Patents

Literature

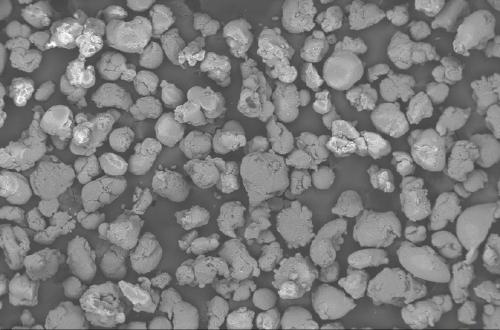

38results about How to "Regular particle shape" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Artificial graphite negative-pole material, preparation method therefor and lithium-ion battery

ActiveCN110642247AImprove stabilityRegular particle shapeCarbon compoundsCell electrodesChemistryHigh energy

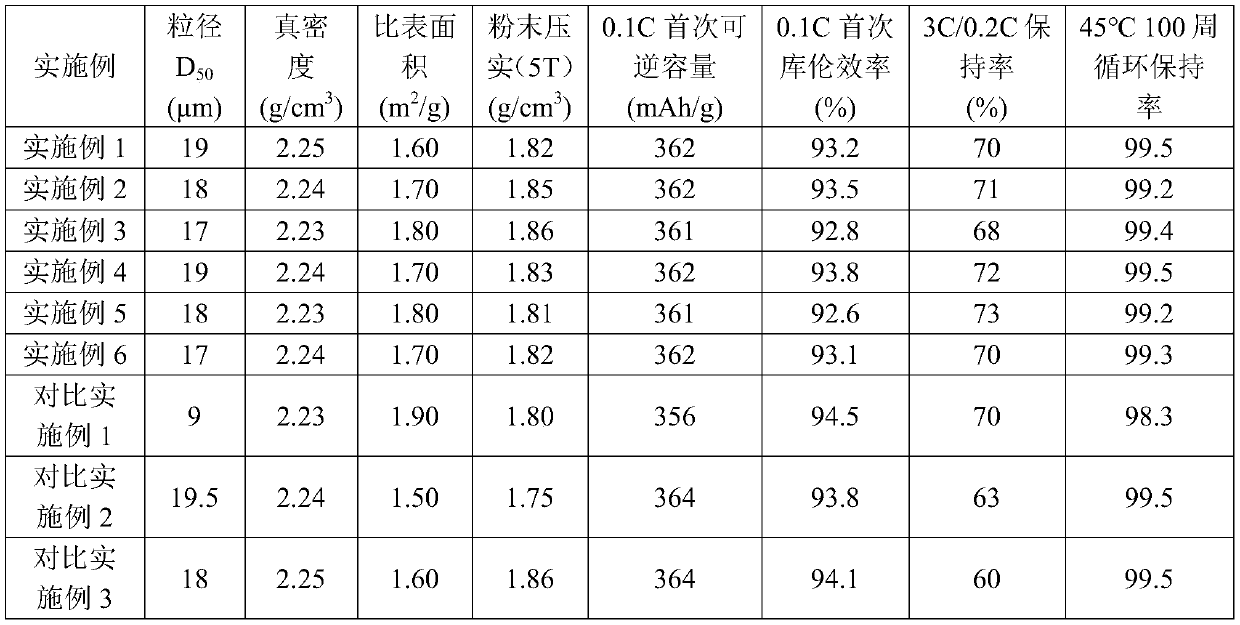

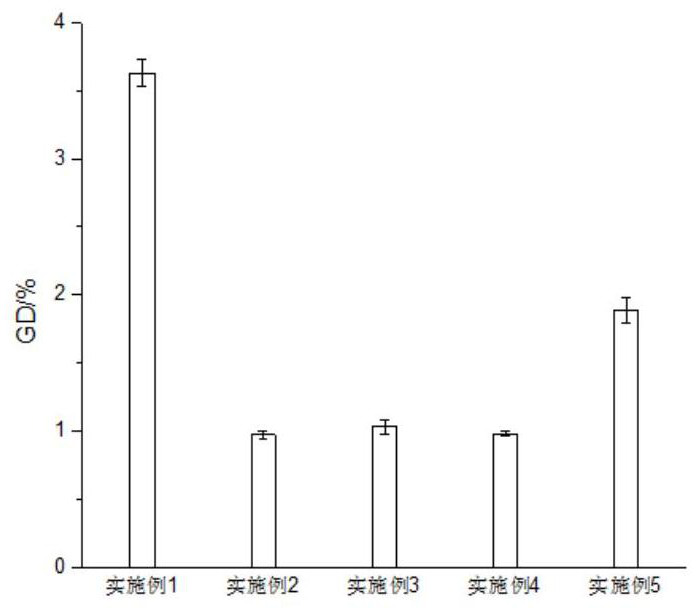

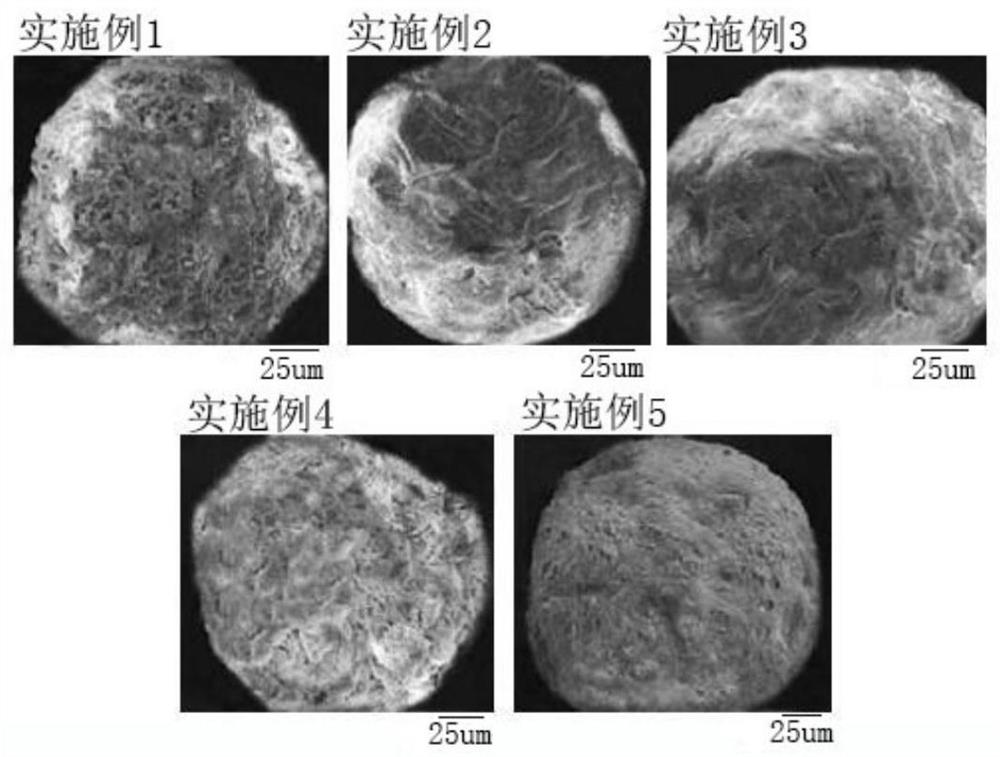

The invention discloses a preparation method for rate type artificial graphite negative-pole material with high energy density. The preparation method comprises the following steps: subjecting raw material cokes to coarse breaking and pulverizing directly or coarse breaking, high-temperature modifying and then pulverizing, and carrying out reshaping treatment, so as to obtain primary granules A; kneading the primary granules A and an organic carbon source, then, carrying out dynamic thermal coating, and carrying out screening, so as to obtain primary granules B; uniformly mixing the primary granules A with a binder, then, subjecting the mixture to granulating in a granulating reactor, and carrying out screening, so as to obtain secondary granules C; subjecting the primary granules B and the secondary granules C to graphitizing separately, and carrying out screening, so as to obtain graphitized primary granules B and graphitized secondary granules C; and uniformly mixing the graphitizedprimary granules B and the graphitized secondary granules C proportionally, and carrying out screening, thereby obtaining a finished product. The preparation method is simple in process and easy in quality control; and by applying the artificial graphite negative-pole material prepared by adopting the method to a lithium-ion battery, the lithium-ion battery is large in capacity, good in cycle andexcellent in quick charging performance.

Owner:贵州凯金新能源科技有限公司

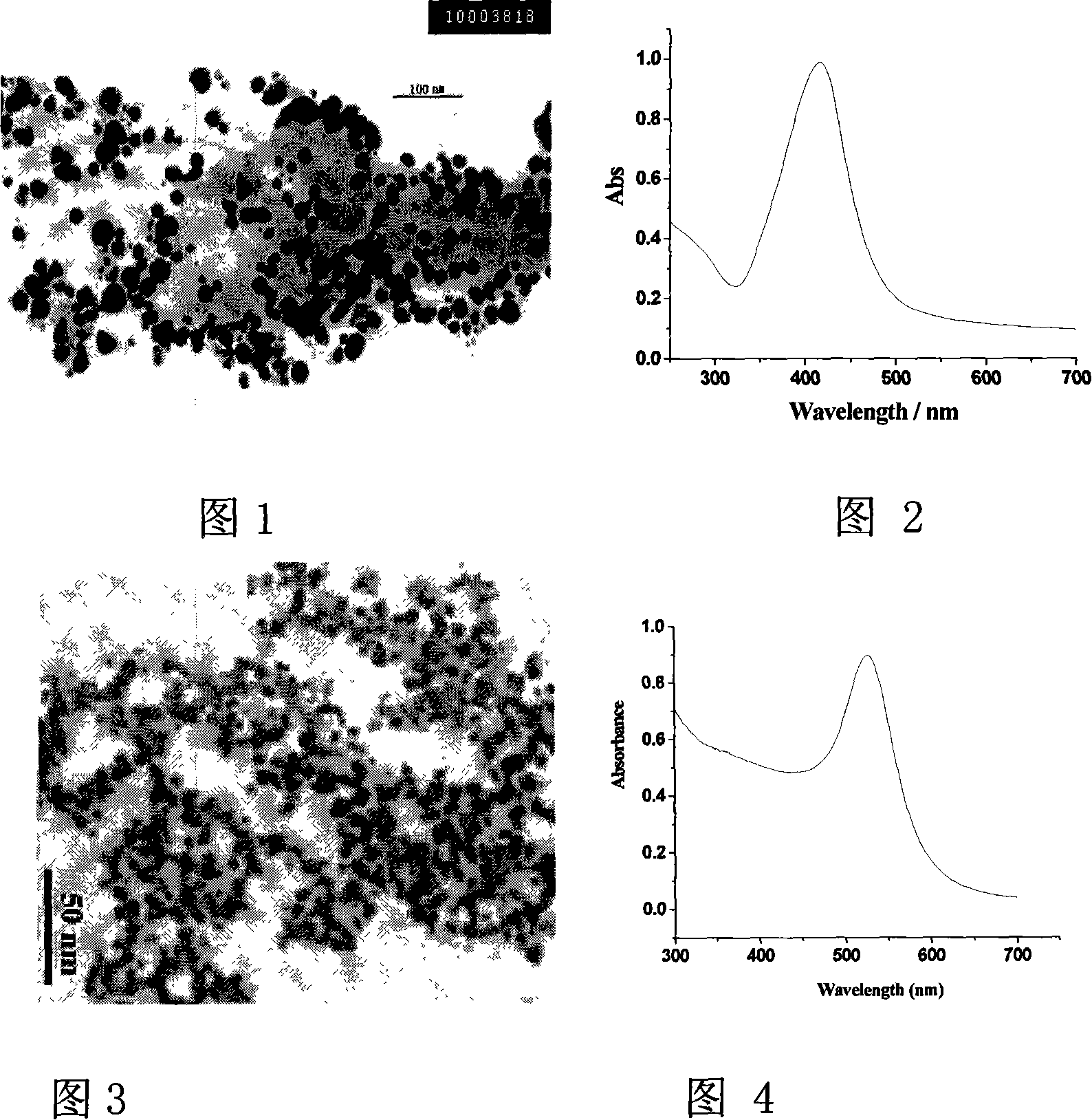

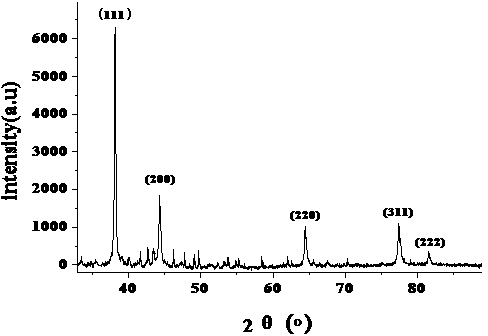

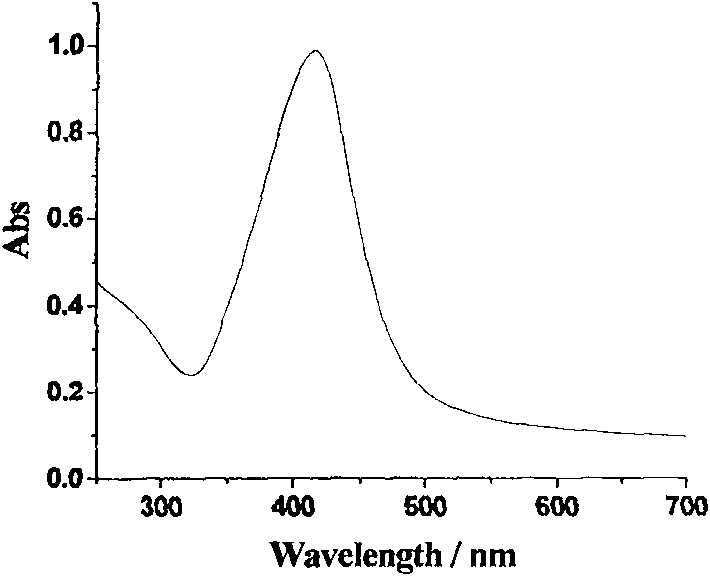

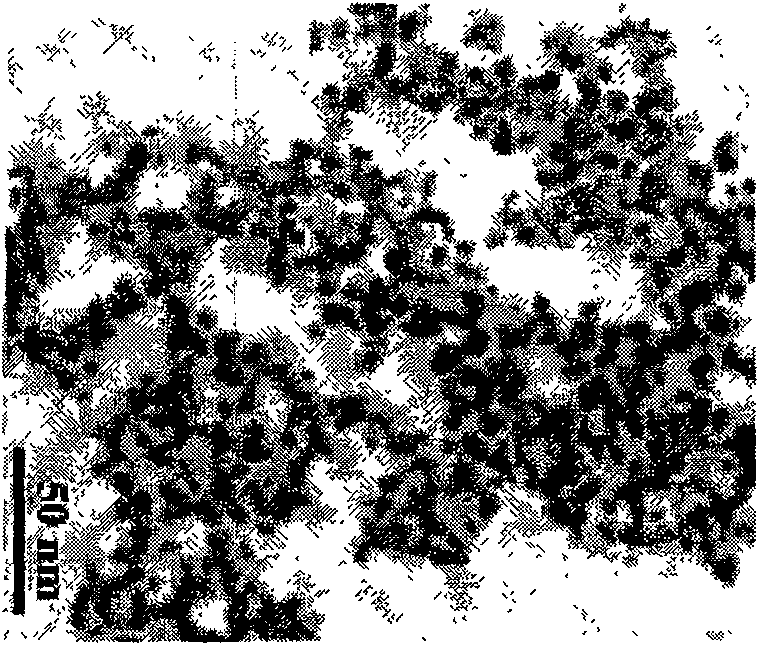

Microwave preparing method for nanometer silver or gold

The present invention discloses a microwave producing method for nano-silver or gold; the reactants are added into the reactor according to the proportion of 1 to 1; the reactants are silver nitrate or auric chloride acid and starch or sodium carboxymethyl cellulose; the reactor is put into a microwave oven; with a mixer of a rotation speed of 100 / min and the microwave power of 0.3 Kw, the reaction time of the reactant starch is one hour while the time of the reactant sodium carboxymethyl cellulose is seven hours; the solution is dried by air or vacuum freeze or spraying after the reaction is over to produce nano-silver or gold powder or concentrated to nano-silver or gold colloid of the needed consistency through vacuum concentration. The present invention discards the ordinary reducing agent in thermochemical synthesis and takes the microwave heating to replace the traditional local heating method and realize homogeneous growing of nano-silver or gold; the grain size distribution of the nano-silver and gold is narrow and the grain shapes are regular; the method is widely used in biochemical and antiseptic material field.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

Process for preparating medical polyvinyl chioride resin with high polymerization

InactiveCN1657545ARegular particle shapeConcentrated resin particle size distributionCatheterSingle useDisperser

A process for preparing the medical polyvinyl chloride resin with high polymerization degree includes such steps as adding vinyl chloride, trigger, disperser, assistant and water to reactor, polymerizing reaction, adding reaction-stopping agent, removing excessive vinyl chloride, centrifugal dewatering and drying.

Owner:上海天原集团天原化工有限公司

Preparation method of PVC (polrvinyl chloride) resin with high porosity and low film coverage rate

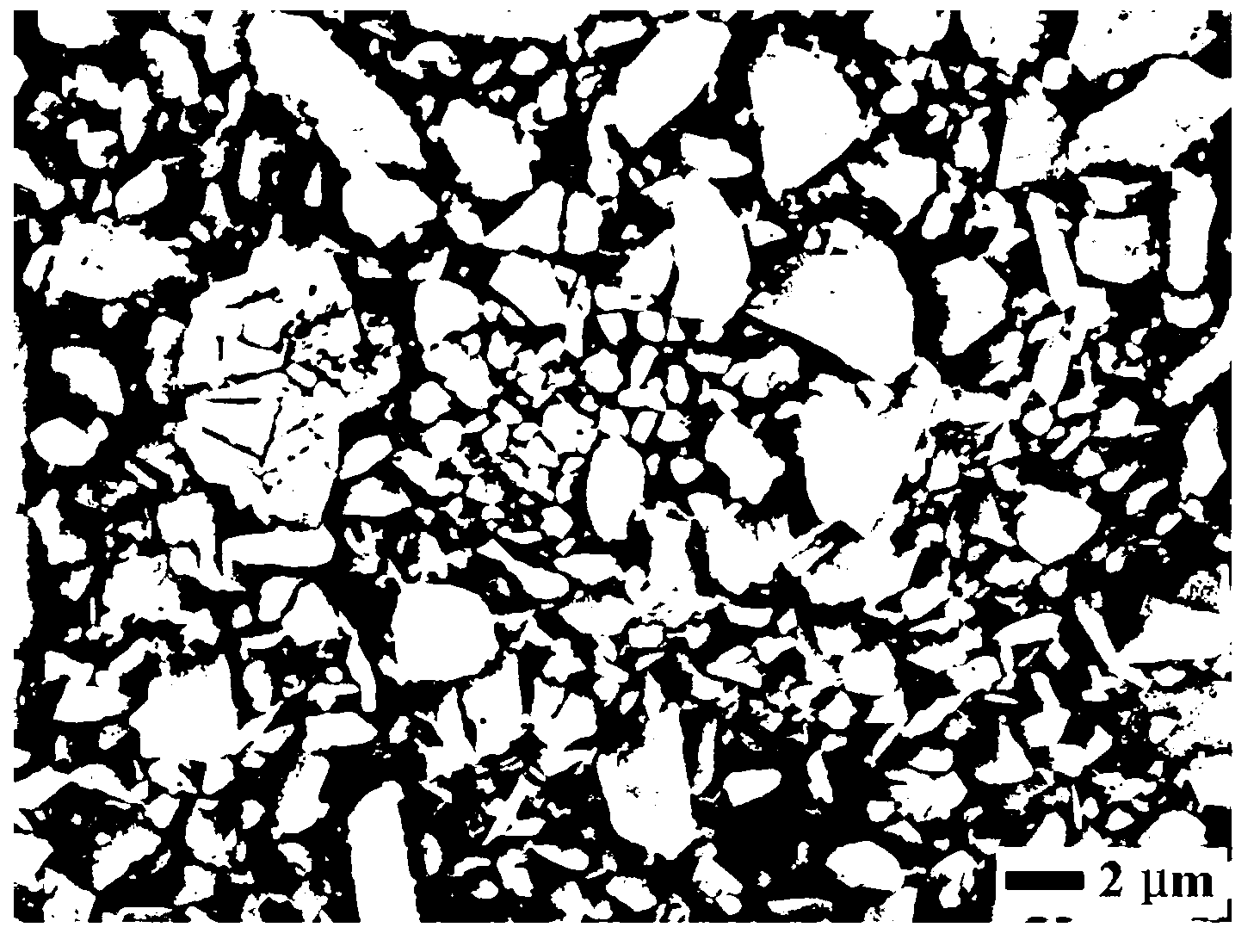

The invention discloses a preparation method of a PVC resin with high porosity and low film coverage rate, which adopts suspension polymerization. The preparation method is characterized in that the preparation method comprises the following steps: 1, adding water, a vinyl chloride monomer, a composite dispersion system, a porosity conditioning agent, a chain transferring agent, a pH buffer and an initiator to a polymerization reactor; 2, carrying out a polymerization reaction on above materials in the polymerization reactor under conditions that the pressure is 0.90-1.20MPa and the temperature is 50-75DEG C; 3, adding a reaction terminator when the polymerization temperature is maintained and the polymerization pressure is decreased to 0.1-0.30MPa; 4, discharging the residual vinyl chloride monomer; and 5, collecting the target product from reaction products, wherein the composite dispersion system is a mixture of partially-alcoholized polyvinyl alcohol and partially-alcoholized hydroxypropyl methyl cellulose. The PVC resin prepared with the method disclosed in the invention has the advantages of high porosity, less fisheye, low film coverage rate, structured particle form, concentrated resin particle size distribution, and easy residual monomer removal.

Owner:CHINA PETROLEUM & CHEM CORP

Polyvinyl alcohol, and preparation method and application thereof

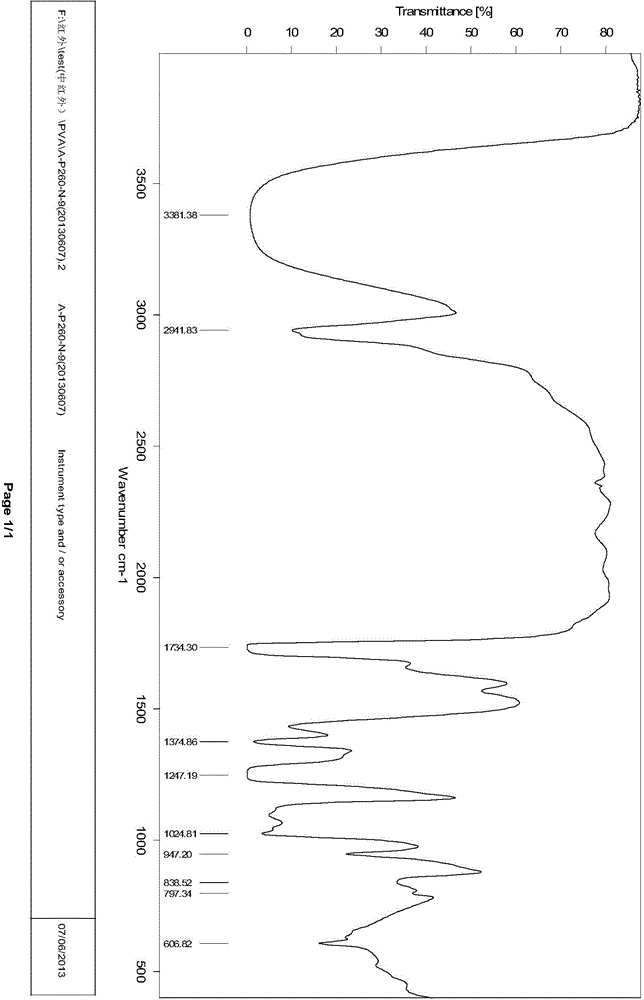

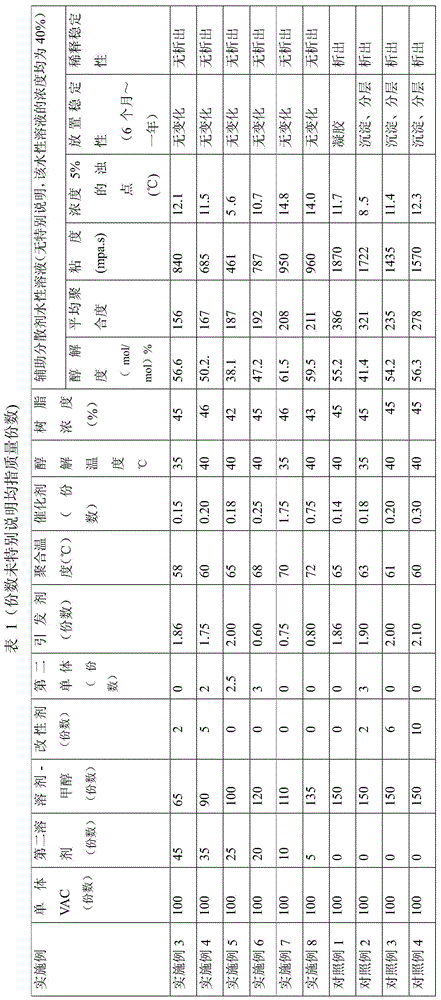

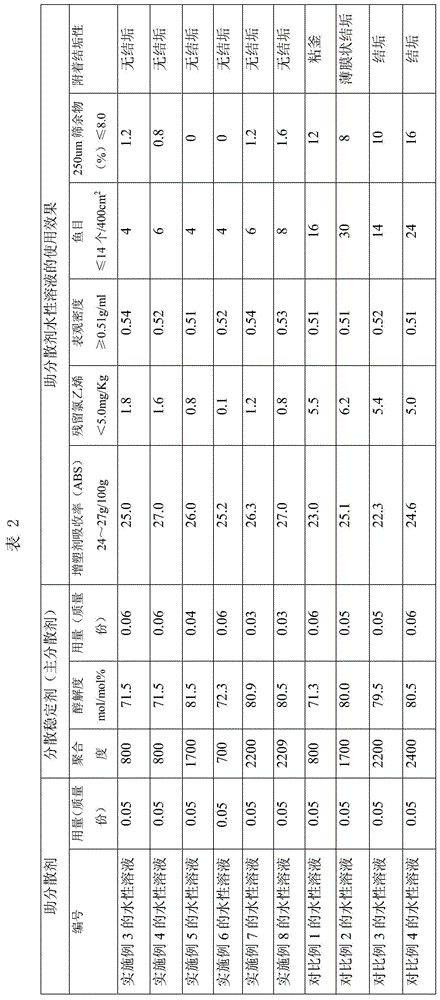

The invention provides polyvinyl alcohol, which is characterized by having the average degree of polymerization in a range of 50-500, the alcoholysis degree in a range of 30-65 mol%, and the viscosity no more than 1500 mPa*s. Polyvinyl alcohol is prepared into an aqueous solution, which is taken as an auxiliary dispersant for suspension polymerization of vinyl polymers. The cloud point of an aqueous solution, the concentration of which is 5 wt%, (that is, a polyvinyl alcohol aqueous solution of 5 wt%), is no less than 1 DEG C and less than 15 DEG C. The viscosity measured at 25 DEG C of an aqueous solution, the concentration of which is 40 wt%, is no more than 1500 mpa*s. Gel and layering don't appear in an aqueous solution, the concentration of which is in a range of 30wt%-50wt%, in at least one year, so that the aqueous solution is extremely excellent in stability.

Owner:CHINA PETROCHEMICAL CORP +1

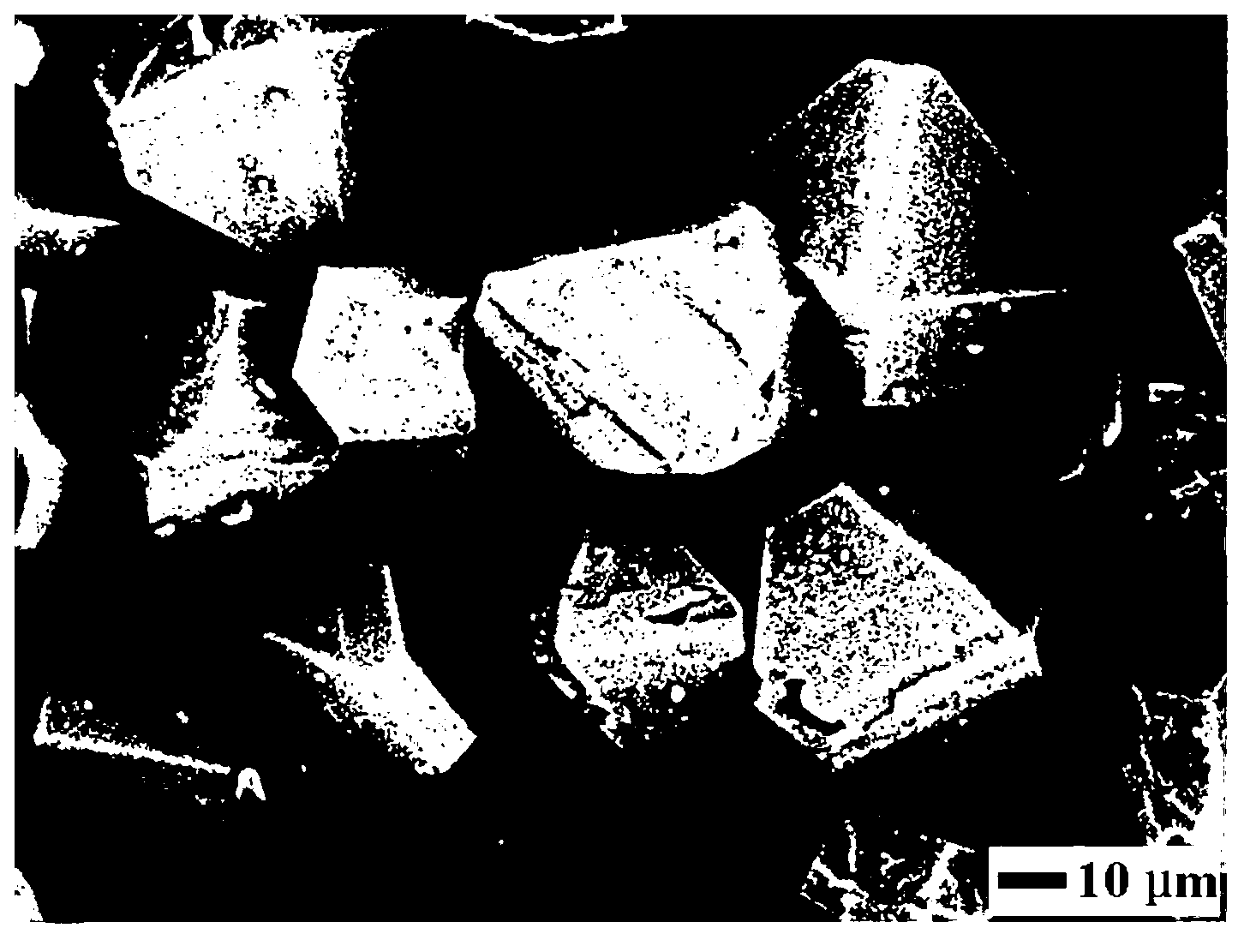

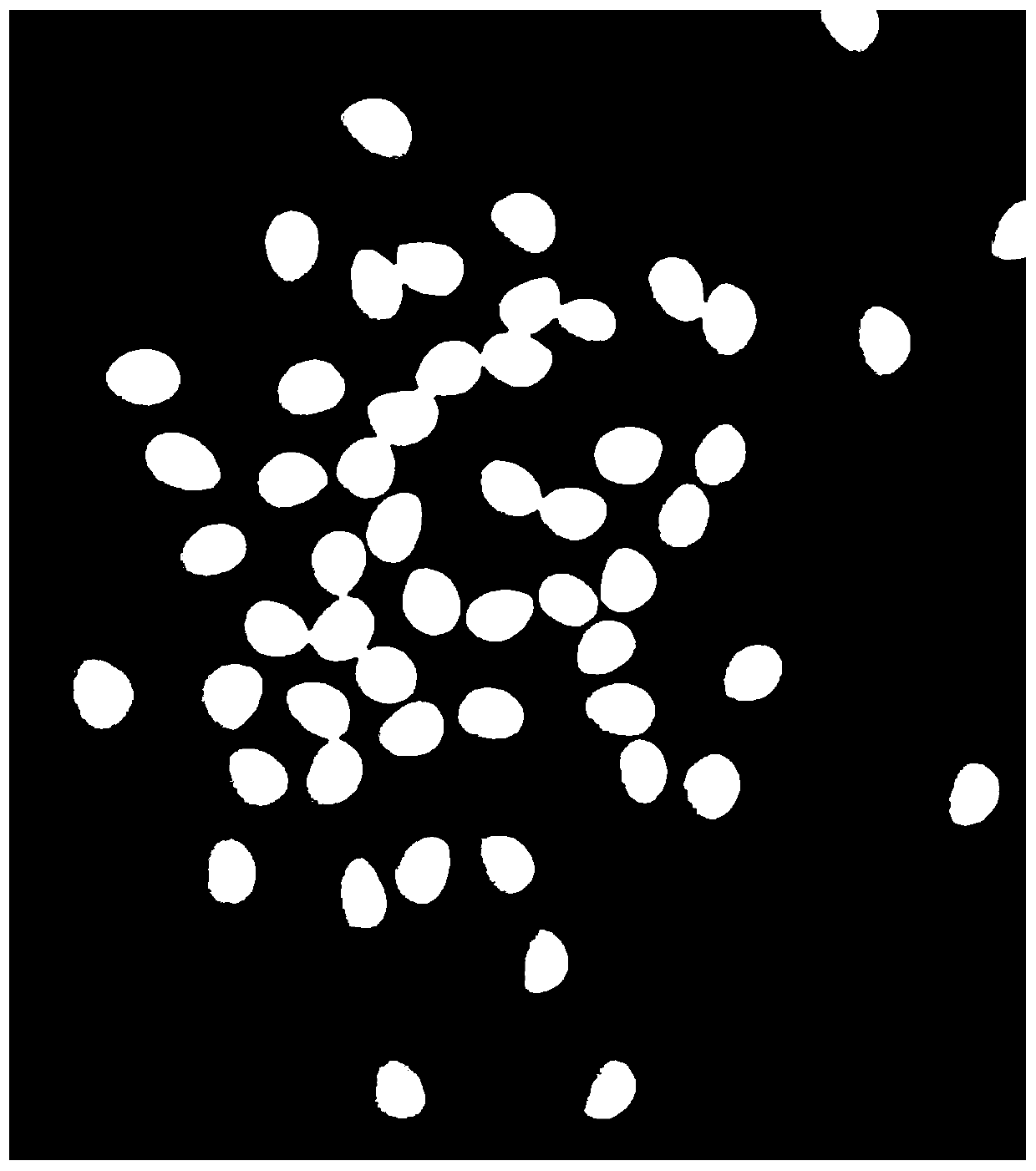

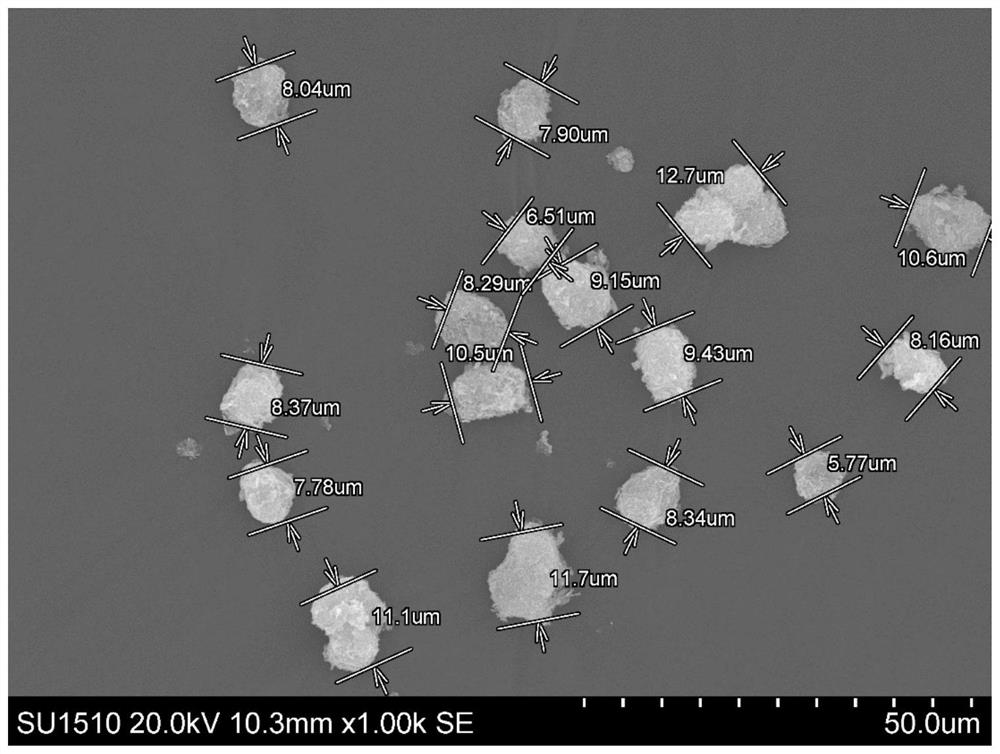

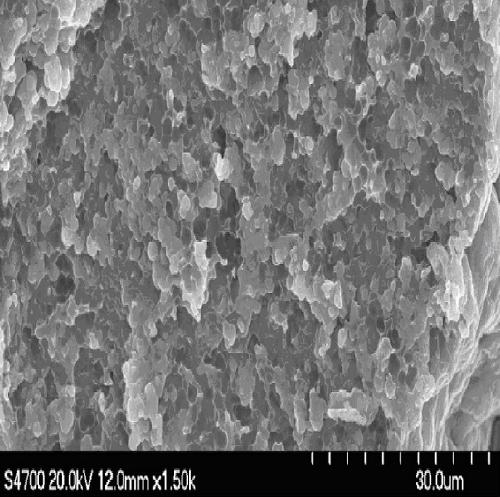

Preparation method of hexaazaisowurtzitane crystal

ActiveCN103214325ARegular particle shapeUniform particlesExplosive working-up apparatusSingle substance explosivesMechanical crushingTwo step

The invention discloses a preparation method of a hexaazaisowurtzitane crystal. The preparation method of the hexaazaisowurtzitane crystal comprises the following steps of: carrying out wet-crushing onto explosives until the particle dimension is 0.1 micron to 5 microns, centrifuging, washing, freezing and drying the crushed materials; placing the material in the step I to a solvent for carrying out ultrasonic treatment, heating, re-filtering, washing and drying under the standing condition or the stirring condition to obtain a hexaazaisowurtzitane explosive crystal. According to the preparation method of the hexaazaisowurtzitane crystal, the high-quality explosive crystal product, which is prepared by a preparation technology adopting a two-step process including mechanical crushing and solvent thermal-induction growing, is regular in particle shape, jewel-shaped, uniform in particle dimension, smooth in surface, less in internal defects of the crystal, and lower in mechanical sensitivity. Besides, the preparation method of the hexaazaisowurtzitane crystal is simple in process, gentle in reaction conditions, good in reproducibility, high in yield and suitable for large-scale industrial production.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Method for producing high-degree of polymerization polyvinyl chloride resin by using suspension method

The invention discloses a method for producing high-degree of polymerization polyvinyl chloride resin by using a suspension method, which comprises the following steps of: step 1, charging by adopting a constant-temperate water feeding technology, a whole-process airtight feeding technology and a DCS (Distributed Control System) automatic control technology; step 2, producing the high-degree of polymerization polyvinyl chloride resin by adopting a low-temperature method; and step 3, obtaining the high-degree of polymerization polyvinyl chloride resin with a degree of polymerization of 1700-3000. With the adoption of the method for producing the high-degree of polymerization polyvinyl chloride resin by using the suspension method, the high-degree of polymerization polyvinyl chloride resin with a degree of polymerization of 1700-3000 can be produced in a 70 m<3> polymerization kettle system, has the advantages of low energy consumption, large batch production and stable quality and can be produced in the whole year.

Owner:HANGZHOU ELECTROCHEM GROUP

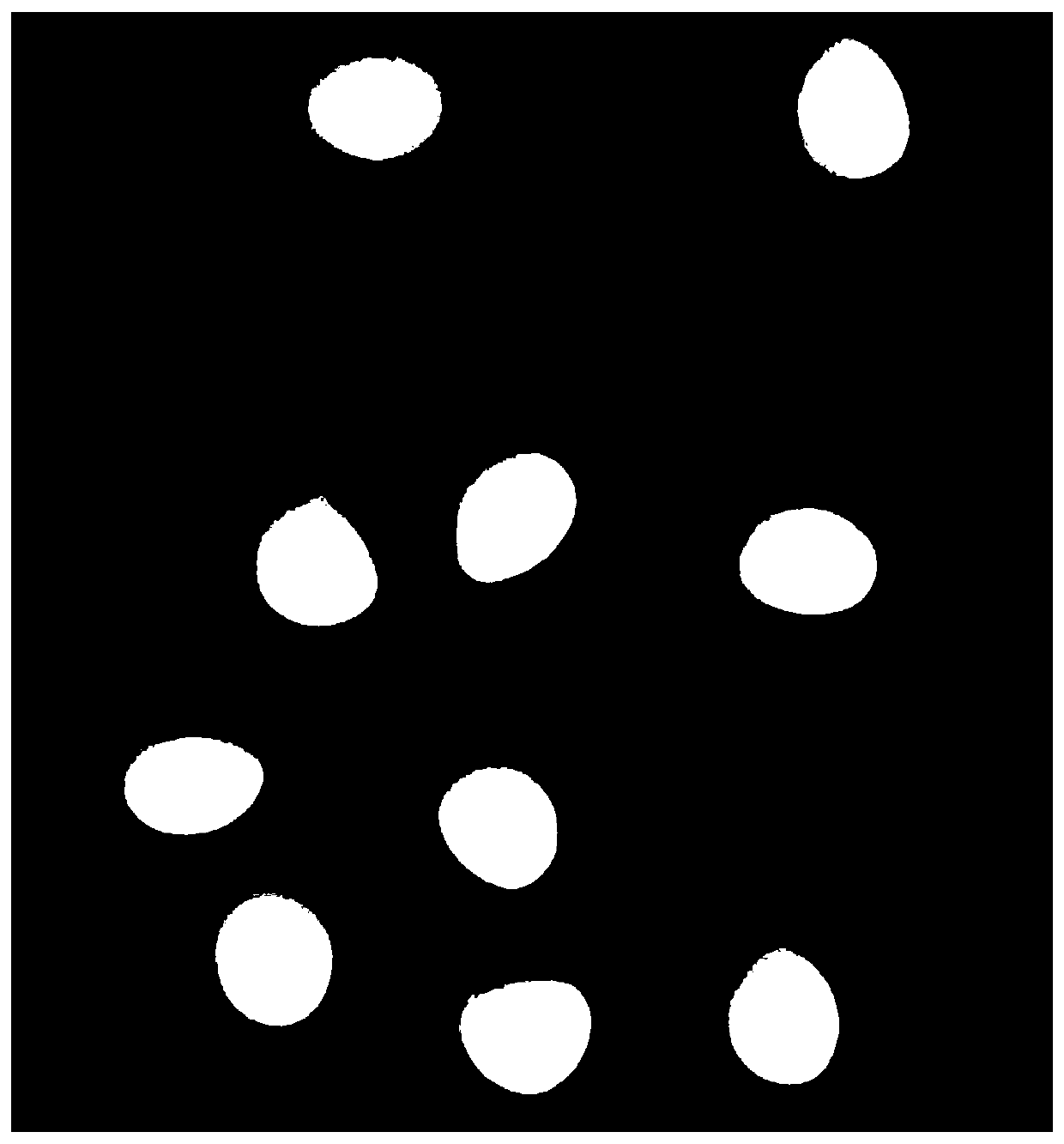

Method for preparing submicron polycrystalline diamond abrasive with narrow particle size distribution

ActiveCN102250582AWide particle size distributionNarrow particle size distributionOther chemical processesMicrometerGranularity

The invention relates to a method for preparing submicron polycrystalline diamond abrasive with narrow particle size distribution, which comprises the following steps: (1) preparing pulp; (2) reshaping; and (3) centrifugally grading. In the invention, a submicron diamond product can be prepared by reshaping polycrystalline diamond powder of a particle size of 0.5 to 10 micrometer in a planet mill, superfine mill or supersonic pneumatic mill and grading in a high-speed centrifugal machine, wherein the particle sizes of the product may be 0.125 micrometer, 0.25 micrometer, 0.5 micrometer, 0.75 micrometer, 1 micrometer and 1.5 micrometers. The performance of the product is represented by the narrow particle size distribution of the product and regular particle shape. The product of the method is very suitable for fine polishing of sapphire, precision ceramics, optical crystals and metal molds; and after a sapphire wafer for an LED substrate is polished by the 0.5-micrometer diamond prepared by the method, the surface roughness of the sapphire wafer is 2.81 nanometers. The method is short in production period and is convenient for enlarging production scale.

Owner:盘锦国瑞升科技有限公司

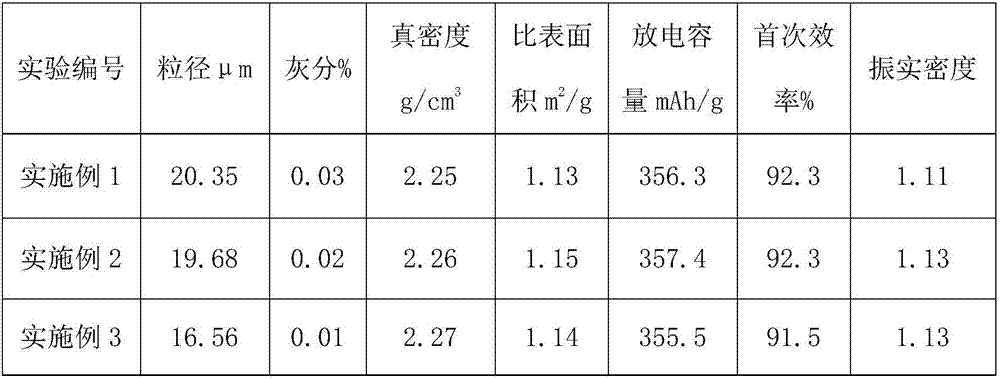

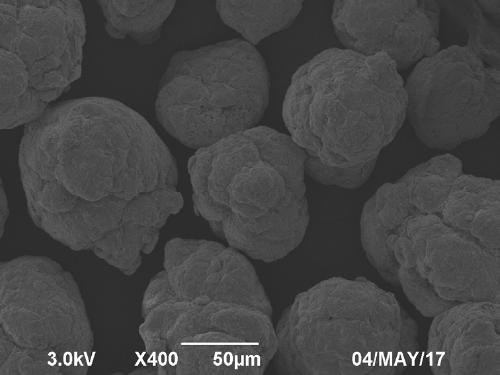

Composite graphite negative electrode material for lithium ion batteries and preparation method thereof

InactiveCN107316983AHigh tap densityRegular particle shapeCell electrodesSecondary cellsGramSurface modification

The invention discloses a composite graphite negative electrode material for lithium ion batteries and a preparation method thereof. The preparation method comprises the following steps: mixing a synthetic graphite raw material, a natural graphite raw material and an adhesive in a mass proportion of 100: (55 to 65): (3 to 7); under inert gas shielding, putting the mixed materials into a low-temperature surface modification reaction kettle, warming and stirring to obtain a cladding body; carrying out carbonizing treatment on the cladding body; enabling the cladding body through carbonizing treatment to enter into a fusing machine for normal temperature modification to prepare a fusing body, and carrying out graphitization treatment on the fusing body in inert gas to prepare the negative electrode material for lithium ion batteries. According to the graphite negative electrode material for lithium ion batteries disclosed by the invention, the specific capacity is not smaller than 355 mAh / g, and the first charging and discharging efficiency is more than 91.0%; and the graphite negative electrode material has relatively high gram volume, is extremely high in rate capacity and cycle performance and stable in performance, and can be widely applied to negative electrode materials of the lithium ion batteries.

Owner:NINGBO SHANSHAN NEW MATERIAL TECH

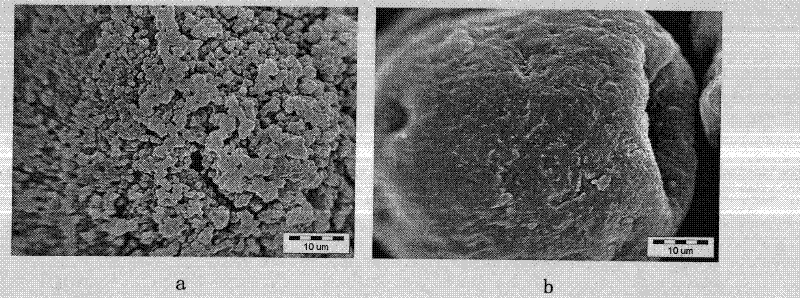

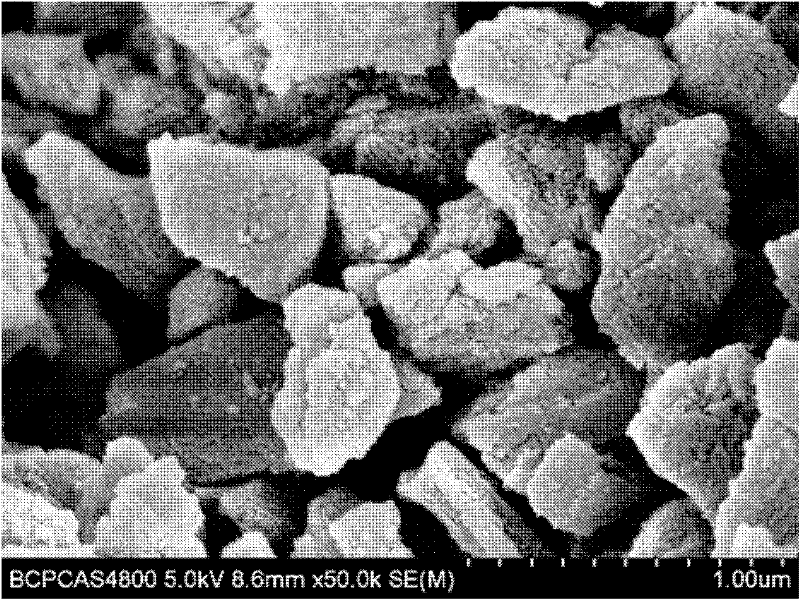

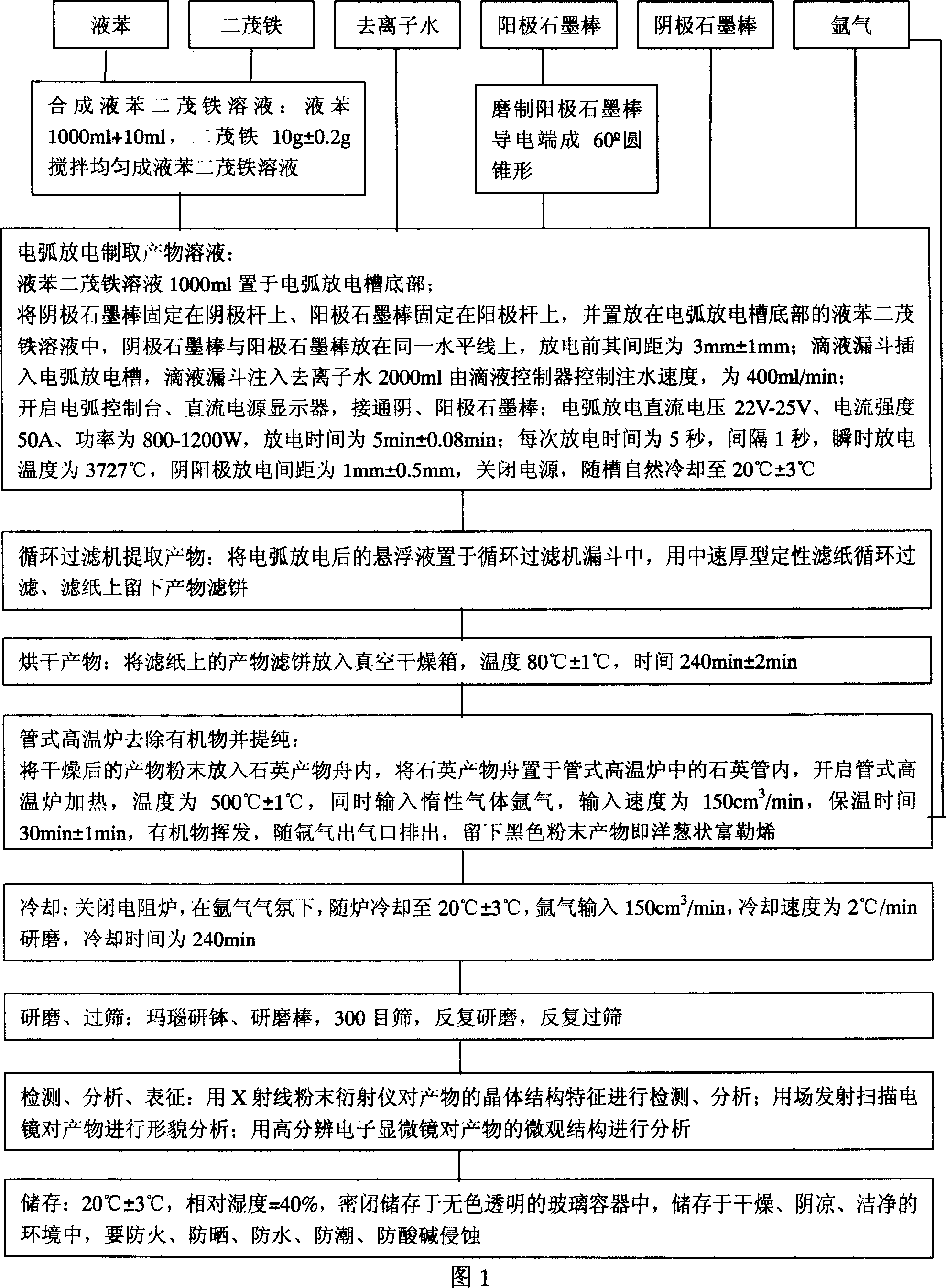

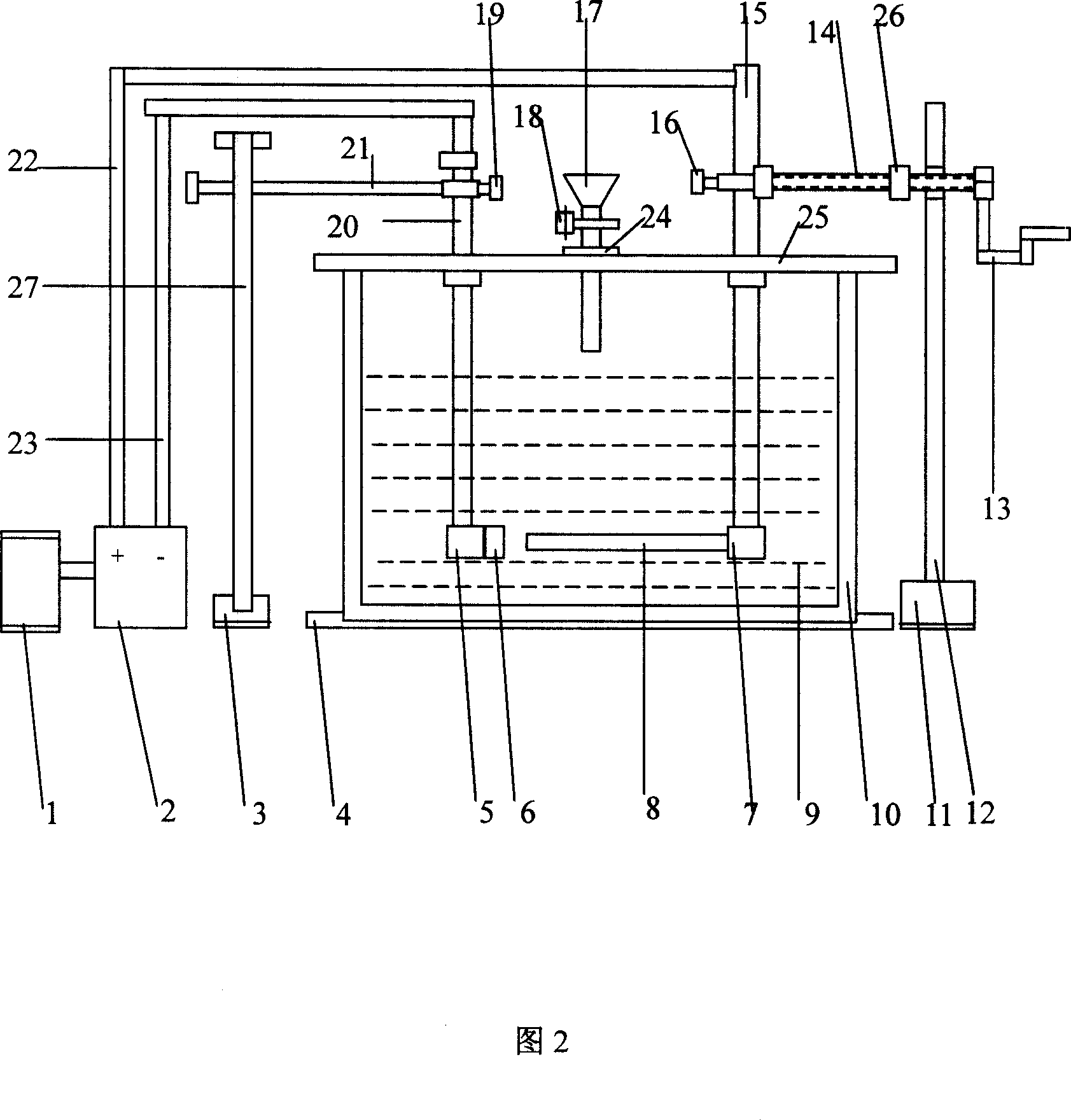

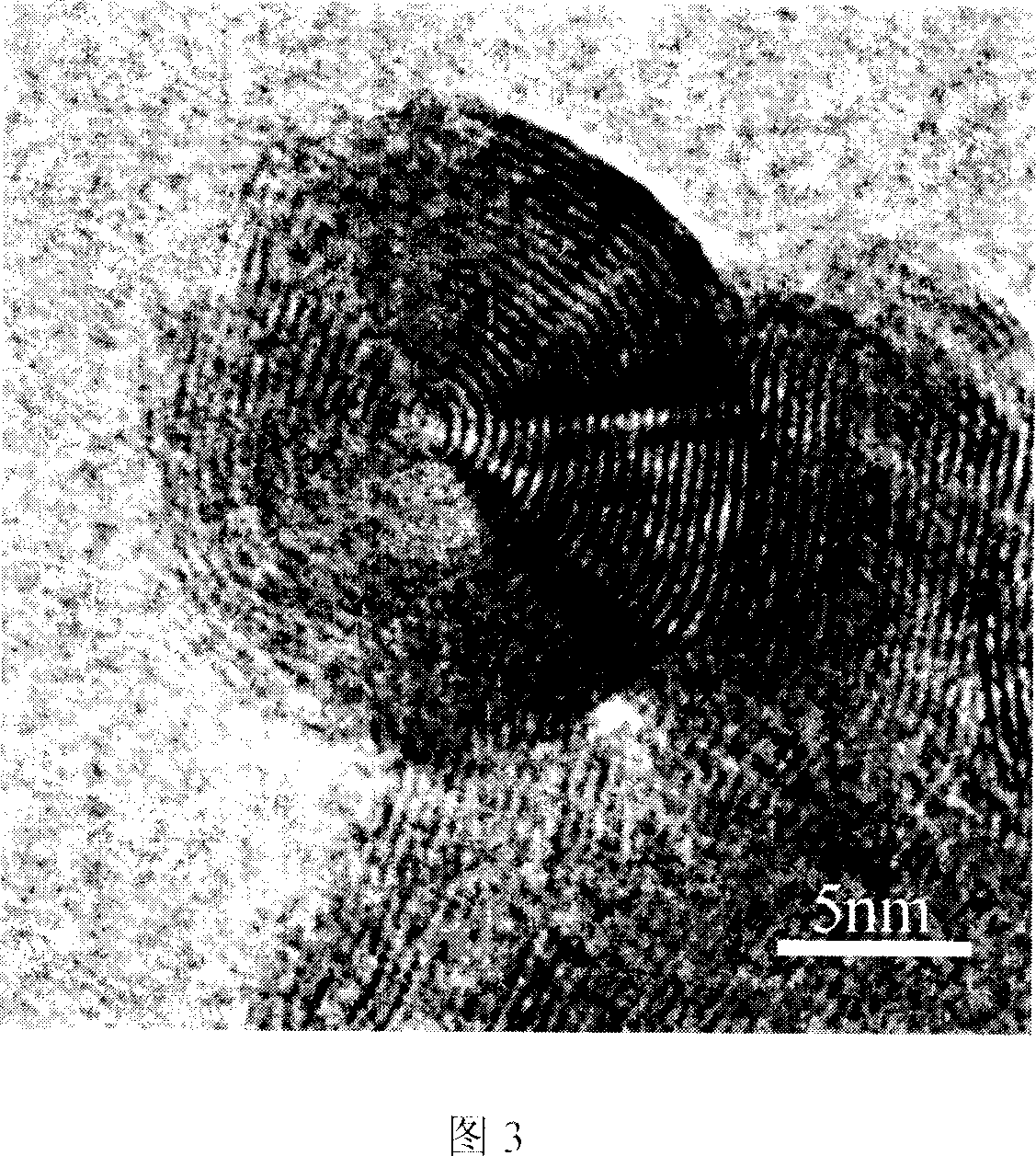

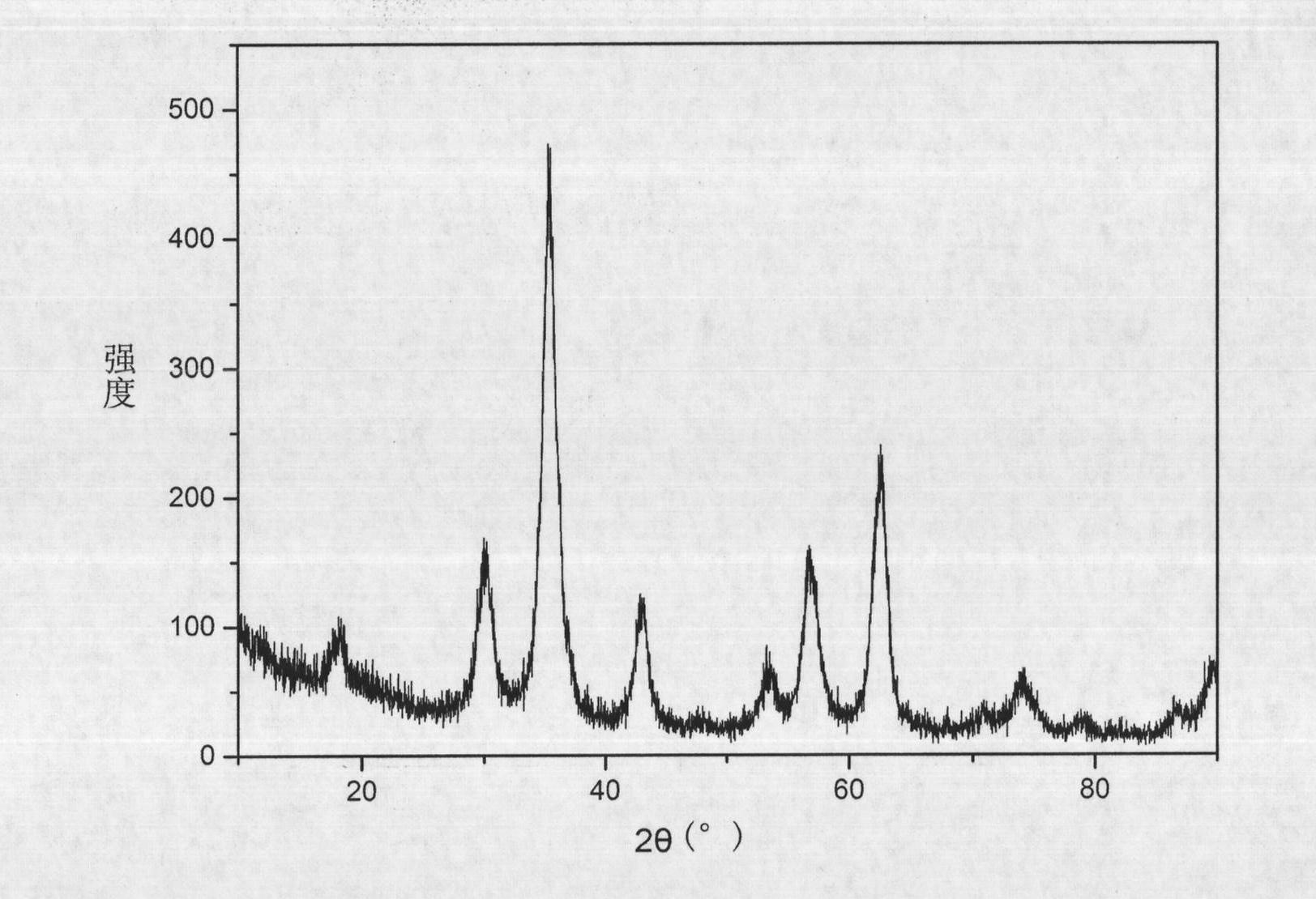

Liquid benzene medium arc discharge process of preparing onion-shaped fullerene

The present invention is liquid benzene medium arc discharge process of preparing onion-shaped fullerene. Through arc discharge with liquid benzene as material and discharge medium, ferrocene as catalyst, deionized water as coolant, air as isolator and graphite rod as electrodes, inside arc discharge trough, and at DC voltage of 22V-25 V, current of 50 A and power of 800-1200 W, suspension solution is prepared; and through further filtering in a filtering machine, purification in a tubular high temperature furnace, grinding, sieving and vacuum drying, nanometer level onion-shaped fullerene is obtained at yield of 70 %. The nanometer level onion-shaped fullerene has regular layered molecule arrangement, powder size of 10-30 nm, stable chemical and physical properties and high graphitization degree, and may be used in many industrial fields.

Owner:TAIYUAN UNIV OF TECH

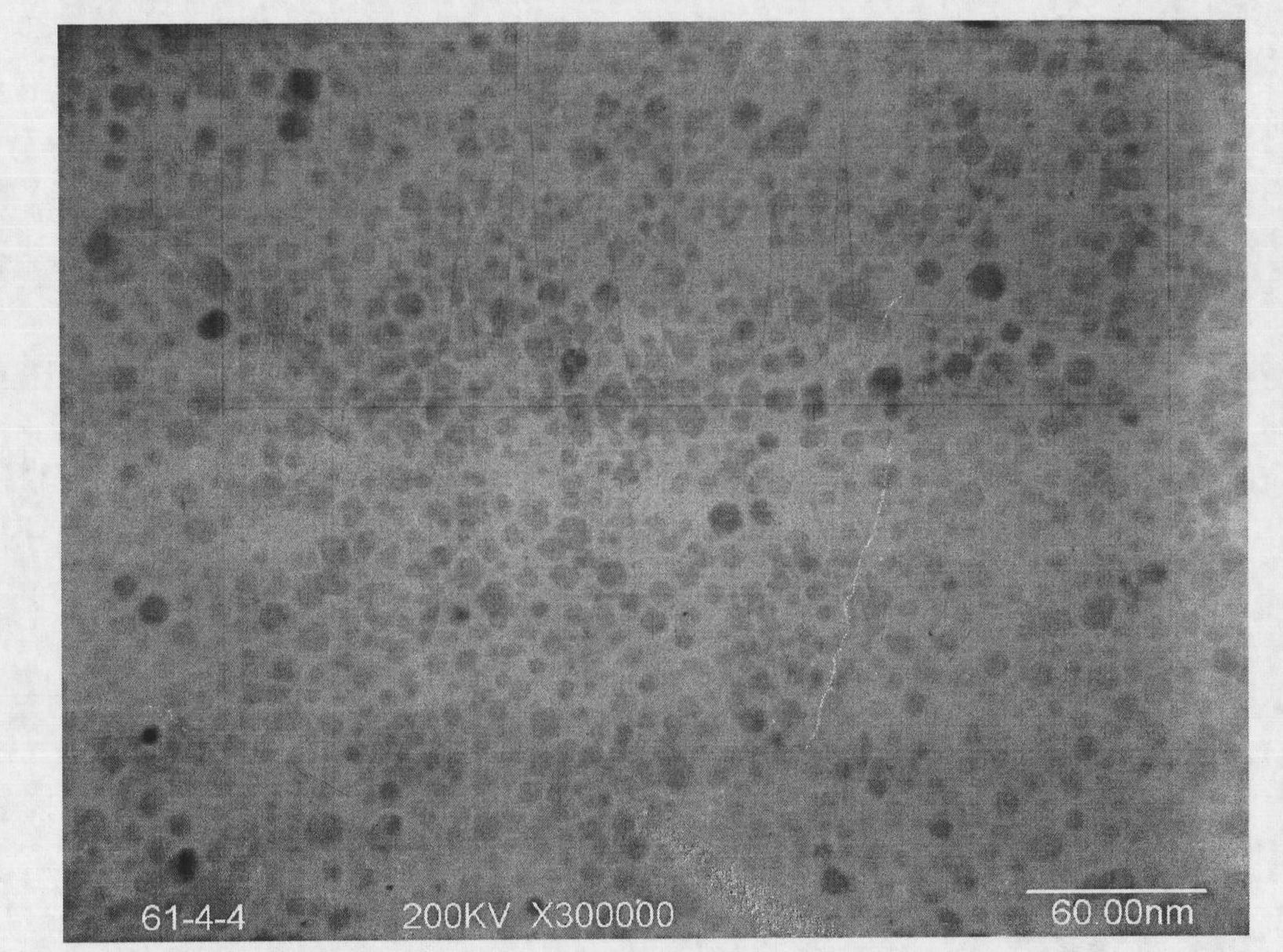

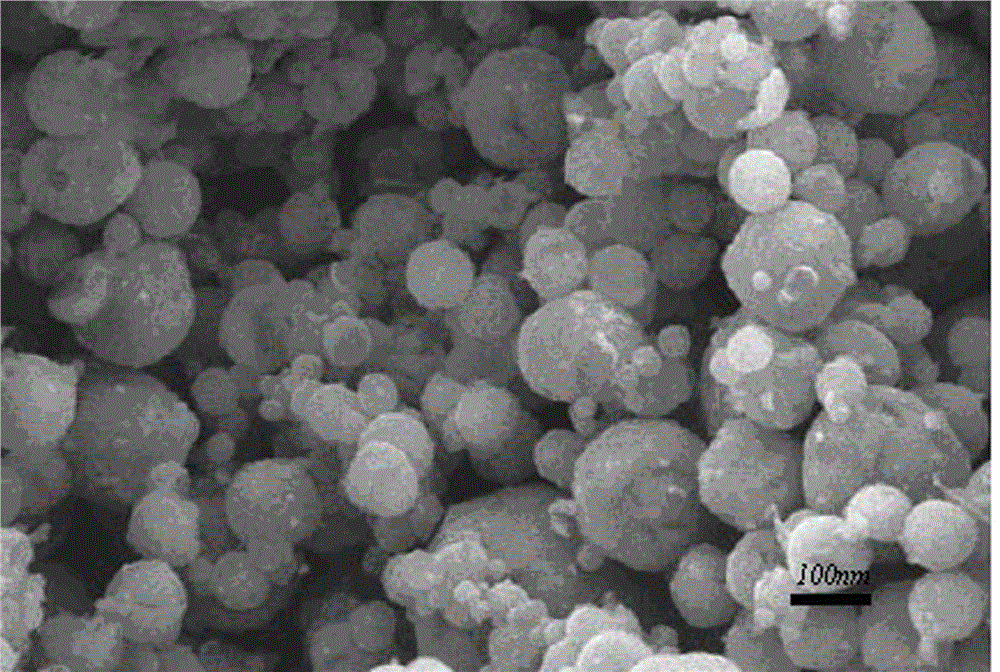

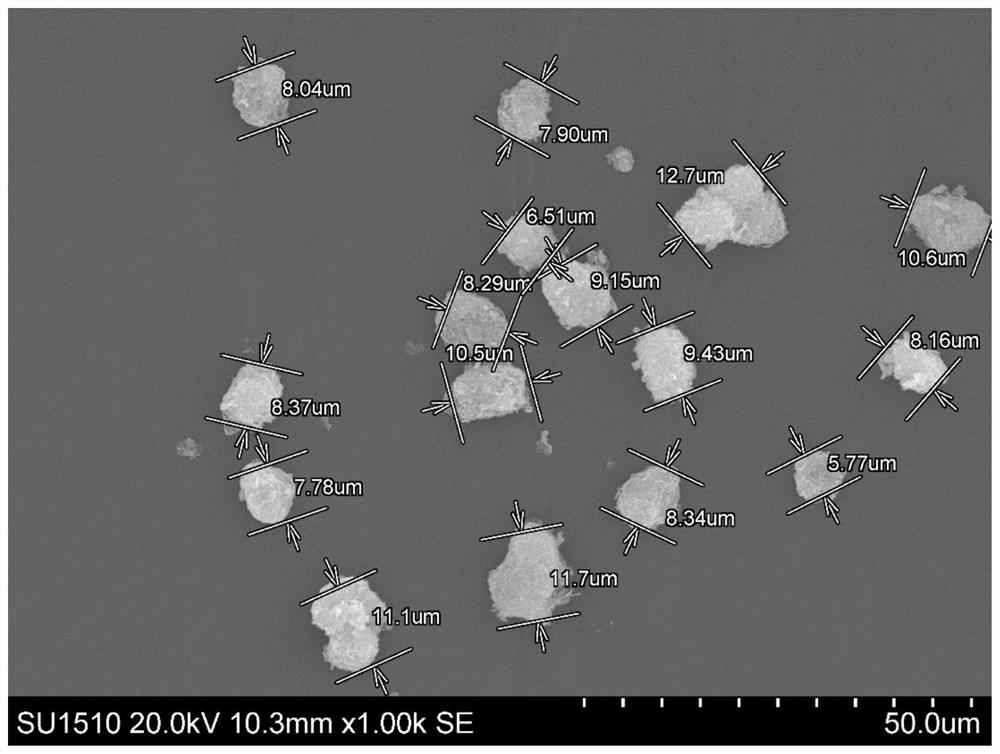

Preparation method of monodisperse ferrum-acid-nickel-zinc nano material

InactiveCN101851011AReduce manufacturing costEasy to operateNanostructure manufactureNickel compoundsAir atmosphereNitrogen gas

The invention provides a preparation method of a monodisperse ferrum-acid-nickel-zinc nano material. In the method, acetylacetone nickel, acetylacetone zinc and acetylacetone ferrum are used as raw materials, octadecylamine is used as a ligand, diphenyl ether is used as a solvent, and thus the monodisperse ferrum-acid-nickel-zinc nano material is prepared by adopting high-temperature pyrolysis in an air atmosphere. The invention has the characteristics that the octadecylamine is adopted as one ligand and is also a solvent during reaction so that the raw materials are saved; the method has no need of nitrogen protection; and the conditional operation is simplified, and the preparation cost is lowered. The ferrum-acid-nickel-zinc nano material prepared by using the method has the advantages of high purity and regular particle shape, wherein the particles are both regularly approximate spheres, and the sizes of the nano particles are 6-12 nm.

Owner:BEIJING UNIV OF CHEM TECH

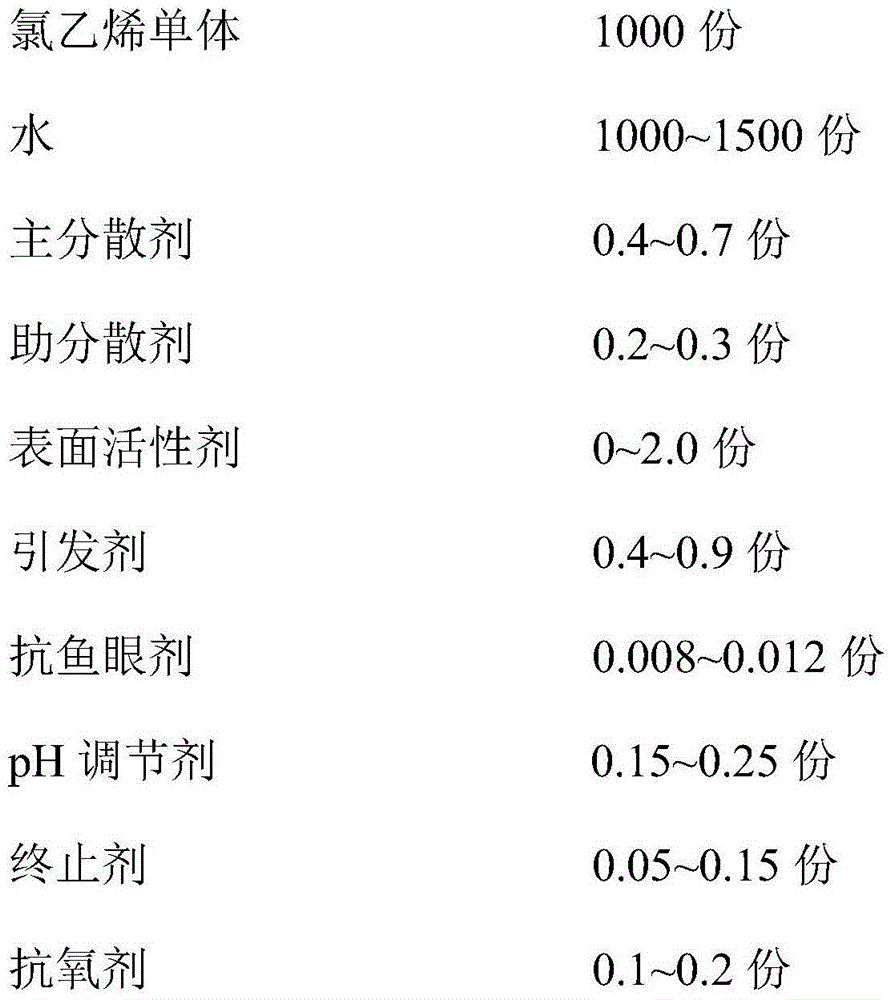

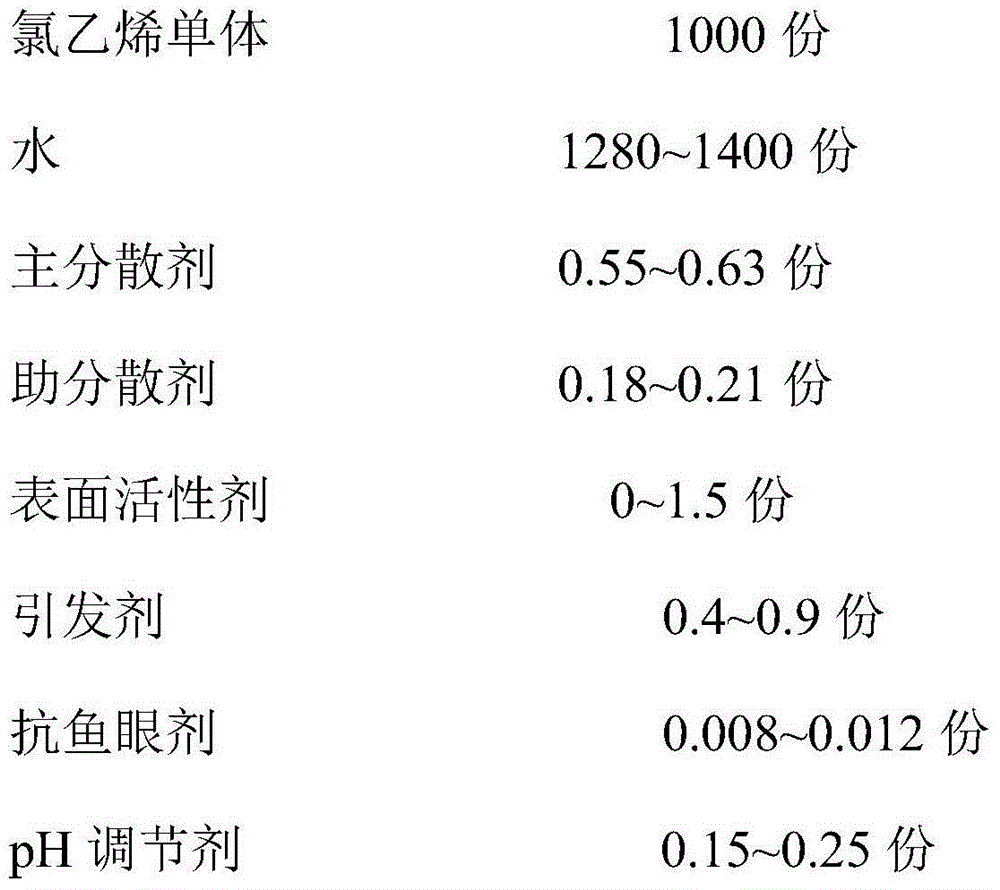

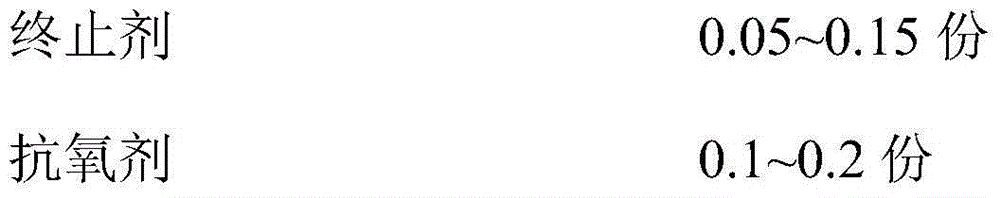

Preparation method of special PVC resin for CPVC

InactiveCN105199026AReduced particle size distribution widthImprove inner qualityChlorinated polyvinyl chlorideAntioxidant

The invention discloses a preparation method of special PVC resin for CPVC. The method includes the steps that water, a main dispersing agent, an assistant dispersing agent, a surface active agent, VCM, an initiating agent, an anti-fisheye agent and a pH regulating agent are added into a reaction kettle to be subjected to a polymerization reaction for 4.5-5.5 h at 50-65 DEG C, and then a terminator and an antioxidant are added into the reaction system at the same time to obtain the special PVC resin for CPVC. According to the special PVC resin, prepared through the method, for CPVC chlorination, the particle size distribution width of the resin is reduced, the particle shape of the resin is regular, and the inherent quality of the resin is improved. The polymerization reaction is stable in the production process, the quality repeatability of all batches of resin is good, and therefore the novel assistant compound preparation method can be applied to large kettle industrial production.

Owner:SHANGHAI CHLOR ALKALI CHEM

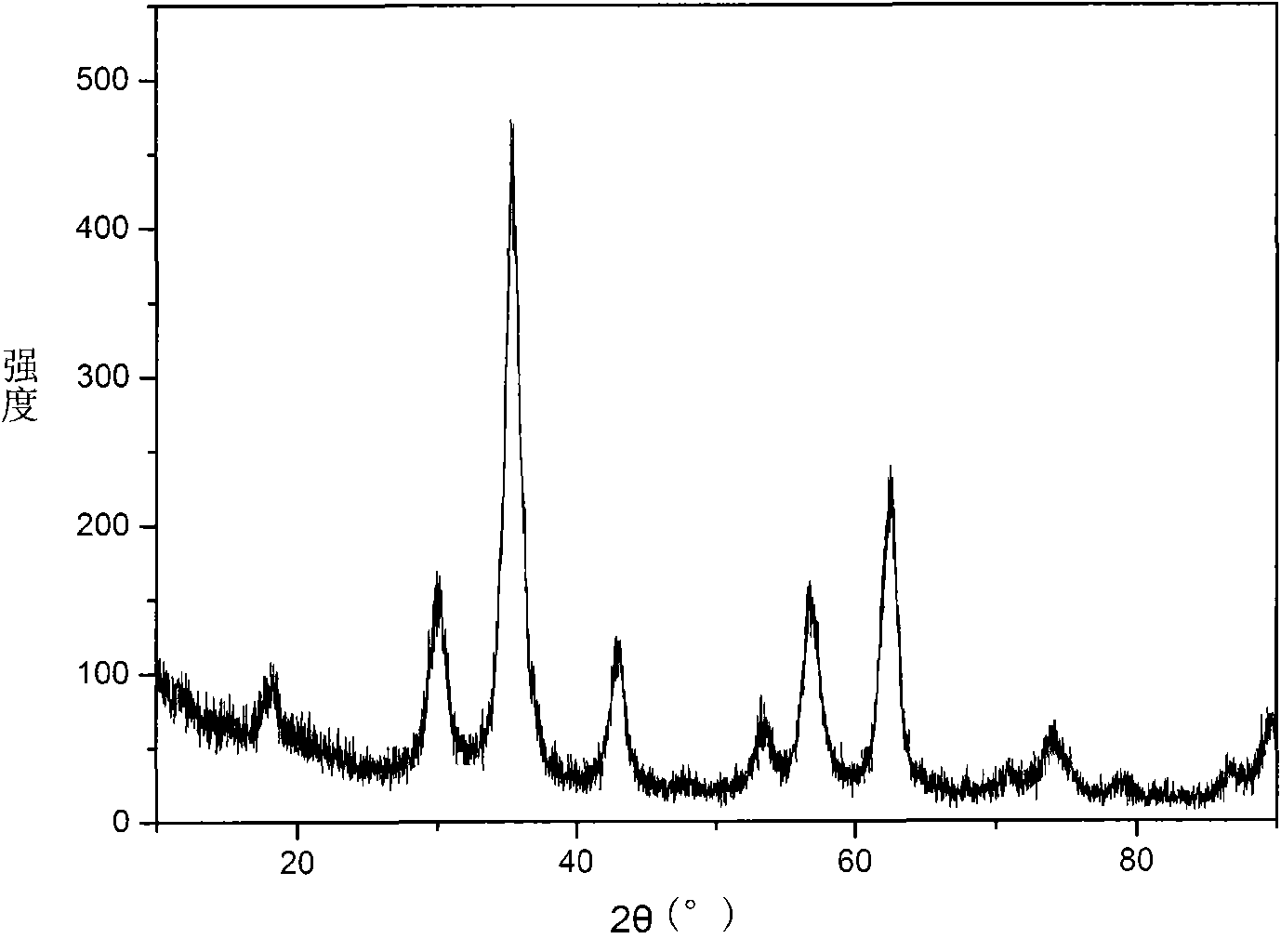

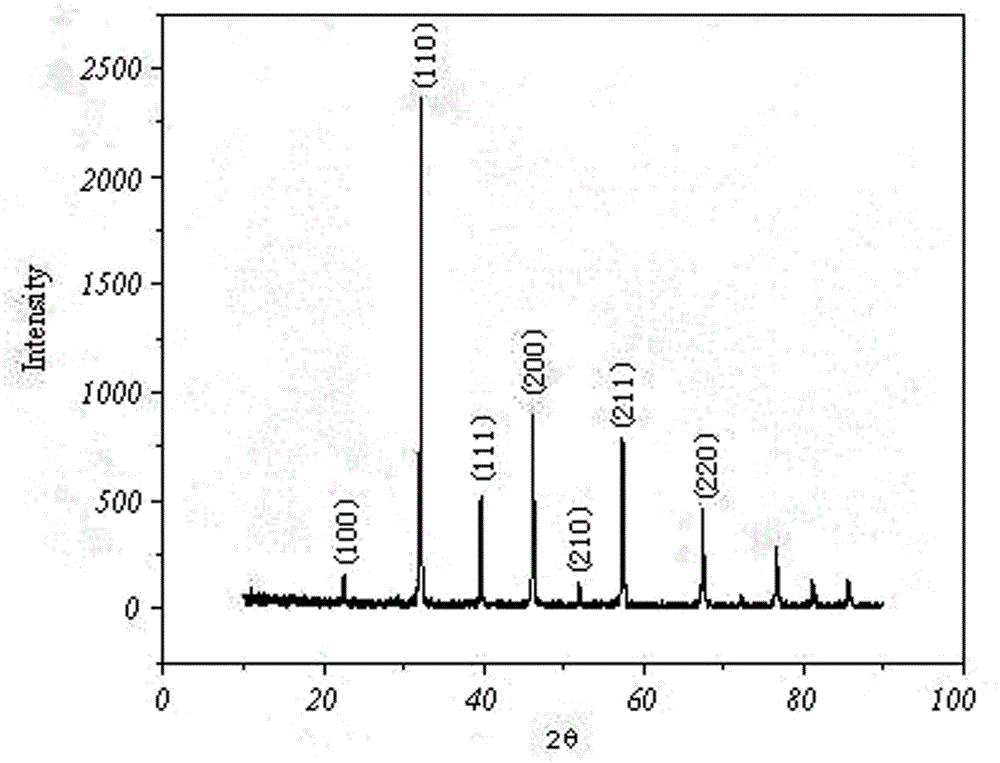

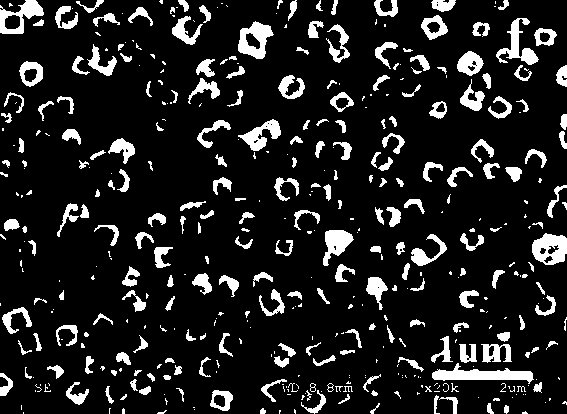

Preparation method of novel nano manganese lithium titanate LiMnxTiO4 cathode material

InactiveCN105576199AEasy reunionEasy to manufactureMaterial nanotechnologyCell electrodesPhysical chemistryManganese

The invention relates to a preparation method of a novel nano manganese lithium titanate cathode material. The preparation method comprises: firstly, preparing a manganese lithium titanate precursor by combining a solvothermal method with a solid phase method; then preparing the carbon coated nano manganese lithium titanate cathode material by utilizing a high-temperature calcination method. By testing, the material is relatively structured in morphology, has a size of about 50 to 200 nanometers, and has a high crystallinity degree and excellent electrochemical performance. Meanwhile, the material is relatively simple in steps of a synthetic process, is easy for controlling the process, and is suitable for large-scale industrial production.

Owner:SHANDONG GOLDENCELL ELECTRONICS TECH

Drepn process of polyvinyl chloride resin with composite dispersant system

The method for preparing polyvinyl chloride resin by adopting composite dispersion system includes the following steps: adding vinyl chloride monomer and composite dispersion system into polymerization reactor, and making them produce polymerization reaction under the condition of conventional polymerization. The composition and weight ratio of said composition dispersion system are IB:IC:ID=1:0.60-0.70:0.17-0.42, in which IB is polyvinyl alcohol, IC is hydroxypropyl methyl cellulose and IC is PVA with low alcohol-solubility, for example one of LM-22 and LW-300.

Owner:SHANGHAI CHLOR ALKALI CHEM

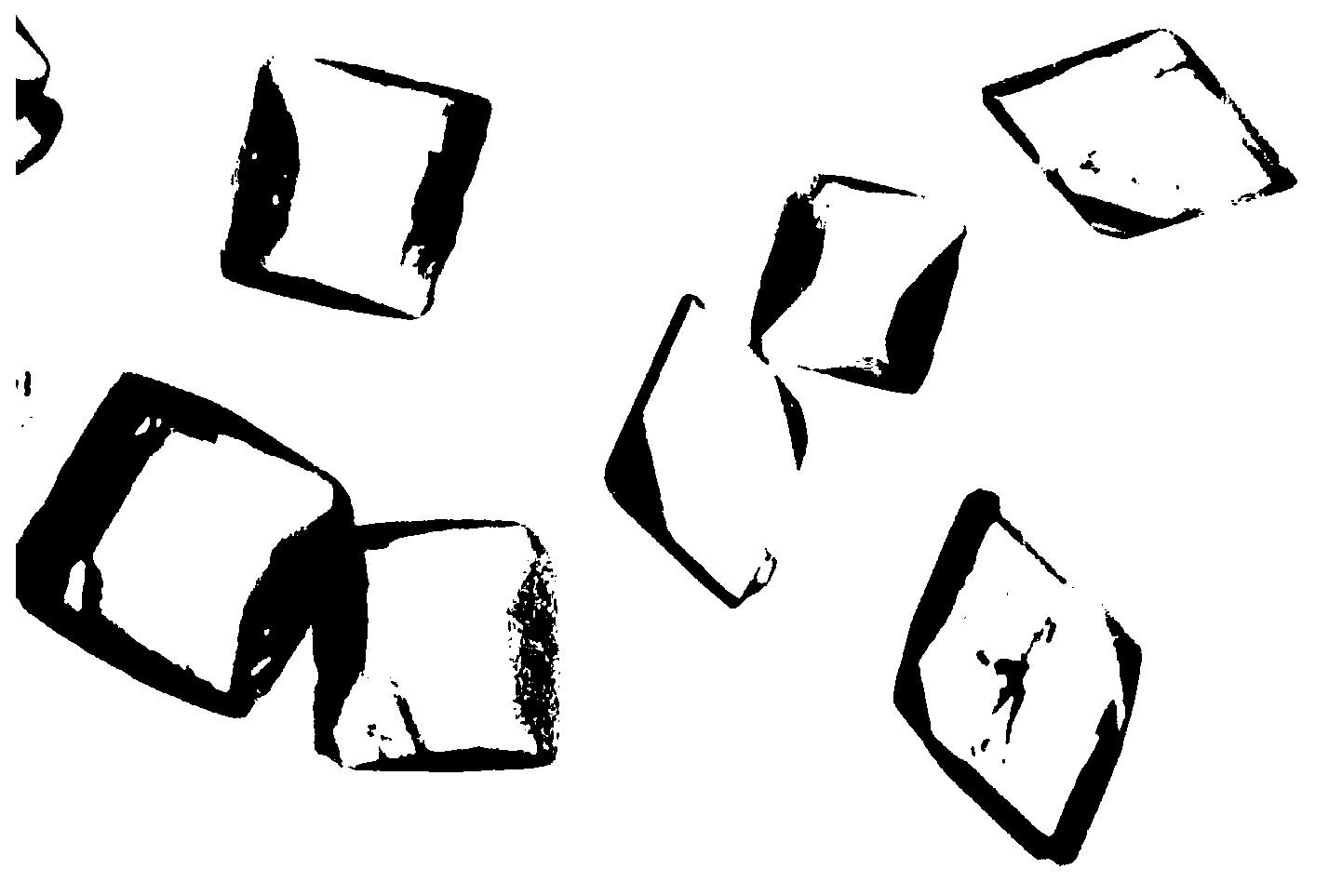

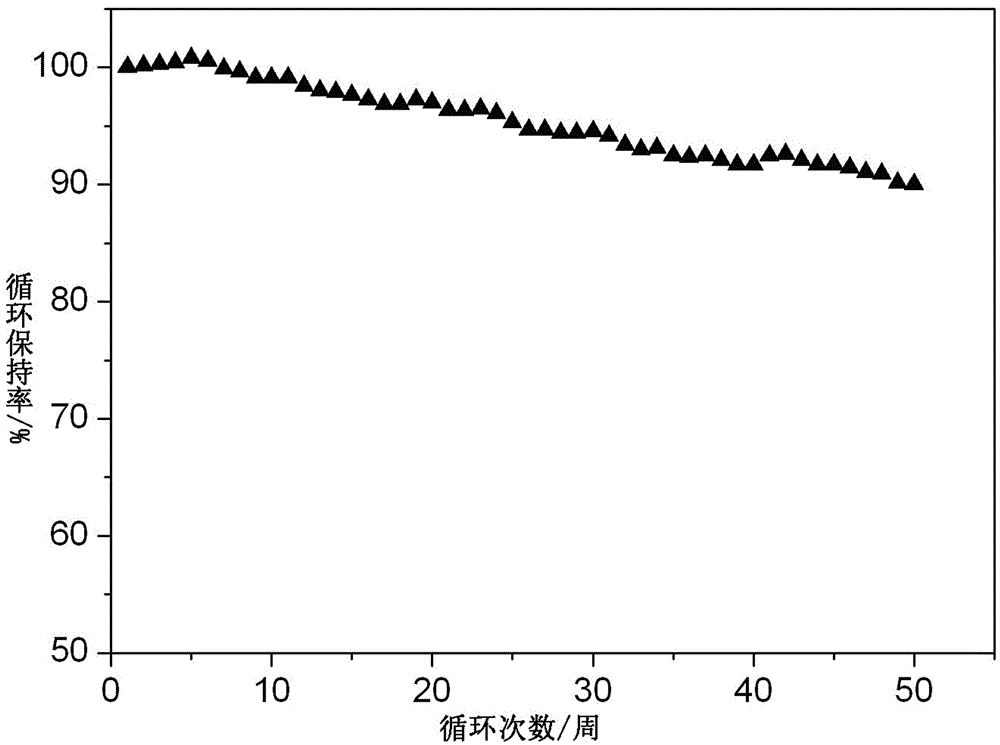

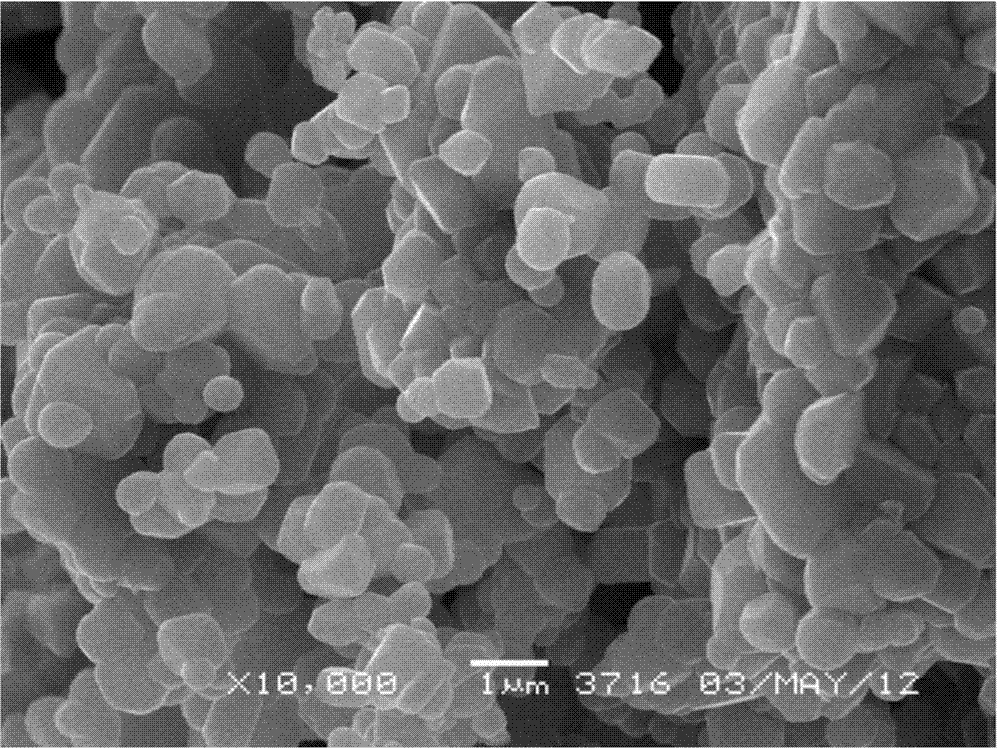

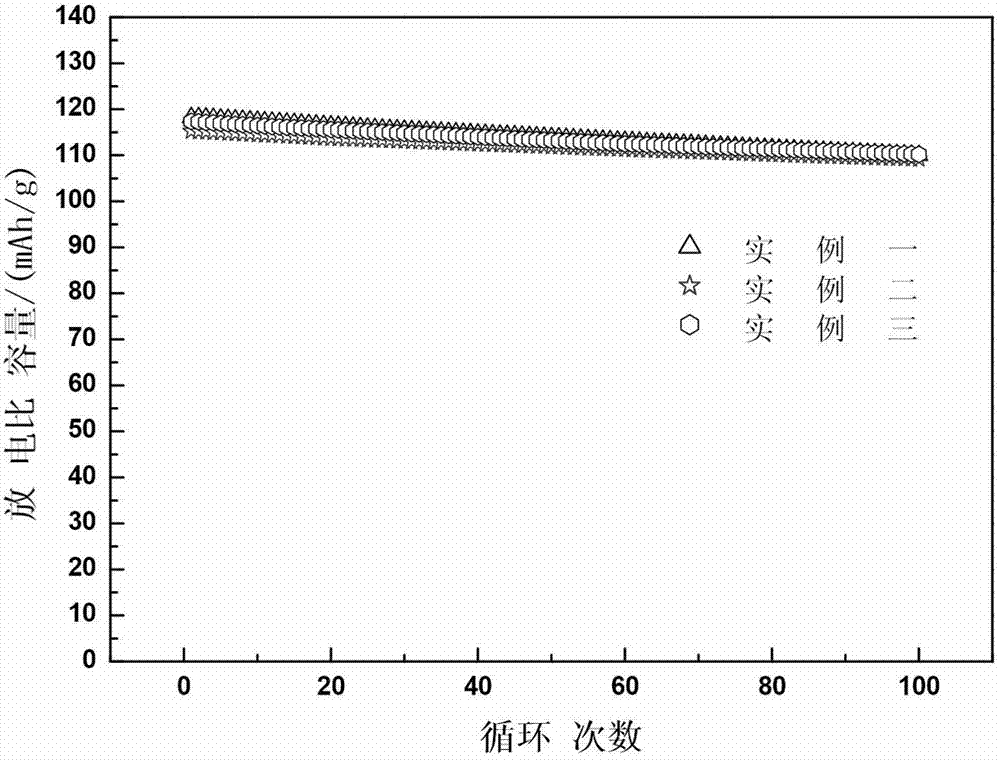

Lithium manganese oxide spinel of anode materials of lithium ion batteries and method for manufacturing lithium manganese oxide spinel

InactiveCN102916175BRegular particle shapeLow impurity contentCell electrodesManganates/permanganatesElectrical batteryPhysical chemistry

The invention discloses lithium manganese oxide spinel of anode materials of lithium ion batteries. The specific surface area of the lithium manganese oxide spinel ranges from 0.2m<2> / g to 0.6m<2> / g, the content of K ions in the lithium manganese oxide spinel is lower than 800ppm, the content of other impurities in the lithium manganese oxide spinel is lower than 200ppm, the compaction density of the lithium manganese oxide spinel is higher than 3.35g / cm<3>, the initial discharge capacity of a 0.1C button battery is higher than 115mAh / g, and the 100-cycle capacity fading is lower than 8%. The method includes proportioning a lithium source, a manganese source and doping metal additives, and presintering the manganese source at the temperature ranging from 500 DEG C to 1000 DEG C; mixing the presintered manganese source, the lithium source and the doping metal additives to obtain a mixed raw material; performing multi-section sintering for the mixed raw material to obtain a sintered sample, washing the sintered sample by water, and centrifugally spinning and drying the sintered sample; and screening and grading to obtain a lithium manganese oxide product. The lithium manganese oxide product is regular in granule morphology, high in compaction density, low in impurity content and good in both processability and electric performance.

Owner:HUNAN CHANGYUAN LICO CO LTD

Semi-dry nano silver synthesis method

The invention discloses a semi-dry nano silver synthesis method. The method includes mixing silver nitrate and agar at the mass ratio of 1:1 to 5:1, adding deionized water in mass of 5 to 8 times of the agar and grinding fully; adding sodium carbonate to adjust pH value to 8 to 9 till pasting, reacting for 0.5 to 6 h at the temperature of 65 to 90 DEG C, freezing and drying in vacuum, and obtaining agar-protected silver powders. According to the method, the sol-gel method for nano silver synthesis is abandoned, reductive monosaccharide is generated by accurately controlling agar homogeneous hydrolysis by controlling dosage of reaction system water and system pH value, homogeneous controllable nano silver reducing generation is implemented, the agar serves as protective agent for the nano-silver synthesis, particle aggregation is avoided, the obtained nano silver has fine dispersion, shapes of particles are structured, reacting condition is mild, synthesis system is simple, and the method is adaptive to industrial production.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

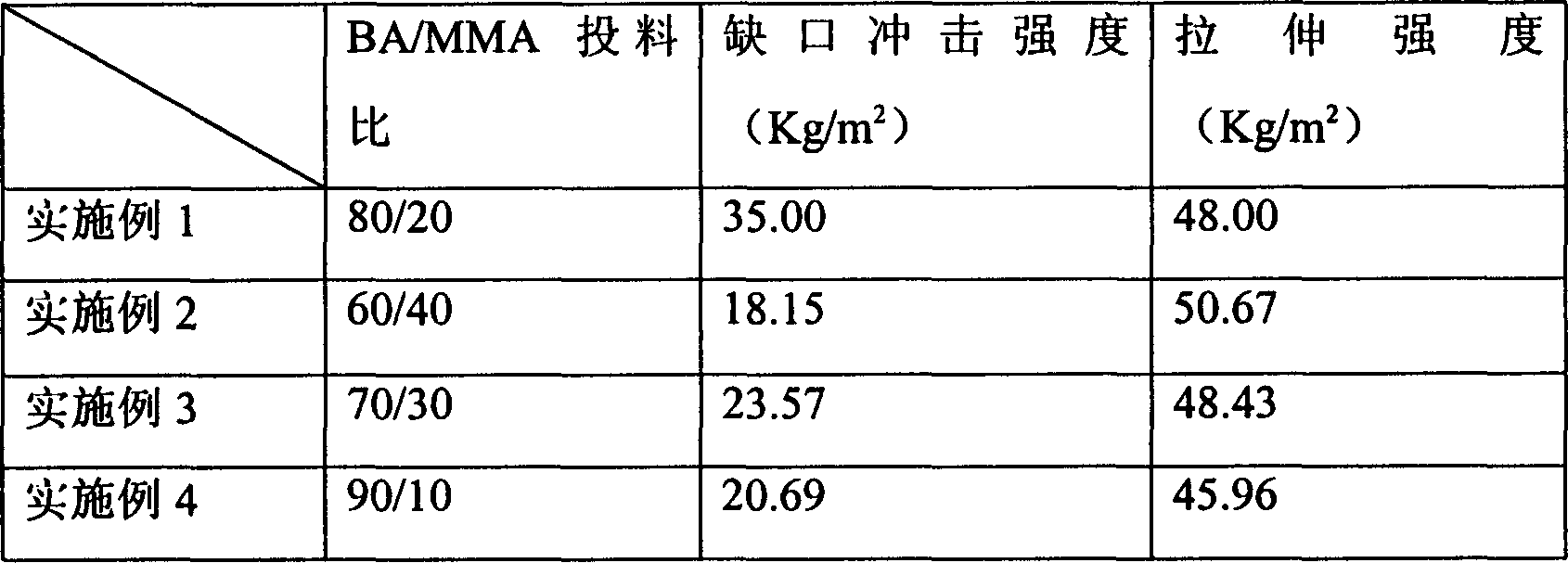

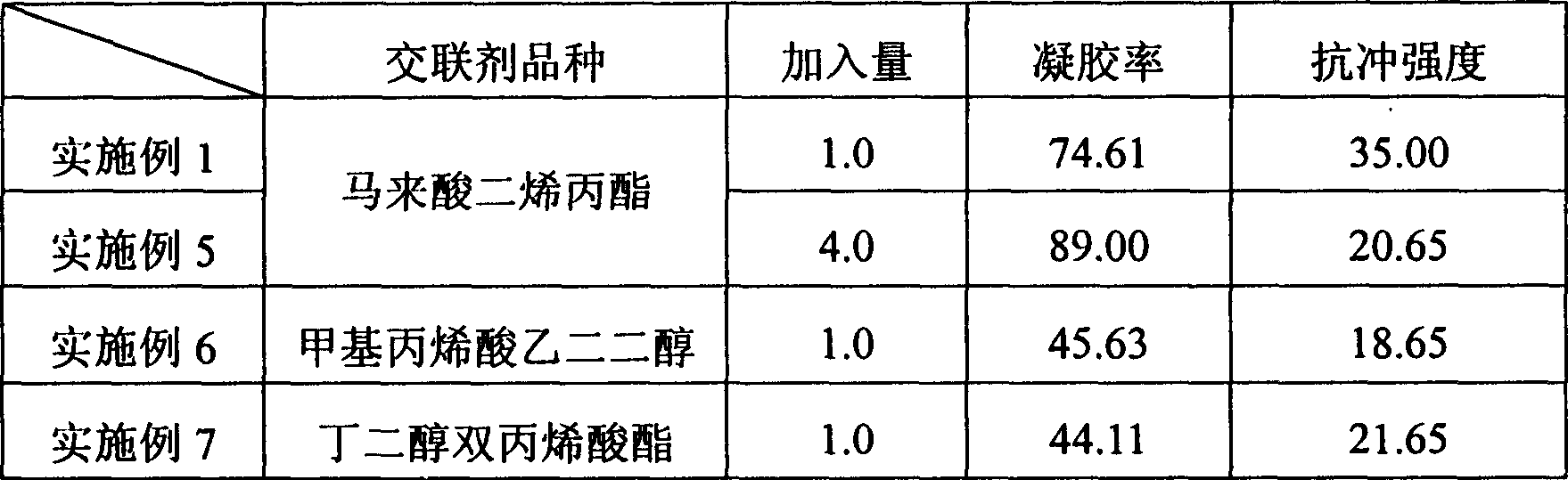

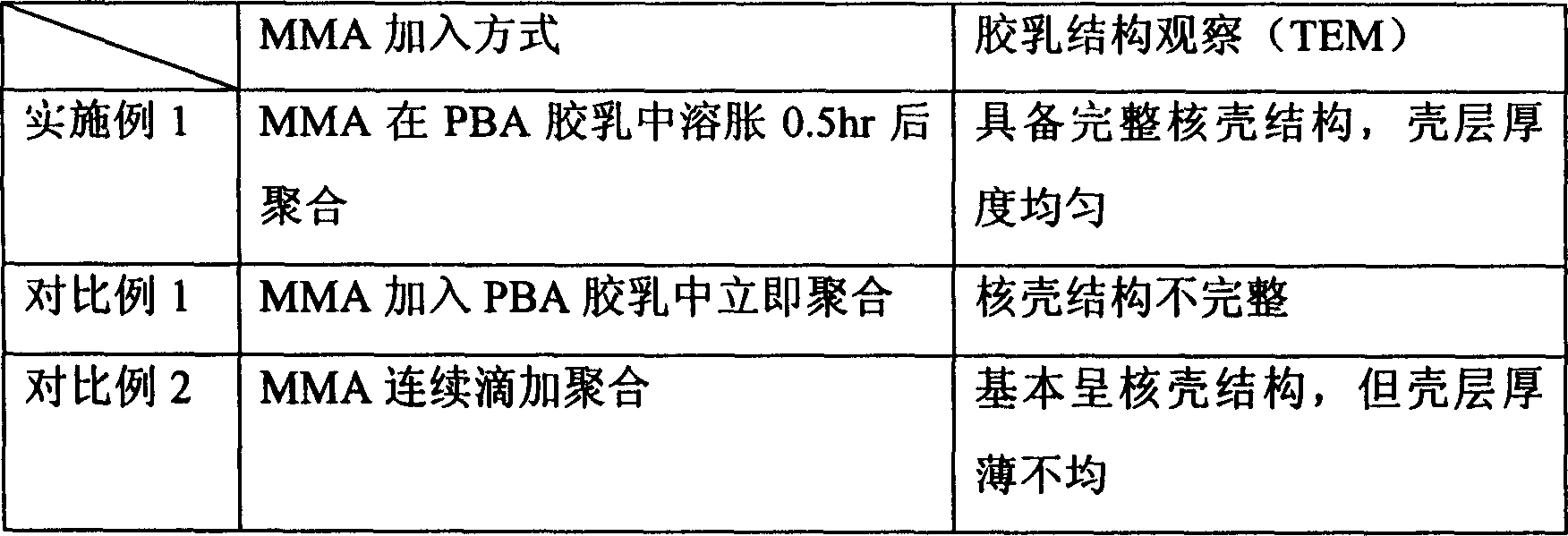

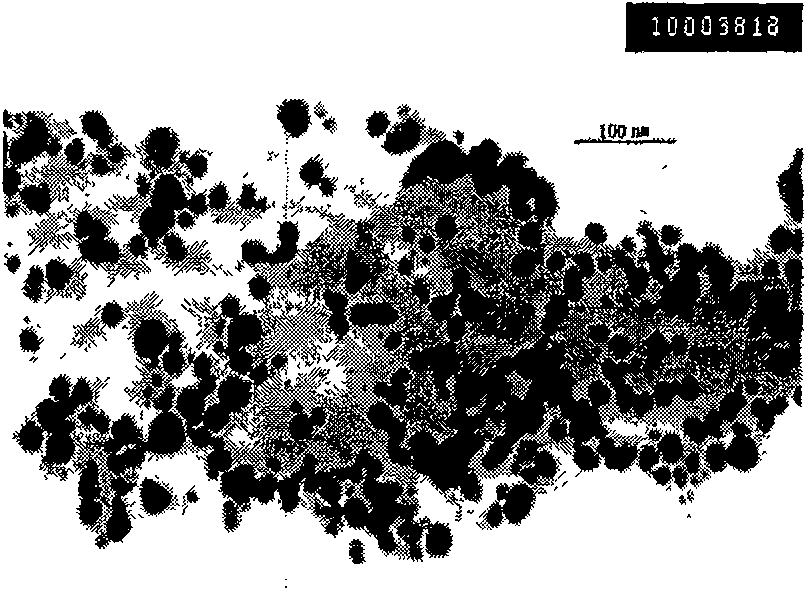

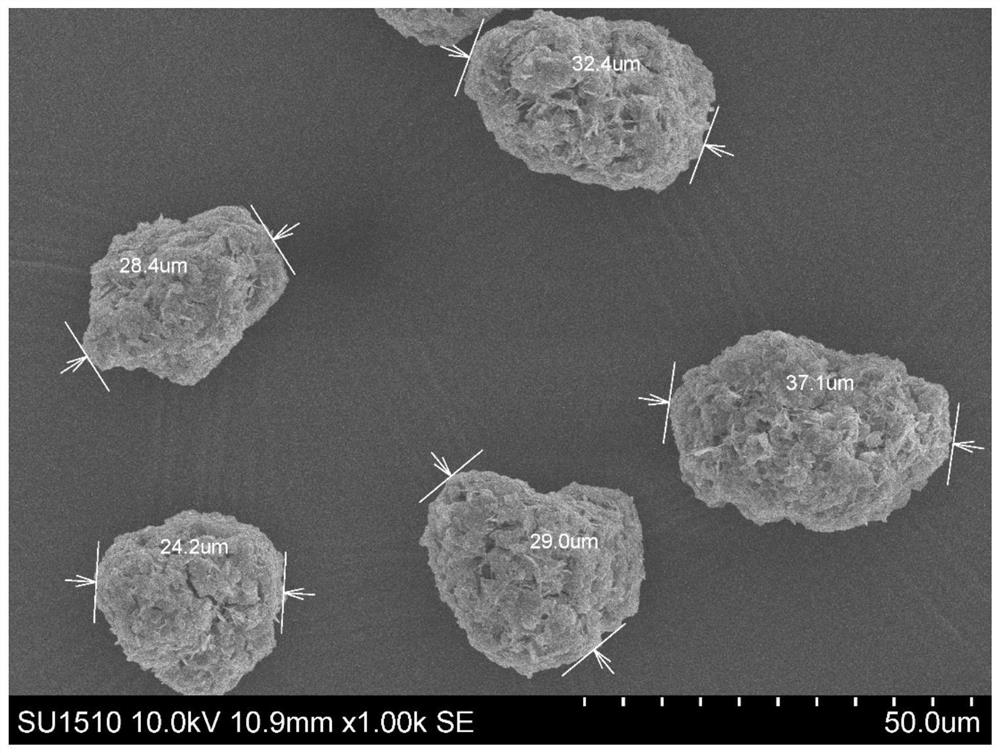

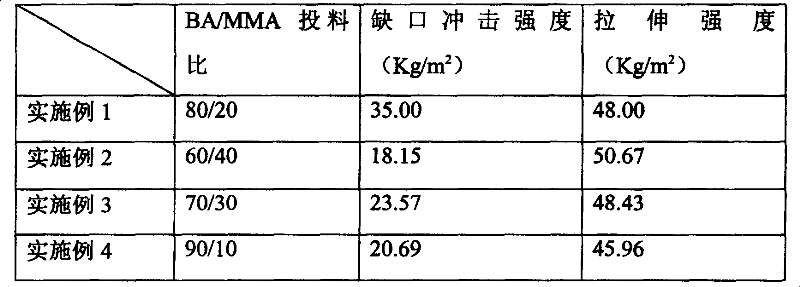

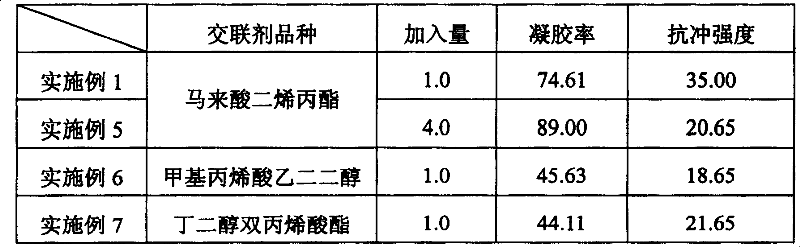

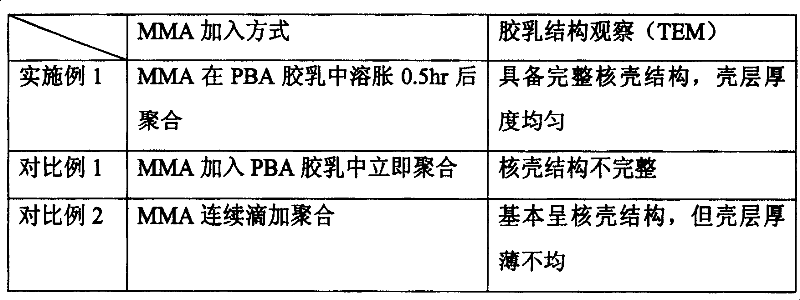

Method for producing polyvinyl chloride special for high-impact-resisting building material product

The present invention discloses the production process of polyvinyl chloride resin specially for high antishock building material product. Composite polyacrylate latex grain is first prepared through multiple-step emulsion polymerization, then pH regulated to neutrality and grafting polymerized with vinyl chloride suspension to prepare vinyl chloride grafted acrylate copolymer. The copolymer may be used widely in specially shaped material, pipe, plate and other plastic building material with antishock performance requirement.

Owner:SHANGHAI CHLOR ALKALI CHEM

Microwave preparing method for nanometer silver or gold

InactiveCN100563879CAchieve homogeneous hydrolysisPromote hydrolysisFreeze-dryingParticle-size distribution

The invention discloses a microwave preparation method of nano-silver or nano-gold. Reactants are added into a reactor at a ratio of 1:1. When preparing nano-silver, the reactants are silver nitrate and carbonylmethyl cellulose sodium. When preparing nano-gold The reactants are chloroauric acid and sodium carboxymethyl cellulose; the reactor is put into a microwave reaction chamber, the rotating speed is a stirrer at 100 rpm, the microwave power is 0.3 kilowatts, and the reaction time is It was 7 hours; after the reaction, the solution was air-dried or vacuum freeze-dried or spray-dried to obtain nano-silver or nano-gold powder, or concentrated to a desired concentration of nano-silver or nano-gold colloid. The present invention abandons the conventional reducing agent in the thermochemical synthesis of nano-silver or nano-gold, replaces the traditional local heating method with microwave heating, realizes the homogeneous growth of nano-silver or nano-gold, the particle size distribution of nano-silver or nano-gold is narrow, and the particles Regular shape.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

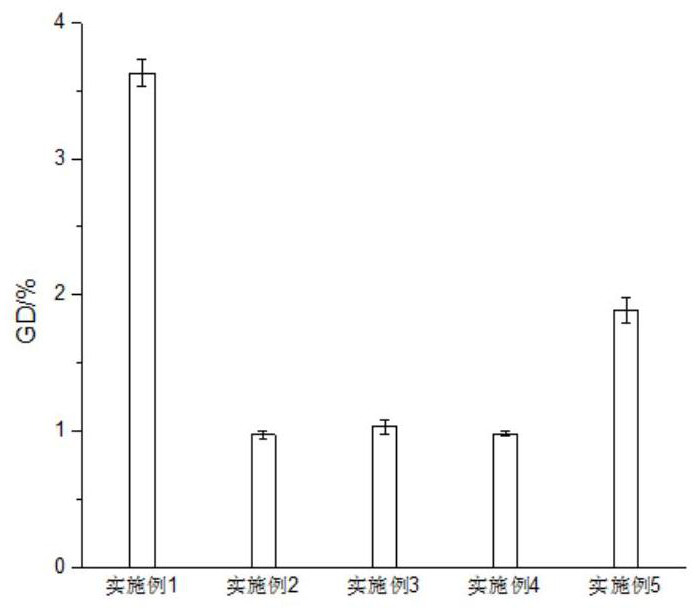

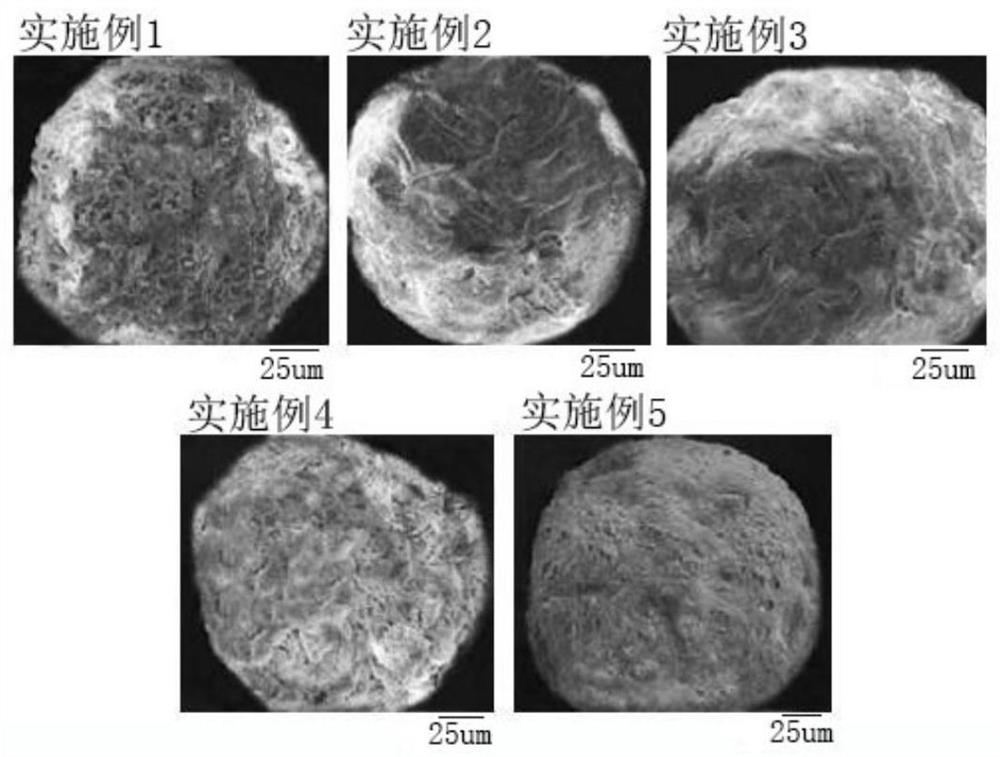

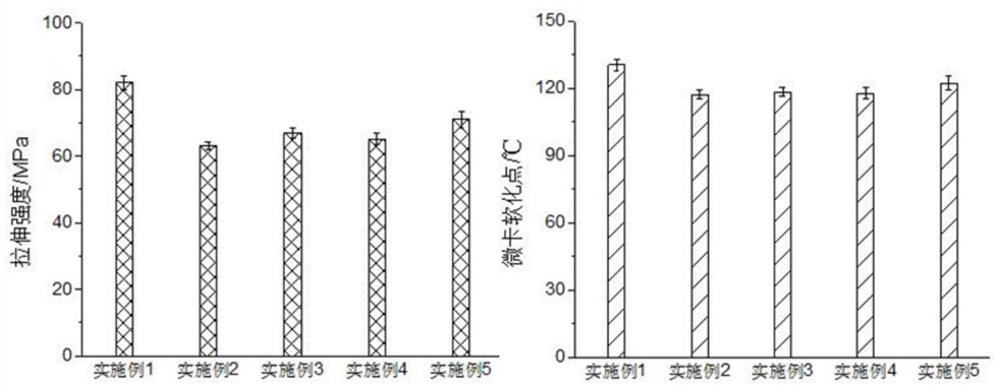

CPVC pipe and preparation method thereof

The invention provides a CPVC pipe and a preparation method thereof, which belong to the field of high polymer materials and comprise the following steps: preparing PVC resin by adopting a binary composite dispersion system consisting of polyvinyl alcohol with alcoholysis degree of 78-82 mol% and dioctyl adipate according to a mass ratio of 2:1-3, and preparing CPVC-g-MHA by adopting a chlorination in-situ grafting method; and blending the prepared CPVC gMHA with a stabilizer, a processing aid, an impact modifier and the like to prepare the CPVC pipe. The CPVC pipe and the preparation method thereof provided by the invention have the advantages of good toughness, good heat resistance, high strength, simplicity, easiness in processing, high efficiency and lower cost.

Owner:任丘市华凯通信设备有限公司

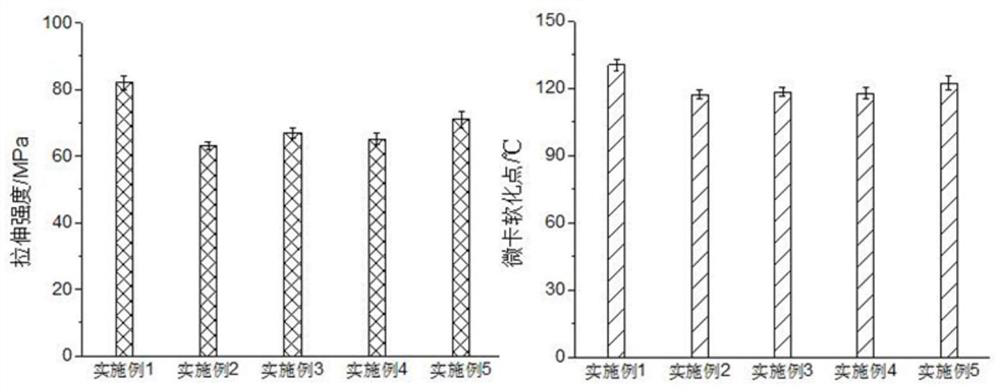

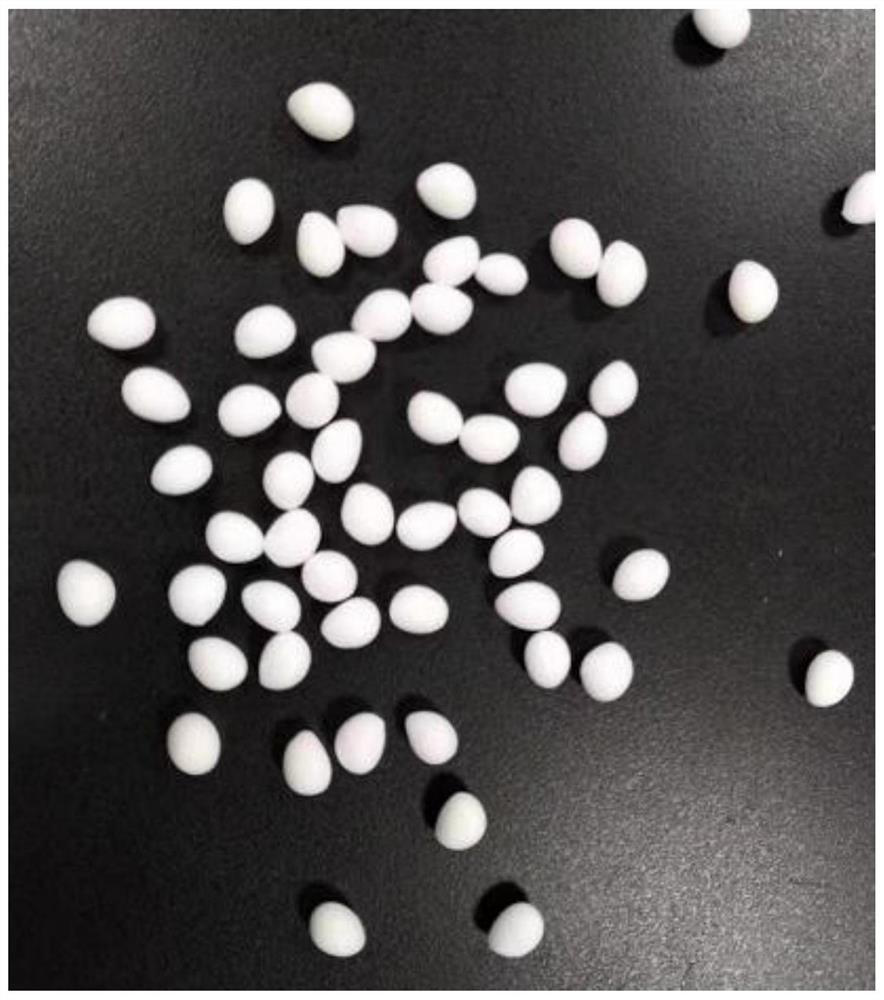

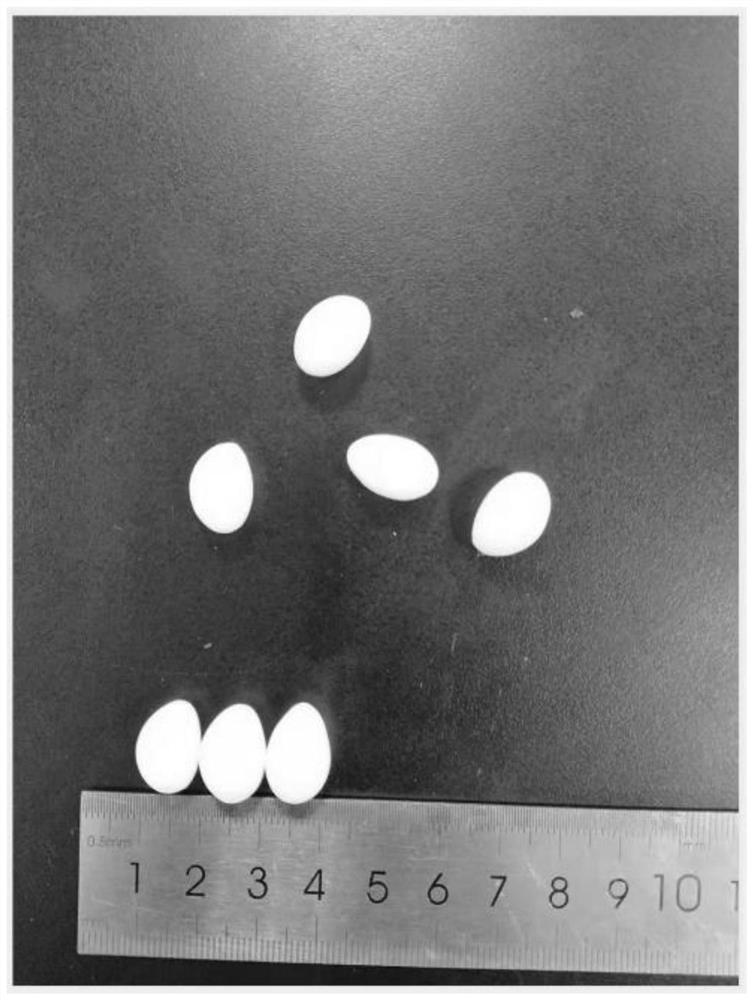

Low-pressure kettle type preparation method of thermoplastic polyester elastomer foamed particles

The invention belongs to the field of preparation of functional foaming materials. The invention particularly relates to a low-pressure kettle type preparation method of thermoplastic polyester elastomer foamed particles. The preparation method comprises the following steps: fully mixing initial materials, spraying a liquid foaming agent as a spraying liquid onto an obtained initial raw material mixture, granulating by a granulator, carrying out high-pressure heating and heat preservation treatment on obtained granules in a reaction kettle, carrying out normal-pressure high-temperature foaming, and filtering after full foaming to obtain the foamed particles.

Owner:CHANGZHOU SHUNXIANG NEW MATERIAL TECH CO LTD

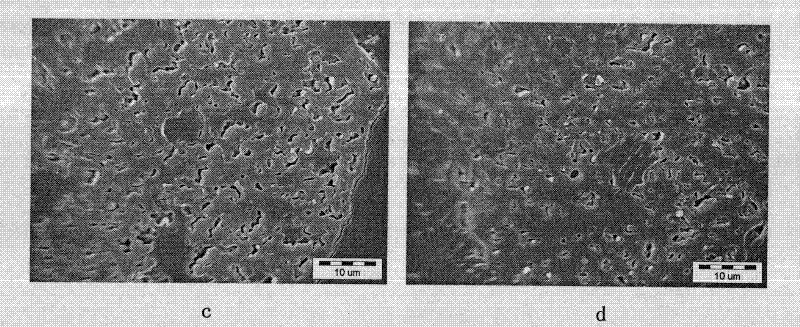

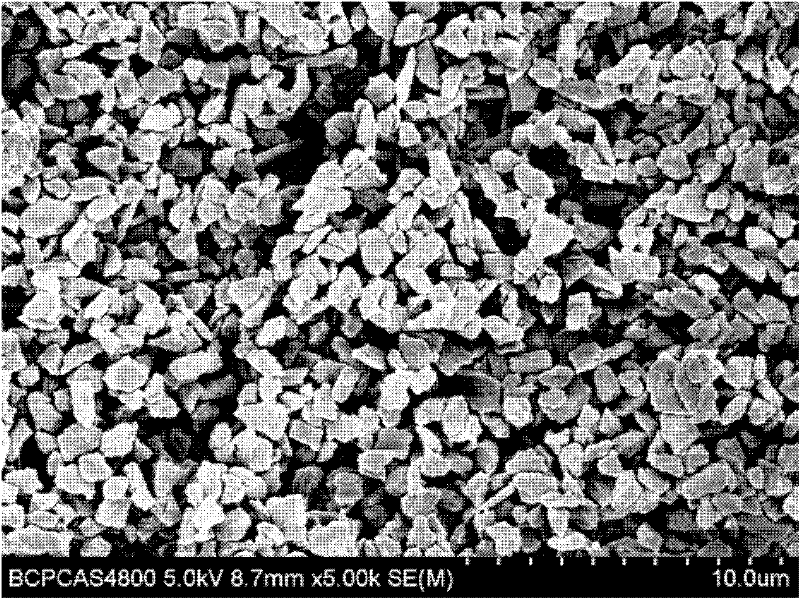

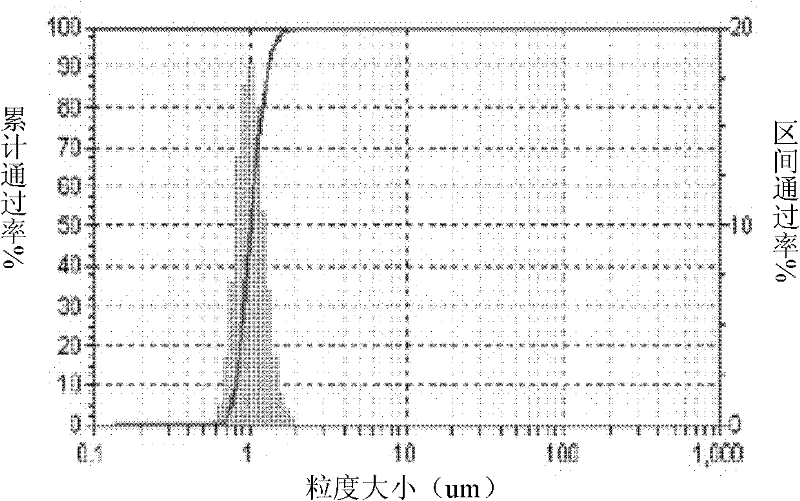

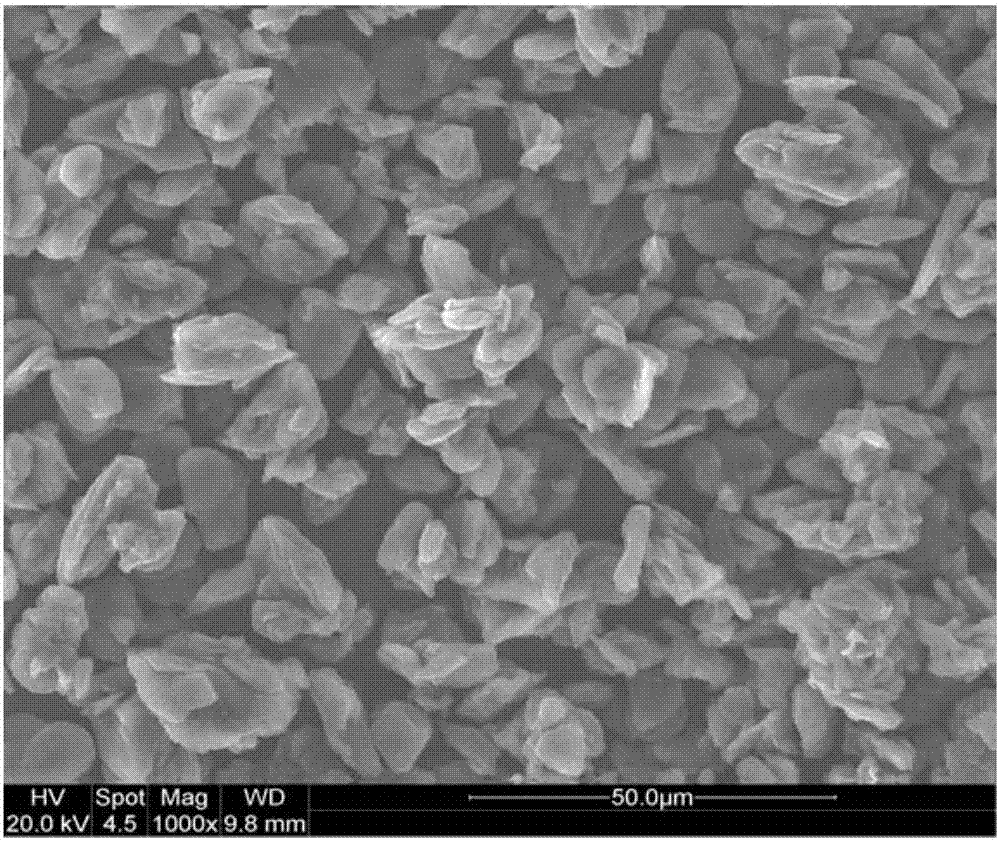

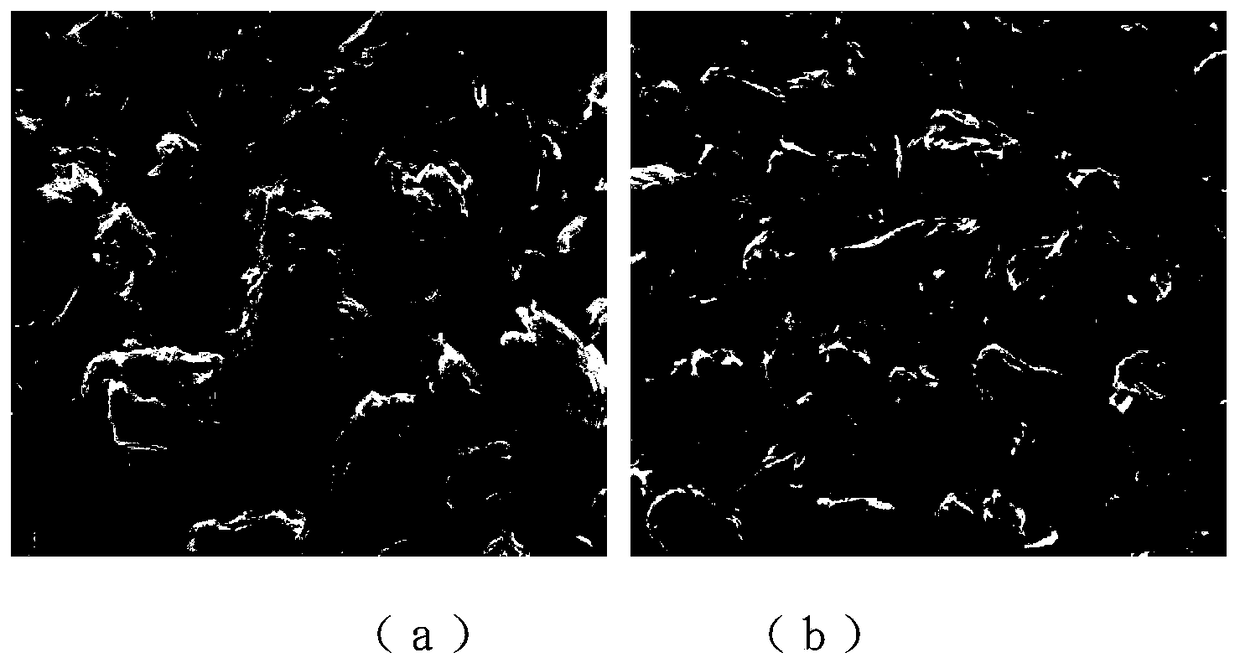

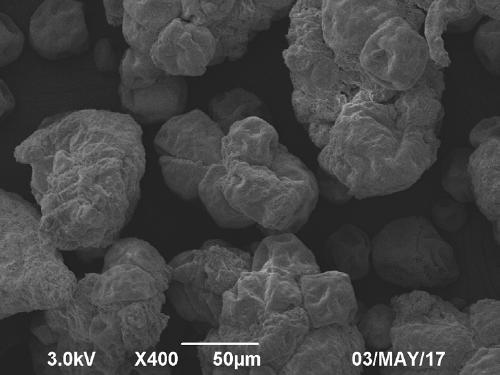

A kind of pretreatment method of artificial graphite material and obtained product and application

ActiveCN103879997BIncrease compaction densityRegular particle shapeGraphiteCell electrodesPretreatment methodElectrical battery

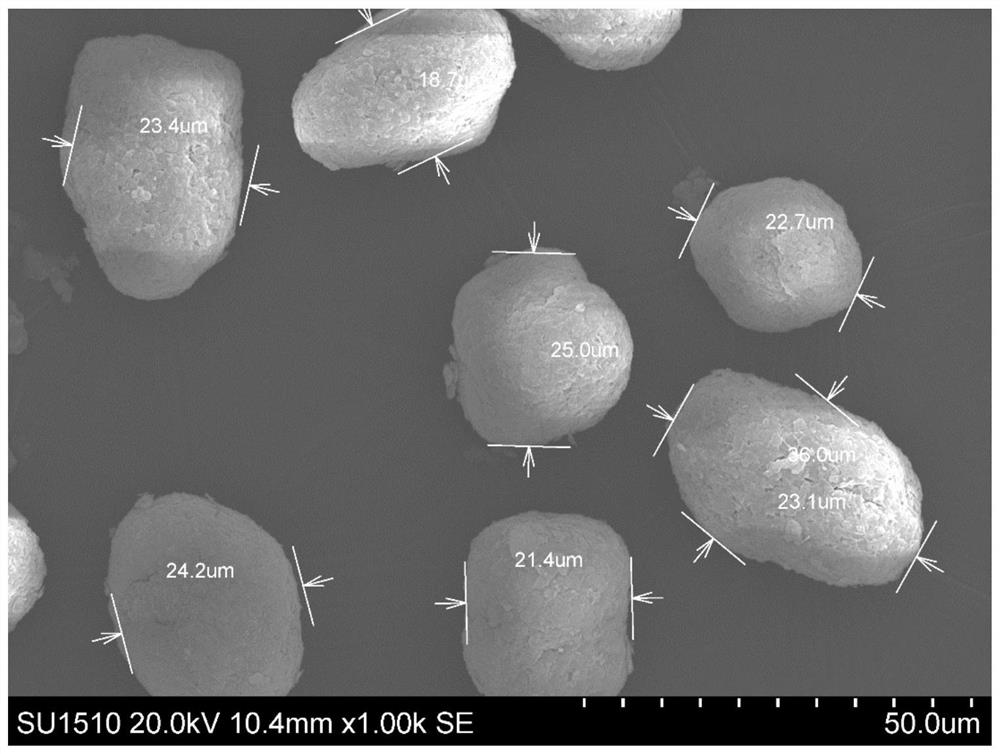

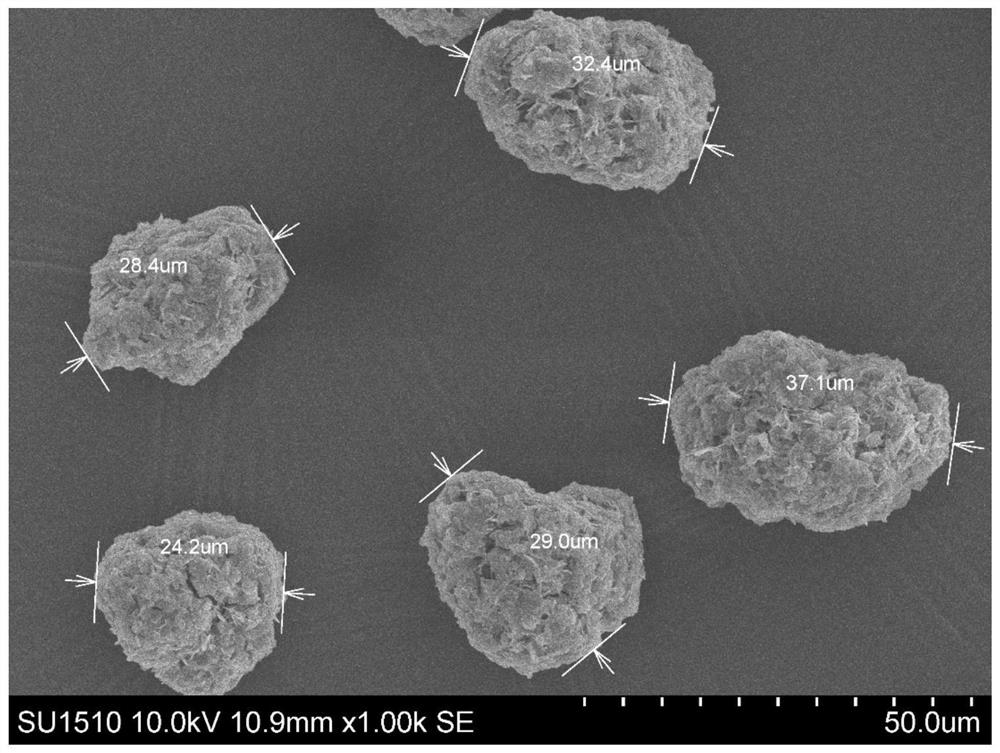

The invention discloses a pretreatment method of an artificial graphite material, which is characterized by comprising the following steps: (1) drying an artificial graphite material with a D50 of 16-22 microns to reach a water percent of not more than 2% of the total mass of the material, so as to obtain a dry artificial graphite material; (2) mixing the dry artificial graphite material obtained in step (1) in a high-speed modification fusion machine with a rotating speed of 1700-2200 r / min for 3-30 min, and then sieving to obtain the product. The invention also provides an artificial graphite material prepared by the pretreatment method of an artificial graphite material, and an application in preparation of cell anode materials. The tap density of the artificial graphite material of the invention is significantly improved; the whole particle size distribution is not affected, and the distribution of large and small particles is more uniform; the regularity of the morphology is improved, the morphology is modified to be more complete and uniform, and the performance of capacity and efficiency is not affected; the properties are stable, and almost no difference exists between batches.

Owner:SHANGHAI SHANSHAN TECH CO LTD

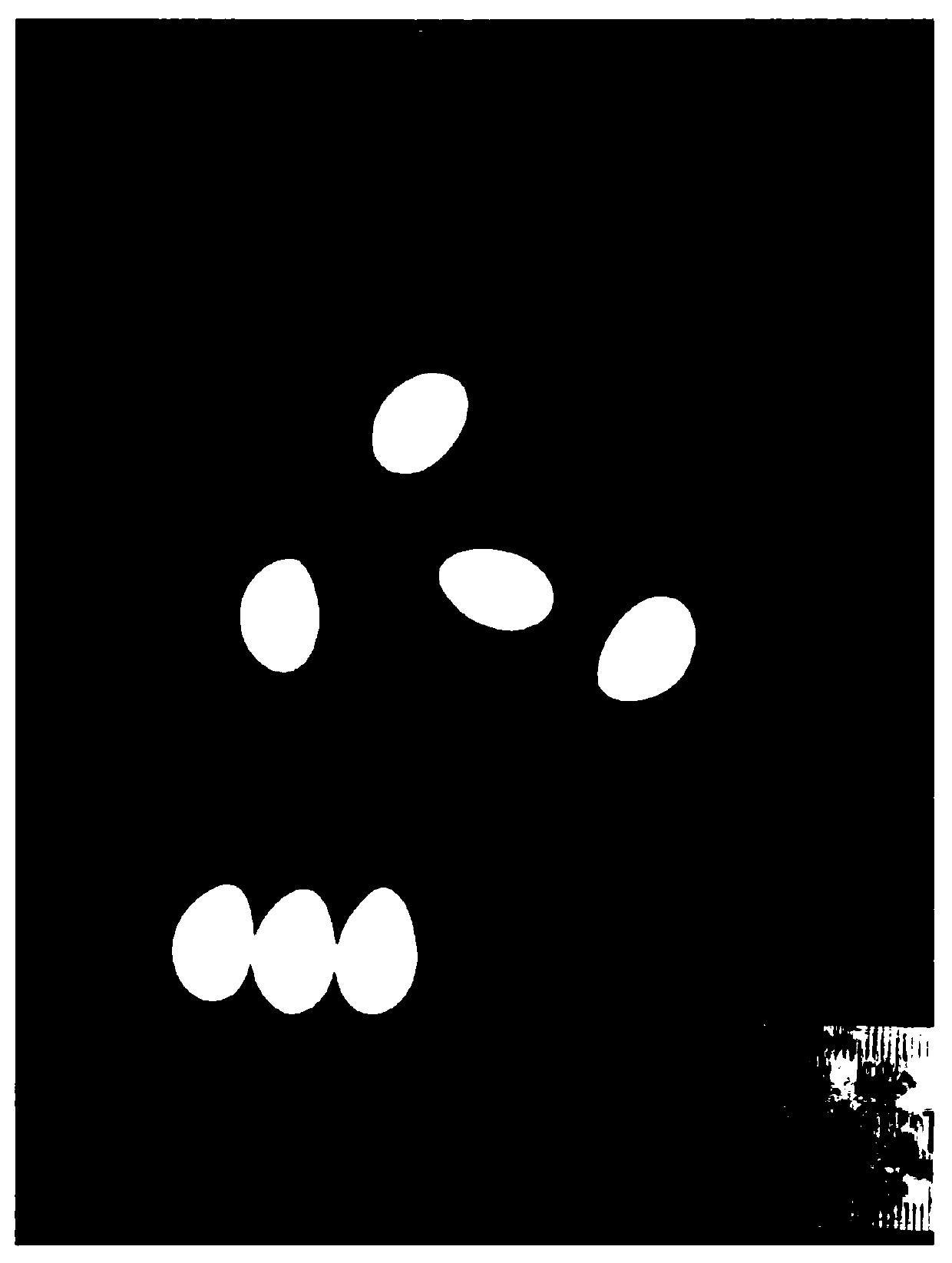

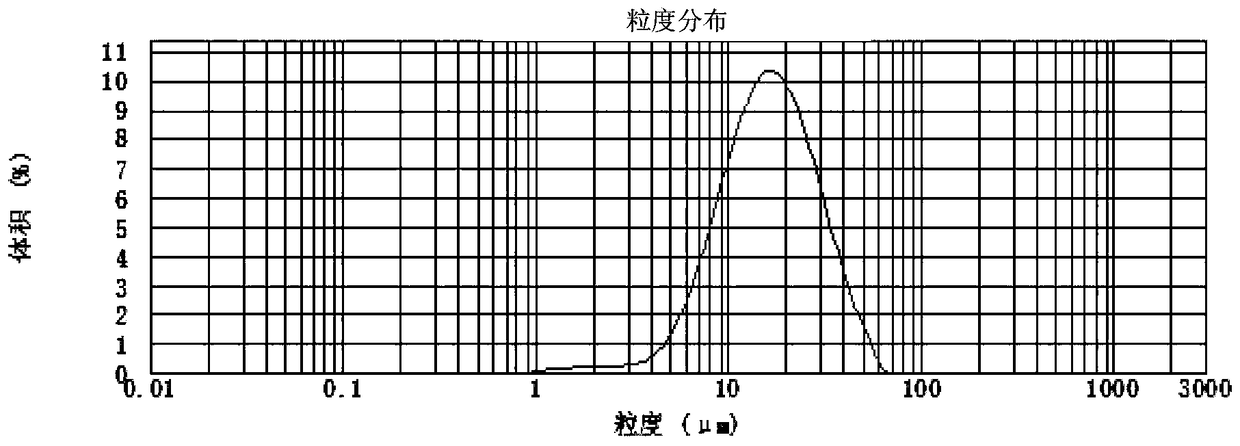

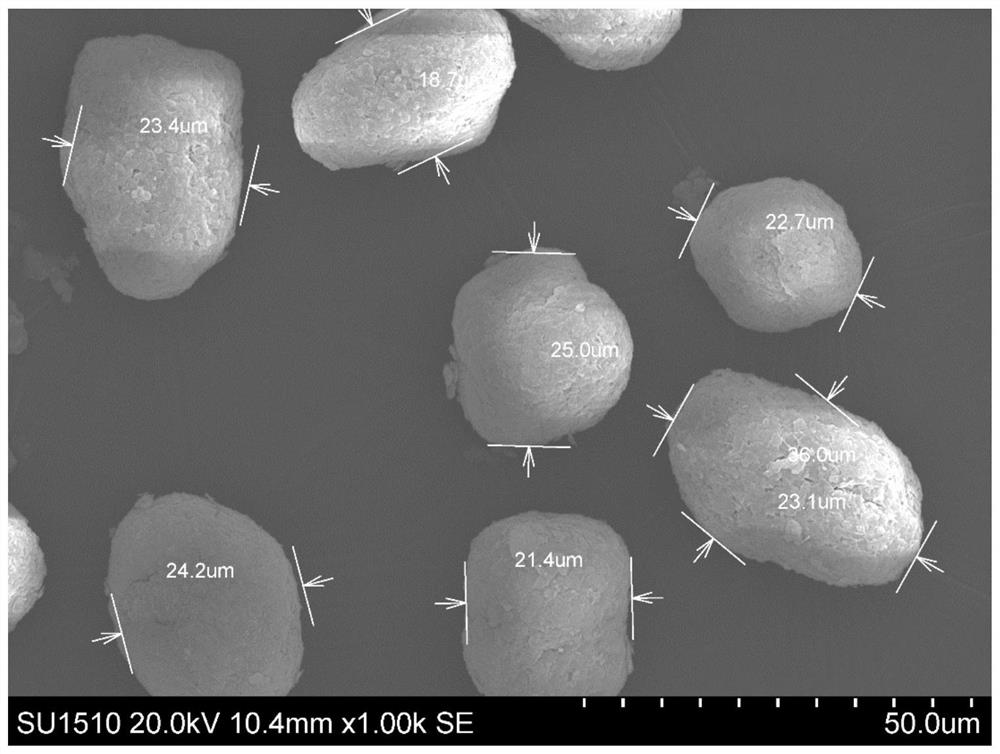

Preparation method of spherical magnesium diethoxylate

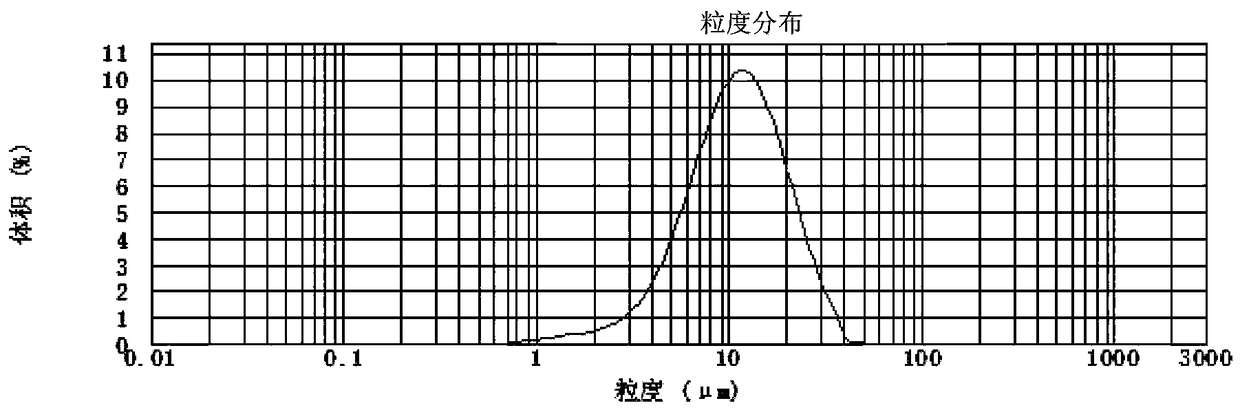

ActiveCN112299984AParticle size controllableUniform particle sizeOrganic compound preparationCarboxylic acid salt preparationAlcoholActive agent

The invention provides a method for preparing magnesium diethoxylate, which comprises the following steps of: by using metal spherical magnesium powder and absolute ethyl alcohol as raw materials, adding elemental iodine and a cosolvent to prepare spherical magnesium diethoxylate. The particle size of the obtained spherical magnesium diethoxylate ranges from 1 micron to 200 microns, and the span of particle size distribution is smaller than 3. The cosolvent is added into the reaction system, the particle size of the obtained magnesium diethoxylate can even reach 5 [mu] m to 15 [mu] m, and compared with a traditional method of adding a surfactant, silicone oil or span and the like, the method has the advantages that the cosolvent is easier to remove, impurity residues are avoided, and post-treatment is more convenient. The method has the advantages of low reaction temperature, stable reaction, short reaction time and no discharge of environment-unfriendly substances, and is suitable forlarge-scale industrial production.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Color printing ink powder and preparation method therefor

InactiveCN105388717AGood climate adaptabilityRegular particle shapeDevelopersAcrylic resinColor printing

The invention relates to color printing ink powder and a preparation method therefor, and belongs to the technical field of ink powder preparation. The color printing ink powder is prepared from the following components by weight: 60-70 parts of pigment powder, 10-15 parts of modified starch, 10-20 parts of styrene-acrylic resin, 10-15 parts of talcum powder, and 1-5 parts of sodium silicate. The preparation method comprises: uniformly mixing the pigment powder, the modified starch, the talcum powder and sodium silicate, and ball-milling for 30-35 minutes; adding 100-110 parts by weight of de-ionized water, then adding the styrene-acrylic resin, heating to 50-56 DEG C, and keeping the temperature for 50-55 minutes; washing a mixture with de-ionized water 8-10 times heavier than the mixture, filtering the washed mixture, and drying the filtered mixture into granular materials; and screening the materials, selecting granules of 2-10 microns, and drying the granules at 50-55 DEG C for 30-40 minutes to obtain the color printing ink powder. The ink powder is regular and uniform in granule shape, clear in development imaging, distinct in color layer, suitable for use in various different machines, relatively low in preparation cost, and easy for industrialized production.

Owner:赖清甜

Method for producing polyvinyl chloride special for high-impact-resisting building material product

The present invention discloses the production process of polyvinyl chloride resin specially for high antishock building material product. Composite polyacrylate latex grain is first prepared through multiple-step emulsion polymerization, then pH regulated to neutrality and grafting polymerized with vinyl chloride suspension to prepare vinyl chloride grafted acrylate copolymer. The copolymer may be used widely in specially shaped material, pipe, plate and other plastic building material with antishock performance requirement.

Owner:SHANGHAI CHLOR ALKALI CHEM

A kind of preparation method of polyvinyl chloride resin special for chlorination

The invention relates to a preparation method of special polyvinyl chloride resin for chlorination. The method comprises the following steps: uniformly premixing a quality agent and vinyl chloride monomer in advance, adding deionized water, a dispersing agent I, a dispersing agent II, a PH regulator, a heat stabilizer, a chain transfer agent and an initiator into a polymerization reactor to perform polymerization reaction, ensuring that the quality agent adopts water soluble polyvinyl alcohol with low polymerization degree and low alcoholysis degree, and the dispersing agent I adopts grafted polyvinyl alcohol copolymer resin, and adopting special production technology to premix the quality agent and the vinyl chloride monomer in advance. The special polyvinyl chloride resin for chlorination, prepared through the method, has the advantages that the particle surface films are less or no film exists, the resin particle shapes are regular, the structure is loose, pore distribution is uniform, the degree of concentration of resin particle sizes is high, polymerization reaction is stable during production, and the quality repeatability of all batches of resin is good, and the special polyvinyl chloride resin is particularly applicable to the preparation of chlorinated polyvinyl chloride resin through chlorination.

Owner:XINJIANG CORPS MODERN GREEN CHLOR ALKALI CHEM ENG RES CENT LTD +1

A kind of preparation method of spherical diethoxymagnesium

ActiveCN112299984BParticle size controllableUniform particle sizeOrganic compound preparationCarboxylic acid salt preparationChemical industryAnhydrous ethanol

The invention provides a method for preparing diethoxymagnesium, which comprises using metal spherical magnesium powder and absolute ethanol as raw materials, adding iodine simple substance and a cosolvent to prepare spherical diethoxymagnesium. The particle size range of the obtained spherical diethoxymagnesium is 1-200um, and the span of the particle size distribution is less than 3; by adding a co-solvent to the reaction system, the particle size of the obtained diethoxymagnesium can even reach 5um-15um, and Compared with the traditional method of adding surfactant, silicone oil or spar, the method is easier to remove the cosolvent, has no residue of impurities, and is more convenient for post-processing. The method of the present invention has lower reaction temperature, stable reaction and shorter reaction time. Short, no environmentally unfriendly substance discharge, suitable for large-scale industrial production.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Color printing toner and preparation method thereof

InactiveCN104536274AGood climate adaptabilityRegular particle shapeDevelopersPolymer scienceAcrylic resin

The invention relates to a color printing toner and a preparation method thereof, and belongs to the technical field of toner preparation. The color printing tone is prepared from the following raw materials in parts by weight: 60-70 parts of pigment powder, 10-15 parts of modified starch, 10-20 parts of styrene-acrylic resin, 10-15 parts of talcum powder and 1-5 parts of sodium silicate. The preparation method comprises the following steps: mixing pigment powder, modified starch, talcum powder and sodium silicate evenly; carrying out ball-milling for 30-35 minutes; adding 100-110 parts of deionized water; adding styrene-acrylic resin, heating to 50-56 DEG C, and keeping for 50-55 minutes; cleaning with 8-10fold deionized water, filtering and drying into a granular material; and screening the material, selecting 2-10micron granules, and drying at 50-55 DEG C for 30-40 minutes, so as to obtain the product. The toner granules are regular and uniform in shape, clear to develop and image, distinct in color layer, suitable for different models, and relatively low in preparation cost; and industrialized production is easy to achieve.

Owner:FOSHAN MINGQIAN TECH

A kind of cpvc pipe material and preparation method thereof

The invention provides a CPVC pipe material and a preparation method thereof, belonging to the field of polymer materials, comprising polyvinyl alcohol having an alcoholysis degree of 78-82 mol% and dioctyl adipate in a mass ratio of 2:1-3 The binary composite dispersion system prepared PVC resin, prepared CPVC-g-MHA by chlorinated in-situ grafting method, and blended the obtained CPVC-g-MHA with stabilizers, processing aids, impact modifiers, etc. Prepare CPVC pipe. The CPVC pipe material provided by the invention and the preparation method thereof have the advantages of good toughness, good heat resistance, high strength, simple and easy processing, high efficiency and low cost.

Owner:任丘市华凯通信设备有限公司

A kind of autoclave type preparation method of thermoplastic polyester elastomer foamed particles

The invention belongs to the field of preparation of functional foaming materials, and particularly relates to a low-pressure kettle-type preparation method of thermoplastic polyester elastomer foaming particles. First, the initial materials are fully mixed, and then the liquid foaming agent is sprayed on the initial raw materials as a spray liquid. After the mixture is loaded, it is granulated by a granulator, and the obtained granules are first subjected to high-pressure heating and heat preservation treatment in a reactor, and then foamed at normal pressure and high temperature, and filtered after sufficient foaming to obtain foamed particles.

Owner:CHANGZHOU SHUNXIANG NEW MATERIAL TECH CO LTD

Vinyl chloride-butyl acrylate copolymer resin with ultralow polymerization degree and preparation method thereof

The invention relates to the technical field of vinyl chloride-butyl acrylate copolymer resin and particularly relates to vinyl chloride-butyl acrylate copolymer resin with ultralow polymerization degree and a preparation method thereof. The vinyl chloride-butyl acrylate copolymer resin with ultralow polymerization degree is prepared from the following raw materials: desalted water, a vinyl chloride monomer, a compound dispersant, a compound initiator, chain transfer agent mercaptoethanol and butyl acrylate. According to the vinyl chloride-butyl acrylate copolymer resin, acrylate is used as amain body; the vinyl chloride monomer is introduced; mercaptoethanol is used as the chain transfer agent of polymerization reaction; acrylate, the vinyl chloride monomer and the mercaptoethanol are copolymerized with the compound dispersant and the compound initiator to obtain the vinyl chloride-butyl acrylate copolymer resin with ultralow polymerization degree. Compared with the conventional chloroacylic resin and PVC resin, the vinyl chloride-butyl acrylate copolymer resin with ultralow polymerization degree has the advantages of low polymerization degree, high apparent density, low viscosity, regular particle shape and high resin flowability; meanwhile, the vinyl chloride-butyl acrylate copolymer resin is short in plasticizing time and easier to shape and process, and has more extensiveapplication fields in subsequent processing and application.

Owner:XINJIANG ZHONGTAI CHEM CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com