Alumina-magnesite carbon brick for 300t steel ladle impact region and preparation method thereof

A technology of alumina-magnesia-carbon brick and impact zone, which is applied in the field of refractory materials, can solve the problems of excessive erosion and short service life, and achieve the effects of reducing porosity, improving service life and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

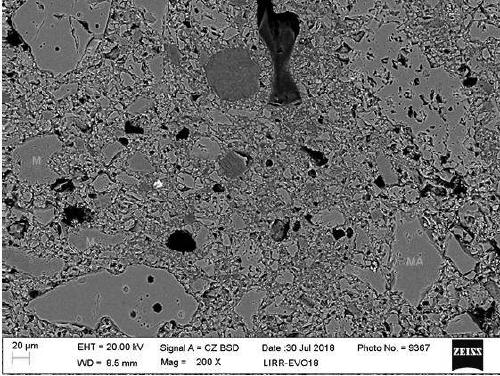

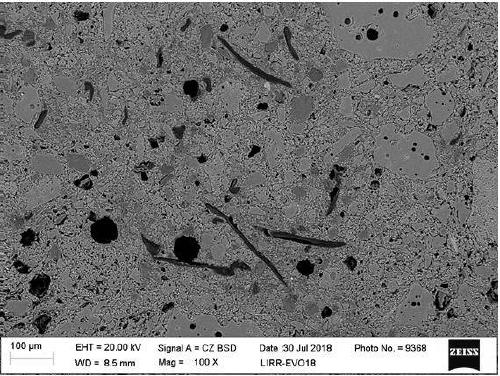

[0021] A 300-ton aluminum-magnesia-carbon brick for the impact zone of a ladle. The aluminum-magnesia-carbon brick is made of brown corundum, fused magnesia, dicalcium high-purity magnesia, flake graphite, carbon black and metal aluminum powder, and added Resin powder and phenolic resin are mixed uniformly and then pressed and baked to obtain. Both the brown corundum and dicalcium high-purity magnesia have independent particle size distributions to form a tightly packed and bonded structure during baking to improve the quality of aluminum-magnesium-carbon bricks. strength; the brown corundum has a four-level gradation, and is 5-3mm, 3-1mm, 1-0mm and no more than 0.074mm, and the dicalcium high-purity magnesia has a two-level gradation, and is 1-0mm respectively and not more than 0.074mm; the particle diameters of the fused magnesia and metal aluminum powder are respectively 3-1mm and not more than 0.074mm; every 100kg of the raw materials contains 15.5kg of 5-3mm brown corundum...

Embodiment 2

[0025] A 300-ton aluminum-magnesia-carbon brick for the impact zone of a ladle. The aluminum-magnesia-carbon brick is made of brown corundum, fused magnesia, dicalcium high-purity magnesia, flake graphite, carbon black and metal aluminum powder, and added Resin powder and phenolic resin are mixed uniformly and then pressed and baked to obtain. Both the brown corundum and dicalcium high-purity magnesia have independent particle size distributions to form a tightly packed and bonded structure during baking to improve the quality of aluminum-magnesium-carbon bricks. strength; the brown corundum has a four-level gradation, and is 5-3mm, 3-1mm, 1-0mm and no more than 0.074mm, and the dicalcium high-purity magnesia has a two-level gradation, and is 1-0mm respectively and not more than 0.074mm; the particle diameters of the fused magnesia and metal aluminum powder are respectively 3-1mm and not more than 0.074mm; every 100kg of the raw materials contains 12.5kg of 5-3mm brown corundum...

Embodiment 3

[0029] A 300-ton aluminum-magnesia-carbon brick for the impact zone of a ladle. The aluminum-magnesia-carbon brick is made of brown corundum, fused magnesia, dicalcium high-purity magnesia, flake graphite, carbon black and metal aluminum powder, and added Resin powder and phenolic resin are mixed uniformly and then pressed and baked to obtain. Both the brown corundum and dicalcium high-purity magnesia have independent particle size distributions to form a tightly packed and bonded structure during baking to improve the quality of aluminum-magnesium-carbon bricks. strength; the brown corundum has a four-level gradation, and is 5-3mm, 3-1mm, 1-0mm and no more than 0.074mm, and the dicalcium high-purity magnesia has a two-level gradation, and is 1-0mm respectively and not more than 0.074mm; the particle diameters of the fused magnesia and metal aluminum powder are respectively 3-1mm and not more than 0.074mm; every 100kg of the raw materials contains 14kg of 5-3mm brown corundum, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com