Patents

Literature

710results about How to "High heating temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Remelted ingestible products

ActiveUS20130274296A1Reduce exposureHigh heating temperatureBiocideTobacco preparationSemi solidTemperature sensitive

A method of preparing an orally ingestible hard boiled product, comprising: i) heating a sugar material to a first temperature sufficient to liquefy the sugar material; ii) cooling the liquefied sugar material to provide a cooled sugar material having a solid or semi-solid form; iii) heating the cooled sugar material to a second temperature, which is lower than the first temperature; iv) combining the sugar material with one or more temperature sensitive ingredients before, during, or after said heating step iii), but after said cooling step ii), such that an intimate mixture of the second liquefied sugar material and the one or more temperature sensitive ingredients is provided; and v) cooling the intimate mixture to form an orally ingestible product. Orally ingestible hard boiled products prepared according to this method are also provided.

Owner:R J REYNOLDS TOBACCO COMPANY

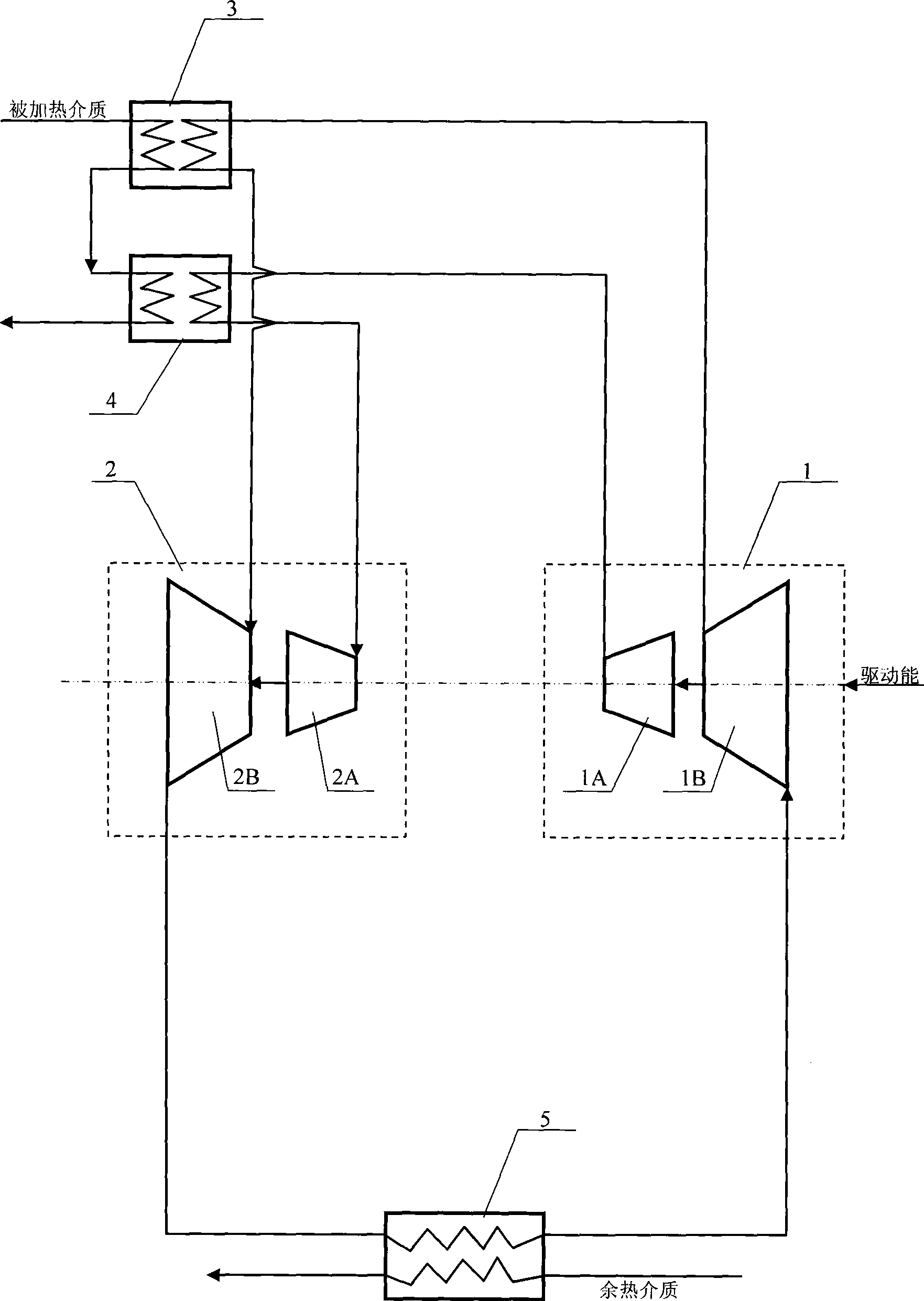

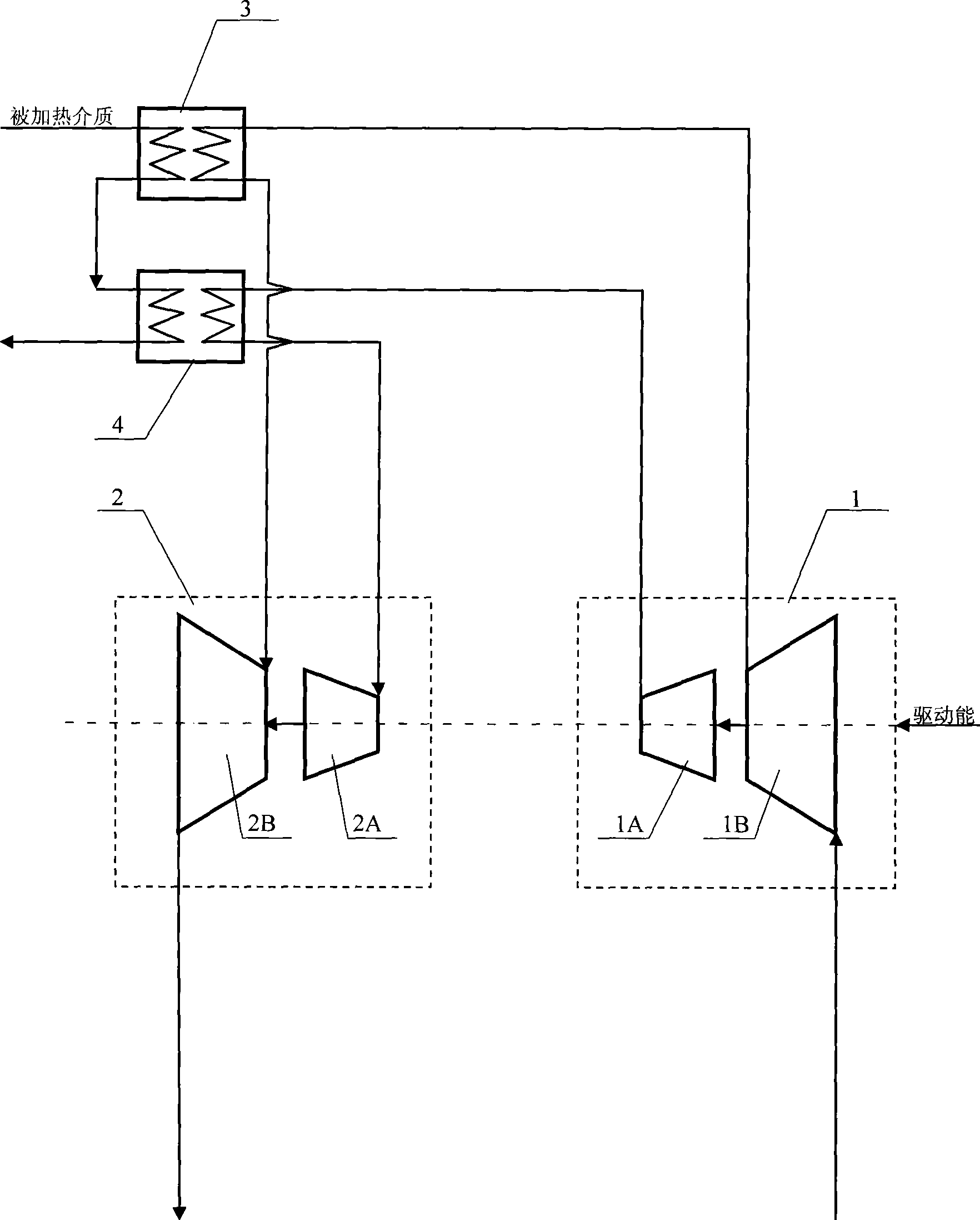

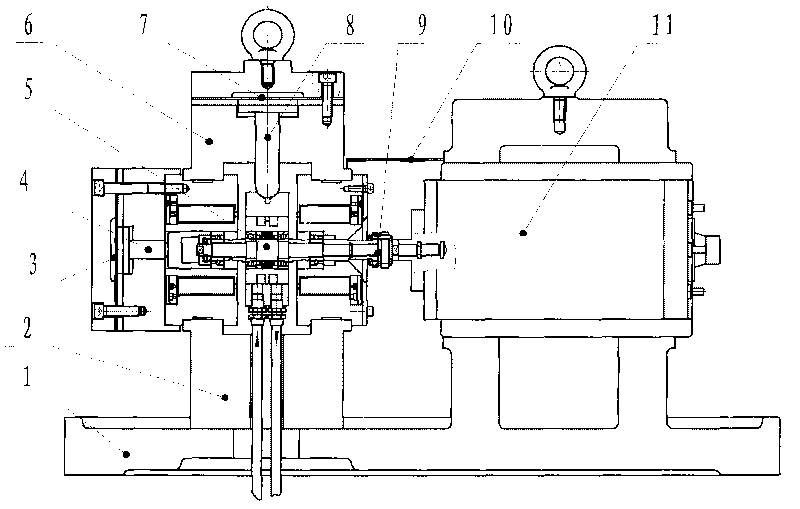

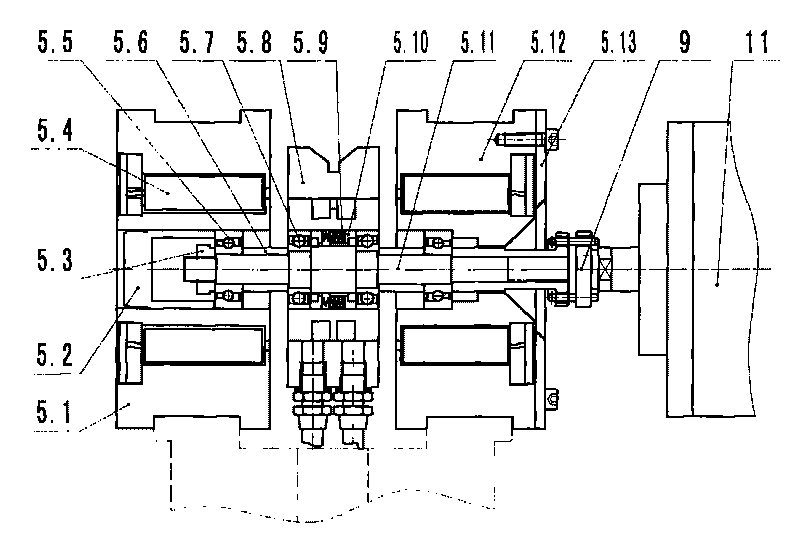

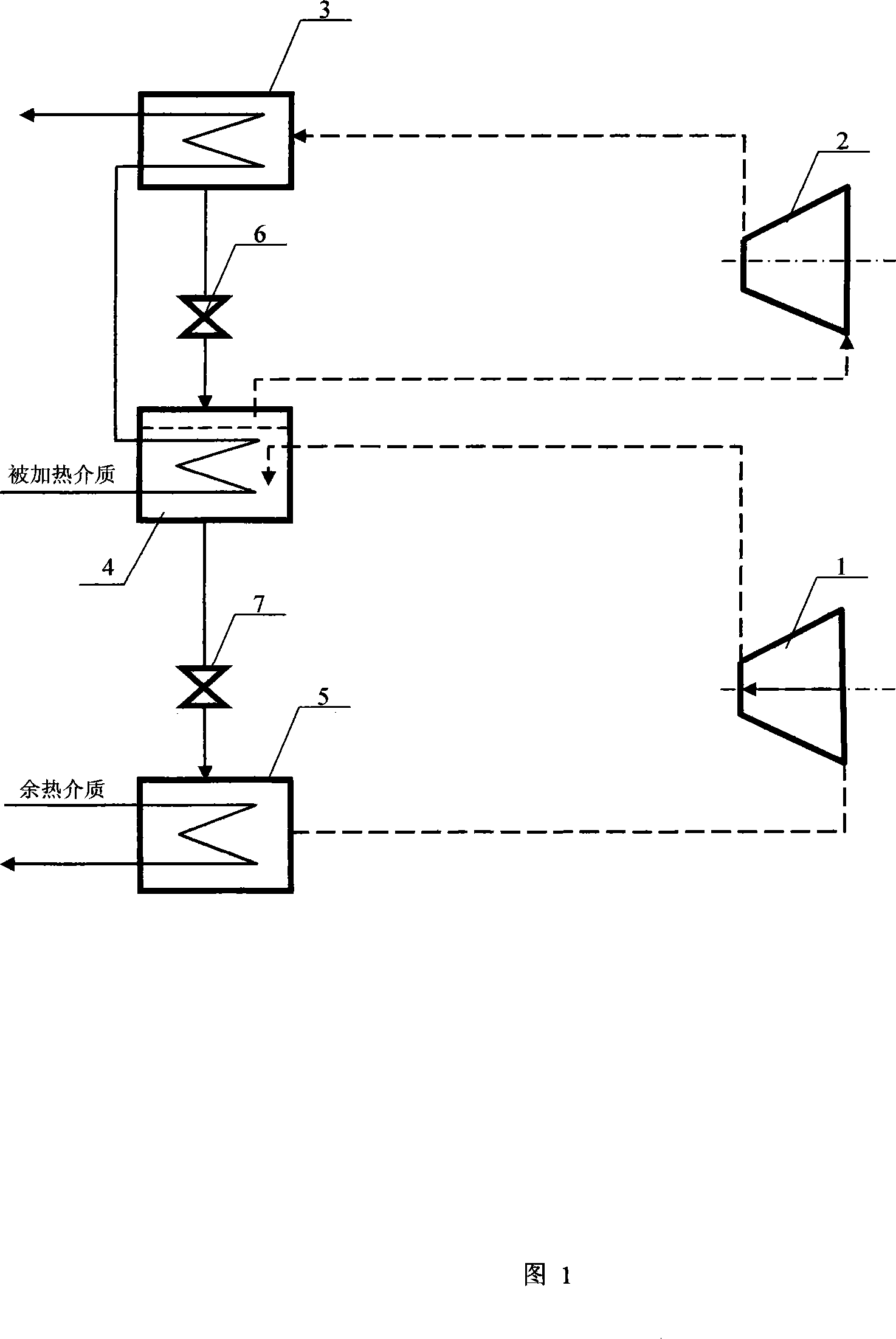

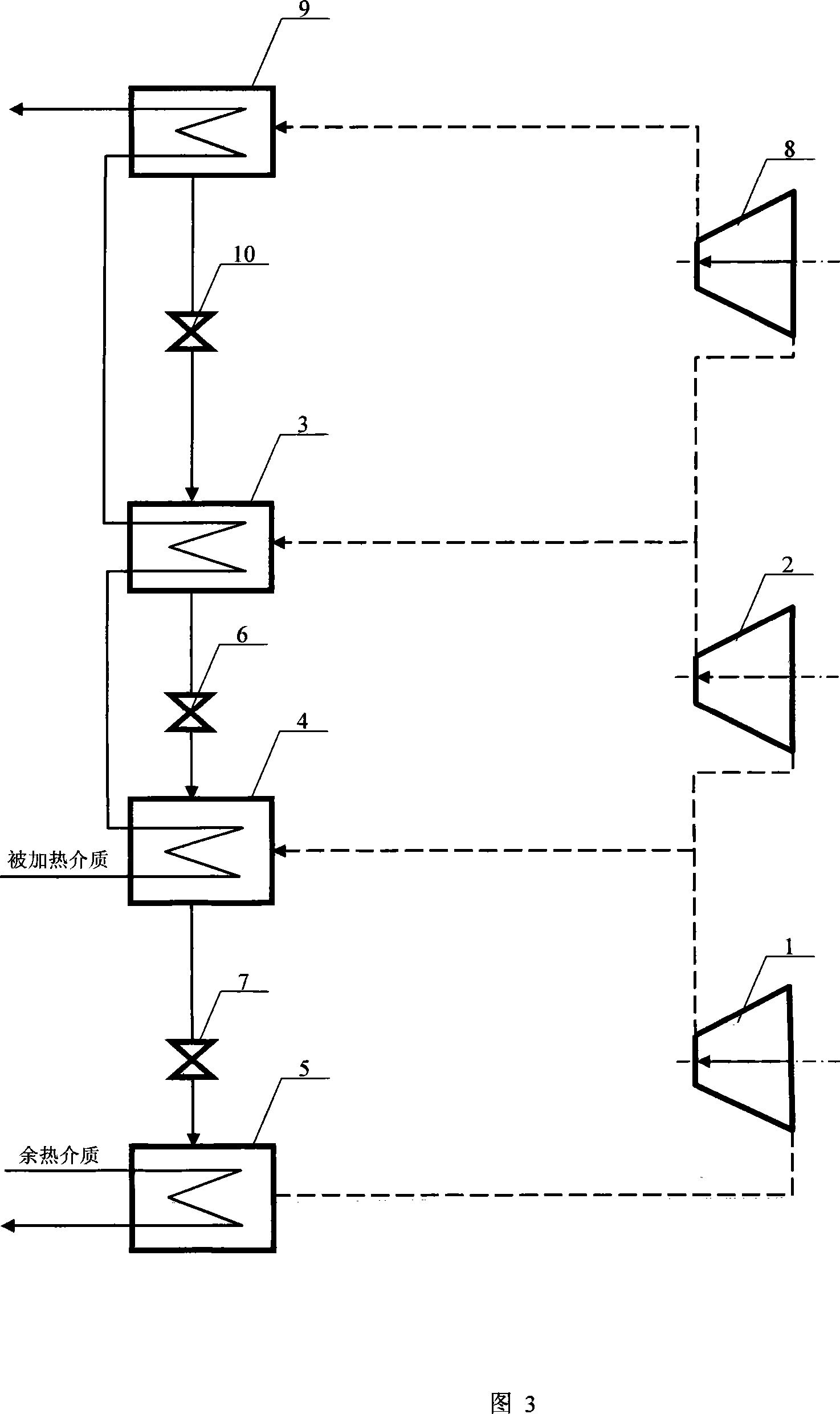

Segmented compression-segmented heat supply-segmented expansion gas compression type units

ActiveCN101504205AReduce power consumptionReduce the compression ratioCompression machines with non-reversible cycleSuperheatersPerformance indexEngineering

A subsection compression-subsection heat supply-subsection gas expanding compression type machine set belongs to the technical field of heat pumps / refrigeration, and consists of a compressor, an expander, a heat exchanger, a second heat exchanger and a low-temperature heat exchanger. Gas working substances absorbing heat from the low-temperature heat exchanger and raising temperature enter the compressor; after the gas working substances are compressed in a low pressure compression section, a part of the gas working substances are provided for the heat exchanger to complete the heating of a heated medium at an initial stage; the part of the gas working substances enter the expander and is expanded at a low pressure expansion section; the other part of the gas working substances are provided for the second heat exchanger to complete the heating of a second stage of the heated medium after continuously passing through the whole compression process and raising temperature, and enter the expander from an inlet of the high pressure expansion section of the expander for expanding; the gas working substances completing the expanding work flow through the low-temperature heat exchanger to absorb the heat and raise the temperature and enter the compressor; and a heat regenerator is added to form a regenerative machine set. The gas expanding compression type machine set reduces temperature difference of heat transmission and improves the performance index; when taken as a heat pump, the gas expanding compression type machine set is particularly suitable for occasions with high heating temperature and wide range; and when used for refrigeration, the gas expanding compression type machine set can reduce power consumption.

Owner:李华玉

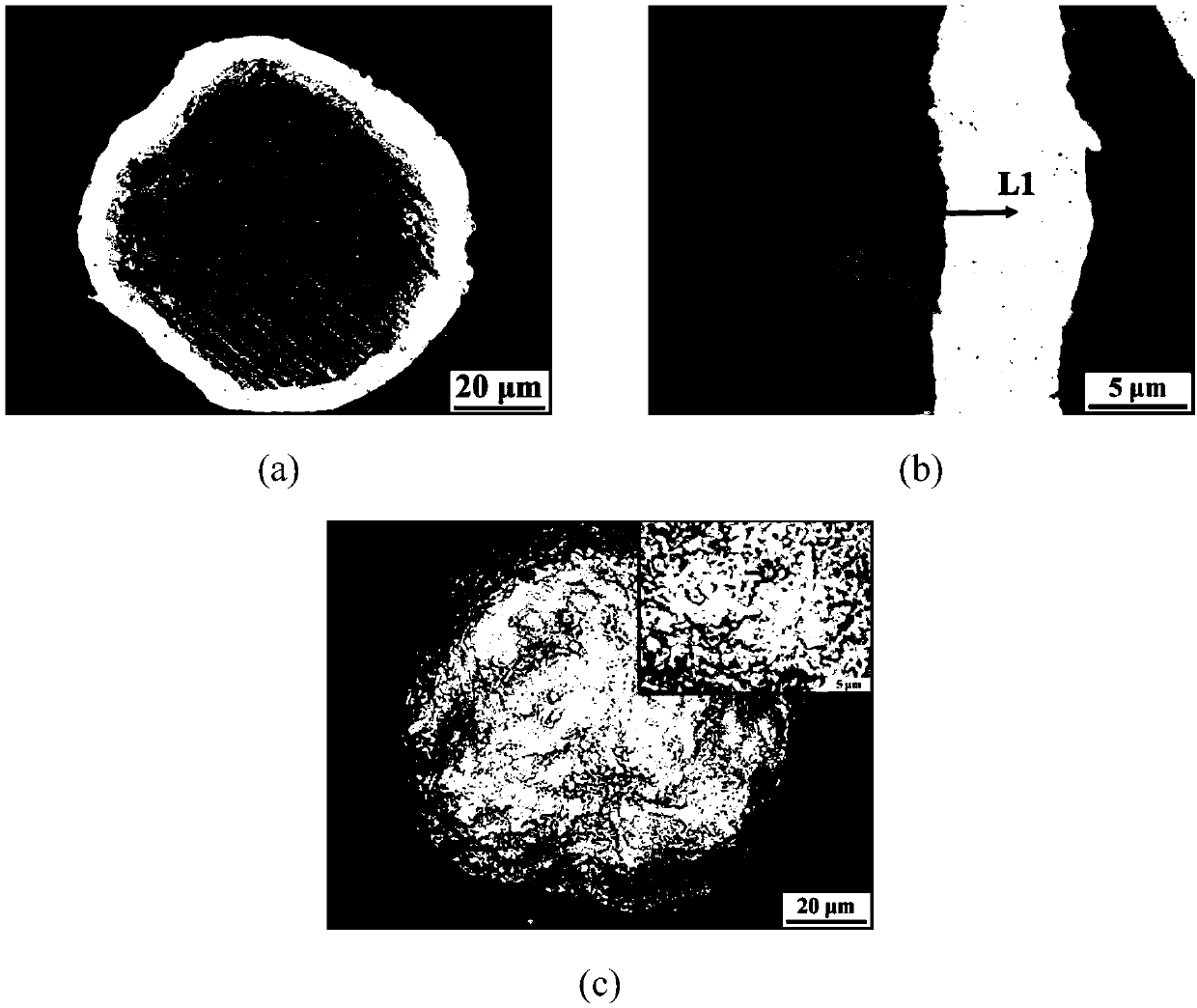

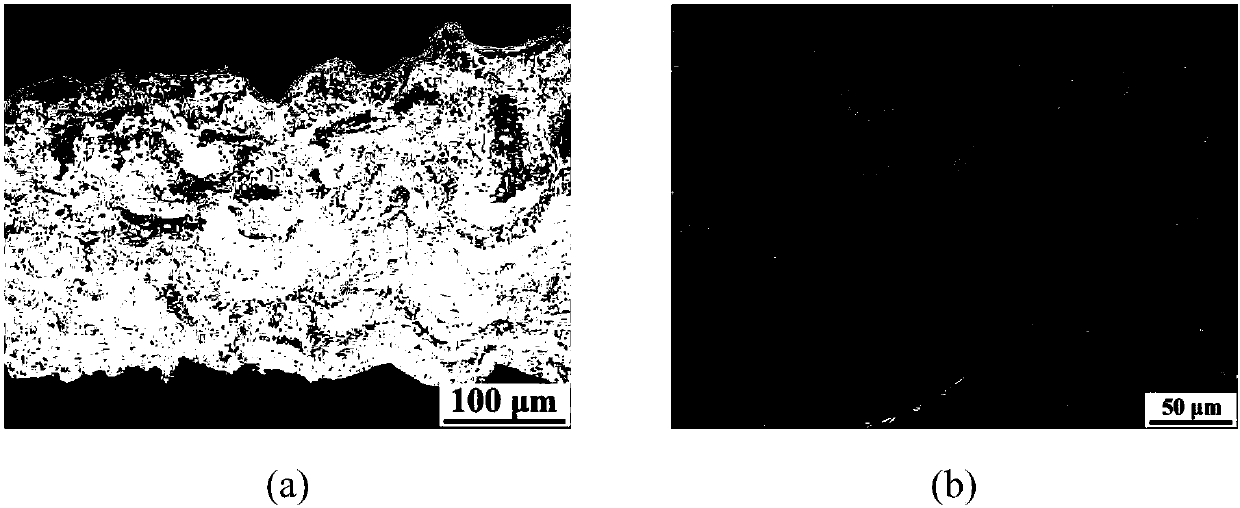

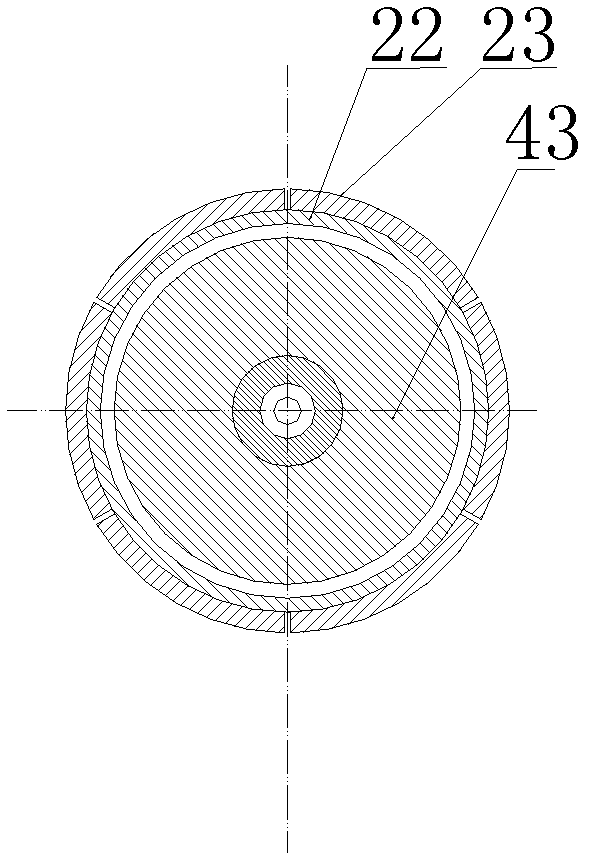

Preparation process and device of nano-particle reinforced bimetal composite

InactiveCN101914767ALow melting pointImprove toughnessMetallic material coating processesCorrosionBonding strength

The invention relates to a preparation process and a device of a nano-particle reinforced bimetal composite, the nano-particle reinforced bimetal composite comprises the following chemical components by weight percent: 6-25% of Cr, 4-18% of Ni, 1.0-4% of Mo, 1.0-1.8% of Si, 1.2-3% of Mn, 0.4-2.2% of B, 0.1-1.2% of MgO, 0.2-2% of CaF2, 0.2-0.7% of C, 0.2-0.8% of Nb, not more than 0.9% of one or the combination of CeO2, Y3O2 and La2O3, 0.0-0.8% of Co, and the balance of Fe, and mixed particles of nano-sized carbides, nitrides, borides or carbonitrides are added in alloy powder. The vacuum induction melting and the cladding processes and equipment are adopted for melting and cladding the mixture on a workpiece, the thickness of a cladding layer is 0.1-25mm, the cladding layer contains 1%-50% of nano-reinforcing particles of one or the combination of the carbides, the nitrides, the borides and silicides, and the cladding layer has special performances of wear resistance, corrosion resistance, electrical conductivity, self-lubrication performance and the like. A coating layer and a base material form the metallurgical bonding, thereby having high bonding strength, overcoming the drawbacks in various coating processes at home and abroad, leading the coating layer to avoid the defects of shrinkage cavities, inclusion, cracking, shedding and the like and having the advantages of high heating temperature, fast speed, high production efficiency, small energy consumption, simple preparation process and low cost.

Owner:丁家伟

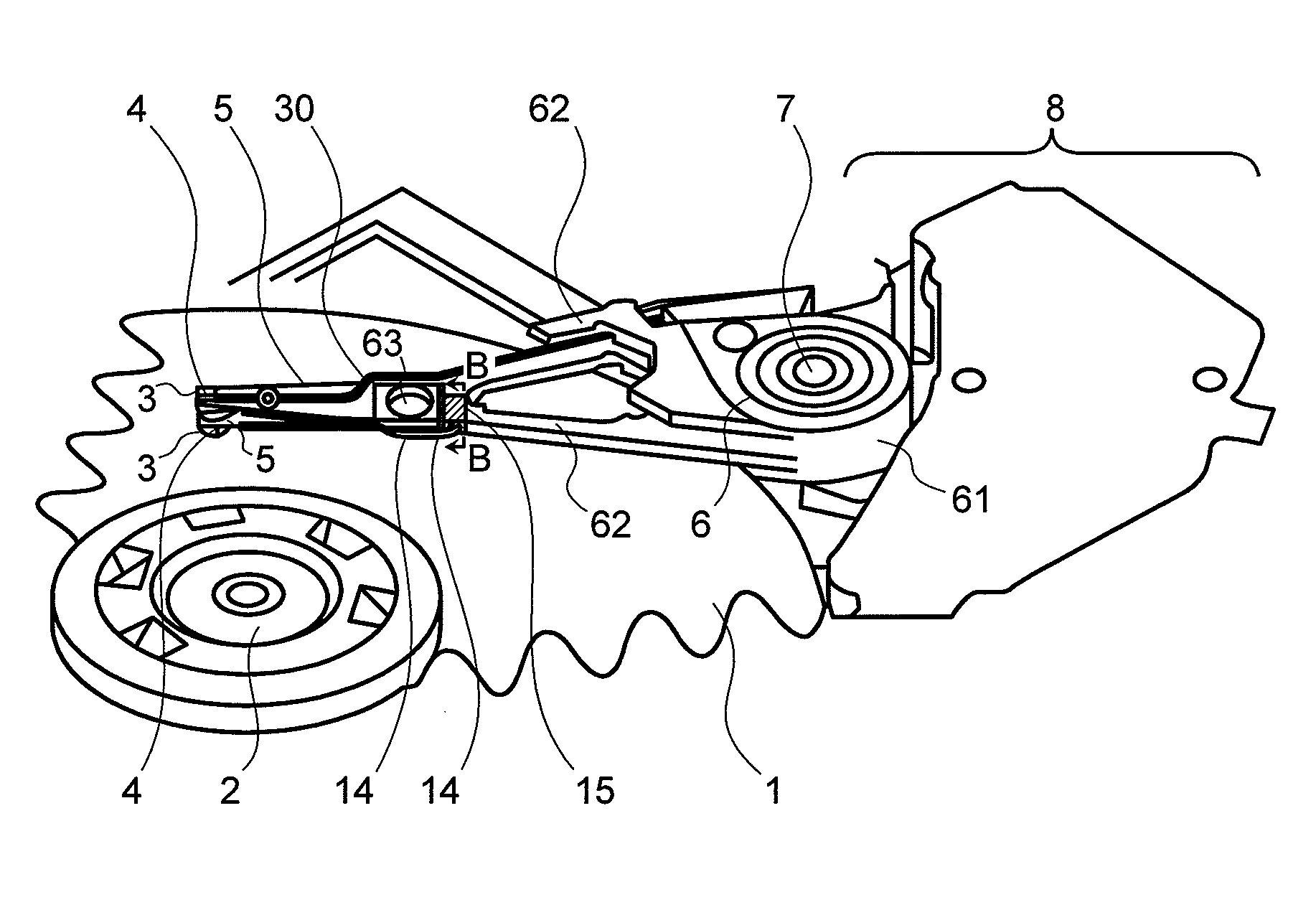

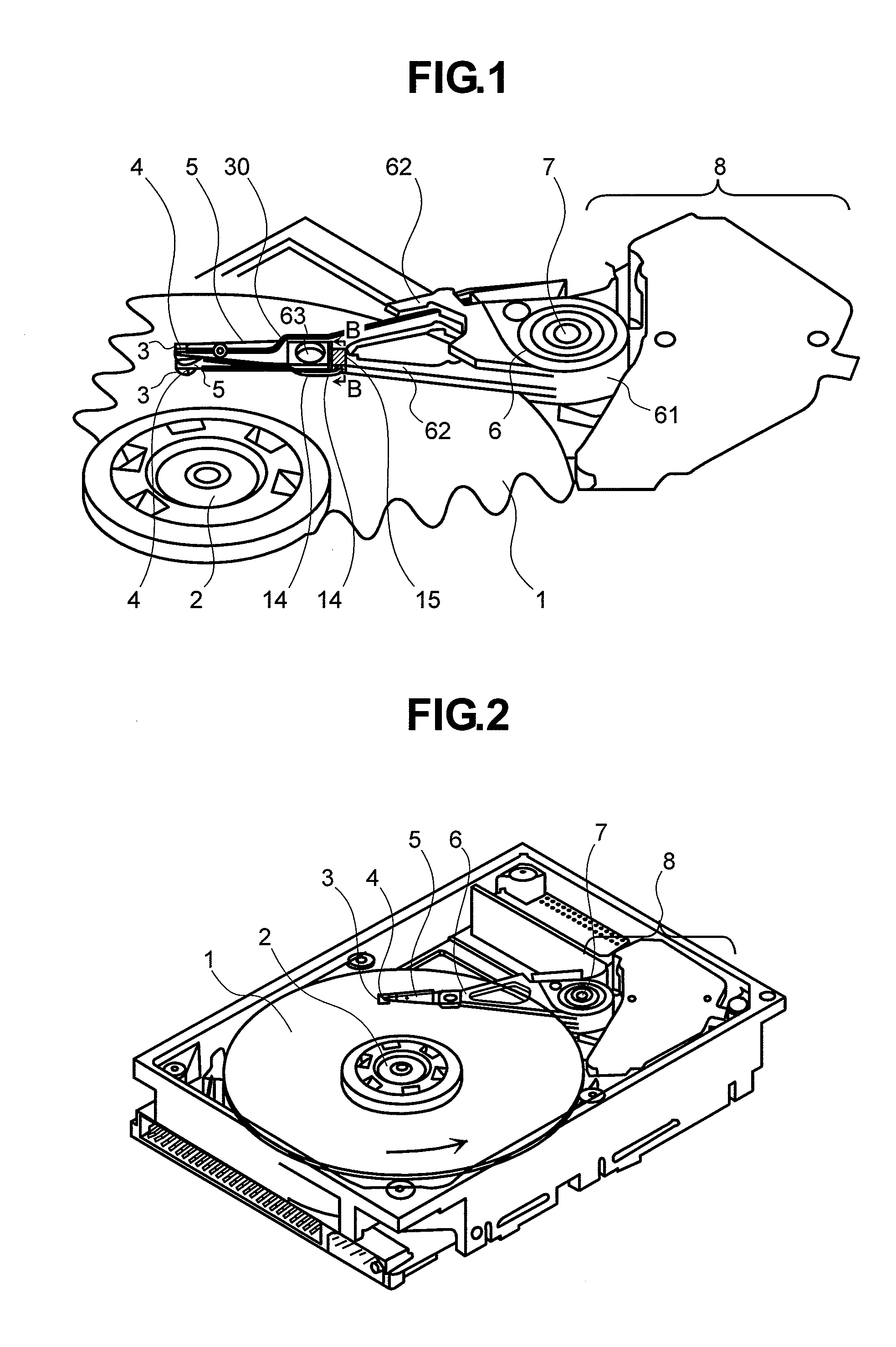

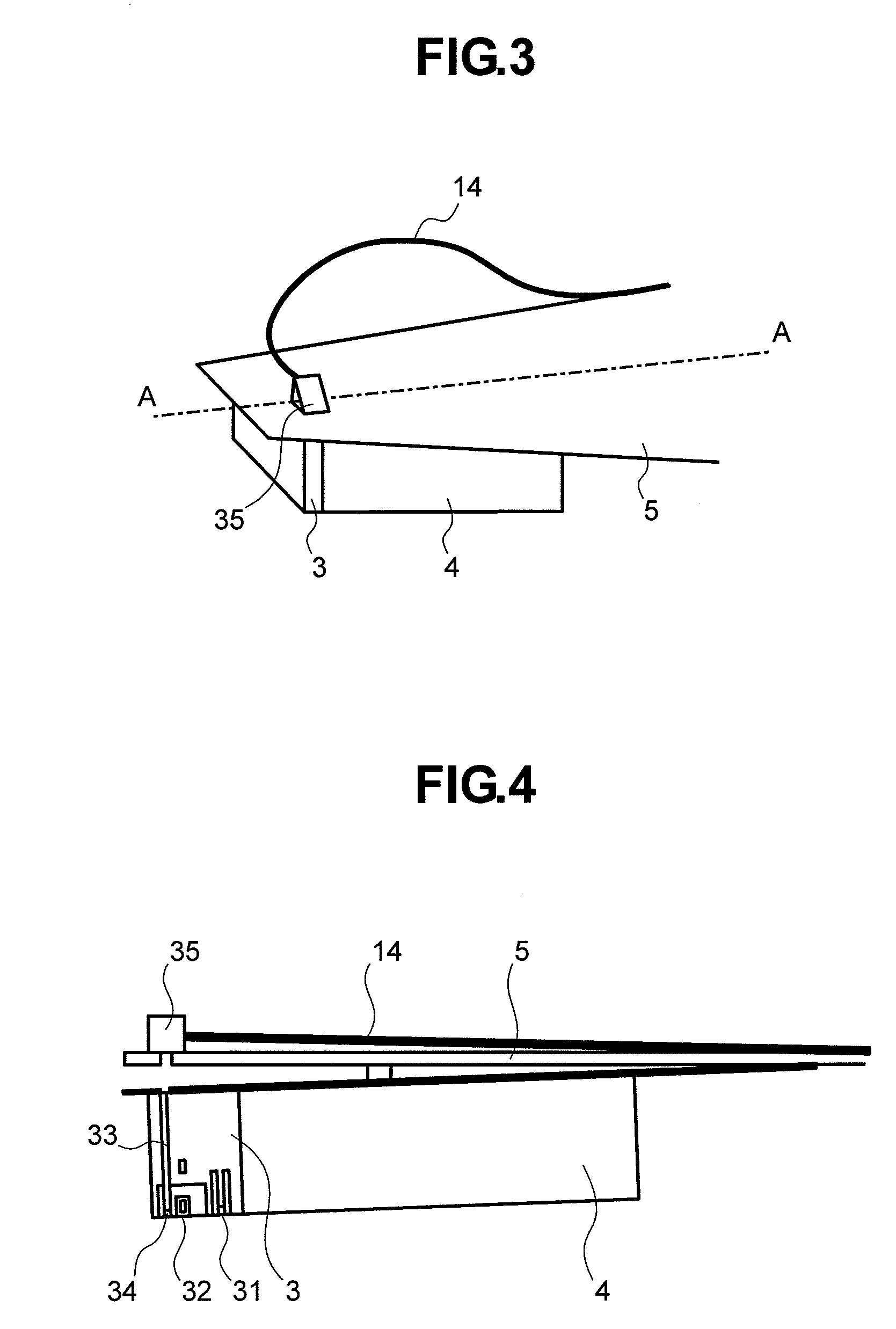

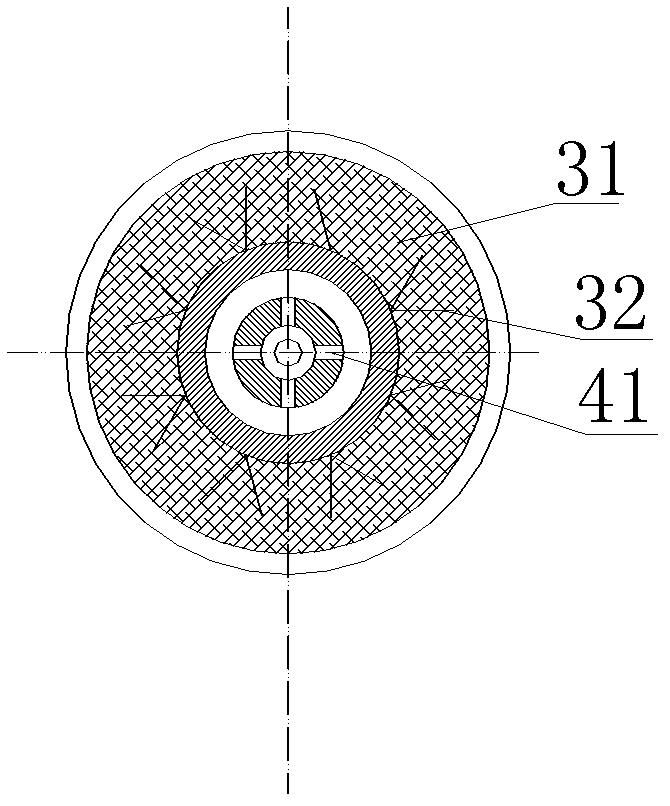

Thermally assisted magnetic recording head support mechanism

InactiveUS20080130155A1Reduce transmission lossHigh heating temperatureCombination recordingRecord information storageHeat-assisted magnetic recordingEngineering

[Problem] In a thermally assisted magnetic recording head support mechanism, an increase in the temperature of a heat source for supplying an optical near-field transducer with light, due to heat generation by the heat source, is checked while holding back an increase in weight of a slider and lessening transmission loss of light.[Solution] The thermally assisted magnetic recording head support mechanism is made up such that a suspension 5 has one end holding a slider 4 on which a magnetic head 3 having a read element 31, write element 32, and an optical near-field transducer 34 is mounted, and the other end of the suspension 5 is held by a carriage 6. The optical block 15 provided with one light source 10, and an optical switching mechanism capable of switching a guidance destination of irradiated light from light source 10 is attached to an arm 62 or a support 61 of the carriage 6 having a wide heat release area, thereby guiding light from the optical block 15 to the optical near-field transducer 34 via an optical waveguide 14.

Owner:HITACHI LTD

High-temperature high-speed test method for sealed bearing

InactiveCN101718625AImprove the state of stressEasy to achieve high speedMachine bearings testingElectricityComputer control system

The invention relates to a high-temperature high-speed test method for a sealed bearing, which comprises the following steps of: firstly designing a testing device, installing two sets of testing accompanying bearings on a testing main shaft, and pretightening through a set of spring and a pressure ring; installing the two sets of testing bearings at the left end and the right end of the testing main shaft, connecting an electric main shaft through a shaft coupling and additionally covering a shield; starting cooling circulating water, adding cooling water into a loading sleeve, starting a hydraulic station, an electric main shaft variable-frequency driving system and a computer control system, applying 20-30 percent of the maximum axial test load and 20-30 percent of the maximum radial test load to the testing bearings, starting the electric main shaft to reach 15-20 percent of the highest rotational speed and running for 15-25 minutes after the heating temperature reaches a set value, and then sequentially adding axial loads and radial loads and increasing the rotational speed of the electric main shaft so as to reach the highest rotational speed when the power consumption current of the electric main shaft tends to be steady; and carrying out computer data processing for the data and images in different time periods of the whole testing process and working out a test conclusion.

Owner:LUOYANG BEARING SCI & TECH CO LTD

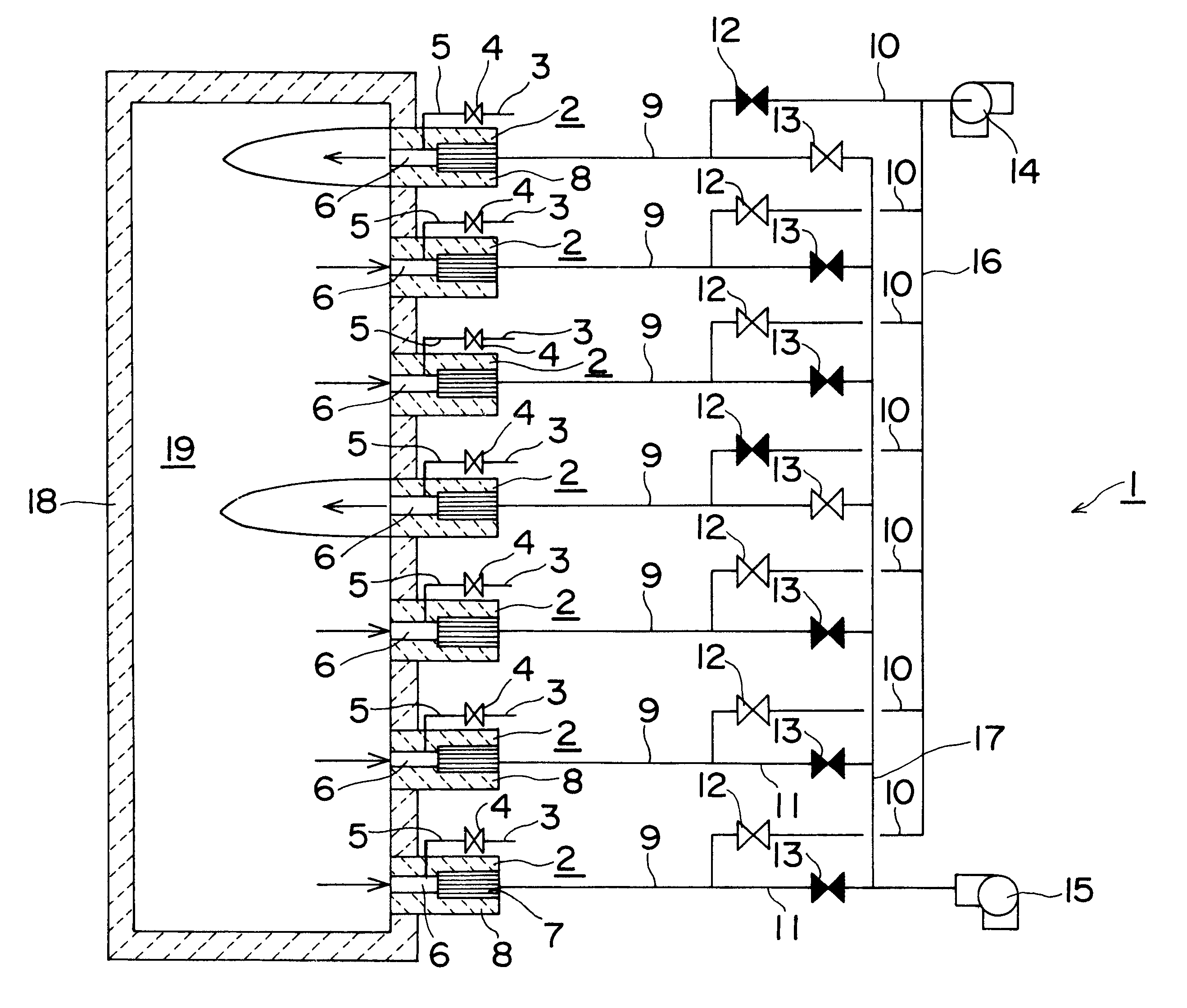

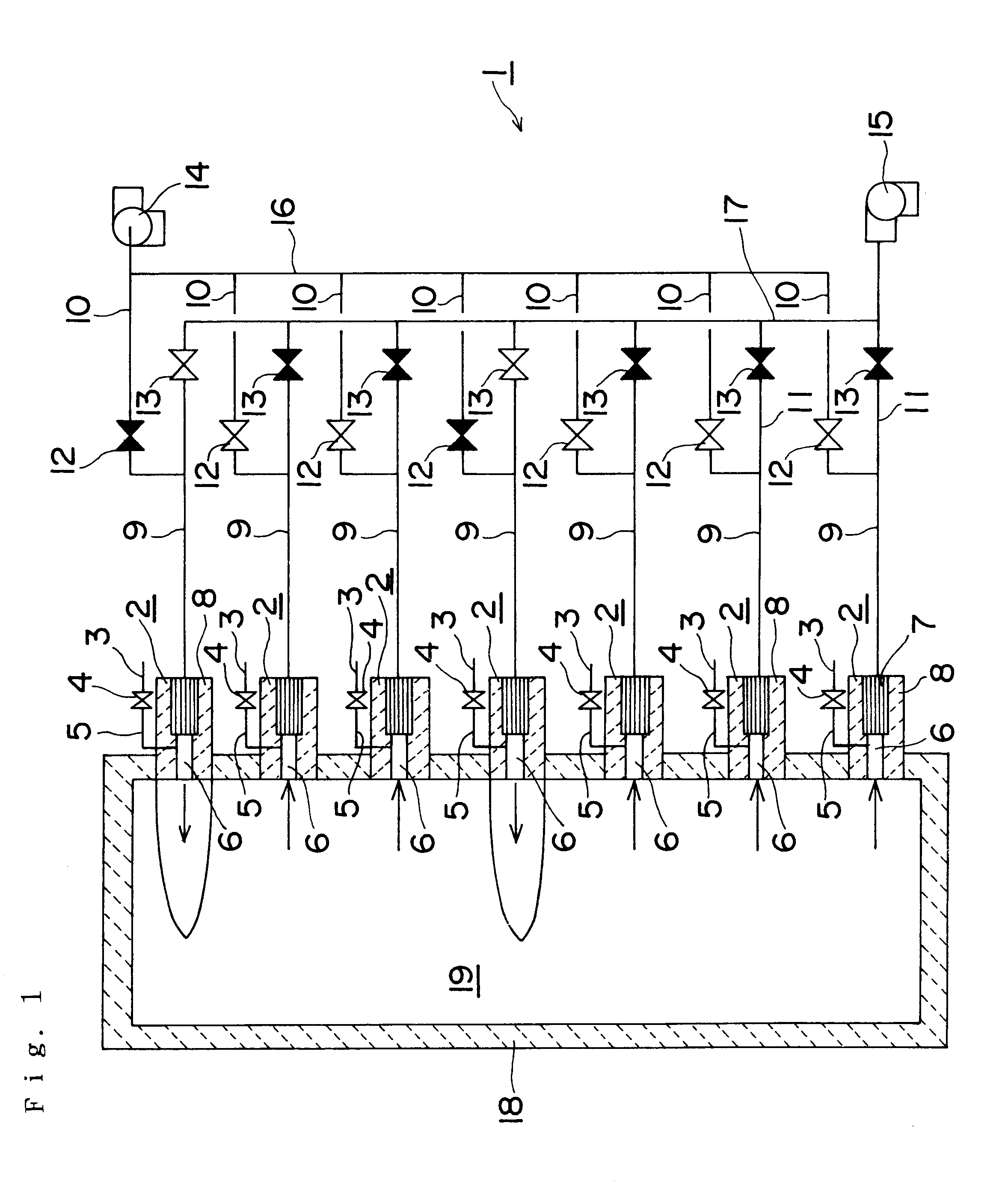

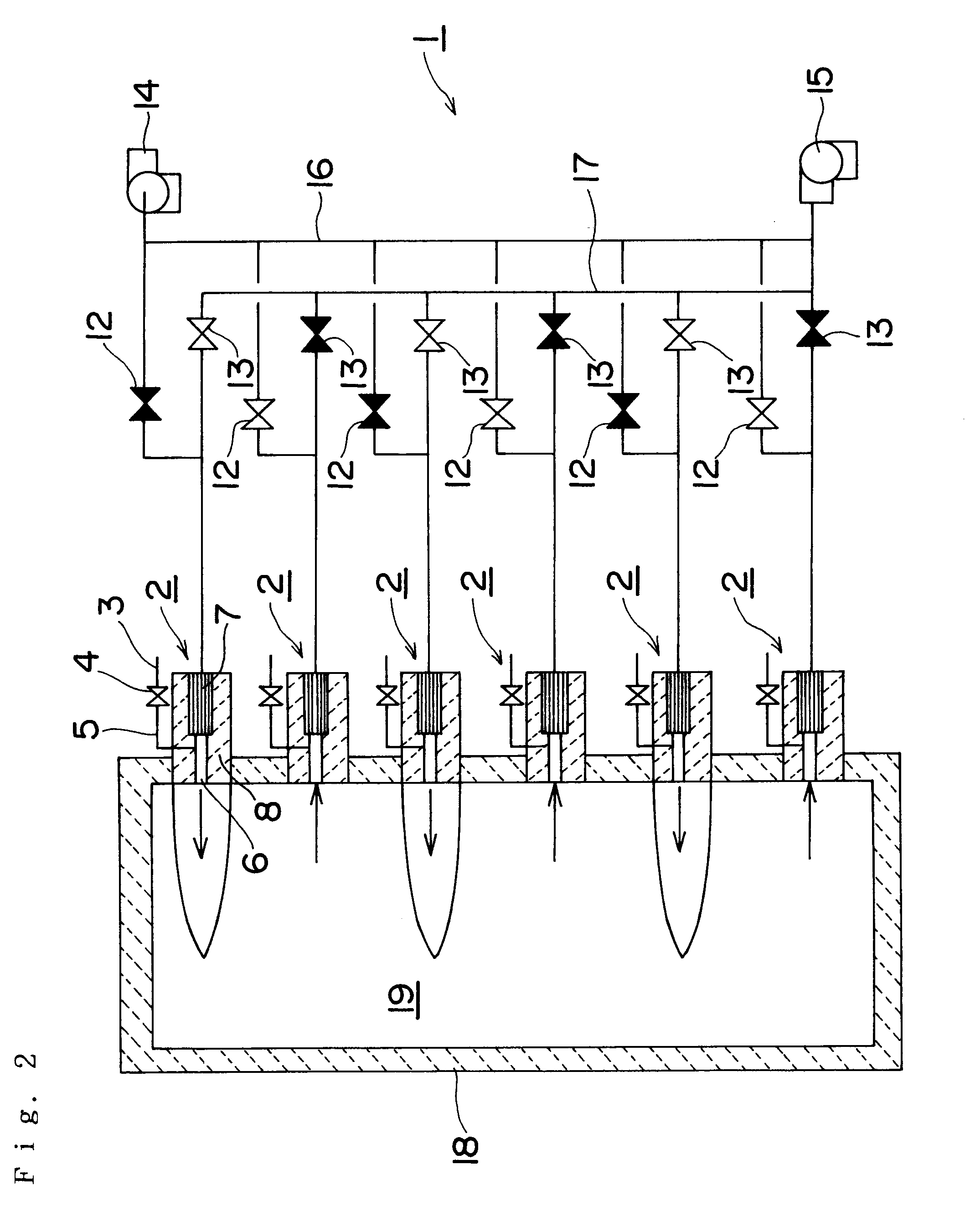

Inter-switching heat accumulating regenerative burner system

InactiveUS6234789B1Reduce rateImprove heat transfer performanceBurnersDomestic stoves or rangesCombustion systemProcess engineering

The present invention provides an alternate changeover regenerative burner system suitable for use as a heat source for an industrial furnace and the like where re-increase in temperature is relatively-often carried out; an alternate changeover regenerative burner constituted by a burner 2 having a regenerator 7 and air supply / exhaust switching mechanisms 12 and 13 for switching connection with an air supply system 17 and an exhaust system 16 of the burner 2 is regarded as a module unit; and three or more units of the alternate changeover regenerative burner constitute a combustion system 1; a ratio of the number of the burners 2 performing combustion and the number of the burners 2 being stopped is variable; and combustion is controlled in such a manner that all the units sequentially repeat alternate regenerative combustion with the units forming no fixed pairs. According to the present invention, a flow velocity of air injected from a burner throat can be variable irrespective of a quantity of combustion; the flow velocity of air emitted from the burner throat can be maintained high even if the operation is carried out with a quantity of combustion lower than the burner capacity; and a non-stationary flame can be formed in a wider range.

Owner:NIPPON FURNACE KOGYO KAISHA LTD

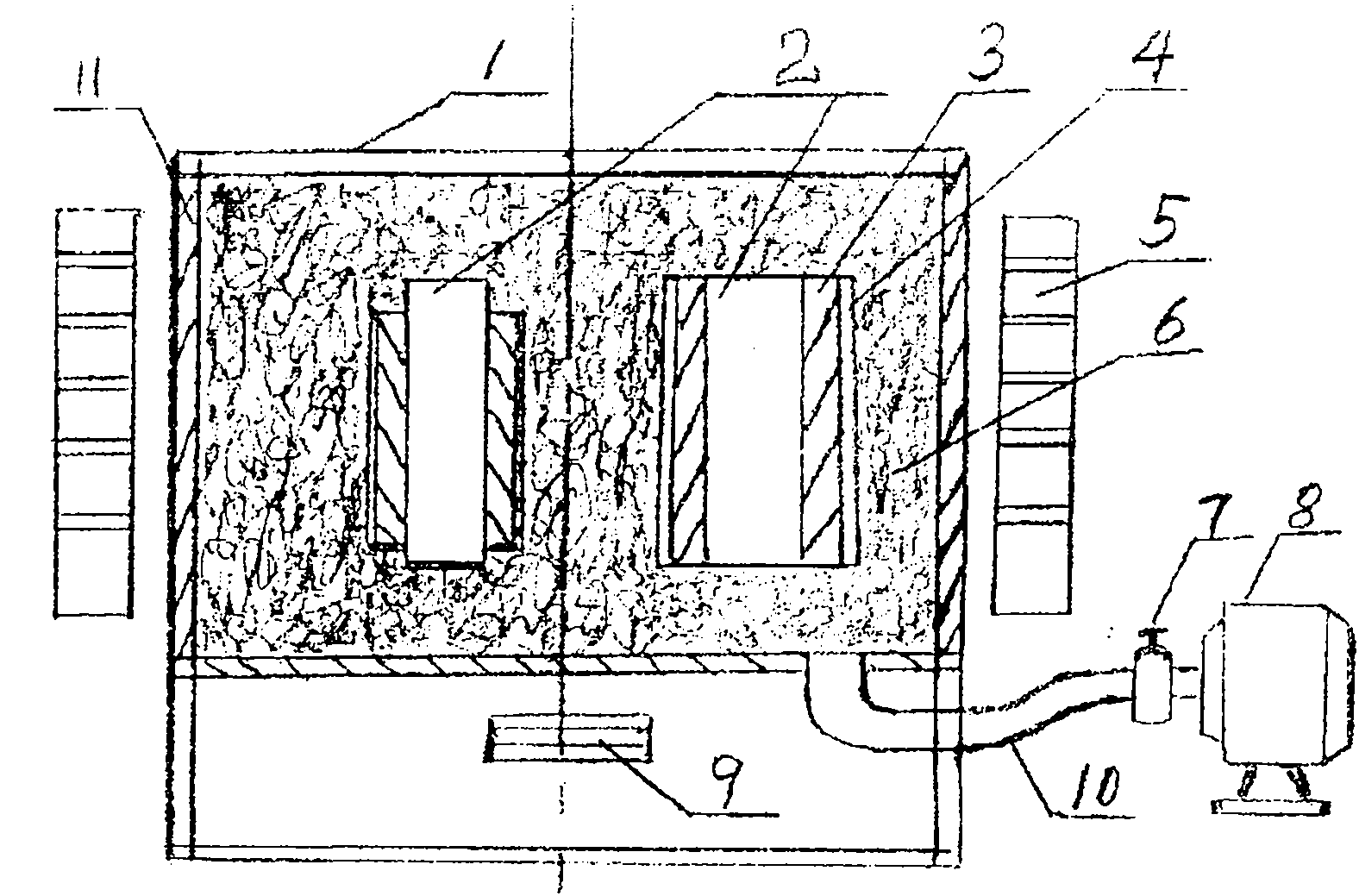

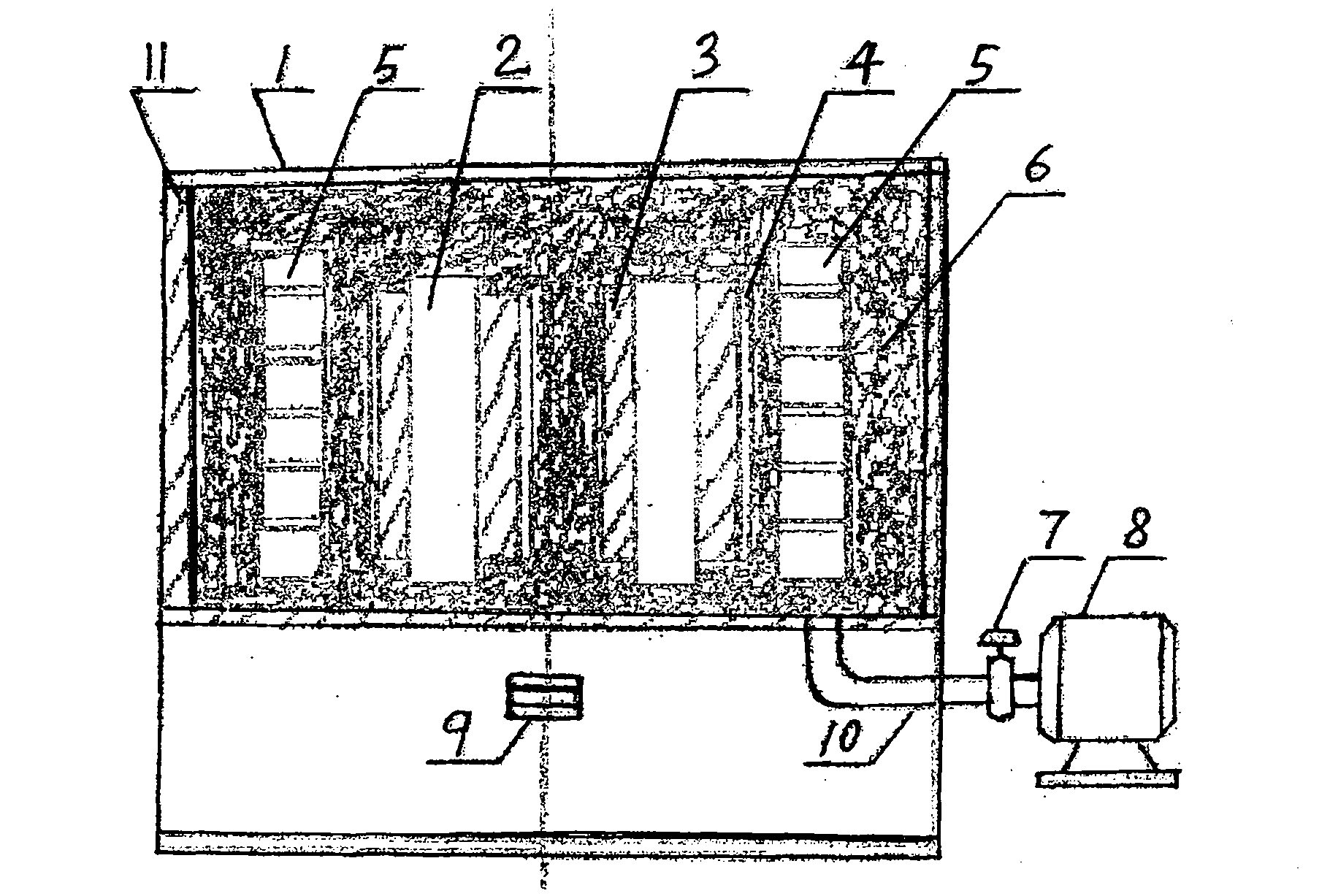

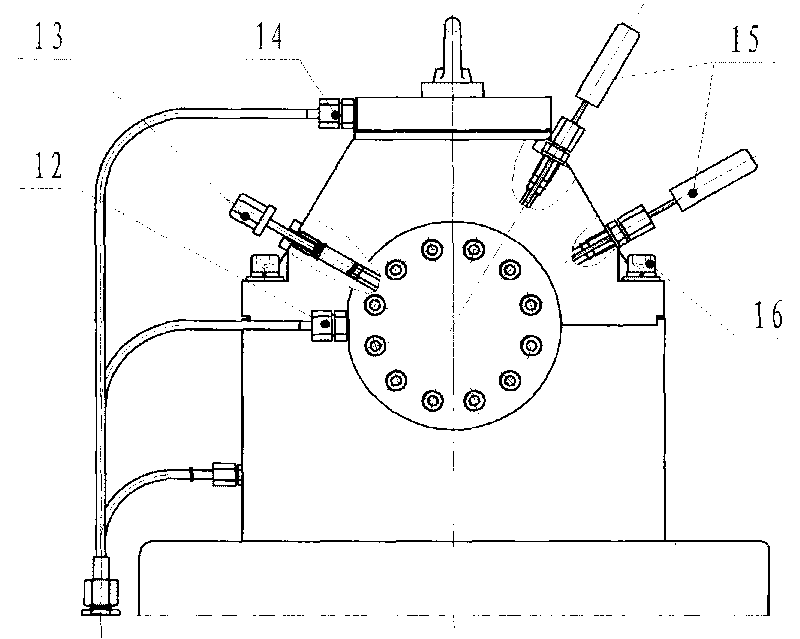

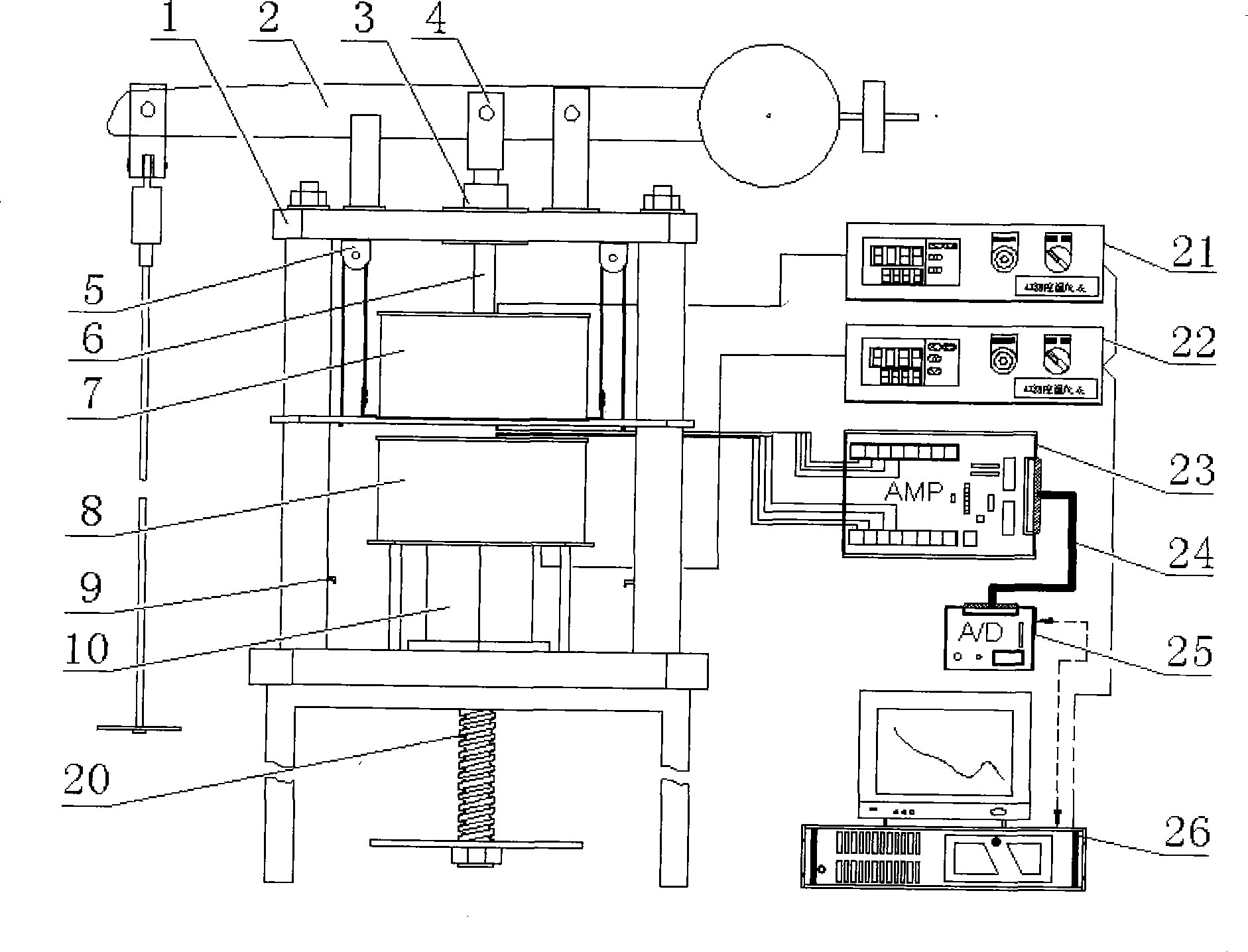

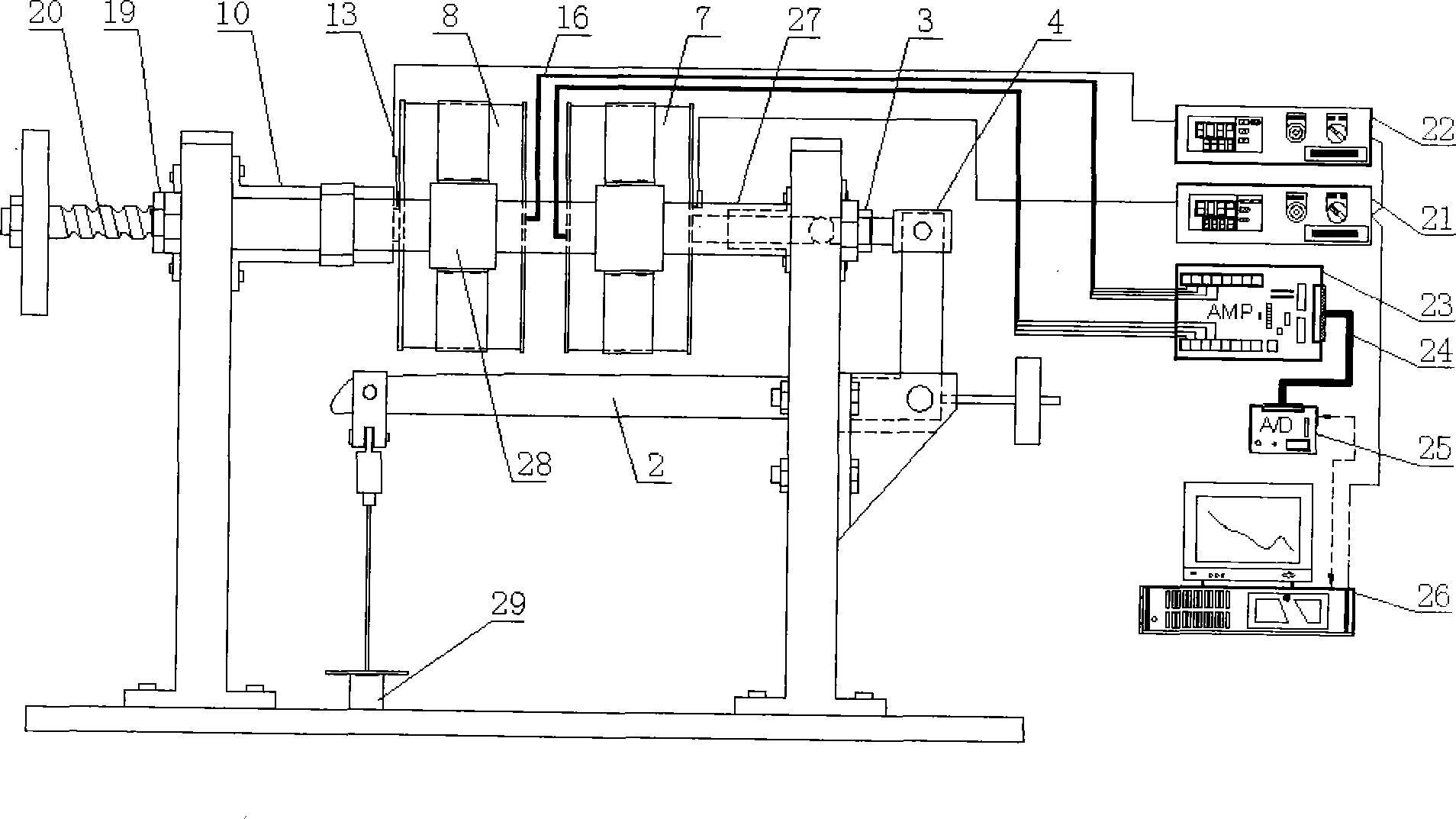

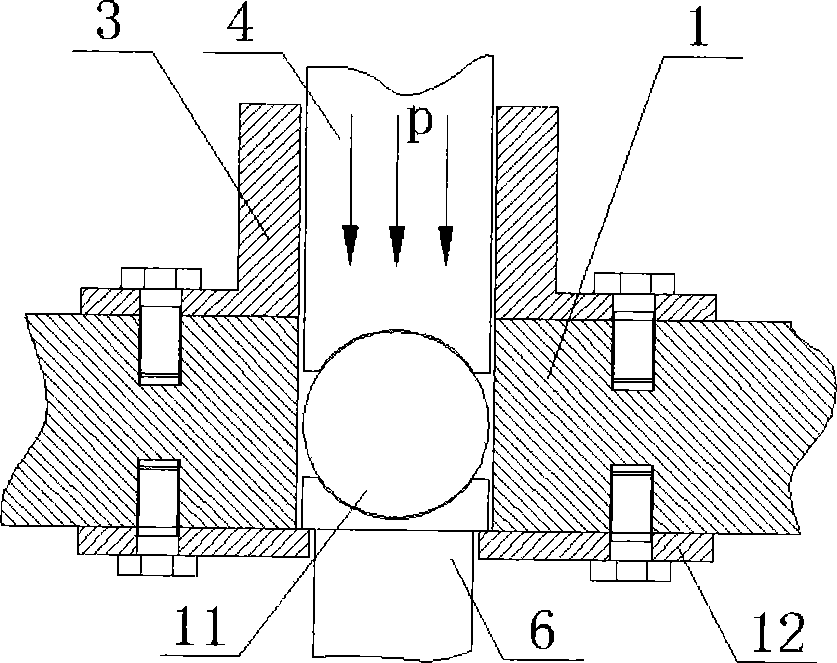

Solid interface contact heat exchange coefficient measurement method and apparatus based on transient method

InactiveCN101393150ARealize dynamic contactHigh heating temperatureMaterial thermal conductivityMaterial heat developmentEngineeringHigh heat

The invention relates to a method and a device for measuring solid interface contacted heat transfer coefficient based on a transient method. The method comprises the following steps: a lever loading device 2 is connected with a pressure turning joint 4, a centering ball 11, a low temperature sample connecting rod 6 and a low temperature sample 14 in turn from the top to the bottom; a positioning block bears pressure in advance; and a thread transmission shaft 20 pushes a high temperature sample 15 out of a heating furnace through a high temperature sample supporting rod 17, contacts and jacks up the low temperature sample 14 to transfer the pressure to the contact surface. A temperature control thermocouple 13 of the heating furnace is connected with a program control meter, the output end of the program control meter is connected in parallel and then is connected with an industrial computer 26 through an RS232 converter, a temperature detecting thermocouple 16 is connected with a preposition multi-path gate amplifier 23 and an A / D converter plate 25 in turn to acquire and process temperature signals of measured points in real time as well as compile a FORTRAN calculation module by applying a counter heat transfer arithmetic. The method has the advantages of high measuring temperature, quick acquisition and practical measuring principle, and is suitable for the research field of solid thermal processing.

Owner:DALIAN UNIV OF TECH

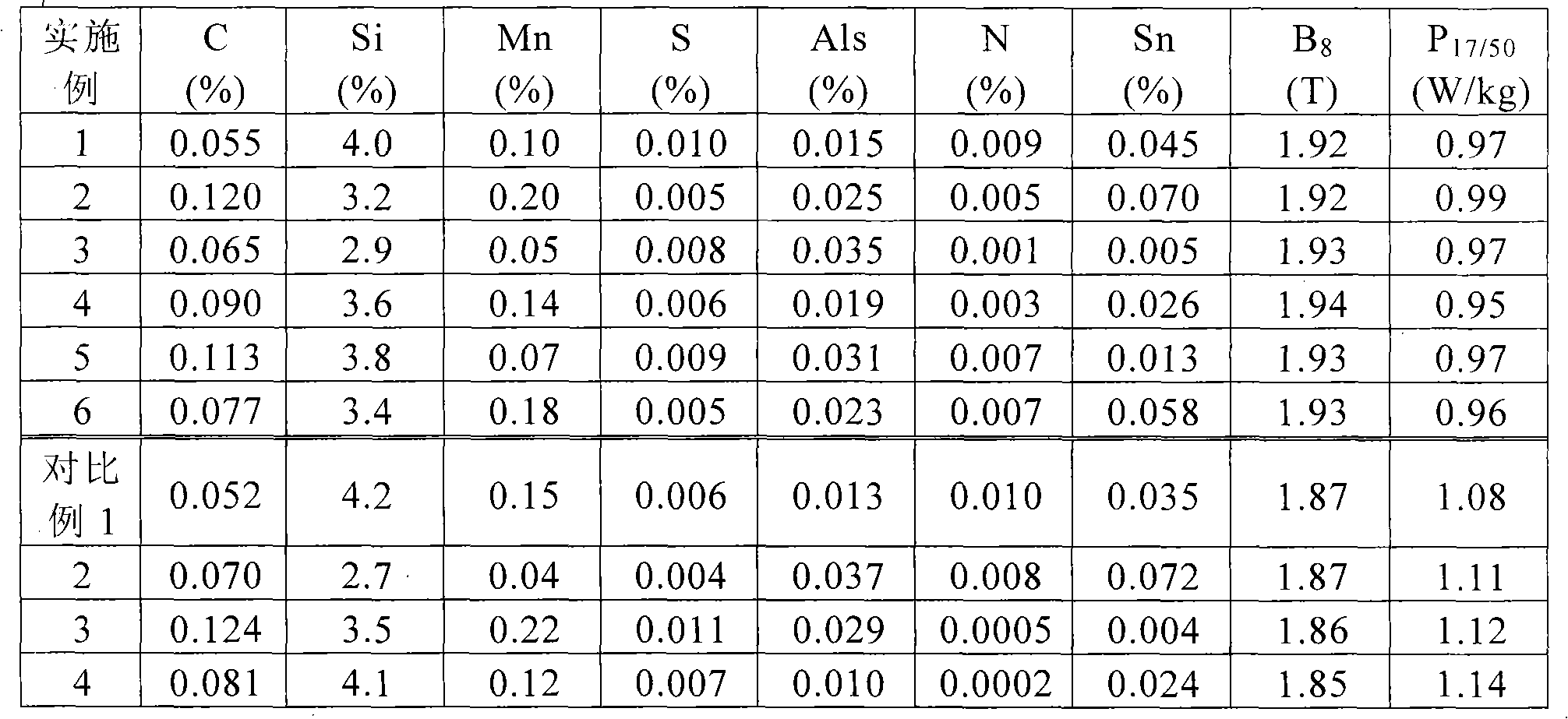

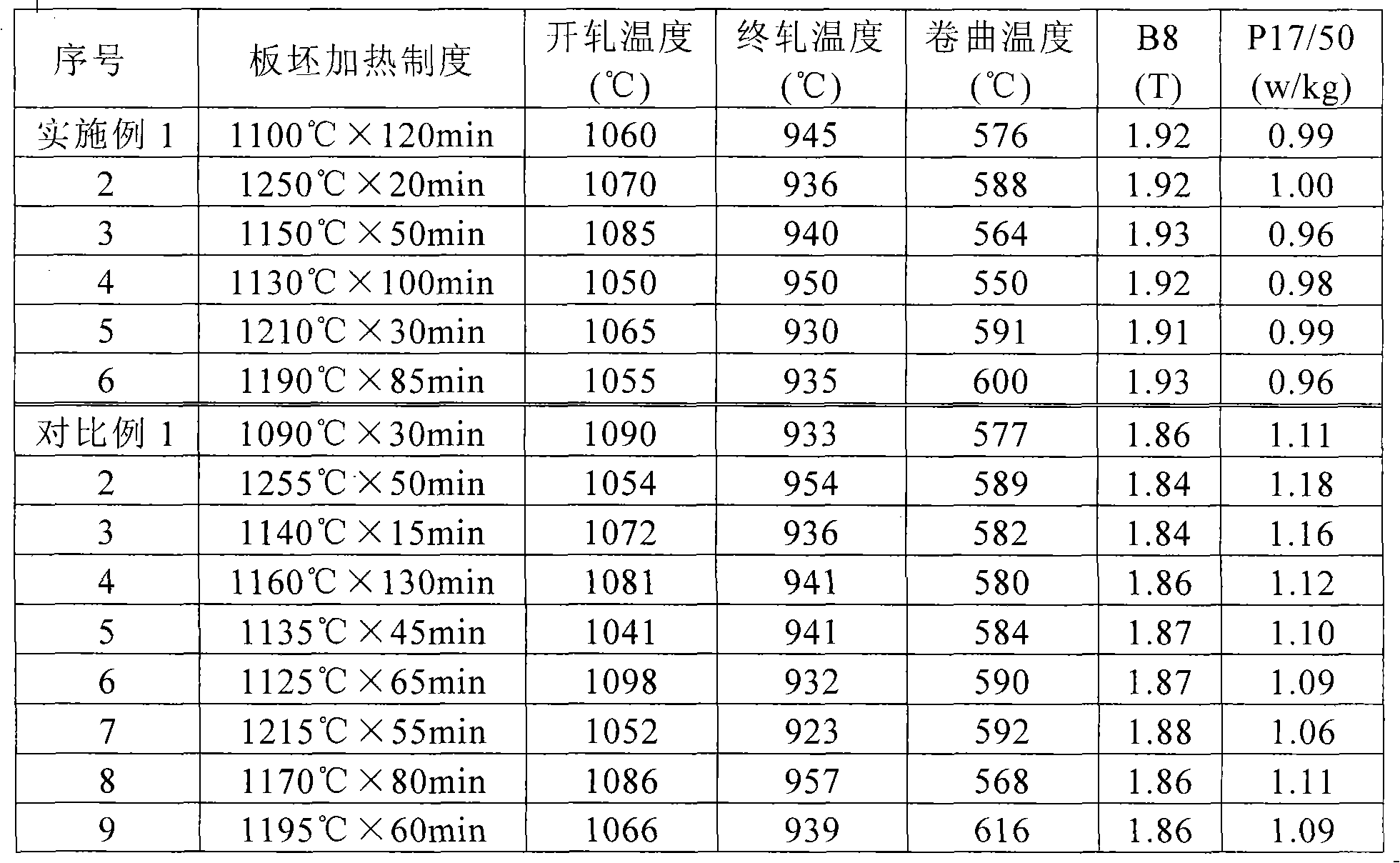

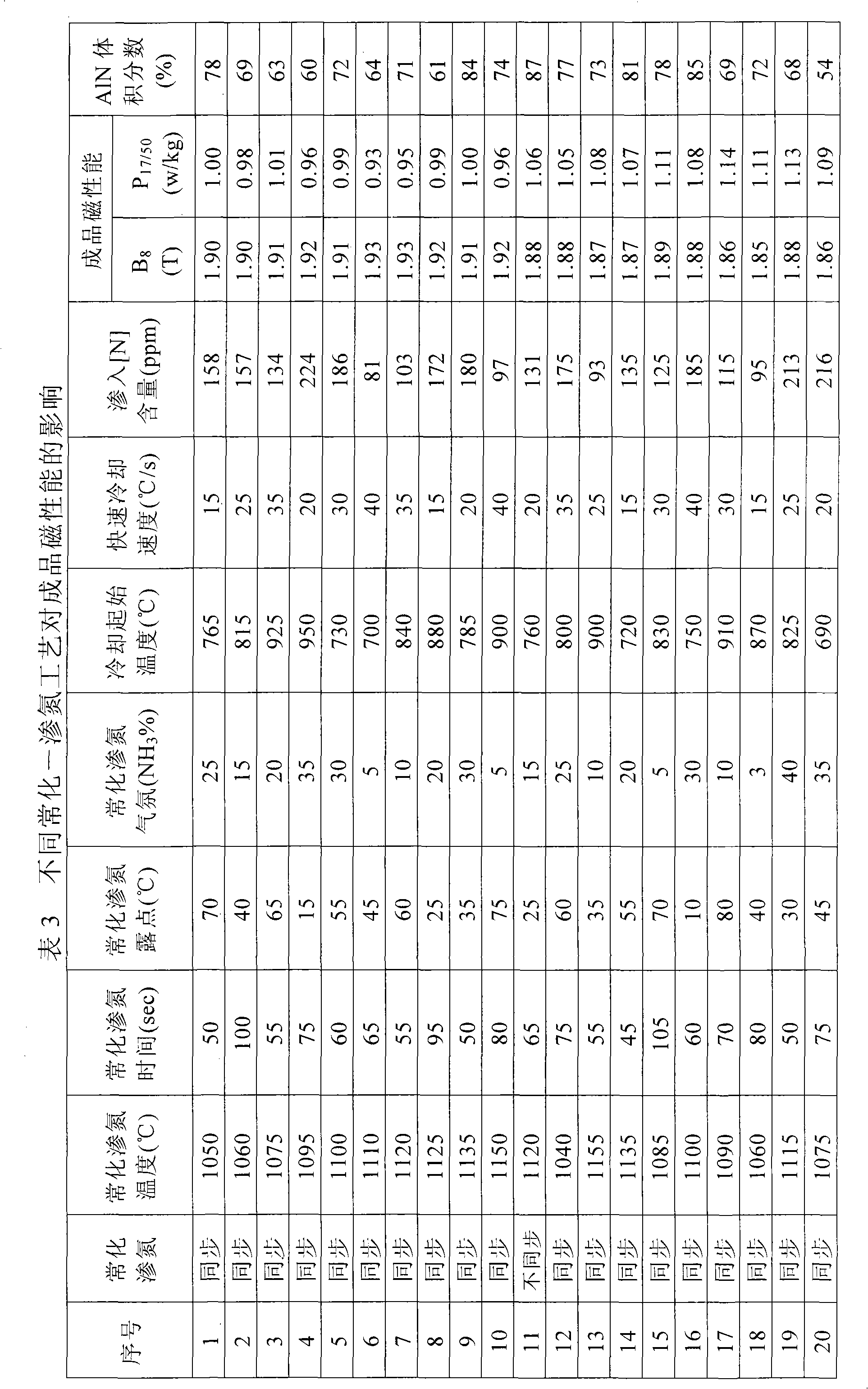

Production method of high magnetic induction oriented silicon steel

ActiveCN101845582AIncrease contentPrevent transverse crackingSolid state diffusion coatingSiliconAtmosphere

The invention relates to a production method of high magnetic induction oriented silicon steel, comprising the steps of smelting, continuous casting, hot rolling, normalization, decarbonization and annealing, MgO coating, high-temperature annealing and insulation coating, wherein the normalization comprises the steps that: normalization is carried out on a hot rolling plate, nitridation is finished synchronously, the temperature of normalization and nitridation is 1050-1150 DEG C, the atmosphere is 5-35% NH3 (volume percentage), and the balance of gas is N2; after the normalization and nitridation, the N content nitrided into the hot rolling plate is 60-250ppm; and normalization cooling is carried out, the initial temperature of fast cooling is 700-950 DEG C, and the fast cooling speed with the temperature of being reduced to 550 DEG C is 15-40 DEG C / sec. The production method solves the problem of difficult nitridation in the decarbonization procedure when a low-temperature plate blank heating technology is used for producing the high magnetic induction oriented silicon steel, carries out synchronous nitridation on the hot rolling plate in the normalization procedure, and leads the following procedure of decarbonization and annealing techniques to be simplified and easily controlled, thus not only being capable of obtaining a high magnetic induction oriented silicon steel product with excellent performance and simultaneously leading the production cost to be reduced.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for rolling thin high-strength steel plate of single-frame steckel mill

ActiveCN102179406ASolve the problem of excessive rolling forceSolve quick stopRoll force/gap control deviceTemperature control deviceFurnace temperatureSheet steel

The invention discloses a method for rolling a thin high-strength steel plate of a single-frame steckel mill. The method comprises the following steps: producing the finished product of a high-strength steel plate with a thickness less than 10 millimeters by using a blank with the thickness of 150 millimeters and the length more than 10 meters; and then acquiring the thin high-strength steel plate with qualified property and plate shape by controlling a tapping temperature, a coiler furnace temperature, a reduction in last pass, a roller force, a final rolling speed and a high pressure water de-scaling system. When the rolling method is used for producing the thin steel plate, the thin high-strength steel plate is rolled by utilizing the heat preservation function of front and back mill coiler furnaces and controlling the tapping temperature of the blank, the reduction in the last rolling pass, the roller force and the final rolling speed, and the acquired plate shape and property of the steel plate are both qualified, thereby increasing the rolling mill capacity and achieving high plate yield and high property yield.

Owner:NANJING IRON & STEEL CO LTD

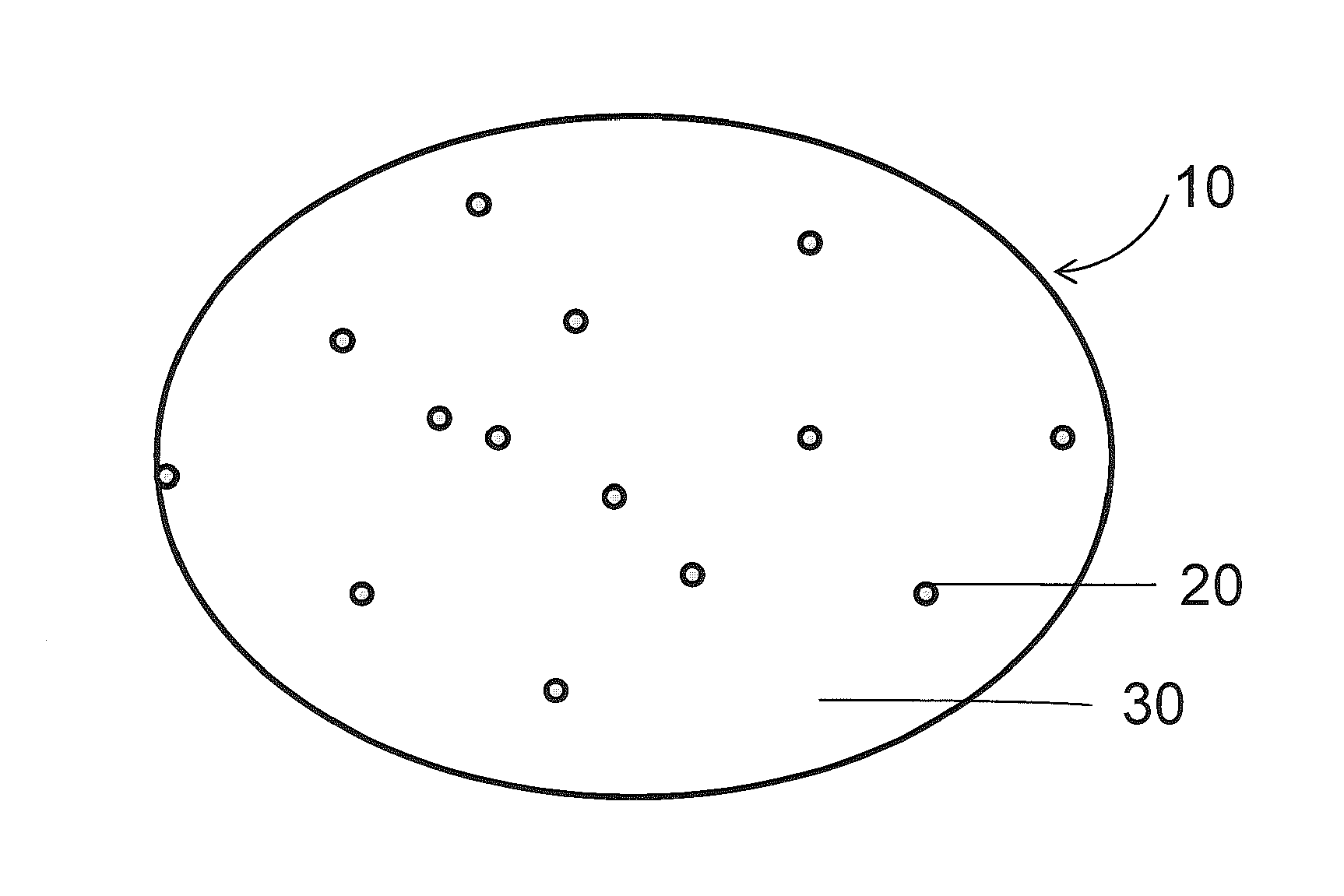

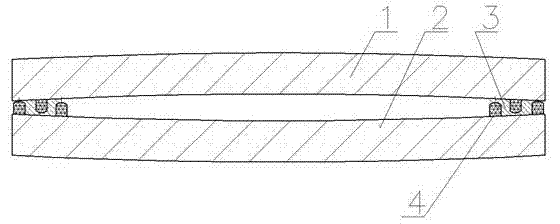

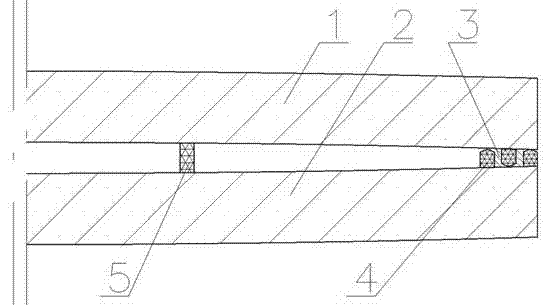

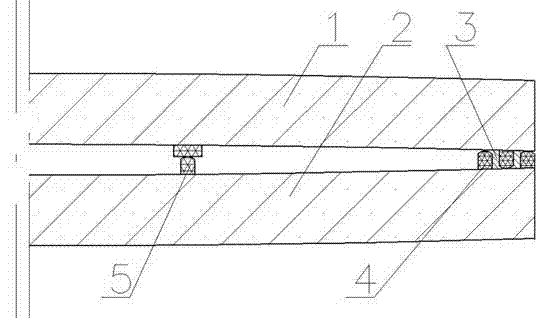

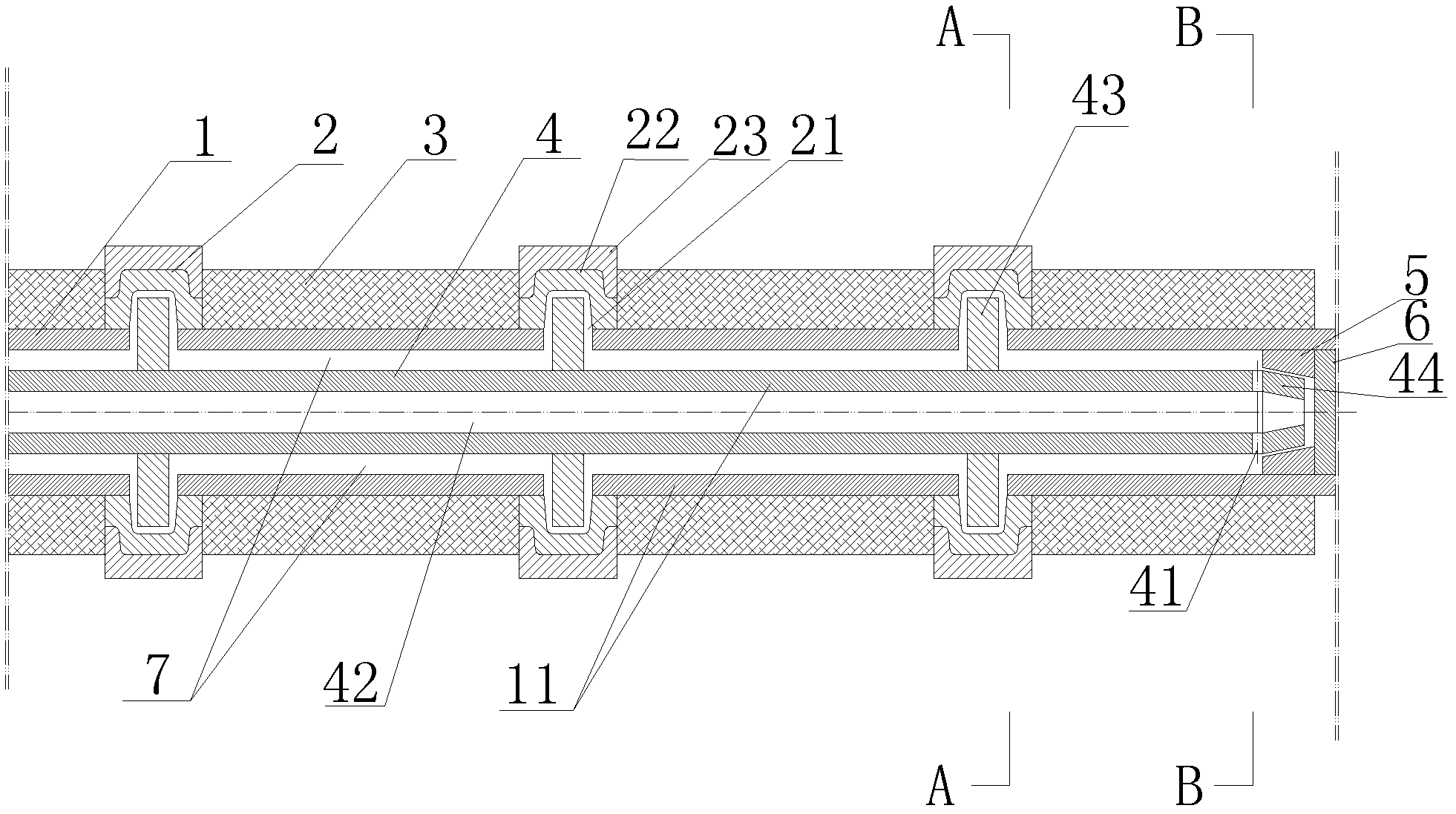

Flat vacuum glass welded by using metal welding material and provided with strip frame edge sealing, and manufacturing method thereof

InactiveCN102976592AExtend your lifeGuaranteed tightnessGlass reforming apparatusGlass productionAlloyGlass manufacturing

The present invention relates to a vacuum glass, which is characterized in that peripheries of an upper glass and a lower glass of the vacuum glass comprise edge sealing strip frames, and a metal welding material or an alloy welding material is adopted to integratedly weld the upper glass and the lower glass in a vacuum edge sealing furnace, such that vacuum glass manufacturing is simple, and a sealing effect is ensured through engagement of the upper edge sealing strip frame and the lower edge sealing strip frame. The manufacturing method has characteristics of simple process, low cost, high production efficiency, reliable sealing and good sealing effect. With the technology, large mass manufacturing of the vacuum glass with no gas exhaust port through the one-step method can be achieved. In addition, with the method, the universal vacuum glass can be manufactured, and the tempered vacuum glass can be manufactured.

Owner:戴长虹

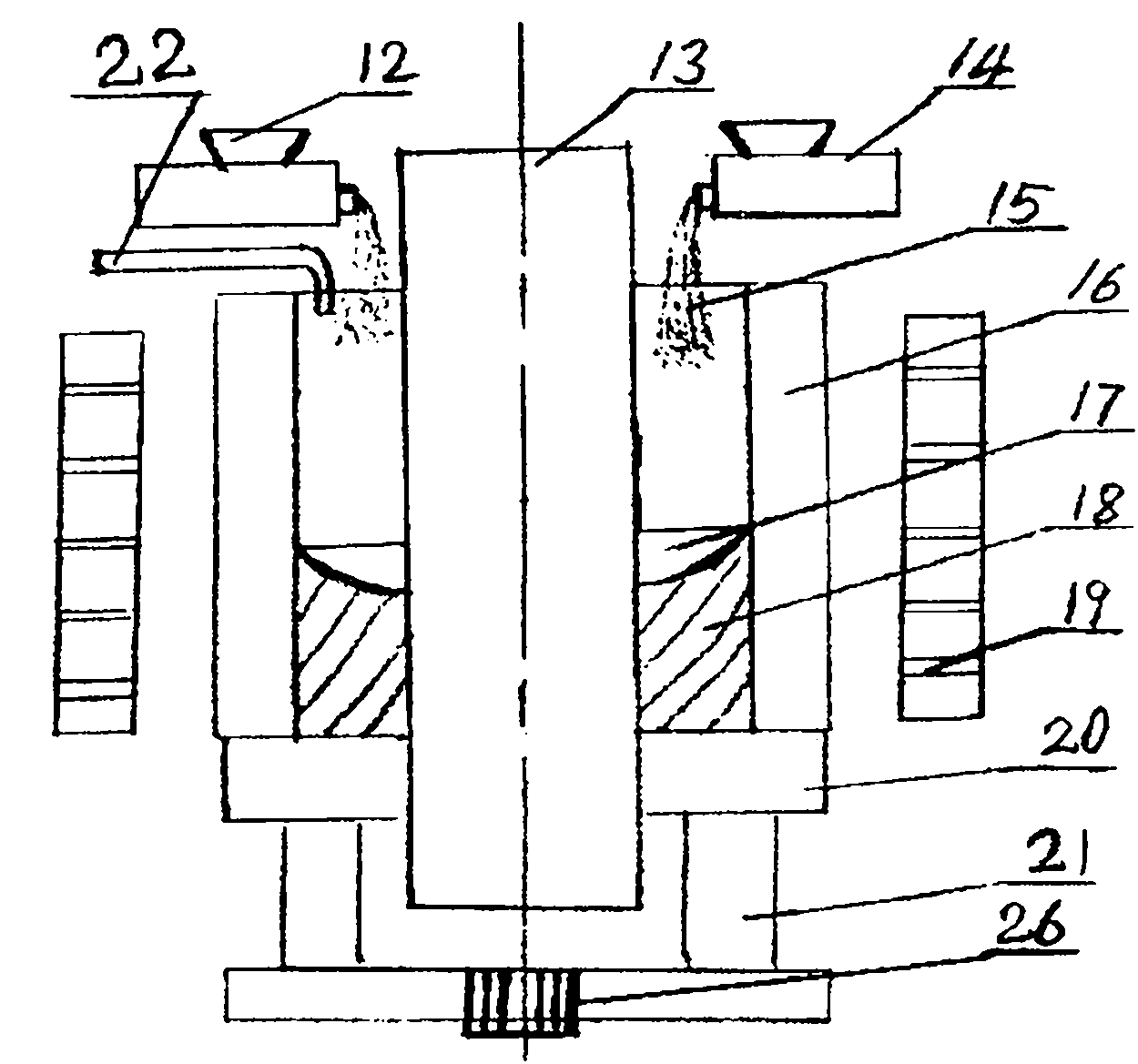

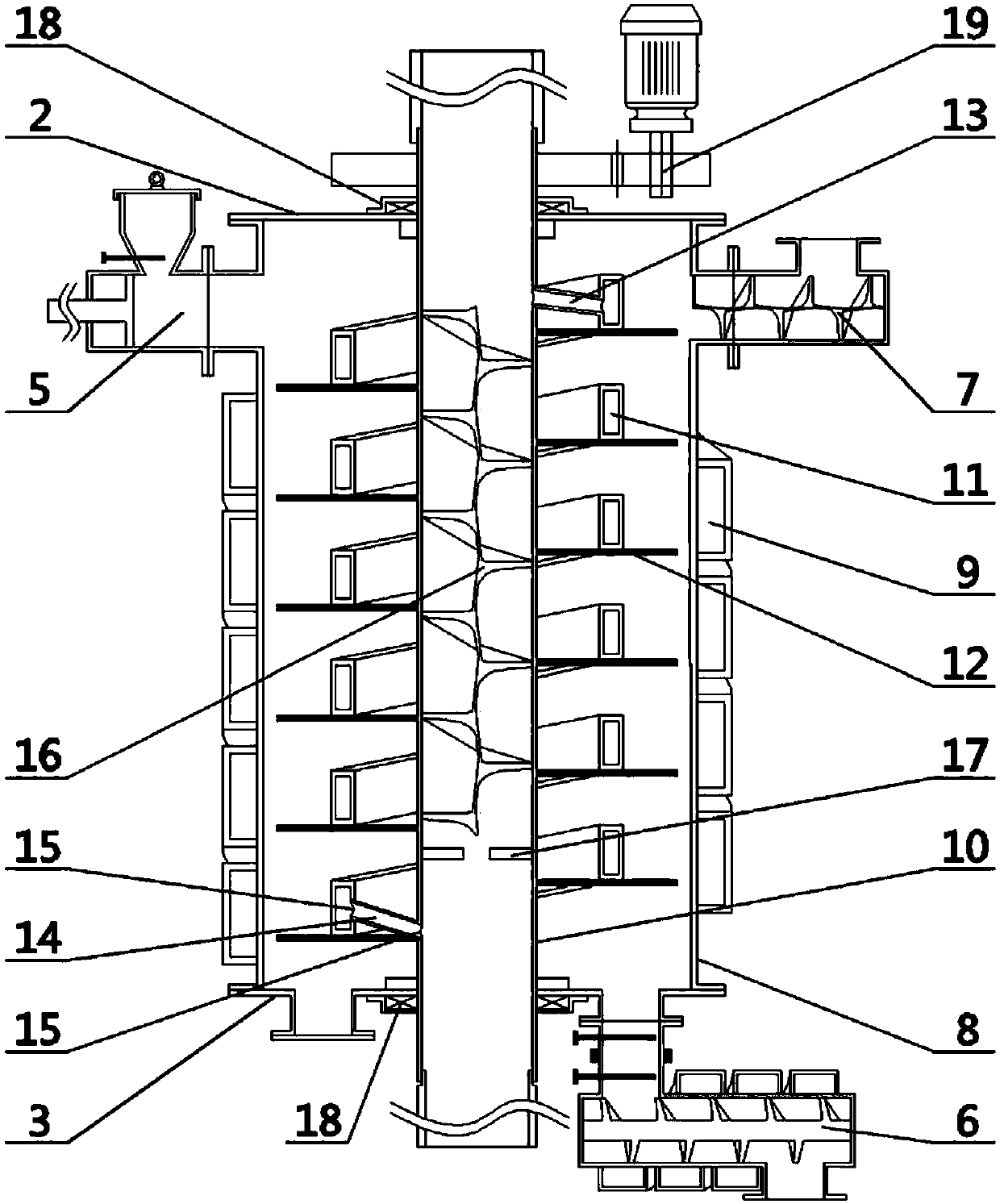

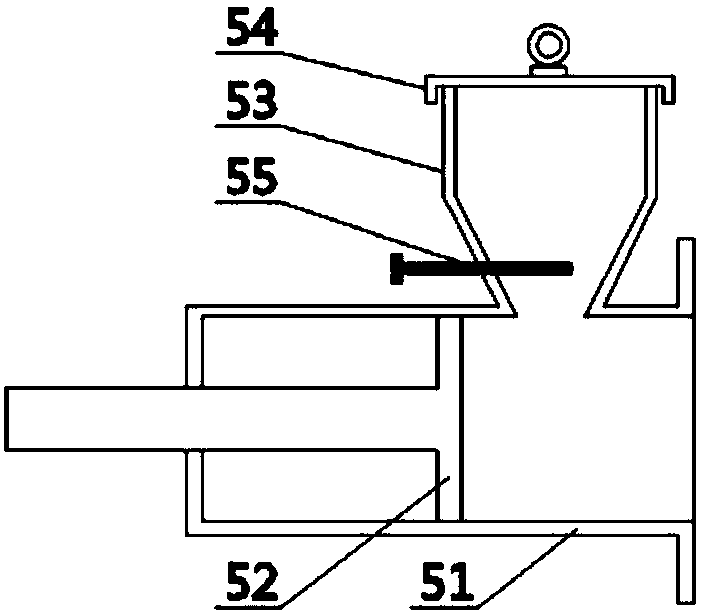

Vertical multidirectional heating organic solid waste pyrolysis device

ActiveCN107649491AExtended stayRelease fullyTransportation and packagingSolid waste disposalSlagEngineering

The invention discloses a vertical multidirectional heating organic solid waste pyrolysis device. Closed pyrolysis space is formed among an outer barrel body, an inner barrel body, an upper end coverand a lower end cover of the device. A spiral coiled pipe serving as an outer heating channel is coiled on the outer wall of an outer barrel of the device, and a feeding opening connected with a feeding device and a gas outlet connected with a pyrolysis gas guide-out device are formed in the outer side face of the upper portion of the outer barrel. A spiral pipe barrel is coiled on the periphery of a center barrel of the device, the spiral pipe barrel is fixed through blades on the outer side of the center barrel, the two ends of the spiral pipe barrel communicate with the center barrel, a spiral plate is arranged in the center barrel, and therefore a heating gas spiral channel is formed in the center barrel, and a flow limiting hole plate is arranged below the spiral plate. The center barrel is driven by a variable frequency motor, and the lower sealing cover is provided with a slag outlet connected with a slag outlet device. The vertical multidirectional heating organic solid waste pyrolysis device is provided with an inner heating heat source and an inner heating heat source, the inner heat source is divided into a center heat source and a middle heat source, and the pyrolysis device guarantees material anaerote continuity. By means of the spiral channel, the heating area and the heating gas retention time are greatly increased, heat can be fully released, and the productioncapacity can be improved.

Owner:青岛伊诺威能源化工新技术有限公司

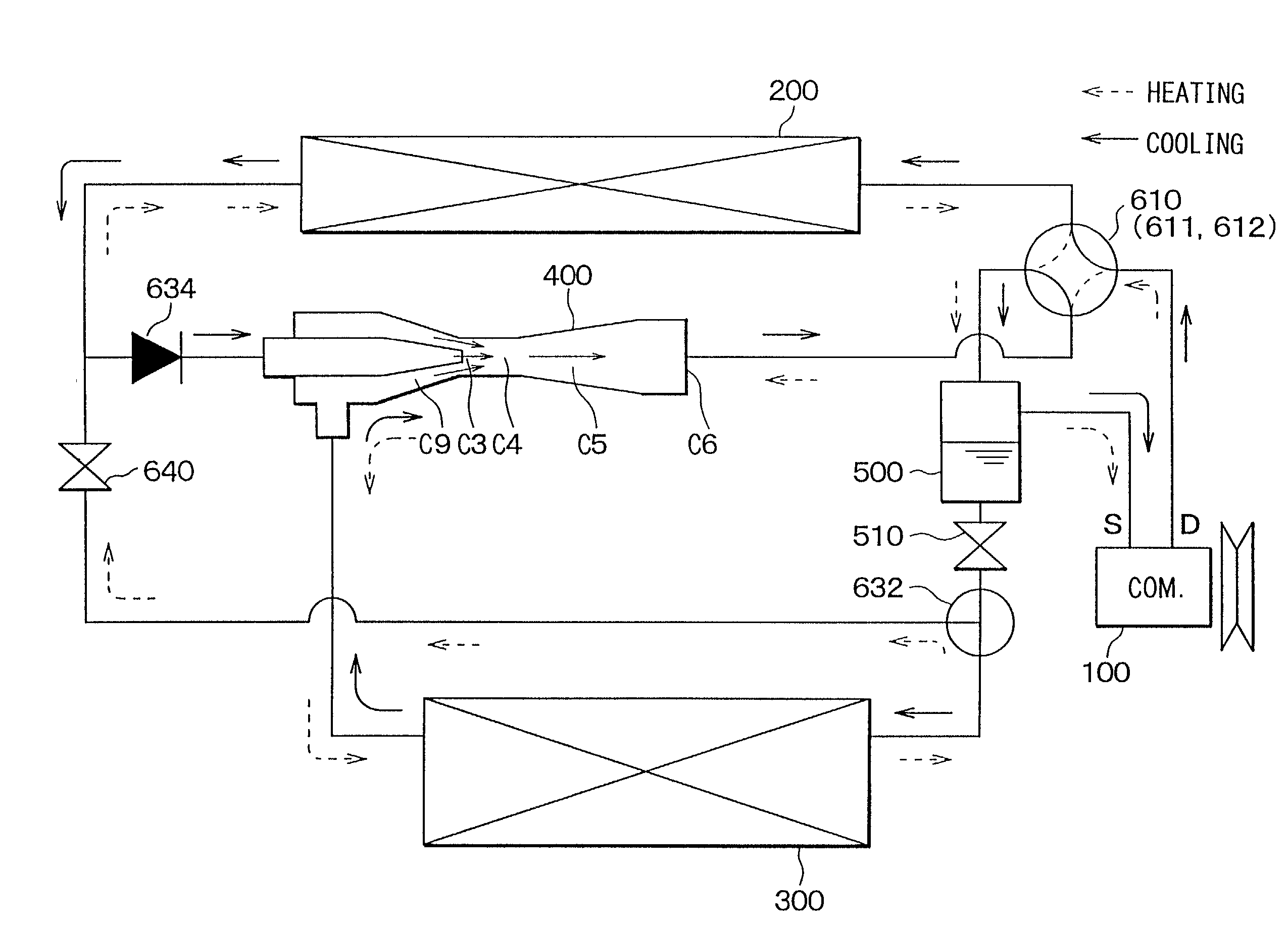

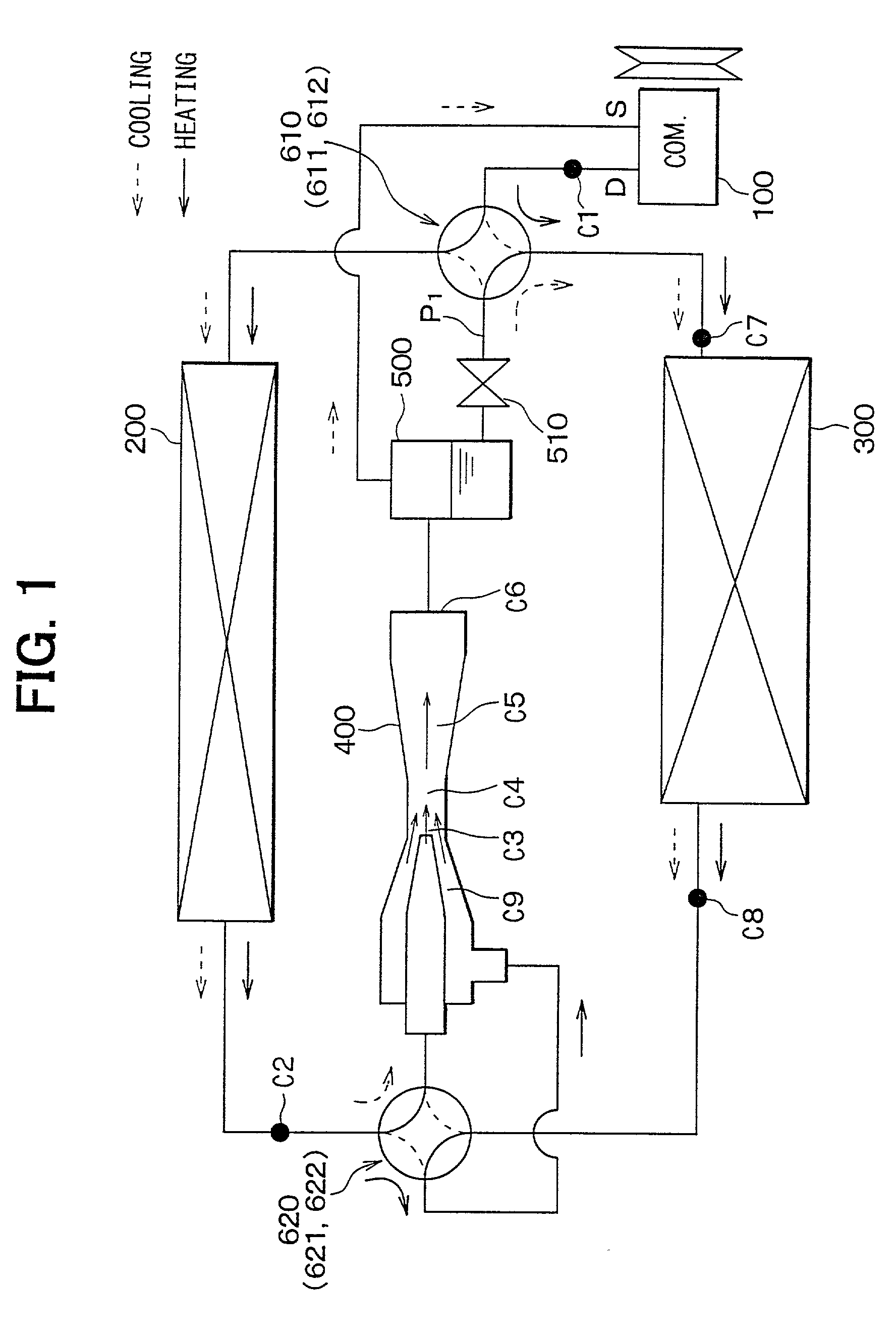

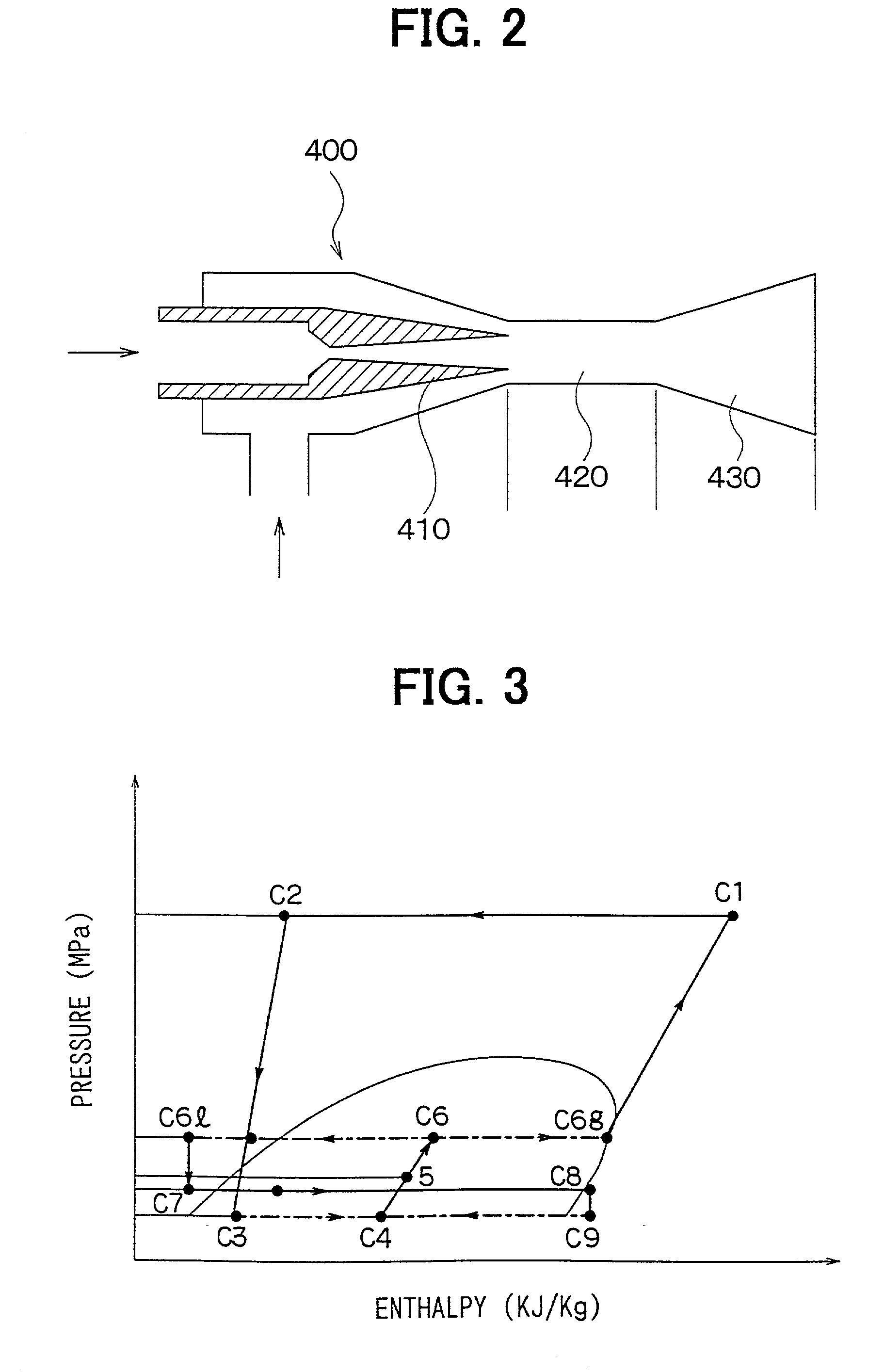

Ejector cycle system

InactiveUS20020124592A1High heating temperatureImprove performanceCompression machines with non-reversible cycleVehicle heating/cooling devicesEngineeringHigh pressure

In an ejector cycle system, high-pressure side refrigerant is decompressed by an ejector in cooling operation for cooling a compartment, and is decompressed by a fixed restrictor in heating operation for heating the compartment. Therefore, in the heating operation, the pressure of refrigerant to be sucked into a compressor can be made lower, and the temperature of refrigerant discharged from the compressor is increased. Alternatively, in the cooling operation, a flow direction of refrigerant flowing through at least one of an exterior heat exchanger and an interior heat exchanger is identical to that in the heating operation.

Owner:DENSO CORP

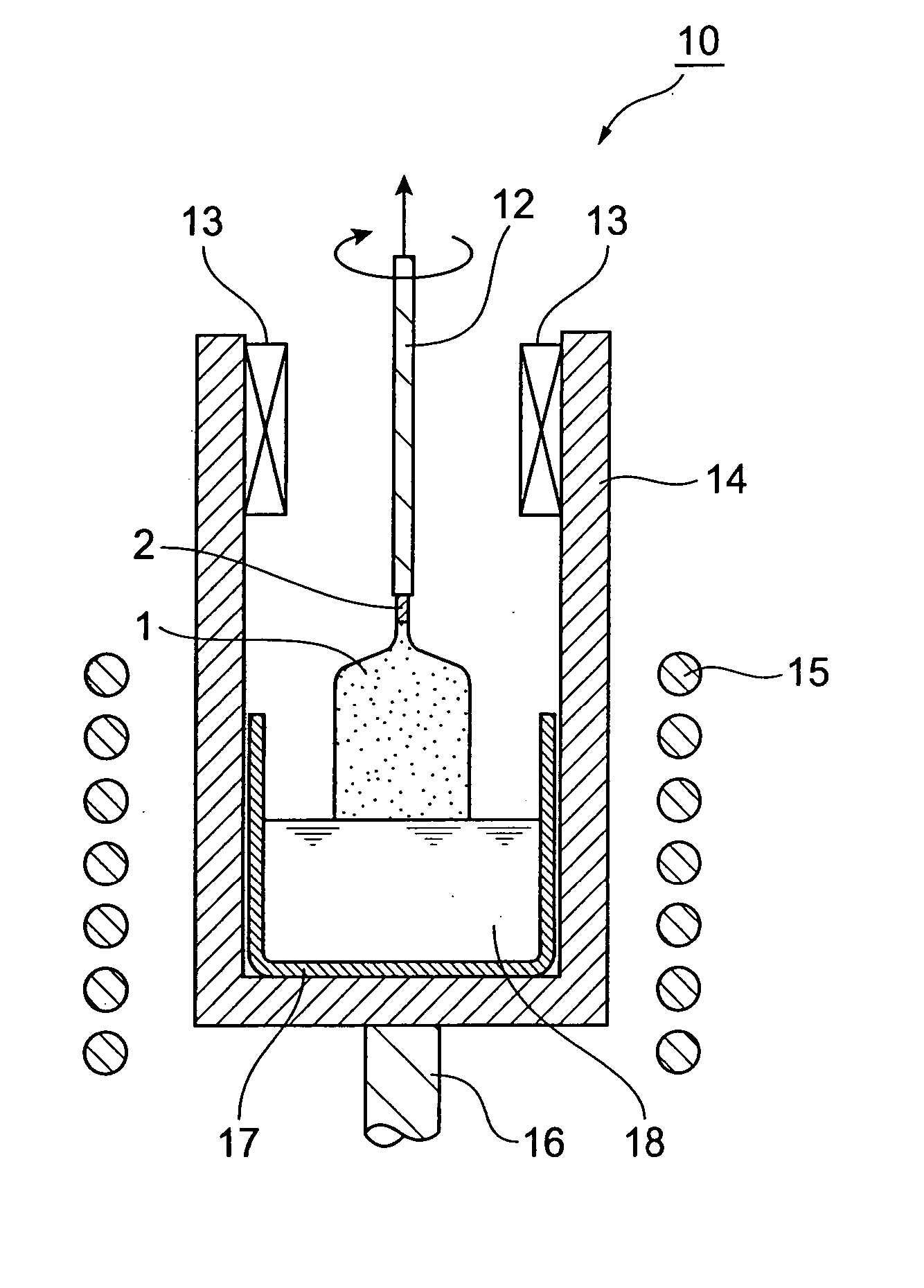

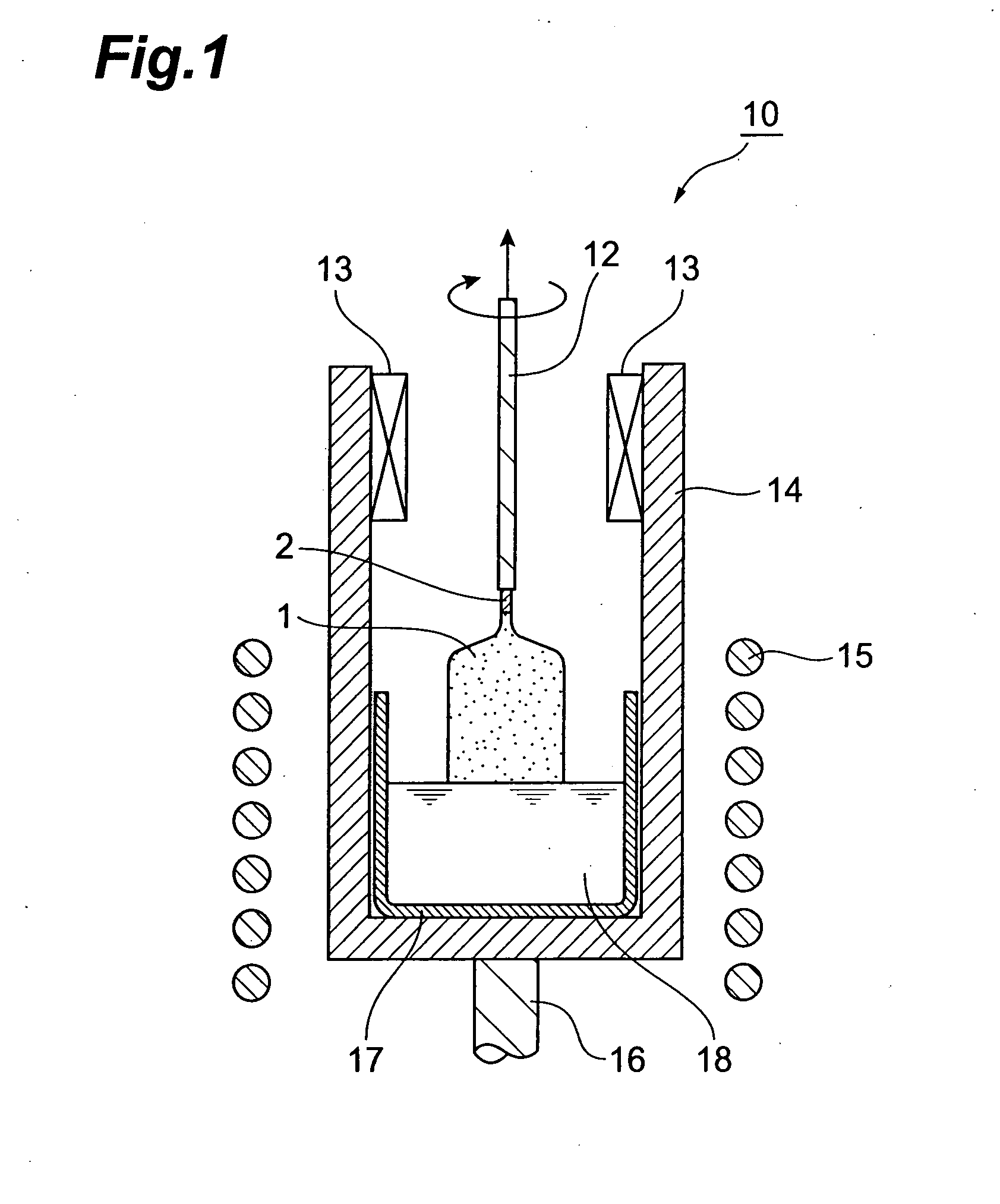

Scintillator single crystal and process for its production

InactiveUS20070292330A1Improve variationImprove light outputPolycrystalline material growthBy pulling from meltCeriumSingle crystal

The scintillator single crystal of the invention is a specific cerium-activated silicate single crystal wherein the total content of one or more elements selected from the group consisting of elements belonging to Groups 4, 5, 6 and Groups 14, 15, 16 of the Periodic Table is no greater than 0.002 wt % based on the total weight of the single crystal.

Owner:HITACHI CHEM CO LTD

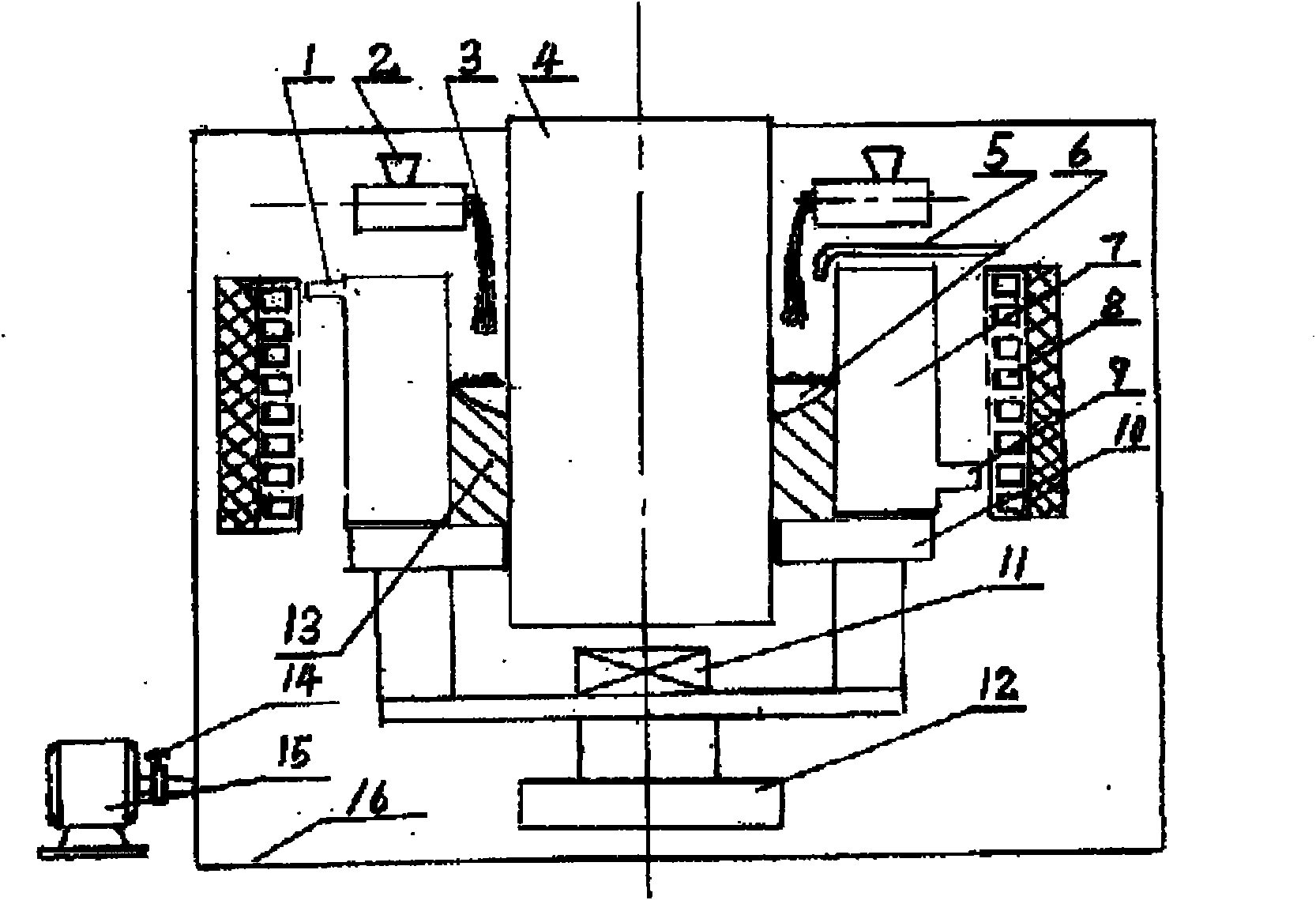

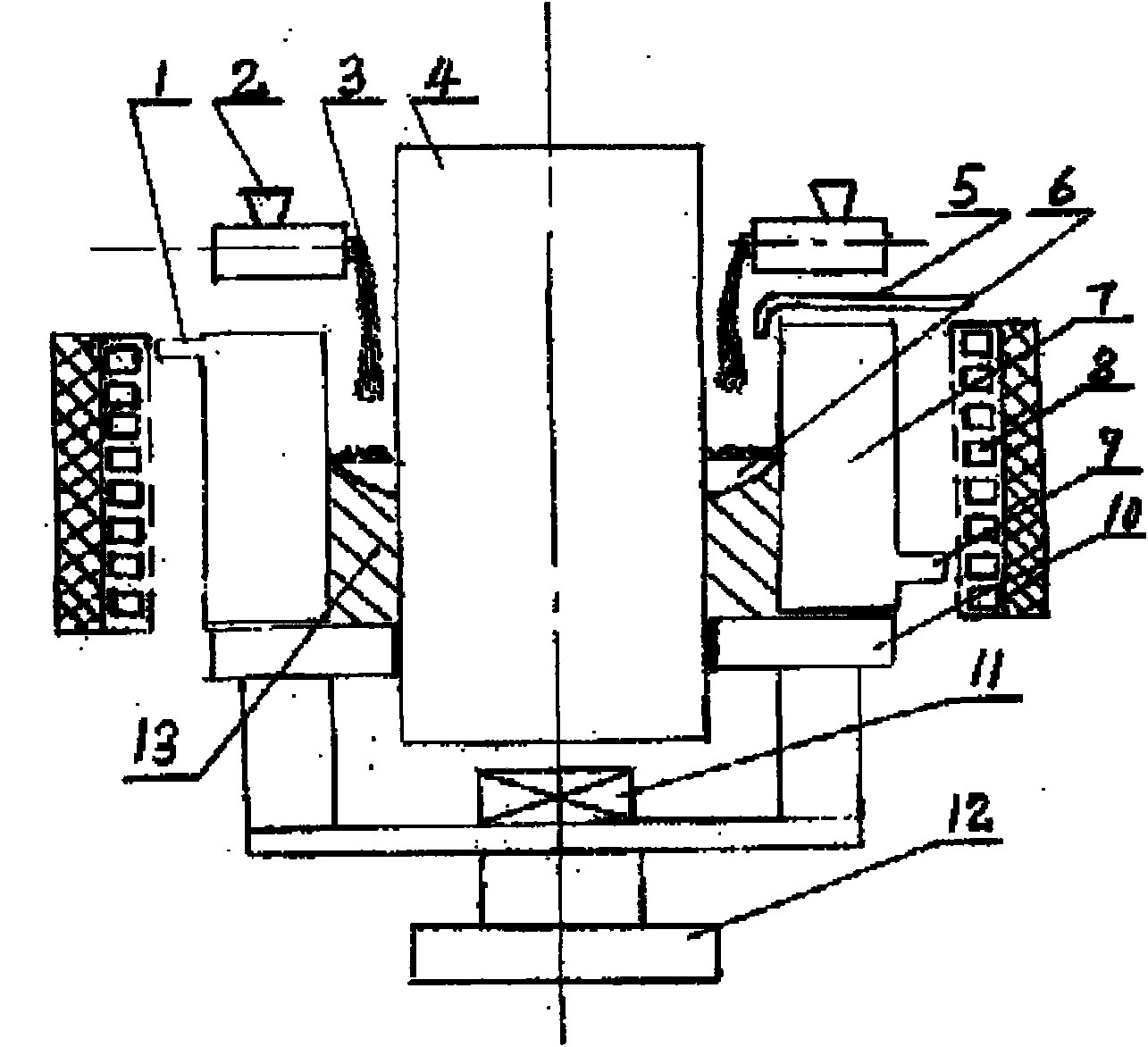

Micro-nano-alloy bimetal composite material preparation technique and device thereof

The invention relates to a micro-nano-alloy bimetal composite material preparation technique and a device thereof; one of wear-resistant and corrosion-resistant ferrous metal material, non-ferrous metal material and various self-fluxing alloy is prepared into power; then, the powder is added with less than or equal to 0.8% of one or combination in CeO2, Y2O3 and La2O3, 0.3-1.5% of MgO, 0.3-1.8% of CaF2, 0.0-1.5% of B, 0.1-0.8% of Nb, 0.1-1.0% of Ti, 0.1-2.0% of grain refining and recrystallization inhibitor according to the mass percent; or the powder is added with 1-40% of carbide, nitride, micro-nano or nano particles of boride; and the mixture is put into a high-energy stirring ball grinding mill for grinding and ball milling, so that the micro-nano or nano alloy powder can be prepared. A variable frequency induction heating device is adopted for cladding and melting vacuum or inert gas, so that a workpiece can be melted and coated with a micro-nano or nano scale alloy cladding layer which has the grain size of 0.1-35mm and is wear-resistant and corrosion-resistant, and the bimetal composite material can be prepared. The invention overcomes the defects in various coating techniques in China at present, can complete the preparation of the workpiece with the cladding layer having high thickness for once, does not need repeated coating and sintering, has high material utilization rate, low machining allowance and preparation cost, simple preparation technique and high production efficiency.

Owner:泰州海天机械配件有限公司

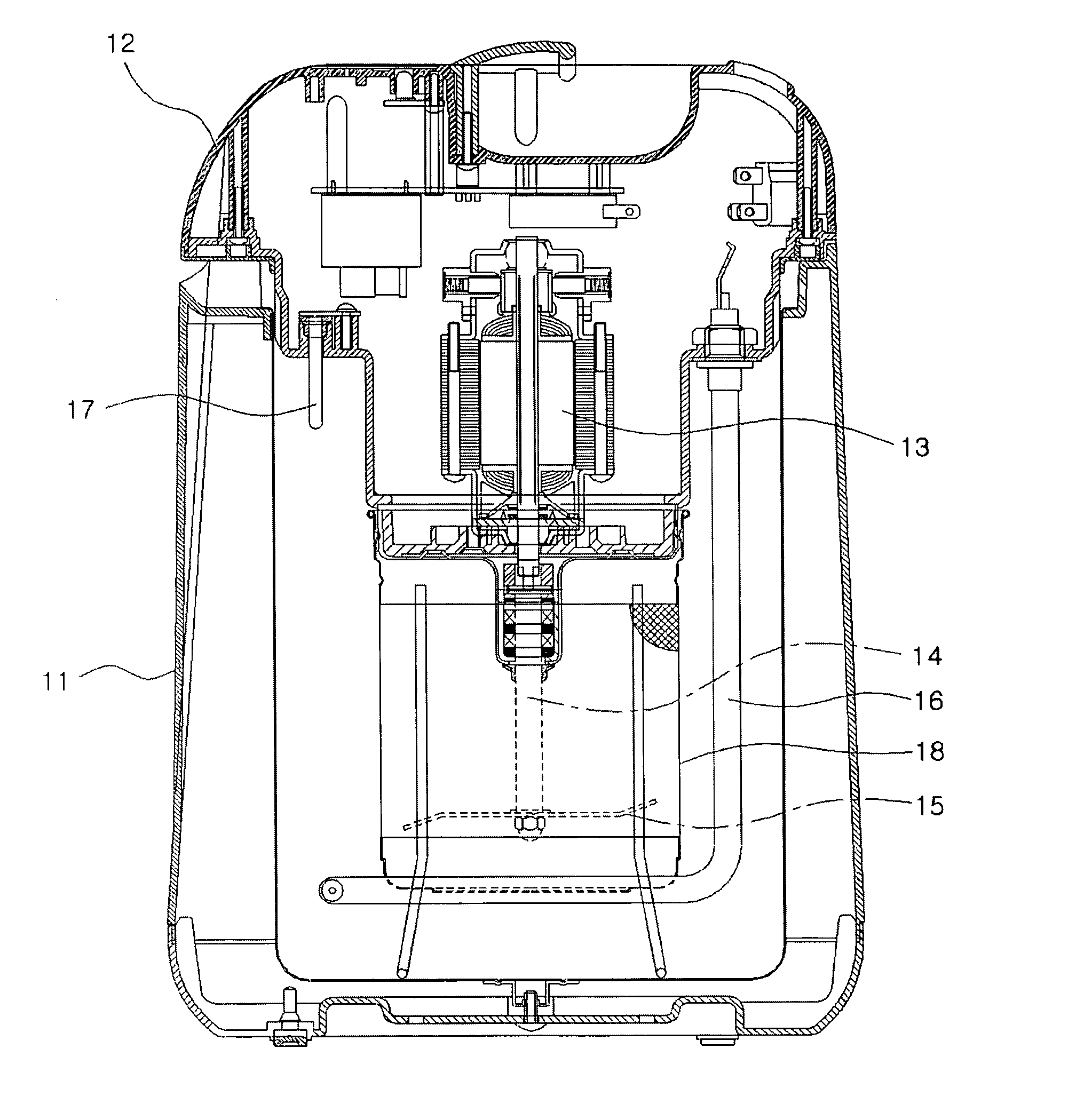

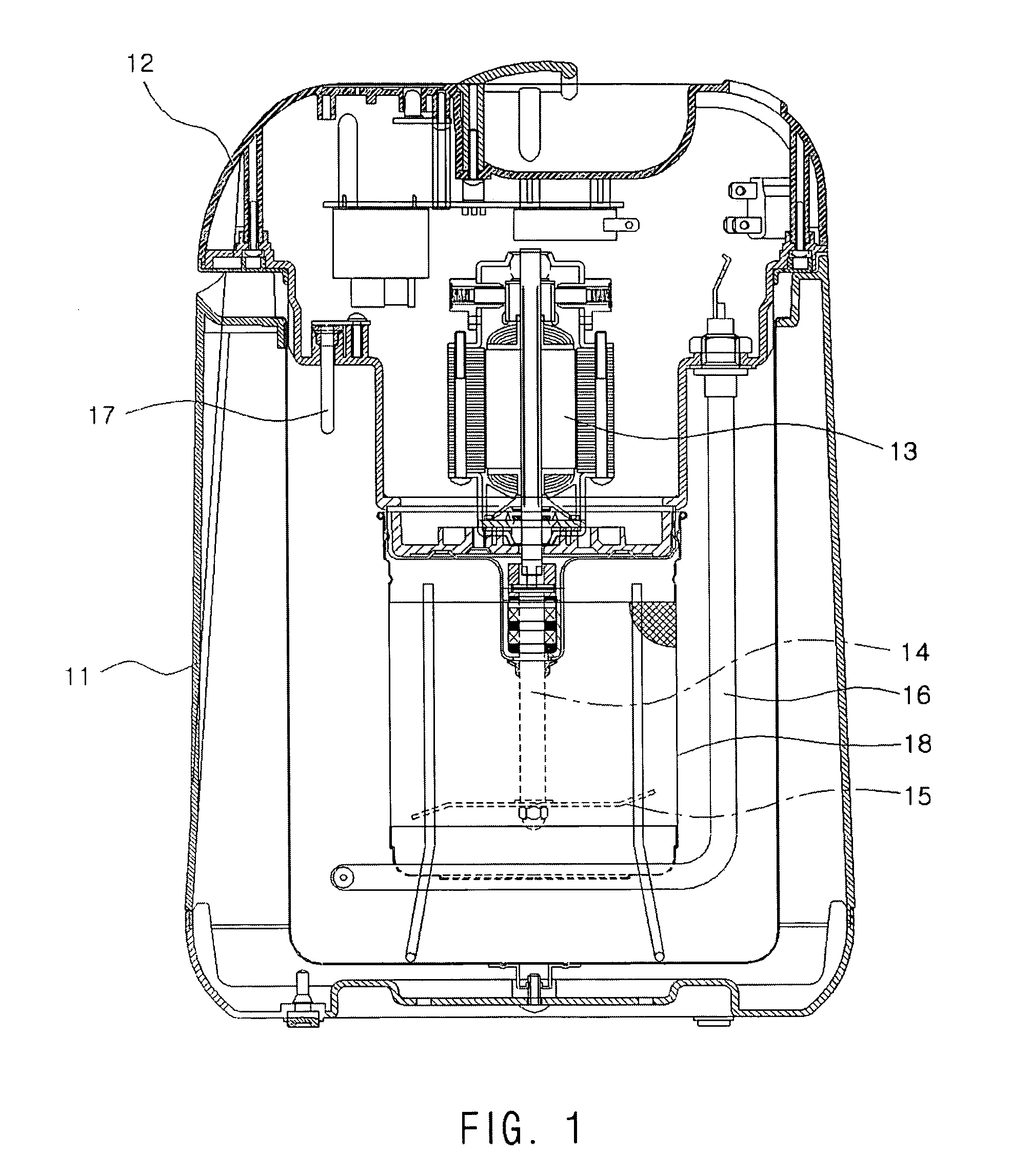

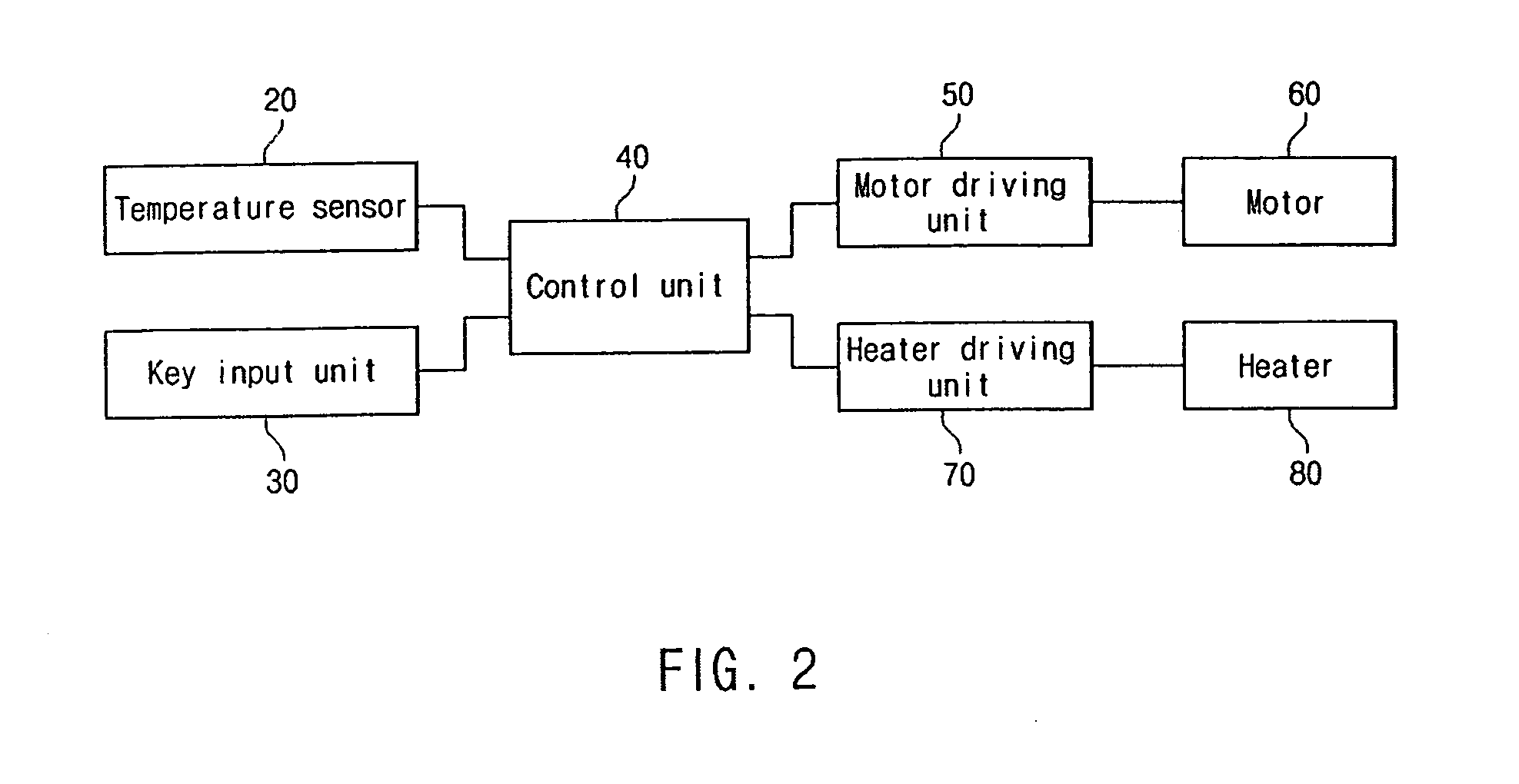

Heating control apparatus and method for controlling household bean milk and bean curd makers

InactiveUS20050051032A1Reduce power consumptionHigh heating temperatureBoiling over preventionBeverage vesselsAgricultural engineeringGround-bean

Heating control apparatus and method for controlling household bean milk and bean curd makers, which set a primary heating temperature to be relatively low, thus preventing beans from being excessively finely ground during a grinding process while reducing power consumption, in use. The control apparatus and method set a secondary heating temperature to be relatively high to heat the beans for a short period of time, in use, in a household bean milk and bean curd maker, thus sufficiently boiling the ground beans while reducing power consumption. A temperature sensor senses a temperature and a key input device allows a user to input commands. A control increases a primary heating temperature sufficiently to prevent beans from being excessively finely ground, and maintains a secondary heating temperature sufficiently long after the beans are ground, to cause the beans to be sufficiently boiled, while reducing power consumption.

Owner:KIM HONG BAE

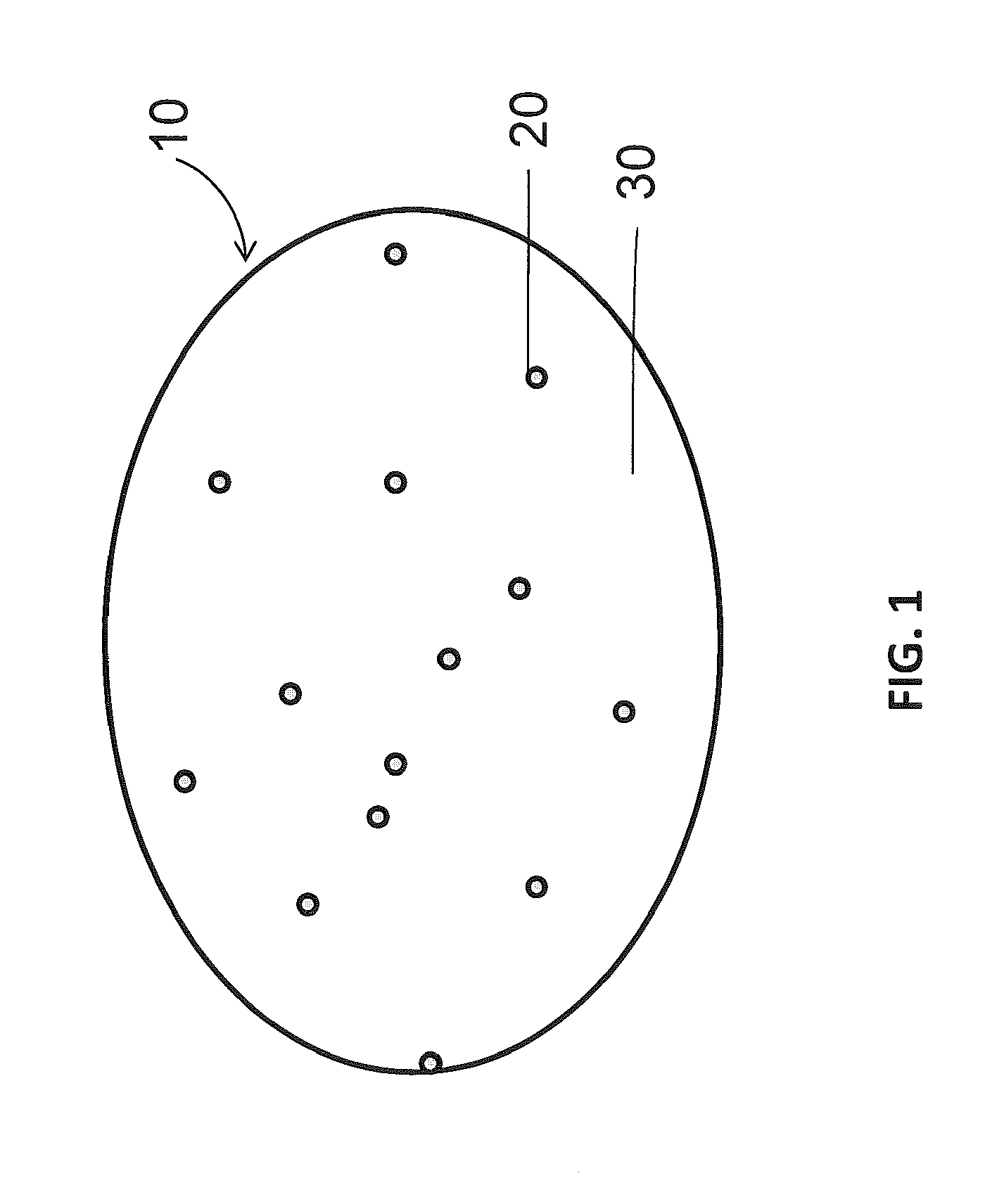

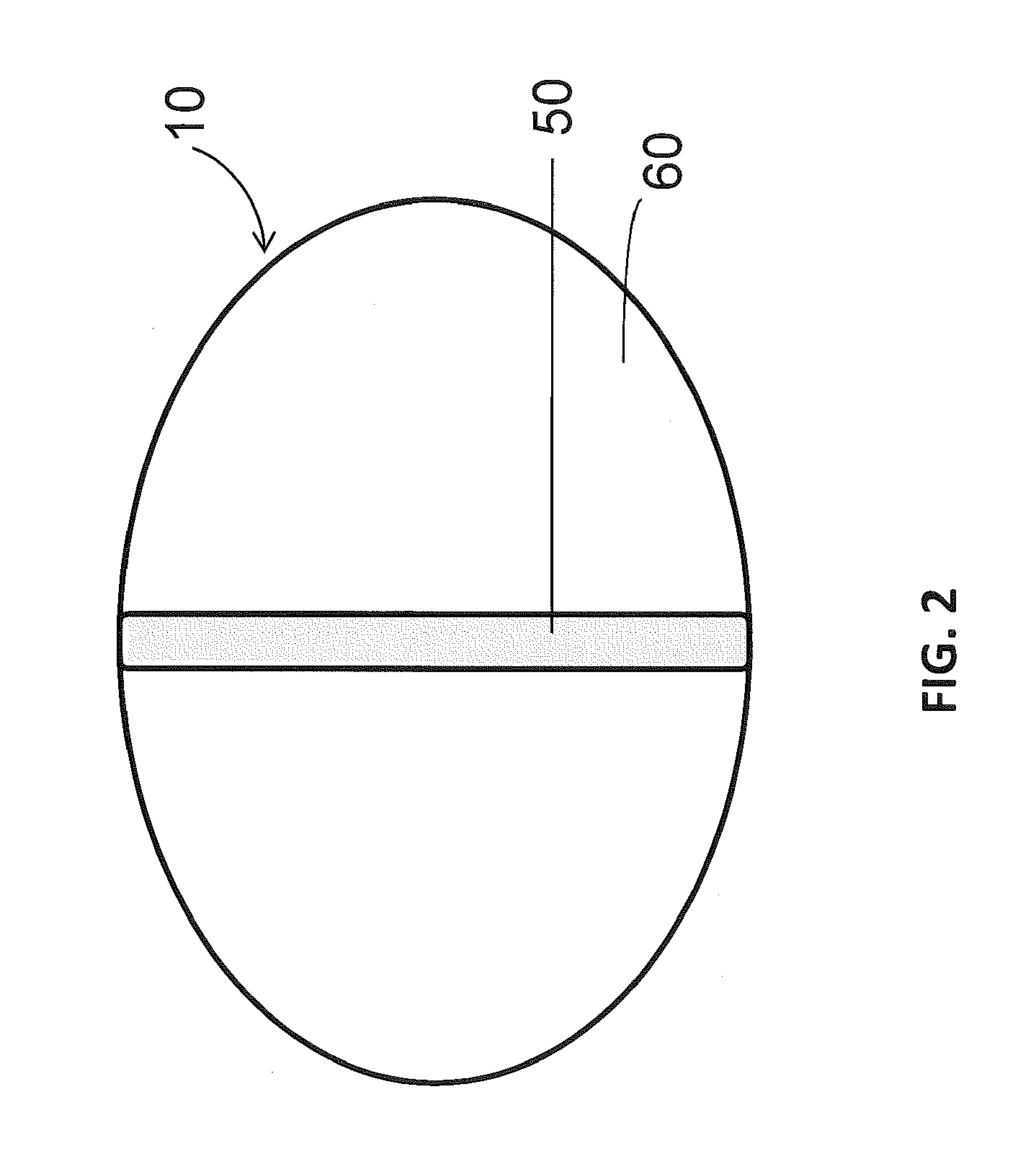

Metal solder-welded and strip frame-edge-sealed convex vacuum glass and manufacturing method thereof

InactiveCN102951826AReduce tensile stressHigh transparencyGlass reforming apparatusGlass productionMetalEdge banding

The invention relates to vacuum glass. The vacuum glass is characterized in that each of upper glass and lower glass is convex surface glass, edge sealing strip frames are arranged at the welded peripheries of the upper glass and the lower glass, and the upper glass and the lower glass are welded together by utilizing metal or alloy solder in a vacuum edge sealing furnace; and the manufacturing of the vacuum glass is simpler and more convenient, and the matching of the upper and the lower edge sealing strip frames can ensure a good sealing effect. The method has the advantages of simpleness in manufacturing process, low cost, high production efficiency, reliability in sealing and connecting and good sealing effect; the one-step large-batch preparation of the vacuum glass without exhaust ports can be realized by utilizing the technology, and the manufactured vacuum glass is strong in resistance to wind pressure and good in heat insulation and sound insulation; and the method can be used for manufacturing the ordinary vacuum glass and is particularly suitable for manufacturing tempered vacuum glass.

Owner:戴长虹

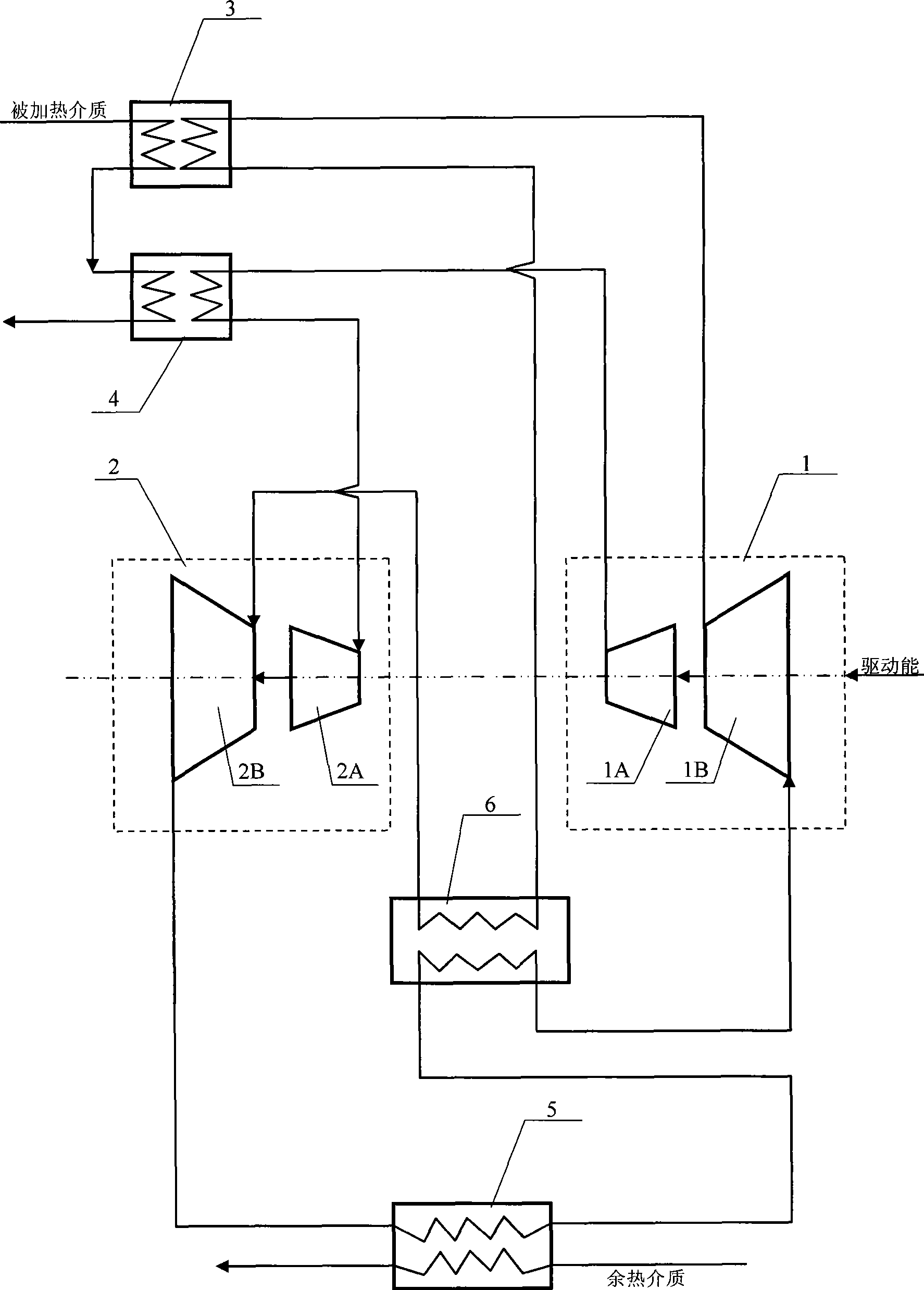

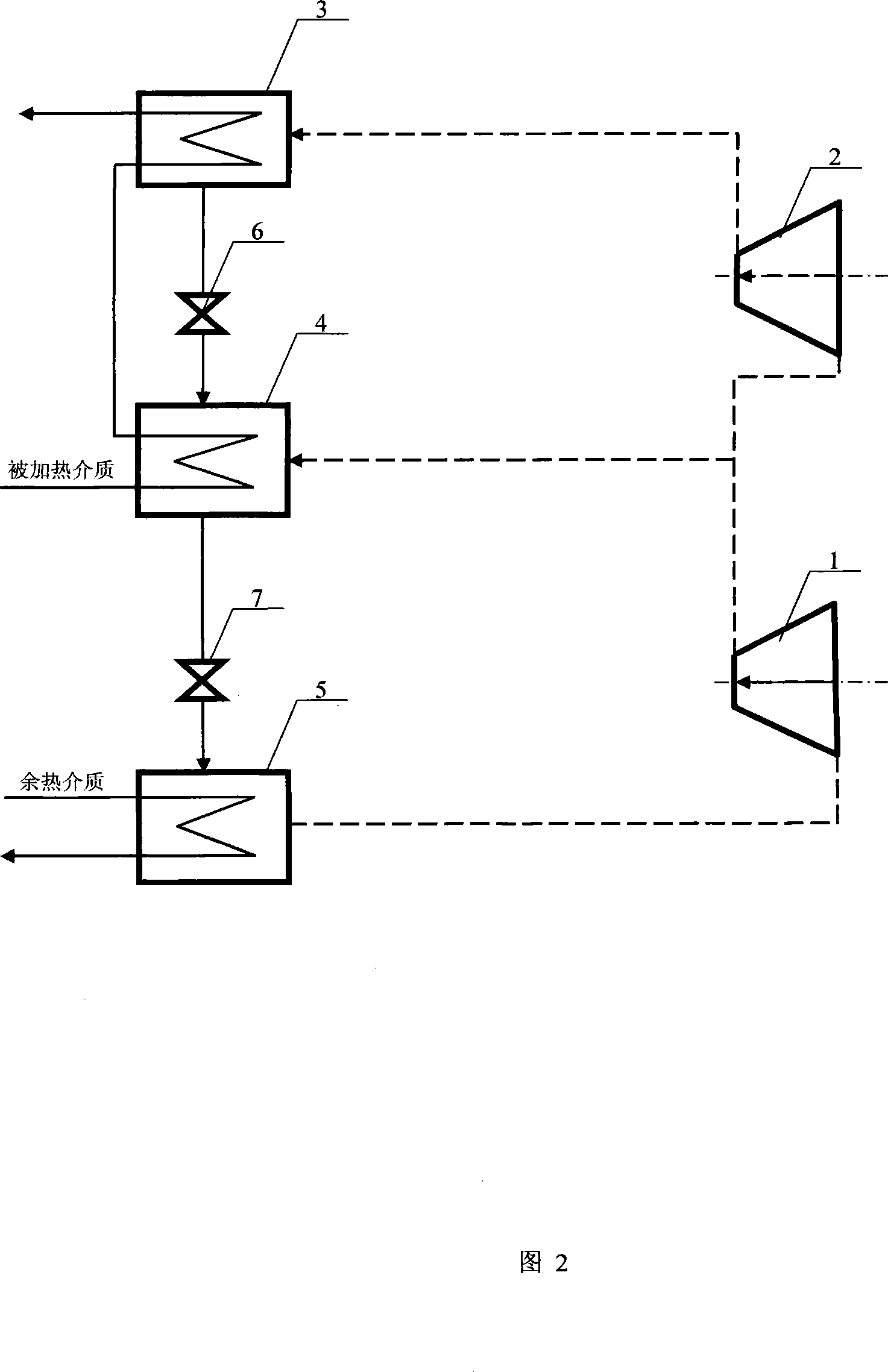

Grade compression-segmenting heat-taking type steam compression heat pump

ActiveCN101226013AImprove performance indexLow performance indexHeat pumpsCompression machines with cascade operationTemperature differenceEngineering

The invention provides a multistage compression and stepwise heat utilization steam compression heat pump, which belongs to the technical field of waste heat utilization and heat pump refrigeration. Aiming at the shortcomings of the single condensation to heat release unit in stage compression and inter-stage cooling, the heat pump provides the steam compression unit which comprises two or more compressors, two or more condensers, an evaporator and a throttle valve, and the steam compression unit can implement condensation and heat release to outside respectively by each compression and heat moving flow. A low temperature compression and heat release flow is composed of a low-pressure compressor and condenser, a throttle valve and a evaporator; a high-temperature compression and heat moving flow is composed of a high-pressure compressor and condenser, a throttle valve and other parts by virtue of the structure of the low-temperature compression and heat moving flow; the residual heat medium can release heat by flowing through the evaporator; the heat medium absorbs heat by flowing through the each compression and heat moving flow. The multistage compression and stepwise heat utilization steam compression heat pump has the advantages that: the heat transfer temperature difference is reduced; the unit performance index is improved; while being used as a heat pump, the heat pump is particularly suitable for the occasion with high heat supply temperature and wide range, and can be used for refrigeration and power consumption reduction.

Owner:李华玉

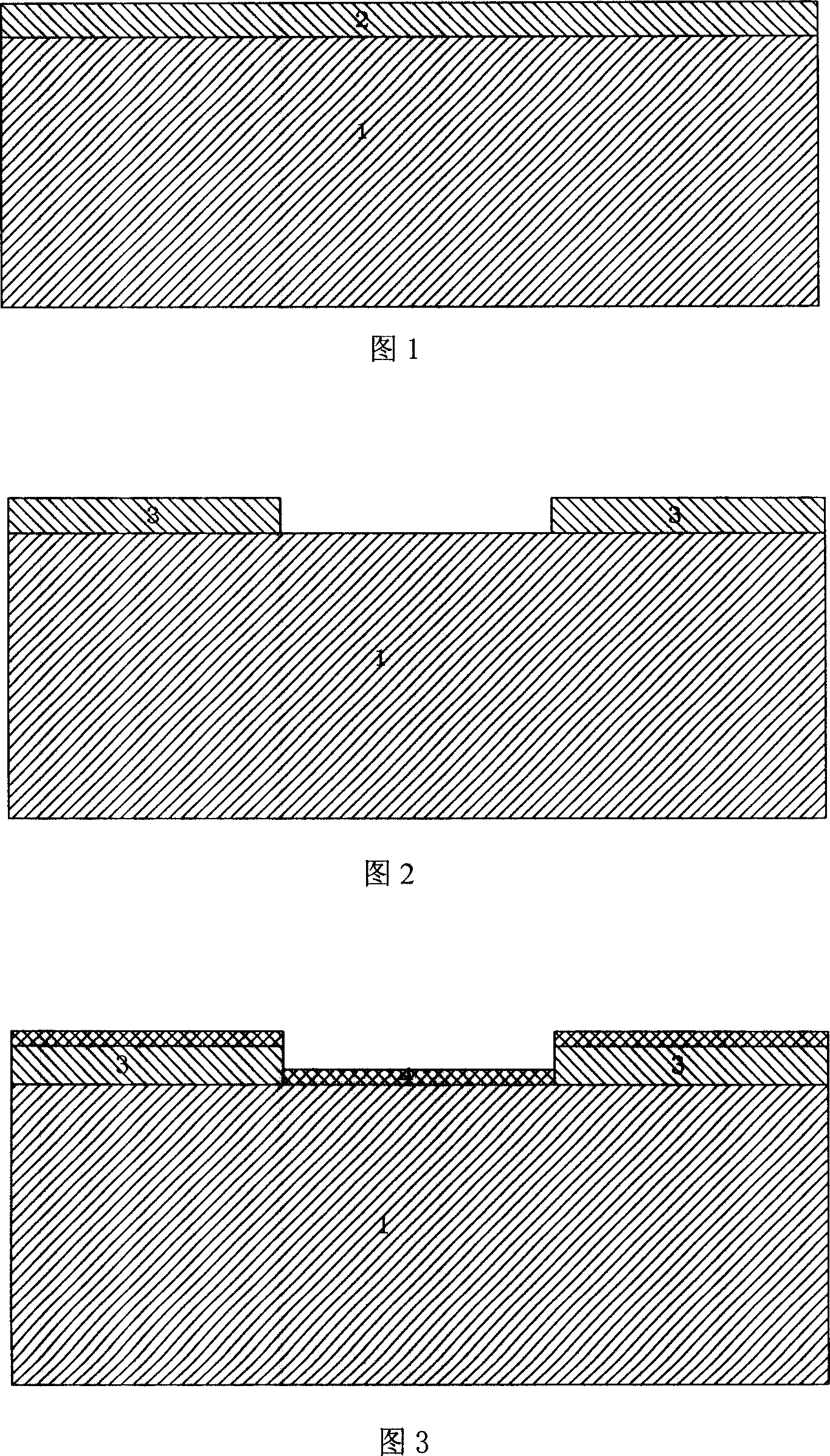

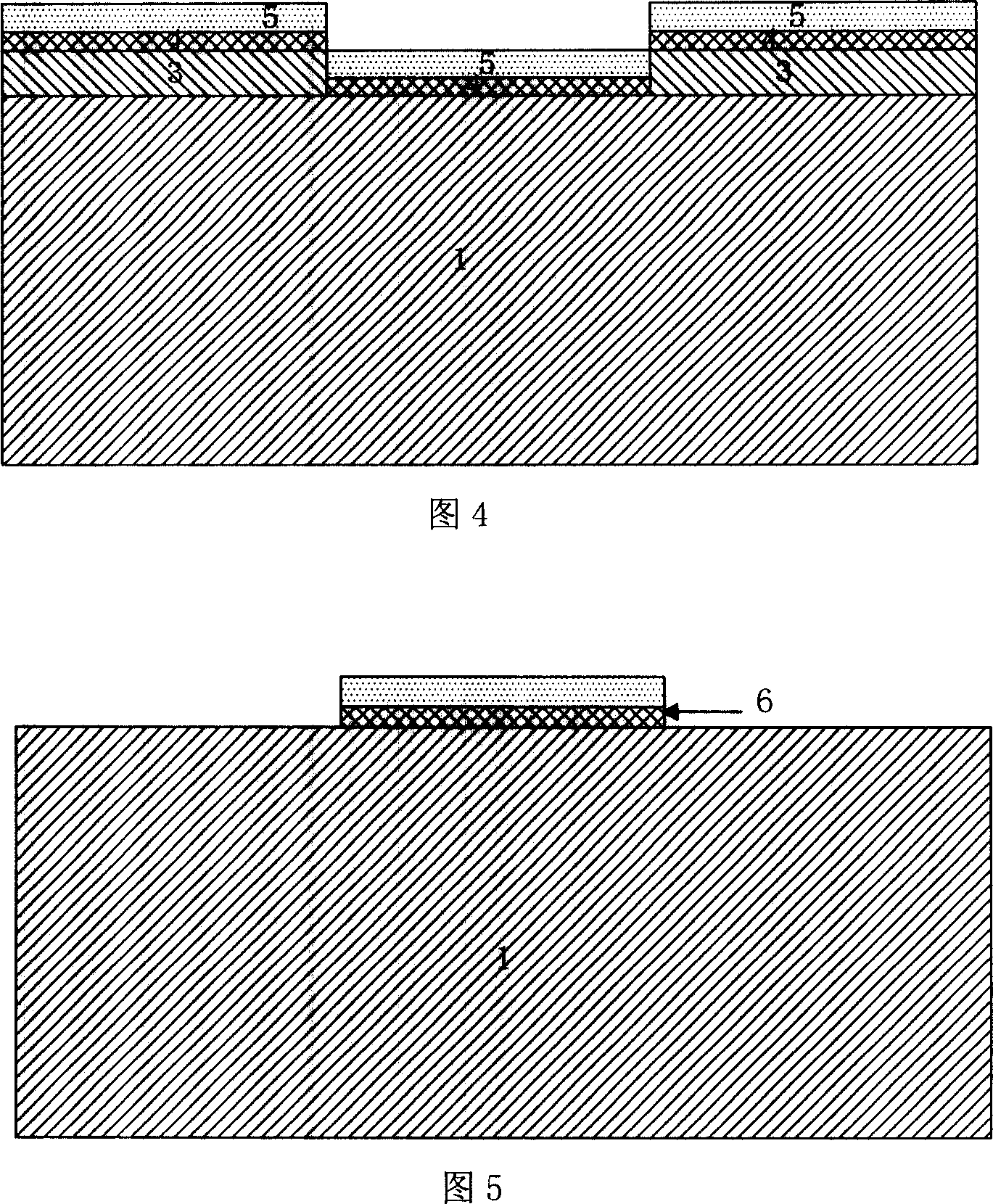

Stripping preparation method of graphics platinum/titanium metal thin film

This invention relates to a preparation method for peeling off patternized Pt / Ti films including: preparing a sacrifice layer on a chip, patternizing the sacrifice layer by a photoetching technology, etching the sacrifice layer at the place reserving the Pt / Ti metal film and reserving the sacrifice layer at the place where the Pt / Ti metal film is peeled off, preparing a Pt / Ti metal film on the patternized sacrifice layer and discharging the sacrifice layer to peel off a pattern of the film.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

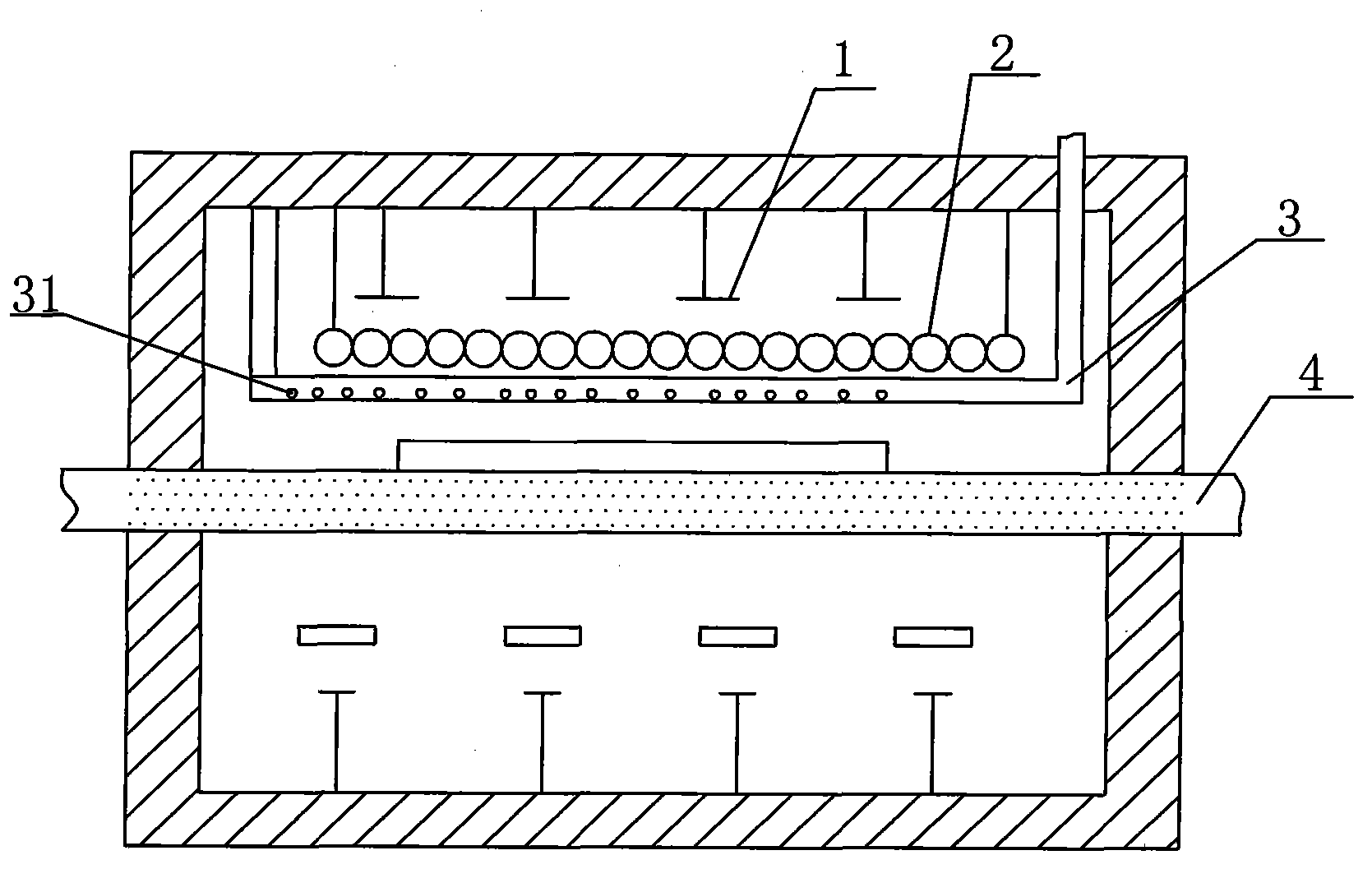

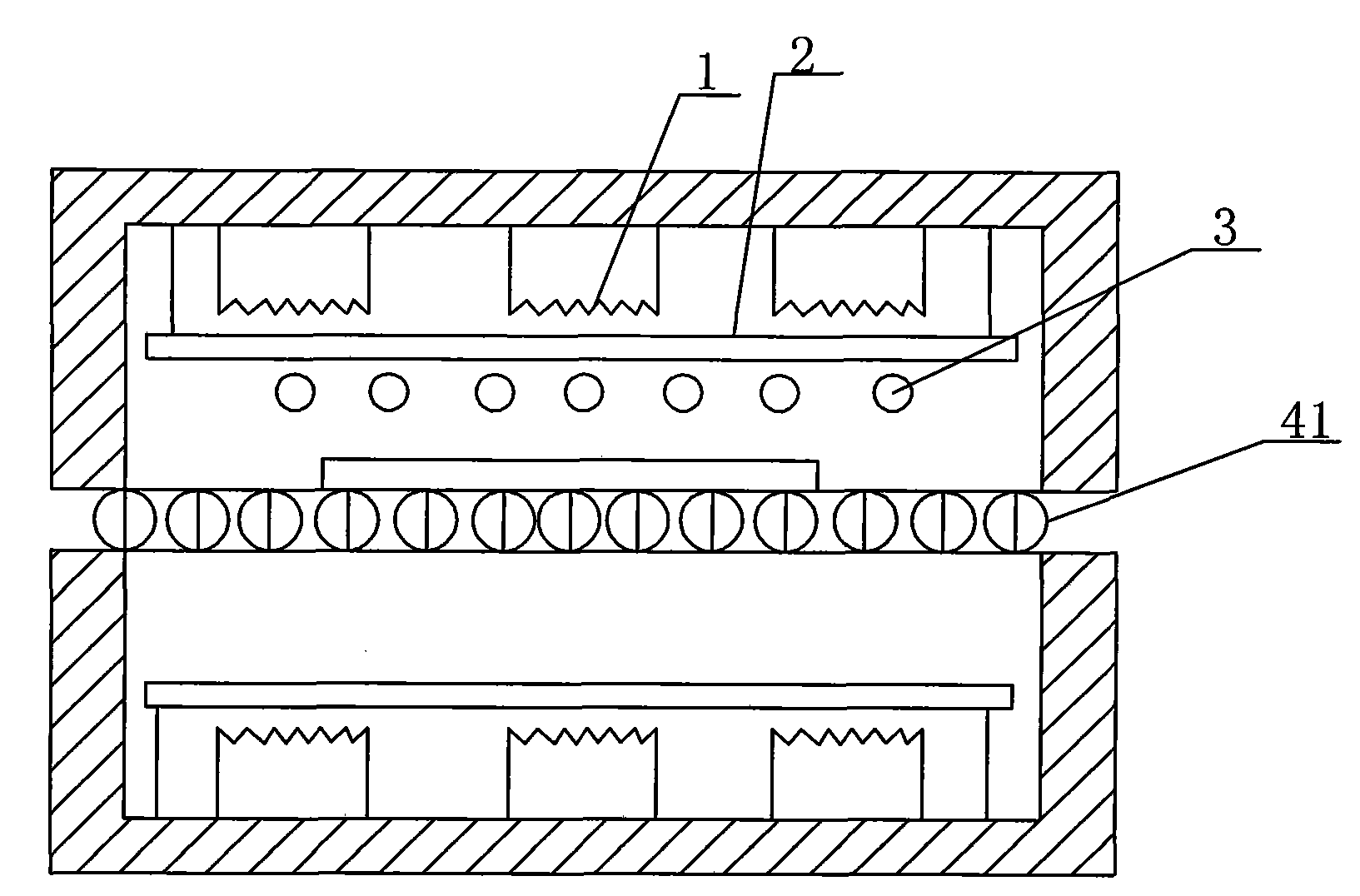

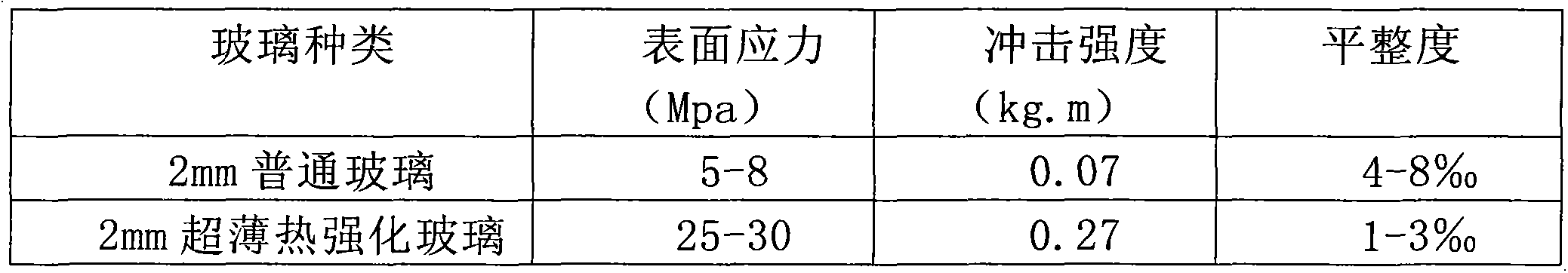

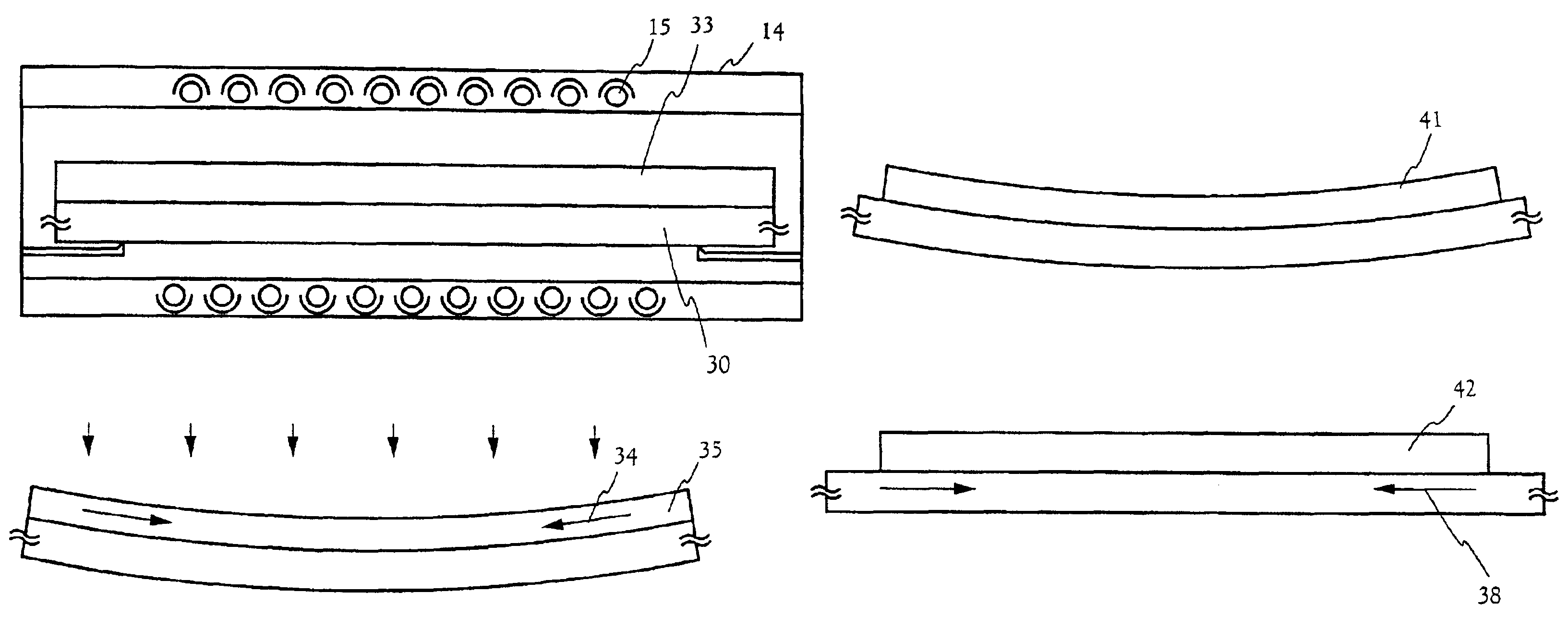

Manufacturing method of ultrathin heat-reinforced glass

InactiveCN103319082AHeating fastRadiation area is largeGlass tempering apparatusGlass manufactureToughness

The invention discloses a manufacturing method of ultrathin heat-reinforced glass. The manufacturing method comprises the following steps of: flatly placing ultrathin glass with the thickness of 1.8-2.2mm on a rolling way, adjusting the pressure of convection air in a toughening furnace to be 2000-4000pa / cm<2> with the convection time of 30-50s, simultaneously using the rolling way to drive the glass to do reciprocating movement for 40-50S in the toughening furnace at a speed of 20-30mm / s, and then adjusting the operating speed of the rolling way to be 160-175mm / s till the glass is heated to be 623-630 degrees. The glass manufactured by utilizing the method has the advantages that the generation of 'white mist' is avoided, and the glass is good in flatness, high in strength and good in toughness.

Owner:CHANGZHI SHENGLONG IND

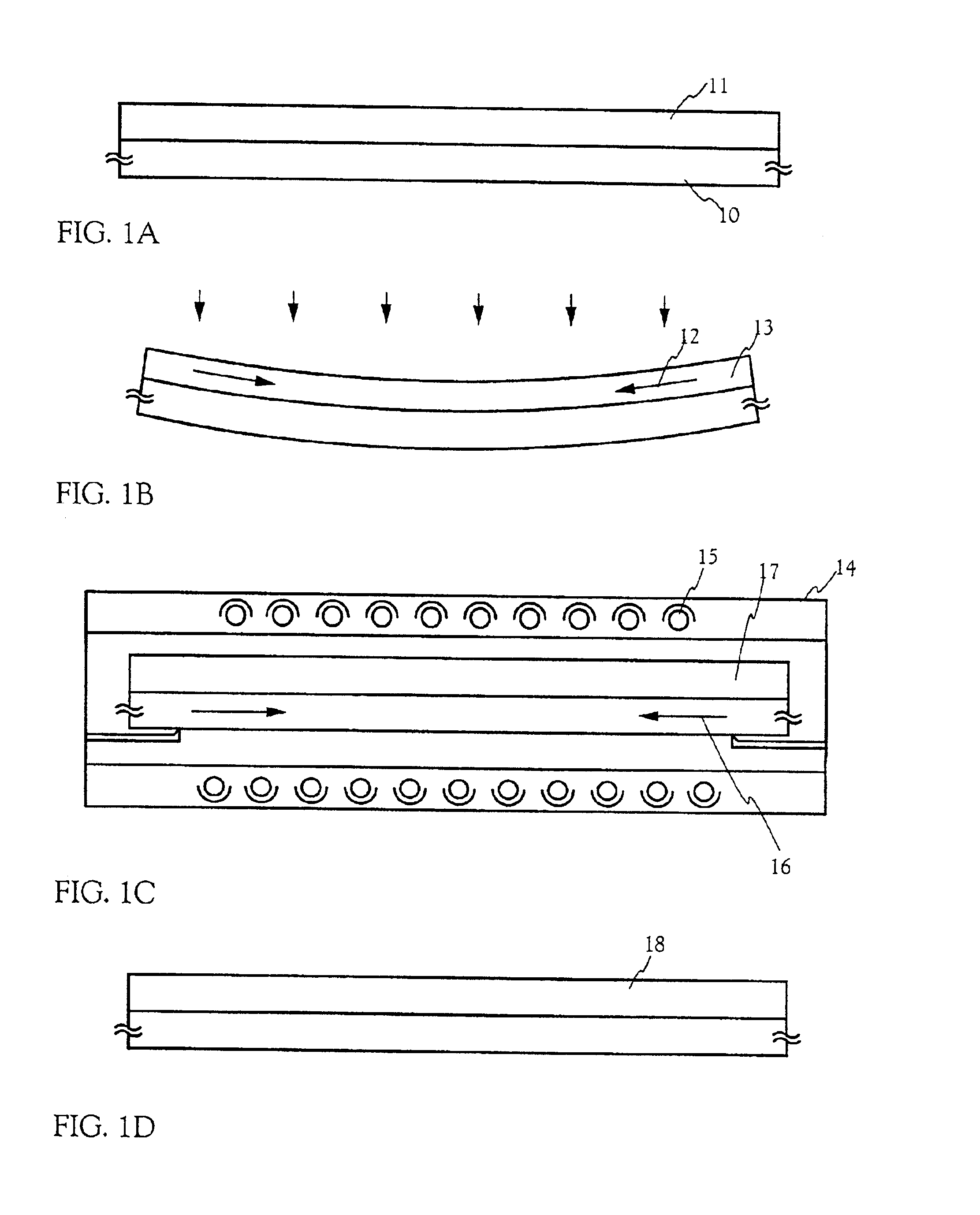

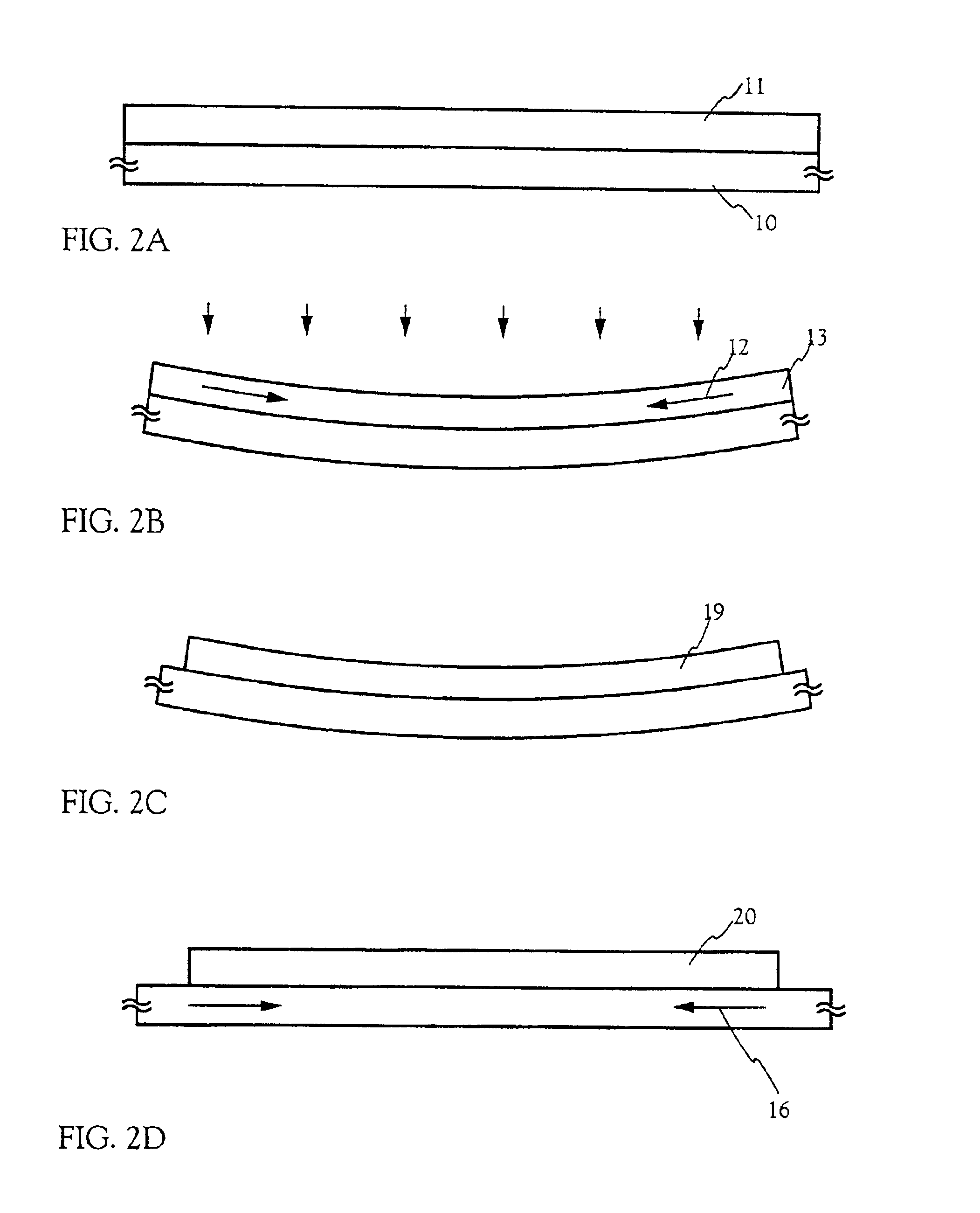

Method of manufacturing a semiconductor film with little warp

InactiveUS7160784B2Reduce radiationNot easy to changeSemiconductor/solid-state device manufacturingSemiconductor devicesOptoelectronicsLaser beams

Owner:SEMICON ENERGY LAB CO LTD

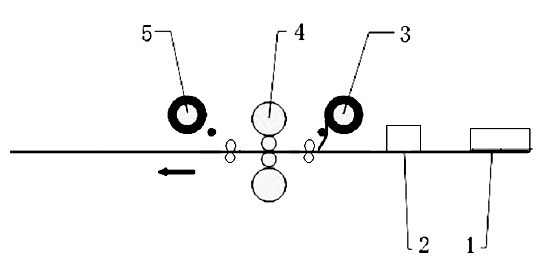

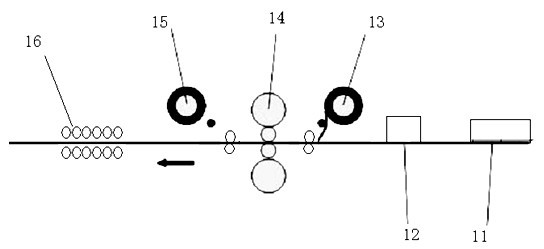

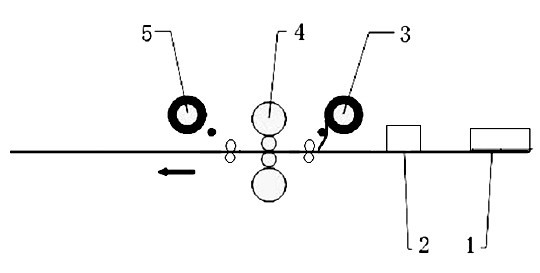

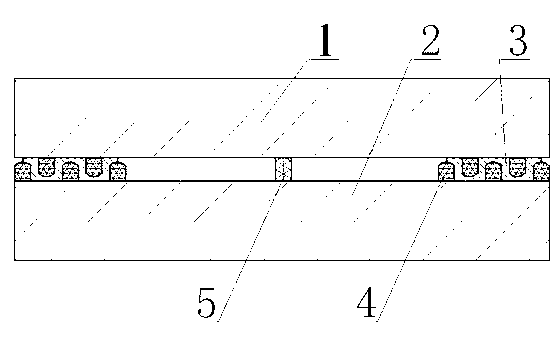

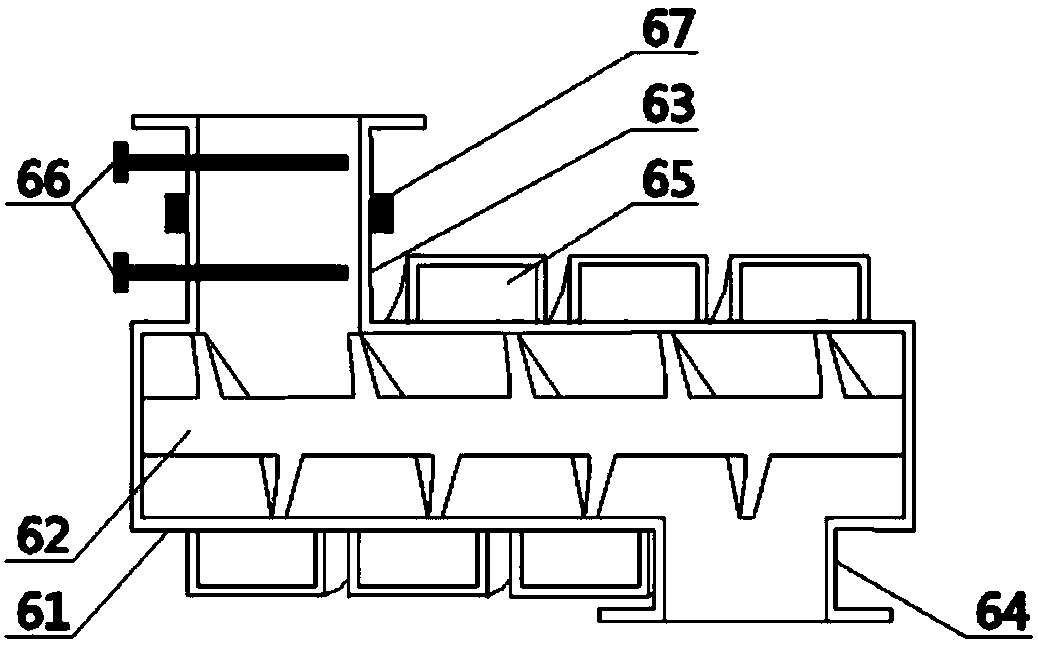

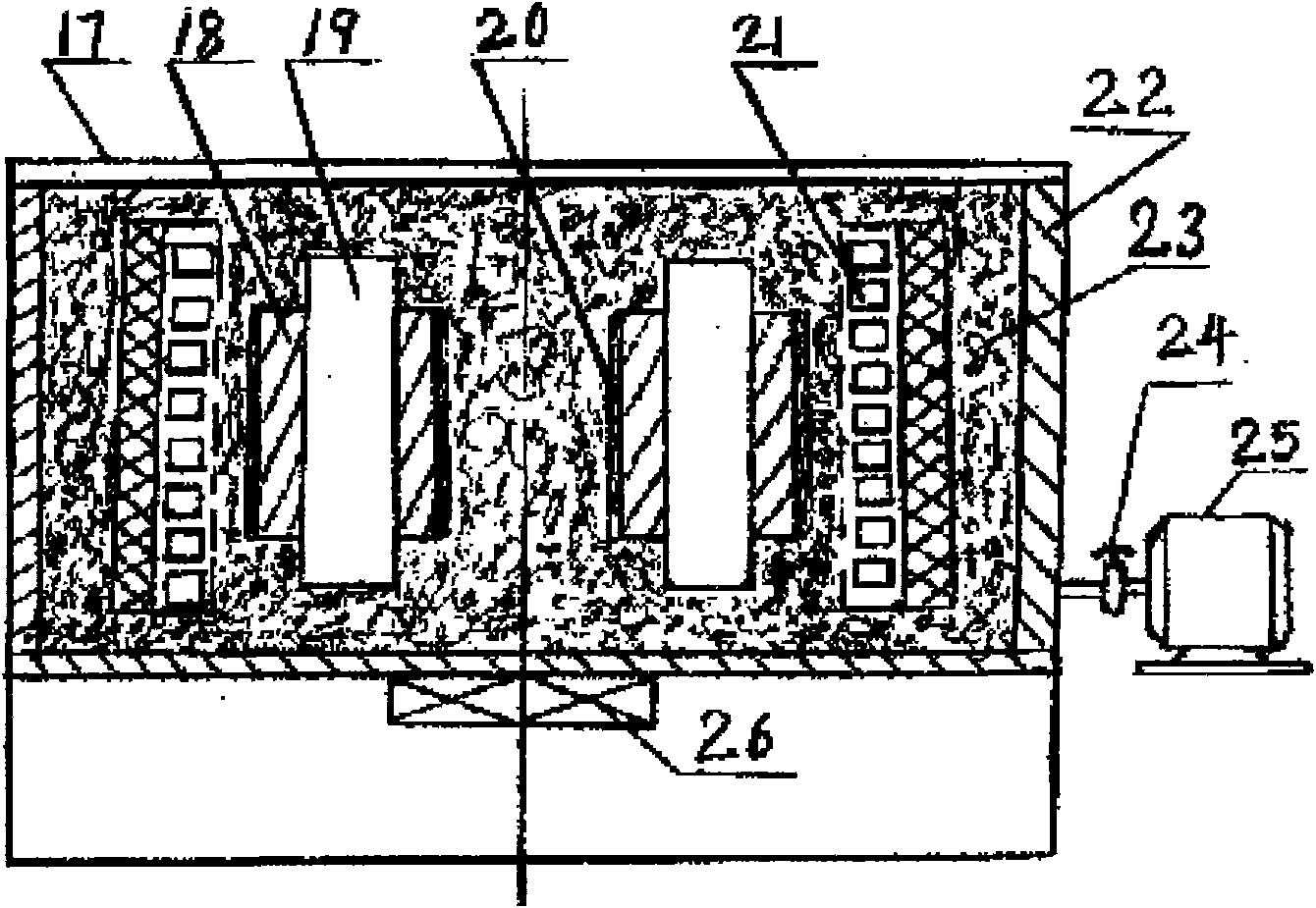

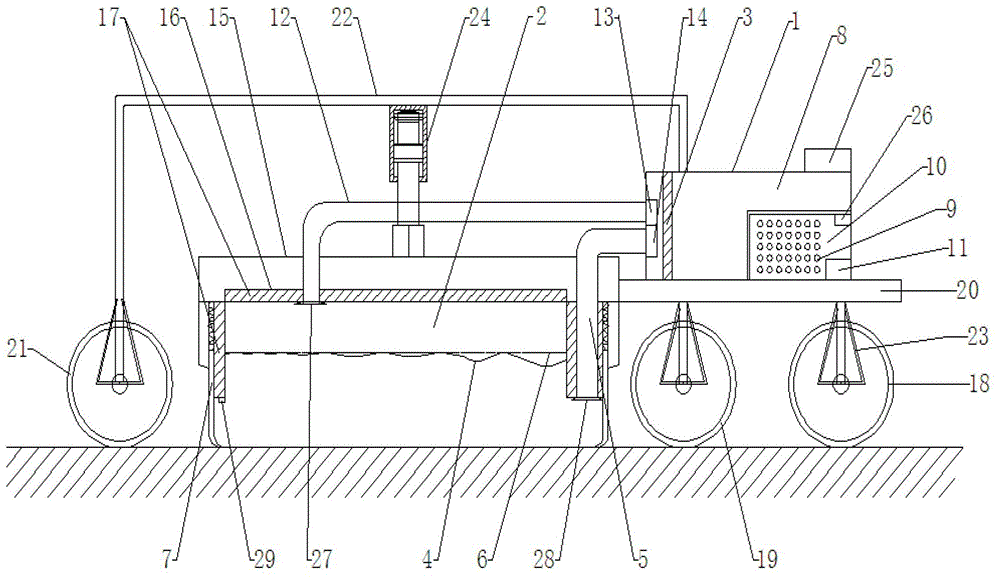

Asphalt pavement in-place hot recycling heating device

ActiveCN103147381AImprove heat utilizationReduce heat lossRoads maintainenceHeating systemReturn channel

The invention discloses an asphalt pavement in-place hot recycling heating device. The asphalt pavement in-place hot recycling heating device comprises a traveling mechanism and a heating system used for heating an asphalt pavement, wherein the heating system comprises a hot air generator used for generating hot air and a heating chamber used for guiding the hot air to the asphalt pavement and then heating the asphalt pavement, the lower end of the heating chamber is open, the open end is buckled on the asphalt pavement to be closed, and the heating chamber and the hot air generator are communicated with each other through an air intake channel and an air return channel in a circulating manner. The asphalt pavement in-place hot recycling heating device provided by the invention can be used for recycling low-temperature hot air after heat energy transfer with the pavement, and compared with the prior art, the asphalt pavement in-place hot recycling heating device can improve the utilization ratio of heat energy, reduce the heat energy loss and environmental pollution, save energy, reduce the construction cost, and realize sufficient and effective heat energy transfer between the hot air and the asphalt pavement so as to improve the heating depth and temperature, reduce the fuel consumption, save the energy and reduce the construction cost under the condition of reaching the required heating depth and temperature.

Owner:CHONGQING JIAOTONG UNIVERSITY

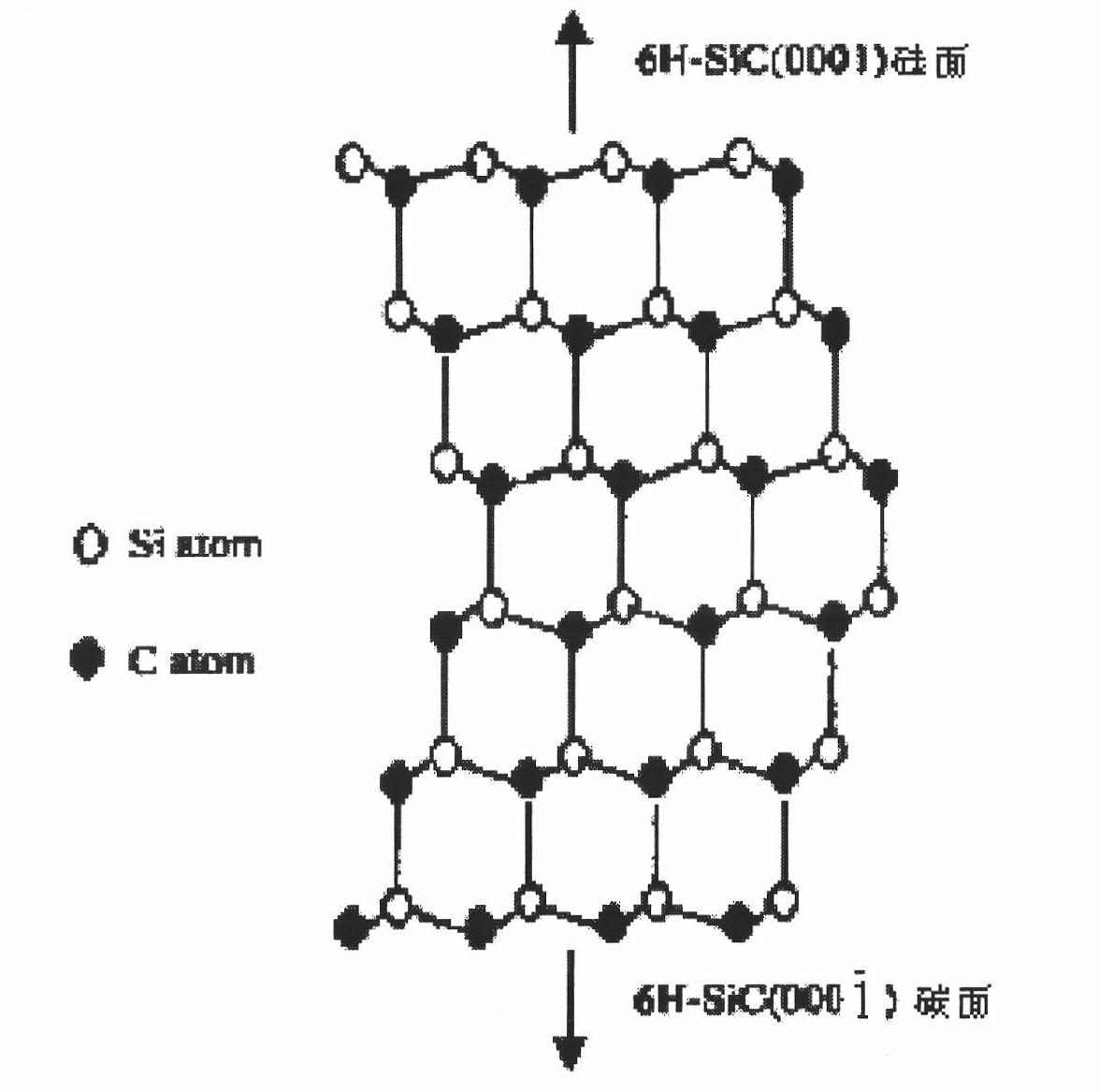

Method for growing graphene on large-diameter 6H-SiC carbon surface

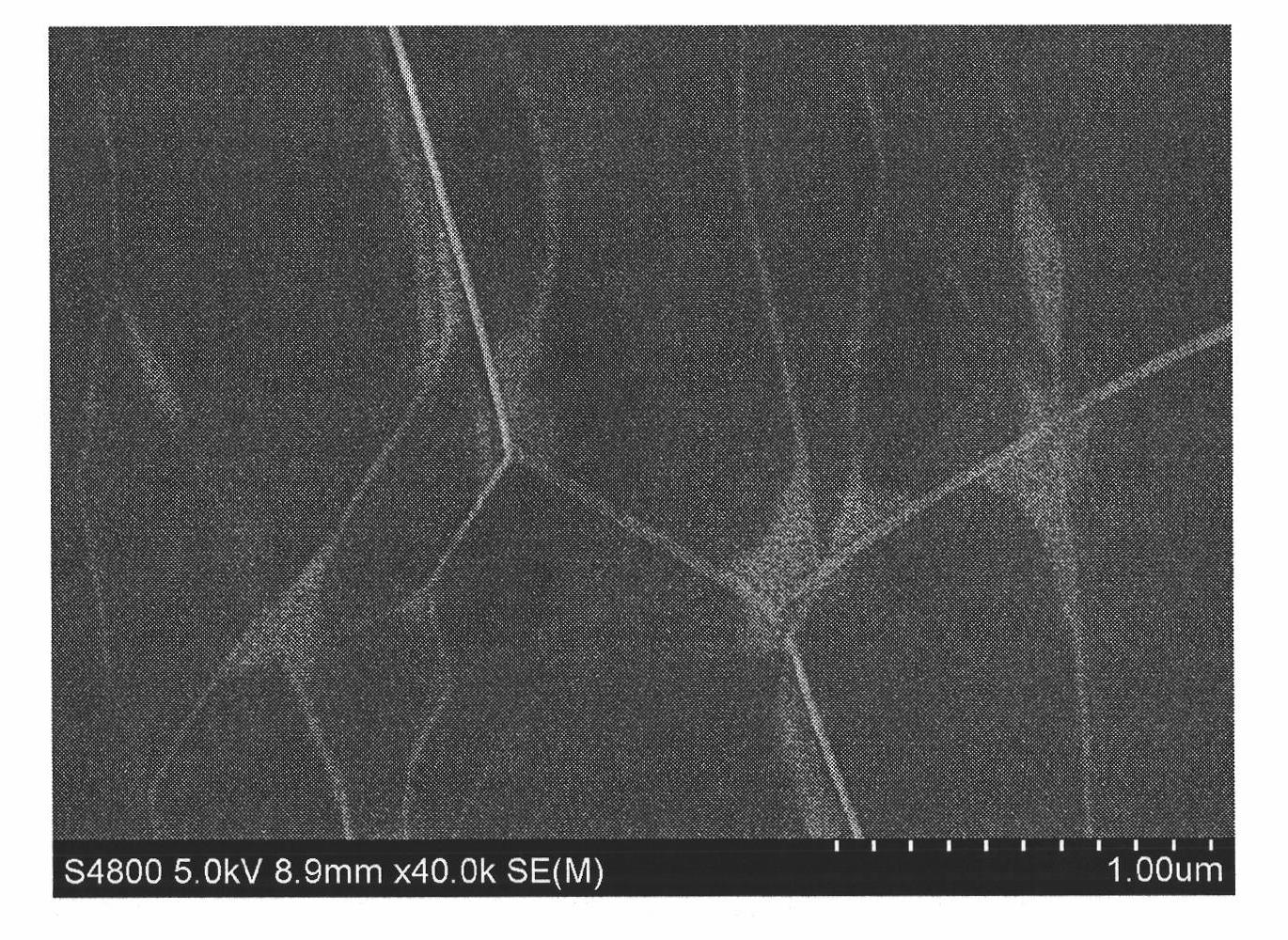

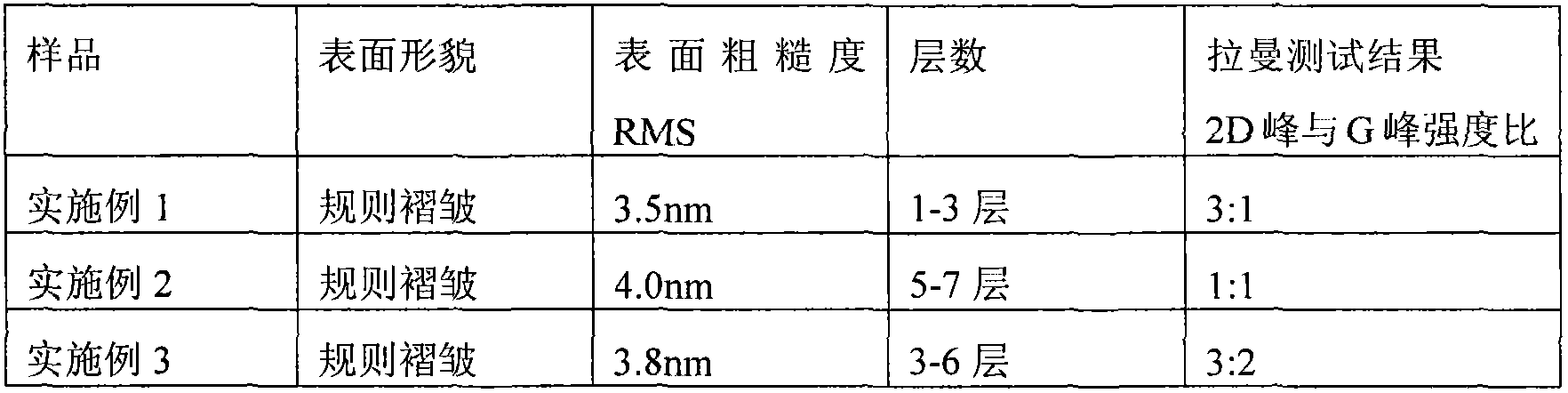

ActiveCN102051677AReduce the number of layersImprove uniformityPolycrystalline material growthUnder a protective fluidCrucibleSingle crystal

The invention relates to a method for growing graphene on a large-diameter 6H-SiC carbon surface, which comprises the following steps: polishing and cleaning a 6H-SiC wafer carbon surface; horizontally placing the upward carbon surface in a graphite tray in a single crystal growth furnace crucible; vacuumizing until the vacuum degree is 1*10<-7>mbar; quickly heating to 1700-1750 DEG C; introducing high-purity argon gas; then slowly heating to 1750-1950 DEG C; and insulating for 1-10 minutes, thereby finishing the growth of the graphene. By the method provided by the invention, a substrate does not have a damaged layer, the grown graphene is distributed on the whole surface of the substrate, and the number of layers of the graphene can be controlled at 1 to 10. The method is simple and easy to operate and can be used for preparing high-quality graphene.

Owner:SHANDONG UNIV

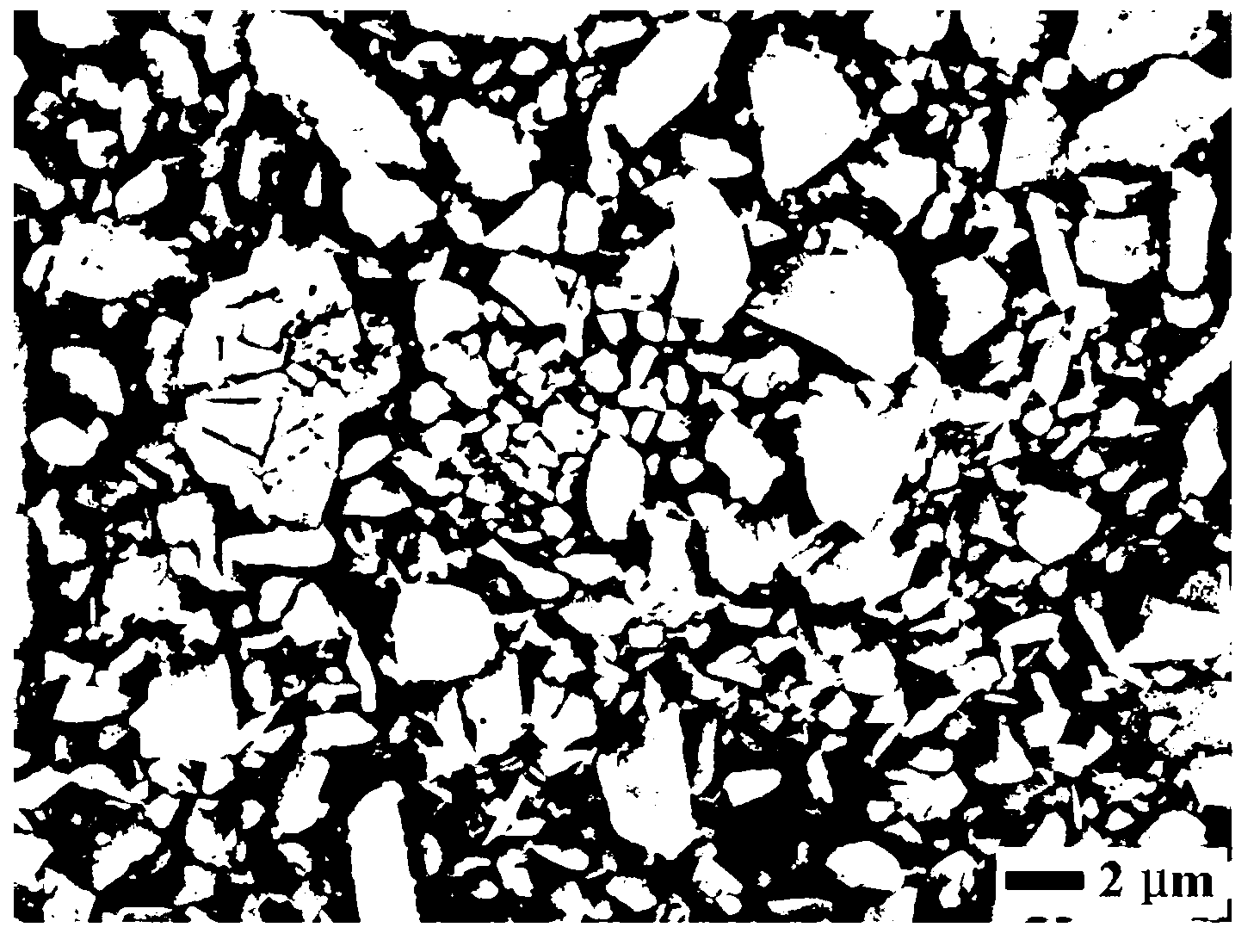

Corrosion-resistant fully dense thermal spraying metal alloy coating and preparation method thereof

ActiveCN107761035AHigh heating temperatureEliminate tiny poresMolten spray coatingCorrosion resistantParticle beam

The invention discloses a corrosion-resistant fully dense thermal spraying metal alloy coating and a preparation method thereof and belongs to the technical field of preparation of spraying materials.According to the technical scheme, the preparation method comprises the following steps: spraying composite metal powder of a high-melting-point metal coating structure with a self-adhesive effect byutilizing a thermal spraying method so as to prepare a metal alloy coating which is highly dense, excellent in bonding with a matrix and excellent in bonding with a deposited particle interface; andperforming cold spraying or traditional shot blasting on the dense metal alloy coating to produce a high-speed steel shot particle beam with directivity, spraying the particle beam to the coating surface at a certain relative movement speed, and densifying the metal coating based on a plastic distortion effect produced by high-speed particle collision, thereby obtaining the cast-block-like fully dense metal alloy coating with excellent corrosion resistance. The method is simple in operation, wide in raw material source and high in preparation efficiency. According to the method, the metal alloy coating with excellent corrosion resistance of which the density is close to that of the block can be prepared.

Owner:XI AN JIAOTONG UNIV

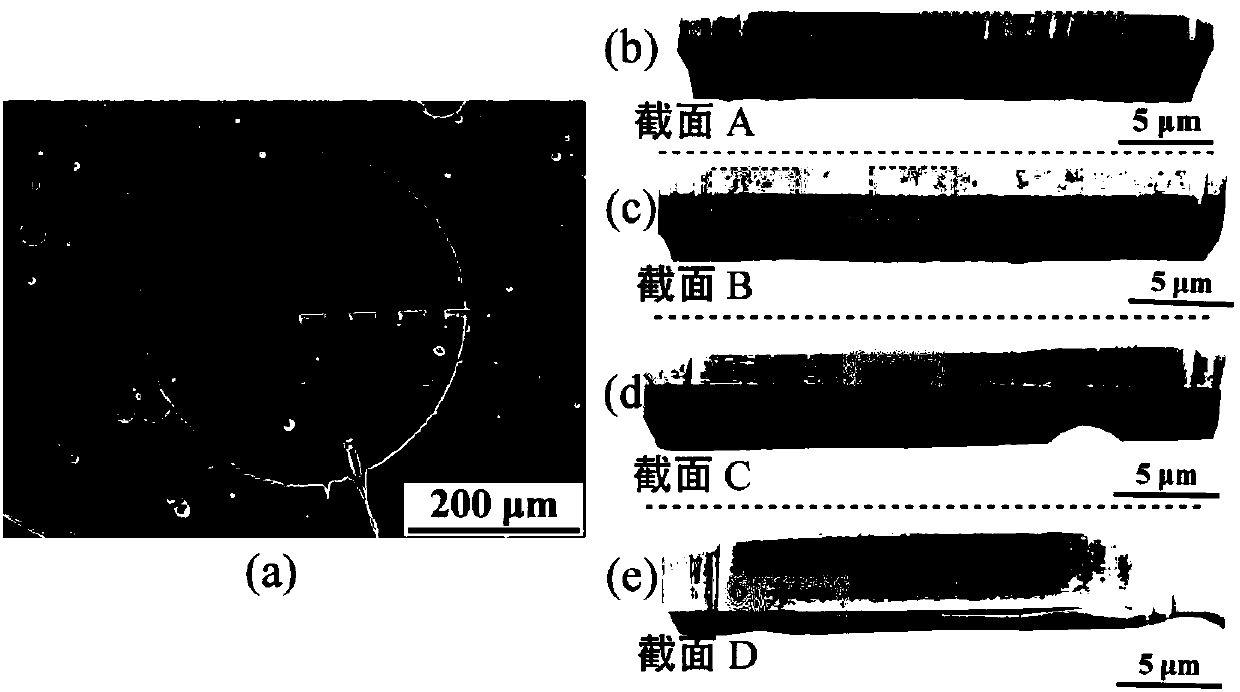

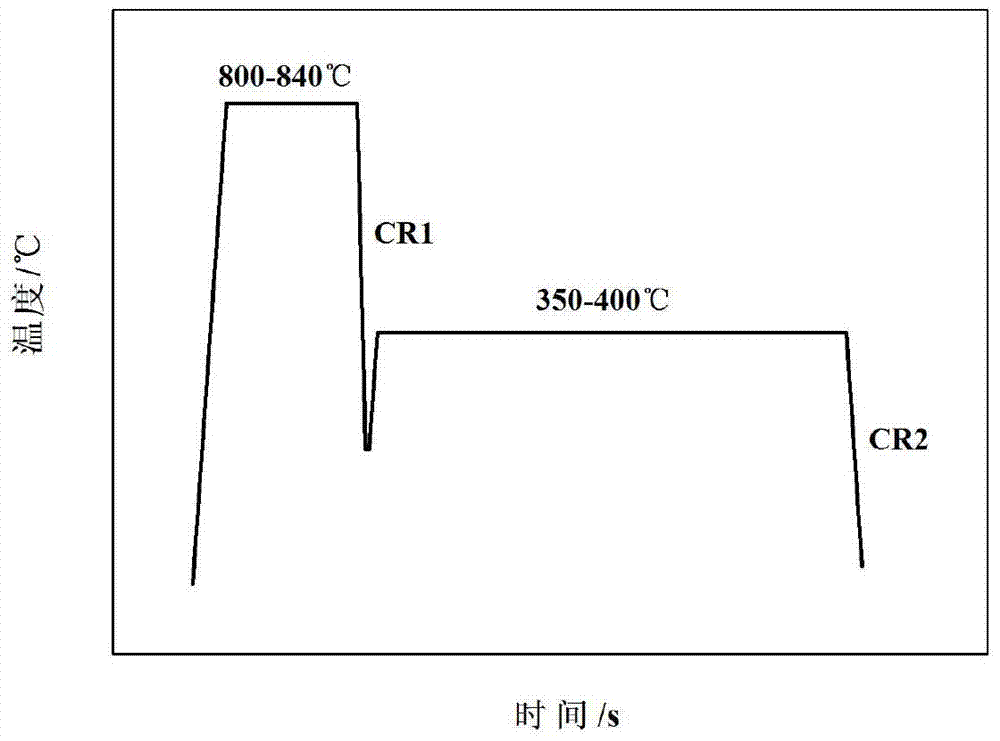

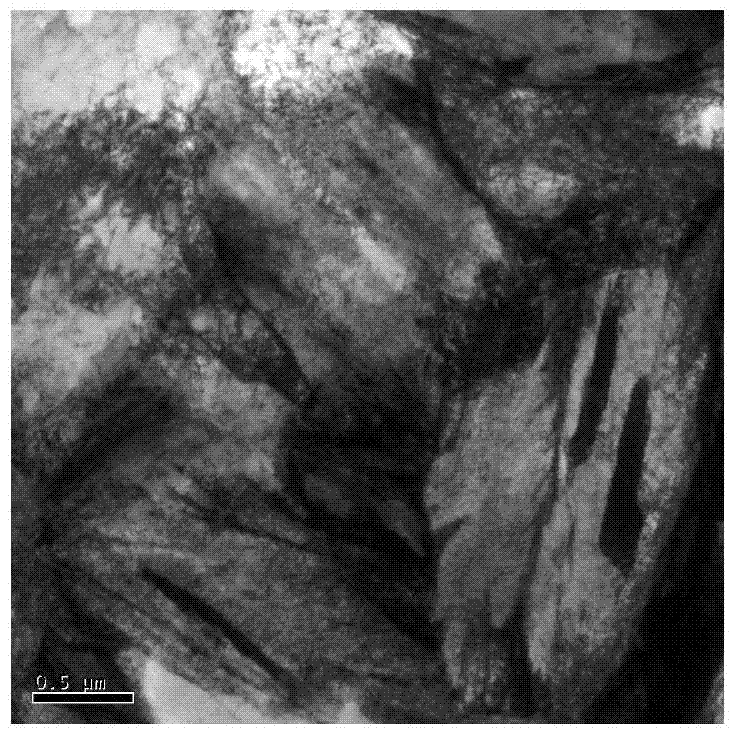

High-strength cold-rolled steel plate with TRIP (transformation induced plasticity) effect and production method thereof

InactiveCN104726767AGuaranteed StrengthGuaranteed high plasticityRoom temperatureContinuous annealing

The invention discloses a high-strength cold-rolled steel plate with TRIP (transformation induced plasticity) effect, which comprises the following chemical components in percentage by weight: 0.15-0.25% of C, 0.5-1.5% of Si, 1.0-2.0% of Mn, 0.1-0.5% of Ni, at most 0.02% of P, at most 0.005% of S, 0.02-0.08% of Al, and the balance of Fe and inevitable impurities. The method comprises the following steps: continuous annealing: the heating temperature is 800-840 DEG C, the holding time is 150-180 seconds, the cooling rate is greater than or equal to 50 DEG C / second, the quenching temperature is 250-280 DEG C, the partitioning temperature is 350-400 DEG C, and the partitioning time is 300-600 seconds; and air cooling to room temperature. The tensile strength is greater than 1000 MPa, and the elongation percentage is greater than 18%.

Owner:ANGANG STEEL CO LTD

High-temperature furnace roller for CSP (Compact Strip Production) heating furnace

InactiveCN102618716ASimple structureEasy to makeCharge manipulationFurnace typesHeating furnacePipe support

The invention discloses a high-temperature furnace roller for a CSP (Compact Strip Production) heating furnace. The high-temperature furnace roller comprises a tubular roller body steel shaft, wherein the outer wall of the roller body steel shaft is provided with roller rings at intervals; the outer wall of the roller body steel shaft between adjacent roller rings is provided with a heat-insulating lining; a water-cooling pipe is arranged in the roller body steel shaft; one end of the water-cooling pipe is provided with a water-cooling pipe supporting clamp seat; a roller body end head baffleplate which is hermetically connected with the inner wall of the roller body steel shaft is arranged outside the end part of the water-cooling pipe supporting clamp seat; a first cavity is formed between the roller body steel shaft and the water-cooling pipe; the pipe wall of the water-cooling pipe close to the water-cooling pipe supporting clamp seat is provided with water outlet through holes which are uniformly distributed along circumference; and the water outlet through holes are communicated with a water inlet end in the water-cooling pipe and the first cavity to form a closed water path. The high-temperature furnace roller has the advantages of simple structure, convenience and quickness in manufacturing, convenience in use and maintenance, low cost, application temperature reaching up to 1,300 DEG C and suitability for being widely applied to the technical field of thermal equipment of industrial furnaces.

Owner:武汉钢铁有限公司

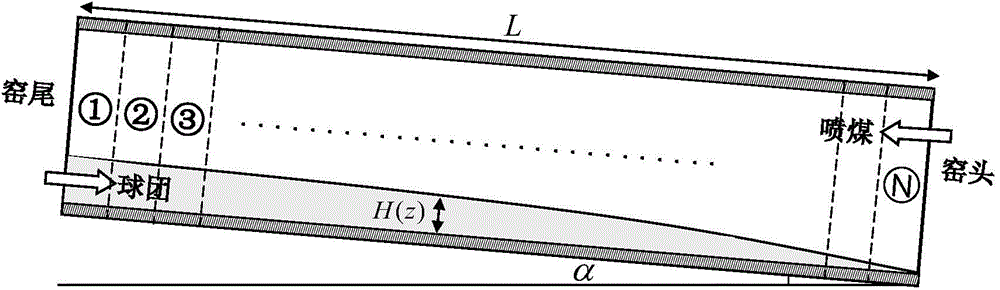

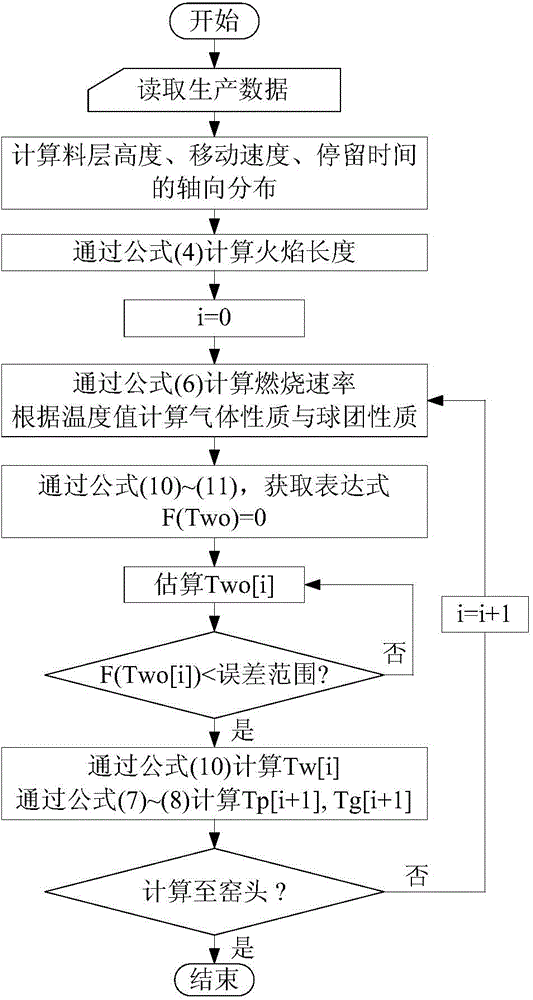

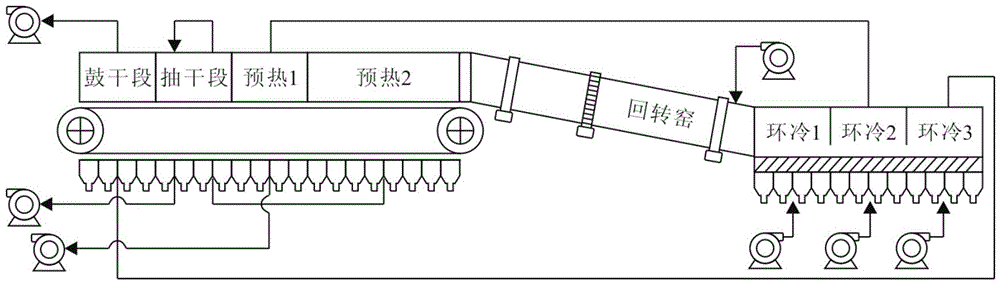

Pellet production method based on prediction of compressive strength of pellets in rotary kiln

ActiveCN104480300AHigh compressive strengthReduce porositySpecial data processing applicationsThermal engineeringHysteresis

The invention discloses a pellet production method based on prediction of compressive strength of pellets in a rotary kiln. The method comprises the following steps: 1) collecting related operation parameters of the rotary kiln; 2) establishing a motion model of the pellets in the rotary kiln; 3) measuring and calculating average residence time T of the pellets in the rotary kiln; 4) measuring flame length FL and the distribution of burning rate Rfuel of fuel in the flame length; 5) measuring the distribution of temperature of the pellets Tp along the kiln length direction z in the rotary kiln; 6) measuring a predicted value of the strength of the pellets; and 7) performing online control on process parameters of the rotary kiln according to the predicted value Qp of the compressive strength of the pellets. By using the method for online prediction of the thermal engineering state and the strength of the pellets in the rotary kiln, the transparency of the production process is increased, the control difficulty caused by information hysteresis is reduced, the risks of low finished product rate, accretion of the rotary kiln and the like caused by insufficient strength of the pellets can be reduced, and the thermal engineering operation of the rotary kiln is optimized in an online manner; and the energy consumption can be reduced and the production benefits can be improved.

Owner:CENT SOUTH UNIV

High tensile cold-rolled steel sheet excellent in ductility and in strain aging hardening properties, and method for producing the same

InactiveUS6692584B2Improve ductilityImprove stamping effectFurnace typesHeat treatment furnacesSheet steelHigh intensity

The present invention provides a high tensile cold-rolled steel sheet having superior ductility, strain age-hardening characteristics, and crash resistance properties, and also provides a manufacturing method therefor. As a particular means, a thin cold-rolled steel sheet containing 0.05% to 0.30% of C, 0.4% to 2.0% of Si, 0.7% to 3.0% of Mn, 0.08% or less of P, 0.02% or less of Al, and 0.0050% to 0.0250% of N on a mass % basis is manufactured in which N / Al is 0.3 or more. This thin cold-rolled steel sheet is heated to a temperature between (an Ac1 transformation point) and (an Ac3 transformation point+50° C.), is cooled at a cooling rate of 5 to 150° C. / second in the range of at least 600 to 500° C., and is held in the temperature range of 350 to 500° C. This steel sheet has superior ductility, strain age-hardening characteristics having a DeltaTS of 50 MPa or more, and crash resistance properties.

Owner:JFE STEEL CORP

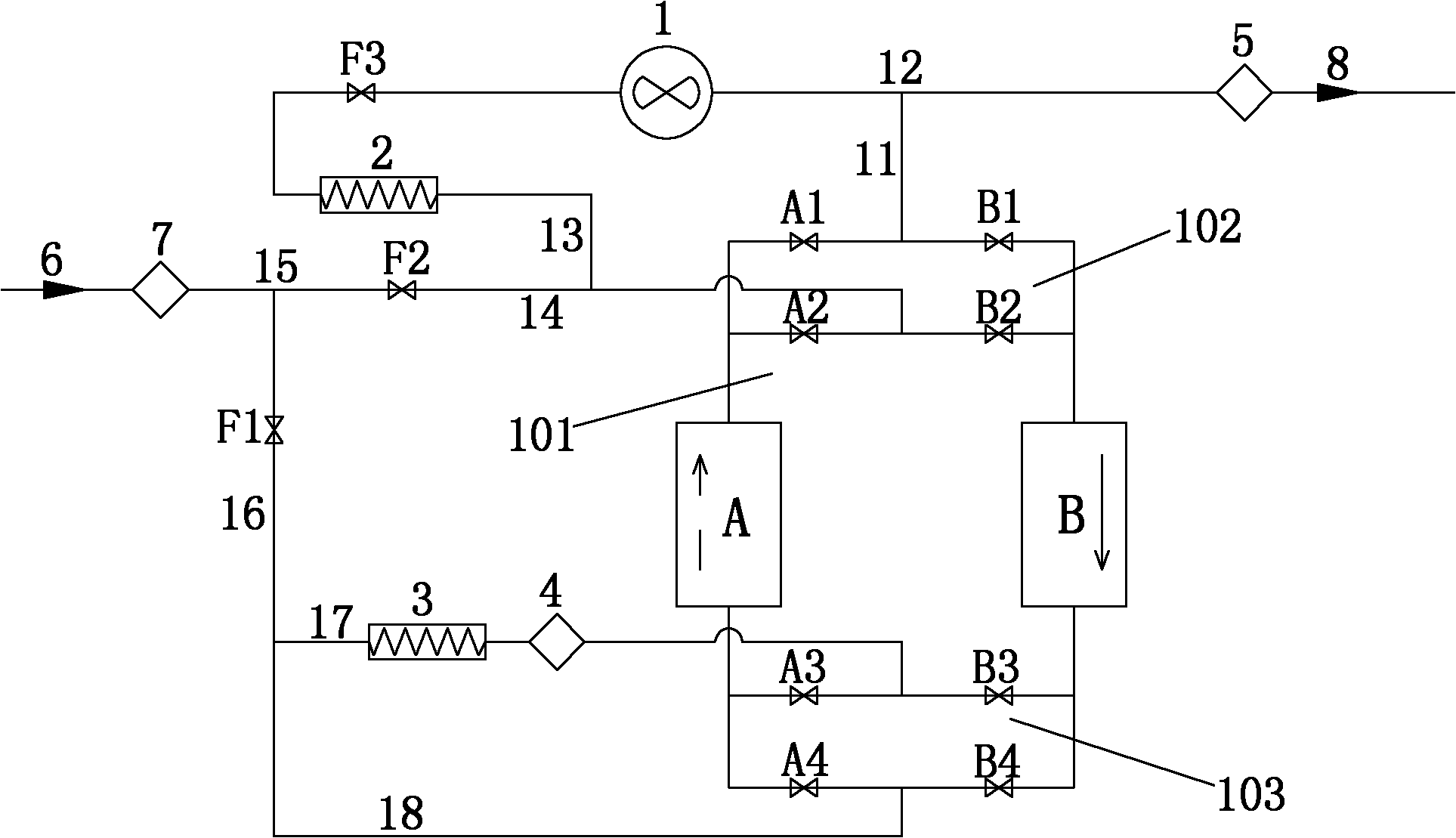

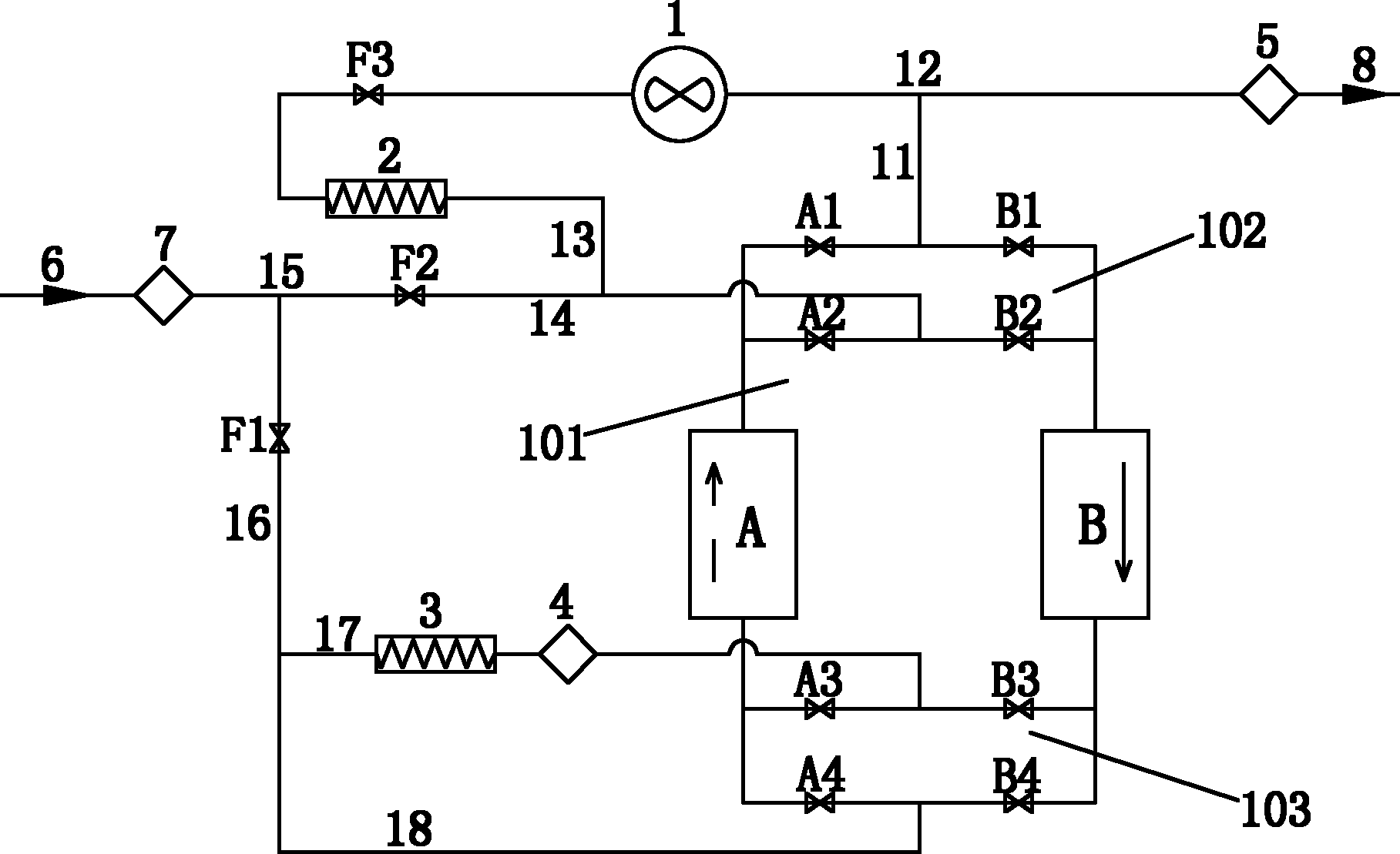

Process and device for drying adsorption type compressed gas regenerated by using compression heat

ActiveCN102101003ARemarkable effect of energy saving and consumption reductionAchieve regenerationGas treatmentDispersed particle separationEngineeringProcess engineering

Aiming at overcoming the defects of the traditional absorption drying method and a large adsorption type compressed air dryer, the invention provides a process and device being used for drying an adsorption type compressed gas regenerated by using compression heat, being capable of obtaining a drying gas with lower dew point and recycling a blast-cold gas. According to the invention, an exhaust and pressure-reduction process does not exist, the regenerated and heated blast-cold gas is recycled, the compressed air and the energy are saved, and the energy consumption is lowered.

Owner:XIAN UNIONFILTER PURIFICATION EQUIP

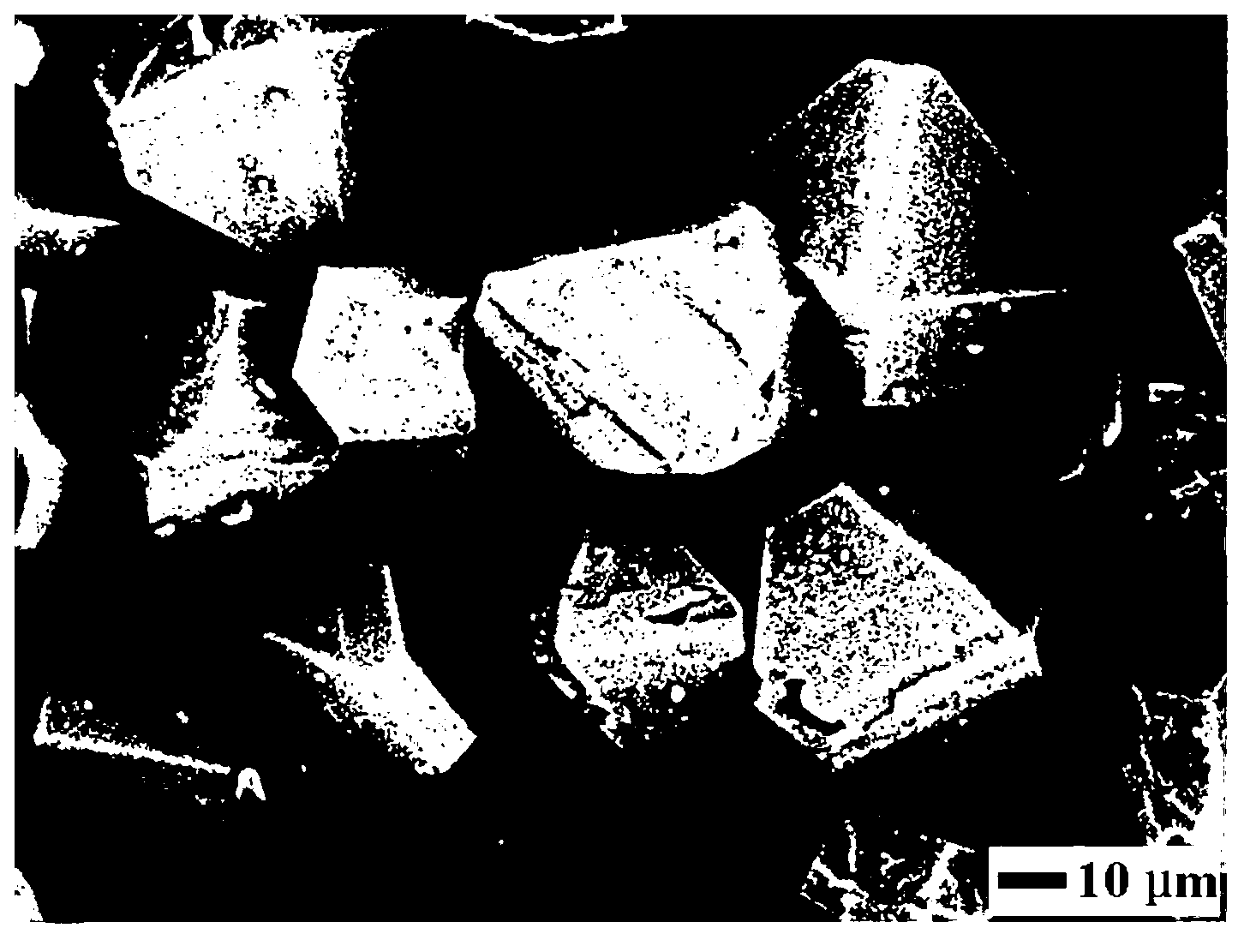

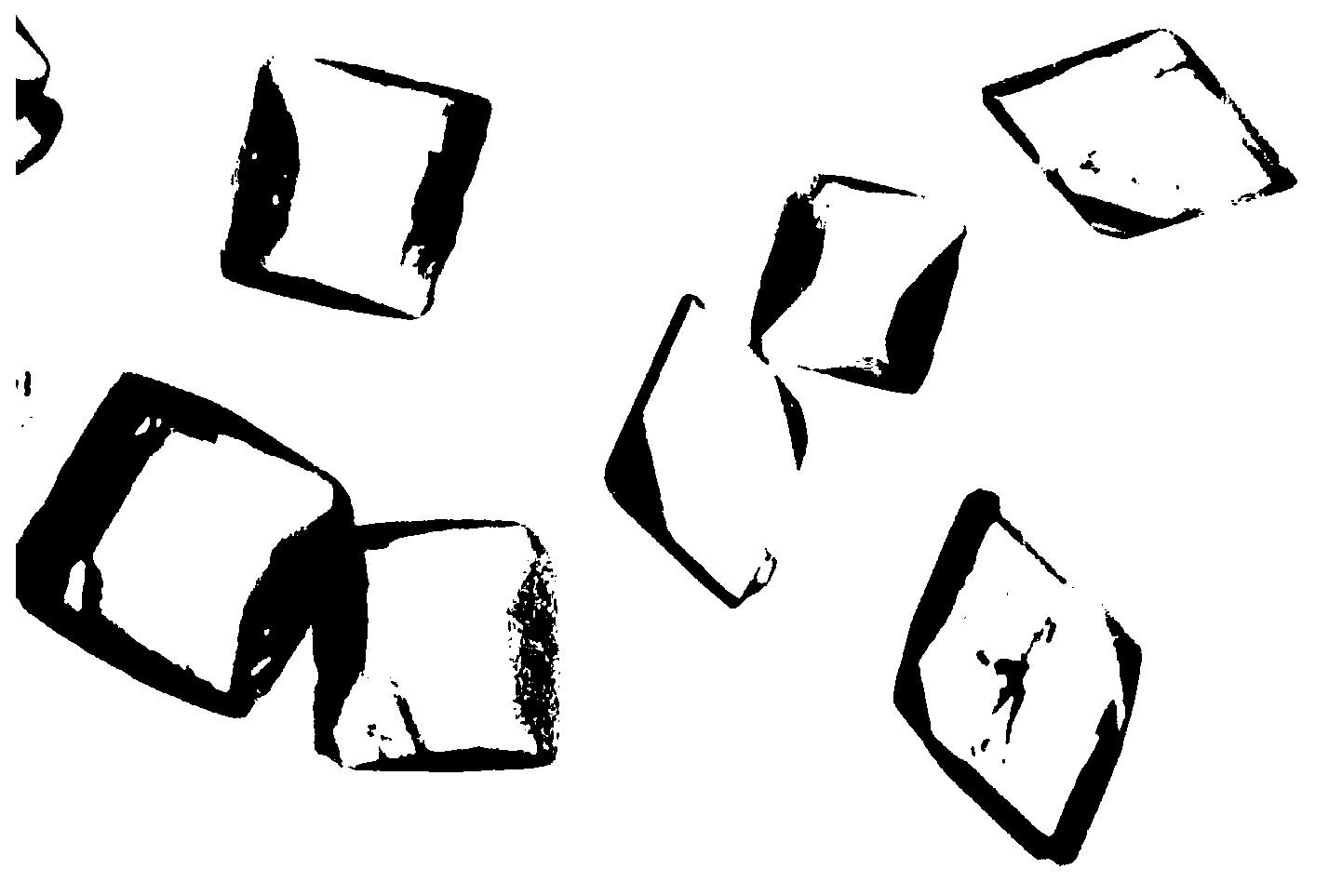

Preparation method of hexaazaisowurtzitane crystal

ActiveCN103214325ARegular particle shapeUniform particlesExplosive working-up apparatusSingle substance explosivesMechanical crushingTwo step

The invention discloses a preparation method of a hexaazaisowurtzitane crystal. The preparation method of the hexaazaisowurtzitane crystal comprises the following steps of: carrying out wet-crushing onto explosives until the particle dimension is 0.1 micron to 5 microns, centrifuging, washing, freezing and drying the crushed materials; placing the material in the step I to a solvent for carrying out ultrasonic treatment, heating, re-filtering, washing and drying under the standing condition or the stirring condition to obtain a hexaazaisowurtzitane explosive crystal. According to the preparation method of the hexaazaisowurtzitane crystal, the high-quality explosive crystal product, which is prepared by a preparation technology adopting a two-step process including mechanical crushing and solvent thermal-induction growing, is regular in particle shape, jewel-shaped, uniform in particle dimension, smooth in surface, less in internal defects of the crystal, and lower in mechanical sensitivity. Besides, the preparation method of the hexaazaisowurtzitane crystal is simple in process, gentle in reaction conditions, good in reproducibility, high in yield and suitable for large-scale industrial production.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

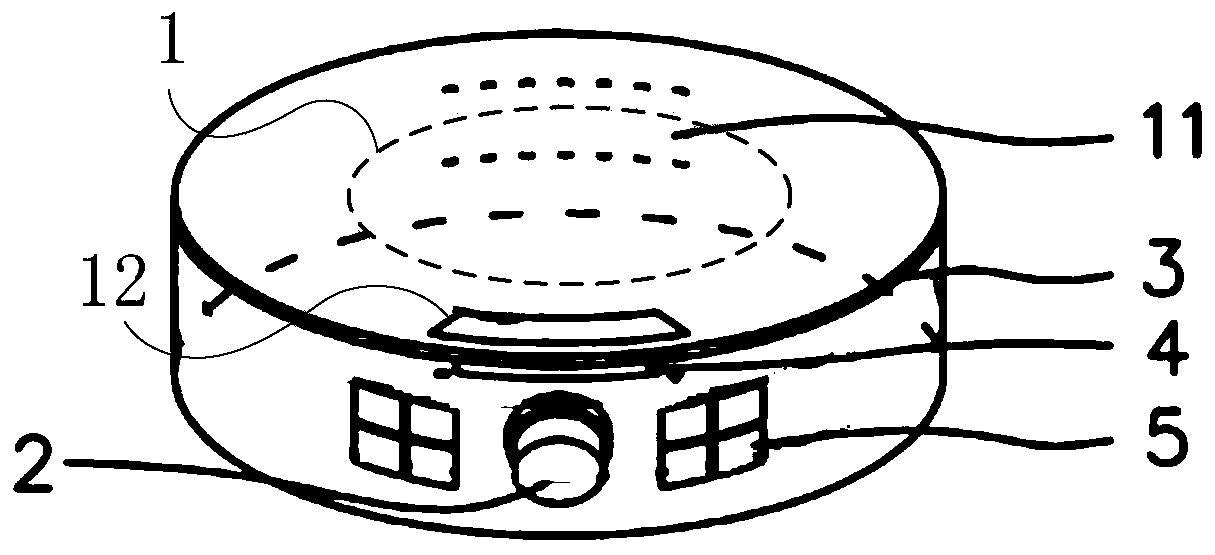

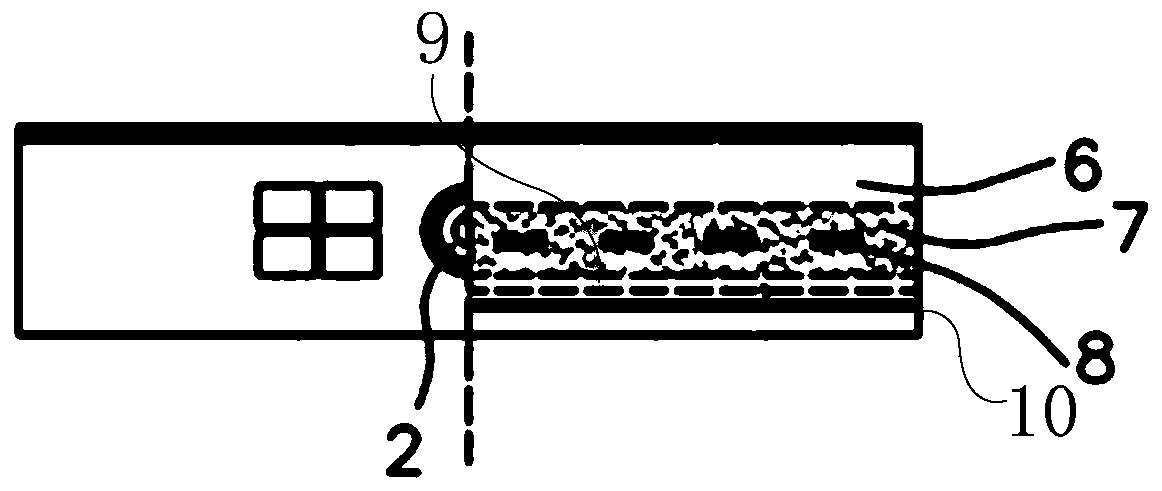

Multifunctional household electric heating furnace

InactiveCN110056916AHigh heating temperatureImprove power utilization efficiencyDomestic stoves or rangesLighting and heating apparatusElectric arc furnaceThermal insulation

The invention discloses a multifunctional household electric heating furnace. The multifunctional household electric heating furnace comprises a shell , wherein a heating area is arranged on the uppersurface of the shell; the electric heating furnace further comprises a heat dissipation protection layer, a heating assembly and a heat insulation reflecting plate; the heating assembly is arranged below the heating area, and the heating assembly is provided with at least one layer of heating unit, the heating assembly is used for generating the heat required by heating a kettle; the heat dissipation protecting layer is arranged between the heating area and the heating assembly, the heat dissipation protection layer is used for absorbing and transferring heat to the heating area, the heat insulation reflecting plate is arranged at the bottom side of the heating assembly, and the heat insulation reflecting plate is used for isolating and reflecting heat to the heating area. According to the technical scheme, the heating rate and the electric energy utilization efficiency of the electric heating furnace are improved, the heating temperature of the electric heating furnace is improved, meanwhile, the cooling time of the furnace surface is reduced, and the use experience of a user is optimized.

Owner:TANWENG BEIJING TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com