Patents

Literature

73results about How to "Shorten plasticizing time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

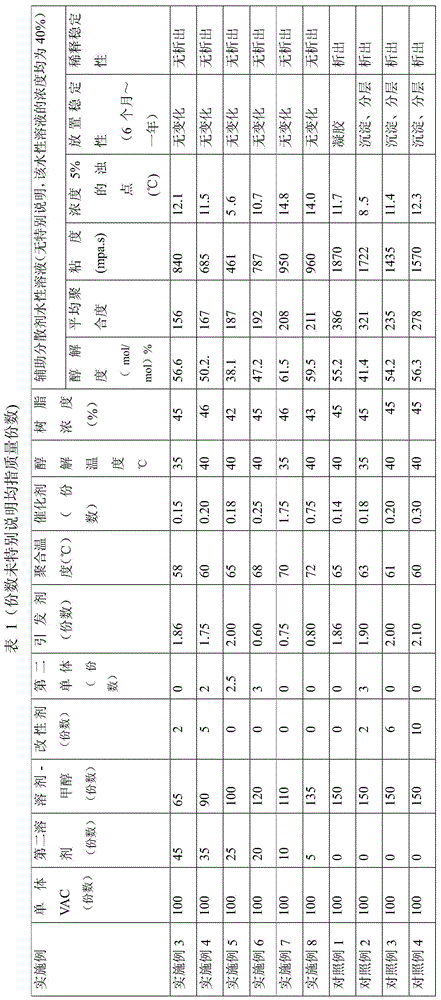

Polyvinyl alcohol, preparation method and applications

The invention provides polyvinyl alcohol. The polyvinyl alcohol is characterized in that the average polymerization degree is no higher than 500, the blocking degree is 0.50-0.85, and the alcoholysis degree is 35mol%-65mol%. The provided polyvinyl alcohol with a low polymerization degree, a low alcoholysis degree and a low viscosity has especially excellent viscosity stability. When the provided polyvinyl alcohol is used for a vinyl polymer suspension polymerization reaction, the monomer droplet disperse dispersion capability is strong, the dispersion stability is good, and the provided polyvinyl alcohol is free from vinyl polymer polymerization conditions. The pores of the prepared vinyl polymers are distributed uniformly and the porosity is high. The removal performance of reaction residual monomers is good, the absorption capability of added plasticizers is excellent during the subsequent processing process, the processing properties are excellent, plasticizing time can be shortened, and the fisheye number is decreased.

Owner:CHINA PETROCHEMICAL CORP +1

Polyvinyl alcohol, and preparation method and application thereof

The invention provides polyvinyl alcohol, which is characterized by having the average degree of polymerization in a range of 50-500, the alcoholysis degree in a range of 30-65 mol%, and the viscosity no more than 1500 mPa*s. Polyvinyl alcohol is prepared into an aqueous solution, which is taken as an auxiliary dispersant for suspension polymerization of vinyl polymers. The cloud point of an aqueous solution, the concentration of which is 5 wt%, (that is, a polyvinyl alcohol aqueous solution of 5 wt%), is no less than 1 DEG C and less than 15 DEG C. The viscosity measured at 25 DEG C of an aqueous solution, the concentration of which is 40 wt%, is no more than 1500 mpa*s. Gel and layering don't appear in an aqueous solution, the concentration of which is in a range of 30wt%-50wt%, in at least one year, so that the aqueous solution is extremely excellent in stability.

Owner:CHINA PETROCHEMICAL CORP +1

Manufacturing technique for EPE pearl wool

The invention discloses a manufacturing technique for EPE pearl wool. Jinpaomu serves as a raw material nucleating agent, a butane agent and monostearin serve as an accessory foaming agent and an anti-shrinking agent correspondingly, due to accessory matching, raw material foaming is sufficient, and accessories do not influence one another; raw materials are fed into the foaming agent for preheating treatment firstly, the preheating temperature is 50 DEG C, the preheated raw materials are subject to plasticizing heating, the plasticizing time can be shortened, and the problem of uneven melt density caused by uneven temperature during plasticizing heating can be solved; the mold opening temperature is 168 DEG C, the molding state of melt can be kept at the temperature, the amorphous form of the melt due to too high temperature can be prevented, and the condition that curing of the melt cannot be subject to traction due to too low temperature is avoided; after a sheet passes through a sizing drum, the width is 1.5 m through sizing, the width of the sheet is determined by the sizing drum, and the width facilities machining and treatment of the sheet in the later period; after the sheet is extended, burrs are removed, the step of removing the burrs is increased, and therefore the attractiveness of the sheet can be improved, and scrap edges can be removed.

Owner:ANQING SHENGHUA PAPER PACKAGING

Functional calcium carbonate and method for producing the same

ActiveCN101456969AIncrease dosageDosage remains the samePigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsInterface layerPerformance index

The invention discloses a functionality calcium carbonate and a preparation method thereof. The functionality calcium carbonate is prepared by compound treatment technology of 'wet method + dry method' of superfine coarse whiting, fine calcium carbonate particle, nanometer calcium carbonate and a modification agent. The functionality calcium carbonate of the invention can promote resin plasticization, reduce melt viscosity, improve melt fluidity and melt intensity, make product surface smooth and fine and have the function of processing an addition agent ACR, and meanwhile is provided with the function of strengthening coupling and excellent surface modification effects. Appropriate increasing of padding of the system does not affect each performance index of the product. The functionality calcium carbonate and the preparation method thereof has the advantages of improving dispersivity and compatibility of each component of prescription system, improving plasticity of bonding strength of interface layer, having excellent interface layer performance, realizing the function of annealing strengthening and strengthening.

Owner:NANJING XIEHE CHEM

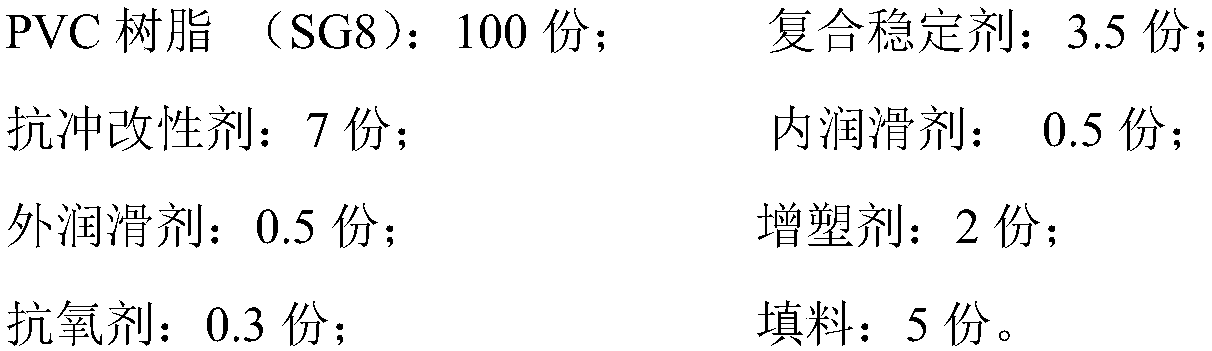

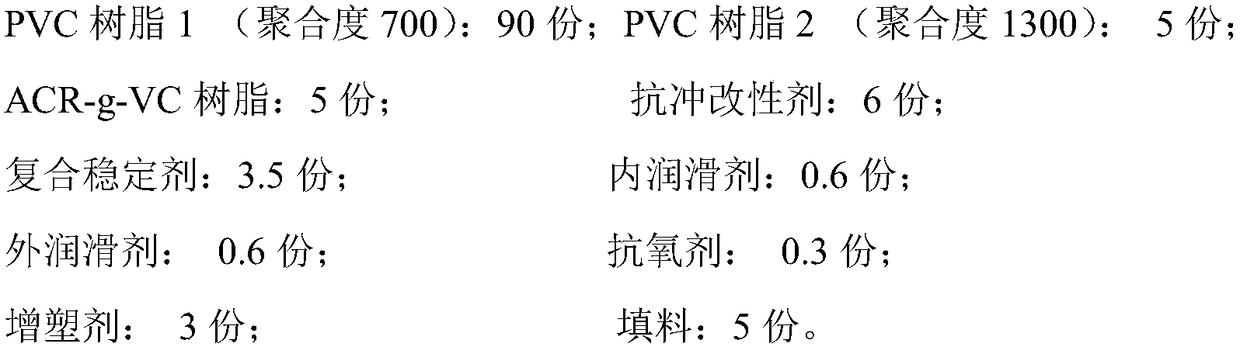

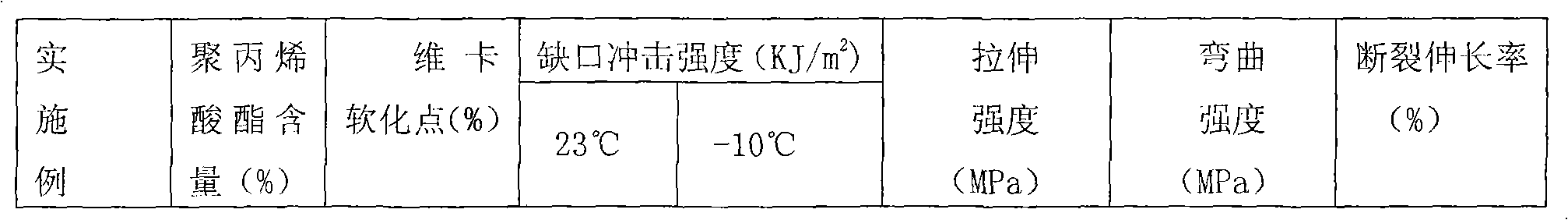

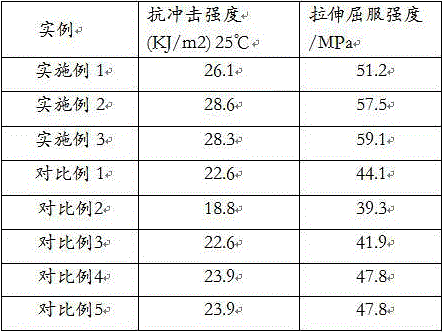

High-strength and high-toughness polyvinyl chloride injection molded composition and preparation method thereof

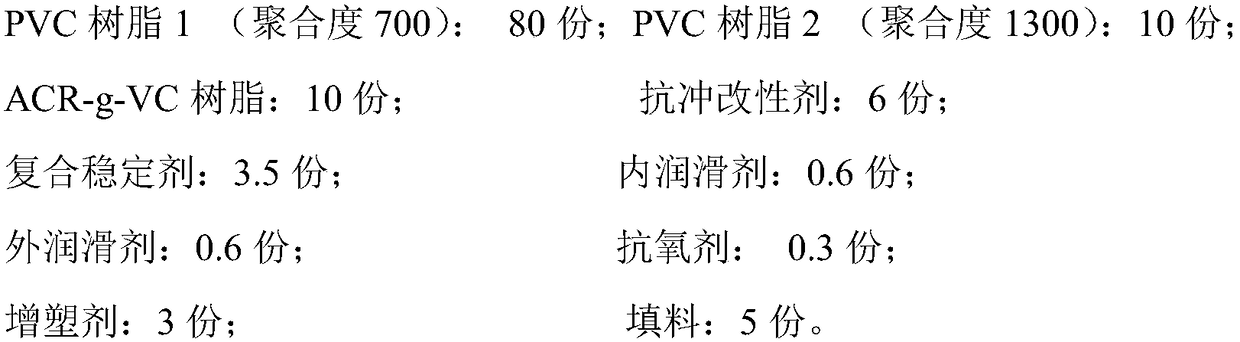

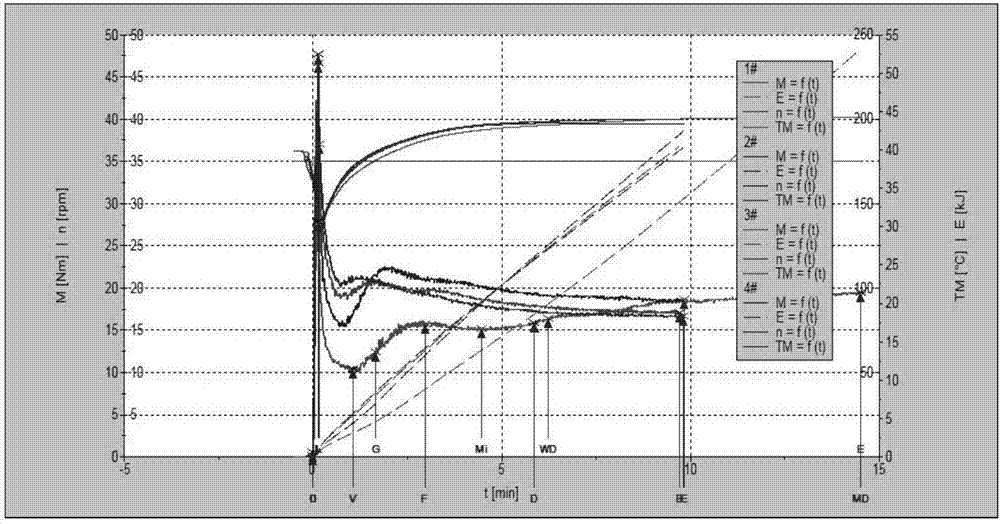

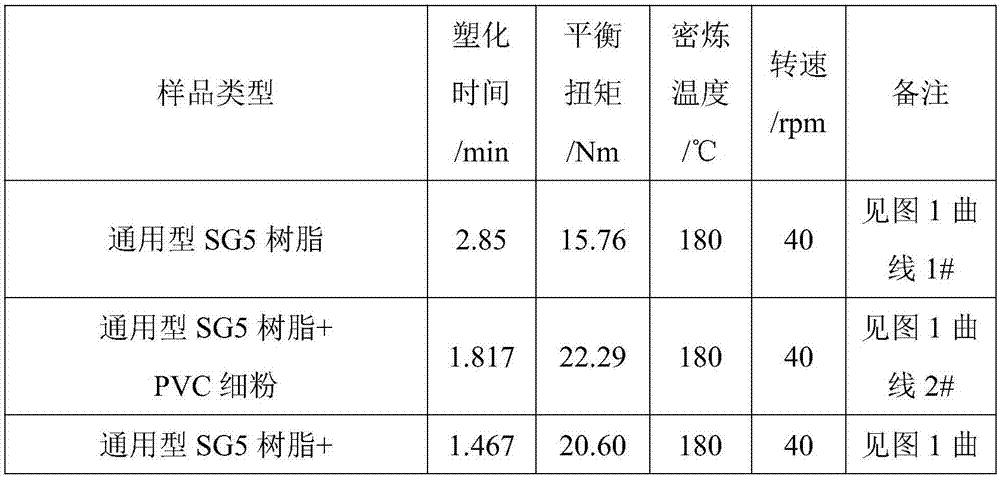

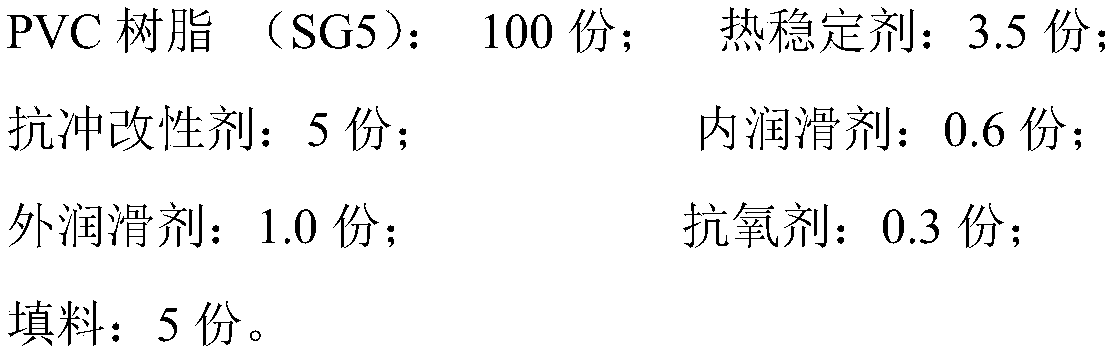

The invention discloses a high-strength and high-toughness polyvinyl chloride injection molded composition and a preparation method thereof. The composition comprises, by weight, 50-90 parts of PVC (polyvinyl chloride) resin 1, 5-20 parts of PVC resin 2, 5-40 parts of ACR-g-VC (acrylic graft vinyl chloride) resin, 3-10 parts of parts of impact modifier, 4-6 parts of compound stabilizer, 0.5-2 parts of internal lubricant, 0.5-1.2 parts of external lubricant, 1-5 parts of fillers, 1-3 parts of plasticizer and 0.1-1 part of antioxygen. The preparation method includes: weighing the ingredients according to a formula about weight ratios, placing in a high-speed mixer, mixing to obtain a polyvinyl chloride mixture, adding the polyvinyl chloride mixture into a tapered double-screw extruder, melting, extruding, pelletizing and packaging. Compared with a product prepared according to a formula adopting normal SG8 type PVC resin, the high-strength and high-toughness polyvinyl chloride injectionmolded composition has the advantages that plasticizing time can be shortened by more than 20%, and impact strength can be enhanced by more than 10 times.

Owner:YIBIN TIANYUAN GRP CO LTD

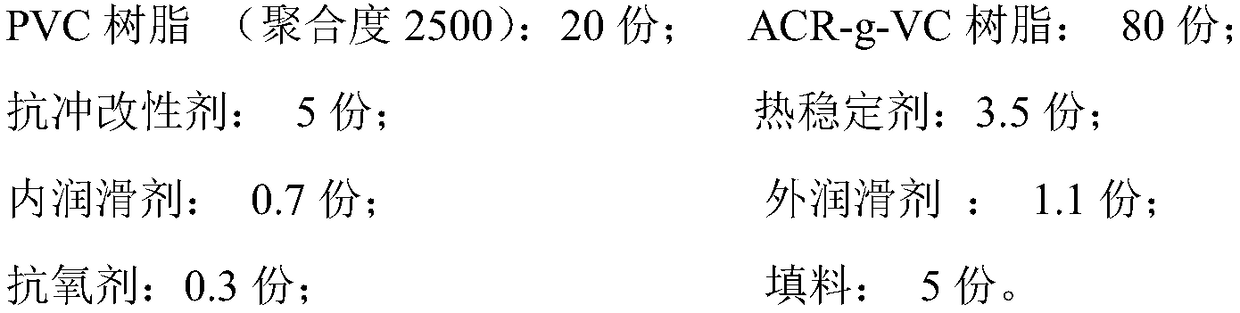

High-impact high-flowability PVC (polyvinyl chloride) formula and preparation method thereof

The invention discloses a high-impact high-flowability PVC (polyvinyl chloride) formula and a preparation method thereof. The high-impact high-flowability PVC formula is prepared from the following ingredients in parts by weight: 60 to 95 parts of PVC resin, 3 to 50 parts of ACR-g-VC resin, 3 to 15 parts of PVC fine powder, 2 to 5 parts of composite stabilizing agents, 0.5 to 2 parts of inner lubricating agents, 0.5 to 1 part of outer lubricating agents and 20 to 50 parts of calcium carbonate. A conventional extrusion process is used; low-polymerization-degree PVC fine powder and ACR-g-VC resin (chloroethylene-n-butyl acrylate graft copolymers) are added; the inner plasticization effects of low-polymerization-degree PVC resin and the chloroethylene-n-butyl acrylate graft copolymers is mainly utilized; the plasticization performance is improved in a cooperated way; the plasticization time is shortened; meanwhile, the anti-impact performance of the plastic product is obviously improved.

Owner:YIBIN TIANYUAN GRP CO LTD +1

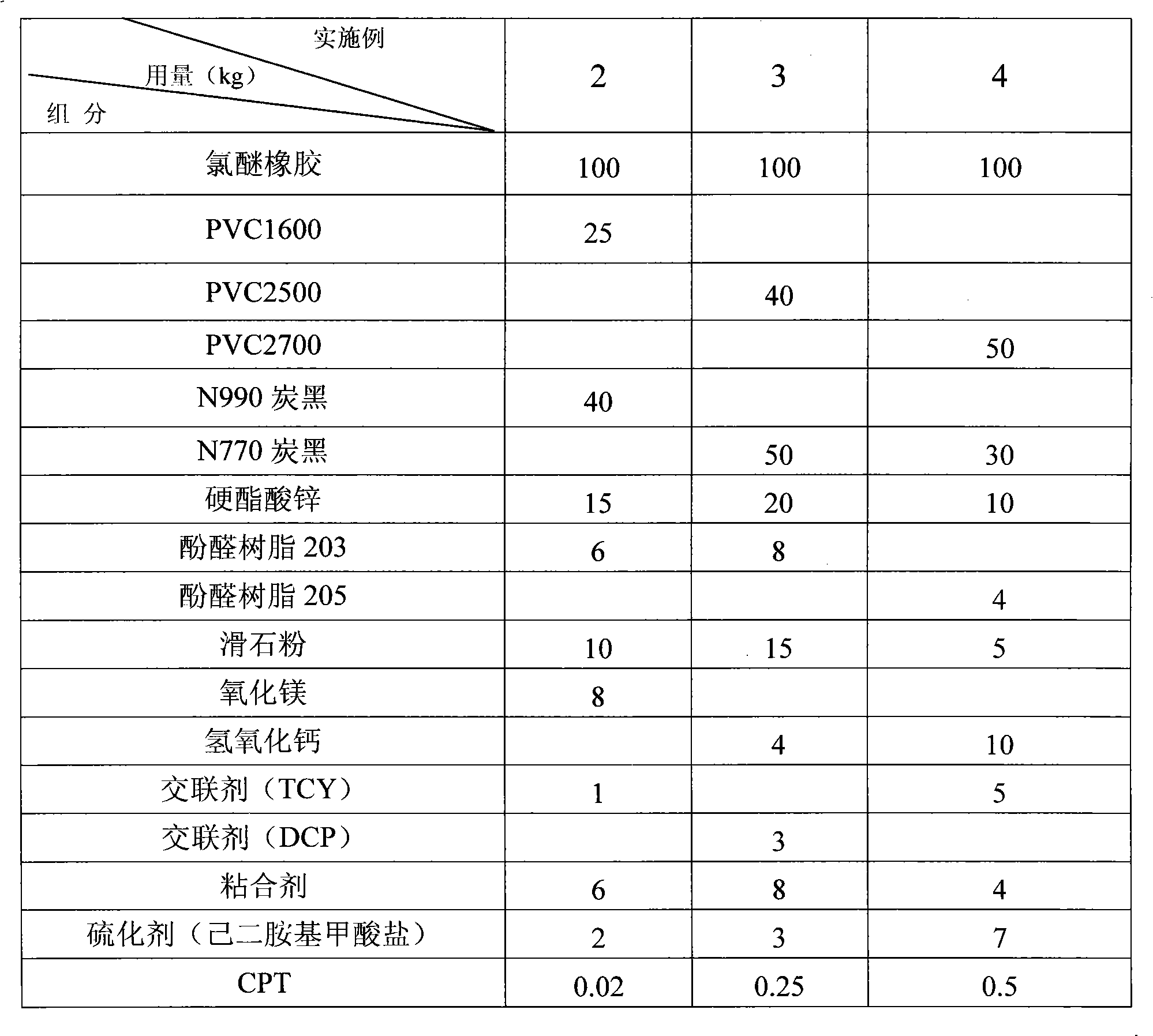

Material for anti-seepage rubber layer of inner tube of air conditioning hose and method for preparing same

The invention discloses a material for an anti-seepage rubber layer of an inner tube of an air conditioning hose and a method for preparing the same. The material comprises the following components in part by mass: 100 parts of epichlorohydrin rubber, 20 to 50 parts of PVC1300-2700, 10 to 20 parts of stabilizer, 5 to 15 parts of anti-aging agent, 4 to 8 parts of phenolic resin, 2 to 8 parts of barium / tin stabilizer, 30 to 50 parts of carbon black, 5 to 15 parts of talcpowder, 4 to 10 parts of acid acceptor, 1 to 5 parts of cross-linking agent, 4 to 8 parts of adhesive and 1 to 4 parts of vulcanizing agent. The method comprises the following steps of: placing the PVC and the components except the cross-linking agent and the adhesive in an internal mixer and plasticating the components for 8 to 16 minutes at the temperature of between 150 and 160 DEG C; placing the materials in an open mill, adding the cross-linking agent and the adhesive into the materials under the condition that the roller temperature is less than or equal to 60 DEG C, allowing the mixture to pass through the roller for 3 to 4 times in small thickness, triangularly packaging the mixture for 5 to 6 times and discharging sheets. The rubber material provided by the formula of the invention has the characteristics of freon resistance, novel refrigerant resistance, hot oil resistance, aging resistance and the like; and meanwhile, the process is simple and the manufacturing cost is low.

Owner:仝国磊

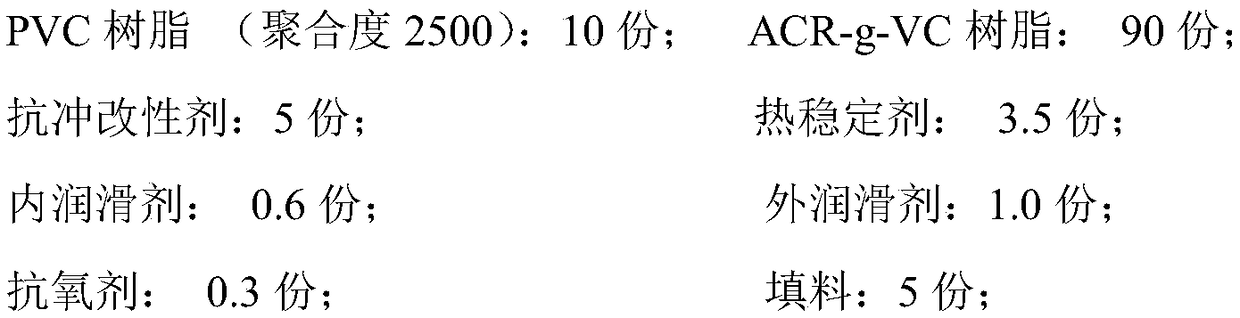

Formula and preparation method of high-strength and high-toughness polyvinyl chloride pipe material

The invention discloses a formula and a preparation method of a high-strength and high-toughness polyvinyl chloride pipe material. According to the formula, the high-strength and high-toughness polyvinyl chloride pipe material comprises, by weight, 10-40 parts of PVC (polyvinyl chloride) resin, 60-90 parts of ACR-g-VC (acrylic graft vinyl chloride) resin, 2-10 parts of impact modifier, 2-5 parts of heat stabilizer, 0.5-2 parts of internal lubricant, 0.5-1.2 parts of external lubricant, 1-20 parts of fillers and 0.1-1 part of antioxygen. The preparation method includes: weighing the ingredientsaccording to the formula, placing in a high-speed stirrer, mixing to obtain a polyvinyl chloride mixture, melting, extruding and pelletizing. A pipe material product prepared by the preparation method has the advantages of high plasticizing speed, high processability, great surface color, high impact resistance, high tensile strength, high weather resistance and the like.

Owner:YIBIN TIANYUAN GRP CO LTD

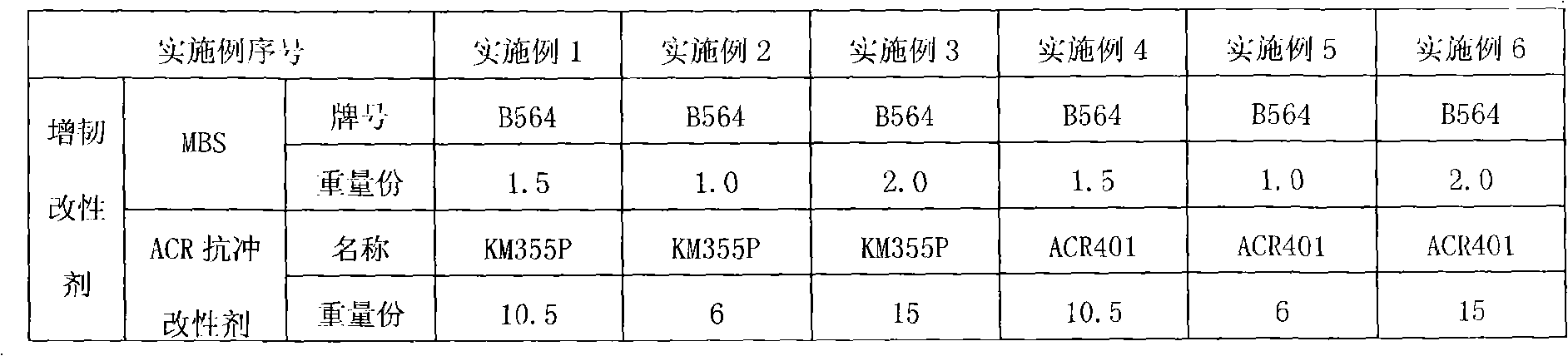

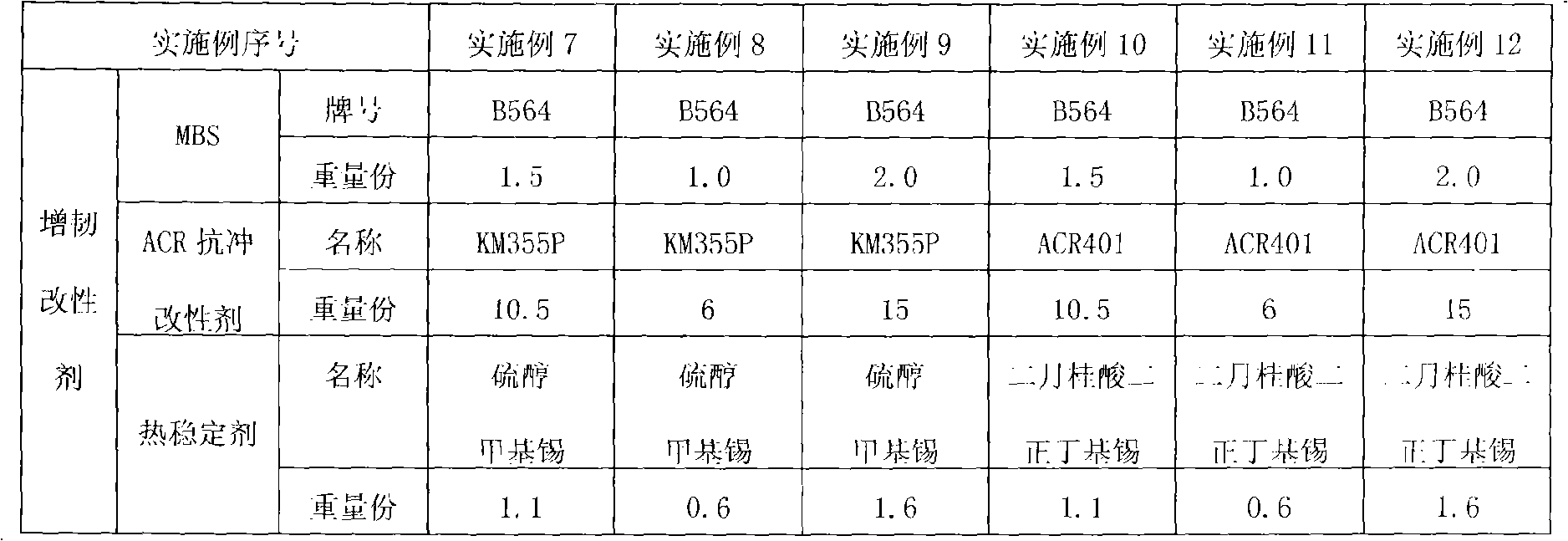

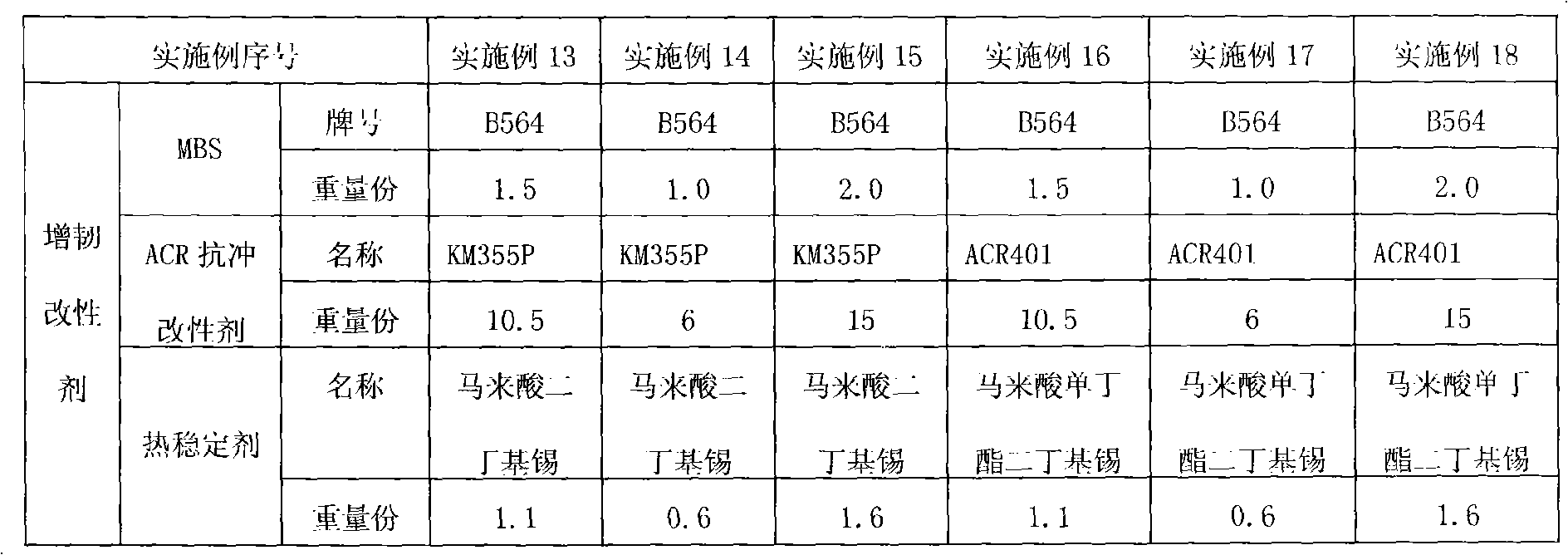

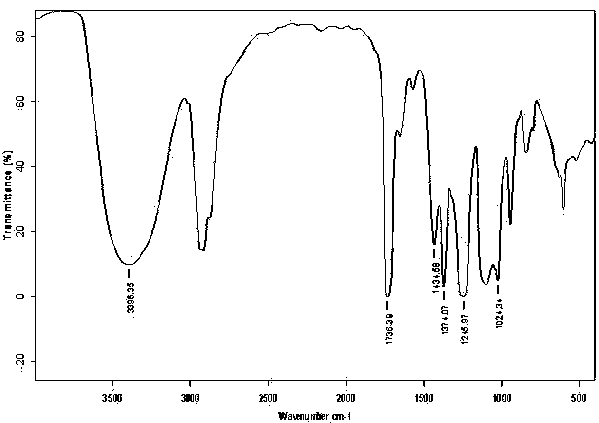

Polyvinyl chloride toughening modifier

InactiveCN101565530AImprove impact resistanceHigh surface glossRigid pipesMethylmethacrylatesPolyvinyl chloride

The invention discloses a polyvinyl chloride toughening modifier, which comprises 1.0 to 2.0 portions of methylmethacrylate butadine stryrene copolymer which is also called MBS, and 6 to 15 portions of acrylates impact modifier which is also called ACR impact modifier; and the portion of the compositions is weight portion. The polyvinyl chloride toughening modifier has good toughening and modification effects on polyvinyl chloride.

Owner:干方明

Nano polyvinyl chloride pipe and preparation method thereof

InactiveCN101157784AShorten plasticizing timeGood uniformity of plasticizationPolyvinyl chlorideResin-Based Composite

The invention relates to a nanometer polyvinyl chloride pipe and a preparation method thereof. According to weight ratio, raw materials of the nanometer polyvinyl chloride pipe comprise nanometer polyvinyl chloride resin, calcium carbonate, and PME-100 strengthening and toughening agent, etc. The preparation method is that: first, the raw materials needed are fully mixed in a high level mixing pot and a low level mixing pot; then the materials mixed are transported to an extruder production line to do extruding molding, thereby gaining the nanometer polyvinyl chloride pipe. The invention is characterized in that the invention is not only environment-friendly, but also solves the problems of insufficiency of thermal stability, initial coloring and products reddened and zinc burned, bad weather resistance and copper erosion, etc. During the mixing process of the preparation method, the plasticizing time is shortened, leading to a good plasticizing uniformity and being in favor of the basic extrusion molding process to the modification polyvinyl chloride. The mechanical property of the invention is distinctively higher than the common polyvinyl chloride resin and nanometer blending composite resin. The anti-impact performance and other performances are greatly enhanced The shock strength is two times the common resin products, and in particular the products has good shock strength in low temperature; in addition, the invention has good bending performance, thus being applied to no digging laying and repairing, etc.

Owner:XINJIANG BLUE RIDGE TUNHE CHEM IND JOINTSTOCK

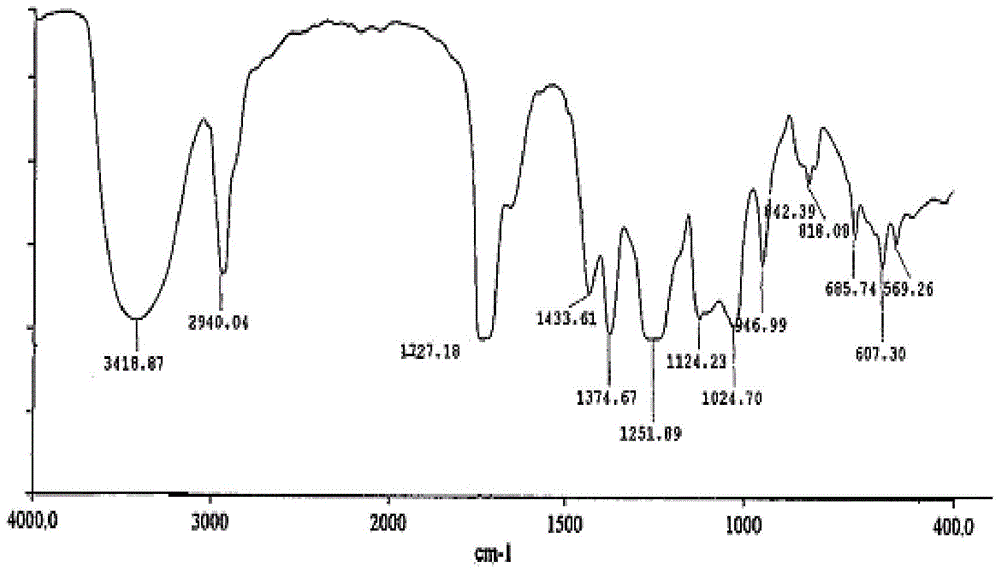

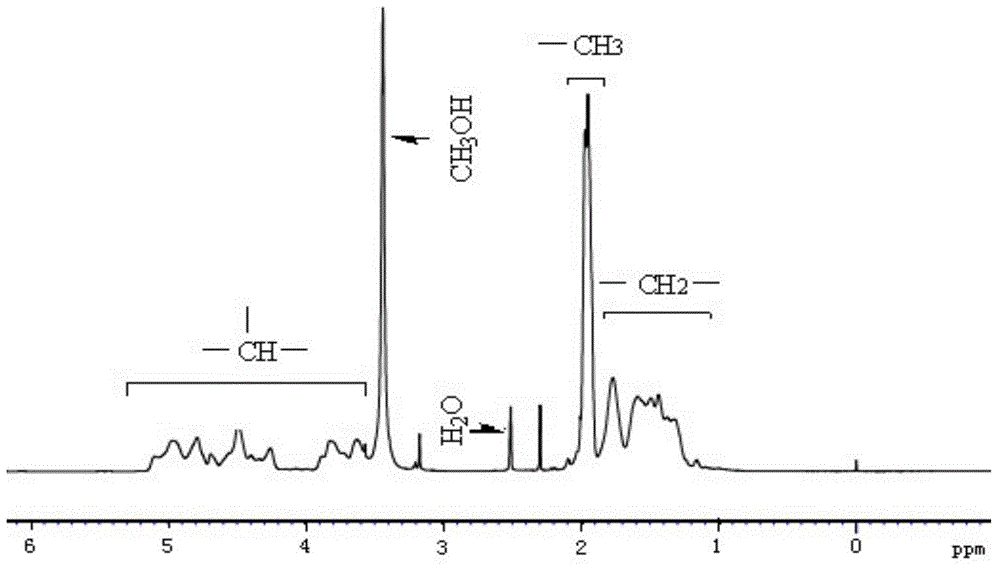

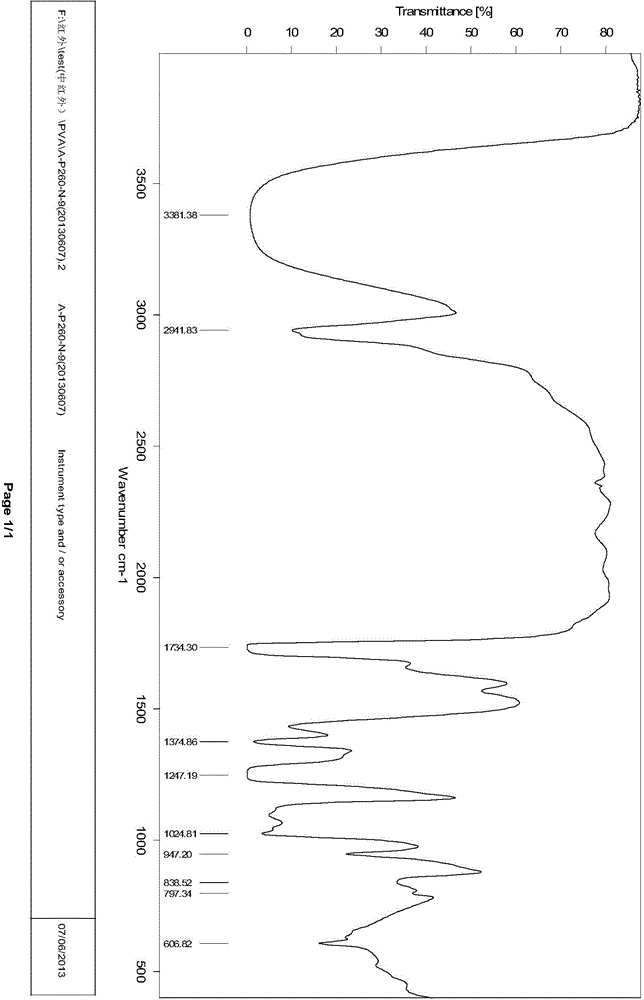

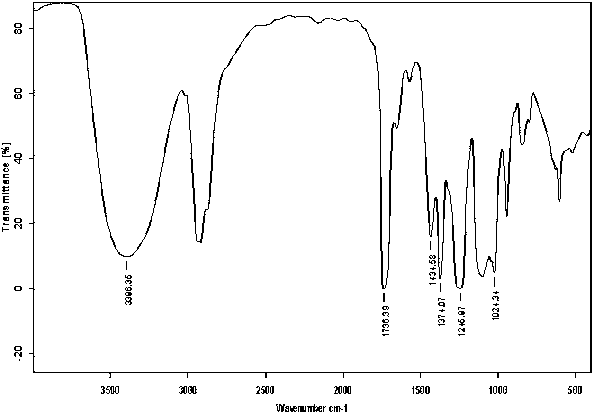

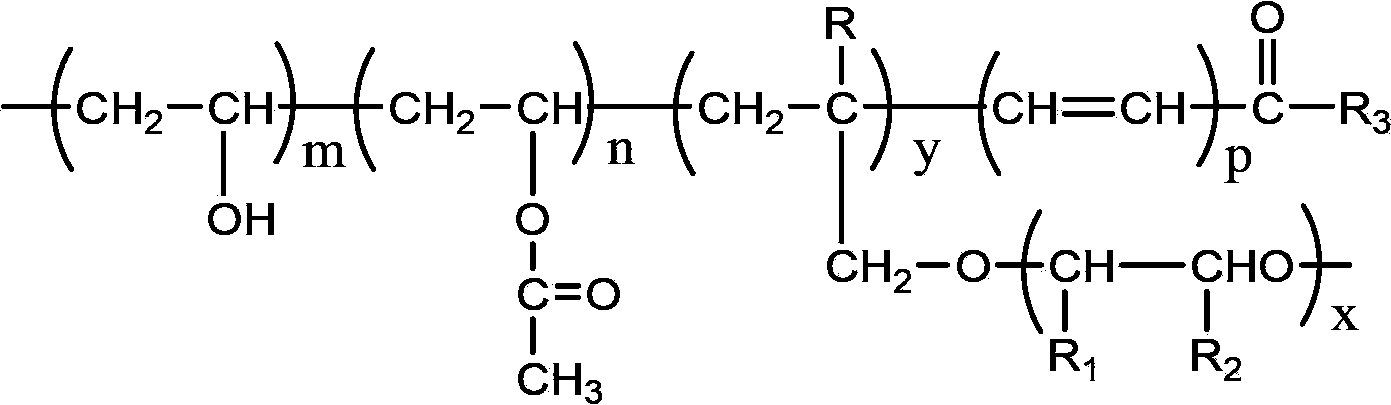

Modified polyvinyl alcohol, preparation method and use thereof

ActiveCN103788305AStrong absorption capacityExcellent absorption capacity, excellent processing performanceDispersion stabilityPorosity

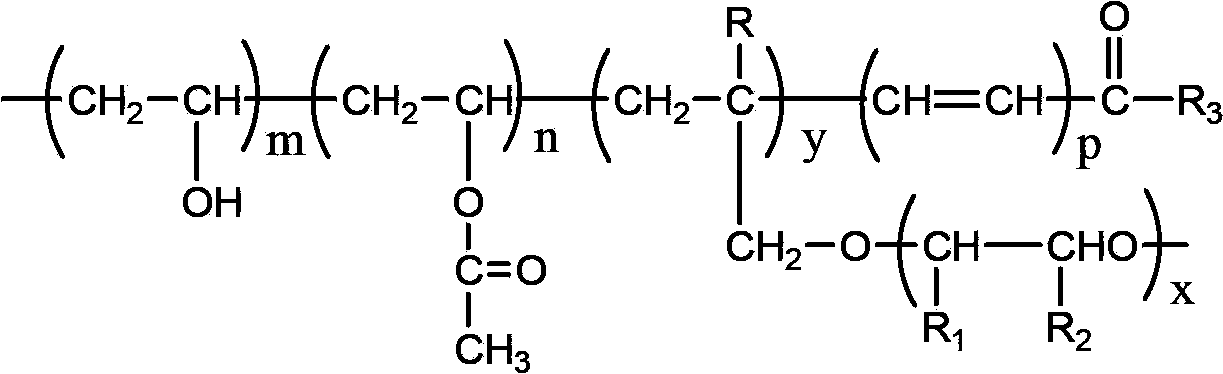

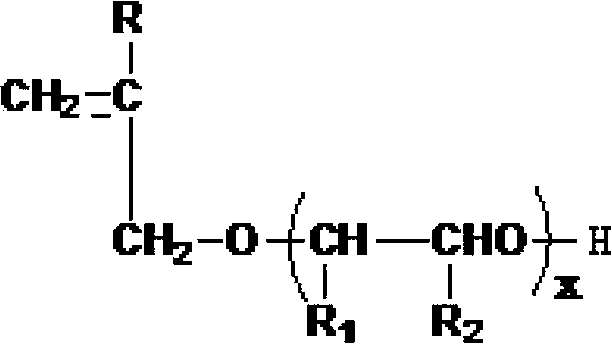

The invention relates to modified polyvinyl alcohol, which has the following structure formula, wherein m, n, x, y, p are integers, n is more than 30 and is less than 135, m is more than 20 and is less than 165, m / (m+n) is 40-55 mol%, x is more than or equal to 1 and is less than 20, y is more than 1 and is less than 20, P is more than or equal to 0 and is less than 5, R is hydrogen atom or methyl, and R1, R2 and R3 are hydrogen or alkyl. According to the present invention, after the modified polyvinyl alcohol is used for vinyl polymer suspension polymerization reactions, the strong dispersion capability on monomer drops is provided, the dispersion stability is good, and influence of the vinyl polymer polymerization condition does not exist; and the prepared vinyl polymer has characteristics of high porosity distribution uniformity, high porosity and good removal of remaining monomers of the reaction, and the plasticizer added during the subsequent processing process has characteristics of excellent absorption ability, excellent processability, shortened plasticizing time and reduced number of the fish-eyes.

Owner:CHINA PETROCHEMICAL CORP +1

Preparation method of high-impact polyacrylate grafting vinyl chloride emulsion copolymer resin

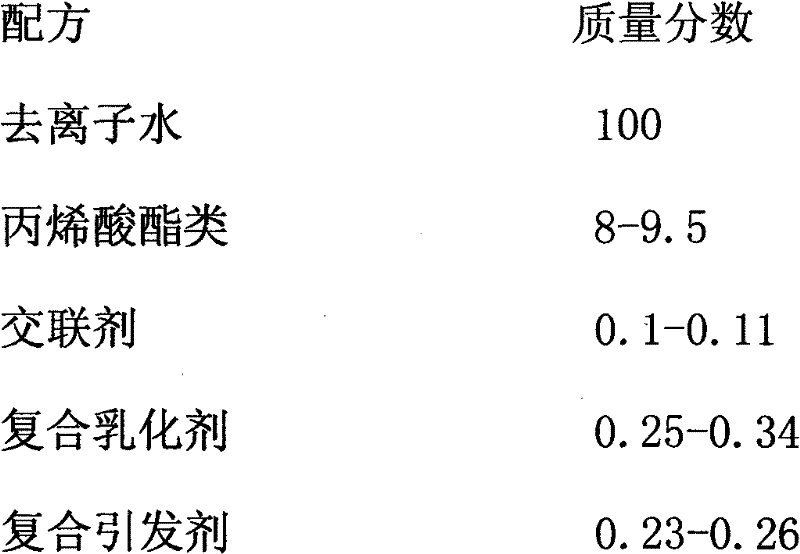

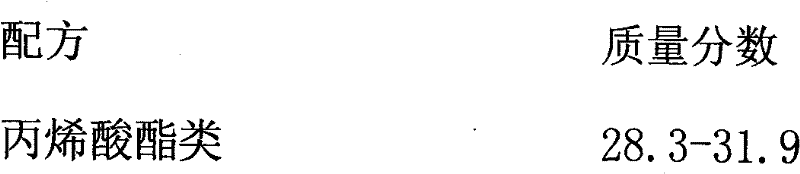

The invention relates to the technical field of vinyl chloride resin, in particular to a preparation method of high-impact polyacrylate grafting vinyl chloride emulsion copolymer resin. A single emulsifier and a single initiator are adopted by the original synthesis process, and tests proof that the single emulsifier can enable polymer latex not to be stable, and therefore, a stable polymerization product can not be obtained; the single initiator enables a polymerization system not to be stable, and reaction is difficult to control; freezing demulsification, filtering, washing, drying and the like are adopted as treatment processes of a vinyl chloride grafting copolymer emulsion to form a thick and big aggregated particle structure, and the product performance is low; moreover, much wastewater and many waste residues are generated in the process. In the invention, the stability of the latex is ensured by adopting a compound emulsifier and a compound initiator, which ensures that the latex has better average particle diameter, the polymerization system is stable and the reaction is easy to control; centrifugal spray drying is adopted to treat emulsion resin, and thereby, a good resin product with even particle size distribution and good processing performance can be obtained; and the wastewater and the waste residues are not generated, the process flow is short and the energy can be saved and the consumption can be lowered.

Owner:河北盛华化工有限公司

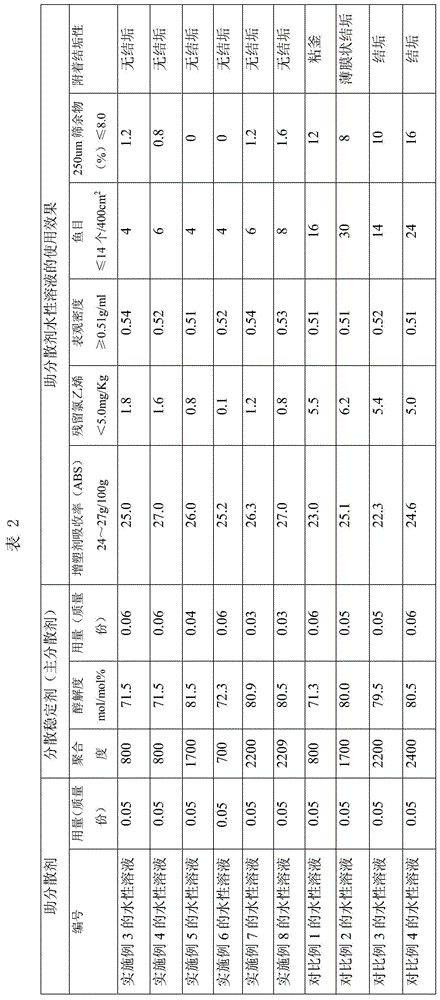

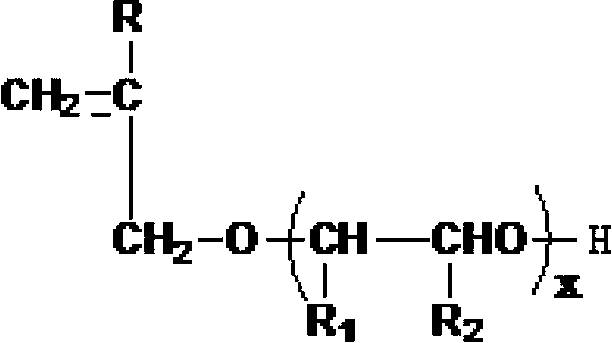

Auxiliary dispersant and preparation method

The invention relates to an auxiliary dispersant, which is an aqueous solution of polyvinyl alcohol possessing a following structural formula: (img file='dest_path_image001.TIF' wi='399' he='125' / ), wherein m, n, x, y and p are integers, n is less than 135 and greater than 30, m is less than 165 and greater than 20, m / m+n is 40mol%-55mol%, x is greater than or equal to 1 or less than 20, y is less than 20 and greater than 1, p is greater than or equal to 0 or less than 5; R is hydrogen atom or methyl, R1, R2, R3 are hydrogen or alkyl. The auxiliary dispersant is used in a suspension polymerisation reaction of vinyl, and has strong dispersing capability and good dispersing stability to the monomer droplets, the influence of polymerization condition of vinyl compounds can not generated; the prepared vinyl polymer has the advantages of uniform porosity distribution and high porosity amount, and has good removal performance to the residual monomer from the reaction, a plasticizer with excellent absorption capability is added during a subsequent processing process, The processing property is excellent, the plasticizing time can be shortened, and fish eye number is reduced.

Owner:CHINA PETROCHEMICAL CORP +1

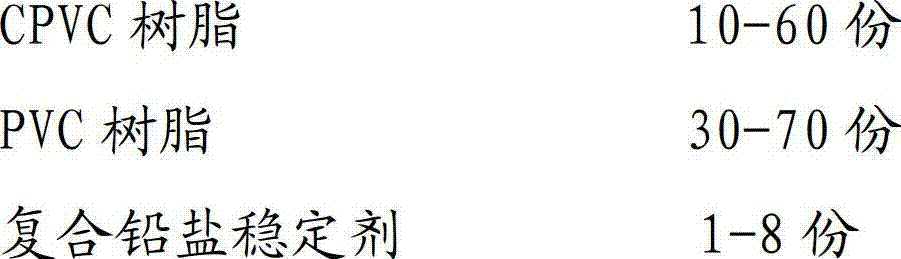

High-temperature-resistant weatherproof fireproof chlorinated polyvinyl chloride (CPVC) corrugated board with low heat conductivity, and preparation method of chlorinated polyvinyl chloride (CPVC) corrugated board

ActiveCN102924851AImprove corrosion resistanceReduce thermal conductivity and heat absorptionStabilizing AgentsChemical stability

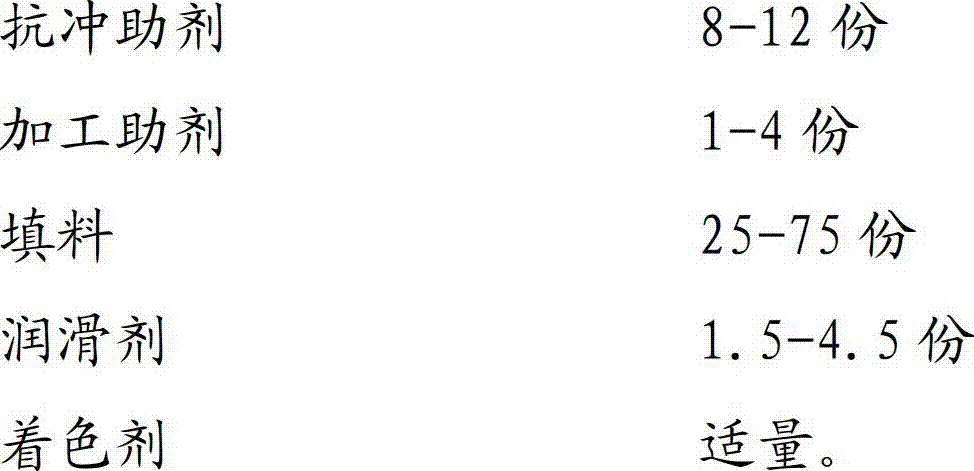

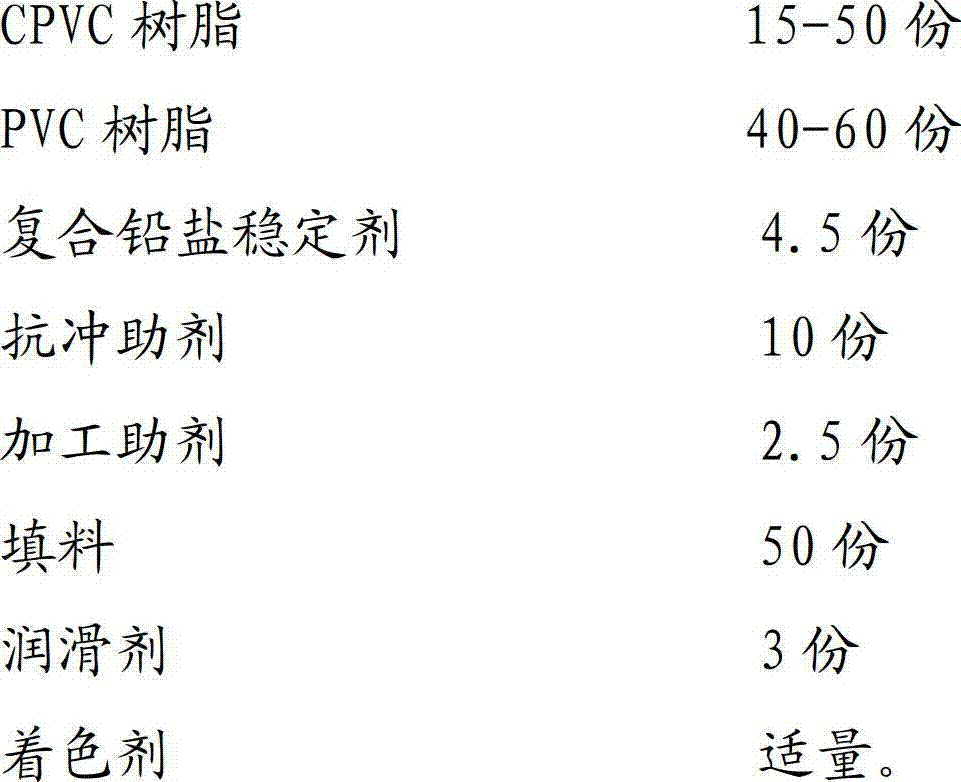

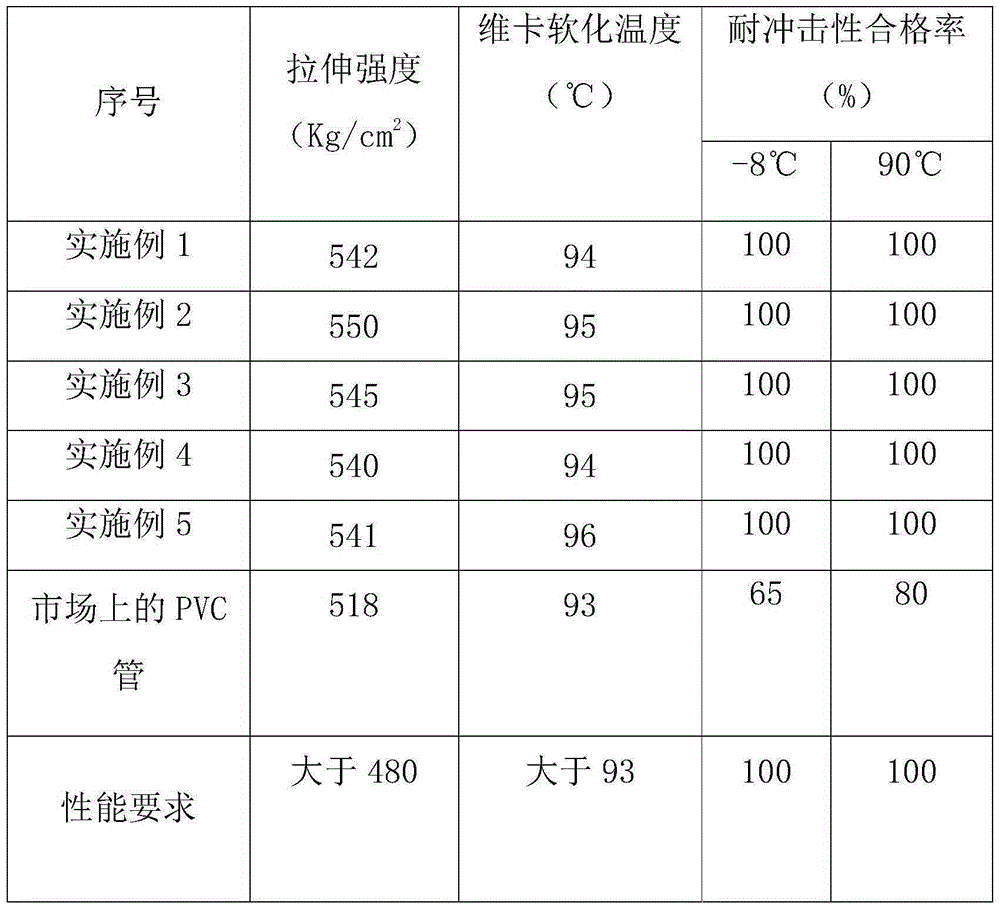

The invention discloses a high-temperature-resistant weatherproof fireproof chlorinated polyvinyl chloride (CPVC) corrugated board with low heat conductivity, and a preparation method of the chlorinated polyvinyl chloride (CPVC) corrugated board. The corrugated board is prepared from the following raw materials by weight: 10-60 parts of CPVC resin, 30-70 parts of PVC (polyvinyl chloride) resin, 1-8 parts of composite lead salt stabilizer, 1-4 parts of processing aids, 8-12 parts of anti-impact aids, 25-75 parts of filler, 1.5-4.5 parts of lubricant, and a reasonable amount of colorant. The corrugated board has the advantages of high mechanical strength, excellent weatherability, high aging resistance and chemical stability and the like, and the formed raised corrugated board has higher thickness uniformity and uniform stress distribution, thereby being not easy to break due to stress concentration.

Owner:山东高信化学股份有限公司

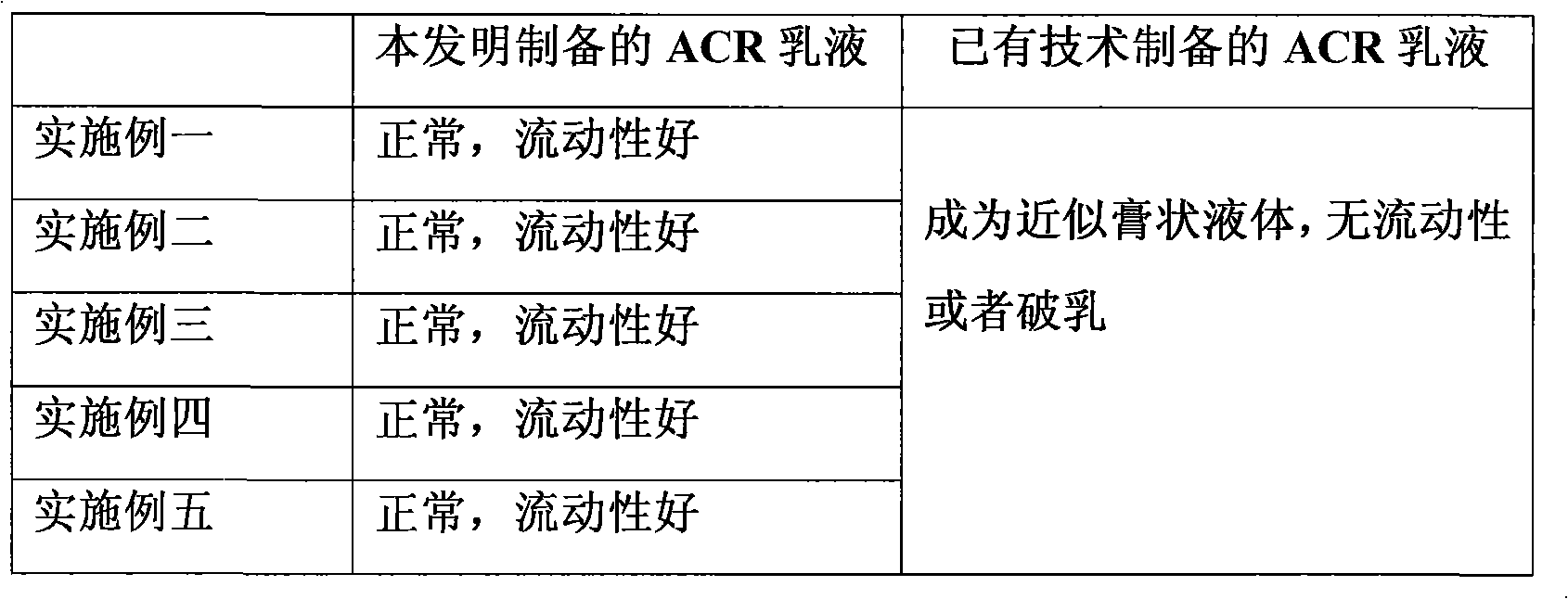

Uses of methallyl hydroxide sodium dimercaptosulphanate in PVC processing aid

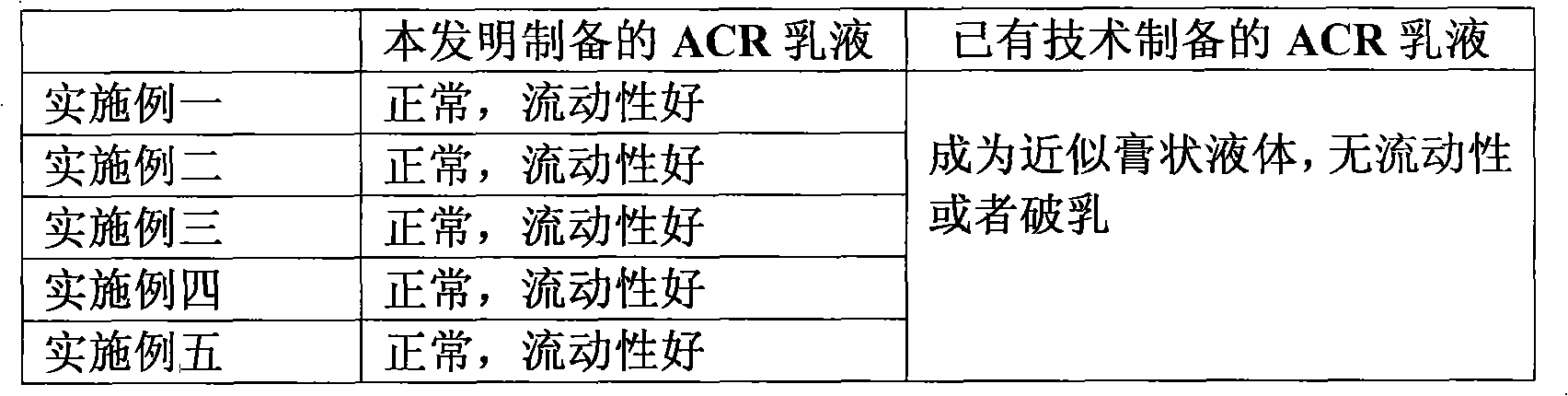

The invention provides methyl allyl hydroxypropyl sodium sulfonate as an emulsifier for a PVC processing aid ACR emulsion polymerization reaction. The methyl allyl hydroxypropyl sodium sulfonate is taken as a reactive emulsifier, which can carry out polymerization reaction with the monomer of raw material during the processing aid ACR emulsion polymerization reaction process. The adoption of the reaction emulsifier has following advantages: as the reactive emulsifier has polymerization activity, the carbon-carbon double bond functional group can participate in the emulsion polymerization reaction, the reactive emulsifier not only has the function of a conventional emulsifier but also can be bonded to the surface of polymer particles by a manner of covalent bond and become part of the polymer; therefore, after polymerization, the emulsifier molecules are bonded to the surface of emulsoid particles by a manner of more stable covalent bond and the processing aid ACR emulsion prepared has better stability. Besides, the degree of adhering to a spray tower during the drying process of the processing aid ACR emulsion is reduced and spray drying rate is improved. The degree of fusion between the processing aid ACR and a PVC resin is not affected and the plasticizing time of PVC can be shortened to some extent.

Owner:SHANDONG RUIFENG CHEM

Polyvinyl chloride tubular product and preparation method thereof

The invention discloses a polyvinyl chloride tubular product and a preparation method thereof and relates to the field of plastic tubular products. The polyvinyl chloride tubular product is prepared from, by weight, 75 parts of PVC, 25 parts of light calcium carbonate, 3-5 parts of a heat stabilizer, 1-3 parts of a lubricant, 5-8 parts of CPE, 2-5 parts of ACR and 0.8-1.5 parts of molybdate red, and the preparation method comprises the seven process steps of raw material weighing, hot mixing, cooling mixing, extrusion, vacuum cooling, cutting and flaring for forming and packaging. The preparation method is simple, the production efficiency is high, the preparation process is simple, low in cost and high in preparation efficiency, the prepared polyvinyl chloride tubular product is good in tensile property and impact resistance, and brittle failure does not easily occur.

Owner:ANHUI RUIFENG PIPE IND CO LTD

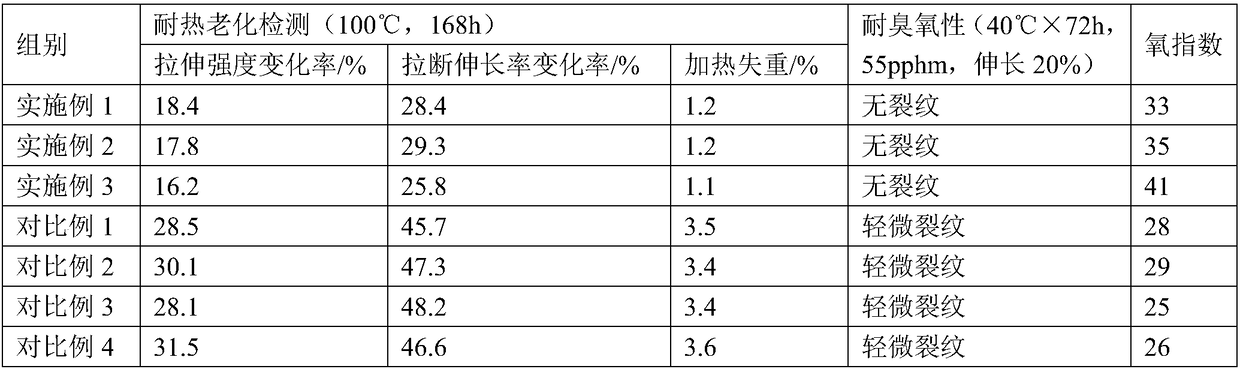

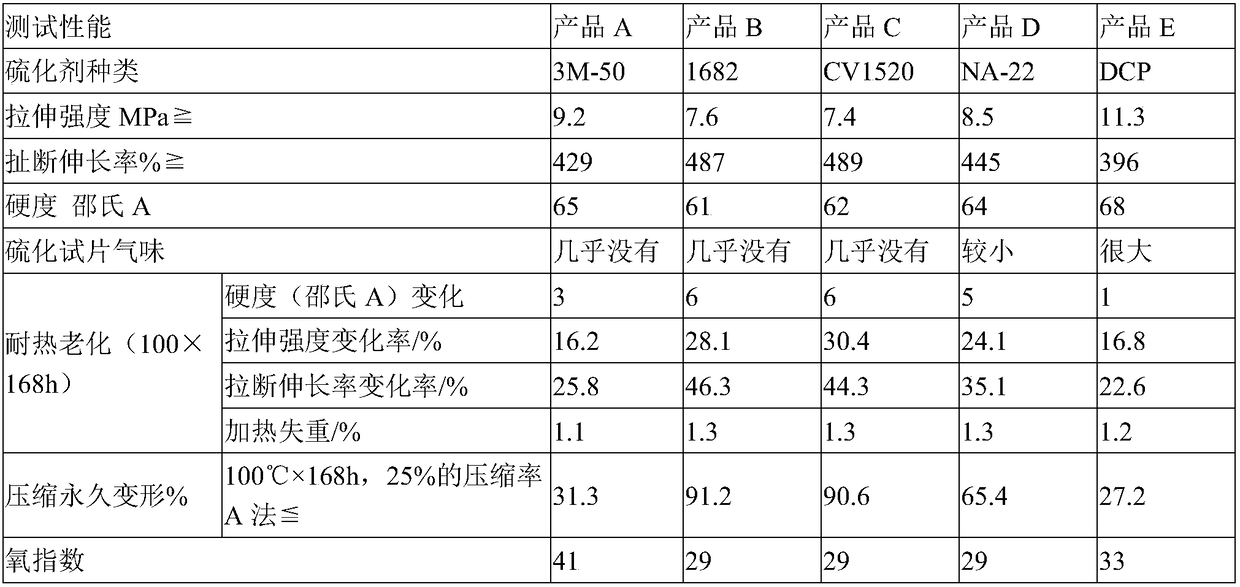

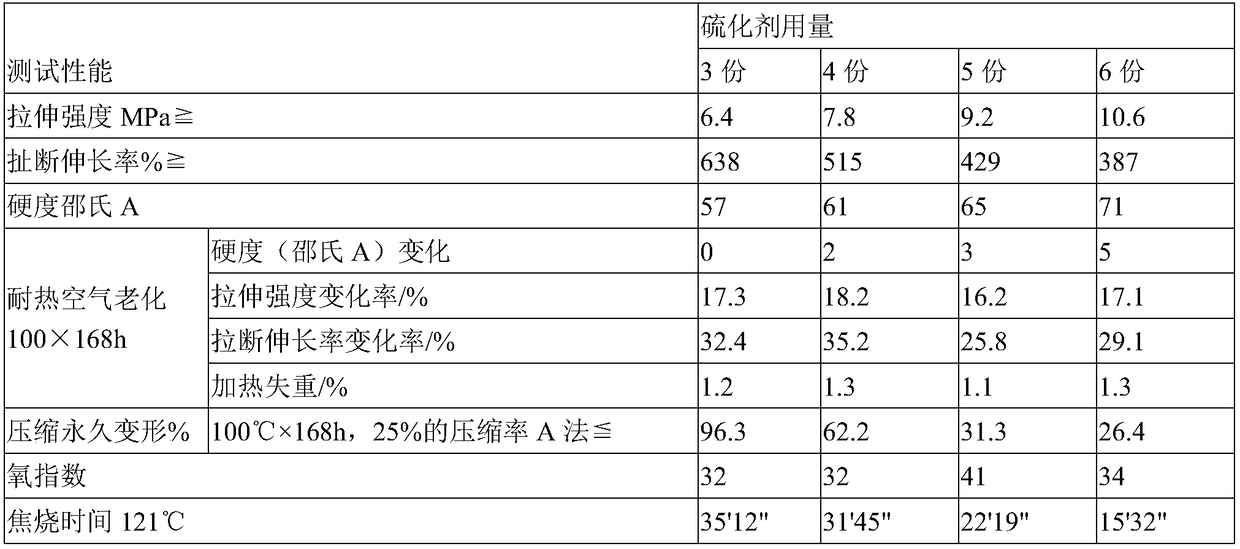

Novel chlorinated polyethylene rubber compound material and method for preparing same

The invention relates to a novel chlorinated polyethylene rubber compound material, in particular to a novel chlorinated polyethylene rubber compound material for preparing sealing strips and a methodfor preparing the novel chlorinated polyethylene rubber compound material. The novel chlorinated polyethylene rubber compound material comprises, by weight, 100 parts of rubber-based chlorinated polyethylene, 7-10 parts of magnesium hydroxide, 35-40 parts of semi-reinforced 774 carbon black, 60-70 parts of 990 carbon black, 0.5-1 part of stearic acid, 2-3 parts of calcium stearate, 15-20 parts ofkaolin E2, 25-32 parts of dioctyl terephthalate, 4-6 parts of antimony trioxide, 0.5-1 part of protection wax and 4.5-5.5 parts of vulcanizing agents ECHOS 808 3M-50. The novel chlorinated polyethylene rubber compound material and the method have the advantage that the novel chlorinated polyethylene rubber compound material is excellent in ageing resistance, ozone resistance, flame retardance andmechanical property and low in cost and can be used for preparing the flame-retardant building sealing strips. The invention further provides a method for preparing the sealing strips.

Owner:HANGZHOU KELI CHEM CO LTD

Preparation technique of television case

The invention belongs to the technical field of home appliance processing, and discloses a preparation technique of a television case. The technique comprises the following steps: 1) weighing raw materials; 2) preparing a modifier A; 3) preparing a modifier B; 4) preparing a modifier C; 5) preparing a modifier D; 6) preparing main materials; and 7) melting and setting. The preparation technique is simple and feasible. The prepared case has the advantages of favorable mechanical properties, favorable insulativity and favorable heat dispersion.

Owner:HANGZHOU FUYANG GAOBO INFORMATION TECH SERVICE

PVC injection molding material and PVC injection molding method capable of forming high-light mirror surface effect on surface of product

InactiveCN107746520AImprove appearance qualityPromote plasticizationMolten stateDioctyl terephthalate

The invention discloses a PVC injection molding material and a PVC injection molding method capable of forming a high-light mirror surface effect on the surface of a product. The PVC injection moldingmaterial comprises the components in percentage by weight: 30-50% of PVC resin, 15-25% of dioctyl terephthalate, 18.5-38% of calcium carbonate, 2-8% of stabilizer and 1.5-2% of methyl methacrylate and acrylonitrile copolymers. The injection molding method comprises the steps: firstly, uniformly stirring the components; heating the components to be in a molten state; closing a mold; carrying out filling, carrying out injection molding by an injection molding machine, wherein the injection molding pressure at the first stage is 15-30Bar, the flow at the first stage is 15-35mm / s, the injection molding time at the first stage is 2-5s, the injection molding pressure at the second stage is 15-30Bar, the flow at the second stage is 20-40mm / s, the injection molding time at the second stage is 1-3s, the injection molding pressure at the third stage is 10-25Bar, the flow at the third stage is 10-25mm / s, and the injection molding time at the third stage is 2-4s; maintaining the pressure; carrying out cooling; and carrying out demolding. By using the injection molding method disclosed by the invention, a high-light mirror surface effect can be formed on the surface of the product, the requirement of a terminal client to the appearance of the product can be met, and meanwhile, the competitiveness of the product on the market can be improved.

Owner:常熟利星光电科技有限公司

Laminated tubular product for high-rise water drainage and manufacturing method thereof

ActiveCN106380735AImprove thermal stabilitySmall particle sizePotassium persulfatePolyvinyl chloride

The invention belongs to the technical field of plastic tubular products, and in particular, relates to a laminated tubular product for high-rise water drainage and a manufacturing method thereof. The laminated tubular product is composed of the following components: polyvinyl chloride resin, a stabilizer, stearic acid, modified ACR, titanium dioxide, modified nano calcium carbonate and the like; preparation of the modified ACR comprises the following steps: (1) seed emulsion preparation: with butyl acrylate and styrene as monomers, adding a lauryl sodium sulfate emulsifier and a potassium persulfate initiator, stirring and heating to prepare a seed emulsion; (2) inner core preparation: continuing to add the potassium persulfate initiator and the butyl acrylate and styrene monomers, and introducing tetrafluoroethylene gas, to prepare an inner core; and (3) outer shell preparation: continuing to add the lauryl sodium sulfate emulsifier and the potassium persulfate initiator, adding methyl methacrylate, and adding modified nano SiO2, to prepare an outer shell; and (4) carrying out spray drying, to prepare the modified ACR. The vinyl chloride tube has the advantages of good impact resistance and good pressure resistance.

Owner:HUZHOU JINJIE IND CO LTD

Preparation method of high-impact polyacrylate grafting vinyl chloride emulsion copolymer resin

The invention relates to the technical field of vinyl chloride resin, in particular to a preparation method of high-impact polyacrylate grafting vinyl chloride emulsion copolymer resin. A single emulsifier and a single initiator are adopted by the original synthesis process, and tests proof that the single emulsifier can enable polymer latex not to be stable, and therefore, a stable polymerization product can not be obtained; the single initiator enables a polymerization system not to be stable, and reaction is difficult to control; freezing demulsification, filtering, washing, drying and thelike are adopted as treatment processes of a vinyl chloride grafting copolymer emulsion to form a thick and big aggregated particle structure, and the product performance is low; moreover, much wastewater and many waste residues are generated in the process. In the invention, the stability of the latex is ensured by adopting a compound emulsifier and a compound initiator, which ensures that the latex has better average particle diameter, the polymerization system is stable and the reaction is easy to control; centrifugal spray drying is adopted to treat emulsion resin, and thereby, a good resin product with even particle size distribution and good processing performance can be obtained; and the wastewater and the waste residues are not generated, the process flow is short and the energy can be saved and the consumption can be lowered.

Owner:河北盛华化工有限公司

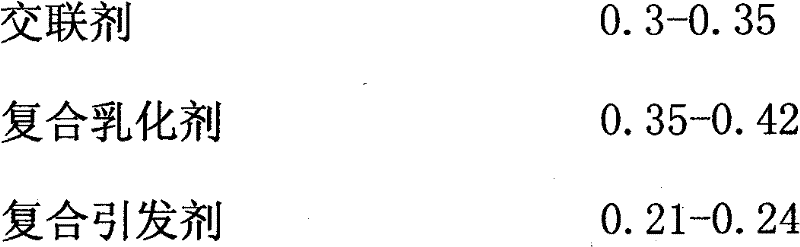

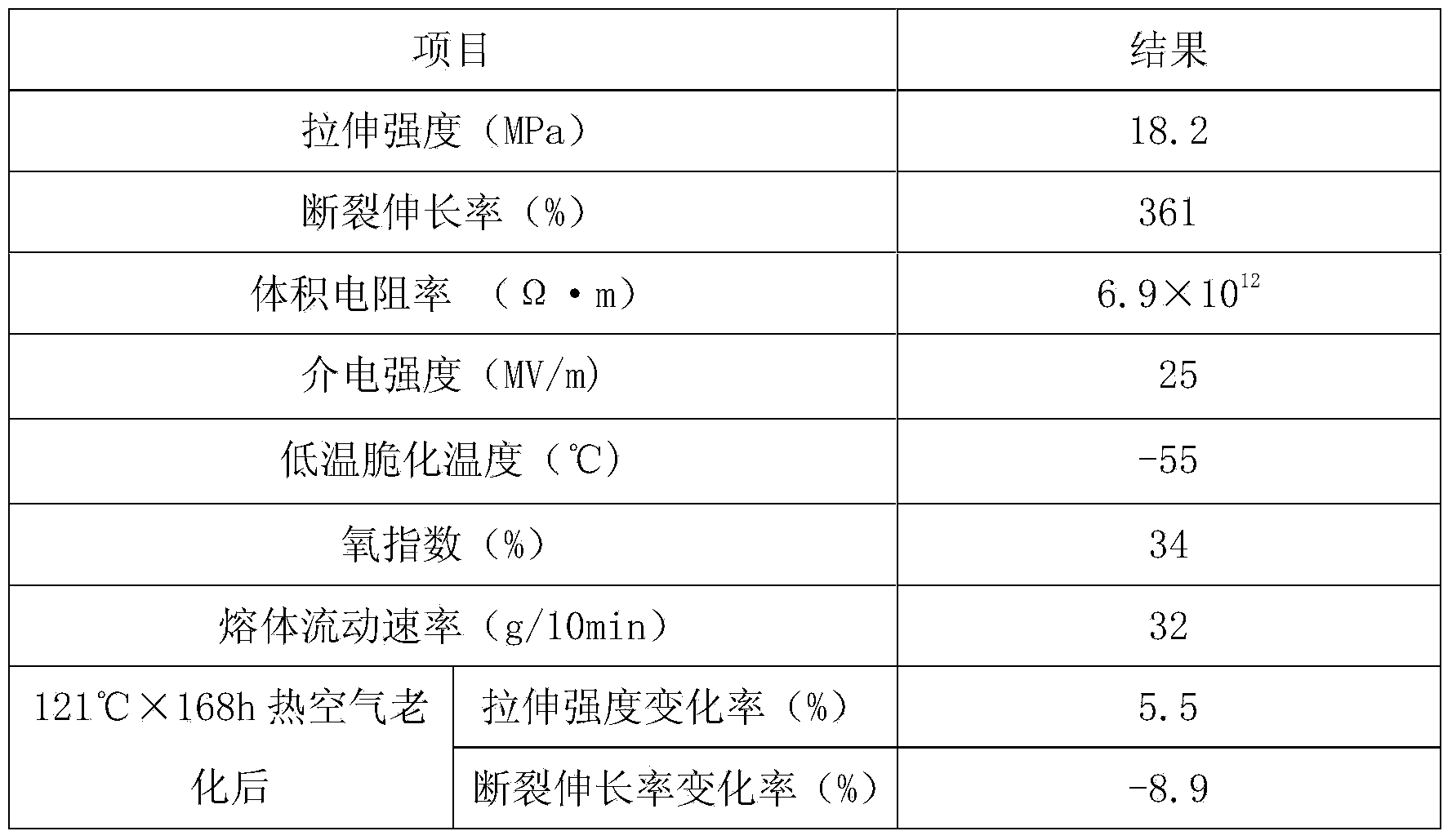

Preparation method of TPU (thermo plastic polyurethanes) calendered film

InactiveCN103802340AShorten plasticizing timeReduce processing costsFlat articlesWork in processUltimate tensile strength

The invention provides a preparation method of a TPU (thermo plastic polyurethanes) calendered film. The method comprises the following specific steps: 1, plasticizing TPU particles by an extruder to form a semi-finished product; 2, filtering and re-plasticizing the semi-finished product by a filter; 3, processing by using four-roller forming equipment, so as to form the film. The TPU film prepared by the preparation method has excellent physical properties such as tensile strength and tear strength, and has excellent quality; the quality of the product is improved by sufficient plasticizing, and the processing cost of a film product is reduced.

Owner:上海吉龙经济发展有限公司

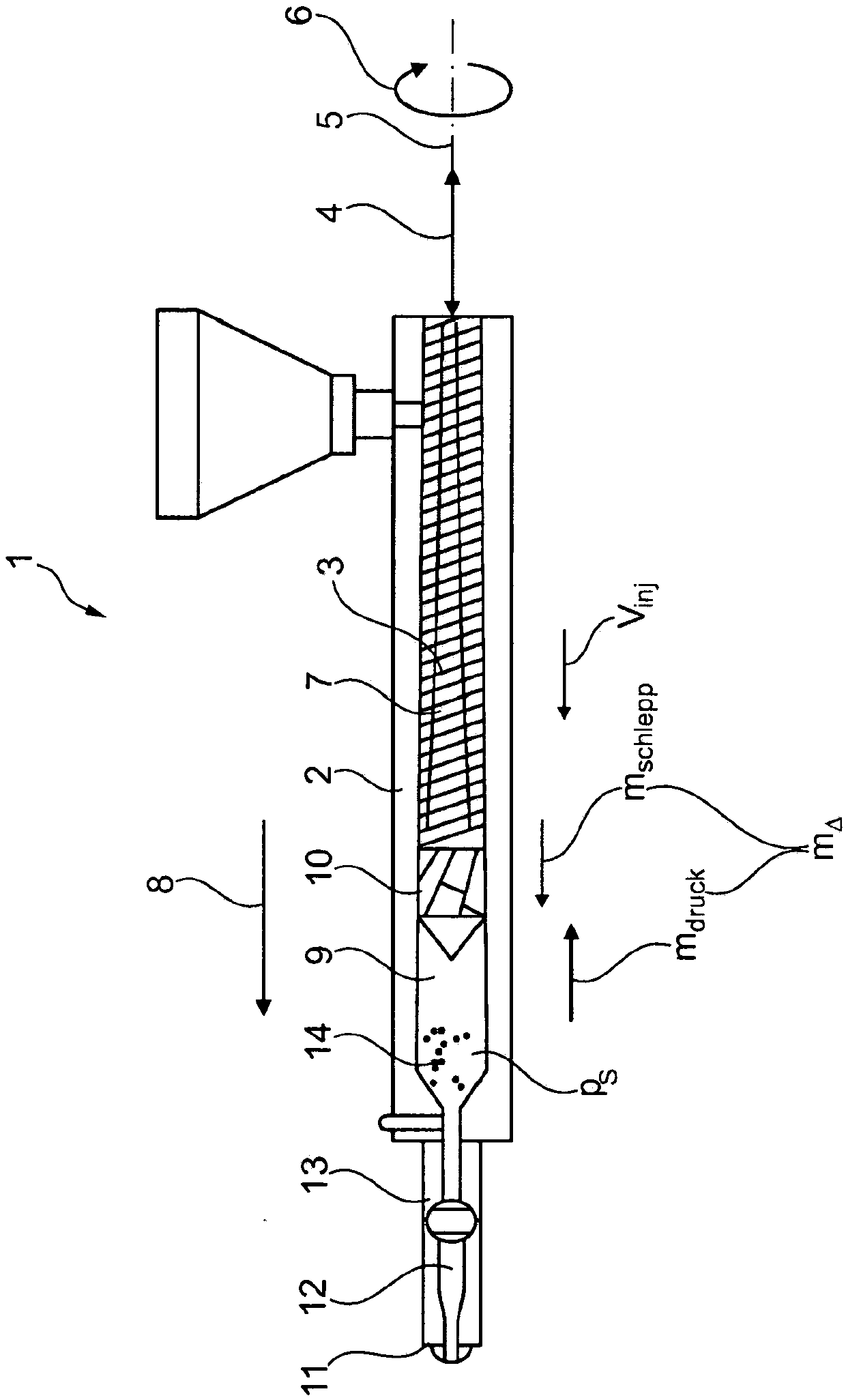

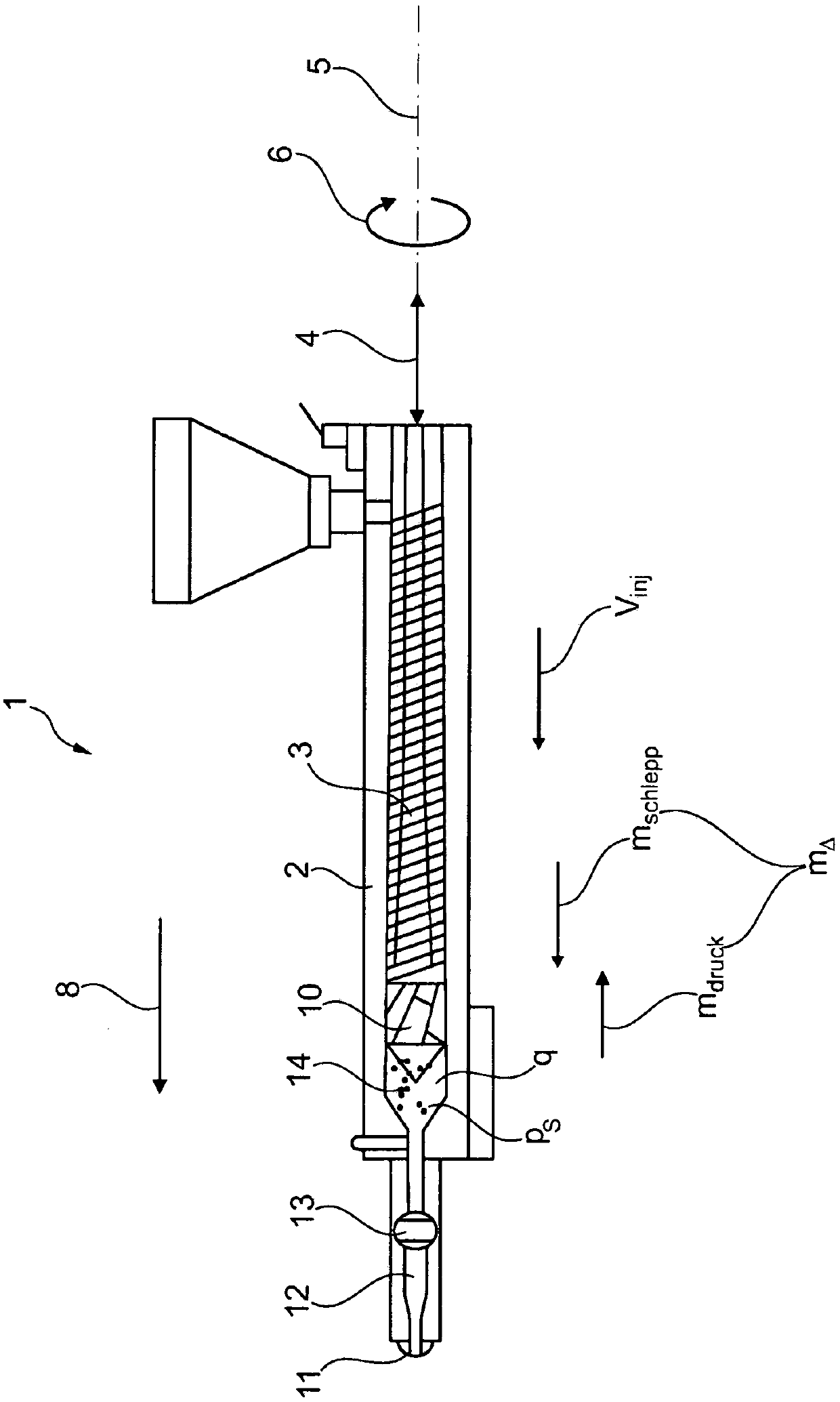

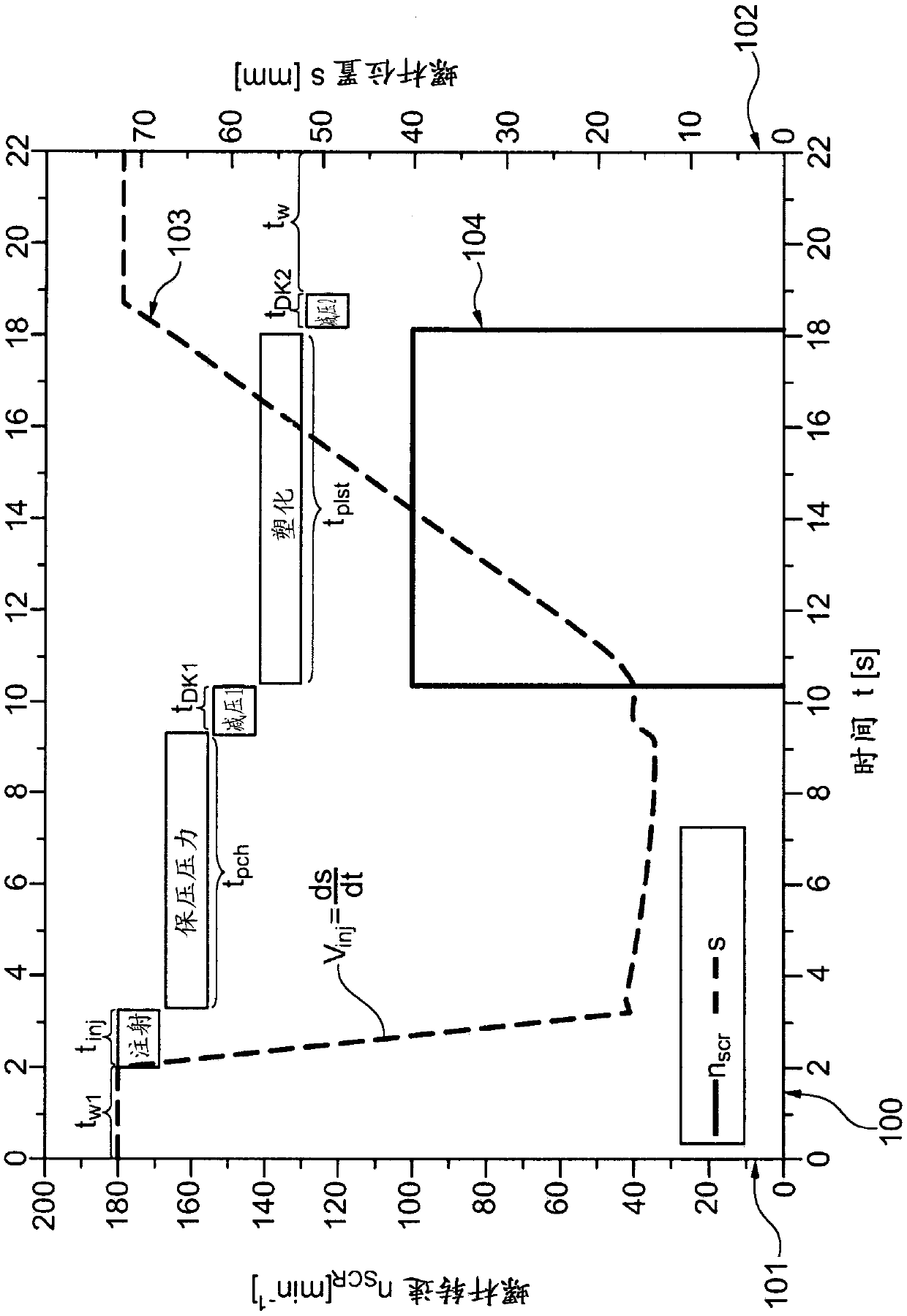

Method for operating an injection-moulding machine

The invention relates to a method for operating an injection-moulding machine, having at least one plasticization device (2, 3) with at least one plasticization screw (3) which can be driven in rotation about a screw longitudinal axis (5) and so as to be movable in translation along the screw longitudinal axis (5), wherein, by way of the plasticization device (2, 3), a plastics melt (14) for injection into a mould cavity is provided in a screw antechamber (9), wherein, for the injection of the plastics melt (14) into the mould cavity, that is to say at least during an injection phase and during a follow-up pressure phase, the plasticization screw (3) is driven both in translation and in rotation by way of at least one drive device, wherein the driving of the plasticization screw (3) in rotation is performed with a rotational speed (nscr) such that a backflow (mdruck) of the melt from the screw antechamber (9) back into screw flights (71) of the plasticization screw (3) owing to a translational injection movement of the plasticization screw (3) has superposed on it an opposing delivery flow (mschlepp) effected by way of the rotation of the plasticization screw (3), wherein a flow difference (m[delta]) between backflow (mdruck) and opposing delivery flow (mschlepp) arises, and the flow difference (m[delta]) is, at least during the injection phase, influenced by influencing of therotational speed (nscr) of the plasticization screw (3), and the method is performed without using a backflow preventer.

Owner:KRAUSSMAFFEI TECH GMBH

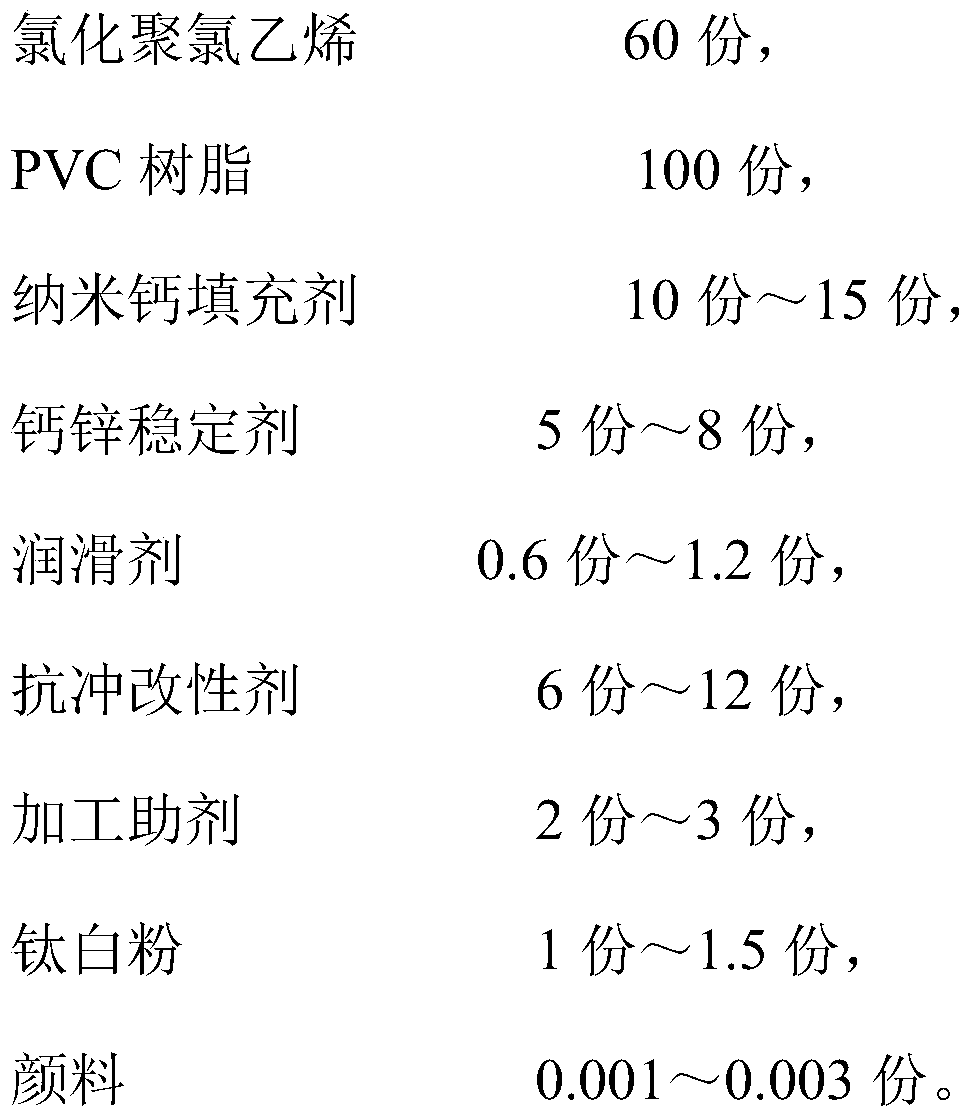

PVC heat-resistant pipe and preparation method thereof

InactiveCN111117114AImprove insulation performanceEfficient weather resistancePolymer scienceChlorinated polyvinyl chloride

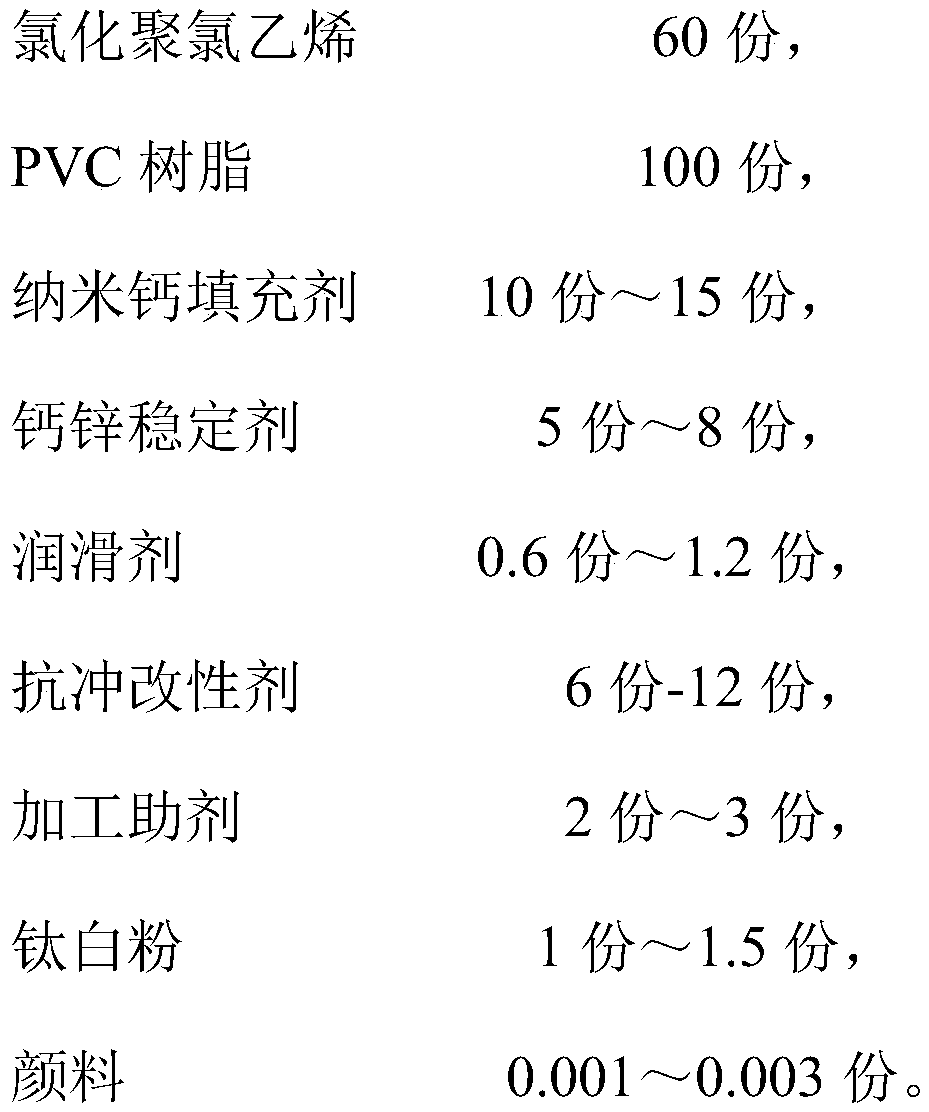

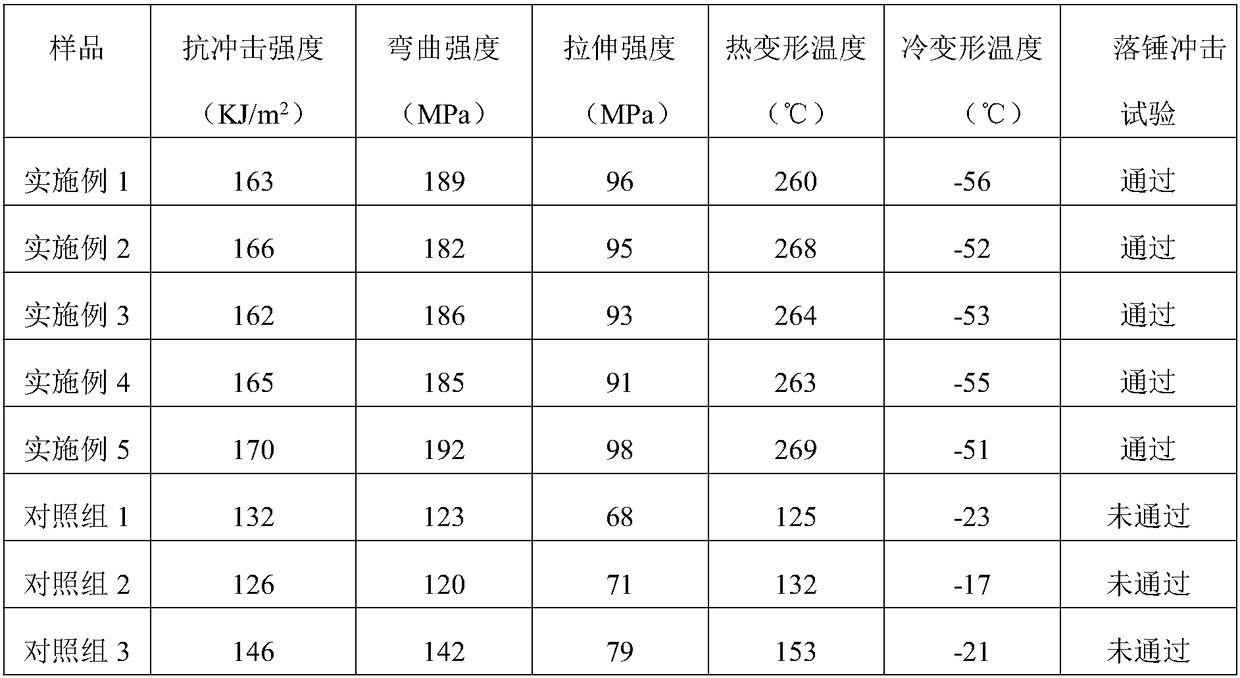

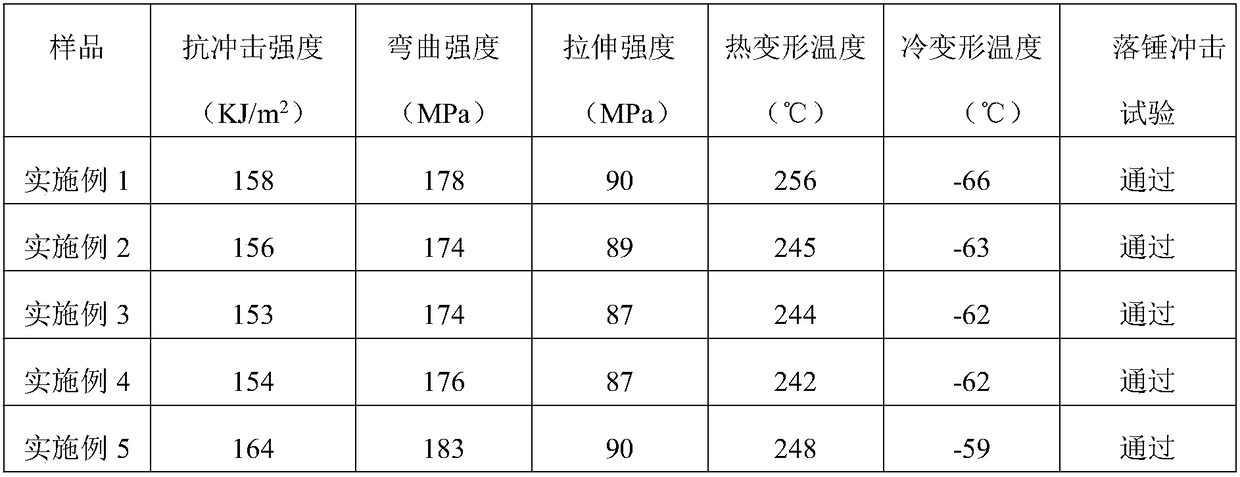

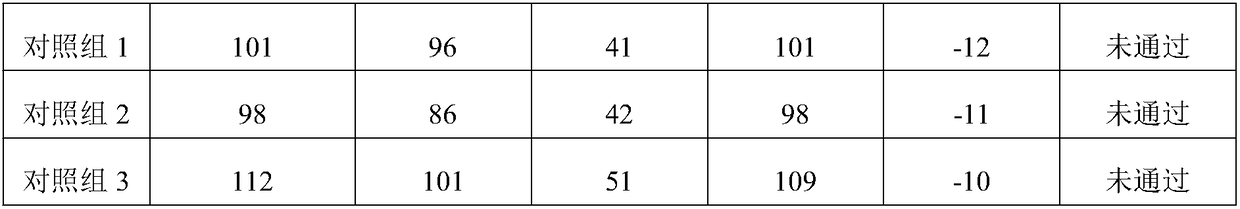

The invention discloses a PVC heat-resistant pipe and a preparation method thereof. The PVC heat-resistant pipe is prepared from the following components in parts by mass: 60 parts of chlorinated polyvinyl chloride, 100 parts of PVC resin, 10-15 parts of nano calcium filler, 5-8 parts of calcium-zinc stabilizer, 0.6-1.2 parts of lubricant, 6-12 parts of anti-impact modifier, 2-3 parts of processing aid, 1-1.5 parts of titanium dioxide and 0.001-0.003 part of pigment. According to the formula, the components are properly selected, compatibility is reasonable, and the prepared PVC pipe is excellent in comprehensive performance in all aspects and particularly high in heat resistance.

Owner:SHANGHAI SHANGSU HLDG GRP

Drepn process of polyvinyl chloride resin with composite dispersant system

The method for preparing polyvinyl chloride resin by adopting composite dispersion system includes the following steps: adding vinyl chloride monomer and composite dispersion system into polymerization reactor, and making them produce polymerization reaction under the condition of conventional polymerization. The composition and weight ratio of said composition dispersion system are IB:IC:ID=1:0.60-0.70:0.17-0.42, in which IB is polyvinyl alcohol, IC is hydroxypropyl methyl cellulose and IC is PVA with low alcohol-solubility, for example one of LM-22 and LW-300.

Owner:SHANGHAI CHLOR ALKALI CHEM

Carbon fiber reinforced plastic pipe and preparation process thereof

InactiveCN108570179AImprove thermal stabilityThe formula is scientific and reasonableFiberState of art

The invention relates to a carbon fiber reinforced plastic pipe and a preparation process thereof, solving the technical problem in the prior art that a plastic pipe has insufficient toughness and isnot resistant to aging, and the toughness changes significantly due to temperature change. The carbon fiber reinforced plastic pipe is prepared from the following raw materials in parts by weight: 100-200 parts of polyethylene resin, 4-12 parts of chopped carbon fiber, 8-50 parts of an impact modifier, 0.1-12 parts of hyperbranched polyamide, 4-20 parts of graphene, and 4-15 parts of zinc oxide. The preparation process is widely used in the field of plastic pipes.

Owner:威海南海新能源材料有限公司

High-fluidity PVC cable material and preparation method thereof

ActiveCN104109304AShorten plasticizing timeGuaranteed mechanical propertiesPolymer scienceStearic acid

The invention discloses a high-fluidity PVC cable material and a preparation method thereof. The material is prepared by the following raw materials by weight: 60 to 80 of SG-3-type PVC resin, 20 to 30 of high-fluidity SAN resin, 10 to 15 of high-fluidity PBT resin, 20 to 30 of dioctyl phthalate, 10 to 15 of dioctyl terephthalate, 12 to 16 of calcium carbonate, 10 to 15 of decanedioic acid, dibutyl ester, 5 to 10 of mineral oil , 15 to 20 of siliceous shale, 10 to 15 of vermiculite powder, 5 to 10 of composite filler, 8 to 12 of decabromodiphenyl oxide, 4 to 7 of ammonium dihydrogen phosphate, 2 to 3 of zinc stearate , 1 to 2 of calcium stearate, 2 to 3 of oxidized polyethylene wax and 1 to 2 of a processing aid ACR401. The cable material has good fluidity performance and extrusion shaping processing performance on the premise of ensuring the mechanical performance.

Owner:安徽荣鹏智能装备有限公司

Anti-aging injection molding formula

The invention provides an anti-aging injection molding formula which comprises the following raw materials of PVC resin, polycaprolactone, lignin, silicone oil, barium stearate, cadmium stearate, zincstearate, borax, methyl cellulose and calcium carbonate. Compared with the prior art, the anti-aging injection molding formula disclosed by the invention has the following beneficial effects that service life of a manufactured plastic product is greatly prolonged, PVC resin plasticizing time can be shortened, PVC resin processing fluidity is improved, an injection molded part has high strength and is not prone to be broken, and normal work of the injection molded part is ensured.

Owner:夏百庆

Functional calcium carbonate and method for producing the same

ActiveCN101456969BIncrease dosageDosage remains the samePigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsInterface layerPerformance index

The invention discloses a functionality calcium carbonate and a preparation method thereof. The functionality calcium carbonate is prepared by compound treatment technology of 'wet method + dry method' of superfine coarse whiting, fine calcium carbonate particle, nanometer calcium carbonate and a modification agent. The functionality calcium carbonate of the invention can promote resin plasticization, reduce melt viscosity, improve melt fluidity and melt intensity, make product surface smooth and fine and have the function of processing an addition agent ACR, and meanwhile is provided with the function of strengthening coupling and excellent surface modification effects. Appropriate increasing of padding of the system does not affect each performance index of the product. The functionality calcium carbonate and the preparation method thereof has the advantages of improving dispersivity and compatibility of each component of prescription system, improving plasticity of bonding strengthof interface layer, having excellent interface layer performance, realizing the function of annealing strengthening and strengthening.

Owner:NANJING XIEHE CHEM

Uses of allyloxy hydroxide sodium dimercaptosulphanate in PVC processing aid

The invention provides allyloxy hydroxypropyl sodium sulfonate as an emulsifier for a processing aid ACR emulsion polymerization reaction. The allyloxy hydroxypropyl sodium sulfonate is taken as a reactive emulsifier, which can carry out polymerization reaction with the monomer of raw material during the processing aid ACR emulsion polymerization reaction process. The adoption of the reactive emulsifier has following advantages: as the reactive emulsifier has polymerization activity, the carbon-carbon double bond functional group can participate in the emulsion polymerization reaction, the reaction emulsifier not only has the function of a conventional emulsifier but also can be bonded to the surface of polymer particles by a manner of covalent bond and become part of the polymer; therefore, after polymerization, the emulsifier molecules are bonded to the surface of emulsoid particles by a manner of more stable covalent bond and the processing aid ACR emulsion prepared has better stability. Besides, the degree of adhering to a spray tower during the drying process of the processing aid ACR emulsion is reduced and spray drying rate is improved. The degree of fusion between the processing aid ACR and a PVC resin is not affected and the plasticizing time of PVC can be shortened to some extent.

Owner:SHANDONG RUIFENG CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com