Patents

Literature

66results about How to "Increase wetting angle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

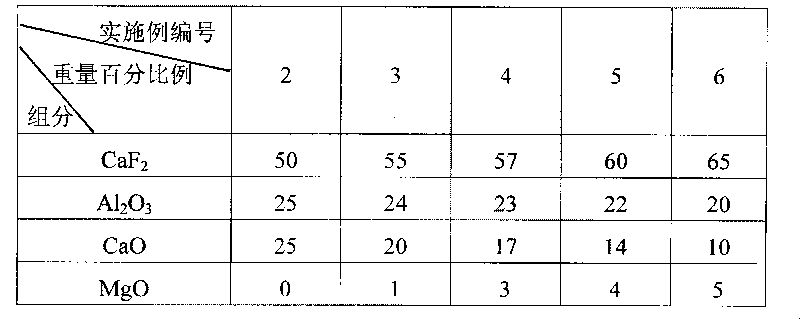

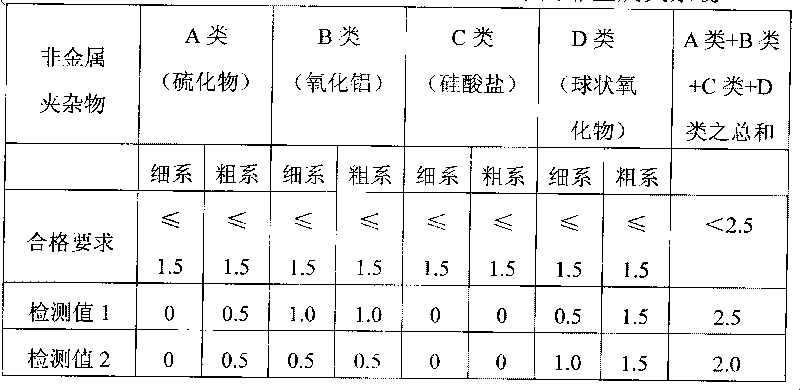

Electroslag remelting quaternary slag system for preparing high-purity stainless steel

The invention discloses an electroslag remelting quaternary slag system for preparing high-purity stainless steel. The electroslag remelting quaternary slag system is characterized by comprising the following compositions in percentage by weight: 50 to 65 percent of CaF2, 20 to 25 percent of Al2O3, 10 to 25 percent of CaO and 0 to 5 percent of MgO. The quaternary slag system is adopted for electroslag remelting, can effectively reduce the non-metallic inclusion content of the steel and improves the purity of the steel under the condition of non-protective atmosphere and has the characteristics of little investment, low use cost and easy realization.

Owner:PANGANG GROUP JIANGYOU CHANGCHENG SPECIAL STEEL

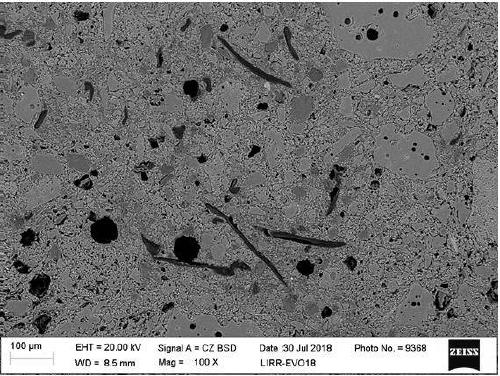

MgAlON combined aluminum magenisum permeable brick and preparation method thereof

The invention particularly relates to an MgAlON combined aluminum magenisum permeable brick and a preparation method of the MgAlON combined aluminum magenisum permeable brick. The technical scheme comprises the following steps of: taking 55-65 wt% of sintered corundum grains, 25-35 wt% of aluminum oxide fine powder, 2-10 wt% of metal aluminum powder and 2-10 wt% of fused magnesite fine powder as raw materials; then, additionally adding phenolic resin which is 2-6 wt% of the raw materials and grinding and agitating; carrying out mechanical pressing; drying under the condition of 180-220 DEG C for 12-24 hours; raising the temperature to 1500-1700 DEG C by a temperature-rising speed of 2-5 DEG C / min; and keeping the heat for 3-5 hours to prepare the MgAlON combined aluminum magenisum permeable brick. The prepared MgAlON combined aluminum magenisum permeable brick has the characteristics of high density, larger high-temperature strength, good thermal shock resistance, capability of being not wetted by liquid steel and strong corrosion resistance to slag.

Owner:WUHAN UNIV OF SCI & TECH

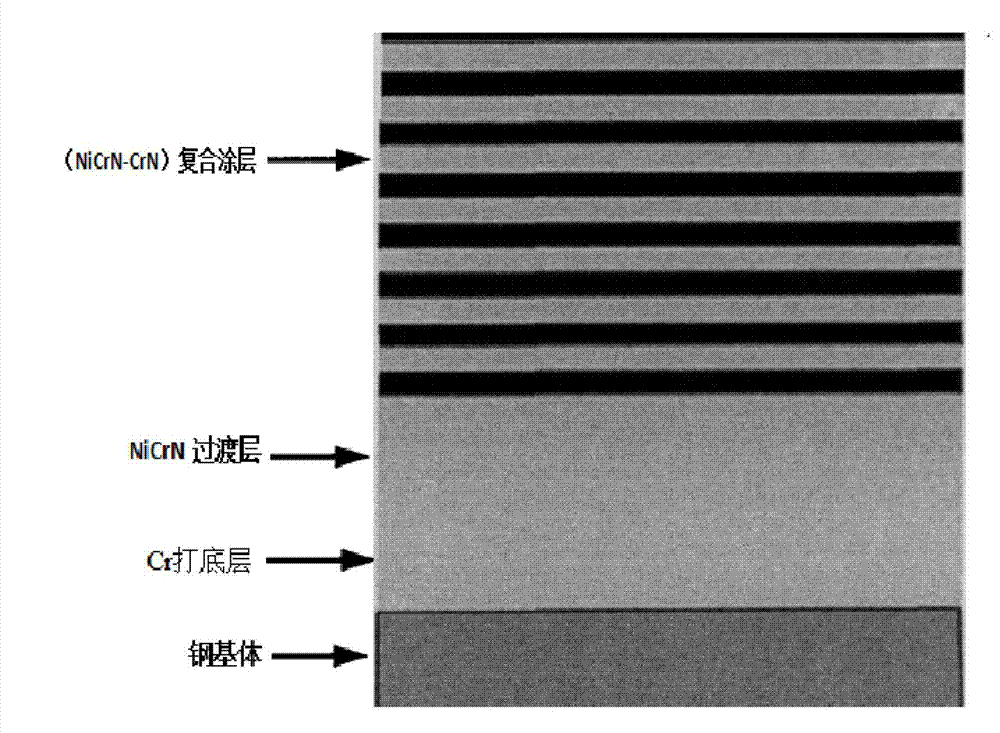

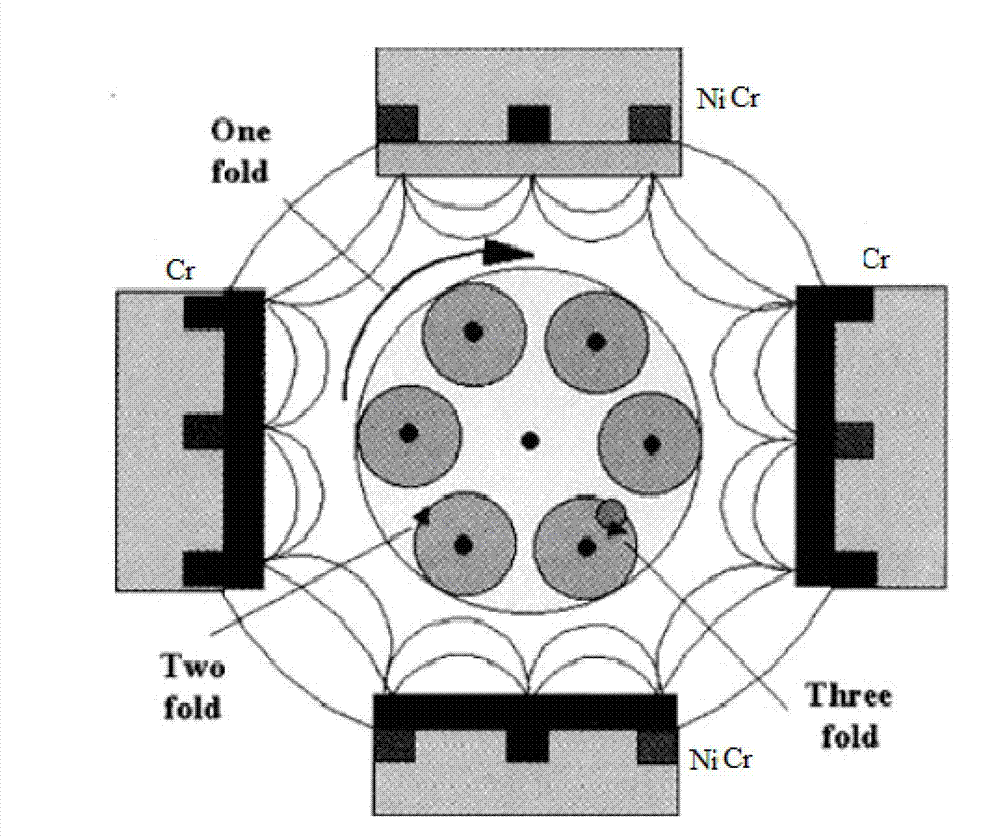

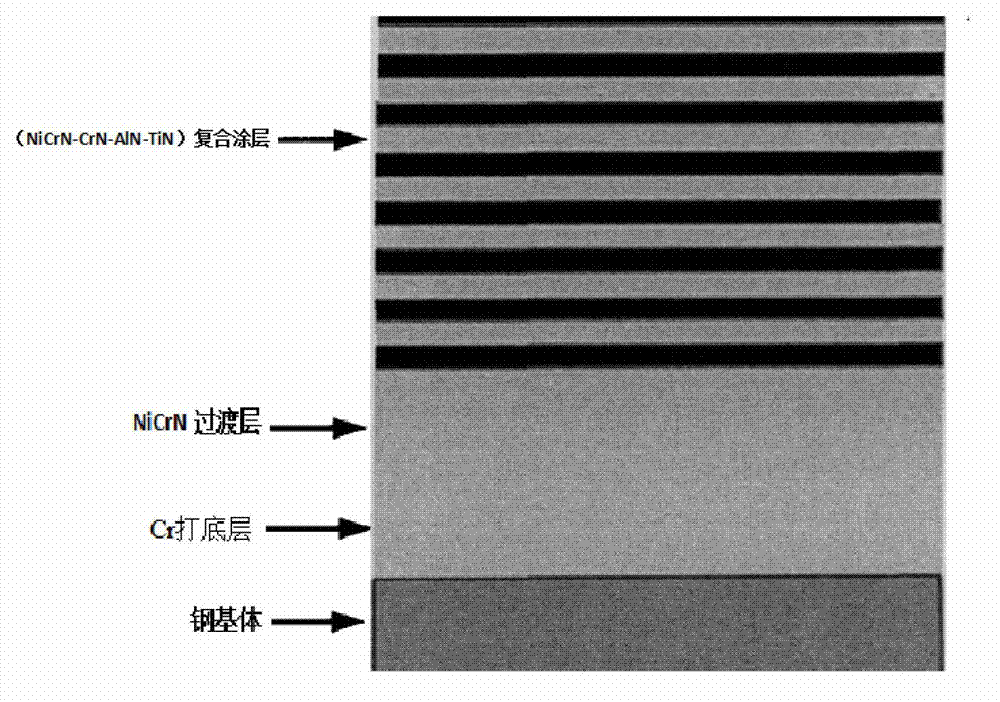

Product containing NiCrN ternary coating and preparation method thereof

ActiveCN103029366AHigh bonding strength of membrane baseImprove toughnessVacuum evaporation coatingSputtering coatingOrganic solventCritical load

The invention discloses a product containing an NiCrN ternary coating. On the product, a Cr layer is used as a bottom layer, an NiCrN layer is used as a transition layer, and a plurality of NiCrN-CrN composite coatings are deposited on the NiCrN transition layer, so that the thickness of the composite coating reaches 2-5 mu m. By adopting the multilayer gradient design and nitriding technique before filming, the invention greatly enhances the film-base bonding strength of the coating. The critical load of the gradient coating prepared by the invention in a scarification test is up to 75N which is much higher than that of a related coating prepared by any other method or technique; and the hardness of the product containing an NiCrN ternary coating can reach 2780HV. The invention greatly enhances the shock resistance, abrasion resistance, friction resistance and heat stability on the surface of a mold or cutter, and greatly lowers the friction factor and weight loss rate by abrasion. The NiCrN ternary coating greatly enhances the wetting angle of mold steel for organic solvents, which indicates that the coating can greatly improve the demoldability of the mold.

Owner:郎溪品旭科技发展有限公司

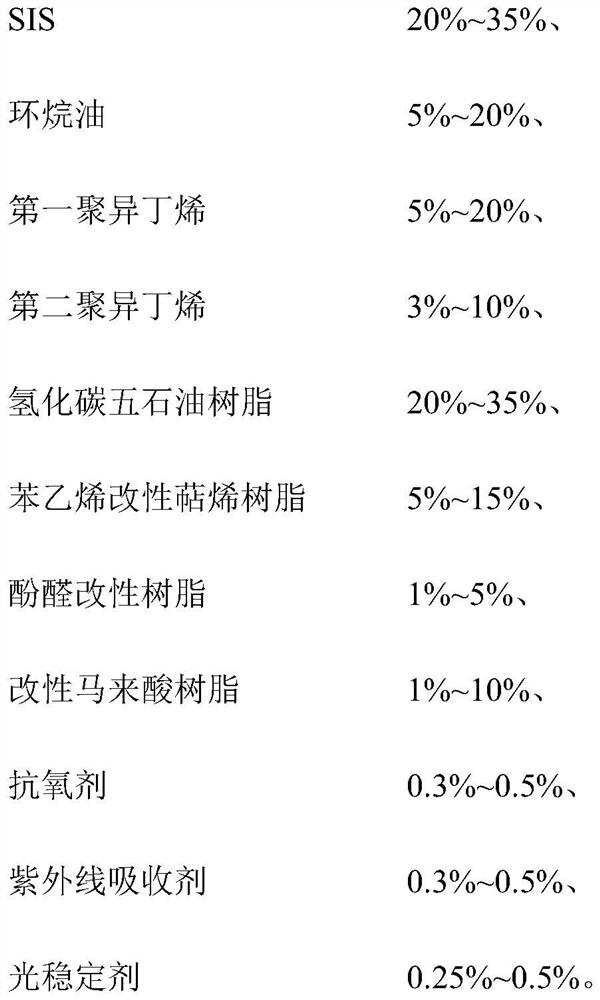

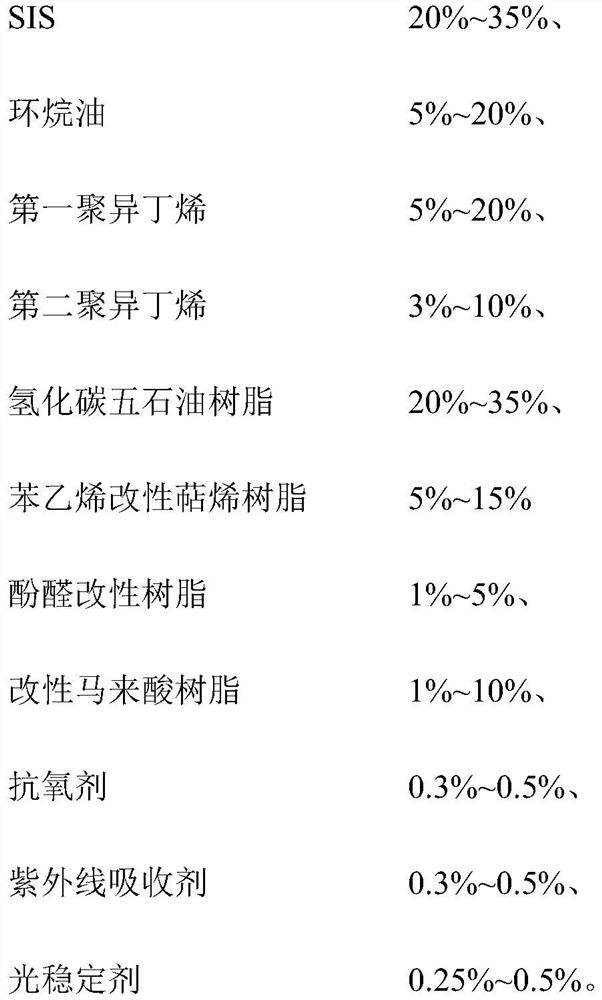

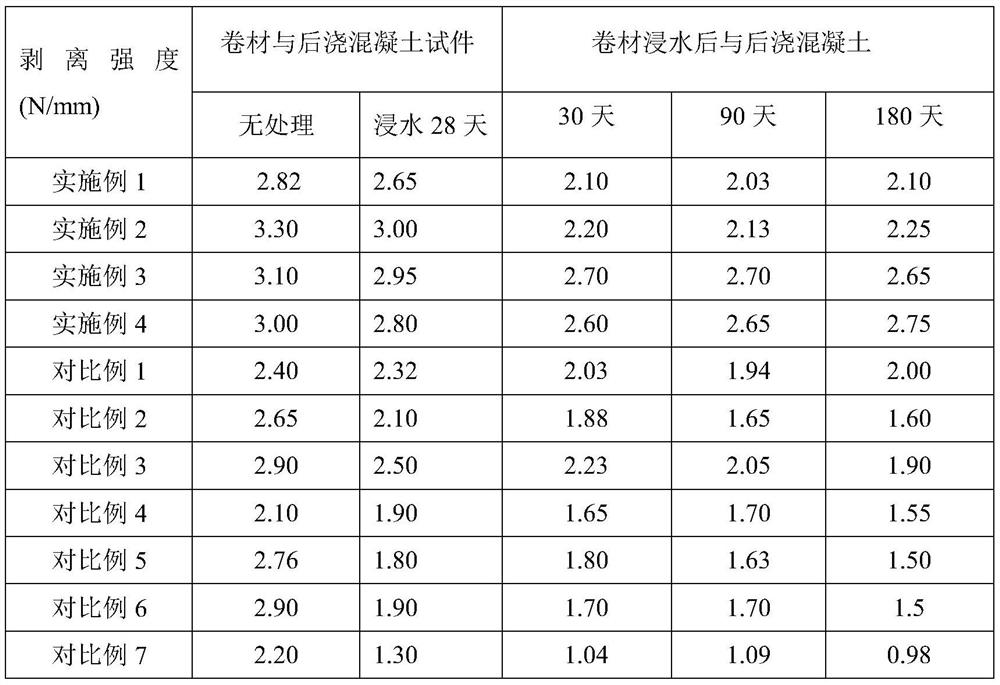

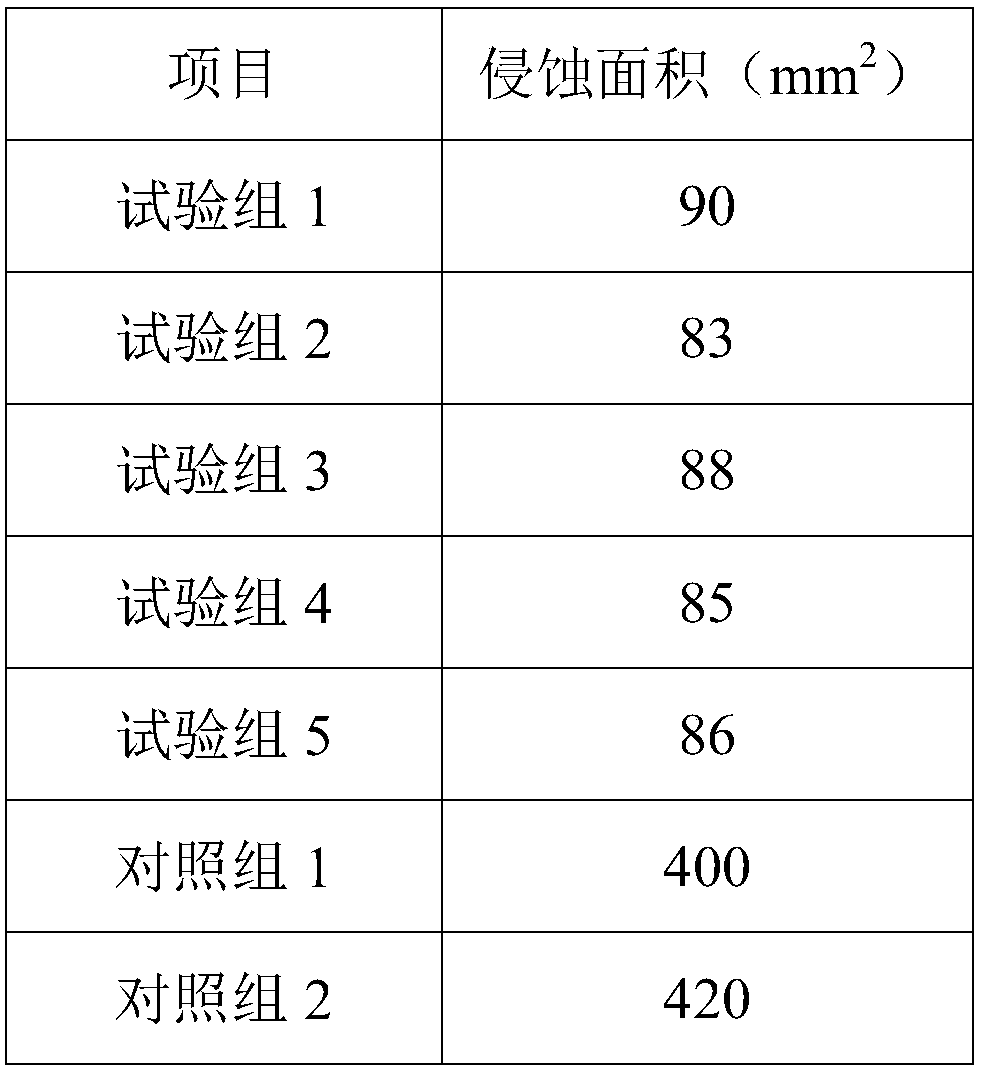

Non-asphalt-based pre-paved waterproof coiled material with high water soaking resistance and preparation method of non-asphalt-based pre-paved waterproof coiled material

ActiveCN112852359ALow water absorptionIncrease wetting angleMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesPolymer scienceHydrolysate

The invention provides a non-asphalt-based pre-paved waterproof coiled material with high water soaking resistance and a preparation method thereof. The non-asphalt-based pre-paved waterproof coiled material comprises a polymer sheet layer, a polar hot-melt pressure-sensitive adhesive layer and a strong-hydrophobicity isolation sand layer, and the polar hot-melt pressure-sensitive adhesive comprises the following raw materials: SIS, naphthenic oil, first polyisobutene, second polyisobutene, hydrogenated C5 petroleum resin, styrene modified terpene resin, phenolic modified resin, modified maleic resin, an antioxidant, an ultraviolet light absorber and a light stabilizer. The high-hydrophobicity isolation sand is inorganic mineral particles treated by coupling agent hydrolysate. The prepared non-asphalt-based pre-paved waterproof coiled material has the characteristic of excellent water soaking resistance, after being soaked in water for 180 days, the isolation sand covered on the coiled material is still not easy to fall off, and the bonding surface at the lap joint can still keep a good bonding state, so that the good construction application performance of the coiled material is ensured.

Owner:江苏雨中情防水材料有限责任公司

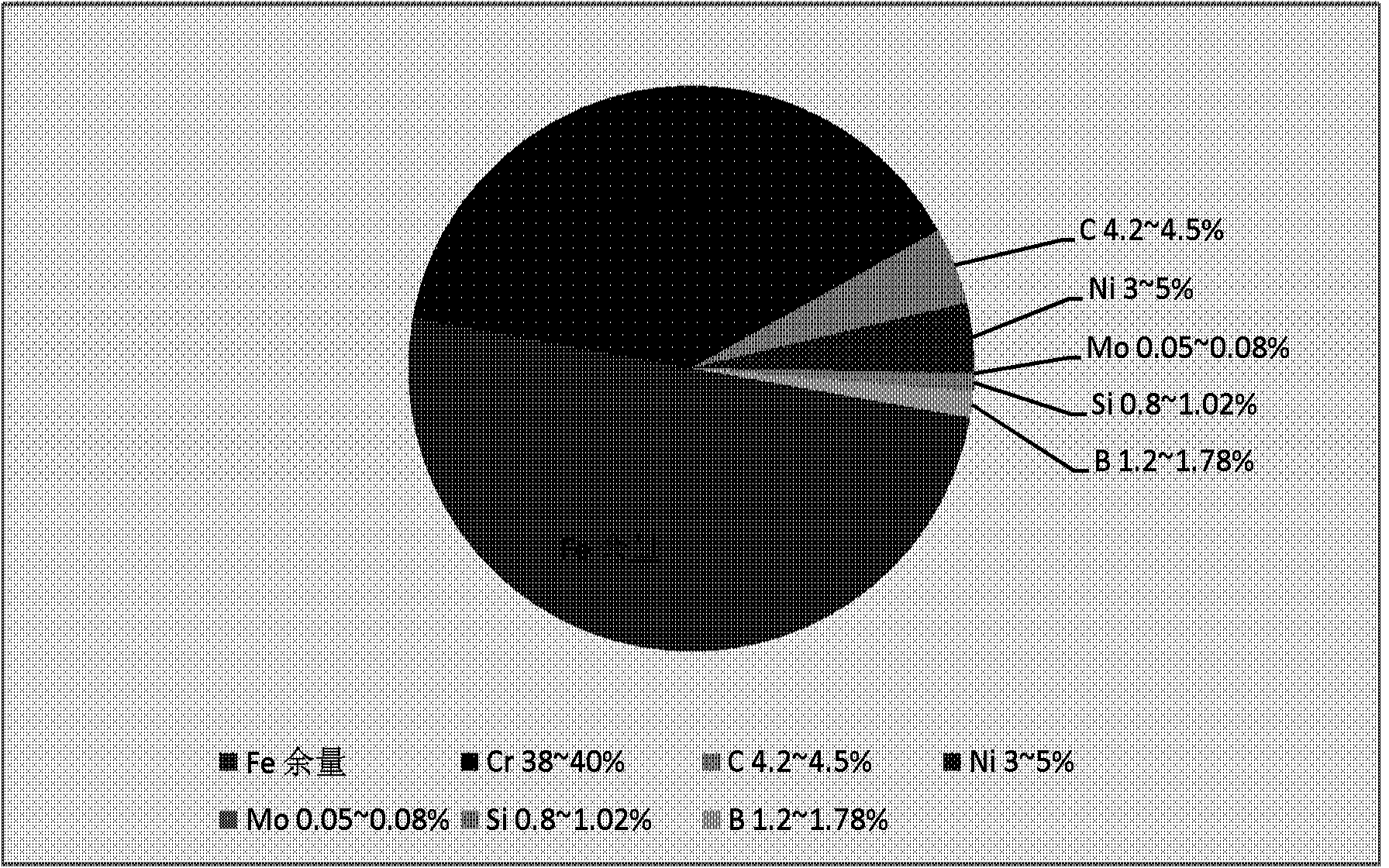

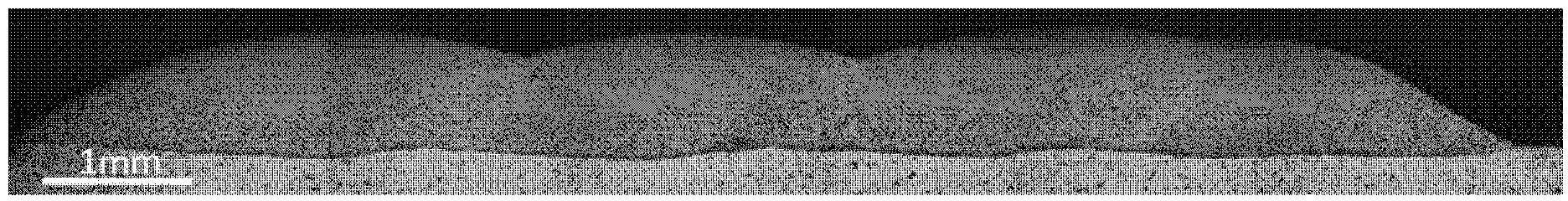

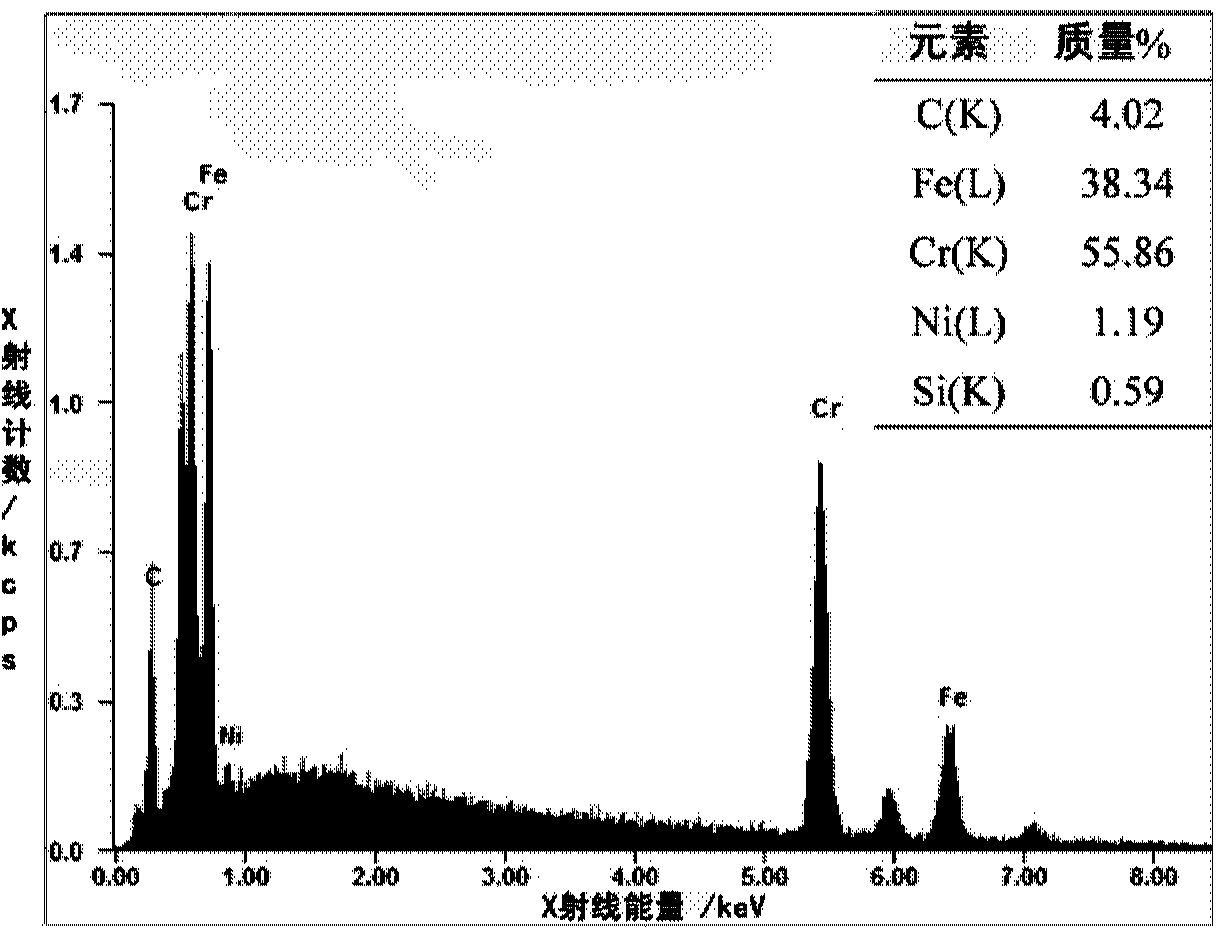

Iron-based composite powder high in chromium content for laser cladding

ActiveCN103752818AHigh hardnessImprove wear resistanceMetallic material coating processesCrack freeHardness

The invention discloses iron-based composite powder high in chromium content for laser cladding. The iron-based composite powder high in chromium content for laser cladding is composed of the chemical compound of Cr3C2, Cr and Fe, Ni, Mo, Si and B. The iron-based composite powder high in chromium content for laser cladding comprises, by mass, 38%-40% of Cr, 4.2%-4.5% of C, 3%-5% of Ni, 0.05%-0.08% of Mo, 0.8%-1.02% of Si, 1.2%-1.78% of B and the balance Fe. The particle size of the iron-based composite powder is between +140 meshes and -325 meshes. The iron-based composite powder is high in carbon content and chromium content, the hardness of a coating can be effectively improved, requirements of the laser cladding technology of iron-based base materials such as carbon steel and stainless steel can be met, a cladding layer of a sample of the iron-based composite powder is free of cracks and macroscopic pores, all the components are distributed evenly, the hardness of the iron-based composite powder can reach HV0.21000 and is five times that of a base body, the corrosion resistance of the iron-based composite powder cladding layer is improved due to the high chromium content, and the iron-based composite powder is suitable for normal temperature, high temperature, abrasion resistance and corrosion resistance working conditions.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Aluminum-magnesium casting material for ladle liner and preparation method thereof

The invention relates to an aluminum-magnesium casting material for a ladle liner and a preparation method thereof. ACcording to the technical scheme, the method comprises the following steps: preparing 50-65wt% of microporous alumina particles serving as aggregate; preparing 10-15wt% of fine corundum particles, 15-30wt% of fine corundum powder, 2-8wt% of magnesium oxide powder, 2-8wt% of alpha-A12O3 powder and 2-8wt% of aluminum powder silica gel which are used as base materials; adding water which accounts for 3-10wt% of the sum of the aggregate and the base materials; evenly agitating, and molding in a vibrating manner; carrying out heat preservation at 100-150 DEG C for 12-36 hours, so as to prepare the aluminum-magnesium casting material for the ladle liner. The aluminum-magnesium casting material for the ladle liner prepared by the method has excellent slag resistance and thermal shock stability, and the service life of the aluminum-magnesium casting material for the ladle liner can be effectively prolonged.

Owner:WUHAN UNIV OF SCI & TECH

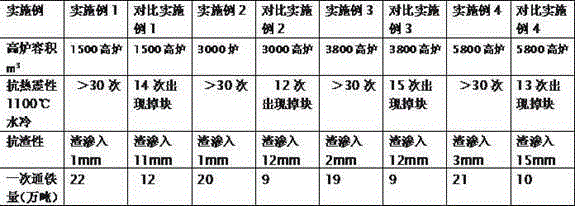

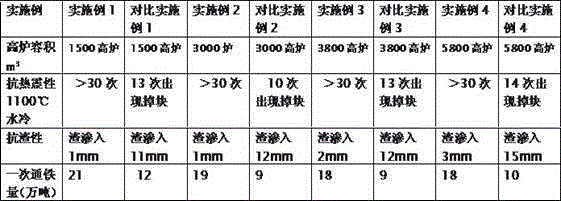

Large blast furnace main iron runner castable

InactiveCN105152669AImprove corrosion resistanceImprove thermal shock resistanceChromium nitrideThermal shock

The invention relates to a large blast furnace main iron runner castable, and belongs to the field of refractory castables. The large blast furnace main iron runner castable is prepared from, by weight, 5-8 parts of 8-5 mm chromium nitride, 15-20 parts of 5-3 mm chromium nitride, 10-15 parts of 3-1 mm sillimanite, 8-15 parts of 1-0 mm calcium chromate, 2-5 parts of partial clay powder, 3-7 parts of cobaltous oxide aluminum powder, 5-10 parts of cutting powder, 3-8 parts of amorphous graphite powder, 1-2 parts of composite charcoal powder, 0-3 parts of molybdenum trioxide powder, 3-5 parts of alumina micro powder, 1-5 parts of magnesium oxide iron powder, 1-3 parts of rho-aluminum oxide, 0-5 parts of electric smelting pure calcium aluminate cement and an addition agent, wherein the addition agent is prepared from, by weight, 0.1-0.2 part of calcium lignosulphonate, 0.01-0.05 part of nanometer potato powder, 0.01 part of malic acid and 0.1 part of C12H14N4O5S2. A blast furnace iron runner made of the castable has the advantages of being good in thermal shock resistance, high in corrosion resistance, large in iron exchanging amount and long in life.

Owner:张婷

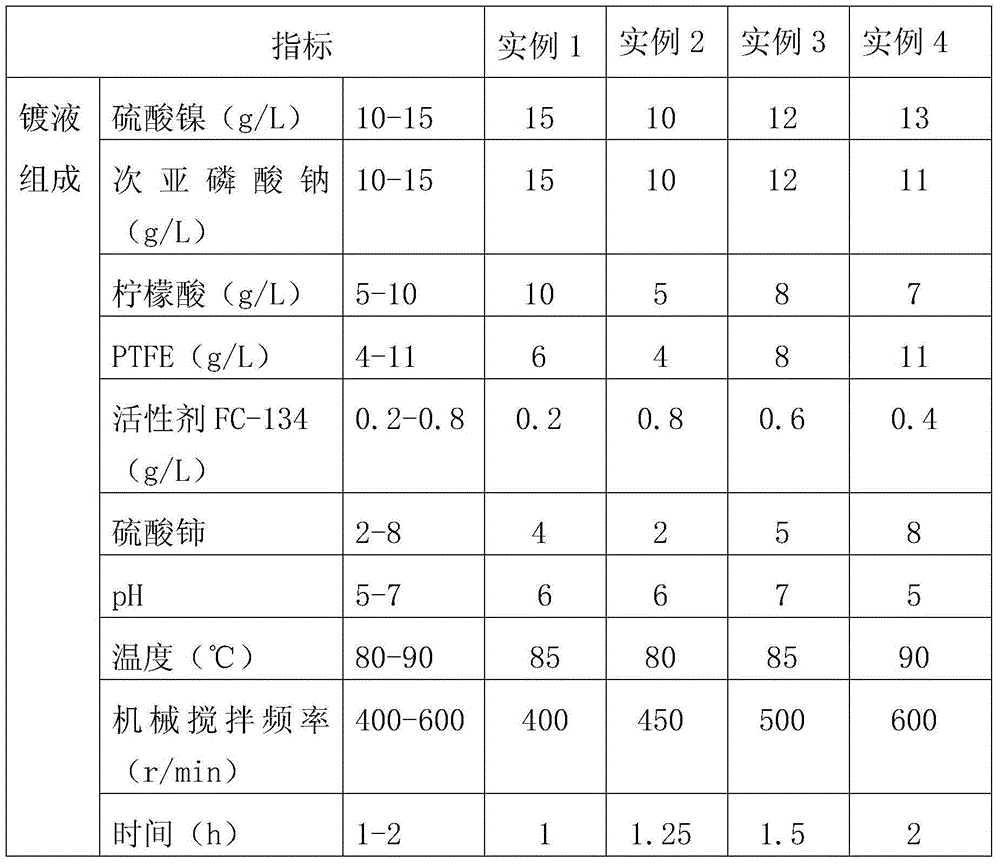

Preparation process of chemical plating rare earth cerium Ni-P-PTFE (Polytetrafluoroethylene) composite coating

ActiveCN104419919ASimple processLow costLiquid/solution decomposition chemical coatingActive agentPtfe composite

The invention relates to a preparation method of a chemical sedimentation rare earth cerium Ni-P-PTFE (Polytetrafluoroethylene) composite coating. Based on a chemical Ni-P-PTFE composite plating process and the characteristics of a rare earth cerium atom, the Ni-P-PTFE composite coating is prepared on a steel 20 matrix by virtue of a mechanical stirring method. The method comprises the following specific steps of pretreating a sample; preparing a plating solution containing 10-15g / L nickel sulfate, 10-15g / L sodium hypophosphite, 5-10g / L citric acid and 2-8g / L cerium sulfate; preparing a mixed solution of 4-11g / L PTFE emulsion and 0.2-0.8g / L an active agent FC-134; mixing the plating solution with the mixed solution; cleaning the sample; activating with hydrochloric acid; washing with water; plating; and washing with water and drying. The Ni-P-PTFE composite coating prepared by the preparation method, which is disclosed by the invention, has the advantages of small friction coefficient, good wear resistance and antifouling property and the PTFE particles in the coating are evenly distributed.

Owner:PETROCHINA CO LTD +1

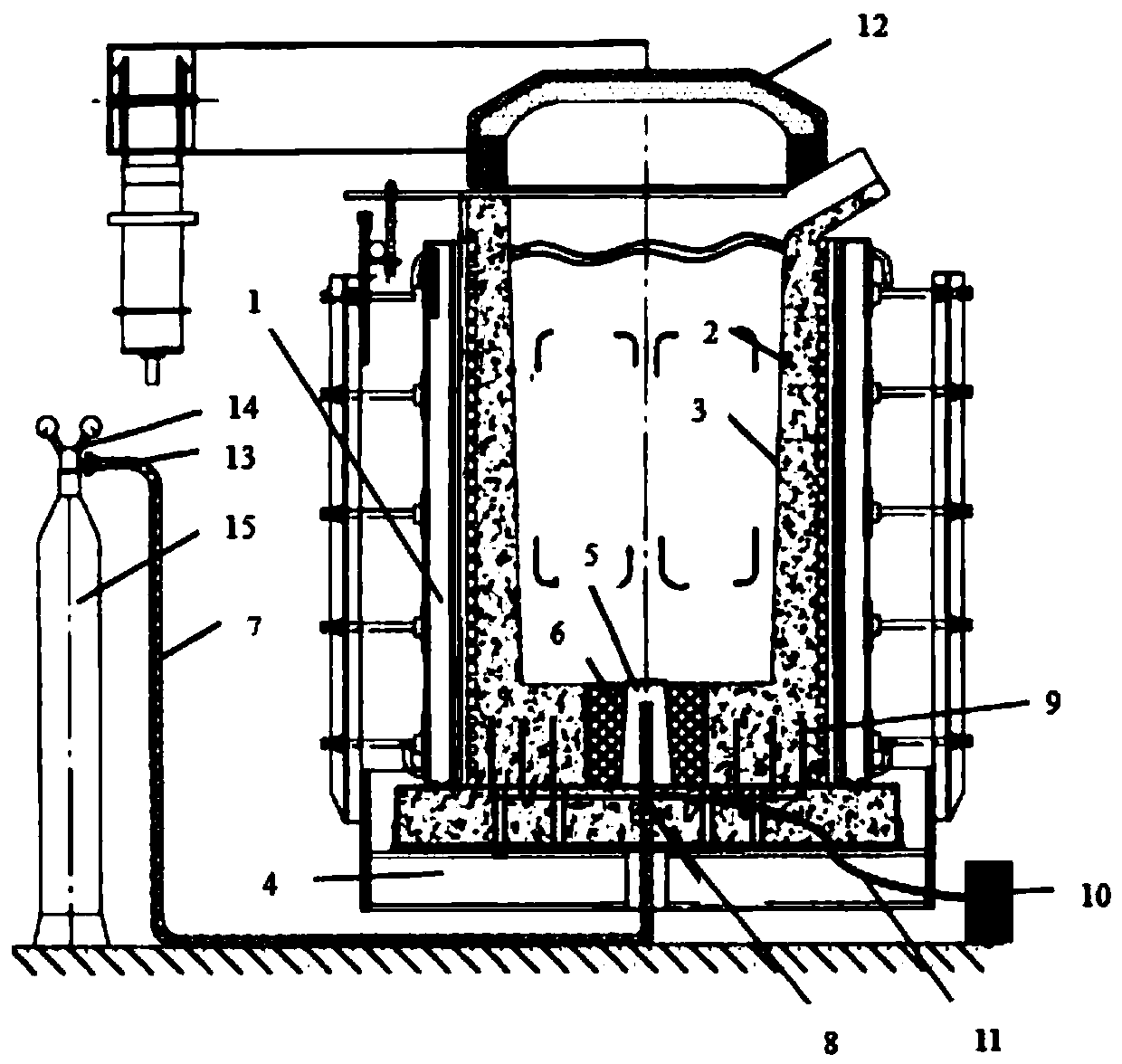

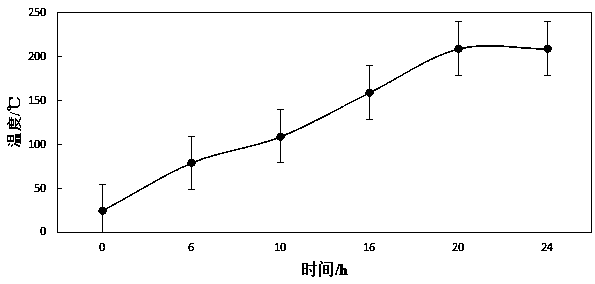

Ladle bottom argon blowing air brick for smelting high-purity high manganese steel

The invention discloses ladle bottom argon blowing air brick for smelting high-purity high manganese steel. The air brick is prepared from the following materials: forsterite sand, fused magnesia, corundum, sodium silicate, sodium permanganate, an explosion-proof admixture, a polycarboxylate dispersion water reducing agent and water. Uniformly-distributed tiny pores can be formed in the air brickdisclosed by the invention, and the permeation volume is 1.5 times or more than 1.5 times of the permeation volumes of slit and diffuse air bricks; argon is permeated in molten steel through the plurality of pores, so that the purification rate of the molten steel is obviously increased, and the contents of oxygen and hydrogen in the molten steel are reduced; the problems that a small number of straight thick holes are caused by slag-clearing iron oxygen burning, the argon intensively passes through the molten steel and quickly escapes from the liquid level and the like are solved; the purification rate of the molten steel is obviously increased.

Owner:广西长城机械股份有限公司

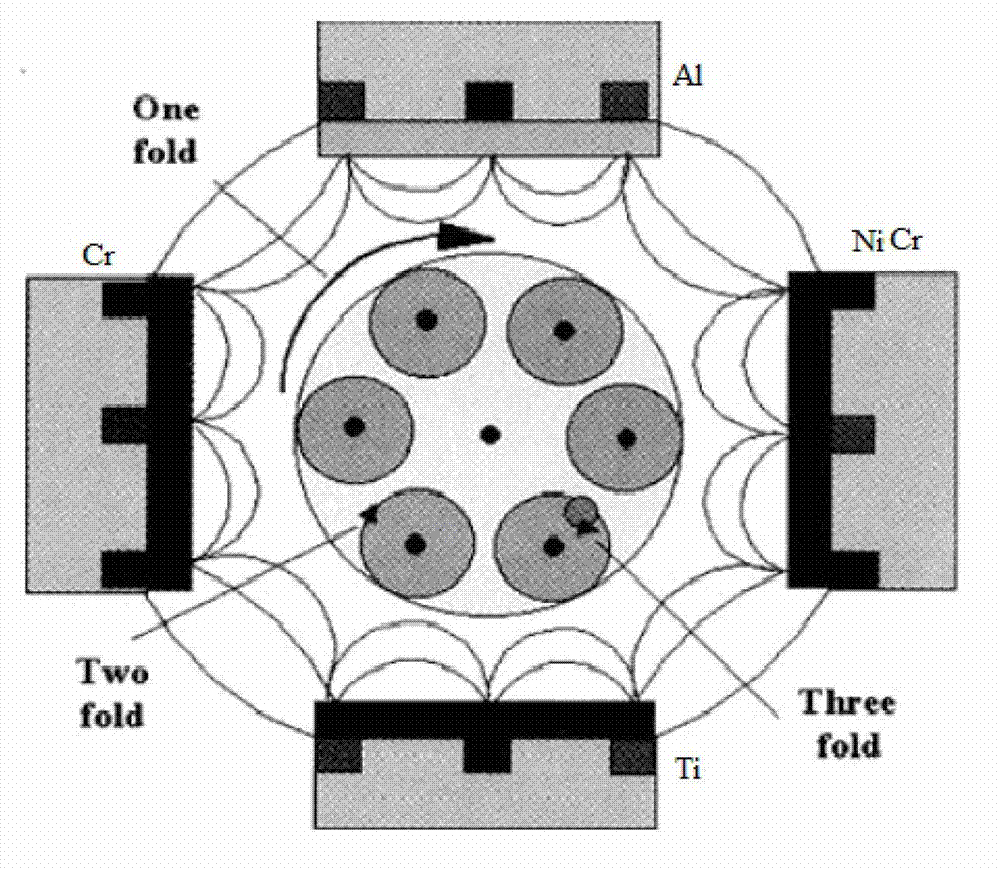

Product containing CrNiTiAlN quinary coating and preparation method thereof

ActiveCN103045998AHigh bonding strength of membrane baseImprove toughnessVacuum evaporation coatingSputtering coatingOrganic solventCritical load

The invention discloses a product containing a CrNiTiAlN quinary coating. The product takes a Cr layer as a bottom layer and takes an NiCrN layer as a transition layer, wherein a plurality of NiCrN-CrN-AlN-TiN composite coatings with the thickness are deposited on the NiCrN layer, and the thickness of the composite coatings can achieve 2-5 mu m; and according to the product disclosed by the invention, a multi-layer gradient design and a nitriding process before film plating are adopted, so that a coating-substrate bonding strength is greatly improved, and the critical load of the prepared gradient coatings in a scratch test is as high as 68N, which is relatively higher than related plated layers prepared by other methods and processes. The hardness of the product containing the CrNiTiAlN quinary coating can achieve 2880HV; the anti-impact, wear-resistant and anti-friction performances and the thermal stability of the surfaces of a mold and a cutter are greatly improved, and the friction coefficient and the rate of weight loss caused by wear are greatly reduced; and the wetting angle of mold steel to an organic solvent is improved, thereby showing that the coating can be used for greatly improving the demolding performance of the mold.

Owner:郎溪品旭科技发展有限公司

Long-acting hydrophobic anti-ice coating and preparation method thereof

ActiveCN109233600ALow melting pointGood anti-icing effectWax coatingsPolyurea/polyurethane coatingsEpoxyRoad surface

The invention discloses a long-acting hydrophobic anti-ice coating which comprises a material A, a material B and paraffin powder, wherein the material A includes polyurethane, a long-acting hydrophobic anti-ice agent and a polyurethane curing agent; the material B includes a water-borne epoxy resin and a water-borne epoxy resin curing agent. The long-acting hydrophobic anti-ice coating disclosedby the invention is capable of effectively preventing pavement from icing under frozen, rainy and snowy weather and is capable of achieving the effects of thawing and damaging the ice layer and thinning the ice layer under extremely severe weather; a snow thawing agent is continuously released under the vehicle load on pavement and is capable of exerting a long-acting stable effect; after such a long-acting hydrophobic anti-ice coating is directly adhered to the bituminous pavement or is roll-coated on the bituminous pavement, the freezing disaster of pavement can be effectively reduced; the long-acting hydrophobic anti-ice coating has a great significance in guaranteeing traffic safety under icy and snowy weather.

Owner:WUHAN MUNICIPAL CONSTR GROUP +1

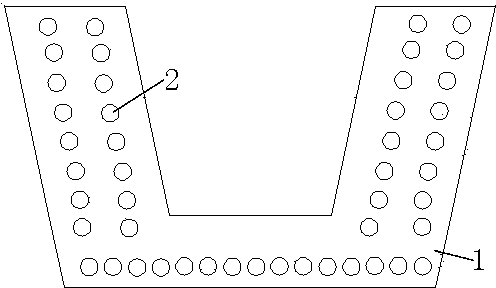

Gravity flow ventilating fast compensation material for sublimation ladle air brick

The invention relates to automatic flow venting rapid mending material for the refined ladle venting brick. The invention is characterized in that the material consists of the ingredients according to the weight proportion as follows: Al2O3 of 80 to 95, wedding agent of 3 to 15, detonation suppression of 0.1 to 0.5 and preservative agent of 1 to 5. The invention has the advantages of rapid sintering, good venting, no seeping steel, long service life and easy operation.

Owner:鞍山盛晨耐火材料有限公司

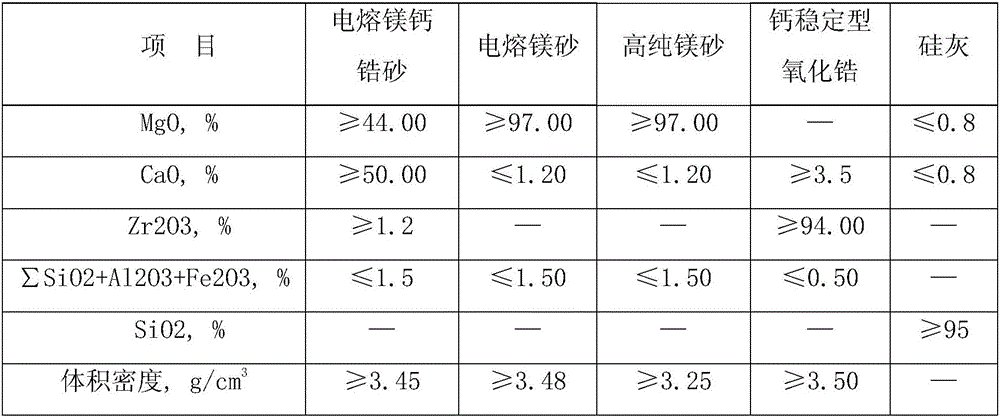

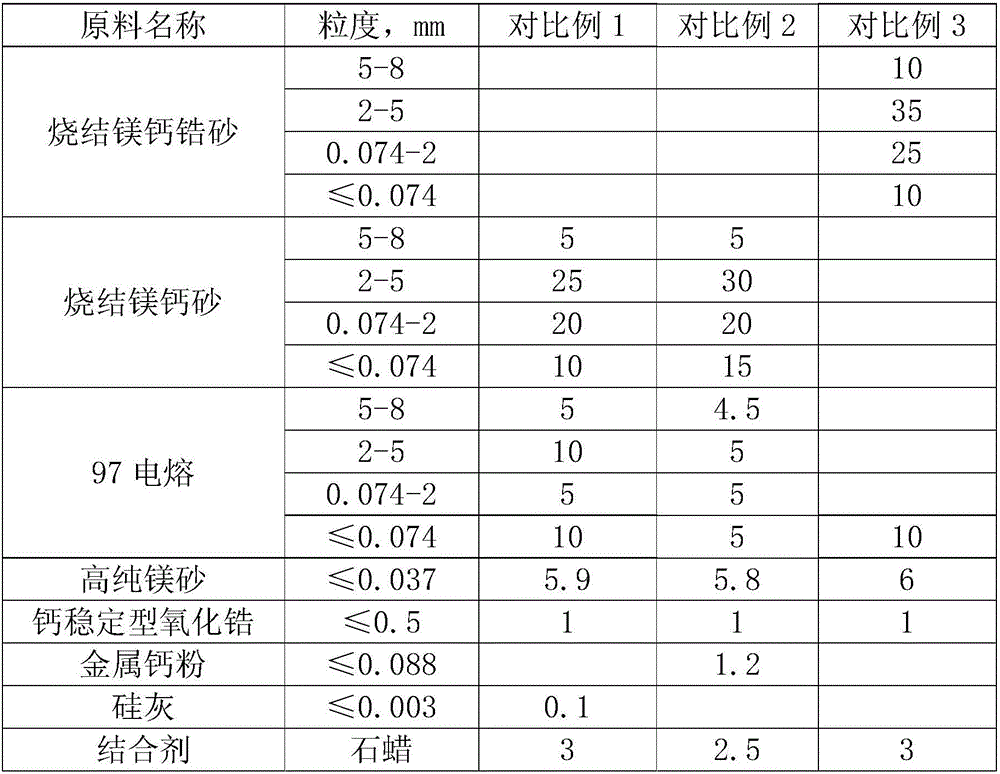

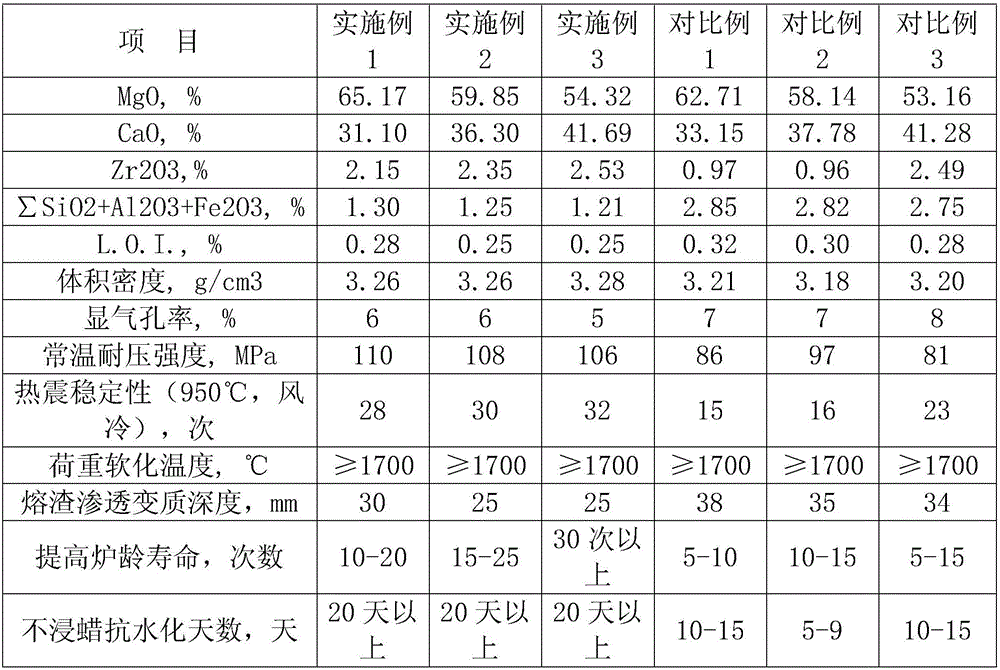

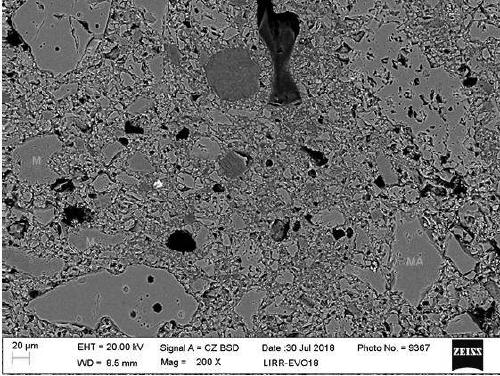

Zirconium composite high-performance electrofused magnesium-calcium zirconium brick and manufacturing method thereof

The invention belongs to the technical field of refractories for steel smelting furnaces, and in particular relates to a zirconium composite high-performance electrofused magnesium-calcium zirconium brick and a manufacturing method thereof; the zirconium composite high-performance electrofused magnesium-calcium zirconium brick comprises 5-10% of electrofused magnesium-calcium zirconium sand with a partical size of 5-8mm, 20-35% of electrofused magnesium-calcium zirconium sand with a partical size of 2-5mm, 20-30% of electrofused magnesium-calcium zirconium sand with a partical size of 2-0.074mm, 10-15% of electrofused magnesium-calcium zirconium sand fine powder with a partical size of 0.074mm or less, 1-5% of electrofused magnesium sand with a partical size of 5-8mm, 1-10% of electrofused magnesium sand with a partical size of 2-5mm, 1-5% of electrofused magnesium sand with a partical size of 2-0.074mm, 5-10% of electrofused magnesium sand fine powder with a partical size of 0.074mm or less, 5-10% of electrofused magnesium sand super-fine powder with a partical size of 0.037mm or less, 0.5-1.2% of calcium stabilized zirconia with a partical size of 0.5mm or less, 0.5-2% of metal calcium powder with a partical size of 0.088mm or less, 0.1-0.5% of silica fume with a partical size of 0.003mm or less and 2-5% of a binder. The method can obviously improve the physical and chemical performance indexes of the magnesium-calcium zirconium brick, anti-penetration, anti-erosion, anti-erosion and anti-spalling and other use performances of the magnesium-calcium zirconium brick can be improved, and most importantly, the magnesium-calcium zirconium brick can meet the requirements of current smelting conditions.

Owner:LIAONING ZHONGMEI HIGH TEMPERATURE MATERIAL CO LTD

Dimetridazole soluble powder and preparation method thereof

ActiveCN105919942AIncrease wetting angleImprove solubilityAntibacterial agentsPowder deliverySolubilityLactose

The invention belongs to the technical field of veterinary chemical medicinal preparations, and particularly relates to a dimetridazole soluble powder and a preparation method thereof. The dimetridazole soluble powder is prepared from the following components in parts by weight: 18-22 parts of dimetridazole and 10-15 parts of hydrophilic carrier, and the balance of glucosum anhydricum or lactose anhydrous supplemented to 100 percent, wherein the hydrophilic carrier is one or more of PVP K30, poloxamer 188 and sodium lauryl sulfate. According to the dimetridazole soluble powder, the specific surface area of an insoluble medicine can be improved, and the wetting property can be increased, so that solubility of dimetridazole can be improved, the dissolving time is shortened, and the aim of clinical drinking water administration can be achieved. The dimetridazole has good bioavailability and good medicinal effect.

Owner:爱力迈(安徽)动物药业有限公司

Castable for main trough of middle-sized blast furnace

InactiveCN105254316AImprove corrosion resistanceImprove thermal shock resistanceAl powderChromium nitride

The invention relates to a castable for a main trough of a middle-sized blast furnace and belongs to the field of refractory castables. The castable is prepared from the following components in parts by weight: 5 to 8 parts of 8-5mm tabular corundum, 15 to 20 parts of 5-3mm chromium nitride, 10 to 15 parts of 3-1mm sillimanite, 8 to 15 parts of 1-0mm calcium chromate, 2 to 5 parts of slightly viscous clay powder, 3 to 7 parts of cobaltous oxide aluminum powder, 5 to 10 parts of cutting powder, 3 to 8 parts of amorphous graphite powder, 1 to 2 parts of composite carbon powder, 0 to 3 parts of molybdenum trioxide powder, 3 to 5 parts of alumina micro powder, 1 to 5 parts of magnesium oxide iron powder, 1 to 3 parts of rho aluminium oxide and 0 to 5 parts of electric smelting pure calcium aluminate cement; it is assumed that the sum of the total weight parts of main ingredients is 100%, then additives comprise the following components in part by weight: 0.1 to 0.2 part of calcium lignosulphonate, 0.01 to 0.05 part of nanometer potato powder, 0.01 part of malic acid and 0.1 part of C12H14N4O5S2. The main trough of the blast furnace prepared with the castable has the advantages of good thermal shock resistance, strong erosion resistance, a big iron influx and a long service life.

Owner:张婷

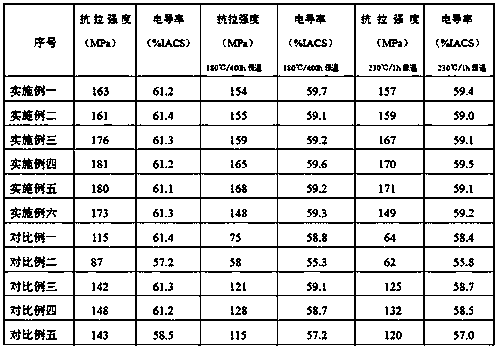

Carbon nano-reinforced aluminum-based conductor material and preparation method

The invention discloses a carbon nano-reinforced aluminum-based conductor material and a preparation method. Nano-silicon dioxide chemically grows on the surface of graphene oxide, reduced graphene oxide@silicon dioxide carbon nano-powder is prepared in a high-temperature sintering process, the mixed powder is blown into a melt through inert gas, and stirring, purification and casting are prepared. Silicon dioxide nano-particles grow on the surface of graphene, so that an agglomeration reaction in a reduction process for graphene oxide is avoided, a wetting angle of graphene and the aluminum melt is reduced, and graphene is prevented from floating onto the surface of the aluminum melt and into the melt to be agglomerated in an adding process. A graphene@silicon dioxide reinforcement is high in chemical stability, and improves the heat stability of an aluminum-based composite material with an aluminum- zirconium phase. According to the carbon nano-reinforced aluminum-based conductor material and the preparation method, the problem of insufficient strength and heat resistance of the aluminum-based composite material for limiting a conductor in an application process is solved. The compactness of the aluminum-based composite material produced by a casting method reaches 100%, the strength is increased by 25% and above, and the heat resistance is improved by 20-50 DEG C and above.

Owner:冷金凤

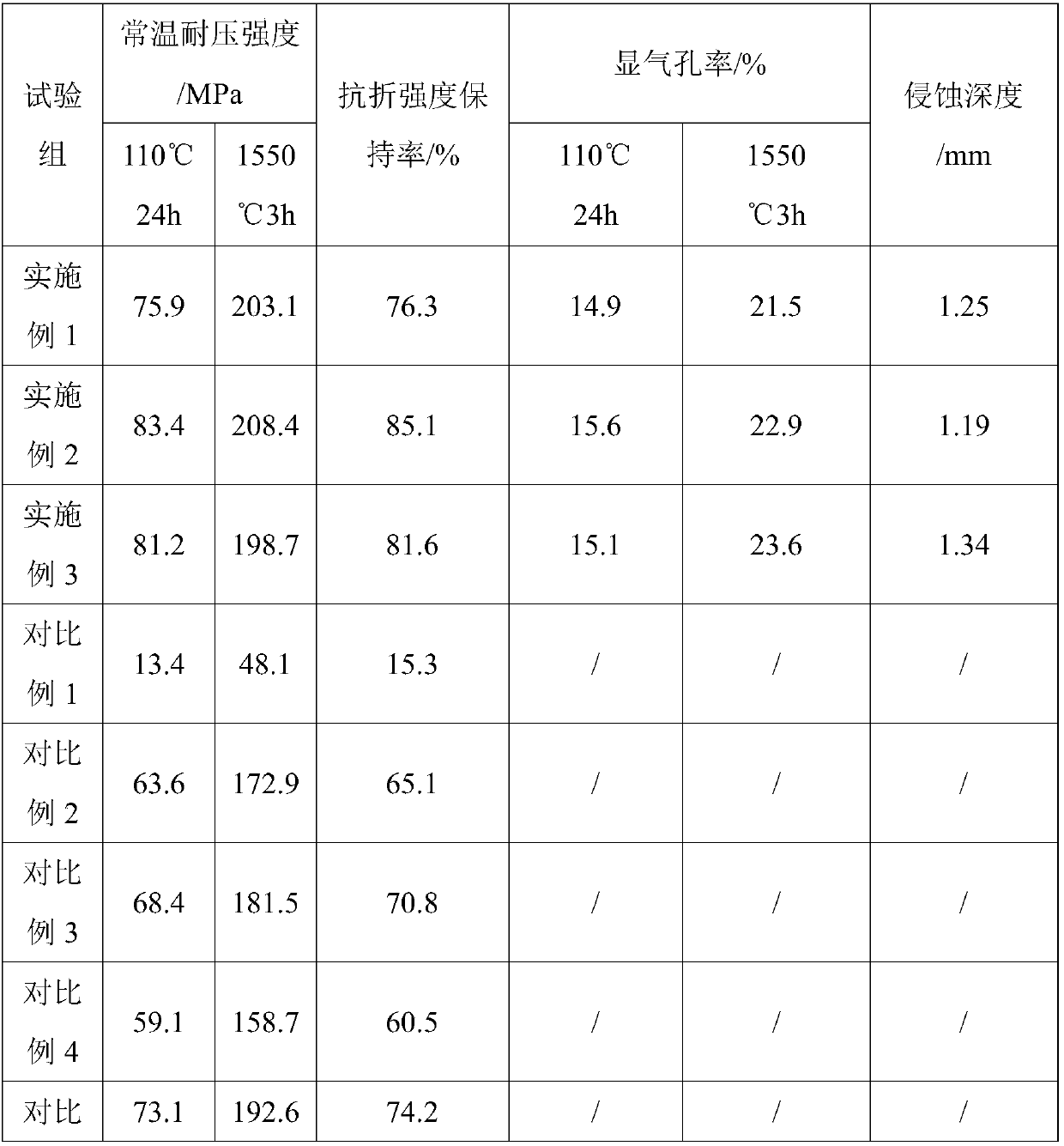

Alumina-magnesite carbon brick for 300t steel ladle impact region and preparation method thereof

The invention relates to an alumina-magnesite carbon brick for a 300t steel ladle impact region. The brick is obtained by using brown aluminum oxide, fused magnesite, dicalcium high-purity magnesia, crystalline flake graphite, carbon black and metal aluminum powder as raw materials, adding resin powder and phenolic resin into the raw materials, performing uniform mixing and performing baking afterpressing shaping, wherein the brown aluminum oxide and dicalcium high-purity magnesia have the independent particle diameter grading respectively; the brown aluminum oxide has the four stages of grading which are respectively 5 to 3 mm, 3 to 1 mm, 1 to 0 mm and at most 0.074 mm; the dicalcium high-purity magnesia has two stages of grading which are respectively 1 to 0 mm and at most 0.074 mm. Thebrown aluminum oxide and the dicalcium high-purity magnesia at different particle diameter grading are used as main bodies; the fused magnesite, the medical aluminum powder, the crystalline flake graphite and the carbon black are used as auxiliary materials and are mixed; then, the resin powder and the phenolic resin are added for pressing; drying is performed at a certain process curve, so thatthe pore rate is effectively reduced; the volume density and the pressure-resistant intensity of the alumina-magnesite carbon brick are improved; the service life is further prolonged.

Owner:洛阳源华冶金高温材料有限公司

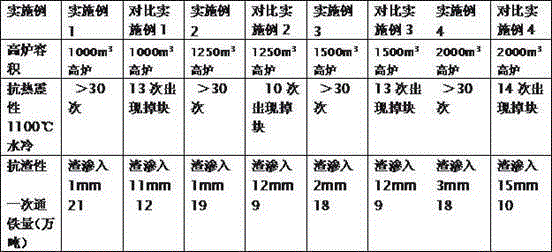

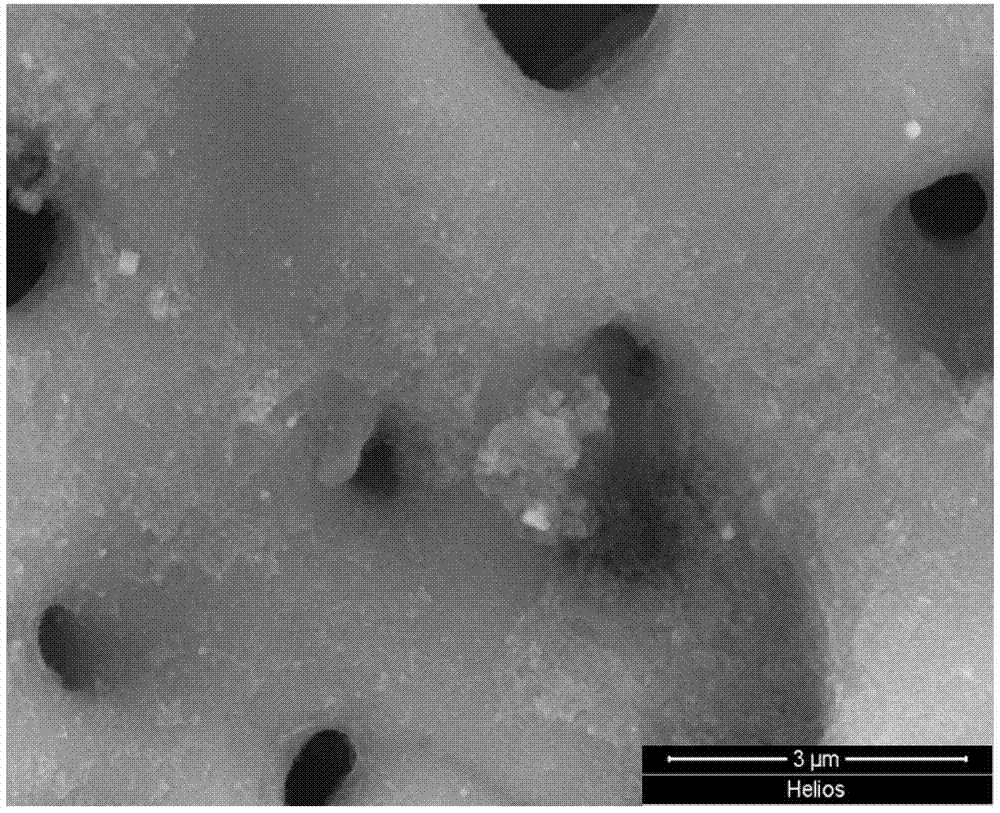

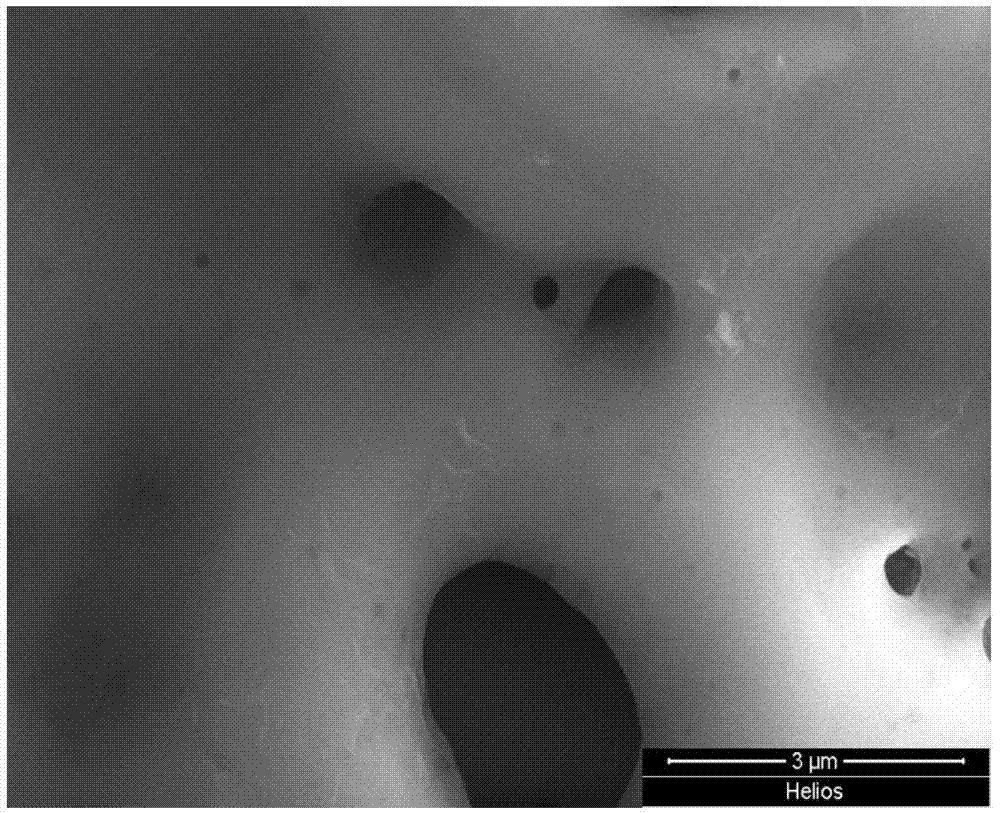

Preparation method of iron runner sialon casting body

The invention discloses a preparation method of an iron runner sialon casting body. The method comprises the following step: embedding a pipe easy to burn out in an iron runner casting body; and forming a pipe inlet and a pipe outlet in the wall of an iron runner. When the iron runner is used, the pipe easy to burn out is burnt out to form a channel, nitrogen is fed in the channel; and when the flows of the inlet and the outlet of the nitrogen channel are the same, the outlet of the channel is closed and the feeding of the nitrogen is stopped; and a filling material is pressed into the channel. The air-cooled iron runner sialon casting body prepared by using the method is high in cooling efficiency, so that the service life of the iron runner is further prolonged. The integrated iron runner sialon casting body can be used for improving the whole thermal state strength of the iron runner by dozens of times; and the iron runner material contains nitrides, so that a wetting angle of the iron runner material to slag iron is enlarged. Thus, the slag erosion resistance and the penetration resistance of the iron runner are greatly improved. Therefore, the service life of the iron runner is prolonged. As a result, the cost of an enterprise is reduced; and the generation of industrial wastes and the waste of fire-resistant raw material resources are reduced, namely, the environmental-friendly effect is achieved.

Owner:巩义市时创新材料孵化器有限公司

Anti-seepage castable

The invention relates to a castable and particularly discloses an anti-seepage castable which is prepared from the following raw materials in parts by weight: 53-76 parts of flint clay, 13-21 parts ofmagnesia fine powder, 8-14 parts of baryta feldspar powder, 4-10 parts of cement, 2-7 parts of a seepage-proofing agent, 3-9 parts of nanometer potato powder, 4.5-9 parts of potash feldspar fine powder, 1.5-4 parts of silicon carbide, 9-16 parts of calcium hexaluminate, 2.5-7.5 parts of sodium aluminate and 0.1-0.6 part of 2-morpholineethanesulfonic acid. The anti-seepage castable has excellent seepage-proofing performance.

Owner:ANHUI RUITAI NEW MATERIALS TECH

Castable for main iron trough

InactiveCN105198467AImprove corrosion resistanceImprove thermal shock resistanceAl powderChromium nitride

The invention relates to a castable for a main iron trough. The castable comprises a main material and an additive, wherein the main material comprises components in parts by weight as follows: 5-8 parts of 10-5mm magnesium titanate, 15-20 parts of 5-3 mm chromium nitride, 10-15 parts of 3-1 mm sillimanite, 8-15 parts of 1-0 mm calcium chromite, 2-5 parts of clay powder, 3-7 parts of cobaltous oxide aluminum powder, 5-10 parts of cutting powder, 3-8 parts of amorphous graphite powder, 1-2 parts of composite carbon powder, 0-3 parts of molybdenum trioxide powder, 3-5 parts of alumina micropowder, 1-5 parts of magnesium oxide iron powder, 1-3 parts of rho aluminum oxide and 1-5 parts of fused calcium aluminate cement; the additive comprises, in parts by weight, 0.1-0.2 parts of calcium lignosulfonate, 0.01-0.05 parts of nano potato powder, 0.01 parts of malic acid and 0.1 parts of C12H14N4O5S2 on the basis that the parts of the main material by weight adds up to 100%. The blast furnace iron trough prepared with the castable has the characteristics of good thermal shock resistance, high corrosion resistance, large iron influx and long service life.

Owner:汤炼芳

Preparation method of hydrophobic micro-arc oxidation bioactive coating with titanium surface

ActiveCN103046103ASimple methodNo pollution in the processSurface reaction electrolytic coatingPlasma electrolytic oxidationMicro arc oxidation

The invention provides a preparation method of hydrophobic micro-arc oxidation bioactive coating with titanium surface, which relates to the field of titanium surface modification and aims at solving the problem that when soaked in a body liquid, a micro-arc oxidation coating prepared by the traditional method is easy to corrode due to a small wetting angle, and therefore, the biological activity of the coating loses effectiveness. The preparation method provided by the invention comprises the steps of: 1, polishing and washing the surface of a titanium test sample; 2, preparing a micro-arc oxidation electrolyte; 3, carrying out micro-arc oxidation for 5-15 minutes under the conditions that the temperature of the electrolyte is 10 DEG C-60 DEG C, the impulse voltage is 250-550 V, the working efficiency is 200-1000Hz, and the duty ratio is 4-20 percent; and 4, washing and drying to obtain the coating. The preparation method provided by the invention is simple in technology, short in period, low in cost and is easy for large-scale generation of the coating. The preparation method is applied to the field of medical equipment.

Owner:HARBIN INST OF TECH

Castable

InactiveCN105330311AImprove corrosion resistanceImprove thermal shock resistanceCobaltMolybdenum trioxide

The invention relates to castable. The castable is prepared from a main material and additives. The main material is prepared from, by weight, 5-8 parts of 8-5 mm barium aluminate, 15-20 parts of 5-3 mm chromium mononitride, 10-15 parts of 3-1 mm sillimanite, 8-15 parts of 1-0 mm calcium chromite, 2-5 parts of clay-like powder, 3-7 parts of cobalt aluminum oxide powder, 5-10 parts of cutting powder, 3-8 parts of amorphous graphite, 1-2 parts of composite powdered carbon, 0-3 parts of molybdenum trioxide powder, 3-5 parts of alumina micro powder, 1-5 parts of magnesium oxide iron powder, 1-3 parts of rho aluminum oxide and 0-5 parts of electric-smelted pure calcium aluminate cement. With the main material accounting for 100% by weight in total, the additives are prepared from, by weight, 0.1-0.2 part of calcium lignosulfonate, 0.01-0.05 part of nanometer dried potato powder, 0.01 part of malic acid and 0.01 part of C12H14N4O5S2. A blast furnace iron runner made of the castable has the advantages of being good in thermal shock resistance, high in corrosion resisting performance, large in iron exchanging amount and long in service life.

Owner:山国强

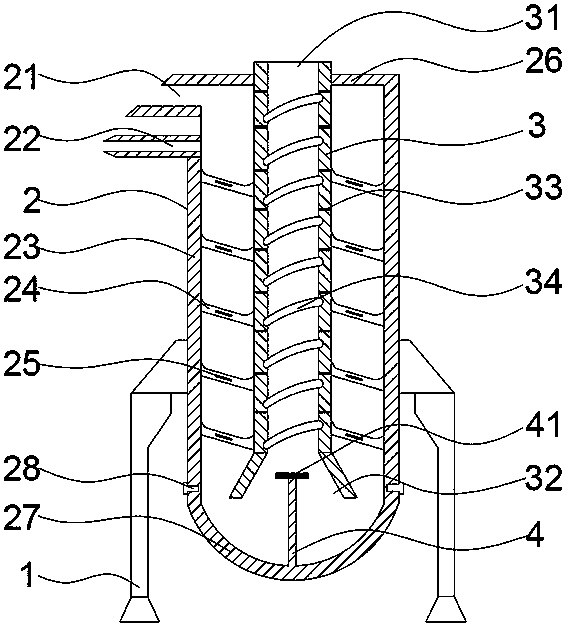

Spiral type heating dryer with materials being loaded separately

InactiveCN107560357AQuality improvementAvoid stickingDrying gas arrangementsDrying chambers/containersPulp and paper industryIndustrial dryer

The invention provides a spiral type heating dryer with materials being loaded separately, and belongs to the field of industrial dryers. The spiral type heating dryer comprises an outer drying cylinder, an inner drying cylinder and a supporting column, wherein the supporting column supports and is fixedly connected with the outer drying cylinder; the outer drying cylinder comprises an outer cylinder body, a top cover and a cylinder bottom, wherein openings are formed in the upper end and the lower end of the outer cylinder body, the top cover is fixedly connected with the upper end of the outer cylinder body and seals the opening at the upper end of the outer cylinder body, and the cylinder bottom is fixedly connected with the lower end of the outer cylinder body and seals the opening atthe lower end of the outer cylinder body; a strut is mounted in the center of the cylinder bottom, a suction fan is mounted at the top end of the strut, and the top end of the upper part of the side wall of the outer cylinder body is provided with a material inlet and a hot air pipeline which penetrate through the side wall of the outer cylinder body; the inner drying cylinder and the outer cylinder body are arranged coaxially; a guiding plate with a downward spiral is arranged on the area between the inner wall of the outer cylinder body and the outer wall of the inner drying cylinder, and agroove with an upward spiral is formed in the inner wall of the inner wall of the inner drying cylinder; and a first heating element is arranged in the cylinder wall of the inner drying cylinder, anda second heating element is arranged in the guiding plate. According to the double spiral structure of the spiral type heating dryer, damp materials can be quickly and evenly dried, and adhesion and hardening of the materials in the dryer is not easy to occur.

Owner:兰溪市捷喜食品加工技术有限公司

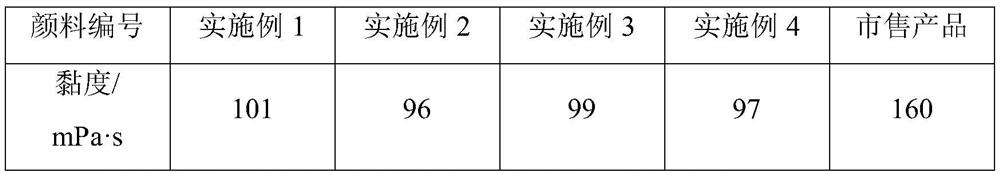

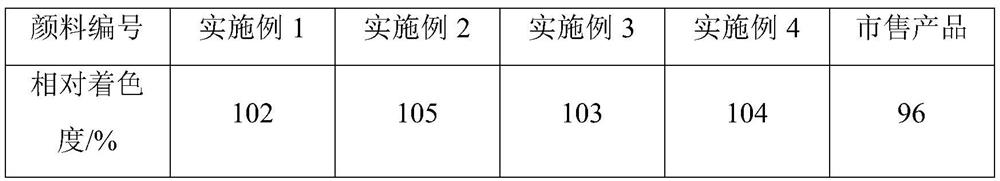

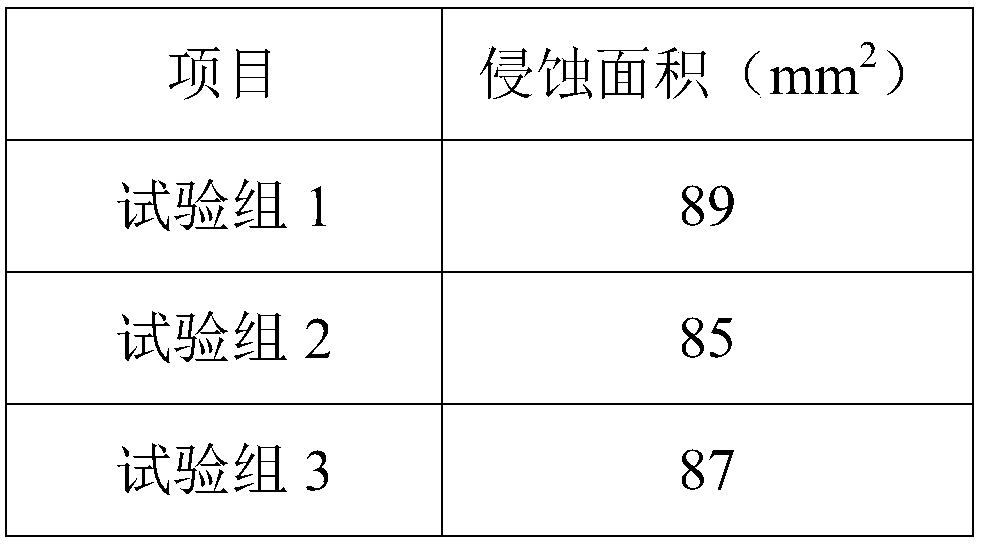

Preparation method of pigment red 57: 1

Provided is a process for preparing pigment red 57: 1. Through process improvement and adding of 2-aminophenol-4-sulfonic acid, 1-amino-2-naphthol-4-sulfonic acid or 3-amino-4-methoxybenzenesulfonic acid as a second coupling component, inter-particle force is attenuated, and particle size and color light are changed. Meanwhile, triethanolamine dodecylbenzene sulfonate, 4-hydroxybutyrate hydrazineand 4-hydroxybutyl acrylate are selected as a modifying substance and a dispersing agent to enhance the coloring power, effectively control the pigment crystal growth and improve the flowability. Microwave drying is adopted to improve the drying efficiency and avoid crystal form dehydration conversion. Airflow mill drying is adopted to reduce the average particle size of the pigment and increase the coloring strength. The pigment prepared by the technology effectively solves the problems of poor flowability, low coloring strength and the like of the traditional pigment.

Owner:PENGLAI XINGUANG PIGMENT CHEM

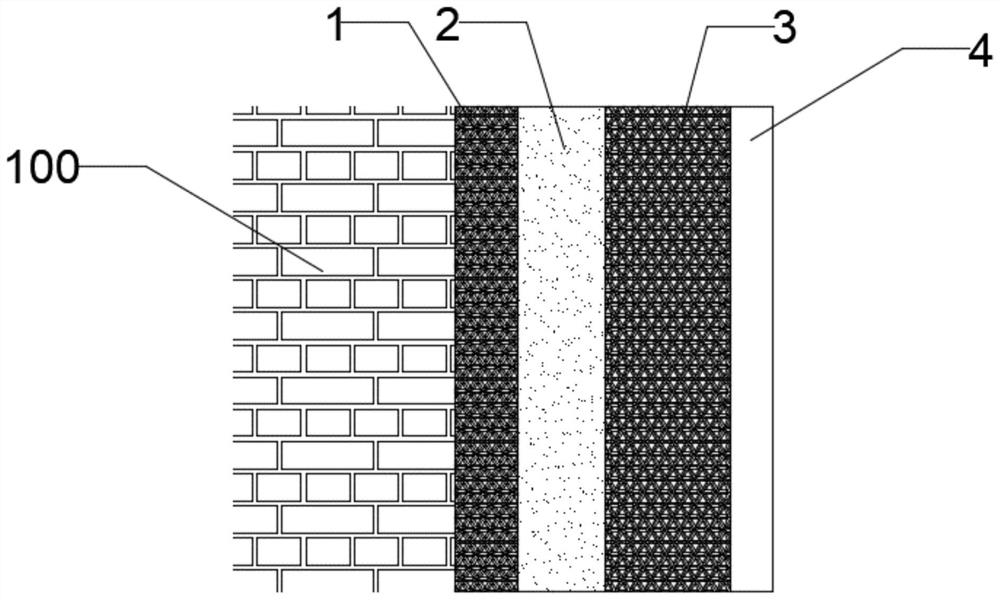

Waterproof and anti-crack external wall insulation structure for building

ActiveCN113073800AImprove waterproof performanceGood waterproof and crack resistanceCovering/liningsInsulation layerPortland cement

The invention relates to a waterproof and anti-crack external wall insulation structure for a building. The waterproof and anti-crack external wall insulation structure comprises a first waterproof and anti-crack layer, an insulation layer and a second waterproof and anti-crack layer, wherein the first waterproof and anti-crack layer, the insulation layer and the second waterproof and anti-crack layer are arranged in sequence near a wall, the insulation layer is located between the first waterproof and anti-crack layer and the second waterproof and anti-crack layer, both the first waterproof and anti-crack layer and the second waterproof and anti-crack layer are prepared from waterproof and anti-crack mortar materials, and the waterproof and anti-crack mortar materials are prepared from the following components in parts by weight: 100 parts of portland cement, 500 to 650 parts of medium sand, 90 to 110 parts of water, 32 to 66 parts of fly ash, 10 to 30 parts of modified halloysite nanotubes, 8 to 24 parts of polypropylene fibers, 3 to 10 parts of redispersible latex powder and 1 to 3 parts of water reducing agents. According to the waterproof and anti-crack external wall insulation structure, the construction steps of a product can be reduced through the waterproof and anti-crack mortar materials, the accurate and stable appearance of the product can be guaranteed, and the construction process is rapid and efficient.

Owner:苏邑设计集团有限公司

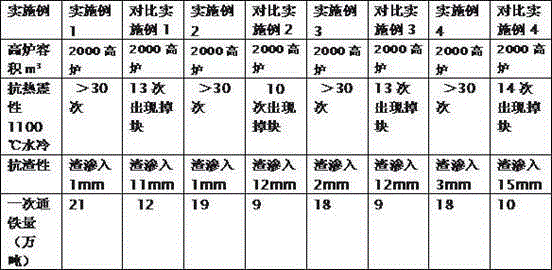

Castable for 2000m<3> blast furnace supporting iron runner

InactiveCN105218124AImprove corrosion resistanceImprove thermal shock resistanceMulliteChromium nitride

The invention relates to a castable for a 2000m<3> blast furnace supporting iron runner. The castable comprises a main material and an additive, wherein the main material comprises the following components in parts by weight: 5-8 parts of 5mm-8mm zirconium mullite, 15-20 parts of 3mm-5mm chromium nitride, 10-15 parts of 1mm-3mm sillimanite, 8-15 parts of 0-1mm calcium chromate, 2-5 parts of clay powder, 3-7 parts of cobalt aluminum oxide powder, 5-10 parts of cutting powder, 3-8 parts of amorphous graphite powder, 1-2 parts of composite carbon powder, 0-3 parts of molybdenum trioxide powder, 3-5 parts of alumina micro powder, 1-5 parts of magnesium iron oxide powder, 1-3 parts of rho alumina and 0-5 parts of electric-fused pure calcium aluminate cement; the additive comprises the following components in parts by weight of 100% of the main material: 0.1-0.2 part of calcium lignosulphonate, 0.01-0.05 part of nano potato powder, 0.01 part of malic acid and 0.1 part of C12H14N4O5S2. The blast furnace supporting iron runner prepared from the castable has the characteristics of good thermal shock resistance, strong erosion resistance, high iron influx and long service life.

Owner:万燕杰

Preparation method of refractory castable

The invention relates to the technical field of castables, and concretely discloses a preparation method of a refractory castable. The refractory castables comprises, by weight, 55-78 parts of brown fused alumina, 12-19 parts of kyanite powder, 2-7 parts of celsian powder, 5-11.5 parts of calcium aluminate cement, 3-8.5 parts of calcium sulfate, 2-9.5 parts of calcium fluoride, 1.5-4.5 parts of ananti-seepage aid, 4.5-9 parts of explosion-proof fibers, 1.5-4 parts of a dispersant, 6-14 parts of sodium silicate, 2.5-7.5 parts of potassium silicate and 0.1-0.5 part of rare earth. The preparation method comprises the following steps: co-grinding the brown fused alumina, calcium sulfate, calcium fluoride and the anti-seepage aid in a vibration mill for 40-60 min to obtain homogenized powder,mixing the homogenized powder with other components, and performing uniform mixing in order to obtain the refractory castable. The refractory castable obtained in the invention has an excellent anti-seepage property.

Owner:ANHUI RUITAI NEW MATERIALS TECH

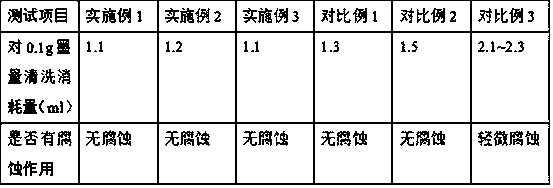

Printing ink cleaning agent

InactiveCN108410251AImprove utilizationImprove hydrophobicityChemical paints/ink removersBacillus licheniformisWater insoluble

The invention discloses a printing ink cleaning agent and belongs to the field of cleaning agents. A biological emulsifier prepared by the invention is characterized in that culture extraction and treatment of heat-liking and oil-biting bacillus licheniformis are adopted, utilization of water-insoluble substrates can be promoted to enable the water-insoluble substrates to be related to cell walls,the hydrophobic property of cells is improved, the water-insoluble substrates are emulsified and solubilized, binding to long chain hydrocarbon and long chain acid is enhanced, grease in printing inkis easy to dissolve, organic matters such as synthetic resin can be decomposed, biological oxygen acquisition can be realized by the action of the biological emulsifier, and the biological emulsifierhas anti-oxidation and anti-aging effects and also inhibits the propagation of germs. The printing ink cleaning agent disclosed by the invention solves the problems that kerosene and gasoline servingas solvents for traditional printing ink cleaning agents at present are flammable and explosive and have a corrosion effect on a rubber blanket and an ink roller of a printing machine.

Owner:方建波

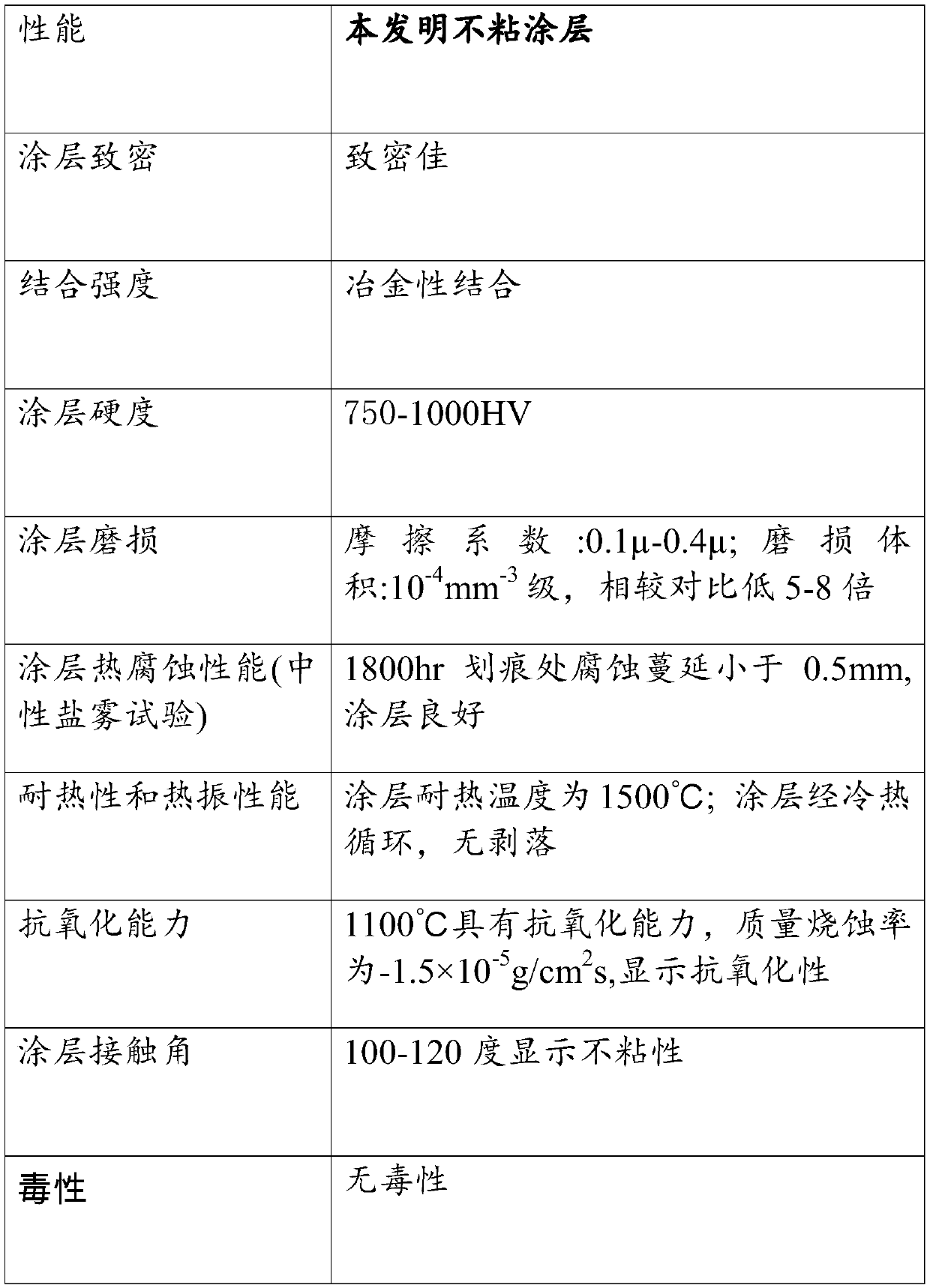

A kind of manufacture method of non-stick coating

ActiveCN108817637BReduce porosityHigh bonding strengthFireproof paintsCooking-vessel materialsCrazingFluoride

The invention discloses a manufacturing method for a non-stick coating. The non-stick coating comprises a substrate layer arranged on the inner surface of a pot body, wherein a first transition layeris arranged on the substrate layer; a second transition layer is arranged on the first transition layer; and a surface layer is arranged on the second transition layer. According to the non-stick coating which does not contain fluoride and is in metallurgical bonding, the substrate layer adopts a high-temperature-resistant binder material which is low in aluminum-nickel melting point and is good in wettability, is easily bonded with matrix, and is excellent in adhesion; each layer of paint is mixed progressively, so that the boning performance is good, and therefore, the paint is not liable todrop; a micro structure of the coating continuously changes in a special direction, and mechanical properties and the structure of the coating gradually change in the thickness direction, so that a thermal stress interface generated inside the coating as a result of great difference of physical parameters between metal matrix and a ceramic layer is eliminated, and therefore, the purpose of relieving thermal stress is achieved, and cracks are prevented. Besides, the non-stick coating is simple in manufacturing process, is easy to operate and is low in cost.

Owner:FUJIAN UNIV OF TECH

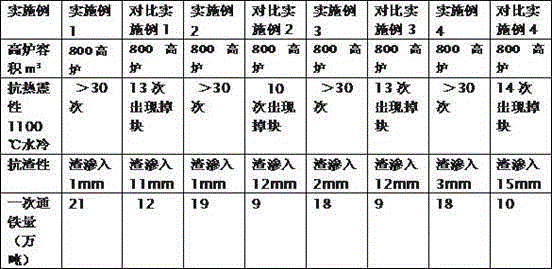

Casting material for 800m<3> blast-furnace branch iron trough

InactiveCN105272302AImprove corrosion resistanceImprove thermal shock resistanceChromium nitrideCobalt

The invention relates to a casting material for a 800m<3> blast-furnace branch iron trough. The casting material comprises a main material and an additive, wherein the main material comprises the following components in parts by weight: 5-8 parts of 8-5mm magnesium silicate, 15-20 parts of 5-3mm chromium nitride, 10-15 parts of 3-1mm sillimanite, 8-15 parts of 1-0mm calcium chromite, 2-5 parts of slightly-viscous clay powder, 3-7 parts of cobalt-aluminum oxide powder, 5-10 parts of cutting powder, 3-8 parts of amorphous graphite powder, 1-2 parts of compound carbon powder, 0-3 parts of molybdenum trioxide powder, 3-5 parts of aluminium oxide micropowder, 1-5 parts of magnesium-iron oxide powder, 1-3 parts of Rho aluminium oxide and 0-5 parts of electrically-smelted pure calcium aluminate cement; the additive comprises the following components in parts by weight according to the total weight part 100% of the main material: 0.1-0.2 part of calcium lignosulphonate, 0.01-0.05 part of nano potato powder, 0.01 part of malic acid and 0.1 part of C12H14N4O5S2. The blast-furnace iron trough prepared by the casting material has the characteristics of good thermal shock resistance, strong anti-erosion performance, large iron influx and long service life.

Owner:万燕杰

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com