Corrosion-resistant fully dense thermal spraying metal alloy coating and preparation method thereof

A metal alloy, thermal spraying technology, applied in the direction of metal material coating process, coating, melting spraying, etc., can solve the problem of unsuitable shape and structure, and achieve the effect of increasing the heating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A method for preparing a corrosion-resistant fully dense thermal sprayed metal alloy coating, comprising the steps of:

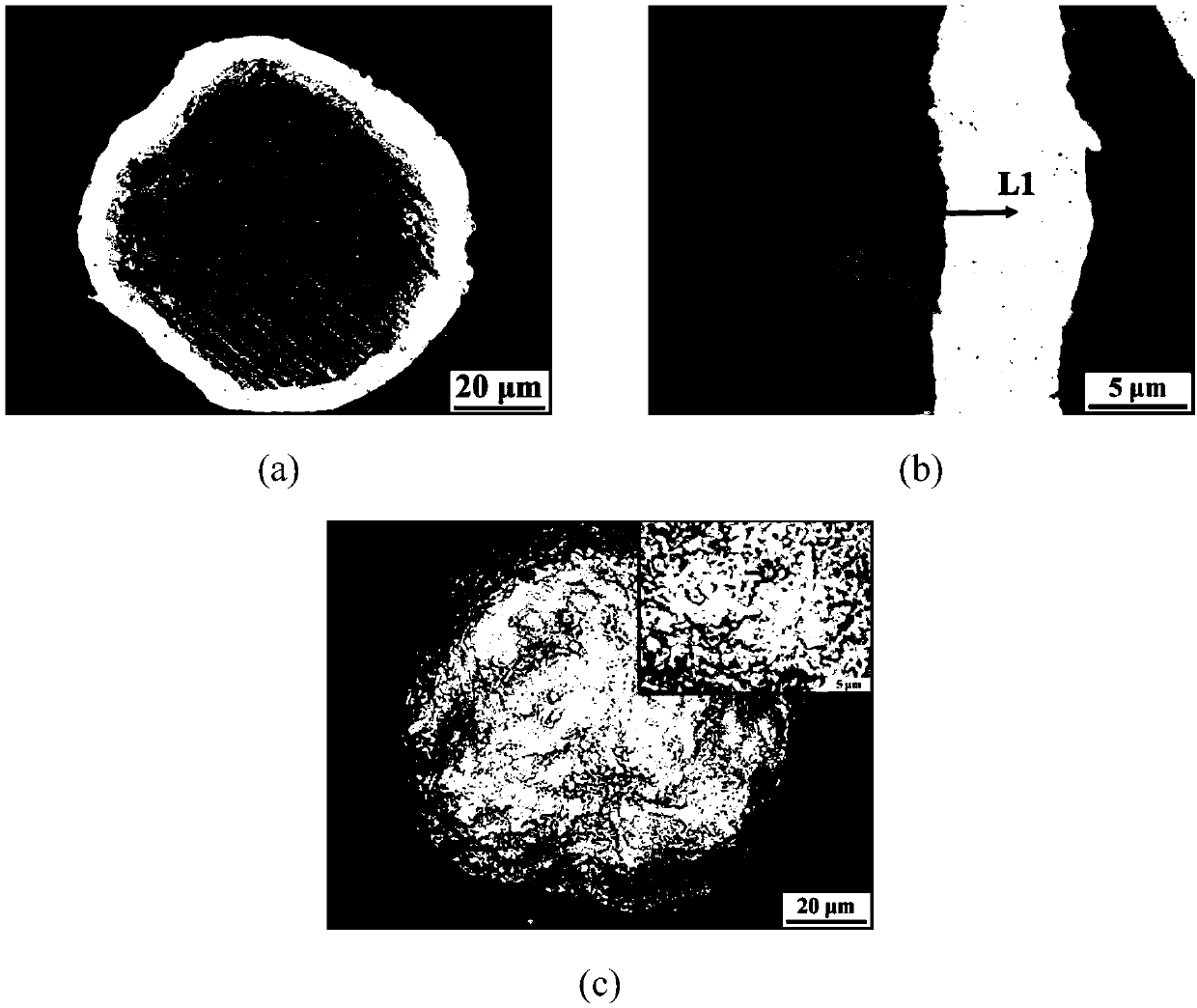

[0037] Step 1: Using Mo and Ni20Cr as typical coating shell materials and core materials as initial materials, the Mo-coated NiCr core-shell structure NiCr-20Mo composite powder prepared by ball milling mechanical alloying and subsequent heat treatment is used for coating preparation. See structure figure 1 , figure 1 Among them, (a) is the cross-sectional structure of NiCr-20Mo powder (low magnification); (b) is the cross-sectional structure of NiCr-20Mo powder (high magnification); (c) is the surface morphology of NiCr-20Mo powder; figure 1 It can be seen that the dense Mo shell is completely and uniformly coated on the surface of the NiCr core powder particles, and the Mo and NiCr core particles are metallurgically bonded together through a thin intermediate diffusion layer, thus ensuring that the particles are heated in the plasma jet. In the p...

Embodiment 2

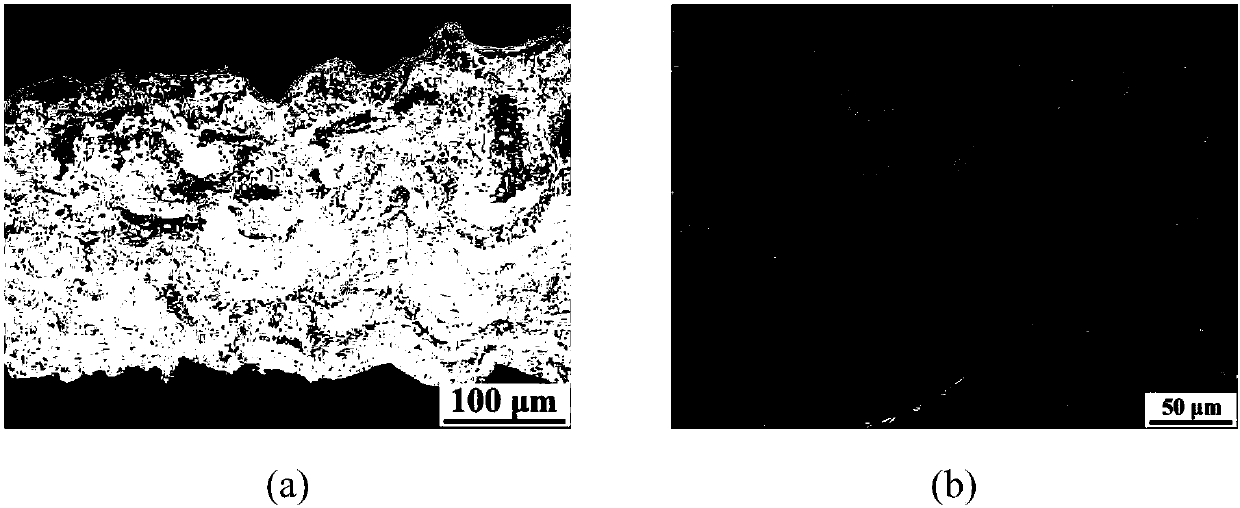

[0045] Using Mo-coated stainless steel powder as the spraying material, a 300-micron thick high-molybdenum stainless steel coating is prepared by plasma spraying on the surface of ordinary carbon steel substrates, and the coating is shot-peened with a hand-held shot-peening gun, of which 100-mesh steel is used for shot-peening Ball, the compressed air pressure for accelerating the steel ball is 0.3MPa. The corrosion resistance of ordinary low-carbon steel sprayed with coatings by electrochemical methods shows that its electrochemical potential and corrosion current are not affected by the substrate, and are completely equivalent to the coating itself, that is, the coating has achieved a good effect on the low-carbon steel substrate. Complete corrosion protection.

Embodiment 3

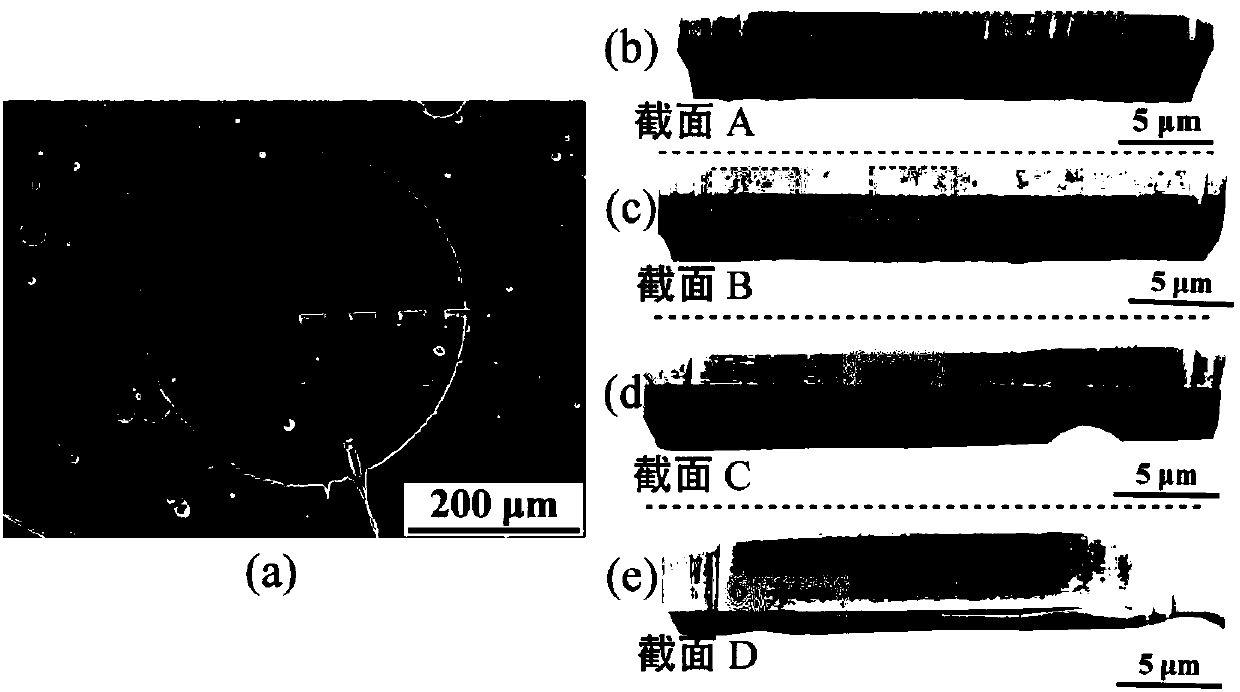

[0047] Use Mo-coated FeAl powder as the spraying powder, and use plasma spraying to prepare a 150-micron thick coating on the surface of heat-resistant steel, and use a hand-held sandblasting gun to carry out shot peening treatment on the coating, wherein the shot peening uses 60-mesh steel balls, compressed The air pressure is 0.4MPa. The corrosion resistance test for 50 hours under the simulated corrosive atmosphere of a garbage incinerator at 400°C to 650°C shows that the coating prepared by the present invention has basically no sulfidation corrosion, chloride corrosion, hydrochloric acid corrosion, etc., and has excellent high temperature corrosion resistance performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com