Pellet production method based on prediction of compressive strength of pellets in rotary kiln

A technology of compressive strength and production method, which is applied in the field of iron and steel metallurgy, and can solve problems such as compressive strength prediction, large differences in belt roasting machines, and no related reports.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

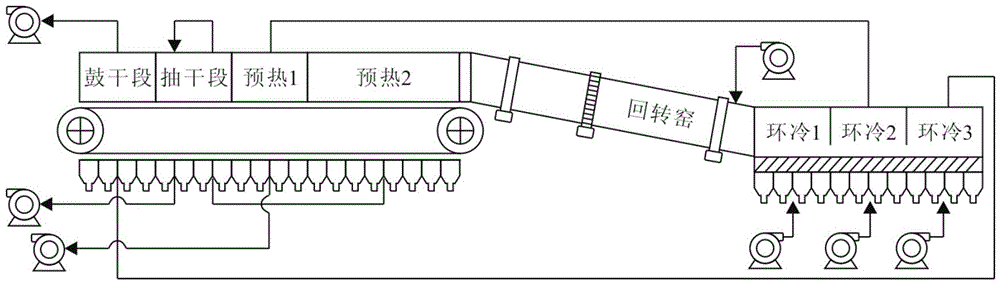

[0118] image 3 It is a typical grate machine-rotary kiln pellet production process. Taking the online prediction of pellet strength in the rotary kiln in this process as an example, the specific implementation of the present invention will be further described. This example is to further illustrate the present invention, but not to limit the scope of the invention.

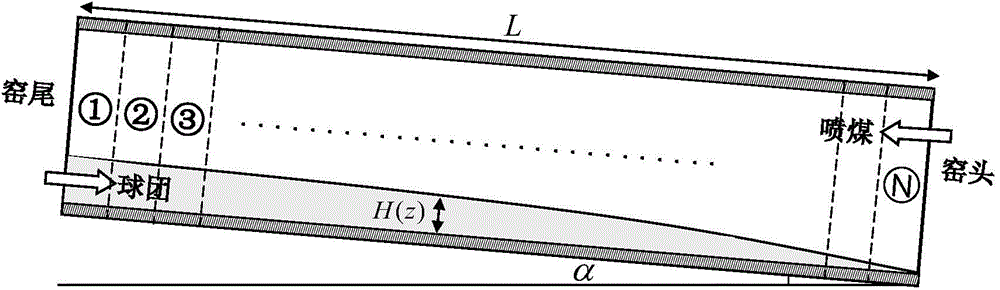

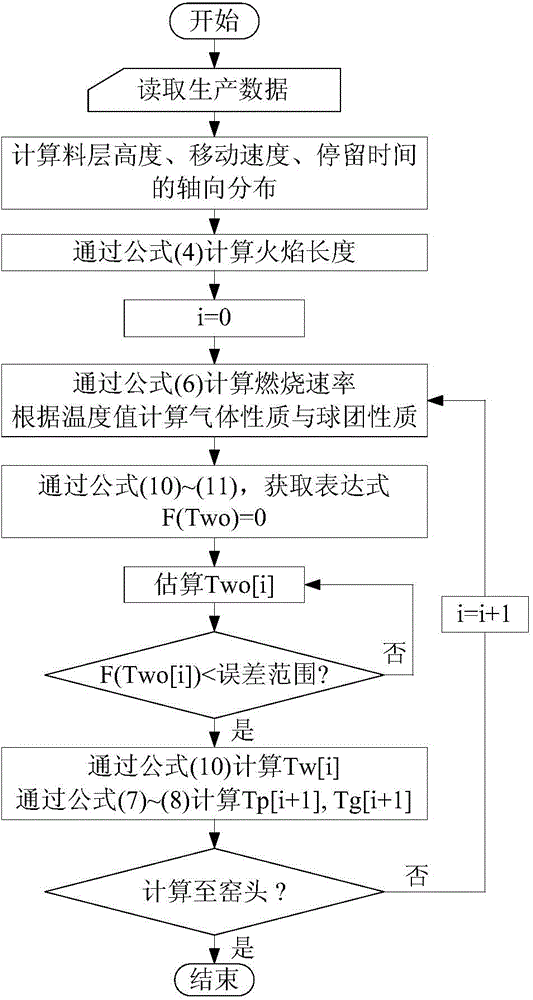

[0119] The equipment parameters of the rotary kiln in the example are: effective length 45.72m, inner diameter 6.86m, refractory brick thickness 0.25m, steel plate thickness 0.04m, burner diameter 0.50m, rotary kiln inclination angle 4°; raw material parameters in the example are: pellets The average particle size is 10mm, the pellet porosity is 0.27, the dynamic angle of repose is 42°, the calorific value of coal is 29MJ / kg, and the carbon, hydrogen, oxygen, and nitrogen contents of coal are 77.60%, 3.76%, 17.23%, and 0.25% respectively; The production status parameters detected on-site at all times are shown i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com