Patents

Literature

613 results about "Decabromodiphenyl oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Decabromodiphenyl ether (also known as decaBDE, deca-BDE, DBDE, deca, decabromodiphenyl oxide, DBDPO, or bis(pentabromophenyl) ether) is a brominated flame retardant which belongs to the group of polybrominated diphenyl ethers (PBDEs).

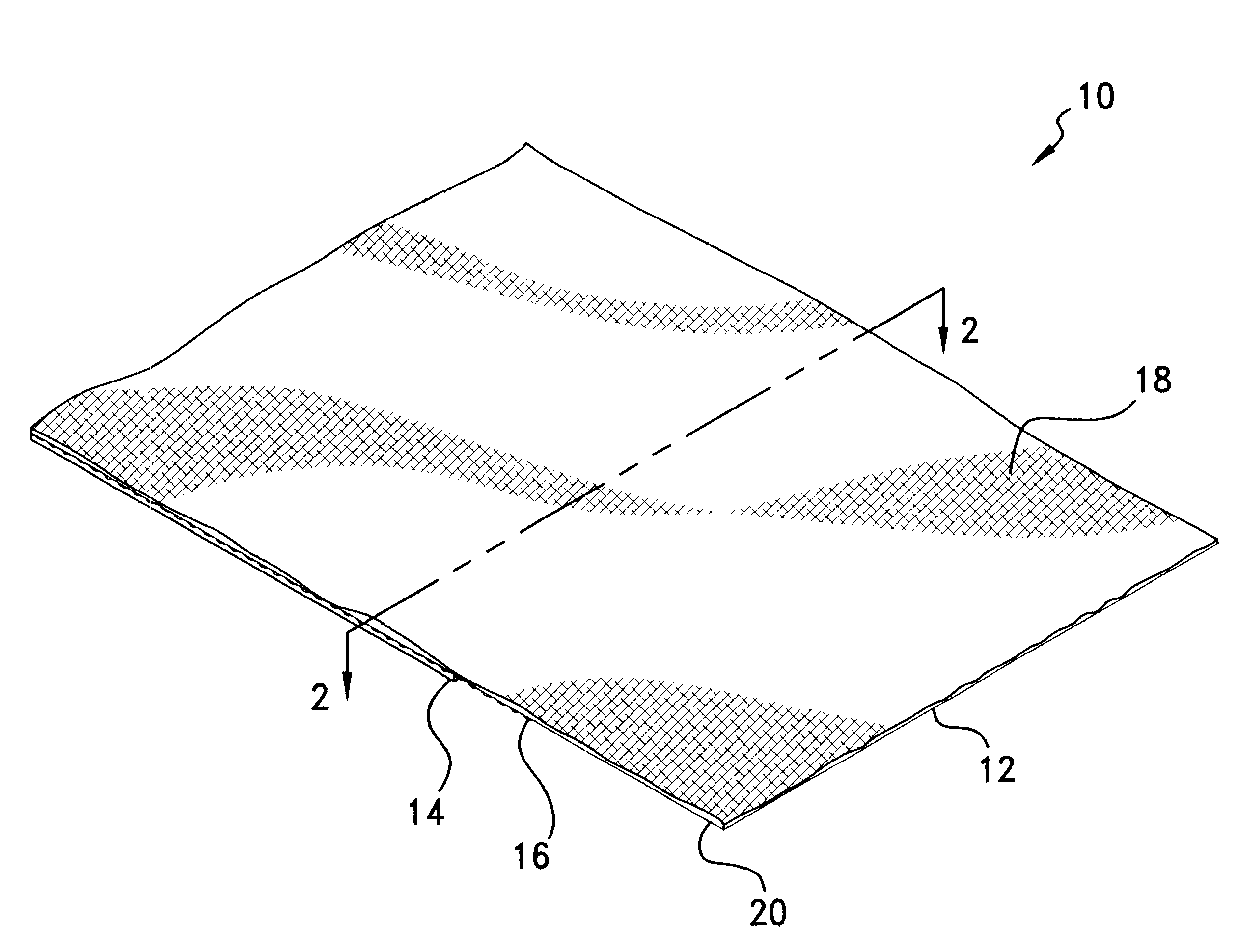

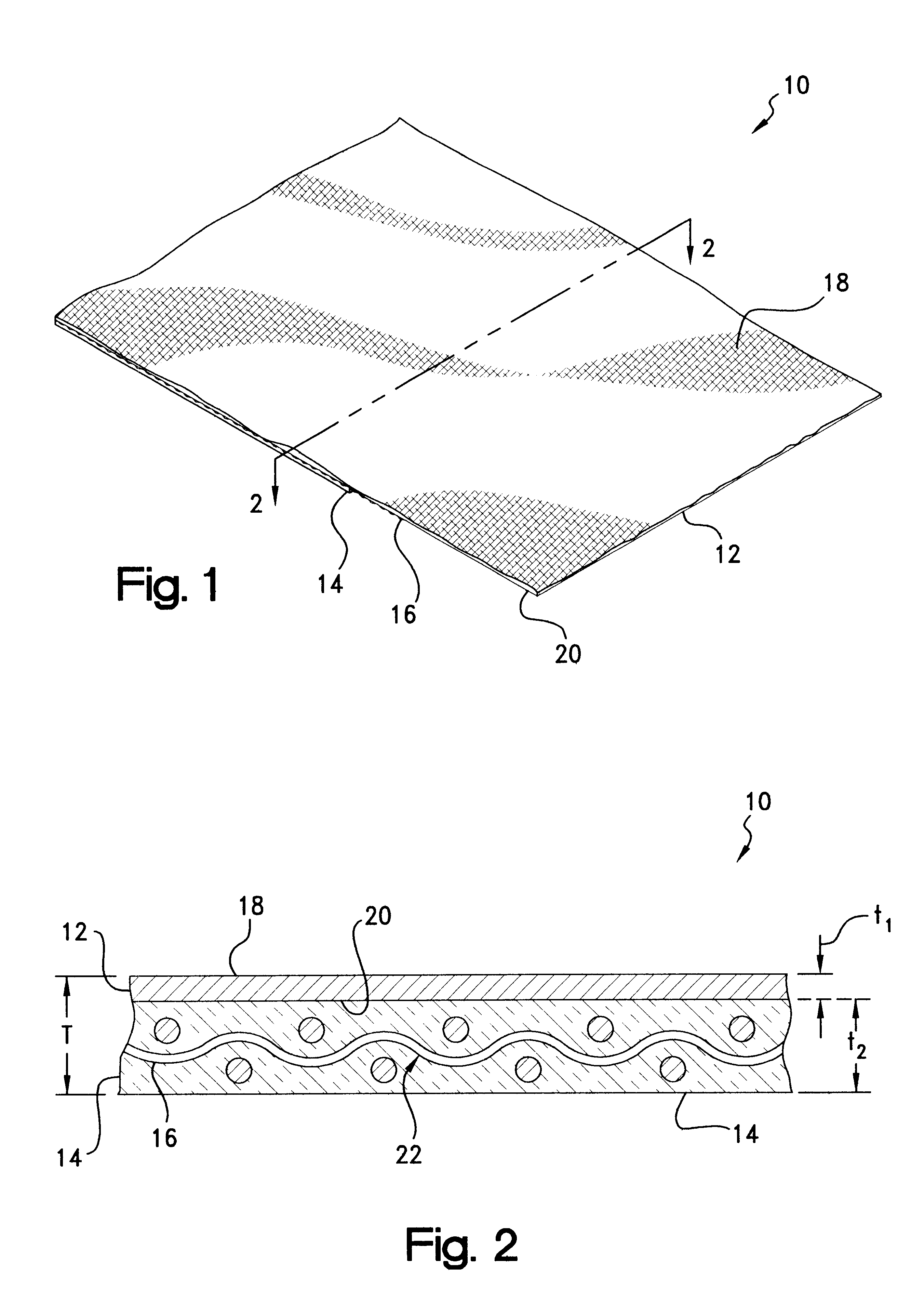

Intumescent, flame retardant pressure sensitive adhesive composition for EMI shielding applications

InactiveUS6410137B1Readily apparentGood physical propertiesScreening gaskets/sealsSynthetic resin layered productsDecabromodiphenyl etherPolybrominated Biphenyls

A flame retardant, intumescent pressure sensitive adhesive (PSA) composition for EMI shielding gaskets, tapes, wraps, and the like. The composition is formulated as an admixture of: (a) a PSA component; (b) a halogenated first flame retardant component; (c) a metal-based second flame retardant component; and (d) a filler component of expandable, intercalated graphite particles. In a representative embodiment the PSA component (a) is acrylic-based, the halogenated first flame retardant component (b) is a polybrominated diphenyl compound such as decabromodiphenyl oxide or decabromodiphenyl ether, the metal oxide-based second flame retardant component (c) is antimony oxide, antimony trioxide, or antimony pentoxide, and the filler component (d) is graphite flake.

Owner:PARKER INTANGIBLES LLC

Flame-retardant and environmentally-friendly polyurethane cable material and its preparation method

ActiveCN102977585AImprove flame retardant performanceExcellent non-flammabilityElastomerDecabromodiphenyl ether

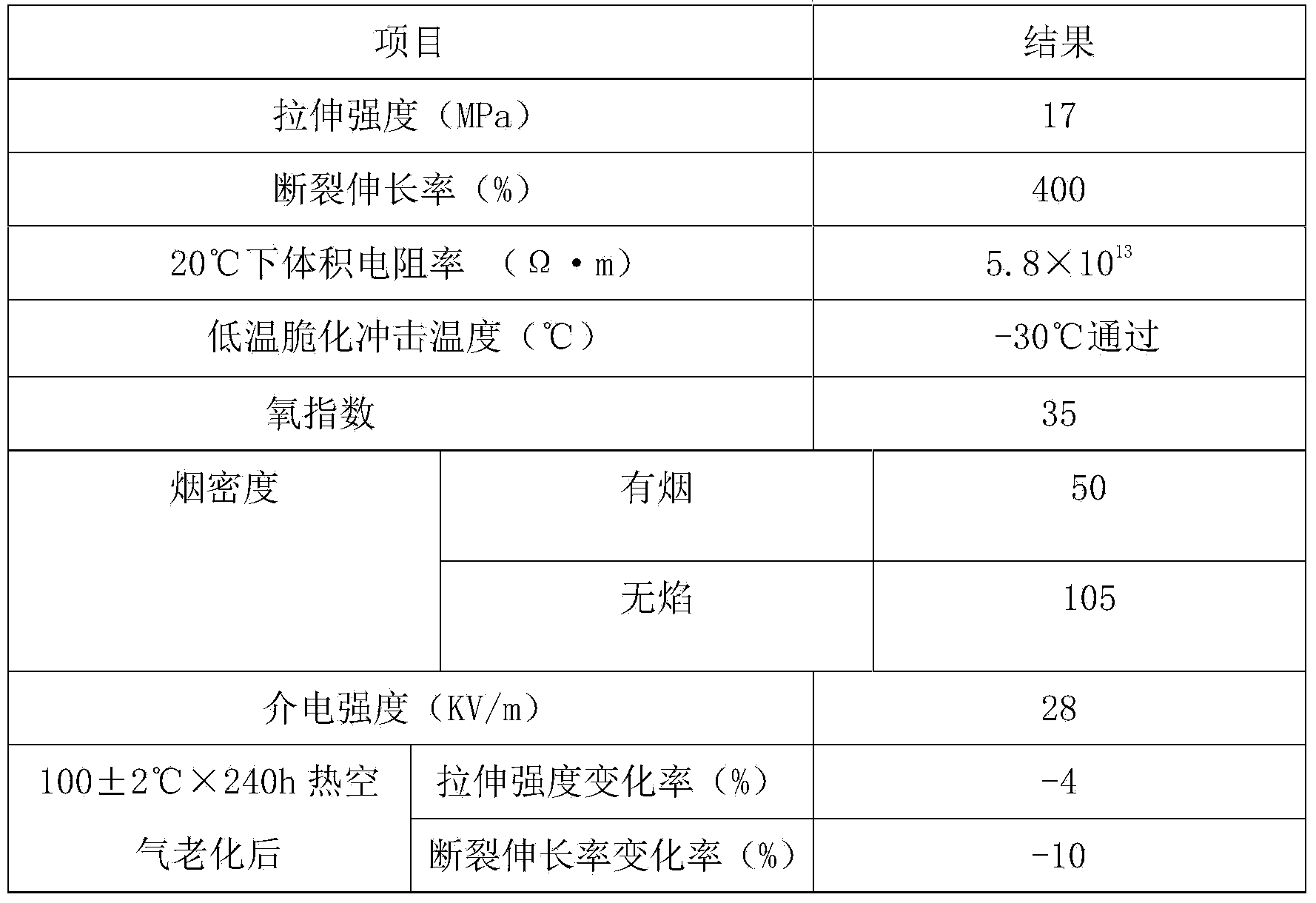

The invention provides an flame-retardant and environmentally-friendly polyurethane cable material. The cable material is prepared from the following raw materials, by weight, 20-30 parts of chloroprene rubber, 60-80 parts of a polyurethane thermoplastic elastomer, 8-10 parts of acrylonitrile-butadiene rubber, 8-10 parts of chlorinated paraffin, 0.5-1.0 part of stearic acid, 1-3 parts of barium stearate, 4-6 parts of iron oxide, 0.5-1.0 part of ammonium trimolybdate, 30-50 parts of precipitated silica, 10-13 parts of modified argil, 0.5-1.0 part of capsaicin, 0.1-0.3 parts of an antioxidant AW, 0.5-1.5 parts of a promoter TMTD, 0.2-0.5 parts of sulfur, 8-10 parts of decabromodiphenyl oxide, 12-15 parts of antimony (III) oxide and 6-8 parts of zinc borate hydrate. The cable material has the advantages of excellent flame retardation, very less smoke in combustion, no generation of toxic gases or corrosive gases, good low temperature resistance, good oil resistance, and good abrasion resistance, and the cables processed through using the cable material can prevent the harms of mice and termites and simultaneously have the efficacies of low smoke, environmental protection and flame retardation.

Owner:蚌埠尚维知识产权运营有限公司

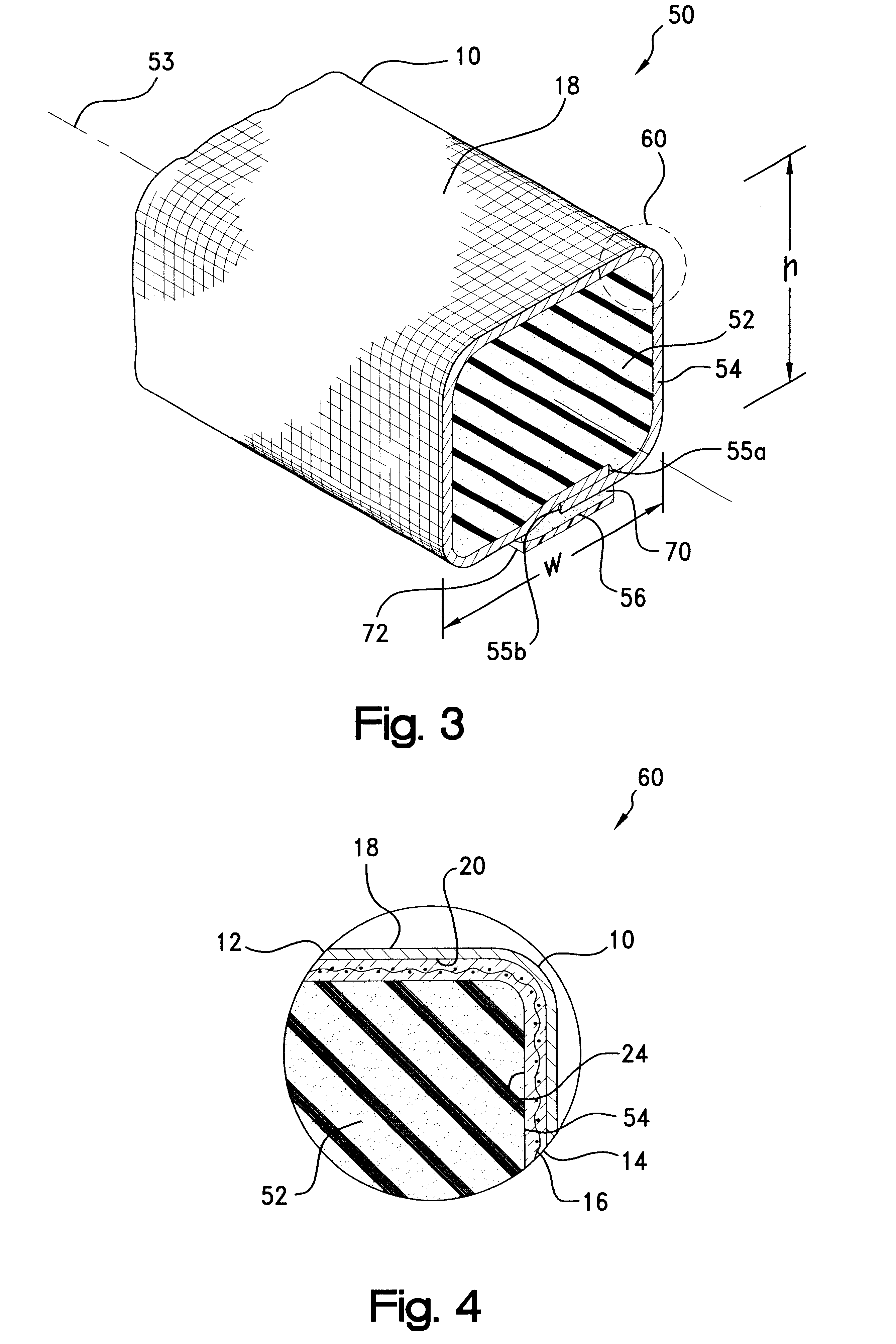

Fluorinated silicone rubber anti-pollution flashover coating for extra-high voltage and preparation method thereof

ActiveCN101597463ALower surface energyReduce adhesionCoatingsDecabromobiphenyl etherAluminium hydroxide

The invention provides a fluorinated silicone rubber anti-pollution flashover coating for extra-high voltage and a preparation method thereof; the fluorinated silicone rubber anti-pollution flashover coating (short for FRTV) has the following compositions by mass percent: 5-30 percent of fluorinated silicone rubber, 10-30 percent of silicon rubber, 4-8 percent of nanometer grade gas-phase white carbon black, 0.5-8 percent of compound fire retardants, 0.2-0.5 percent of firming agent, 0.01-0.05 percent of catalyst, 0.02-0.08 percent of antioxidant, 2-8 percent of flatting agents, 0.2-0.4 percent of de-foaming agent, 0.1-0.5 percent of paint and 30-60 percent of solvent. The compound fire retardant is composed of inorganic aluminium hydroxide and organic decabromodiphenyl oxide, wherein comprising 1-6 percent of the inorganic aluminium hydroxide and 0.5-3 percent of the organic decabromodiphenyl oxide. The preparing process of the coating is simple, and the coating has good weather ability, oil resistance and longer service life.

Owner:WUHAN NARI LIABILITY OF STATE GRID ELECTRIC POWER RES INST +1

High-strength wearable floor rubber and process for preparing same

The high-strength flooring rubber mainly comprises (by mass portions) styrene-butadiene rubber 60-100 parts, natural rubber 40-60 parts, butylbenzene rubber with high styrene content 40-60 parts, stearic acid 3-8 parts, zinc oxide 3-6 parts, accelerating agent 3-7 parts, anti-aging agent 0.5-1.5 parts, Coumarone 3-8 parts, paraffin chloride 1-2 parts, pottery clay 100-200 parts, white carbon black 80-120 parts, light calcium 100-200 parts, coupling agent 3-8 parts, phenol resin 5-10 parts, HMT 0.5-1.0 part, sulfur 5-8 parts, decabromodiphenyl oxide 5-15 parts, antimony trioxide 5-15 parts, and aluminum hydroxide 30-100 parts. The preparation consists of plasticization, adaptation, pugging, calendaring, extrusion, modeling and sulfidization.

Owner:恒昌(昆山)精密模具有限公司 +2

Ethylene-propylene-diene monomer rubber used for manufacturing wind energy cable and preparation method thereof

ActiveCN102617942AImprove mechanical propertiesEasy to stretchPolymer scienceDecabromobiphenyl ether

The invention discloses an ethylene-propylene-diene monomer rubber used for manufacturing a wind energy cable and a preparation method thereof. The ethylene-propylene-diene monomer rubber comprises the following components: 90-110 parts of ethylene-propylene-diene monomer rubber, 1-4 parts of anti-aging agent, 0.2-0.5 part of stearic acid, 2-9 parts of paraffin oil, 2-5 parts of lead sulfate tribasic, 1-4 parts of zinc oxide, 80-120 parts of activated kaolin, 0.3-1.5 parts of coupling agent, 0.5-2.6 parts of cross-linking agent, 0.5-2.0 parts of assistant crosslinker, 1-3 parts of semi-reinforcing carbon black, 1-4 parts of plasticizer, 0.5-2 parts of antimonous oxide, 0.5-2 parts of zinc borate, 1-5 parts of basic magnesium carbonate, 1-4 parts of antioxygen, 0.1-0.5 part of sulphur, 2-5parts of epoxidized soybean oil, 5-15 parts of decabromodiphenyl ether, 12-30 parts of antimony oxide and 2-5 parts of organic modified bentonite. The material has the advantages of wide applicable temperature range, god performance and long service life.

Owner:无锡市远登电缆有限公司

Irradiation crosslinking low-smoke halogen-free flame-retardant polyolefin cable material for photovoltaic cables

The invention provides an irradiation crosslinking low-smoke halogen-free flame-retardant polyolefin cable material for photovoltaic cables. The cable material is prepared from the following raw materials in parts by weight: 40-50 parts of polyethylene (PE), 30-40 parts of polyvinyl chloride resin, 20-30 parts of CSM2305, 10-12 parts of ethylene-acrylate copolymer, 10-15 parts of epichlorohydrin rubber T3100, 5-10 parts of epoxidized soybean oil, 2-3 parts of carbonyl iron powder, 10-12 parts of high abrasion carbon black N330, 5-10 parts of light calcium carbonate, 1-2 parts of zinc oxide, 5-10 parts of wollastonite powder, 4-5 parts of vermiculite, 1-2 parts of polytetrafluoroethylene micro powder, 1-2 parts of graphite, 1-2 parts of nano boron carbide, 2-3 parts of ferric oxide, 0.1-0.2 part of UV-O, 0.1-0.2 part of UV-53, 0.1-0.2 part of flame retardant TBC, 10-12 parts of aluminium hypophosphite, 5-8 parts of decabromodiphenyl ether, 8-10 parts of dioctyl terephthalate, 6-8 parts of trioctyl trimellitate, 8-10 parts of triethyl citrate, 1-2 parts of calcium stearate, 0.2-0.4 part of stearic acid, 0.1-0.2 part of oxidized polyethlene wax, 0.2-0.3 part of ethylene bis stearamide, 0.1-0.2 part of DCP, and 12-15 parts of modified filler. The cable material has the characteristics of high flame retardance, high ultraviolet resistance and high ageing resistance, and meanwhile, has a good mechanical property, and is environment-friendly.

Owner:温州市粤来电子加速器应用有限公司

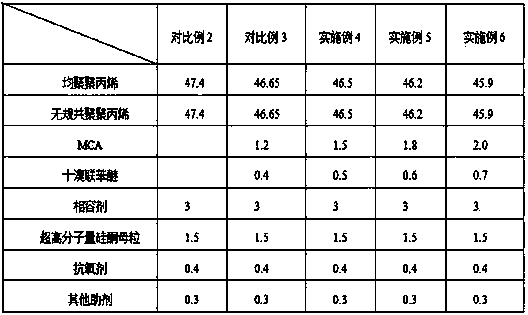

Method for preparing fire-fighting noise rreduced, skidproof material of road surface in tunnel

ActiveCN1760279AImprove fire resistanceDoes not smoke and burnPaving detailsBuilding insulationsFiberDecabromobiphenyl ether

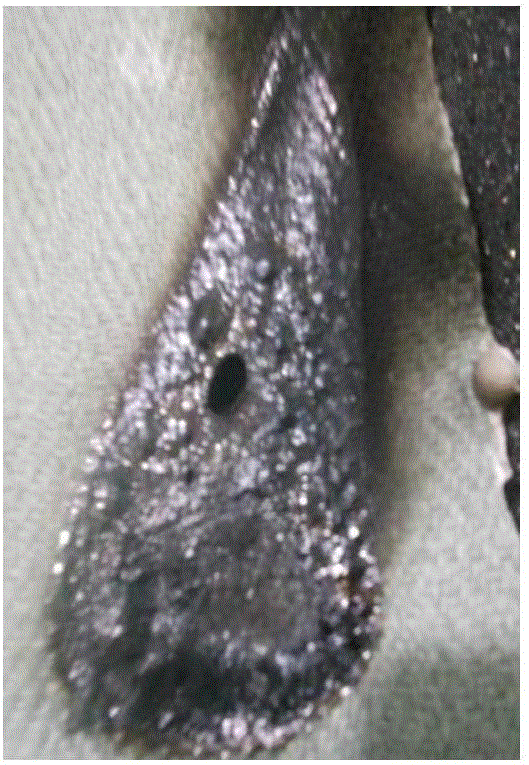

A fire-proof, noise-reducing and antiskid material for the pavement in tunnel is prepared through preparing flame-retarding smoke-inhibiting agent from decabromodiphenyl ether, Sb2O3, aluminium hydroxide and smoke inhibitor, preparing modified high-viscosity flame-retarding asphalt from styrene-butanediene-styrene block copolymer, activated rubber powder, stabilizer, antioxidizing agent, said flame-retarding smoke-inhibiting agent and asphalt matrix, choosing mineral material consisting of aggregate and filler, and mixing it with said modified asphalt and fibers.

Owner:WUHAN MUNICIPAL CONSTR GROUP

Burnthrough-resistant water-based fire retardant glue for spinning

The invention provides burnthrough-resistant water-based fire retardant glue for spinning. The burnthrough-resistant water-based fire retardant glue is prepared from the following components in parts by weight: 100 parts of a water-based adhesive, 10 to 100 parts of a halogen flame retardant, 3 to 100 parts of a synergistic flame retardant, 0 to 30 parts of an auxiliary and 0 to 100 parts of water, wherein the water-based adhesive is prepared from ethylene-vinyl acetate copolymer emulsion and an auxiliary adhesive; the solid content of the ethylene-vinyl acetate copolymer emulsion is 20 to 56 percent; the weight ratio of the water-based adhesive to the halogen flame retardant is (1 to 8) to 1; the halogen flame retardant is prepared from one or more of decabromodiphenyl ether, decabromodiphenyl ethane, tri(2,3-dibromo propyl) isocyanuric acid ester, tri(tribromophenyl) cyanurate, ethylene bis (tetrabromophthalimide), tetrabromo bisphenol A, hexabromocyclododecane, octo-bromo-ether, chlorine ester resin, ploy (vinylidene chloride) resin, brominated styrene, brominated epoxy resin, polyvinyl chloride, chlorinated paraffin and methyl chloride.

Owner:WUJIANG HONGYUAN SPRAY WEAVING CO LTD

Water flame-retardant paint

The water flame-retardant paint consists of emulsion, deionized water, filming assistant, dispersant, wetting agent, thickener, defoaming agent, fireproof agent, fireproof assistant, stuffing and pigment. The fireproof agent and fireproof assistant consists of Sb2O3, decabromodiphenyl oxide, nano zinc oxide colloid, aluminium hydroxide, native soda and zinc borate. The paint has the features of being waterproof, aging resistant, mildewproof and fireproof.

Owner:王崇高

Warm mix flame-retardant modified asphalt and preparation method thereof

ActiveCN101817983AImprove flame retardant performanceHigh smoke suppression effectBuilding insulationsMolten statePolymer modified

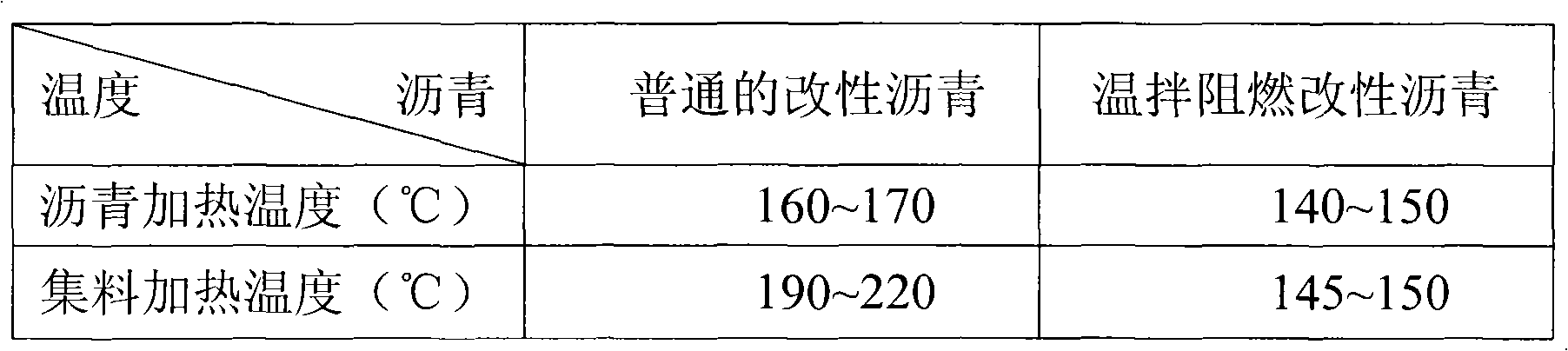

The invention discloses a warm mix flame-retardant modified asphalt and a preparation method thereof. The method comprises the following steps of: heating polymer modified asphalt to the temperature of between 100 and 120 DEG C into a melting state, stirring to dehydrate the asphalt, and heating and maintaining the polymer modified asphalt at the temperature of between 140 and 150 DEG C; adding warm mix flame-retardant modifiers into the polymer modified asphalt, adding with stirring, wherein the adding order is an organic viscosity reducer, a decabromodiphenyl oxide, an antimonous oxide, a hydrated magnesium silicate and a smoke-suppressing flame-retardant assistant in turn, and stirring for about 30 to 40 minutes, wherein in the process of adding and stirring, the temperature of the polymer modified asphalt is controlled between 140 and 150 DEG C; and finally, obtaining the warm mix flame-retardant modified asphalt. The warm mix flame-retardant modified asphalt can reduce the construction temperature of asphalt concrete, reduce the production energy consumption, save the production cost, reduce the smoke emissions in the construction of the asphalt concrete, and improve the construction environments, and has higher flame retardance and smoke suppression performance.

Owner:SHENZHEN OCEANPOWER NEW MATERIALS TECH

Flame-proof ABS factory formula and its production method

InactiveCN1765985AImprove flame retardant performanceIncreased melt flow ratePolymer scienceDecabromobiphenyl ether

The invention relates to product formula and preparation method of a flame-proof ABS. Wherein, the formula comprises mainly: ABS resin, antimony trioxide, decabromodiphenyl oxide, coupling-treated aluminum hydroxide, anti-oxidant 168, tricresyl phosphate, chlorinated polyethylene (CPE), polyvinyl chloride (PVC), EBS, magnesium stearate, SBS, nano-SiO2, and zinc borate. The preparation method comprises: mixing the ABS resin and tricresyl phosphate in high-speed mixer, adding other materials; putting into double screw extruder; cooling, granulating, screening, drying, and packaging. This product has well properties with low cost.

Owner:王崇高

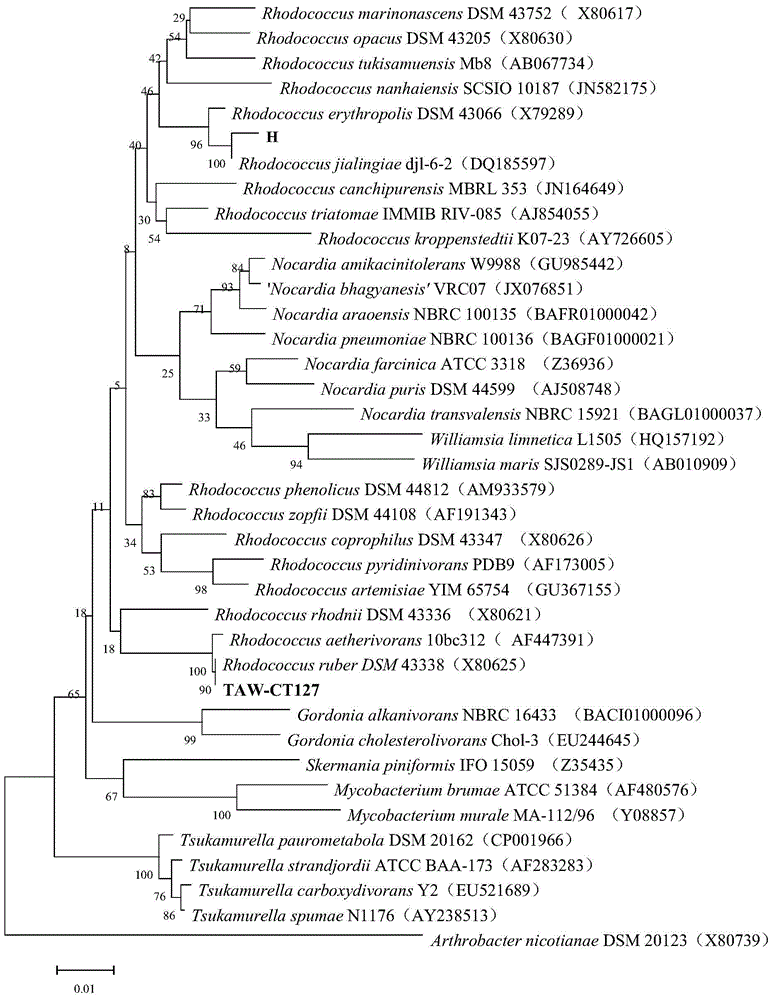

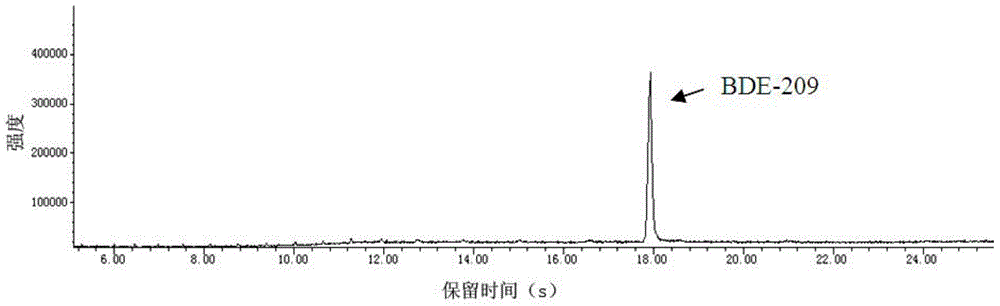

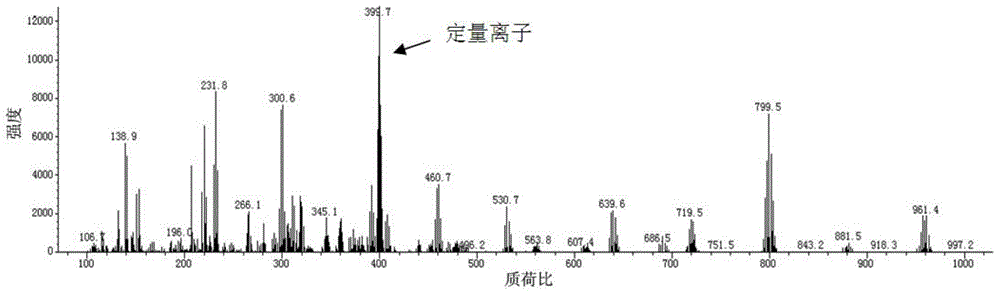

Rhodococcus ruber and application thereof in preparing decabromodiphenyl oxide degrading agent

The invention provides a Rhodococcus ruber and application thereof in preparing a decabromodiphenyl oxide degrading agent, relating to application of microbes. The collection number of the Rhodococcus ruber TAW-CT127 is CCTCC NO.M 2015212. The Rhodococcus ruber TAW-CT127 can be used in preparing the decabromodiphenyl oxide degrading agent. The decabromodiphenyl oxide is the unique carbon source in the decabromodiphenyl oxide degradation culture medium. After the Rhodococcus ruber TAW-CT127 is cultured in the degradation culture medium using decabromodiphenyl oxide as the unique carbon source at 28 DEG C under the pH value of 7.4 at the shaking table rotation frequency of 160 rpm, the degradation rate of the Rhodococcus ruber for decabromodiphenyl oxide is up to 91%.

Owner:XIAMEN UNIV

Anti-flaming antisepsis leather coating and preparation method thereof

InactiveCN105925099AImprove water resistancePrevent penetrationFireproof paintsAntifouling/underwater paintsDecabromodiphenyl etherTriterpenoid saponin

The invention discloses an anti-flaming antisepsis leather coating which is composed of, by weight, 2-3 parts of hydrous zinc borate, 1-1.5 parts of linoleic acid calcium soap, 0.1-0.2 part of triterpenoid saponin, 0.7-1 part of calcium naphthenate, 1.7-2 parts of polyvinylpyrrolidone, 0.8-1 part of polyacrylamide, 1.6-2 parts of stannous chloride, 0.1-0.13 part of triethanolamine, 190-200 parts of methyl methacrylate, 3-4 parts of lauryl sodium sulfate, 0.1-0.2 part of urotropine, 0.2-0.3 part of ammonium persulfate, 6-7 parts of a 20%-25% formaldehyde solution, 16-20 parts of zinc acetate, 4-7 parts of silver nitrate, 1-2 part of decabromodiphenyl ether and 0.4-1 part of sodium lauryl sulfate. The anti-flaming antisepsis leather coating has a good antibacterial property and excellent moisture permeability and water resistance. Leather coated with the obtained emulsion is good in antibacterial property and excellent in hygiene property.

Owner:CHUZHOU VOCATIONAL & TECHN COLLEGE

Static conducting flame-retardant rubber for oil tank seal tape

ActiveCN101328290AMeet the requirements of static conduction and flame resistanceWith static conduction and flame retardant performanceOther chemical processesLarge containersParaffin waxPolymer science

The invention relates to a static electricity conductive flame retardant rubber for an oil tank sealing strip. The rubber takes butyronitrile rubber as a main raw material, which is mixed with stearic acid, zinc oxide, acetylene carbon black, semi reinforcing carbon black, aluminum hydroxide, decabromodiphenyl ether, antimony trioxide, chlorinated paraffin wax, antiager 4010NA, antiager A, sulfur, accelerant CZ, accelerant TMTM, coumarone and dioctyl phthalate, and the mixture undergoes the mixing by an internal rubber mixer, and the rubber is bonded on both sides of a gum dipping framework by a calender and is subject to the sulfuration to prepare the static electricity conductive flame retardant sealing strip. The surface resistance of the product is less than 3x10<8>Ohm, and the burning performance is no less than FV-1 class, the rubber of the invention meets the requirements of an steel oil tank on the static electricity conduction and the flame retardation of the rubber sealing strip.

Owner:ANQING SPECIAL RUBBER & PLASTIC PROD

Bitumen flame-proof modifier

InactiveCN101153116AImprove road performanceGood dispersionBuilding insulationsPolyolefinDecabromobiphenyl ether

The present invention discloses an asphalt flame retardant modifier which is granular. According to the weight portion, the composition is: 20 portion to 45 portion of decabromodiphenyl ether or decabromophenylethane, 15 portion to 30 portion of hydrated magnesium silicate, 5 portion to 15 portion of smoke-suppressant, 1 portion to 10 portion of fatty acid of C16-C18 as coupling agent, and 15 portion to 25 portion of polyolefin. The present invention also discloses a preparation method of the asphalt flame retardant modifier. The asphalt flame retardant modifier of the present invention has good road performances and has the characteristics of good dispersion, easy addition, security, environmental protection and so on. The present invention improves the production efficiency, has no environmental pollution in working, and less equipment corrosion. The flame retardant composition is proper; the synergic effects of a plurality of flame retardants are made full use of; the materials are directly blended and added; the present invention simplifies the production process and reduces the production cost.

Owner:SHENZHEN OCEANPOWER NEW MATERIALS TECH

Anti-cracking waterproof high-performance asphalt cable material and preparing method thereof

InactiveCN105778227AReduce injectionReduce aggregationPlastic/resin/waxes insulatorsBuilding insulationsEpoxyCrack resistance

The invention discloses an anti-cracking waterproof high-performance asphalt cable material. The cable material is prepared from, by weight, 94-96 parts of high-density polyethylene, 15-17 parts of decabromodiphenyl ether, 7-9 parts of antimonous oxide, 2-3 parts of metallocene polyethylene, 2-3 parts of nano-magnesium hydroxide, 4-5 parts of cyclohexane, 0.2-0.3 part of gamma-aminopropyl triethoxy silane, 4-6 parts of silicon carbide, 3-4 parts of zinc oxide, 2-3 parts of graphene, 9-11 parts of asphalt, 1-1.3 parts of accelerant DM, 2-3 parts of epoxy linseed oil, 10-12 parts of ethylene-vinyl acetate copolymer and 10-13 parts of absolute ethyl alcohol. By means of a series of modification, viscosity is reduced, fluidity is improved, compatibility with a base material is improved, flame retardant master batch and anti-breakdown modified master batch are added, and therefore the cable material is higher in high-temperature stability and low-temperature crack resistance, flexible, waterproof, resistant to abrasion, economical and durable and absorbs shock.

Owner:ANHUI AICS SCI & TECH GROUP

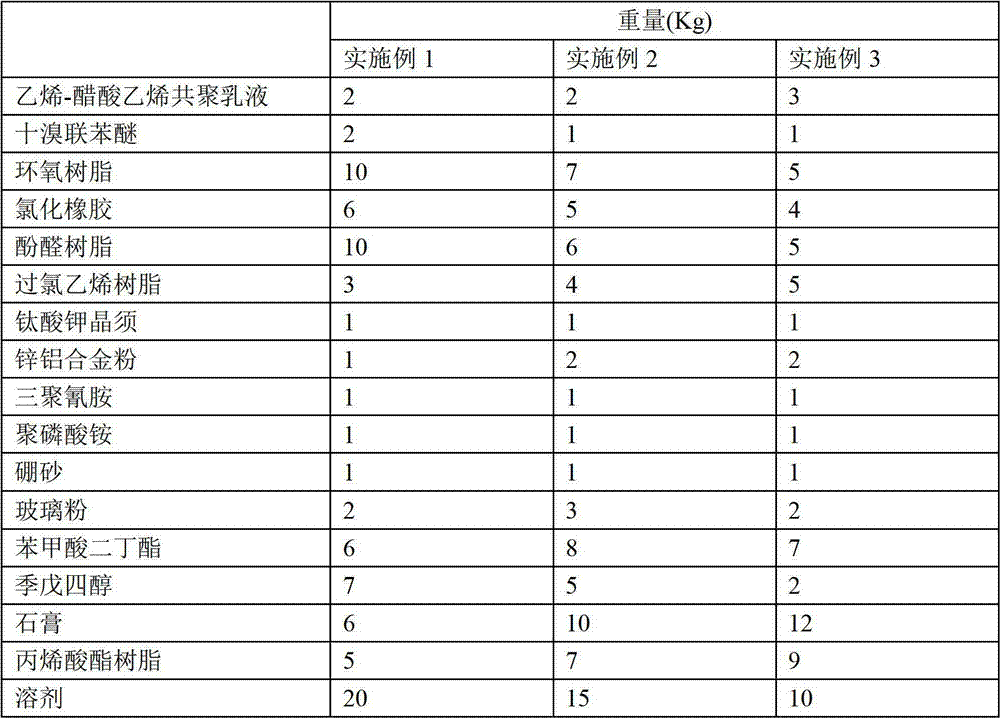

Corrosion-resistant fireproof coating

InactiveCN102850902AImprove adhesionEffective flame retardantFireproof paintsRubber derivative coatingsEpoxyDecabromodiphenyl ether

The invention provides a corrosion-resistant fireproof coating, which belongs to the technical field of coatings. The corrosion-resistant fireproof coating comprises, by weight, 2 to 3 parts of ethylene-vinyl acetate copolymer emulsion, 1 to 2 parts of decabromodiphenyl ether, 5 to 10 parts of epoxy resin, 4 to 6 parts of chlorinated rubber, 5 to 10 parts of phenolic resin, 3 to 5 parts of perchlorethylene resin, 1 part of potassium titanate whisker, 1 to 2 parts of zinc-aluminum alloy powder, 1 part of melamine, 1 part of ammonium polyphosphate, 1 part of borax, 2 to 3 parts of glass powder, 5 to 8 parts of dibutyl benzoate, 2 to 7 parts of pentaerythritol, 6 to 12 parts of gypsum, 5 to 9 parts of acrylate resin and 10 to 20 parts of a solvent. The fireproof coating provided by the invention has excellent corrosion resistance and has fire resistance in accordance with national regulations.

Owner:苏州市德莱尔建材科技有限公司

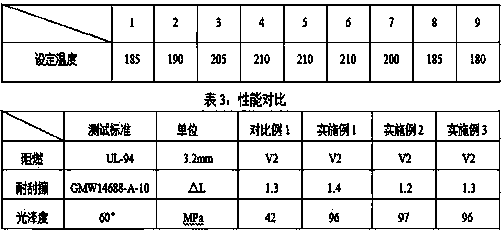

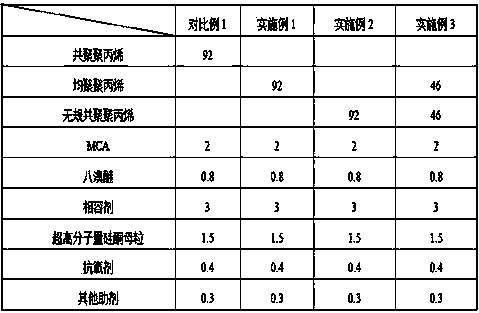

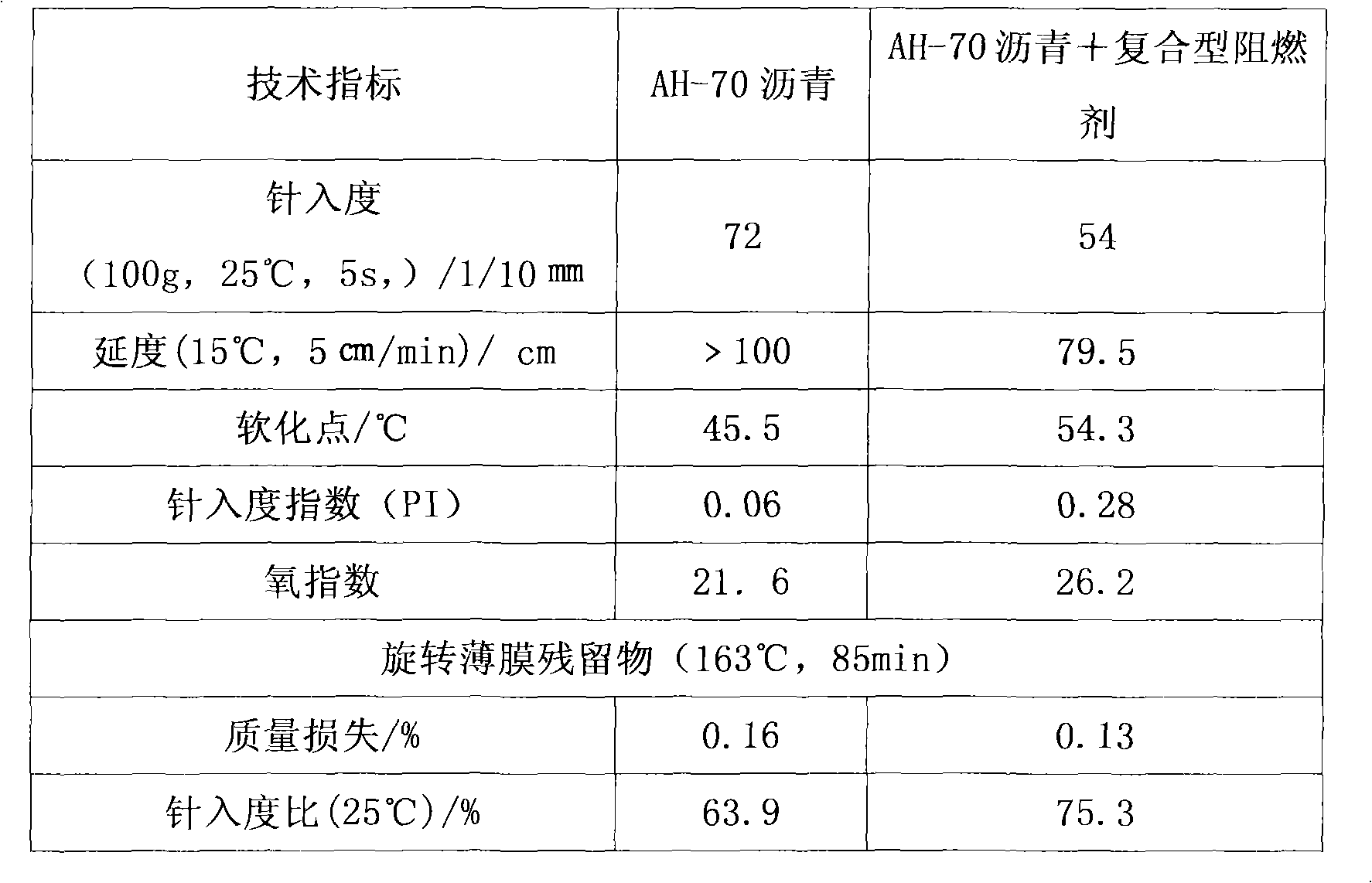

High-glossiness flame-retardant scratch-resistant polypropylene composition and preparation method thereof

ActiveCN104231431AGood synergistic effect of flame retardantReduce the effect of glossinessPolymer scienceDecabromobiphenyl ether

The invention relates to a high-glossiness flame-retardant scratch-resistant polypropylene composition and a preparation method thereof. The composition is prepared from the following components in parts by weight: 91-95 parts of polypropylene, 1-2 parts of MCA (melamine cyanurate), 0.5-1 part of flame-retardant synergistic agent, 2-3 parts of compatilizer, 1-1.5 parts of silicone master batch, 0.2-0.6 part of antioxidant and 0.2-0.4 part of other assistant. The nitrogenous halogen-free environment-friendly flame retardant melamine cyanurate (MCA) and environment-friendly bromic synergistic flame retardant octabromoether or decabromodiphenyl oxide are reasonably proportioned to implement the V-1-grade flame retardancy of the material; a proper amount of silicone master batch is added to enhance the scratch resistance of the material; and small amounts of flame retardant and silicone master batch are added to implement the V-1-grade flame retardancy and scratch resistance of the material while reducing the influence on the glossiness of the material, thereby obtaining the high-glossiness flame-retardant scratch-resistant polypropylene material.

Owner:上海日之升科技有限公司

Flame-retardant resin composition with positive resistance temperature coefficient

InactiveCN1699510ASpeed up the flowSmall resistance dispersionFireproof paintsDecabromobiphenyl etherDecabromodiphenyl oxide

Disclosed is a flame-retardant resin composition with positive resistance temperature coefficient, which comprises 30-60% LLDPE, 10-30% chlorinated polyethylene, 15-25% conductive carbon black, 10-20% decabromodiphenyl oxide and antimony trioxide common flame retardant, 5-10% processing adjuvant. The heating cables produced from the composition have good tensile property, bending property and gumming ageing characteristics.

Owner:PETROCHINA CO LTD

Composite fire retardant used for asphalt mixture and preparation method thereof

The invention relates to a fire retardant added into an asphalt mixture and a preparation method thereof. The composite fire retardant provided by the invention consists of an organic brominated flame retardant, an inorganic synegetic flame retardant, a smoke suppressant, organic monotmorillonite, asphalt and polyethylene, wherein the adopted organic brominated flame retardant can be one or a mixture of a plurality of decabromodiphenyl ether, octabromodiphenyl ether, decabromodiphenylethane, ethylene bistetrabromophthalimide and the like; the inorganic synegetic flame retardant is flame retardant antimony trioxide or molybdenum oxide or the mixture of the flame retardant antimony trioxide and the molybdenum oxide; the organic monotmorillonite is organic modified nano-laminated silicate; the asphalt is lake asphalt or building petroleum asphalt or the mixture of the lake asphalt and the building petroleum asphalt; and the polyethylene is linear low-density polyethylene. The composite fire retardant provided by the invention has high flame retardant performance and high temperature stability and can be added into the asphalt mixture on the spot for construction.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

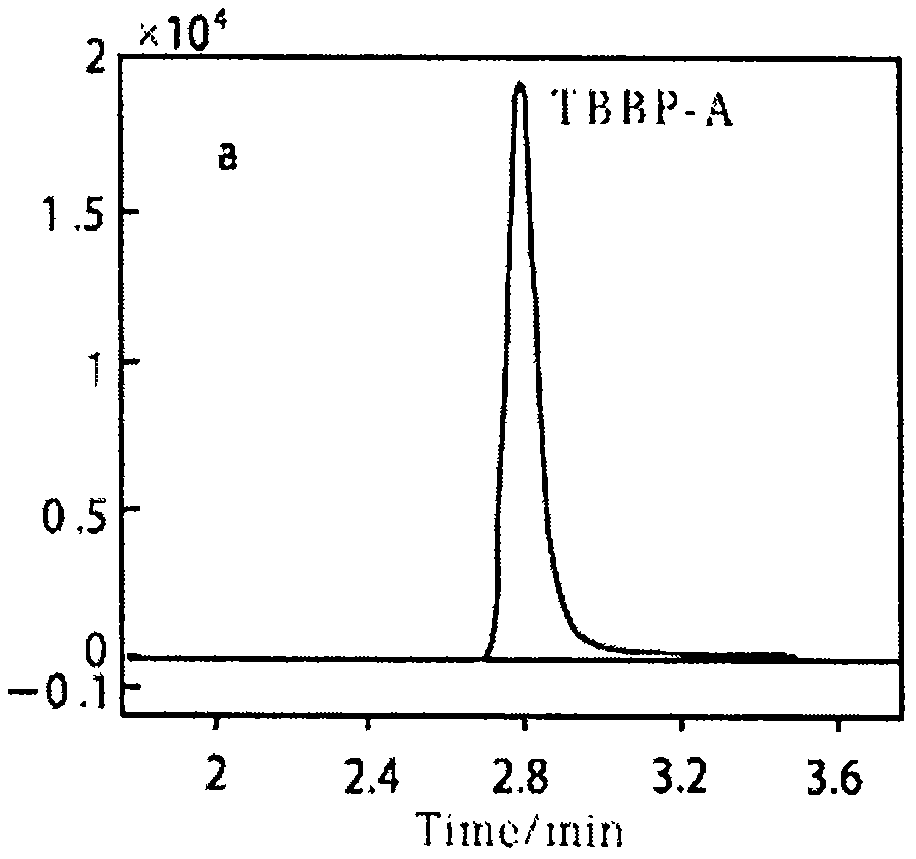

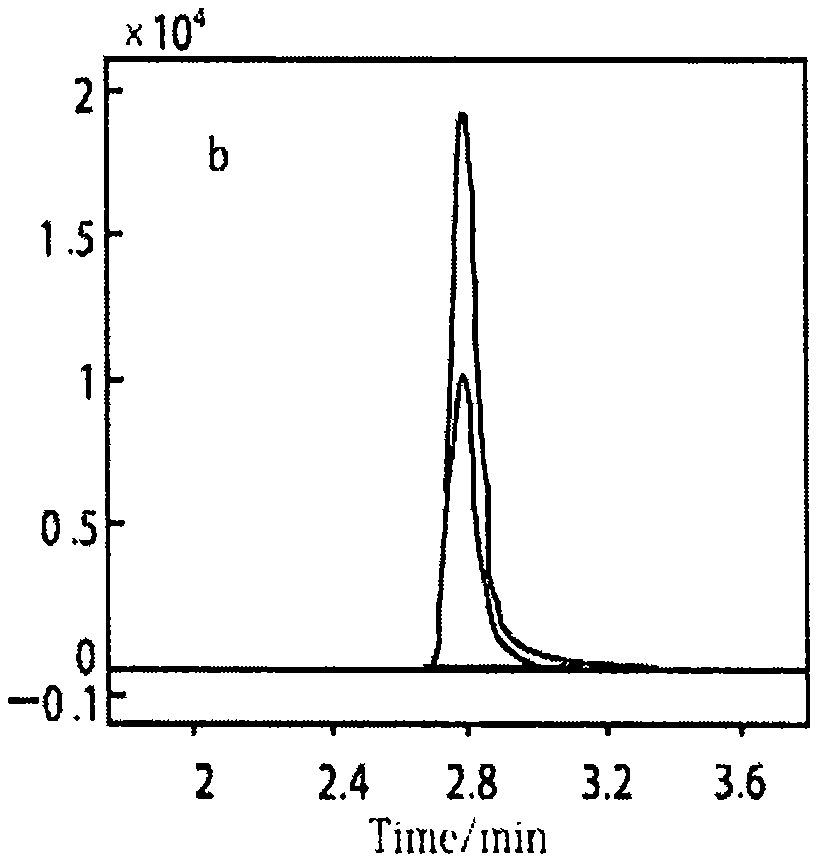

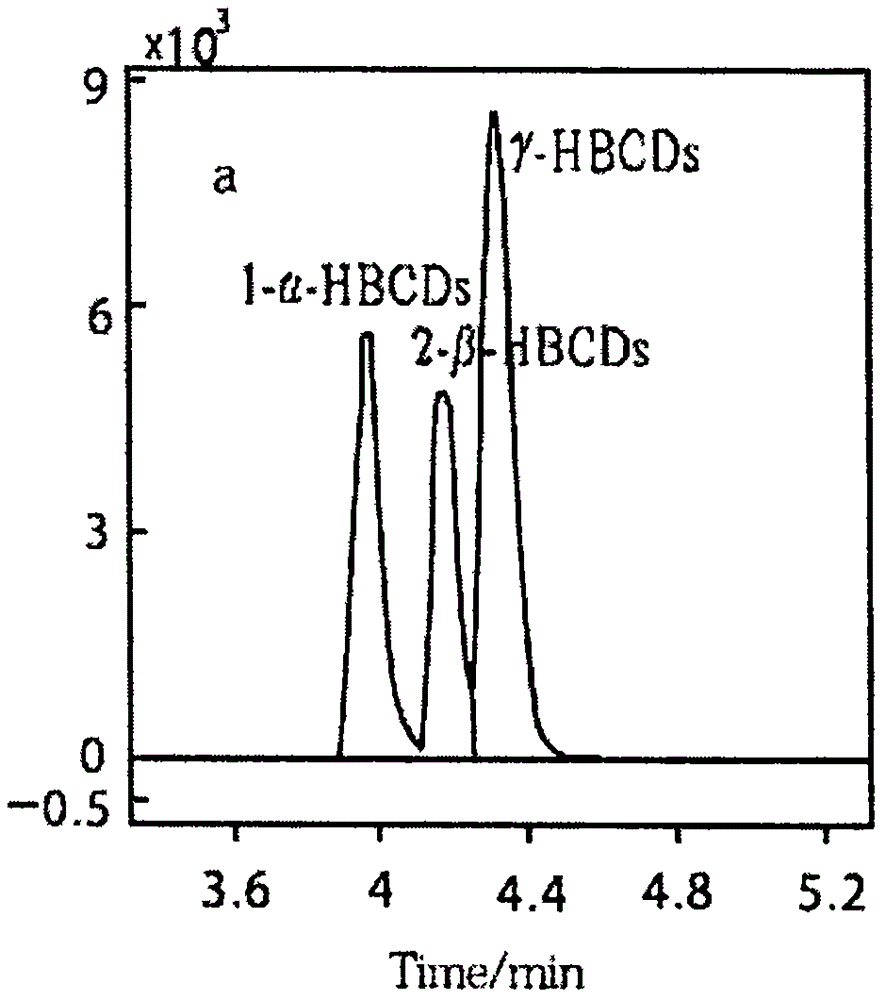

Method for detecting content of tetrabromobisphenol A, decabromodiphenyl ether and hexabromocyclododecane brominated flame retardants in aquatic product

ActiveCN106124643AGuaranteed accuracyGuarantee stabilityComponent separationTetrabromobisphenol ADecabromodiphenyl ether

The invention provides a method for detecting the content of tetrabromobisphenol A, decabromodiphenyl ether and hexabromocyclododecane brominated flame retardants in an aquatic product. The method is characterized by comprising the following steps that the content of the tetrabromobisphenol A, decabromodiphenyl ether and hexabromocyclododecane brominated flame retardants in the aquatic product is measured by establishing accelerated solvent extraction-fast liquid chromatography-tandem mass spectrometry, an aquatic product sample needing to be detected is separated through a C18 chromatographic column, gradient elution is conducted by taking water and methyl alcohol as mobile phases, detection is conducted in a mass spectrum multi-reaction monitoring mode, the matrix standard is corrected, quantitative determination is conducted through an external standard method, and confirmation is conducted. The detection method has the advantages that operation is easy and convenient, and detection is fast and accurate; by establishing the method for simultaneously detecting the tetrabromobisphenol A, decabromodiphenyl ether and hexabromocyclododecane brominated flame retardants in the aquatic product, physical health and life safety of consumers are guaranteed, a great practical significance is achieved for promoting sustainable and healthy development of aquatic product processing industry, and a beneficial technical reserve is provided for a food industry supervision department and a detection mechanism.

Owner:ZHOUSHAN INST FOR FOOD & DRUG CONTROL

Monocomponent PRTV anti-pollution-flashover paint and preparation method thereof

InactiveCN103923562AIncrease the pollution flashover voltage of the external insulationGuaranteed uptimeFireproof paintsPolymer scienceDecabromobiphenyl ether

The invention discloses monocomponent PRTV anti-pollution-flashover paint and a preparation method thereof. The monocomponent PRTV anti-pollution-flashover paint is composed of the following materials in parts by weight: 28-38 parts of polydimethylsiloxane, 10-19 parts of hydroxyl-terminated fluorine-containing polysiloxane, 3-5 parts of nanometer silica, 1-3 parts of a coupling agent, 0.5-1 part of a catalyst, 2-3 parts of decabromodiphenyl ether, 1-2 parts of a pigment and 40-50 parts of a solvent. The monocomponent PRTV anti-pollution-flashover paint has the beneficial effects that a fluorine material and a nanometer material are organically combined and blended with silicone rubber, silicone rubber is taken as main base rubber and fluorosilicone rubber is taken as auxiliary base rubber; and the monocomponent PRTV anti-pollution-flashover paint has the main technical advantages of being good in flame retardant effect, substantially reduced in cost.

Owner:滕州市智星电力电子工程有限公司

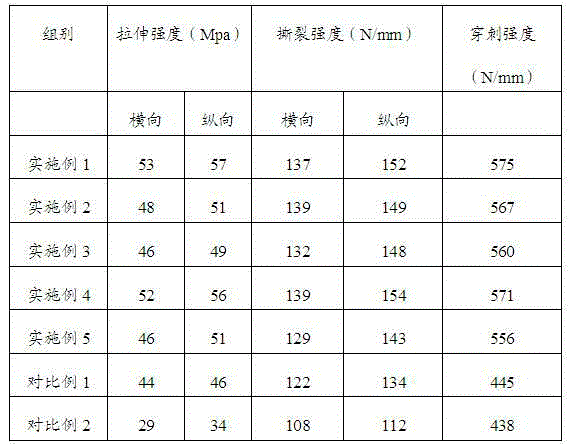

Courier bag material and preparation method of courier bag

InactiveCN102911429AHigh strengthImprove puncture resistanceLow-density polyethyleneLinear low-density polyethylene

The invention belongs to the technical field of packing materials and particularly relates to a courier bag material. The courier bag material comprises the following components: 35-45 parts of low-density polyethylene, 5-10 parts of high-density polyethylene, 50-55 parts of linear low-density polyethylene, 5-10 parts of mica, 3-7 parts of calcium carbonate, 1-9 parts of palygorskite, 1-4 parts of decabromodiphenyl ether, 1-5 parts of antimony trioxide, 1.5-2.0 parts of chlorinated polyethylene, 0.1-0.25 part of antioxidant, 0.1-2 parts of coupling agent and 0.3-0.8 part of zinc stearate. Compared with the prior art, by optimizing a formula of the courier bag material, the courier bag made of the courier bag material has the characteristics of high strength, puncture resistance, laceration resistance, and better heat resistance, wear resistance and flame retardancy, thus improving the security and practicability of the courier bag significantly and being widely applicable to various courier bags.

Owner:GUANGDONG TENGEN IND GRP CO LTD

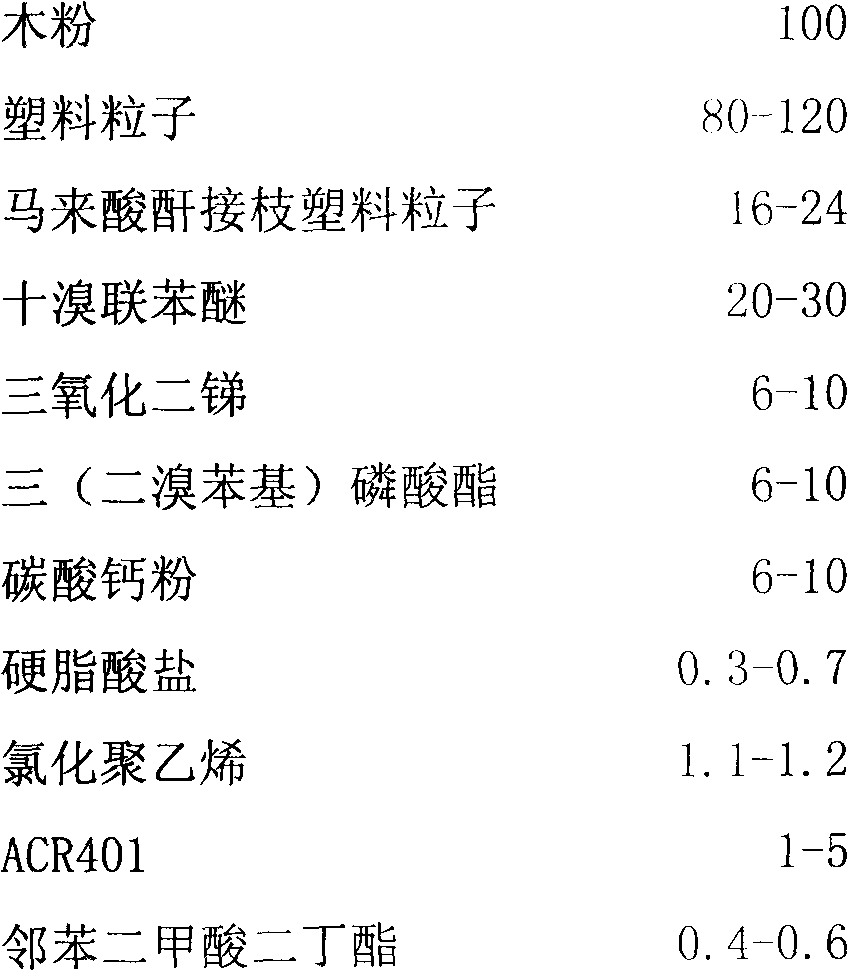

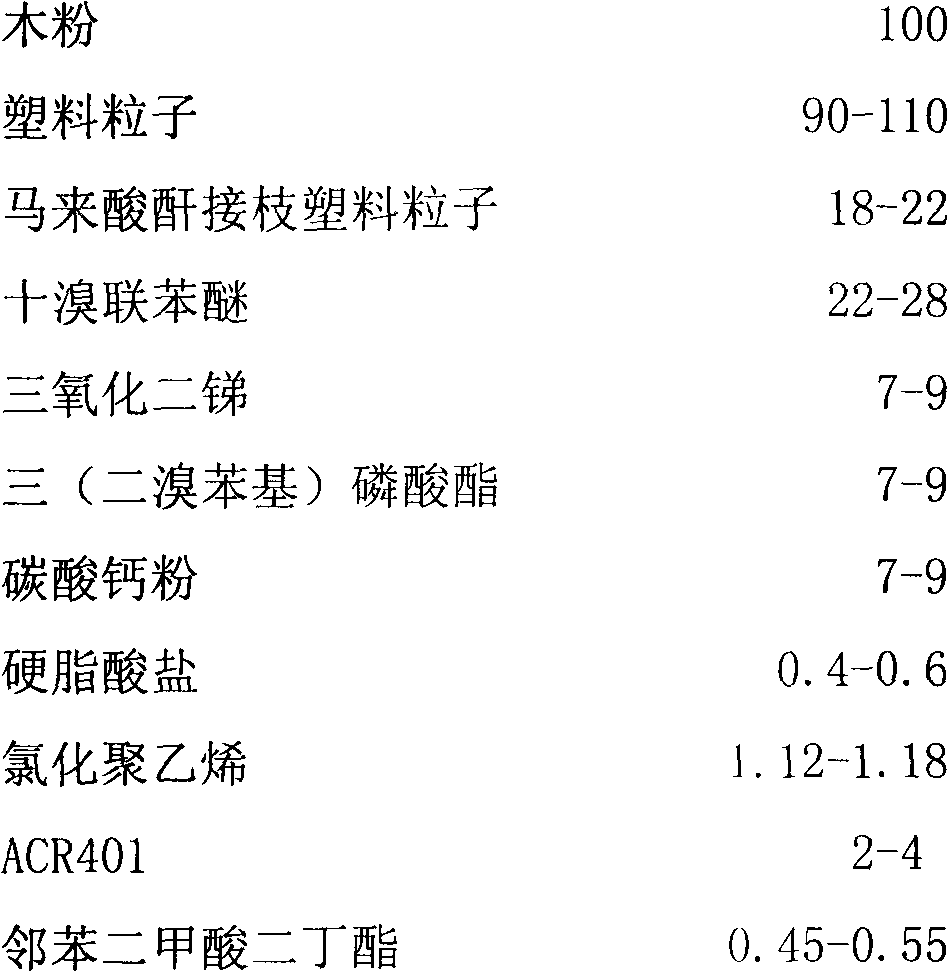

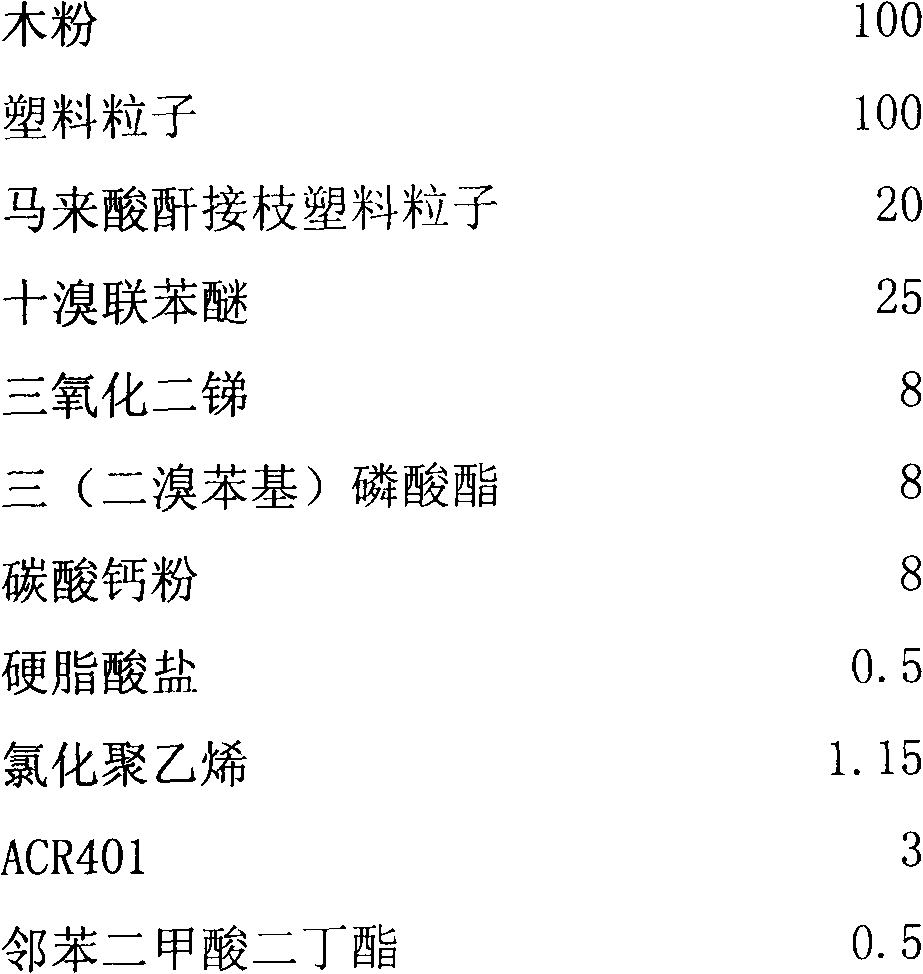

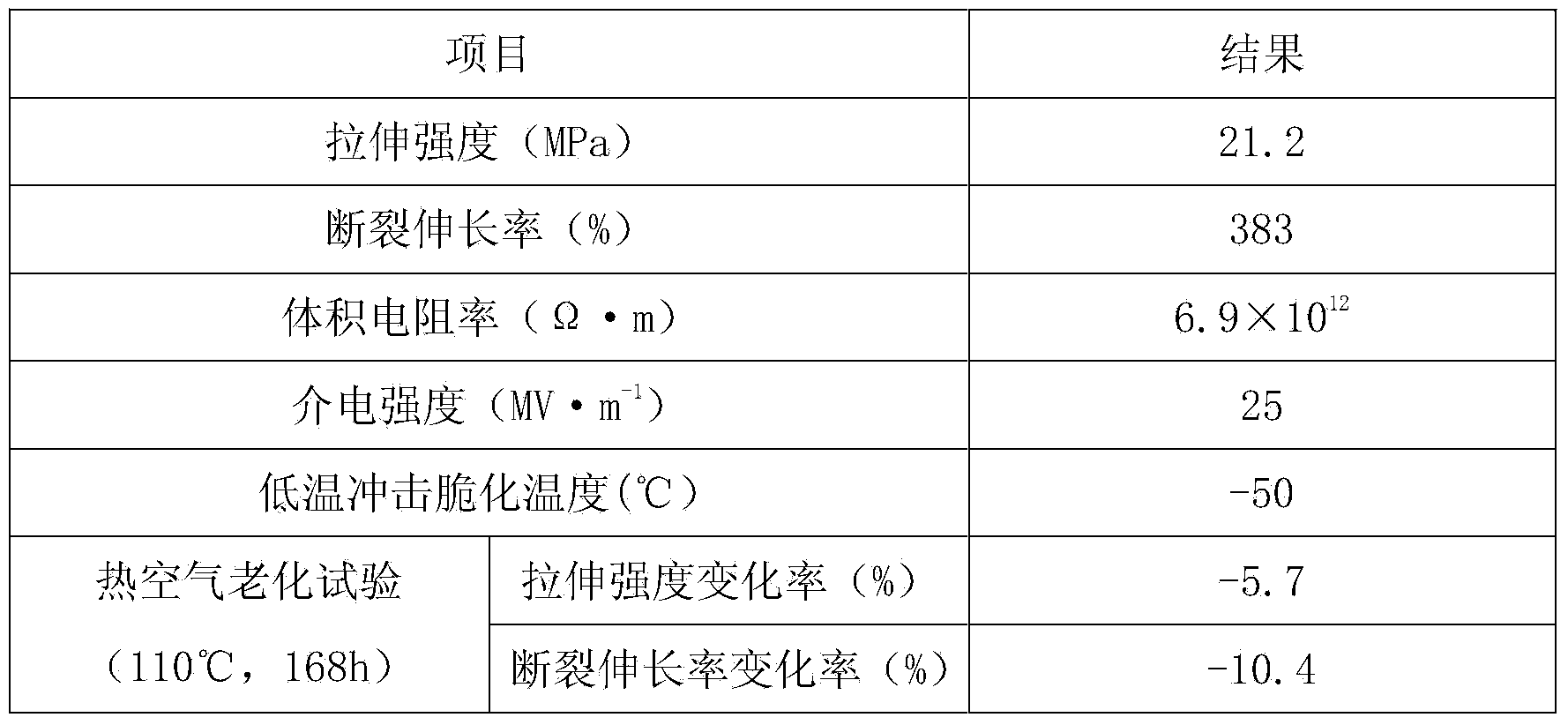

High efficiency flame retardant plastic-wood composite sheet and its preparation method

The invention relates to a plastic-wood composite material, especially a high efficiency flame retardant plastic-wood composite sheet and its preparation method. In the invention, tris(dibromopropyl) phosphate is employed to improve the flame retardance of wood powder, and decabromodiphenyl oxide and antimonony oxide are adopted for their synergism to improve the flame retardance of plastic particles. Additionally with other auxiliary agents and an extrusion technology, the high efficiency flame retardant plastic-wood composite sheet can be formed. The high efficiency flame retardant plastic-wood composite sheet provided in the invention has the advantages of convenient production and manufacturing, low production cost, environmental friendliness, excellent mechanical property and flame retardance, and can be widely used in many fields needing flame retardance.

Owner:江苏福瑞森塑木科技股份有限公司

Anticorrosive paint

The invention discloses anticorrosive paint which comprises, by mass, the following materials of 2-5 parts of allyl heptanoate, 1-4 parts of 4-methyl guaiacol, 1-2 parts of acetylacetone selenium, 4-9 parts of polyamide resin, 2-4 parts of 3-chlorine-2-carboxyl propyl trimethyl ammonium chloride, 1-3 parts of chromic chloride, 3-7 parts of vinylidene chloride, 2-5 parts of tetrabutylammonium bromide, 0.2-0.5 part of yttrium oxide, and 3-6 parts of decabromodiphenyl ether. The anticorrosive paint is not only convenient to use, easy to produce and manufacture, good in painting performance, and good in wettability for object surfaces, but also rapid in paint film drying, good in mechanical capacity, and good in acid-base resistance property, water resisting property, and resistance to organic solvent.

Owner:NANTONG HAISHUN CHEM

Cold-resistant PVC sheath material for cable and preparation method thereof

InactiveCN103524930AHigh tensile strengthStrong impact resistanceInsulated cablesInsulated conductorsEpoxyPolyvinyl chloride

The invention discloses a cold-resistant PVC sheath material for a cable and a preparation method thereof. The sheath material comprises the following raw materials in parts by weight: 75-95 of SG-4 type polyvinyl chloride, 15-25 of chlorosulfonated polyethylene, 10-15 of chloroprene rubber, 10-15 of dioctyl epoxy tetrahydrophthalate, 5-10 of di-isobutyl adipate, 4-7 of ACR, 2-3 of N,N'-ethylene hisstearamide, 8-12 of dipropylene glycol dibenzoate, 1-1.5 of an antioxidant 246, 10-15 of decabromodiphenyl oxide, 5-10 of ammonium polyphosphate, 1-2 of dibasic lead phosphite, 1-2 of tribasic lead sulfate, 2-3 of barium stearate, 4-8 of epoxidized soybean oil, 3-6 of titanium dioxide, 20-30 of acetylene carbon black, 5-10 of calcined loess, 10-15 of active calcium carbonate, and 4-6 of a composite filler. The sheath material has high cold resistance, has the low temperature impacting brittleness temperature of up to -50 DEG C, also still maintains excellent tensile strength, impact resistance, abrasion resistance, aging resistance and the like under a low temperature condition, is durable in use, and has broad application prospects.

Owner:WUHU HANGTIAN SPECIAL CABLE FACTORY

Waterproof anti-corrosion flame retardant coating for airplane and preparation method thereof

InactiveCN101665657AExtended service lifePrevents delamination and even damageFireproof paintsAnti-corrosive paintsJet aeroplaneDecabromobiphenyl ether

The invention relates to a waterproof anti-corrosion flame retardant coating for an airplane and a preparation method thereof. The coating is prepared from tung oil, ethylene-vinyl acetatecopolymer emulsion, decabromodiphenyl oxide and magnesium hydroxide according to the weight ratio of 60-80:10-30:5-10:5-10. The waterproof anti-corrosion flame retardant coating for the airplane uses the tung oilhaving the characteristics of waterproof property, anticorrosion, high temperature resistance, and the like as the main material, matches the decabromodiphenyl oxide and magnesium hydroxide with theflame retardant function and uses the ethylene-vinyl acetatecopolymer emulsion as the adhesive. Therefore, when applied on the surface of a structural component of the airplane to form an adhesive film with the waterproof, anti-corrosion and flame retardant effects, the waterproof anti-corrosion flame retardant coating can prevent material lamination or even damage caused when the external moisture and corrosive substances enter the inside of the structural component and has flame retardant effect, thereby prolonging the service life of the structural component and ensuring good safety.

Owner:CIVIL AVIATION UNIV OF CHINA

Formulation of military sole

The invention relates to a formulation of a sole, in particular to formulation of a military sole, comprising the formulations for forming an outer bottom and a middle layer of the sole, wherein the formulation of the outer bottom based on the parts by weight comprises: 47-51 parts of nature rubber, 49-53 parts of chloroprene rubber, 0.7-0.9 part of vulcanizing agent S-80, 2.4-2.6 parts of accelerating agent, 1.9-2.1 parts of magnesium oxide, 4.5-5.5 parts of zinc oxide, 4.5-5.5 parts of antimony oxide, 1.9-2.1 parts of stearic acid, 1.9-2.1 parts of zinc stearate, 20-24 parts of high wear resistance carbon black, 2-4 parts of engine oil 46#, 6-8 parts of dibutyl ester, 1.4-1.6 parts of anti-aging agent, 0.8-1.2 parts of paraffin wax and the like; and the formulation of the middle layer based on the parts by weight comprises: 47-51 parts of nature rubber, 49-53 parts of chloroprene rubber, 0.9-1.1 parts of sulphur, 2.5-2.7 parts of accelerating agent, 4.5-5.5 parts of zinc oxide, 1.9-2.1 parts of magnesium oxide, 3.8-4 parts of antimony oxide, 6.3-6.7 parts of decabromodiphenyl oxide, 1.9-2.1 parts of stearic acid and the like. The sole prepared by the formulation has good wear resistance and folding resistance, and has the performances of oil resistance, acid-base resistance, inflaming retarding, static electricity prevention and the like, thus meeting the military requirements.

Owner:JIHUA 3513 IND

Flame-retardant rubber material capable of protecting high-risk chemicals and method for preparing same

ActiveCN102977478AEffective protectionSolve the problem of large polarity differenceRubber materialDecabromodiphenyl ether

The invention discloses a flame-retardant rubber material capable of protecting high-risk chemicals and a method for preparing the same, belongs to the technical field of rubber and solves the problems of single function and poor quality due to single rubber type, and difficult formation of homogeneous phase while compounding a plurality of types of rubbers of the existing rubber. The flame-retardant rubber material capable of protecting high-risk chemicals is composed of the following components according to parts by weight: 30-80 parts of chlorinated butyl rubber, 30-10 parts of butadiene styrene rubber, 40-10 parts of neoprene, 2.0 parts of sulfur, 0.8-1.2 parts of accelerant TT, 0.8-1.2 parts of accelerant DM, 30 parts of high abrasion proof carbon black, 8-15 parts of decabromodiphenyl ether, 8-20 parts of antimonous oxide, 5-15 parts of chlorcosane, 5.0 parts of zinc oxide, 2.5 parts of stearic acid and 2.0 parts of antiager D. The flame retardant rubber material effectively overcomes the shortcomings of single function and poor quality of single rubber type; the product is capable of effectively protecting high-risk chemicals and highly corrosive materials, and thus can be widely applied to effectively protecting the feet, the head and the skin.

Owner:SHANXI XINHUA CHEM +1

Bacillus subtilis and application thereof for degrading decabromodiphenyl oxide

InactiveCN101921716APromote degradationLow costBacteriaMicroorganism based processesFuranDecabromobiphenyl ether

The invention discloses bacillus subtilis DB-2 and application thereof for degrading decabromodiphenyl oxide. The bacillus subtilis is preserved in China Center for Type Culture Collection (CCTCC) on 27th November 2009 with the preservation number of CCTCC No:M 209286. The bacillus subtilis has stronger degrading ability and is capable of debrominating decabromodiphenyl oxide to generate free bromonium ions. The bacillus subtilis does not generate high-toxicity secondary pollutants of polybrominated dibenzo-p-dioxins, polybrominated dibenzo-furans, low-brominated diphenyl ether, and the like after being biodegraded, and can be used for treating the pollution of the decabromodiphenyl oxide in the environment, thereby providing a decabromodiphenyl oxide degrading bacterium with low cost and high efficiency and without secondary pollution for treating the decabromodiphenyl oxide in chemical sludge or wastewater.

Owner:GUANGDONG INST OF MICROBIOLOGY GUANGDONG DETECTION CENT OF MICROBIOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com