Patents

Literature

167 results about "Intermediate bulk container" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

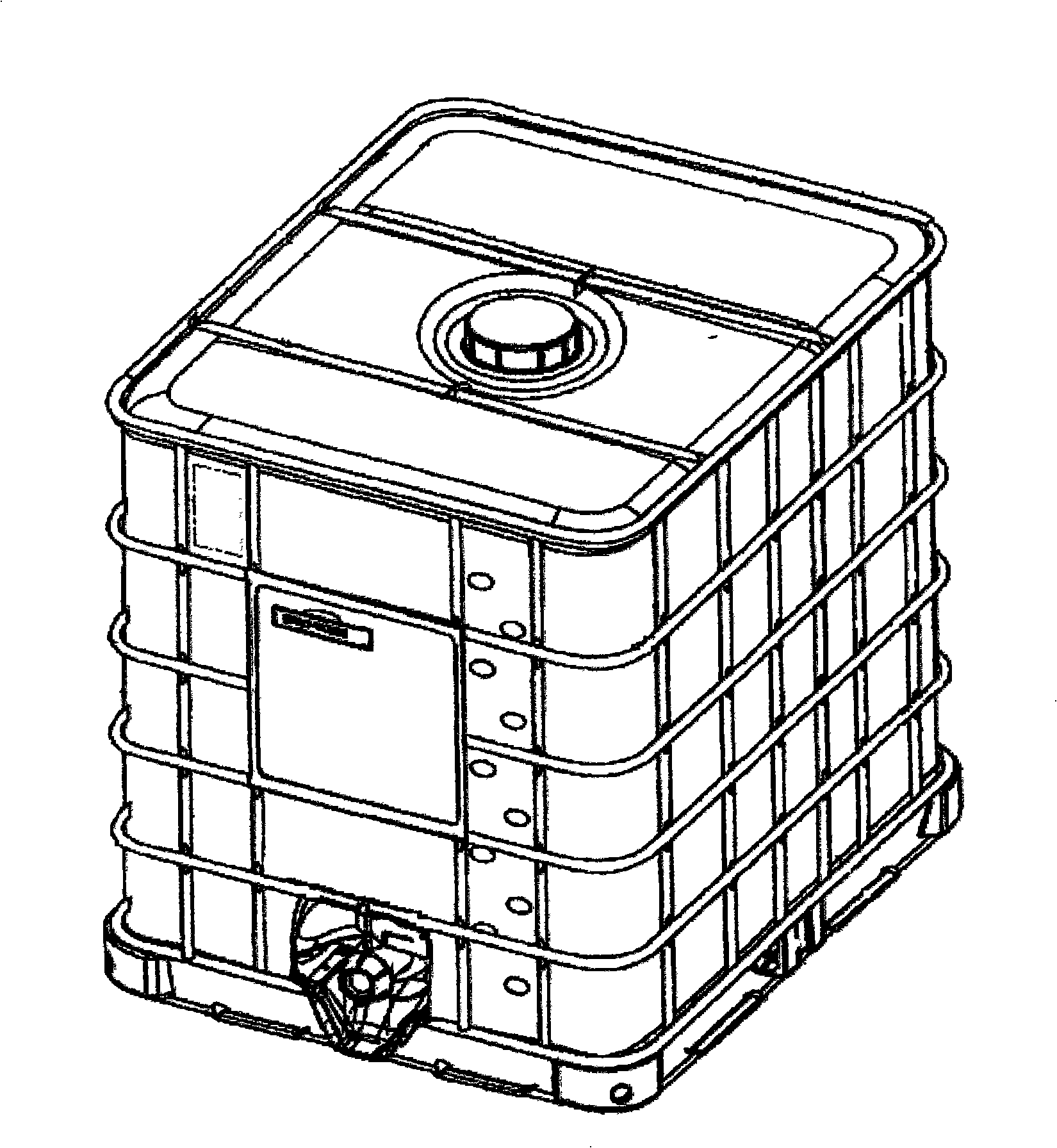

Intermediate bulk containers (also known as: IBC tote, IBC tank, IBC or pallet tanks), are reusable, multi-use industrial-grade containers engineered for the mass handling, transport and storage of liquids, semi-solids, pastes, or solids. The two main categories of IBC tanks are flexible IBCs and rigid IBCs.

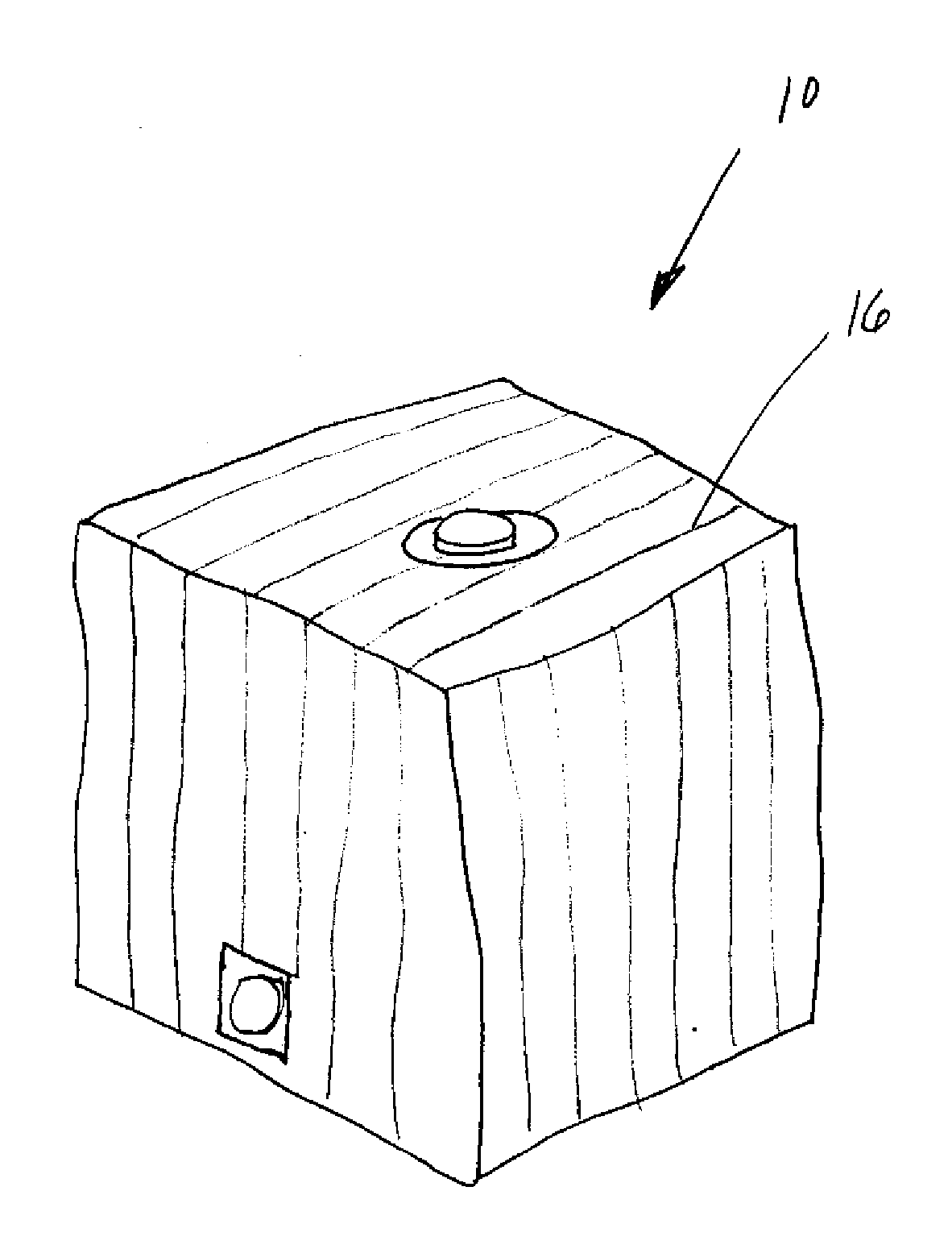

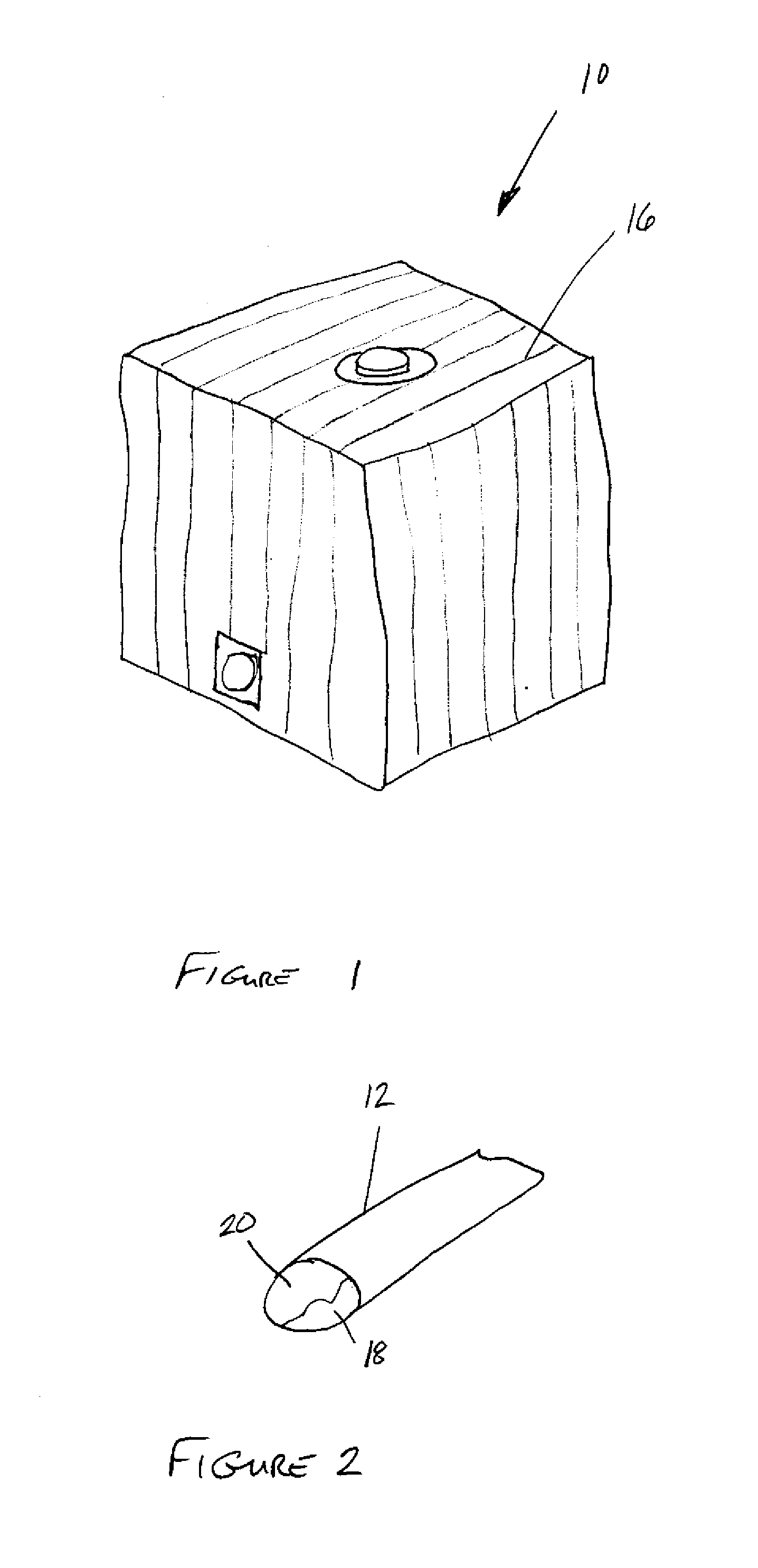

Support for cage and bottle style intermediate bulk container

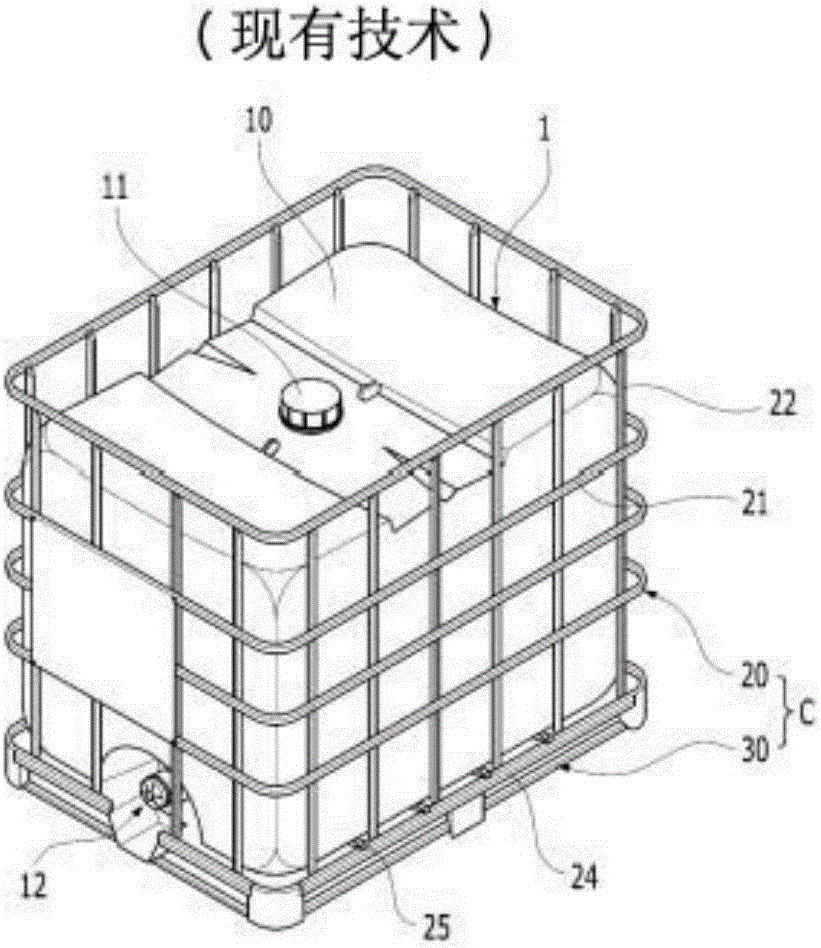

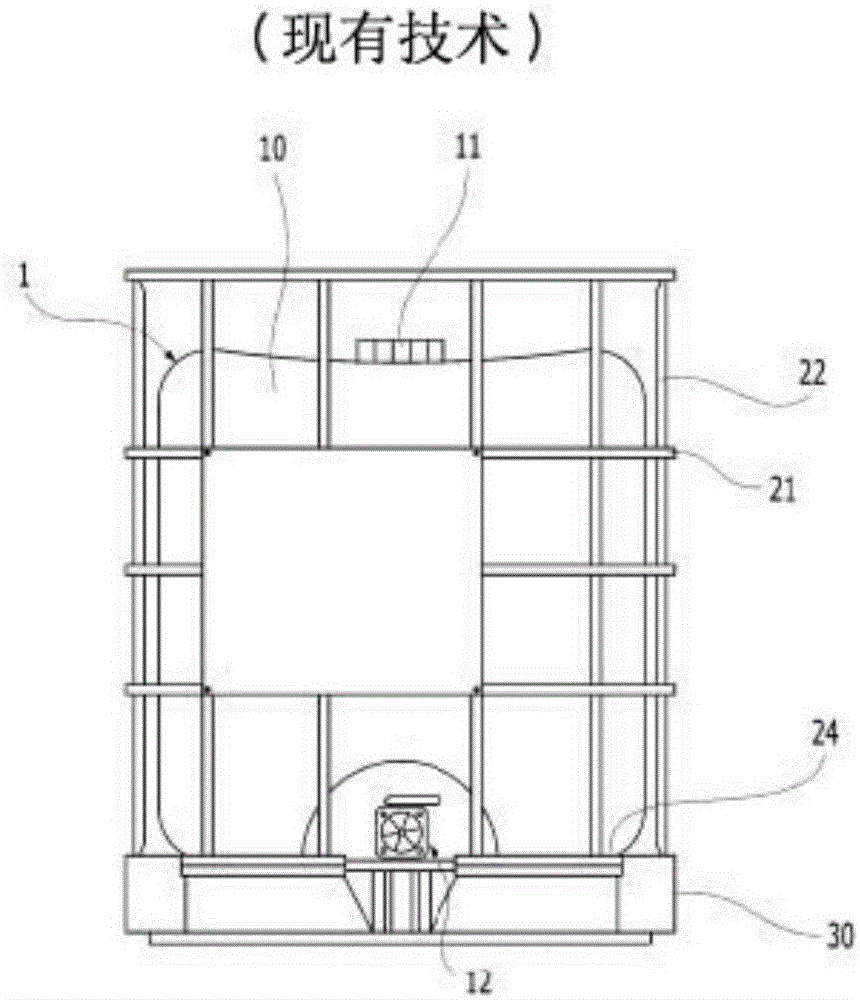

InactiveUS20060027582A1Improves Structural IntegrityAvoid squeezingLarge containersLinings/internal coatingsIntermediate bulk containerCombined use

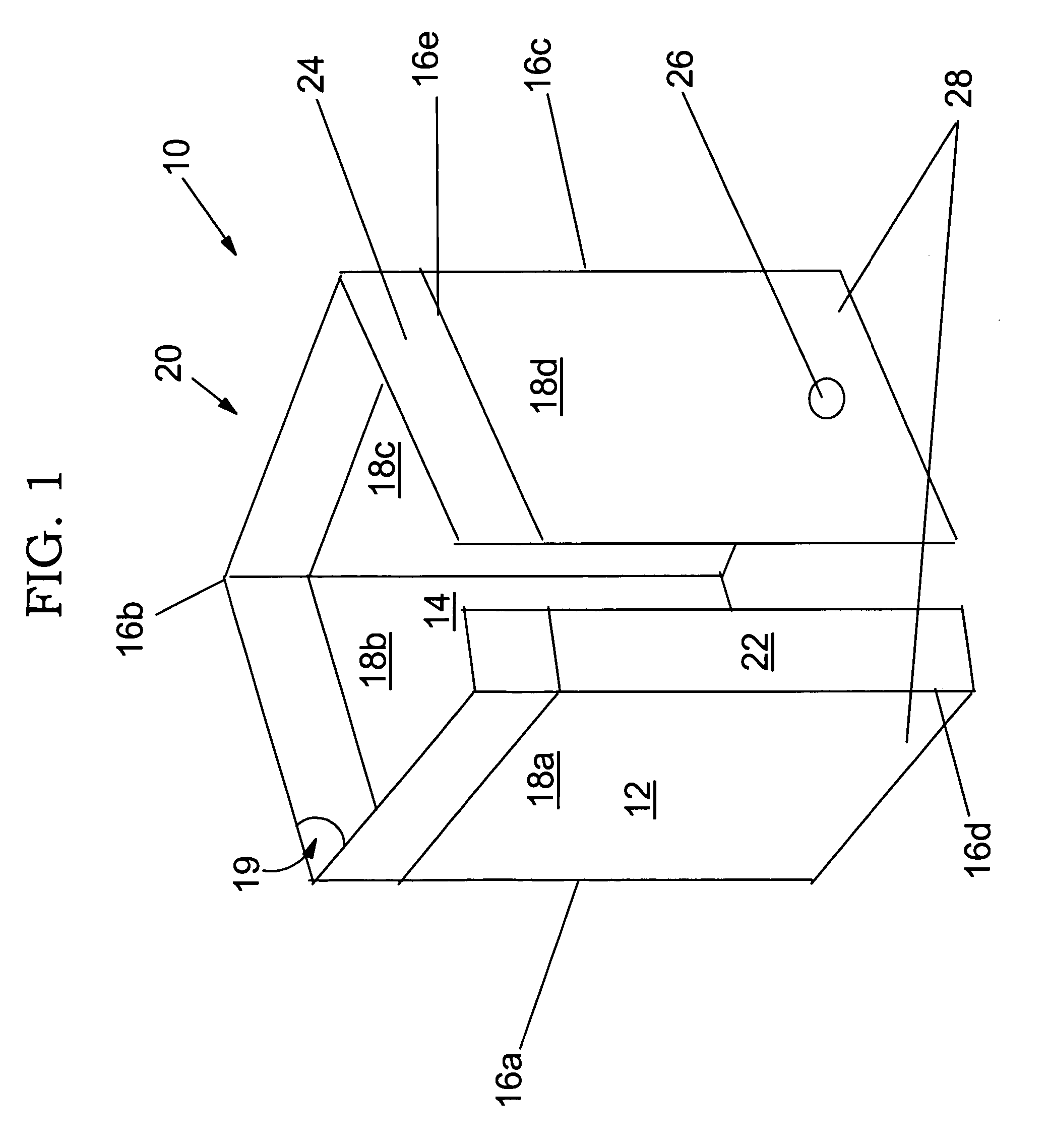

The present invention provides a system and method for using a liner in conjunction with the cage of a bottle and cage type IBC. The invention involves use of a support that is placed inside the cage of a bottle and cage type IBC. In one embodiment, the support may be a thin sheet of material that conforms to the inner surface of the cage. In an alternative embodiment, the support may be a bottle from a cage and bottle type IBC that has been modified by removing the discharge valve spout. In the case that a liner is used in conjunction with the cage, the support forms a barrier between the liner and the cage to prevent the liner from extruding through the bars of the cage. An aperture in the support may allow a discharge valve of a liner to extend outwardly for easy access to the item.

Owner:BEACH JOHN E

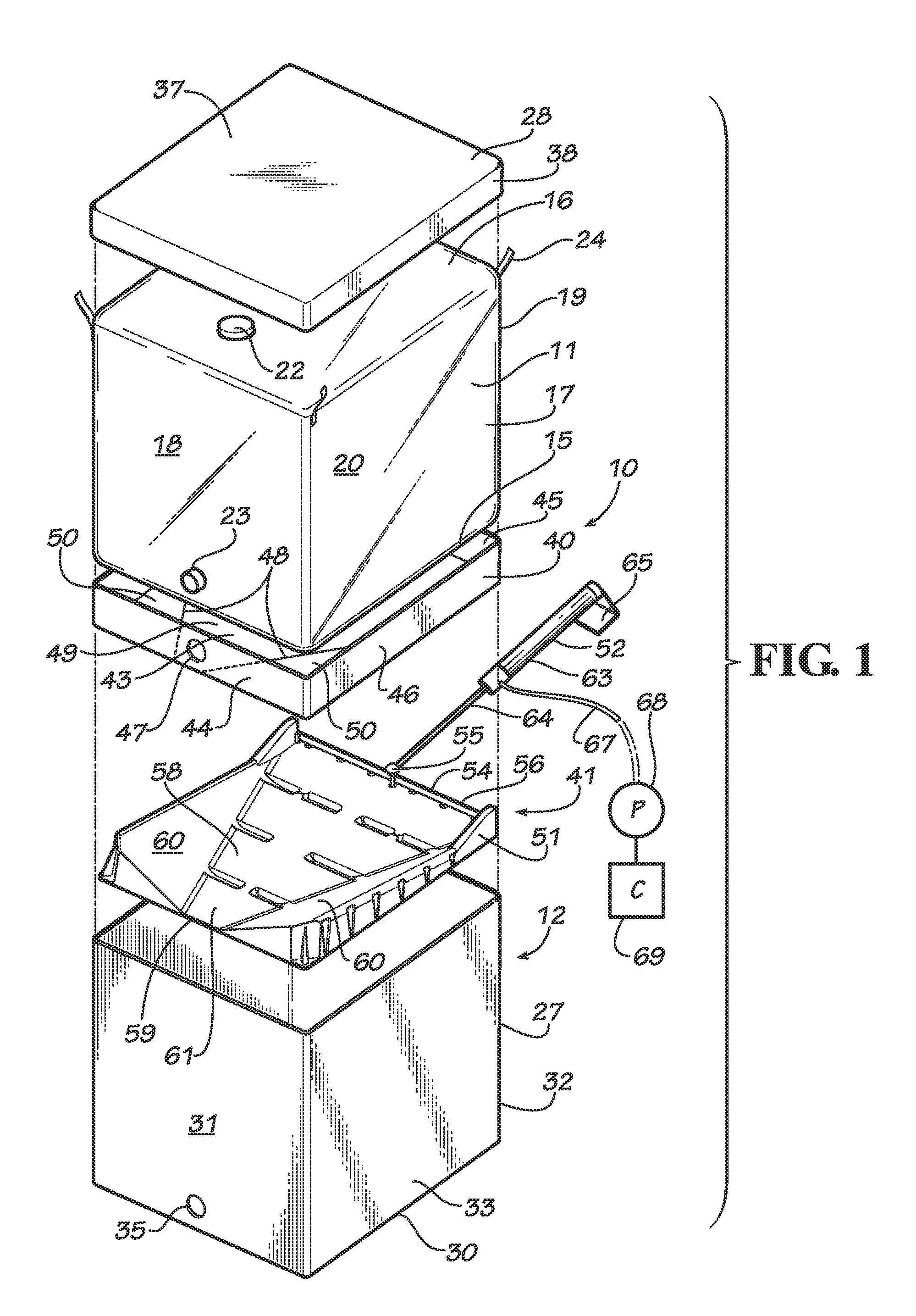

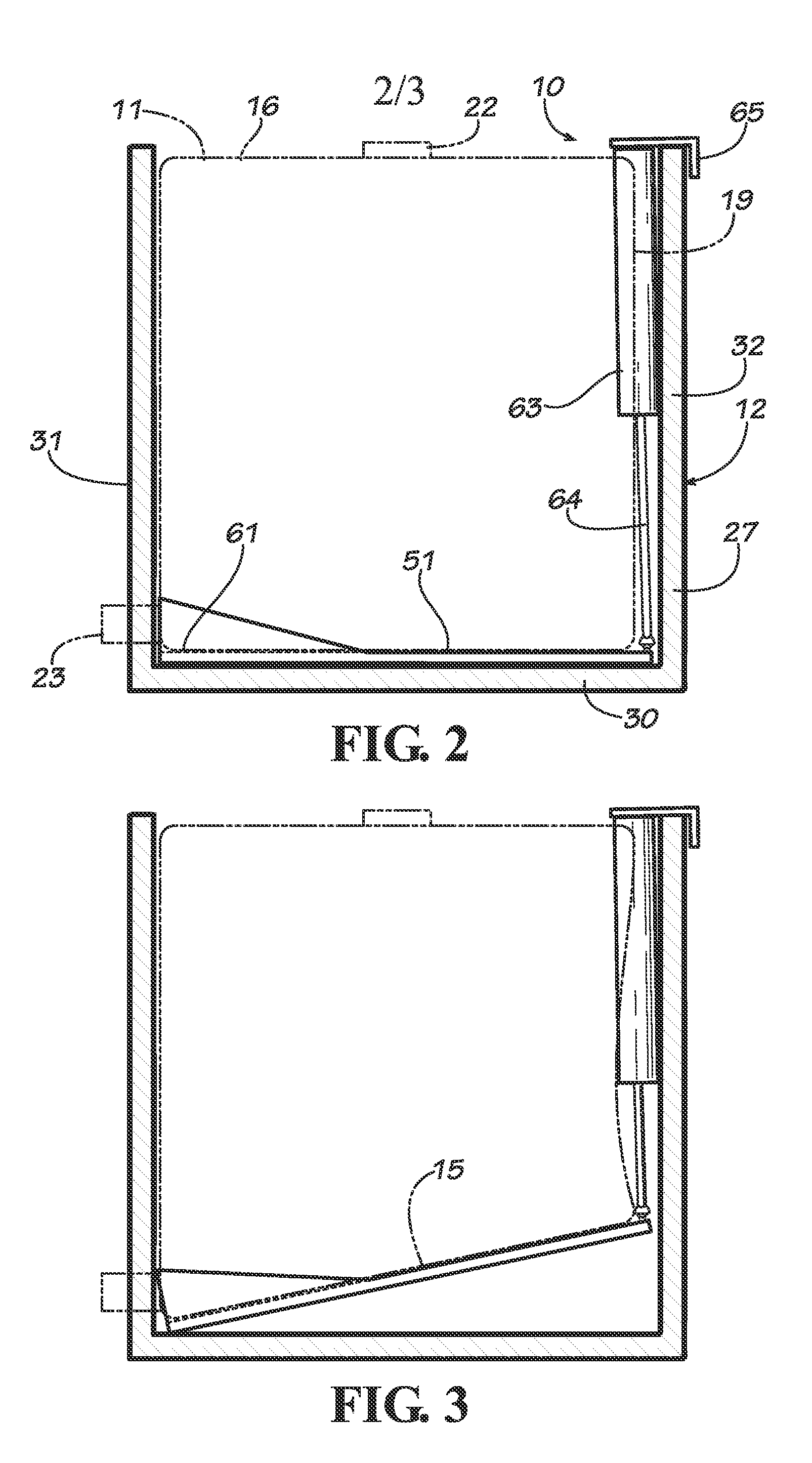

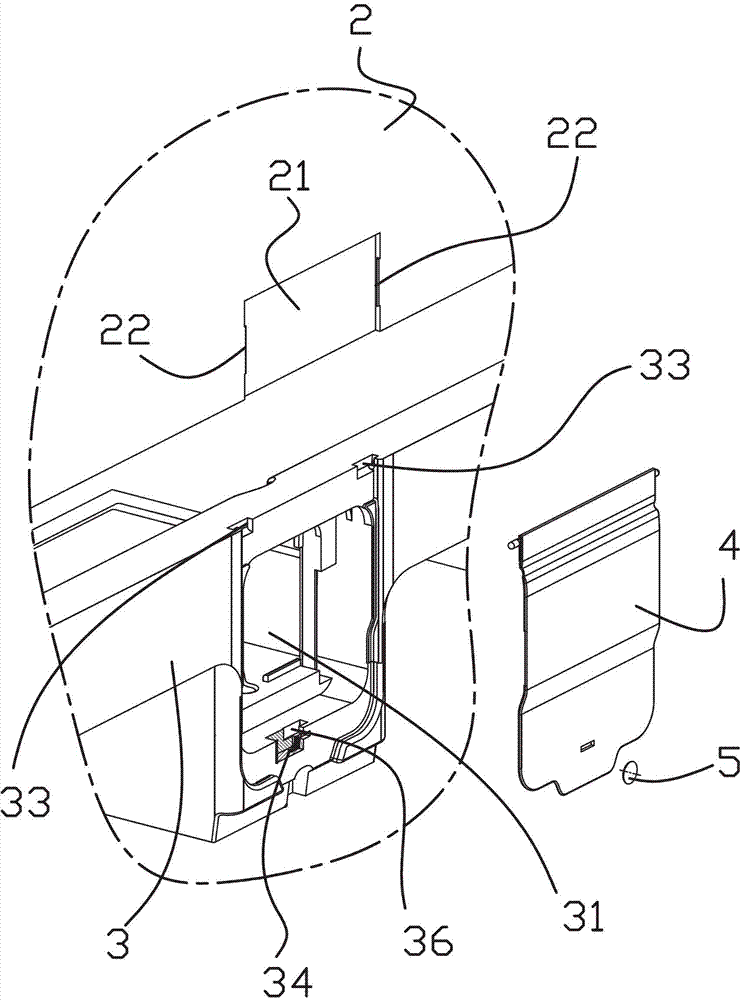

Liner sump dispensing system

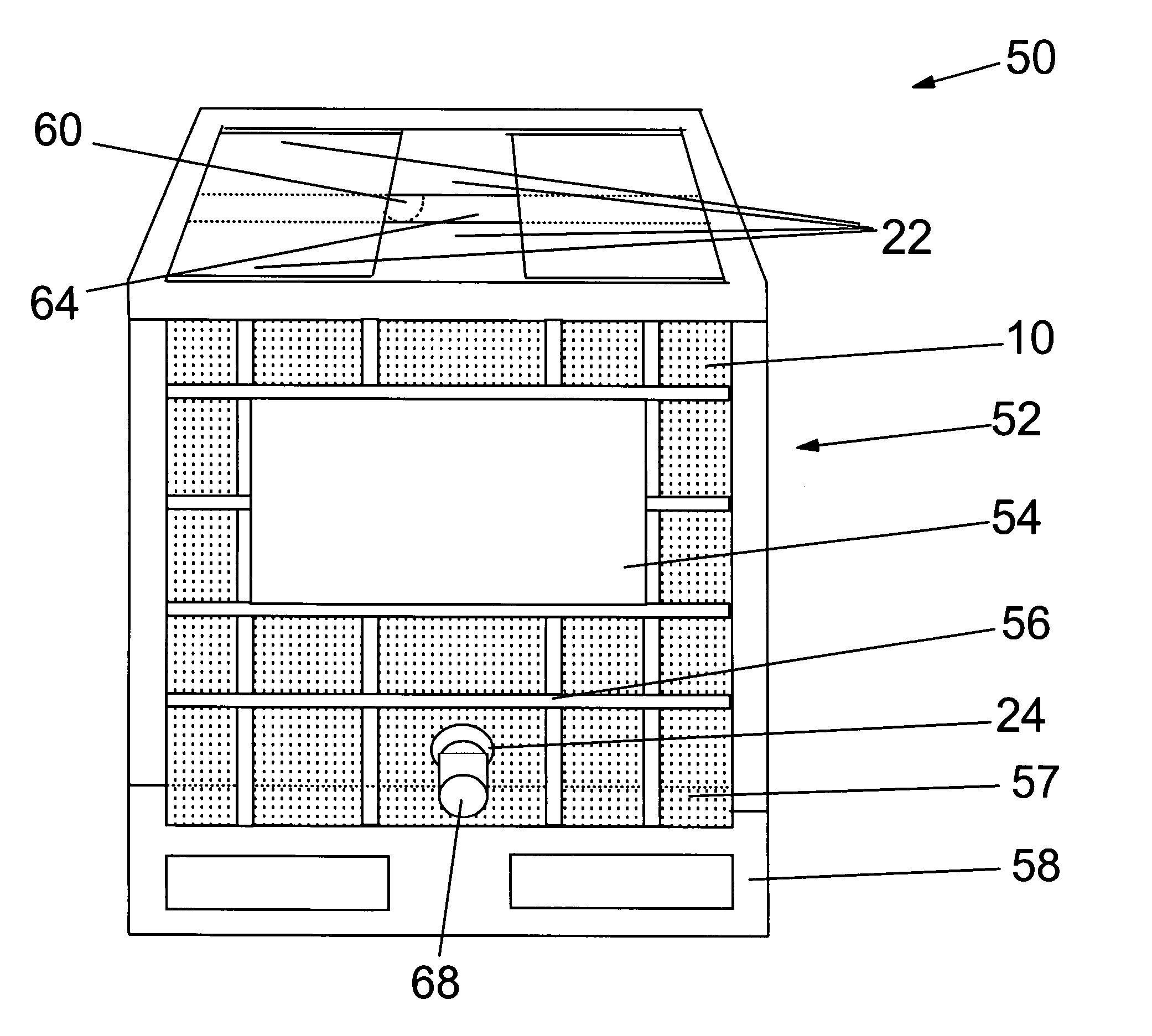

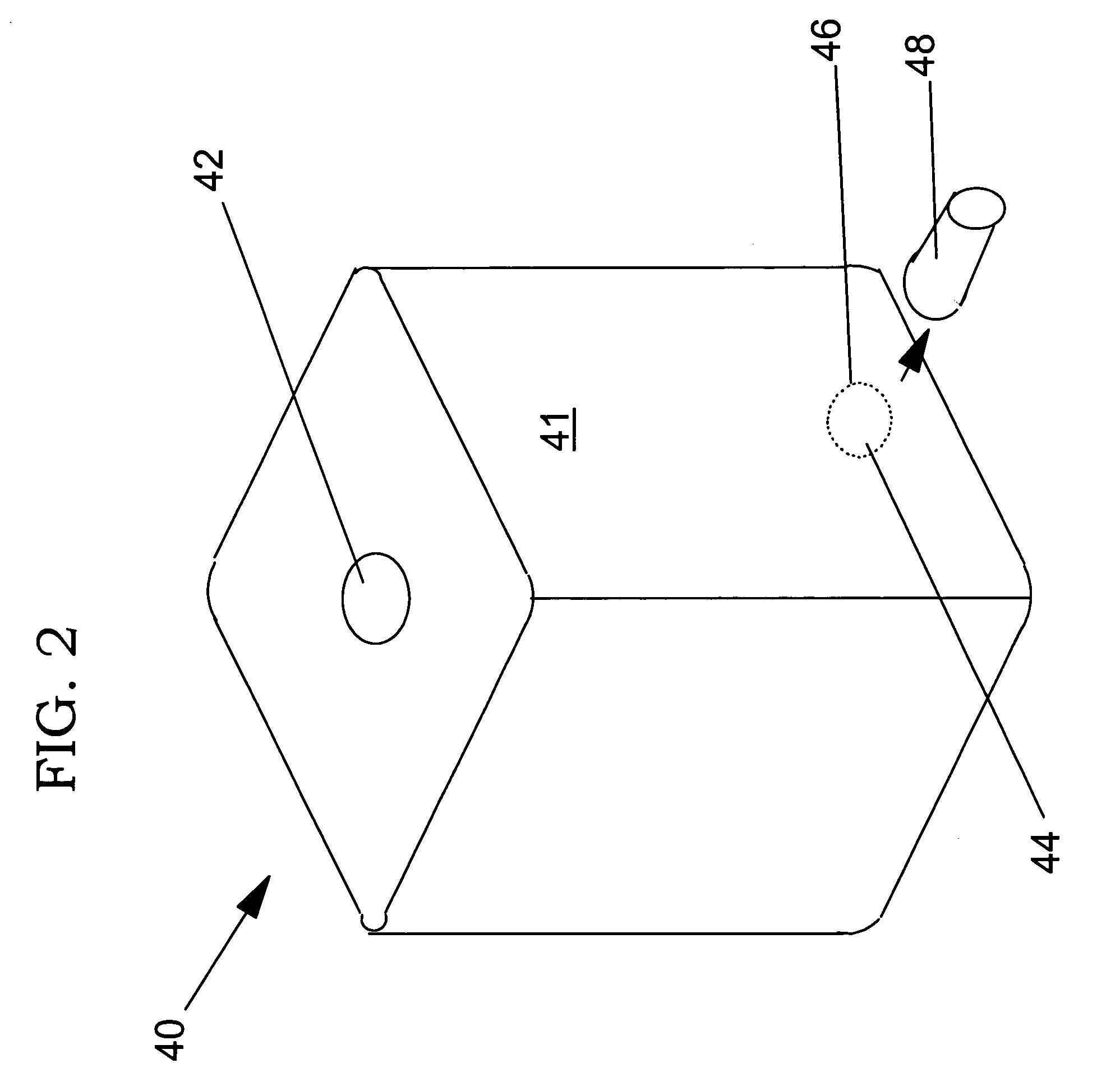

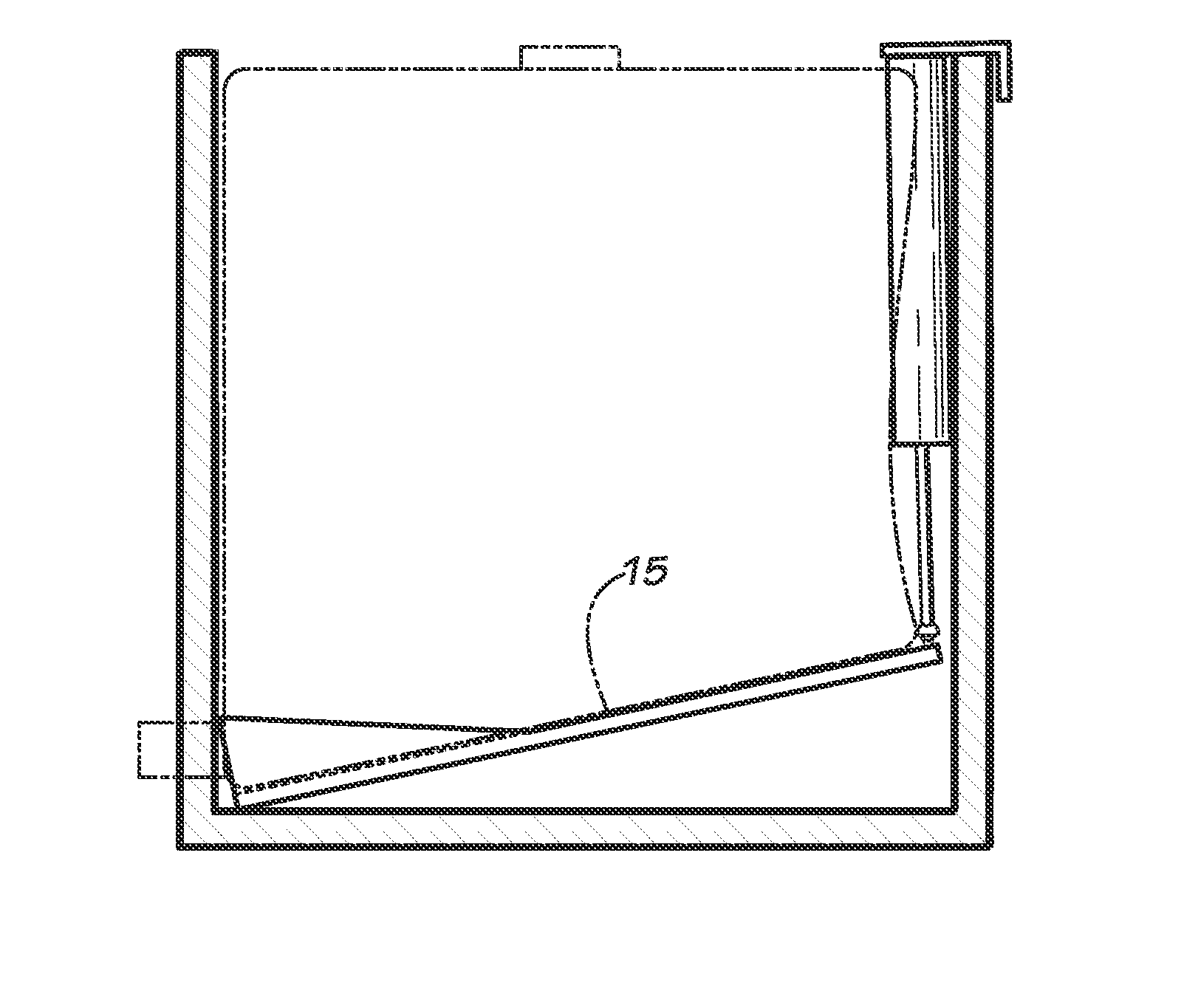

A liner sump dispensing system (10) is disclosed which is used in conjunction with a liner (11) and an intermediate bulk container (12). The liner sump dispensing system includes a liner cassette (40) and a tilting device (41). The liner cassette is mounted to the bottom of the liner. The tilting device includes a tray (51) and a reciprocating pneumatic arm (52) having a pneumatic cylinder (63) and a piston rod (64) pivotally coupled to a rear end (54) of the tray. The tray has a trapezoidal shaped floor (58) and a pair of inclined wings (60) extending upwardly along an incline from the floor. A L-shaped mounting flange (65) adapted to be coupled to the top end of the container is coupled to the end of the pneumatic cylinder opposite from the tray. The actuation of the pneumatic cylinder tilts the tray to tilt the liner bottom end.

Owner:GRAYLING INDS

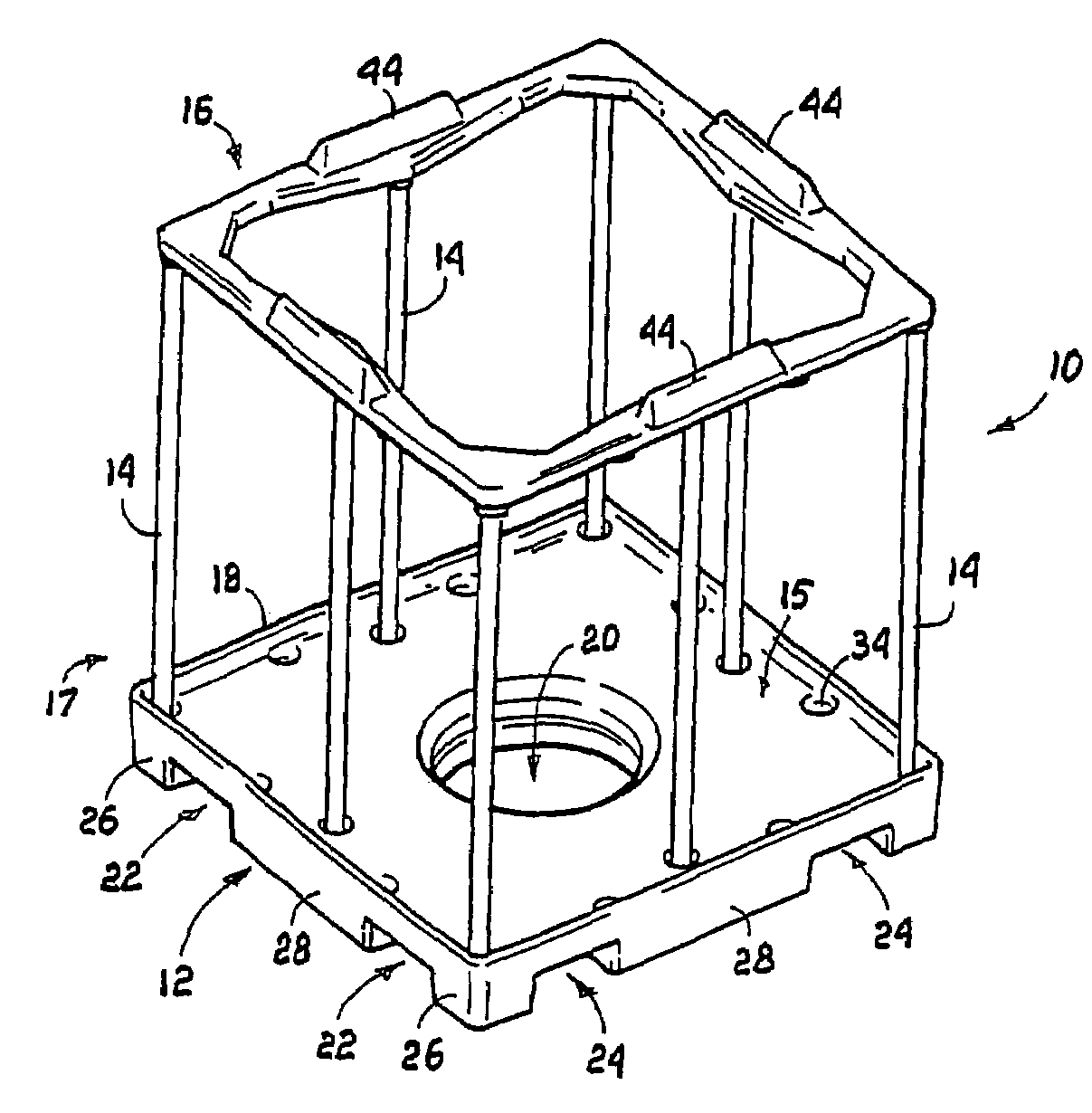

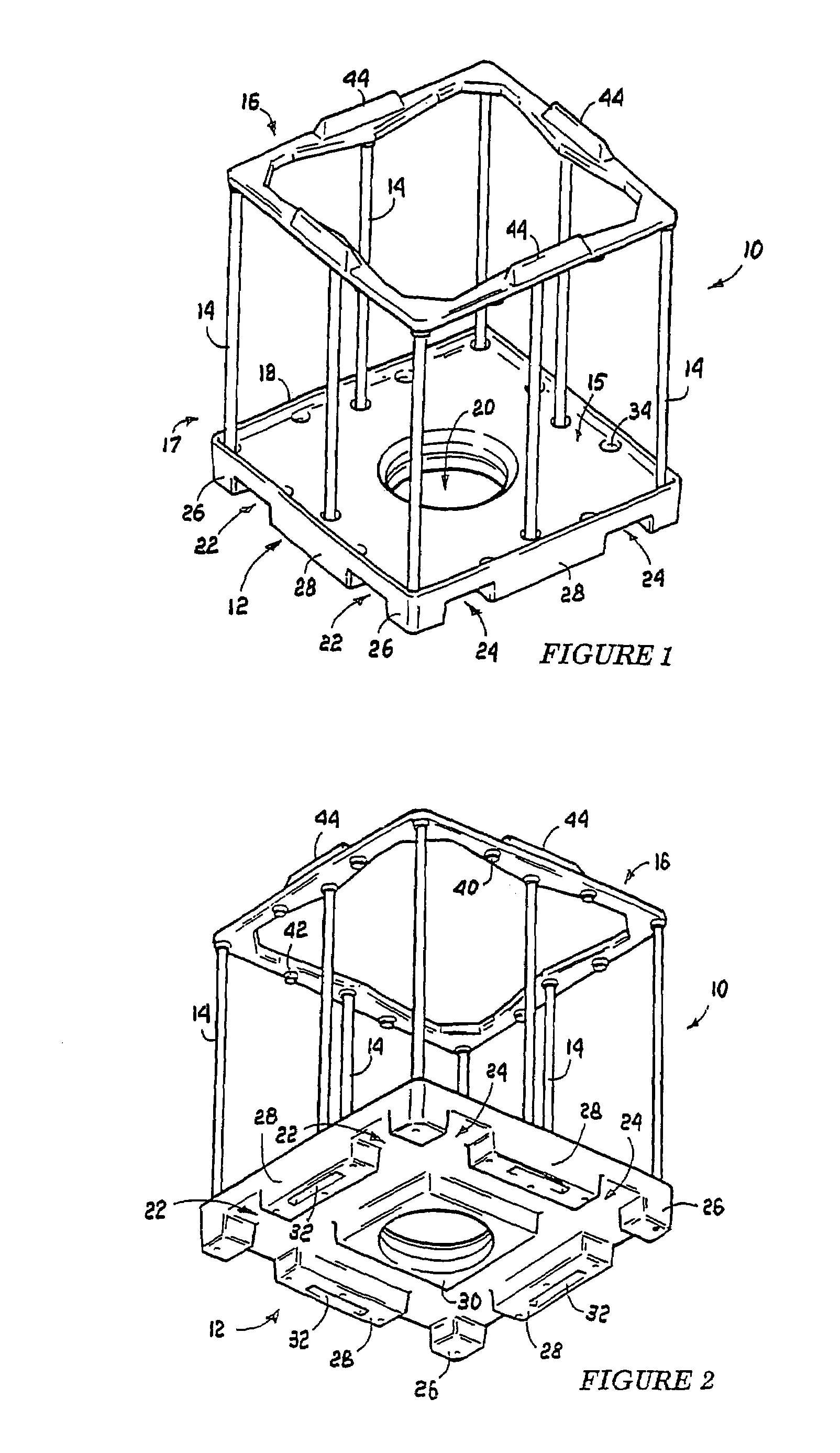

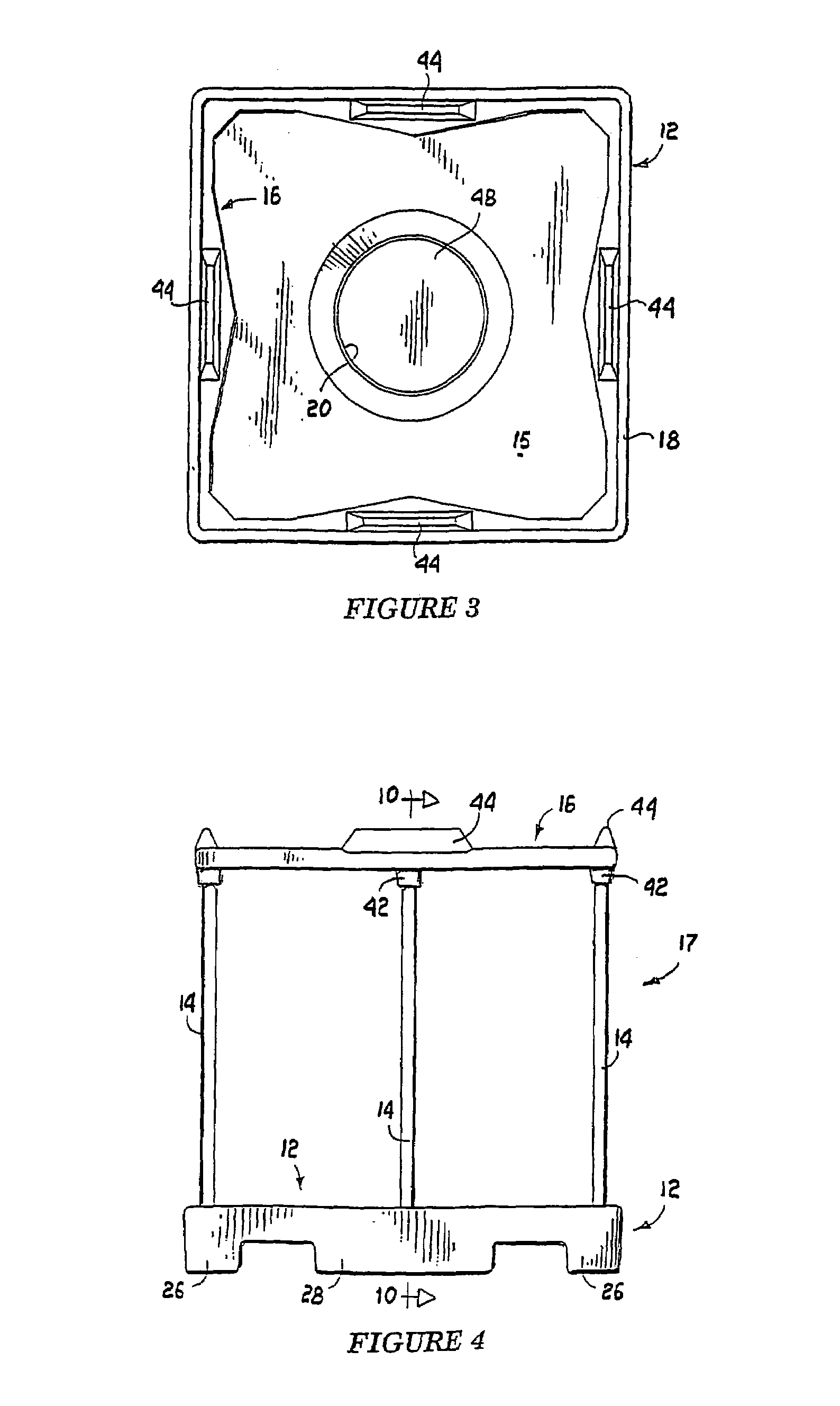

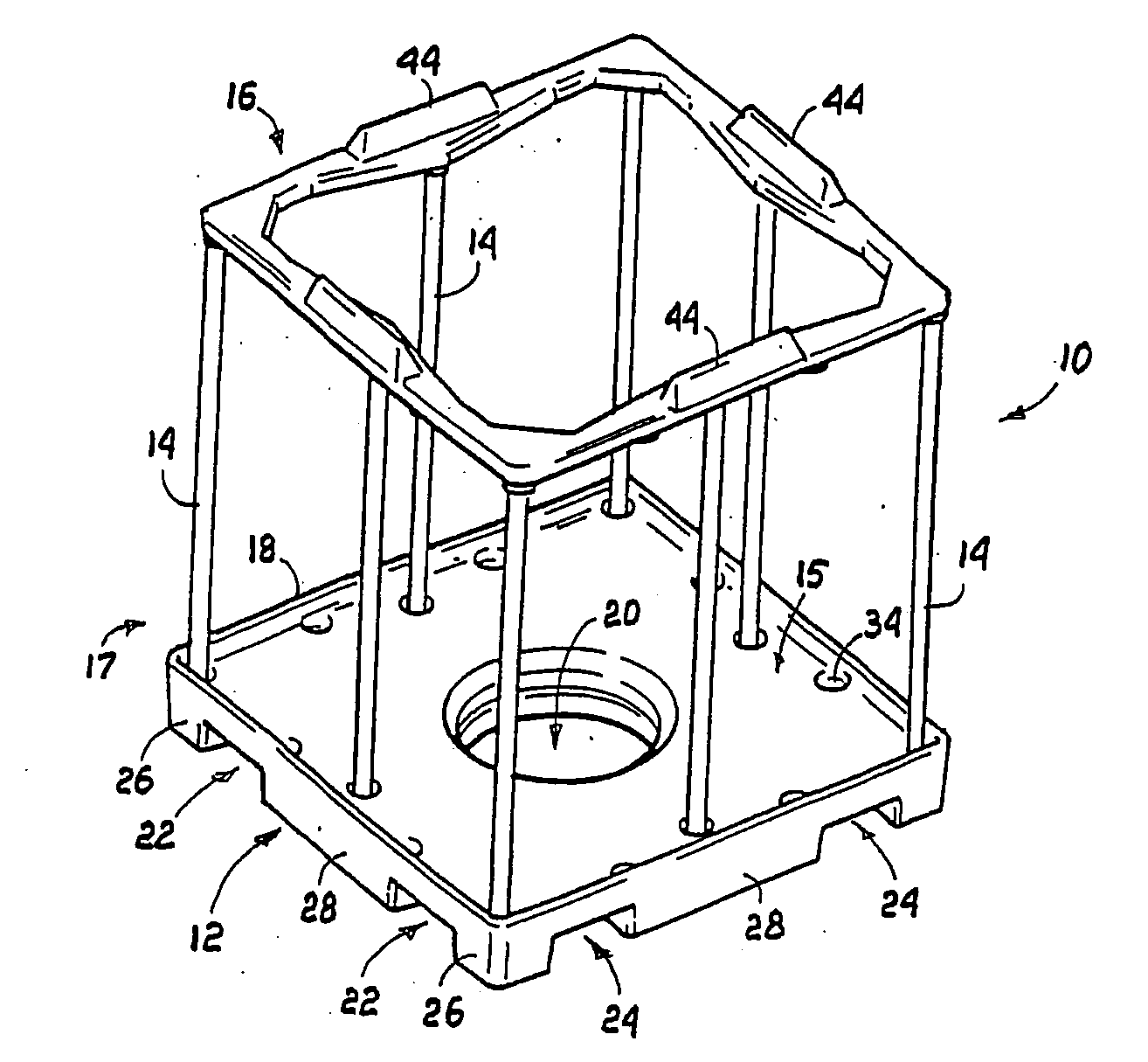

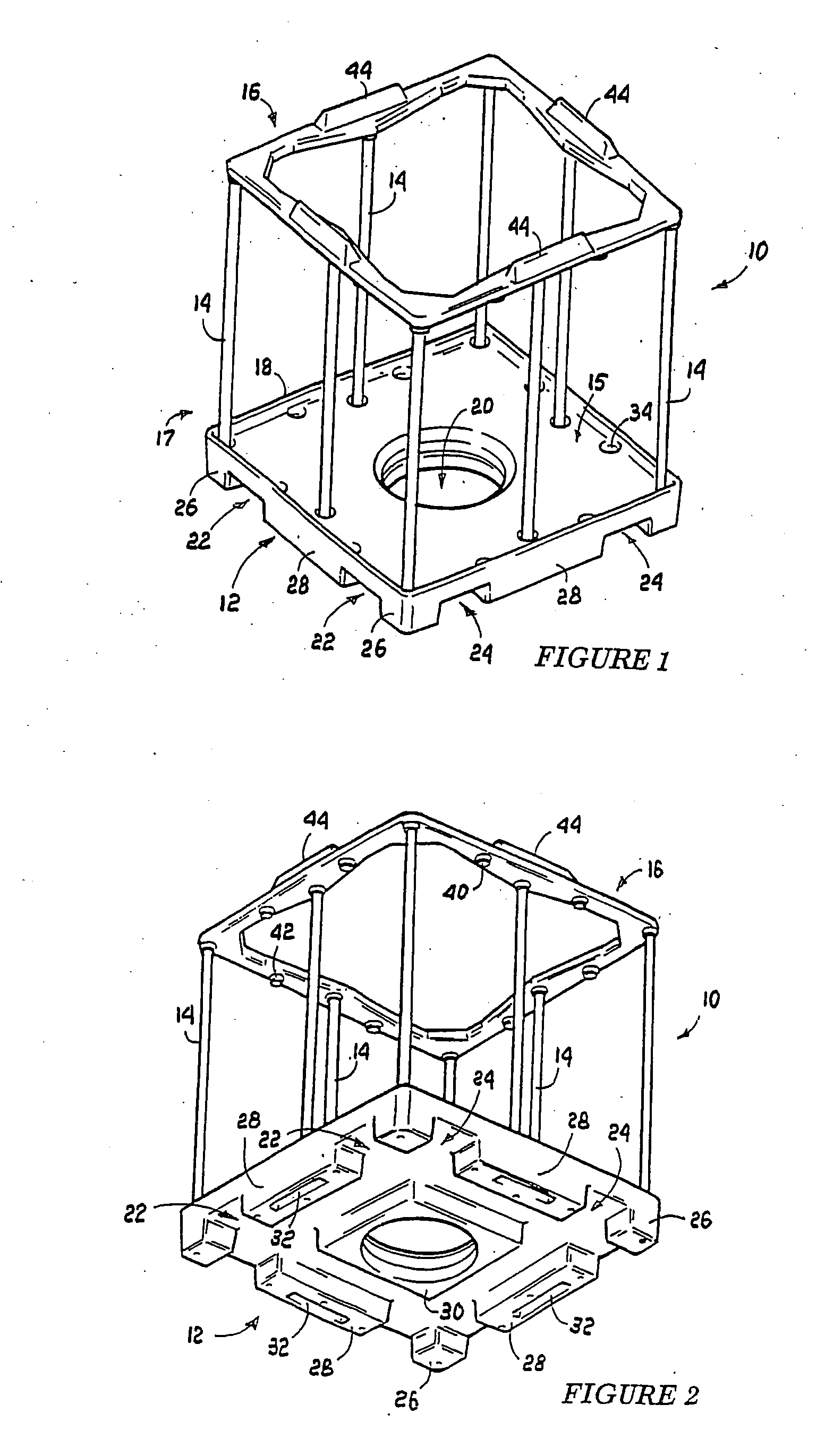

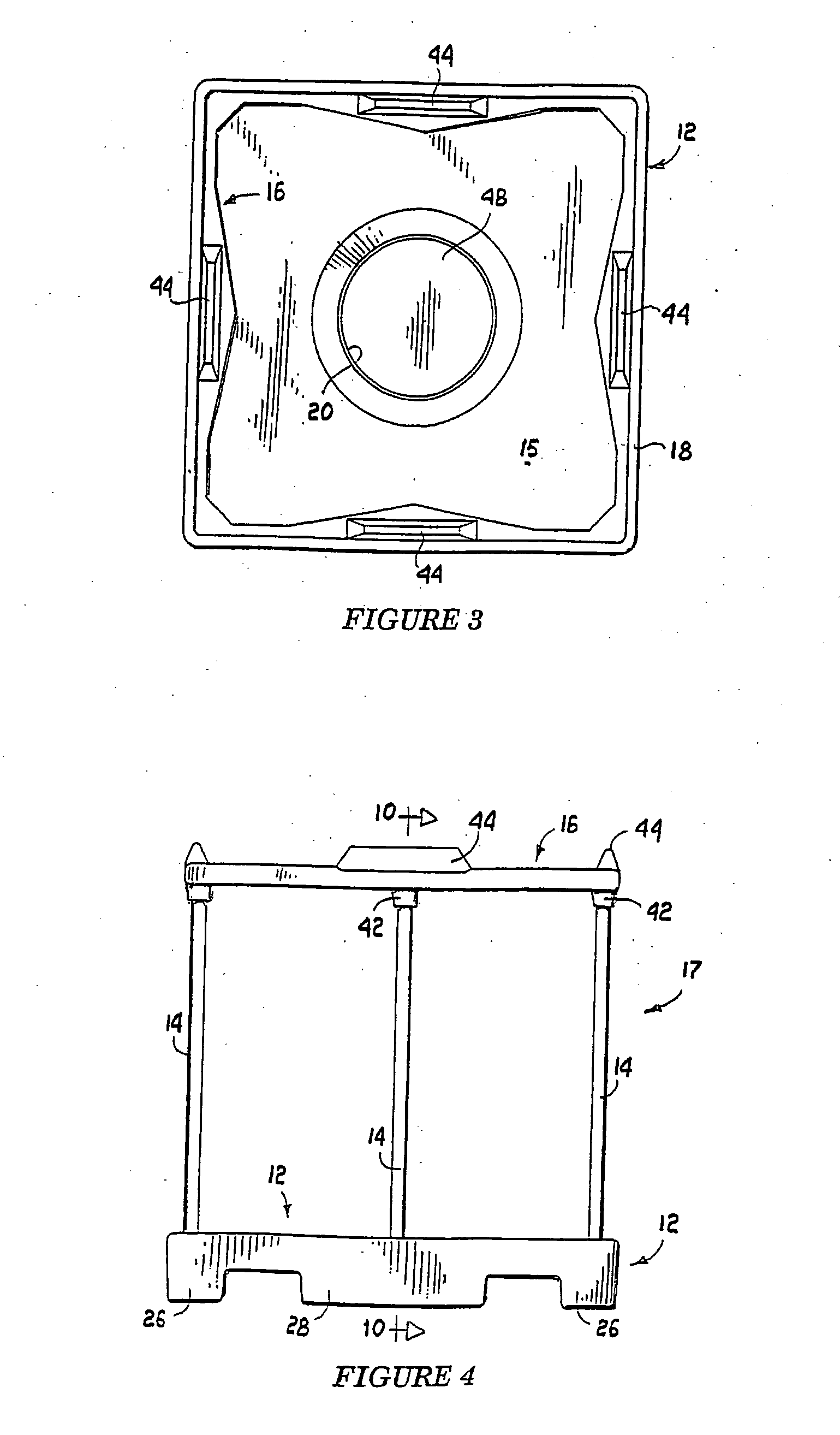

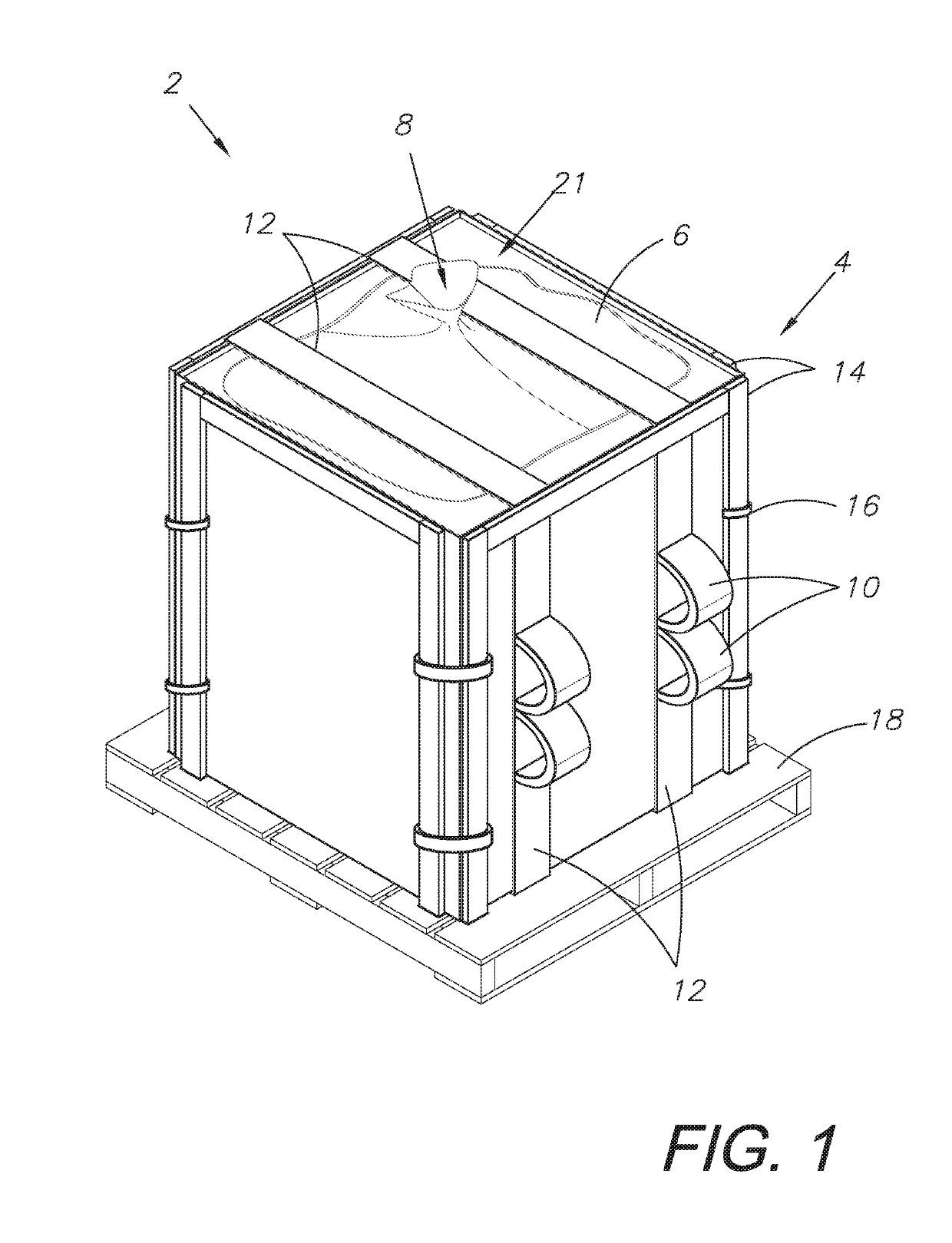

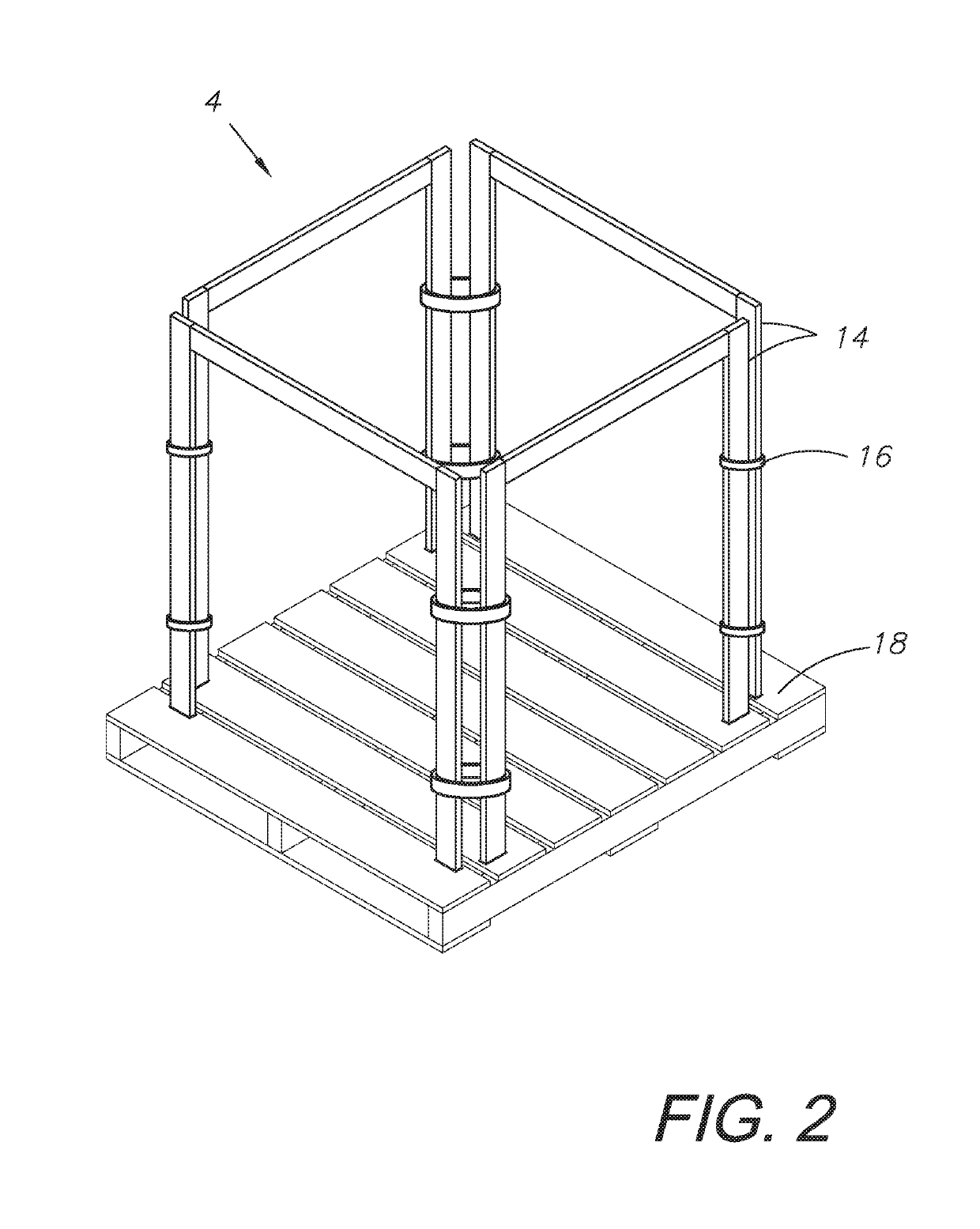

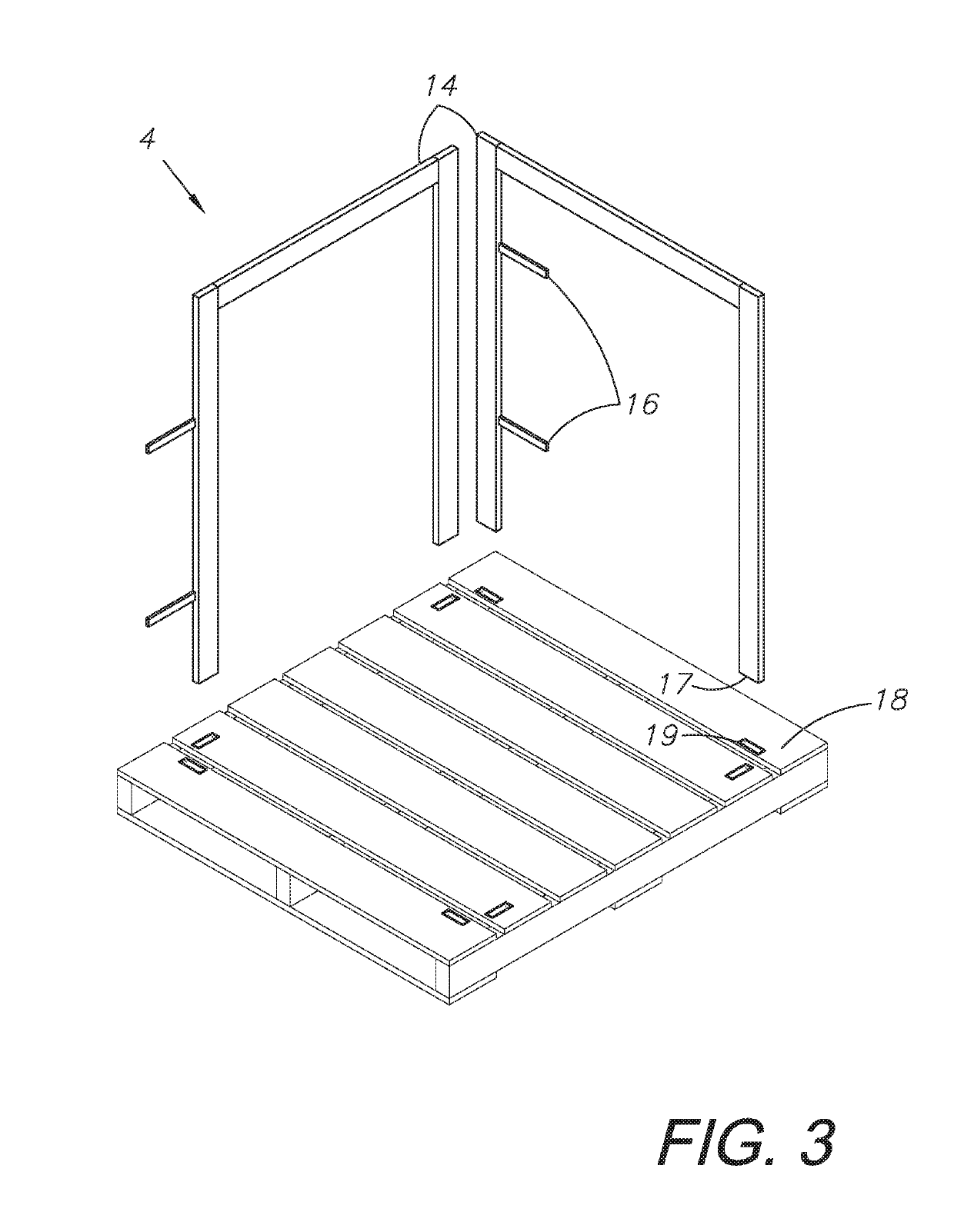

Intermediate bulk container with pallet and pole supported upper member

Owner:ALMAR PACKAGING INT

Intermediate bulk container

An intermediate bulk container (10) comprising a storage container (50) which is made from a suitable flexible material, a forklift pallet base (12) including pole engaging formations (34) on its upper surface (15) which are arranged about its periphery (18), a plurality of poles (14) the lower ends of which are releasably engageable with formations (34) on the pallet base (12) to provide a support cage for the storage container (50), a holed pole location member (16) including pole engaging formations (40) with which the upper ends of the poles (14) are engageable to lock the poles (14) together to inhibit transverse outward bulging of the storage container (50) from between the poles (14) and to preserve the container support cage (17) against a load in the storage container (50) with the underside of the pallet base (12) and the upper surface of the pole locating member (16) including formations (32, 44) which are releasably engageable with compatible formations on containers below and above it in a stack.

Owner:ALMAR PACKAGING INT

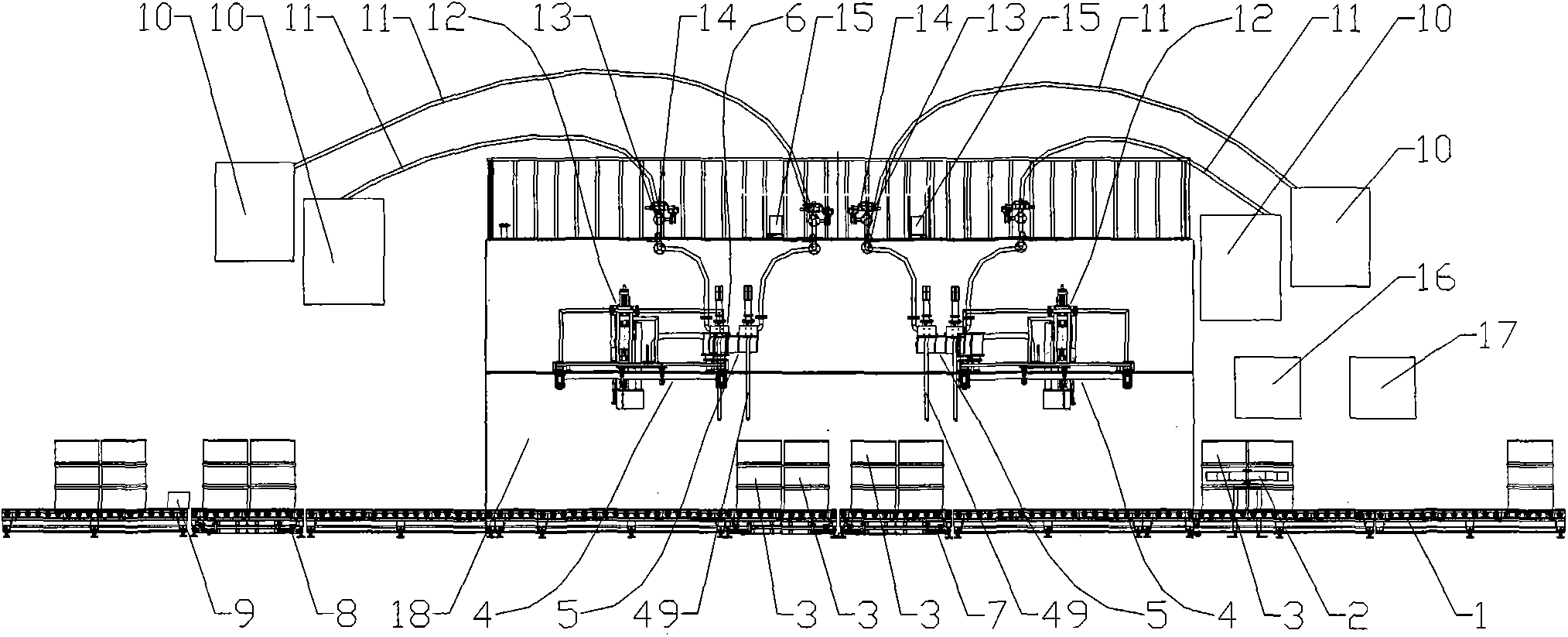

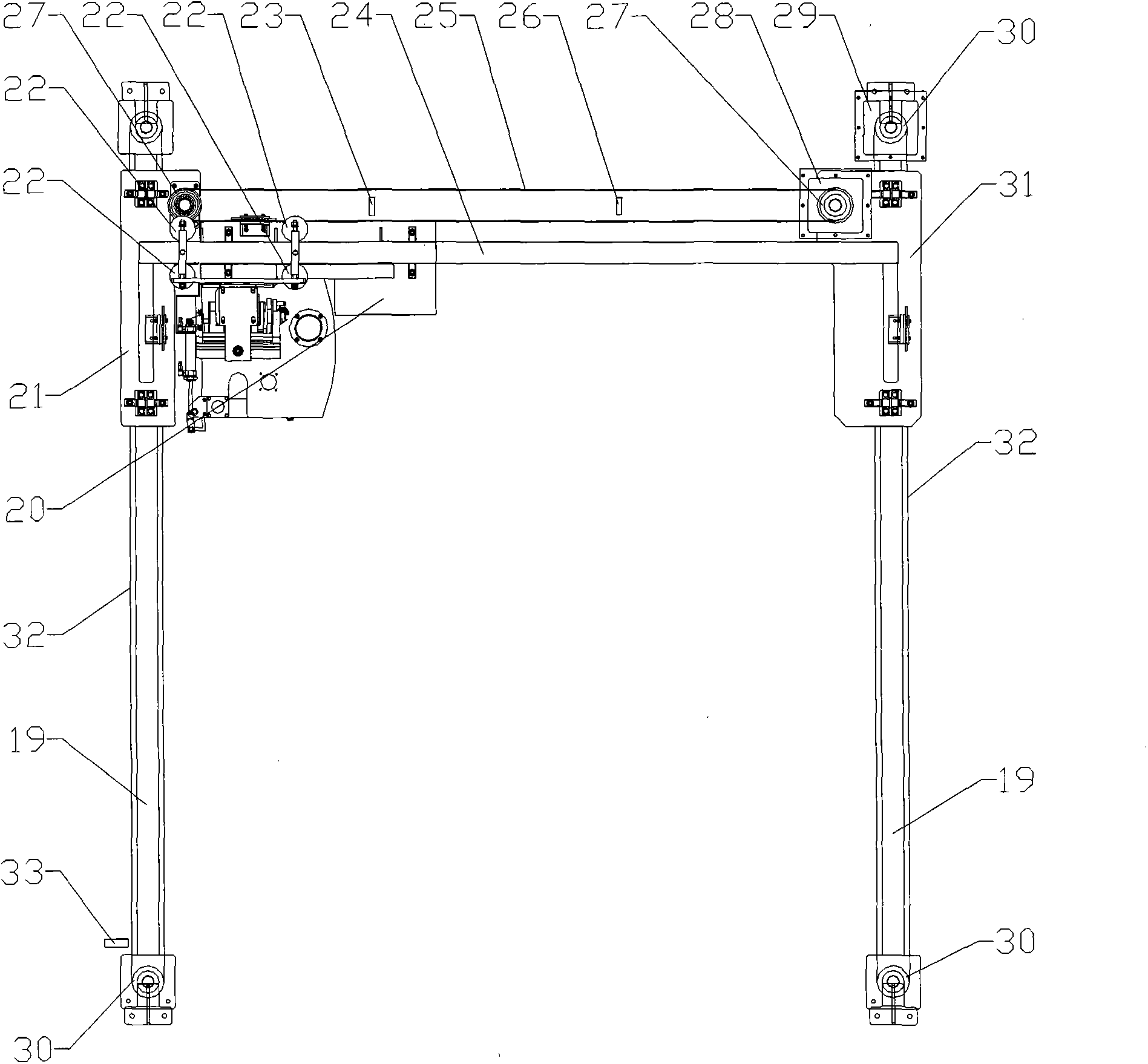

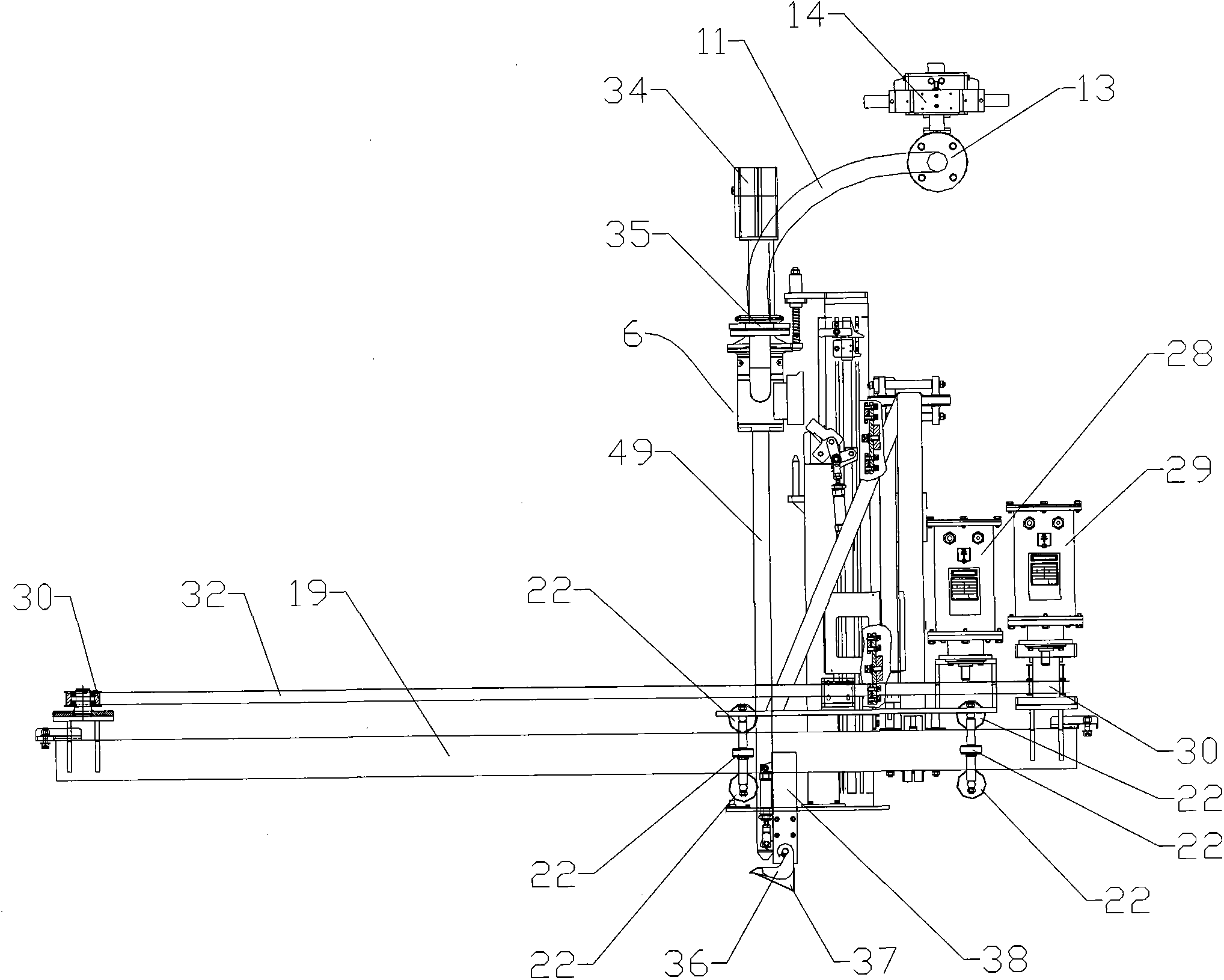

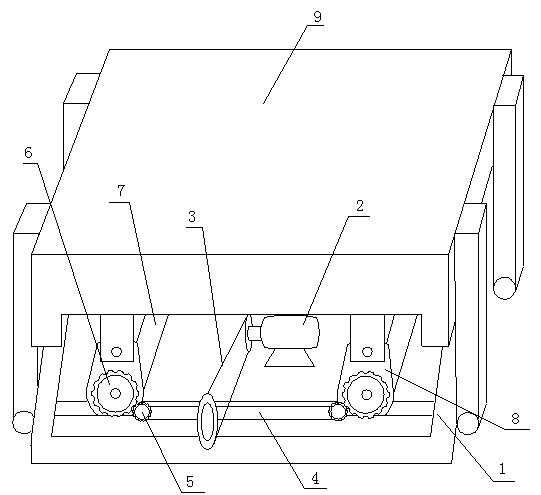

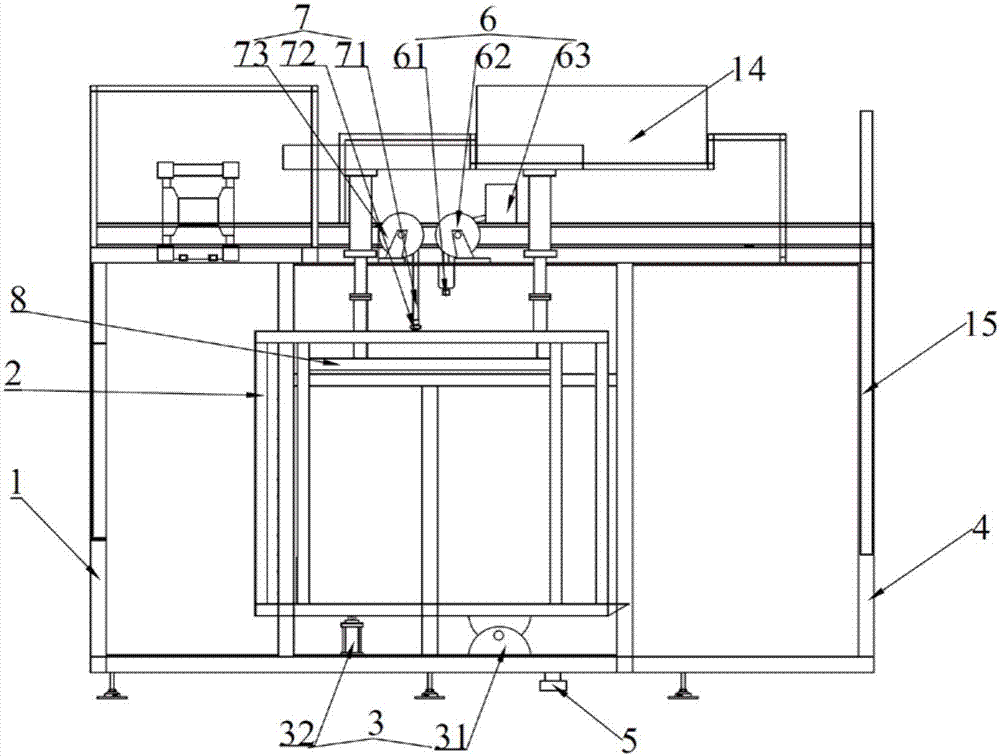

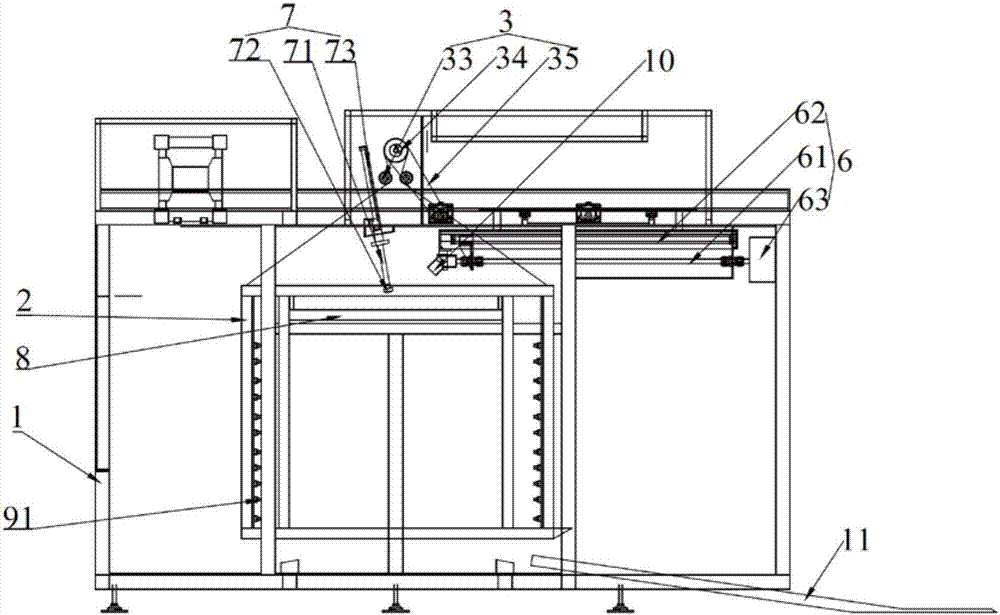

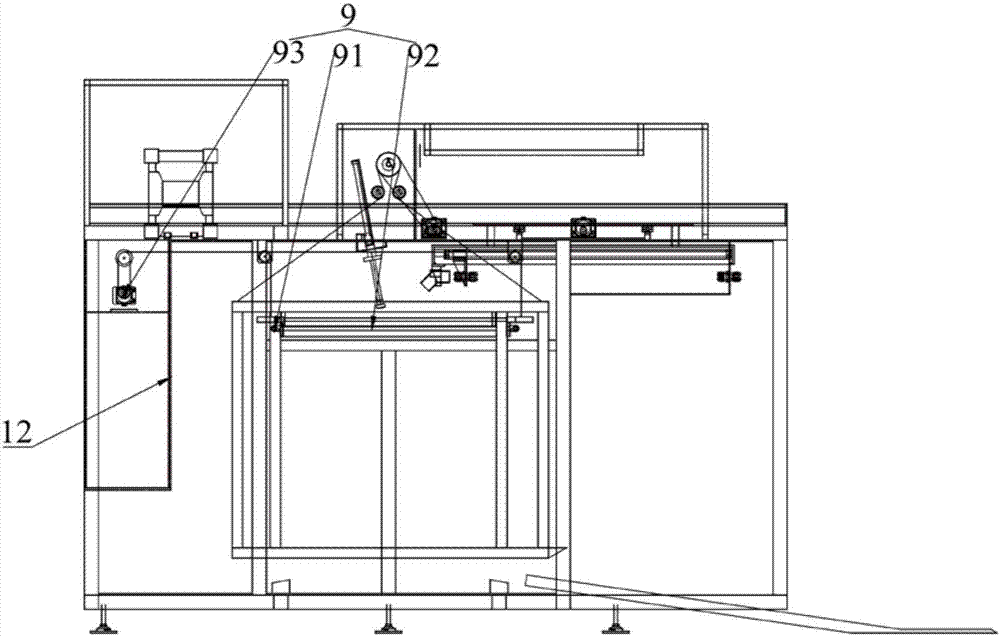

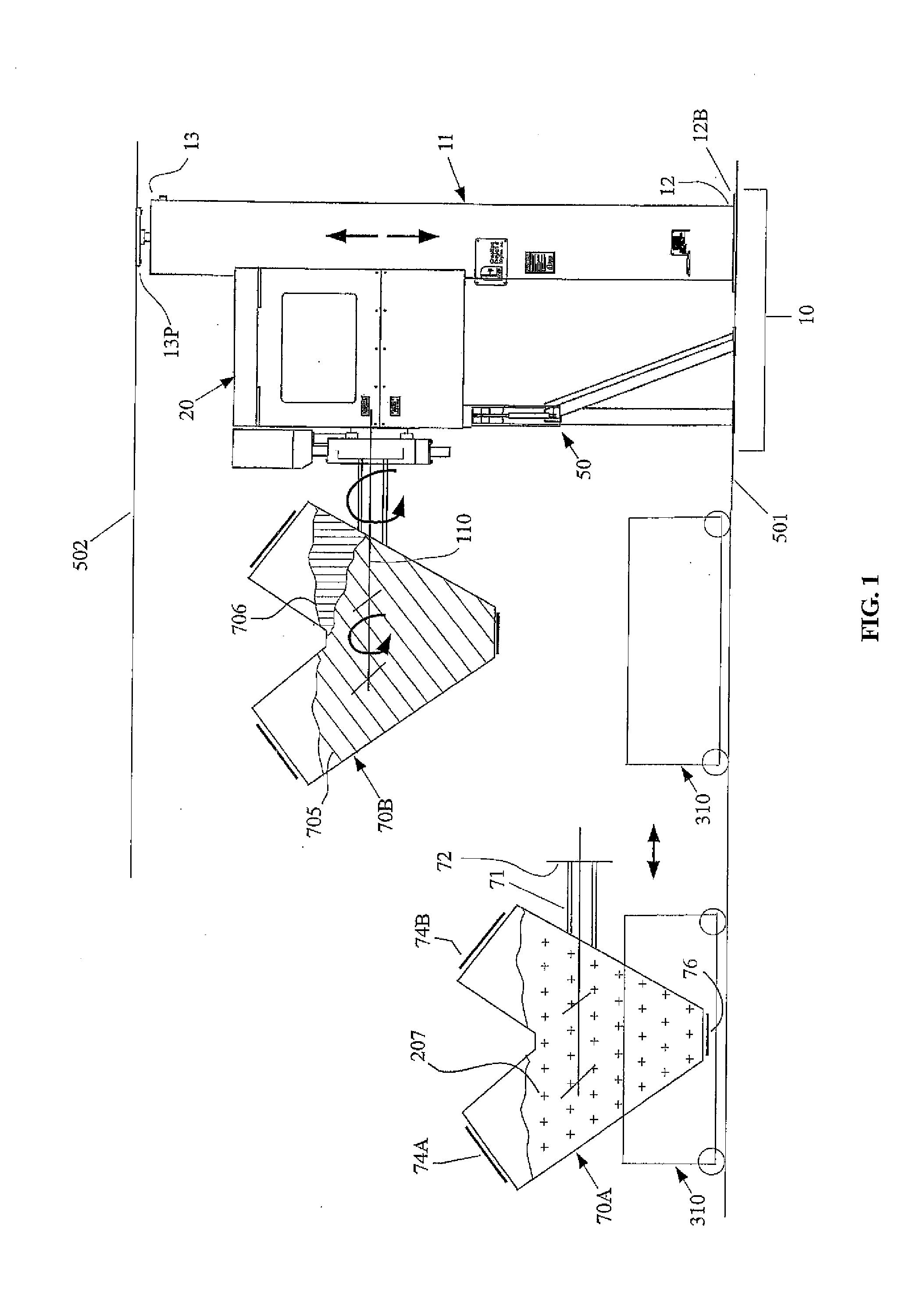

Full-automatic filling system for multi-variety material buckets and filling method of system

ActiveCN103523728AImprove efficiencyIncrease productivityBarrels/casks fillingIntermediate bulk containerEngineering

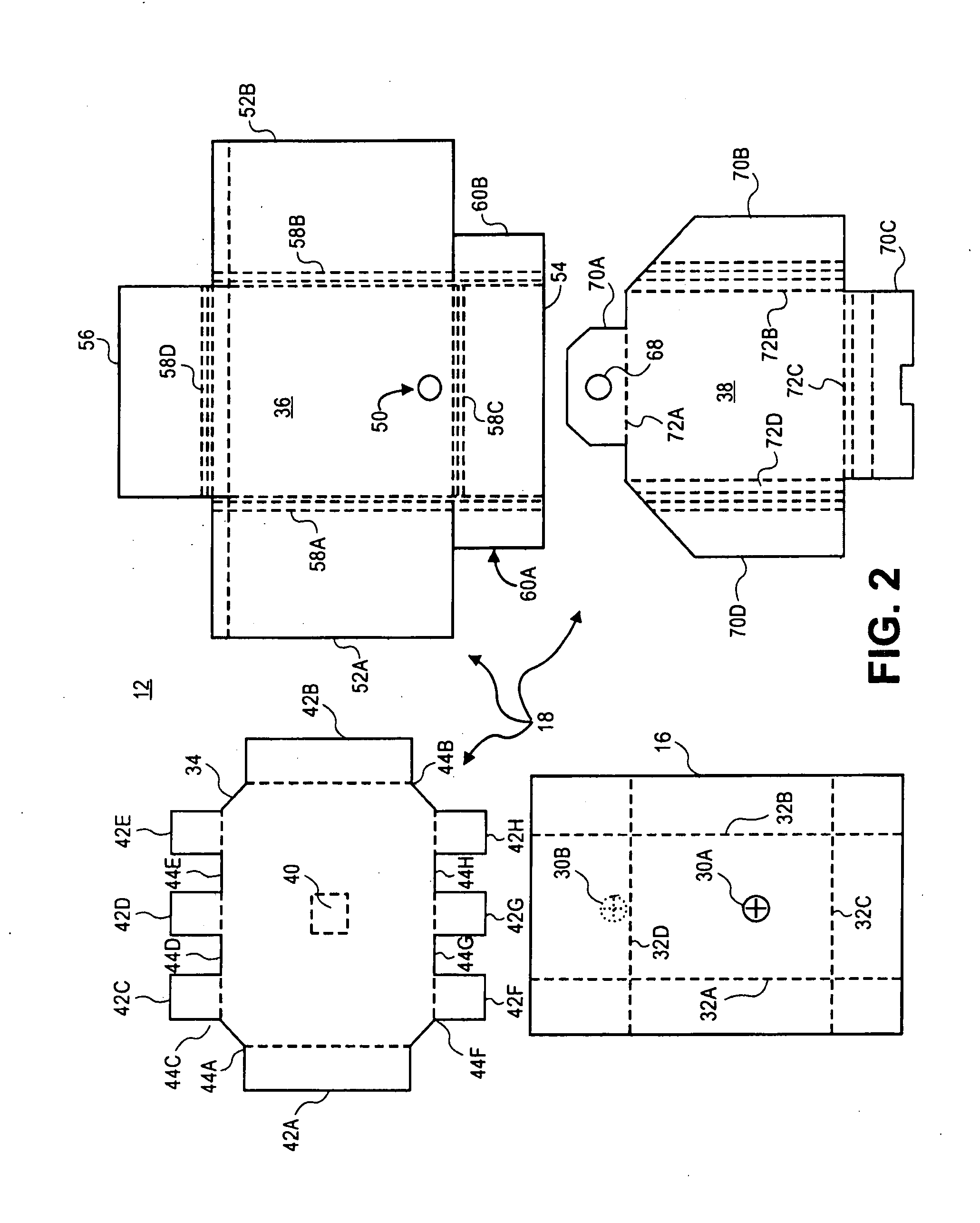

The invention discloses a full-automatic filling system for multi-variety material buckets and a filling method of the system. The full-automatic filling system comprises an engine body (18), wherein two groups of sliding mechanisms (4) are arranged on the engine body (18), filling mechanisms (12) are arranged on the sliding mechanisms (4), automatic exchanging mechanisms are arranged on the filling mechanisms (12), and two visual sensors (15) are arranged on the engine body (18) between the two groups of sliding mechanisms (4). The automatic exchanging mechanisms are arranged on the filling mechanisms, so that materials on two trays can be simultaneously filled, eight 200-L round buckets or two 1,000-L IBCs (Intermediate Bulk Containers) can be filled once, and two materials can be simultaneously filled; the two trays are conveyed below the corresponding visual sensors through a conveying mechanism to be filled, and compared with a traditional filling system, the full-automatic filling system has the advantages that the efficiency is increased by several times, the production efficiency is high, and the production cost is low.

Owner:CHANGCHUN BEIFANG INSTR EQUIP

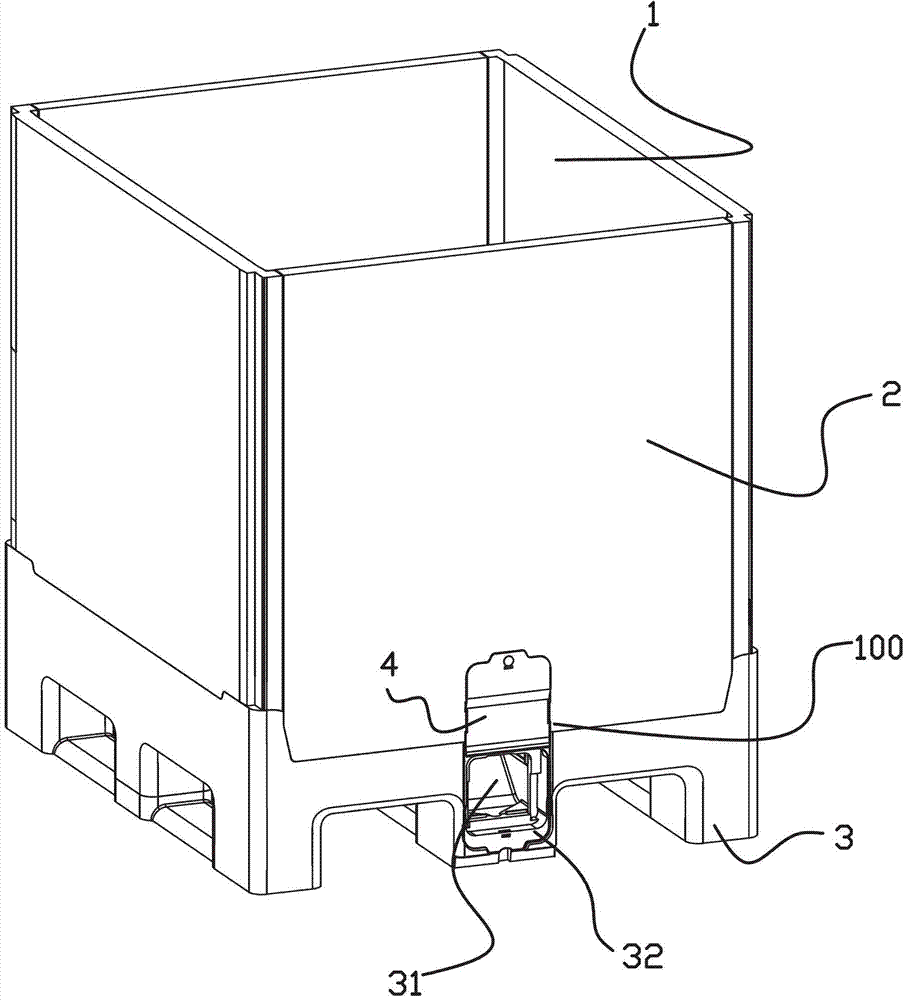

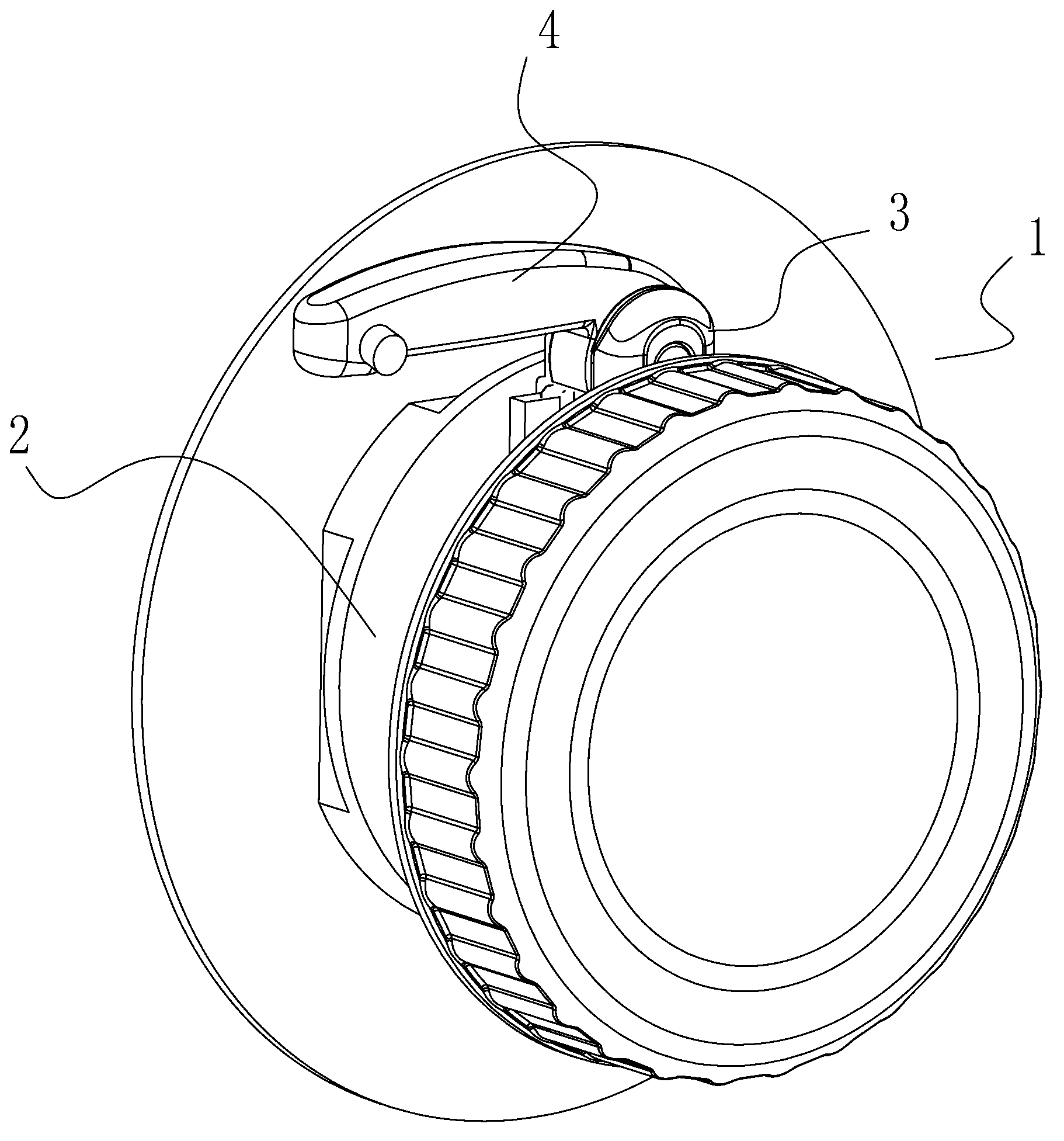

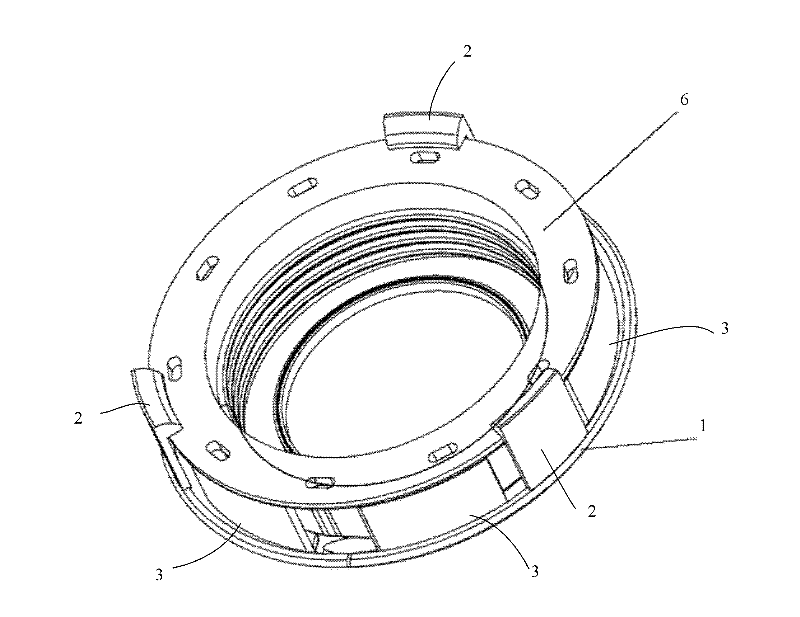

Cover device and container for covering built-in valve mounting passage opening in composite type midsize bulk container

ActiveCN102785829ASimple structureEasy to operateLarge containersNon-removalbe lids/coversIntermediate bulk containerEngineering

Owner:SHANGHAI HONGYAN RETURNABLE TRANSIT PACKAGINGS CO LTD

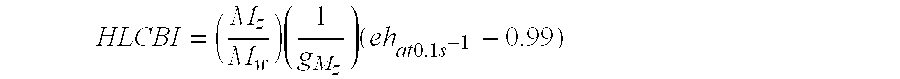

Polymer composition for use in blow moulding

ActiveUS8802768B2Good dimensional stabilityLarge containersMixingIntermediate bulk containerPolymer science

A novel polymer composition is described comprising ethylene homopolymers and / or copolymers of ethylene with C3-C8-alpha-olefins which polymer composition has a density of from 0.940 to 0.949 g / cm3, a melt index (HLMI) according to DIN EN ISO 1133:2005, condition G at 190° C. and 21.6 kg, of from 3 to 7 g / 10 min. and a Hostalen Long Chain Branching Index (HLCBI) of from 3 to 8, and which polymer composition is produced by polymerisation with one or more Ziegler catalysts in a series of at least two polymerization reactors. The new polymer composition can in particular be used for blow moulding of intermediate bulk containers.

Owner:BASELL POLYOLEFINE GMBH

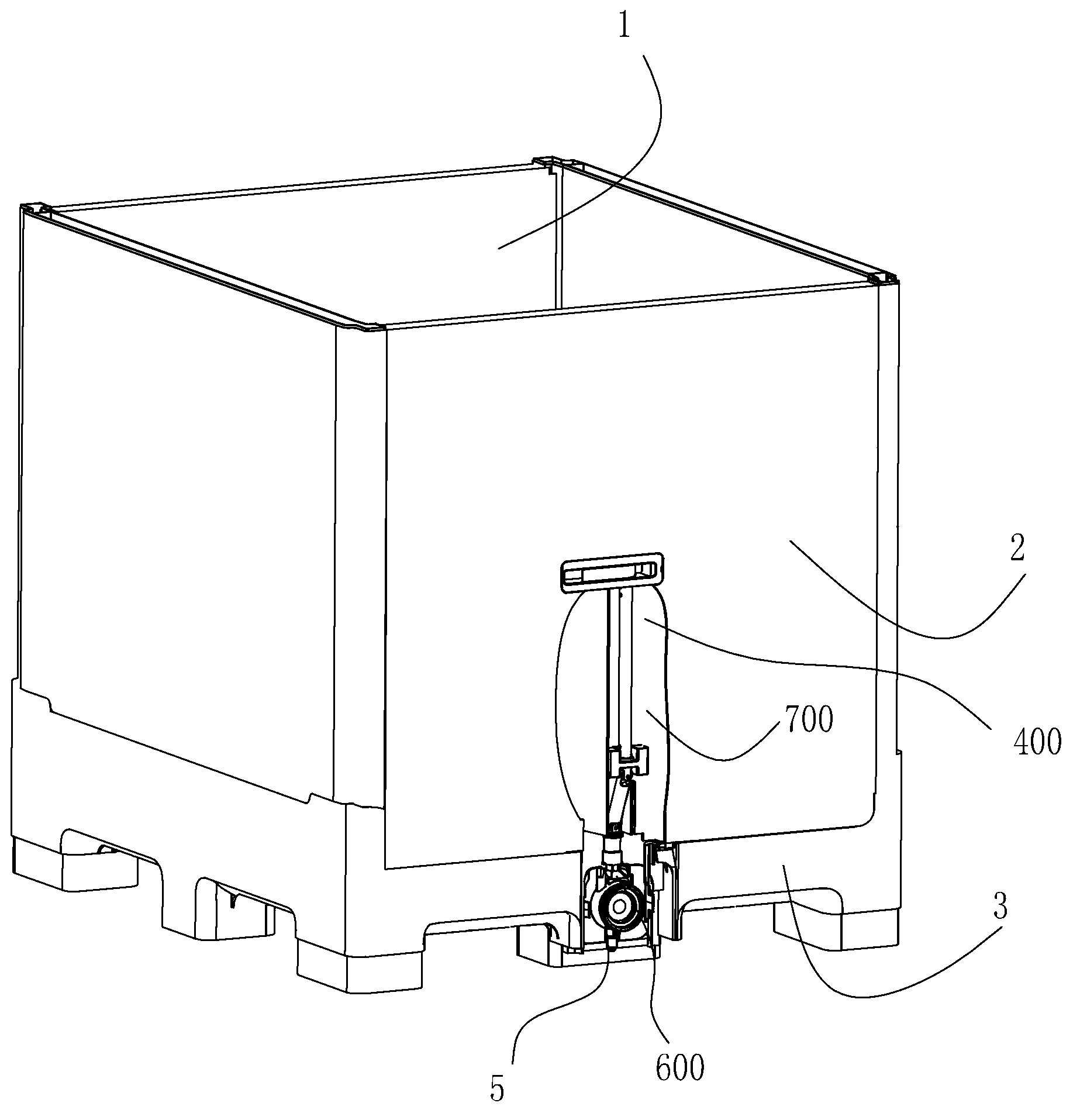

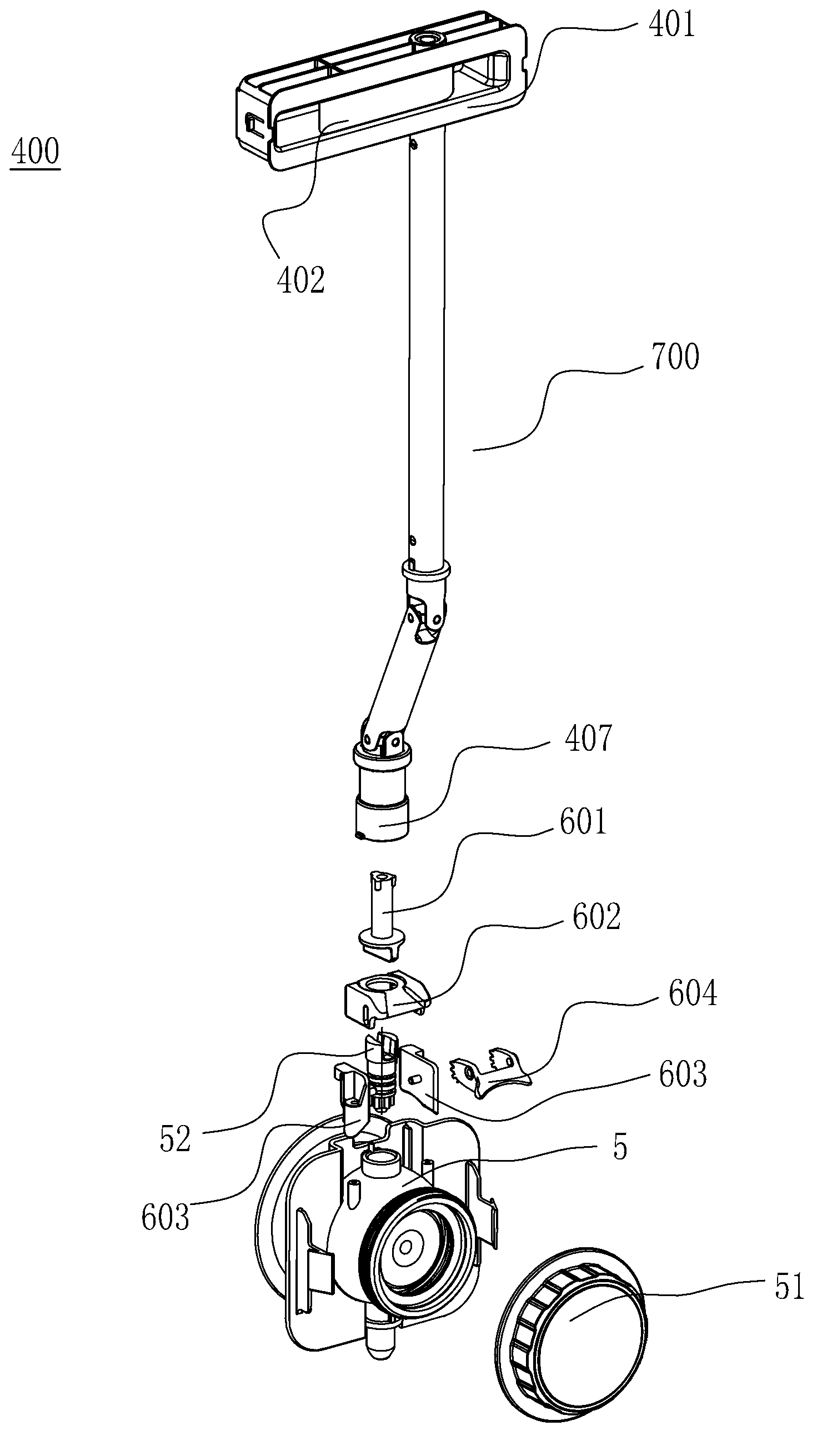

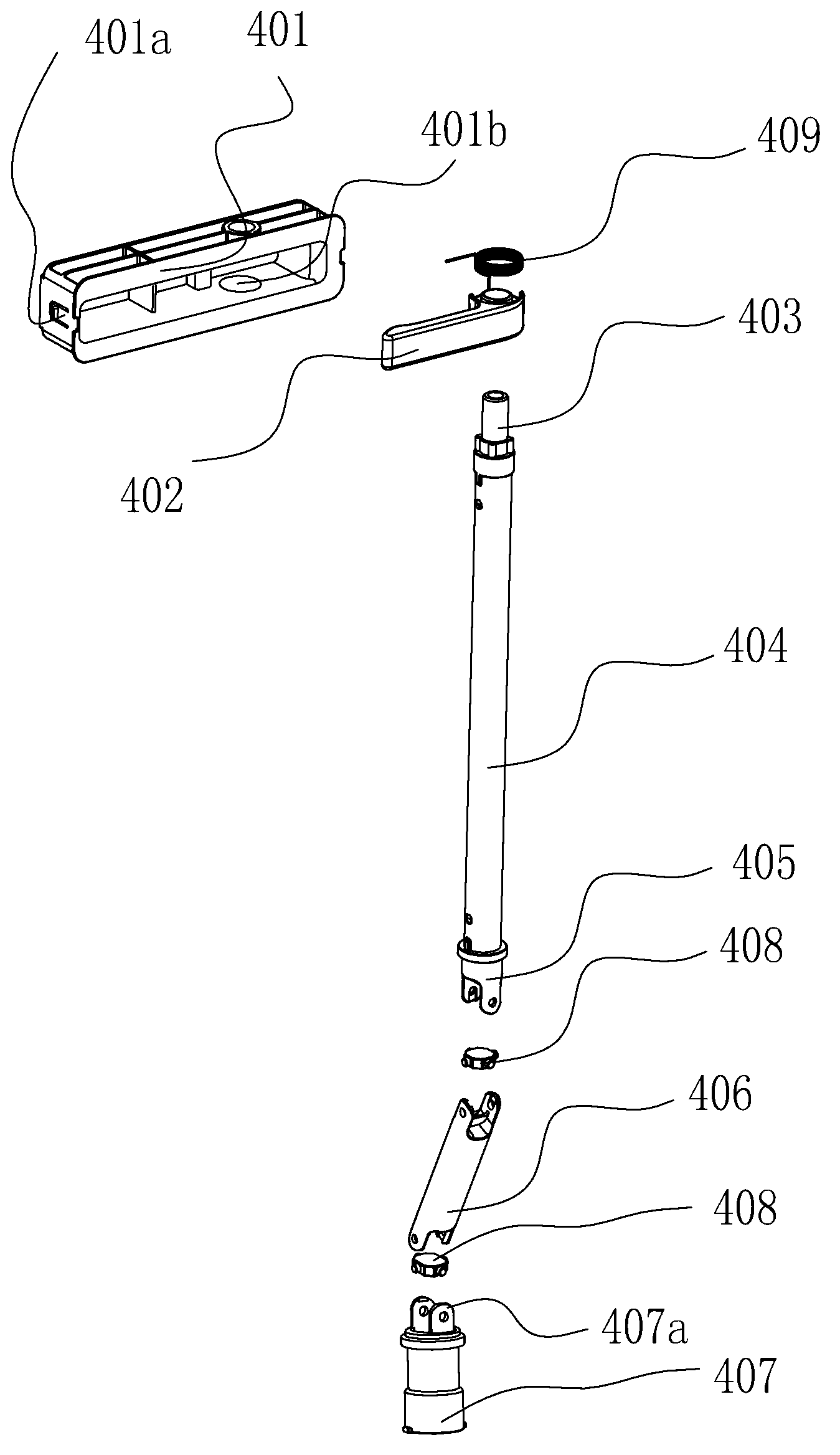

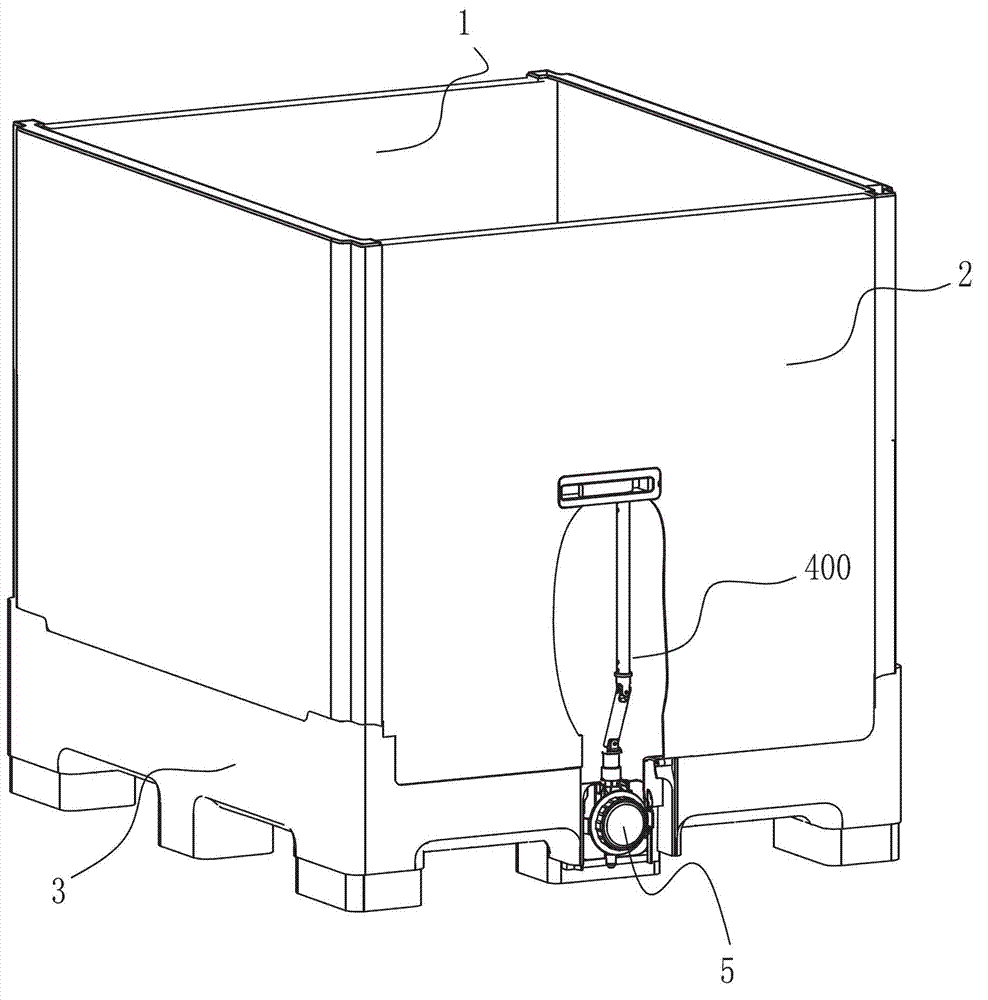

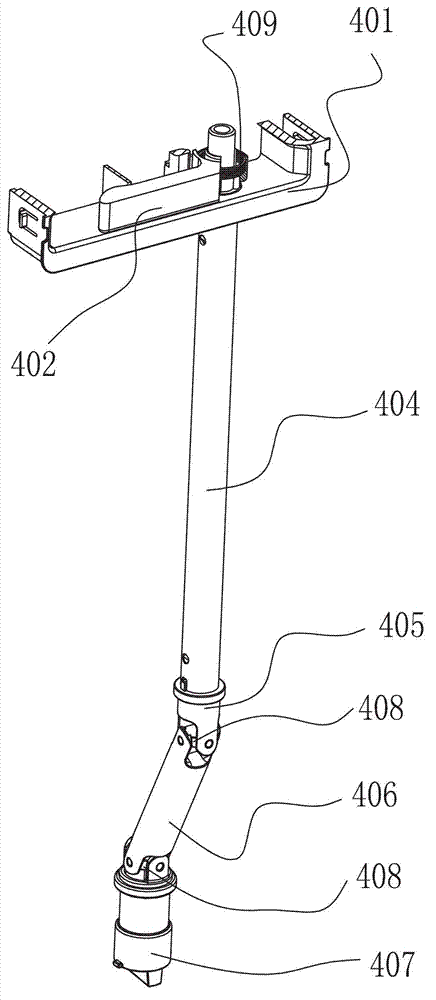

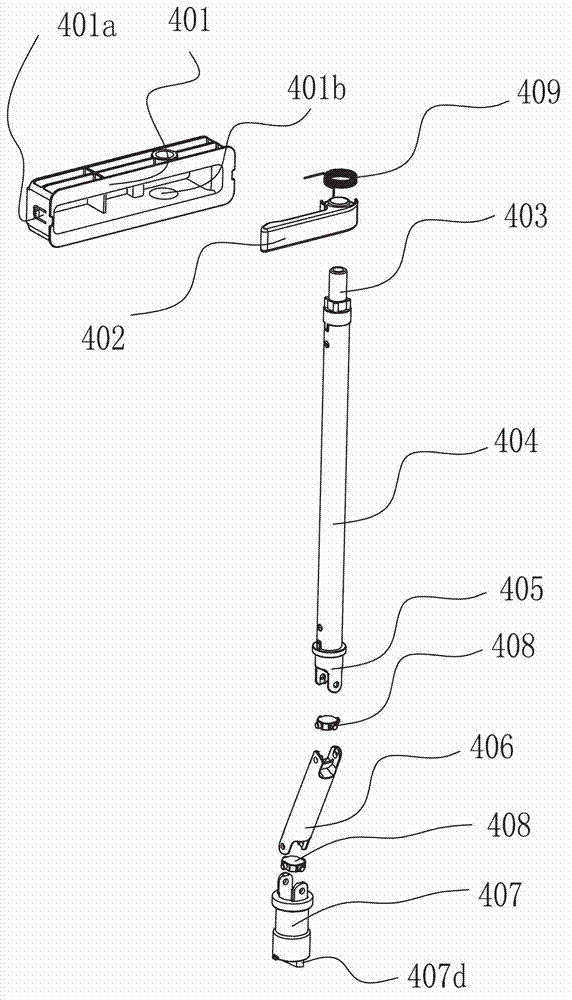

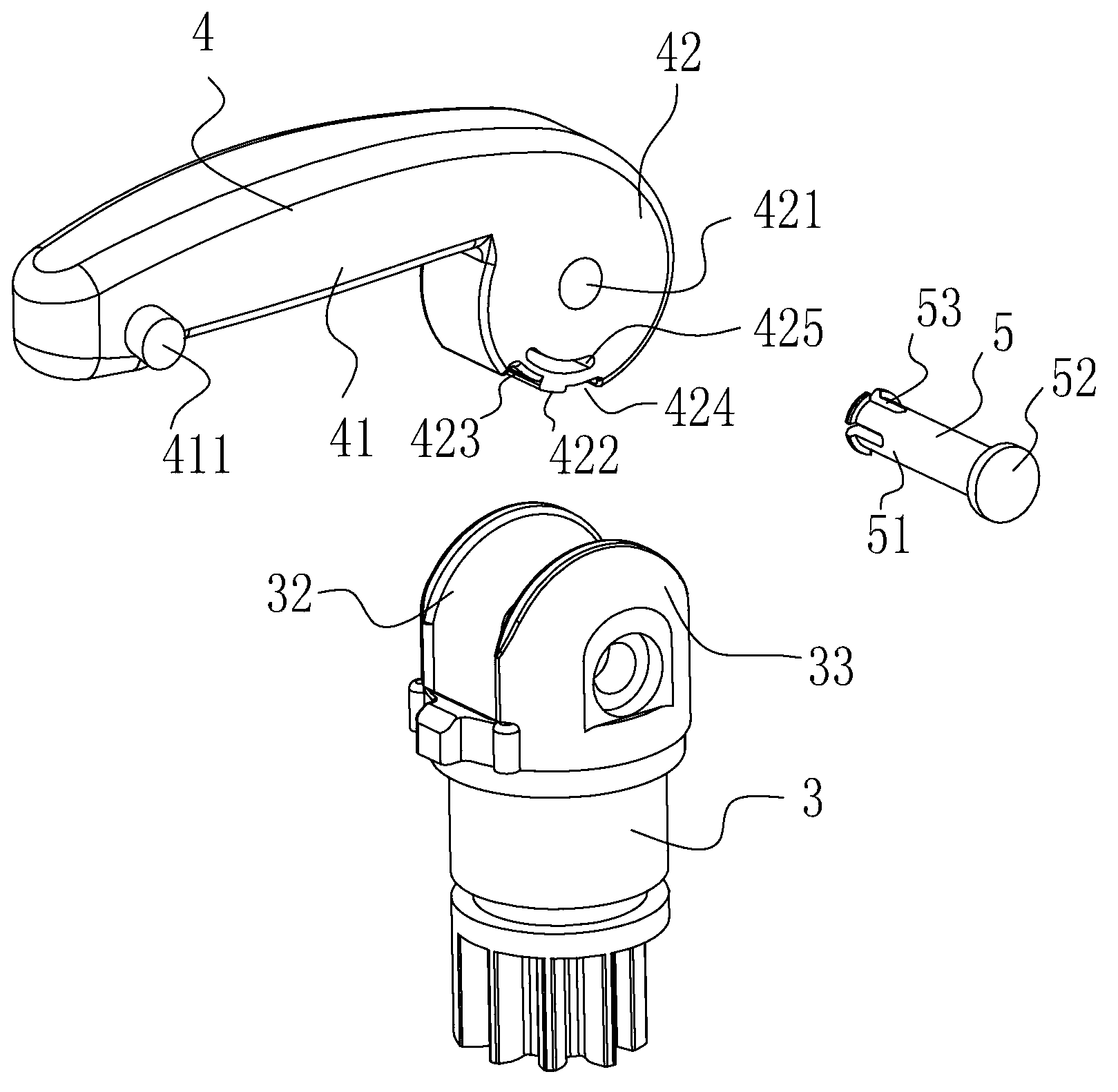

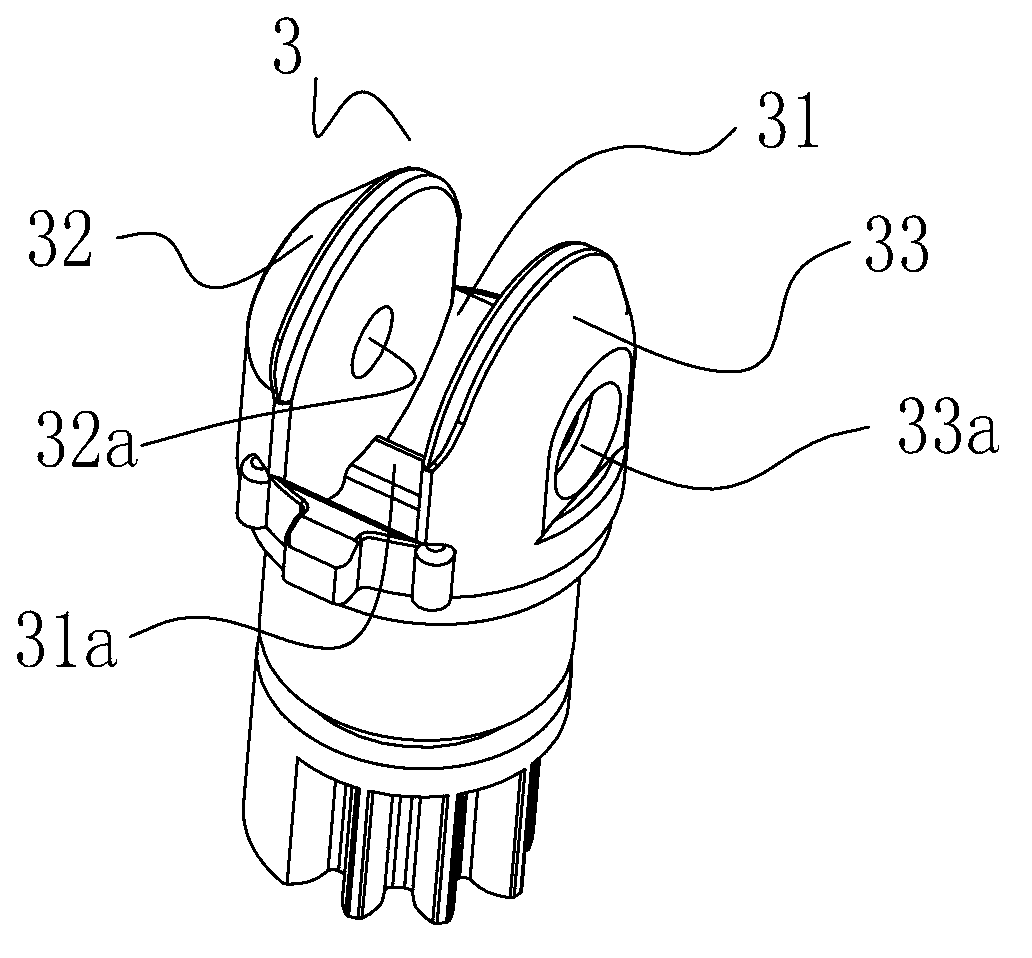

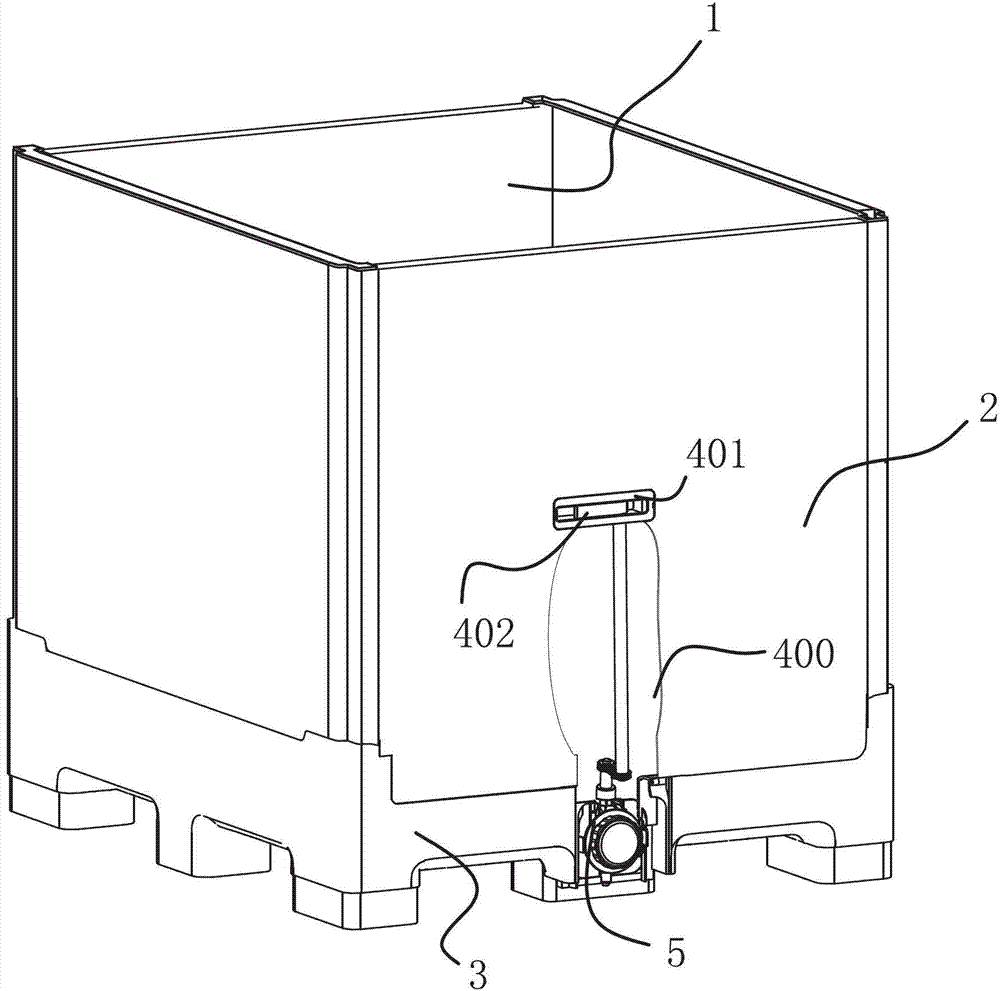

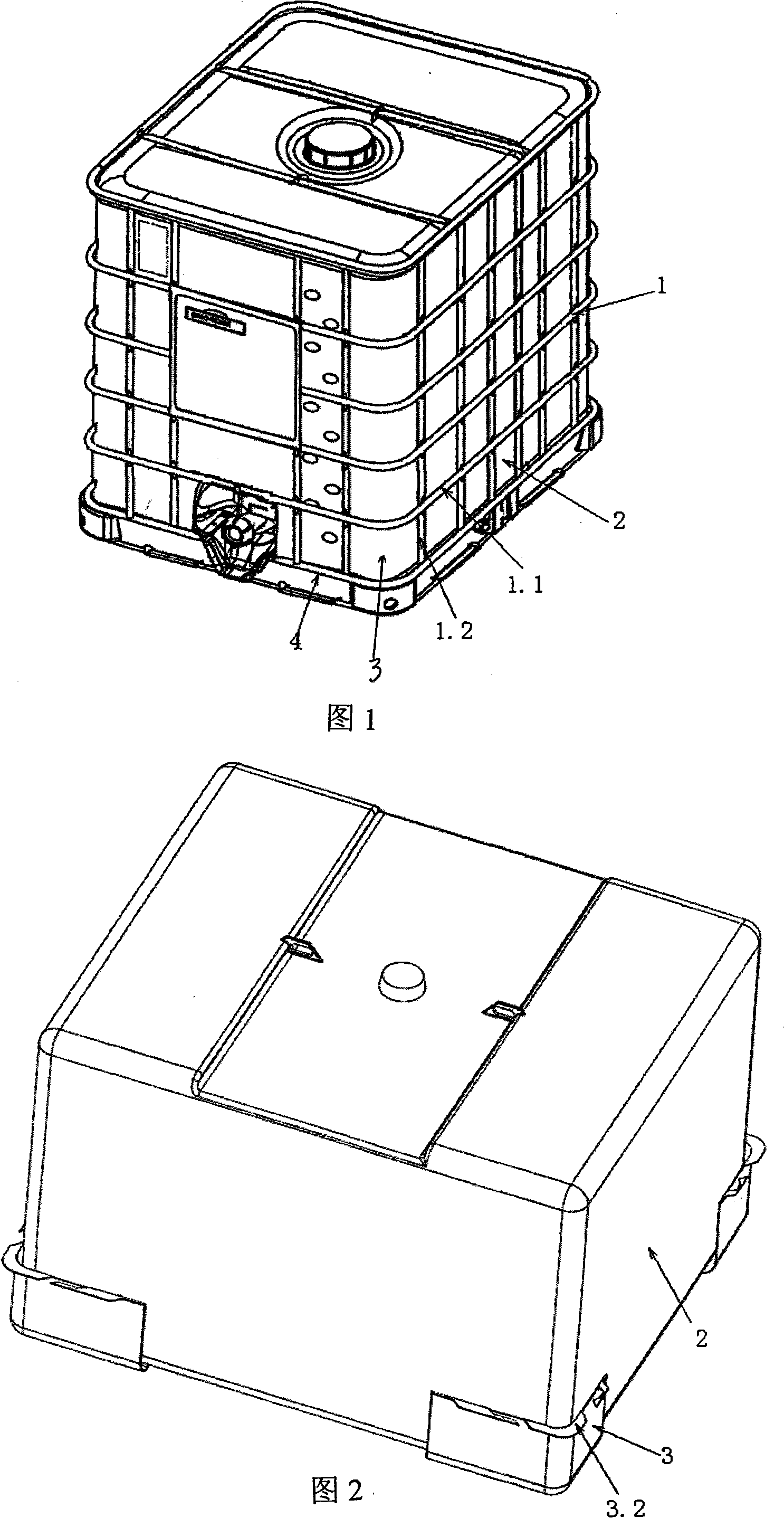

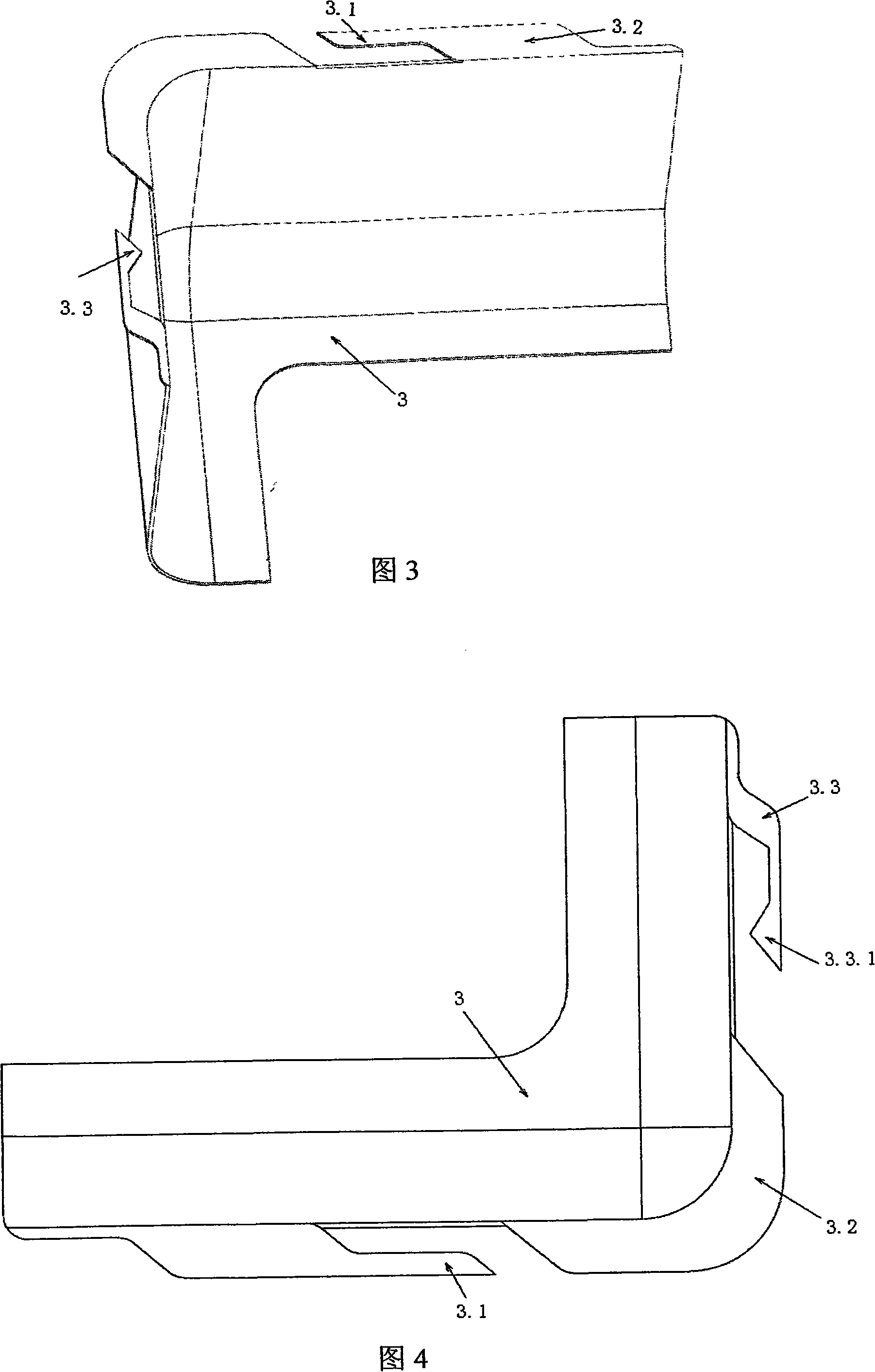

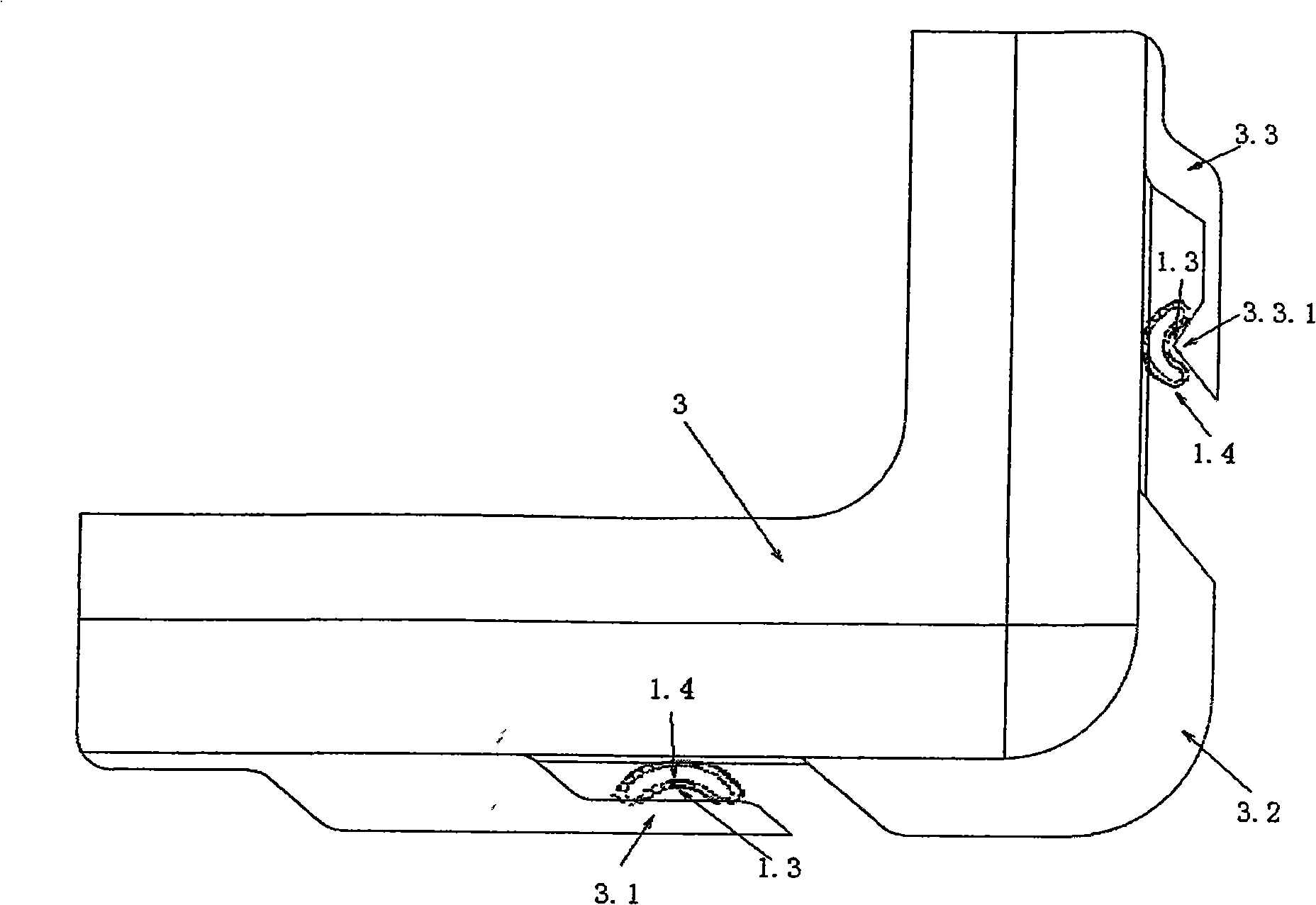

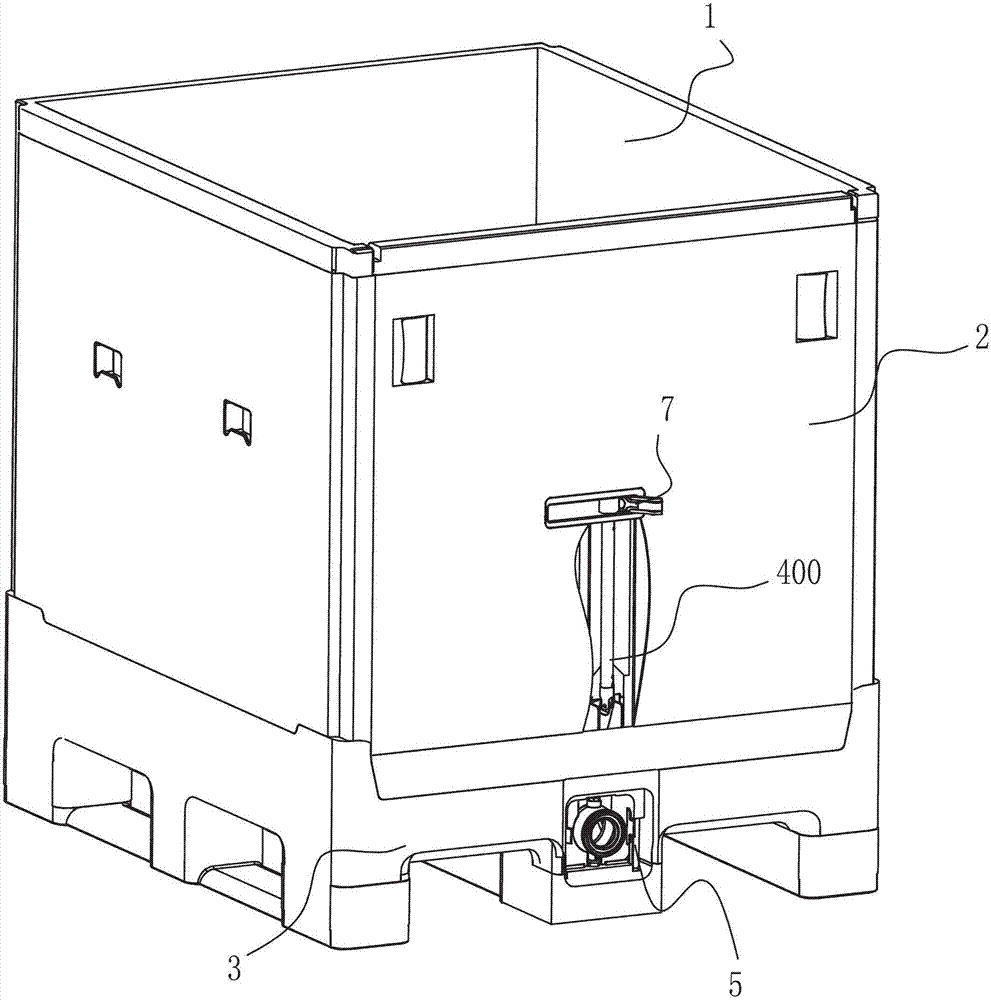

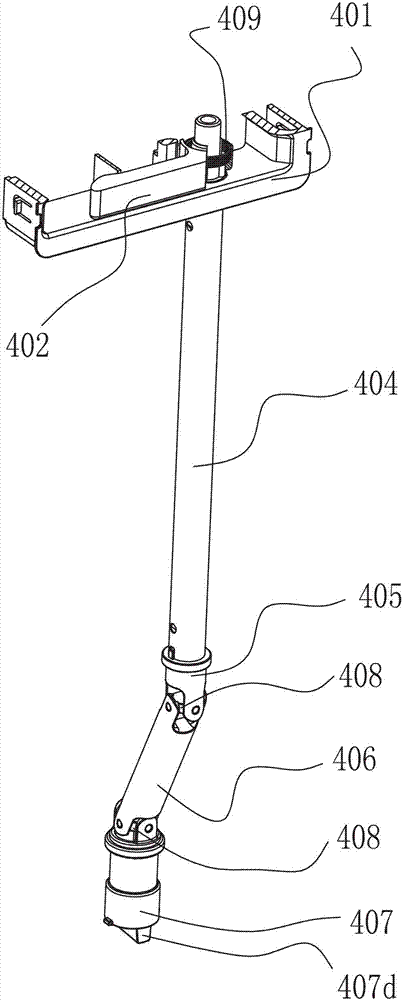

Valve opening-closing device used for compound type medium-sized bulk container and container

ActiveCN102840381AAvoid accidental openingEasy to useOperating means/releasing devices for valvesLarge containersIntermediate bulk containerEngineering

Provided is a valve opening-closing device used for a compound type medium-sized bulk container and a container. The container comprises a base seat and side boards, and a valve is arranged on the bottom of the container. The valve opening-closing device used for the compound type medium-sized bulk container and the container are characterized in that the opening-closing device comprises a handle, a transmission device, a valve opening-closing mechanism and a clutch device, the handle is arranged on the side boards of the container and connected with the transmission device, the transmission device is used to transmit motion acting on the handle to the valve opening-closing mechanism to achieve opening and closing of a valve, and the clutch device is used to enable engagement and disengagement of the transmission device and the valve opening-closing mechanism to be achieved or engagement and disengagement of the valve opening-closing mechanism and the valve to be achieved. In the valve opening-closing device, the operating handle is arranged on an appropriate position of a side surface of the container, and therefore operation such as bending down or squatting on the ground in the process of opening and closing the valve is avoided. The valve opening-closing device used for the compound type medium-sized bulk container and the container are convenient to use, and can prevent opening the valve by accident.

Owner:SHANGHAI HONGYAN RETURNABLE TRANSIT PACKAGINGS CO LTD

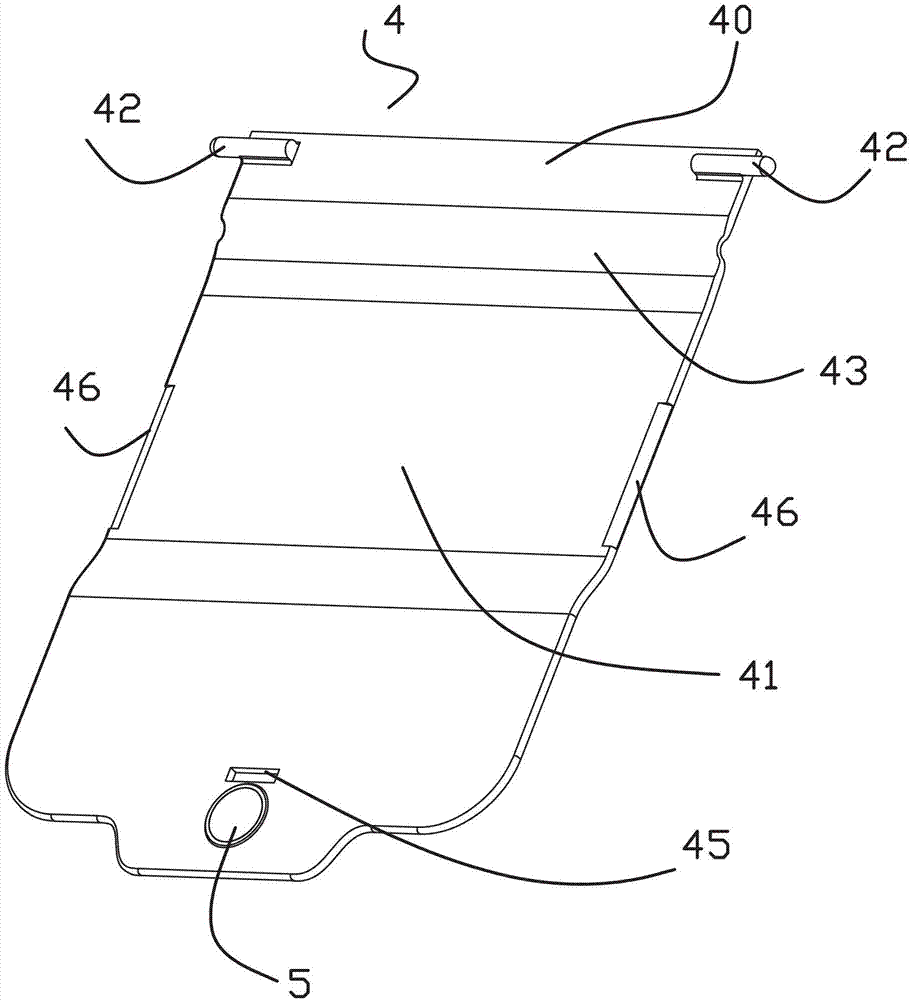

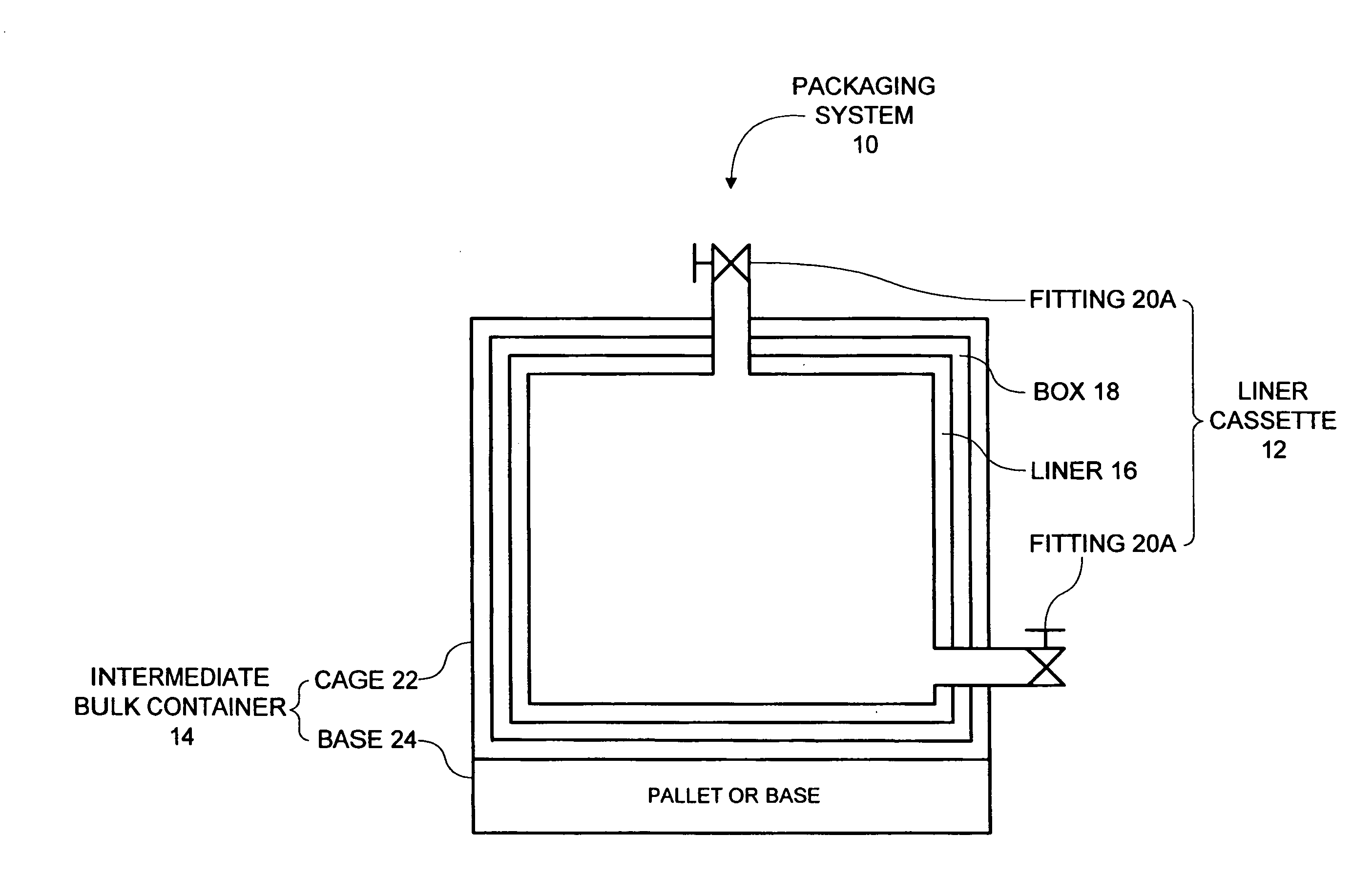

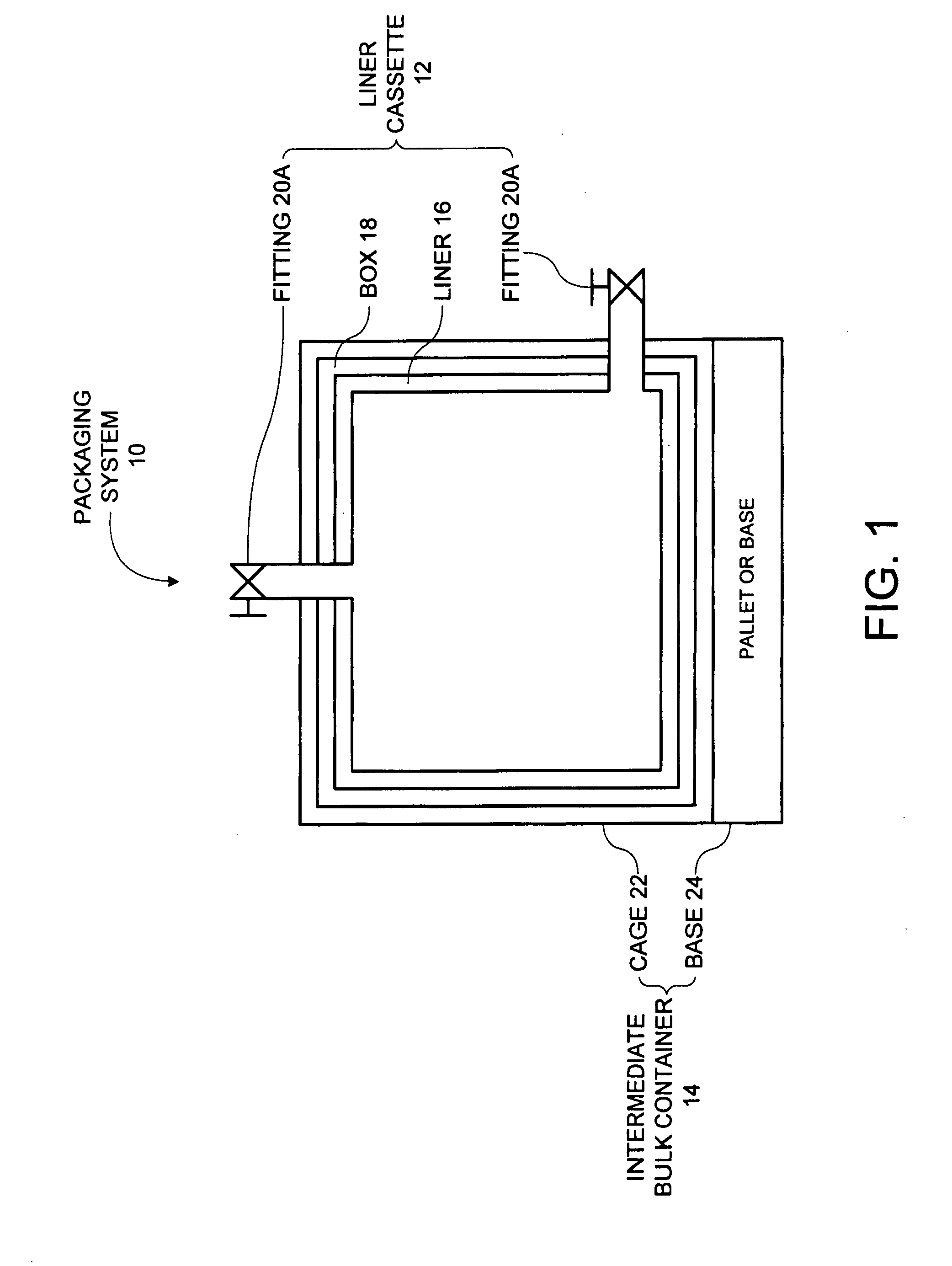

Collapsible bulk cage liner

ActiveUS20080067176A1Large containersLinings/internal coatingsIntermediate bulk containerEngineering

A liner cassette for use with an existing intermediate bulk container includes a box and a liner. The box is configured to unfold within the intermediate bulk container and the liner is configured to fit within the box. The liner cassette includes two configurations. In a first configuration, the box and liner may be folded substantially flat to facilitate transportation. In a second configuration, the box and liner are configured to provide a liquid containment system for the existing intermediate bulk container.

Owner:GREIF INC

Net-based baffles for flexible intermediate bulk containers

InactiveUS20050105833A1Volume occupiedMinimized volumeWarp knittingBagsIntermediate bulk containerEngineering

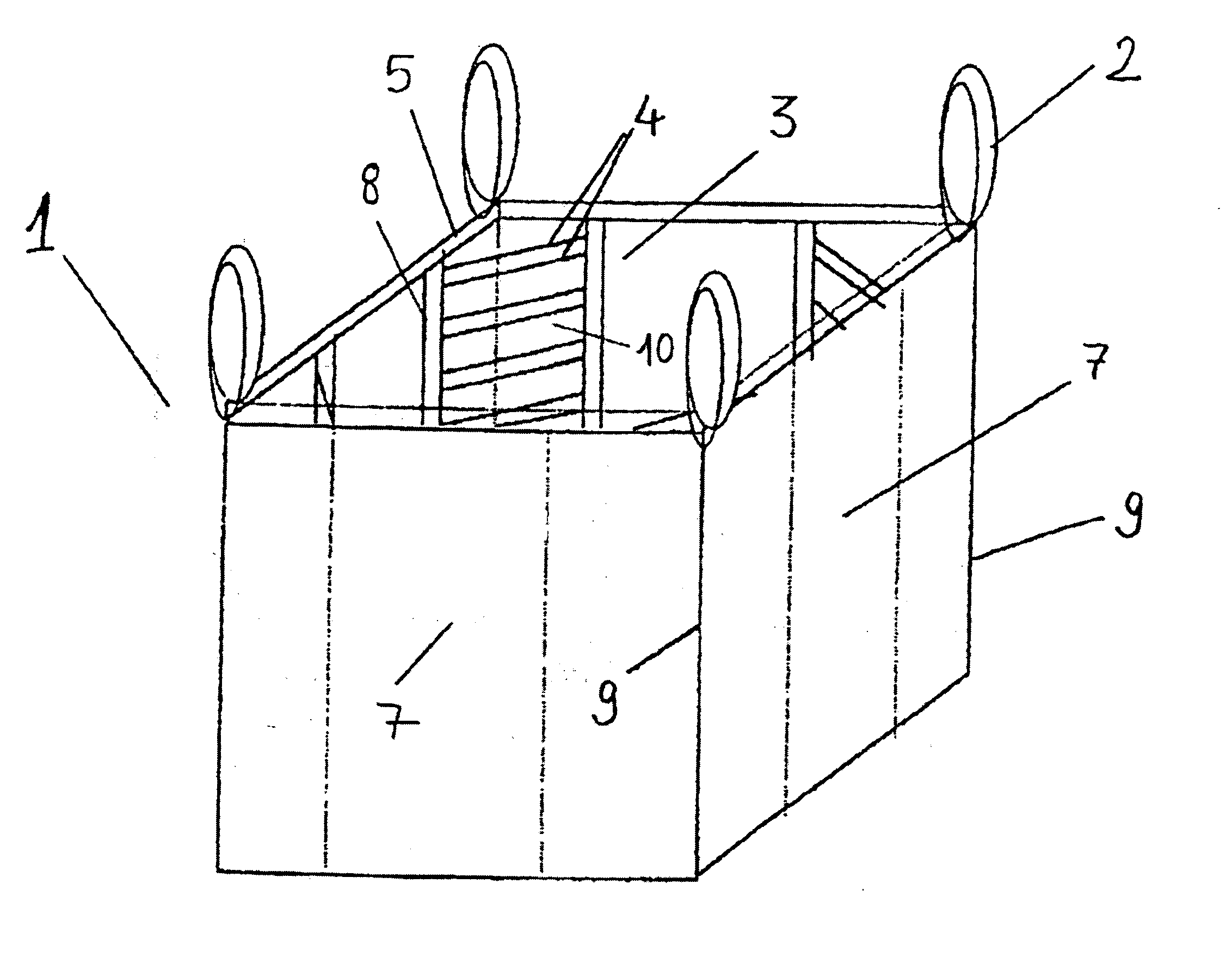

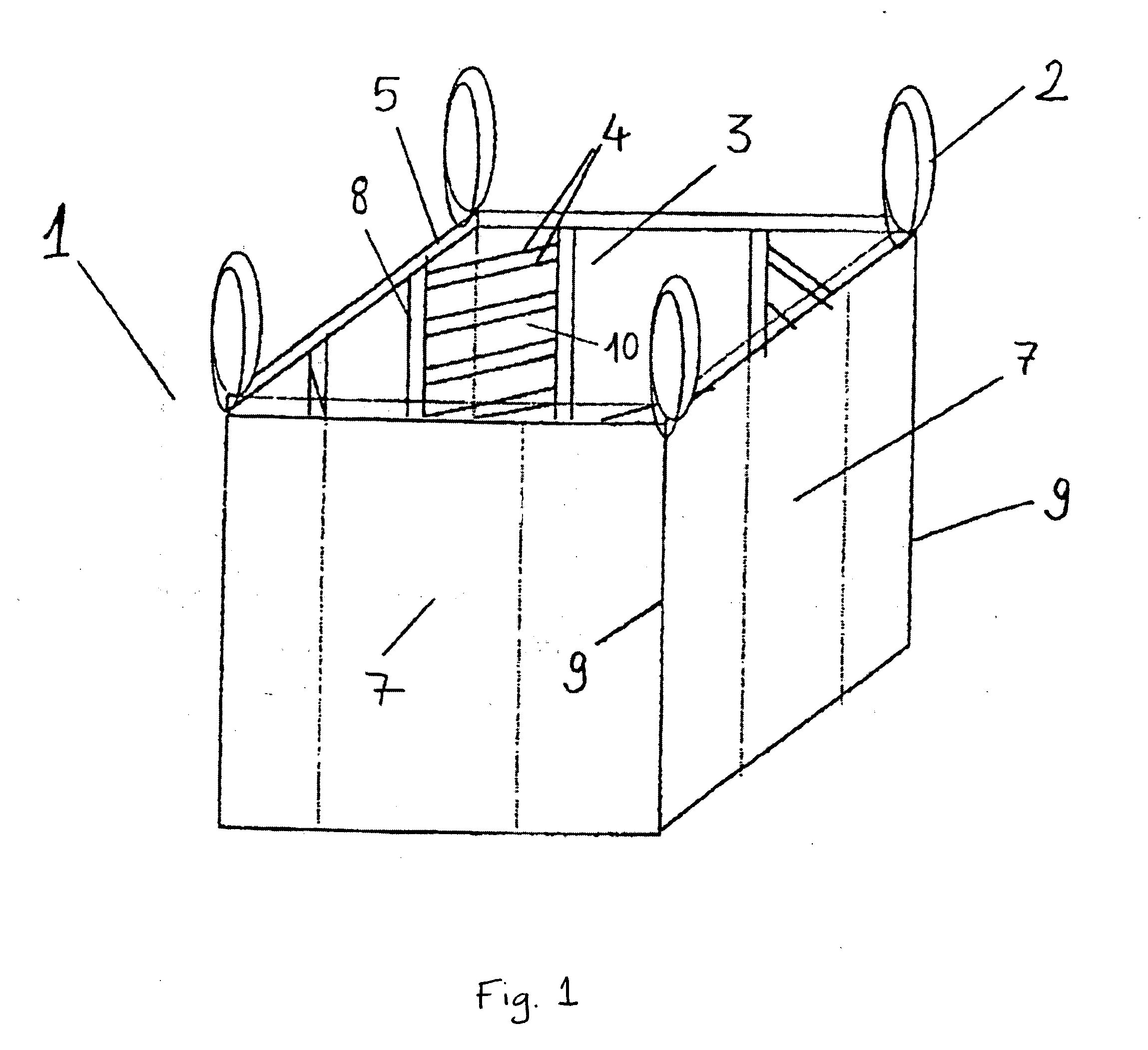

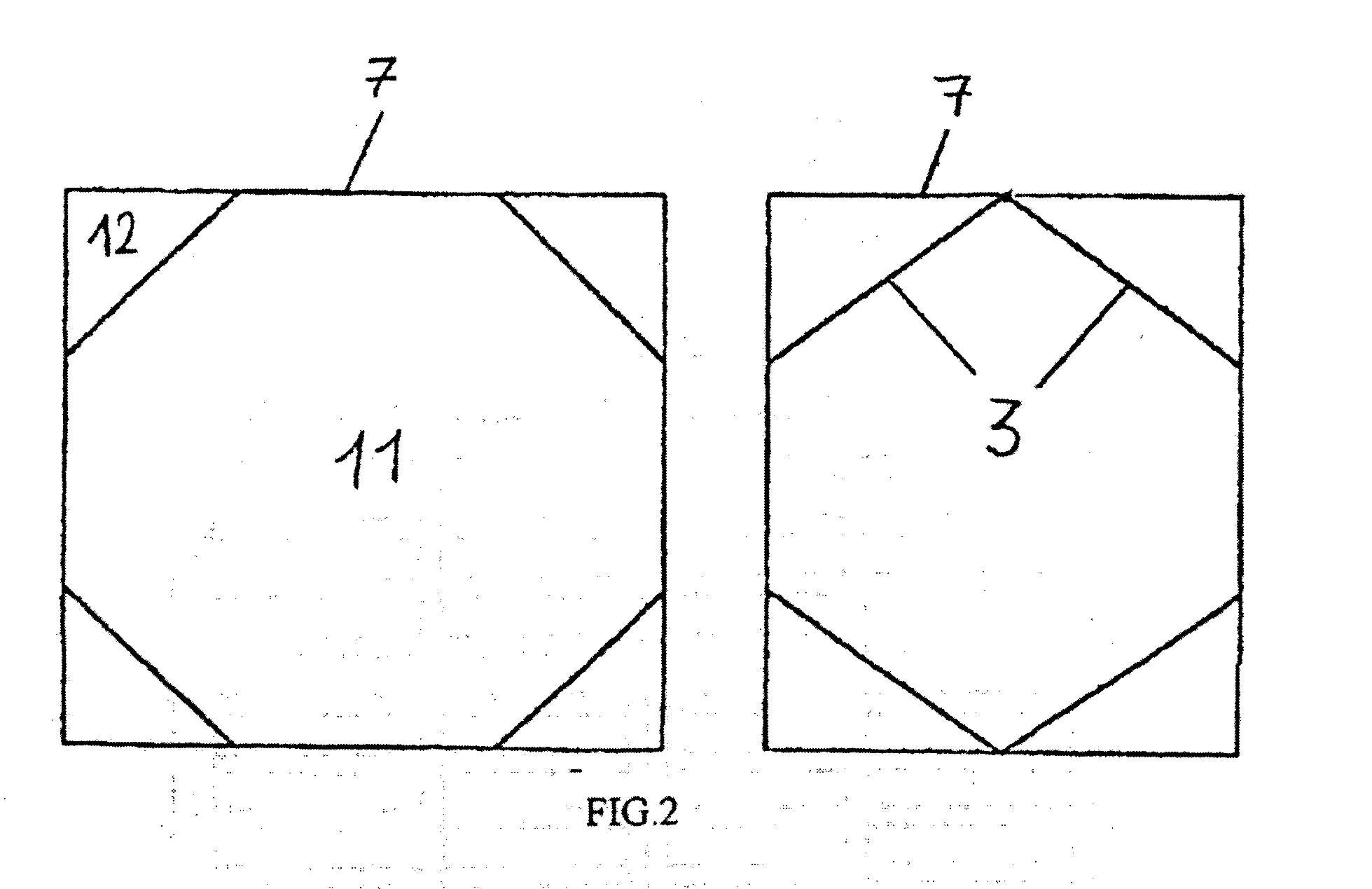

A flexible intermediate bulk container (FIBC) for transferring various type of materials, including industry-based granule materials, fine materials like sugar, flour, comprising baffles sewed to edge region of the FIBCs for preventing bulging formation on lateral surfaces thereof so defining an essential volume and subsidiary volume in the FIBC and said baffles having holes for promoting material transfer between the essential volume and subsidiary volume the development comprising said baffle (3) formed as a net structure having plurality of filaments (4), plurality of net passages (10) between these filaments (4) and connection elements (8) the filaments (4) are attached thereon.

Owner:SUNJUT SUNI JUT SANAYI VE TICARET

Flexible intermediate bulk container having optimum discharge of hazardous charge

InactiveUS20060269711A1Improve the immunityEasy dischargeLayered productsLarge containersYarnIntermediate bulk container

A flexible intermediate bulk container having the ability to discharge hazardous charges without combustion, thereby enabling the container to contain incendiary materials without risk of combustion. The flexible intermediate bulk containers may permit safe handling of materials whether or not the materials are grounded. Unlike many prior art systems, the flexible intermediate bulk container need not include an anti-static coating to function, thereby resulting in cost savings. The electrostatic yarn of the present invention may be incorporated into any bag or container system without any modifications in the process. The electrostatic yarn may also be used in either flat or circular weave. The electrostatic yarn may also be included in fabrics other than containers or bags.

Owner:NOBLE FIBER TECH

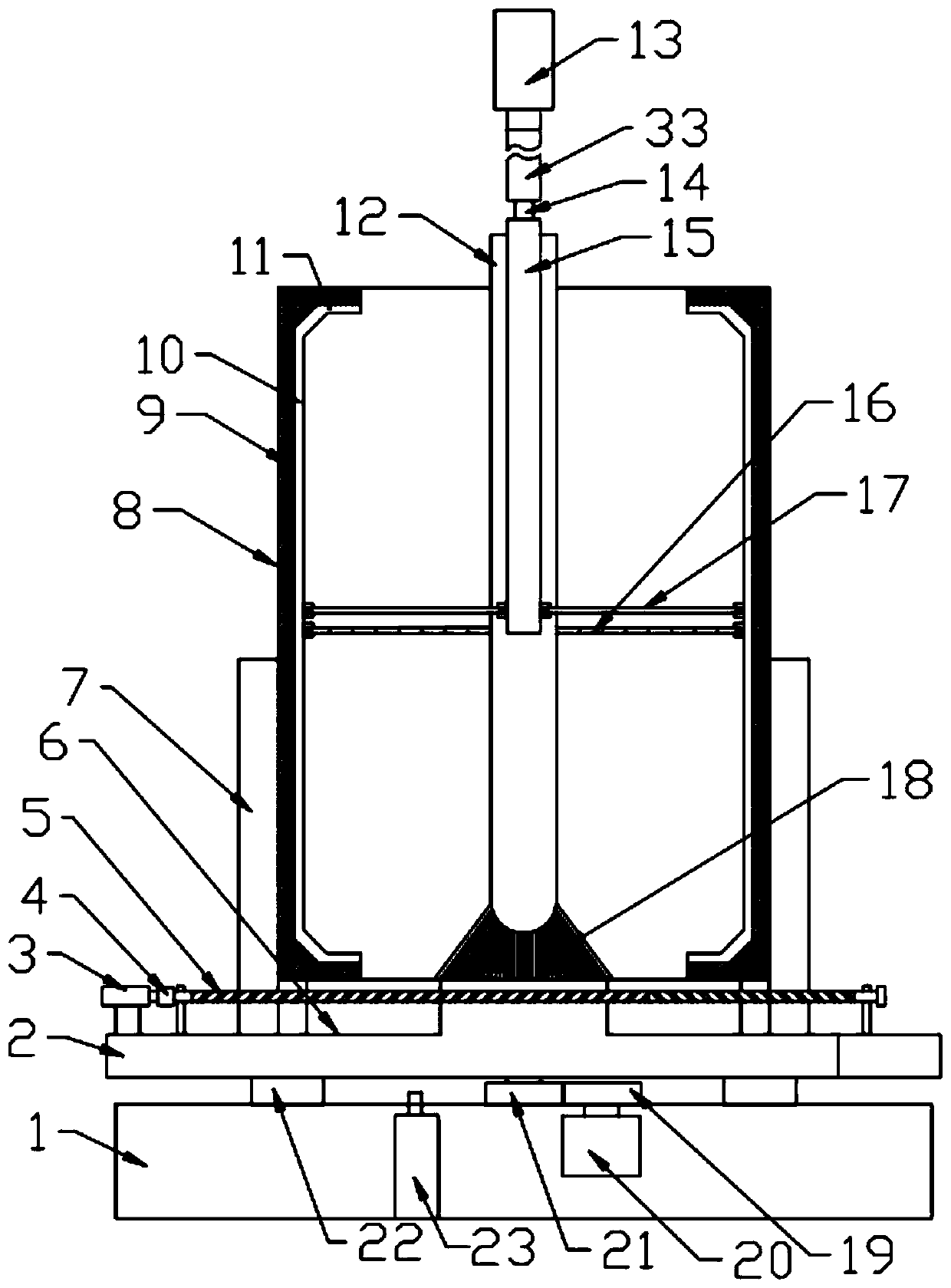

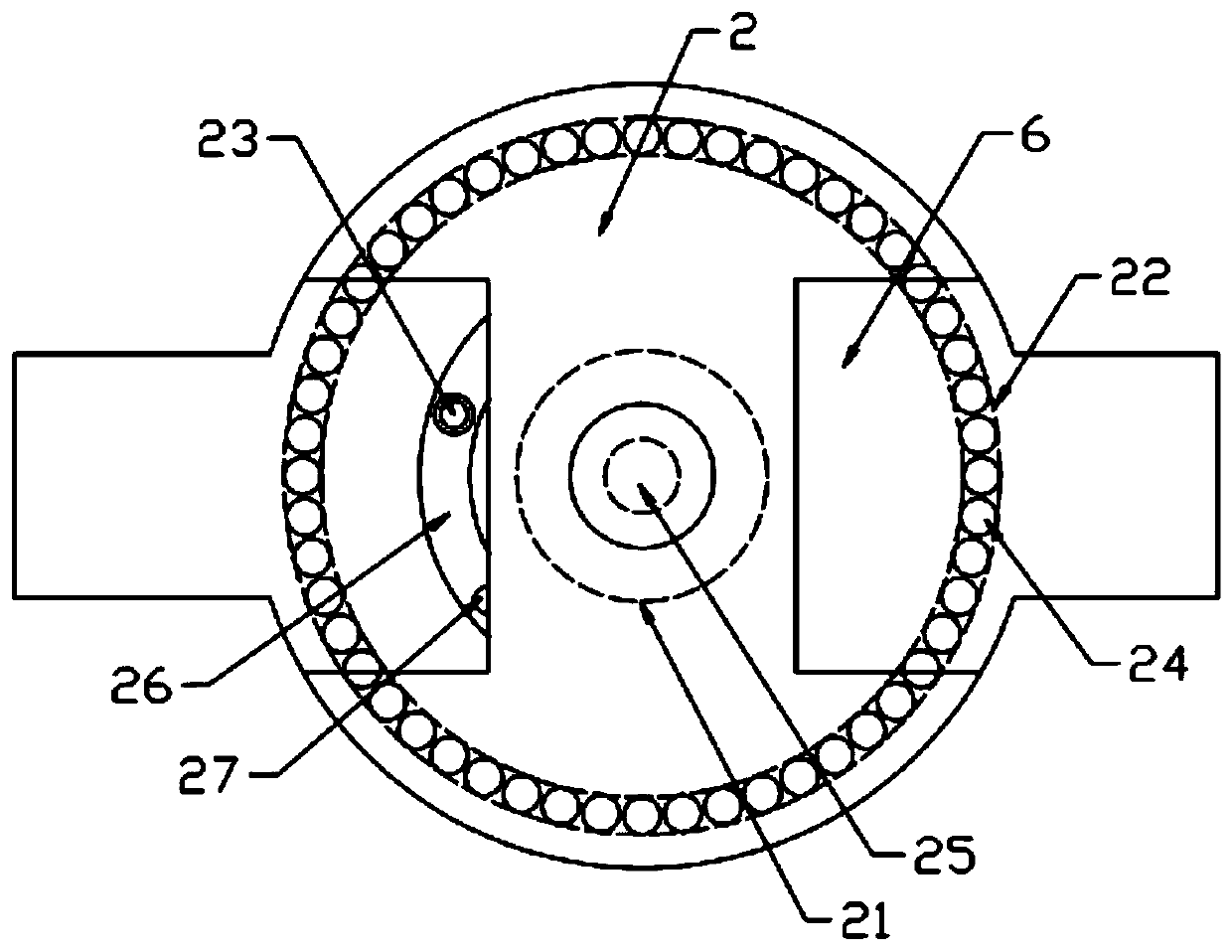

Vibrating table for detecting intermediate bulk container

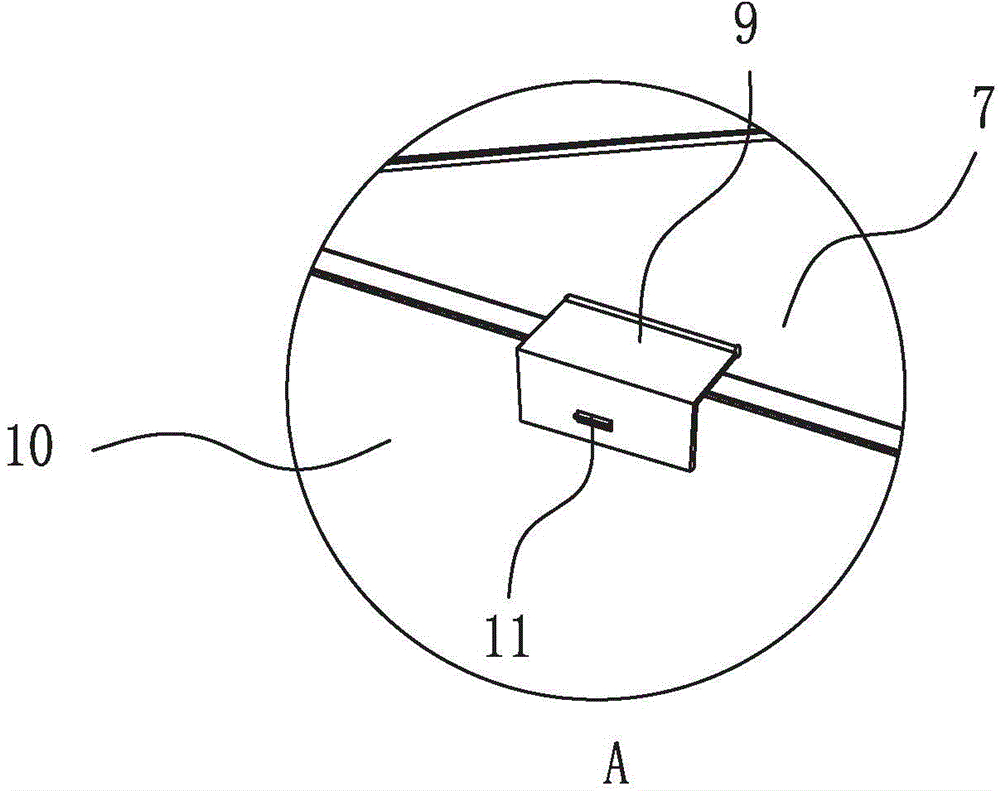

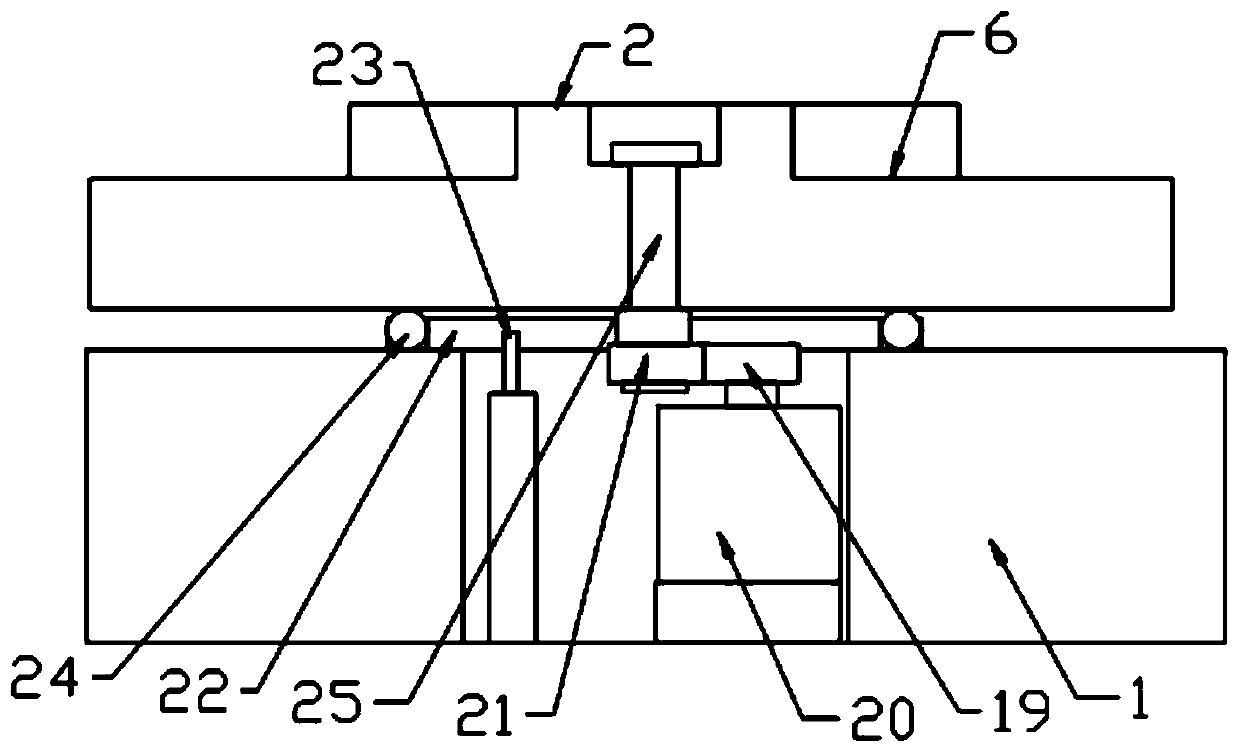

InactiveCN102759436APrevent fallingIncrease speedVibration testingFluid-tightness measurement using fluid/vacuumIntermediate bulk containerGear wheel

The invention relates to a vibrating table for detecting an intermediate bulk container. The vibrating table is characterized by comprising a base (1), a motor (2) and a vibrating platform (9), wherein two slave transmission shafts (7) are in bilateral symmetry with arranged on the base (1), front ends of the left and right slave transmission shafts (7) are provided with a gear wheel (6) respectively; a master transmission shaft (4) is arranged between the left and right slave transmission shafts (7); the output end of the motor (2) is connected with the master transmission shaft (4) through a belt pulley (3); two ends of the master transmission shaft (4) are provided with pinions (5); the pinions (5) and the gear wheels (6) are matched with each other; two cams (8) are sleeved on the left and right slave transmission shafts (7) respectively; and the bottom of each cam (8) is connected with the bottom of the vibrating platform (9) through a pin roll. The vibrating table for detecting the intermediate bulk container has the advantages of strong bearing capability, high synchronization and high safety.

Owner:江阴康爱特包装股份有限公司

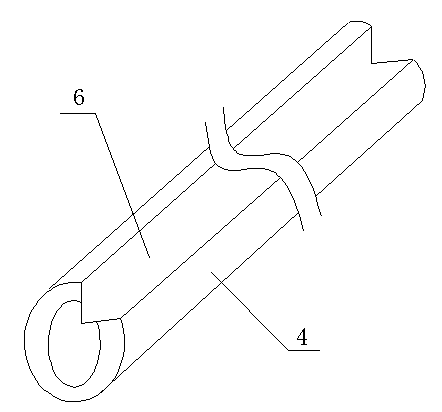

Valve opening/closing device for medium bulk container and container thereof

ActiveCN102808989ADoes not increase fold rateEasy to useOperating means/releasing devices for valvesDischarging meansIntermediate bulk containerEngineering

The invention relates to a valve opening / closing device for a medium bulk container and the container thereof, wherein the container includes a base and a side plate; a valve is mounted at the bottom of the container; the opening / closing device includes a handle, a transmission gear and a valve opening / closing mechanism; the handle is mounted on the side plate of the container and connected with the transmission gear; at least a part of the transmission gear is arranged in the cavity formed by the two side walls of the side plate of the container or in the groove formed on the side plate, and transmits the force acted on the handle to the valve opening / closing mechanism to realize the opening / closing of the valve. In the valve opening / closing device, the operating handle is arranged at the suitable position above the side plate of the container and the transmission gear is arranged between the two side walls or in the groove on the side plate, therefore opening / closing operation of the valve requires not the operator to bend or squat, the whole volume fraction of the container is not influenced, and the folding ratio is not increased by folding the medium bulk container.

Owner:SHANGHAI HONGYAN RETURNABLE TRANSIT PACKAGINGS CO LTD +1

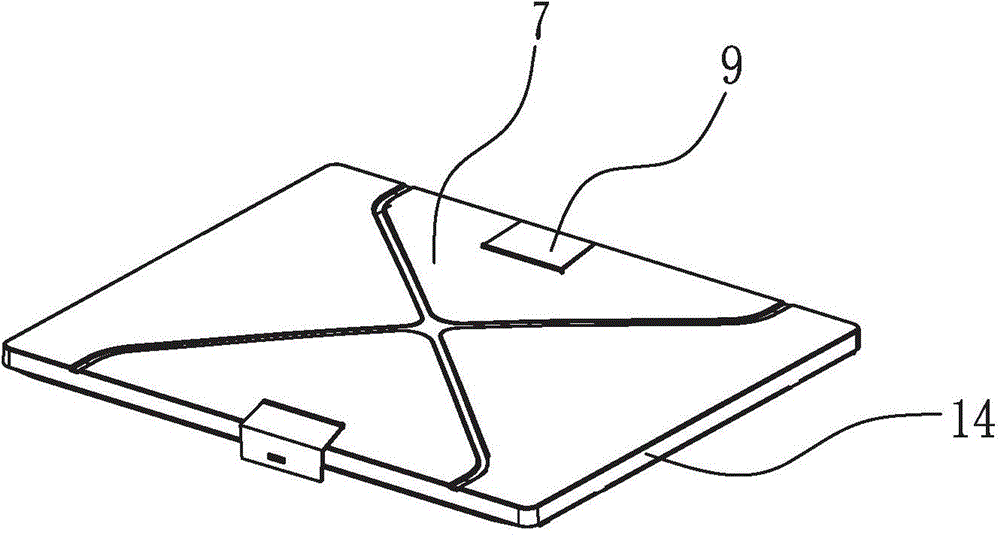

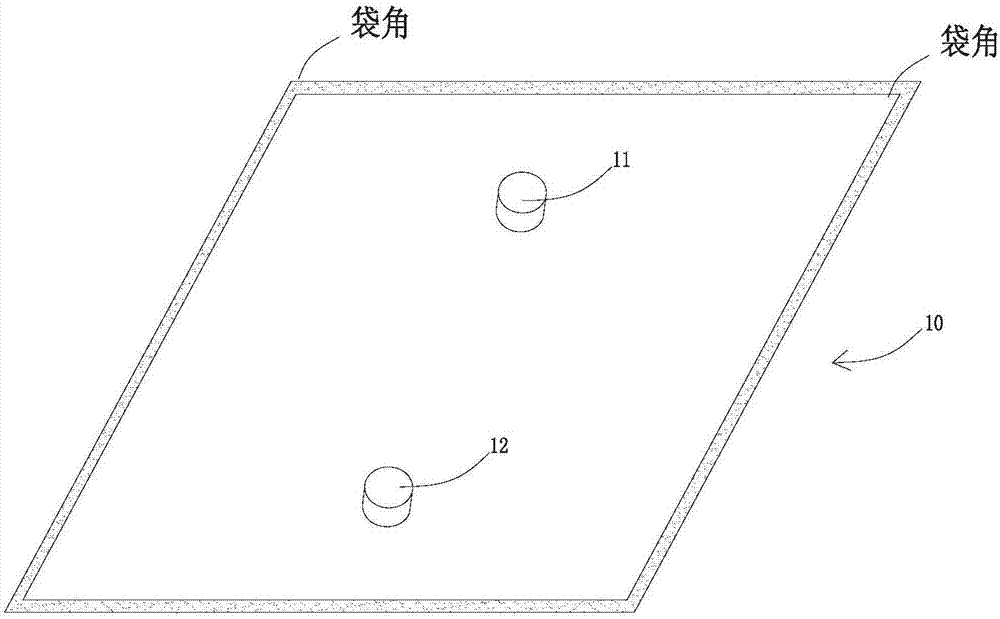

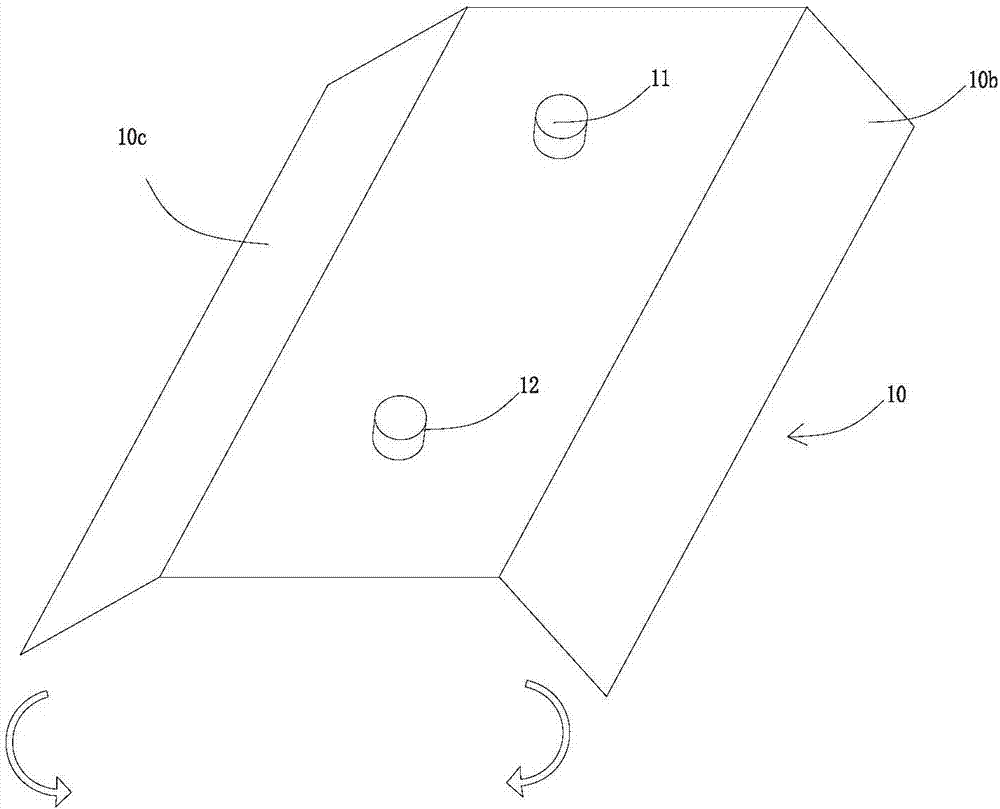

Lining bag for middle-sized bulk container

ActiveCN104097853AReduced inner wall areaIncrease profitPackagingIntermediate bulk containerPulp and paper industry

The invention discloses a lining bag in favor of thick liquid discharge. The lining bag comprises a lining bag body, a discharge outlet and a pouring opening, wherein the pouring opening is in sealing connection with the lining bag body, and the liquid is poured into the lining bag by the pouring opening; the discharge outlet is in sealing connection with the lining bag body, and the liquid is discharged out of the lining bag by the discharge outlet; the lining bag is used for storing the liquid, and the lining bag body has elasticity, so that when the liquid is poured, the surface area of the lining bag body is increased and the volume of the lining bag is increased along with the pouring of the liquid; when the liquid is discharged, the surface area of the lining bag body is reduced and the volume of the lining bag is reduced along with the discharging of the liquid. By adopting the lining bag, the use ratio of the liquid, particularly the thick liquid, is increased favorably, waste is reduced, and cost is lowered; meanwhile, the actions of manually extruding and discharging residual liquid are omitted, and labor is saved.

Owner:SHANGHAI HONGYAN RETURNABLE TRANSIT PACKAGINGS CO LTD

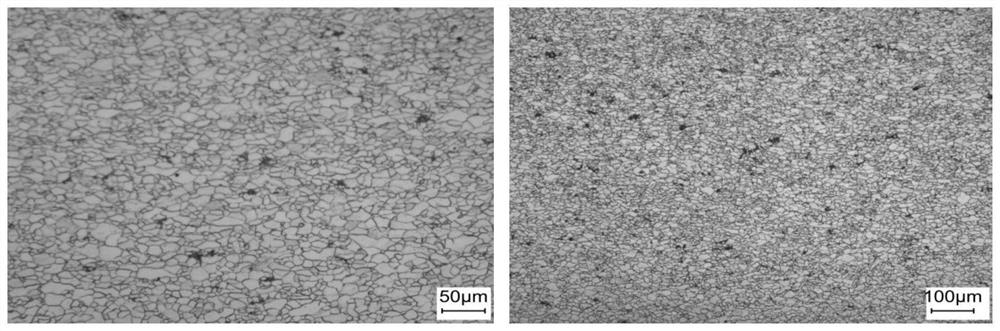

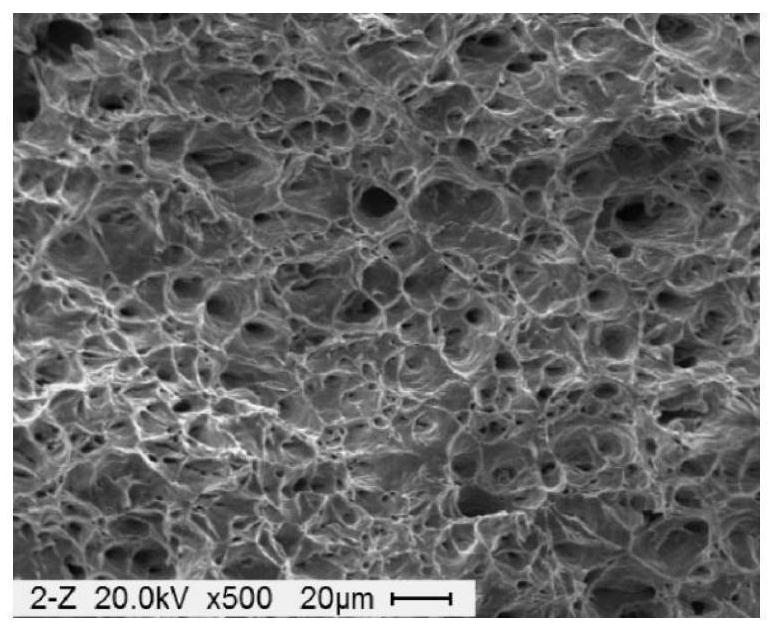

Hot-dip galvanized high-strength IF steel for Ti series intermediate bulk container and manufacturing method thereof

PendingCN111809107AHigh strengthReduce manufacturing costIntermediate bulk containerSolid solution strengthening

The invention discloses hot-dip galvanized high-strength IF steel for a Ti series intermediate bulk container and a manufacturing method thereof. P, Si and Mn elements are appropriately added to an IFsteel substrate for solid solution strengthening so as to ensure strength; an Ti alloying element is added for eliminating interstitial atoms and achieving precipitation strengthening; and an appropriate amount of B element is added for inhibiting segregation of P at the grain boundary, thus, the relatively high percentage elongation after fracture and the relatively low yield ratio are ensured,and meanwhile the tensile strength is improved; and the manufacturing method achieves the yield strength of 220-280MPa, the tensile strength of 340-410MPa, the percentage elongation after fracture greater than or equal to 32% (tensile inspection: L0=80mm, b=20mm), n value greater than or equal to 0.17, and r value greater than or equal to 1.5 for a finished product by combining the ability and characteristics of production equipment, smelting and a continuous annealing technology through a 2250mm hot rolling mill, and a pickling continuous rolling mill, and ensures a relatively low yield ratioand a relatively good stamping performance.

Owner:BAOTOU IRON & STEEL GRP

Foldable handle assembly, and valve and middle-sized bulk container provided with same

ActiveCN103075564ANot easy to losePlug valvesOperating means/releasing devices for valvesIntermediate bulk containerCentre of rotation

The invention provides a foldable handle assembly, and a valve and a middle-sized bulk container provided with the same. The foldable handle assembly is applied to the valve in the middle-sized bulk container. The valve comprises a valve body, a valve core and a valve rod, wherein the valve rod is used for driving the valve core to move to realize opening and closing of the valve. A handle in the handle assembly is connected to the valve rod and can rotate around a rotation central axis on the valve rod; and when the valve is required to be opened or closed, the handle rotates around the rotation central axis to an unfolded state to open the valve. When the valve is welded on an inner container bag or arranged in the middle-sized bulk container, the handle rotates around the rotation central axis to a folded state to reduce the occupied space of the valve. According to the handle assembly provided by the invention, the handle can be switched between the unfolded state and the folded state; and when the handle is in the folded state, the occupied space of the handle is small, so that the handle does not influence the inner container bag for welding the valve on the middle-sized bulk container. Moreover, the handle is prevented from being damaged easily after being folded.

Owner:SHANGHAI HONGYAN RETURNABLE TRANSIT PACKAGINGS CO LTD

Valve opening/closing device for medium bulk container and container thereof

ActiveCN102808990ADoes not affect volume ratioEasy to useOperating means/releasing devices for valvesDischarging meansIntermediate bulk containerValve opening

The invention relates to a valve opening / closing device for a medium bulk container and the container thereof, wherein the container includes a base and a side plate; a valve is mounted at the bottom of the container; the opening / closing device includes a handle, a transmission gear and a valve opening / closing mechanism; the handle is mounted on the side plate of the container and connected with the transmission gear; and the transmission gear transmits the force acted on the handle to the valve opening / closing mechanism to realize the opening / closing of the valve. In the valve opening / closing device, the operating handle is arranged at the suitable position above the side plate of the container, therefore opening / closing operation of the valve requires not the operator to bend or squat, and the valve opening / closing device is convenient and practical; furthermore the torque of the operation can be adjusted by adjusting the transmission ratio of the transmission gear, thereby facilitating the control of the operating force.

Owner:SHANGHAI HONGYAN RETURNABLE TRANSIT PACKAGINGS CO LTD +1

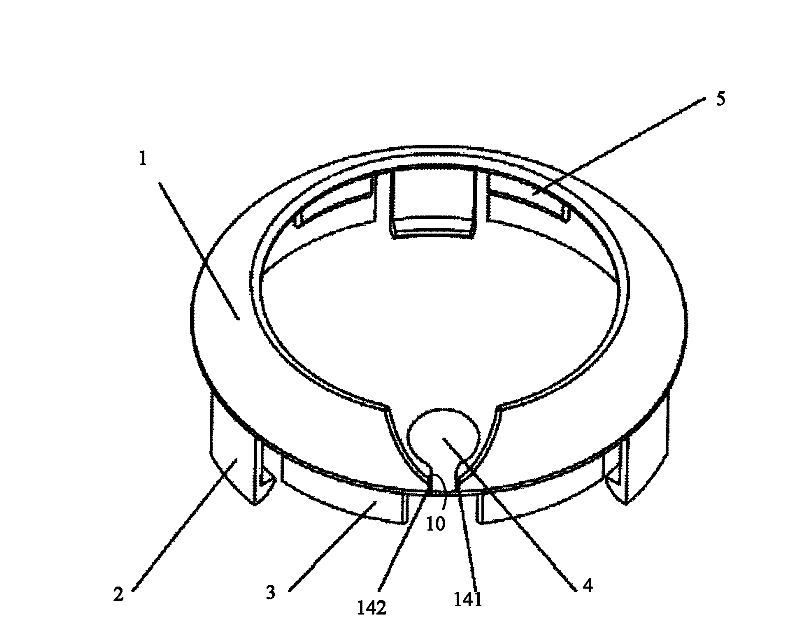

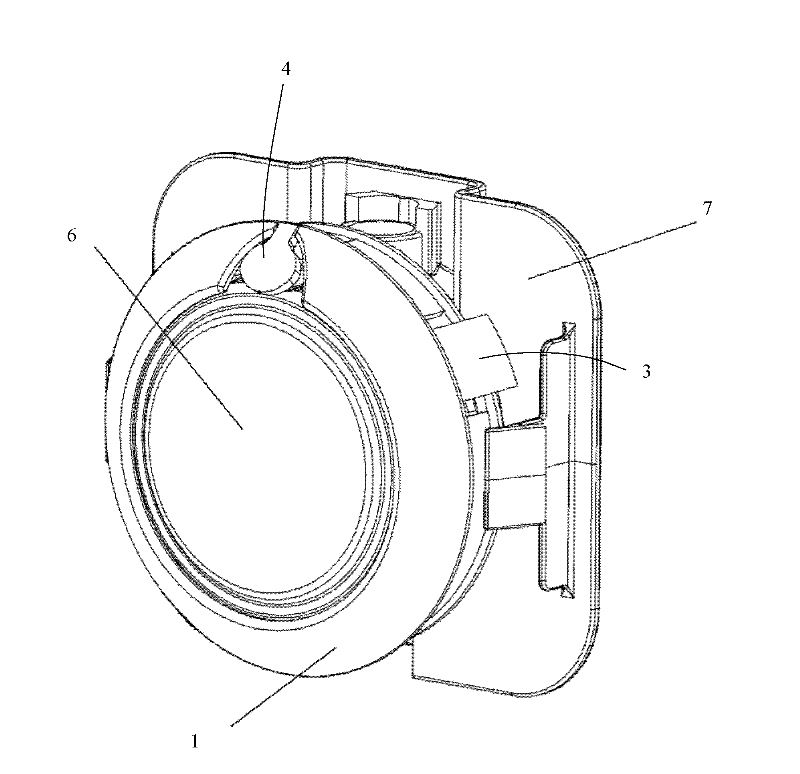

Composite medium-sized bulk container anti-theft device and its sliding anti-theft cover

ActiveCN102285487ARealize blind operationAchieve anti-theft effectLarge containersLocking devicesIntermediate bulk containerEngineering

The invention relates to a composite intermediate bulk container antitheft device and a slipping-type antitheft cover thereof. The slipping-type antitheft cover comprises an annular shell. The annular shell is provided with a large end and a small end. Fastening hooks extend from the large end of the annular shell. The annular shell is provided with a tearing handle. The tearing handle fills the opening of the annular shell and is connected with at least one side of the opening of the annular shell through a tearing line. The slipping-type antitheft cover disclosed by the invention has the advantages that the antitheft cover is convenient to operate, the intentional calibration is not required, the blind operation can be realized, the cover can be easily fastened on a valve cover, the working efficiency is improved, the antitheft cover is convenient to open, the falling of excessive parts does not exist, the environment is not affected, the antitheft cover cannot be restored after theantitheft cover is damaged, the antitheft effect is good and the valve cover can be repetitively used.

Owner:SHANGHAI HONGYAN RETURNABLE TRANSIT PACKAGINGS CO LTD

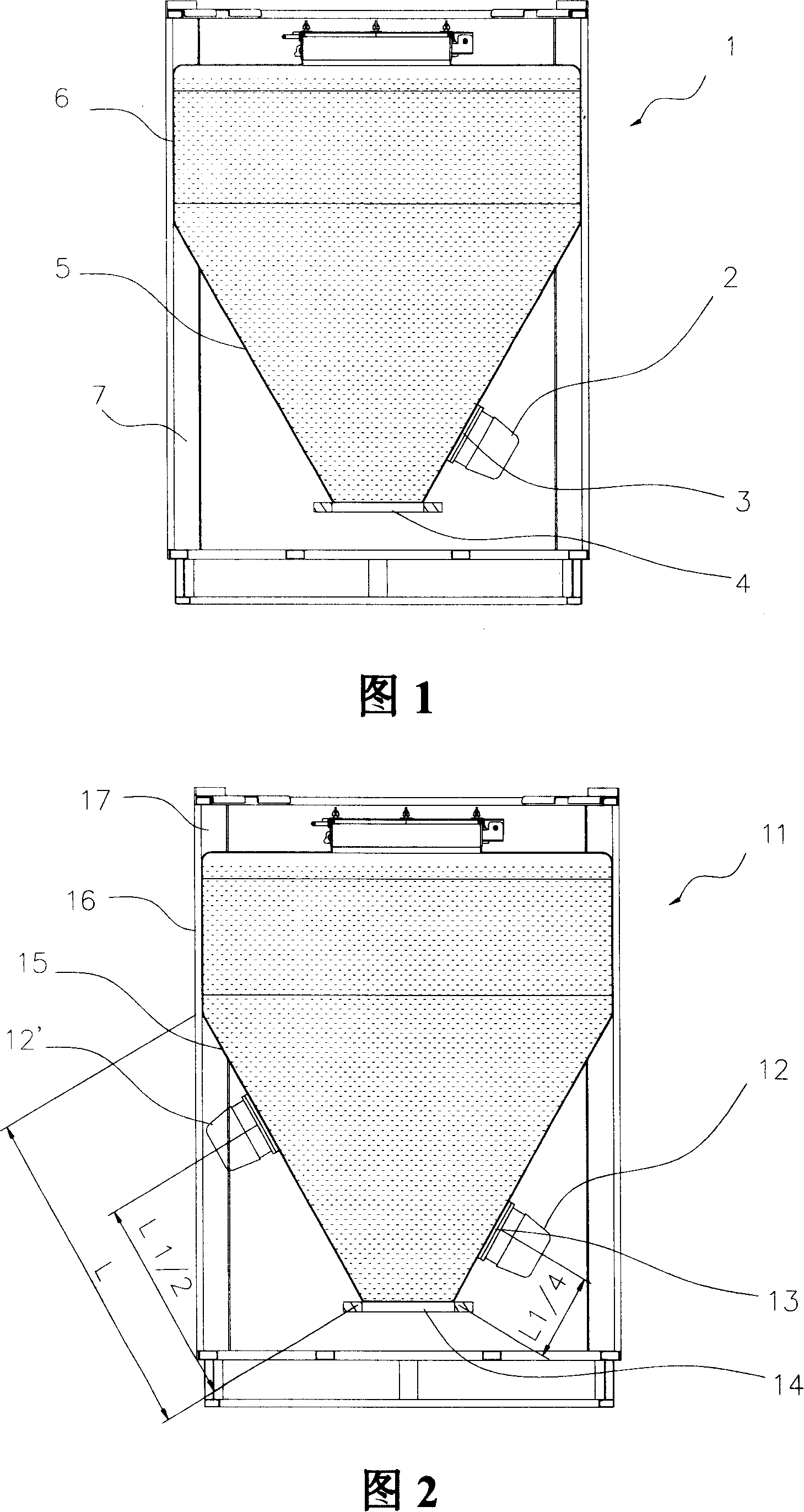

Powder material discharging method and powder medium-sized bulk container

InactiveCN101148216ASmooth nestingLarge containersLoading/unloadingIntermediate bulk containerEngineering

The present invention relates to one kind of intermediate bulk container (IBC) for powder material and its material discharging method. The IBC includes at least one inclined lower sealing end and one outlet in the bottom of the lower sealing end, and there is at least one vibrating unit connected to the outside of the lower sealing end. The vibrating unit makes the IBC vibrate to avoid blocking. The present invention has low cost, easy installation, easy use and easy maintenance.

Owner:CHINA INTERNATIONAL MARINE CONTAINERS (GROUP) CO LTD

Intermediate bulk container cleaning system and cleaning method

ActiveCN110314909AEasy to cleanImprove cleaning efficiencyHollow article cleaningIntermediate bulk containerEngineering

The invention discloses an intermediate bulk container cleaning system. The system comprises a liquid pumping device and a cleaning device, wherein the cleaning device comprises a intermediate bulk container table and a cleaning head arranged at the upper part of the intermediate bulk container table, wherein the intermediate bulk container table comprises an object placing table, an intermediatebulk container clamping device arranged on the object placing table and an object placing table rotating device connected to the bottom of the object placing table, the cleaning head comprises a spraying pipe and a telescopic cleaning brush head, and the spraying pipe and the telescopic cleaning brush head extend into the intermediate bulk container and wash the inner wall of an intermediate bulkcontainer. According to the intermediate bulk container cleaning system and cleaning method, the inner wall of the intermediate bulk container is cleaned, the cleaning capacity is good, cleaning is thorough, the cleaning efficiency is high, precipitates on the inner wall of the intermediate bulk container can be thoroughly removed, and the intermediate bulk container can be conveniently reused.

Owner:XUANCHENG HENGTAI ELECTRONICS CHEM MATERIAL

IBC (Intermediate Bulk Container) lining bag, intermediate bulk container with lining bag and use method of lining bag

InactiveCN106742822ACause activityEasy to installLarge containersIntermediate bulk containerEngineering

The invention provides an IBC (Intermediate Bulk Container) lining bag, an intermediate bulk container with the lining bag and a use method of the lining bag, and relates to the field of chemical articles. The IBC lining bag comprises a bag body, wherein an opening is formed in the top of the bag body; a feeding part is connected with the opening in a sealed manner; a discharge part is connected with the bottom of the bag body in a sealed manner; the feeding part comprises an outer-layer protection film and an inner-layer storage film from outside to inside in sequence; the top end surface of the outer-layer protection film is wrapped by a first sealing ring; and the top of the inner-layer storage film is directly sealed. The invention further relates to the intermediate bulk container with the lining bag. The IBC lining bag is arranged inside the IBC. The invention further relates to the use method of the lining bag. The use method mainly comprises procedures of charging air and exhausting air through the discharge part. By adopting the technical scheme of the invention, chemical raw materials inside the intermediate bulk container can be rapidly recycled, mounting procedures of the lining bag can be also reduced, and thus the cost can be reduced.

Owner:吴江市科欣包装材料厂

Cleaning device for intermediate bulk container for liquid chemicals

ActiveCN107088568ASimple structureExtract completelyHollow article cleaningIntermediate bulk containerCompound (substance)

The invention discloses a cleaning device for an intermediate bulk container for liquid chemicals. The cleaning device for the intermediate bulk container for the liquid chemicals comprises a cleaning chamber, an intermediate bulk container carrying frame and an overturning mechanism, wherein an intermediate bulk container inlet-outlet is formed in one side of the cleaning chamber; a cleaning waste liquid outlet is formed in the bottom end of the cleaning chamber; the overturning mechanism is used for driving the intermediate bulk container carrying frame to overturn in the inner cavity of the cleaning chamber; a limit element matched with the intermediate bulk container is arranged on the intermediate bulk container carrying frame; and an inner liquid pumping assembly for the intermediate bulk container and an inner wall cleaning assembly for the intermediate bulk container are arranged at the top end of the intermediate bulk container carrying frame. The cleaning device for the intermediate bulk container for the liquid chemicals is simple in structure; the structure is capable of ensuring a clean environment for cleaning operation through the arrangement of the cleaning chamber and the intermediate bulk container carrying frame capable of overturning; and the intermediate bulk container carrying frame drives the intermediate bulk container to overturn, so that a residual liquid and a cleaning liquid in the intermediate bulk container can be thoroughly pumped away, and the usage amount of the cleaning liquid and the treatment amount of a cleaning waste liquid are reduced.

Owner:JIANGYIN JIANGHUA MICROELECTRONICS MATERIAL

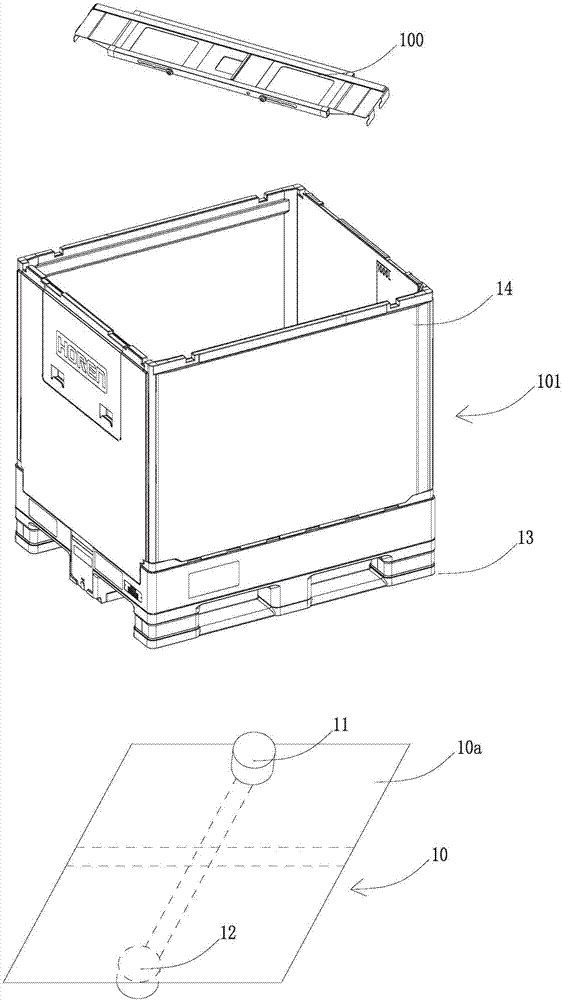

Lightweight transport, storage and delivery system

ActiveUS20190255982A1Easy to engageReduce the overall heightVehicle with pivoted armsLarge containersIntermediate bulk containerEngineering

Reusable, flexible, lightweight, low cost flexible intermediate bulk containers (FIBCs) for the delivery of granular proppant material for fracing that will allow the transport of higher weights of proppant, such as sand, per truck load. The invention includes a container made of a high strength, flexible material with a top opening for loading and deploying the proppant. The container can be lifted and deployed with a fork truck or crane. Alternatively, proprietary deployment systems, such as a conveyor system, can be used to quickly and efficiently deploy the proppant from the container at a desired site.

Owner:ONEILL KEVIN M

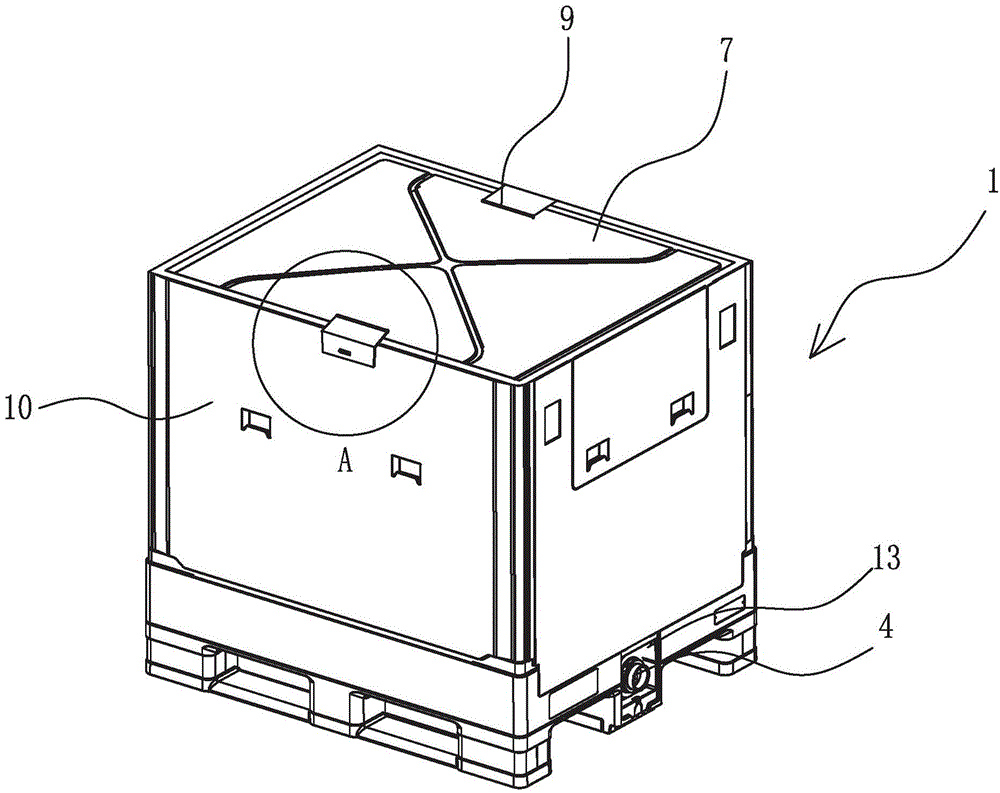

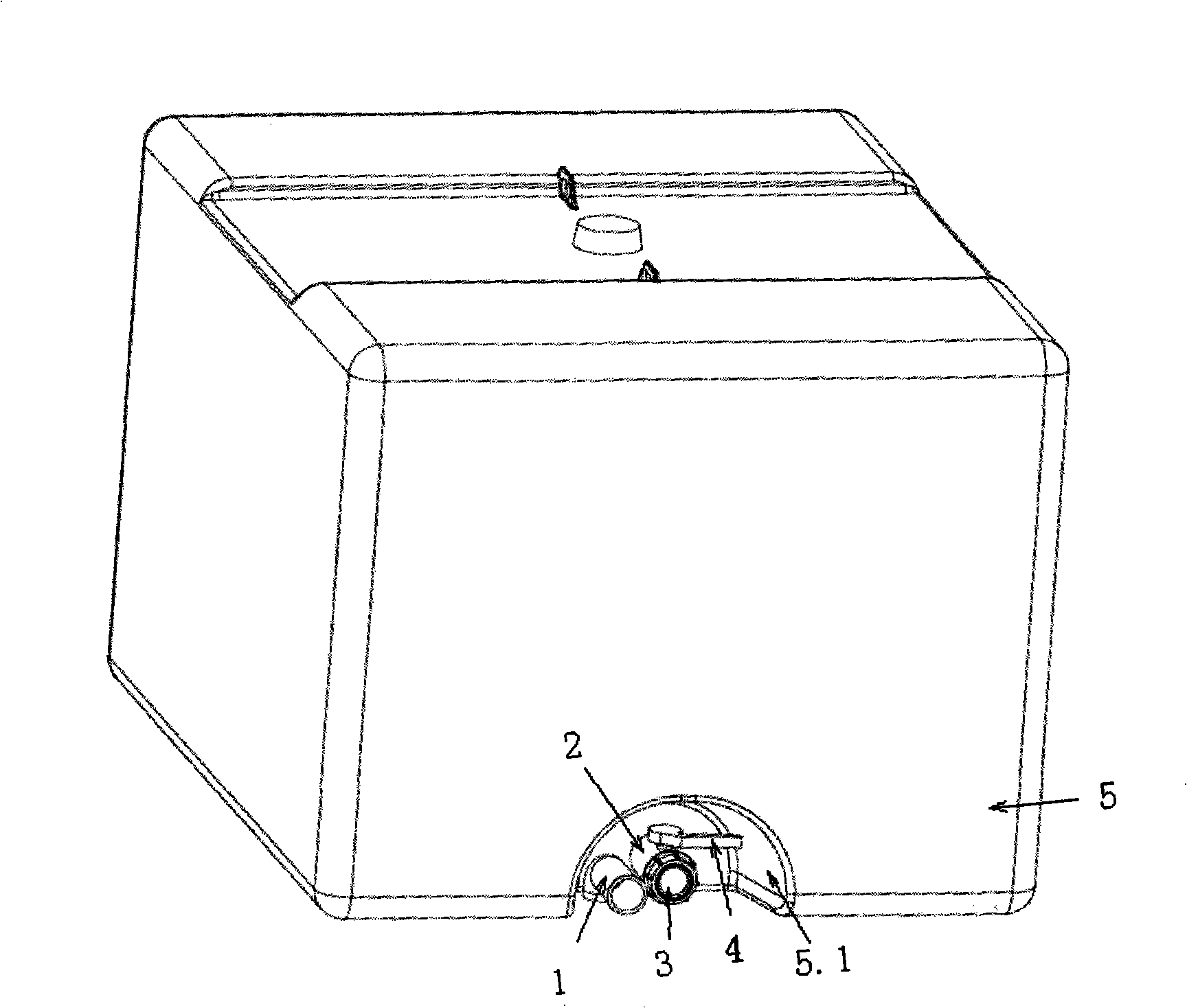

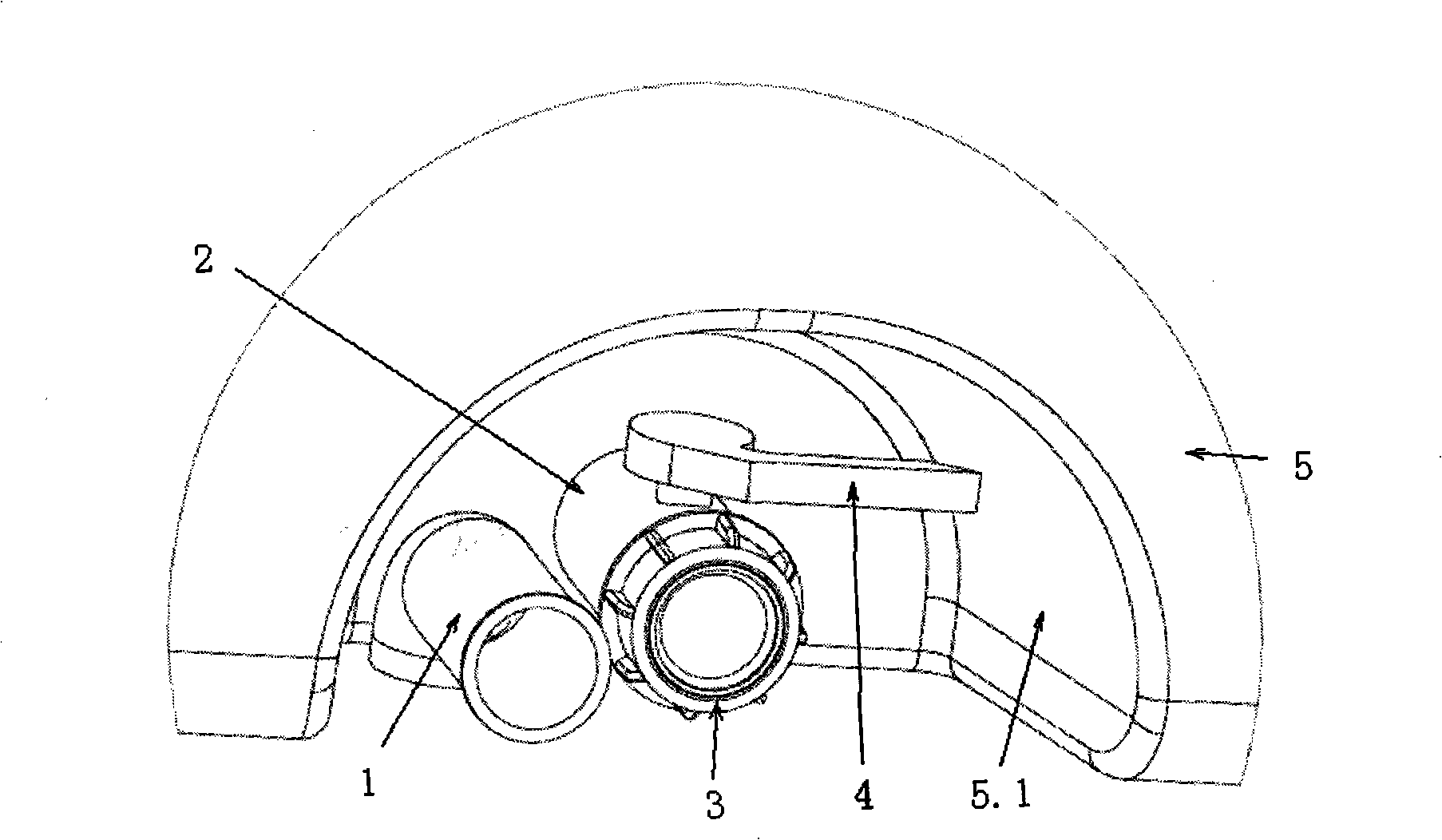

Novel medium-sized bulk loading container with liquid discharge lid

ActiveCN101342956AImprove sealingRealize the liquid discharge functionCapsClosure capsIntermediate bulk containerEngineering

The invention relates to a new medium-sized bulk container with a liquid tapping cover. The bulk container comprises an internal barrel(5) which is provided with a liquid tapping port(2)at the lower part of one side; the wall of the internal barrel(5)at the periphery of the liquid tapping port(2)sinks, forming a dent(5.1); a liquid tapping valve(4)is arranged on the liquid tapping port(2) and a liquid tapping cap(3)is covered on the port of the liquid tapping valve(4). The bulk container is characterized in that the liquid tapping cap(3)is provided with a through hole(3.1) at the middle and an interior lid(3.2)and a gasket ring(3.3)are embedded in the through hole(3.1); the gasket ring(3.3)is arranged at the internal side of the interior lid(3.2); an extension tube(1), arranged outside the liquid tapping port(2), is disposed inside the dent(5.1). The bulk container can fix the extension tube well while not affecting the normal work of the liquid tapping valve.

Owner:江阴康爱特包装股份有限公司

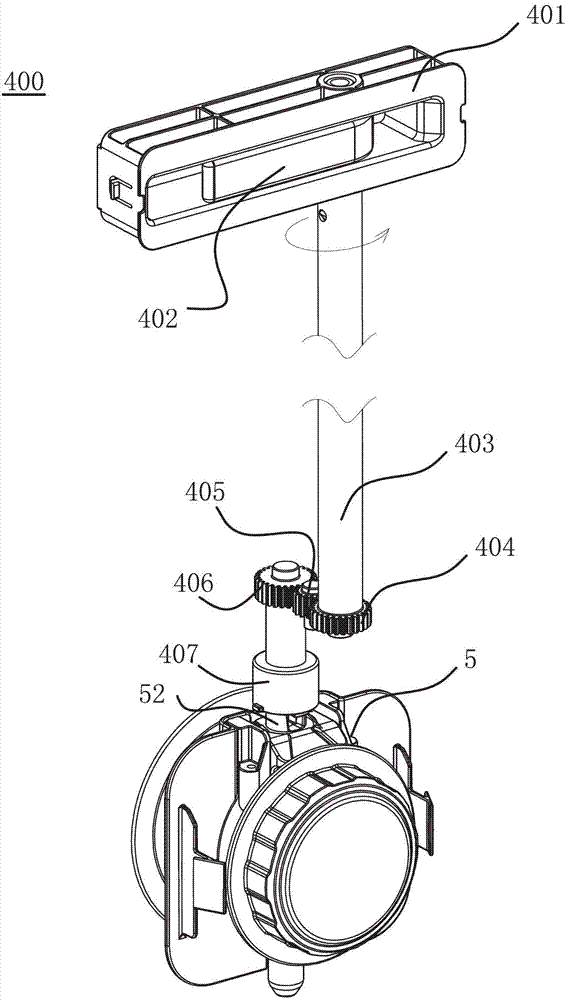

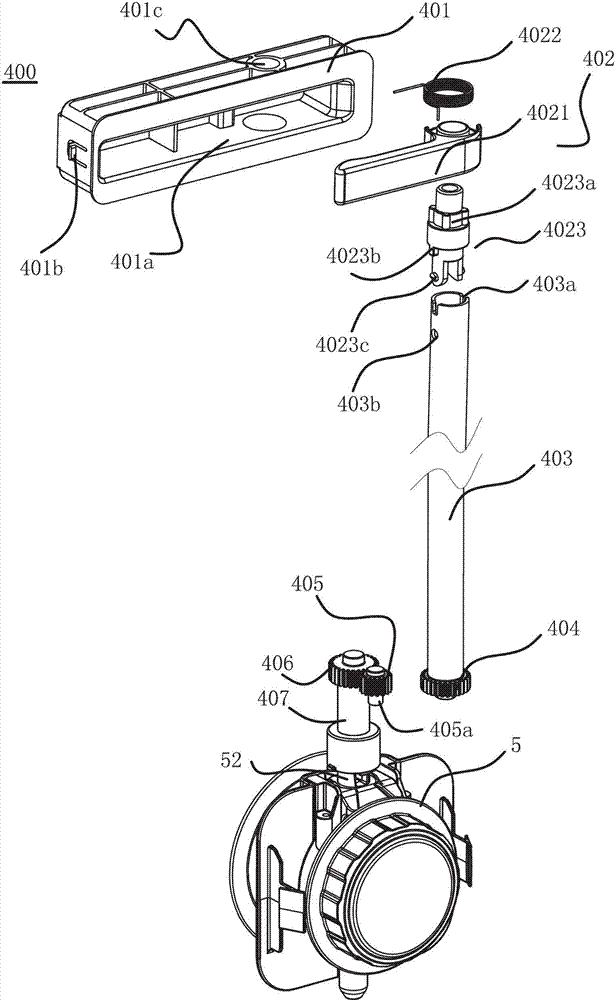

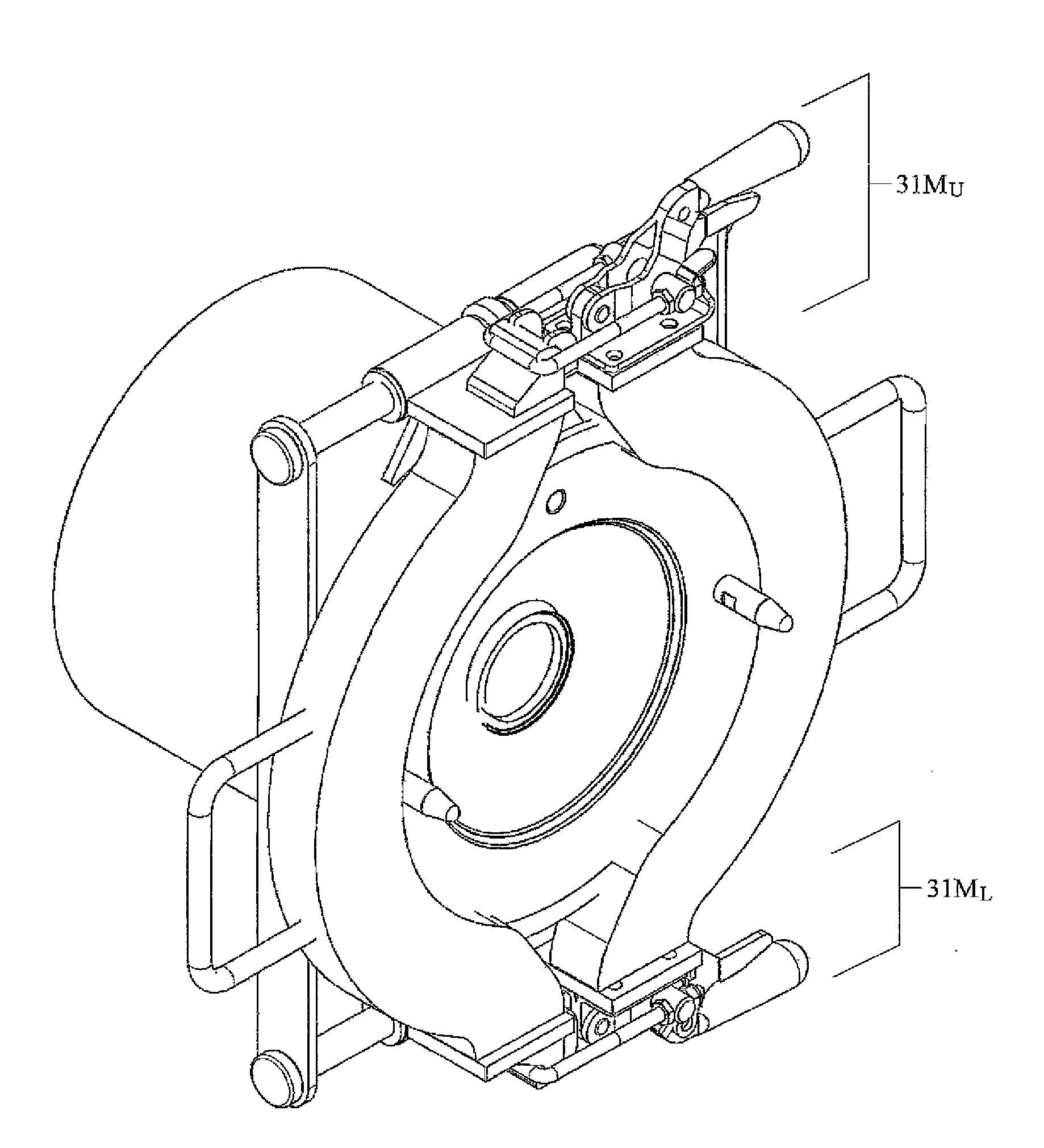

Post/Pedestal-Mounted IBC Mixing/Blending Machine

ActiveUS20130329518A1Enhanced mixing processReduce wasteRotating receptacle mixersRotary stirring mixersIntermediate bulk containerDrive motor

A blending machine, for homogenizing materials deposited within an intermediate bulk container (IBC), includes: a frame; a drive motor; a clamp disk rotatably supported by the frame and coupled to the drive motor to drive disk rotation; first and second jaw clamps movably mounted to the frame; and a drive mechanism to drive the jaw clamps to translate toward each other and rotatably secure the IBC's boom to the rotatable clamp disk. A clutch, a torque limiter, and a limit switch limit the pressure applied by the clamps, and the extent of their travel to optimize clamping and rotatability. The blending machine is moveably mounted to a pedestal, and elevated by an actuator. A blending bar within the IBC is coupled through the boom to the clamp disk, and driven to rotate to blend the materials, in addition to mixing by rotation of the ICB.

Owner:BRODERICK CLIFFORD

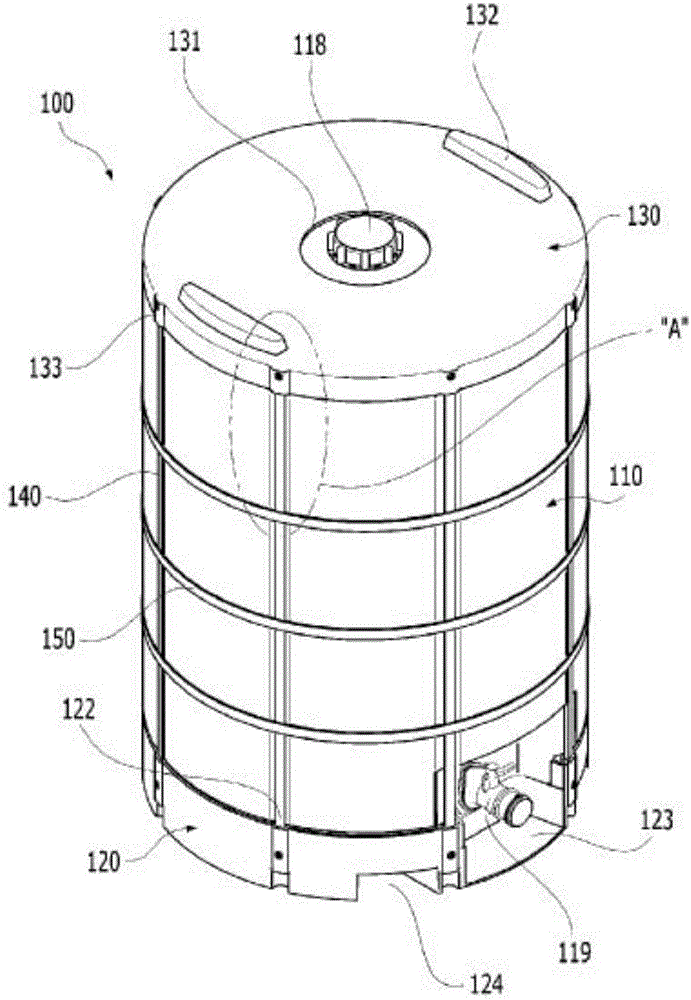

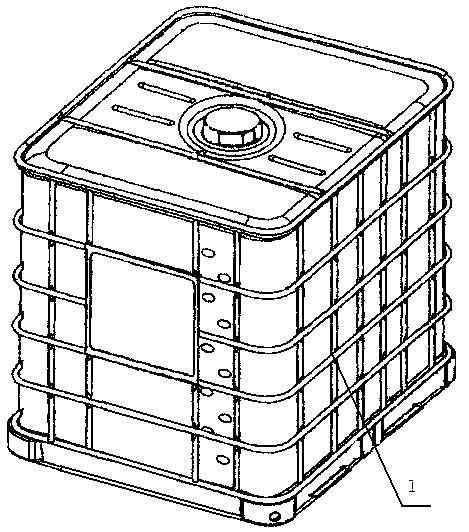

Intermediate bulk container

InactiveCN105980268AReduce weightReduce manufacturing costBagsSacksIntermediate bulk containerSynthetic resin

The present invention relates to an intermediate bulk container which can contain and store dangerous articles such as liquid chemicals or other various kinds of liquid content and can be vertically stacked and, more specifically, to an intermediate bulk container which is configured to: reduce the total weight of the container such that manufacturing costs are reduced by forming most of components except for vertical support bars are made of synthetic resin materials with respect to an intermediate bulk container formed in a size capable of containing approximately one ton of content; and stably maintain a stacked state even though the intermediate bulk container which is heavy due to approximately one ton of liquid contained therein is stacked in a plurality of layers by preventing a container body formed from a synthetic resin material from expanding so as to rupture or from being damaged. The present invention comprises: a plurality of vertical mounting grooves which are placed at certain intervals in a circumferential direction of the container, and which are formed in a longitudinal direction of the container; a plurality of vertical support bars mounted in the vertical mounting grooves; a plurality of horizontal mounting grooves which are placed at certain intervals in the longitudinal direction of the container, and which are formed in the circumferential direction of the container; and a plurality of horizontal support bands mounted in the horizontal mounting grooves, wherein the vertical support bars and the horizontal support bands are installed so as to cross each other.

Owner:HANS ENG

Auxiliary filling equipment, liquid filling system and liquid filling method

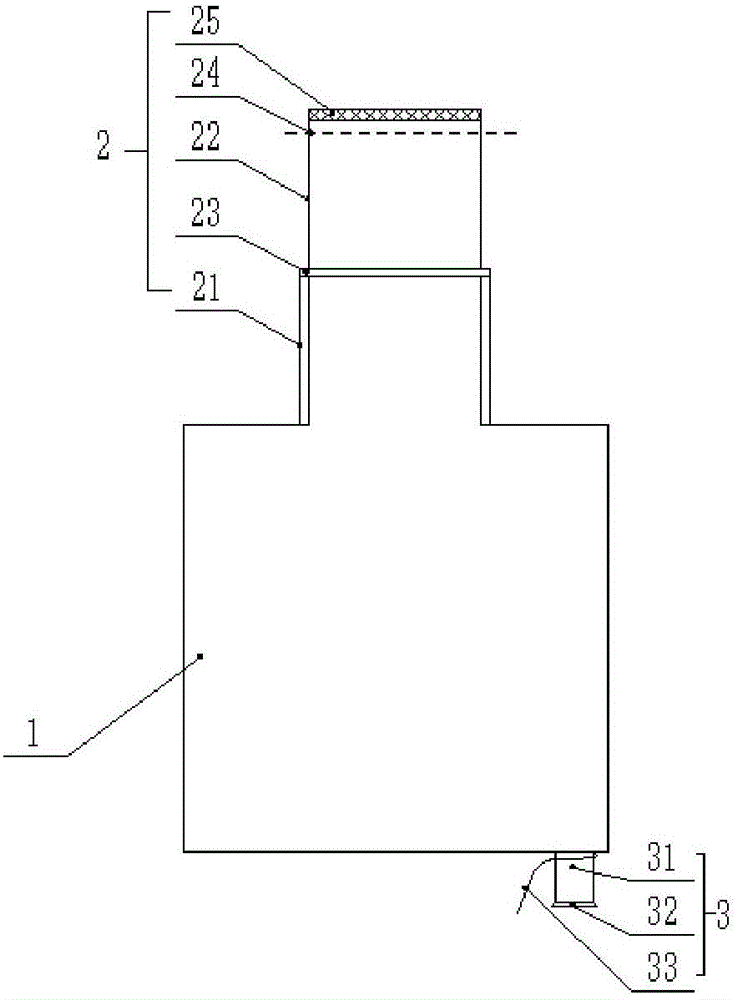

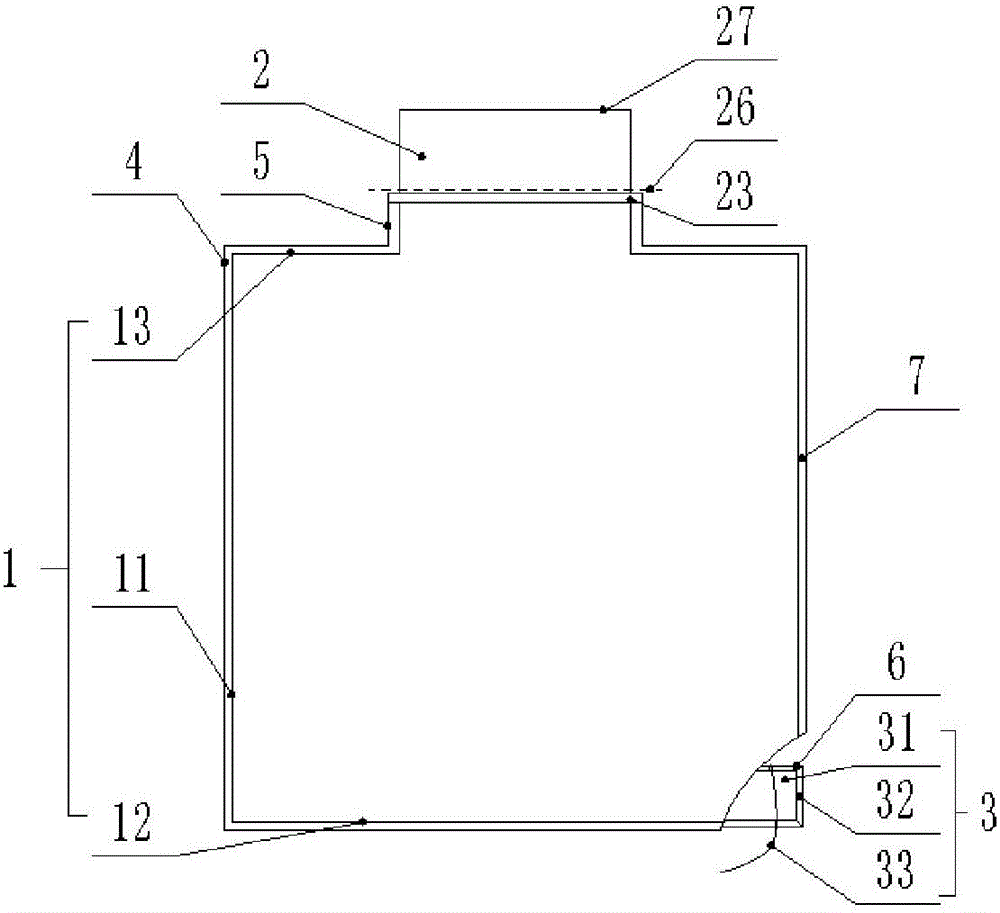

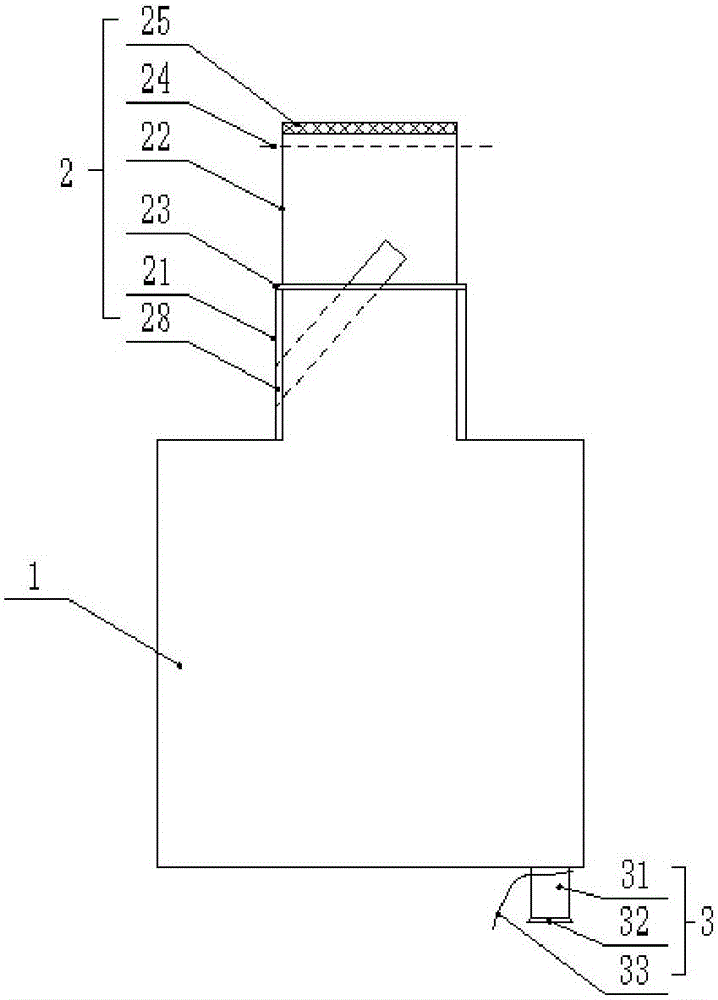

PendingCN107244436ALabor savingImprove filling efficiencyLiquid materialIntermediate bulk containerEngineering

The invention discloses auxiliary filling equipment, a liquid filling system and a liquid filling method. The liquid filling system comprises the auxiliary filling equipment, a medium bulk container and a lining bag; a filling opening is formed in the lining bag; the medium bulk container is provided with a base and a side board; and the side board is connected with the base. The auxiliary filling equipment comprises a slowly-placing device and a clamping device, wherein the clamping device is used for clamping a part of a bag and connected with the slowly-placing device; and the slowly-placing device and the clamping device are arranged so that in the bag filling process, the clamped part of the bag moves through the slowly-placing device. The liquid filling system and the auxiliary filling equipment can achieve improvement of the liquid filling efficiency.

Owner:SHANGHAI HONGYAN RETURNABLE TRANSIT PACKAGINGS CO LTD

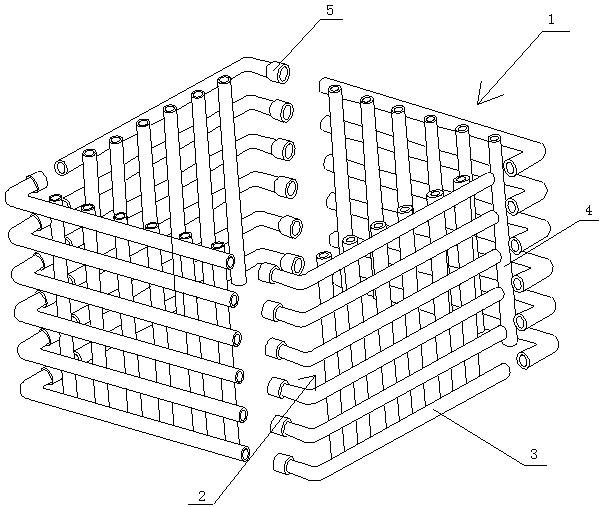

Quickly detached and installed intermediate bulk container framework

InactiveCN102807020AEasy to stackEasy to transportRigid containersVertical tubeIntermediate bulk container

The invention relates to a quickly detached and installed intermediate bulk container framework and belongs to the technical field of packaging containers. The framework is characterized by comprising an outer framework (1), wherein the outer framework (1) consists of four framework components (2); each framework component (2) is formed by welding a plurality of L-shaped horizontal tubes (3) which are horizontally parallel to one another and a plurality of vertical tubes (4) which are vertically parallel to one another; sleeve heads (5) are arranged at ends of short straight sections of the horizontal tubes (3) and are connected with ends of long straight sections of adjacent horizontal tubes (3) and fixed with the ends by bolts; and V-shaped grooves (6) are formed on surfaces of the horizontal tubes (3) and the vertical tubes (4). According to the framework, the outer framework is divided into the four framework components, so that the outer framework is convenient to stack and transport and the quick detachment and installation capacity is high.

Owner:江阴康爱特包装股份有限公司

Novel medium bulk container with corner guard

ActiveCN101332919AReduce riskEasy to replaceLarge containersRigid containersIntermediate bulk containerEngineering

The invention relates to a novel intermediate bulk container with corner armors, comprising a plastic inner bladder (2) and a peripheral frame (1); the peripheral frame (1) is installed at the periphery of the plastic inner bladder (2); the peripheral frame (1) is mutually welded and circled with a plurality of horizontal circular tubes (1.1) and vertical circular tubes (1.2); the bottom of the peripheral frame (1) is provided with a tray (4); the plastic inner bladder (2) is put on the tray (4) at the bottom of the peripheral frame (1). The invention is characterized in that four corners at the bottom of the plastic inner bladder (2) are all wrapped with a corner armor (3). The invention protects the plastic inner bladder by increasing independent corner armors at the external layers of the four corners of the plastic inner bladder. As adopting independent design, the corner armors can be conveniently replaced, and the corner armors can be conveniently replaced once the corner armors at the corners are damaged, thereby greatly reducing the maintenance cost.

Owner:江阴康爱特包装股份有限公司

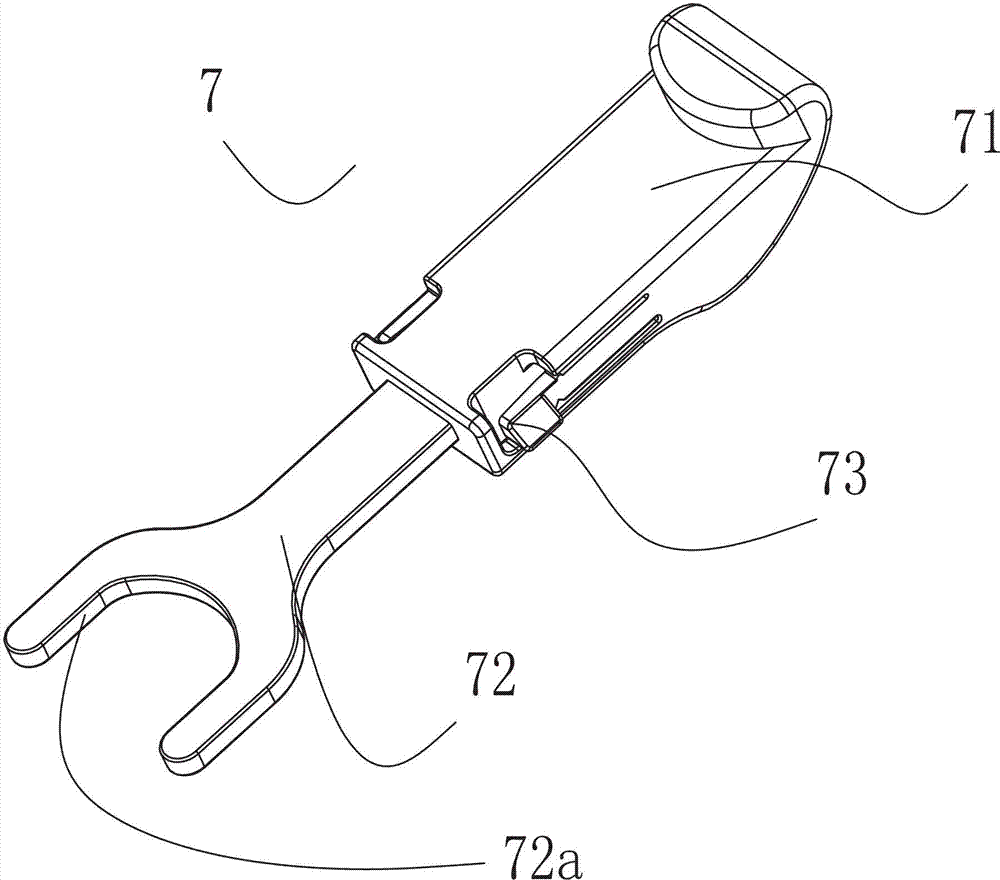

Standby start and stop gear for valve in complex intermediate bulk container and container

ActiveCN102829238AEasy loading and unloadingOperating means/releasing devices for valvesDischarging meansIntermediate bulk containerExternal cause

The invention provides a standby start and stop gear for a valve in a complex intermediate bulk container, and the container. The container comprises a base, a side plate, the valve, and a valve start and stop gear; the valve is arranged at the bottom of the container; the valve start and stop gear is used for starting and stopping the valve; the standby valve start and stop gear is arranged in the container, and comprises a handle and a standby start and stop member; the handle is connected with the standby start and stop member; and the standby start and stop member can be matched with a valve rod of the valve so as to start and stop the valve when the valve start and stop gear fails. In case the valve start and stop gear does not work due to an external cause, self-fatigue and damage, etc., and the standby start and stop gear can be taken out, so that the purpose of temporarily starting and stopping the valve can be achieved by cooperation of the standby start and stop gear and the valve rod of the valve; when being not used, the standby start and stop gear is arranged at any part of the container; and the standby start and stop gear can be assembled and disassembled easily, and can be used repeatedly or used in a disposable manner.

Owner:SHANGHAI HONGYAN RETURNABLE TRANSIT PACKAGINGS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com