Patents

Literature

728results about "Evaporator regulation/control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

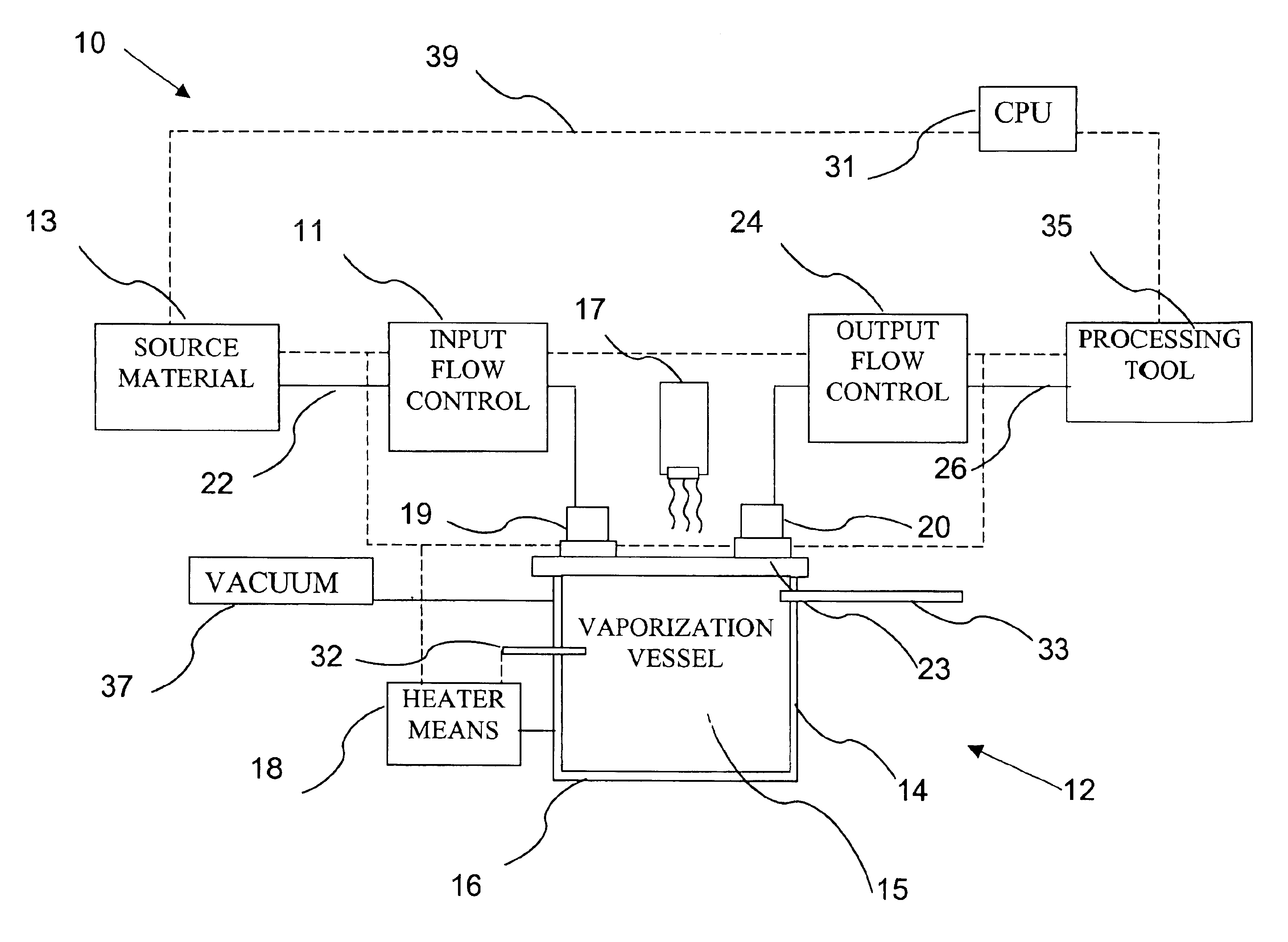

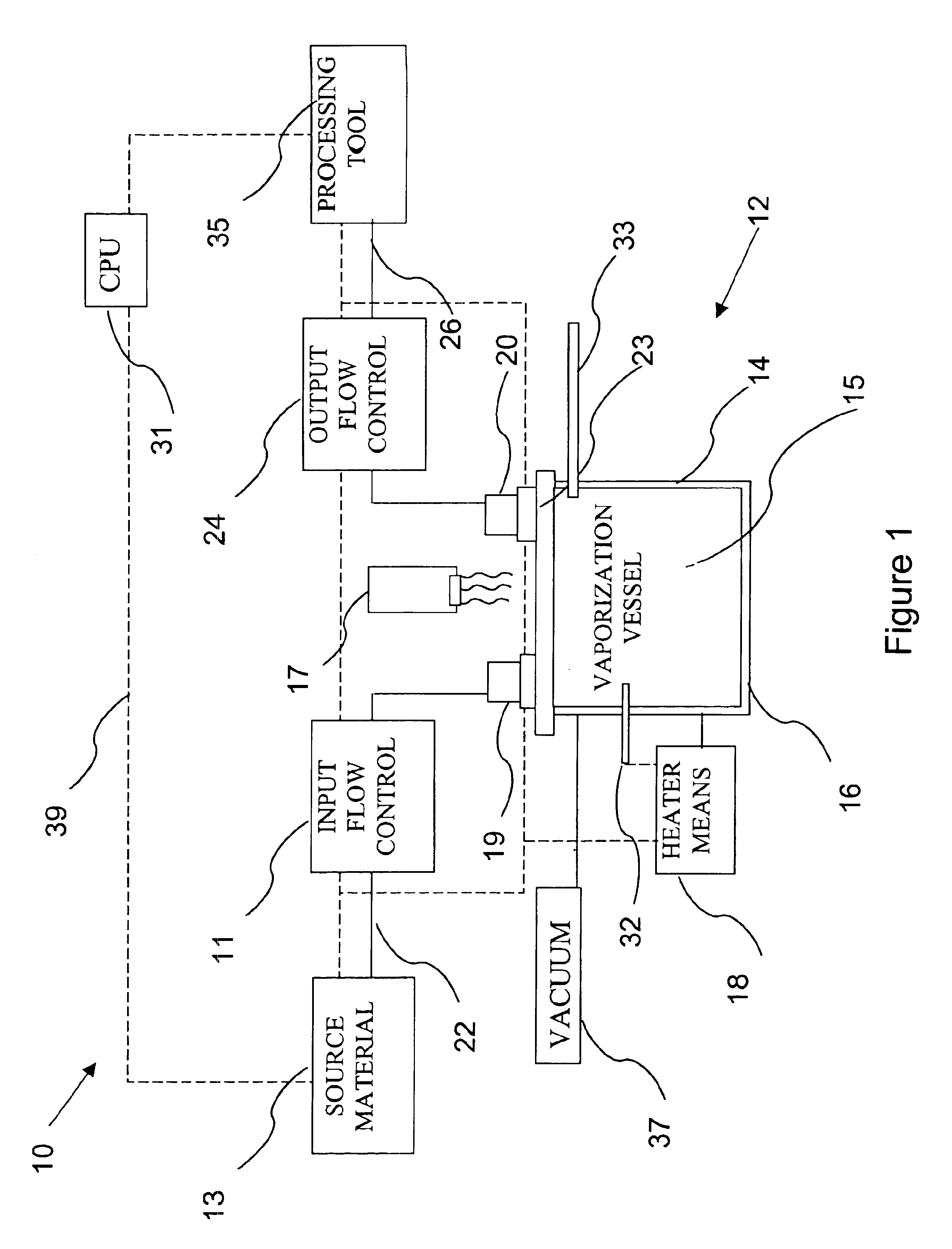

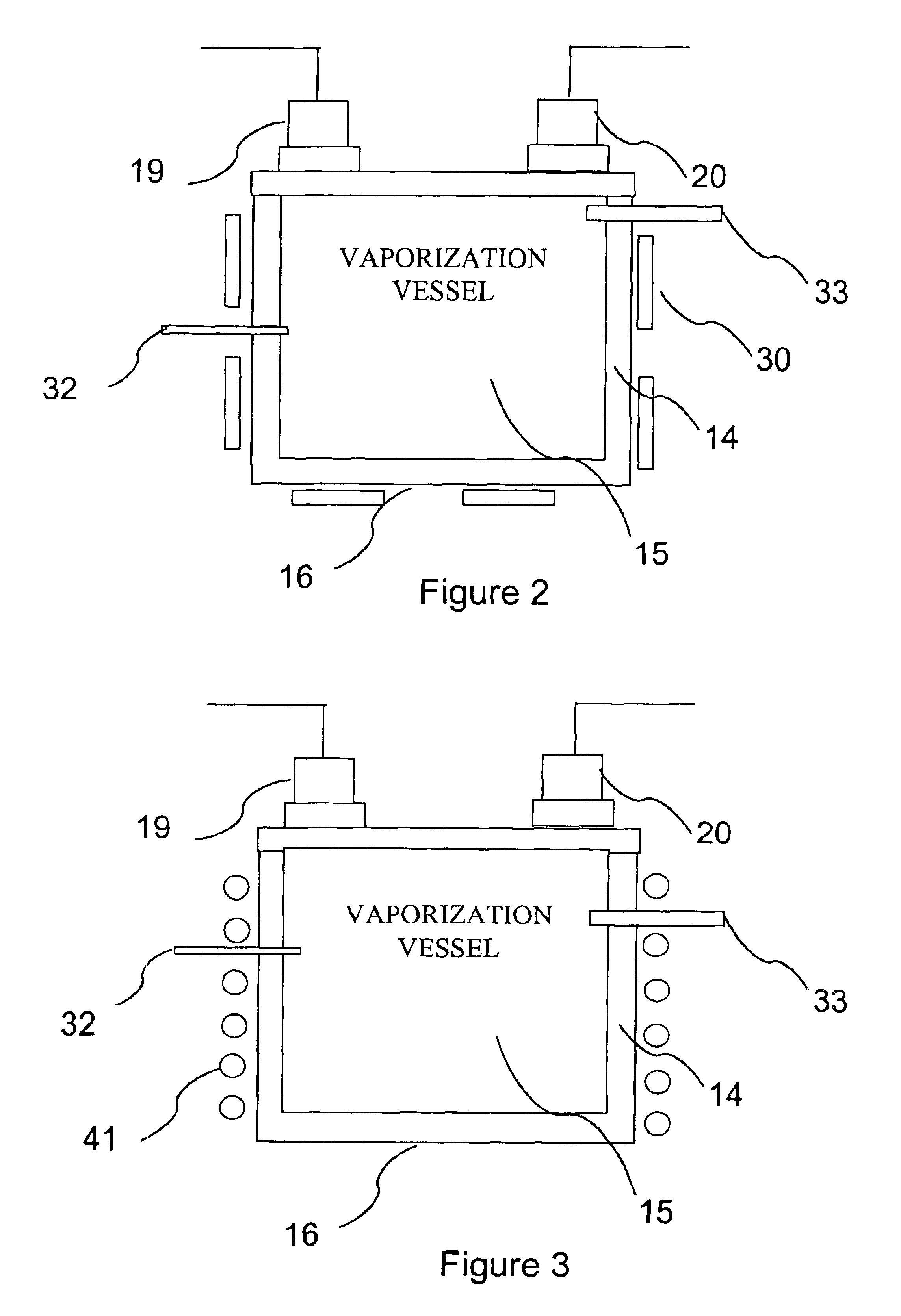

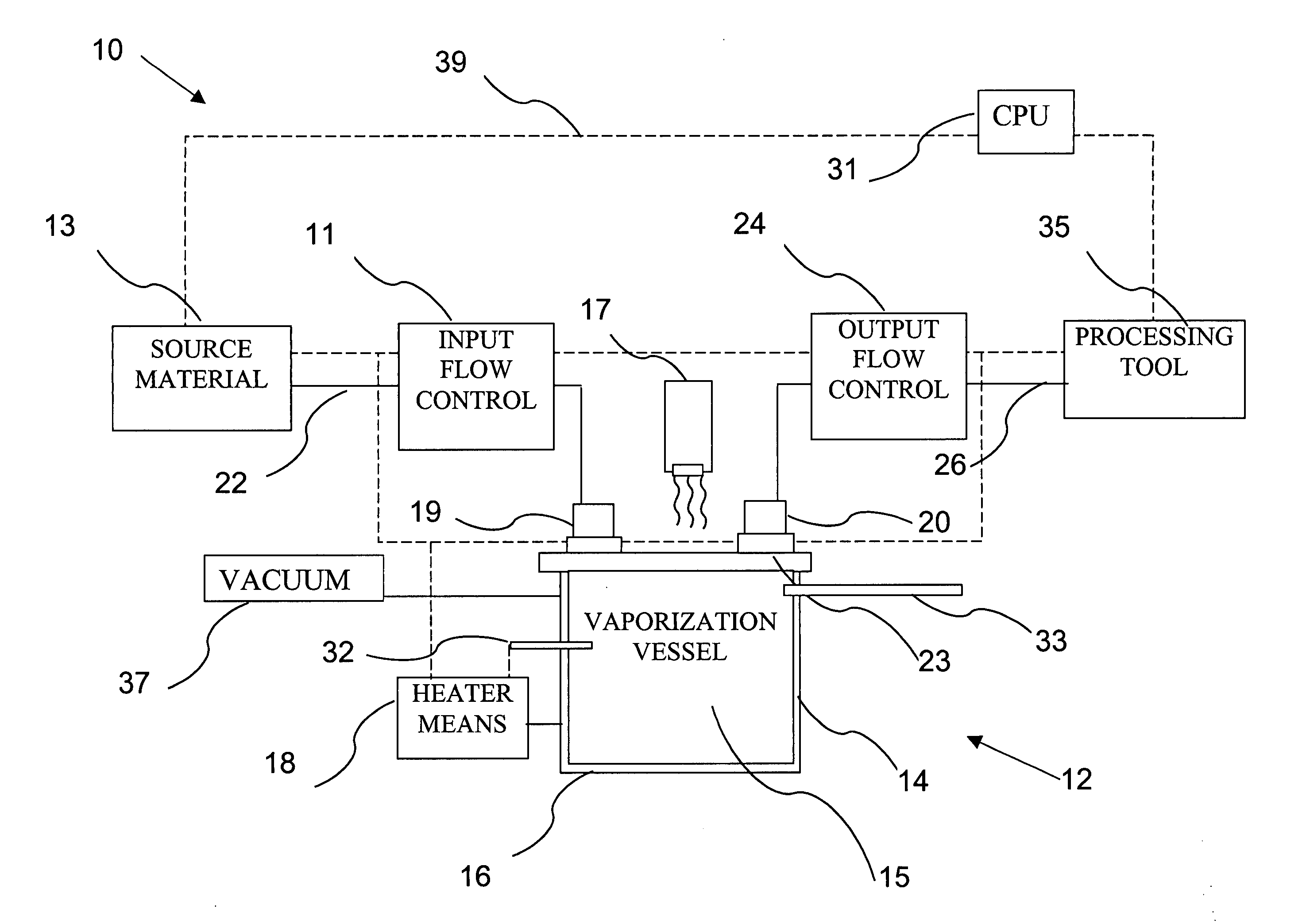

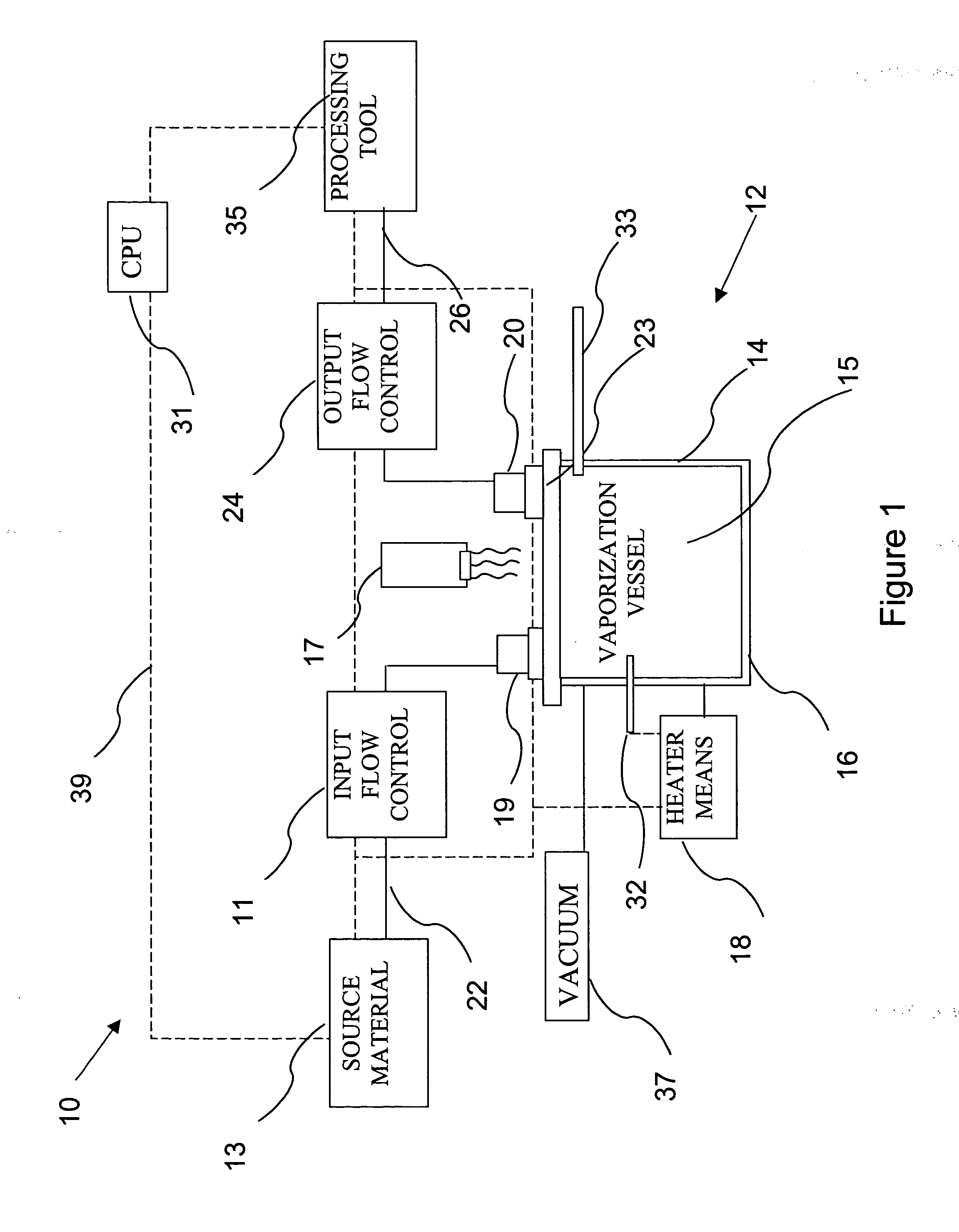

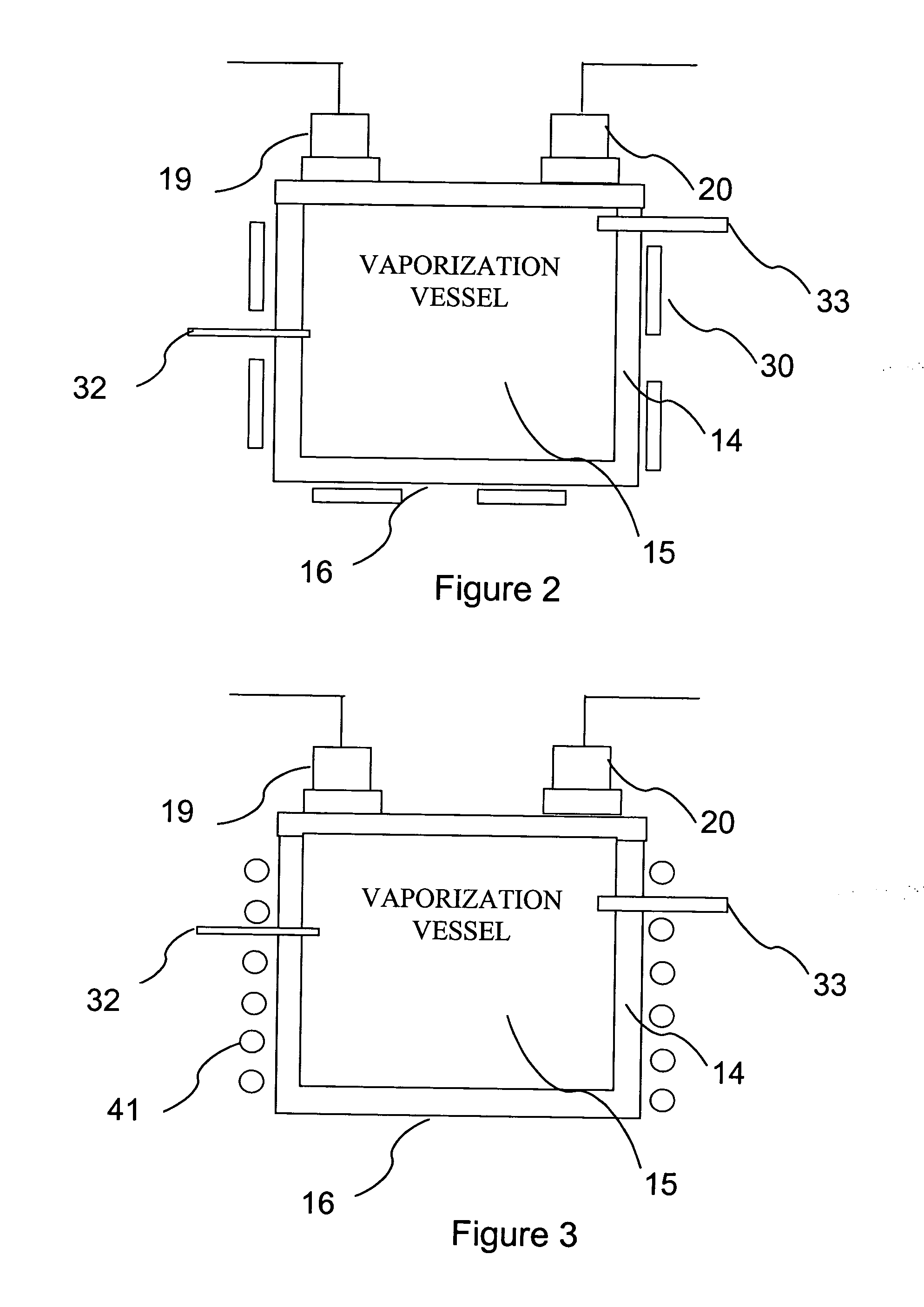

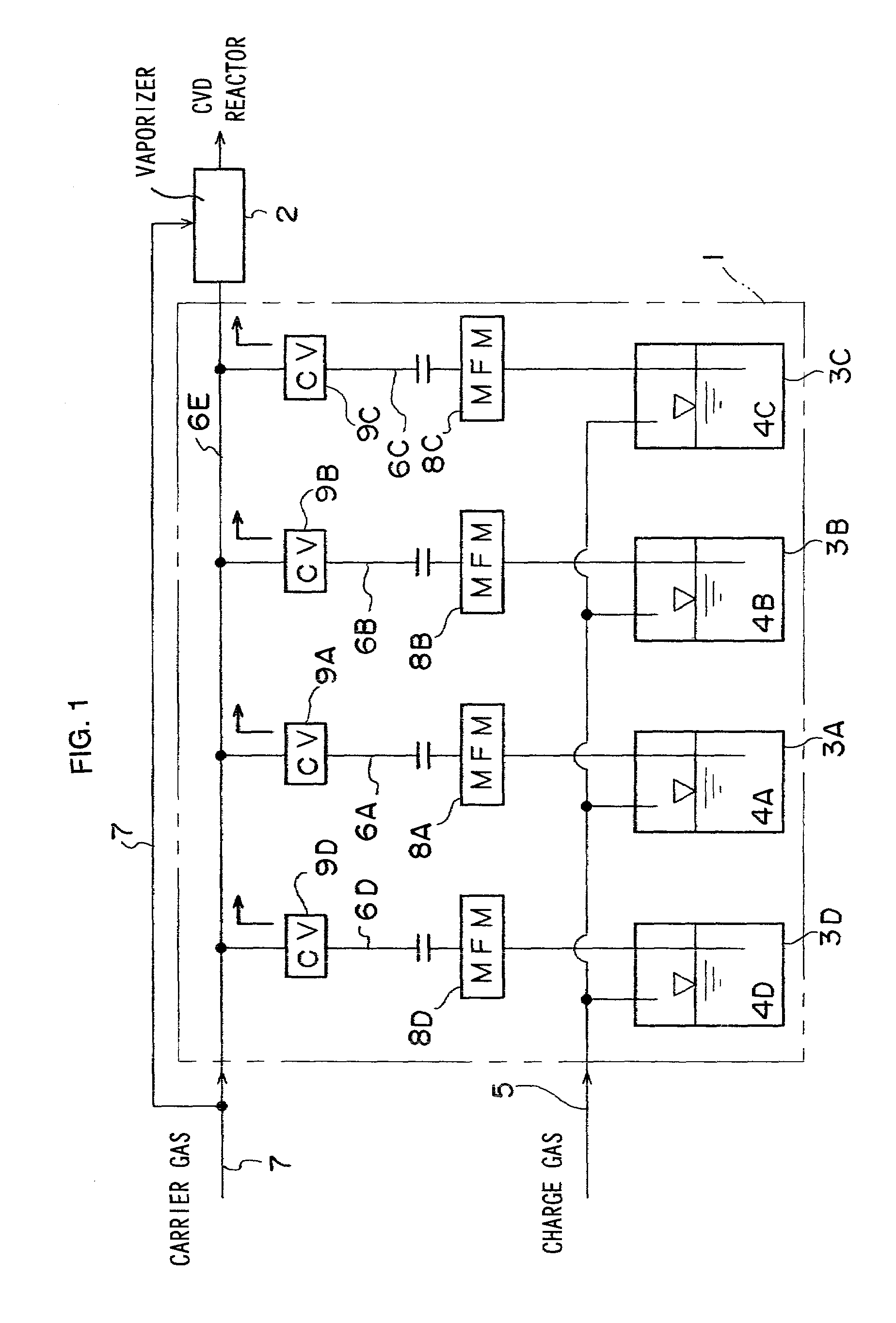

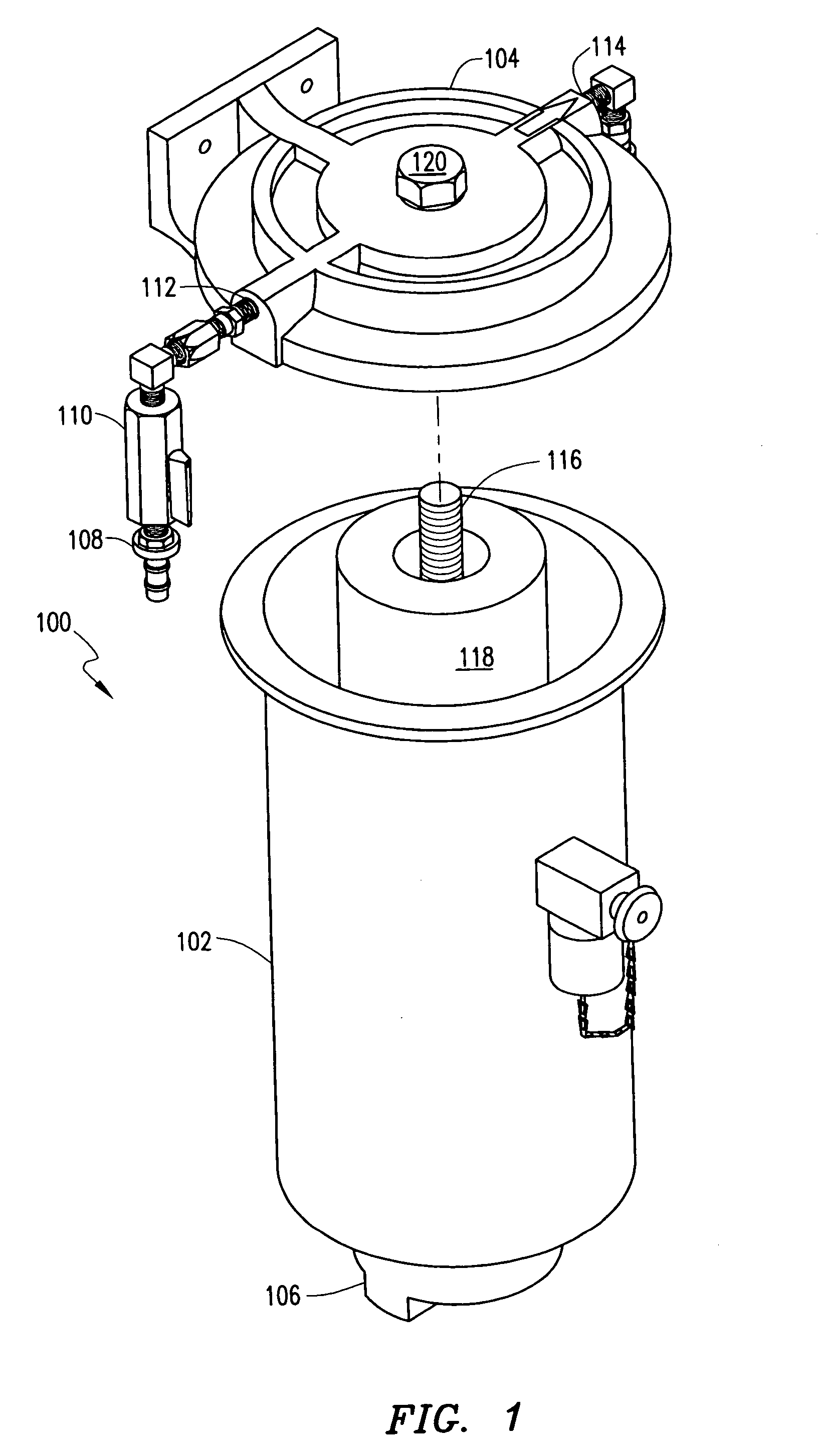

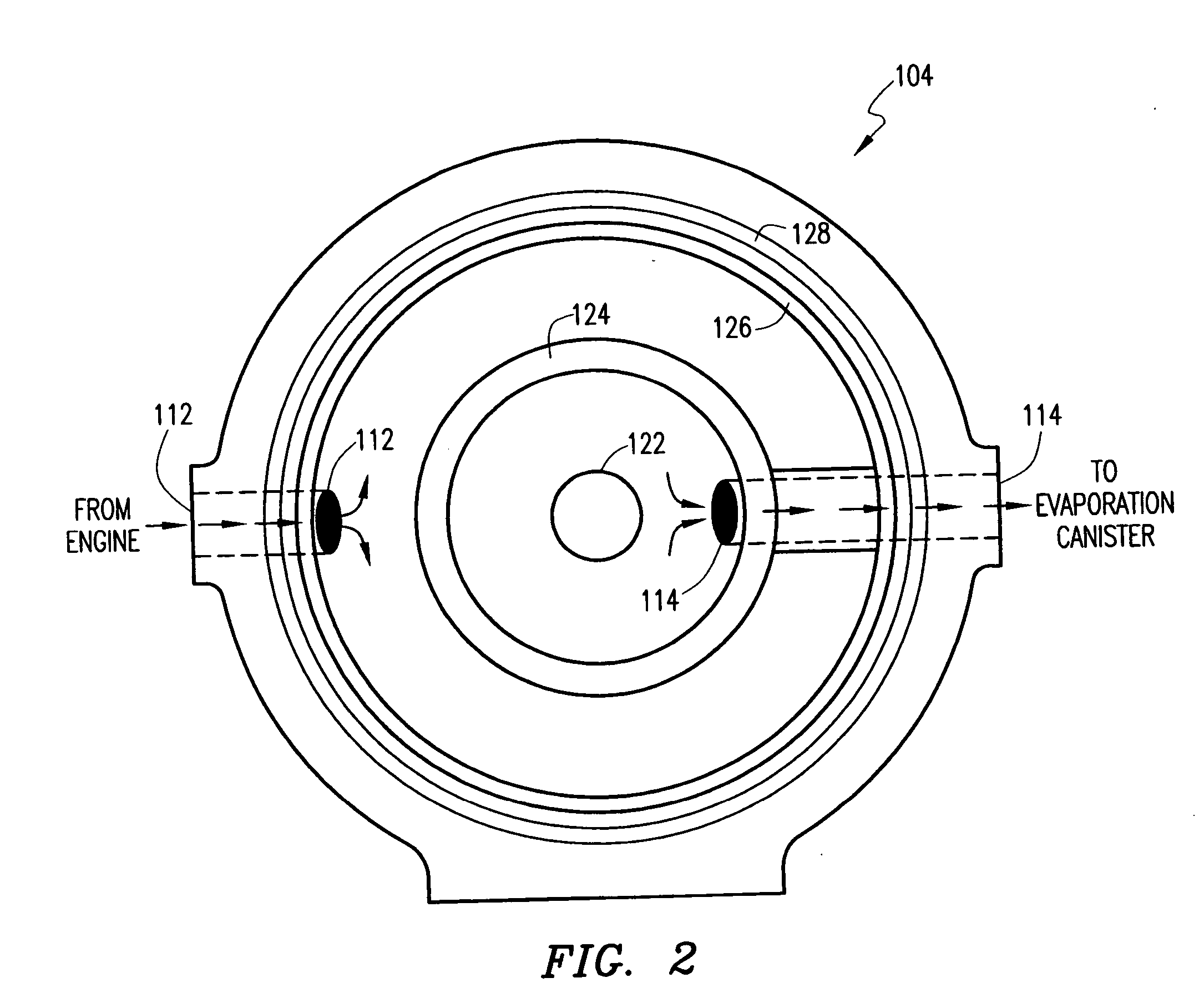

Delivery systems for efficient vaporization of precursor source material

InactiveUS6909839B2Precise deliveryVacuum evaporation coatingSputtering coatingControl flowSource material

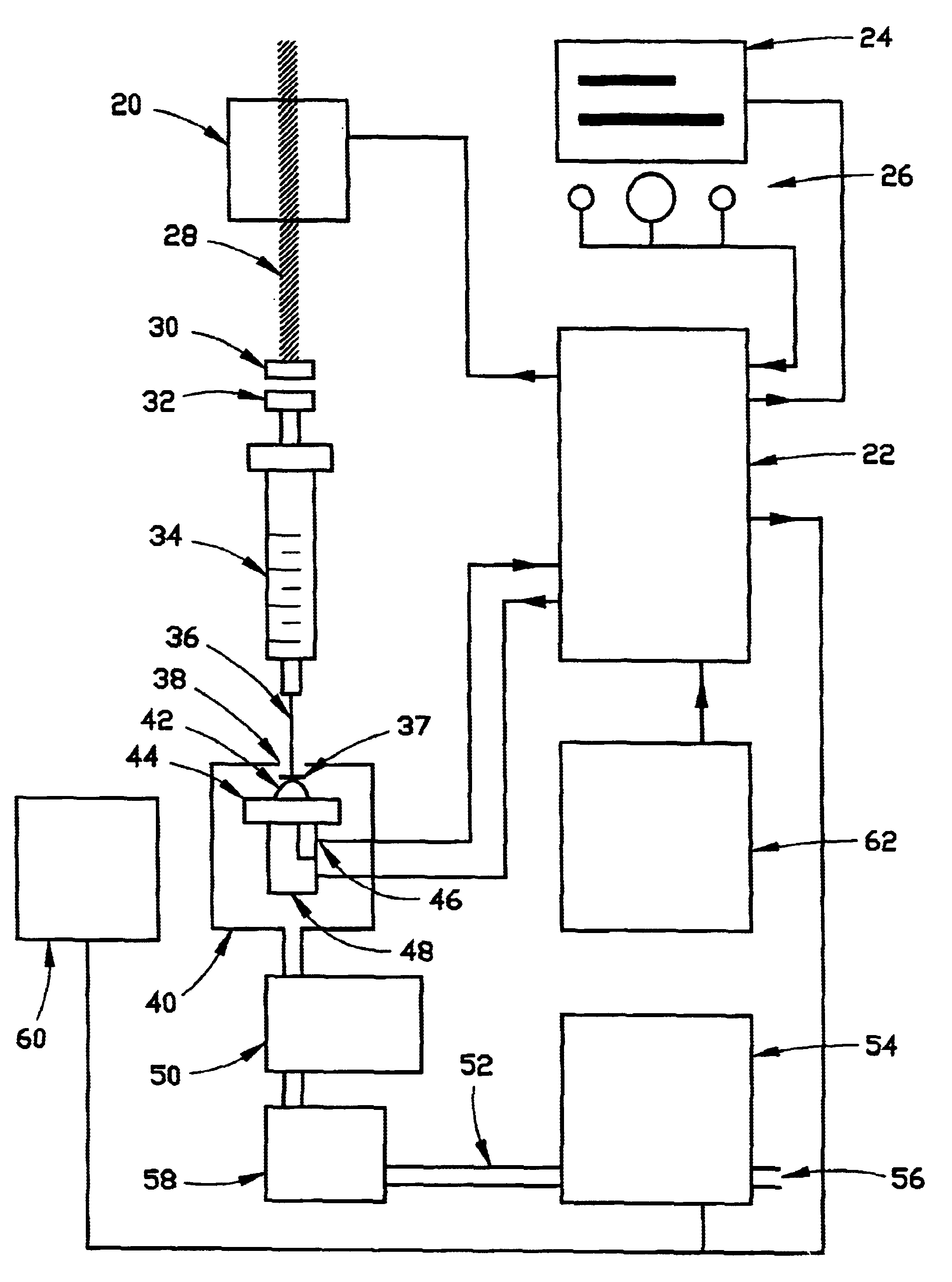

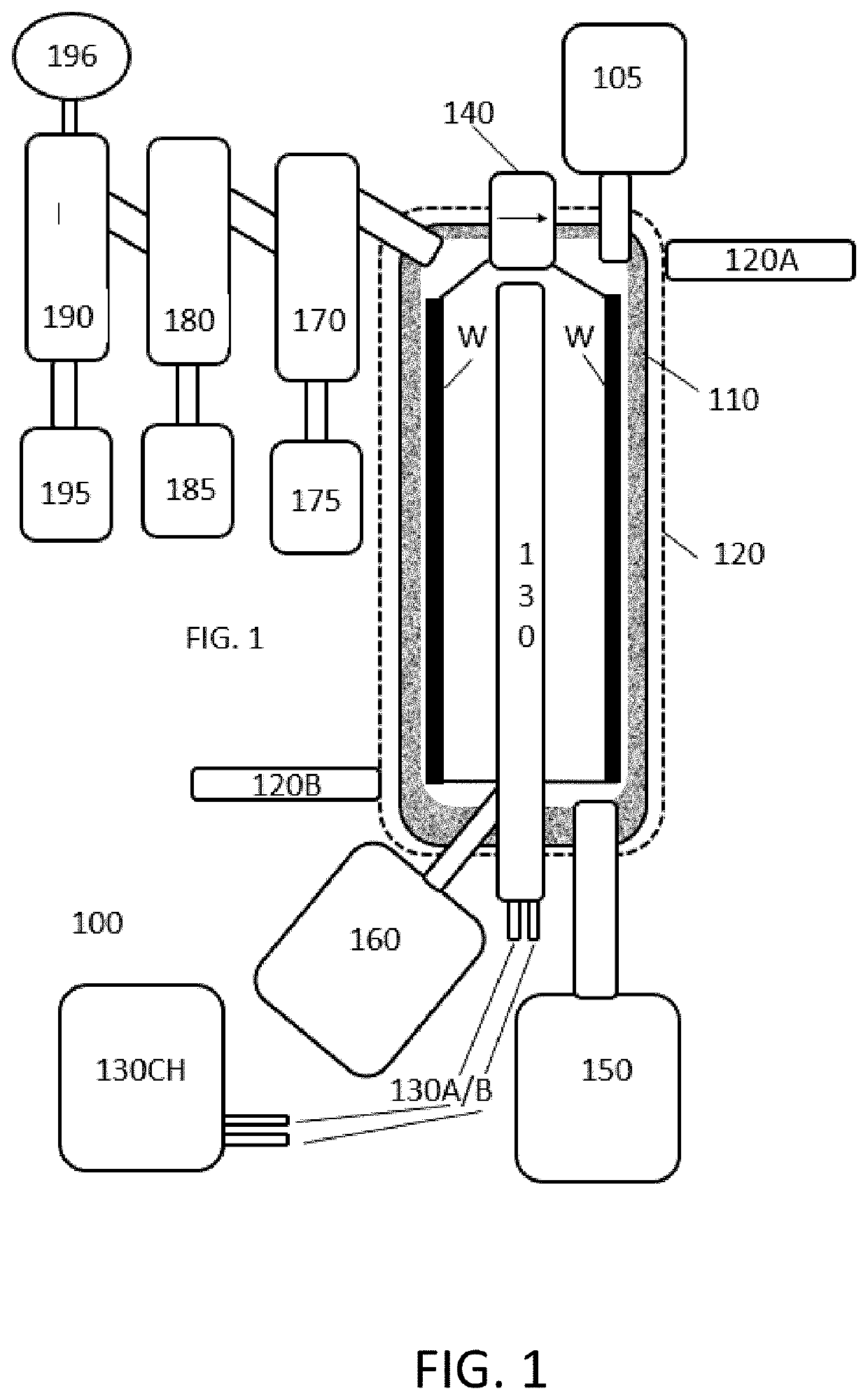

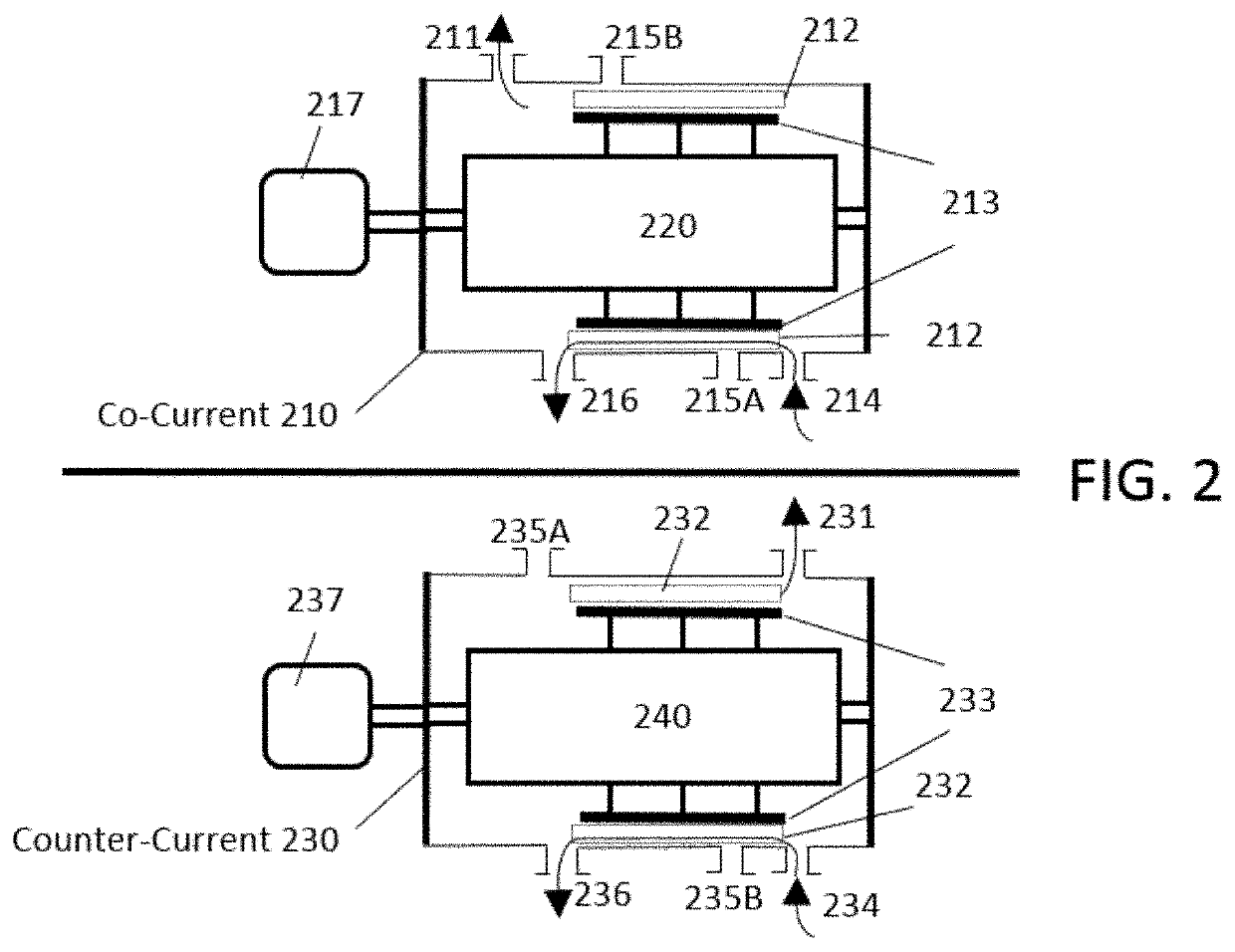

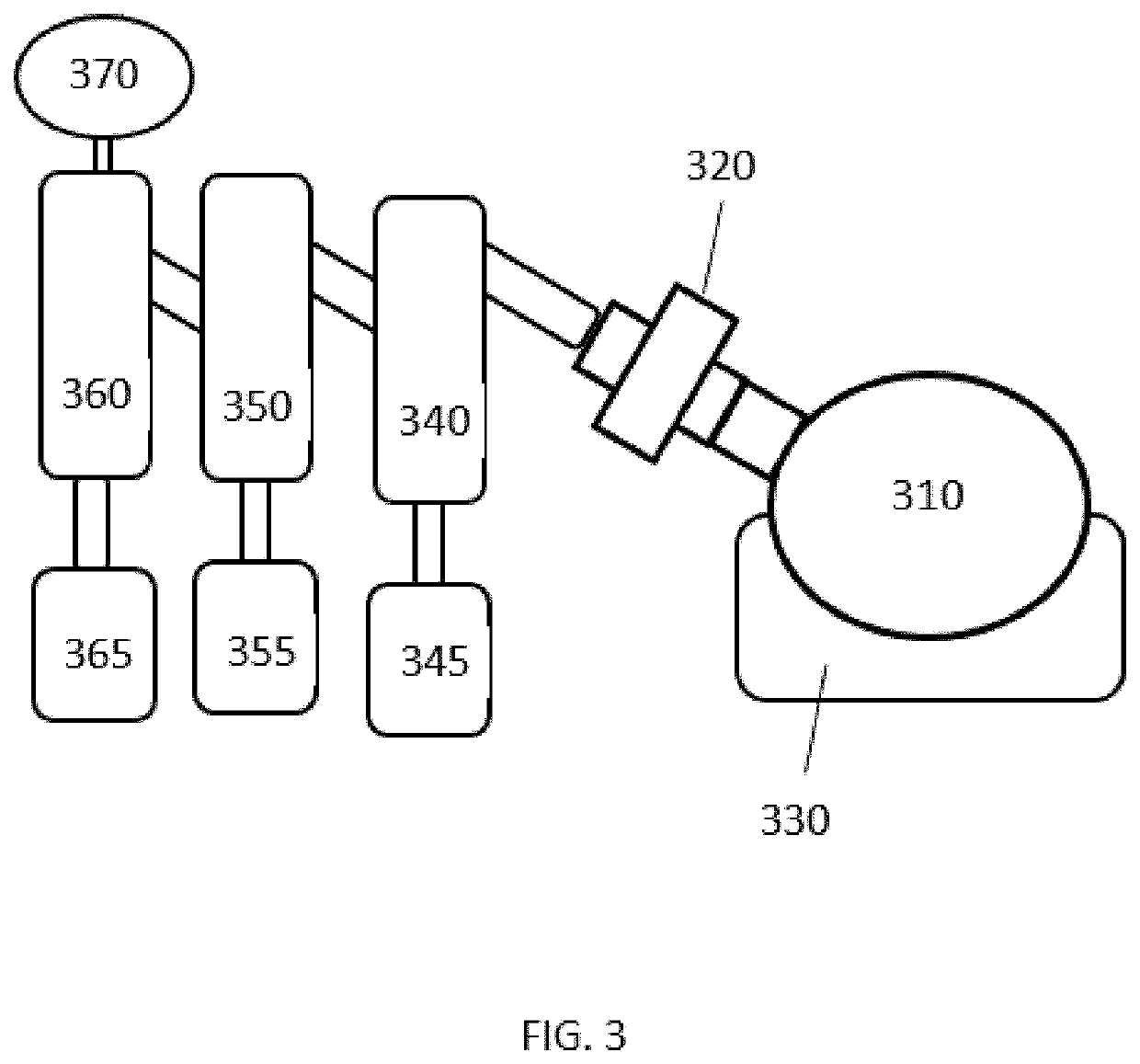

The present invention relates to a delivery system for vaporizing and delivering vaporized solid and liquid precursor materials at a controlled rate having particular utility for semiconductor manufacturing applications. The system includes a vaporization vessel, a processing tool and a connecting vapor line therebetween, where the system further includes an input flow controller and / or an output flow controller to provide a controlled delivery of a vaporizable source material to the vaporization vessel and a controlled flow rate of vaporized source material to the processing tool.

Owner:ENTEGRIS INC

Delivery systems for efficient vaporization of precursor source material

InactiveUS20050019026A1Precise deliveryVacuum evaporation coatingSemiconductor/solid-state device manufacturingControl flowSource material

The present invention relates to a delivery system for vaporizing and delivering vaporized solid and liquid precursor materials at a controlled rate having particular utility for semiconductor manufacturing applications. The system includes a vaporization vessel, a processing tool and a connecting vapor line therebetween, where the system further includes an input flow controller and / or an output flow controller to provide a controlled delivery of a vaporizable source material to the vaporization vessel and a controlled flow rate of vaporized source material to the processing tool.

Owner:ENTEGRIS INC

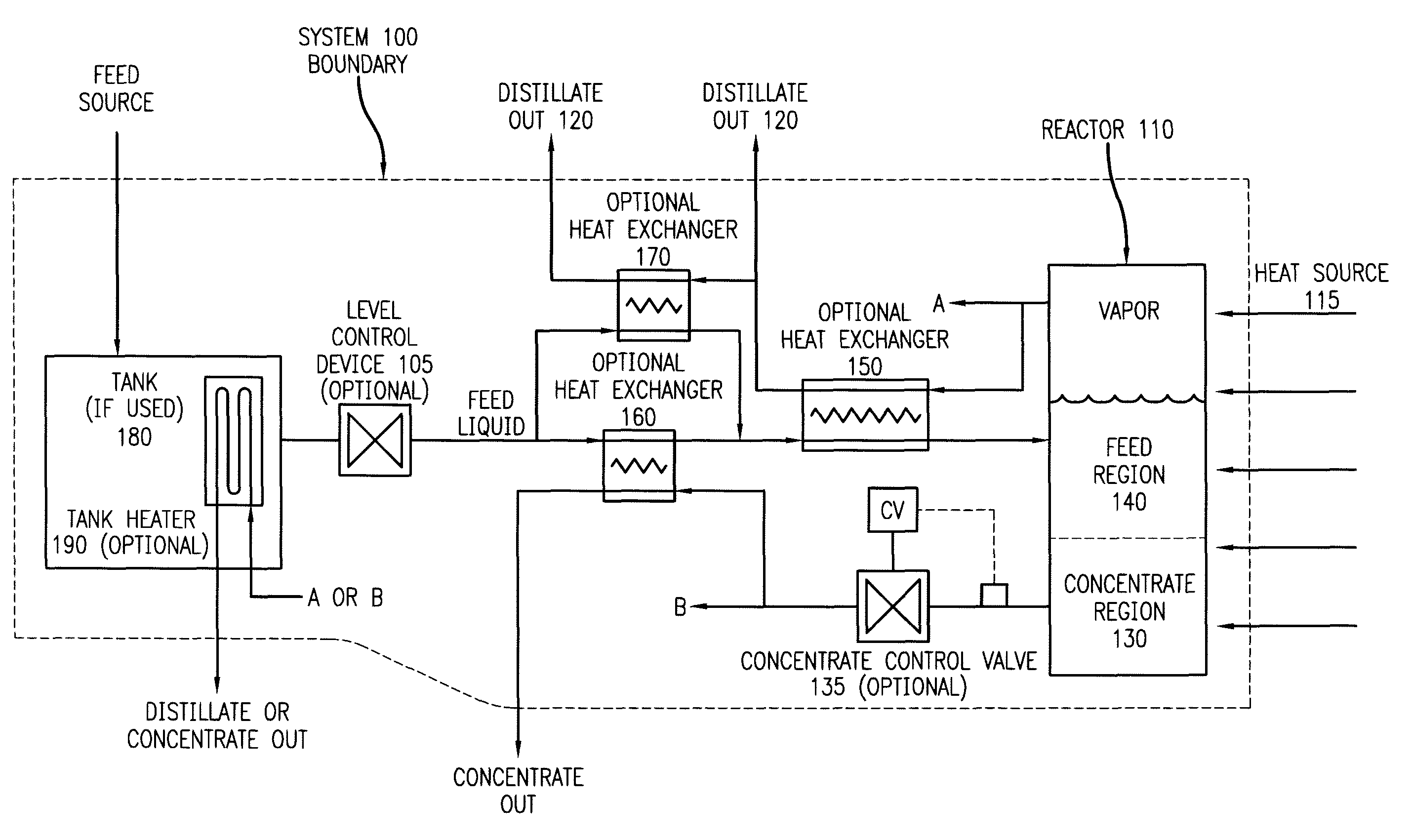

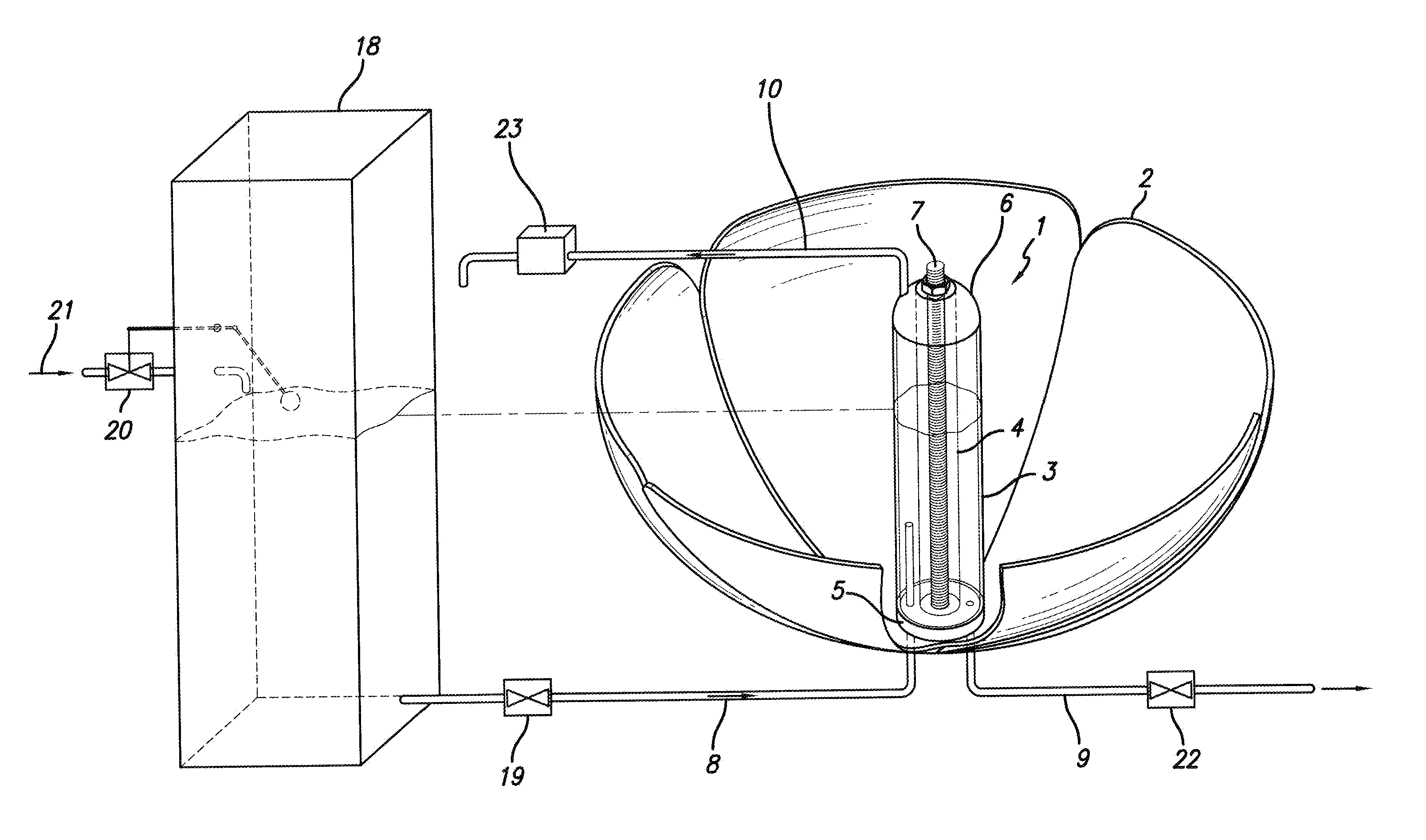

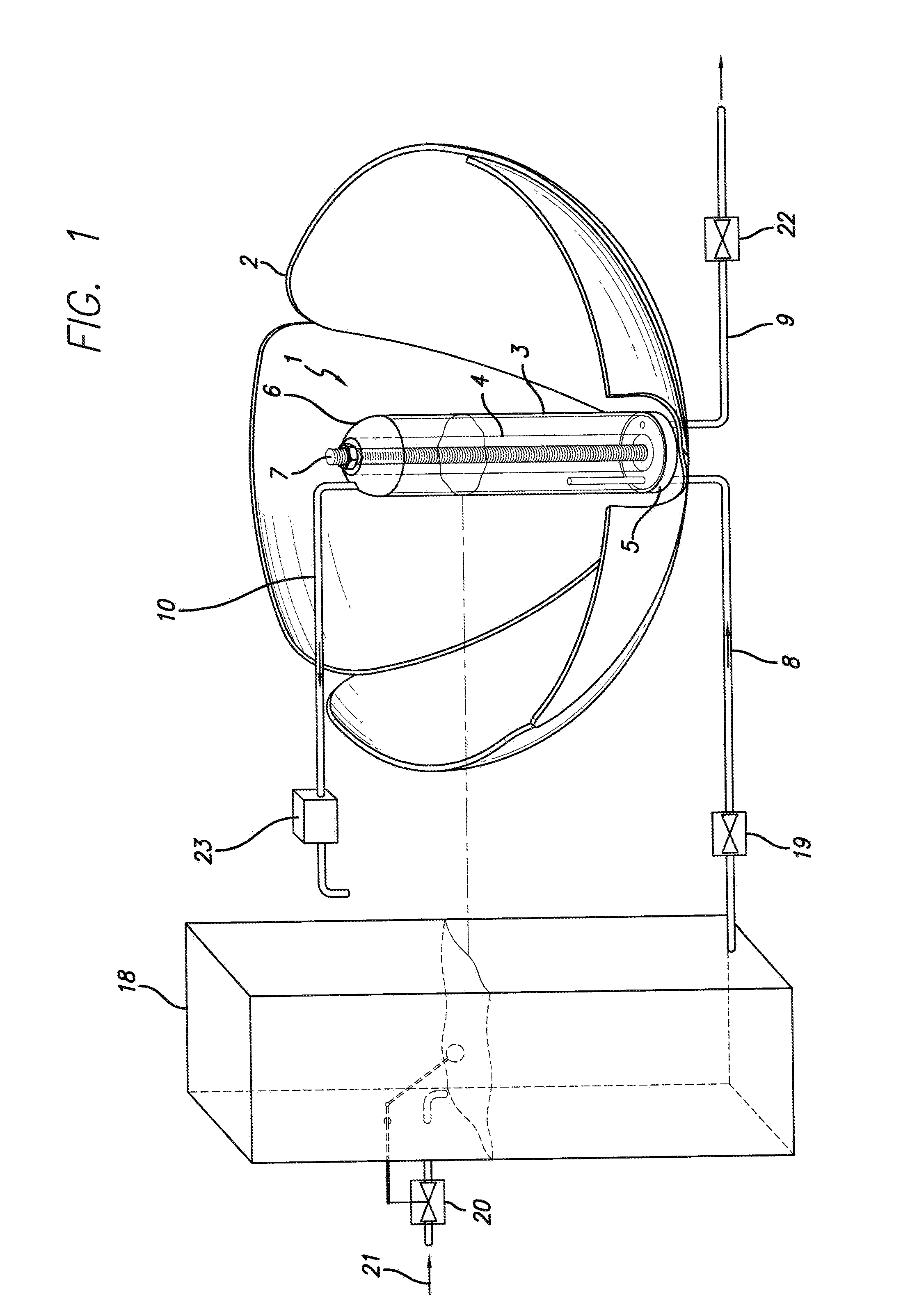

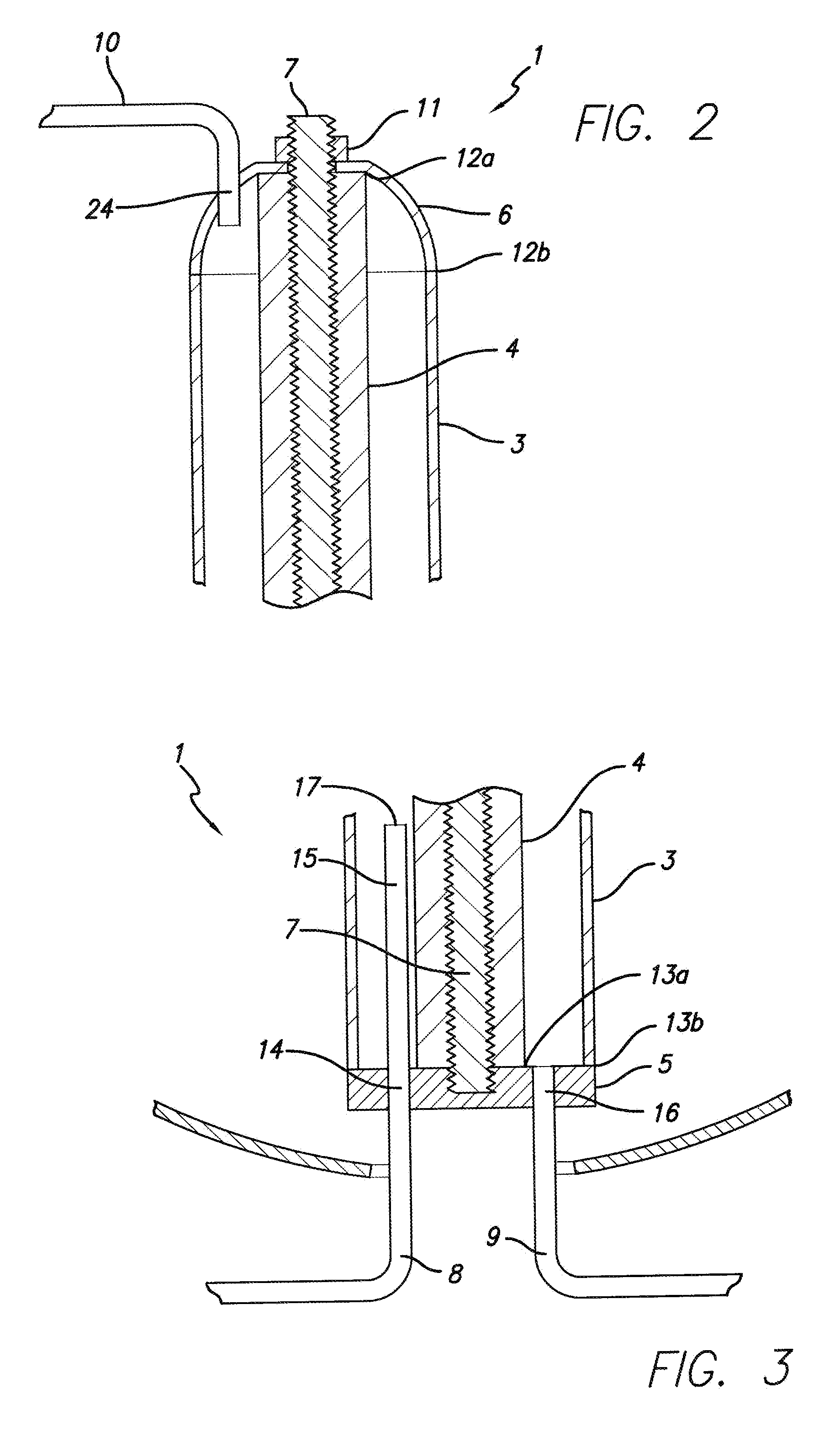

Solar distillation device

A solar distillation apparatus utilizing a substantially vertical reactor assembly is disclosed. The reactor includes a tubular outer shell, a base, a cap, and a central tension member. The annular space between the outer tube and the central tension member forms the reactor chamber. Seawater or other feed liquid enters the reactor chamber through the base plate. Reflected or direct solar energy heats the feed liquid, generating low pressure vapor. The vapor exits the reactor through the cap structure or the base. The concentrate left behind settles by gravity to the bottom region of the reactor's liquid column. Extension tubes on the feed openings allow feed liquid to enter the liquid column above the concentrate layer and avoid excessive mixing of the feed liquid and the concentrate. The concentrate exits the reactor through one or more openings in the base.

Owner:MCCLURE MILES

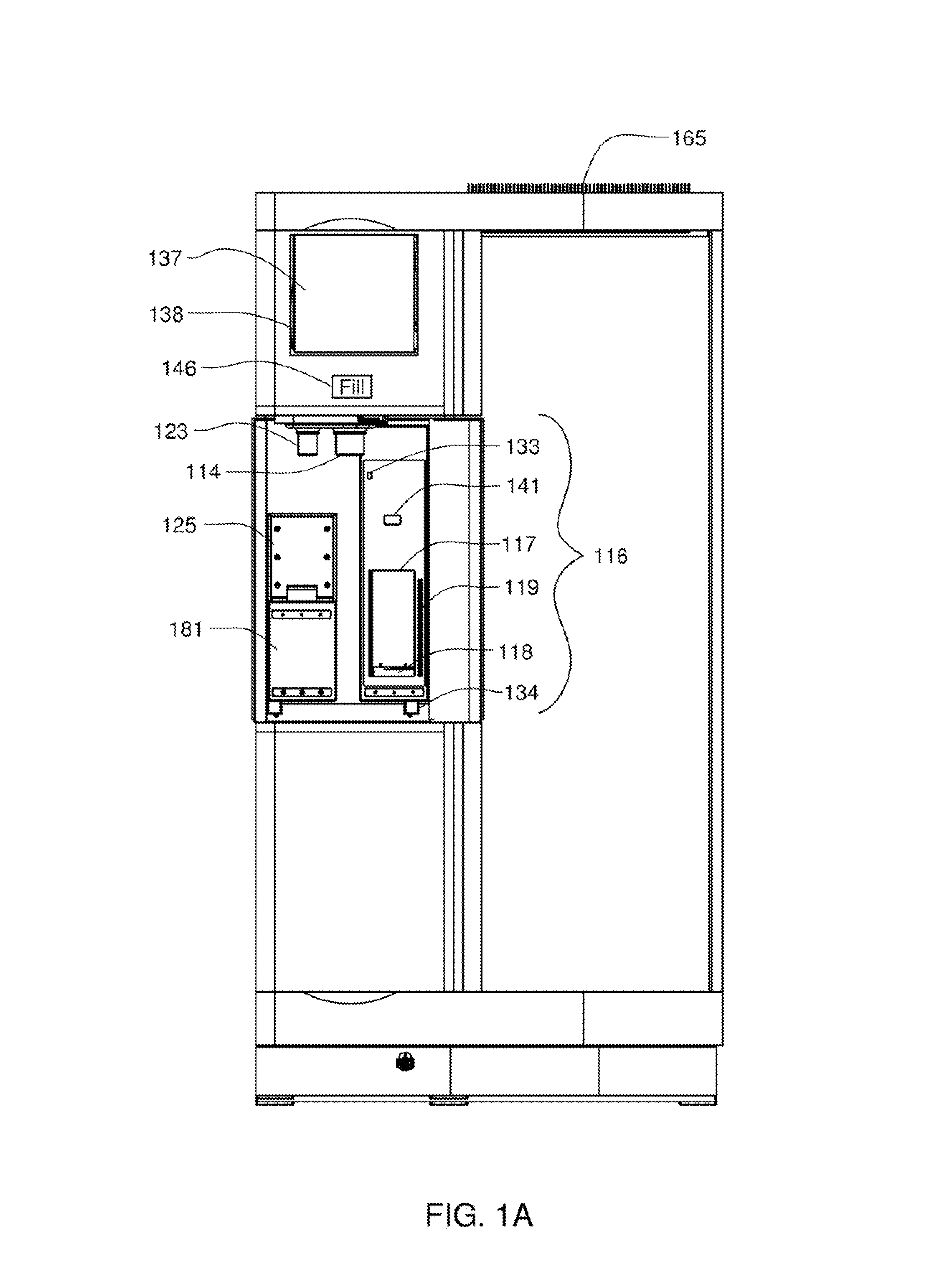

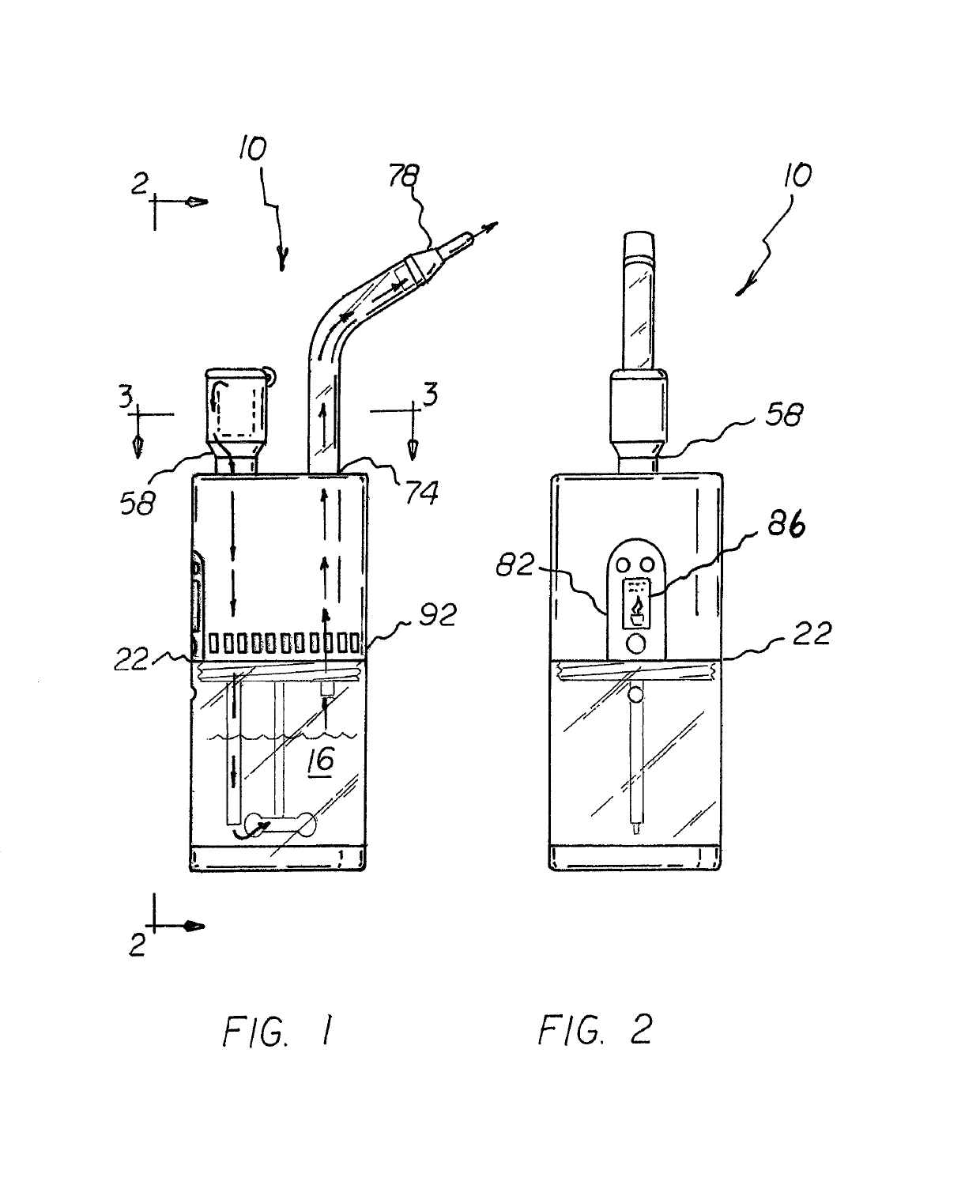

Water vending apparatus

ActiveUS8359877B2Prevents sediment buildupLesser rateEvaporation with vapour compressionLighting and heating apparatusWater vaporSteam distillation

A water vending apparatus is disclosed. The water vending system includes a water vapor distillation apparatus and a dispensing device. The dispensing device is in fluid communication with the fluid vapor distillation apparatus and the product water from the fluid vapor distillation apparatus is dispensed by the dispensing device.

Owner:DEKA PROD LLP

Micro liquid evaporator

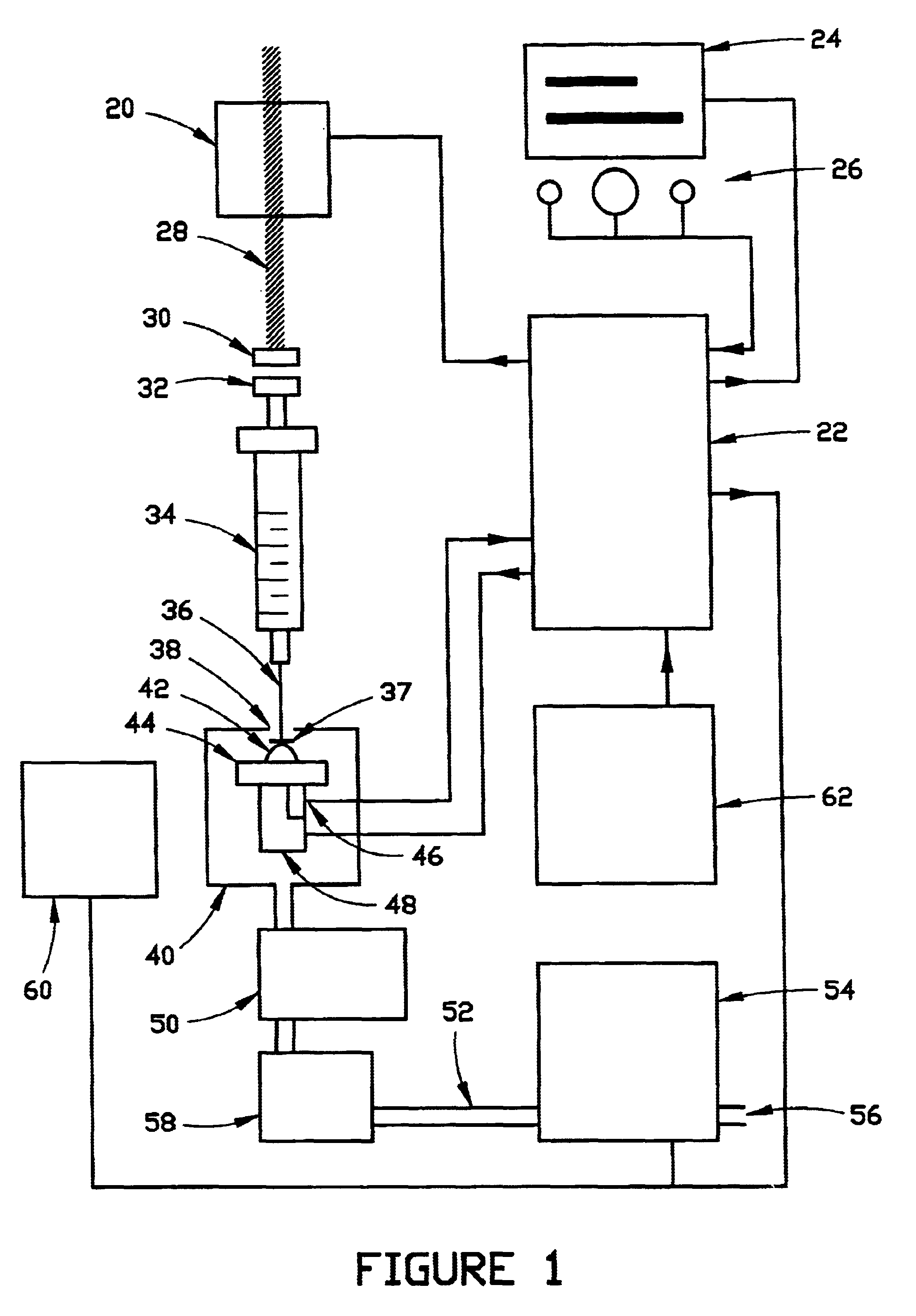

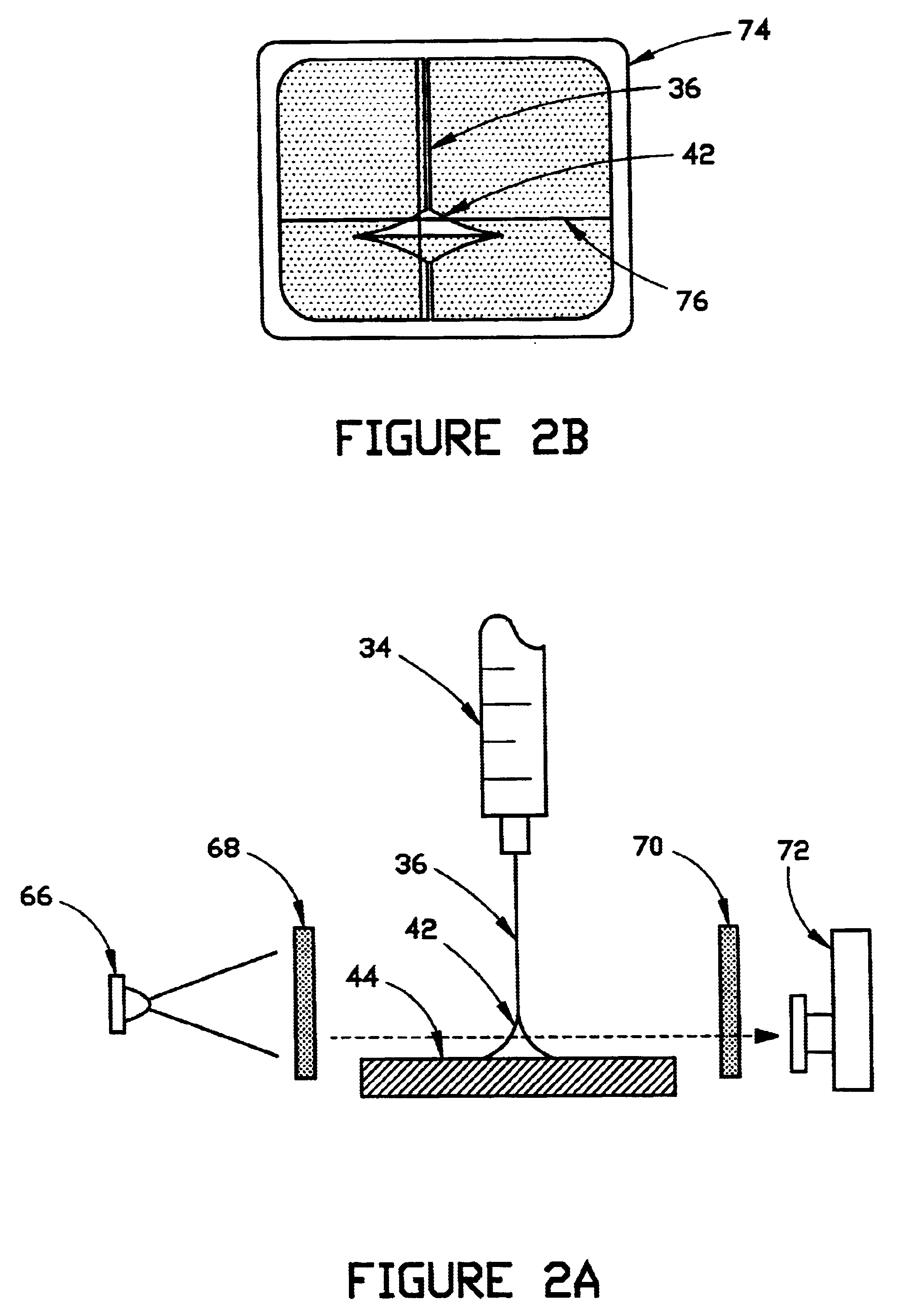

InactiveUS6620620B1Accurate measurementReduce the amount requiredAnalysis using chemical indicatorsLevel controlBoiling pointEvaporation

The drop-by-drop evaporation of a liquid or solution is controlled by monitoring the disappearance of each successive droplet and by actuating the deposition of the next droplet until the desired volume is deposited. In the case of a solution, non-volatile residue (NVR) is collected on a deposition surface plate as a relatively small mound. One of a variety of methods may be employed to measure the evaporative behavior of each droplet and to key the deposition procedure. The process is preferably carried out employing a clean deposition surface plate that is maintained at or below the boiling point of the particular liquid or solvent being deposited. The environment is preferably controlled so that inadvertent contamination is precluded from interfering, and thus the method permits the automatic, micro-processor controlled evaporation of liquids with the resultant deposition of non-volatile residues from solutions within relatively short periods of time. The deposited residue may then be quantified at levels down to and below about 1 ug / mL (1 mg / L) by one of several means for determining the amount of non-volatile residue remaining.

Owner:ERA SYSTEMS CORPORATION

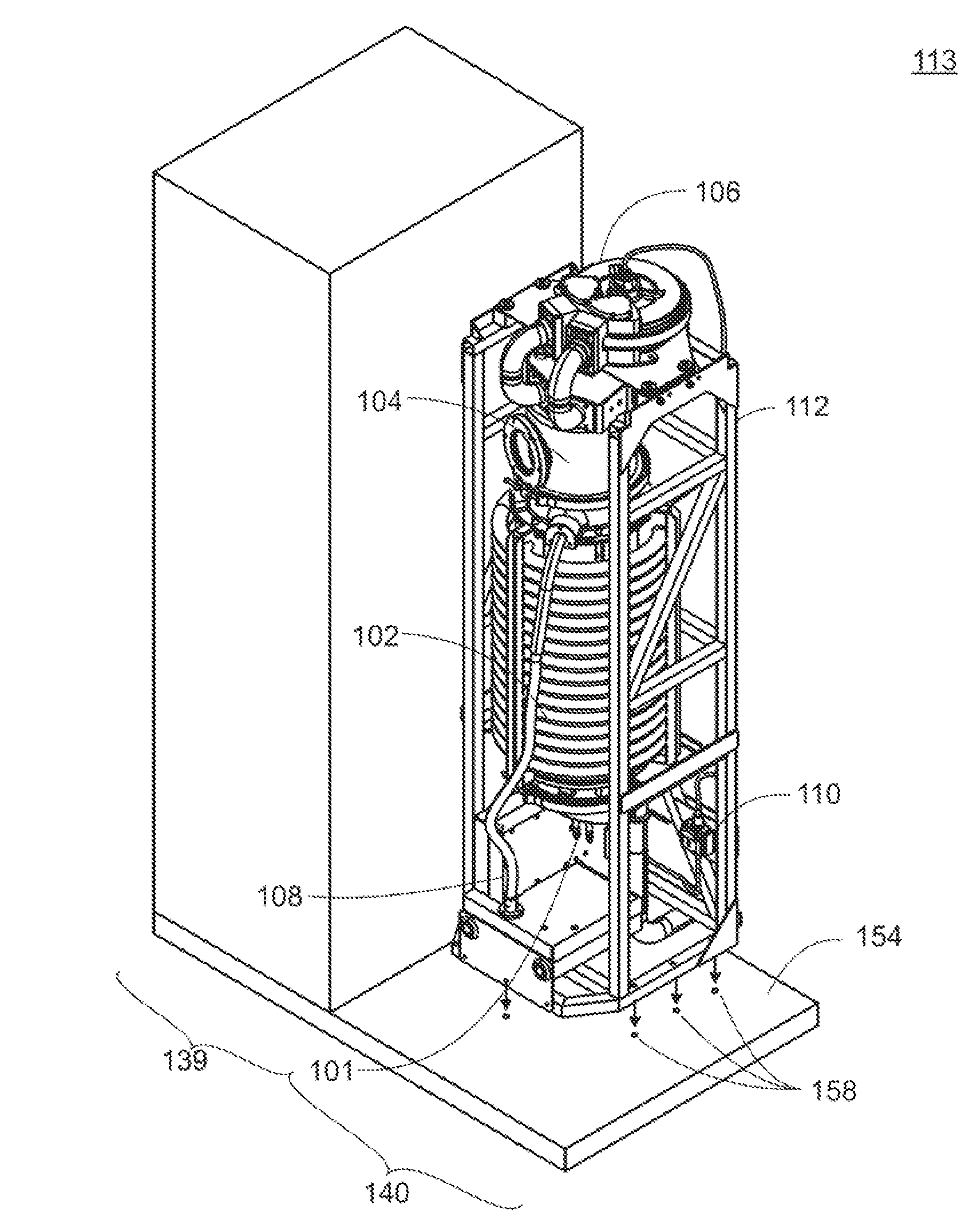

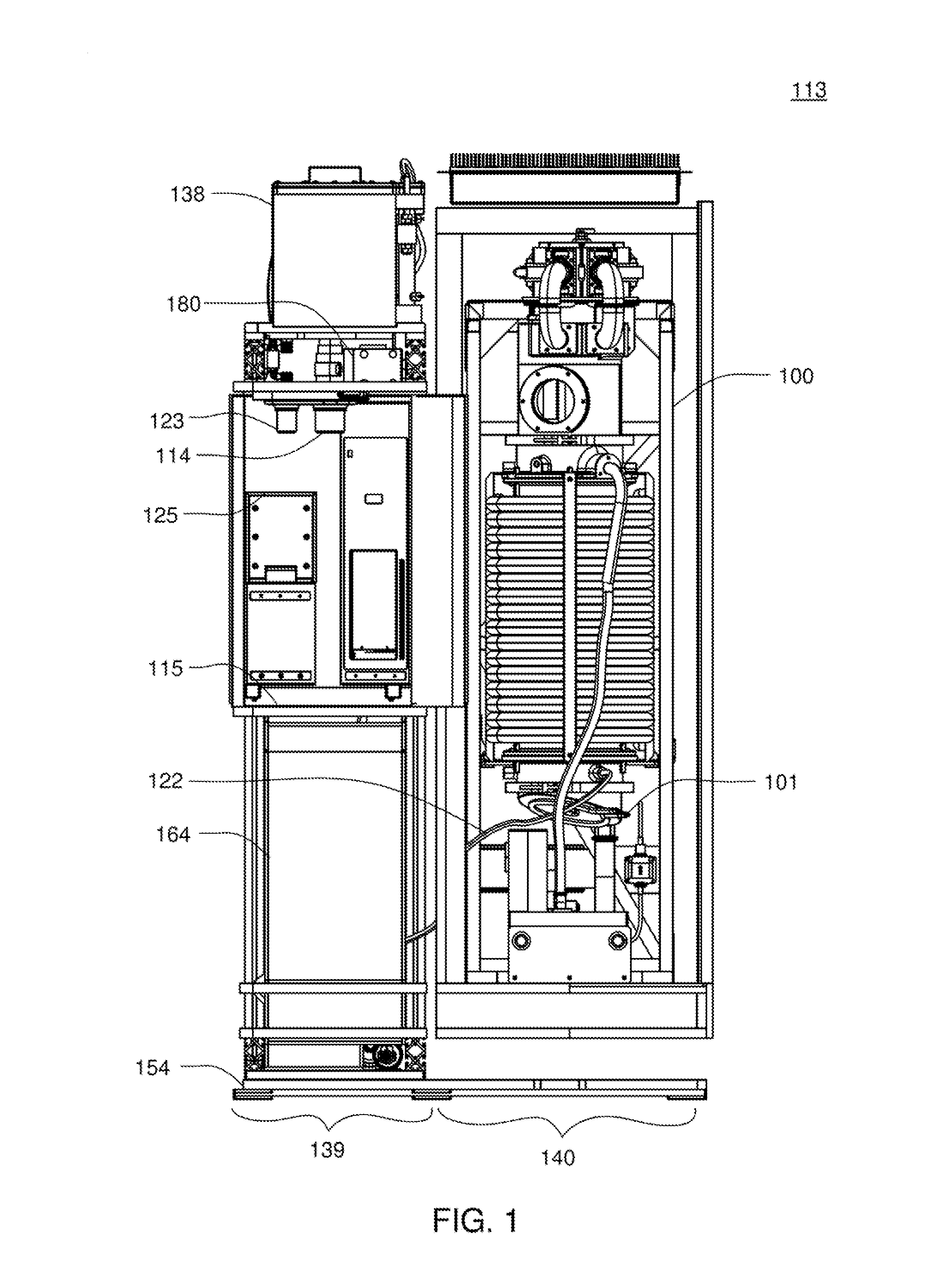

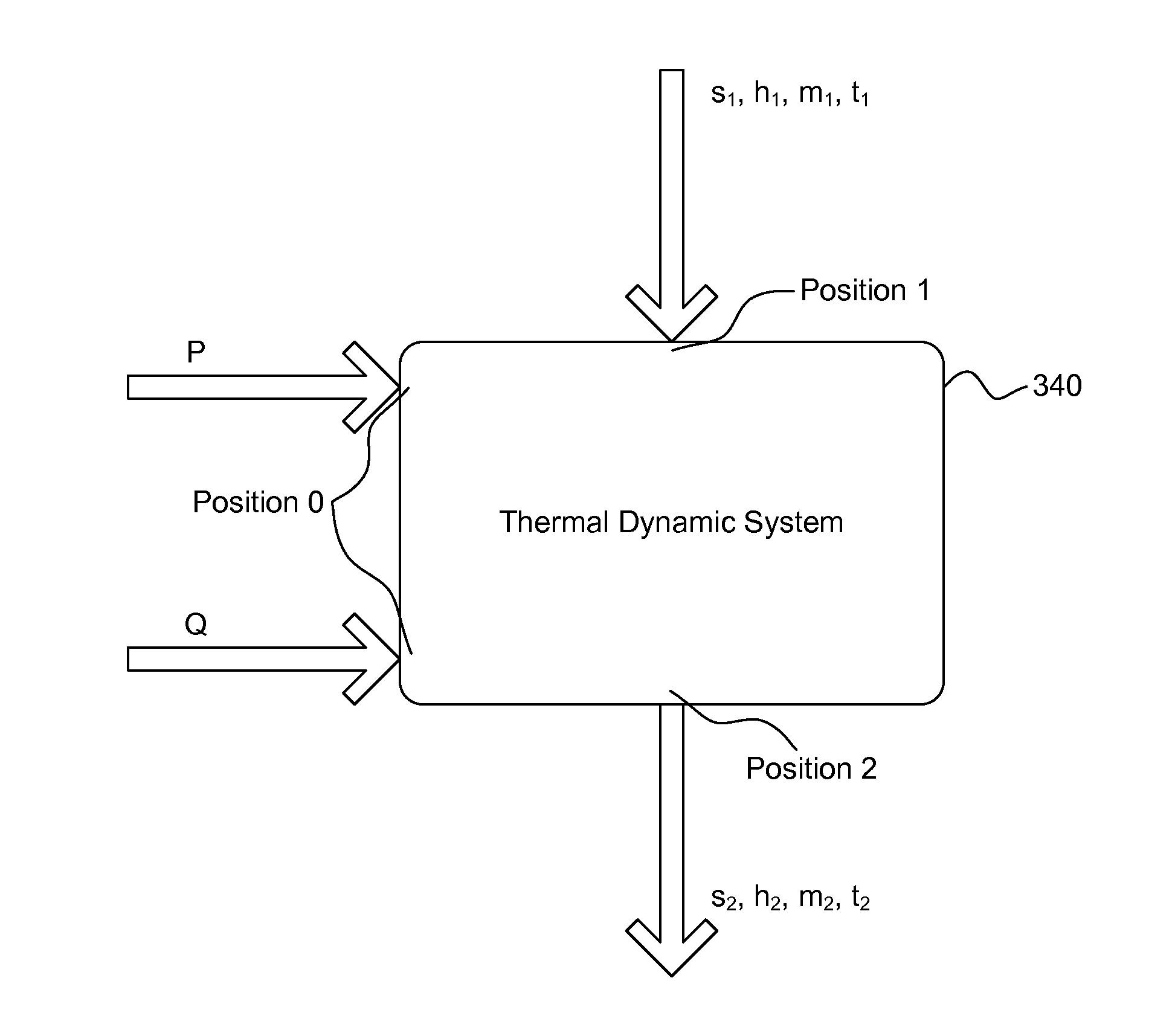

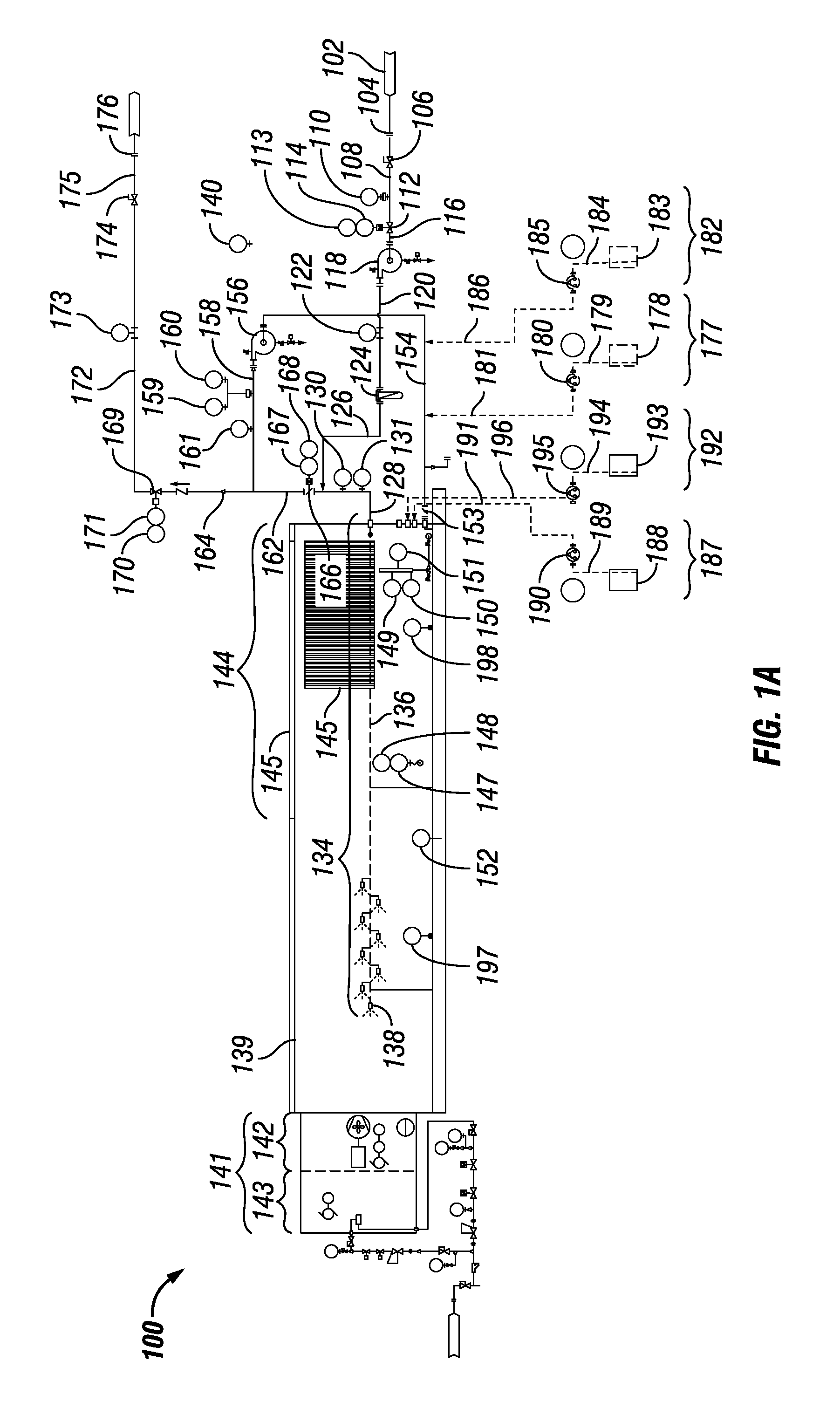

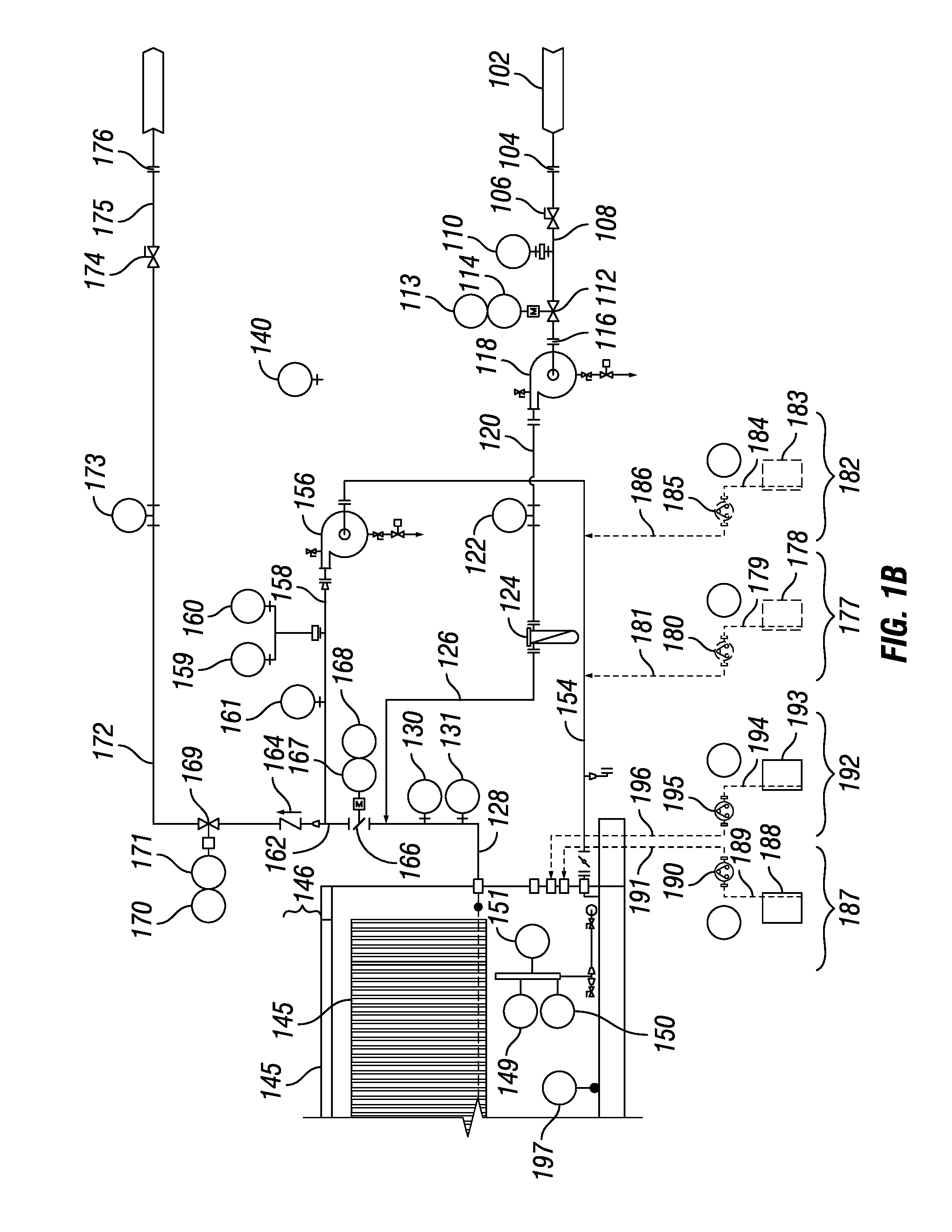

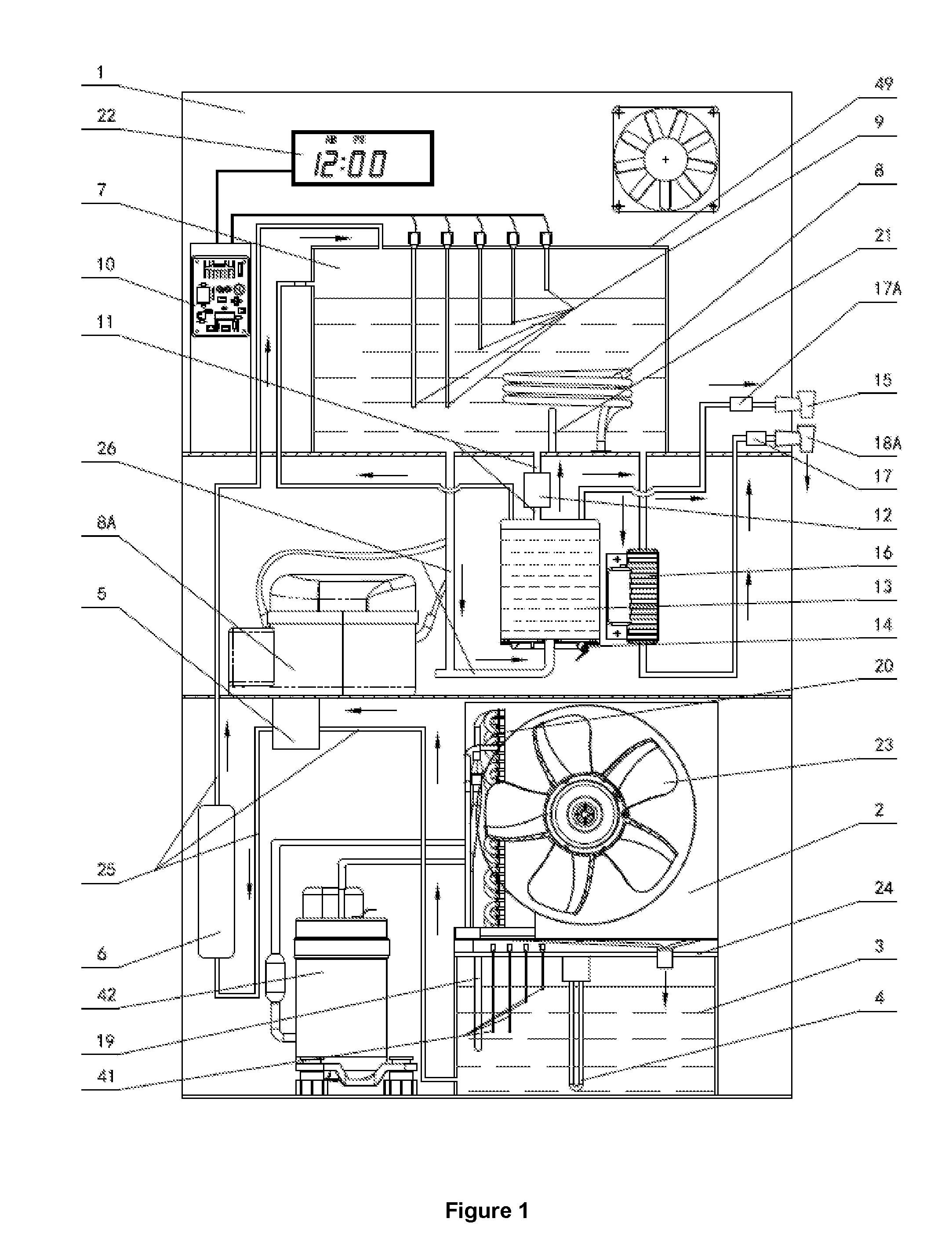

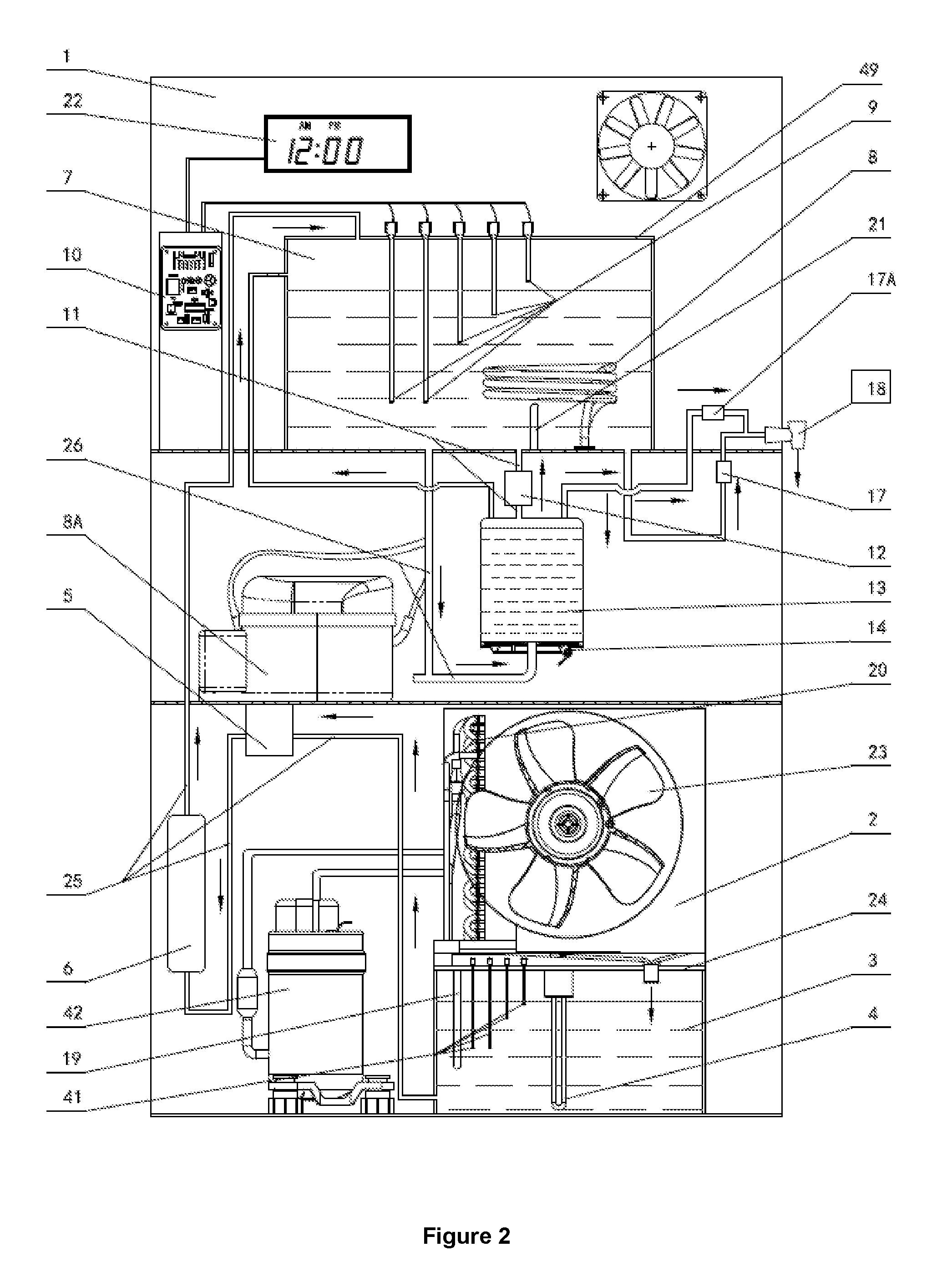

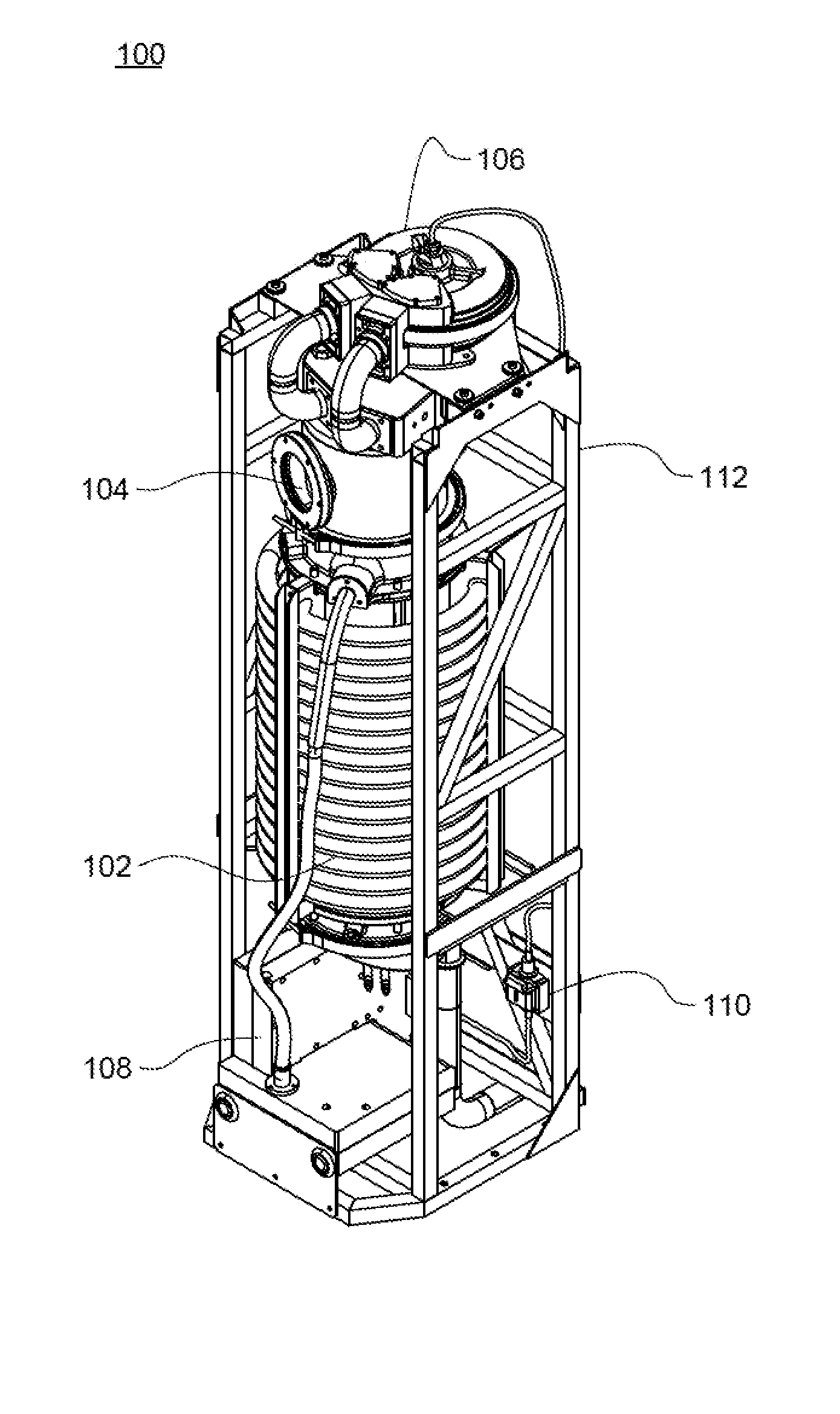

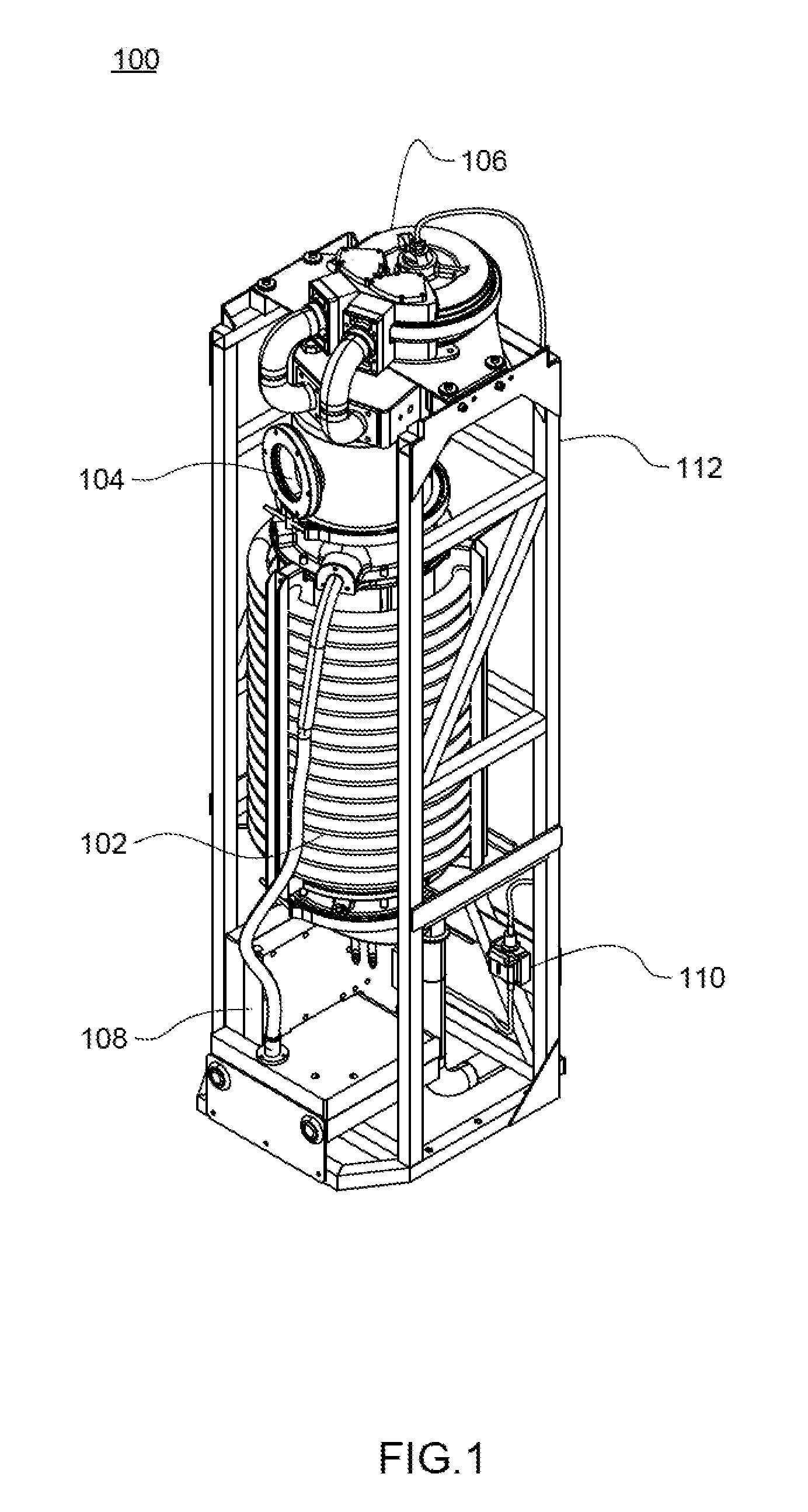

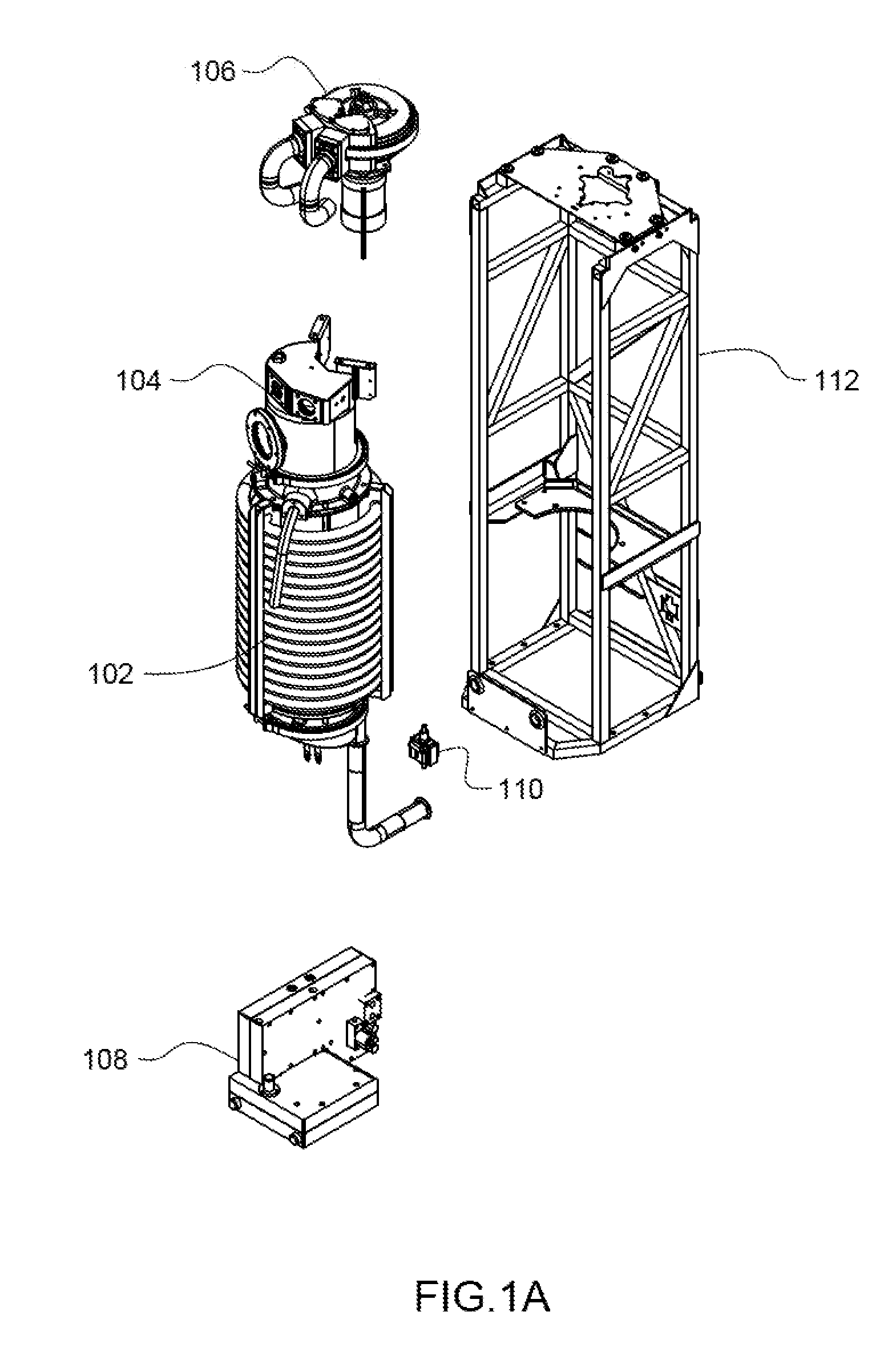

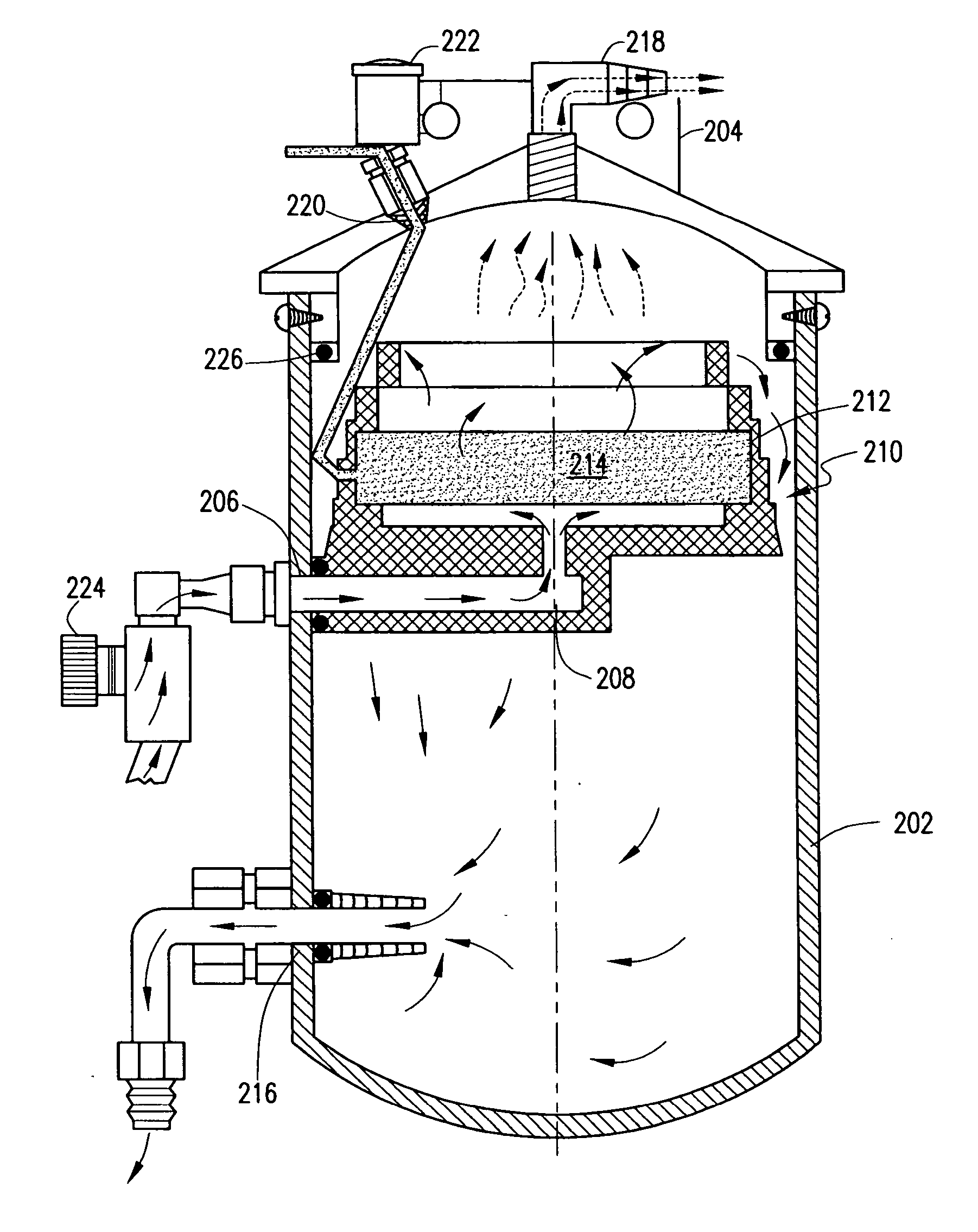

Water vapor distillation apparatus, method and system

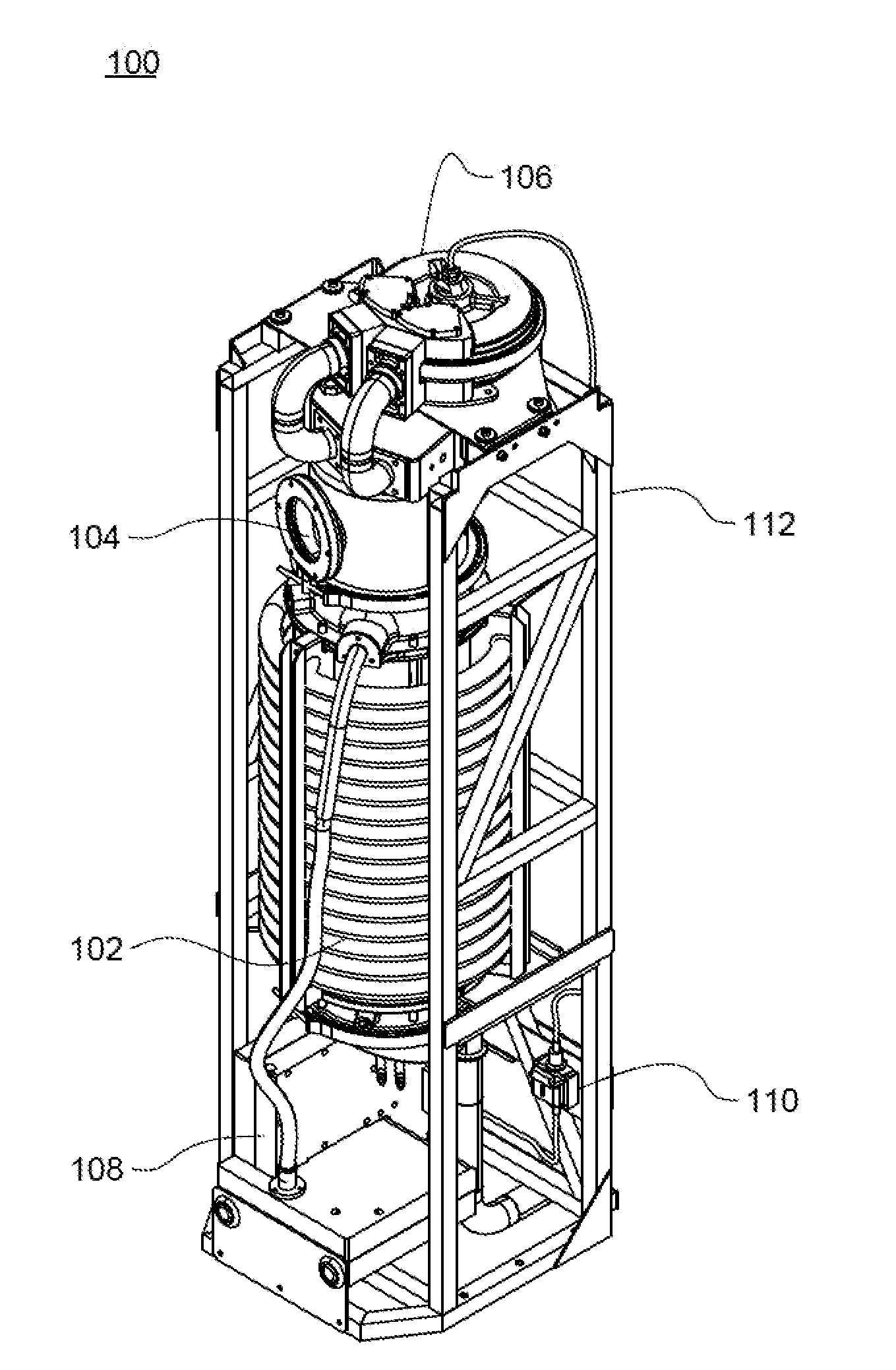

ActiveUS20120006670A1Distillation regulation/controlSpecific water treatment objectivesWater vaporControl system

A fluid vapor distillation apparatus. The apparatus includes a source fluid input, and an evaporator condenser apparatus. The evaporator condenser apparatus includes a substantially cylindrical housing and a plurality of tubes in the housing. The source fluid input is fluidly connected to the evaporator condenser and the evaporator condenser transforms source fluid into steam and transforms compressed steam into product fluid. Also included in the fluid vapor distillation apparatus is a heat exchanger fluidly connected to the source fluid input and a product fluid output. The heat exchanger includes an outer tube and at least one inner tube. Also included in the fluid vapor distillation apparatus is a regenerative blower fluidly connected to the evaporator condenser. The regenerative blower compresses steam, and the compressed steam flows to the evaporative condenser where compressed steam is transformed into product fluid. The fluid vapor distillation apparatus also includes a control system.

Owner:DEKA PROD LLP

Methods and Apparatuses for Water Purification

ActiveUS20130175155A1Low costLow energy methodEvaporation with vapour compressionEvaporator accessoriesEngineeringEvaporation chamber

An apparatus for generating purified liquid from an input liquid, comprises, an evaporation chamber, wherein the evaporation chamber is flooded with the input liquid; and a condensation chamber having channels, wherein the channels are disposed in the input liquid, wherein liquid-saturated gases are generated from the input liquid in the evaporation chamber, wherein the liquid-saturated gases are guided into a first end of the channels, and wherein the purified liquid is outputted at a second end of the channels.

Owner:CHANG HUEI MENG

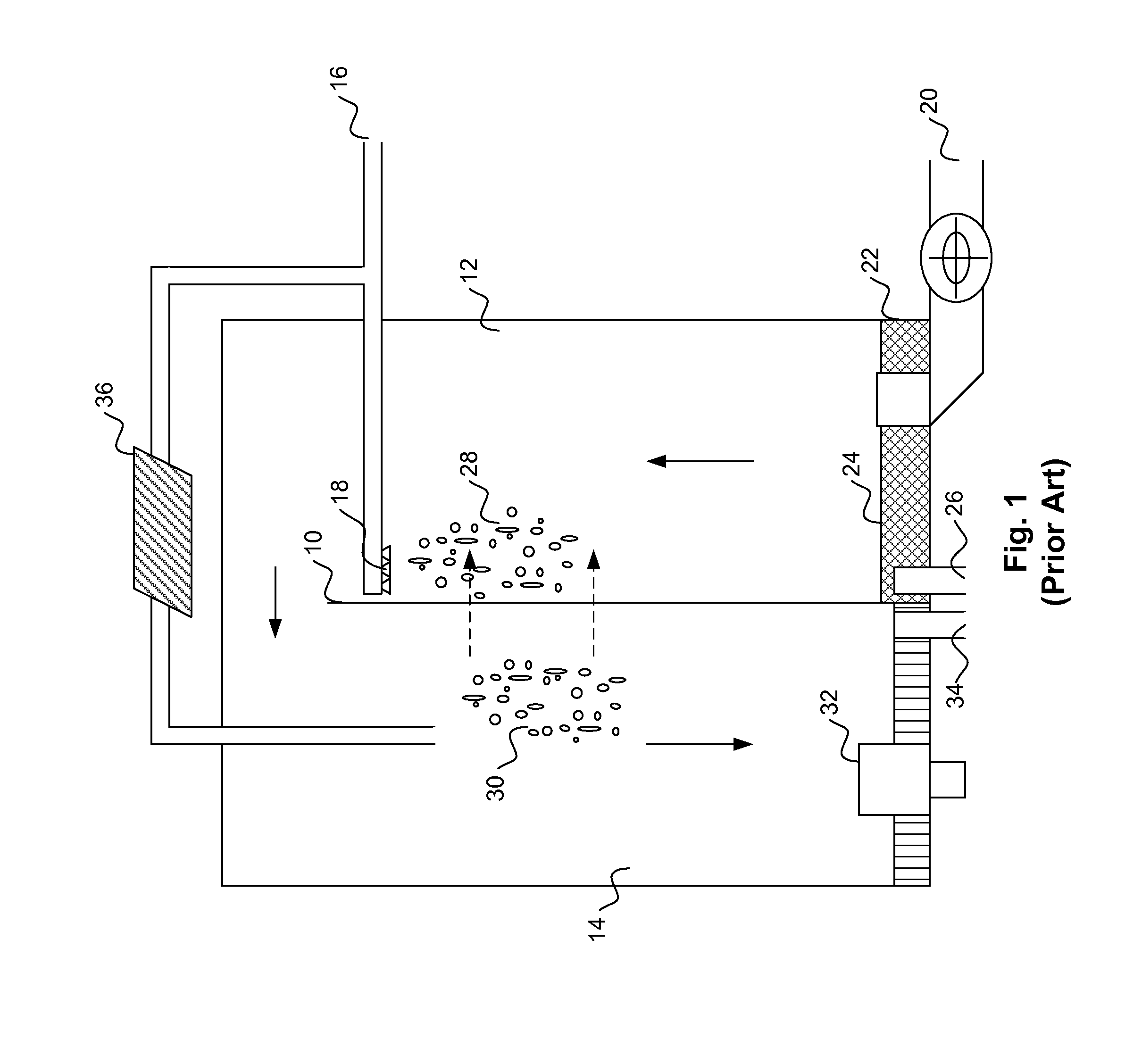

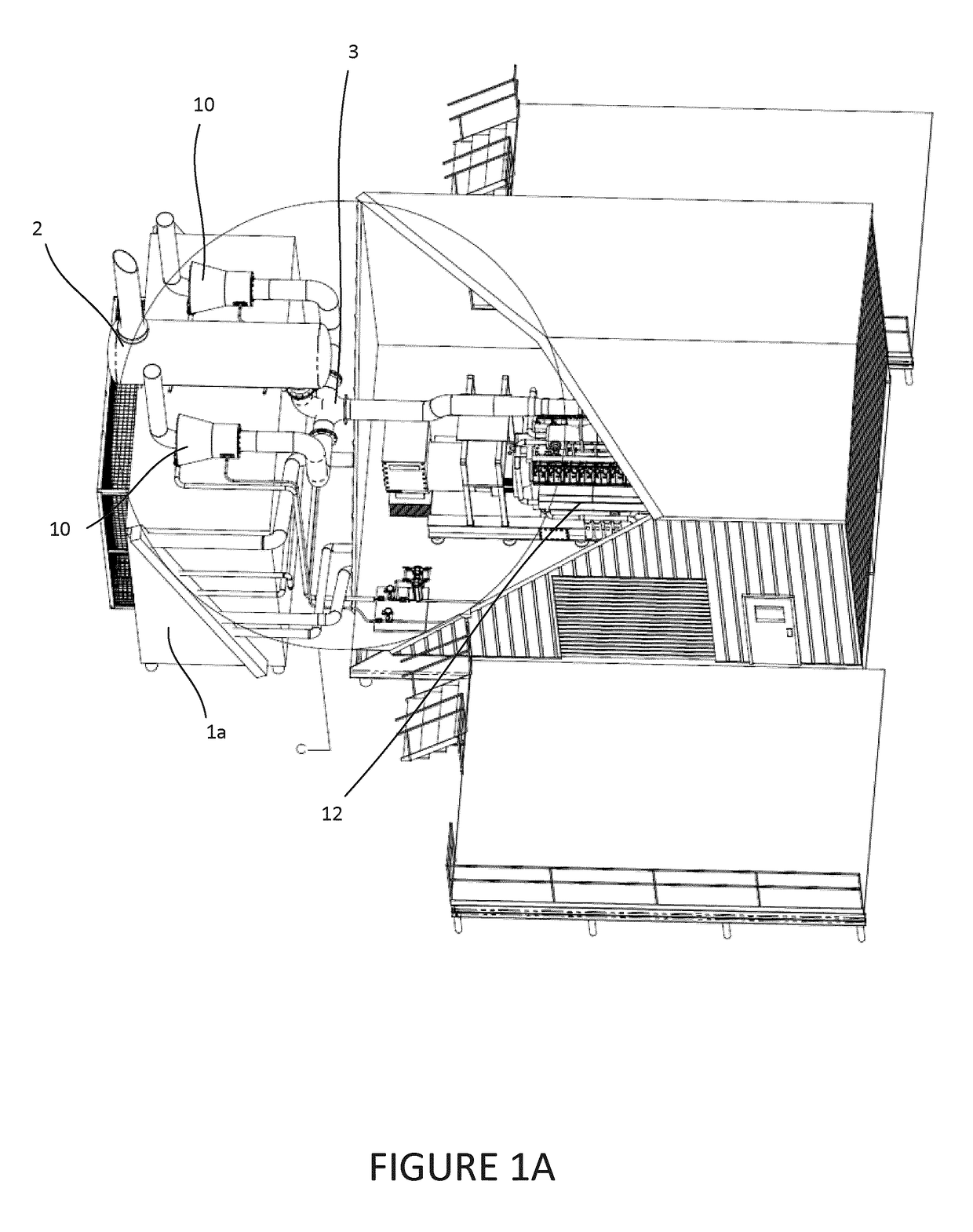

Containerized system and method for spray evaporation of water

InactiveUS20160362307A1Maximizes evaporation rateLimit size of water dropletGeneral water supply conservationEnergy based wastewater treatmentWastewaterEvaporation

A system for spray evaporating water comprising: a wastewater inlet; a pump, where an outlet of the wastewater inlet is fluidly connected to an inlet of the pump and wherein an outlet of the pump is fluidly connected to an inlet of a manifold; a spray nozzle, wherein an outlet of the manifold is fluidly connected to an inlet of the spray nozzle; a container, wherein an upper portion of the container is enclosed with a demister element and wherein the outlet of the spray nozzle discharges into the container; and a discharge outlet, wherein a bottom of the container is fluidly connected to the discharge outlet. A method of spray evaporating water is also disclosed.

Owner:ENERGY WATER SOLUTIONS LLC

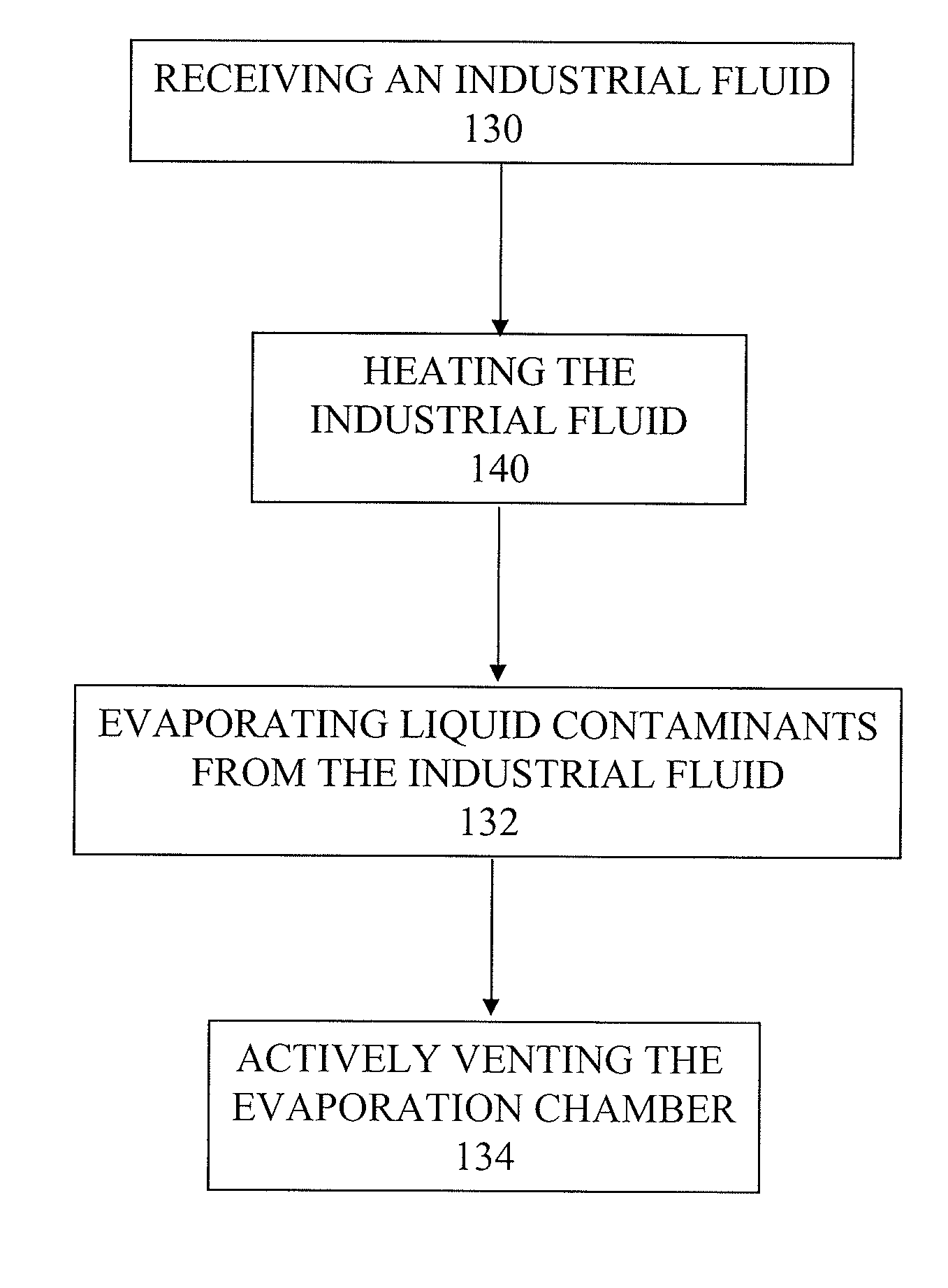

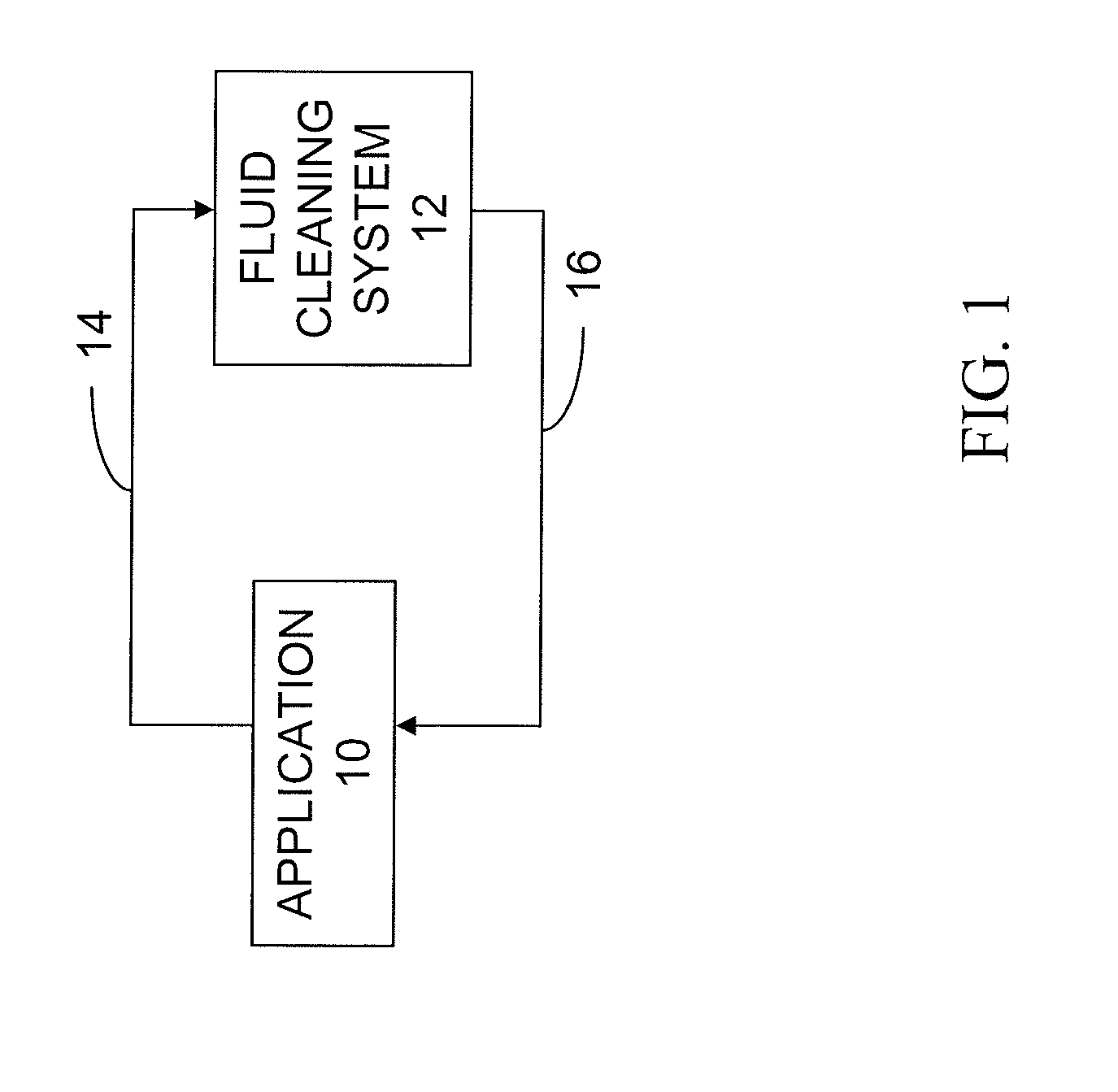

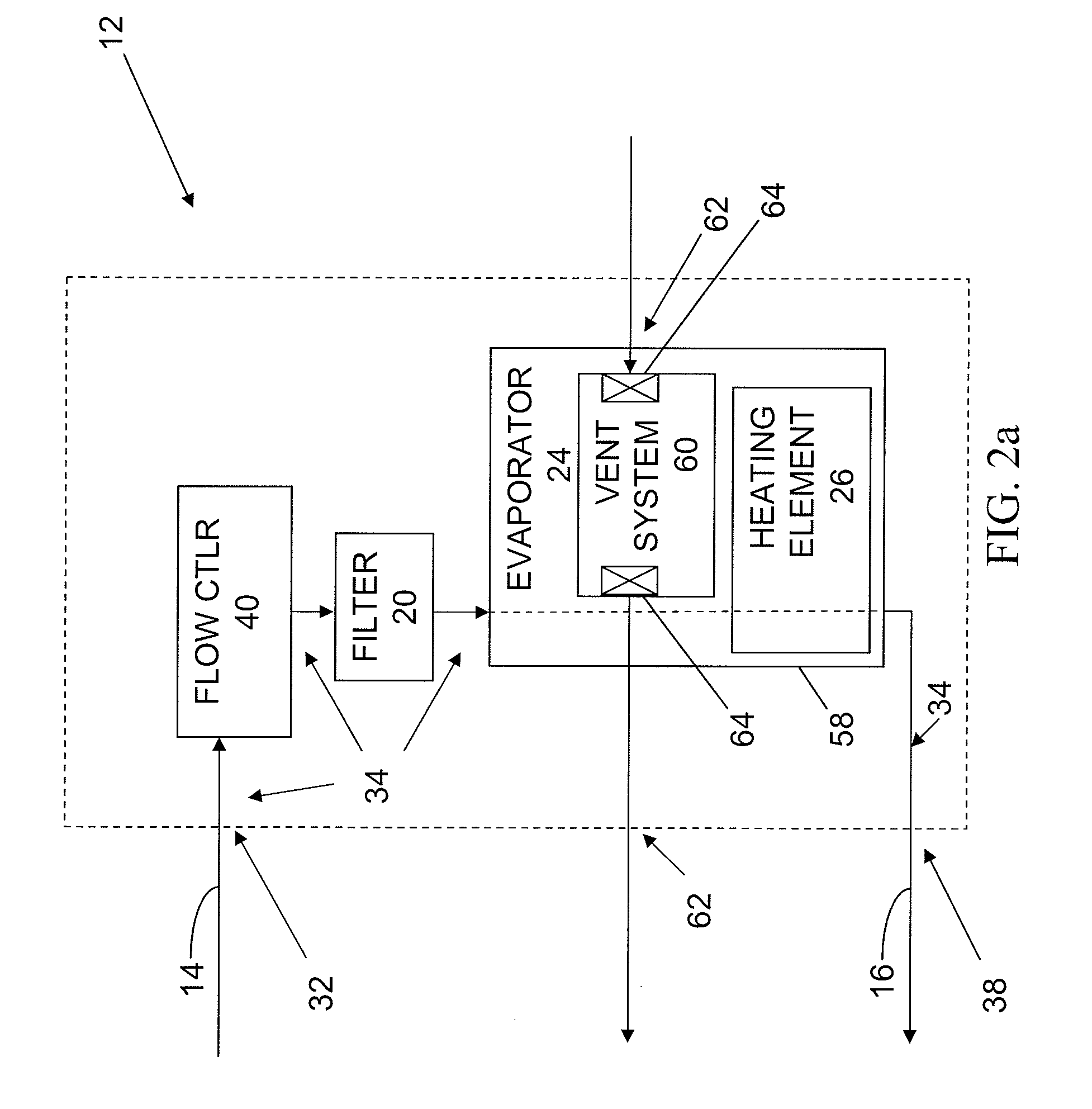

Method and apparatus for fluid cleaning

InactiveUS20100025341A1Easy to changeImprove performanceEvaporator accessoriesSettling tanks feed/dischargeEngineeringFluid supply

A fluid cleaning system including a fluid supply port, a fluid return port, an evaporator including an air intake vent and an air exhaust vent, a ventilation system connected to the evaporator, and a fluid line. The evaporator includes a ventilation air path through the evaporator and connected to the intake vent and the exhaust vent in the evaporator. The evaporator also includes an active airflow device located along the ventilation path. The fluid line connects the evaporator between the fluid supply port and the fluid return port.

Owner:OIL PURIFICATION SYST

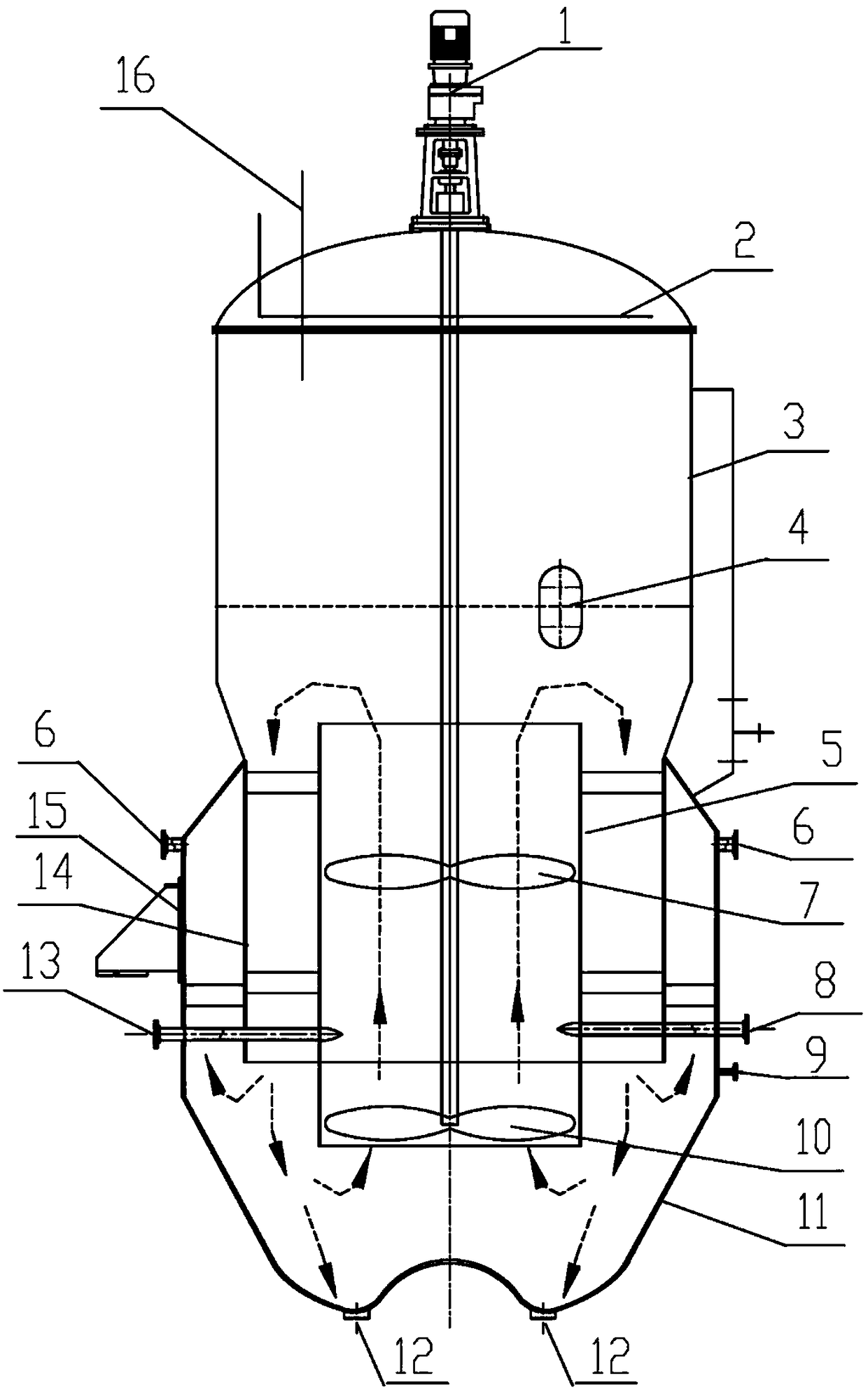

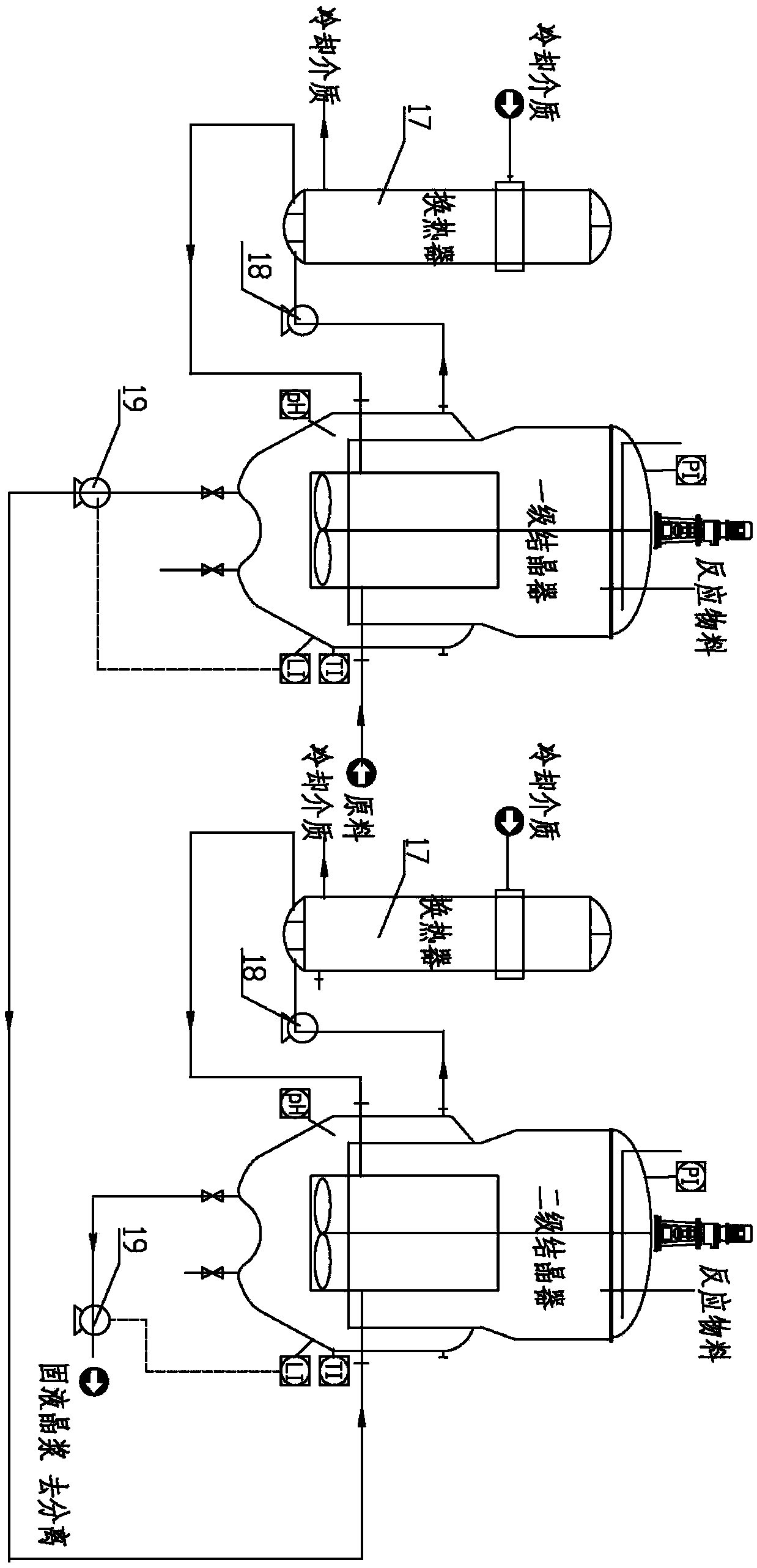

Self-circulating crystallizer and multistage continuous crystallization method

ActiveCN108939599AReduce the chance of collision nucleationStable particle sizeEvaporator accessoriesSolution crystallizationGranularityEvaporation

The invention relates to a self-circulating crystallizer and a multistage continuous crystallization method. The crystallizer sequentially comprises a kettle head, an upper cylinder body, a middle cylinder body and a bottom hole-shrinkage cylinder body with a W-shaped bottom from top to bottom, wherein a steam outlet and / or a feeding hole are / is arranged on the kettle head, an annular spraying pipe is arranged at the lower part of the kettle head; a middle straight cylinder section is arranged in the middle cylinder body, a flow guiding cylinder is arranged in the middle straight cylinder section, and a stirrer is arranged in the flow guiding cylinder; the diameter of the middle cylinder body is larger than that of the upper cylinder body, and the diameter of the upper cylinder body is larger than that of the middle cylinder body; and the lower part of the upper cylinder body and the upper part of the middle cylinder body are respectively connected with the circumference of the top ofthe middle straight cylinder section via a hole-shrinkage transition section, and a discharging hole is formed in the W-shaped bottom. The invention provides the method for realizing multistage continuous evaporation, cooling or reaction crystallization through the series connection of the crystallizer, the prepared crystals are large in granularity and uniform in particle size, the problems thatthe product granularity is small, equipment is seriously scaled, a pipeline is blocked, and the like in the continuous crystallization process are improved, and the operation period of the continuouscrystallization process is prolonged.

Owner:TIANJIN UNIV

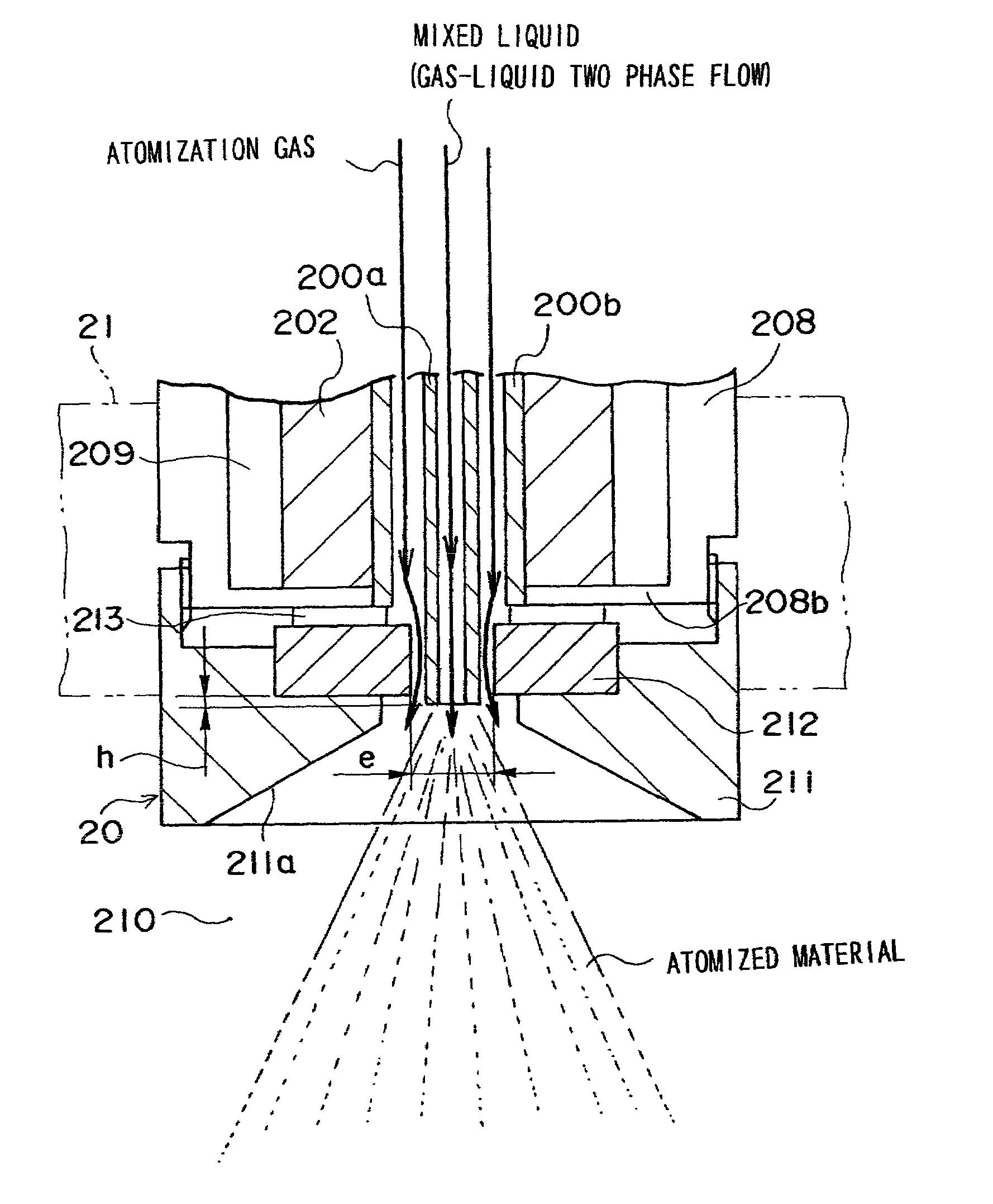

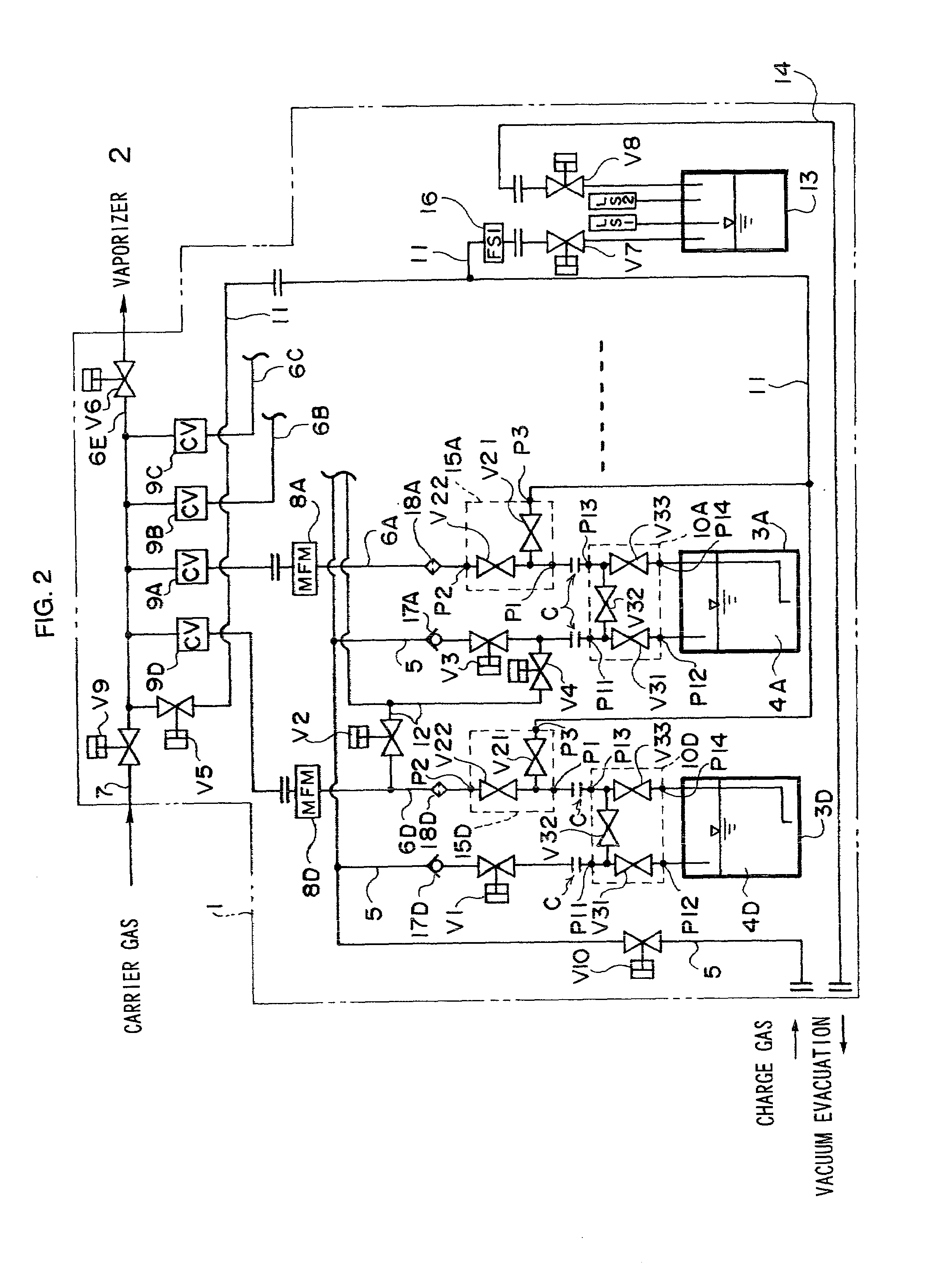

Liquid substance supply device for vaporizing system, vaporizer, and vaporization performance appraisal method

InactiveUS7163197B2Suppress generationImprove controllabilityUsing liquid separation agentMixing methodsVaporizationEngineering

In a liquid substance supply device, a three port two valve directional control valve is provided in a transfer line, and a substance container and the transfer line are connected together by a four port three valve directional control valve in such a way that the four port three valve directional control valve and the substance container can be removed from the transfer line as a unit. Furthermore, in a vaporizer, an orifice member is provided to surround the end portion of an internal conduit in which flows a mixture substance consisting of a gas and a liquid substance mixed therewith, and gas for atomization is spouted into a vaporization chamber through a gap defined between the internal conduit and the orifice member. Yet further, the temperature of a vaporization surface in the vaporization chamber can be controlled independently in correspondence with the nature of the liquid substance.

Owner:ULVAC INC

Devices and methods for collecting, sanitizing, and dispensing condensed forms of atmospheric water

InactiveUS20160244951A1General water supply conservationSpecific water treatment objectivesLine filterWaste management

Devices and methods for condensing, cooling, heating, sanitizing, and dispensing drinkable water that is collected from atmospheric water vapor are disclosed. The devices generally include a dehumidifier that is configured to harvest and condense atmospheric water vapor within the device; and a collection tank that is configured to receive and collect condensed atmospheric water vapor within the dehumidifier. The devices further include a first means for heating water within the collection tank to a temperature that is effective to kill bacteria; and a first tube that fluidly connects the collection tank with a cold water tank. The first tube includes one or more in-line filters through which water must travel to reach the cold water tank. The devices further include a second means for heating water within the cold water tank to a temperature that is effective to kill bacteria, and a second tube that fluidly connects the cold water tank with a hot water tank.

Owner:YUI GEORGE

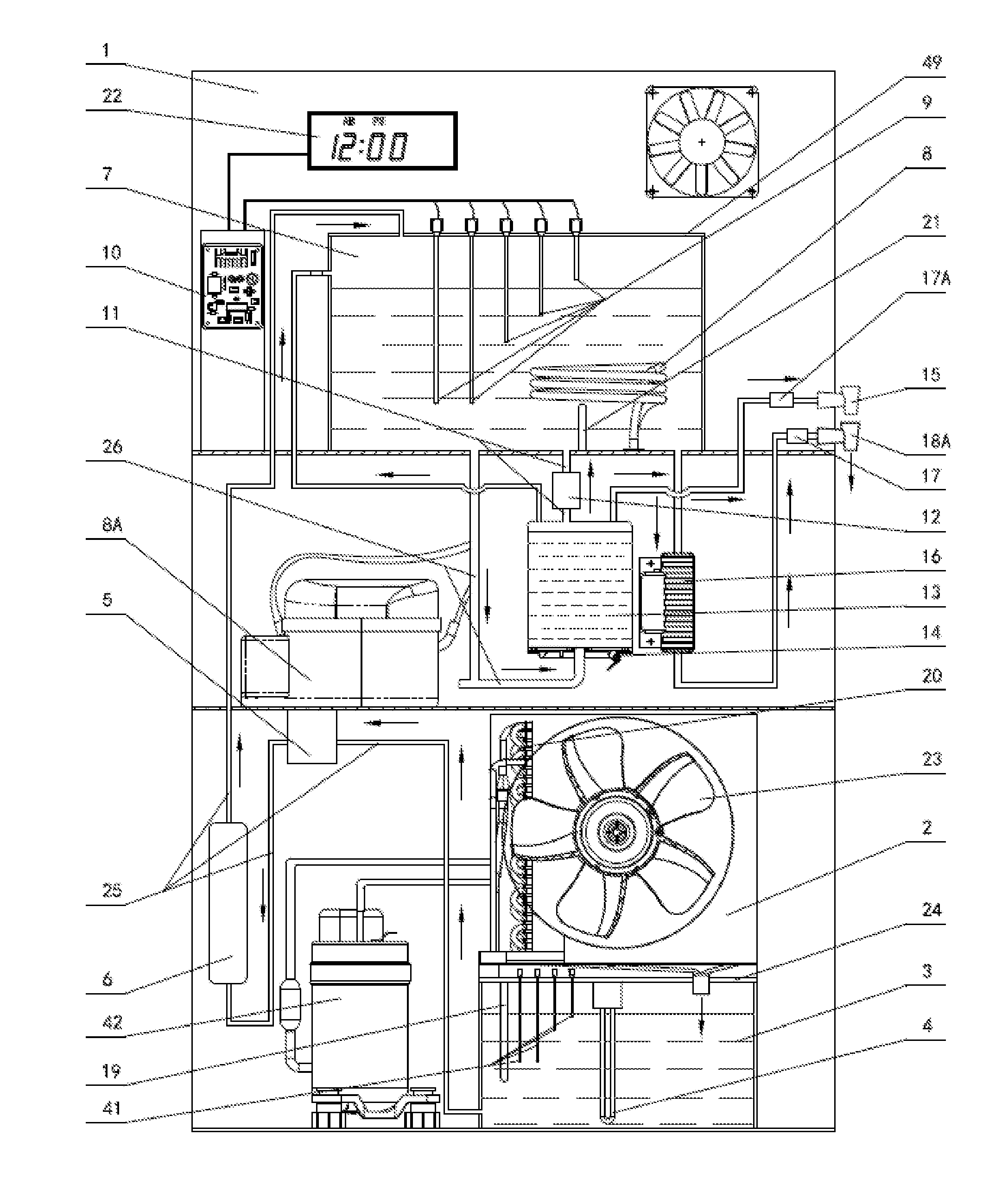

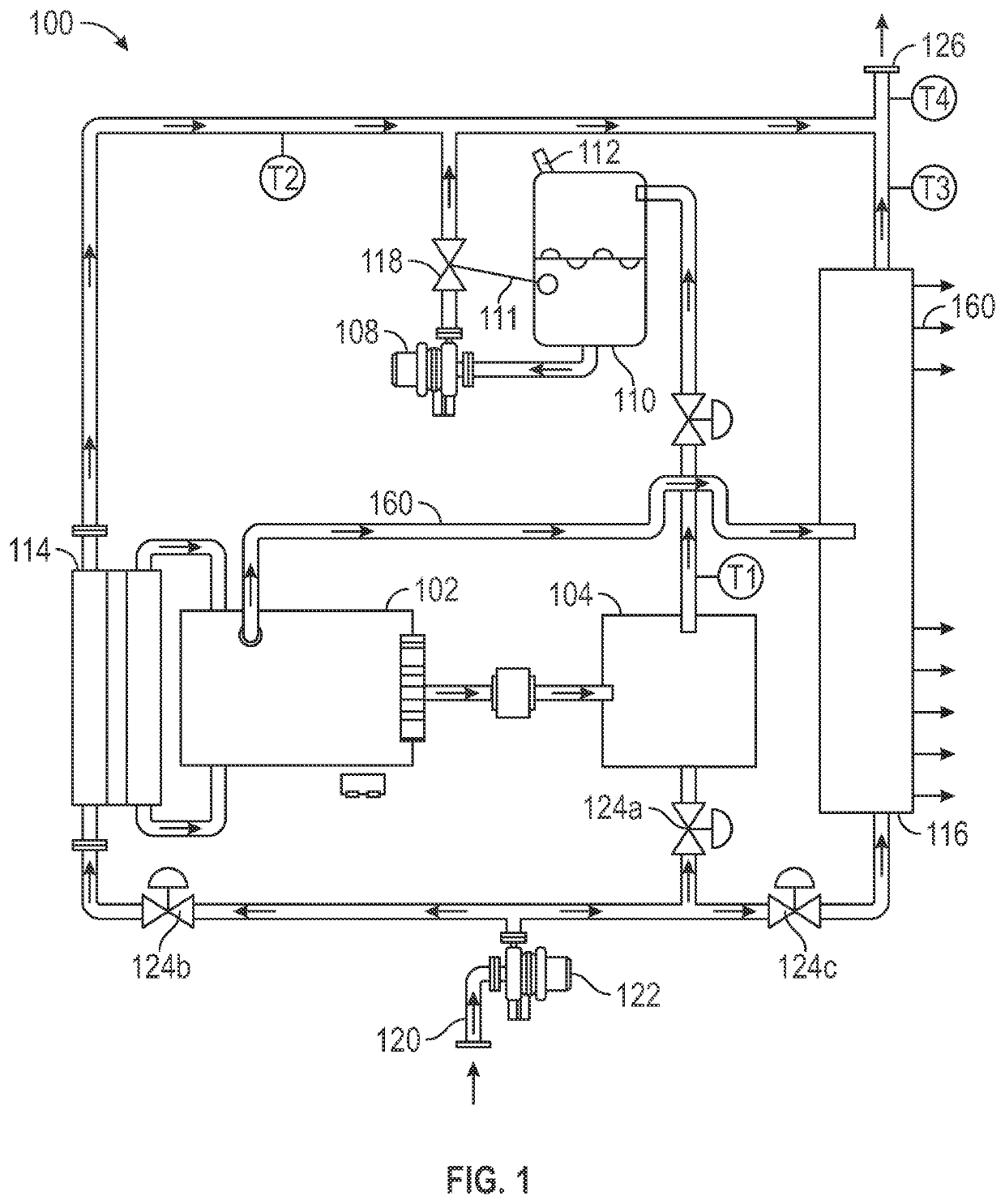

Water vapor distillation apparatus, method and system

ActiveUS8505323B2Lighting and heating apparatusDistillation regulation/controlControl systemDistillation

A fluid vapor distillation apparatus. The apparatus includes a source fluid input, and an evaporator condenser apparatus. The evaporator condenser apparatus includes a substantially cylindrical housing and a plurality of tubes in the housing. The source fluid input is fluidly connected to the evaporator condenser and the evaporator condenser transforms source fluid into steam and transforms compressed steam into product fluid. Also included in the fluid vapor distillation apparatus is a heat exchanger fluidly connected to the source fluid input and a product fluid output. The heat exchanger includes an outer tube and at least one inner tube. Also included in the fluid vapor distillation apparatus is a regenerative blower fluidly connected to the evaporator condenser. The regenerative blower compresses steam, and the compressed steam flows to the evaporative condenser where compressed steam is transformed into product fluid. The fluid vapor distillation apparatus also includes a control system.

Owner:DEKA PROD LLP

System for decontaminating water and generating water vapor

ActiveUS20120267232A1Increase pressureSteam generation using mechanical energyWater treatment parameter controlWater vaporVaporization

Owner:VERNO HLDG +1

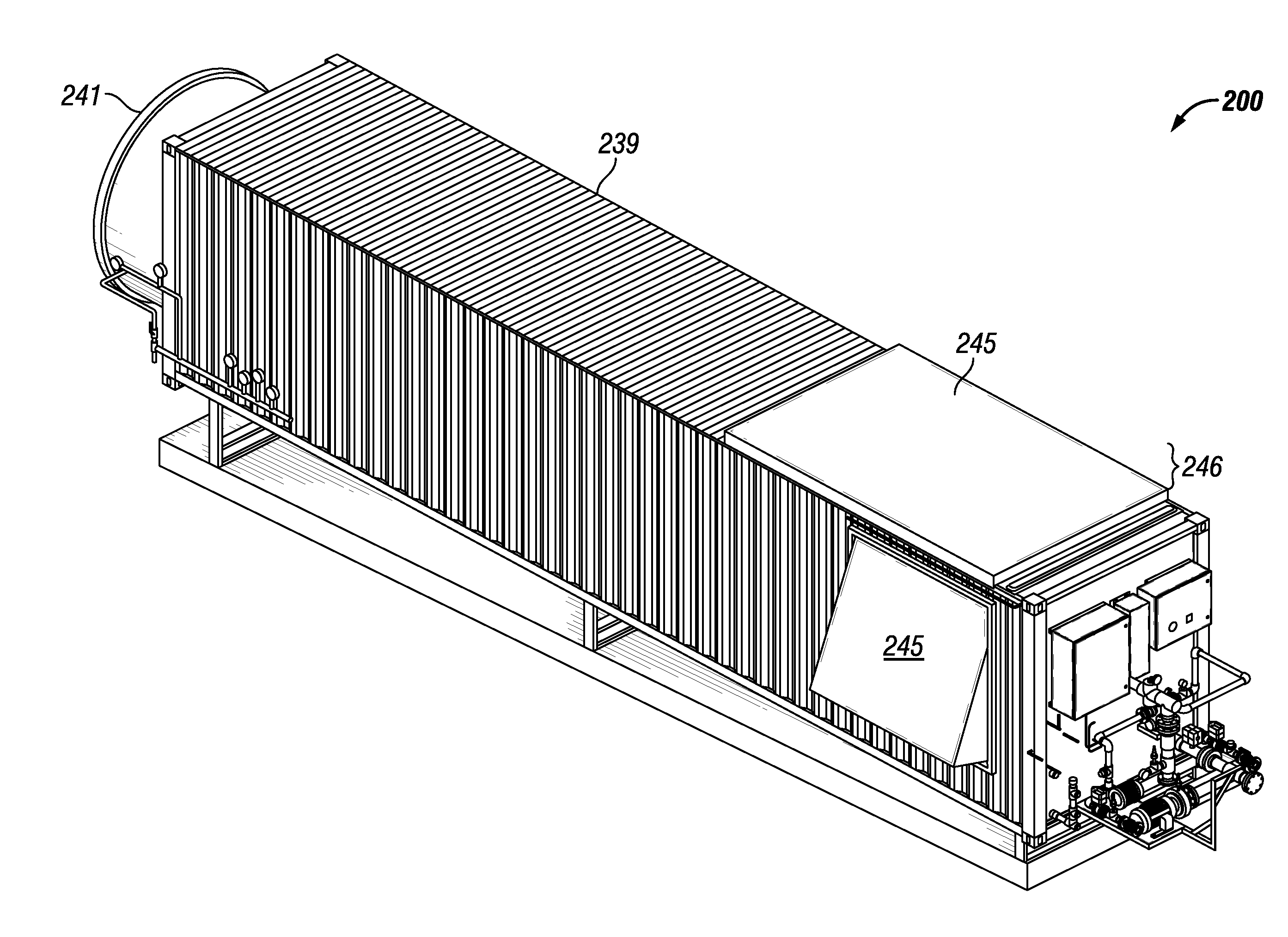

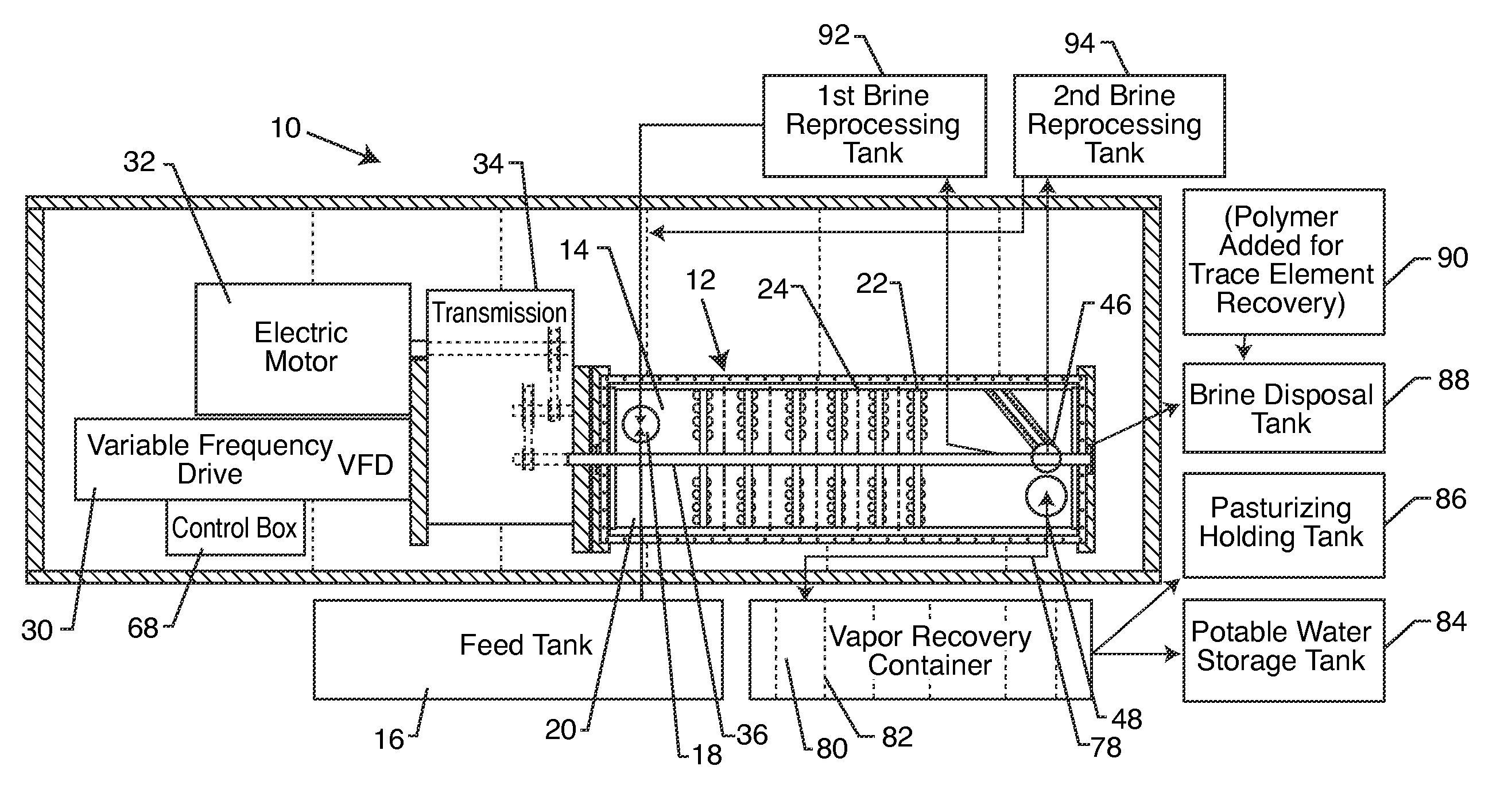

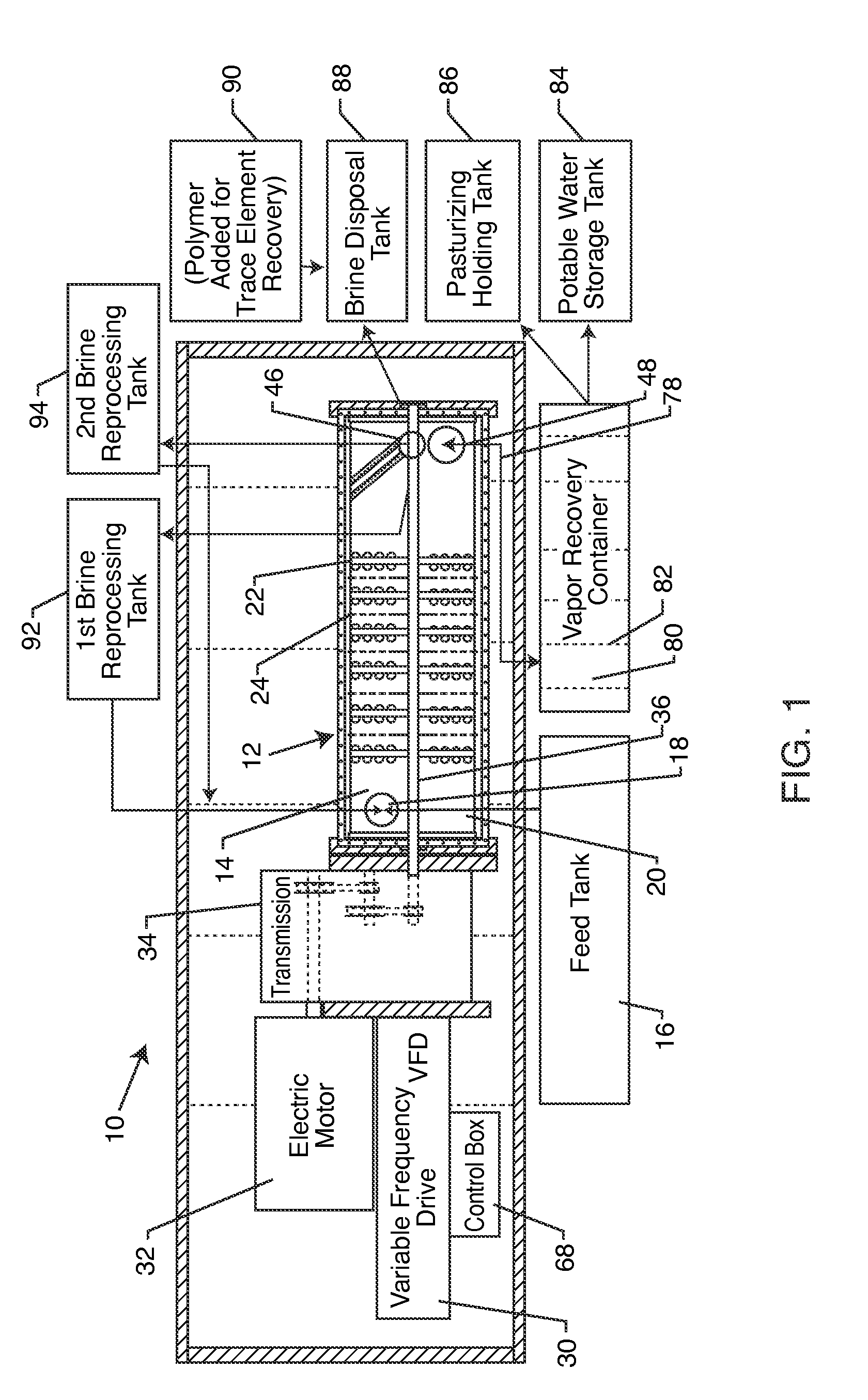

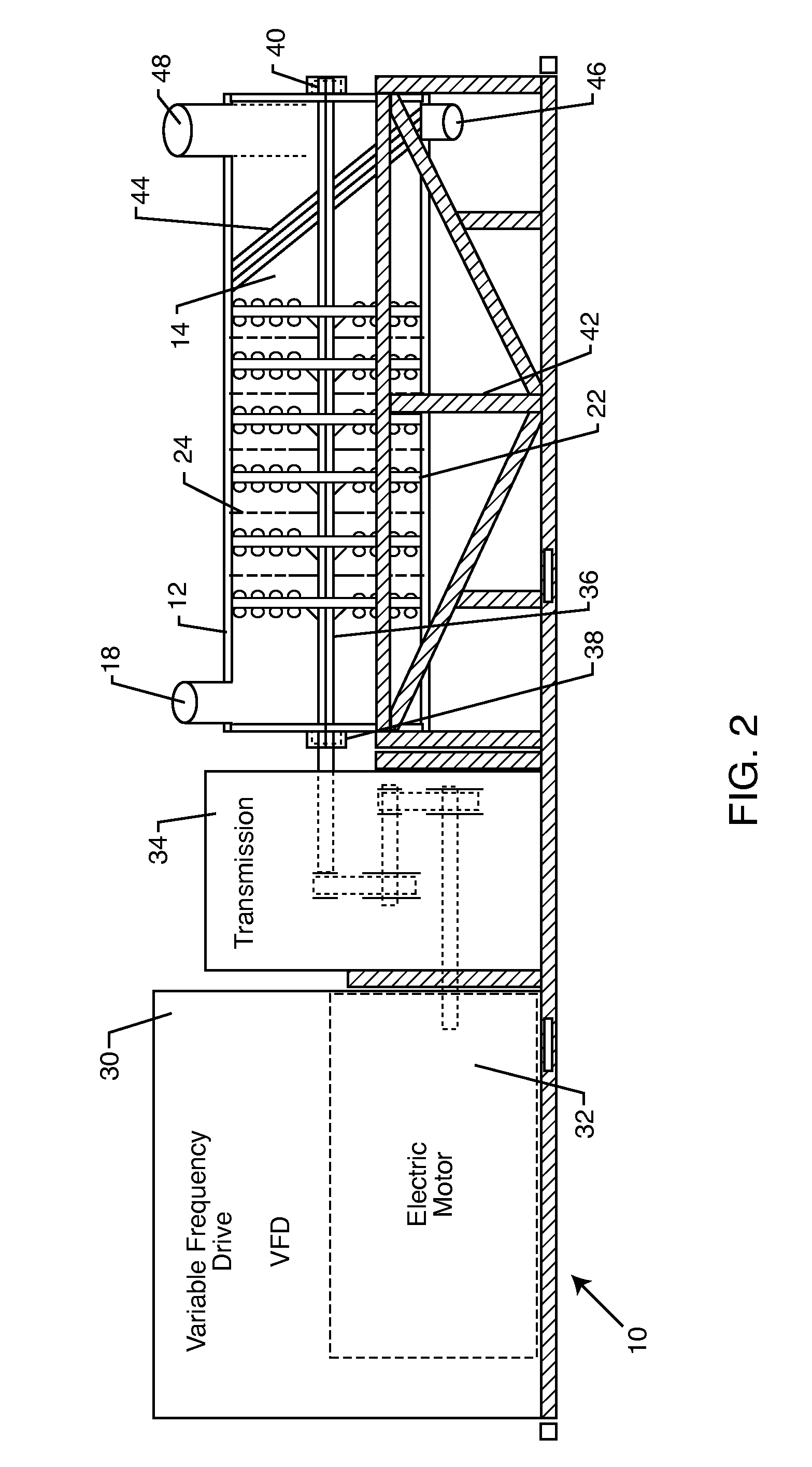

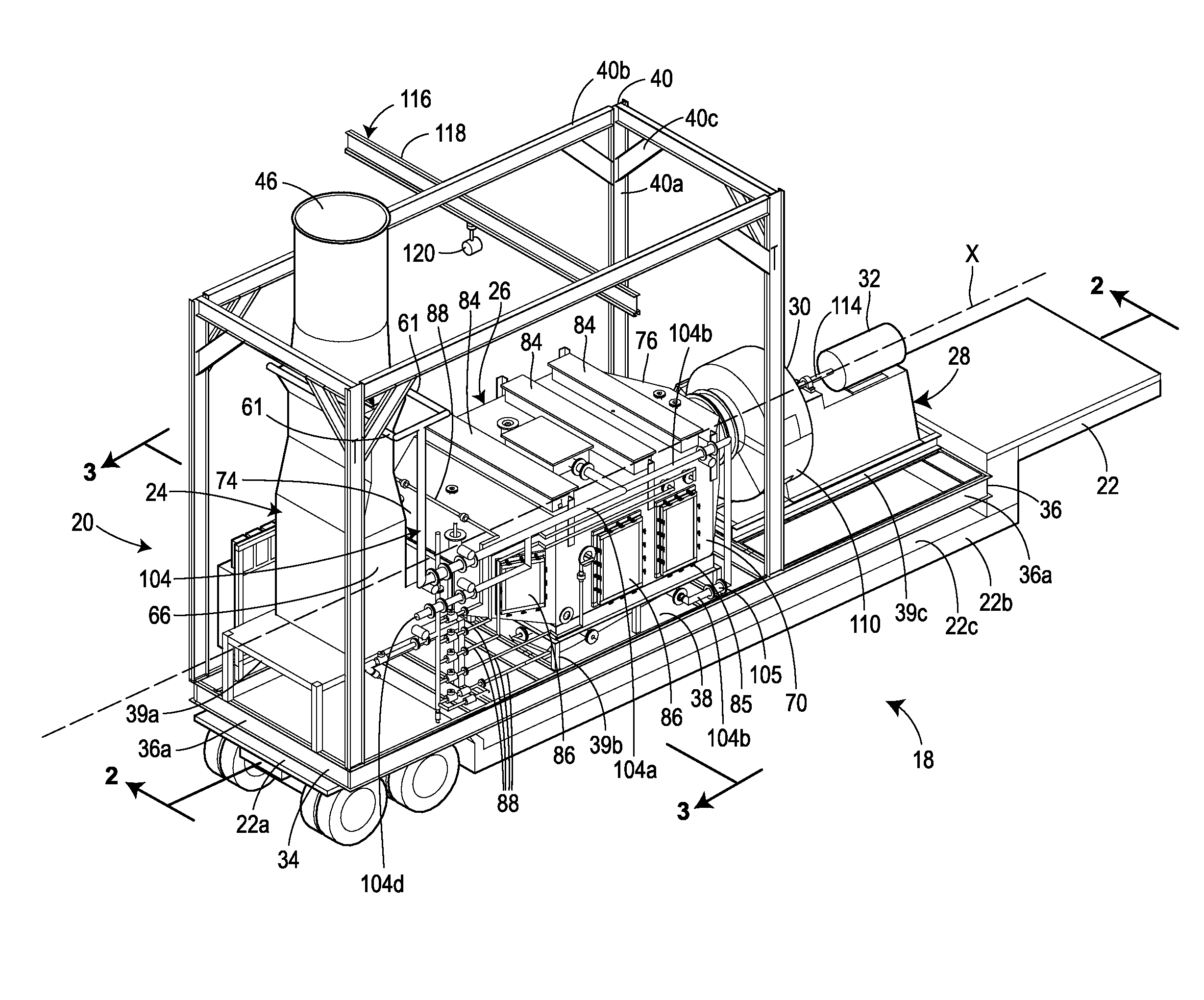

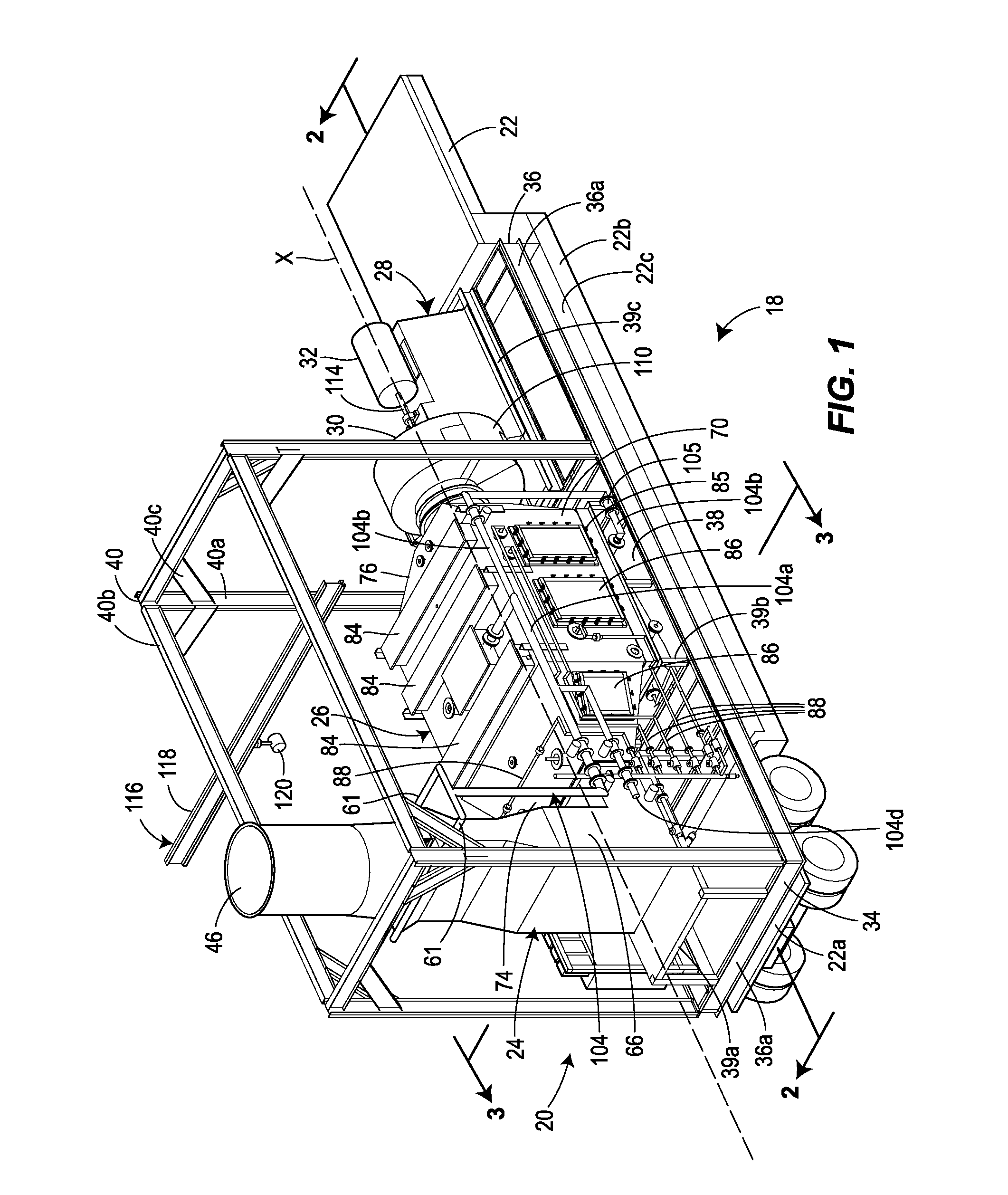

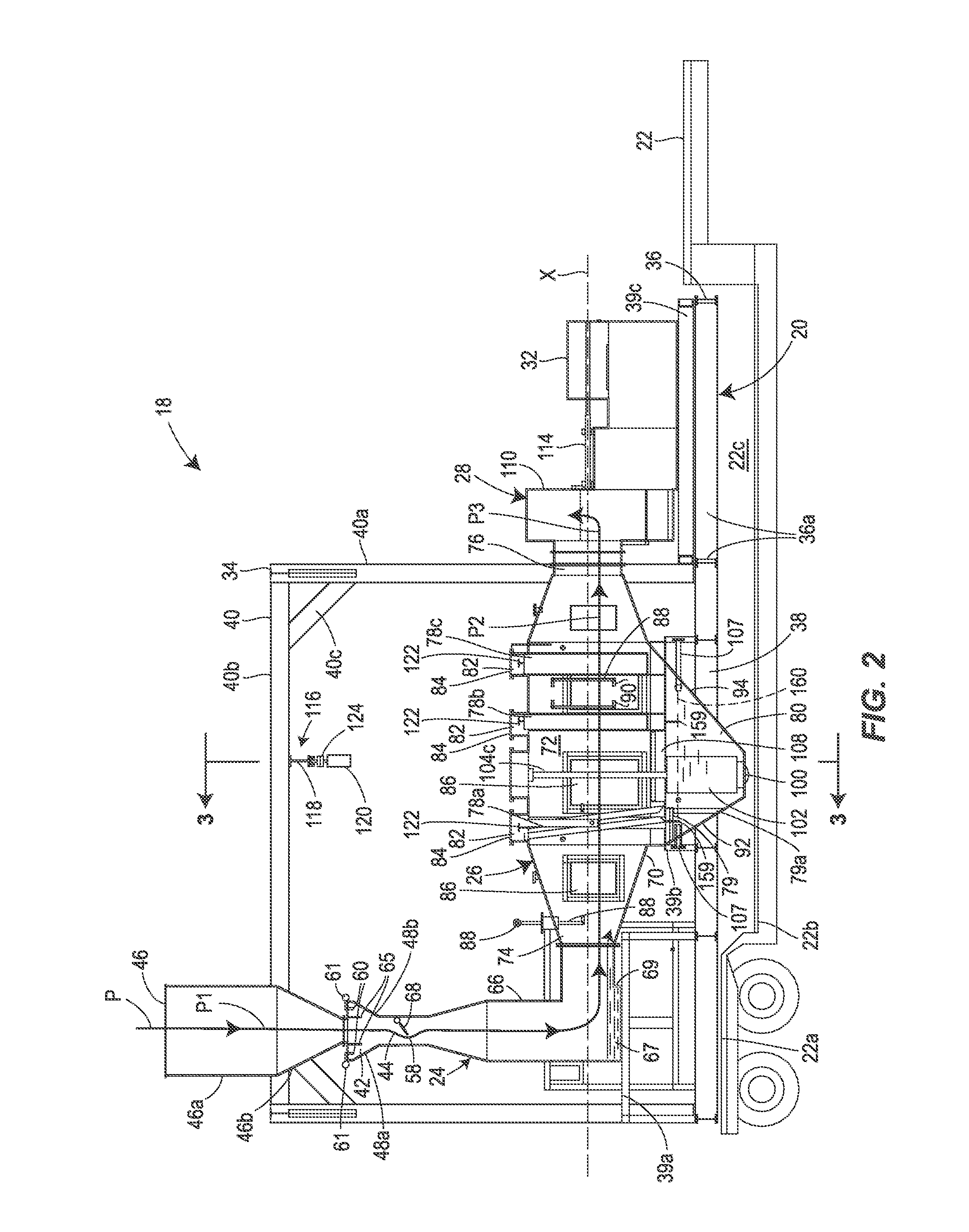

Wastewater concentration system

InactiveUS20150157953A1Easy to scaleEffective treatment capacityCombination devicesAuxillary pretreatmentVapor–liquid separatorControl system design

A wastewater concentrator system is portable and scalable to effectively process up to forty thousand gallons of wastewater per day and more. The system has a portable assembly including a liquid evaporator assembly, gas-liquid separator, and exhaust assembly carried by a skid, which can be carried as a single unit on a mobile platform. The liquid evaporator assembly includes wastewater injection nozzles arranged to minimize buildup of material inside a mixing chamber. The gas-liquid separator has top access doors for installing and removing demister panels through a top wall and a sump adapted to provide scalability of the system to larger processing capacities while maintaining the portability. The system is adapted for connection to a plurality of heated gas sources and includes a control system designed to maintain a selected operating condition regardless of variations in the amount of heated gases supplied.

Owner:HEARTLAND TECH PARTNERS

Method of and system for fluid purification

InactiveUS20040140271A1Hydrocarbon distillationLiquid hydrocarbon mixture productionInternal combustion engineEvaporation chamber

A method of and system for purifying fluid of an internal combustion engine or hydraulic system utilizes an evaporation chamber separate from a filtering chamber. A metering valve may be oriented between the filtering chamber and the evaporation chamber to control the flow of fluid to the evaporation chamber.

Owner:OIL PURIFICATION SYST

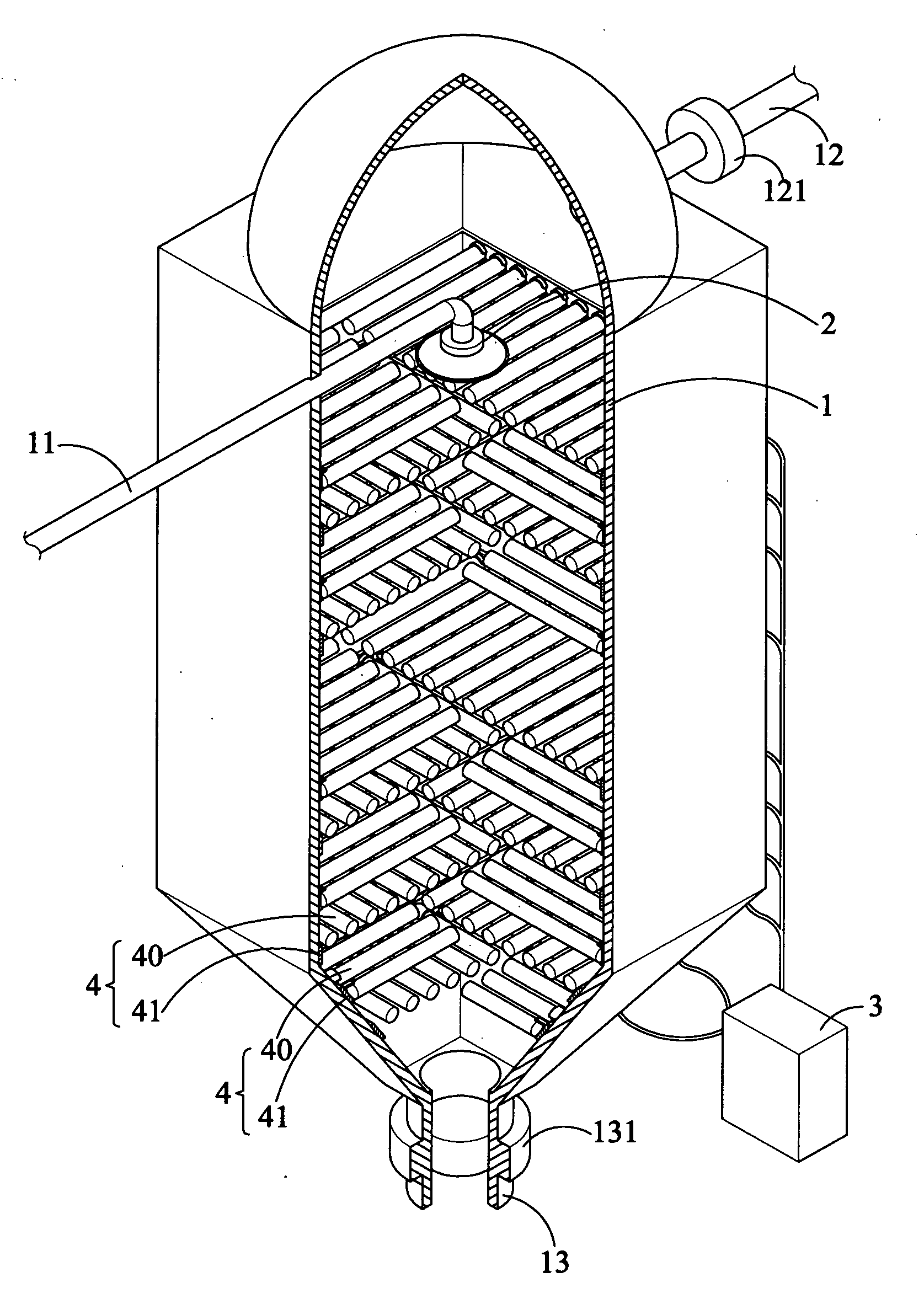

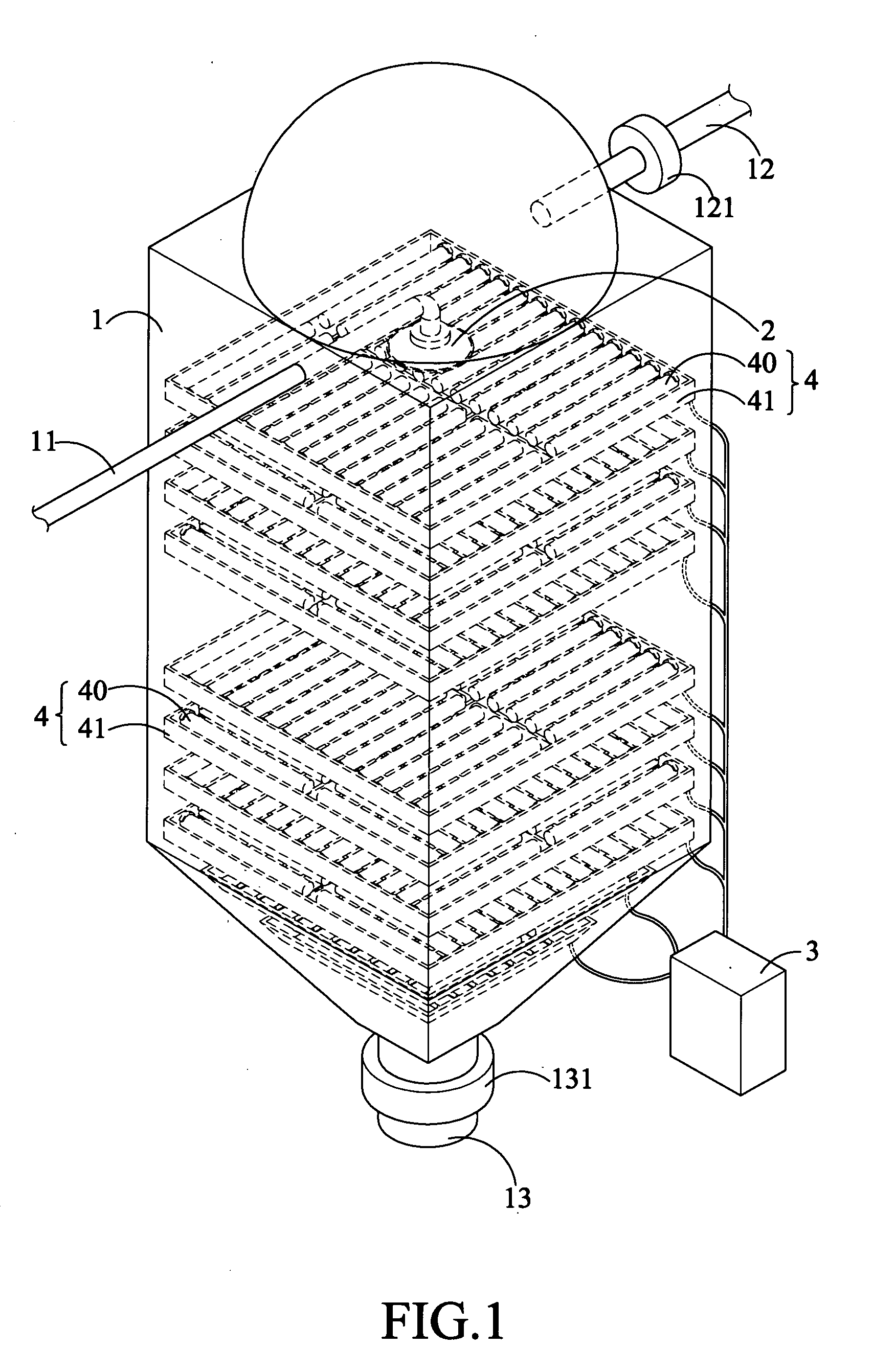

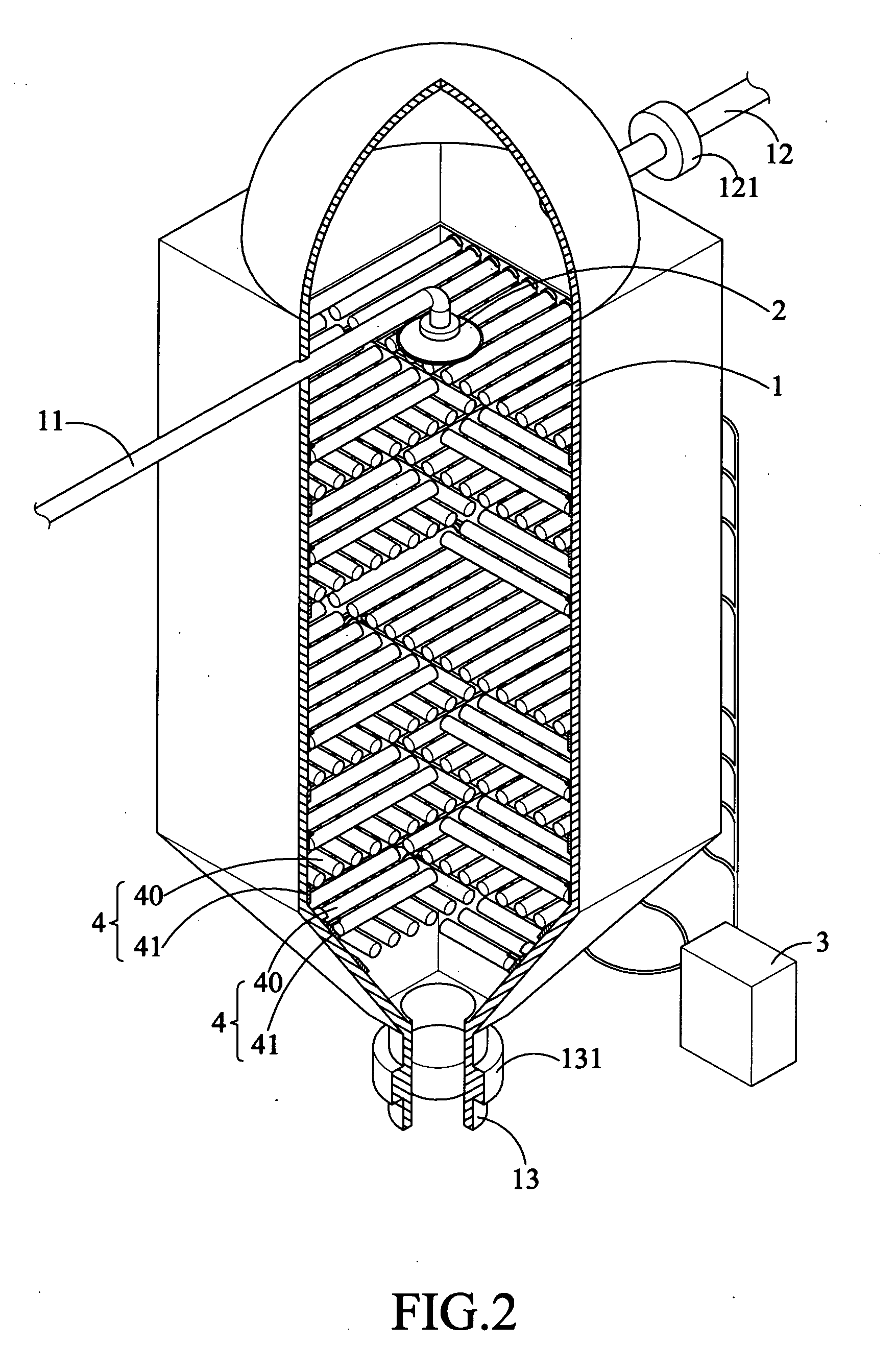

Porous honeycomb water treatment device

InactiveUS20090166170A1Distillation regulation/controlEvaporator regulation/controlParticulatesWorking fluid

A porous honeycomb water treatment device washes out deposited salt automatically with high heat exchange rate to produce sufficient fresh water, a hollow, vacuum, and high pressure distillation column, where salt water alternatively heated up to 100° C. or cooled down to 0˜18° C.; a bottom product exit (13) formed at a bottom of the fractionator (1); an inlet pipe (11) disposed above the fractionator (1) injects salt water in the fractionator (1); a top product outlet pipe (12) disposed above the fractionator (1) discharges water vapor out of the fractionator (1); and at least, one tray (4) disposed inside the fractionator (1) equidistantly arranged in neat stack; the tray (4) is composed of a plurality of heat pipe (40) filled with working fluid mixed with nano-scale metallic particulates; the heat pipes (40) are arrayed in parallel and equidistantly supported on a hollowed-out frame (41) at an inclined angle (θ).

Owner:SUN GARY

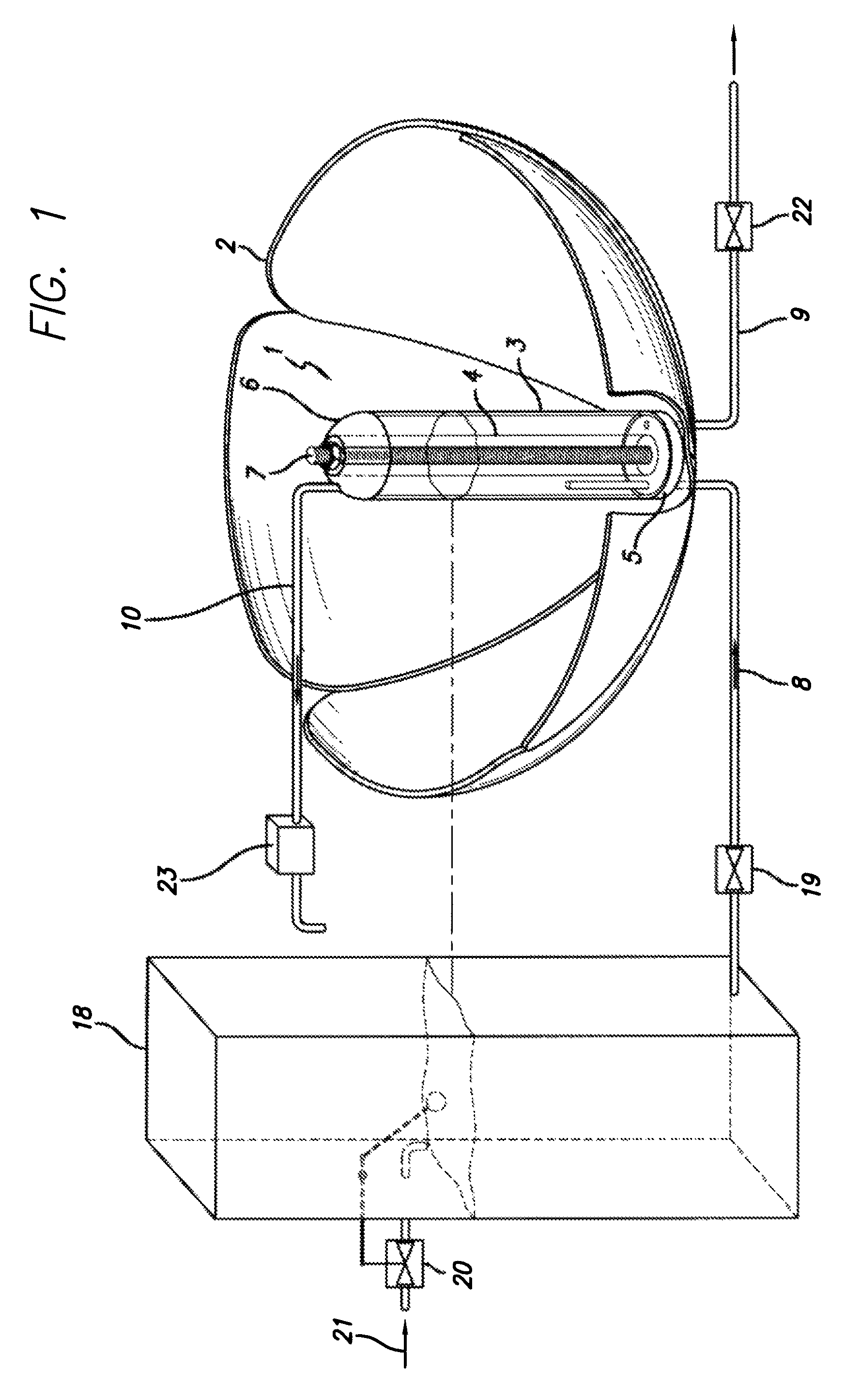

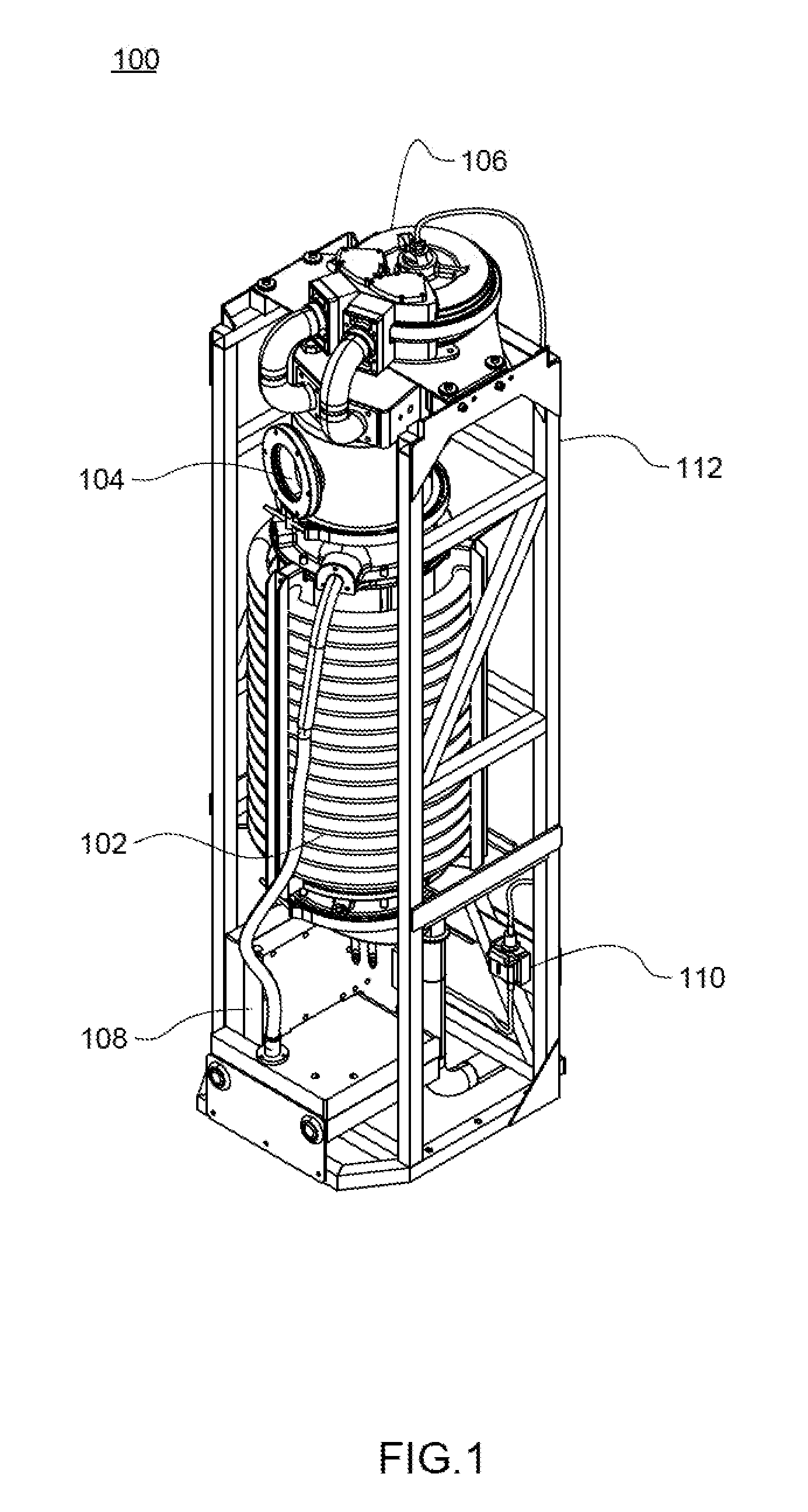

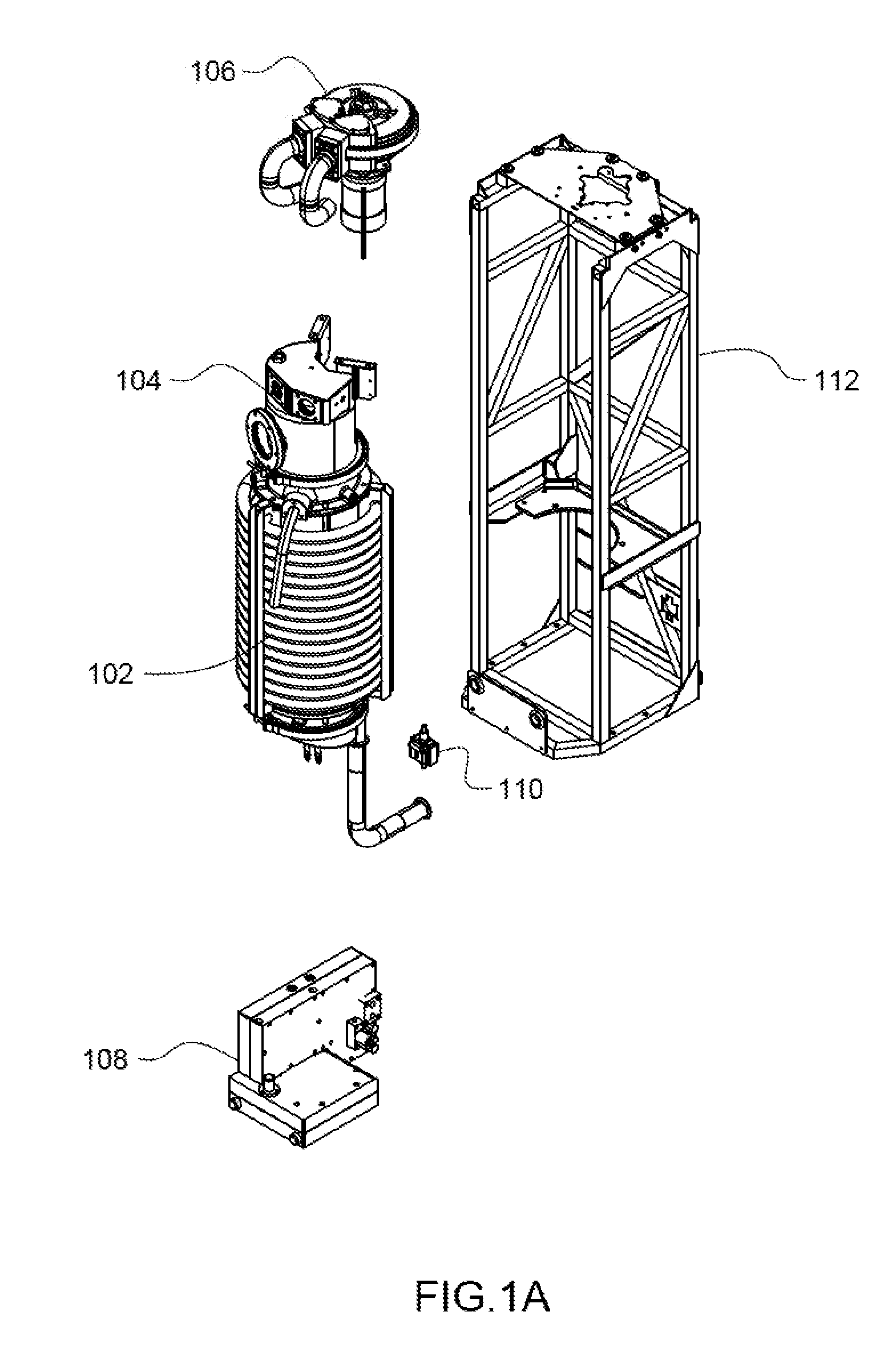

Water cooled vaporizing system

InactiveUS10321714B1Easily and efficiently manufactured and marketedDurable and reliable constructionBatteries circuit arrangementsTobacco pipesEngineeringMechanical engineering

A housing assembly is formed of upper and lower cases with top and bottom plates and an intermediate plate separating the upper and lower cases. An agitation assembly includes water in the lower case. A plurality of paddles submerged in the water are rotatable to agitate the water. An inlet assembly includes an inlet pipe having a top end above the top plate and a bottom end submerged in the water. A heating assembly includes a chamber interiorly and a cylinder exteriorly forming an annular passageway terminating at the top end of the inlet pipe. A heating coil system within the vaporizing chamber is adapted to vaporize the selected material whereby vapors released will tumble down the annular passageway then down the inlet pipe into the water. An outlet assembly includes an outlet pipe having a top end and a bottom end terminating below above the water.

Owner:KANE RANDY M

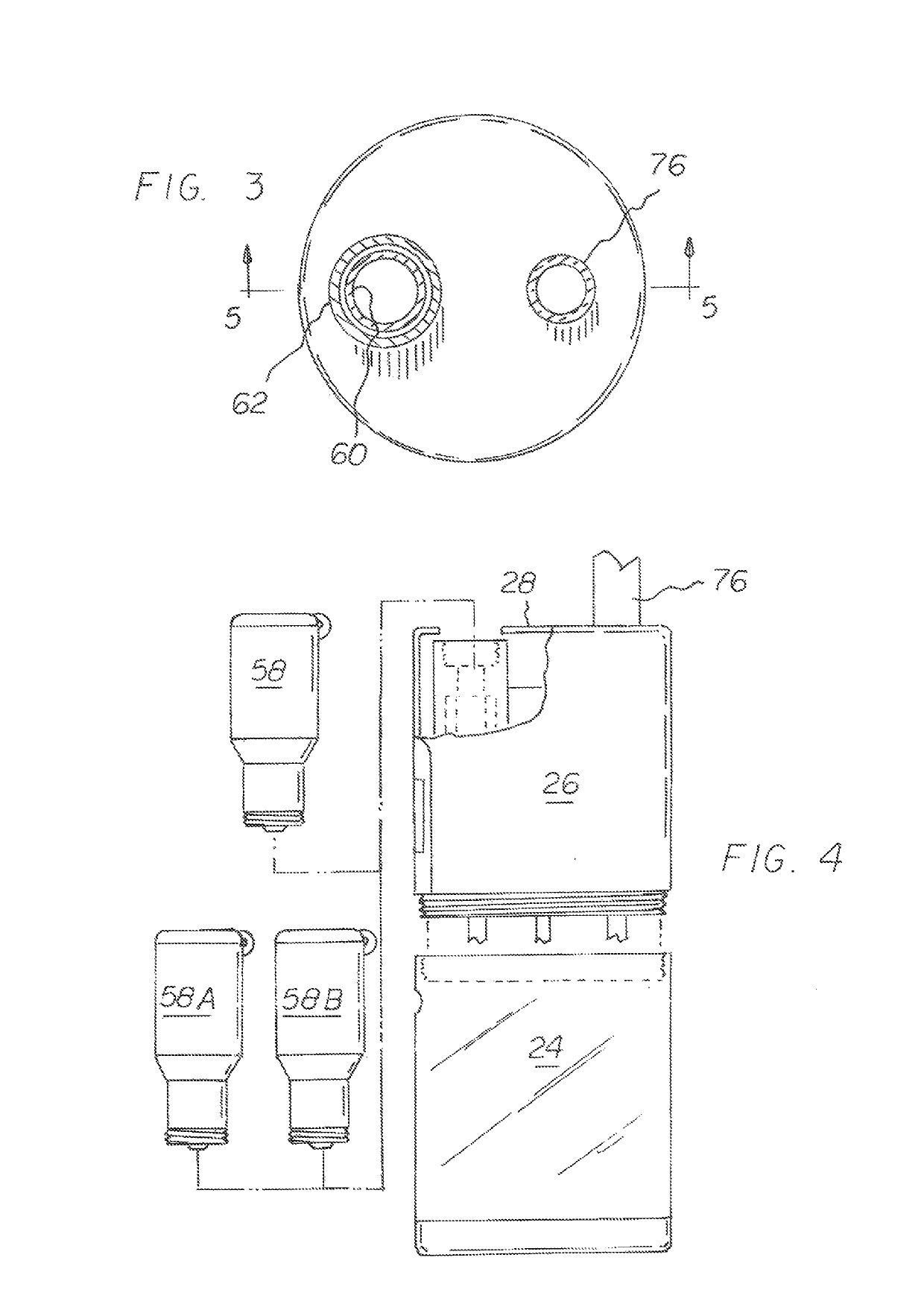

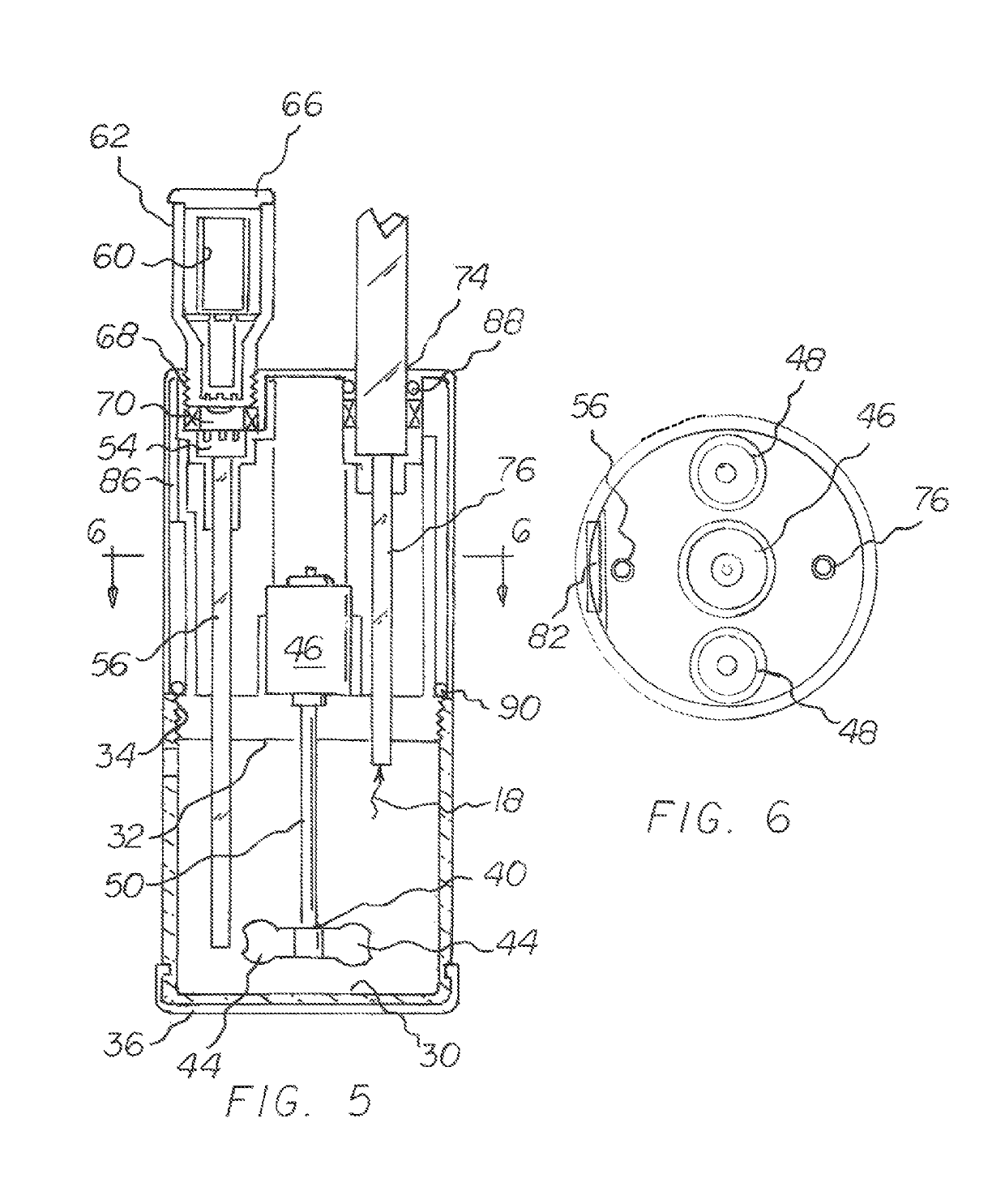

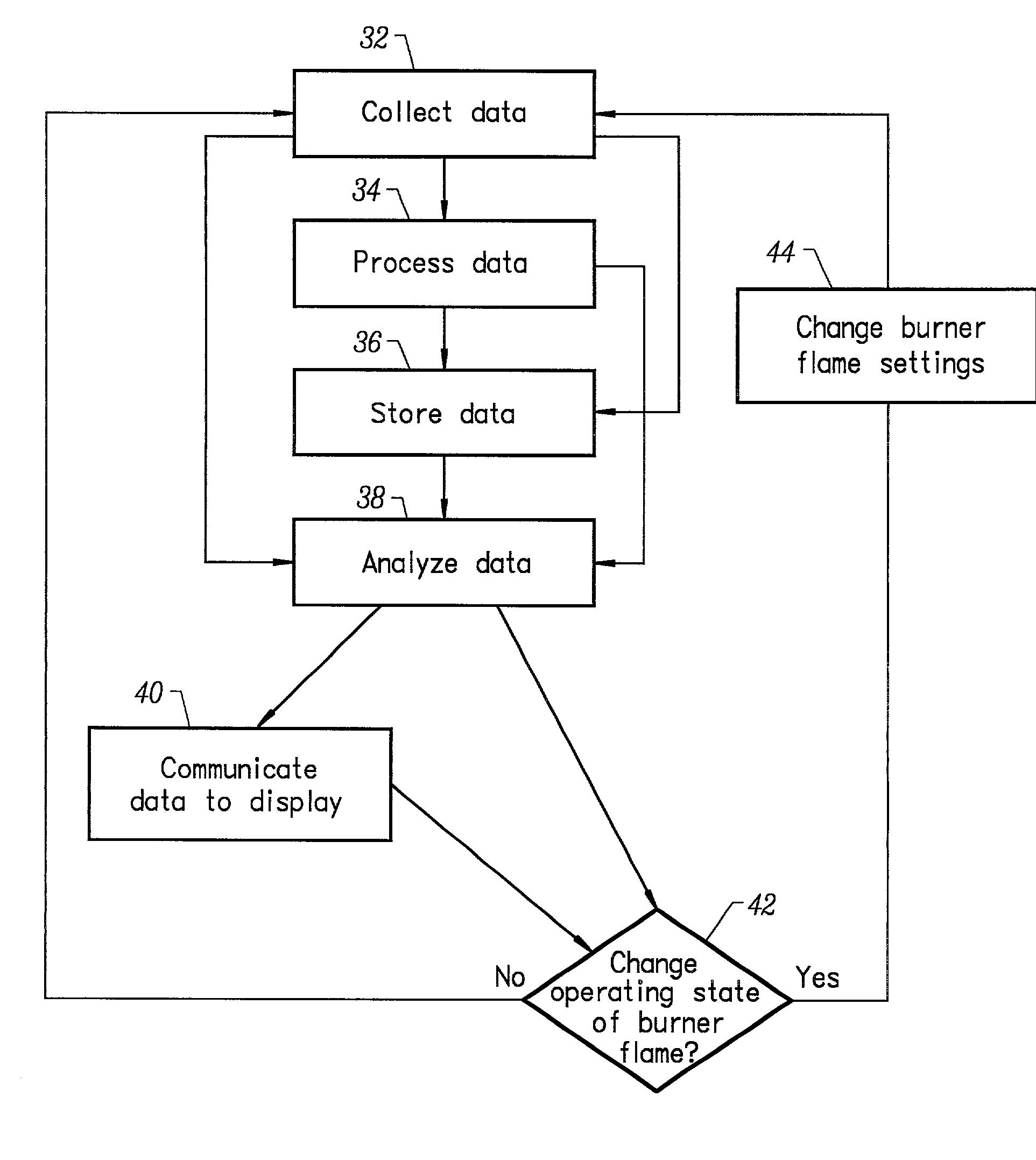

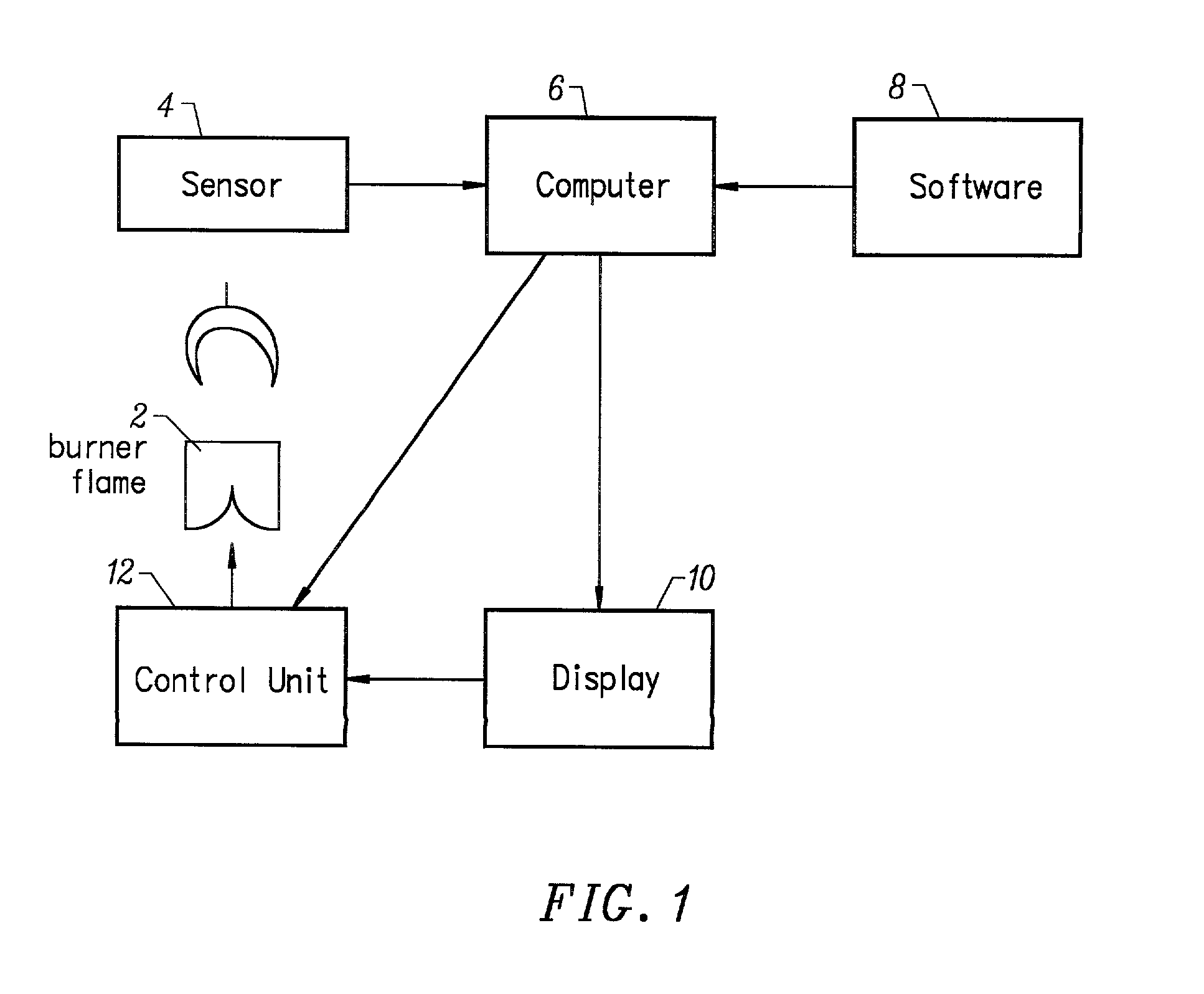

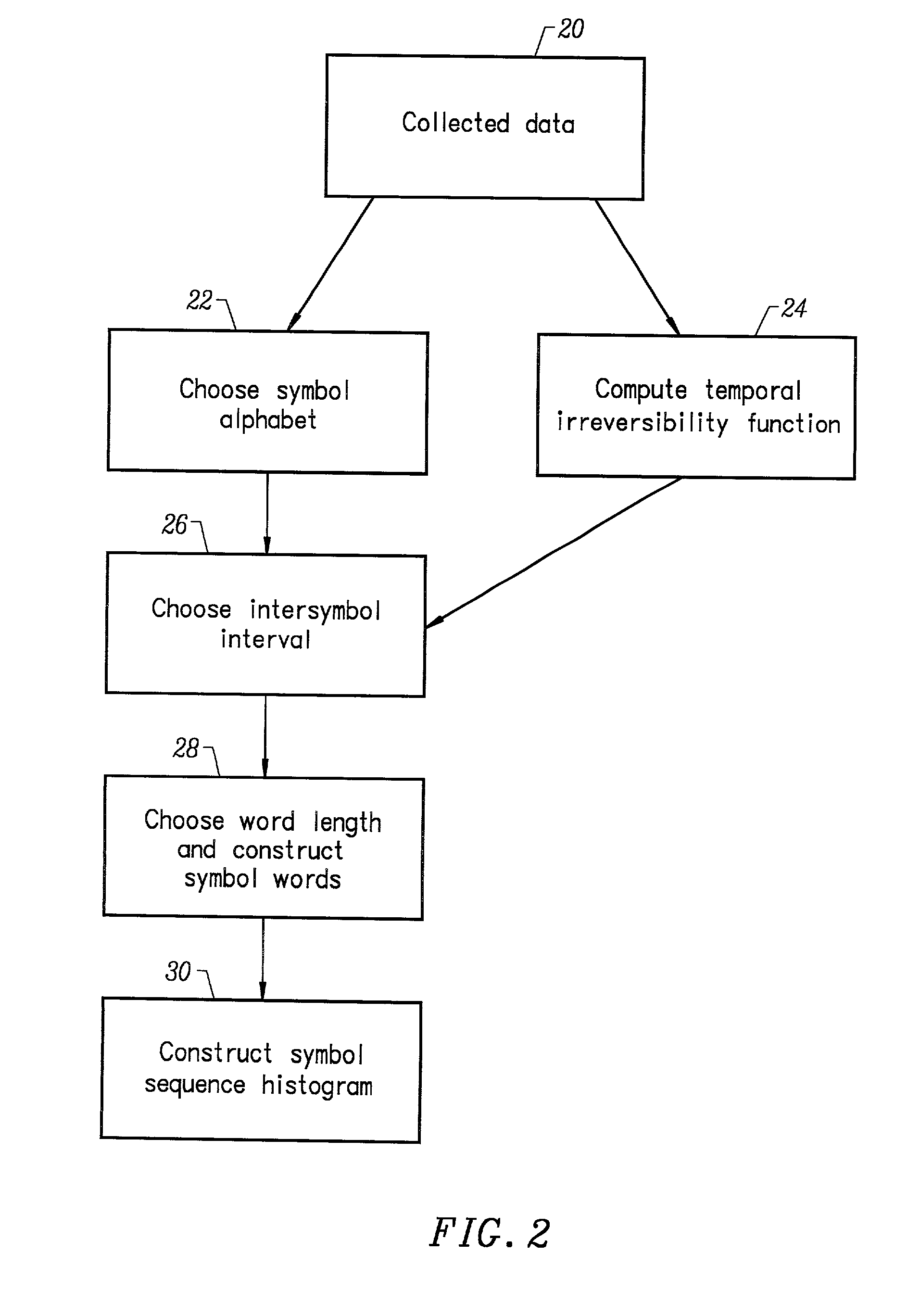

Application of symbol sequence analysis and temporal irreversibility to monitoring and controlling boiler flames

InactiveUS20030093246A1Sampled-variable control systemsError detection/correctionSequence analysisChaos theory

The current invention provides a method and apparatus, which uses symbol sequence techniques and / or temporal irreversibility derived from chaos theory to monitor the operating state of individual burner flames on a appropriate time scale. Both the method and apparatus of the present invention may be used optimize the performance of burner flames.

Owner:ELECTRIC POWER RES INST INC

Solar distillation device

A solar distillation apparatus utilizing a substantially vertical reactor assembly is disclosed. The reactor consists of a tubular outer shell, a base, a cap, and a central tension member. The annular space between the outer tube and the central tension member forms the reactor chamber. Seawater or other feed liquid enters the reactor chamber through the base plate. Reflected or direct solar energy heats the feed liquid, generating low pressure vapor. The vapor exits the reactor through the cap structure or the base. The concentrate left behind settles by gravity to the bottom region of the reactor's liquid column. Extension tubes on the feed openings allow feed liquid to enter the liquid column above the concentrate layer and avoid excessive mixing of the feed liquid and the concentrate. The concentrate exits the reactor through one or more openings in the base.

Owner:MCCLURE MILES

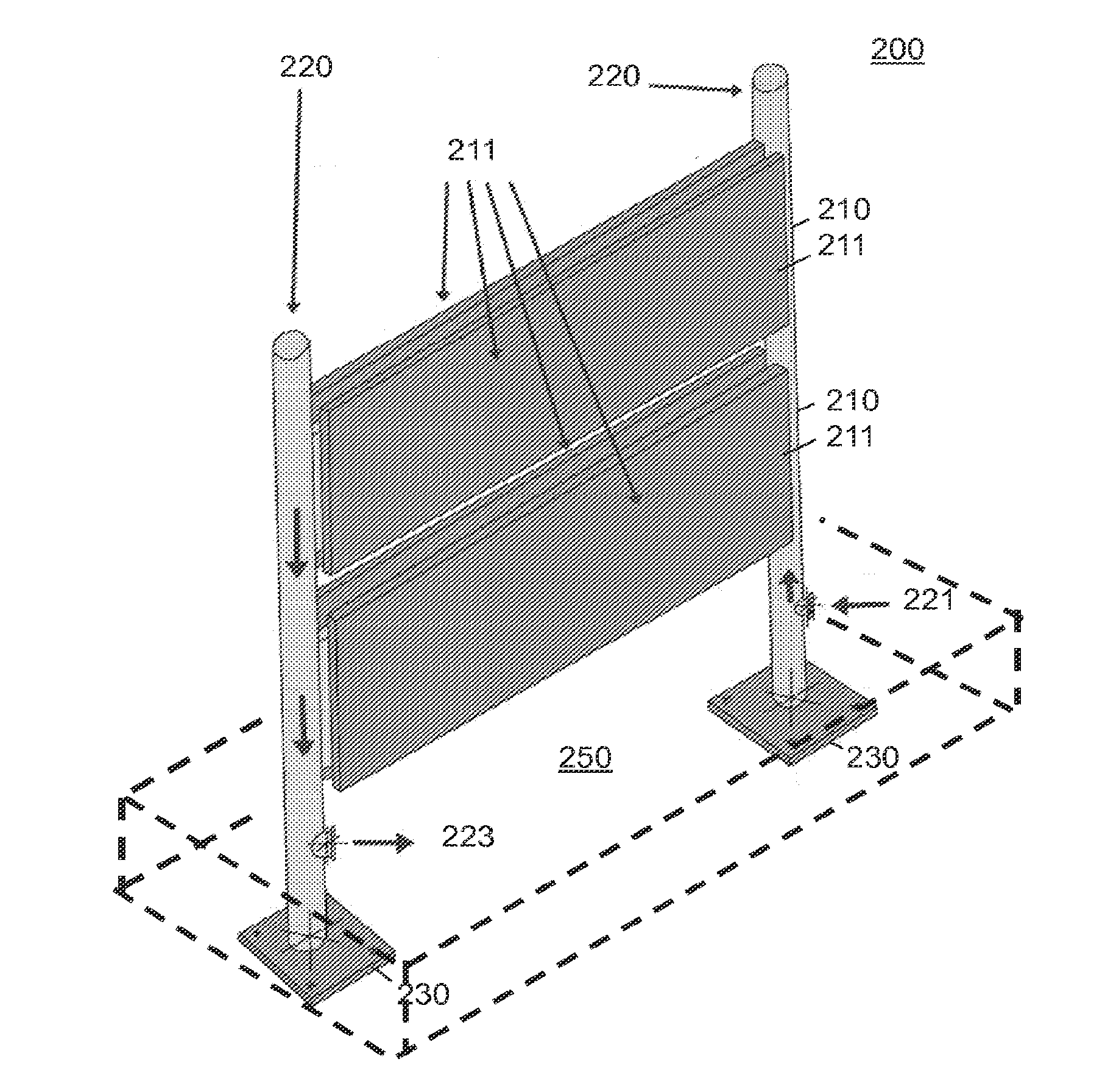

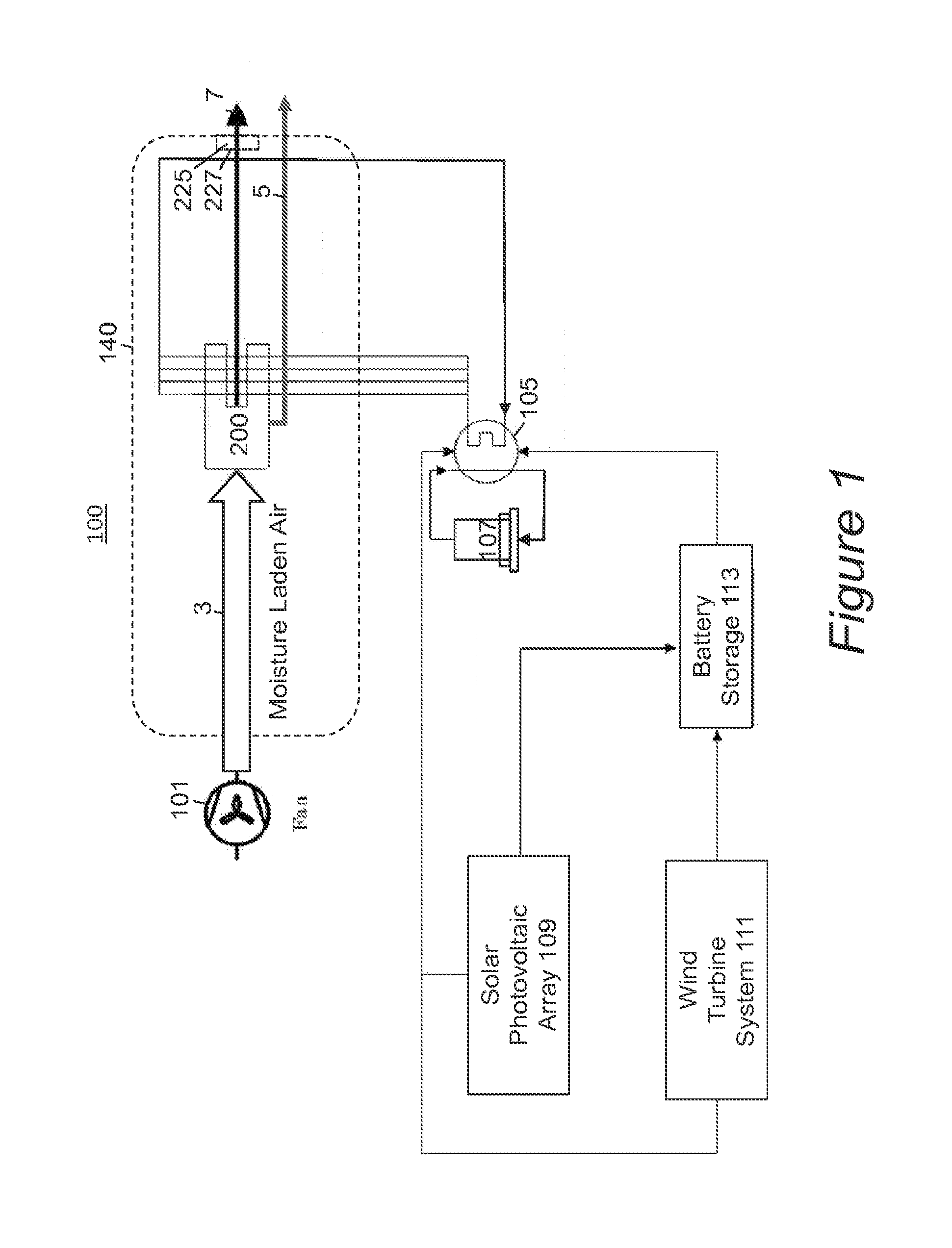

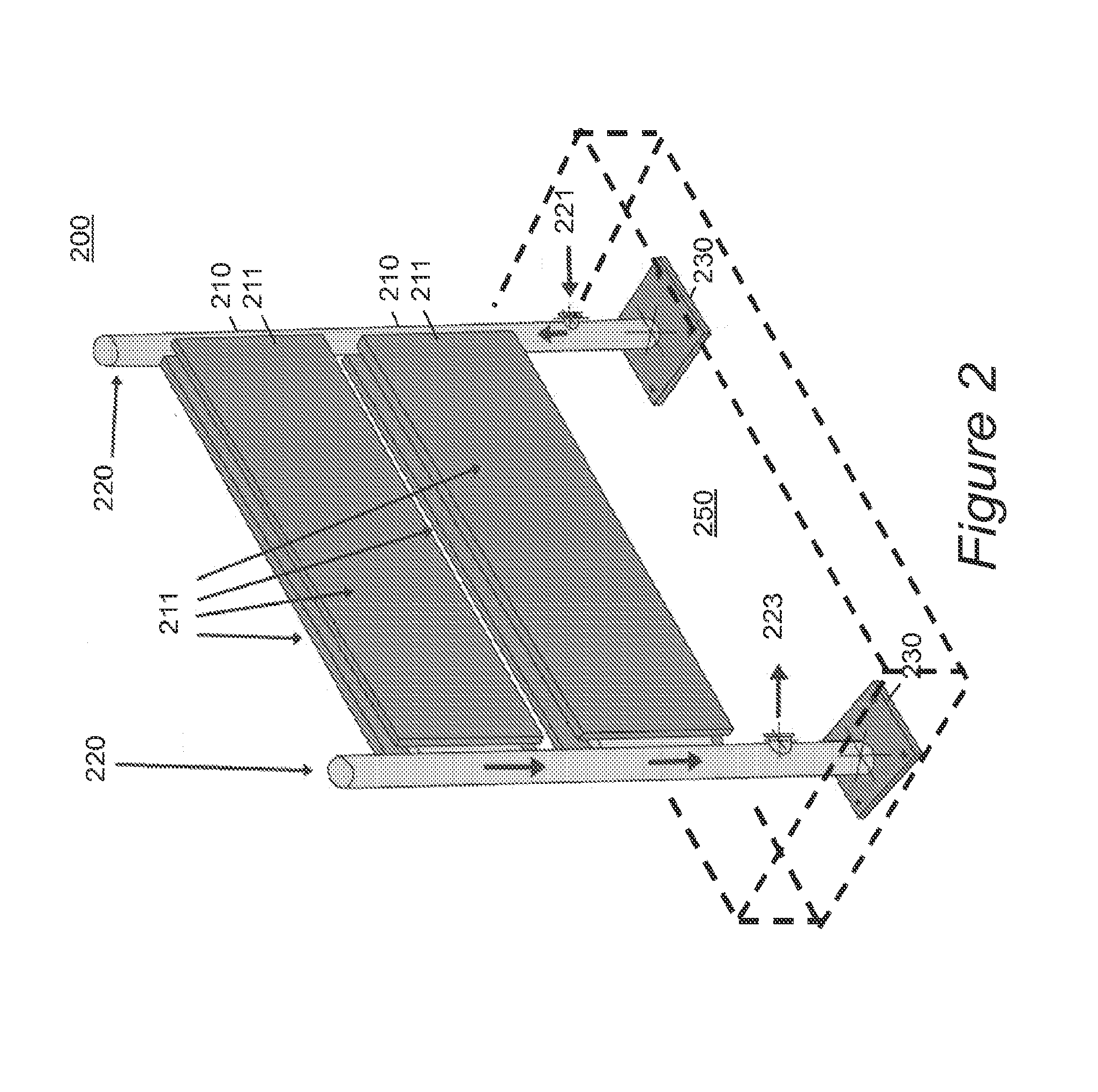

Water harvester and purification system

ActiveUS20160229706A1Reduce the temperatureMoisture to condenseWater treatment parameter controlGeneral water supply conservationWater vaporAtmospheric air

An optimized system creates potable water from water vapor in the atmosphere, or purifies salt water or contaminated water. The system employs a condenser having multiple metal condensation surfaces. These condensation surfaces are cooled by coolant passing through conduits attached to the condensation surfaces. The coolant is cooled by a cooling unit. Power is supplied to the cooling unit by solar photovoltaic panels, or wind turbines, or the electric grid. The system can be mobile or fixed and can produce potable water at remote locations. The system may employ an evaporator which evaporates non-potable water into an air stream. The evaporator includes a solar or gas heater which increases the temperature of the air. Metals may be extracted from the salt water. If sewage is used, solid organic waste may be processed into combustible gas which is burned by an engine running a generator to power that system.

Owner:ACKERMAN JOHN R

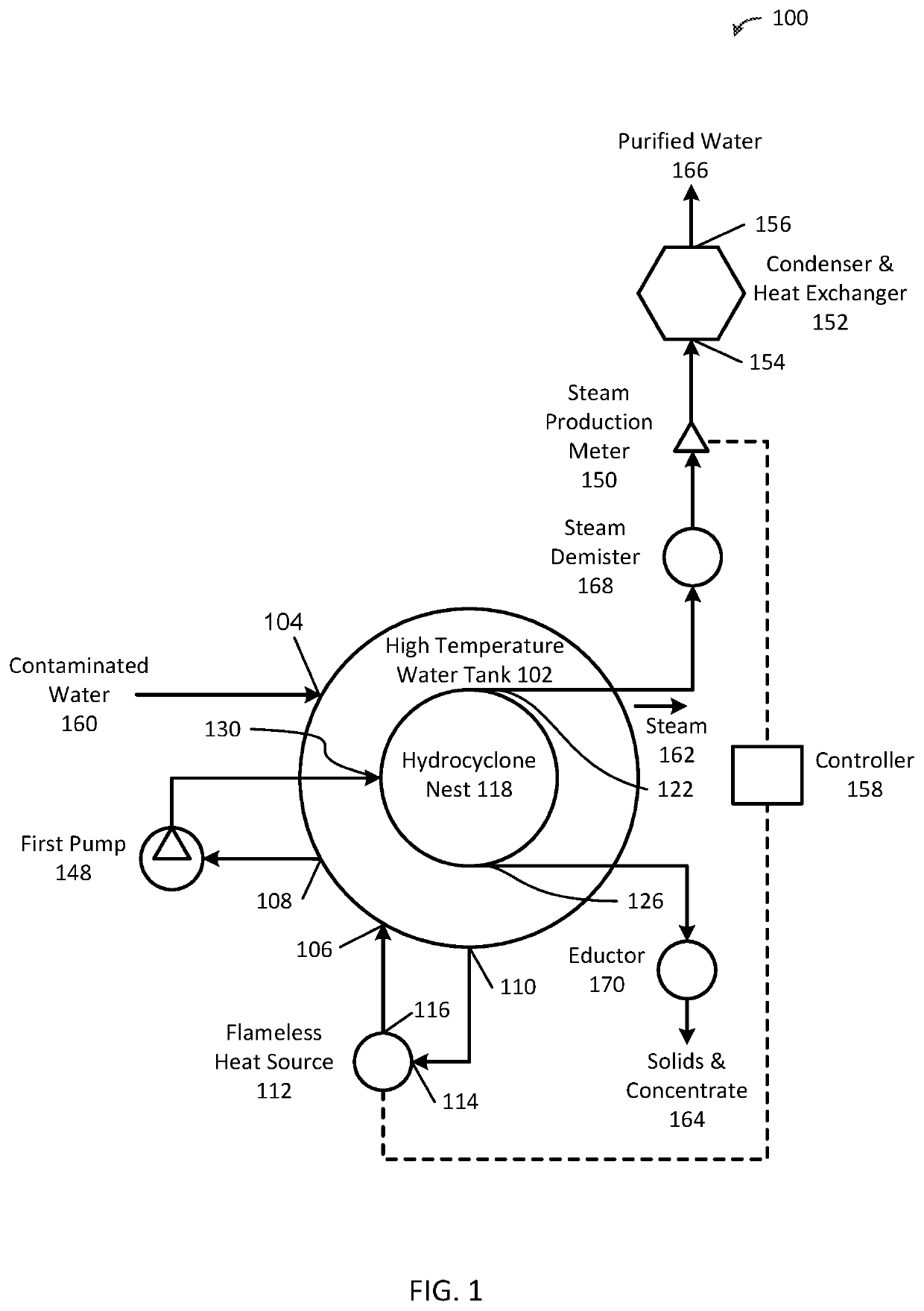

System and method for water purification

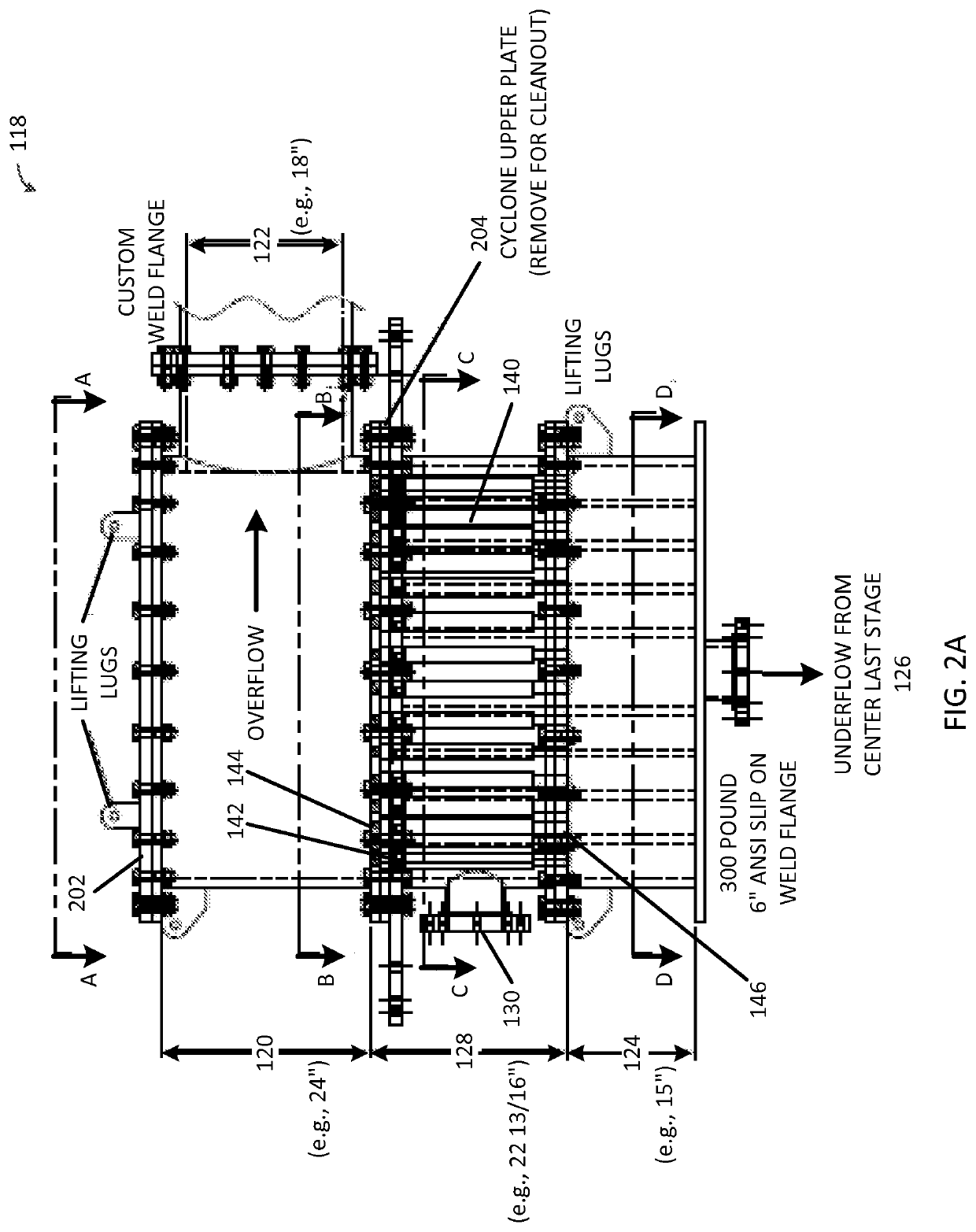

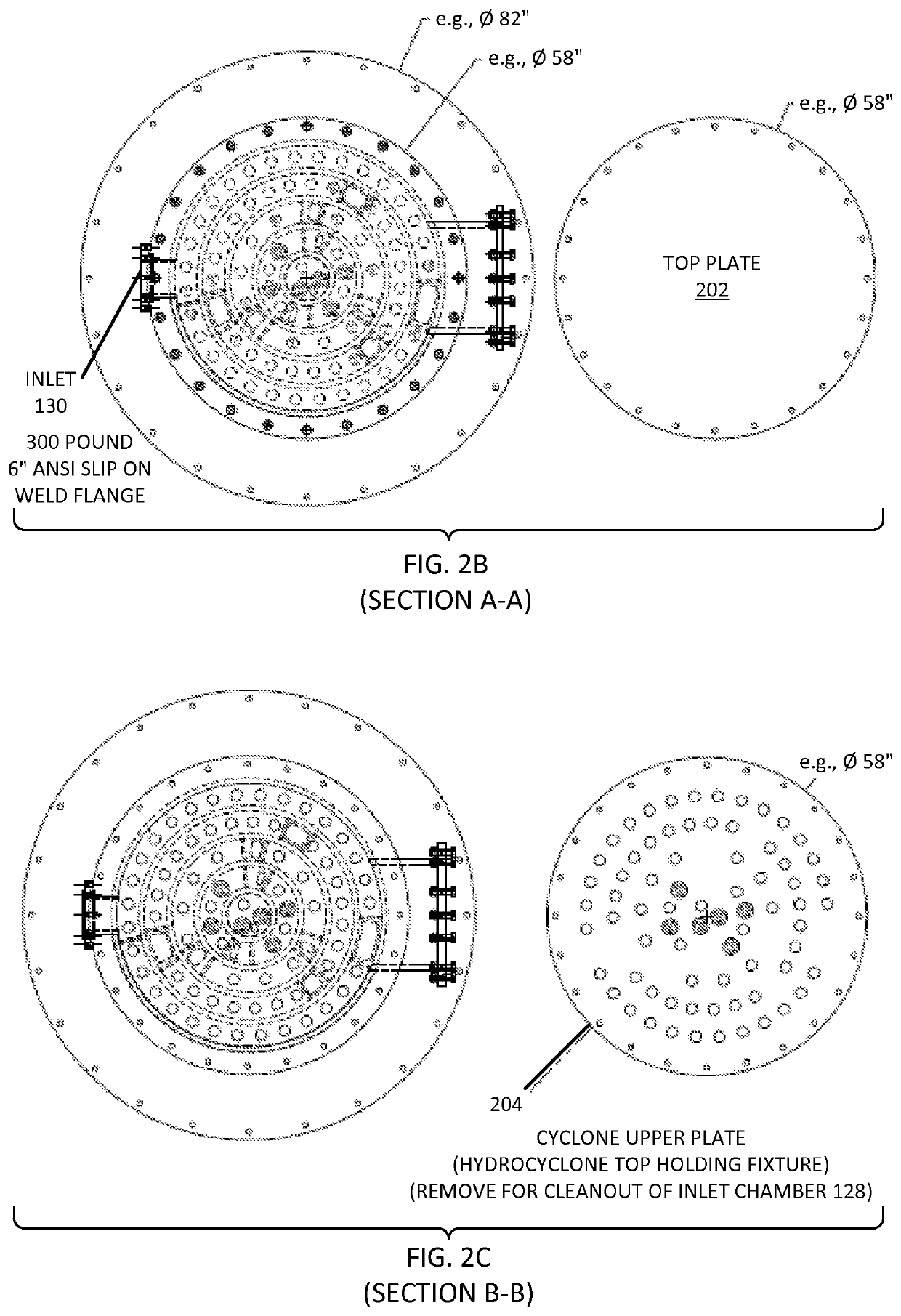

A water purification system includes a high temperature water tank, a flameless heat source, a cylindrical vessel (hydrocyclone nest), a first pump, a steam production meter, and a steam condenser and heat exchanger. The contaminated water is heated within the high temperature water tank using the flameless heat source. The heated contaminated water heats the cylindrical vessel and one or more sets of hydrocyclones. The heated contaminated water is pumped into the cylindrical vessel such that the heated contaminated water enters a tangential inlet of the hydrocyclones, the hydrocyclones separate the heated contaminated water into steam and solids / concentrate, the steam exits through an overflow of the hydrocyclones and a first outlet of the cylindrical vessel, the solids / concentrate exit through an underflow of the hydrocyclones and a second outlet of the cylindrical vessel. The steam is condensed into purified water using the steam condenser and heat exchanger.

Owner:CLOUDBURST SOLUTIONS

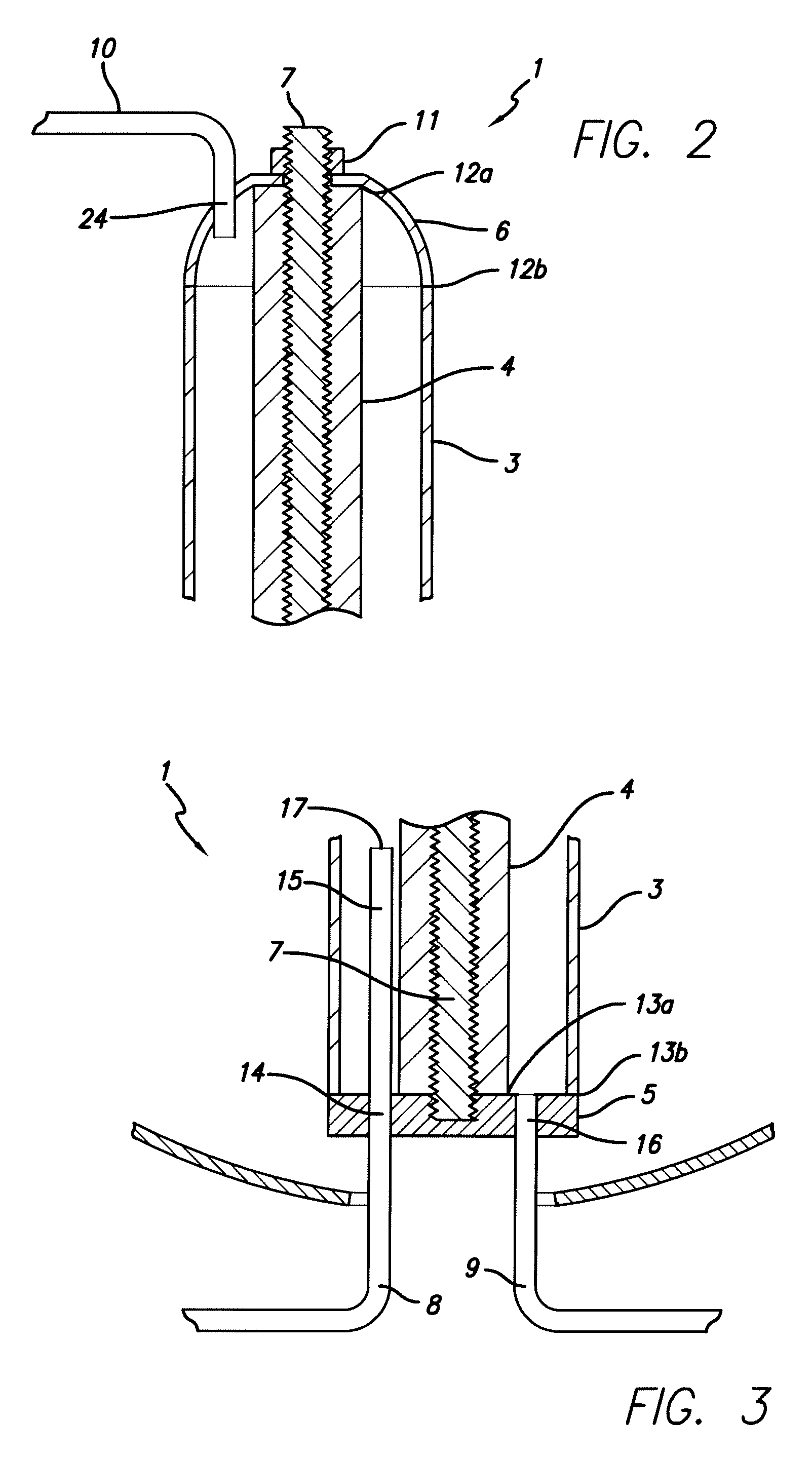

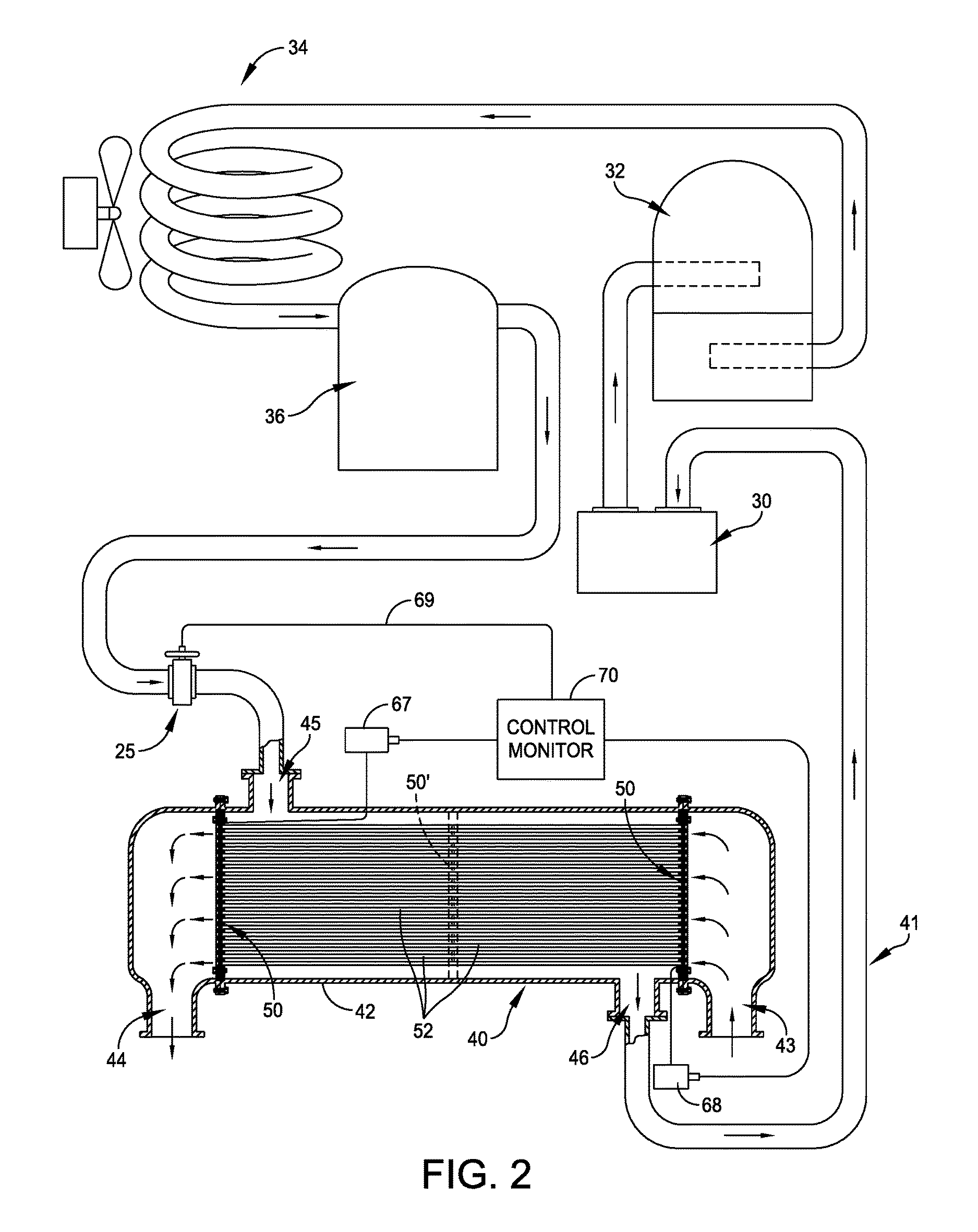

Multi-segmented tube sheet

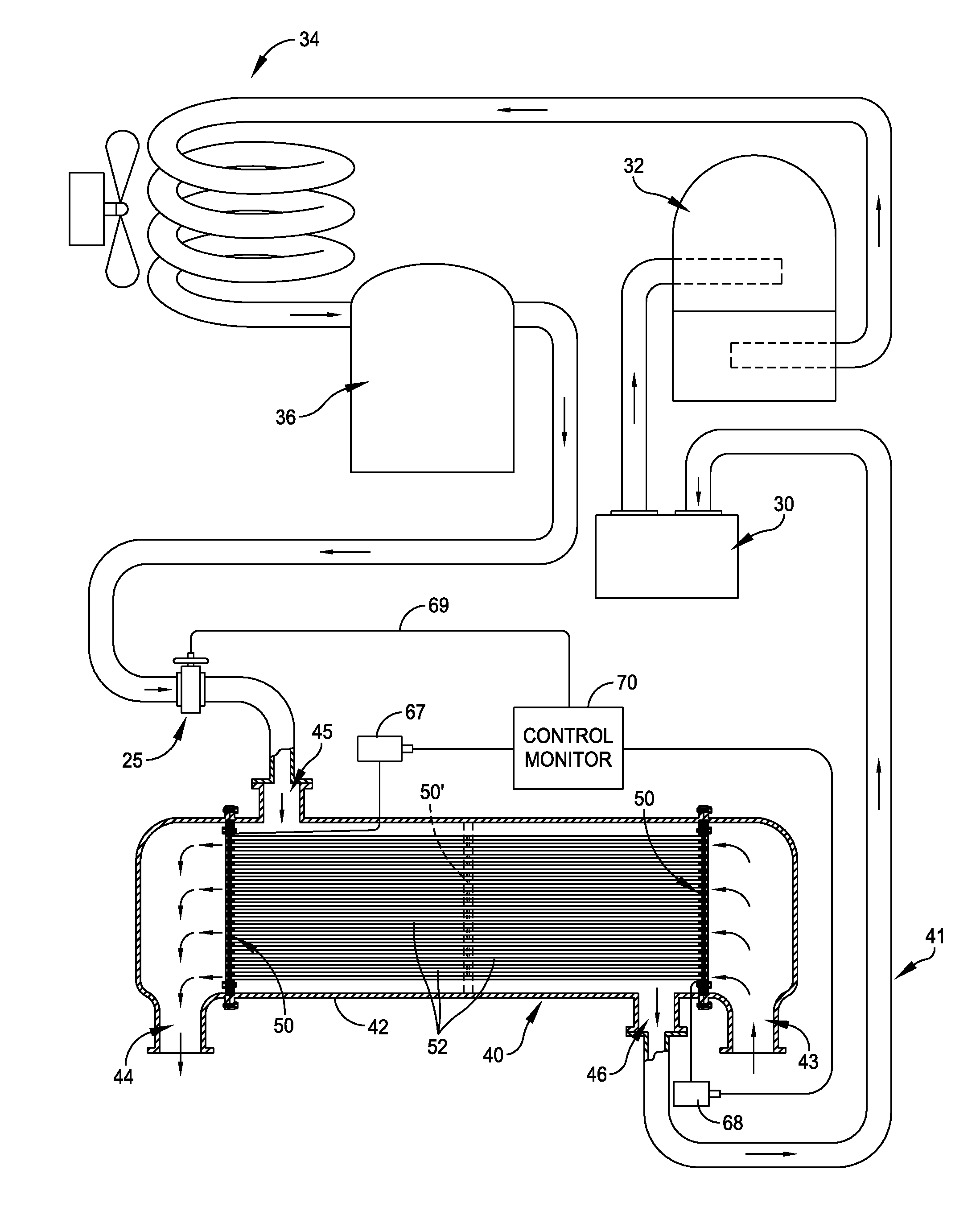

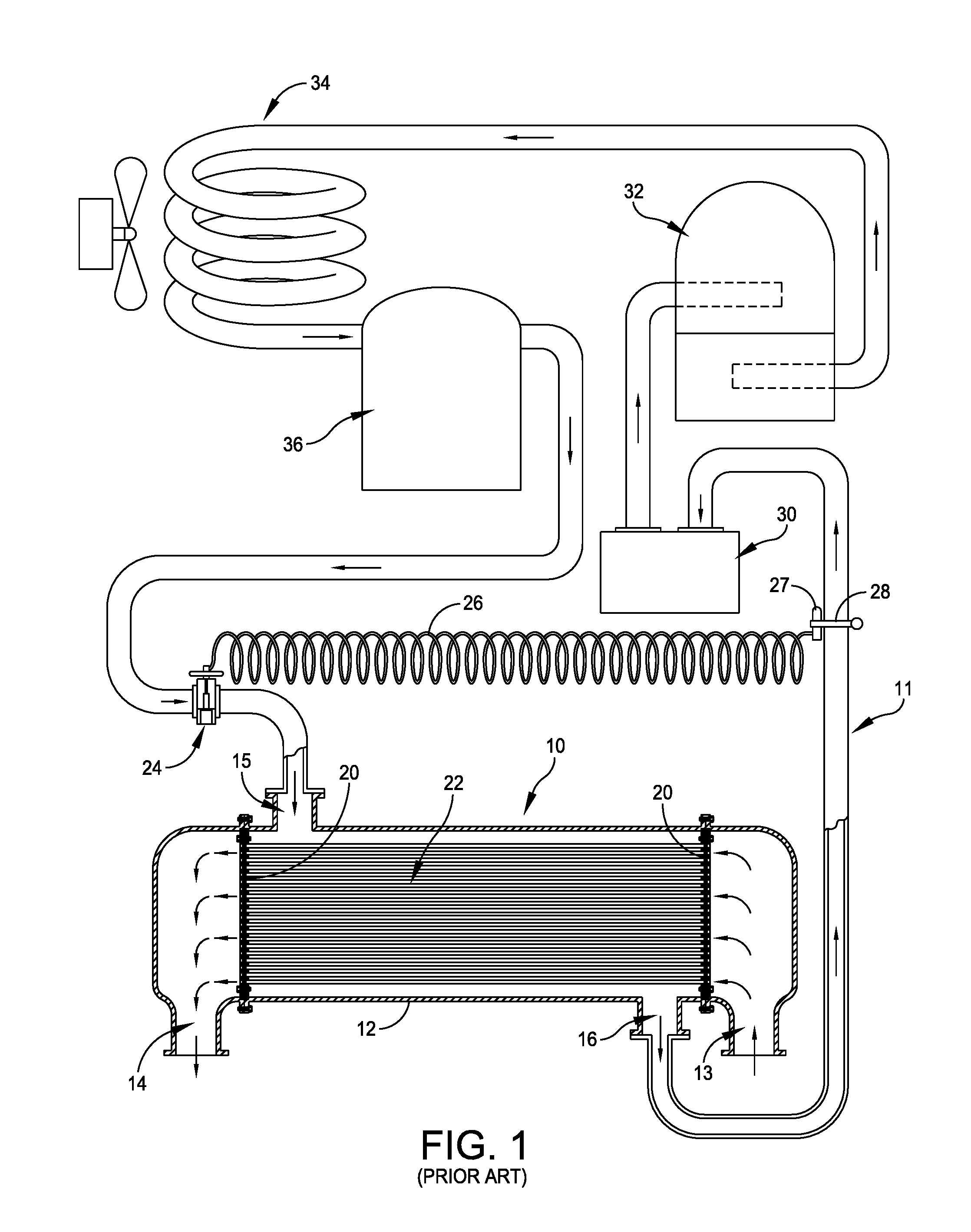

ActiveUS9581395B2Reduce thicknessHeat exchanger casingsStationary tubular conduit assembliesEngineeringControl valves

A heat exchanger that is constructed with a heat exchanger shell having inlet and outlet plenums and fluid inlet and outlet ports, and a tube sheet construction disposed in the heat exchanger shell. The tube sheet construction includes at least two separate tube sheets and a plurality of tubes that extend between the separate tube sheets. Each tube sheet includes at least two planar tube sheet segments and a interstitial layer disposed between the at least two tube sheet segments, and at least one sensor element supported by each of the interstitial layers. A control monitor controls flow through the shell by a feedback control from the sensor to an inlet control valve and / or a stimulus device excites the media layer. In an alternate embodiment opposed position sensor elements may be provided at opposite sides of the tube sheet construction.

Owner:NEPTUNE BENSON INC

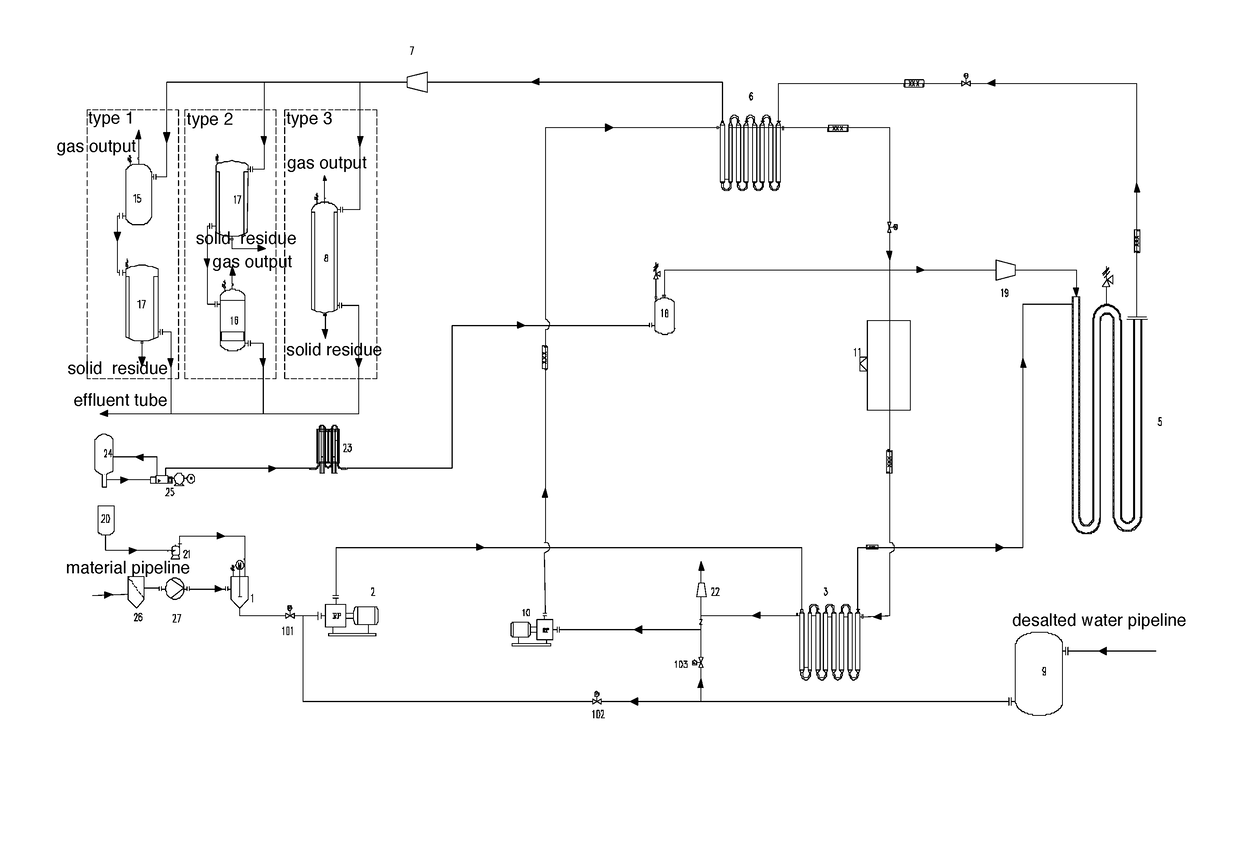

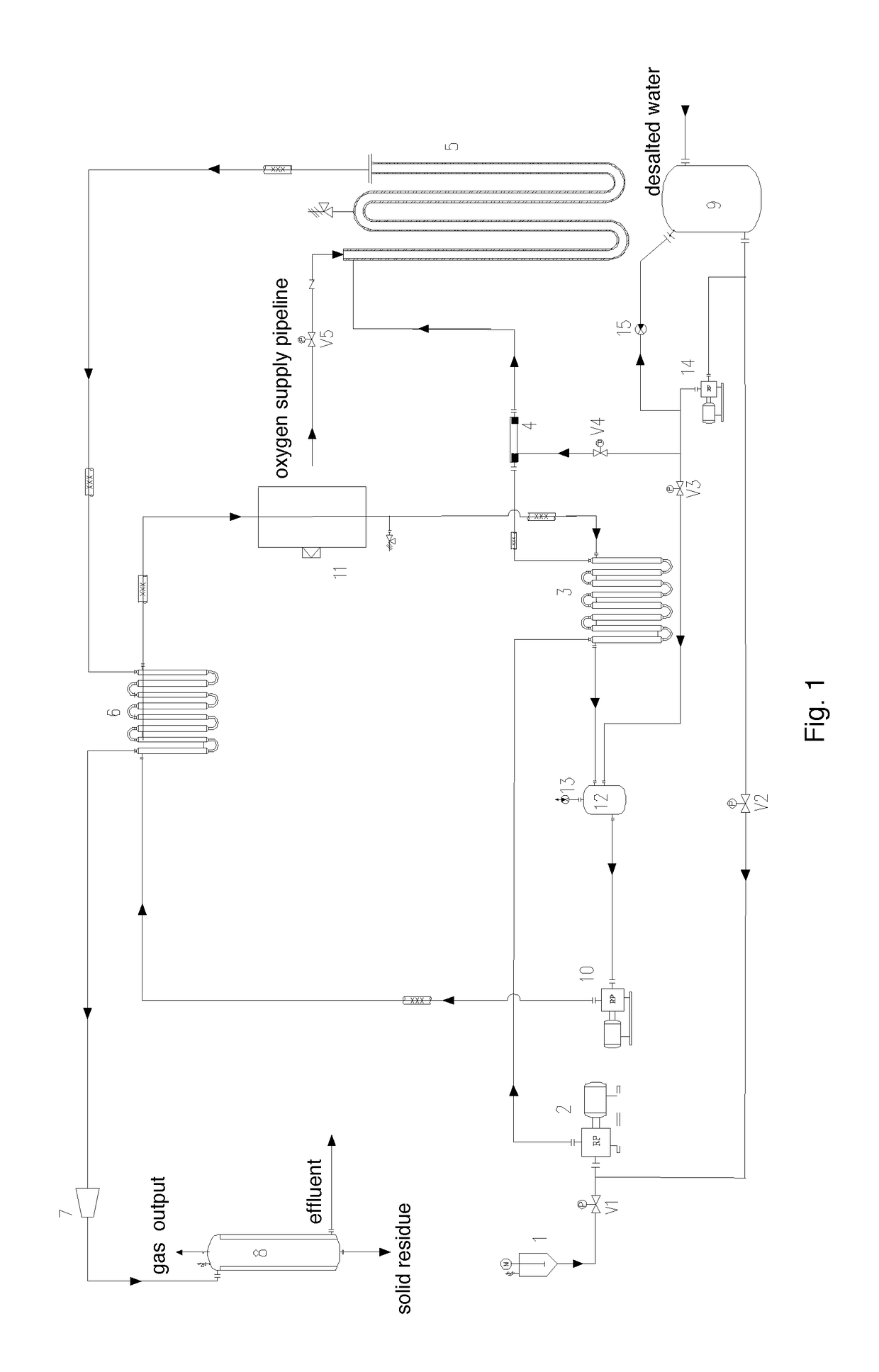

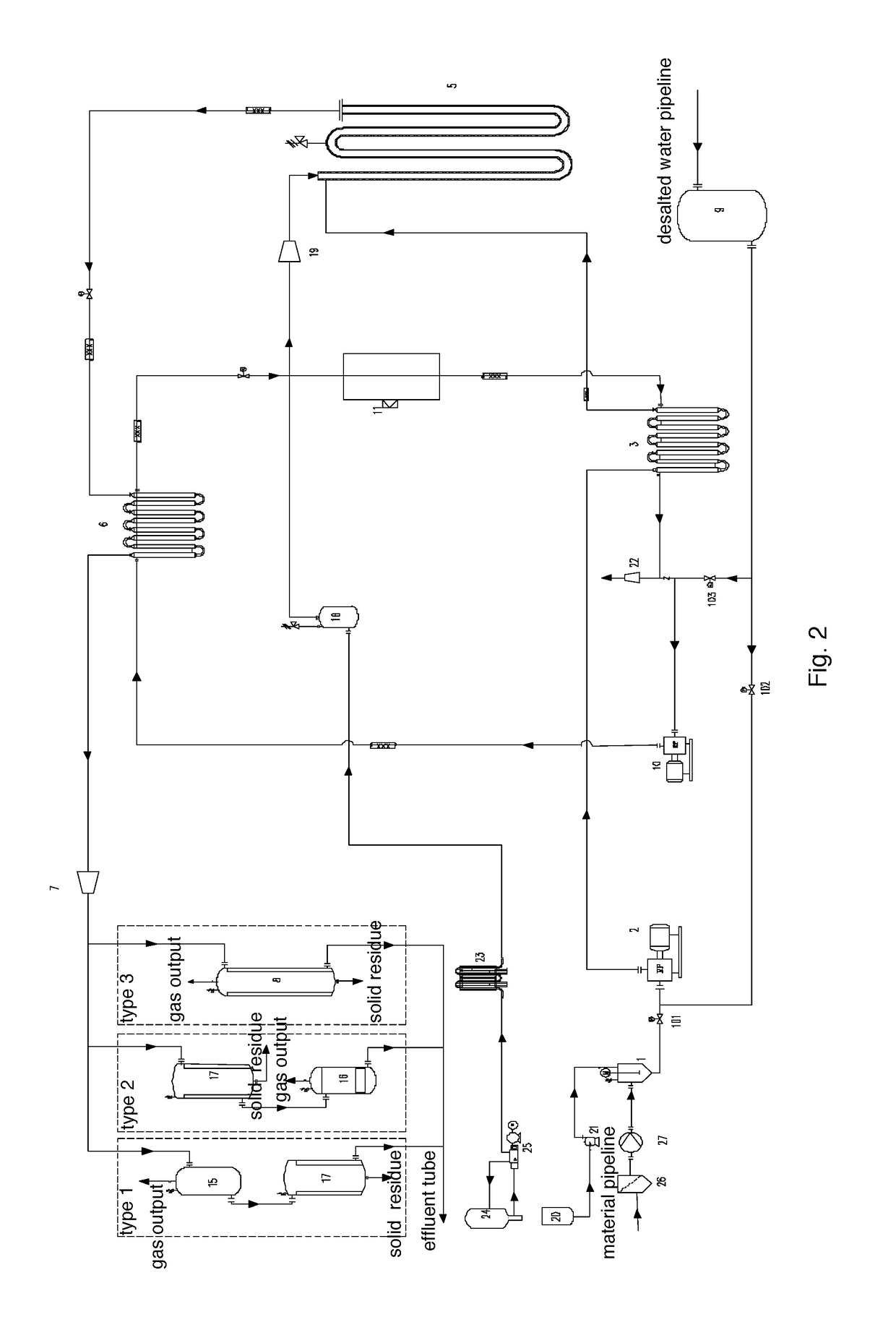

Indirect heat transfer supercritical water oxidation system and control method thereof

InactiveUS20170297941A1Low investment costAvoid risk of cloggingWater treatment parameter controlSludge treatment by oxidationAutomatic controlWorking pressure

An indirect heat transfer supercritical water oxidation system includes a supercritical water oxidation reactant system and an intermediate medium circuit. A control method thereof includes controlling two-process pressure and temperature increase, controlling pressure and temperature decrease and controlling normal operation. The present invention focuses on automatic control strategy of engineering practice of the indirect heat transfer supercritical water oxidation system. The system heating process adopts the idea of circulating heating, which effectively reduces the investment of the heating equipment avoids the mismatch between the working pressure of the two processes, and ensures effectiveness of the heat transfer between supercritical pressure fluid in the inner tube and the outer tube of the preheater / heat exchanger during subsequent heating process. The effective control of a reaction temperature and overpressure protection of critical equipment ensure a process effect and system safety.

Owner:XI AN JIAOTONG UNIV +1

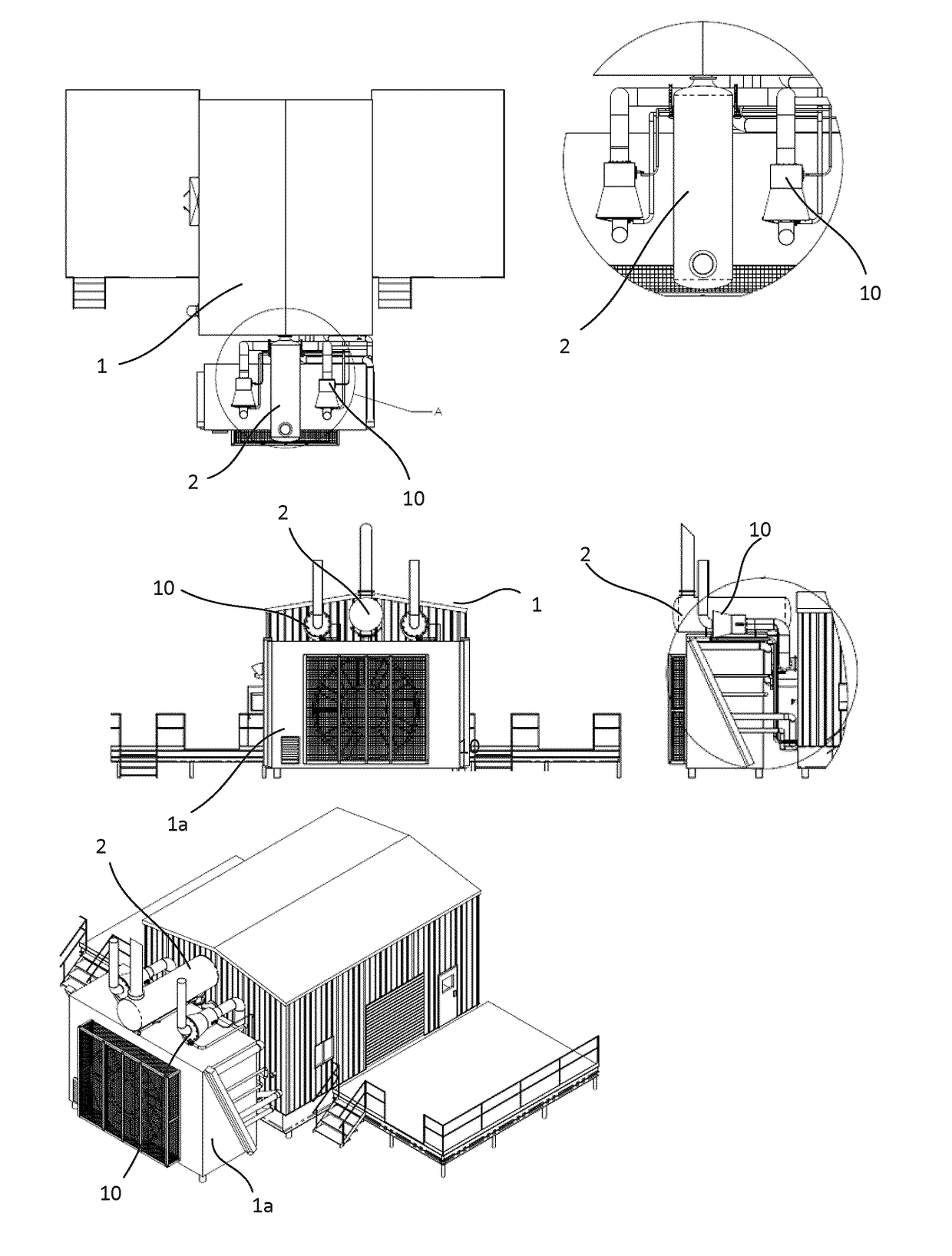

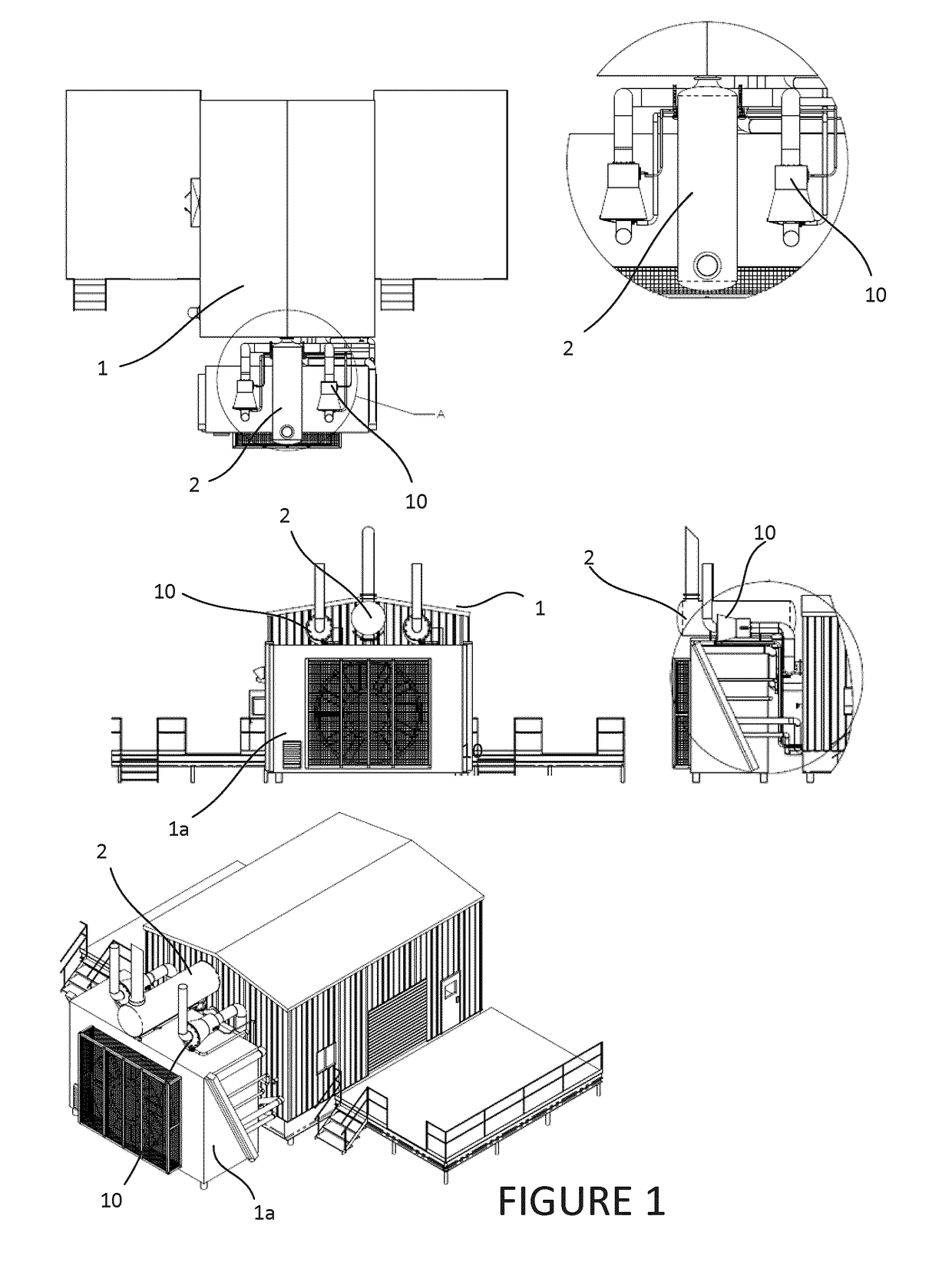

Method and apparatus for sharing co-generated energy when processing essential elements derived from plant matter

Methods and apparatus consistent with the present disclosure may provide electrical energy and thermal to extraction or separation equipment. Methods and apparatus consistent with the present disclosure may extract and concentrate essential elements plant matter. An amount of wasted heat energy collected from a engine that powers an electrical generator may be provided to an evaporation or separation process when electrical power is provided to extraction or separation processing equipment. Computers or electronics that control equipment consistent with the present disclosure may be remotely controlled via a mobile electronic device, when desired. Such computers or electronics may receive sensor data related to the operation of plat matter extractors, related separation equipment, or other equipment may be used to manage a production line. As such, methods and apparatus consistent with the present disclosure may extract essential elements from cannabis plant matter and process those essential elements into cannabis extracts or isolates.

Owner:HOSPODOR ANDREW DAVID +1

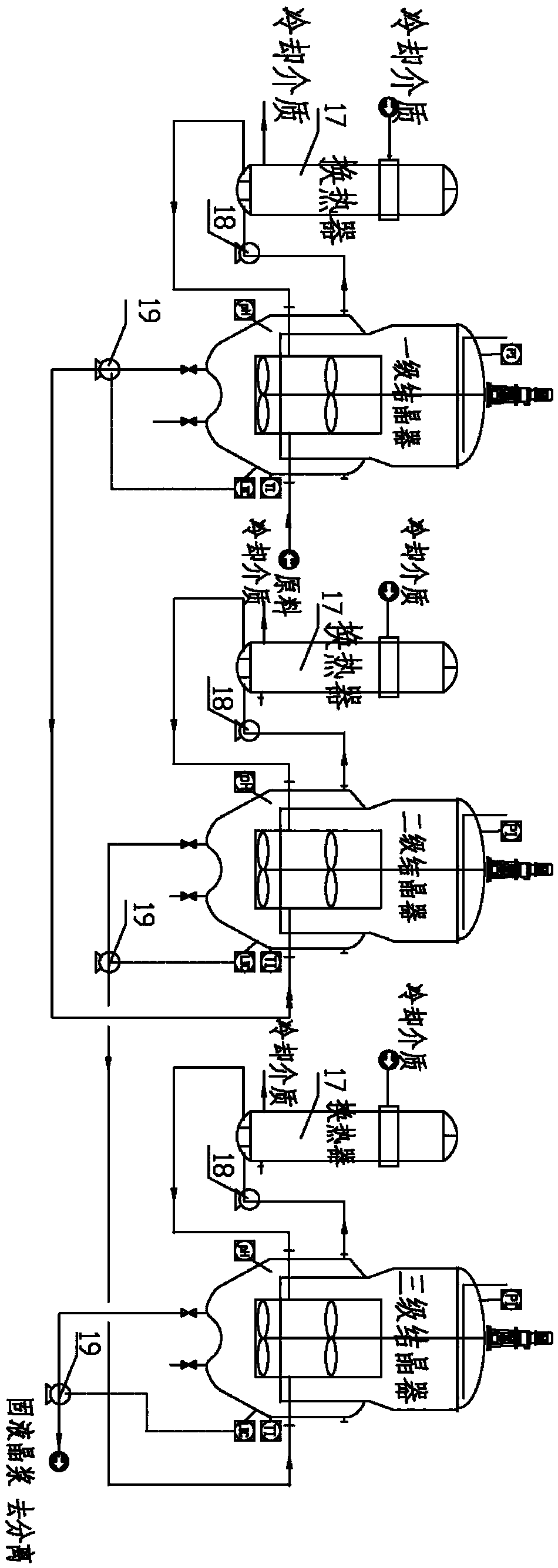

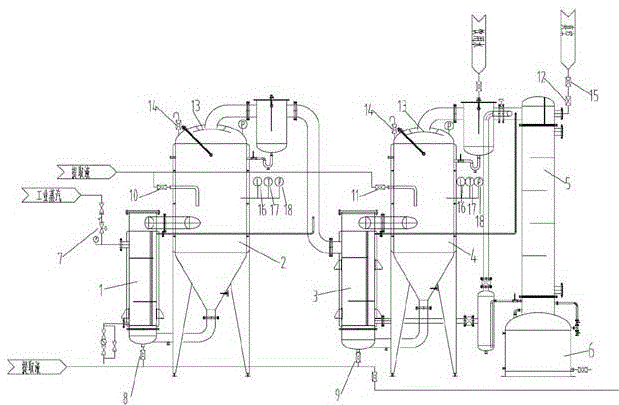

Control method for double-effect concentration process of Chinese traditional medicines

InactiveCN105536274AEasy to controlQuality improvementEvaporator accessoriesEvaporator regulation/controlChinese traditionalEngineering

The invention discloses a control method for the double-effect concentration process of traditional Chinese medicines. The double-effect concentration process of traditional Chinese medicines is carried out in a concentrator. The control method comprises the following steps: starting-up and confirmation; feeding control; control of temperature and pressure in the concentration process; defoaming control; vacuum protection control; control of liquid supplementation in the concentration process; liquid discharging of a liquid receiver; batch turning control; judgment of the terminal point of concentration; and liquid discharging control. Thus, the method provided by the invention realizes precise control of parameters of the double-effect concentration process of traditional Chinese medicines and provides a novel technology to improve traditional Chinese medicine product quality stability and modernization of traditional Chinese medicines.

Owner:SUZHOU ZEDAXINGBANG MEDICAL TECH

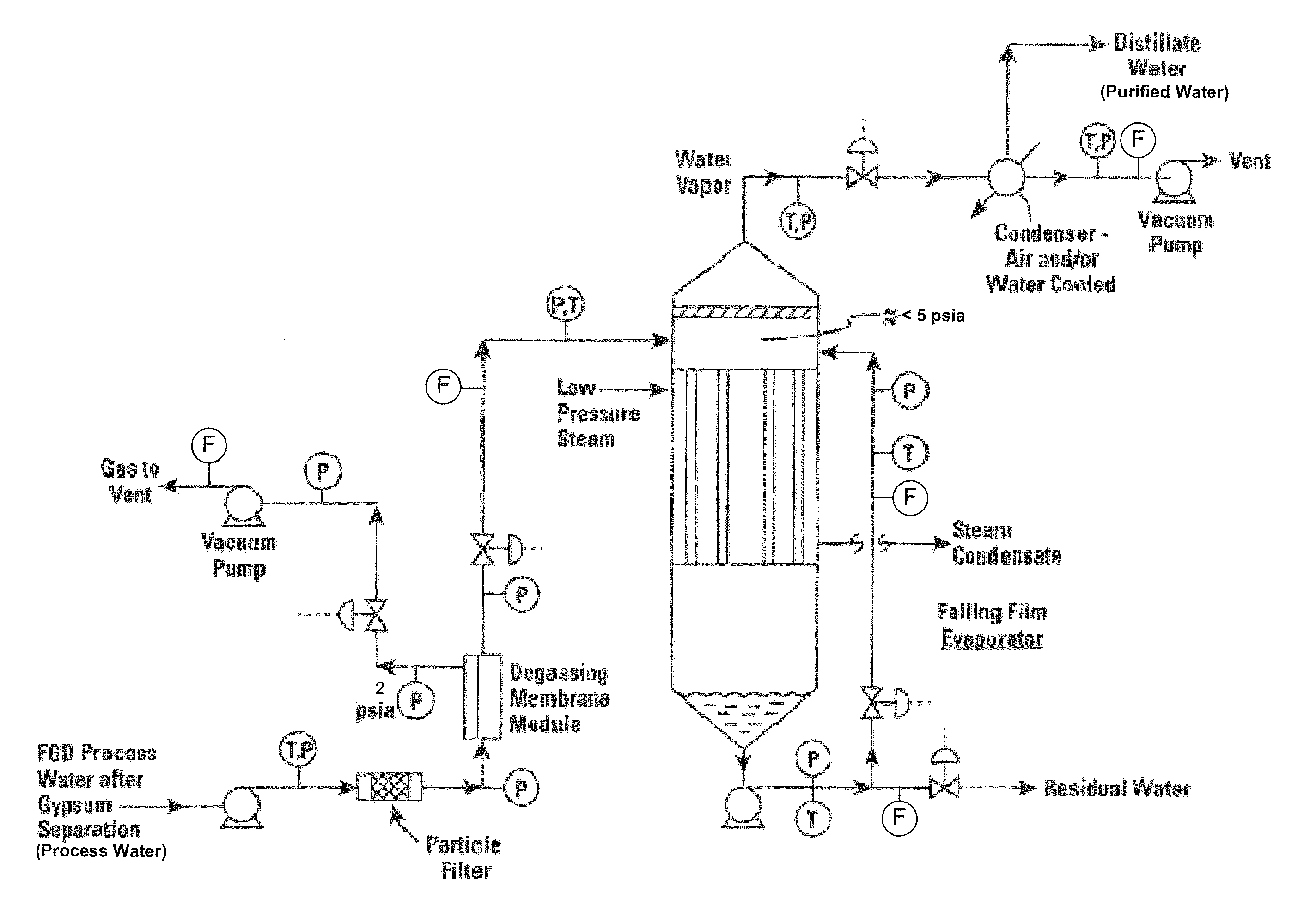

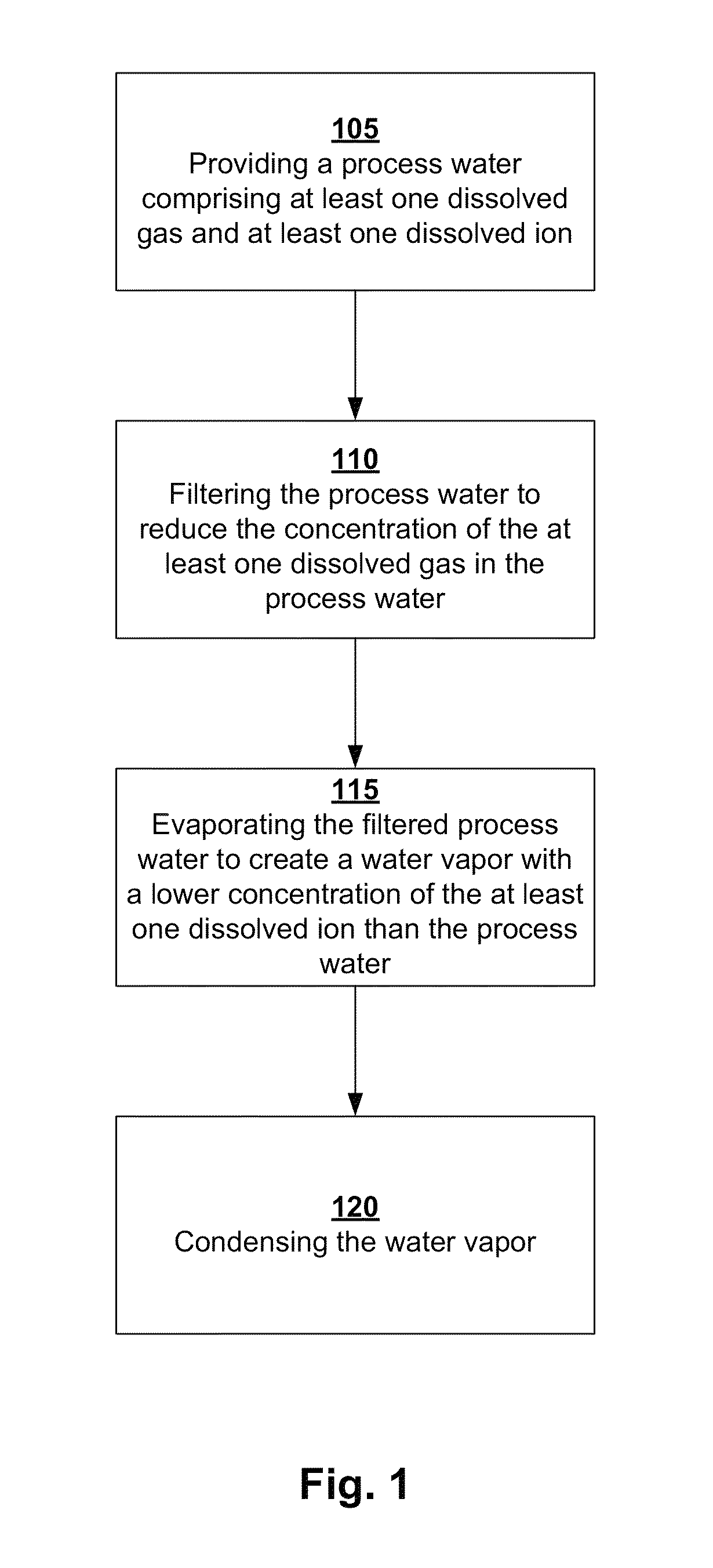

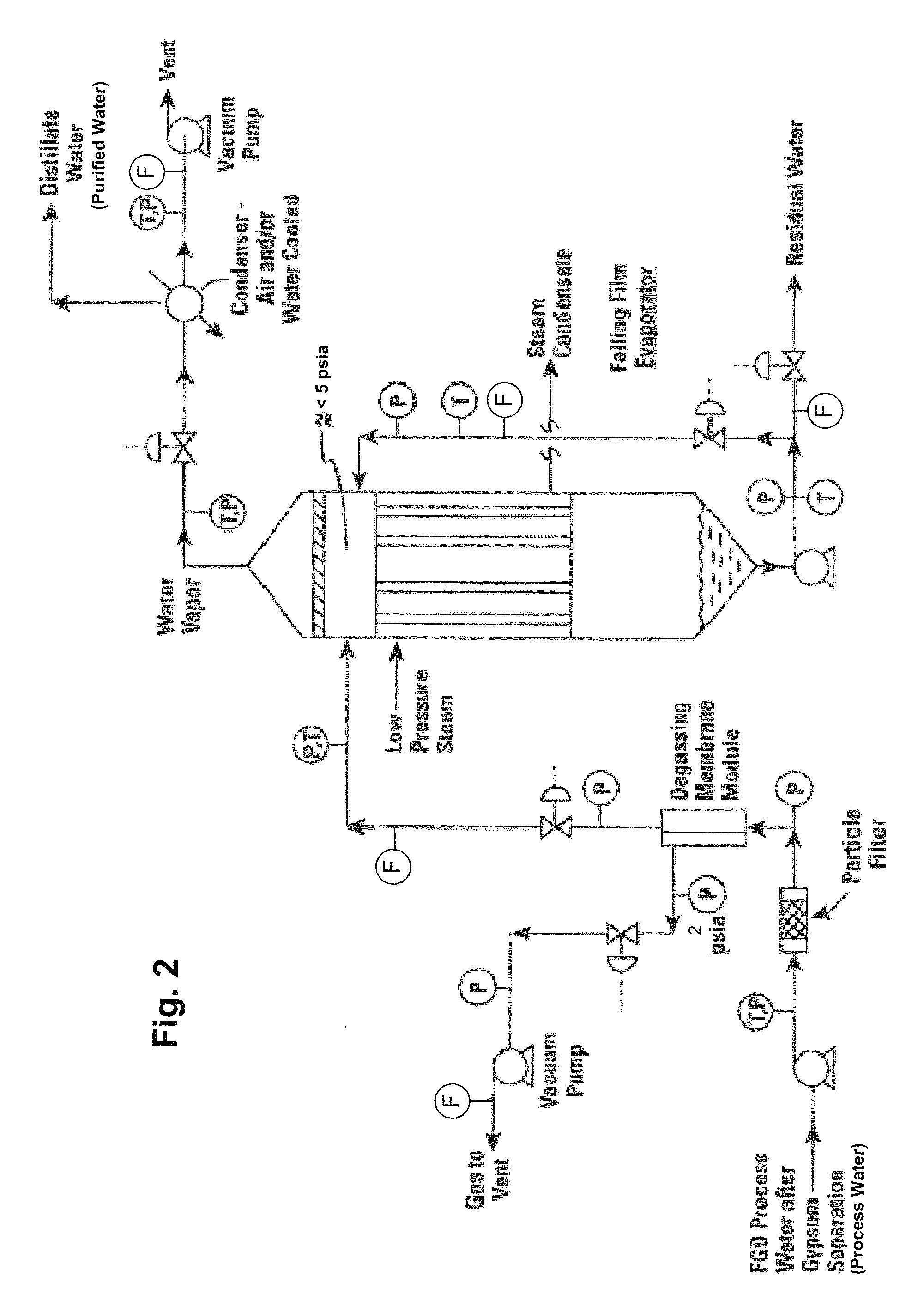

Systems and methods for purifying process water

Disclosed are methods for purifying a process water, which can comprise providing a process water comprising a first concentration of a first dissolved gas and a first concentration of a first dissolved ion, filtering the process water to create a filtered process water comprising a second concentration of the first dissolved gas, and evaporating the filtered process water to create a water vapor comprising a second concentration of the first dissolved ion that is less than the first concentration of the first dissolved ion.

Owner:THE SOUTHERN CO

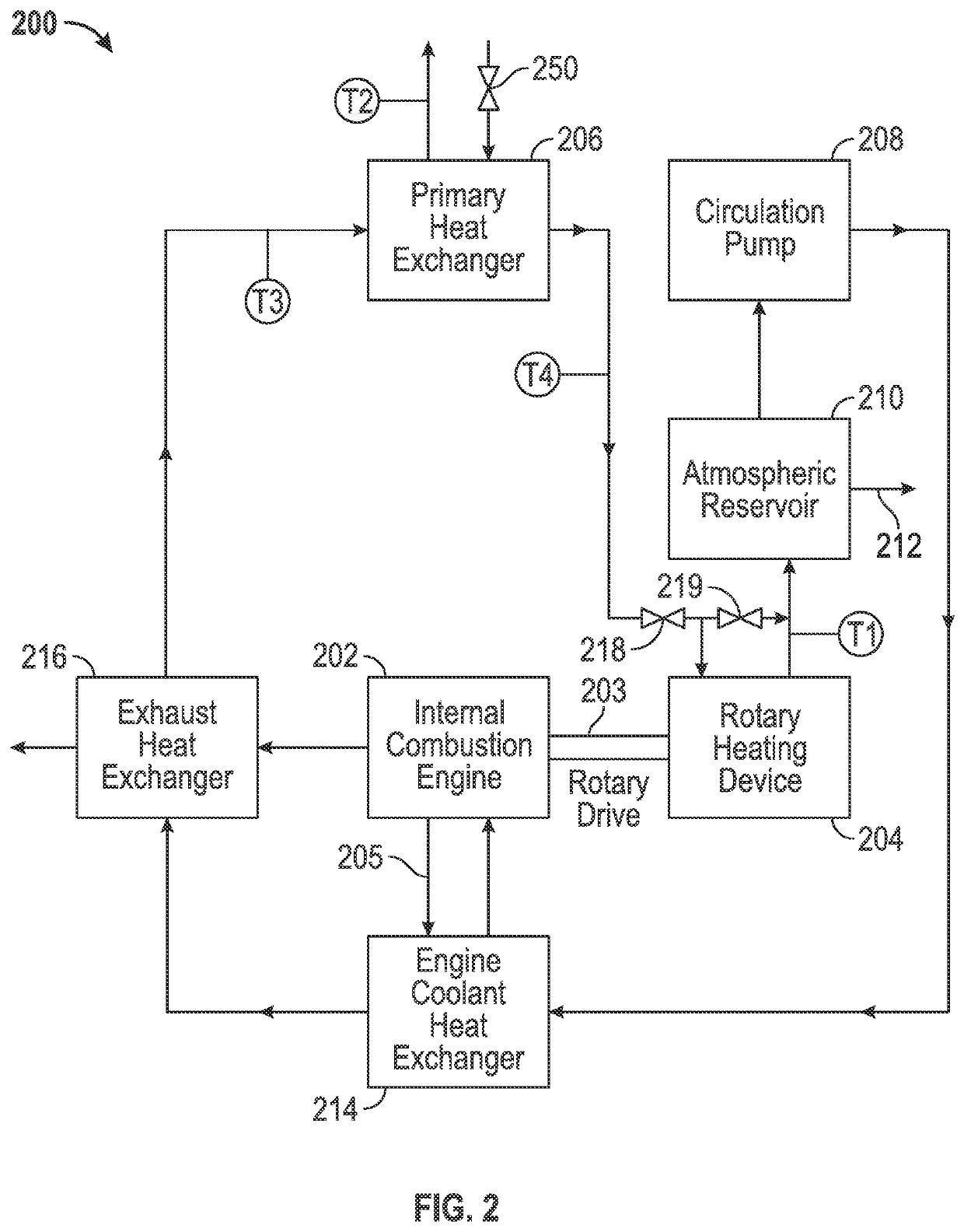

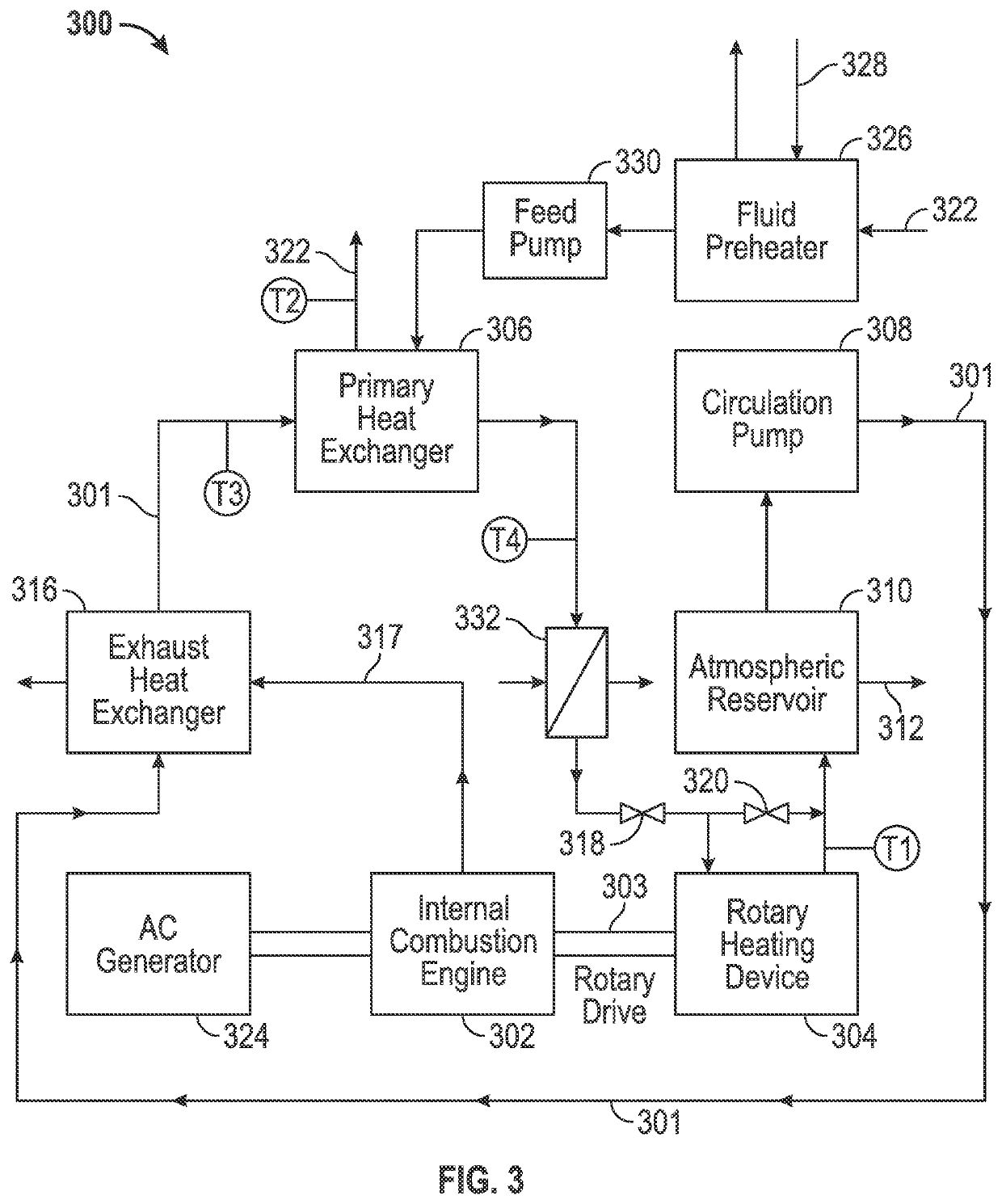

Methods and systems for heating and manipulating fluids

InactiveUS20200206651A1Water treatment parameter controlEnergy recuperation in distillationEngineeringMechanical engineering

Systems and methods are provided for heating and manipulating a fluid to heat the fluid, evaporate water from the fluid, concentrate the fluid, separate the fluid into fractions; and / or pasteurize the fluid, comprising a closed-loop heating subsystem coupled to a primary fluid-to-fluid heat exchanger, and one or more fluid manipulation subsystems also coupled to the primary fluid-to-fluid heat exchanger.

Owner:PHOENIX CALIENTE

Apparatus, systems and methods for management of raw water and emissions utilizing heat and/or pressure energy within combustion gas sources

InactiveUS20180215632A1Quick interactionIncrease the areaWaste water treatment from quariesUsing liquid separation agentParticulatesAtmospheric air

The invention relates to methods, systems and apparatus for distributed management of raw water and internal combustion engine (ICE) gas emissions generated during industrial operations. One aspect of the invention at least partially utilizes a hot gas air knife to increase or partially increase surface area between a raw water and a hot gas in order to vaporize a proportion of the aqueous phase of the raw water and concentrate contaminants within a residual raw water concentrate. The water vapor generated by the vaporization process may be demisted, discharged directly to the atmosphere or alternatively condensed and captured for use. Another aspect relates to how the liquids and gasses interact to continuously flush the surfaces of the system which may help mitigate scaling issues. The invention may help facilitate rapid transfer of ICE combustion gas particulate and ICE combustion gas chemicals onto and into the raw water as it concentrates.

Owner:HORIZON OILFIELD SOLUTIONS

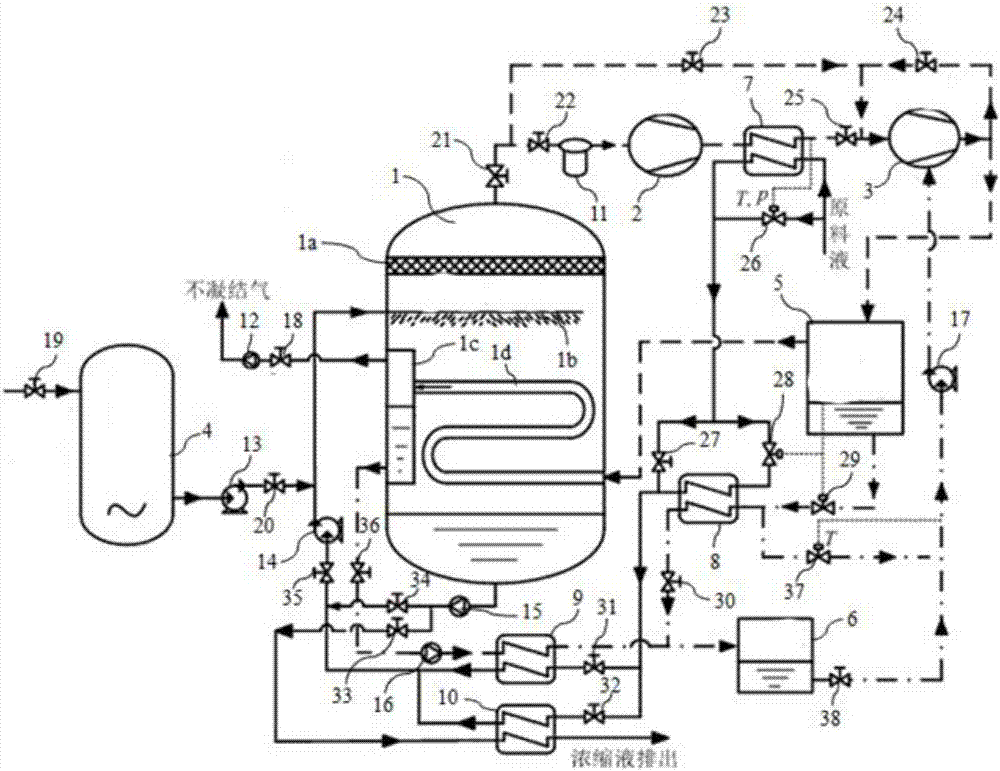

Mechanical steam recompression system and control method

ActiveCN107213659AImprove energy efficiencyImprove performanceDistillation regulation/controlEvaporator accessoriesVapor–liquid separatorHigh energy

The invention provides a mechanical steam recompression system comprising an evaporative condenser, a centrifugal compressor, a screw compressor, an electric water heater, a vapor-liquid separator and a fresh water box. The evaporative condenser communicates with the centrifugal compressor and the screw compressor; a first valve and a drain separator are arranged between the evaporative condenser and the centrifugal compressor; a second valve is arranged between the evaporative condenser and the screw compressor; the centrifugal compressor communicates with the screw compressor; an outlet of the screw compressor communicates with the an inlet of the screw compressor; and the screw compressor communicates with a condensing tube of the evaporative condenser through the vapor-liquid separator. The mechanical steam recompressing system provided by the invention is a mechanical steam recompressing system which has no need to start heat-source steam, can realize a high vapor pressure ratio (Saturated temperature rise of compressed steam) and high vapor flow, and has higher energy efficiency. In addition the mechanical steam recompression system has functions of expanding the application range of conventional mechanical steam recompression systems and realizing industrial energy conservation.

Owner:HUAWEI TEHCHNOLOGIES CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com