Mechanical steam recompression system and control method

A mechanical steam and recompression technology, applied in the direction of distillation adjustment/control, evaporator adjustment/control, steam generation, etc., can solve the problems of not too high operating pressure ratio, increased system cost, high energy consumption, etc., and achieve industrial energy saving , improved performance, high energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the above objects, features and advantages of the present invention more comprehensible, specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0029]System embodiment

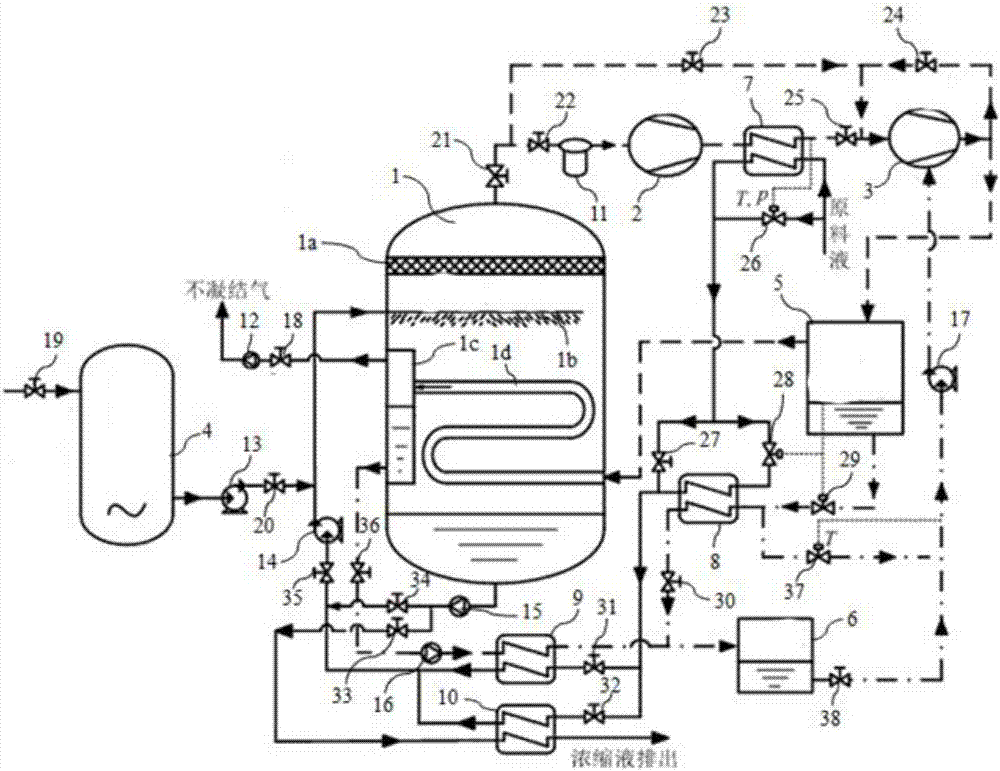

[0030] like figure 1 Shown: a mechanical vapor recompression system, including evaporative condenser 1, centrifugal compressor 2, screw compressor 3, electric water heater 4, vapor-liquid separator 5 and fresh water tank 6, the top of the evaporative condenser 1 is set There is a filter screen 1a, a spray pipe 1b is arranged below the filter screen 1a, a water collection tank 1c and a condensation pipe 1d communicating with the water collection tank 1c are arranged below the spray pipe 1b, and the water collection tank 1c The air outlet is provided with an exhaust valve 18 and a vacuum pump 12, the inlet of the spray pipe 1b is connected to the outlet of the electric water heater 4 through the pipeline provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com