Patents

Literature

1118 results about "Excess heat" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

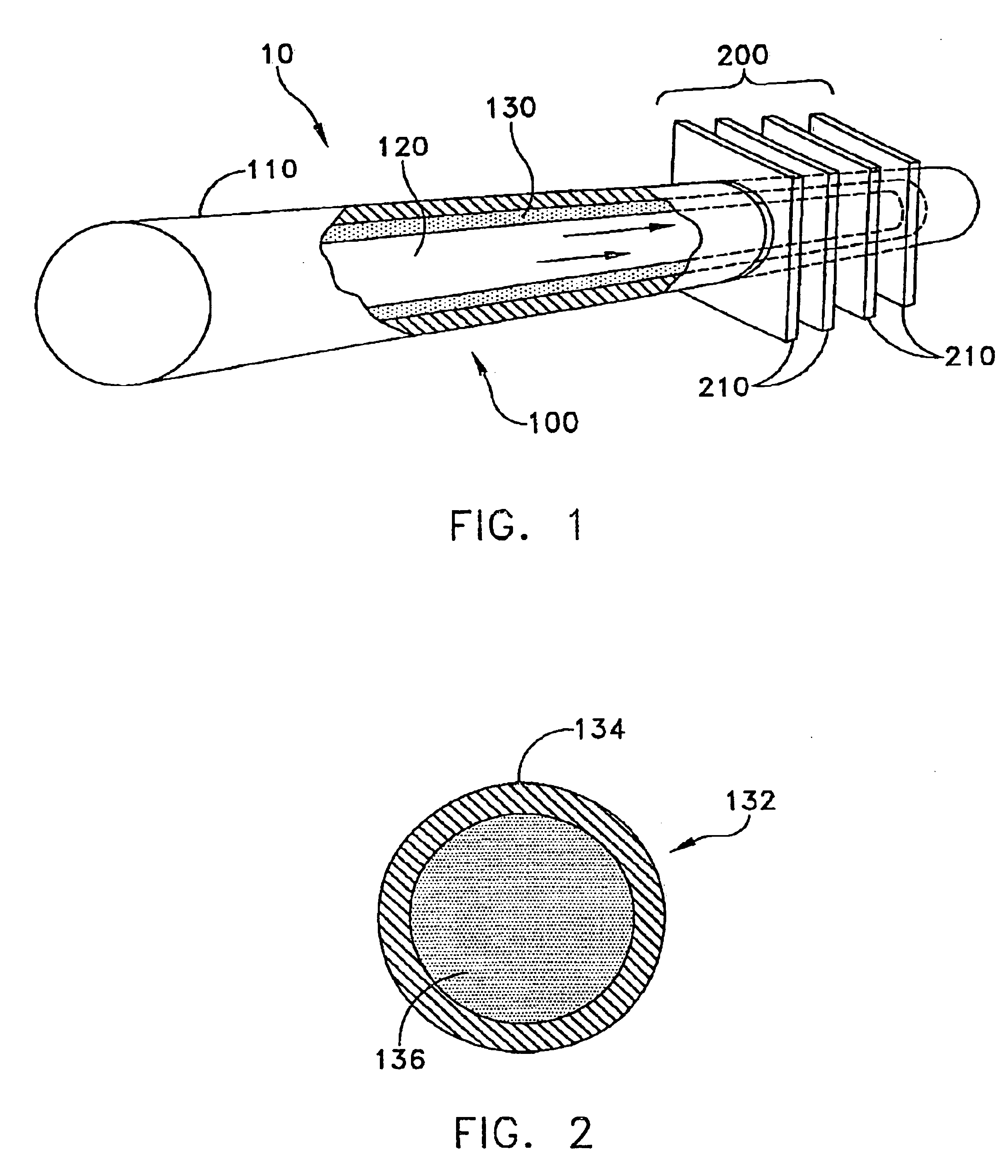

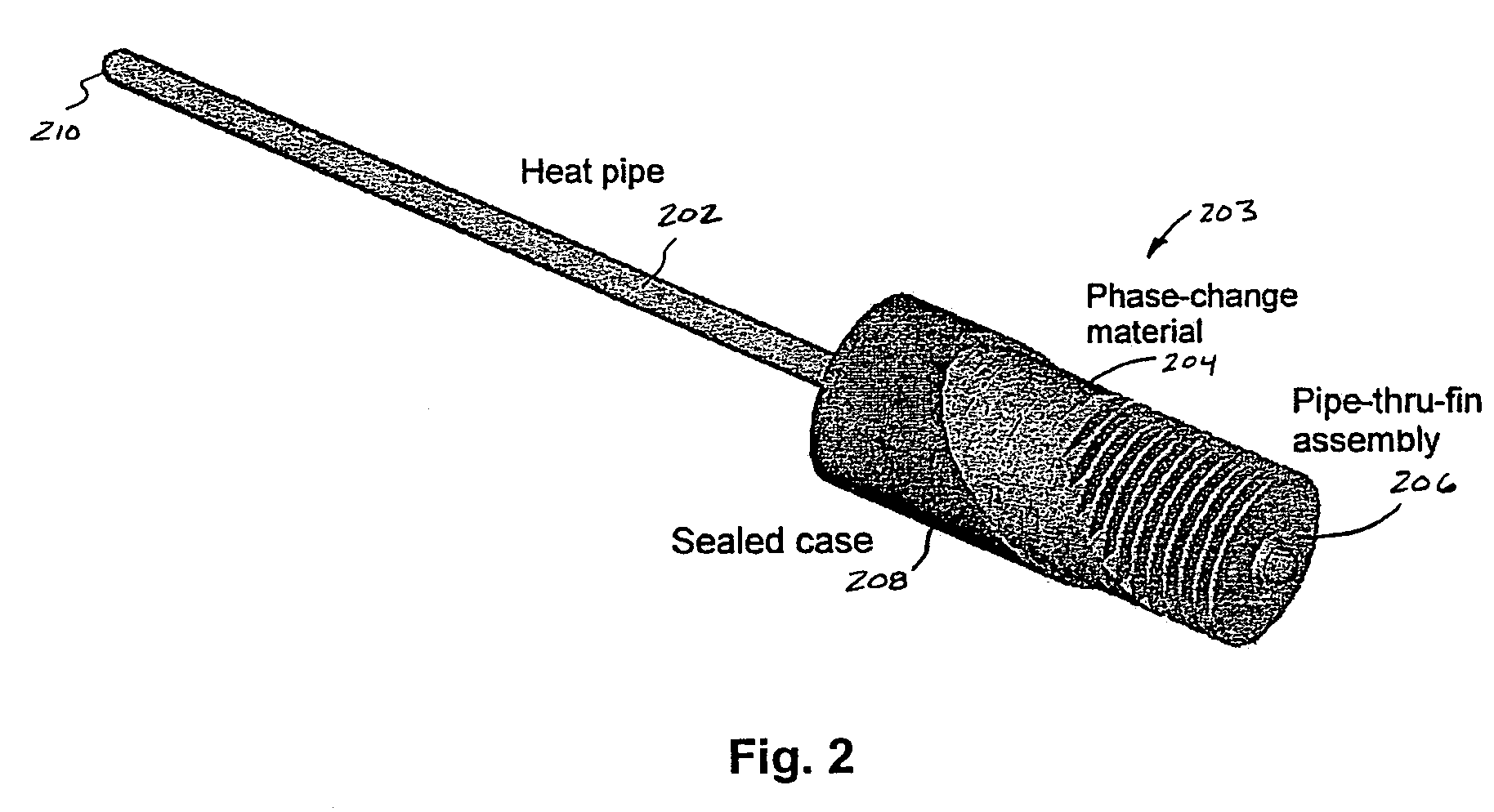

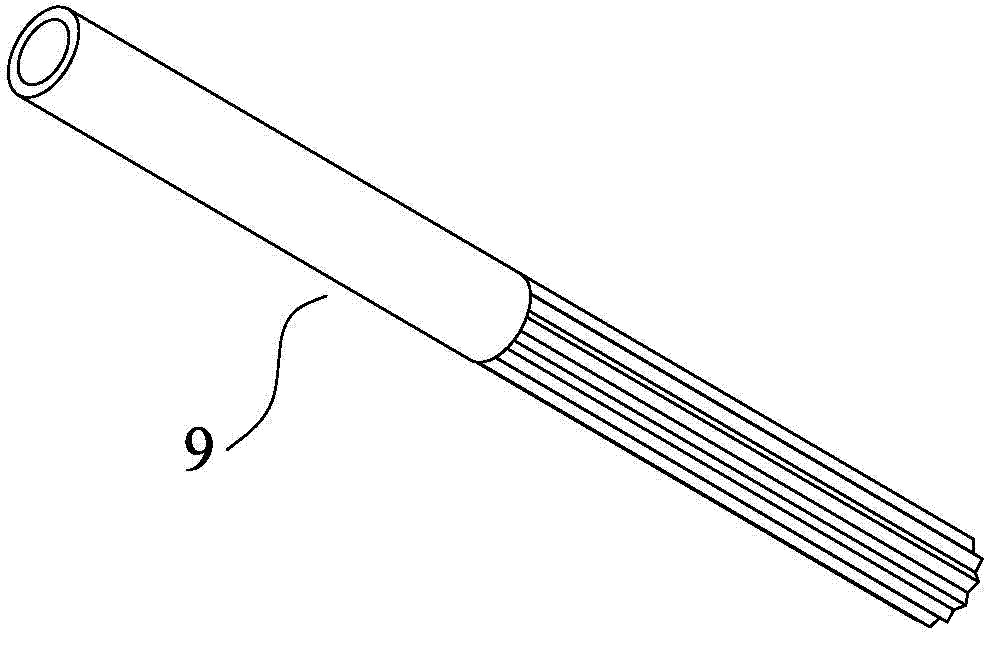

Heat pipe having a wick structure containing phase change materials

InactiveUS6889755B2Heat storage plantsSemiconductor/solid-state device detailsEngineeringPhase change

A wick for use in a heat pipe is provided incorporating particles of micro-encapsulated phase change material bonded together to form the wick. Use of a wick structure comprising micro-encapsulated PCM particles has the advantage of providing an additional heat absorber. This greatly enhances the ability of the heat pipe to absorb excess heat and may help to prevent damage to the heat pipe or heat generating component, such as an electronic device, especially at times of peak thermal loads.

Owner:THERMAL

Methods for integrated circuit module packaging and integrated circuit module packages

ActiveUS7445968B2Impedence networksSemiconductor/solid-state device detailsThermal isolationComputer module

Owner:SKYWORKS SOLUTIONS INC

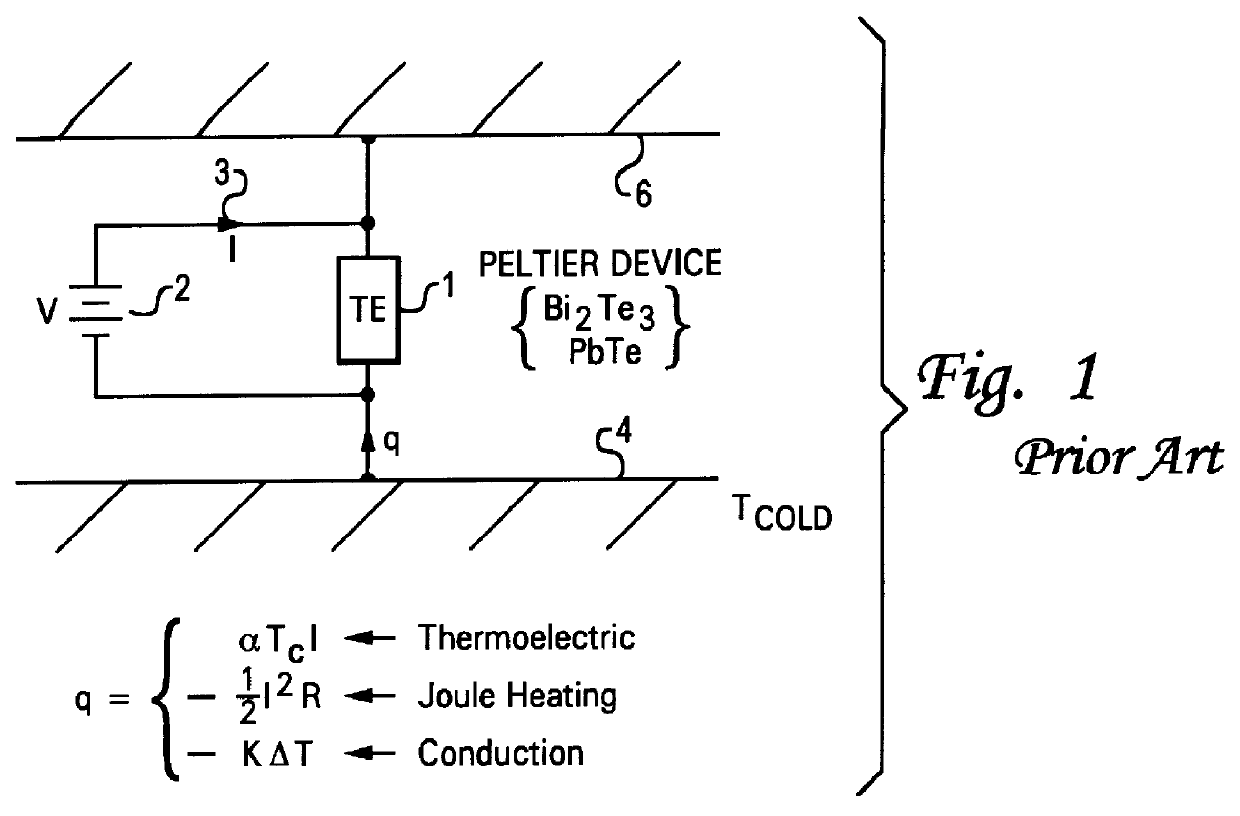

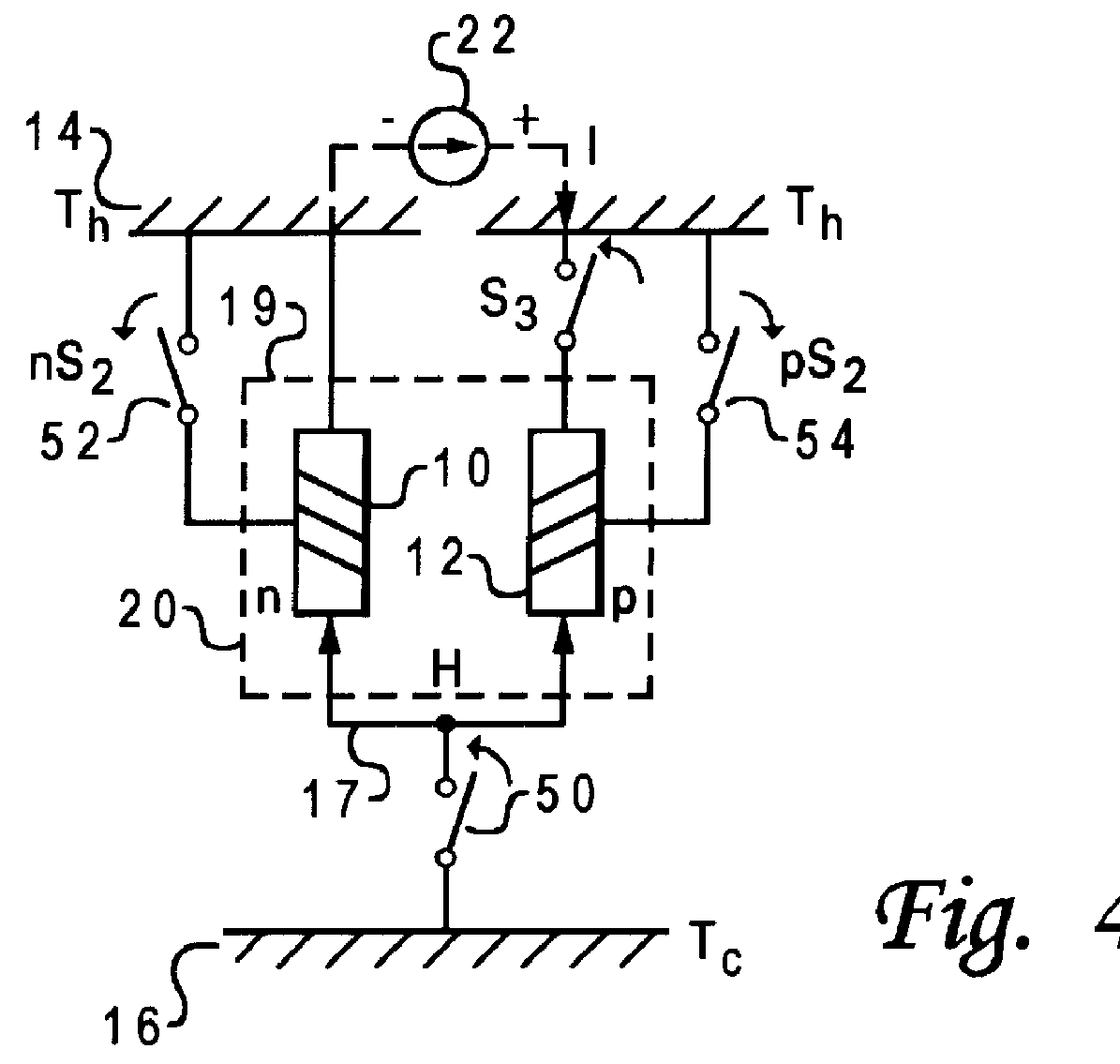

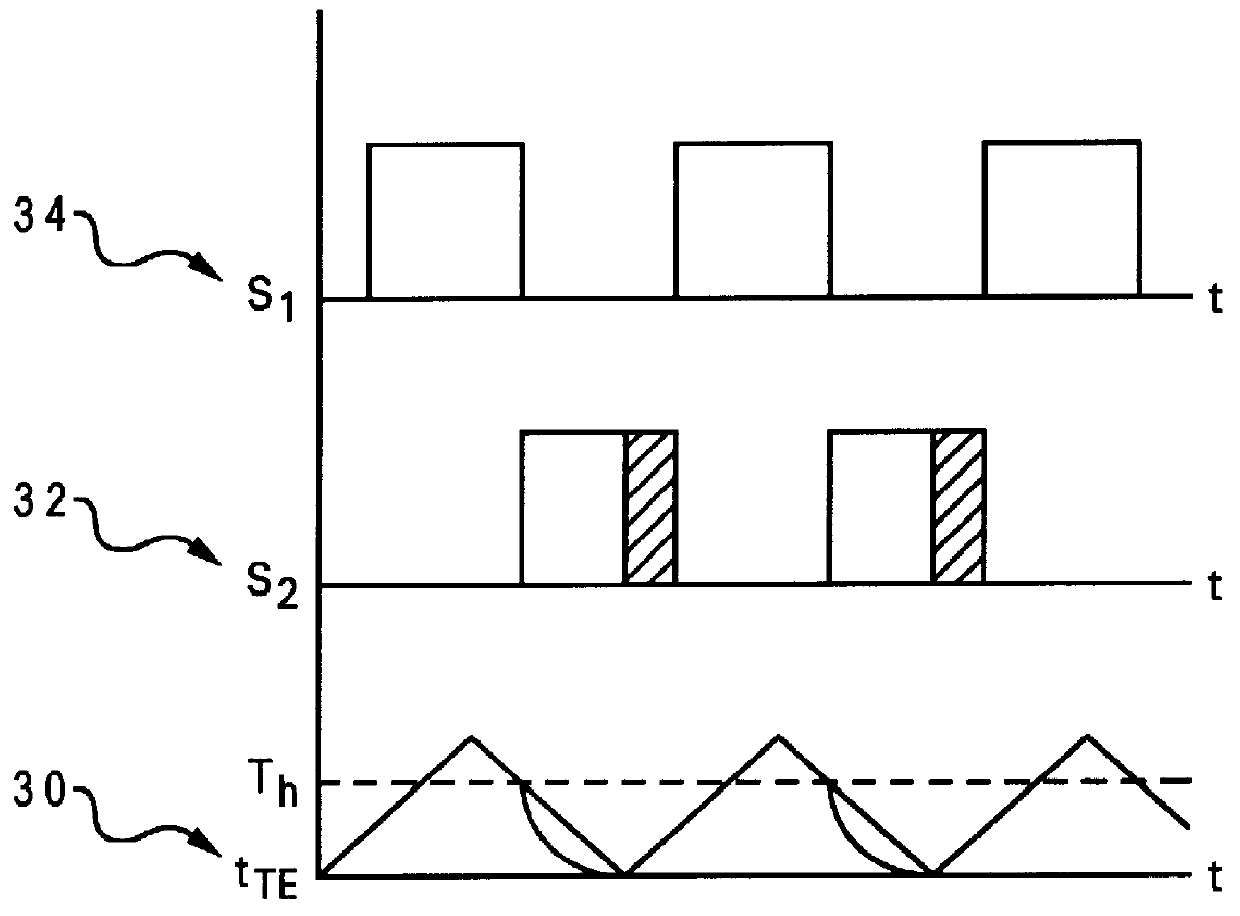

Enhanced duty cycle design for micro thermoelectromechanical coolers

InactiveUS6161388AMachines using electric/magnetic effectsThermoelectric devicesThermoelectric coolingEngineering

A thermoelectric cooling apparatus which includes a Peltier device or a thermoelectric element coupled to a hot source and a cold sink. The hot source dissipates heat produced by the thermoelectric element. The cold sink is coupled to a mass to be cooled. A means for supplying power to the thermoelectric element is provided and a means for selectively thermally coupling the thermoelectric element to the hot source is provided. Selectively thermally switching the thermoelectric element to the hot source allows heat to be dissipated to the hot source when the thermoelectric element possesses excess heat. Dissipating the excess heat when the excess heat is present allows higher efficiencies to be attained in thermoelectric cooling.

Owner:IBM CORP

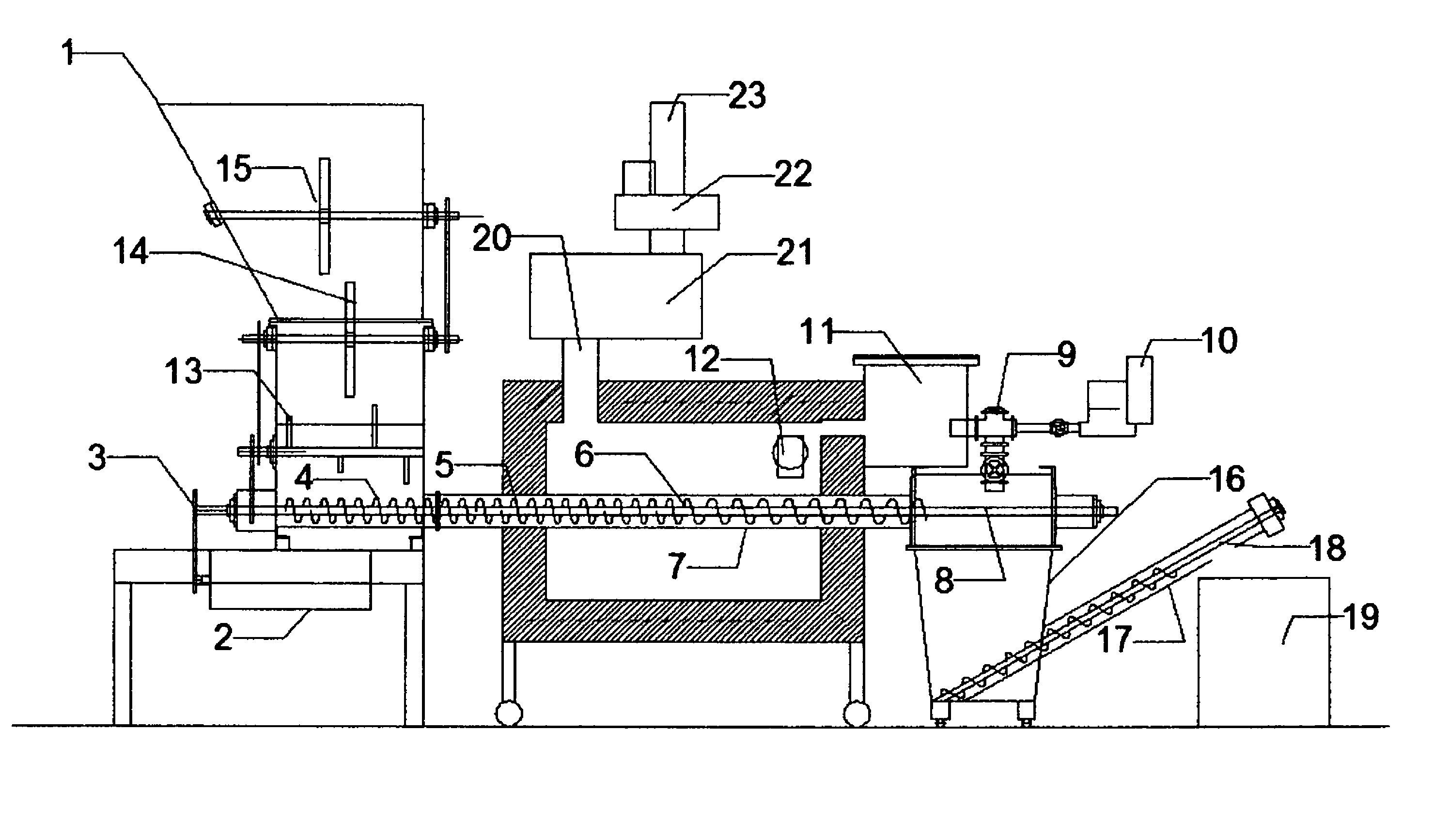

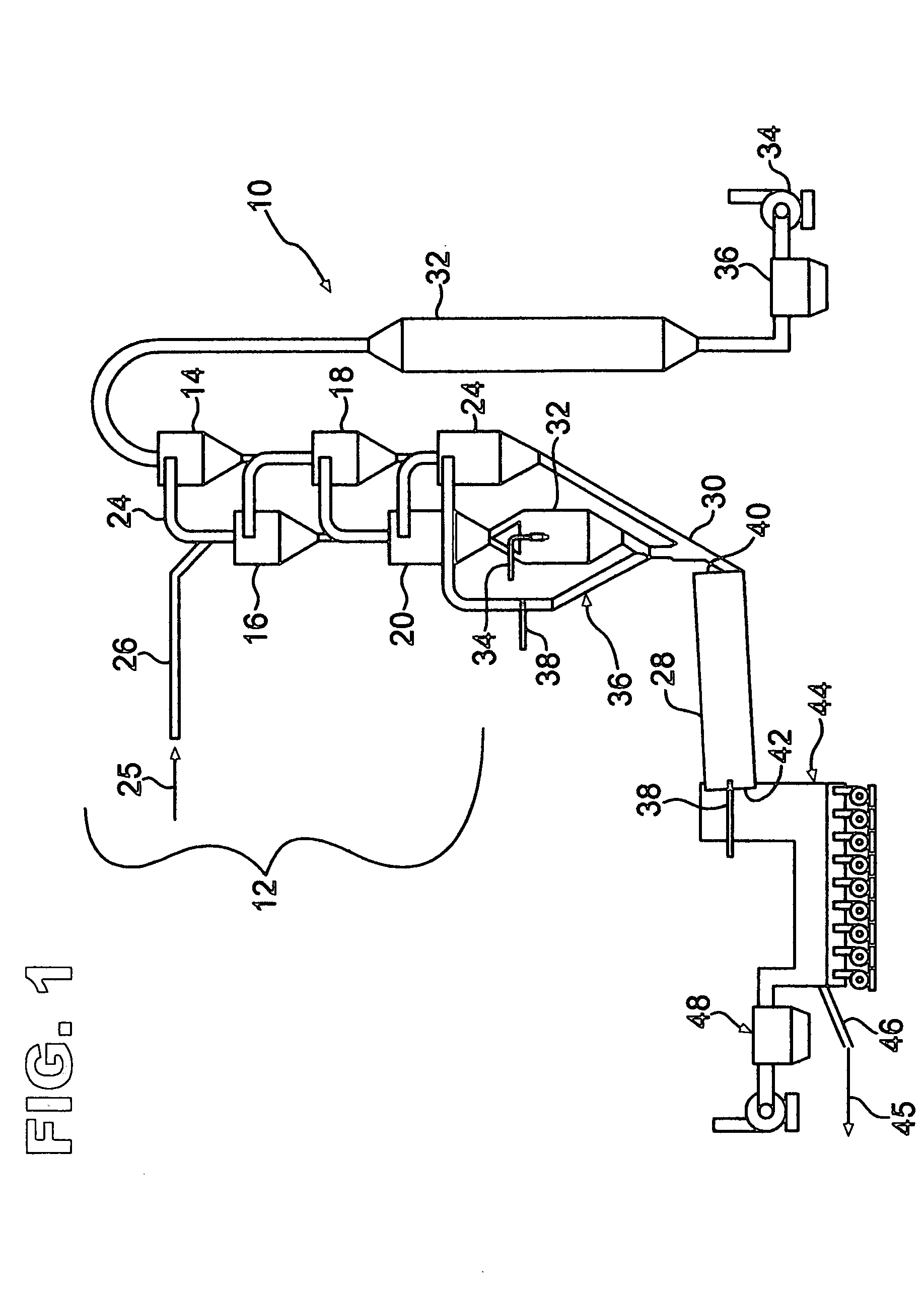

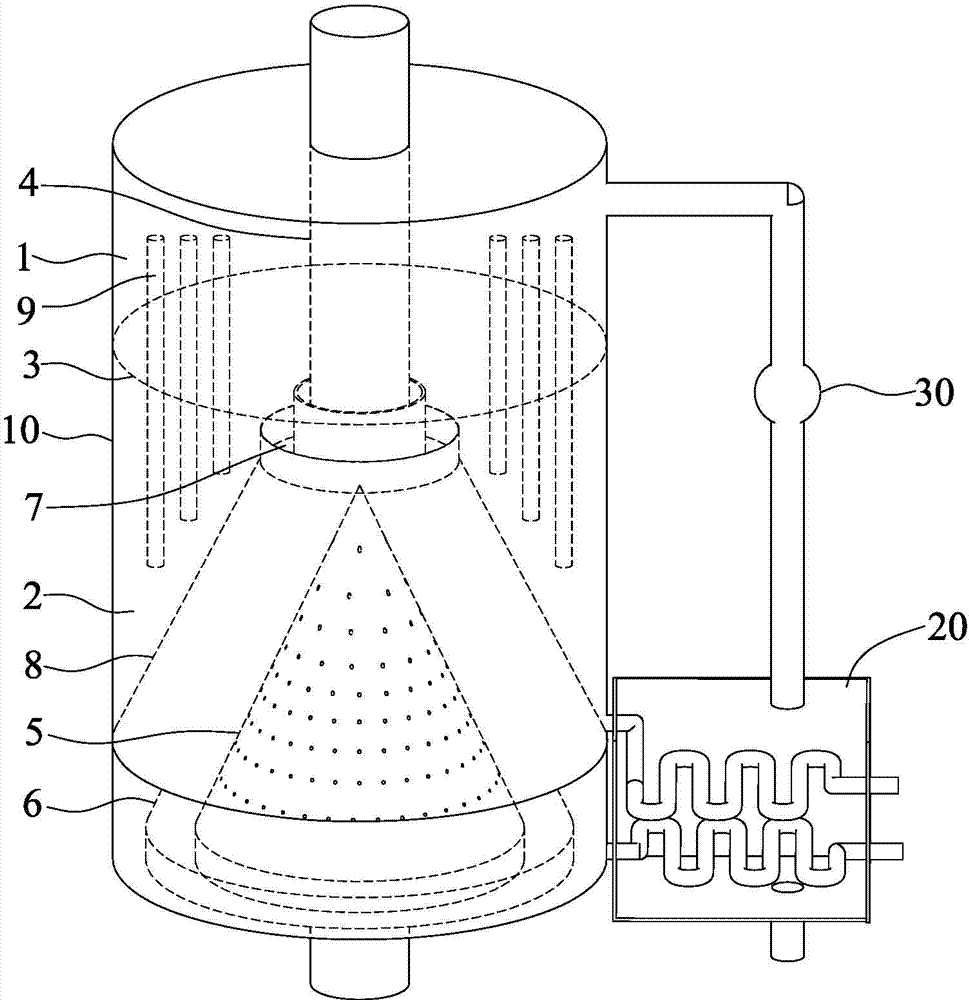

Process and device for the pyrolysis of feedstock

InactiveUS7947155B1Thermal non-catalytic crackingCombustible gas coke oven heatingVolatilesEngineering

This invention involves pyrolysis of feedstock by introducing carbonaceous feedstock, into a hopper and moving it into a reactor tube enclosed in an oven, generating heat within the oven that is in part transferred to the feedstock, heating it to sufficient temperature to pyrolyze the feedstock into useful volatiles and char. A Venturi system produces a negative pressure directing volatiles into a pyro-gas oven producing heat necessary for pyrolysis and generating useful excess heat. The extruded pyrolysis char has uses including charcoal fuel, soil amendments, and activated charcoal while liquids can be produced for processing into fuels. Excess heat may be used to heat water, steam, and air, may be used in air heating and cooling systems, perform mechanical work with a Stirling engine or generate electricity on the order of 100 kW and higher. The system may be operated in a carbon neutral or even carbon negative manner, allowing sequestration of atmospheric carbon dioxide.

Owner:GREEN LIQUID & GAS TECH

Cover

A cover of a conventional type, in particular for beds, which has at least one flexible layer of a light, insulating material and which is designed to the desired heat retention in the bed, is equipped in view of an improved moisture regulation and a dissipation of the moisture released by the body as well as excess heat in such a manner that the layer is provided with ventilation openings.

Owner:SANDERS SA

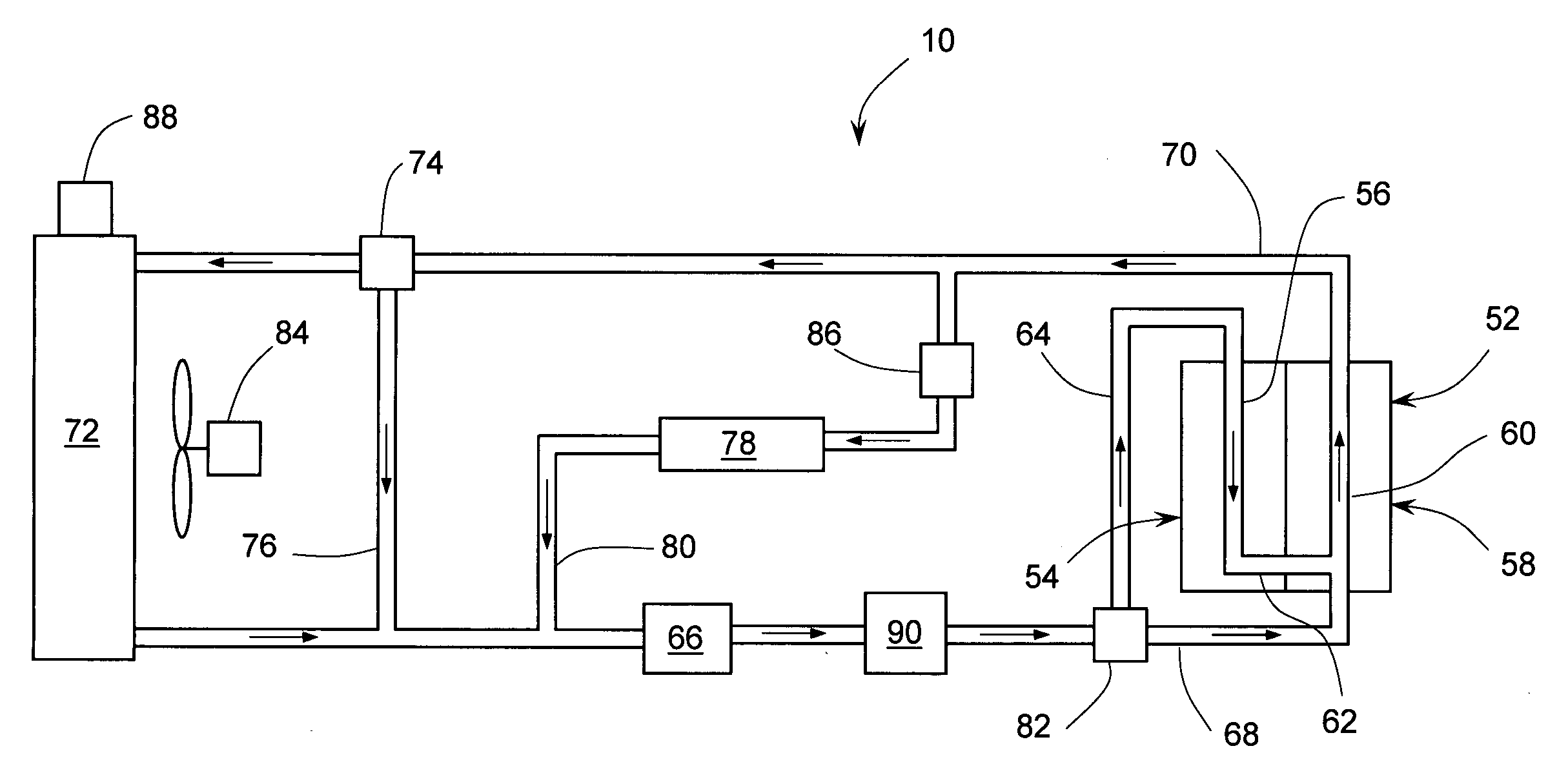

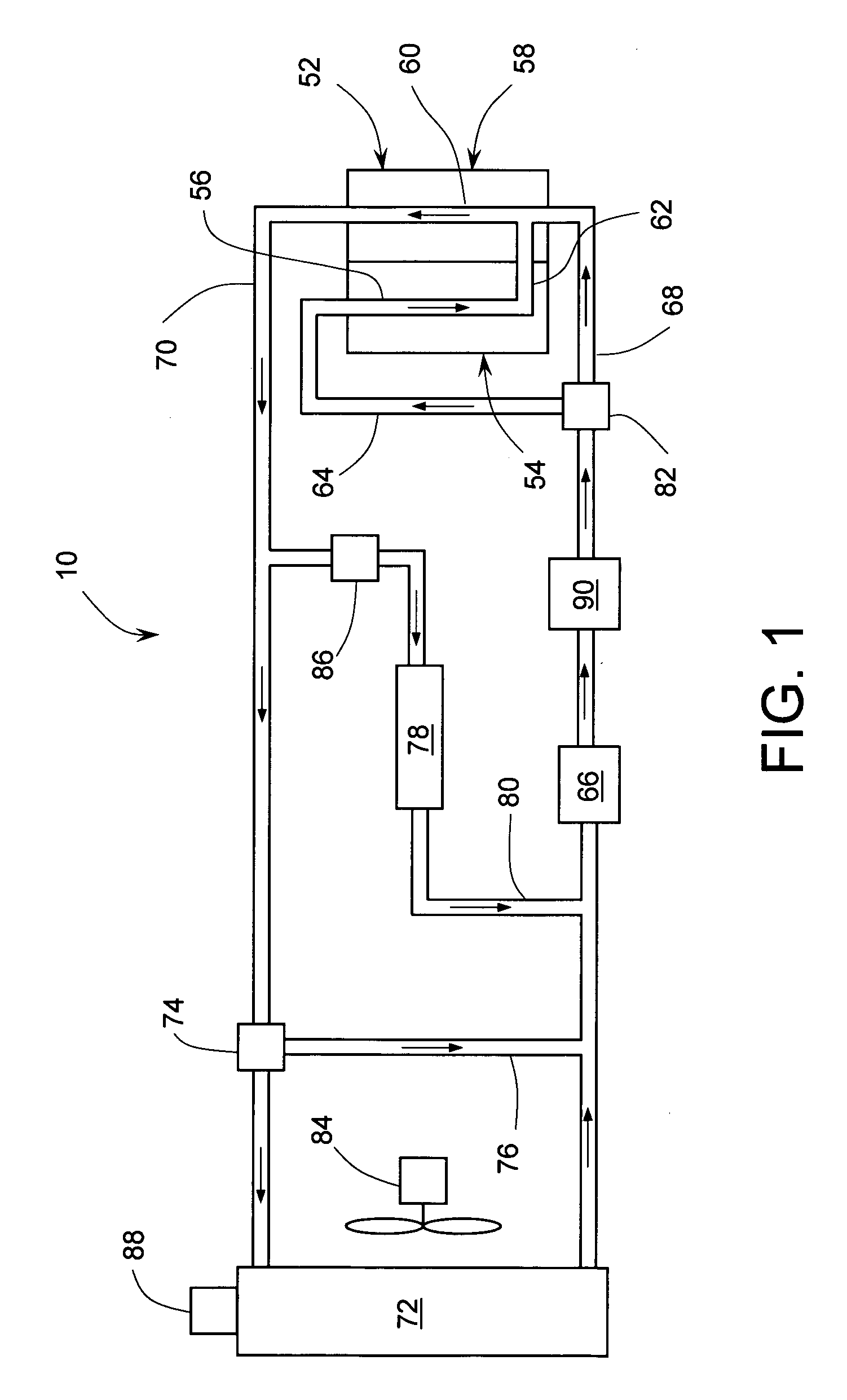

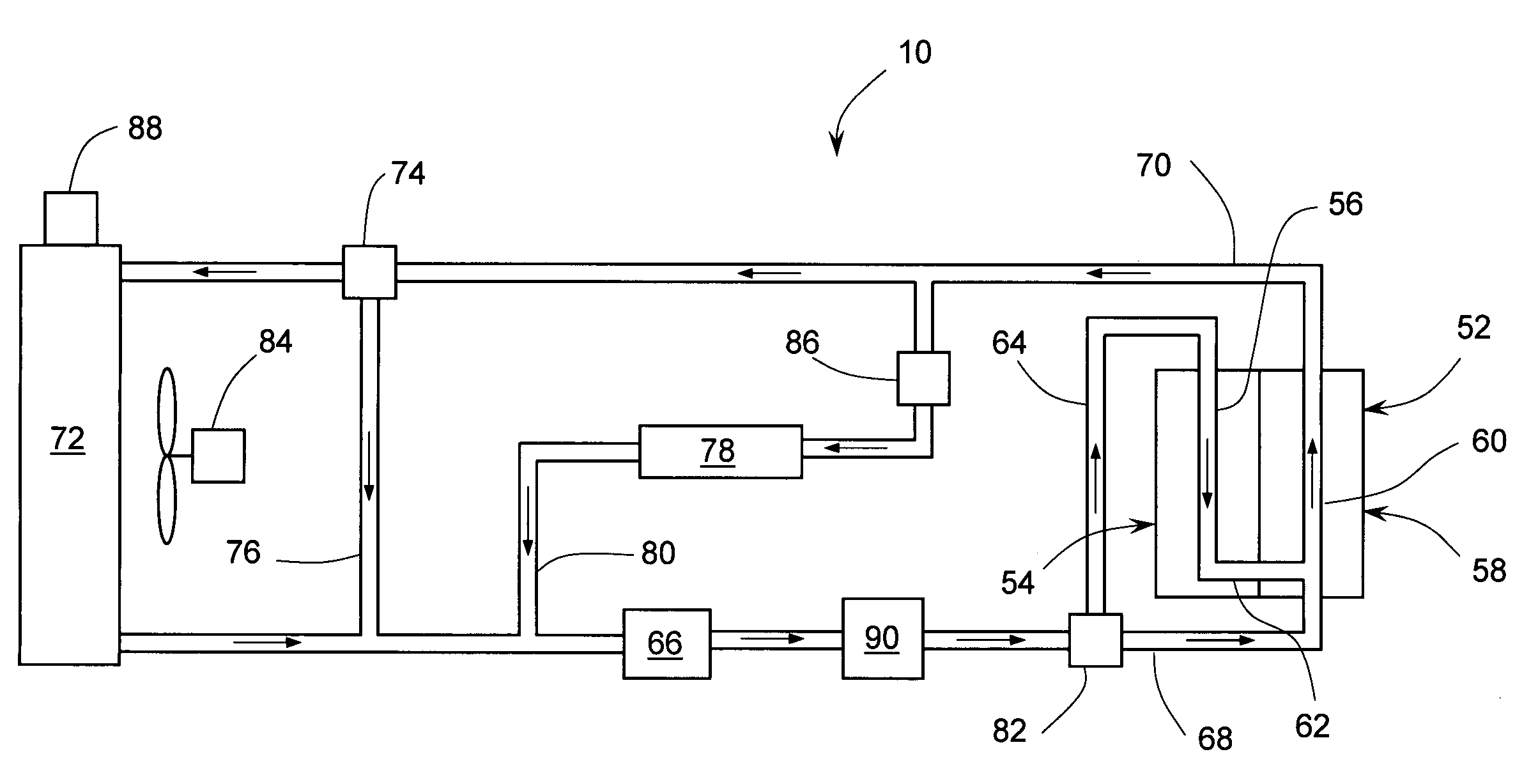

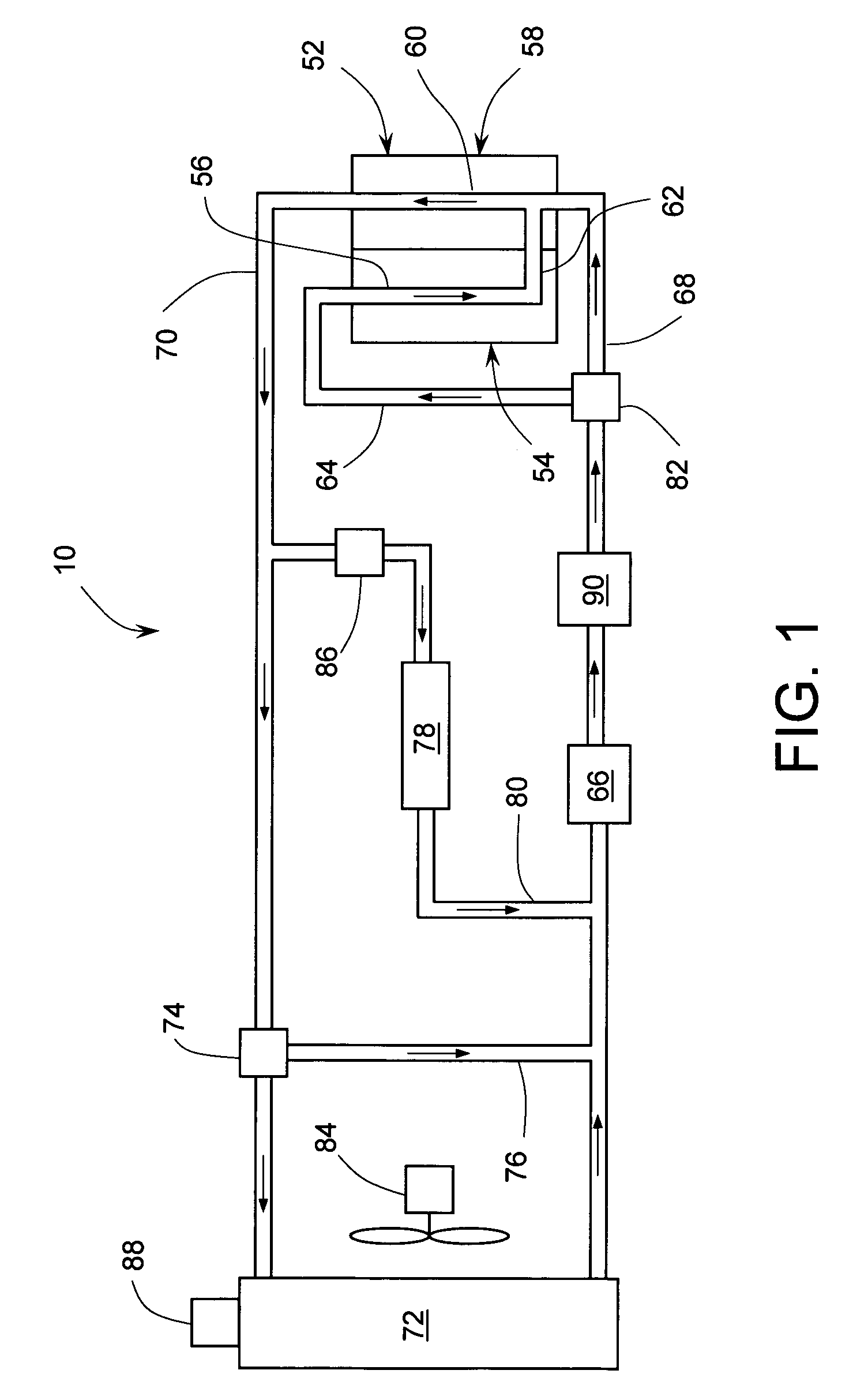

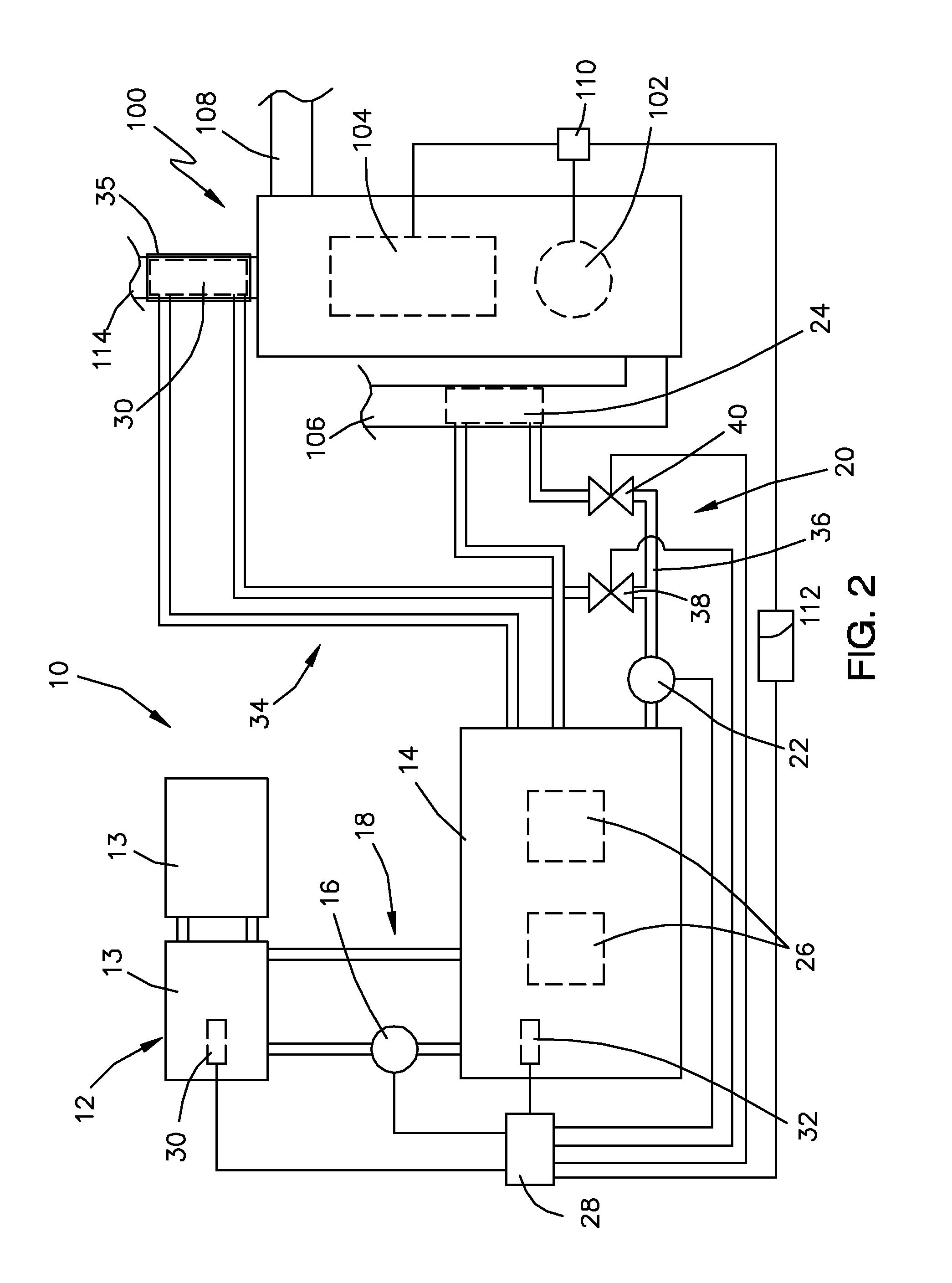

Engine cooling system with overload handling capability

InactiveUS20090205590A1Suitable for mass productionSimple and compactLiquid coolingReinforcing meansMobile vehicleInternal combustion engine

A cooling system for an internal combustion engine incorporating a heat accumulator to temporarily store heat during peak heat loads. In automotive vehicles, the heat accumulator may store excess heat generated during vehicle acceleration or hill climbing and it may dissipate stored heat during vehicle cruise, deceleration, or engine idle. The heat accumulator contains phase change material with a solid-to-liquid transition temperature higher than the normal operating temperature of the cooling system. The invention enables reducing the size and weight of engine cooling system without compromising its performance. This is particularly important for improving fuel economy and reduction of emission in automotive vehicles. In addition, the invention enables reducing the coolant inventory in the system thereby allowing for faster engine warm-up and reduced emissions of harmful pollutants during a cold engine start. The invention may be also used for thermal management of engine oil, transmission fluid, or hydraulic fluid.

Owner:AGWEST

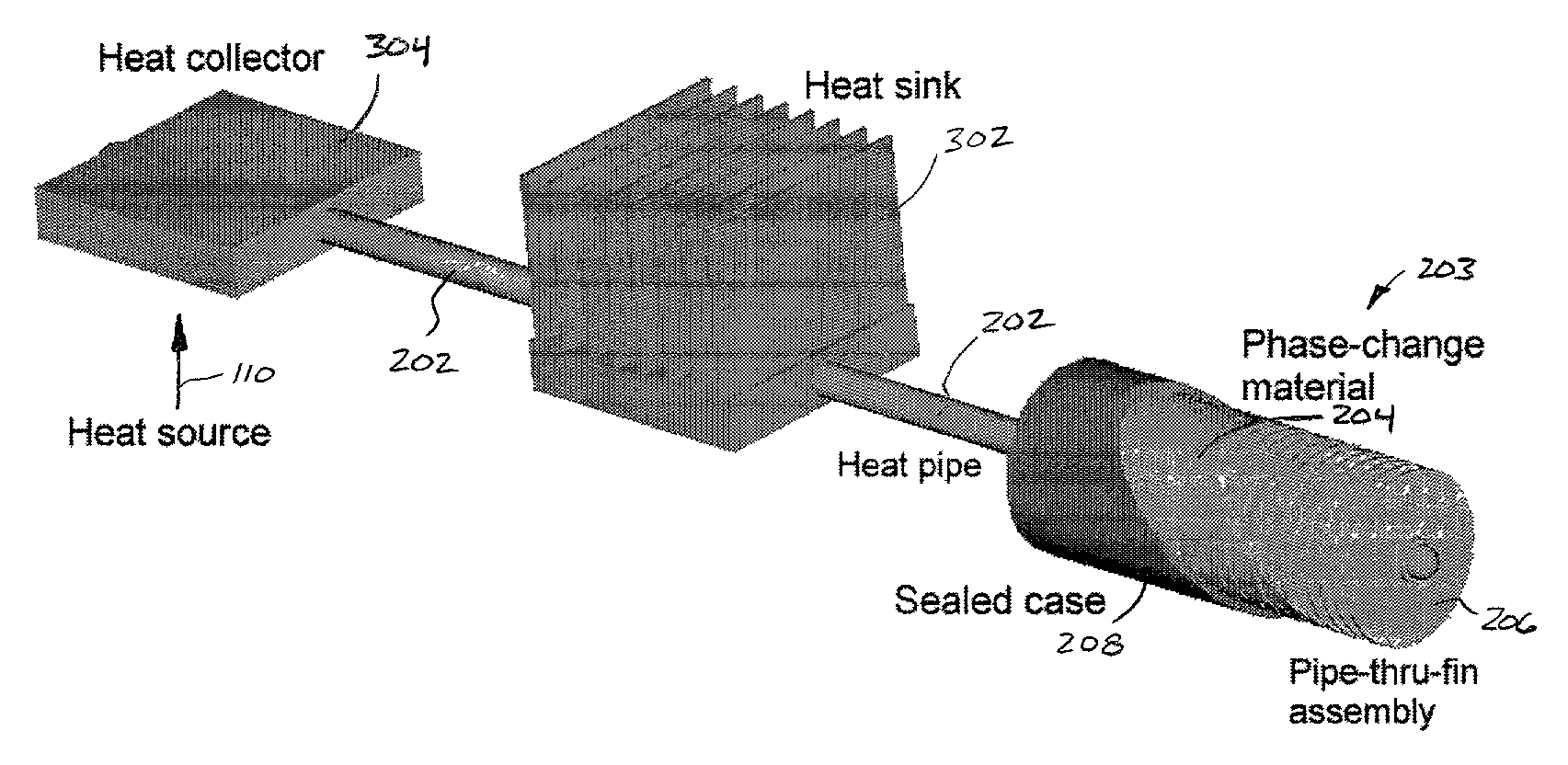

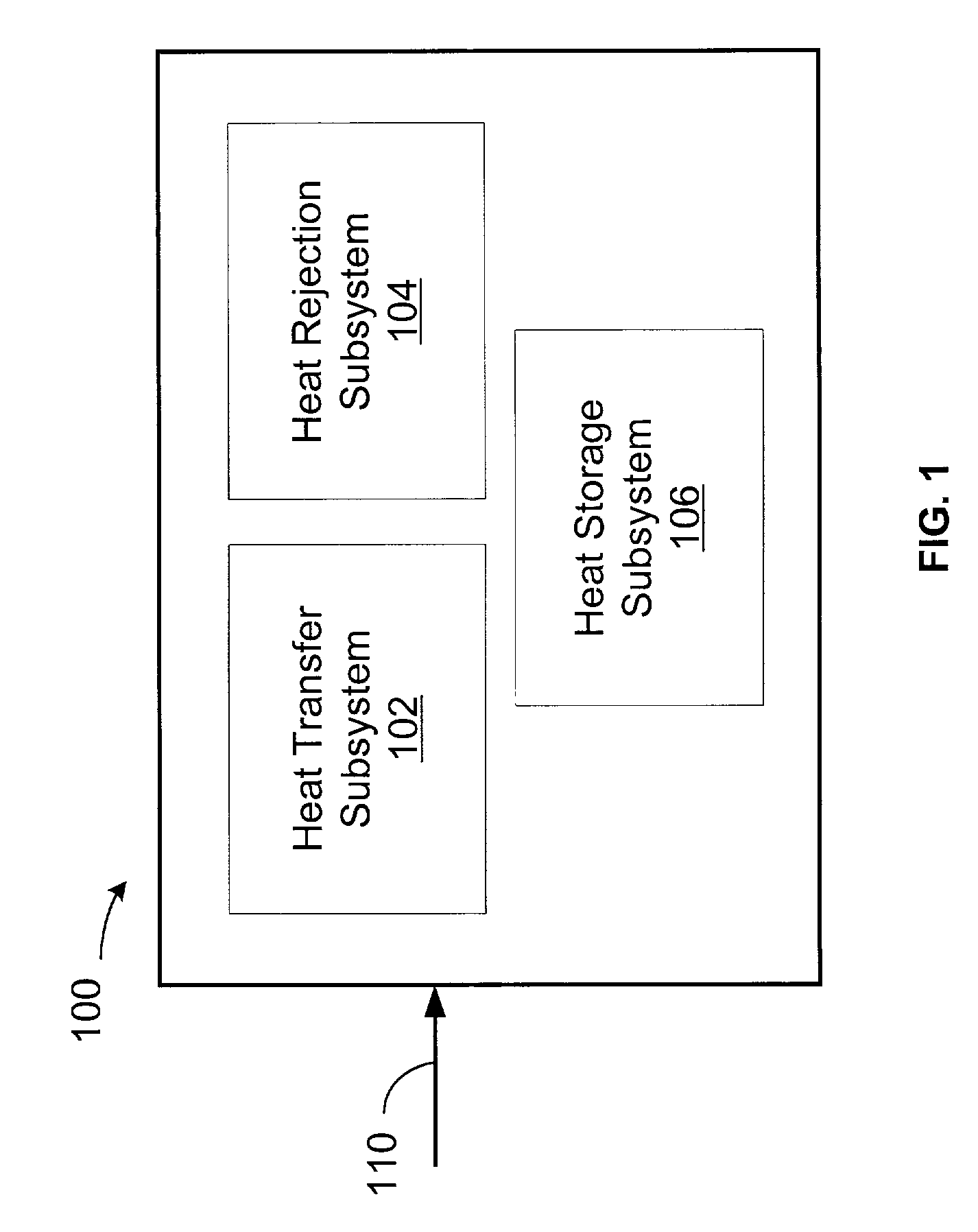

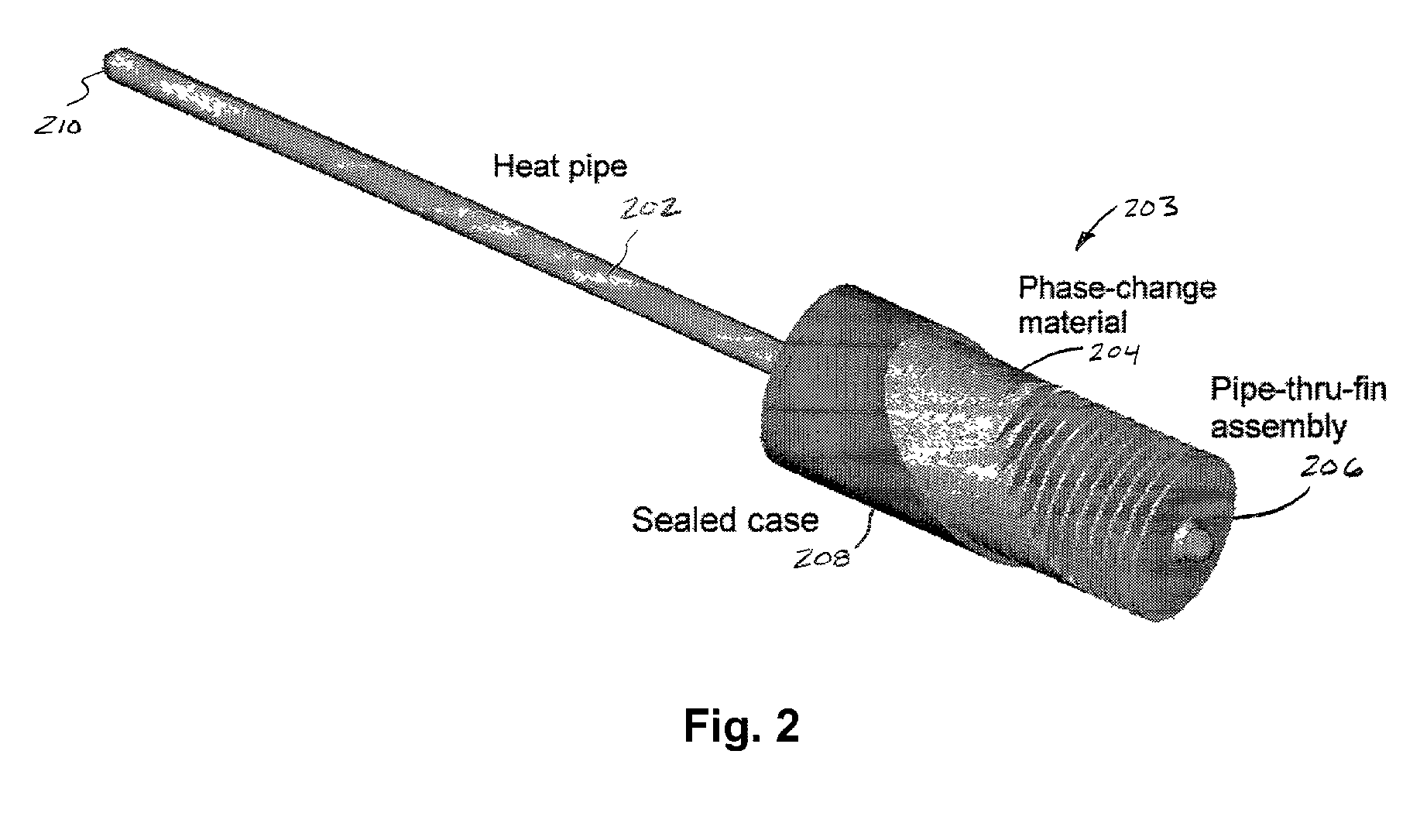

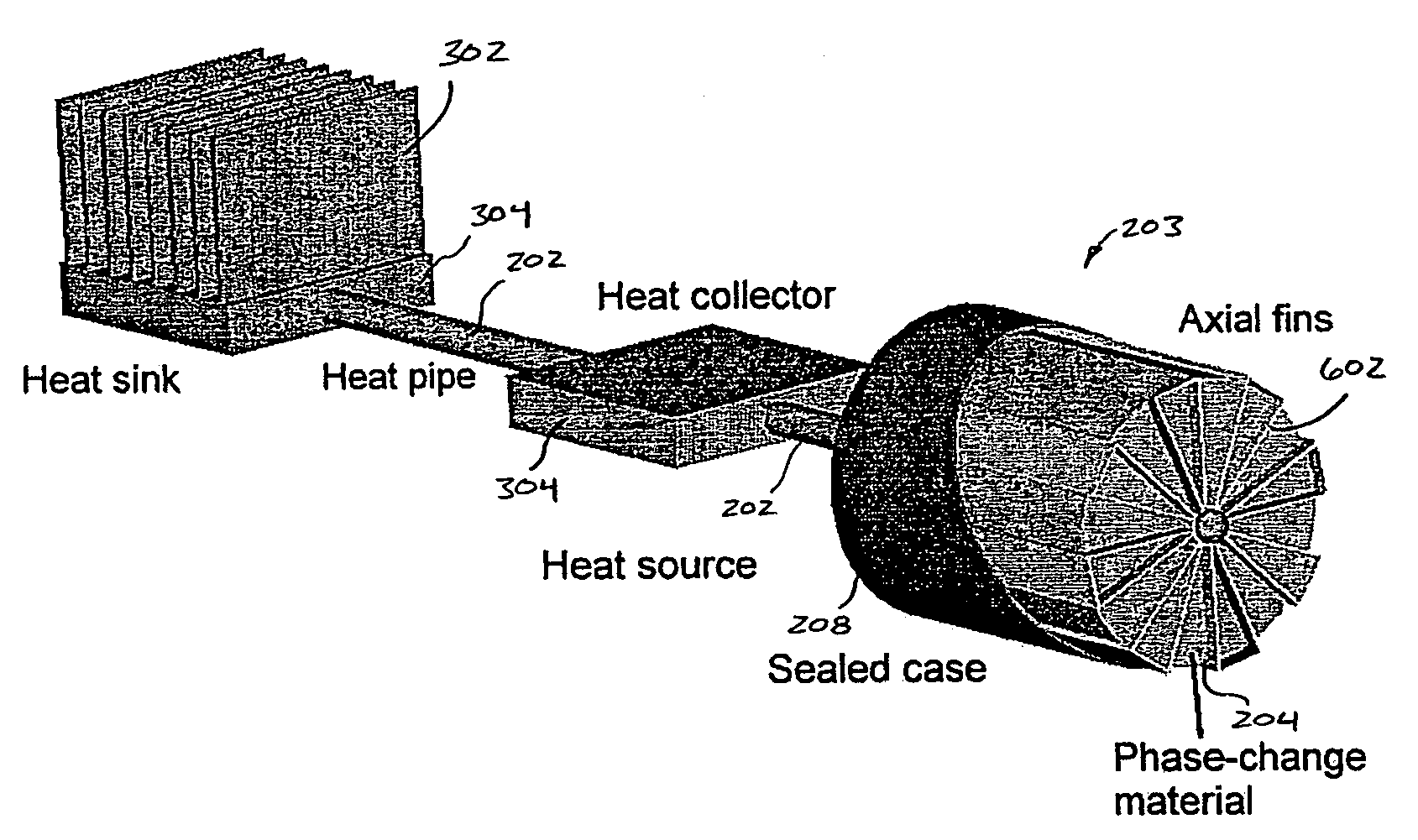

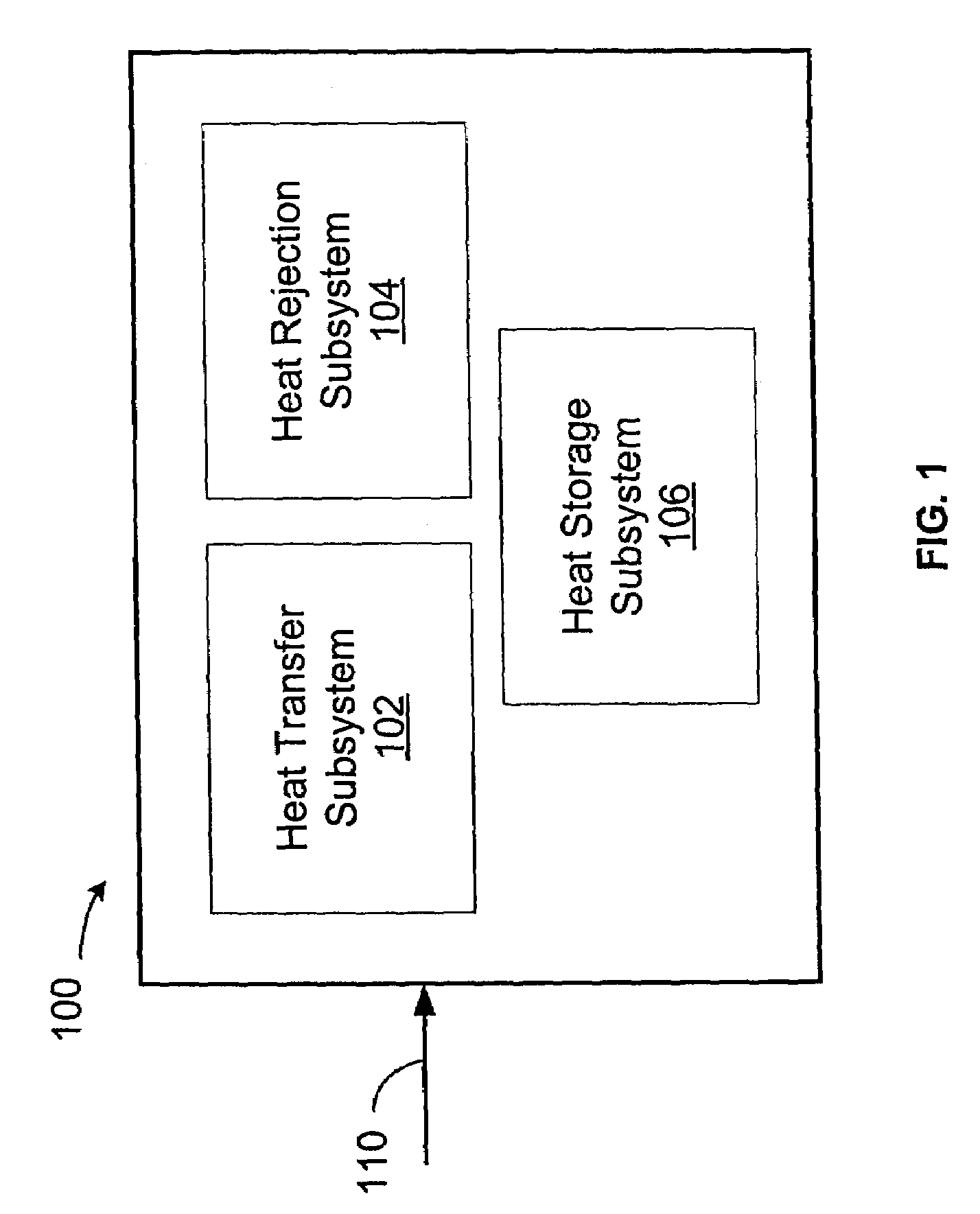

Phase-change heat reservoir device for transient thermal management

InactiveUS6997241B2Good flexibilitySmall sizeCentral heating with accumulated heatHeat storage plantsHeat rejectionThermal solution

A heat transfer system is presented for managing thermal transients, thus providing engineers greater flexibility in designing thermal solutions for applications subject to transient heat-generation. A heat reservoir device for managing a heat input subject to transient conditions includes a heat transfer subsystem having a first end and a second end, where the first end is thermally coupled to the heat input; a heat storage subsystem coupled to the second end of the heat transfer subsystem, where the heat storage subsystem comprises a phase change material responsive to the transient conditions. The excess heat load during transient operation is temporarily absorbed by the latent heat of fusion when the phase change material changes its phase from solid to liquid. Subsequently, the absorbed heat can be released back to the ambient via a heat rejection subsystem. This allows engineers to design smaller heat sinks capable of accommodating given transient conditions. This results in heat sinks which are lower cost and smaller size, or which reduce the requirement to provide higher airflow, thereby also decreasing cost and noise, and increasing reliability.

Owner:ENERTRON INC

Phase-change heat reservoir device for transient thermal management

InactiveUS7191820B2Good flexibilitySmall sizeHeat storage plantsSemiconductor/solid-state device detailsHeat rejectionThermal solution

Owner:ENERTRON INC

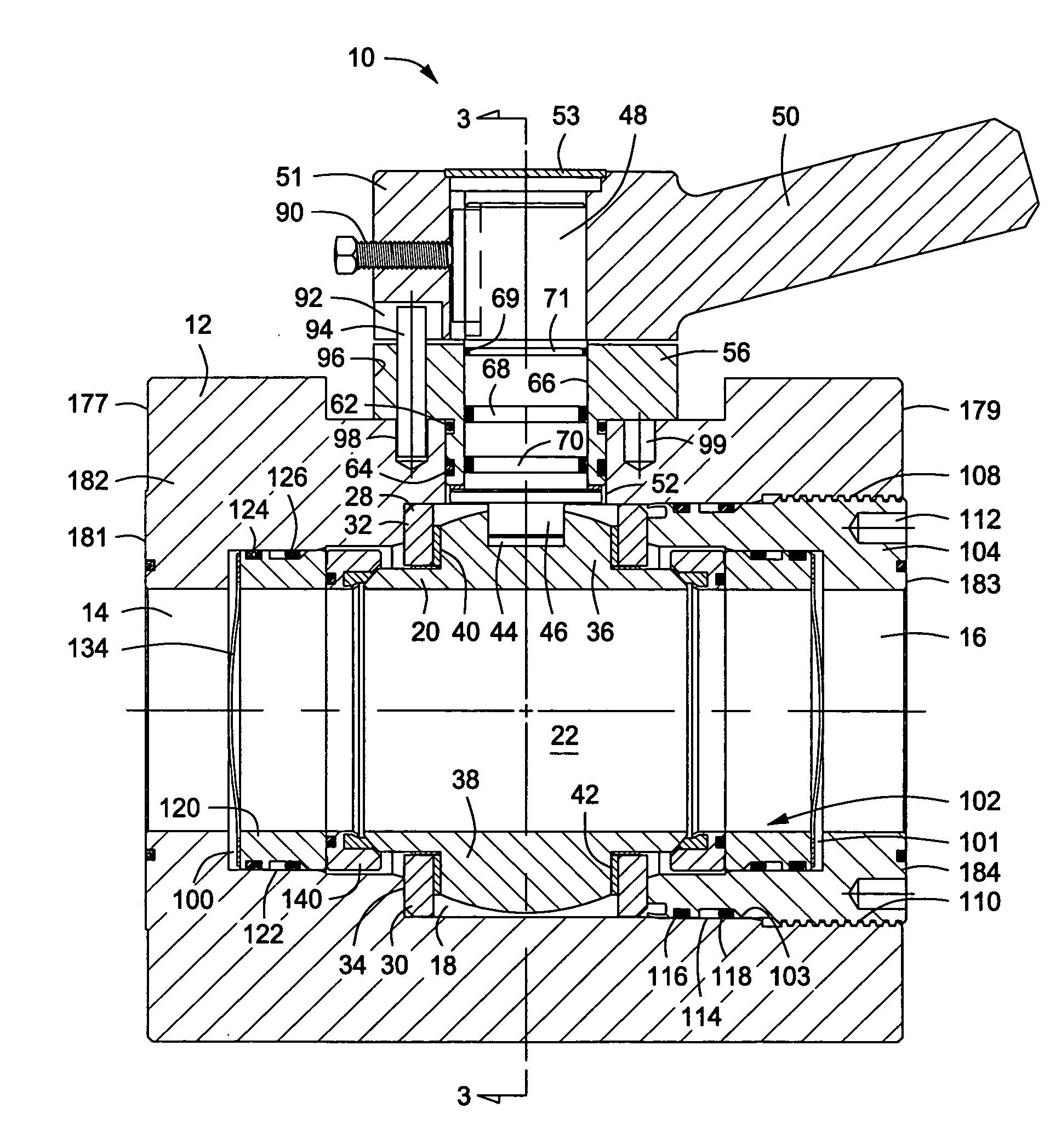

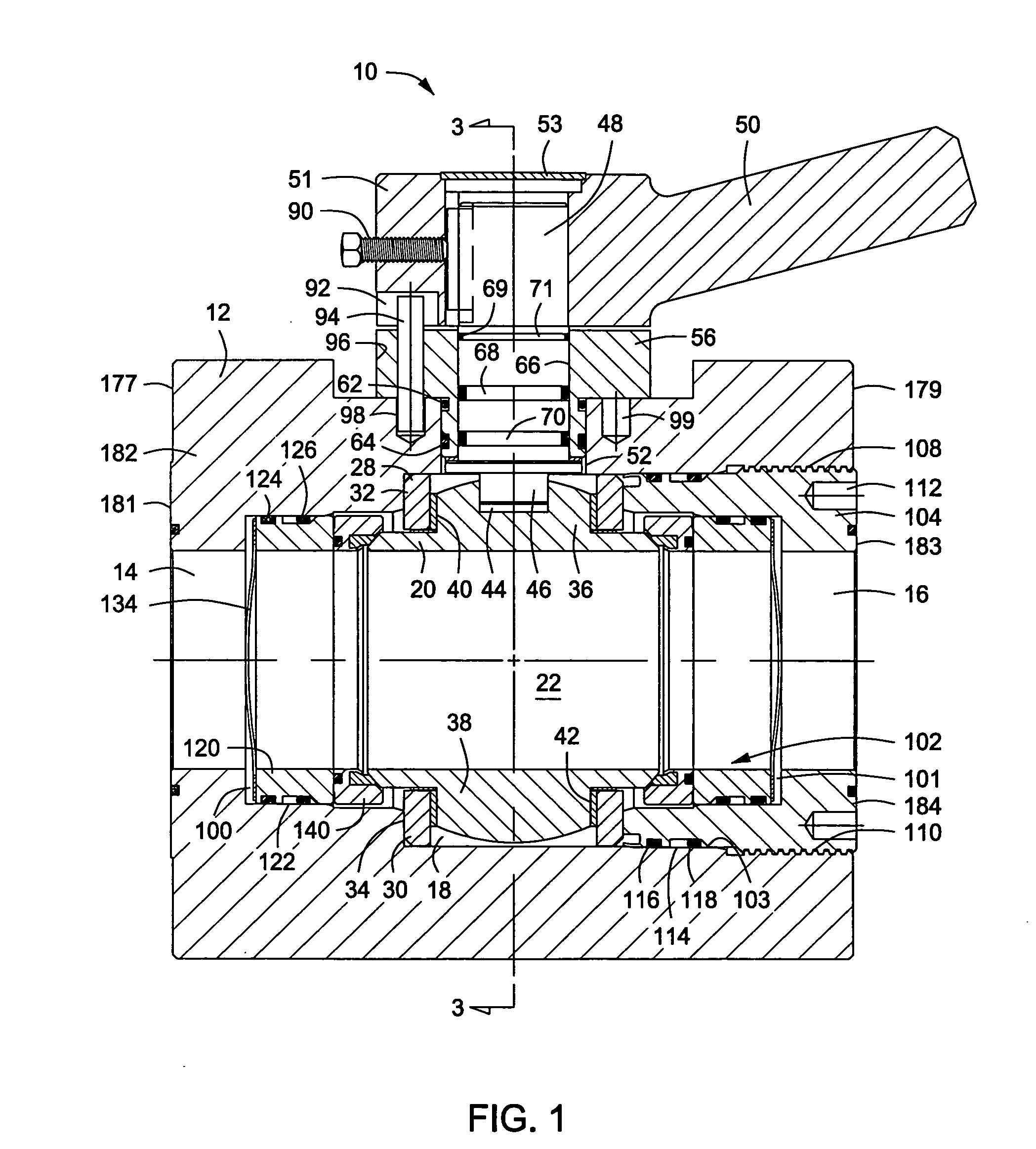

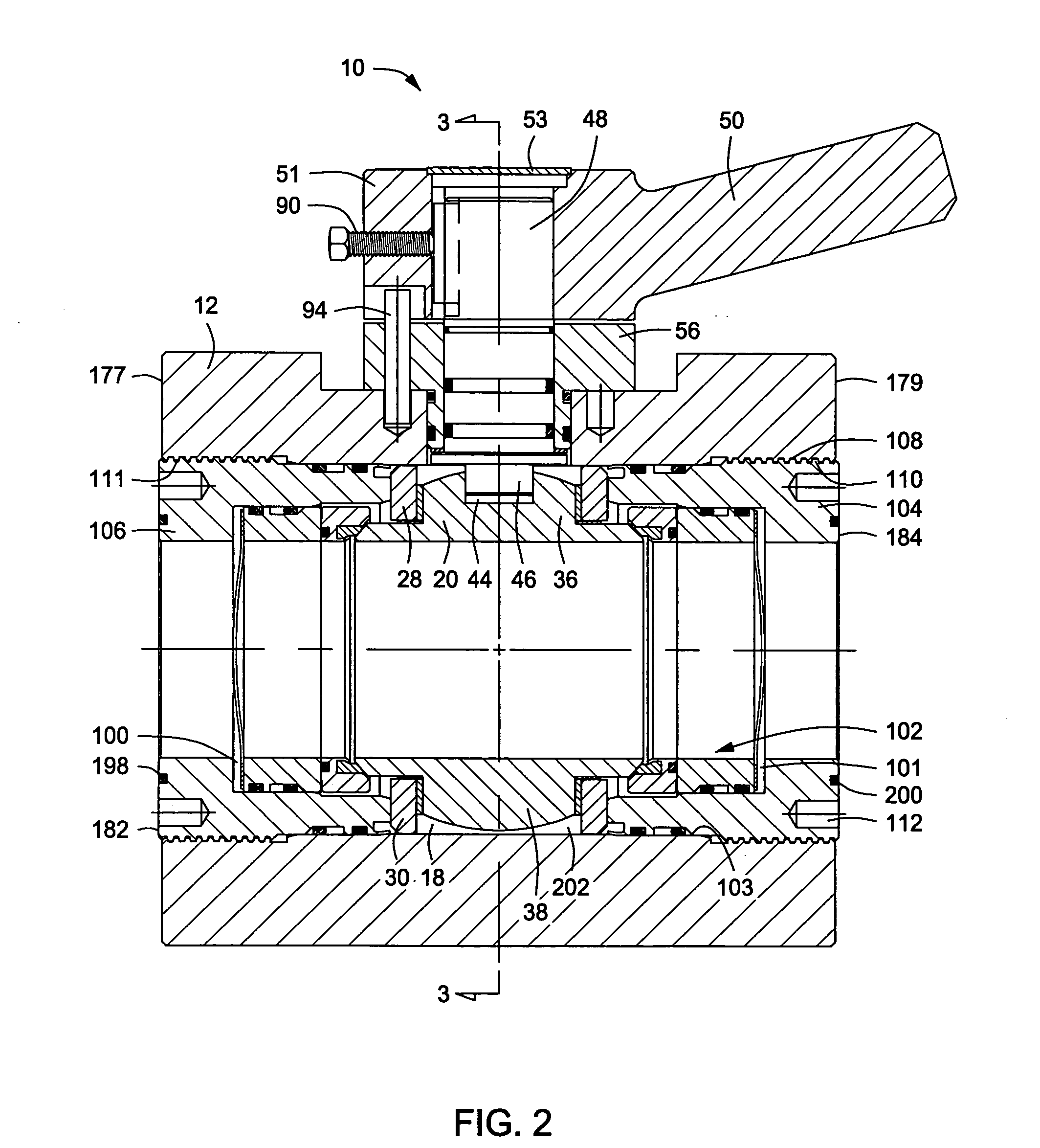

Ball valve having self-centering seats

InactiveUS20090095931A1Improve sealingAvoid small quantitiesPlug valvesValve housingsSpherical formTrunnion

A trunnion type ball valve having valve seats that are laterally moveable within seat recesses of the valve and establish sealing engagement with a valve ball member that is trunnion supported for rotational movement between open and closed positions. The valve seat members are self-centering for optimum sealing engagement with the spherical sealing surface of the ball member. The internal geometry of the seat assemblies are designed to permit optimum flow through the valve mechanism even under circumstances where the seat members are located in laterally off-center relation with respect to the centerline of the flow passages due to self-centering seat movement. The ball valve is readily adapted for fire-safe application via the use of heat resistant seals and metal-to-metal sealing of components to prevent or minimize leakage in the event of seal destruction or degradation by excess heat.

Owner:PHOENIX COMPACT VALVES

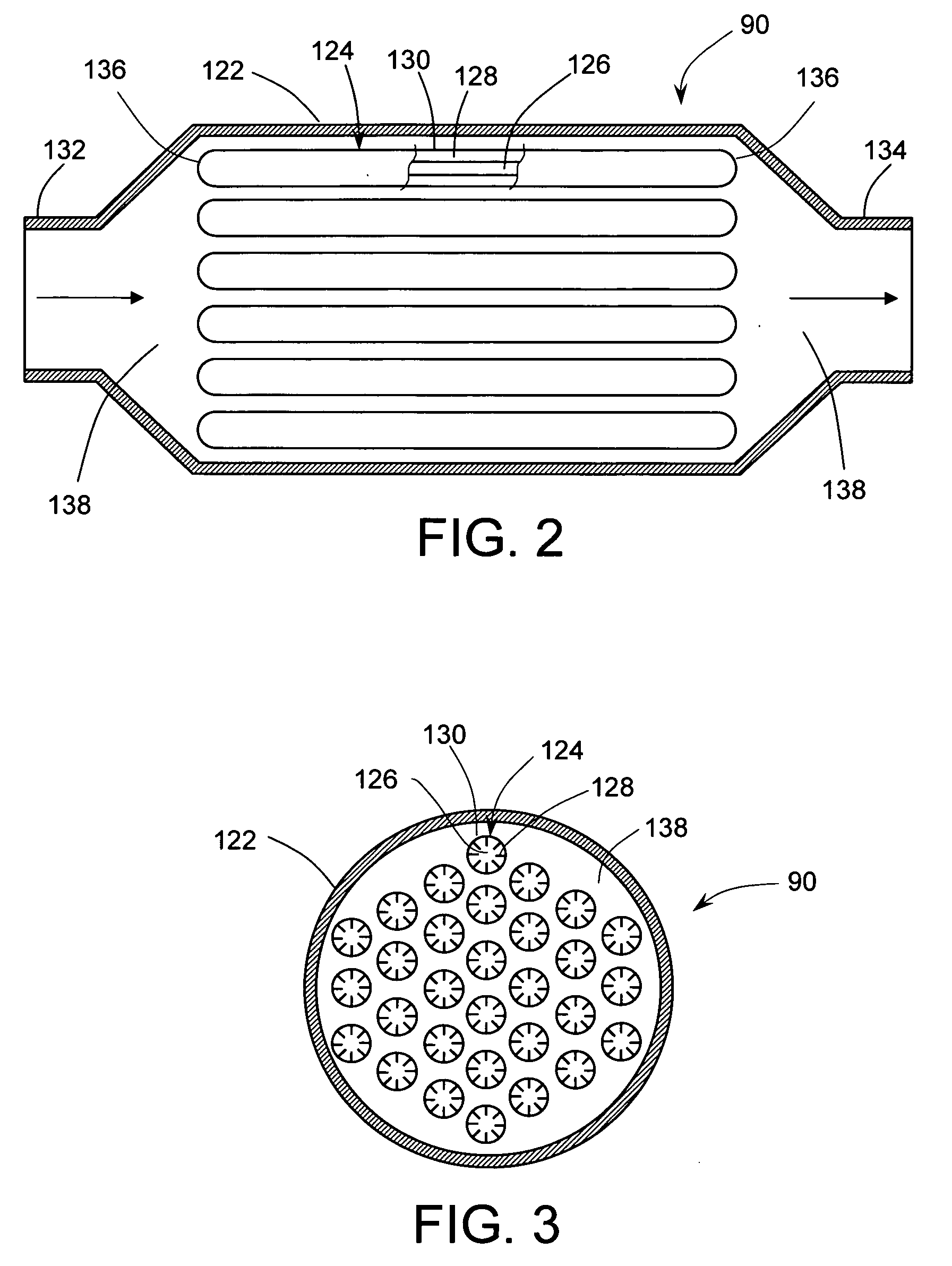

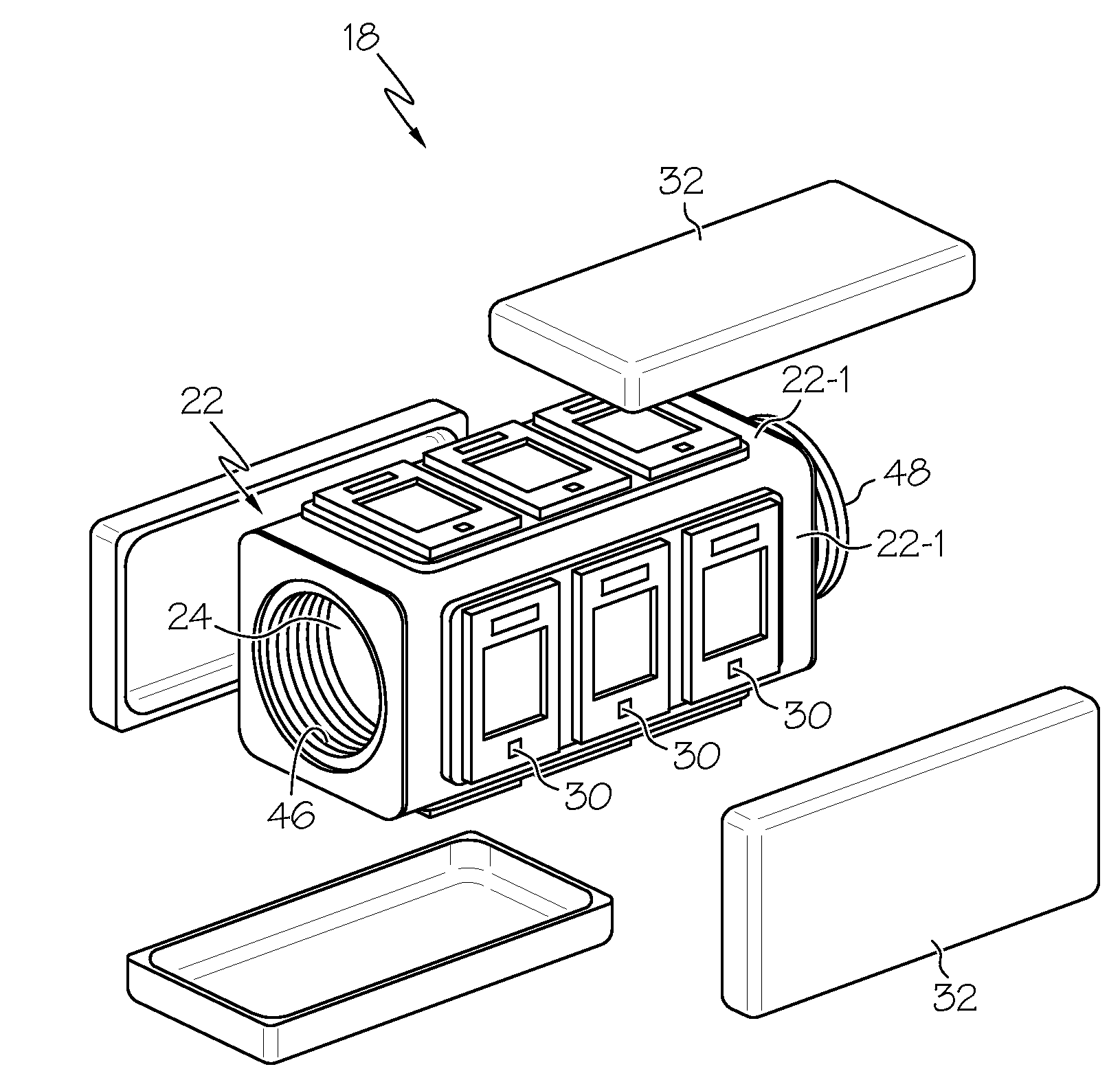

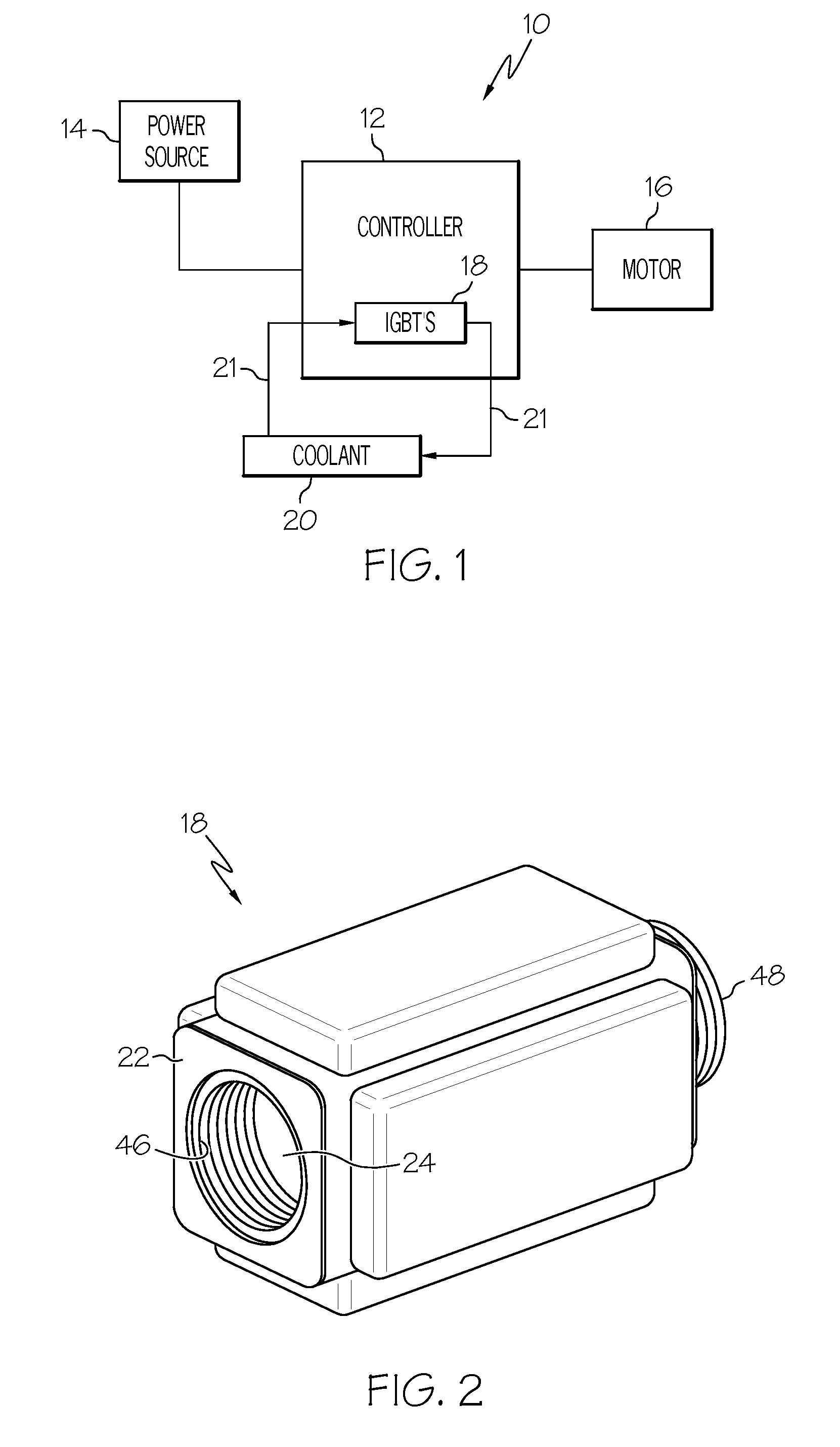

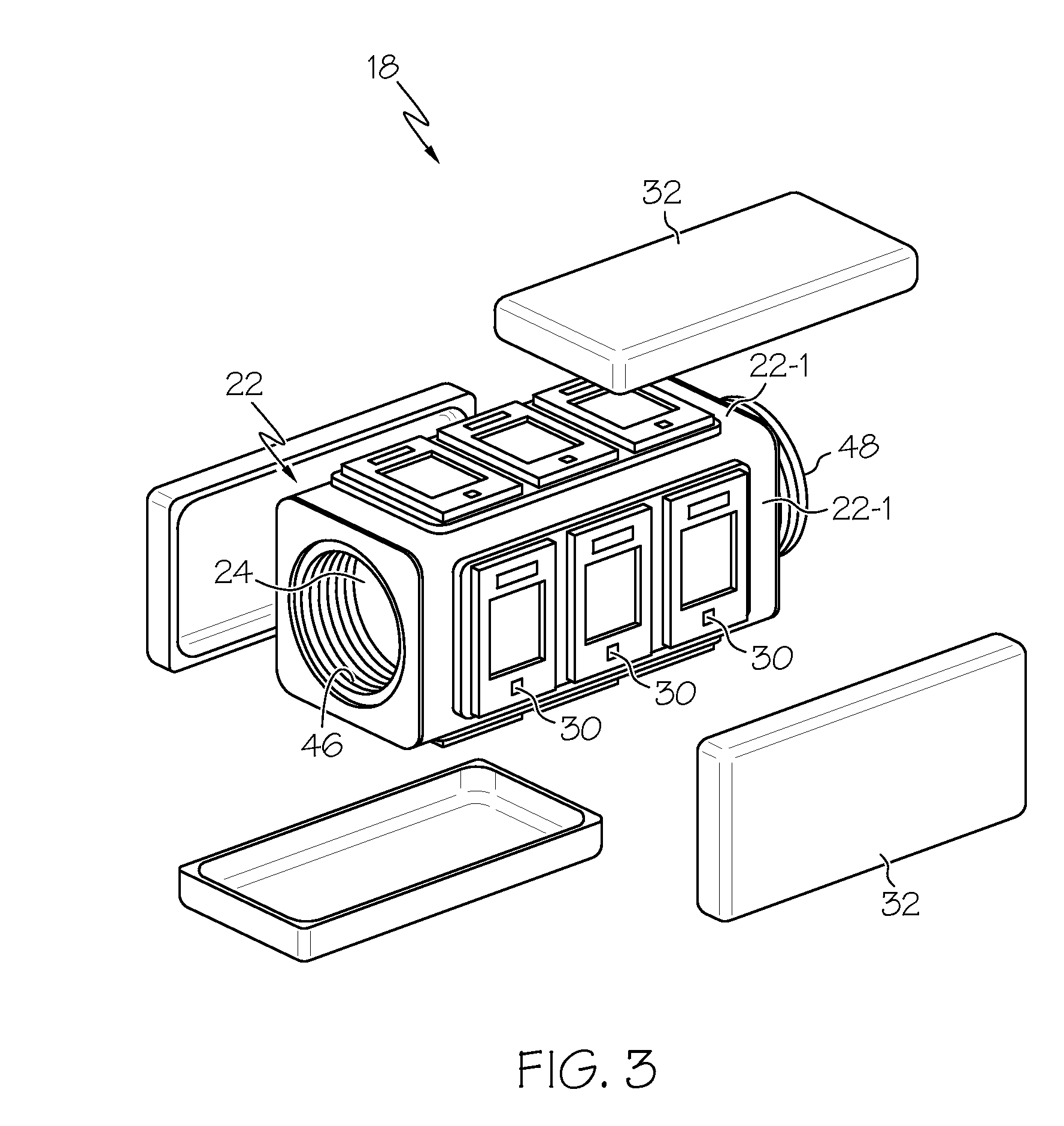

IGBT packaging and cooling using PCM and liquid

Owner:HONEYWELL INT INC

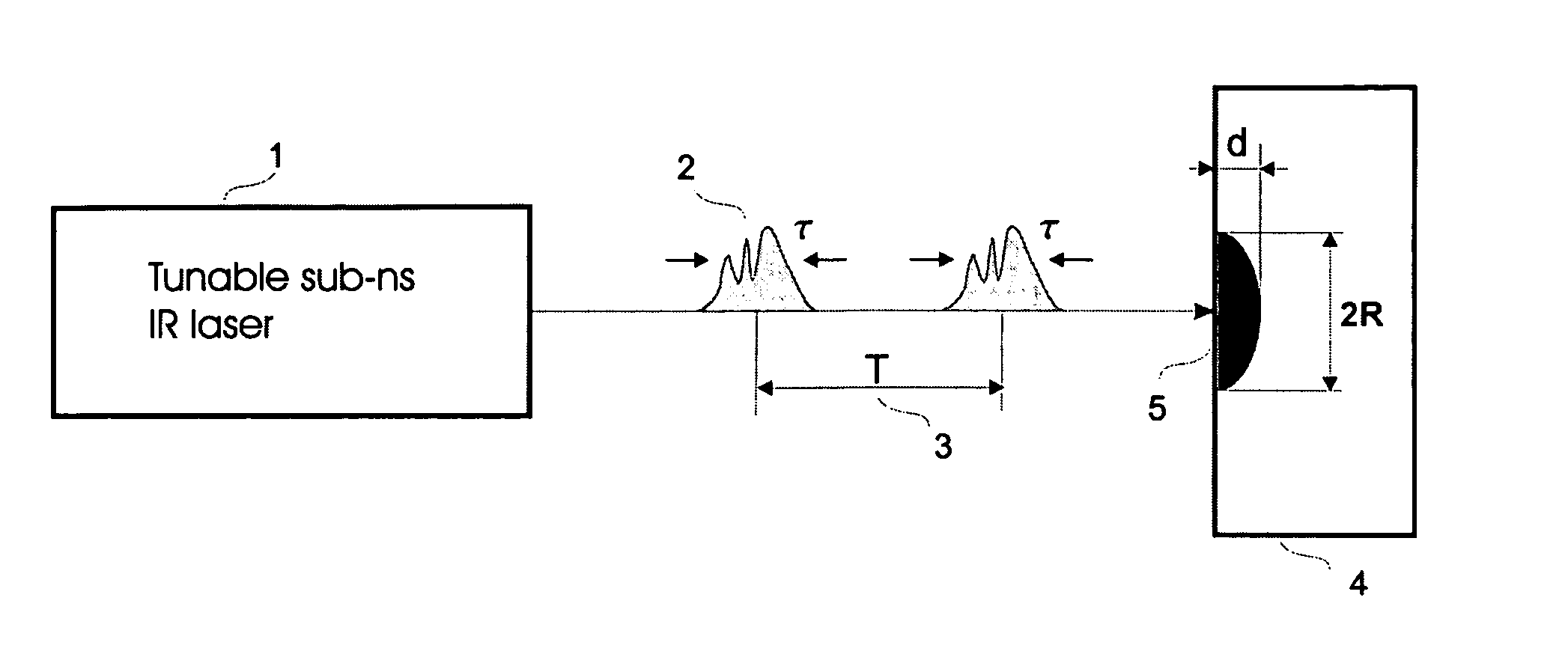

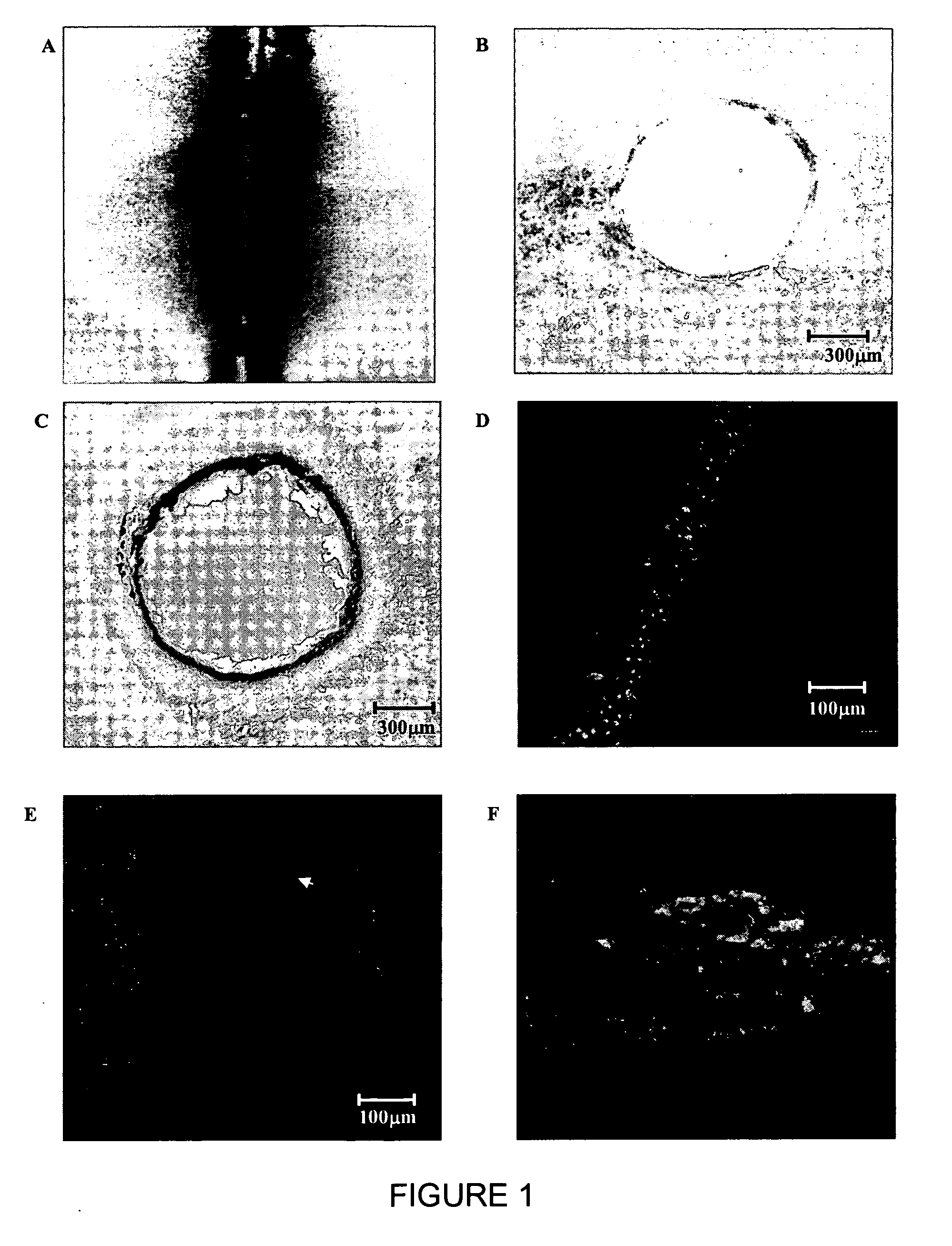

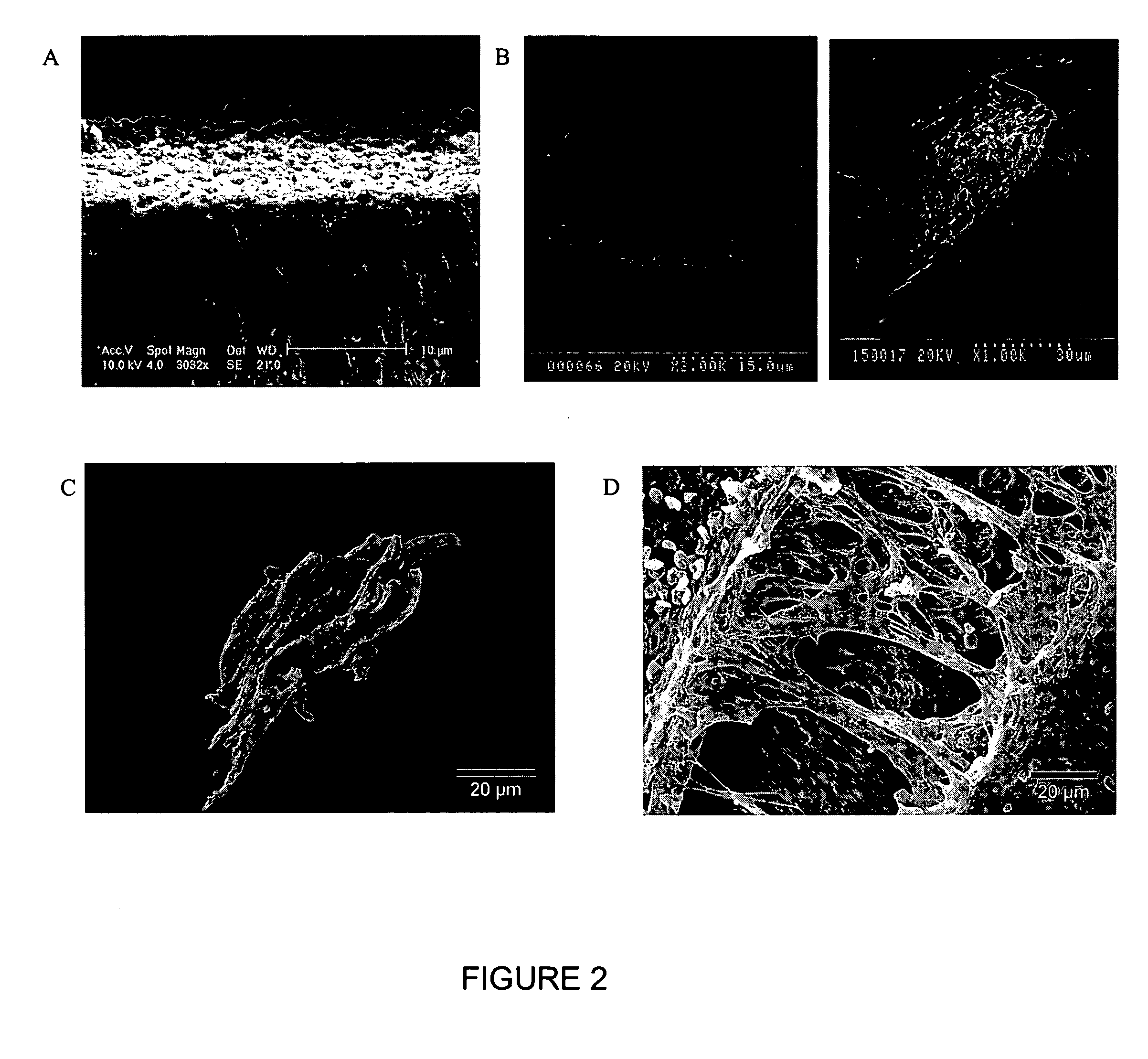

Laser selective cutting by impulsive heat deposition in the IR wavelength range for direct-drive ablation

ActiveUS20060195072A1Material efficiencyImprove efficiencySurgical instrument detailsLight therapyHeat depositionThermal expansion

The present invention provides a method of laser processing of materials, specifically laser induced ablation processes for laser removal of material particularly important in medical and dental applications in which the laser removal of material should be done in such a way as to not damage any of the surrounding soft or hard biomaterial. The ablation process is achieved by impulsive heat deposition (IHD) by direct and specific excitation of short lived vibrations or phonons of the material in such a way as to not generate highly reactive and damaging ions through multiphoton absorption. The heat deposition and ensuing ablation process under prescribed time and wavelength conditions for laser irradiation is achieved faster than heat transfer to surrounding tissue by either acoustic or thermal expansion or thermal diffusion that otherwise would lead to excess heat related damage. The result is that all the deposited laser energy is optimally channelled into the ablation process in which the inertially confined stresses from both photomechanical expansion forces and thermally driven phase transitions and associated volume changes constructively interfere to drive the most efficient ablation process possible with minimal damage to surrounding areas by either ionizing radiation or heat effects. By choosing a specific range of wavelengths, spatial and temporal shaping of infrared laser pulses, the energy can be optimally deposited in a manner that further increases the efficiency of the ablation process with respect to minimizing collateral damage.

Owner:LIGHT MATTER INTERACTION

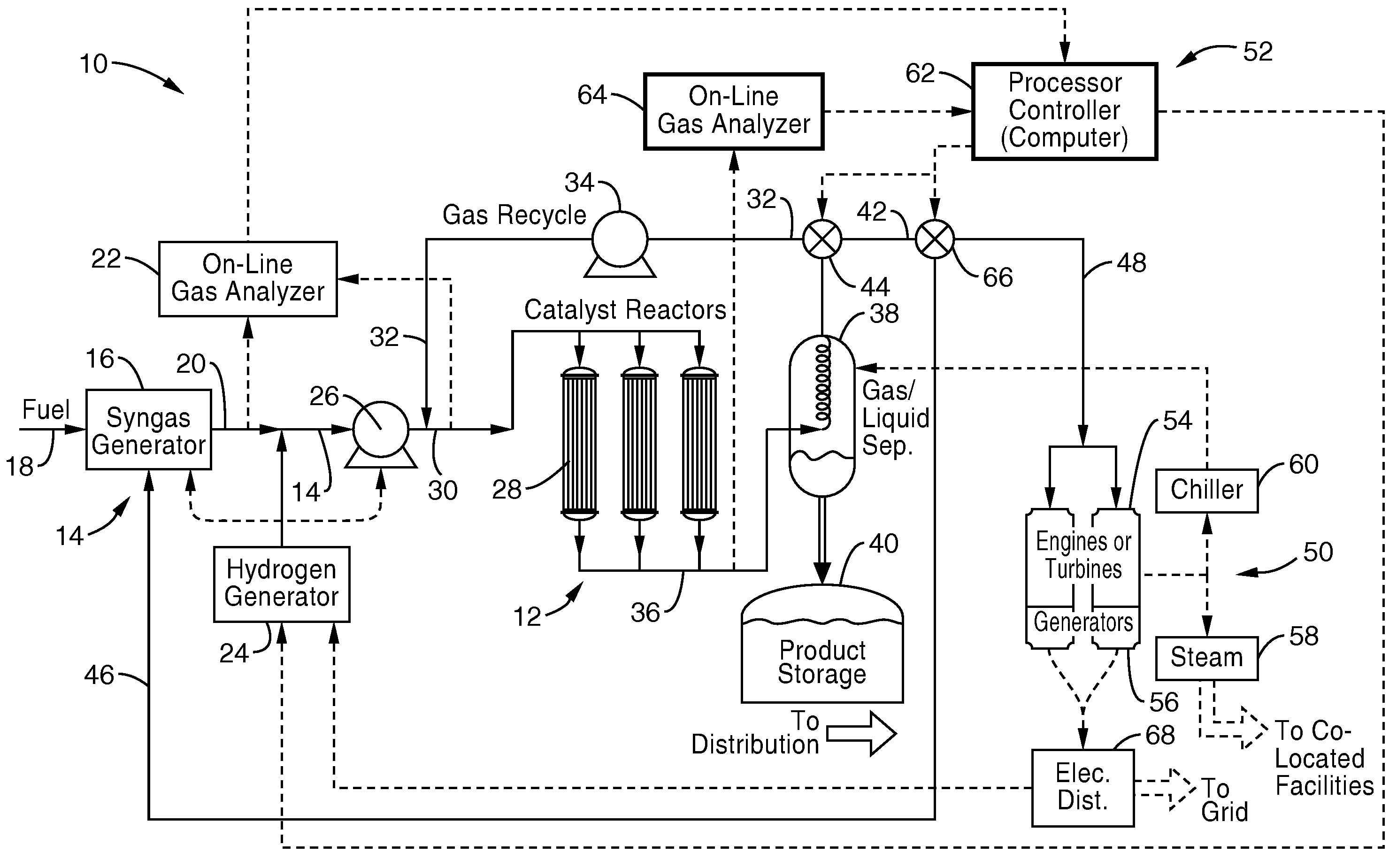

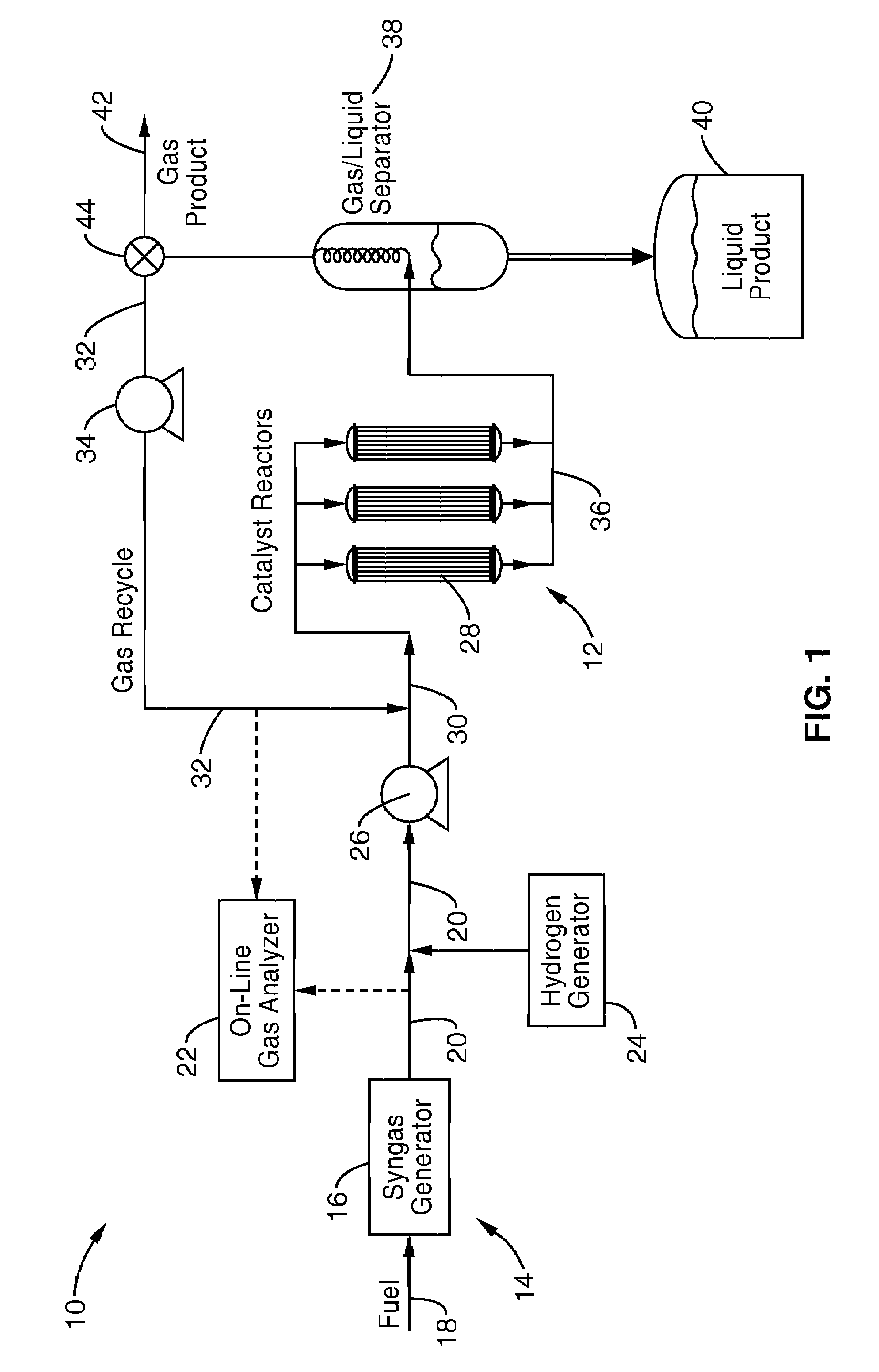

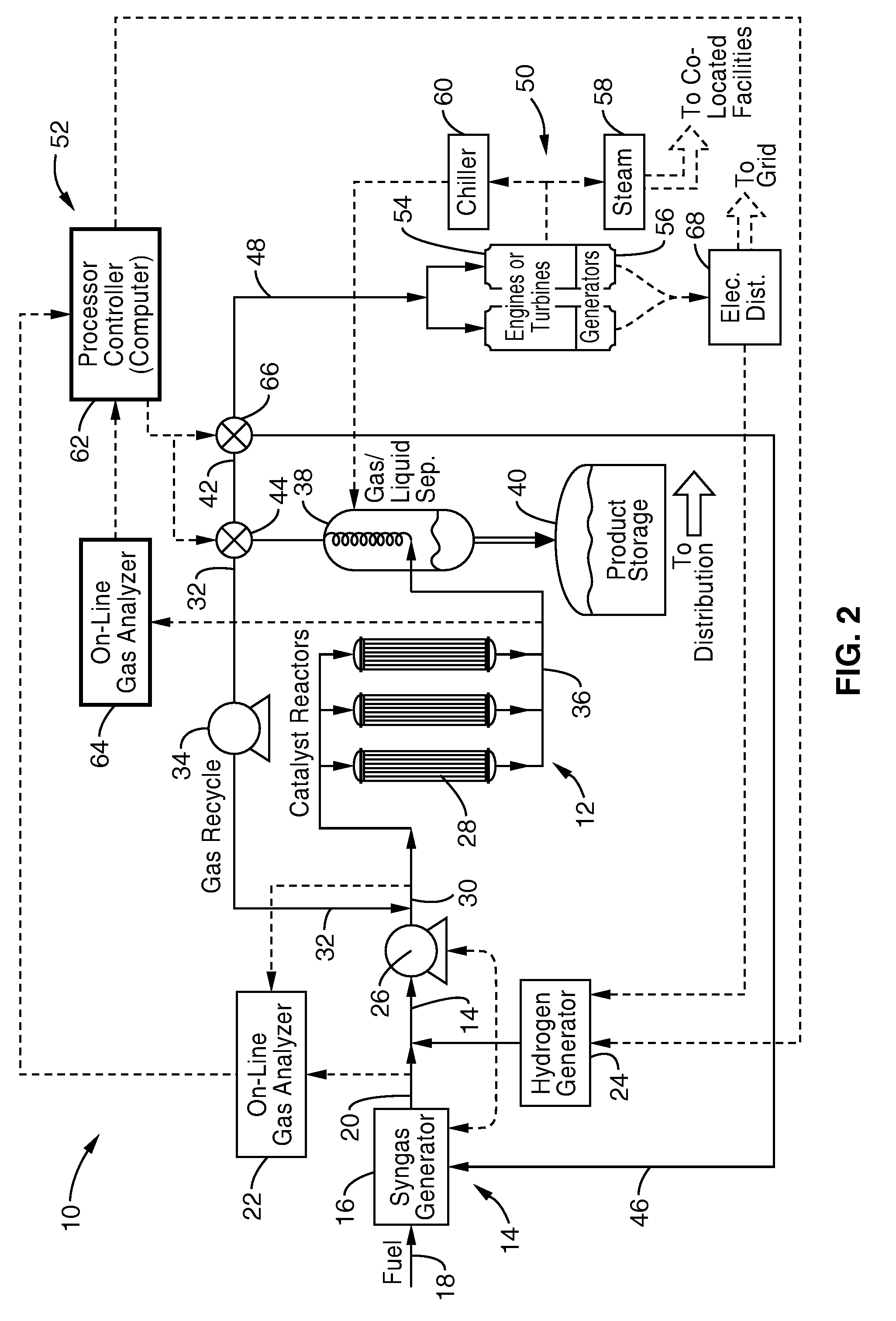

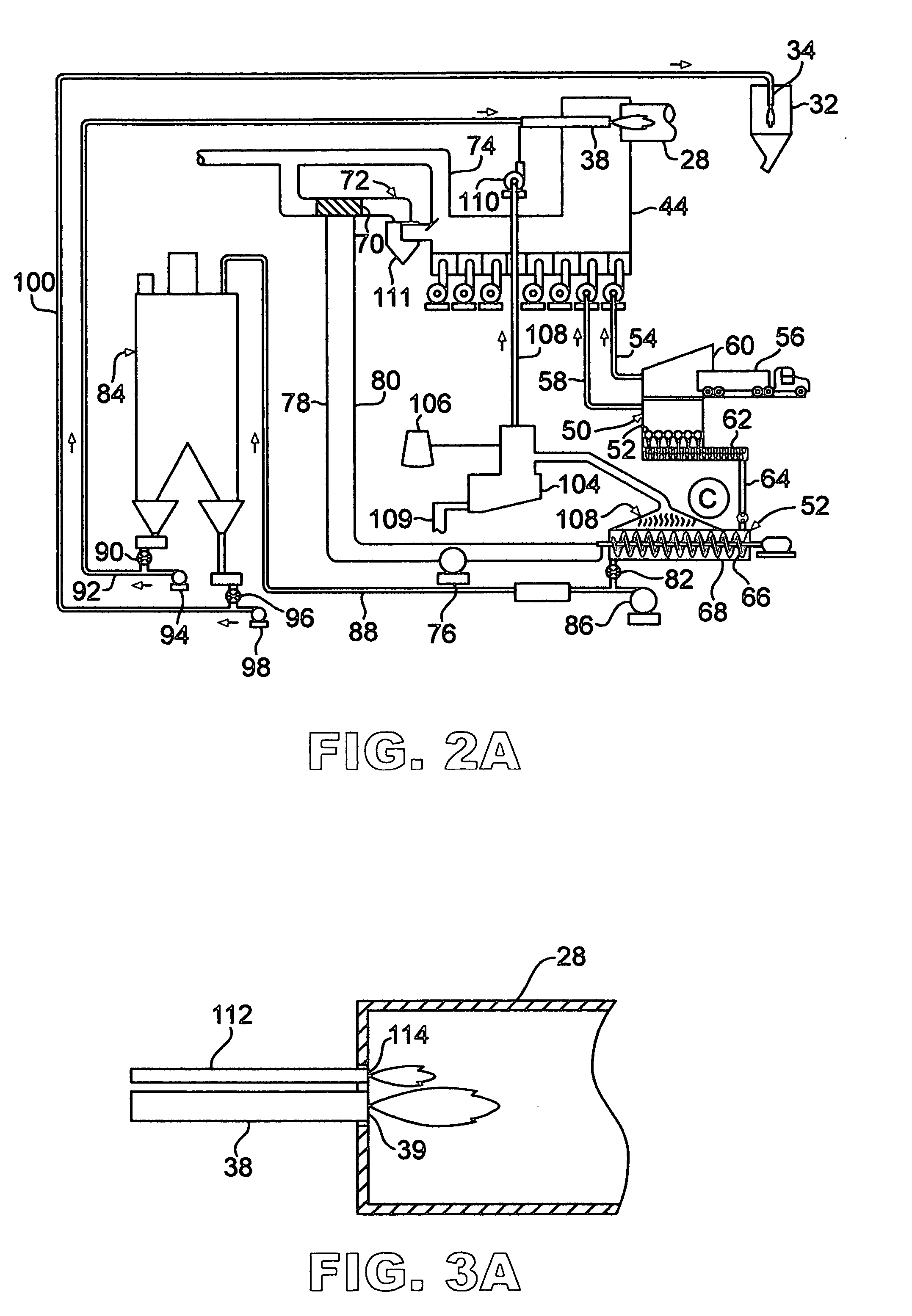

Energy efficient system and process for the continuous production of fuels and energy from syngas

InactiveUS20100175320A1Maximizes carbon conversionMaximize efficiencyEngine fuctionsBiofuelsChilled waterLiquid fuel

A system and apparatus is provided that maximizes mass and energy conversion efficiencies in an integrated thermochemical process for the conversion of fossil fuel or renewable biomass to synthesis gas. The system combines gasification, catalytic conversion of gas to liquid, electricity generation, steam and chilled water generation with a system controller to maximize the conversion efficiency from syngas to merchantable products over the efficiency of syngas alone burned as a fuel. A clean synthesis gas stream is introduced into a catalytic reactor that utilizes specially formulated catalysts to generate liquid fuel from CO and H2 while concentrating CH4 and other combustible, but non-reactive gases in the syngas product stream. The methane rich stream is introduced into an engine for the production of electricity and heat while the unreacted CO and H2 can be recycled to produce additional liquid fuel. Excess heat can be used for other co-located processes and facilities.

Owner:GREYROCK ENERGY INC

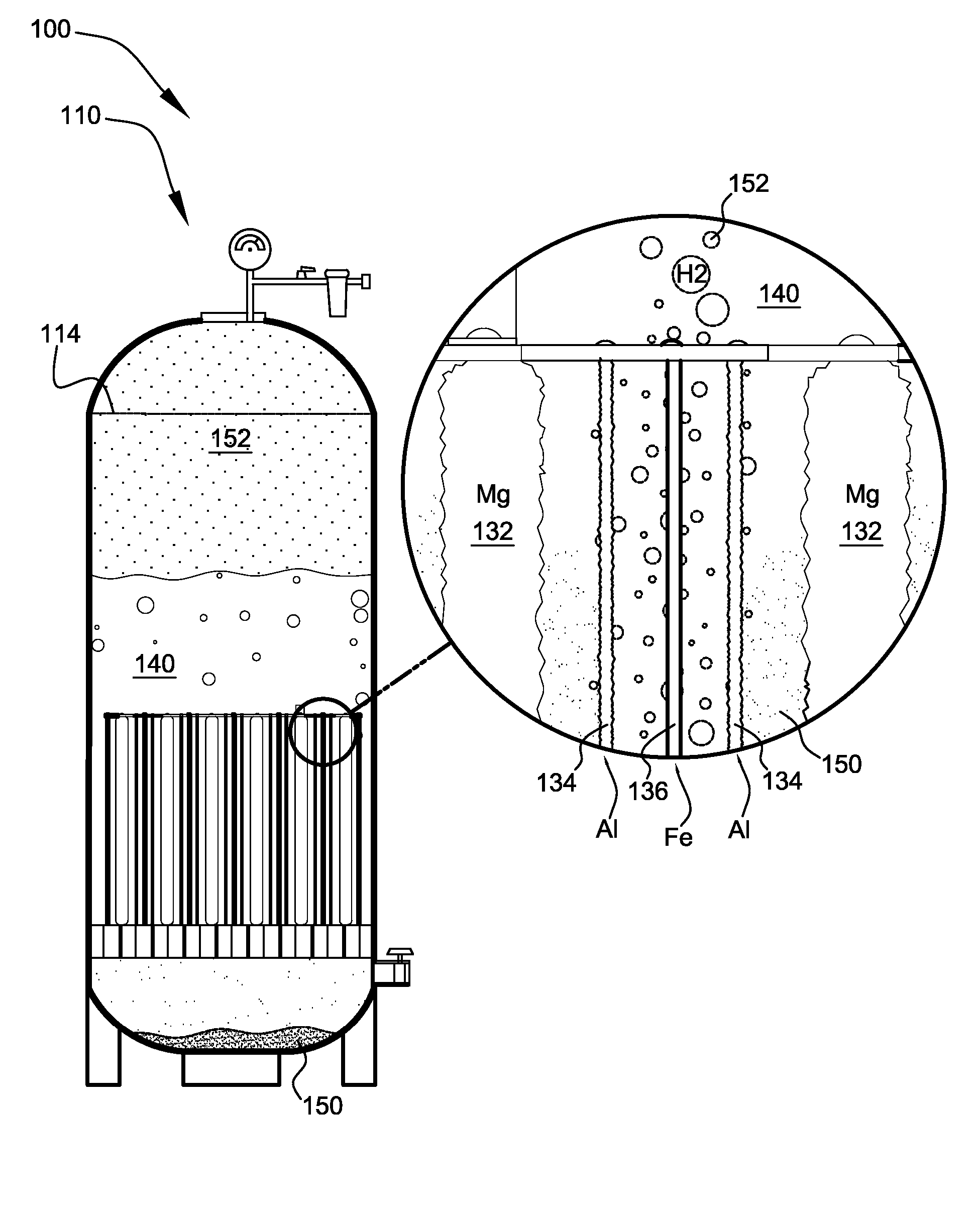

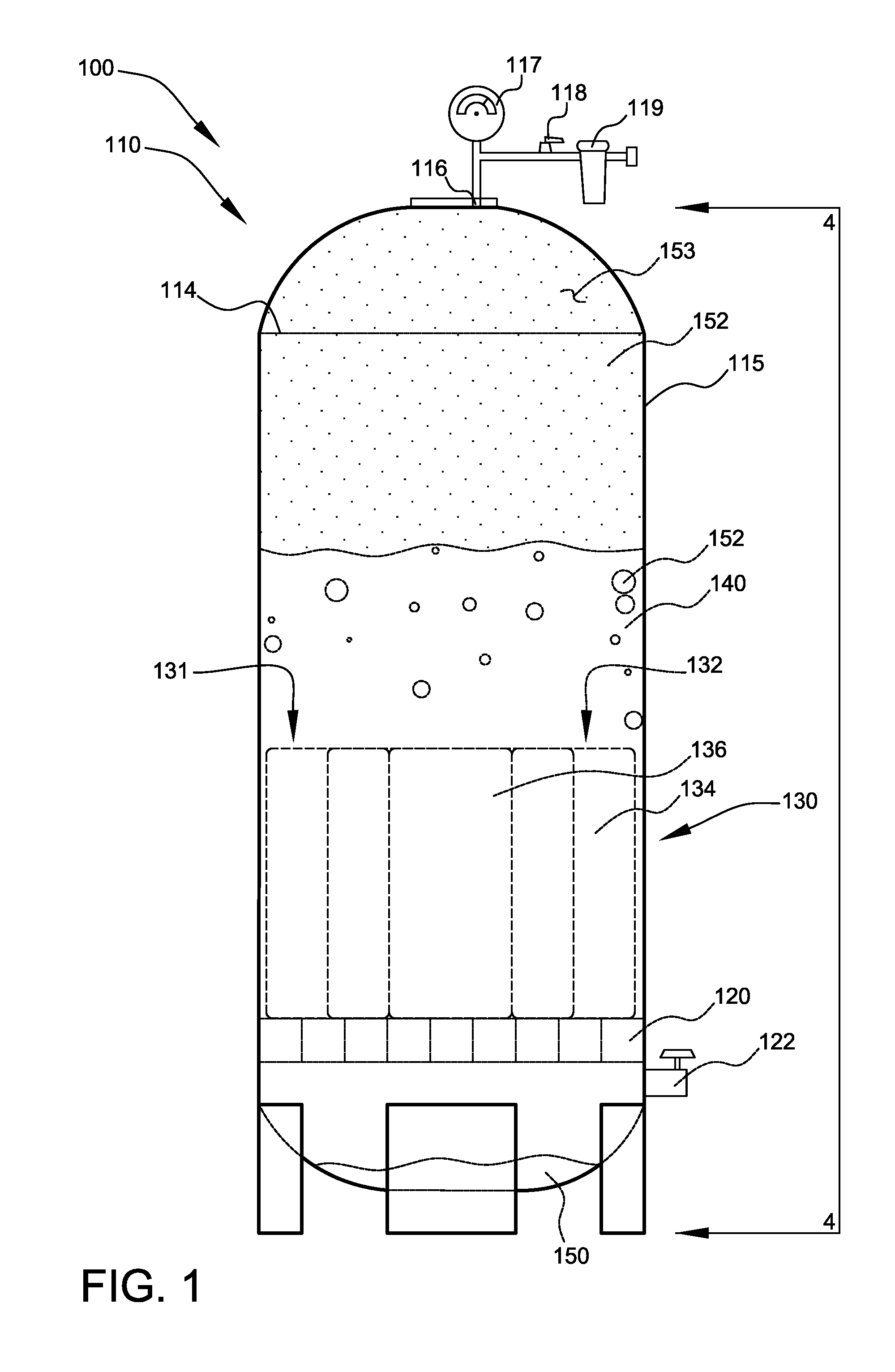

Hydrogen Energy Systems

InactiveUS20070039815A1Avoid overall overheatingEfficiently safely easily provideCellsAluminium compoundsPetroleumDiesel engine

A hydrogen energy system comprising galvanic hydrogen generators and hydrogen input manifolds for vehicle engines. The galvanic hydrogen generators generate hydrogen gas, magnesium hydroxide, and heat by the galvanic reaction of magnesium anodes with steel cathodes in salt water. Heat exchangers channel excess heat to a heat sink such as a thermocouple, Stirling engine, hot water system, etc. The hydrogen input manifold is bolted between the engine block and the air intake manifold of a gasoline or diesel engine. Hydrogen gas is injected into the hydrogen input manifold to provide supplementary fuel to the engine, lowering the amount of petroleum that is used.

Owner:BARTEL BRIAN G

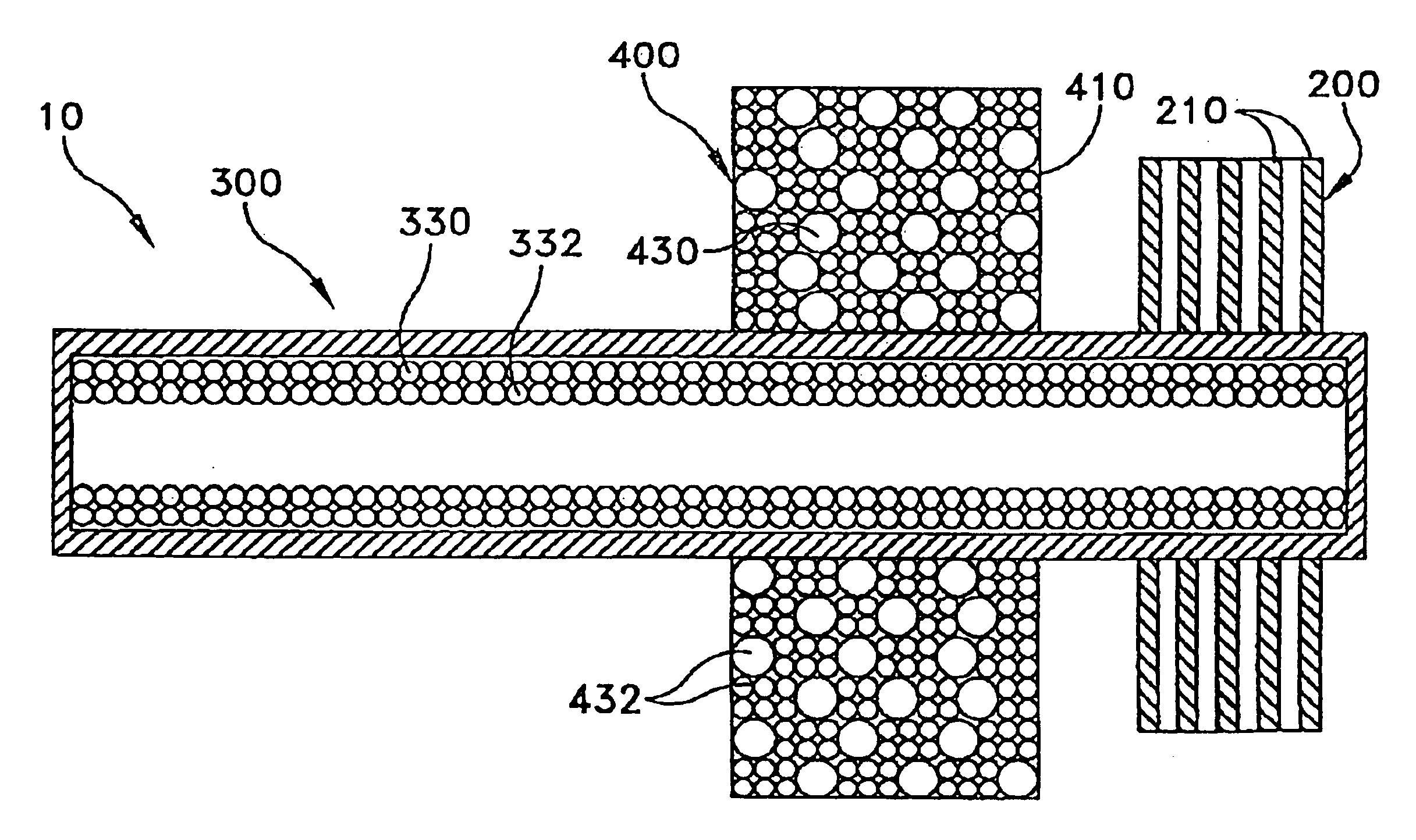

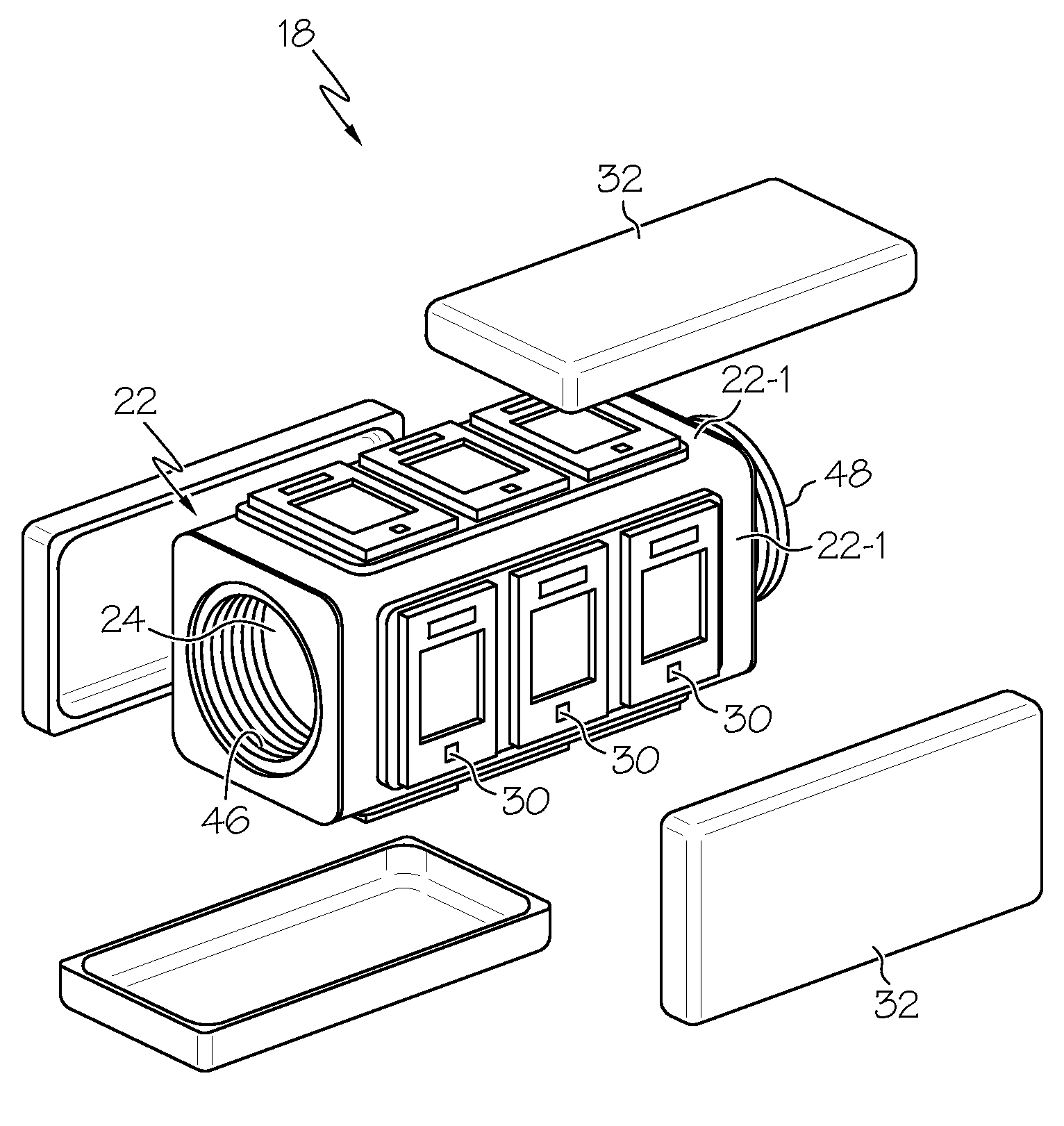

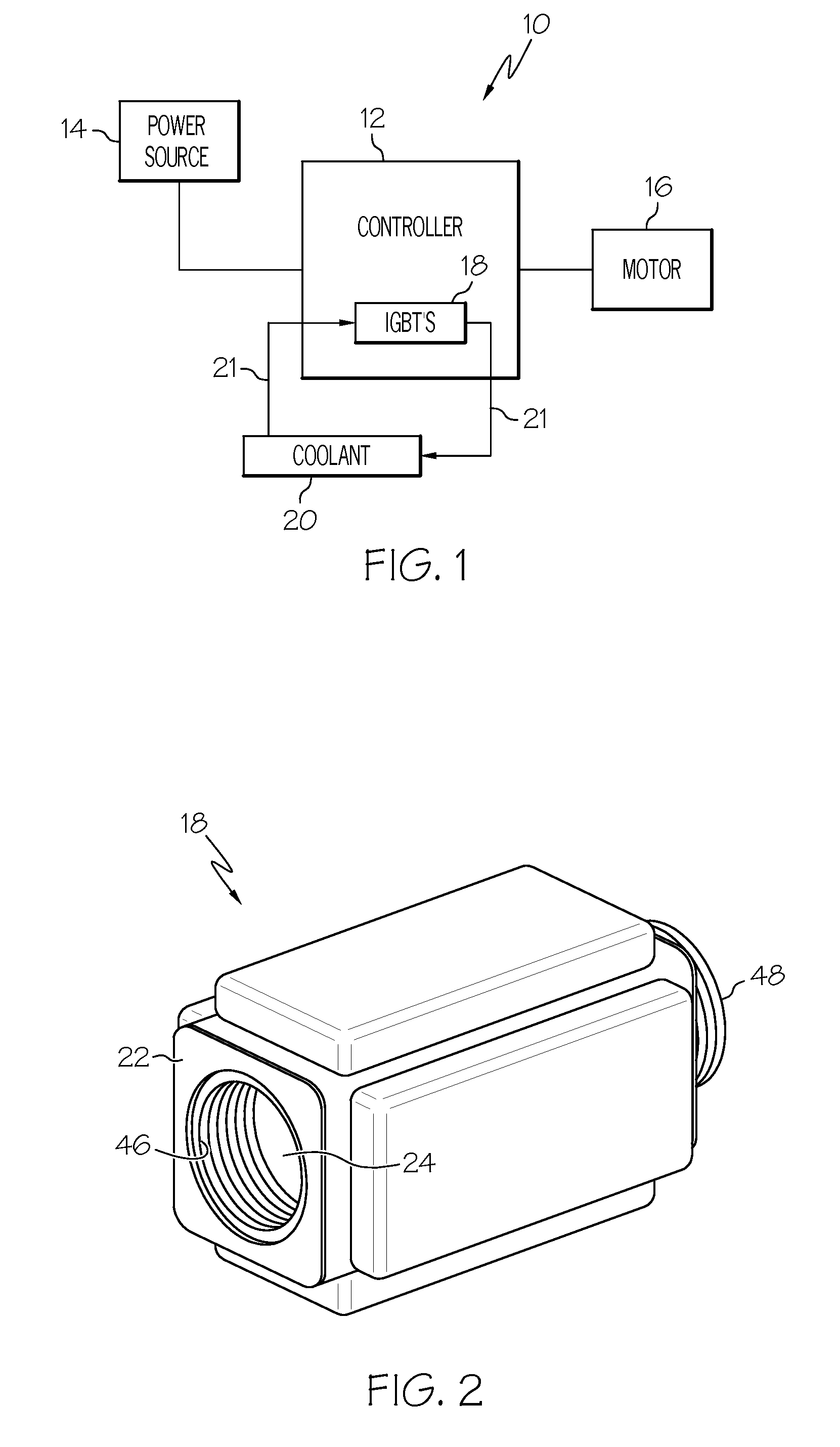

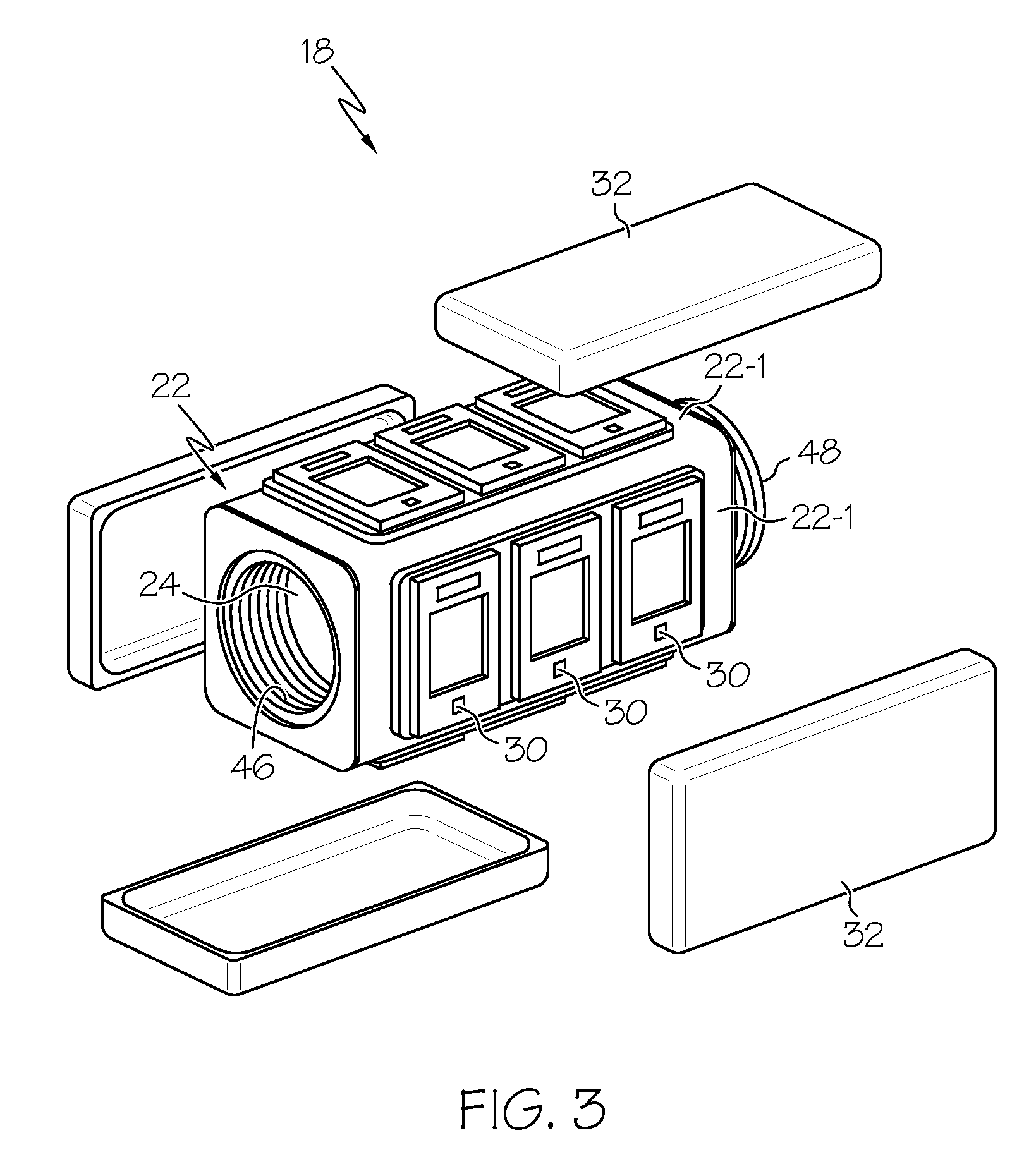

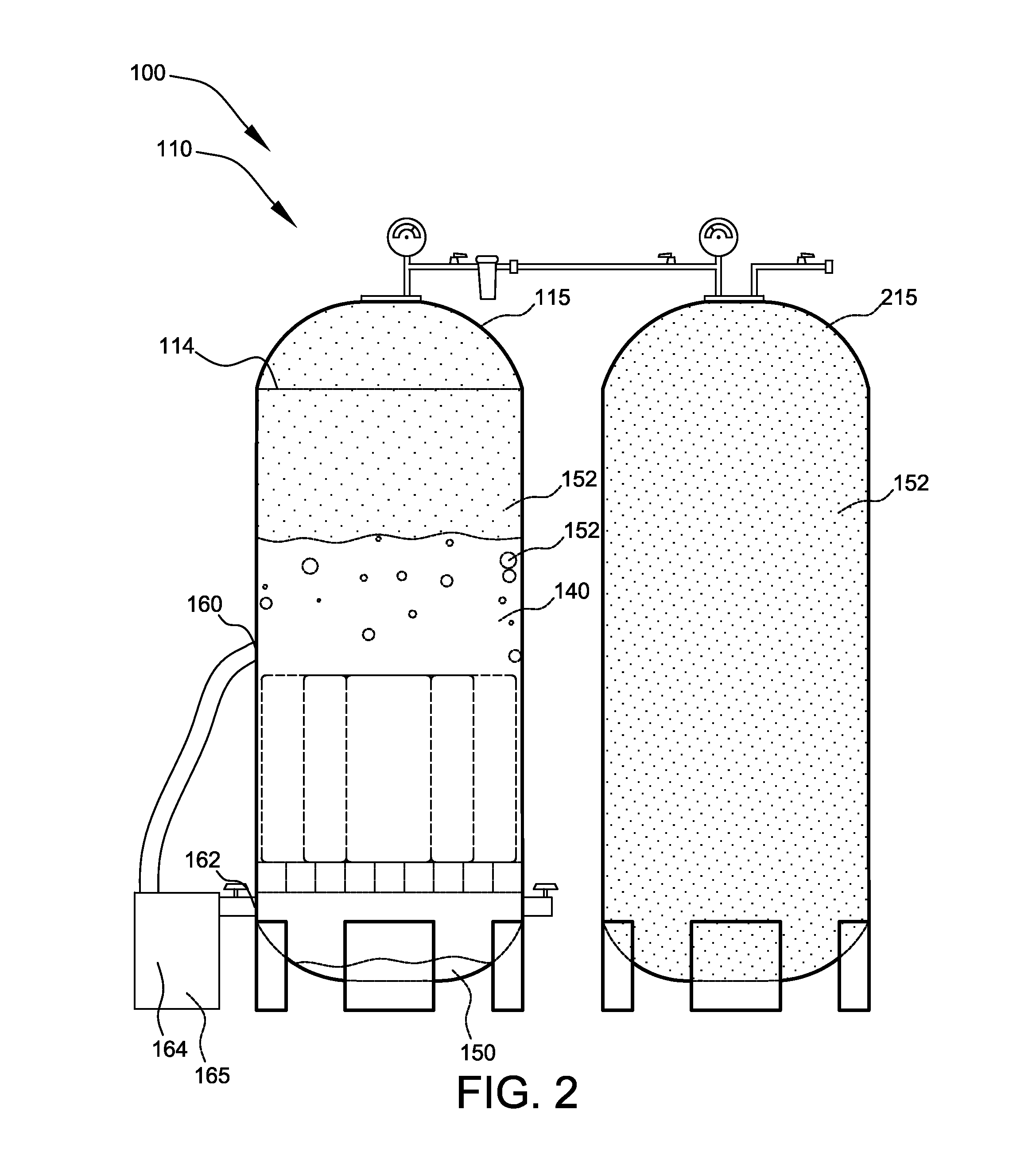

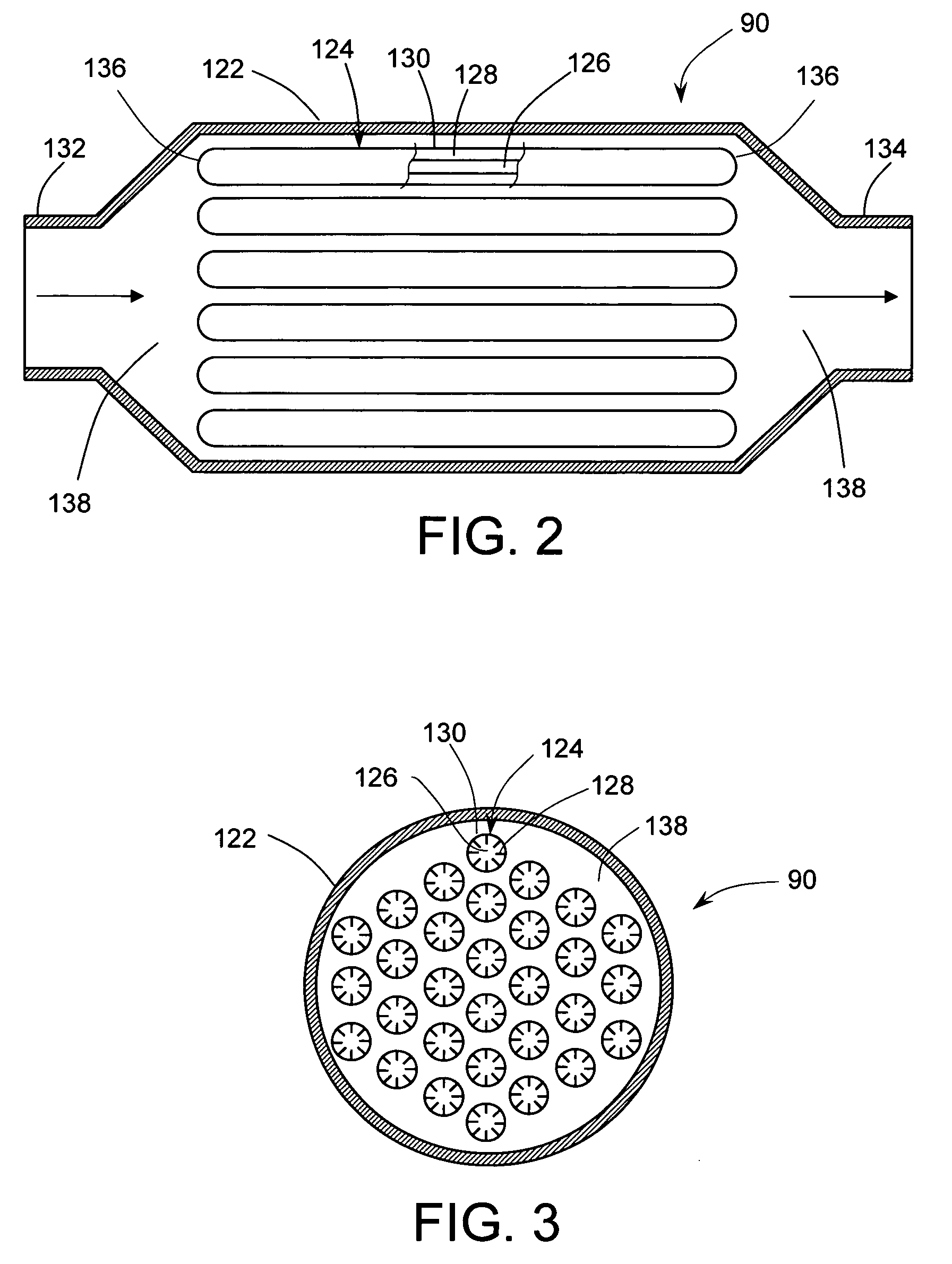

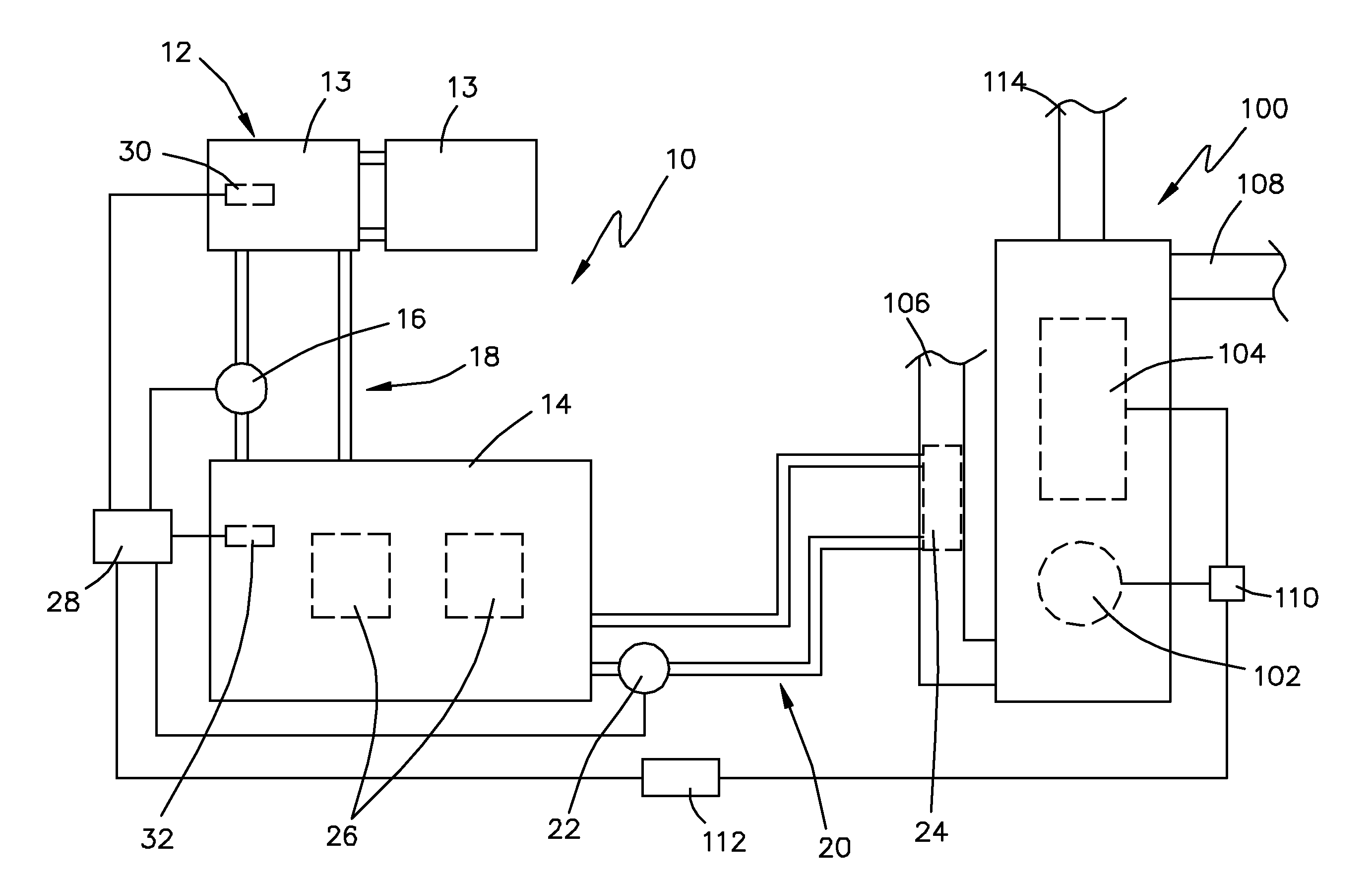

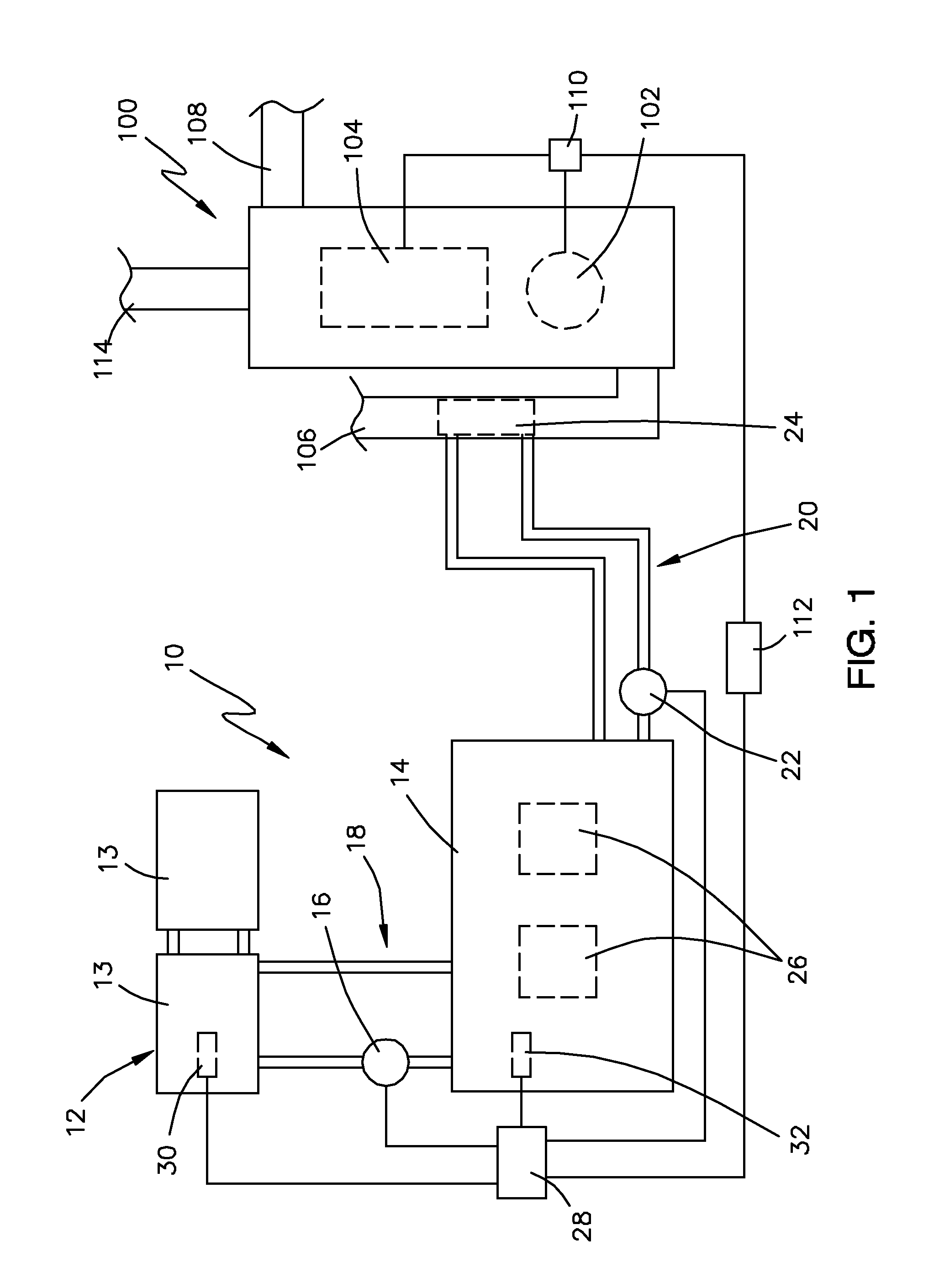

IGBT packaging and cooling using PCM and liquid

InactiveUS20090284923A1Indirect heat exchangersHeat exchange apparatusPower control systemEngineering

A power control system may use power semiconductor devices such as insulated gate bipolar transistors (IGBT's) in a switching unit to provide motor control. The IGBT's may be cooled with a system that is configured and sized to provide proper cooling at steady-state operating conditions of the switching unit. The IGBT's may be placed in thermal communication with a compartment that may contain phase change material (PCM). When and if the switching unit is operated under transient high load conditions, excess heat may be absorbed by melting of the PCM. When steady state operating conditions are restored the PCM may solidify and release its latent heat to a coolant. The PCM may thus act as a thermal buffer for the cooling system and thus may provide that the cooling system may be minimally sized.

Owner:HONEYWELL INT INC

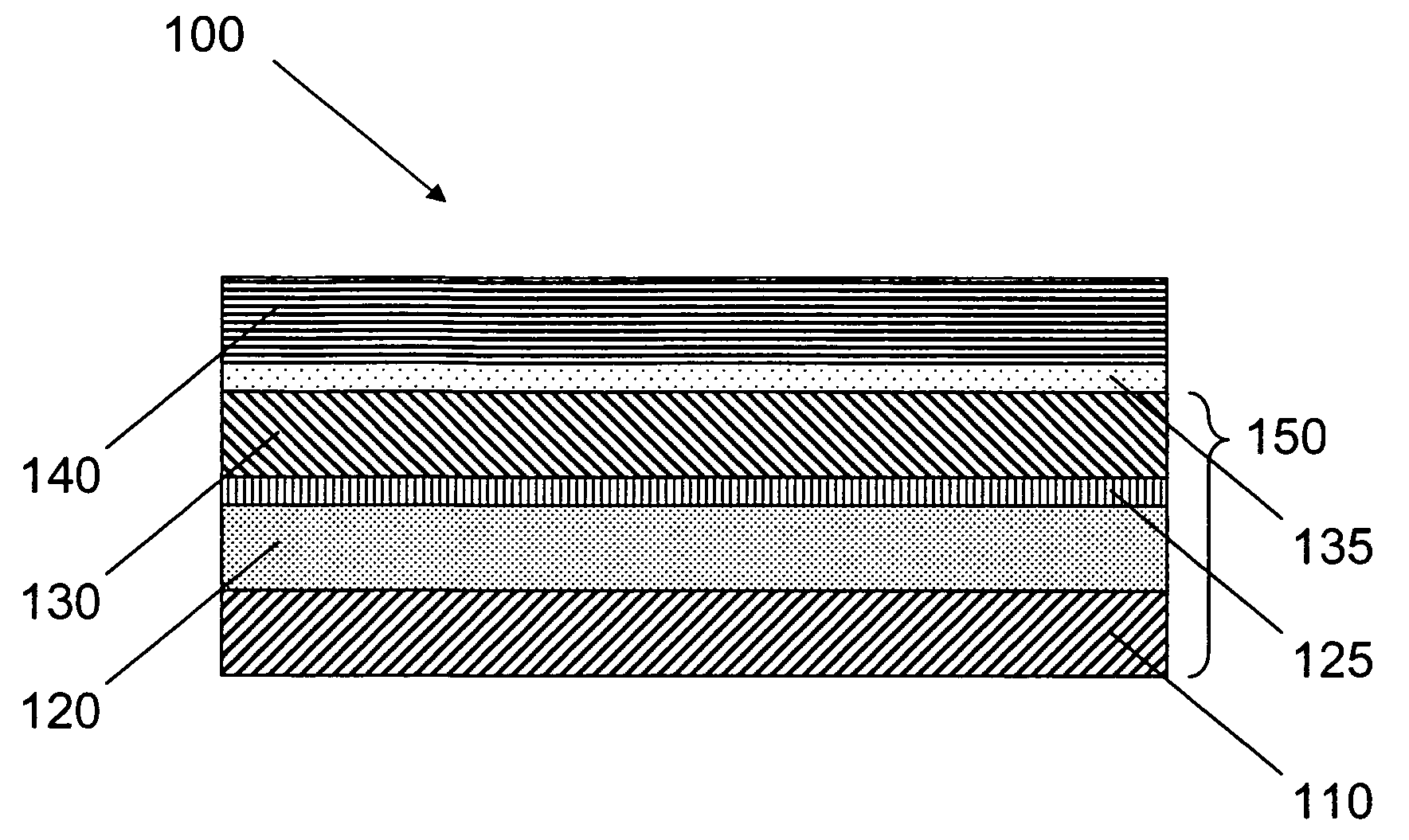

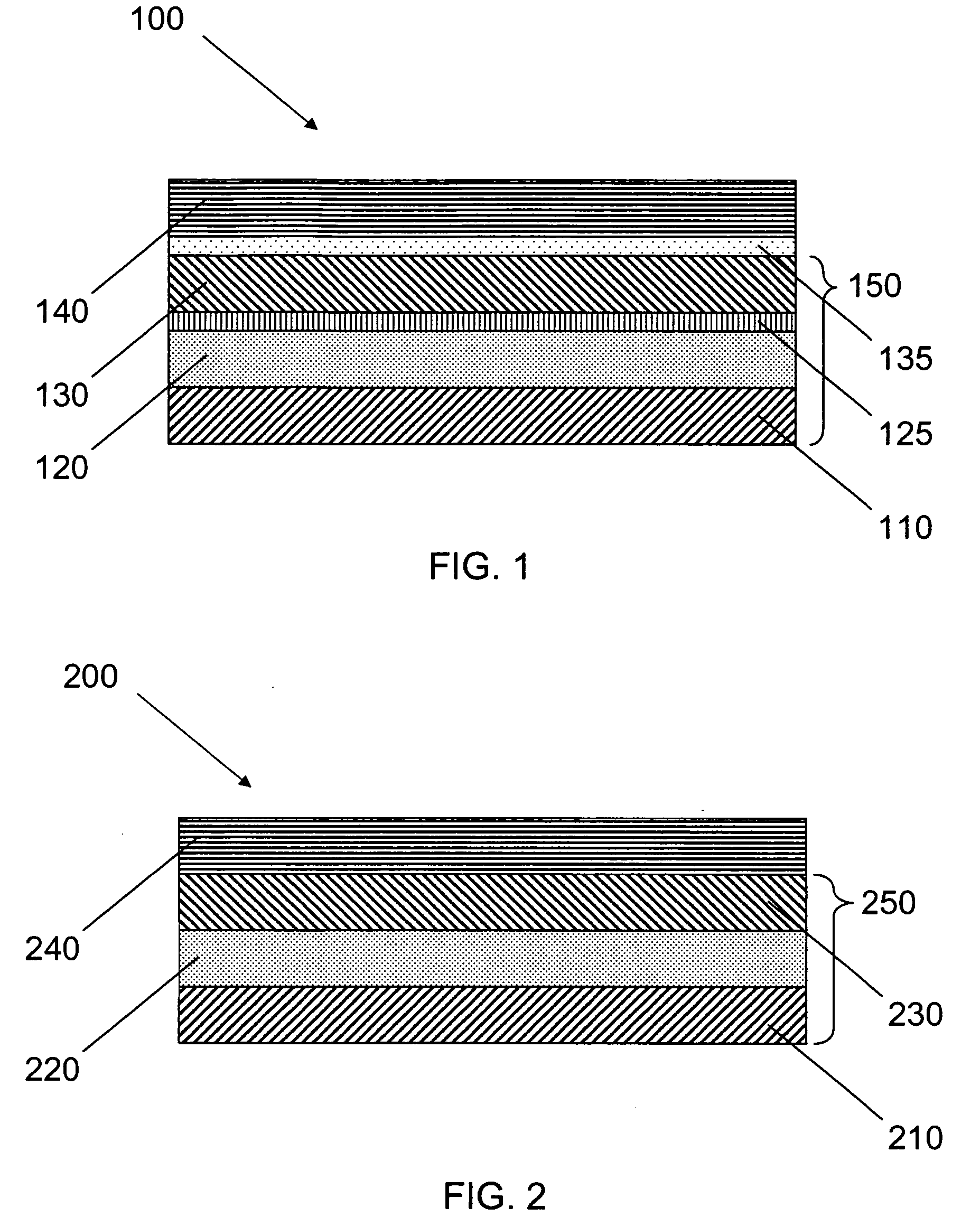

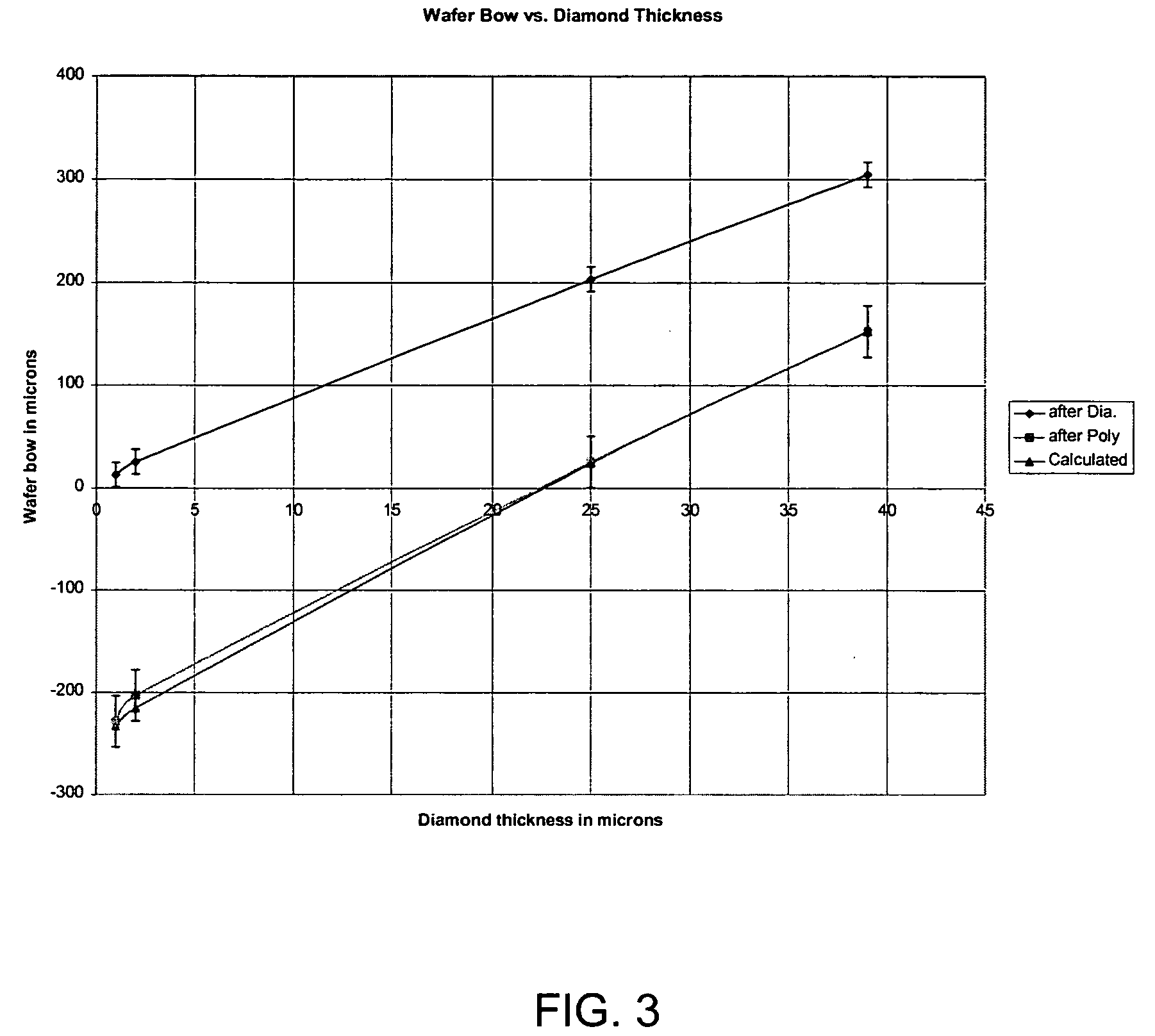

Wide bandgap semiconductor layers on SOD structures

InactiveUS20060113545A1Semiconductor/solid-state device manufacturingSemiconductor devicesBroadbandOpto electronic

Multi-layered structures containing GaN on SOD (silicon / diamond / silicon) substrates are described. The unique substrate / epilayer combination can provide electronic materials suitable for high-power and opto-electronic devices without commonly observed limitations due to excess heat during device operation. The resulting devices have built-in thermal heat spreading capability that result in better performance and higher reliability.

Owner:SP3 +1

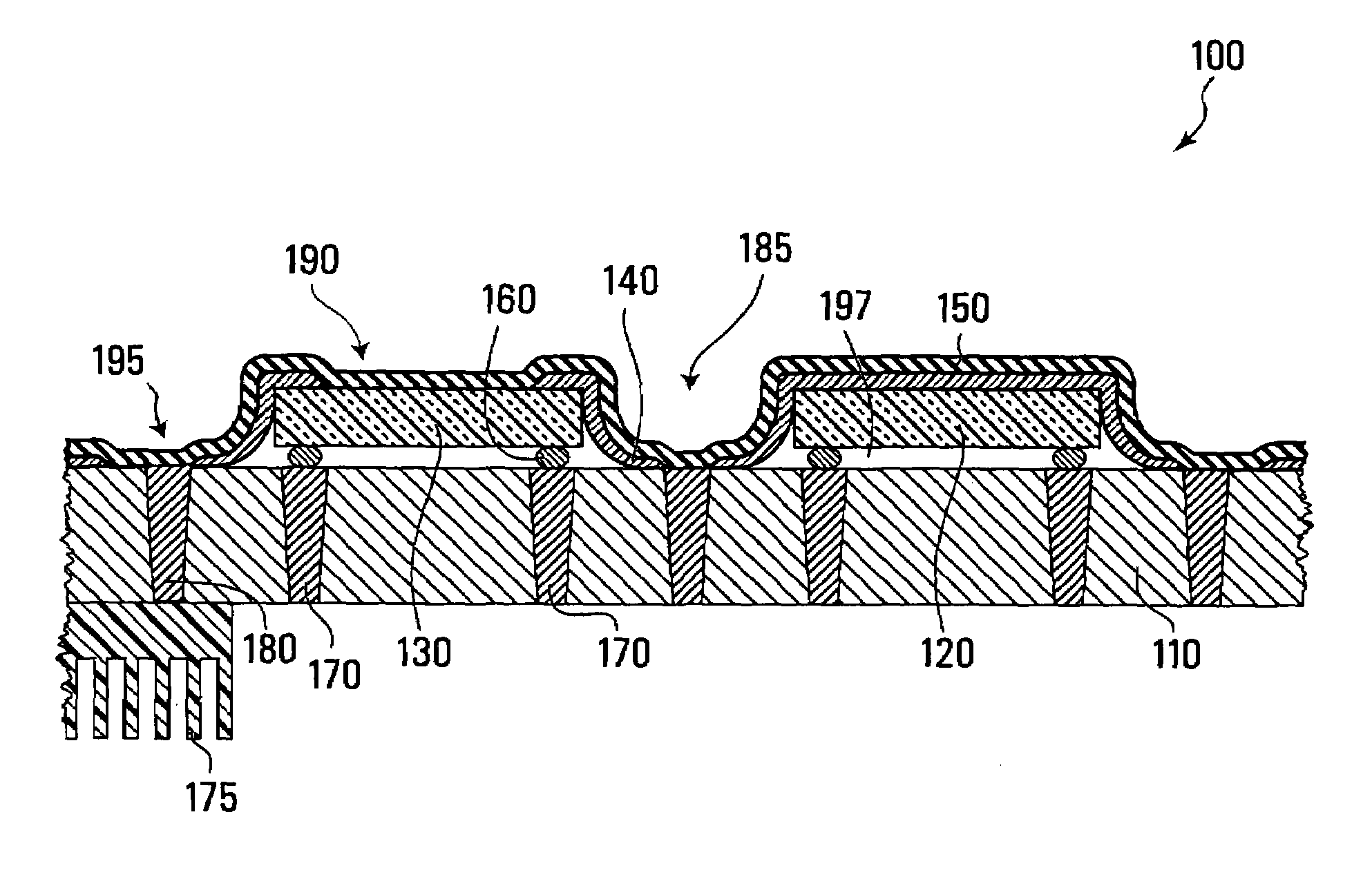

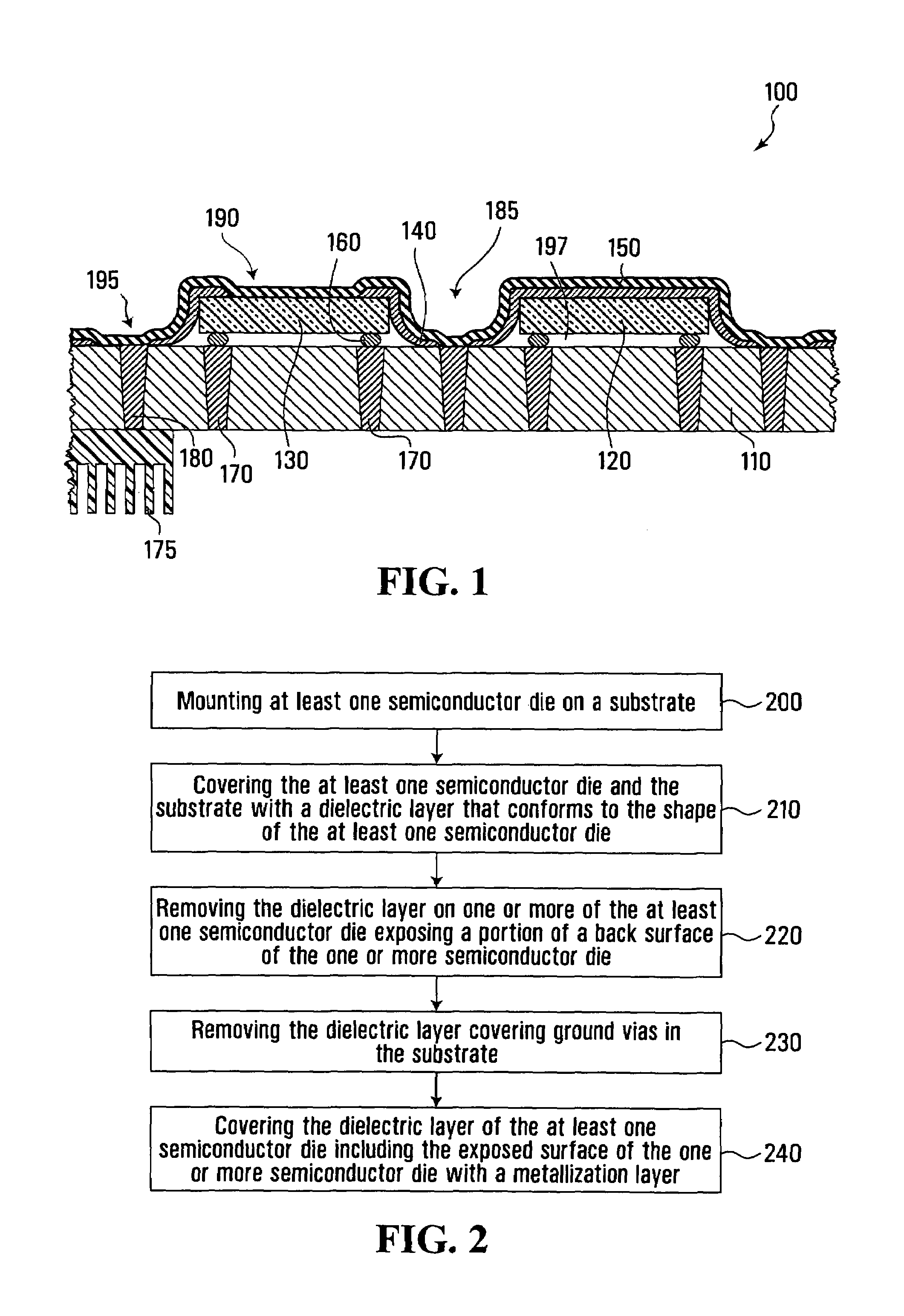

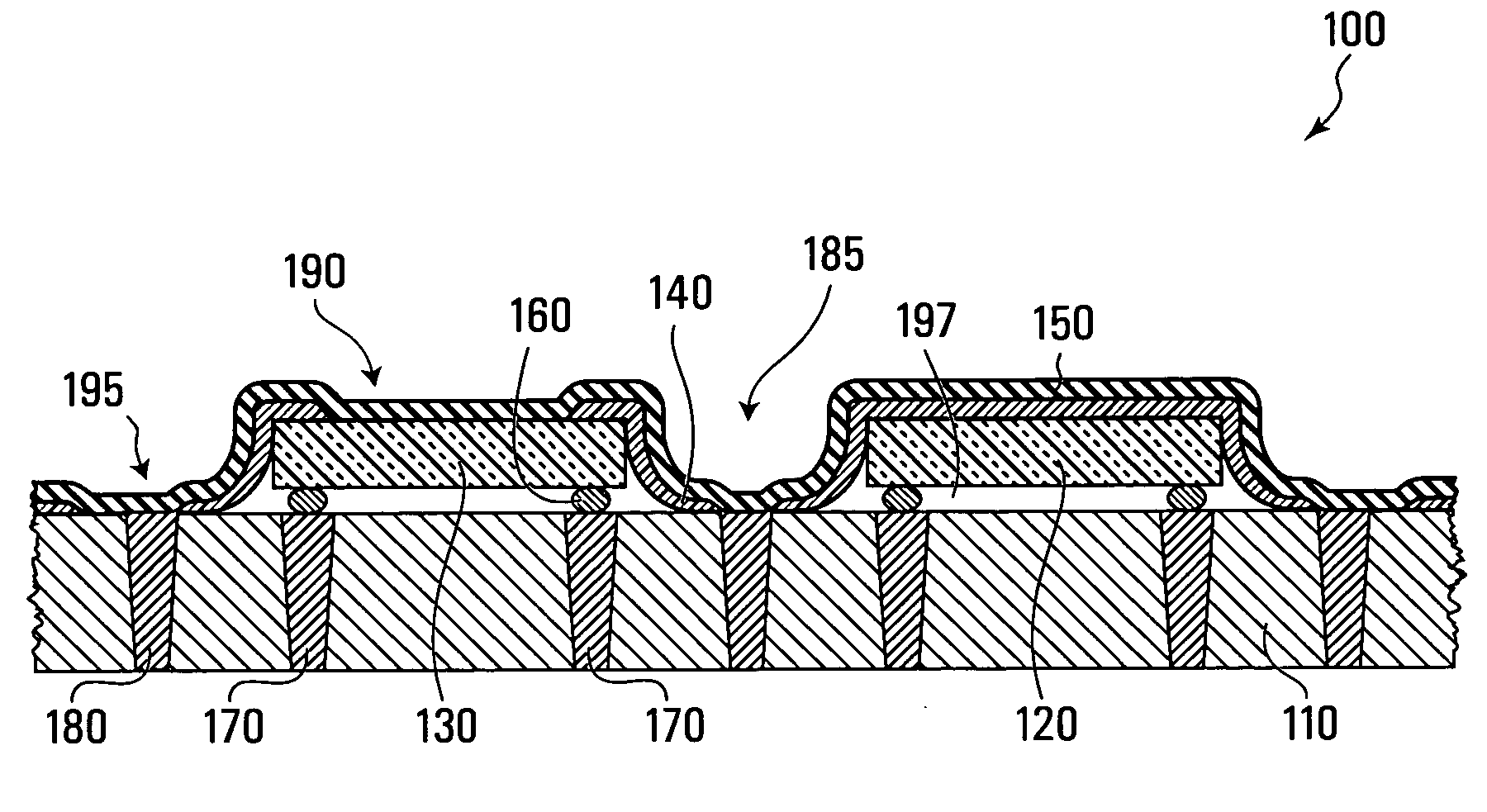

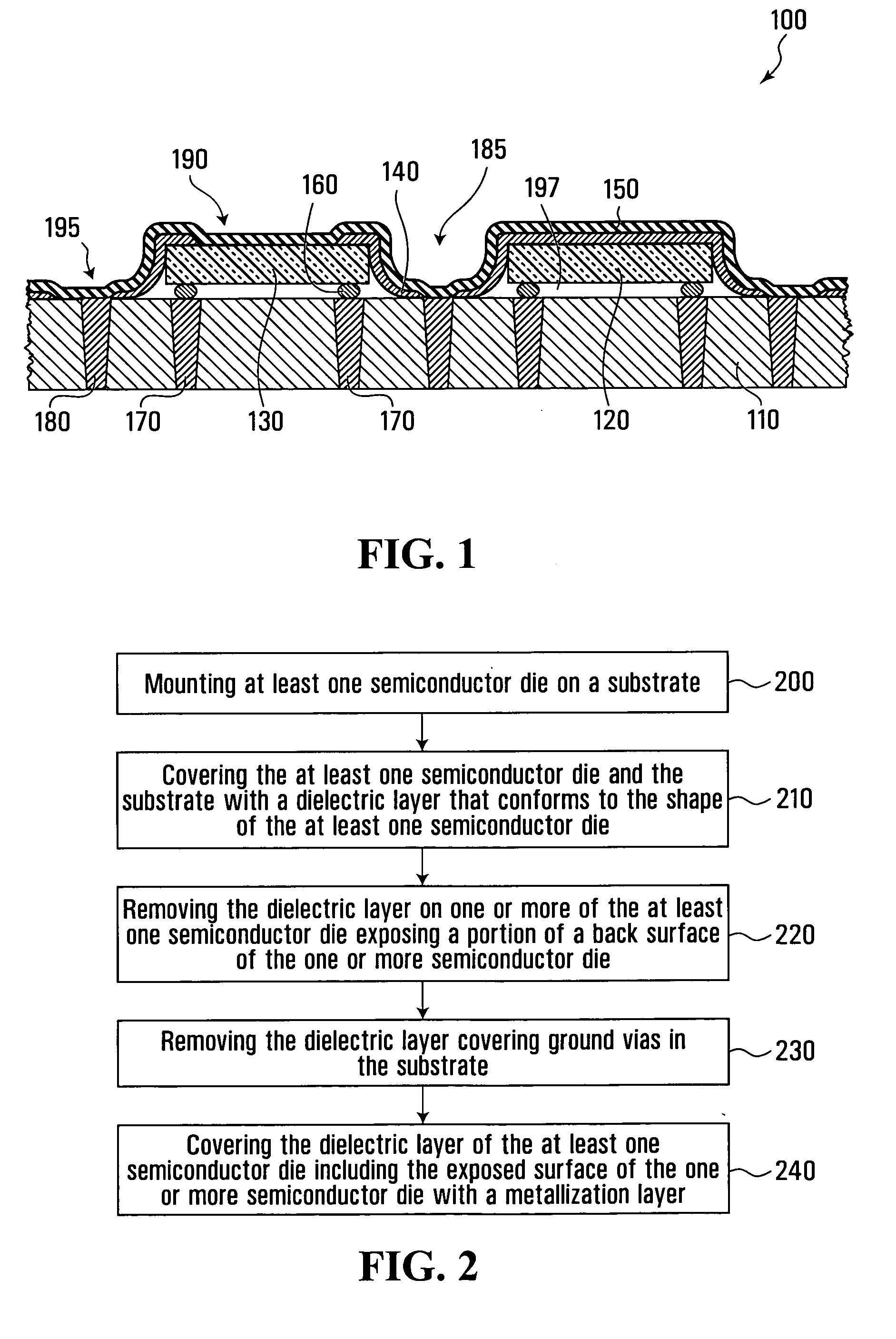

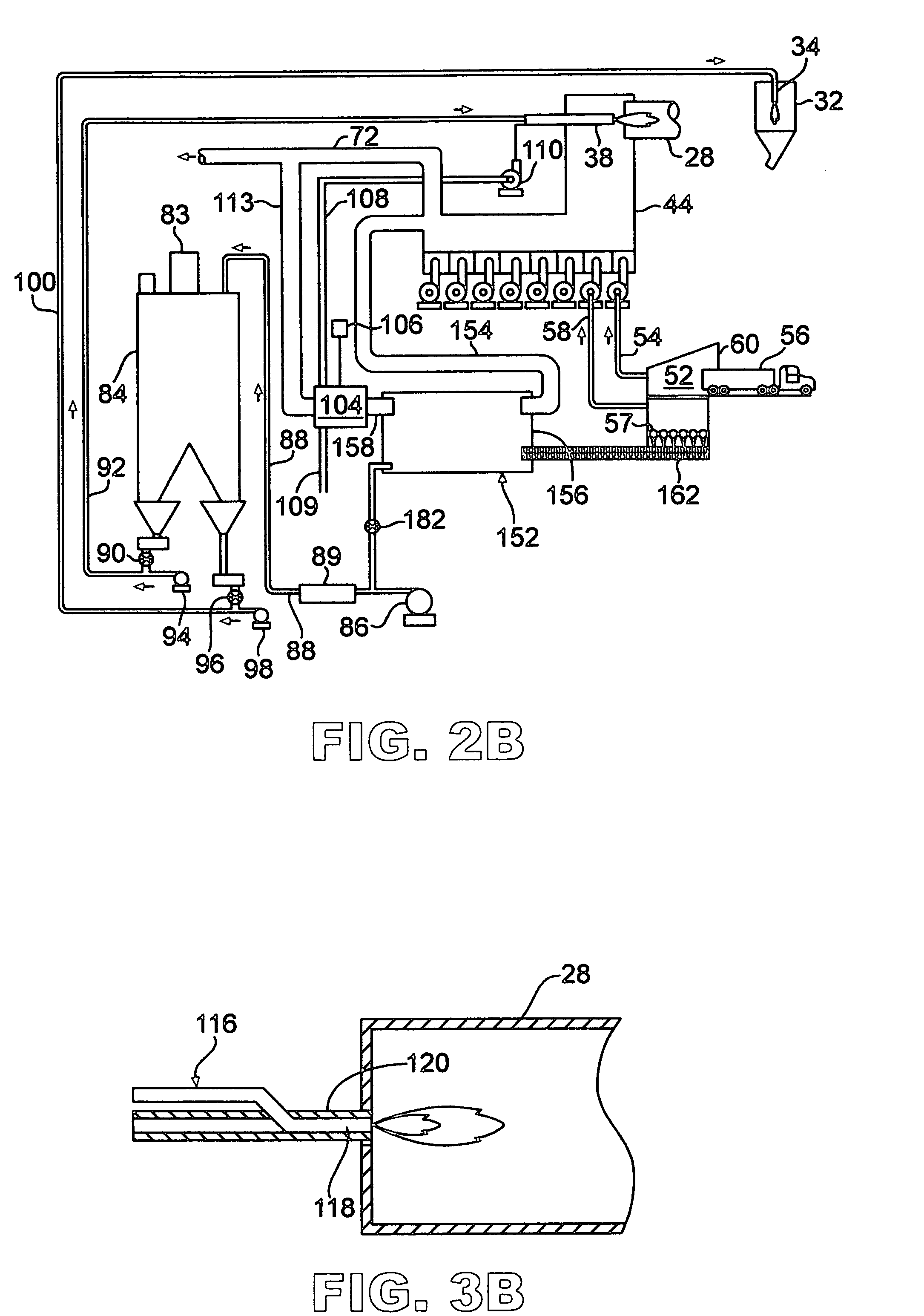

Methods for integrated circuit module packaging and integrated circuit module packages

ActiveUS20070138614A1Impedence networksSemiconductor/solid-state device detailsThermal isolationElectromagnetic interference

In order to achieve electromagnetic and / or thermal isolation between components in close proximity to each other on a common module substrate, an alternate package and method for manufacturing the package is provided. Inventive methods utilize a grounded, metal-coated overmold for a IC module package that can provide an alternate thermal path to heat sink high power components generating excess heat energy and / or provide general electromagnetic shielding and isolation between two integrated circuits in very close proximity that are susceptible to electromagnetic interference. A dielectric layer conformably covers semiconductor dies mounted on a substrate. On some semiconductor dies, a portion of the dielectric layer is removed from the back surface of the semiconductor dies to allow direct contact between the exposed back surface of the dies and a metallization layer forming part of the overmold. This direct contact allows heat energy to be drawn away from the dies. The metallization layer also acts to shield the dies from disruptive electromagnetic energy radiated from other dies in close proximity.

Owner:SKYWORKS SOLUTIONS INC

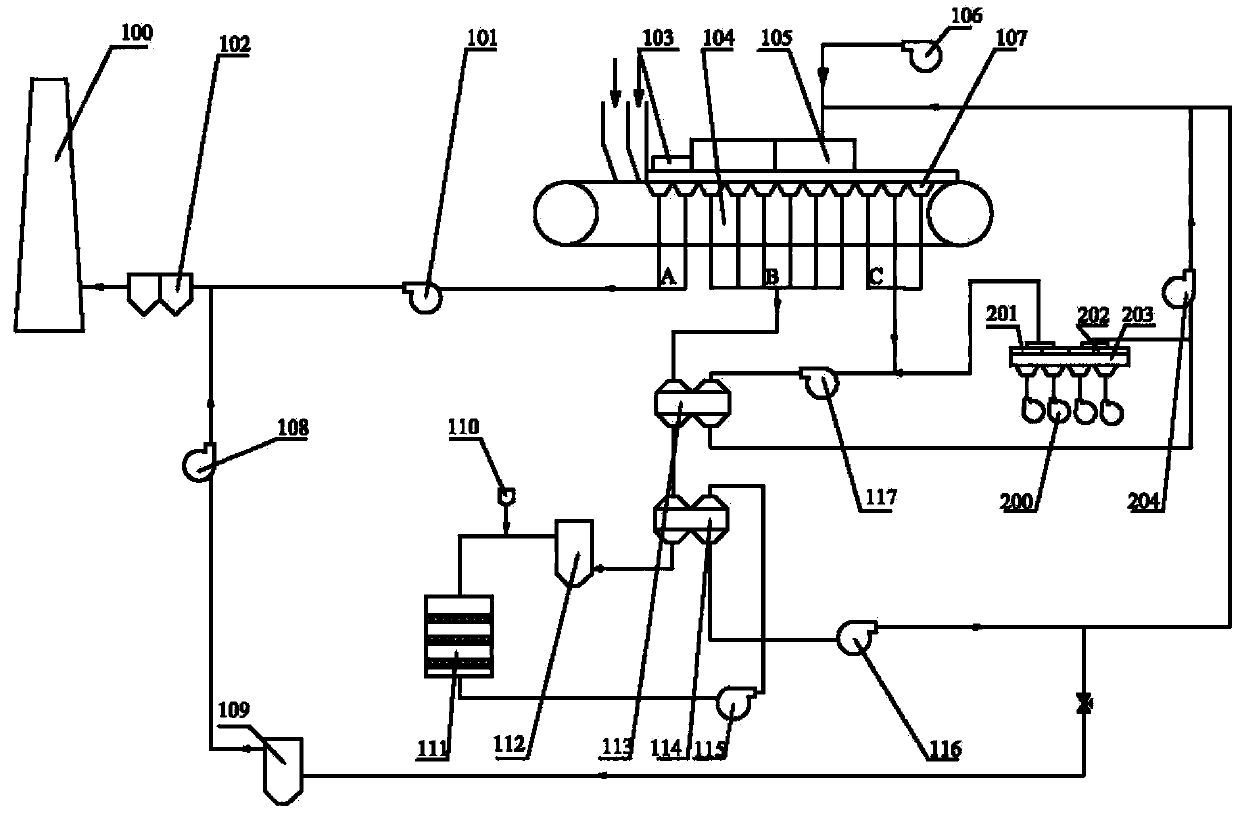

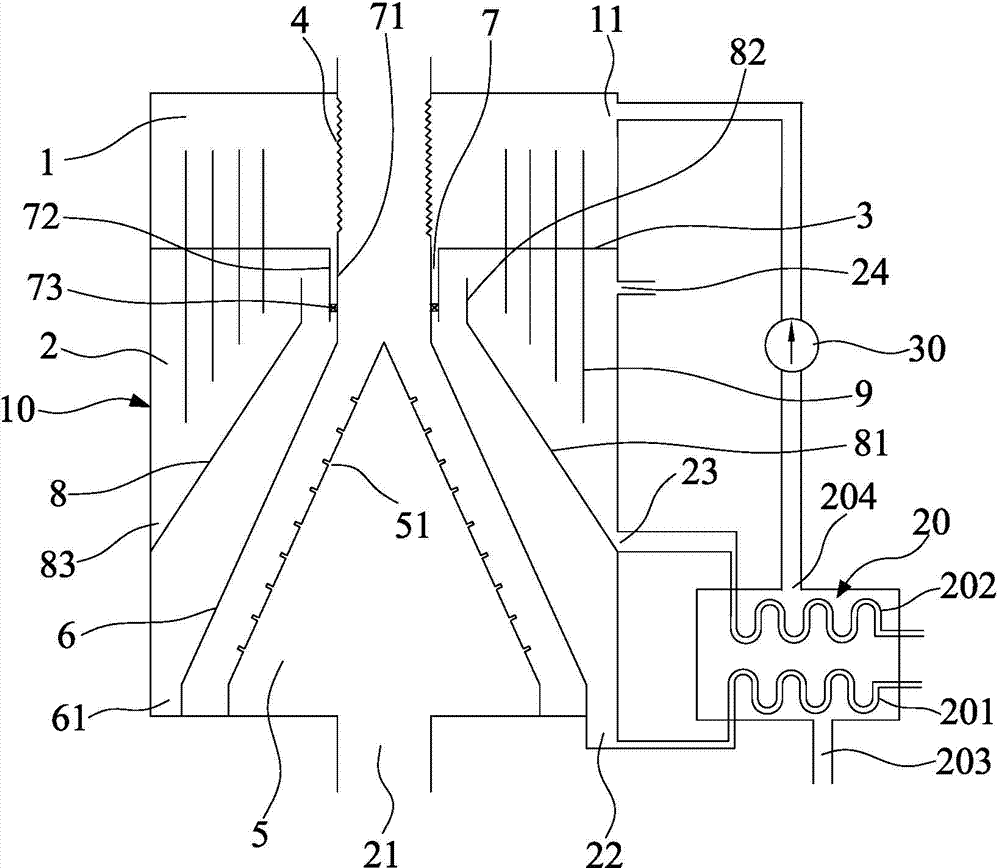

Sintering energy-saving technique and system capable of removing multiple pollutants

InactiveCN104195326ACompact structureOptimize layoutDispersed particle separationAir quality improvementSinter PlantMulti pollutant

The invention discloses a sintering energy-saving technique capable of removing multiple pollutants. Flue gas discharged by a sintering wind box on the lower part of a sintering machine is sequentially divided into section A flue gas positioned at the head of the sintering machine, section B flue gas positioned in the middle of the sintering machine, and section C flue gas positioned at the tail of the sintering machine; the section A flue gas is discharged after being subjected to dust removal treatment; and the section C flue gas is used for preheating the section B flue gas, the preheated section B flue gas is denitrified and divided into two parts, one part is discharged after being subjected to desulfurization treatment, and the other part is sent into the sintering machine together with the section C flue gas to perform circulating sintering. The invention also discloses a sintering energy-saving system capable of removing multiple pollutants. The technique and system can treat dust, oxynitrides, sulfur dioxide, fluorides, heavy metals and many other pollutants in the sintering flue gas, can utilize the excess heat of the flue gas of the main flue of the sintering machine and the flue gas discharged by the cooling machine, and can lower the energy consumption of the sintering plant, thereby implementing energy saving and emission reduction.

Owner:ZHEJIANG UNIV

Engine cooling system with overload handling capability

InactiveUS7735461B2Emission reductionReducing coolant inventoryLiquid coolingCoolant flow controlInternal combustion engineHydraulic fluid

A cooling system for an internal combustion engine incorporating a heat accumulator to temporarily store heat during peak heat loads. In automotive vehicles, the heat accumulator may store excess heat generated during vehicle acceleration or hill climbing and it may dissipate stored heat during vehicle cruise, deceleration, or engine idle. The heat accumulator contains phase change material with a solid-to-liquid transition temperature higher than the normal operating temperature of the cooling system. The invention enables reducing the size and weight of engine cooling system without compromising its performance. This is particularly important for improving fuel economy and reduction of emission in automotive vehicles. In addition, the invention enables reducing the coolant inventory in the system thereby allowing for faster engine warm-up and reduced emissions of harmful pollutants during a cold engine start. The invention may be also used for thermal management of engine oil, transmission fluid, or hydraulic fluid.

Owner:AGWEST

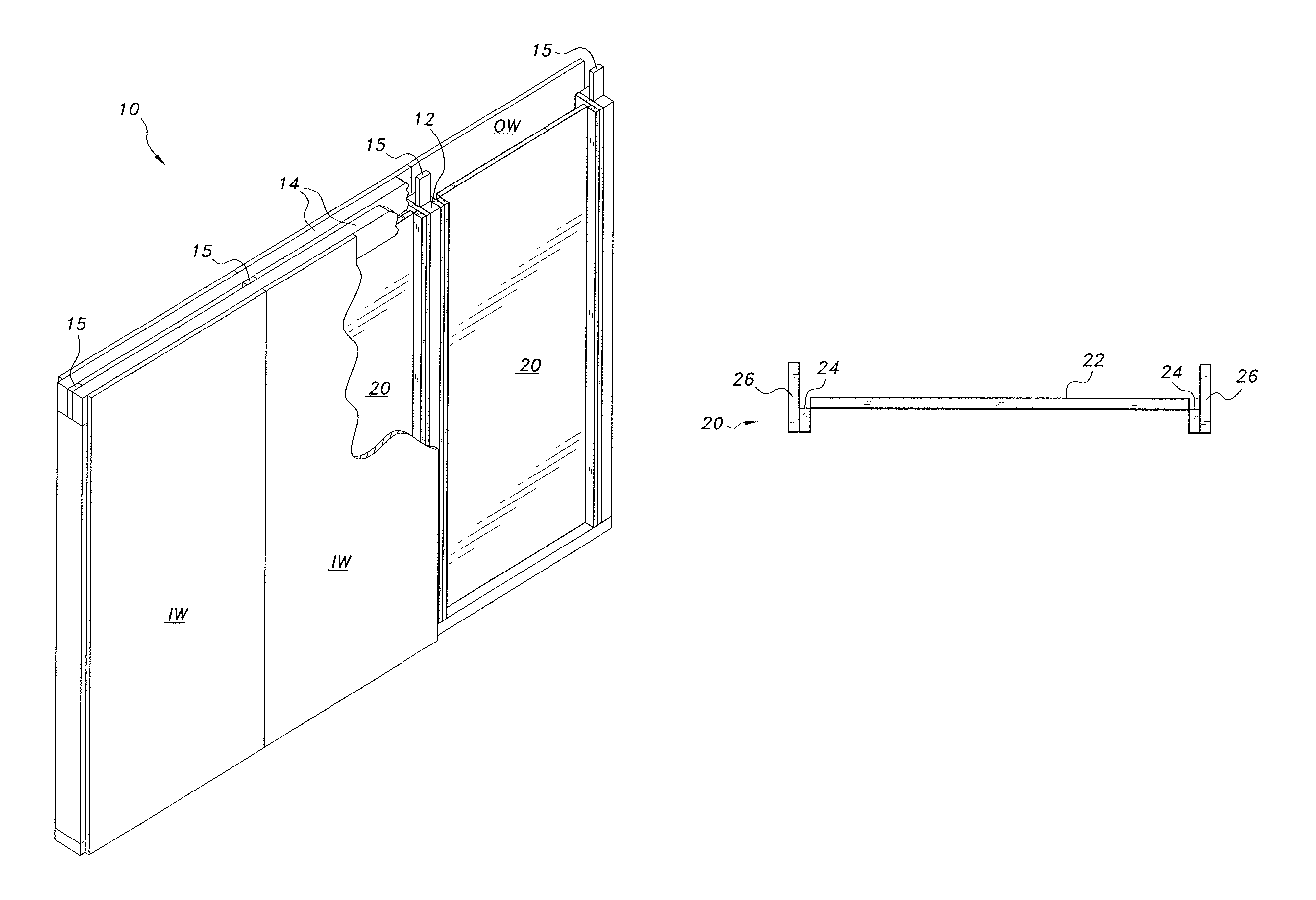

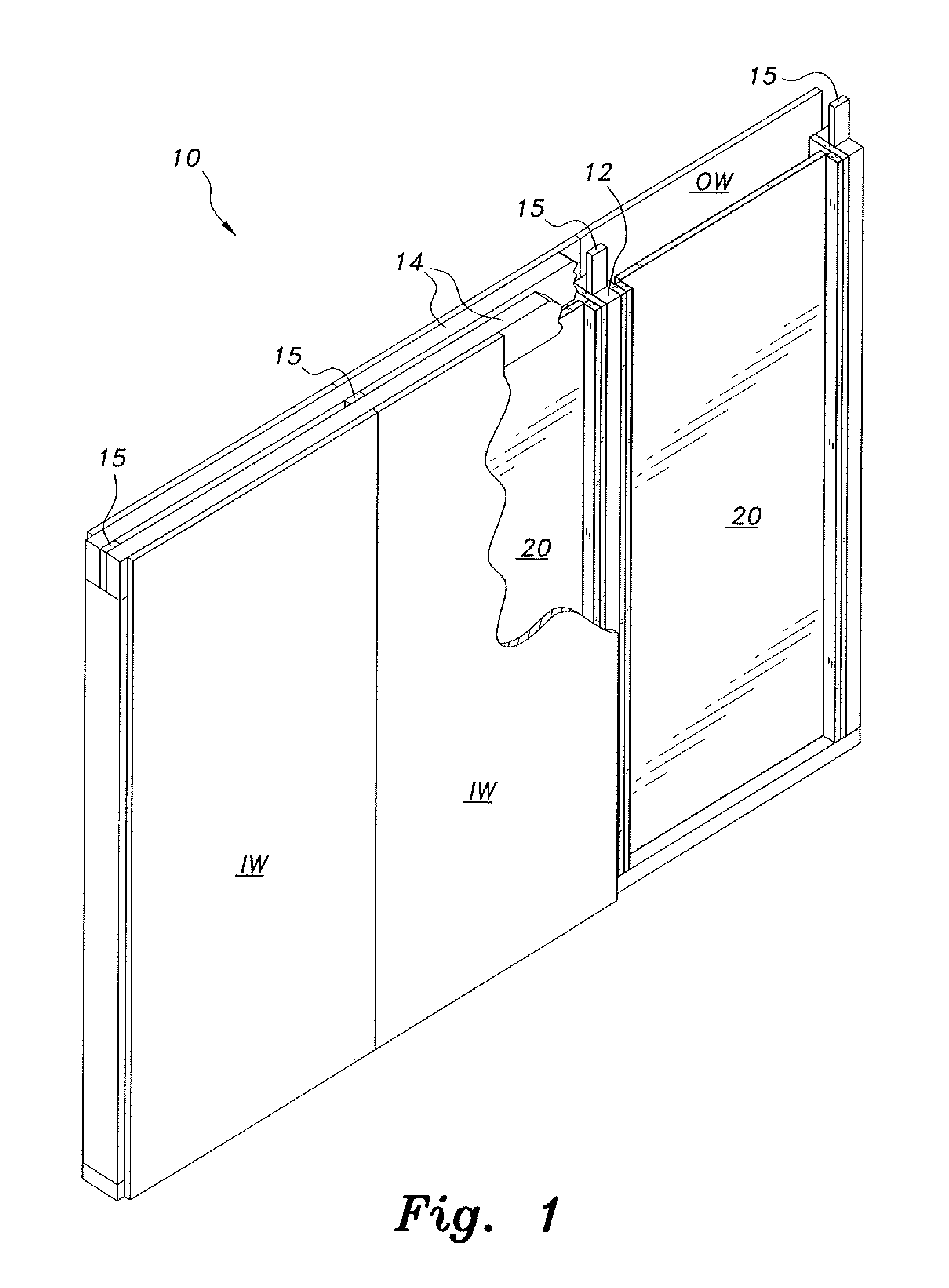

Thermal energy venting system

ActiveUS8528284B2Minimal costsMinimal expenditureBuilding roofsLighting and heating apparatusThermal energyThermal energy storage

Owner:ASPENSON MARK A

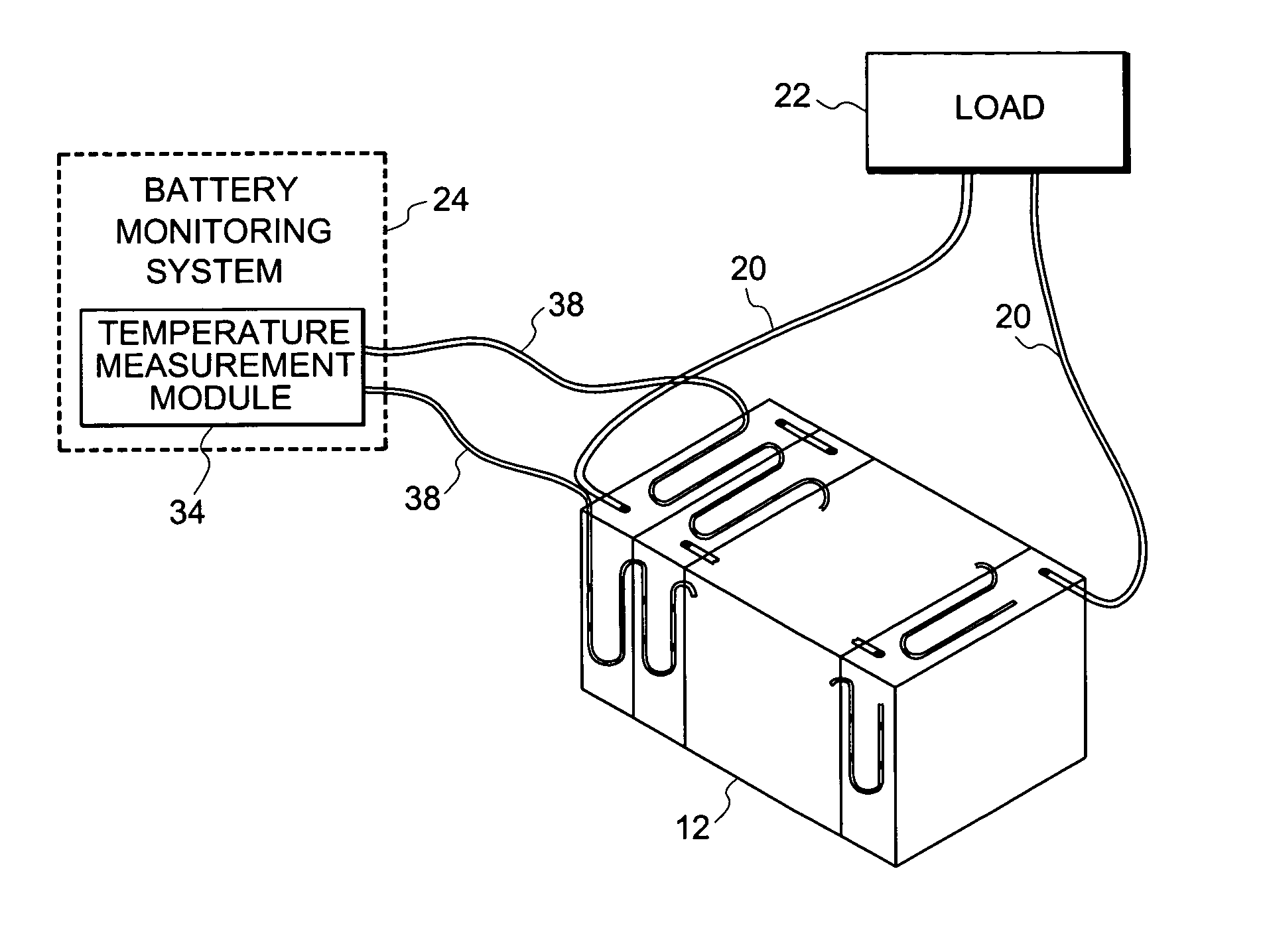

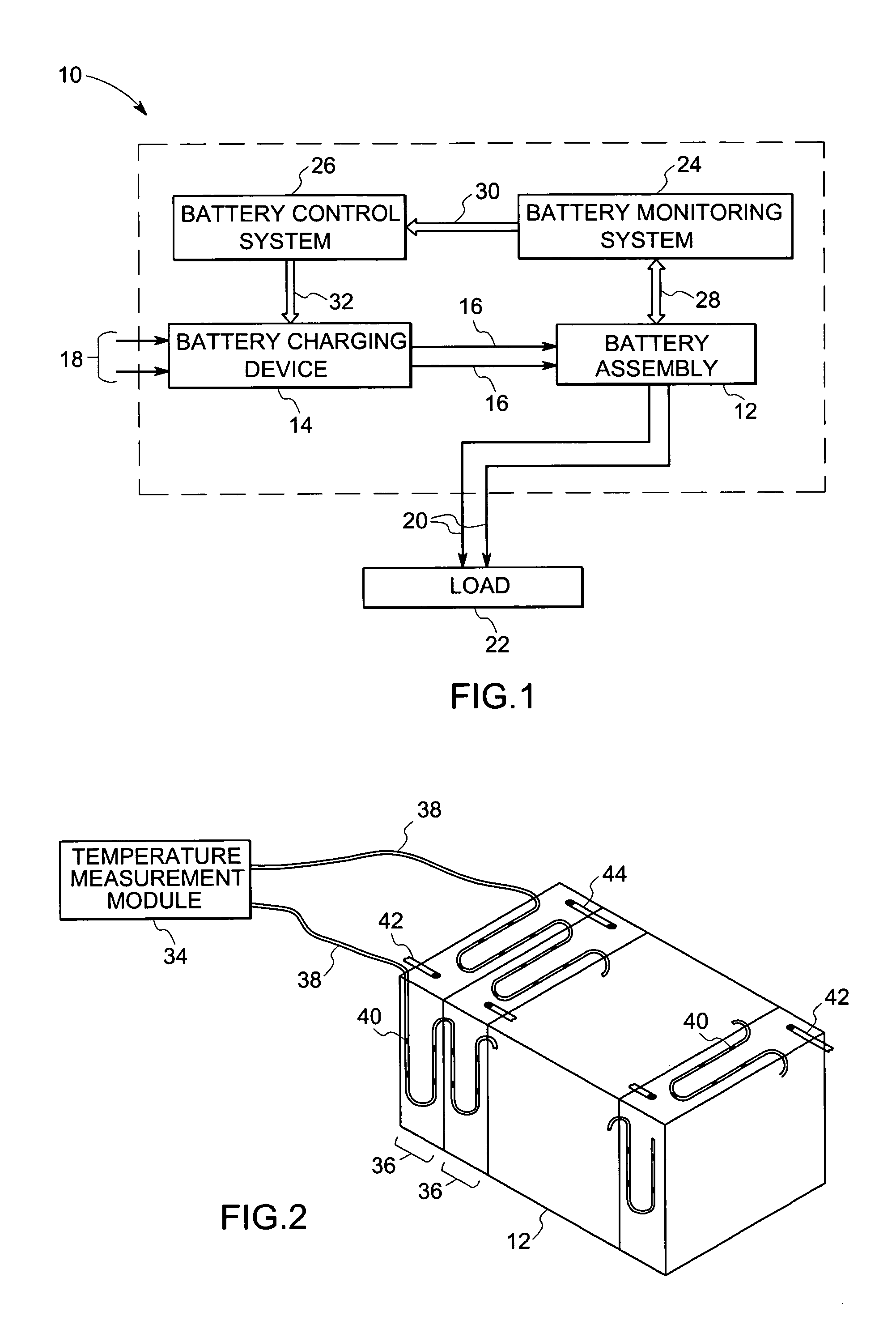

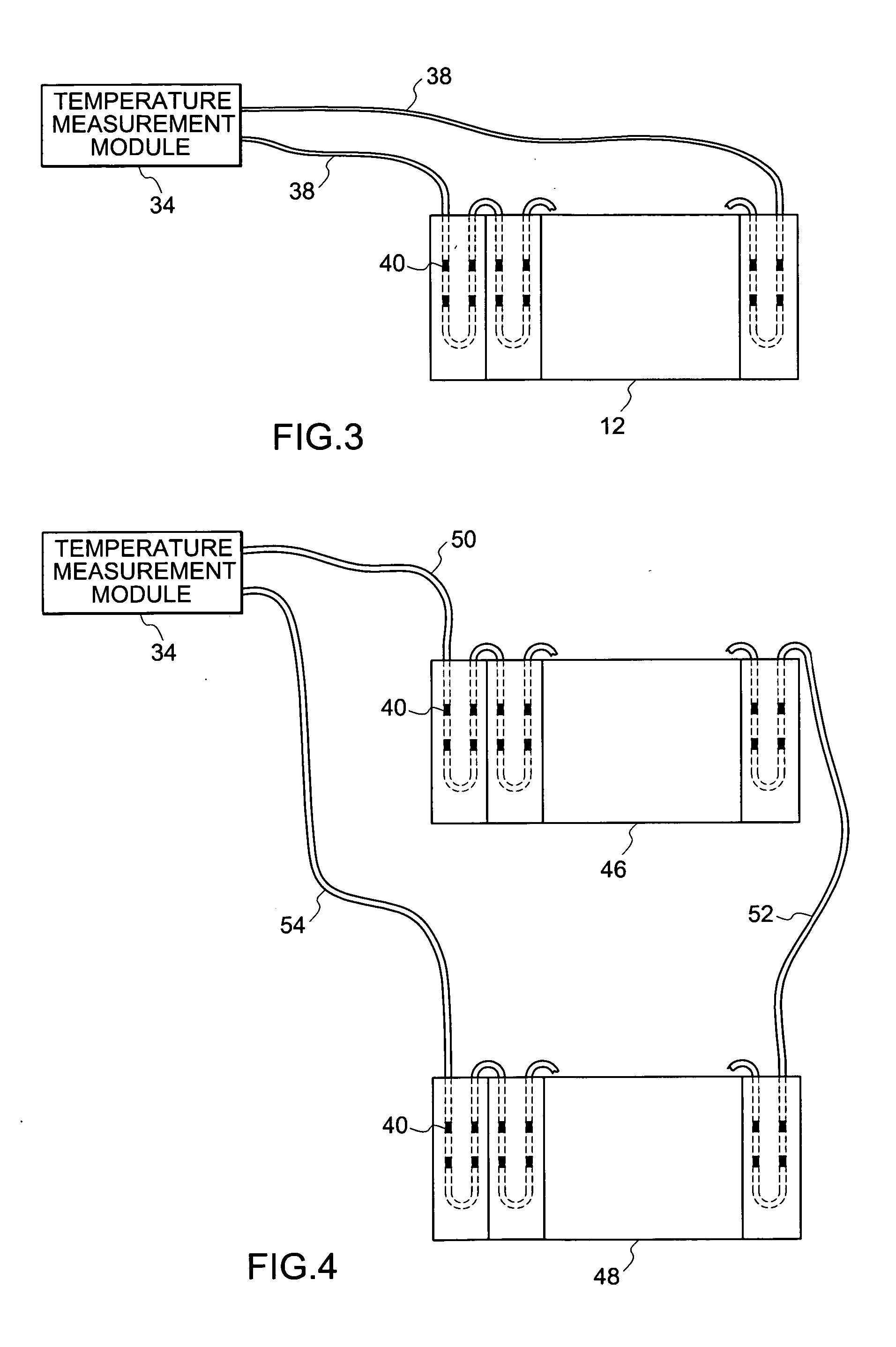

Optical battery temperature monitoring system and method

ActiveUS20050213867A1Effective monitoringEffective controlBatteries circuit arrangementsElectrical testingTemperature controlMonitoring temperature

Several methods for measuring and monitoring temperature have been presented for systems requiring temperature monitoring. In one implementation, the system has been applied to battery assemblies. Temperature measurements for every part of the battery assembly are disclosed. In one aspect the surface temperature of a battery assembly is measured. In another aspect, the internal temperature of the battery assembly is measured. In other aspects, the internal and external temperatures of several battery assemblies are measured. Based on the measured temperature, control signals are generated by a control system to switch down the power of the battery charging system so as to prevent excess heat generation.

Owner:GENERAL ELECTRIC CO

Phase change heat-conducting thermal silicone grease composition for central processing unit (CPU) radiating and preparation method thereof

ActiveCN103214848AImprove thermal conductivityImprove heat transfer performanceHeat-exchange elementsParaffin waxPhysical chemistry

The invention discloses a phase change heat-conducting thermal silicone grease composition for central processing unit (CPU) radiating. The phase change heat-conducting thermal silicone grease composition is prepared from the following raw materials in parts by weight: 5-10 parts of base oil, 5-10 parts of paraffin, 1-3 parts of vinyl trimethoxy silane, 80-90 parts of heat-conducting filler. The method for preparing the phase change heat-conducting thermal silicone grease composition for CPU radiating comprises the following steps: 1) performing particle size distribution on the heat-conducting filler; 2) mixing the compounded heat-conducting filler and vinyl trimethoxy silane in ethanol, regulating the pH of the solution to be 3-4, heating to the temperature of 70-80 DEG C, stirring for 2-4 hours, removing ethanol, and obtaining a modified inorganic filler; and 3) heating 5-10 parts by weight of paraffin to be melted, adding 5-10 parts by weight of base oil and the modified inorganic filler prepared in the previous step, and fully mixing to prepare the phase change heat-conducting thermal silicone grease composition. The phase change heat-conducting thermal silicone grease is high in heat-conducting coefficient and high in heat transfer capacity, and the excessive heat of the CPU can be rapidly derived, so that the service life of the CPU is prolonged, and the preparation process is simple.

Owner:SHENZHEN XINYA NEW MATERIALS CO LTD

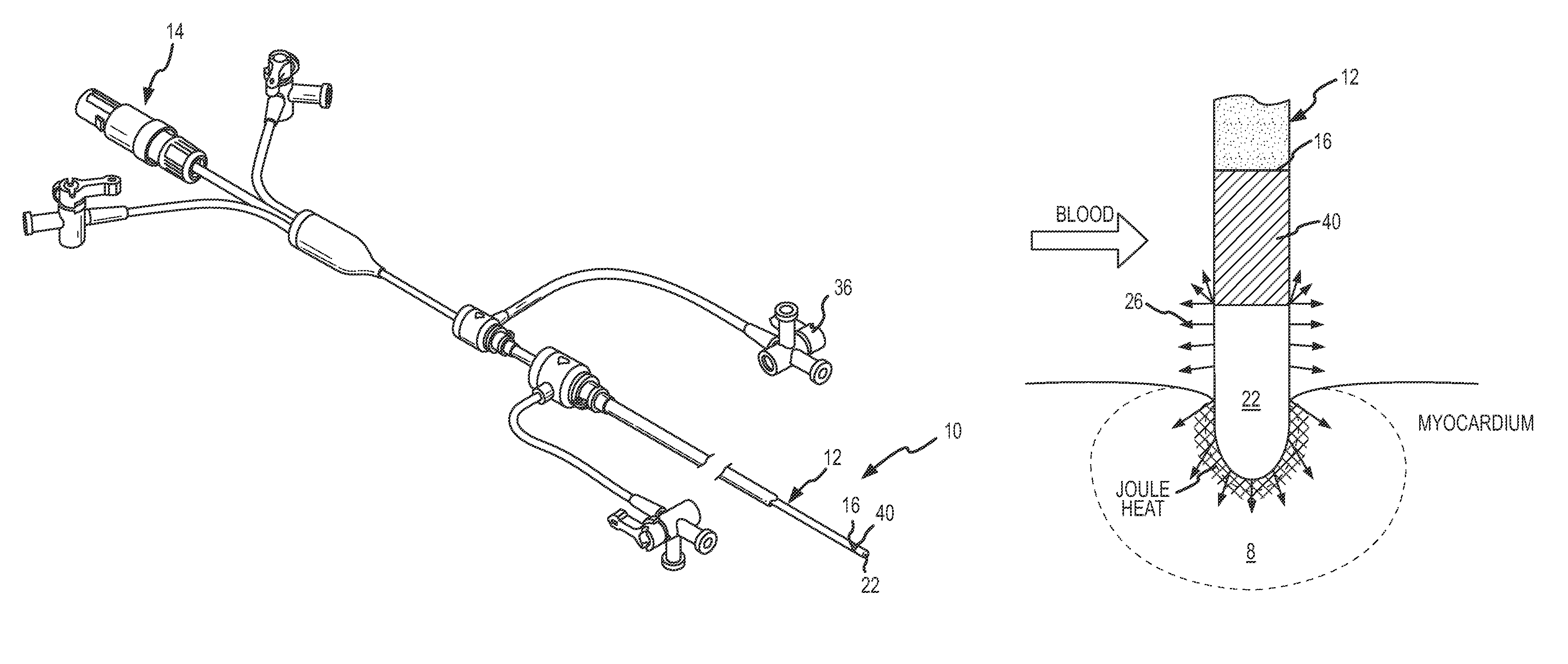

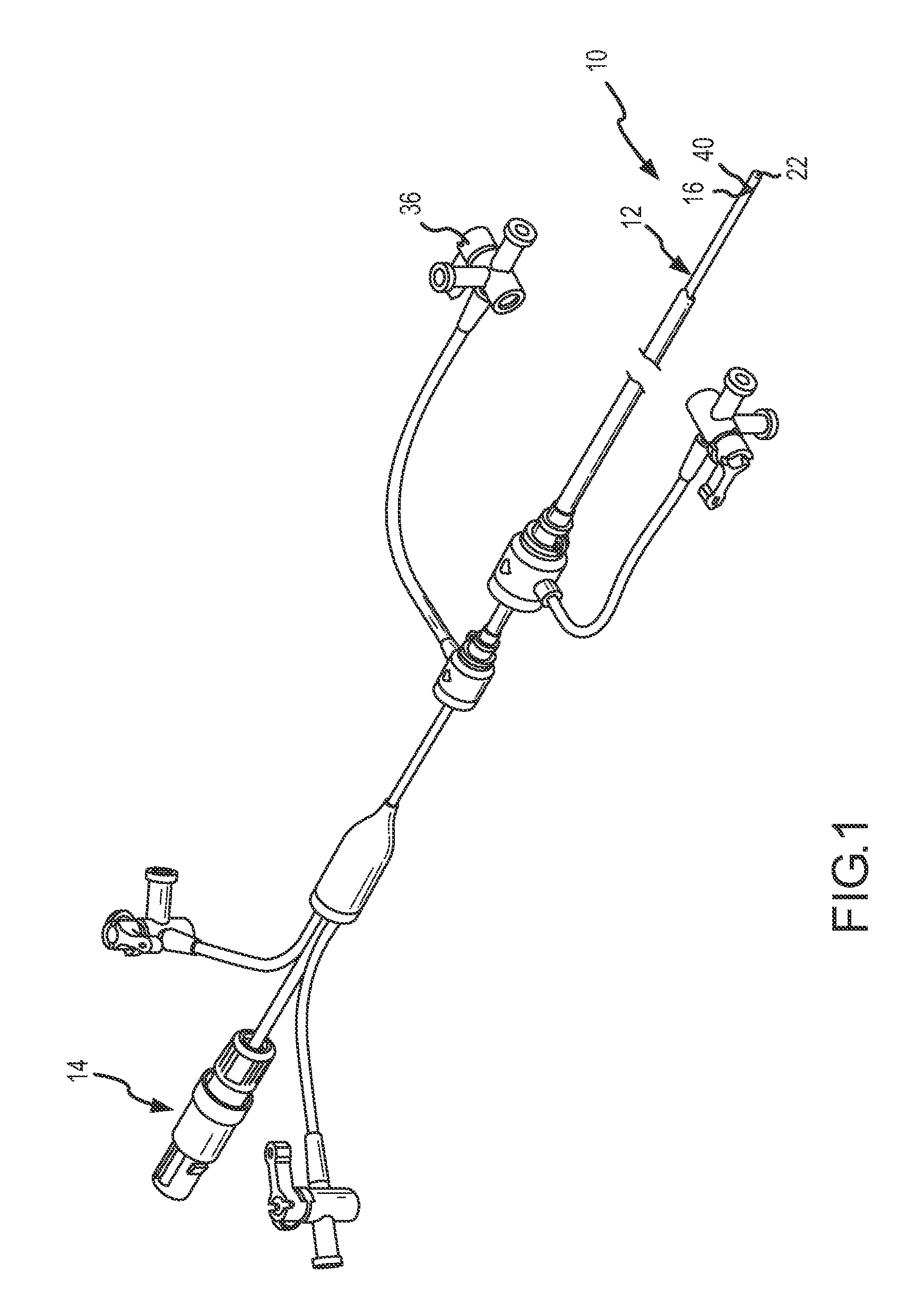

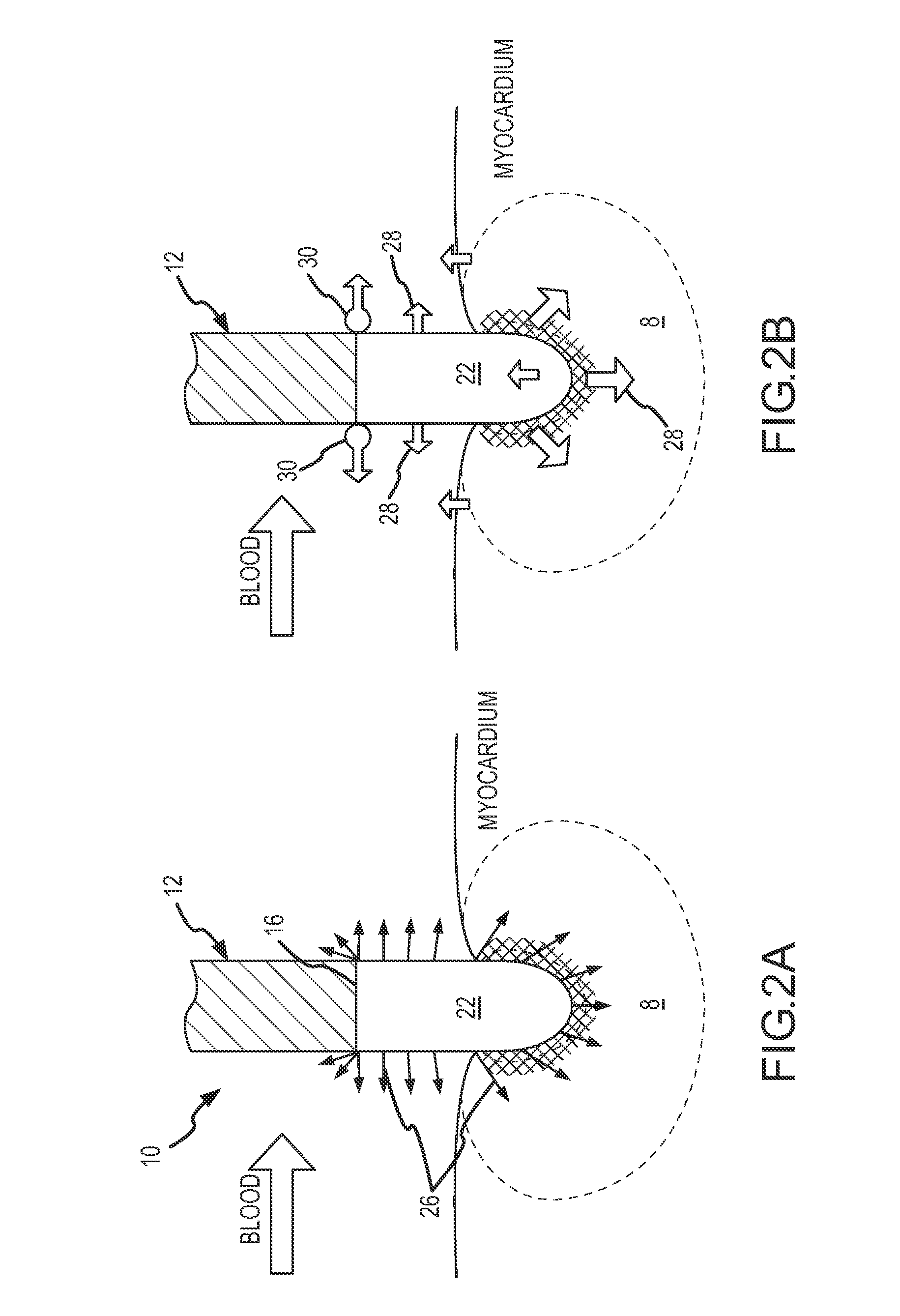

Ablation catheter with thermally mediated catheter body for mitigating blood coagulation and creating larger lesion

ActiveUS8449537B2Avoid overall overheatingIncrease surface areaSurgical instruments for heatingThermal contactBlood coagulations

An ablation catheter is provided for ablating internal tissue of a patient. The catheter includes a distal end that is adapted to be inserted into a body cavity relative to a desired location therein (e.g., within the heart). An ablation electrode is connected relative to the distal end of the catheter for providing ablation energy to patient tissue. A heat sink is provided that is in thermal contact with the ablation electrode. The heat sink, in addition to being in thermal contact with the ablation electrode, is electrically isolated from the ablation electrode. This allows the heat sink to conduct heat away from the ablation electrode without dissipating electrical energy from the electrode. In this regard, the heat sink may prevent build-up of excess heat within the electrode that may result in blood coagulation and / or tissue charring.

Owner:ST JUDE MEDICAL ATRIAL FIBRILLATION DIV

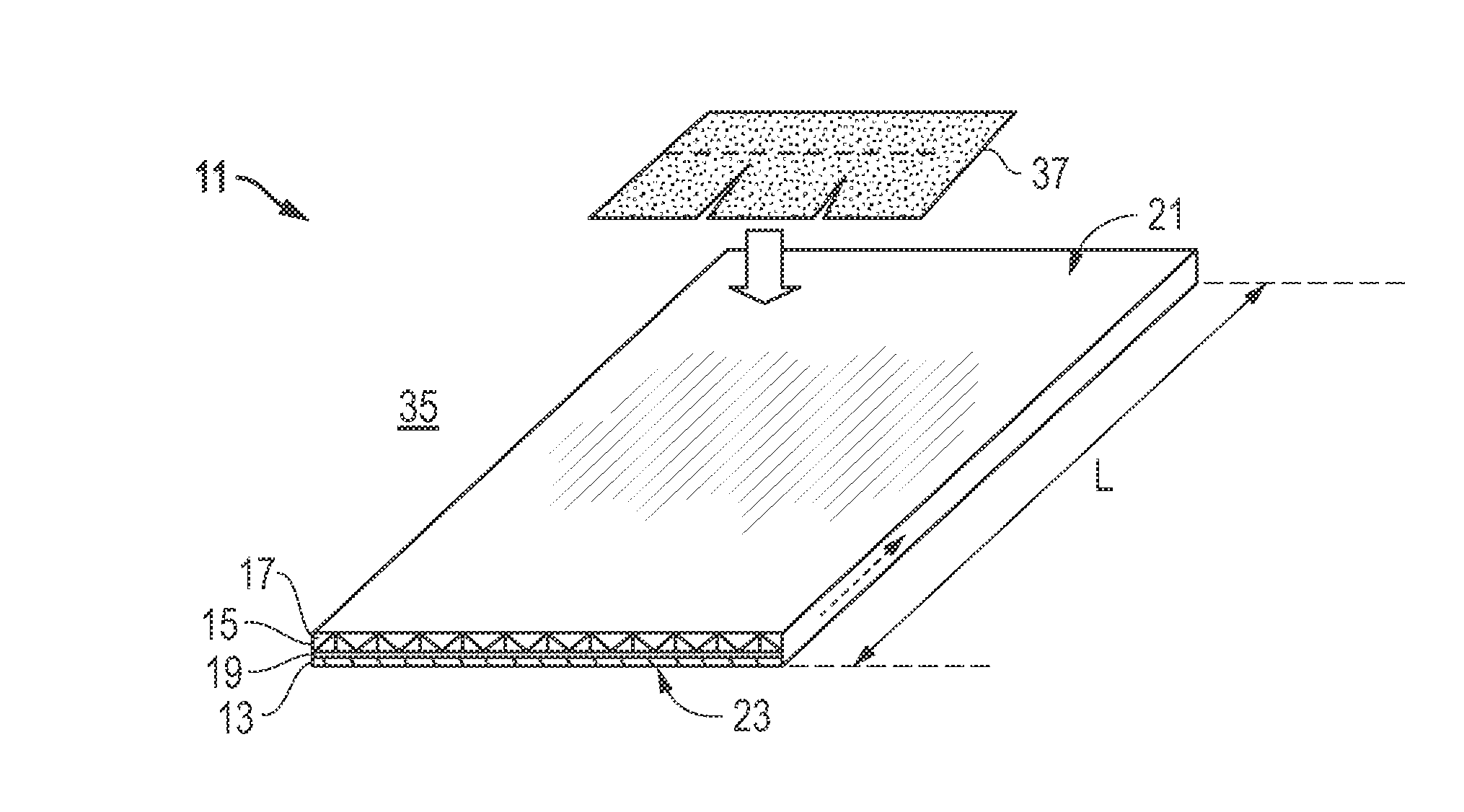

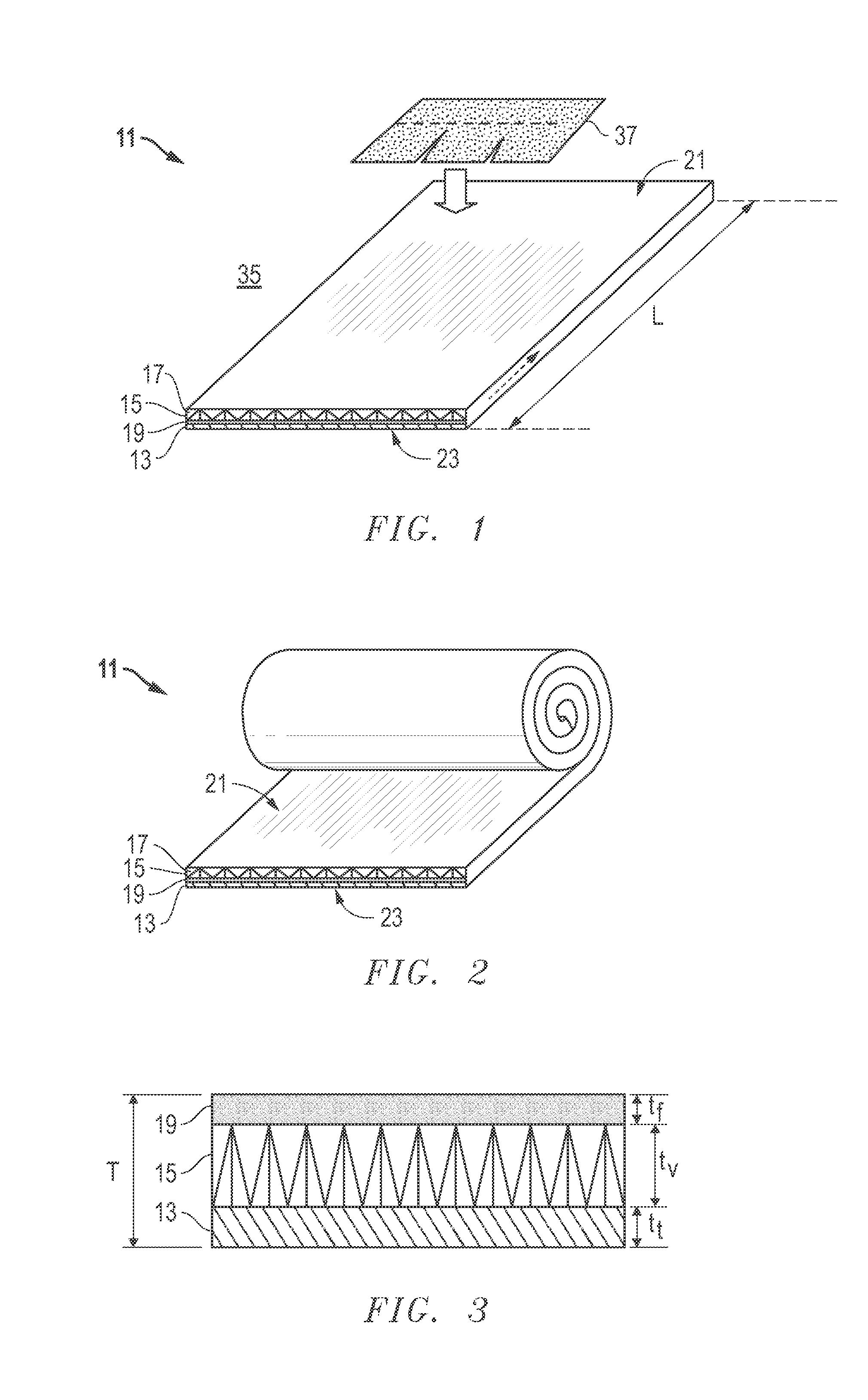

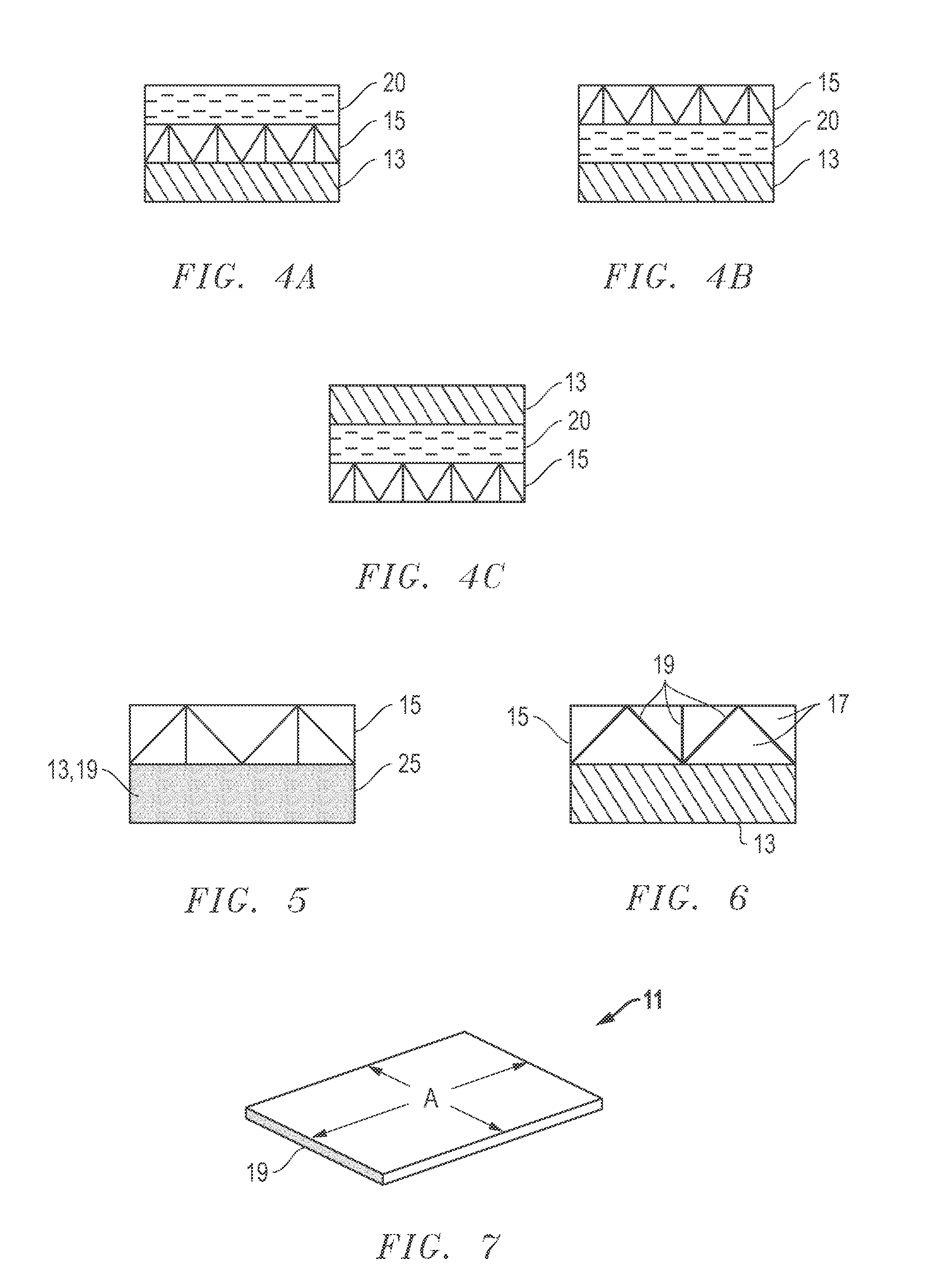

System, method and apparatus for thermal energy management in a roof

A roof product has a thermal heat storage layer, a vent layer with channels for transferring excess heat through a length of the roof product, and a flame retardant to suppress fire through the vent layer. These three materials form a unitary structure. The roof product may have a radiant layer, the thermal heat storage layer and the vent layer to form the unitary structure. The roof products are assembled in an abutting configuration on the roof of a building. The vent layer vents excess heat from an eave of the roof up to a ridge of the roof and out to atmosphere. The roof products manage thermal energy in the roof by storing thermal heat with the unitary roof product during a heating cycle; venting excess heat through the unitary product; and releasing the stored thermal heat from the unitary product into or out of the building during a cooling cycle.

Owner:CERTAINTEED CORP

Method and apparatus for drying wet bio-solids using excess heat from a cement clinker cooler

InactiveUS20050274067A1Avoid landfill disposalDrying solid materials with heatBiofuelsCement manufacturingChiller

Method and apparatus for drying wet bio-solids by utilizing waste heat from a clinker cooler in a cement making process.

Owner:LEHIGH CEMENT

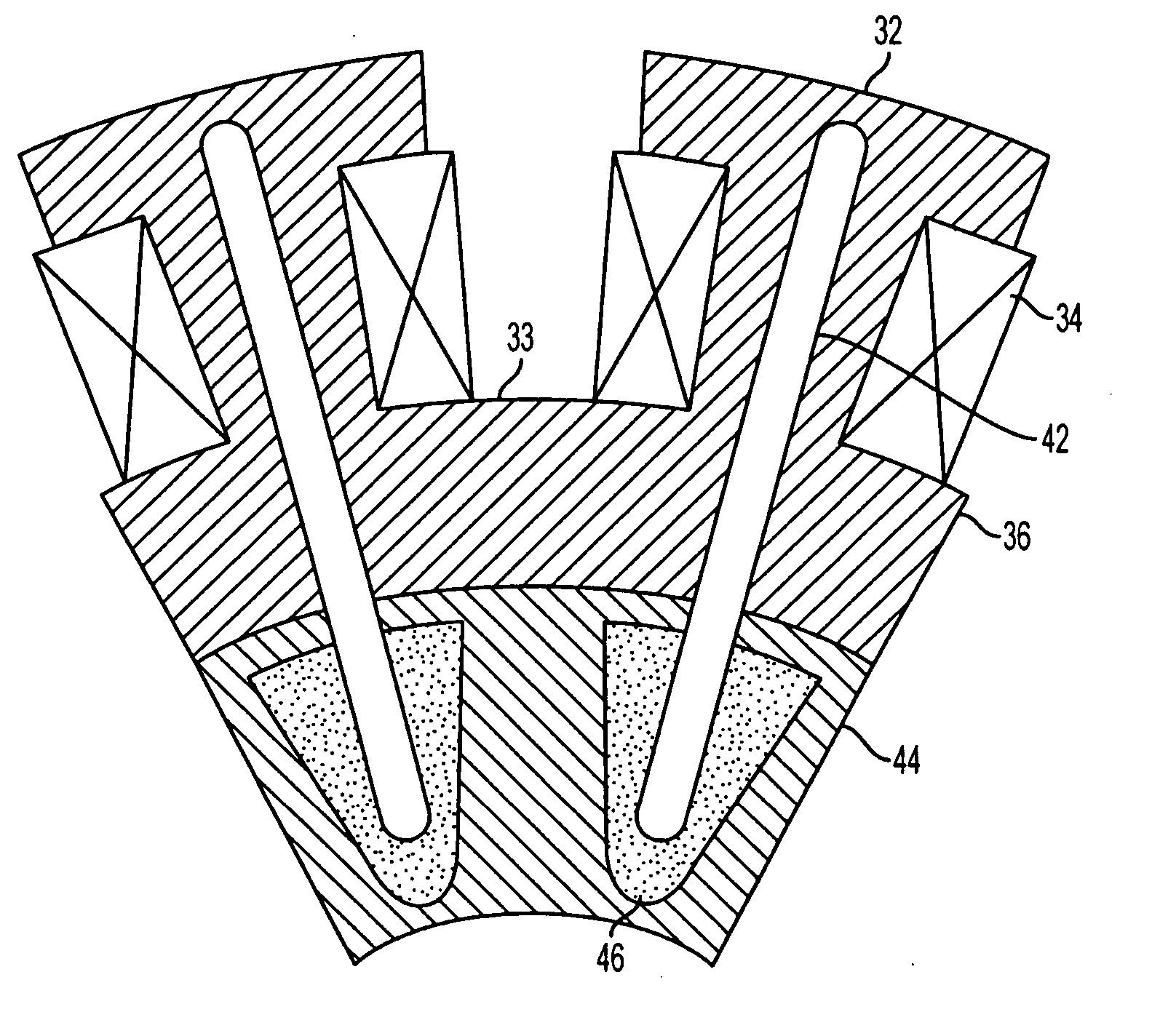

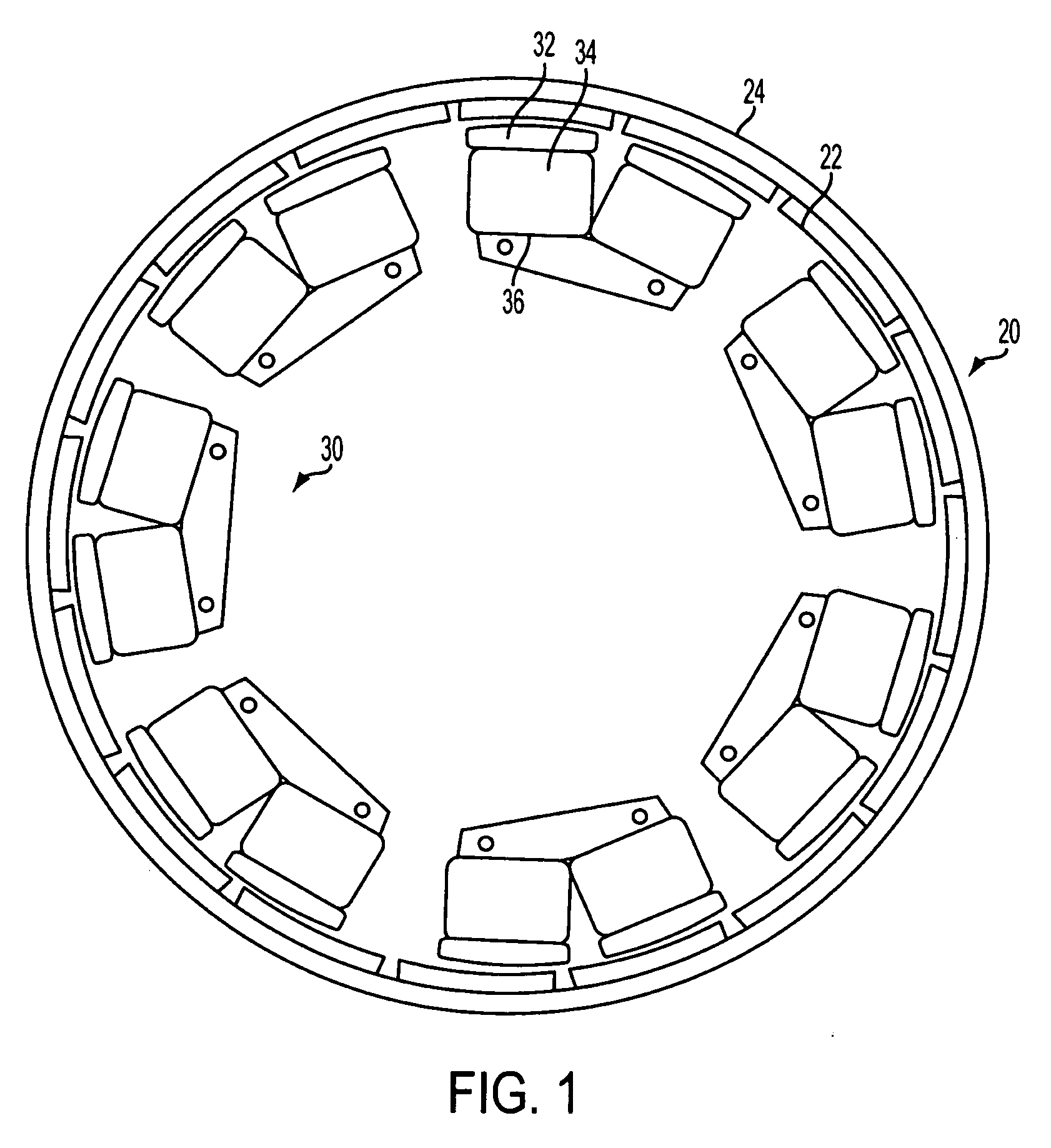

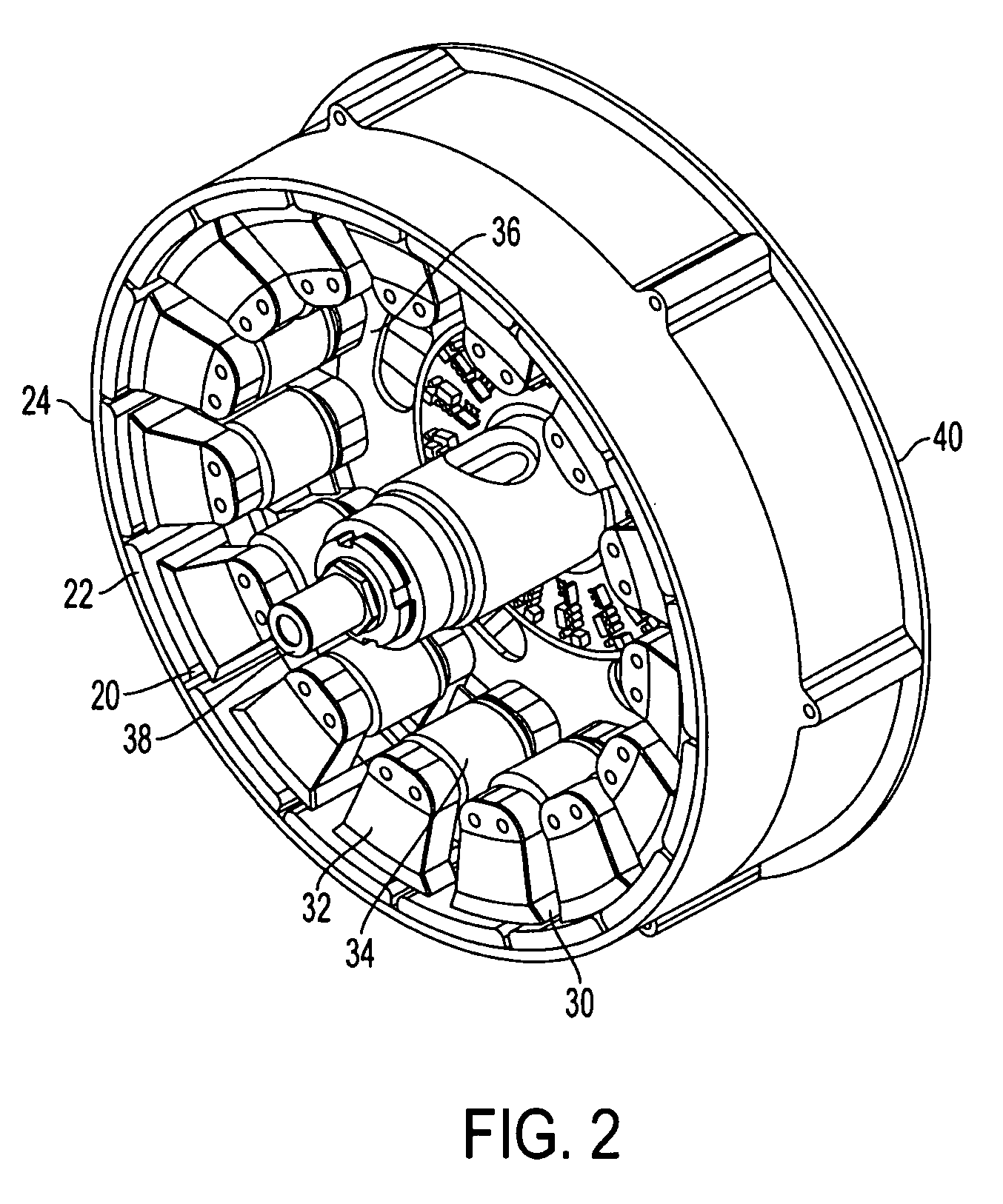

Dynamoelectric machine having heat pipes embedded in stator core

InactiveUS20060038450A1Minimum heat dissipationMagnetic circuit rotating partsMagnetic circuit characterised by magnetic materialsNuclear engineeringElectric machine

Thermal management of an electric machine is implemented by selecting a stator core configuration in accordance with an intended machine application and determining the minimum heat dissipation necessary to maintain the temperature of the core segment configuration at peak excitation within acceptable limits is determined. A core model is used to ascertain thermal distribution at peak excitation. In accordance therewith, a pattern in the selected core segment configuration is established for placement of at least one heat pipe for removing heat from the core. Preferably, heat pipes are located at high thermal points in the core segment and oriented in alignment with mapped lines of flux. By placing the heat pipe either at the center of the core or at a recessed boundary layer between the core and winding, the heat pipe can capture and conduct excess heat away from the heat generating areas of the core, thus maintaining the core and the excitation windings at desired temperature.

Owner:BLUWAV SYST LLC

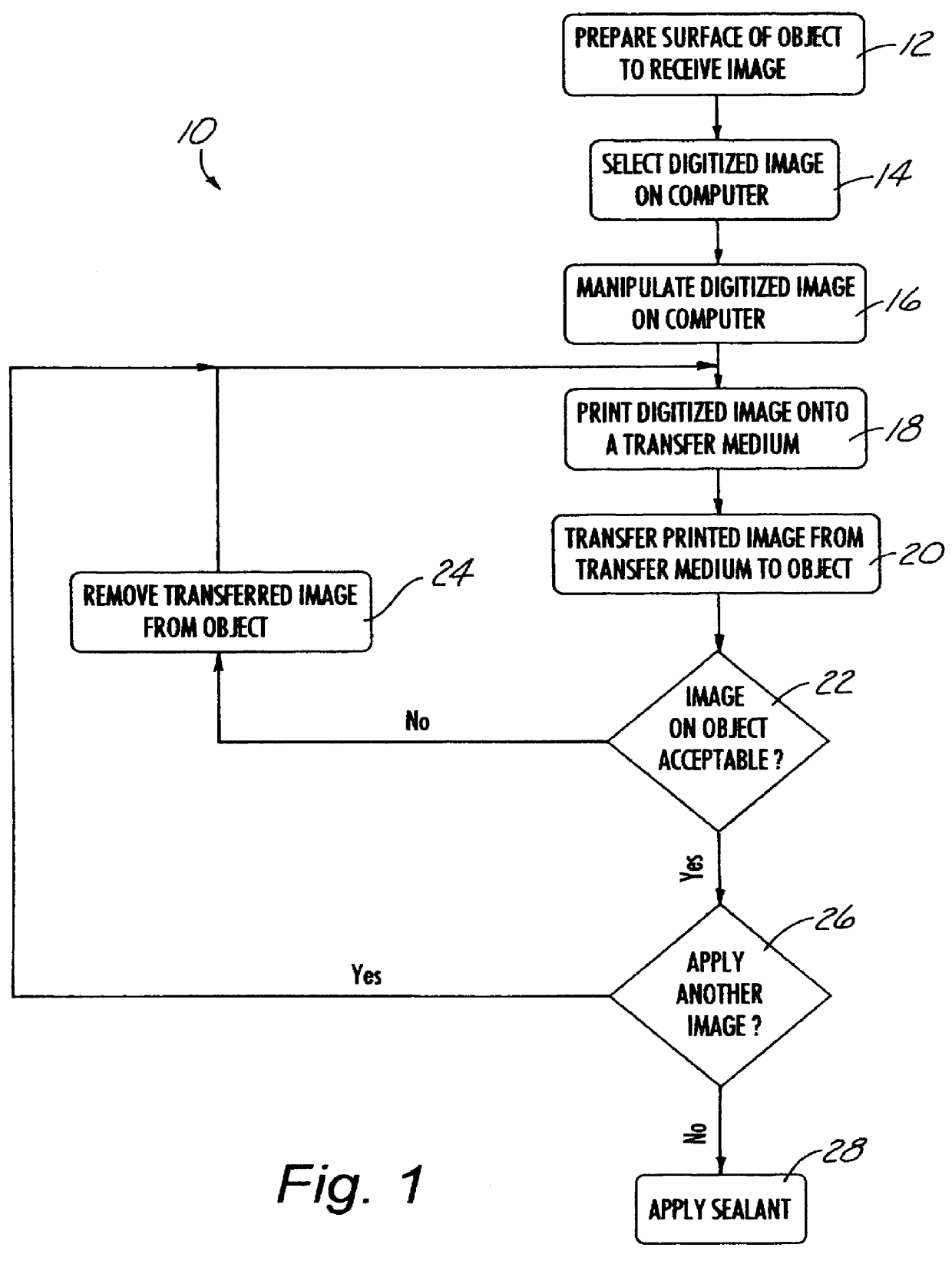

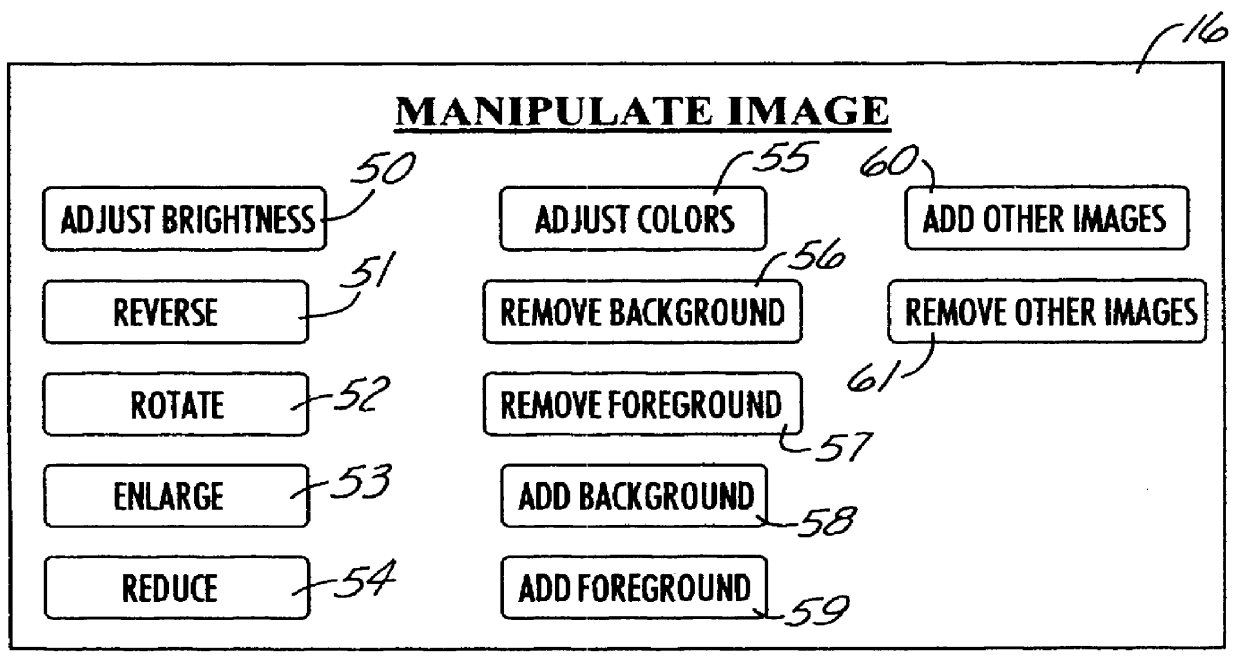

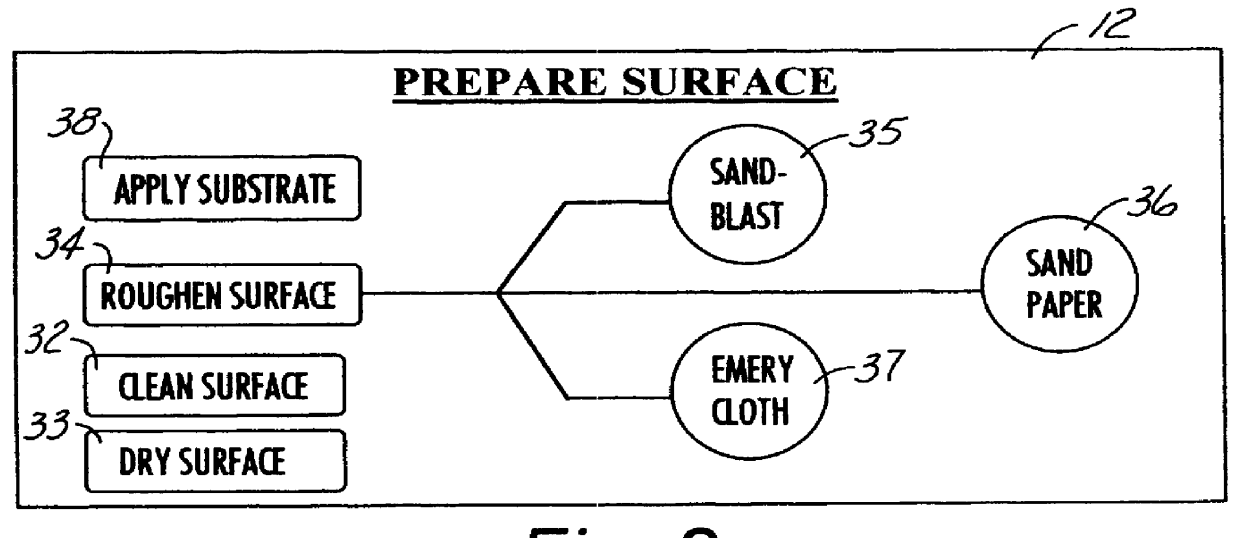

Method for transferring an image from a first medium to a second medium at ambient temperature

An application for an improved method of transferring an ink image from one medium to a second medium at ambient temperature is disclosed. A digitized image is selected to be printed on a ink type printer on a computer device. Prior to printing, the image can be manipulated in various way on the computer device. The image is printed onto a non-absorbent medium utilizing the ink type printer. The image is then transferred from the non-absorbent medium to the object on which it is desired to have the image. No excess heat is required for the transfer process. Pressure is applied to the back side of the non-absorbent medium to assist in the image transfer. Prior to transferring the ink image, the surface of the object can be prepared by marring or application of a suitable substrate.

Owner:3M INNOVATIVE PROPERTIES CO

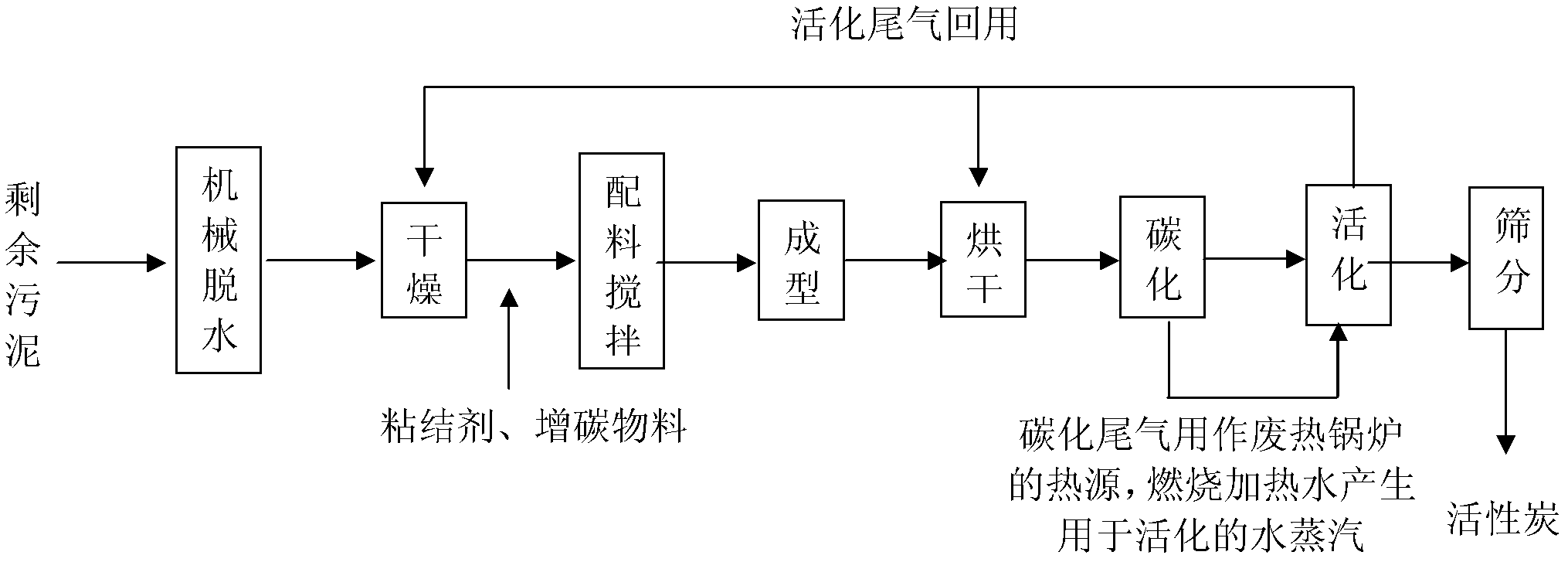

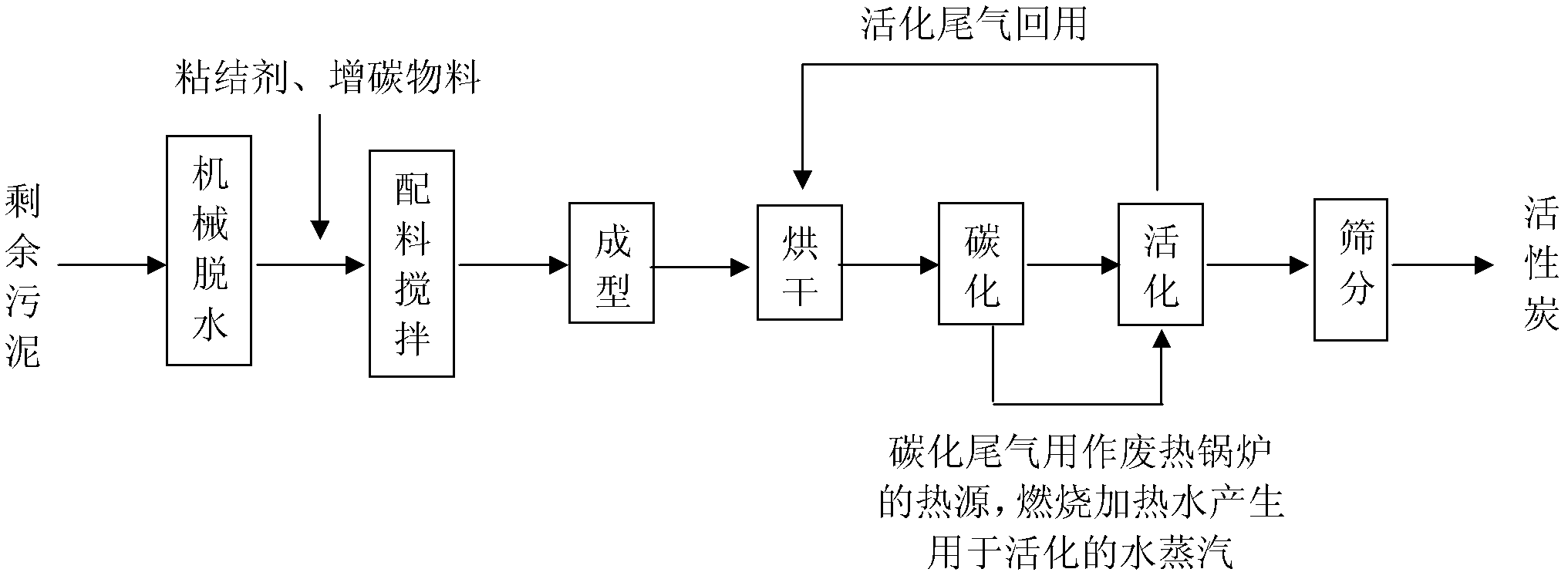

Method for preparing activated carbon by physical activation of excess sludge

InactiveCN102432007AAlleviate shortagesWide variety of sourcesCarbon compoundsEnergy inputActivated carbonSocial benefits

The invention relates to a recycling disposal of industrial solid waste, in particular a method for preparing activated carbon by physical activation of excess sludge. The method comprises taking excess sludge generated by sewage treatment as raw material, utilizing water vapour as activating gas and preparing sludge activated carbon by physical activation. The invention takes large amount of excess sludge generated by sewage treatment as raw material to prepare activated carbon and realizes highly efficient utilization of energy resources by multi-type excess heat recycling, therefore, the generated activated carbon product has low energy consumption. Compared with chemical activation, the physical activation has no large amount of waste water generation during the preparation process and the production process is clean and environment friendly. The invention has excellent economic, ecological and social benefits.

Owner:NANJING UNIV OF TECH

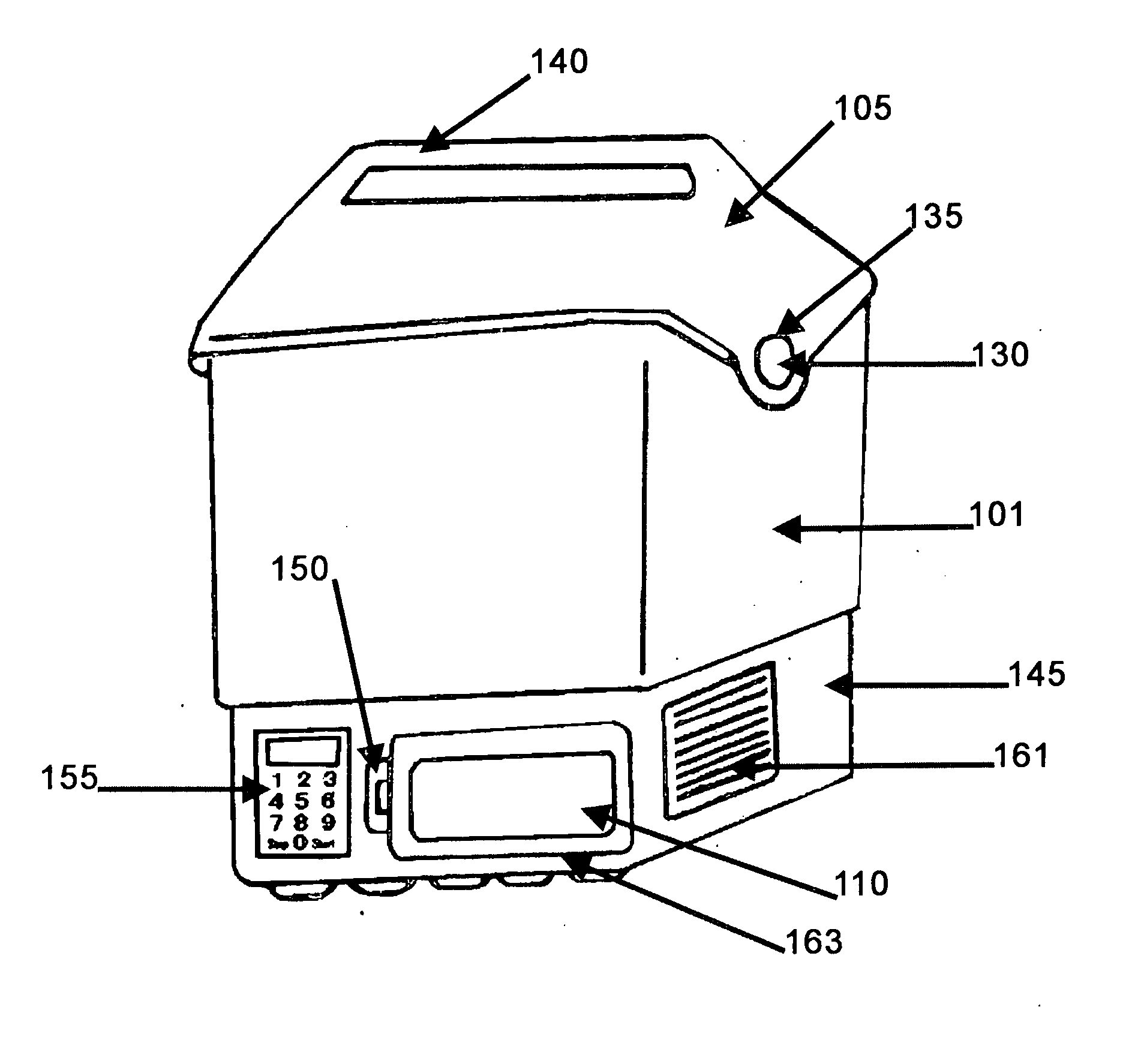

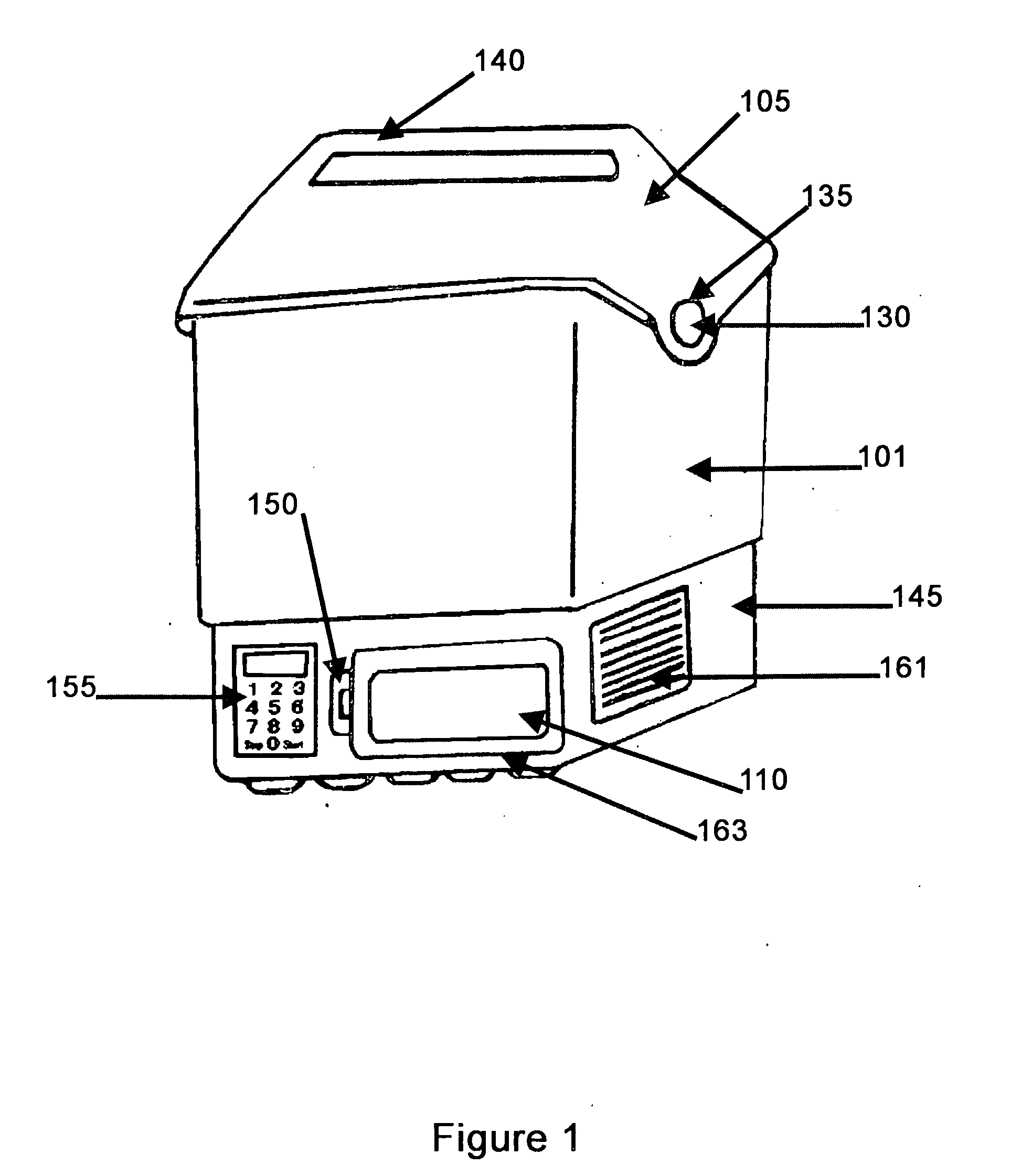

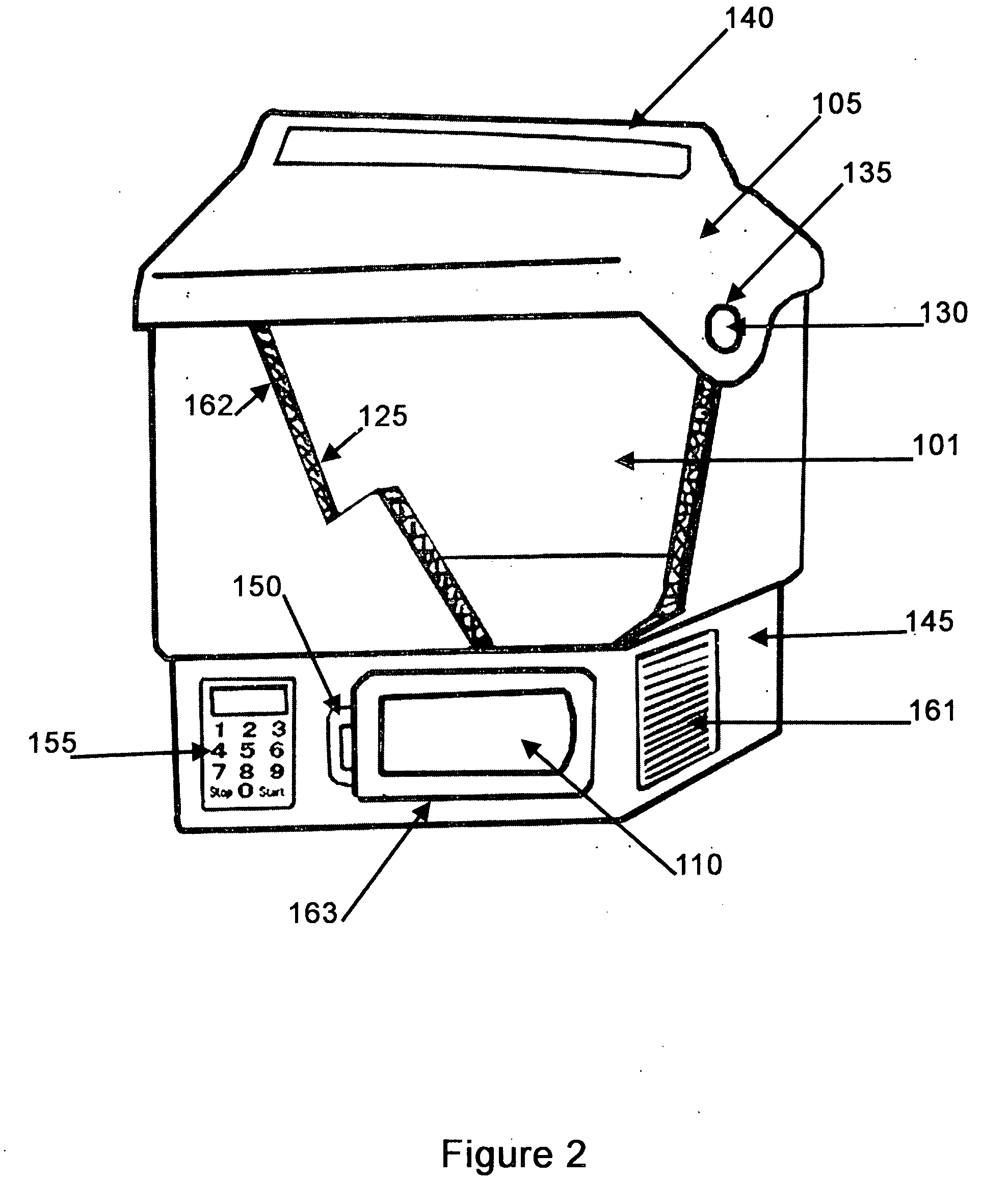

Portable food storage and preparation device

InactiveUS20080190914A1Easy to transportMicrowave heatingThermally-insulated vesselsMicrowave ovenFood storage

An apparatus for portable food storage and preparation is shown. The apparatus has an impact resistant housing. An insulated portion is contained within the housing and is configured for storage of chilled food and beverage items. A lid covers the insulated portion. A microwave oven is contained within a portion of the housing below the insulated portion and is configured for heating food and beverage items to a desired serving temperature. A control panel is mounted to the housing for controlling the microwave oven. A vent is mounted to the housing for venting excess heat from the microwave oven. An internal power source is provided for operating the microwave oven. A handle is provided for easy transportation of the housing by an individual.

Owner:DANIELLE B A GIBSON REVOCABLE TRUST

Efficient machine for desalting sea water

InactiveCN102765770AImprove energy utilizationImprove heat transfer performanceGeneral water supply conservationSeawater treatmentSprayerHigh energy

The invention discloses an efficient machine for desalting sea water. The efficient machine for desalting sea water mainly comprises a sea water desalting device and a water supply tank, wherein the sea water desalting device comprises a high-pressure water chamber, a heat exchange chamber, a pipe sheet, a transversely fluted tube, an sprayer, a heat exchange surface, a film forming device, a baffle and a plurality of heat pipes; and a sewage draining cooling pipe and a desalted water cooling pipe are arranged inside the water supply tank. According to the efficient machine for desalting sea water, the technology of using smoke to release heat on high-speed spraying by an orifice spraying method is adopted, so that the heat transfer coefficient of the device is improved; the technology of using the excess heat of the smoke is preheated on the sea water, so that the smoke is secondarily used in the device, and the energy use ratio of the device is improved; the two-stage preheating technology of the fed material sea water is adopted, so that the temperature of the preheated sea water is raised; and the technology of using the film forming device to form rotary water film at the heat exchange surface of a round table body is adopted, so that the heat transfer effect and the evaporation effect of a water side are effectively improved. Therefore, the efficient machine for desalting sea water has the advantages of high energy use ratio and good heat transfer effect, and is suitable for the demands of places, such as ships, islands and enterprises on middle or small sea water desalting devices.

Owner:JIMEI UNIV

Method and apparatus for solar heating air in a forced draft heating system

InactiveUS20080127965A1Improve heat storage capacityRoof covering using slabs/sheetsSolar heating energyEngineeringHeat transfer fluid

A solar heating system for use in combination with a forced draft heating system for heating ventilation air of a building. The solar heating system includes a solar collector assembly for heating a liquid circulated through the assembly. The heated liquid is stored in an insulated storage tank where it can be circulated through a heat exchanger positioned in an air duct of the forced draft heating system as need to heat air flow through the duct. The use of a liquid as the heat transfer fluid and providing a storage facility for heated liquid permits the heating system to operate for a period of time after the sun sets or becomes ineffective in providing solar radiation until the heat stored in the liquid becomes exhausted. To increase the heat storage capacity of the liquid, one or more heat sinks can be utilized to absorb excess heat from the liquid and then transfer the absorbed heat back to the liquid when an opposite thermal gradient exists. Additionally, the heating system can recover waste heat from hot combustion gases exhausted from a fuel-fired forced draft heating system.

Owner:BURTON ANDY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com