Patents

Literature

145results about How to "Smooth nesting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

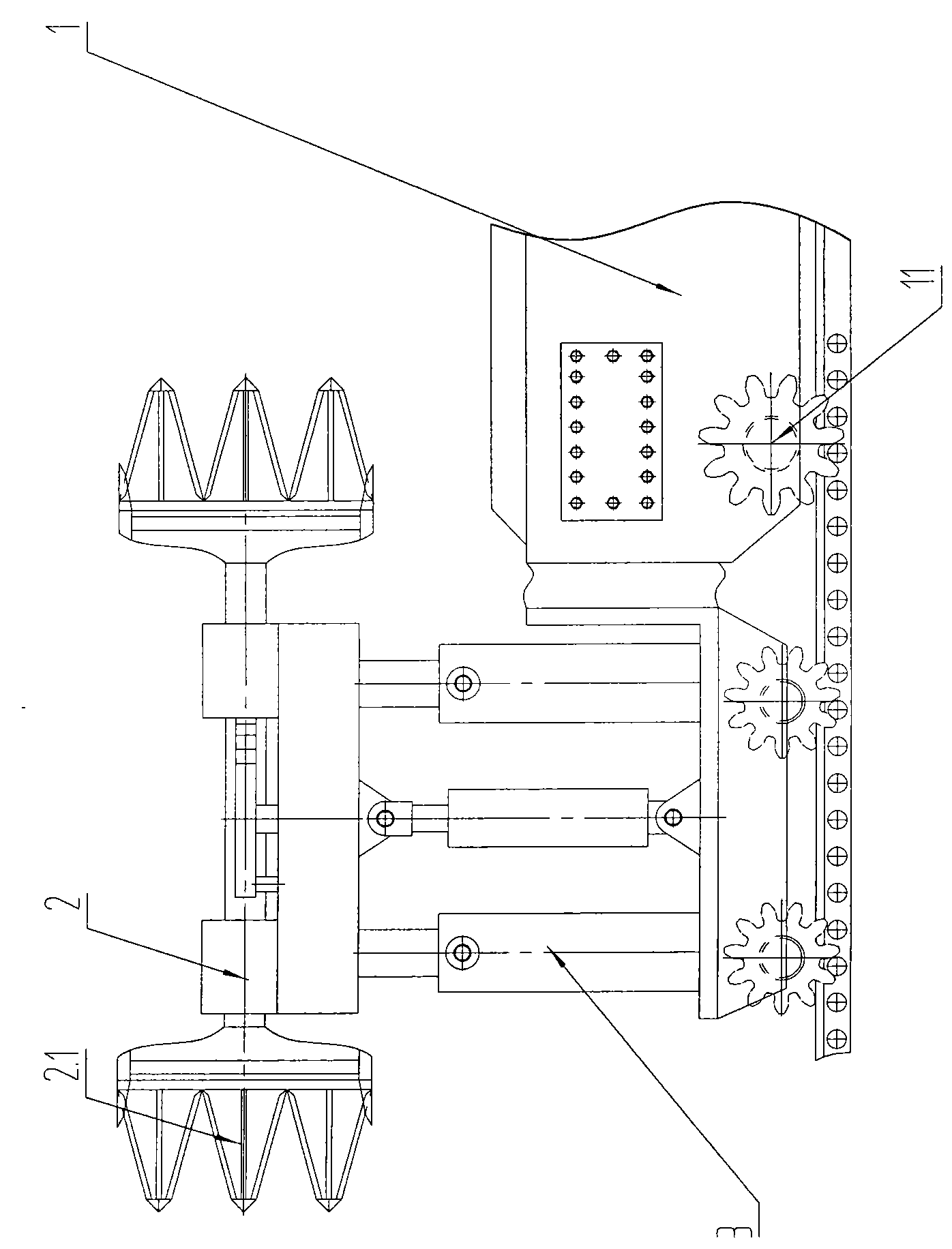

Bidirectional pounding and cutting excavating method and bidirectional pounding and cutting excavator for implementing same

ActiveCN103089259AReduce the number of adjustmentsExtend your lifeDriving meansReciprocating motionEngineering

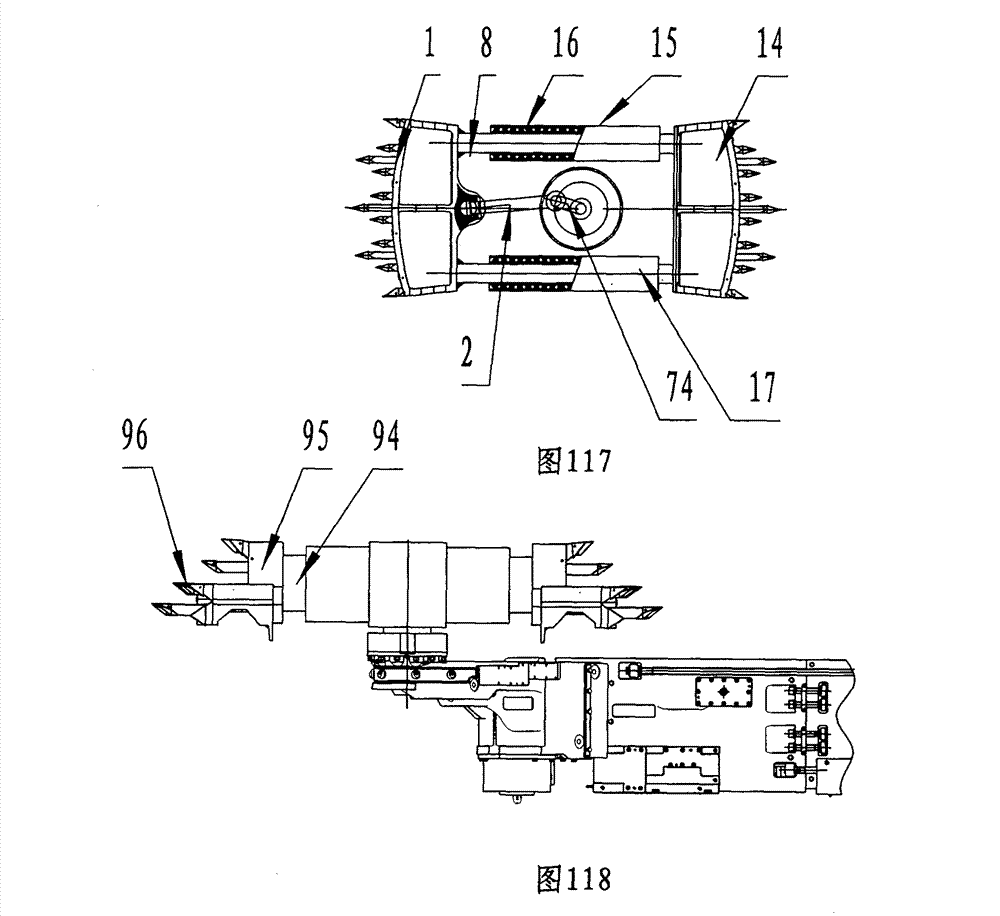

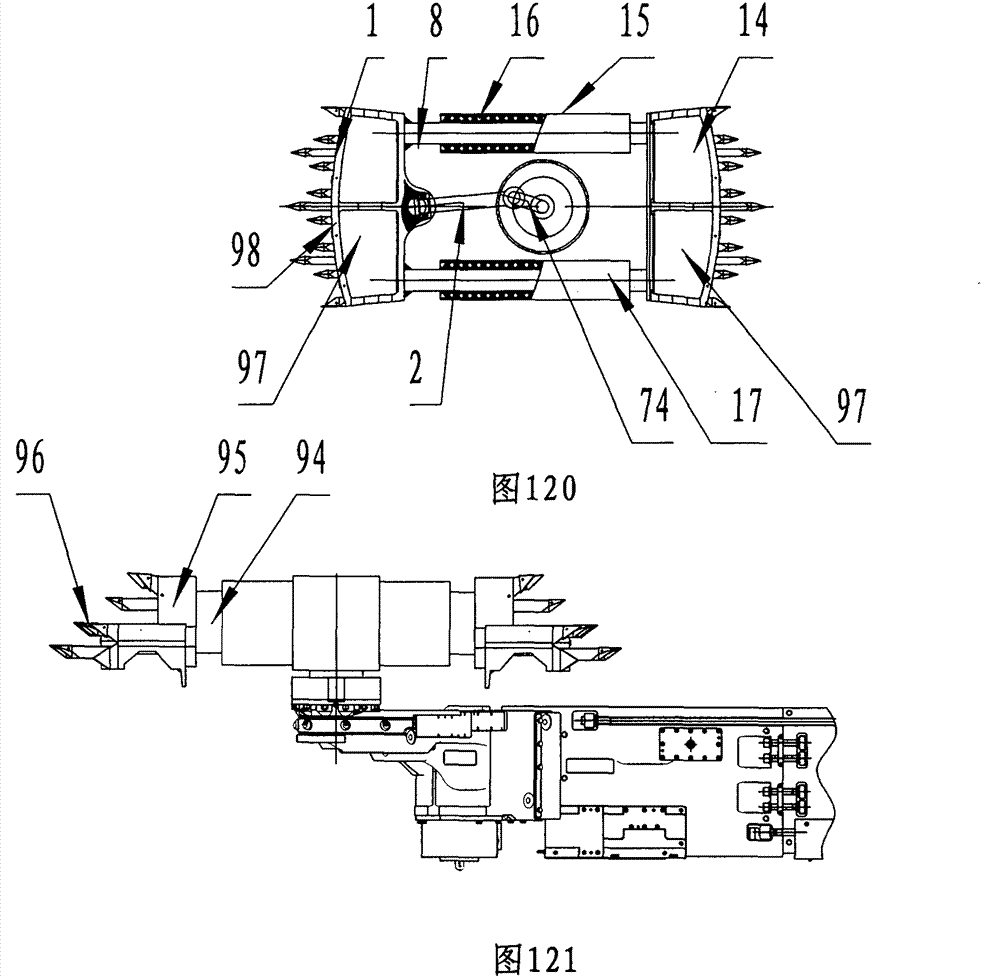

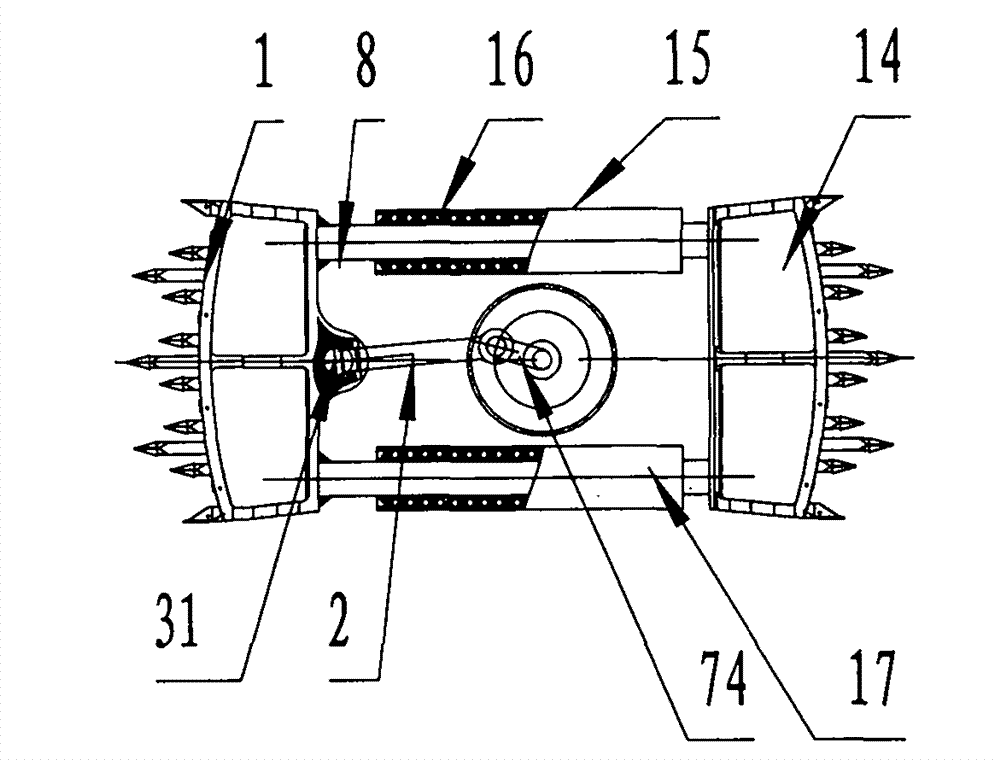

The method provided by the invention comprises the following steps: a machine body, a walking part, a lifting part, a reciprocating pounding part and the like are arranged; a pounding guide element and the like are arranged on a pounding guide device; pounding heads are arranged at two ends of the pounding guide element, so that a power pounding element drives the pounding guide element; the reciprocating pounding part is arranged on the lifting part; the lifting part is arranged on the machine body; and the walking part drives the machine body to move ahead and retreats so as not to turn the machine body to excavate and drop materials forward and backward. Equipment provided by the invention comprises the machine body, the walking part, the lifting part, the reciprocating pounding part and the like; the reciprocating pounding part comprises the pounding guide device, the pounding driving device and the like; the pounding heads are both arranged at two ends of the pounding guide element; the pounding driving device comprises the power pounding element and the like; the power pounding element drives the pounding guide element to move in a reciprocating mode; the pounding guide element drives the pounding heads to pound; the reciprocating pounding part is arranged on the lifting part; the lifting part is arranged on the machine body; the walking part drives the machine body to move ahead and retreat so as not to turn the machine body to excavate and drop materials forward and backward.

Owner:刘素华

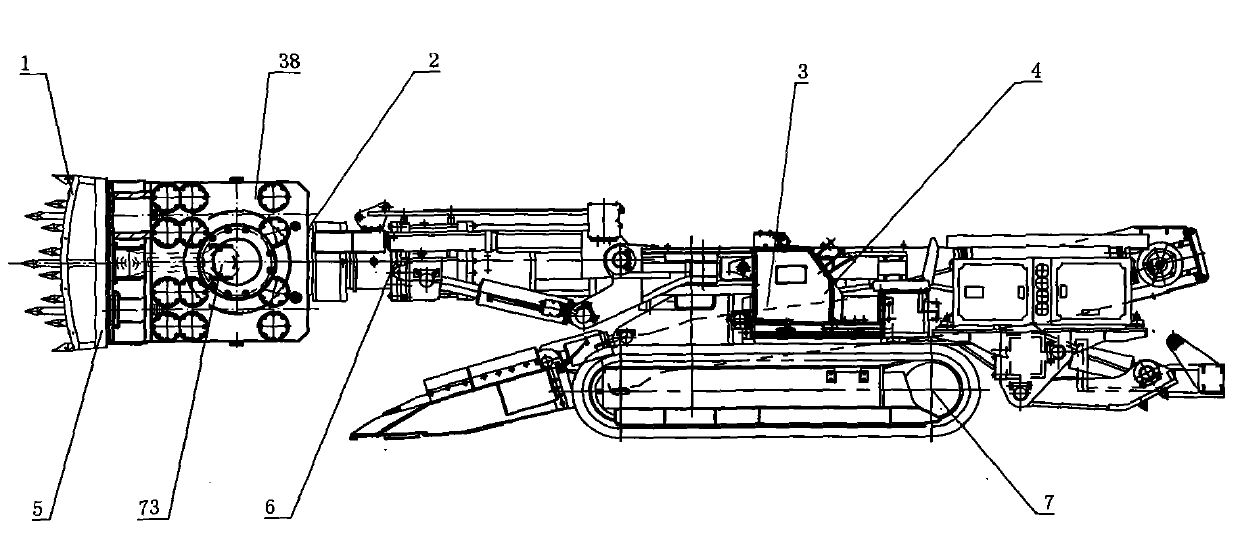

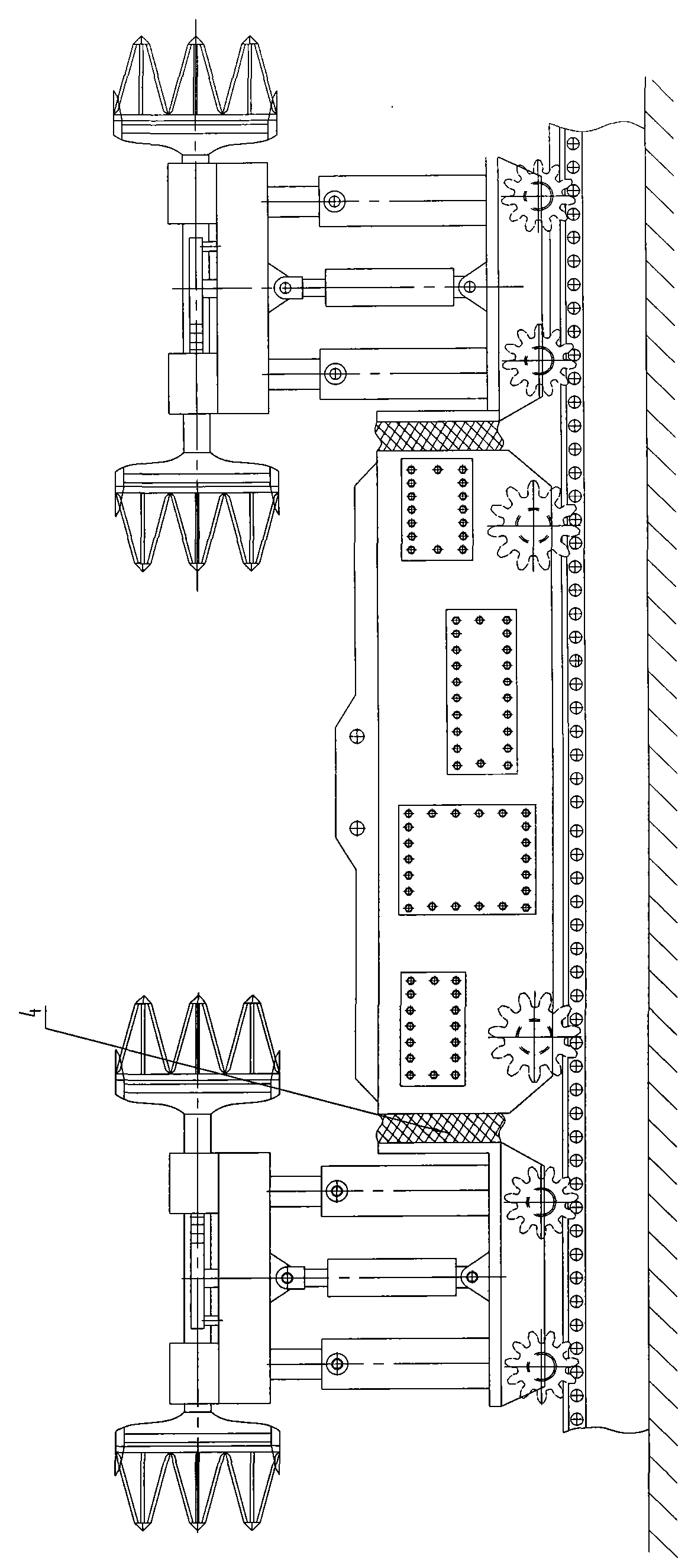

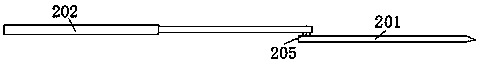

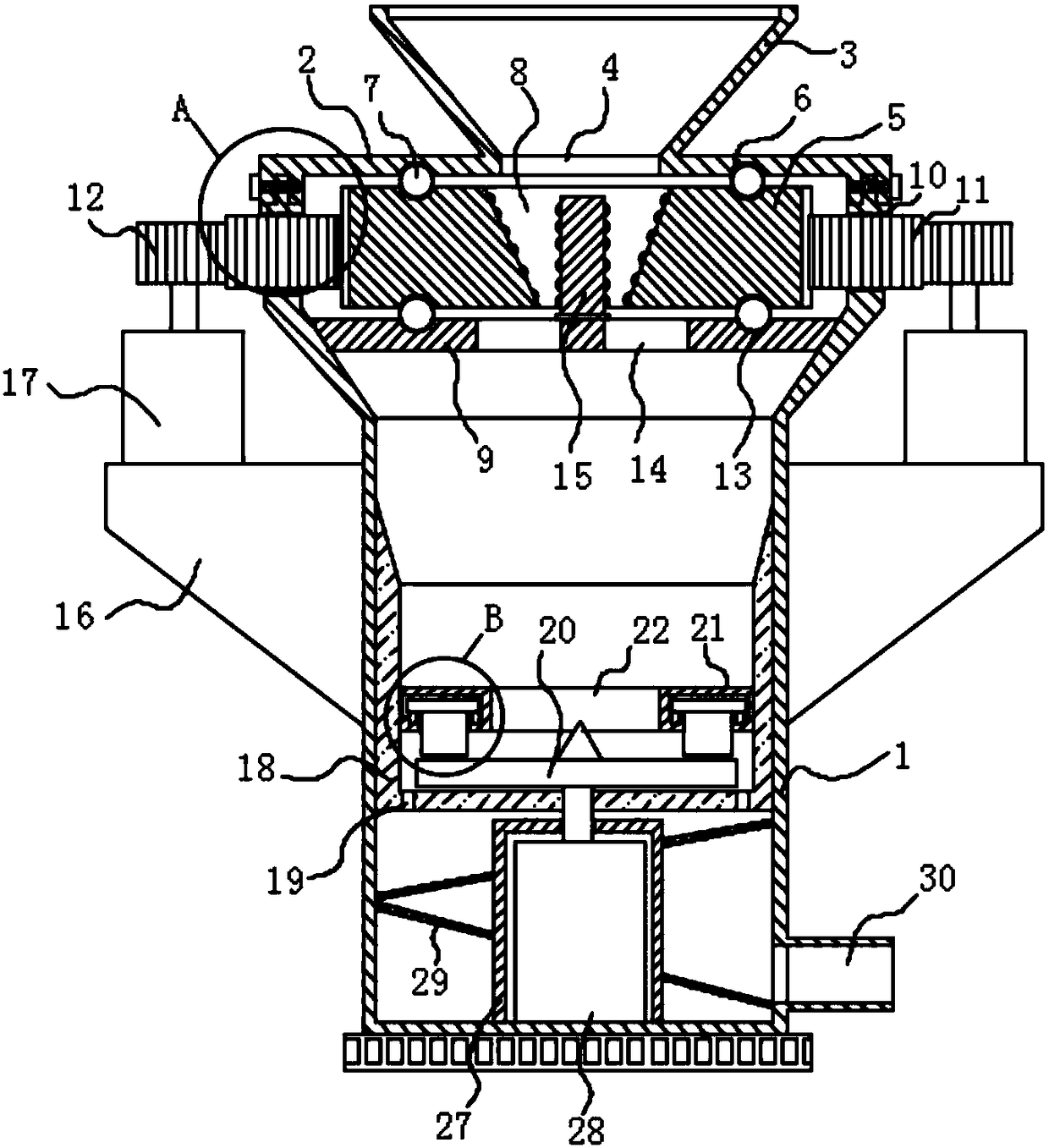

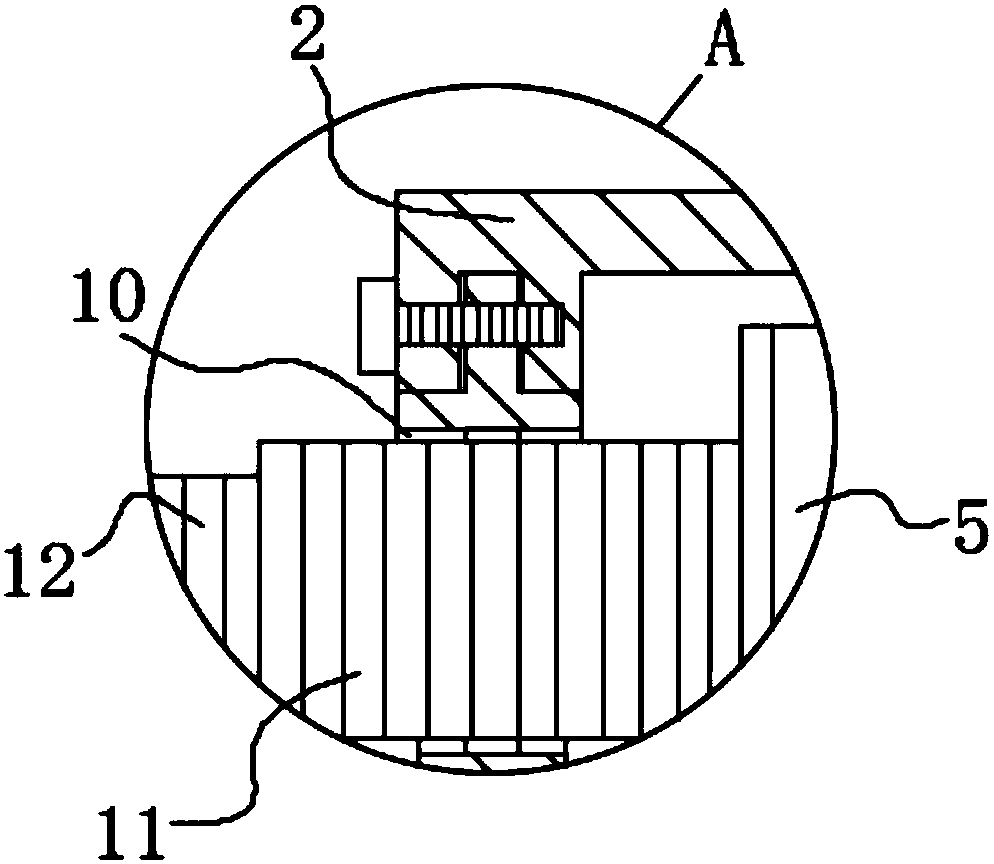

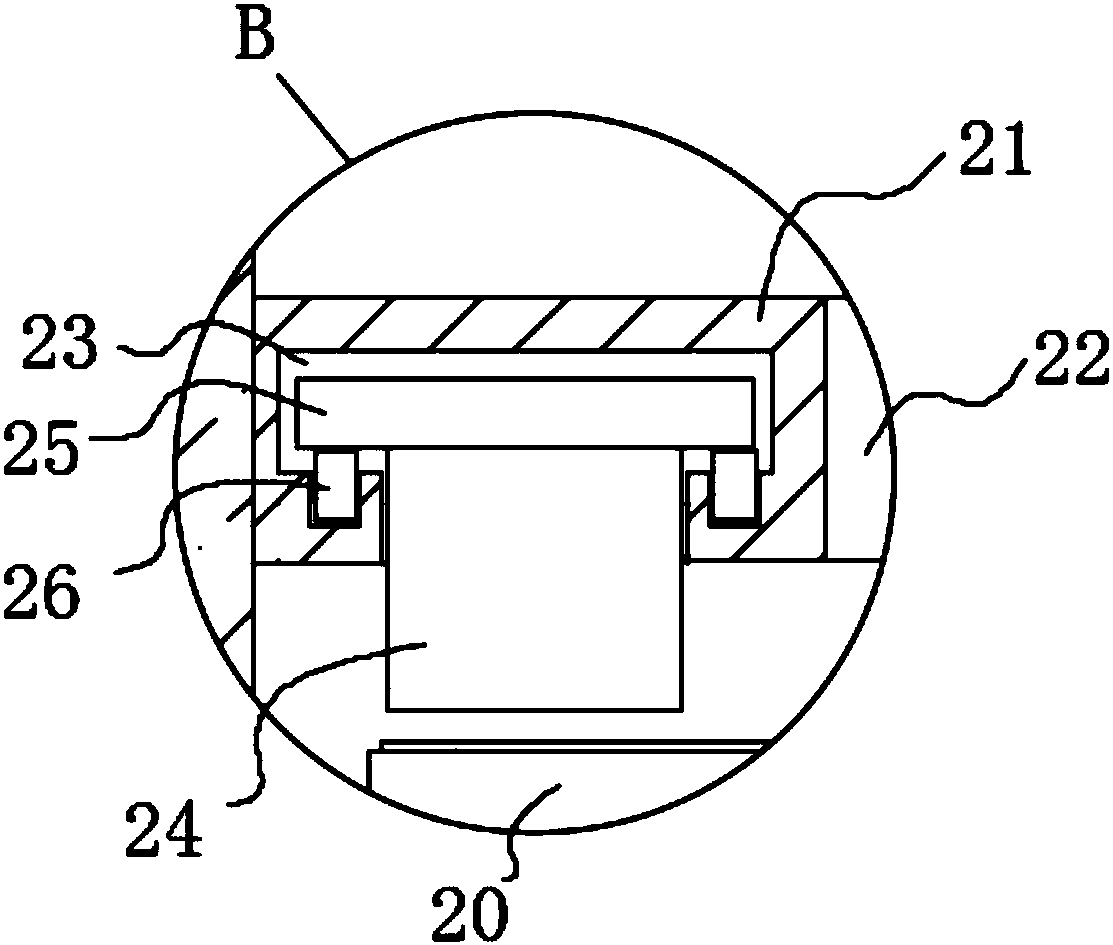

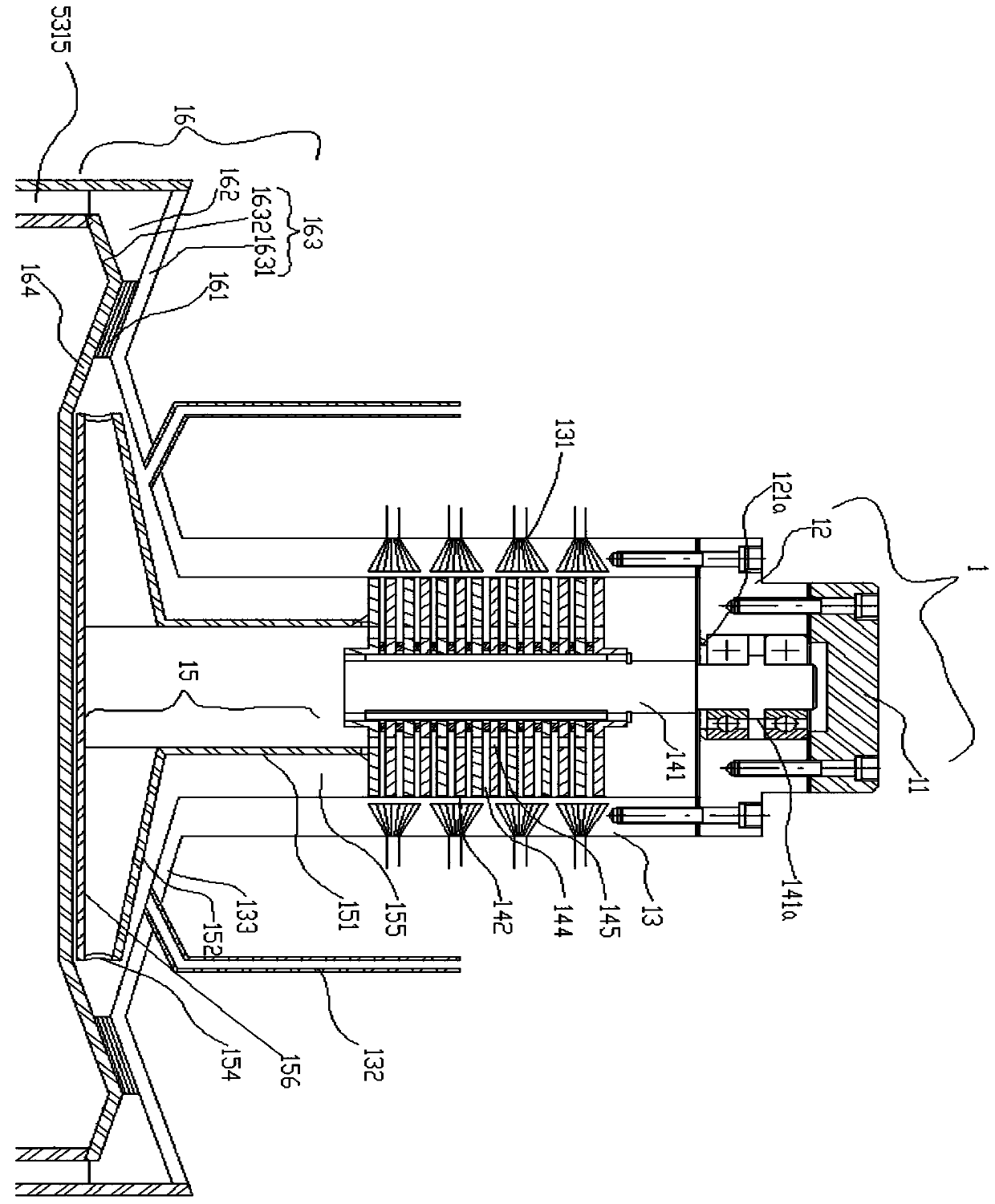

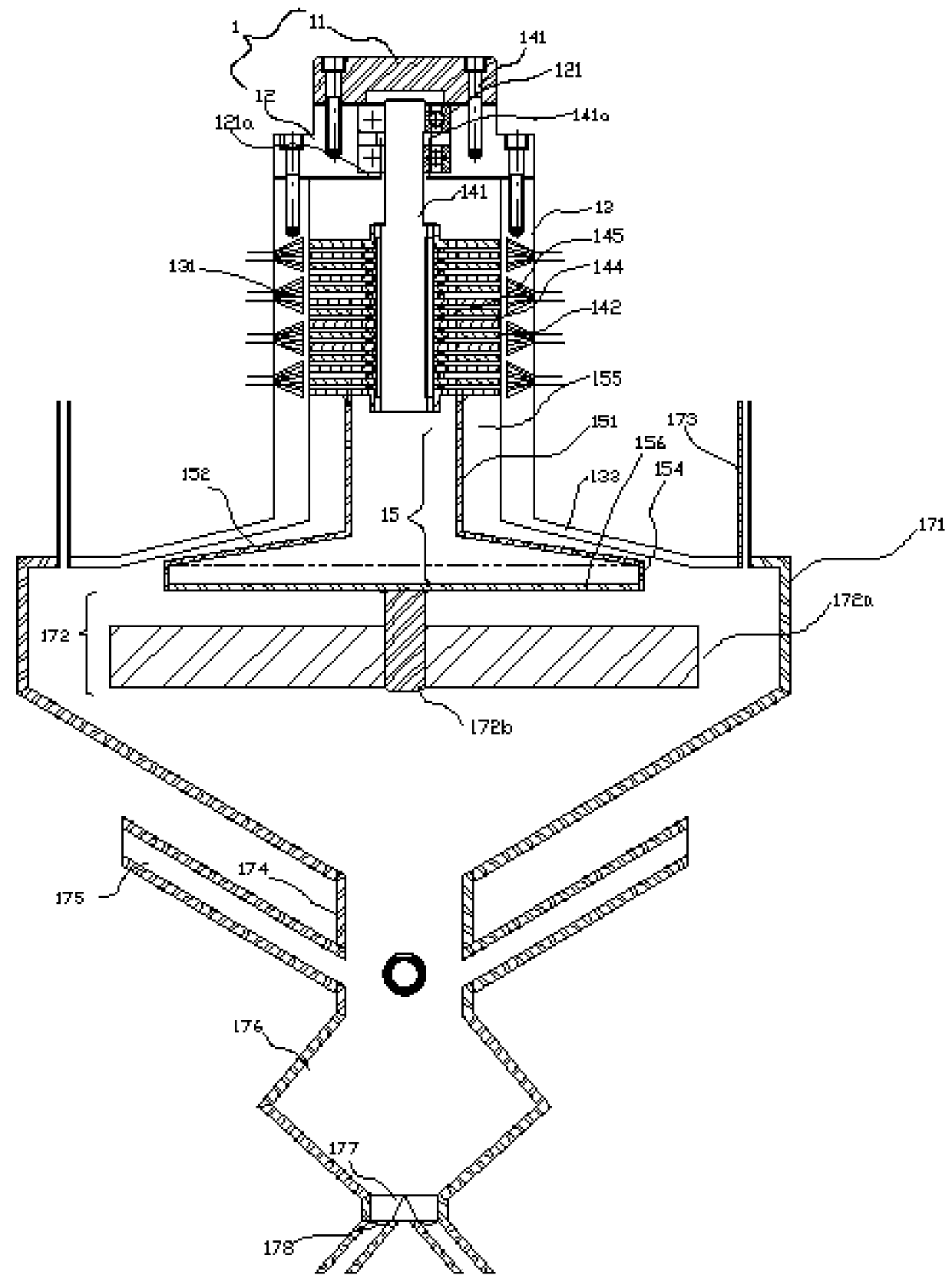

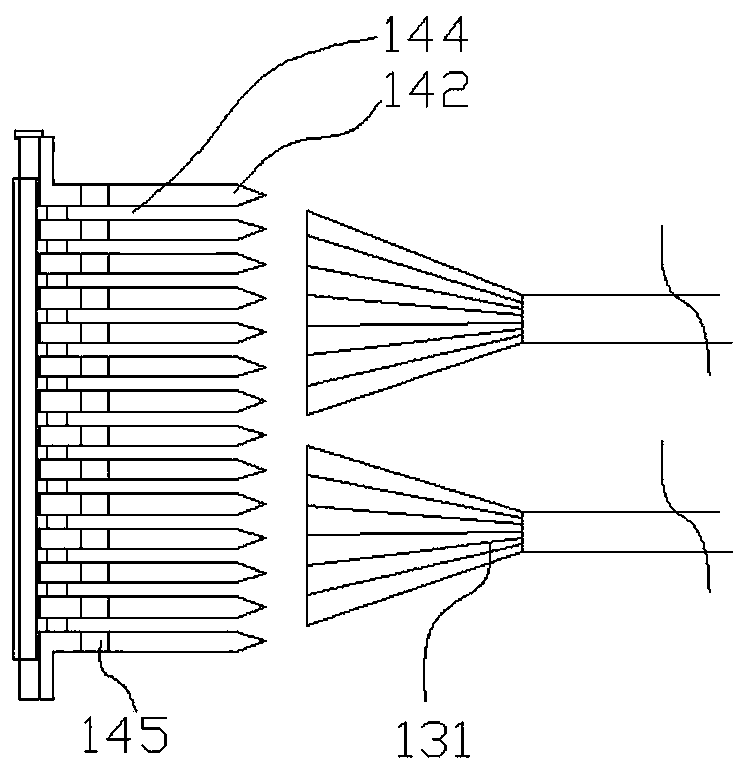

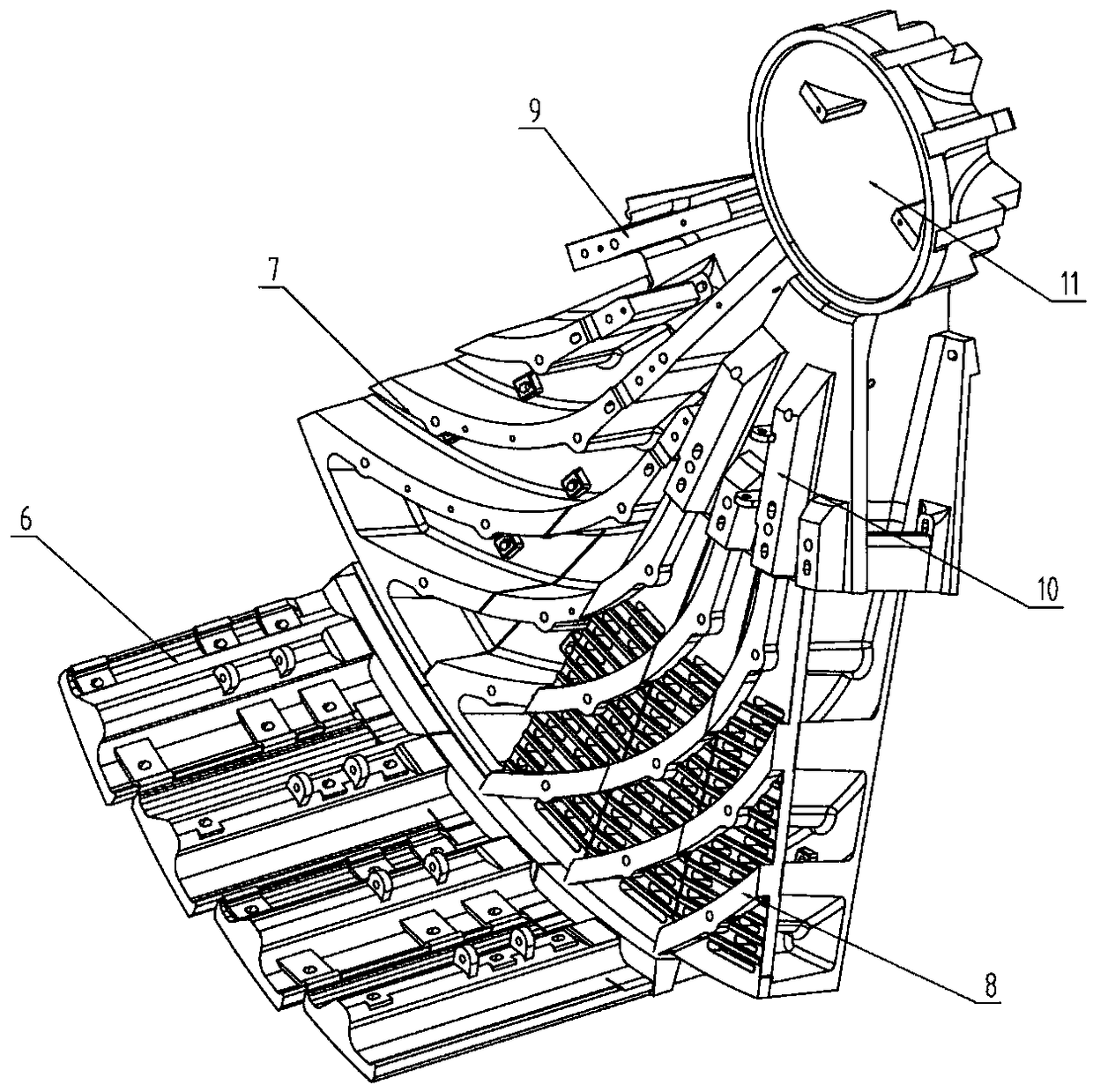

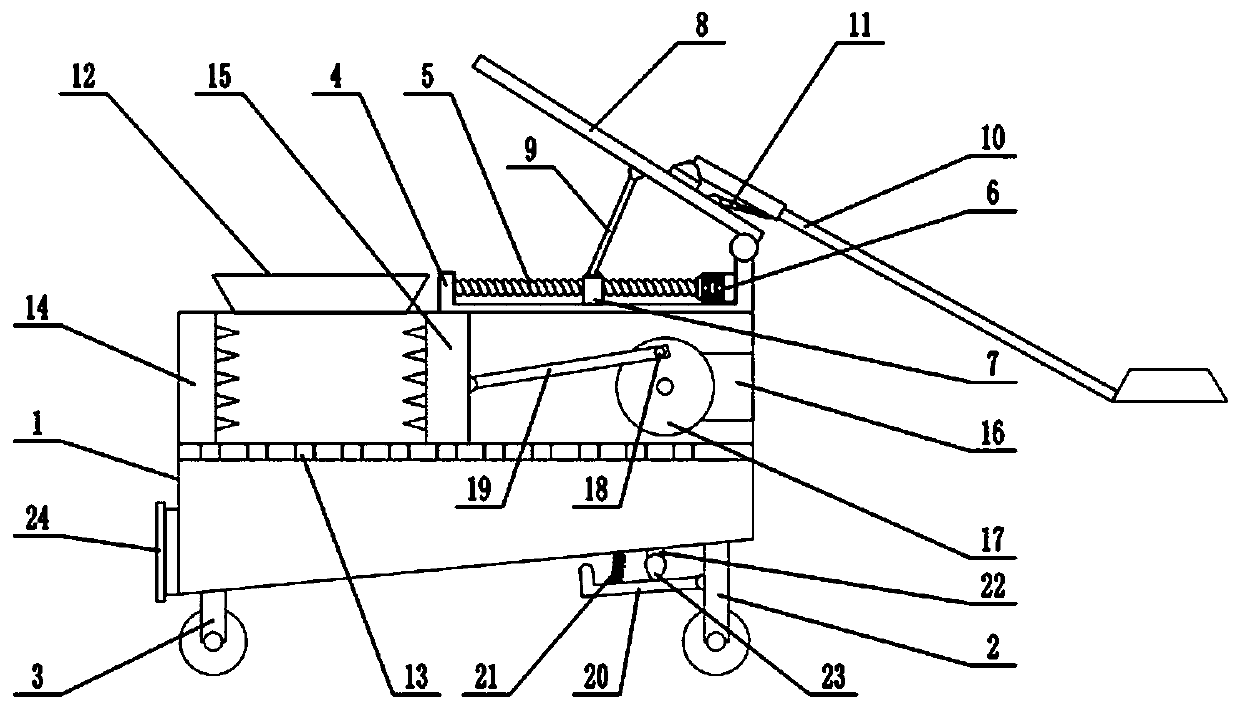

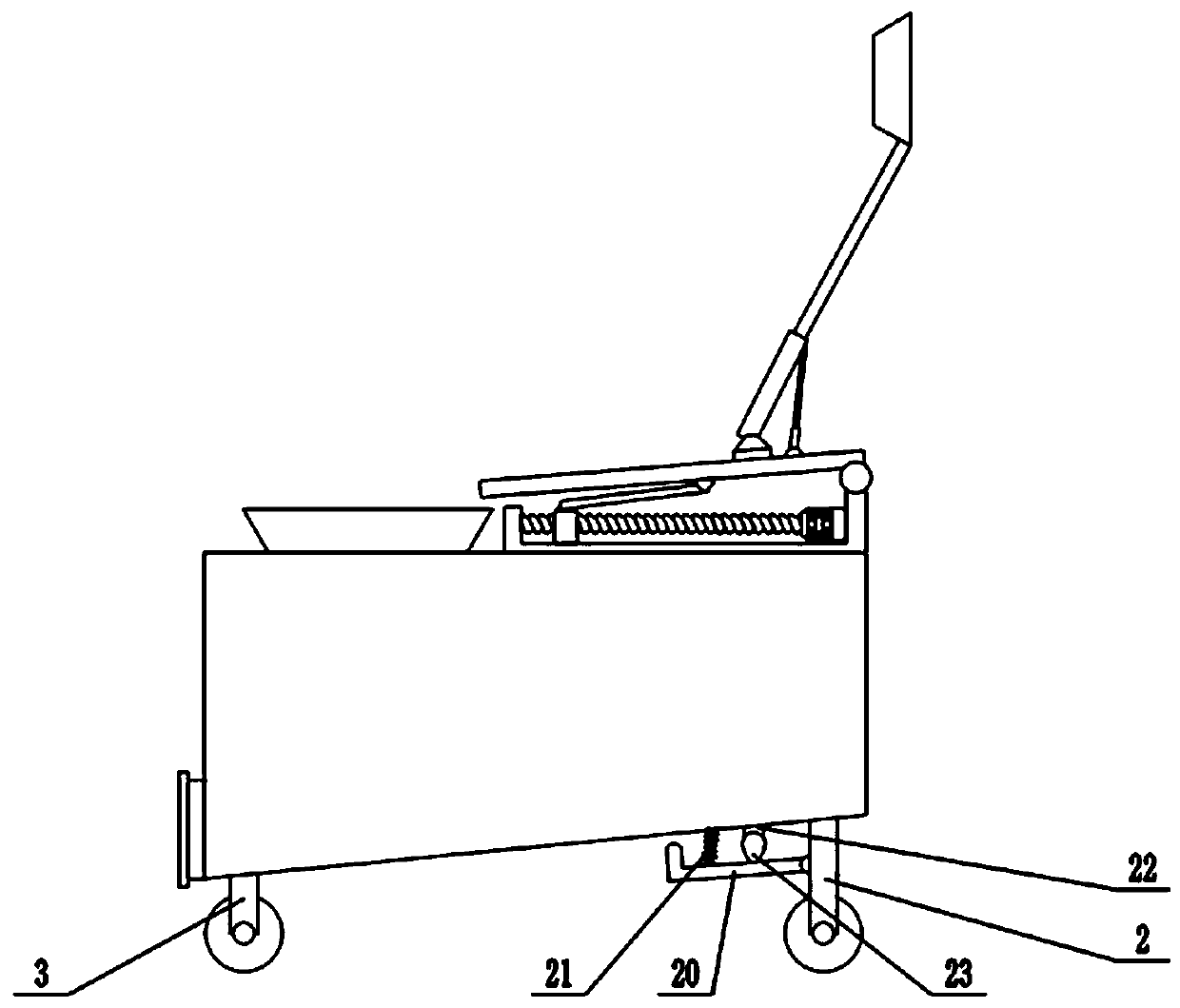

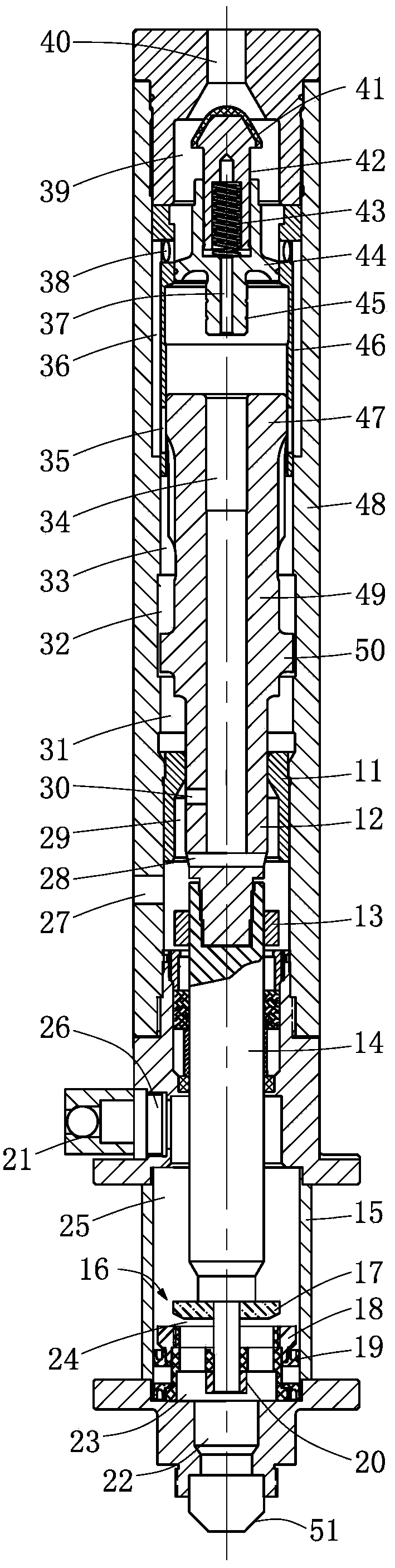

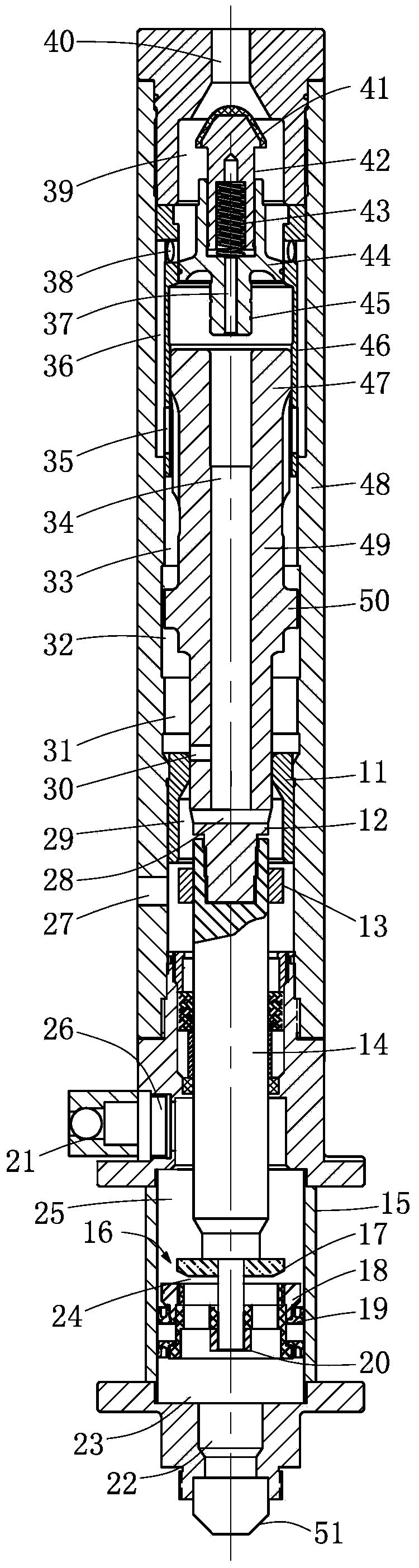

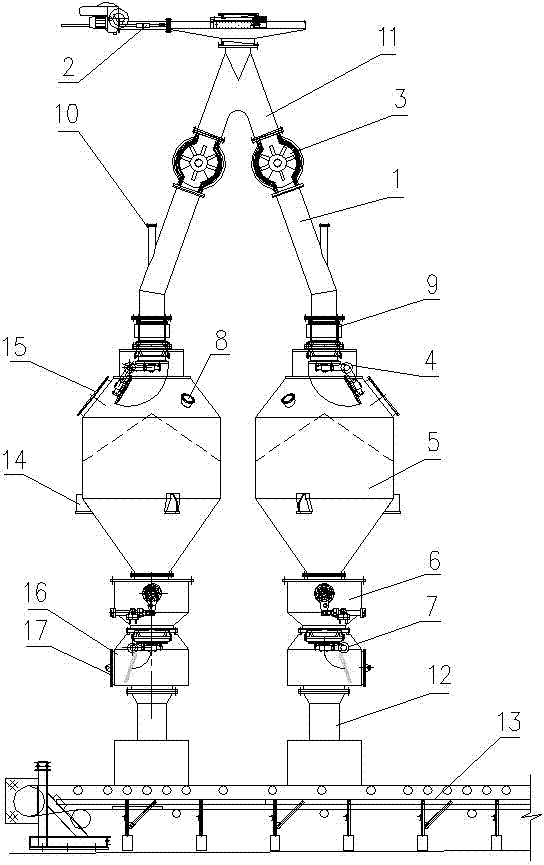

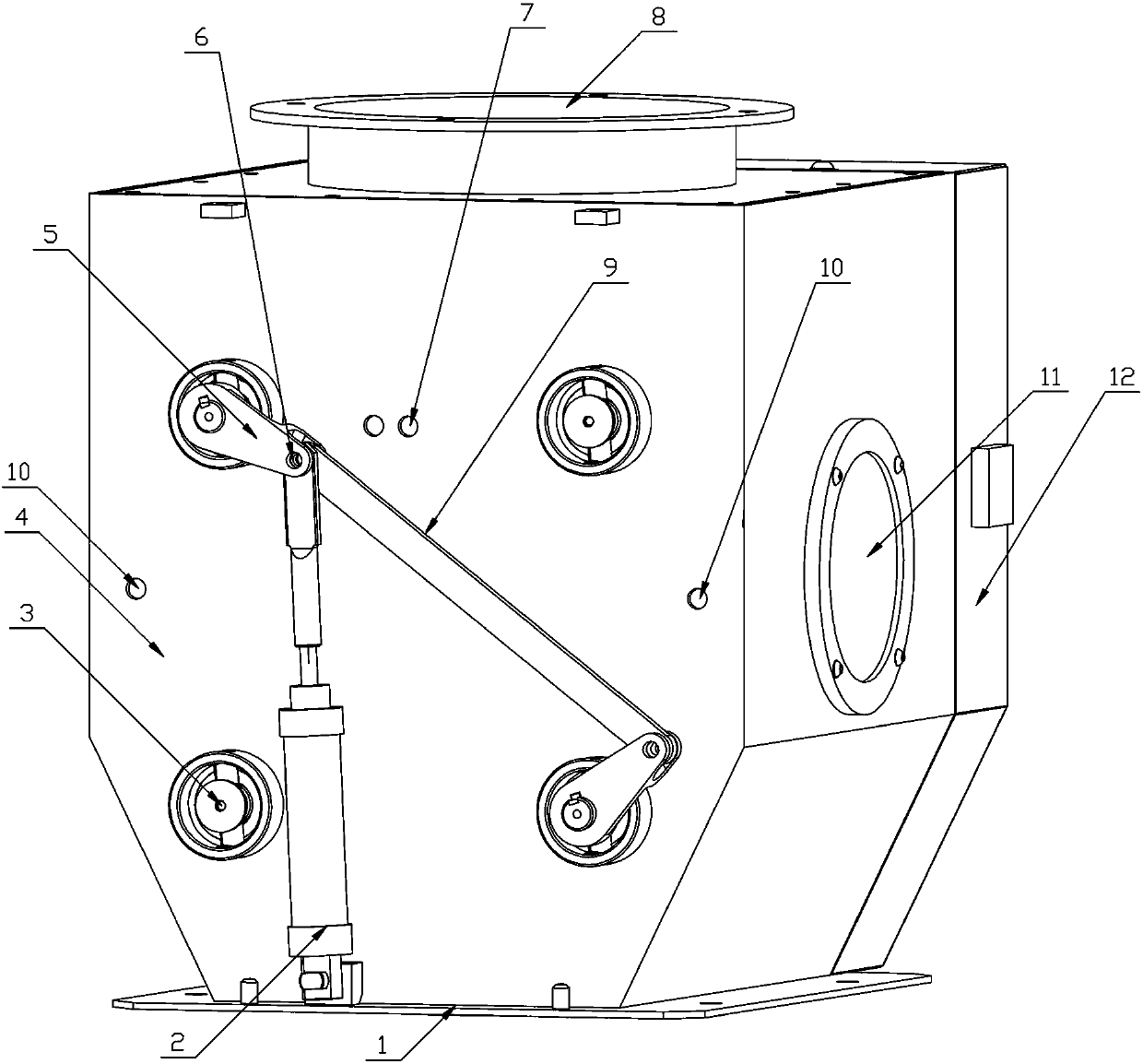

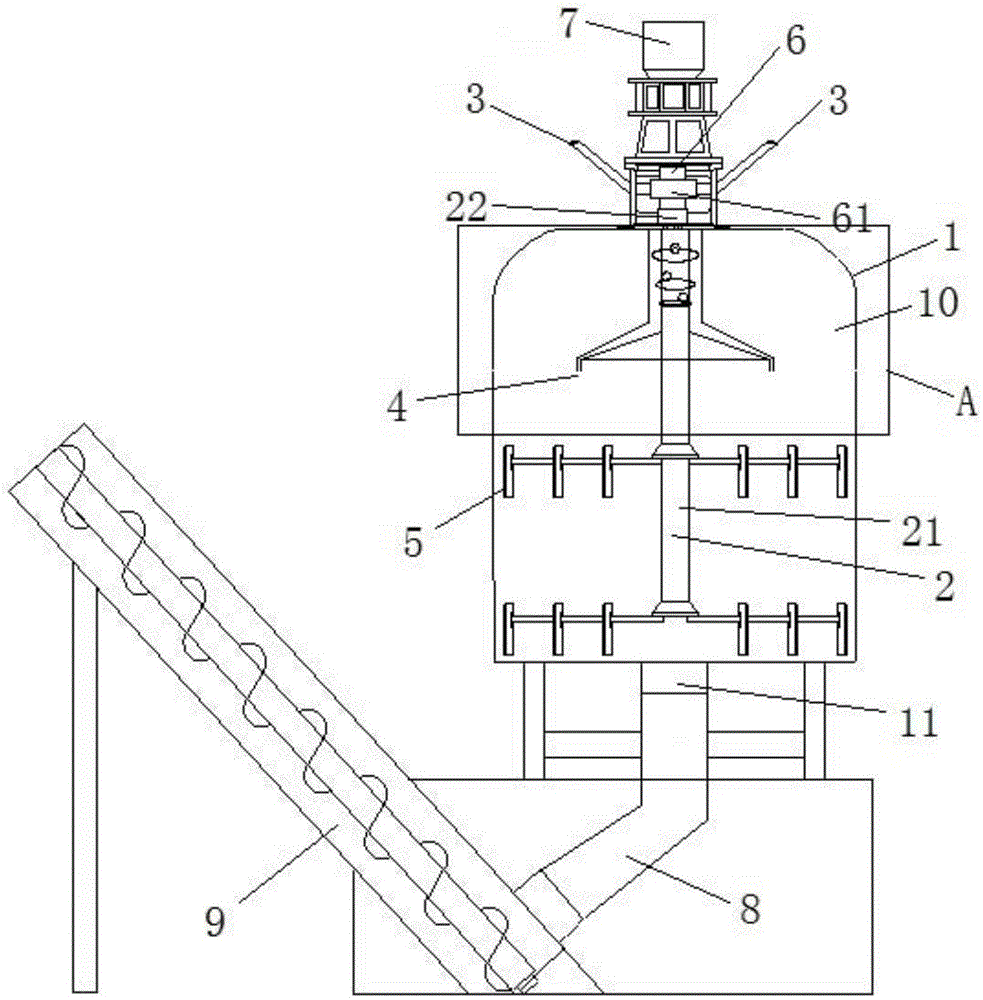

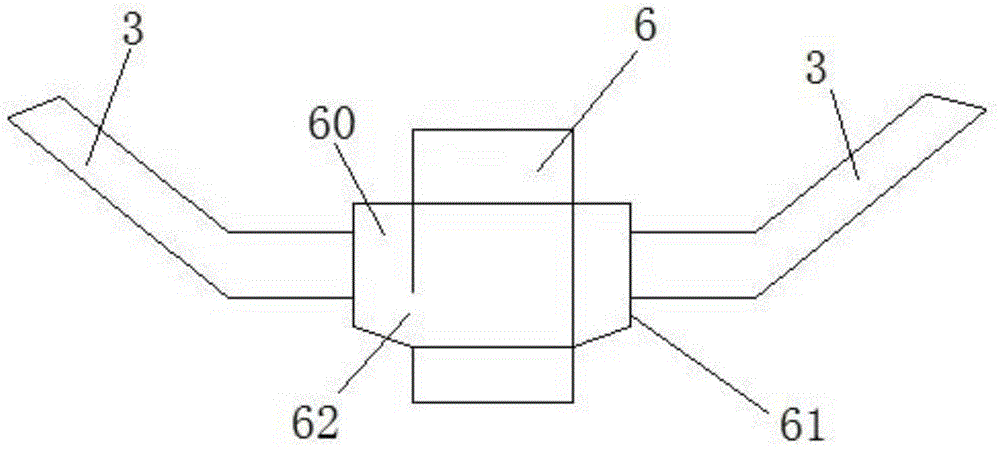

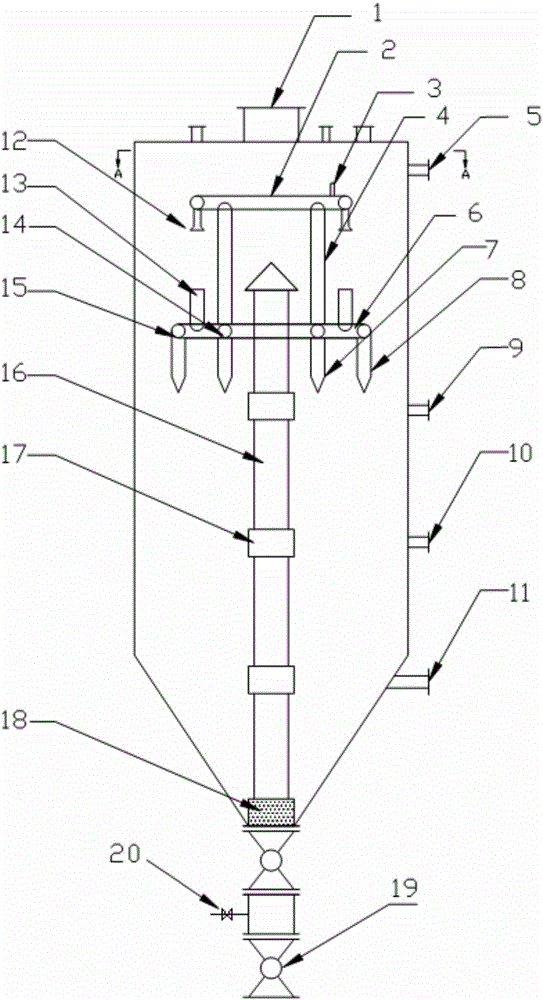

Method and apparatus for converting rotary motion into reciprocating impact motion

ActiveCN103498673APass smoothlySmooth nestingDriving meansPercussion drillingDrive shaftReciprocating motion

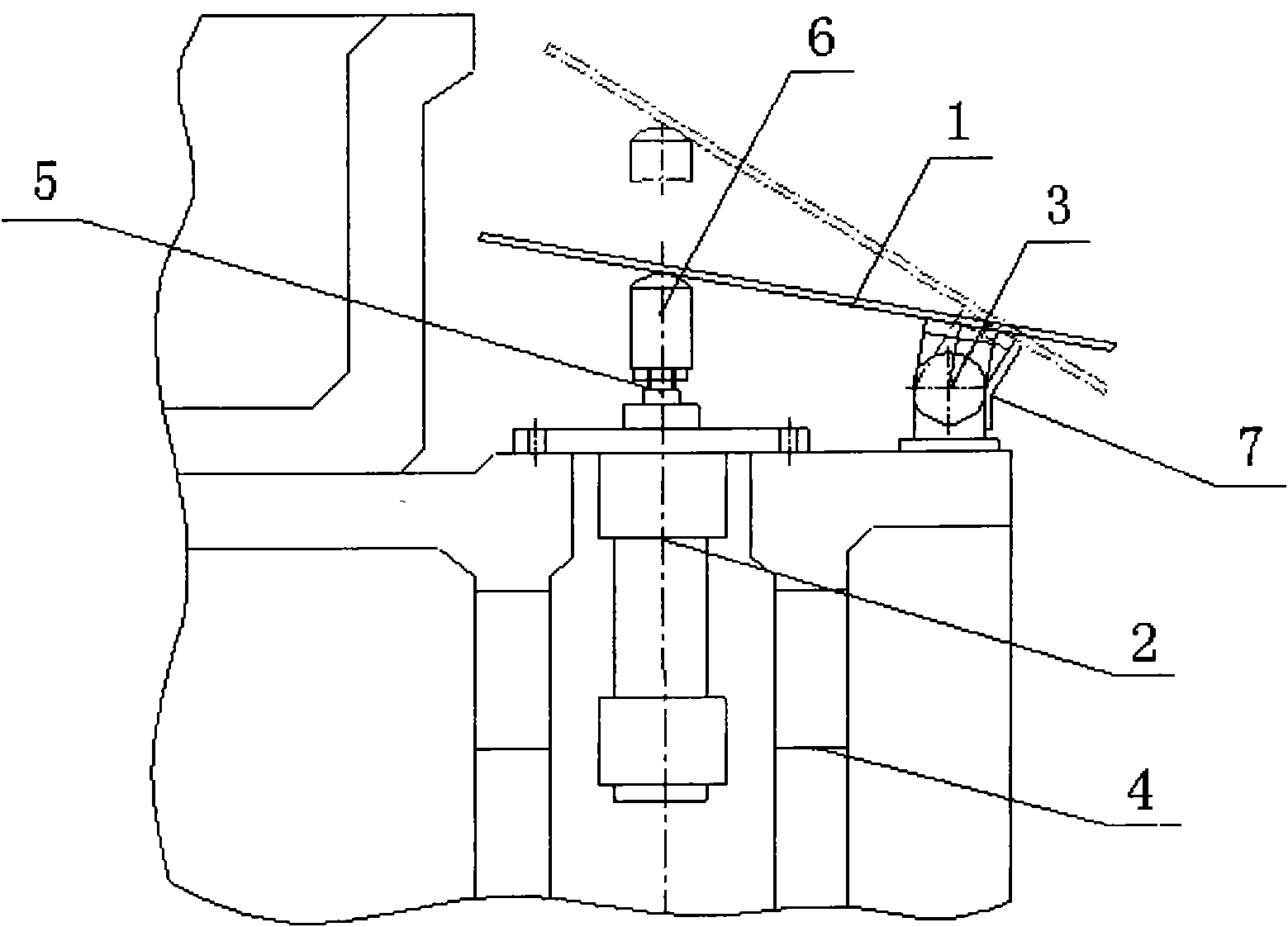

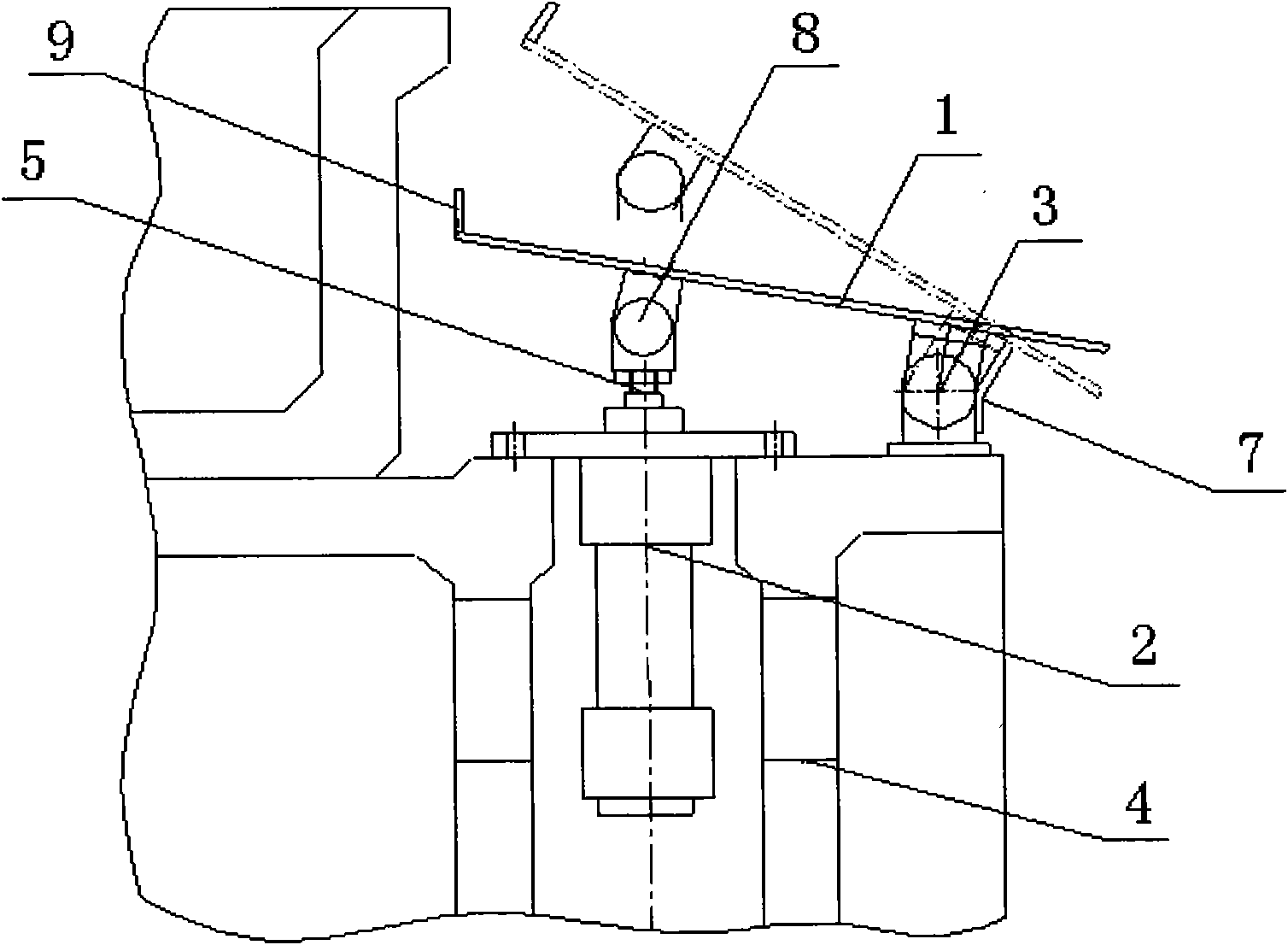

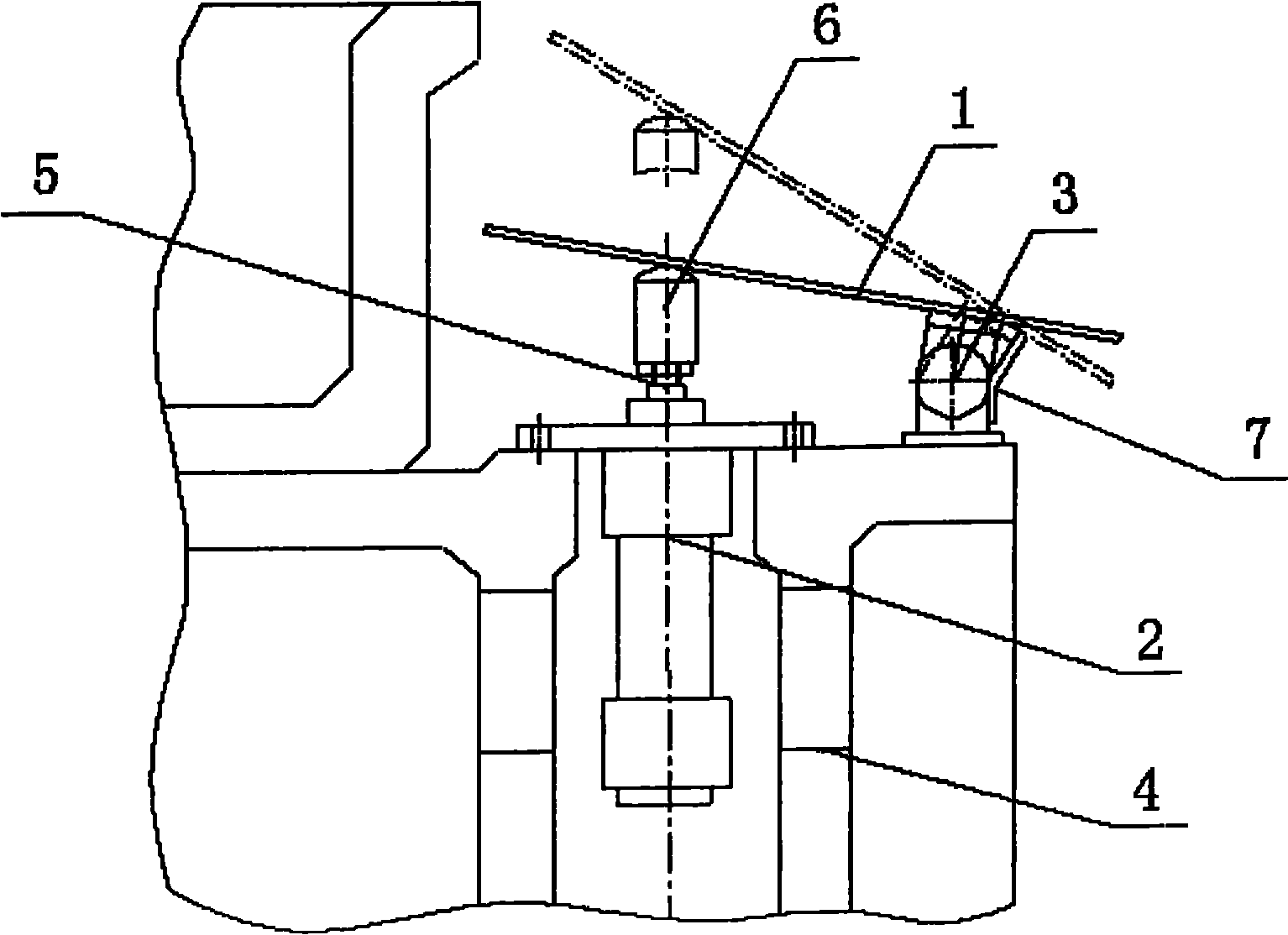

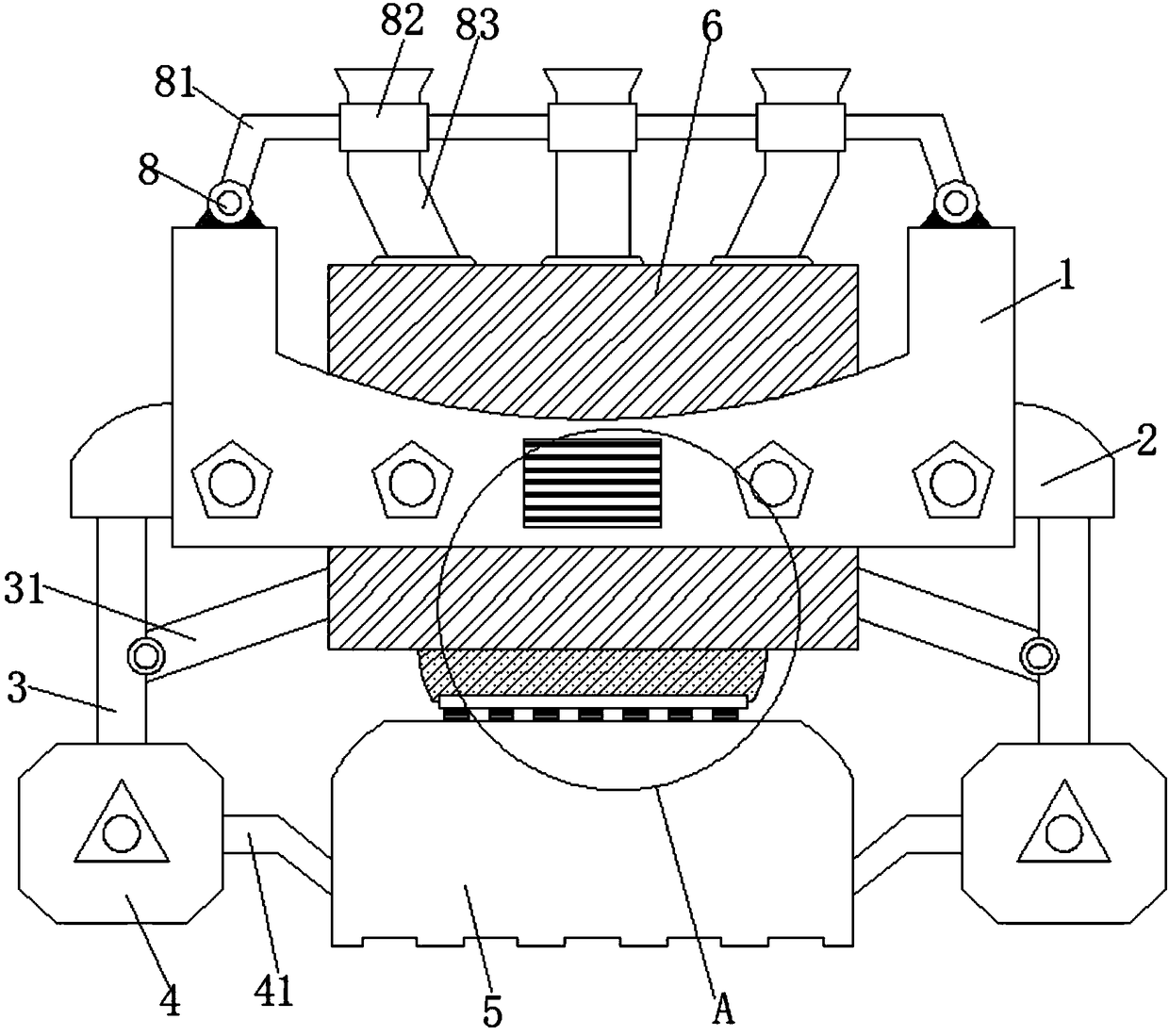

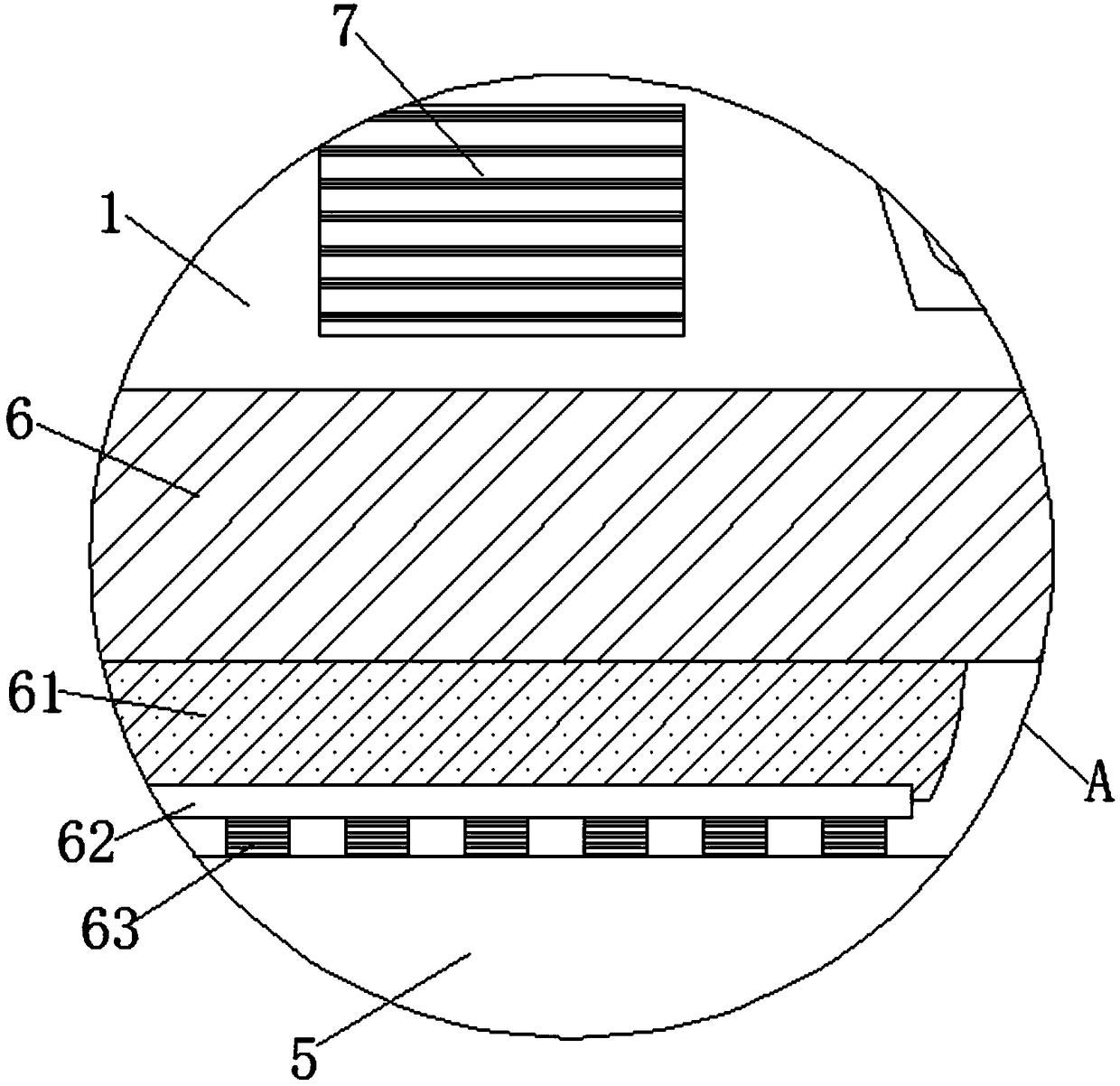

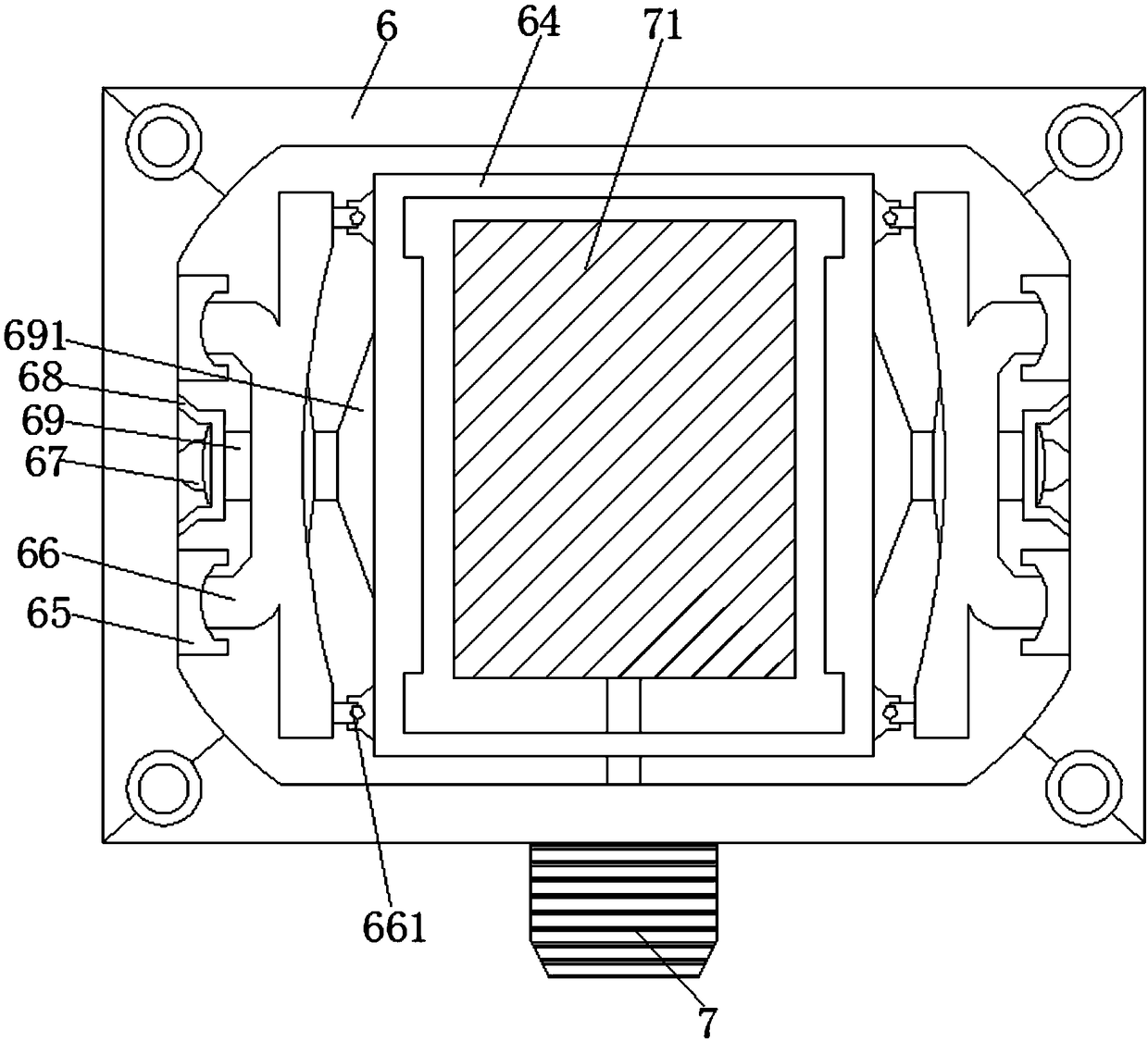

A method and device for converting rotary motion to reciprocating percussion motion. The device comprises a machine body (4), a travel portion (7), and a reciprocating percussion portion (5). The reciprocating percussion portion (5) comprises a percussion drive mechanism (2), a rocker arm (6), and a percussion head (1). The percussion drive mechanism (2) comprises a percussion power source member (11), a transmission component, and a crankshaft (10). The percussion power source member (11) comprises a motor, and the motor comprises a power output shaft (14). The transmission component comprises a power gear (13) and a transmission gear (12). The power gear (13) is mounted on the power output shaft (14). The transmission gear (12) drives the crankshaft (10). The transmission component comprises a transmission shaft. The power output shaft (14) is perpendicular to the rocker arm (6), and is parallel to the transmission shaft and the crankshaft (10) so that the transmission gear (12) drives the crankshaft (10) to convert rotary motion to reciprocating motion; or the power output shaft (14) is parallel to the rocker arm (6), the crankshaft (10) is driven to convert rotary motion to reciprocating motion after the power direction is changed by a power bevel gear and a transmission bevel gear. The crankshaft (10) drives the percussion head (1) to perform reciprocating percussion. The travel portion (7) drives the machine body to travel. The machine body (4) drives the reciprocating percussion portion (5) to move and work continuously. The device applies to the mining field or mechanical engineering field, and has advantages such as strong structural strength and a small amount of maintenance.

Owner:刘素华

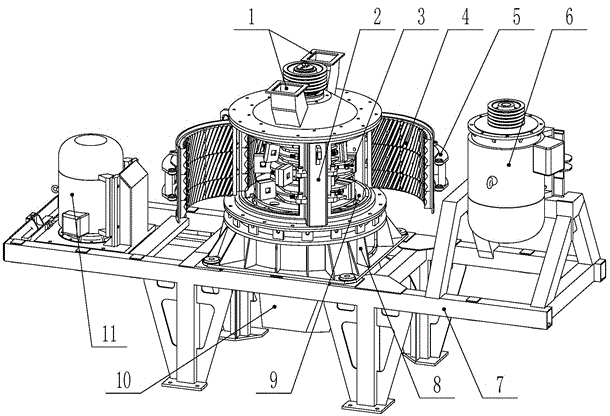

Vertical combined crushing and grinding machine

The invention provides a vertical combined crushing and grinding machine. The vertical combined crushing and grinding machine comprises an integral support, a grinding cavity seat, a cylinder body, a vertical rotor body, a spiral impact plate, a discharge hopper, charge hoppers, a turnover door, a grinding cavity wall lining plate, an electromotor, a crushing mechanism and a grinding mechanism. The vertical combined crushing and grinding machine enables the material crushing and grinding processes to be realized by one machine, is compact in structure and small in occupied area, saves the process, and improves the efficiency. Materials are impacted and crushed at high speed by a hammer head on a tower-shaped hammer seat in a spiral through crushing cavity, are thrown to the turnover door, are rebounded to the hammer head on the tower-shaped hammer seat, and are crushed repeatedly in the way, so as to guarantee relatively sufficient crushing. A centrifugal rotation roller acts on a grinding cavity wall lining plate, the materials are ground and crushed to 1mm below, and the qualified materials discharged from the discharge hopper finally are uniform in granularity and high in crushing ratio. In addition, the crushing and grinding cavity of the through combined crushing and grinding machine of the design is difficult to block, is smooth in material discharge and is long in service life, and the industrial cost is reduced.

Owner:四川皇龙智能破碎技术股份有限公司

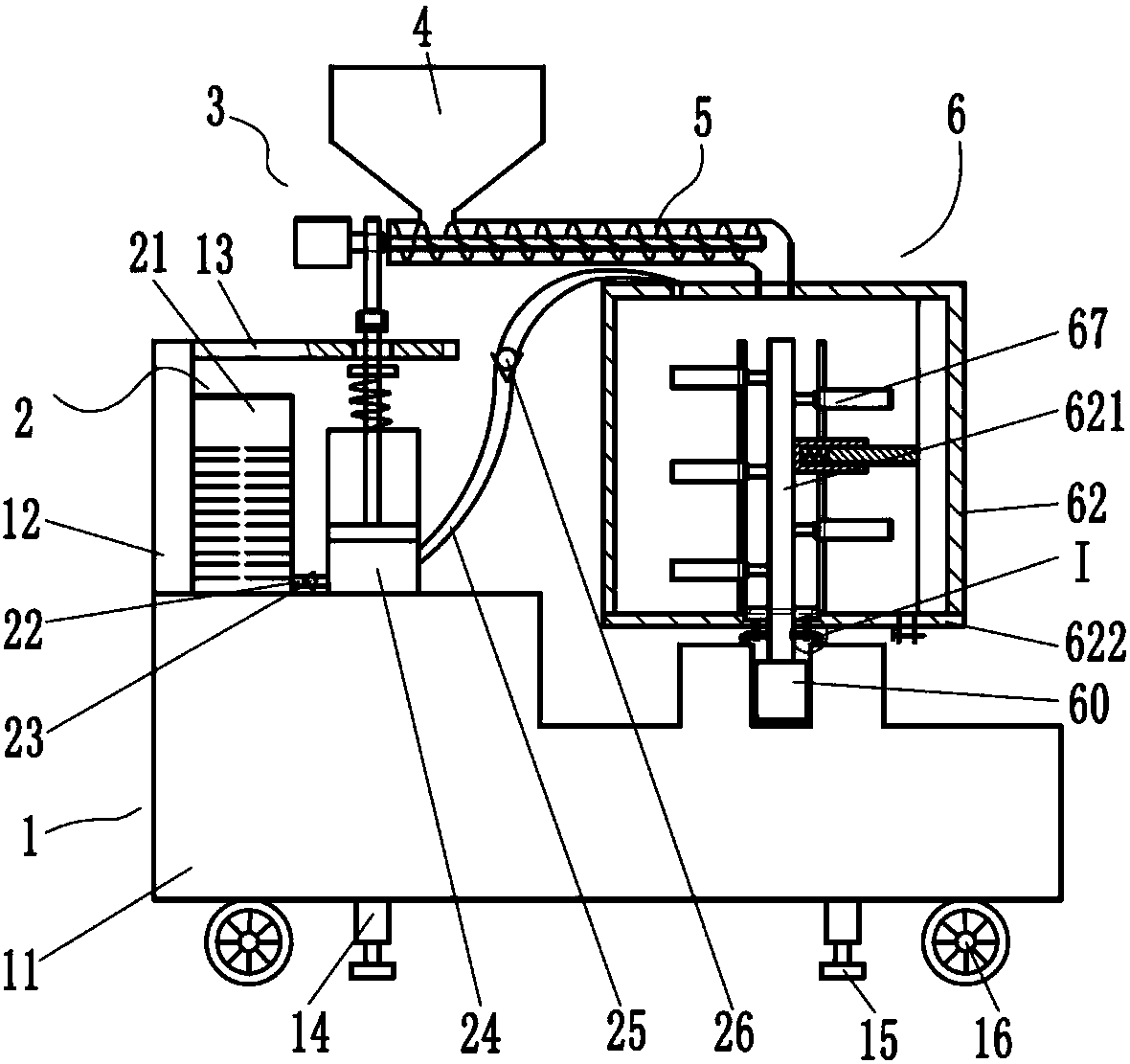

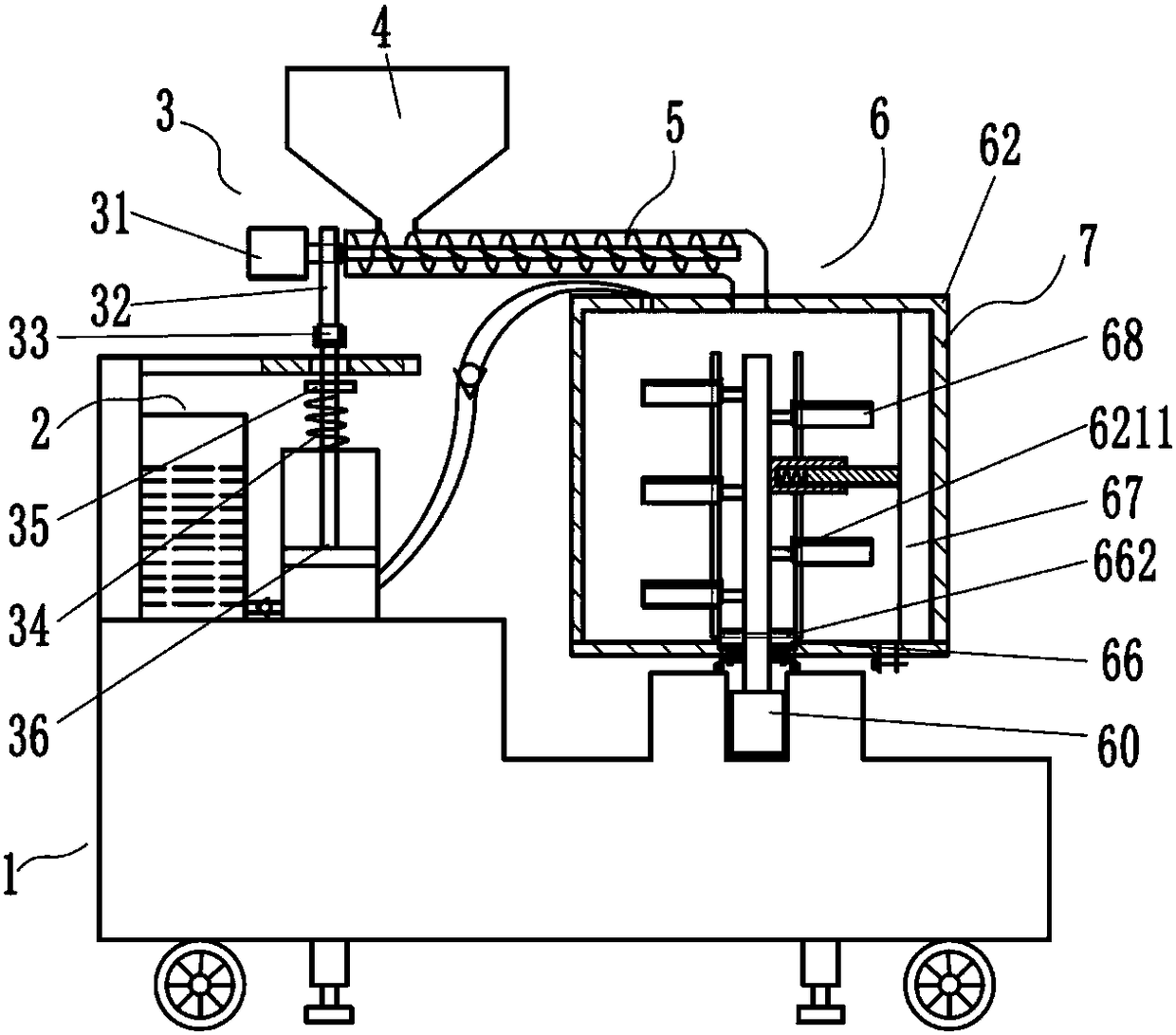

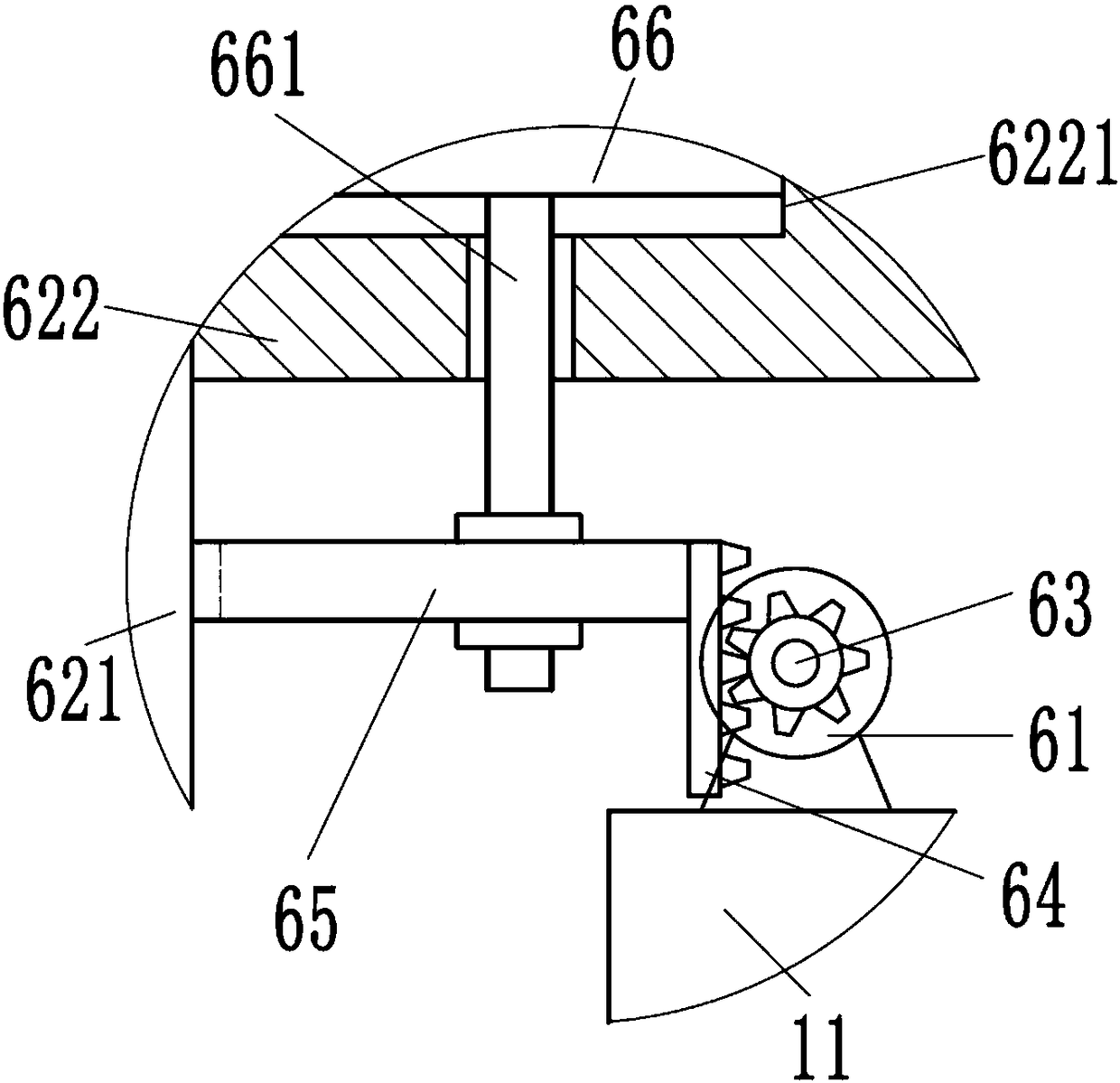

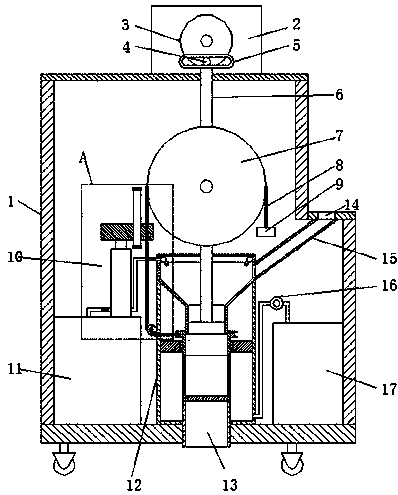

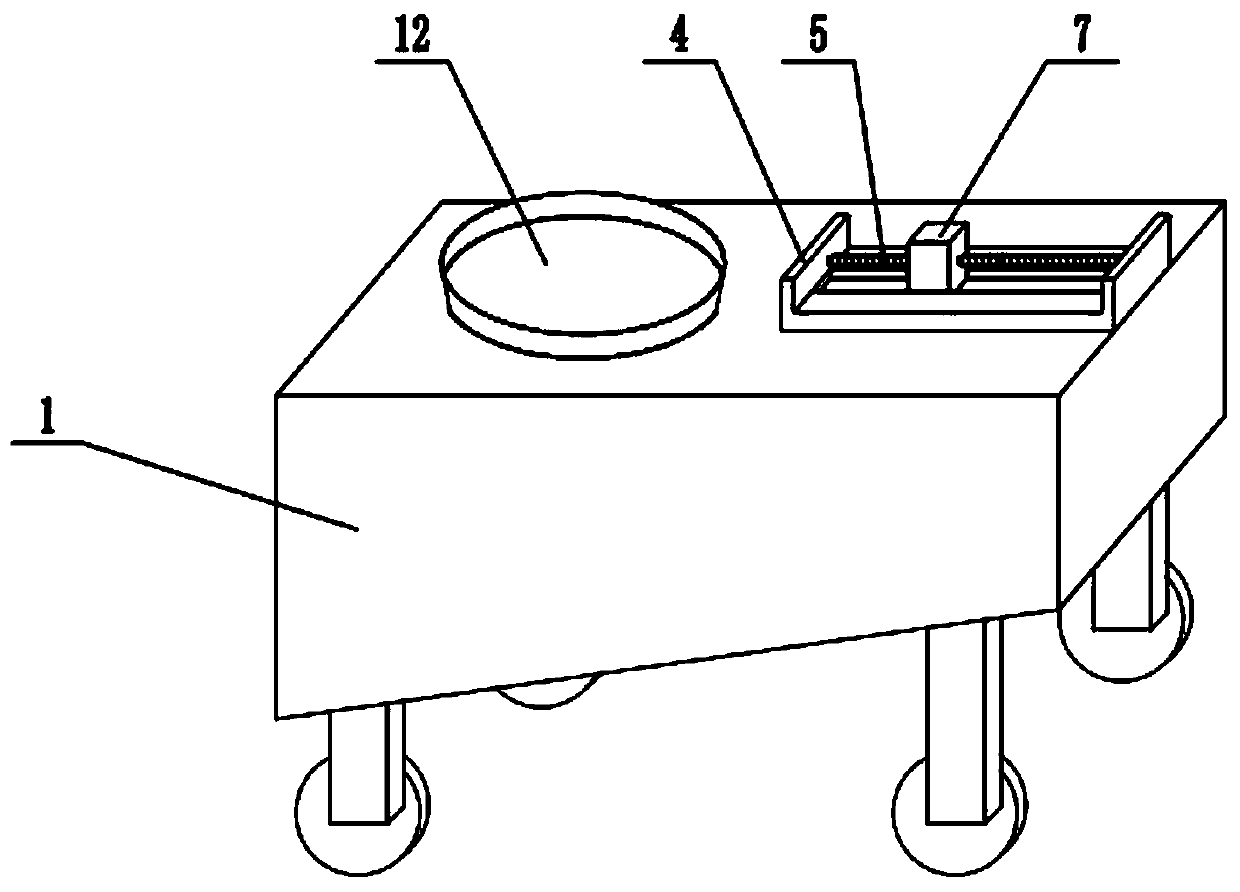

Engineering cement mixing device

InactiveCN108394029AEasy dischargeStir wellDischarging apparatusCement mixing apparatusDischarge efficiencyMotor drive

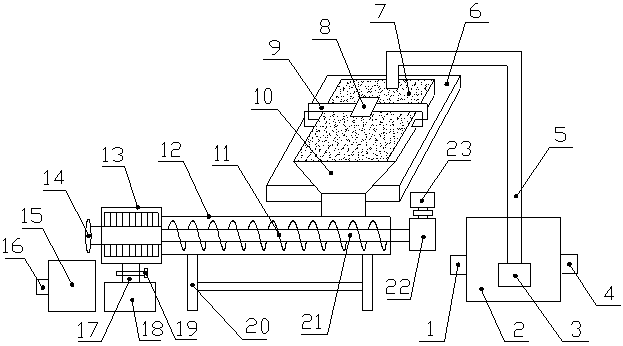

The invention discloses an engineering cement mixing device. The engineering cement mixing device comprises a bracket, a mixing and stirring mechanism, a spiral conveying device, a water supply systemand a driving mechanism; the mixing and stirring mechanism comprises a blade angle adjusting mechanism; blades of the mixing and stirring mechanism can be rotated by any angle under the effect of theblade angle adjusting mechanism; the spiral conveying device is used for feeding the mixing and stirring mechanism; the water supply system comprises a water tank, a cylinder block, a piston rod anda spring; the water tank communicates with the cylinder block; the piston rod slidingly cooperates with the cylinder block; the piston rod moves to suck water in the water tank into the cylinder blockand to pump into a stirring barrel; the spring is used for returning the piston rod; the driving mechanism comprises a first motor and a cam; the cam is fixedly arranged on an output shaft of the first motor; the cam can drive the piston rod to move; and meanwhile, the first motor drives the spiral conveying device to work. The engineering cement mixing device is excellent in mixing effect, highin discharge efficiency and convenient to use.

Owner:WENZHOU POLYTECHNIC

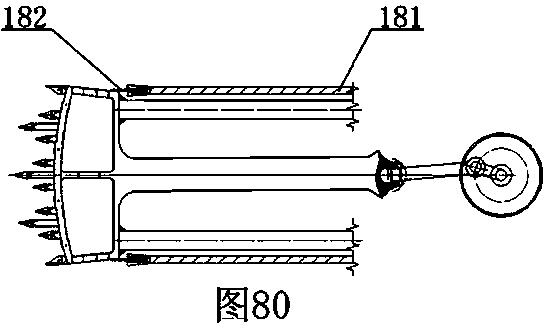

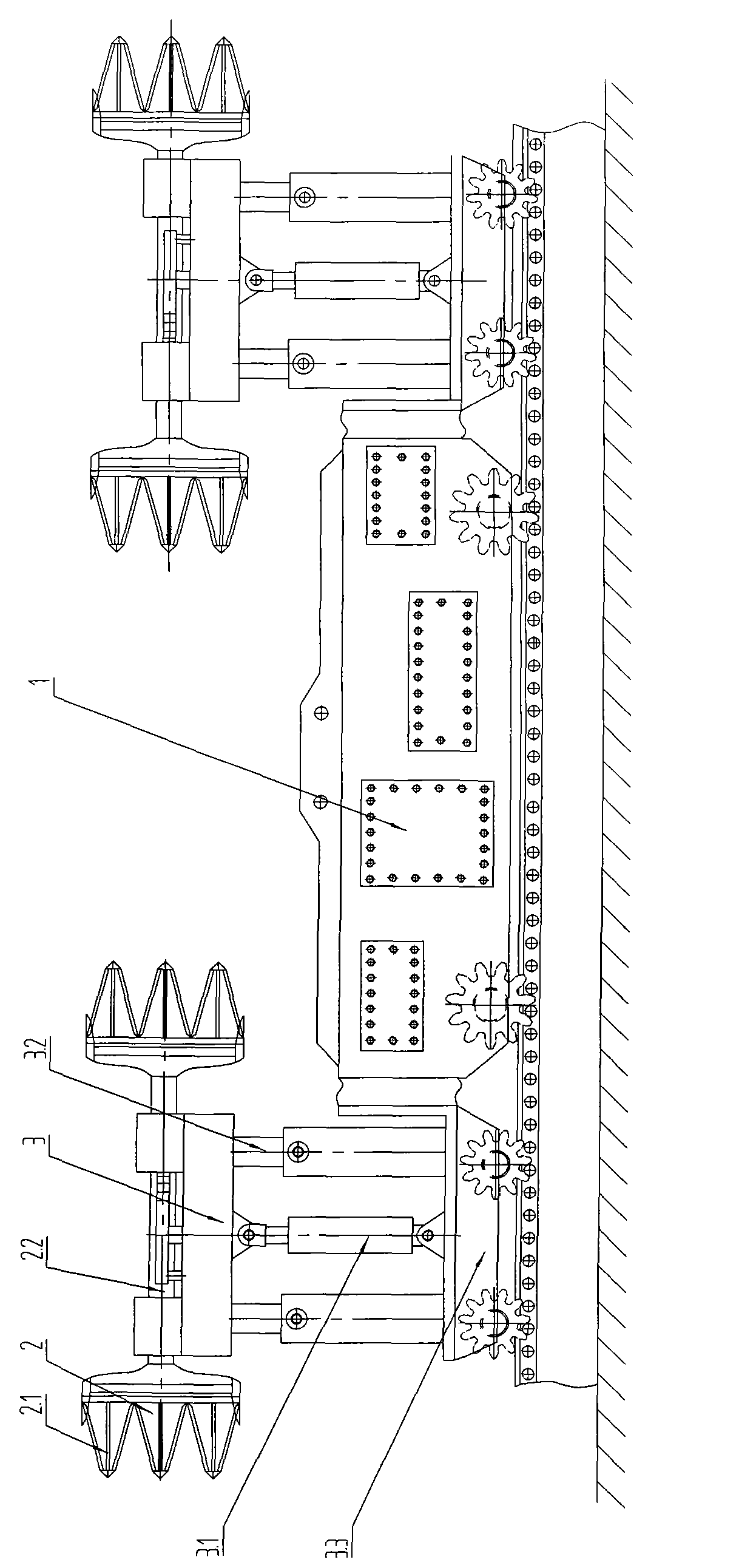

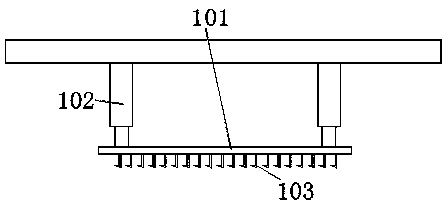

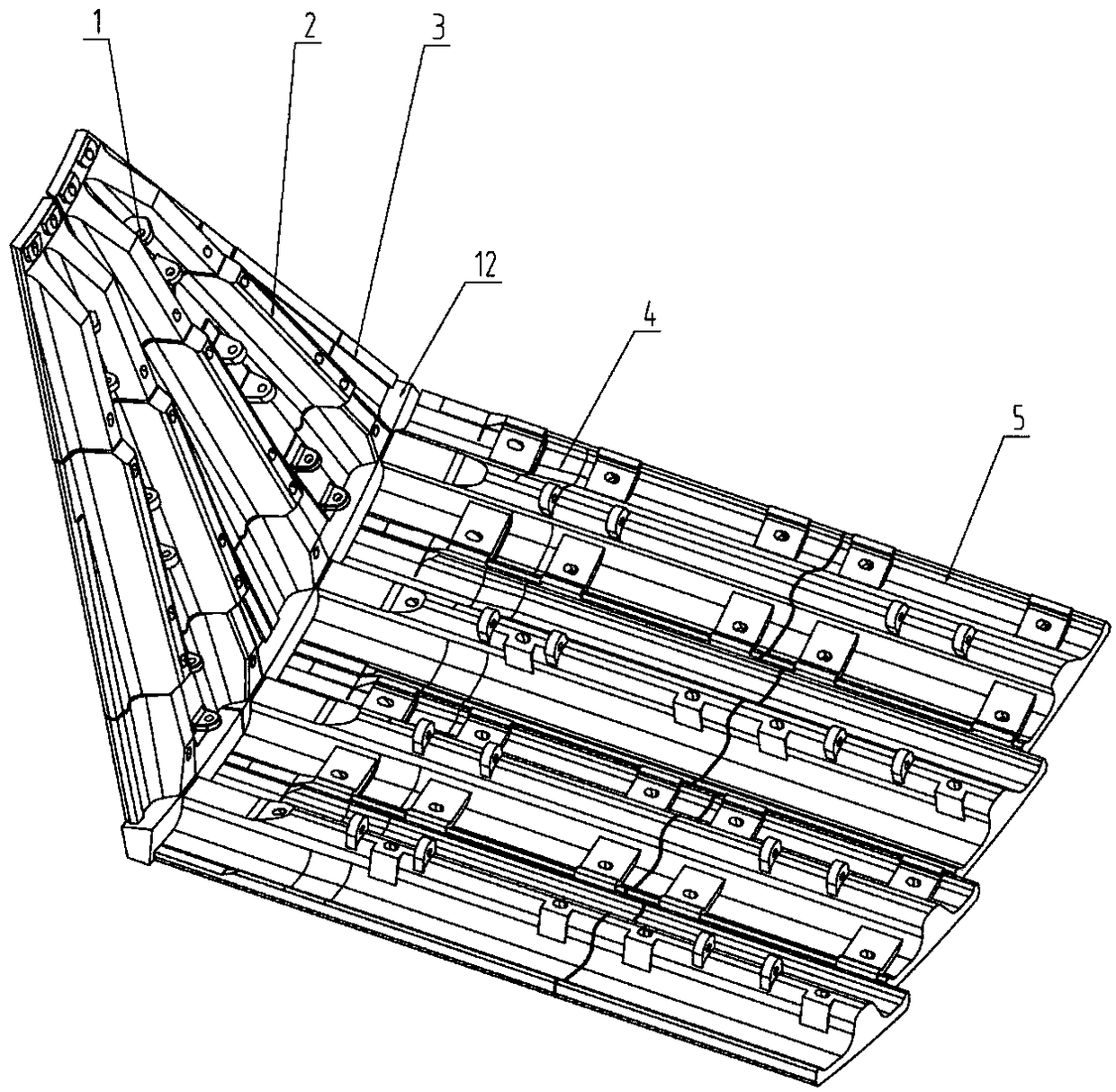

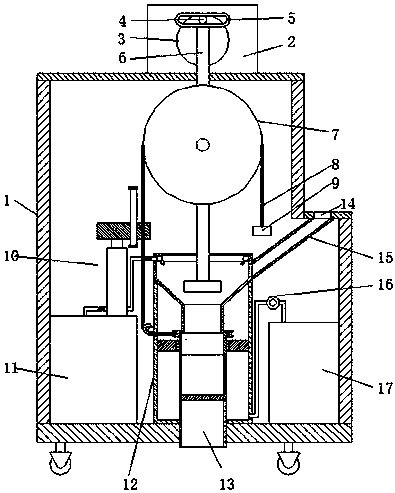

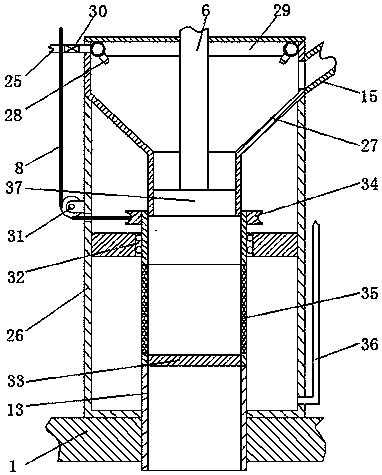

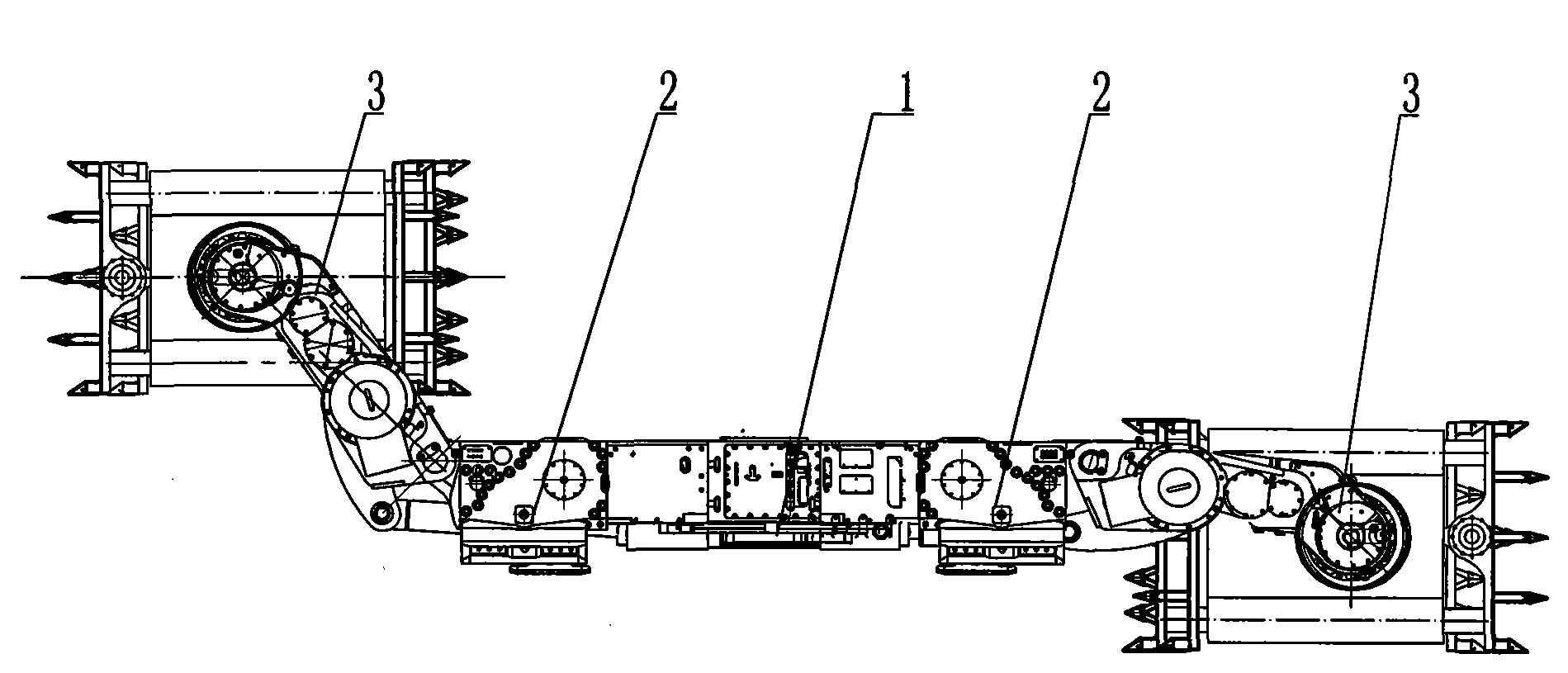

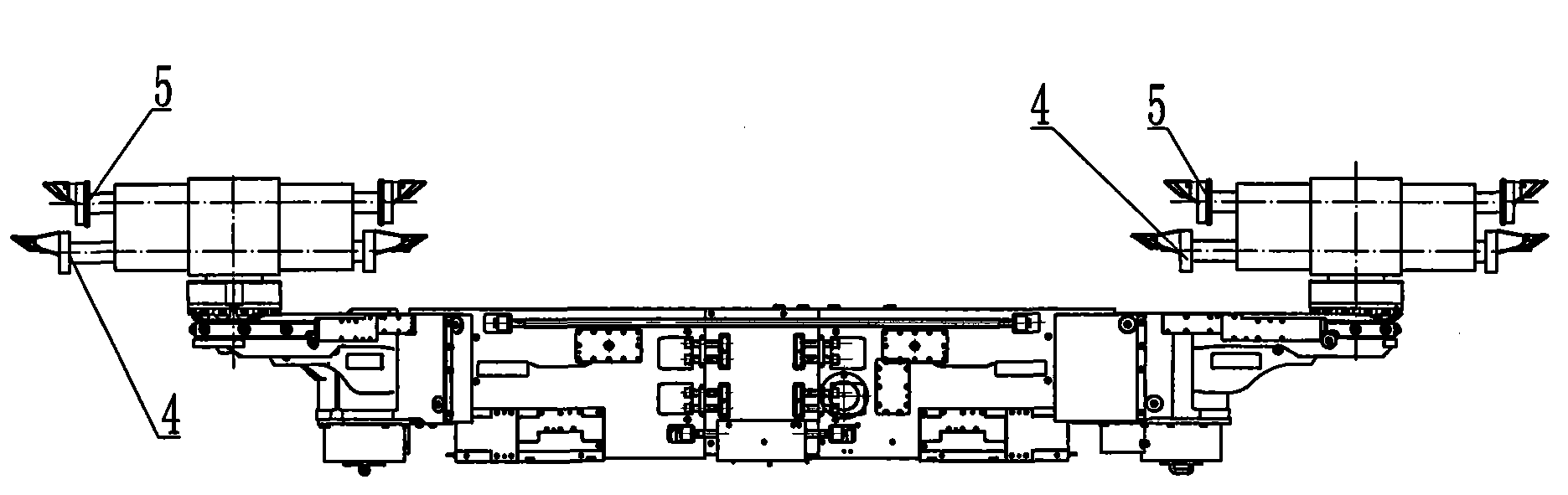

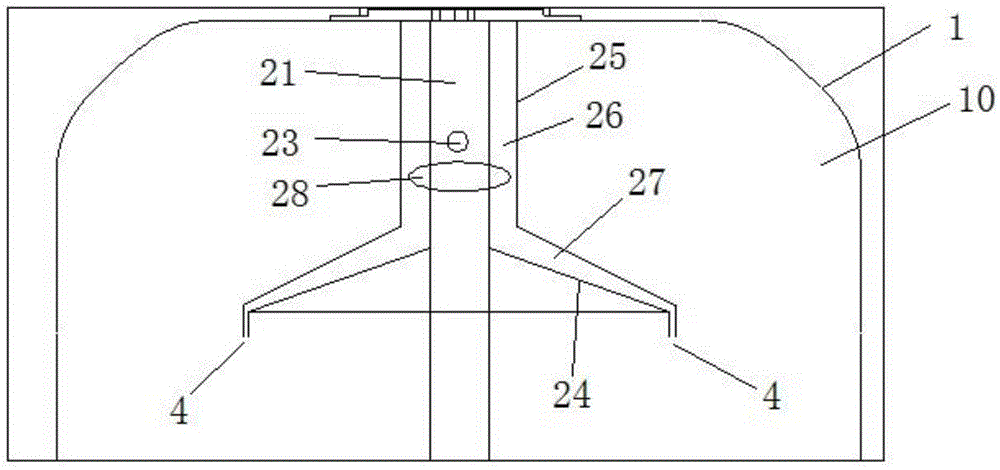

Method for retaining vertical impact of impacting mechanism and vertical-lift impact-cutting digger implementing same

InactiveCN103206213AIncrease arm lengthReduce farewellDriving meansCutting machinesEngineeringFuselage

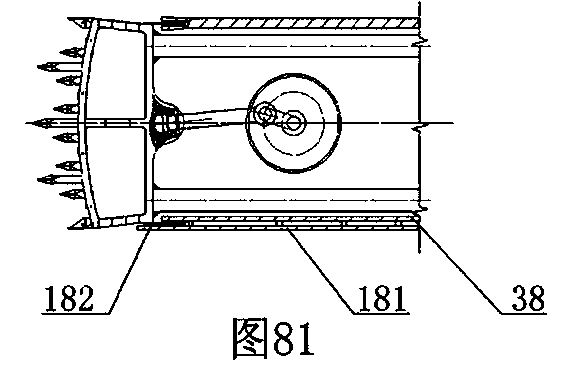

The invention specifically relates to a method for retaining vertical impact of an impacting mechanism and a vertical-lift impact-cutting digger implementing the method, belonging to the field of machinery, especially to the field of mining. The digger comprises a body, the impacting mechanism and a vertical lift mechanism, wherein the impacting mechanism comprises a guiding member and an impacting head, the vertical lift mechanism comprises a vertical lift driving unit, a lifting and moving part, a supporting seat and the like, the lifting and moving part is movably connected with the supporting seat, the supporting seat is connected with the body, the impacting mechanism is arranged on the lifting and moving part, the vertical lift driving unit drives the lifting and moving part to vertically move up and down, and the lifting and moving part drives the impacting mechanism to vertically rise and fall. The digger provided by the invention has the advantages of a long service life, a small amount of maintenance, high work efficiency, shortened body length and applicability to a complex usage occasion.

Owner:刘素华

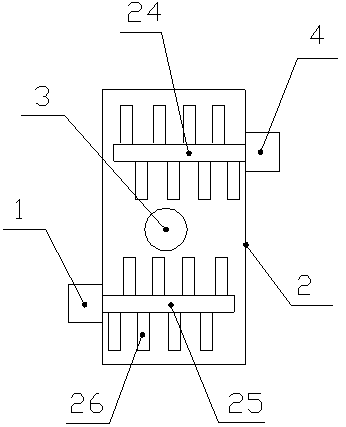

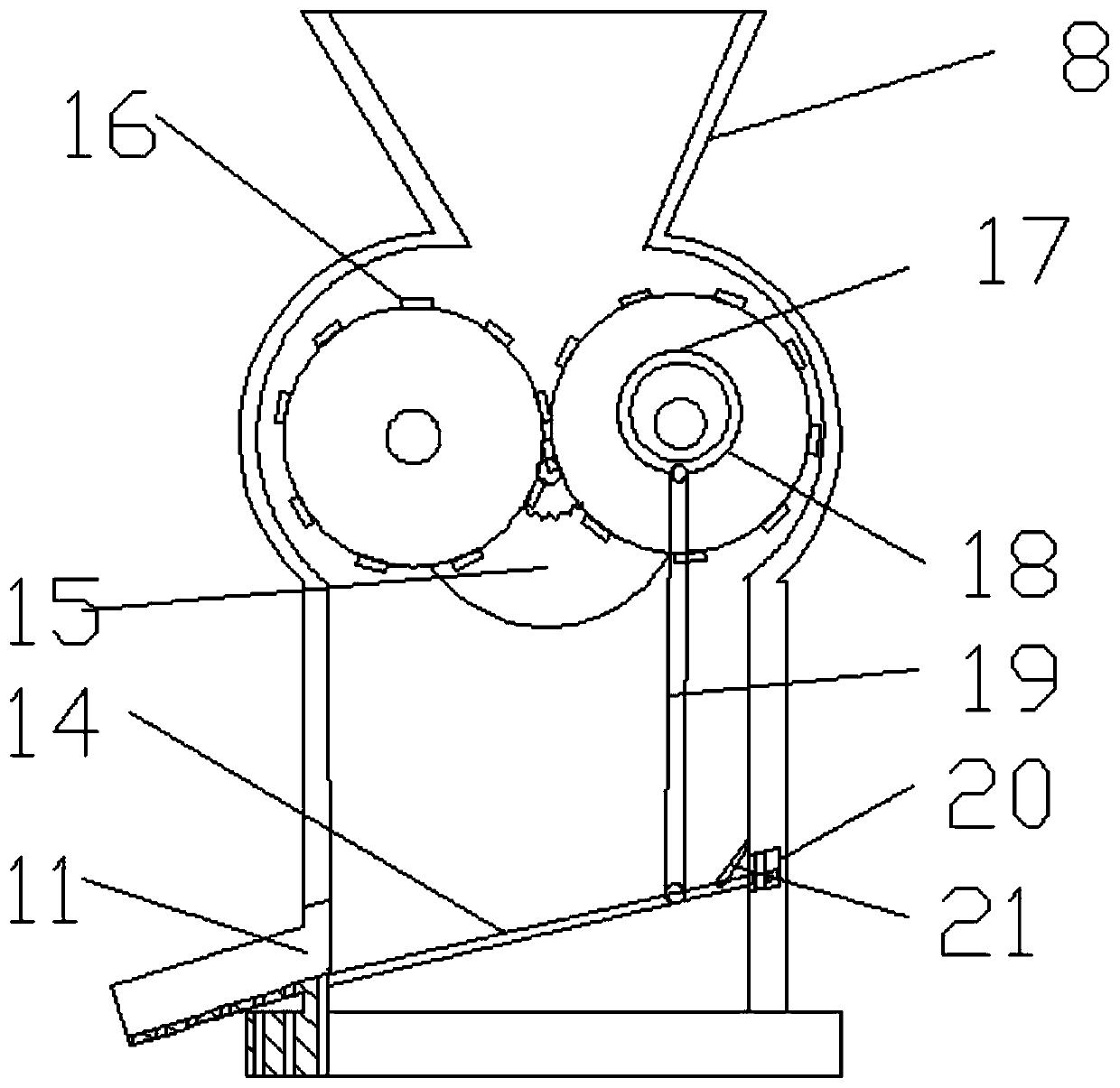

Fabric surface pilling removal equipment

InactiveCN108486815AEfficient removalRealize automatic nestingMechanical cleaningPressure cleaningEngineeringDust collector

The invention provides fabric surface pilling removal equipment which comprises a frame and two groups of pilling removal mechanisms, wherein a fabric is arranged between the two groups of pilling removal mechanisms; the two groups of pilling removal mechanisms are respectively arranged on a frame top plate and a frame bottom plate; each pilling removal mechanism comprises a pilling scraping device, a shearing device and a dust removal device; the pilling scraping device comprises a scraper and two first electric push rods; a plurality of uniformly distributed scraping hooks are arranged on the scraper; the shearing device comprises shear blades, a second electric push rod and a mounting plate; the dust removal device comprises an exhaust fan, a first dust collector, a second dust collector and a lint roller. According to the fabric surface pilling removal equipment disclosed by the invention, the two groups of upper and lower pilling removal mechanisms are used for removing pilling ontwo sides of the fabric, the pilling on two sides of the fabric can be simultaneously eliminated, the pilling removal mechanisms comprises the pilling scraping devices, the shearing devices and the dust removal devices, automatic discharging is realized, manual discharging by a user is avoided, and discharging smoothness is realized.

Owner:JIANGSU DANMAO TEXTILE

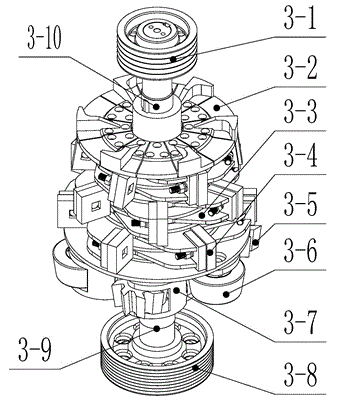

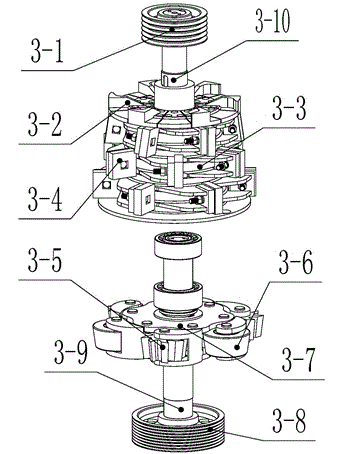

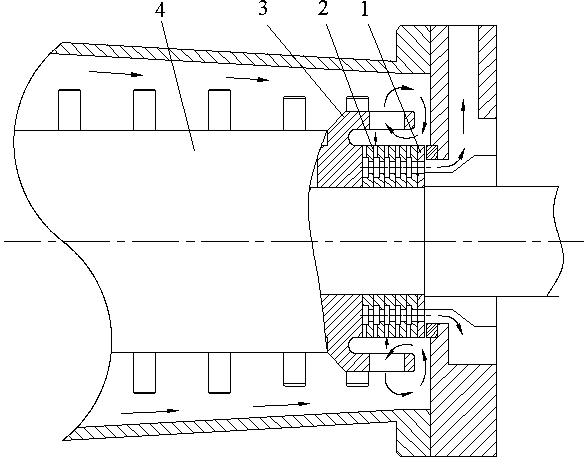

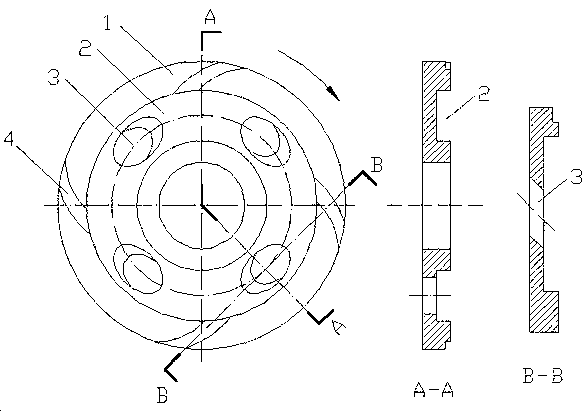

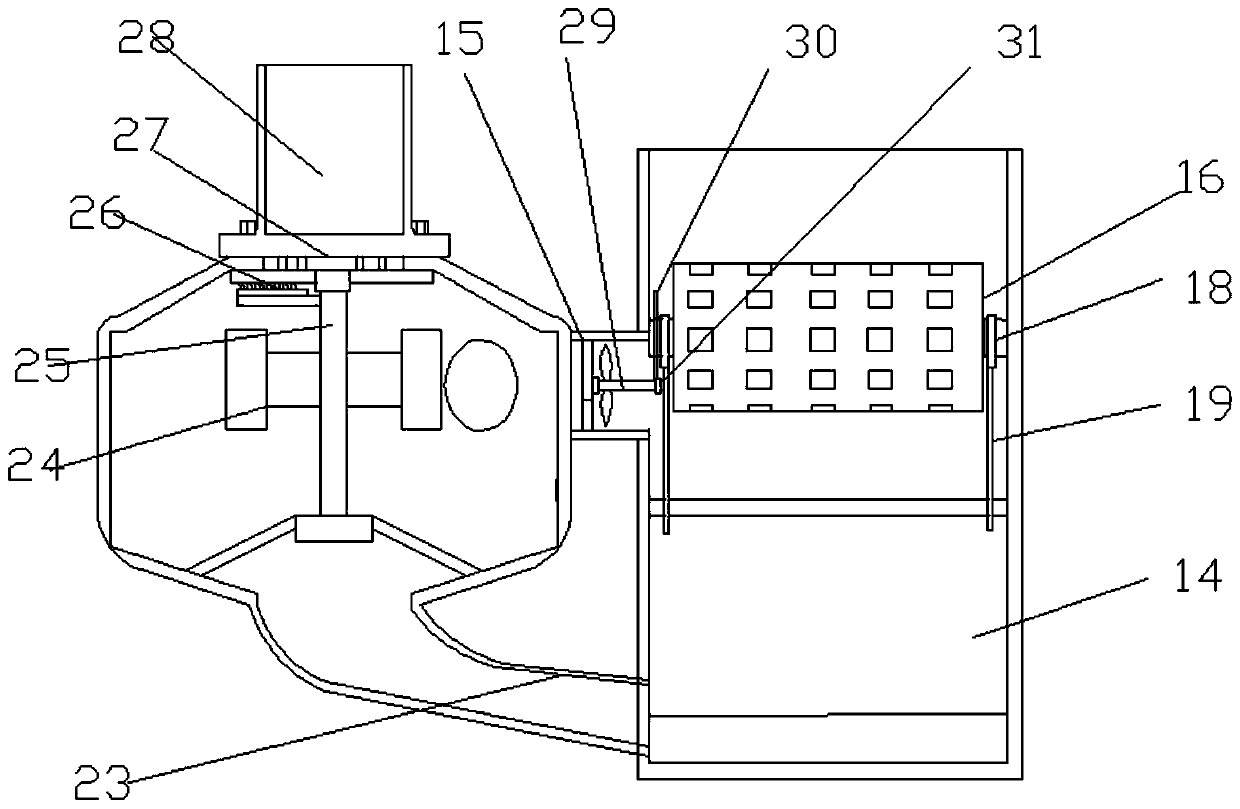

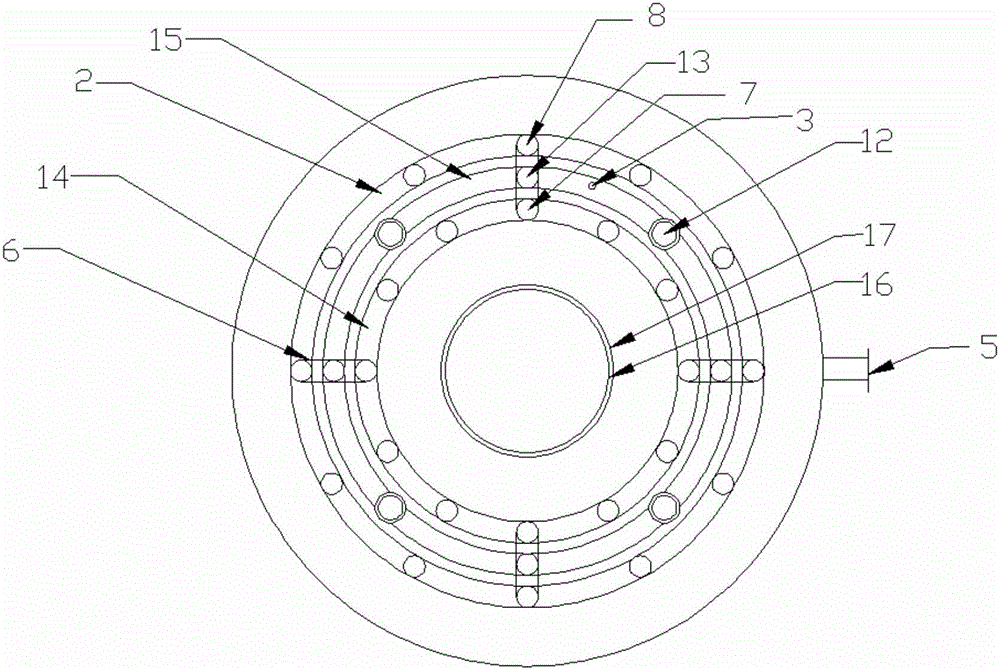

Overlapped turbine type bead separator of medium stirring mill

The invention relates to an overlapped turbine type bead separator of a medium stirring mill. The overlapped turbine type bead separator comprises a static ring, an overlapped turbine set and an outer turbine, wherein the static ring is inlaid in the side of a discharging chamber wall, close to a grinding chamber; each turbine blade is provided with a plurality of vortex chutes, a plurality of inclined holes and an annular diversion trench, which are all communicated with one another. One side of the overlapped turbine set clings to the outer turbine, and the other side of the overlapped turbine set is separated from the static ring to form a proper annular discharging clearance; and when a rotor and the turbine set are driven by a main shaft to rotate, the vortex chutes among laminations generate a centripetal absorption force for driving slurry to enter the annular diversion trench, and the inclined holes arranged in the annular diversion trench are used for driving the slurry to be discharged from a discharging hole along the axial direction. Beads are radially thrown away and do radial circulated motion under the action of a centrifugal force generated when the outer turbine rotates, so that the beads are prevented from being accumulated around the bead separator, and the discharge of materials can not be blocked. The overlapped turbine type bead separator is low in manufacturing cost; by using the overlapped turbine type bead separator, the grinding efficiency is greatly increased and the granularity of particles in primarily-ground slurry is remarkably reduced; and compared with the traditional product of the same type, the overlapped turbine type bead separator can be used for increasing the yield by 50-130%.

Owner:深圳市叁星飞荣机械有限公司

Scrap chute mechanism

The invention aims to provide a scrap chute mechanism which can smoothly discharge materials under a condition that the height of a lower mould is small so as to reduce limit on design of the mould. The scrap chute mechanism comprises a scrap chute and an air cylinder, wherein the scrap chute is arranged on a lower mould body through a hinge; the air cylinder is vertically arranged at the lower part of the scrap chute; the end of a piston rod of the air cylinder is movably connected with or pushes against the bottom of the scrap chute. When the mechanism works, the piston rod of the air cylinder reciprocates vertically and constantly under the action of air, and the piston rod can jack the scrap chute up when moving upwards; the scrap chute can only rotate around the hinge because the scrap chute is limited by the hinge under the scrap chute; the angle of the scrap chute is increased in the rotating process, and scrap can be smoothly discharged. The scrap chute mechanism has a simple structure and can discharge smoothly under a condition that the angle of the scrap chute is small, therefore the design limit of the mould is reduced, and the reliability of automatic production is improved.

Owner:CHERY AUTOMOBILE CO LTD

Solid-liquid separation processor

PendingCN109260806AWell mixedEasy to transportSludge treatmentTransportation and packagingSlagPulp and paper industry

The invention discloses a solid-liquid separation processor. The solid-liquid separation processor comprises a slag liquid storage box and an extrusion screw conveyor, a stirring motor A is connectedto the front part of the left side of the slag liquid storage box, a stirring shaft A is connected with the output shaft of the stirring motor A, a stirring motor B is connected with the rear part ofthe right side of the slag liquid storage box, and a stirring shaft B is connected with the output shaft of the stirring motor B; stirring blades are installed on the stirring shaft A and the stirringshaft B, a diving cutting pump is arranged in the middle of the slag liquid storage box, a discharging pipe is connected with the output end of the diving cutting pump, a filter sieve net is arrangedbelow the other end of the discharging pipe, and a feeding hopper is connected with the front end of the filter sieve net; and an extrusion drying box is connected with the left end of the extrusionscrew conveyor, the left side of the extrusion drying box is provided with a discharging port, and the lower end of the extrusion drying box is provided with a liquid outlet. The solid-liquid separation processor has the advantages that the operation is easy and convenient, the separation and collecting efficiency is high, the filter sieve net is not prone to being blocked, separation is even andthorough, the processing time is shortened, the processing cost is lowered, and the processor is suitable for large-scale processing.

Owner:禹州华德环保科技有限公司

Fast and efficient sand making machine

InactiveCN108187862APrevents clogging of grinding discsIncrease contact surfaceCocoaGrain treatmentsCrushed stoneEngineering

The invention discloses a fast and efficient sand making machine comprising a sand making machine body; the upper end of the interior of the sand making machine body is provided with a gear crushing disc; the middle portion of the upper surface of the gear crushing disc is provided with a tapered material groove penetrating through the bottom surface; a clapboard is fixedly arranged in the interior of the sand making machine body and located below the gear crushing disc; the middle portion of the upper surface of the clapboard is fixedly provided with a guide grinding rod; the inner side surfaces of drive gear shafts are both meshed with the outer side surface of the gear crushing disc; the inner side surfaces of driving gear shafts are both meshed with the outer side surface of the outerside surfaces of the drive gear shaft; the outer side end of the lower surfaces of fixed discs are provided with annular limiting grooves; and loop-shaped sliding plates are arranged in the annular limiting grooves in an inserting mode. In the process of grinding crushed stones into sand, particle sizes of the crushed stones are reduced first, and bad feeding and clogging of a grinding disc causedby the large particle sizes of crushed stones during milling is prevented; and the arrangement of the loop-shaped sliding plates increases the contact surface between a milling disc and the crushed stones when grinding the grinding disc, and the efficiency of the crushed stone grinding is improved.

Owner:宣城万德机械制造有限公司

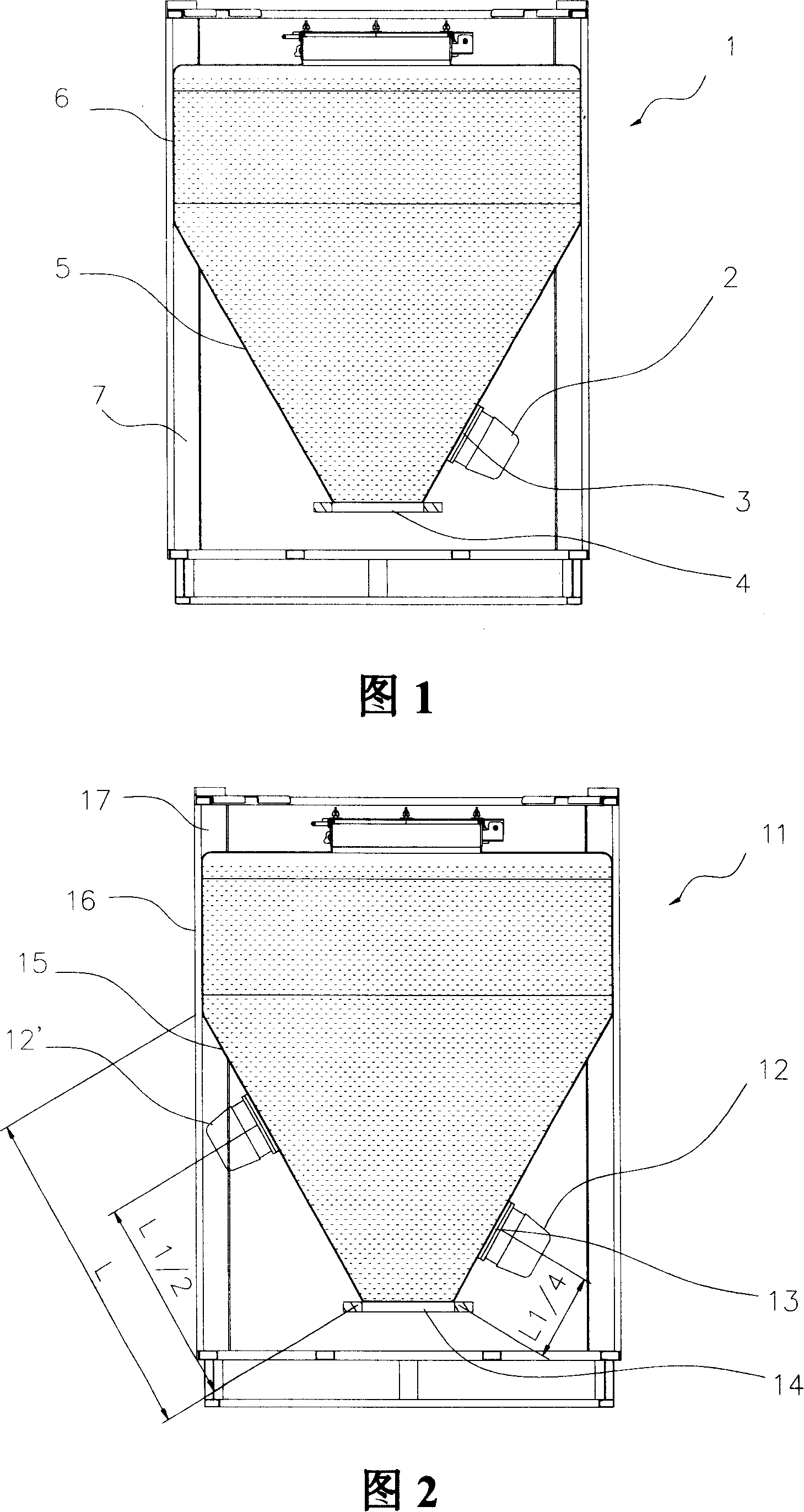

Powder material discharging method and powder medium-sized bulk container

InactiveCN101148216ASmooth nestingLarge containersLoading/unloadingIntermediate bulk containerEngineering

The present invention relates to one kind of intermediate bulk container (IBC) for powder material and its material discharging method. The IBC includes at least one inclined lower sealing end and one outlet in the bottom of the lower sealing end, and there is at least one vibrating unit connected to the outside of the lower sealing end. The vibrating unit makes the IBC vibrate to avoid blocking. The present invention has low cost, easy installation, easy use and easy maintenance.

Owner:CHINA INTERNATIONAL MARINE CONTAINERS (GROUP) CO LTD

Jet atomization device and flotation device with same

ActiveCN111570099AMicrobubble System EquilibriumImprove mineralization efficiencyRotating receptacle mixersFlow mixersPhysicsElectric machinery

The invention discloses a jet atomization device and a flotation device with the same. The jet atomization device comprises a jet atomization device; the jet atomization device further comprises a double-connection-wheel jet agitation mechanism and a shearing emulsification device; the jet atomization device comprises an atomization cylinder, a rotating shaft, a laminar flow guide disc, a conicalflow guide cover and a flow guide cover chassis. The double-connection-wheel jet agitation mechanism comprises a flotation tank, a supporting frame, a pretreatment bin, a rotary connecting rod, a driving impeller, an agitation impeller, a flow guide cylinder and a circulating pump. The shearing emulsification device comprises an emulsification tank, a medicament spray head, a fixed fluted disc, arotary fluted disc and a speed compensation motor. Foaming agent atomization, collecting agent emulsification, size pre-mixing and flotation are integrated, and therefore, equipment size and occupiedarea are greatly reduced; and meanwhile, the energy consumption of ore pulp is decreased; the equipment has a foaming agent atomization function, a collecting agent emulsification function and a jet air suction drive stirring flotation function, and therefore, mineral separation efficiency is improved.

Owner:ANHUI UNIV OF SCI & TECH

Wear-resistant lining plate for large self-grinding machine / large semi-self-grinding machine

ActiveCN108704722AAvoid bloatingAvoid excessive wearGrain treatmentsDischarge efficiencyWear resistant

The invention discloses a wear-resistant lining plate for a large self-grinding machine / a large semi-self-grinding machine. The wear-resistant lining plate is characterized in that the bottom platesof a feeding end inner ring lining plate body, a feeding end middle ring lining plate body and a feeding end outer ring lining plate body of the wear-resistant lining plate are provided with first lifting strips which are increased in height correspondingly, and are provided with long strip bosses for increasing the wear resistance of the bottom plates correspondingly; a feeding end barrel liningplate body, a middle section barrel lining plate body and a discharging end barrel lining plate body are provided with second lifting strips with the sections of asymmetric structures; an outer ring ore pulp lifter is provided with large arc-shaped third lifting strips, long bolts and short bolts; a grid plate is provided with large arc-shaped fourth lifting strips, and an inner ring ore pulp lifter is provided with fifth long lifting strips and sixth short lifting strips which are arranged at intervals; and a discharging device is of an integral structure and is provided with seventh short lifting strips. According to the wear-resistant lining plate, the problem that in the prior art, the service life of a feeding end lining plate body is relatively low, the discharging efficiency of a grinding machine is low and the number of the lining plates is too large are effectively solved.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

Waste collecting device for surgical nursing

InactiveCN110451137AReduce the risk of infectionImplementing sensory control works wellWaste collection and transferRefuse receptaclesMedical wasteInfection risks

The invention relates to the field of medical waste collection equipment, in particular to a waste collecting device for surgical nursing. The waste collecting device comprises a box body, wherein a driving part is fixed at the top of the outer side of the box body, a solid-liquid separating mechanism and a disinfecting mechanism are fixed in the box body, the driving part is connected with the solid separating mechanism through a lifting rod, a wire coil is in a fixed-axis rotational connection with the middle of the lifting rod and is wound with a draw rope which is connected with the disinfecting mechanism, and the disinfecting mechanism is connected with inside of the solid-liquid separating mechanism through a pipeline. According to the waste collecting device for surgical nursing, medical waste is disinfected while being collected, disinfecting treatment is performed while medical waste is collected, so that the infection risk of medical workers and other patients is reduced, infection control work is better carried out in the hospital, besides, the disinfected medical waste can be subjected to solid-liquid separation, solid and liquid medical waste is separately collected, and concentrated treatment is facilitated.

Owner:PEOPLES HOSPITAL OF HENAN PROV

Mobile mining equipment

InactiveCN111420732AEasy dischargeAvoid cloggingLarge containersSlitting machinesMining engineeringStructural engineering

The invention relates to the technical field of mining, in particular to mobile mining equipment. The mobile mining equipment comprises a shell, a front wheel support, a rear wheel support, a movableplate and a bucket, wherein the front wheel support and the rear wheel support are mounted at the bottom of the shell; the upper surface of the shell is fixedly connected with a fixing frame; the movable plate is hinged to the right end of the fixing frame; a first connecting rod is hinged to the upper surface of a sliding block, the top end of the first connecting rod is hinged to the lower surface of the movable plate, the upper surface of the movable plate is hinged with the bucket, a sieve plate is arranged inside the shell, the left inner wall of the left side of the shell is fixedly connected with a left crushing plate, the upper surface of the sieve plate is slidably connected with a right crushing plate, the left crushing plate and the right crushing plate are used for crushing coal, the crushed coal passes through the sieve plate and falls to the bottom of the shell, the bottom of the shell is inclined, the crushed coal can be discharged through a discharge port, the bottom ofthe shell is knocked by a knocking hammer, and the bottom of the shell is vibrated, so that the coal is discharged from the discharge port, and the discharge process is smoother.

Owner:JIANGSU VOCATIONAL INST OF ARCHITECTURAL TECH

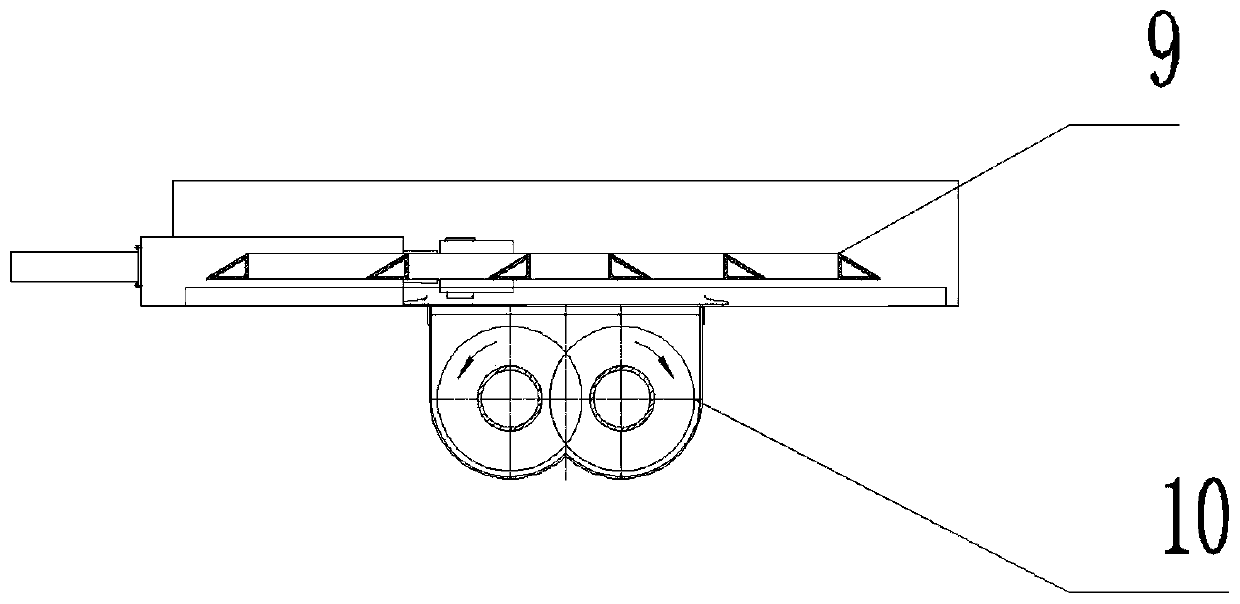

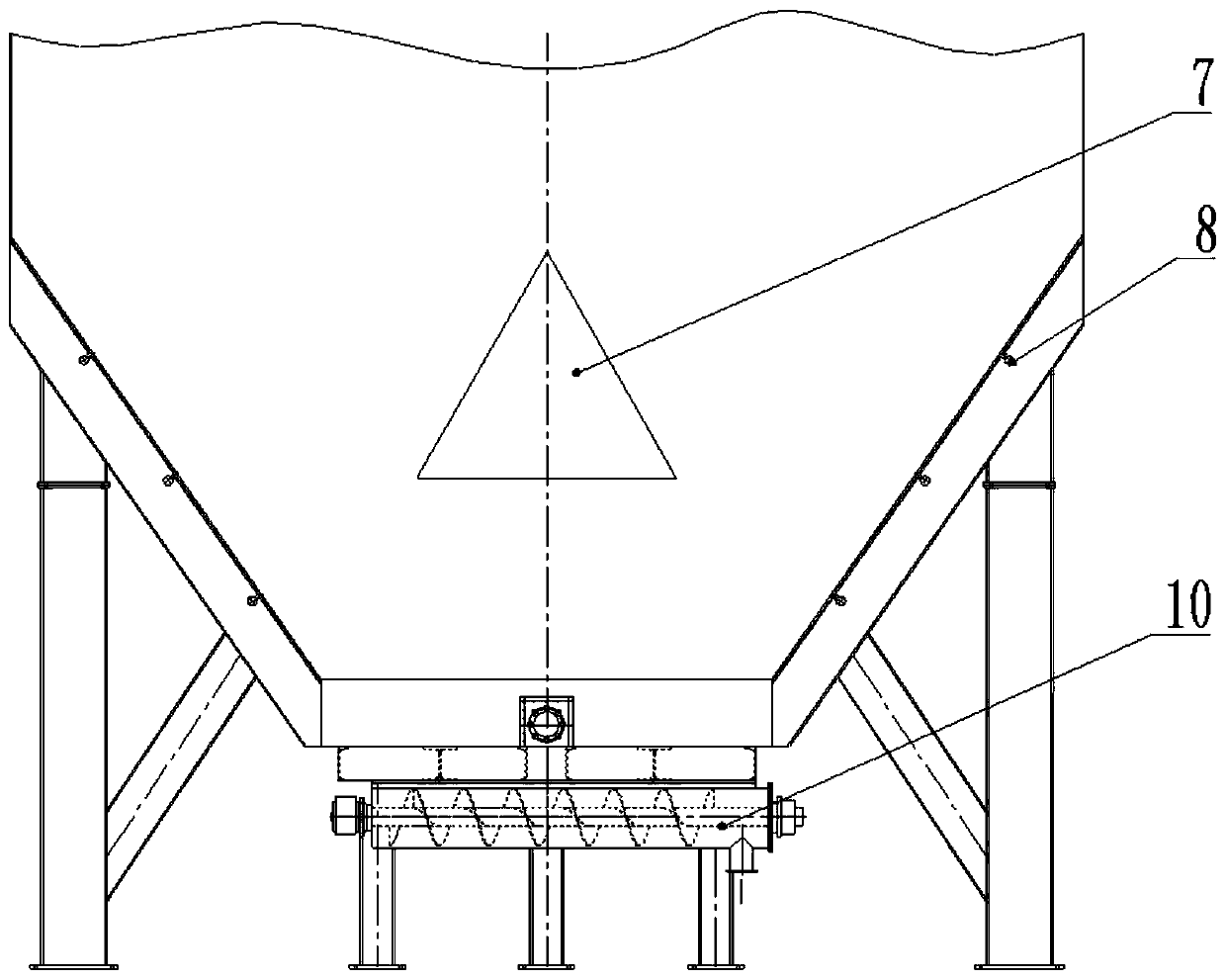

Rake-free separation tailing thickening sand bin

PendingCN110152359ACan't play the role of deliverySmooth dischargeSettling tanks feed/dischargeCentrifugal force sediment separationFlocculationHigh concentration

The invention relates to a rake-free separation tailing thickening sand bin, and aims to solve the problems that tailing concentration equipment in the prior art is complex in structure, low in sand discharging concentration and unsmooth in discharging. The rake-free separation tailing thickening sand bin comprises a sand bin body, a flocculation feeding tube, a center feeding barrel with a middleseparation plate, a tailing feeding tube, an overflow groove, an annular sedimentation cone, a sliding frame fluidization device and a double-screw discharging device. Through design of the structure, flow field variation of a material flow in the sand bin is changed, and the flocculation agglomeration speed of fine particle tailings is accelerated; and meanwhile, a mechanical sliding frame fluidization sand-discharging technology is adopted, so that smooth sand discharging under a condition of highest underflow concentration is realized. The rake-free separation tailing thickening sand bin has the outstanding advantages of small size, simple structure, low manufacturing cost, high concentration efficiency, high underflow concentration and the like.

Owner:北京金诚信矿山技术研究院有限公司

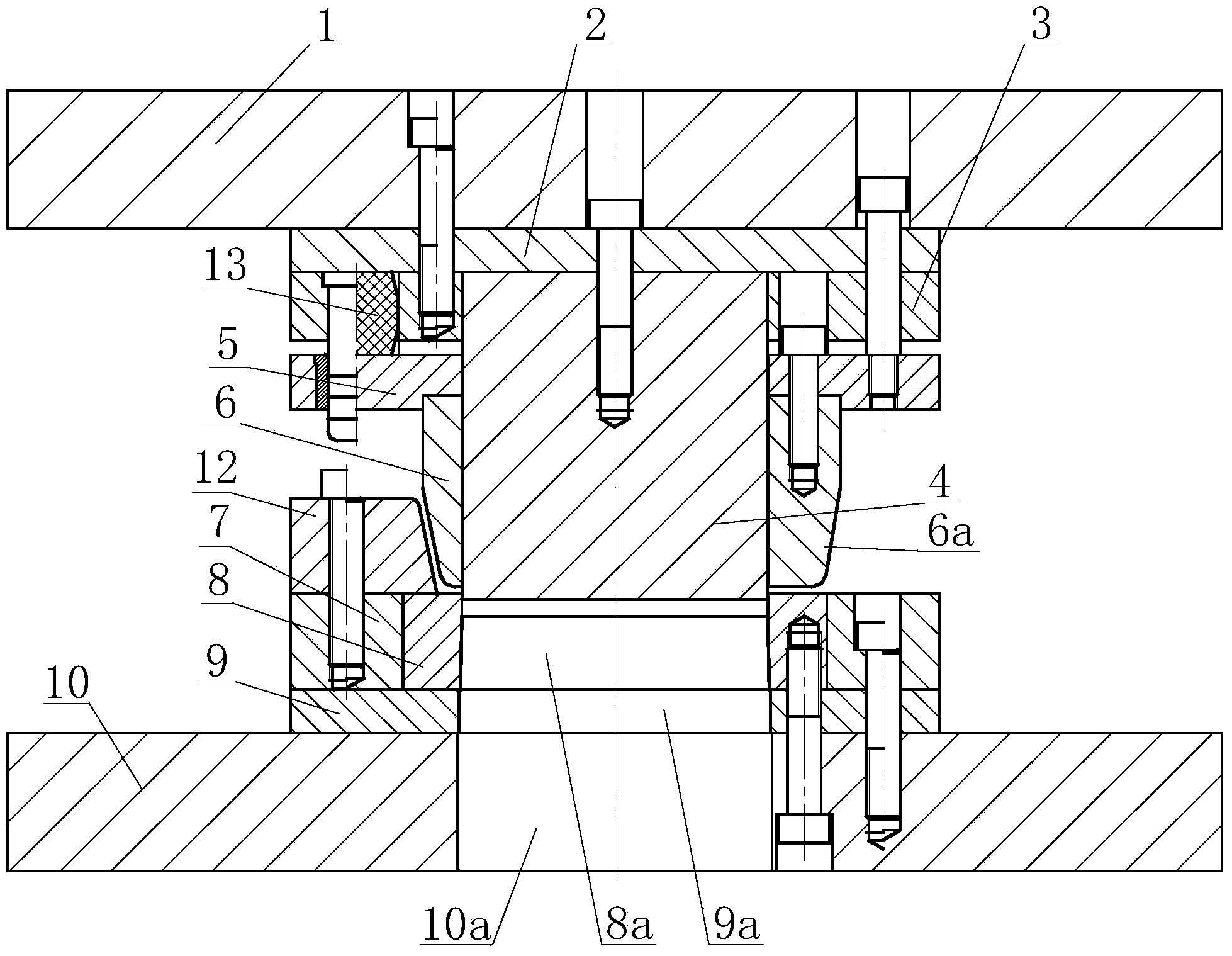

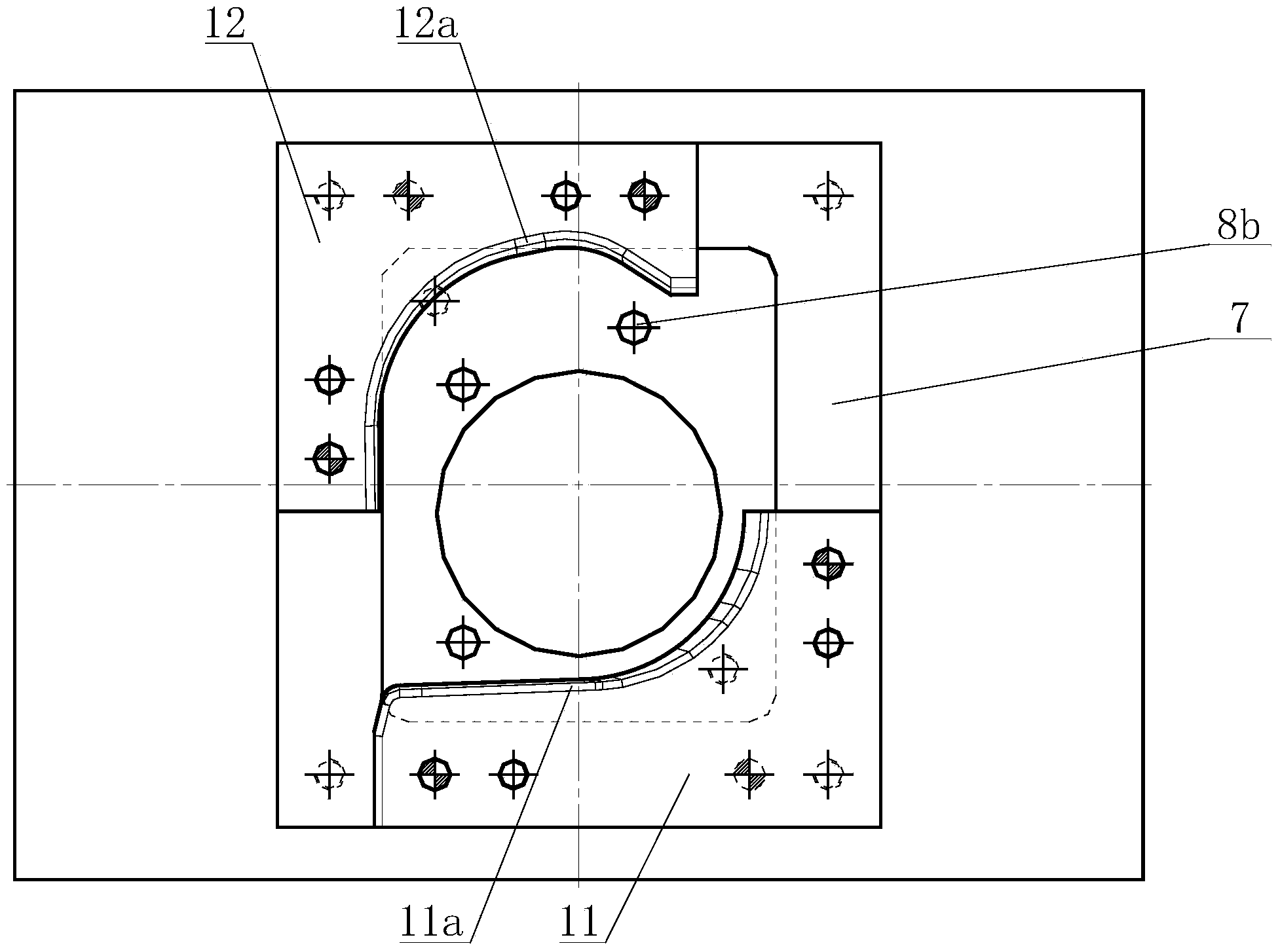

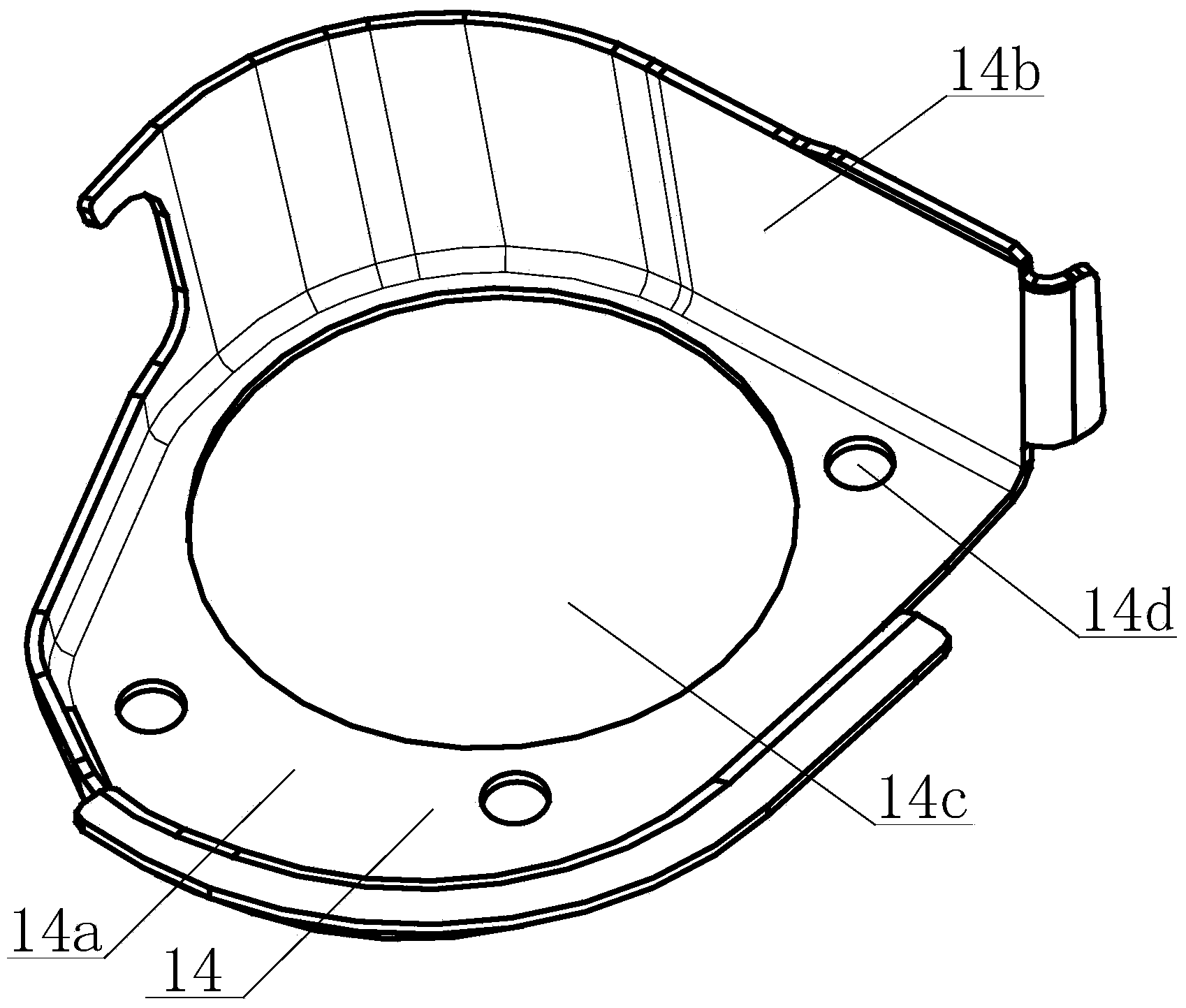

Punching die of rear suspension installation bracket

ActiveCN103949535AEasy dischargeAvoid cloggingPerforating toolsMetal-working feeding devicesPunchingEngineering

The invention relates to a punching die of a rear suspension installation bracket. The punching die comprises an upper die and a lower die, wherein the upper die comprises an upper die plate, an upper padding plate, an upper fixing plate, a punching head, a pressing plate and a male die, the lower die comprises a female die insert, a female die, a lower padding plate, a lower die plate, a right L-shaped locating block and a left L-shaped locating block, an elastic element is embedded in the left side of the upper fixing plate, the lower end of the elastic element is connected with the pressing plate, the punching head is clamped in the middle part of the upper fixing plate and the pressing plate, the upper end of the male die is fixedly connected with the middle lower part of the pressing plate, the lower end of the punching head penetrates through the male die, the female die is installed in the female die insert, the left L-shaped locating block is fixed at the left rear part of the upper part of the male die and the male die insert, and the right L-shaped locating block is fixed at the right front part of the upper part of the male die and the male die insert. The punching die of the rear suspension installation bracket has the advantages of reasonable structure design, convenience in control, high punching efficiency and the like, and the locating size of a to-be-punched part is guaranteed, so that the repair rate is reduced, the part is automatically separated, and convenience is provided for the use of an operator.

Owner:芜湖中瑞汽车零部件有限公司

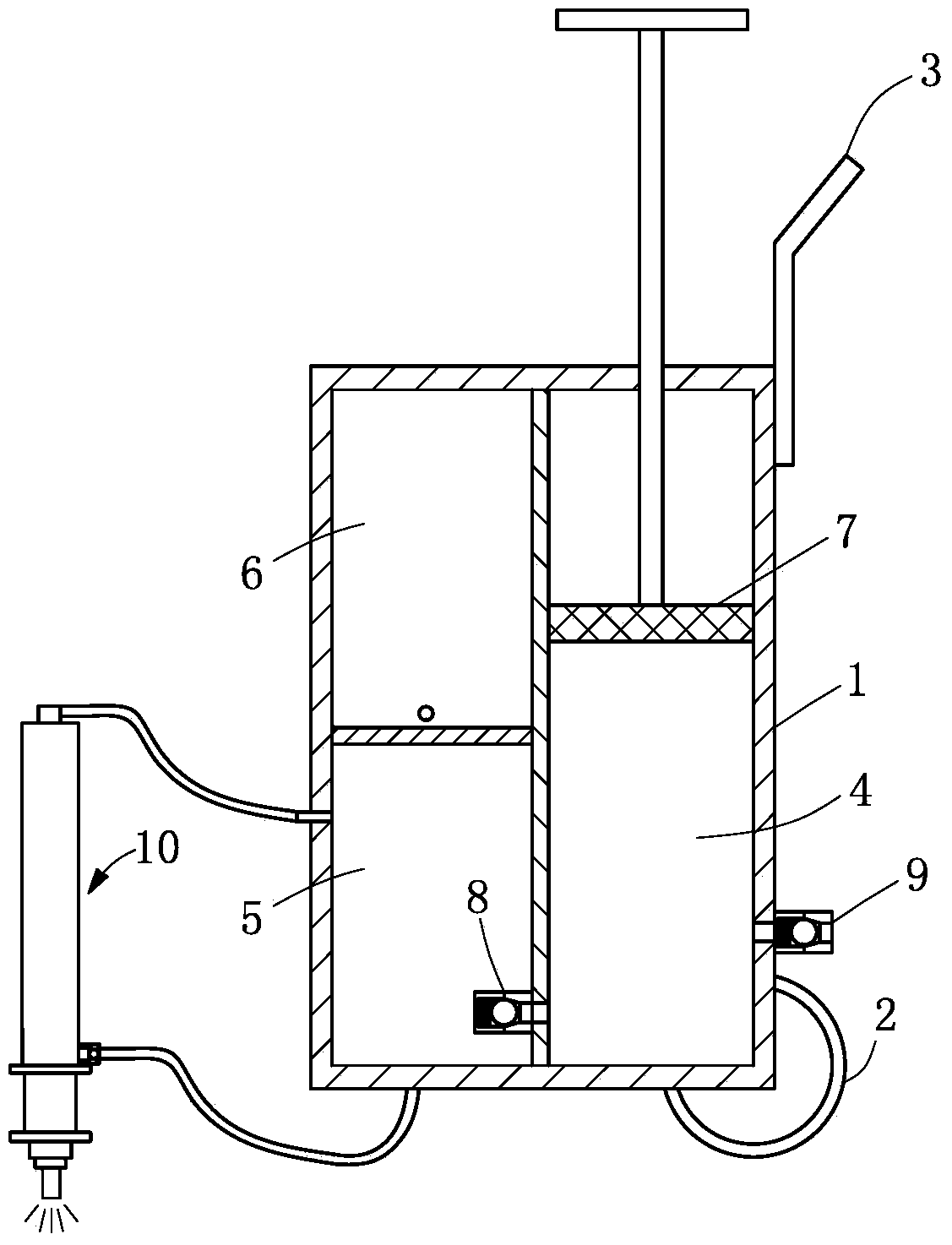

High-pressure washer

ActiveCN103480527AWill not stick to each otherOvercoming the disadvantages of relying on powerSingle-unit apparatusViscous liquidEngineering

The invention discloses a high-pressure washer, and belongs to the technical field of washing equipment. The high-pressure washer comprises a cabinet. A piston cavity, an air storage cavity and a material storage cavity are formed in the cabinet. The air storage cavity is positioned below the material storage cavity. The piston cavity is positioned on one side of the air storage cavity and communicated with the same through a single-way valve. A manual piston is slidably mounted in the piston cavity. The air storage cavity and the material storage cavity are both connected to a handheld pneumatic nebulizer. An air inlet of the handheld pneumatic nebulizer is communicated with the air storage cavity through an air pipe. A feed port of the handheld pneumatic nebulizer is connected with the material storage cavity through a rubber pipe. By the high-pressure washer, the problems that conventional high-pressure washers have poor effect in extracting viscous liquid and are greatly influenced by power sources are solved; the high-pressure washer is widely applied to manufacture of high-pressure washers.

Owner:NINGBO FUSLE MECHANICAL MFG

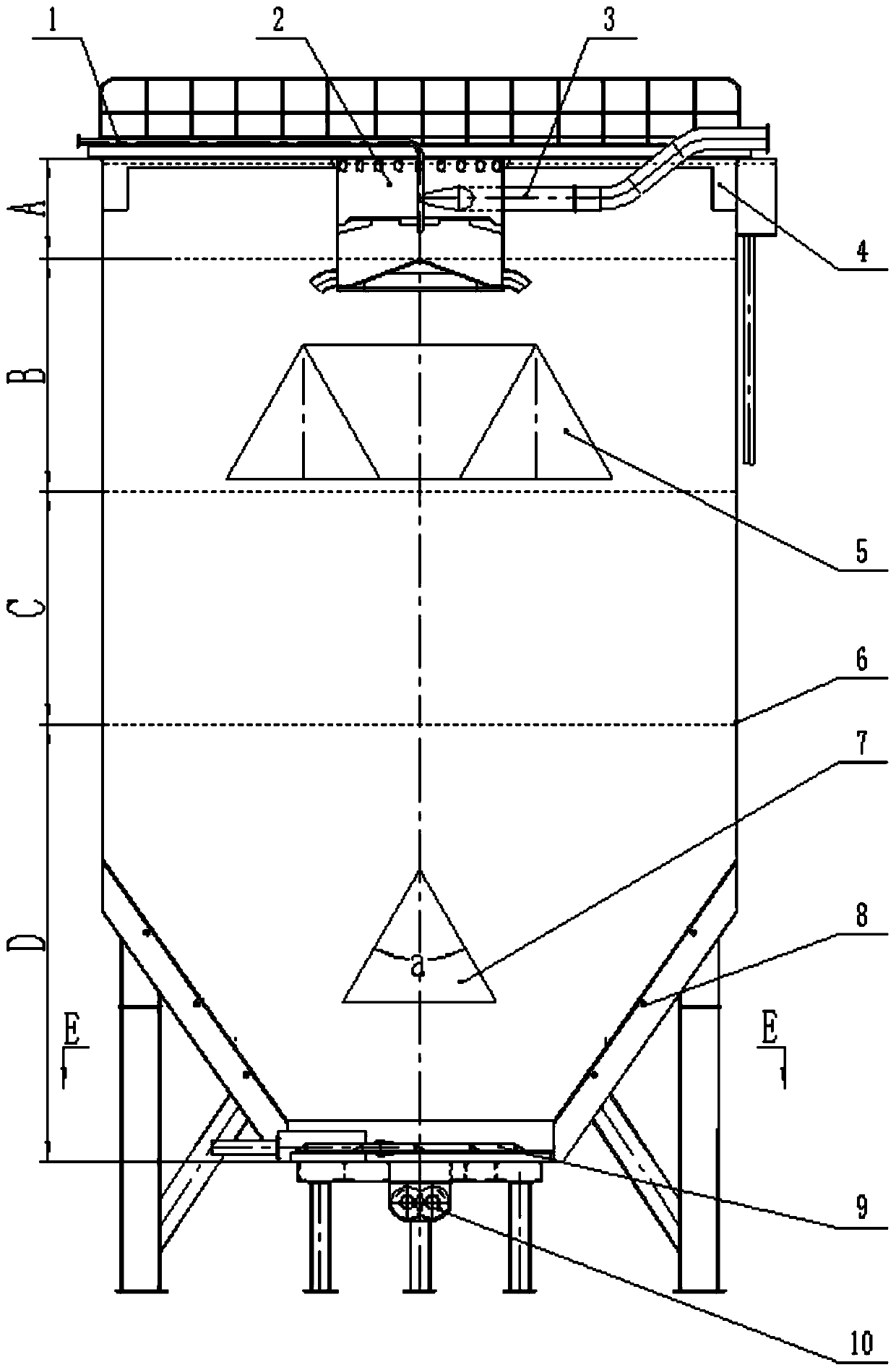

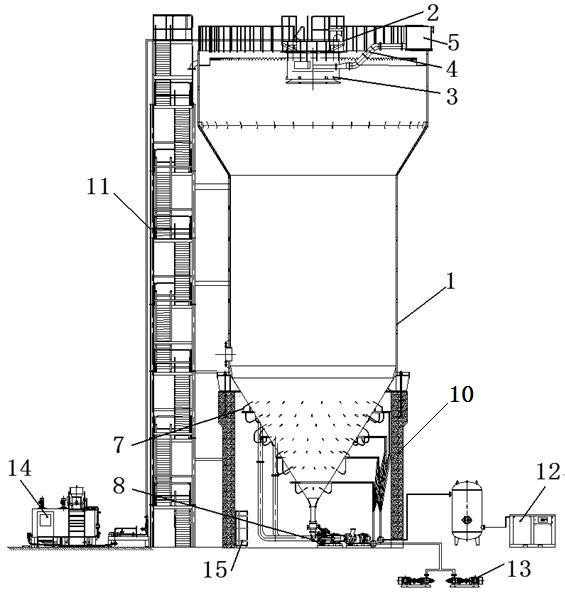

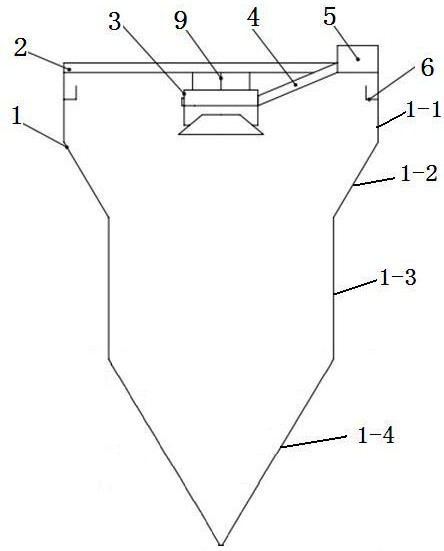

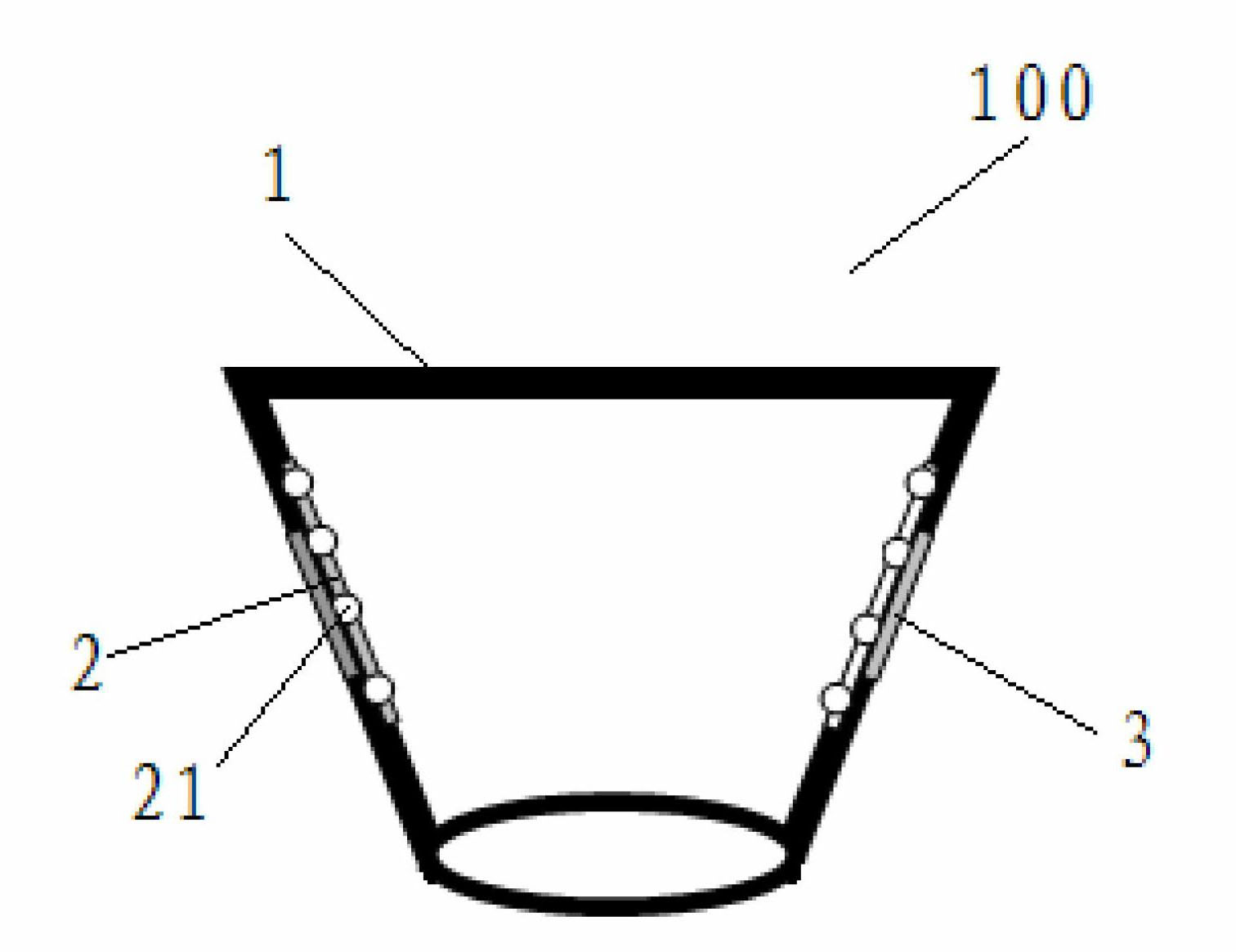

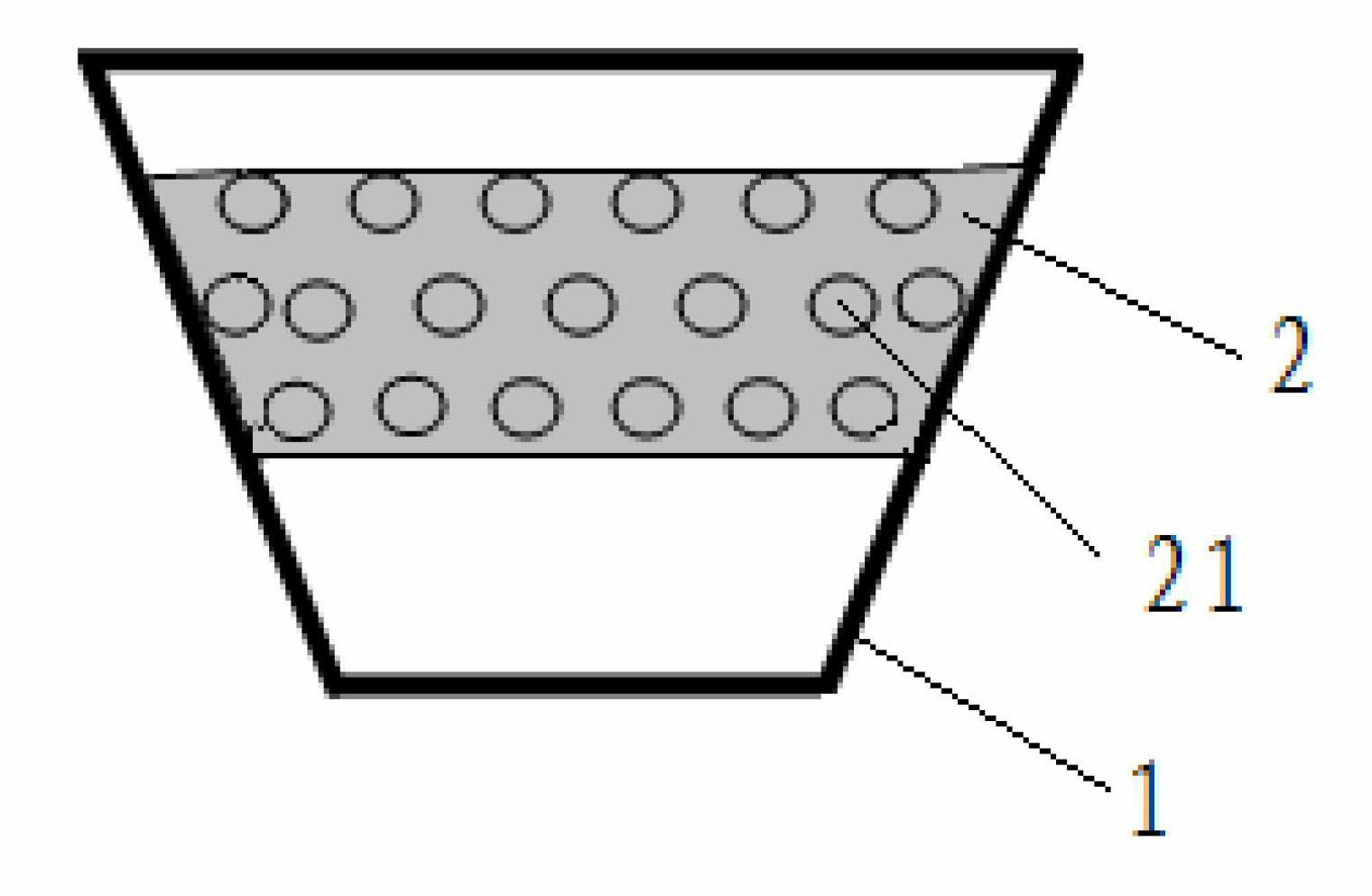

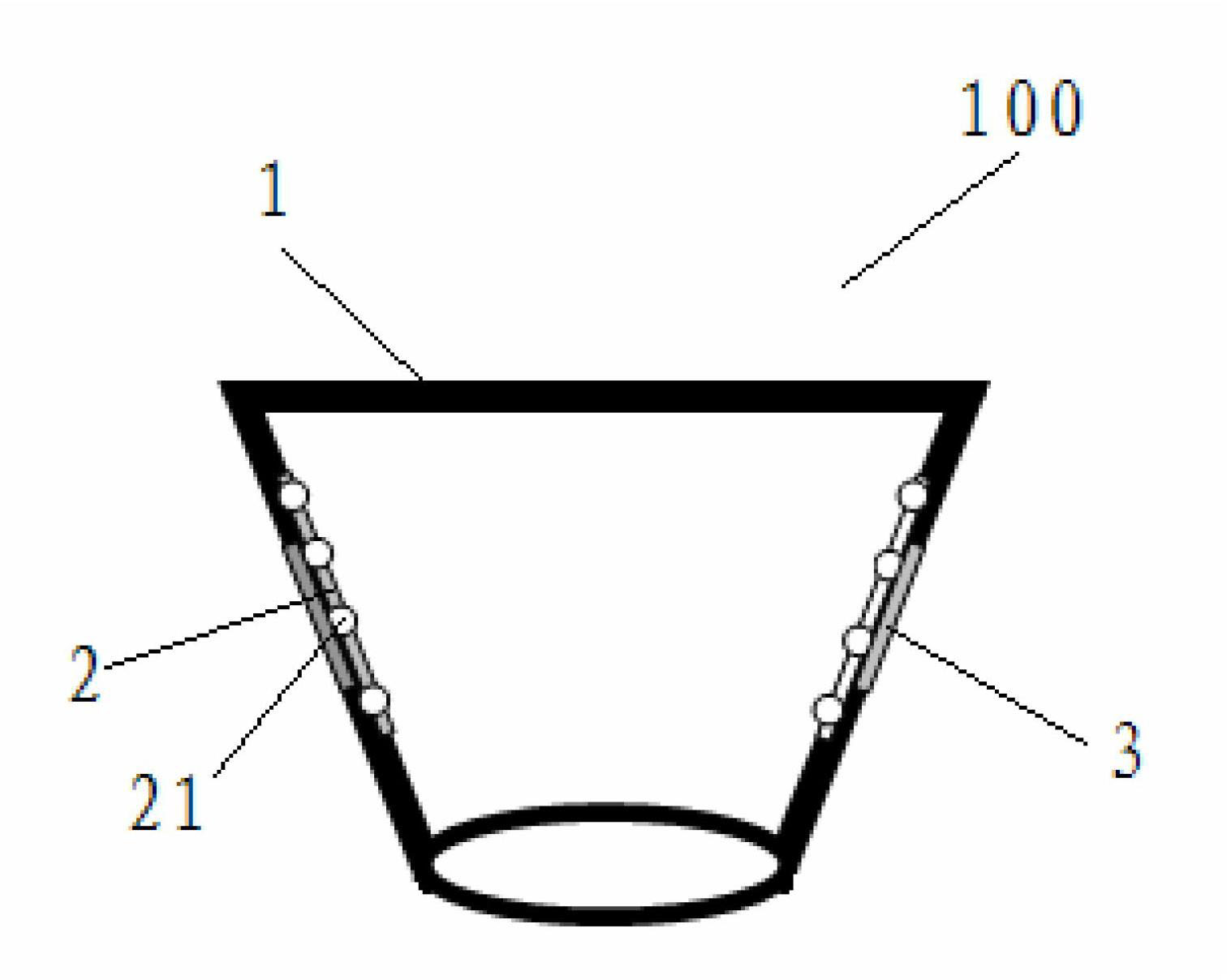

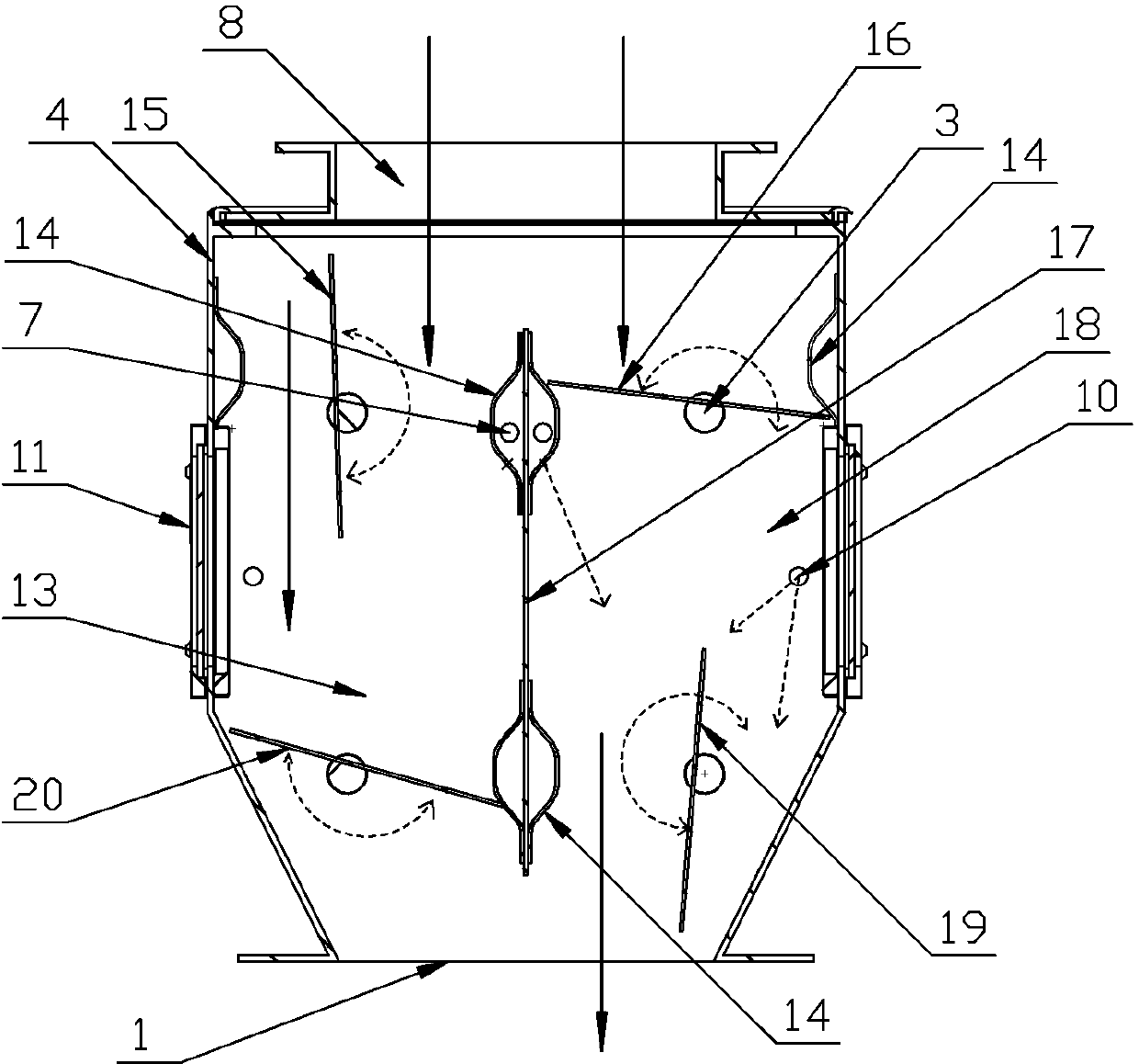

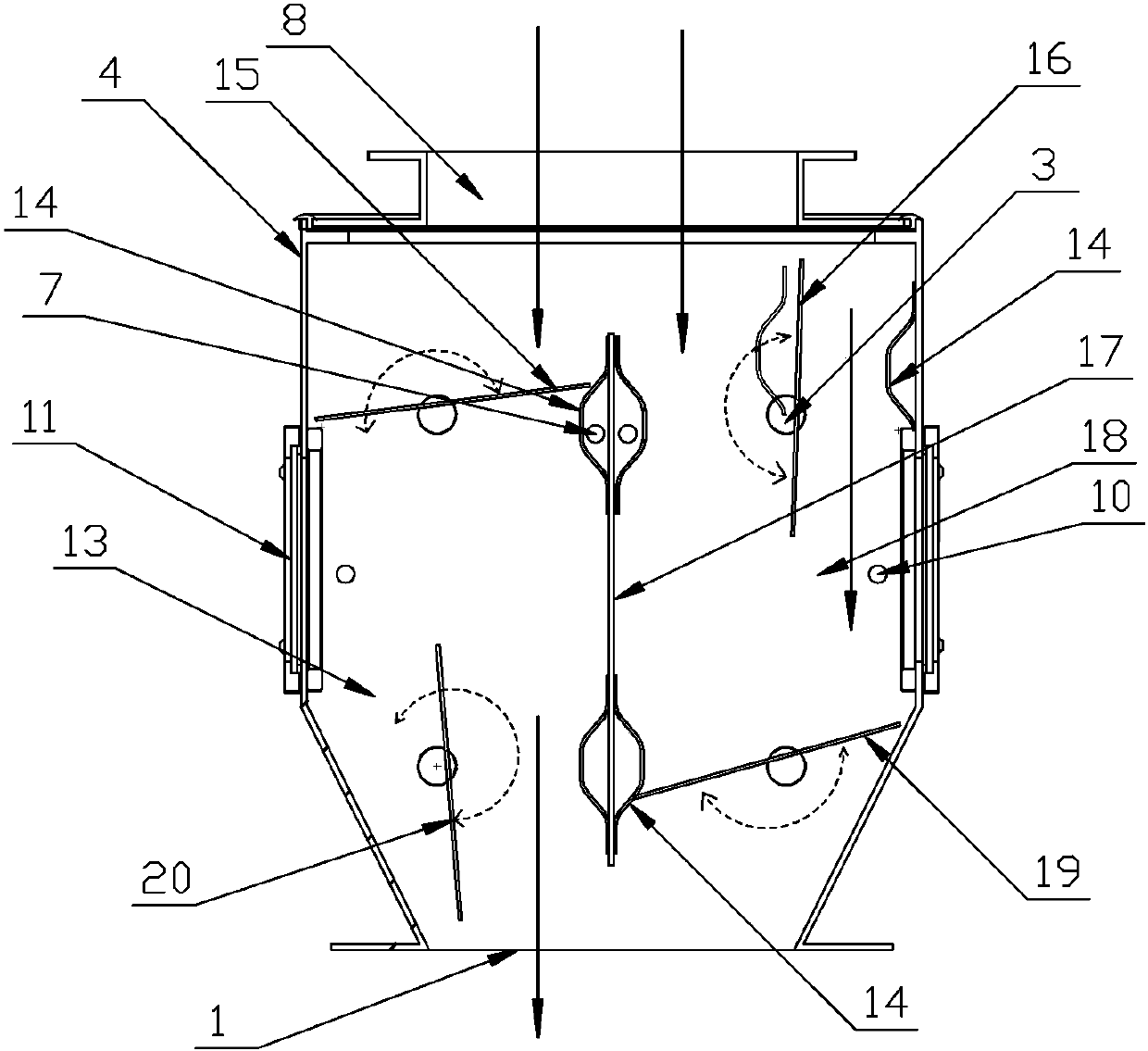

Fine-fraction high-concentration tailing filling and thickening device

ActiveCN113513363AImprove concentrationImprove the cycle efficiency of mining and chargingWaste water treatment from quariesWater/sewage treatment by centrifugal separationEngineeringSlurry

The invention discloses a fine-fraction high-concentration tailing filling and thickening device which comprises a tank body part, a wind-water slurry making system, an underflow conveying system, an electric control system, a flocculating agent preparing and adding system and the like. The wind-water slurry making system comprises an annular water pipe group and an annular gas pipe group; annular water pipes of all layers of the annular water pipe group and annular air pipes of all layers of the annular air pipe group are located at different height positions and distributed in an inverted cone shape, the annular water pipes and the annular air pipes of each layer are respectively connected with a plurality of high-pressure rubber water (air) spraying pipes, valves and external water (wind) slurry making nozzles; and the annular water pipes are connected with a water supply and drainage header pipe, and the annular air pipes are connected with an air supply and exhaust header pipe. By means of the fine-fraction high-concentration tailing filling and thickening device, the material storage capacity is large, the mining and filling circulation efficiency of a mine is improved, no power part exists, fault points are few, power consumption is low, and the operation cost is low; and long-time continuous steady-state slurry discharging is achieved, the stability of technological parameters and the working efficiency of filling operation are improved, the concentration capacity of the thickening device is improved, and the continuity of filling operation of the thickening device is guaranteed.

Owner:山金重工有限公司

Air inflation awl for pulverized coal gasification device

InactiveCN102676233APrevent backflowGuaranteed delivery effectGranular/pulverulent flues gasificationEngineeringExternal pressure

The invention disclose an air inflation awl for a pulverized coal gasification device. The air inflation awl comprises a taper-shaped barrel and a reinforcement part, wherein the taper-shaped barrel is provided with at least one air inflation area made of sintering metal; the reinforcement part is arranged on the wall of the taper-shaped barrel and at least covers the air inflation area; and a plurality of through holes are formed in the reinforcement part. According to the air inflation awl for the pulverized coal gasification device, which is disclosed by the embodiment of the invention, the strength of the air inflation awl is improved by arranging the reinforcement part covered on the air inflation area, so that the air inflation awl can bear a higher internal and external pressure difference, the highest internal and external pressure difference of 1Mpa, which can be borne by the traditional air inflation awl, is improved to 5Mpa so as to greatly lower the damage possibility of the air inflation awl and prolong the service life of the air inflation awl to lower the cost, meanwhile, the parking times of the air inflation awl are reduced, and the production efficiency is improved. In addition, according to the air inflation awl disclosed by the embodiment of the invention, the phenomenon that the pulverized coal flows back can be effectively prevented, and the pulverized coal conveying effect is guaranteed.

Owner:BEIJING YINGDE QINGDA TECH

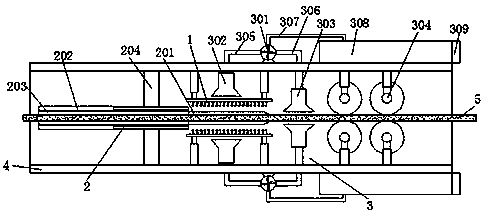

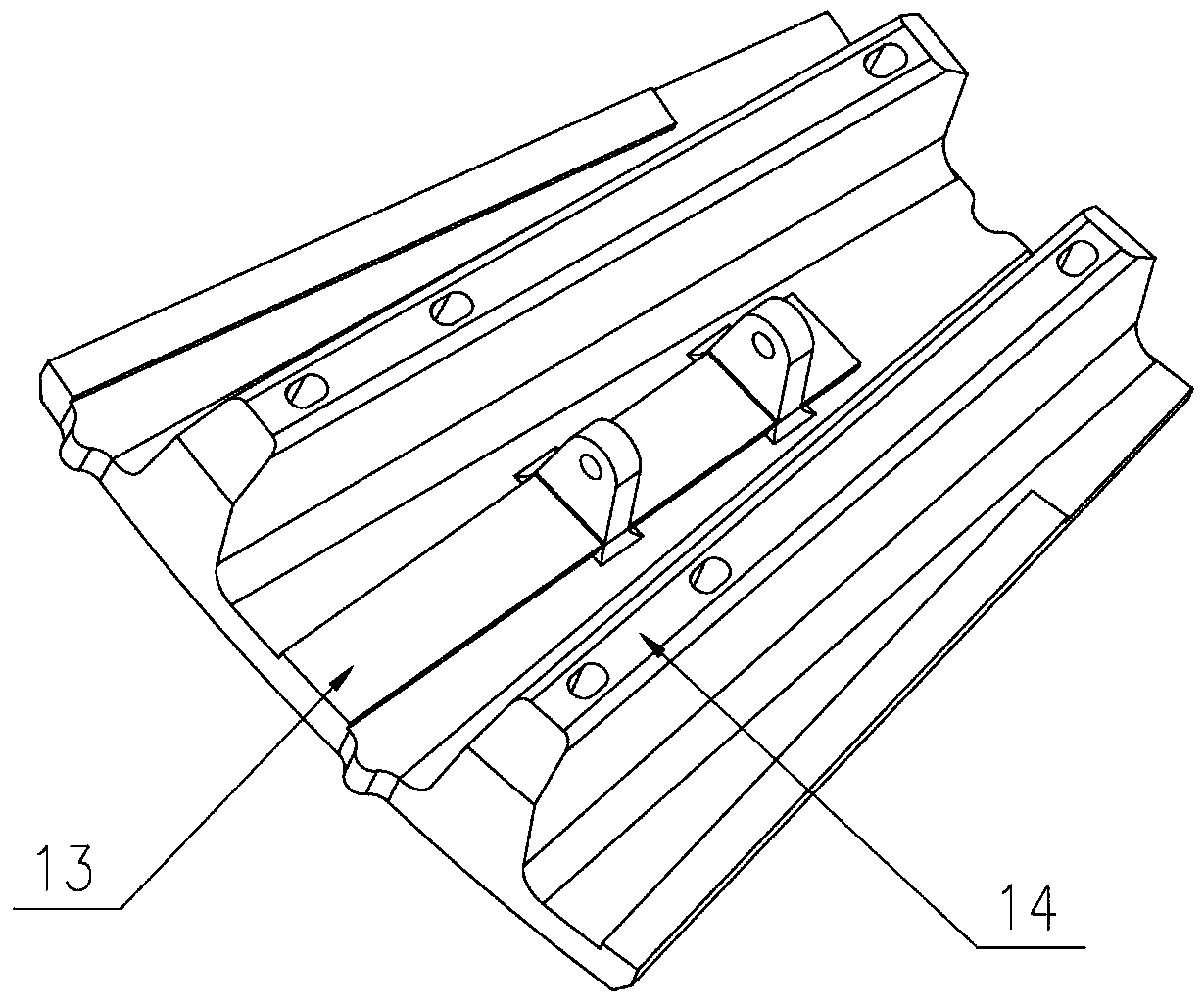

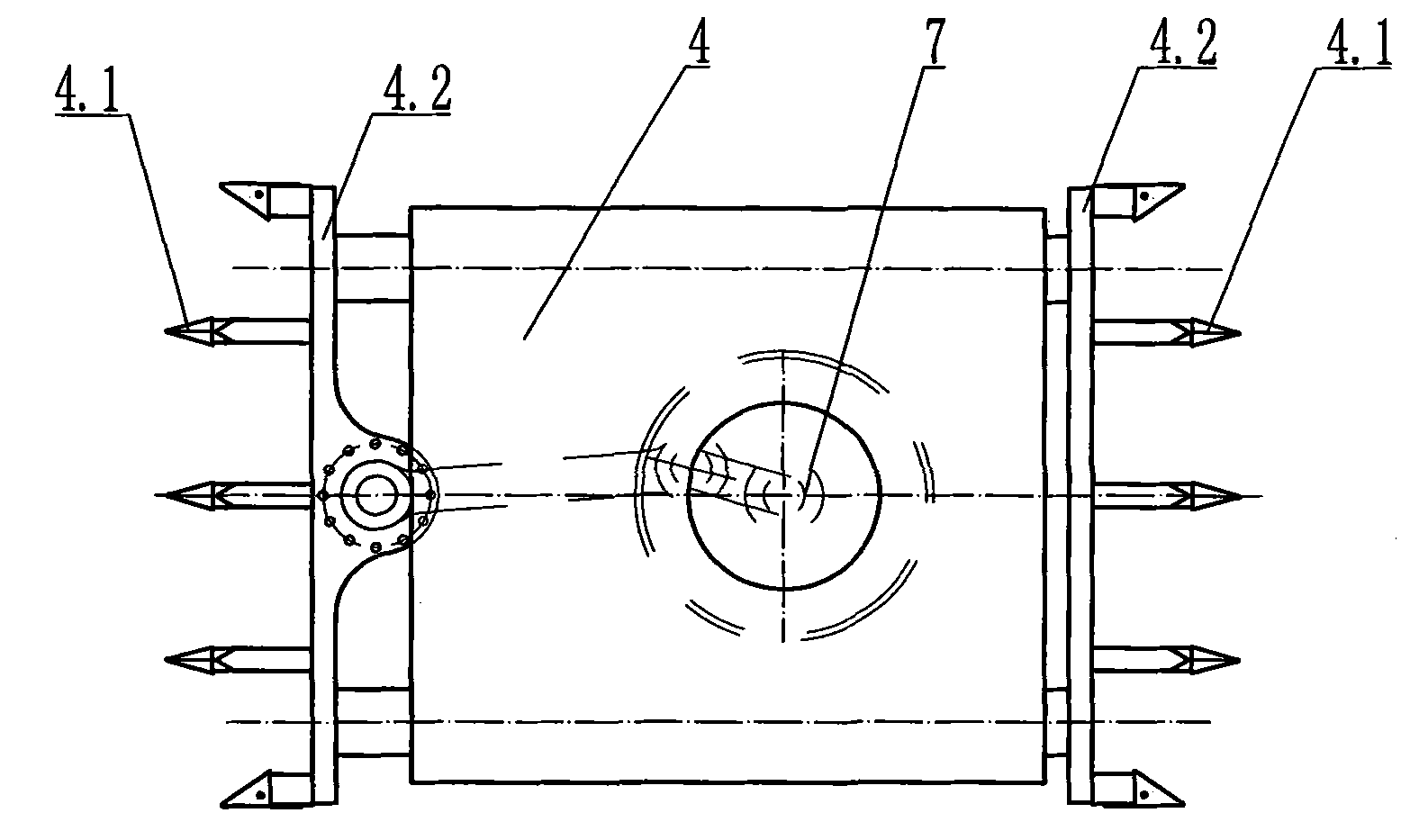

High-efficiency non-clamping impact-blanking digging method and high-efficiency non-clamping impact-blanking digger

ActiveCN103388474ASolve the problem of not being able to continuously collect materialsBlanking smoothlySlitting machinesCutting machinesEngineeringMechanical engineering

A high-efficiency mining machine for percussing falling-materials without trapping materials. A machine body of the mining machine is provided with a falling-material percussion mechanism (3). The falling-material percussion mechanism (3) comprises an outer-layer-material percussion mechanism (4) and an inner-layer-material percussion mechanism (5). The outer-layer-material percussion mechanism (4) comprises outer-layer-material percussion teeth (4.1). The outer-layer-material percussion teeth are disposed so that materials percussed down by the inner-layer-material percussion mechanism flow out through gaps between the outer-layer-material percussion teeth and / or a discharge hole (8) is reserved in the outer-layer-material percussion mechanism so that materials percussed down by the inner-layer-material percussion mechanism flow out through the discharge hole (8) of the outer-layer-material percussion mechanism. The inner-layer-material percussion mechanism comprises inner-layer-material percussion teeth (5.1). The inner-layer-material percussion mechanism and the outer-layer-material percussion mechanism work with each other to implement percussion and discharge of falling-materials. Also disclosed is a high-efficiency mining method for percussing falling-materials without trapping materials. The mining machine has a simple structure and works in a reliable way.

Owner:刘素华

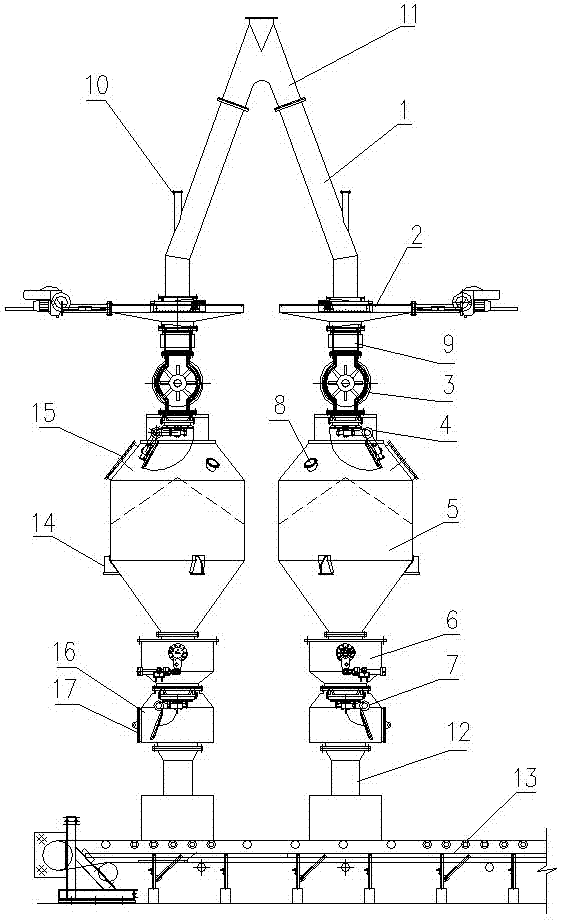

Material discharge device for vertical furnace

InactiveCN102925614ARealize continuous dischargeEnsure continuous and efficient operationShaft furnaceEngineeringGate valve

The invention discloses a material discharge device for a vertical furnace, comprising a material blanking pipe, a gate valve, a rotating material discharge valve, an upper sealing valve, a discharged material tank, a material flow regulating valve and a lower sealing valve. The material discharge pipe is provided with at least two material dividing pipes; the gate valve is arranged at the inlet of the material discharge pipe or the outlets of the material dividing pipes; the rotating material discharge valve is arranged on the material dividing pipes and below the gate valve; the upper sealing valve is connected with the outlet of the rotating material discharge valve or the outlets of the material dividing pipes; the discharged material tank is connected with the outlet of the upper sealing valve; the material flow regulating valve is connected with the outlet of the discharged material tank; the lower sealing valve is connected with the outlet of the material flow regulating valve; and the discharged material tank is provided with a uniform pressure discharge interface. Due to the alternative work of equipment on the material flow paths of the material dividing pipes, the furnace material can be discharged continuously, and the vertical furnace can work continuously and efficiently. As the discharged material tank is provided with the uniform pressure discharge interface, the vertical furnace can discharge materials smoothly under pressure or normal pressure, and the material discharge device can work reliably and stably. The equipment in the material discharge device adopts the module design and can be repaired independently, so that the repair time is saved, and the maintenance cost is reduced.

Owner:CISDI ENG CO LTD

Energy-saving type positive and negative pressure pneumatic air seal machine

ActiveCN103420169ABalanced and stable workGuaranteed sealing performanceBulk conveyorsInlet channelPositive pressure

The invention relates to an energy-saving type positive and negative pressure pneumatic air seal machine which is provided with a shell, wherein a feed port is formed in the upper part of the shell, a discharge port is formed in the lower part of the shell, a partition is vertically arranged in the middle of a cavity of the shell, so as to divide the inner cavity of the shell into a front discharge channel and a back discharge channel, and an upper blade and a lower blade are installed in each discharge channel by an upper rotating shaft and a lower rotating shaft. The energy-saving type positive and negative pressure pneumatic air seal machine is characterized in that a front sealing plate and a back sealing plate are installed on the upper part of the partition, a plurality of air blowing holes are formed in the front sealing plate and the back sealing plate, a front air inlet channel and a back air inlet channel are formed between the front and back arc-shaped sealing plates and the partition, and air inlets corresponding to the front and back air inlet channels are formed in the shell and externally connected with air inlet pipes; the upper rotating shaft in the front discharge channel and the lower rotating shaft in the back discharge channel extend to one side outside the shell, the lower rotating shaft in the front discharge channel and the upper rotating shaft in the back discharge channel extend to the other side outside the shell, and linkage transmission mechanisms are installed between the respective two rotating shafts on both sides of the shell. The energy-saving type positive and negative pressure pneumatic air seal machine can be applied to a positive and negative pressure wind transported or dust removal system, the problem that the existing valve type air seal machine cannot be suitable for a discharge port positive pressure wind network system is solved, and the energy-saving type positive and negative pressure pneumatic air seal machine is mainly suitable for pneumatic transmission and ventilation dust removal systems in industries of grains, feedstuff, food processing plants, medicine, chemical engineering, tobaccos, metallurgy, cement and the like.

Owner:HUANGSHI LIANGFENG MACHINERY

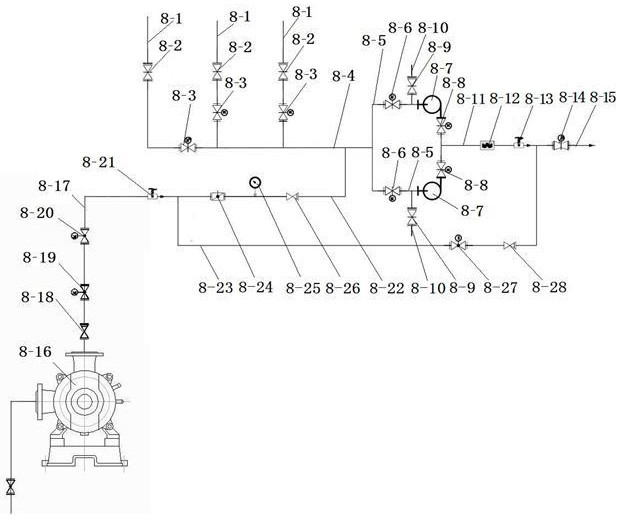

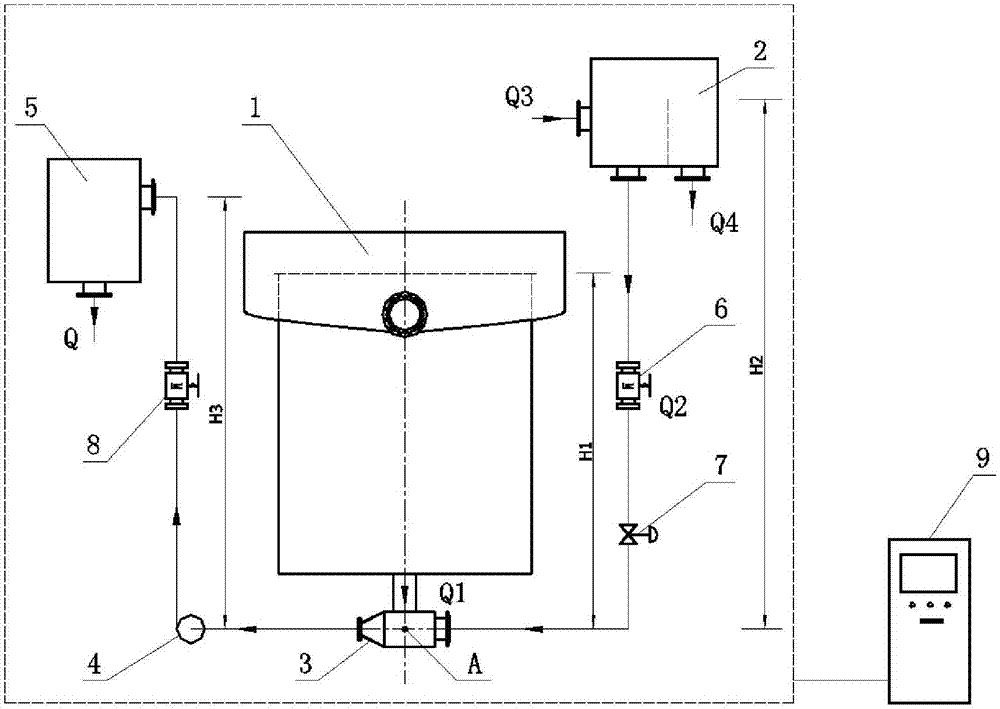

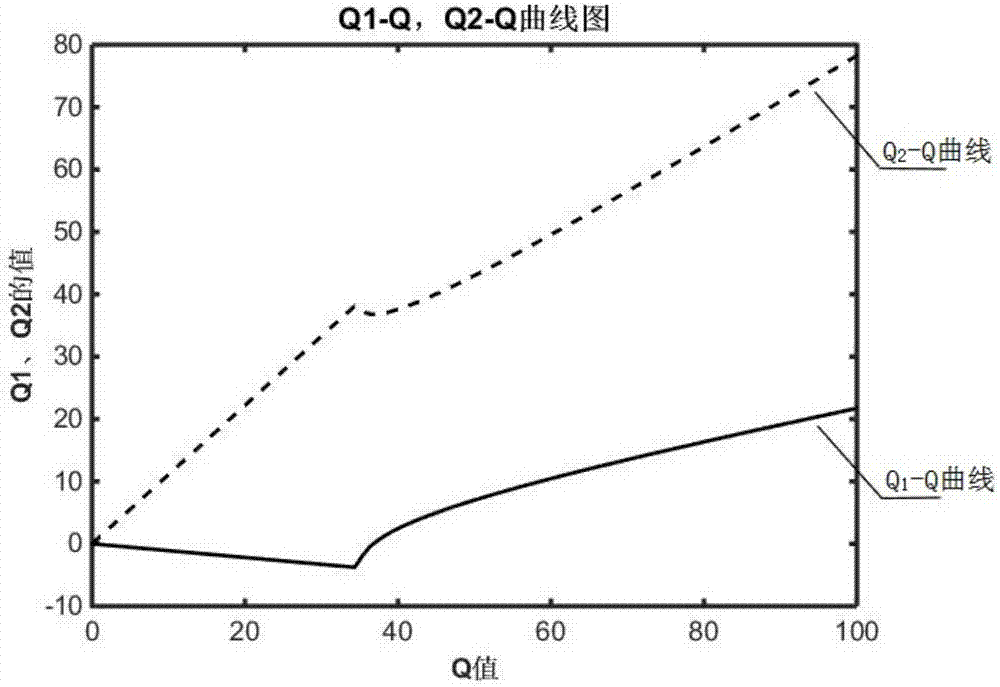

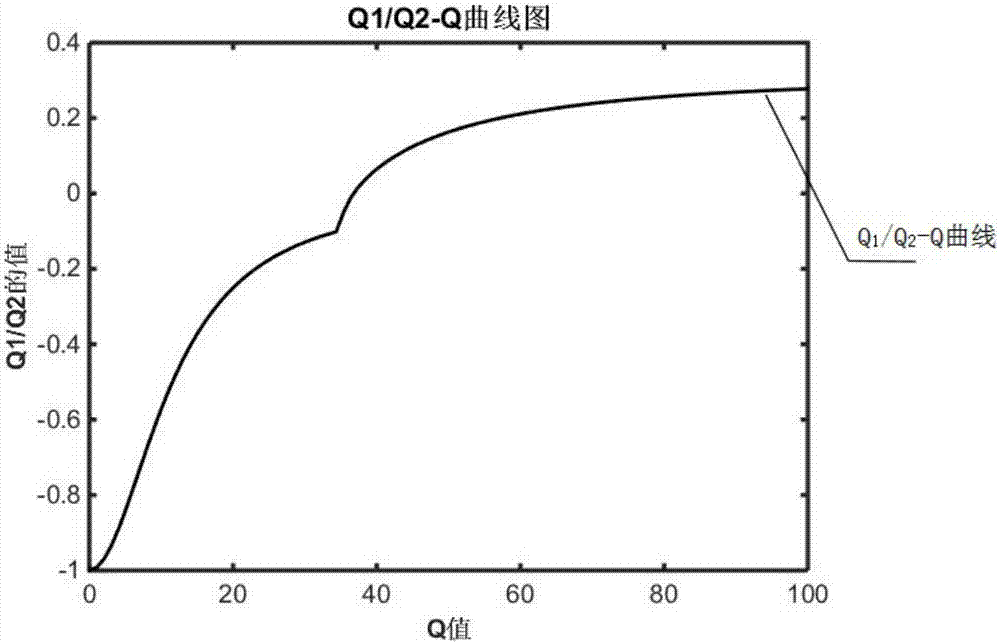

Quantitative and continuous tailings discharging system and method of coarse slime sorting machine

InactiveCN107876207AAvoid easy cloggingSolve easy blockageWet separationHeight differenceEngineering

The invention discloses a quantitative and continuous tailings discharging system and method of a coarse slime sorting machine. The coarse slime sorting machine comprises a sorting machine cylinder, and the upper end of the sorting machine cylinder is provided with a downflow weir. The lower end of the sorting machine cylinder communicates with a discharging pump feeding pipe, and the geometricalheight difference between the downflow weir and the discharging pump feeding pipe is a constant H1. A water replenishing and pressure stabilizing box and a discharging and flow stabilizing box are arranged above the sorting machine cylinder. The lower end of the water replenishing and pressure stabilizing box communicates with the discharging pump feeding pipe through a second branch pipe. The geometrical height difference between the overflow liquid level of the water replenishing and pressure stabilizing box and the discharging pump feeding pipe is a constant H2. The second branch pipe is provided with a water replenishing flow meter and an electric control valve. The side wall of the discharging and flow stabilizing box communicates with the discharging pump feeding pipe through a thirdbranch pipe, and the third branch pipe is provided with a discharging flow meter. The geometrical height difference between the overflow liquid level of the discharging and flow stabilizing box and the discharging pump feeding pipe is a constant H3. The water replenishing flow meter, the discharge flow meter, a discharging pump and the electric control valve are electrically connected with the control terminal.

Owner:TIANJIN MEITENG TECH CO LTD

Crushing and dedusting equipment for mining stone

PendingCN111437921AAvoid accumulationGuaranteed filter resistanceReversed direction vortexGrain treatmentsGear wheelElectric machinery

The invention relates to the technical field of mining equipment, in particular to crushing and dedusting equipment for mining stone. The crushing and dedusting equipment for the mining stone comprises a base, a crushing shell and a cyclone separator, wherein the crushing shell and the cyclone separator are fixedly mounted on the base, crushing rollers are rotationally arranged in the crushing shell and are coaxially and fixedly connected with drive gears, one drive gear is coaxially and fixedly connected with a driven belt pulley, a motor is fixedly mounted on the outer side wall of the crushing shell, an output shaft of the motor is coaxially and fixedly connected with a driving belt pulley, an inclined sloping plate is arranged at the bottom in the crushing shell, the cyclone separatortangentially communicates with the side wall of the crushing shell through a gas inlet pipe, fan blades are rotationally arranged in the gas inlet pipe and coaxially and fixedly connected with a second gear, one crushing roller is coaxially and fixedly connected with a first gear, and a filter plate is fixedly connected with the top of the cyclone separator. The crushing and dedusting equipment for the mining stone has the advantages of being simple in structure, convenient to operate, high in treatment capacity and low in production cost, realizing smooth discharging and facilitating popularization and implementation.

Owner:长兴大合机械有限公司

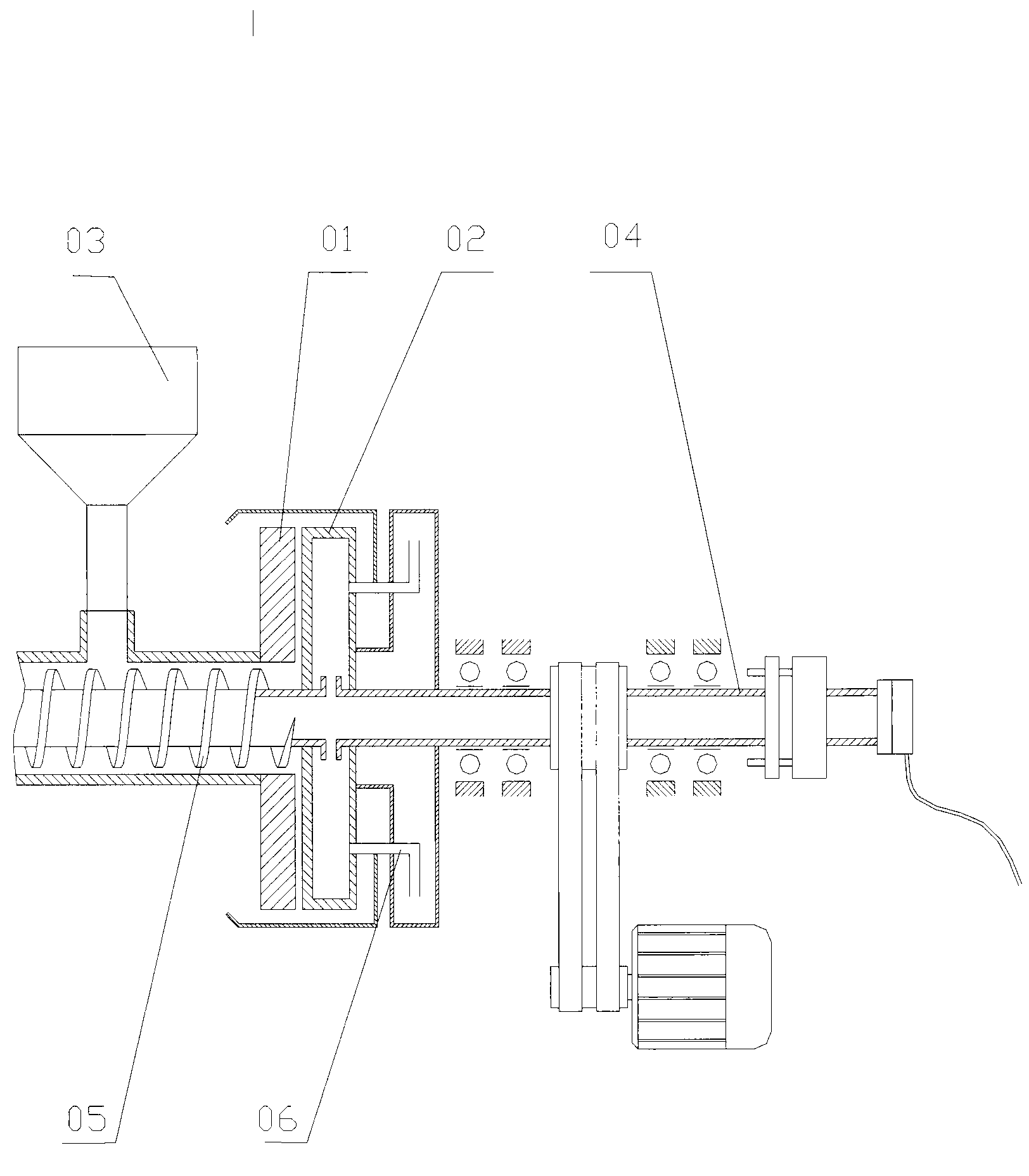

Autonomic feeding system

InactiveCN105643800ALow costImprove mixing uniformityDischarging apparatusCement mixing apparatusFan bladeMixing chamber

The invention provides an automatic feeding system. The automatic feeding system comprises a mixing chamber, a rotary drum, a drive structure, material conveying tubes, discharge holes and mixing fan blades, wherein the mixing chamber is provided with a mixing space, and the bottom of the mixing chamber is provided with a discharge port; the rotary drum can be rotatably mounted in the mixing chamber, is provided with a first section positioned in the inner part of the mixing space and a second section upwards extending out of the mixing space, and the second section and the part, connected to the second section, of the first section is provided with a rotary drum inner cavity; the drive structure drives the rotary drum to rotate through a connecting structure; the at least two material conveying tubes are used for conveying raw materials into the rotary drum inner cavity through the connecting structure; the discharge holes are used for conveying the raw materials into the mixing space from the rotary drum inner cavity; and the mixing fan blades are mounted on the first section, are opposite to the discharge holes up and down, and are used for mixing and uniformly stirring the raw materials discharged from the discharge holes. According to the feeding device, the amount of the raw materials input into the material conveying tubes is controlled, so that the amount of finished products discharged from the discharge holes can be controlled, and therefore, special accommodating equipment and a control device are not required to be arranged, and the equipment cost can be reduced.

Owner:汪振朴

Yellow peel treatment process and yellow peel treatment equipment for quartz mine or alkalifeldspar mine

The invention discloses a yellow peel treatment process and yellow peel treatment equipment for quartz mine or alkalifeldspar mine. The yellow peel treatment process comprises the following steps: crushing the quartz mine or the alkalifeldspar mine into mineral particles with particle sizes of 10-20mm, feeding the mineral particles in a drying barrel of a rotary kiln and heating the mineral particles to 150-210 DEG C, then transferring the mineral particles into a soaking cleaning kettle and soaking the mineral particles with hydrochloric acid for 8 hours, then draining hydrochloric acid, transferring the quartz mineral particles or the alkalifeldspar mineral particles in a cleaning phase, and cleaning the mineral particles in a mist-spraying manner through clear water after neutralization pressure-filtration; and unloading while cleaning the mineral particles until the pH value of water is 6.0-6.5, and drying the obtained mineral particles through the drying barrel of the rotary kiln to obtain a finished product. According to the yellow peel treatment process and the yellow peel treatment equipment, which are disclosed by the invention, the quartz mine or the alkalifeldspar mine is soaked and cleaned through a kettle body integrating a soaking function and a cleaning function, heated by virtue of hot air, and soaked through adopting a mist-spraying cleaning method instead of a cleaning pool, thus equipment investment is reduced, repeated use of acid is benefited, cleaning water consumption is reduced, yellow peel removal efficiency is increased, and the yellow peel treatment process and the yellow peel treatment equipment are suitable for large-scale production.

Owner:陆植才 +1

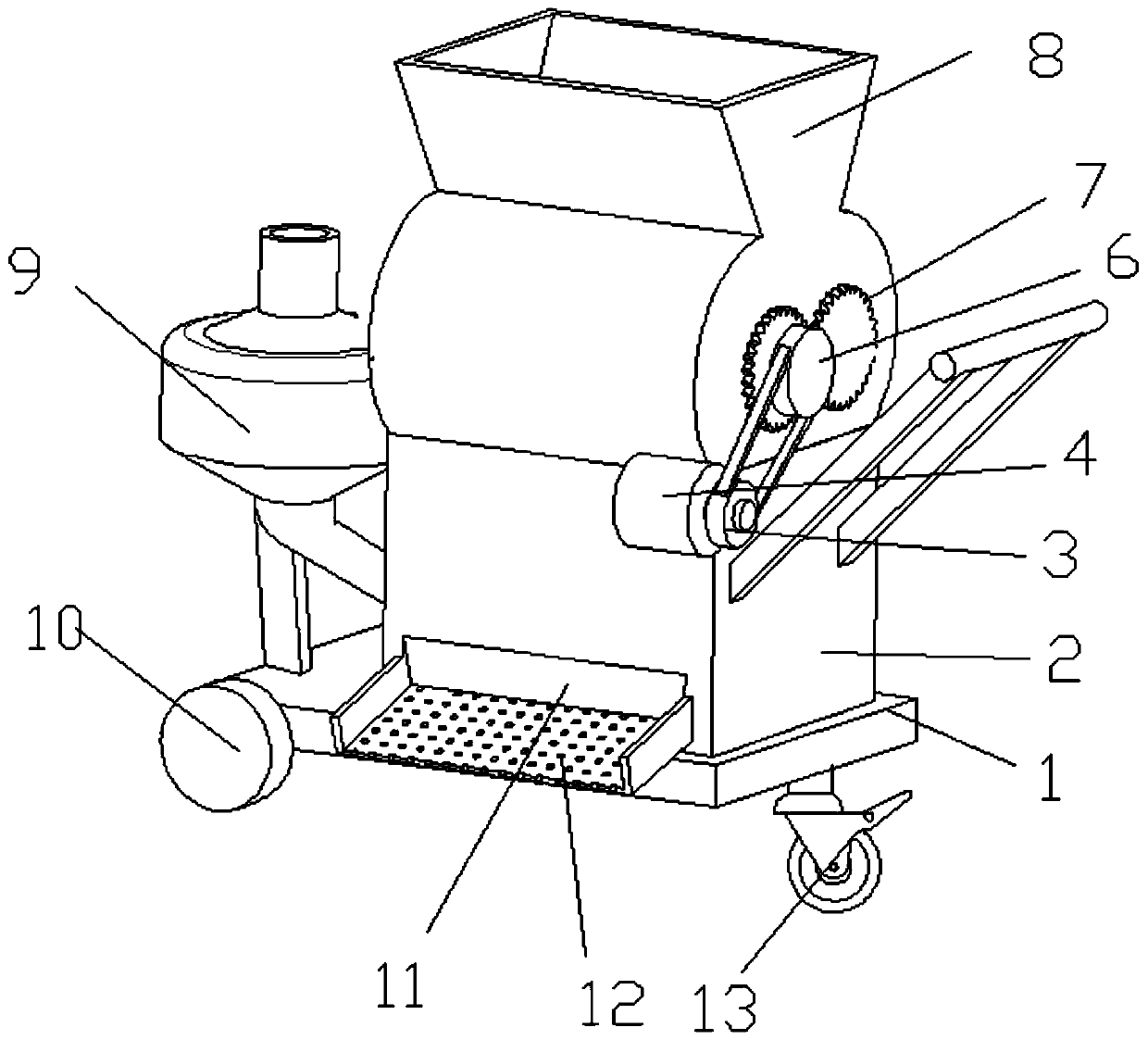

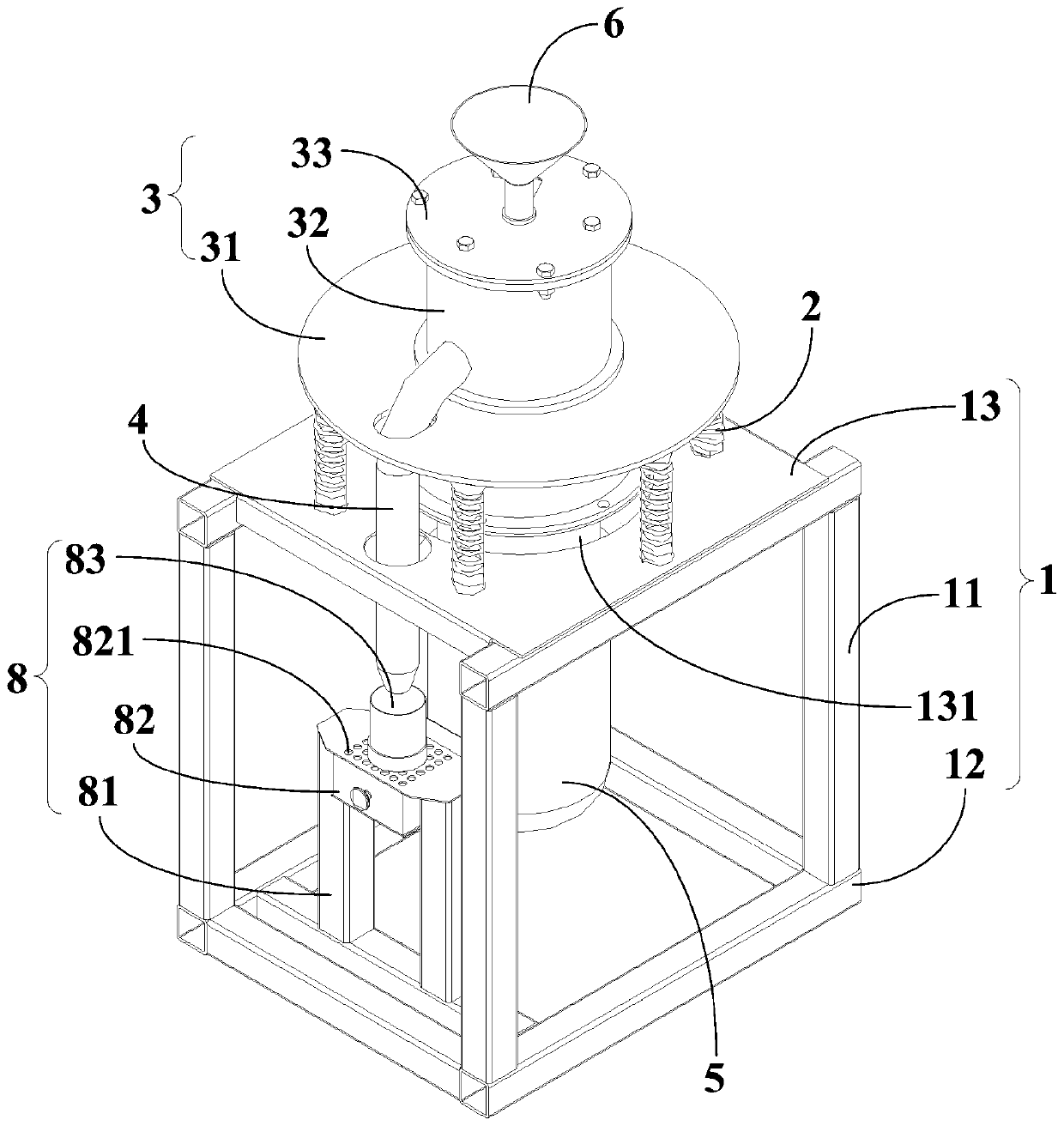

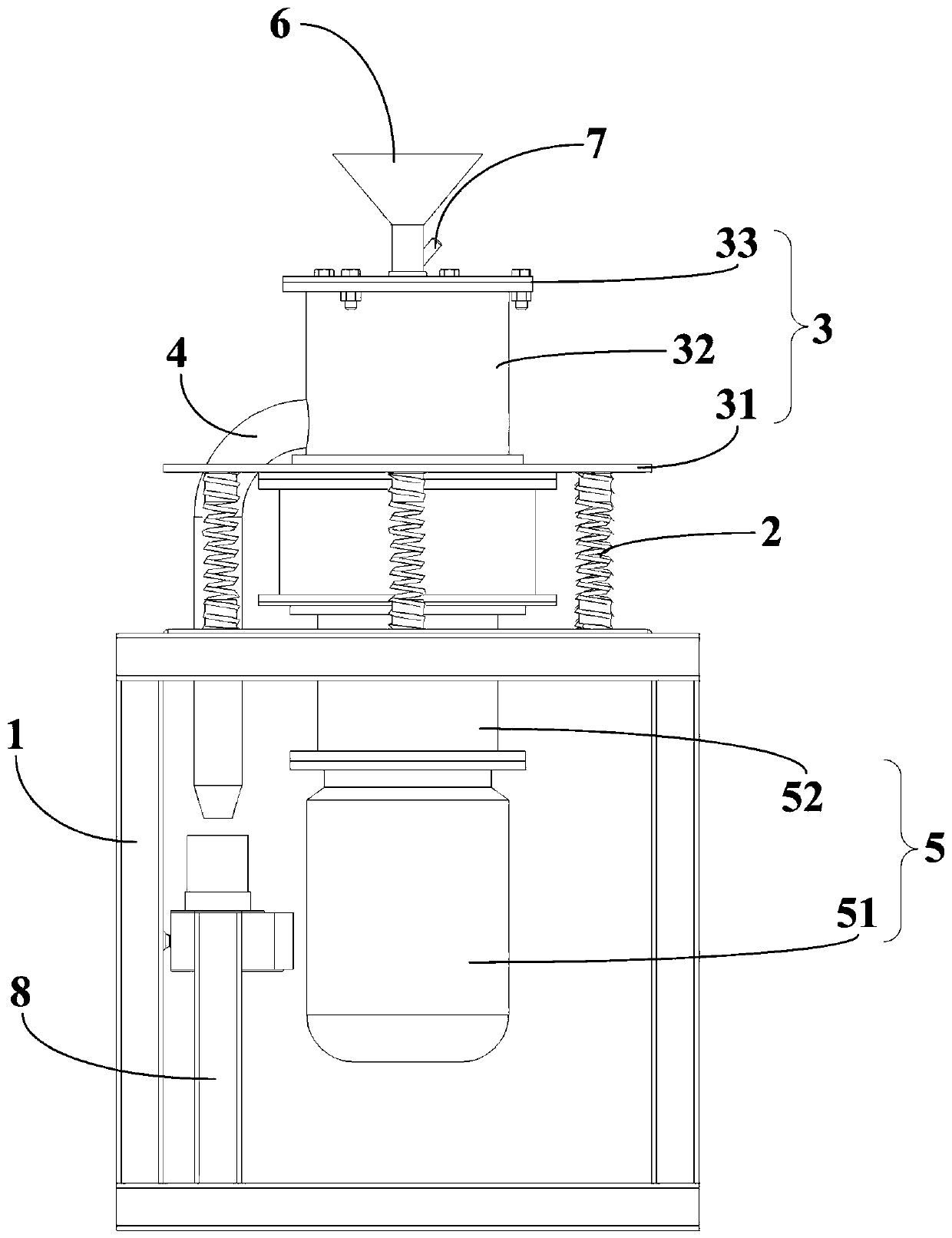

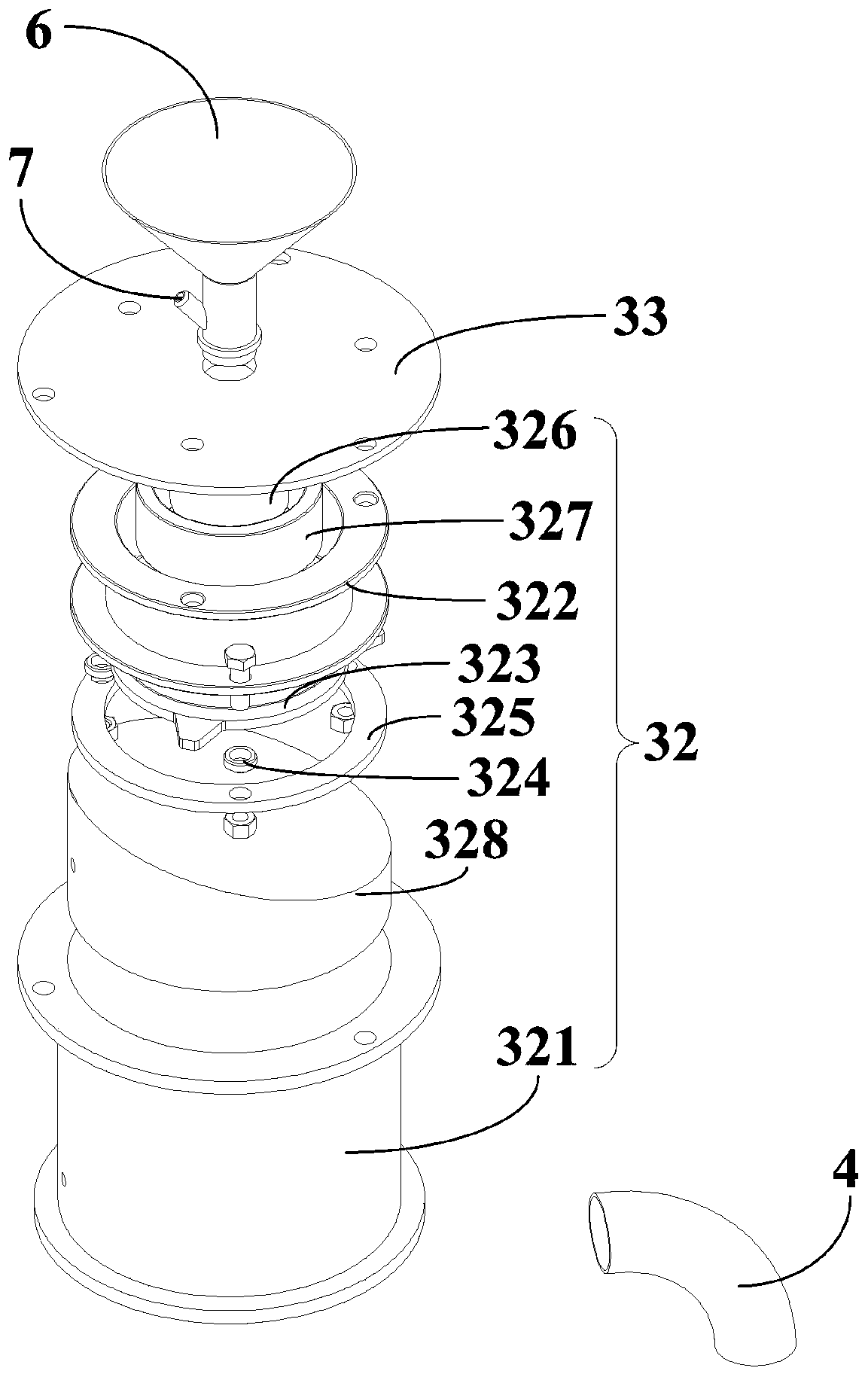

Novel sample preparation pulverizer

PendingCN110694769AReasonable designSimple structurePreparing sample for investigationCleaning using gasesStructural engineeringMechanical engineering

The invention discloses a novel sample preparation pulverizer. The pulverizer comprises a rack, a grinding part, a discharging part and a driving part. The grinding part is fixed to the rack by meansof a damping spring, a grinding bowl, an impact block, an impact ring and a discharging slide carriage are arranged inside the grinding part, under the driving effect of the driving part, the grindingbowl, the impact block and the impact ring are driven to vibrate, due to the fact that a powder discharge gap is formed between a bowl bottom and a bowl body of the grinding bowl, the bowl bottom canrotate within a certain range under the vibration effect relative to the bowl body, the movable bowl bottom can effectively avoid sample blocking, and discharging is smooth, so that a ground powder sample inside the bowl body is discharged to the discharging slide carriage along with the powder discharging gap and discharged to the discharging part along with a discharging hole correspondingly formed in the discharging slide carriage, and then the sample is collected into a sample tank. The novel sample preparation pulverizer effectively overcomes the technical defects that in the prior art,a sample preparation pulverizer cannot perform automatic collection and cleaning is not convenient and has the good market application prospect.

Owner:镇江市科瑞制样设备有限公司

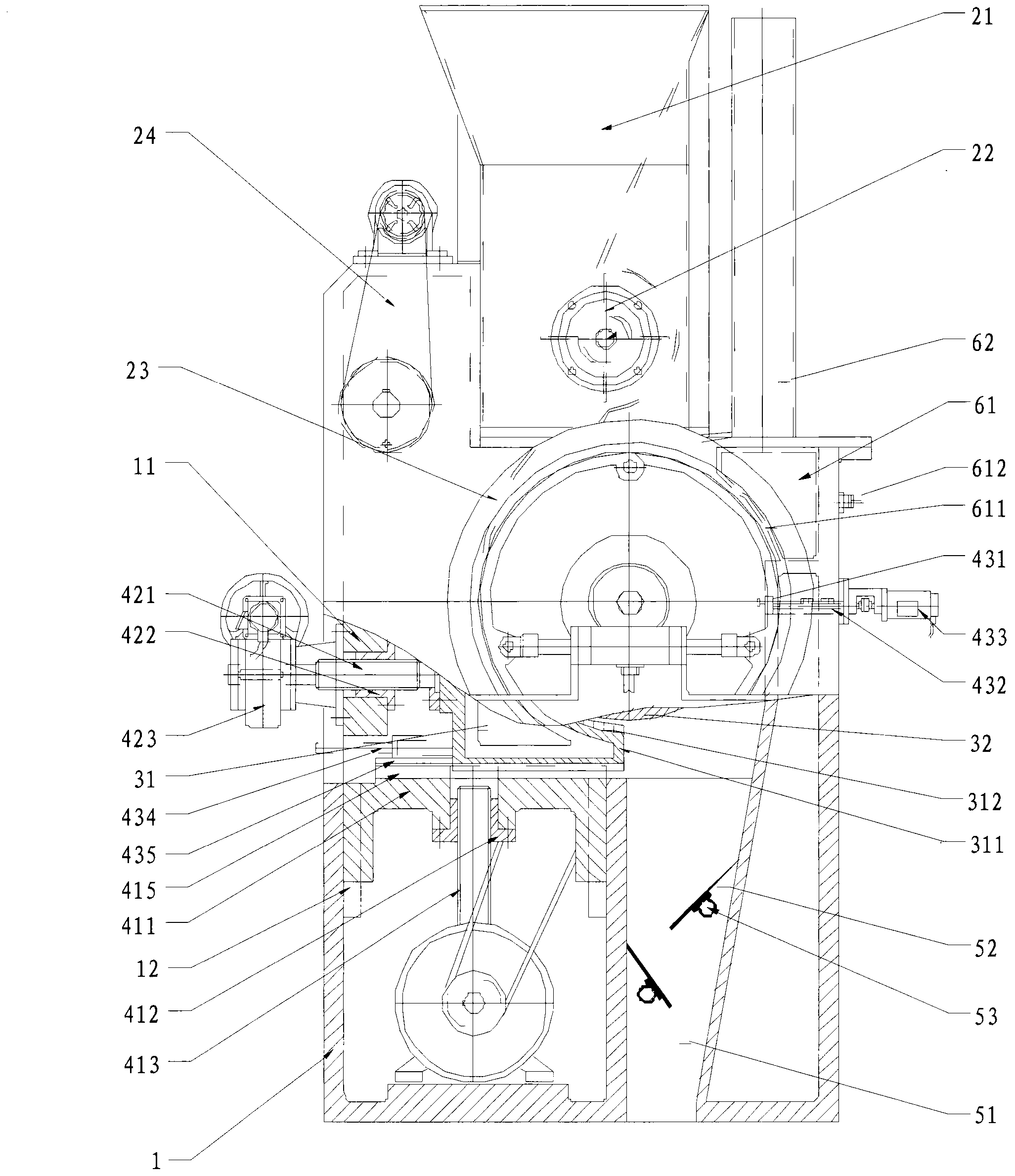

High-efficiency and energy-saving material grinder

ActiveCN103182338AEvenly take turns feedingBurn out preventionGrain treatmentsEngineeringEnergy analysis

The invention discloses a high-efficiency and energy-saving material grinder which comprises a rack, a feeding mechanism, a cutter component, a cutter adjusting device, a discharging device and an air cooling device. The feeding mechanism comprises a storage bin, a uniform feeder, a pusher plate and a stepping drive component for driving the uniform feeder and the pusher plate to move materials intermittently. The cutter component comprises a fixed cutter bed and a movable cutter drum, which have arc-shaped parallel working surfaces and are coaxial to each other. The cutter adjusting device comprises a gap measurement and control component, a horizontal adjustment mechanism and a vertical adjustment mechanism; the horizontal adjustment mechanism and the vertical adjustment mechanism are connected with the fixed cutter bed and push the fixed cutter bed to move; and the gap measurement and control component dynamically measures the gap between the fixed cutter bed and the movable cutter drum and controls the motions of the horizontal adjustment mechanism and the vertical adjustment mechanism. The discharging device comprises a discharge passage, a discharge plate and a vibrator. The air cooling device comprises an arc-shaped guide jet device and an exhaust duct, the arc-shaped guide jet device is provided with an air inlet and a plurality of jet holes facing the working surface of the movable cutter drum. The material grinder has the advantages of high efficiency, low energy consumption, long cutter life and high product quality.

Owner:卢小平 +1

Blanking type environment-friendly papermaking raw material processing and pulping equipment based on three-pipe channel

InactiveCN108411670AReduce deliveryEasy to processRaw material divisionRaw material pretreatmentMotor drivePulp and paper industry

The invention relates to the technical field of environmental protection and discloses blanking type environment-friendly papermaking raw material processing and pulping device based on a three-pipe channel. The equipment comprises a mechanical positioning frame; fixing convex blocks are protruded on the two sides, located on the outer surface, of the mechanical positioning frame respectively; supporting frames are inserted into the bottoms of the inner sides of the two fixing convex blocks respectively; one ends of the bottoms of the two supporting frames penetrate through and extend to the middles of inner cavities of two octagonal supporting bases respectively, and connecting protection frames are welded to one sides of the two octagonal supporting bases respectively; one ends of the two connecting protection frames are welded to the two sides of a material receiving box respectively, and a processing device penetrates through and is connected to the middle of an inner cavity of themechanical positioning frame. According to the blanking type environment-friendly papermaking raw material processing and pulping equipment based on the three-pipe channel, a motor drives a materialstirring device to rotate so that not only can raw materials for pulping be processed, but also impurities attached to the raw materials can be precipitated through a centrifugal force during pulpingto prevent the situation that environmental pollution is caused when the impurities are discharged to the outside.

Owner:闫光

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com