Patents

Literature

256 results about "Multiple-effect evaporator" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A multiple-effect evaporator, as defined in chemical engineering, is an apparatus for efficiently using the heat from steam to evaporate water. In a multiple-effect evaporator, water is boiled in a sequence of vessels, each held at a lower pressure than the last. Because the boiling temperature of water decreases as pressure decreases, the vapor boiled off in one vessel can be used to heat the next, and only the first vessel (at the highest pressure) requires an external source of heat. While in theory, evaporators may be built with an arbitrarily large number of stages, evaporators with more than four stages are rarely practical except in systems where the liquor is the desired product such as in chemical recovery systems where up to seven effects are used.

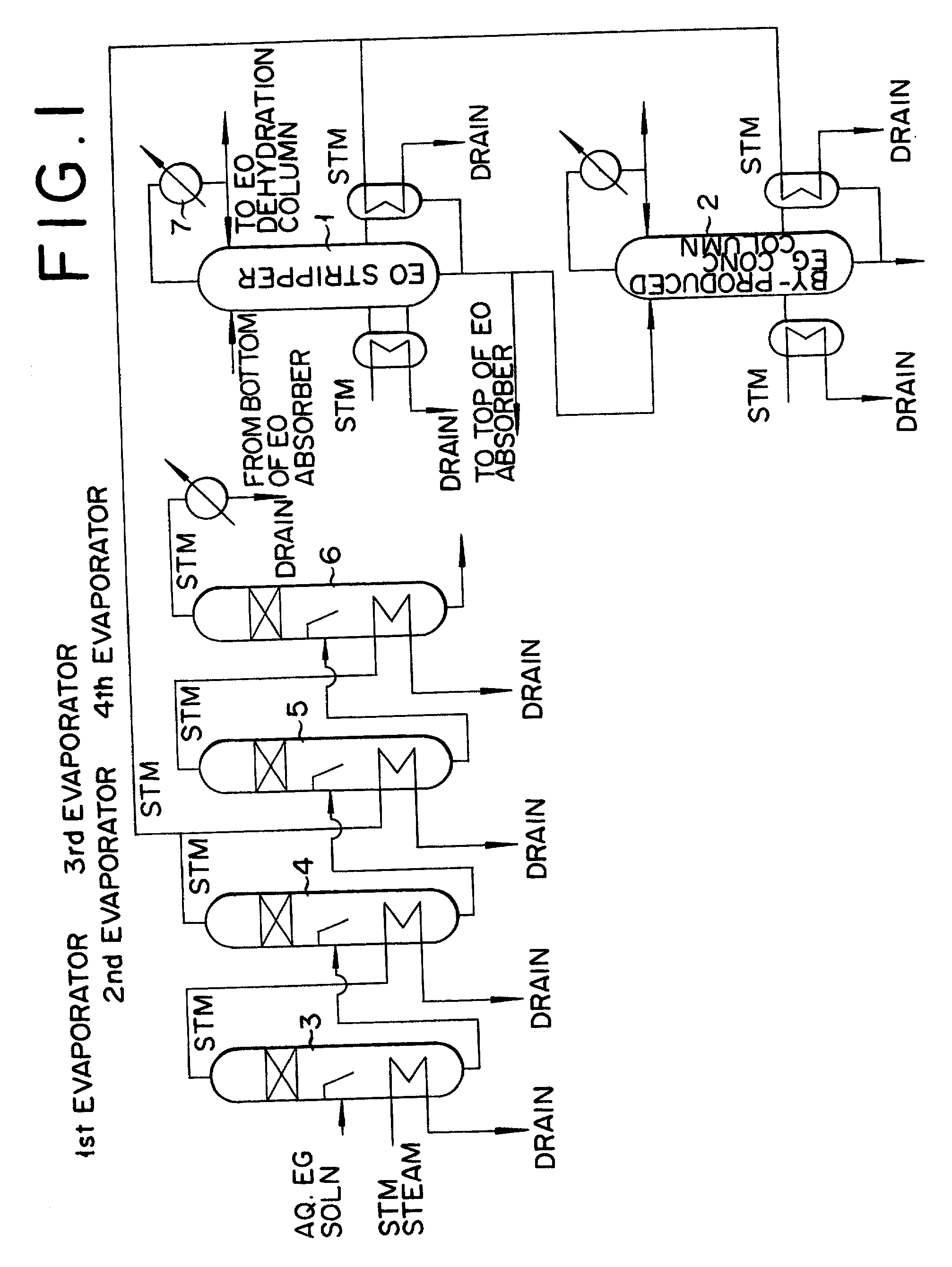

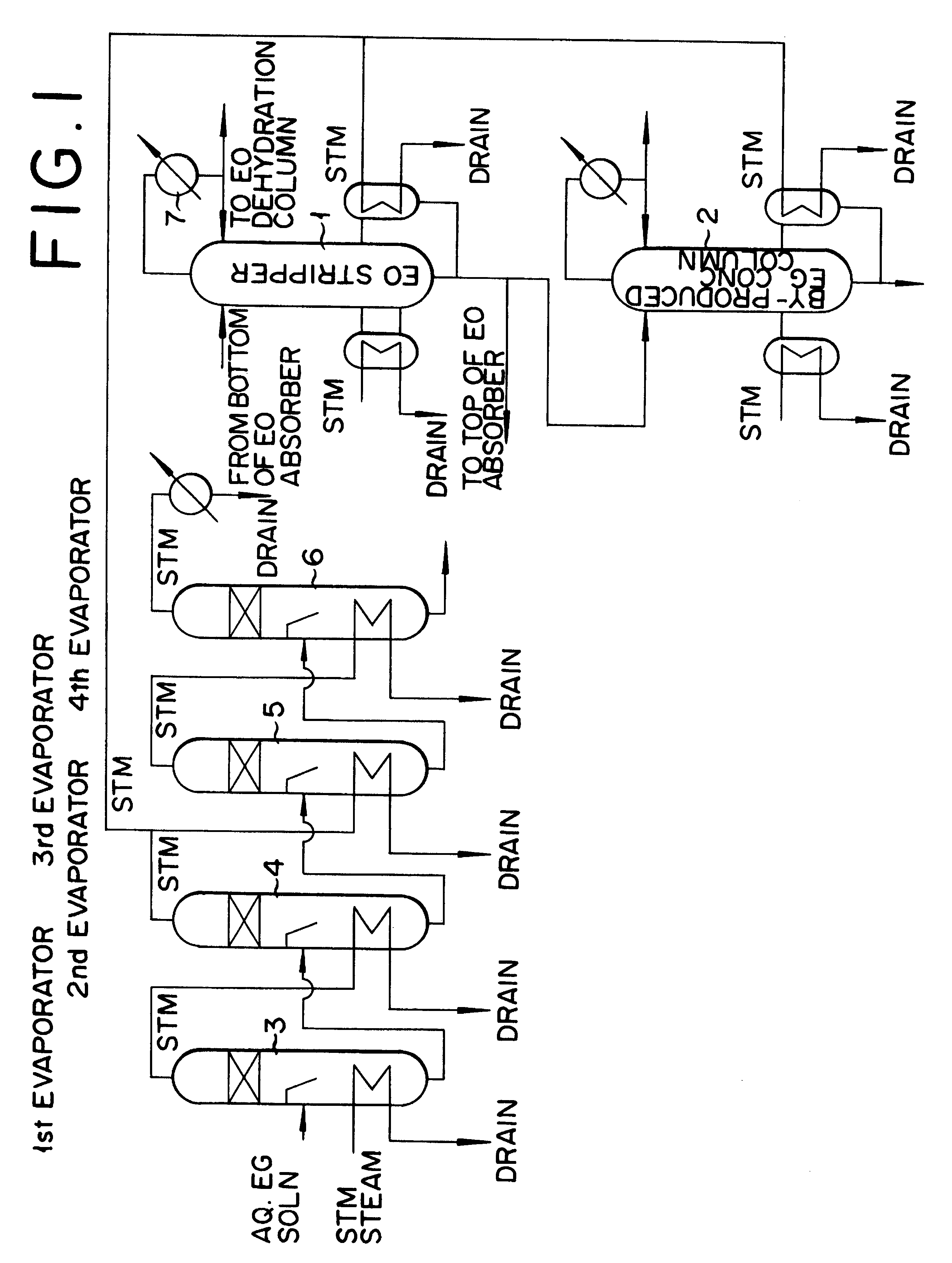

Method for production of ethylene oxide

InactiveUS20020010378A1Efficient comprehensive utilizationEffective utilization can be attainedOxygen-containing compound preparationOrganic compound preparationEthylene oxideMultiple-effect evaporator

In a composite process for subjecting ethylene to catalytic gas phase oxidation thereby obtaining ethylene oxide and causing this ethylene oxide to react with water thereby obtaining ethylene glycol, a method for producing the ethylene glycol is provided which permits effective utilization of the energy at the step for dehydrating and concentrating the resultant aqueous ethylene glycol solution. In the production of ethylene glycol by the supply of the aqueous ethylene glycol solution to a concentrating treatment at the multi-effect evaporator, the method contemplated by this invention for the production of ethylene glycol comprises utilizing as the source of heating at least one specific step the steam generated in the multi-effect evaporator.

Owner:RECOVERYCARE COM +1

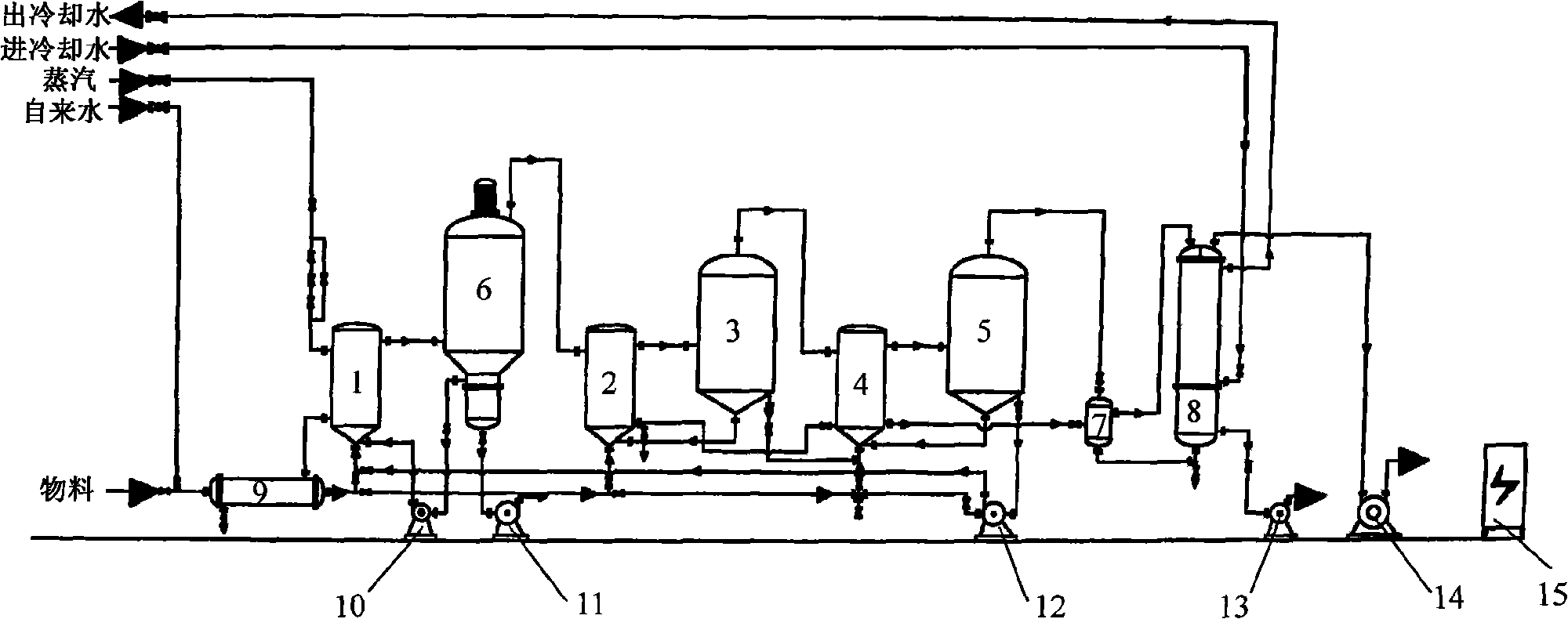

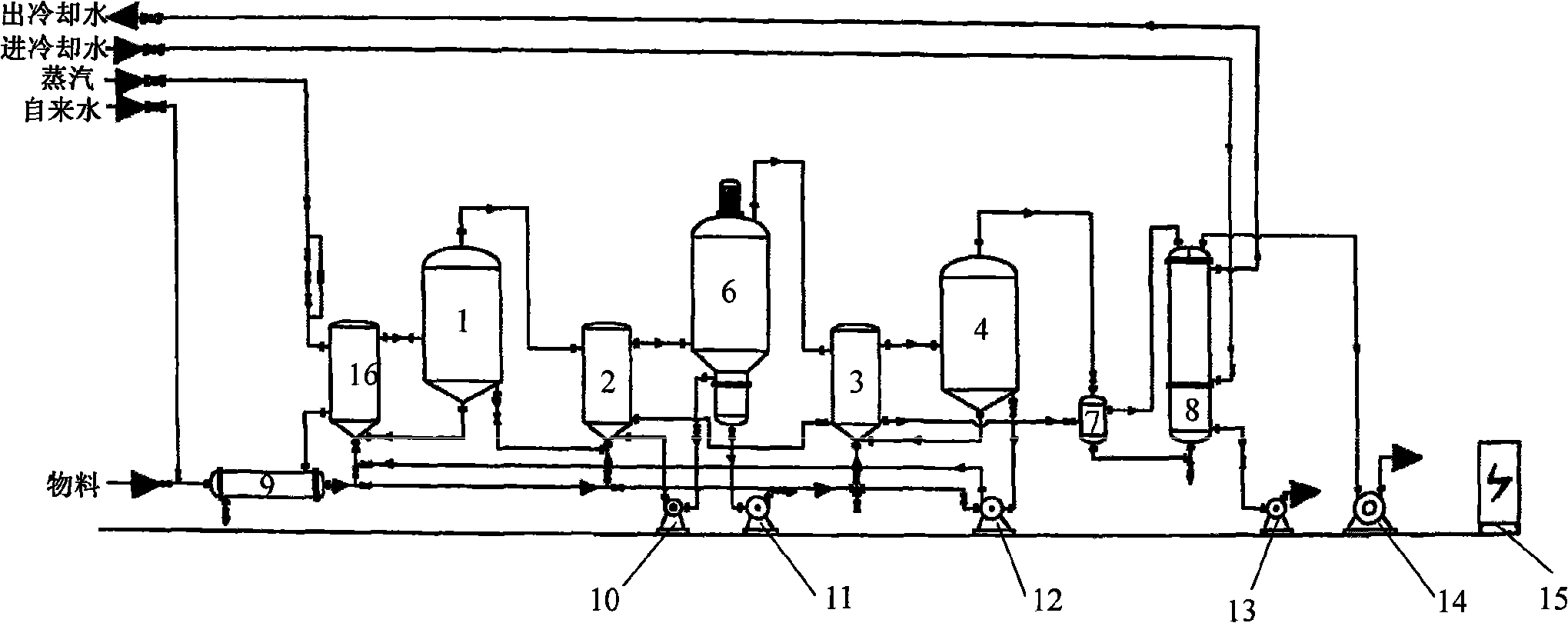

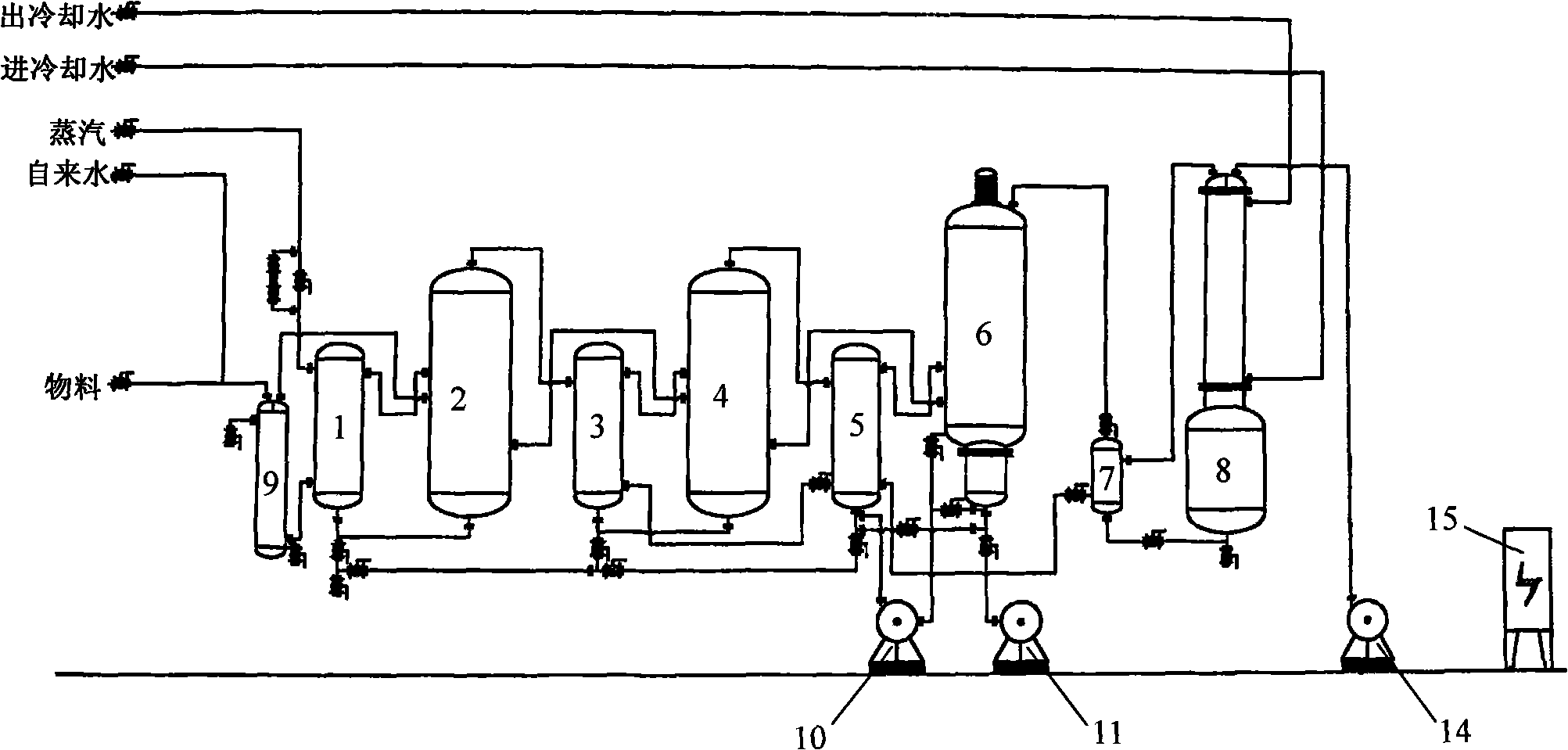

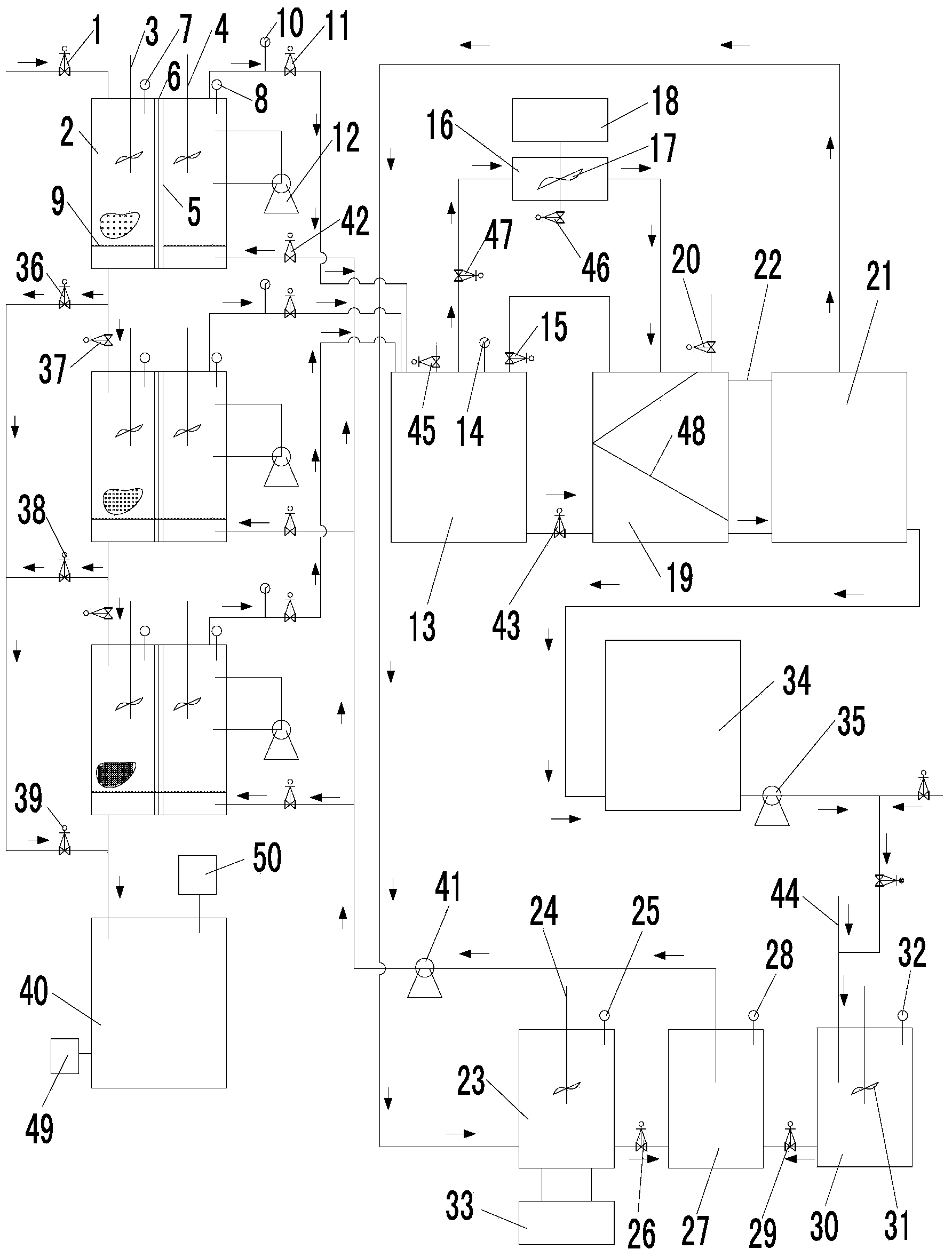

Multifunctional multiple-effect automatic continuous evaporative crystallization technique and crystallization device

InactiveCN101306260AEasy to separateReduce manufacturing costSolution crystallizationMultiple-effect evaporationOrganic solventEconomic benefits

The invention relates to an evaporative crystallization process, in particular to the multifunctional multi-effect automatic continuous evaporative crystallization process and a crystallization device. The process preheats unsaturated water solution or organic solution of materials and carries out the continuous evaporation to the material liquid by a multi-effect evaporator, the temperature of the multi-effect evaporator is gradually reduced and the vacuum degree is gradually increased; when the concentration of the material liquid achieves the saturation, the material liquid enters a crystallizer for the flash evaporation crystallization, and products after the crystallization are subjected to the solid-liquid separation in a centrifuge; the unsaturated solution after the centrifugalization is sent back to the device for the further evaporation crystallization, and the evaporated water or the organic solvent is recycled for use after cooling, thereby realizing the continuous production. The evaporative crystallization process can greatly reduce the labor use and improve the productivity, thereby directly bringing economic benefits to enterprises which use the device and simultaneously reducing the national energy consumption.

Owner:项公浩

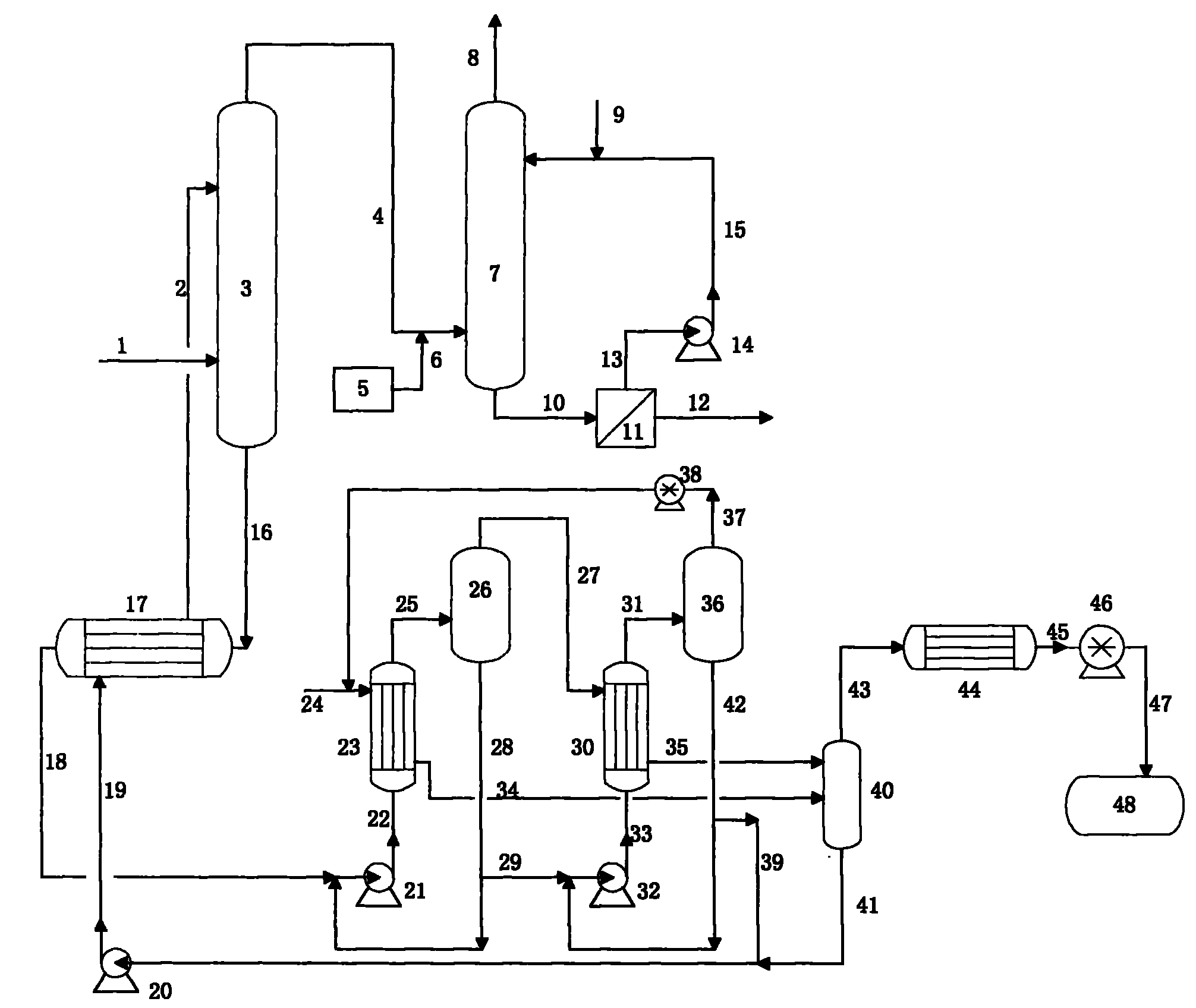

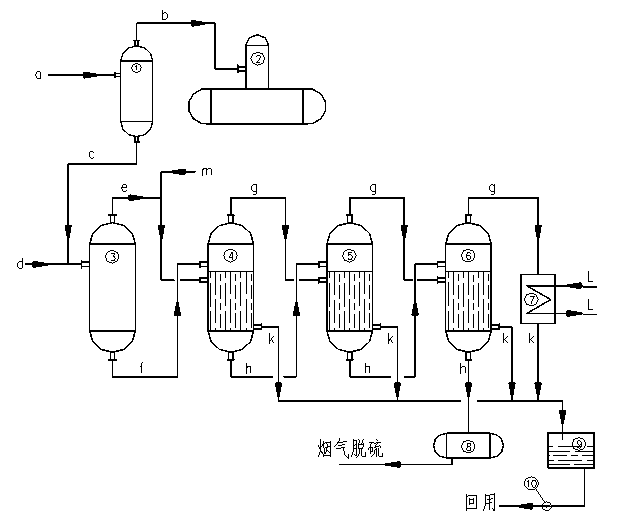

Recycled flue gas desulfurization and denitration method

The invention relates to a recycled flue gas desulfurization and denitration method, which sequentially comprises the following steps of: introducing flue gas of SO2 and NOx into a desulfurizing tower, and absorbing the SO2 with a desulfurizing agent (barren liquor) in the desulfurizing tower; desorbing the desulfurizing agent (rich liquor) which absorbs the SO2 through a multi-effect evaporator,releasing the SO2 gas, and concentrating the SO2 gas into liquid SO2 through condensation drying; making the desulfurized flue gas enter a denitration tower, injecting gaseous ozone from an ozone generator, oxidizing the NO in the flue gas, absorbing the oxidized NO by using a denitrifier to form nitrate; crystallizing and separating out the nitrate in the solution after the nitrate reaches certain concentration, and filtering and drying to obtain the nitrate product. The method turns the wastes into wealth, and the SO2 and NOx in the flue gas are recycled by higher-additional value liquid SO2 and nitrate products, so that the recycling and value maximization in the desulfurization and denitration process is realized. Due to the adoption of the technical scheme, the high desulfurization and denitration rate can be achieved, the desulfurization rate is over 96 percent, the denitration rate is more than 90 percent, and the purity of the nitrate product is over 96 percent. The method hasthe advantages of simple desulfurization and denitration process, low investment, and low operation cost for desulfurization and denitration, and solves the problems that the conventional desulfurization and denitration process has high cost, generates a side product of a mixture of sulfuric acid (sulfate) and nitric acid (nitrate), and has low additional value.

Owner:EAST CHINA UNIV OF SCI & TECH

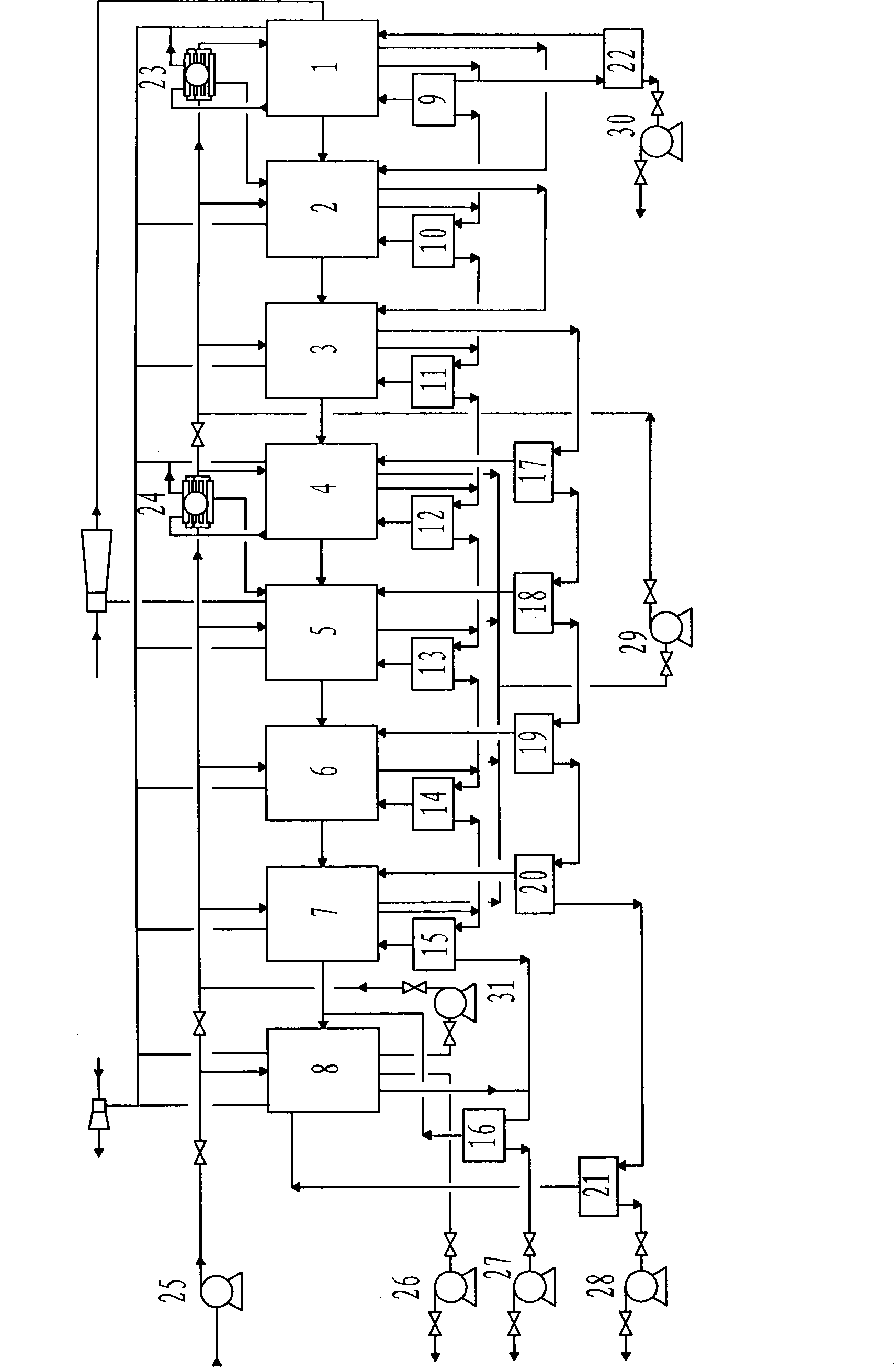

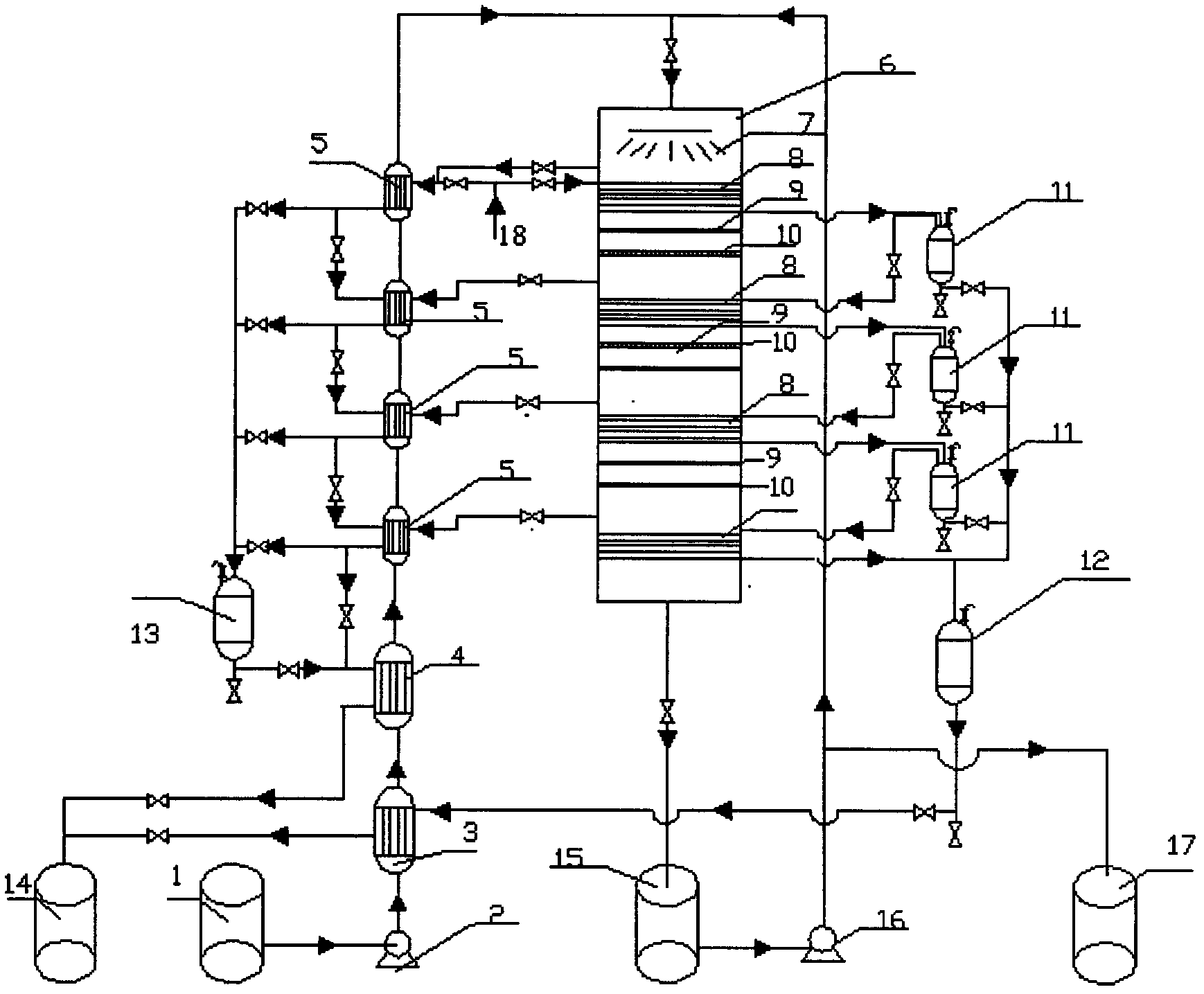

Low temperature multiple-effect distillation seawater desalination system and process flow thereof

InactiveCN101462780AImprove desalination efficiencyImprove efficiencyGeneral water supply conservationSeawater treatmentSaline waterDistillation

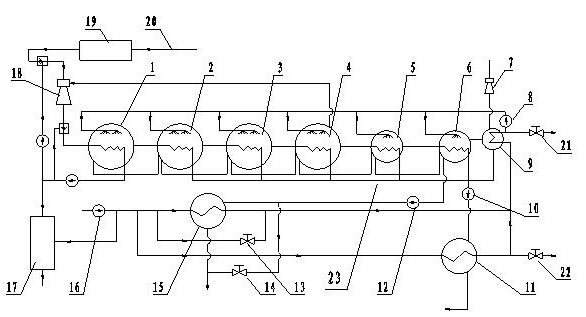

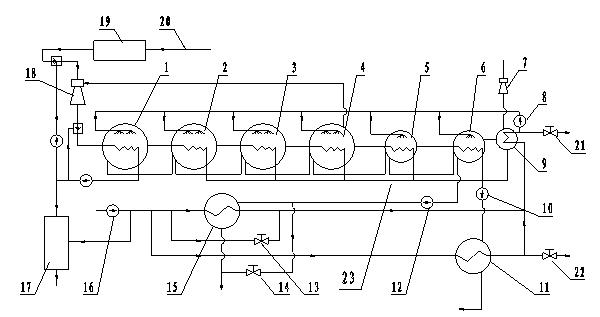

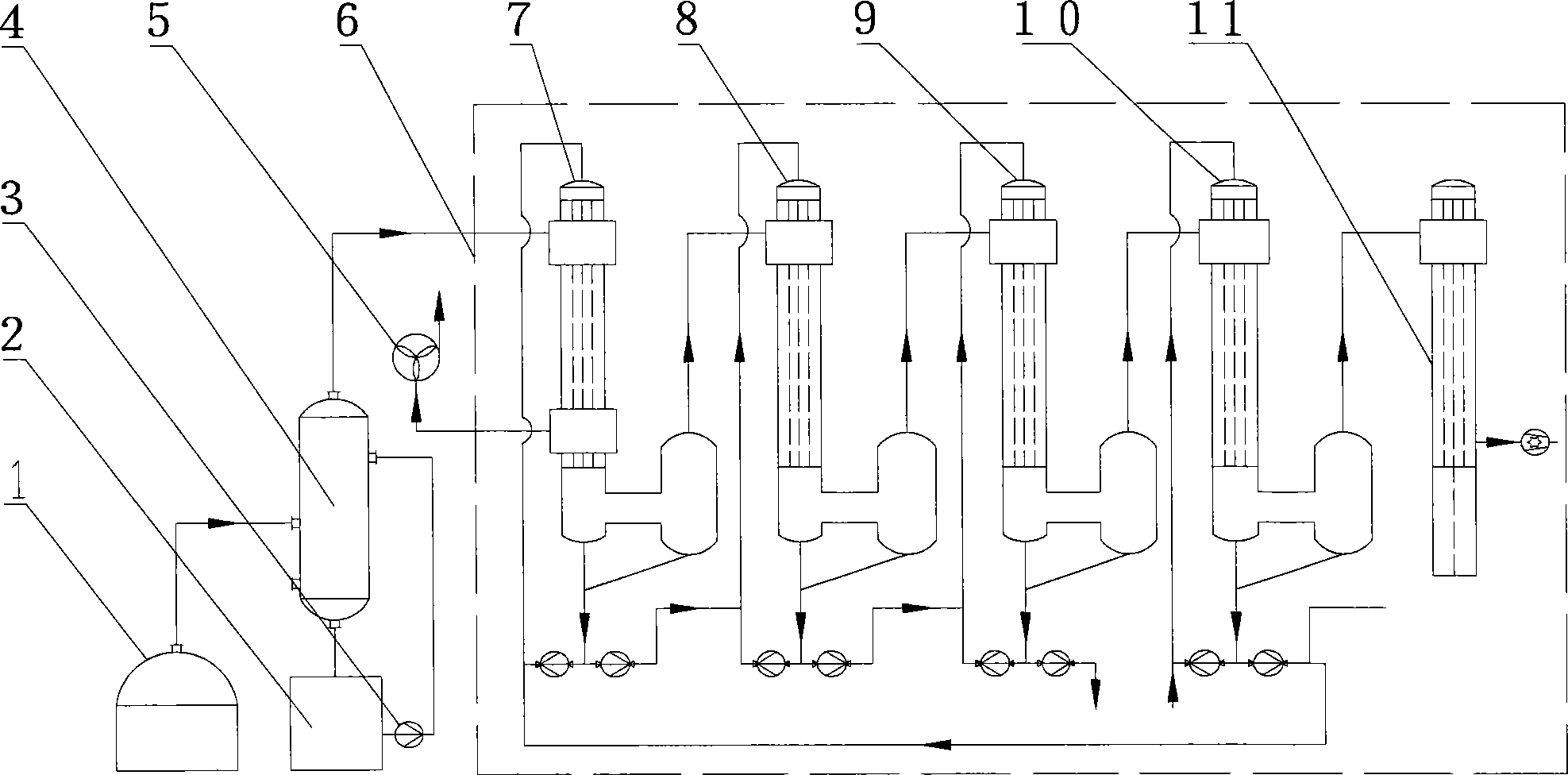

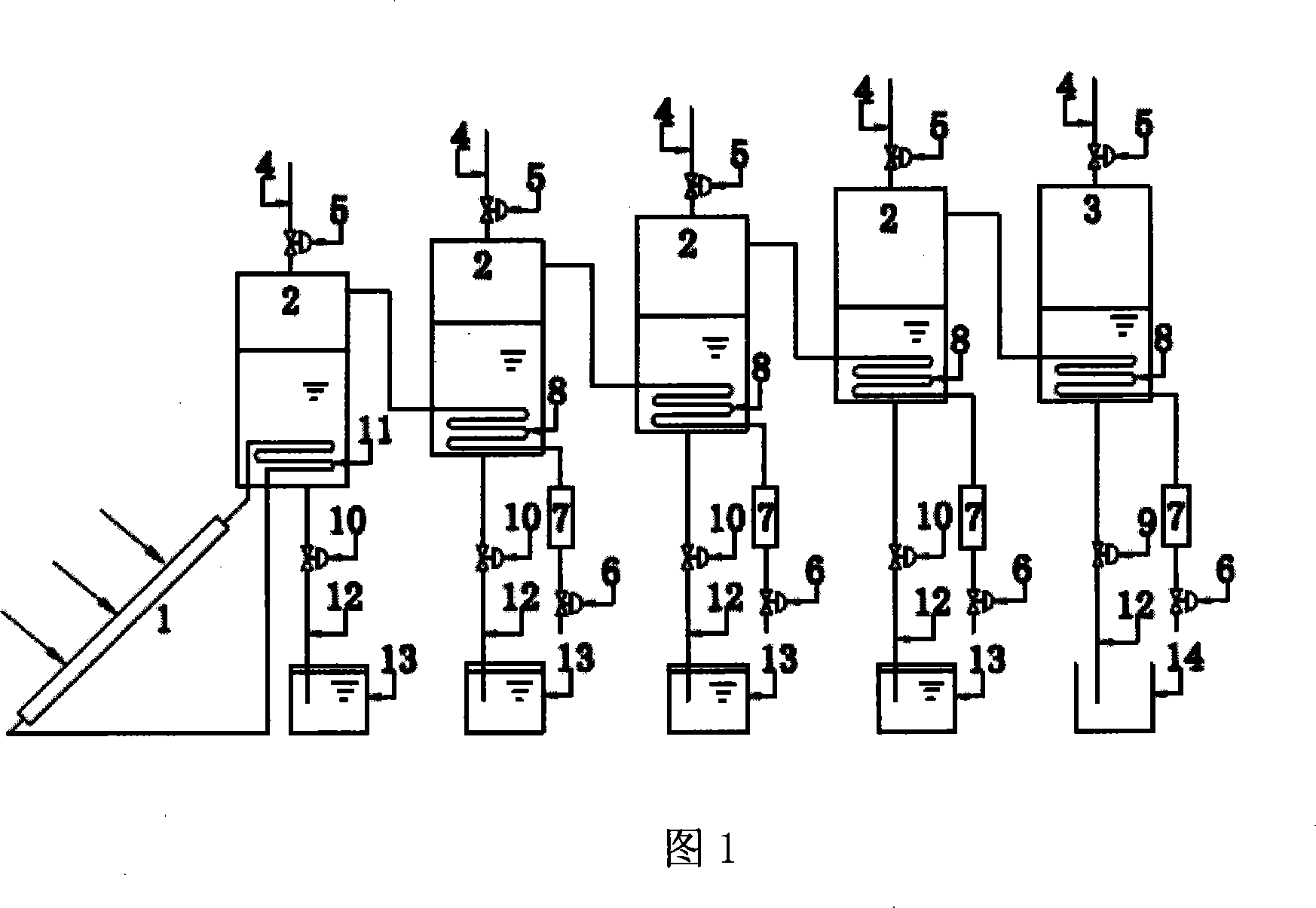

The invention discloses a low-temperature multieffect seawater distillation desalting system. The system comprises a plurality of multi-effect evaporator sets; each evaporator set is at least provided with a heater for preheating feeding seawater; an effect intermediate pump is arranged between two adjacent multi-effect evaporators; and one end of a condenser is connected with a raw material water pump, and the other end of the condenser is connected with the last evaporator set of the plurality of the multi-effect evaporator sets. The invention also discloses a process flow for utilizing the low-temperature multieffect seawater distillation desalting system to desalt seawater; the evaporators of the low-temperature multi-effect seawater distillation desalting system are divided into a plurality of sets; each set feeds in parallel; simultaneously, the front of the feeding seawater of the highest-temperature effect evaporator of each set is provided with a heater; residual strong brine of the front evaporator set is collected and beaten to the next evaporator set through the effect intermediate pump, and so on; a product water and strong brine flow in a ladder shape in a series of flash tanks and are gradually subjected to flash evaporation and cooling; steam obtained through flash evaporation enters the evaporator; and finally, the product of the cooled water and the strong brine are pumped out through a corresponding water pump respectively.

Owner:TIANJIN SEA WATER DESALINATION & COMPLEX UTILIZATION INST STATE OCEANOGRAPHI

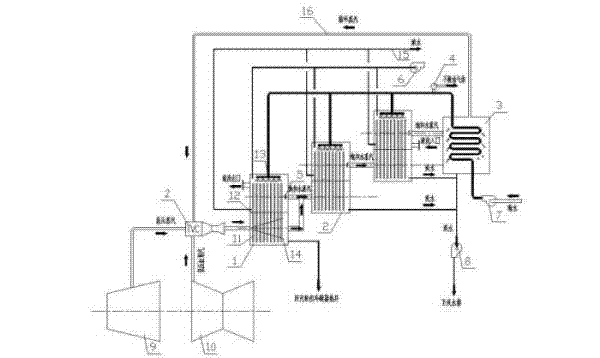

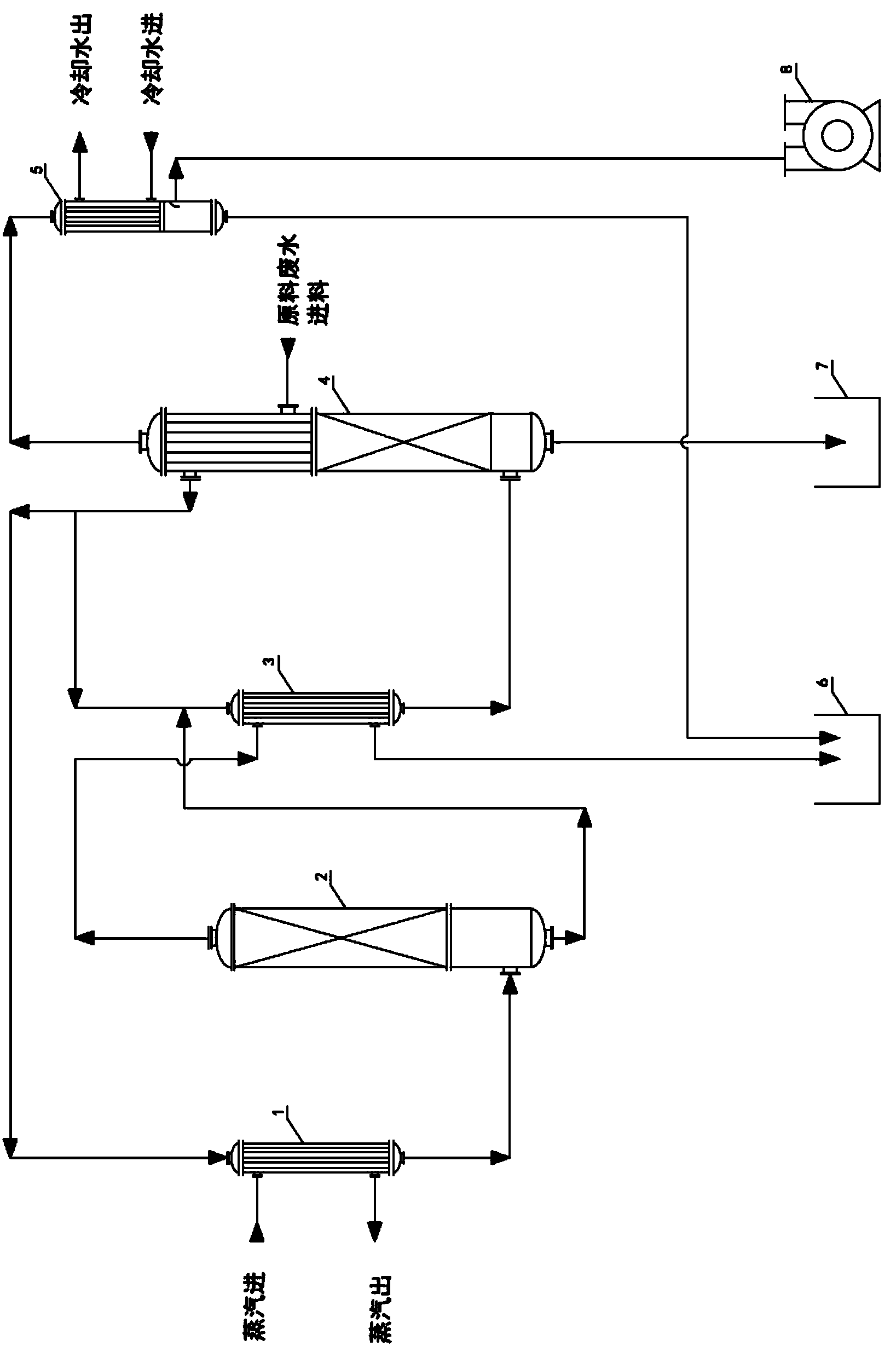

Heat-pipe low-temperature multi-effect sea water desalinating system and process flow

ActiveCN102557168AIncrease profitAchieve fadeGeneral water supply conservationSeawater treatmentEngineeringVacuum pump

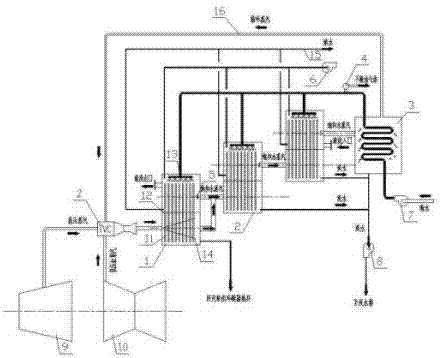

The invention discloses a heat-pipe low-temperature multi-effect sea water desalinating system which comprises a plurality of groups of heat-pipe multi-effect evaporators, a steam injector TVC (Thermal Vapor Compressor), a cooler, an air water release device, a steam-water separator, a water ring vacuum pump, a sea water pump, a fresh water pump, a turbine intermediate pressure cylinder and a turbine low pressure cylinder. The invention also discloses a process flow of the heat-pipe low-temperature multi-effect sea water desalinating system, comprising the steps of: extracting steam through the turbine intermediate pressure cylinder, ejecting circulation steam in the cooler and exhaust steam of the turbine low pressure cylinder through the steam injector TVC to ensure that the circulation steam and the exhaust steam of the turbine low pressure cylinder are changed into higher-quality steam to enter the heat-pipe evaporators, condensing and releasing heat of the steam at a heat absorption end through a heat pipe, transferring the heat to heating and atomized sea water at the other end; heating next-stage sea water through taking the heated and vaporized sea water as the heat source of the next multi-effect evaporator while cooling the heated and vaporized sea water to generate fresh water; heating the sea water which cools the last-stage steam entering the cooler and exhausting the generated non-condensable gas through the air water release device; pumping the non-condensable gas of the multi-effect evaporators through the water ring vacuum pump to ensure that the system runs in a negative-pressure state; and discharging concentrated water out of the system through a pipeline and pumping the fresh water to a fresh water tank through a permeated water pump.

Owner:国能朗新明环保科技有限公司

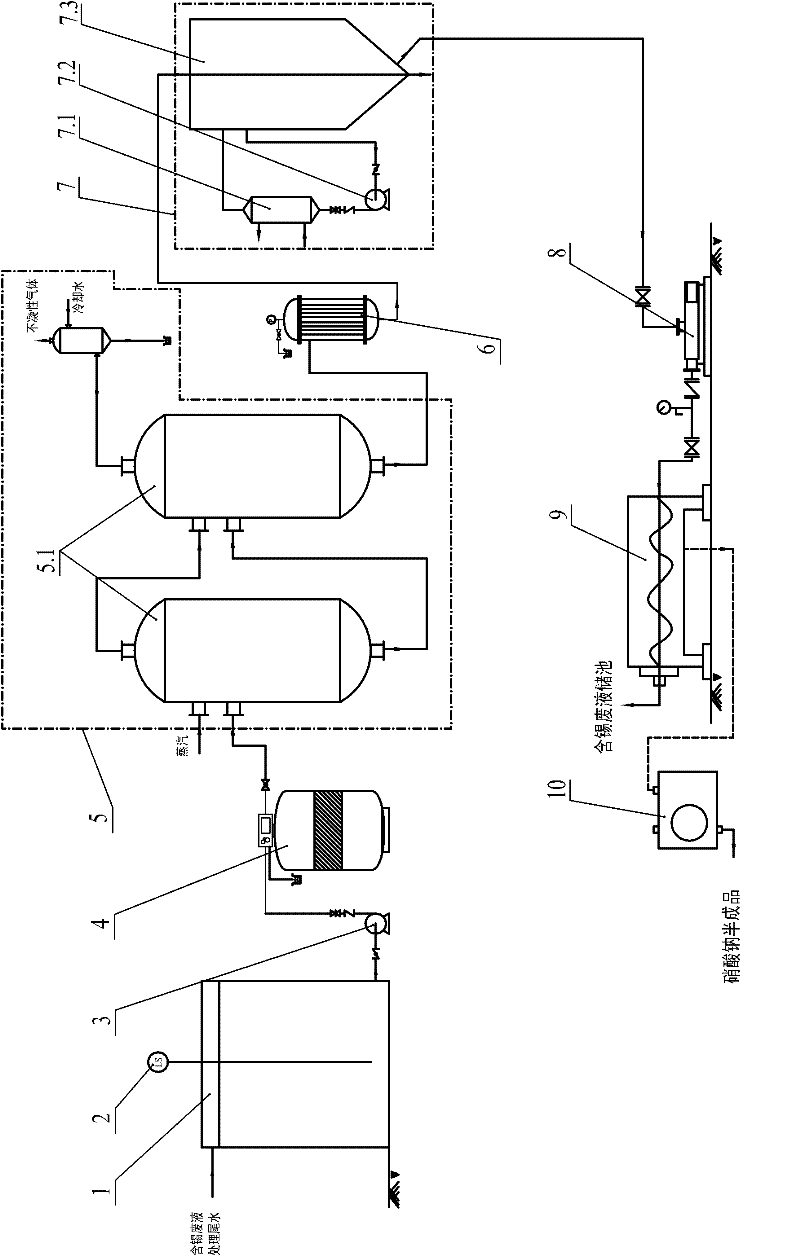

Method for purifying smelting waste acid

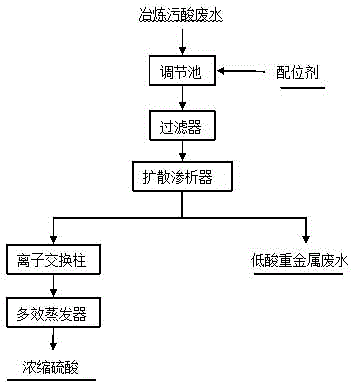

ActiveCN104445095AEfficient removalAchieve separationSulfur-trioxide/sulfuric-acidSmall footprintIon-exchange resin

The invention discloses a method for purifying smelting waste acid. The method comprises the following steps: adding a coordination agent into a centralized inflow adjusting pool of waste acid discharged from a sulfuric acid smelting system, stirring uniformly, and filtering the mixture in a filter to further remove insoluble granular impurities; separating dilute acid nearly containing no metal ion and low-acid wastewater through a diffusion dialyzer; adsorbing such residual anion impurities as fluorine and chlorine in the dilute acid through ion exchange resin, concentrating the dilute acid in a multi-effect evaporator and recycling the dilute acid in the sulfuric acid system; further treating the low-acid wastewater to reach the national sewage drainage standard. The method disclosed by the invention can be used for quickly and efficiently separating acid from heavy metal ions in the smelting waste acid, the separated dilute acid can be recycled in a sulfuric acid production procedure after being concentrated, and the method has the advantages of low energy consumption and few residues, and can be used for effectively and comprehensively recycling resources in the waste acid. The wastewater treatment cost is low, and the economic benefit is good. The process is simple, the occupation area of equipment is small and industrialized application is easy to achieve.

Owner:CENT SOUTH UNIV

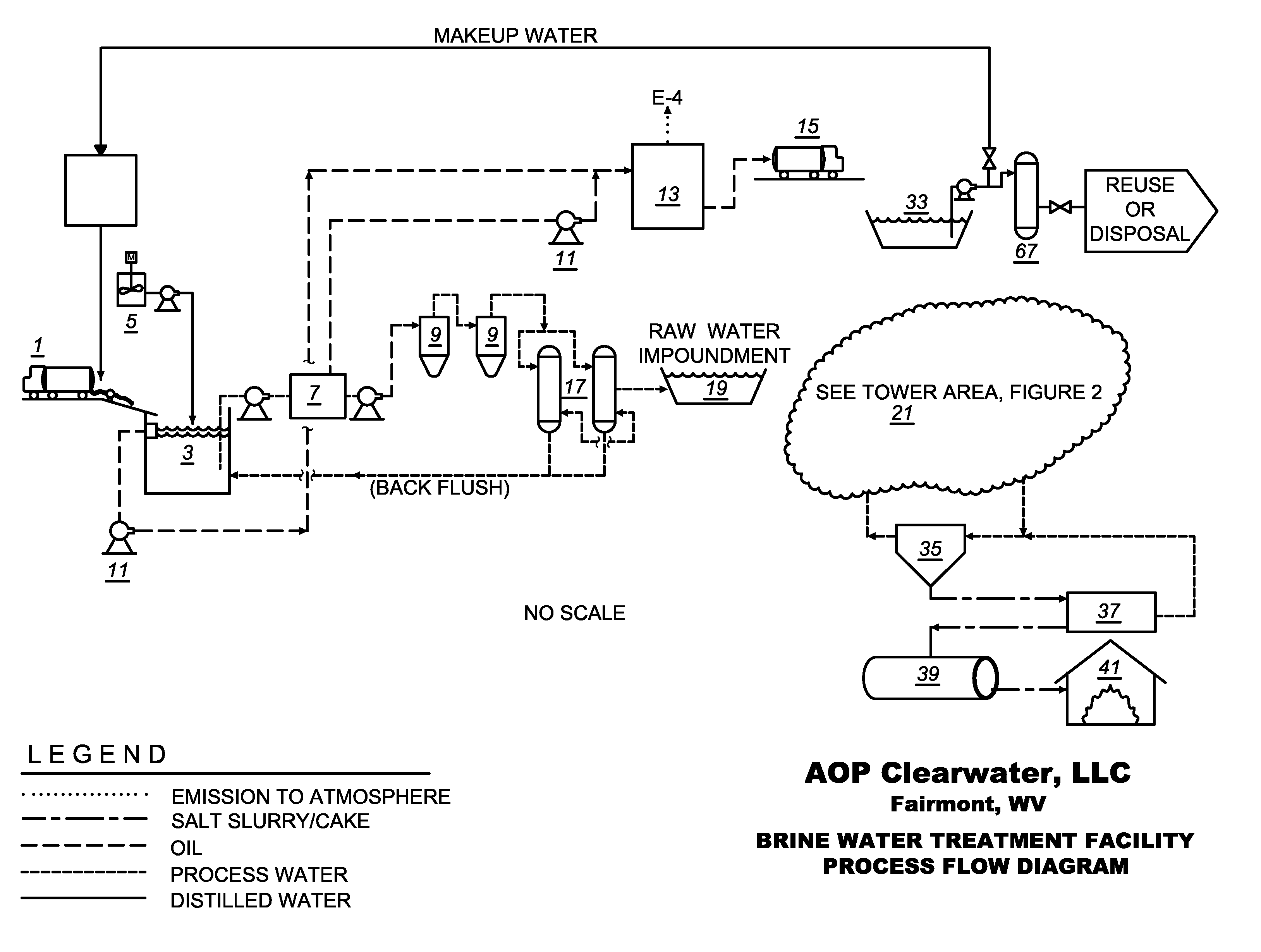

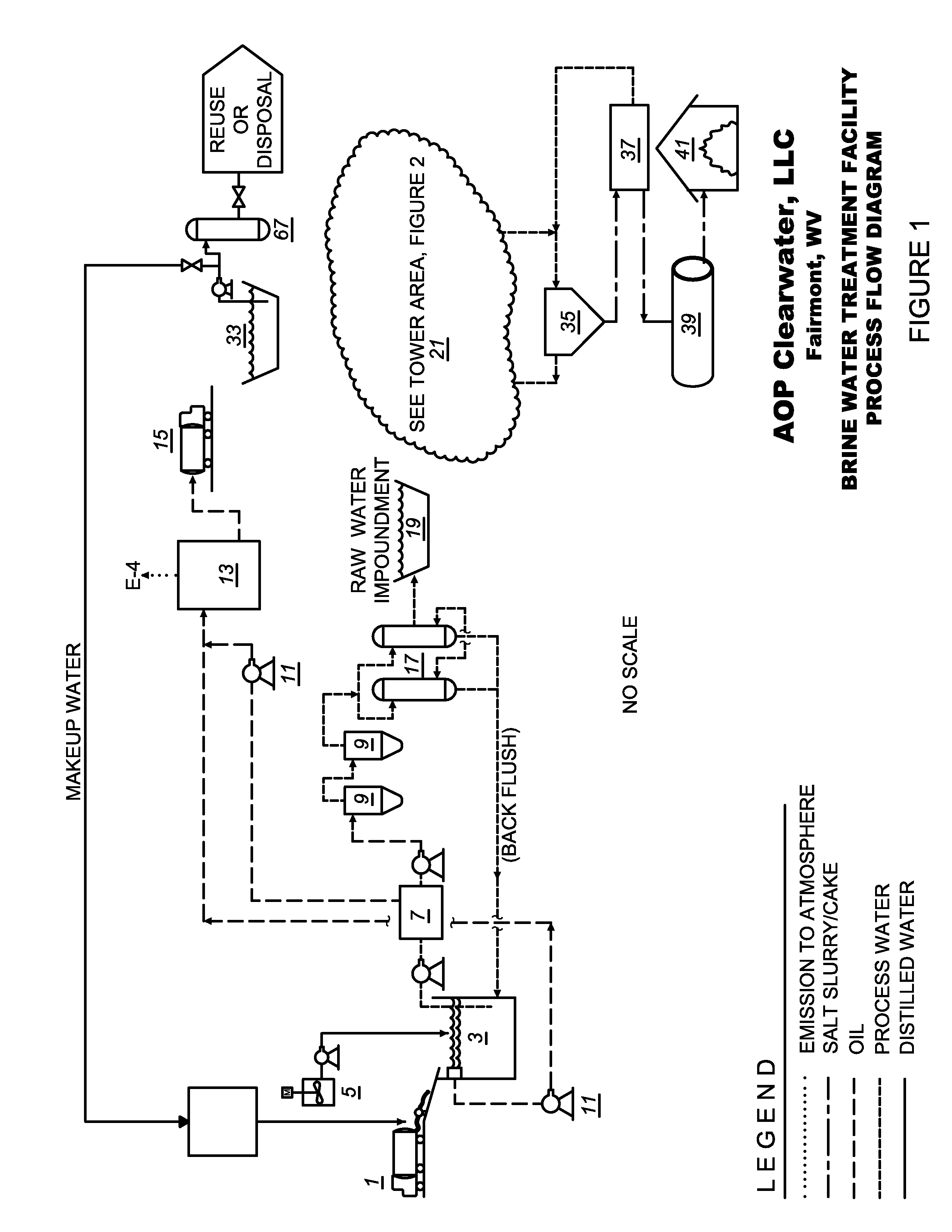

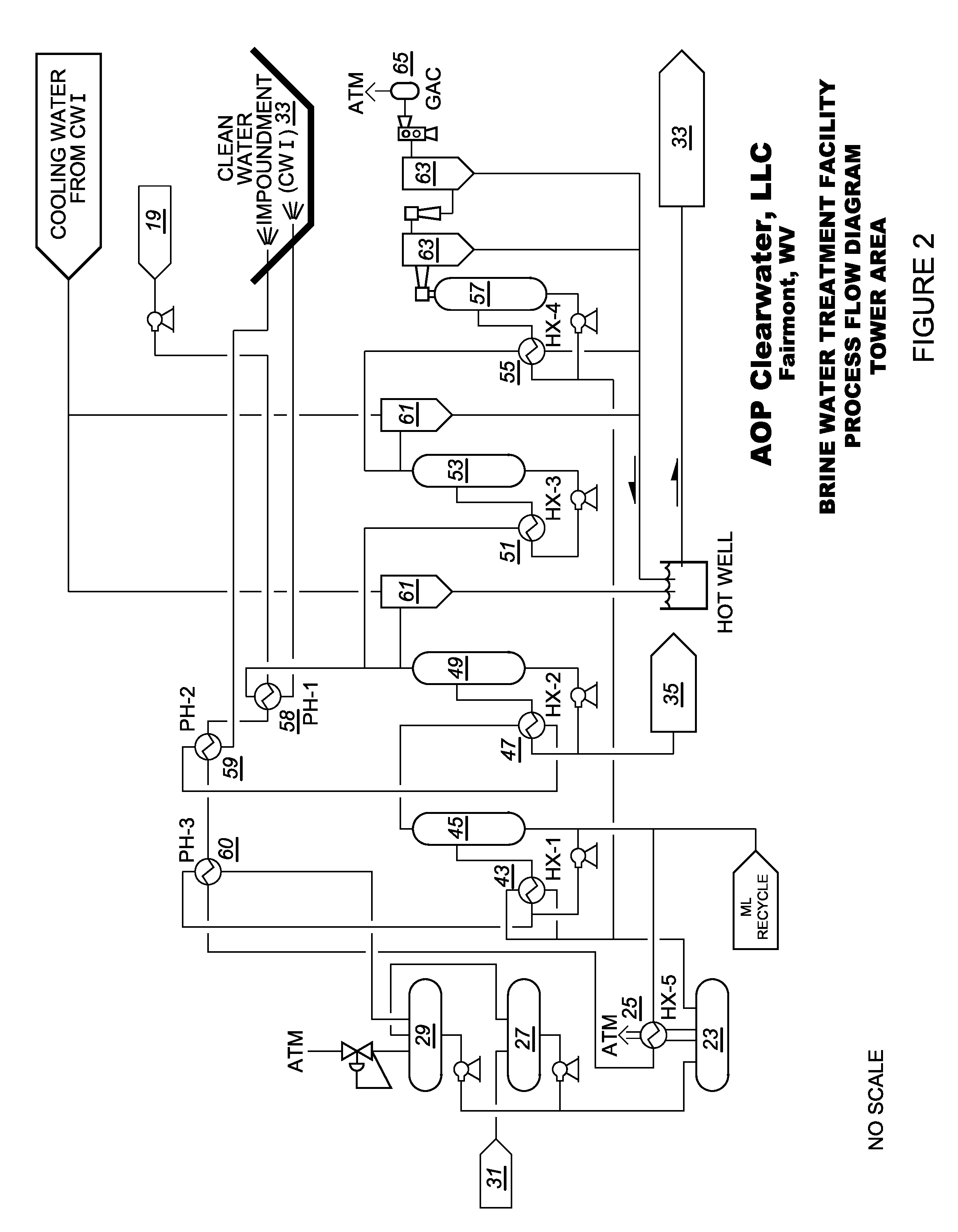

Brine water recycle process

Embodiments provided herein include methods and apparatuses for purification and recycling of hydrofracture water used in natural gas drilling and production. Embodiments include removal of dissolved solids by precipitation with sodium sulfate and by evaporation using, for example, a multiple effect evaporator.

Owner:FAIRMONT BRINE PROCESSING

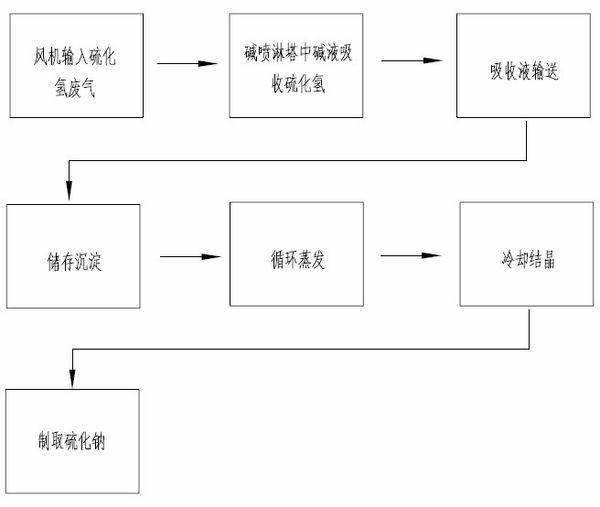

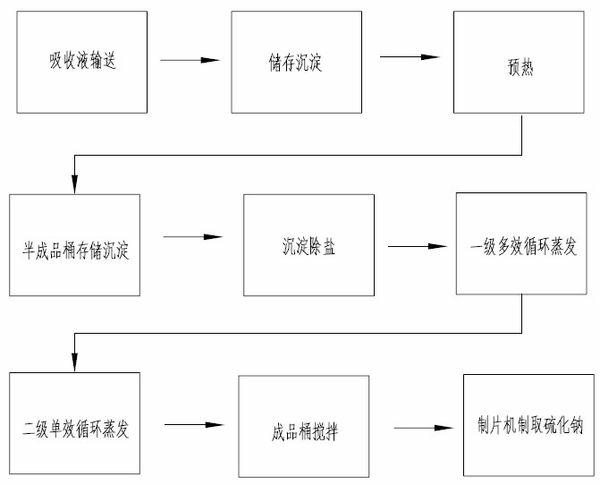

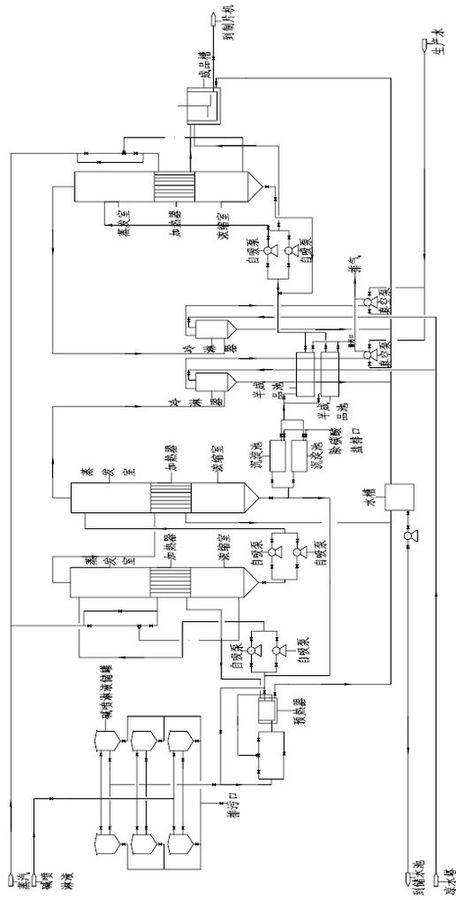

Method for preparing sodium sulfide from hydrogen sulfide waste gas produced in production of viscose fibre

InactiveCN102515112AAchieve optimized generationIncrease production costAlkali metal sulfides/polysulfidesImpurityWaste gas

The invention relates to the field of production of viscose fibre in the textile industry, in particular to a method for preparing sodium sulfide from hydrogen sulfide waste gas produced in the production of the viscose fibre. The method comprises the steps as follows: A, the waste gas is fed into an alkali spray tower; B, hydrogen sulfide is absorbed in an alkali liquor in the alkali spray tower; C, impurities are removed; D, a preheated absorption liquid is delivered into a primary multi-effect evaporator; E, a solution is subject to settlement and desalination; F, the desalinated solution is filled into a semi-finished product barrel, and caustic soda is added into the desalinated solution; G, the solution in the semi-finished product barrel is delivered into a secondary single-effect evaporator; H, after undergoing the secondary evaporation, the solution is filled into a finished product barrel, and then is stirred for crystallization; and I, crystal sodium sulfide is made into tablets. The method has the advantage of realizing the optimal generation of sodium sulfide through the setting of processing parameters such as the size of main equipment, the pore diameter of a delivery pipeline, wind volume, wind velocity, the concentration of the alkali liquor, absorption time, circulating evaporation time, evaporation temperature, evaporation vacuum degree, precipitation time, stirring velocity, the rotational speed of a tablet making machine, and the like.

Owner:YIBIN HIEST FIBER +2

Energy-saving low-temperature multiple-effect seawater desalting device

ActiveCN101948148ALow running costReduce pollutionGeneral water supply conservationSeawater treatmentSteelmakingEngineering

The invention discloses an energy-saving low-temperature multiple-effect seawater desalting device, which is used for solving the problems of high operation cost and unstable operation of a desalting device. The energy-saving low-temperature multiple-effect seawater desalting device comprises a steam ejector, evaporators and a condenser, wherein multiple effect evaporators are connected in series; after improvement, the heat source of the device consists of a steel mill off-gas pipeline and a waste heat boiler; the waste heat boiler converts steel mill waste heat off-gas into saturated steam and overheat steam; the saturated steam and overheat steam are introduced into the first effect evaporator through the steam ejector; and the outlet of the last effect evaporator is connected with the condenser. The energy-saving low-temperature multiple-effect seawater desalting device has the advantages that: a, the waste heat boiler is introduced, the steel mill off-gas is fully utilized, the energy is saved, the operating cost of the device is reduced, and the pollution of the steelmaking off-gas on the environment is reduced; and b, the heat of finished water and strong brine is fully utilized, the temperature of the seawater at the inlet and outlet of the condenser is kept stable through intelligent pipeline control despite of the change of the temperature of seawater, and the equipment has the stable and optimized running state.

Owner:HEBEI HONGRUN NUCLEAR EQUIP SCI & TECH CO LTD

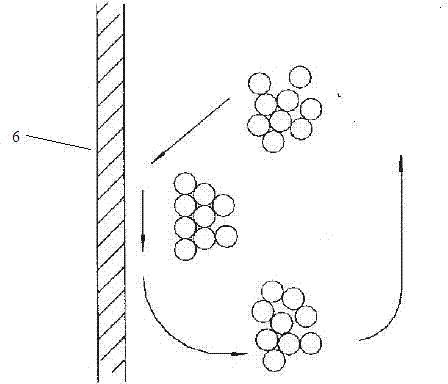

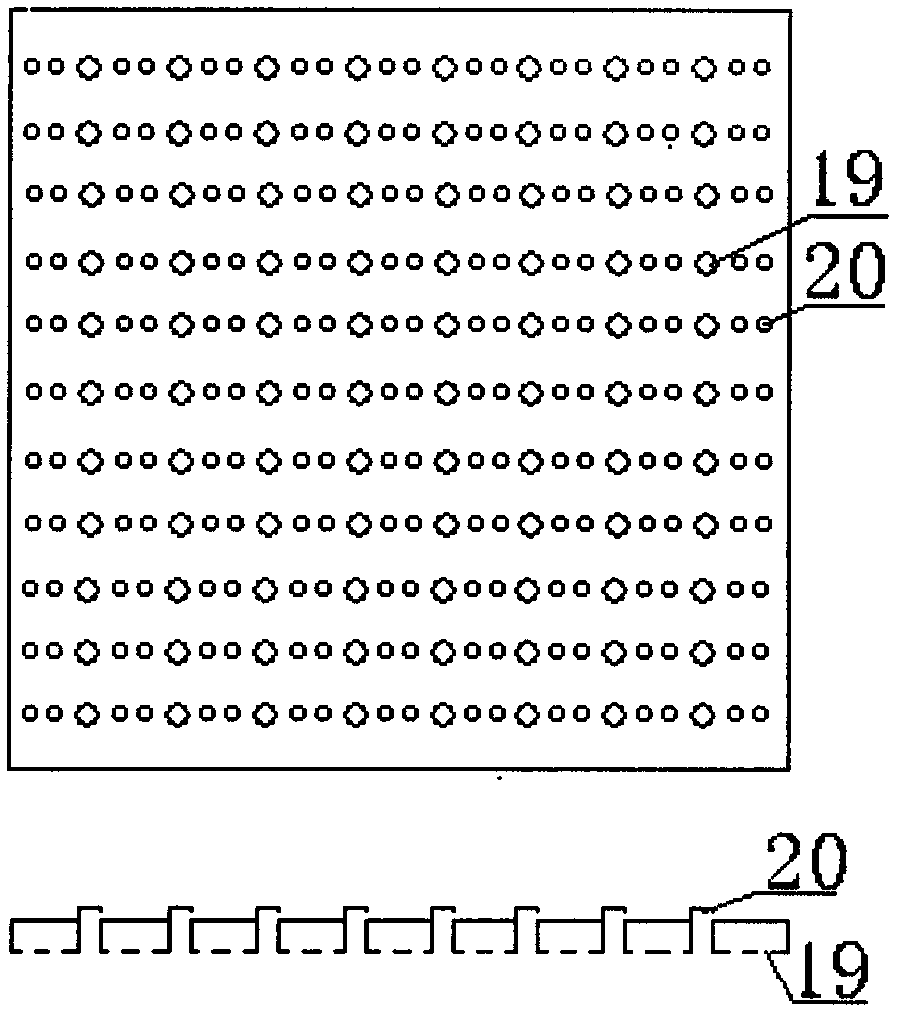

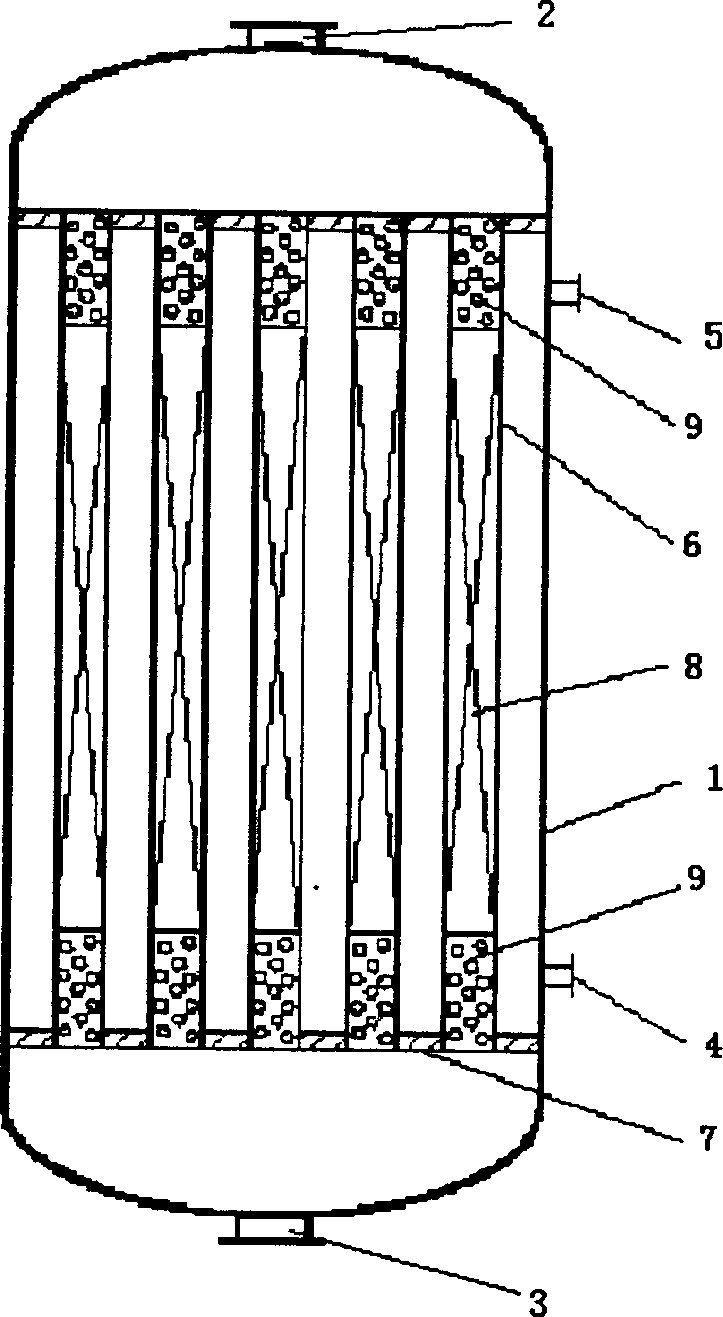

Full-automatic descaling multi-effect evaporator

ActiveCN102921179AFast flowAvoid formingEvaporator accessoriesMultiple-effect evaporationMultiple-effect evaporatorEngineering

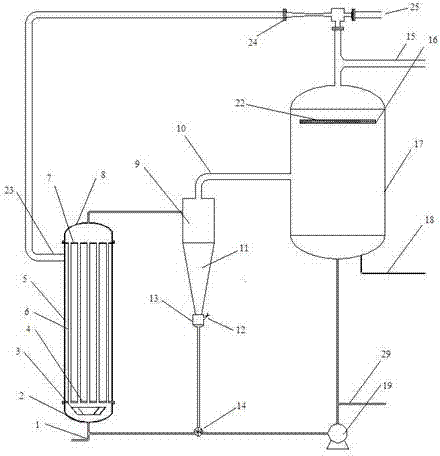

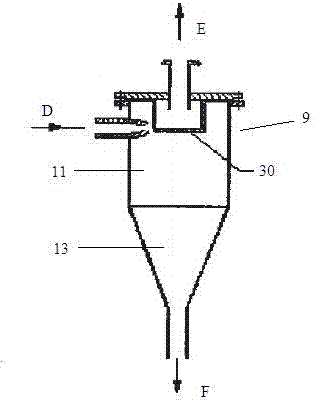

The invention discloses a full-automatic descaling multi-effect evaporator, which comprises a heater and an evaporation chamber, wherein a granule distributor which can make fluid be distributed to tube nests of the heater uniformly is arranged at the bottom of the heater; and a granule separator is also arranged between the heater and the evaporation chamber. Due to the adoption of the technical scheme, the full-automatic descaling multi-effect evaporator has the advantages that a descaling process can be simplified, heat transfer is enhanced, and a heat transfer coefficient is increased, so that the evaporator can clean and remove scales online to realize continuous production. According to the optimized technical scheme, an intensifier ring is arranged in the granule separator, and a granule separation chamber and a granule storage chamber are also formed in the granule separator, so that liquid forms a vortex which rotates at high speed when passing through the cylindrical granule separation chamber under the action of centrifugal force formed by the intensifier ring to do circular rotary motion, so that granular solids are separated from the liquid quickly.

Owner:JIANGSU HUATAI HEAVY IND EQUIP

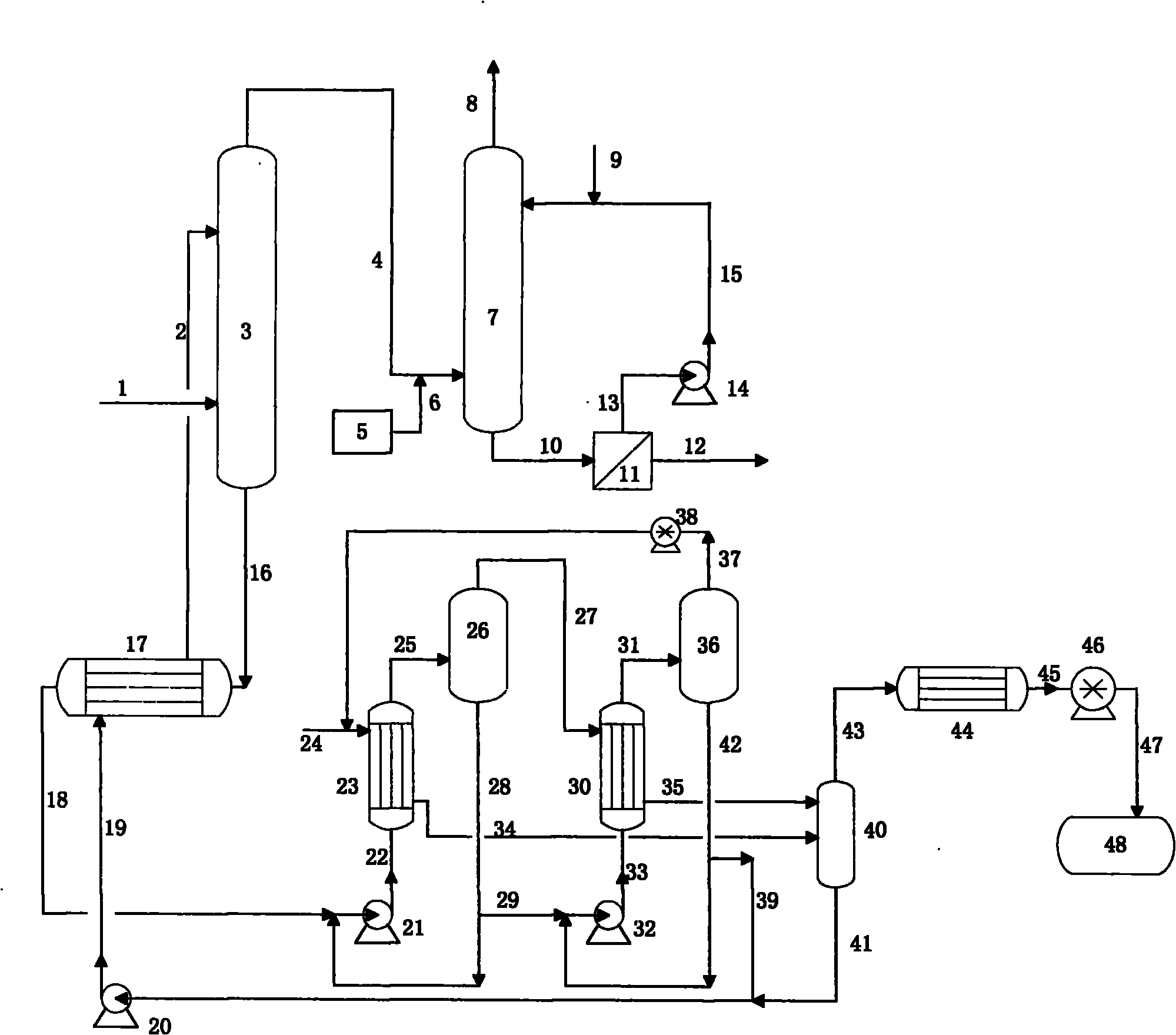

Method for production of ethylene glycol

InactiveUS6417411B2Efficient comprehensive utilizationSmall consumptionOxygen-containing compound preparationOrganic compound preparationGas phaseEthylene oxide

In a composite process for subjecting ethylene to catalytic gas phase oxidation thereby obtaining ethylene oxide and causing this ethylene oxide to react with water thereby obtaining ethylene glycol, a method for producing the ethylene glycol is provided which permits effective utilization of the energy at the step for dehydrating and concentrating the resultant aqueous ethylene glycol solution. In the production of ethylene glycol by the supply of the aqueous ethylene glycol solution to a concentrating treatment at the multi-effect evaporator, the method contemplated by this invention for the production of ethylene glycol comprises utilizing as the source of heating at least one specific step the steam generated in the multi-effect evaporator.

Owner:RECOVERYCARE COM +1

Treatment process for wastewater from N-(Phosphonomethyl)iminodiacetic acid production

InactiveCN101428935AReduce processing costsPromote environmental protectionTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentSteam pressureFiltration

The invention discloses a method for treating PMIDA (N-(phosphonomethyl)iminodiacetic acid) production wastewater, which comprises the following steps: 1) the PMIDA production wastewater is sent into equipment with a compound evaporator and a vacuum system, and is separated into a saturated concentrated solution containing sodium chloride and evaporable water at a steam pressure of between 0.1 and 0.4MPa and a vacuum degree of between 0.05 and 0.08MPa; the concentrated solution containing the sodium chloride is cooled to crystallize the sodium chloride; and the solid-liquid separation is performed; 2) separating medium is sent into a curing container, a curing agent is added, and innoxious solid mud and a filtrate are obtained after the washing and filtration; 3) after the evaporable water and the filtrate are mixed, a neutralizing agent is used to adjust the pH value to between 6 and 8; 4) an oxidant is added in neutralized wastewater for oxidation; and 5) a treated oxidized liquid is aerated and then enters the prior biochemical system to obtain treated water. The method can greatly reduce the treatment cost for the PMIDA production wastewater, can also extract partial useful constituents in the PMIDA production wastewater, can be recycled, and is favorable for the environmental protection.

Owner:SICHUAN BEIER CHEM GROUP

Comprehensive utilization method of thermal power plant boiler wastewater

The invention provides a comprehensive utilization method of thermal power plant boiler wastewater. The comprehensive utilization method comprises the following process steps: (1) continuous boiler wastewater goes into a continuous blowdown flash tank for reduced-pressure flashing; secondary steam generated after flashing is guided out of the upper part of the continuous blowdown flash tank and into a deaerator; (2) the hot wastewater at the bottom of the continuous blowdown flash tank is guided into a boiler periodic blowdown flash tank for further reduced-pressure flashing together with regular boiler wastewater; (3) the secondary steam generated by flashing from the periodic blowdown flash tank serves as a heat source and is guided into a low-temperature multiple-effect evaporator group, and bottom salt-containing wastewater also goes into the low-temperature multiple-effect evaporator group as the evaporated liquid; (4) the condensed water generated by the low-temperature multiple-effect evaporator group and the steam condensed water out of a cooler are collected to a condensed water tank by use of a condensation header and then fed into a boiler water supply system by use of a condensed water pump to be recycled; a thickened liquid generated by performing multiple-effect evaporation on the salt-containing wastewater is recycled into a thickened liquid recovery tank and then fed into a wet boiler flue gas desulphurization system used as a desulfurizing agent for desulphurization.

Owner:CHINA CEC ENG

High-temperature seawater desalting and distillation device and method

ActiveCN102424436AHigh heating temperatureIncrease water production ratioGeneral water supply conservationSeawater treatmentHigh concentrationDistillation

Owner:天津海泽惠科技发展有限公司

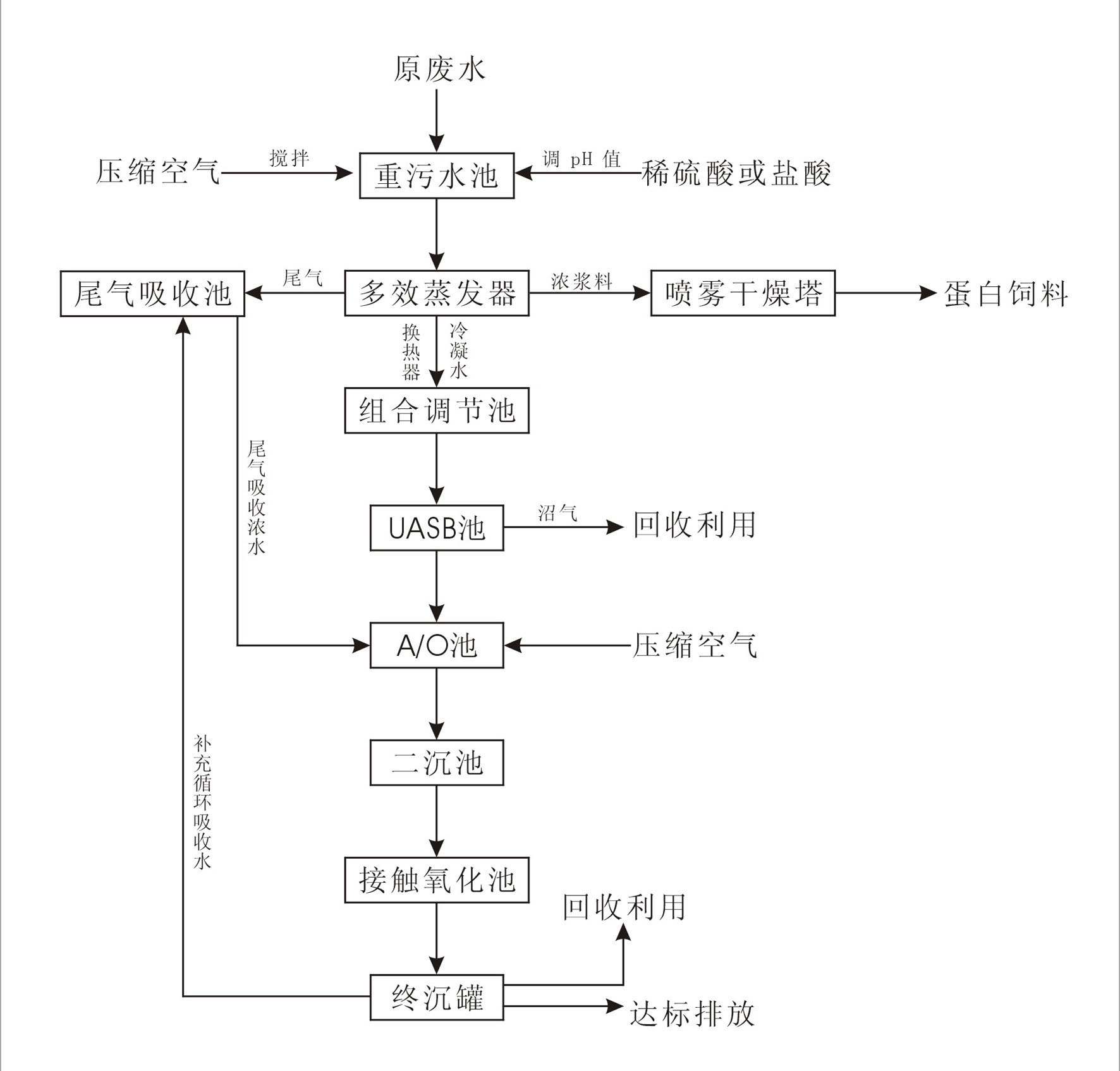

Method for treating riboflavin fermentation waste water

ActiveCN102010104AReduce processing difficultySolve the B/C valueAnimal feeding stuffWaste based fuelSolid matterFermentation

The invention discloses a method for treating riboflavin fermentation waste water, which comprises the following steps of: concentrating and drying the waste water after extracting riboflavin fermentation liquor by using a multi-effect evaporation system; drying concentrated dense size to obtain a large amount of solid protein feed; and putting condensed condensate water in a multi-effect evaporator into a biochemical system, and treating the condensate water by adopting an 'anaerobic upflow anaerobic sludge blanket (UASB), anaerobic / oxic (A / O) and contact oxidization decoloration' method. The method changes the conventional sewage treatment mode, effectively separates solid matters in riboflavin production waste water, reduces the sewage treatment difficulty, and solves sewage biochemical oxygen demand / chemical oxygen demand (B / C) values, thereby ensuring that the sewage can be biochemically degraded more easily and the waste water can be discharged up to standard. Simultaneously, the solid protein feed is recovered, and the up-to-standard waste water is recycled for blending, fermentation water replenishing, extracting working section and / or greening and the like, thereby saving water resources. The biogas generated by anaerobic treatment is collected for comprehensive utilization, thereby saving energy sources and realizing comprehensive utilization of resources.

Owner:GUANGJI PHARMA MENGZHOU

Comprehensive utilization technology of viscose fiber acid wastewater

ActiveCN106145496AAchieve reuseNo emissionsWater treatment parameter controlSpecific water treatment objectivesFiberReverse osmosis plant

Comprehensive utilization technology of viscose fiber acid wastewater includes the steps: firstly, filtering the viscose fiber acid wastewater by a filter, removing suspended matters in the wastewater and treating filtered solution in a next step; secondly, leading the filtered solution into a reverse osmosis system to obtain membrane concentrated solution and membrane permeate liquid, directly reusing the membrane permeate liquid as process water and treating the membrane concentrated solution in a step C; finally, leading the membrane concentrated solution obtained by reverse osmosis treatment into a multi-effect evaporator for concentration, feeding the membrane concentrated solution into a crystallizing tank for crystallization to obtain sodium sulfate crystals. Crystallized mother liquid is sulfuric acid, contains sodium sulfate and zinc sulfate and can be directly reused in a coagulating bath. By membrane combination technology, the sulfuric acid, the zinc sulfate, the sodium sulfate and the water are recycled, the problems of zinc discharge and solid waste are solved, and resources are comprehensively utilized.

Owner:SHANGHAI KAIXIN ISOLATION TECH CO LTD

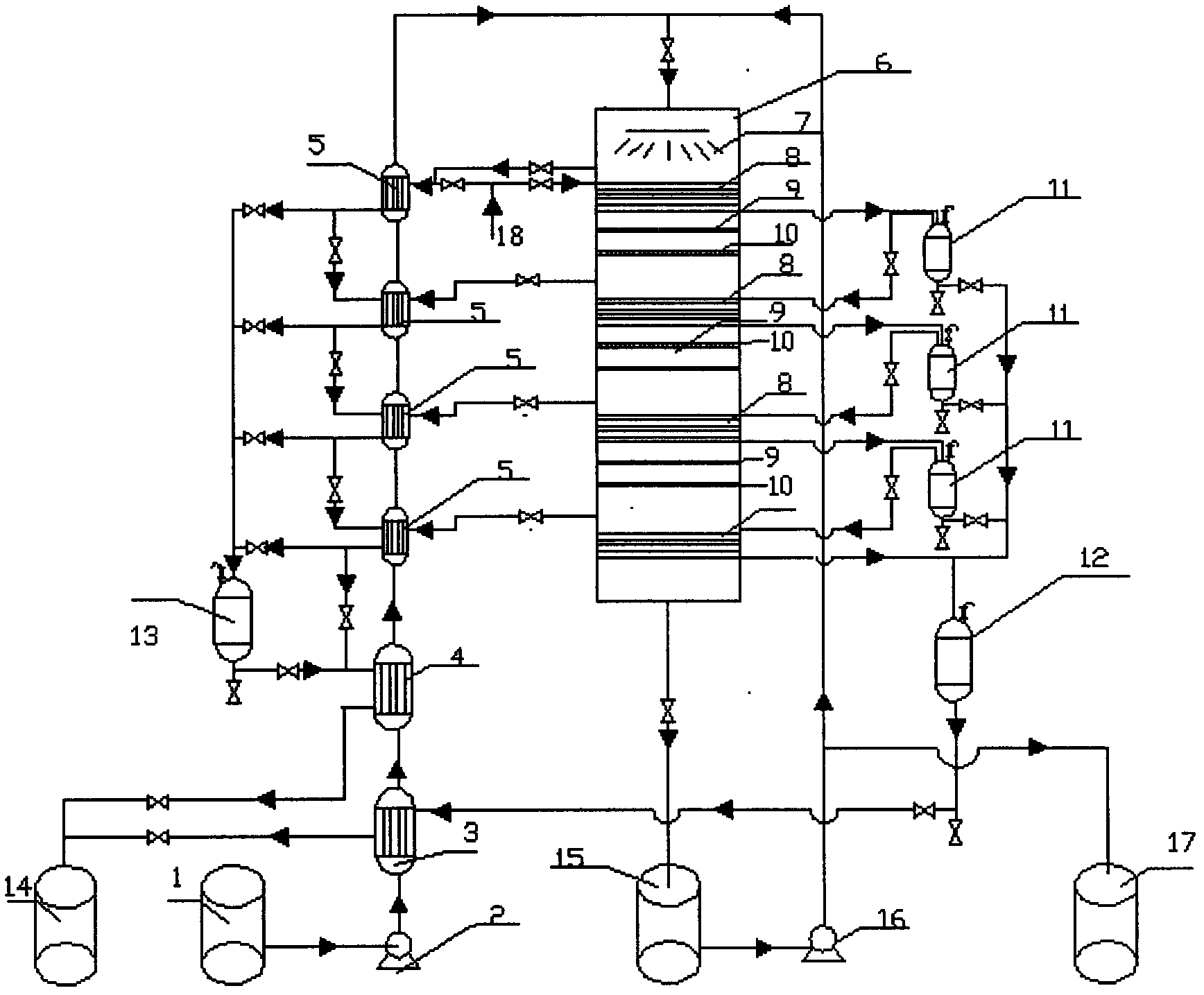

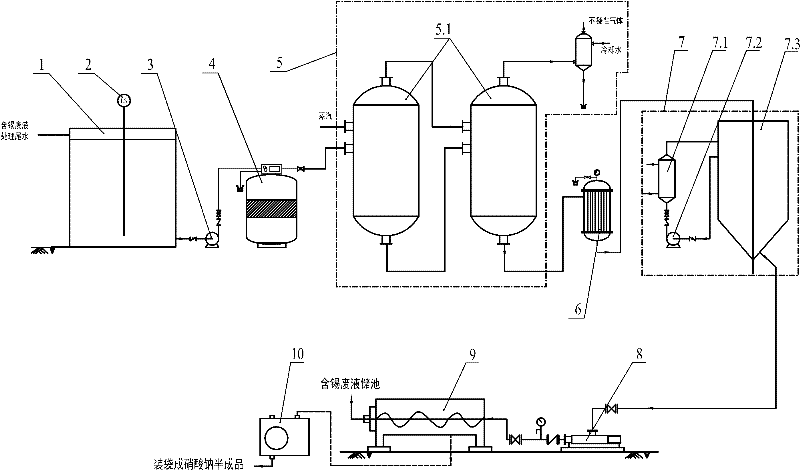

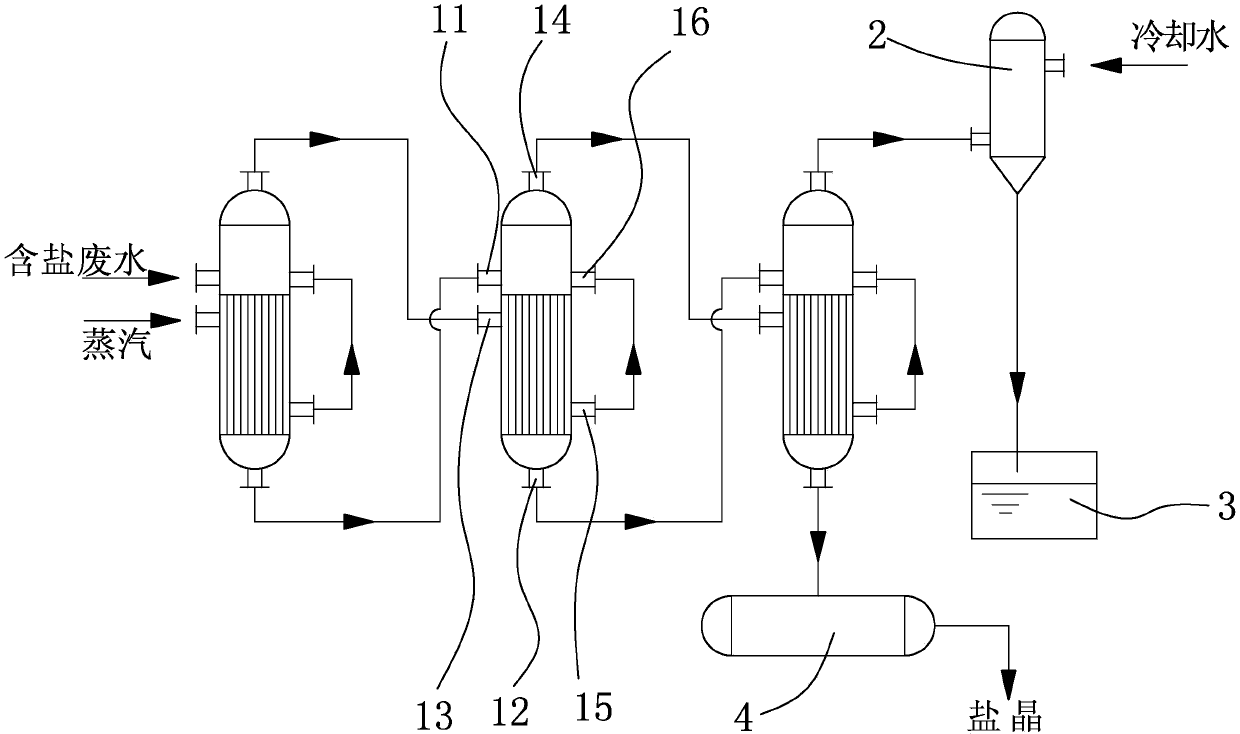

System and technology for recovering sodium nitrate from tin-containing waste liquid treatment tail water

ActiveCN102351220AEasy to operate and manageGuaranteed operating efficiencyAlkali metal nitratesMultistage water/sewage treatmentFiltrationSlag

The invention relates to a system and a technology for recovering sodium nitrate from tin-containing waste liquid treatment tail water. The system for recovering sodium nitrate from tin-containing waste liquid treatment tail water comprises a waste water storage pool, a purification refining device, a multi-effect evaporator, a filter, a crystallization device, a centrifugal machine and a drying machine. The technology for recovering sodium nitrate from tin-containing waste liquid treatment tail water comprises the following steps of collecting tin-containing waste liquid treatment tail water, storing the collected tin-containing waste liquid treatment tail water in the waste water storage pool, feeding the tin-containing waste liquid treatment tail water in the waste water storage pool into the purification refining device to carry out purification refining, feeding the tin-containing waste liquid treatment tail water subjected to purification refining into the multi-effect evaporator, feeding steam into the multi-effect evaporator to carry out circulation evaporation, feeding the steam obtained by the previous step into the filter to carry out heat filtration, feeding the filtrate into the crystallization device to carry out crystallization to obtain crystals, carrying out centrifugation of the obtained crystals by the centrifugal machine to obtain solid slag and a mother solution, transferring the solid slag to the drying machine to carry out drying to obtain a sodium nitrate finished product, and feeding the mother solution back to the waste water storage pool for recycle. The system for recovering sodium nitrate from tin-containing waste liquid treatment tail water has the advantages of relatively low recovery cost, simple and convenient operation management, long-term and stable operation and no discharge of pollutants.

Owner:无锡金品环境技术有限公司

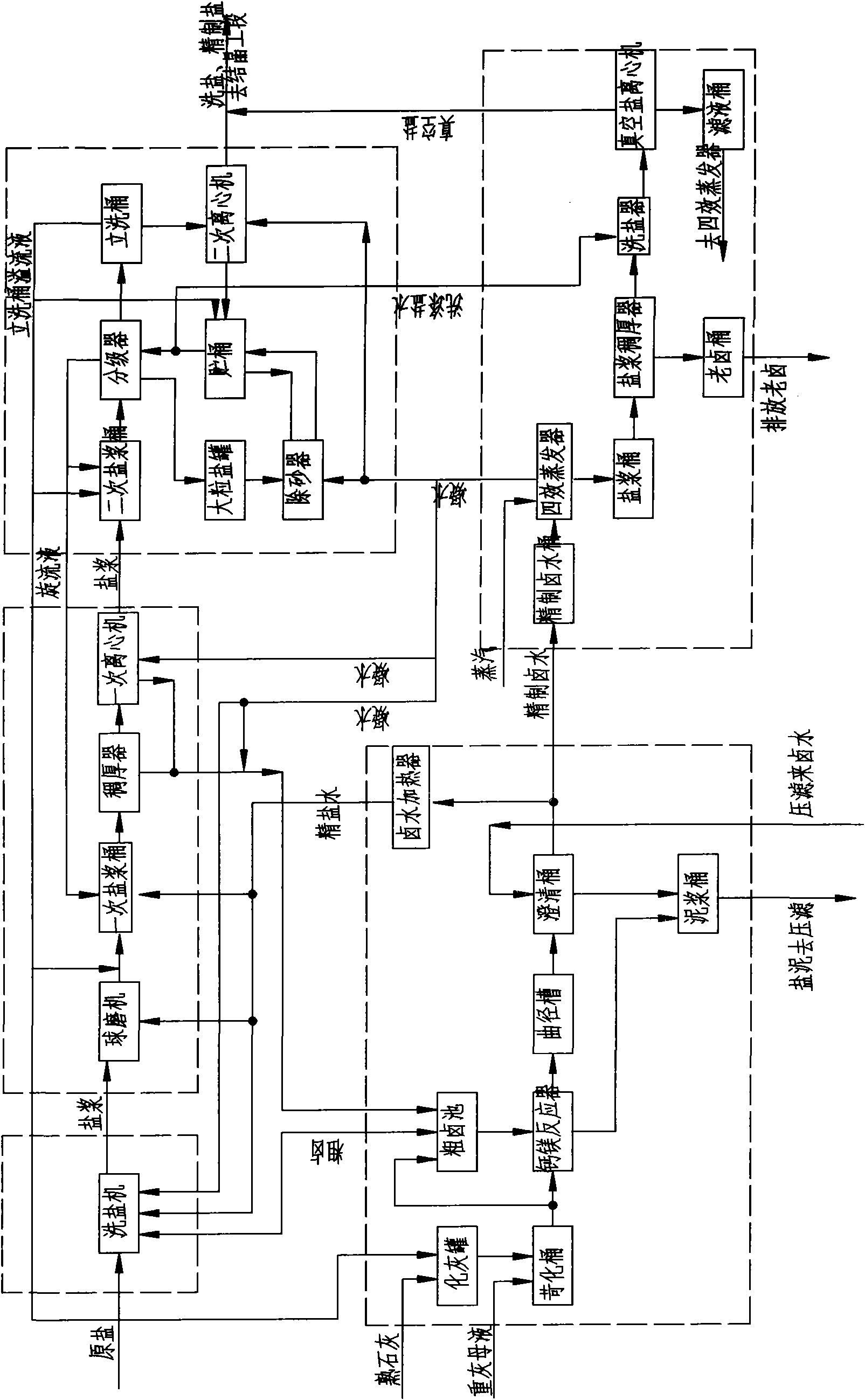

Process for refining crude salt

ActiveCN101628722AReduce lossQuality assuranceMultistage water/sewage treatmentAlkali metal chloridesSalt waterEngineering

The invention discloses a process for refining crude salt. A salt-leaching step comprises the following steps: sending crude salt to a salt leaching device, a ball mill, a primary salt slurry barrel, a thickener and a primary centrifuge in sequence; then sending salt slurry separated from the primary centrifuge to a secondary salt slurry barrel, a classificator and an immediate washing barrel for washing and thickening; then using condensate water to wash the salt slurry after entering the secondary centrifuge so as to remove bittern, thereby obtaining qualified leached salt; a crude bittern treatment step comprises the following steps: mixing leaching crude bittern in the salt leaching step in a crude bittern pool, and subsequently sending to a calcium-magnesium reactor so as to remove Ca<2+> and Mg<2+>; then entering a clarifying tank for clarifying; after increasing the temperature of the clarified clear liquor by a bittern heater, sending portion of clarified clear liquor to a refining bittern barrel for vacuum salt manufacturing with portion of clarified clear liquor for salt leaching use; and a vacuum salt manufacturing step comprises the following steps: sending refined salt water in the refining bittern barrel to a multi-effect evaporator for evaporating; finally discharging separated solid salt to the salt slurry barrel, the salt slurry thickener and the vacuum centrifuge, thereby obtaining leached salt. The method reduces the crude salt loss and lowers the content of SO4<2-> in the leached salt.

Owner:TIANJIN BOHUA YONGLI CHEM IND

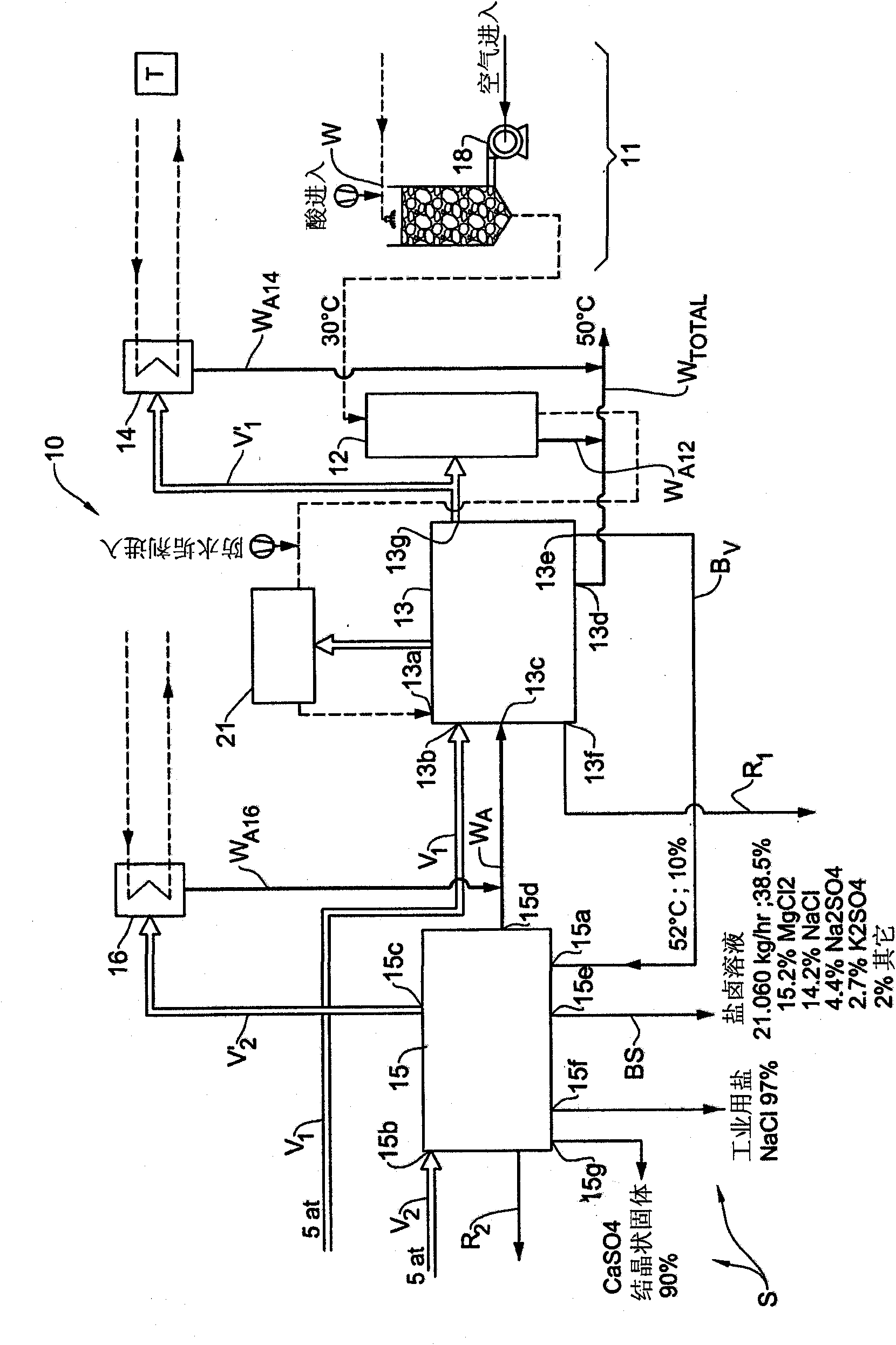

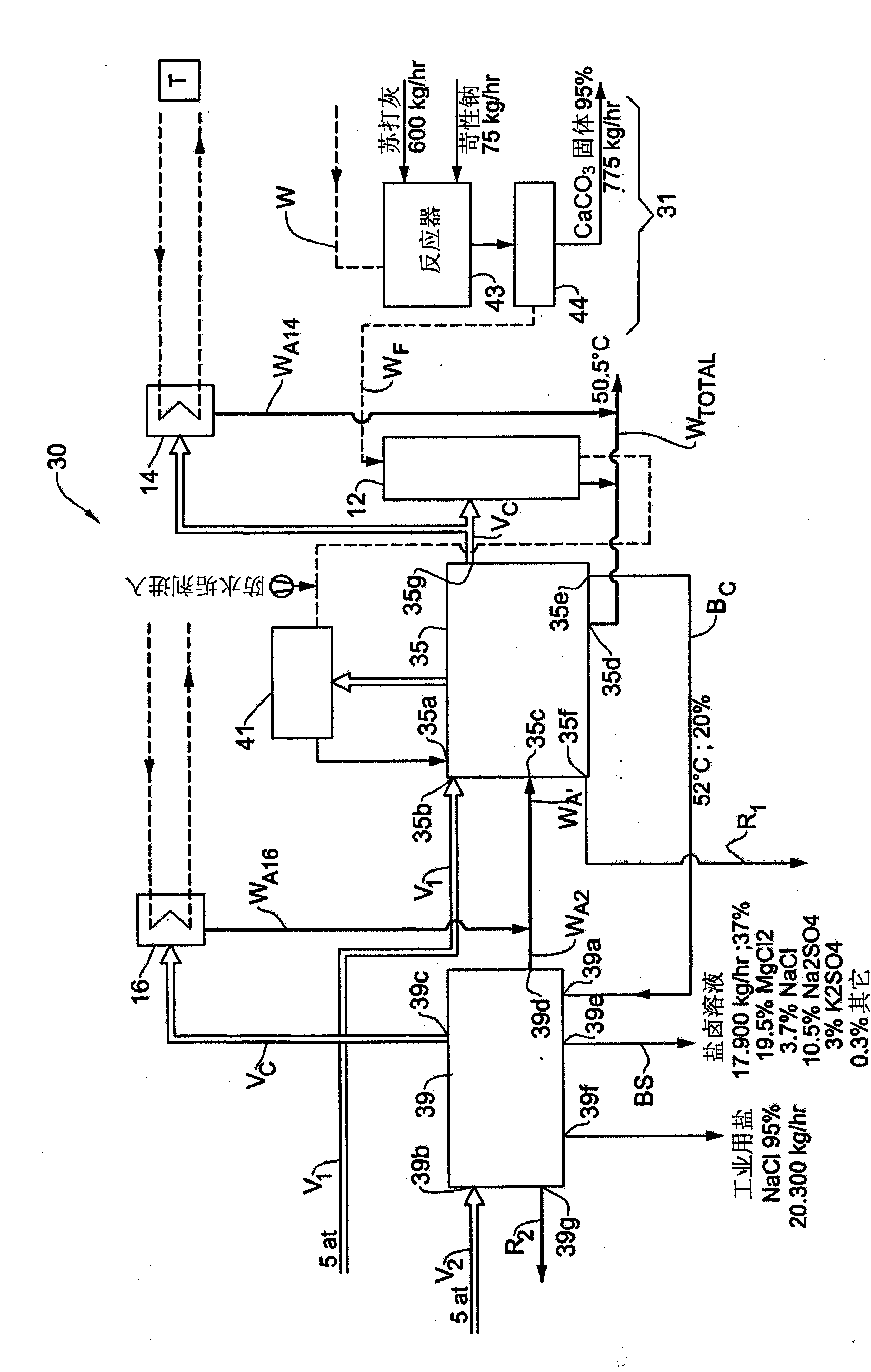

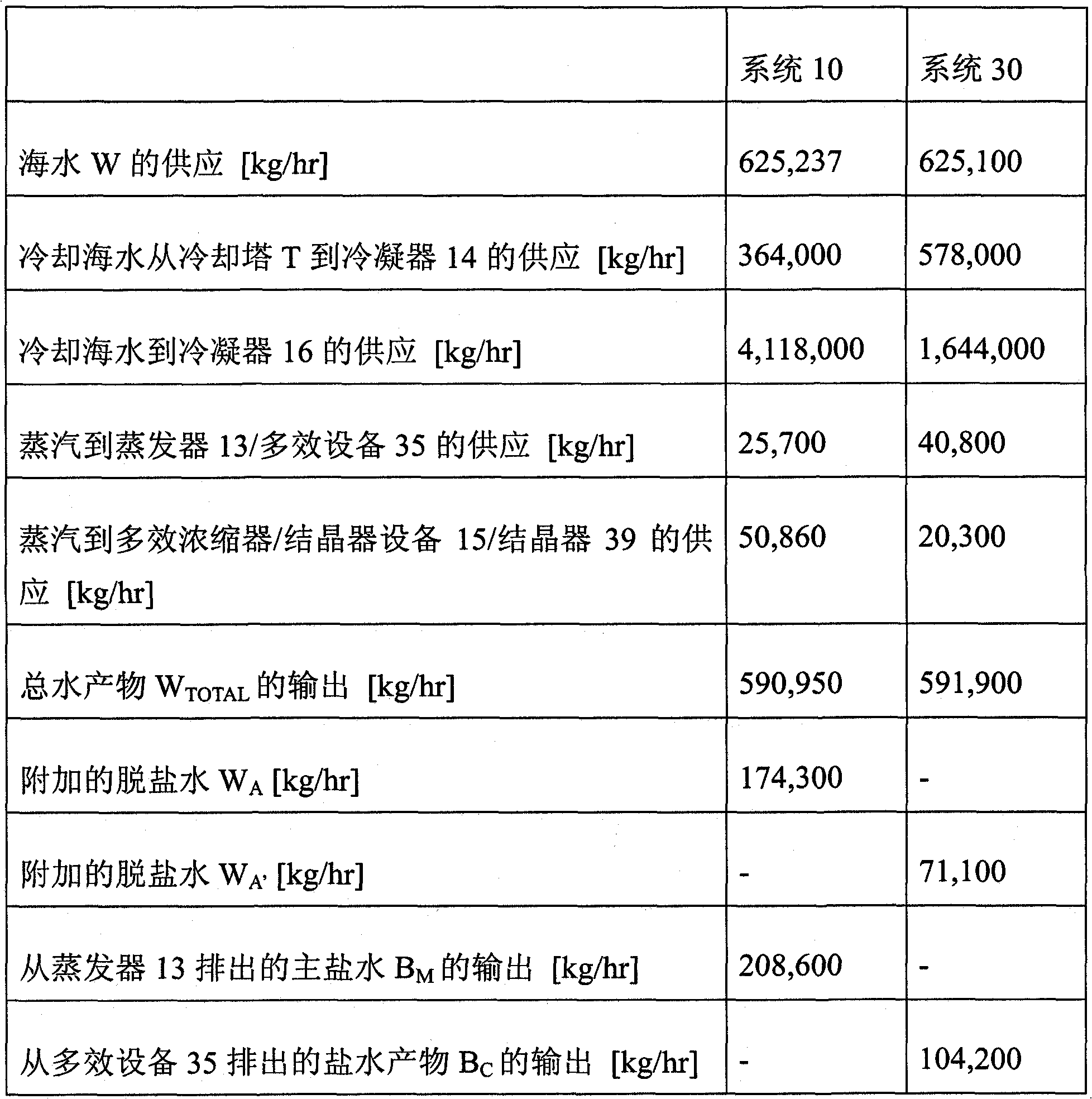

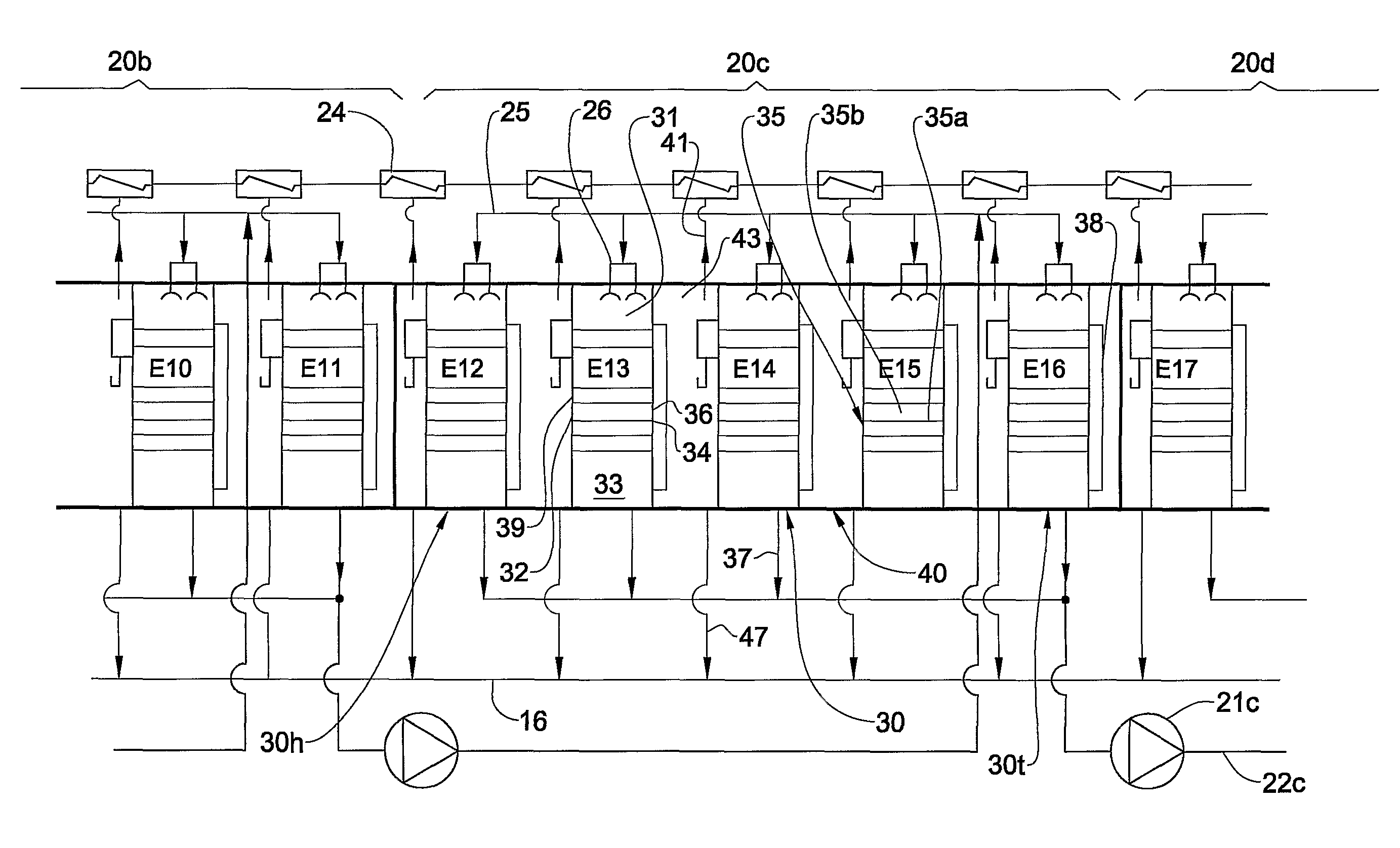

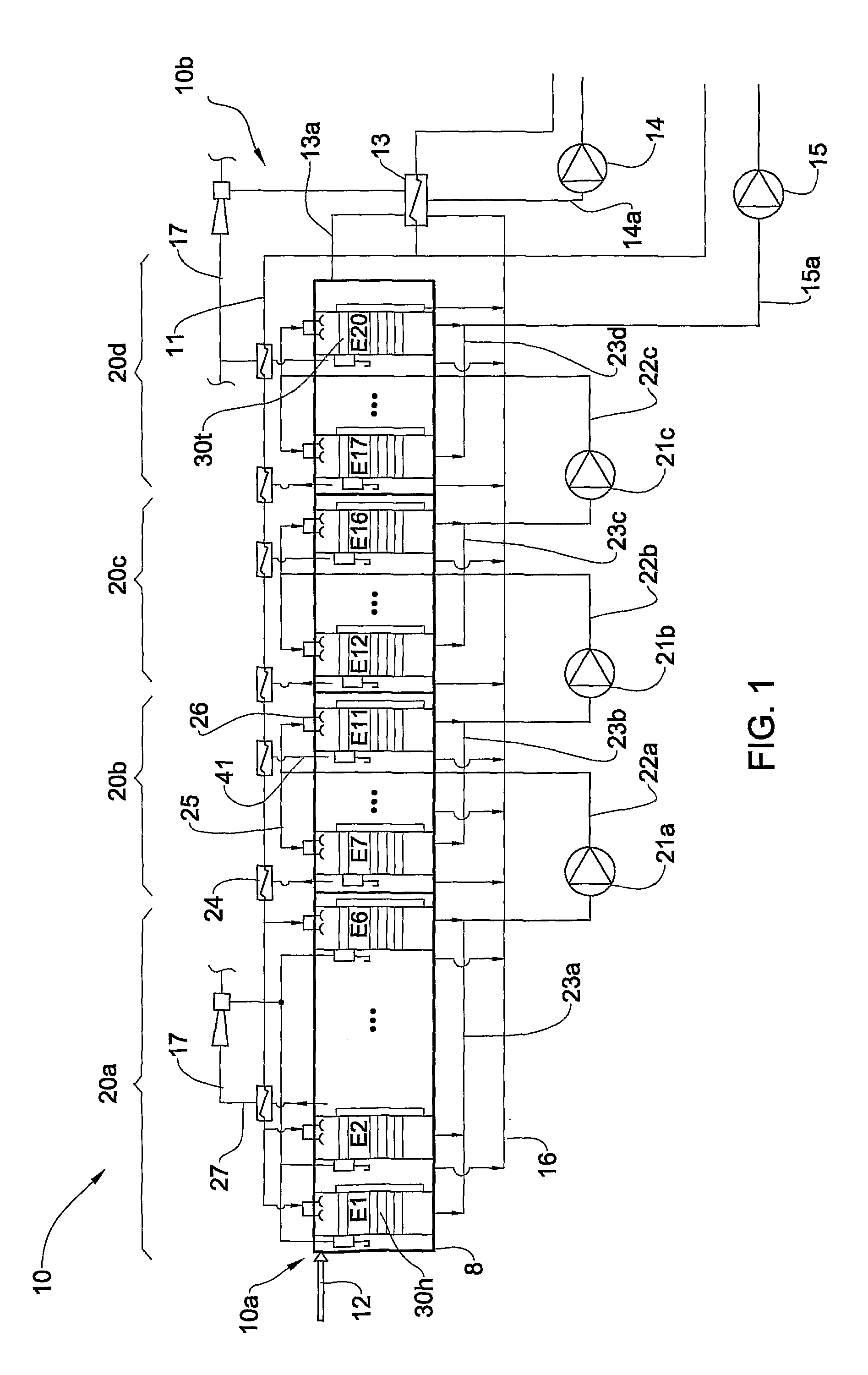

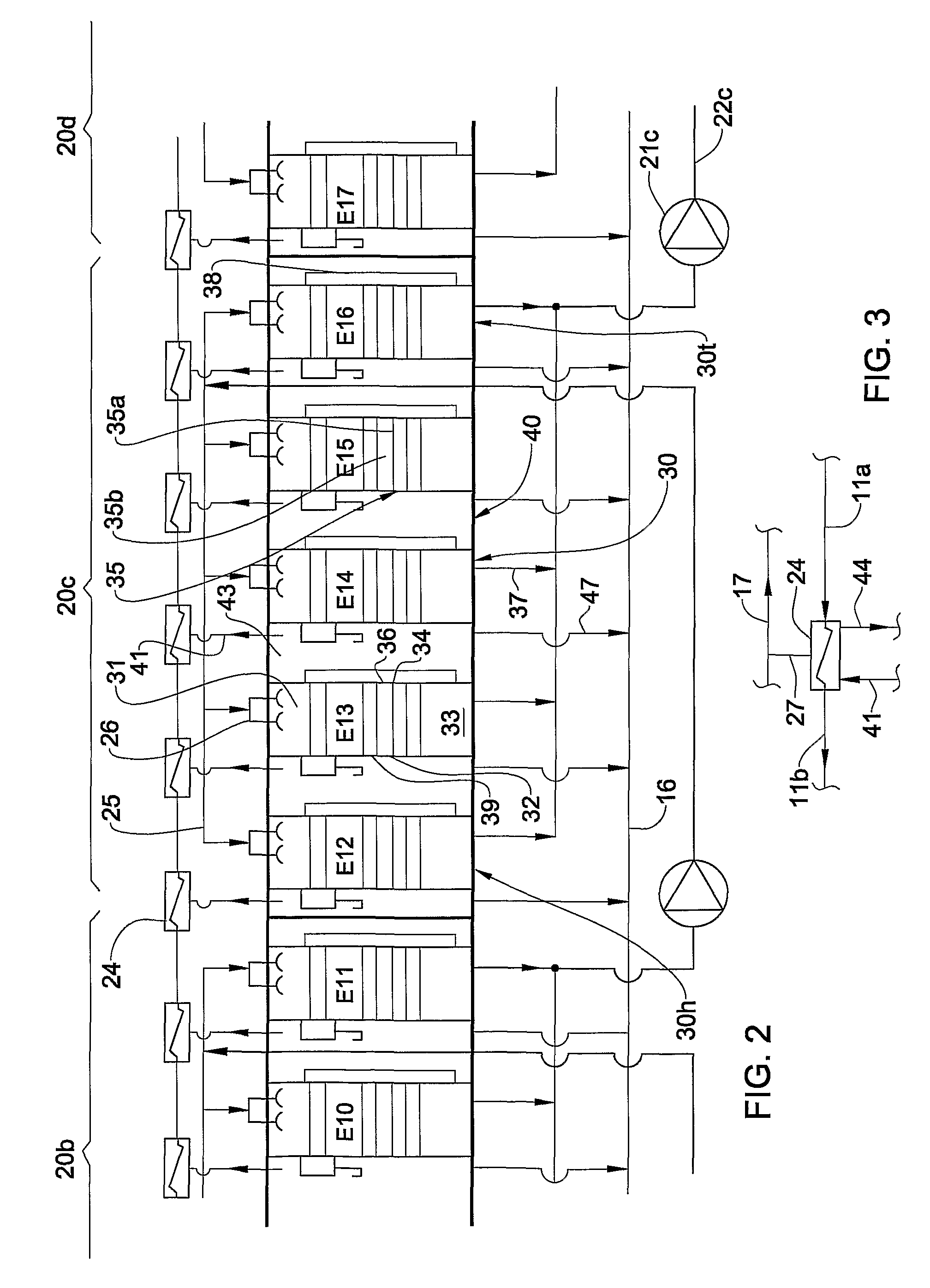

Improved water desalination system

A system and method for desalination of seawater W having an original water salinity and an original water concentration of scale forming components, the system comprising: a pre-treatment sub-system for at least partial removal from said water W of said scale forming components, producing thereby a pre-treated feed water having a first concentration of scale forming components lower than said original concentration of scale forming components; a forward feed flow multi-effect evaporator adapted for distillation of said pre-treated feed water, producing thereby main desalted water product WM having a desalted water salinity lower than said water salinity, and main brine having a salt concentration of approximately 10%; a concentrator adapted for receiving therein said main brine and concentrating it, producing thereby more concentrated brine with an increased salt concentration of approximately 20%-22%, and releasing a first additional desalted water product W1; and a crystallizer for receiving said more concentrated brine, adapted for crystallization thereof to obtain at least solid salt products and releasing a second additional desalted water product W2.

Owner:IDE TECHNOLOGIES

Dead steam reclaiming method and equipment thereof

InactiveCN101097115ASave energyWith energy savingDrying solid materials with heatDrying gas arrangementsRecovery methodMultiple-effect evaporator

The invention discloses a waste gas recovery method and device in waste heat utilizing technique domain, which is characterized by the following: generating waste gas from amidon by-product drying process; leading in maize milk condensing device; proceeding condensed process fro the maize milk; setting the waste gas recovery device as tube bundle dryer, maize milk condensing device and waste gas outlet on the tube bundle dryer; setting the maize milk condensing device as multi-effect evaporator; setting the evaporator as tube pass and shell pass; arranging washing gas tower between the tube bundle dryer and the maize milk condensing device. This invention possesses lower energy consumption, which can save energy from the maize milk condensing production.

Owner:山东泓洲化工机械有限公司

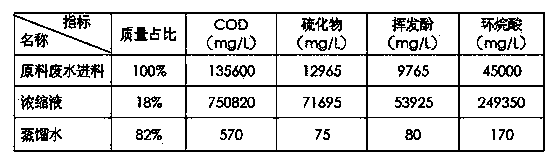

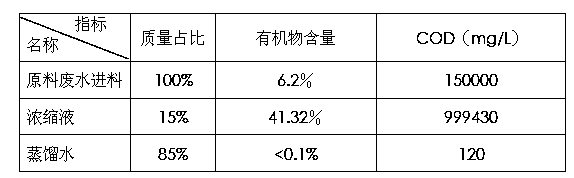

High-concentration organic waste water evaporating and concentration processing method

ActiveCN103482715AHigh organic contentHigh calorific valueWater contaminantsWater/sewage treatment by heatingHigh concentrationDistilled water

The invention discloses a high-concentration organic waste water evaporating and concentration processing method. A combination of a multi-effect evaporator and a fractionating tower is used for efficient separation of organic matter and water. Feeding waste water is preheated through countercurrent flow and efficient utilization of heat is achieved. The method is especially suitable for waste water which has high organic concentration (COD is larger than or equal to 20000mg / L) and complicated components and is hard to degrade biochemically. Organic waste water is deposited, filtered, preheated and evaporated in a multi-effect mode and undergoes fractional distillation, so that the organic matter concentration of obtained water is quite low (COD is smaller than or equal to 1000mg / L). Compared with traditional multi-effect evaporation and concentration, the efficient utilization of heat is achieved, the organic matter concentration of distilling water outlet is obviously reduced, and therefore the loads for biologically processing follow-up distilled water are relieved and the follow-up procedure of processing the distilled water is avoided. Emission reaching the standard is directly performed.

Owner:惠州TCL环境科技有限公司

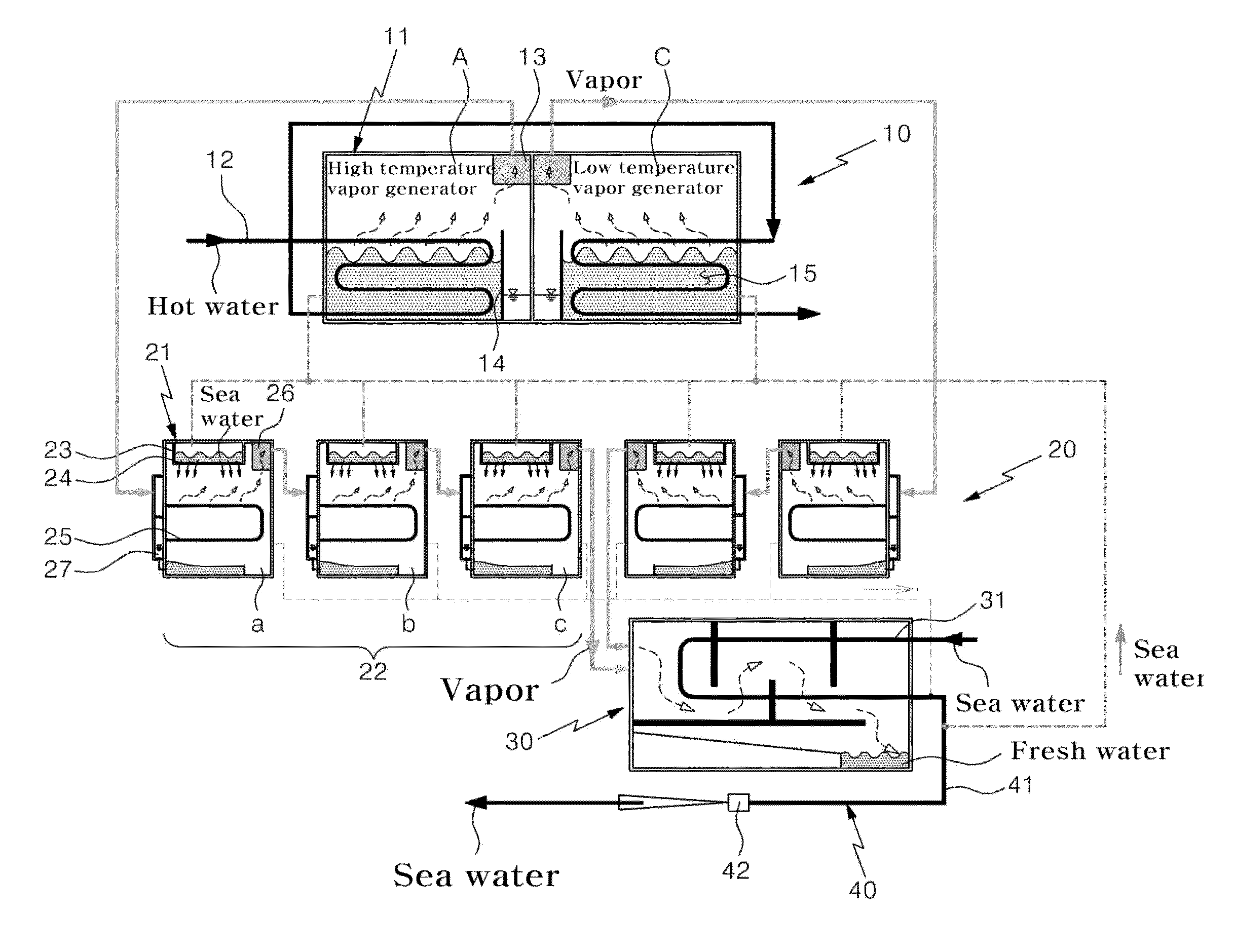

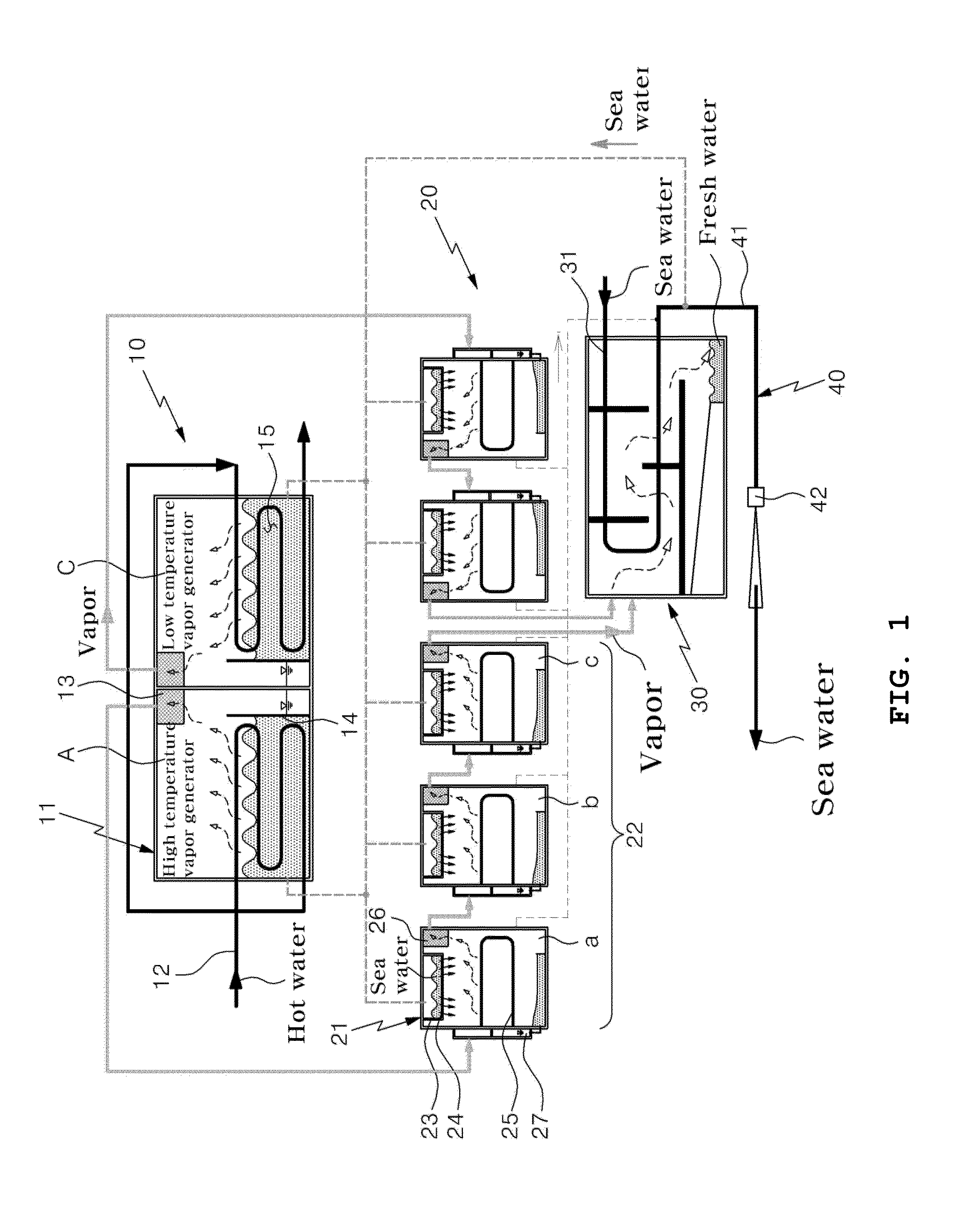

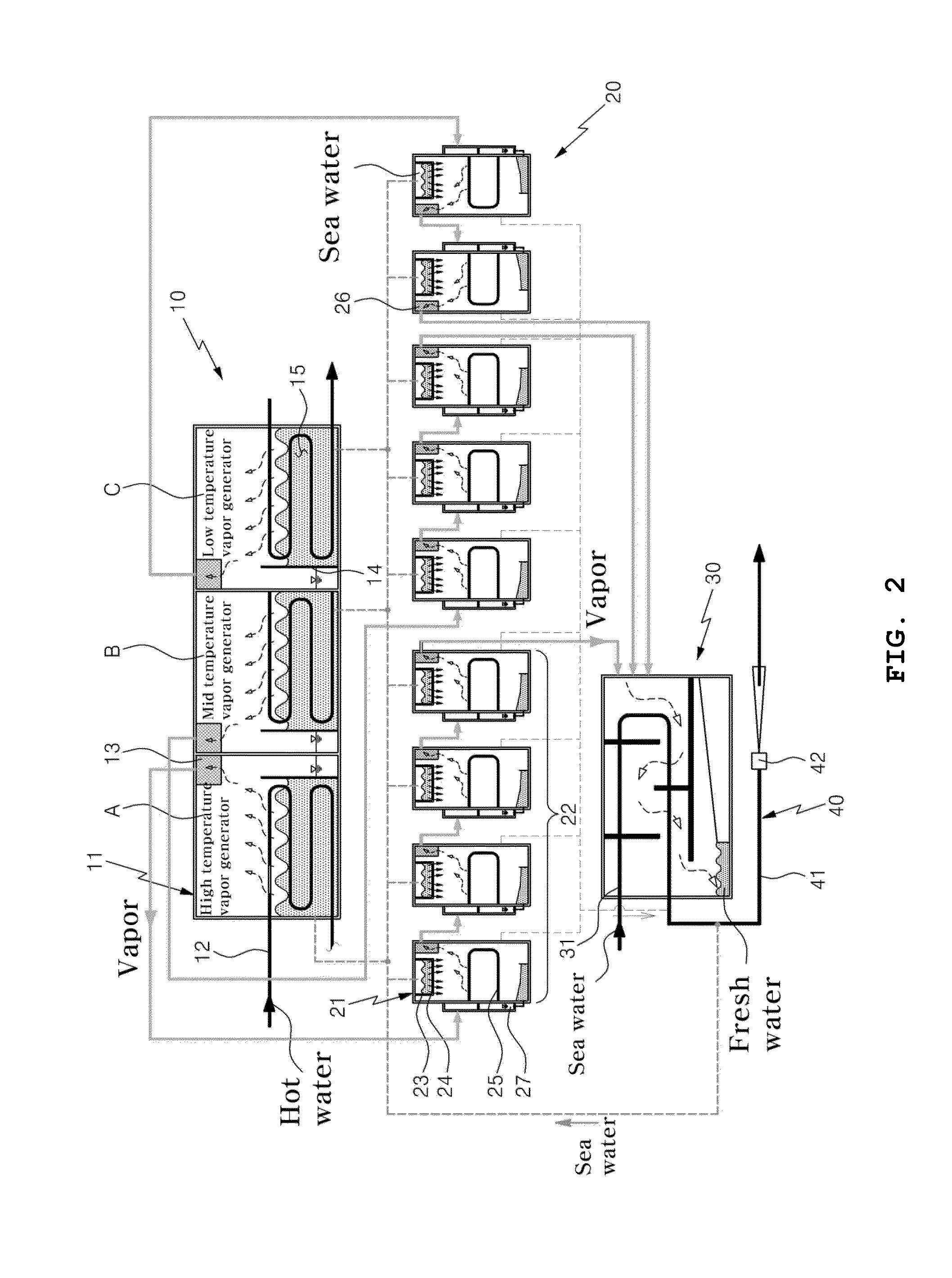

Evaporative desalination device of multi stage and multi effect using solar heat

ActiveUS20130270100A1Increased freshwater productionEconomic feasibilityGeneral water supply conservationSeawater treatmentLiquid stateDesalination

Disclosed is an evaporative desalination device of multi-stage and multi-effect using solar heat constructed in multi stage and multi effect as a desalination device that is capable of not only increasing fresh water output but also resolving a problem of conventional desalination device having series structure as well, through constructing: a multi stage vapor generator that generates vapor by passing a hot water supply pipe successively through a plurality of vapor generators to evaporate sea water inside thereof; a multi effect vapor generator that uses vapor in the respective vapor generators as heat source and forms a plurality of evaporator groups; and a discharge unit that condenses vapor in the multi effect generator by sea water to discharge fresh water in liquid state, and returns and supplies portions of discharged sea water to the multi stage vapor generator and the multi effect evaporator.

Owner:KOREA INST OF ENERGY RES

Multiple-effect distillation device and method for desalting sea water or brackish water only by using solar

InactiveCN101219817ARealize multiple reuseAvoid phenomena that affect normal operationGeneral water supply conservationSeawater treatmentBrackish waterDistillation

The invention discloses a multi-effect distillation device only by using solar energy to desalt sea water or brackish water and the method. The device comprises three parts: a solar energy collector, a multi-effect evaporator and a condenser. The method of the device for desalting the sea water or the brackish water comprises the processes: vacuum of each effect evaporator is regulated; steam generated in each effect evaporator sequentially enters a condensation heat exchange tube in a next effect evaporator through a steam outlet of the effect evaporator; after the condensation, the fresh water is obtained, and energy for vaporizing the sea water or brackish water in the effect evaporator is provided. The invention has the advantages of simple desalting process and device as well as reliable operation and running and no consumption of other energy except that the solar energy supplies heat, which is particularly applied to areas short of the fresh water but rich in the sea water, brackish water and the solar energy.

Owner:TIANJIN UNIV

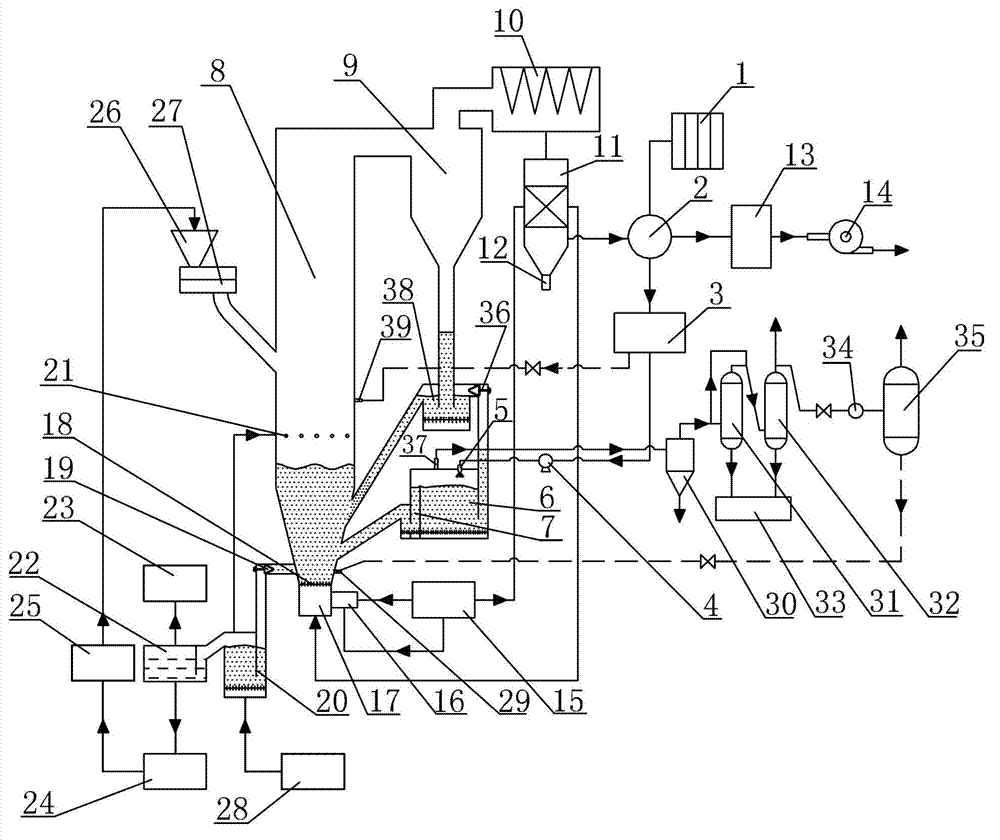

Device and method for recycling gasified and burned alkali for straw pulp papermaking black liquor circulating fluidized bed

ActiveCN102864674AEfficiently provideSolve processing problemsRegeneration of alkali lyeAir preheaterSlag

The invention provides a device and a method for recycling gasified and burned alkali for a straw pulp papermaking black liquor circulating fluidized bed and relates to the device and the method for recycling the alkali of papermaking black liquor. The device and the method are used for solving the problems that the prior art is difficult to be used for recycling the straw pulp papermaking black liquor, the auxiliary fuels are added to a recycling process and the running cost is increased. The device comprises a multi-effect evaporator, a disc evaporator, a thick black liquor tank, a pump, a spraying gun, a gasifying chamber, a feedback valve, a waste heat boiler, an air pre-heater, a bag-type dust collector, a draught fan, a cone valve, a heat exchange chamber, a dissolving tank, a causticizer, a chain plate type slag conveyor, a drier, a secondary air fan, a second gas-solid separator, a tar condensing tower, a spraying dehydrating tower, a sewage treatment plant, a water annular compressor, an air storage tank, a circulating ash distributing chamber and a circulating fluidized bed, wherein the dissolving tank is respectively communicated with the causticizer and the chain plate type slag conveyor and the chain plate type slag conveyor is communicated with the drier. The device provided by the invention is used for recycling the alkali of the straw pulp papermaking black liquor.

Owner:哈尔滨工大华实环保科技有限公司

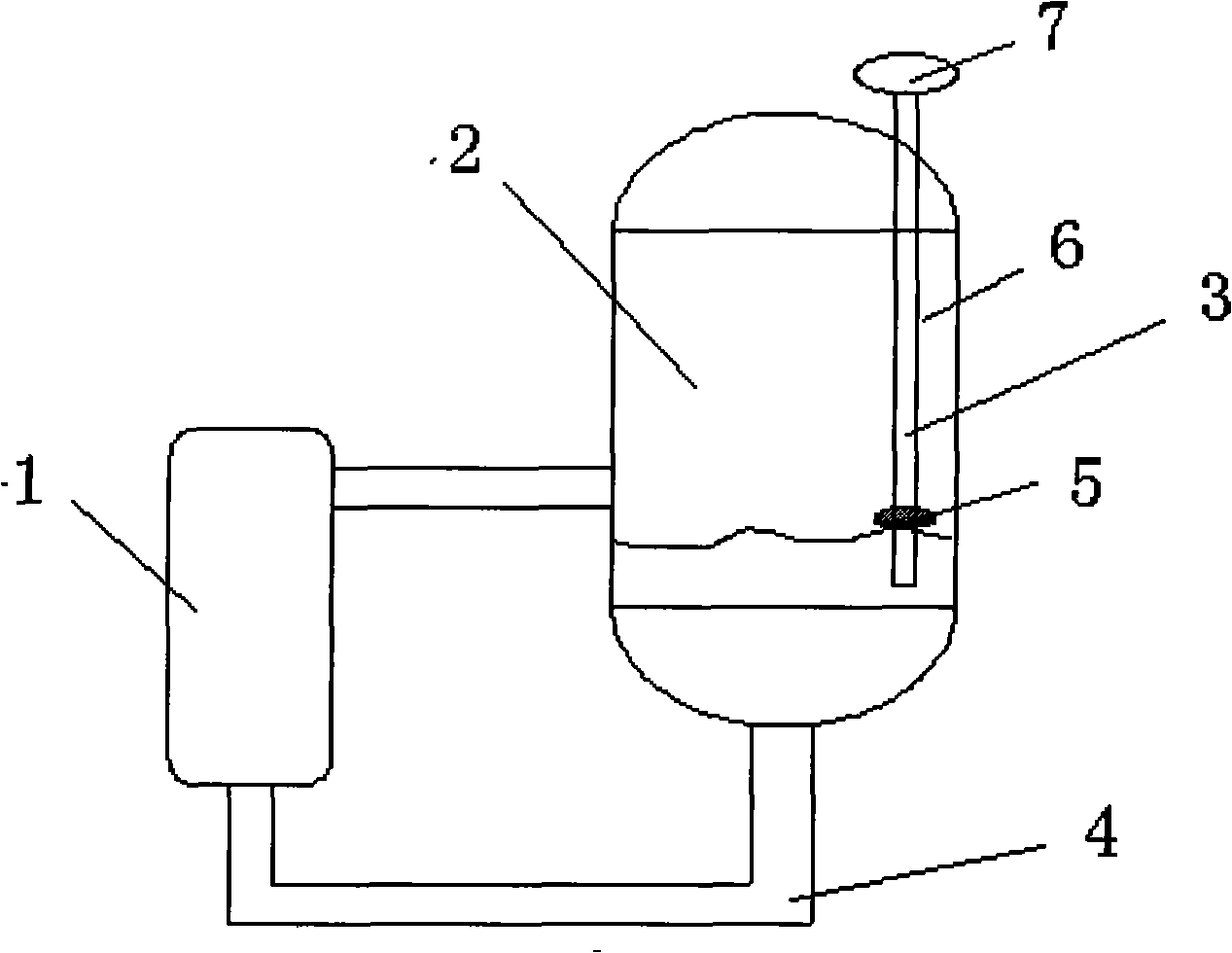

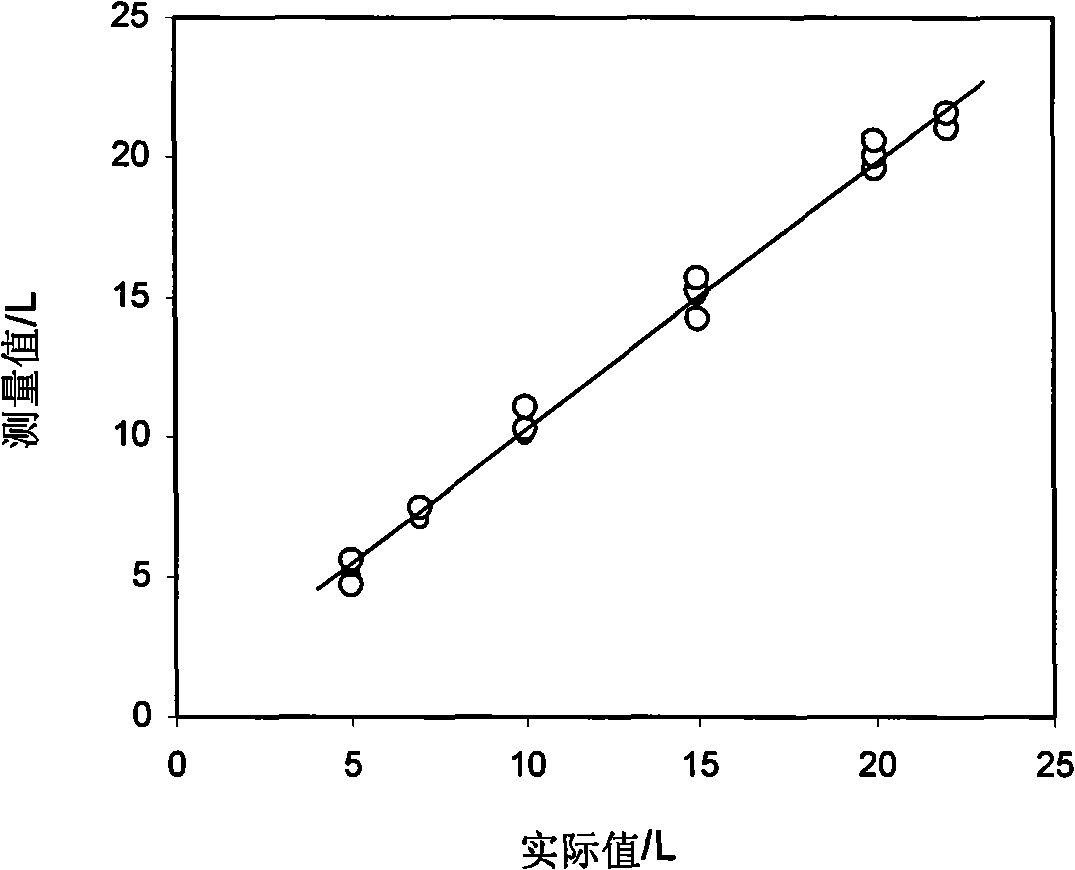

Liquid level on-line measurement method based on magnetic buoyancy

ActiveCN101403631ATimely measurementSolve technical problems of measurementLevel indicators by floatsAutomatic controlMultiple-effect evaporator

The invention provides a liquid level online measuring method based on the magnetic buoyancy. Through calibrating the corresponding volume of the liquid level in a multiple effect evaporator, the function relationship between the volume and the liquid level is constructed, and the function is inputted into a computer, thereby measuring the evaporation liquid volume; and the density function Rho and the temperature correction coefficient k of the condensed liquid evaporation process are measured, and the relevant parameters are inputted in to the computer, thereby measuring the mass of the evaporation liquid. The invention provides a liquid level measuring method based on the principle of magnetic floater, the aim is to solve the technical problem of condensed liquid measurement in the vacuum boiling state, to achieve the real automatic control of the condensed process, to reduce the condensed process differences of traditional Chinese medicine between different batches, and to provide a new technology for improving the production quality stability and the modernization of the traditional Chinese medicine. The invention has the advantages of reasonable design, simple preparation of the multiple effect evaporator, and low cost.

Owner:苏州浙远自动化工程技术有限公司

Energy-saving fine chemical wastewater deep treatment system and treatment method

ActiveCN104326616AEfficient ConcentrationEasy to implementChemical industryMultistage water/sewage treatmentColligative propertiesFine chemical

The invention relates to an energy-saving fine chemical wastewater treatment system and treatment method. The system comprises a forward osmosis membrane concentration device and a multi-effect evaporator, wherein the forward osmosis membrane concentration device comprises FO membrane closed exchange boxes, a drawn liquid recycling device and a clear water recovery device, at least one stage of FO membrane closed exchange box is arranged, the drawn liquid recycling device is connected with each stage of the FO membrane closed exchange box through an electric valve respectively, the clear water recovery device is connected with the drawn liquid recycling device, and all the stages of FO membrane closed exchange boxes are sequentially connected through liquid discharge electric valves and connected with a mother liquid incineration furnace through overtaking electric valves. The method is designed against high osmotic pressure property of fine chemical wastewater, and by preparing drawn liquid with relatively high colligative property and utilizing the osmotic pressure difference caused by differences in colligative property of a solution, the fine chemical wastewater can be efficiently concentrated, water resources can be simultaneously recycled, and electric energy is produced; and the operation process realizes automatic interlocking control, and the operation way can be adjusted according to different water inlet conditions.

Owner:山东省环科院环境工程有限公司

Multi-effect evaporator

A multi-effect evaporator, having an upstream and a downstream end, adapted for distillation of water. It comprises a plurality of effects serially connected and arranged into groups. Each group has a common parallel water feed inlet adapted to supply all effects in the group with feed water. The evaporator further includes a main feed water line in fluid communication with the most upstream group. An array of heaters is disposed along the line, adapted for heating the feed water before its entry into the effects of the latter group. Each effect comprises means for forwarding the second outlet vapor into one of the heaters for heating the feed water. Each group comprises a pump adapted to extract the concentrate from the effects of the group and pump it into the common parallel water feed of an adjacent downstream group.

Owner:I D E PROJECTS LTD

High-efficiency and energy-saving multi-effect evaporator system

ActiveCN103739025AImprove adaptabilityWater/sewage treatment by heatingMultiple-effect evaporationWastewaterMultiple-effect evaporator

The invention provides a high-efficiency and energy-saving multi-effect evaporator system which comprises a multi-effect evaporation set, a condensing tank and a circulation pool, wherein the multiple-effect evaporation set comprises series-connected evaporators with more than two effects, each evaporator is provided with a feeding hole, a discharging hole, a steam inlet and a steam outlet; the feeding hole of the first-effect evaporator is a general feeding hole of the evaporation set, a steam inlet of the first-effect evaporator is a general steam inlet of the evaporation set, a discharging hole of a final-effect evaporator is a total discharging hole of the evaporation set, a steam outlet of the final-effect evaporator is a general steam outlet of the evaporation set, a discharging hole of the former-effect evaporator is communicated with a feeding hole of a second-effect next-effect evaporator, a steam outlet of the former-effect evaporator is communicated with a steam inlet of the next-effect evaporator, the condensing tank is communicated with the general steam outlet, and the circulating pool is communicated with the condensing tank. The multi-effect evaporator system disclosed by the invention is high in efficiency, energy-saving, and good in adaptability. The high-efficiency and energy-saving multi-effect evaporator system can be used for treating high-salt content wastewater.

Owner:广州市金龙峰环保设备工程股份有限公司

Pretreatment method of epoxy resin desalinization wastewater

ActiveCN102557316AFully purifiedEasy to removeMultistage water/sewage treatmentNature of treatment waterEpoxyChemical oxygen demand

The invention relates to a wastewater treatment method, in particular to a pretreatment method for epoxy resin desalinization wastewater. The pretreatment method comprises the following steps of: storing desalinization wastewater in a wastewater storage tank, naturally settling for 1 day to precipitate epoxy resin with larger particle size, discharging epoxy resin precipitate at the bottom of the wastewater storage tank, pumping supernatant to a reaction kettle, adjusting the pH value to 11-13, heating, stirring for 1-3h while maintaining the temperature at 70-120 DEG C, introducing steam for at least 30min, condensing and recovering volatile gas with a condenser, pumping reaction liquid to a settling tank, carrying out plate-frame pressure filtration to remove gelatinized epoxy resin, and pumping filtrate to a multi-effect evaporator for concentration by evaporation. By adopting the process provided by the invention, epoxy resin, epoxy chloropropane, methyl isobutyl ketone and other impurities in the desalinization wastewater are effectively removed, the wastewater is sufficiently purified before entering the multi-effect evaporator, and the problems that the multi-effect evaporator pipeline is easy to block and the distilled water is high in COD (Chemical Oxygen Demand) are solved.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

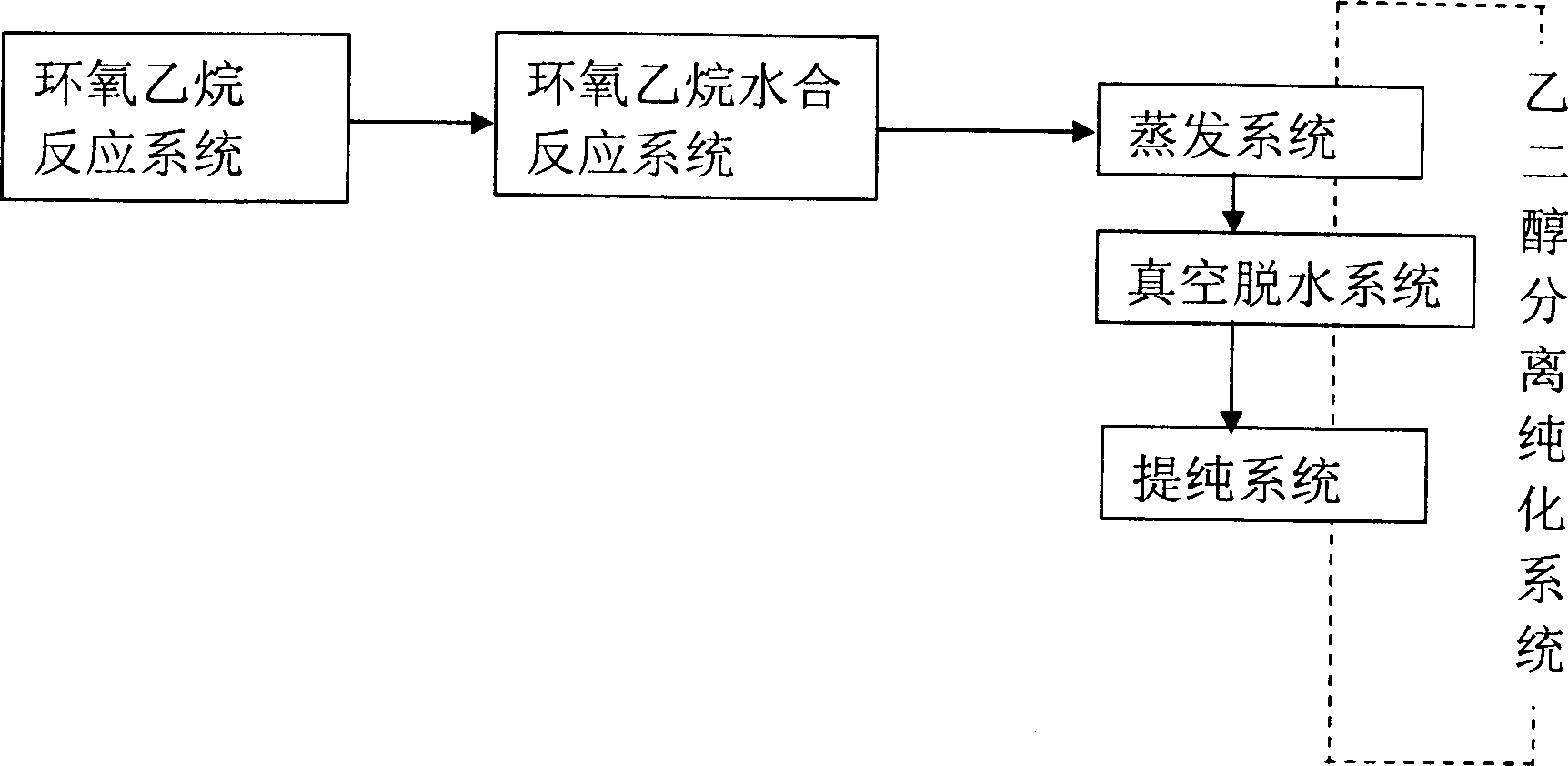

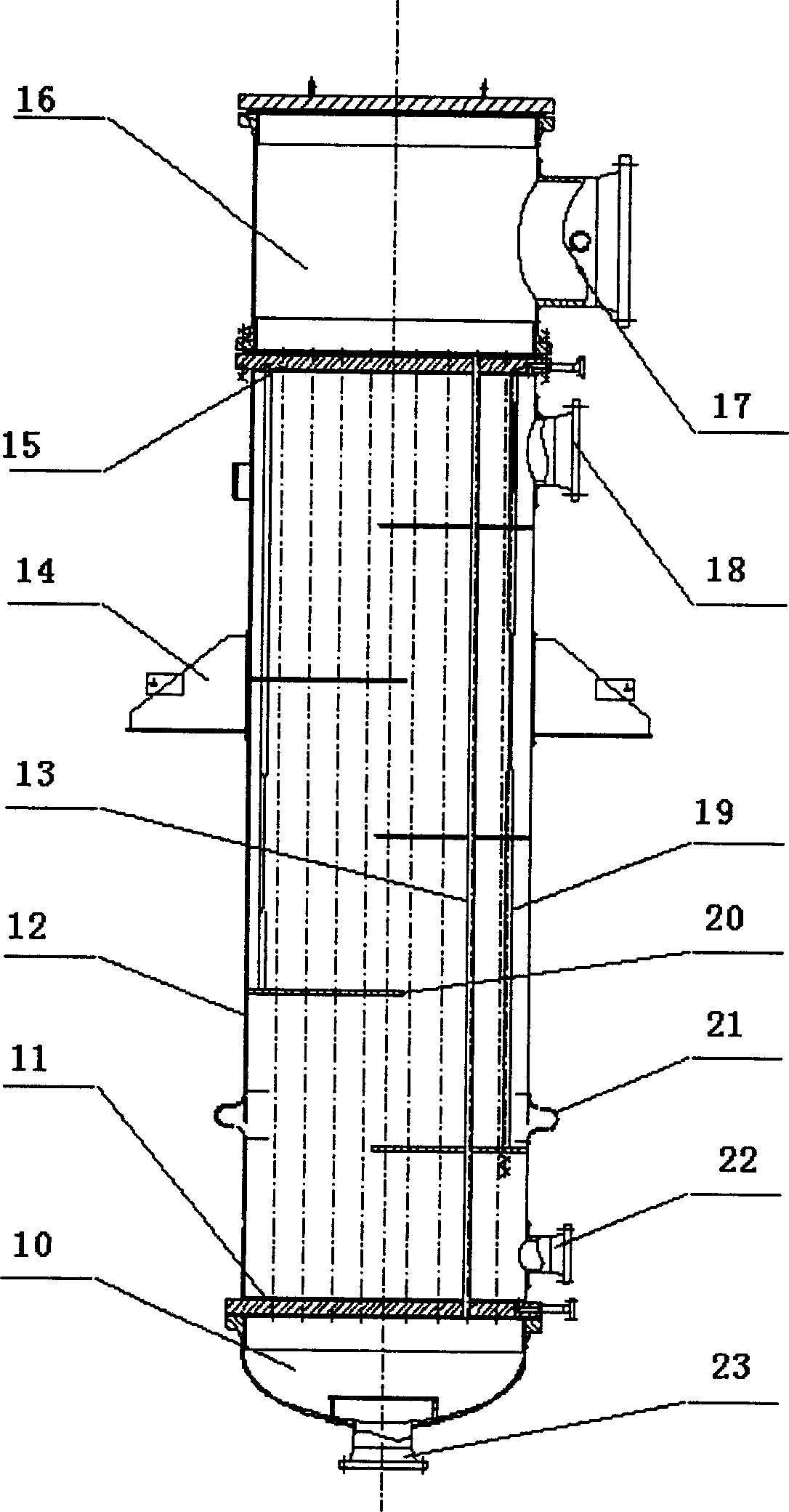

System for preparing ethylene glycol from ethane via epoxyethane

InactiveCN1807376AAvoid pollutionImprove corrosion resistancePreparation by hydrolysisHydration reactionReboiler

The invention provides a system to prepare glycol, which comprises: an oxirane reaction system with a tube-row fixed bed reactor with the tube size within 40~50mm, an oxirane hydration reaction system, a glycol evaporation system with a multi-effect evaporator system in series and a heat exchanger with low-pressure steam as heat source, and a vacuum dewatering system with a pre-heater arranged in front of the tower to heat the feeding solution to or more than its bubble point temperature; Wherein, the reboiler in the evaporation system has tube plate as dual-face composite structure steel plate, basic material layer as carbon steel, tube side composite layer as Monel alloy, and shell side composite layer as stainless steel. This invention takes small land, needs low investment, solves effectively the corrosion protection and coking problems for device, and has well economic benefit.

Owner:CHINA HUANQIU CONTRACTING & ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com