole design method is clear in logic, the normal work of the pier is kept during construction, the inconvenience caused when a traditional piling ship is driven into pile groups for construction and damage caused to existing pile foundations are effectively avoided; in addition, the whole design method is simple, cost is easy to control, and the construction period and construction quality can be effectively ensured in actual application.

Owner:HOHAI UNIV

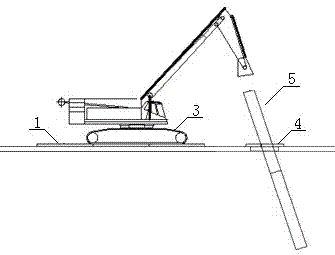

Multifunctional tool frame

InactiveCN103802082AOrderly storageReasonable structureWork tools storageComputer scienceStainless steel material

Owner:STATE GRID CORP OF CHINA +1

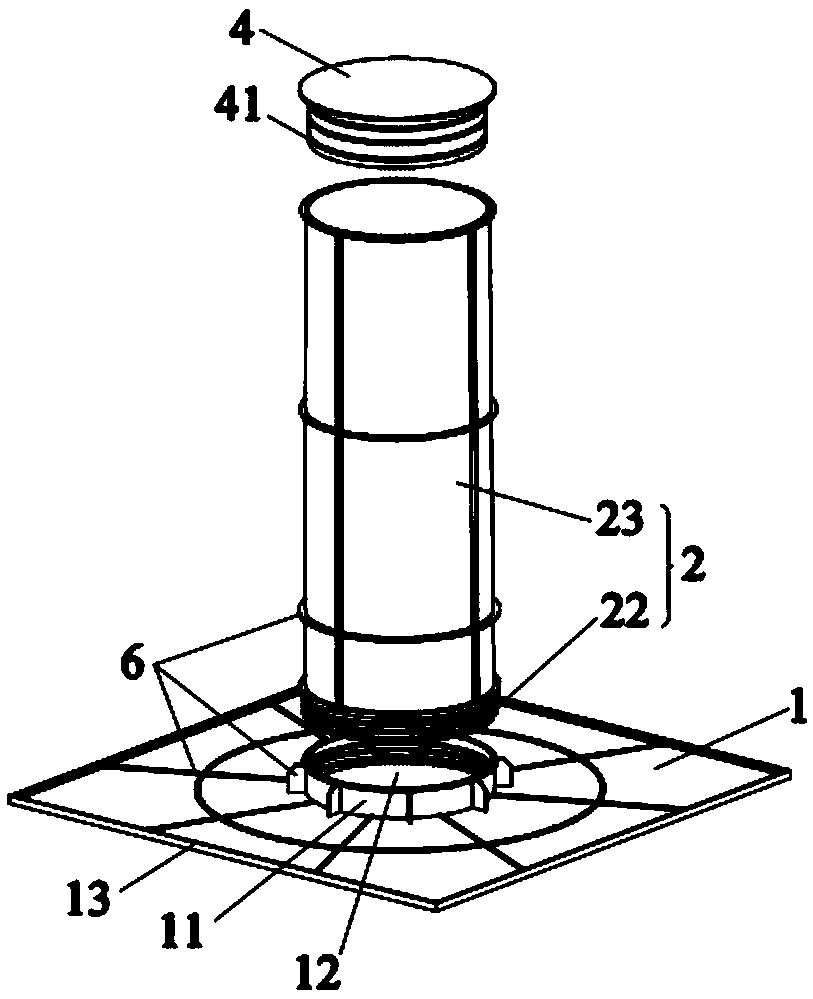

Wafer board mould and construction method thereof

PendingCN108643566AAvoid construction inconvenienceReduce construction difficultyForms/shuttering/falseworksArchitectural engineeringRebar

The invention relates to the related technical field of buildings, discloses a wafer board mould and further discloses a construction method of the wafer board mould. The wafer board mould comprises base plates, cylinders and clamping strips. The lower ends of the cylinders are detachably connected with the base plates, and the clamping strips are used for being connected with the adjacent base plates. The base plates and the cylinders of the wafer board mould can be detached, binding of hidden beam steel bars between the wafer board moulds and fixing and sealing of the mould base plates can be more convenient and easier, the construction difficulty is lowered, the construction quality is ensured, and the construction efficiency is improved; and in addition, the base plates of the wafer board mould are fixed through the clamping strips, the construction method is greatly simplified, the construction process is reduced, the mould base plates are fixed more conveniently and more rapidly,the construction workload is decreased, the construction speed is increased, and meanwhile the fixing quality of the mould base plates is improved.

Owner:SHANGHAI BAOYE GRP CORP

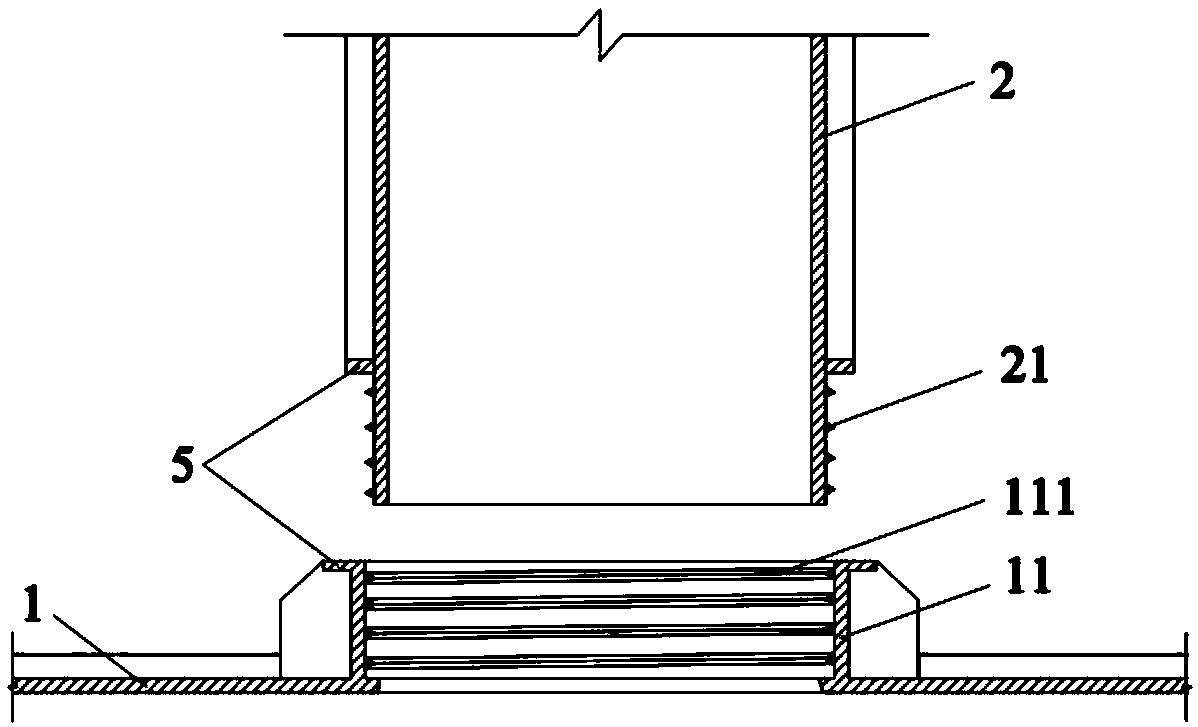

Castable for 2000m<3> blast furnace supporting iron runner

InactiveCN105218124AImprove corrosion resistanceImprove thermal shock resistanceMulliteChromium nitride

The invention relates to a castable for a 2000m<3> blast furnace supporting iron runner. The castable comprises a main material and an additive, wherein the main material comprises the following components in parts by weight: 5-8 parts of 5mm-8mm zirconium mullite, 15-20 parts of 3mm-5mm chromium nitride, 10-15 parts of 1mm-3mm sillimanite, 8-15 parts of 0-1mm calcium chromate, 2-5 parts of clay powder, 3-7 parts of cobalt aluminum oxide powder, 5-10 parts of cutting powder, 3-8 parts of amorphous graphite powder, 1-2 parts of composite carbon powder, 0-3 parts of molybdenum trioxide powder, 3-5 parts of alumina micro powder, 1-5 parts of magnesium iron oxide powder, 1-3 parts of rho alumina and 0-5 parts of electric-fused pure calcium aluminate cement; the additive comprises the following components in parts by weight of 100% of the main material: 0.1-0.2 part of calcium lignosulphonate, 0.01-0.05 part of nano potato powder, 0.01 part of malic acid and 0.1 part of C12H14N4O5S2. The blast furnace supporting iron runner prepared from the castable has the characteristics of good thermal shock resistance, strong erosion resistance, high iron influx and long service life.

Owner:万燕杰

An assembled lattice frame beam

InactiveCN109811776BAvoid construction inconvenienceVegetation is durableGrowth substratesCulture mediaEnvironmental resource managementStructural engineering

Owner:JILIN UNIV

Construction method of pre-building supported and settled foundation on ground and fixing after pre-pressing for high-rise building with basement

The invention discloses a construction method of pre-building a supported and settled foundation on ground and fixing after pre-pressing for a high-rise building with a basement. The method comprises the following steps: constructing the whole building including the basement on the ground in advance; arranging a grid supporter at the position of a structural base plate, wherein the grid supporter is used to transfer a vertical load of the building and balance the lateral pressure of the soil around an outer wall; arranging supporting piles which extend to the ground; arranging alternate force-transferring devices capable of being lifted and temporarily fixed between the supporting piles and the grid supporter, thereby moving the building downwards completely and stably; arranging a flexible cut waterproof curtain at the position of the outer wall of the basement, thereby reducing the downward cutting resistance of the outer wall during the downward moving process of the building; when the building moves downwards to a preset position, pre-pressing the construction piles one by one by utilizing the dead load of the building and a special loading device to finish the set settling of single piles in advance; loading a non-pile supporting building in blocks and finishing the set settling in advance; after the dead load of the upper building reaches a preset value, completely descending the building to a designed height; and pouring the base plate and finishing the final fixing of the building.

Owner:CHINA CONSTR THIRD ENG BUREAU GRP CO LTD

An embedded external prestressing implementation system and its construction method for strengthening RC columns

ActiveCN112096108BRegulating excavationAdjust winding densityStrutsBuilding repairsPre stressArchitectural engineering

The invention discloses an embedded external prestressing implementation system and a construction method for strengthening RC columns, which include steel strand laying grooves, prestressed steel strands, end anchoring devices, prestressed transverse stretching devices, traction line lifting devices and Prestressing device. The surface of the reinforced concrete column to be reinforced is opened in the form of m coiled helical strand routing trough and n vertical grooves; prestressed horizontal tensioning devices are arranged at the intersection of the vertical grooves and the steel strand laying grooves; the pulling wire lifting device includes pulling wires and m a traction line buckle; when the prestressing device pulls the traction line downward, m A pull wire clip will squeeze m A prestressed transverse tension device, so that m A transverse tensioning component is stretched transversely, thereby making the prestressed steel strand transversely stretched. The present invention adopts the way of transverse stretching, and only needs to provide 1 / 5~1 / 7 of the stretching force during longitudinal stretching to achieve the expected stretching effect. At the same time, it adopts anchoring first and then tensioning, which facilitates anchoring at the end and greatly reduces the difficulty of anchoring.

Owner:HOHAI UNIV

Casting material for 800m<3> blast-furnace branch iron trough

InactiveCN105272302AImprove corrosion resistanceImprove thermal shock resistanceChromium nitrideCobalt

The invention relates to a casting material for a 800m<3> blast-furnace branch iron trough. The casting material comprises a main material and an additive, wherein the main material comprises the following components in parts by weight: 5-8 parts of 8-5mm magnesium silicate, 15-20 parts of 5-3mm chromium nitride, 10-15 parts of 3-1mm sillimanite, 8-15 parts of 1-0mm calcium chromite, 2-5 parts of slightly-viscous clay powder, 3-7 parts of cobalt-aluminum oxide powder, 5-10 parts of cutting powder, 3-8 parts of amorphous graphite powder, 1-2 parts of compound carbon powder, 0-3 parts of molybdenum trioxide powder, 3-5 parts of aluminium oxide micropowder, 1-5 parts of magnesium-iron oxide powder, 1-3 parts of Rho aluminium oxide and 0-5 parts of electrically-smelted pure calcium aluminate cement; the additive comprises the following components in parts by weight according to the total weight part 100% of the main material: 0.1-0.2 part of calcium lignosulphonate, 0.01-0.05 part of nano potato powder, 0.01 part of malic acid and 0.1 part of C12H14N4O5S2. The blast-furnace iron trough prepared by the casting material has the characteristics of good thermal shock resistance, strong anti-erosion performance, large iron influx and long service life.

Owner:万燕杰

A construction method for a theater decorative wall

ActiveCN108979038BFits flat against the wallGuaranteed visual qualityCovering/liningsWallsThin membraneStructural engineering

Owner:浙江大丰建筑装饰工程有限公司

Automatic painting device for putty powder on circular groove wall of television background wall

ActiveCN112324097AWith automationAvoid construction inconvenienceBuilding constructionsFixed frameEngineering

The invention relates to home decoration equipment, and particularly relates to an automatic painting device for putty powder on a circular groove wall of a television background wall. The automatic painting device for the putty powder on the circular groove wall of the television background wall can quickly paint the putty powder on the circular groove wall, can paint the putty powder in all directions, and cannot contaminate the putty powder on a body in the painting process. The automatic painting device for the putty powder on the circular groove wall of the television background wall comprises a fixed frame, wherein mounting frames are respectively arranged on two sides of the fixed frame; a fixed base is arranged between the positions, near one side of each mounting frame, of the fixed frame; and a rotating rod is rotationally arranged on the other side of the fixed base. The automatic painting device adopts a mode of driving a brush block to rotate by a connecting frame, and adopts a mode of rotating a transmission gear on an arc tooth belt to enable the brush block to move to the inner side every time rotating by one lap, so that the putty powder on the circular groove wallcan be automatically and quickly painted.

Owner:江苏中装建设有限公司

Branch iron runner castable material

InactiveCN105347820AImprove corrosion resistanceImprove thermal shock resistanceChromium nitrideCobalt

The invention relates to a branch iron runner castable material. The branch iron runner castable material comprises a main material and an additive. The main material comprises, by weight, 5-8 parts of magnesium titanate with particle sizes of 3-5mm, 15-20 parts of chromium nitride with particle sizes of 5-3mm, 15-20 parts of sillimanite with particle sizes of 3-1mm, 8-15 parts of calcium chromite with particle sizes of 1-0mm, 2-5 parts of clay-like powder, 3-7 parts of cobalt aluminum oxide powder, 5-10 parts of cutting powder, 3-8 parts of amorphous graphite powder, 1-2 parts of composite carbon powder, 0-3 parts of molybdenum trioxide powder, 3-5 parts of alumina micro-powder, 1-5 parts of iron magnesium oxide powder, 1-3 parts of Rho alumina and 1-5 parts of fused pure calcium aluminate cement. Based on the total weight part of the above main materials, a weight part of calcium lignin sulphonate is 0.1-0.2, a weight part of nanometer potato powder is 0.01-0.05, a weight part of malic acid is 0.01 and a weight part of C12H14N4O5S2 is 0.1. A blast furnace iron runner prepared from the castable material has the characteristics of good thermal shock resistance, corrosion resistance, large iron influx and long service life.

Owner:汤炼芳

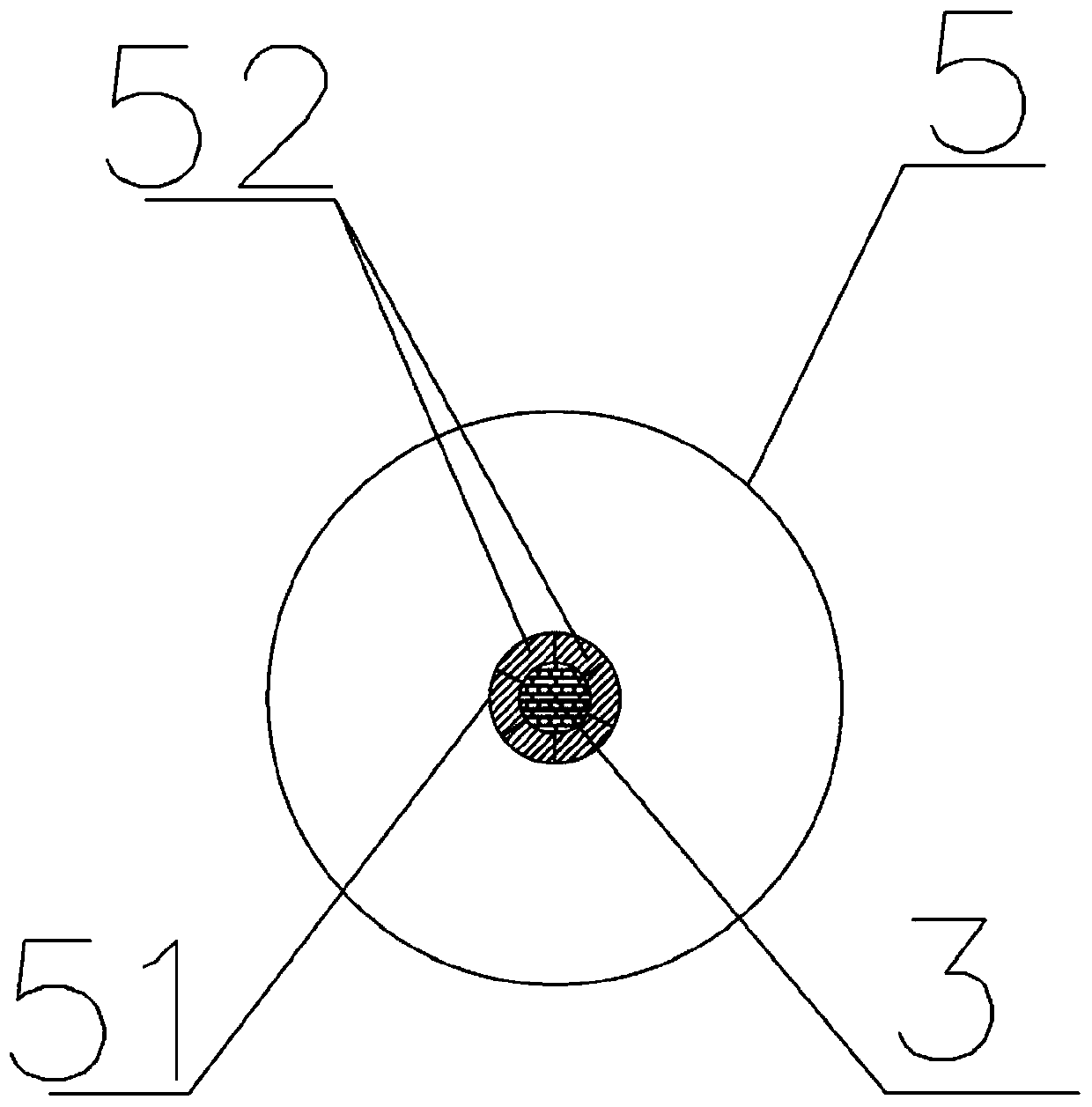

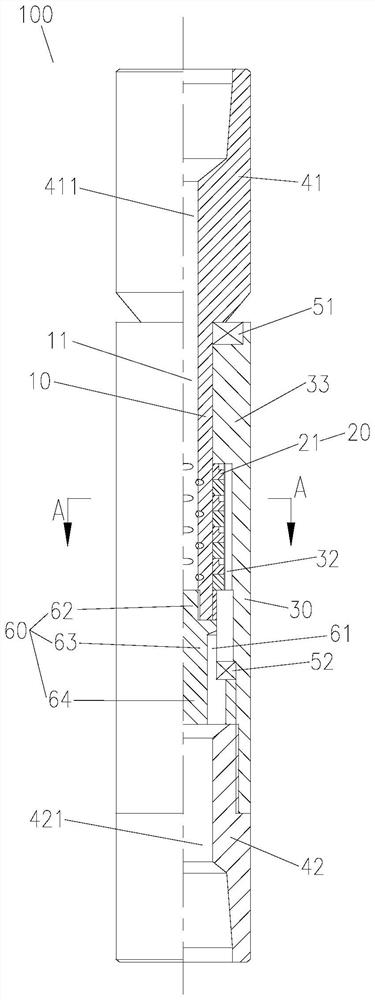

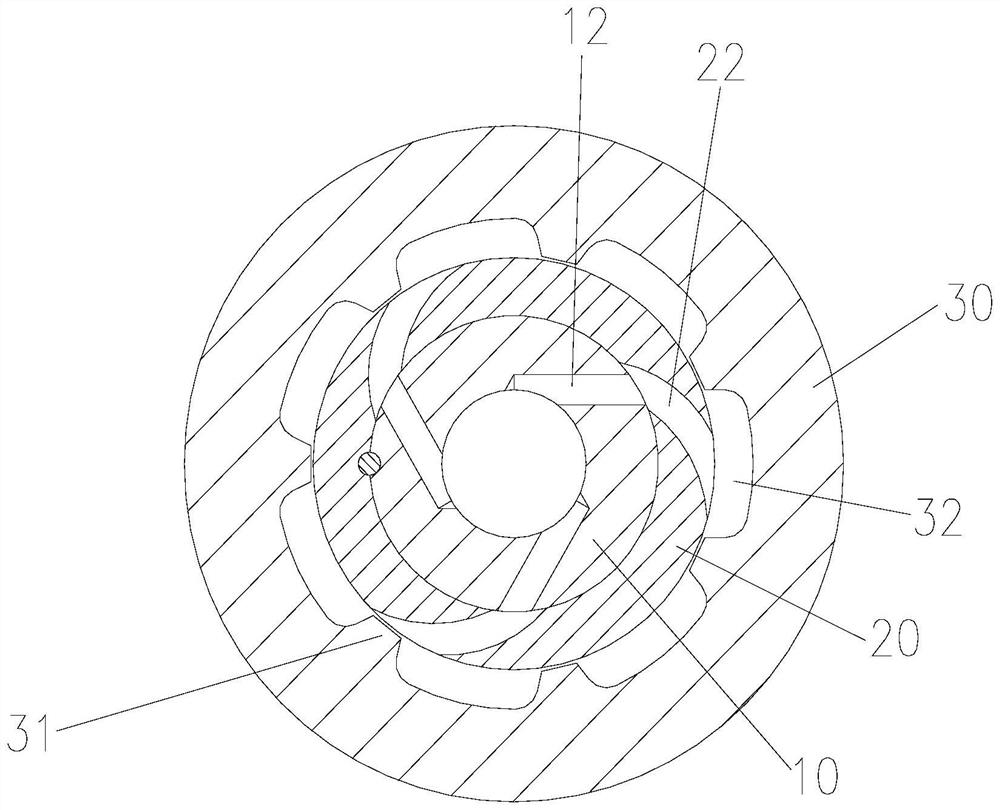

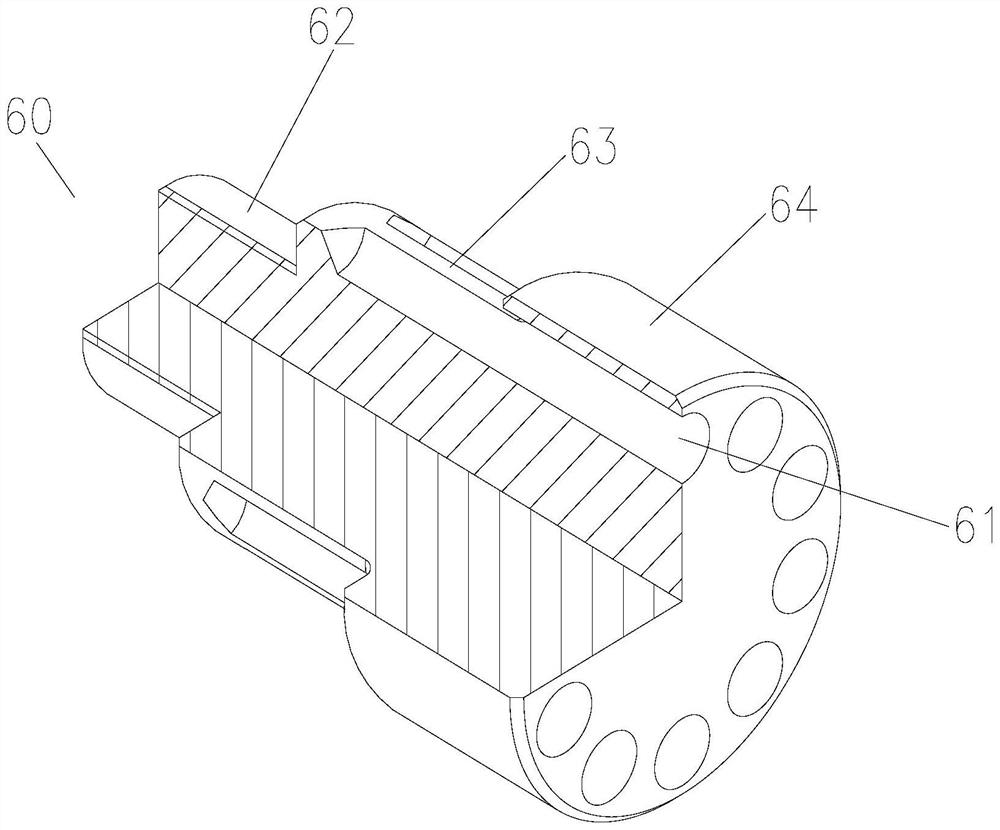

Power device and drilling and grinding tool

ActiveCN114293940AAvoid construction inconvenienceSolve the inconvenience of constructionBorehole/well accessoriesDrive shaftEngineering

The invention provides a power device and a drilling and grinding tool, the power device comprises a driving shaft assembly, the driving shaft assembly is provided with a circulation channel and a plurality of circulation holes, the first end of each circulation hole is communicated with the circulation channel, and the second end of each circulation hole extends to the peripheral wall of the driving shaft assembly; the second end of each circulation hole deviates from a preset angle relative to a corresponding preset radial line in the circumferential direction of the driving shaft assembly; the outer side of the driving shaft assembly is sleeved with the outer shell part, and the outer shell part and the driving shaft assembly are arranged at intervals; liquid entering the circulation channel flows out through the multiple circulation holes so as to generate driving force on the shell part or the driving shaft assembly, then one of the driving shaft assembly and the shell part is of a stator structure, the other one of the driving shaft assembly and the shell part is of a rotor structure, and the rotor structure is used for being connected with a drilling and grinding device or a flushing device. The power device solves the problem that a driving mode adopted by a drilling and grinding tool in the prior art is inconvenient to construct.

Owner:JEREH ENERGY SERVICES

Castable for branch iron trough of 1,250 m<3> blast furnace

InactiveCN105198466AImprove corrosion resistanceImprove thermal shock resistanceAluminum silicateChromium nitride

The invention relates to a castable for a branch iron trough of a 1,250 m<3> blast furnace. The castable comprises a main material and an admixture, wherein the main material comprises components in parts by weight as follows: 5-8 parts of 8-5-mm aluminum silicate, 15-20 parts of 5-3-mm chromium nitride, 10-15 parts of 3-1-mm sillimanite, 8-15 parts of 1-0-mm calcium chromite, 2-5 parts of meta-clay powder, 3-7 parts of cobalt oxide aluminum powder, 5-10 parts of cutting powder, 3-8 parts of amorphous graphite powder, 1-2 parts of composite carbon powder, 0-3 parts of molybdenum trioxide powder, 3-5 parts of alumina micro-powder, 1-5 parts of magnesium oxide iron powder, 1-3 parts of rho alumina and 0-5 parts of fused pure calcium aluminate cement; in terms of the total parts by weight of the main material being 100%, the admixture comprises 0.1-0.2 parts by weight of calcium lignosulphonate, 0.01-0.05 parts by weight of nano dried potato powder, 0.01 parts by weight of malic acid and 0.1 parts by weight of C12H14N4O5S2. The blast furnace iron trough prepared from the castable has the characteristics of good thermal shock resistance, good erosion resistance, high iron flux and long service life.

Owner:万燕杰

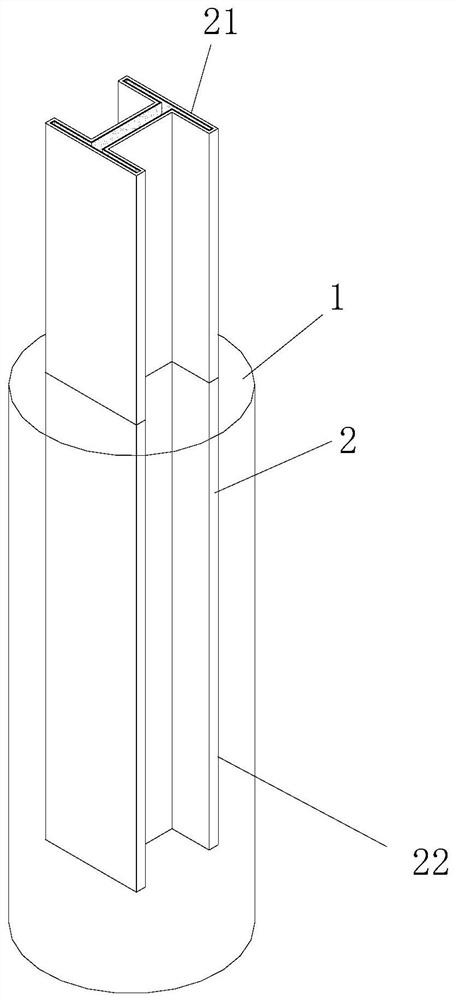

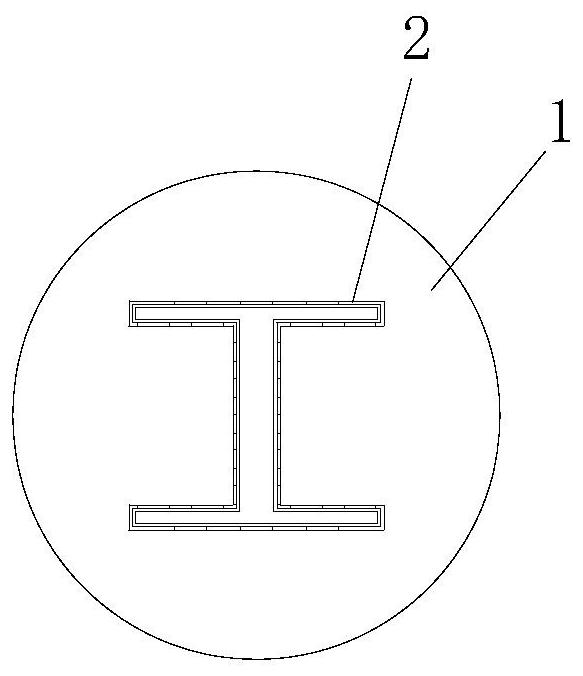

Profile steel or steel pipe cast-in-situ bored pile and construction method thereof

InactiveCN112095588AAvoid construction inconvenienceShorten production timeBulkheads/pilesEngineeringPipe

The invention relates to a profile steel or steel pipe cast-in-situ bored pile and a construction method thereof. The cast-in-situ bored pile comprises a pile body, wherein the pile body is filled with retarded concrete; profile steel or a steel pipe is inserted into the axis position of the pile body in a penetrating manner; an upper extension part is arranged at the upper part, positioned on thepile body, of the profile steel or the steel pipe; a contraction part is arranged at the lower part, positioned on the pile body, of the profile steel or the steel pipe; and the contraction part hasa certain depth from the bottom of the concrete. The invention further provides the construction method of the profile steel or steel pipe cast-in-situ bored pile. The construction method is simple and convenient to operate, the construction efficiency is improved, and the quality of the pile body is improved.

Owner:SHANGHAI FOUND ENG GRP

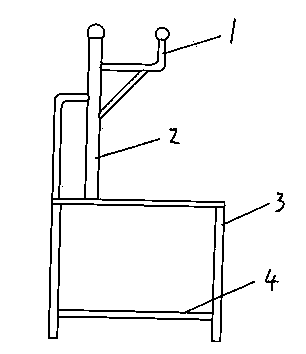

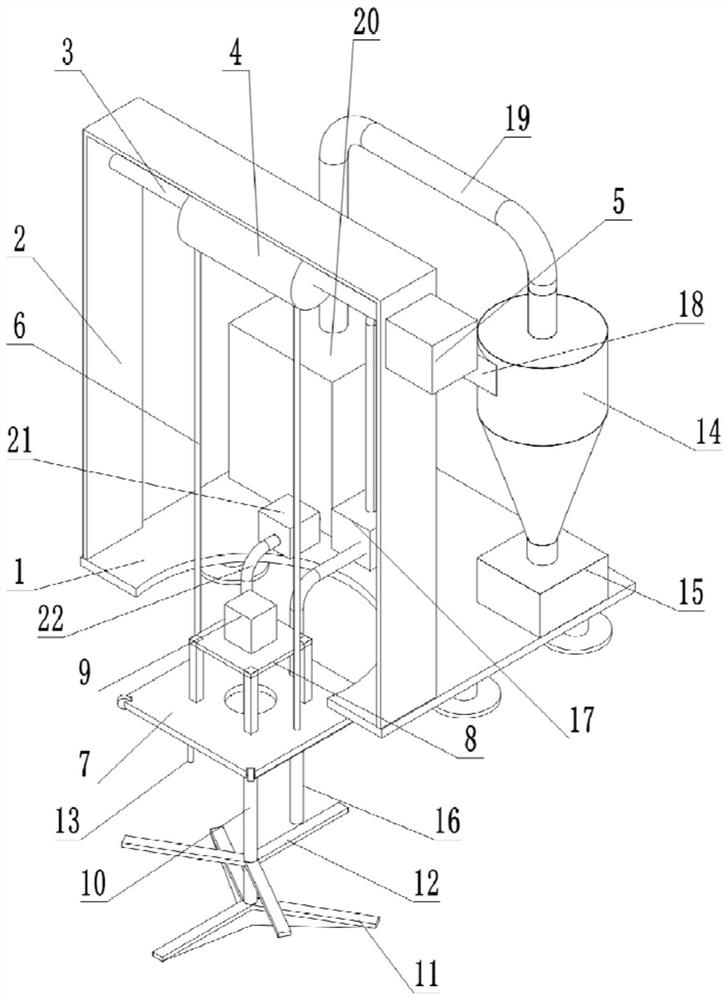

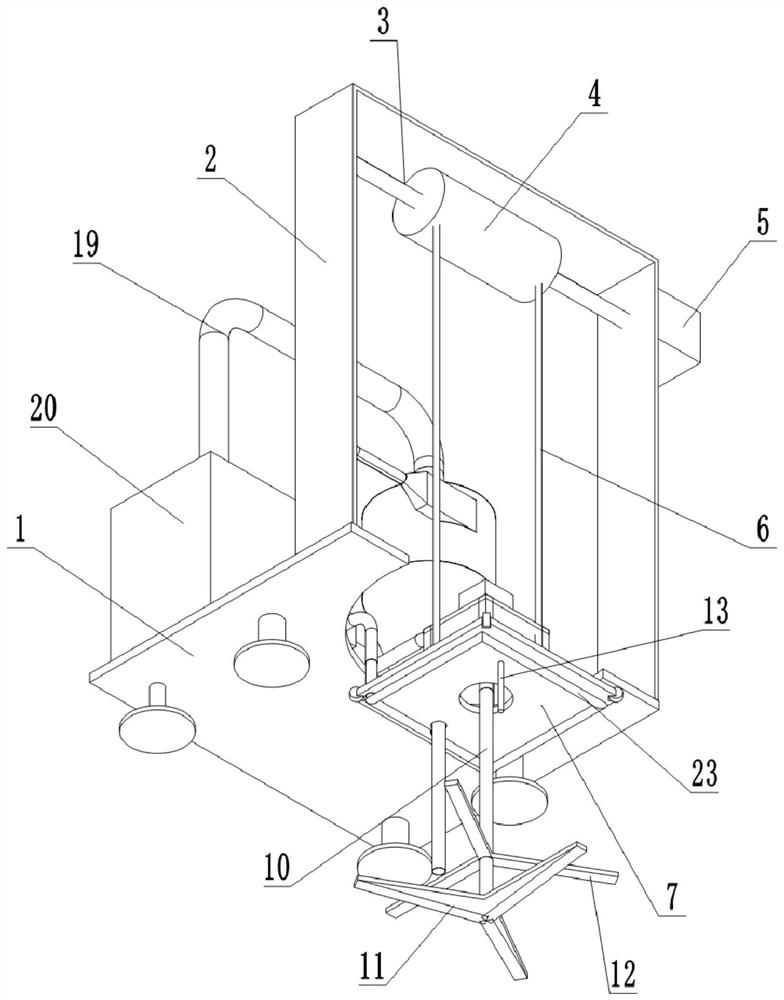

Cleaning device for deep pile core soil of prefabricated pipe pile

PendingCN114541398AAvoid construction inconvenienceGuaranteed cleaning effectBulkheads/pilesEngineeringEnvironmental geology

The invention relates to the technical field of prefabricated pipe piles, in particular to a cleaning device for deep pile core soil of a prefabricated pipe pile. Comprising a hoisting mechanism, a digging mechanism and a suction mechanism, the hoisting mechanism comprises a mounting bottom plate, a mounting frame is arranged on the mounting bottom plate, a first rotating shaft is arranged at the upper end of the mounting frame, a winding reel is arranged in the middle of the first rotating shaft, at least two sets of inhaul cables are wound around the winding reel, and a first motor used for rotating the first rotating shaft is arranged at one end of the mounting frame. The digging mechanism comprises a hanging plate matched with the pipe diameter of the prefabricated pipe pile, one ends of the two sets of inhaul cables are symmetrically fixed to the hanging plate, a mounting base is arranged on the hanging plate, a second motor is arranged on the mounting base, and a second rotating shaft with one end fixedly connected with the second motor is arranged at the output end of the second motor. According to the technical scheme, the problems that in the prior art, pile core soil in the deep position of a prefabricated pipe pile is difficult to remove through a pipe pile hole cleaning machine, and the pile core soil in the deep position of the prefabricated pipe pile is difficult to remove are solved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Casting material for branch iron runner of 500 m3 blast furnace

InactiveCN105439573AImprove corrosion resistanceImprove thermal shock resistanceMulliteChromium nitride

The present invention relates to a casting material for a branch iron runner of a 500 m3 blast furnace, and belongs to the field of refractory casting materials. The casting material comprises the following components in parts by weight: 5-8 parts of 8-5 mm magnesium silicate, 15-20 parts of 5-3 mm chromium nitride, 10-15 parts of 3-1 mm mullite, 8-15 parts of 1-0 mm chromic acid calcium, 2-5 parts of clay powder, 3-7 parts of cobalt oxide aluminum powder, 5-10 parts of cutting powder, 3-8 parts of amorphous graphite powder, 1-2 parts of composite carbon powder, 0-3 parts of molybdenum trioxide powder, 3-5 parts of alumina micro powder, 1-5 parts of magnesium oxide iron powder, 1-3 parts of rho aluminium oxide and 0-5 parts of melting pure calcium aluminate cement; Based on the total weight of the above main materials of 100%, the additive comprises: 0.1-0.2 part of calcium lignosulfonate, 0.01-0.05 part of nanometer potato powder, 0.01 part of malic acid and 0.1 part of C12H14N4O5S2. The iron runner of the blast furnace prepared by the casting material has the advantages of good thermal shock resistance, corrosion resistance, large iron influx and long service life.

Owner:万燕杰

A piling method for wharf based on crawler construction machinery

InactiveCN104711983BGuaranteed normal operationAvoid construction inconvenienceBulkheads/pilesArchitectural engineeringPile driver

The invention relates to a wharf piling method based on crawler-type construction machinery. The ground of the existing wharf is used as a supporting surface, and a crawler crane and a crawler-type piling machine are used to successively set them on the steel plates laid on the ground of the construction wharf, and carry out the piling on the pile body. Hoisting and driving to realize the reinforcement construction for the existing wharf. The logic of the whole design method is clear, and at the same time of construction, the normal operation of the wharf is maintained, effectively avoiding the inconvenience of traditional piling ships driving into the pile group for construction, and Damage to the original pile foundation; not only that, the whole design method is simple, the cost is easy to control, and in practical application, the construction period and construction quality can be effectively guaranteed.

Owner:HOHAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com