Patents

Literature

101results about How to "Realize automatic nesting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

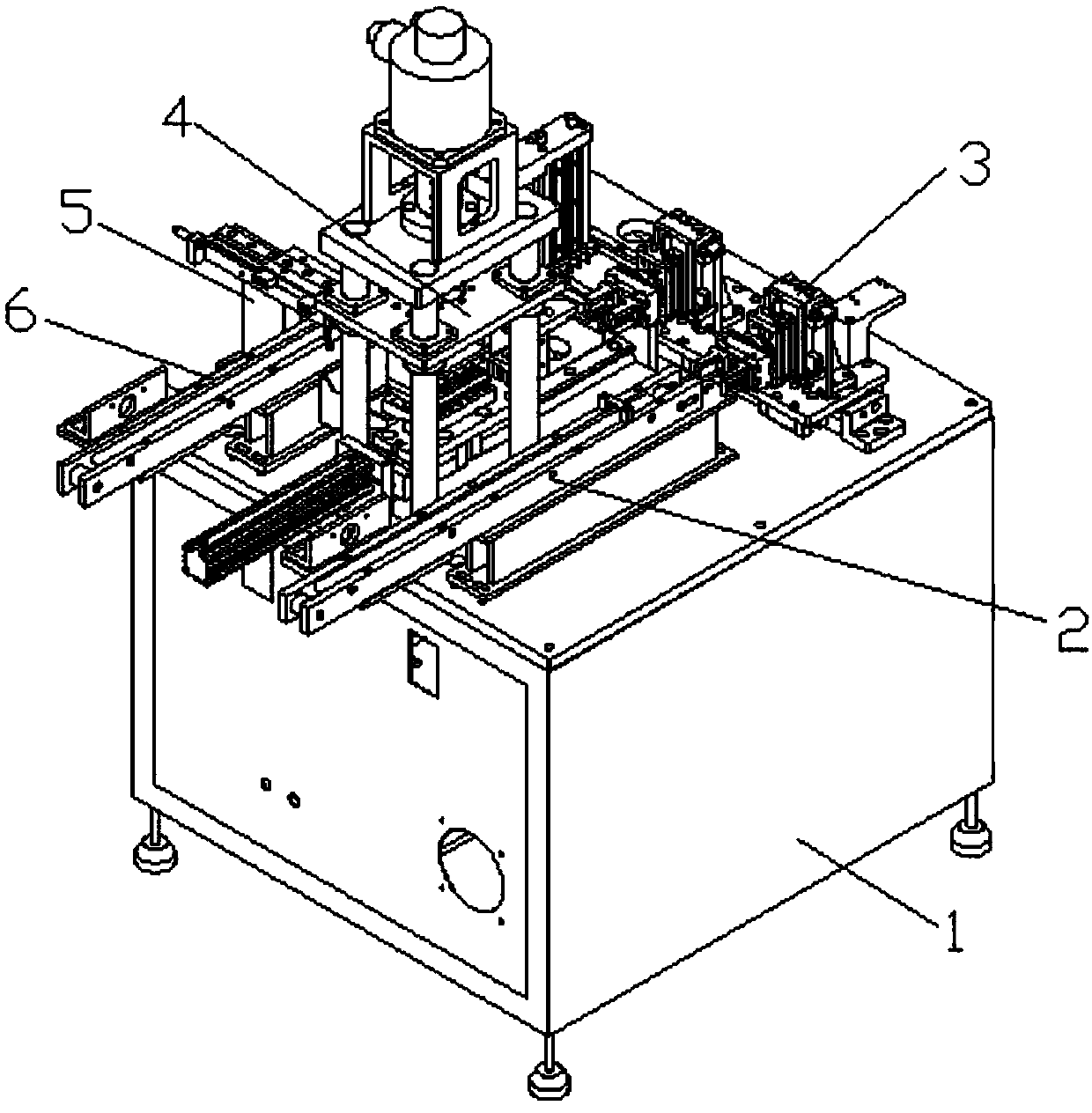

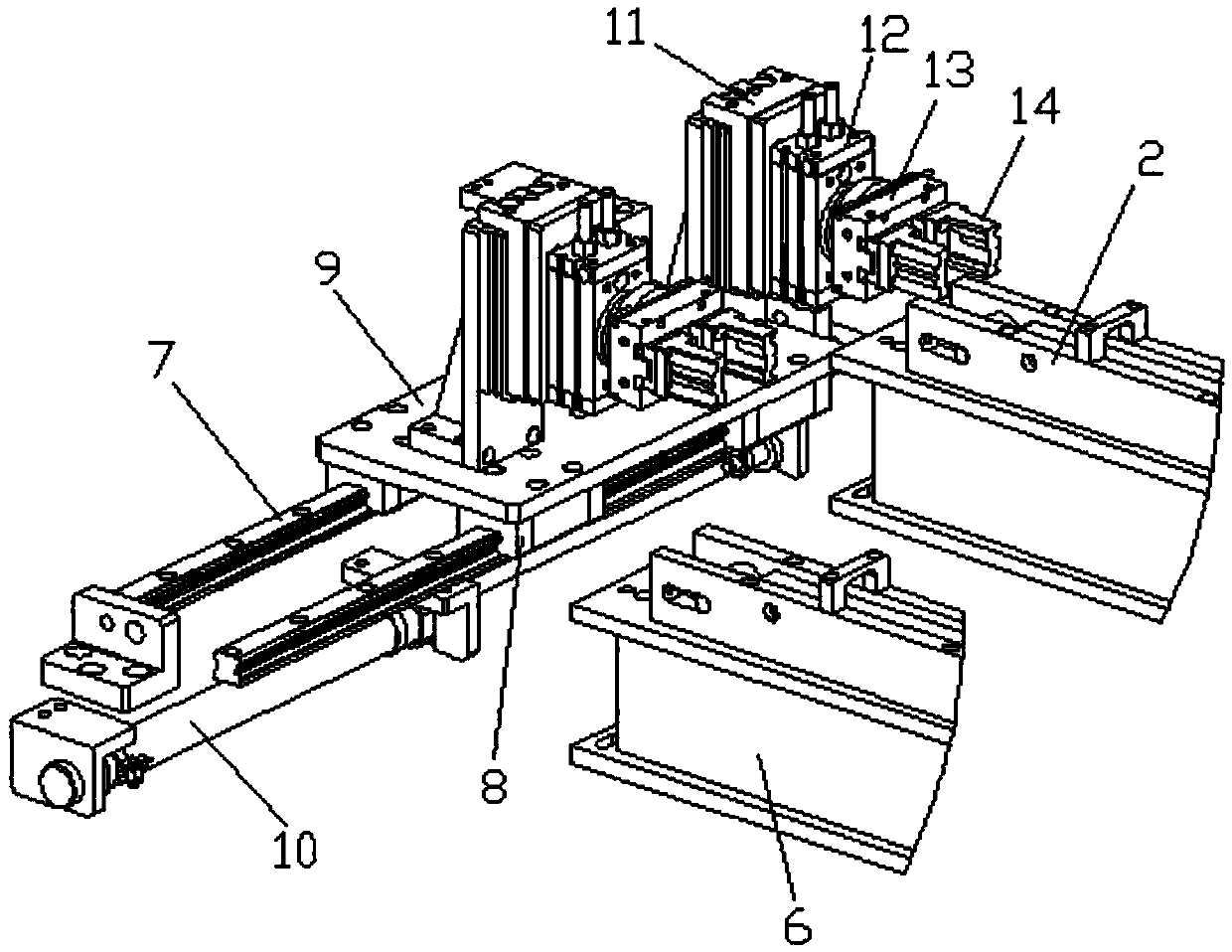

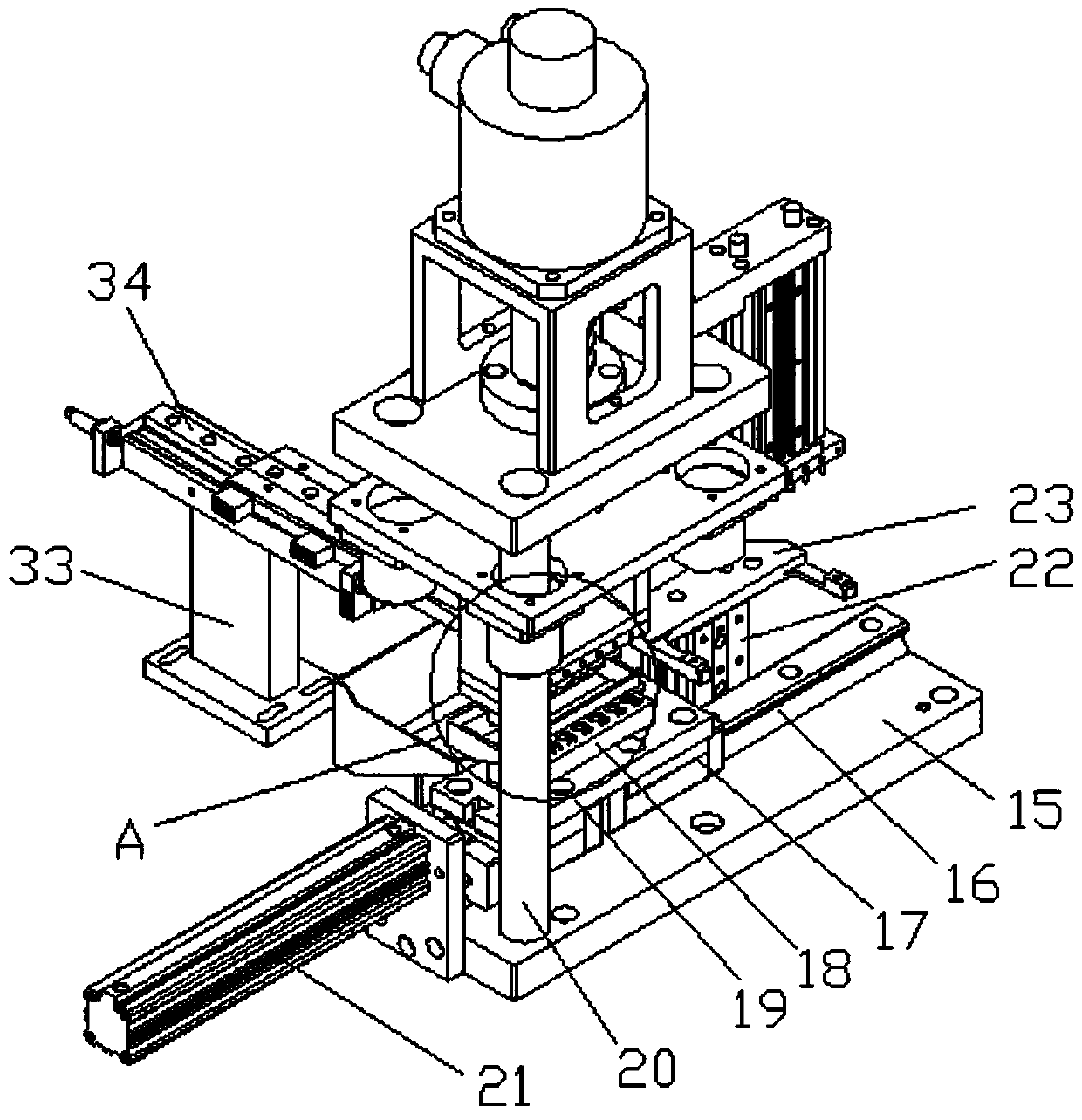

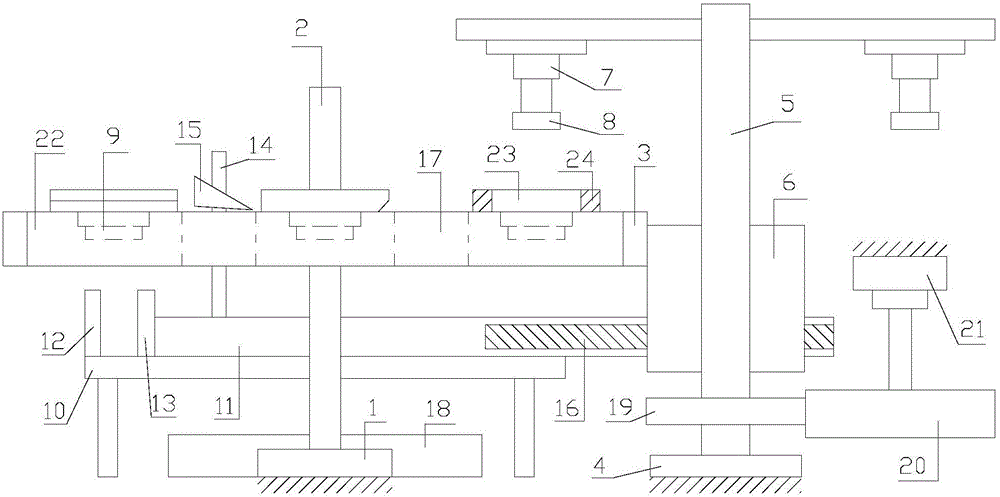

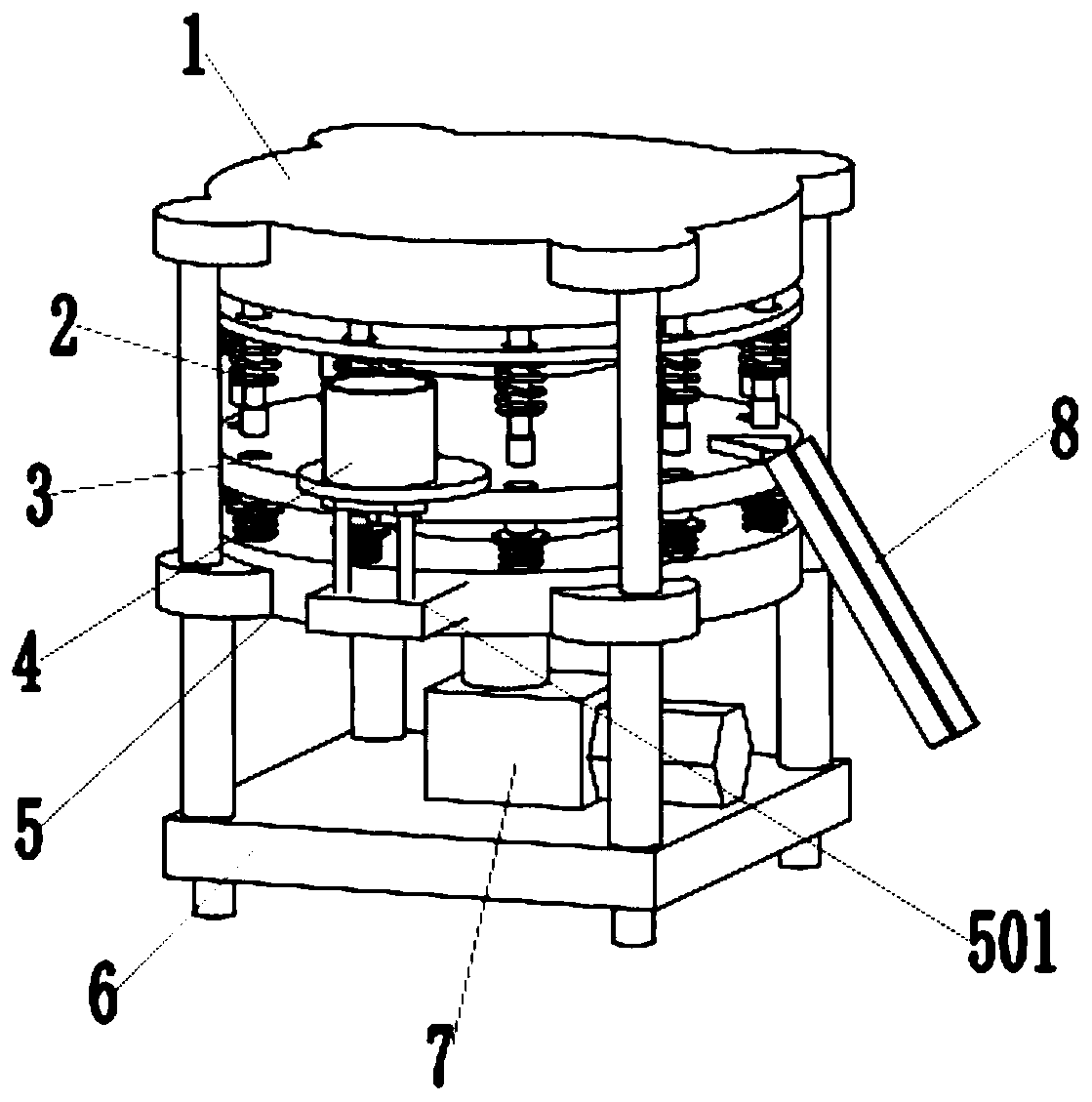

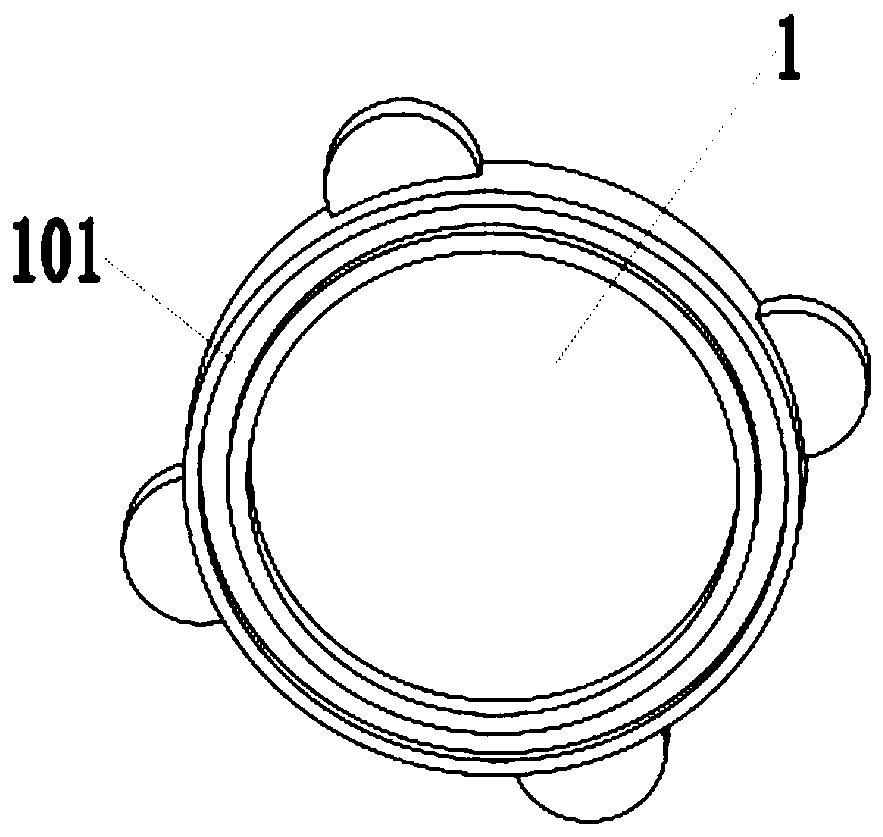

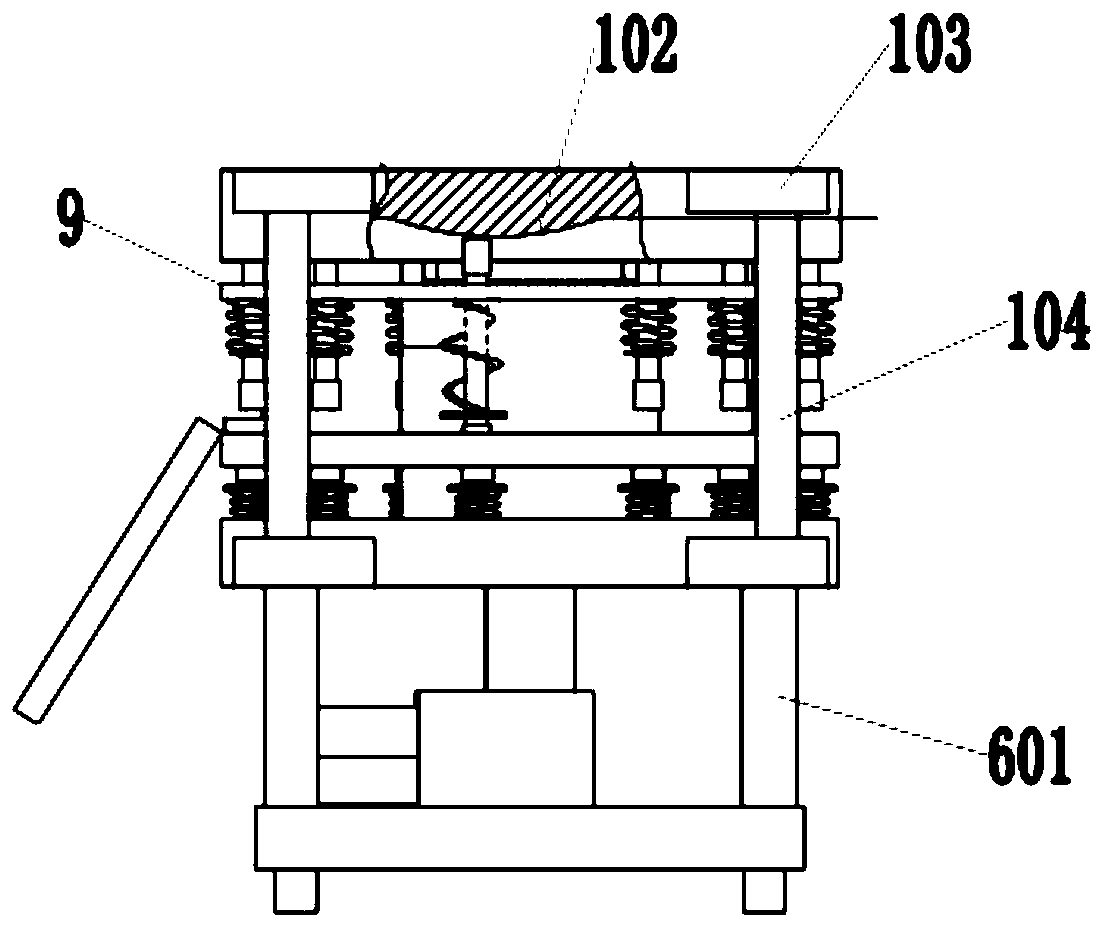

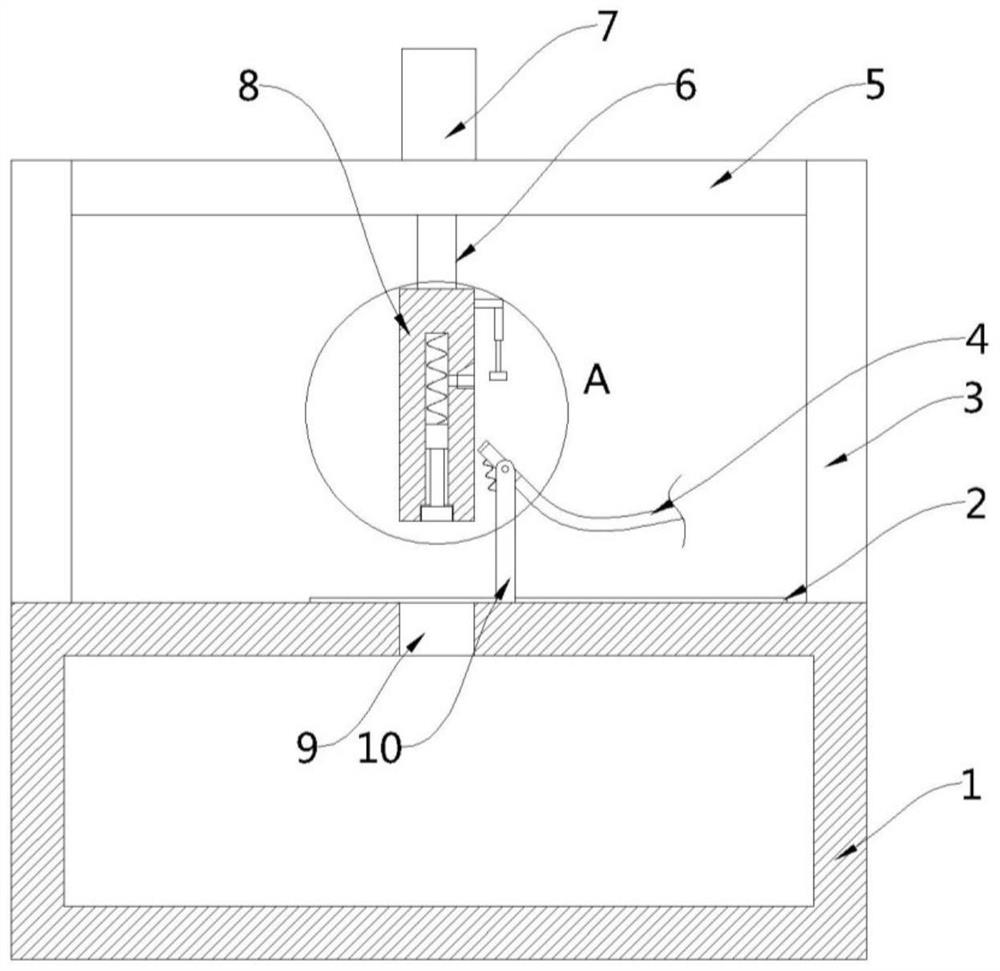

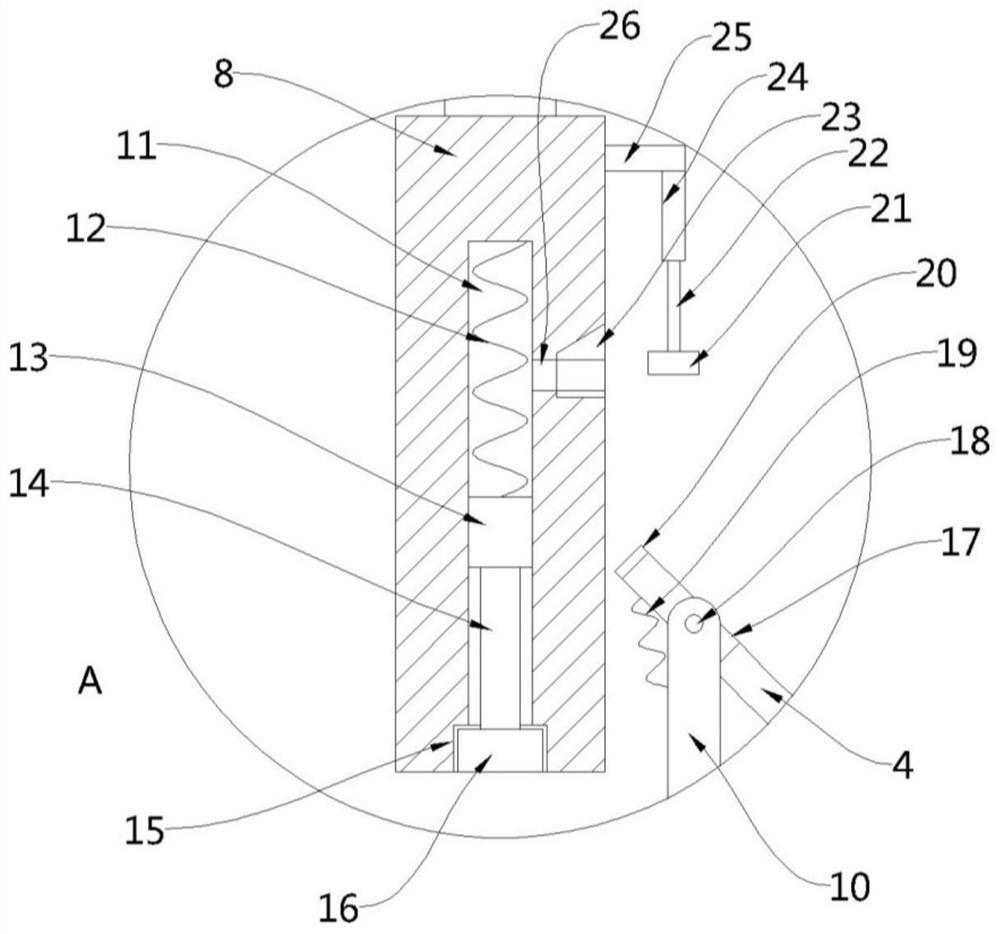

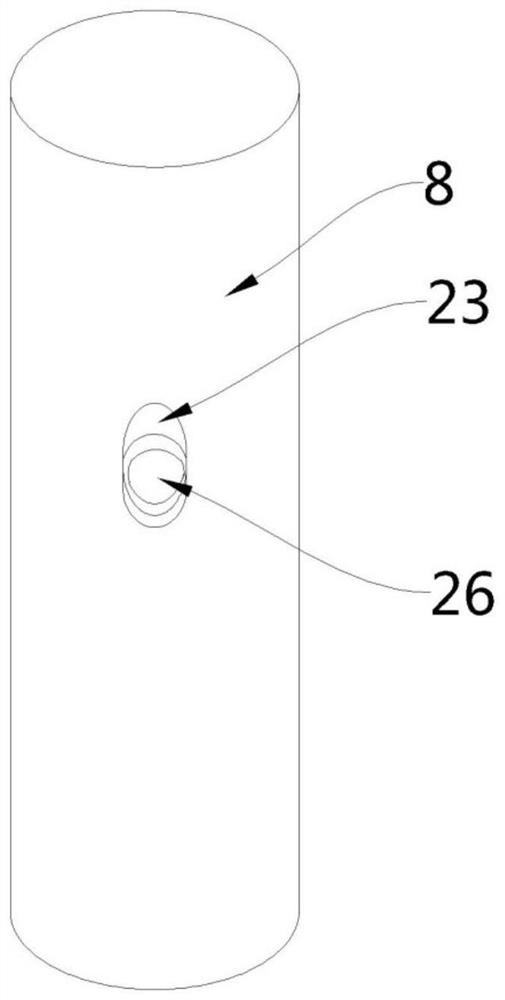

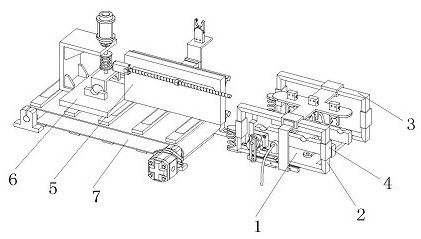

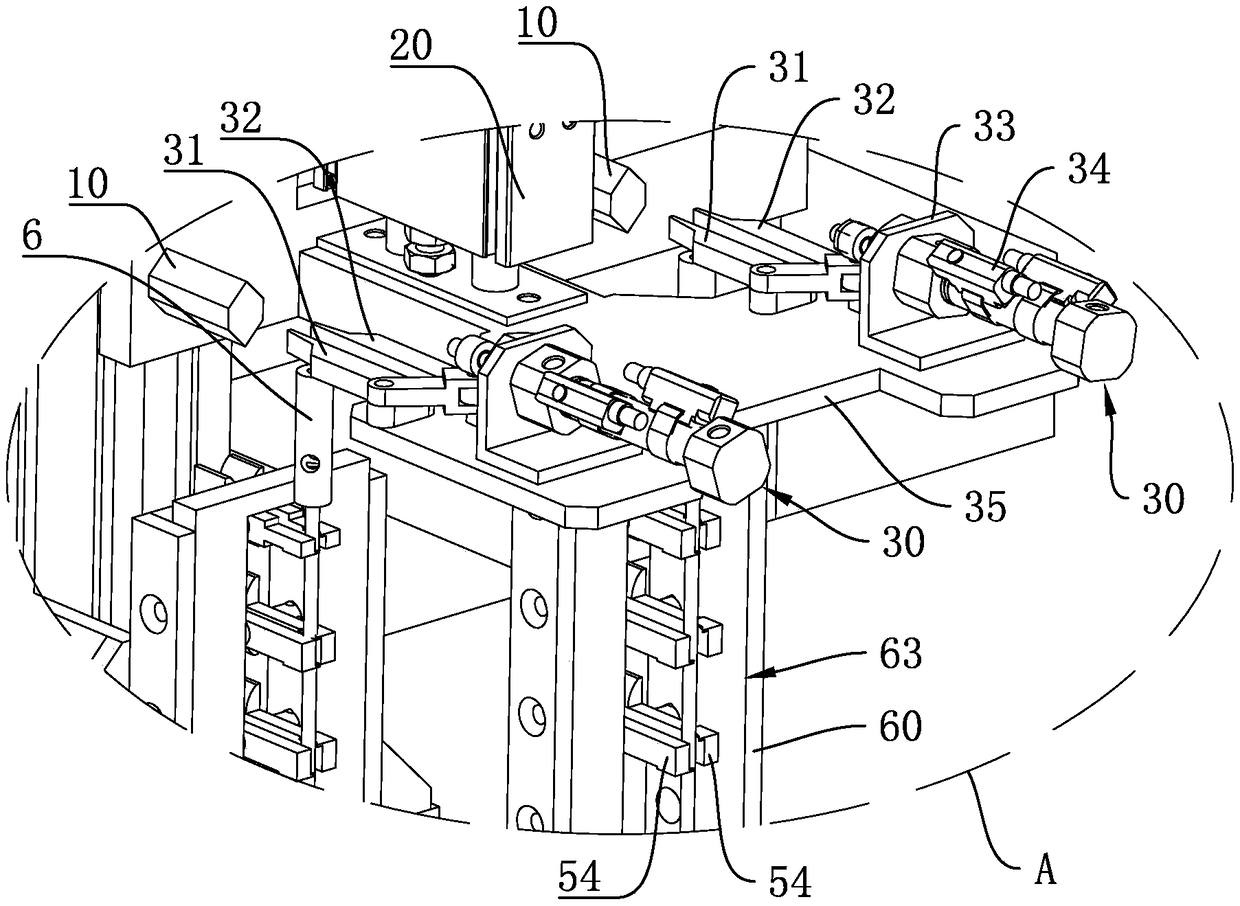

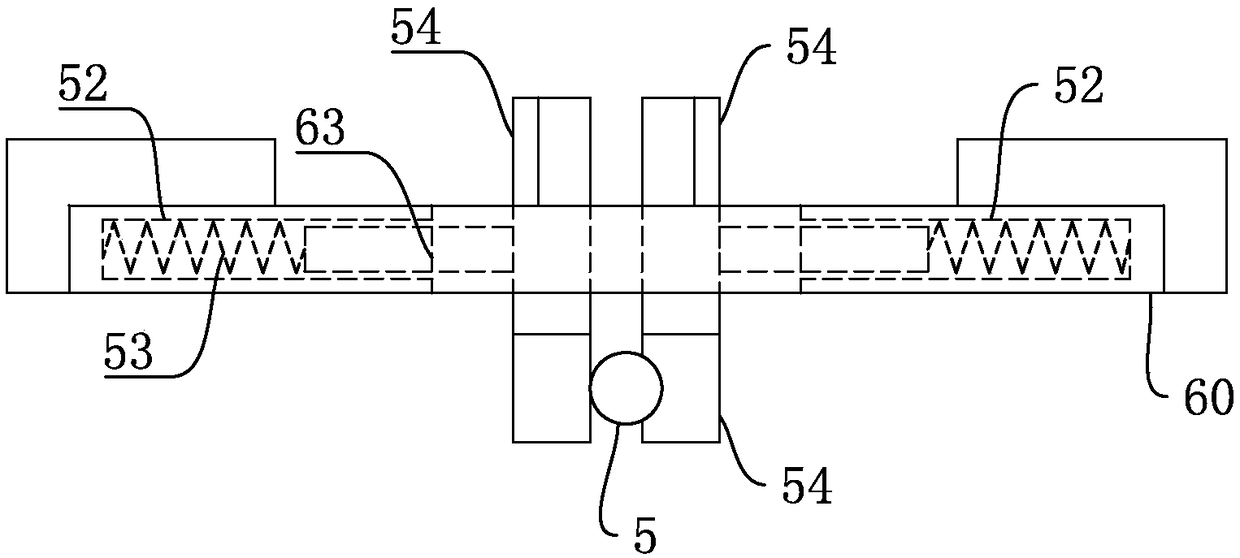

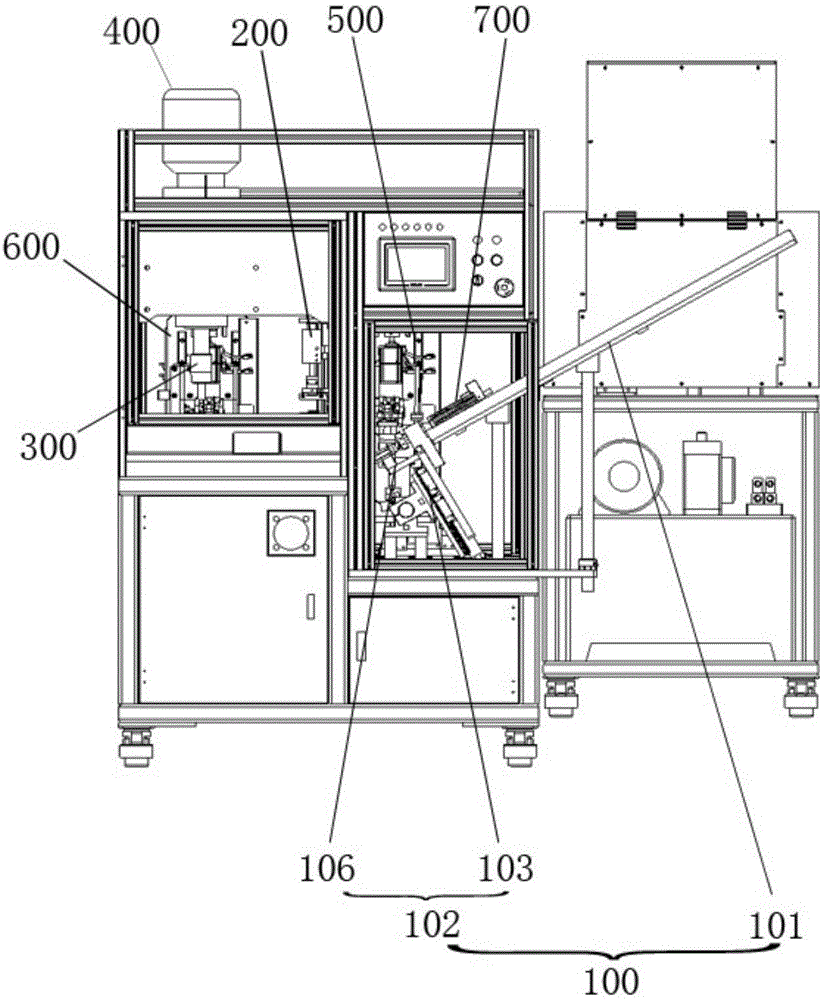

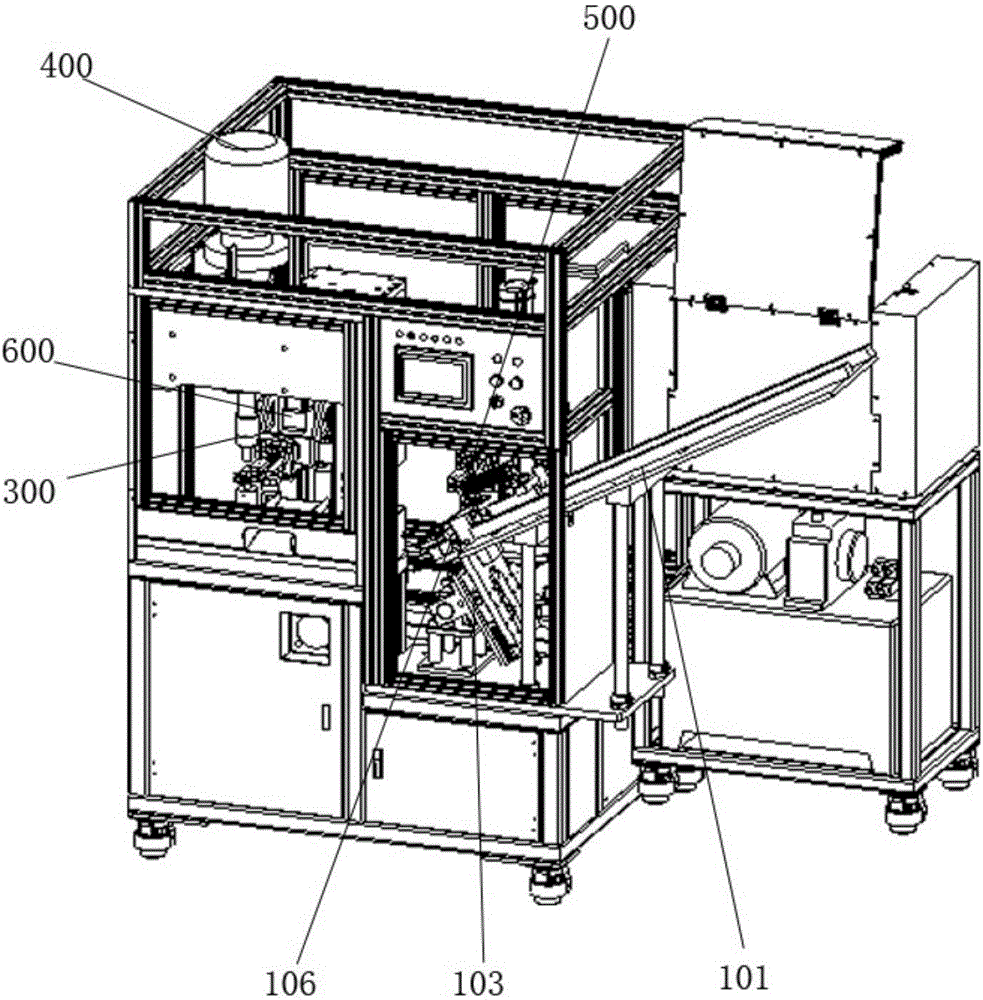

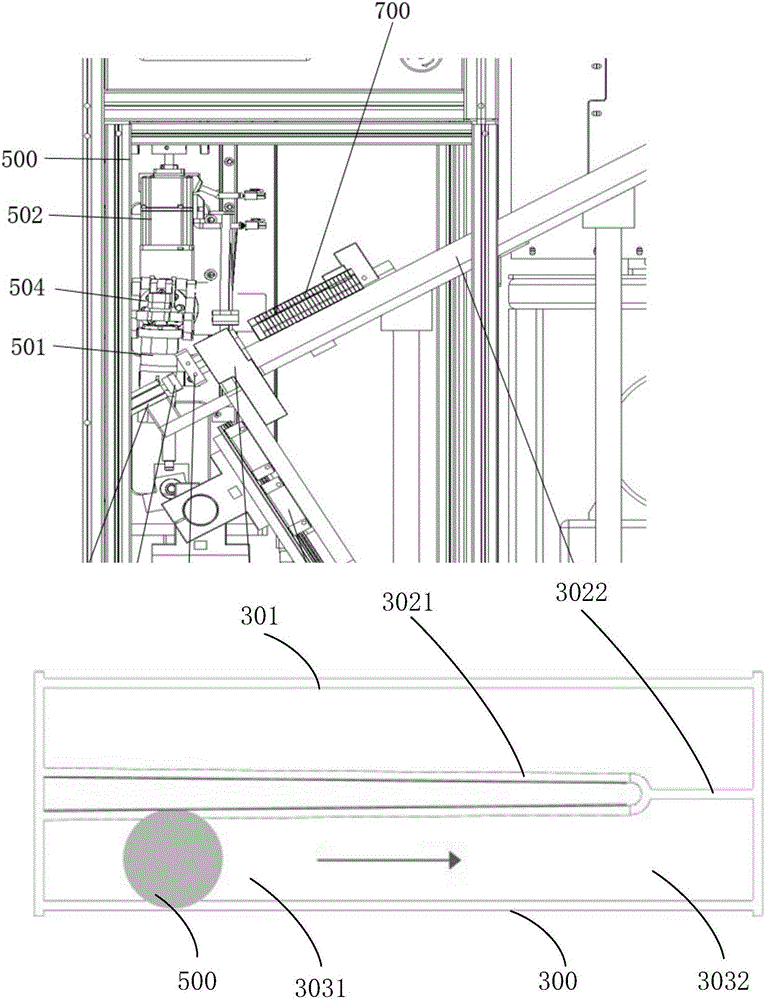

Automatic press-fitting machine of button motor

InactiveCN107803640ARealize automatic nestingIncrease productivityMetal working apparatusConveyor partsEngineeringMechanical engineering

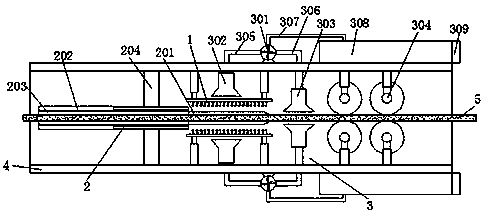

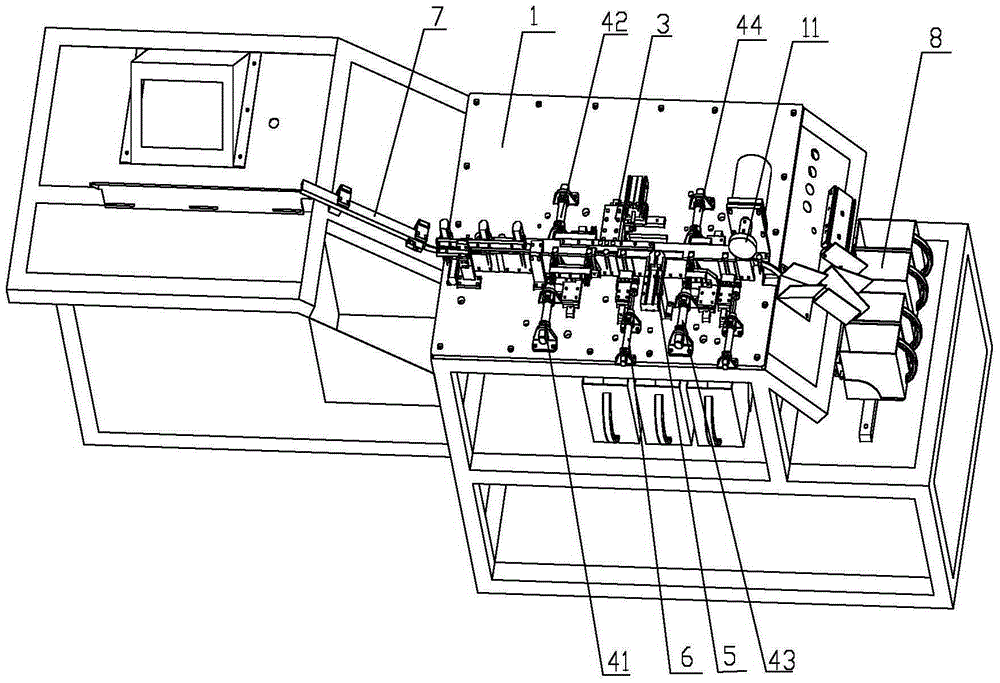

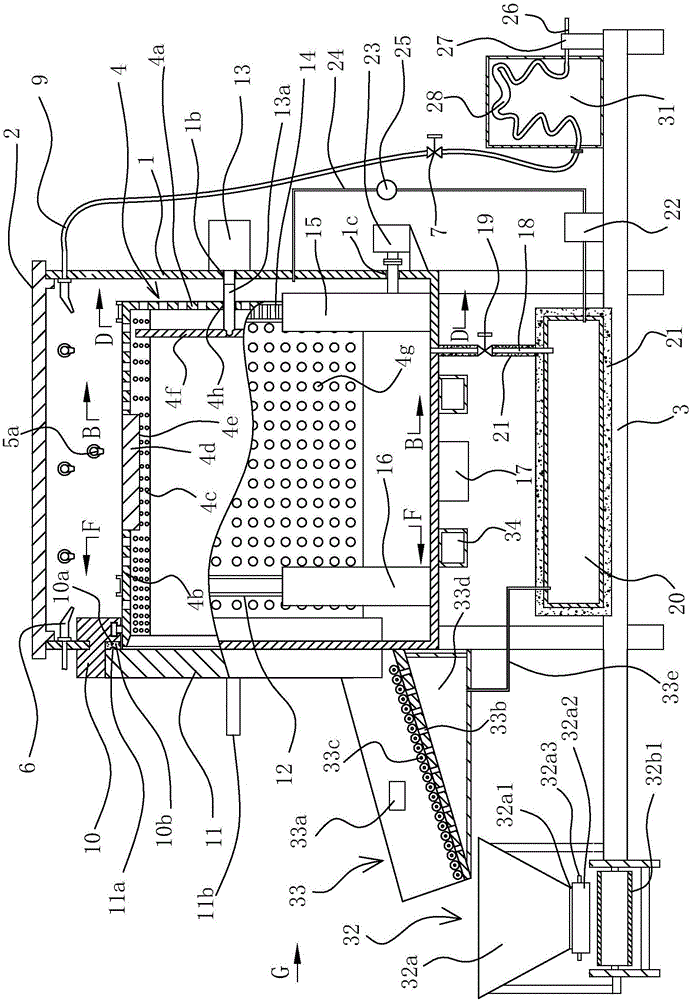

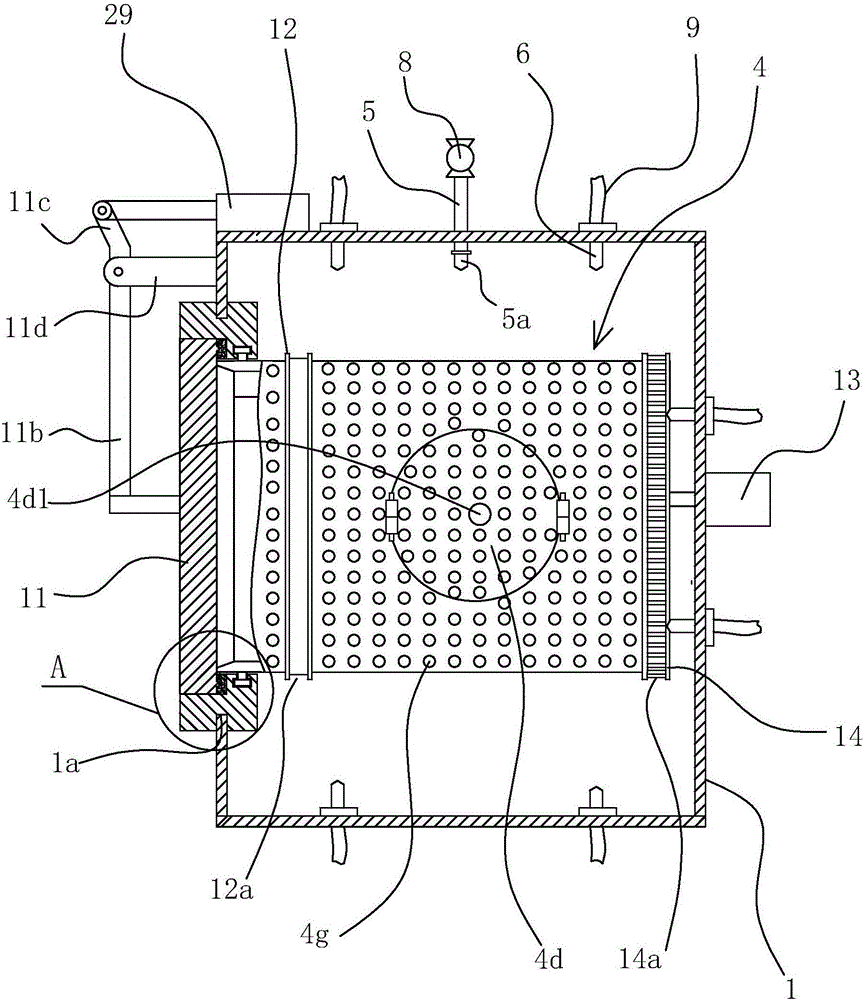

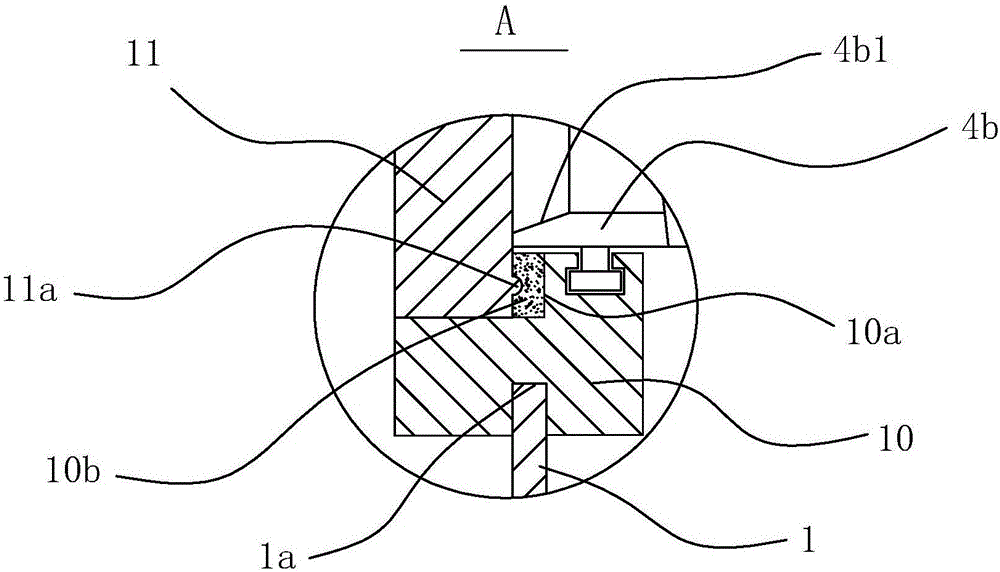

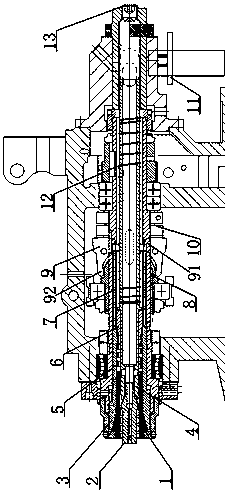

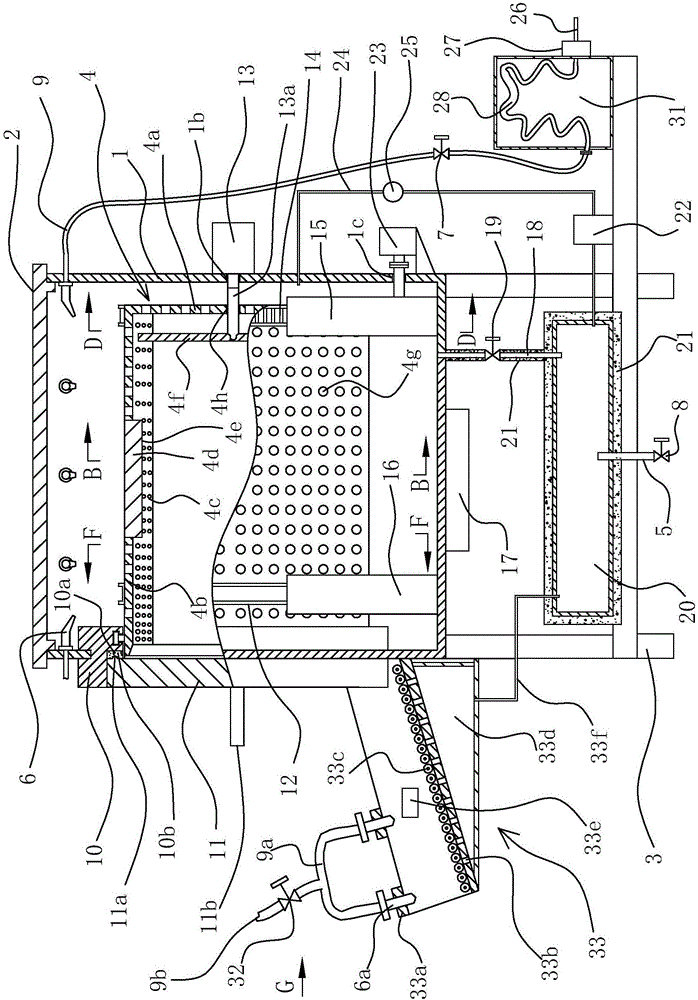

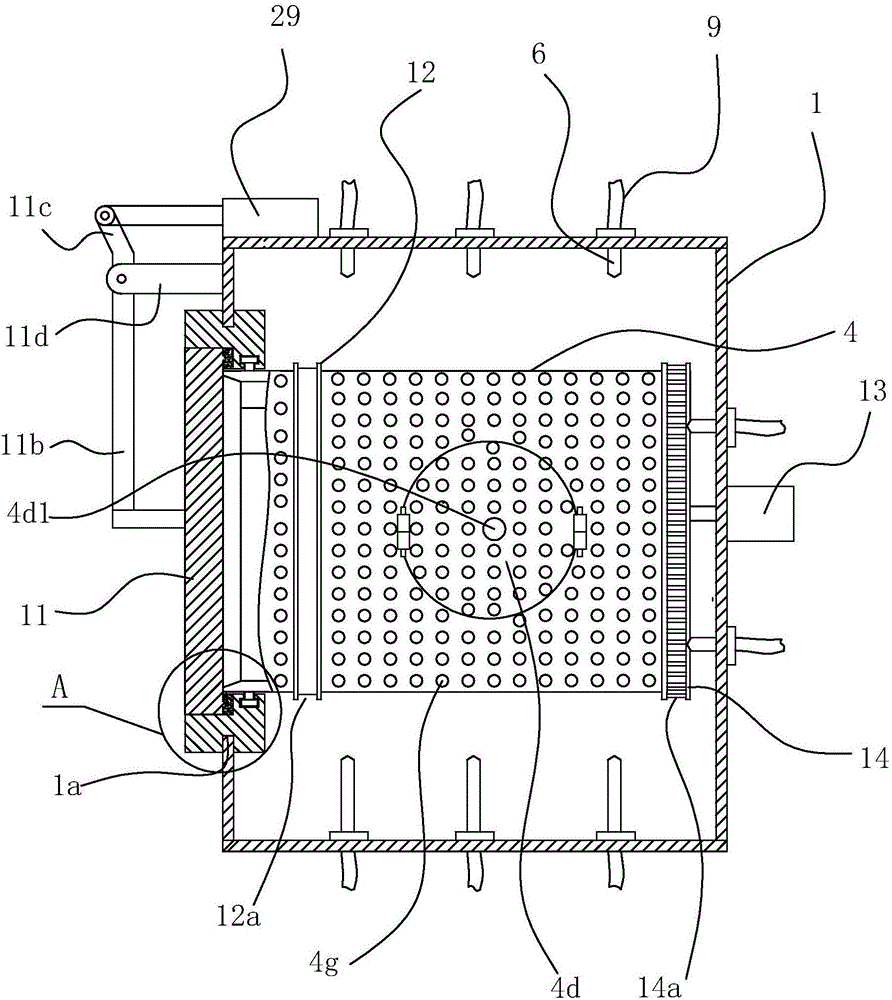

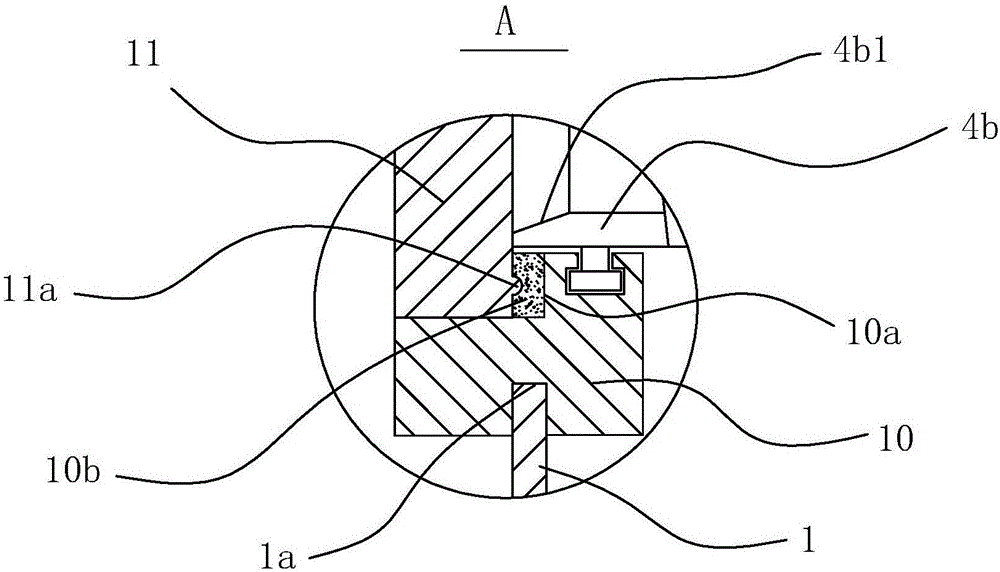

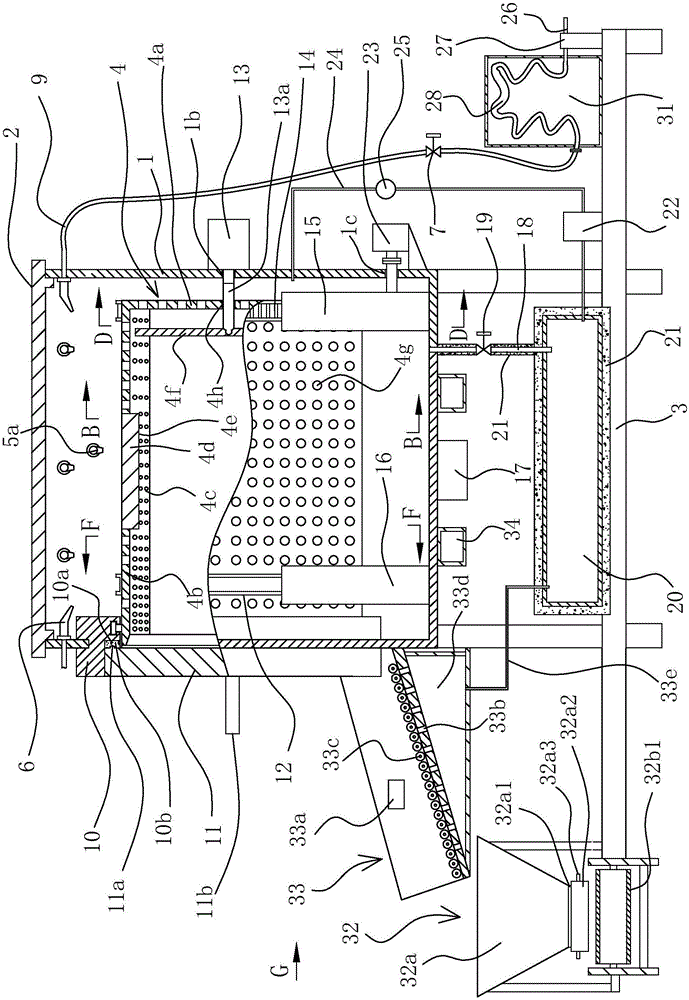

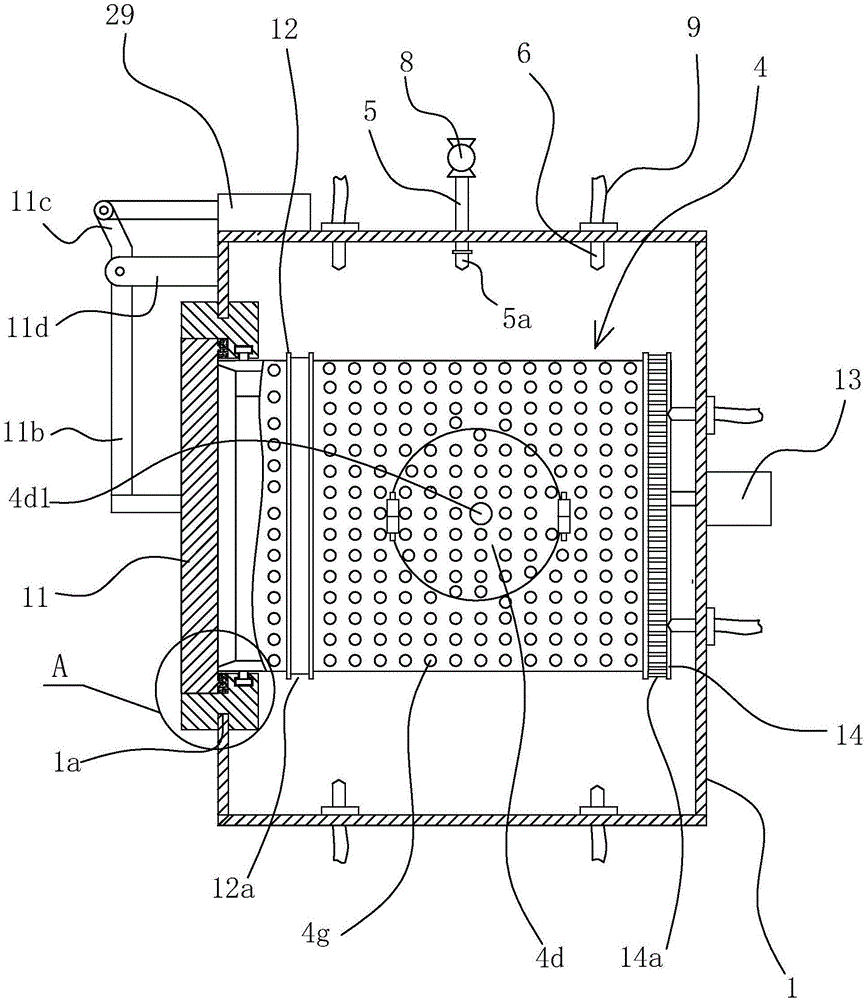

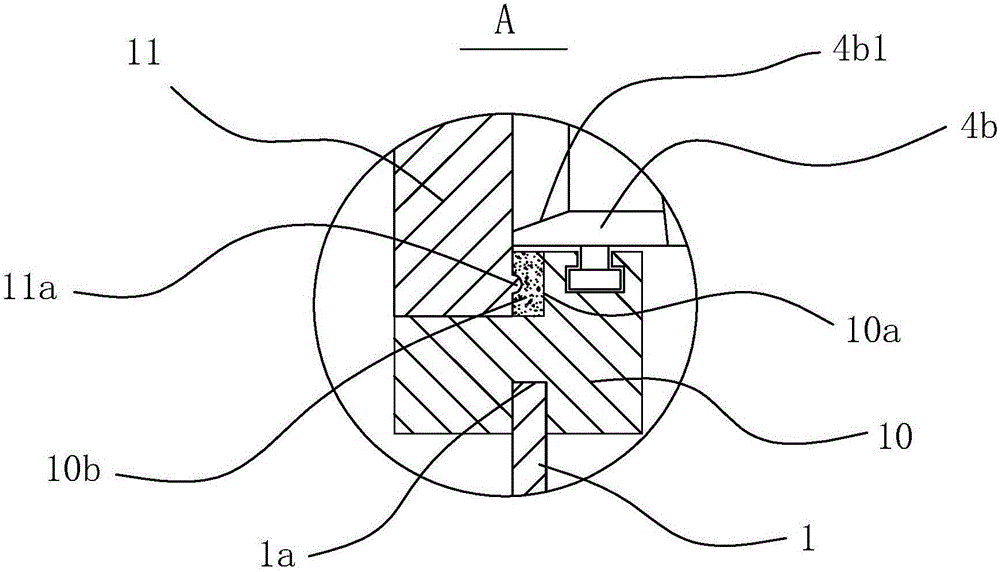

The invention relates to a button motor automatic pressing machine, which includes a frame, on which a feeding mechanism and a pressing mechanism that cooperate with each other are arranged, and the feeding mechanism includes an upper cover arranged on the frame in front of the pressing mechanism The feeding track and the feeding and conveying device set on the right side of the pressing mechanism to cooperate with the feeding track of the upper cover, the feeding carrier of the upper cover is placed on the feeding track of the upper cover, and the right side of the pressing mechanism is provided. Pressing device, the pressing device includes a pressing lifting cylinder vertically arranged on the pressing mechanism, the lower end of the push rod of the pressing lifting cylinder is connected with a pressing seat, and the lower part of the pressing seat is vertically arranged to cooperate with the feeding carrier of the upper cover. The pressing rod of the press-fitting servo motor drives the press-fit lifting seat to slide up and down, and the press-fit lifting seat drives the shell pressing device to cooperate with the carrier, and the upper cover and the bottom shell of the button motor are pressed tightly together. Realize the automatic pressing of the button motor, improve the stability of the product, and improve the production efficiency.

Owner:DONGGUAN UNIV OF TECH

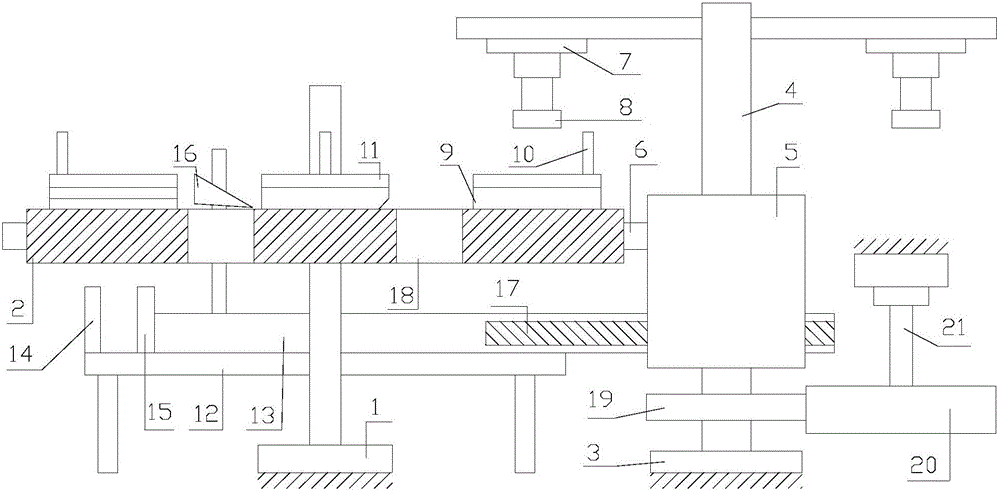

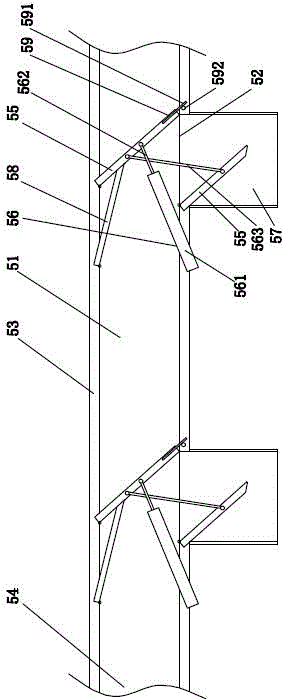

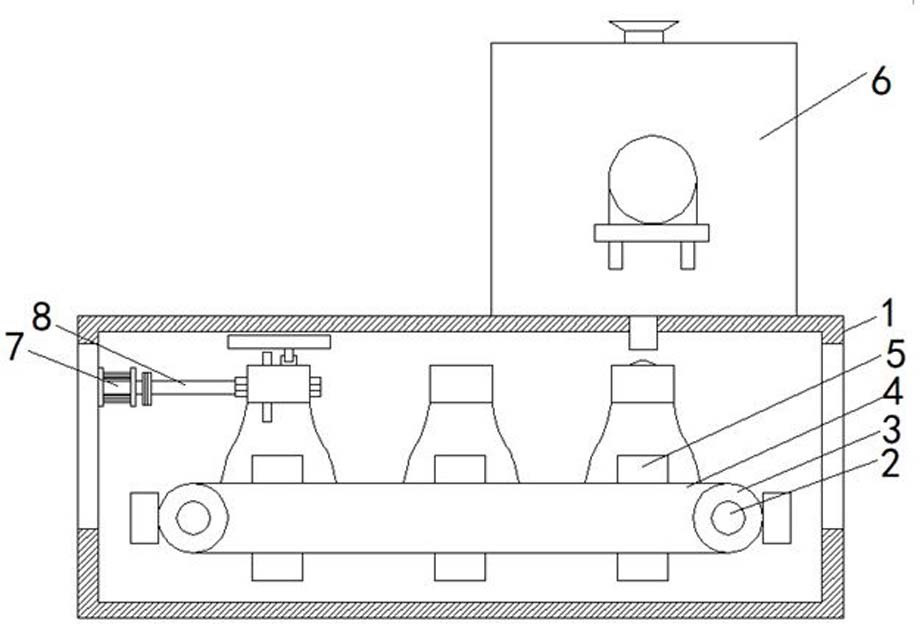

Device capable of continuously performing stamping machining

InactiveCN105750390ARealize automatic nestingFit closelyStripping-off devicesPressesMachine partsMachining

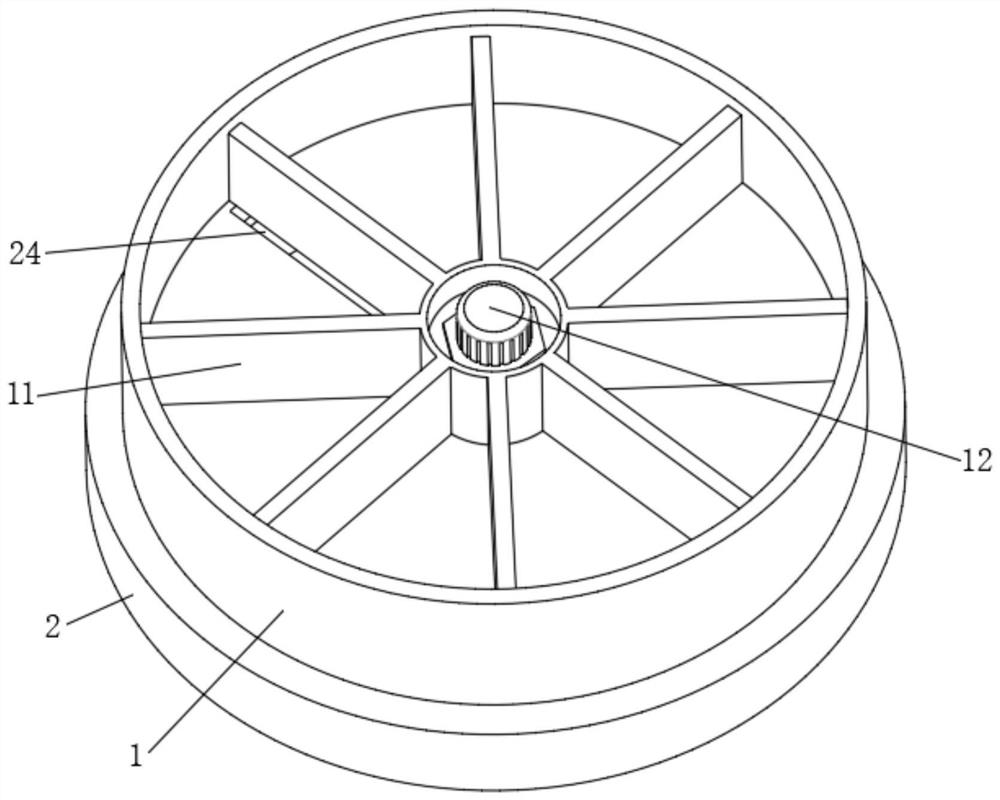

The invention discloses a device capable of continuously performing stamping machining. The device comprises a supporting part and a machining part, wherein the supporting part comprises a bracket, a supporting shaft, a turntable and a plurality of dies; the supporting shaft is mounted on the bracket in a rotating manner, and is vertically arranged; the turntable is mounted on the supporting shaft; a first wheel tooth is arranged on the circumferential surface of the turntable; the plurality of dies are mounted on the turntable, and uniformly surround the supporting shaft; the machining part comprises a support frame, a rotating shaft, a plurality of stamping mechanisms and a driving mechanism; the support frame and the rotating shaft are arranged on one side of the turntable; the rotating shaft is mounted on the support frame in the rotating manner, and is vertically arranged; a second wheel tooth matched with the first wheel tooth is locally arranged on the circumferential surface of the rotating shaft; when the rotating shaft rotates a cycle, the turntable rotates by an angle beta, wherein beta is an included angle of every two adjacent dies and the center of the turntable. The device has good stamping effects and high machining accuracy.

Owner:WUHU HONGFEI MACHINERY CO LTD

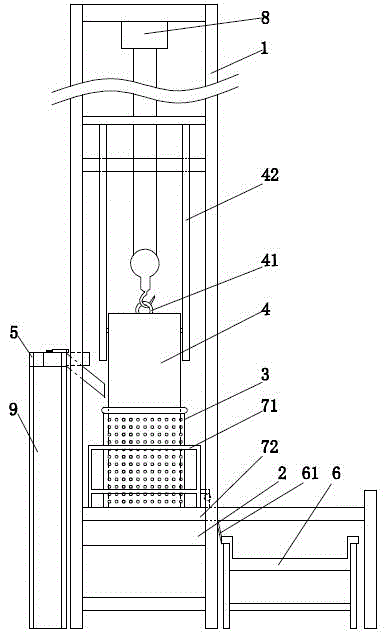

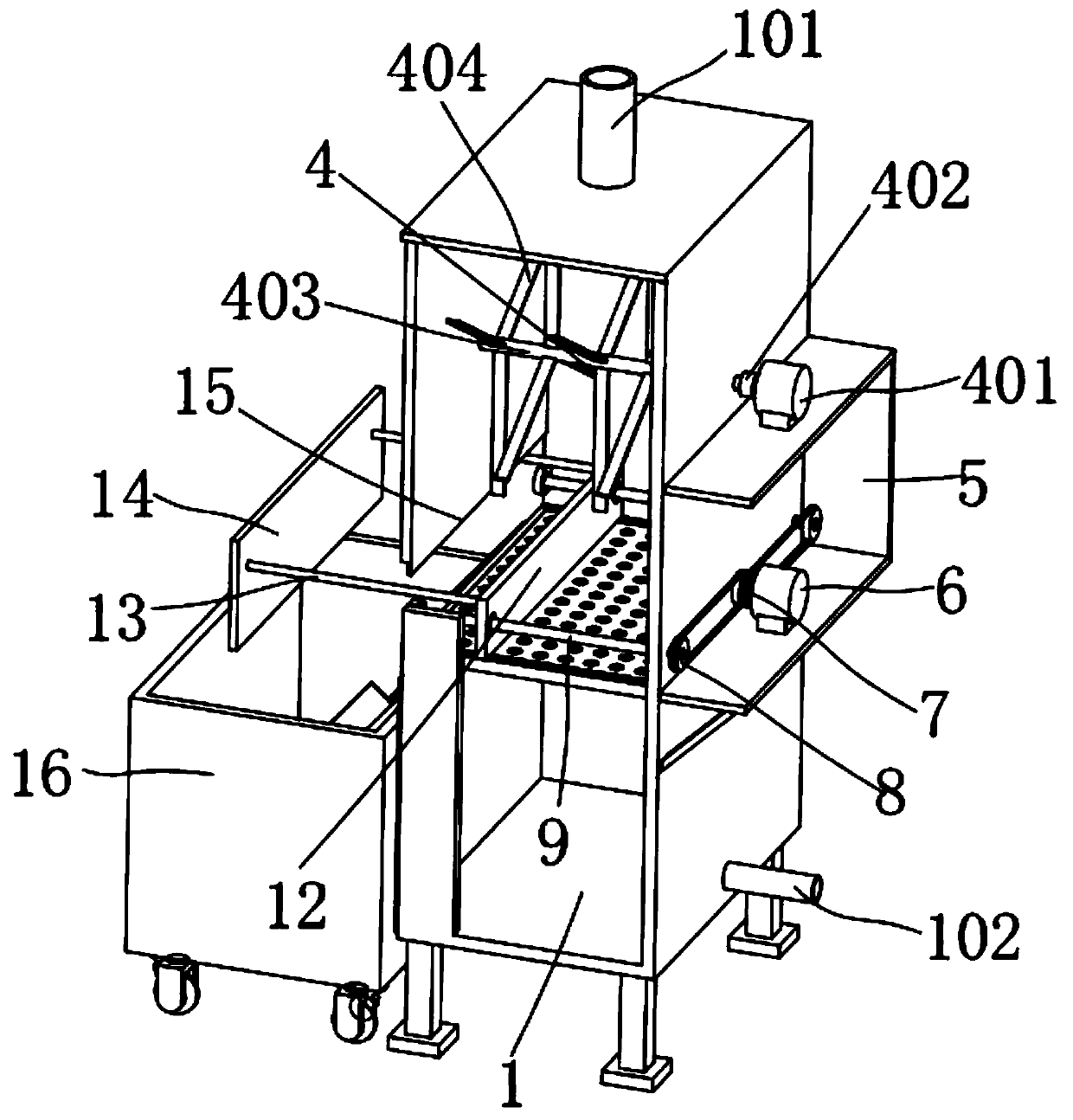

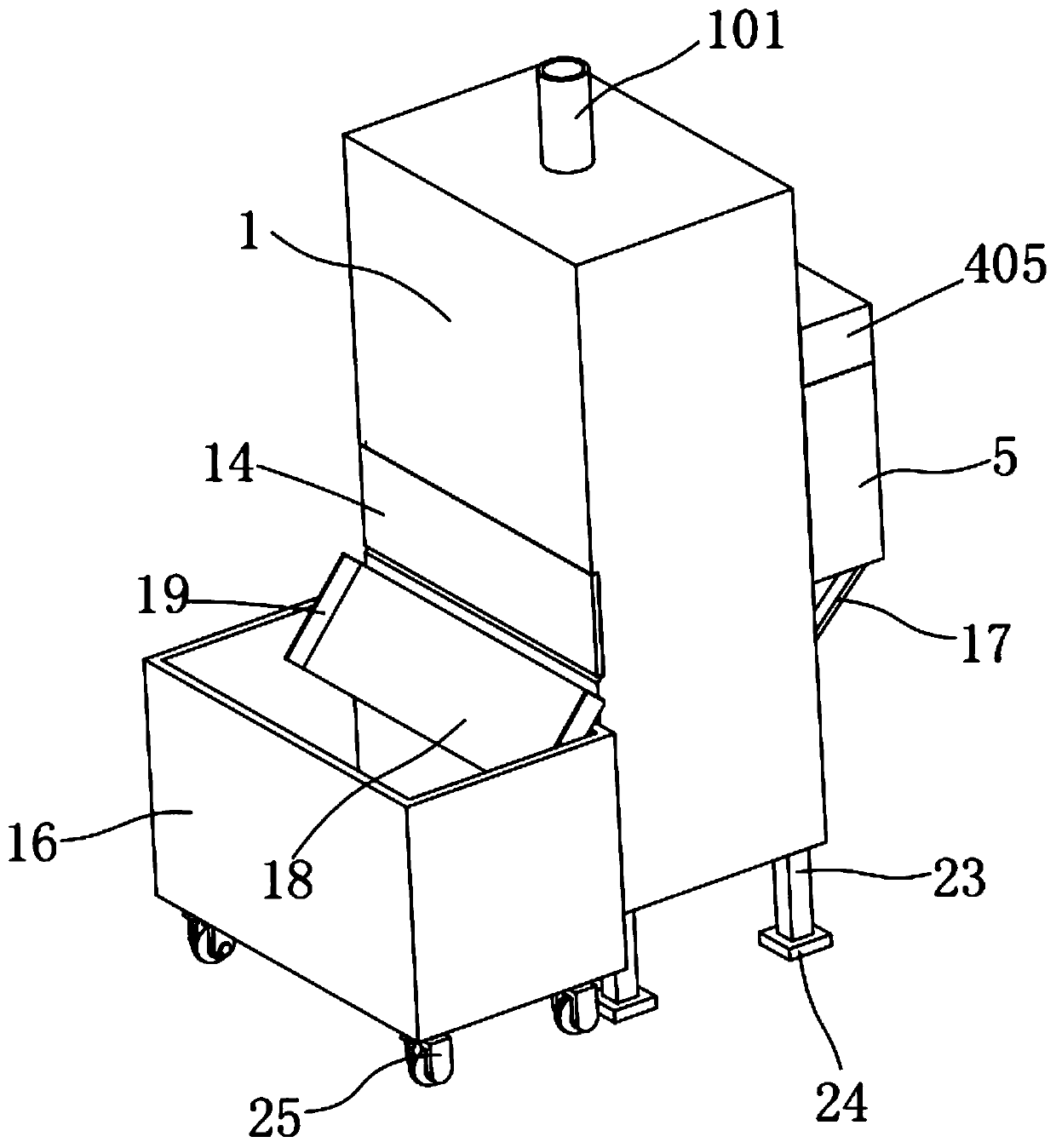

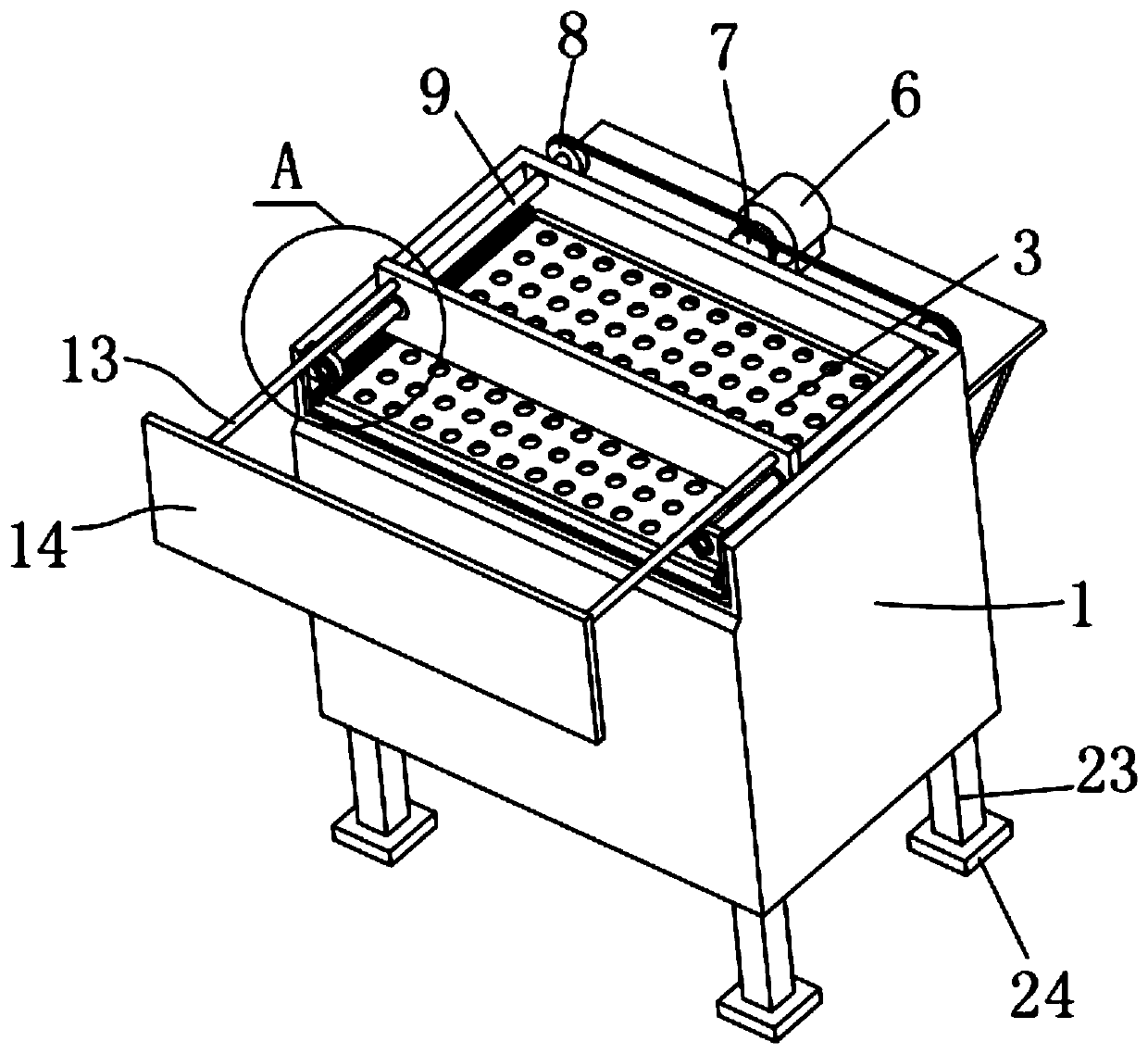

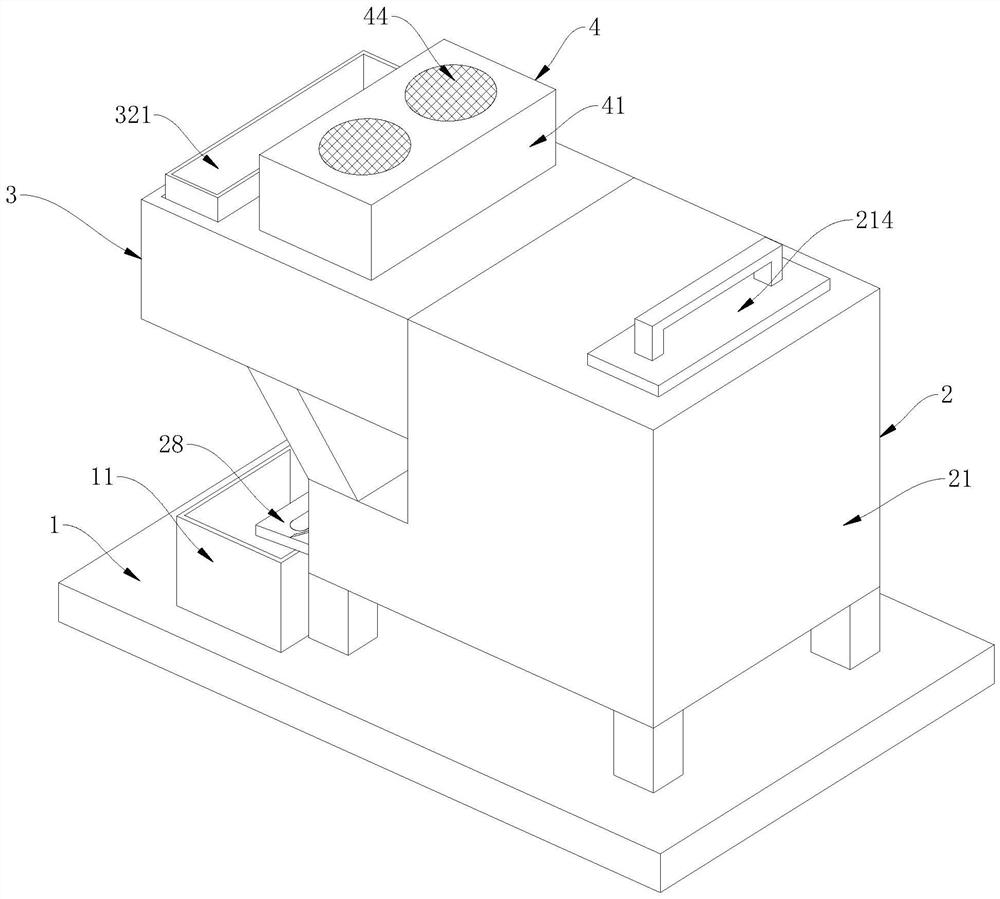

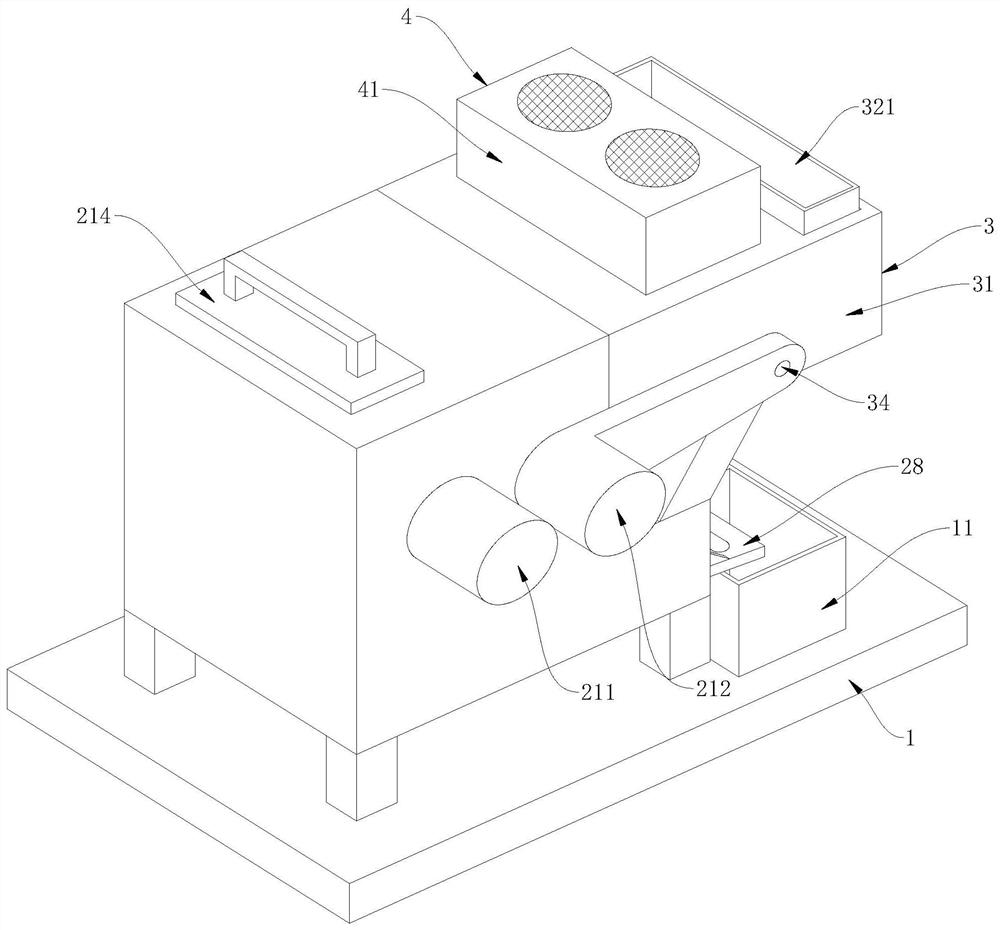

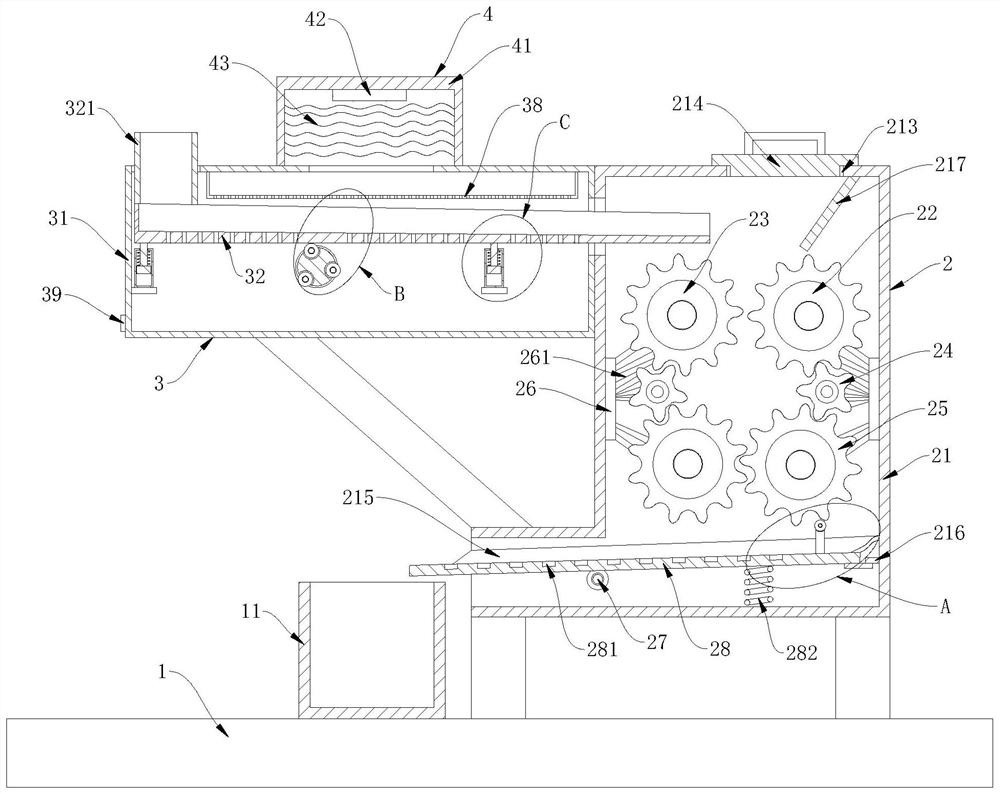

Fabric surface pilling removal equipment

InactiveCN108486815AEfficient removalRealize automatic nestingMechanical cleaningPressure cleaningEngineeringDust collector

The invention provides fabric surface pilling removal equipment which comprises a frame and two groups of pilling removal mechanisms, wherein a fabric is arranged between the two groups of pilling removal mechanisms; the two groups of pilling removal mechanisms are respectively arranged on a frame top plate and a frame bottom plate; each pilling removal mechanism comprises a pilling scraping device, a shearing device and a dust removal device; the pilling scraping device comprises a scraper and two first electric push rods; a plurality of uniformly distributed scraping hooks are arranged on the scraper; the shearing device comprises shear blades, a second electric push rod and a mounting plate; the dust removal device comprises an exhaust fan, a first dust collector, a second dust collector and a lint roller. According to the fabric surface pilling removal equipment disclosed by the invention, the two groups of upper and lower pilling removal mechanisms are used for removing pilling ontwo sides of the fabric, the pilling on two sides of the fabric can be simultaneously eliminated, the pilling removal mechanisms comprises the pilling scraping devices, the shearing devices and the dust removal devices, automatic discharging is realized, manual discharging by a user is avoided, and discharging smoothness is realized.

Owner:JIANGSU DANMAO TEXTILE

Automatic discharging method

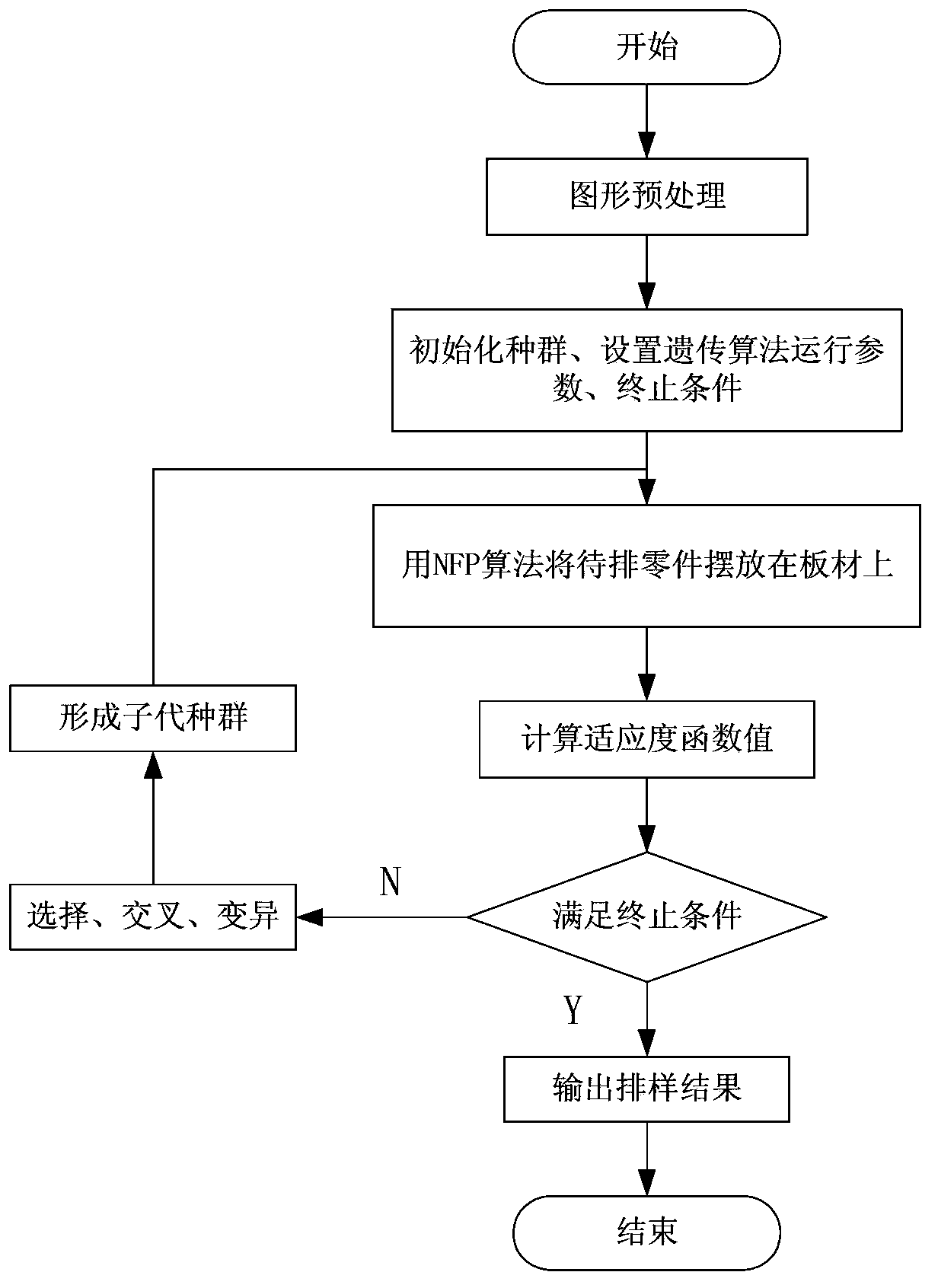

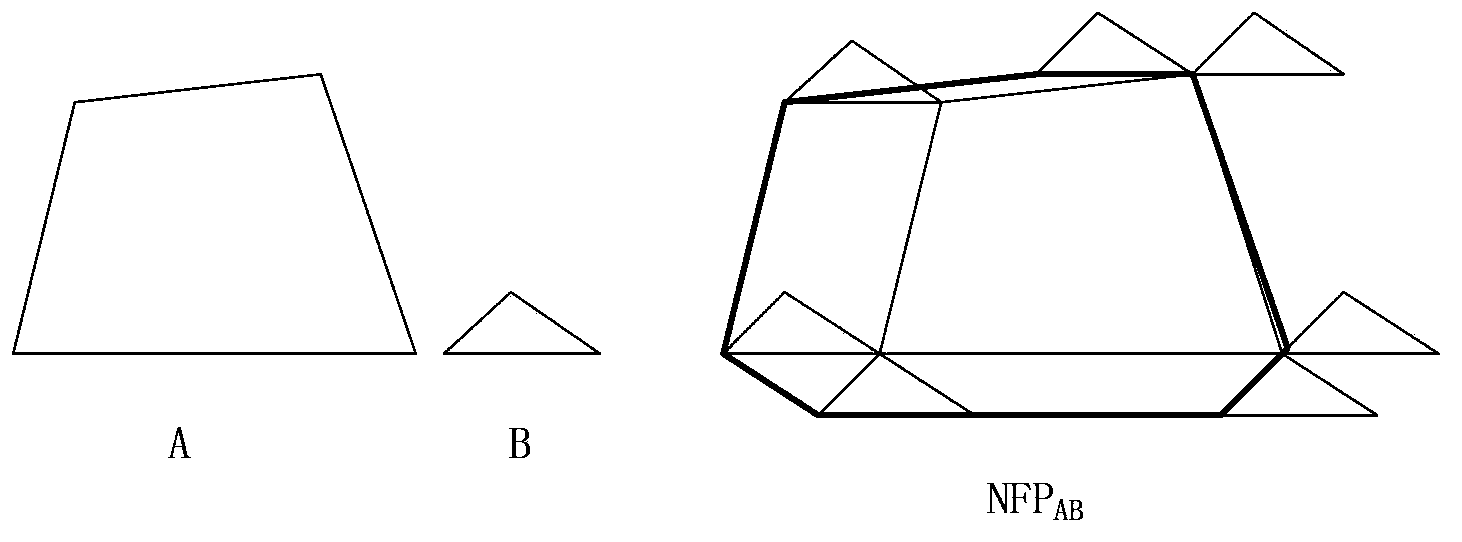

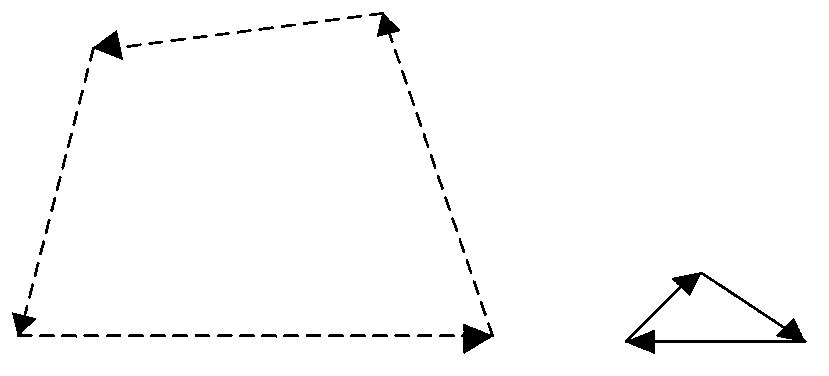

InactiveCN104281722AImprove automatic nesting efficiency andIncrease profitGenetic modelsSpecial data processing applicationsMutationMathematical model

The invention discloses an automatic discharging method which comprises the following steps that a genetic algorithm is adopted to set up an algorithm mathematical model, a drawing of parts to be discharged is loaded, and the parts to be discharged are preprocessed; the genetic algorithm is subjected to initialization which comprises group initialization and setting of operation parameters and end conditions of the genetic algorithm; the parts to be discharged are placed on plates according to a gene sequence in the algorithm mathematical model, and the fitness values of all individuals in a group are calculated; judgment of the end conditions is carried out, if the end conditions are not met, the group is subjected to selection operation, crossover operation and mutation operation to obtain a next-generation group, and the last step is executed again; if the end conditions are met, the optimal solution is output. According to the method, automatic discharging is achieved through effective combination of the genetic algorithm and the computer graphics, the sequence and the placement angle of the parts to be discharged can be generated randomly through the genetic algorithm, the parts to be discharged are placed on the plates through an algorithm of no-fit polygon, and automatic discharging efficiency and the utilization rate of the plates are improved.

Owner:GUANGZHOU INST OF ADVANCED TECH CHINESE ACAD OF SCI

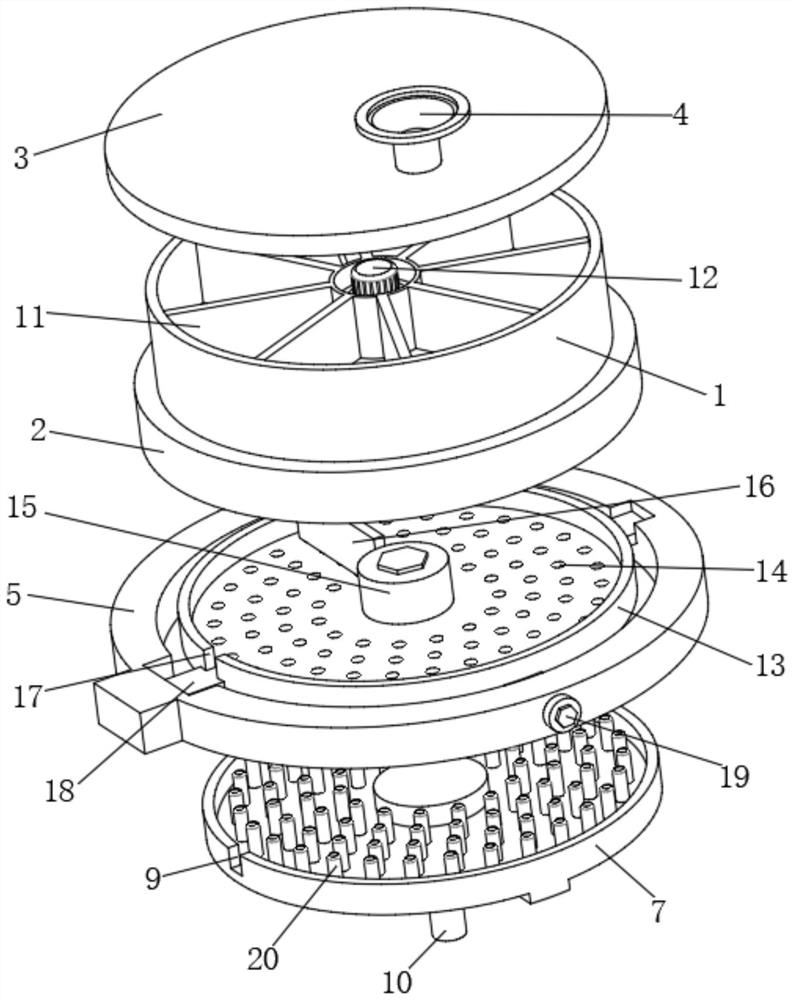

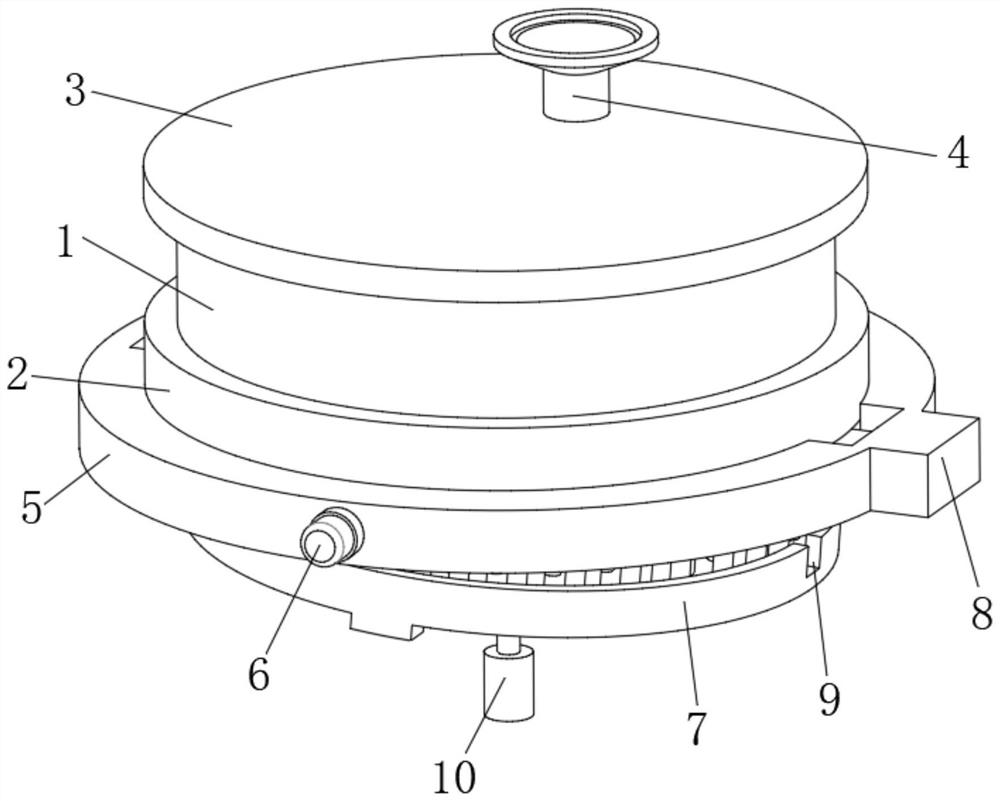

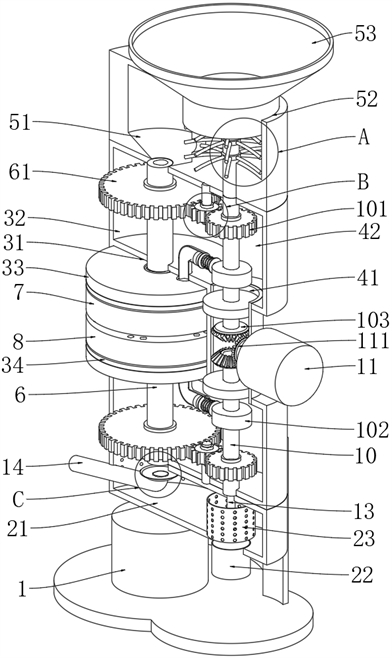

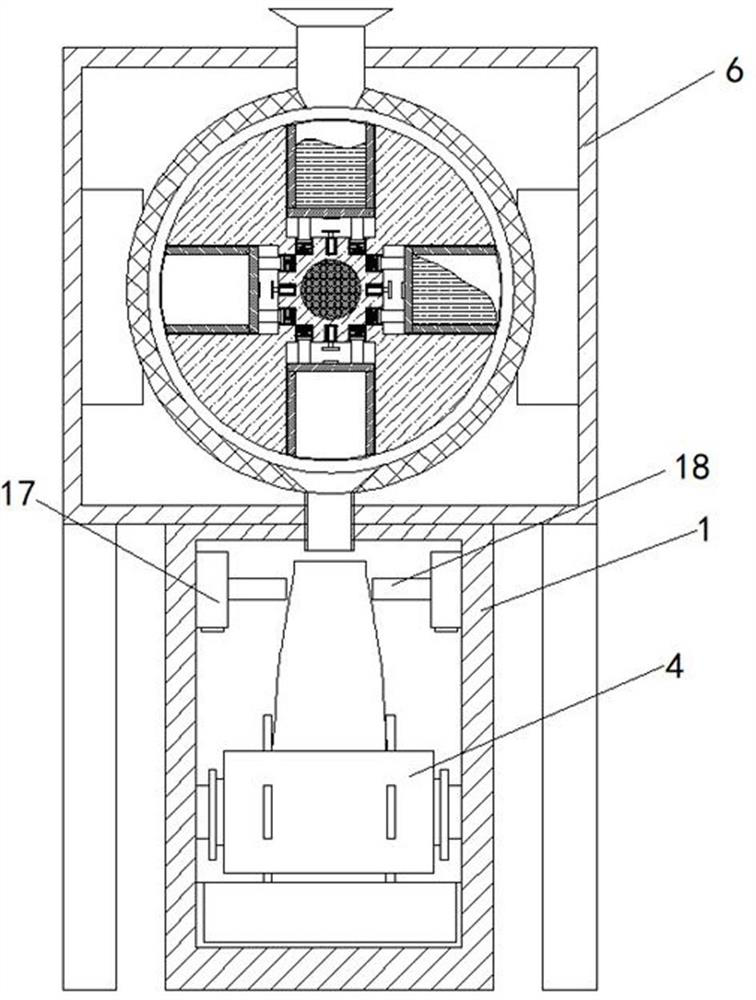

Tablet press for producing tablets

The invention discloses a tablet press for producing tablets. The tablet press comprises a pressure disc, the die punching rods, a die pressing rod, a feeder, a tray, a base and a motor. The upper endof the base is connected with the tray, the upper end of the tray is connected with the pressure disc, and a pressing mold disc is arranged between the pressing disc and the tray; the motor is arranged at the upper end of the base and is connected with the die pressing disc through a rotating shaft, an upper rotating disc is arranged between the pressing die disc and the pressing disc and is connected with the rotating shaft, and a lower rotating disc is arranged between the pressing die disc and the tray and is connected with the rotating shaft; the punching die rods are arranged on the upper side and the lower side of the pressing die disc; the punching die rods are arranged at the two sides of the pressing die disc, the punching die rod arranged above the pressing die disc penetrates through the upper rotating disc to be connected with the pressing disc in a sliding manner, and the punching die rod arranged below the pressing die disc penetrates through the lower rotating disc to be connected with the tray in the rotating manner; a pressing die hole is formed on the pressing die disc, the feeder matched with the pressing die hole is arranged at one side of the tray, and a discharging sliding way is arranged at one side of the pressing die disc.

Owner:SHANDONG KANGFUSEN BIOTECH CO LTD

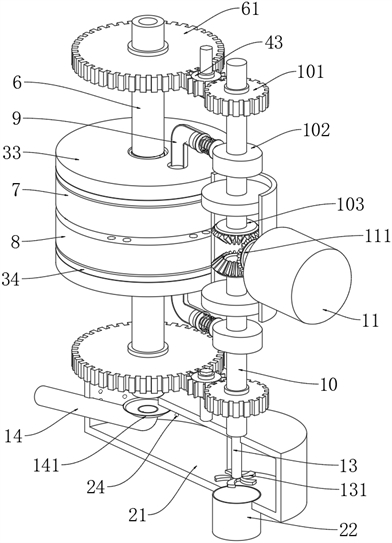

System capable of stamping work-pieces continuously

InactiveCN105817515ARealize automatic nestingRealize receiptShaping toolsMetal-working feeding devicesEngineeringGear tooth

The invention discloses a system capable of continuously punching workpieces, which comprises a bracket, a support wheel, a plurality of molds, a mounting frame, a rotating shaft, a running wheel, a first punching mechanism, a second punching mechanism, a driving mechanism, a position sensor, a control The support wheel is installed on the bracket in rotation, the support wheel is set horizontally, and the circumferential surface of the support wheel is provided with the first gear teeth in continuous distribution; multiple molds are installed on the support wheel, and the rotation of the multiple molds on the support wheel The center is evenly distributed, and the included angle between two adjacent molds and the center of rotation of the supporting wheel is β; the rotating shaft is placed on one side of the supporting wheel, and the rotating shaft is connected to the mounting frame in rotation, the rotating shaft is set vertically, and the rotating wheel is installed on the rotating shaft , the axis of the runner coincides with the axis of the rotating shaft, the situation on the circumferential surface of the runner is provided with the second gear teeth matched with the first gear teeth, and the rotation angle of the support wheel is β every time the runner rotates one cycle. The invention has high processing effect and high processing precision.

Owner:WUHU HONGFEI MACHINERY CO LTD

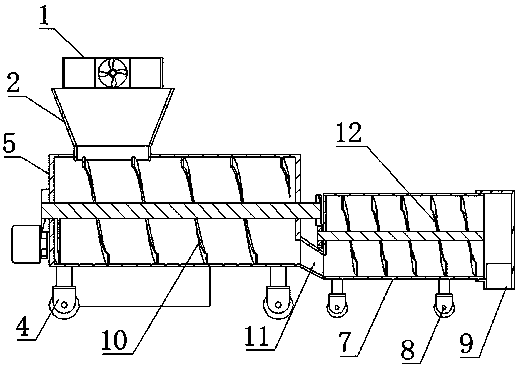

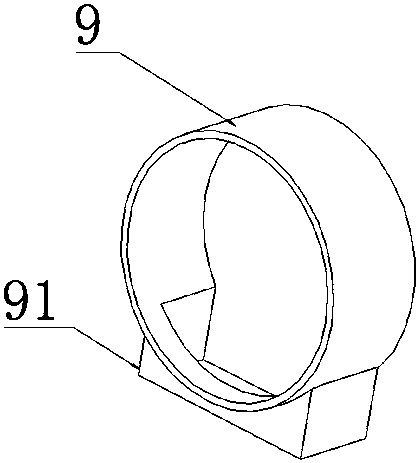

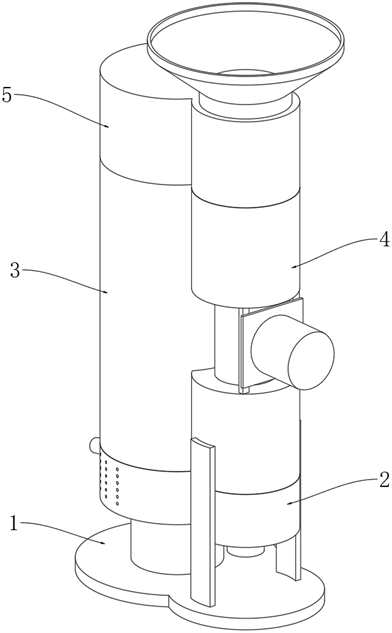

Injection molding machine with material sorting structure at feeding port and use method of injection molding machine

InactiveCN113263690AEfficient sortingRealize automatic feedingSievingScreeningEngineeringInjection molding machine

The invention relates to the technical field of feeding of injection molding machines, in particular to an injection molding machine with a material sorting structure at a feeding port and a using method of the injection molding machine. The injection molding machine comprises a feeding frame, wherein a cover plate with a feeding hopper is arranged at the upper end of the feeding frame, and multiple sets of fan-shaped rotating plates which are rotationally installed and distributed in a circumferential array manner are arranged in an inner cavity of the feeding frame; and a fixed circular ring frame is arranged at the lower end of the feeding frame, and a rotating sieve plate for limiting the rotating angle is arranged in an inner cavity of the fixed circular ring frame. The injection molding machine has the beneficial effects that the fan-shaped rotating plates are arranged, so that the feeding amount is controlled, then raw materials are efficiently sorted through cooperation of a scraping plate and a screening plate, and the purpose of automatic feeding is achieved in cooperation with an obliquely-arranged blanking disc; and by arranging the rotary sieve plate, the purpose of ejection cleaning is achieved through limiting rotation when sieve holes are cleaned, the purpose of automatic discharging is achieved through angle inclination of the sieve plate during cleaning, and the cleaning efficiency of the sieve plate is greatly improved.

Owner:王建青

Concentration method in production process of ferment cordyceps sinensis fungus powder

ActiveCN108905240ALow boiling pointPipeliningEvaporator accessoriesEvaporator regulation/controlDiaphragm pumpEnrichment methods

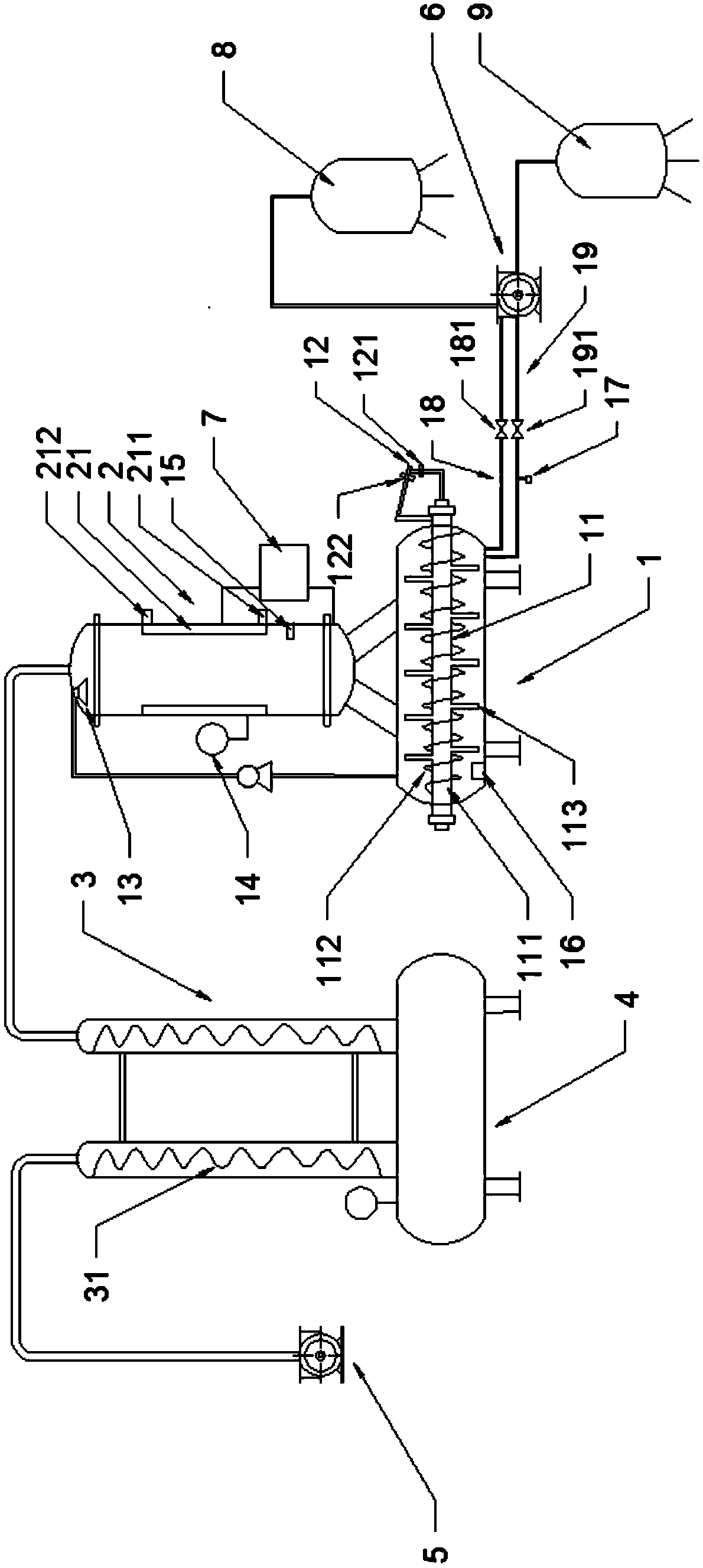

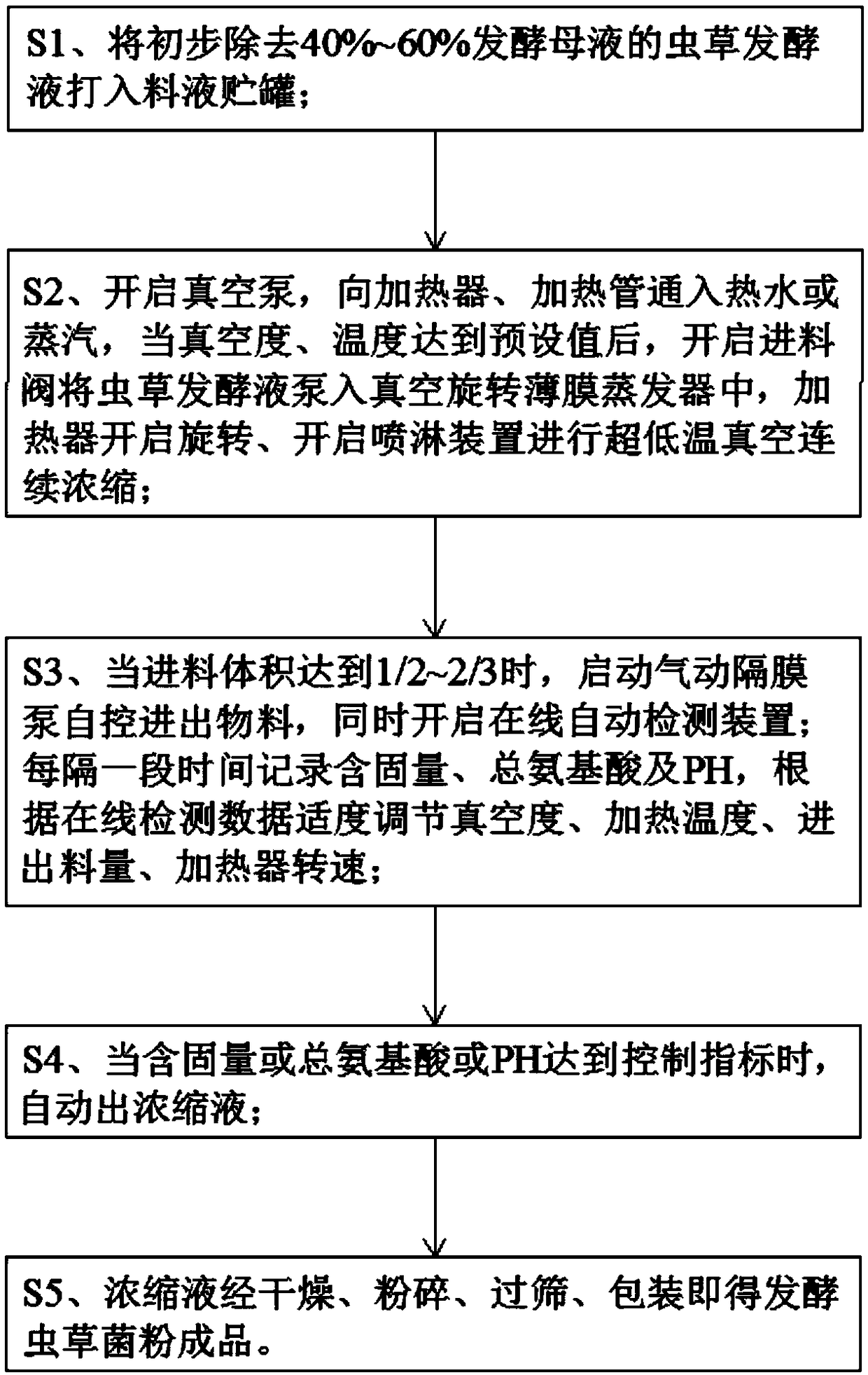

The invention provides a concentration method in the production process of ferment cordyceps sinensis fungus powder. The method comprises the following steps: S1, injecting a cordyceps sinensis fermenting liquid which is subjected to the removal of 40%-60% of a fermenting mother liquid into a liquid storage tank; S2, turning on a vacuum pump, introducing hot water or water vapor into a heater anda heating pipe, pumping the cordyceps sinensis fermenting liquid into a vacuum rotary film evaporator when the vacuum degree and the temperature reach preset values, starting the rotation of the heater, and turning on a spraying device to carry out ultralow-temperature vacuum continuous concentration; S3, turning on a pneumatic diaphragm pump to automatically control the material feeding and discharging when the volume of the fed material reaches 1 / 2-2 / 3, simultaneously turning on an online automatic detecting device, recording the solid content, the total amino acids and the pH value at regular intervals, and moderately adjusting various concentration technical parameters according to the online detected data; S4, when the solid content or the total amino acids or the pH values reach thecontrol indexes, automatically discharging a concentrated liquid; and S5, drying the concentrated liquid, carrying out crushing, sieving and packaging to obtain a finished product of the ferment cordyceps sinensis fungus powder. The product provided by the invention has high quality and effective components of the product are preserved greatly.

Owner:JIANGXI GUOYAO PHARMA LLC

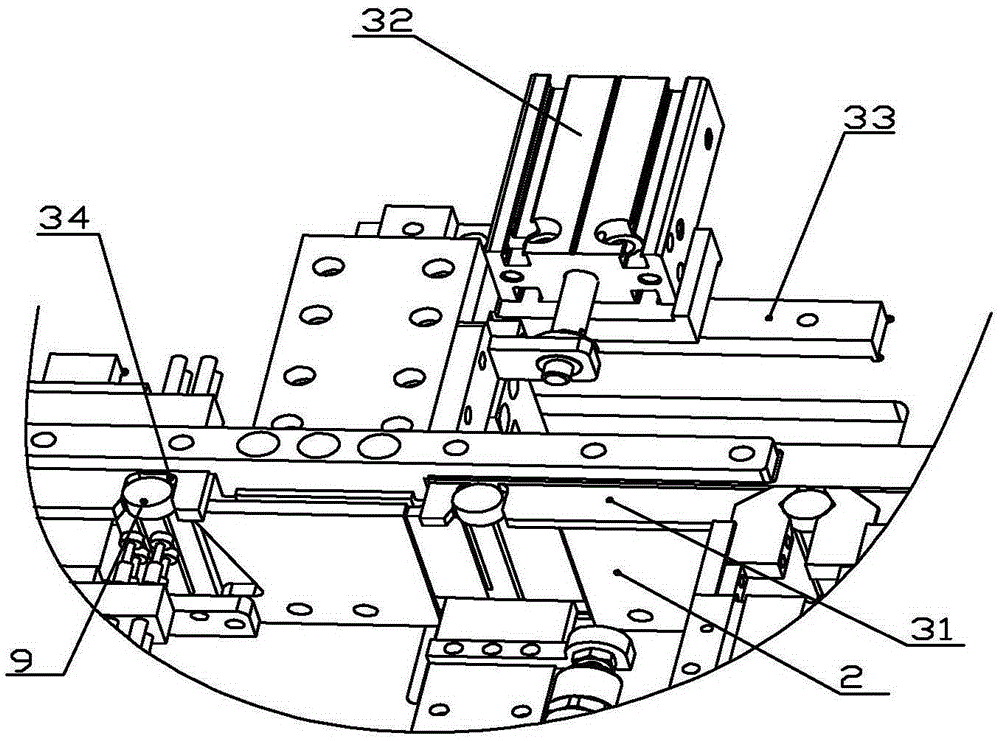

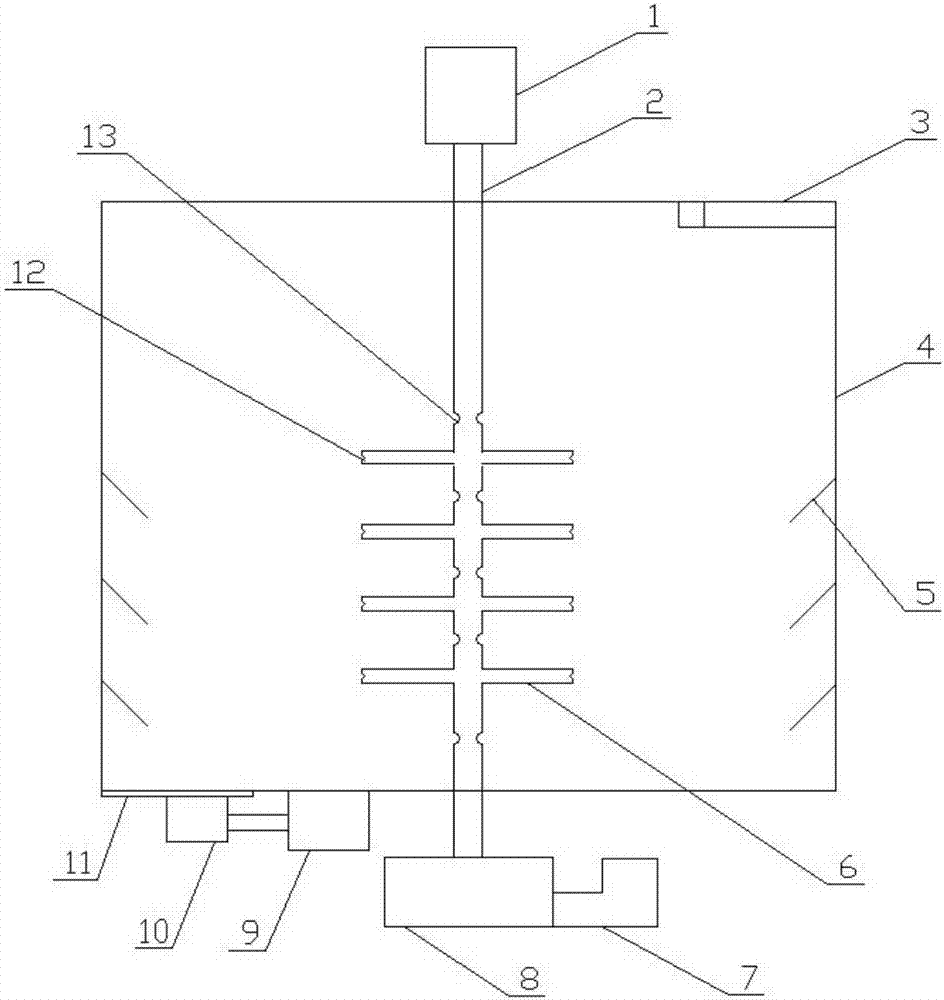

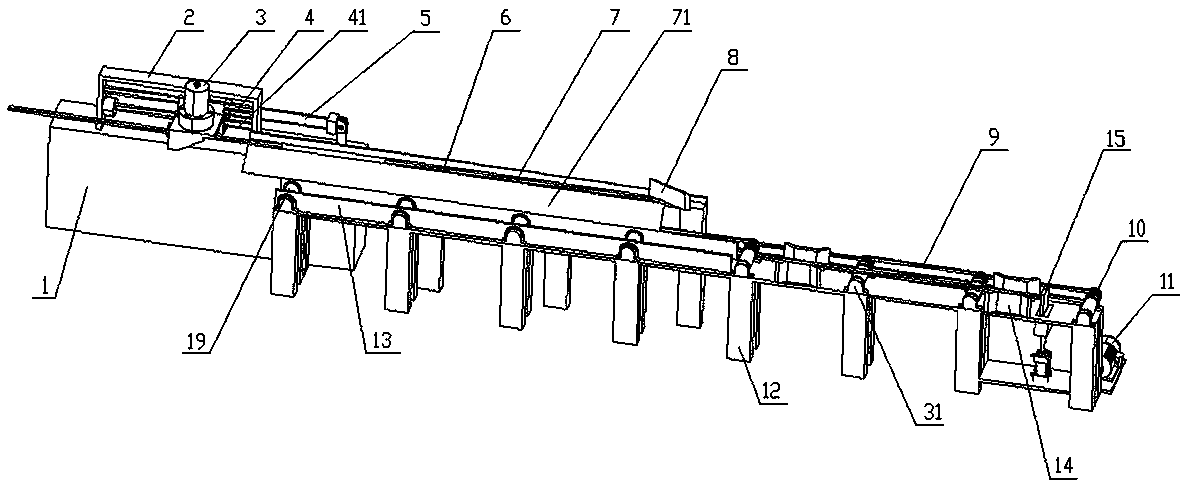

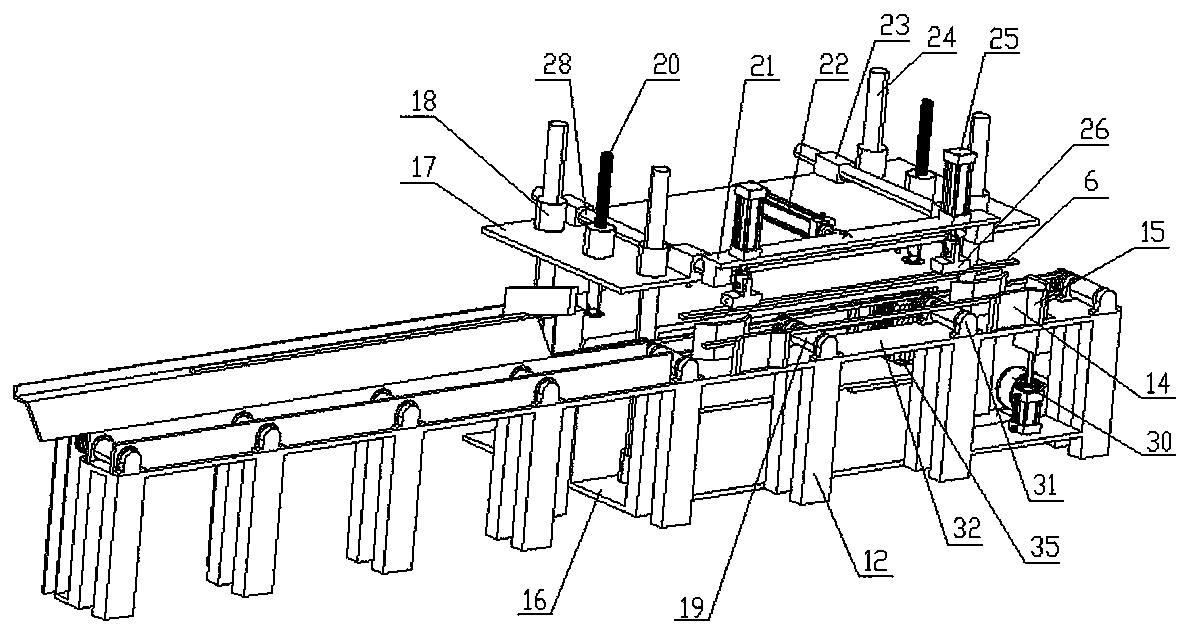

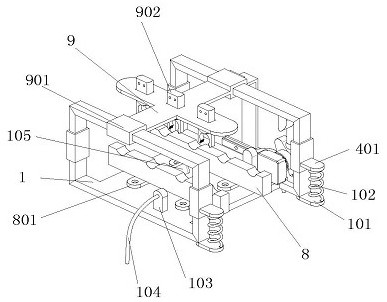

Testing system of electronic element with pins

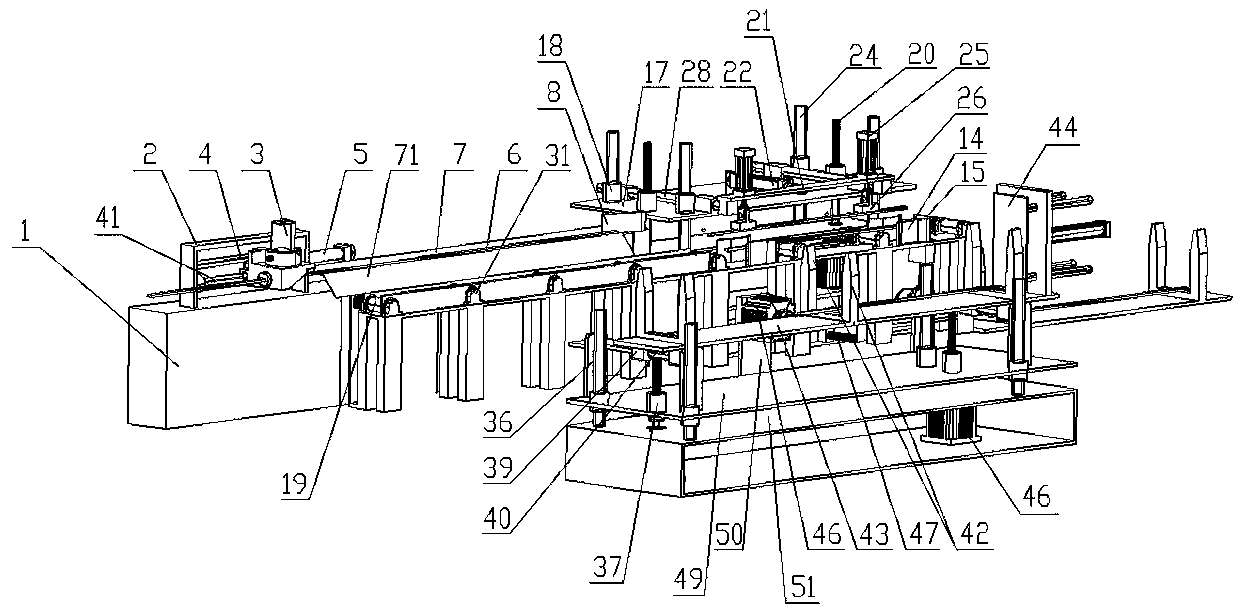

ActiveCN105242161ALabor savingReduce manufacturing costElectrical testingEngineeringElectronic component

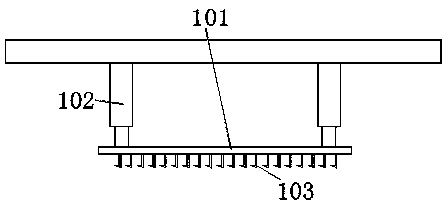

The invention discloses a testing system of an electronic element with pins. The testing system comprises a rack, track, a transmission mechanism, and at least two testing mechanisms. The track is fixedly connected to the rack. The transmission mechanism is arranged at one side of the track and consists of a transmission plate, a first cylinder, and a second cylinder; the transmission plate is arranged above the track; and one side of the transmission plate is fixedly connected with the first cylinder and at least two notches are arranged at the other side of the transmission plate. Besides, the testing mechanisms contain testing machines, probe groups, and third cylinders; the probe groups are fixedly connected to fixed plates; and each probe group contains at least two probes. According to the testing system, testing and marking can be completed automatically; the time and effort are saved; and the production cost is lowered.

Owner:山东宝乘电子有限公司

Decolorizing and filtering device in paracetamol preparation process and decolorizing and filtering method of decolorizing and filtering device

ActiveCN113750569AGood decolorization effectPromote adsorption decolorization effectUltrafiltrationSeparation with moving sorbentsActivated carbonReciprocating motion

The invention relates to the technical field of decolorizing and filtering equipment, and discloses a decolorizing and filtering device in a paracetamol preparation process and a decolorizing and filtering method of the decolorizing and filtering device. The decolorizing and filtering device comprises a decolorizing tank, a feeding cylinder is arranged at the positions, on the two sides of a liquid inlet pipe, of the top end of the decolorizing tank, and supporting plates are arranged on the outer walls of the two sides of a material shoveling cylinder. The material shoveling cylinder is arranged at the bottom of a top plate of the decolorizing tank through supporting springs at the upper ends of the supporting plate, the top end of the material shoveling cylinder extends to an inner cavity of the feeding cylinder, a feeding opening is formed in the outer wall of one side of the material shoveling cylinder, and the bottom of the material shoveling cylinder is of an open structure. Connecting rings are arranged on the outer wall of a bottom port of the material shoveling cylinder through fixing inclined rods, and the connecting rings on the two sides of the lower end of the liquid inlet pipe are connected through a transverse plate. To-be-decolored liquid falls from the liquid inlet pipe and impacts a shifting plate to drive a rotating roller to rotate, when the rotating roller rotates, ejector rods at the tail end of the shifting plate on the outer wall of the rotating roller sequentially rotate to eject the transverse plate to move downwards, and a supporting spring is matched to pull the material shoveling cylinder to do up-and-down reciprocating motion in a communicating pipe, so that the material shoveling cylinder intermittently extends into the feeding barrel, activated carbon particles enter the material shoveling cylinder from the feeding opening, and automatic intermittent discharging is achieved.

Owner:LIANYUNGANG CONLE PHARMA CO LTD

Semiautomatic settling type pickle squeezer

The invention discloses a semiautomatic settling type pickle squeezer, and belongs to the technical field of squeezing equipment. The semiautomatic settling type pickle squeezer comprises a machine frame, a squeezing platform, a bottomless filter tube, a solid squeezing tube, a feeding device, a material collecting device and a filter tube moving device, wherein the squeezing platform is arranged on the machine frame and is used for carrying the squeezing force, the bottomless filter tube is positioned on the squeezing platform, the solid squeezing tube is matched with the bottomless filter tube, the feeding device is used for feeding materials into the bottomless filter tube, the material collecting device is in seamless connection with the squeezing platform, the filter tube moving device is used for moving the bottomless filter tube to a position above the material collecting device, and the solid squeezing tube is connected with a lifting device driving the solid squeezing tube to ascend and descend. Great gravity of the solid squeezing tube per se is used for squeezing food materials and extruding water, the squeezing platform achieves a support effect on the solid squeezing tube, the pressure is greatly increased, the consumed squeezing time is short, the production efficiency is improved, the settling design is adopted, an additional pressure exertion element is not needed, and the structure is simpler and more effective.

Owner:四川红七公食品有限公司

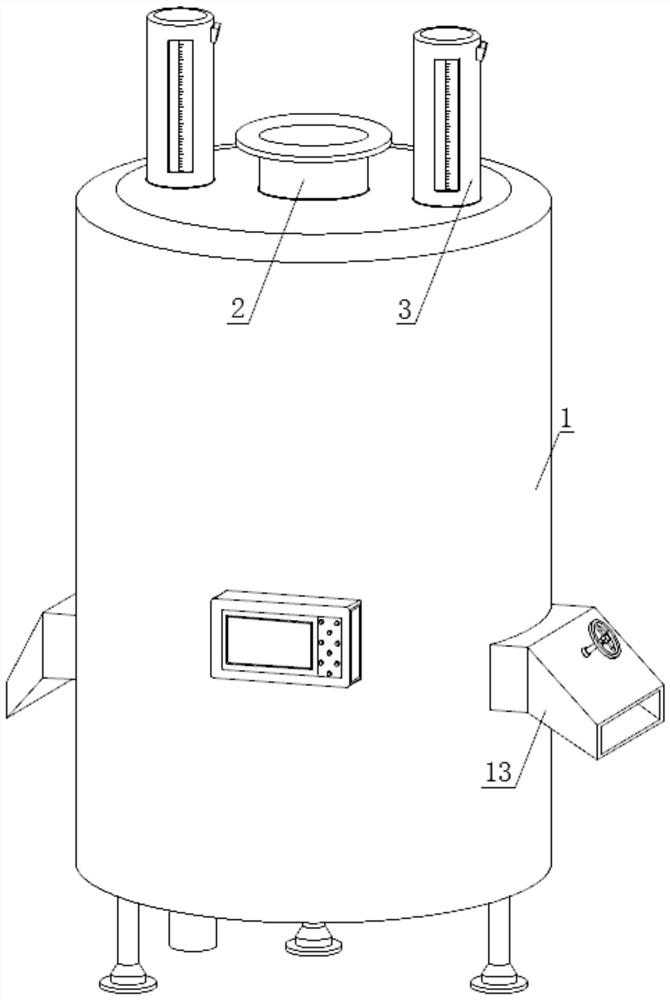

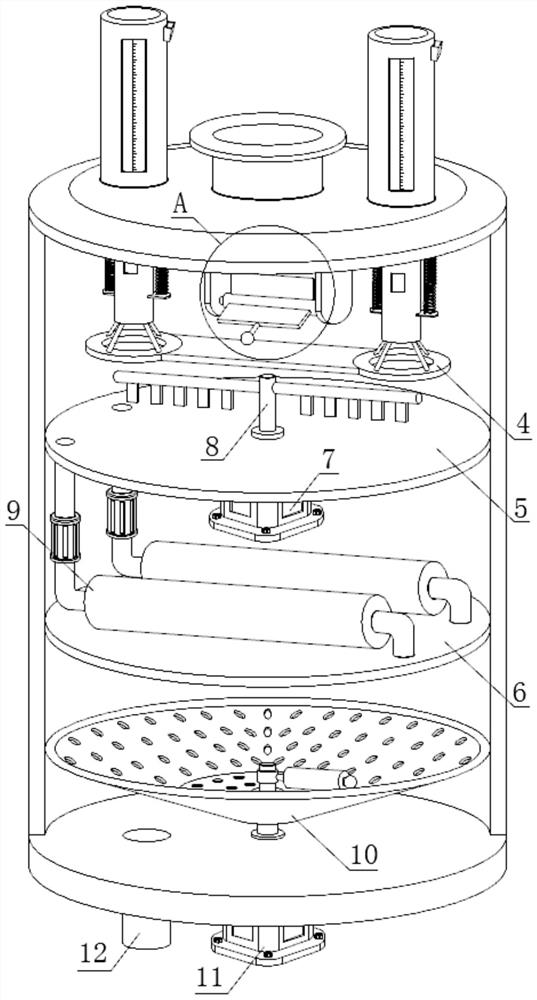

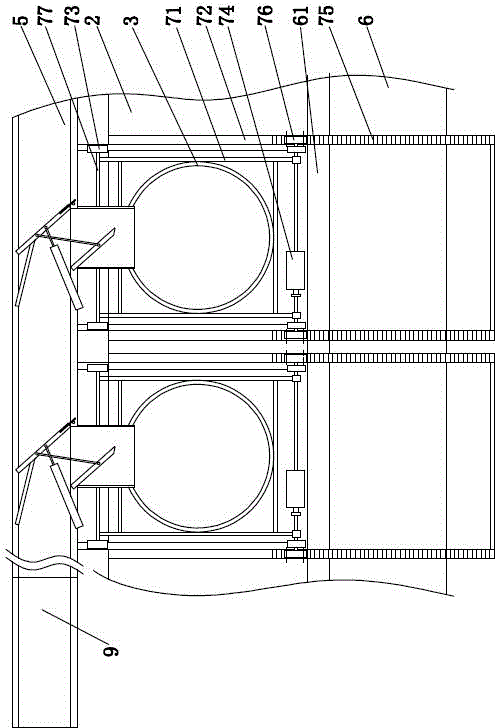

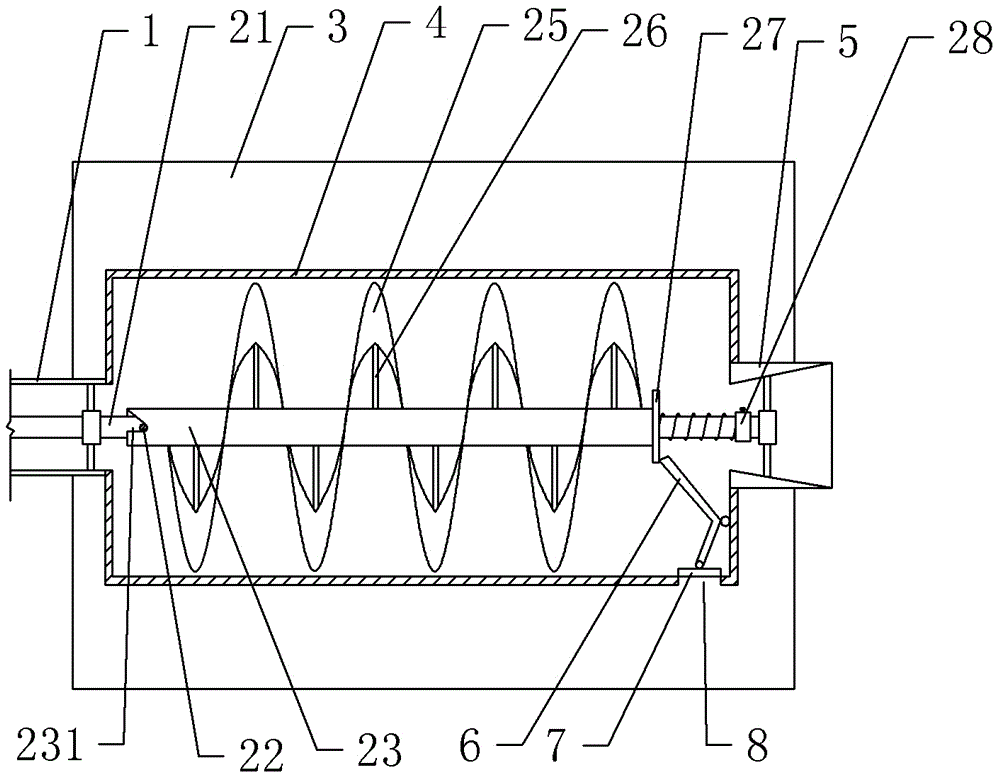

Sleeve-fish steaming device for fishing boat

ActiveCN106418296ARealize automatic nestingImprove work efficiencyMeat/fish preservation by heatingSpray nozzleEngineering

The invention provides a sleeve-fish steaming device for a fishing boat, and belongs to the technical field of food processing equipment. The sleeve-fish steaming device for the fishing boat comprises a steaming box, a steaming cylinder is arranged in the steaming box, a connecting sleeve is mounted on the side wall of the steaming box, an open end of a cylinder body is rotatably connected onto the connecting sleeve, a driving mechanism is arranged between the steaming cylinder and the bottom of the steaming box, stirring vanes are arranged on the inner wall of the cylinder body, a push plate is arrange din the steaming cylinder, a power mechanism is arranged on the steaming box, a sealing door is hinged on the outer wall of the steaming box, a base is arranged on the lower portion of the steaming box, a middle water tank is arranged on the base, communicated with the bottom of the steaming box through a discharge pipe and communicated with the inside of the steaming box through a water return pipe, a plurality of spray nozzles are arranged at the upper end of the steaming box, air outlets of the spray nozzles face the steaming cylinder, a water supply pipe is arranged at the upper end of the steaming box, an exhaust gas heating pipe and a heater are arranged at the bottom of the steaming box, a discharging hopper is arranged on the outer wall of the steaming box, and conveying device for conveying sleeve-fishes is arranged on the base. The sleeve-fish steaming device has the advantages that the sleeve-fish steaming device is high in working efficiency, energy is saved and the like.

Owner:ZHEJIANG OCEAN UNIV

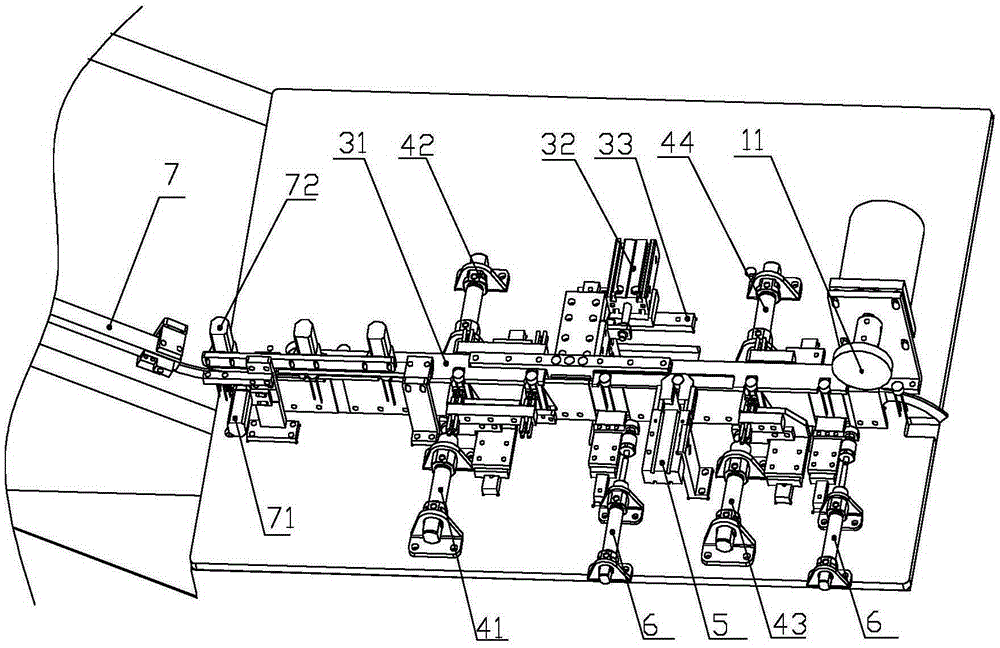

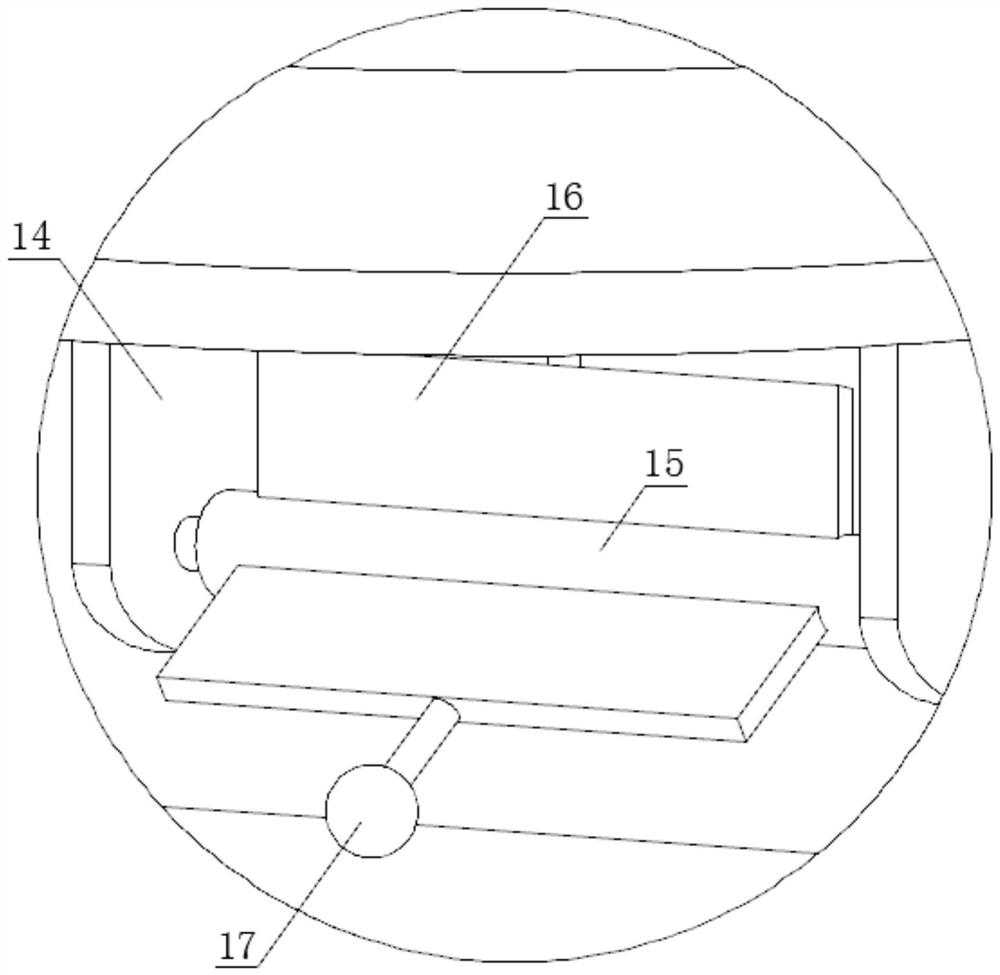

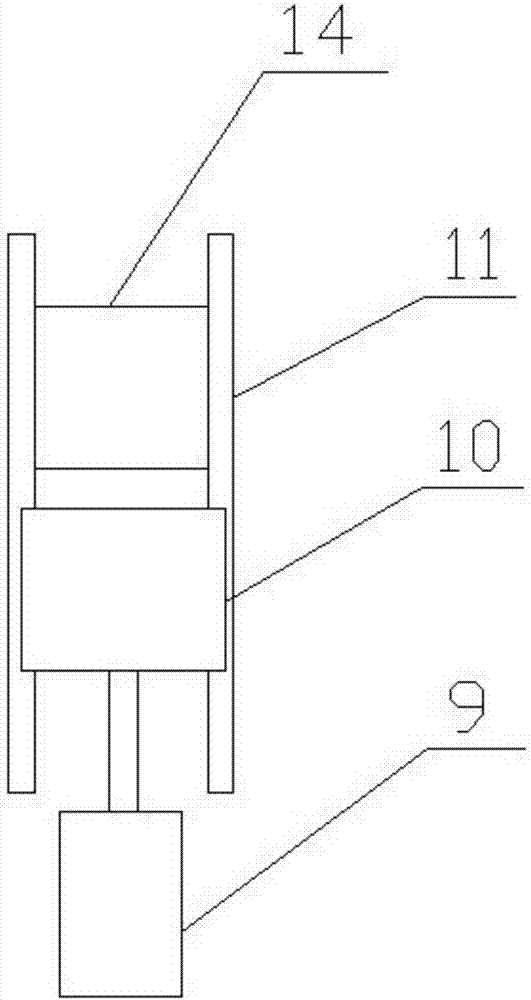

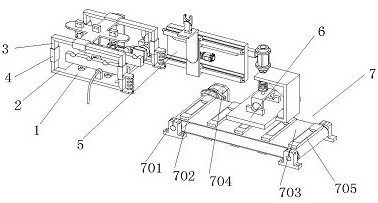

Automatic discharge device for back spindle

InactiveCN108788838ARealize automatic nestingSimple and fast operationPositioning apparatusMetal working apparatusProcess efficiencyEngineering

The invention discloses an automatic discharge device for a back spindle. The automatic discharge device comprises an elastic chuck, an ejector pin, a chuck sleeve and a bar charge hole, wherein the ejector pin is positioned in the elastic chuck; the elastic chuck is positioned in the chuck sleeve; the ejector pin is in threaded connection with a pushing rod I; the chuck sleeve is in threaded connection with a limiting sleeve; a return spring is arranged between the elastic chuck and the limiting sleeve; one end, close to the bar charge hole, of the chuck sleeve is in contact with a pushing rod II; the other end of the pushing rod II is in contact with a short arm of an opening-closing claw; a long arm of the opening-closing claw is in contact with a pneumatic performer; an ejecting springis arranged between the elastic chuck and the bar charge hole; and one side of the bar charge hole is equipped with an inducting switch. The automatic discharge device realizes an automatic chargingfunction and an automatic discharge function of the back spindle, is simpler and more convenient to operate, and is higher in processing efficiency.

Owner:HUBEI YIXING INTELLIGENT EQUIP CO LTD

Metal gasket blanking die for machining

InactiveCN112077197ARealize automatic nestingAvoid accumulationEjection devicesStructural engineeringGas supply equipment

The invention provides a metal gasket blanking die for machining, and belongs to the technical field of metal gasket machining. The metal gasket blanking die comprises a bottom box, a discharging holeis formed in the middle of the upper part of the bottom box, two groups of mutually symmetrical support vertical plates are fixedly arranged at the edge of the upper part of the bottom box, and the upper parts of the two groups of support vertical plates are connected through a support transverse plate; and a blanking tool corresponding to the discharging hole is arranged between the two groups of support vertical plates. In the embodiment of the invention, after a metal base material is blanked by the blanking tool, a pipe pressing assembly can drive an air inlet hard pipe to rotate, so thatone end of the air inlet hard pipe is in butt joint with an air inlet hole, and compressed air is injected into a mounting channel through an air inlet hose and the air inlet hard pipe by utilizing external air supply equipment so as to drive a piston, a connecting rod and a material pushing head to move downwards; and the blanked metal sheets are pushed into the bottom box from the discharging hole, automatic discharging of the metal sheets is achieved, the metal sheets are prevented from being accumulated in the discharging hole, and the advantage of being convenient to discharge is achieved.

Owner:李存贺

Back spindle automatic discharging device

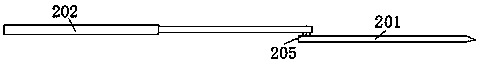

InactiveCN103028988ARealize automatic nestingSimple and fast operationPositioning apparatusMetal working apparatusEngineeringShort arms

The invention relates to a back spindle automatic discharging device which comprises an elastic chuck, an ejector pin, a chuck sleeve and a bar feed inlet. The ejector pin is positioned in the elastic chuck; the elastic chuck is positioned in the chuck sleeve; the ejector pin is in threaded connection with a first push rod; the chuck sleeve is in threaded connection with a limiting sleeve; a return spring is arranged between the elastic chuck and the limiting sleeve; one end of the chuck sleeve, which is close to the bar feed inlet, is in contact with a second push rod; the other end of the second push rod is in contact with a short arm of an opening and closing jaw; a long arm of the opening and closing jaw is in contact with a pneumatic actuator; an ejector spring is arranged between the elastic chuck and the bar feed inlet; and one side of the bar feed inlet is provided with an inductive switch. According to the invention, functions of automatically clamping and discharging a back spindle are implemented; and the back spindle automatic discharging device is simpler and more convenient to operate and has higher processing efficiency.

Owner:陈胜喜

Concentration evaporator for sodium sulfide

ActiveCN106621416AReduce labor burdenAvoid inefficient heat transferEvaporator accessoriesAlkali metal sulfides/polysulfidesBiochemical engineeringSodium sulphide

The invention discloses a concentration evaporator for sodium sulfide. The concentration evaporator comprises a heating chamber and a heat exchange cylinder. A discharging port is formed in the side wall of the heat exchange cylinder, a stirring mechanism is arranged in the heat exchange cylinder and comprises a rotating shaft, a sleeve, a support and a spiral band, the rotating shaft and the heat exchange cylinder are coaxial, the sleeve sleeves the rotating shaft and is in running fit with the rotating shaft, the support is fixedly connected with the sleeve, the spiral band is arranged on the support, a clamp groove is formed in one end of the sleeve, a fixing pin matched with the clamp groove is arranged on the rotating shaft, a push plate is arranged at the other end of the sleeve, a spring for keeping the sleeve contacting with the fixing pin is arranged on the rotating shaft, a cover plate is arranged at the discharging port, a lever is hinged onto the inner wall of the heat exchange cylinder, one end of the lever is hinged to the cover plate, the other end of the lever is abutted to the push plate, and a second driving mechanism for driving the rotating shaft to rotate is arranged on the heating chamber. The concentration evaporator solves the problem of inconvenience in discharging operation of a heat exchange cylinder in the prior art, and automatic discharging is realized.

Owner:安徽立科环保设备有限公司

Prefiltering device for oil-containing waste liquid in ship production

InactiveCN110180234ARealize automatic nestingNo need for manual nestingStationary filtering element filtersLiquid wasteEngineering

The invention discloses a prefiltering device for oil-containing waste liquid in ship production. The device comprises a treating box, wherein a mounting rack is fixed inside the treating box, a meshscreen is fixed on the mounting rack, a stirring mechanism is arranged on the upper side of the mesh screen, a first servo motor is arranged on the outer side of the treating box, an output shaft of the first servo motor is connected with a first belt pulley, second belt pulleys are in transmission connection to two sides of the first belt pulley, each second belt pulley is in key connection witha screw rod, a transmission nut is in threaded connection on each screw rod, the transmission nuts are inlaid in a material pushing plate, connecting rods are welded to two sides of the upper end of the material pushing plate, a material baffle block is welded to the end parts of the connecting rods, and is in tight contact with a discharge hole, and a recycling box is arranged on the lower side of the discharge hole. Through the structure, filtered impurities can be automatically discharged and recycled, the filtering speed is increased through stirring for the liquid, and further, work efficiency is greatly improved.

Owner:CHINA MERCHANTS HEAVY IND SHENZHEN +1

Structure improved squid steaming device

The invention provides a structure improved squid steaming device, and belongs to the technical field of food processing devices. The structure improved squid steaming device comprises a steaming box, wherein the steaming box is internally provided with a steaming barrel, a connecting sleeve is installed on the side wall of the steaming box, an opening end of a barrel body is rotationally connected onto the connecting sleeve, a drive mechanism and a limit support mechanism are arranged between the steaming barrel and the bottom of the steaming box, stirring wings are arranged on the inner wall of the barrel body, a push plate is arranged in the steaming barrel, a power mechanism is arranged on the steaming box, a sealing door is hinged to the outer wall of the steaming box, an opening and closing mechanism is arranged on the steaming box, a middle water tank is arranged below the steaming box, the middle water tank communicates with the bottom of the steaming box through a vent tube, a valve III is arranged on the vent tube, the middle water tank communicates with the interior of the steaming box through a water return tube, a filter and a water pump are arranged on the water return tube, an air nozzle I is arranged at the upper end of the steaming box, and a discharge hopper is arranged on the outer wall of the steaming box. The structure improved squid steaming device has the advantages of being high in working efficiency, energy-saving and the like.

Owner:ZHEJIANG OCEAN UNIV

Dry-mixed mortar and preparation method thereof

ActiveCN110818313ARaise the firing temperatureShorten the setting timeCement mixing apparatusCelluloseCarboxymethyl cellulose

The invention provides dry-mixed mortar which is prepared from the following raw materials in parts by weight: 100- 150 parts of a modified polyurethane / diatomite composite material, 20-30 parts of expanded vermiculite, 25-35 parts of hollow glass beads, 5-12 parts of medium sand, 7-18 parts of sodium carboxymethyl cellulose, 15-30 parts of gypsum, 5-10 parts of EVA rubber powder, 3-7 parts of styrene, 3-7 parts of a chlorine salt antifreezing agent, 1-5 parts of an aliphatic water reducing agent, 10-20 parts of fly ash and 10-15 parts of a mineral admixture. The dry-mixed mortar is good in cohesiveness, high in strength, high in waterproof capacity and good in thermal-insulation fireproof effect, and has wide application prospects.

Owner:江苏省苏安能节能建材科技有限公司

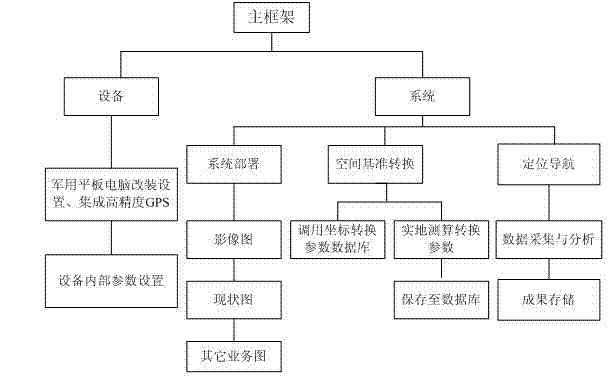

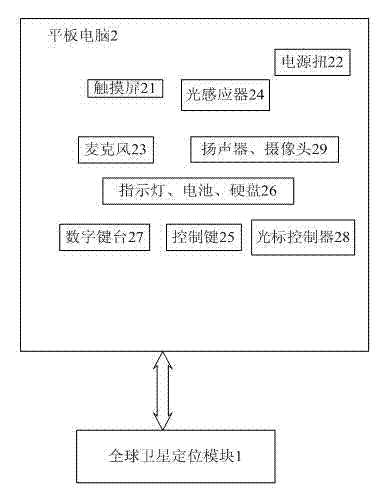

Equipment and method for converting space references of land supervision data

InactiveCN102831180ARealize automatic nestingReceive in real timeSpecial data processing applicationsTablet computerData space

The invention discloses equipment and a method for converting space references of land supervision data. The equipment comprises a global positioning satellite module (1) and a tablet computer (2), wherein the global positioning satellite module (1) is used for receiving and processing global positioning satellite signals and transmits signal data to the tablet computer (2); and the tablet computer (2) is used for receiving the signal data and converting the space references of global positioning satellite measuring data according to the signal data. The method comprises the following steps of 1, configuring global environments of a land supervision data space reference conversion system; and 2, configuring land supervision tasks at this time. The equipment and the method have functions of GPS (global positioning system) positioning and navigating, land supervision data acquisition and data storage, and automatic superposition of field acquired data, field monitoring data and a base map, the precision of data acquired by the equipment meets requirements on land supervision business, the land supervision data with large bytes can be stored, and the equipment is convenient to carry.

Owner:SOUTHEAST UNIV

Impurity removal device for sound insulation glass production and using method thereof

InactiveCN113731541ARealize automatic nestingImprove adsorption capacityDrying machines with non-progressive movementsCleaning using liquidsIron removalElectric machine

The invention discloses an impurity removal device for sound insulation glass production and a using method thereof, and relates to the technical field of glass processing. The impurity removal device comprises a mounting base plate, a smashing and iron removing mechanism, a drying mechanism and a heating mechanism, the smashing and iron removing mechanism comprises a smashing box fixedly arranged at the top of the mounting base plate, a first motor is fixed to the back face of the smashing box, the output end of the first motor extends into the smashing box and is fixedly provided with a first smashing wheel, a second motor is fixedly arranged on the back face of the smashing box, the output end of the second motor extends into the smashing box and is fixedly provided with a second smashing wheel, and a protective pad is fixedly arranged in the smashing box. Through the arrangement of the smashing and iron removing mechanism, third smashing wheels drive a screening plate to shake while crushing raw materials, so that scrap iron in the raw materials is more easily adsorbed by electromagnets, the iron removing efficiency is ensured, meanwhile, the shaking screening plate realizes automatic discharging, and operation of users is convenient.

Owner:湖南鑫哲科技发展有限公司

Waste glass crushing mechanism

ActiveCN113245038AImprove crushing effectRealize automatic proper feeding and grindingDirt cleaningCocoaProcess engineeringGlass particle

The invention discloses a waste glass crushing mechanism. The waste glass crushing mechanism comprises a base, a separation box is installed above the base, a crushing box and a power box are installed above the separation box, a crushing box is jointly installed above the crushing box and the power box, and the interior of the crushing box comprises a crushing cavity formed in the middle. Two material guide pipes are symmetrically and rotationally inserted into the crushing cavity, an extrusion pipe is slidably inserted into each material guide pipe, and an upper grinding disc and a lower grinding disc are mounted on the two extrusion pipes correspondingly. According to the waste glass crushing mechanism, through reverse rotation regular extrusion grinding of the upper grinding disc and the lower grinding disc, the crushing effect is improved, automatic and appropriate feeding grinding can be achieved, separation of glass particles and glass dust is achieved by forming directional airflow in a dust cavity, the environment is protected, the recycling treatment difficulty is lowered, meanwhile, automatic discharging is achieved, and the operation is more convenient.

Owner:南通金硕工程玻璃有限公司

Mixing-type mineral flotation machine

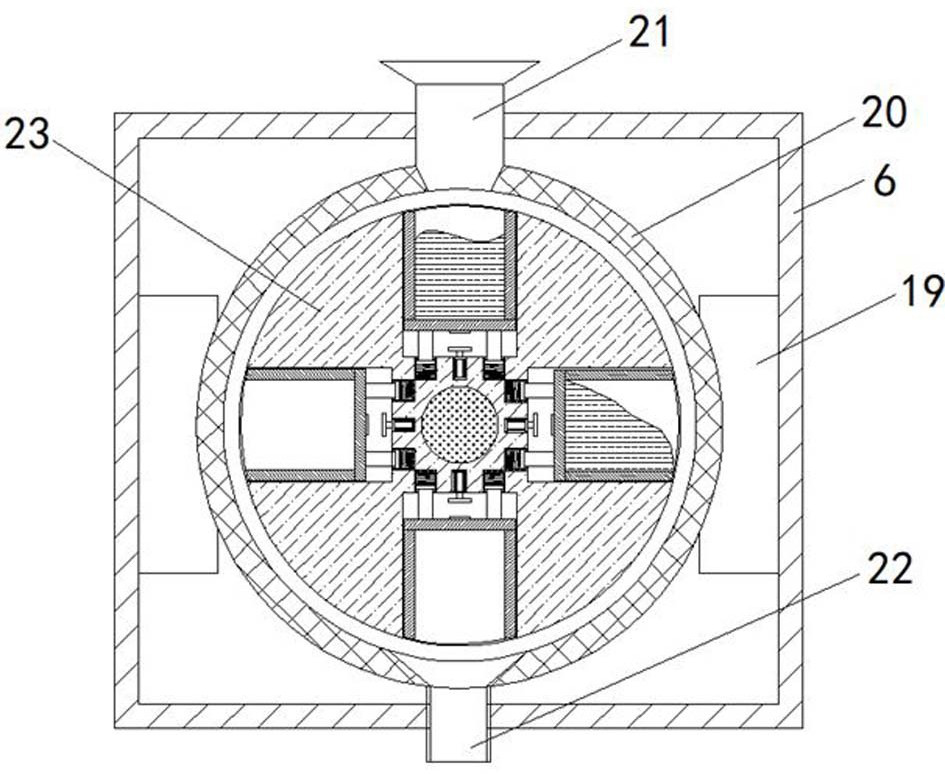

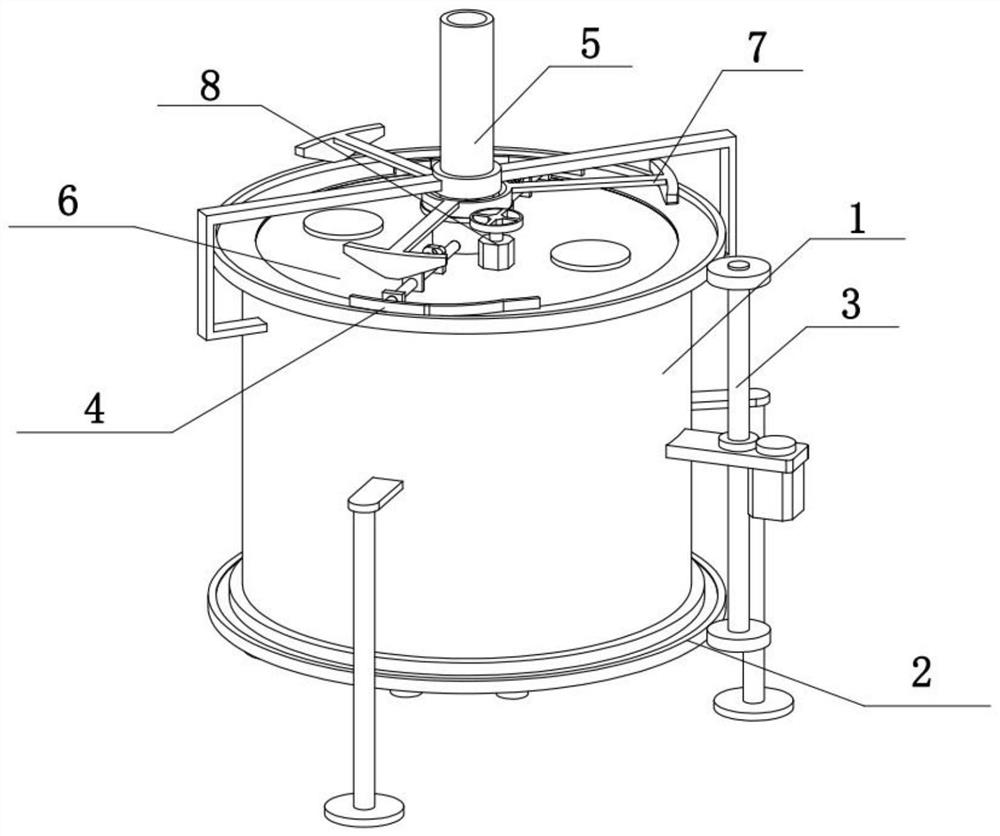

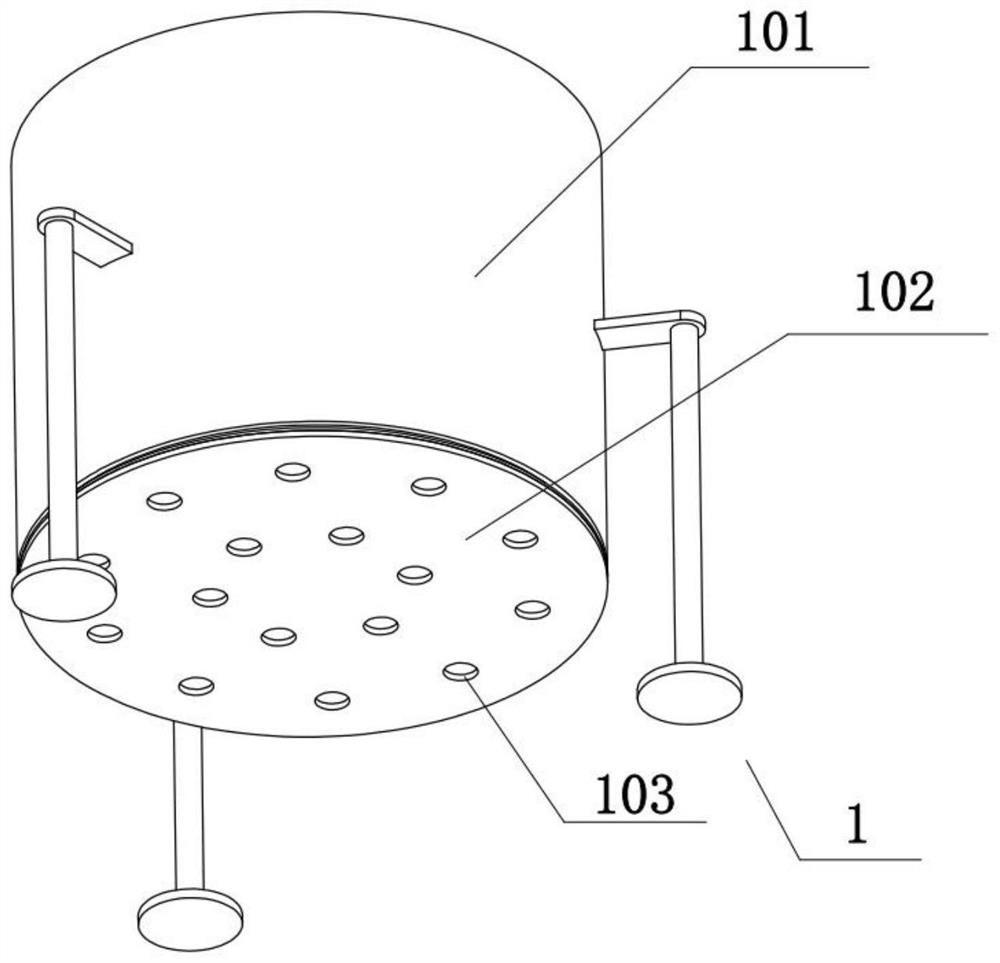

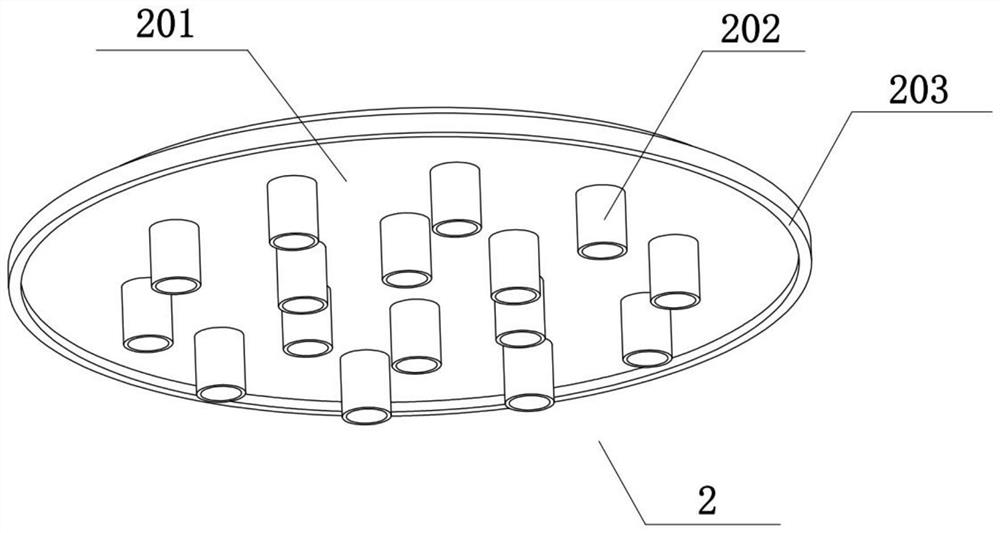

A hybrid mineral flotation machine, the flotation machine includes a flotation box and a hollow central shaft, the top of the flotation box is provided with a feed port, the bottom is provided with a discharge port, and the central shaft is from top to bottom. The bottom runs through the flotation box, and is installed on the flotation box through bearings and bearing seats; the upper end of the central shaft is closed and connected to the drive motor, and the lower end is connected to the inflation device; the central shaft in the flotation box is fixedly installed with the central shaft Connected stirring tube, with several air outlets on the stirring tube; the inflation device includes an inflation chamber and an air pump connected to the inflation chamber, the lower end of the central shaft extends into the inflation chamber, and is connected with the flotation tank through bearings and bearing seats . The hybrid mineral flotation machine provided by the invention is simple in structure and easy to use, effectively increases the amount of foaming in flotation, reduces labor workload of workers, and improves mineral processing efficiency.

Owner:李婷

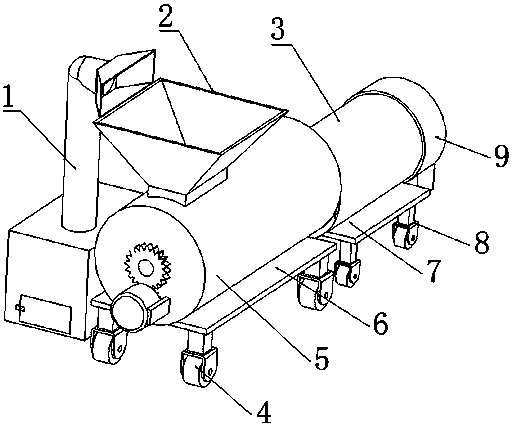

Squid cooking machine provided with cooking drum

ActiveCN106616561ARealize automatic nestingImprove work efficiencyFood scienceEngineeringMechanical engineering

The invention provides a squid cooking machine provided with a cooking drum and belongs to the technical field of food processing equipment. The squid cooking machine provided with the cooking drum comprises a cooking box with an opening in the upper end, wherein a connecting sleeve is mounted on the cooking box, the cooking drum is arranged in the cooking box and comprises a drum body and a bottom plate, an opening is formed in one end of the drum body, the bottom plate is arranged at the other end of the drum body, a plurality of through holes I are formed in the drum body and the bottom plate, the opening end of the drum body is rotationally connected to one end, located in the cooking box, of the connecting sleeve, a driving mechanism and a limiting support mechanism are arranged between the cooking drum and the cooking box, a plurality of stirring wings with V-shaped cross sections are arranged on the inner wall of the drum body circumferentially, a plurality of through holes I are formed in the stirring wings, a push plate is arranged in the cooking drum in a rolling manner in the axial direction, a plurality of through holes I are formed in the push plate, and a power mechanism is further arranged on the cooking box. The squid cooking machine has the advantages that the work efficiency is high, small vibration is produced during work of the cooking drum, the cooking drum can be cleaned automatically and the like.

Owner:ZHEJIANG OCEAN UNIV

Flat steel production device with cutting-off, blanking and discharging functions

PendingCN107755777ARealize automatic cut offRealize automatic nestingShearing machinesMetal working apparatusProduction lineEngineering

Owner:WUXI TIANCHI STEEL BAND CO LTD

Intelligent production line for Meitan turquoise bud tea

PendingCN112537470AAdjust the weightRealize quantitative weighingWrapper twisting/gatheringSolid materialProcess engineeringMaterial distribution

The invention relates to the technical field of related technologies for tea processing, and discloses an intelligent production line for Meitan turquoise bud tea. The intelligent production line comprises a machine box, wherein the two sides of the inner walls of the machine box are rotatably connected with rotating shafts, the outer walls of the rotating shafts are sleeved with rolling wheels, and the outer walls of the rolling wheels are fixedly sleeved with a conveying belt; and a material distribution box is fixedly installed on the outer wall of the top end of the machine box, the innerwall of the material distribution box is rotatably connected with a rotating rod, and the outer wall of the rotating rod is fixedly sleeved with a material distribution frame. Electric heating wires on the outer wall of a hot sealing head work to seal a packaging bag containing tea, therefore, workers do not need to spend a large amount of time in tea packaging for observation in the working process, the workload of the workers is reduced, and meanwhile the working efficiency of the whole packaging work is improved.

Owner:GUIZHOU YANGCHUNBAIXUE TEA IND

Stirring device for food processing

InactiveCN112742265AWell mixedRealize automatic nestingShaking/oscillating/vibrating mixersTransportation and packagingStructural engineeringMechanical engineering

The invention relates to the technical field of food processing equipment, in particular to a stirring device for food processing, which has the advantage of being capable of filling sausages while discharging, and comprises a supporting assembly, a filling assembly, an adjusting assembly, a switch assembly, a stirring assembly, a discharging assembly, a cleaning assembly and a driving assembly. The filling assembly is rotationally connected onto the supporting assembly, the adjusting assembly is fixedly connected to the supporting assembly, the switch assembly is rotationally connected to the upper end of the supporting assembly, the filling assembly and the switch assembly are both in meshing transmission with the adjusting assembly, the discharging assembly is connected to the supporting assembly, the stirring assembly is fixedly connected to the supporting assembly, and the cleaning assembly is rotationally connected to the discharging assembly. The cleaning assembly is in meshing transmission with the discharging assembly, the stirring assembly is in meshing transmission with the discharging assembly, the driving assembly is fixedly connected to the discharging assembly, and the driving assembly is in meshing transmission with the cleaning assembly.

Owner:李志伟

Semiconductor intelligent detection structure

ActiveCN113634516ARealize automatic nestingAchieve positioningSortingStructural engineeringMechanical engineering

The invention discloses a semiconductor intelligent detection structure, and belongs to the field of semiconductor detection. The semiconductor intelligent detection structure comprises a base plate, wherein four fixed vertical rods are arranged at the top end of the base plate; a movable frame is arranged above the base plate; two fixed flanges are arranged at the bottom end of the base plate; the fixed flanges are connected with movable flanges; two filling frames are arranged at the top end of the base plate; the bottom ends of the two filling frames are fixedly connected with the top surface of the base plate through mounting flanges; four curve grooves are formed in the filling frames; three pinching air cylinders are fixedly mounted on an adjusting plate; the distances among the three pinching air cylinders are the same; a carrying assembly is further arranged between the base plate and a pressure detection assembly; and the carrying assembly is arranged below the carrying assembly. According to the semiconductor intelligent detection structure, when the adjusting plate slides back and forth, the three pinching air cylinders push diode materials on the four curve grooves to the previous curve groove, and the diode material on the most curve groove is pinched by the carrying assembly.

Owner:江苏煜晶光电科技有限公司

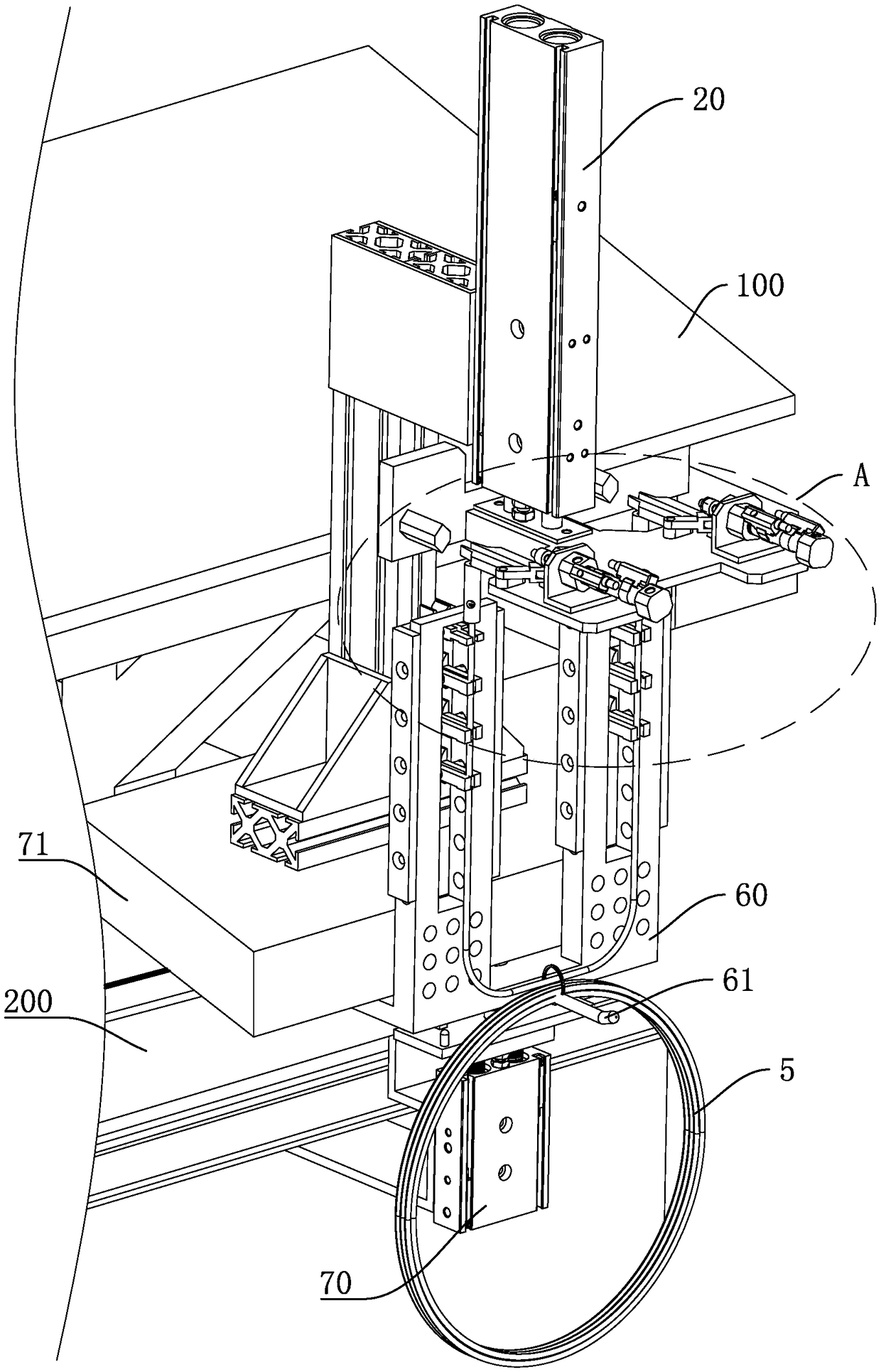

Optical fiber sorting device and optical fiber assembly line

ActiveCN109375319AImprove assembly efficiencyAvoid damageCoupling light guidesGlass productionEngineeringAssembly line

The invention discloses an optical fiber sorting device and an optical fiber assembly line. The device comprises a tooling plate and two grasping mechanisms. The tooling plate is provided with a plurality of clamping blocks, each of the clamping blocks is connected to the tooling plate by a spring, two adjacent clamping blocks in the same plane in the multiple clamping blocks form a pair, the clamping blocks are arranged in two rows on the tooling plate, each pair of the clamping blocks is used for abutting each other to clamp an end of an optical fiber, two ends of the optical fiber face up and are sleeved with plastic sleeves, and two ends of the optical fiber just face the two grasping mechanisms. The grasping mechanisms are used for clamping or loosening the plastic sleeves, and the grasping mechanisms are connected to a vertical driving mechanism which is used for driving the grasping mechanisms to move up and down such that the plastic sleeves clamped by the two grasping mechanisms pass through two ends of the optical fiber. The optical fiber sorting device also comprises two pushing blocks, and each of the pushing blocks is used for moving up and down to abut against a pairof two clamping blocks in clamping blocks of one row to open the two clamping blocks.

Owner:CHENGDU UNIV OF INFORMATION TECH +1

Automatic riveting machine and usage method thereof

The invention discloses an automatic riveting machine and a usage method thereof. The automatic riveting machine comprises a feeding device, a rivet-pressing device, a riveting device, a vibrating plate for pre-putting a fitting and conveying the fitting to the rivet-pressing device, a first grabbing device and a second grabbing device, wherein the first grabbing device and the second grabbing device are used for grabbing a workpiece, the feeding device comprises a feeding groove for pre-arranging the workpiece and a conveying device for conveying the workpiece, the vibrating plate is connected with the rivet-pressing device, the rivet-pressing device and the riveting device are adjacently arranged on the same horizontal plane, the first grabbing device is arranged between the conveying device and the rivet-pressing device for back and forth movement, and the second grabbing device is arranged between the rivet-pressing device and the riveting device for back and forth movement. Automatic discharging, automatic rivet pressing and automatic riveting of the whole technological process are achieved through the two grabbing devices and matching of the feeding device, the rivet-pressing device and the riveting device, potential safety hazards existing in traditional semi-automatic manual operation are avoided, and the product production efficiency is improved.

Owner:GUANGZHOU SONGCHUAN AUTOMATION EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com