Method and technique for eliminating particle surface envelope in solution with ultrasound wave, and uses

A particle surface, ultrasonic technology used in the field of separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

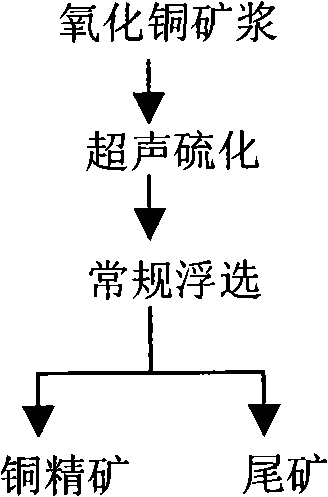

[0023] Embodiment 1: A kind of ultrasonic vulcanization process method of copper oxide ore

[0024] The copper oxide ore has a particle size of -200 mesh and contains 1% copper. The conventional vulcanization process is adopted, using sodium sulfide as the vulcanizing agent. After vulcanization and flotation, the output copper concentrate contains 1% copper.

[0025] Under the above process conditions, increase the process conditions of ultrasonic irradiation to the solution. In the solution filled with copper oxide ore, an ultrasonic emitting device is installed. The ultrasonic emitting device emits ultrasonic waves when the copper oxide ore solution is vulcanized. The ore particles are impacted, and the ultrasonic impact is used to remove the surface coating of the copper oxide ore particles, so that the particles expose their own surface and accelerate the vulcanization process. The ultrasonic frequency is 15-200kHz, and the sound intensity is 0.5-200w / cm 2 , the ultrason...

Embodiment 2

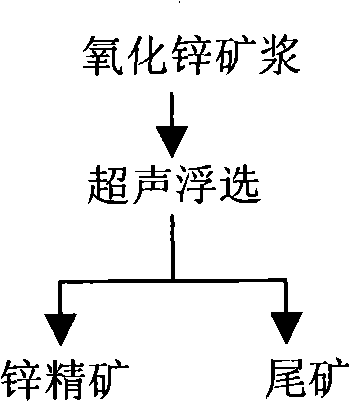

[0027] Embodiment 2: A kind of zinc oxide ore ultrasonic flotation process

[0028] Zinc oxide ore particle size -200 mesh, zinc content 5.99%, conventional flotation process, using XMT-1# chemical flotation, primary flotation output zinc concentrate grade 7.07% zinc, zinc concentrate yield 18%.

[0029] Under the above process conditions, increase the process conditions of ultrasonic irradiation to the solution. In the solution filled with zinc oxide ore, an ultrasonic emitting device is installed. The ultrasonic emitting device emits ultrasonic waves during the flotation of the zinc oxide ore solution. The ultrasonic wave passes through the zinc oxide ore solution and produces Impact, using ultrasonic impact to remove the coating on the surface of zinc oxide ore particles, so that the particles expose their own surface, and accelerate the flotation process. The ultrasonic frequency is 15-128kHz, and the sound intensity is 0.5-50w / cm 2 , Ultrasonic wave and flotation synchr...

Embodiment 3

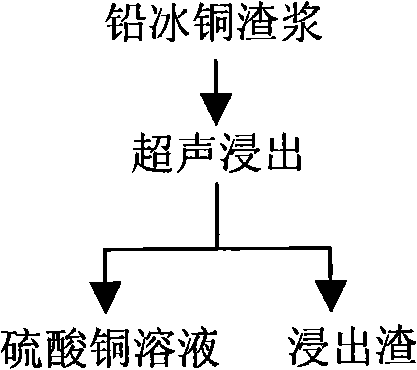

[0031] Embodiment 3: A kind of ultrasonic leaching process of lead matte slag

[0032] Lead matte slag particle size -200 mesh, copper content 45.98%, using conventional leaching process, leaching temperature 85 ℃. The leaching time is 360 minutes, the output copper sulfate solution concentration is 24.30g / L, and the copper leaching rate is 49.08%.

[0033] Under the above process conditions, increase the process conditions of ultrasonic irradiation to the lead matte slag solution. In the solution filled with lead matte slag, an ultrasonic emitting device is set, and the ultrasonic emitting device sends ultrasonic waves when the lead matte slag solution is leached, and the ultrasonic wave passes through the lead matte slag solution, and the lead ice in the lead matte slag solution is The copper slag particles are impacted, and the ultrasonic impact is used to remove the surface coating of the lead matte slag particles, so that the particles expose their own surfaces and acceler...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com