Method for purifying nano carbon fiber of multi-wall carbon nano-tube

A technology of multi-walled carbon nanotubes and carbon nanofibers, which is applied in the field of purification of carbon nanotubes/carbon nanofibers, can solve problems such as destruction, uneven oxidation reaction, structural integrity changes of carbon nanotubes/carbon nanofibers, and improve crystallization degree, improved structural integrity, and improved thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

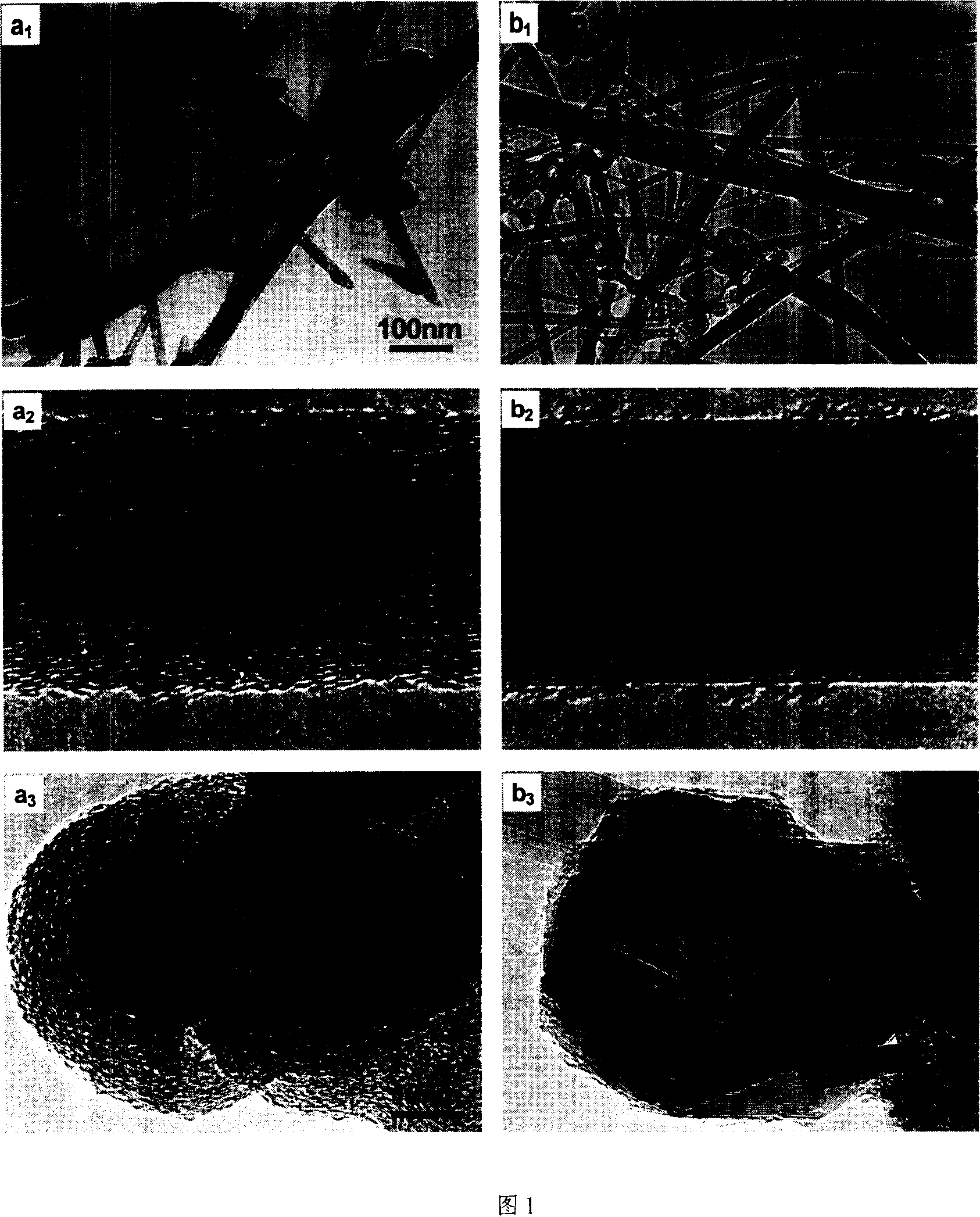

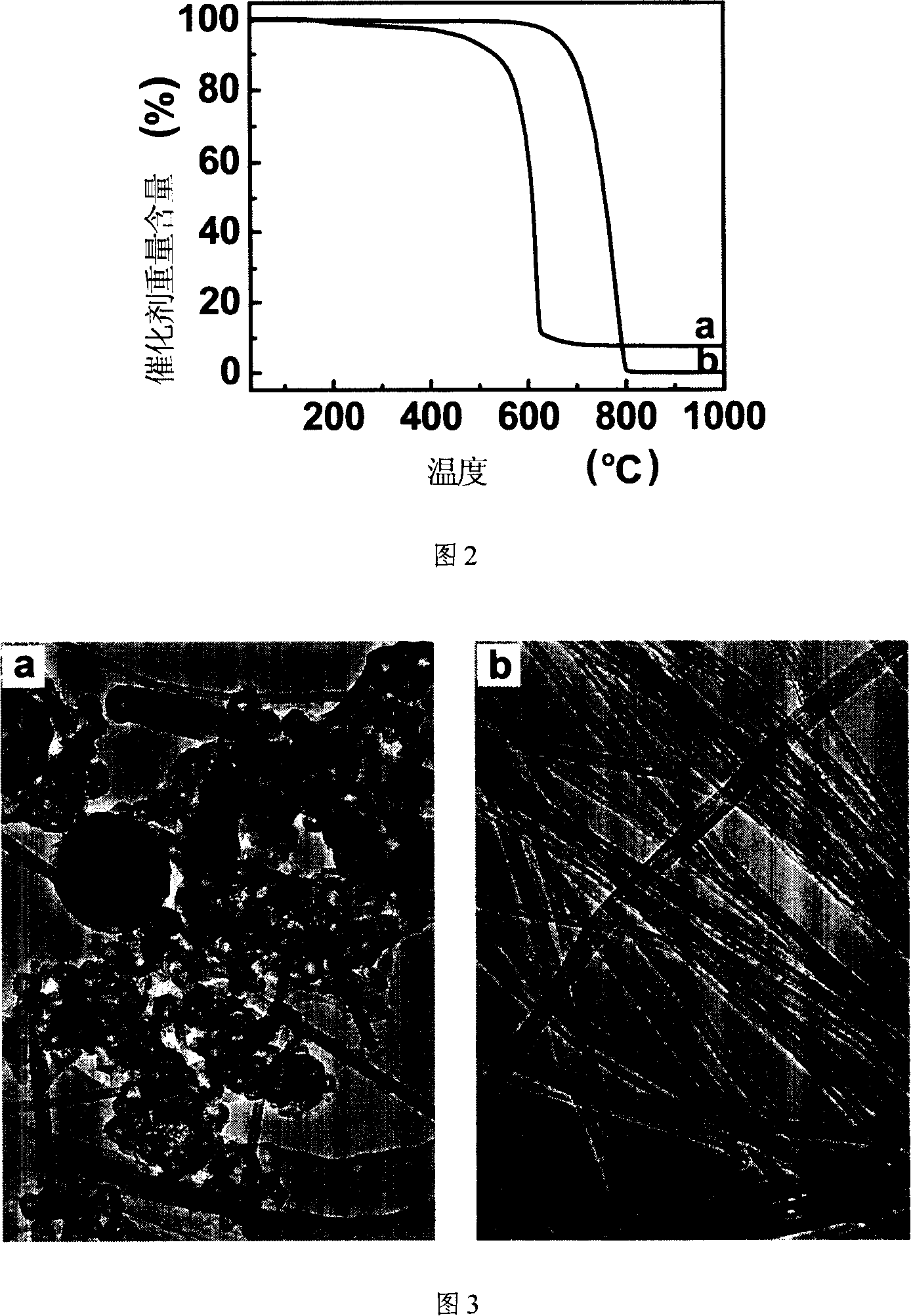

[0021] The multi-walled carbon nanotube samples (diameter 20-100nm) prepared in batches by CCVD method are placed in a graphite crucible, then placed in a graphitization furnace, heated to 2500-2700°C under argon protection, the holding time is 60min, and cooled to Samples were taken out at room temperature. The film-like carbon nanotube samples after graphitization were crushed with a pulverizer (with a particle size of 10-100 mesh) for later use. Polymer dispersant (Dispers710) was prepared into a 0.08wt% solution with ethanol. Add 0.5 g of graphitized carbon nanotubes into 100 g of dispersant solution, stir magnetically for 60 min, and then vibrate ultrasonically for 20 min in an ultrasonic cleaner to obtain a black suspension of carbon nanotubes. Then filter the suspension with a 400-mesh filter, re-disperse the filter cake ultrasonically in ethanol, wash and filter it several times until the filtrate becomes colorless and clear. The finally obtained filter cake is purif...

Embodiment 2

[0024] The nano-carbon fiber samples (diameter 300-500nm) prepared in batches by CCVD were placed in a graphite crucible, then placed in a graphitization furnace, heated to 2200-2500°C under the protection of argon, and kept for 120 minutes, then cooled to room temperature and taken out. . The graphitized film-like carbon nanofiber samples were crushed with a pulverizer (with a particle size of 10-100 mesh) for later use. Sodium lauryl sulfate was prepared as a 0.1 wt% solution with water. Add 0.5 g of graphitized carbon nanofiber samples into 120 g of dispersant solution, stir magnetically for 60 minutes, and then vibrate ultrasonically for 90 minutes in an ultrasonic cleaner to obtain a suspension of black carbon nanofiber samples. Then filter the suspension with a 400-mesh filter, re-disperse the filter cake ultrasonically in water and wash and filter it several times until the filtrate becomes colorless and clear. The filter cake finally obtained is the purified nano-car...

Embodiment 3

[0026]The multi-walled carbon nanotube samples (diameter 20-100nm) prepared in batches by CCVD method are placed in a graphite crucible, then placed in a graphitization furnace, heated to 2800-2900°C under argon protection, the holding time is 30min, and cooled to Samples were taken out at room temperature. The film-like carbon nanotube samples after graphitization were crushed with a pulverizer (with a particle size of 10-100 mesh) for later use. The dispersant (Hydropalat 1080) was formulated as a 0.15 wt% solution in water. Add 0.5 g of graphitized carbon nanotubes into 100 g of dispersant solution, stir magnetically for 60 minutes, and then vibrate ultrasonically for 30 minutes in an ultrasonic cleaner to obtain a suspension of black carbon nanotubes. Then filter the suspension with a 400-mesh filter, re-disperse the filter cake ultrasonically in water and wash and filter it several times until the filtrate becomes colorless and clear. The finally obtained filter cake is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com