Patents

Literature

3278results about "Evaporator accessories" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

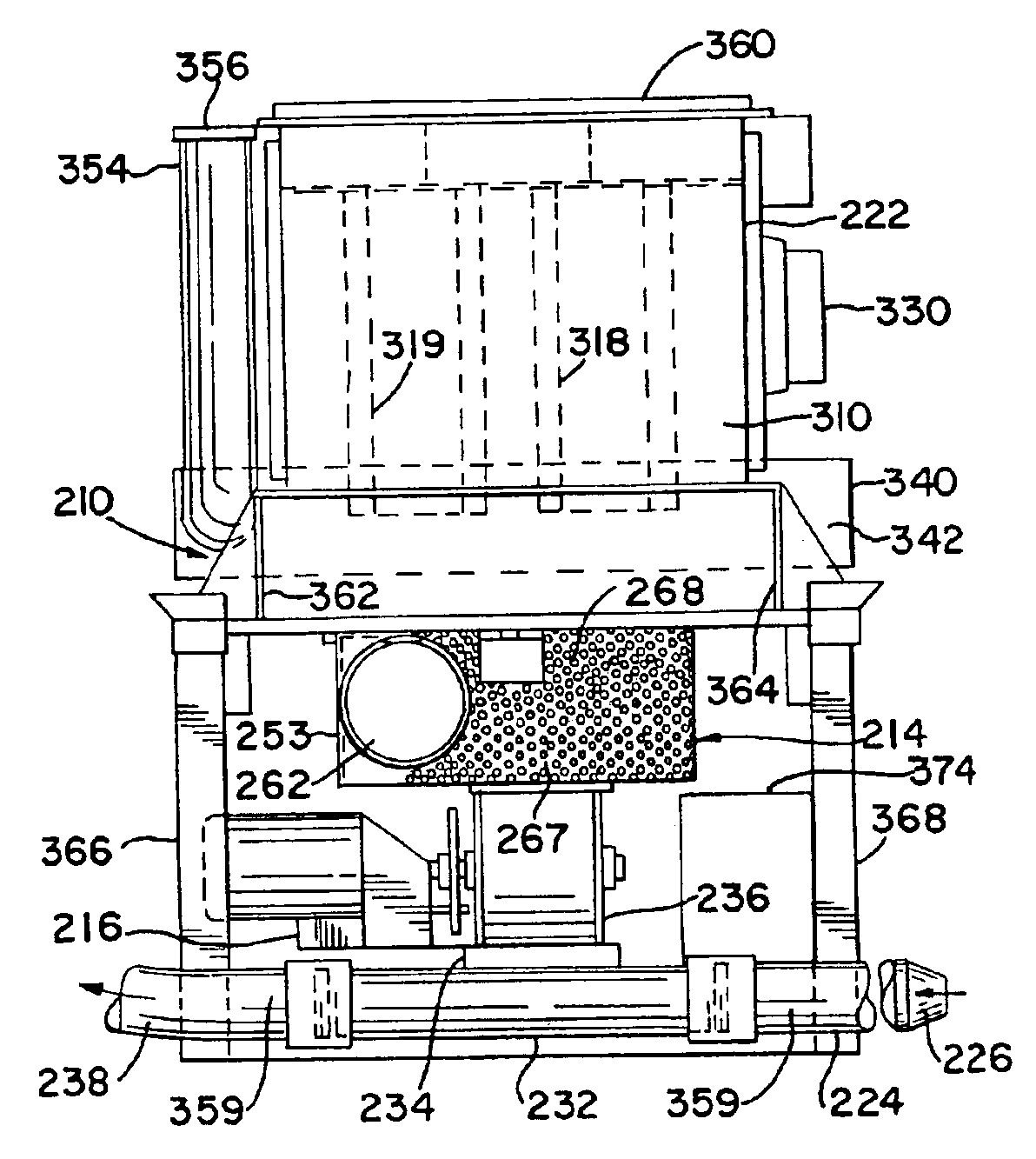

Vacuum loader

InactiveUS6936085B2Efficient and effective and safeCombination devicesAuxillary pretreatmentCycloneFiber

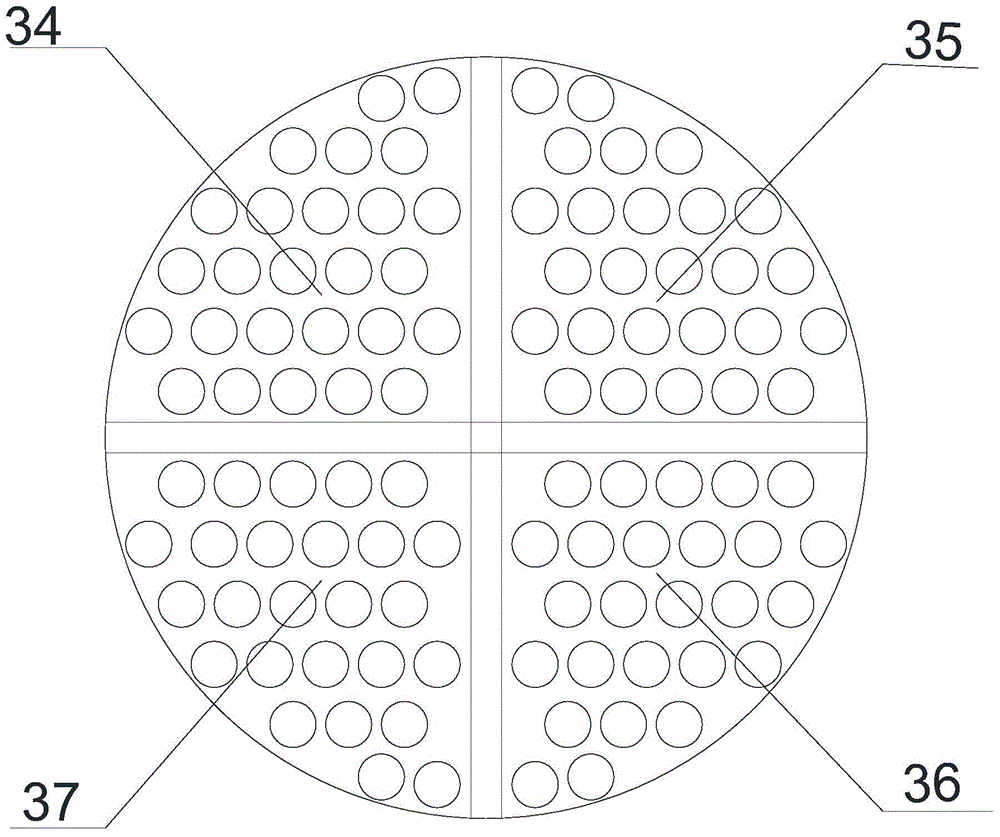

A specially arranged vacuum loader and industrial dust collector with a perforated plate tangential cyclone separator is provided to efficiently remove, readily collect, effectively separate and safely dispose of wet, dry and fibrous materials, including liquids and slurries. The special vacuum loader and industrial dust collector has a solids-gas separation compartment comprising a tangential cyclone separator, preferably a perforated plate tangential separator, which is positioned generally alongside and laterally offset from one or more filtering compartments to minimize turbulence and re-entrainment of the collected particulate material.

Owner:DEMARCO VACUUM CORP

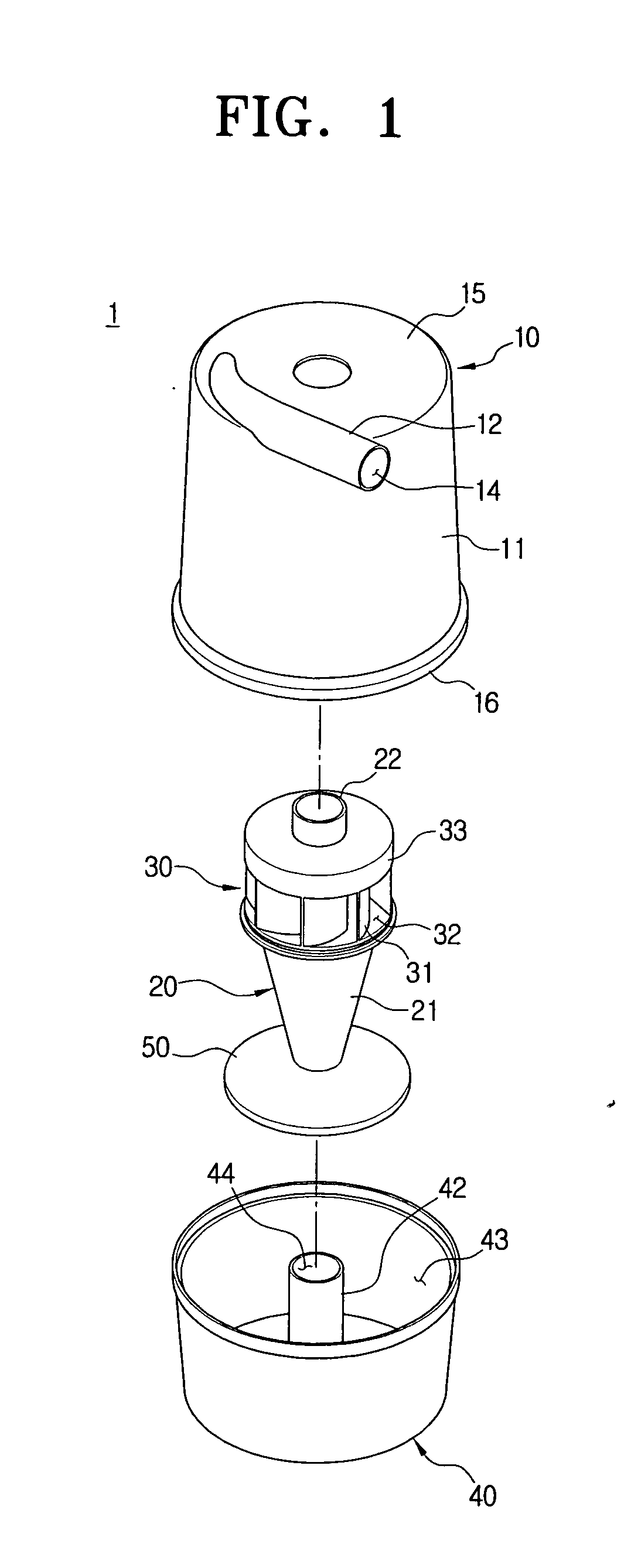

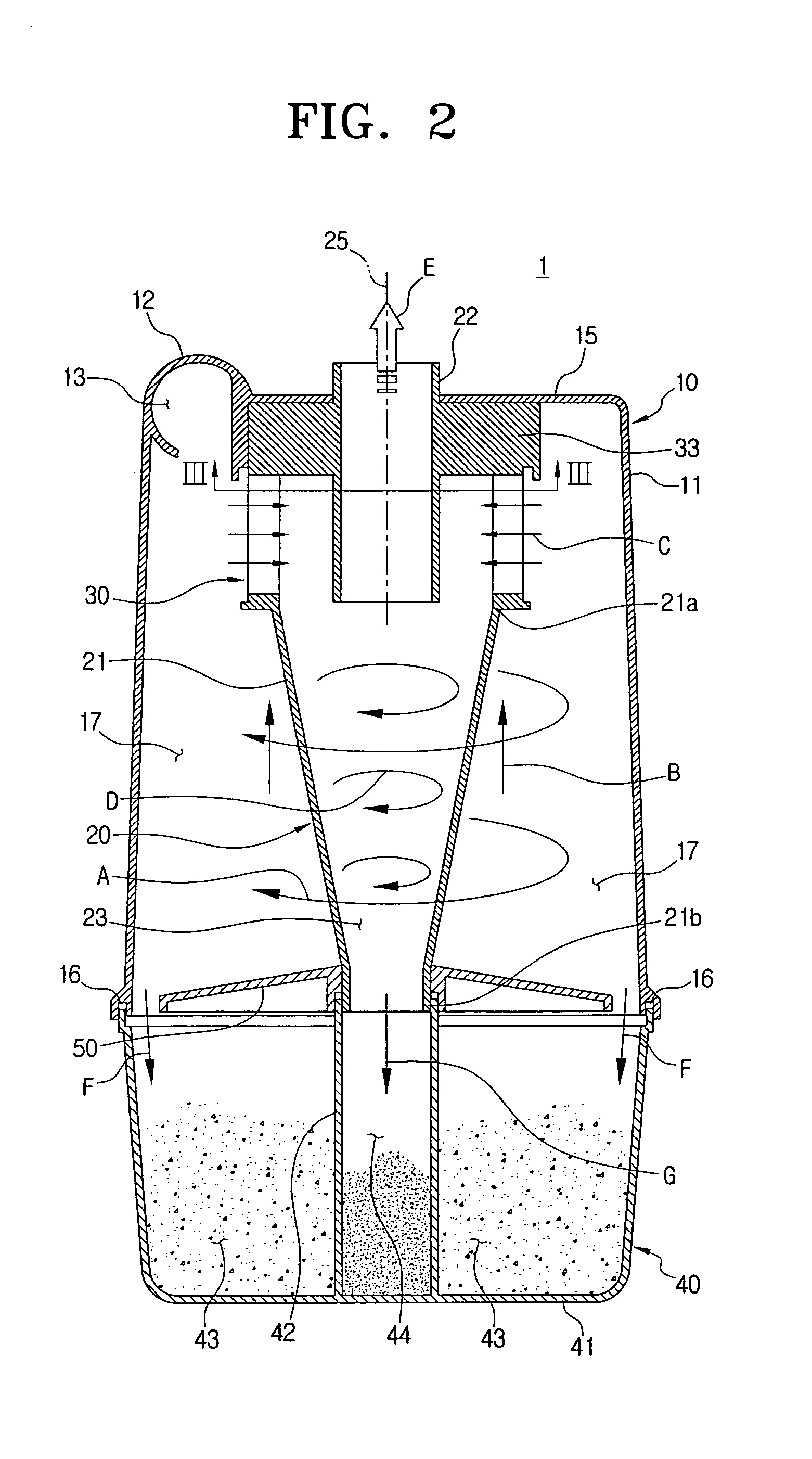

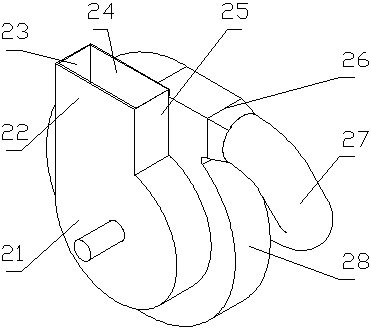

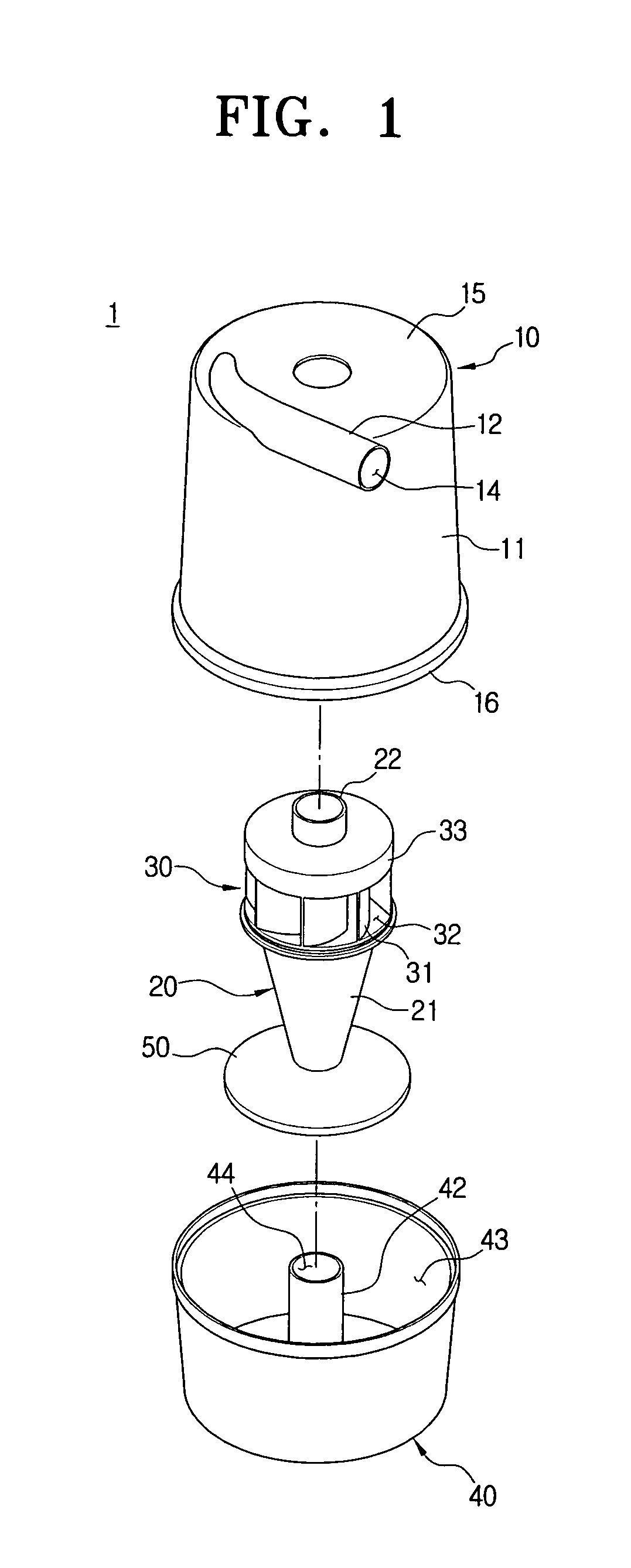

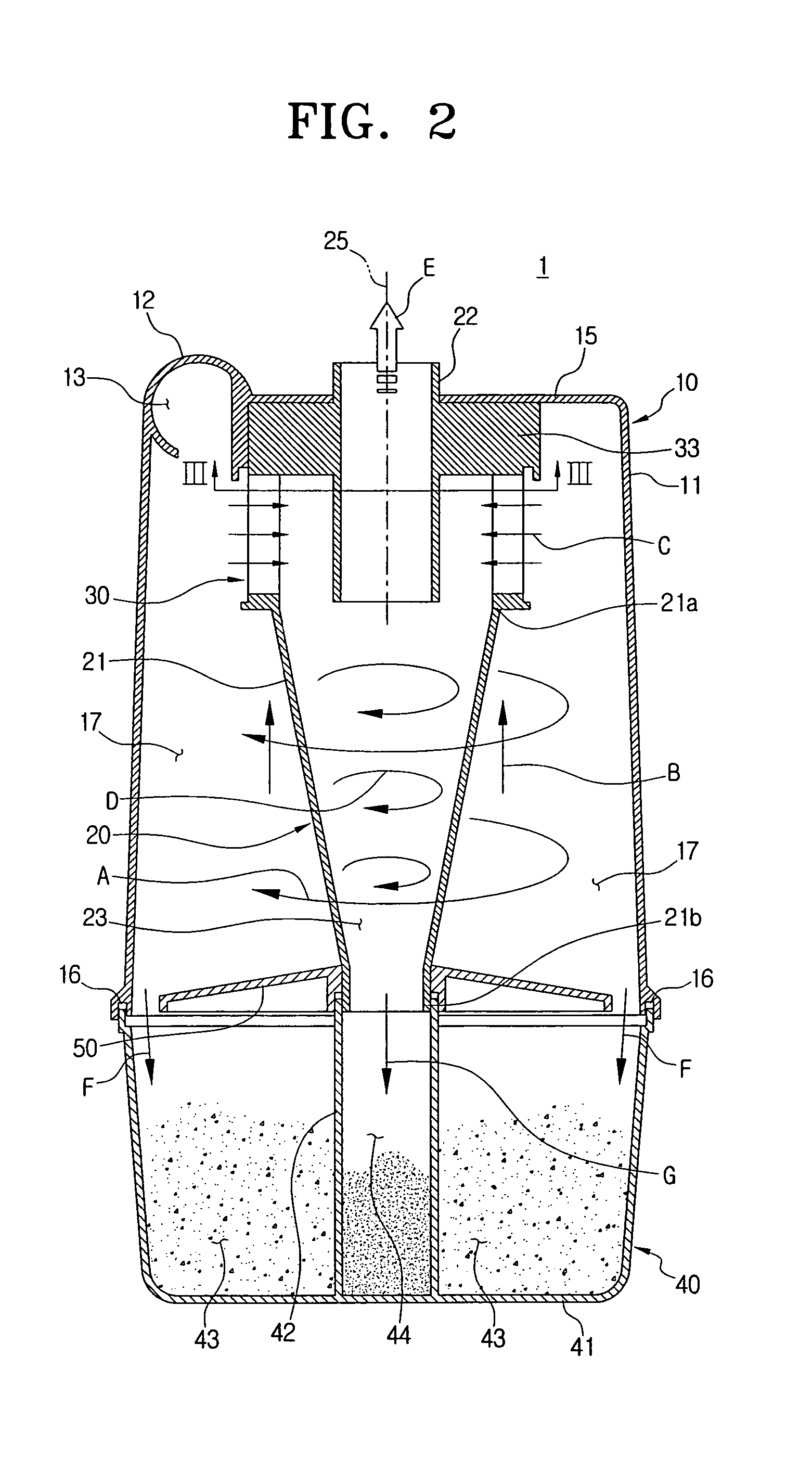

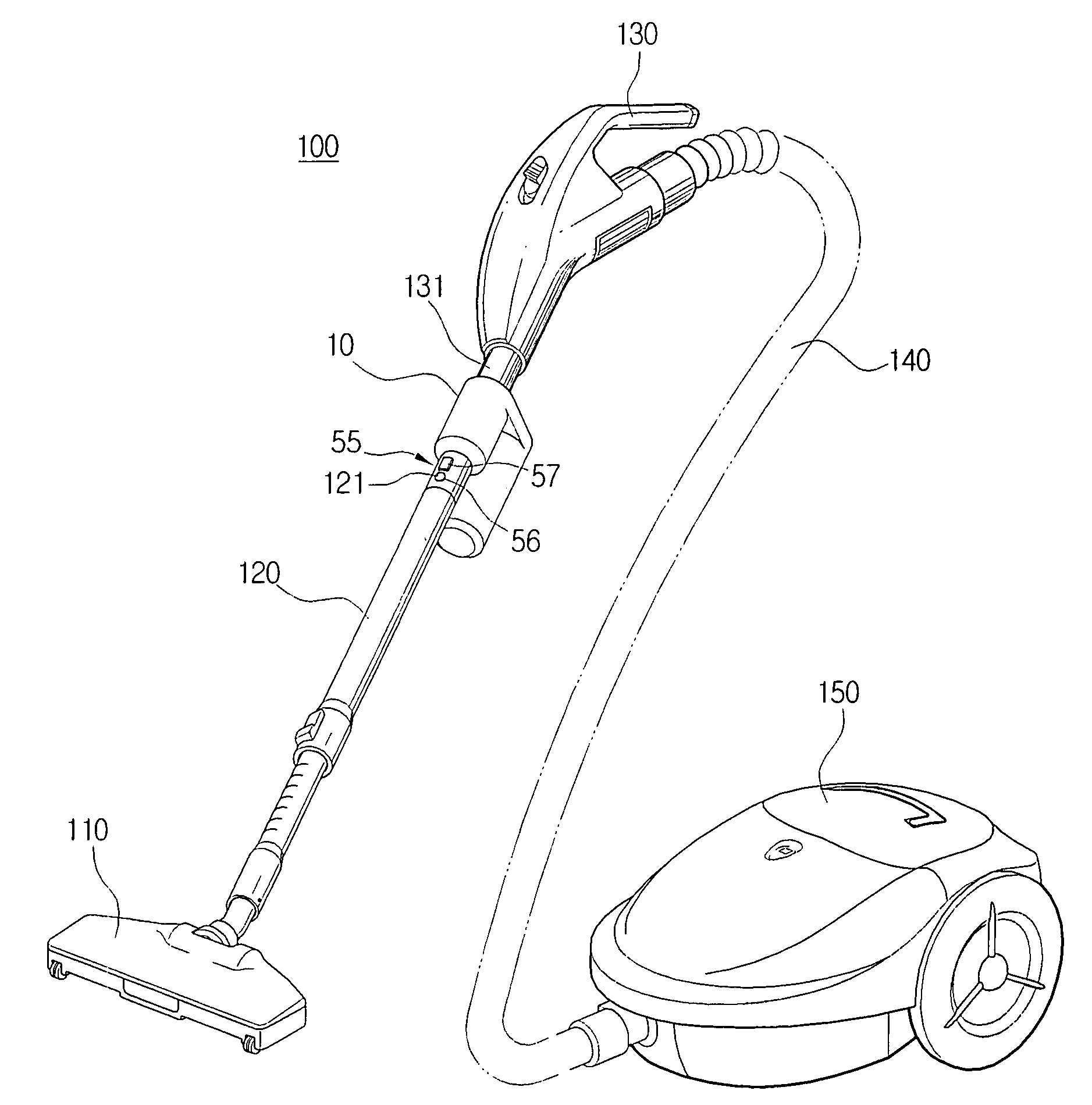

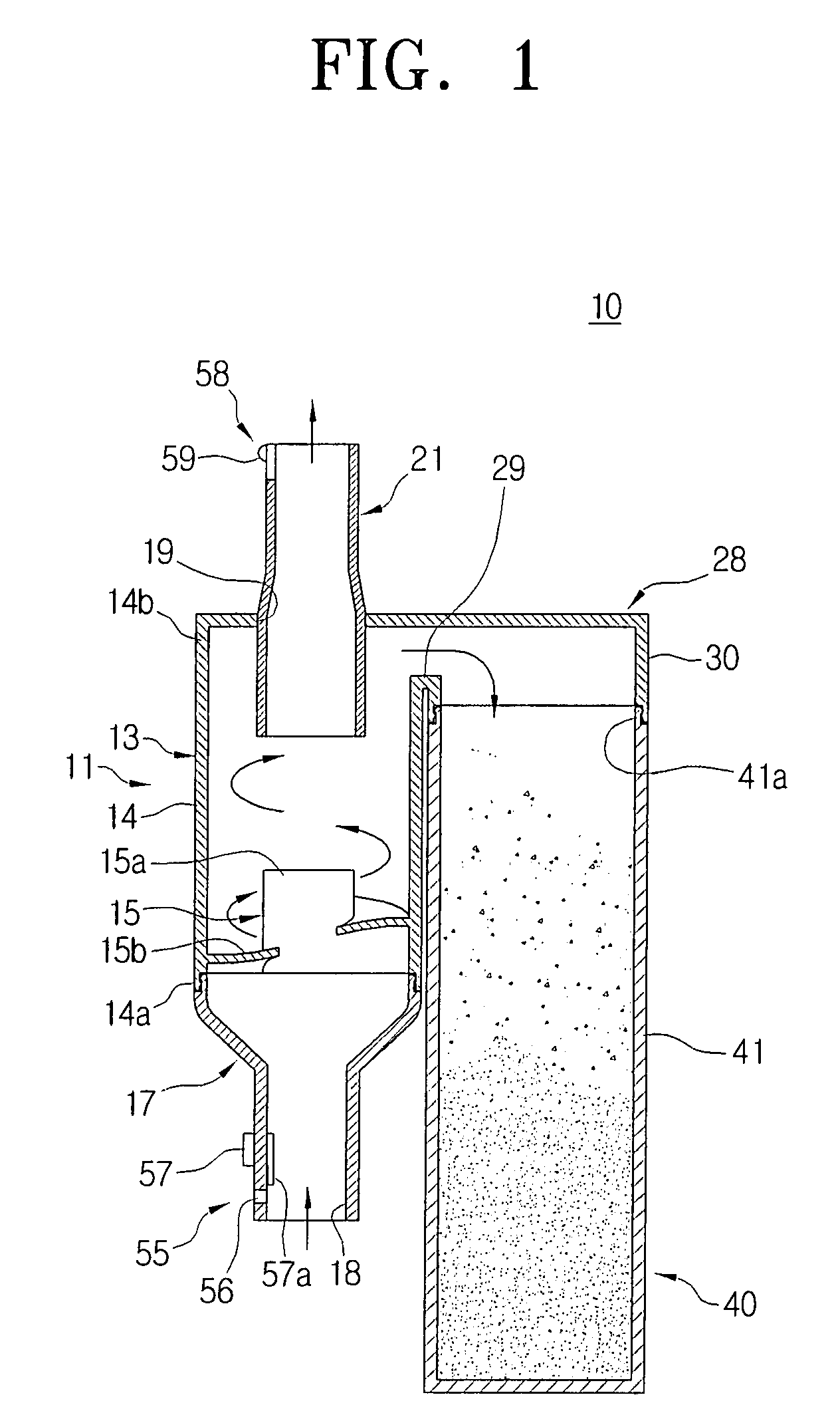

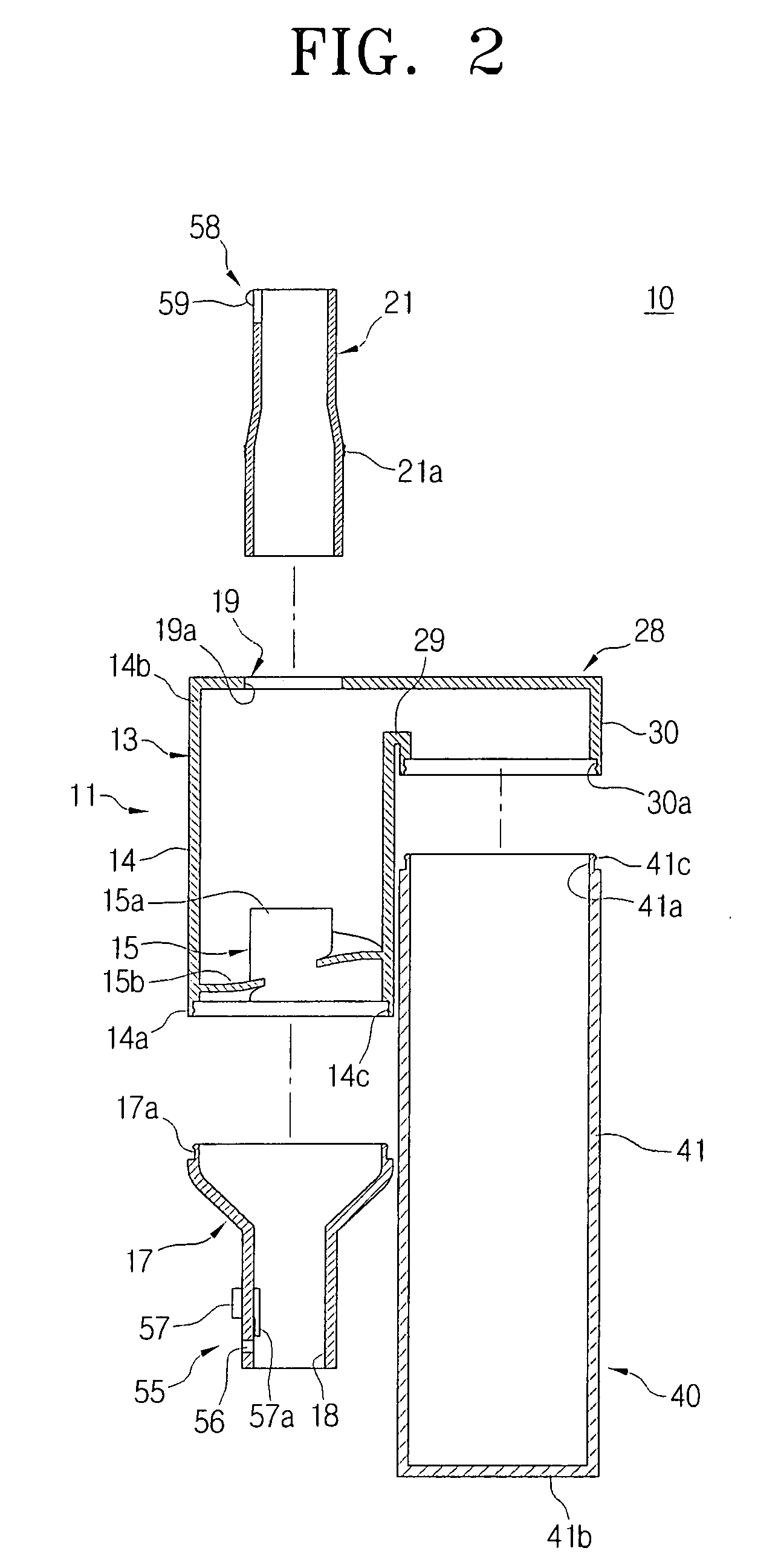

Cyclone dust collecting apparatus for vacuum cleaner

ActiveUS20070199284A1Small pressure lossHigh fine dust collecting efficiencyCleaning filter meansCombination devicesCycloneEngineering

The present disclosure relates to a cyclone dust collecting apparatus for a vacuum cleaner having a high fine dust collecting efficiency. The cyclone dust collecting apparatus includes a first cyclone having an air suction hole through which dust-laden air is drawn-in, the first cyclone forcing the dust-laden air to downwardly whirl in a space under the air suction hole so as to centrifugally separate dust from the dust-laden air; a second cyclone disposed inside the first cyclone, the second cyclone forcing semi-clean air entering from the first cyclone to downwardly whirl so as to centrifugally separate fine dust from the semi-clean air; and an air guiding member forcing the semi-clean air discharged from the first cyclone to directly enter the second cyclone and, the air guiding member having a plurality of guiding blades radially disposed in at least one circular shape based on a vertical axis of the second cyclone.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

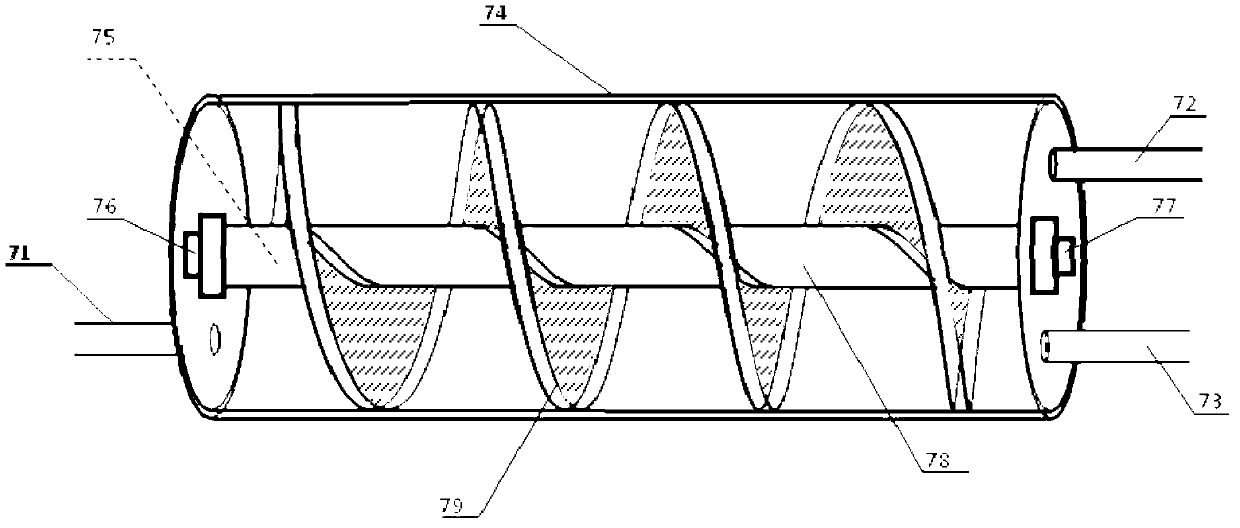

Mill for drying and pulverizing high-moisture and high-viscosity material and application method thereof

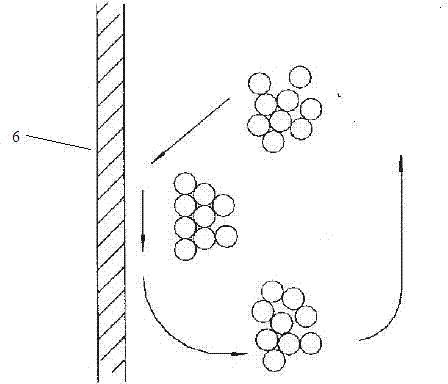

ActiveCN107694135ASolve the problem of hanging on the wallSolve the problem of dry millingEvaporator accessoriesGrain treatmentsImpellerEngineering

The invention provides a Yunjie mill. The Yunjie mill adopts a Yunjie mill main engine composed of a shell body, a rotor with a powder mill and a grading function and an inner circulating pipe, so that materials are pulverized and dried at the same time in a high-speed circulating flowing process in an inner circulating channel composed of an inner circulating pipe, a pulverizing impeller, a spacebetween the pulverizing impeller and an inner wall of a barrel body and the like; a wall remaining problem of the inner circulating channel is solved by utilizing an impact effect of a high-speed material flow; the wall remaining problem of an outer circulating channel is solved by controlling the moisture content of materials, discharged by the main engine, through a grading impeller; the defects of equipment in the inventive patent 2015110139212 are overcome and a method and a product of the inventive patent 2015110139212 are economically realized; the invention provides an application method of the Yunjie mill, so that the drying and pulverizing problem of high-moisture and high-viscosity materials including vegetable materials, meat, liquid materials and the like is solved; a solutionwith good economical efficiency is provided for processing feed and preparing a medicine which takes a volatile component as a functional component.

Owner:KUNMING TEKANG TECH CO LTD

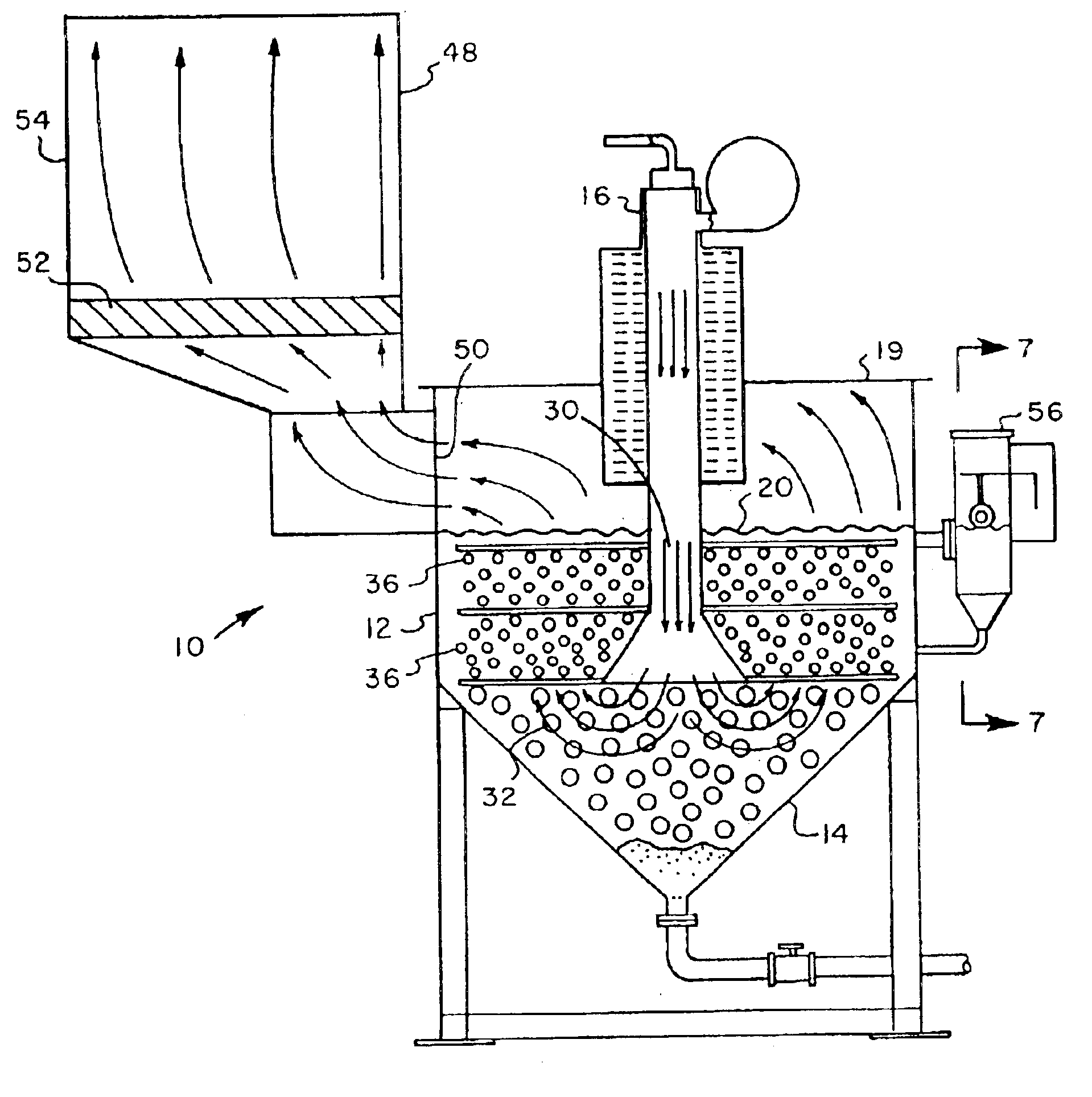

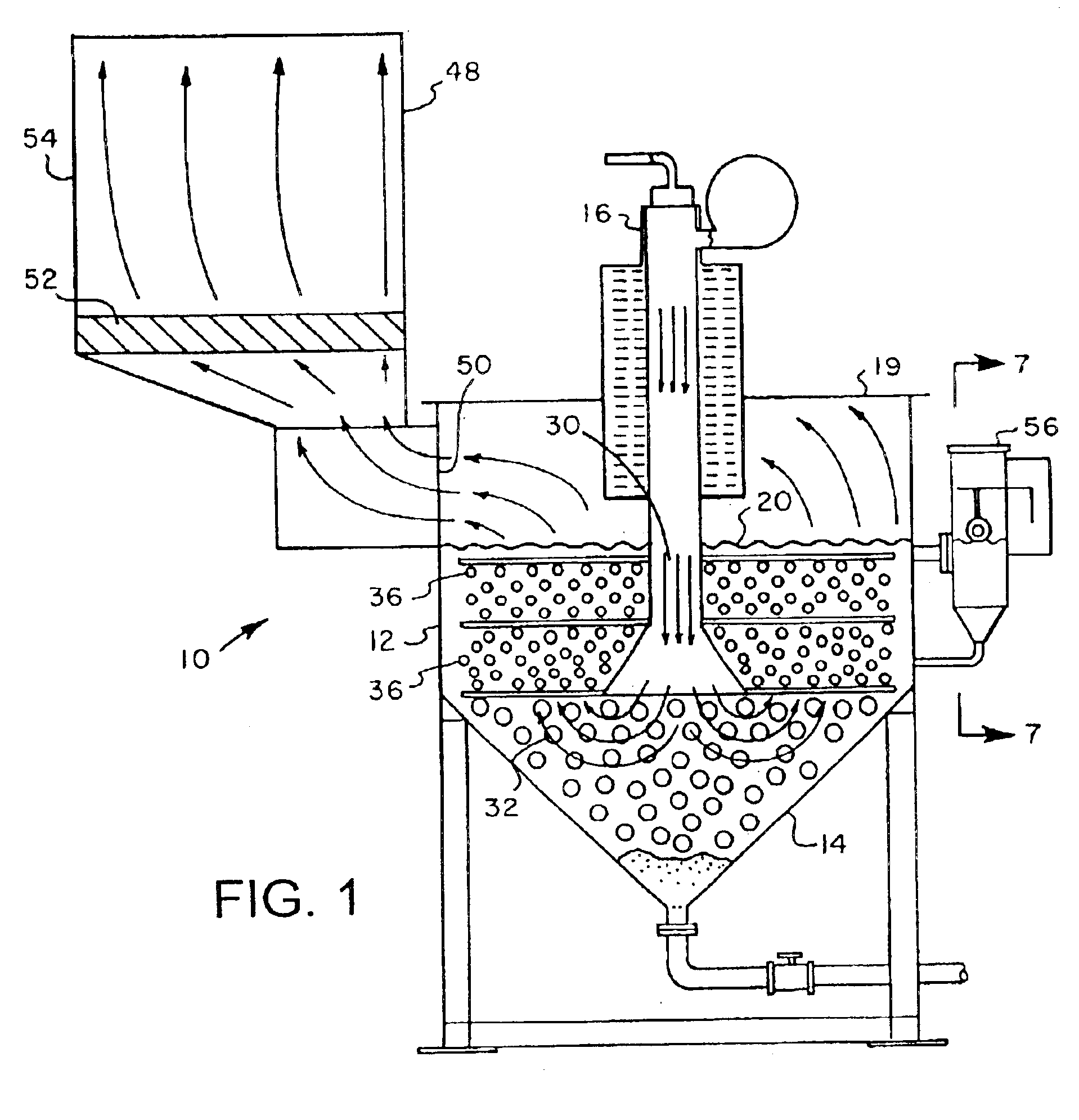

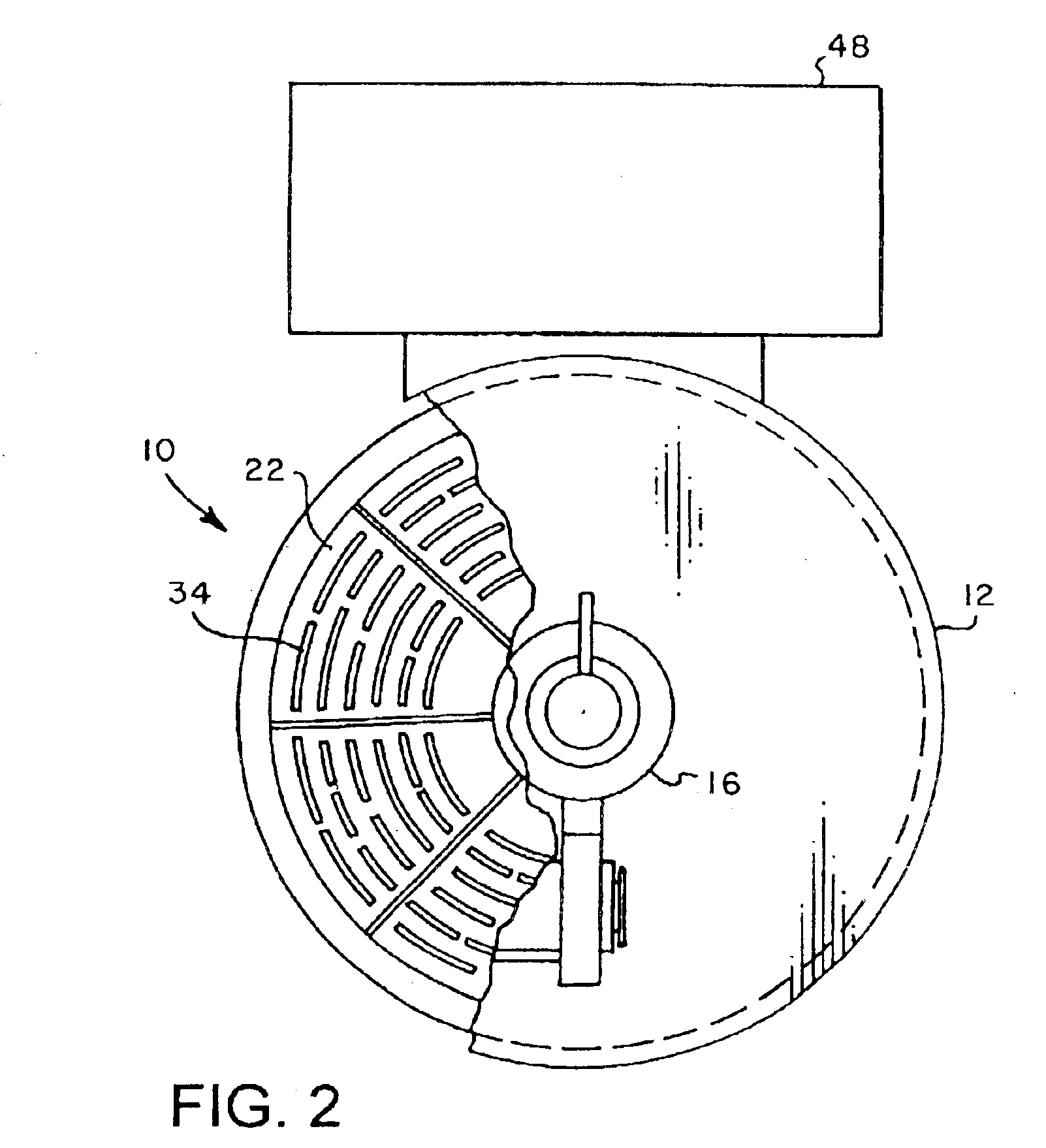

Compact evaporation apparatus

InactiveUS6913671B2Improve thermal efficiencyEfficient evaporationEvaporator accessoriesEvaporators/condensersCombustion chamberCombustor

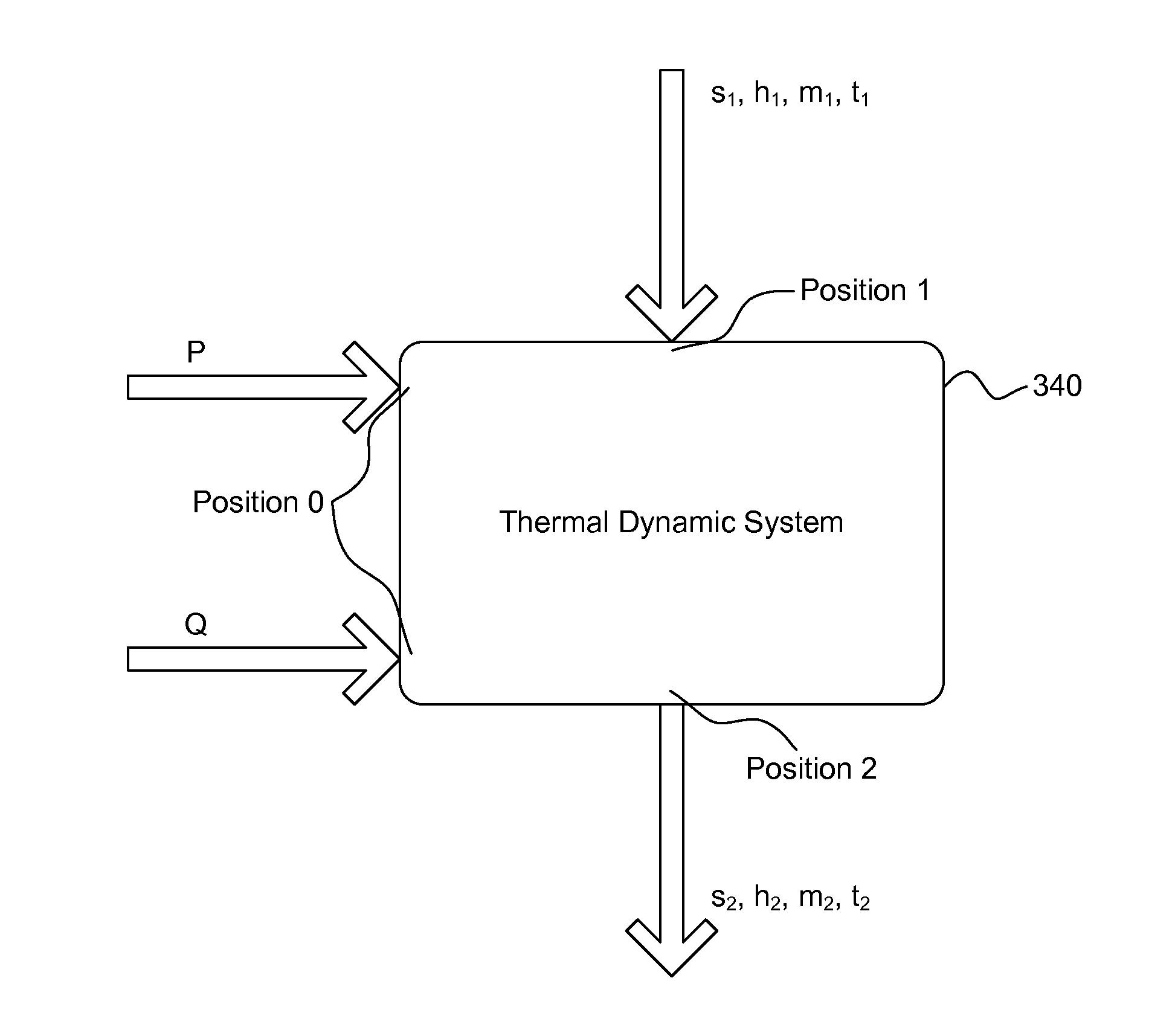

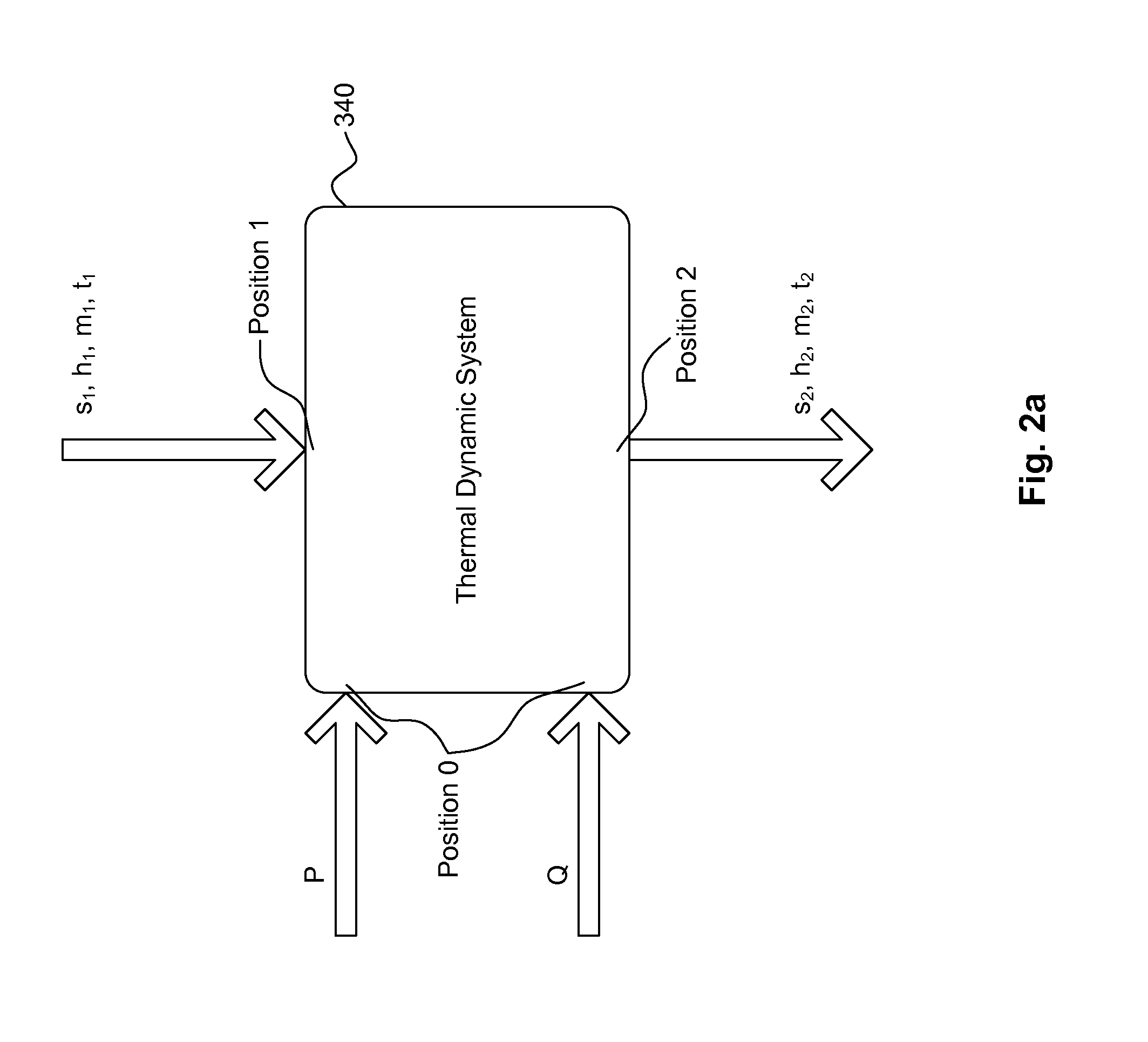

A compact evaporation apparatus includes an evaporator vessel with a sloped, bottom chamber. A combustion chamber is mounted to a top of the vessel, with a burner mounted to a top of the combustion chamber, the combustion chamber sized to achieve total combustion of an air / gas mixture supplied to the burner before being released below a liquid surface in the vessel. At least one turbulence diverter plate is located within the vessel beneath the liquid surface, the diverter plate being a submerged perforated plate extending horizontally from the combustion chamber, such that hot combustion gasses are released below the diverter plate, and as large gas bubbles rise to the surface they pass through small perforations in the diverter plate, thereby breaking large, hot gas bubbles into small bubbles, the gas to liquid contact area being maximized to increase system efficiency.

Owner:BOLTON DANNY R +1

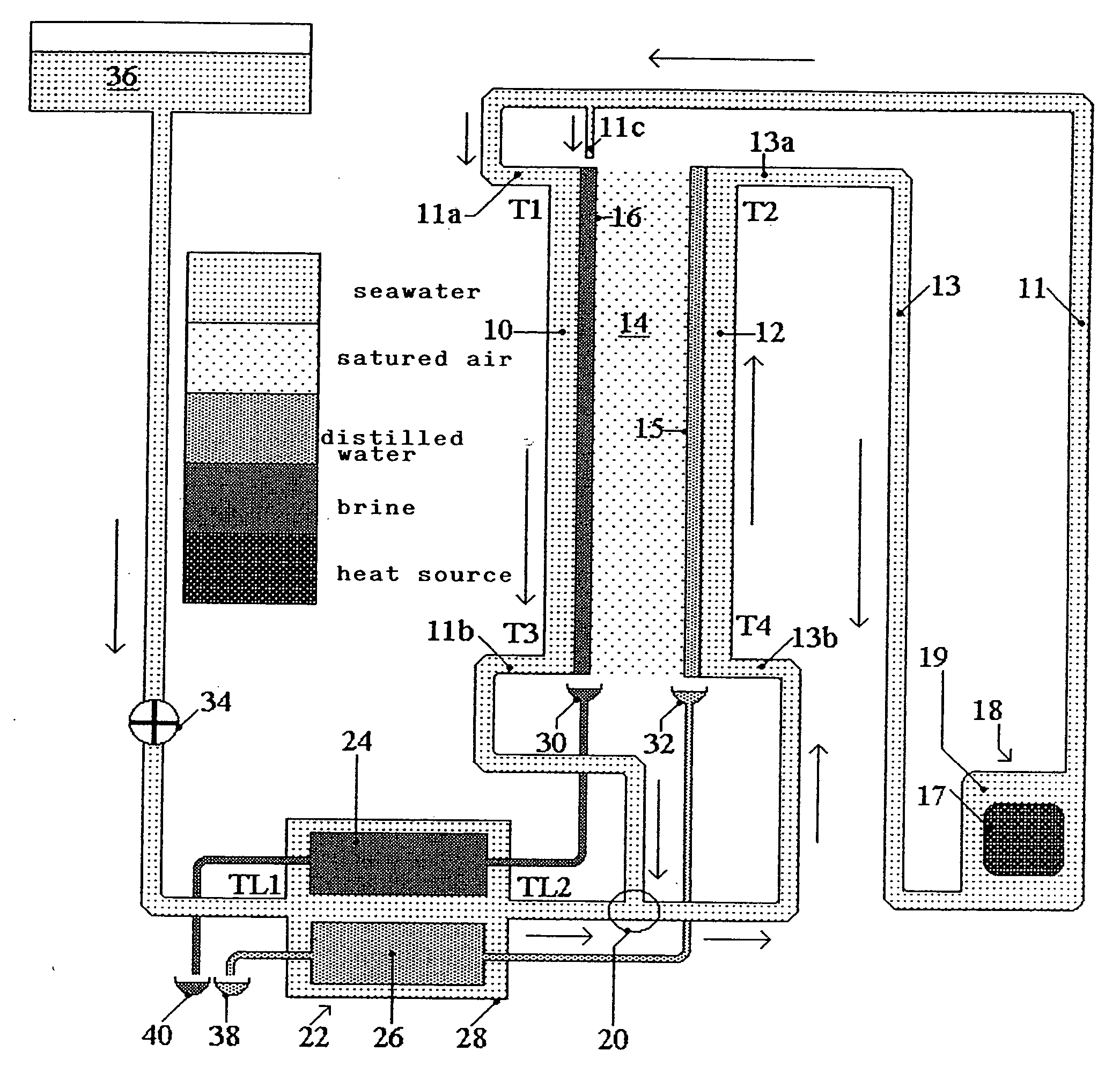

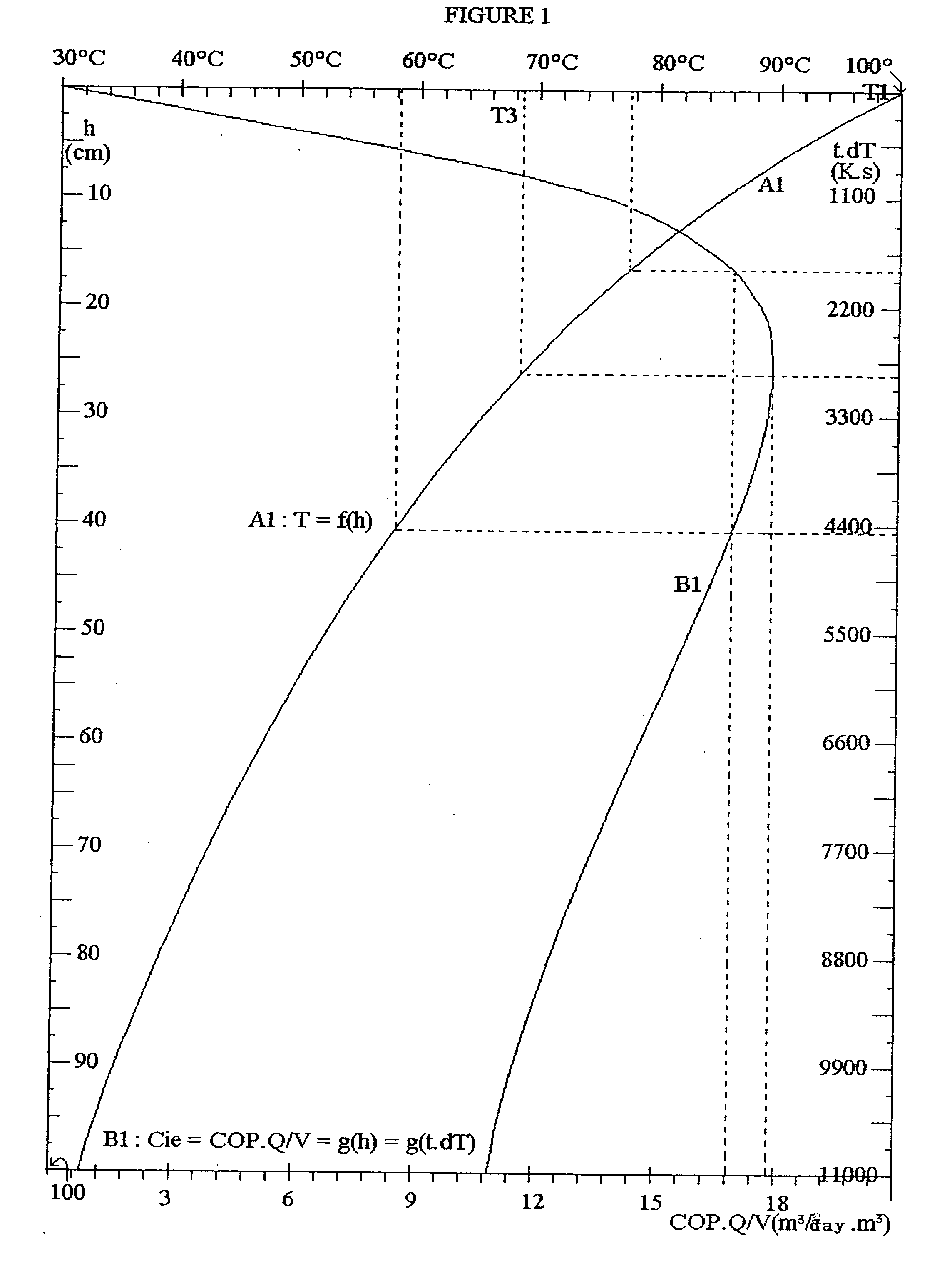

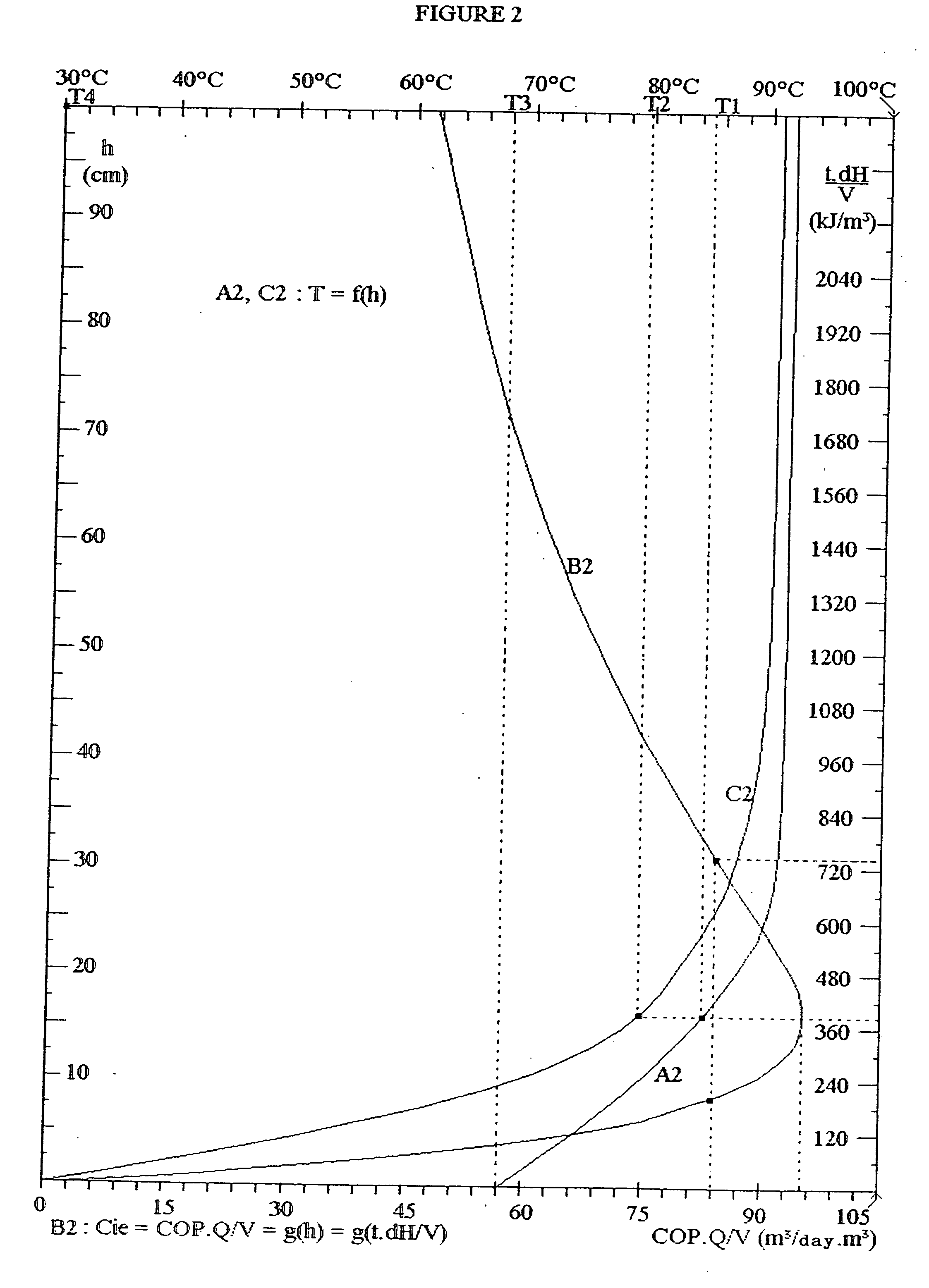

Distillation methods and devices in particular for producing potable water

InactiveUS20060272933A1Improve efficiencyHigh densityGeneral water supply conservationAuxillariesEngineeringSeawater

The inventive device is embodied in the form of a chamber-oven for diffusing vapour and saturated hot air which circulate in a closed circuit by natural convection. Said device is embodied in the form of a domestic-use solar energy collecting device provided with a greenhouse whose surface is equal to 1 m2 and produces from 50 to 100 litres / day of distilled water. The device comprises a distillation unit arranged between two furnaces (59′, 79′) in a temperature-controlled container (48′). Said distillation unit comprises 100 flat thin hollow plates having a surface of 20 dm2 by face and an active volume of 200 dm3. The fine and tensioned walls (54) of said plates are provided with a hydrophilic coating (60′) and internal (56′) and inter-plate (58′) spaces. The lower chimney (59′) comprises a greenhouse (118′, 119′) whose bottom is embodied in the form of an impermeable black layer provided with a thin hydrophilic carpet on the rear part thereof. Saturated hot air at a temperature of 80° C. enters inside (56′) hollow plates from bellow and exits from the top at a temperature of 50° C. A high chimney (79′) is provided with a monoblock heat exchanger (84′) which is transversed by a non-potable water to be distilled which, afterwards is spread warm (40° C.) over the hydrophilic coating (60′). During passage through the heat exchanger (84) the air is cooled to 30° C. and moved down by gravity to the inter-plate spaces (58′) and exits therefrom at a temperature of 78° C. The distilled water condensed in the plates and by the heat exchanger is collected and removed. Brine is received in the bottom of the inter-plate space and distributed along the thin hydrophilic carpet of the bottom (122′) of the greenhouse. An air current passes along said hot carpet is heated and saturated and enters the plates. The brine liquor finally flows in an air-preheating tank (63′) which is emptied each morning. The greenhouse can be substituted by a heating tube transversed by a heating fluid or associated with another steam-jet tube. The more powerful chamber-ovens can produce at least 200 m3 / day of distilled water for collective consumption. Said invention can be used for salt removal from seawater, co-generating electricity and potable water and for producing food concentrates.

Owner:THE THIRD MILLENIUM WATER

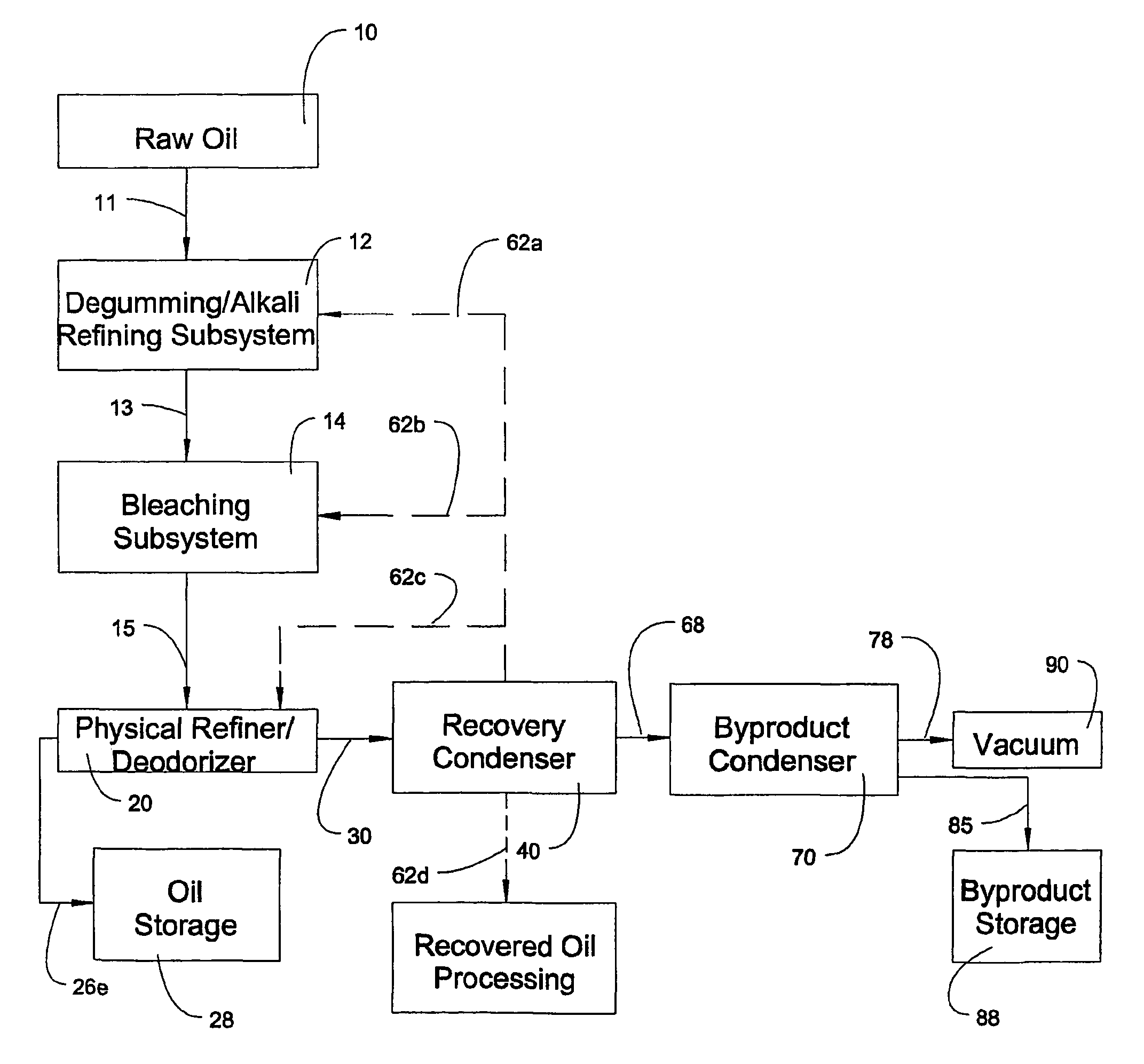

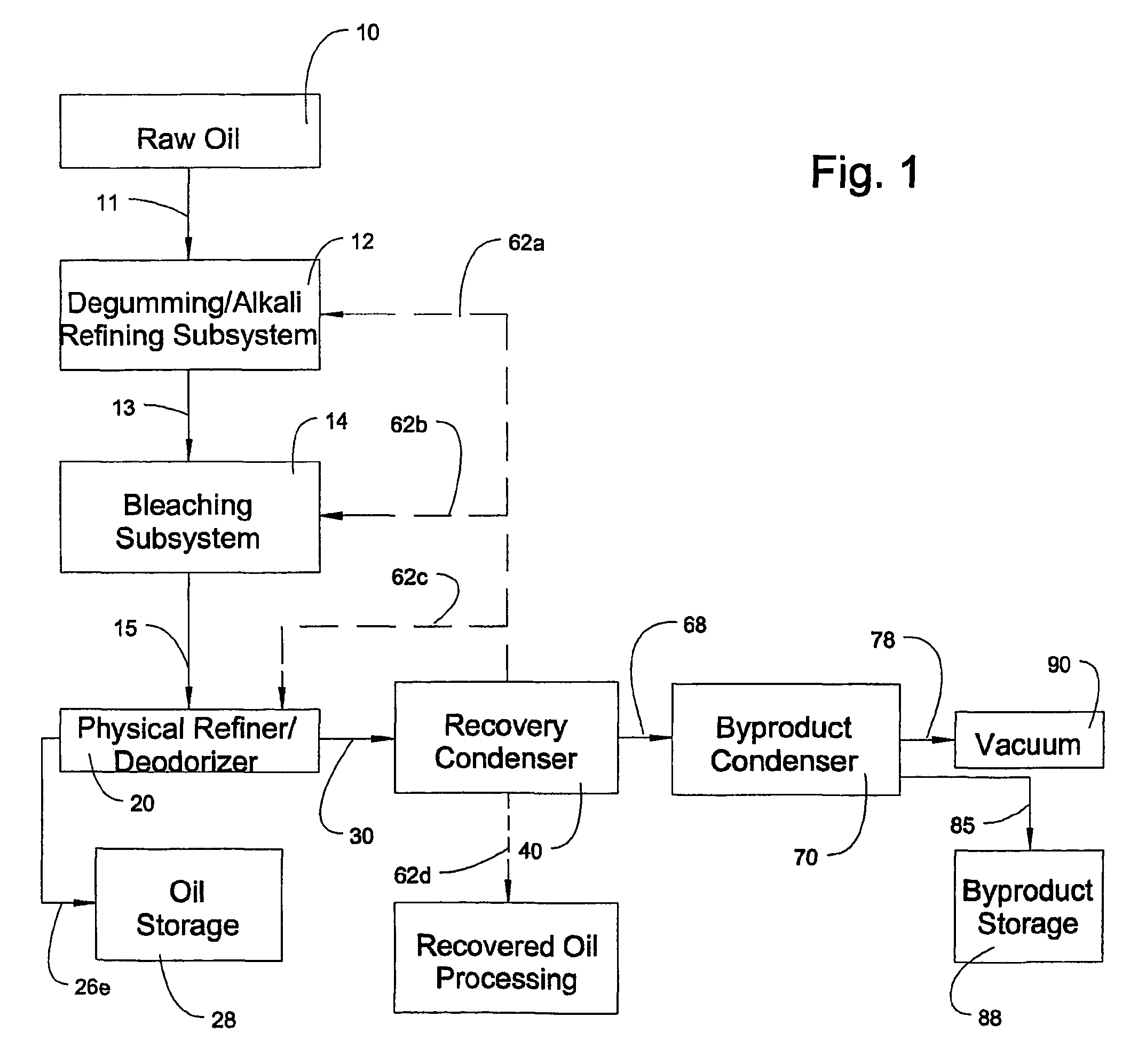

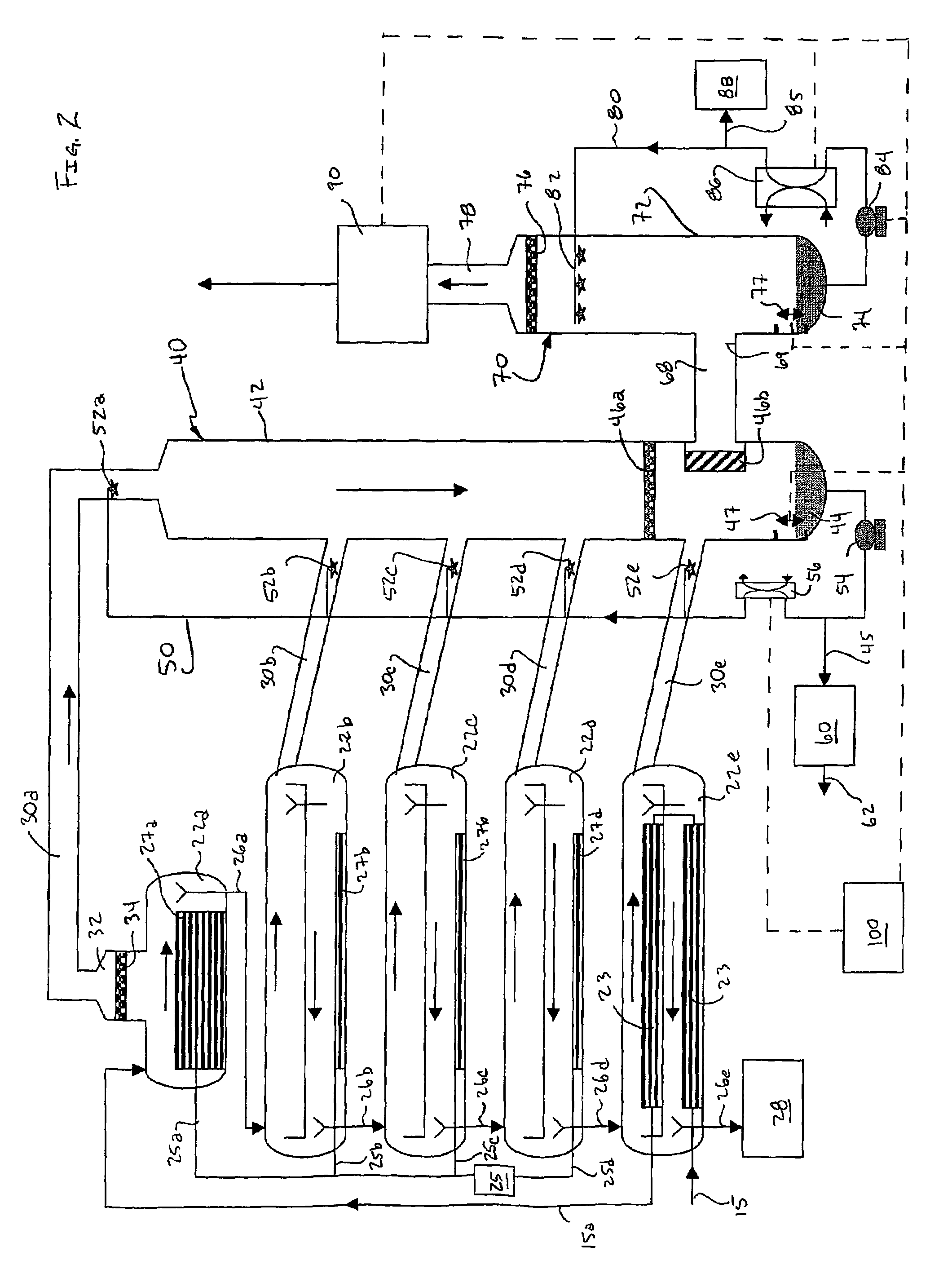

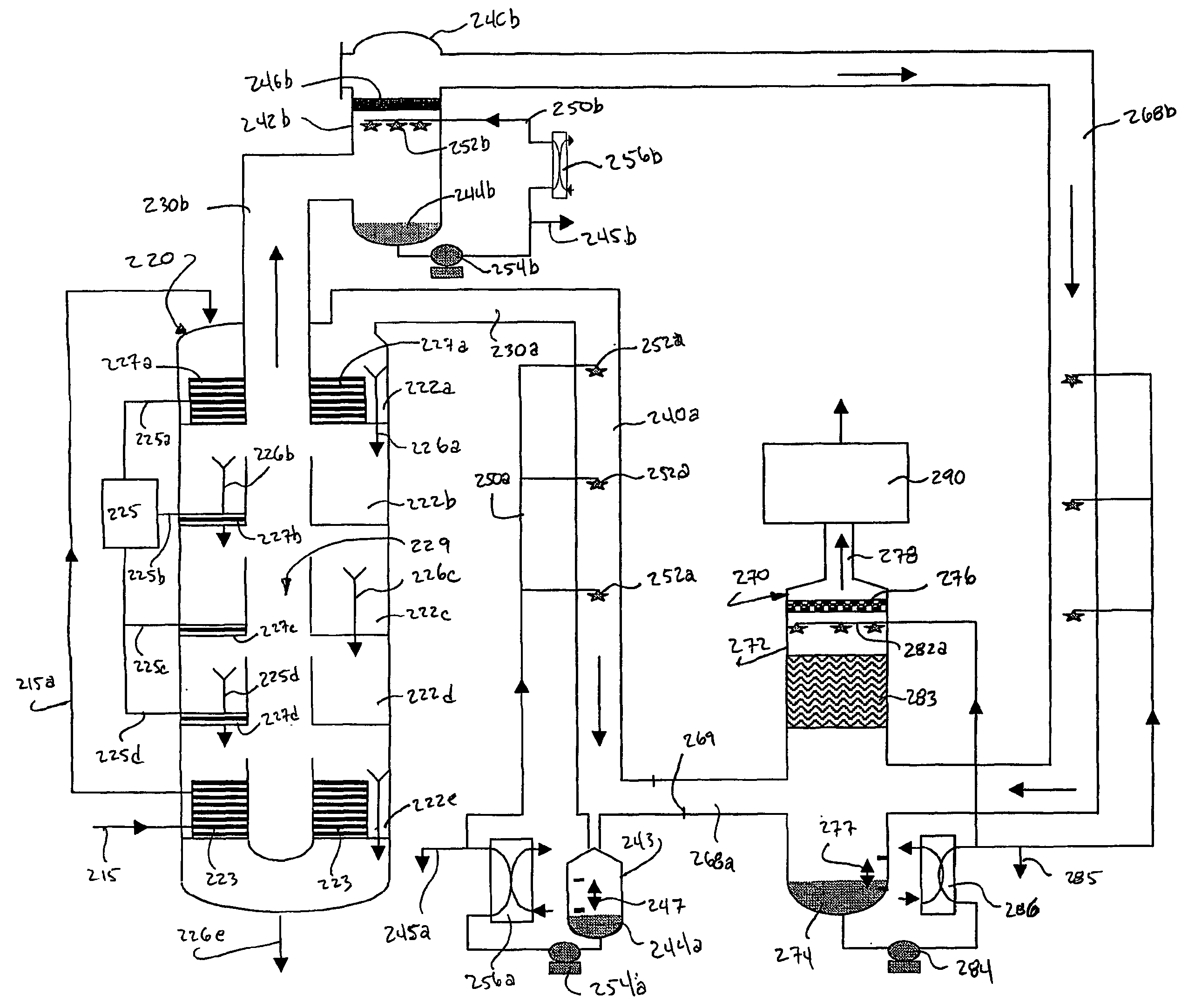

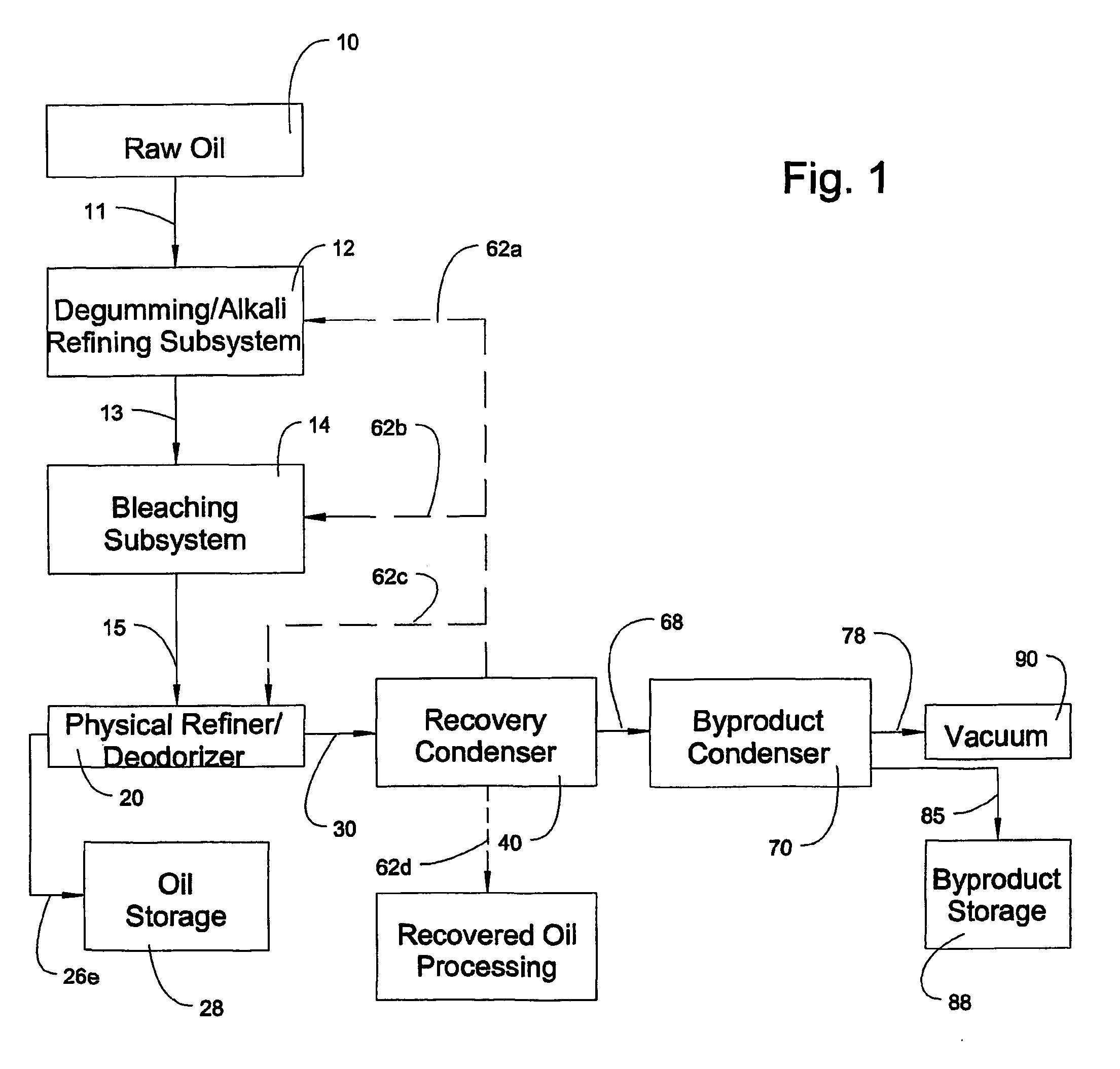

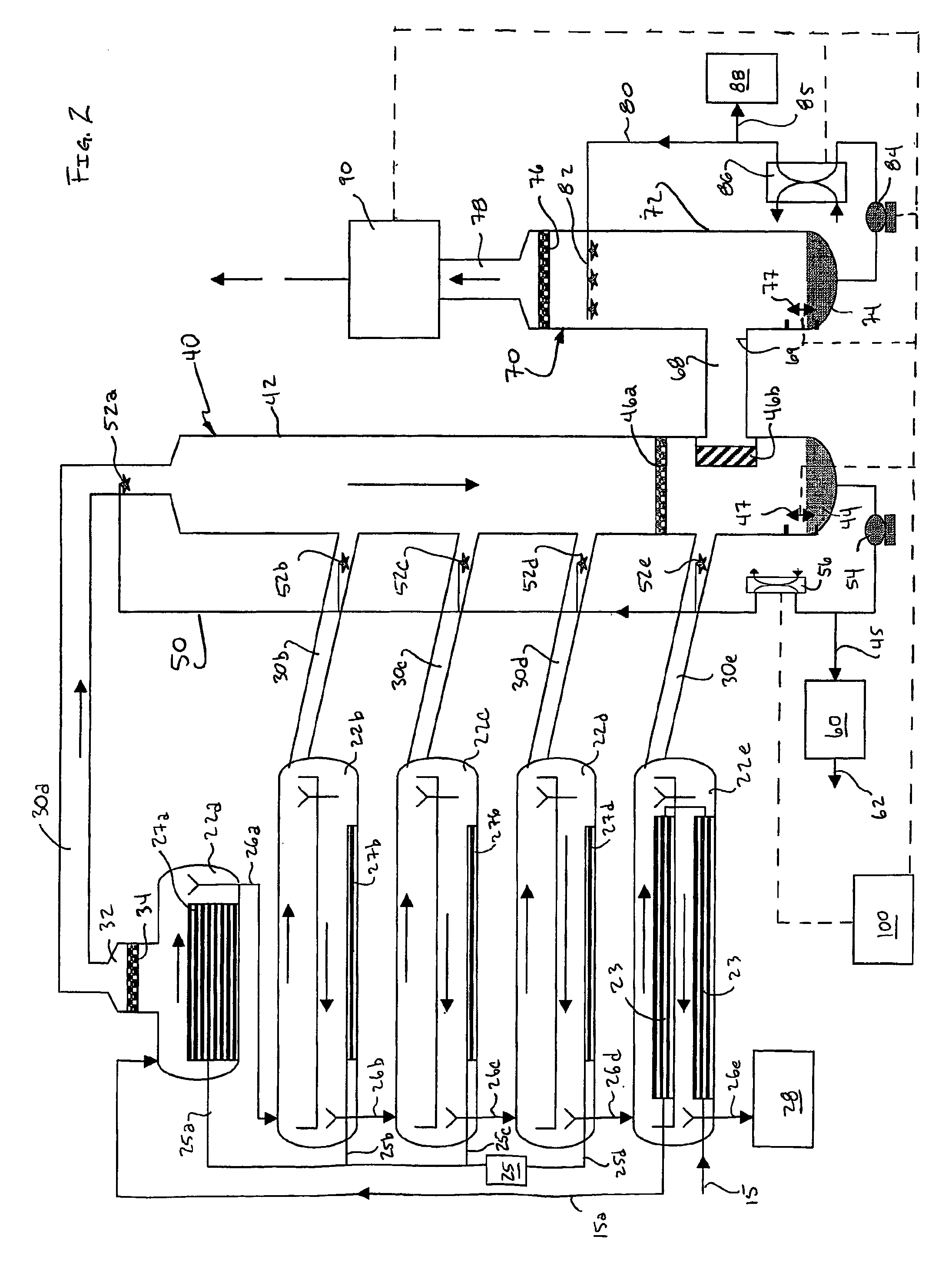

Method and apparatus for processing vegetable oils

The present invention provides certain improvements in methods for processing vegetable oils and apparatus for carrying out such methods. One embodiment provides a method for processing a partially processed oil including glycerides and a volatilizable impurity fraction. The partially processed oil may processed by driving off a first volatiles stream comprising a portion of the glycerides and at least a portion of the volatilizable impurity fraction, leaving a deodorized oil. The first volatiles stream may be introduced into a first condensing chamber and a glyceride-rich, impurity-poor first condensate may be condensed from the first volatiles stream, leaving a glyceride-poor, impurity-rich second volatiles stream. The second volatiles stream may be passed into a second condensing chamber and a glyceride-poor, impurity-rich second condensate may be condensed from the second volatiles stream.

Owner:CARGILL INC

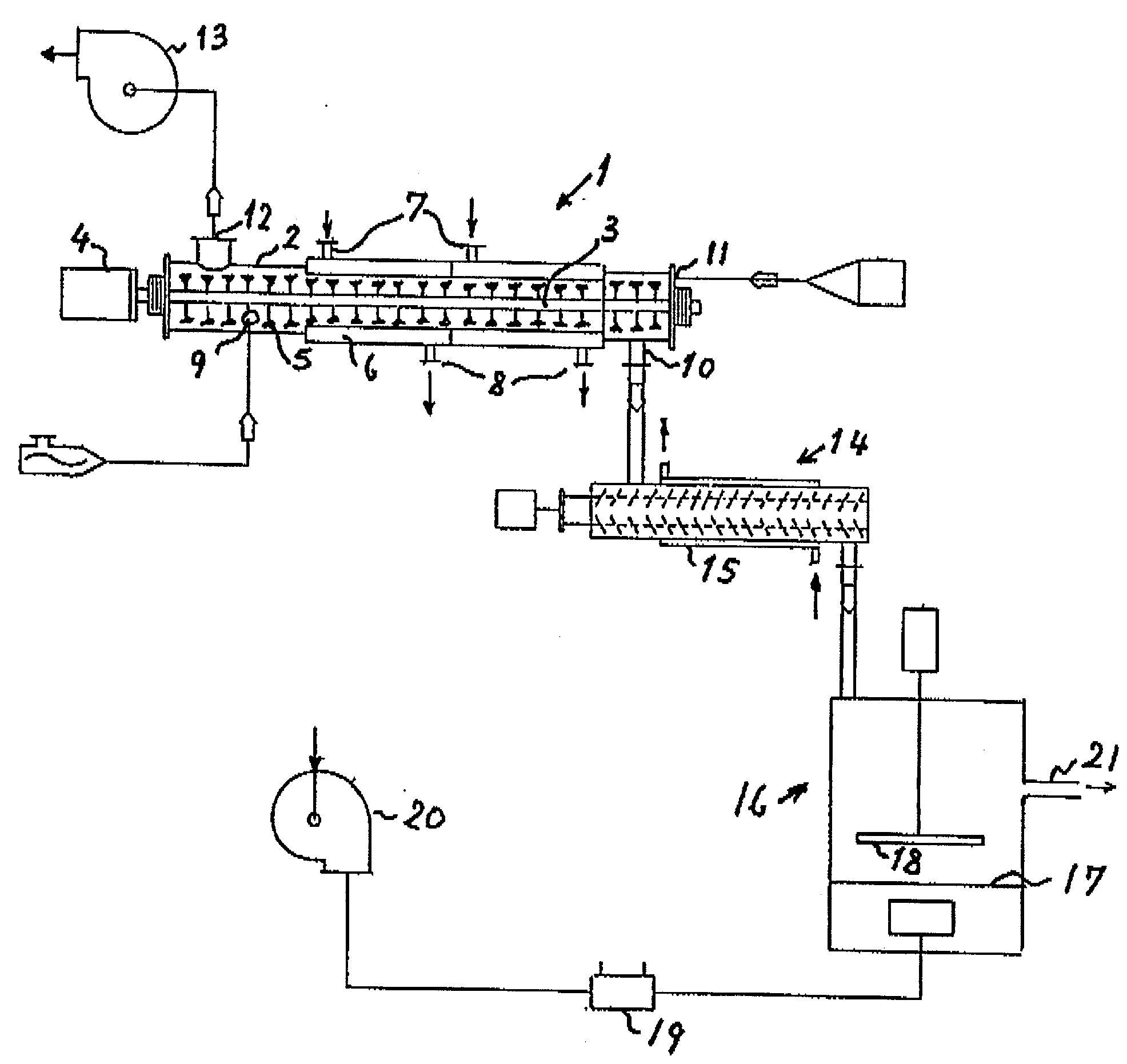

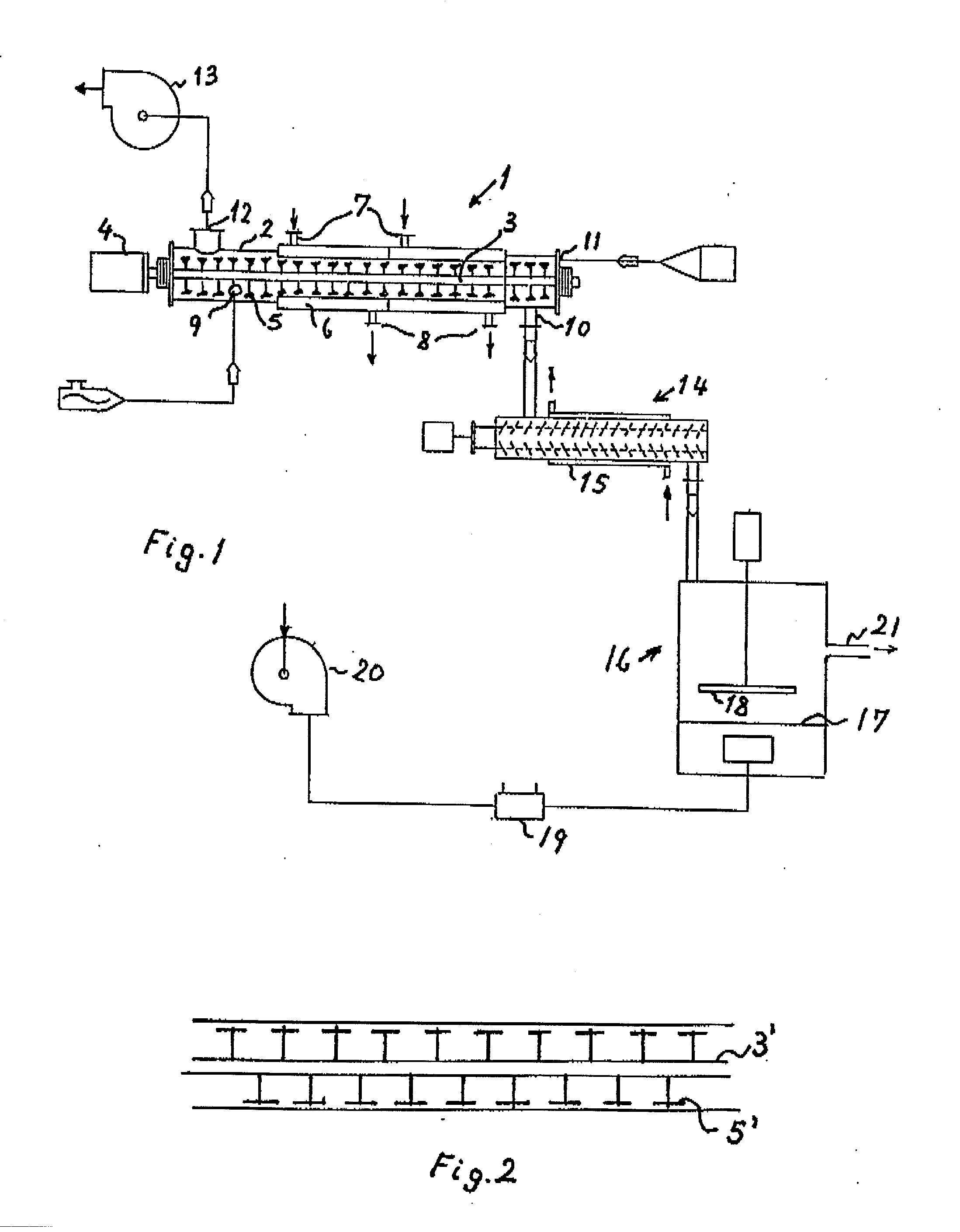

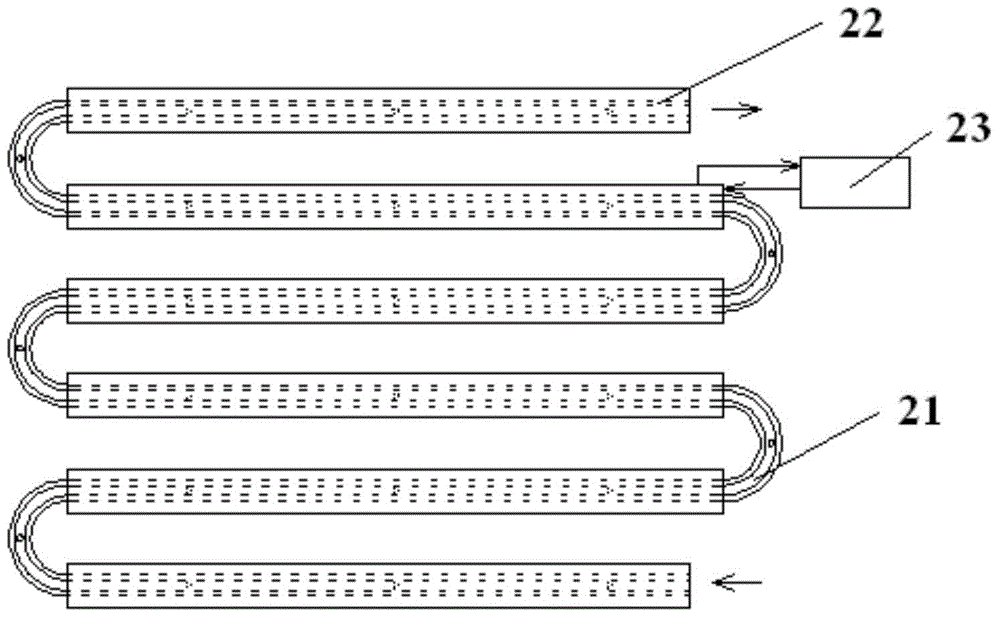

Process for the removal of volatile compounds from mixtures of substances using a micro-evaporator

InactiveUS7442277B2Bacterial antigen ingredientsDrying using combination processesSubstance useVolatile organic compound

A process for the removal of at least one volatile compound from a reactive or unreactive mixture of substances with the aid of at least one micro-evaporator, the micro-evaporator displaying channels for carrying the mixture of substances having a hydraulic diameter of 5 to 1000 μm and a specific evaporator surface area of at least 103 m2 / m3.

Owner:BAYER MATERIALSCIENCE AG

Measuring instrument and concentration measuring device

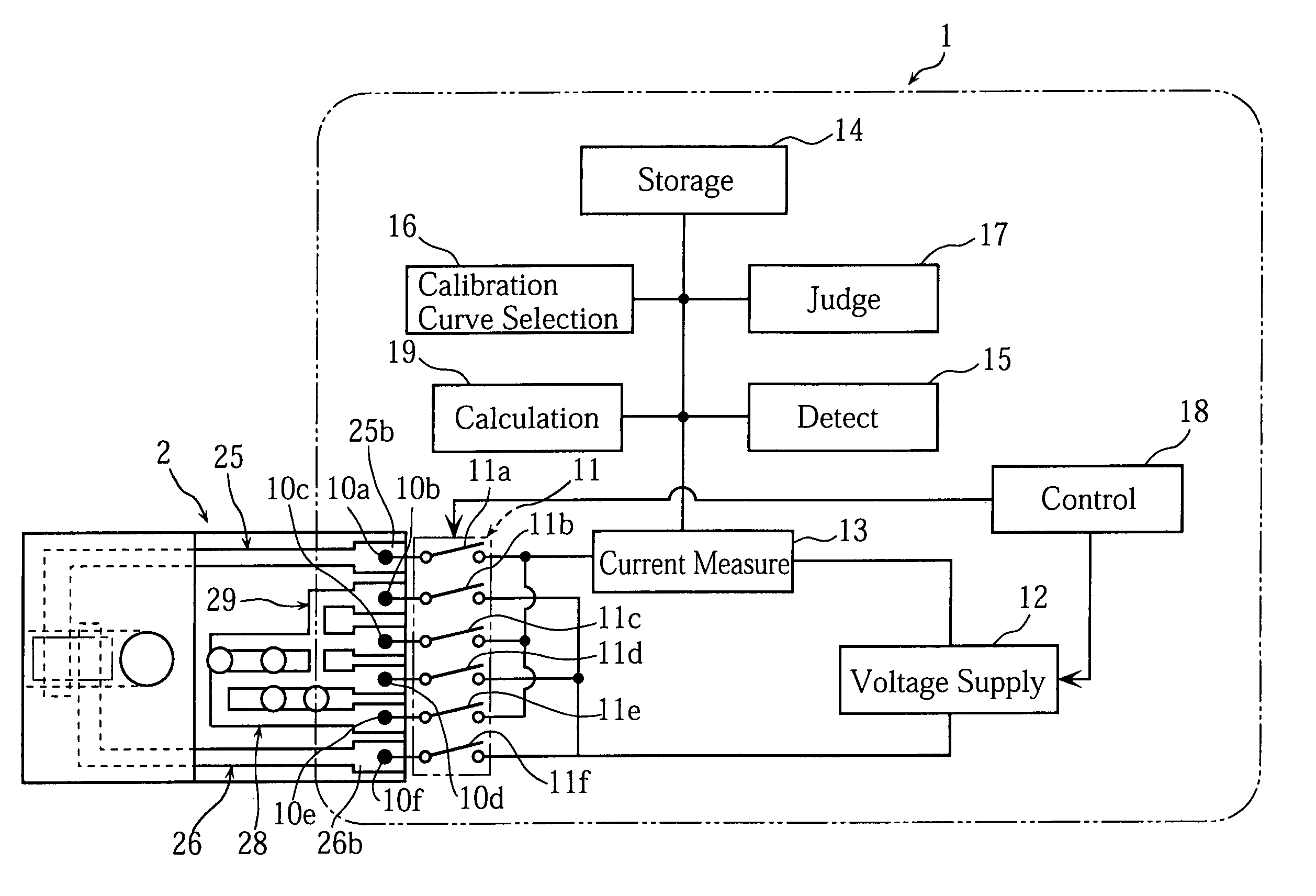

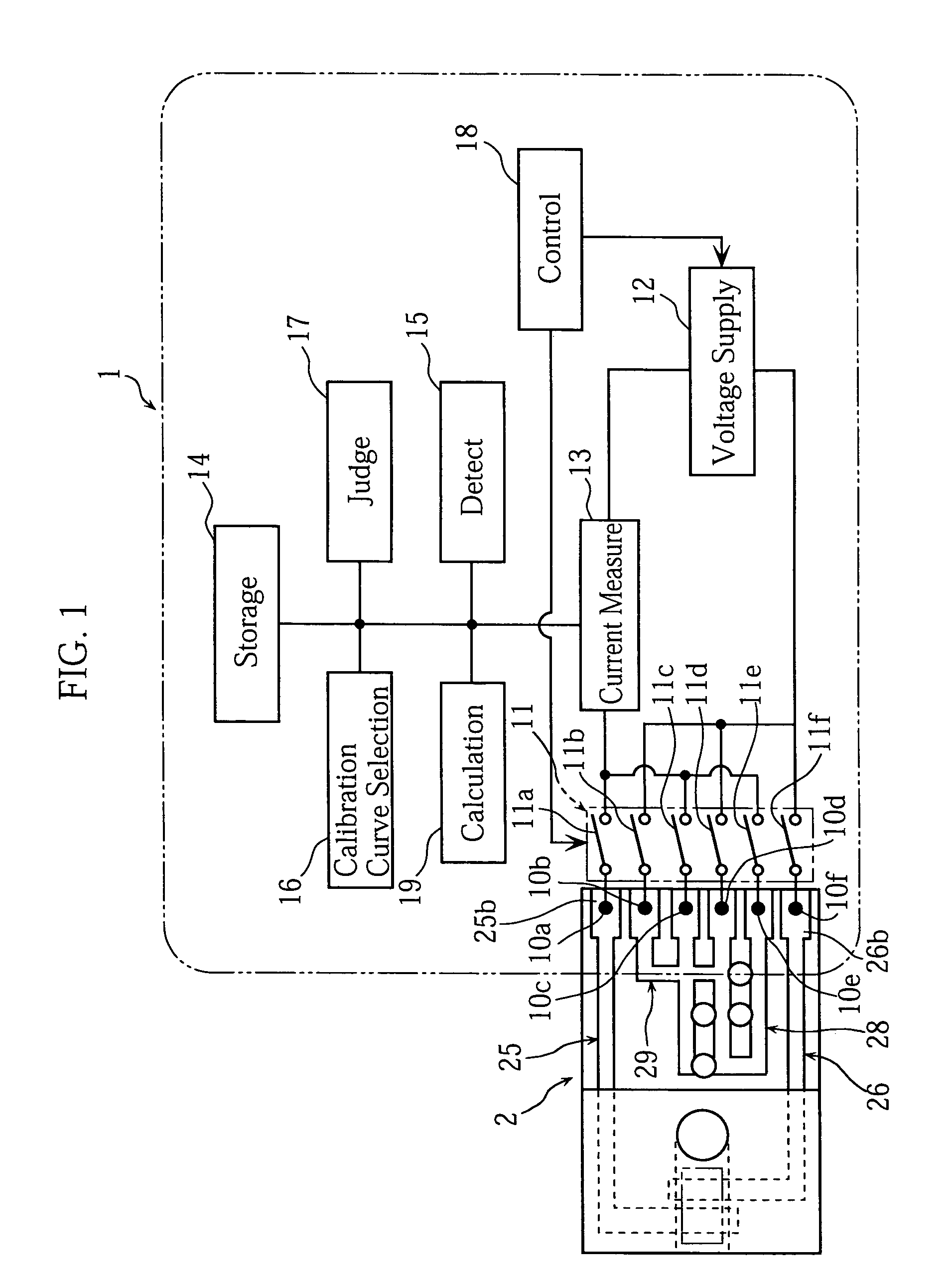

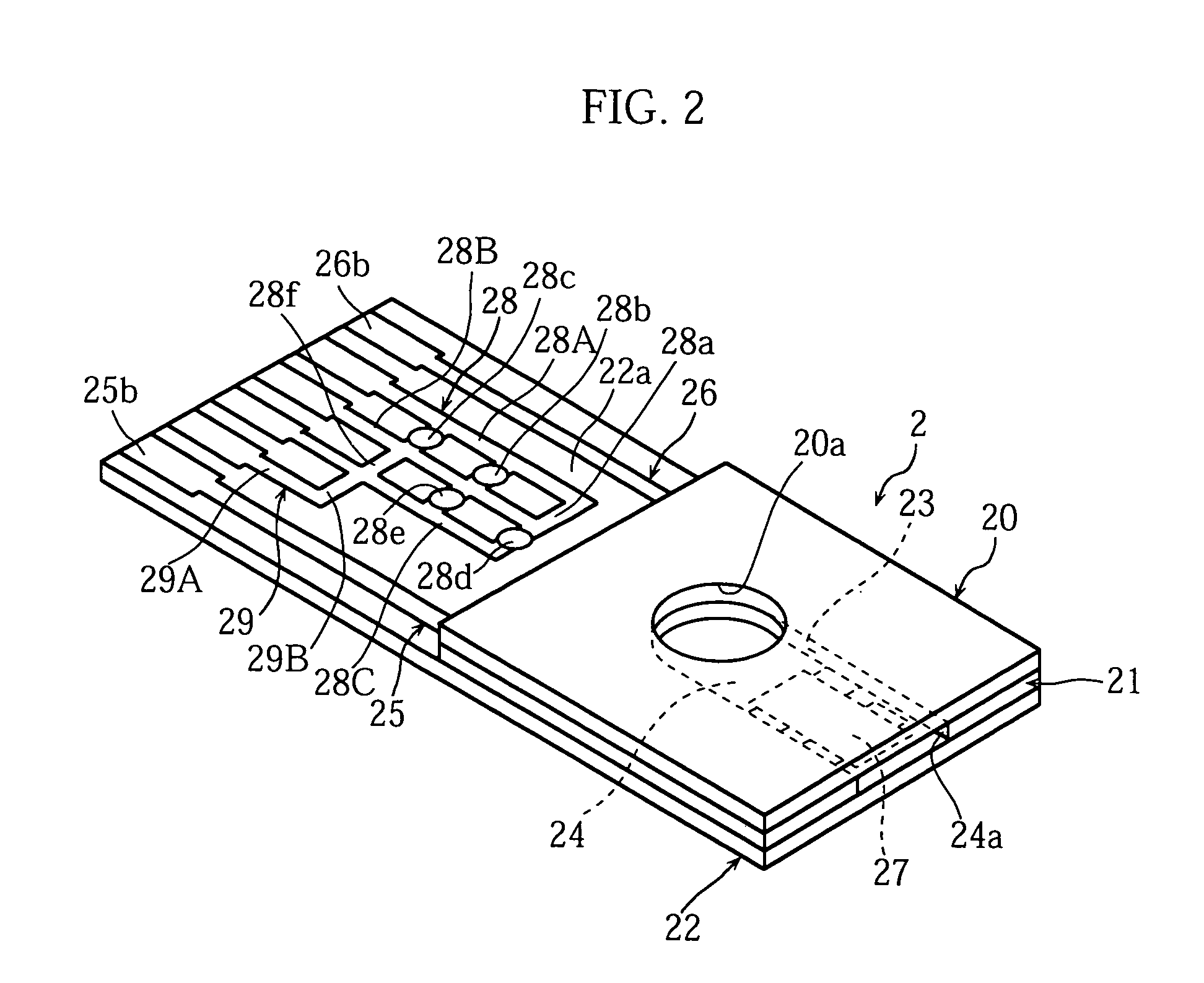

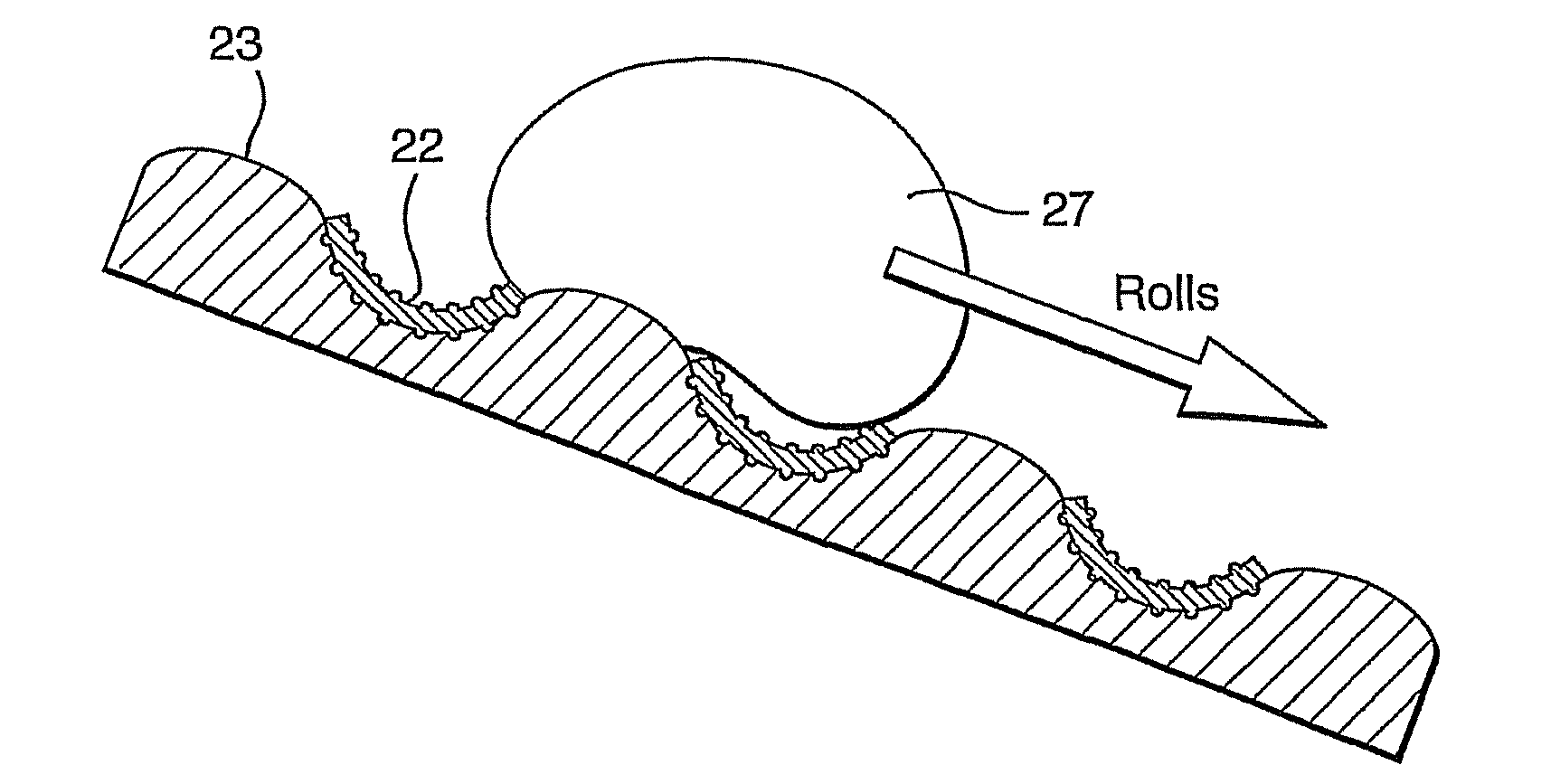

ActiveUS7491303B2Prevents incorrect concentration measurementProduction cost advantageImmobilised enzymesBioreactor/fermenter combinationsElectricityMeasuring instrument

The measurement instrument includes an attribute information output section to output attribute information about the attributes of the measurement instrument as an electric physical value. The attribute information is based on at least one of the conditions including a resistance of the attribute information output section, a location of the attribute information output section, and the size of a region on which the attribute information output section is formed. The attribute information may be used to select the calibration curve suitable for the measurement instrument. The attribute information may be one that relates to a specific measurement standard applied to the measurement instrument.

Owner:ARKRAY INC

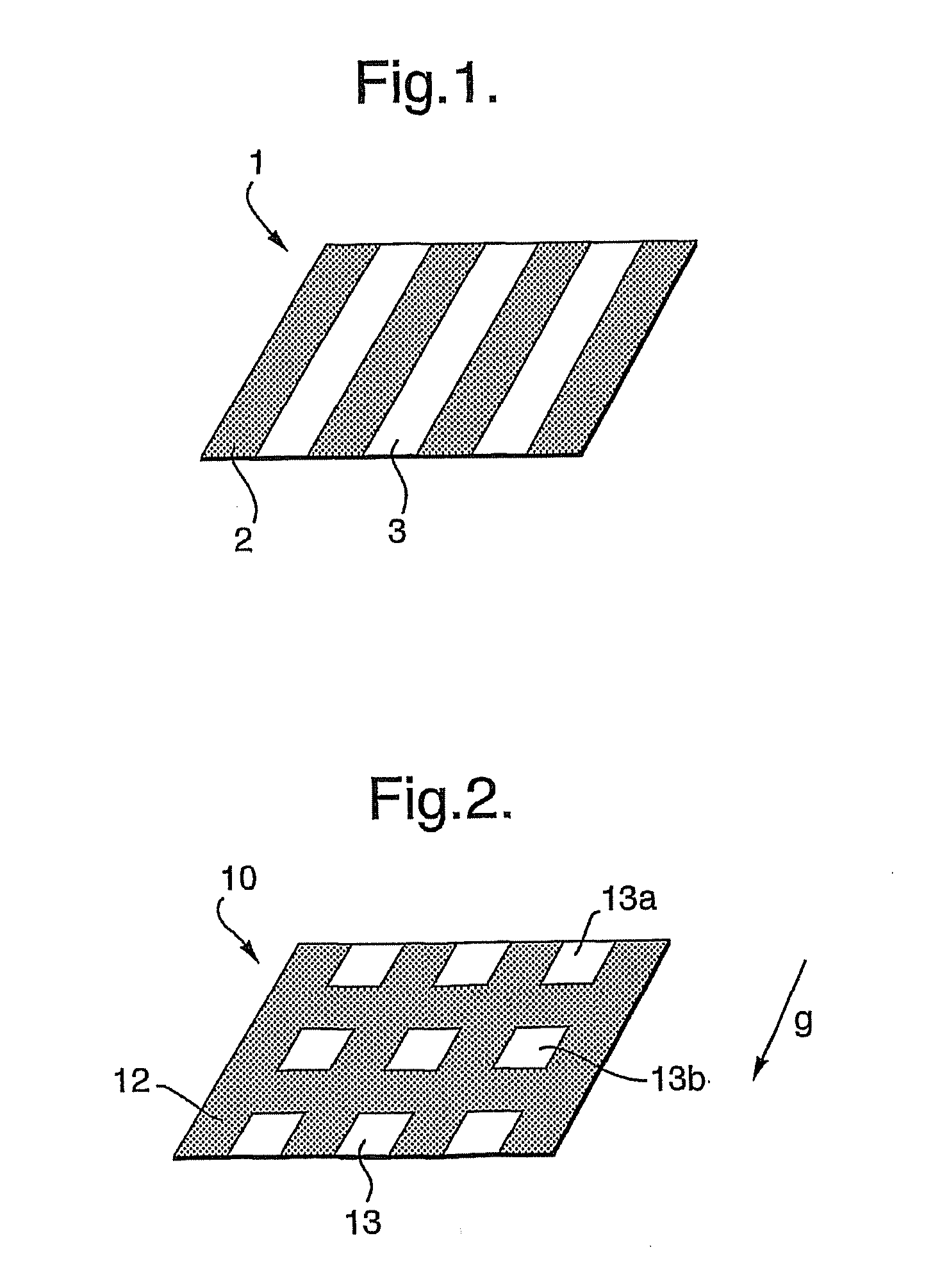

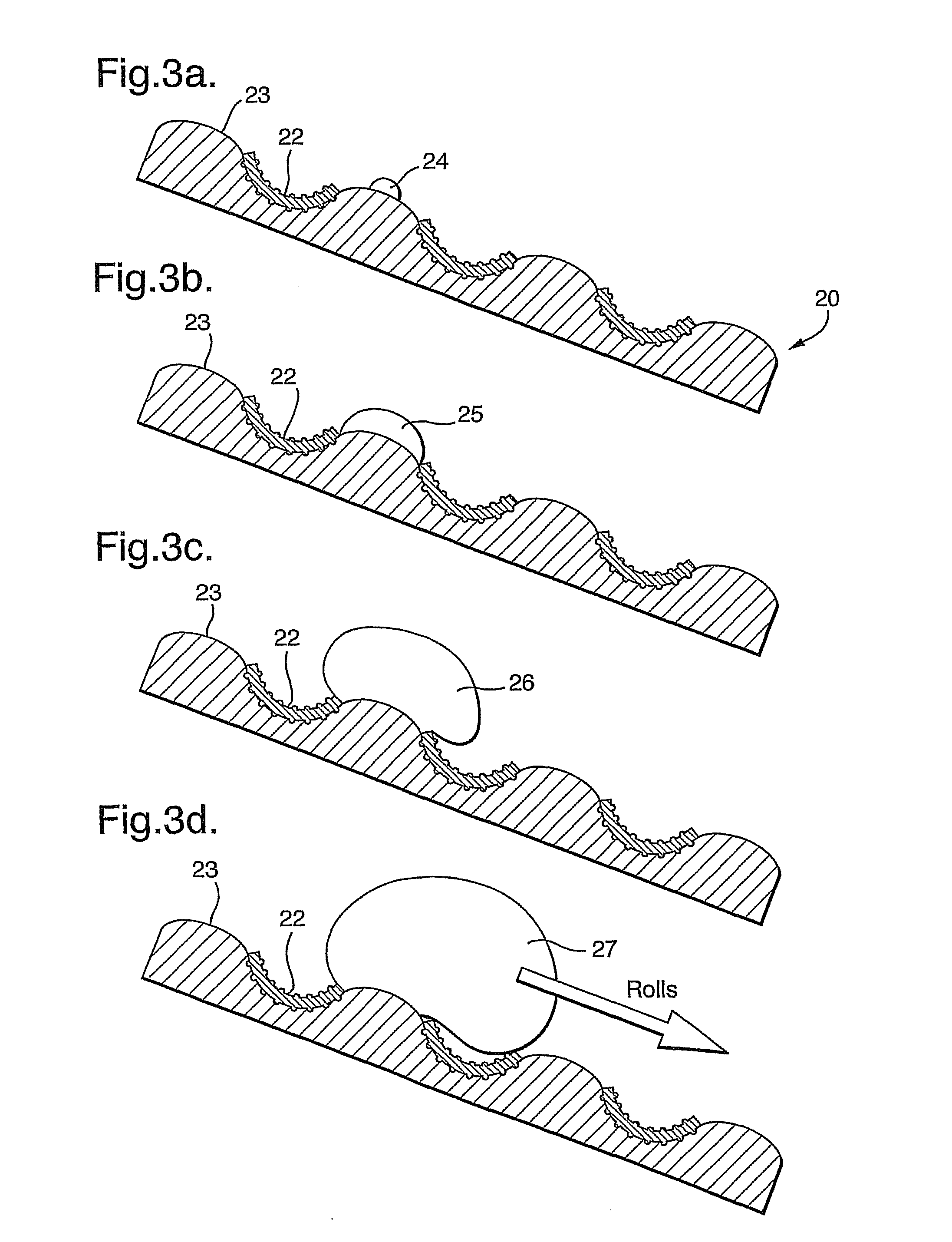

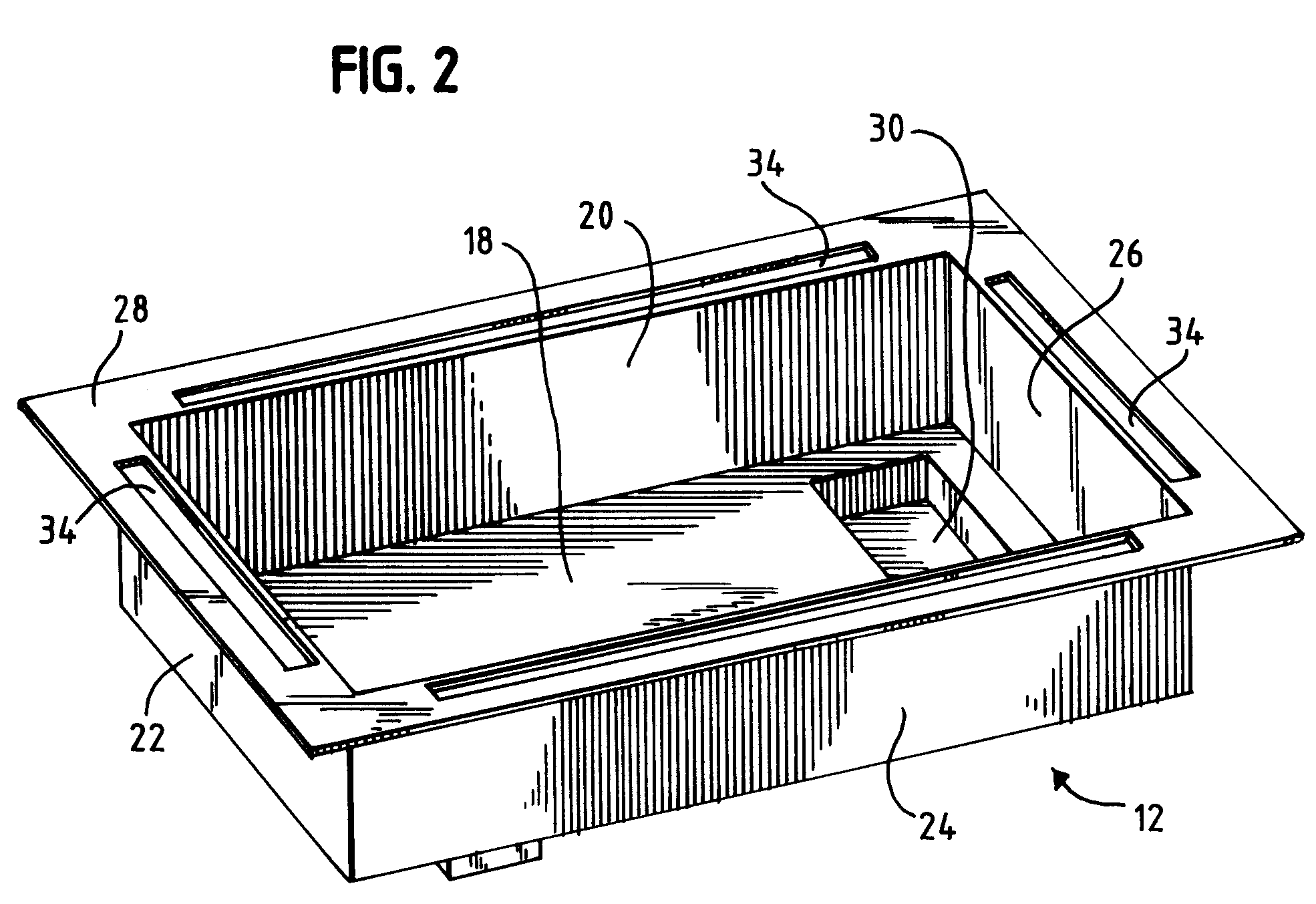

Surface for promoting droplet formation

A surface (30) suitable for promoting the formation of droplets of liquid (35) is provided comprising alternating regions of liquid repelling (32) and liquid attracting (33) material in at least one direction across the surface wherein the diameter of the droplets is controlled by the size of the smallest dimension of the liquid attracting material. The surface (30) may be textured and / or form a pattern. Also disclosed are a method and a system of collecting a liquid (35) carried by or condensed out of a vapour comprising passing a vapour across such a surface (30) and a method of purifying a liquid by passing a vapour containing droplets of a liquid over such a surface.

Owner:QINETIQ LTD

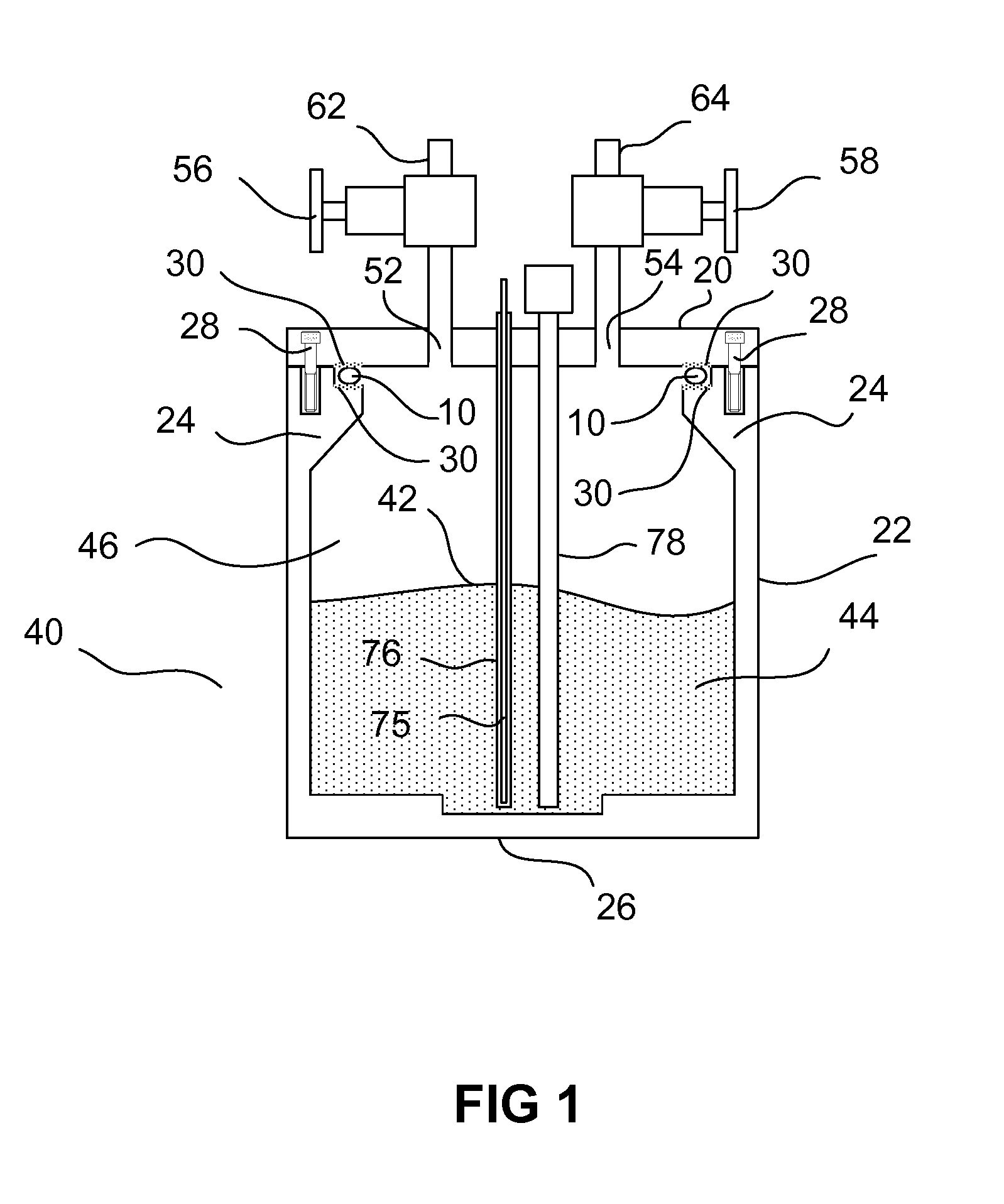

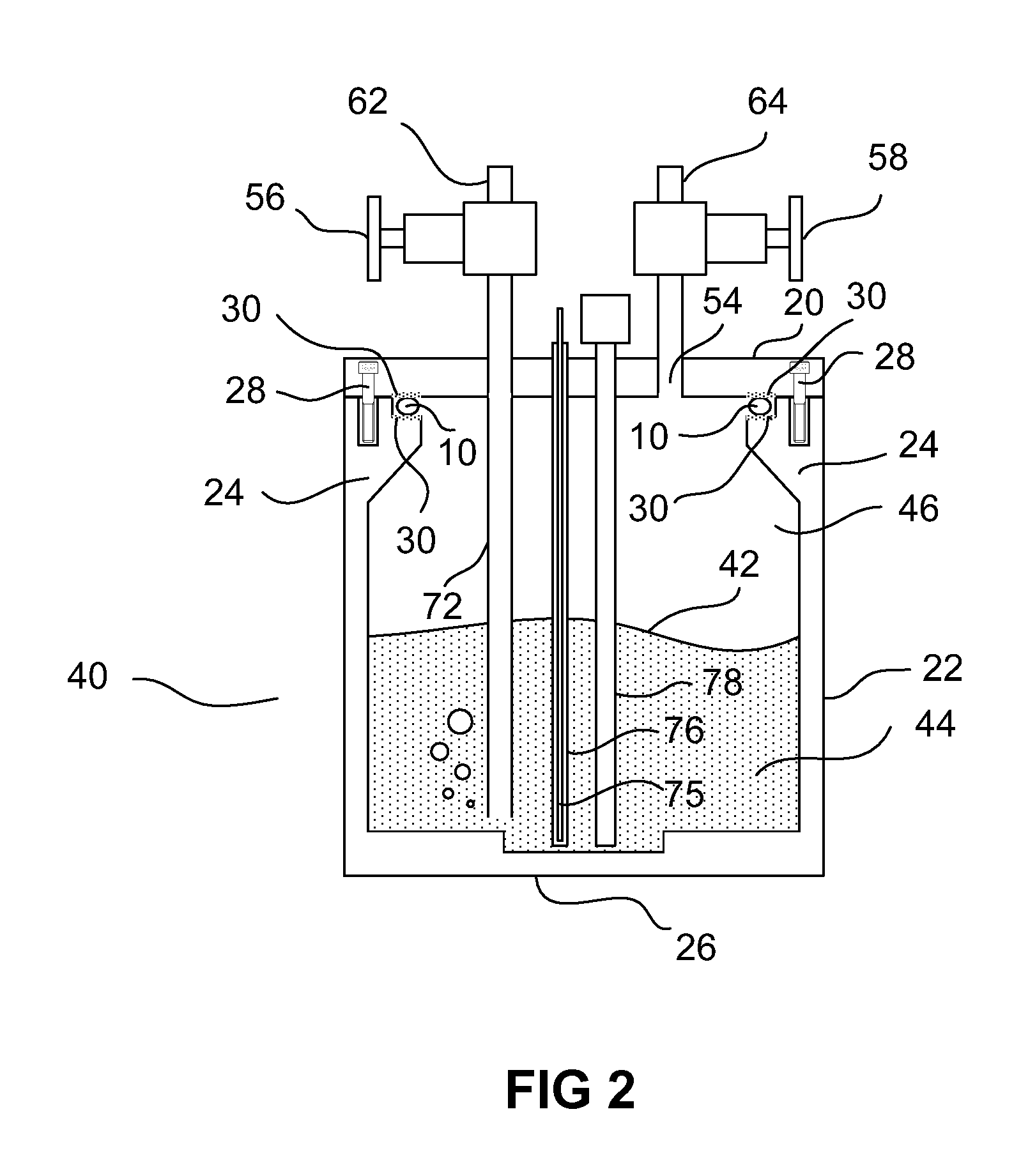

Vacuum Devolatilizer

Provided is a vacuum devolatilizer for use in a polymer manufacturing or processing plant. The devolatilizer comprises a vacuum chamber having an inlet for a polymer melt, an outlet for a polymer melt, a vacuum port through which volatiles may be removed and a stirrer shaft port for the entry of a stirrer shaft. The stirrer shaft passes through the at least one stirrer shaft port and extends into the vacuum chamber and carries an agitation means. The stirrer shaft seal is associated with each stirrer shaft port for sealing against the stirrer shaft and each stirrer shaft seal has an external portion outside the vacuum chamber. The devolatilizer is provided with a motor located outside of the vacuum chamber for rotating shaft and comprises means for blanketing the external portion of the stirrer shaft seal with a low oxygen content gas or vapor, e.g., nitrogen, helium, steam, or carbon dioxide.

Owner:EXXONMOBIL CHEM PAT INC

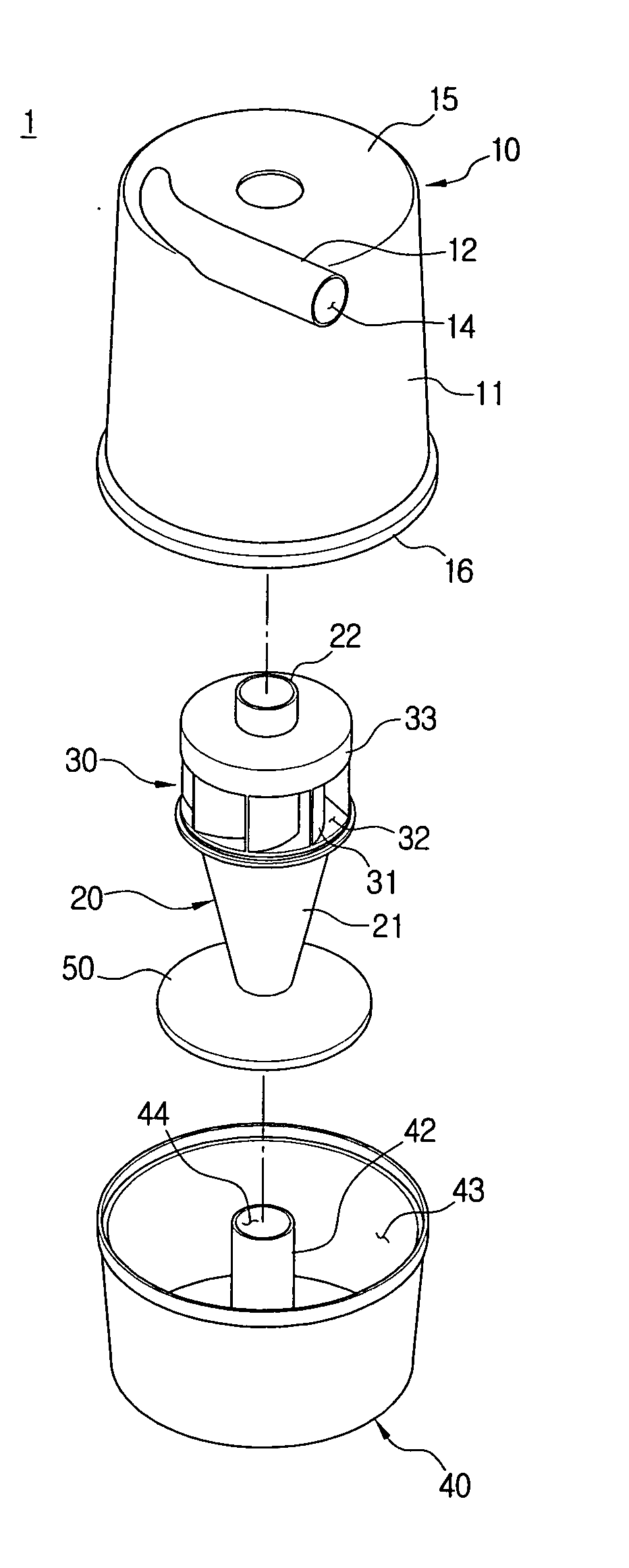

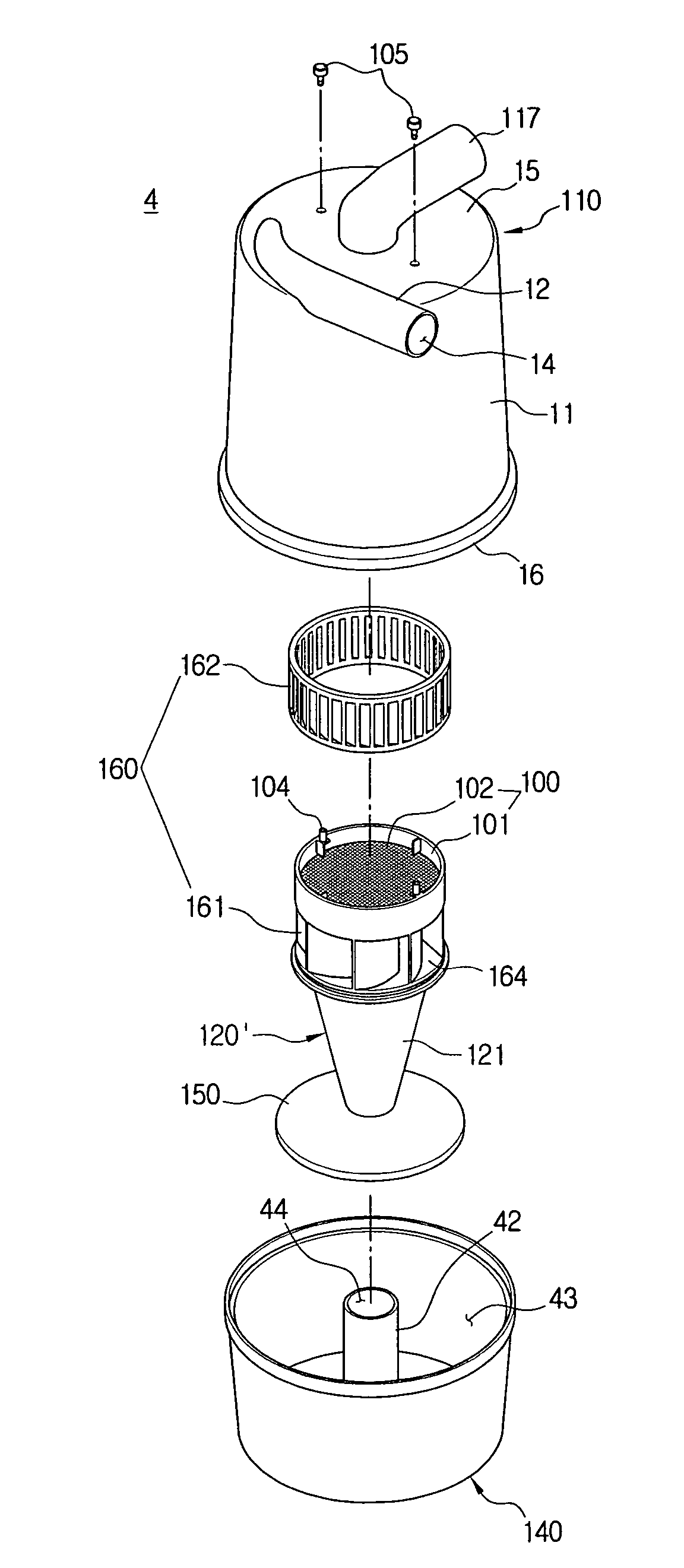

Cyclone dust collecting apparatus for vacuum cleaner

ActiveUS7678166B2Small pressure lossHigh fine dust collecting efficiencyCleaning filter meansCombination devicesCycloneEngineering

The present disclosure relates to a cyclone dust collecting apparatus for a vacuum cleaner having a high fine dust collecting efficiency. The cyclone dust collecting apparatus includes a first cyclone having an air suction hole through which dust-laden air is drawn-in, the first cyclone forcing the dust-laden air to downwardly whirl in a space under the air suction hole so as to centrifugally separate dust from the dust-laden air; a second cyclone disposed inside the first cyclone, the second cyclone forcing semi-clean air entering from the first cyclone to downwardly whirl so as to centrifugally separate fine dust from the semi-clean air; and an air guiding member forcing the semi-clean air discharged from the first cyclone to directly enter the second cyclone and, the air guiding member having a plurality of guiding blades radially disposed in at least one circular shape based on a vertical axis of the second cyclone.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

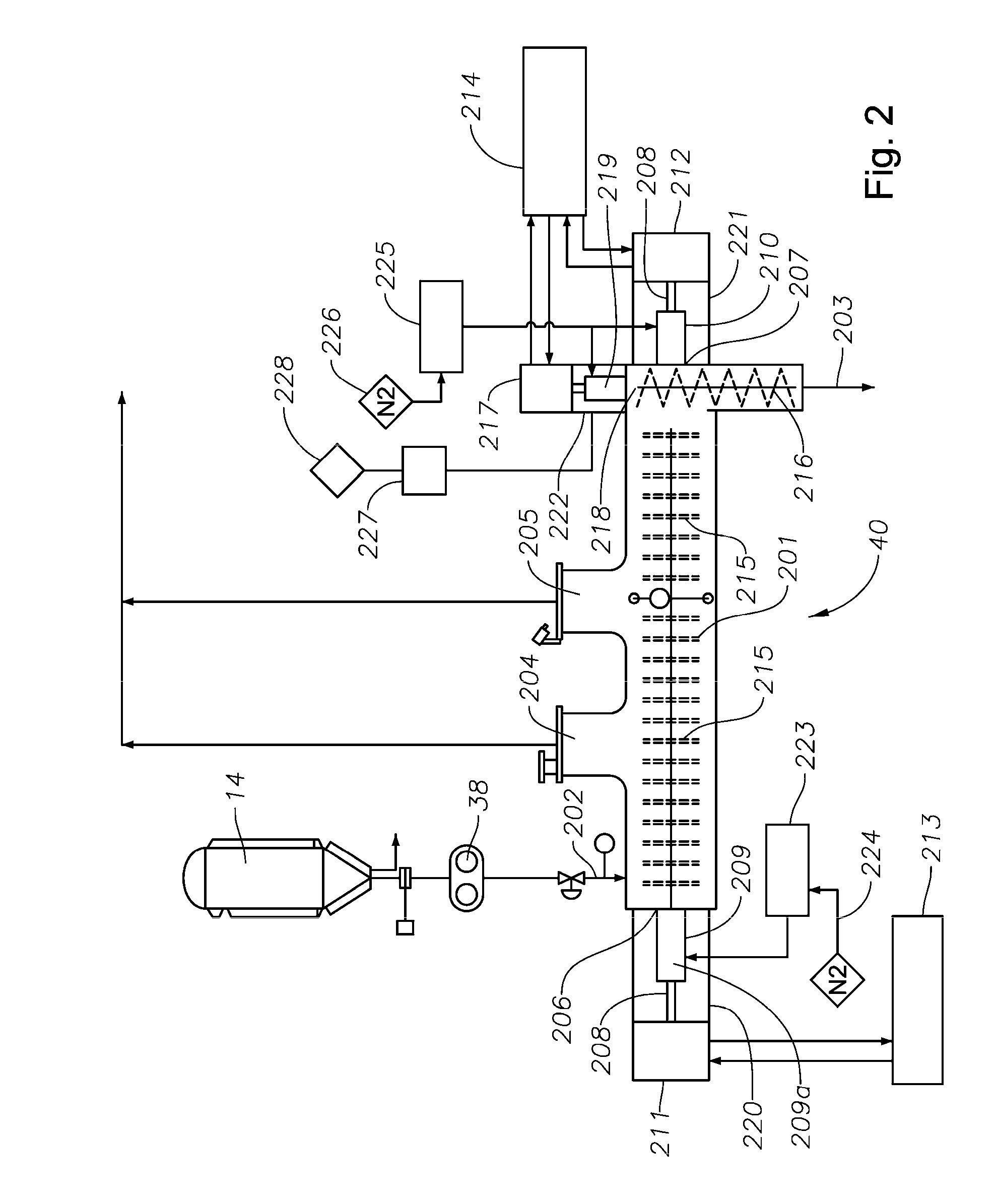

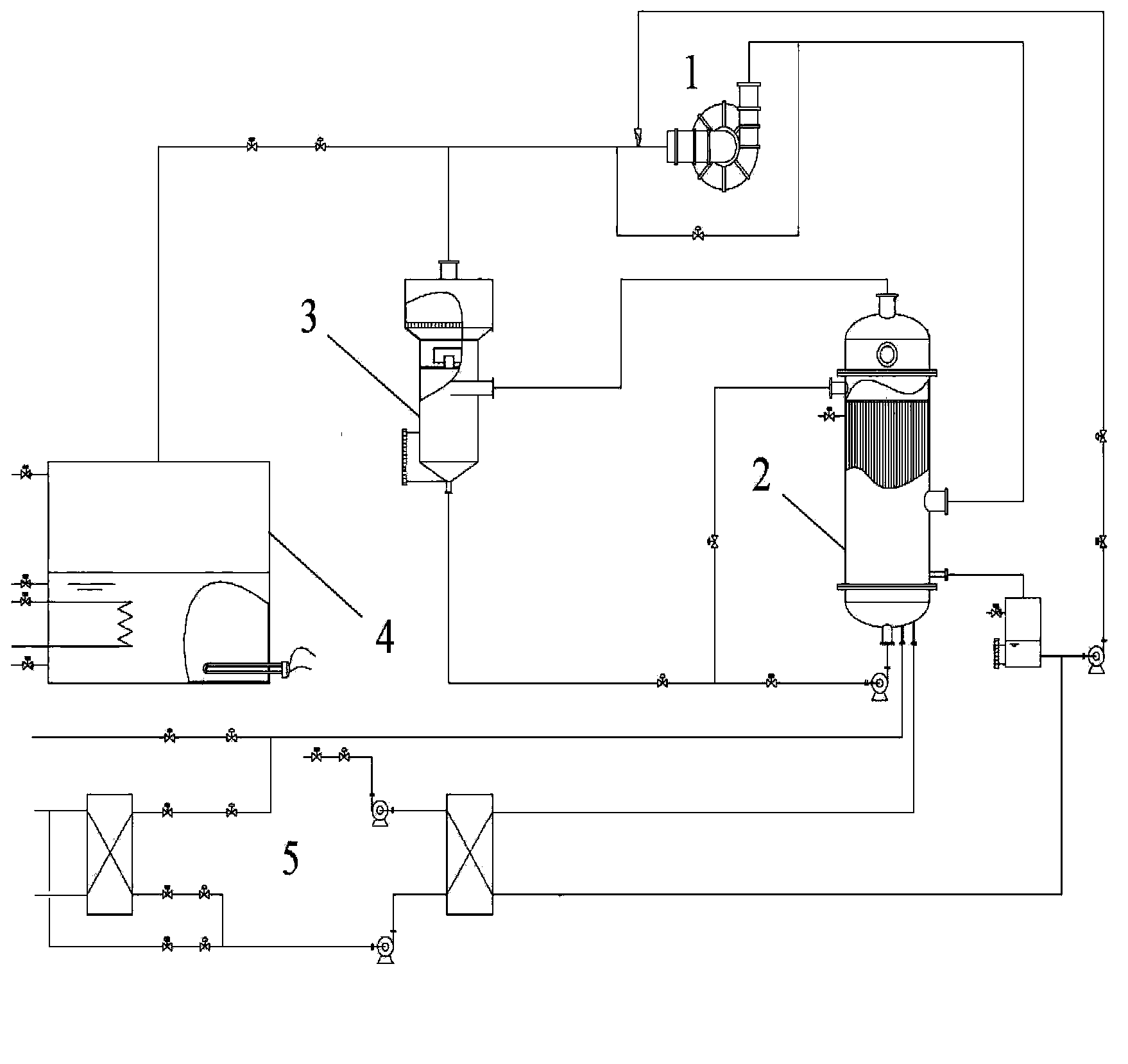

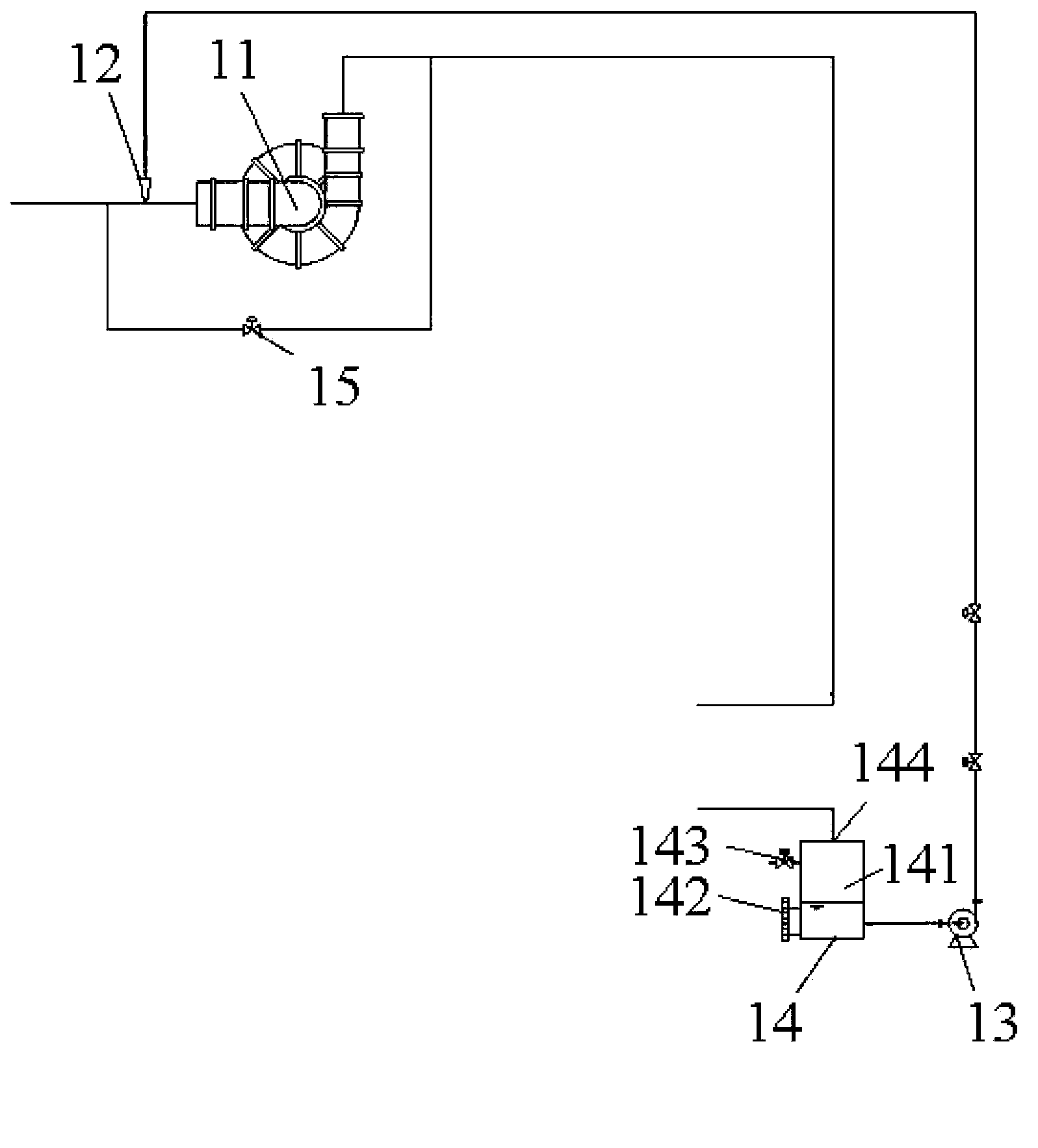

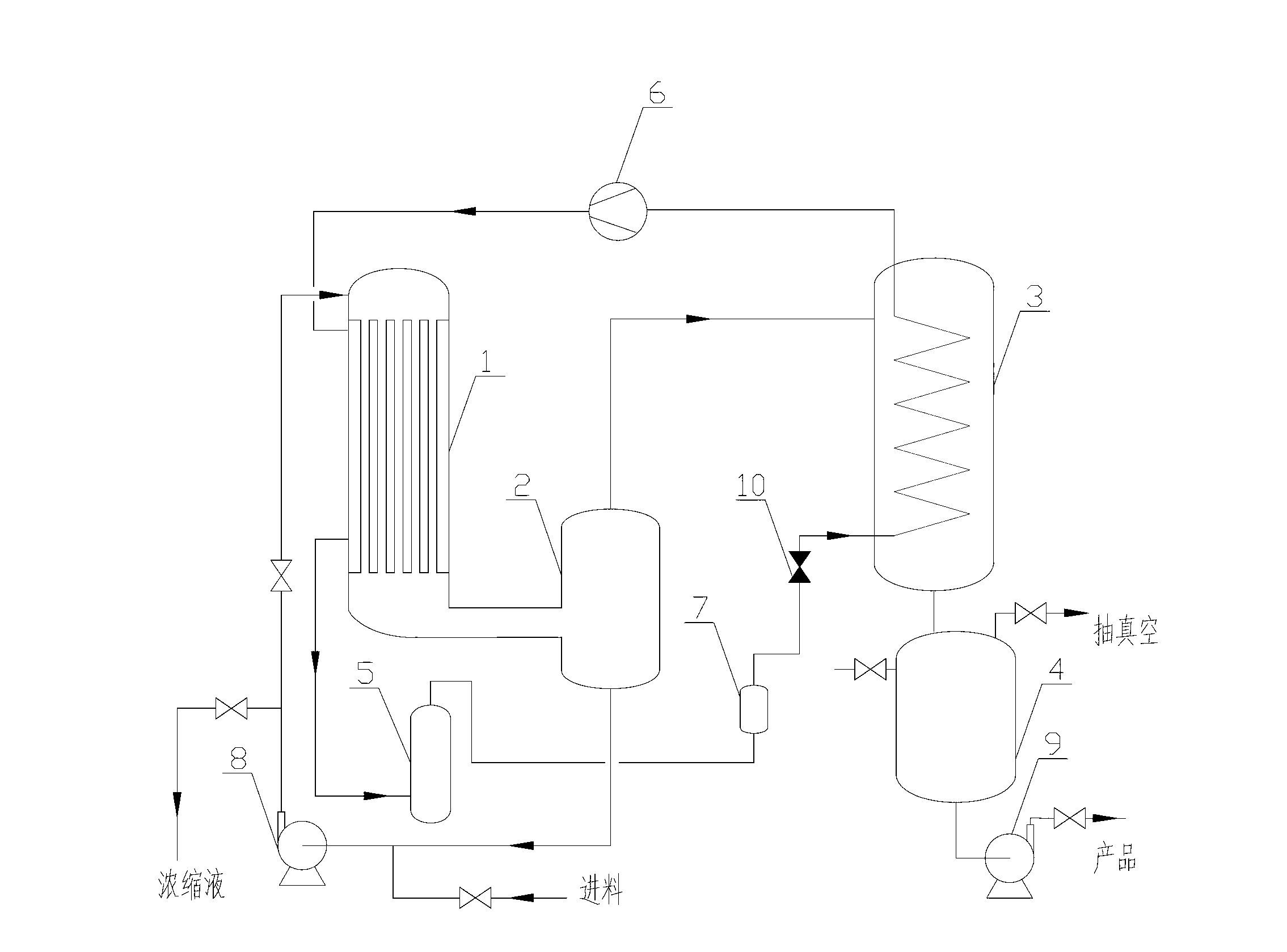

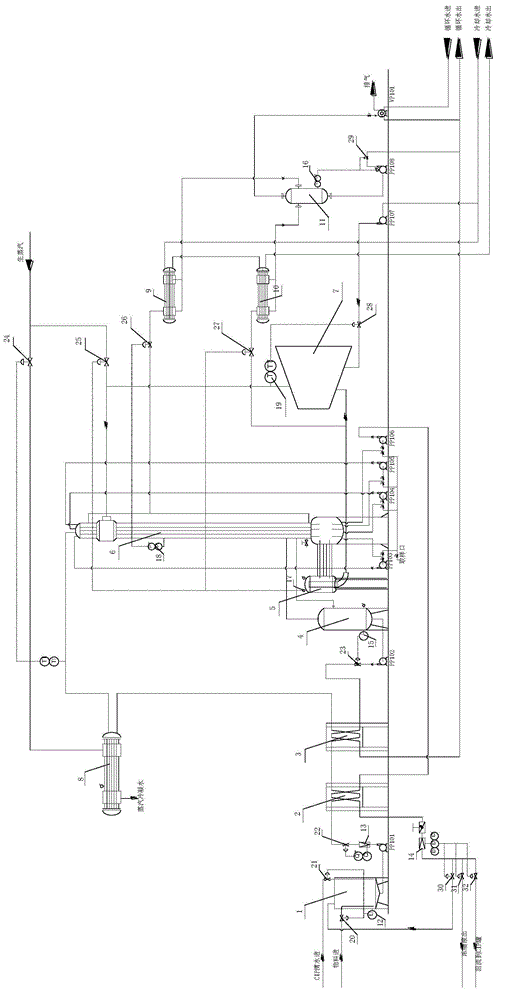

MVR heat pump evaporation system

ActiveCN103908788AReduce consumptionFast startupEvaporator accessoriesEvaporators with vertical tubesWater vaporEvaporation

The invention discloses an MVR heat pump evaporation system, which comprises a water vapor compression system, an evaporator, a separator, an energy storage water tank and a waste heat recovery system. The vapor outlet of the energy storage water tank and the vapor outlet of the separator are both in connection with the vapor inlet of the water vapor compression system, the vapor outlet of which is connected to the vapor inlet of the evaporator. The vapor outlet of the evaporator is connected to the vapor inlet of the separator, and the stock solution inlet and the concentrated solution outlet of the evaporator are both in connection with the waste heat recovery system. The MVR heat pump evaporation system provided by the invention recovers low grade waste heat, i.e. makes use of the energy storage water tank to convert hot water sensible heat into low-pressure vapor latent heat for recycling during starting, thus enhancing the start-up speed of the system, avoiding the influence of non-condensable gas air circulation in the system on compressor performance, recovering all the latent heat of secondary vapor generated in a solution evaporation process, saving primary energy, greatly reducing the energy consumption during solution evaporation, and avoiding pollution.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

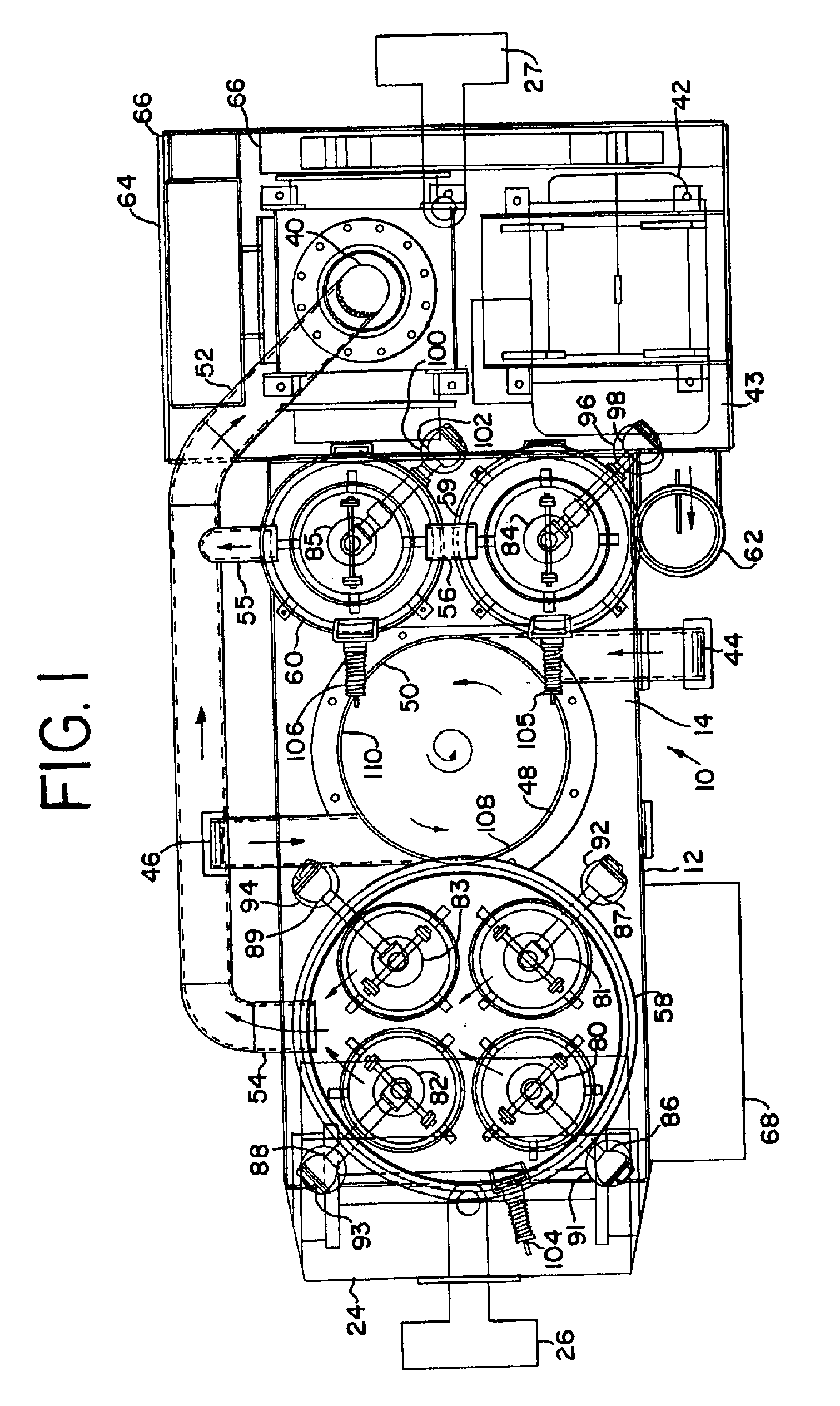

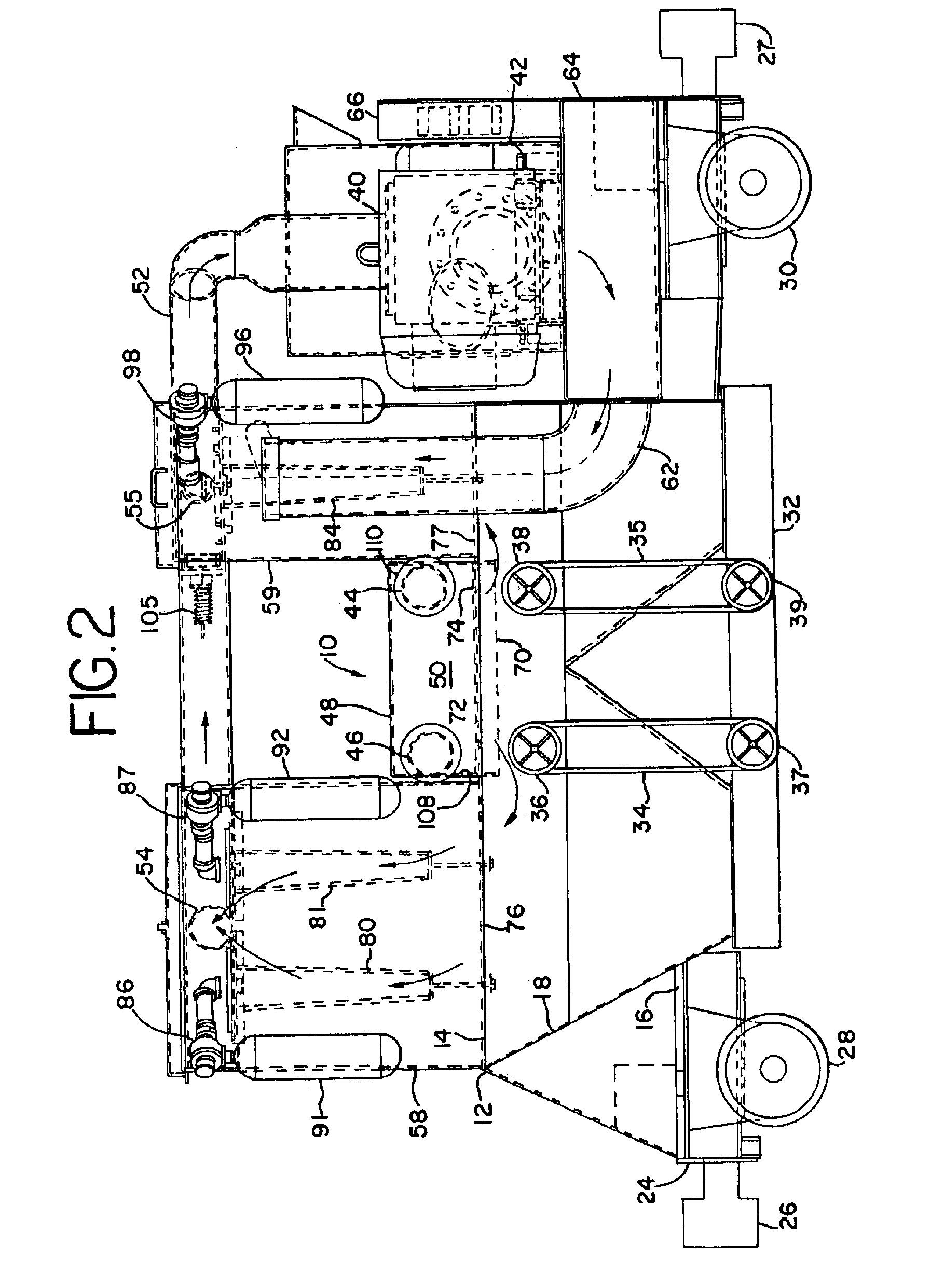

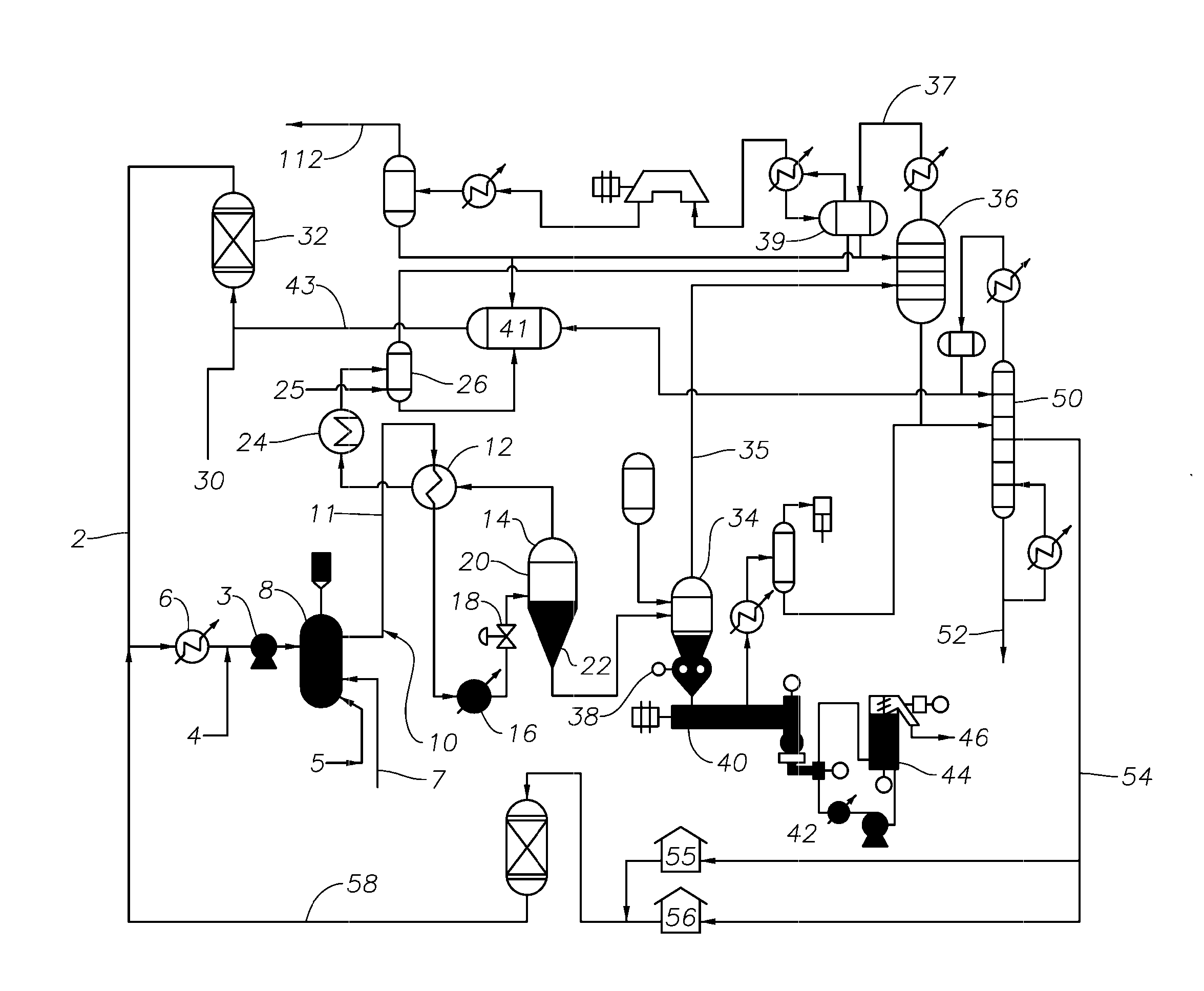

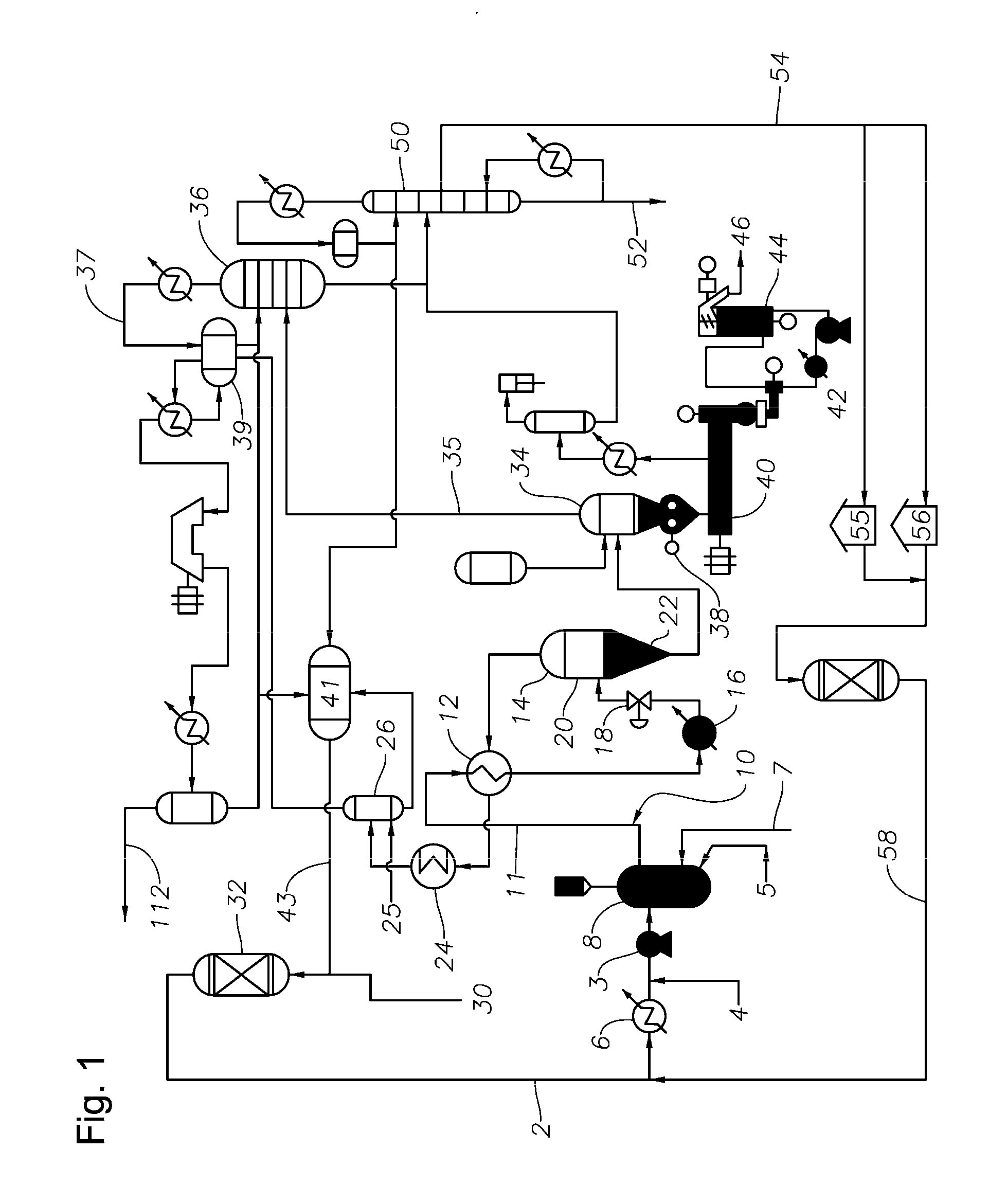

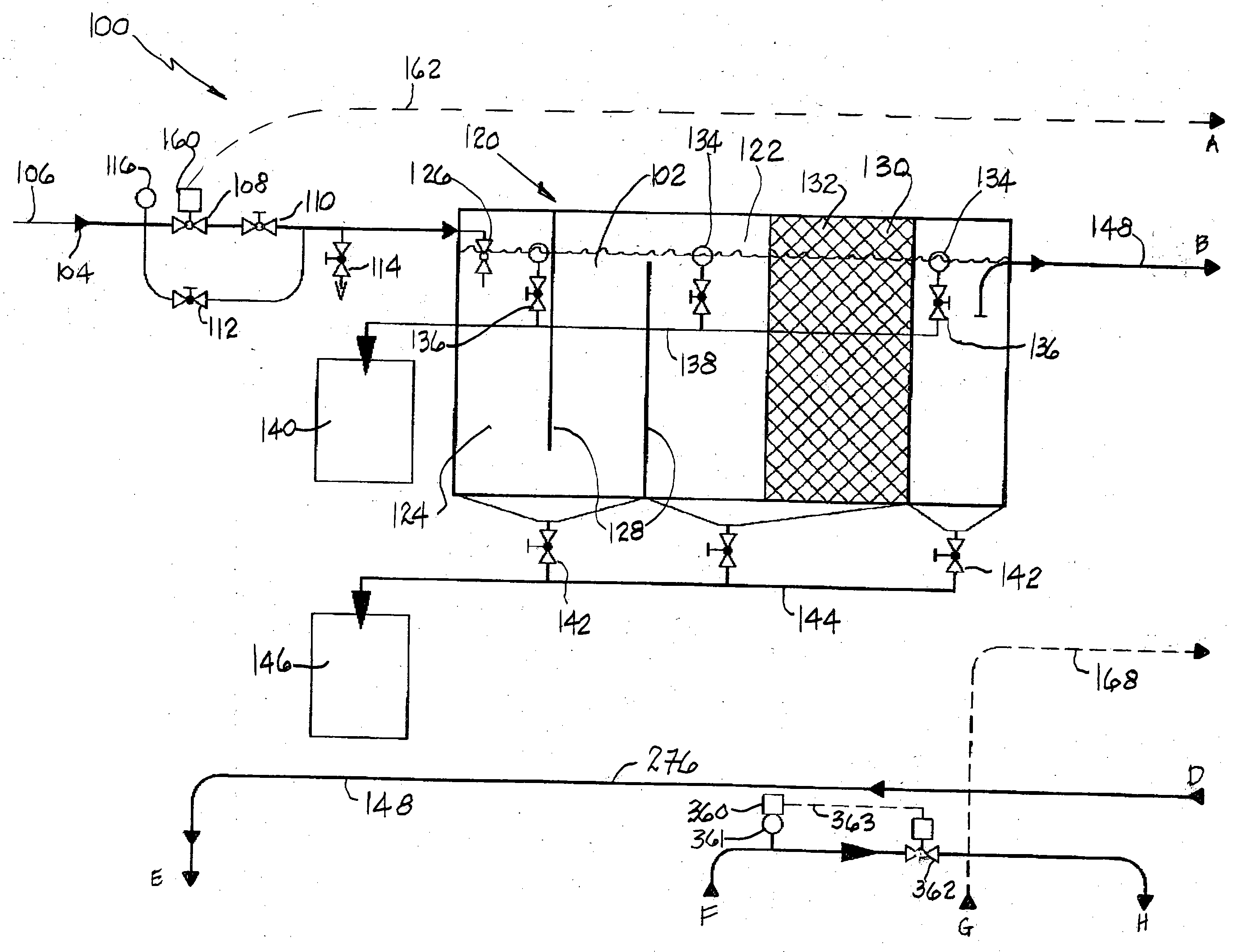

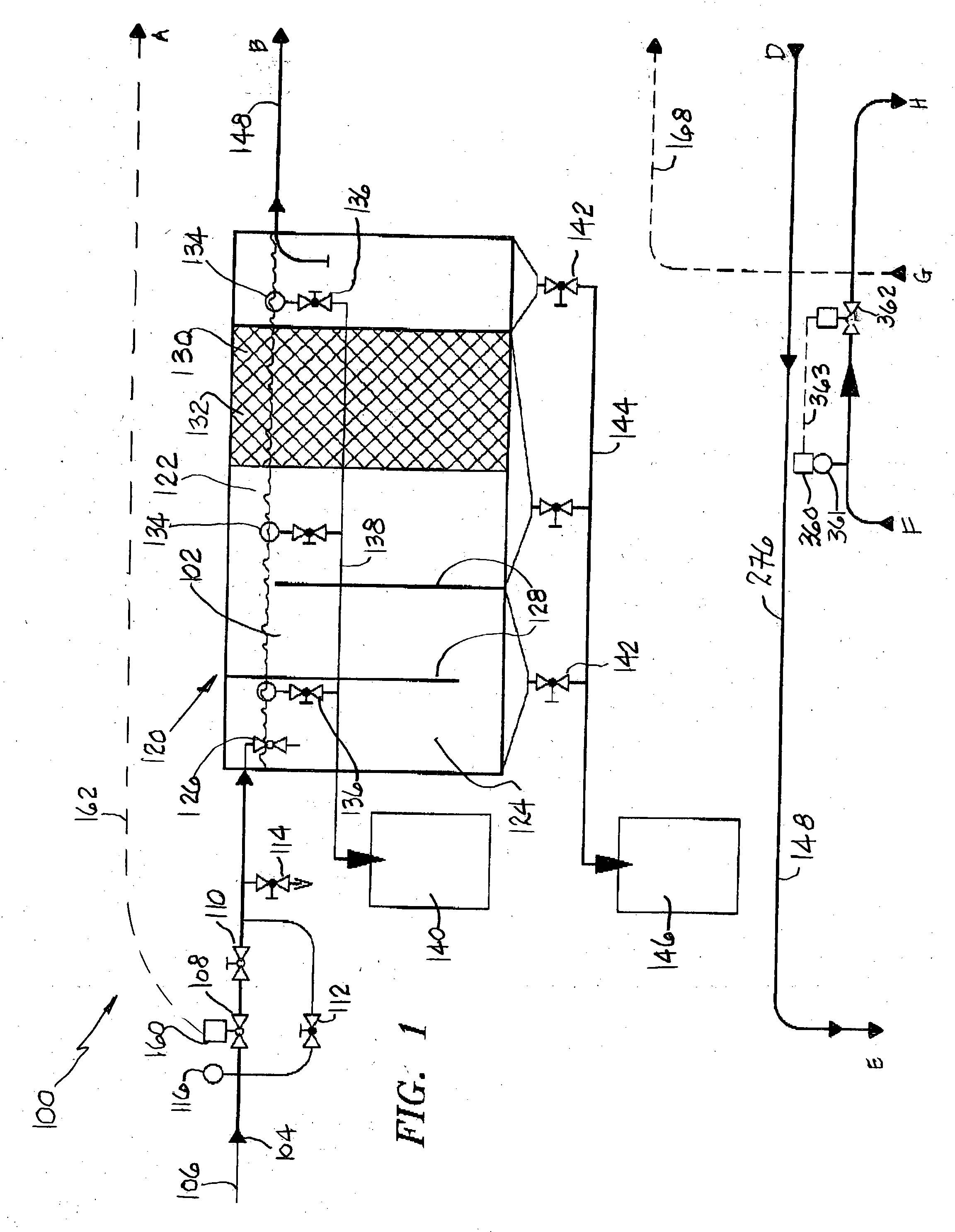

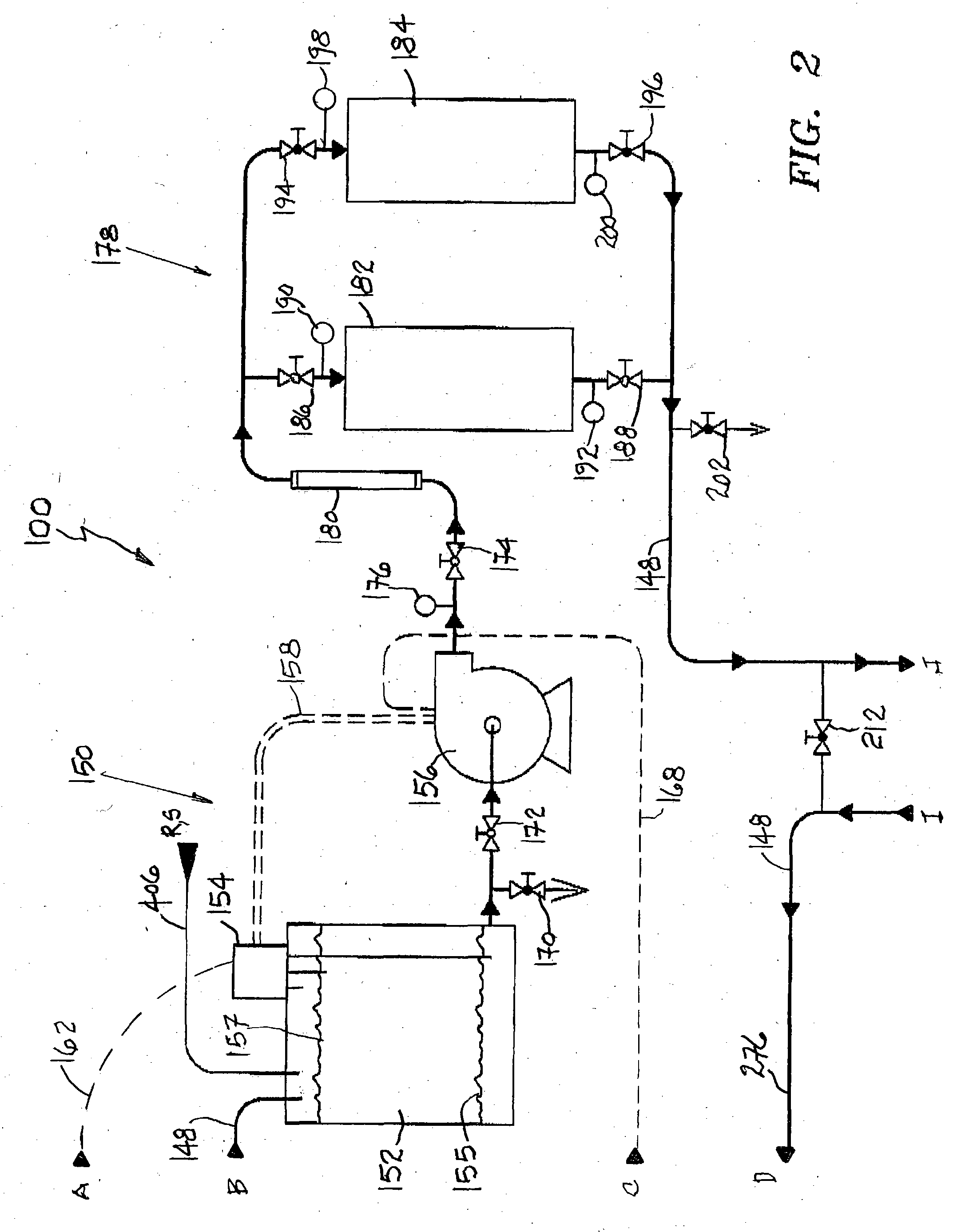

Method and apparatus for processing vegetable oils

InactiveUS7597783B2Fatty oils/acids recovery from wasteOrganic compound preparationVegetable oilVolatiles

Methods for processing oils and apparatus for carrying out such methods are disclosed herein. One embodiment provides a method for processing a partially processed oil, wherein the oil includes glycerides and a volatilizable impurity fraction. The partially processed oil may be processed by driving off a first volatiles stream having a portion of the glycerides and at least a portion of the volatilizable impurity fraction, leaving a deodorized oil. The first volatiles stream may be introduced into a first condensing chamber and a glyceride-rich, impurity-poor fraction may be condensed from the first volatiles stream, leaving a glyceride-poor, impurity-rich second volatiles stream. The second volatiles stream may be passed into a second condensing chamber and a glyceride-poor, impurity-rich second condensate may be condensed from the second volatiles stream.

Owner:CARGILL INC

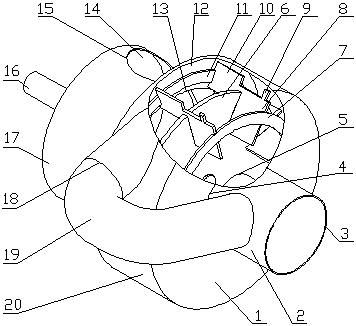

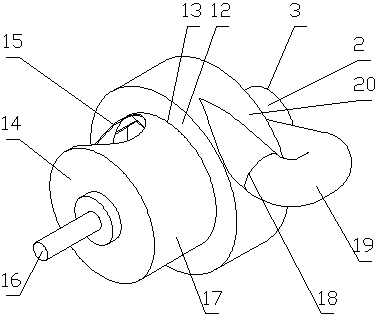

Cyclone dust-separating unit for use in vacuum cleaner

InactiveUS20080289306A1Improve efficiencySimple structureSuction filtersReversed direction vortexPower flowEngineering

A cyclone dust-separating unit is provided that includes a whirling current generating unit to rotate air drawn in through a suction nozzle, and a dust collecting bin having opened and closed ends to collect and store dust separated by a whirling current. The generating unit and the bin are separate tube members, and the generating unit includes a cyclone body having a first end with an air inlet and a second end with an air outlet, a spiral guide member on the first end to guide air flowed in through the air inlet in a spiral shape, an outflow pipe on the second end to extend to the outside of the cyclone body while penetrating through the air outlet, and a dust guide to connect a dust discharging opening with the opened end and to guide dust or dirt discharged through the dust discharging opening, to the opened end.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

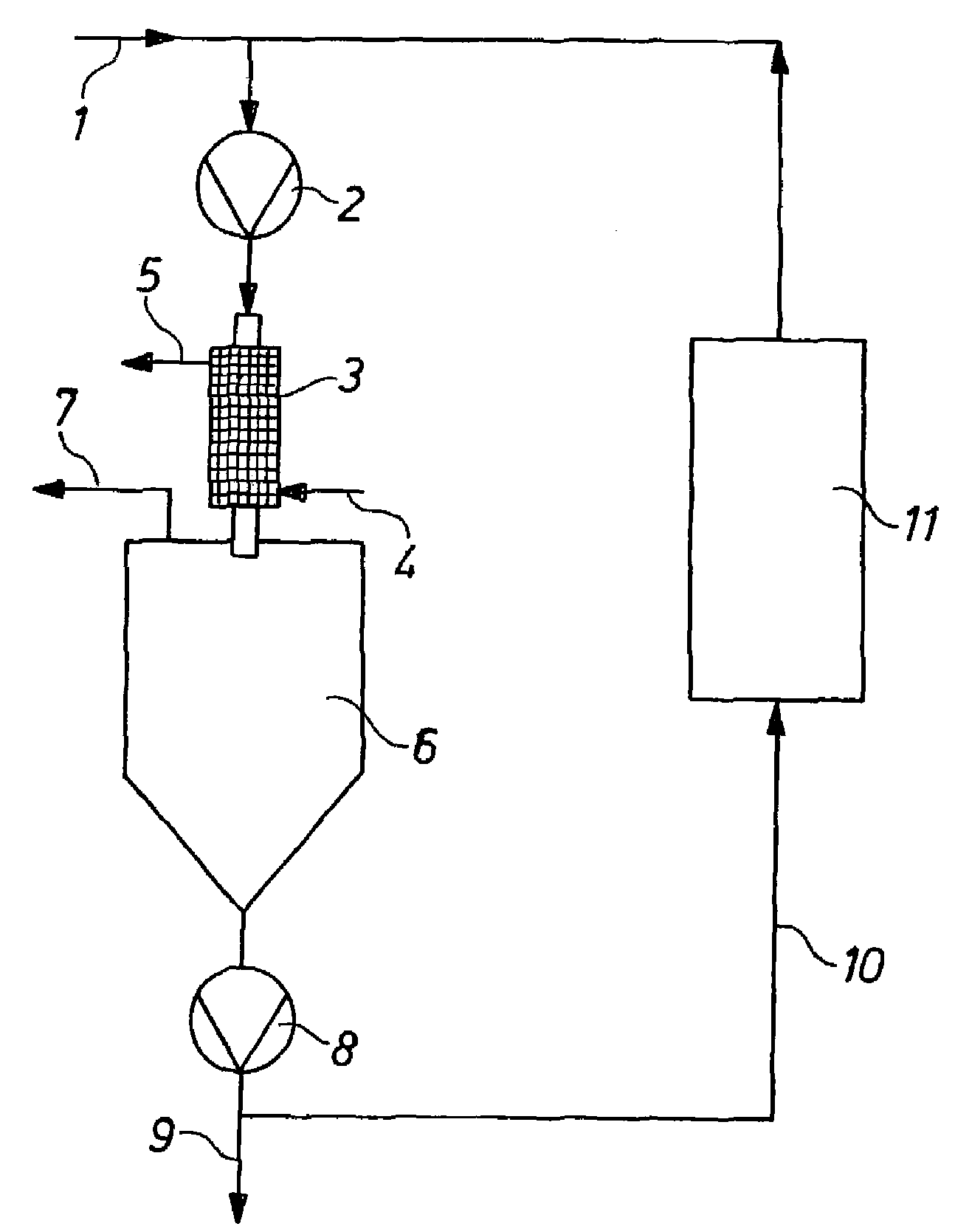

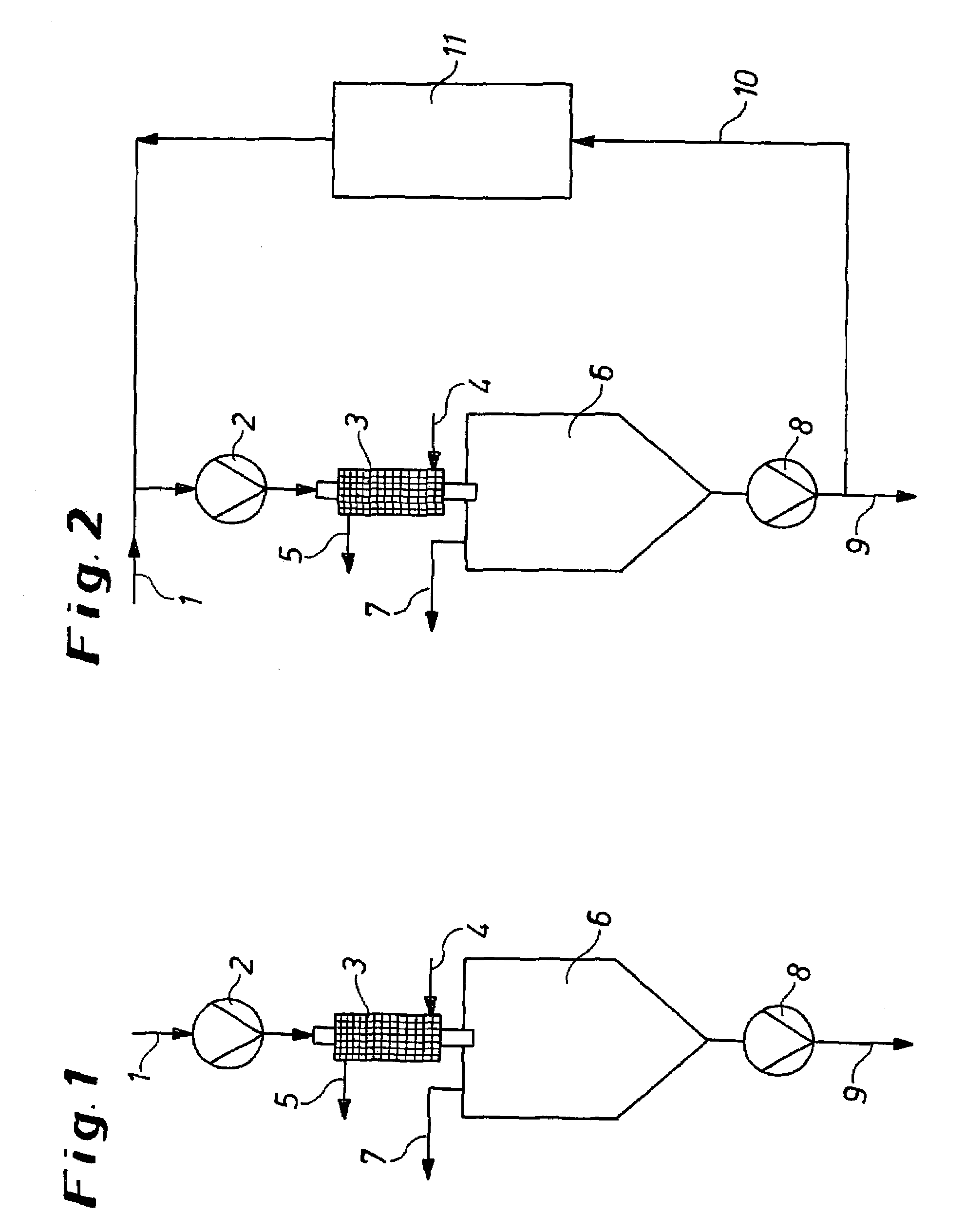

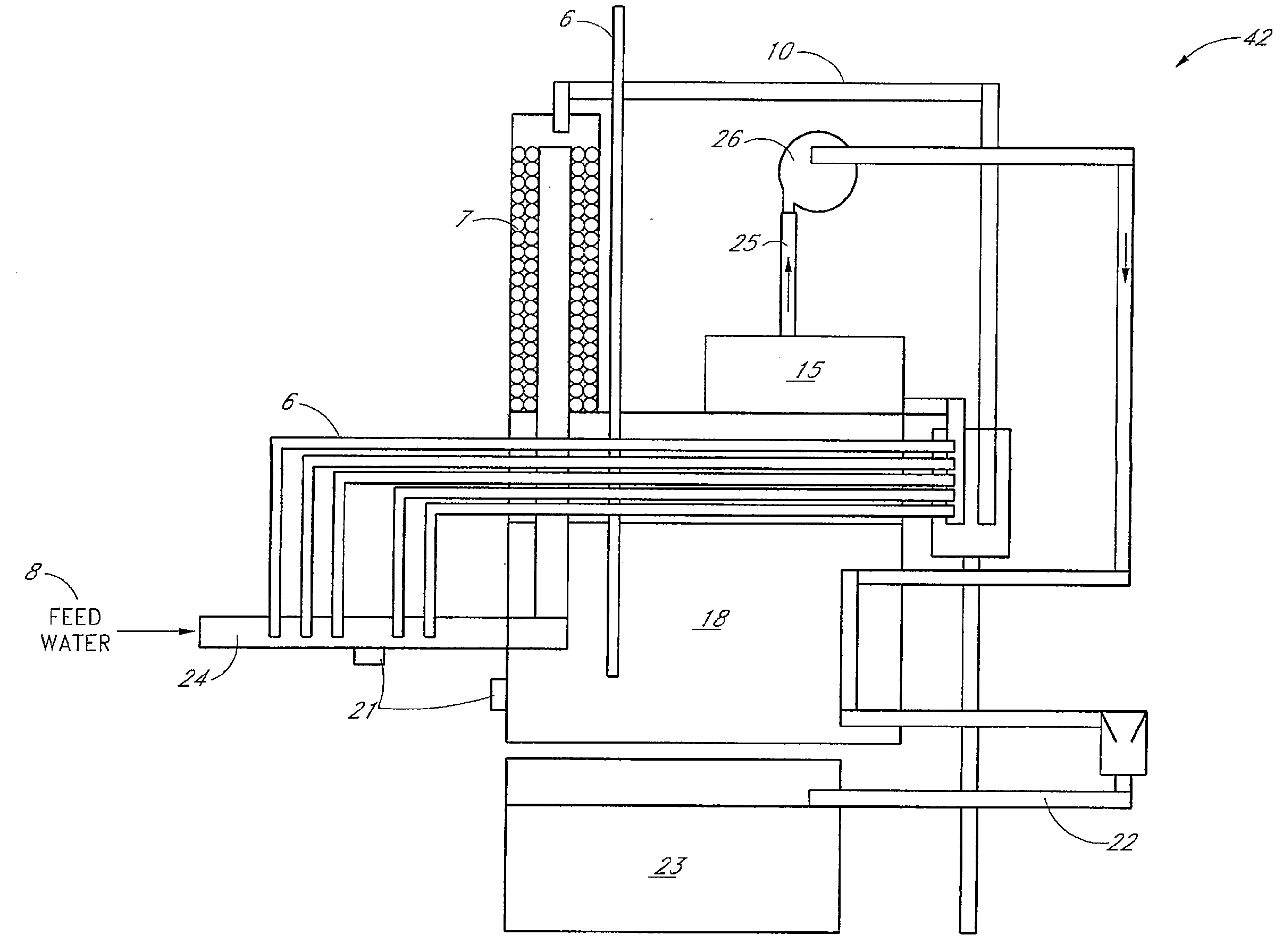

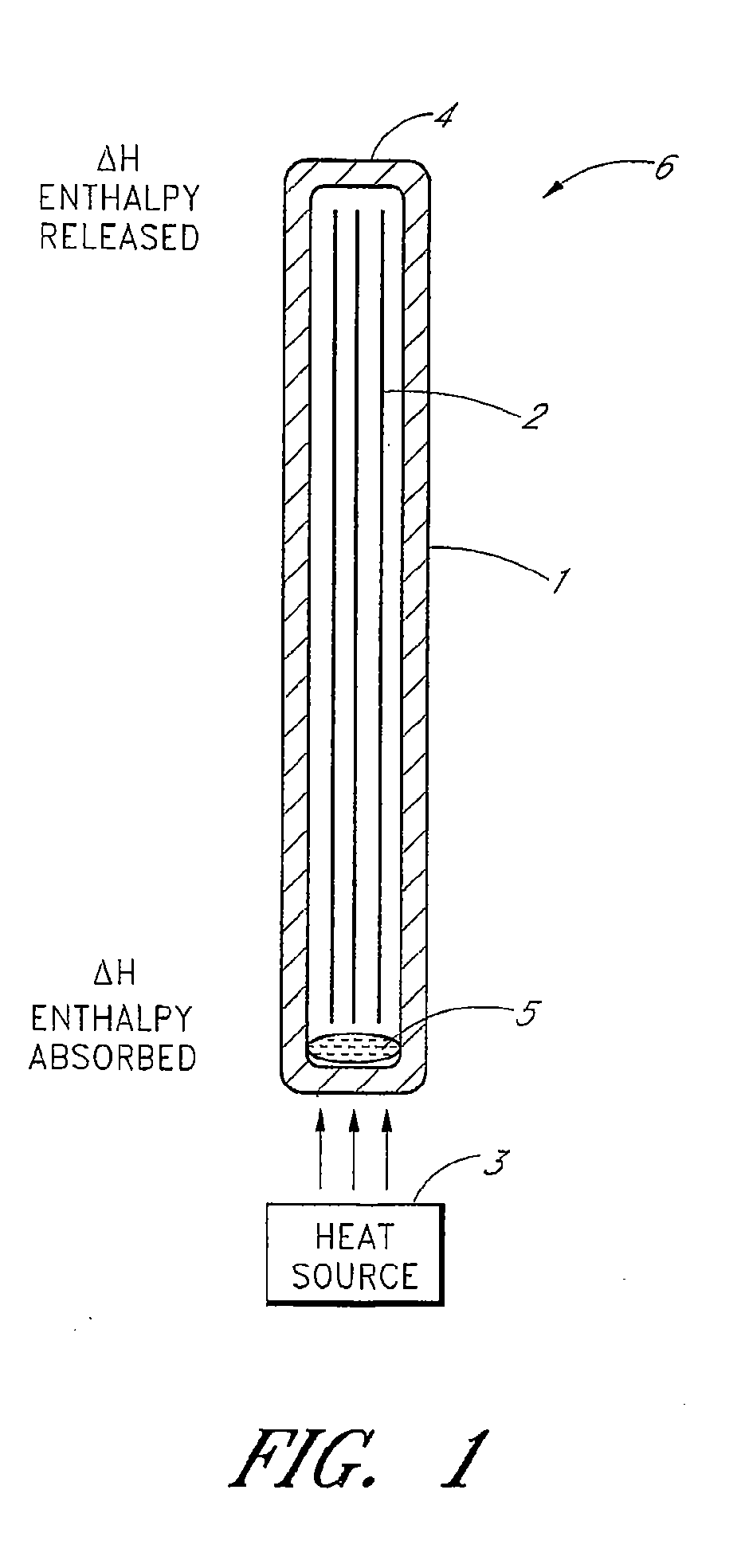

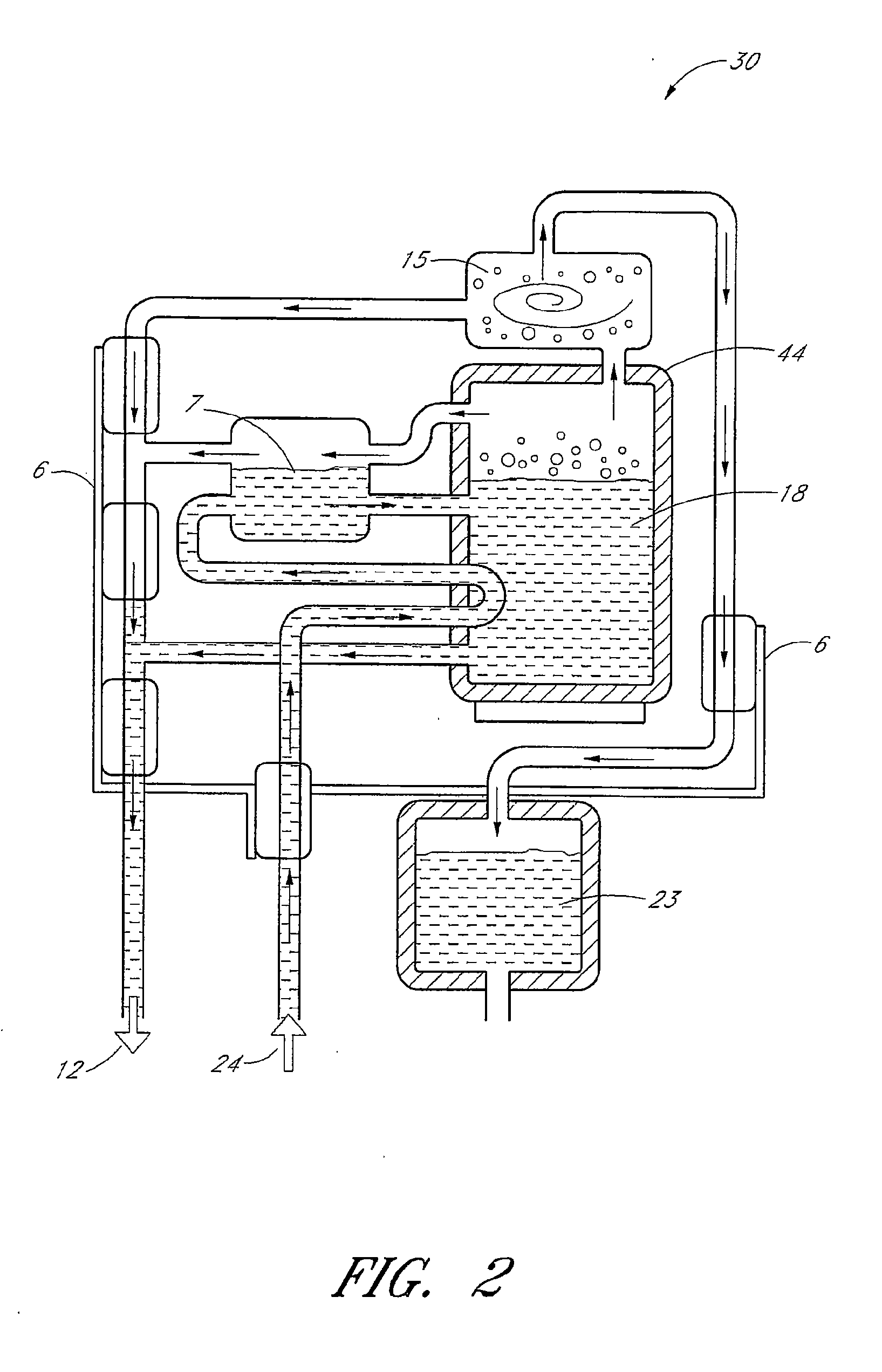

Energy-efficient distillation system

InactiveUS20090218210A1Reduce foulingLiquid degasification with auxillary substancesEvaporator accessoriesEngineeringDistillation

Methods and devices are provided for an energy-efficient distillation system (42). An energy-efficient distillation system (42) can include a fluid inlet (24), one or more heat-yielding purification elements (7, 15, 44) downstream of the fluid inlet (24), one or more heat pipes (6), and a fluid outlet (23) downstream of the heat-yielding purification element (7, 15, 44). The heat-yielding purification element (7, 15, 44) can be, for example, a degasser (7), a demister (15), or an evaporation chamber (44). A heat pipe (6) has a first end operably connected to the heat-generating purification element(s) (7, 15, 44), a second end operably connected to the fluid inlet (24), and a body therebetween. The heat pipe (6) is configured to transfer latent heat energy from the first end to the second end, thereby heating a fluid (8) within the fluid inlet (24). The distillation system (42) can also include one or more descaling elements (21) for reducing scale formation of the fluid (8).

Owner:SYLVAN SOURCE

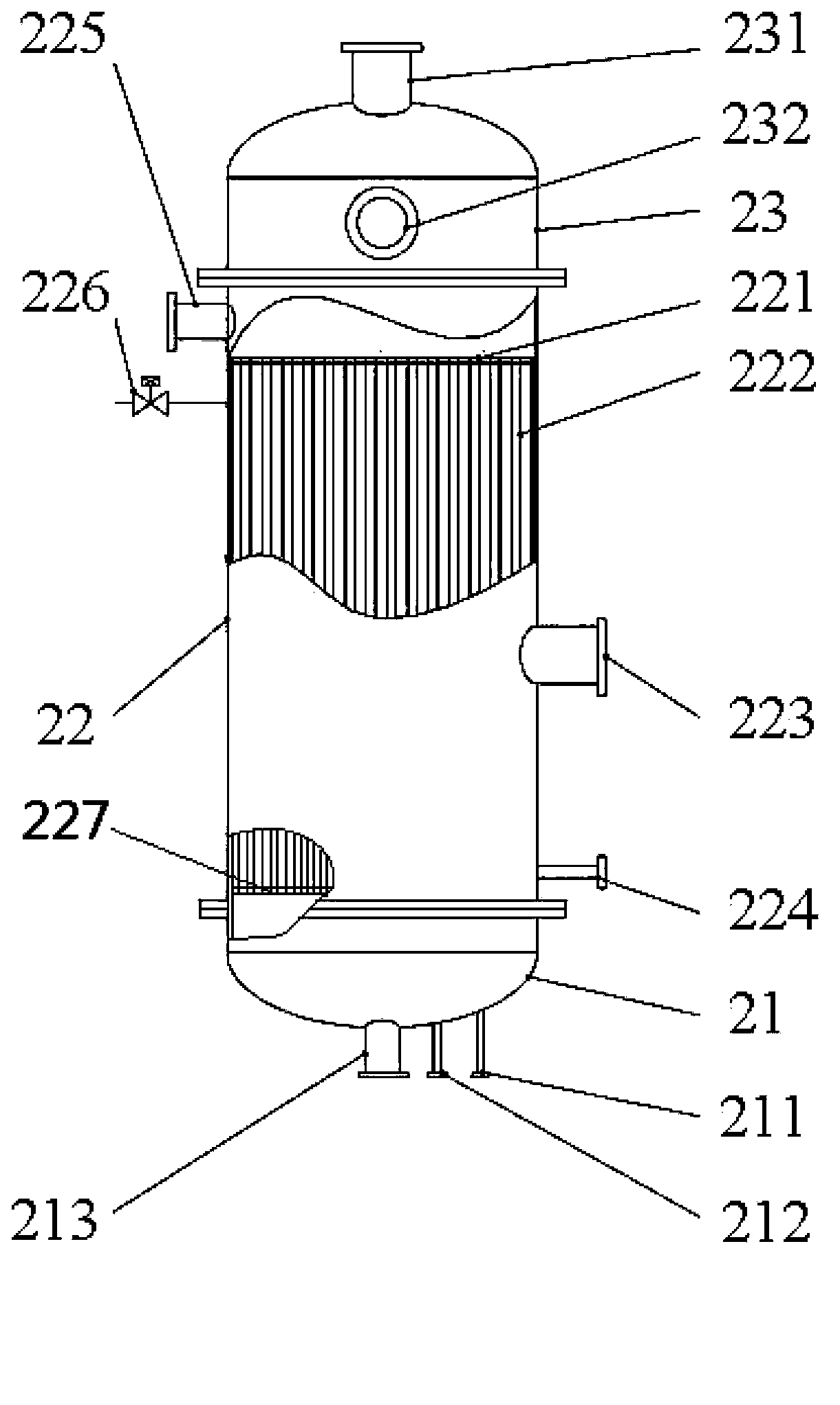

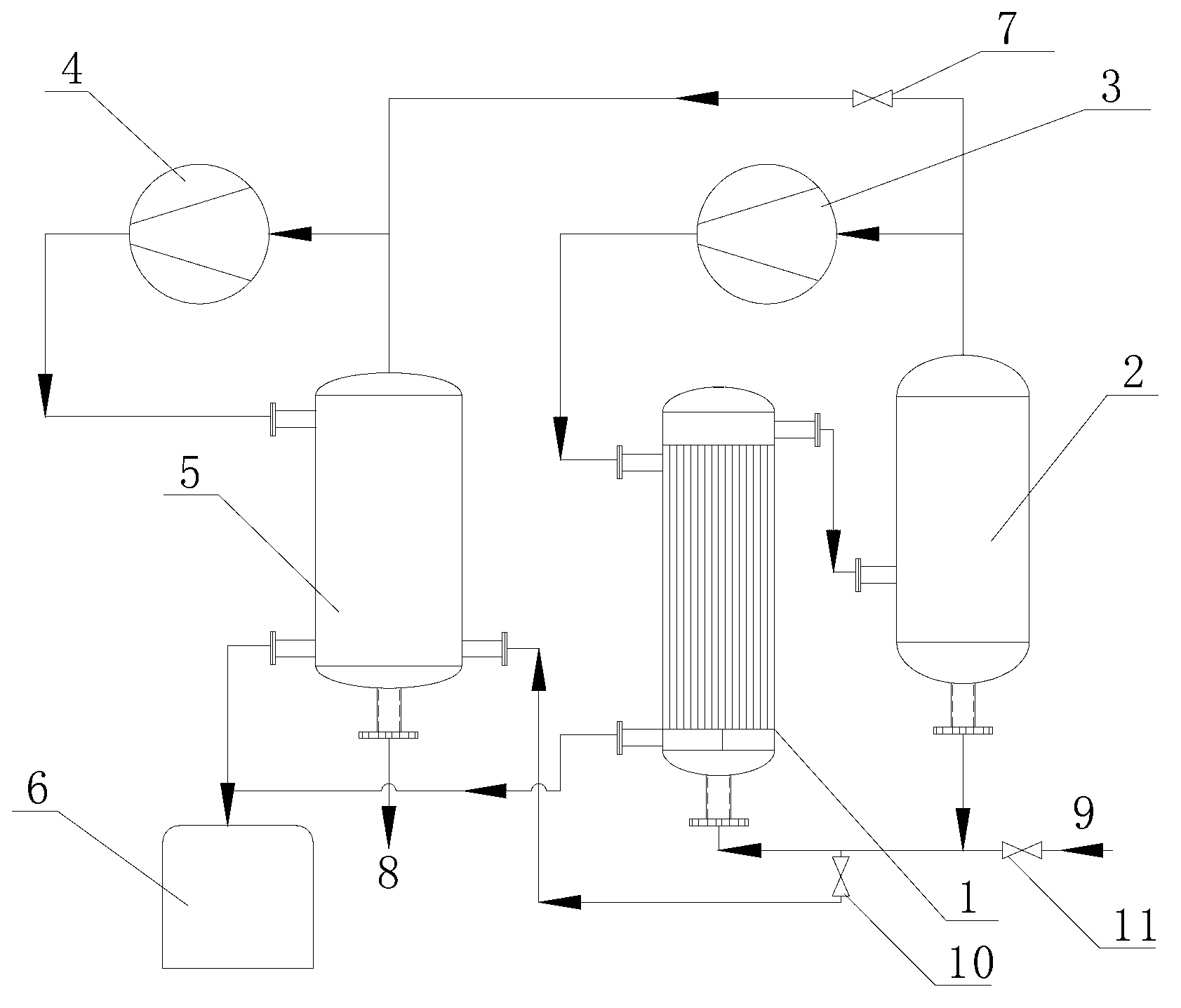

Heat pump type low-temperature evaporating device and method

InactiveCN102698451AEvaporator accessoriesMultiple-effect evaporationSteam condensationChemical separation

The invention relates to a heat pump type low-temperature evaporating device and method, belonging to the technical fields of chemical separation, energy conservation and emission reduction. The method is characterized in that a solvent is evaporated and condensed in the heating circulation process of a heat-carrying medium, so that the aim that a thermosensitive material liquid is evaporated and concentrated or an organic solvent is recovered at the low temperature can be achieved; the heat pump type low-temperature evaporating device mainly comprises a material liquid evaporator, a gas-liquid separator, a secondary steam condenser, a condensate tank, a heat medium storage tank, a heat medium steam compressor, a filter, a material liquid pump, a condensate pump, a throttling device and a pipeline valve, wherein a single-effect or multi-effect falling-film evaporator is used as the material liquid evaporator. The material liquid evaporating temperature is controlled to be within the range of 25-60 DEG C by adjusting the system vacuum degree; and the system heating capacity is controlled to be matched with the evaporation capacity by adjusting the input power of the compressor at the variable frequency. The heat pump type low-temperature evaporating device and method have the beneficial effects and advantages that the gas emission is reduced, so that the environment is protected, and the energy is saved; and furthermore, the active ingredients of the material liquid can be maintained by low-temperature evaporation, equipment is seldom corroded, and a pipeline is not easily blocked, so that the equipment cost is lowered.

Owner:DALIAN UNIV OF TECH

Multi-phase separation system

InactiveUS20050005772A1Minimizes probabilitySolid sorbent liquid separationVacuum distillation separationGas phaseLiquid state

A multi-phase separation system utilized to remove contaminants from fluids includes a pre-filtering module for filtering a contaminated fluid to provide a filtered contaminated fluid. A condenser module receives the filtered contaminated fluid and a contaminated gas phase for condensing the contaminated gas phase to a contaminated liquid. A phase reaction chamber converts the filtered contaminated fluid to a contaminated mist wherein the mist is subjected to a low energy, high vacuum environment for providing a first change of phase by separating into a contaminated gas phase and a liquid mist phase. The contaminated gas phase is carried out of the phase reaction chamber by a carrier air. A vacuum pump provides the low energy, high vacuum environment in the phase reaction chamber and delivers the contaminated gas phase to the condenser module for condensation providing a second change of phase.

Owner:LIQUID SEPARATION TECH & EQUIP

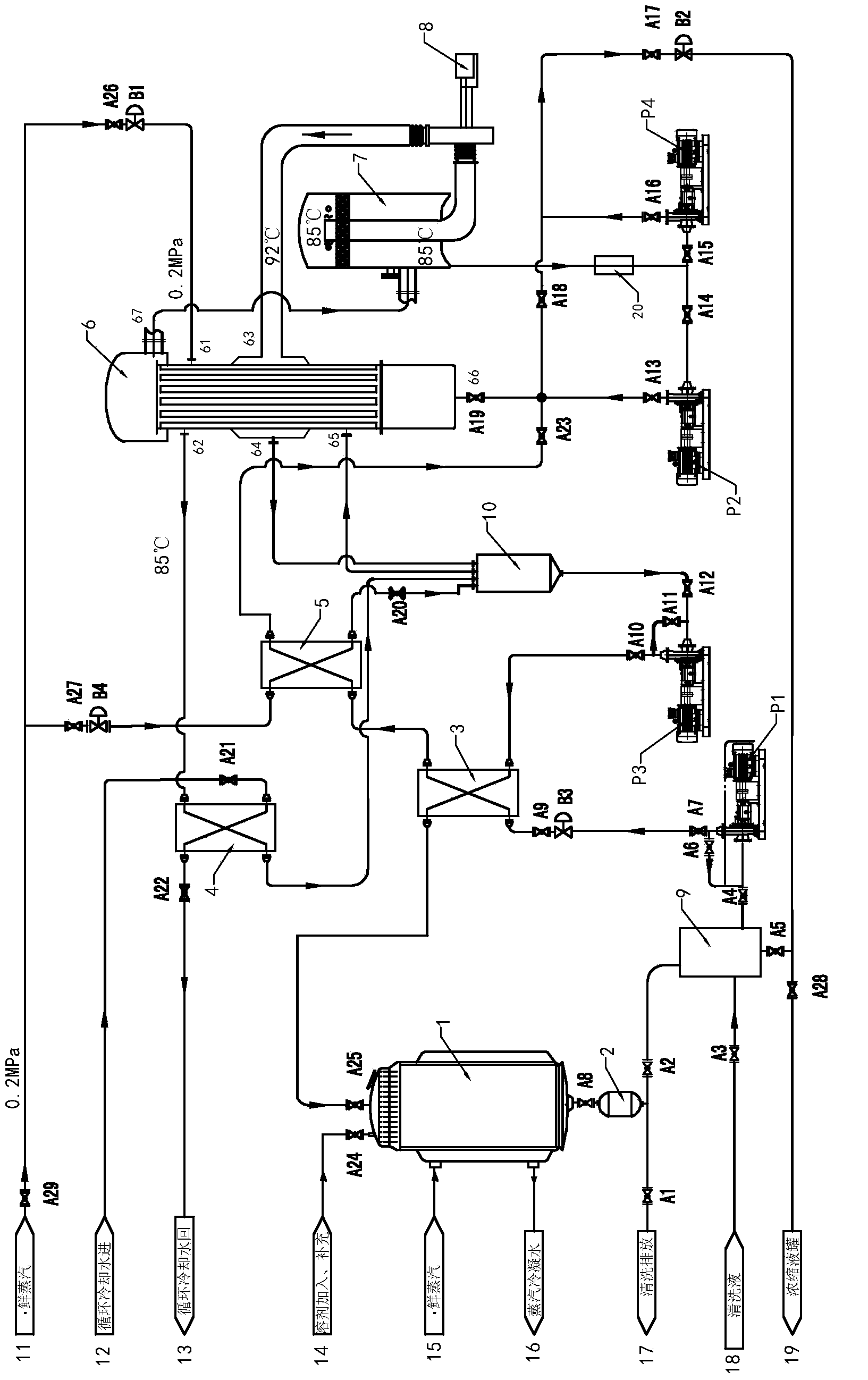

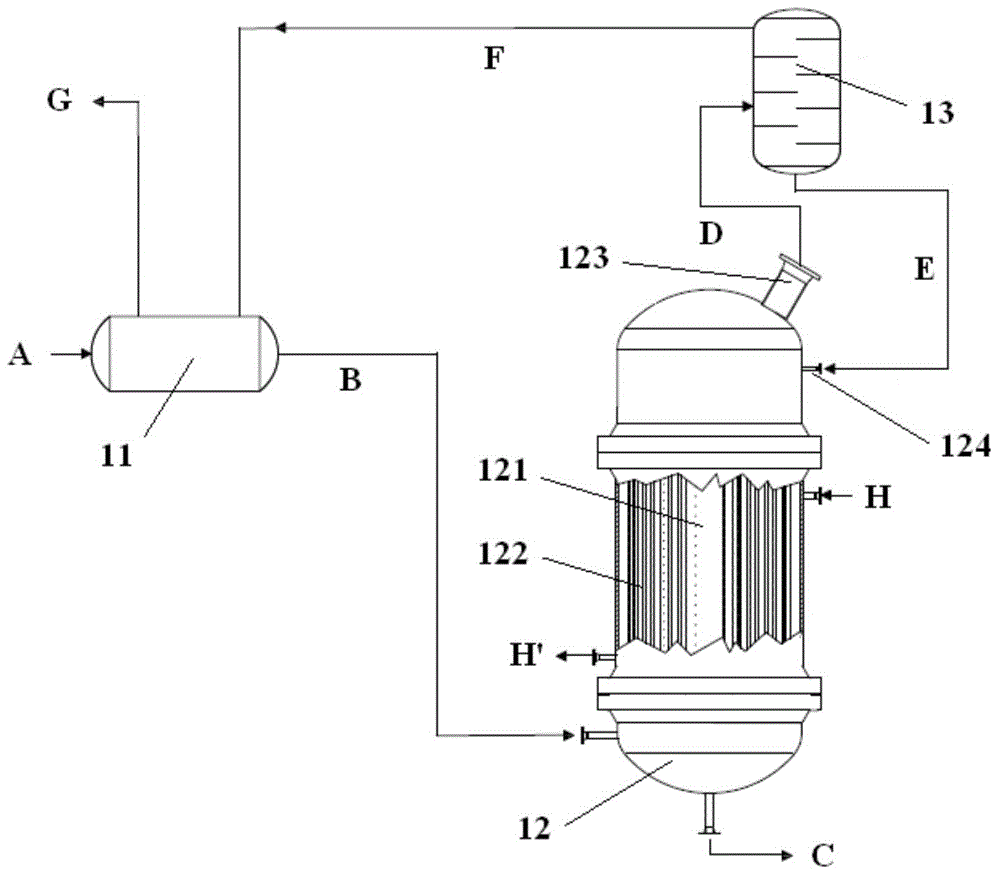

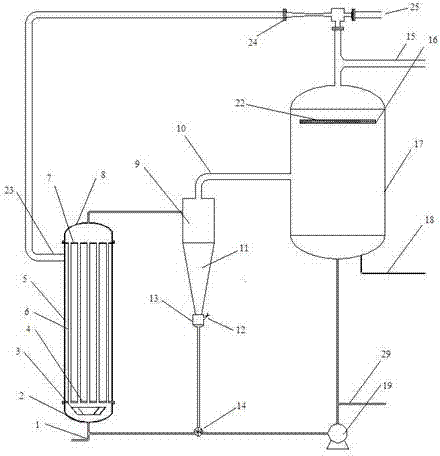

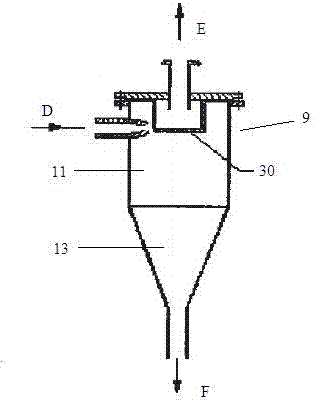

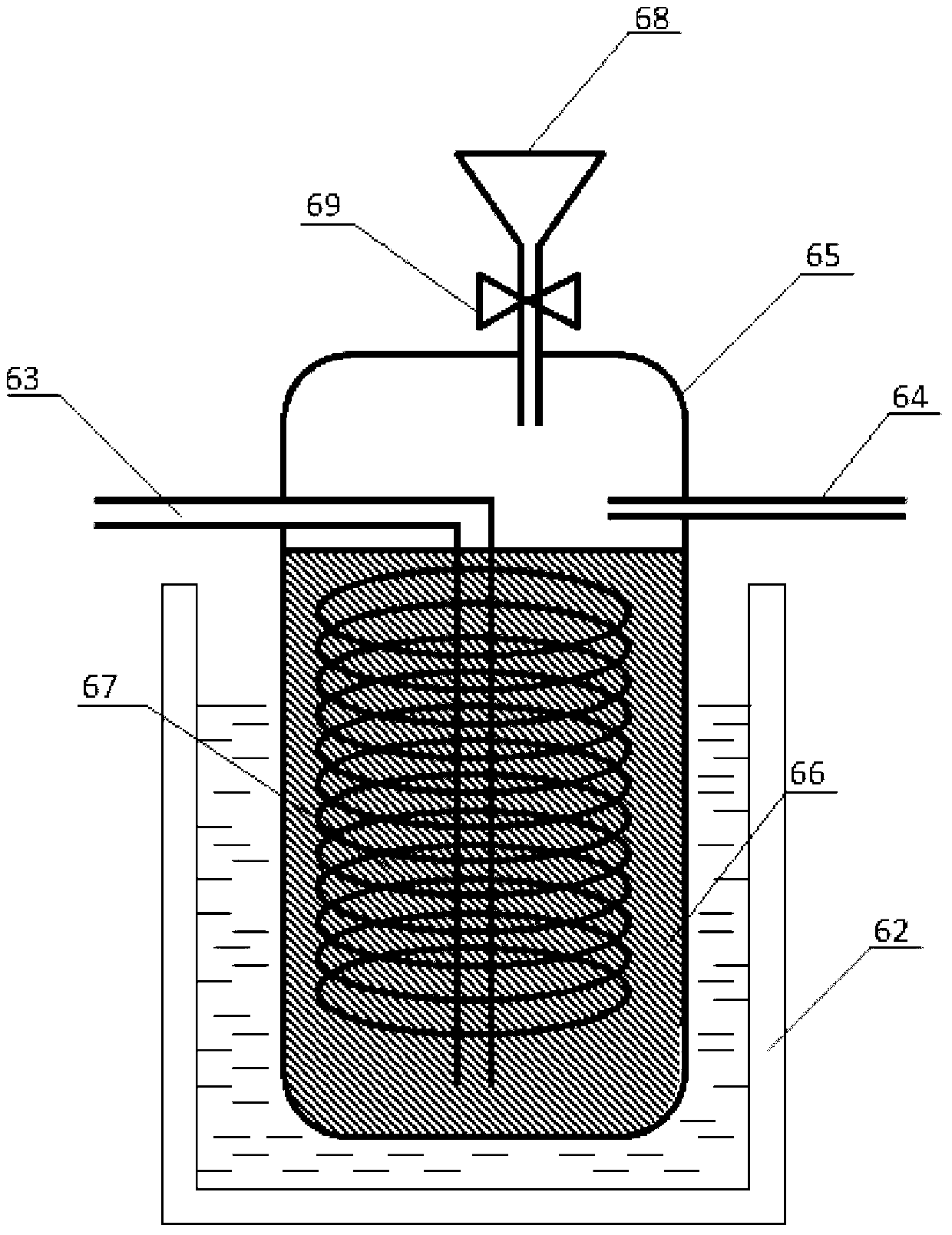

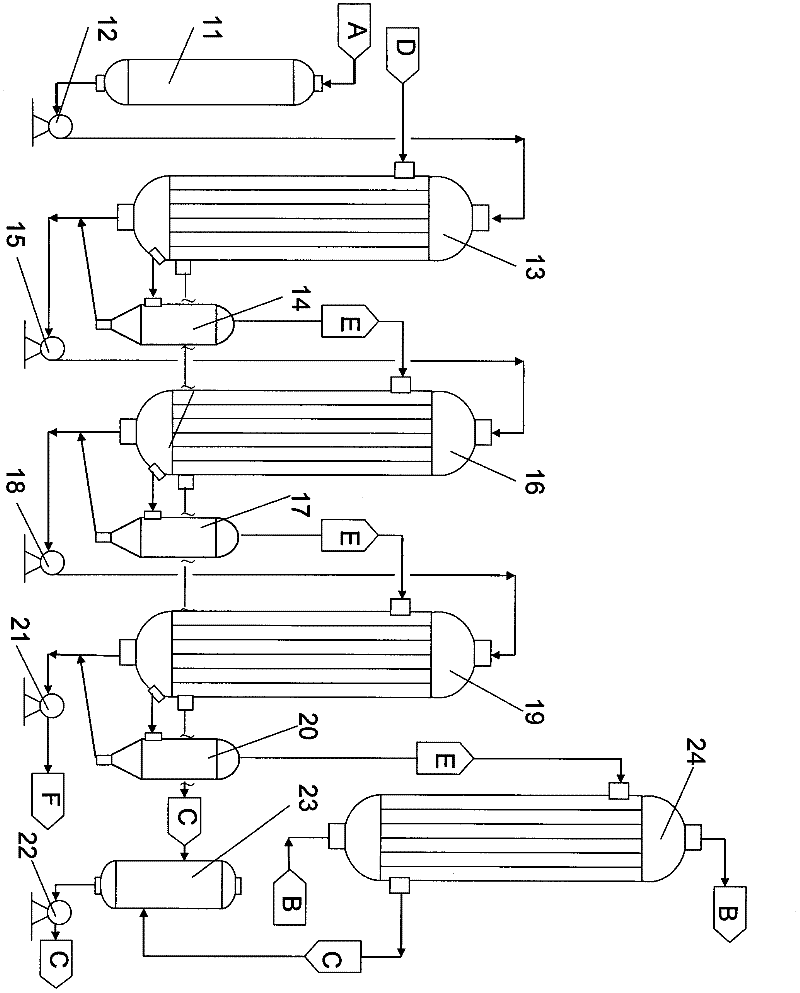

Heat cycle extraction concentration method for traditional Chinese medicine

ActiveCN103893991ALow boiling pointHigh extraction rateEvaporator accessoriesSolid solvent extractionAutomatic controlAutomated control system

The invention relates to a heat cycle extraction concentration method for traditional Chinese medicine. According to the method, a suit of equipment is used, heat cycle and solvent cycle are reached through microcomputer control in a sealing system consisting of extraction and concentration, and the temperature, pressure and flow speed are controllable (low temperature extraction is permitted), thus the energy consumption and solvent consumption are furthest saved, and the extracting solution quality is improved and stabilized. The system mainly consists of a traditional Chinese medicine extracting tank, a filter, an extracting solution heat exchanger, a rising film evaporator, a gas-liquid separator, a steam compressor, a circulating pump, a concentrated liquor tank, a PLC full automatic control system, an operating platform, an electric instrument control cabinet and a valve. A fully sealed negative pressure extraction concentration system is formed in the extracting tank, the rising film evaporator and the gas-liquid separator, so that automatic heat conversion and condensate water reutilization during the medicine cycle extraction concentration process are realized, the degree of automation, safety performance and environmental performance are improved, and the method is convenient to operate, low in energy consumption and low in human cost.

Owner:广东世信药业有限公司

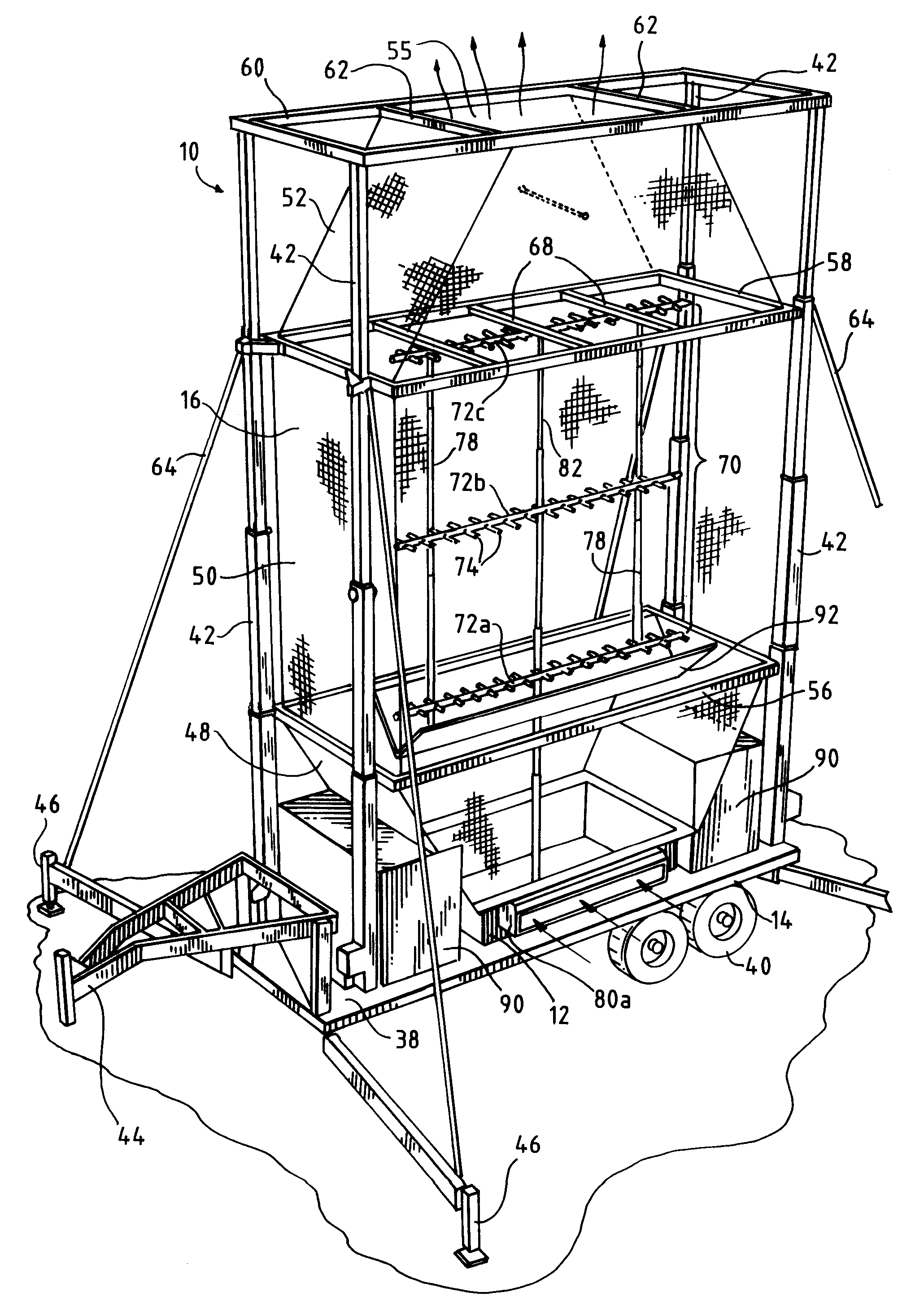

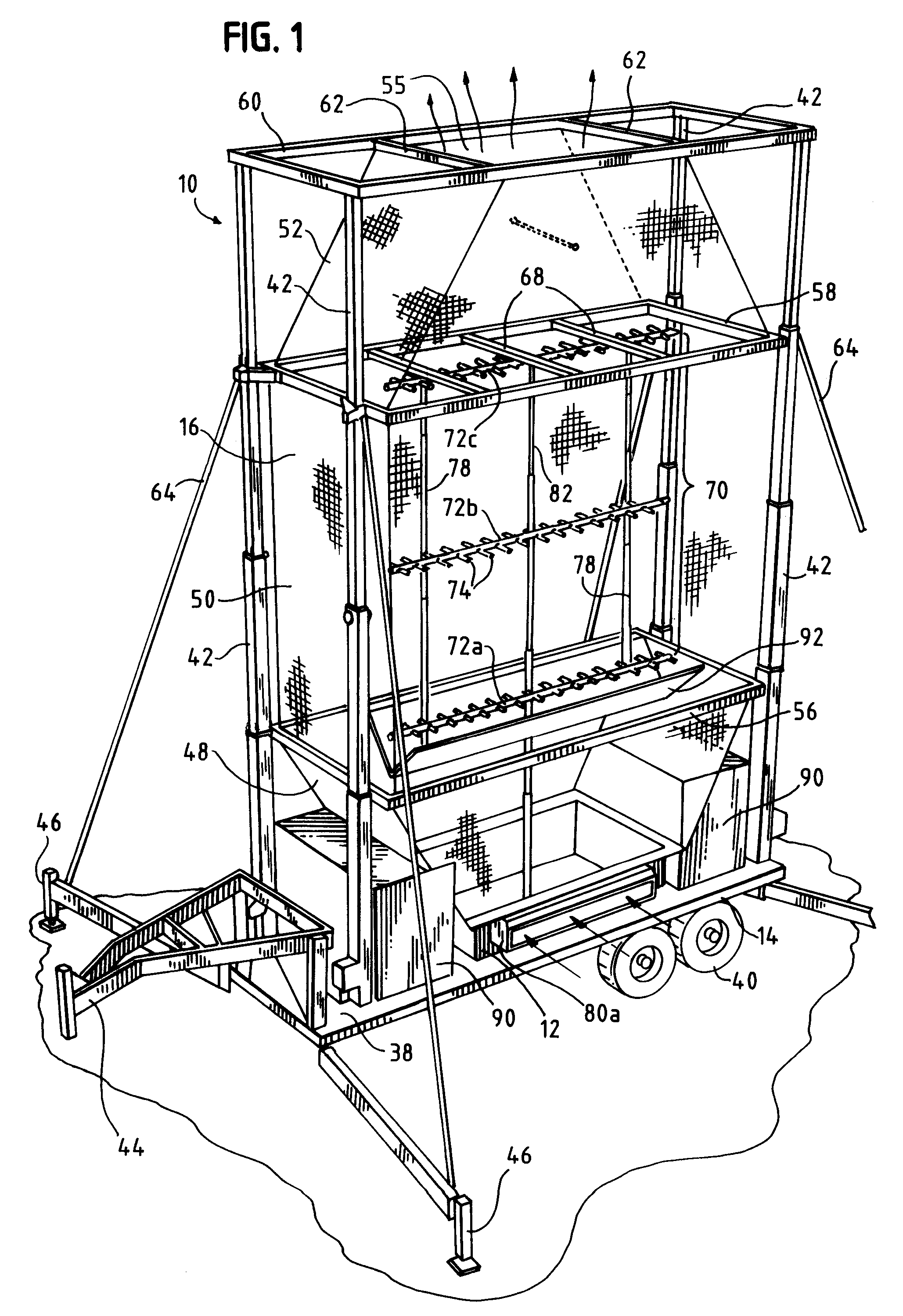

Portable evaporation chamber

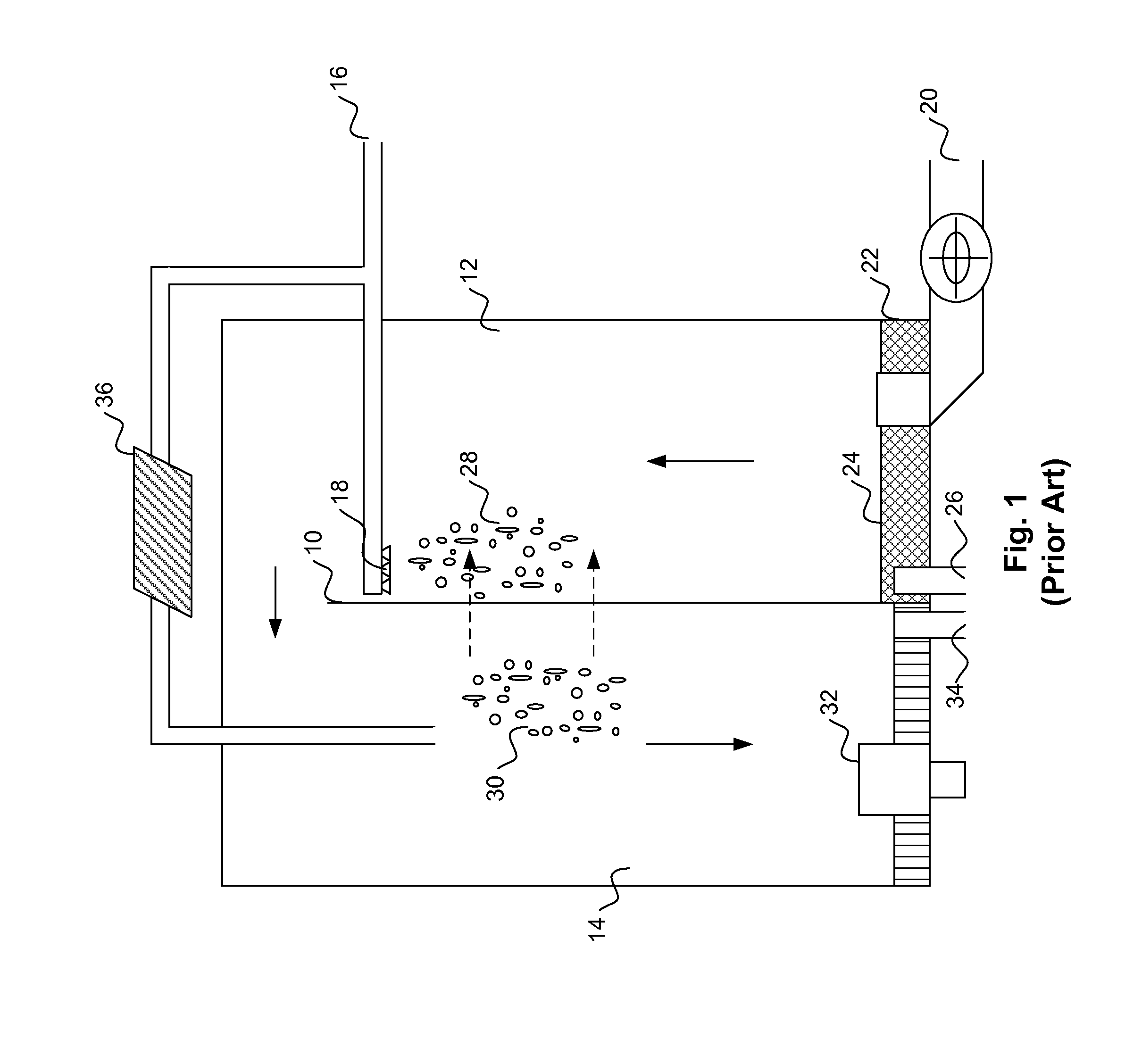

InactiveUS7722739B2Speed up evaporationImprove stabilityMechanical conveying coke ovensEvaporator accessoriesZero temperatureWastewater

A self-contained evaporation system for use in disposing of excess water from oil and gas drilling operations is provided. The system includes a water holding tank in which the wastewater is preheated, an evaporation chamber mounted over the holding tank and having an open top, a nozzle system located within the chamber for producing a fine liquid mist, and fans disposed within the chamber for producing an air flow that carries the mist out the open top of the chamber. The system can be set up and taken down by one person in an hour or less, can be used with pond or tank operations, and is capable of operating in high winds and sub-zero temperatures. The system can be carried and mounted on a trailer for easy transport to and from various drilling sites.

Owner:EVAPORITE SYST

Process and plant for evaporative concentration and crystallization of a viscous lactose-containing aqueous liquid

InactiveUS20030196957A1Crystallization separationSugar crystallisationLiquid crystallineParticulates

Crystalline alpha-lactose monohydrate is recovered frown a viscous lactose-containing aqueous liquid by subjecting said liquid to simultaneous heating, removal of evaporated vapor and mechanical agitation at high shear rate to provide a crystallization promoting decrease of the viscosity of the liquid with crystals formed and suspended therein to progressively concentrate the agitated liquid and simultaneously crystallize lactose therefrom. Subsequent cooling, drying, and disintegration yield particulate alpha-lactose monohydrate.

Owner:NIRO

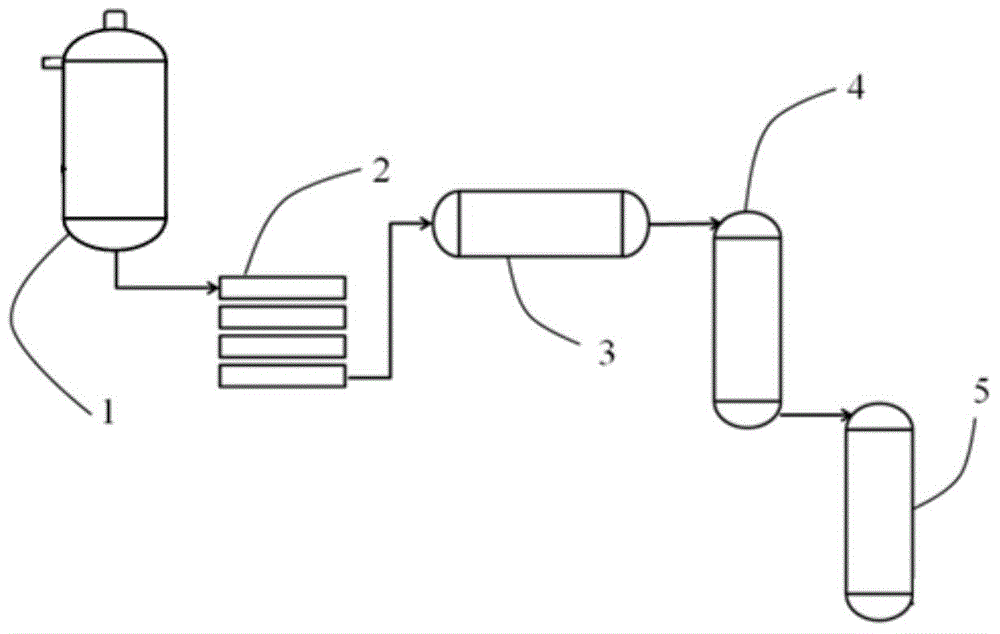

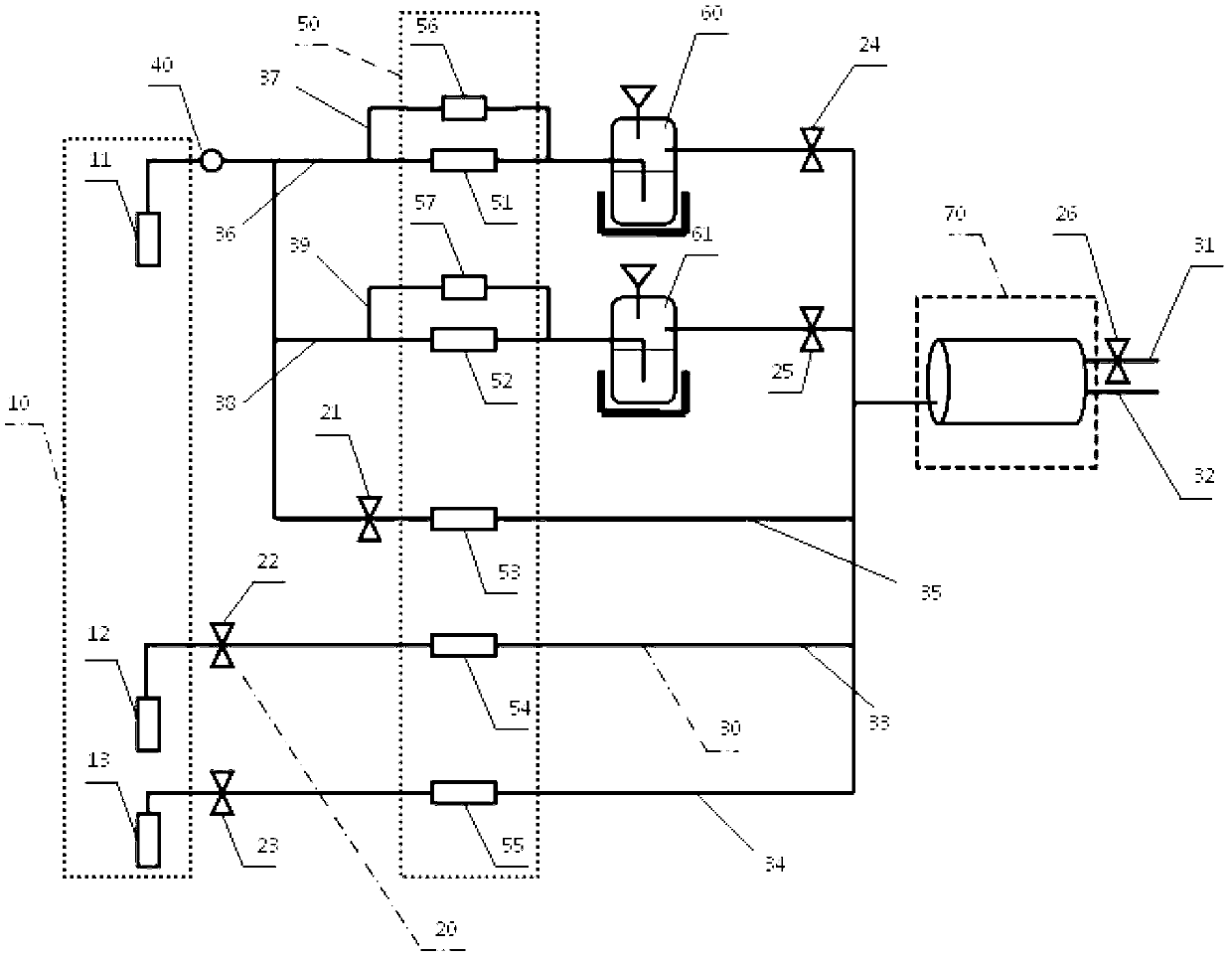

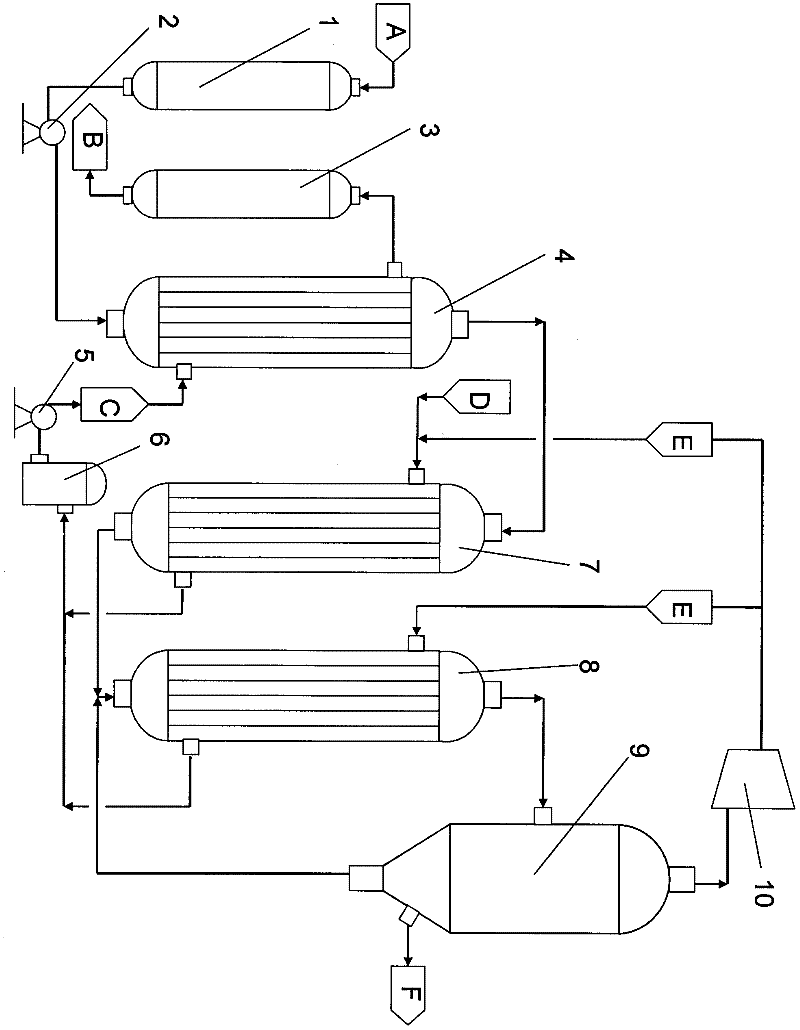

MVR continuous evaporation system

InactiveCN104667550AStable feed flowThere will be no cut-off stateEvaporator accessoriesMultiple-effect evaporationVapor–liquid separatorSteam condensation

The invention discloses an MVR continuous evaporation system. The system can be applied to the requirements on different evaporation pressures, and automatic control of continuous and stable feeding and continuous discharging can be realized. The system disclosed by the invention comprises a raw material balance tank, a main body evaporator, a gas-liquid separator, a condensate storage tank, a steam compressor, a vacuum system and at least three heat exchange devices which are connected by virtue of pipelines, control valves and related pumps, wherein the bottom of the raw material balance tank is connected with the inlet of a feeding pump and is connected with an interval inlet of the top end of the main body evaporator by virtue of a heat exchange device; multiple evaporation intervals are contained in the main body evaporator; a gas-liquid collection cavity is formed in the bottom end of the main body evaporator and is connected with the next evaporation interval by virtue of a booster pump; the concentrated solution in the final evaporation interval is used for preheating the raw materials by virtue of the heat exchange devices; the shell pass of the main body evaporator is connected with the condensate storage tank; and steam condensate is connected with the heat exchange devices by virtue of the condensate storage tank, and the raw materials can be preheated.

Owner:NANJING UNIV OF TECH

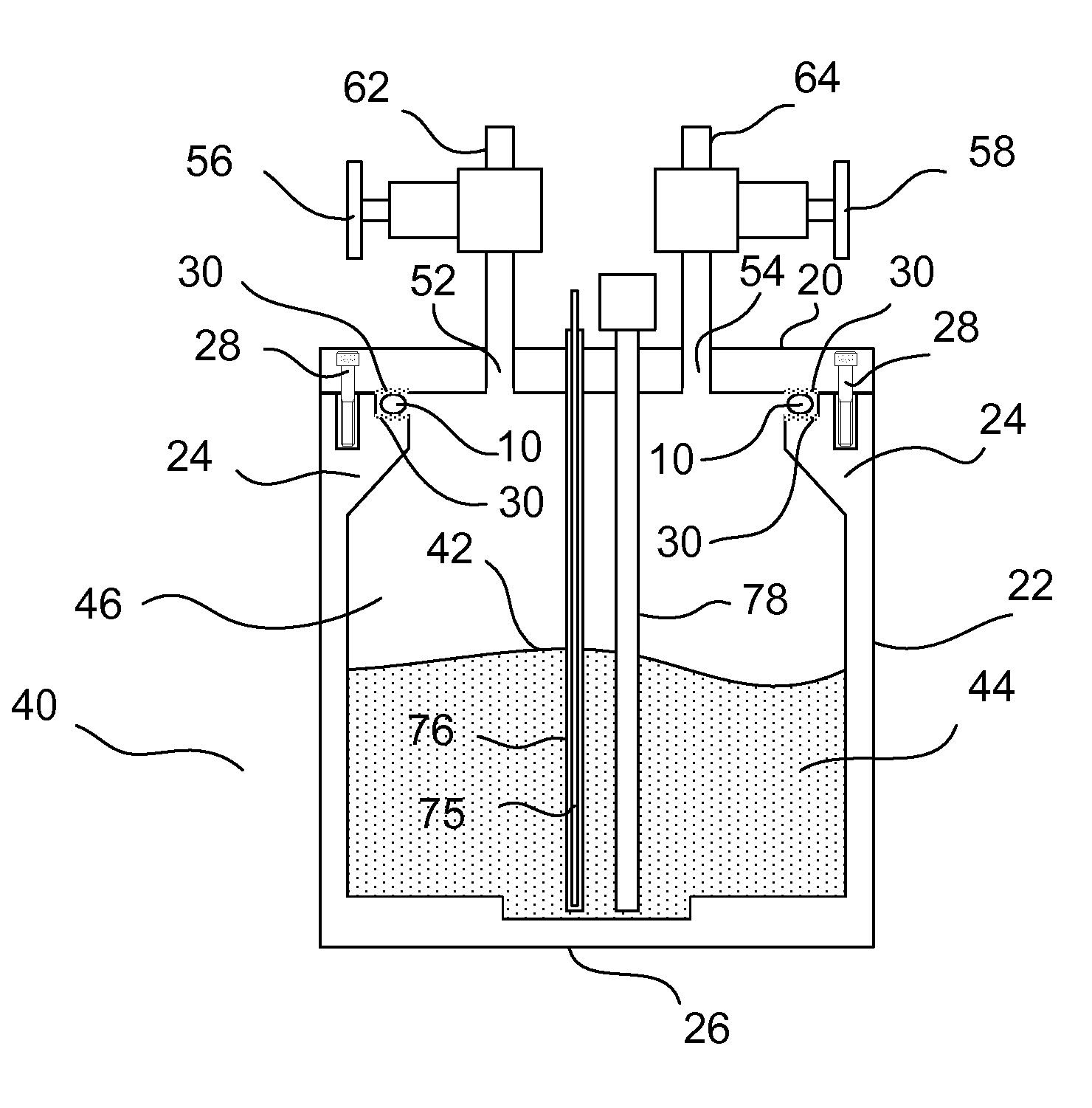

Methods and Apparatuses for Water Purification

ActiveUS20130175155A1Low costLow energy methodEvaporation with vapour compressionEvaporator accessoriesEngineeringEvaporation chamber

An apparatus for generating purified liquid from an input liquid, comprises, an evaporation chamber, wherein the evaporation chamber is flooded with the input liquid; and a condensation chamber having channels, wherein the channels are disposed in the input liquid, wherein liquid-saturated gases are generated from the input liquid in the evaporation chamber, wherein the liquid-saturated gases are guided into a first end of the channels, and wherein the purified liquid is outputted at a second end of the channels.

Owner:CHANG HUEI MENG

Production equipment and method of polyamide 5X

ActiveCN105885037ASuitable for continuous polymerization processGuaranteed uptimeEvaporator accessoriesChemical/physical/physico-chemical stationary reactorsPolyamideProcess engineering

The invention provides production equipment and method of polyamide 5X. The production equipment comprises a concentration device, a prepolymerization device, a pressure reducing device, a separating device and a final polymerization device which are connected in sequence. The concentration device, the prepolymerization device, the pressure reducing device, the separating device and the final polymerization device are adopted in the production equipment of polyamide 5X, operation of all production links is guaranteed, and the production equipment and method are especially suitable for producing polyamide 5X.

Owner:CATHAY R&D CENT CO LTD +2

Diptube apparatus and method for delivering vapor phase reagent to a deposition chamber

InactiveUS20080178809A1Easy to cleanIncrease usageLiquid surface applicatorsContainer filling methodsSemiconductor materialsGas phase

This invention relates to a liquid phase reagent dispensing apparatus having a diptube and alsoa metal seal aligned and in contact with hardened opposing flat surfaces of top wall member and a protuberance[ [;]]on a side wall member, wherein said hardened opposing flat surfaces of said top wall member and said protuberance have a hardness greater than the hardness of said metal seal.The apparatus further has a temperature sensor and a source chemical level sensor extending through a centrally located portion of the top wall member and generally vertically downwardly to a cavity centrally located on the a bottom wall member [ [,]] . The dispensing apparatus may be used for dispensing of reagents such as precursors for deposition of materials in the manufacture of semiconductor materials and devices.

Owner:PRAXAIR TECH INC

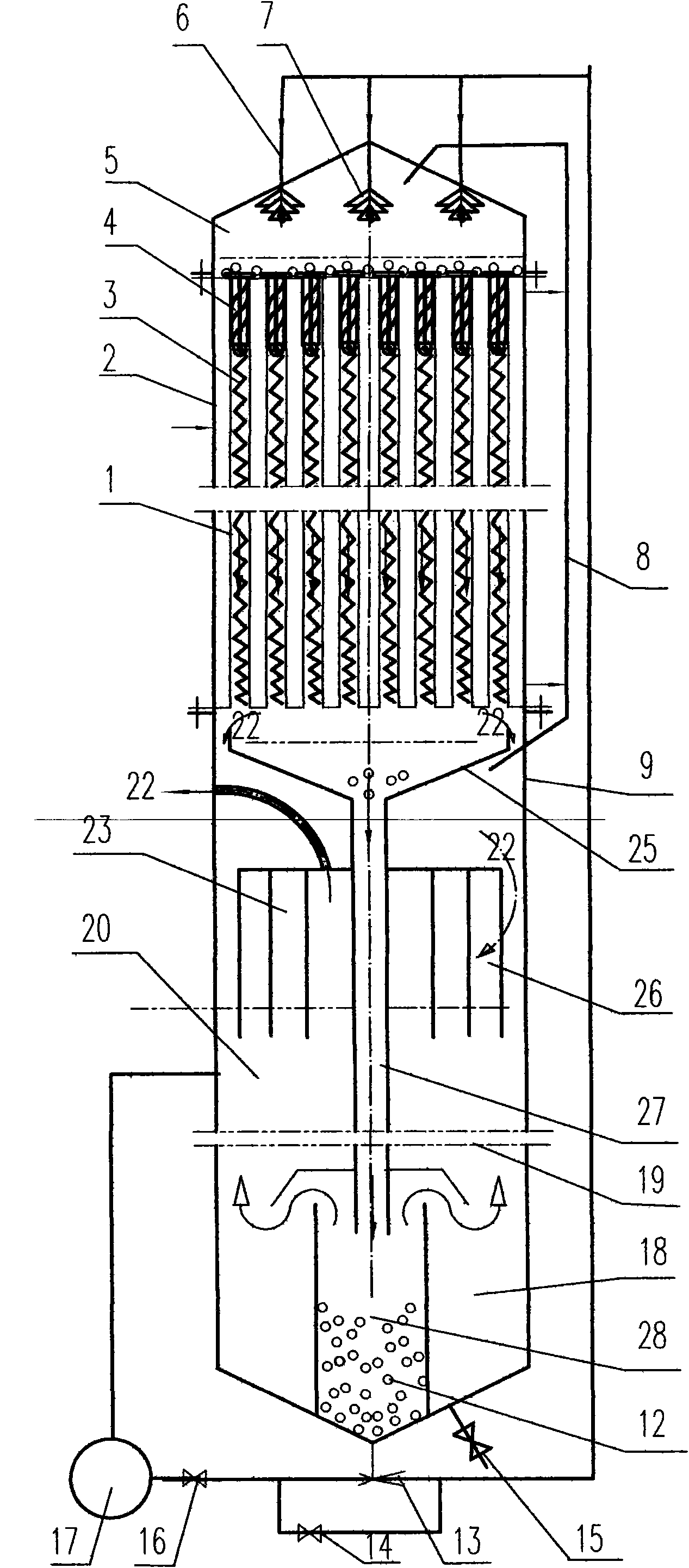

Full-automatic descaling multi-effect evaporator

ActiveCN102921179AFast flowAvoid formingEvaporator accessoriesMultiple-effect evaporationMultiple-effect evaporatorEngineering

The invention discloses a full-automatic descaling multi-effect evaporator, which comprises a heater and an evaporation chamber, wherein a granule distributor which can make fluid be distributed to tube nests of the heater uniformly is arranged at the bottom of the heater; and a granule separator is also arranged between the heater and the evaporation chamber. Due to the adoption of the technical scheme, the full-automatic descaling multi-effect evaporator has the advantages that a descaling process can be simplified, heat transfer is enhanced, and a heat transfer coefficient is increased, so that the evaporator can clean and remove scales online to realize continuous production. According to the optimized technical scheme, an intensifier ring is arranged in the granule separator, and a granule separation chamber and a granule storage chamber are also formed in the granule separator, so that liquid forms a vortex which rotates at high speed when passing through the cylindrical granule separation chamber under the action of centrifugal force formed by the intensifier ring to do circular rotary motion, so that granular solids are separated from the liquid quickly.

Owner:JIANGSU HUATAI HEAVY IND EQUIP

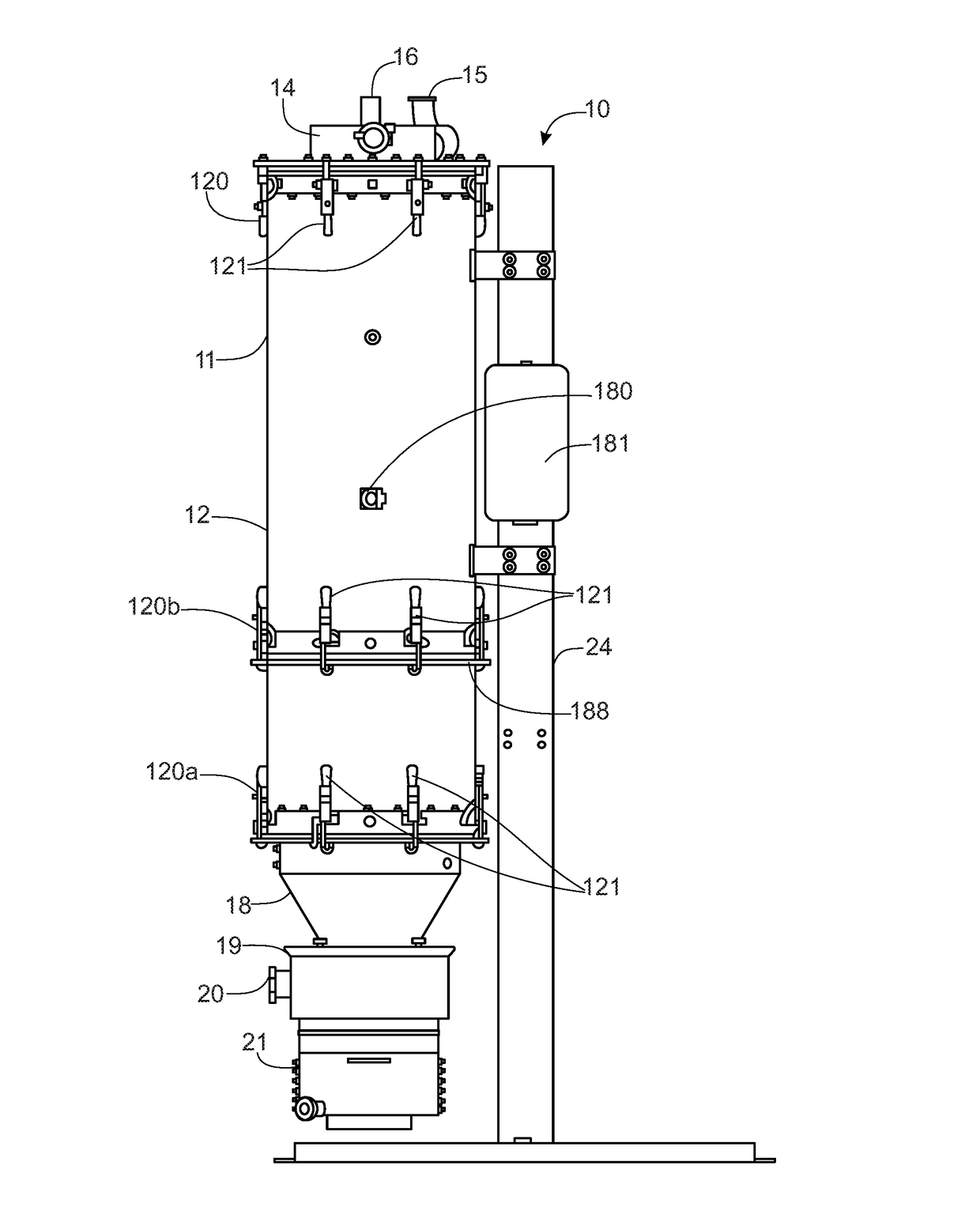

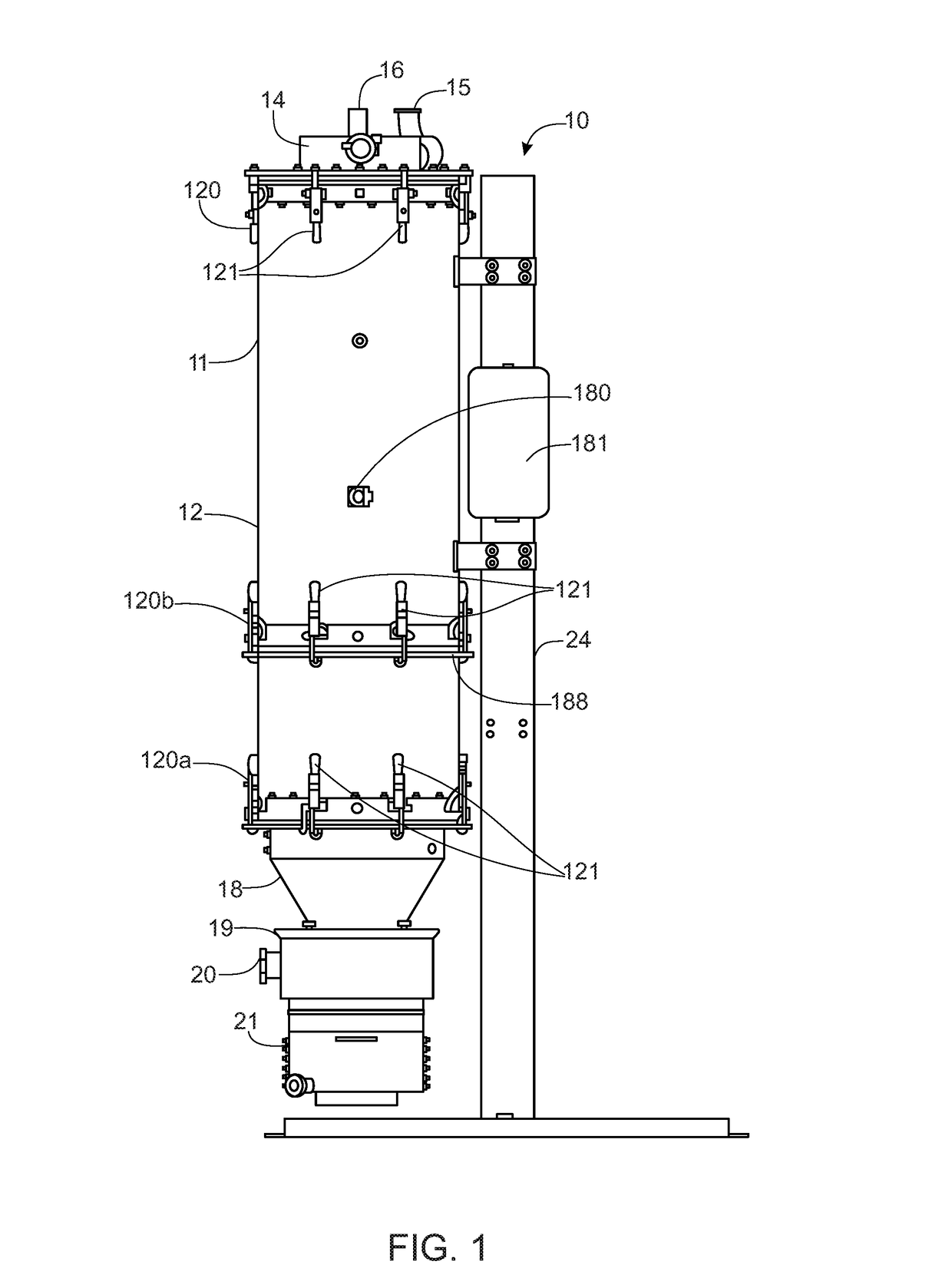

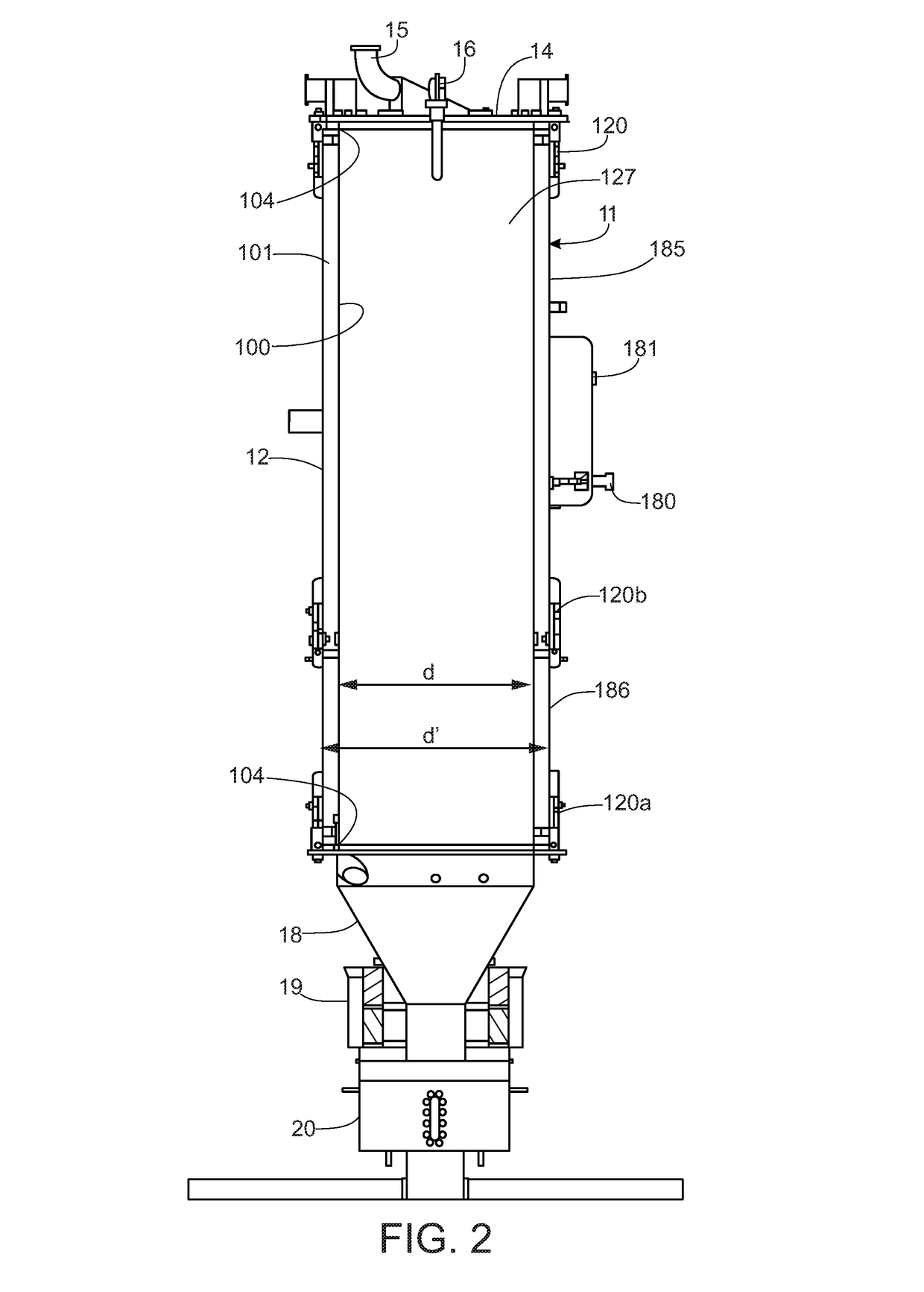

Apparatus and method for spray drying

ActiveUS20170120267A1Easy to operateSmall sizeDrying solid materials with heatDispersed particle filtrationSpray nozzleModular construction

An electrostatic spray dryer for drying liquid into powder including an elongated body defining a drying chamber, a spray nozzle assembly at one end of the drying chamber and a filter element housing and powder collection chamber at an opposite end. A non-structural non-metallic liner is disposed within the elongated body in spaced relation to an inner wall surface for defining an internal drying zone. The liner is releasably supported within the body for enabling selective removal and replacement following a particular usage. The illustrated elongated body has a modular construction comprising a plurality of modules, with at least one being selectively removable and replacement for altering the length of the drying chamber for a particular spray application. The liner also is replaceable with a liner of a length corresponding to the altered length of the drying chamber or with a different diameter for a particular usage.

Owner:SPRAYING SYST

Standard gas distribution device for gas testing system

InactiveCN103341330AEasy to controlImplement configurationFlow mixersRotary stirring mixersGas cylinderProcess engineering

The invention relates to a standard gas distribution device for a gas testing system. The standard gas distribution device comprises a carrier gas bottle and at least one raw gas bottle, wherein the carrier gas bottle is used for providing carrier gas; the raw gas bottle is used for providing raw gas; a gas outlet of the raw gas bottle is communicated with a mixing chamber through a raw gas delivery pipe; a raw gas mass flow controller which is used for regulating and controlling the delivery flow of the raw gas is arranged on the raw gas delivery pipe; a gas outlet of the carrier gas bottle is communicated with the mixing chamber through a carrier gas delivery pipe, and is communicated with the mixing chamber through a liquid saturated steam delivery mechanism capable of delivering liquid saturated steam into the mixing chamber; a carrier gas mass flow controller which is used for regulating and controlling the delivery flow of the carrier gas is arranged on the carrier gas delivery pipe; the mixing chamber can uniformly mix the carrier gas, the raw gas and / or the liquid saturated steam, and outputs needed standard gas. The standard gas distribution device is compact in structure, can distribute various kinds of standard gas, and is high in degree of automation, wide in application range, safe and reliable.

Owner:JIANGSU R & D CENTER FOR INTERNET OF THINGS

Mechanical steam recompression continuous evaporative crystallization system and mechanical steam recompression continuous evaporative crystallization method

ActiveCN103007553ASmall footprintSave spaceEvaporator accessoriesSolution crystallizationGas compressorEvaporation

The invention relates to a mechanical steam recompression continuous evaporative crystallization system and a mechanical steam recompression continuous evaporative crystallization method. The system comprises an evaporation unit and a crystallization unit, wherein the evaporation unit and the crystallization unit are both provided with water steam compressors; material liquid enters the evaporation unit to be evaporated and subsequently is subjected to gas-liquid separation; the separated secondary steam enters a steam compressor to be compressed, and subsequently enters the crystallization unit to be used as heat source heating material liquid; the material liquid which is evaporated and compressed in an evaporator enters the crystallization unit to be crystallized; the secondary steam generated by crystallization enters the steam compressor to be compressed, subsequently enters the crystallization unit and is used as a heat source for heating the materials in the crystallization unit so as to crystallize the materials; and the crystallized materials are discharged. The system is compact in equipment, small in occupied area and small in desired space, and a cooling system can be omitted; and the secondary steam in the evaporation and crystallization process is sufficiently utilized, the latent heat is recycled, and the heat efficiency is improved.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

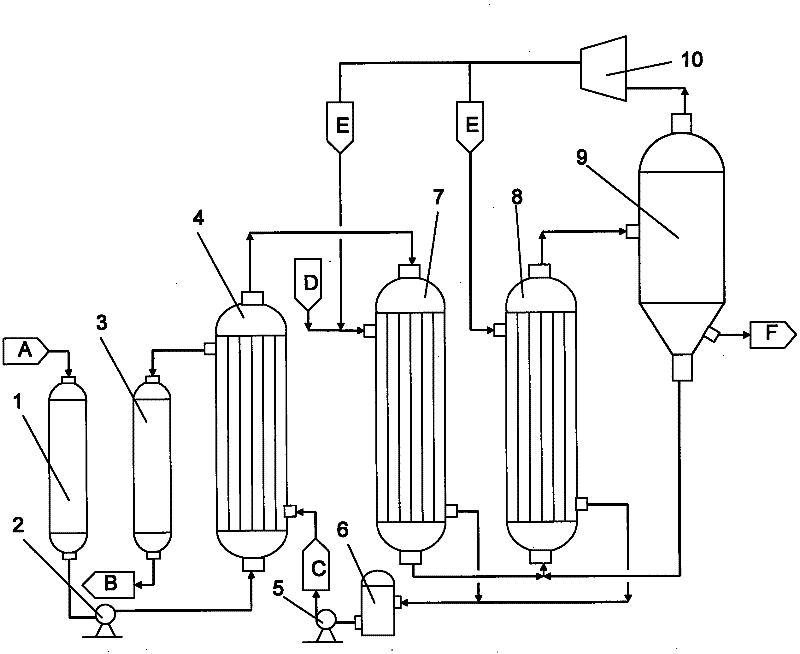

Energy-saving evaporating process and equipment for L-phenylalanine brine solution

ActiveCN102343162ASmall volumeEnergy saving processEvaporator accessoriesMultiple-effect evaporationVapor liquidHeat balance

The invention relates to an energy-saving evaporating process and equipment for a L-phenylalanine brine solution, belonging to the technical field of efficient energy saving and environmental protection. The process comprises the following steps of: preheating a 1 percent concentration of feed solution to 50-60 DEG C with a preheater 4; making the preheated feed solution enter the tube pass and shell pass of a falling film evaporator 7 and a climbing film evaporator 8 for secondary vapor heat exchange at 78-80 DEG C, heating to 70 DEG C, and evaporating in a way of combining a falling film with a climbing film to generate secondary vapor and a concentrated solution; making the secondary vapor and the concentrated solution enter a separator 9 for vapor-liquid separation; making the separated secondary vapor enter a centrifugal compressor 10 for compressing and increasing caloric content, heating to 78-80 DEG C for serving as a heating source of the evaporators 7 and 8, and heating and evaporating the feed solution; discharging the concentrated solution of which the concentration is controlled at 3 percent from the separator 9, and returning the concentrated solution of which the concentration does not reach 3 percent to the climbing film evaporator 8 for continually evaporating and concentrating. The system has the advantages of self-heat balance, small using amount of live vapor, low running cost, high efficiency and saving in energy.

Owner:想莱(常州)节能科技有限公司

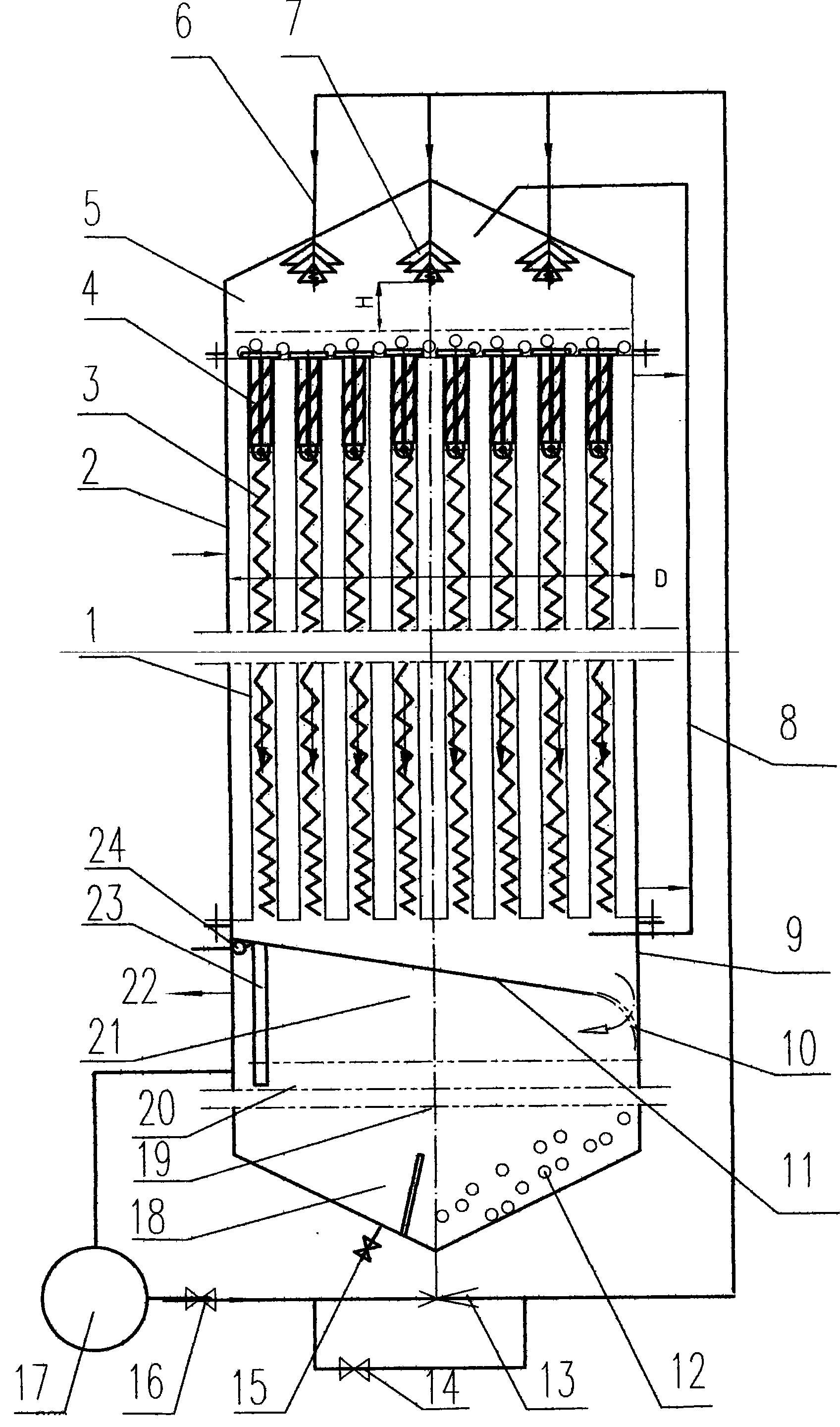

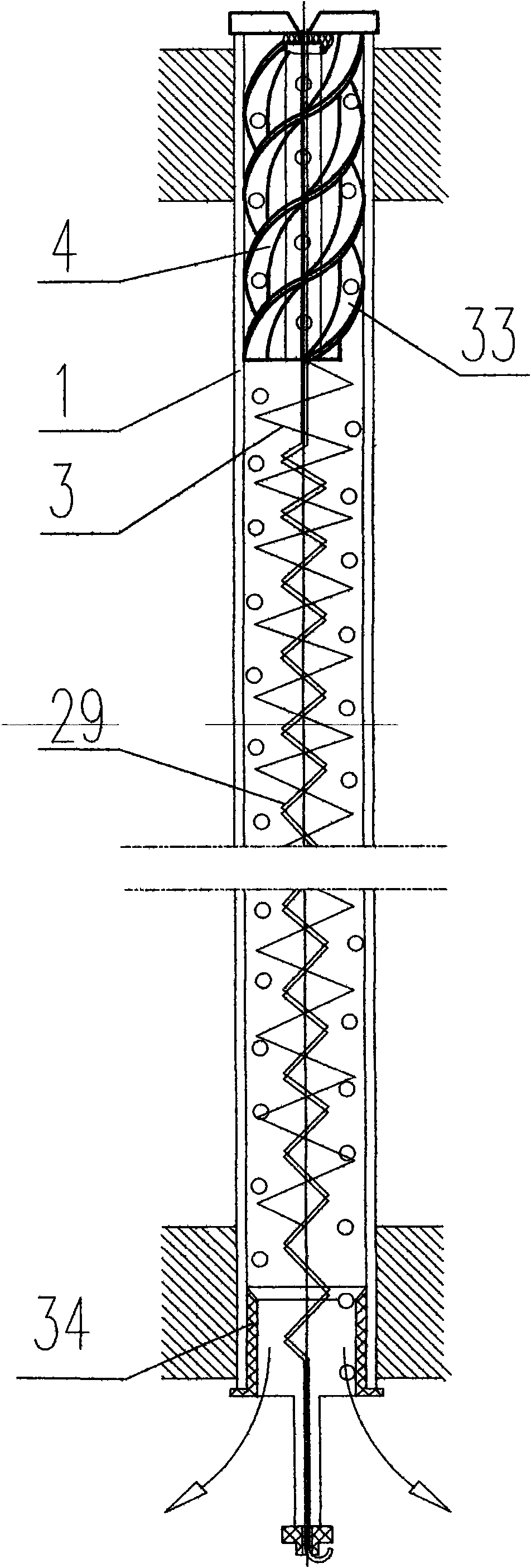

In-tube auto-cleaning antiscale falling-film evaporation device

ActiveCN102641601ASolve the problem of fouling cleaning that is not suitable for falling film flow evaporators in tubesSimple structureEvaporator accessoriesEvaporationEngineering

An in-tube auto-cleaning antiscale falling-film evaporation device. A few fluidized cleaning ceramic balls are added into mother liquor. Uniformly-distributed film-forming screws not only realizes automatic uniform distribution of liquid in each heating tube, but also promotes uniform film formation on tube inner walls. Liquid film screws and steam screws mounted in the heating tubes can significantly increase circumferential component velocities of falling-film liquid flow and secondary steam flow, enhance convection heat transfer of the liquid film, reduce the amount of splashing liquid foams falling directly, enable the fluidized ceramic balls to generate centrifugal force so as to tightly adhere to the tube inner walls for effective cleaning and scale prevention. A lower tube case is provided with a secondary steam liquid foam separation structure, and a circulating tank meeting crystallization requirements, and the structure is compact. The fluidized ceramic balls realize circulating cleaning through venturis, and the concentration of the fluidized balls is adjusted through a by-pass valve. Therefore, the evaporation device which can prevent scale formation in heat tube inner walls can realize auto-cleaning high yield and energy saving, meet requirements for long-term continuous production, and is especially suitable for heat pump evaporation.

Owner:浙江建装工程技术研究有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com