Patents

Literature

607results about "Evaporation with vapour compression" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

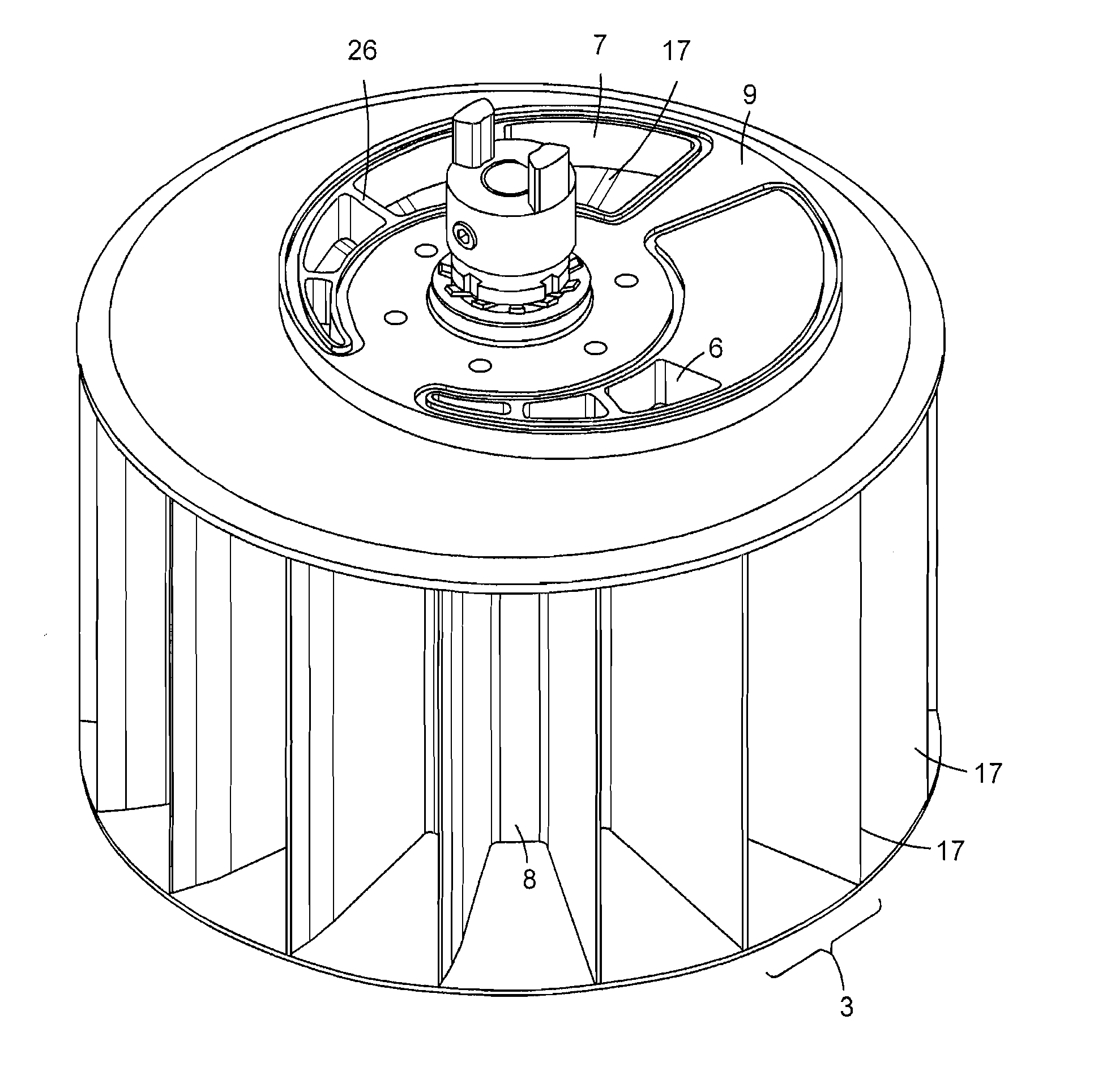

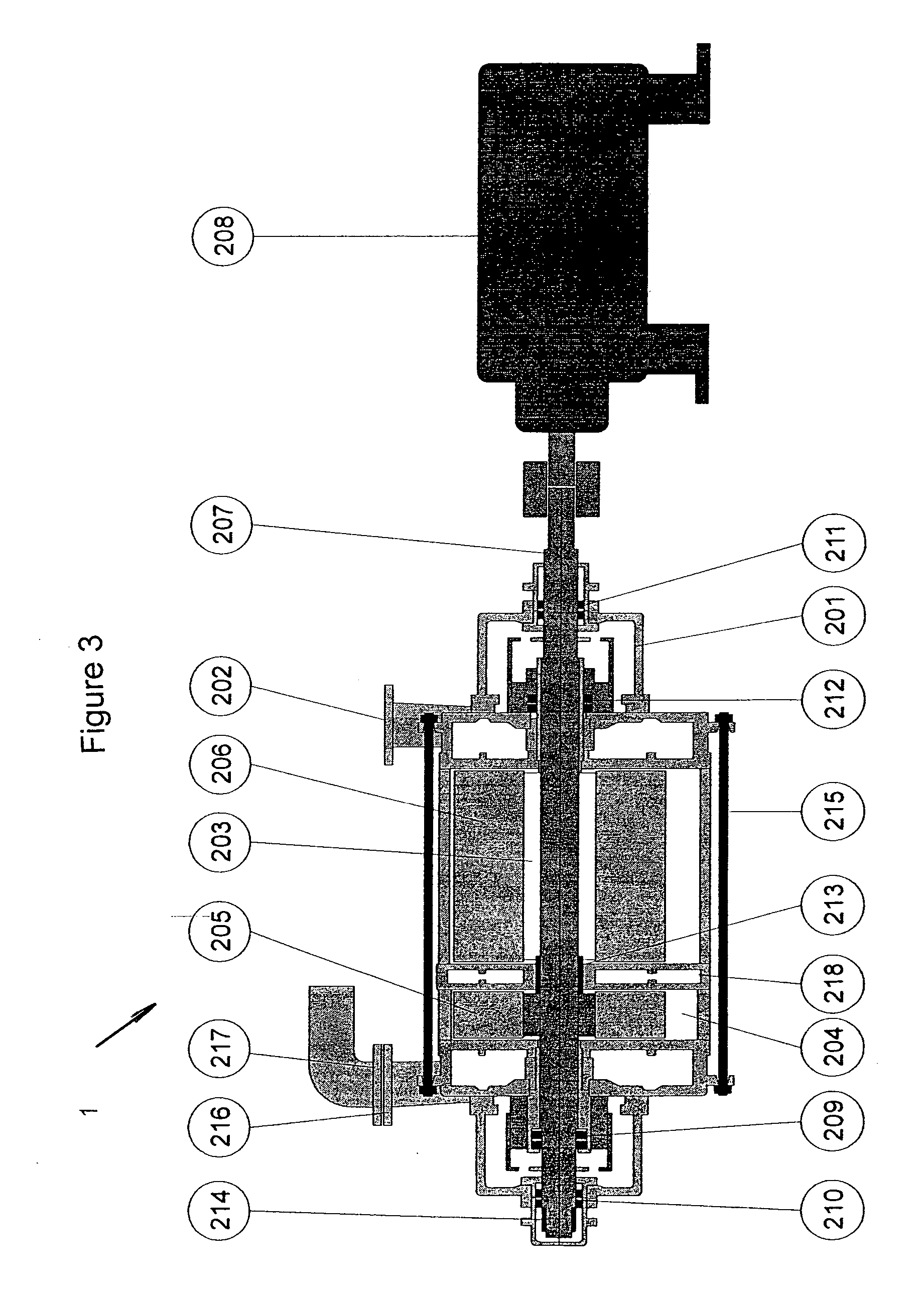

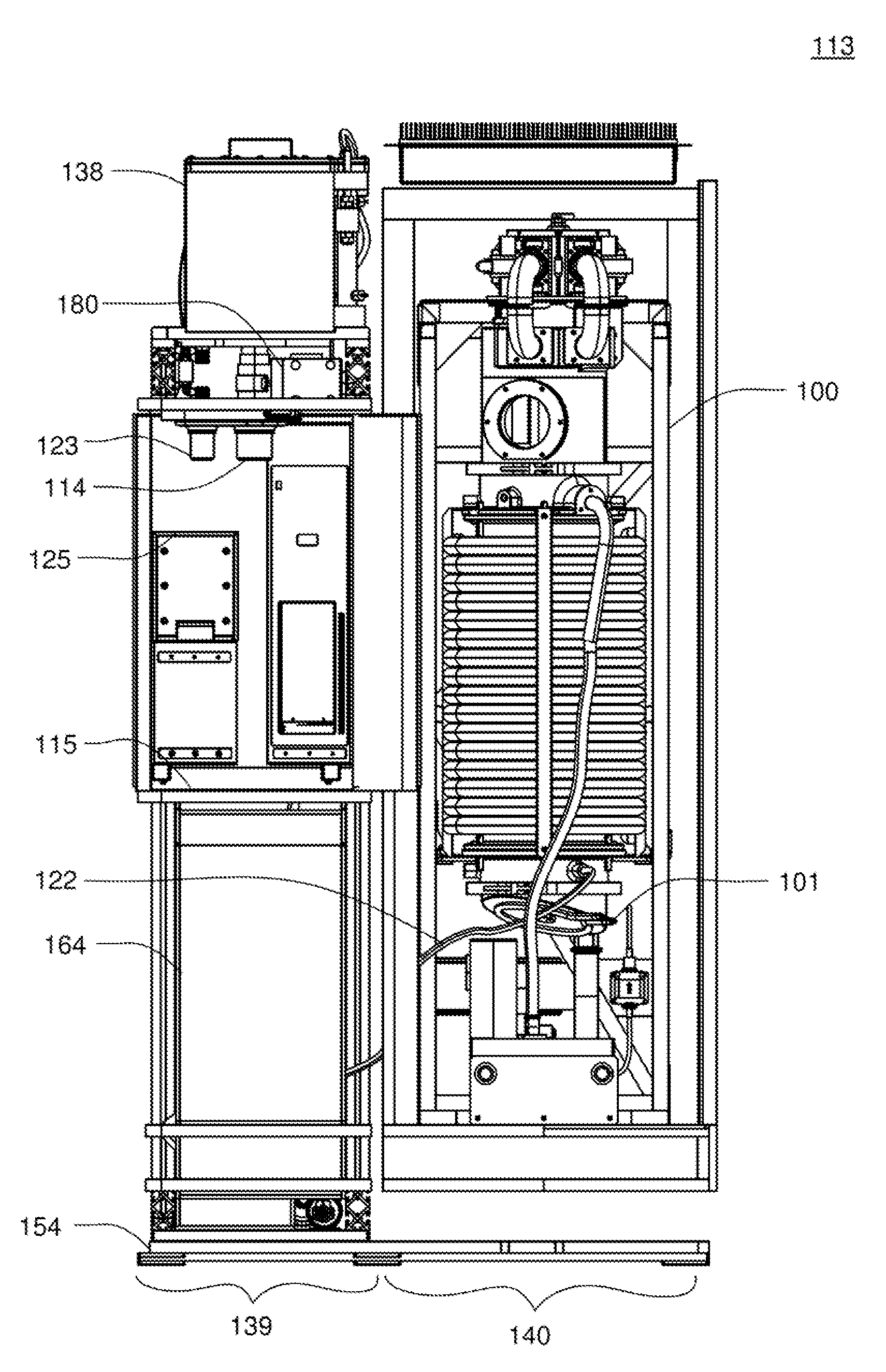

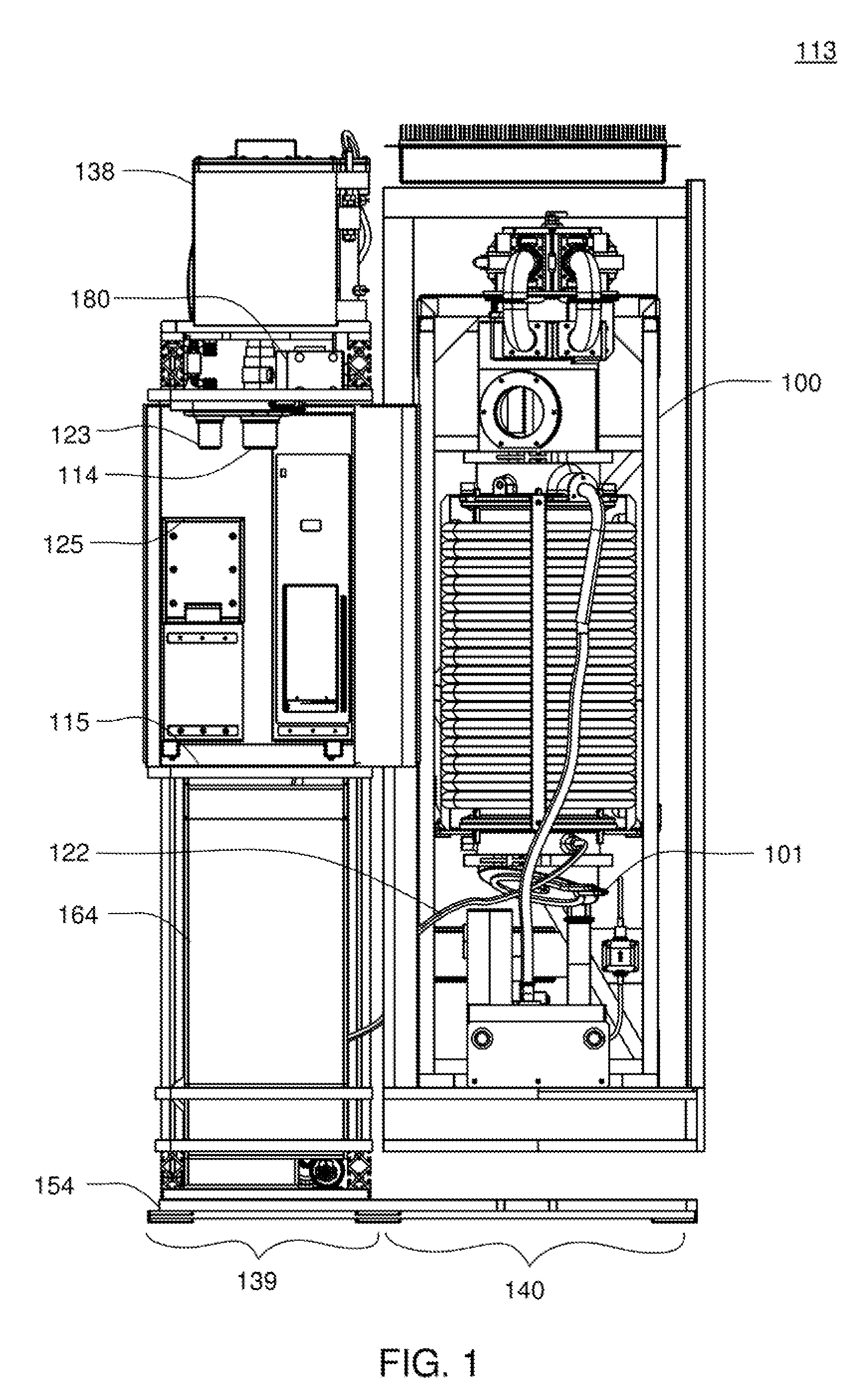

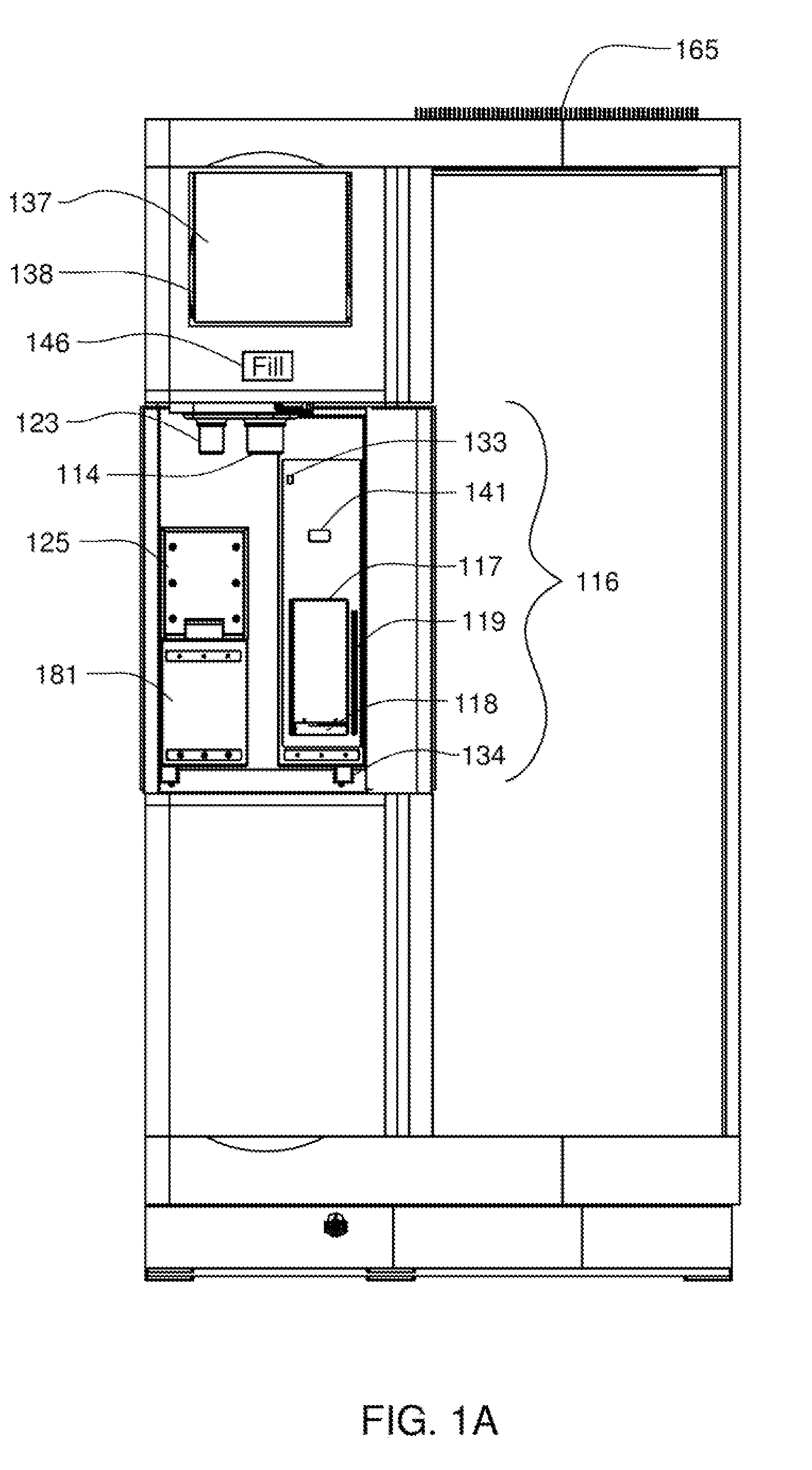

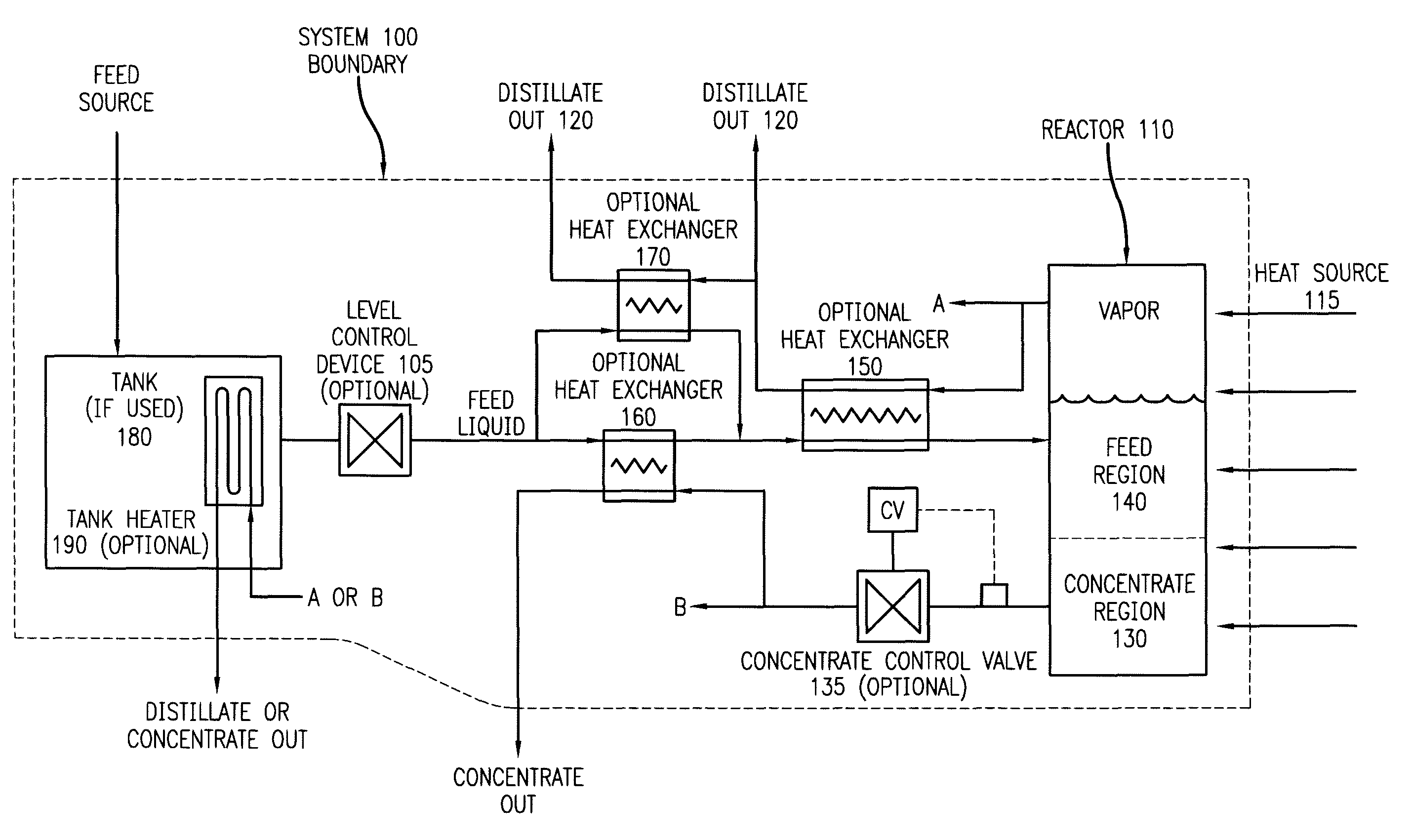

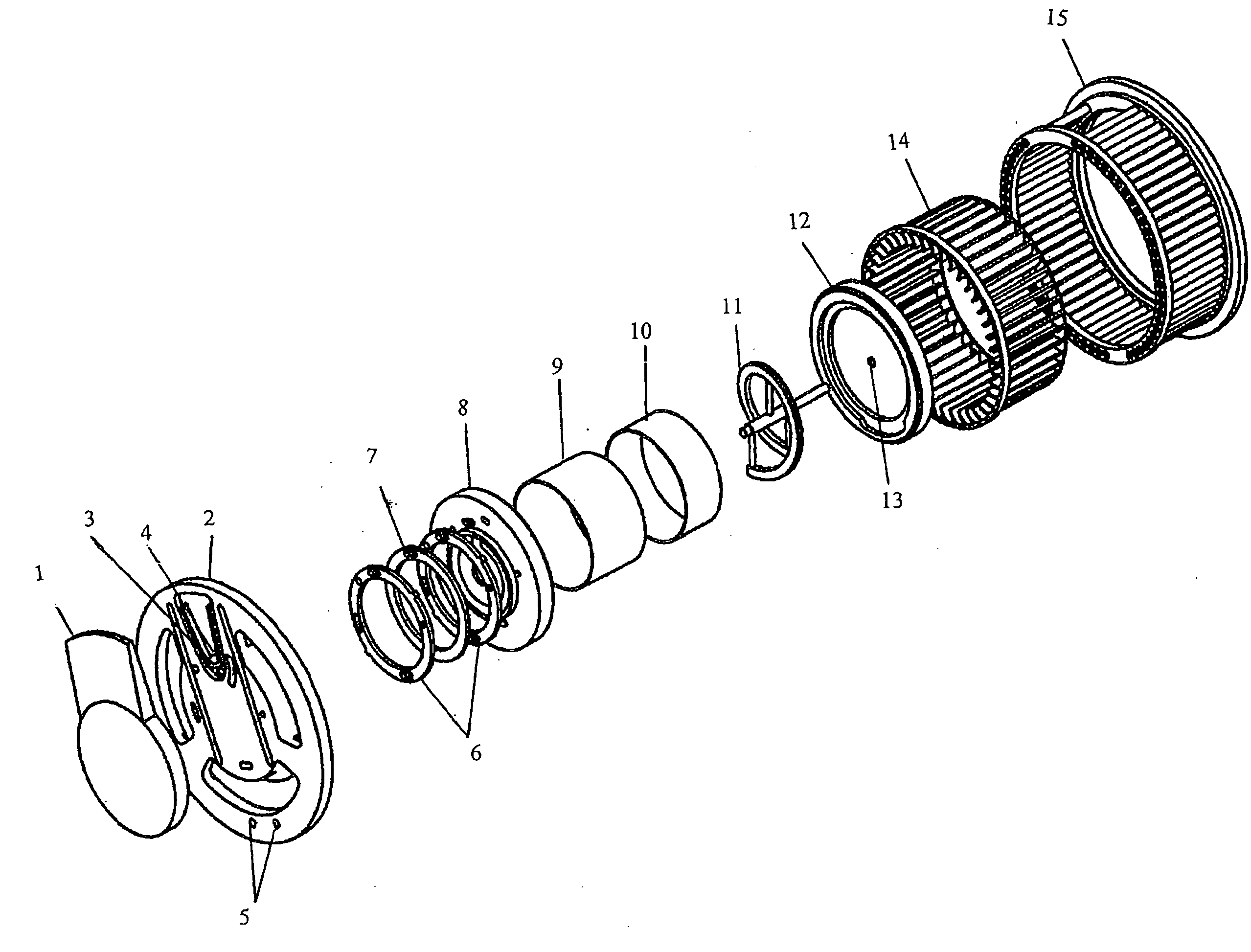

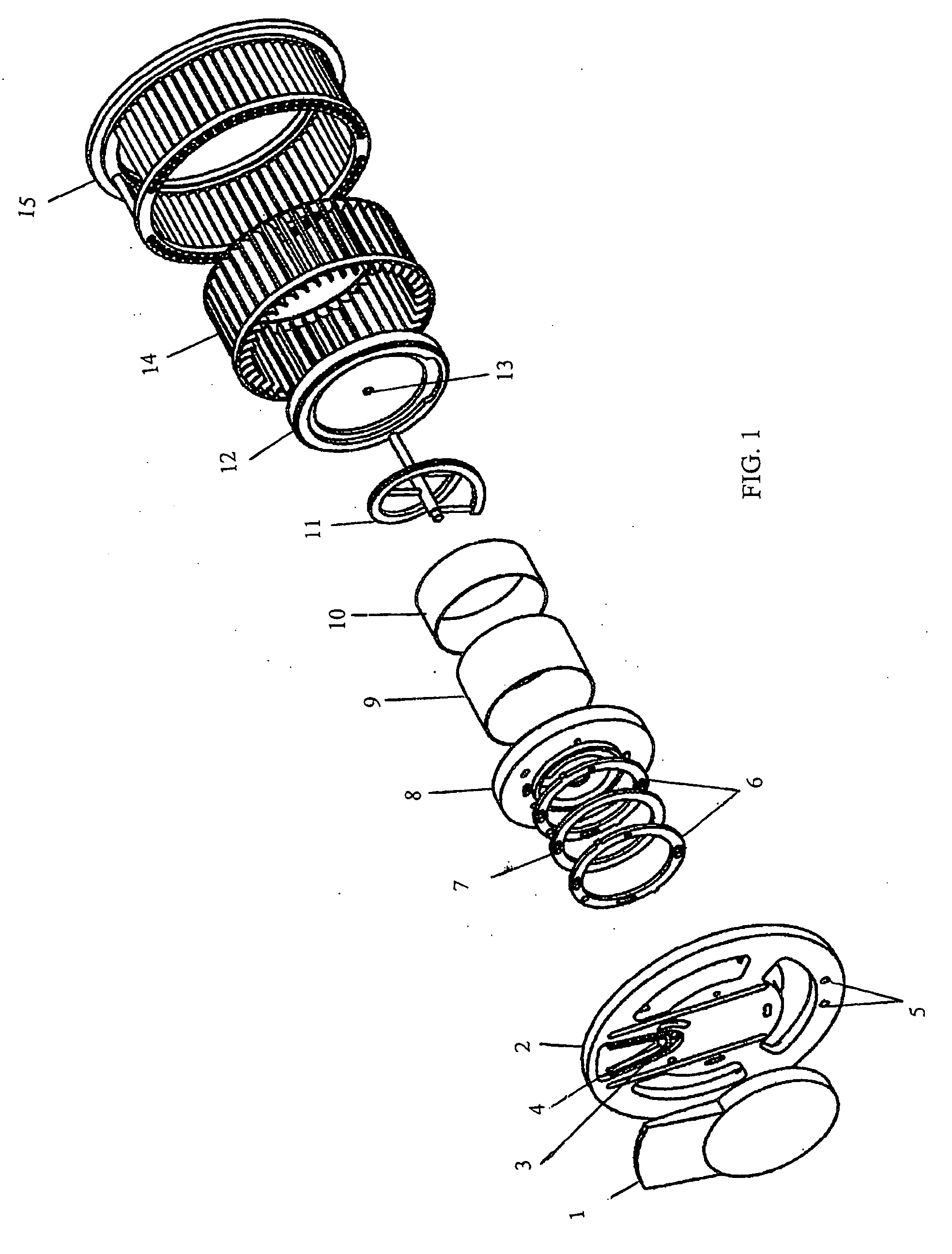

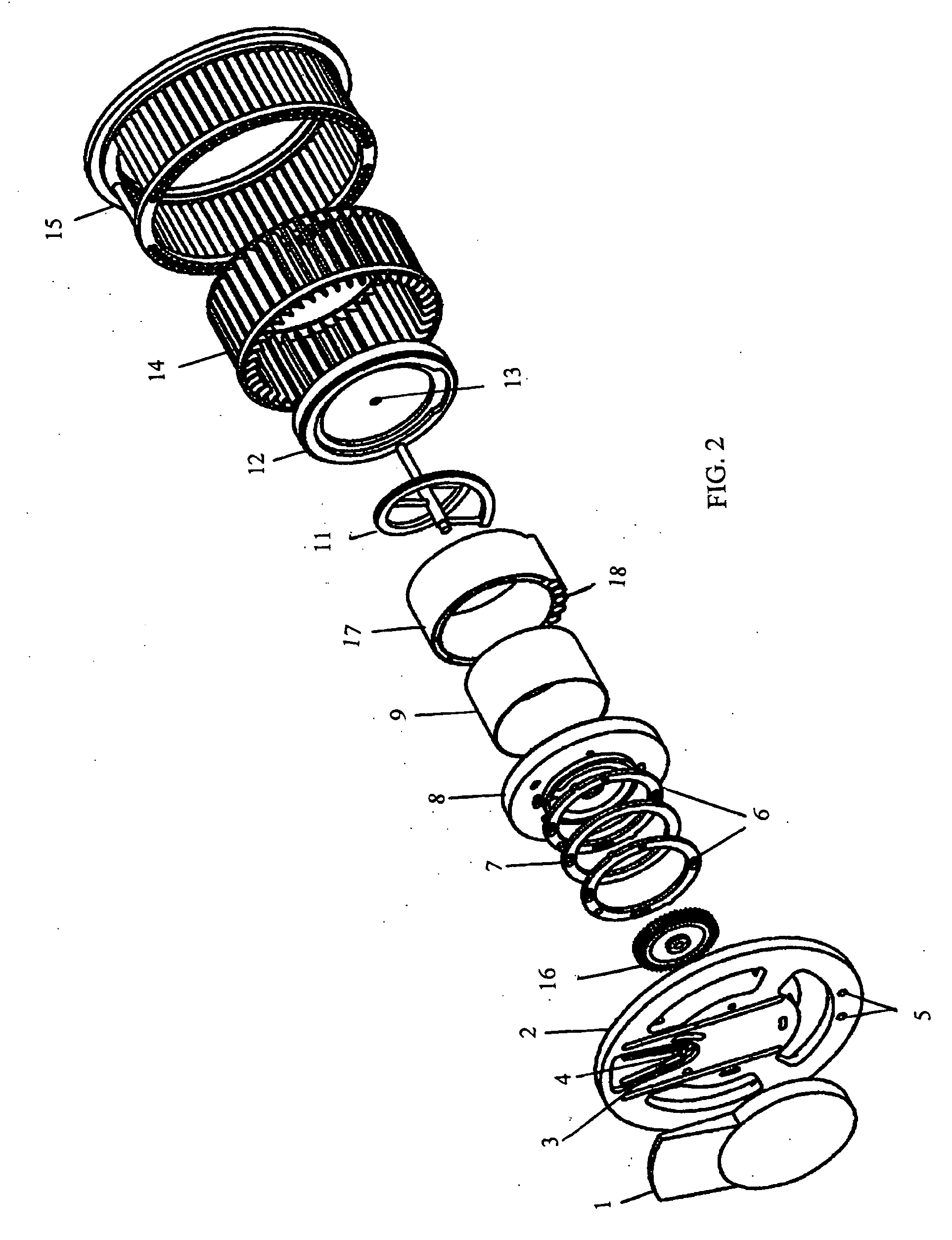

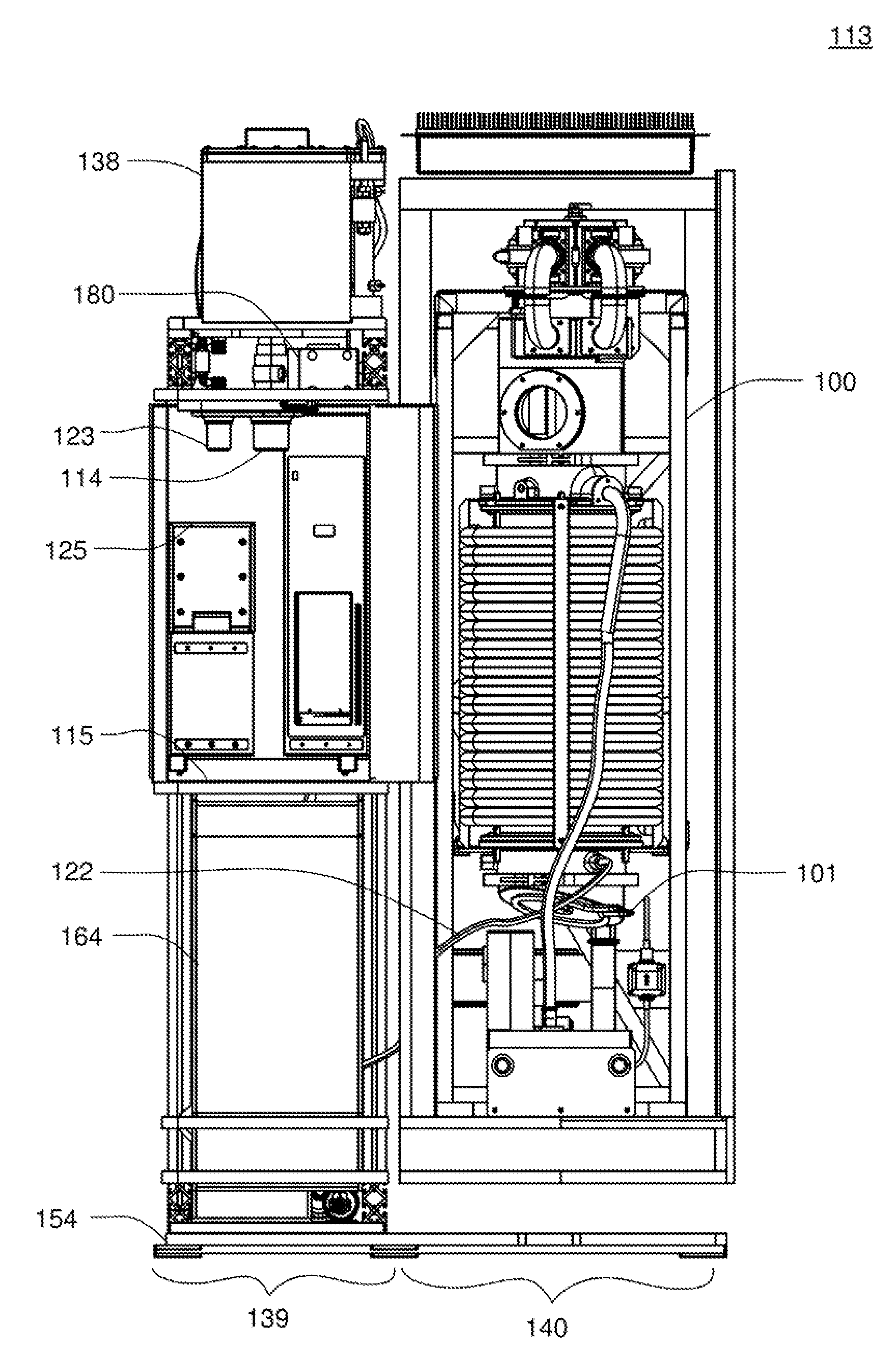

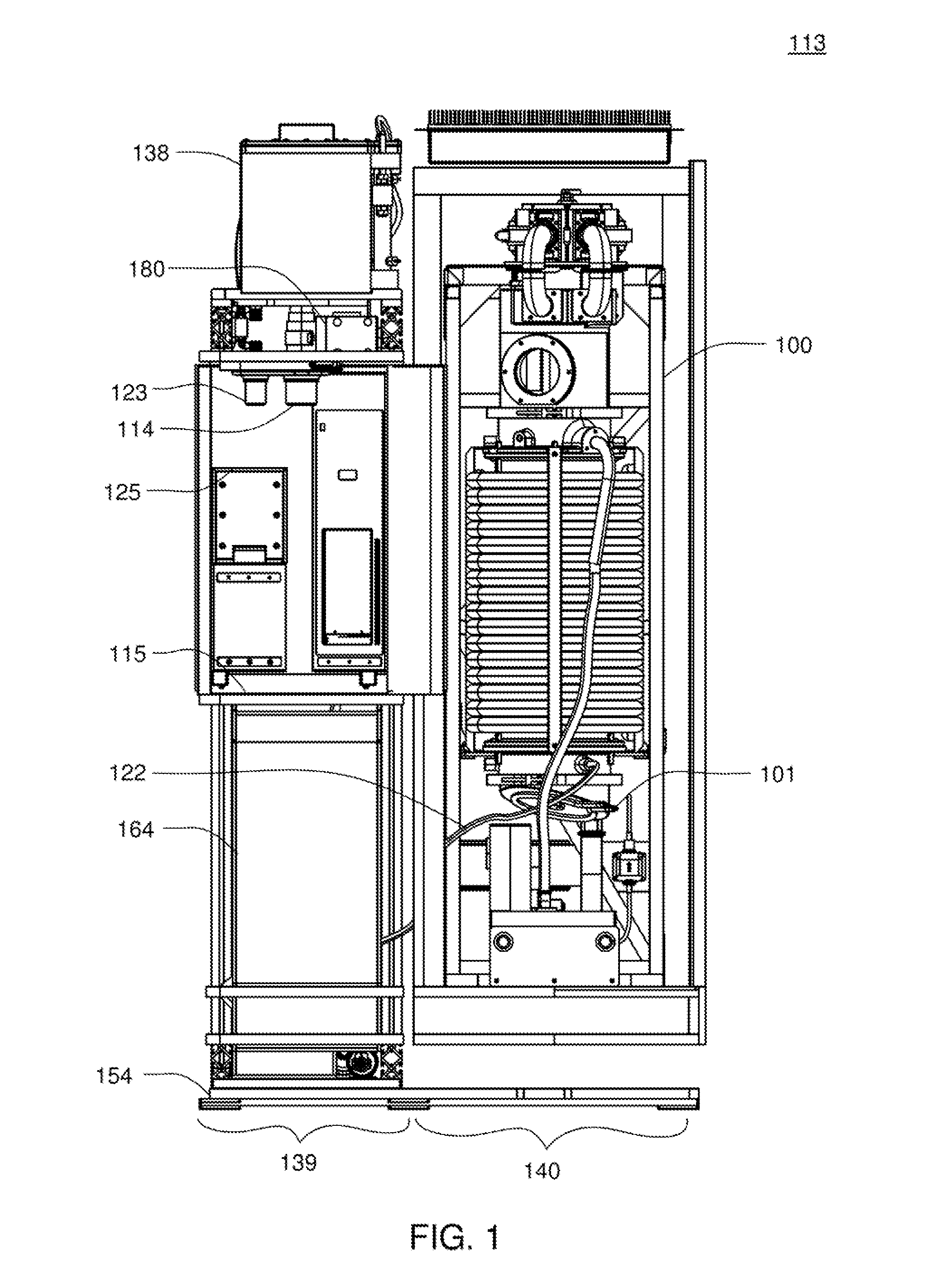

Pressurized vapor cycle liquid distillation

ActiveUS20050016828A1Easy maintenanceMaximize energy efficiencyDistillation regulation/controlUsing liquid separation agentHeat managementDrive shaft

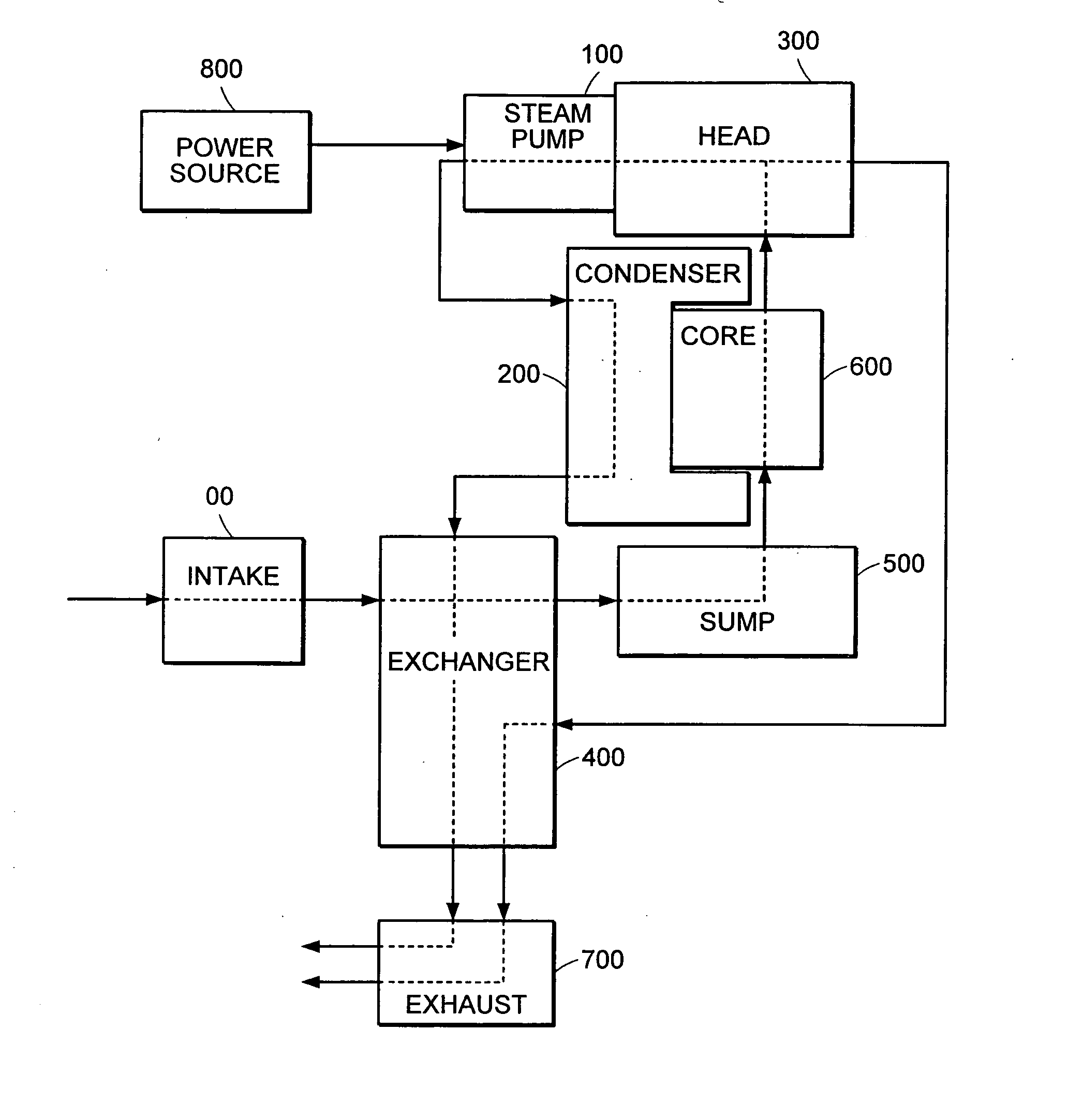

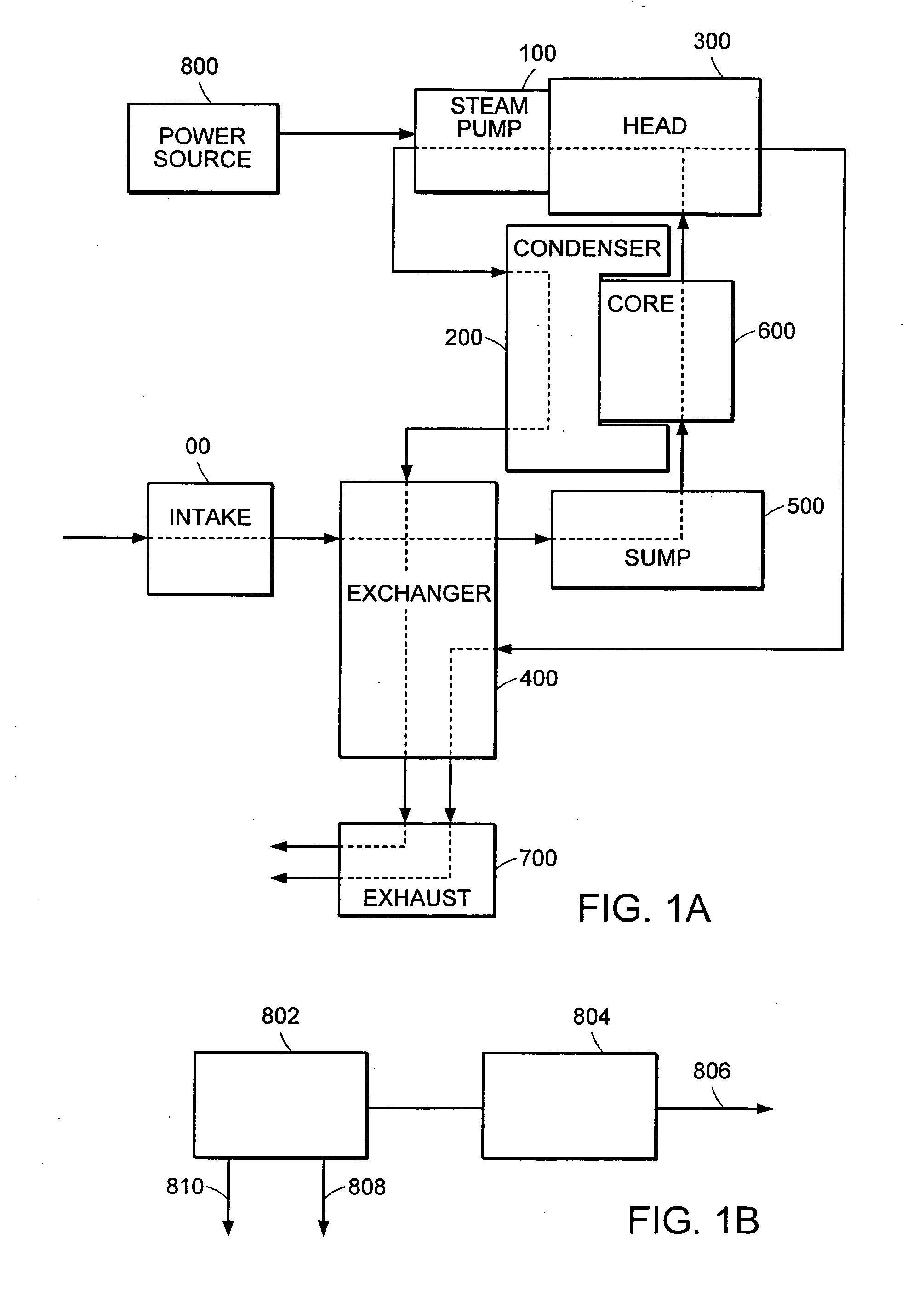

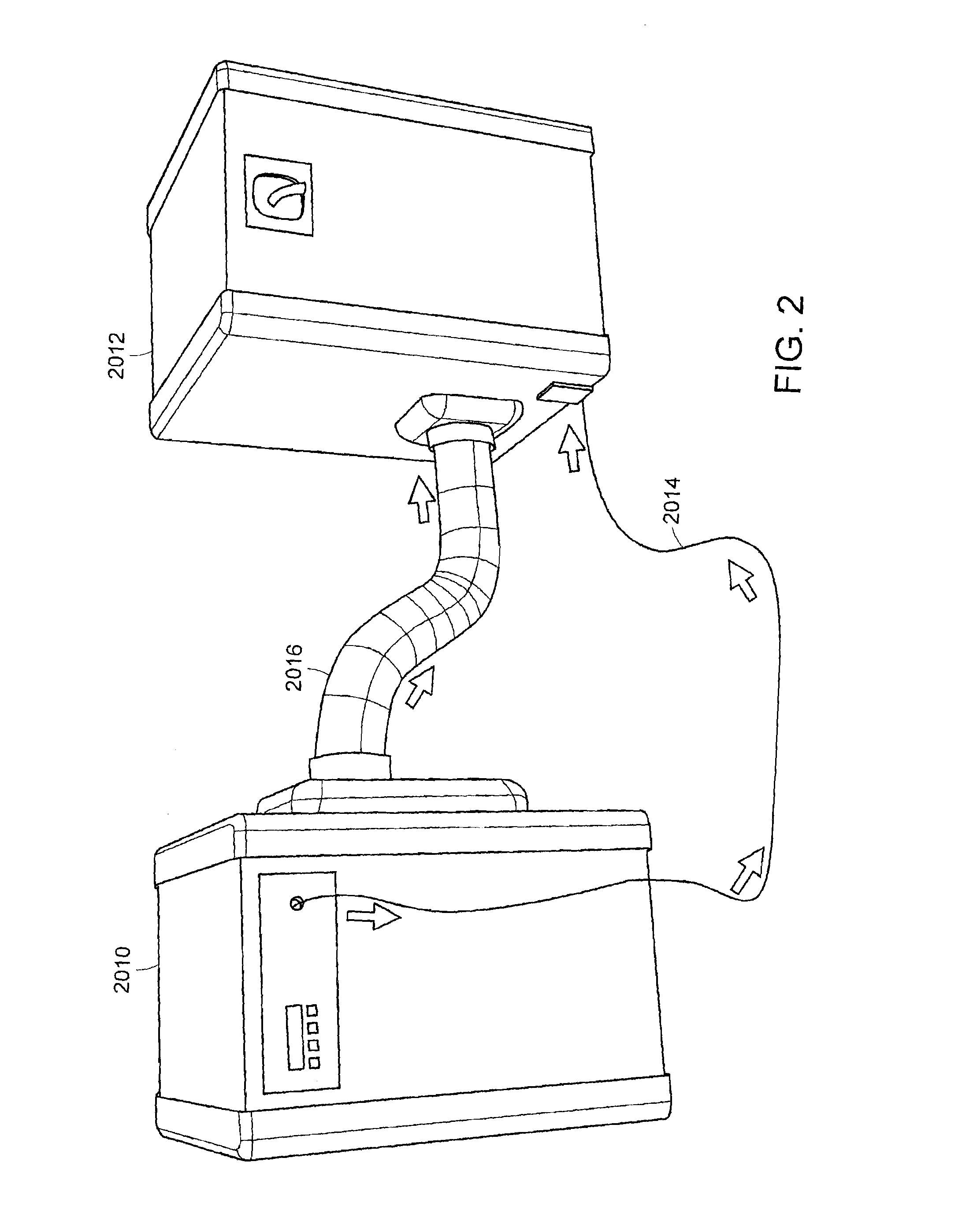

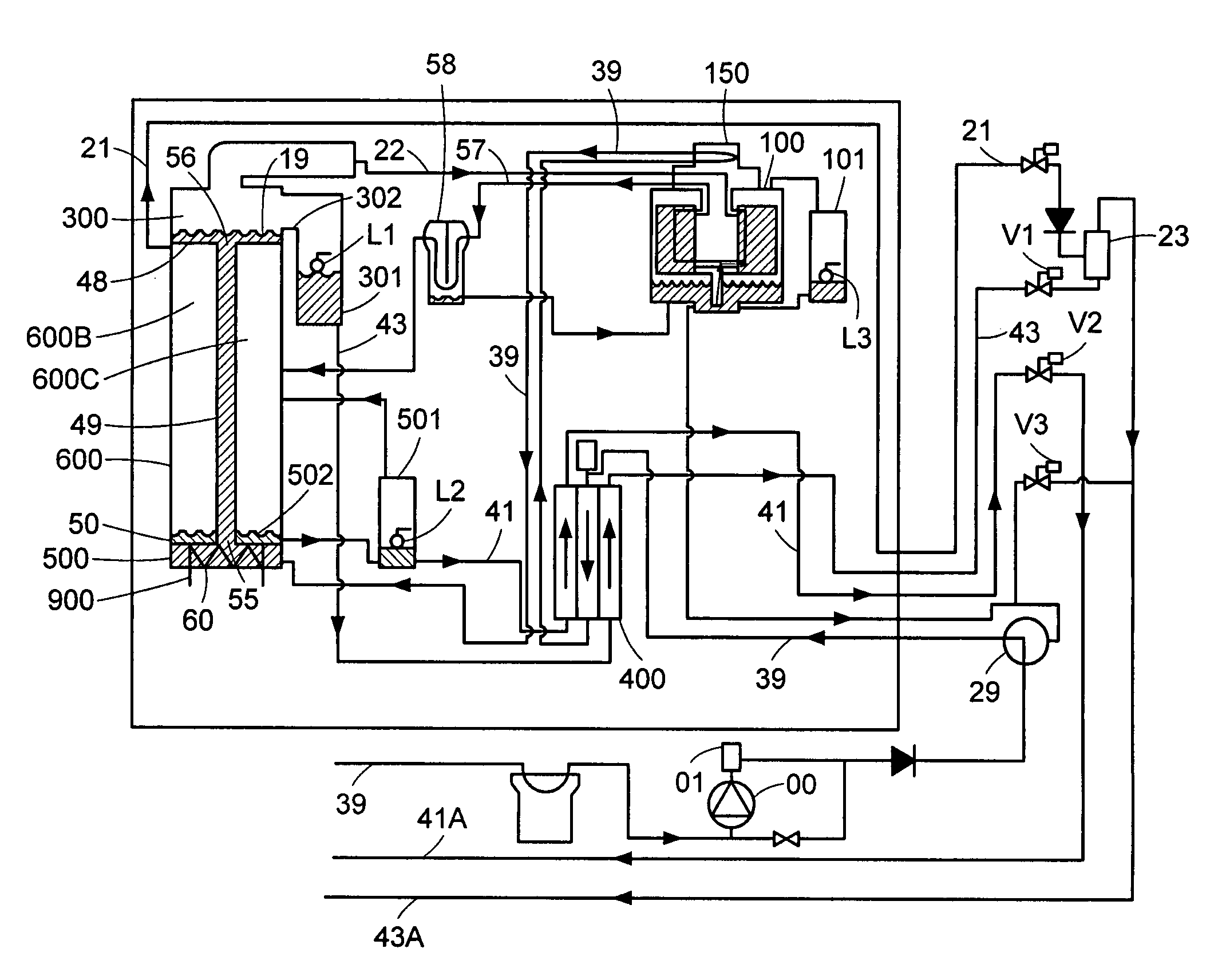

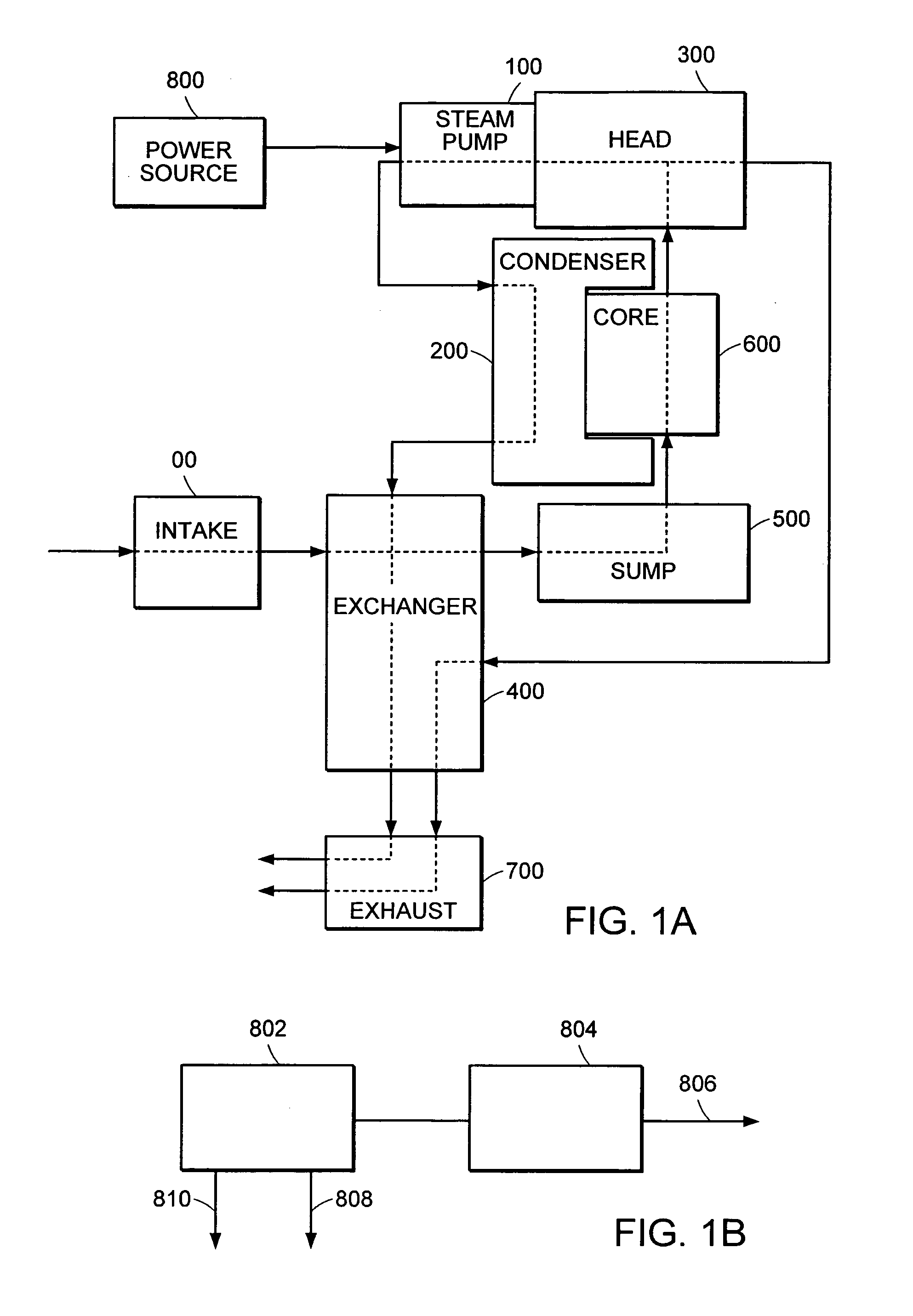

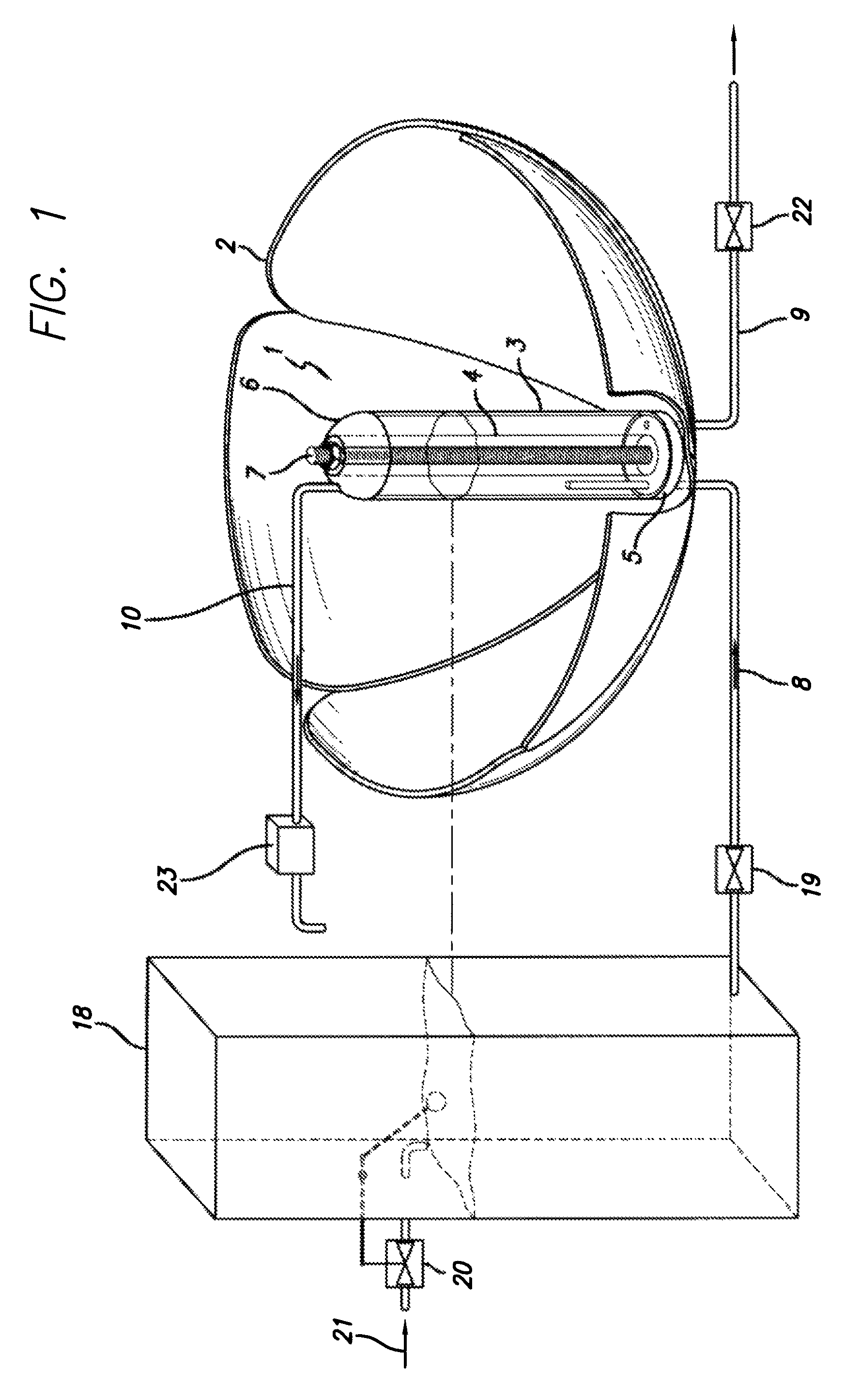

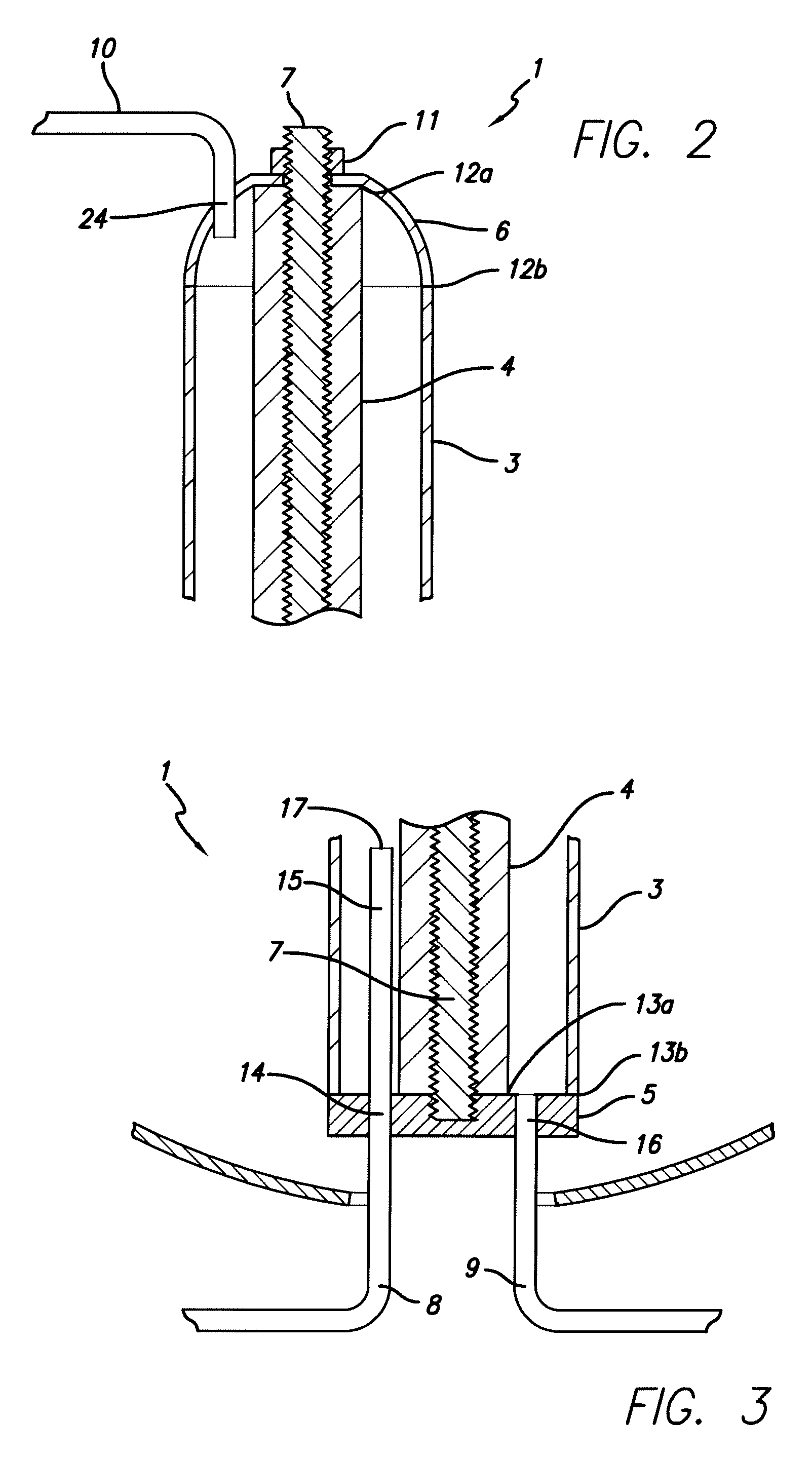

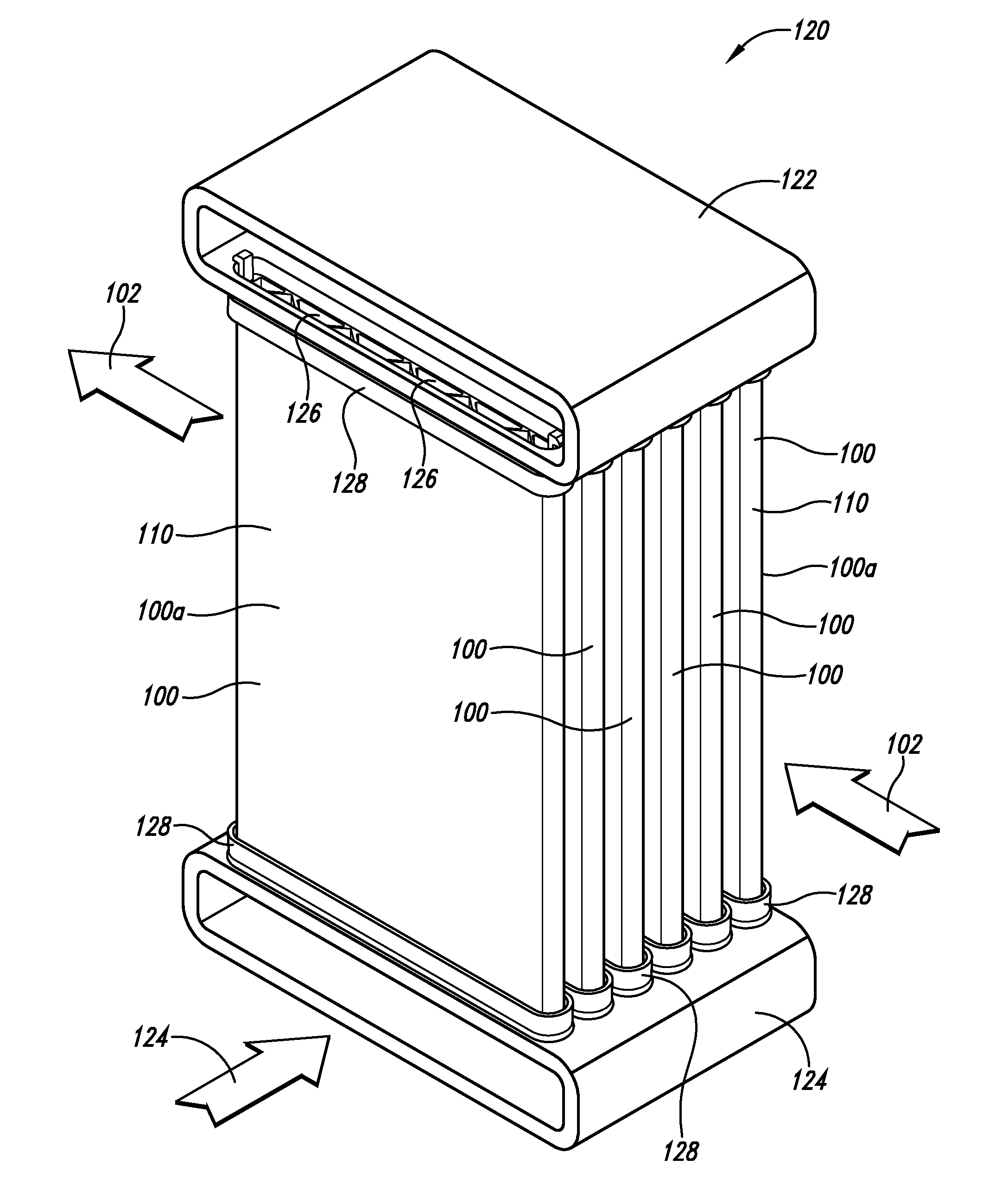

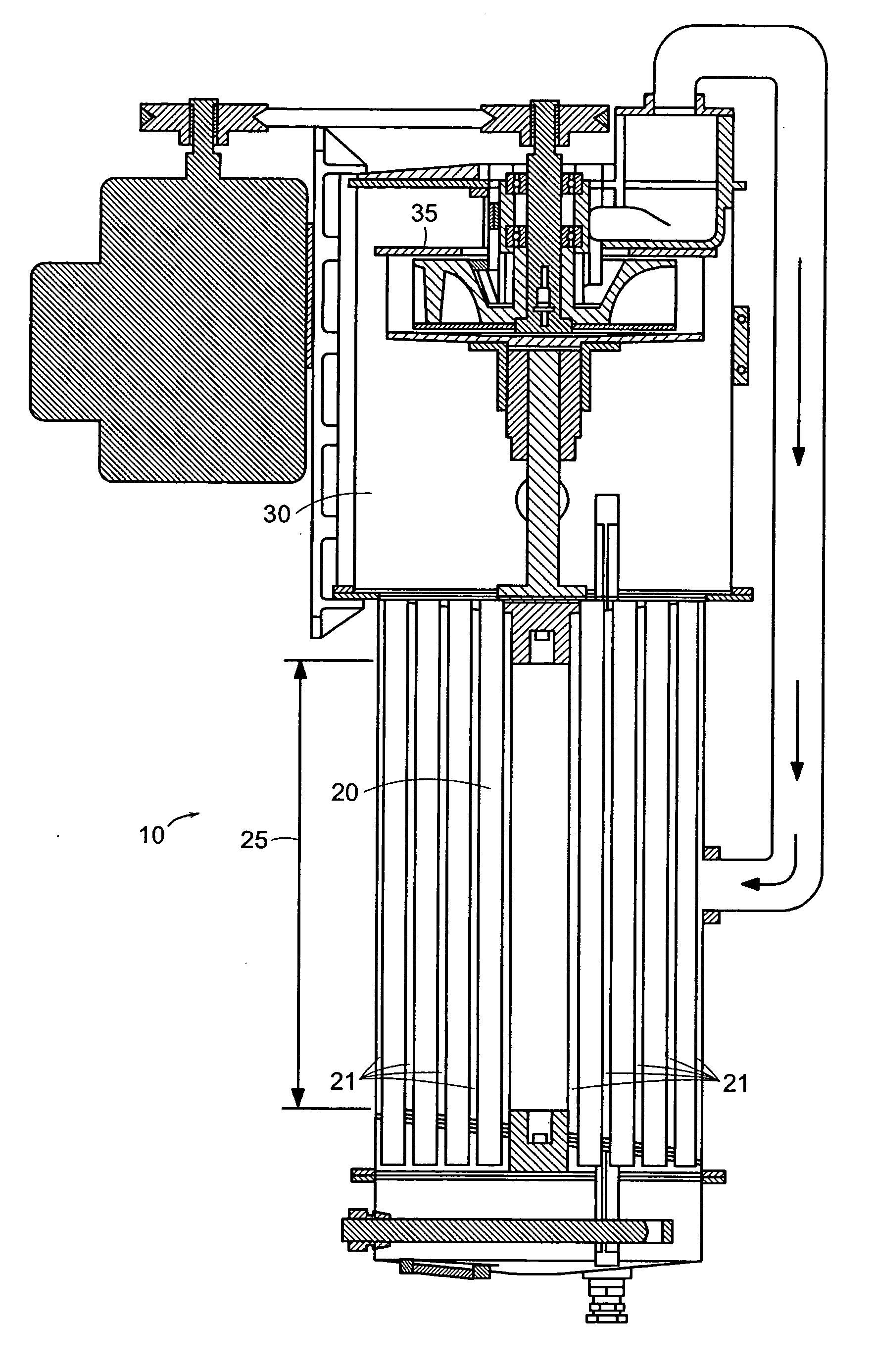

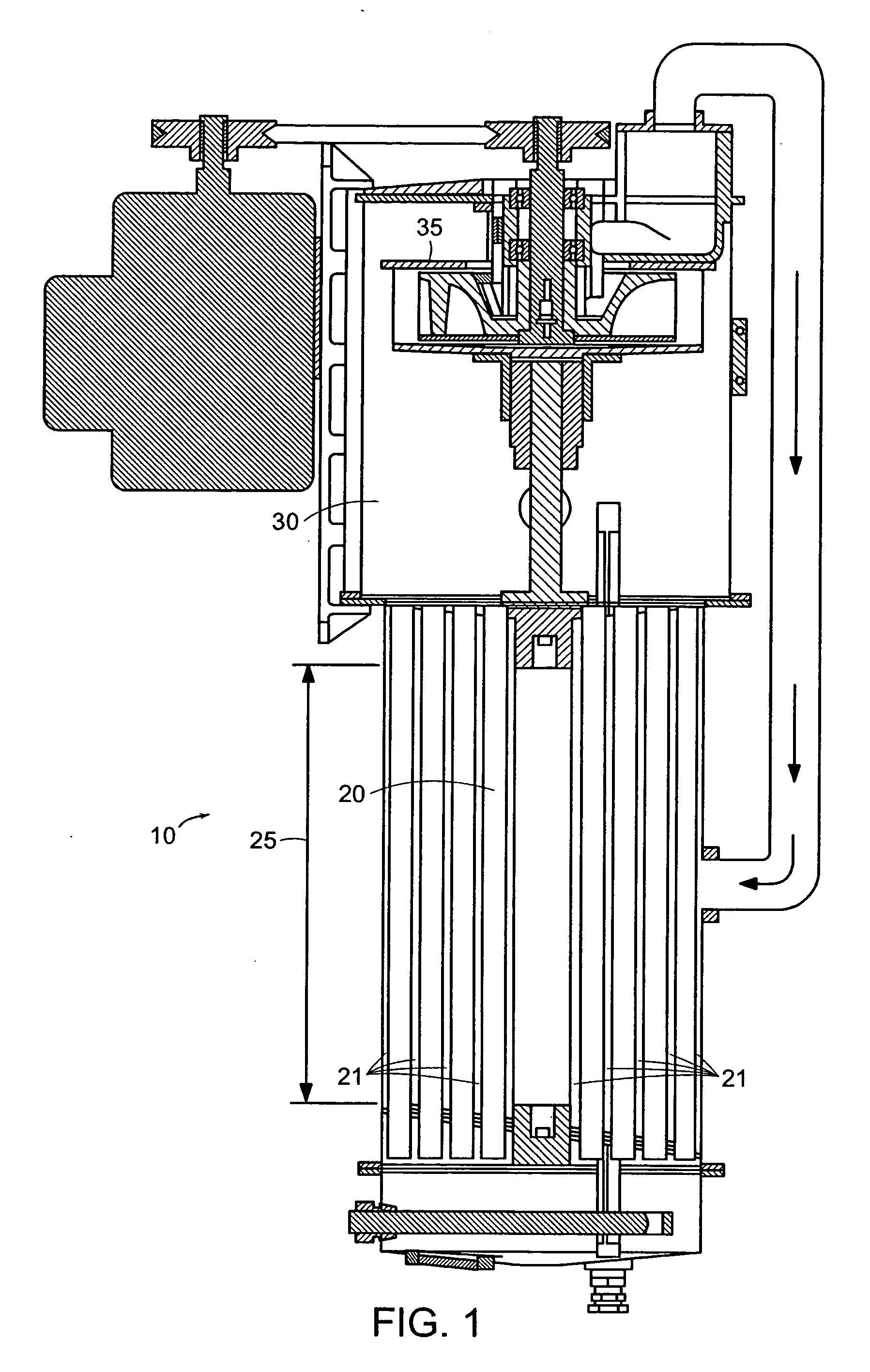

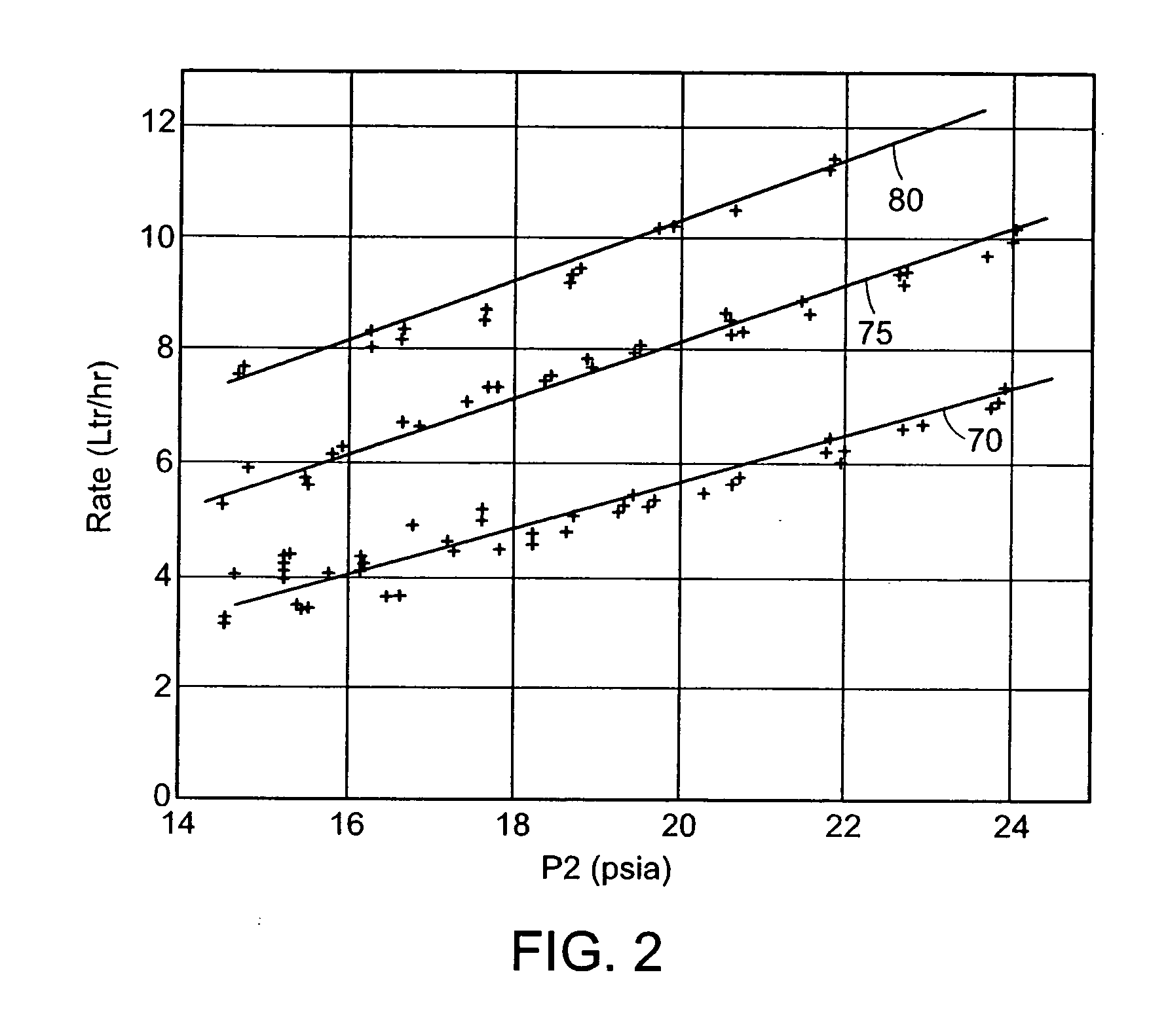

Embodiments of the invention are directed toward a novel pressurized vapor cycle for distilling liquids. In some embodiments of the invention, a liquid purification system is revealed, including the elements of an input for receiving untreated liquid, a vaporizer coupled to the input for transforming the liquid to vapor, a head chamber for collecting the vapor, a vapor pump with an internal drive shaft and an eccentric rotor with a rotatable housing for compressing vapor, and a condenser in communication with the vapor pump for transforming the compressed vapor into a distilled product. Other embodiments of the invention are directed toward heat management, and other process enhancements for making the system especially efficient.

Owner:DEKA PROD LLP

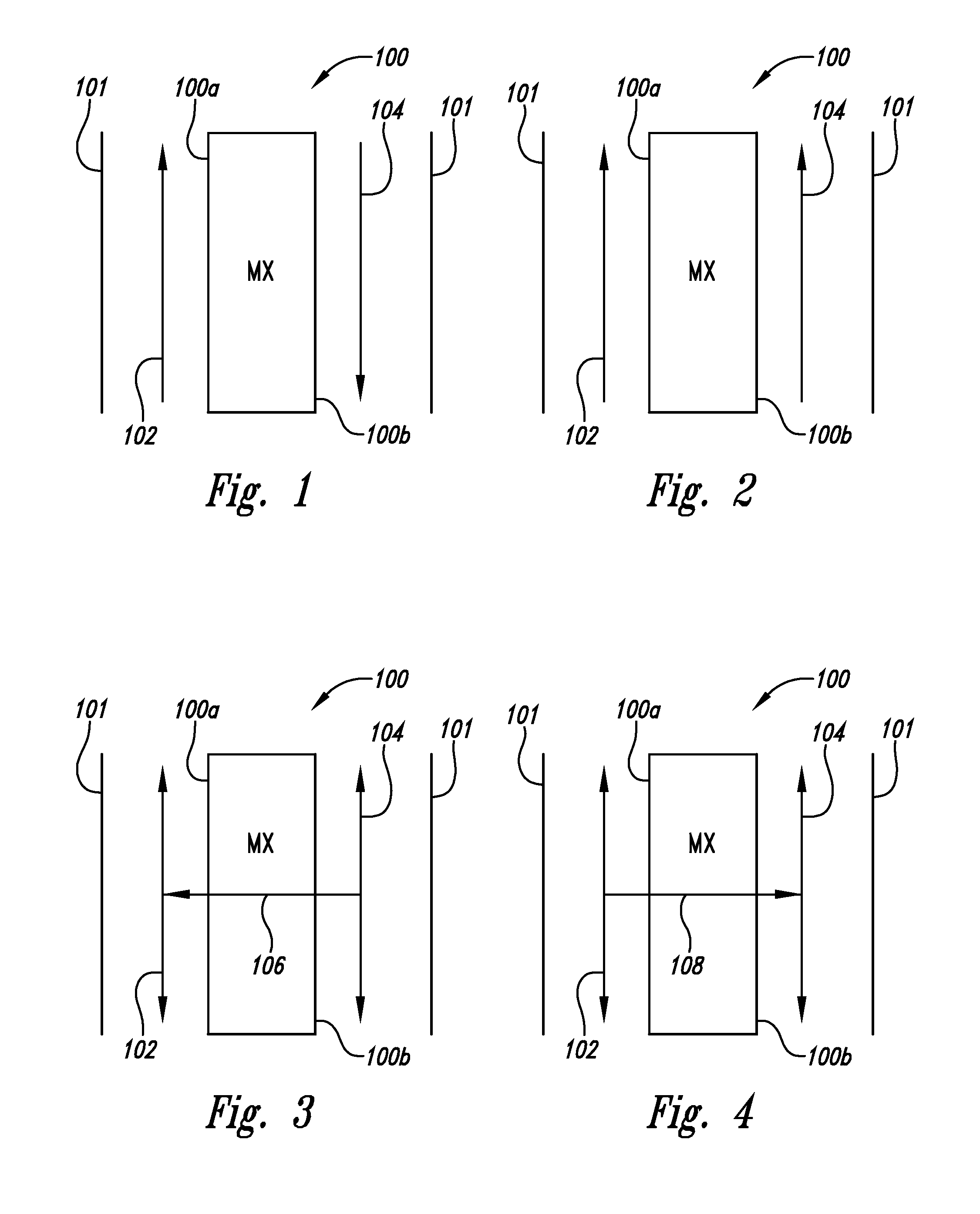

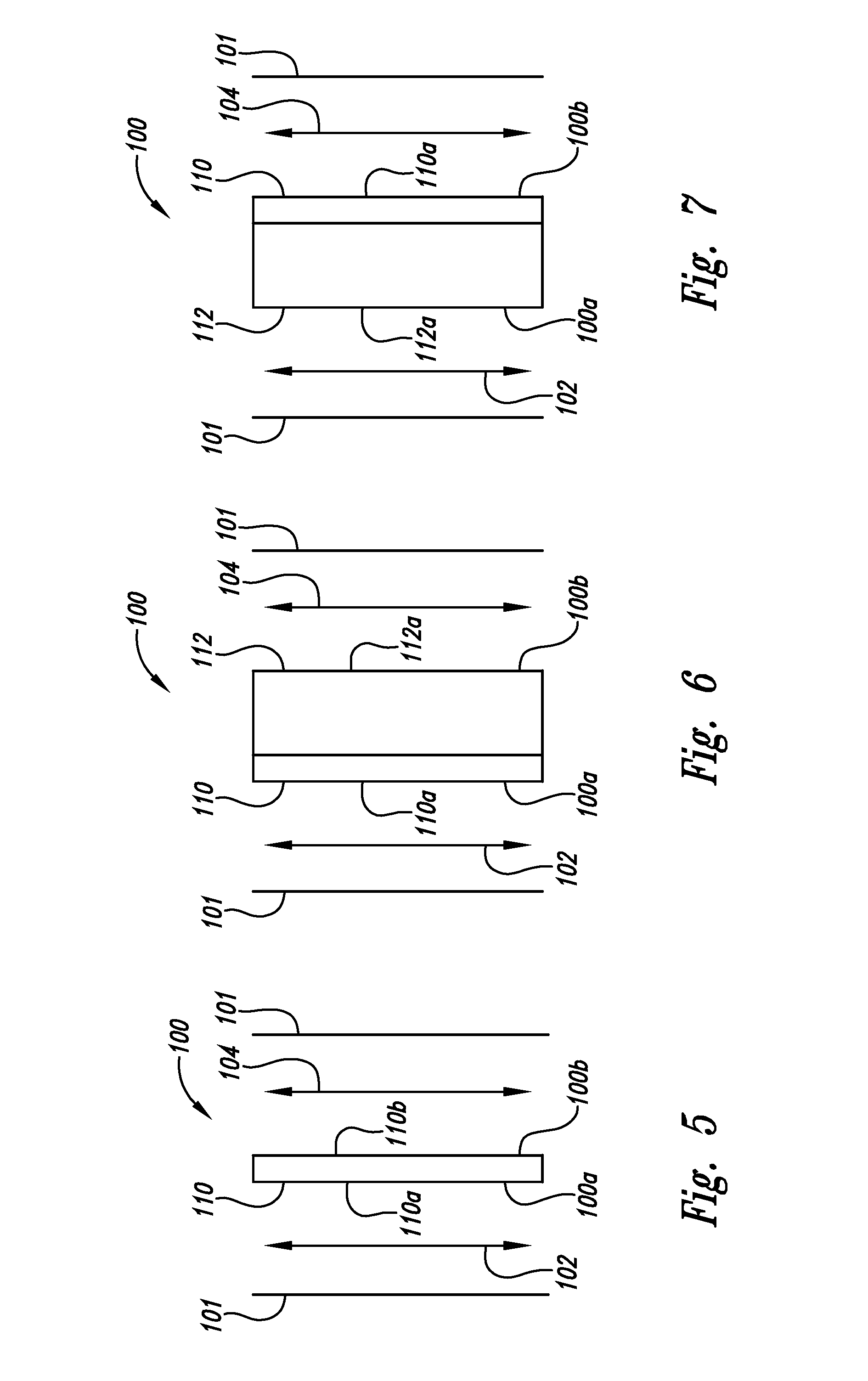

Multi-phase selective mass transfer through a membrane

Disclosed herein are embodiments relating to particular systems comprising a selective transfer membrane that can be utilized in material separation. In certain embodiments, the membrane assembly comprises part of a desalination, distillation, liquid purification, and / or heating and cooling system. Other particular embodiments allow for a high rate of thermal capture by way of the system utilizing a selective transfer membrane. Certain preferred embodiments include a selective transfer membrane comprising an ionomeric polymer that is permeable to high dipole materials.

Owner:TANGREDI PATRICIA

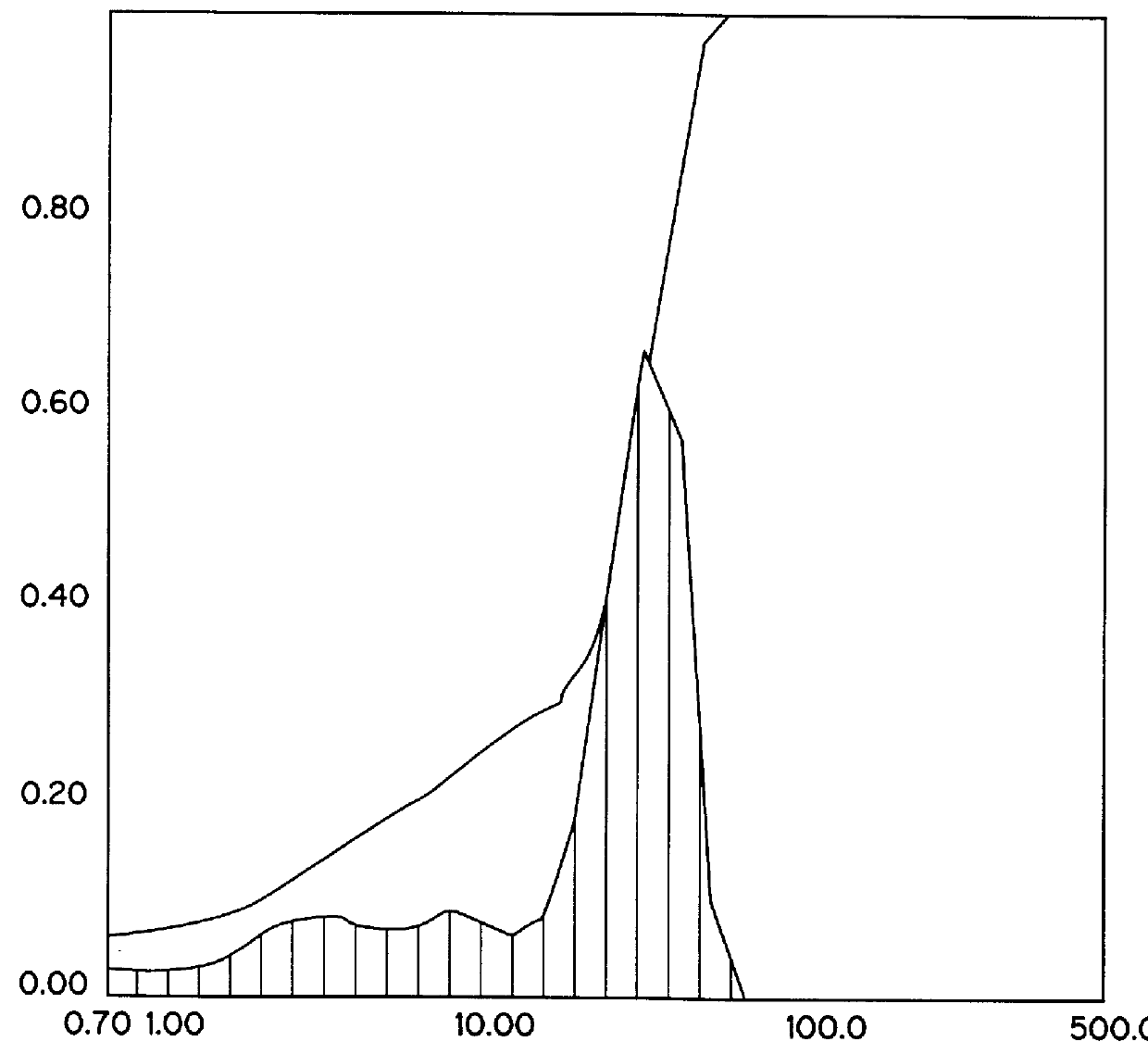

Process for the production of particles or powders

In a novel process for the production of particles or powders, a substance or mixture of substances to be treated is provided in a pressure vessel. A highly compressible fluid is dissolved under pressure in the substance or mixture of substances provided until a solution containing 5% to 90% by weight of said highly compressible fluid has formed. The melting point of said highly compressible fluid is at least around 40 K lower than the melting point of the substance or mixture of substances to be treated. The solution obtained by dissolving said highly compressible fluid in the substance or mixture of substances provided is adjusted to a temperature of up to around 50 K above or below the melting point under atmospheric pressure of the substance or mixture of substances to be treated and is then rapidly decompressed by means of a decompression device in such a way that the temperature falls, downstream of the decompression device, below the solidification point of the substance or mixture of substances to be treated and essentially all of the highly compressible fluid turns gaseous, whereby particles of the substance or mixture of substances provided form. Subsequently, the particles which have formed are removed from the stream of decompressed highly compressible fluid.

Owner:WEIDNER ECKHARD +2

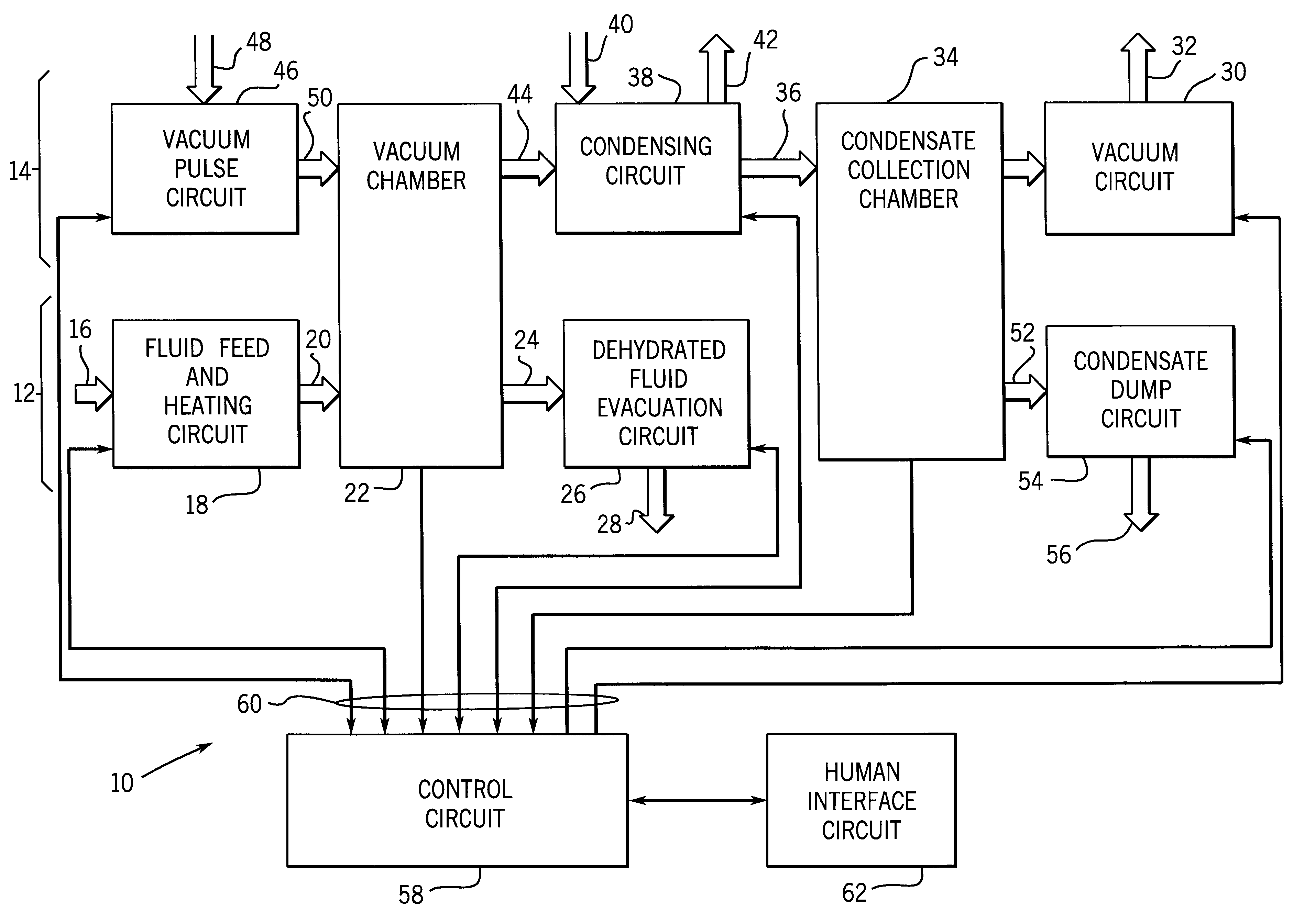

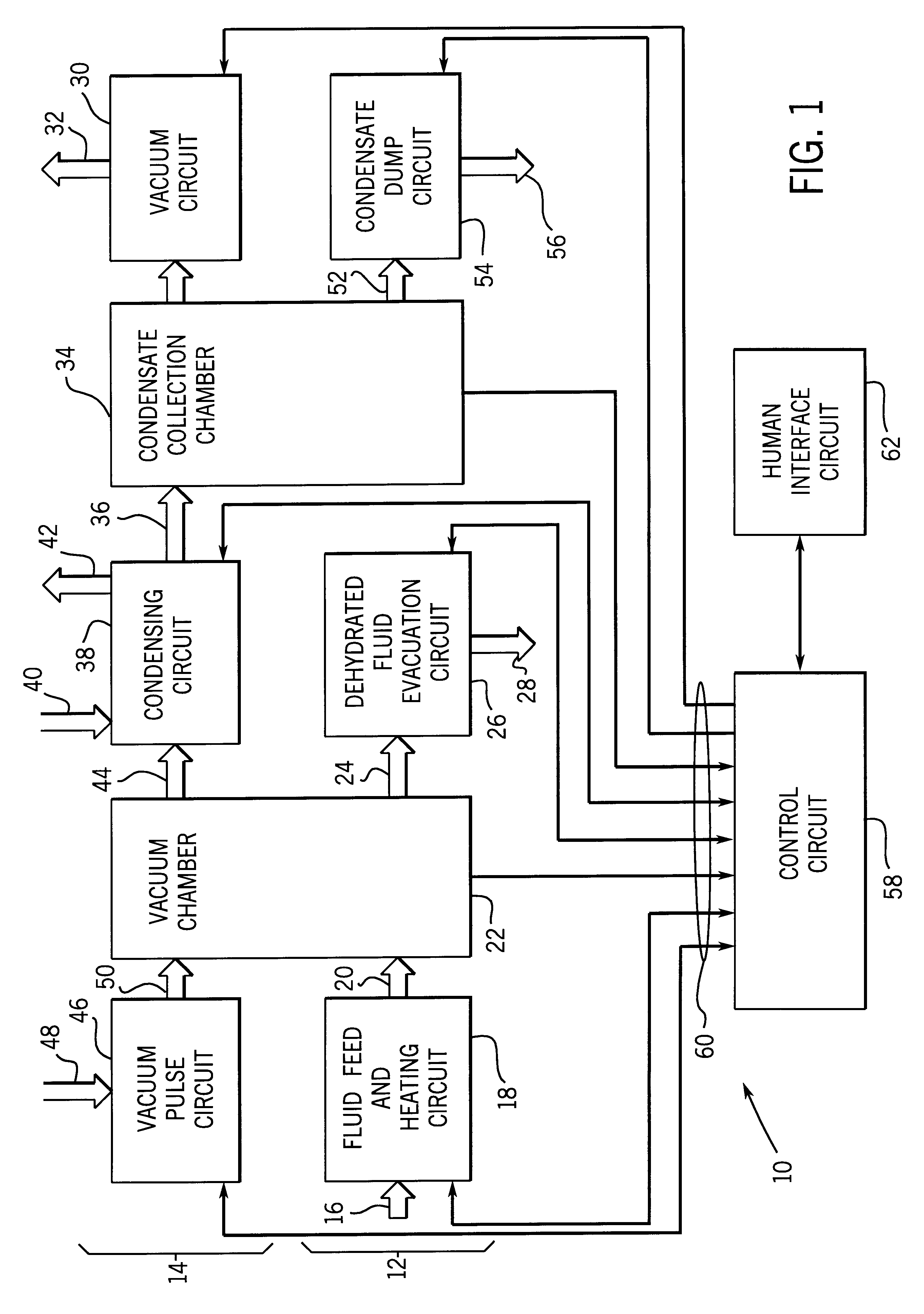

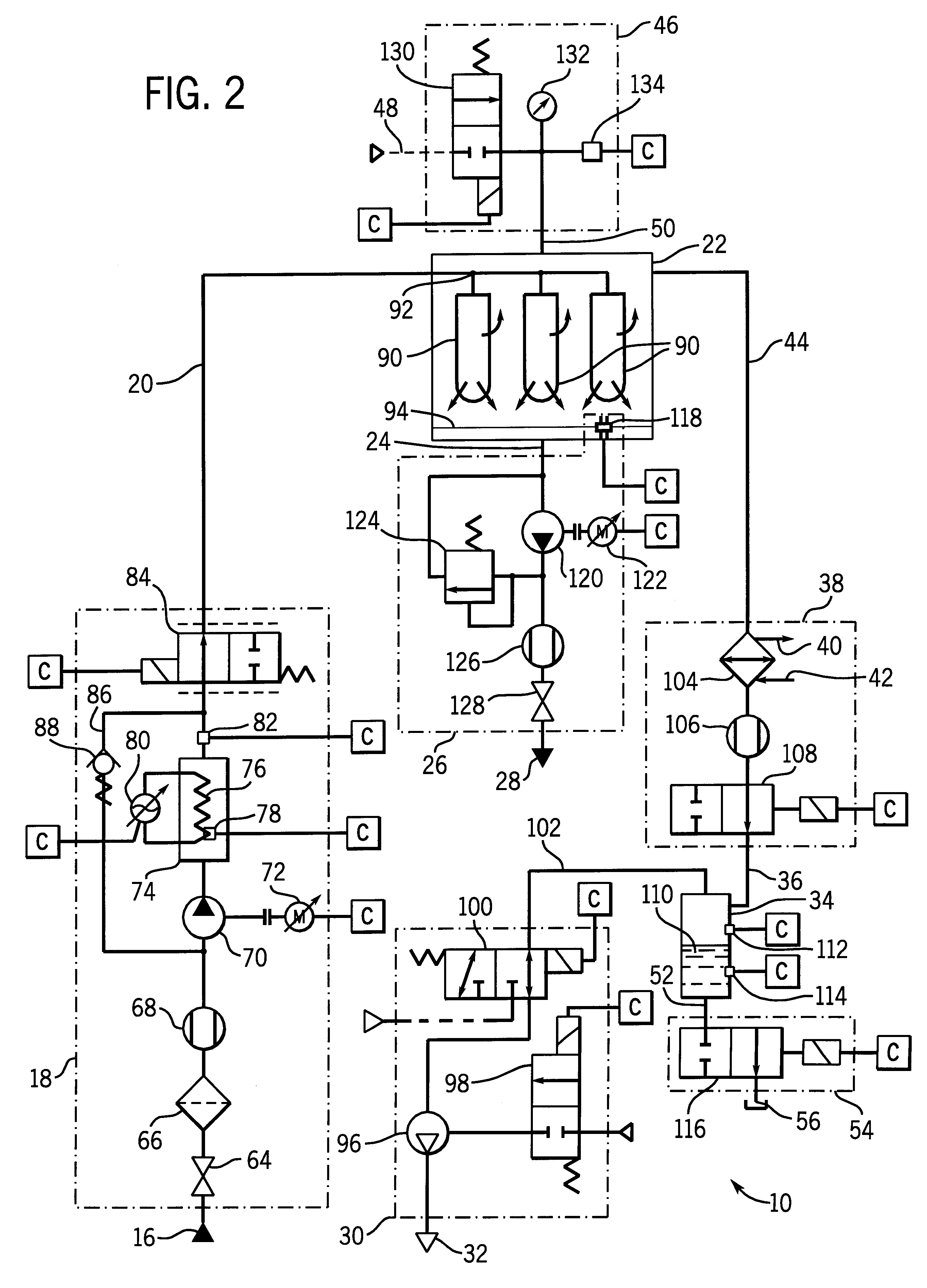

Apparatus for dehydrating oil

InactiveUS6224716B1Distillation regulation/controlEvaporation with vapour compressionVacuum pressureClosed loop

A system for dehydrating lubricating and hydraulic fluids includes a heating circuit and circuitry for creating a vacuum. The heating circuitry introduces a stream of heated fluid into a vacuum chamber in which a partial vacuum is drawn by the vacuum circuit. Aqueous components of the fluid stream are flashed in the vacuum chamber by virtue of the elevated temperature and reduced pressure. Dehydrated fluid is then collected and evacuated from the vacuum chamber. Vapor from the vacuum chamber, including the aqueous components of the fluid stream are collected, condensed and separately evacuated. The heating circuit limits surface temperature of a heating element in a closed-loop manner to avoid degradation of the fluid. The fluid stream is introduced into the vacuum chamber or is recirculated through the heating circuit to maintain a desired level of fluid temperature in a closed-loop manner. The system includes circuits for evacuating dehydrated fluid in a closed-loop manner and for automatically discharging condensate. The technique avoids undesirable foaming of dehydrated fluid within the vacuum chamber. A vacuum pulsing circuit is provided for periodically pulsing vacuum pressure within the vacuum chamber to aid in flashing aqueous components from the heated fluid stream.

Owner:OILQUIP

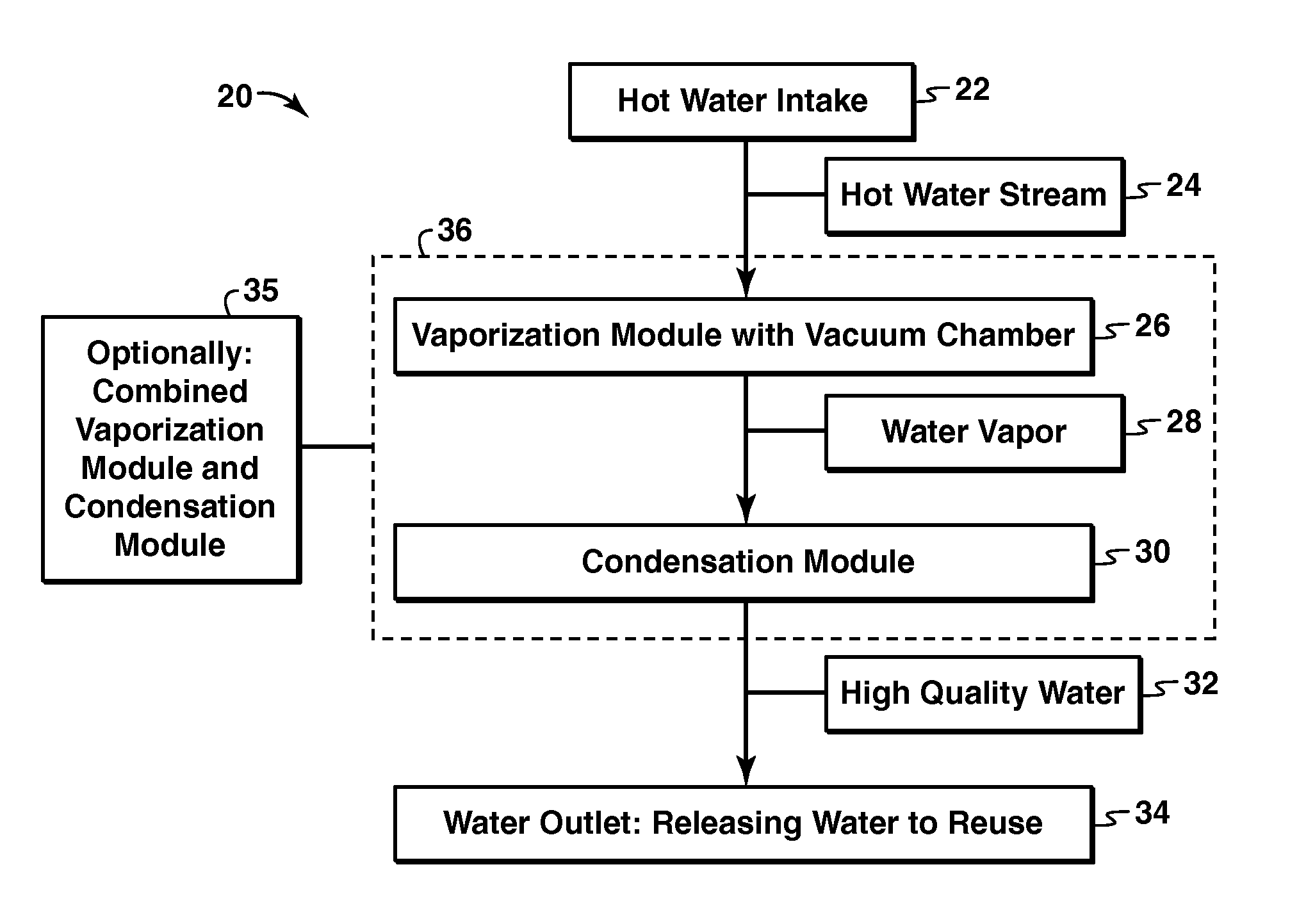

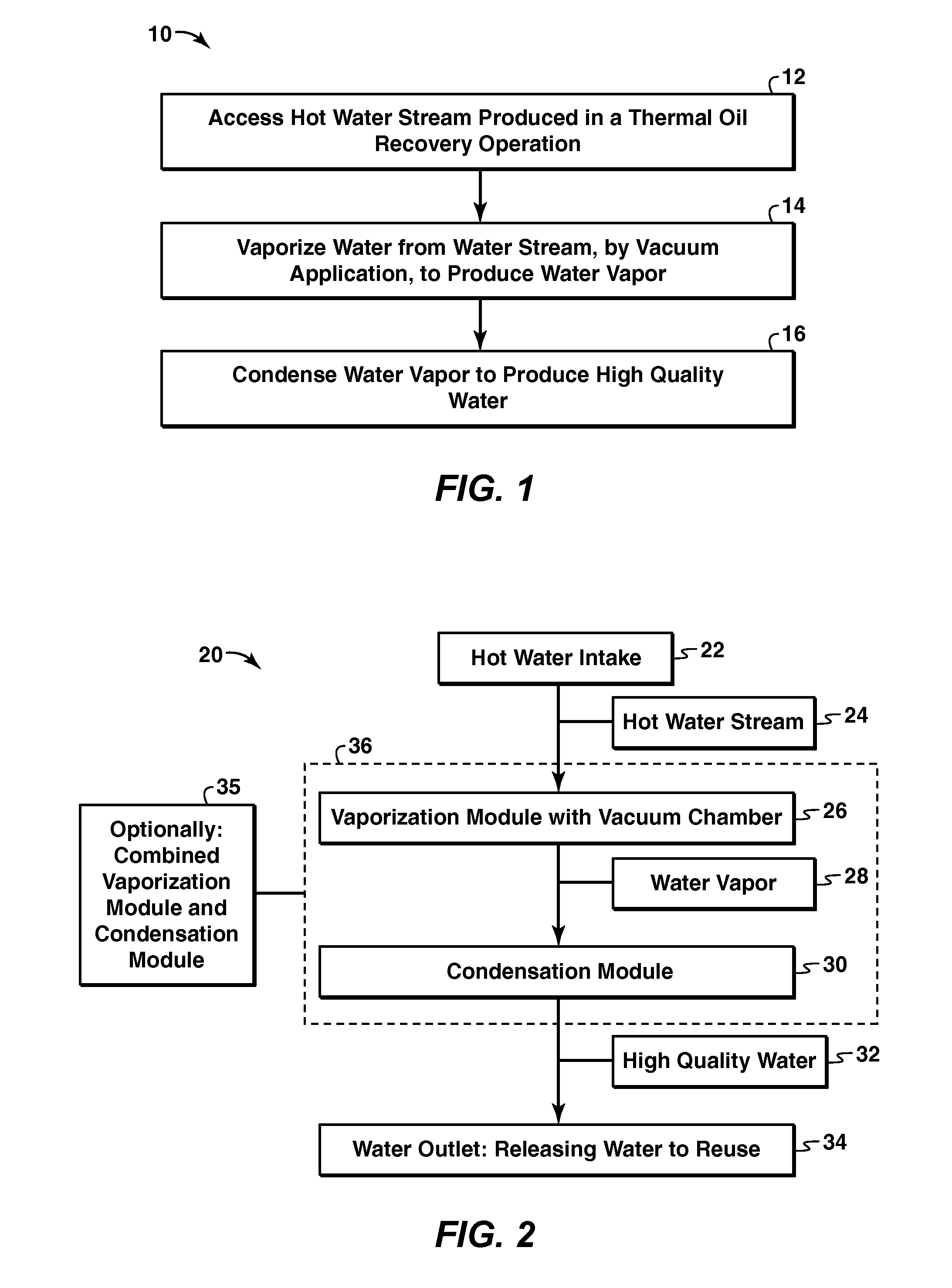

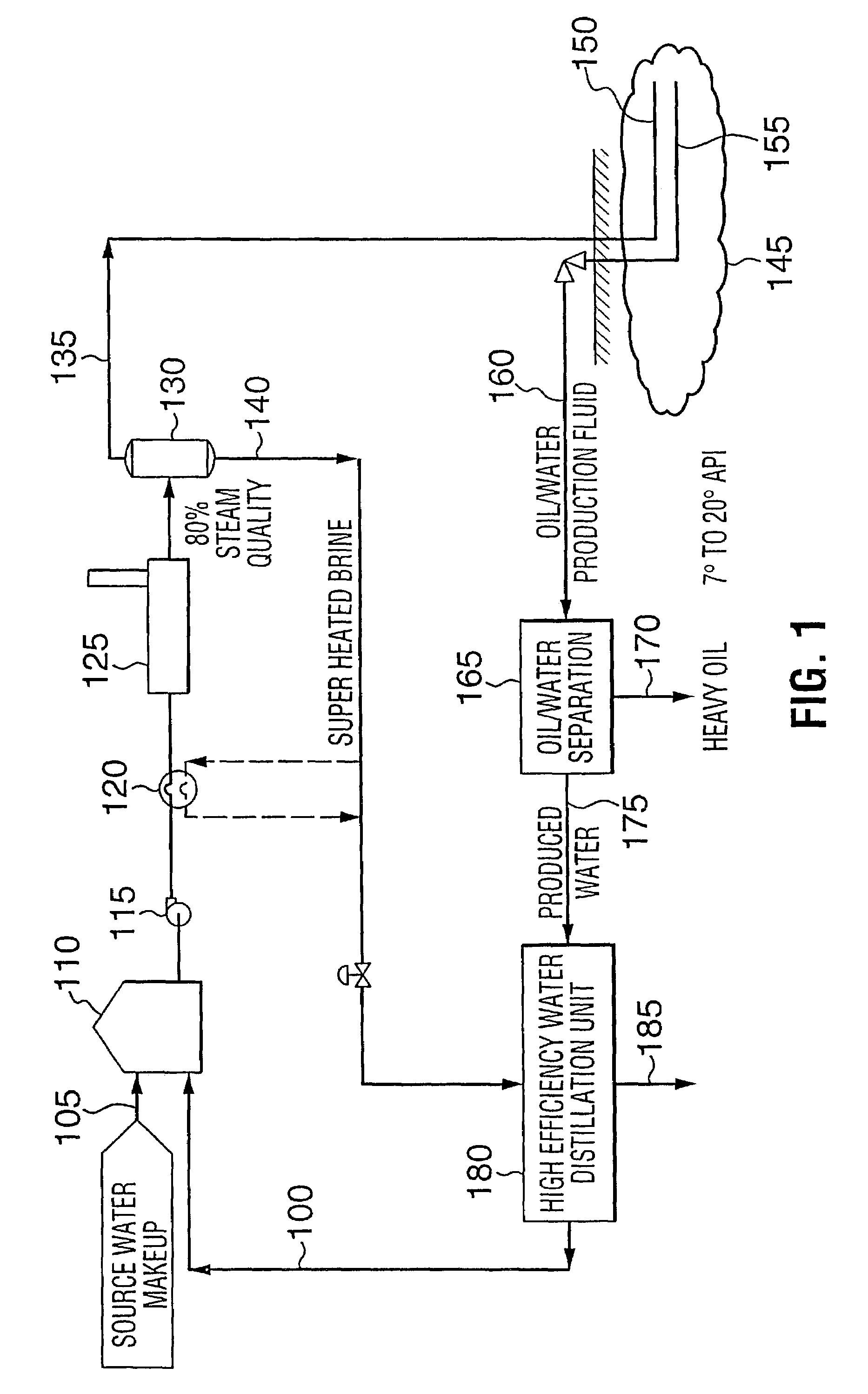

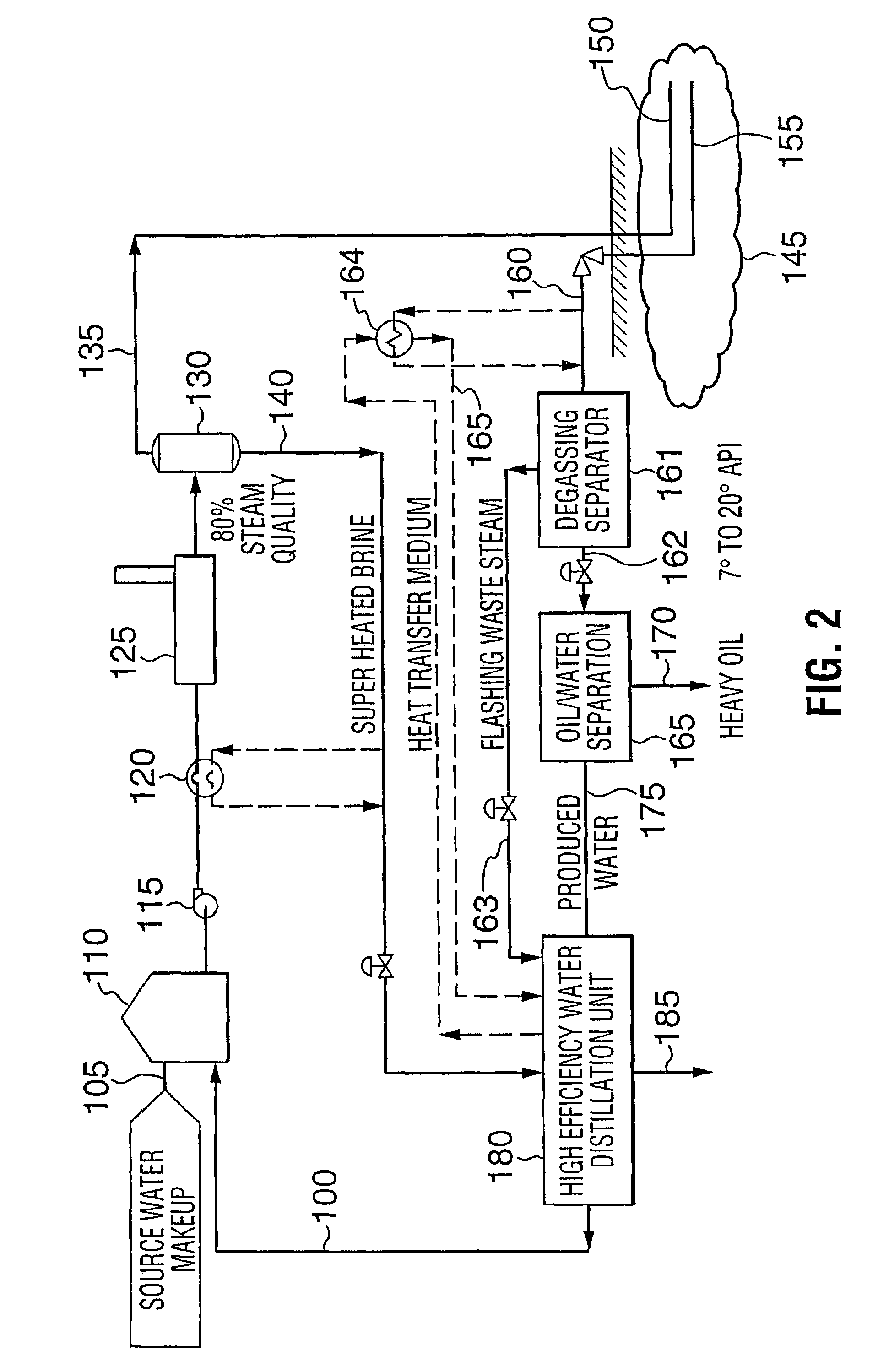

Recovery of high water from produced water arising from a thermal hydrocarbon recovery operation using vaccum technologies

InactiveUS20100282593A1High purityImprove purification effectAuxillariesEvaporation with vapour compressionWater flowVaporization

A method for reducing and re-using waste heat and water resulting from thermal hydrocarbon recovery operations involving accessing a hot water stream produced in a thermal hydrocarbon recovery operation; vaporizing water from the water stream by applying a vacuum, thereby producing water vapor; and condensing the water vapor to produce high quality water. A system is described including a hot water intake interfacing with a hot water stream from a thermal hydrocarbon recovery operation; a vaporization module receiving the hot water stream from the hot water intake, comprising a vacuum chamber in which a vacuum is applied to produce water vapor from the hot water stream; a condensation module in which water vapor produced in the vaporization module is condensed to form high quality water; and a water outlet for releasing the high quality water from the condensation module for re-use within the thermal hydrocarbon recovery operation.

Owner:EXXONMOBIL UPSTREAM RES CO

Pressurized vapor cycle liquid distillation

ActiveUS20070017192A1Easy maintenanceImprove efficiencyCombination devicesDrying using combination processesHeat managementDistillation

Embodiments of the invention are directed toward a novel pressurized vapor cycle for distilling liquids. In some embodiments of the invention, a liquid purification system is revealed, including the elements of an input for receiving untreated liquid, a vaporizer coupled to the input for transforming the liquid to vapor, a head chamber for collecting the vapor, a vapor pump with an internal drive shaft and an eccentric rotor with a rotatable housing for compressing vapor, and a condenser in communication with the vapor pump for transforming the compressed vapor into a distilled product. Other embodiments of the invention are directed toward heat management, and other process enhancements for making the system especially efficient.

Owner:DEKA PROD LLP

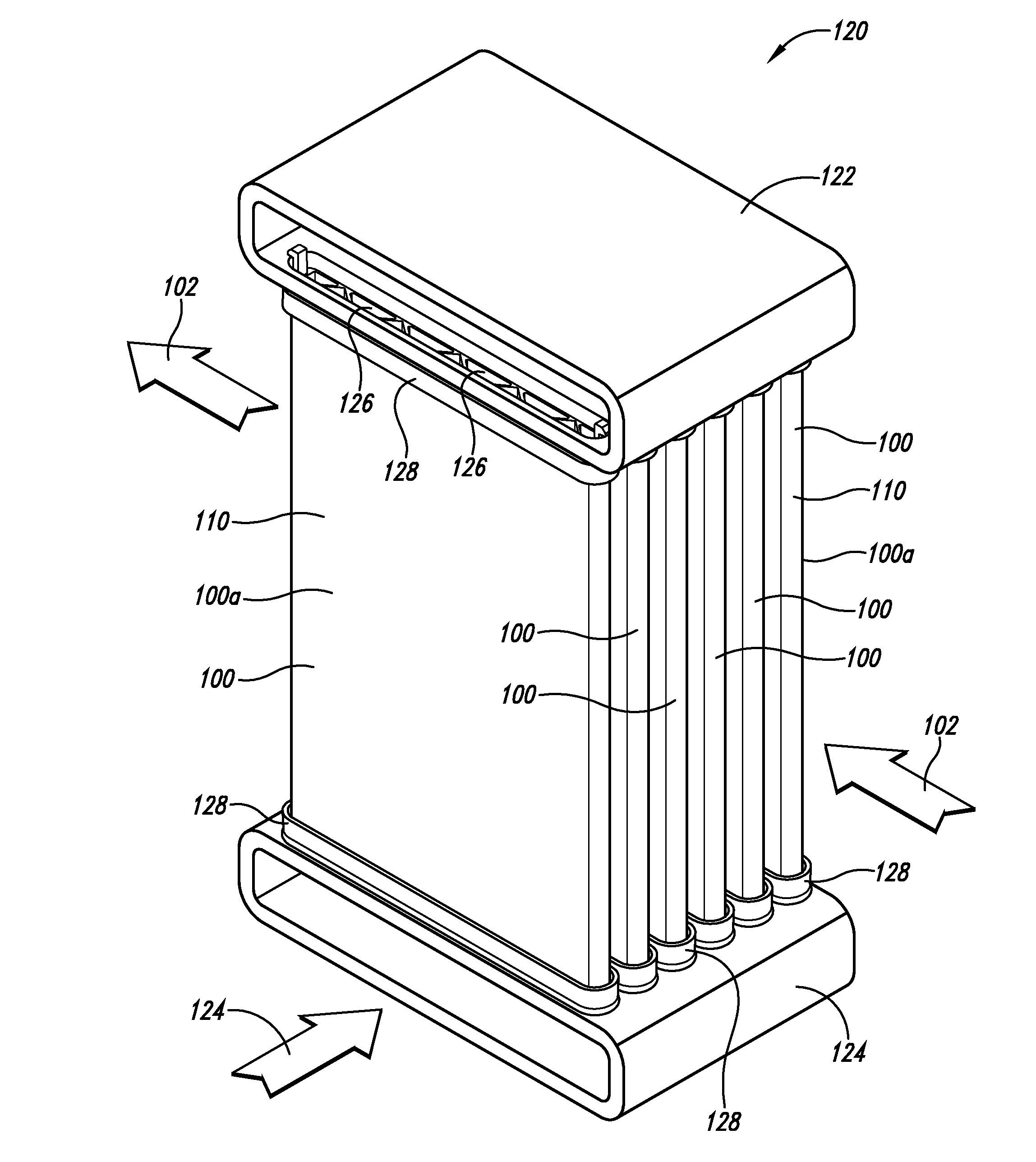

Liquid ring pumps with hermetically sealed motor rotors

ActiveUS7465375B2Easy maintenanceMaximize energy efficiencyGeneral water supply conservationDistillation regulation/controlDrive shaftDistillation

Owner:DEKA PROD LLP

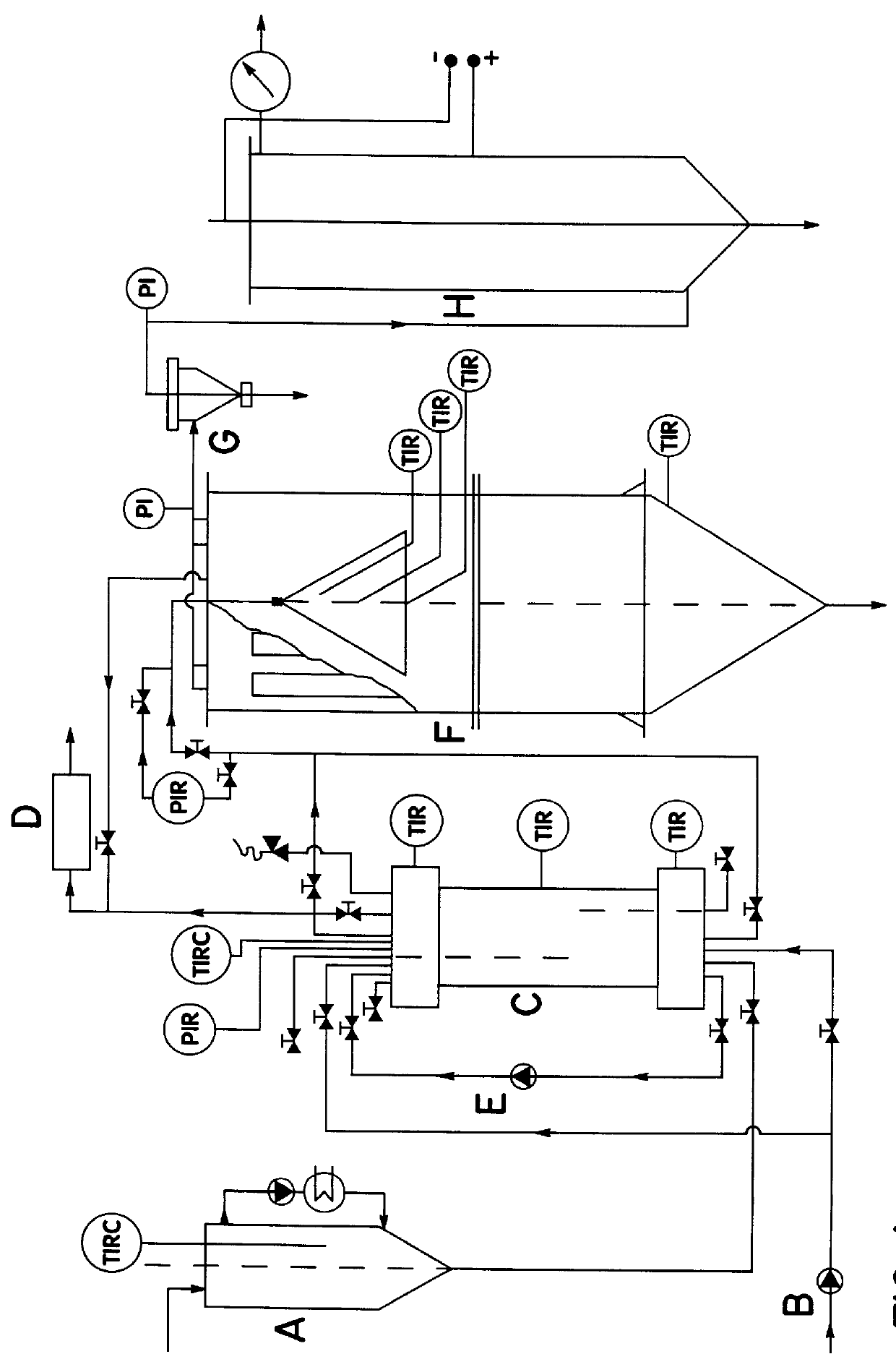

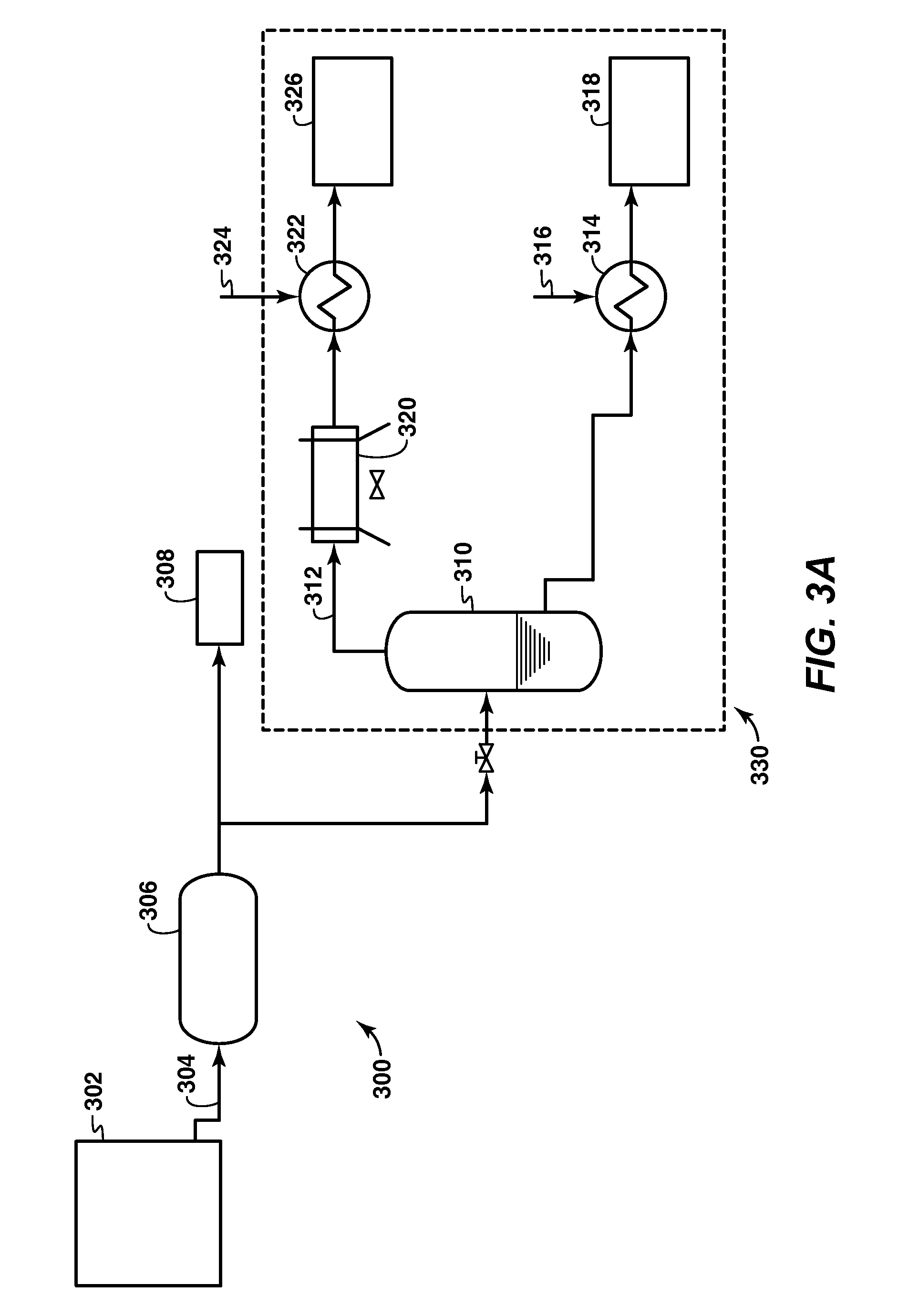

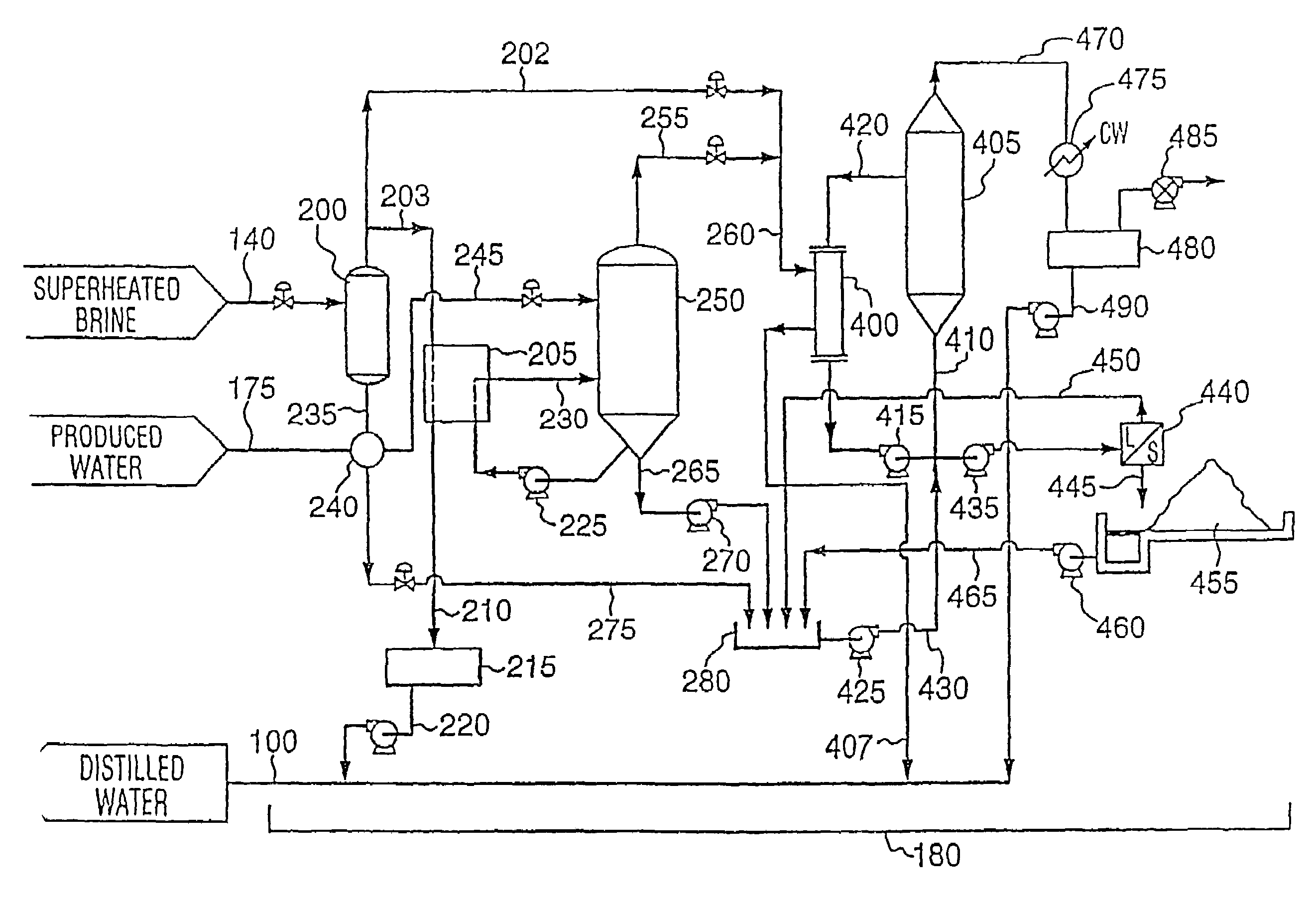

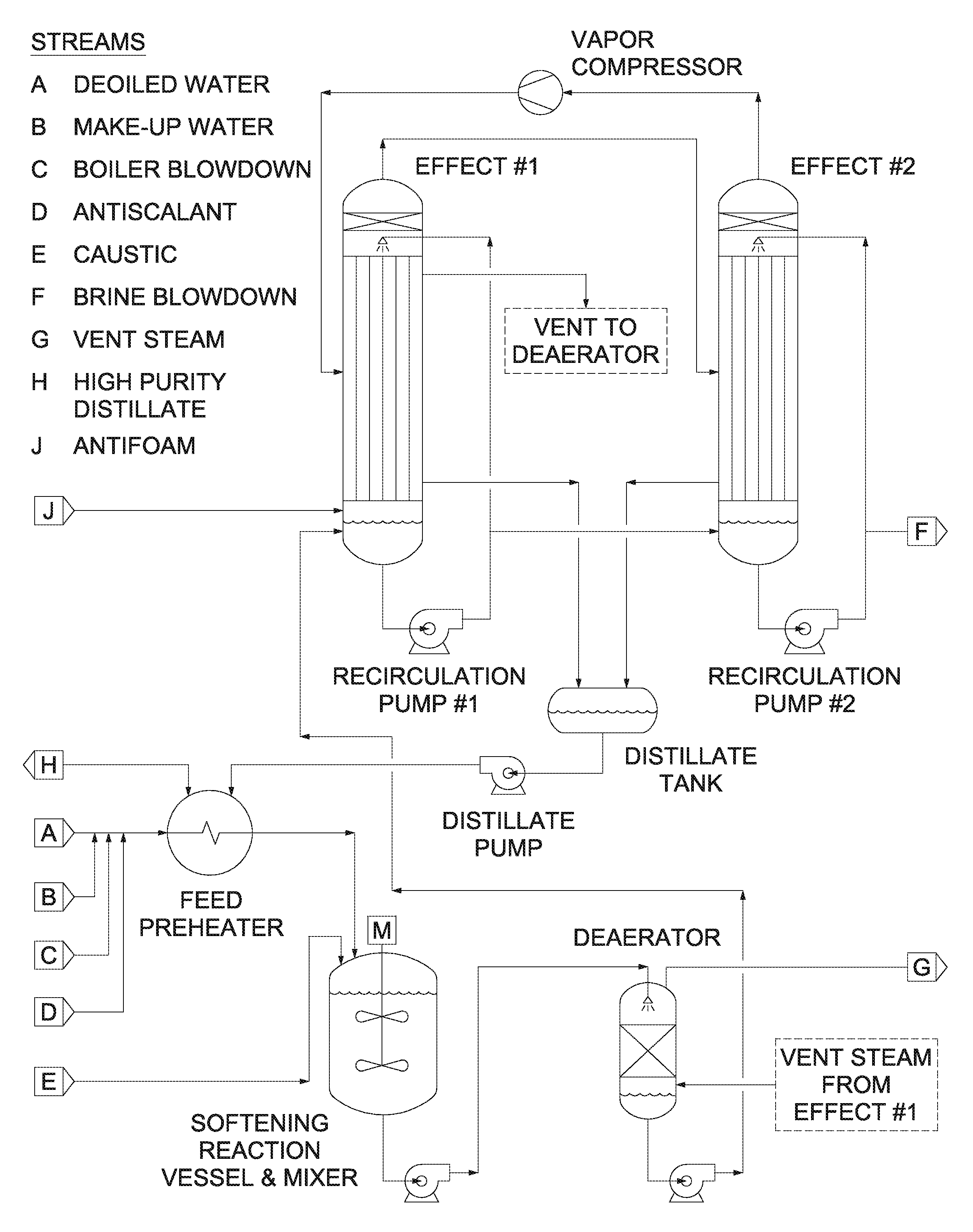

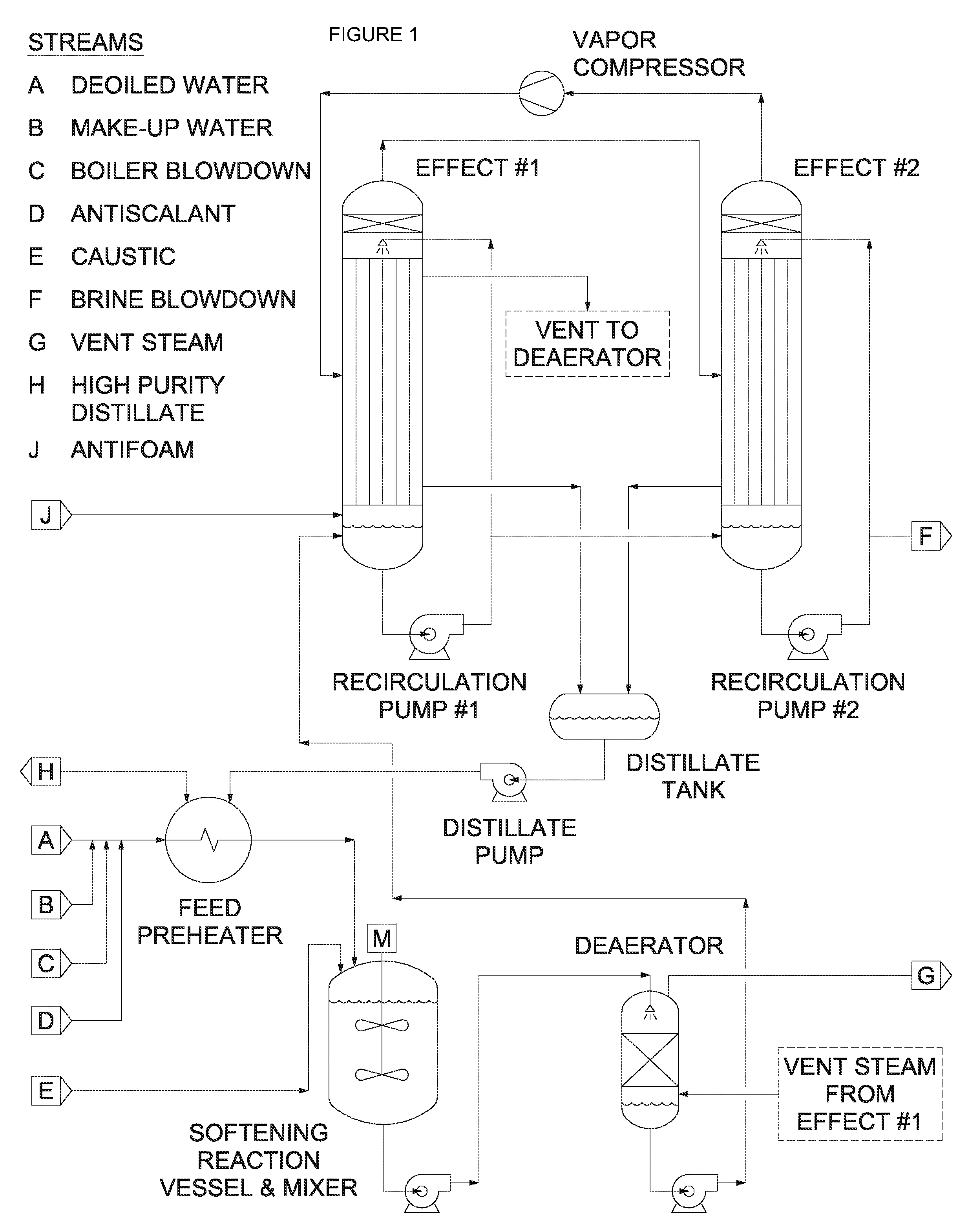

Water treatment process for thermal heavy oil recovery

There is disclosed a method and apparatus for treating produced water from a heavy oil thermal recovery unit to achieve water recovery and recycle levels of greater than 80% and as high as 100% to achieve zero discharge criteria. The method includes the initial steps of capturing the waste heat energy from the high pressure steam separator located downstream of the steam generators. Further, transferring the heat energy into a heated separator and reboiler exchanger to distill oil reservoir produced water and recover distilled water and a concentrated brine or solid product. The heated separator concentrated stream is circulated through the reboiler exchanger to maintain from 1% to about 50% mass vapour in the stream returning to the heated separator and prevent fouling and scaling. The apparatus includes a low pressure waste energy separator, heated separator and vapour compressor in combination with a forced circulation circuit to generate the distilled water.

Owner:FOUNTAIN QUAIL WATER MANAGEMENT LLC +1

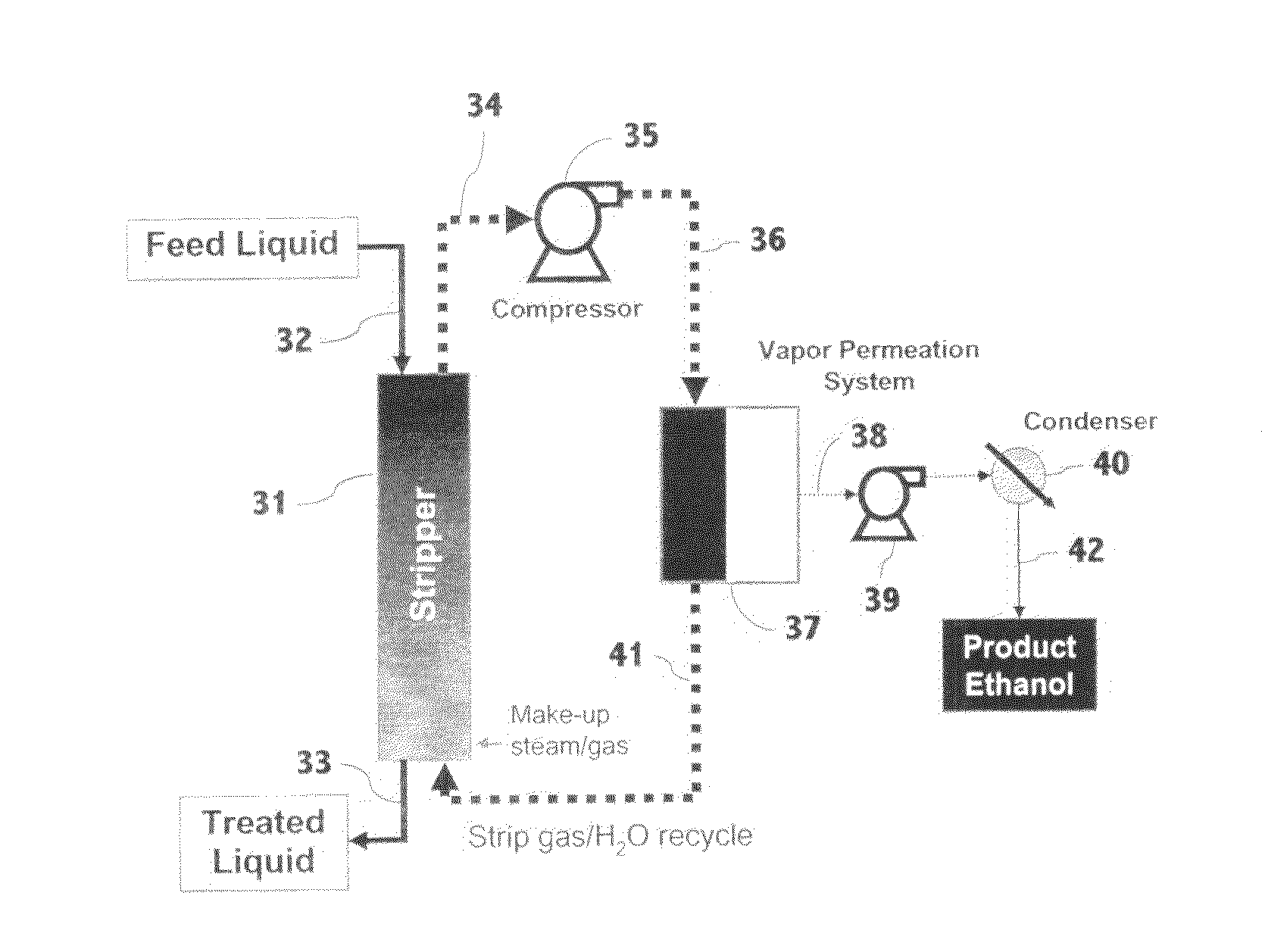

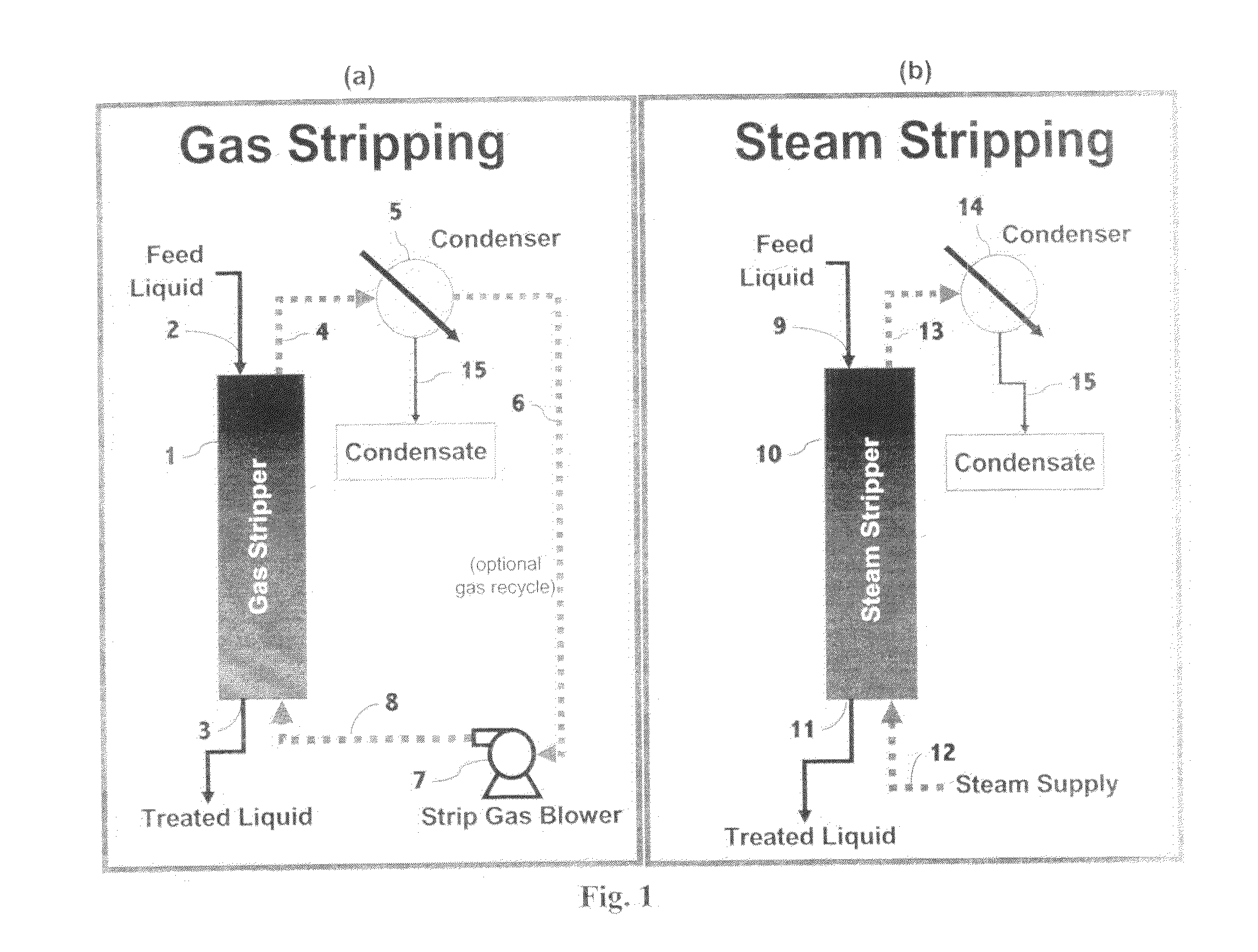

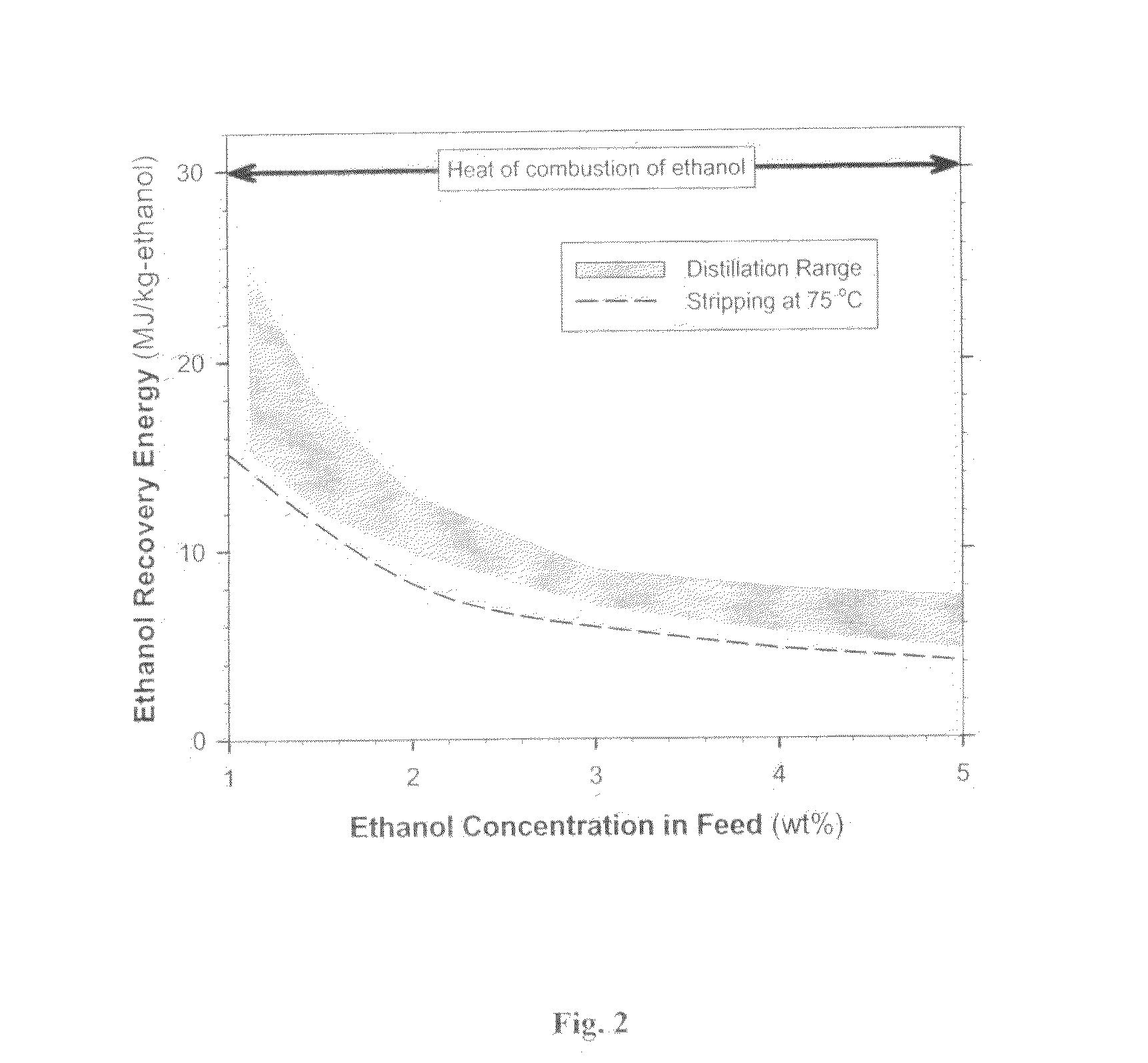

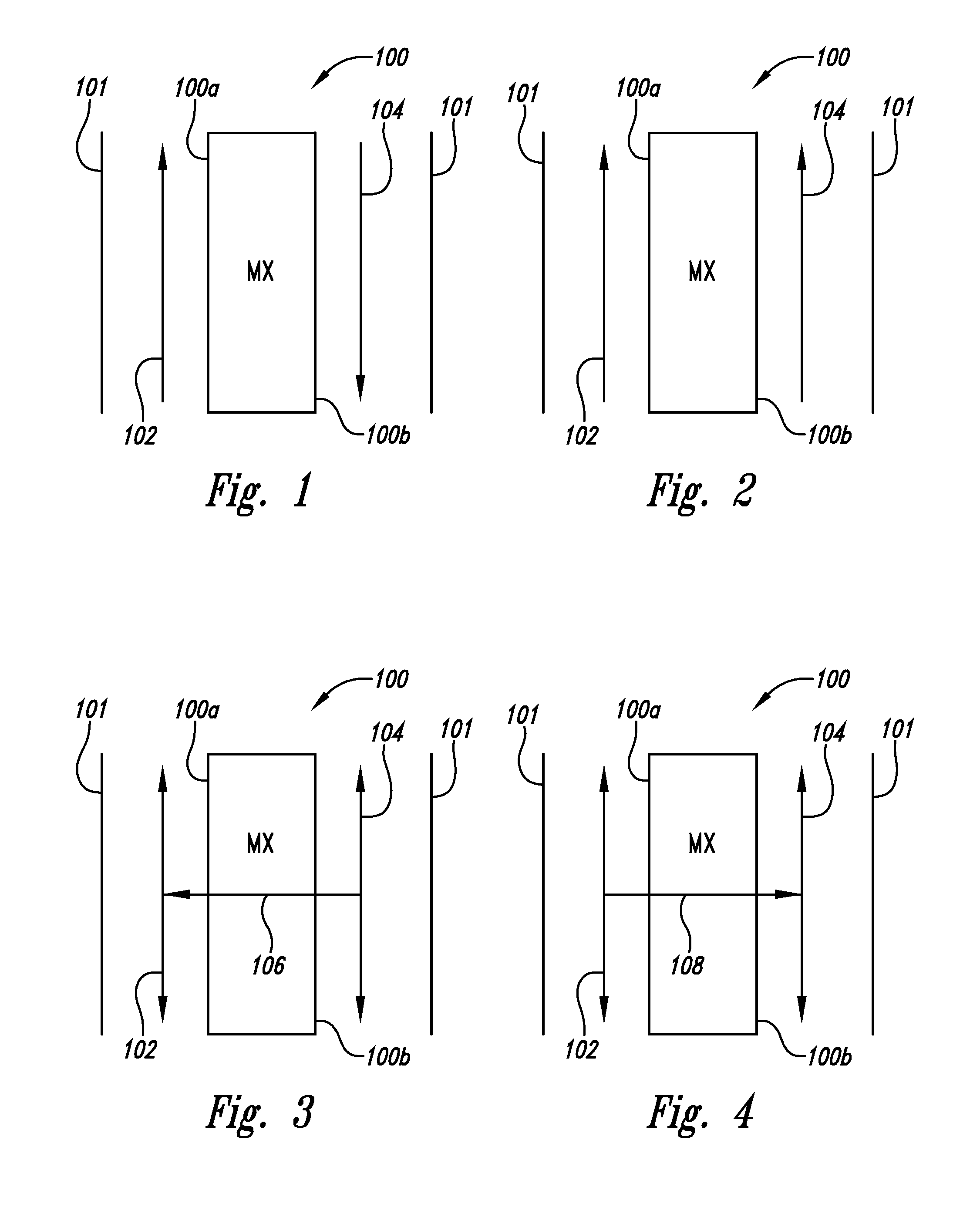

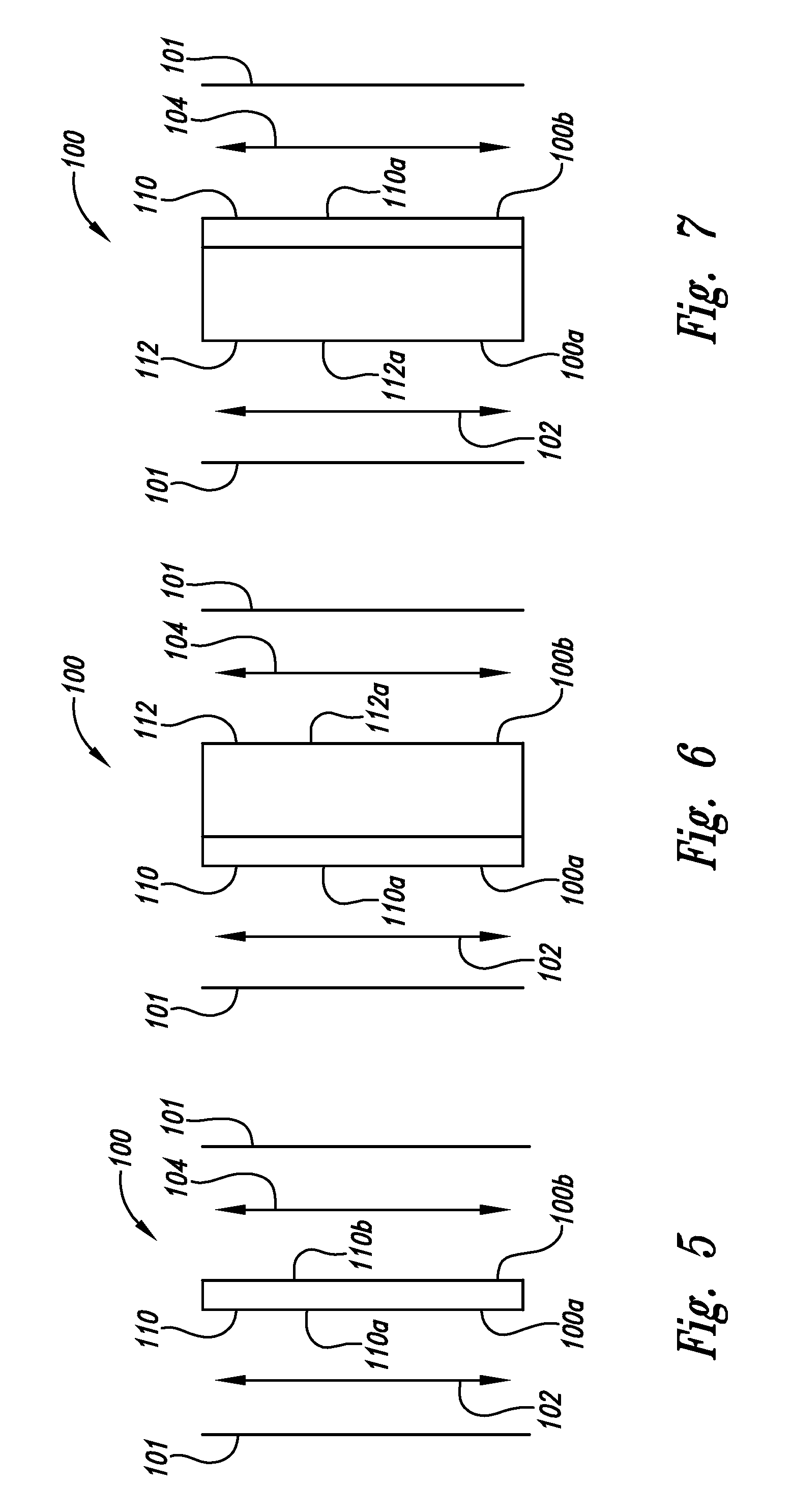

Liquid separation by membrane assisted vapor stripping process

InactiveUS20090057128A1Distillation regulation/controlUsing liquid separation agentImproved methodPermeation

An improved process for separation of liquid mixtures involves vapor stripping followed by mechanical compression of the vapor which is then exposed to a permeation membrane for separation of the compressed vapor.

Owner:VANE LELAND +1

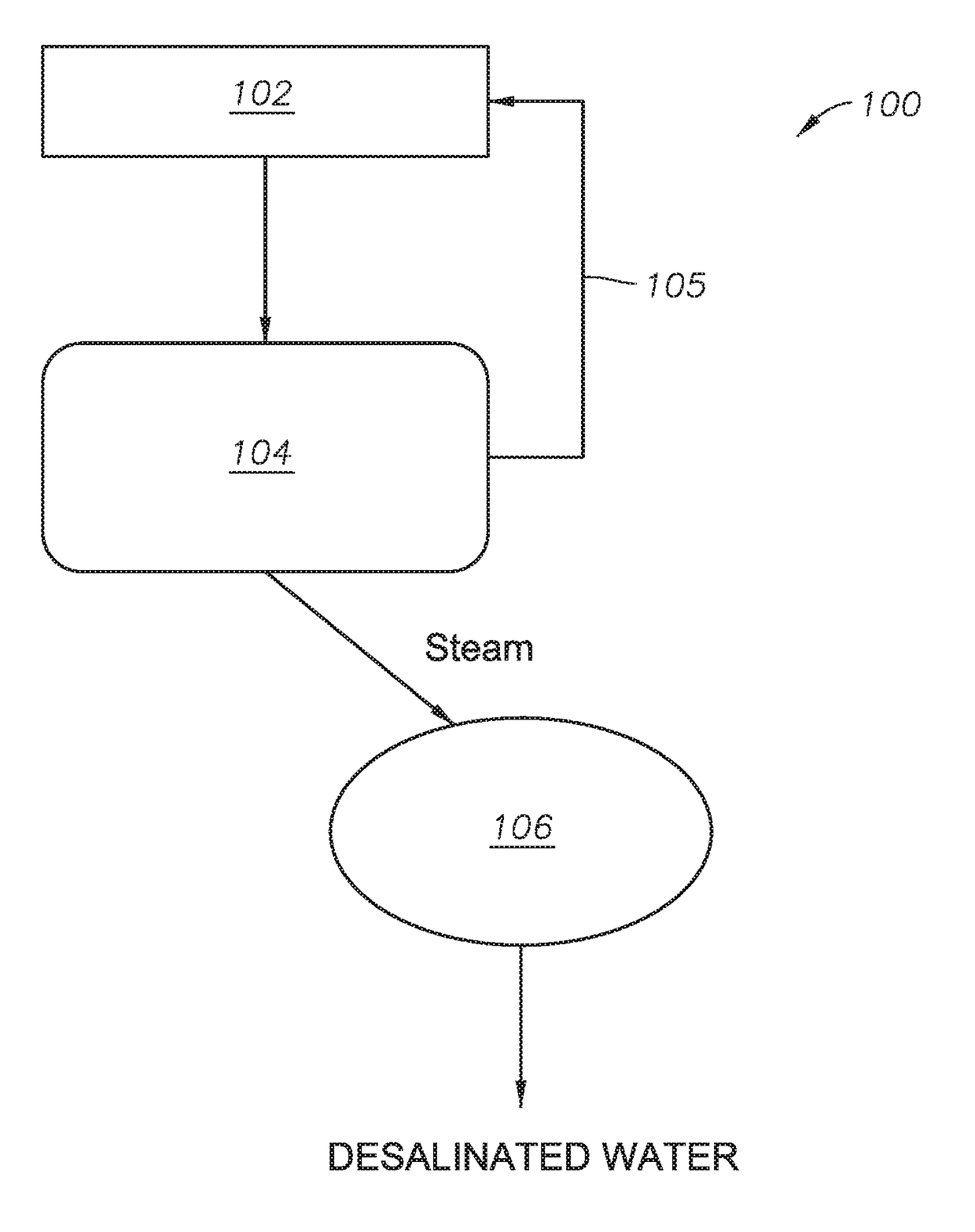

Desalination System

InactiveUS20080083605A1EfficientlyReduce workloadAuxillariesGeneral water supply conservationDesalinationEngineering

In accordance with particular embodiments, a desalination system includes a plurality of evaporators. The plurality of evaporators includes at least a first evaporator and a last evaporator. The plurality of evaporators are arranged in cascading fashion such that a concentration of salt in a brine solution increases as the brine solution passes through the plurality of evaporators from the first evaporator towards the last evaporator. The desalination system also includes a plurality of heat exchangers. An input of each evaporator is coupled to at least one of the plurality of heat exchangers. The system also includes a vapor source coupled to at least one of the plurality of evaporators.

Owner:TERRABON ADVE +1

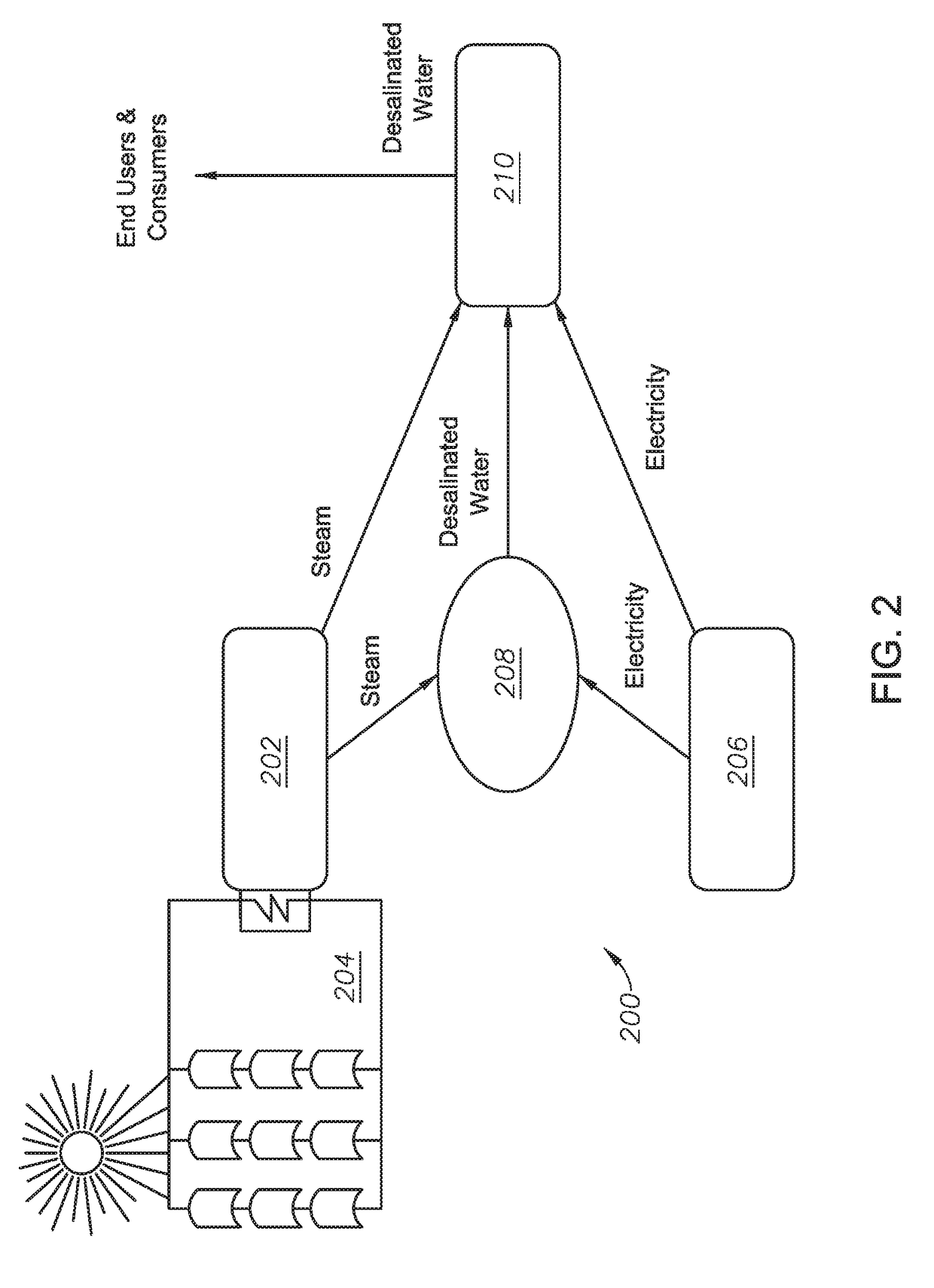

Coupling photovoltaic and concentrated solar power technologies for desalination

ActiveUS10065868B2Eliminate needSolar heating energyGeneral water supply conservationWater sourceEngineering

Systems and methods for the desalination of water are disclosed. A system includes a concentrated solar power (CSP) system, the CSP system operable to concentrate solar energy to increase temperature and pressure of a heat transfer fluid and operable to produce steam utilizing heat from the heat transfer fluid; a photovoltaic (PV) system, the PV system operable to collect solar energy to produce electricity; a desalination system in fluid communication with the CSP system and in electrical communication with the PV system, the desalination system operable to produce desalinated water from a salt water source utilizing the steam from the CSP system and electricity from the PV system; and a pump station in fluid communication with the CSP system and the desalination system, and in electrical communication with the PV system, the pump station operable to transmit the desalinated water to consumers for use.

Owner:SAUDI ARABIAN OIL CO

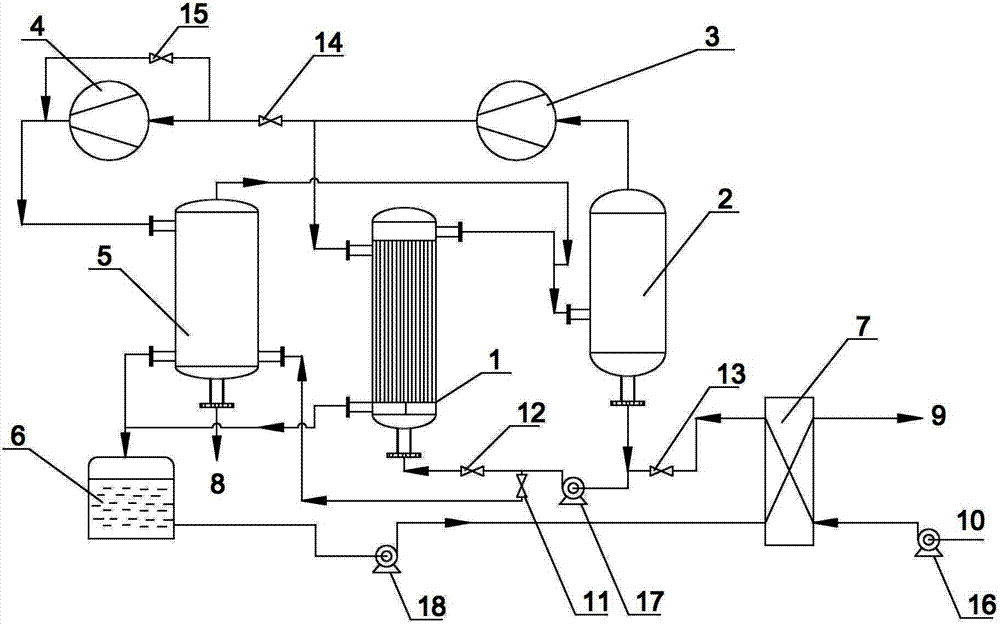

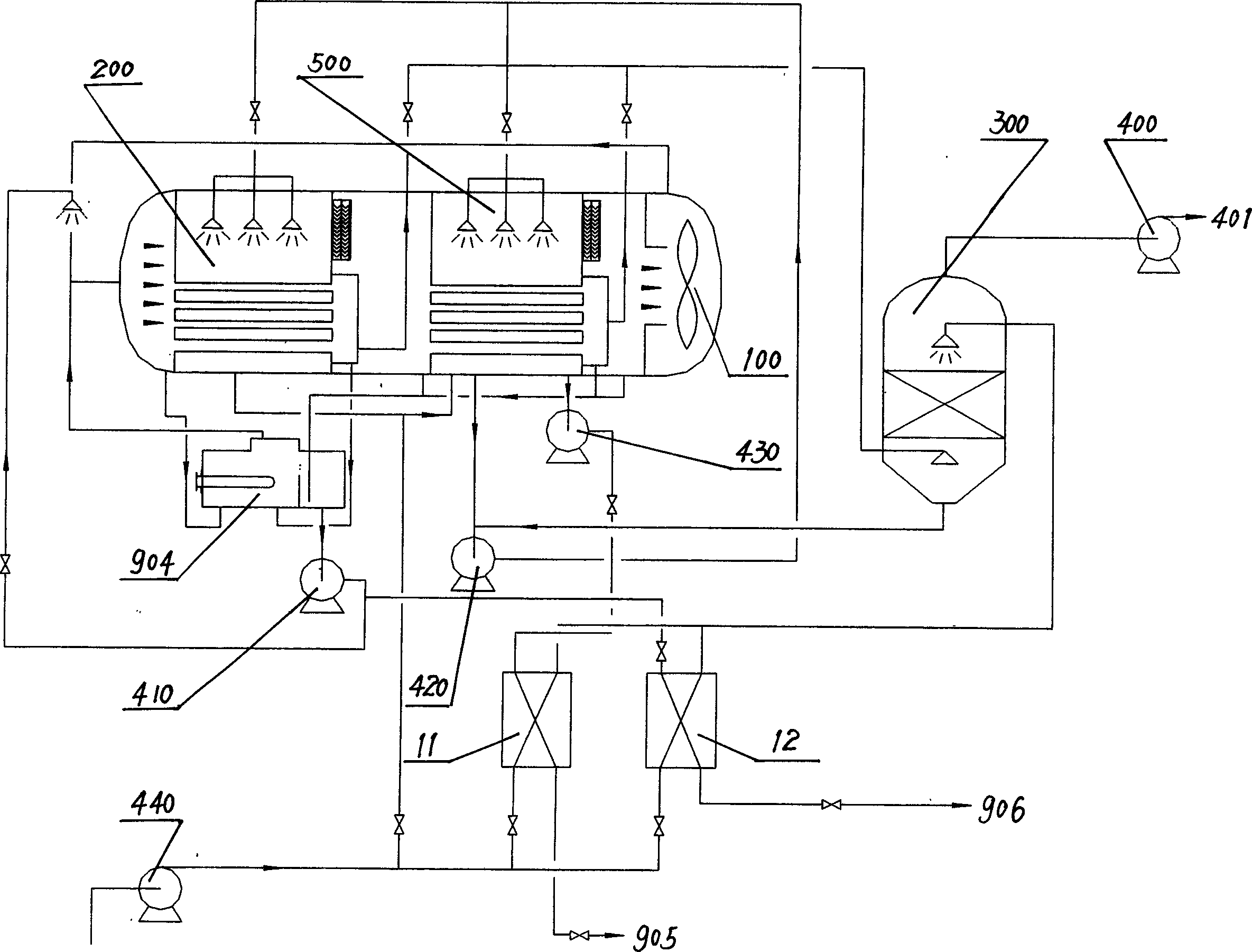

MVR (Mechanical Vapor Recompression) continuous evaporative crystallization system and continuous evaporative crystallization method

ActiveCN103203116ATake advantage ofSmall footprintEvaporation with vapour compressionSolution crystallizationEvaporatorEngineering

The invention relates to an MVR (Mechanical Vapor Recompression) continuous evaporative crystallization system and a continuous evaporative crystallization method. The system comprises an evaporator, a steam-liquid separator, a main steam compressor, an assistant steam compressor and a crystallizer. The outlet of the evaporator is connected with the inlet of the steam-liquid separator. The top outlet of the steam-liquid separator is connected with the main steam compressor which is further communicated with the top inlet of the evaporator. The communicating pipeline of the main steam compressor with the top inlet of the evaporator is provided with a branched pipeline connected to the crystallizer. The branched pipeline is provided with the assistant steam compressor which is provided by a bypass. The bottom outlet of the steam-liquid separator is respectively connected with the inlets of the evaporator and the crystallizer. The top of the crystallizer is connected with the inlet of the steam-liquid separator. The method is carried out by the system. Through reasonable design, the energy-saving economical benefit, the integrity, the reasonability and the agility of the evaporative crystallization technology are further improved. Secondary steam in the evaporating and crystallizing process is adequately utilized, and latent heat is recovered, so that the thermal efficiency is improved.

Owner:江苏迪飞生物技术有限公司

High-speed chamber mixer for catalytic oil suspensions as a reactor for the depolymerization and polymerization of hydrocarbon-containing residues in the oil circulation to obtain middle distillate

InactiveUS20070131585A1Eliminate disadvantagesQuality improvementThermal non-catalytic crackingCatalytic crackingDepolymerizationDistillation

Production of diesel oil from hydrocarbon-containing residues in an oil circulation with separation of solids and product distillation for the diesel oil product by energy input with a high-speed chamber mixer and the use of fully crystallized catalysts that consist of potassium-, sodium-, calcium-, and magnesium-aluminum silicates, wherein the energy input and conversion occur primarily in the high-speed chamber mixer.

Owner:KOCH CHRISTIAN

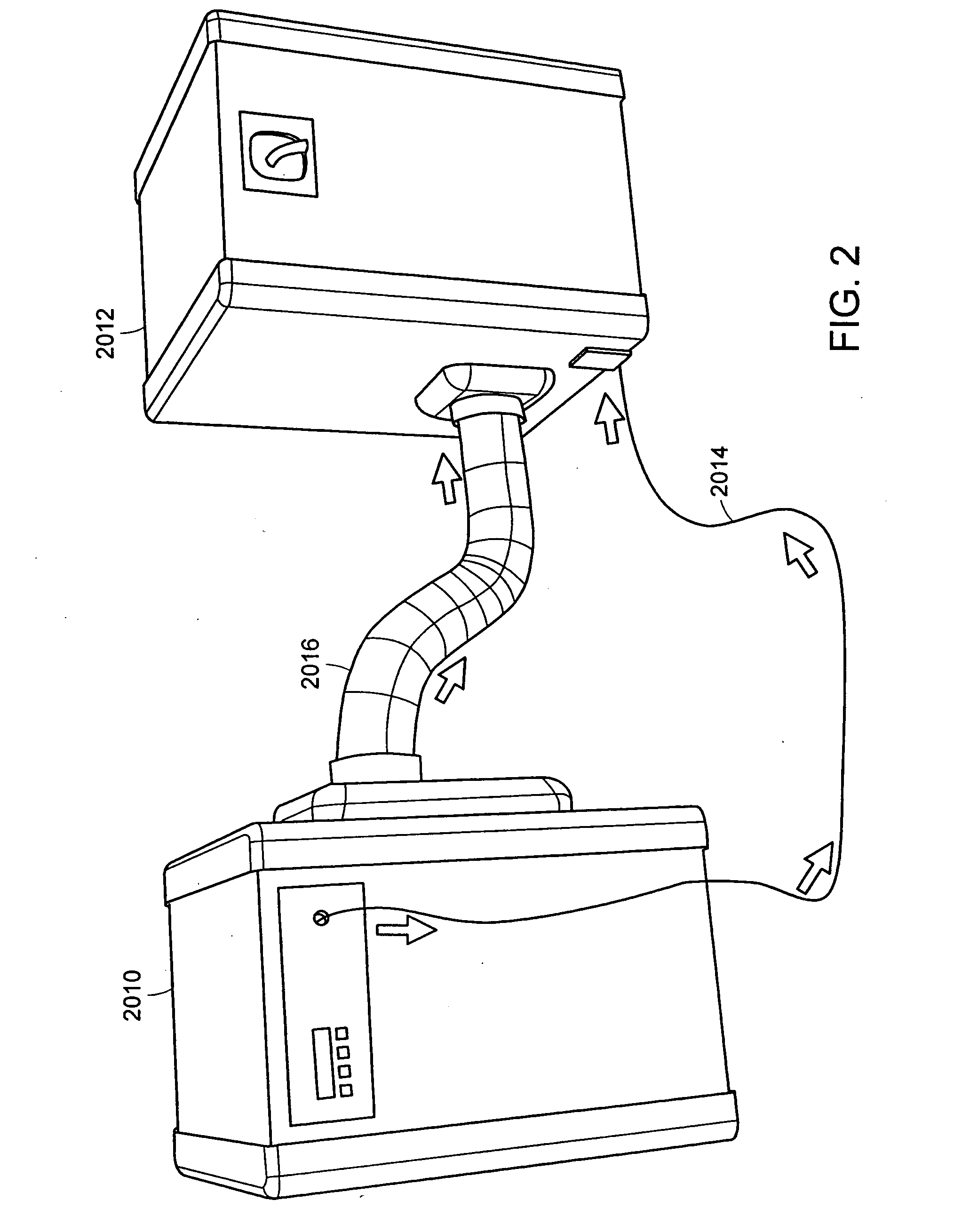

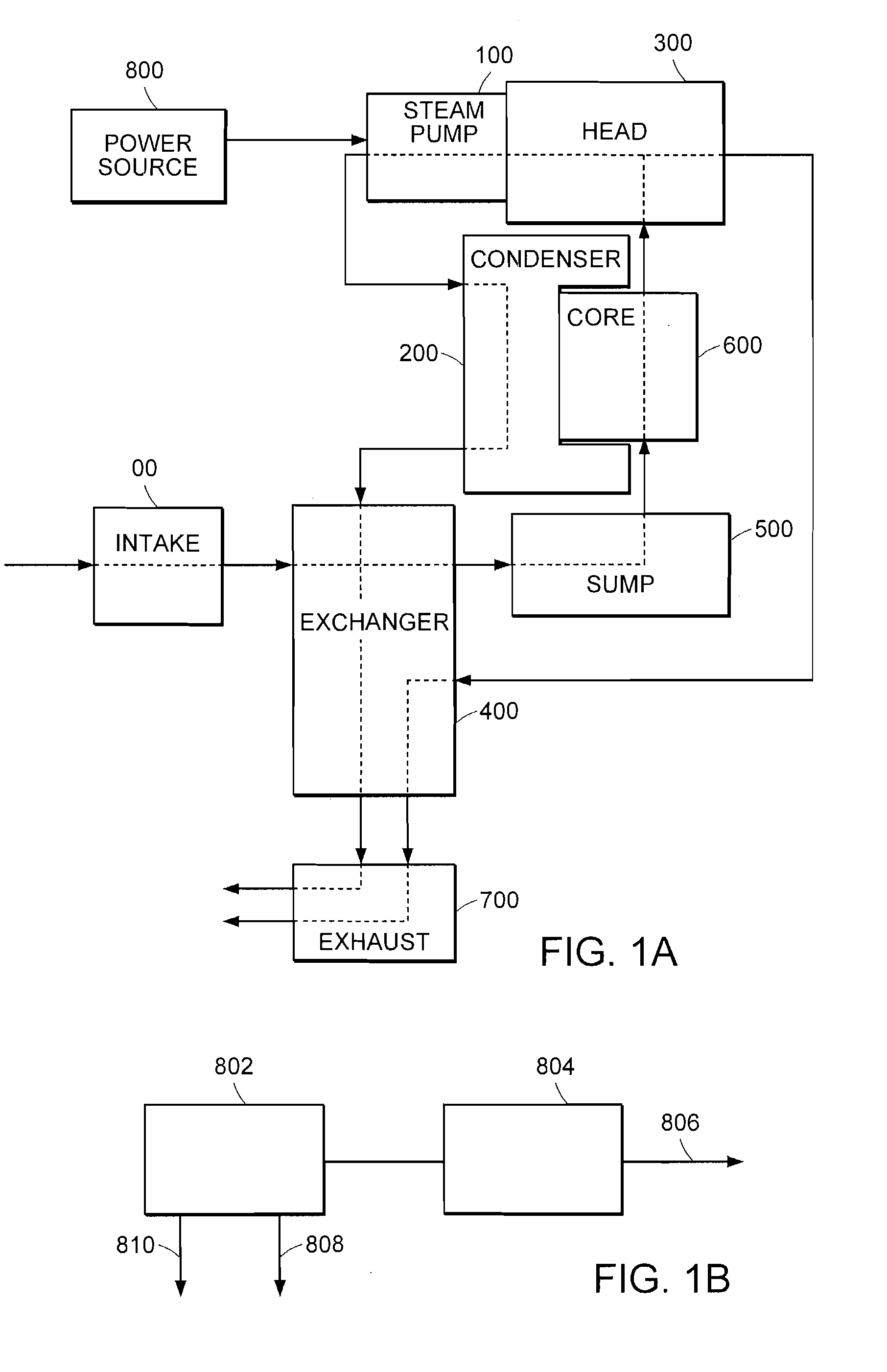

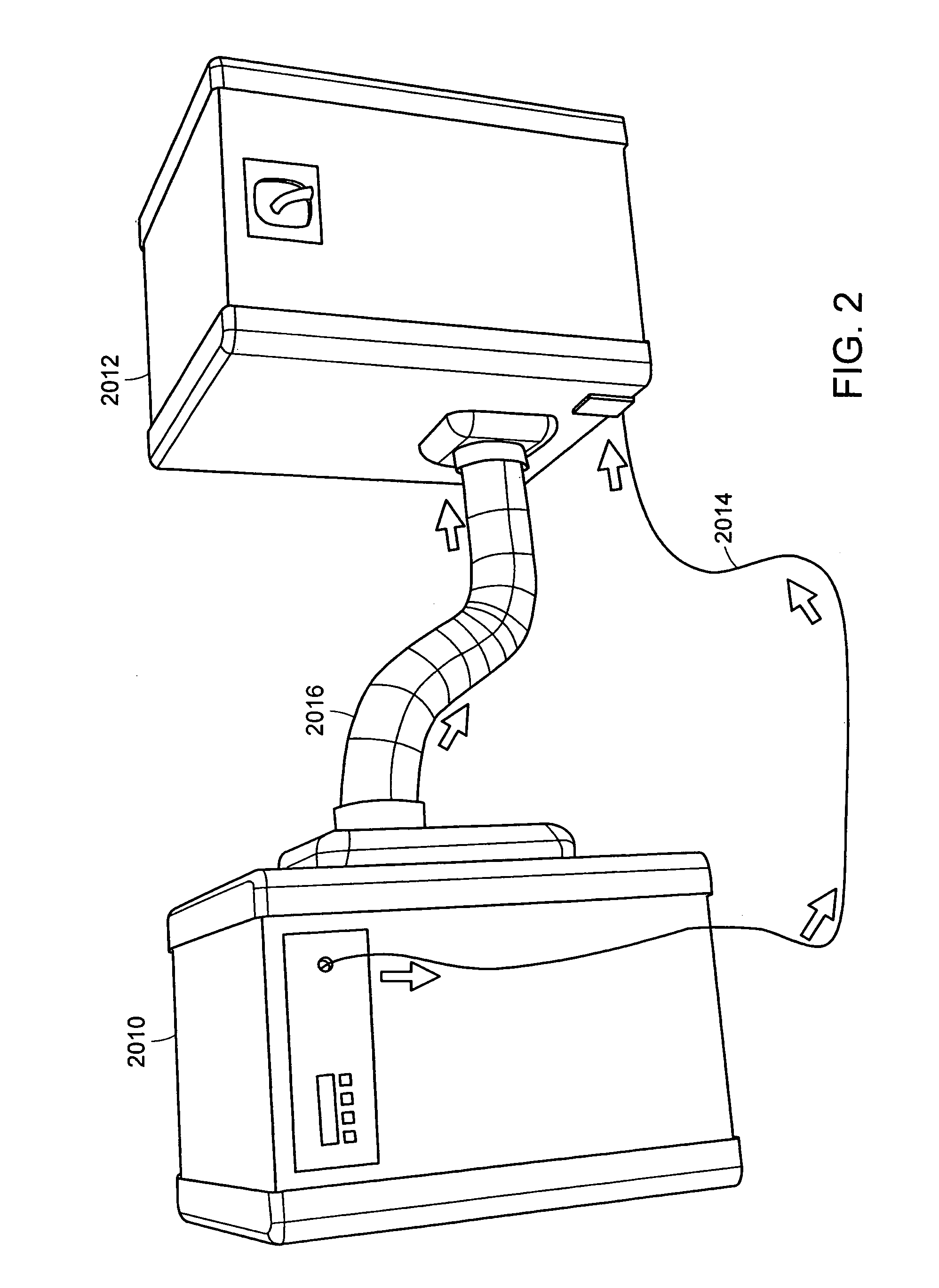

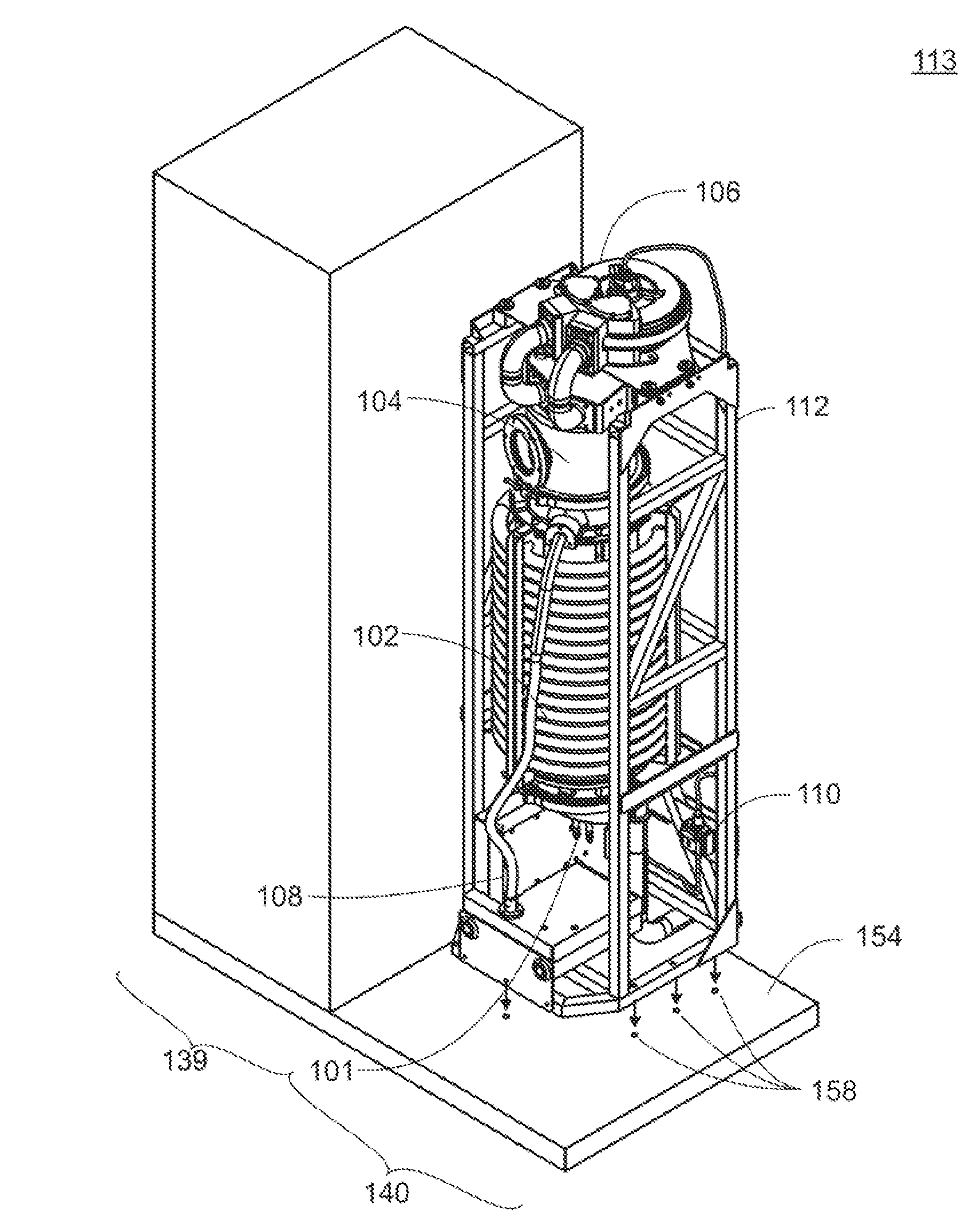

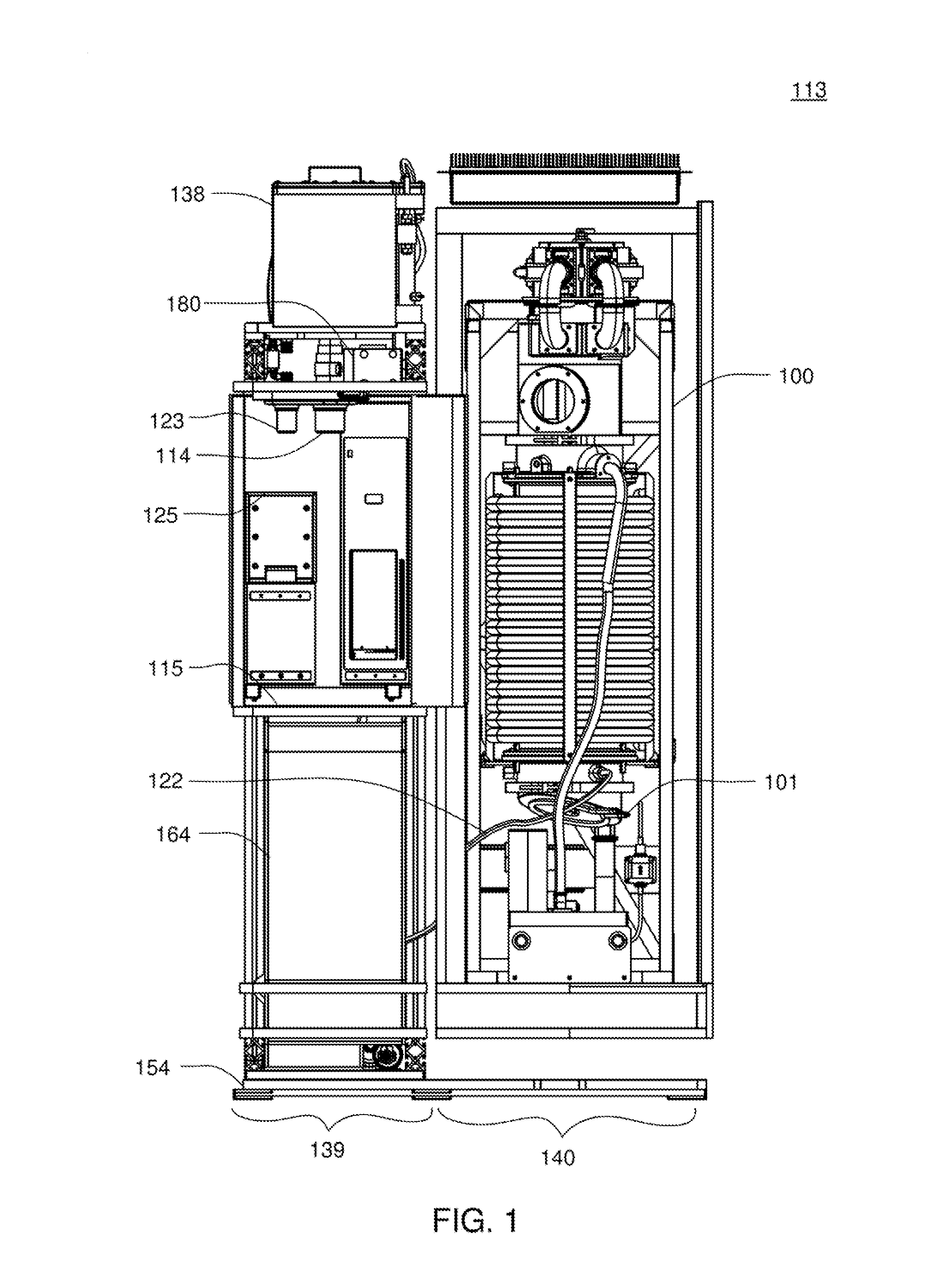

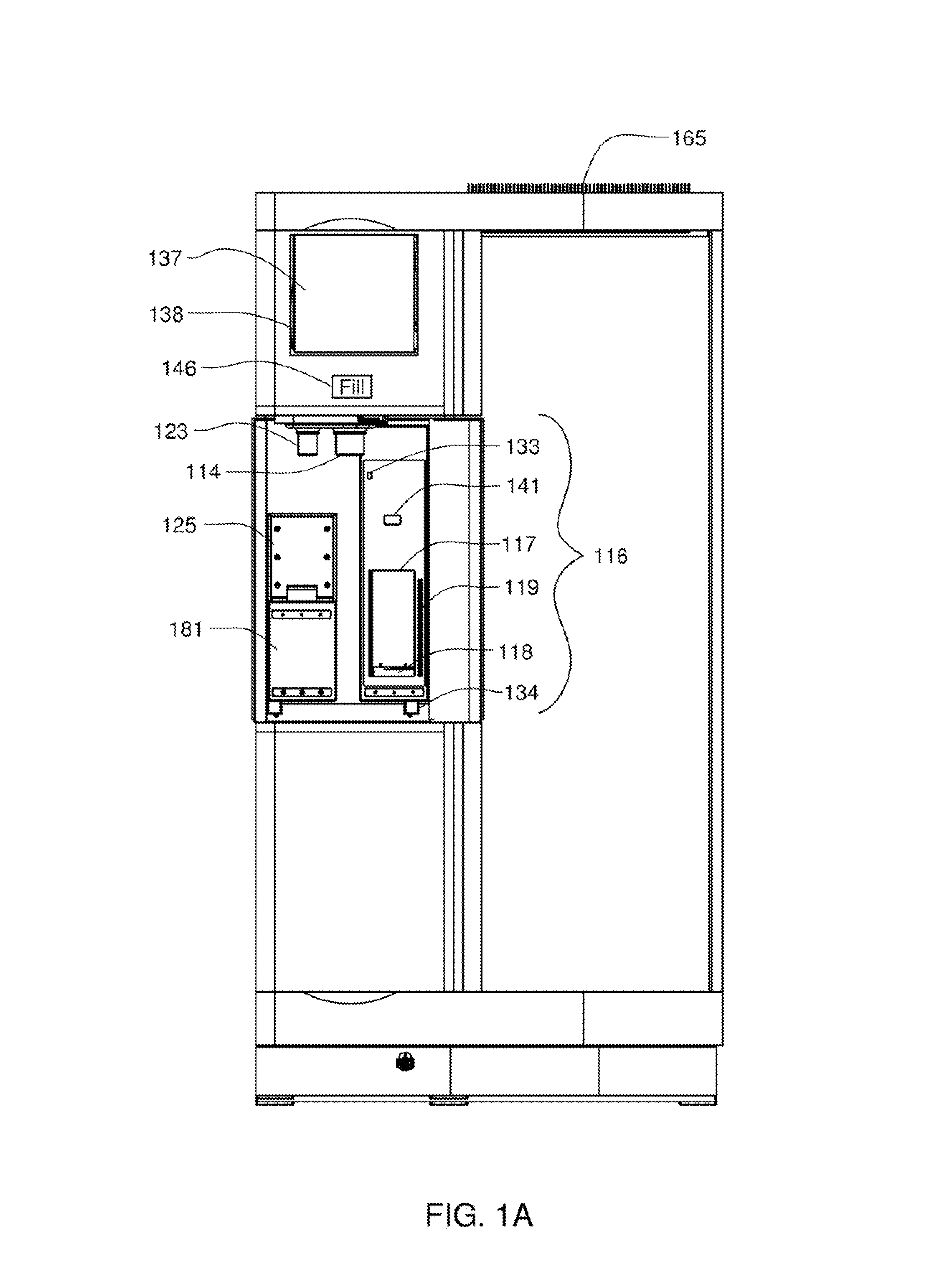

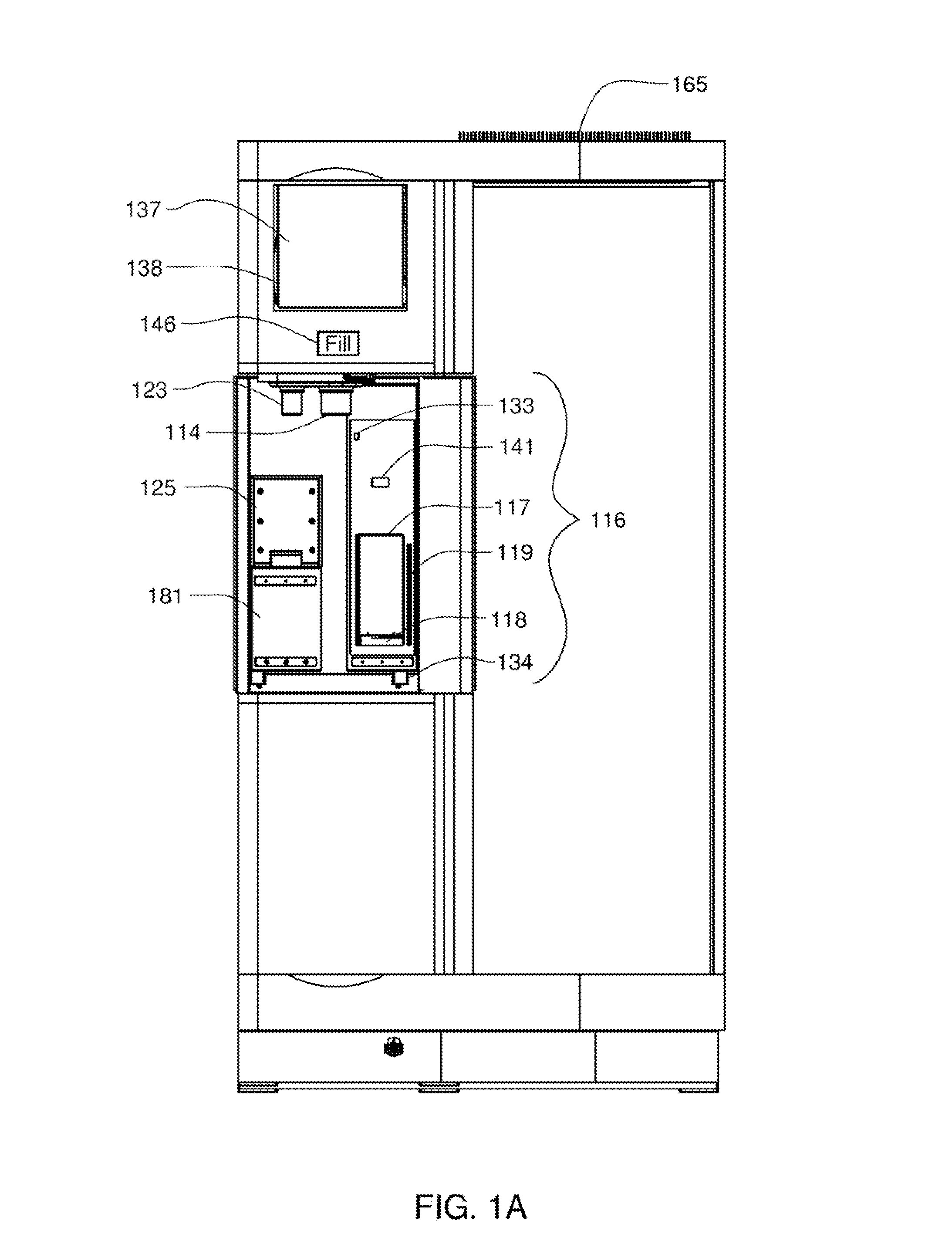

Water Vending Apparatus

ActiveUS20100101929A1Less production ratePrevents sediment buildupWater/sewage treatment by irradiationLighting and heating apparatusWater vaporSteam distillation

A water vending apparatus is disclosed. The water vending system includes a water vapor distillation apparatus and a dispensing device. The dispensing device is in fluid communication with the fluid vapor distillation apparatus and the product water from the fluid vapor distillation apparatus is dispensed by the dispensing device.

Owner:DEKA PROD LLP

Solar distillation device

A solar distillation apparatus utilizing a substantially vertical reactor assembly is disclosed. The reactor includes a tubular outer shell, a base, a cap, and a central tension member. The annular space between the outer tube and the central tension member forms the reactor chamber. Seawater or other feed liquid enters the reactor chamber through the base plate. Reflected or direct solar energy heats the feed liquid, generating low pressure vapor. The vapor exits the reactor through the cap structure or the base. The concentrate left behind settles by gravity to the bottom region of the reactor's liquid column. Extension tubes on the feed openings allow feed liquid to enter the liquid column above the concentrate layer and avoid excessive mixing of the feed liquid and the concentrate. The concentrate exits the reactor through one or more openings in the base.

Owner:MCCLURE MILES

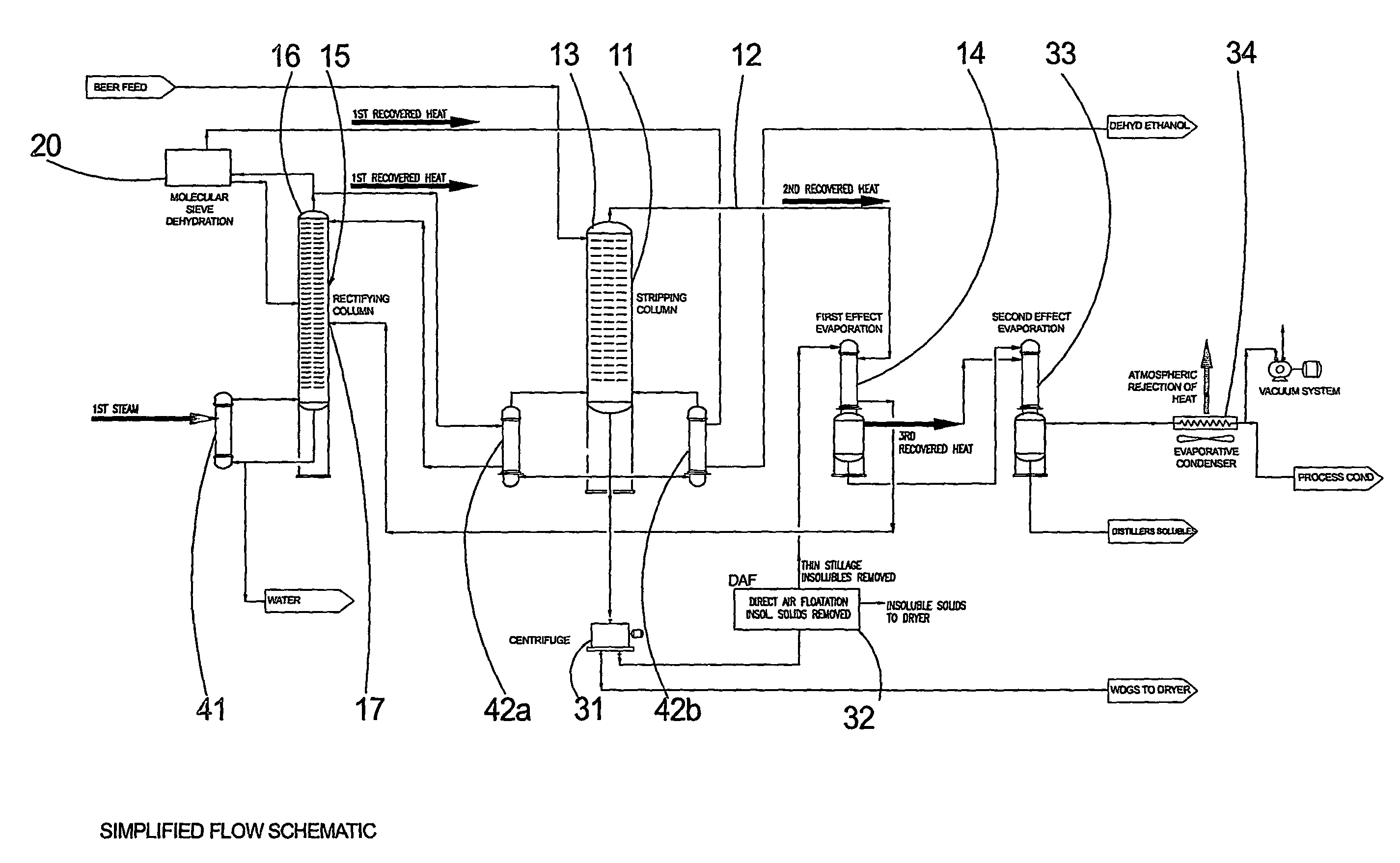

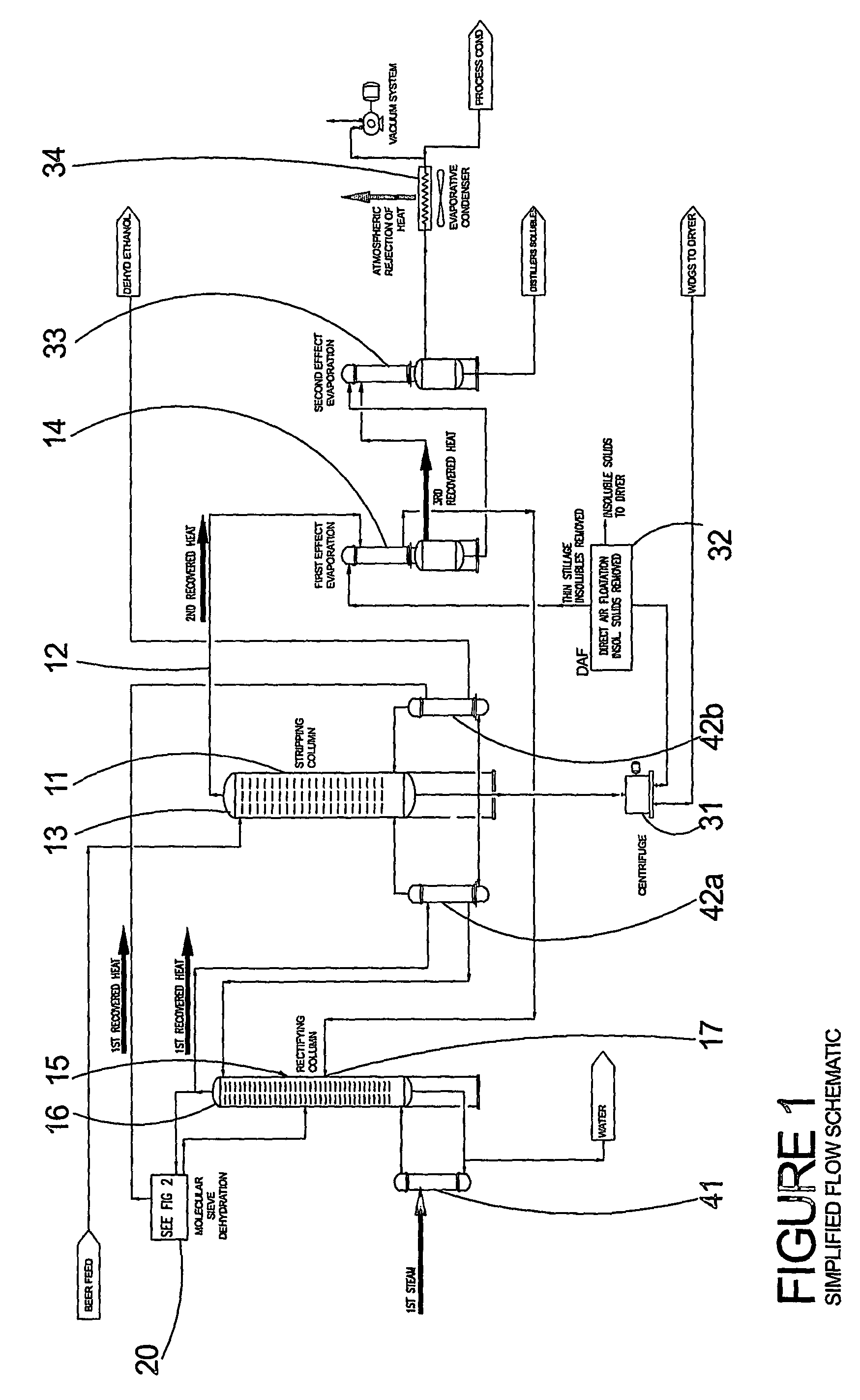

Ethanol distillation with distillers soluble solids recovery apparatus

ActiveUS7867365B2Reduce energy useIncrease concentrationDrying using combination processesDistillation regulation/controlMolecular sieveAnhydrous ethanol

The present invention relates to a system for producing ethanol from an organic source and that operates to purify and dry ethanol from a beer source. The system for producing substantially anhydrous ethanol comprises: (a) a first distillation stripping column; (b) a second distillation rectifying column having a higher operating temperature than said stripping column; (c) a molecular sieve dehydration means in fluid communication with said rectifying column. Heat from the overhead of the second distillation rectifying column and the molecular sieve dehydration are used to heat the first distillation stripping column.

Owner:RCM TECH USA INC

Multi-phase selective mass transfer through a membrane

Disclosed herein are embodiments relating to particular systems comprising a selective transfer membrane that can be utilized in material separation. In certain embodiments, the membrane assembly comprises part of a desalination, distillation, liquid purification, and / or heating and cooling system. Other particular embodiments allow for a high rate of thermal capture by way of the system utilizing a selective transfer membrane. Certain preferred embodiments include a selective transfer membrane comprising an ionomeric polymer that is permeable to high dipole materials.

Owner:TANGREDI PATRICIA

Method and apparatus for phase change enhancement

ActiveUS20050183832A1Distillation regulation/controlVacuum distillation separationEngineeringPhase change

A method of operating an evaporator is described. In evaporator feed water, a Taylor bubble is developed which has an outer surface including a thin film in contact with an inner surface of an outer wall of an evaporator tube. The Taylor bubble is heated as it rises within the evaporator tube so that liquid in the thin film transitions into vapor within the bubble.

Owner:DEKA PROD LLP

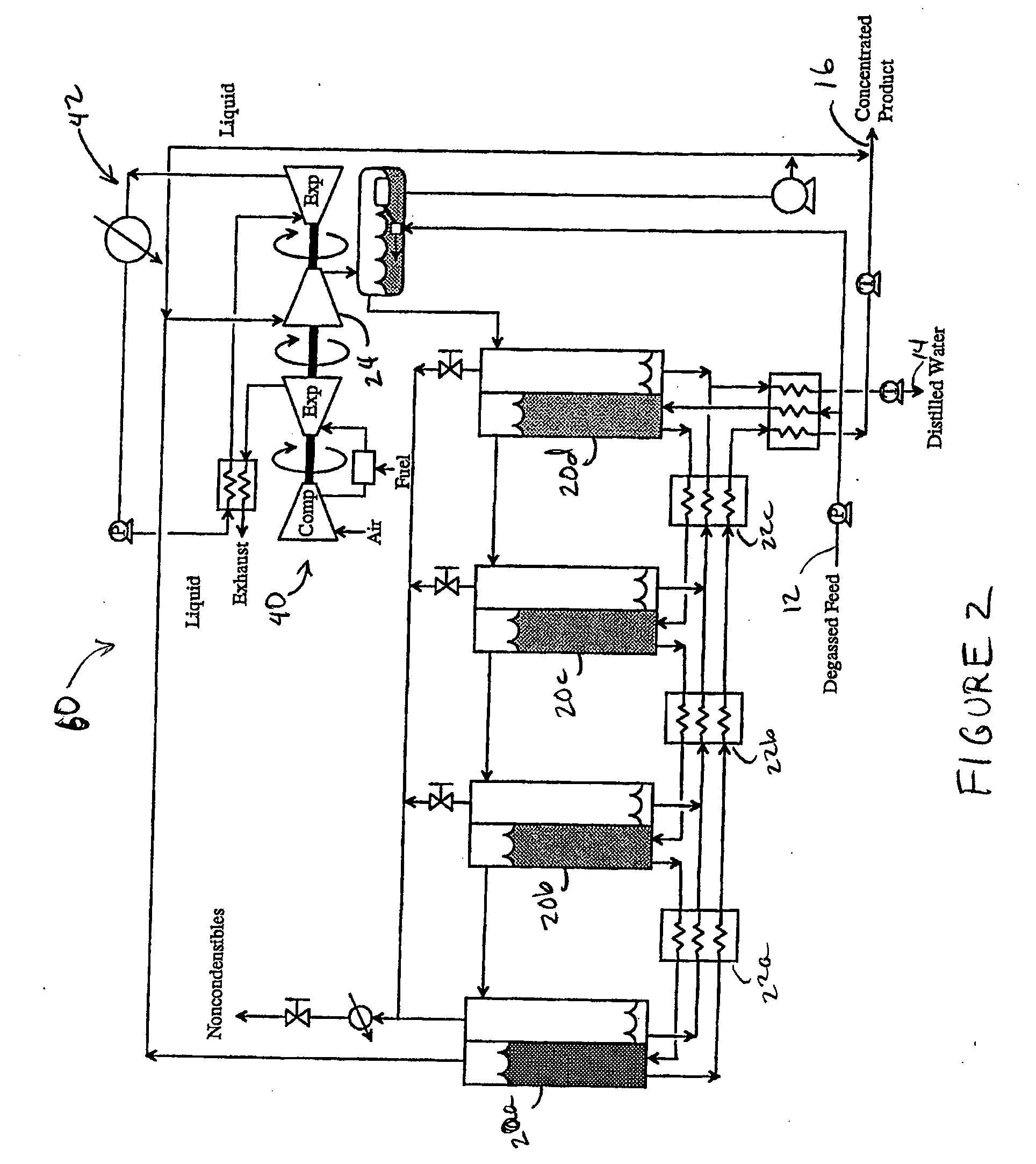

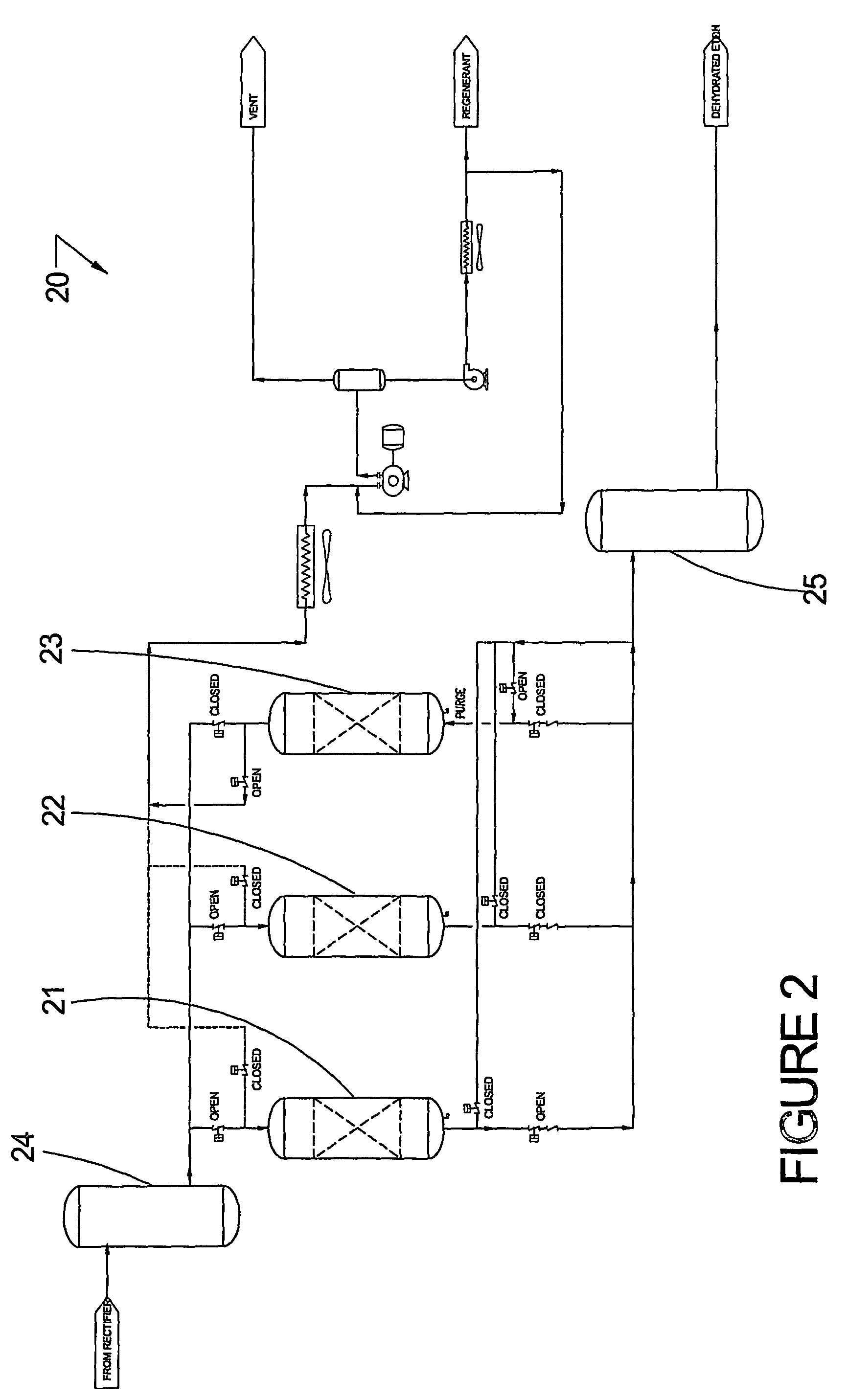

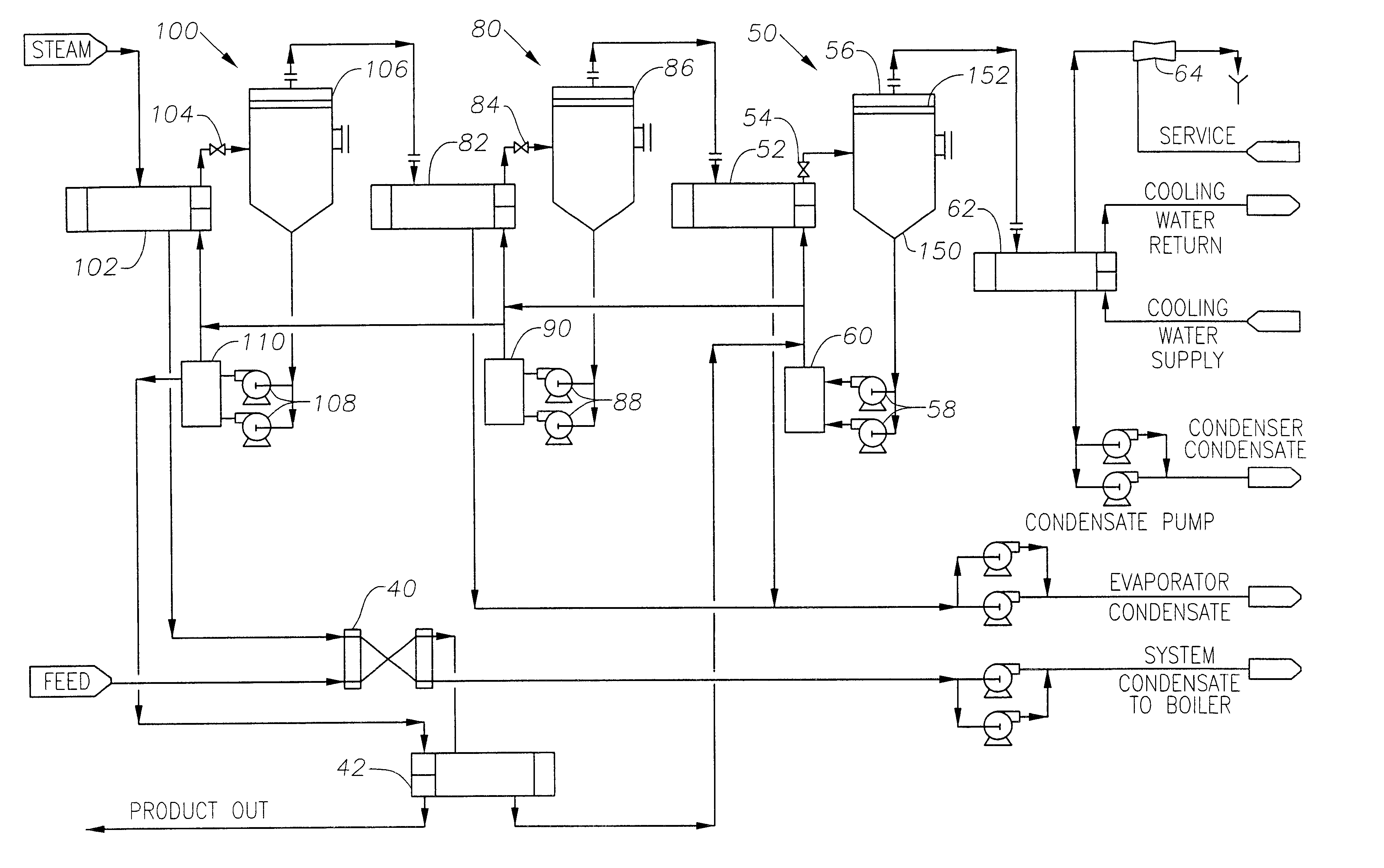

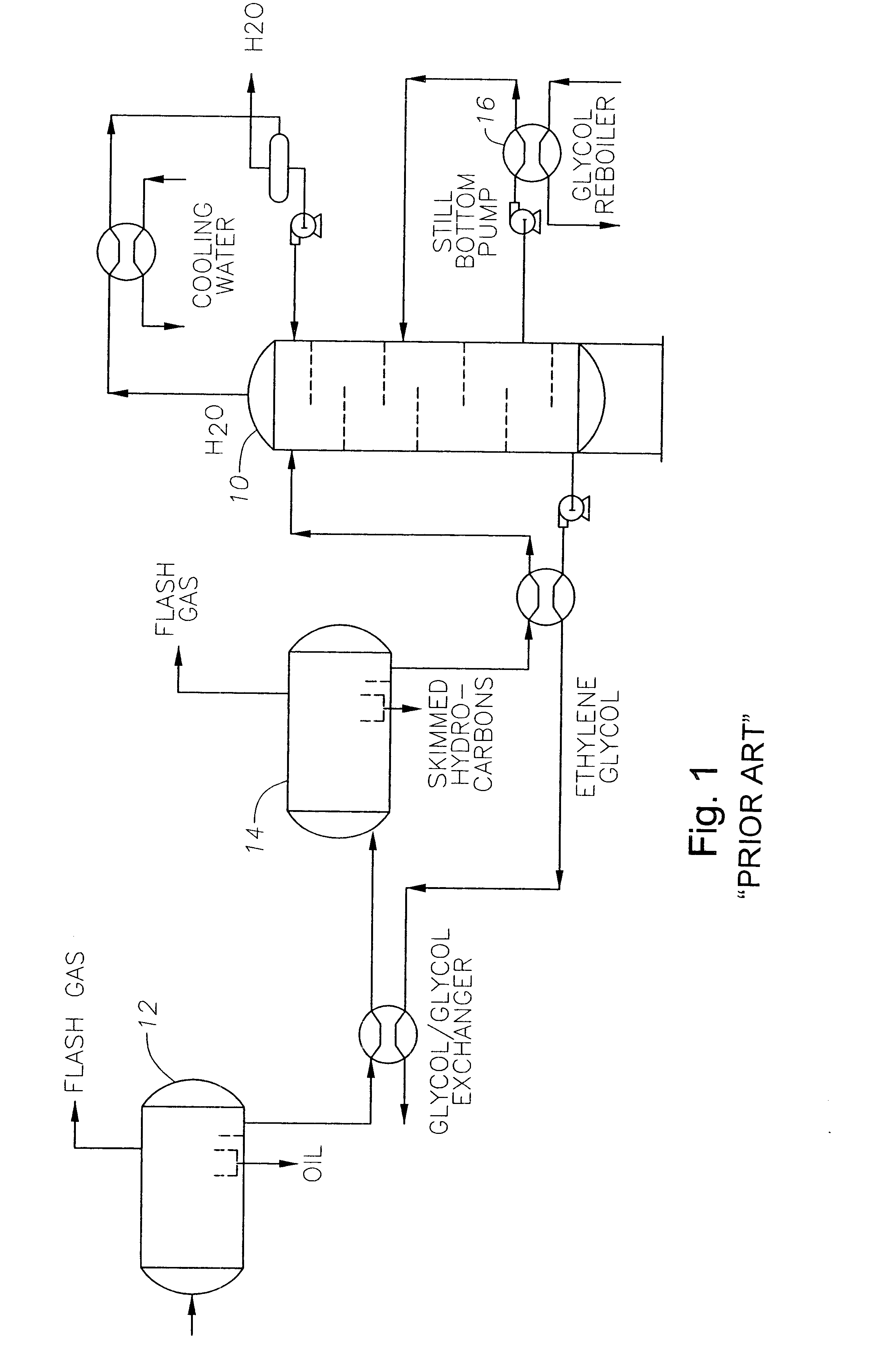

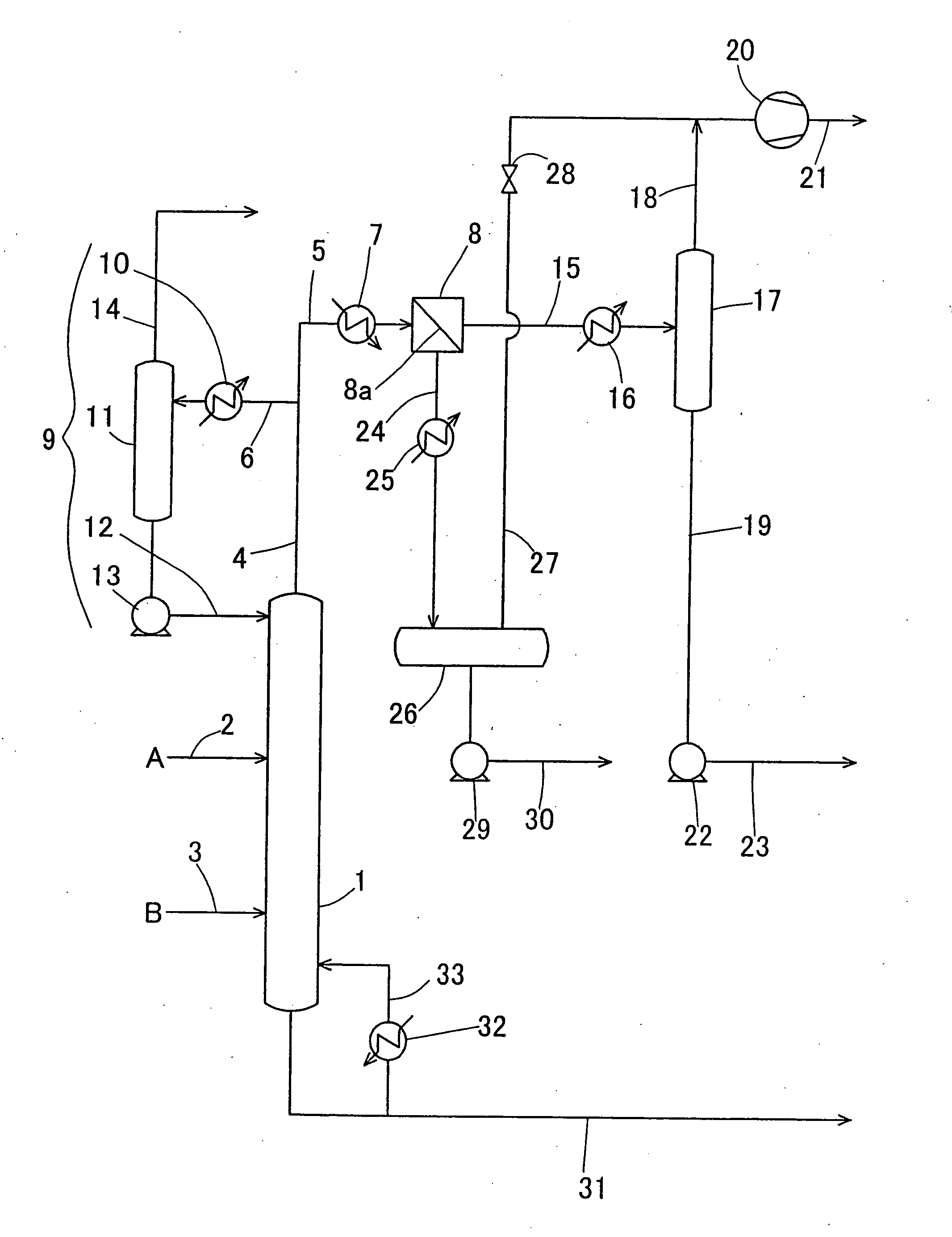

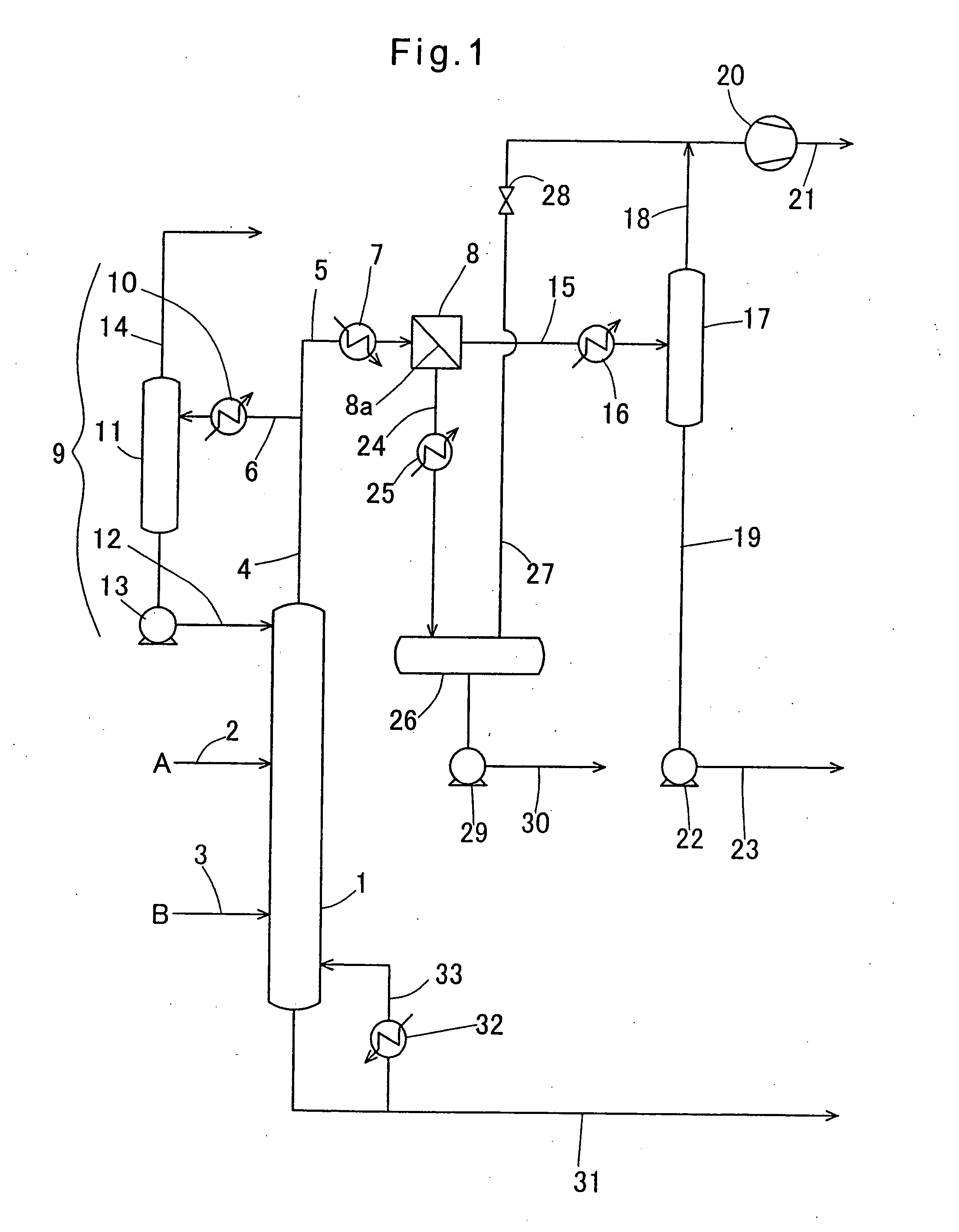

System for recovering glycol from glycol/brine streams

A system for recovering glycol from glycol and brine mixtures produced from oil or natural gas wells that combines energy efficiency with a capability for handling salt and other solids contained in the mixture. The system comprises three effect evaporator systems in series. Each effect evaporator system comprises an evaporator, a separator vessel, product pumps, and a solids removal system.The process utilizes the system to remove salt and other solids as well as excess water leaving a glycol stream that can be reused as a hydrate inhibitor. The process begins by preheating a glycol / brine stream comprising approximately fifty percent (50%) glycol. The stream is then subjected to three evaporation cycles. The first evaporation cycle comprises introducing the preheated stream into a suppressed boiling point evaporator where the stream is heated under a constant pressure. The stream pressure is then dropped to cause a portion of the water contained in the stream to vaporize or flash. The flashing stream is then introduced into a separator vessel where the water vapor is separated from the remaining liquid stream. The water vapor is removed from the separator and condensed. The remaining liquid glycol / brine stream is then pumped from the separator vessel through a solids removal system where precipitated salts and solids are removed. These steps are repeated two additional times. Each time the remaining liquid stream becomes more concentrated with glycol until the finished product is approximately ninety percent (90%) glycol.

Owner:TRANSOCEAN SEDCO FOREX VENTURES LTD

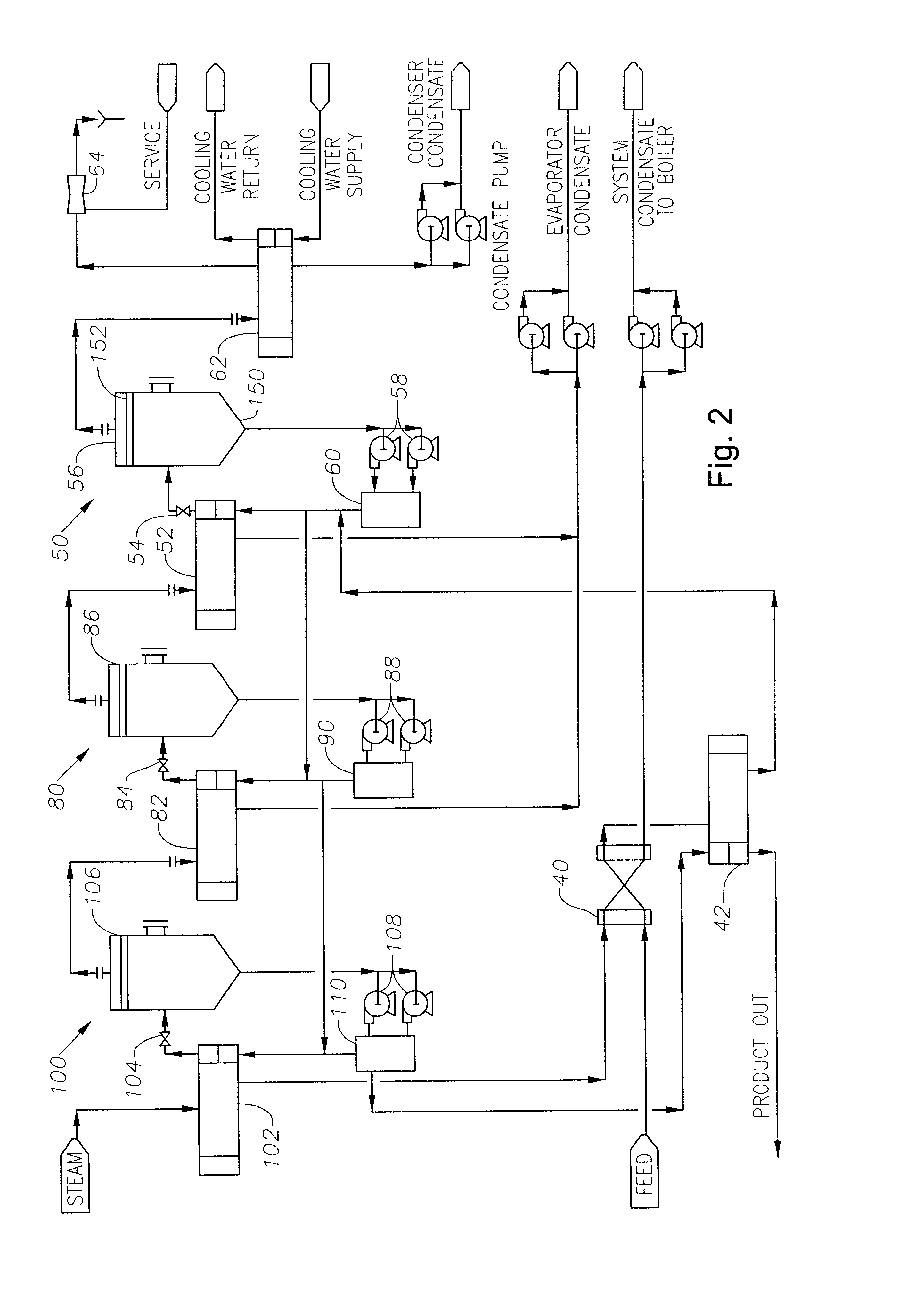

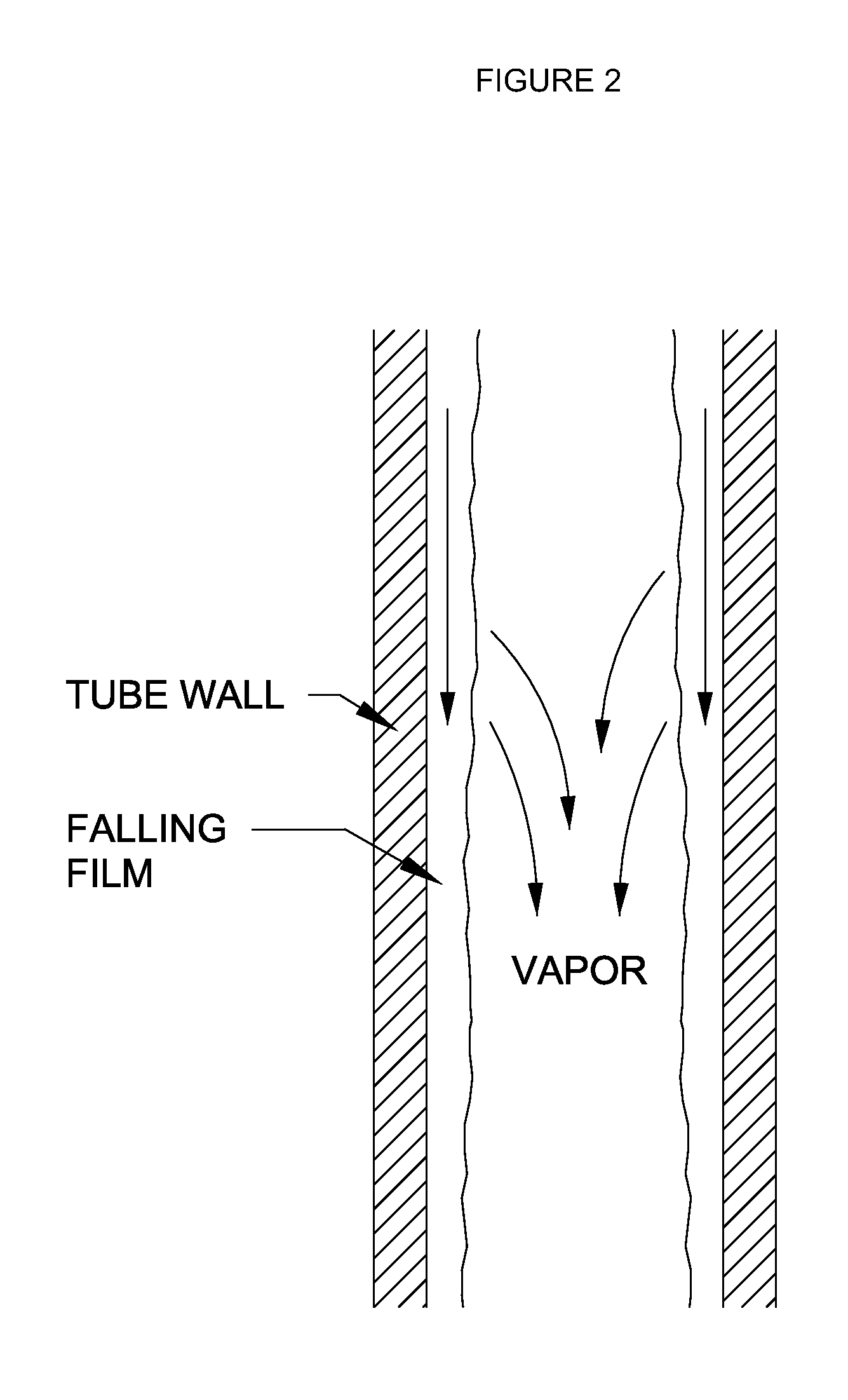

Method for recycling deoiled water using counterflow falling-film evaporators

ActiveUS20120145386A1High speedReduce chemical consumption requirementFatty/oily/floating substances removal devicesEvaporation with vapour compressionWater useSaline water

We provide an evaporator technology for treatment of produced water that may be deoiled water. Systems described herein utilize a vertical tube heat exchanger bundle where the brine is distributed in a falling film along the inside of the tube wall. Condensing steam causes a portion of the deoiled water to evaporate; this water vapor travels upward in a counterflow direction relative to the deoiled water. This evaporator technology provides several design advantages over the conventional vertical tube co-current flow evaporators (where the vapor flows downward with the falling film). These advantages include a minimal total installed cost (TIC) as well as offering optimal design features for water chemistry management.

Owner:AQUATECH INT LLC

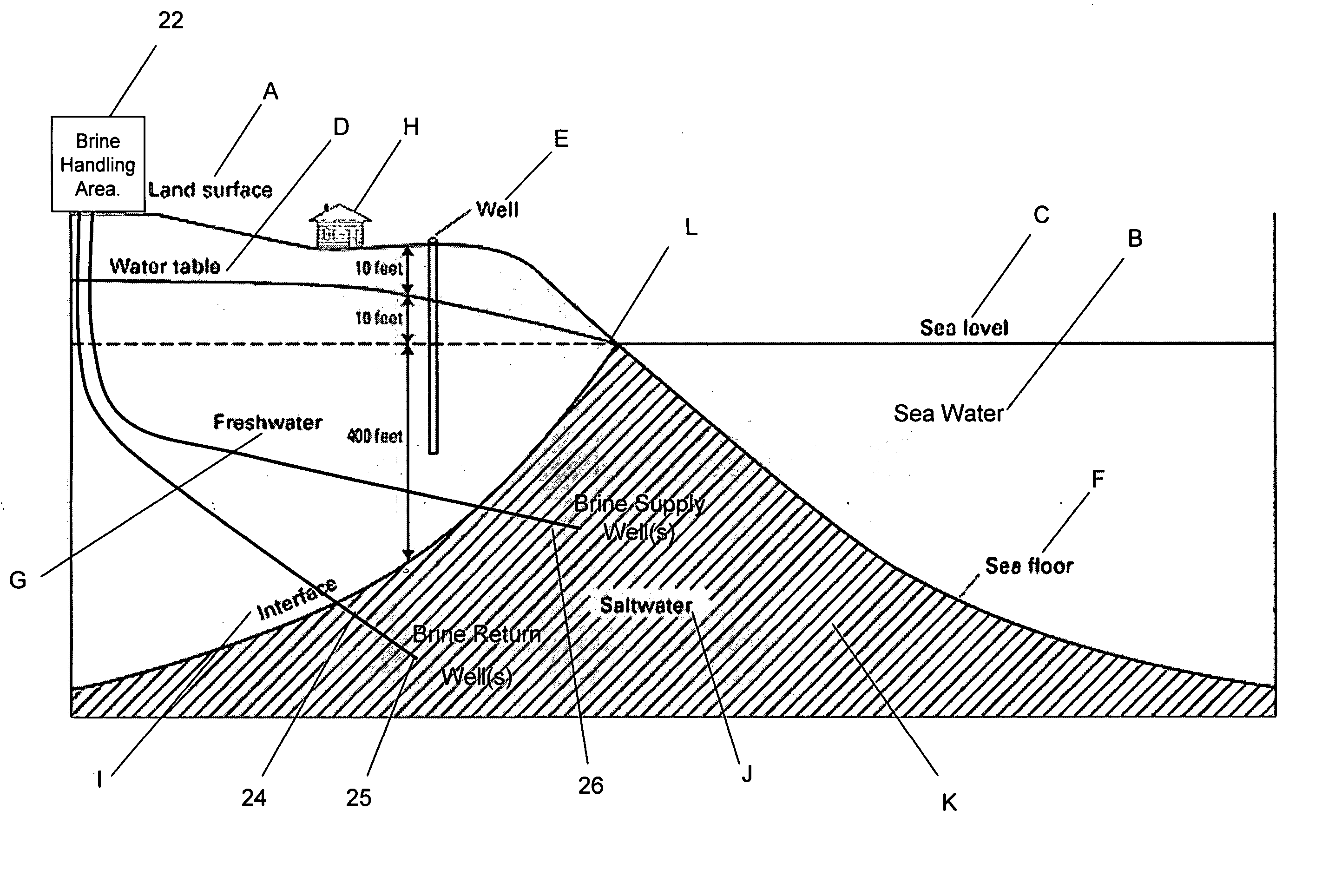

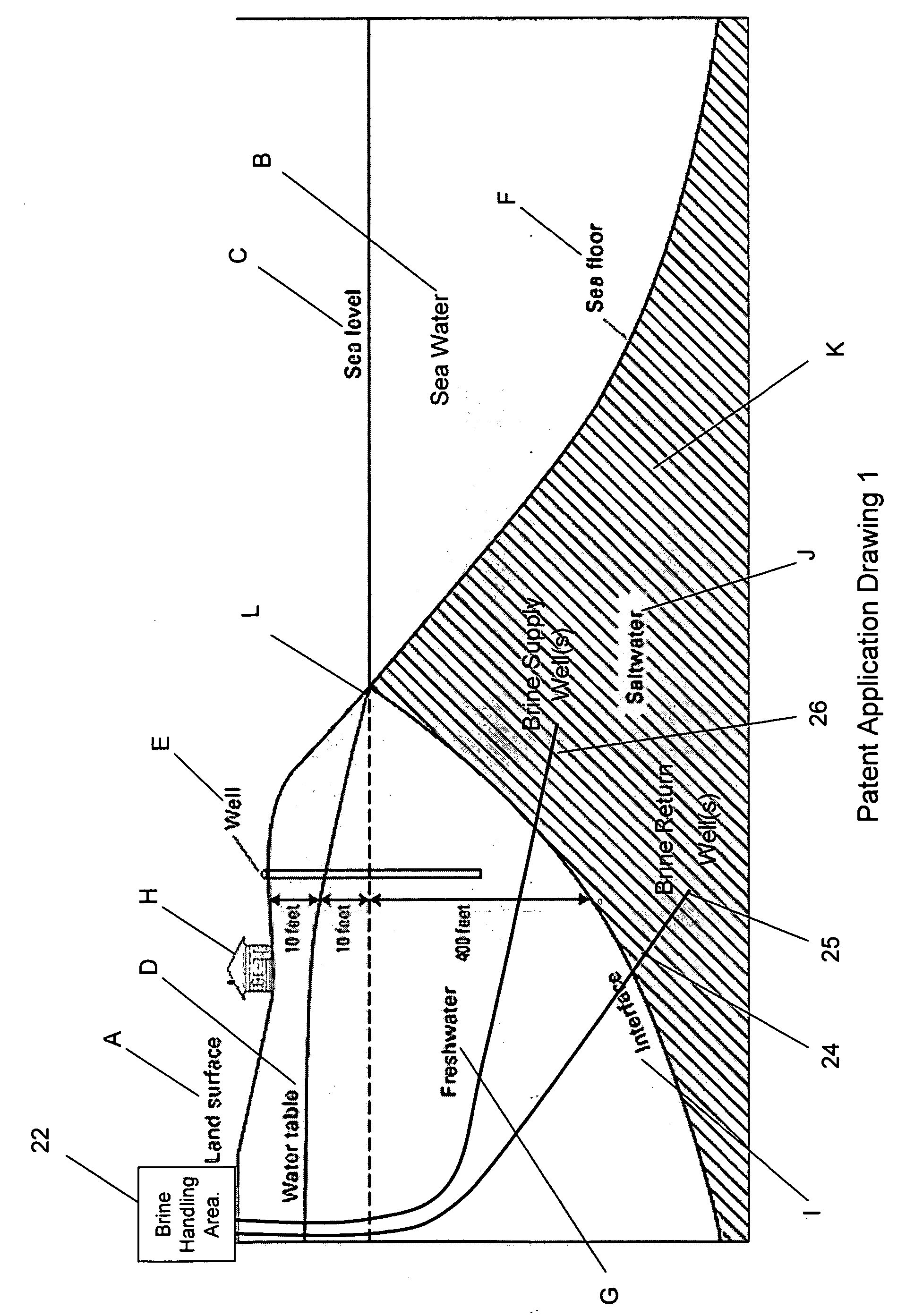

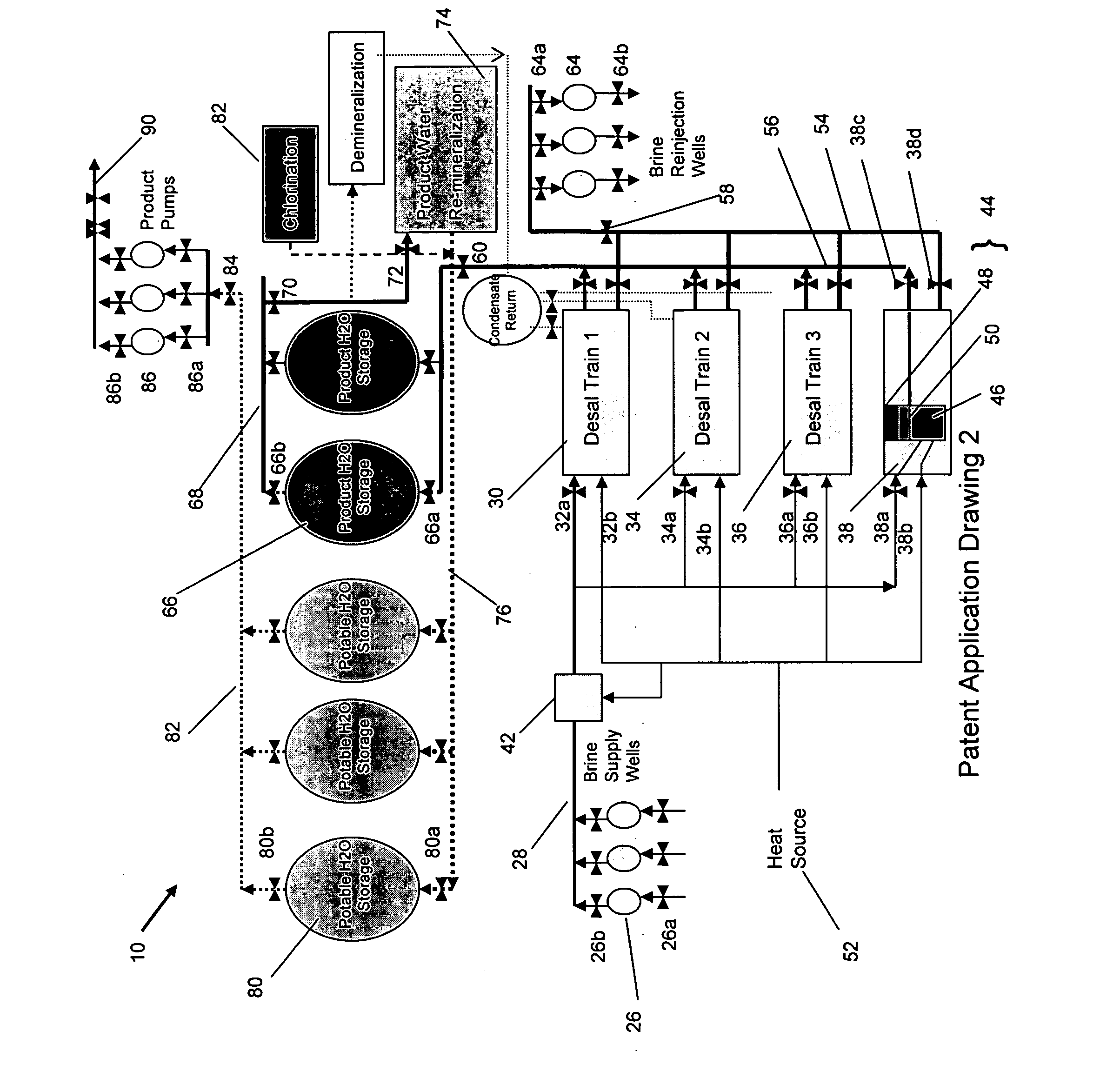

Method and apparatus for desalinating water combined with power generation

InactiveUS20070084778A1Good effectLower cost of capitalGeneral water supply conservationSeawater treatmentThermal energyWater desalination

A method and apparatus for desalinating water combined with power generation, comprising a desalination system used for desalinating coastal seawater and comprising a power generation system, wherein such dual purpose co-generation facility captures the heat vapor exhausted or a steam turbine generator's condenser is replaced by the desalination plant's heat exchanger enabling such captured heat energy to reduce the energy requirements of the desalination plant, and wherein brine solution being treated by the desalination plant is pumped from the substrata sea water table wells having low salt content brackish water.

Owner:ST GERMAIN GIRARD CHARLES +1

Separator, reactor, and method for producing aromatic carboxylic acids

InactiveUS20070213557A1Reduce lossesReduce system sizeOrganic compound preparationDistillation regulation/controlAcetic acidCarboxylic acid

In a process for producing an aromatic carboxylic acid, it is a dehydrating process which can achieve compactification of a step for removing water from a mixture of acetic acid and water produced in the production process, and which can reduce the consumed energy. In a production process of an aromatic carboxylic acid having an oxidation reaction step for producing a slurry of an aromatic carboxylic acid by carrying out liquid-phase oxidation reaction of an alkyl aromatic compound with an oxygen-containing gas in a solvent containing acetic acid in the presence of an oxidation catalyst, at least a portion of a mixture containing acetic acid and water produced in the production steps is separated into a permeable gas mainly comprising water and nonpermeable substances mainly comprising acetic acid, using a separation membrane having water selectivity.

Owner:SEIKI YOSHIO +7

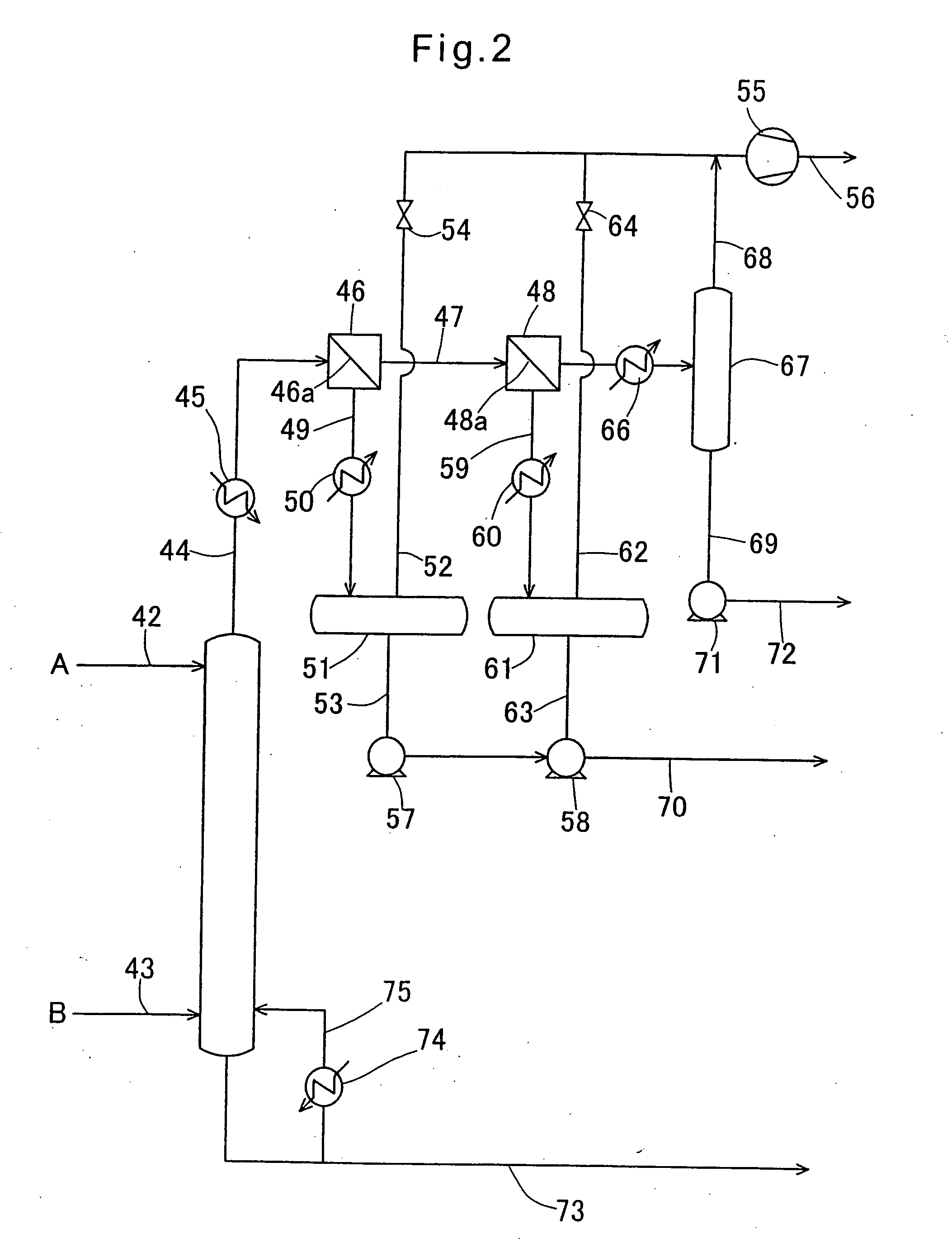

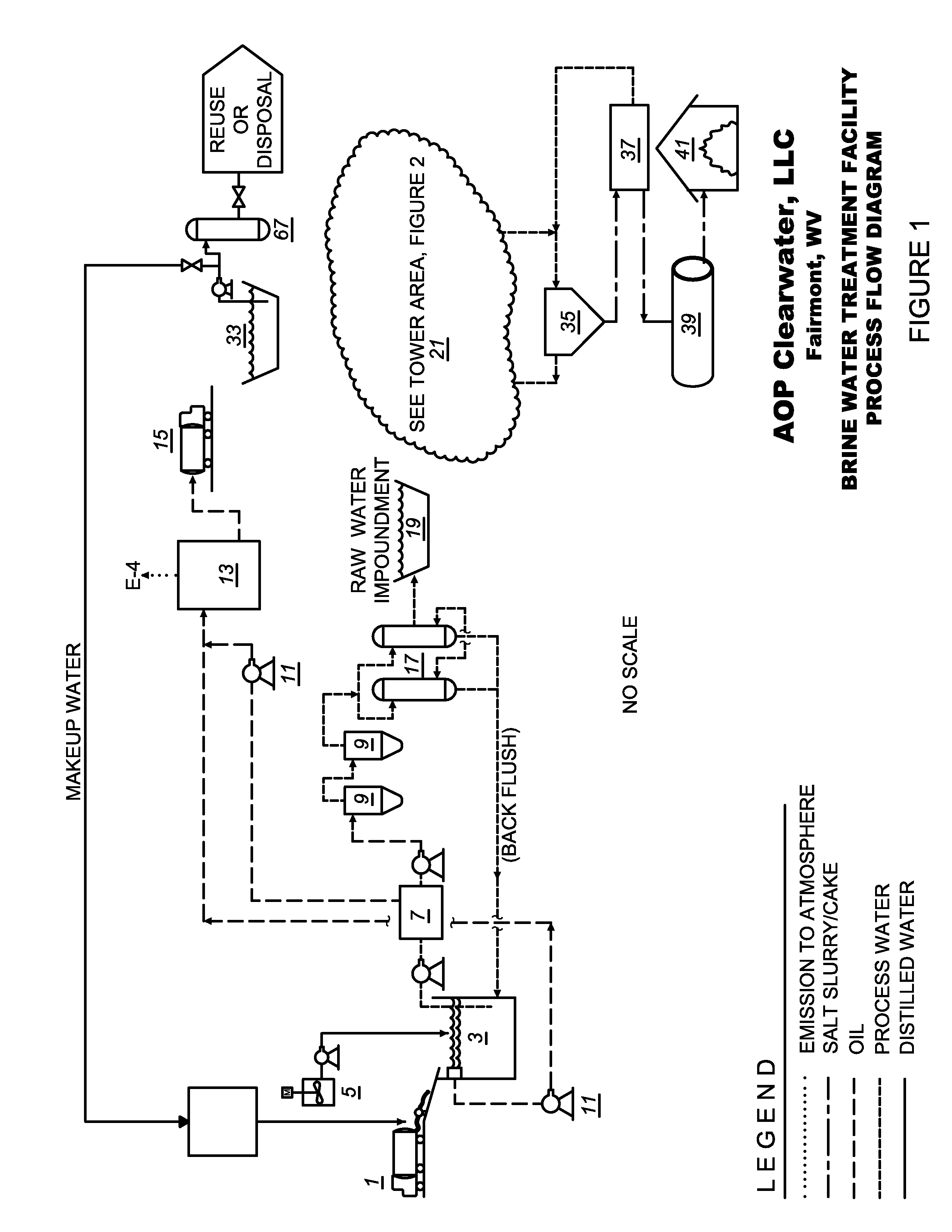

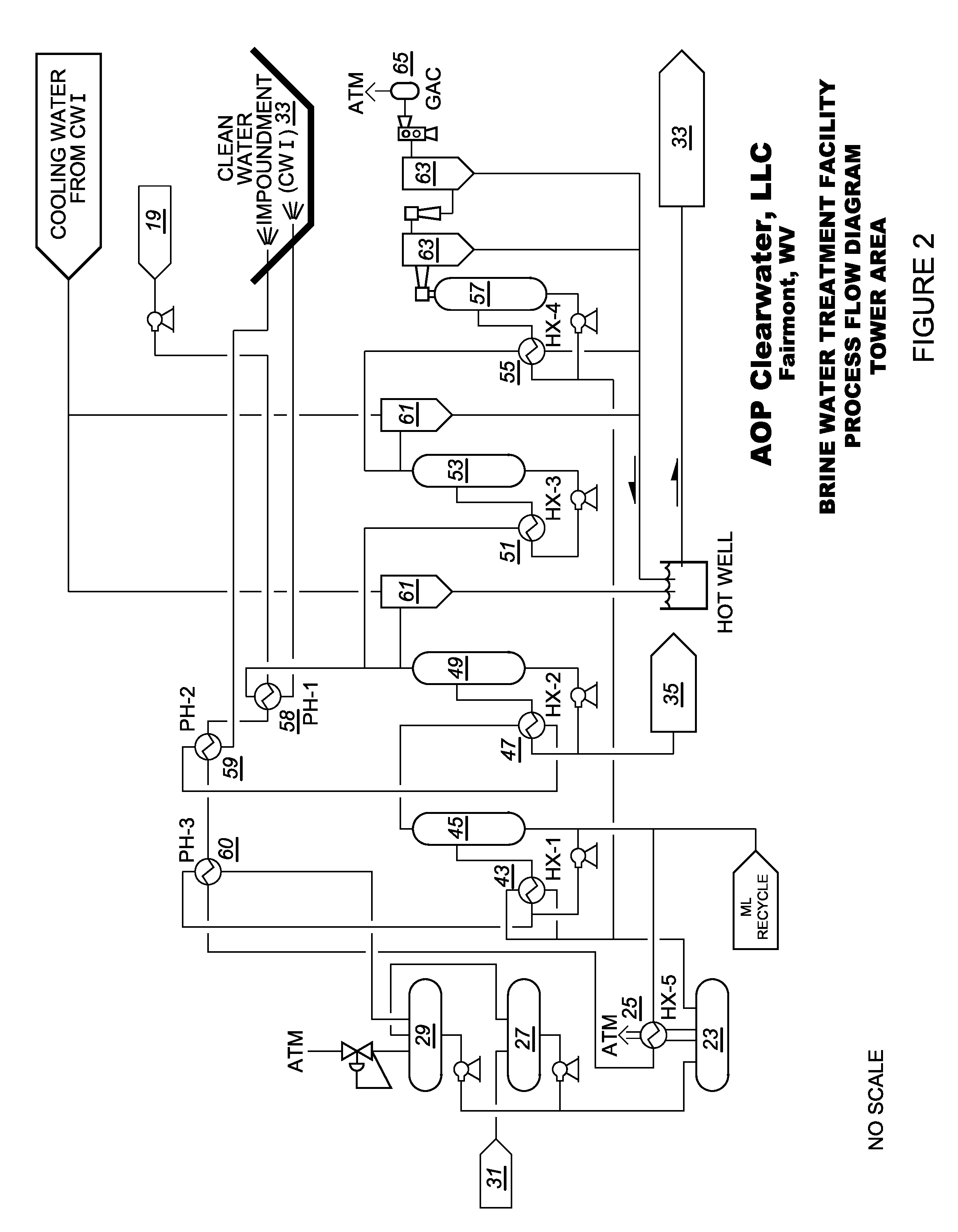

Brine water recycle process

Embodiments provided herein include methods and apparatuses for purification and recycling of hydrofracture water used in natural gas drilling and production. Embodiments include removal of dissolved solids by precipitation with sodium sulfate and by evaporation using, for example, a multiple effect evaporator.

Owner:FAIRMONT BRINE PROCESSING

Multiple application purification and recycling device

InactiveUS20070170049A1Easy constructionFlexible operationDistillation regulation/controlEvaporation with vapour compressionDistillationMultiple applications

A multiple application recycling and purification device has a coaxial core that is horizontally oriented, non-rotating, cylindrical distillation chamber. The enhanced, completely coaxial configuration continuously cleans the entire distillation chamber and spreads a thin film of liquid to enhance distillation and positively aid in the removal of remaining contaminants. Through a timed and positioned valve, the device removes and purges lower-temperature contaminants. Timed valves and sensors control all phases of the distillation to provide a coaxially integrated, stand-alone, adaptable, scalable and maintenance free distillation unit that self-monitors, self-cleans and economically functions to produce the pure distilled liquid, e.g., water. This device can be modified to purify any numerous array of liquids and can be scaled to produce any amount of purified liquids for either household, commercial, or industrial applications.

Owner:MANSUR CORP

Water vending apparatus

ActiveUS8359877B2Prevents sediment buildupLesser rateEvaporation with vapour compressionLighting and heating apparatusWater vaporSteam distillation

A water vending apparatus is disclosed. The water vending system includes a water vapor distillation apparatus and a dispensing device. The dispensing device is in fluid communication with the fluid vapor distillation apparatus and the product water from the fluid vapor distillation apparatus is dispensed by the dispensing device.

Owner:DEKA PROD LLP

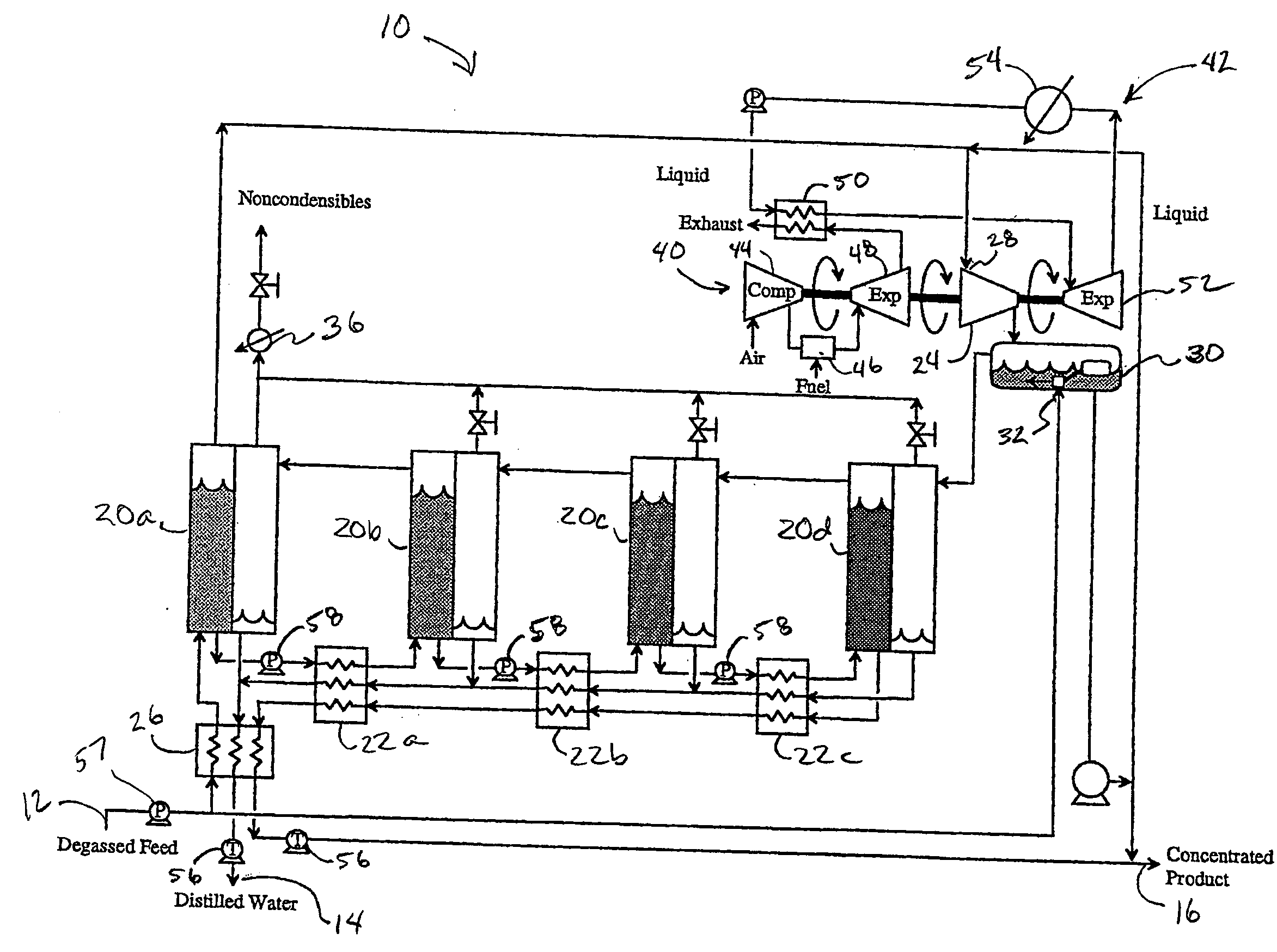

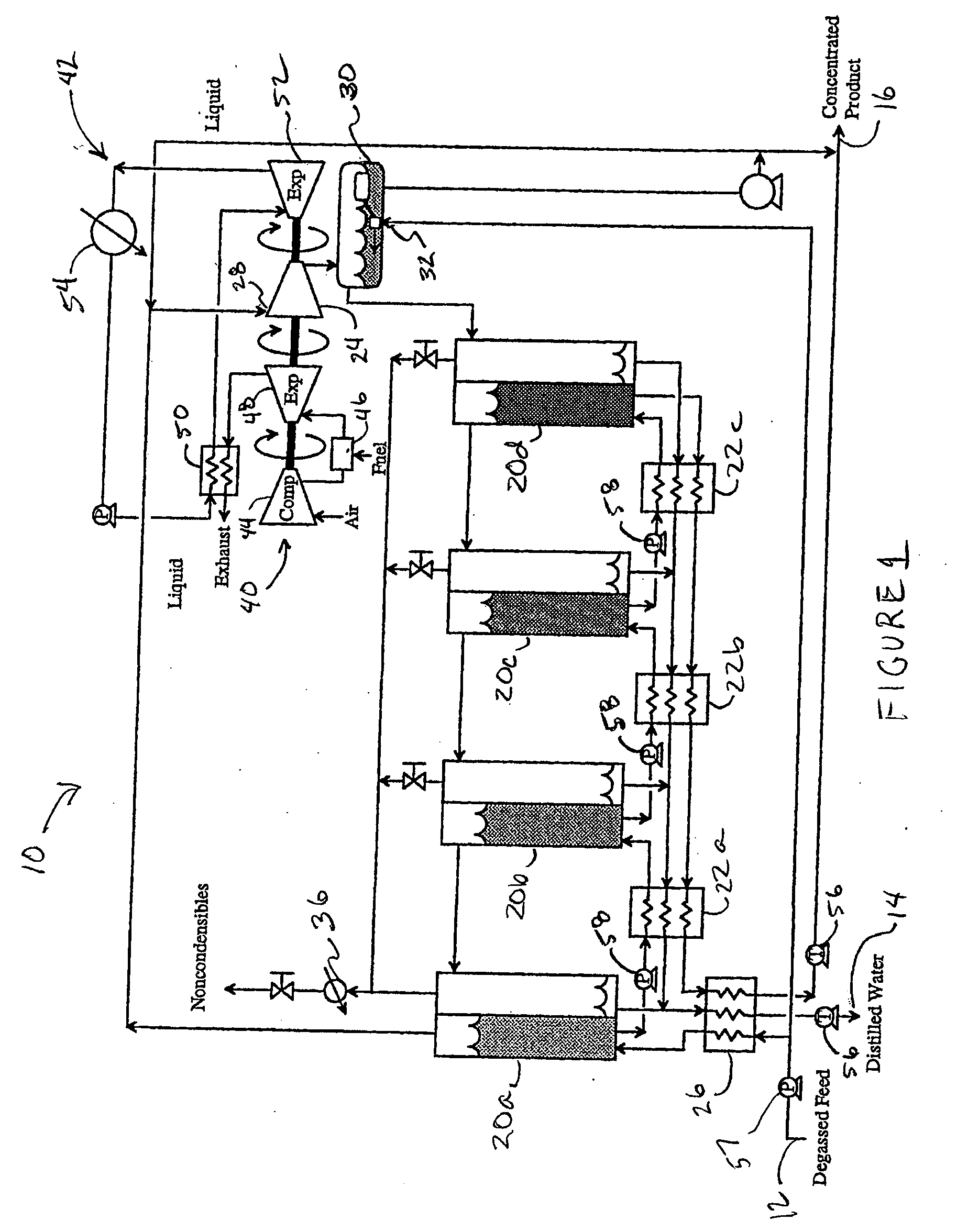

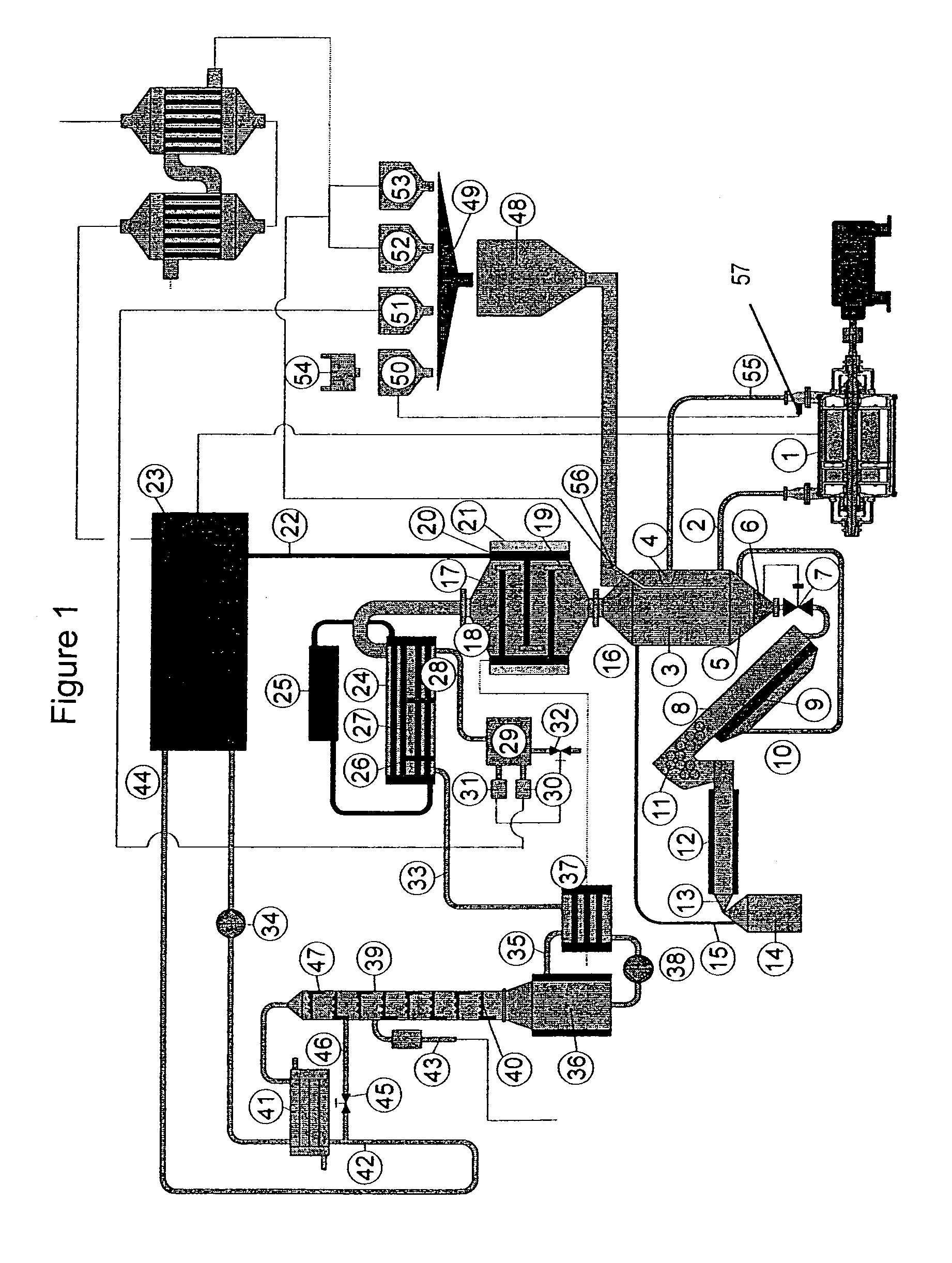

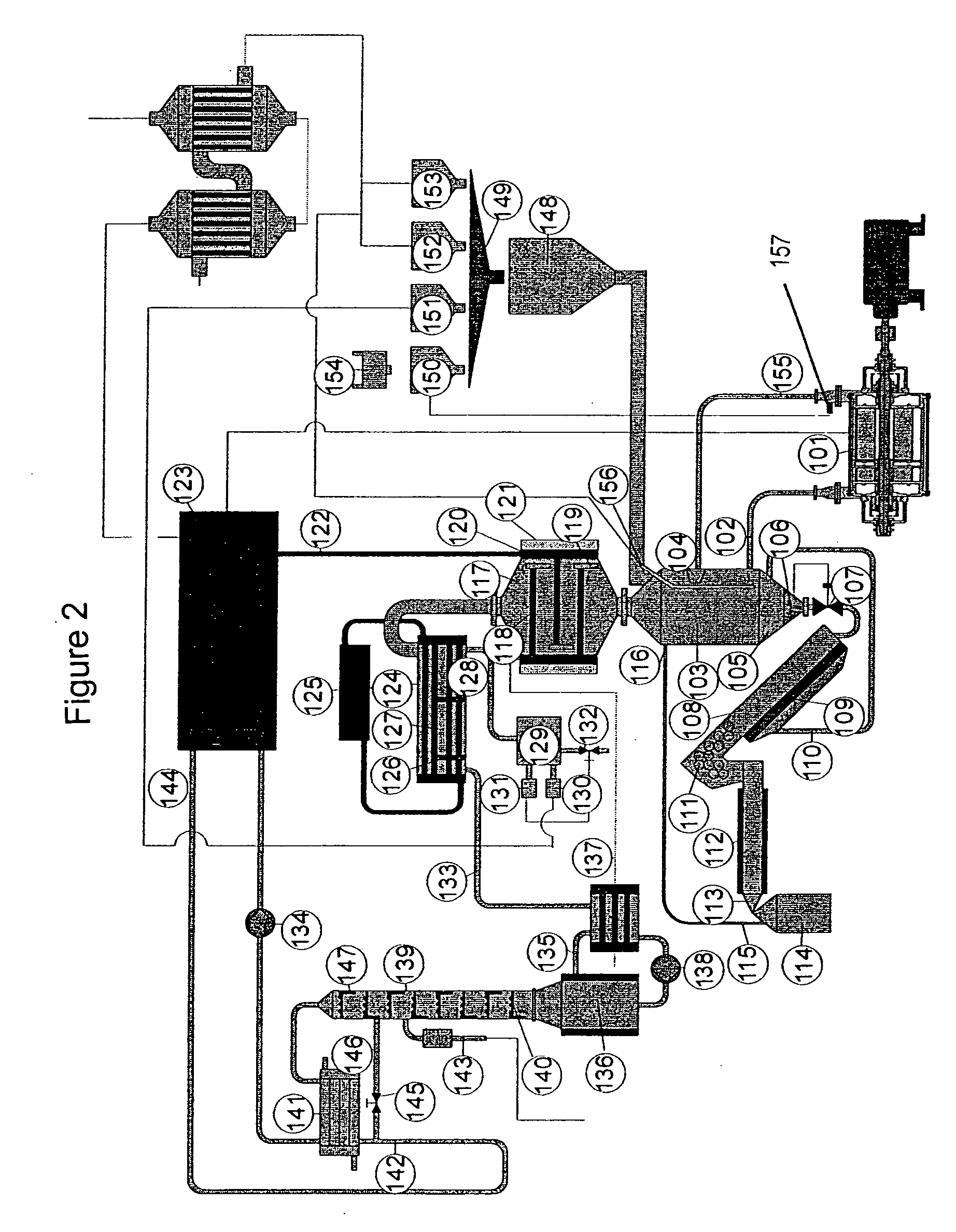

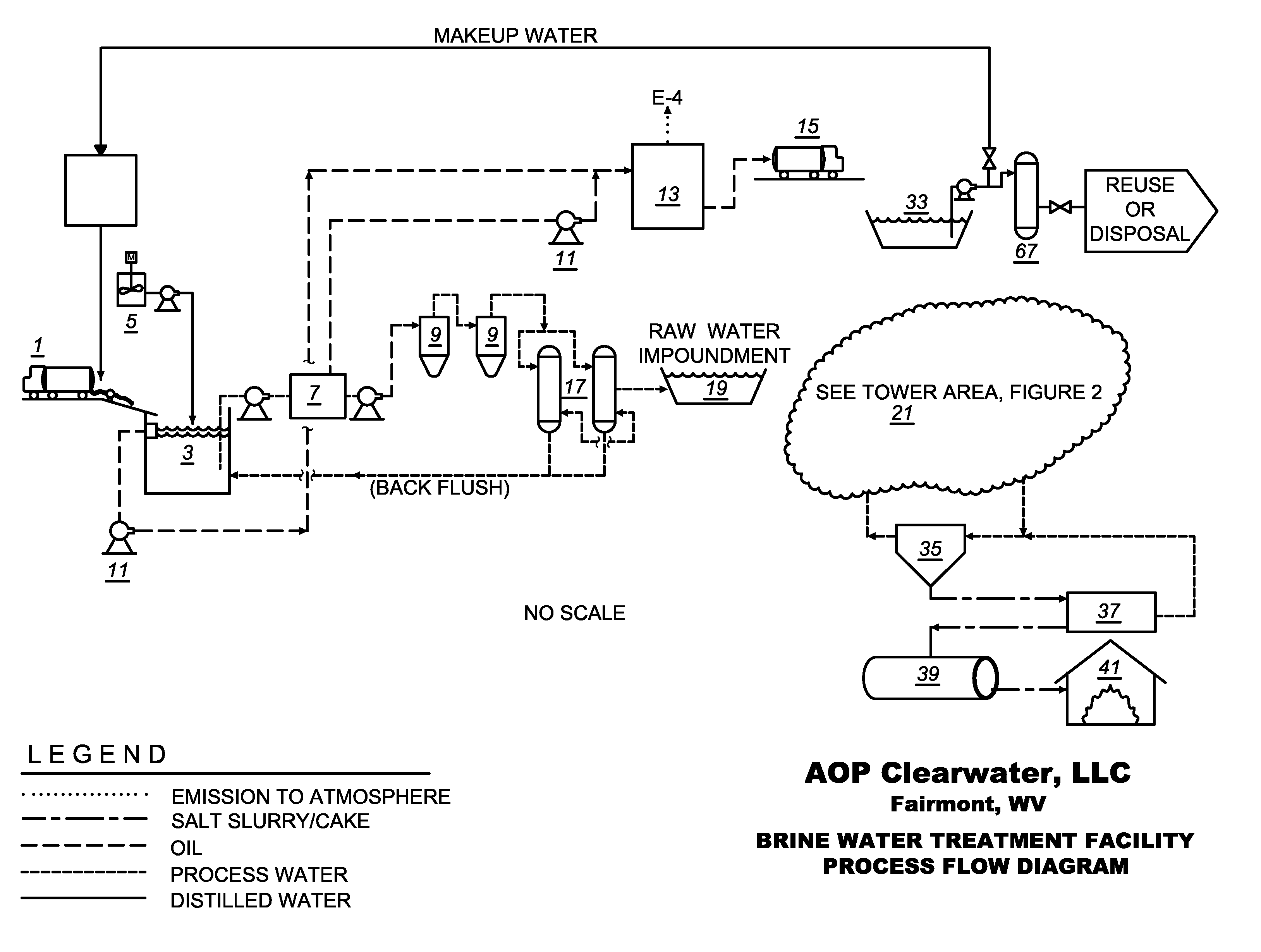

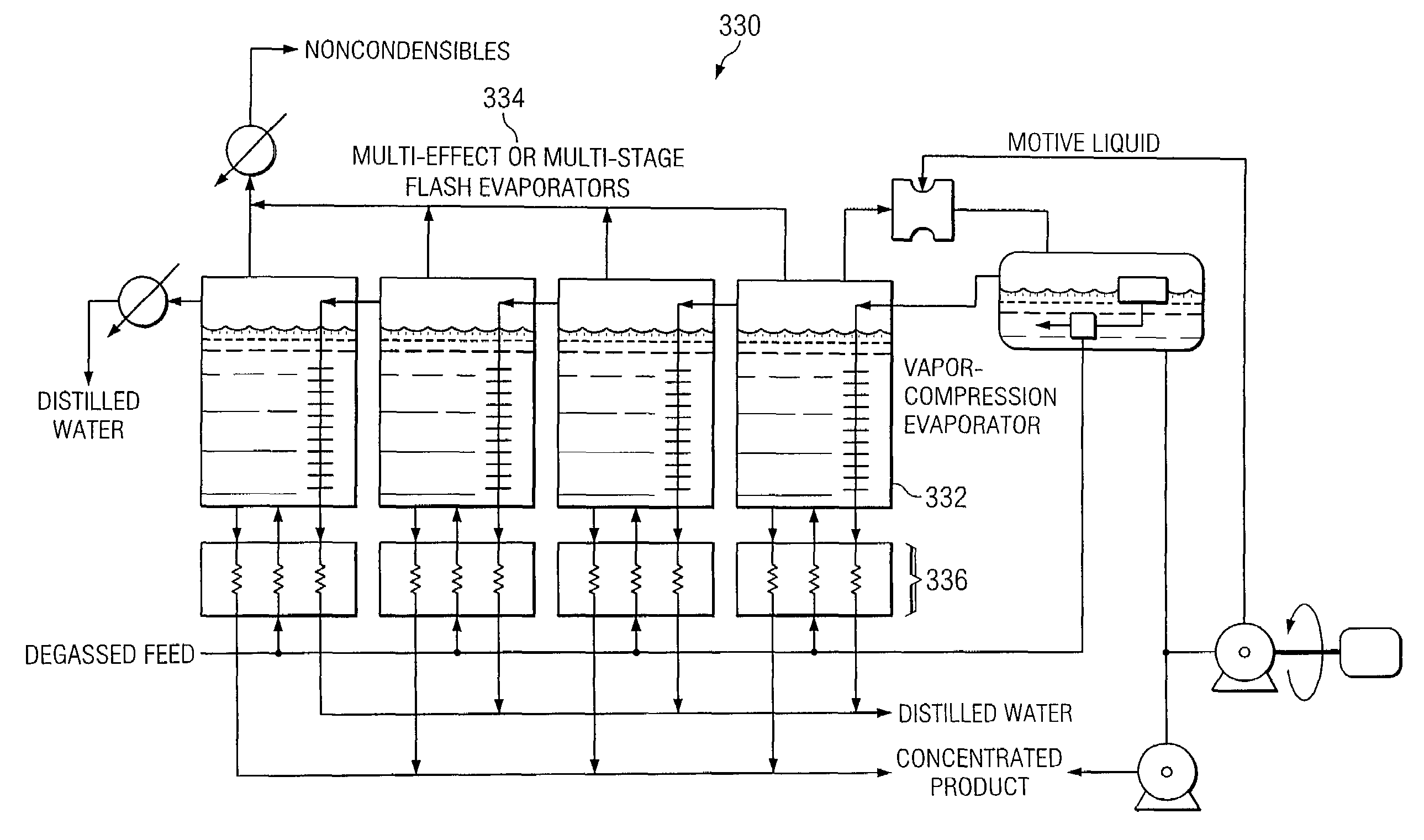

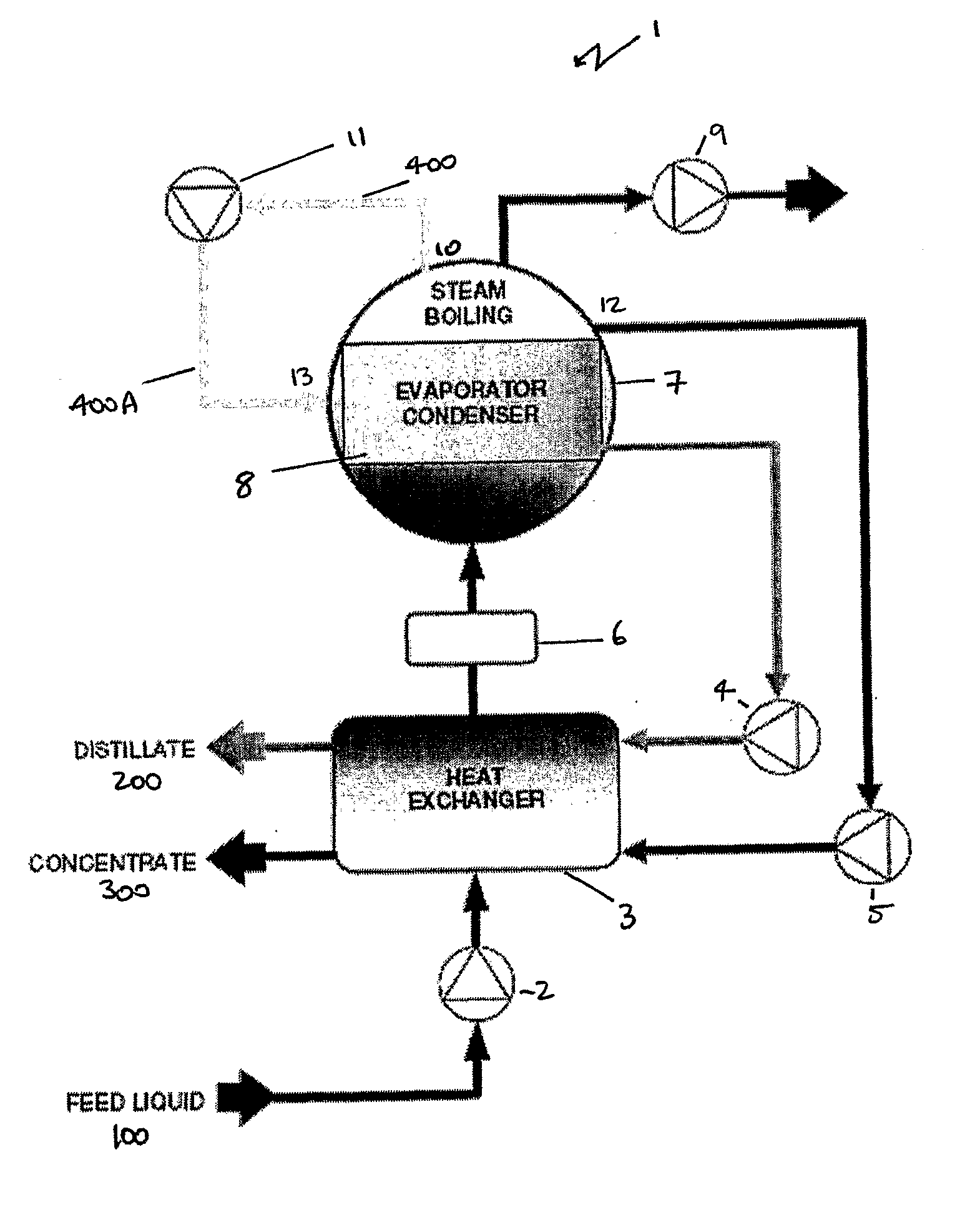

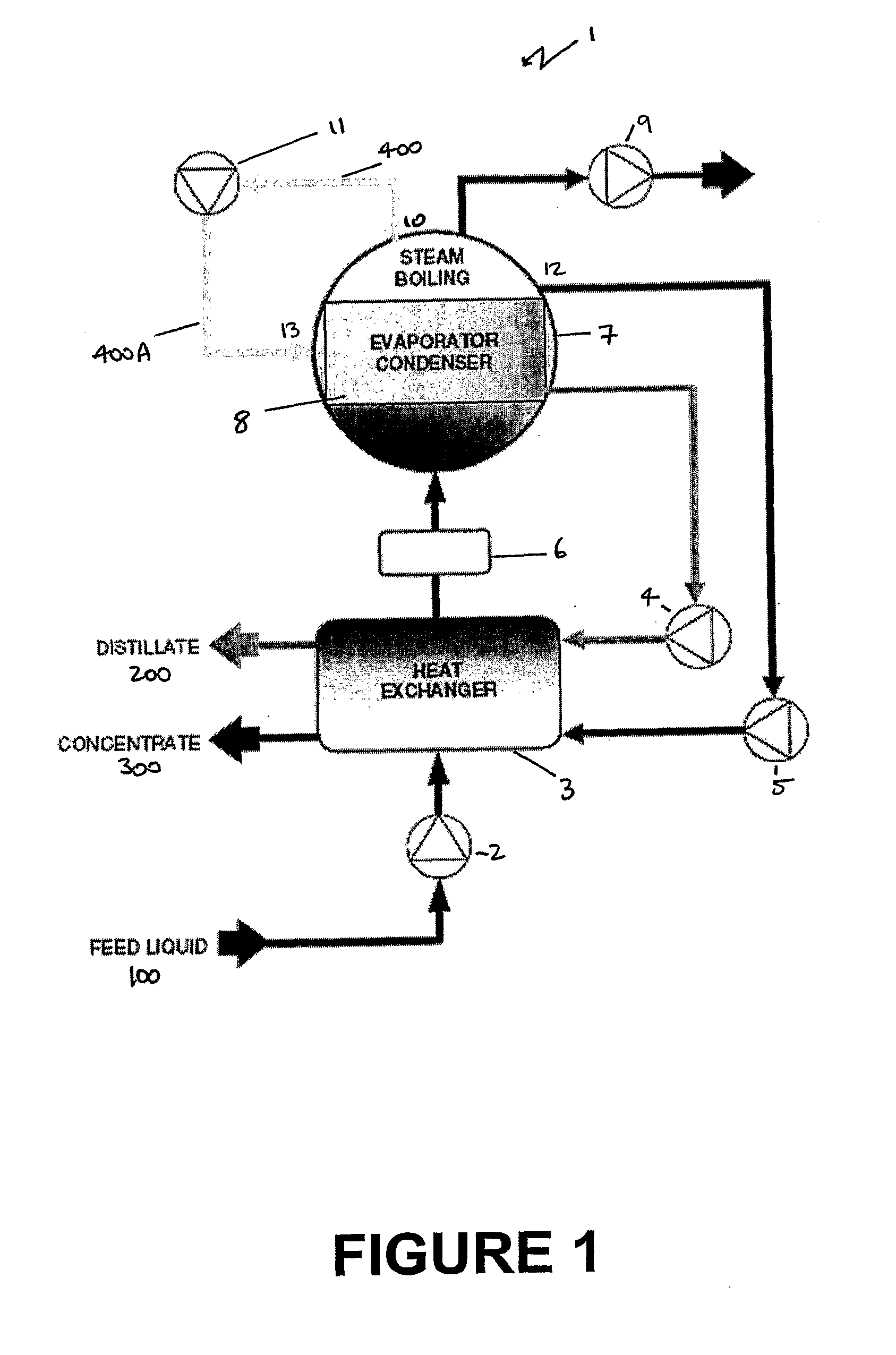

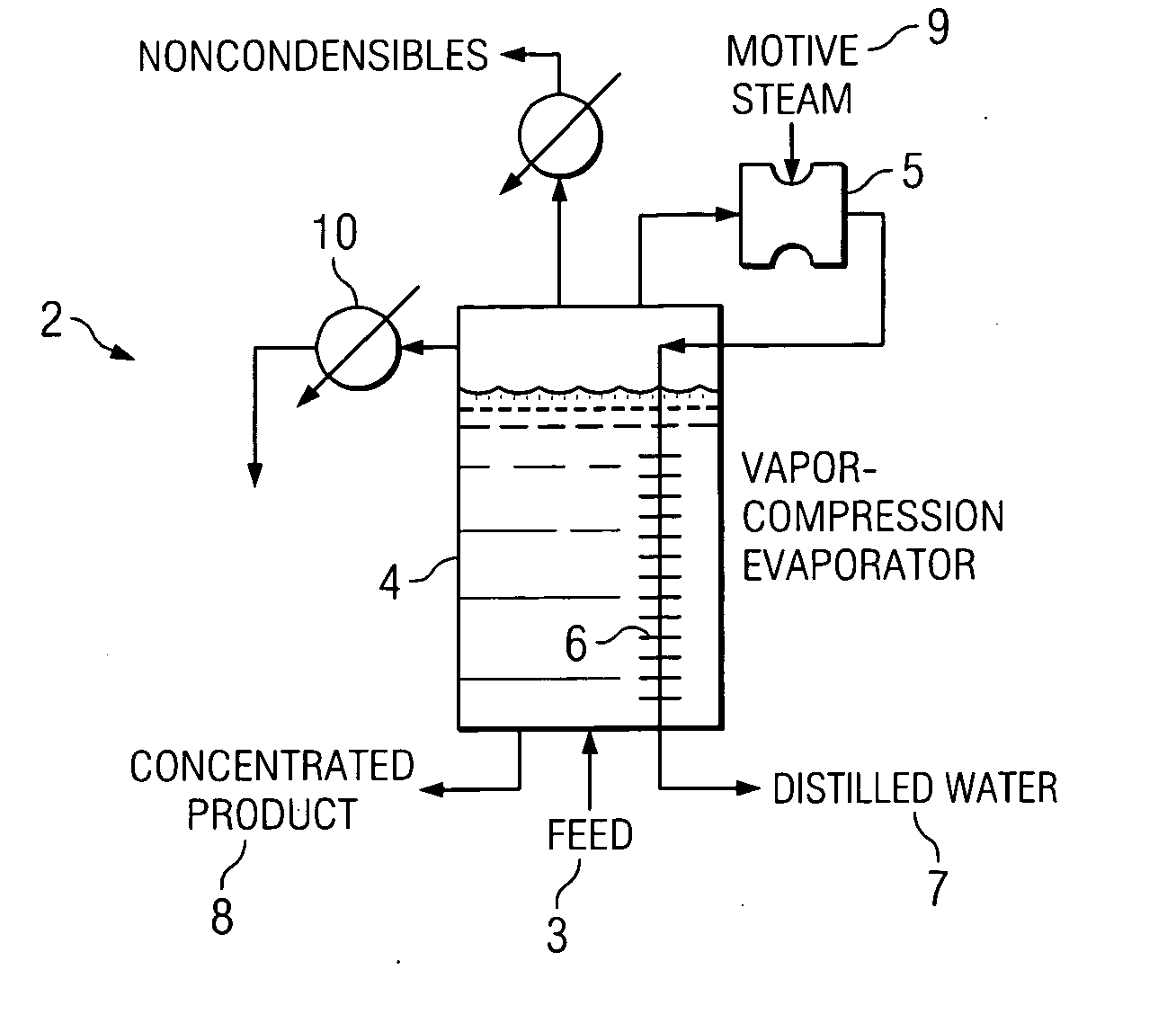

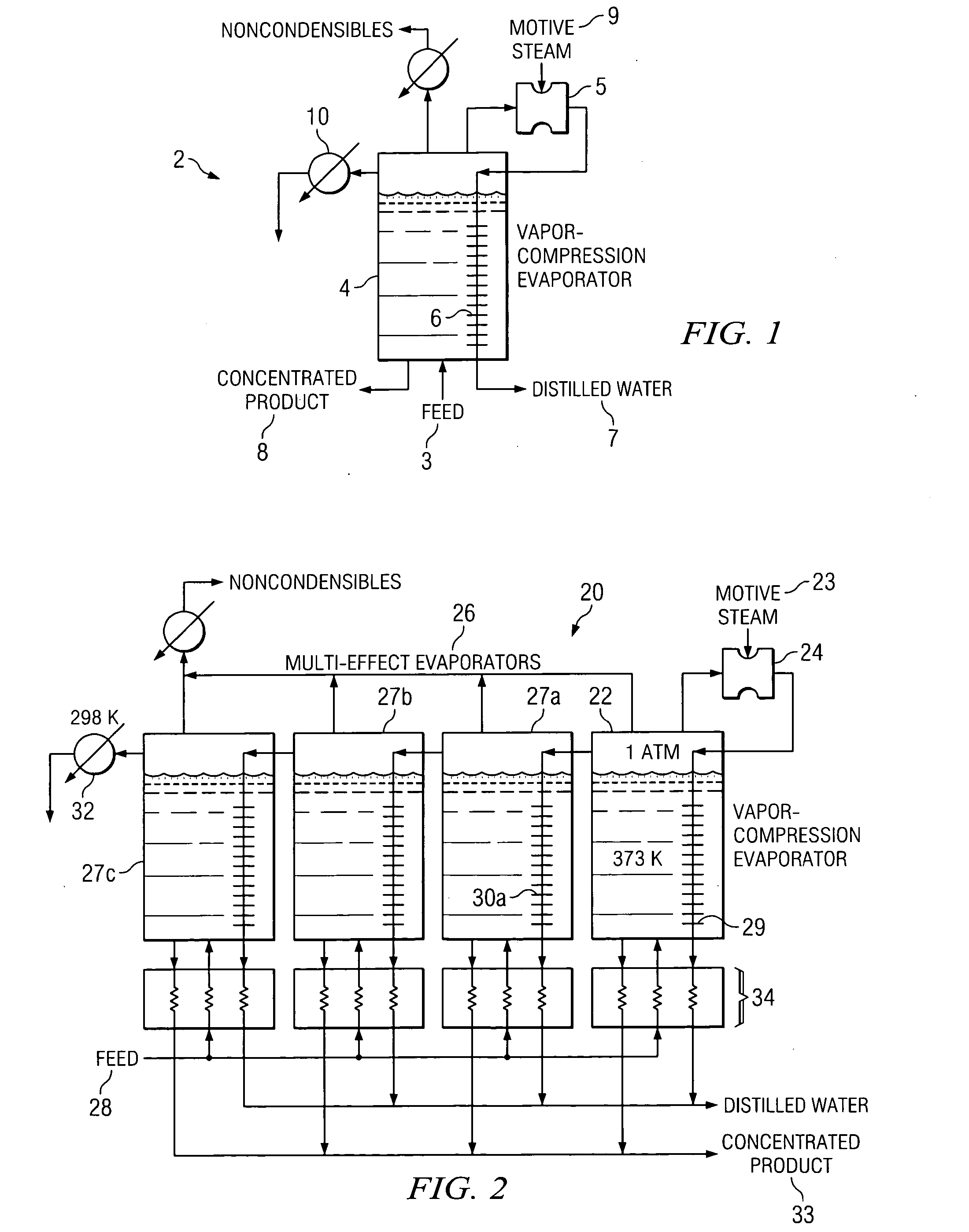

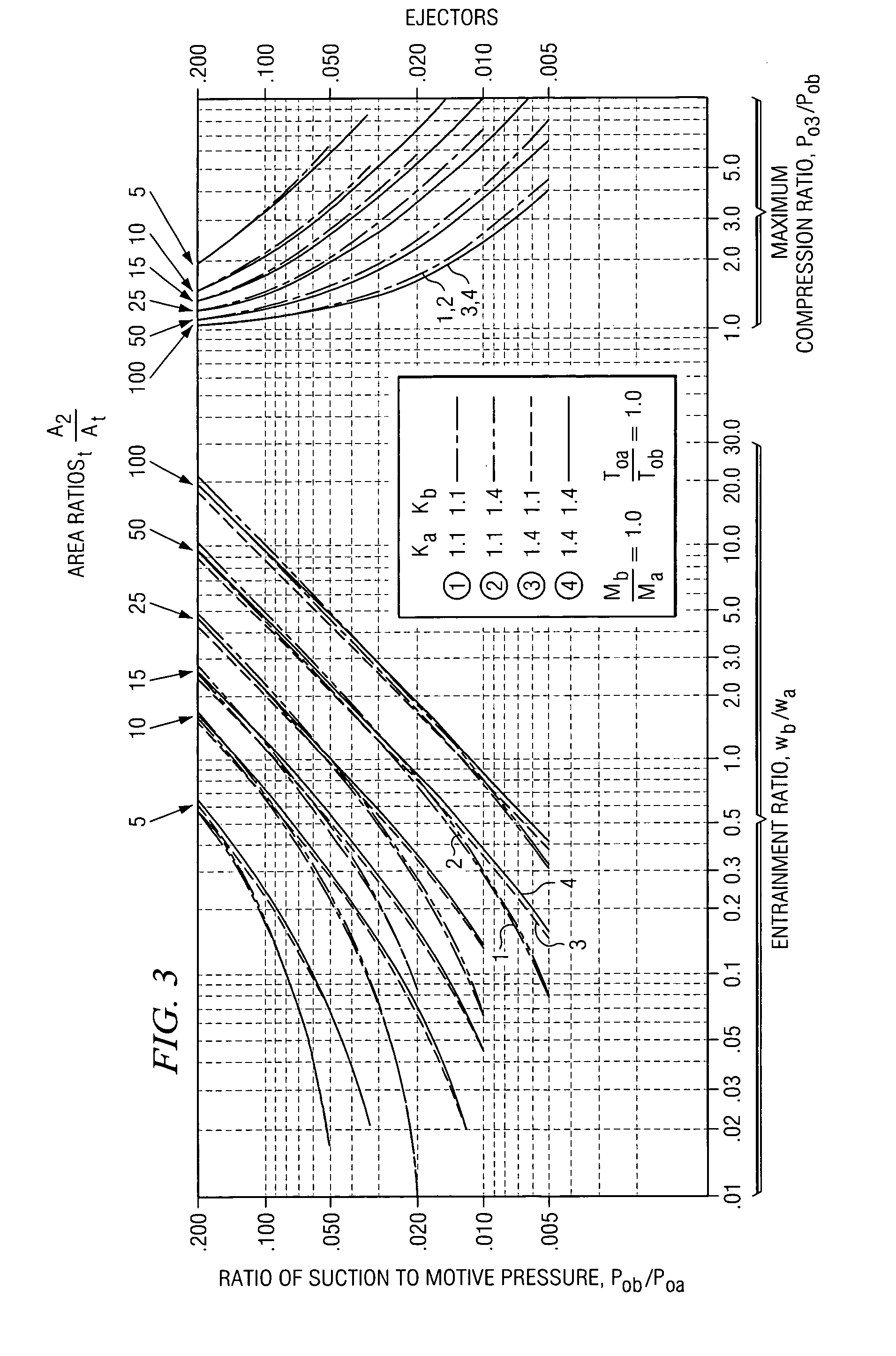

Vapor-compression evaporation system and method

InactiveUS7708865B2Improve efficiencySimple designDrying using combination processesEvaporation with vapour compressionMarine engineeringVapor-compression evaporation

According to one embodiment of the invention, a vapor-compression evaporation system includes a plurality of vessels in series each containing a feed having a nonvolatile component, a mechanical compressor coupled to the last vessel in the series and operable to receive a vapor from the last vessel in the series, a pump operable to deliver a cooling liquid to the mechanical compressor, a tank coupled to the mechanical compressor and operable to separate liquid and vapor received from the mechanical compressor, a plurality of heat exchangers coupled inside respective ones of the vessels, the heat exchanger in the first vessel in the series operable to receive the vapor from the tank, at least some of the vapor condensing therein, whereby the heat of condensation provides the heat of evaporation to the first vessel in the series, and wherein at least some of the vapor inside the first vessel in the series is delivered to the heat exchanger in the next vessel in the series, whereby the condensing, evaporating, and delivering steps continue until the last vessel in the series is reached.

Owner:TEXAS A&M UNIVERSITY +1

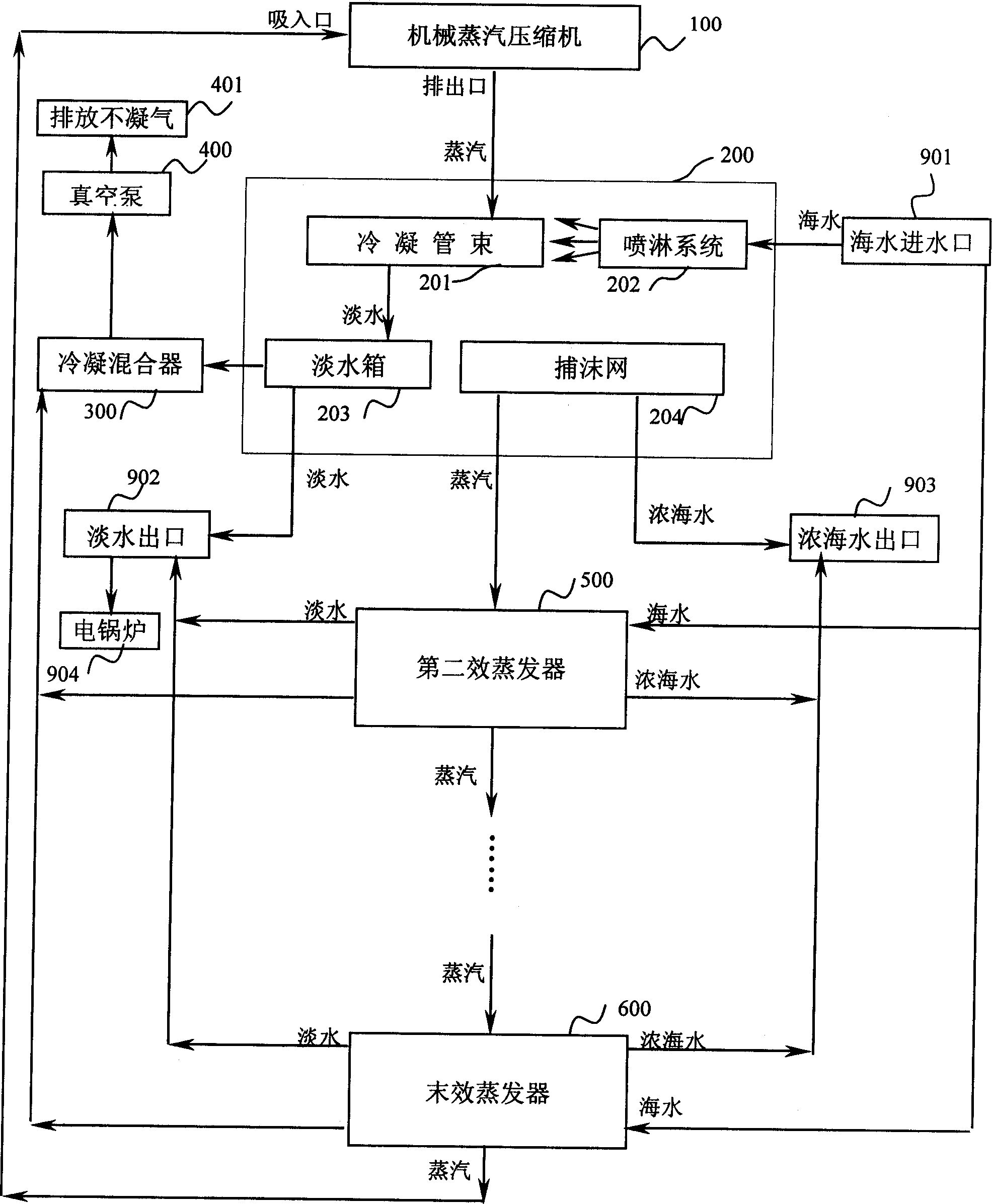

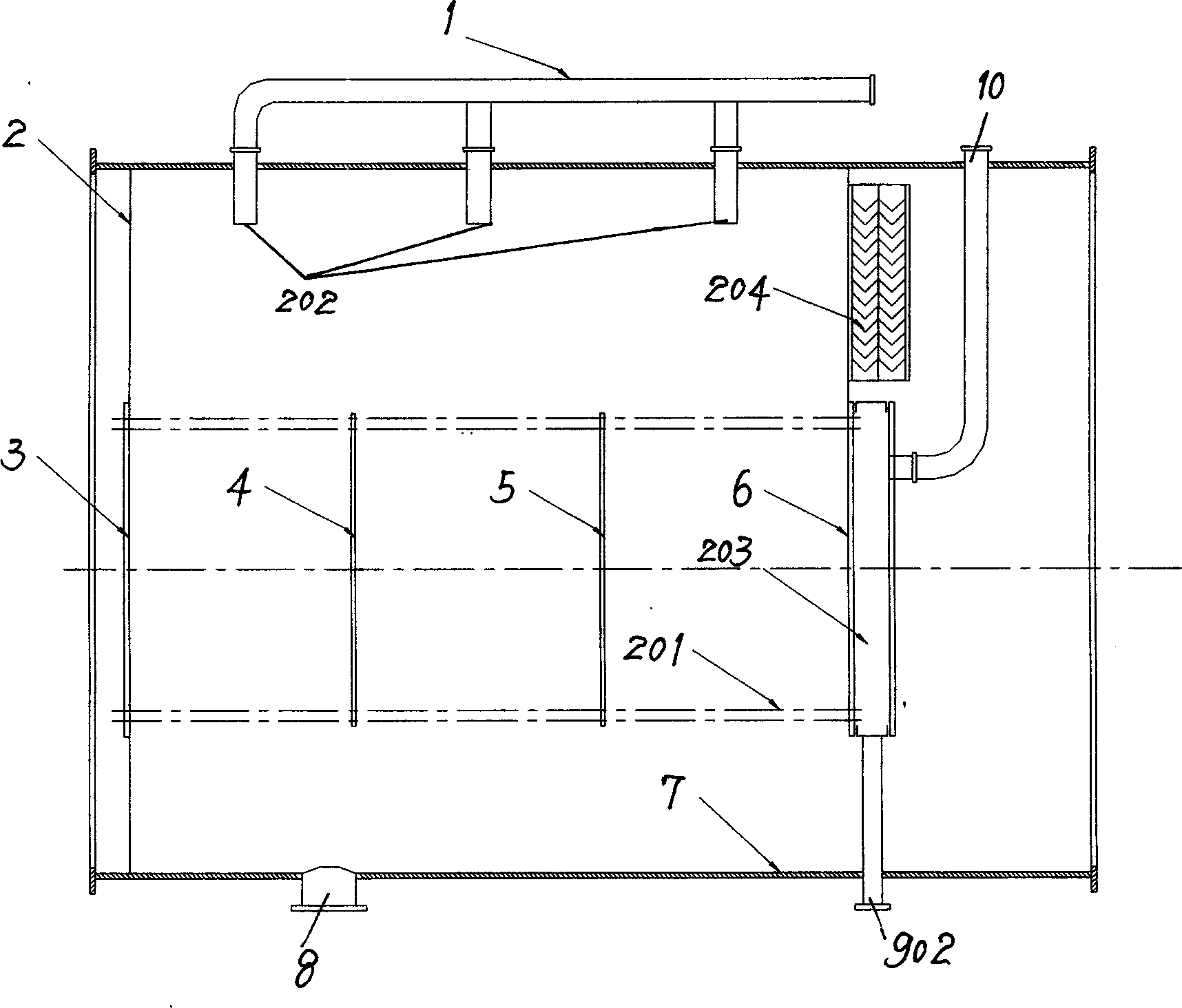

Method and device for desalting sea water using mechanical compression distillation method

InactiveCN1546386AHigh thermal efficiencyLow costGeneral water supply conservationEvaporation with vapour compressionWater useWater desalination

The invention discloses a sea-water distillation apparatus by mechanical compression distillation method which comprises a steam mechanical compressor, a plurality of evaporators and condensation tubes, spraying systems, fresh water tanks and foam trapping nets arranged in the evaporator, wherein the exit of the steam mechanical compressor is connected with the condensation tube in the first evaporator in the multiple evaporators, the condensation tube in the first evaporator is connected with the fresh water tank, the vapor exit of the first evaporator is connected with the condensation tube in the next evaporator, and so on, until the last evaporator, thus multiple effect step by step evaporation is realized by the various evaporators. The invention also discloses a process for sea water desalination by using the sea-water distillator.

Owner:TIANJIN SEA WATER DESALINATION & COMPLEX UTILIZATION INST STATE OCEANOGRAPHI

Water vending apparatus

ActiveUS8511105B2Prevents sediment buildupLesser rateLighting and heating apparatusEvaporation with vapour compressionWater vaporSteam distillation

A water vending apparatus is disclosed. The water vending system includes a water vapor distillation apparatus and a dispensing device. The dispensing device is in fluid communication with the fluid vapor distillation apparatus and the product water from the fluid vapor distillation apparatus is dispensed by the dispensing device.

Owner:DEKA PROD LLP

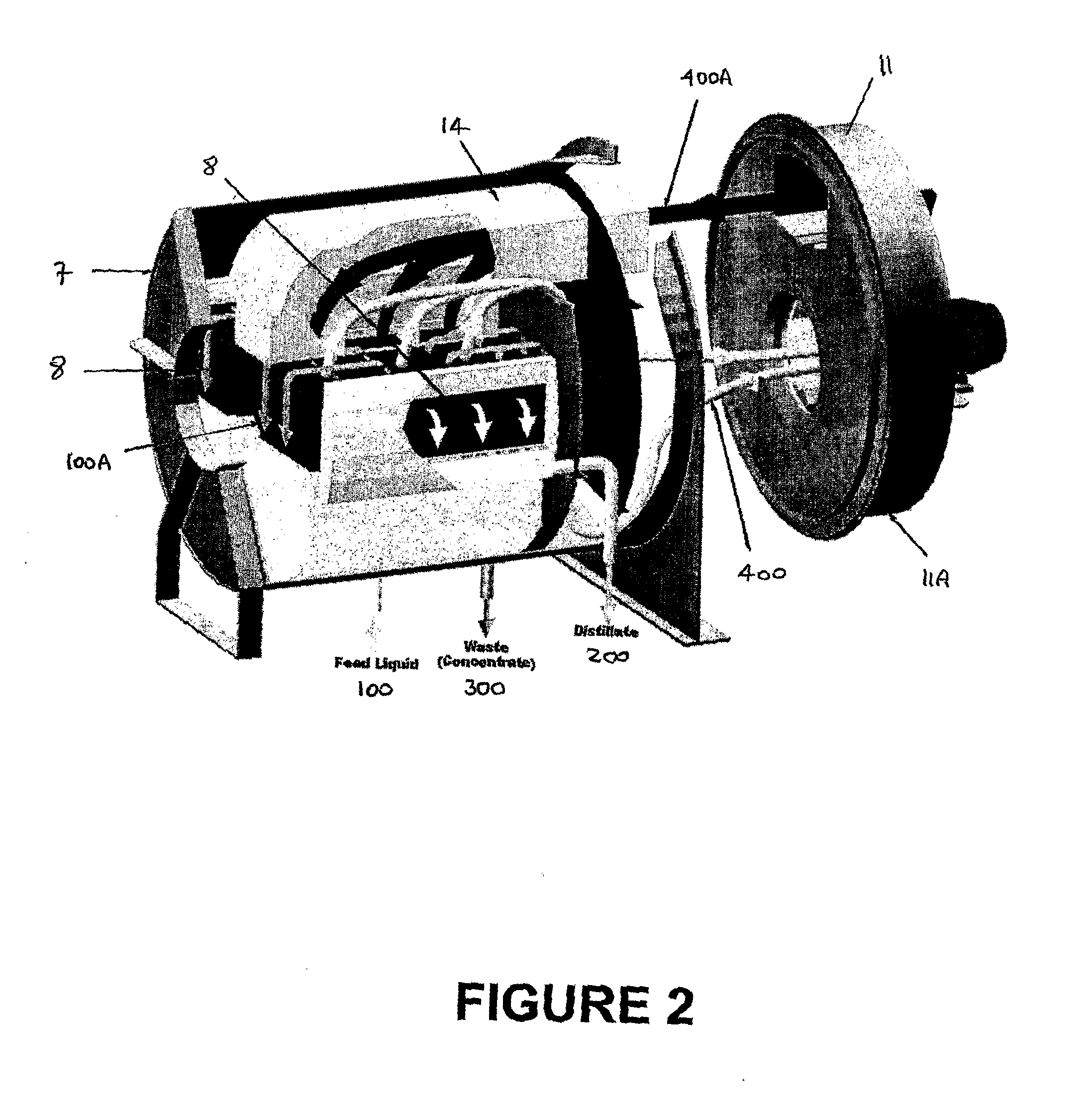

Distillation apparatus

InactiveUS20100200388A1Evaporation with vapour compressionSeawater treatmentPlate heat exchangerDistillation

A modular distillation apparatus including at least one heat exchanger that preheats contaminated liquids; a heater that heats the contaminated liquid from the heat exchanger; an evaporator condenser adapted to boil the contaminated liquid coming out of the heater to produce water vapor and contaminant concentrate, and condense the water vapor into distilled water; a vacuum chamber capable of operating at below atmospheric pressure, the vacuum chamber housing the evaporator condenser and including at least one partition to separate the distilled water from the contaminant concentrate; a vapor compressor operably associated with the vacuum chamber to receive water vapor from the evaporator condenser in the vacuum chamber and pump the water vapor at pressure back through the evaporator condenser, wherein the heat exchanger recovers sensible heat from outgoing condensed distilled water and contaminant concentrate recycled from the vacuum chamber.

Owner:EQUUS ENVIRONMENTAL

Vapor-compression evaporation system and method

InactiveUS20050072662A1Cost-effectiveLower overall pressure dropDrying using combination processesEvaporation with vapour compressionMarine engineeringVapor-compression evaporation

According to one embodiment of the invention, a vapor-compression evaporation system includes a plurality of vessels in series each containing a feed having a nonvolatile component, a mechanical compressor coupled to the last vessel in the series and operable to receive a vapor from the last vessel in the series, a pump operable to deliver a cooling liquid to the mechanical compressor, a tank coupled to the mechanical compressor and operable to separate liquid and vapor received from the mechanical compressor, a plurality of heat exchangers coupled inside respective ones of the vessels, the heat exchanger in the first vessel in the series operable to receive the vapor from the tank, at least some of the vapor condensing therein, whereby the heat of condensation provides the heat of evaporation to the first vessel in the series, and wherein at least some of the vapor inside the first vessel in the series is delivered to the heat exchanger in the next vessel in the series, whereby the condensing, evaporating, and delivering steps continue until the last vessel in the series is reached.

Owner:TEXAS A&M UNIVERSITY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com