High-temperature seawater desalting and distillation device and method

A seawater, high-temperature technology, applied in seawater treatment, general water supply saving, heating water/sewage treatment, etc., can solve the problem that the evaporation temperature is not higher than 72°C, and achieve reliable technical support, low energy consumption, and uniform spraying Effect

Active Publication Date: 2012-04-25

天津海泽惠科技发展有限公司

View PDF8 Cites 19 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] At present, most low-temperature multi-effect seawater desalination devices at home and abroad are horizontal evaporators, and the evap

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Login to View More

Abstract

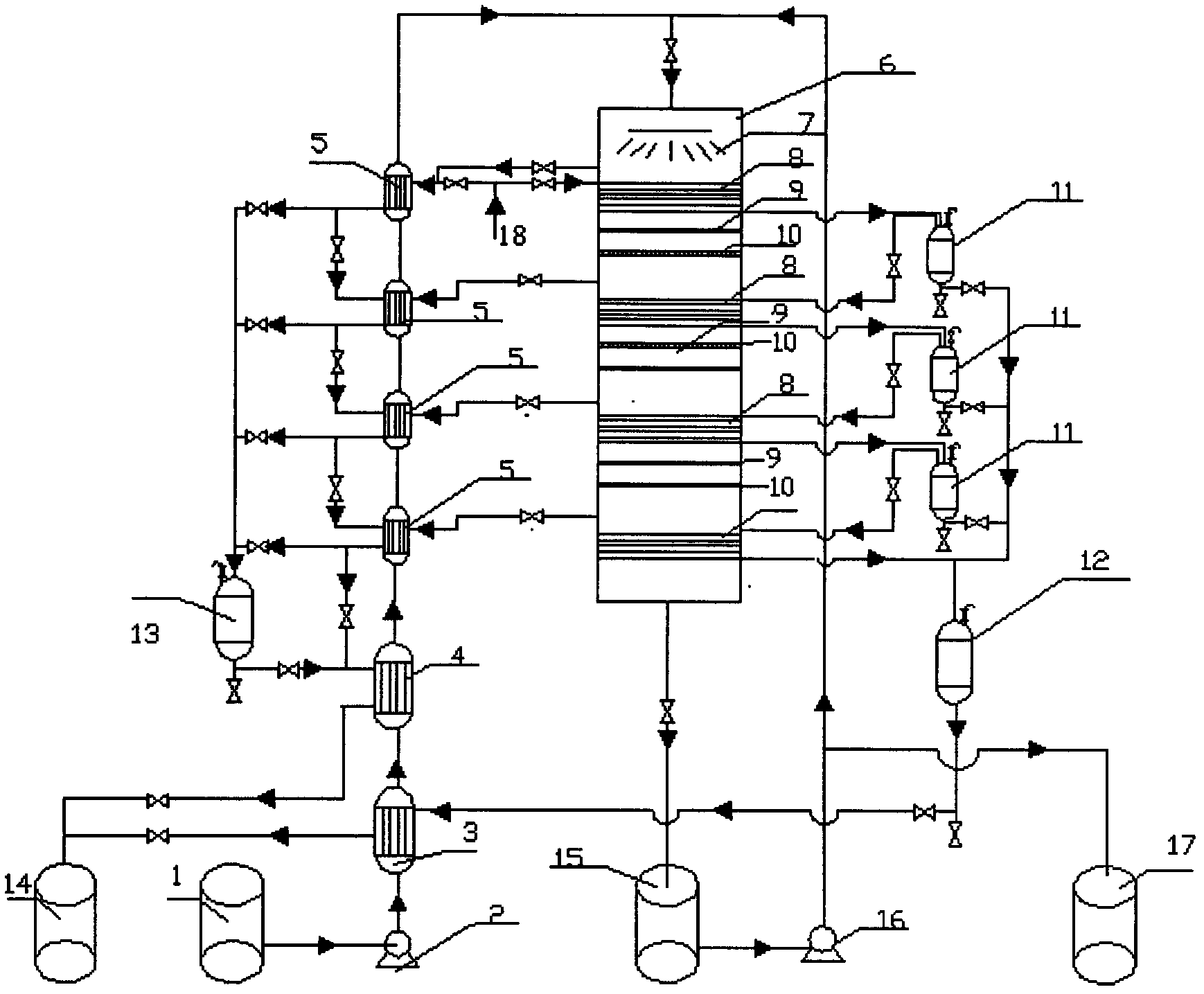

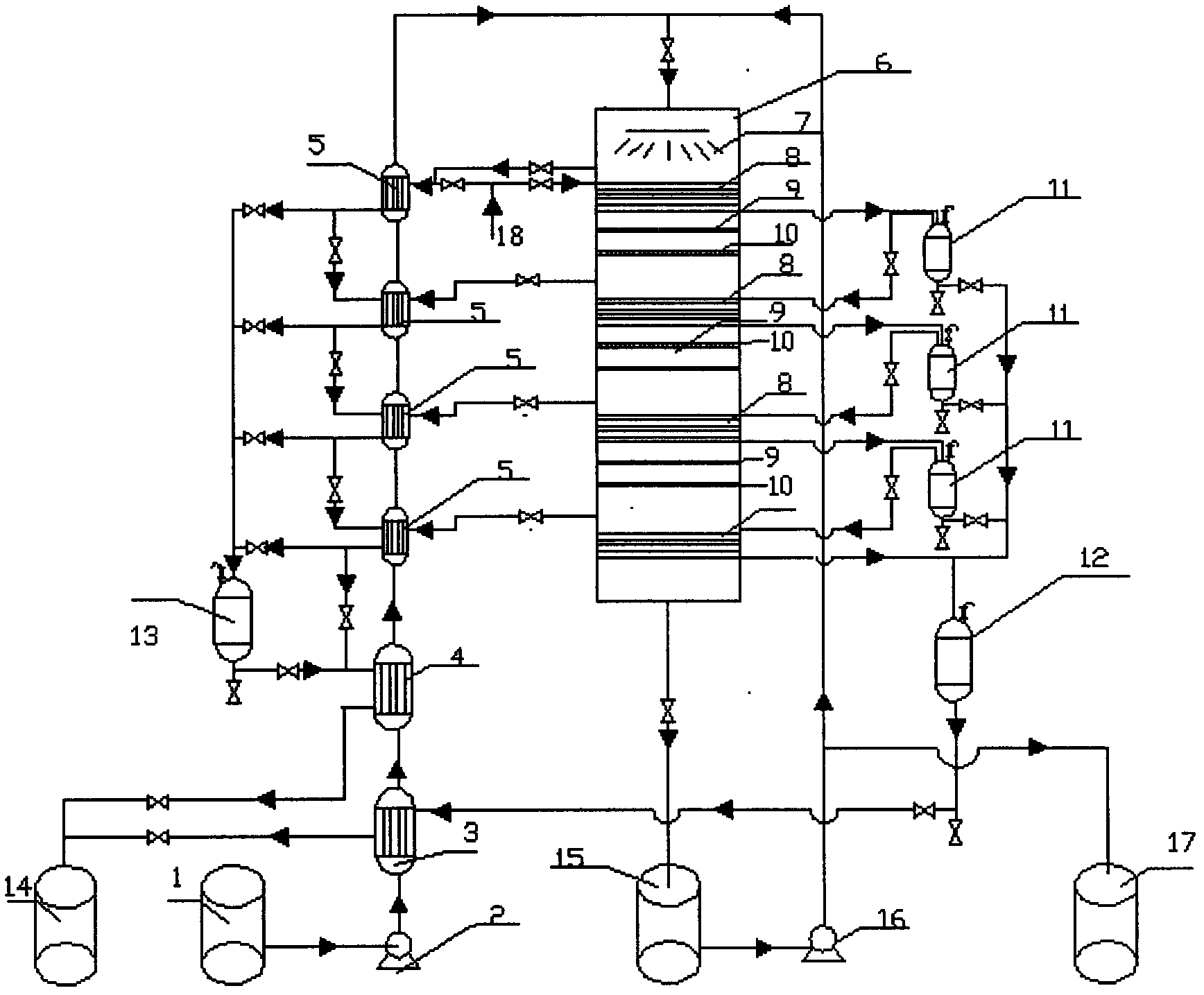

The invention relates to a high-temperature seawater desalting and distillation device and method. The device comprises a preheater, a multi-effect evaporator, respective-effect gas-liquid separators and a circulation pump. A vertical evaporator is adopted, the steam is heated in the equipment initial operating stage for gradually preheating calcium removed seawater stage by stage, secondary steam generated in the evaporation process is used for preheating the seawater, condensed water generated by the respective-effect gas-liquid separators is used for initial seawater preheating, the condensed water after the secondary steam seawater preheating is used for preheating the seawater after the heat exchange by condensed water generated by the separators, the heat efficiency is improved, the heating steam heat loss is reduced, the self afterheat of a system is sufficiently utilized, and the recovery rate of fresh water is improved. The device and the method are applicable to calcium removed or calcium and magnesium removed seawater, the heating temperature can be 40 to 170 DEG C, the heating temperature range is wide, the scale accumulation limitation is avoided, the total dissolved solids (TDS) of the desalted strong brine can be 50000 to 250000 mg/L, and the recovery rate of the fresh water is 40 to 75 percent. High-concentration, high-temperature and high-quality raw materials are provided for factory salt preparation, and the firm foundation is laid for the zero discharge of the seawater desalting.

Description

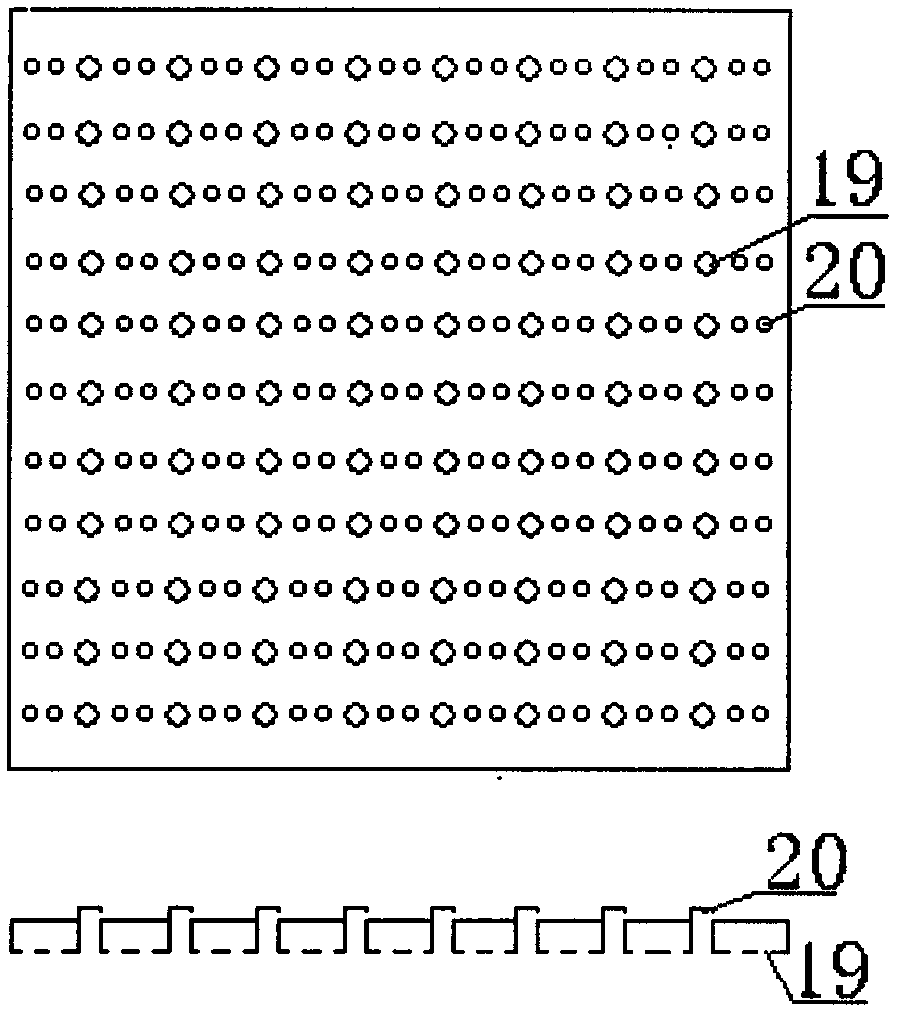

technical field [0001] The invention relates to a high-temperature seawater desalination distillation device and method. It is composed of a primary preheater, a secondary preheater, each effect preheater, a multi-effect evaporator, each effect gas-liquid separator, and a circulating pump. The purpose is to improve the thermal efficiency, reduce the heat loss of heating steam, make full use of the waste heat of the system itself, and achieve the purpose of increasing the recovery rate of fresh water. The present invention is suitable for seawater after decalcification or calcium and magnesium removal, the heating temperature can be 40-170°C, the heating temperature range is wide, and it is not limited by scaling. 40-75%. Background technique [0002] Seawater desalination has been included in the unified planning of national water resources and will become an important supplement to water resources. Therefore, the future development prospect of seawater desalination is ex...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C02F1/04C02F103/08

CPCY02A20/124

Inventor 马敬环

Owner 天津海泽惠科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com