Separator, reactor, and method for producing aromatic carboxylic acids

a technology of aromatic carboxylic acid and separation chamber, which is applied in the preparation of carboxylic compounds, separation processes, refrigeration components, etc., can solve the problems of complex dehydration/distillation steps, poor heat resistance, and insufficient streamlined methods disclosed in these references, so as to reduce the size of the system and reduce the energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

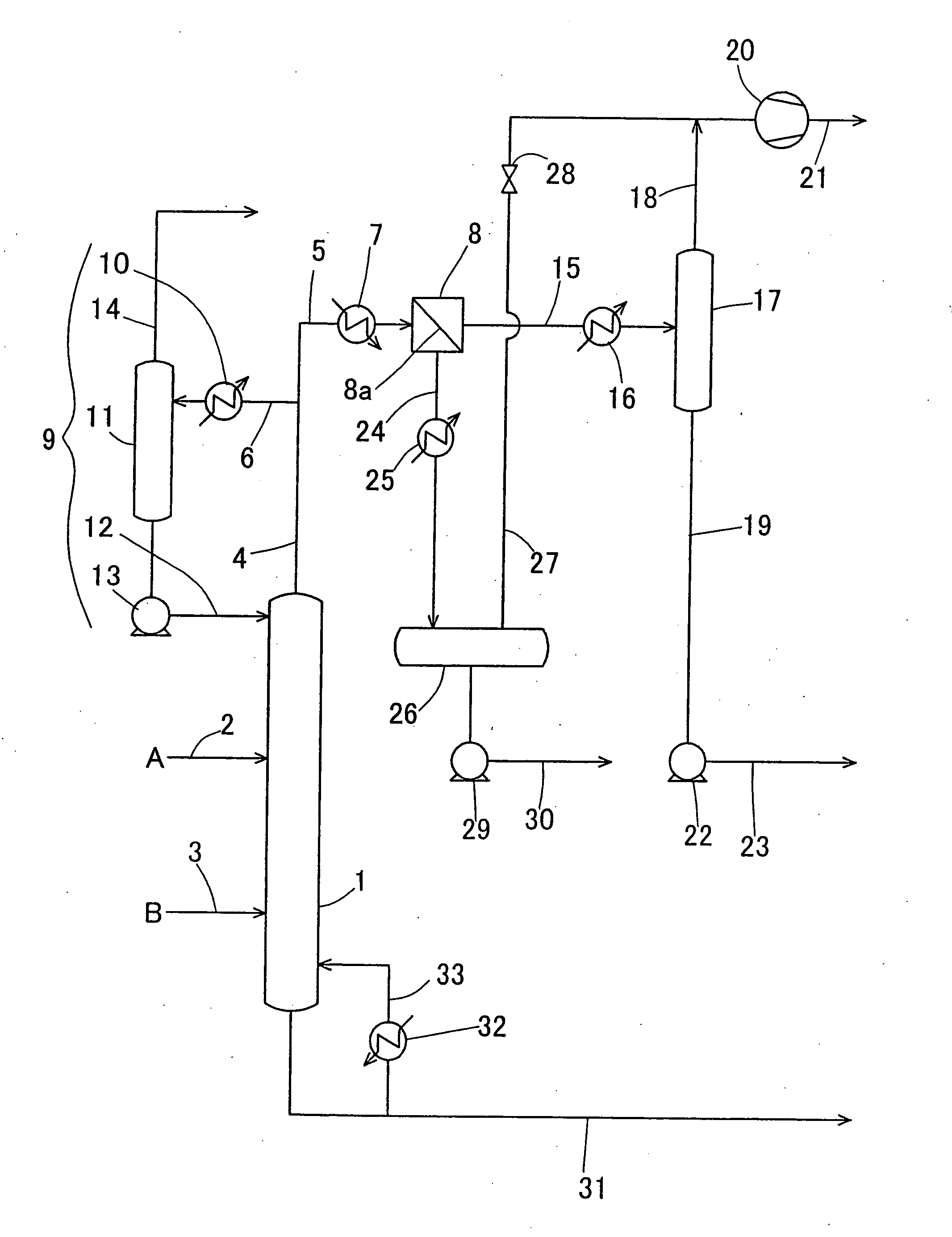

[0071]FIG. 1 shows Embodiment 1 of the present invention, which is a separation system for separating a solution of a mixture of water and acetic acid.

[0072] Typically, the separation system of Embodiment 1 is used to remove water produced by oxidation reaction when producing a terephthalic acid by oxidizing, in a liquid phase, a paraxylene as the raw material using air in a reaction solvent containing acetic acid in the presence of an oxidation catalyst.

[0073] The separation system of Embodiment 1 includes a distillation column 1 having a plurality of fluidized beds such as shelves in the interior thereof. To an upper portion of the column, 78 weight percent of a liquid-phase aqueous solution of acetic acid (liquid-phase feed) is supplied through an upper supply pipe 2, and to a lower portion of the column, 87 weight percent of an aqueous solution of acetic acid and a small amount of nitrogen are supplied as a vapor-phase feed through a lower supply pipe 3. Thus, a mixture of the...

embodiment 2

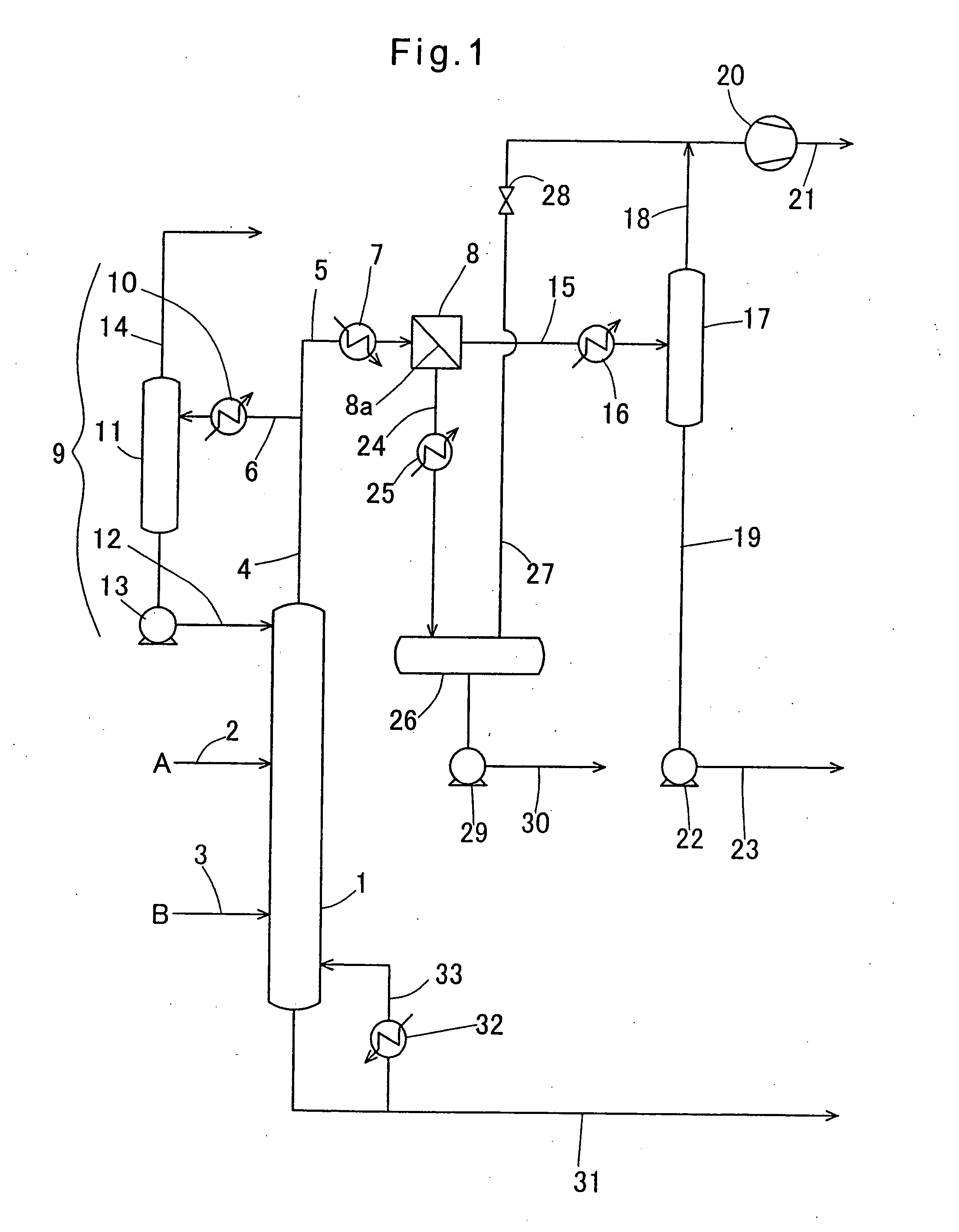

[0096]FIG. 2 shows Embodiment 2 of the present invention, which is a separation system for separating a solution of a mixture of water and acetic acid.

[0097] Like the system of Embodiment 1, the system of Embodiment 2 is typically used to remove water produced by oxidation reaction when producing a terephthalic acid by oxidizing, in a liquid phase, a paraxylene as the raw material using air in a reaction solvent containing acetic acid in the presence of an oxidation catalyst.

[0098] Like the system of Embodiment 1, the system of Embodiment 2 includes a distillation column 41 having a plurality of fluid beds such as shelves in the interior thereof. To an upper portion of the column, 78 weight percent of a liquid-phase aqueous solution of acetic acid (liquid-phase feed A) is supplied through an upper supply pipe 42, and to a lower portion of the column, 87 weight percent of an aqueous solution of acetic acid and a small amount of nitrogen are supplied as a vapor-phase feed B through ...

embodiment 3

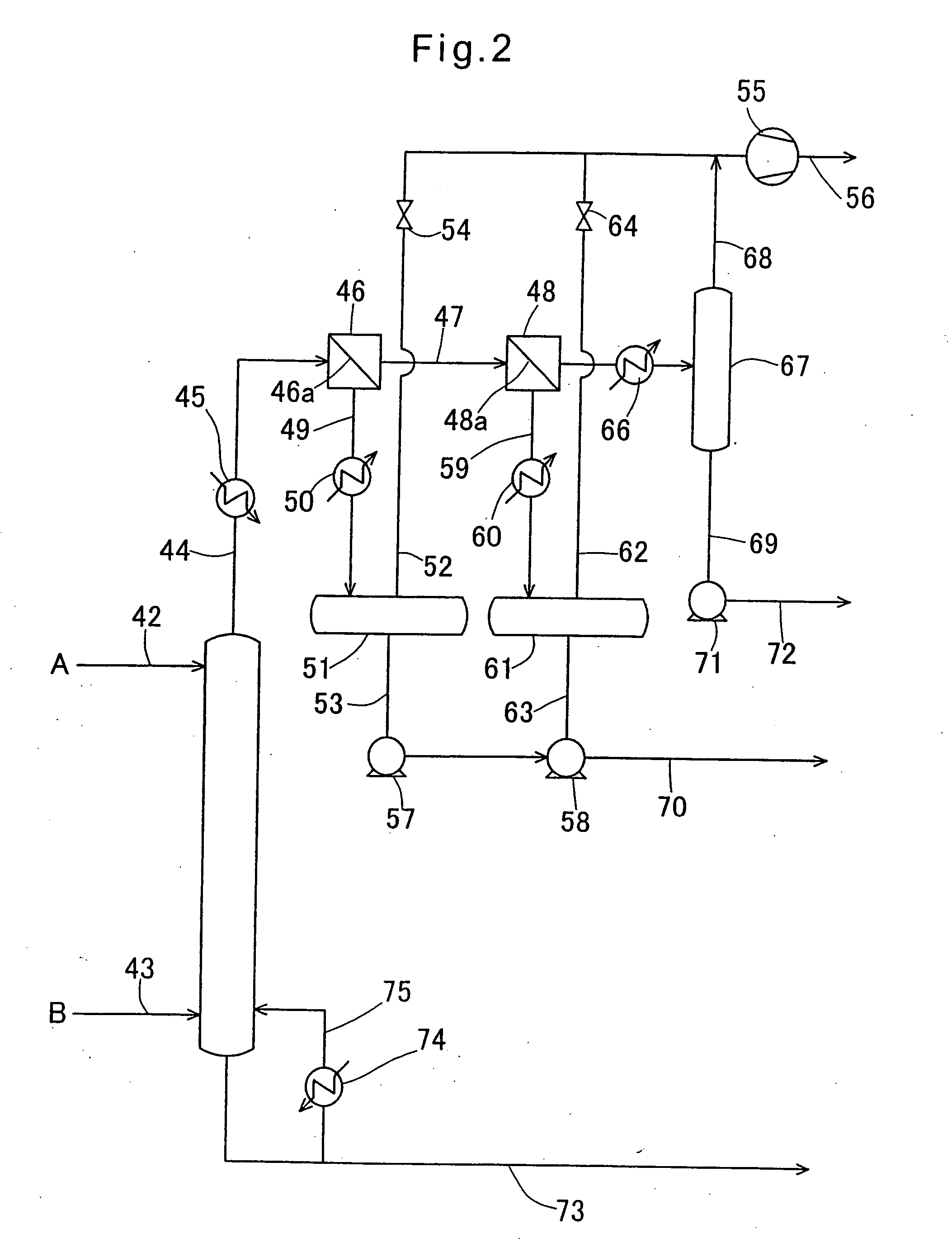

[0124]FIG. 3 shows Embodiment 3, which is a reactor system for synthesizing terephthalic acid according to the present invention.

[0125] This reactor system includes a reactor 81 filled with an oxidation catalyst for paraxylene (such as a cobalt compound). To the reactor 81, a raw material supply pipe 82 is connected through which paraxylene as the raw material, an acetic acid solvent, and an oxidation catalyst are supplied into the reactor. To the top of the reactor 81, a reaction vapor discharge pipe 83 is connected through which reaction vapor produced in the reactor is discharged. Air as an oxidant is supplied into the reactor 81 through an oxidant supply pipe 101.

[0126] To the reaction vapor discharge pipe 83, a first separator 84 including a first separation membrane 84a is connected. The first separation membrane 84a is identical to the separation membrane 8a of Embodiment 1. Thus, it passes a first component which mainly comprises steam, but does not pass a second component...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| thick | aaaaa | aaaaa |

| thick | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com