Patents

Literature

157results about How to "Effective flame retardant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

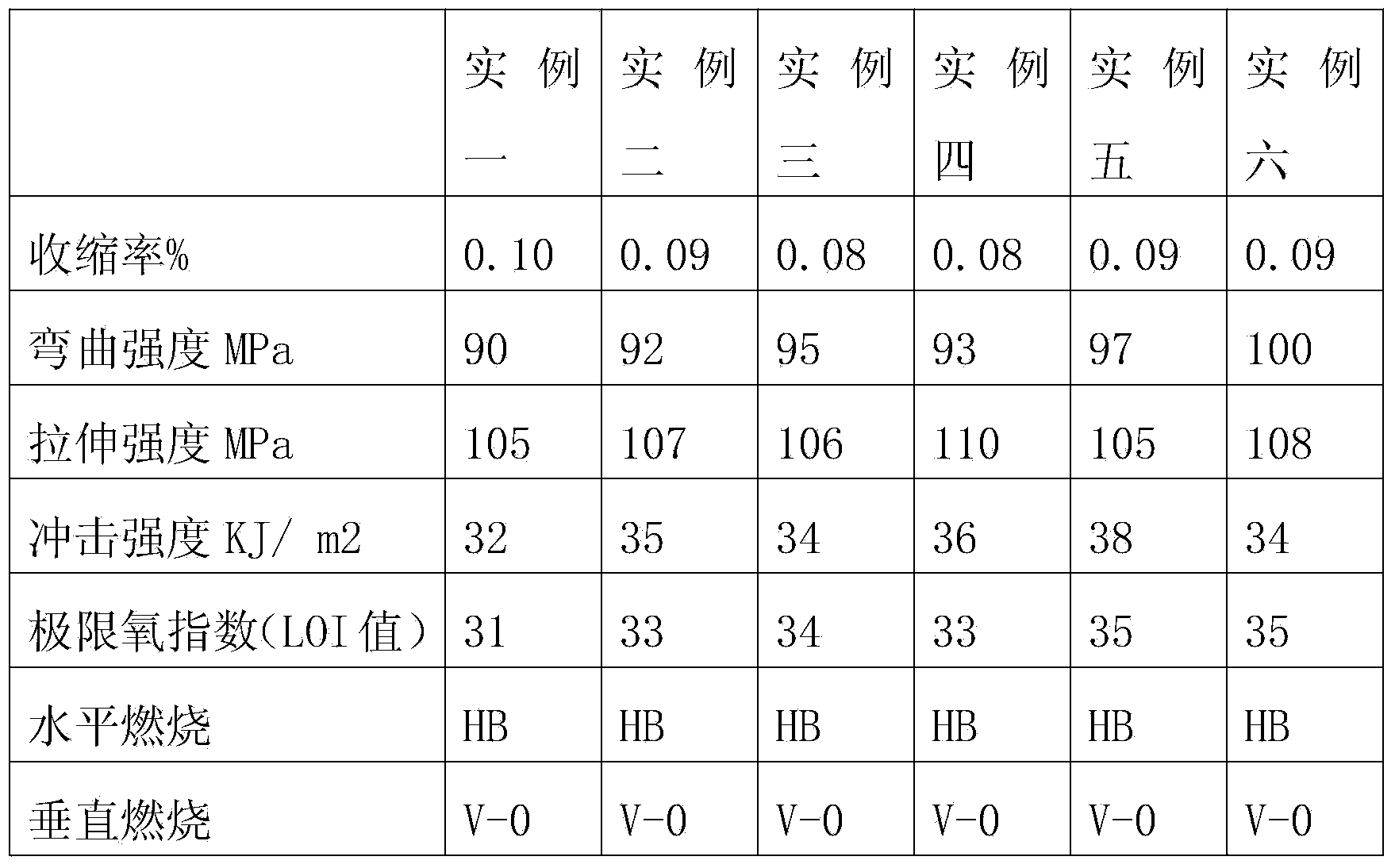

Low-shrinkage medium-temperature-cured high-efficiency flame-retardant unsaturated polyester fiberglass reinforced plastic board and preparation method thereof

The invention discloses a low-shrinkage medium-temperature-cured high-efficiency flame-retardant unsaturated polyester fiberglass reinforced plastic board and a preparation method thereof. The low-shrinkage medium-temperature-cured high-efficiency flame-retardant unsaturated polyester fiberglass reinforced plastic board is prepared from the following components in parts by weight: 50-60 parts of unsaturated polyester resin, 20-30 parts of a low-shrinkage additive, 1-3 parts of an accelerant, 0.5-2 parts of an initiator, 2-5 parts of a medium-temperature curing agent, 0.1-0.5 part of a thickening agent, 8-15 parts of a novel halogen-free flame retardant, 100-130 parts of inorganic filler, 2-3 parts of a release agent and 100-150 parts of fiberglass. The curing degree, the bending strength and the flexibility of the low-shrinkage medium-temperature-cured high-efficiency flame-retardant unsaturated polyester fiberglass reinforced plastic board can be improved; residual styrene in the fiberglass reinforced plastic board is reduced.

Owner:扬州万盛实业有限公司

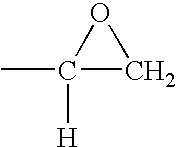

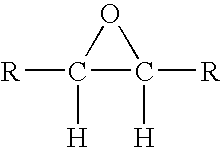

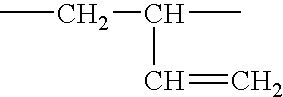

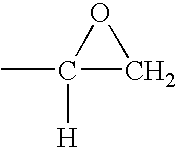

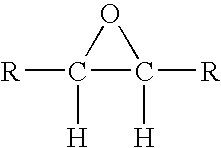

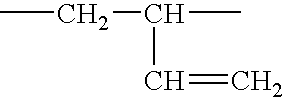

Brominated and epoxidized flame retardants

ActiveUS20100331497A1Effective flame retardantImprove thermal stabilitySimple Organic CompoundsPolymer science

Brominated and epoxidized organic compounds are useful flame retardants for polymers such as polystyrene. The organic compounds contain both bromine and oxirane groups, and have molecular weights of at least 1500. The brominated and epoxidized organic compounds can be prepared by sequentially brominating and epoxiding (in either order) a starting compound that contains multiple non-conjugated carbon-carbon double bonds.

Owner:DOW GLOBAL TECH LLC

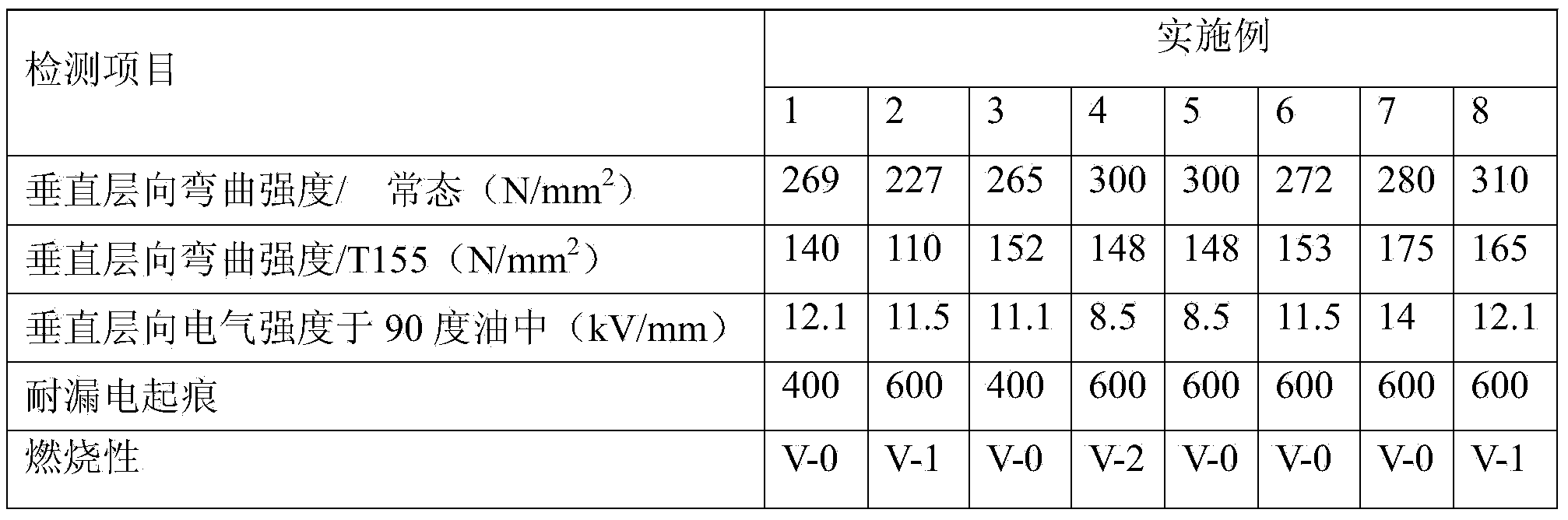

Halogen-free flame-retardant highly-heat-resistant unsaturated polyester glass fiber composite material

ActiveCN103524975AImprove mechanical propertiesImprove electrical performancePolyesterMechanical property

The invention relates to a halogen-free flame-retardant highly-heat-resistant unsaturated polyester glass fiber composite material. Unsaturated polyester resins, low shrink agents, crosslinking monomers, initiating agents, polymerization inhibitors, mold lubricants, halogen-free flame-retardant components and inorganic filling materials are first mixed uniformly, then the above mixture is composited with glass fiber, after curing, solidification is carried out at certain time and temperature, and a halogen-free flame-retardant highly-heat-resistant unsaturated polyester glass fiber composite material is obtained. The method is simple, and the prepared composite material has good comprehensive properties, has excellent mechanical properties at normal state and at high temperature, is halogen-free flame-retardant, and meets environmental protection requirements.

Owner:河北福润达新材料科技有限责任公司

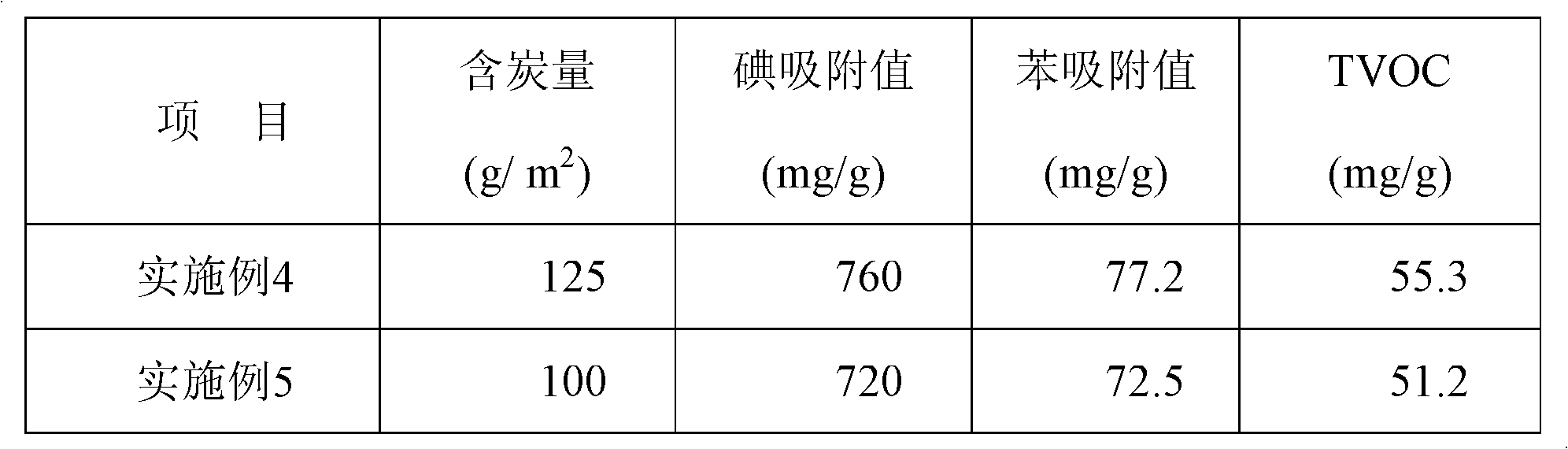

Flame-retardant activated carbon fabric and preparation method thereof

ActiveCN102529254ASimple processGood flame retardant performanceSynthetic resin layered productsActivated carbonChemistry

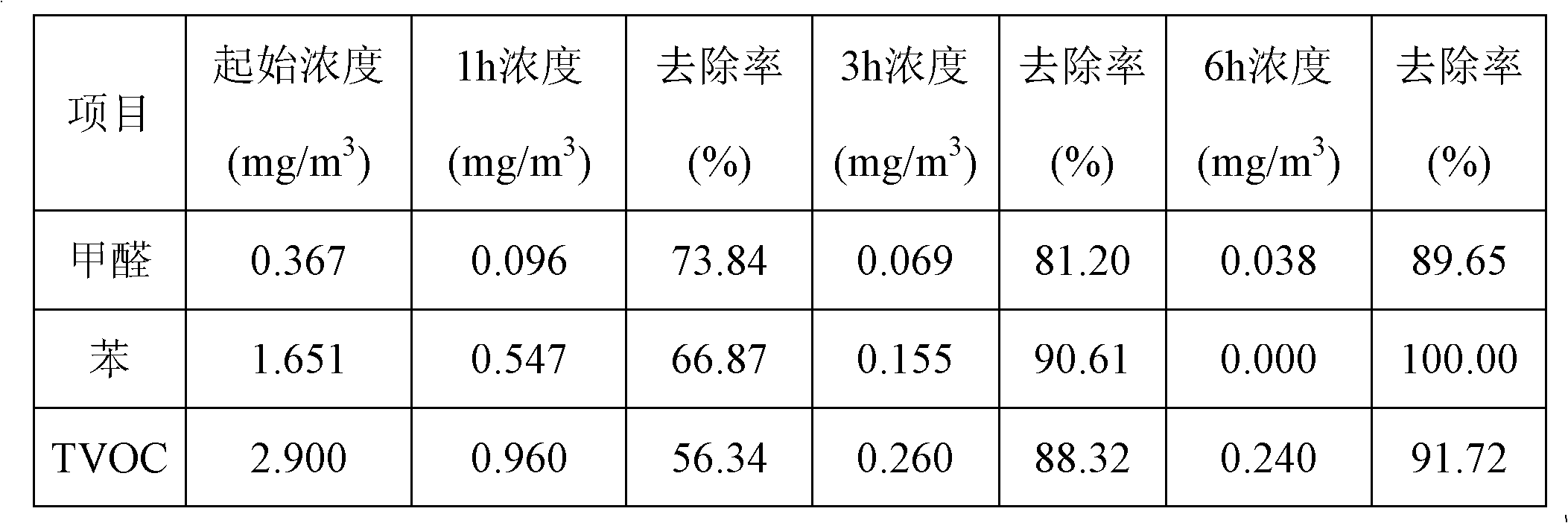

The invention relates to a flame-retardant activated carbon fabric and a preparation method thereof. The flame-retardant activated carbon fabric is characterized in that an activated carbon layer, a water-based adhesive film layer and a hot-melt adhesive powder particle layer are sequentially covered on a base material which is subjected to flame-retardant treatment. The preparation method comprises the following steps of: spraying or padding the base material with an environment-friendly water-based flame retardant and drying; serially coating a prepared activated carbon paste and a water-based flame-retardant hot-melt adhesive powder particle paste on the base material, and drying to obtain the final product of flame-retardant activated carbon fabric. During the drying process, the water-based adhesive film layer is formed between the carbon layer and the hot-melt adhesive powder particle layer. The preparation method of the flame-retardant activated carbon fabric is simple and environment-friendly, and the product has good flame retardant property. Owing to the good adsorption property of activated carbon, the fabric can remove formaldehyde, benzene, TVOC and other harmful gases in the air. When the fabric is used, the fabric can be cut freely and laminated thermally. The flame-retardant activated carbon fabric is easy and convenient to use and has a wide application range.

Owner:WUXI DINGHAO NEW MATERIAL SCI RES

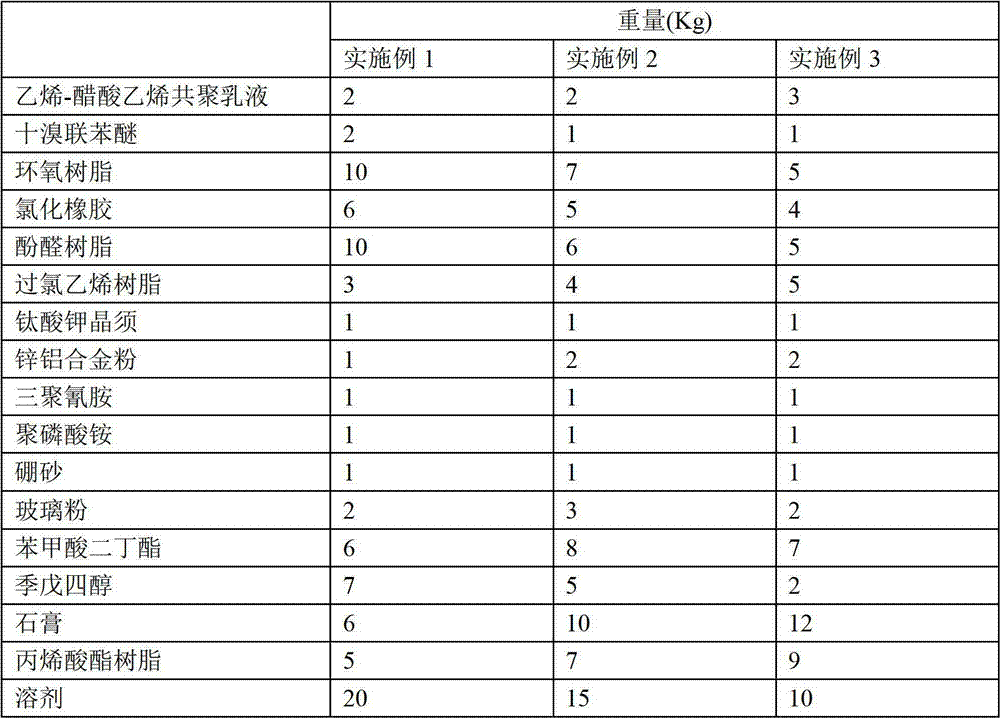

Corrosion-resistant fireproof coating

InactiveCN102850902AImprove adhesionEffective flame retardantFireproof paintsRubber derivative coatingsEpoxyDecabromodiphenyl ether

The invention provides a corrosion-resistant fireproof coating, which belongs to the technical field of coatings. The corrosion-resistant fireproof coating comprises, by weight, 2 to 3 parts of ethylene-vinyl acetate copolymer emulsion, 1 to 2 parts of decabromodiphenyl ether, 5 to 10 parts of epoxy resin, 4 to 6 parts of chlorinated rubber, 5 to 10 parts of phenolic resin, 3 to 5 parts of perchlorethylene resin, 1 part of potassium titanate whisker, 1 to 2 parts of zinc-aluminum alloy powder, 1 part of melamine, 1 part of ammonium polyphosphate, 1 part of borax, 2 to 3 parts of glass powder, 5 to 8 parts of dibutyl benzoate, 2 to 7 parts of pentaerythritol, 6 to 12 parts of gypsum, 5 to 9 parts of acrylate resin and 10 to 20 parts of a solvent. The fireproof coating provided by the invention has excellent corrosion resistance and has fire resistance in accordance with national regulations.

Owner:苏州市德莱尔建材科技有限公司

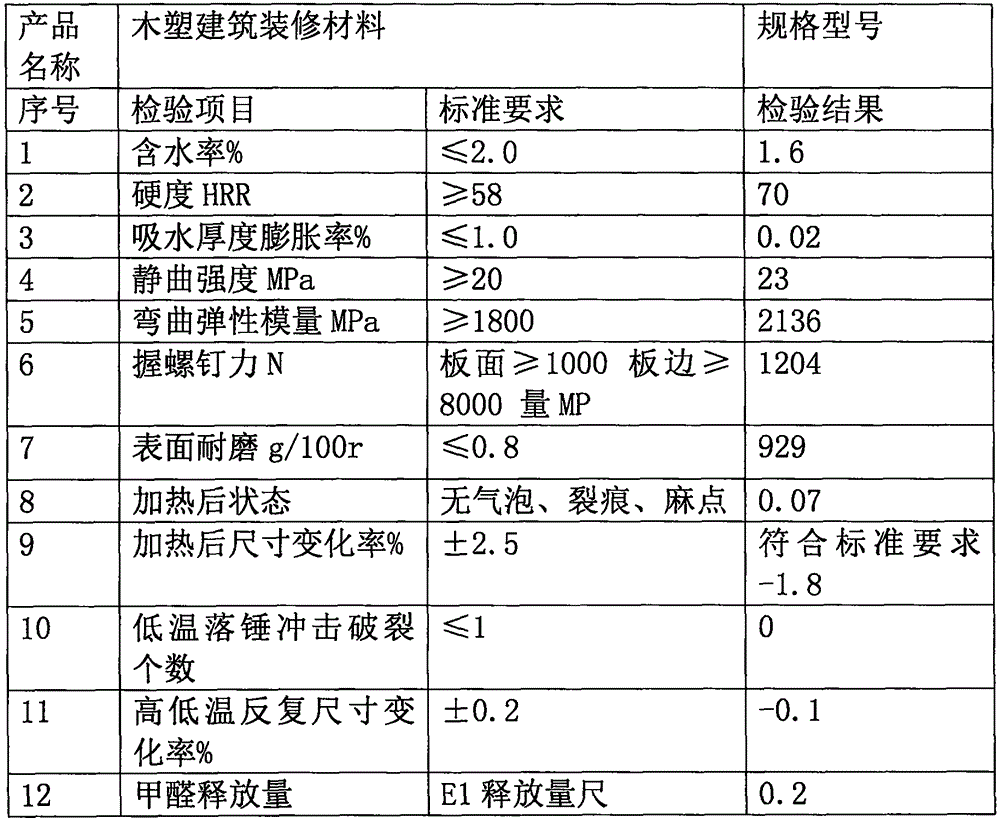

Composite ecological wood

The invention provides composite ecological wood. The wood comprises the following compositions in percentage by weight: 35 to 40 percent of wood meal, 40 to 49 percent of PVC, 2 to 3 percent of calcium carbonate, 4 to 6 percent of a foaming regulator, 4 to 6 percent of a stabilizing agent, 4 to 6 percent of impact-resistant ACR, 0.5 to 1.5 percent of a processing additive ACR, 0.2 to 0.4 percent of toner, an internal lubricant and an external lubricant, a foaming agent accounting for 0.1 to 1 percent of the PVC and a coupling agent accounting for 3 to 5 percent of the wood meal; and when a product is used outdoors, the product also comprises an antioxidant, an ultraviolet absorbent and a light stabilizing agent which have 0.1 to 0.5 percent of weight portions respectively. Compared with the prior art, the composite ecological wood thoroughly overcomes the disadvantages of raw wood, improves the shortage of the raw wood and keeps the particular wooden texture of the raw wood; simultaneously, for the addition of the antioxidant, the ultraviolet absorbent and the light stabilizing agent, the composite ecological wood also prevents photooxidation, fading, cracking and the like caused by ultraviolet irradiation, increases the weather resistance and prolongs the service life.

Owner:孙玉武

Novel dust-inhibiting and fire-retarding covering agent for coal, and preparation method thereof

InactiveCN102464971ALow costEasy to produceOther chemical processesSpontaneous combustionSocial benefits

The invention discloses a novel dust-inhibiting and fire-retarding covering agent for coal, and a preparation method thereof. The dust-inhibiting and fire-retarding covering agent comprises components of, by mass: 4-5% of a film forming agent, 10-12% of a curing agent, 2-3% of a film forming auxiliary agent, 1-3% of a penetrant, 1-3% of a fire retardant, and 74-82% of water. The preparation method of the dust-inhibiting and fire-retarding covering agent comprises steps that: the film forming agent is added and dissolved in water under a certain temperature; the temperature is controlled; the solution is continuously stirred, and the curing agent, the film forming auxiliary agent, the penetrant, and the fire retardant are orderly added to the solution while stirring; the mixture is stirred, until a reaction is sufficiently carried out. The novel dust-inhibiting and fire-retarding covering agent is sprayed onto the surface of coal under a normal temperature, and other equipments and conditions are not required. Within a short time, a flexible and compact continuous high-molecular covering membrane is formed, such that phenomena of dust emission and spontaneous combustion during transportation and stacking processes can be avoided. Therefore, coal economic loss and environmental pollution can be effectively reduced; and great economic benefits and social benefits of environmental protection are provided.

Owner:SHANDONG UNIV OF SCI & TECH

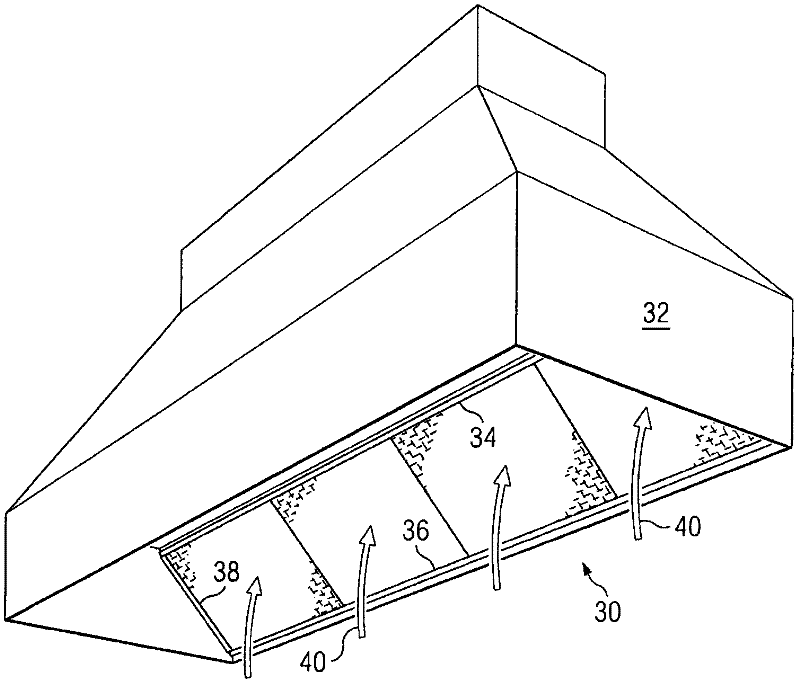

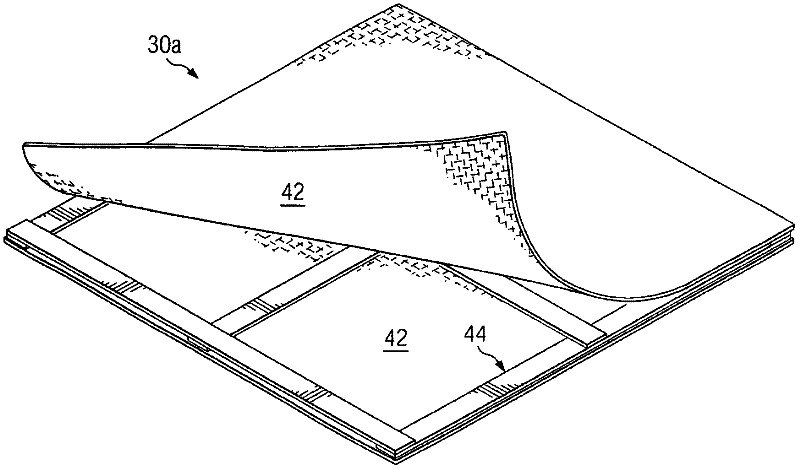

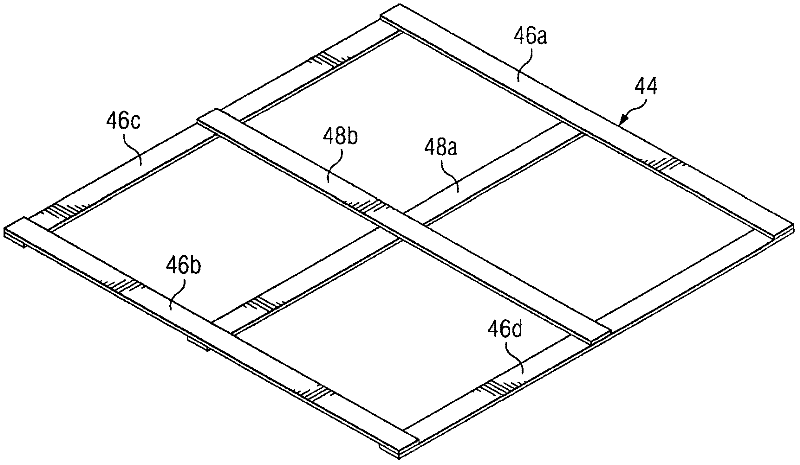

Grease removal apparatus, systems and methods

InactiveCN102165265AEfficient removalEffective flame retardantDomestic stoves or rangesDispersed particle filtrationFiberMetallic materials

A filter assembly includes a filter pad comprising fibers including natural, synthetic and / or hybrid fibers. A stabilizer frame formed of a non-metallic material may be imbedded in the filter pad. The stabilizer frame may be configured to provide support to the filter pad to maintain the filter pad in a generally flat configuration. In accordance with a particular embodiment, the filter pad may be comprised of at least first and second fibrous mats that are coupled together. In this embodiment, the stabilizer frame may be disposed between and coupled with the first and second fibrous mats.

Owner:CLEAN SYST

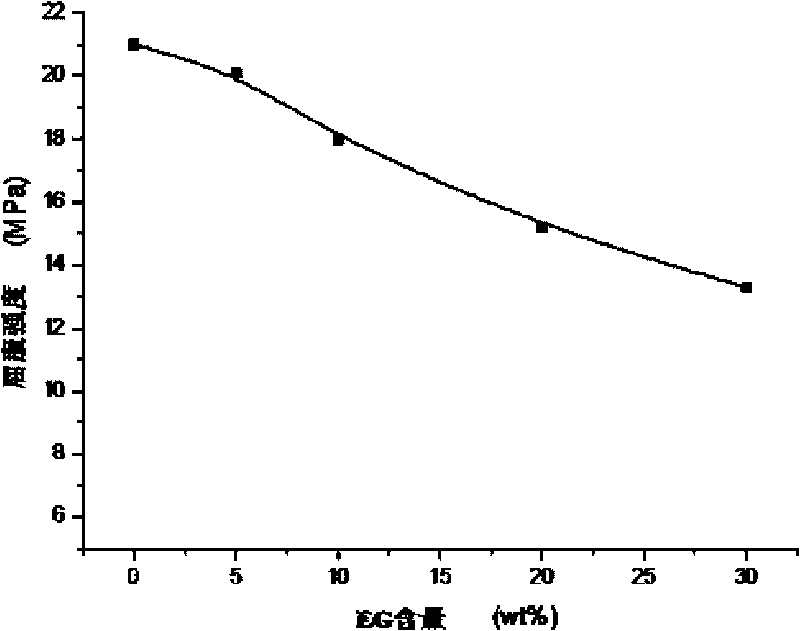

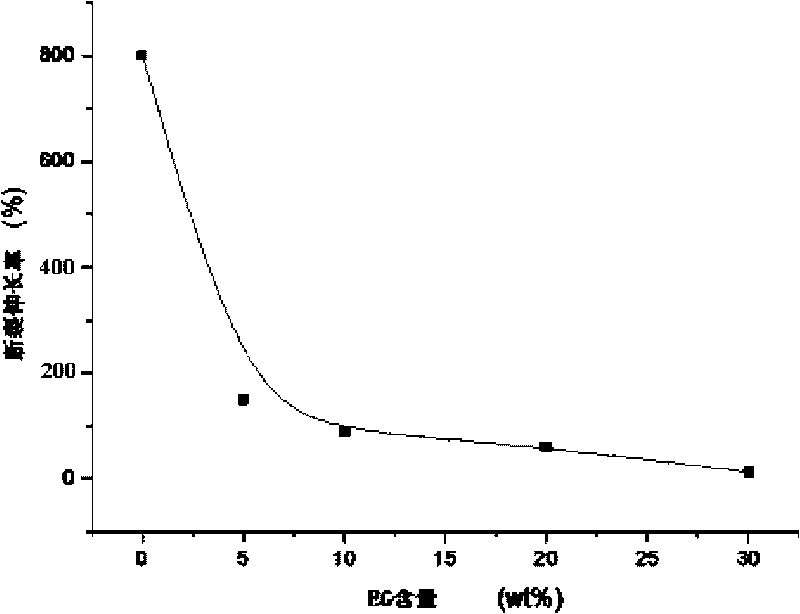

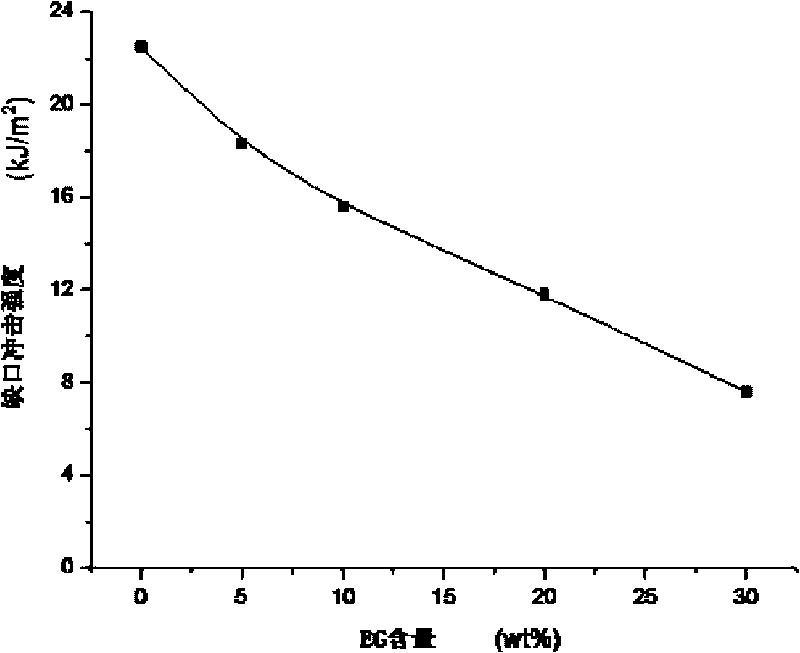

Halogen-free flame-retardant and anti-static polyethylene material, pipe and preparing method thereof

ActiveCN101759900AImprove mechanical propertiesImprove performanceRigid pipesPolymer scienceGraphite

A halogen-free flame-retardant and anti-static polyethylene material, a pipe and a preparing method thereof belong to the processing field of plastic pipes. The present invention aims to provide a halogen-free flame-retardant and anti-static polyethylene material and a pipe prepared from the material. The halogen-free flame-retardant and anti-static polyethylene material is prepared from 70 to 99 shares of polyethylene, 1 to 30 shares of expanded graphite (EG) / polyethylene (PE) superfine composite powder, 1 to 30 shares of synergistic flame retardant and 1 to 5 shares of conductive black by the steps of melting and blending at a temperature of 160 DEG C to 200 DEG C, extruding, granulating and drying. The EG / PE superfine composite powder is made by simultaneously grinding PE and EG with a millstone type mechanochemical reactor, and the granularity of the powder is 1000 meshes. The halogen-free flame-retardant and anti-static polyethylene pipe made from the halogen-free flame-retardant and anti-static polyethylene material prepared according to the present invention has the characteristics of halogen-free flame retardation, high flame-retardant efficiency and excellent comprehensive mechanical properties. Besides, the raw material cost of the halogen-free flame-retardant and anti-static polyethylene pipe can be largely reduced, and the pipe is simply processed and conveniently made.

Owner:SICHUAN JIANNANCHUN GRP CO LTD +2

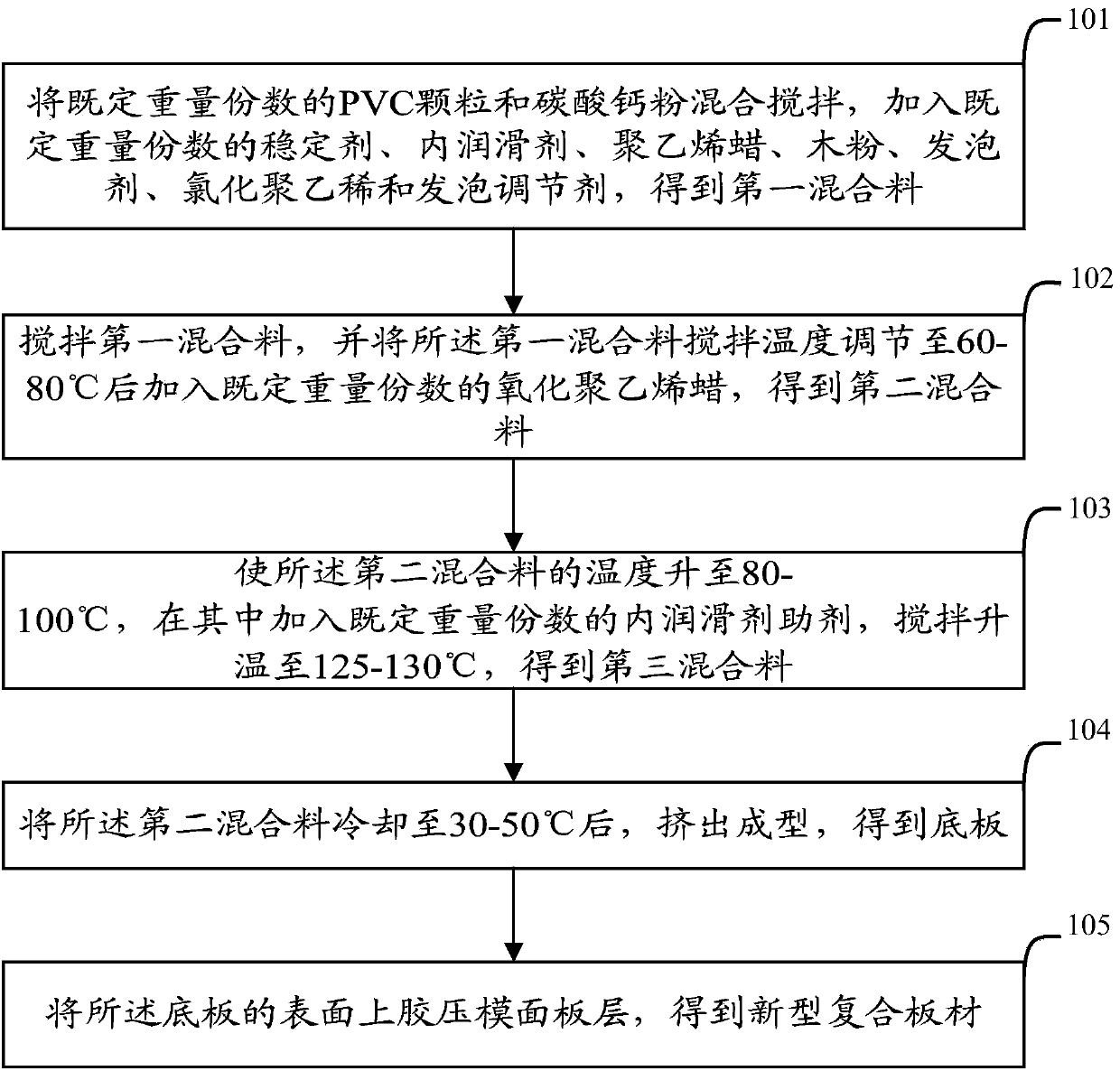

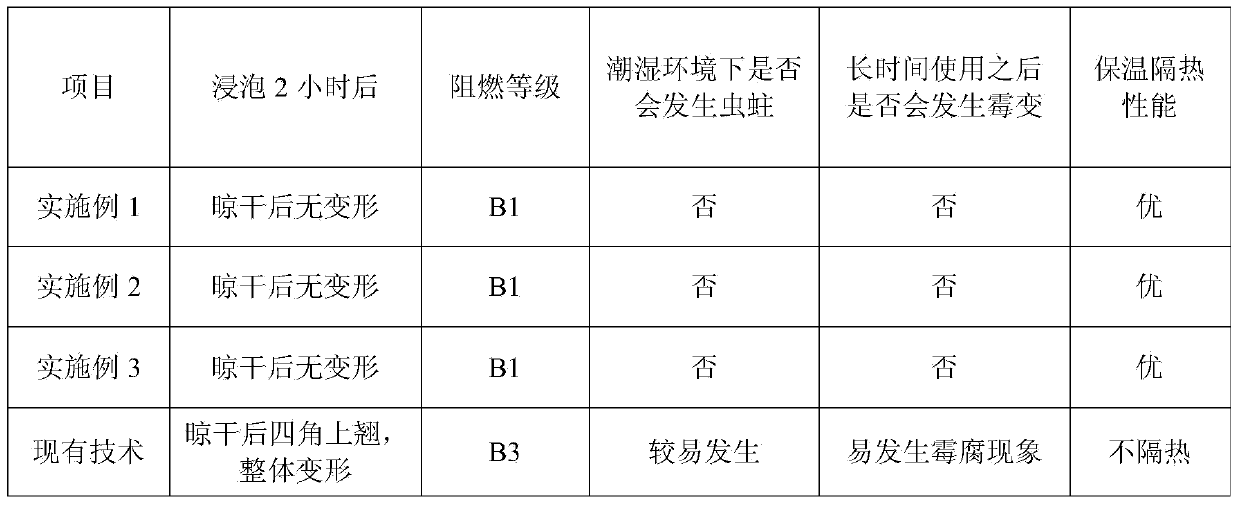

Novel composite board and preparation method thereof

ActiveCN104175660ASave resourcesRaw material environmental protectionSynthetic resin layered productsWood layered productsWaxFoaming agent

The invention relates to the field of building boards and in particular relates to a novel composite board and a preparation method thereof. The novel composite board comprises a bottom board and a panel layer which is stuck on the bottom board, wherein the bottom board comprises the following raw materials in parts by weight: 90-110 parts of PVC particles, 40-60 parts of calcium carbonate powder, 3-6 parts of a stabilizer, 1.0-1.4 parts of a foaming agent, 6-8 parts of a foaming regulator, 0.3-0.5 part of polyethylene wax, 0.3-0.4 part of internal lubricant, 0.2-0.4 part of oxidized polyethylene wax, 4-6 parts of chlorinated polyethylene, 0.5-1.5 parts of an internal lubricant additive and 9-11 parts of wood powder. The novel composite board has the good waterproof and damp-proof effects and solves the problem that common boards in the prior art are soaked by water so as to seriously deform. The novel composite board also has the recycling characteristic and solves the technical problem that a large amount of wood needs to be consumed in wooded boards in the prior art.

Owner:朱青海

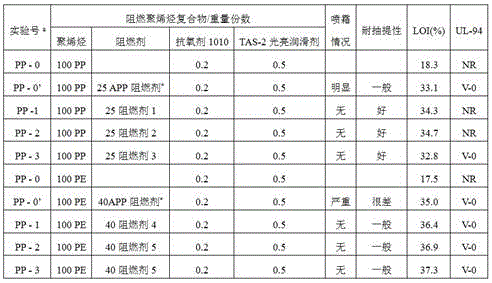

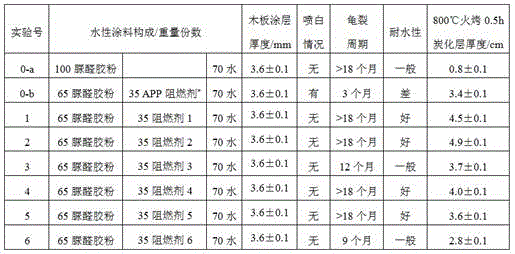

Composite flame retardant and preparation method thereof

ActiveCN106750574AEffective flame retardantGood compatibilityFireproof paintsPolyolefinAcetic anhydride

The invention discloses a composite flame retardant and a preparation method thereof. The composite flame retardant is characterized by being formed by mixing and reacting a chitin compound, a phytic acid compound, acetic anhydride, siloxane, polyamine, white carbon black, urea and water, wherein the chitin compound is at least one of chitin or chitosan; the phytic acid compound is at least one of phytic acid, sodium phytate, potassium phytate, magnesium phytate, calcium phytate, iron phytate, cobalt phytate or zinc phytate. Preparation method of the flame retardant mainly relates to a three-stage mixed reaction process: firstly, uniformly mixing the chitin compound, the phytic acid compound, water, polyamine and white carbon black; then adding acetic anhydride and siloxane to be uniformly mixed; and finally, putting urea to be uniformly mixed, and discharging, cooling and crushing the mixture to obtain a product. The composite flame retardant disclosed by the invention not only can effectively retard flames of polyolefin and woods, but also has good compatibility with polyolefin and an amino resin aqueous coating, and can effectively avoid phenomena of blooming, white spraying, dialyzing and fracturing.

Owner:FUJIAN NORMAL UNIV

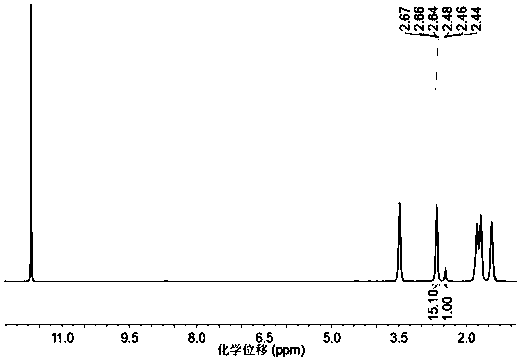

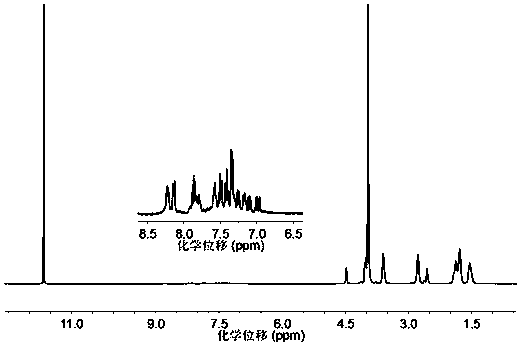

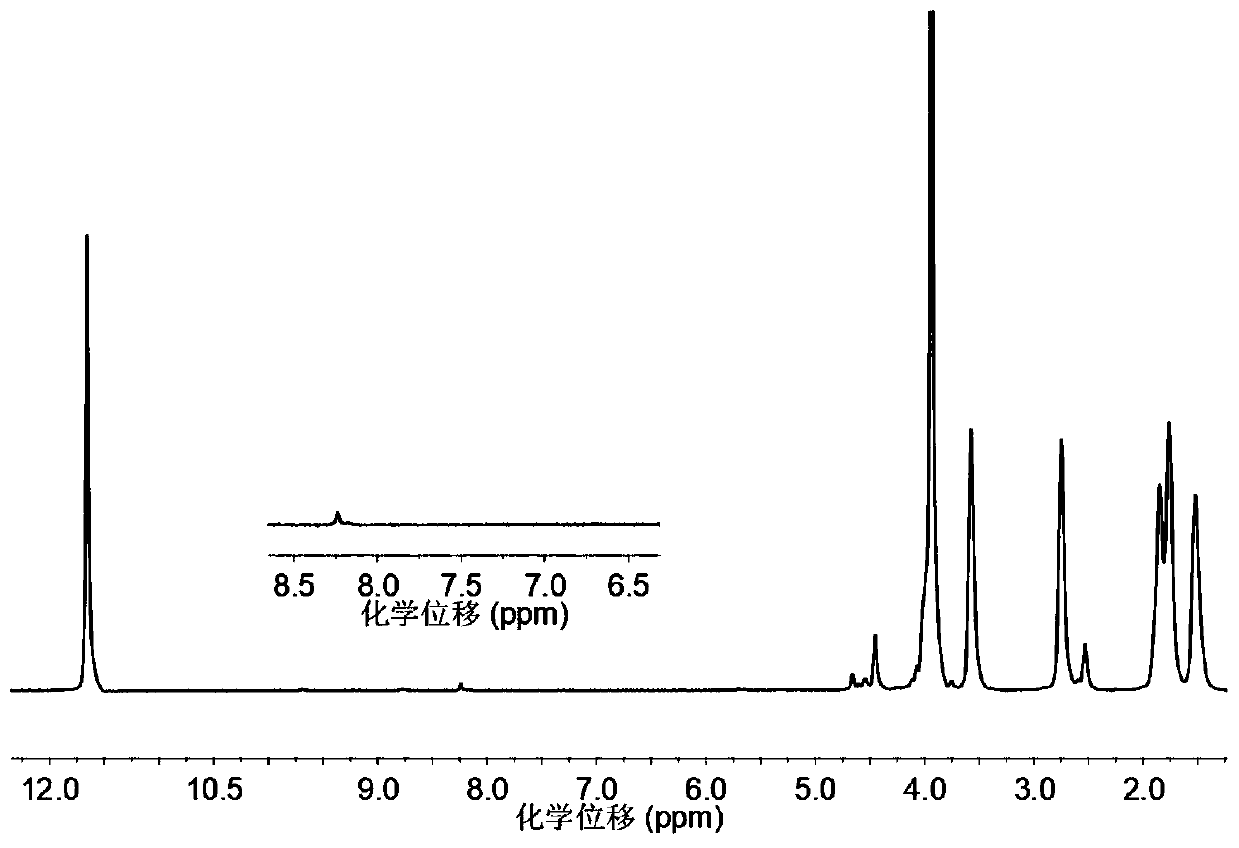

Phosphorus-containing intrinsic flame-retardant thermoplastic nylon elastomer and preparation method thereof

ActiveCN110183649AGood flame retardant efficiency and durabilityNo migration issuesElastomerPolymer science

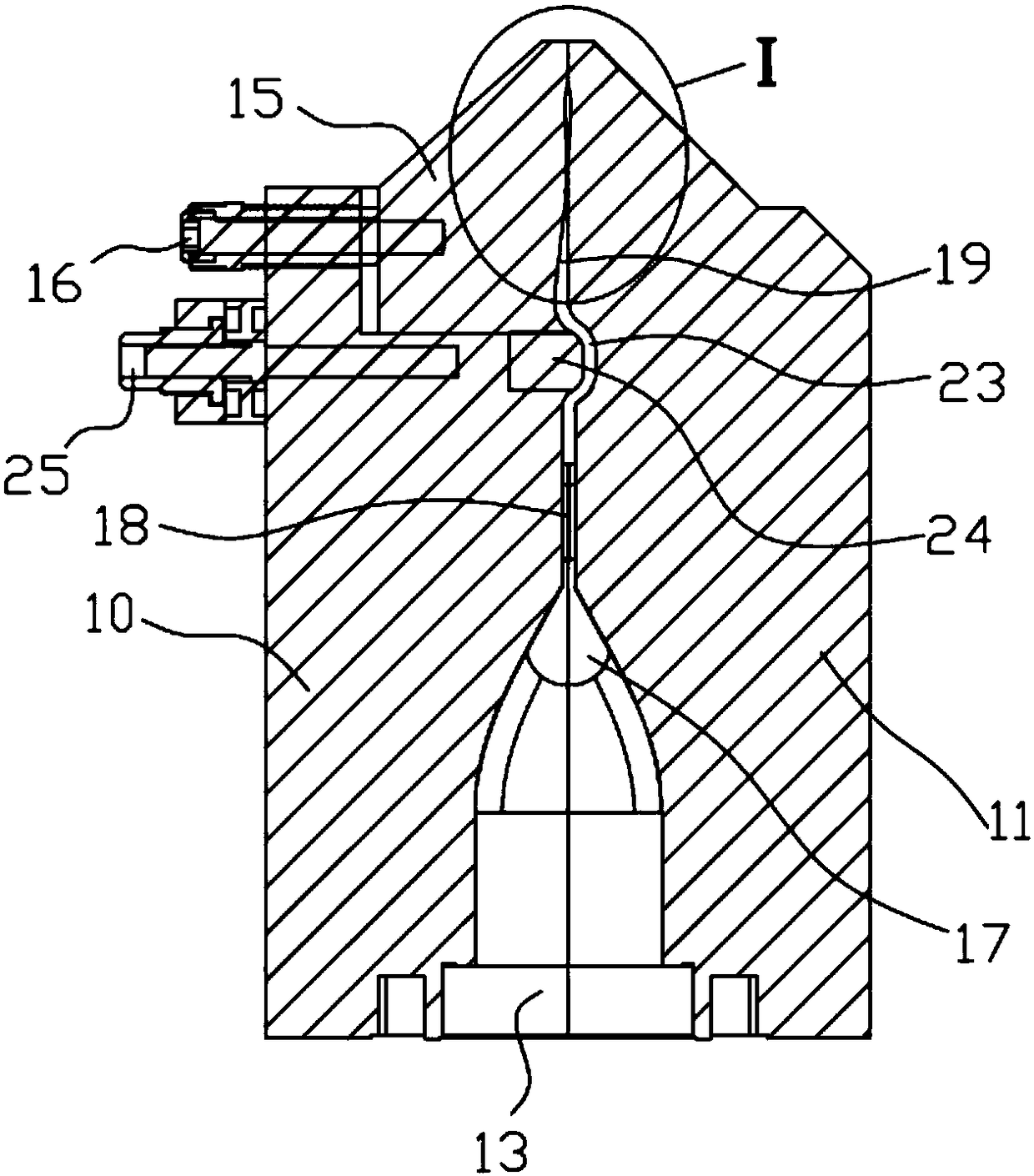

The invention discloses a phosphorus-containing intrinsic flame-retardant thermoplastic nylon elastomer and a preparation method thereof. The phosphorus-containing intrinsic flame-retardant thermoplastic nylon elastomer is a nylon elastomer represented by the following structural general formula [I] obtained by the melt copolymerization reaction of a carboxyl-terminated nylon pre-polymer, a hydroxyl-terminated polyether polyol and a phosphorus-containing diol monomer, or is a nylon elastomer represented by the following structural general formula [II] obtained by the melt copolymerization reaction of a carboxyl-terminated phosphorus-containing nylon pre-polymer and a hydroxyl-terminated polyether polyol. The nylon elastomer is a multi-block copolymer, a phosphorus-containing reactive flameretardant is copolymerized and embedded in the molecular chain of the thermoplastic nylon elastomer, the effective flame retardancy at a low content can be realized, the durability is good, no migration problem exists, the ratio of a soft segment, a hard segment and the flame retardant can be adjusted, and demands of different mechanical properties of different application fields are satisfied under the premise of high efficiency flame retardant. The preparation method is simple, the raw materials are easily available, and the expanding production is favorable.

Owner:SICHUAN UNIV

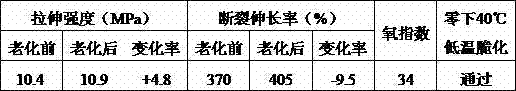

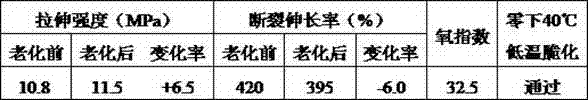

Low-temperature-resistance flame-retardant rubber cable sheath material

ActiveCN103483708AImprove low temperature performanceImprove flame retardant performanceInsulated cablesInsulatorsParaffin waxOxygen

The invention discloses a low-temperature-resistance flame-retardant rubber cable sheath material. The material is prepared by the following steps of mixing 30 percent of chlorinated polyethylene and 10 percent of ethylene-propylene-diene monomer in an internal mixer for 3-4 minutes; adding 0.5 percent of lead monoxide, 290 percent of calcium carbonate, 0.5 percent of N-cumene-N'-phenyl p-phenylenediamine, 3 percent of antimonous oxide, 0.1 percent of magnesium oxide, 5 percent of paraffin hydrocarbon oil and 5 percent of chlorinated paraffin into the internal mixer; finally adding 1 percent of paraffin, 5 percent high-abrasion-resistance carbon black, 3 percent of precipitated silica, 5 percent of talc powder and 0.1 percent of gamma-aminopropyltriethoxysilane, and discharging a mixed sizing material from the internal mixer when the temperature is 90-100 DEG C; mixing the rolled mixed sizing material in the internal mixer, and adding 1.5 percent of dicumyl peroxide and 1.3 percent of 1,3,5-triallylisocyanuric acid when the mixing temperature is 90-120 DEG C. The material can pass a minus 40 DEG C low-temperature brittle experiment, has excellent low temperature resistance, has an oxygen index of more than 32, and is good in flame retardant performance.

Owner:JIANGSU HENGTONG POWER CABLE

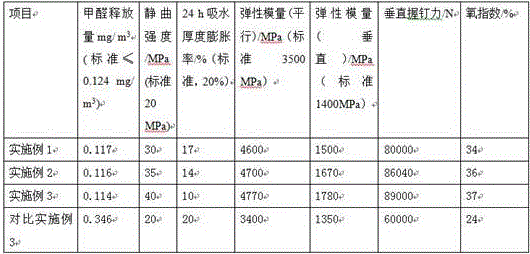

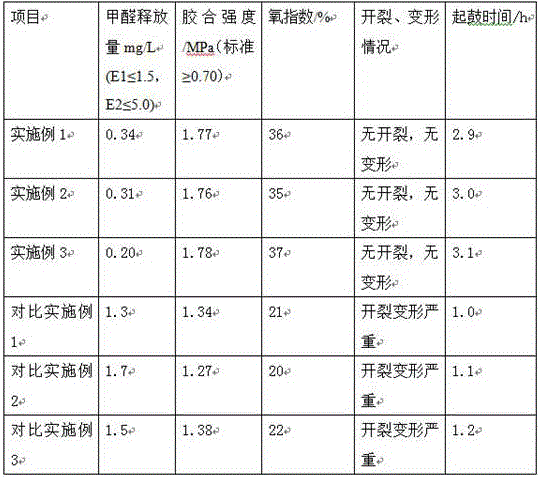

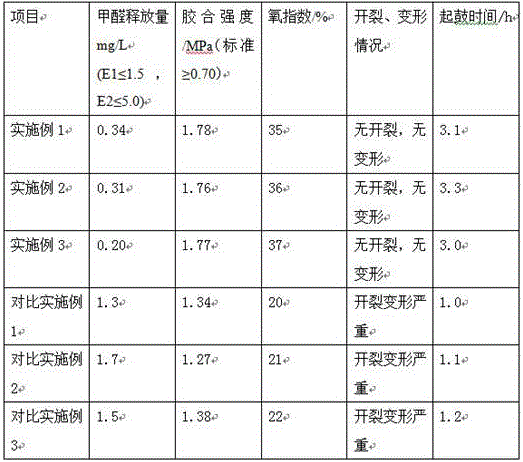

Method for producing flame-retardant oriented strand boards with full eucalyptus wood scraps

InactiveCN106182316AWhite colorGood film formingNon-macromolecular adhesive additivesStarch derivtive adhesivesScrapElastic modulus

The invention provides a method for producing flame-retardant oriented strand boards with full eucalyptus wood scraps. The method comprises the working procedures of material preparation, drying, debarking and impurity removal, sorting and storage, respective gluing on surface layers and a core layer, graded laying, preheating pressing molding, sanding and finishing, and the like, wherein the surface layers are coated with isocyanate sawdust powder compound adhesive, the core layer is coated with flame-retardant compound urea-formaldehyde resin adhesive, core layer shavings are divided to form a three-layer structure which includes a core layer middle layer, a core layer upper surface layer and a core layer lower surface layer, vertical laying is adopted for the core layer middle layer, and transverse laying is adopted for the core layer upper surface layer, the core layer lower surface layer and the surface layers. According to the oriented strand boards produced with the method, the static bending intensity in the parallel direction ranges from 30 MPa to 40 MPa, the parallel elasticity modulus ranges from 4600 MPa to 4770 MPa, the vertical elasticity modulus ranges from 1500 MPa to 1780 MPa, the thickness swelling rate of water absorption of 24 hours ranges from 10% to 17%, the vertical nail-holding power is as high as 89000 N, and the dimensional stability and reliability are good. In addition, the oriented strand boards produced with the method further have the excellent effect of flame retardance.

Owner:广西横县新威林板业有限公司

Environment-friendly bamboo charcoal plate capable of effectively adsorbing and automatically degrading formaldehyde and preparation process of bamboo charcoal plate

The invention discloses an environment-friendly bamboo charcoal plate capable of effectively adsorbing and automatically degrading formaldehyde. The environment-friendly bamboo charcoal plate comprises raw materials in percentage by mass as follows: 10%-50% of 200-mesh high-temperature bamboo particles, 15%-50% of 120-mesh low-temperature bamboo particles, 18%-19% of natural resin, 2%-3% of a composite stabilizer, 1%-2% of a density reduction agent, 2%-7% of bamboo fiber or reed fiber or carbonized bamboo powder, 1%-1.5% of nanoscale titanium dioxide powder, 1%-1.5% of a compatilizer, 0.5%-1% of light calcium carbonate, 0.5%-1% of calcium oxide, 1%-2% of PE (poly ethylene) wax serving as an outer lubricant, 1.5% of stearic acid serving as an inner lubricant, 0.5%-1% of CPE (chlorinated polyethylene), 0.5% of a dispersing agent, 0.5%-1% of a coupling agent and 0.5%-1% of a foaming agent. A preparation process comprises steps of material preparation, mixing, cooling, forming and cutting. With the adoption of the environment-friendly bamboo charcoal plate and the preparation process, the problem that bamboo charcoal cannot be automatically degraded after adsorbing formaldehyde is effectively solved, secondary pollution is avoided, and the charcoal plate has a high environmental protection property and is pollution-free, harmless and recyclable.

Owner:林文海

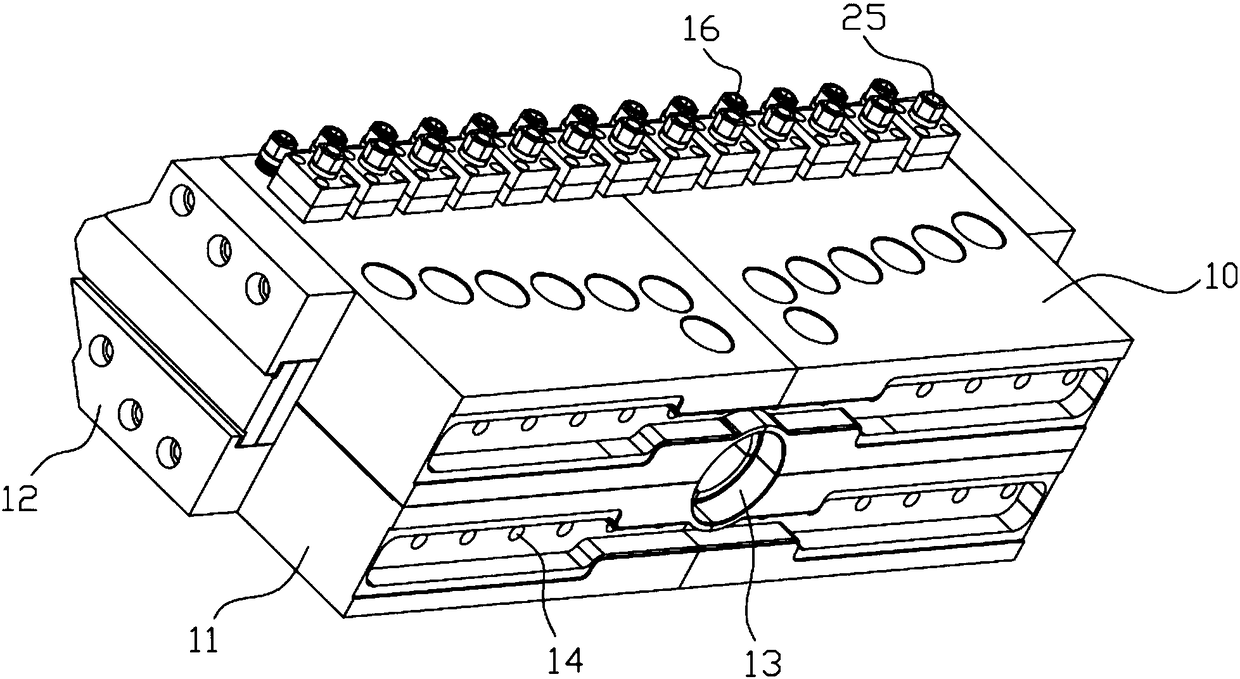

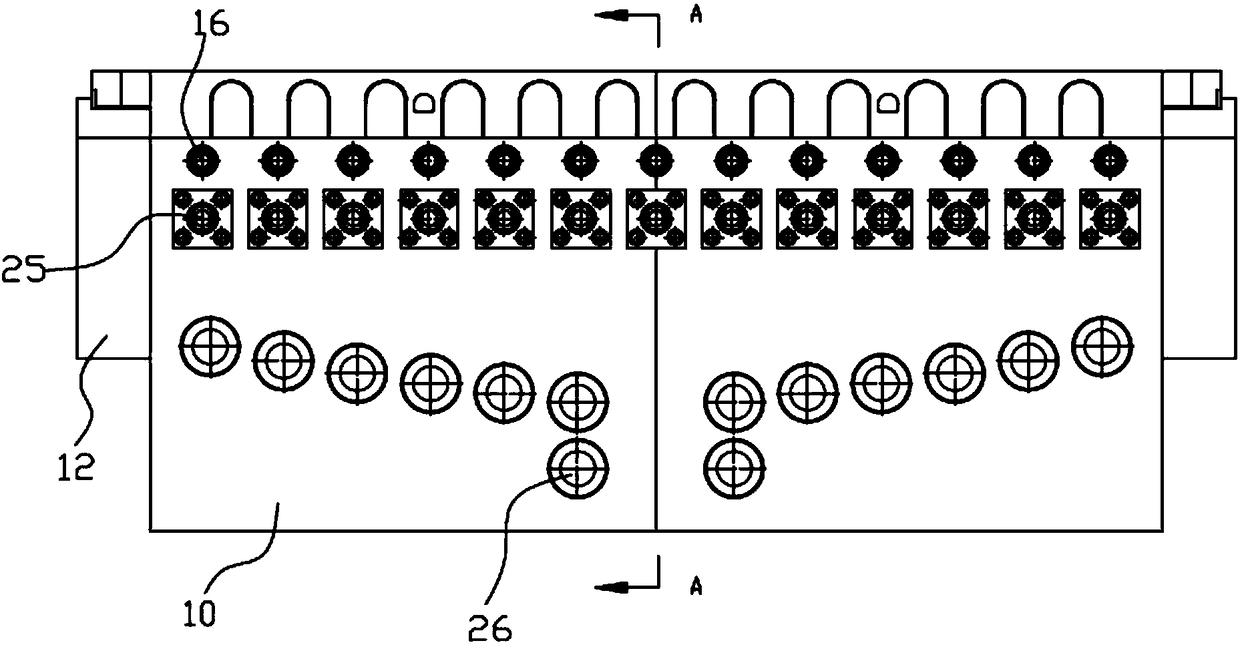

Technology for producing stone-plastic floor, and die head for producing floor substrate

ActiveCN108262932AEvenly heatedIncrease productionSynthetic resin layered productsConstructions elementsGlass fiberChlorinated polyethylene

The invention specifically relate to a technology for producing a stone-plastic floor, and a die head for producing a floor substrate, and belongs to the technical fields of extrusion molding die heads and plastic floor production. The stone-plastic floor comprises a wearing layer, a glass fiber layer and a substrate, and the substrate comprises 80 parts of PVC, 210 parts of calcium powder, 8.3 parts of a calcium and zinc stabilizer, 4.8 parts of chlorinated polyethylene, 2.3 parts of acrylate and 1.6 parts of polyethylene wax. The die head for producing the floor substrate comprises an upperdie and a lower die, one end of the die head is a feed inlet, the other end of the die head is a molding port, the upper die is provided with a movable mouth, the upper die and the lower die are locked to form an extrusion channel, the movable mouth and the lower die are locked to form a molding cavity, the extrusion channel includes a preheating section and an extruding section, the preheating section and the extruding section extend toward two sides of a die cavity, a foaming cavity and a buffering cavity are arranged in the molding cavity, the foaming cavity has a water drop shape and is close to the molding port. The die head can improve the output and the quality of the floor substrate in order to ensure that the stone-plastic floor can meet the requirements of waterproofing and environmental protection.

Owner:台州市黄岩晶威模具有限公司

Flame-retardant shoe sole material and preparation method thereof

The invention discloses a flame-retardant shoe sole material which is characterized by comprising the following components: 90-110 parts of chloroprene rubber, 40-60 parts of carbon black, 15-25 parts of dibutyl ester, 4-8 parts of antimony trioxide, 10-20 parts of chlorinated paraffin, 3-7 parts of zinc white, 1-2 parts of stearic acid, 0.5-1.5 parts of accelerator M, 1-2 parts of accelerator DM, 0.5-1.5 parts of anti-aging agent 4010, 0.5-1.5 parts of anti-aging agent RD, 0.5-1.5 parts of sulfur, 1-5 parts of magnesia and 0.6-1 part of accelerator NA-22. The preparation method comprises the following steps: plastifying, banburying, open milling, cooling, vulcanizing and the like. Various additives are added into the chloroprene rubber and treated, so that the shoe sole material can effectively retard flame when contacting an ignition source and prevent the danger due to combustion of the shoe sole.

Owner:NANJING DONGYA RUBBER & PLASTICS

Energy-saving and environment-friendly wood plastic material

The invention discloses an energy-saving and environment-friendly wood plastic material, which consists of the following raw materials by mass: 40-60 parts of polyvinyl chloride resin powder, 30-40 parts of wood powder, 20-30 parts of calcium carbonate powder, 2-3 parts of a modifier, 3-5 parts of a processing aid, 2-3 parts of a foaming agent, 1-2 parts of a stable solvent, 1-2 parts of a foaming aid, 1-1.5 parts of a lubricant, and 0.5-1 part of a colorant. The wood plastic material has the characteristics of moisture protection, waterproofness, insect prevention, termite prevention, low carbon and energy saving, the product does not contain benzene, has a formaldehyde content of 0.2, which is lower than the EO level standard and meets the European grading standard, can realize recycling, greatly saves wood usage, is suitable for the national policy of sustainable development, and benefits the society. The whole production process does not generate industrial waste gas and waste water, is low in noise, and is in line with various national industrial production environmental protection requirements, thus being suitable for large-scale promotion and application.

Owner:高智慧

Class D fire extinguishing agent and preparation method thereof

ActiveCN104511127APut out the fireAchieve flame retardant catalytic fire extinguishing effectFire extinguisherChlorideSilicone oil

A class D fire extinguishing agent is prepared by using the following components, by mass, 68-74% of sodium chloride, 5-8% of talcum powder, 7-10% of halogen-free flame retardant powder, 4.2-6% of white carbon black, 7-10% of calcium chloride, 1.2-1.7% of silicone oil and 0.3-0.7% of magnesium powder. A preparation method of the class D fire extinguishing agent comprises the following steps: respectively crushing sodium chloride, talcum powder, the halogen-free flame retardant powder, white carbon black and calcium chloride to form powders; and dehydrating sodium chloride, drying, mixing the dried sodium chloride with the talcum powder, the halogen-free flame retardant powder, the white carbon black and calcium chloride, and fully and uniformly mixing at a certain temperature, baking, adding the silicone oil, continuously baking, uniformly mixing, adding the magnesium powder, and uniformly stirring to prepare the finished extinguishing agent. In the invention, the above sodium salt is adopted as a main material, a small amount of the flame retardant is added, and the flame retardant, a catalyst and a metal substance in the sodium salt are effectively introduced and are finally effectively combined in order to effectively extinguish class D metal alkyl substance fires.

Owner:ZHEJIANG YUAN FIRE FIGHTING EQUIP

Method for producing full-eucalyptus plywood with flame-retardant composite urea-formaldehyde resin

InactiveCN106346568AWhite colorGood film formingNon-macromolecular adhesive additivesStarch derivtive adhesivesScavengerAdditive ingredient

The invention relates to a method for producing full-eucalyptus plywood with flame-retardant composite urea-formaldehyde resin, comprising the steps of wood board peeling->veneer drying -> gluing -> three times of cold pressing -> standing for curing->three times of hot pressing ->heat dissipation for curing->slab calibrating and sanding. The method is characterized in that the melamine modified urea-formaldehyde resin is used as the main ingredient in the adhesive; the oxidized starch as adhesive compound, the polyving akohol as toughening agent, the hydrogenated rosin as antioxidant, the polyisocyanate as curing agent, i-butyltriethoxanesilane as bridging agent, phenolic lignin as formaldehyde scavenger and flame retardant agent are added together to produce the flame-retardant composite urea-formaldehyde resin. The flame-retardant composite urea-formaldehyde resin has such advantages as littleformaldehyde residue, perfect flame resistance and lowering combustion temperature by internal endothermic reaction so that the full-eucalyptus parquet contains little formaldehyde residue and has good flame-retardant effectin case of fire disasters.

Owner:南宁市创锦胶合板有限责任公司

Method for producing full-eucalyptus parquet with flame-retardant composite urea-formaldehyde resin

InactiveCN106346584AReduce formaldehyde contentGood gluing propertiesNon-macromolecular adhesive additivesLaminationScavengerToughening

The invention relates to a method for producing full-eucalyptus parquet with flame-retardant composite urea-formaldehyde resin, comprising the steps of wood board peeling->veneer drying -> gluing -> three times of cold pressing -> standing for curing->three times of hot pressing ->heat dissipation for curing->slab calibrating and sanding-> substrate surface gluing -> curing and slotting-> leaching paint, drying and shaping. The method is characterized in that the melamine modified urea-formaldehyde resin is used as the main ingredient in the adhesive; the oxidized starch as adhesive compound, the polyving akohol as toughening agent, the hydrogenated rosin as antioxidant, the polyisocyanate as curing agent, i-butyltriethoxanesilane as bridging agent, phenolic lignin as formaldehyde scavenger and flame retardant agent are added together to produce the flame-retardant composite urea-formaldehyde resin. The flame-retardant composite urea-formaldehyde resin has such advantages as little formaldehyde residue, perfect flame resistance and lowering combustion temperature by internal endothermic reaction so that the full-eucalyptus parquet contains little formaldehyde residue and has good flame-retardant effect in case of fire disasters.

Owner:南宁市林润木业有限公司

High-strength cable material and preparation method thereof

InactiveCN107083046AIncrease elasticityGood physical propertiesPlastic/resin/waxes insulatorsButadiene-styrene rubberCircuit breaker

The invention discloses a high-strength cable material, belonging to the technical field of breaker materials. The high-strength cable material is prepared from the following raw materials in parts by weight: 70-90 parts of thermoplastic polyurethane, 8-11 parts of butadiene styrene rubber, 4-6 parts of carbon black, 40-50 parts of calcium carbonate, 15-25 parts of vinyl acetate ethylene, 3-5 parts of cyanoacrylate, 12-14 parts of glass fibers, 2-4 parts of epoxidized soybean oil, 20-30 parts of a plasticizer, 0.5-2 parts of a crosslinking agent and 0.2-0.8 part of a light stabilizer. The invention further discloses a preparation method of the high-strength cable material. The cable material has high strength and relatively good physical properties.

Owner:山东励仙电力工程有限公司

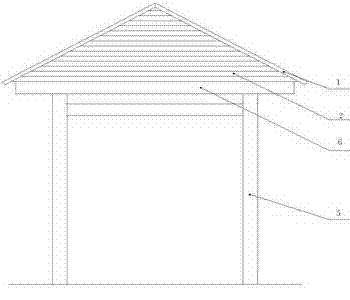

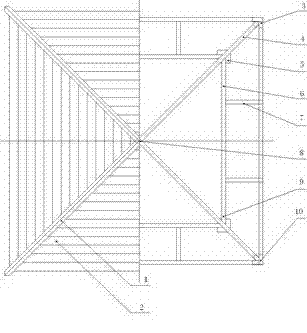

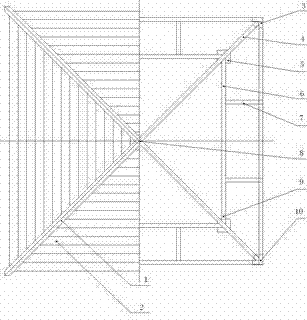

Method for building pavilion by plastic wood profiles instead of wooden materials

InactiveCN102382482AImprove fire performanceNo repairs and maintenance requiredSmall buildingsBuilding materialStructural engineering

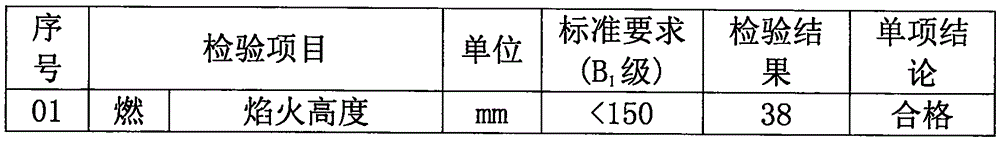

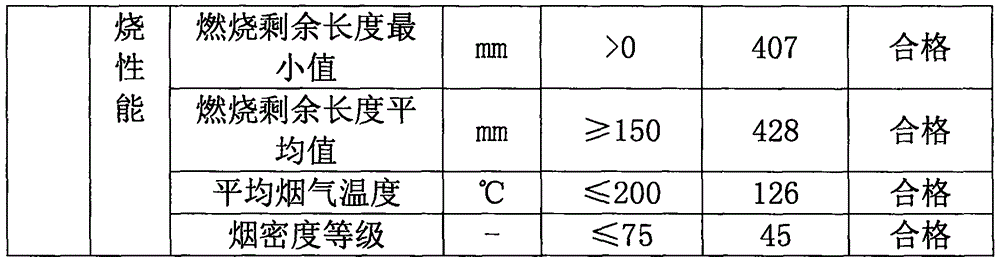

The invention provides a method for building a pavilion by plastic wood profiles instead of wooden materials, which includes steps of manufacturing pre-formed components of the pavilion by plastic wood materials, making supporting parts of bases of vertical columns by square steel, reinforcing inclined beams and crossbeams by three-beam connectors, and reinforcing the crossbeams to form the pavilion by wrap-angle parts. PE (polyethylene) particles and wood shavings are extruded to manufacture profiles of a plastic-wood pavilion after being heated and mixed, the plastic-wood pavilion is high in fireproof performance and effective in flame retarding, the fire rating can reach the B1 level, fire on the plastic-wood pavilion is extinguished automatically, and no poisonous gas is produced. The pavilion cannot crack, cannot be expanded and deformed and is free of maintenance and repair and easy to be cleaned, and accordingly, cost for post maintenance and repair is saved and a great quantity of wood is saved as well. Construction and mounting are simple, short in time and low in labor cost since the pre-formed components are used for building pavilions.

Owner:ZONBONG LANDSCAPE

Process for preparing rubber cable sheath material

ActiveCN103483707AImprove low temperature performanceImprove flame retardant performanceInsulated cablesInsulatorsParaffin waxOxygen

Owner:JIANGSU HENGTONG POWER CABLE

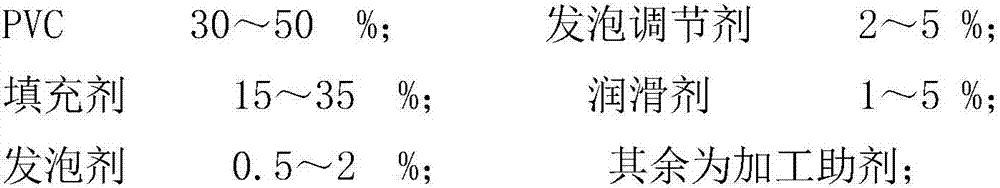

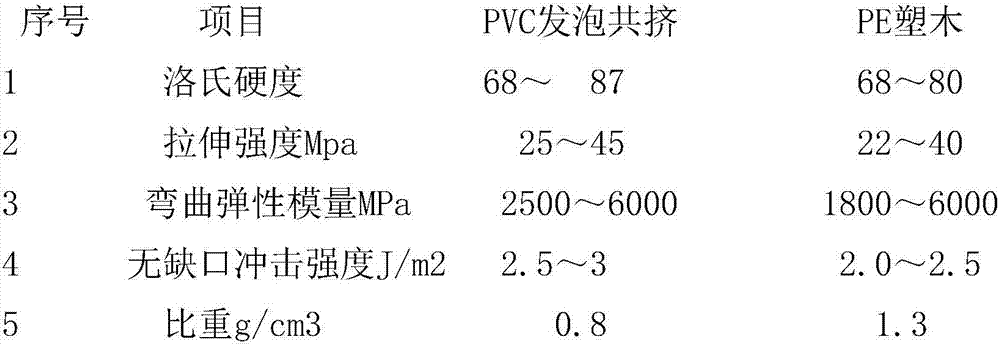

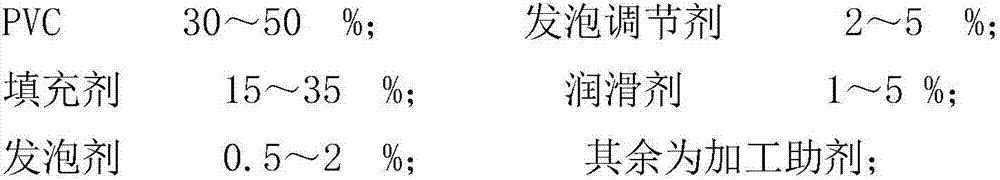

PVC foamed co-extruded floor preparation process

The invention provides a PVC foamed co-extruded floor preparation process, and relates to the technical field of production of plastics-wood materials. The floor preparation process mainly comprises the following steps: material mixing, extrusion foaming, co-extrusion and cooling and shaping production. In the material mixing process, 30-50% of PVC, 2-5% of foaming modifiers, 15-35% of filling agents, 1-5% of lubricating agents, 0.5-2% of foaming agents and processing agents are needed, wherein the percentage sum of all the components is 100%. In the material foaming process, high polymer materials cover foamed base materials through a co-extruder. The floor preparation process has the advantages that the water resistance and moisture resistance are achieved, the problem that the wood product is easy to rot and expand after absorbing water and being affected with the damp in a humid and moist environment is fundamentally solved, the plasticity is high, the personalized modeling can be realized very easily, the individual style is fully embodied, cracking is avoided, expansion is avoided, deformation is avoided, repair and maintenance are not needed, cleaning is facilitated, and later repair and maintenance cost is saved.

Owner:ANHUI SENTAI WPC GRP CO LTD

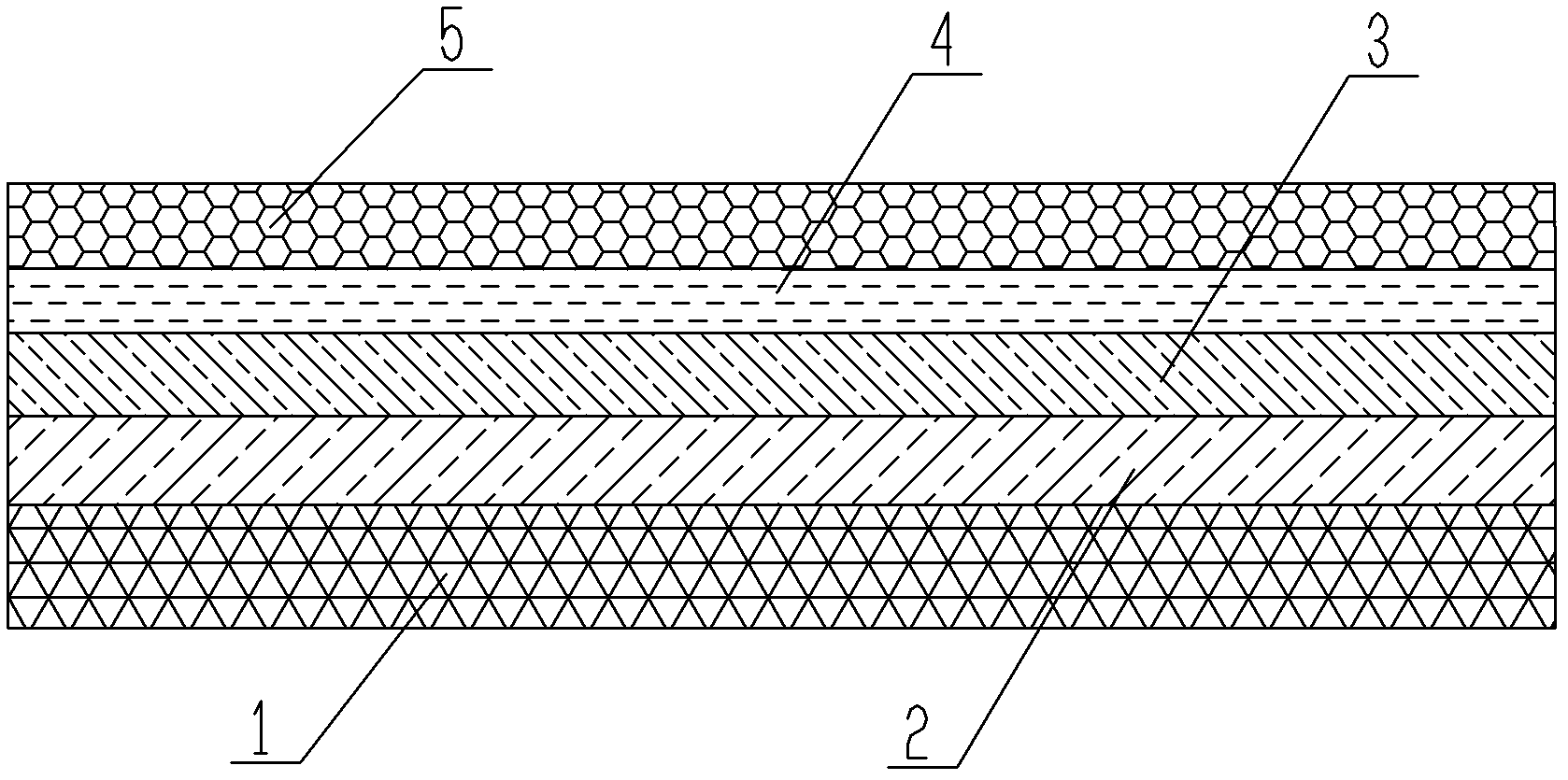

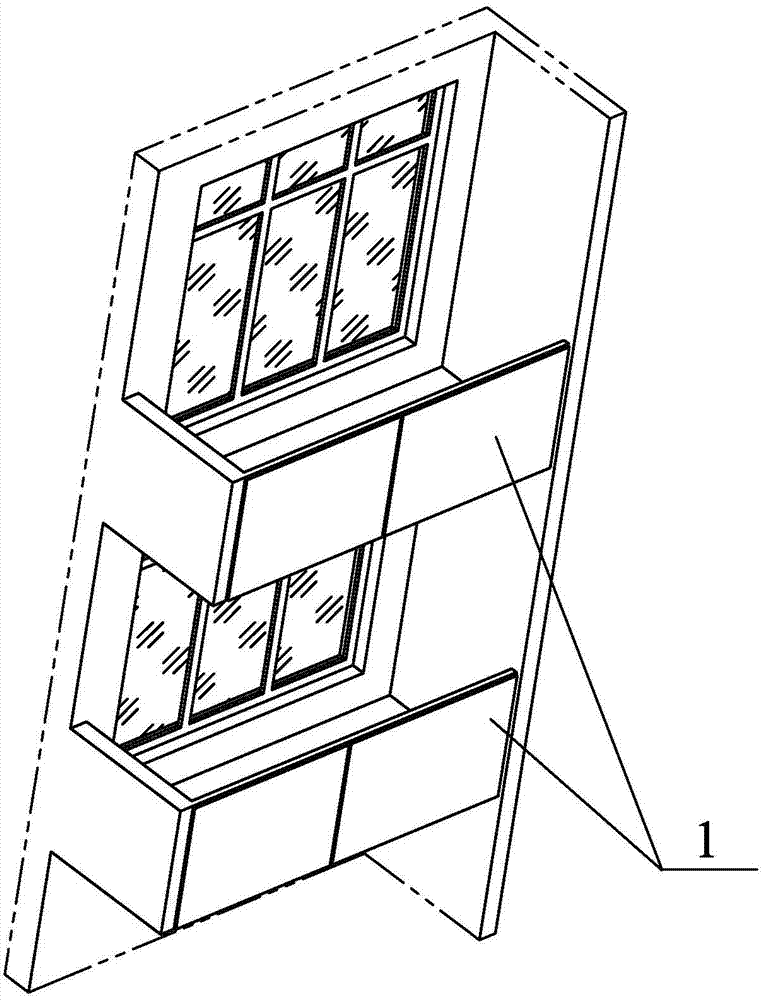

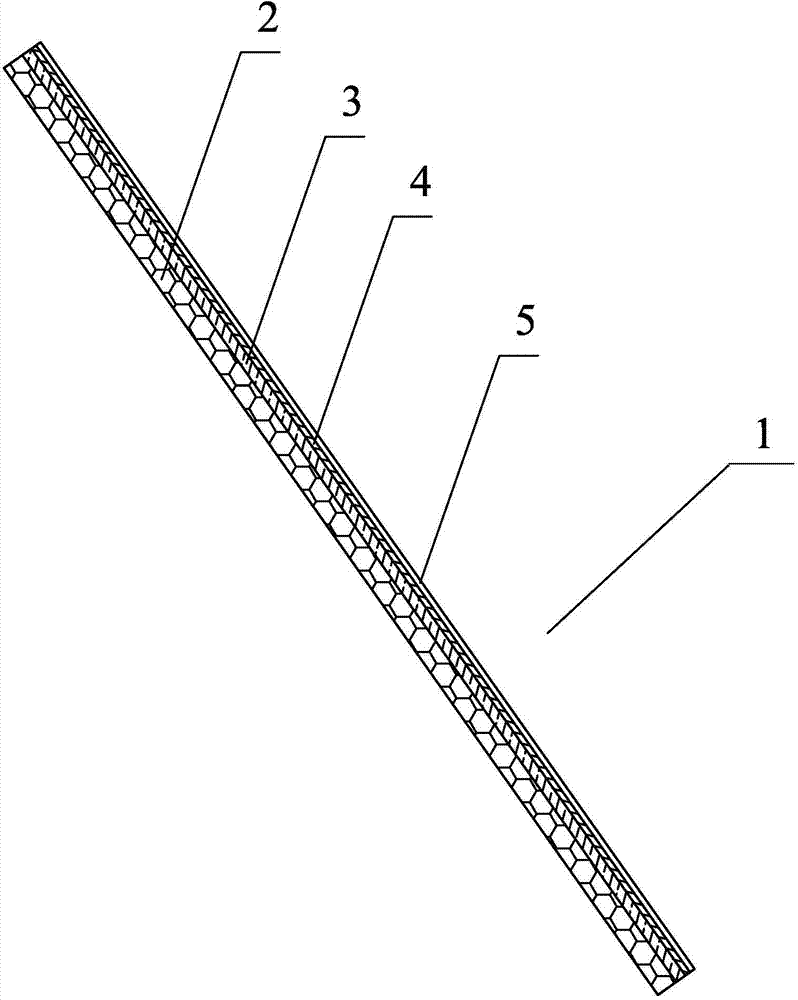

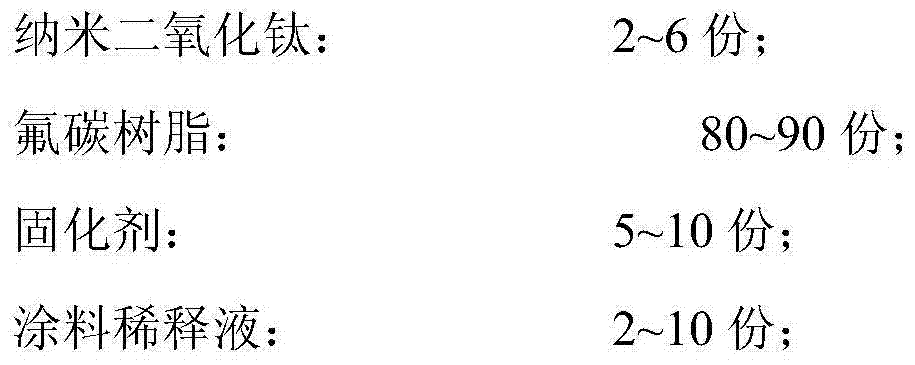

Balcony embedded photovoltaic power generation system and manufacturing method thereof

ActiveCN103944497ANo maintenanceEasy to cleanPhotovoltaic supportsPolyurea/polyurethane coatingsEngineeringBattery pack

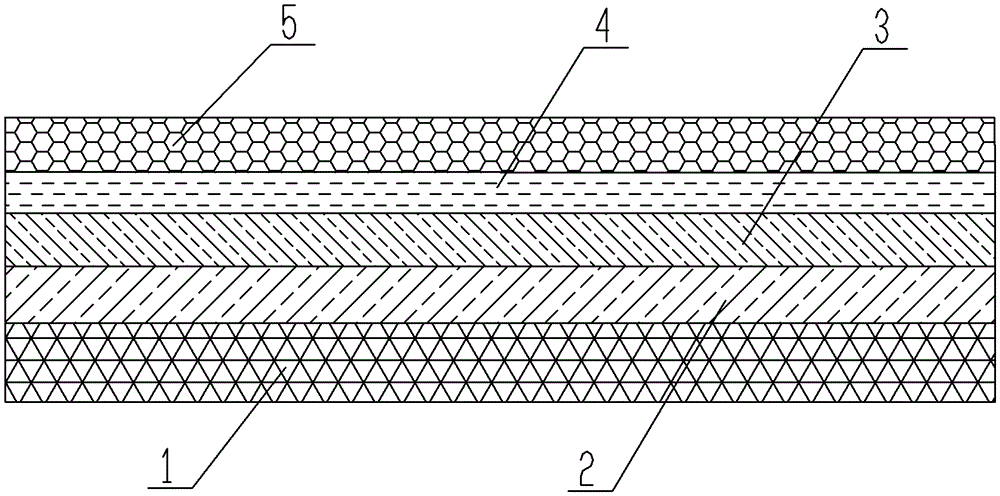

The invention discloses a balcony embedded photovoltaic power generation system which comprises a balcony frame and a guard bar plate (1) fixed to the balcony frame. The guard bar plate (1) is of a layer structure and sequentially comprises a base plate (2), a flexible thin-film battery pack (3) a film layer (4) and a coating layer (5) from interior to exterior, wherein the four layers are fixed into an integral structure, and the base plate (2) is a wood plastic plate and is made of wood plastic composite materials. According to the balcony embedded photovoltaic power generation system, the guard bar plate is directly combined and embedded into the balcony rail frame and plays a role of a balcony coaming, and the aim of photovoltaic power generation through a balcony of a building is achieved.

Owner:深圳老玩童网络有限公司

Composite insulating brick

InactiveCN103967194ALight in massLow thermal conductivityConstruction materialProduction lineAdhesion force

The invention discloses a composite insulating brick. The insulating brick comprises an insulating core layer and a fireproof insulating mortar layer covering an outer layer of the insulating core layer. During production and manufacture, the conventional insulating core layer is mixed, burdened, pressed and molded, and the fireproof insulating mortar layer is prefabricated, compounded and molded on a production line of the insulating core layer. The defects in the prior art are overcome, effective flame retardance can be effectively realized, the material is light in weight, low in heat-conducting property and low in water absorption rate, the adhesive force between the brick and the wall surface and adhesion force between the brick and the surface decoration layer are improved, the tensile strength meets the exterior wall decoration requirement, and the process is simple and convenient to control.

Owner:潜山市新型工程建筑材料有限公司

Wood-plastic floor

The invention belongs to the technical field of floors and particularly relates to a wood-plastic floor. The wood-plastic floor is prepared from, by weight, 80-100 parts of PVC, 60-100 parts of wood materials, 20-40 parts of light calcium carbonate, 1-2 parts of a foaming agent, 4.5-5.5 parts of a stabilizer, 2.5-3.5 parts of a lubricant, 5-8 parts of chlorinated polyethylene, 0.5-2 parts of a plasticizer, 0.5-1.5 parts of a compatibilizer and 1-1.5 parts of an antioxidant, wherein the wood materials comprise rice husk meal and wood meal. The wood-plastic floor is safe, environmentally friendly, good in performance and not prone to deformation. According to the wood-plastic floor, waste materials are effectively utilized, so that resources are saved, and production cost is reduced.

Owner:TIANJIN QI AO SCI & TECH DEV

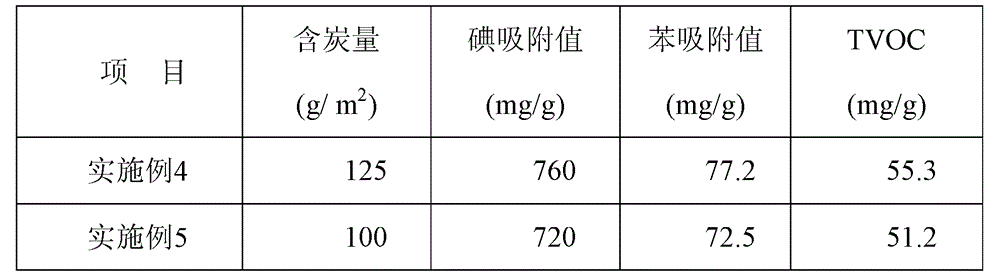

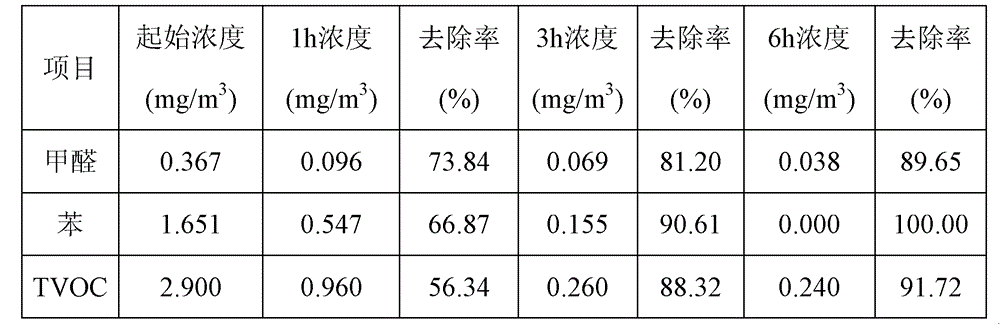

A kind of flame-retardant activated carbon cloth and preparation method thereof

ActiveCN102529254BSimple processProcess environmental protectionSynthetic resin layered productsWater basedEnvironmental resistance

The invention relates to a flame-retardant activated carbon fabric and a preparation method thereof. The flame-retardant activated carbon fabric is characterized in that an activated carbon layer, a water-based adhesive film layer and a hot-melt adhesive powder particle layer are sequentially covered on a base material which is subjected to flame-retardant treatment. The preparation method comprises the following steps of: spraying or padding the base material with an environment-friendly water-based flame retardant and drying; serially coating a prepared activated carbon paste and a water-based flame-retardant hot-melt adhesive powder particle paste on the base material, and drying to obtain the final product of flame-retardant activated carbon fabric. During the drying process, the water-based adhesive film layer is formed between the carbon layer and the hot-melt adhesive powder particle layer. The preparation method of the flame-retardant activated carbon fabric is simple and environment-friendly, and the product has good flame retardant property. Owing to the good adsorption property of activated carbon, the fabric can remove formaldehyde, benzene, TVOC and other harmful gases in the air. When the fabric is used, the fabric can be cut freely and laminated thermally. The flame-retardant activated carbon fabric is easy and convenient to use and has a wide application range.

Owner:WUXI DINGHAO NEW MATERIAL SCI RES

Brominated and epoxidized flame retardants

Brominated and epoxidized organic compounds are useful flame retardants for polymers such as polystyrene. The organic compounds contain both bromine and oxirane groups, and have molecular weights of at least 1500. The brominated and epoxidized organic compounds can be prepared by sequentially brominating and epoxiding (in either order) a starting compound that contains multiple non-conjugated carbon-carbon double bonds.

Owner:DOW GLOBAL TECH LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com