Patents

Literature

705results about How to "Improve the attenuation effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Poxvirus-canine distemper virus (CDV) or measles virus recombinants and compositions and methods employing the recombinants

InactiveUS6309647B1Improve securityImprove security levelSsRNA viruses negative-senseSsRNA viruses positive-senseHemagglutininCanine distemper virus Antigen

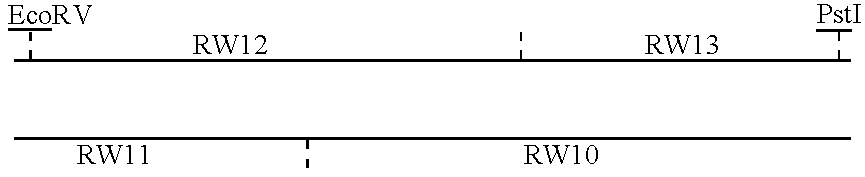

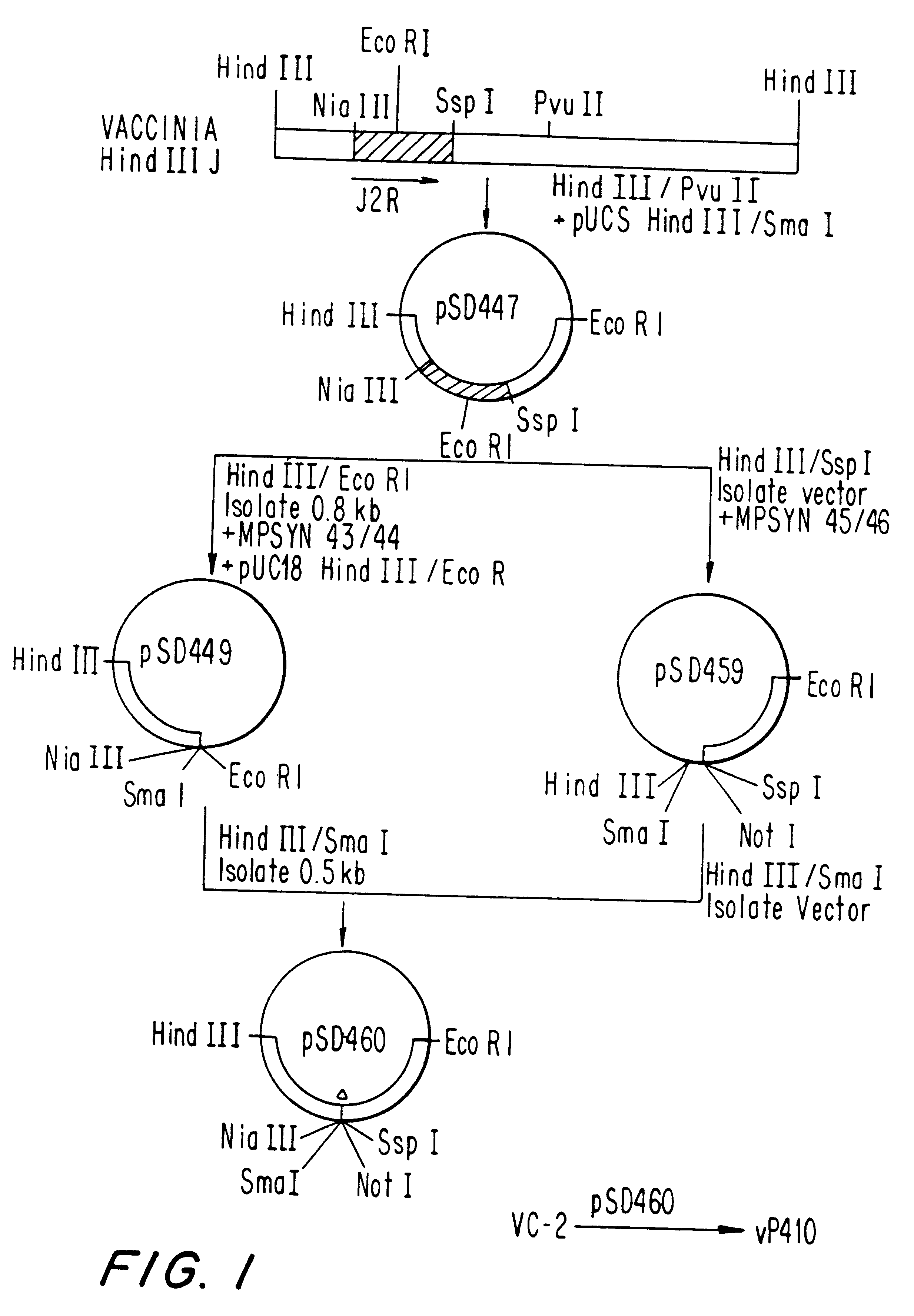

Attenuated recombinant viruses containing DNA coding for a canine distemper virus antigen or measles M or N antigen, as well as methods and compositions employing the viruses, are disclosed and claimed. The recombinant viruses can be NYVAC or ALVAC recombinant viruses. The DNA can code for at least one of: canine distemper virus fusion protein, canine distemper virus hemagglutinin glycoprotein, canine distemper nucleocaspid protein, canine distemper matrix protein, measles virus nucleocaspid protein, and measles virus matrix protein. The recombinant viruses and gene products therefrom are useful for eliciting protection against canine distemper virus and / or measles virus, and, the gene products and antibodies elicited thereby are useful in assays. Additionally, DNA from the recombinants is used for probes or for generating PCR primers.

Owner:AVENTIS PASTEUR LTD

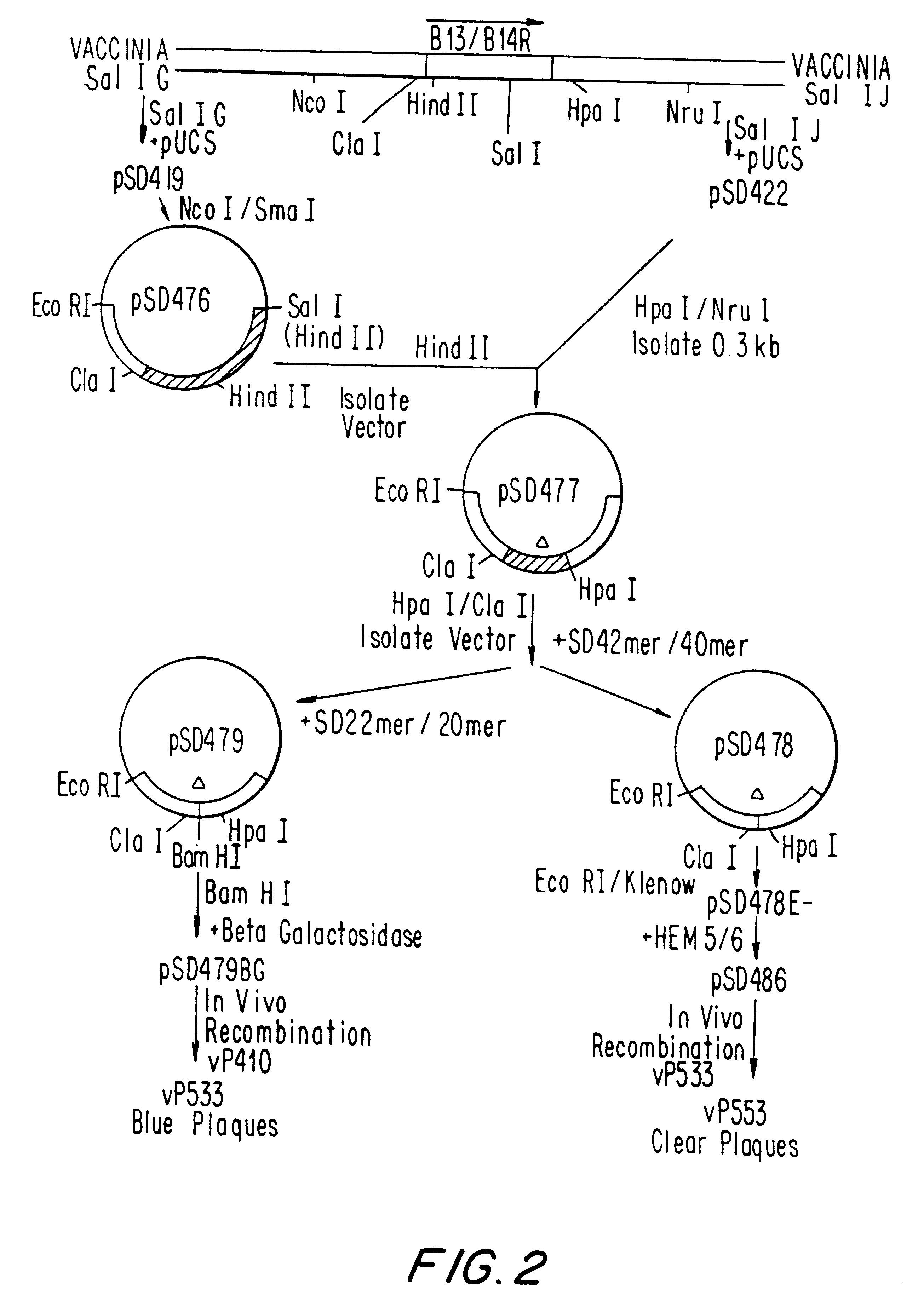

Buffer Tubes for Mid-Span Storage

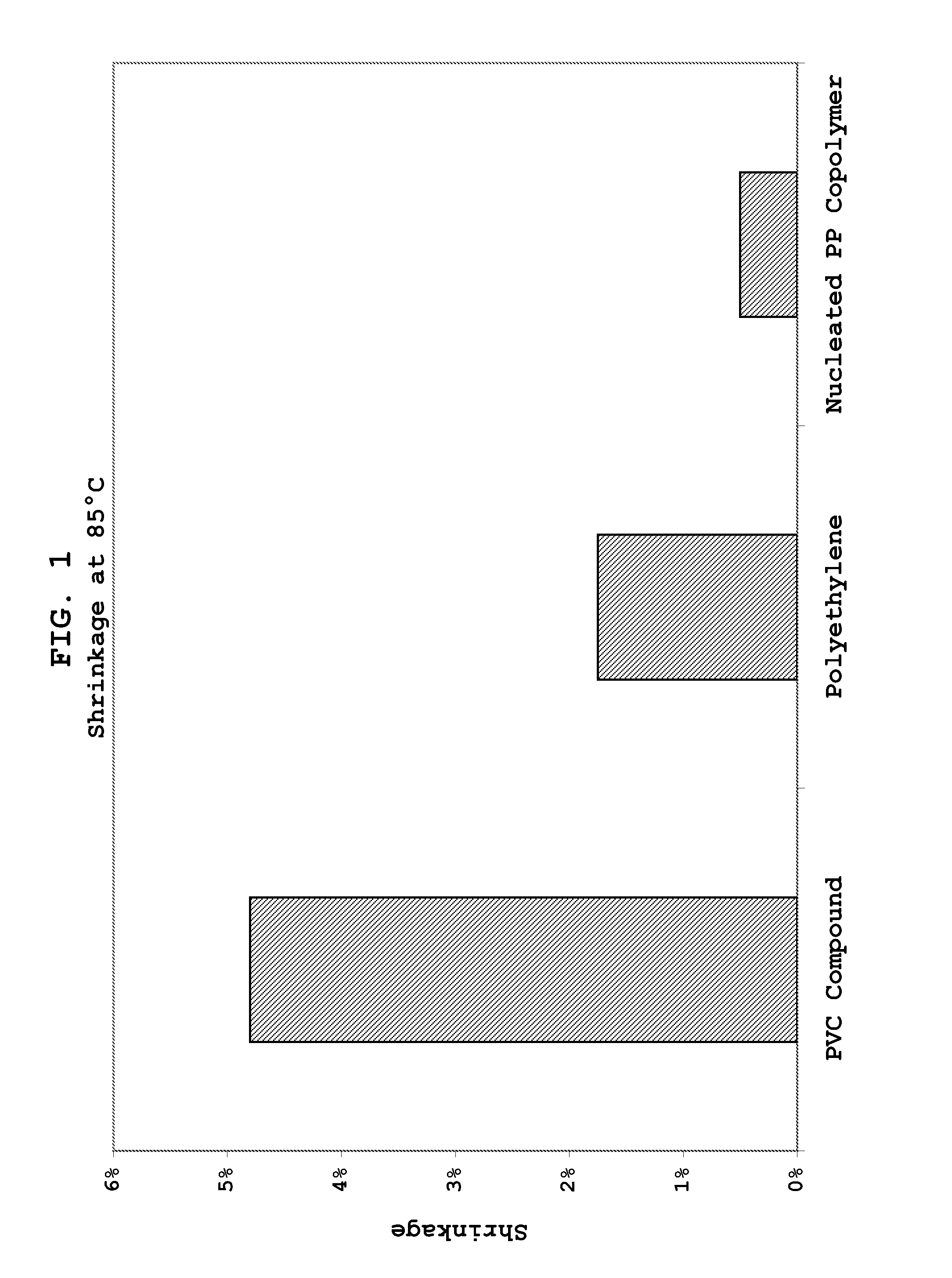

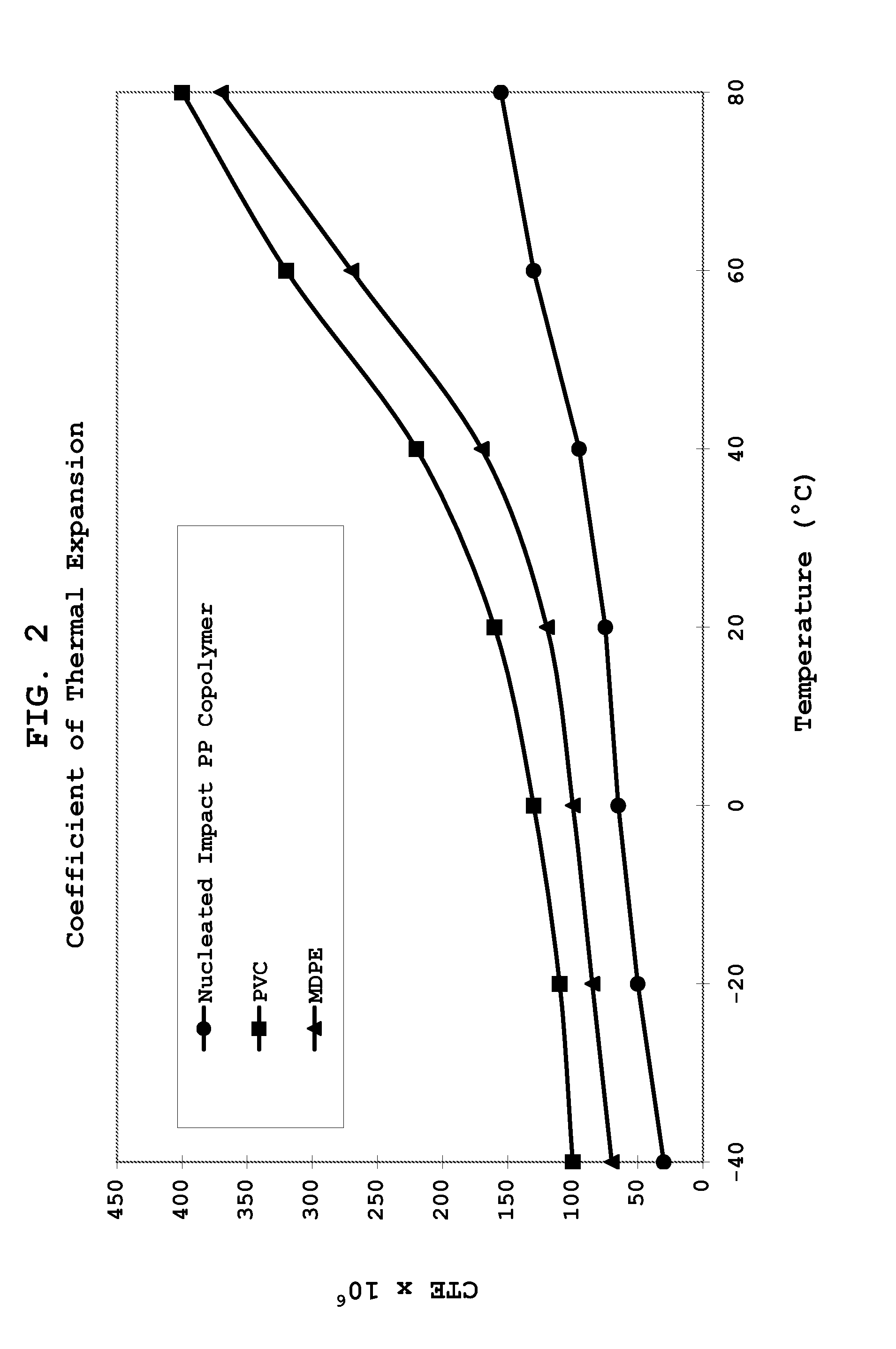

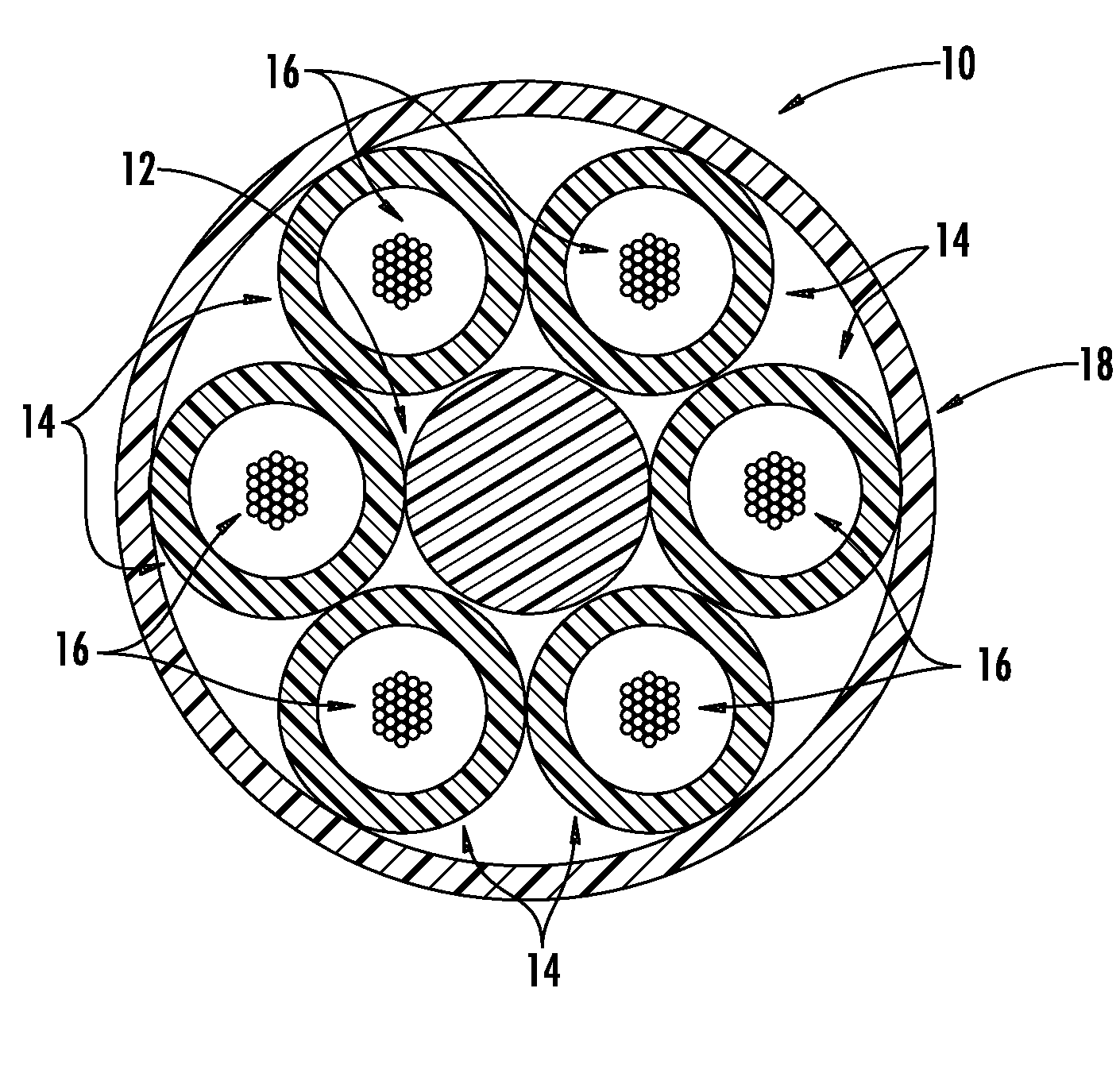

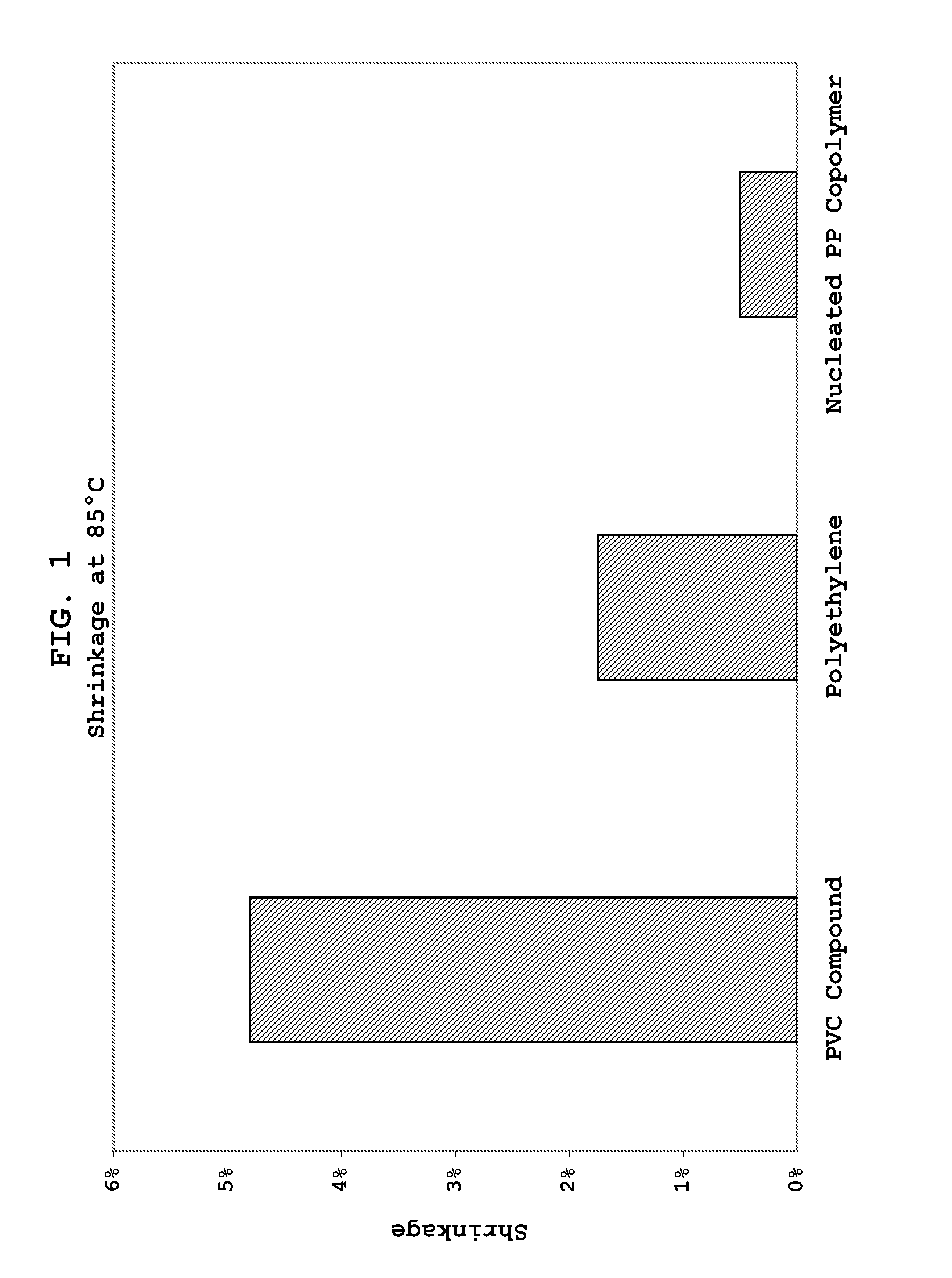

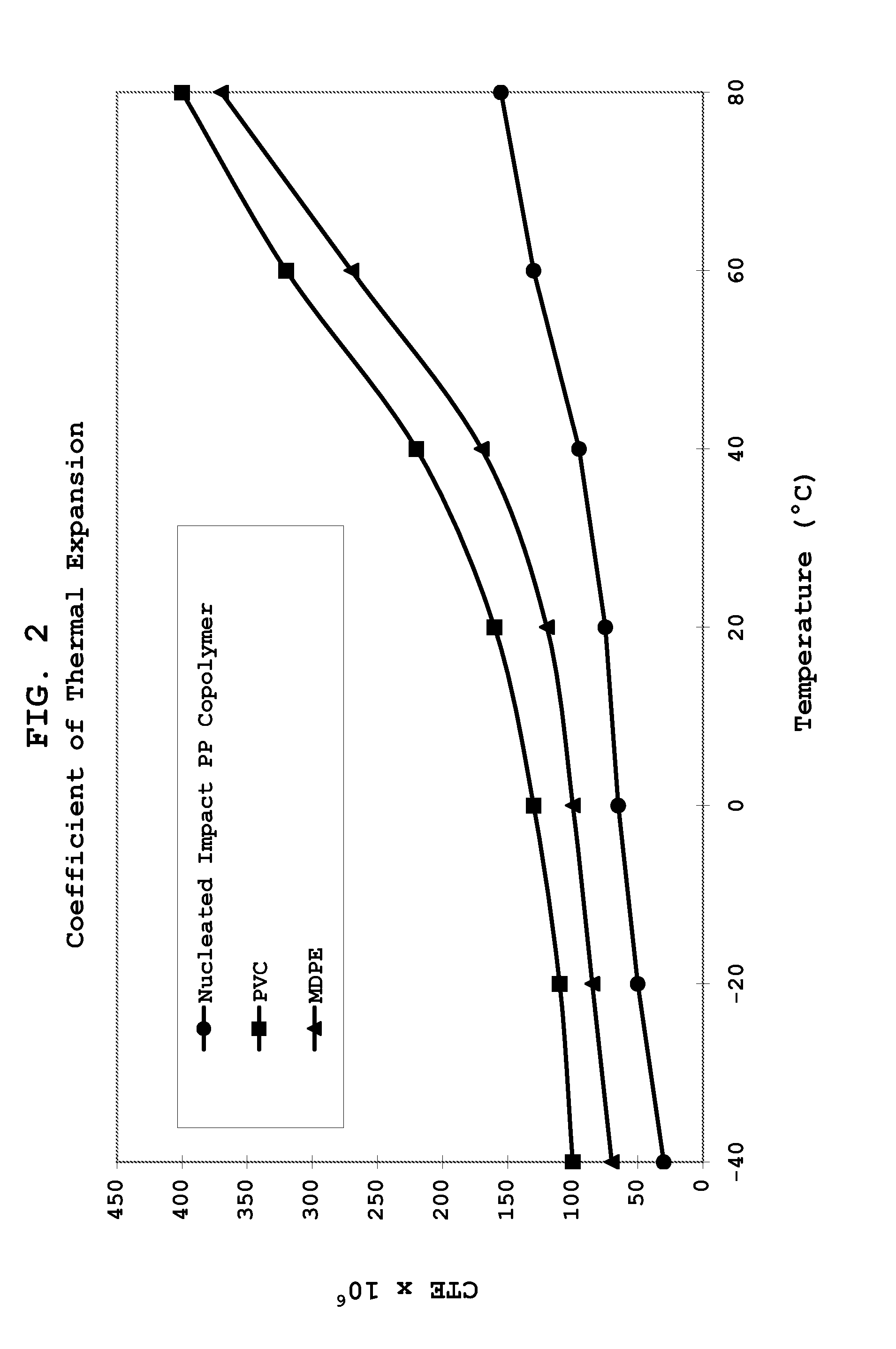

ActiveUS20100067855A1Improve fill factorImprove the attenuation effectFibre mechanical structuresEngineeringMaterials science

Owner:DRAKA COMTEQ BV

Buffer tubes for mid-span storage

ActiveUS7970247B2Improve fill factorImprove the attenuation effectFibre mechanical structuresEngineeringMaterials science

Owner:DRAKA COMTEQ BV

High-fiber-density optical fiber cable

InactiveUS7974507B2High cable fiber densityImprove the attenuation effectOptical fibre/cable installationFibre mechanical structuresEngineeringOptical fiber cable

Owner:DRAKA COMTEQ BV

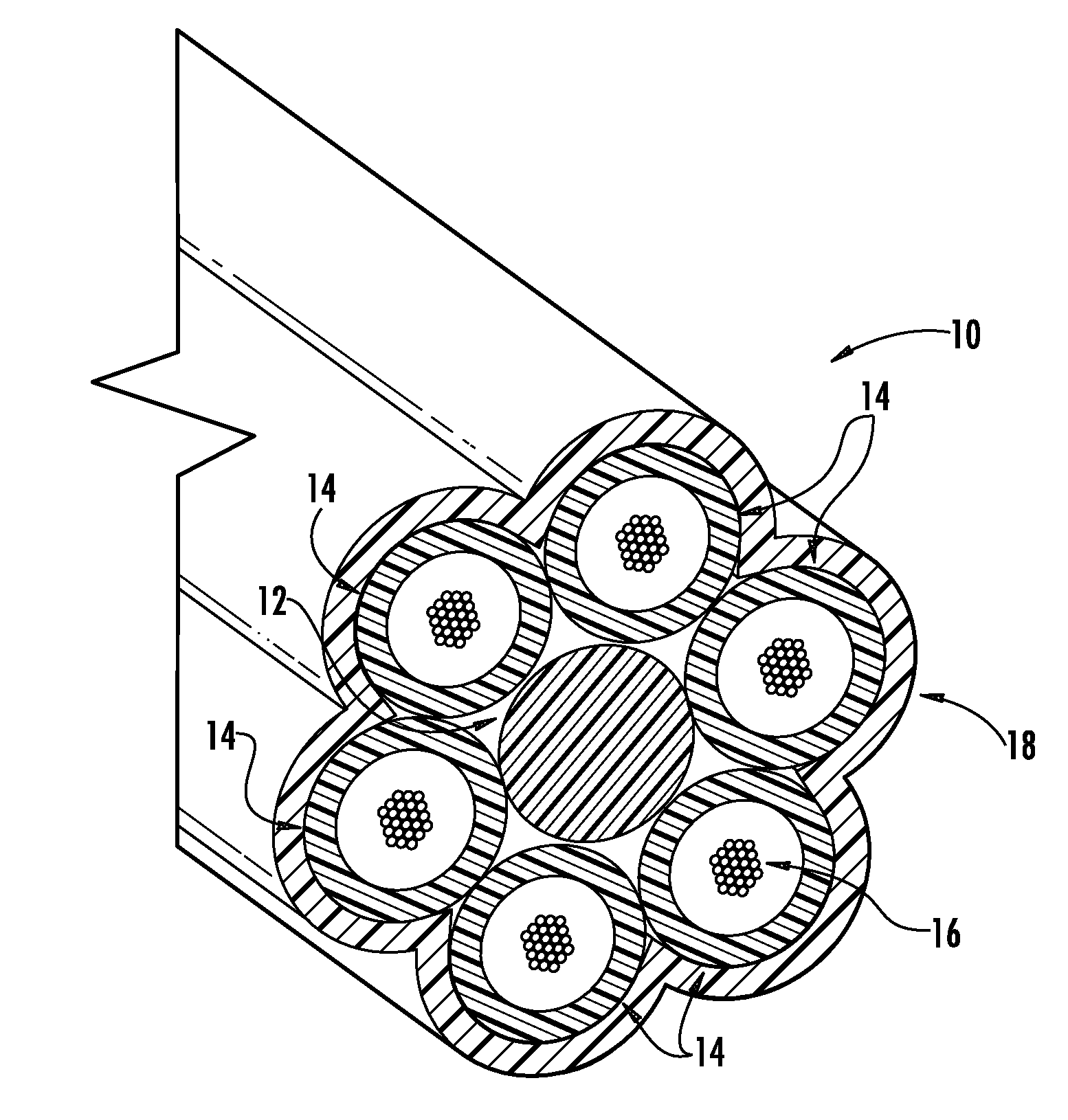

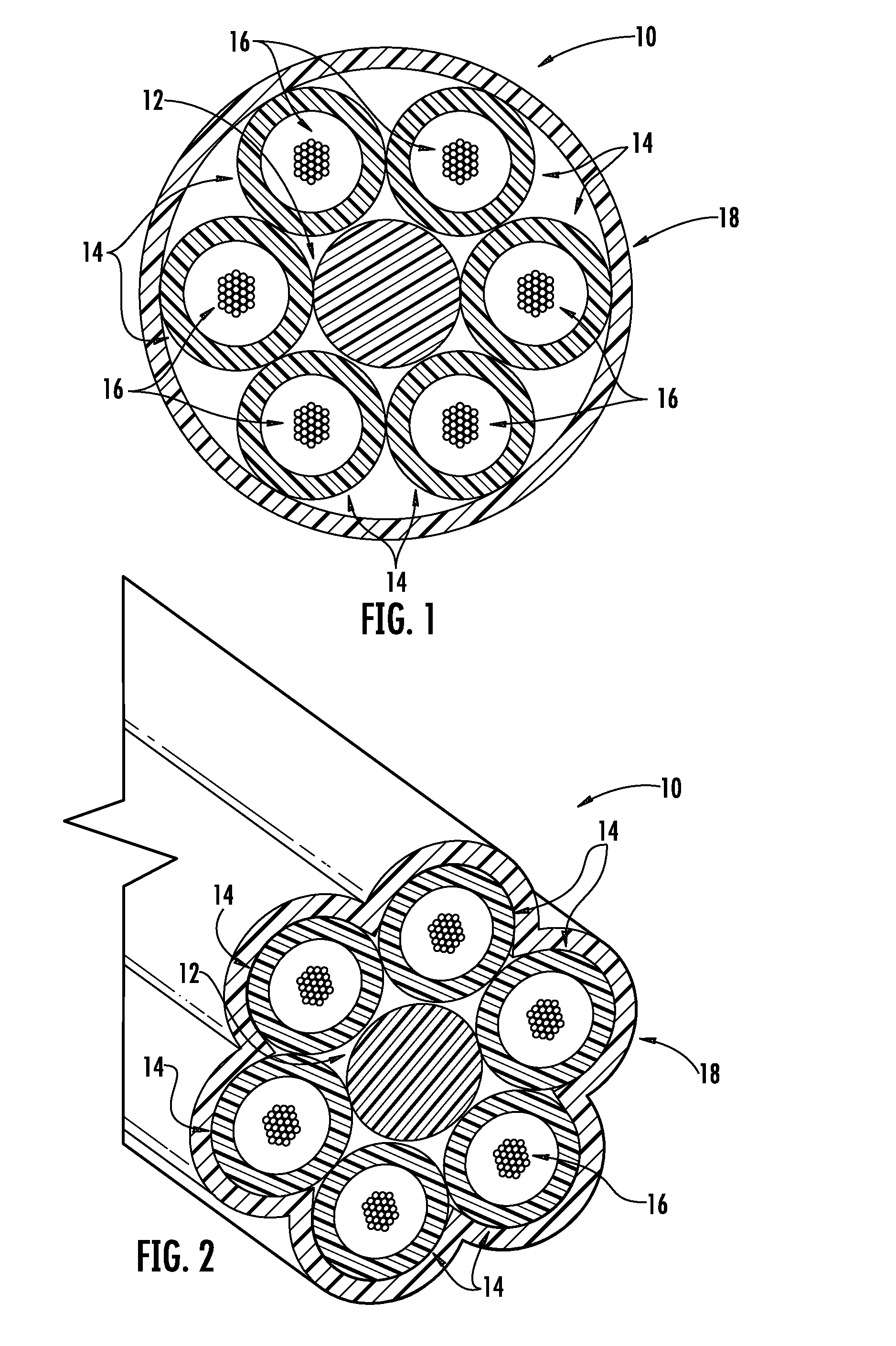

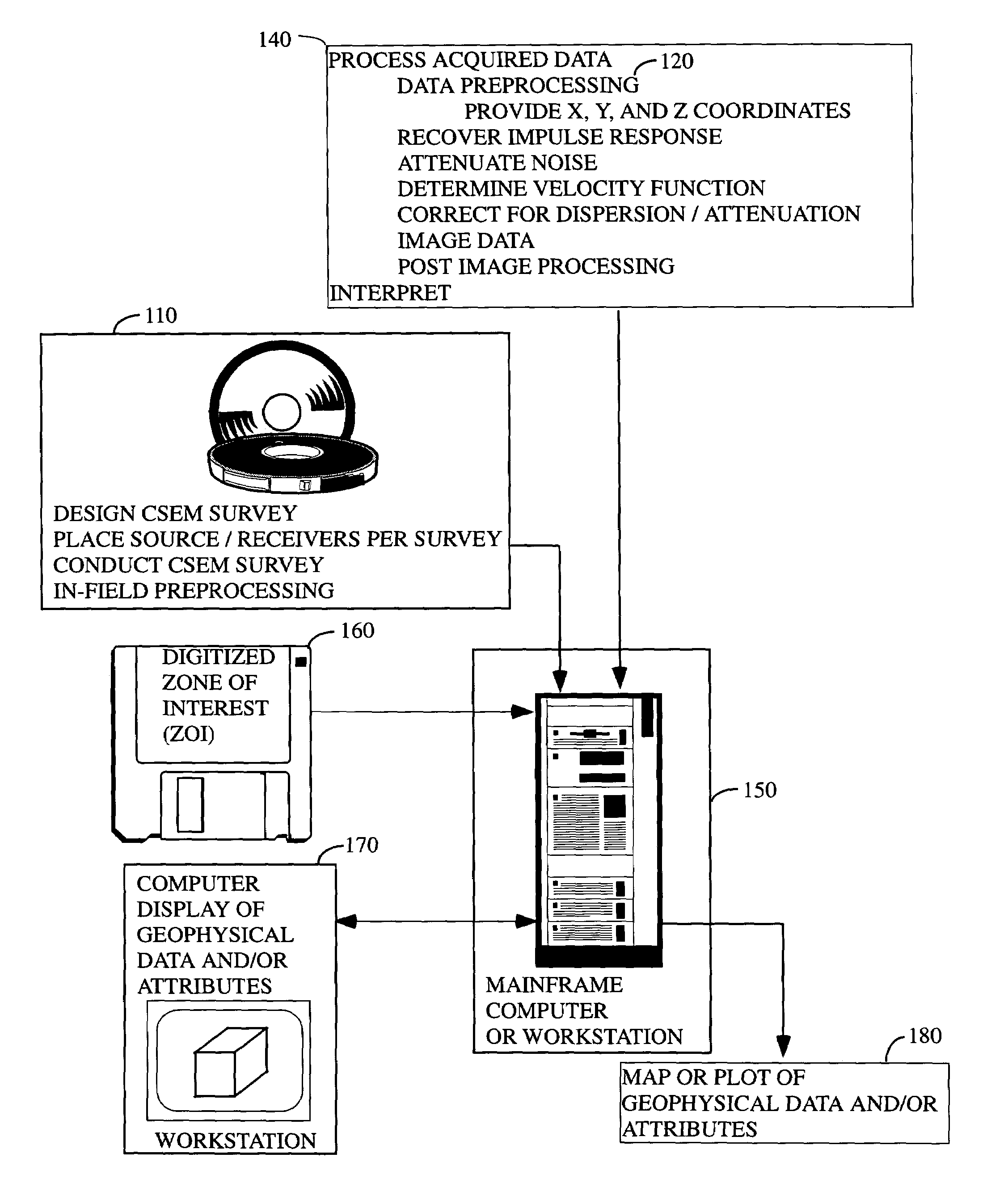

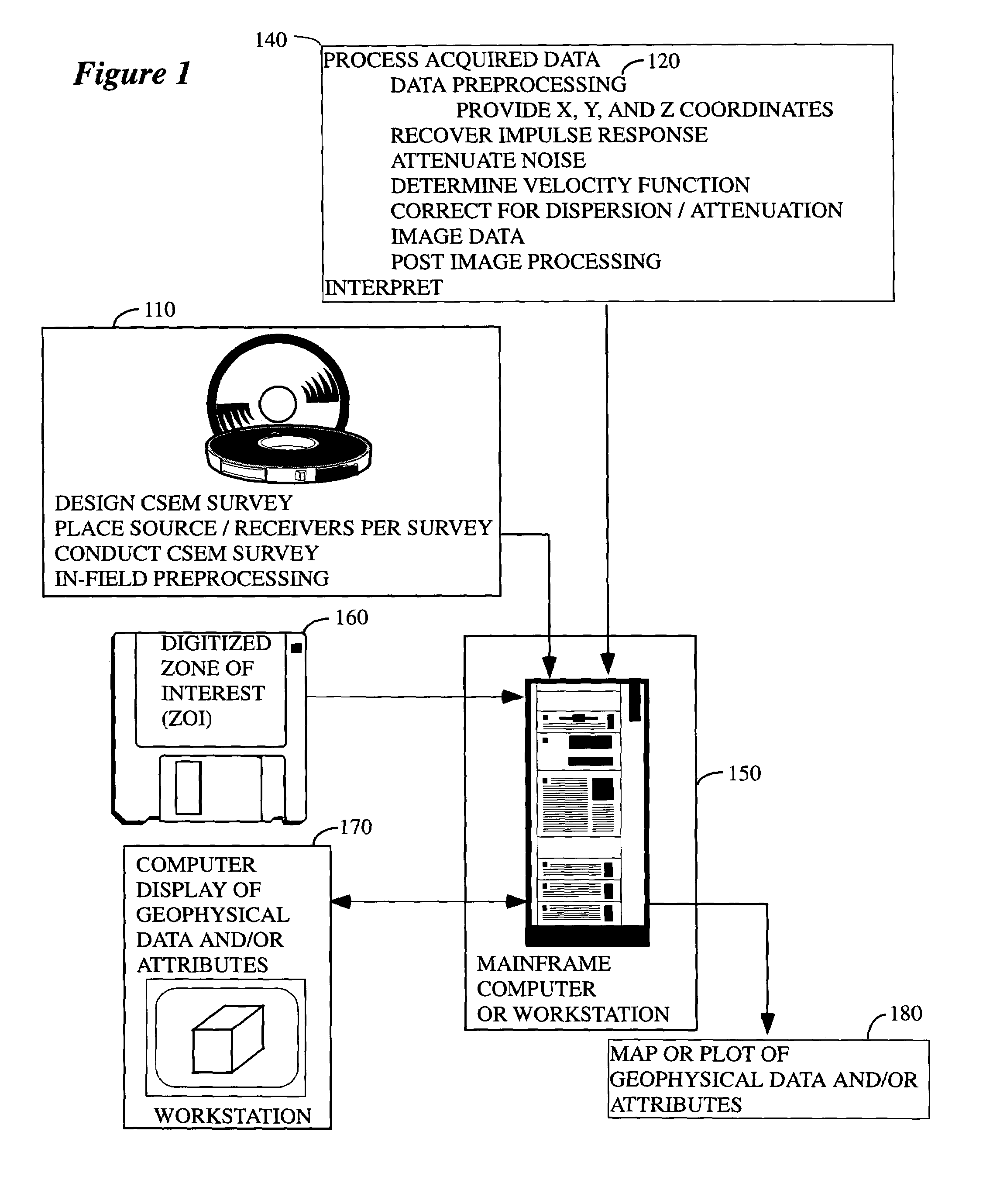

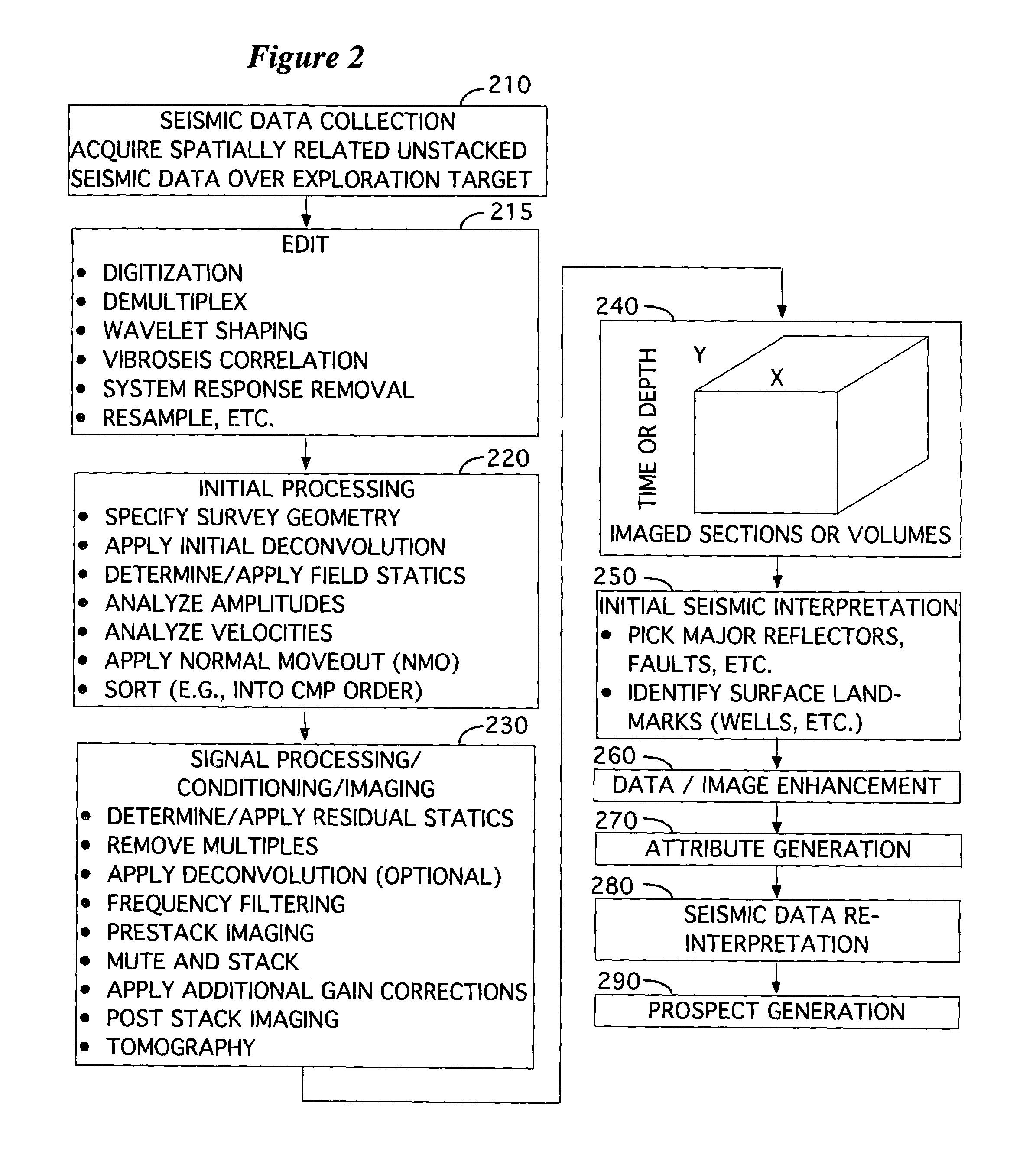

System and method for using time-distance characteristics in acquisition, processing, and imaging of t-CSEM data

InactiveUS7502690B2Enhance the imageEasy to processSeismic signal processingSeismology for water-covered areasUltrasound attenuationControlled source electro-magnetic

There is provided herein a system and method of acquiring, processing, and imaging transient Controlled Source ElectroMagnetic (t-CSEM) data in ways that are similar to those used for seismic data. In particular, the instant invention exploits the time-distance characteristics of t-CSEM data to permit the design and execution of t-CSEM surveys for optimal subsequent processing and imaging. The instant invention illustrates how to correct t-CSEM data traces for attenuation and dispersion, so that their characteristics are more like those of seismic data and can be processed using algorithms familiar to the seismic processor. The resulting t-CSEM images, particularly if combined with corresponding seismic images, may be used to infer the location of hydrocarbon reservoirs.

Owner:BP CORP NORTH AMERICA INC

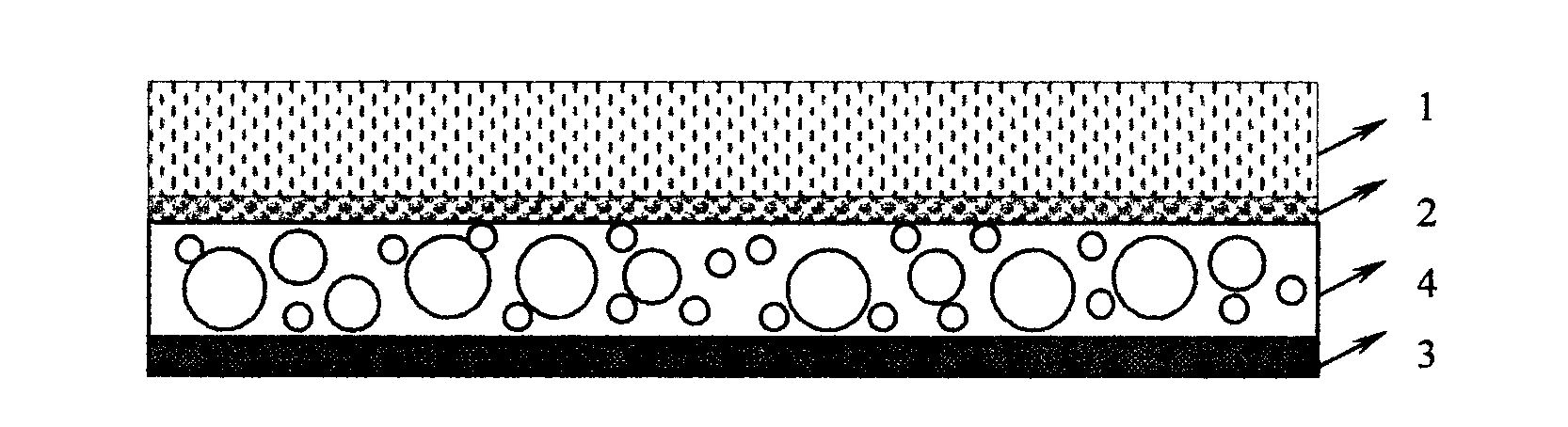

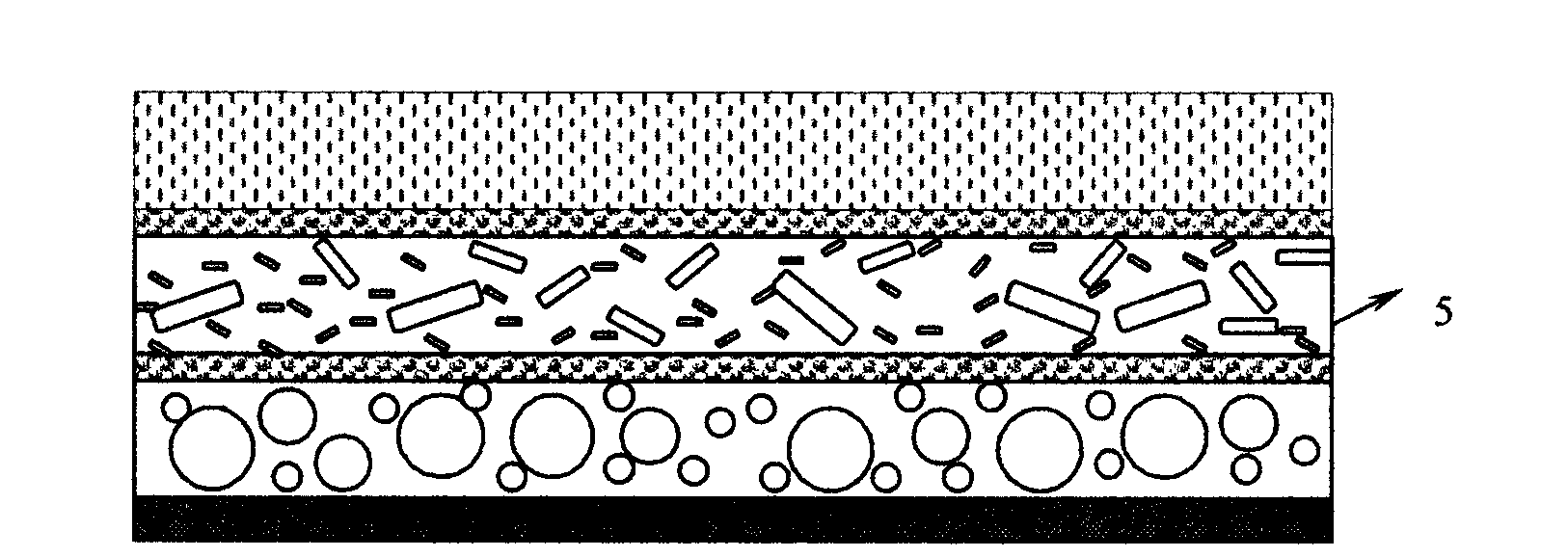

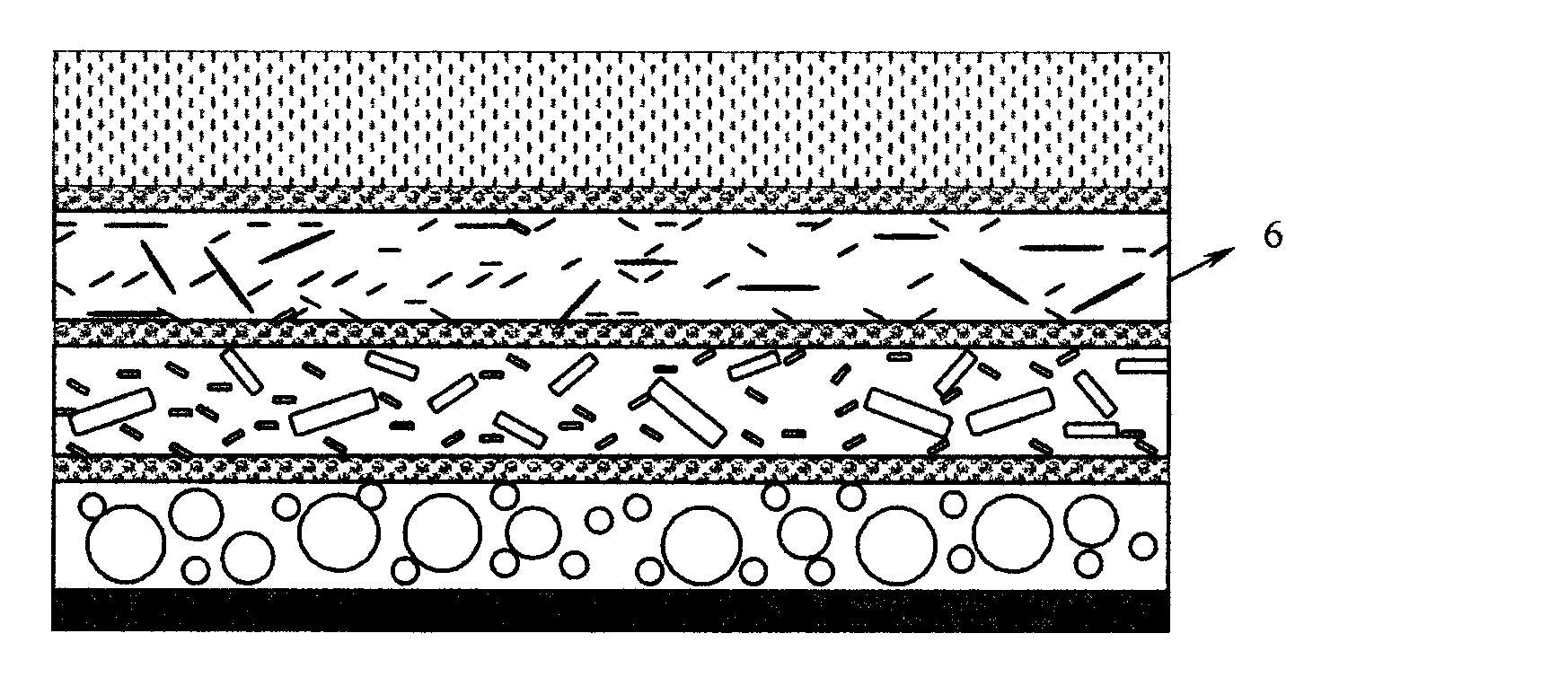

Efficient sound insulation material and manufacturing method thereof

InactiveCN103903608AImprove heat and aging resistanceExcellent ozone resistanceSynthetic resin layered productsSound producing devicesInsulation layerFoaming agent

The invention relates to the field of products of sound insulation material, solves the problems in the prior art that the sound insulation material is poor in sound insulation effect, is incomprehensive in high and low frequency sound insulation, causes pollution and is easy to age, and provides an efficient sound insulation material and a manufacturing method thereof. The efficient sound insulation material includes a sound insulation layer, a sound absorption layer, and a bubble layer, wherein the bubble layer is located between the sound insulation layer and the sound absorption layer. The sound absorption layer is made of a sound insulation compound, and the sound insulation compound is prepared by raw materials of the following substances: a thermoplastic resin, inorganic fillers, and a foaming agent, wherein the inorganic fillers account for 15-80wt%, the foaming agent accounts for 5-15wt%, and the rest is the thermoplastic resin. In the efficient sound insulation material, the fillers with different particle diameters correspond to sound waves of different wave bands or frequencies, and thus consumption of sound energy of different frequencies is relatively comprehensive, and the sound insulation effect is good, so the sound insulation material is suitable for popularization and application.

Owner:浙江艾迪雅汽车部件新材料有限公司

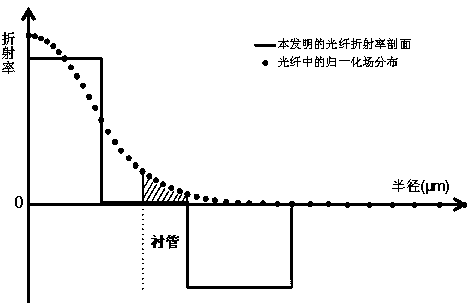

Large-size optical fiber preform and manufacturing method of optical fiber thereof

ActiveCN101891380AImprove the attenuation effectGuaranteed low water peak performanceGlass optical fibreGlass fibre drawing apparatusAccess networkCore (optical fiber)

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

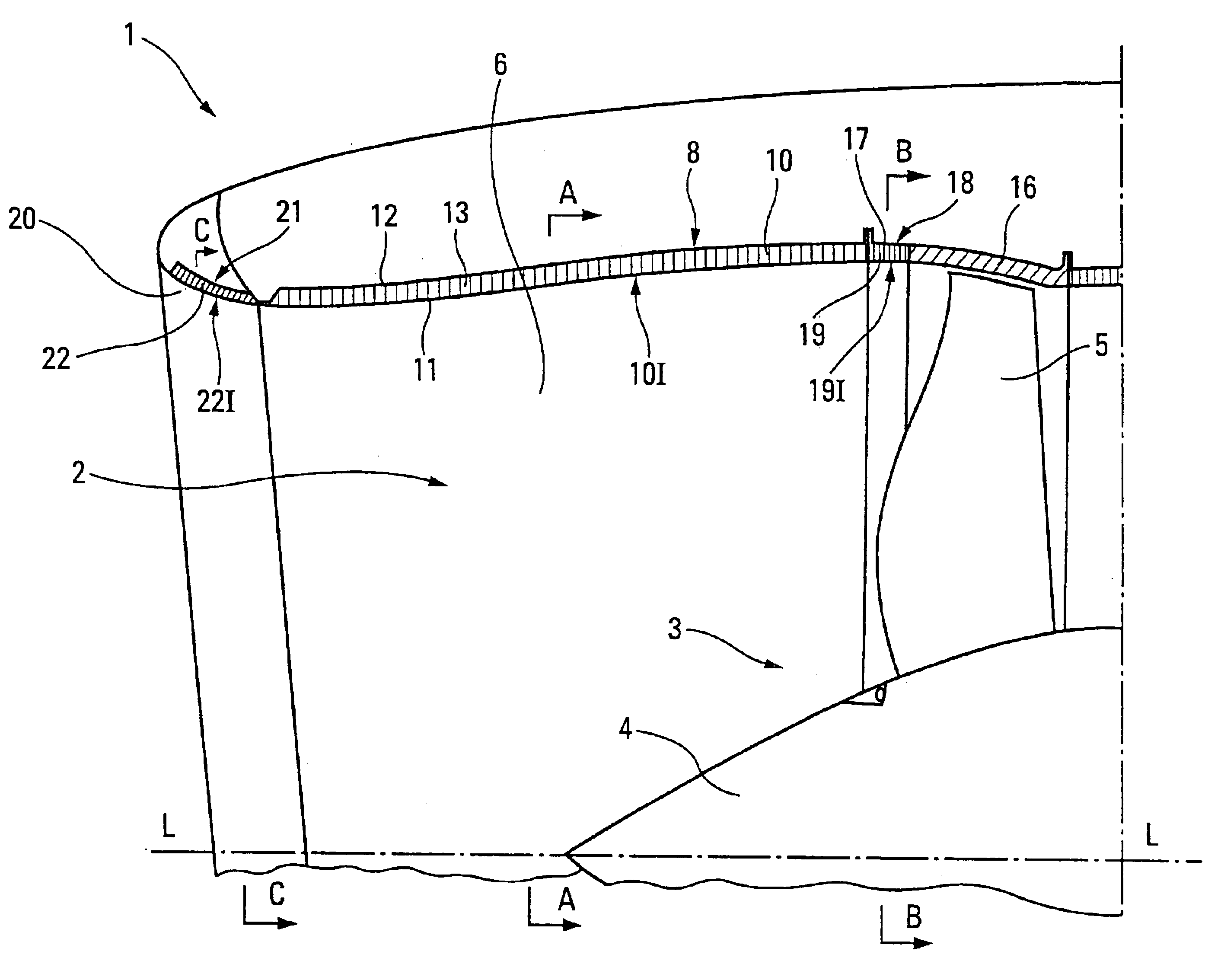

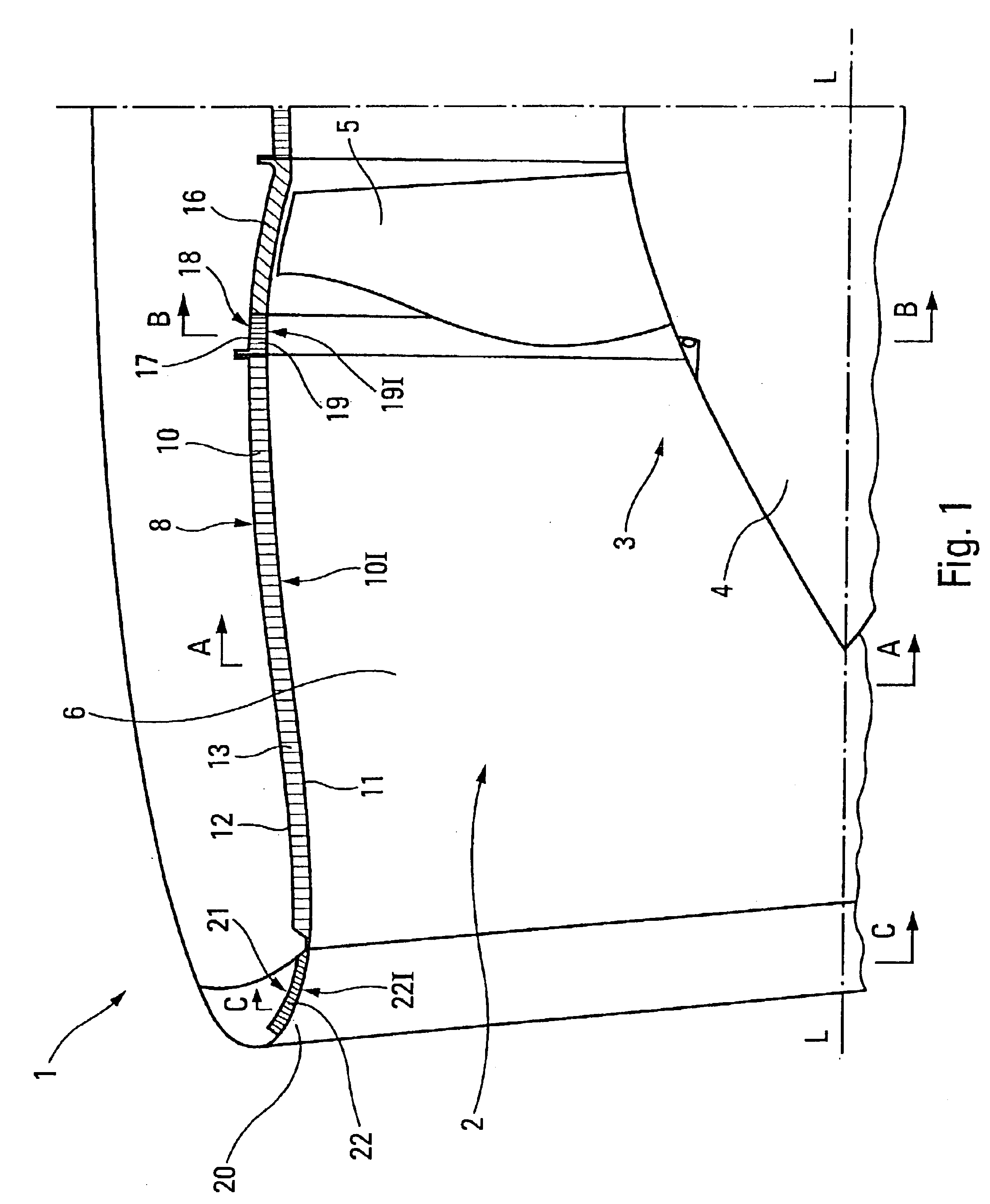

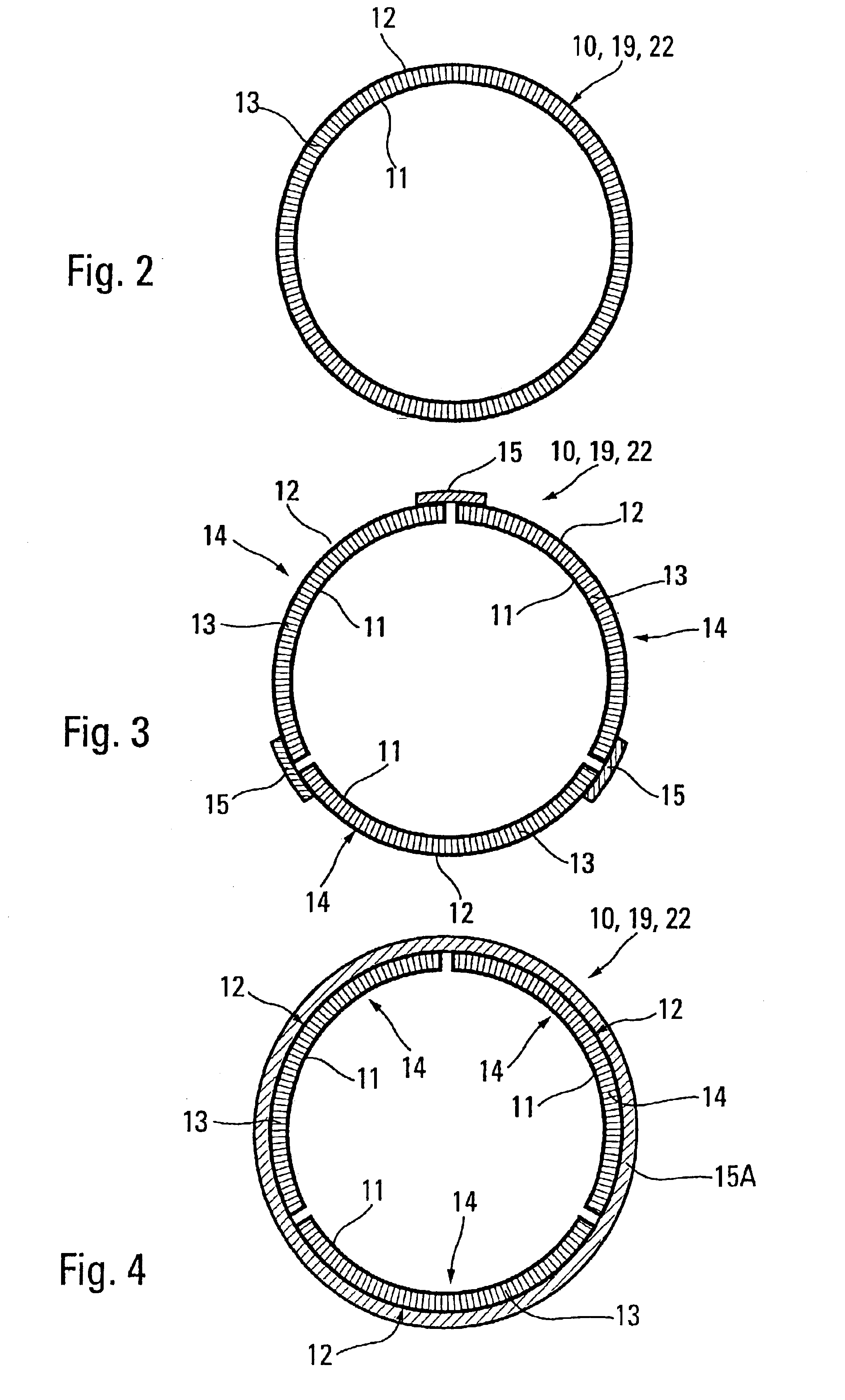

Aircraft engine pod with acoustic attenuation

InactiveUS6896099B2Improve the attenuation effectRemove noiseNoise reduction installationsPump componentsNacelleEngineering

An internal duct of an aircraft engine pod may include a fan and a tubular air intake having a first acoustic attenuation internal tubular piece. The first acoustic attenuation internal tubular piece is acoustically homogeneous, is of the resonator type, and has no internal assembly fish-plate. Additionally, the internal duct may include a tubular fan casing and a tubular transition part for connecting the air intake to the fan casing. An internal face of the tubular transition part is acoustically homogeneous also. Moreover, the internal face of the first acoustic attenuation internal tubular piece and the internal face of the tubular transition part are disposed in aerodynamic continuity.

Owner:AIRBUS OPERATIONS (SAS)

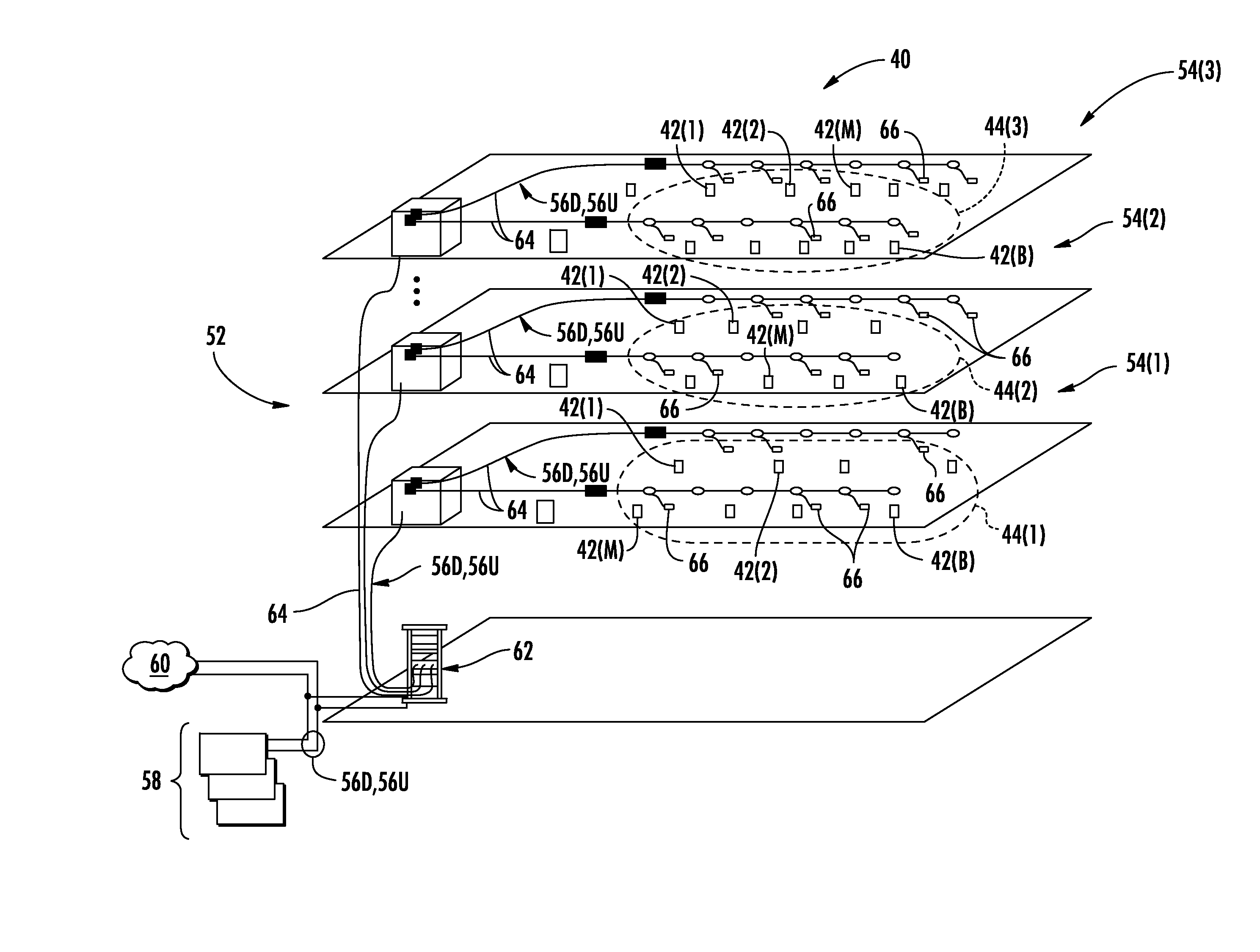

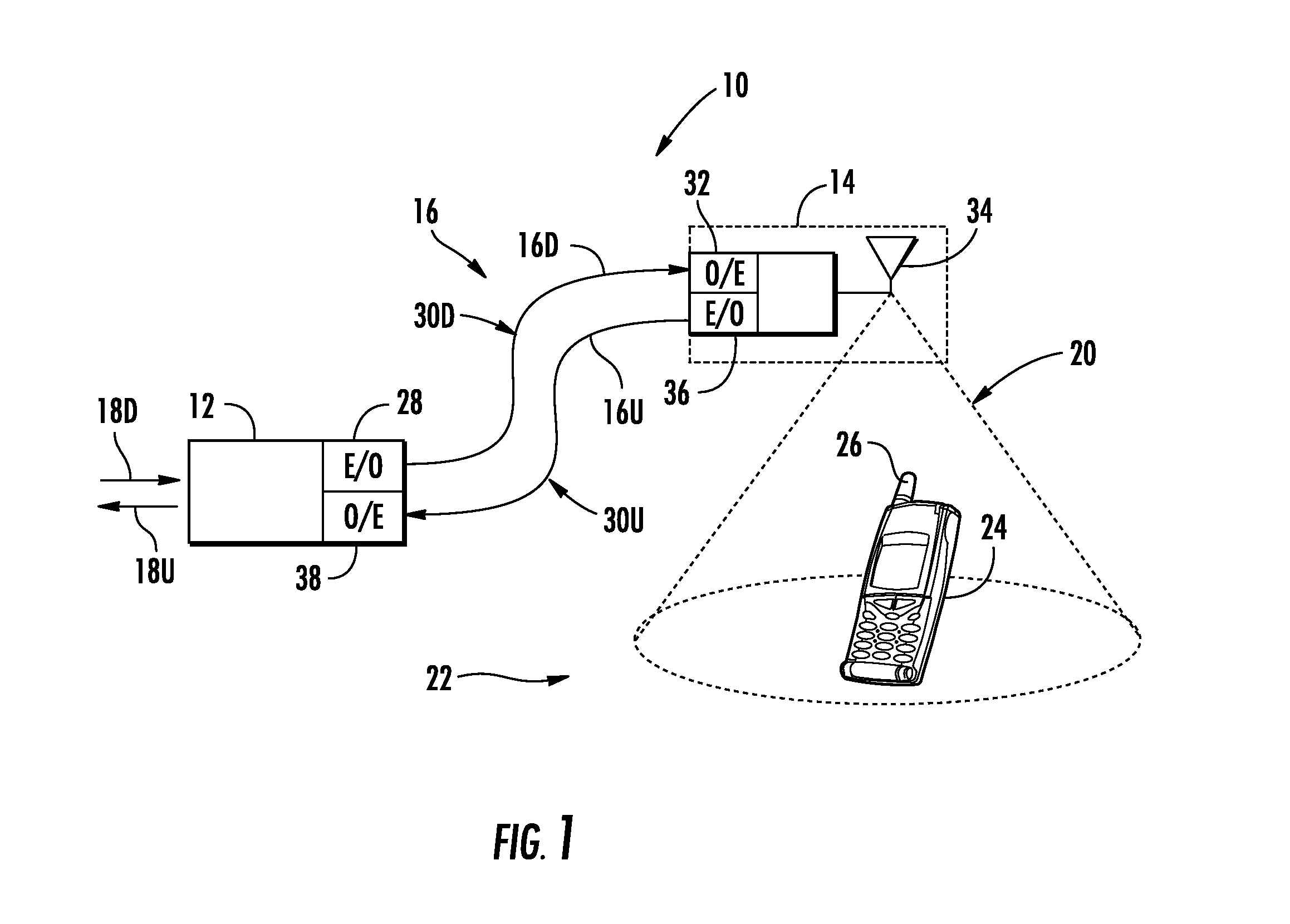

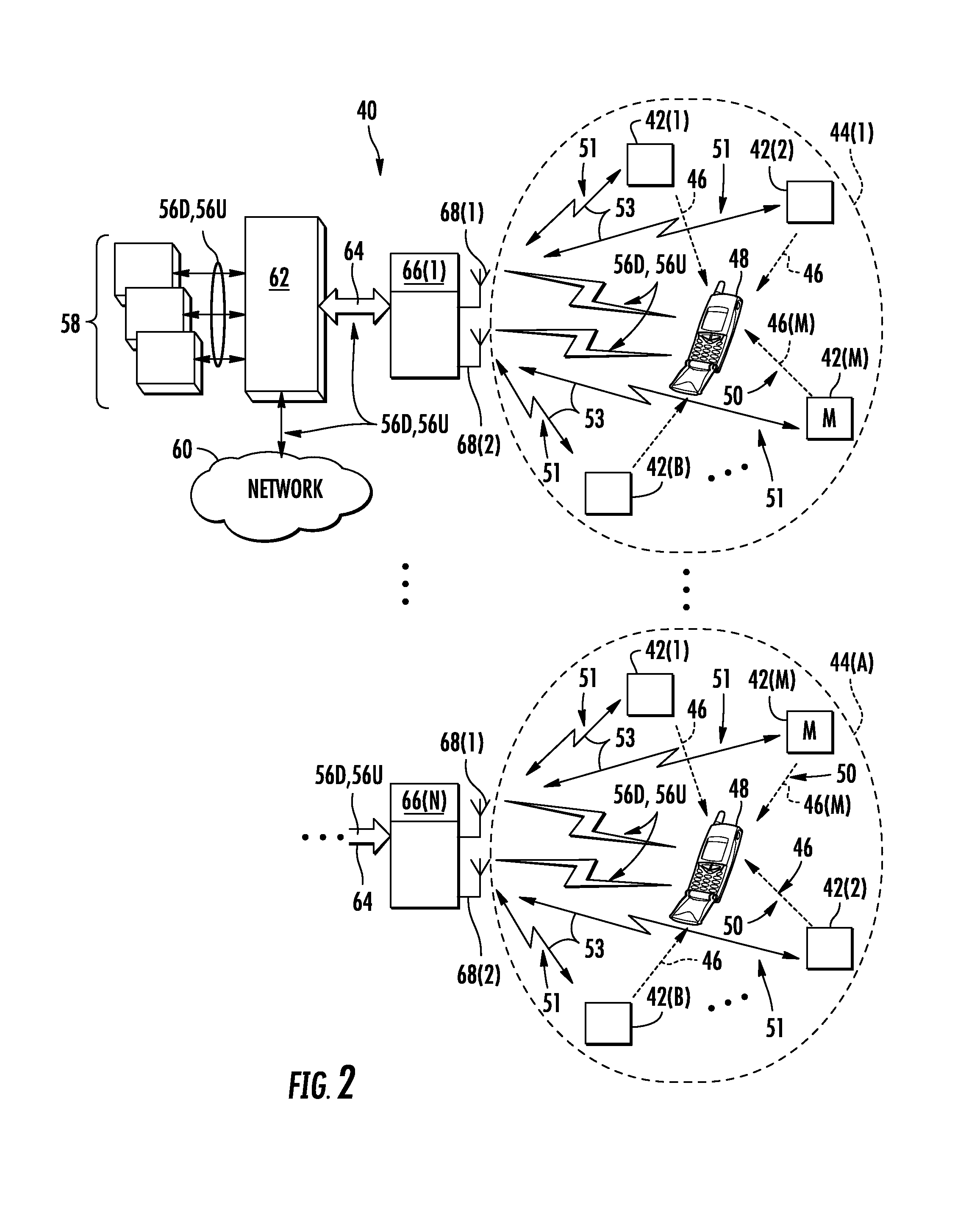

Ultrasound-based localization of client devices in distributed communication systems, and related devices, systems, and methods

InactiveUS20130322214A1Facilitate determining and providingLessened requirement for time resolutionDirection finders using ultrasonic/sonic/infrasonic wavesSonic/ultrasonic/infrasonic transmissionUltrasound attenuationSonification

A plurality of spatially located ultrasound beacons are provided in known locations within a distributed communications system. Each of the ultrasound beacons is configured to emit ultrasound pulses that can be received by client devices in ultrasound communication range of the ultrasound beacons. The client devices are configured to analyze the received ultrasound pulses from the beacons to determine their time-difference of arrival and as a result, their location in the distributed communications systems. Use of ultrasound pulses can provide greater resolution in location determination of client devices since ultrasound waves experience strong attenuation in building walls, ceilings, and floors, thus avoiding detection of ultrasound waves from other ultrasound beacons not located in proximity to the client devices.

Owner:CORNING OPTICAL COMM LLC

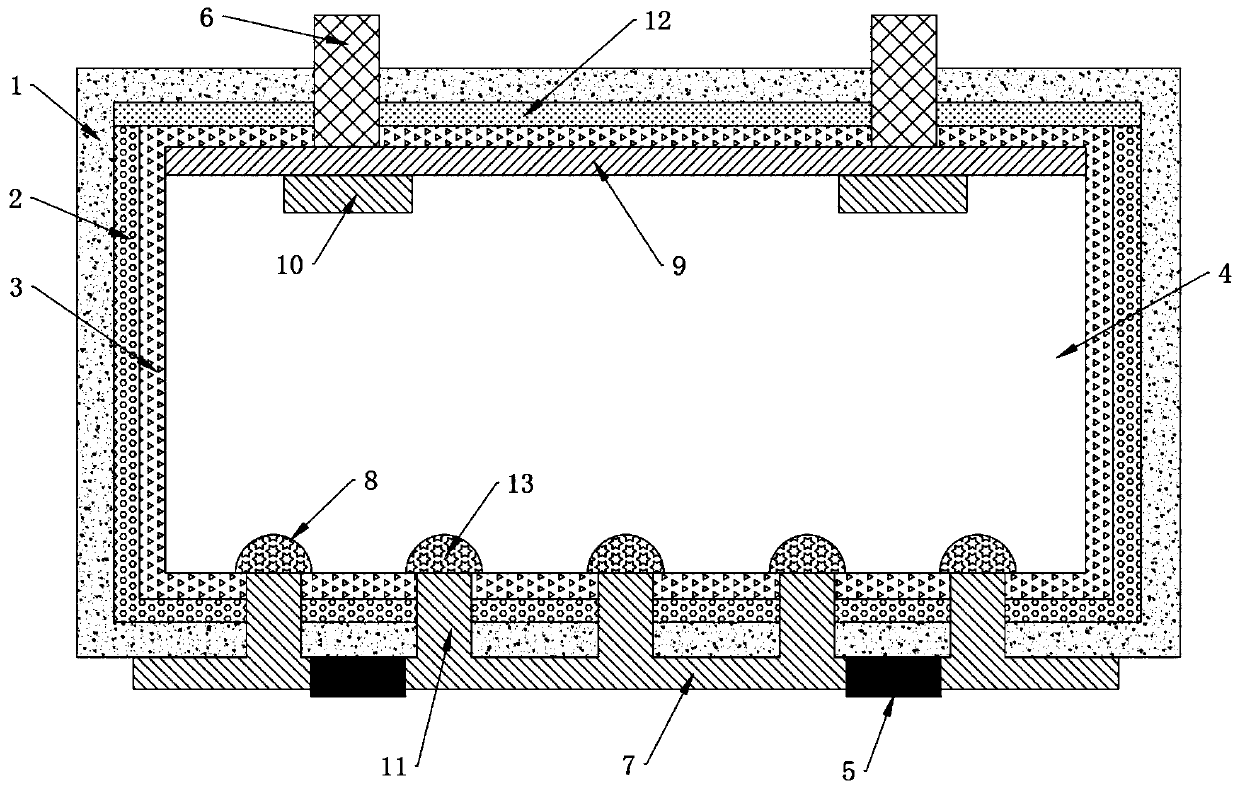

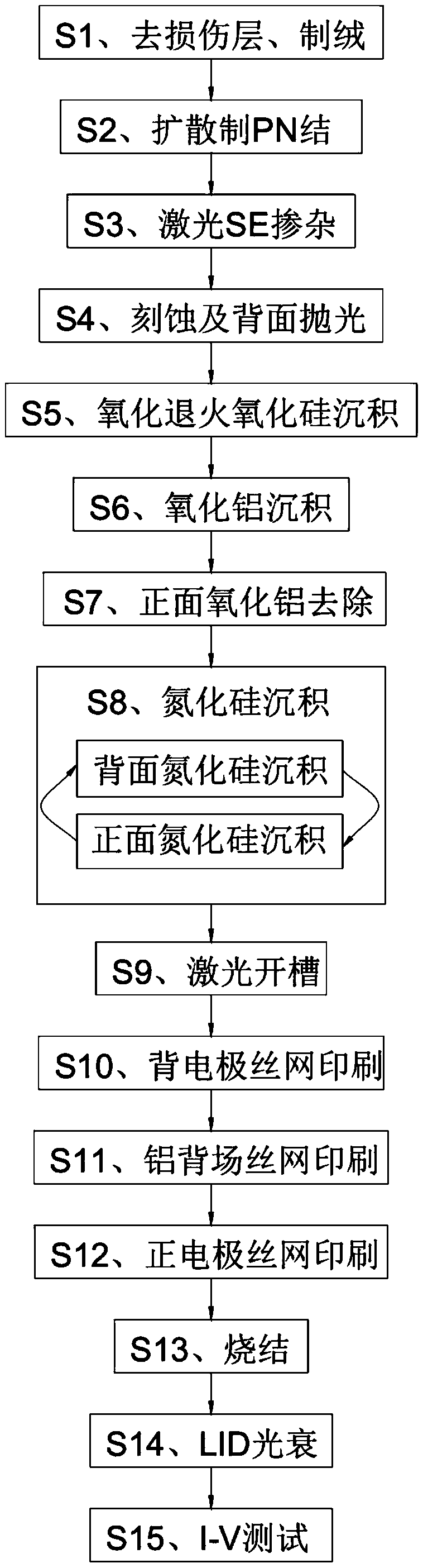

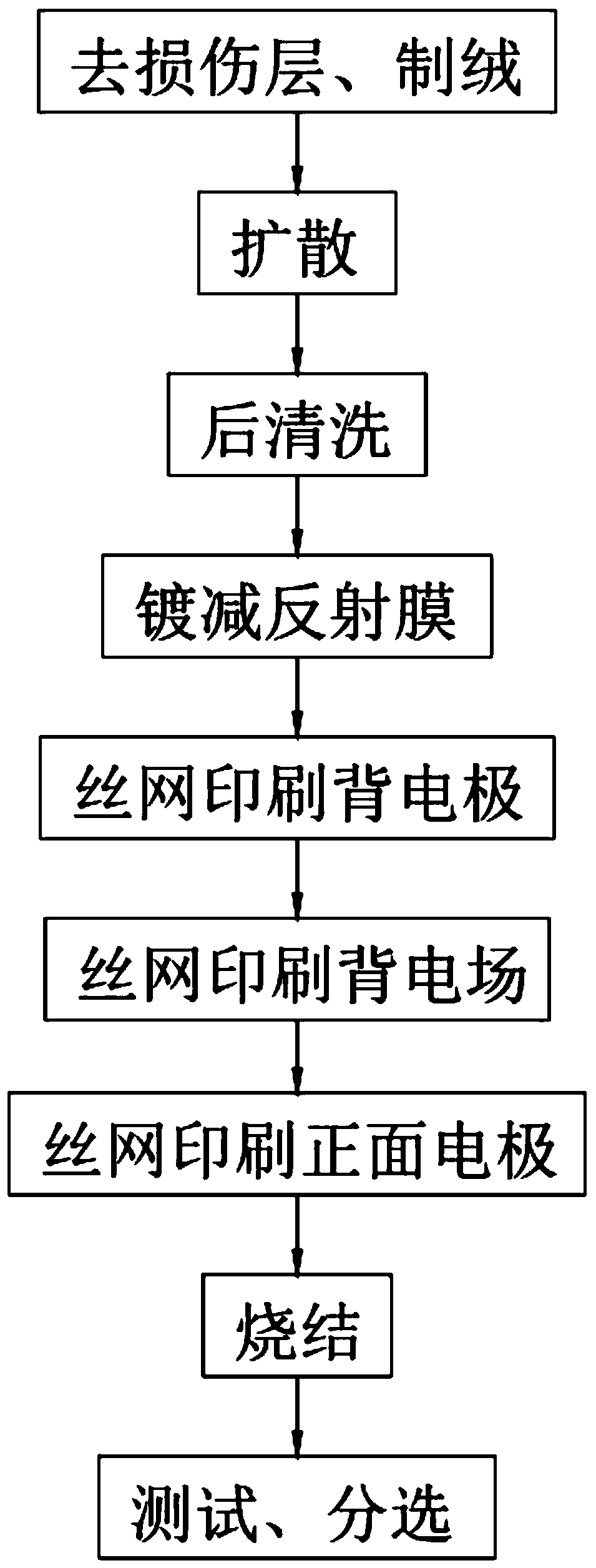

Solar cell with composite dielectric passivation layer structure and preparation process thereof

PendingCN110459615AIncrease short circuit currentIncrease the open circuit voltageFinal product manufacturePhotovoltaic energy generationDielectricRefractive index

The invention discloses a solar cell with a composite dielectric passivation layer structure and a preparation process thereof. A silicon oxide film, an alumina film and a silicon nitride or silicon oxynitride film are deposited in turn on the front, back and sides of a p-type silicon substrate to form a composite dielectric film on the whole surface, and windows are opened locally to lead electrodes out. Through aluminum oxide, silicon dioxide, silicon oxynitride, silicon nitride with different refractive indexes and a back surface passivation layer with a laminated structure of the materials, the back surface recombination rate is greatly reduced, the back reflectivity is improved, the CTM of a module is reduced, and the light attenuation and heat-assisted light attenuation and the anti-PID performance of the cell are improved. The structure can be made on a boron / gallium-doped p-type monocrystalline silicon, p-type polycrystalline silicon or p-type monocrystalline-silicon-like substrate, and a passivation method based on the composite dielectric film passivation structure can be used to manufacture PERC cells, double-sided PERC+ cells and imbricate PERC cells. Based on the preparation process steps and sequence, the corresponding preparation mode and the process parameter range of the laminated structure, the making of the cell can be well completed.

Owner:TONGWEI SOLAR ENERGY CHENGDU CO LID +2

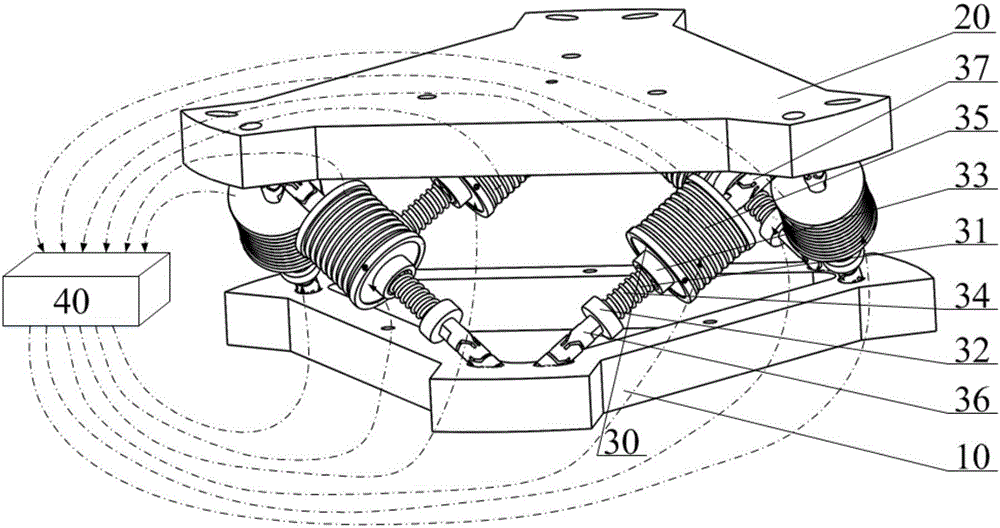

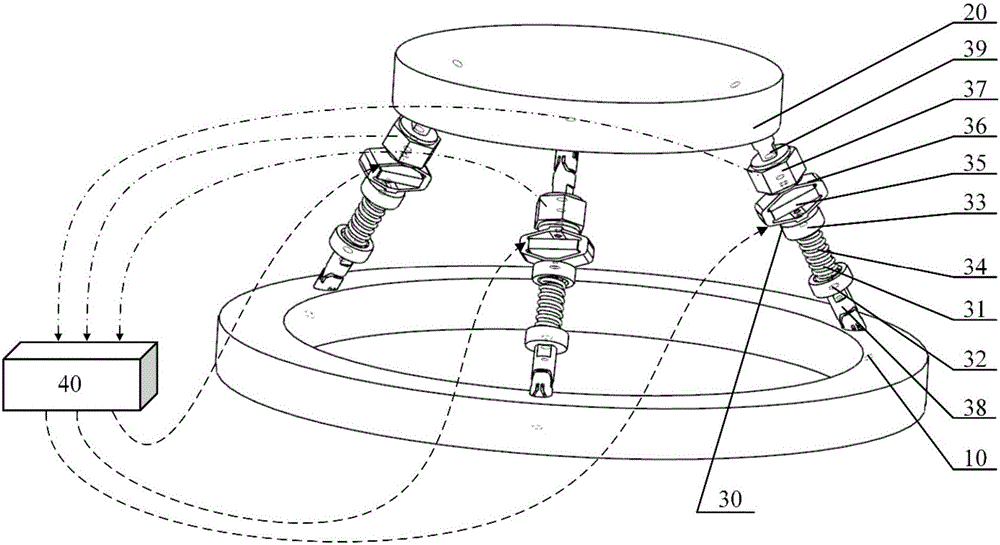

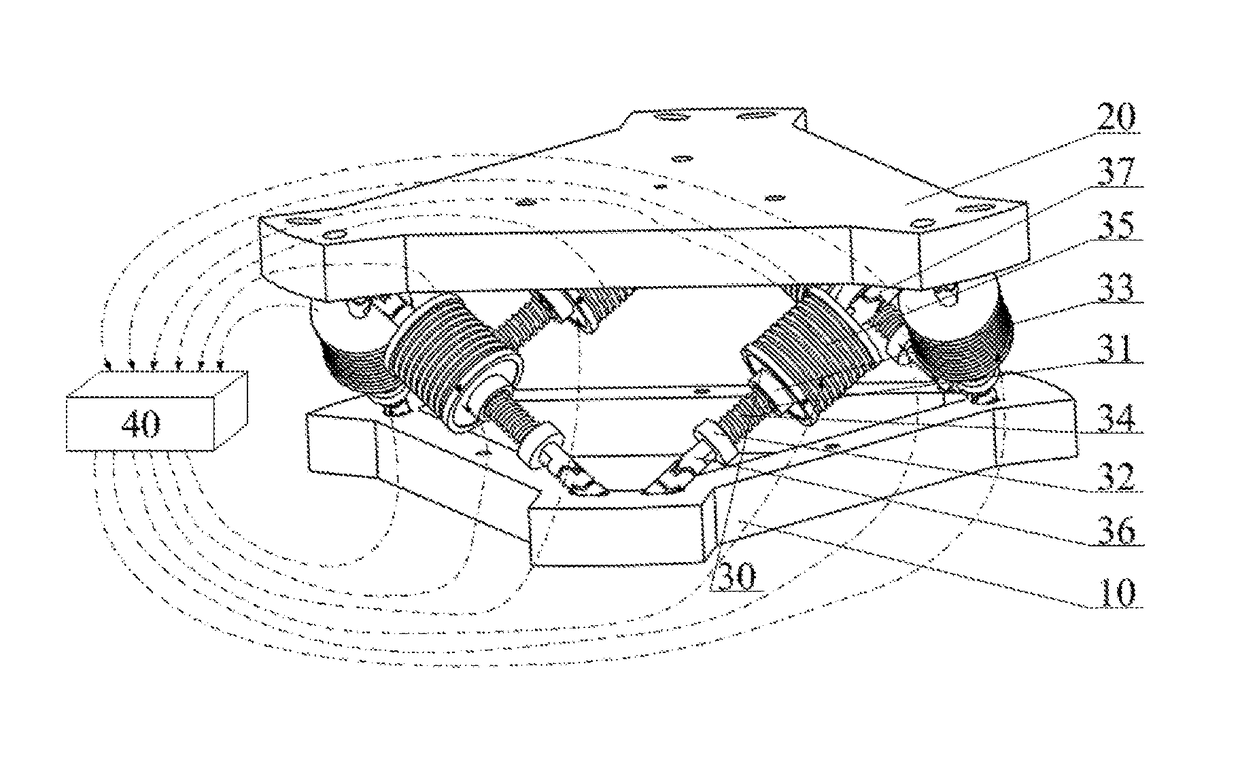

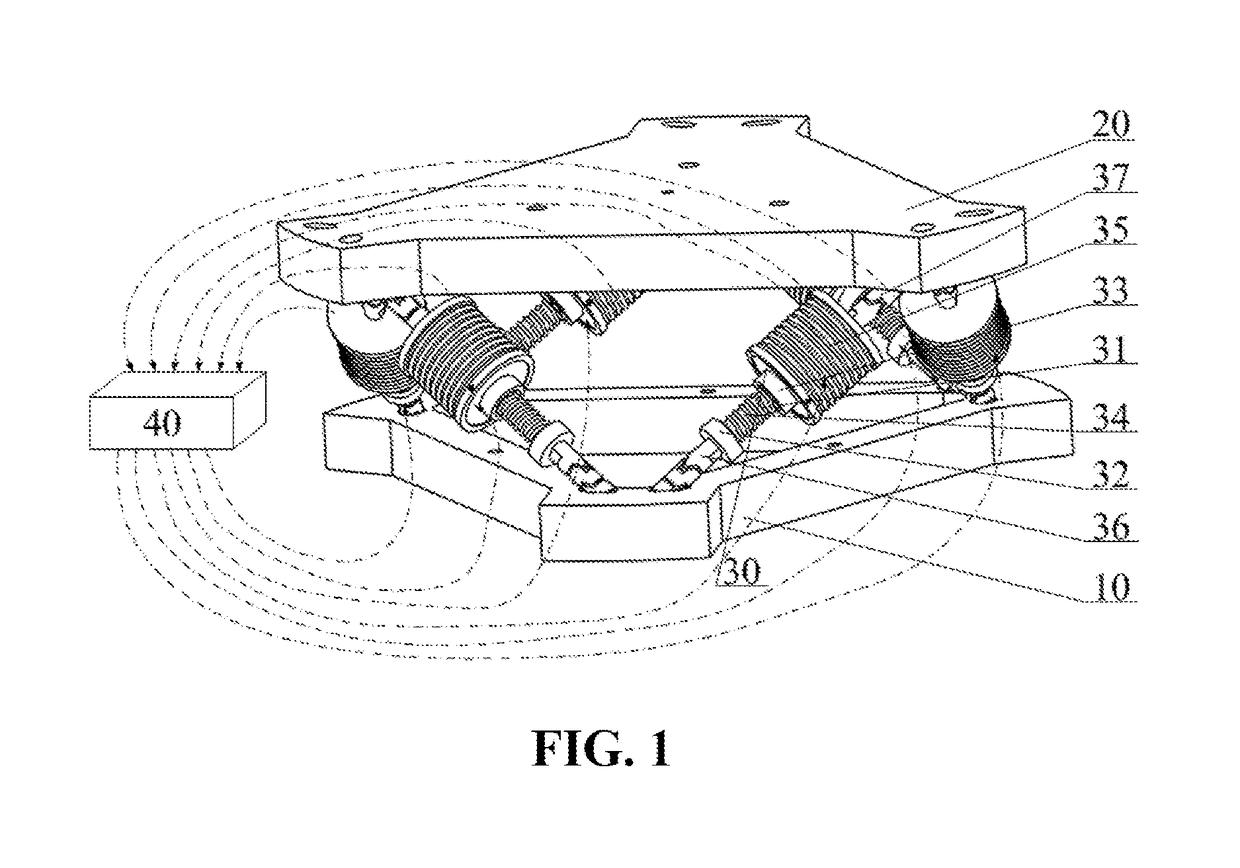

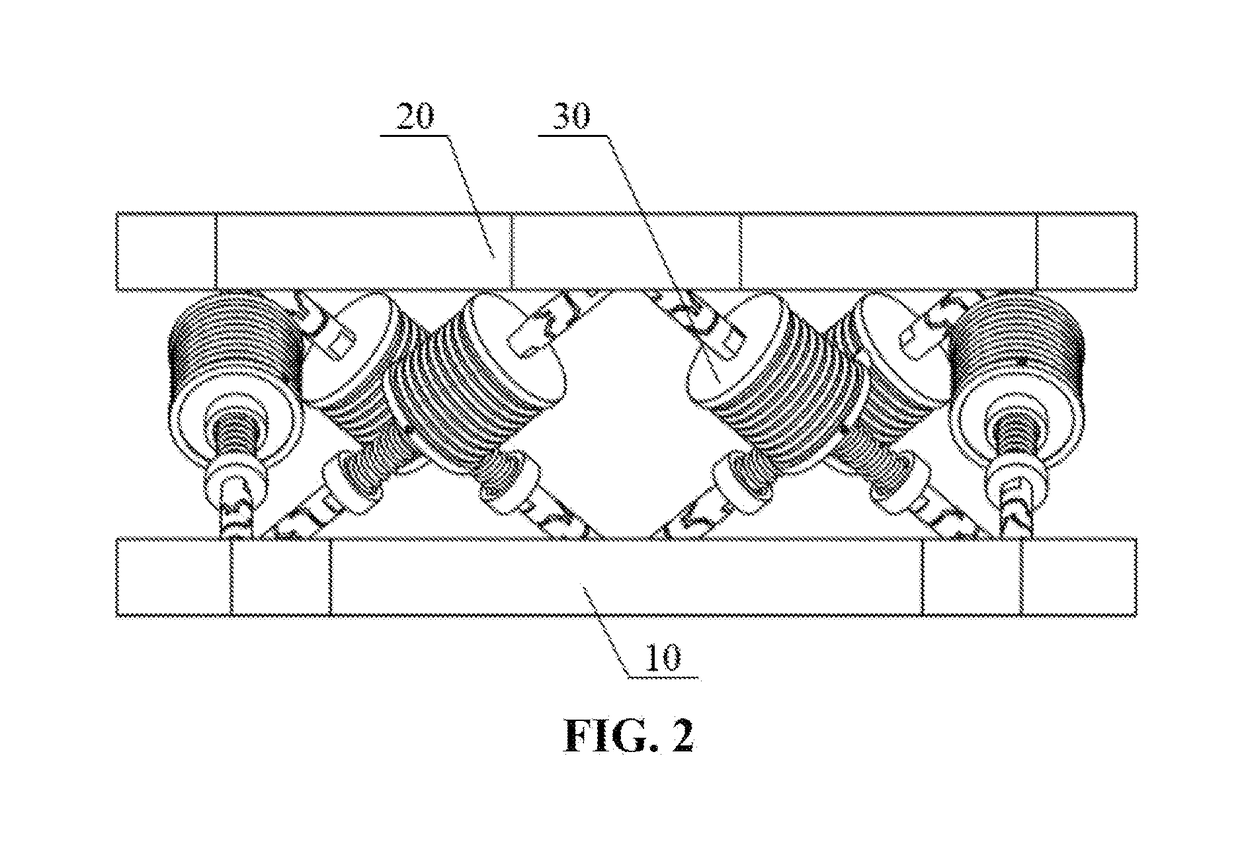

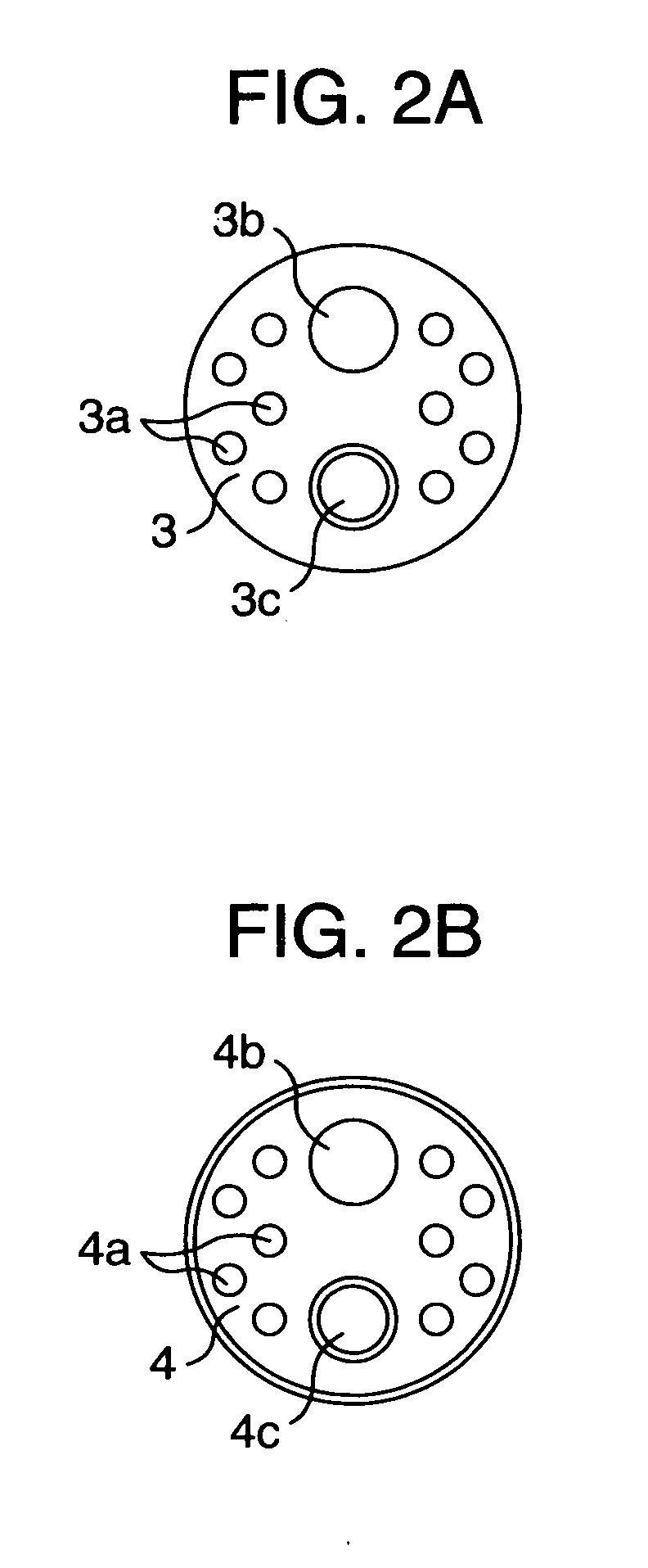

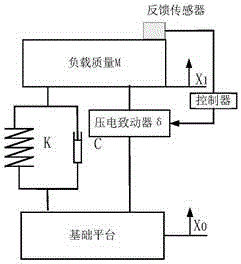

Six-degree-of-freedom micro vibration abatement platform and control method thereof

ActiveCN106286692AChange the stiffnessChange propertiesProgramme controlSpringsControl mannerSingle degree of freedom

Owner:HUAZHONG UNIV OF SCI & TECH

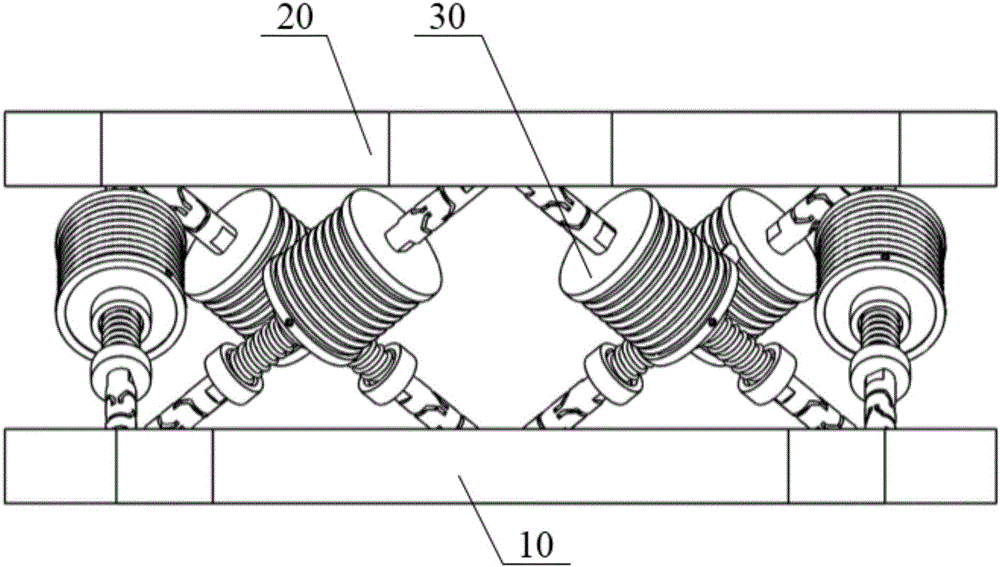

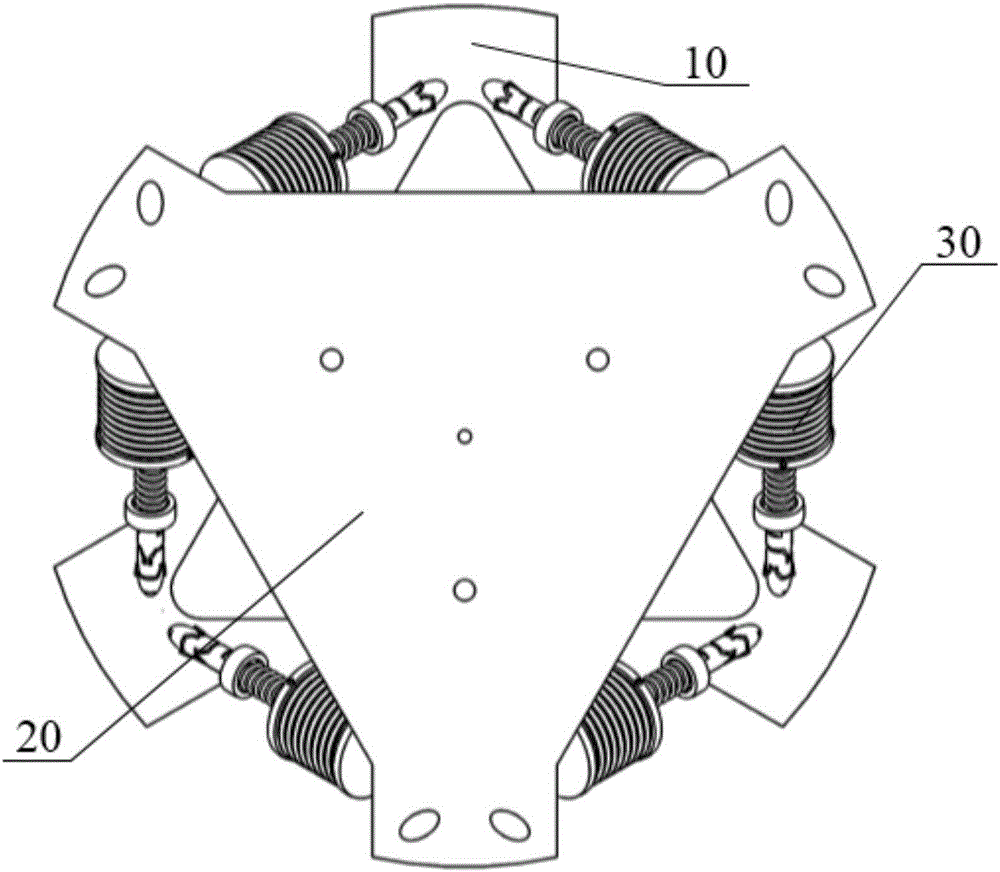

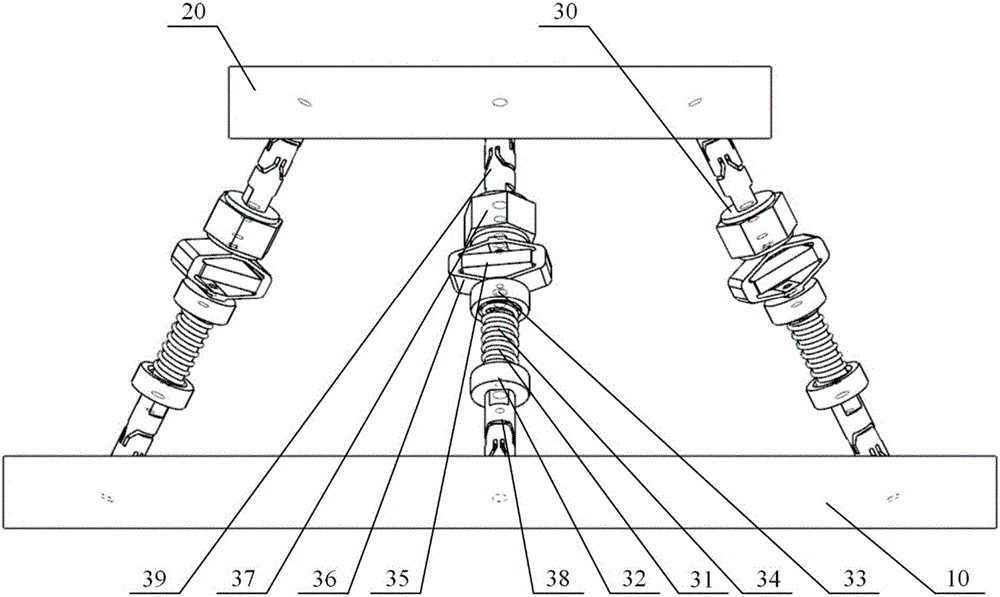

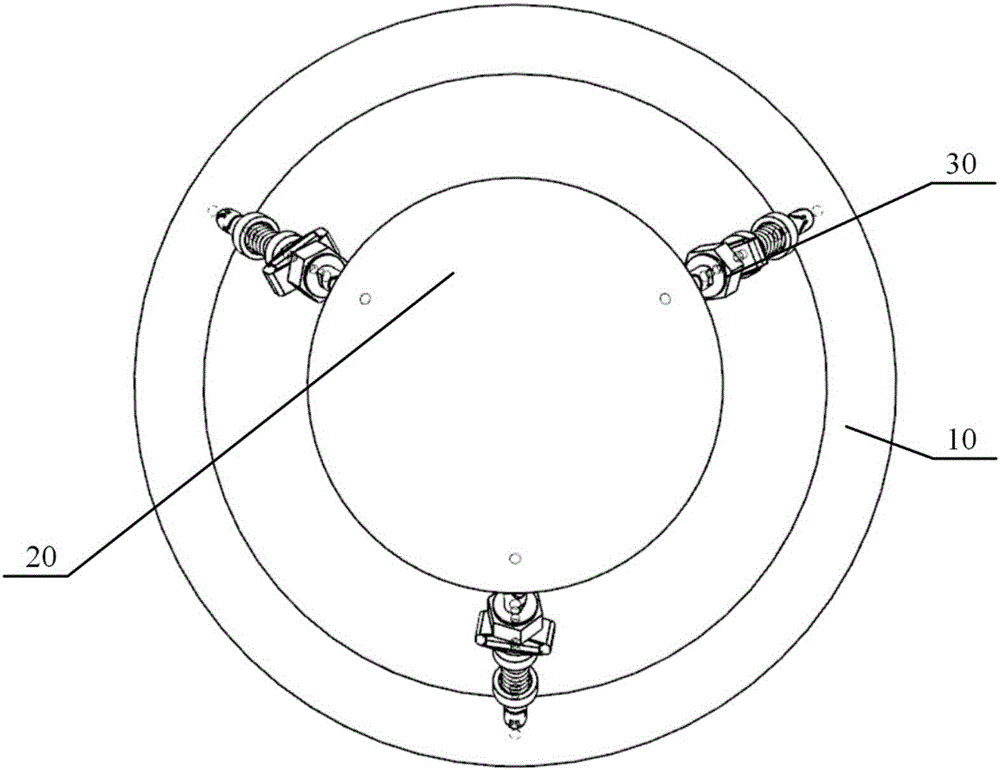

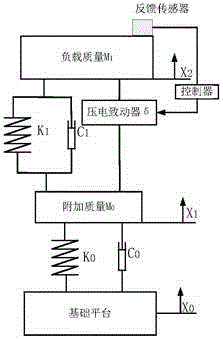

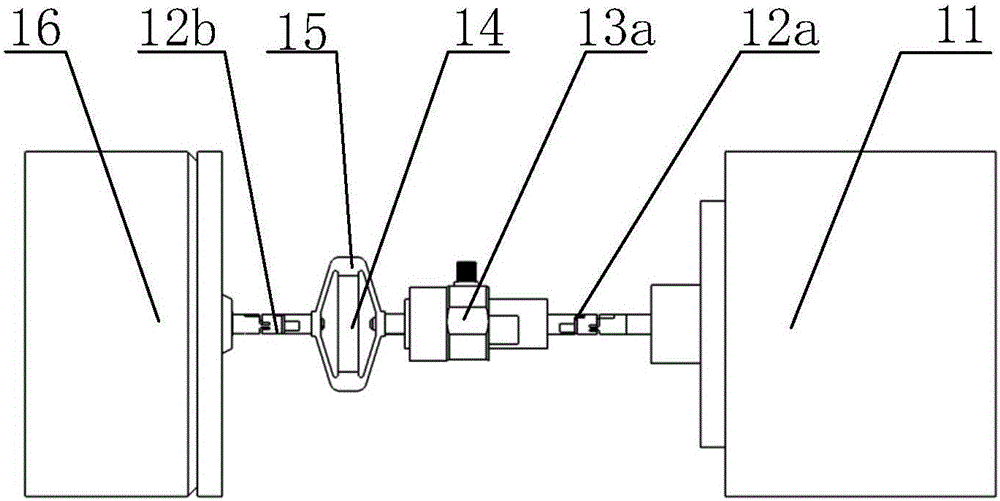

Three degree of freedom micro-vibration suppression platform and control method thereof

ActiveCN105909725AReduce computationSimple Feedback Control StructureControllers with particular characteristicsVibration suppression adjustmentsControl signalControl manner

The invention provides a three degree of freedom micro-vibration suppression platform and a control method thereof, belongs to vibration isolation and suppression devices, and solves problems of complicated structure and complex control method of a prior active-passive composite vibration isolation structure. The platform provided by the invention includes a base platform, a load platform, three sets of single degree of freedom active-passive composite vibration isolation assemblies which are totally identical and a controller. The upper end and the lower end of each single degree of freedom active-passive composite vibration isolation assembly are connected with the load platform and the base platform. The control method provided by the invention includes calculating logic axis translation signals, calculating logic axis control signals, calculating physical axis real time control signals and transmission steps. The platform provided by the invention is simple in structure, adjustable in rigidity, is capable of suppressing and isolating three degree of freedom microvibration in rotation directions of an X axis and a Y axis and a translation direction of a Z axis and is suitable for different occasions. Microvibration of different frequency bands can be dampened effectively and reliable guarantee can be provided for precision machining and measurement equipment in a microvibration environment.

Owner:HUAZHONG UNIV OF SCI & TECH

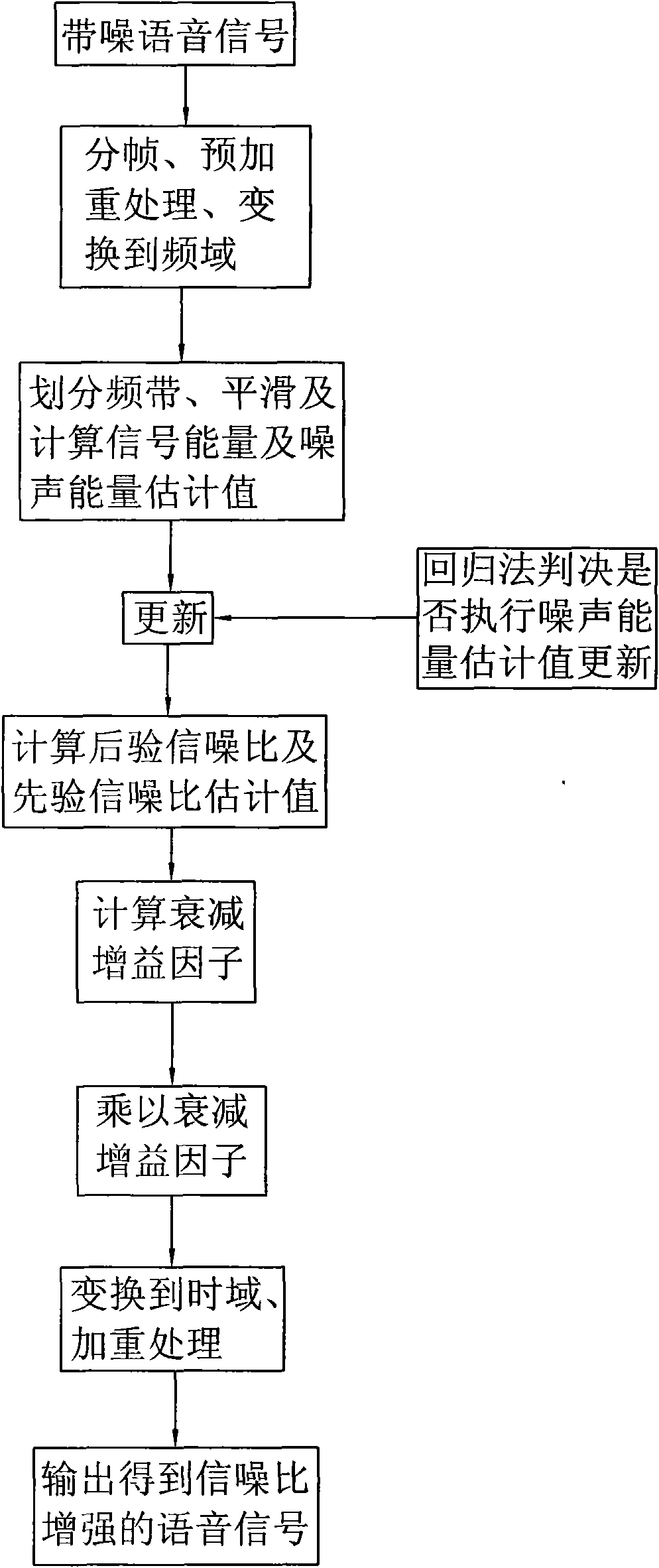

Method for speech enhancement

ActiveCN101599274AGuaranteed intelligibilityDecay fastSpeech analysisTime domainSignal-to-noise ratio (imaging)

The invention provides a method for achieving speech enhancement, which comprises the following steps: performing frame separation and pre-emphasis processing on a noisy speech signal, and transforming the noisy speech signal into a frequency domain; dividing the noisy speech signal into a plurality of frequency bands, calculating the signal energy of each frequency channel, and updating the estimated value of the noise energy; calculating the posteriori signal-to-noise ratio of the current frame, and the estimated value of the priori signal-to-noise ratio; calculating the attenuation factor of each frequency band, and processing the attenuation factor to obtain a speech signal with increased signal-to-noise ratio; and transforming the speech signal after the processing into a time domain, and outputting the speech signal.

Owner:AAC TECH PTE LTD +1

Six-degree-of-freedom micro vibration suppression platform and control method thereof

ActiveUS9777793B1Low dynamic stiffnessNatural frequency can be reducedProgramme controlSpringsSingle degree of freedomControl signal

A six-degree-of-freedom micro vibration suppression platform includes a basic platform, a load platform, six sets of single-degree-of-freedom active and passive composite vibration isolation devices that are exactly the same and a controller. Upper and lower ends of each set of single-degree-of-freedom active and passive composite vibration isolation devices are connected with the load platform and the basic platform, respectively. A control method includes: calculating a logical axis signal, calculating a logical axis control signal, calculating physical axis real-time control signals and a transfer step.

Owner:HUAZHONG UNIV OF SCI & TECH

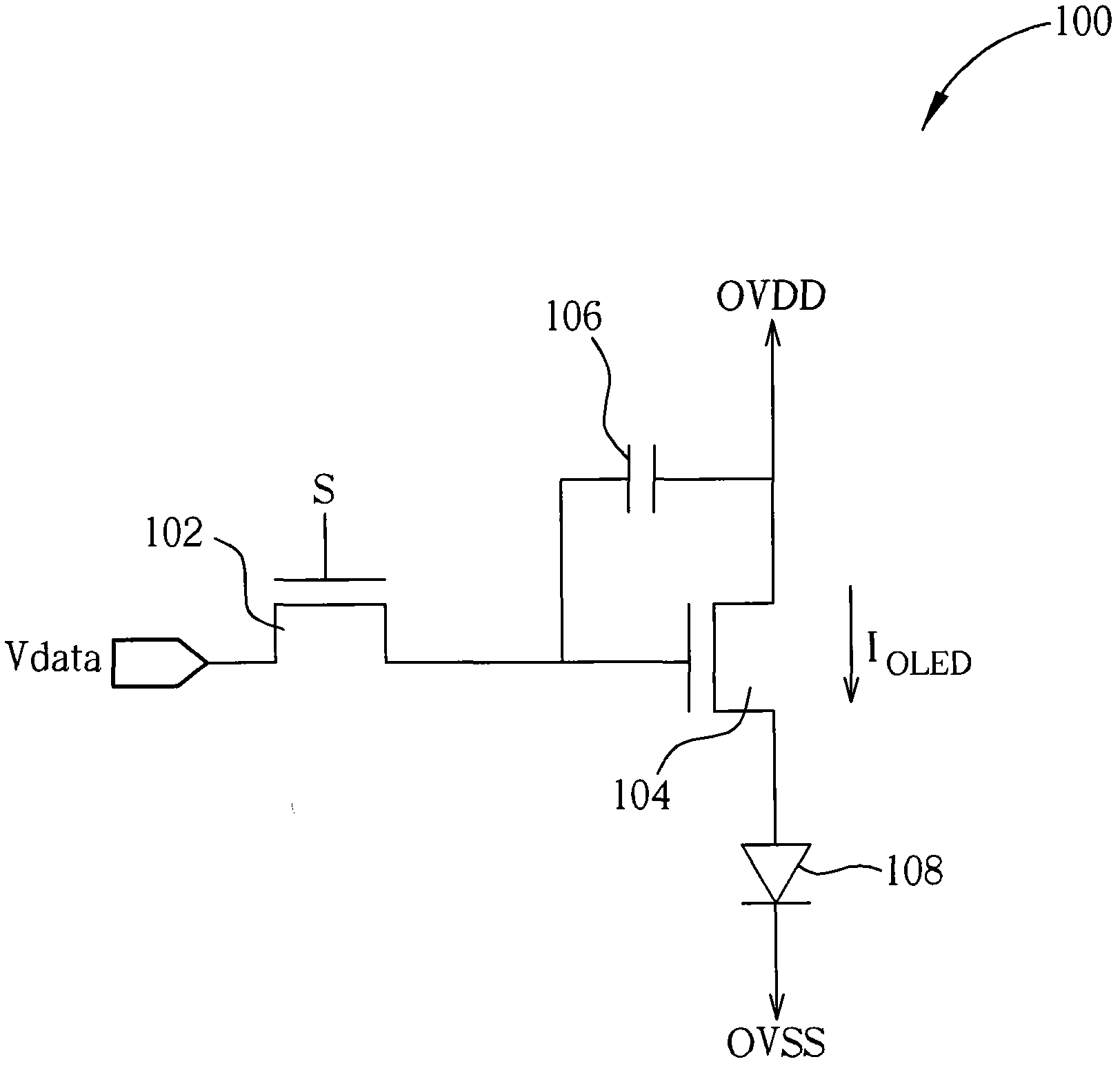

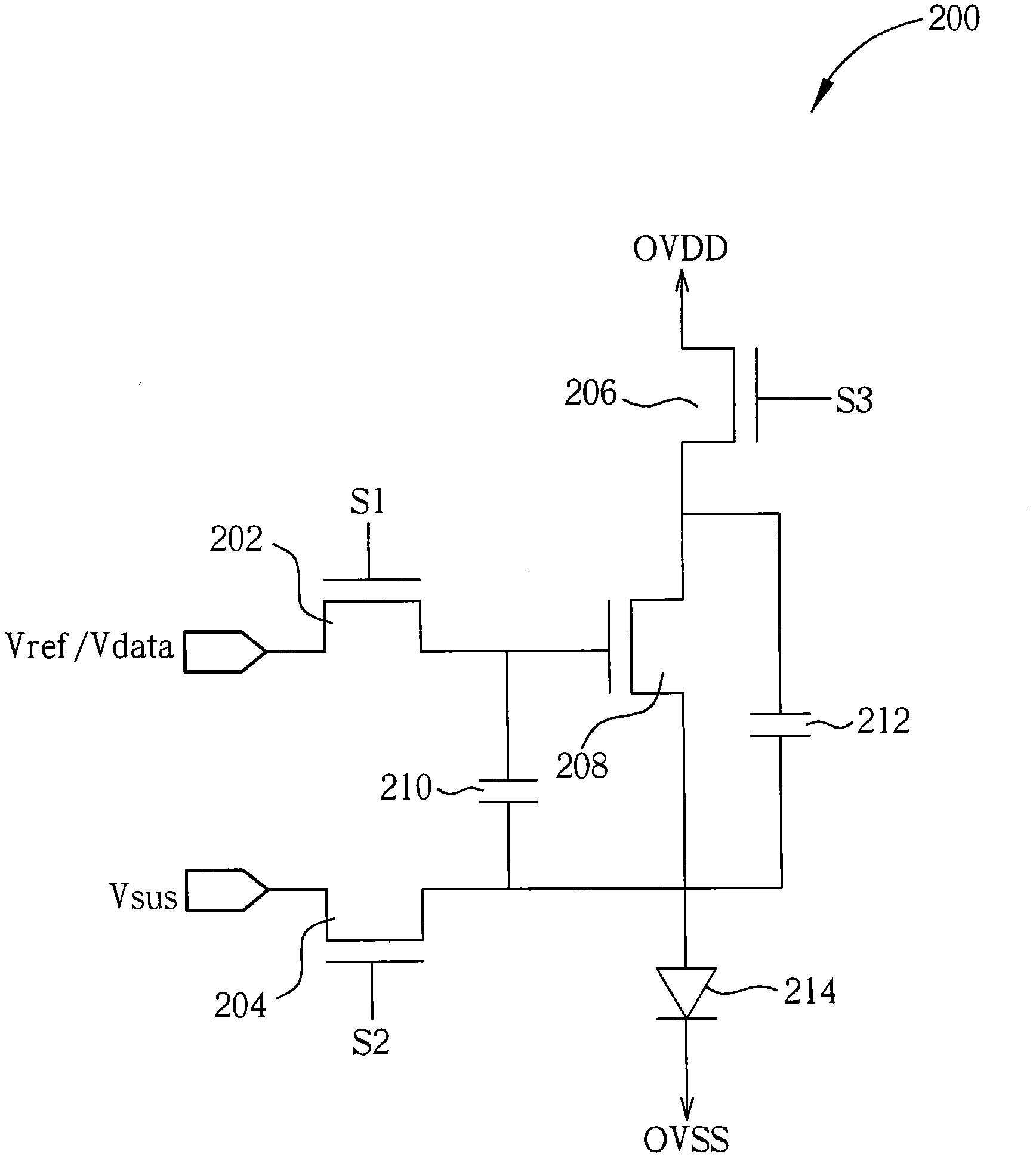

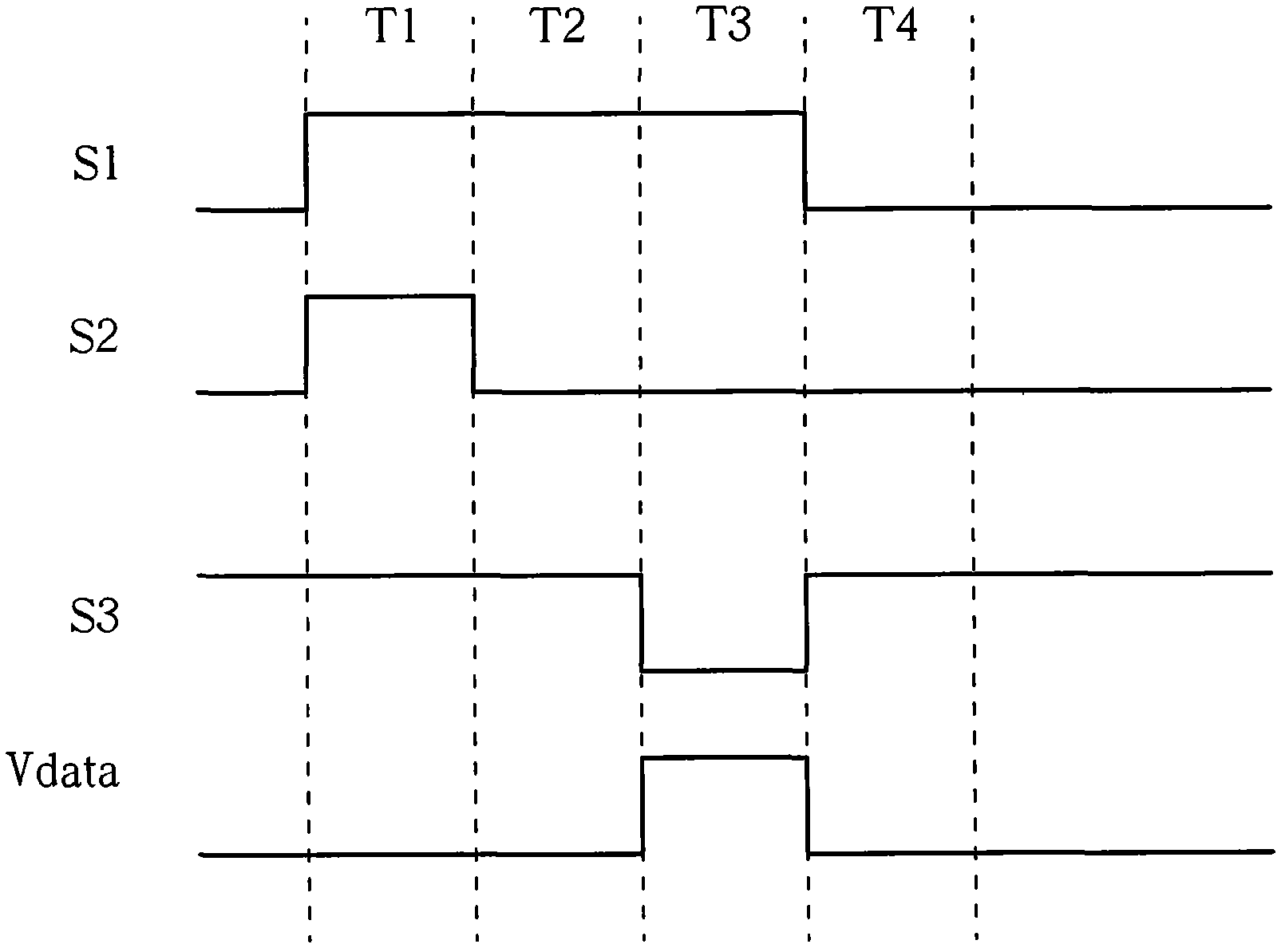

Driving circuit of pixel and method for driving pixel

InactiveCN102005182AImprove the attenuation effectIncrease brightnessStatic indicating devicesCapacitanceDriving current

The invention provides a method for driving a pixel and a driving circuit of the pixel. The method comprises the following steps of: charging the first end and the second end of a first capacitor according to a reference voltage and a reset voltage respectively, and simultaneously switching on a third switch; floating the second end of the first capacitor; charging the first end of the first capacitor according to a data voltage, and switching off the third switch; and floating the first end of the first capacitor, and switching on the third switch. Therefore, a driving current irrelevant with the variation of an N-type thin film transistor process and the span voltage of an organic light-emitting diode can be determined by the voltage difference between the first end and the second end of the first capacitor.

Owner:AU OPTRONICS CORP

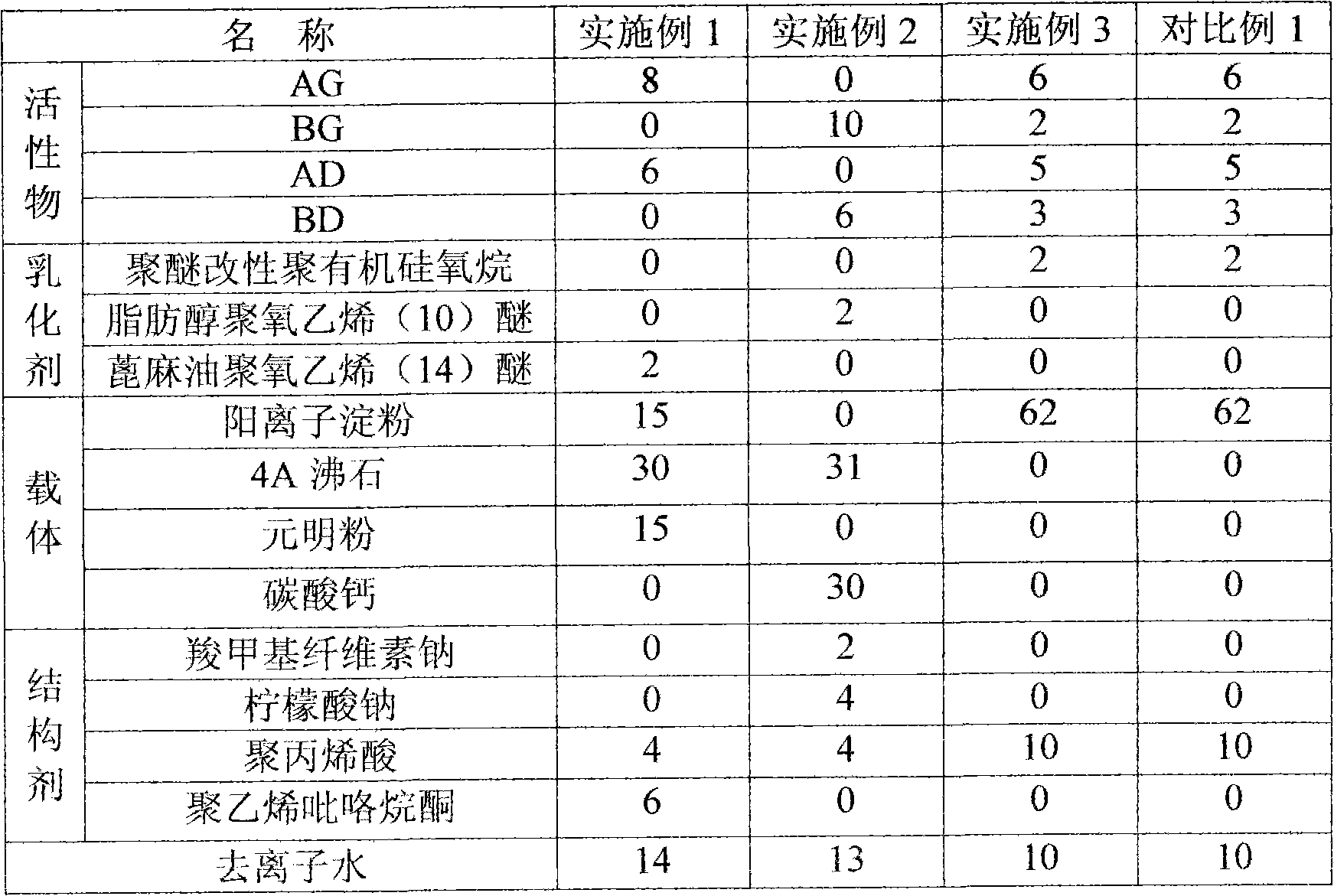

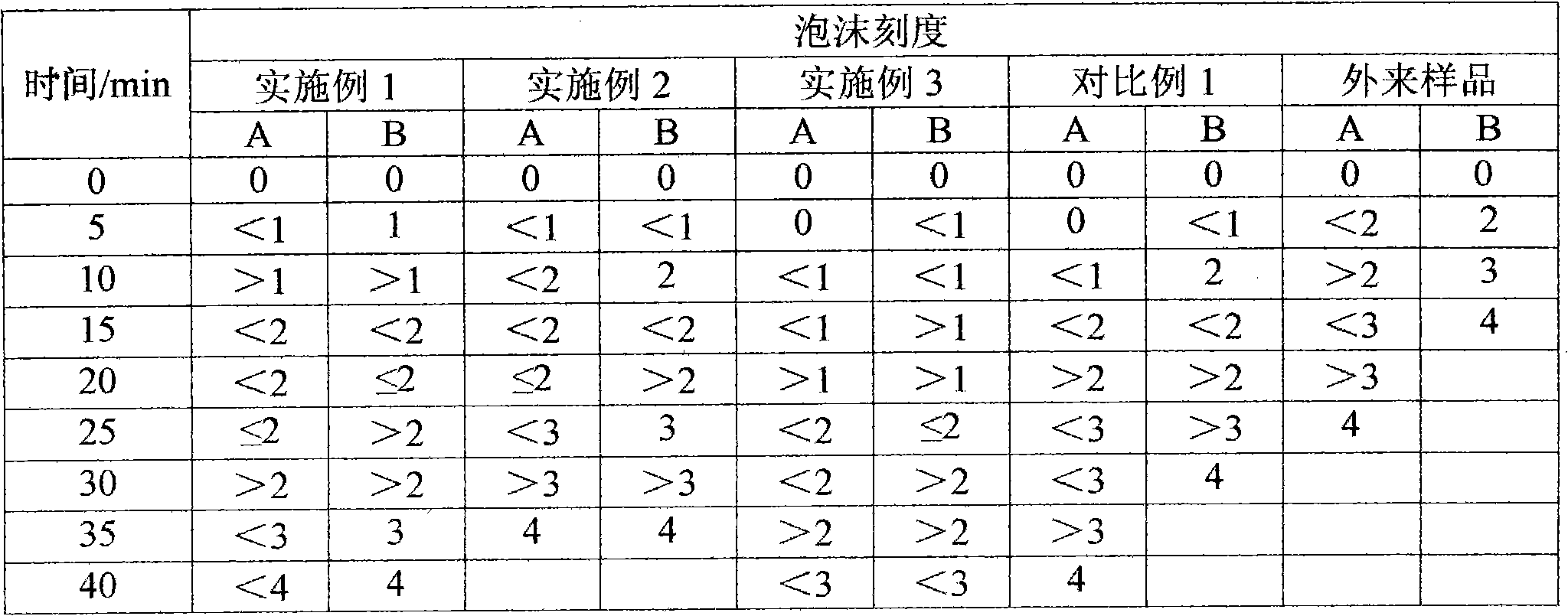

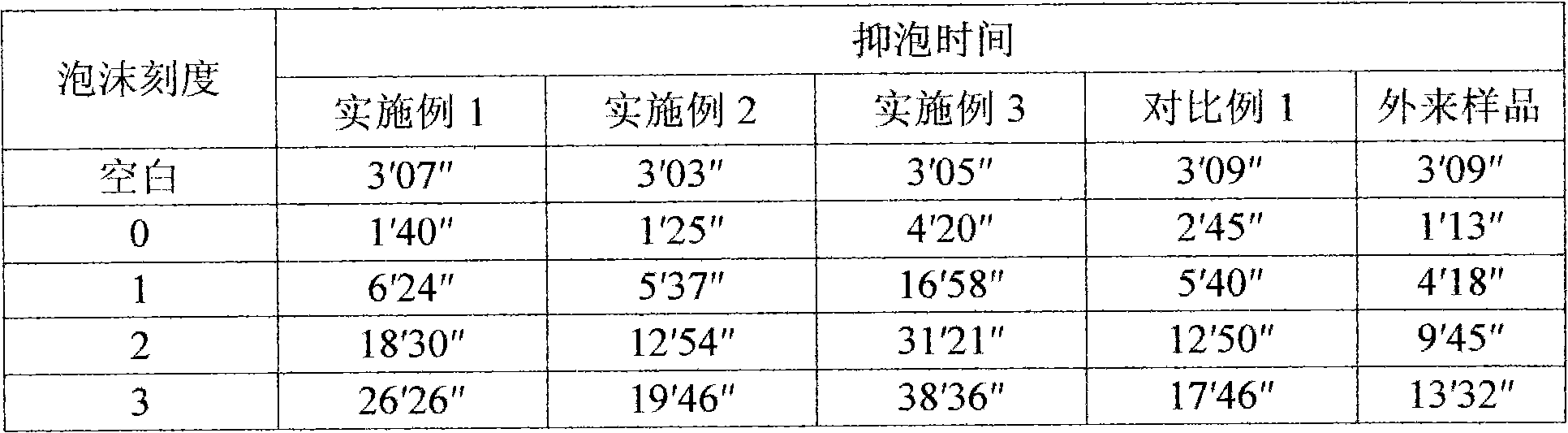

Solid defoaming agent and preparation method

ActiveCN101991976AGood defoaming performanceImprove the attenuation effectFoam dispersion/preventionActive matterDefoaming Agents

The invention provides a solid defoaming agent. The solid defoaming agent consists of the following components in percentage by weight: 50 to 90 percent of carrier, 5 to 20 percent of defoaming active matter, 0.5 to 4 percent of emulsifier, 1 to 30 percent of structural agent and 5 to 15 percent of water. A method for preparing the solid defoaming agent comprises the following steps of: (1) adding the defoaming active matter, the emulsifier and the structural agent into a mixer and fully mixing the components so as to obtain a mixture A; (2) adding an organic carrier into the mixture A and uniformly stirring so as to obtain a mixture B; (3) adding deionized water into the mixture B and uniformly stirring so as to obtain a mixture C; and (4) pelletizing the mixture C by using a pelletizer and drying the obtained particles by using a drier so as to obtain the solid defoaming agent. The solid defoaming agent has high defoaming and foam restraining performance and anti-damping performance, and can be applied to industries such as daily use chemicals, industrial cleaning and the like.

Owner:JIANGSU SIXIN SCI-TECH APPL RES INST CO LTD

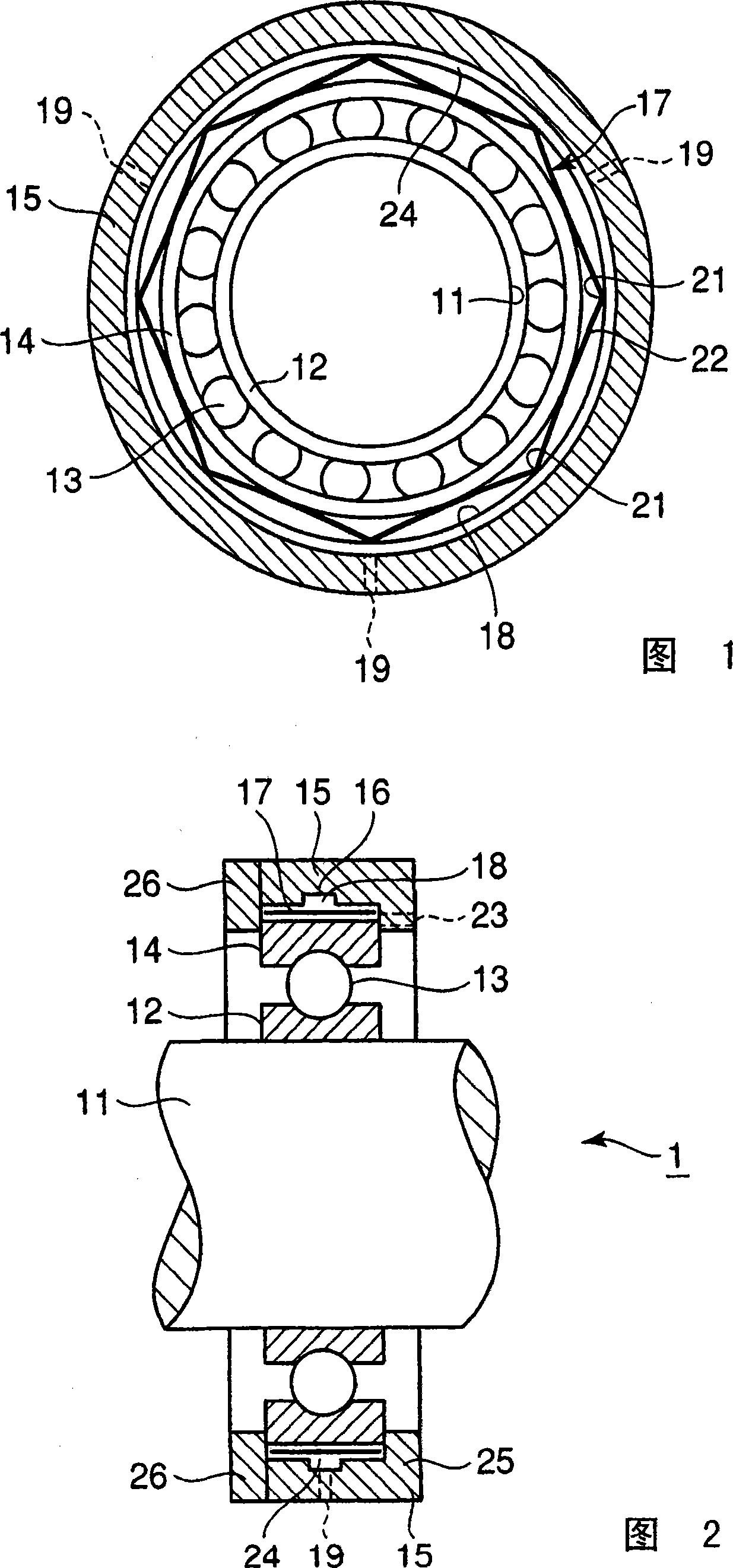

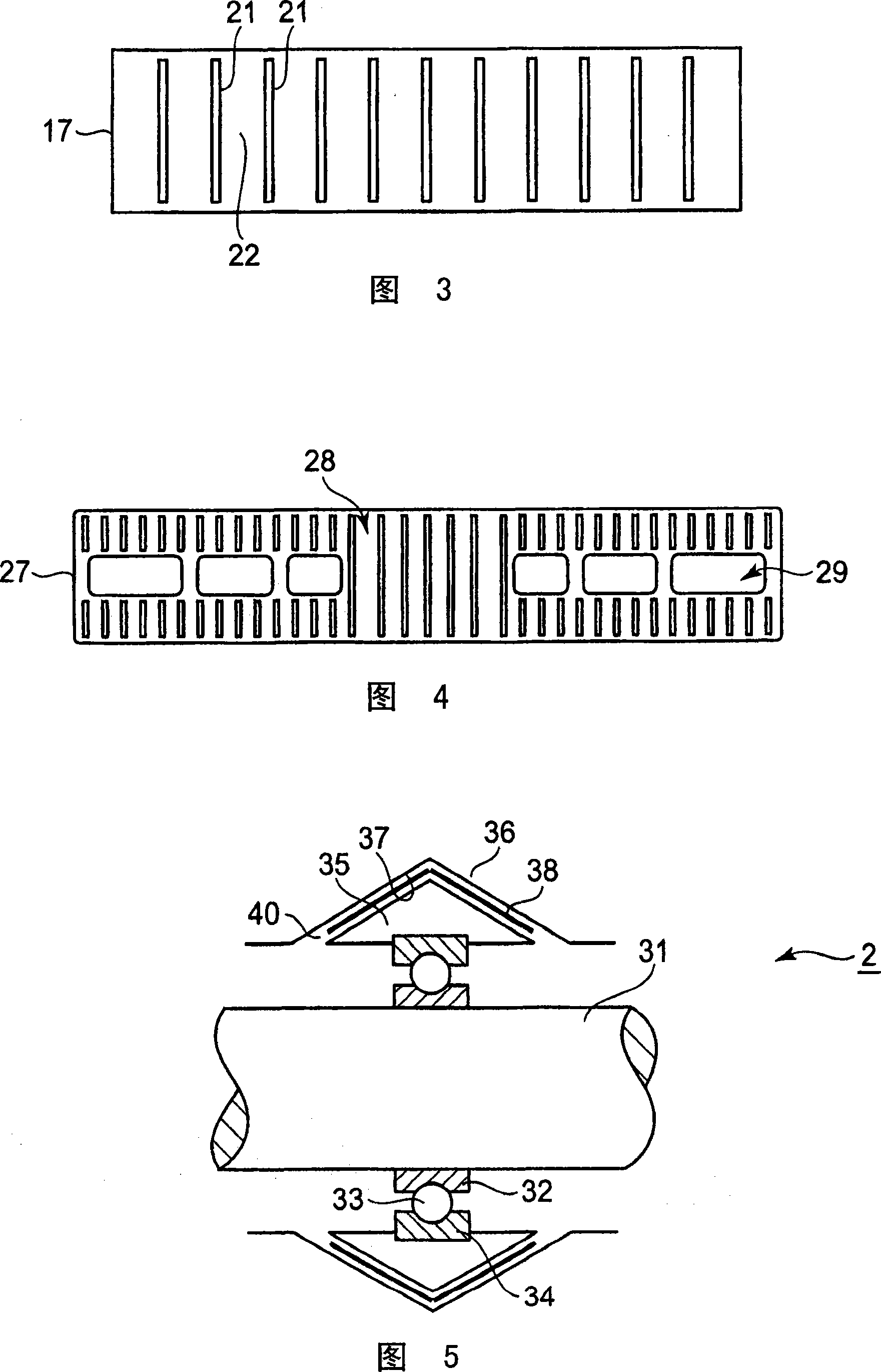

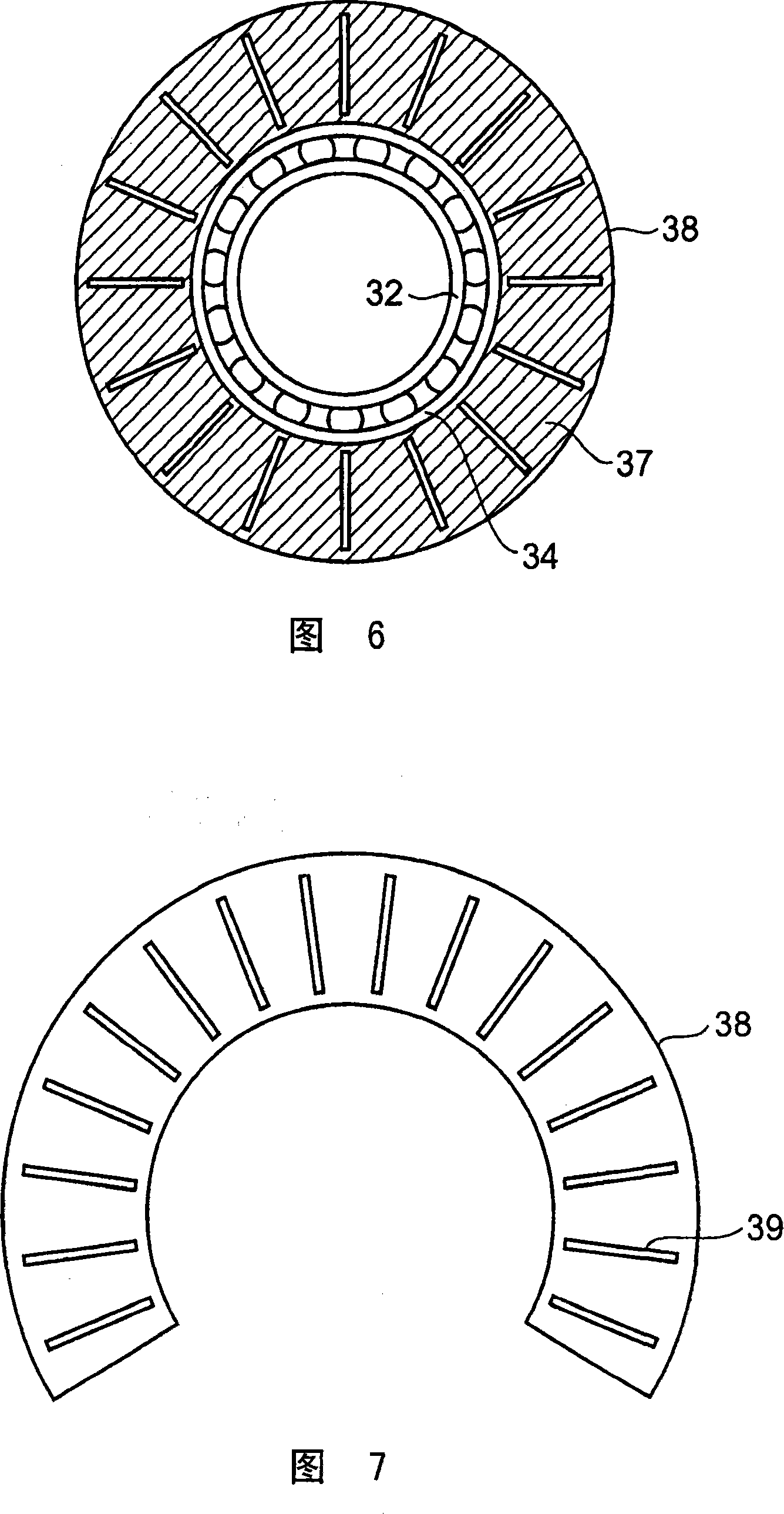

Vibration damping mechanism for bearing

ActiveCN101010521AInhibit sheddingInhibition releaseLeaf springsShaftsRolling-element bearingEngineering

A squeeze film damper bearing easily manufacturable, having excellent productivity, and reduced in size and a vibration damping mechanism for the rolling bearing capable of having an effect on loads in two of radial and thrust directions. In the vibration damping mechanism (1) for the rolling bearing, a storage hole (16) having a diameter larger than the diameter of the outer periphery (14) of the bearing is formed on the inside of a housing (15) and an oil supply hole (19) supplying an oil into the storage hole is formed in the wall of the housing (15), the bearing is inserted into the storage hole to form an annular clearance (18) on the outer periphery of the bearing, and a thin flat plate (17) having a plurality of slits is inserted into the annular clearance along the circumferential direction. The portions of the thin flat plate held by the slits are formed in an elastic beam to elastically support the bearing at a center position, and the vibration of the bearing is damped by a squeeze film action caused by an oil film generated by supplying the oil into the annular clearance.

Owner:KAWASAKI JUKOGYO KK

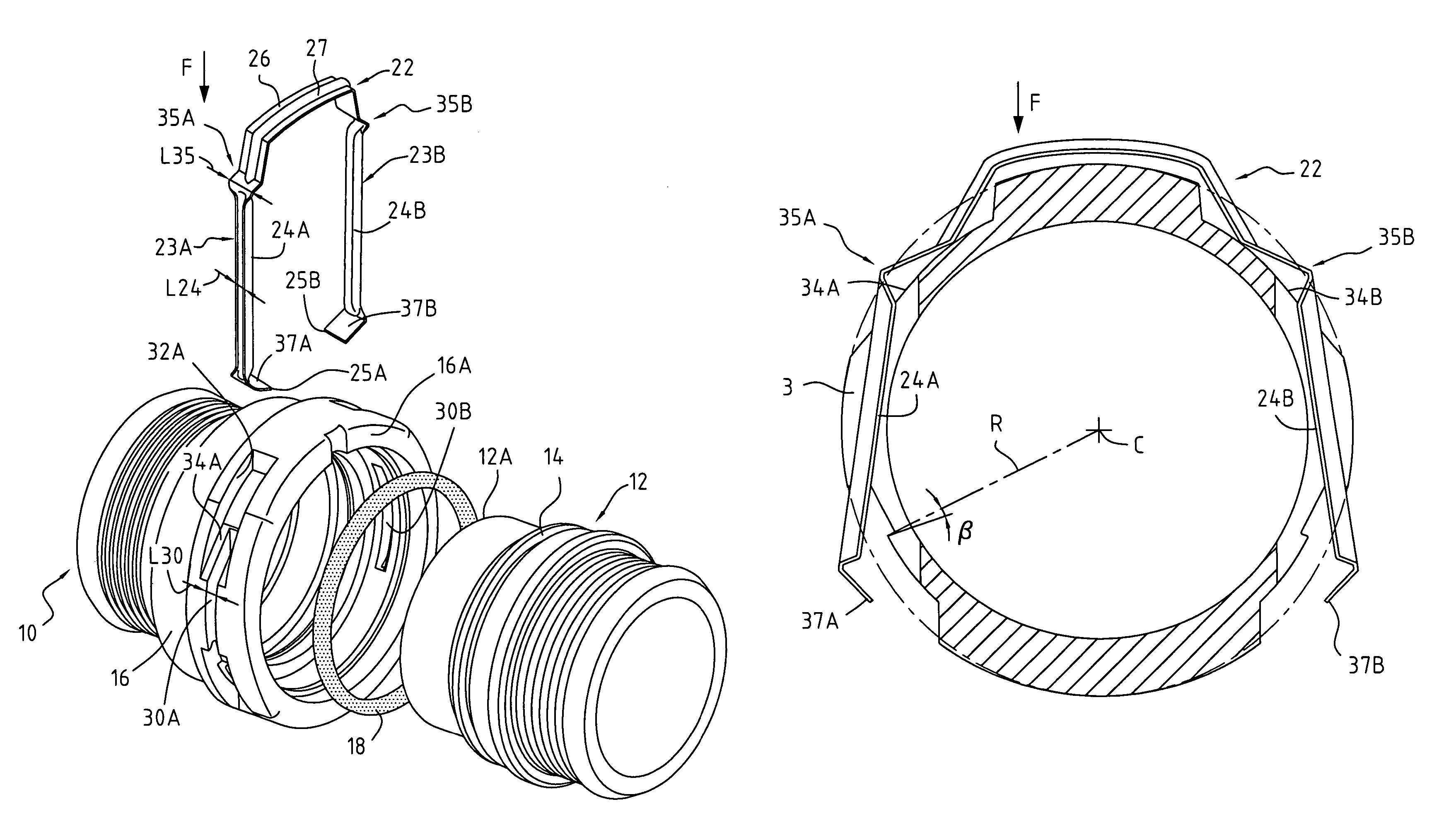

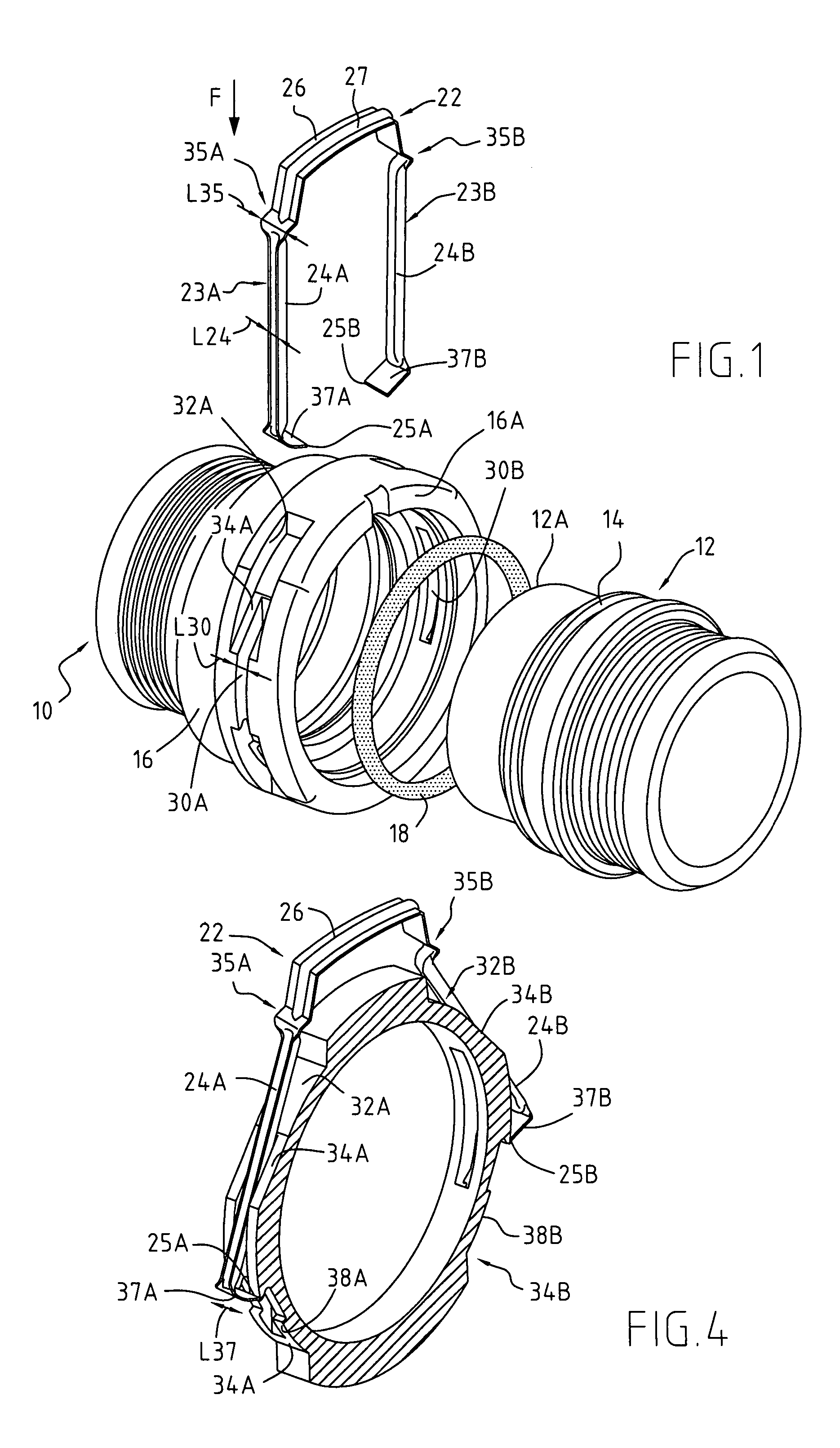

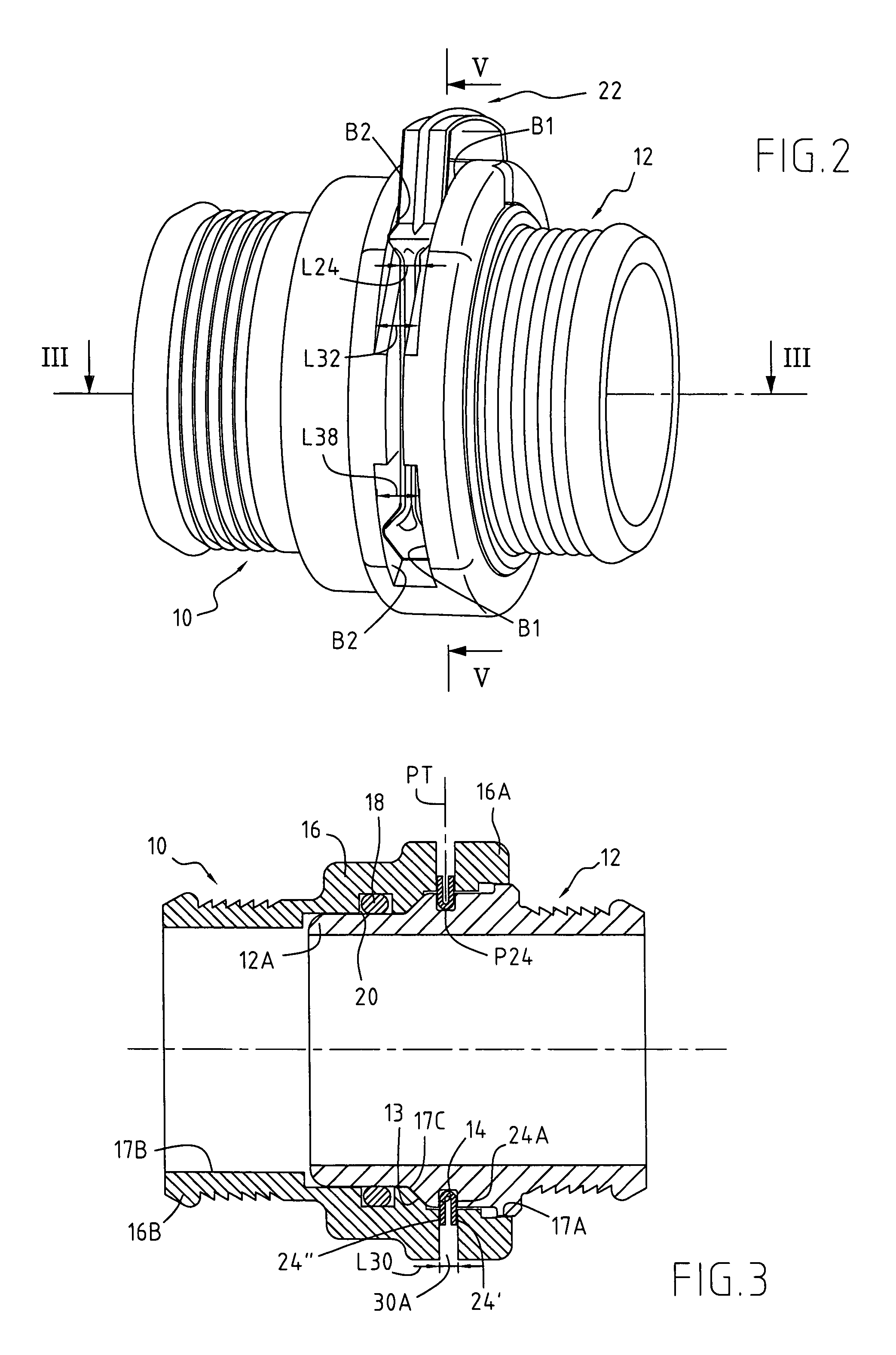

Quick-connect end fitting

Owner:ESTAB CAILLAU SARL

Radiation protective paint

ActiveCN101497757AEasy to useNo secondary electromagnetic pollutionRadiation-absorbing paintsRadiation resistantFilm-forming agent

The invention relates to aqueous radiation-resistant coating belonging to the chemical engineering technology field. The aqueous radiation-resistant coating takes flaky graphite powder, acetylene carbon power, carbonyl iron powder and ferrite power as main materials with electromagnetic wave absorption function and takes diffusant, cement, film forming agent, ammonia and pure water as auxiliary materials. The aqueous radiation-resistant coating has the electromagnetic wave absorption frequency of 1.0-20000 MHz, can attenuate the electromagnetic wave absorption by 2-20 dB according to the different coating thickness, can solve the unsolvable problem of purifying environment polluted with electromagnetic radiation by shielding material and effectively prevent the harm of electromagnetic radiation to surrounding equipment and personnel.

Owner:安徽宇航派蒙健康科技股份有限公司

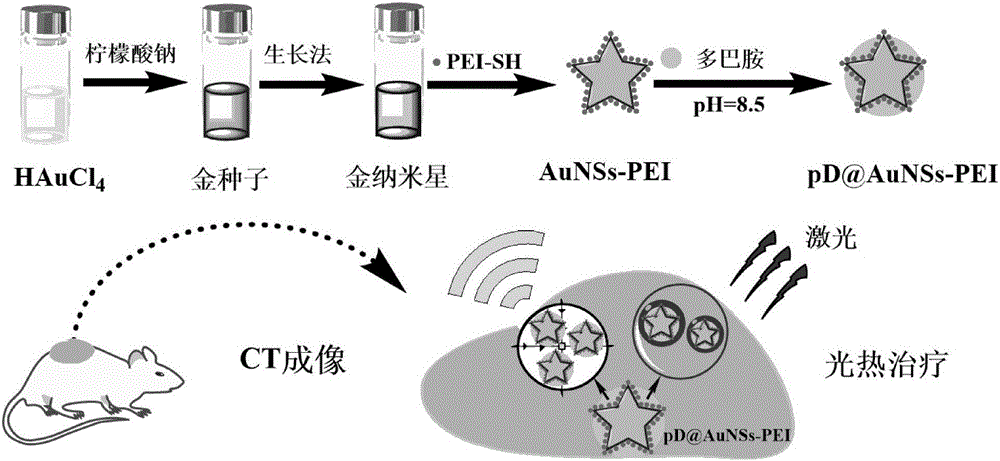

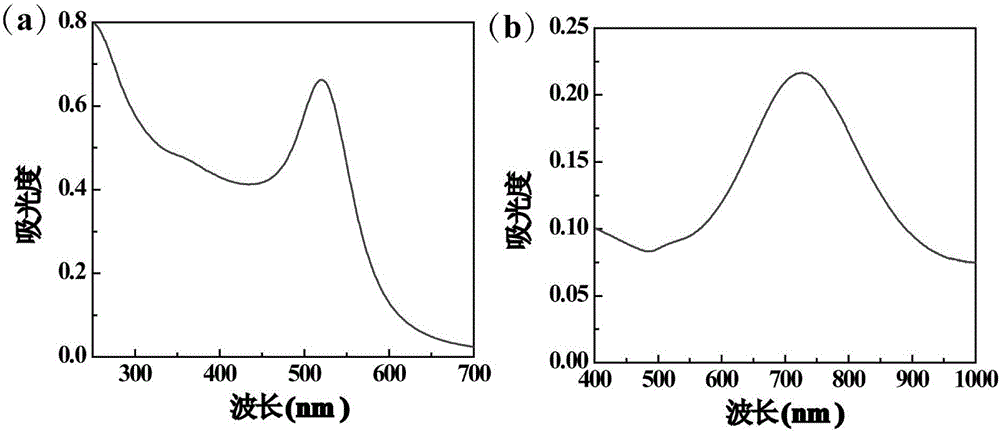

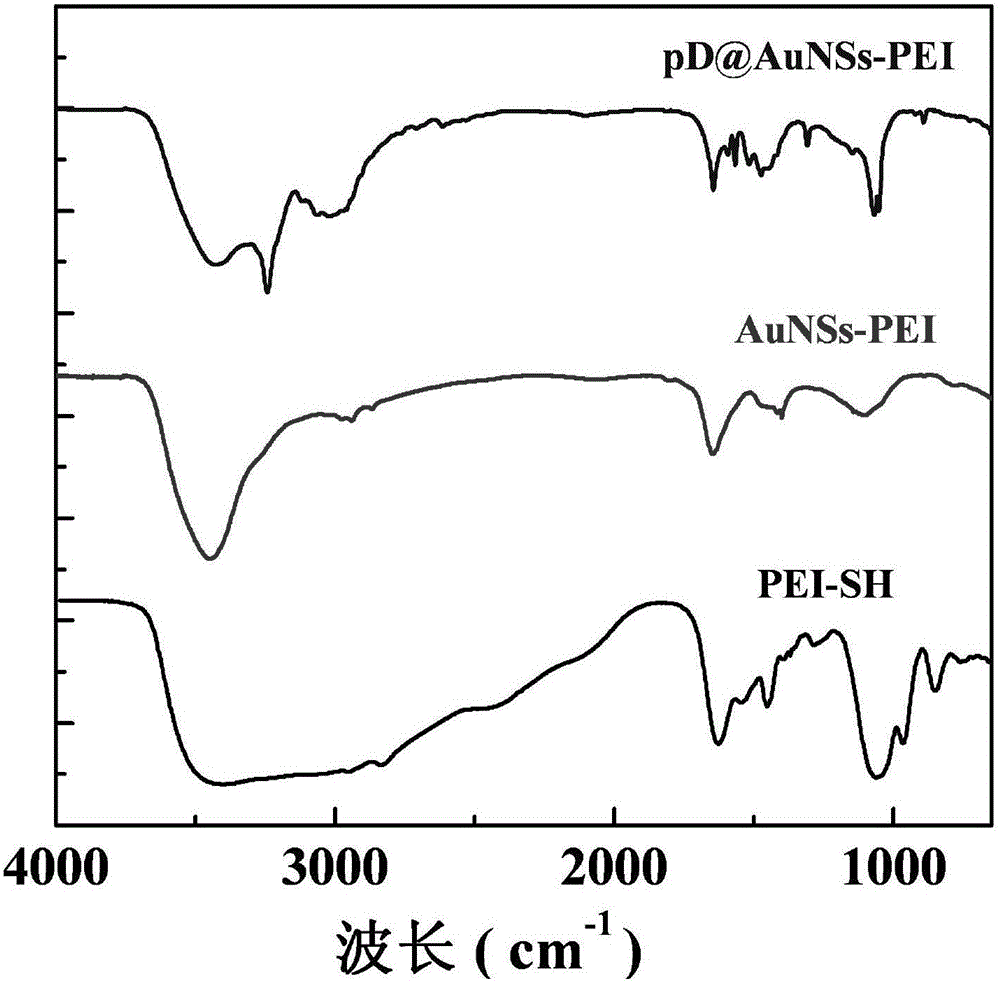

Preparation method for polydopamine-coated polyethyleneimine-stablized gold-nanometer-star photothermal treatment agent

InactiveCN105031647AGood photothermal therapy effectImprove light-to-heat conversion efficiencyEnergy modified materialsX-ray constrast preparationsTreatment fieldMercaptoacetic acid

The invention relates to a preparation method for polydopamine-coated polyethyleneimine-stablized gold-nanometer-star photothermal treatment agent. The preparation method comprises the following steps: preparing a gold seed solution from chloroauric acid and sodium citrate; activating mercaptoacetic acid with EDC, then adding an aqueous PEI solution and carrying out a reaction, dialysis, cooling and drying so as to obtain PEI-SH; adding dopamine hydrochloride into a Tris buffer so as to obtain dopamine Tris buffer; adding the gold seed solution into a chloroauric acid solution, adding a AgNO3 solution and an ascorbic acid solution under stirring, adding PEI-SH after stirring reaction and carrying out a reaction so as to obtain AuNSs-PEI; and adding AuNSs-PEI into the dopamine Tris buffer and carrying out stirring and centrifugation so as to obtain the photothermal treatment agent. The preparation method has the advantages of simplicity, mild reaction conditions, easy operation and industrialization prospects; and the prepared star-like nanometer agent has application potential in the fields of CT imaging diagnosis and photothermal treatment of cancers.

Owner:DONGHUA UNIV

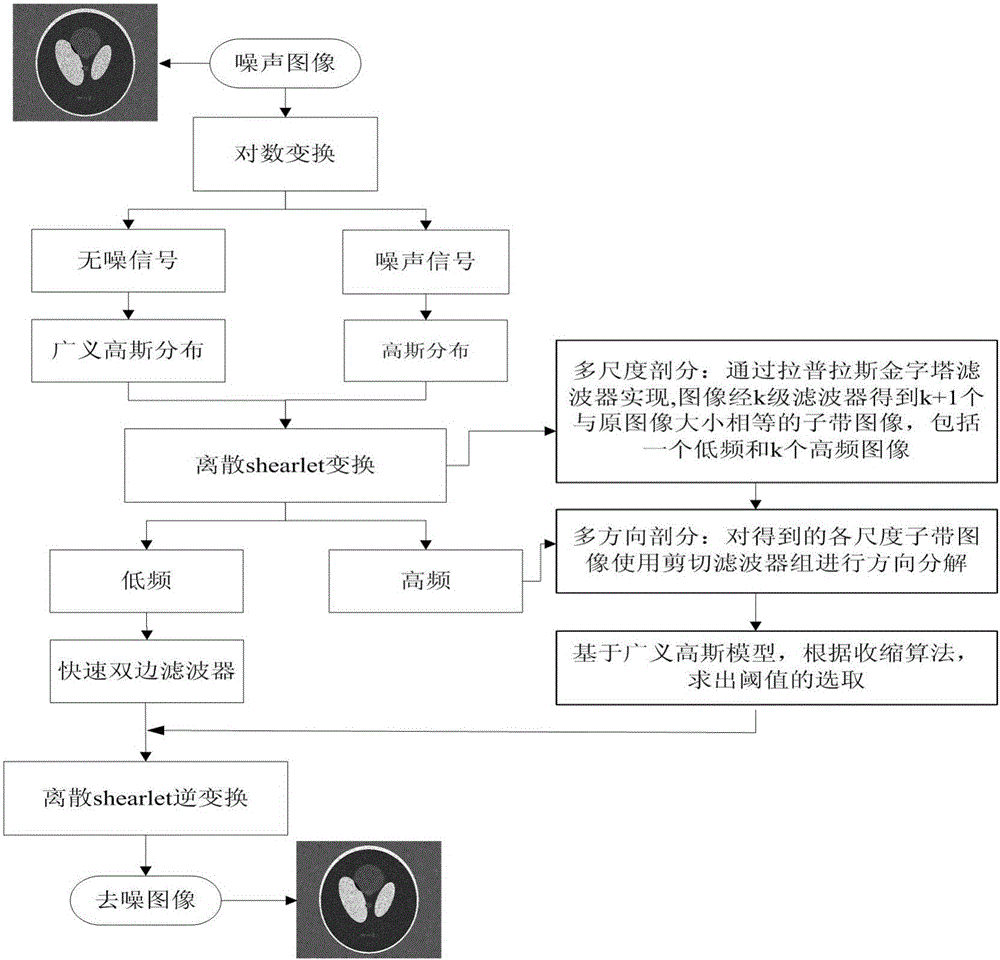

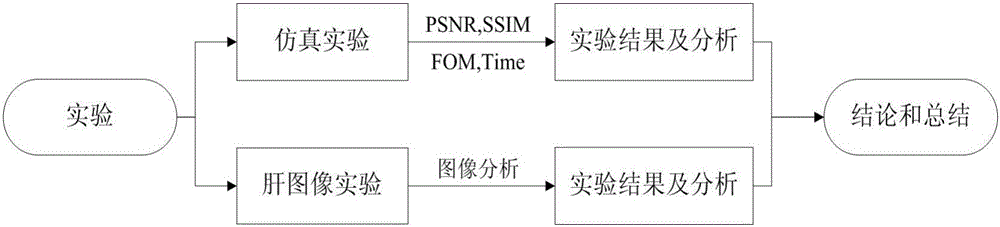

Shearlet transform and fast bilateral filter image denoising method

InactiveCN106127711APromote localizationImprove filtering effectImage enhancementImage analysisUltrasonographyImage denoising

The invention discloses a shearlet transform and fast bilateral filter image denoising method, which comprises the steps of: 1) acquiring an envelope signal of a noise image by using a noise imaging system, and establishing a medical ultrasonic image model; 2) carrying out multiscale and multidirectional decomposition on the medical ultrasonic image model after logarithmic transformation obtained in the step 1) by utilizing a pyramid filter bank; 3) performing threshold method contraction processing on a two-dimensional discrete shearlet transform coefficient of a high-frequency part in each subband image obtained in the step 2); 4) using a fast bilateral filter for filtering shearlet coefficients of low-frequency parts in the step 2); 5) and conducting shearlet inverse transform processing on all the coefficients processed in the step 3) and the step 4), so as to obtain a denoised medical ultrasound images. The introduction of the fast bilateral filter in the shearlet transform and fast bilateral filter image denoising method can effectively improve the denoising performance, and greatly increase the processing efficiency.

Owner:ZHEJIANG COLLEGE OF ZHEJIANG UNIV OF TECHOLOGY

Radiation-proof rubber protective gloves

ActiveCN101894596AImprove the attenuation effectGood mechanical propertiesShieldingBeam energyAntioxidant

The invention discloses radiation-proof rubber protective gloves. The gloves comprise the following components in percentage by weight: 29 to 56 percent of rubber latex, 0.1 to 0.5 percent of sulfur, 0.1 to 2.5 percent of zinc oxide, 0.2 to 0.5 percent of rubber accelerator, 0.3 to 0.5 percent of rubber antioxidant and 40 to 70 percent of radiation-proof material. In the gloves, when the beam energy is 60KVp, the attenuation rate is over 45 percent; when the beam energy is 80KVp, the attenuation rate is over 35 percent; when the beam energy is 100KVp, the attenuation rate is over 26 percent; when the beam energy is 120KVp, the attenuation rate is over 22 percent; and the gloves have very good attenuation effect on X-rays and have good protection effect. The gloves have good mechanical property, the tension at break is more than 16N, the elongation at break is over 750 percent, and the gloves meet the requirement of Disposable Sterilized Rubber Surgical Gloves of GB7543-2006 and have high practical value.

Owner:ZHENJIANG SUHUI LATEX PROD

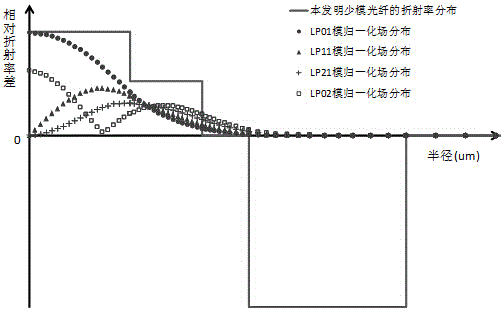

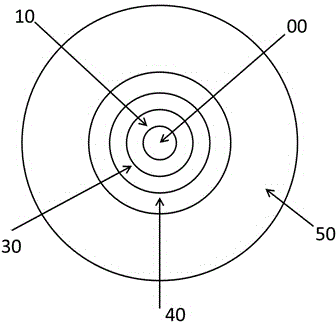

Low-attenuation few-mode fiber

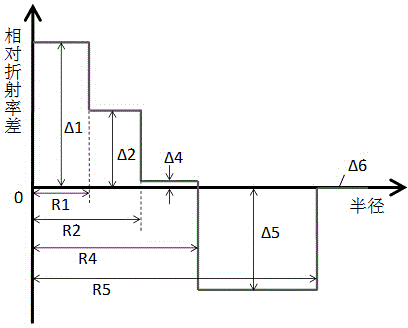

ActiveCN104698534ALow DGD valueLow refractive indexOptical fibre with multilayer core/claddingUltrasound attenuationFew mode fiber

The invention relates to a low-attenuation few-mode fiber. The low-attenuation few-mode fiber is that two core layers are provided; three wrapping layers ware arranged at the outsides of the core layers from inside to outside; the relative refractive rate difference delta 1 of the first core layer is 0.30 to 0.42%, and the radius R1 is 5.4 to 8 microns; the relative refractive rate difference delta 2 of the second core layer is 0.20 to 0.25%, and the radius R2 is 10 to 13 microns; the first wrapping layer is an inner wrapping layer which is closely arranged around the core layers, the relative refractive rate difference delta 4 is -0.02 to 0.02%, and the radius R4 is 13.6 to 17 microns; the second wrapping layer is a sunken wrapping layer which is arranged closely around the inner wrapping layers, the relative refractive rate difference delta 5 is -0.8 to 0.4%, and the radius R5 is 17.5 to 30 microns; the third wrapping layer is an outer wrapping layer which is arranged closely around the sunken wrapping layer and is a pure quartz glass layer. The low-attenuation few-mode fiber supports four stable transmission modes under 1550nm, is relatively small in DGD, simple in process, convenient to manufacture, relatively low in attenuation and relatively high in bending resistance.

Owner:SHANTOU HIGH TECH ZONE AOXING OPTICAL COMM EQUIP

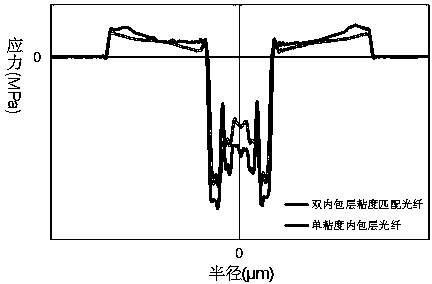

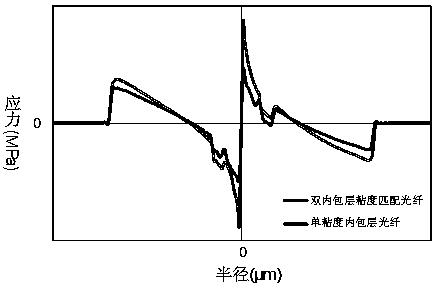

Low-attenuation bending insensitive single mode fiber

InactiveCN104316994AGood attenuation performanceDelay decayOptical fibre with multilayer core/claddingOptical waveguide light guideUltrasound attenuationMicrometer

The invention relates to a low-attenuation bending insensitive single mode fiber which comprises a core layer and wrapping layers. The low-attenuation bending insensitive single mode fiber is characterized in that the relative refractive index difference delta1 of the core layer ranges from 0.30% to 0.38%, the radius R1 of the core layer ranges from 3.5 micrometers to 4.5 micrometers, the four wrapping layers are arranged outside the core layer, the first wrapping layer is a first inner wrapping layer tightly surrounding the core layer, the relative refractive index difference delta2 of the first wrapping layer ranges from -0.02% to 0.02%, the radius R2 of the first wrapping layer ranges from 6.5 micrometers to 8.5 micrometers, the second wrapping layer is a second inner wrapping layer tightly surrounding the first inner wrapping layer, the relative refractive index difference delta3 of the second wrapping layer ranges from -0.02% to 0.02%, the radius R3 of the second wrapping layer ranges from 8 micrometers to 11 micrometers, the third wrapping layer is a downwards-concave wrapping layer tightly surrounding the second inner wrapping layer, the relative refractive index difference delta4 of the third wrapping layer ranges from -0.5% to -0.2%, the radius R4 of the third wrapping layer ranges from 12 micrometers to 20 micrometers, and the fourth wrapping layer is an outer wrapping layer tightly surrounding the downwards-concave wrapping layer and is a pure quartz glass layer. The low-attenuation bending insensitive single mode fiber can be completely matched with a G.652.D optical fiber, and therefore the low attenuation, the large effective area and the bending resistance can be better unified.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

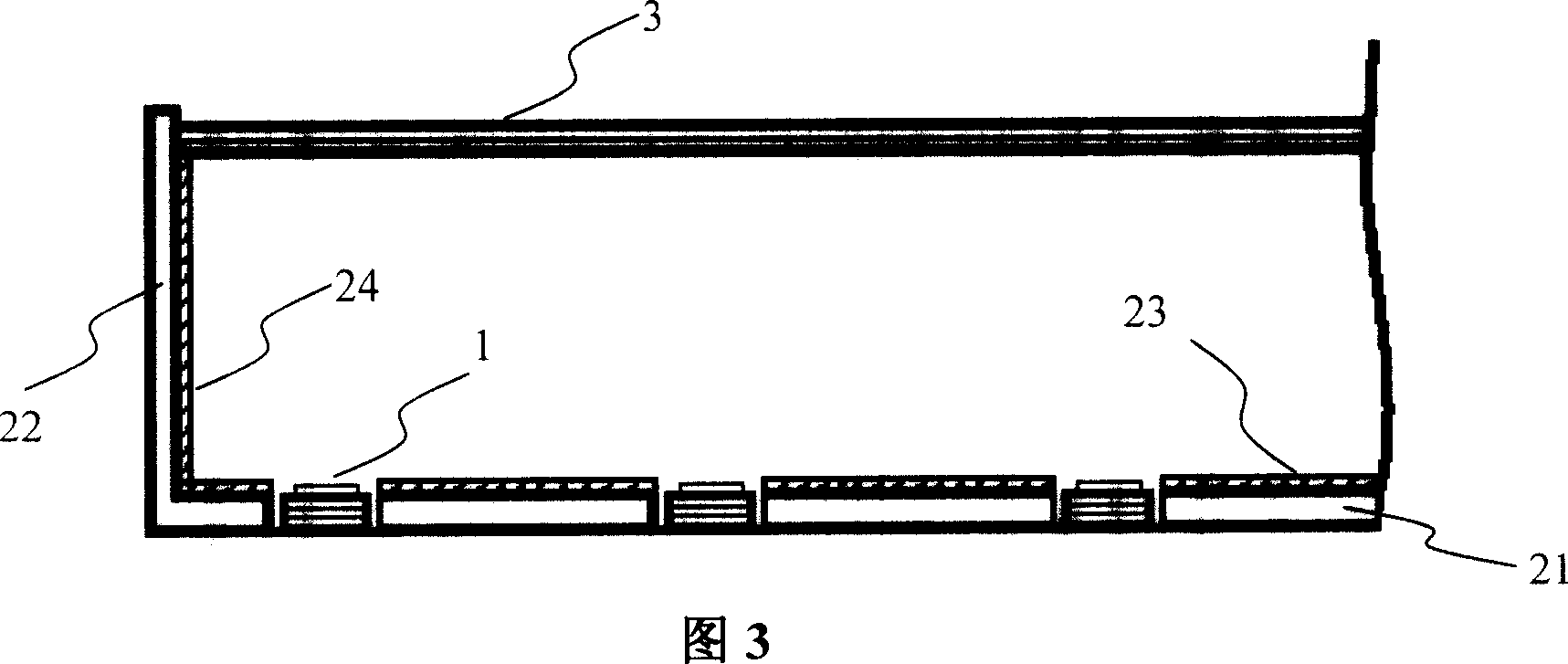

New LED back light module

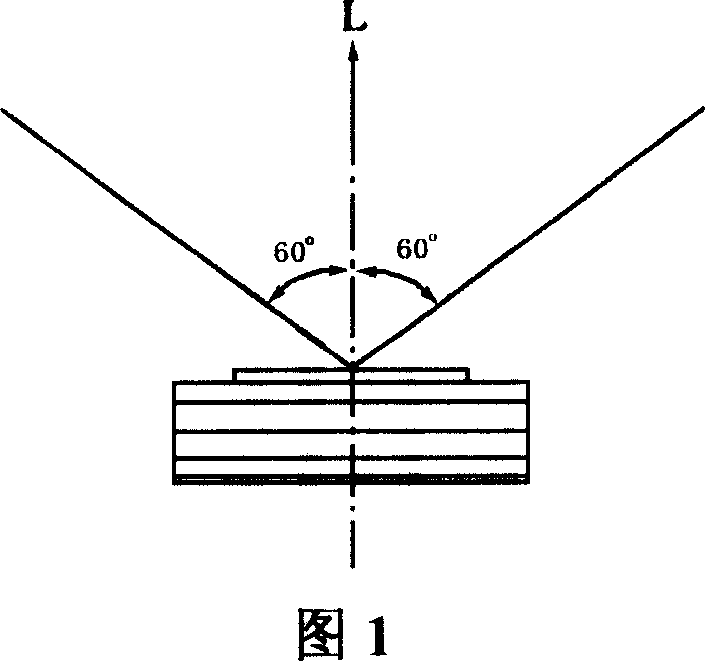

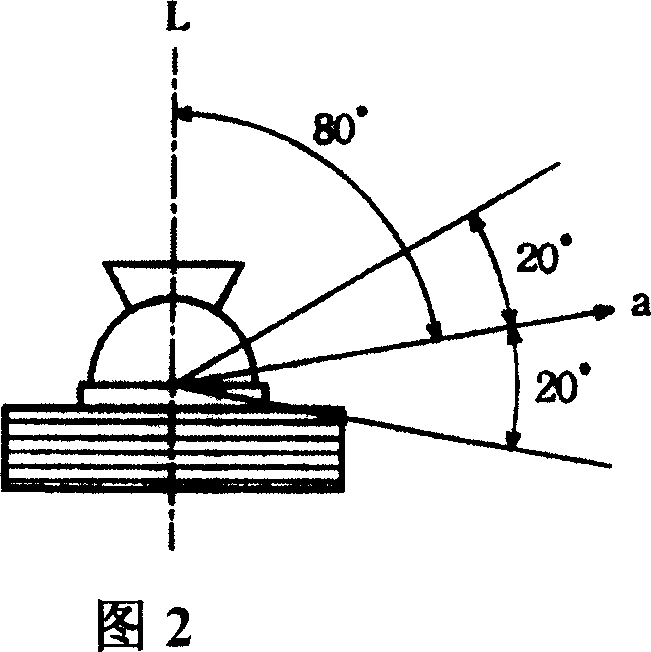

ActiveCN101046576AEasy to implementIncreased Design FreedomNon-linear opticsLensVertical planeLed array

The new LED back light module includes LED units on a base plate, one casing and one light scattering and refracting mechanism with outer vertical plane as the outgoing plane. It features the partially reflecting and partially transmitting optical structure unit set in the light outgoing direction of the LED units and with structure independently to the LED units. The light from the LED' s is transmitted partially and scattered mostly in the optical structure unit so as to avoid LED shade spot in the light outgoing plane of the module. The optical structure unit may be regulated flexibly to reach proper ratio between the transmitted light and the scattered light. The present invention is suitable for various kinds of LED light source.

Owner:BOE TECH GRP CO LTD

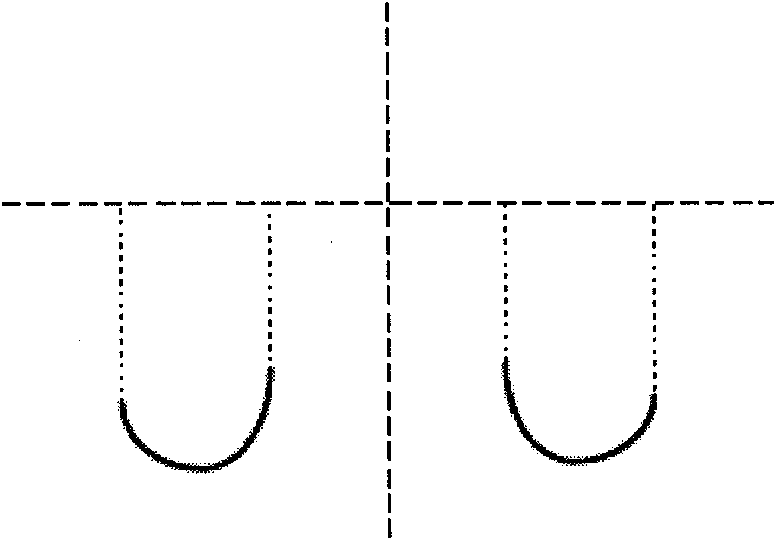

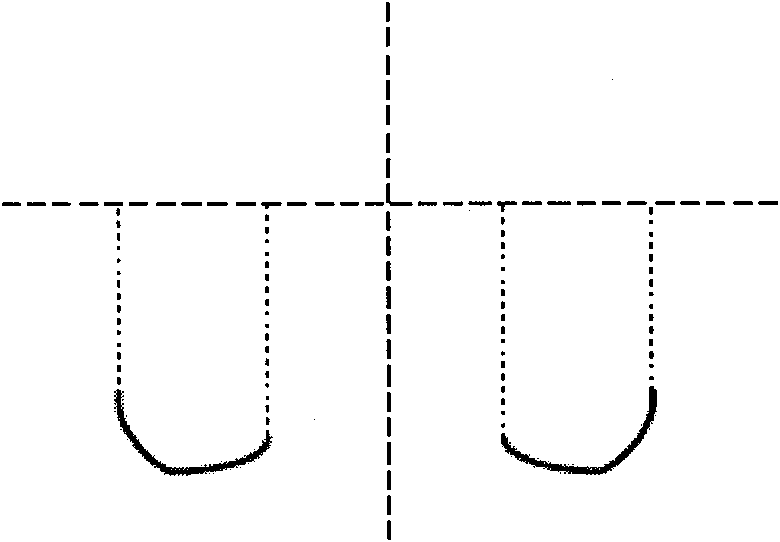

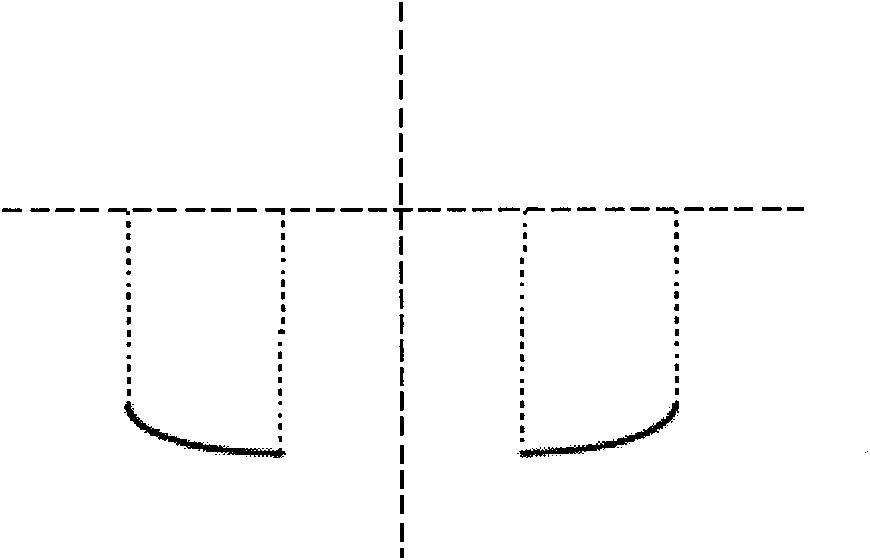

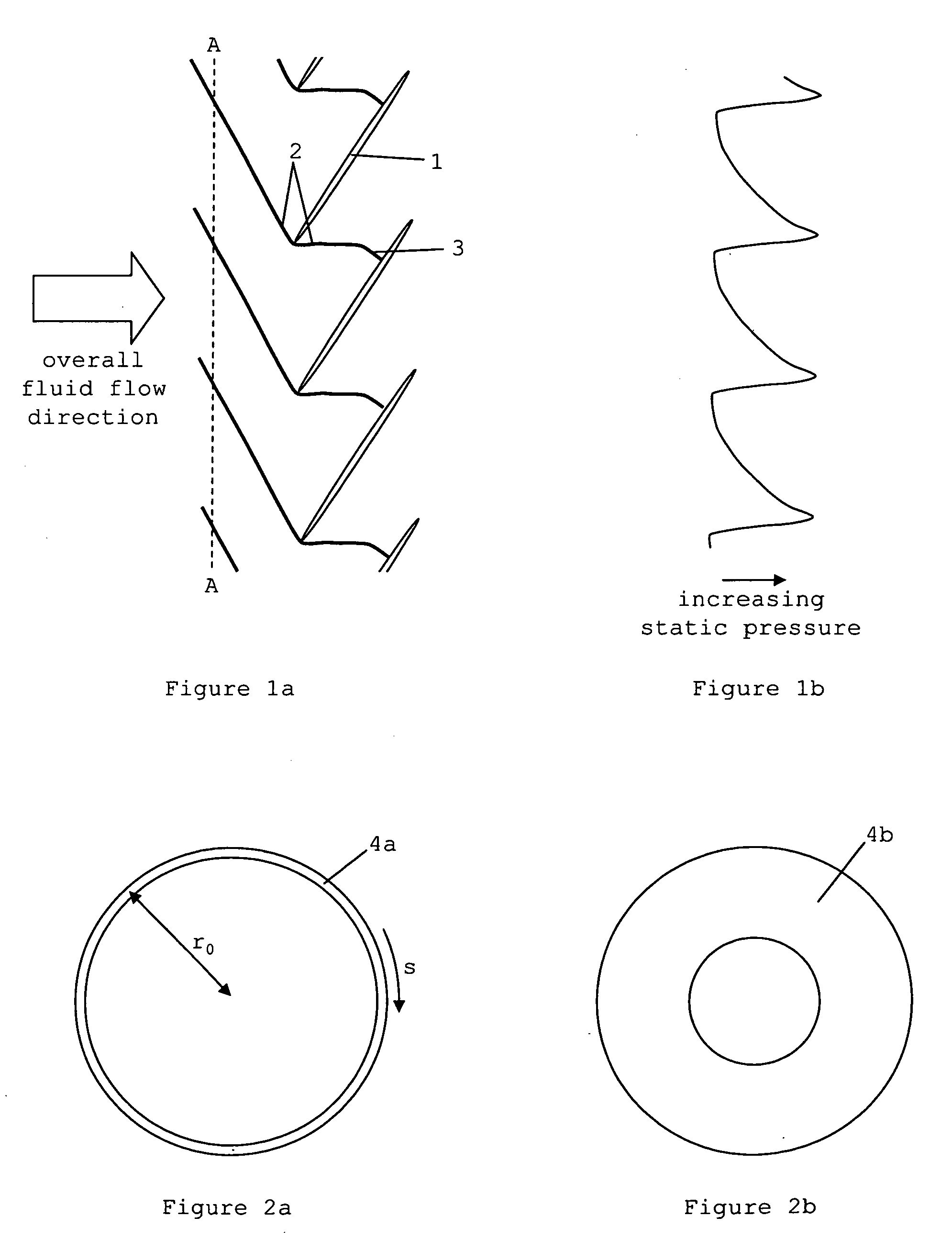

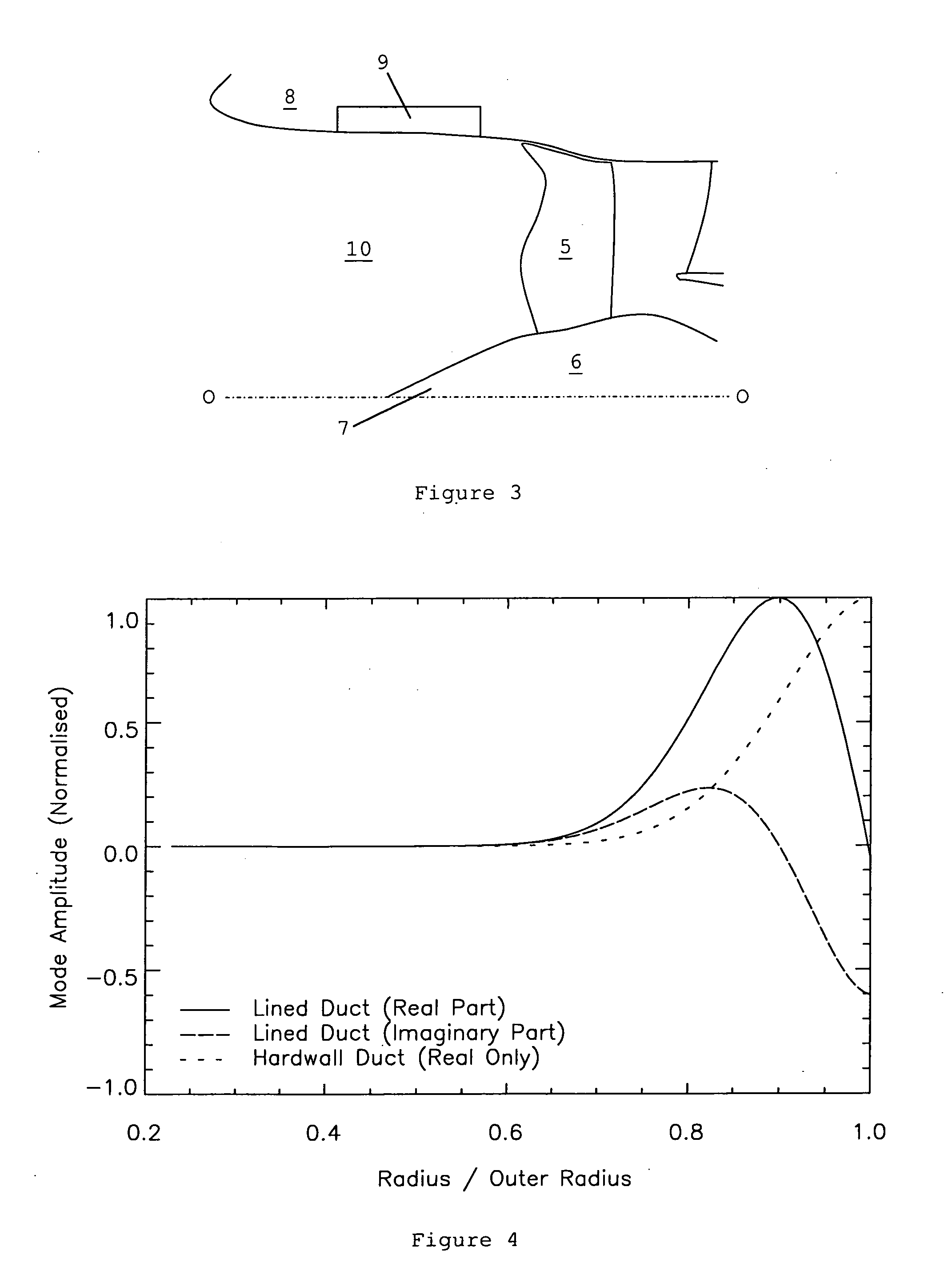

Tone noise reduction in turbomachines

ActiveUS20080181769A1Improve the attenuation effectReduce noiseSupersonic fluid pumpsEngine manufactureClassical mechanicsEngineering

A blade for a turbomachine extends in use, in a radial direction relative to the axis of the turbomachine. The turbomachine has at least one operating condition which generates supersonic fluid flow at the blade. The blade is adapted to provide, at the supersonic operating condition, a leading edge sweep angle which varies such that successive radial positions (i) to (iii) along the leading edge are at respective sweep angle turning points. Position (i) is the radially inner and position (iii) the radially outer of the positions. Position (i) is at or radially outward of the 30% span position, where 0% span is the radially innermost point of the leading edge and 100% span is the radially outermost point of the leading edge.

Owner:ROLLS ROYCE PLC

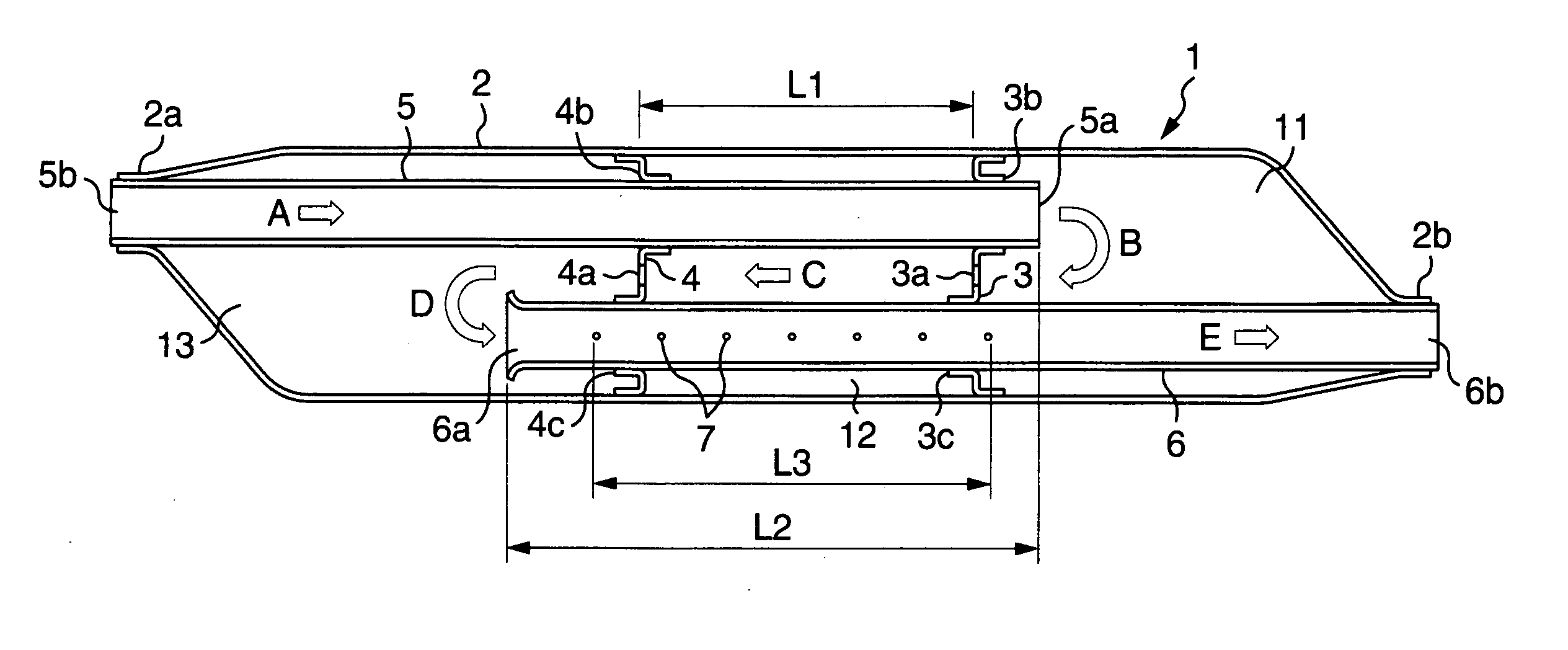

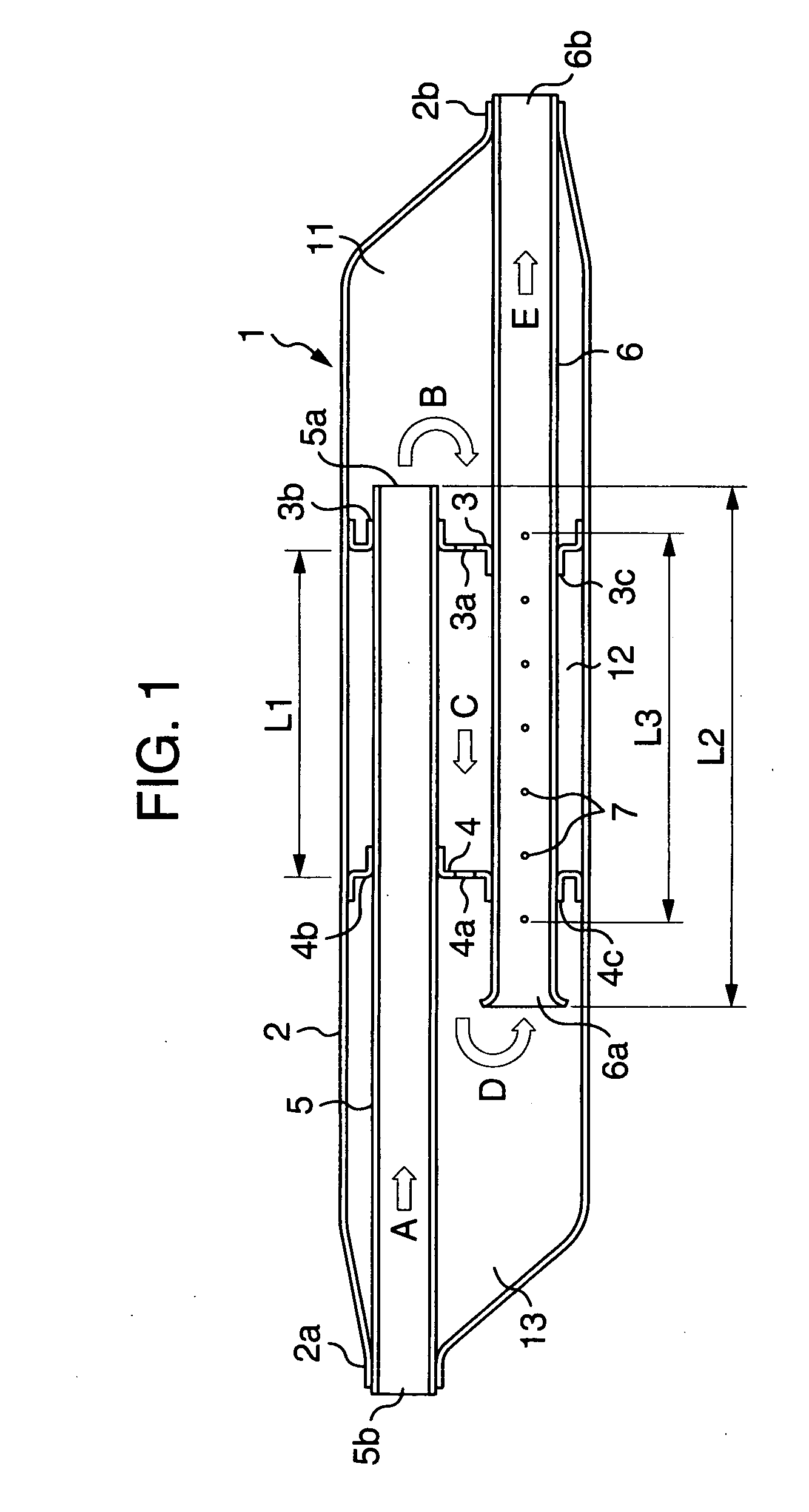

Internal combustion engine silencer

InactiveUS20050224283A1Improve the attenuation effectHigh attenuating effectSilencing apparatusMachines/enginesCombustionEngineering

A muffler for internal combustion engines, in order to achieve a high attenuating effect without reducing the attenuating effect in the high revolution range of the engine, comprising one or more expanding chambers 11 through 13 formed in a muffler 1, an inlet pipe 5 which opens into a expanding chamber 11 and introduces exhaust gas into the muffler 1, and an outlet pipe 6 which opens into other expanding chamber 13 and introduces exhaust gas out of the muffler 1. In the muffler, the exhaust gas discharged through an aperture 5a of this inlet pipe 5 is inverted once or more times in the muffler 1 and is introduced into an aperture 6a of the outlet pipe 6. In a contraflow area L2 in which the flowing direction C of exhaust gas flowing in the expanding chambers 11 through 13 and the flowing direction E of exhaust gas flowing in the outlet pipe 6 are not the same, interference holes 7 composing of a plurality of small holes communicating with the expanding chambers 11 through 13 are bored in the outlet pipe 6. The aperture area of the small holes 7 is kept at not less than 1% but not more than 5% of the surface area of the outlet pipe in the contraflow area L2.

Owner:SANGO CO LTD

Piezoelectric active vibration isolating mechanism and method for reducing inherent frequency of vibrating system

ActiveCN105134866AReduce energy consumptionEasy to useMechanical oscillations controlNon-rotating vibration suppressionElectricityPiezoelectric actuators

The invention discloses a piezoelectric active vibration isolating mechanism which comprises a first force sensor, a spring corrugated pipe, an intermediate mass block, a first flexible hinge, a piezoelectric actuator, a second force sensor, a second flexible hinge and a controller. One end of the first force sensor is connected with a base platform, and the other end of the first force sensor is sequentially connected with the second force sensor, the spring corrugated pipe, the intermediate mass block, the second flexible hinge, the piezoelectric actuator and the first flexible hinge. The first force sensor and the second force sensor are respectively used for detecting the vibrating signals of the base platform and the vibrating signals of a load platform and can respectively transmit the detecting vibrating signals to the controller, and the controller can control the piezoelectric actuator to exert acting force on the load platform to compensate the load platform. By means of a two-stage serial-connection suspending structure, the inherent frequency of the structure is effectively reduced, and micro-vibration low-frequency interference in precision equipment can be effectively restrained.

Owner:HUAZHONG UNIV OF SCI & TECH

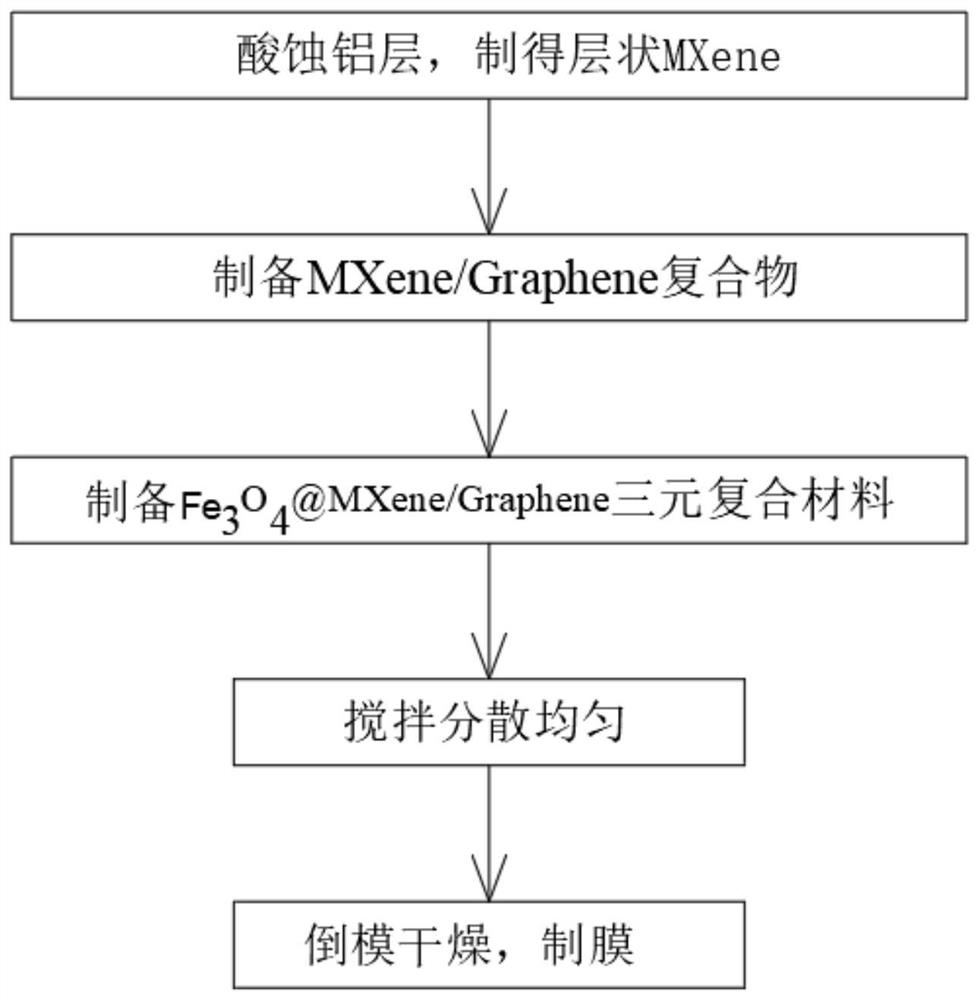

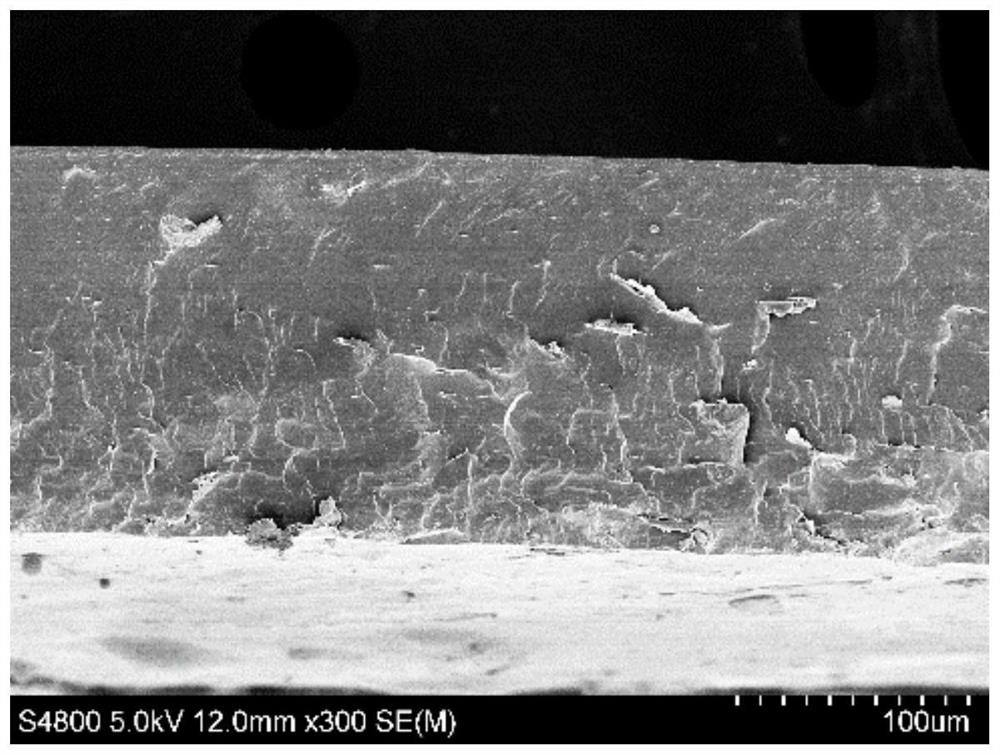

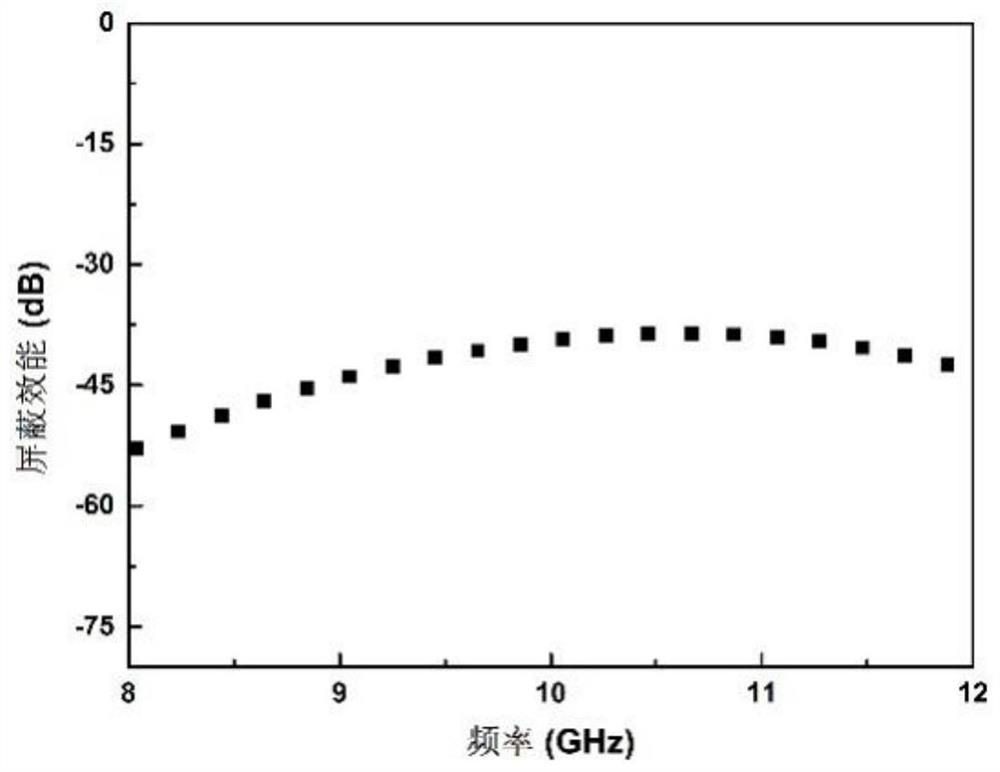

MXene-based flexible polyvinyl alcohol electromagnetic shielding composite film and preparation method thereof

ActiveCN112876712AGood electromagnetic shielding performanceImproving Impedance Matching CharacteristicsWave bandPolyvinyl alcohol

The invention discloses an MXene-based flexible polyvinyl alcohol electromagnetic shielding composite film and a preparation method thereof, and belongs to the technical field of electromagnetic shielding materials. The invention relates to an MXene-based flexible polyvinyl alcohol electromagnetic shielding composite film and a preparation method thereof. The preparation method comprises the following steps of: etching an MAX phase with hydrofluoric acid to obtain layered MXene, then intercalating the MXene and graphene to obtain an MXene / Graphene compound, loading magnetic nanoparticles Fe3O4 on the MXene / Graphene to obtain a Fe3O4@MXene / Graphene ternary composite material, and finally dissolving the Fe3O4@MXene / Graphene ternary composite material and polyvinyl alcohol in deionized water and drying to obtain the polyvinyl alcohol composite film. The obtained polyvinyl alcohol film has very good flexibility and has good compatibility with a composite filler, and the electromagnetic shielding effectiveness in the X wave band can reach 38-52 dB. Layered MXene and graphene with good conductivity are beneficial to multi-reflection attenuation of electromagnetic waves, the impedance matching characteristic is optimized through combination with the magnetic particles Fe3O4, and attenuation of the electromagnetic waves is facilitated.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

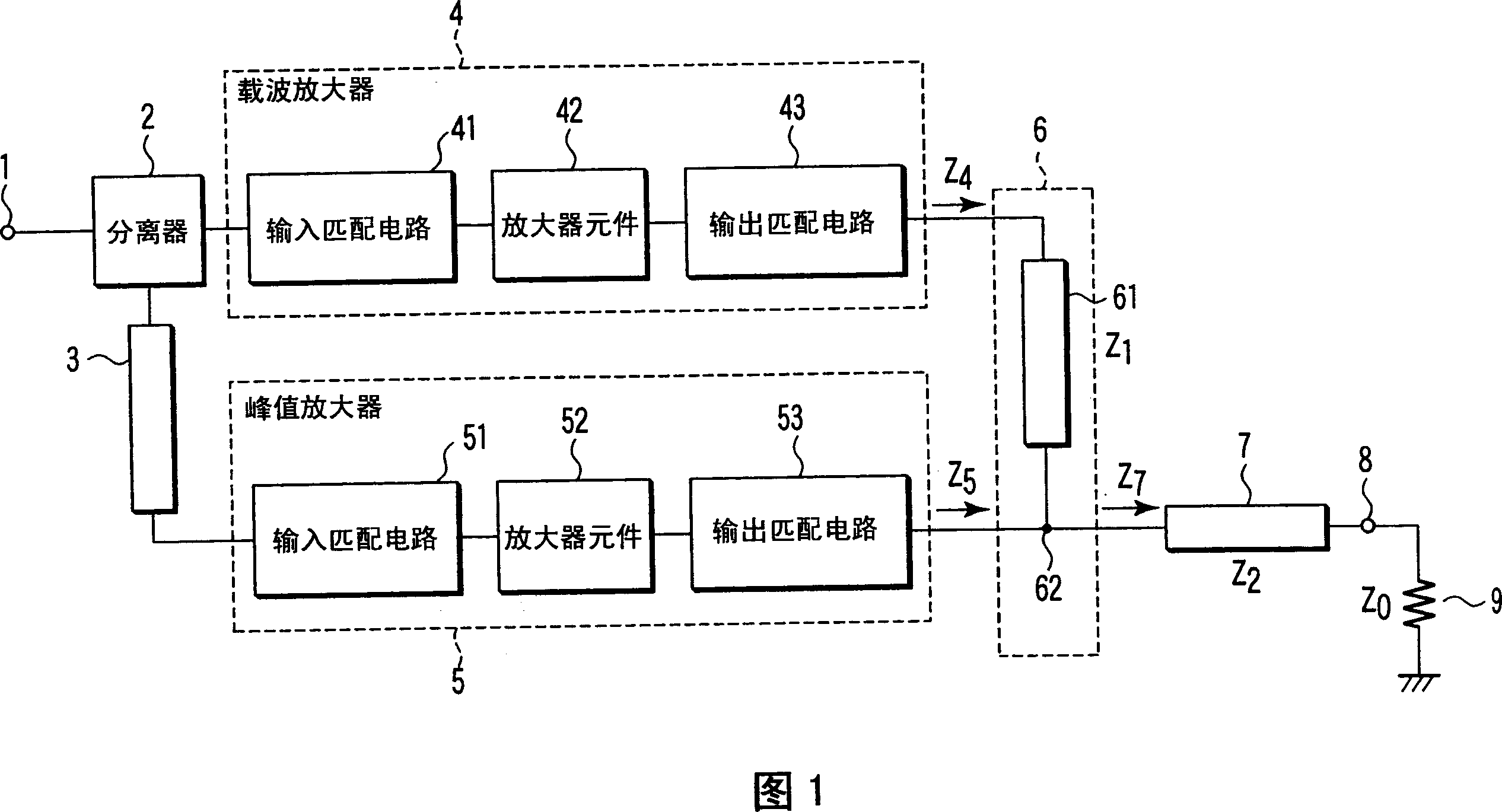

Amplifier device

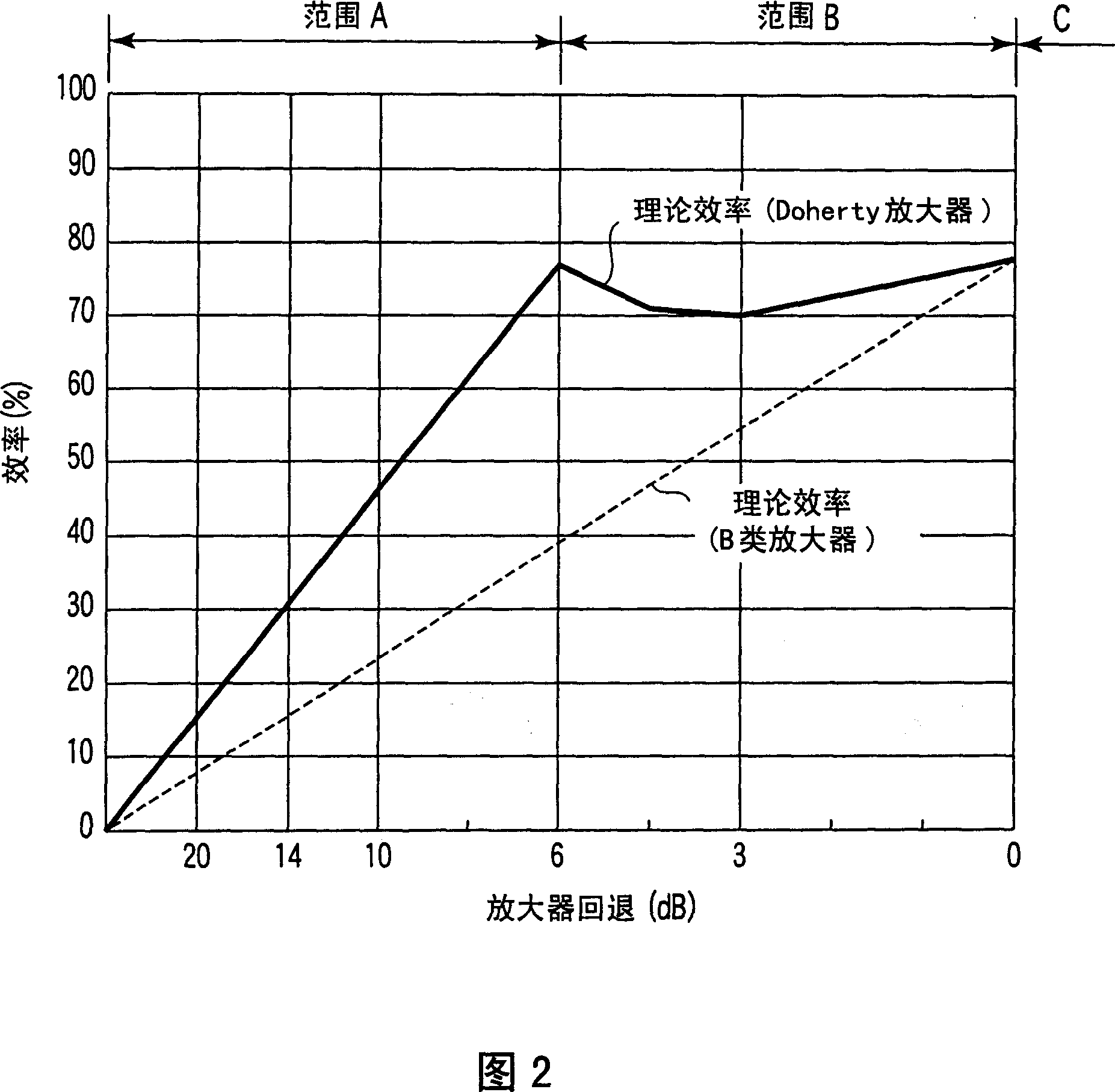

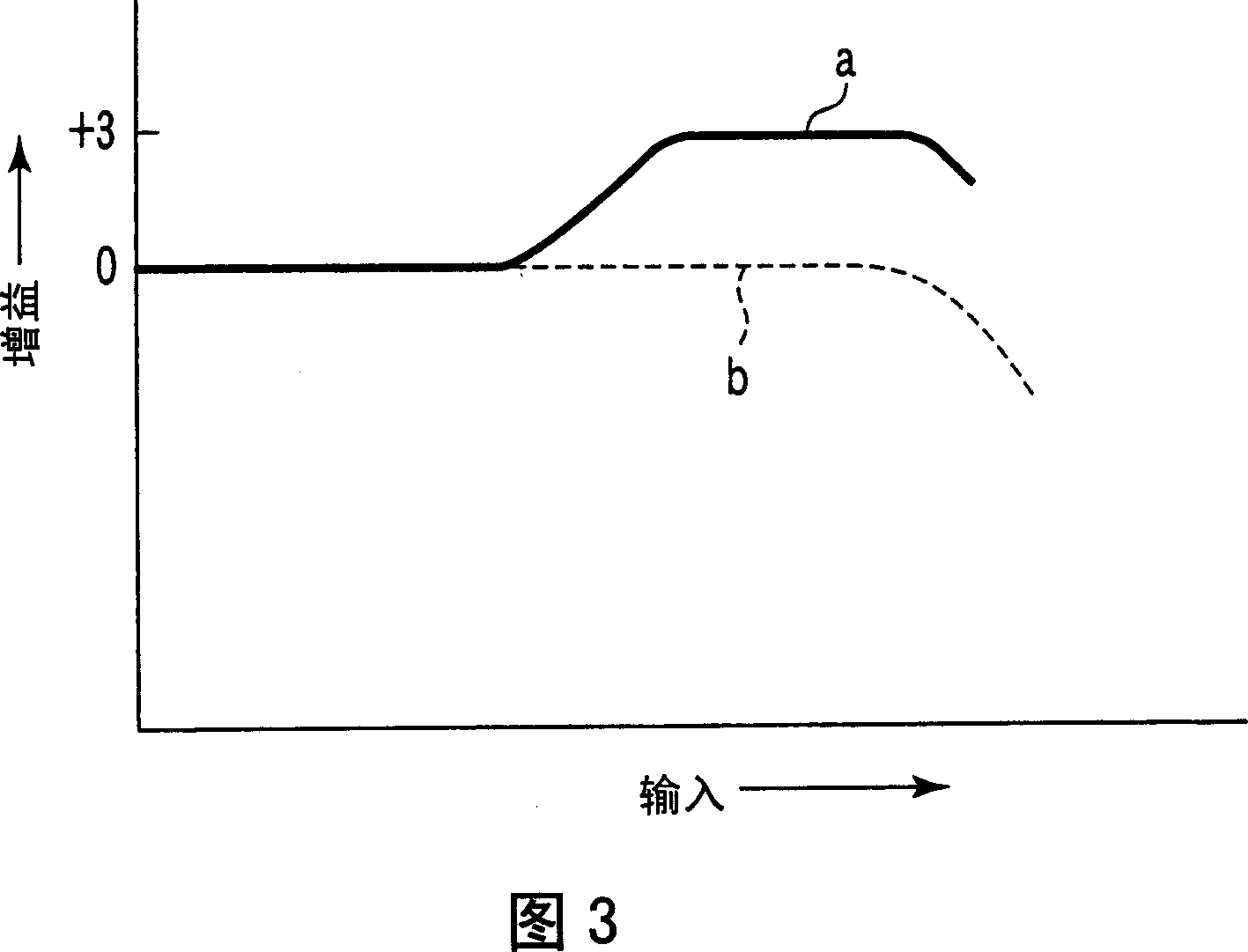

InactiveCN1960165AAmplify the input signalImprove the attenuation effectAmplifier modifications to reduce non-linear distortionAmplifier modifications to raise efficiencyAudio power amplifierEngineering

The first control unit (14) controls the bias applied to the peaking amplifier (5) to: (a) operate the peaking amplifier (5) as class C when the level of the input signal is below a first threshold , (b) when the level of the input signal is higher than a second threshold higher than the first threshold, the peaking amplifier (5) is operated as a class AB with a second conduction angle substantially equal to the second conduction angle a conduction angle, and (c) when the level of the input signal is not lower than the first threshold and is not higher than the second threshold, the peaking amplifier (5) is operated as a class AB with a third conduction angle, the first The third conduction angle is smaller than the first conduction angle.

Owner:KOKUSA ELECTRIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com