Grease removal apparatus, systems and methods

A filter assembly and manufacturing method technology, applied in membrane filters, chemical instruments and methods, separation methods, etc., can solve the problems of insufficient baffles to remove grease, poor effect, etc., to achieve protection and cleanliness and avoid burning damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

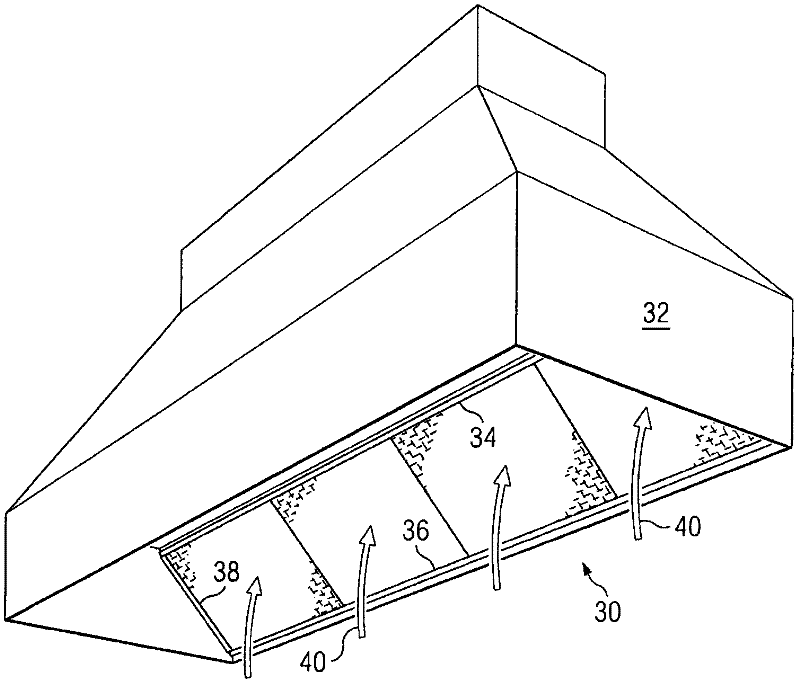

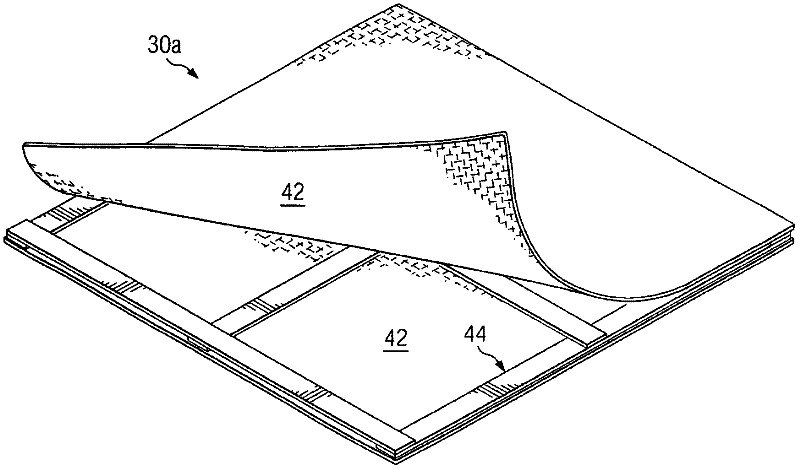

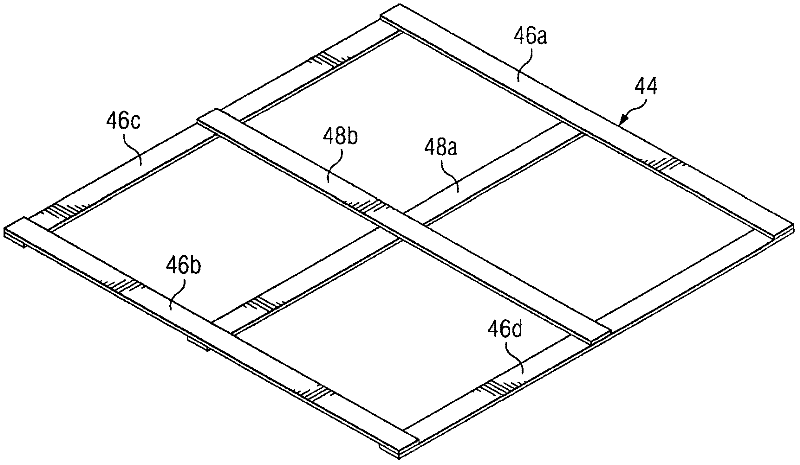

[0034] The present invention relates to grease removal equipment, systems and methods. Particular embodiments of the present invention include a filter assembly, which may be referred to herein as a replaceable grease removal device ("DGRD"), and may be used, for example, in a cooking room exhaust system. In particular embodiments, the DGRD may be formed of materials such that it is substantially "self-supporting," ie, it does not require a metal filter support frame, frame cover, or heat shield. DGRDs can be formed from various materials and in various ways, making them recyclable or disposable. In these embodiments, the DGRD may be conveniently mounted within the hood by simply sliding the DGRD into place on a bracket or by some other similar fastening means or support system within the hood.

[0035] Figure 1-3 DGRD 30 of a particular embodiment is shown in more detail. DGRD 30 is mounted within exhaust hood 32 . Exhaust hood 32 is constructed and arranged so that air ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com