Patents

Literature

1029results about How to "Excellent ozone resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite type high-conductivity polymer material and preparation method thereof

ActiveCN101891914AImprove conductivityAvoid damageNon-conductive material with dispersed conductive materialPolymer scienceConductive polymer

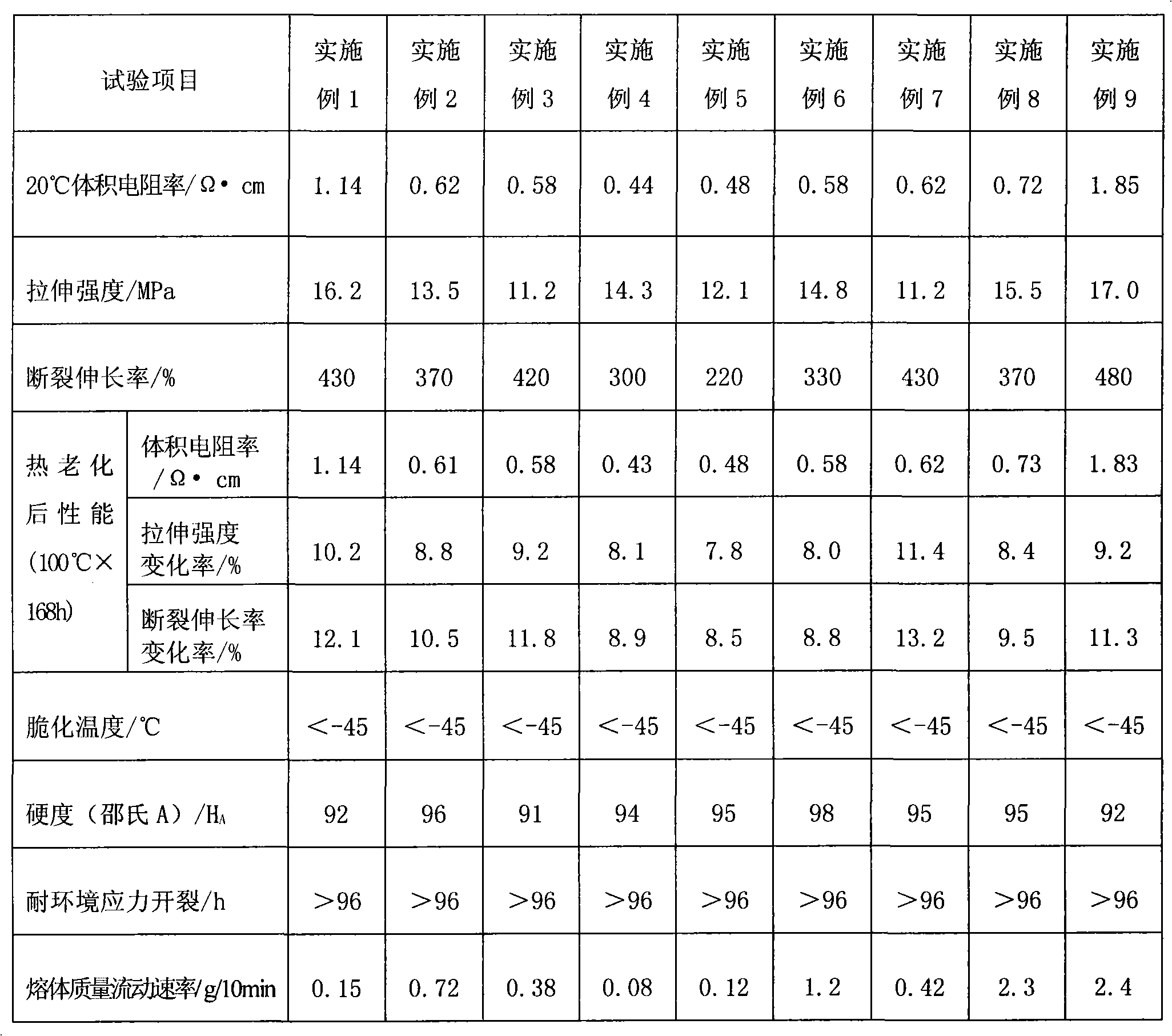

The invention discloses a composite type high-conductivity polymer material and a preparation method thereof, which belongs to the technical field of new materials. The composite type high-conductivity polymer material is characterized by comprising the following raw materials in percentage by weight: 40-62 wt% of base resin compositions, 18-25 wt% of super conductive carbon black, 10-30 wt% of rubber filling oil, 1-3 wt% of low molecular wax, 0.2-0.8 wt% of fluoroelastomer processing aid (PPA), 0.5-2 wt% of lubricant, 1.5-3 wt% of inorganic filler and 0.5-2.5 wt% of other aids. The compositetype high-conductivity polymer material has the advantages of excellent high conductivity, environmental stress cracking resistance, weatherability, ozone resistance, ultraviolet resistance, favorable high temperature resistance, high impact resistance, oil resistance, solvent resistance and mechanical property, and can be used as an environment-friendly conductive polymer sheath material of an combined through earth line, a metal anticorrosive material of other ground cable, a conductive plastic cladding material of a conductive plastic cable positive wire, an optical cable flexible sheath material, and the like.

Owner:SHANDONG KEHONG WIRE & CABLE TECH CO LTD

Oil resistant low temperature resistant rubber composition

InactiveCN101353451AGuaranteed oil resistanceGuaranteed ozone resistancePolymer scienceNitrile rubber

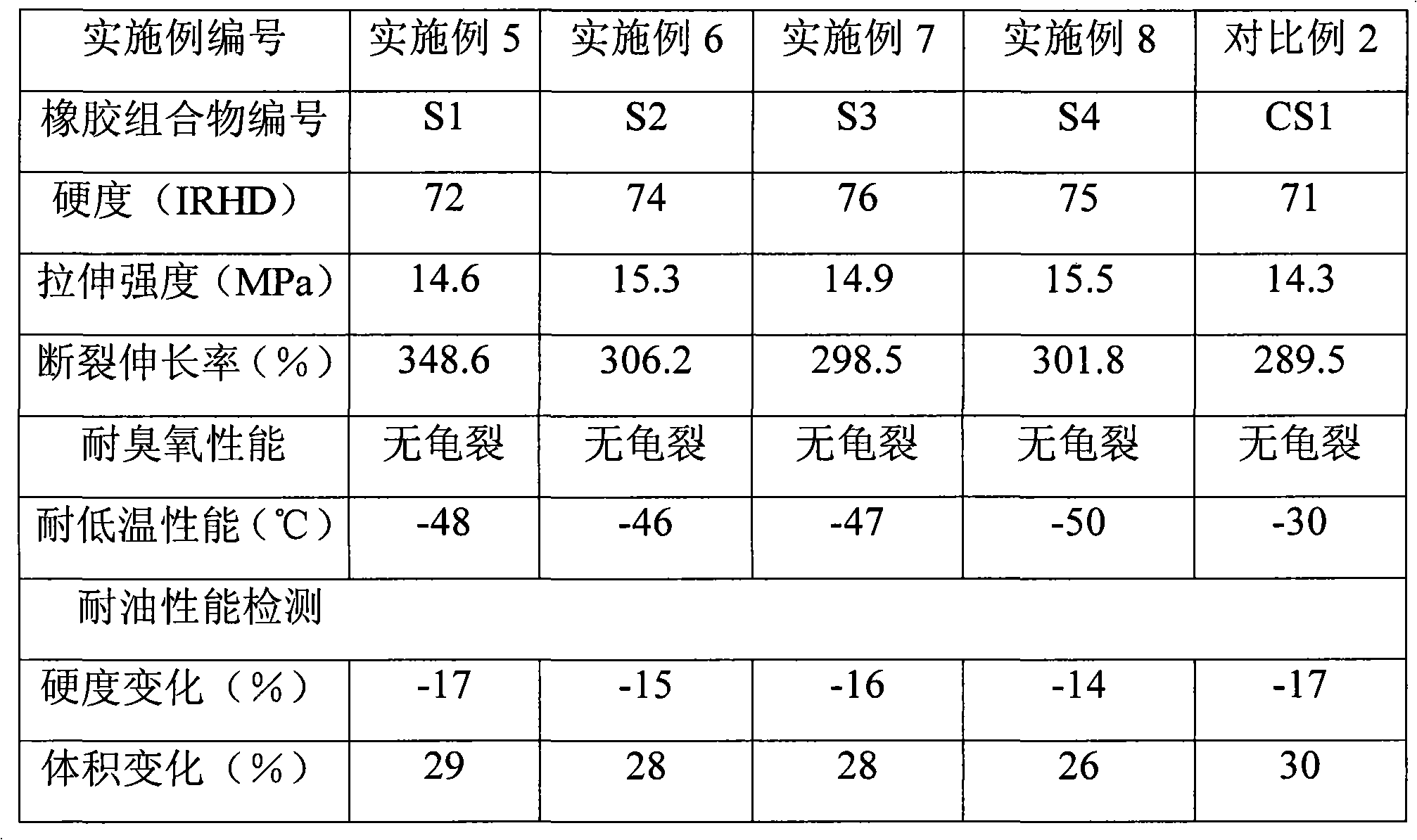

The invention relates to a rubber composite, comprising nitrile rubber, polyvinyl chloride, carbon soot, activator, vulcanizator, age inhibitor, antiscorcher, accelerant and plasticizer, wherein, the plasticizer is ethylhexyl sebacate and adipate. The rubber composite of the invention obviously improves the anti-low temperature performance of the rubber composite while ensuring the anti-oil performance, anti-ozone performance, tensile strength and elongation at break.

Owner:BYD CO LTD

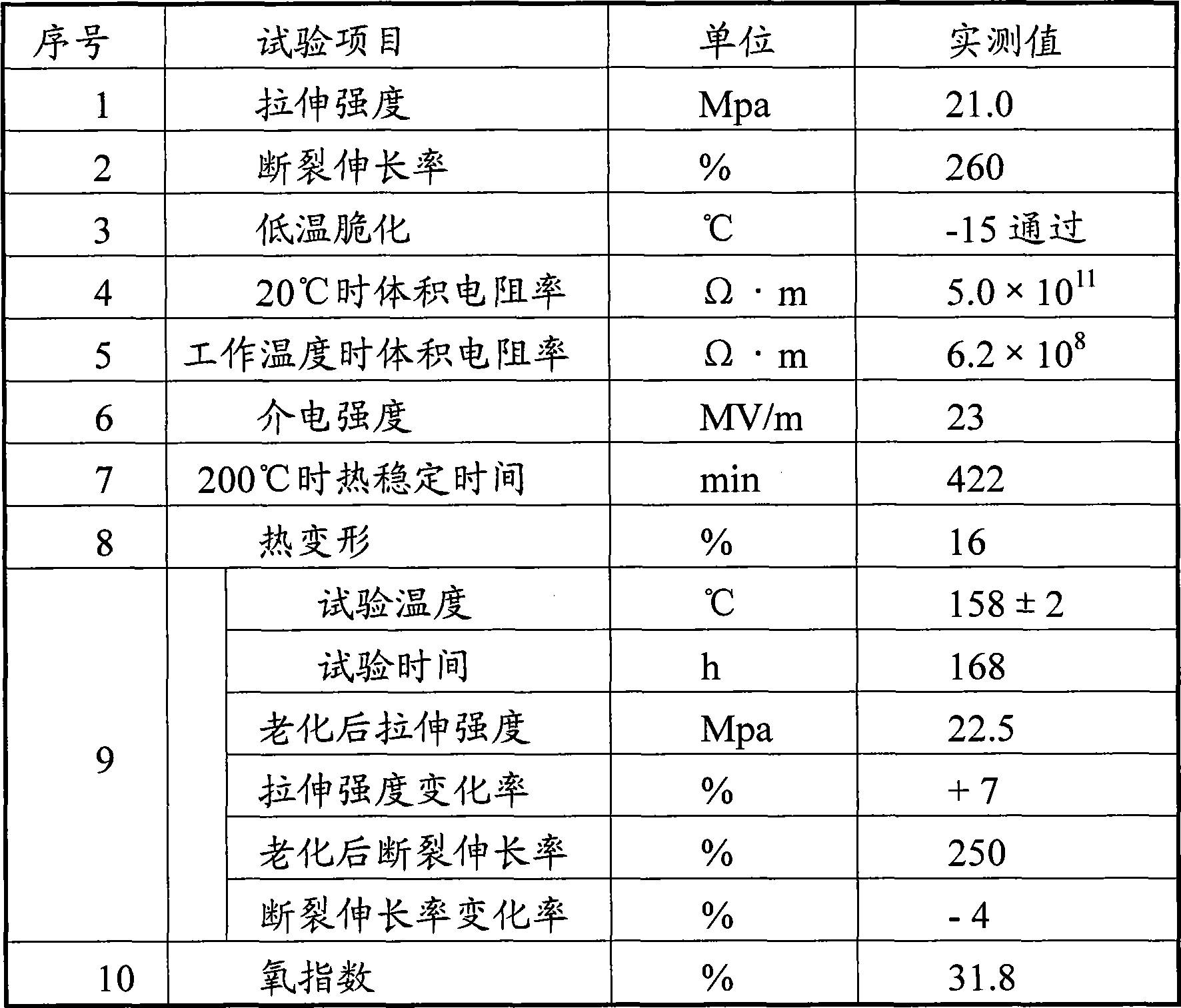

High temperature resistant environment-protective polychloroethylene material for electric wire and cable

InactiveCN101412834AImprove mechanical propertiesImprove insulation performancePlastic/resin/waxes insulatorsInsulated cablesPolyesterPolyvinyl chloride

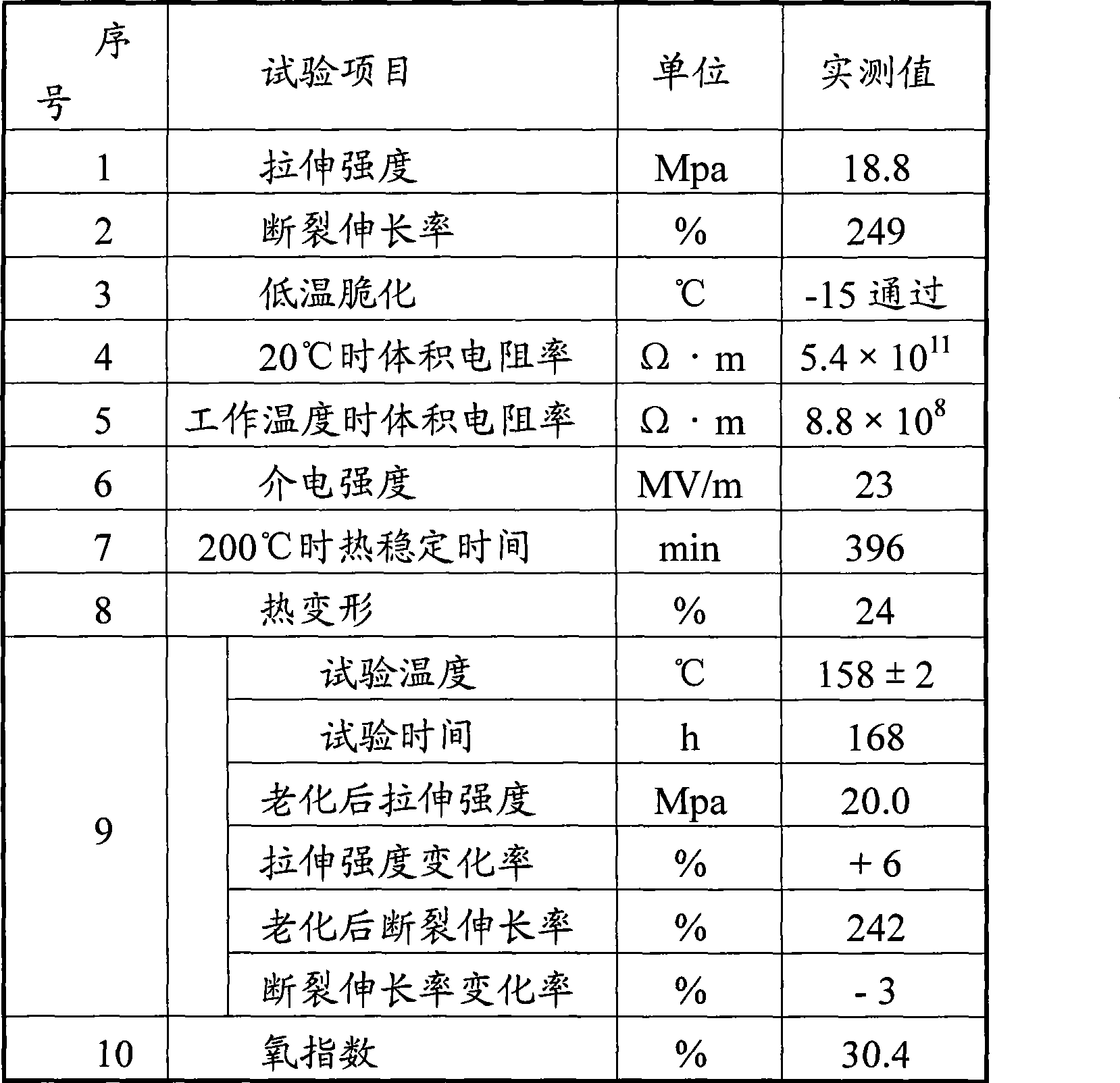

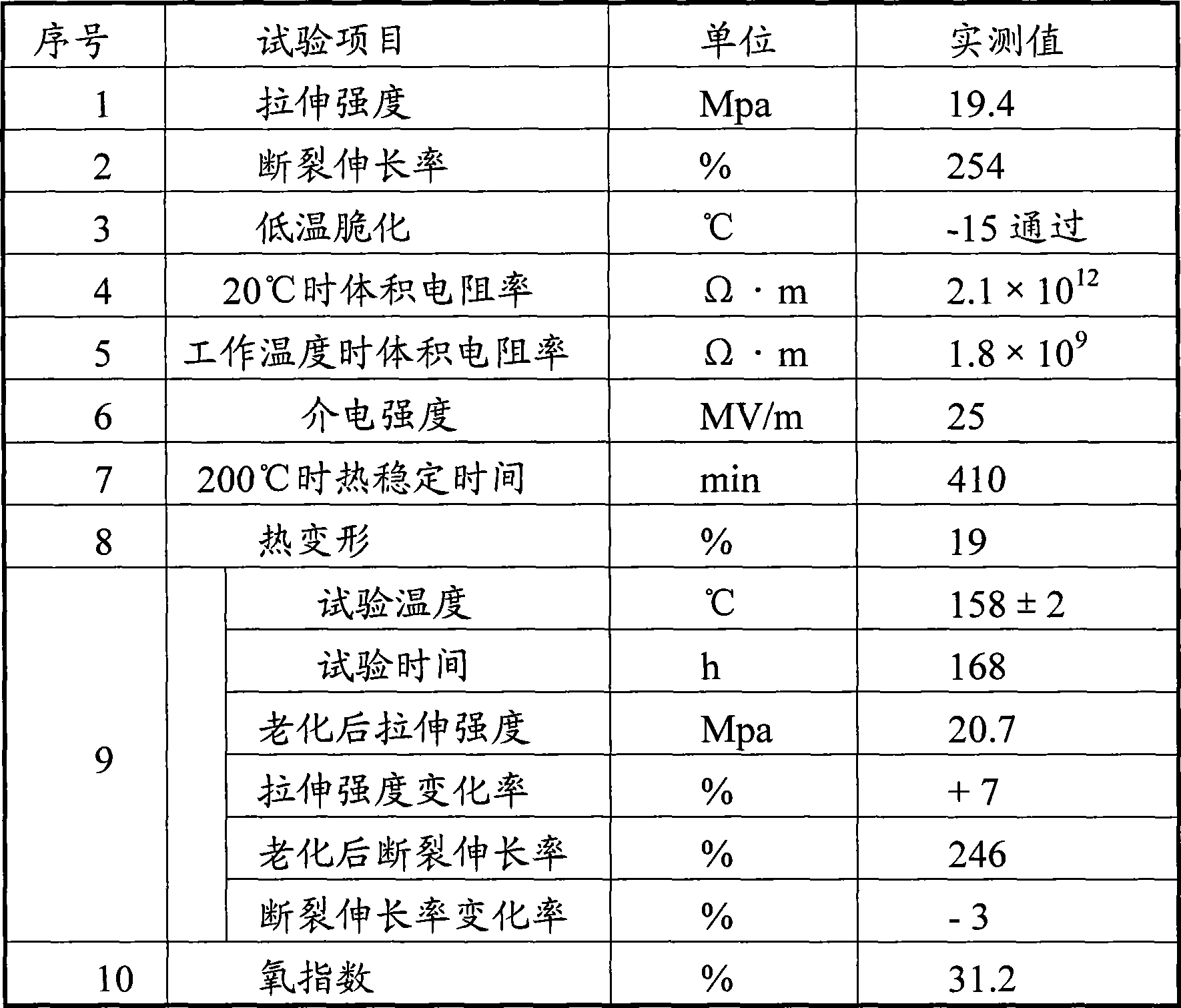

The invention provides a high-temperature resistant environment-friendly polyvinyl chloride material for wires and cables. A raw material formulation mainly comprises the following materials in weight portion: 80 to 120 portions of loose-type polyvinyl chloride resin, 20 to 55 portions of tetraoctyl pyromellitate, 5 to 35 portions of polyester plasticizer and 12 to 18 portions of calcium-zinc stabilizer, wherein the polymerization degree of the loose-type polyvinyl chloride resin is between 2,000 and 3,000; in the calcium-zinc stabilizer, the total content of lead, cadmium, mercury and hexavalent chromium is less than or equal to 10 ppm of the total weight of the calcium-zinc stabilizer; the polyester plasticizer is polypropylene-1, 2-glycol adipate or polypropylene-1, 3-butylene terephthalate; and the molecular weight of the polyester plasticizer is between 3,000 and 4,000. After the material is aged in a hot-air oven for 168 hours at 158 DEG C, the retention rate of tensile strength is up to 106 percent; the retention rate of elongation at break is 97 percent; and the material is good in mechanical physical properties and insulating property. Therefore, the material meets the temperature-resistant requirement on long-term operating temperature at 125 DEG C in UL1581.

Owner:中广核三角洲(江苏)塑化有限公司

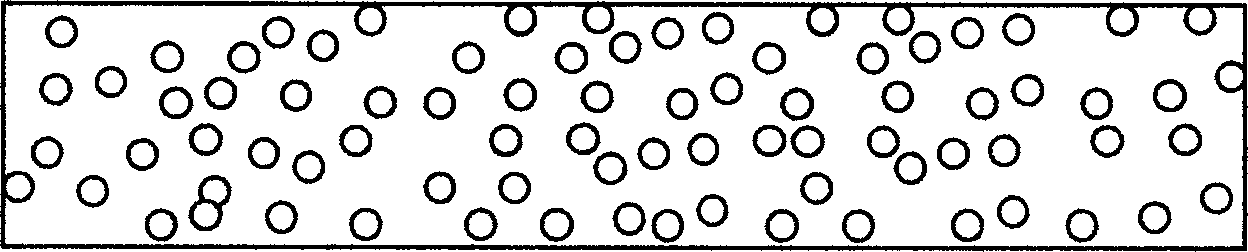

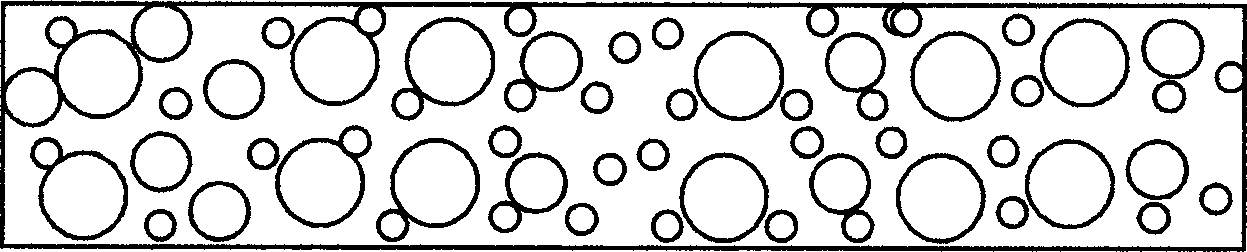

Multimode organic filler/polymer composite damping material and manufacturing method thereof

InactiveCN103897287AImprove shock absorptionImprove heat and aging resistanceSound energyRelaxation effect

The invention relates to a multimode organic filter / polymer composite damping material and a manufacturing method thereof, relates to the field of soundproof materials, aims to solve the problems that in the prior art high efficient soundproof materials do not have a prominent effect, and generate harmful gas, which harms the human health; and provides a multimode inorganic filler / polymer composite damping material. The damping material comprises the following materials: thermoplastic resin and an inorganic filler, which has been subjected to a surface treatment with a coupling agent processing fluid; wherein the inorganic filter accounts for 15 to 80 wt% of the total weight of the damping material, and the balance being thermoplastic resin. In the damping material, the binding between each particle is abnormal, thus the internal friction between incident sound waves in this structure is effectively increased, thus a relaxation effect is generated, and the sound is absorbed. Fillers with different particle sizes are corresponding to sound waves in different bandwidths or frequencies, so sounds in different frequencies can all be absorbed by the damping material, and moreover the damping material has a good soundproof effect, and is suitable for promotion and application.

Owner:浙江艾迪雅科技有限责任公司

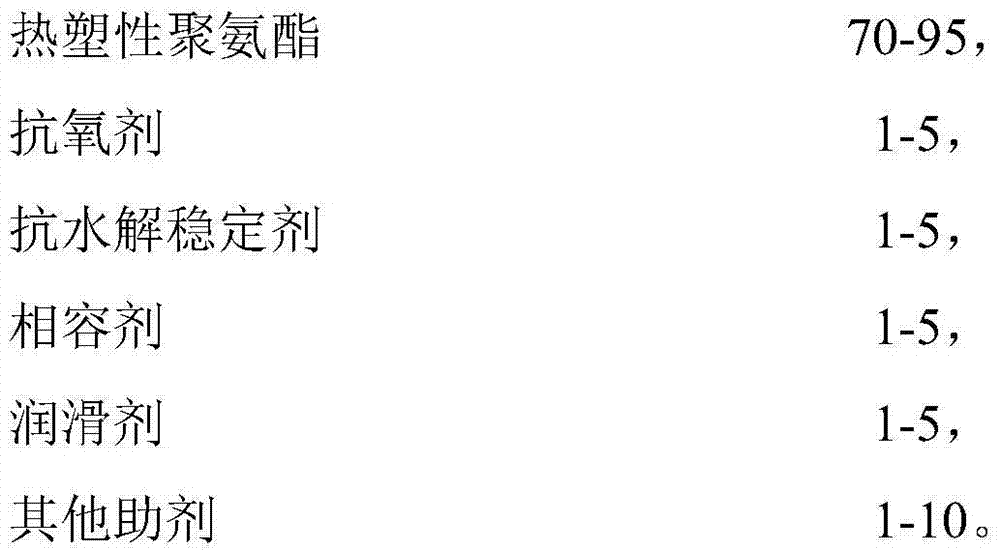

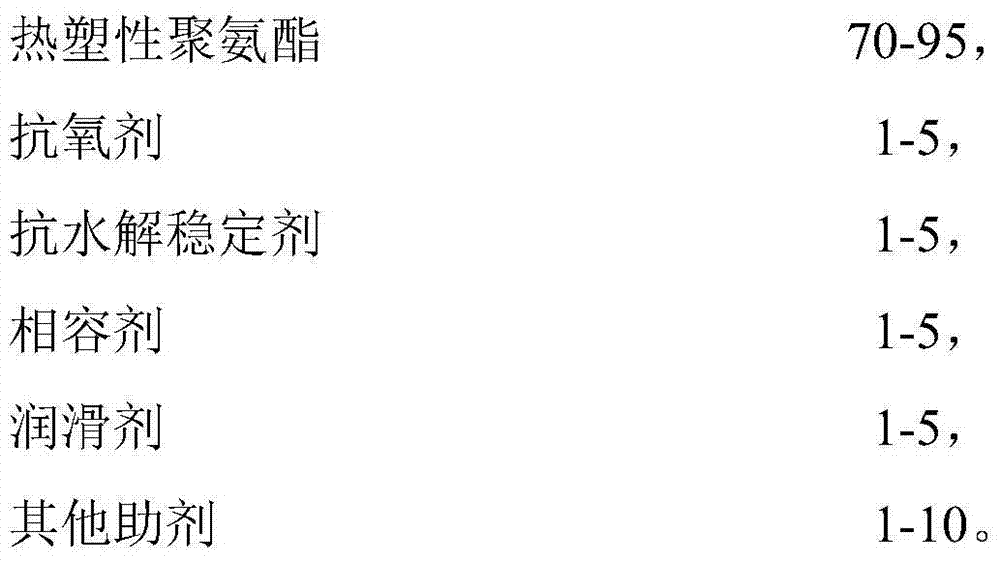

Thermoplastic polyurethane modified composite material for FDM (frequency division multiplexing) 3D printing and preparation method thereof

The invention relates to a thermoplastic polyurethane modified composite material for FDM (frequency division multiplexing) 3D printing and a preparation method thereof. The composite material is prepared from the following components in parts by weight: 70-95 parts of thermoplastic polyurethane, 1-5 parts of antioxidant, 1-5 parts of hydrolysis-resistant stabilizer, 1-5 parts of compatilizer, 1-5 parts of lubricant and 1-10 parts of other assistant. Compared with the prior art, the antioxidant, hydrolysis-resistant stabilizer, lubricant and other assistants are added, so that the modified composite material has the advantages of favorable mechanical properties, high elasticity, favorable wear resistance, higher heat stability, hydrolysis resistance, higher oxidation resistance and higher processability. When being used for FDM 3D printing, the thermoplastic polyurethane modified composite material has the characteristics of smooth printing process, no odor, smooth printing product surface, beautiful appearance, stable size, low tendency to shrinkage, favorable mechanical properties, high flexibility, high heat stability, high hydrolysis resistance, high oxidation resistance and high processability.

Owner:SHANGHAI RES INST OF MATERIALS CO LTD

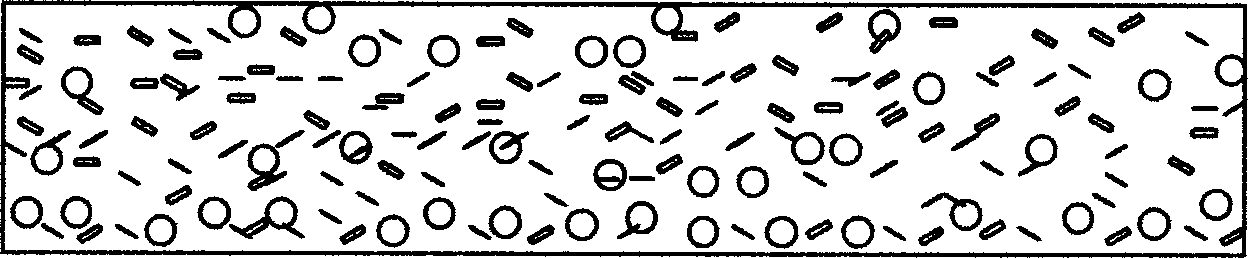

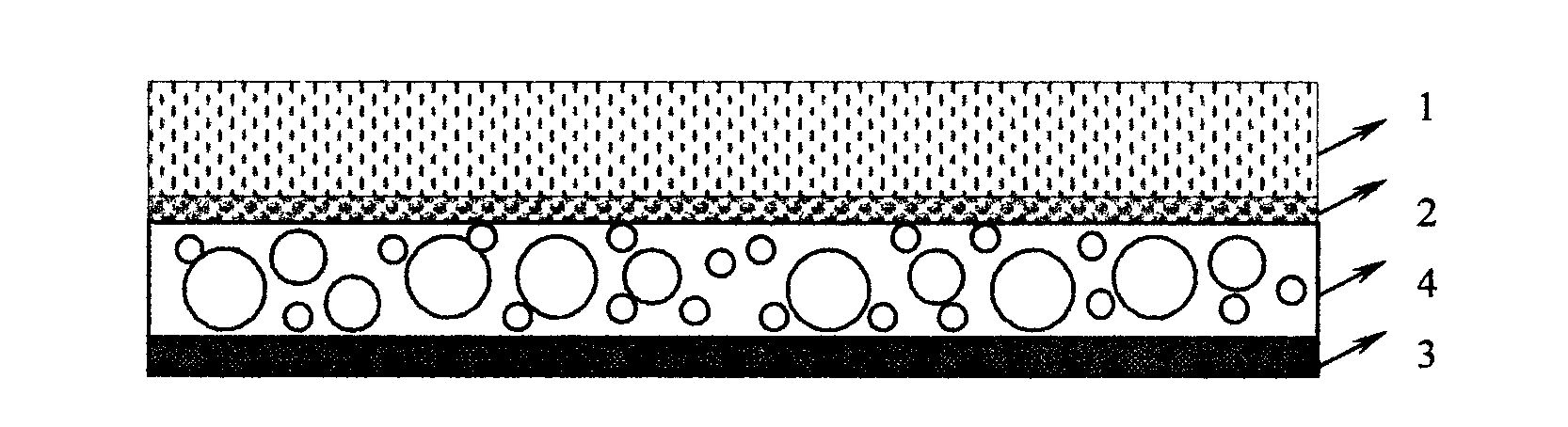

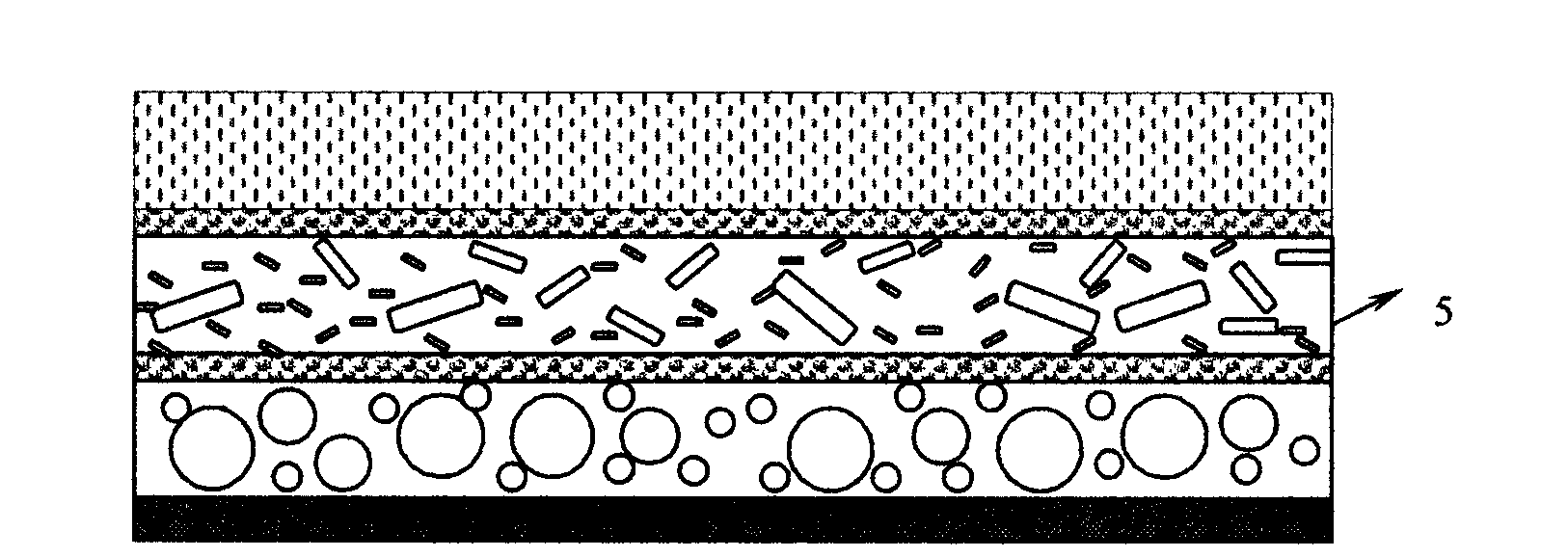

Efficient sound insulation material and manufacturing method thereof

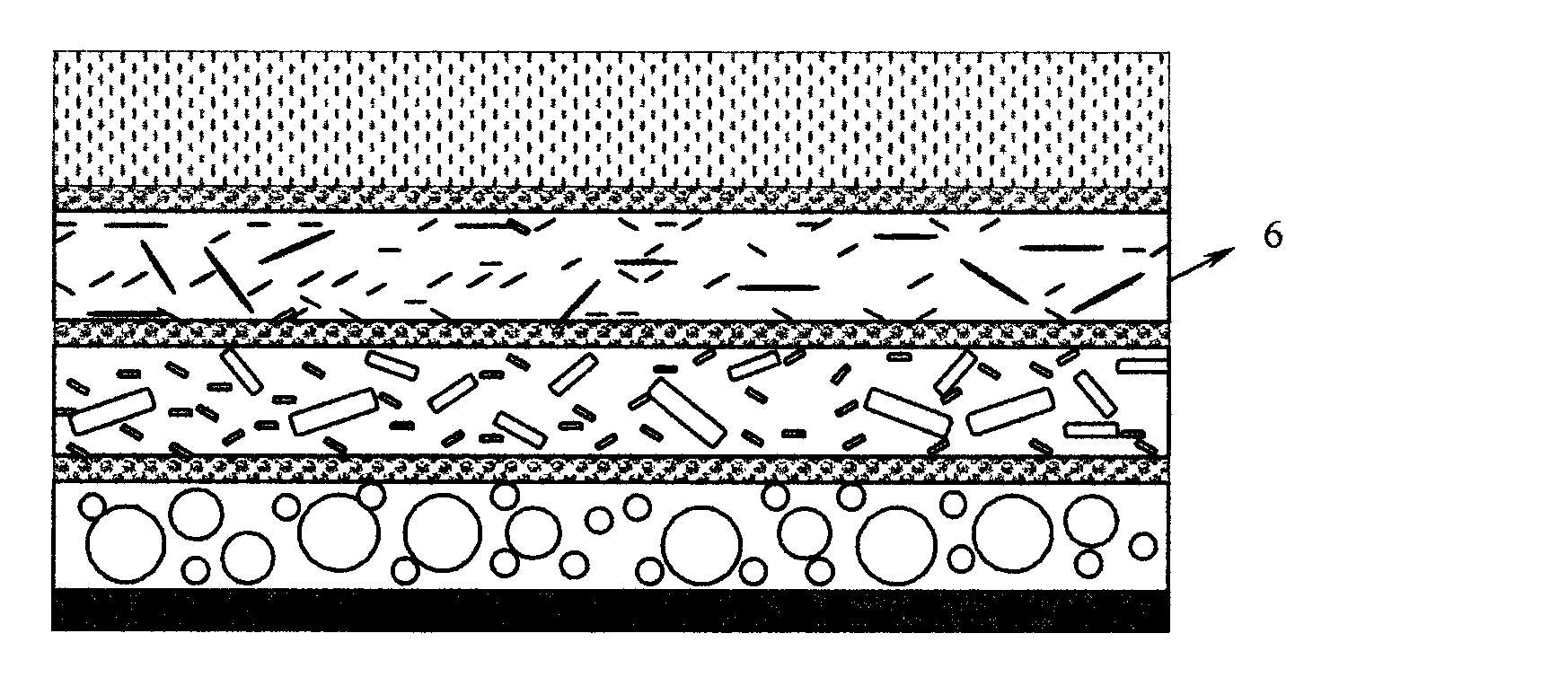

InactiveCN103903608AImprove heat and aging resistanceExcellent ozone resistanceSynthetic resin layered productsSound producing devicesInsulation layerFoaming agent

The invention relates to the field of products of sound insulation material, solves the problems in the prior art that the sound insulation material is poor in sound insulation effect, is incomprehensive in high and low frequency sound insulation, causes pollution and is easy to age, and provides an efficient sound insulation material and a manufacturing method thereof. The efficient sound insulation material includes a sound insulation layer, a sound absorption layer, and a bubble layer, wherein the bubble layer is located between the sound insulation layer and the sound absorption layer. The sound absorption layer is made of a sound insulation compound, and the sound insulation compound is prepared by raw materials of the following substances: a thermoplastic resin, inorganic fillers, and a foaming agent, wherein the inorganic fillers account for 15-80wt%, the foaming agent accounts for 5-15wt%, and the rest is the thermoplastic resin. In the efficient sound insulation material, the fillers with different particle diameters correspond to sound waves of different wave bands or frequencies, and thus consumption of sound energy of different frequencies is relatively comprehensive, and the sound insulation effect is good, so the sound insulation material is suitable for popularization and application.

Owner:浙江艾迪雅汽车部件新材料有限公司

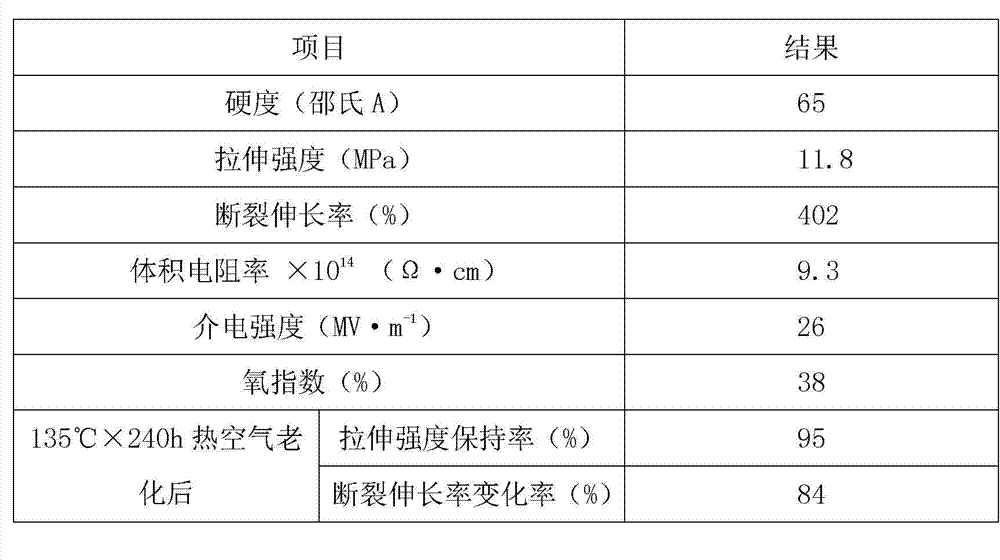

All-steel giant-scale engineering tyre side glue and all-steel giant-scale engineering tyre using the same

The present invention relates to a tyre side rubber with perfect ozone resistance, thermo-oxidative ageing resistance and flex crack resistance, applying ethylene -propylene-diene rubber in single-layer huge full steel engineering tyre; the invention also relates to the full steel huge engineering tyre using the tyre side rubber. The full steel huge engineering tyre using the tyre side rubber of the present invention comprises usable sulfur and / or sulfur rubber mixture, the rubber mixture comprises: a. 10-30 parts by weight of ethylene -propylene-diene rubber; b. 50-90 parts by weight of caoutchouc; c. 0-20 parts by weight of butadiene rubber and / or styrene butadiene rubber; and the total content of the ethylene -propylene-diene rubber, caoutchouc, butadiene rubber and / or styrene butadiene rubber is 100 parts by weight compositions. The tyre side rubber produced according to the formula has perfect ozone resistance, thermo-oxidative ageing resistance and flex crack resistance, the rigidity of the rubber material of the tyre side rubber is 55-70 Shore A, the tension intensity is 15-25 Mpa, the flex crack resistance grade is less than or equal to 6 grade / 300000 times.

Owner:HAOHUA SOUTH CHINAGUILIN RUBBER

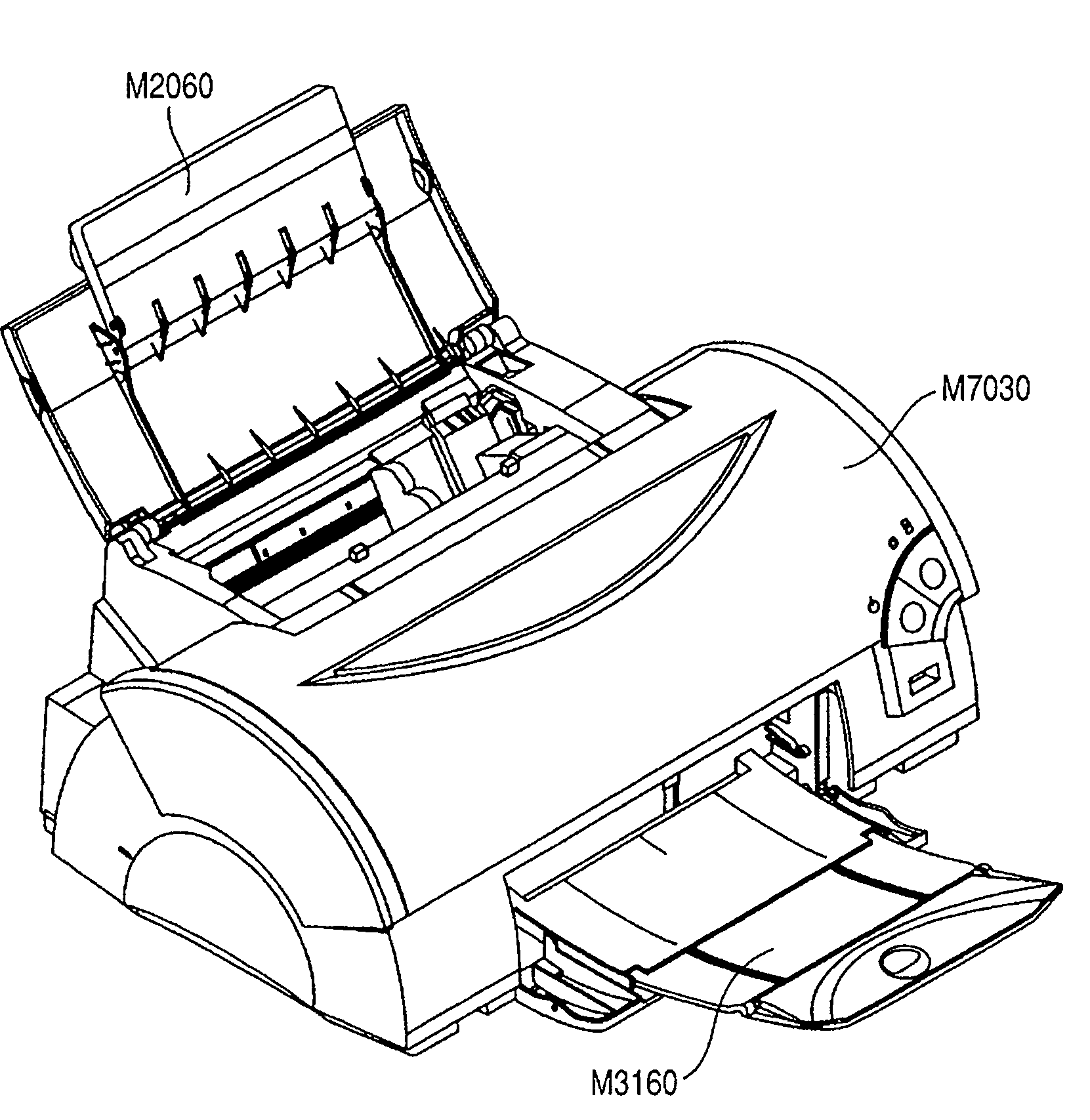

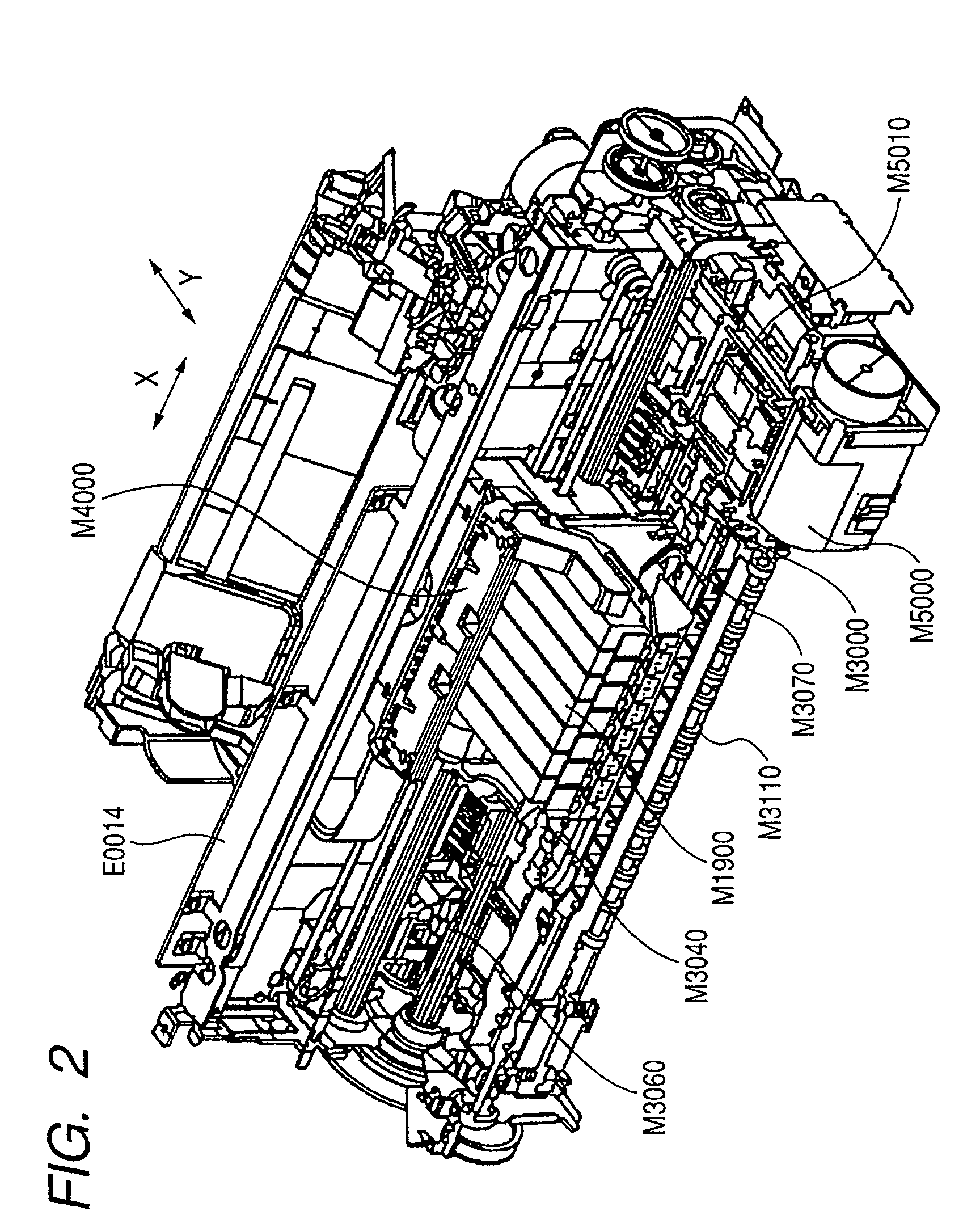

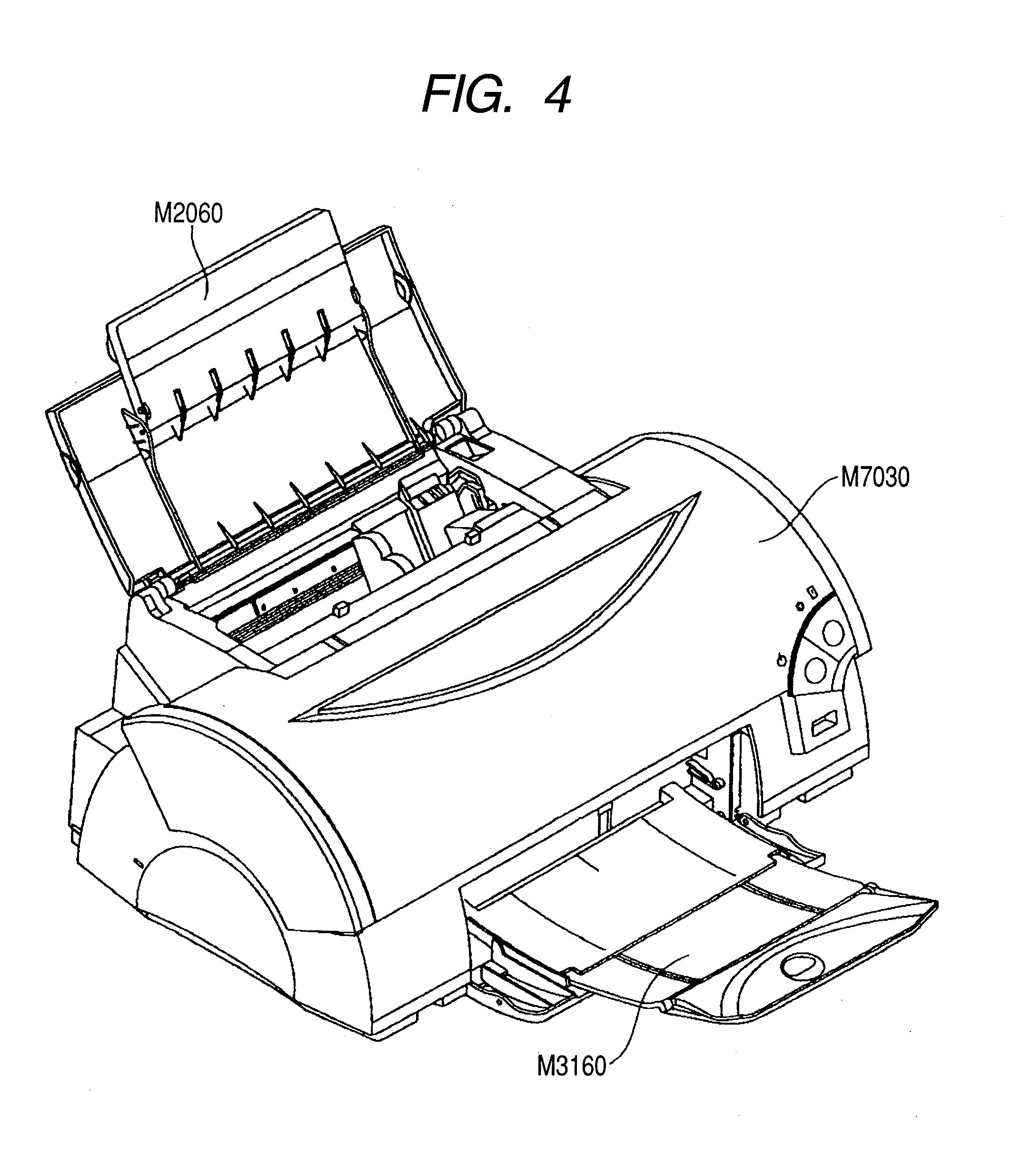

Ink jet black ink, ink set, ink jet recording method, ink cartridge, recording unit, and ink jet recording apparatus

InactiveUS7247196B2Good colorHigh dye concentrationMeasurement apparatus componentsDuplicating/marking methodsDecompositionDiethylene glycol

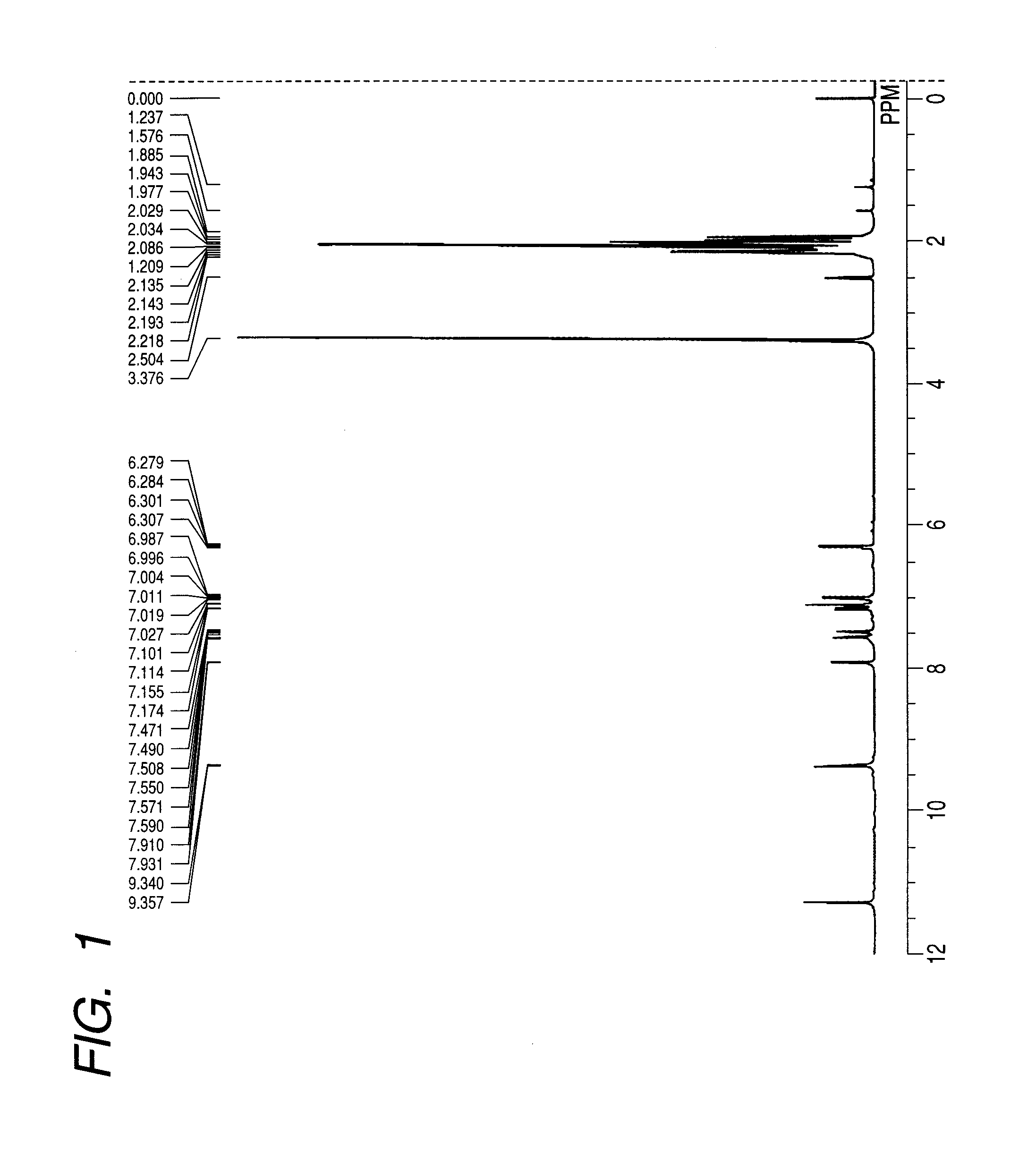

To provide an ink jet black ink which has a favorable tint for ink jet black ink, provides high ozone fastness, a high image density, and high sticking recovery property, and is capable of suppressing the decomposition of a compound represented by the following general formula (I) or a salt thereof at the time of storage for a long time period. The ink jet black ink is an ink jet black ink comprising at least a compound represented by the following general formula (I) or a salt thereof as a coloring material, and ethylene glycol or diethylene glycol, wherein the content of ethylene glycol or diethylene glycol is 15 mass % or more and 30 mass % or less with respect to the total mass of the ink jet black ink.General formula (I)

Owner:CANON KK

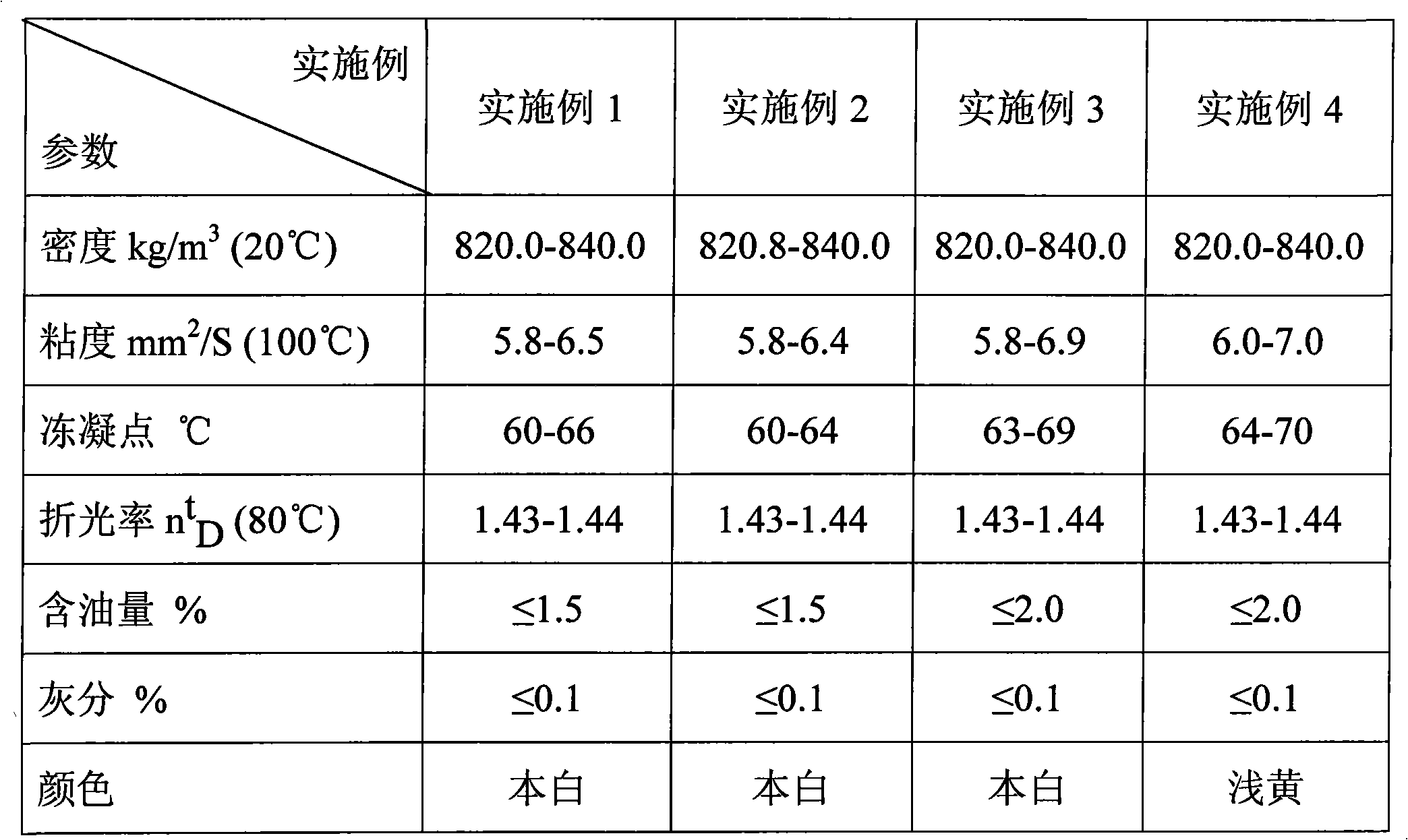

Novel rubber protective wax

The invention discloses a novel rubber protective wax which comprises the following components in percentage by weight: 14-20 percent of paraffin, 55-60 percent of mixed crystal wax, 24-30 percent ofmicrocrystalline wax and 1-2 percent of polyethylene wax. The invention has favorable seal performance and can reinforce the ozone and ageing resistance of a rubber product and prolong the service life of the rubber product.

Owner:上海绿菱特种蜡制品厂

Thermoplastic low-smoke halogen-free flame-retardant environment-friendly sheath material for power cables and preparation method thereof

ActiveCN103122097ADoes not affect physical and mechanical propertiesDoes not affect processabilityInsulated cablesPigment treatment with macromolecular organic compoundsCrack resistanceDimethyl methylphosphonate

The invention discloses a thermoplastic low-smoke halogen-free flame-retardant environment-friendly sheath material for power cables and a preparation method thereof. The thermoplastic low-smoke halogen-free flame-retardant environment-friendly sheath material for power cables comprises the following components in parts by weight: 60-80 parts of EVA (ethylene-vinyl acetate), 20-30 parts of HDPE (high-density polyethylene), 10-15 parts of EPDM (ethylene-propylene-diene monomer), 15-25 parts of compatiblizing agent, 100-150 parts of halogen-free flame retardant, 0.5-1 part of antioxidant 1035, 0.5-1 part of antioxidant DSTP, 1-2 parts of ethylene bis stearamide, 3-5 parts of DCP (dicumyl peroxide), 2-4 parts of zinc oxide, 1-2 parts of calcium stearate, 10-20 parts of dimethyl methyl phosphonate, 30-40 parts of nano kaolin, 2-3 parts of stearic acid and 0.5-1 part of isopropyl tri(dioctylpyrophosphate)titanate. The sheath material disclosed by the invention has the advantages of excellent physical and mechanical properties, excellent flame retardancy, favorable high / low temperature resistance, favorable oil resistance, favorable solvent resistance, favorable wear resistance, favorable ozone resistance, favorable aging resistance, high flexibility, crack resistance and the like, is very durable, environment-friendly and pollution-free, and can completely satisfy the requirements for modern power cables.

Owner:ANHUI HUAJIN CABLE GROUP

High temperature resistance non halogen flame retardant cable sheath material and preparation method thereof

ActiveCN101613506AImprove temperature resistanceOvercome the problem of not being able to prepare high temperature resistant halogen-free flame retardant cable sheathing materialsRubber insulatorsPolymer scienceVulcanization

The invention discloses a high temperature resistance non halogen flame retardant cable sheath material and a preparation method thereof. The high temperature resistance non halogen flame retardant cable sheath material comprises the following components with the following parts by weight: 100 parts of ethylene-propylene-diene monomer (EPDM), 1.5-6 parts of vulcanizing agent, 1.5-6 parts of co-vulcanization agent, 0.5-5 parts of coupling agent, 4-20 parts of antiager, 4-30 parts of softener and 80-250 parts of inflaming retarding filling agent. In the invention, the halogen-free material is adopted, thick smoke, corrosive halogenide gas and other harmful substances are not generated in the process of burning; the cable sheath of the invention features excellent elasticity and tenacity, not only has obvious inflaming retarding effect, but also improves heat-resisting and anti-aging properties, can resist high temperature, and has high mechanical strength and wide application range; in addition, the production process is easy and is convenient for rubber-producing enterprises to achieve self-sufficiency.

Owner:SICHUAN MINGXING CABLE

High-pressure self-packing leather cup rubber for packer and preparation method thereof

The invention discloses high-pressure self-packing leather cup rubber for a packer. The high-pressure self-packing leather cup rubber is prepared from the following raw materials in parts by weight: 30-40 parts of nitrile rubber, 20-30 parts of isoprene rubber, 20-40 parts of ethylene propylene terpolymer 5962 (LANXESS Deutschland), 10-15 parts of fluorosilicone rubber, 3-5 parts of natural rubber, 30-40 parts of high abrasion furnace black N330, 10-15 parts of modified white carbon black, 3-4 parts of antimony trioxide, 8-10 parts of modified wood ash, 4-6 parts of attapulgite, 4-6 parts of meerschaum, 9-11 parts of modified iron tailing slag powder, 0.5-1 part of stearic acid, 0.5-1 part of isocyanate, 0.2-0.4 part of accelerant DM, 0.3-0.6 part of accelerant BZ, 1-2 parts of calcium stearate, 2-4 parts of zinc oxide, 0.2-0.4 part of ferrocene, 1-2 parts of polyethylene wax, 1-2 parts of antioxidant DSTP, 1-2 parts of anti-aging agent, 2-3 parts of coupling agent DL-151 and 16-18 parts of epoxy linseed oil. The rubber disclosed by the invention has excellent ozone resistance, excellent low temperature resistance and heat resistance and is large in operating temperature range and environment-friendly in process, so that the rubber can be used for preparing various packing materials.

Owner:WUHU HENGKUN AUTO PARTS

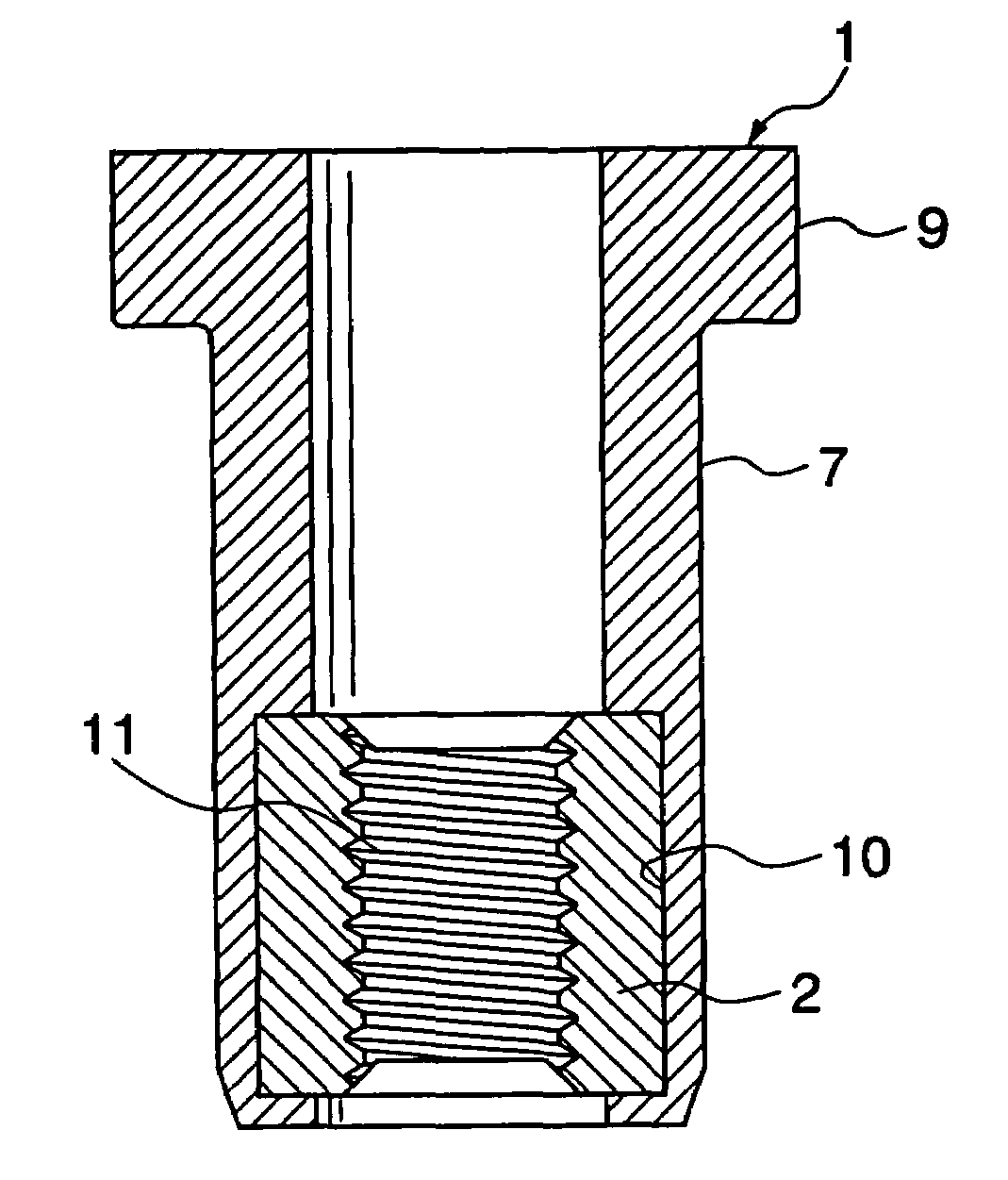

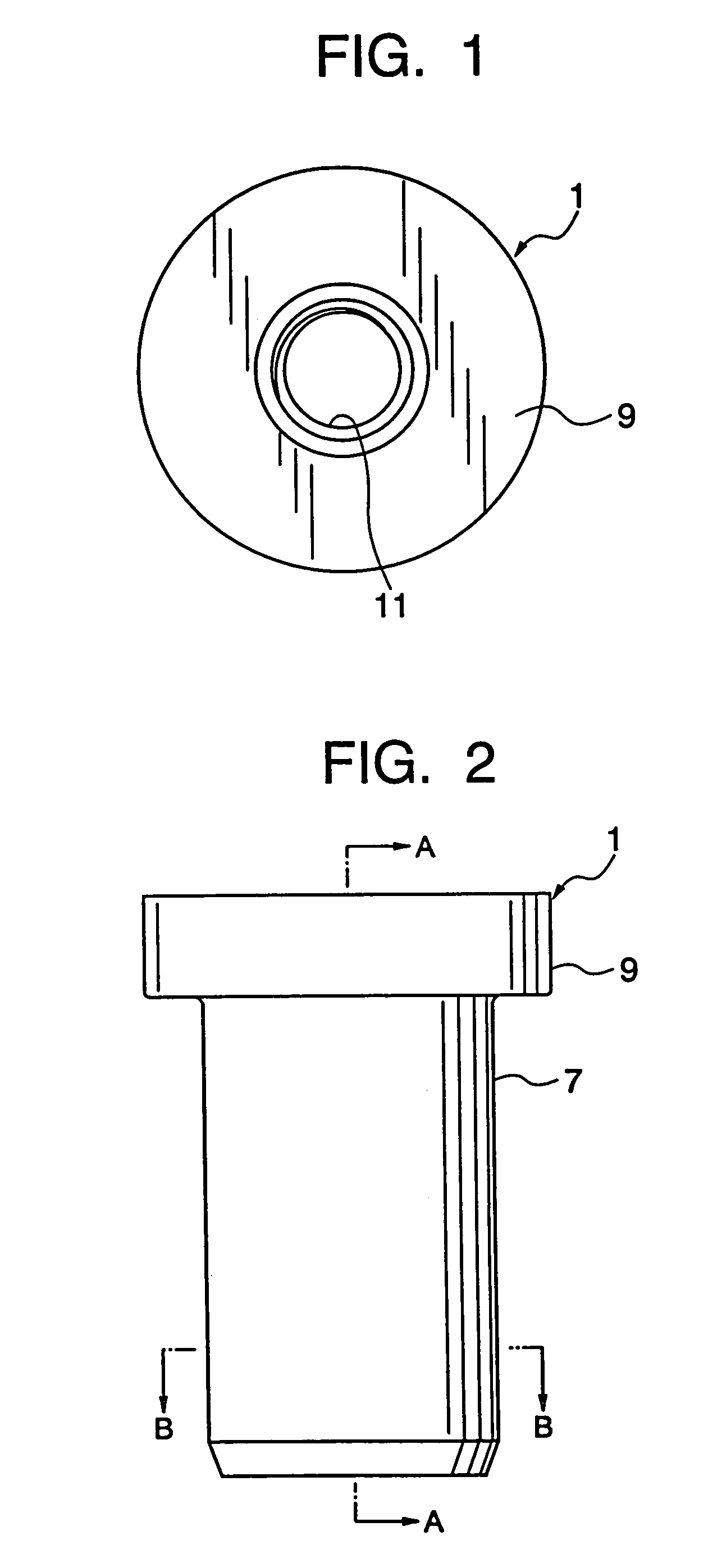

Elastic fastener

An elastic fastener 1 comprises a hollow tubular portion 7, an internally threaded portion 2 provided at one of the ends of the tubular portion 7, and a flange 9 formed at the other end of the tubular portion 7. The tubular portion 7 and the flange 9 are integrally formed of an elastomeric material, such as a styrene-based elastomer, a polyamide-based elastomer and a polyester-based elastomer. The internally threaded portion 2 is formed of a rigid resin material such as a polycarbonate resin. The internally threaded portion 2 is integrally fixed to the tubular portion 7 in a hole of the tubular portion.

Owner:NEWFREY

Heat-conducting silicone rubber electronic casting glue and preparation method and application thereof

InactiveCN103756327AExcellent weather resistanceImprove thermal conductivityCell component detailsChemistryWeather resistance

The invention relates to the technical field of organic silicone rubber, and aims to solve the problems of poor liquidity and heat-conducting property of an existing silicone rubber electronic casting glue. The invention provides a heat-conducting silicone rubber electronic casting glue and a preparation method thereof. The casting glue is prepared by mixing a glue A and a glue B, has excellent weather resistance, heat resistance, ozone resistance, high heat-conducting property and excellent flow properties, and is used for sealing of lithium battery materials.

Owner:HANGZHOU SILICONE WAY TECH

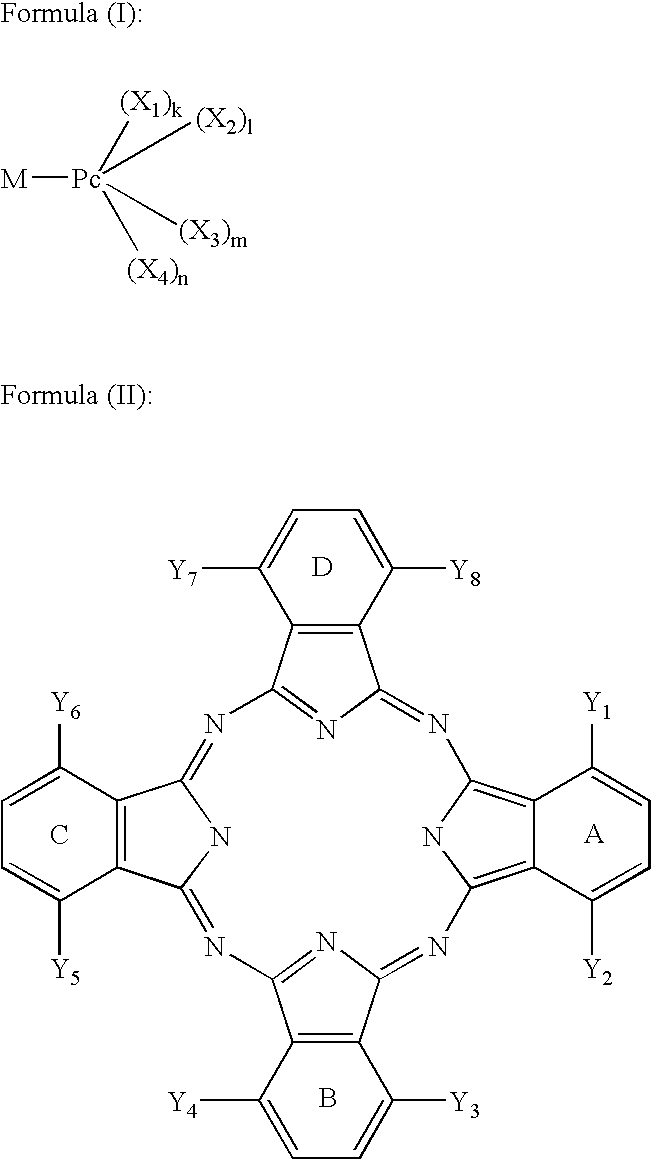

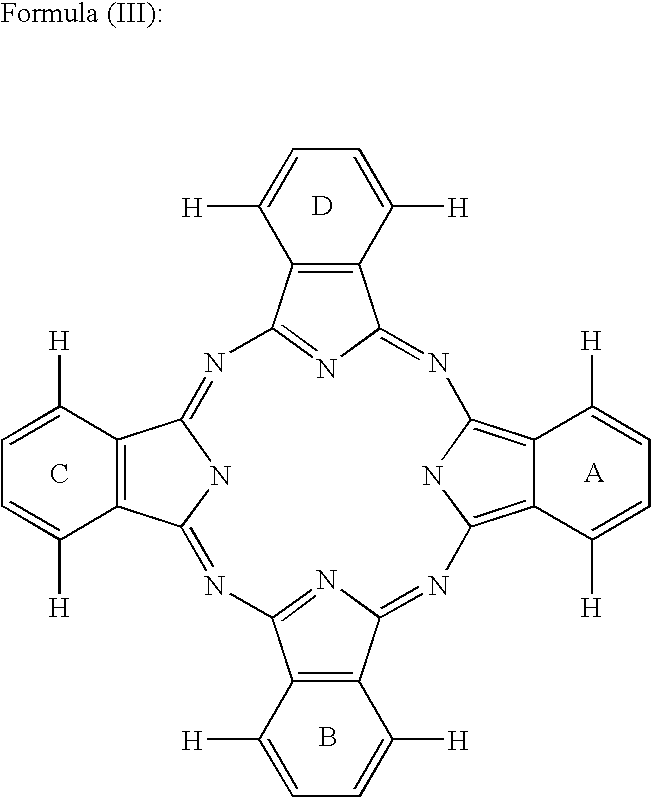

Dye mixture and ink containing the same

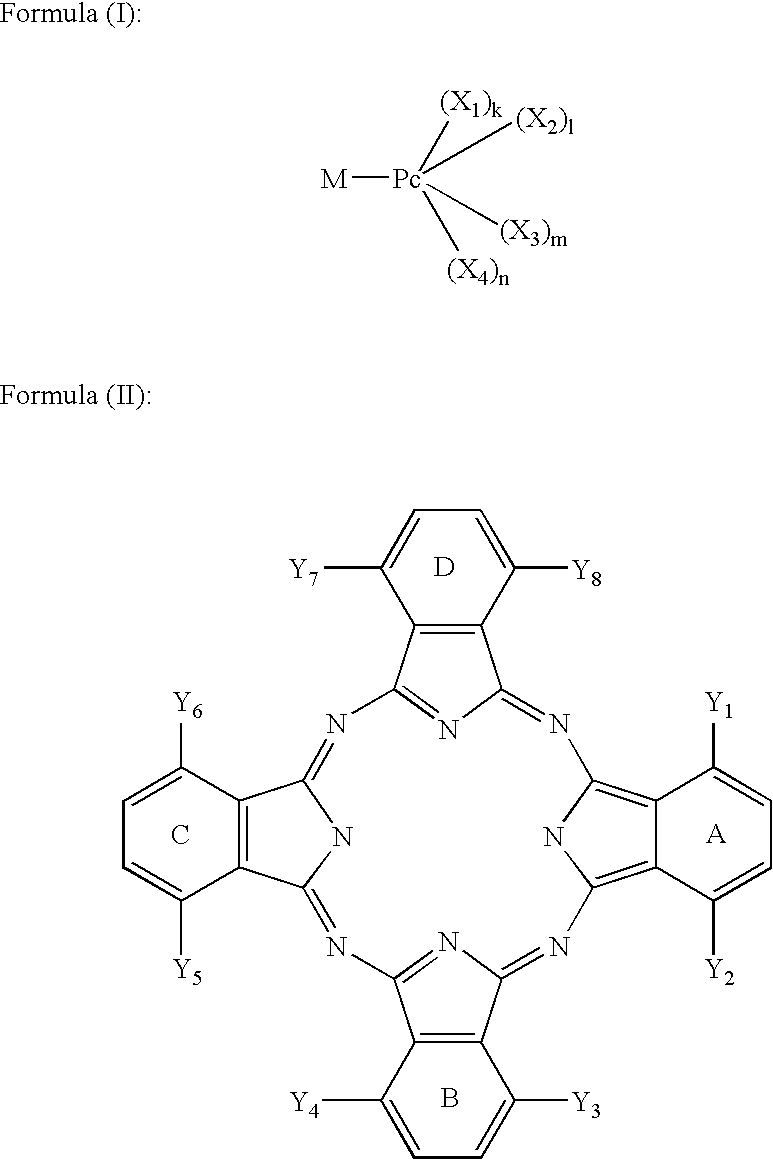

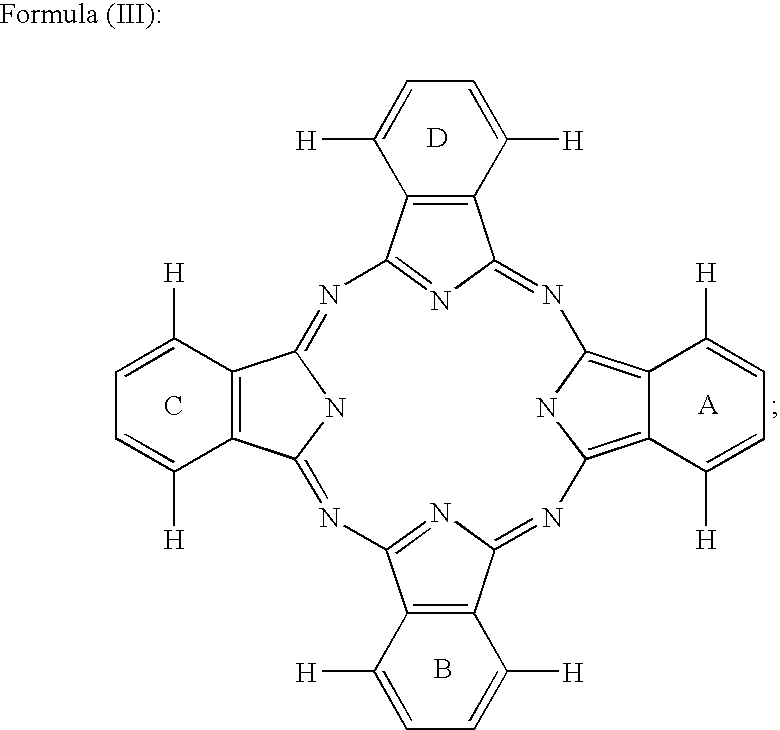

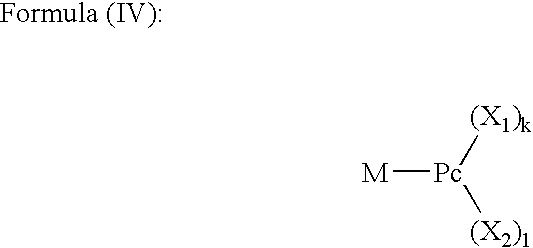

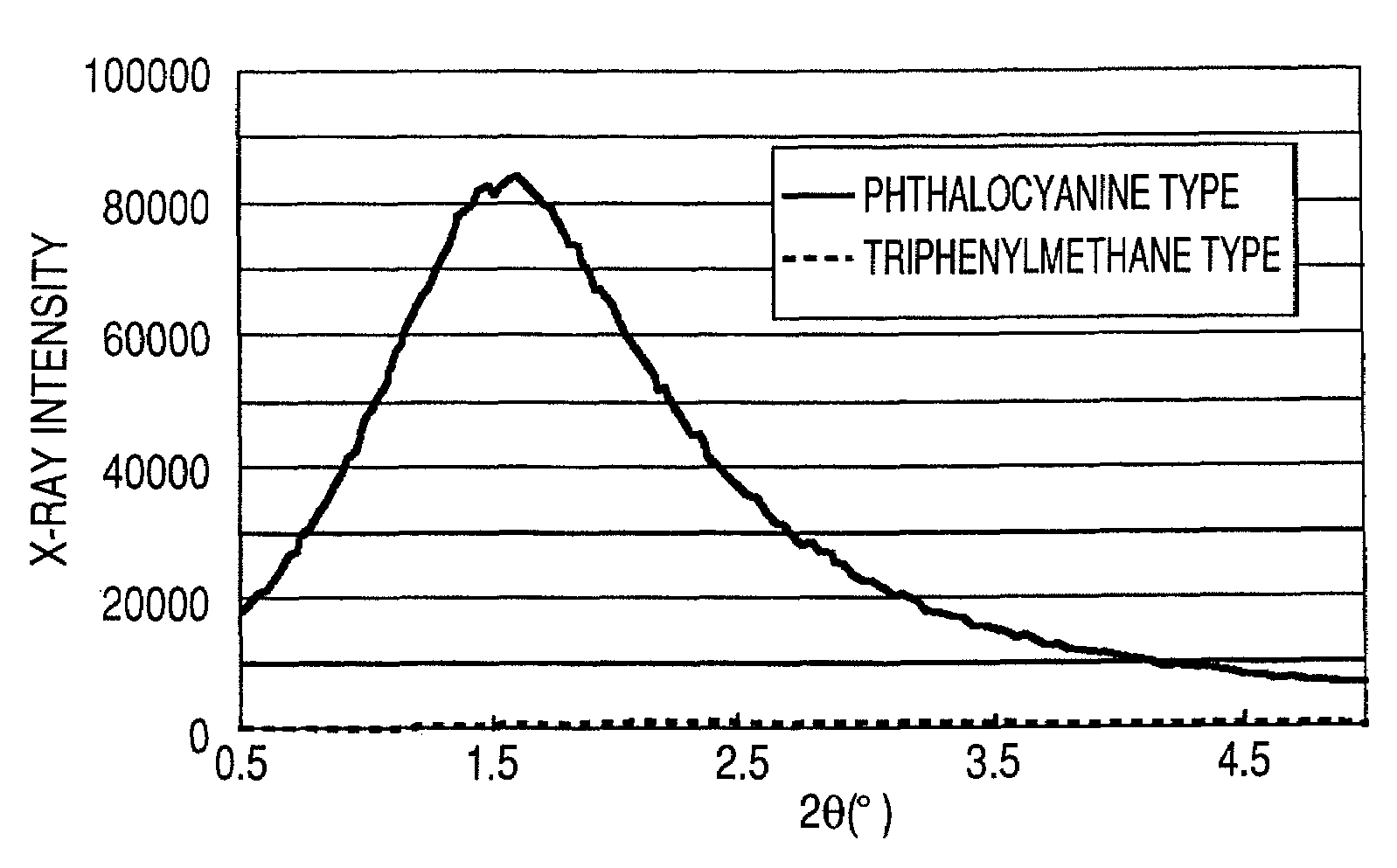

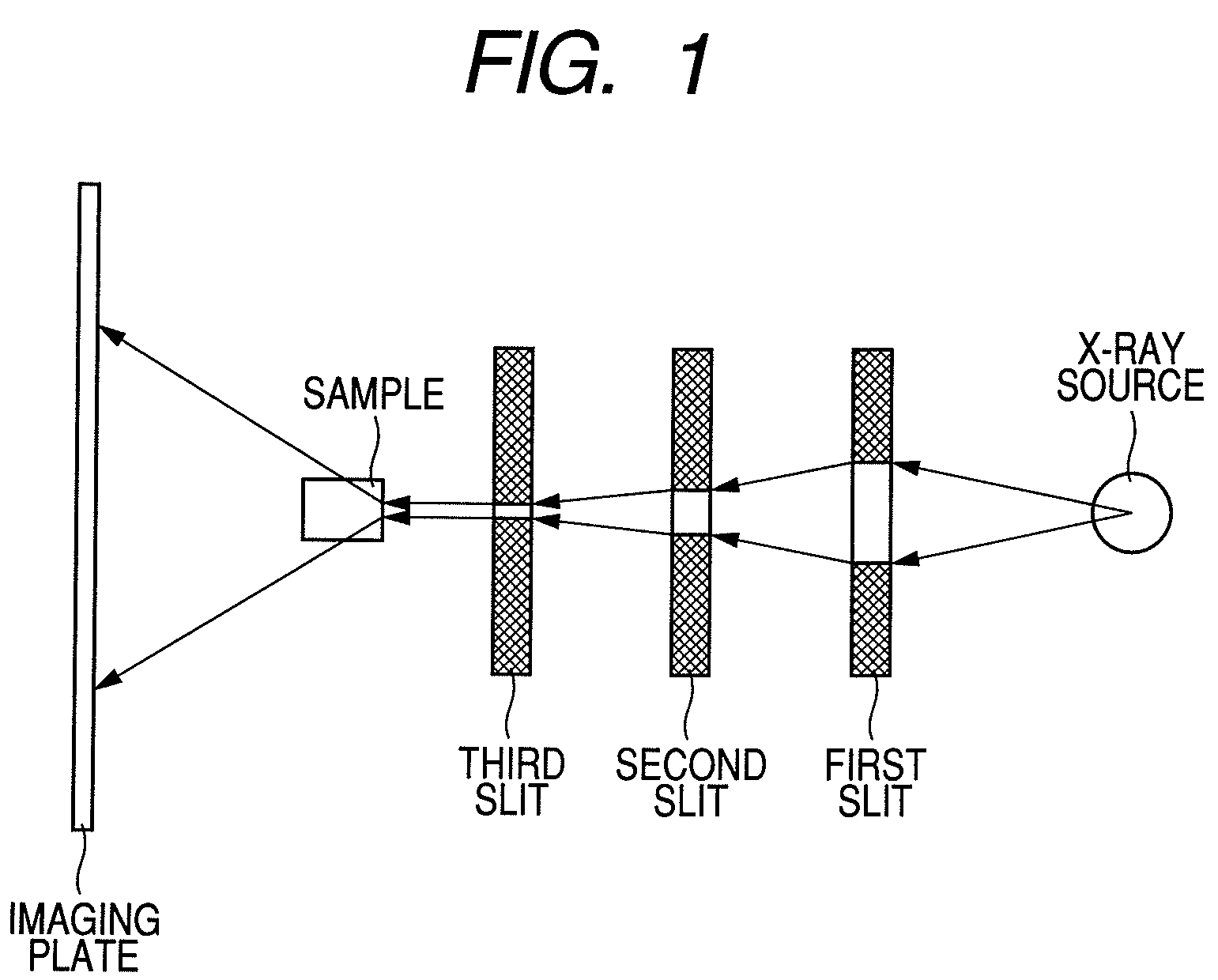

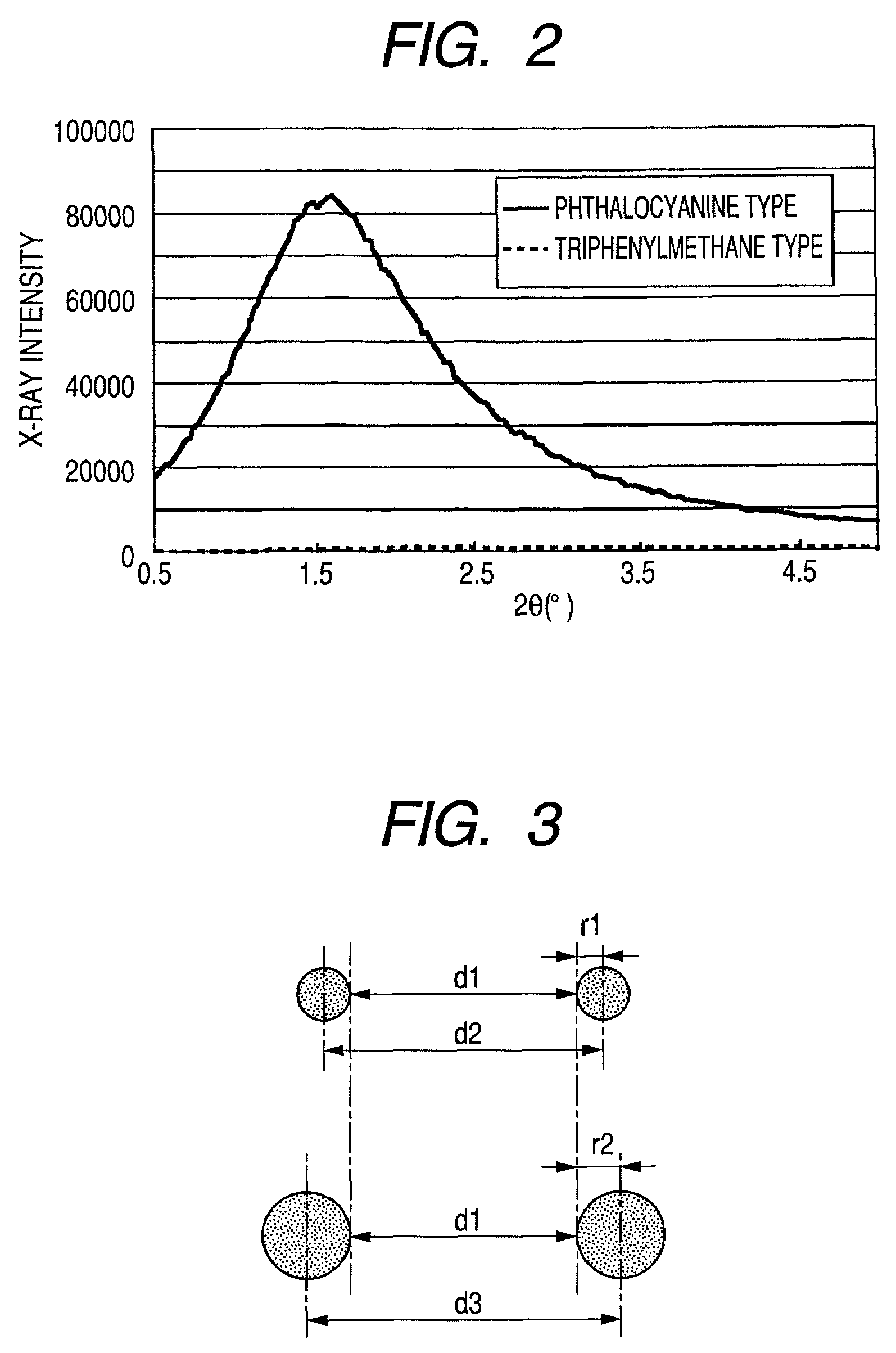

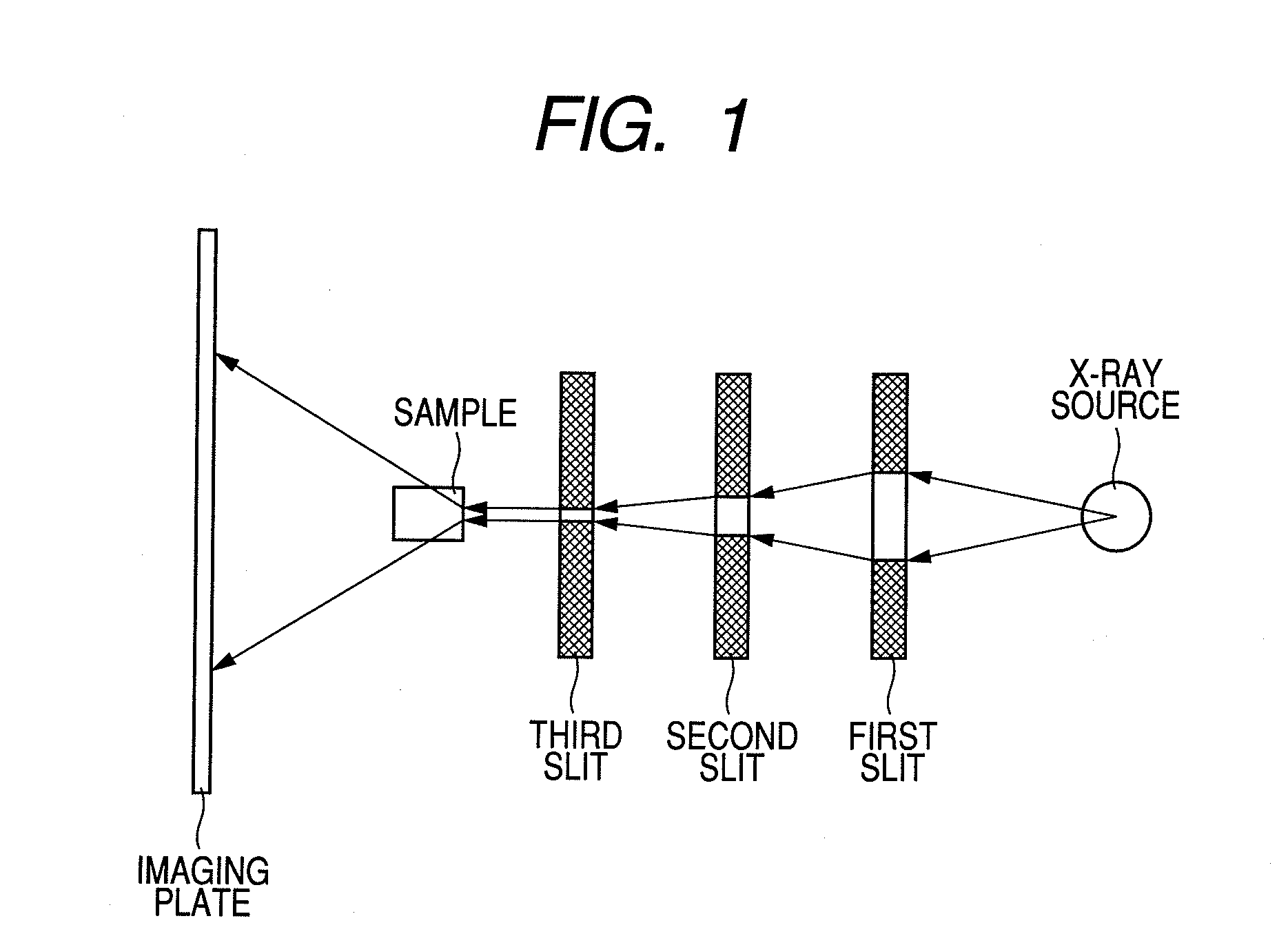

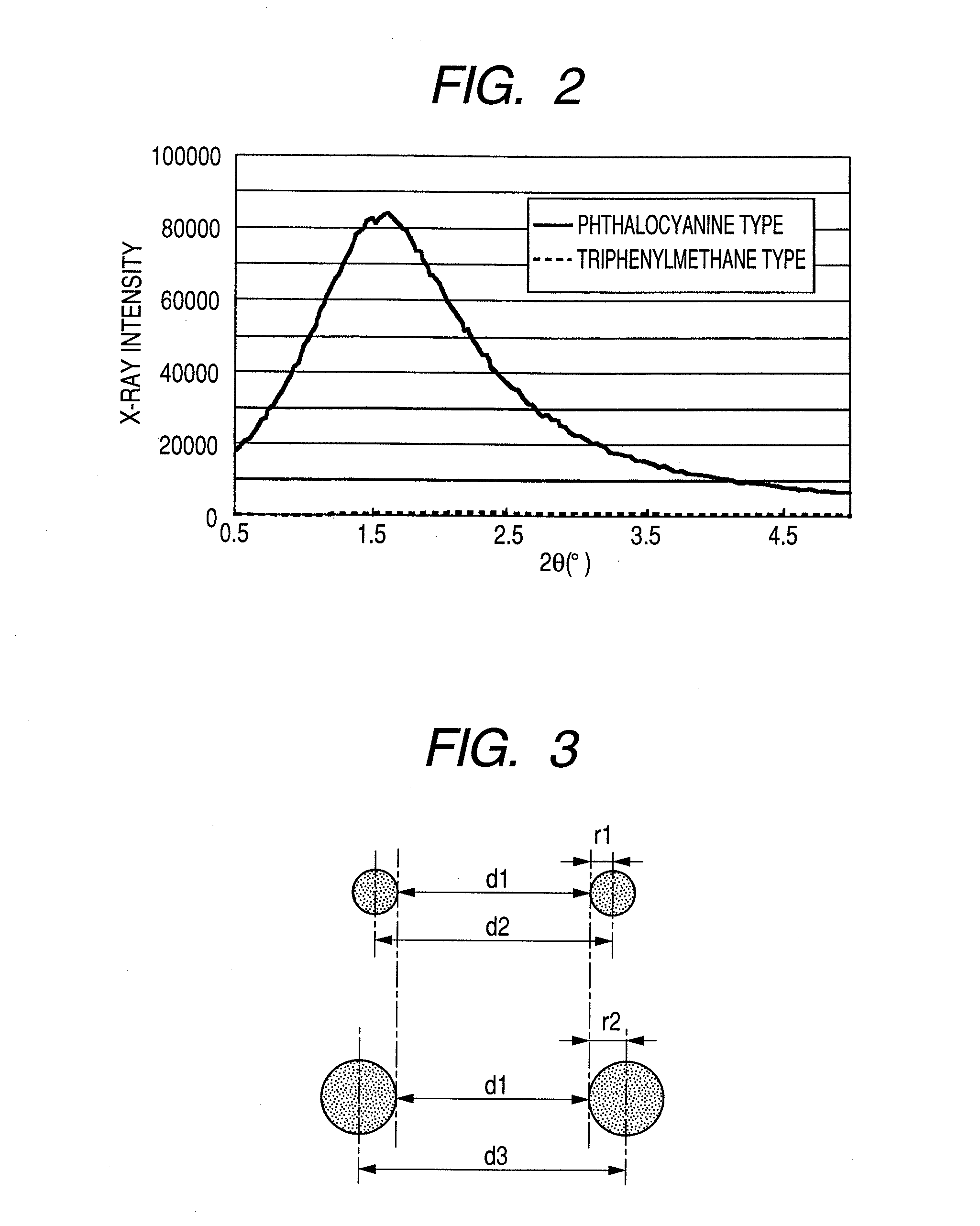

InactiveUS7211134B2Excellent ozone resistanceInksPorphines/azaporphinesPhthalocyanine dyePhotochemistry

A novel compound having sufficiently high fastness to light, heat, humidity and active gas in the environment and a coloring composition using the compound, particularly, an ink for ink jet recording, an ink jet recording method and a method for improving the preservability of formed image, which can form an image having high fastness to light and ozone gas in the environment. A phthalocyanine dye mixture having a specific structure and an ink, an ink for ink jet recording, an ink jet recording method and a method for improving the preservability of formed image, using the phthalocyanine dye mixture.

Owner:FUJIFILM CORP

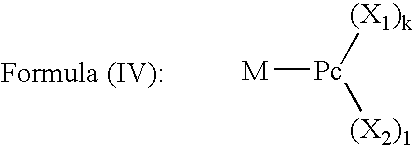

Ink, ink jet recording method, ink cartridge, recording unit, and ink jet recording apparatus

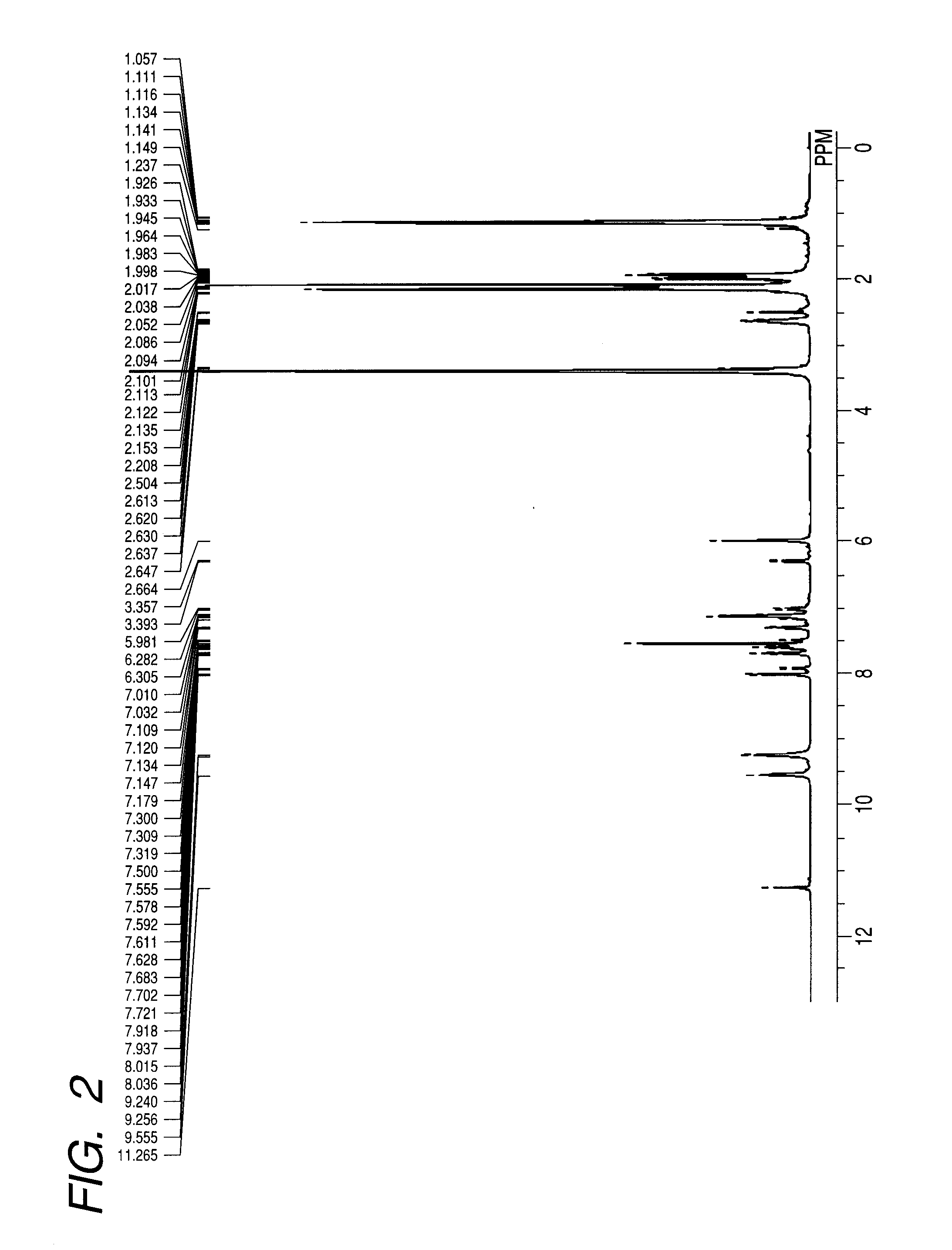

ActiveUS7611571B2Excellent ozone resistancePreferable color toneMeasurement apparatus componentsInksPhthalocyanineCopper

An ink having a cyan color is provided which can form images excellent in ozone resistance in such a high level as to exceed anticipation and having a preferable color tone. The ink includes at least two coloring materials of a first coloring material and a second coloring material, wherein the first coloring material is a compound having a copper phthalocyanine skeleton with a specific structure and the second coloring material is a compound having a copper phthalocyanine skeleton with a specific structure that is different from the first coloring material.

Owner:CANON KK

Single-core cable insulating rubber for low-smoke and zero-halogen flame-resistant rail vehicle with rated voltage of 3000V

ActiveCN101914244ASmall compression deformationImprove mechanical propertiesRubber insulatorsInsulated cablesHalogenFlame resistance

The invention discloses single-core cable insulating rubber for a low-smoke and zero-halogen flame-resistant rail vehicle with rated voltage of 3000V and temperature resistance of a 125 DEG C level. The single-core cable insulating rubber comprises the following components in parts by weight: 100 parts of crude rubber, 2-6 parts of organic peroxide curing agent, 1-5 parts of auxiliary curing agent, 1-4 parts of coupling agent, 3-8 parts of anti-aging agent, 10-25 parts of strengthening agent and 5-10 parts of plasticizing agent. The single-core cable insulating rubber has excellent insulating property and is very soft. A cable produced by the rubber is soft and is easy to bend, install and lay. The single-core cable insulating rubber has excellent insulating property, can continuously and normally work at voltage of 1000V and high temperature of 125 DEG C, can resist climates, ozone, heat, ageing, acid, alkali and fuel oil well and has low-smoke and zero-halogen flame resistance, environmental protection, safety and long service life.

Owner:JIANGSU JUYE CABLE

Ink, ink jet recording method, ink cartridge, recording unit, and ink jet recording apparatus

ActiveUS20080274286A1Excellent ozone resistancePreferable color toneMeasurement apparatus componentsInksPhthalocyanineCopper

An ink having a cyan color is provided which can form images excellent in ozone resistance in such a high level as to exceed anticipation and having a preferable color tone. The ink includes at least two coloring materials of a first coloring material and a second coloring material, wherein the first coloring material is a compound having a copper phthalocyanine skeleton with a specific structure and the second coloring material is a compound having a copper phthalocyanine skeleton with a specific structure that is different from the first coloring material.

Owner:CANON KK

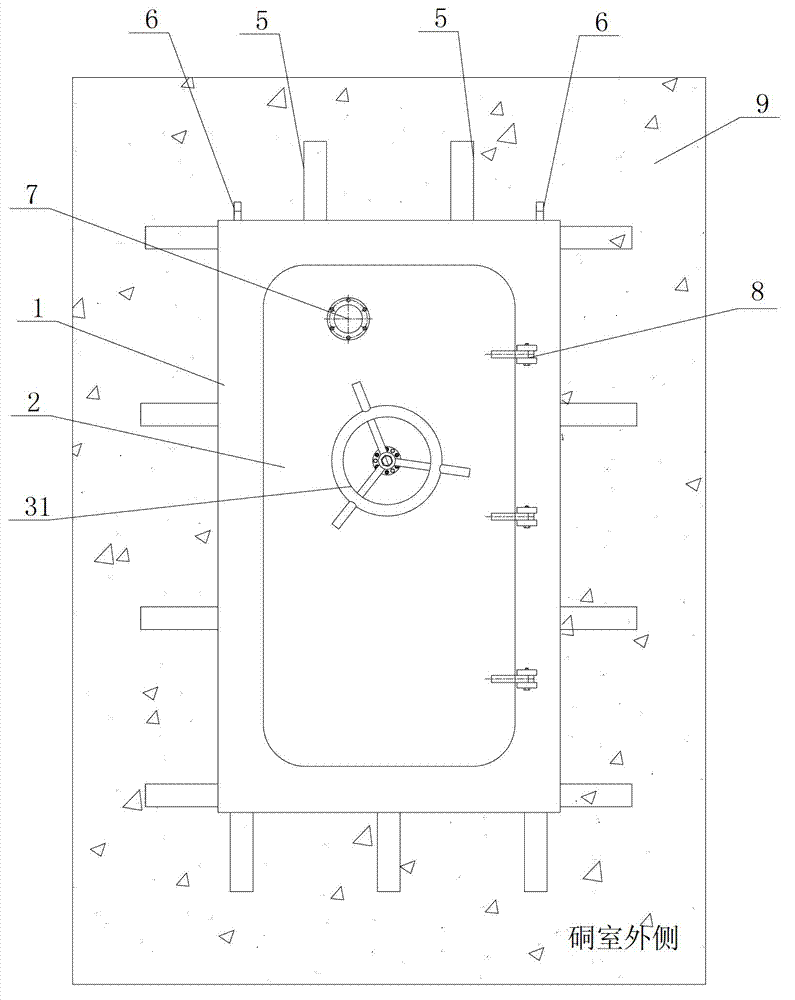

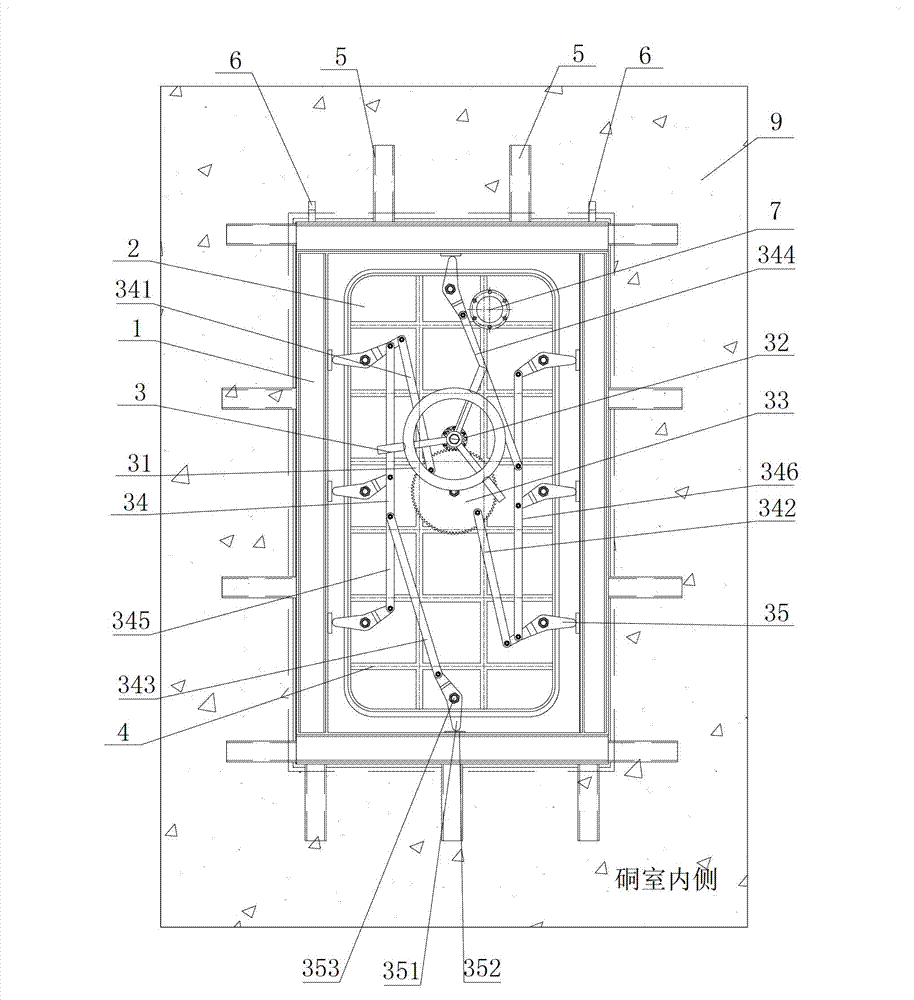

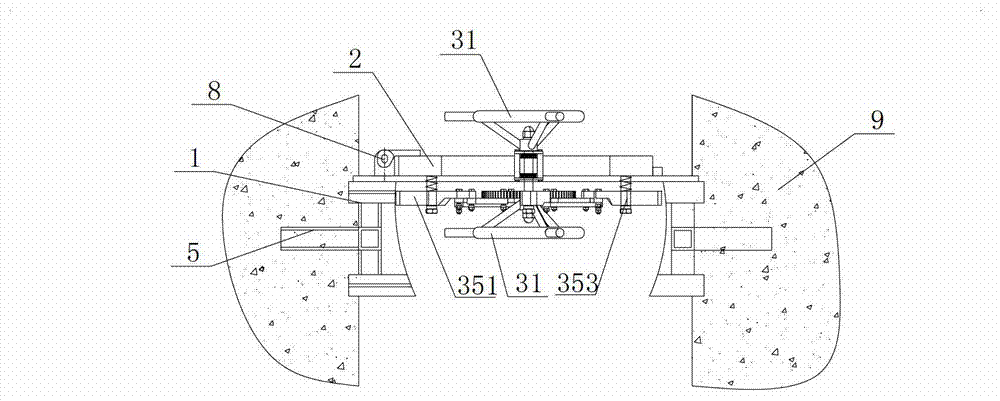

Protective sealing door for underground refuge chamber

ActiveCN102900335AImprove toughnessImprove bindingFireproof doorsConstruction fastening devicesLocking mechanismEngineering

The invention discloses a protective sealing door for an underground refuge chamber. The protective sealing door comprises a door frame and a door plate, wherein the door plate is arranged on the door frame through a rotation shaft; a locking mechanism for locking the door plate on the door frame is arranged on the door plate, a plurality of first reinforcing ribs for reinforcing the strength of the door plate are arranged in the door plate; heat-insulating materials, namely aerogel heat-insulating felts are filled among the reinforcing ribs; at least two annular sealing rings, namely flame-resisting sealing rings are arranged at the joint of the door plate and the door frame; and the periphery of the door plate is locked by the locking mechanism. According to the protective sealing door, the aerogel heat-insulating felts which can bear the temperature of 1,400 DEG C to the maximum are filled in the door plate, so that the door plate can resist high temperature generated during explosion, and the high temperature is insulated out of the refuge chamber; at least two sealing rings which are made of flame-resisting, anti-static, high temperature-resisting and oil-resisting materials are arranged on the contact surface of the door plate and the door frame, so that the protective sealing door has a good sealing effect.

Owner:CCTEG CHINA COAL RES INST

Ethylene-propylene-diene rubber composition with high comprehensive performance and preparation method thereof

InactiveCN102093644AImprove the shortcomings of poor oil resistanceImprove performanceActive agentKetone

The invention provides an ethylene-propylene-diene rubber composition with high comprehensive performance and a preparation method thereof. The ethylene-propylene-diene rubber composition is characterized by being prepared from 75 to 90 mass parts of ethylene-propylene-diene rubber, 10 to 25 mass parts of chlorosulfonated polyethylene rubber, 1.5 to 3 mass parts of anti-aging agent prepared by product of reaction of a ketone and amine, 1 to 3 mass parts of paraphenylenediamine anti-aging agent, 1.5 to 2.5 mass parts of physical anti-aging agent, 0.5 to 1.0 mass parts of stearic acid, 5 to 8 mass parts of active agent, 30 to 50 mass parts of reinforcing agent, 3 to 8 mass parts of plasticizer, 1.5 to 3 mass parts of vulcanizer and 2 to 4 mass parts of accelerator. The invention also provides the preparation method of the rubber composition, which is to blend in an internal mixer or an open mill. The product has high temperature resistance and high comprehensive performance.

Owner:上海众力减振技术有限公司

Nano-wollastonite powder modified ethylene propylene diene copolymer cable material

ActiveCN102964697AImprove flame retardant performanceImprove heat resistancePlastic/resin/waxes insulatorsPolyesterPolymer science

The invention discloses a nano-wollastonite powder modified ethylene propylene diene copolymer cable material, which is prepared FROM the following raw materials in parts by weight: 100-120 parts of Lanxess Deutschland ethylene propylene diene copolymer 3950, 20-30 parts of butyl rubber BBK232, 10-15 parts of SG-3 PVC (polyvinyl chloride) resin, 10-15 parts of trioctyl trimellitate, 2-5 parts of propanediol sebacate polyester, 2-5 parts of epoxidized soybean oil, 5-10 parts of polyethylene wax, 0.2-0.5 part of bisphenol A, 1-2 parts of zinc stearate, 0.5-1 part of lead sulfate tribasic, 1-2 parts of sulphur, 3-5 parts of zinc oxide, 30-40 parts of wollastonite powder, and the like. The cable material not only has excellent flame retardance and incombustibility, but also has the advantages of good high and low temperature resistance, corrosion resistance, water resistance, wear resistance, ozone resistance, ageing resistance and the like at the same time, and is durable in use.

Owner:ANHUI CHUNHUI INSTR CABLE GROUP

1E-level K1-type shrinkable tube used in nuclear power station and preparation method thereof

ActiveCN101661803AImprove flame retardant performanceImprove heat aging resistanceNuclear energy generationContainmentAging propertyFire retardant

The invention relates to a 1E-level K1-type shrinkable tube used in a nuclear power station, which comprises the following components by weight: 40 to 60 parts of base resin, 40 to 60 parts of hexyl-propyl rubber, 30 to 60 parts of flame retardant, 5 to 20 parts of antiradiation agent, 4 to 12 parts of antioxidizer, 2 to 5 parts of lubricant, and 3 to 8 parts of color masterbatch. The preparationmethod of the 1E-level K1-type shrinkable tube used in the nuclear power station comprises the following steps of: taking all the components by weight, carrying out mixed granulation by banburying ormixed granulation by a parallel double-screw extruder, then using a single-screw extruder for extrusion to form the tube, and carrying out radiation cross linking of cobalt 60 or electron accelerator50-180KGy to the tube, wherein the tube after the radiation cross linking expands by 2 to 6 times at the temperature of 90 to 150 DEG C. The shrinkable tube reaches and far exceeds the performance requirement of the 1E-level K1-type shrinkable tube used in the nuclear power station. The 1E-level K1-type shrinkable tube used in the nuclear power station has good flame retardant properties, can passV W-1 combustion test; has excellent heat-proof aging property, with the tensile strength and elongation at break of the product far stronger than the performance requirement; and outstanding intenseradiation-resistant function, and can pass AC withstand voltage test.

Owner:CHANGYUAN ELECTRONICS DONGGUAN +1

Dye mixture and ink containing the same

InactiveUS20050215773A1Excellent ozone resistanceInksPorphines/azaporphinesPhthalocyanine dyeHeat resistance

To provide a novel compound having sufficiently high fastness to light, heat, humidity and active gas in the environment and a coloring composition using the compound, particularly, an ink for ink jet recording, an ink jet recording method and a method for improving the preservability of formed image, which can form an image having high fastness to light and ozone gas in the environment. A phthalocyanine dye mixture having a specific structure and an ink, an ink for ink jet recording, an ink jet recording method and a method for improving the preservability of formed image, using the phthalocyanine dye mixture.

Owner:FUJIFILM CORP

Weatherproof and wear-resisting cable sheath material

InactiveCN104231600AImprove wear resistanceImprove mechanical propertiesInsulated cablesInsulated conductorsEpoxyCopper oxide

The invention discloses a weatherproof and wear-resisting cable sheath material which comprises the following raw materials in parts by weight: 40-60 parts of thermoplastic polyurethane elastomer, 20-30 parts of chloroprene rubber, 20-30 parts of chlorinated polyethylene, 30-45 parts of nano-titanium dioxide / graphene oxide, 10-15 parts of modified nano talcum powder, 20-35 parts of coupling-agent-modified attapulgite, 3-5 parts of activated zinc oxide, 4-9 parts of stearic acid, 10-18 parts of expansible graphite, 3-7 parts of copper oxide, 5-12 parts of ferric oxide, 5-9 parts of coupling-agent-modified ammonium polyphosphate, 3-6 parts of sulfur, 2-3.5 parts of tricresyl phosphate, 0.5-2 parts of oxidic polyethylene, 3.5-4.5 parts of an accelerant TMDT, 2-5 parts of an anti-aging agent, 1-2.8 parts of epoxy flaxseed oil and 1-1.8 parts of triethyl O-acetylcitrate. The weatherproof and wear-resisting cable sheath pipe has the advantages of good weather resistance, high wear resistance, good mechanical property and long service life.

Owner:无为县华祥电缆材料有限公司

High-temperature-resistant rubber sealing ring for automobiles

The invention discloses a high-temperature-resistant rubber sealing ring for automobiles. The high-temperature-resistant rubber sealing ring comprises the following raw materials in parts by weight: 70-90 parts of ethylene-propylene-diene-terpolymer rubber, 10-30 parts of chloroprene rubber, 1-4 parts of an anti-aging agent, 0.8-1.5 parts of active zinc oxide, 0.2-0.4 part of magnesium oxide, 0.5-1.0 part of calcium oxide, 0.6-1.5 parts of butyltin mercaptide, 30-40 parts of modified kaolin, 10-15 parts of magnesium methacrylate, 1-3 parts of a promoter, 6-10 parts of soybean oil, 1-2 parts of ethyl methacrylate, 40-80 parts of paraffin oil, 0.2-0.5 part of triallyl phosphate, 1.0-1.5 parts of a crosslinking agent BIBP, 0.5-1.2 parts of an assistant crosslinking agent TAIC, 0.3-0.5 part of microcrystalline wax, 2-3 parts of a vulcanizing agent and 0.5-1 part of phthalic anhydride. The sealing ring disclosed by the invention has strong weather resistance, corrosion resistance and ozone resistance, and can be suitable for being used as the high-temperature-resistant rubber sealing ring for the automobiles.

Owner:TONGLING SANSHENG ELECTRONICS

Insulation pressure-resistant liner mouth sealing ring and preparation method thereof

InactiveCN101701628AReasonable ratioGood lookingEngine sealsEthylene-propylene-diene-monomerPlasticizer

The invention discloses an insulation pressure-resistant liner mouth sealing ring which comprises the raw materials in parts by weight: 80-100 parts of ethylene-propylene-diene monomer rubber, 1-4 parts of anti-aging agent, 40-80 parts of carbon black, 3-5 parts of peroxide vulcanizing agent, 0.5-2 parts of accelerating agent, 6-10 parts of esters plasticizer and 1-4 parts of dispersing agent. The invention also discloses a preparation method of the insulation pressure-resistant liner mouth sealing ring. Compared with the prior art, the insulation pressure-resistant liner mouth sealing ring has attractive appearance, medium-high rigidity, high compression set resistance, high tensile strength and elongation at rupture, excellent ageing resistance and ozone resistance, more particularly, properties of insulation and voltage resistance, simple process and more reasonable proportion of the raw materials and enables the product to keep excellent properties and attractive appearance under more rigorous use environment.

Owner:QINGDAO TKS SEALING IND

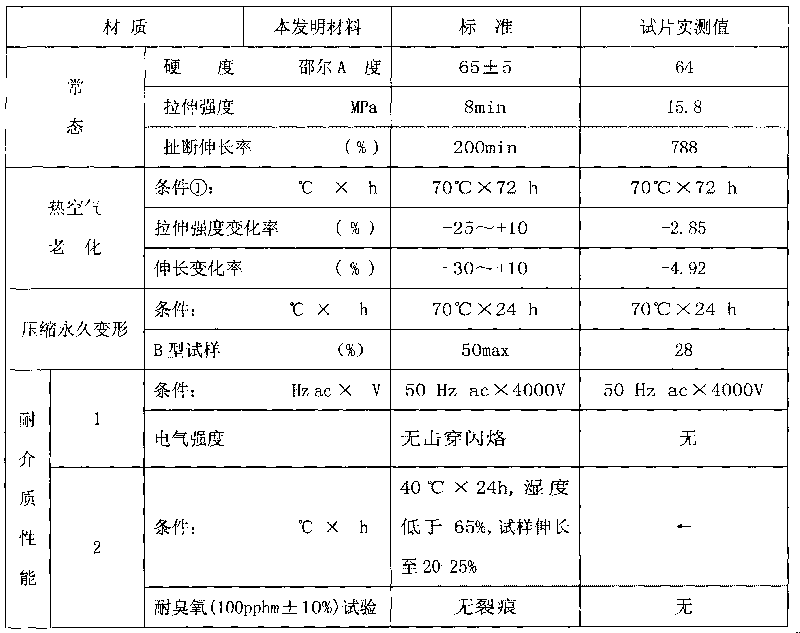

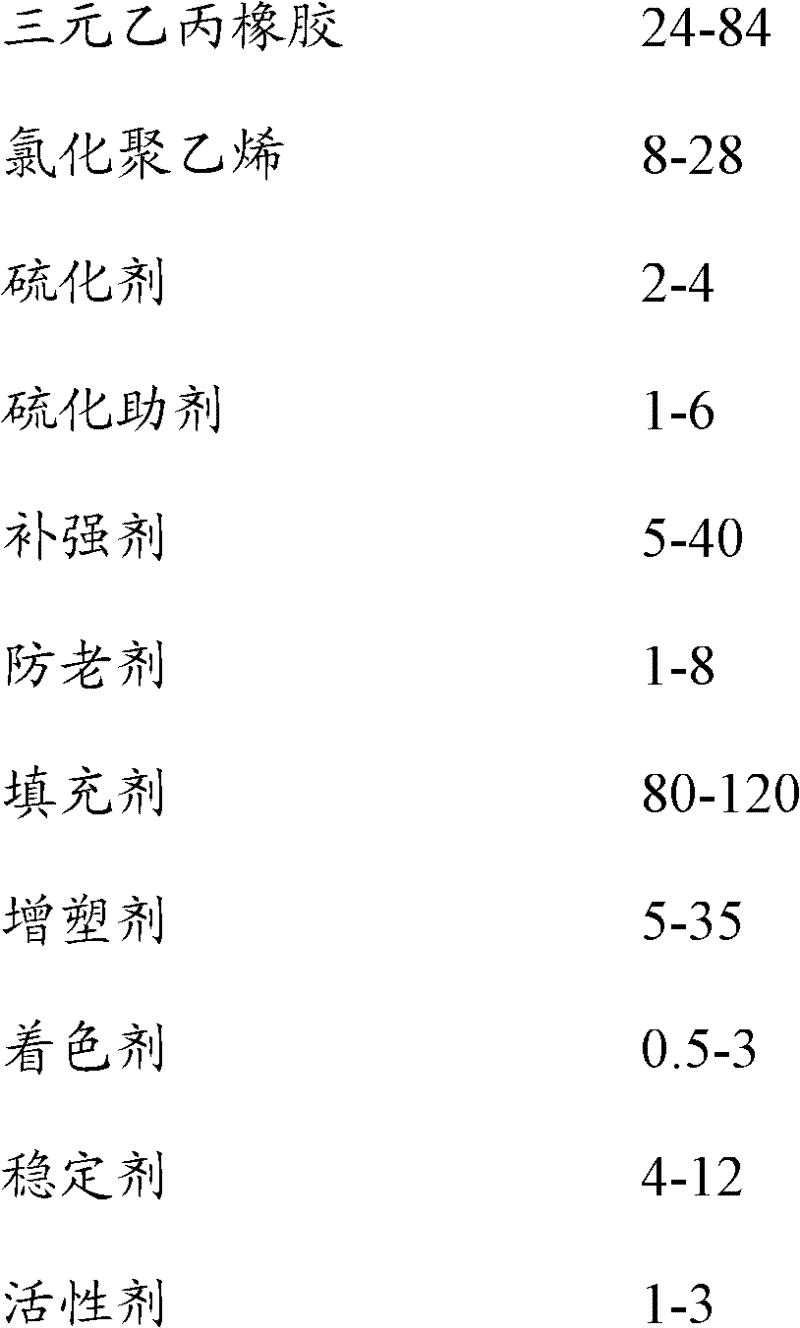

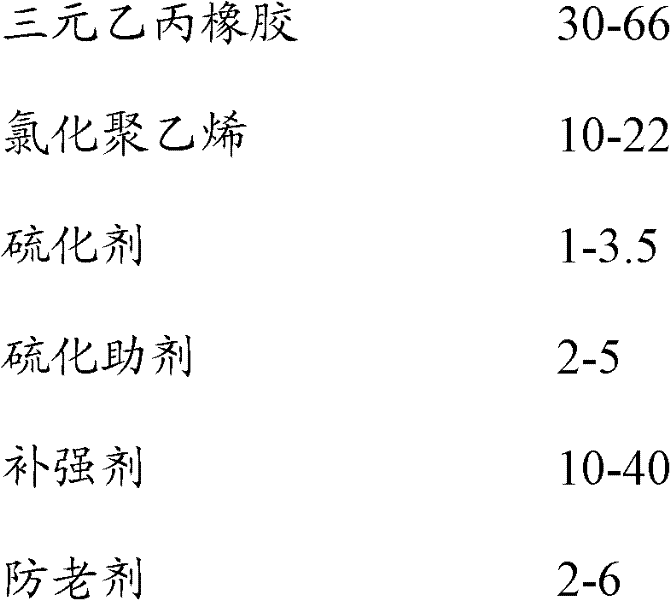

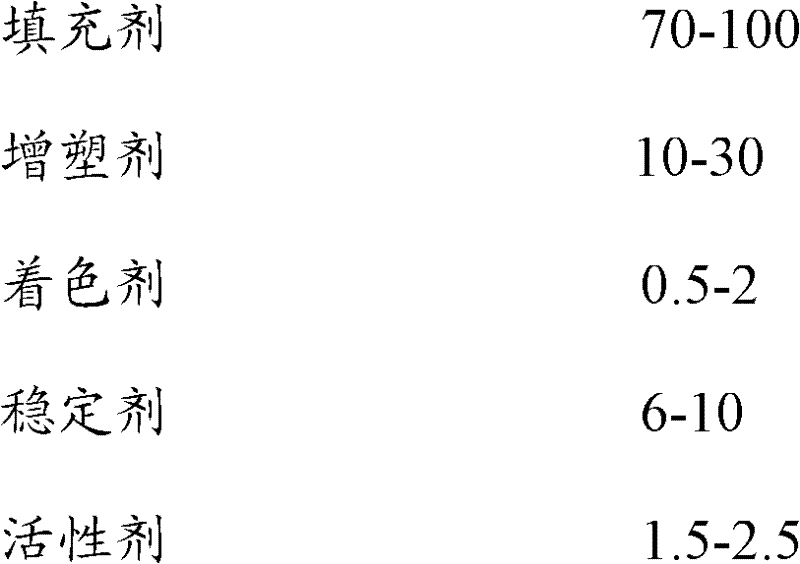

Rubber insulating glue for mine cables

InactiveCN102417663AAccelerated vulcanizationHigh activityPlastic/resin/waxes insulatorsVulcanizationPolymer science

The invention relates to rubber insulating glue for mine cables. Raw materials for the glue comprise, by weight, 24 to 84 of ethylene-propylene terpolymer rubber, 8 to 28 of chlorinated polyethylene, 2 to 4 of a vulcanizing agent, 1 to 6 of a vulcanization aid, 5 to 40 of a strengthening agent, 1 to 8 of an anti-aging agent, 80 to 120 of a filling agent, 5 to 35 of a plasticizer, 0.5 to 3 of a coloring agent, 4 to 12 of a stabilizing agent and 1 to 3 of an active agent, wherein, the mass ratio of ethylene-propylene terpolymer rubber to chlorinated polyethylene is 3:1. According to the invention, chlorinated polyethylene is employed to substitute a part of ethylene-propylene terpolymer rubber, a formula for the raw materials is properly adjusted, and therefore, the prepared rubber insulating glue for mine cables shows the advantage of reduced utilization cost under the prerequisite that the glue meets utilization requirements for mine cables.

Owner:ANHUI LAND GRP

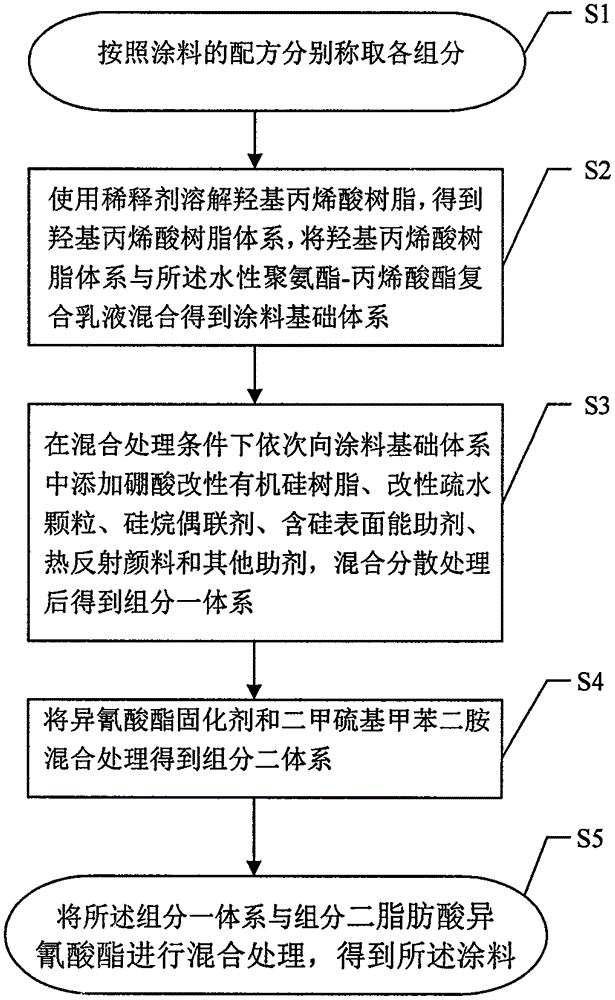

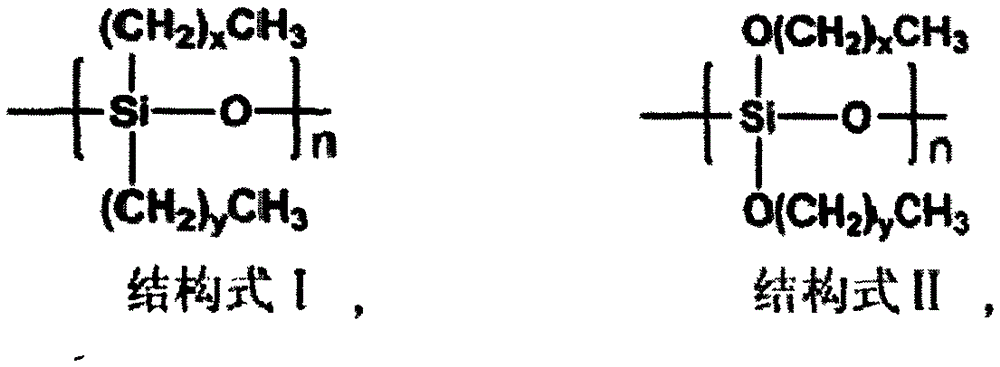

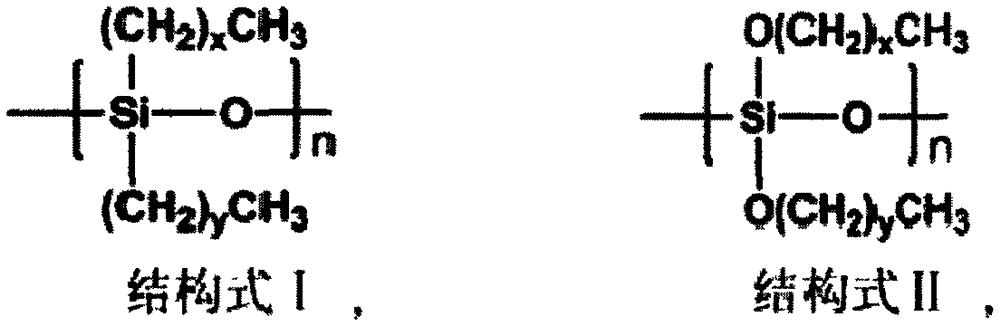

Building facade coating and preparation method thereof

InactiveCN105273603AStrong adhesionImprove impact resistancePolyurea/polyurethane coatingsAcrylic resinBoronic acid

The present invention aims to provide a building exterior facade coating and a preparation method thereof, the coating comprises a component I and a component II, wherein the component I comprises the following components by mass: 45-50 parts of waterborne polyurethane-acrylate ester composite emulsion; 10-25 parts of hydroxyl acrylic resin; 2-10 parts of boronic acid-modified silicone resin; 5-10 parts of modified hydrophobic particles, 1-3 parts of a silane coupling agent; 0.5-4 parts of a silicon-containing surface energy aid; 6-8 parts of a heat reflective pigment; and 1-5 parts of other additives; the component II comprises the following components by mass: 17-25 parts of an isocyanate curing agent; and 3-4 parts of dimethythiotoluene diamine. The building exterior facade coating also has good corrosion resistance, high temperature resistance, good flame retardance, good coating and substrate adhesion, strong hydrophobicity and good environmental performance and other advantages.

Owner:杭州蓝筹企业管理有限公司

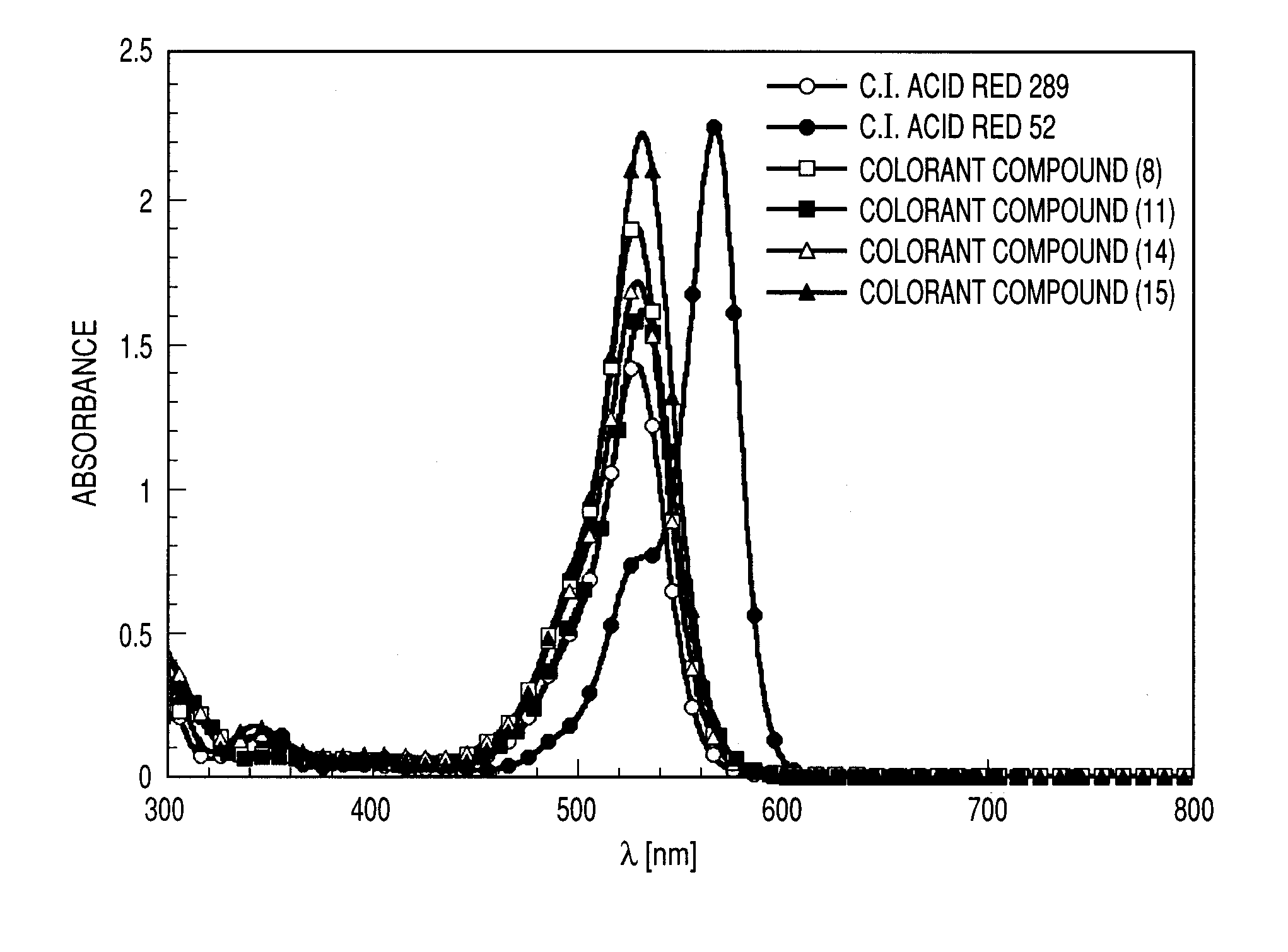

Colorant compound

ActiveUS20110067598A1High magenta coloring abilityImprove light resistanceOrganic chemistryPyronine/xanthon/thioxanthon/selenoxanthan/telluroxanthan dyesArylPhotochemistry

The present invention is a colorant compound represented by the following general formula (1):wherein at least one of R2, R4, R7 and R9 is an acylamino group represented by the following general formula (2):wherein R11 denotes one of an alkyl group, a cycloalkyl group, an aryl group, an arylalkyl group, an alkenyl group and a heterocyclic group; and ‘*’ denotes a bonding site with an aromatic ring of the general formula (1).

Owner:CANON KK

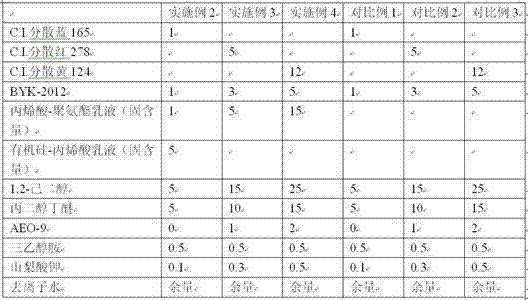

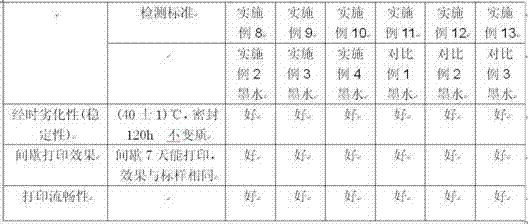

Aqueous disperse dye ink-jet printing ink

The invention aims at providing an aqueous disperse dye ink-jet printing ink with excellent comprehensive performance capable of overcoming the defects of the traditional disperse dye ink-jet printing ink, and a preparation method of the aqueous disperse dye ink-jet printing ink. The aqueous disperse dye ink-jet printing ink has good ink storage stability and good printing fluency; the service time of a disperse dye ink-jet product is greatly prolonged; the aqueous disperse dye ink-jet printing ink can be cured under the irradiation of ultraviolet light (UV); the comprehensive performances of the ink, such as light resistance, water tolerance, chemical resistance, high and low-temperature resistance, rubbing scratch resistance, high brightness and ageing resistance of the ink are improved; the aqueous disperse dye ink-jet printing ink is applicable to an uncoated and non-printing coating medium and is applied to the fields such as digital printing, digital calico printing, digital images, office documents, outdoor inkjet, ceramic tile wallpapers, glass plastics and surface decoration.

Owner:鲁继烈

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com