Rubber insulating glue for mine cables

A rubber insulation and cable technology, which is applied in the field of cable insulation glue, can solve the problems affecting the commercial development of EPDM mining cable rubber insulation glue, the cost increase of EPDM as mining cable rubber insulation glue, and the restriction of the use of EPDM mine cable rubber insulation glue and other issues, to achieve good chemical stability, improve processing safety, improve flame retardancy and oil resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0034] According to the conventional method in this field, the CPE base rubber is first kneaded on a small open mill, and after molding, the EPDM base rubber is added for mixing and masticating. After being fully mixed, all auxiliary materials except the vulcanizing agent and vulcanization aid are added for mixing. Refining, adding vulcanizing agent and vulcanizing aids after molding, kneading, uniform, cooling to obtain insulating rubber, and then insulating extrusion according to conventional methods to obtain mining cable rubber insulating rubber.

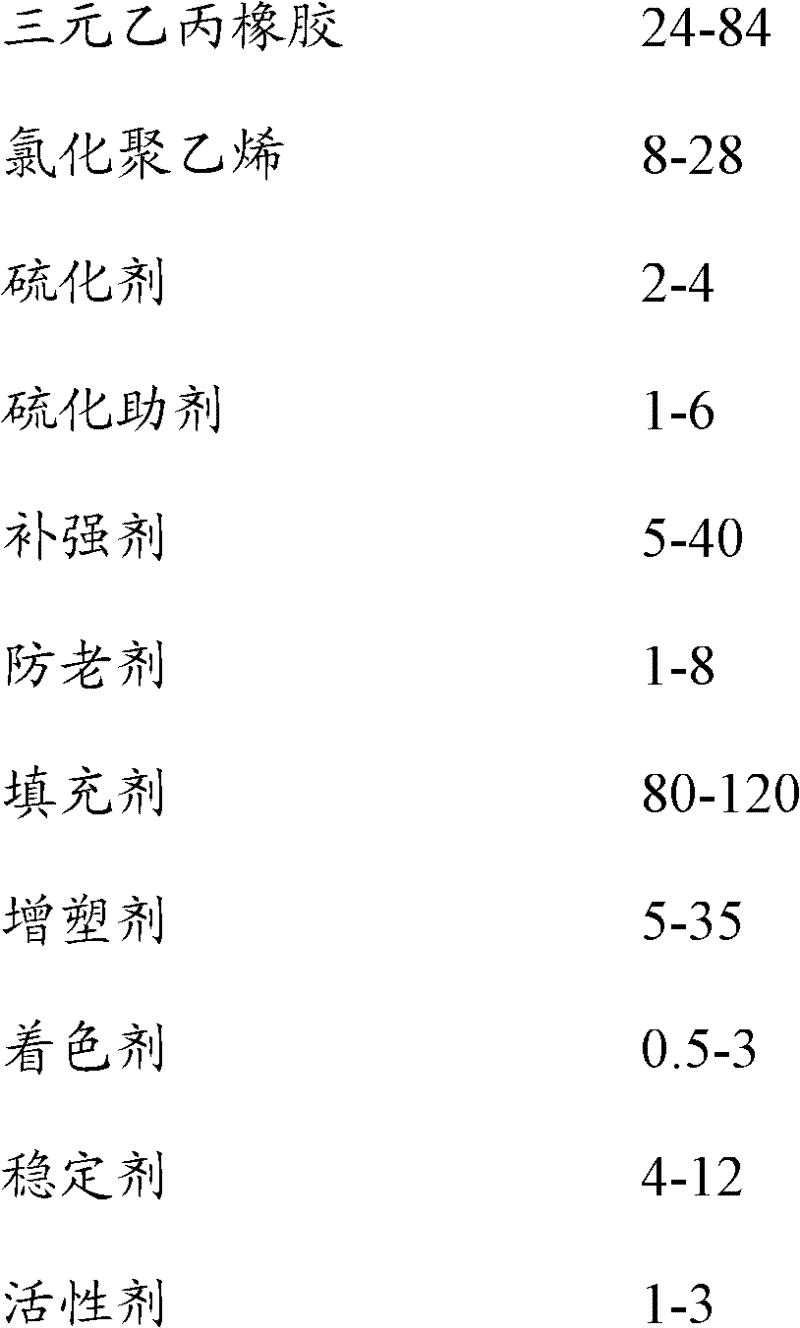

[0035] Shown below is the specific formula of each embodiment.

Embodiment 1

[0037]

[0038]

[0039] Wherein, the mass ratio of EPDM rubber to chlorinated polyethylene is 3:1.

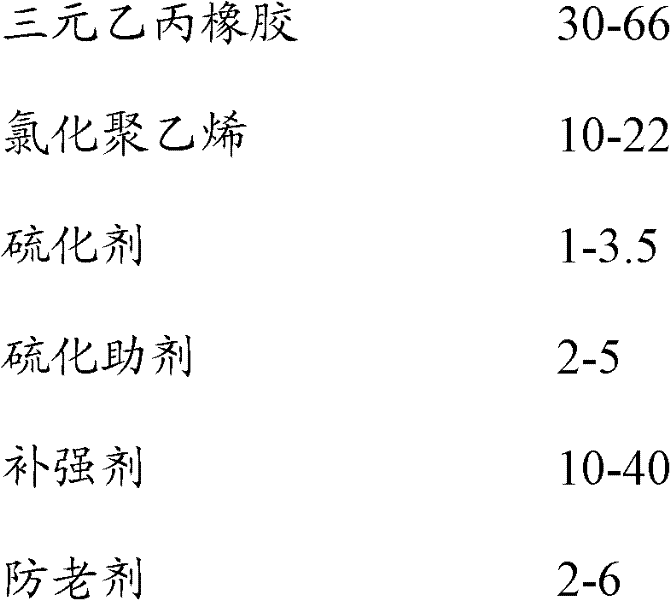

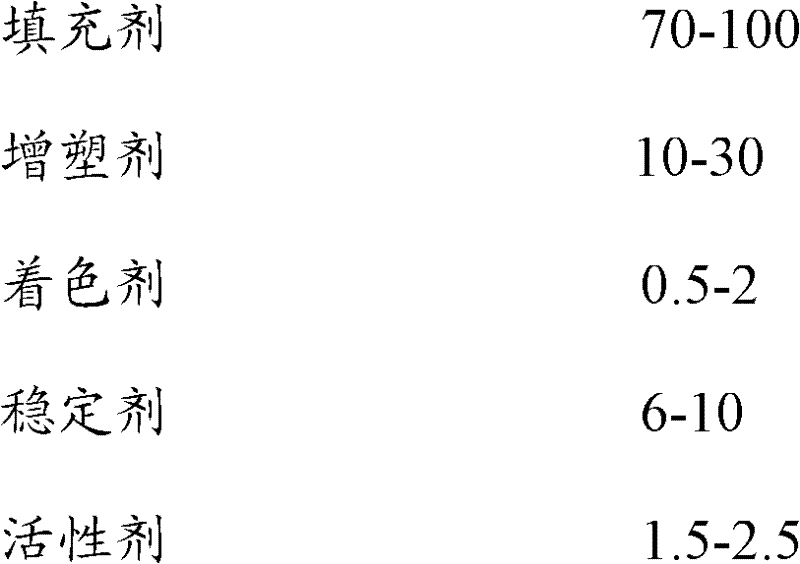

Embodiment 2

[0041]

[0042] Wherein, the mass ratio of EPDM rubber to chlorinated polyethylene is 3:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com