Corrosion-resistant fireproof coating

A fire-resistant coating and corrosion-resistant technology, applied in fire-resistant coatings, anti-corrosion coatings, epoxy resin coatings, etc., can solve the problems of poor corrosion resistance of intumescent fire-resistant coatings, achieve excellent corrosion resistance, and improve adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

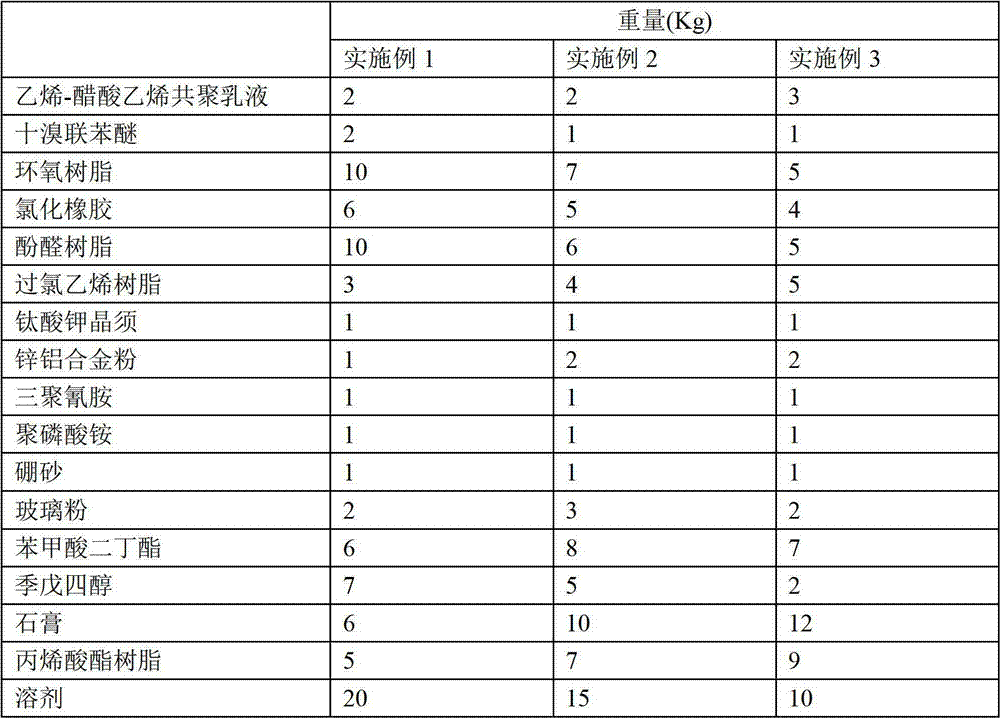

[0011] Each raw material was weighed according to the weight ratio in Table 1.

[0012] The weight proportion of table 1 embodiment 1~embodiment 3

[0013]

[0014] The above-mentioned solvent is selected from ethyl acetate, butyl acetate, and xylene, or a mixture of several in arbitrary proportions.

[0015] The above-mentioned epoxy resin is preferably a bisphenol A type epoxy resin.

[0016] The above-mentioned pigments and fillers can be selected from one of barium sulfate, talc powder, mica powder, aluminum oxide, and magnesium oxide or a mixture of several in any proportion.

[0017] The preparation method is as follows: dissolve the resin with a solvent, then add it, and stir evenly; send it to a three-roller grinder to grind until the fineness is qualified, then disperse it evenly in a mixer, filter and pack.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com