Patents

Literature

1356 results about "Silicone grease" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

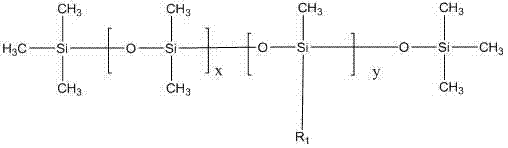

Silicone grease, sometimes called dielectric grease, is a waterproof grease made by combining a silicone oil with a thickener. Most commonly, the silicone oil is polydimethylsiloxane (PDMS) and the thickener is amorphous fumed silica. Using this formulation, silicone grease is a translucent white viscous paste, with exact properties dependent on the type and proportion of the components. More specialized silicone greases are made from fluorinated silicones or, for low temperature applications, PDMS containing some phenyl substituents in place of methyl groups. Other thickeners may be used, including stearates and powdered polytetrafluorethylene (PTFE).

Heat conductive silicone grease composition

ActiveCN102634212AImprove thermal conductivityExtended service lifeHeat-exchange elementsCarbon nanotubeGraphite

The invention discloses a heat conductive silicone grease composition which mainly contains a carbon nano tube, graphite, phase-change capsule particles and silicone oil, wherein the carbon nano tube can speed up the conduction of heat further; the phase-change capsule particles are used for improving the initial temperature absorption velocity of a heat end; the phase-change capsule particles, the carbon nano tube and graphite in a fluid form full-three-dimensional network distribution of particles (phase-change capsule), a line ( the carbon nano tube) and a plane (graphite) in the fluid finally. The heat conductive silicone grease composition provided by the invention has high heat conduction rate and low heat resistivity, the heat radiation efficiency of the heat conductive silicone grease is improved greatly, the service life of the heat conductive silicone grease is prolonged greatly, and the heat conductive silicone grease composition has high practical value.

Owner:HUZHOU MINGSHUO OPTOELECTRONICS TECH CO LTD

Heat conductive silicone grease composition

ActiveCN101294067AReduce dispersionReduce coupling effectHeat-exchange elementsHeat conductingCoupling

The invention discloses a heat-conducting silicone grease composition which mainly consists of organic silicone oil, a silicane coupling agent and heat-conducting powder, wherein the silicane coupling agent covers the surface of the heat-conducting powder; the heat-conducting powder is prepared from powders with larger, intermediate and small diameters; and the concerned metal powder is subjected to heat treatment to form an oxide film on the surface of the metal powder. The heat-conducting silicone grease composition has high heat conductivity and good fluidity; secondarily, the heat-conducting silicone grease composition has high temperature resistance and can keep good heat conductivity and fluidity at 250 DEG C; additionally, the heat-conducting silicone grease composition requires no refrigeration and has the advantages of simplified storage and operation flows and high reliability.

Owner:SHENZHEN BORNSUN INDAL

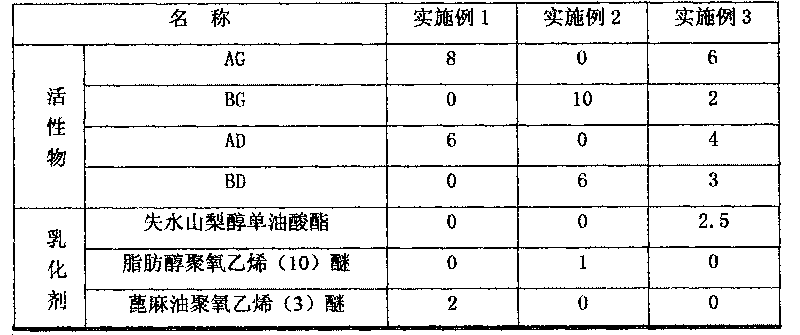

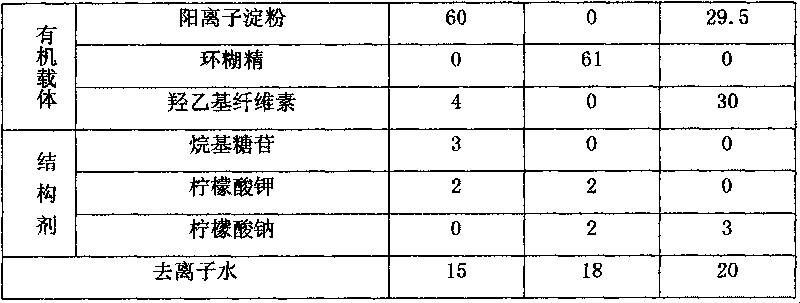

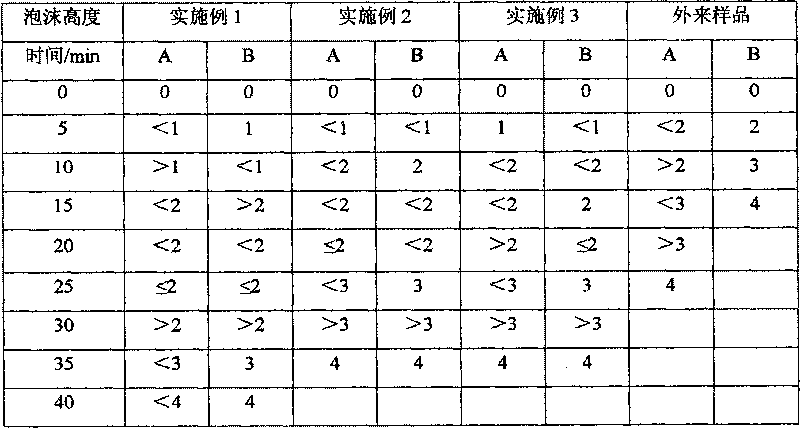

Organosilicon defoaming agent for water-based system and preparation method thereof

The invention discloses an organic silicon defoamer and preparing method in the hydraulic flexible ink and paint, which comprises the following parts: silicon polyether, silicone grease, emulsifier and thickener, wherein the active content is 10-50% corresponding to emulsion; the silicon polyether and silicone grease is 70-90% in the active content; the disperse dielectric adopts deionized water.

Owner:JIANGSU SIXIN SCI-TECH APPL RES INST CO LTD

Efficient silicone defoaming agent

InactiveCN102343165AGood anti-foam performanceGood dispersionFoam dispersion/preventionDispersityEmulsion

The invention discloses an efficient silicone defoaming agent, which mainly comprises a silicone grease mixture, a synergistic agent, a polyether silicone oil emulsifier, an assistant emulsifier, a thickening agent, preservative and water, wherein in an emulsifier emulsion, the silicone grease mixture and the polyether silicone oil emulsifier account for 70-90 percent of the amount of active matters; the active matters account for 5-30 percent of the amount of the emulsion; and water serves as another medium. In the efficient silicone defoaming agent, the foam inhibiting performance is enhanced by using the silicone grease mixture, the defoaming performance and dispersity are improved by using the polyether silicone oil emulsifier, and the silicone grease viscosity and compatibility are lowered and the emulsifying effect is improved by adding the synergistic agent. The efficient silicone defoaming agent has the characteristics of application to waterborne systems, high defoaming speed, good foam inhibiting effect, low using dosage, high chemical inertness, nontoxicity, capability of acting under severe conditions and low cost.

Owner:山东大易化工有限公司

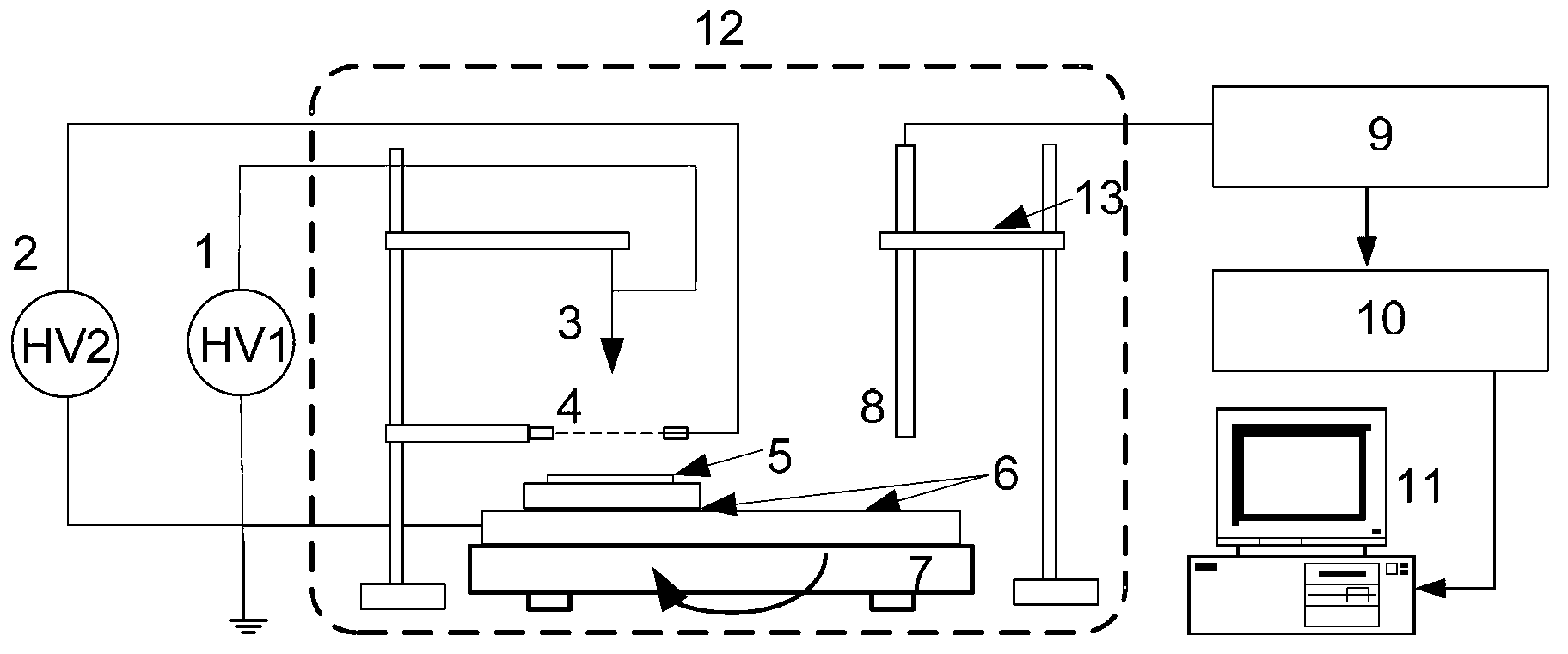

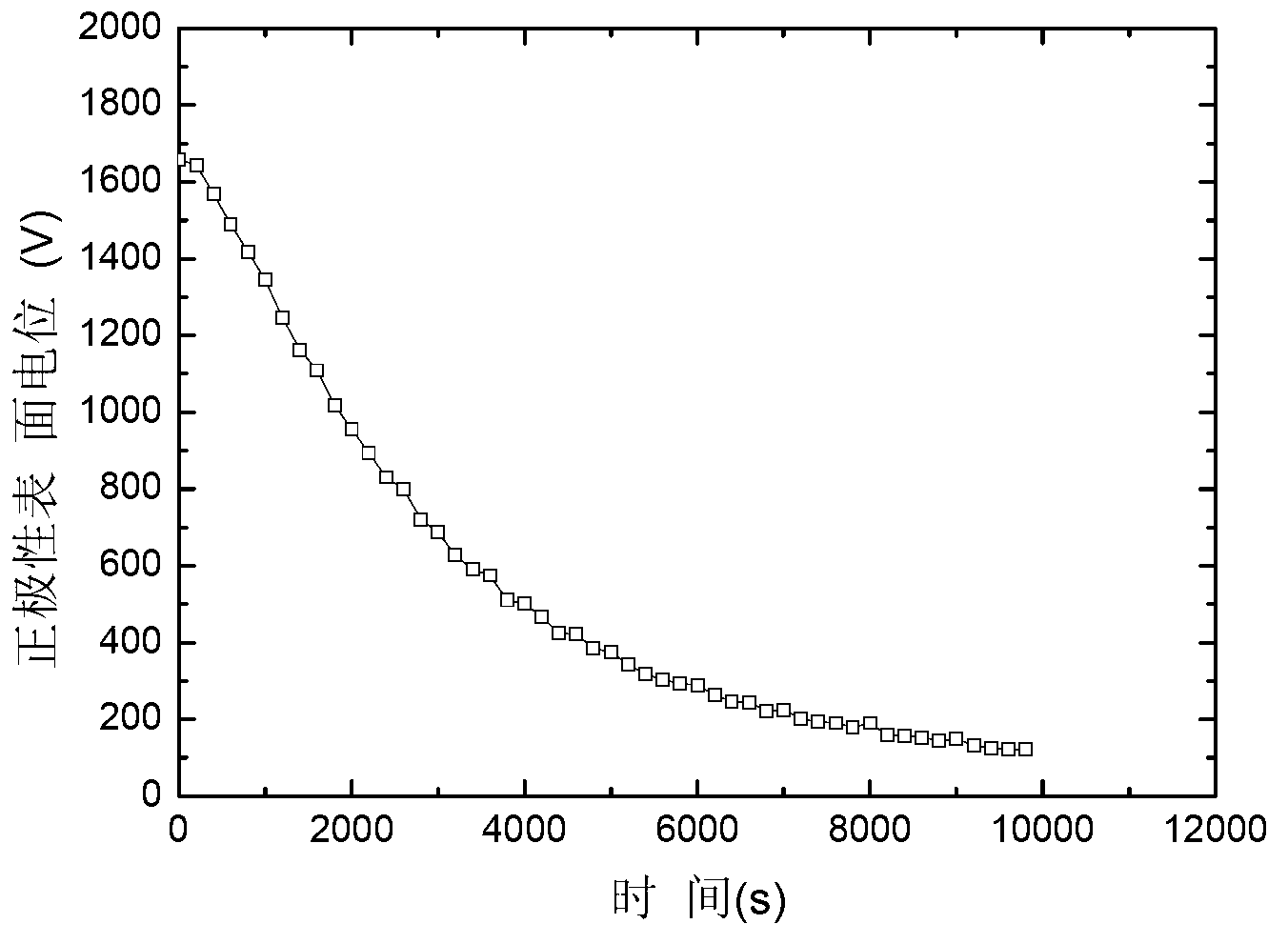

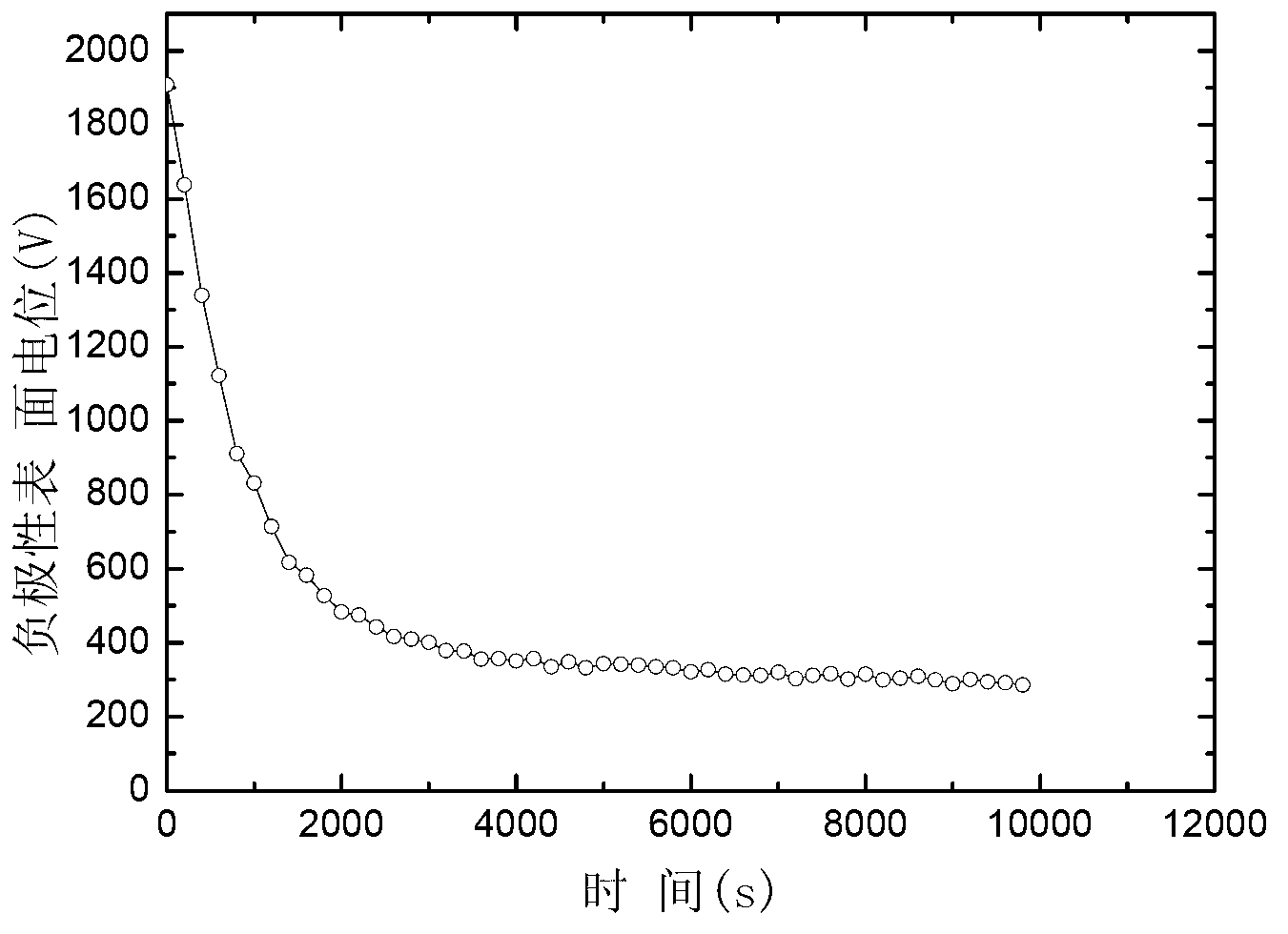

Measuring device and measuring method for trap parameter of solid dielectric material

InactiveCN102841123AFully injectedUniform electric field distributionMaterial analysis by electric/magnetic meansPolymer insulationCorona discharge

The invention discloses a measuring device and method for a trap parameter of solid dielectric. The solid dielectric material is charged by using a three-electrode corona discharge system; a material sample to be tested is placed below a single-needle electrode and a metal mesh electrode; the sample is adhered to a metal disc electrode through conductive silicone grease and is charged by the three-electrode system; after charging is ended, an external voltage is removed, and short circuit discharge is performed to remove surface free loads; surface potential of the measured sample is attenuated; and the trap energy level and the trap density parameter of the material can be calculated through a signal conditioning circuit and a data acquisition system. The measuring device comprises a constant temperature box, the three-electrode coronate charging system, a surface potential measuring system, a sample preheating system, a rotary electrode and a temperature and humidity control system. The invention provides an effective analysis means for research in representation of an aging condition of a polymer insulating material and an aging rule of polymer by the trap parameter and research in aspects such as a solid dielectric surface electrification phenomenon and surface flashover performance influence.

Owner:XI AN JIAOTONG UNIV

Phase change heat-conducting thermal silicone grease composition for central processing unit (CPU) radiating and preparation method thereof

ActiveCN103214848AImprove thermal conductivityImprove heat transfer performanceHeat-exchange elementsParaffin waxPhysical chemistry

The invention discloses a phase change heat-conducting thermal silicone grease composition for central processing unit (CPU) radiating. The phase change heat-conducting thermal silicone grease composition is prepared from the following raw materials in parts by weight: 5-10 parts of base oil, 5-10 parts of paraffin, 1-3 parts of vinyl trimethoxy silane, 80-90 parts of heat-conducting filler. The method for preparing the phase change heat-conducting thermal silicone grease composition for CPU radiating comprises the following steps: 1) performing particle size distribution on the heat-conducting filler; 2) mixing the compounded heat-conducting filler and vinyl trimethoxy silane in ethanol, regulating the pH of the solution to be 3-4, heating to the temperature of 70-80 DEG C, stirring for 2-4 hours, removing ethanol, and obtaining a modified inorganic filler; and 3) heating 5-10 parts by weight of paraffin to be melted, adding 5-10 parts by weight of base oil and the modified inorganic filler prepared in the previous step, and fully mixing to prepare the phase change heat-conducting thermal silicone grease composition. The phase change heat-conducting thermal silicone grease is high in heat-conducting coefficient and high in heat transfer capacity, and the excessive heat of the CPU can be rapidly derived, so that the service life of the CPU is prolonged, and the preparation process is simple.

Owner:SHENZHEN XINYA NEW MATERIALS CO LTD

Heat conductive silicone grease composition and cured product thereof

InactiveCN101104738AImprove thermal conductivityImprove liquidityMaterial nanotechnologySemiconductor/solid-state device detailsConductive materialsContact resistance

Owner:SHIN ETSU CHEM IND CO LTD

Moistureproof type low-smoke halogen-free flame-retarding wire and cable insulation material used for building

ActiveCN103467838AImprove hydrophobicityAvoid short circuit accidentsRubber insulatorsPlastic/resin/waxes insulatorsInsulation layerMoisture absorption

The invention discloses a moistureproof type low-smoke halogen-free flame-retarding wire and cable insulation material used for building. The insulation material comprises components, by weight, 100 parts of vinyl copolymer and / or ethylene propylene rubber, 100-250 parts of halogen-free flame retardants, 1-20 parts of compatilizer, 0.3-5 parts of antioxygen, 0.5-5 parts of lubricants, 0-3 parts of coupling reagents, 0-2 parts of dispersing agents, and 2-20 parts of one or more of vinyl silicone oil, silicone, silicone grease, silicone rubber, and mineral oil. Wires made of the material is low in smoke, free of halogen, incapable of releasing poisonous gas. Flames can be retarded due to the fact that a single stick of wire can vertically combust at combusting time. Moreover, some special addition agents are added in materials of insulation layers or protective sleeve layers, so that the surface hydrophobic property of products is increased and can be used in a high-temperature humid environment for a long time, and short circuit accidents caused by moisture absorption of the wire insulation layers are avoided.

Owner:SHENZHEN WOER HEAT SHRINKABLE MATERIAL +1

Heat-conductive silicone grease composition being high in heat conductivity and low in viscosity, and preparation method of the silicone grease composition

ActiveCN107603224ALiquidity is not affectedLiquidity impactHeat-exchange elementsNetwork structureSilicone grease

The invention discloses a heat-conductive silicone grease composition being high in heat conductivity and low in viscosity and freeness degree, and a preparation method of the silicone grease composition. The heat-conductive silicone grease composition includes organo-polysiloxane, heat conductive filler and other additives. By selecting the heat conductive fillers in multiple dimensions (one-dimension, two-dimension and three-dimension) and multiple scales (micron, submicron and nanometer) and in special ranges, synergistic effect among the multi-dimension and multi-scale fillers is achieved,thus achieving compact stack of the fillers in a local network structure. The heat-conductive silicone grease not only is improved in heat-conductivity but also has good flowability, low viscosity and low freeness degree.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

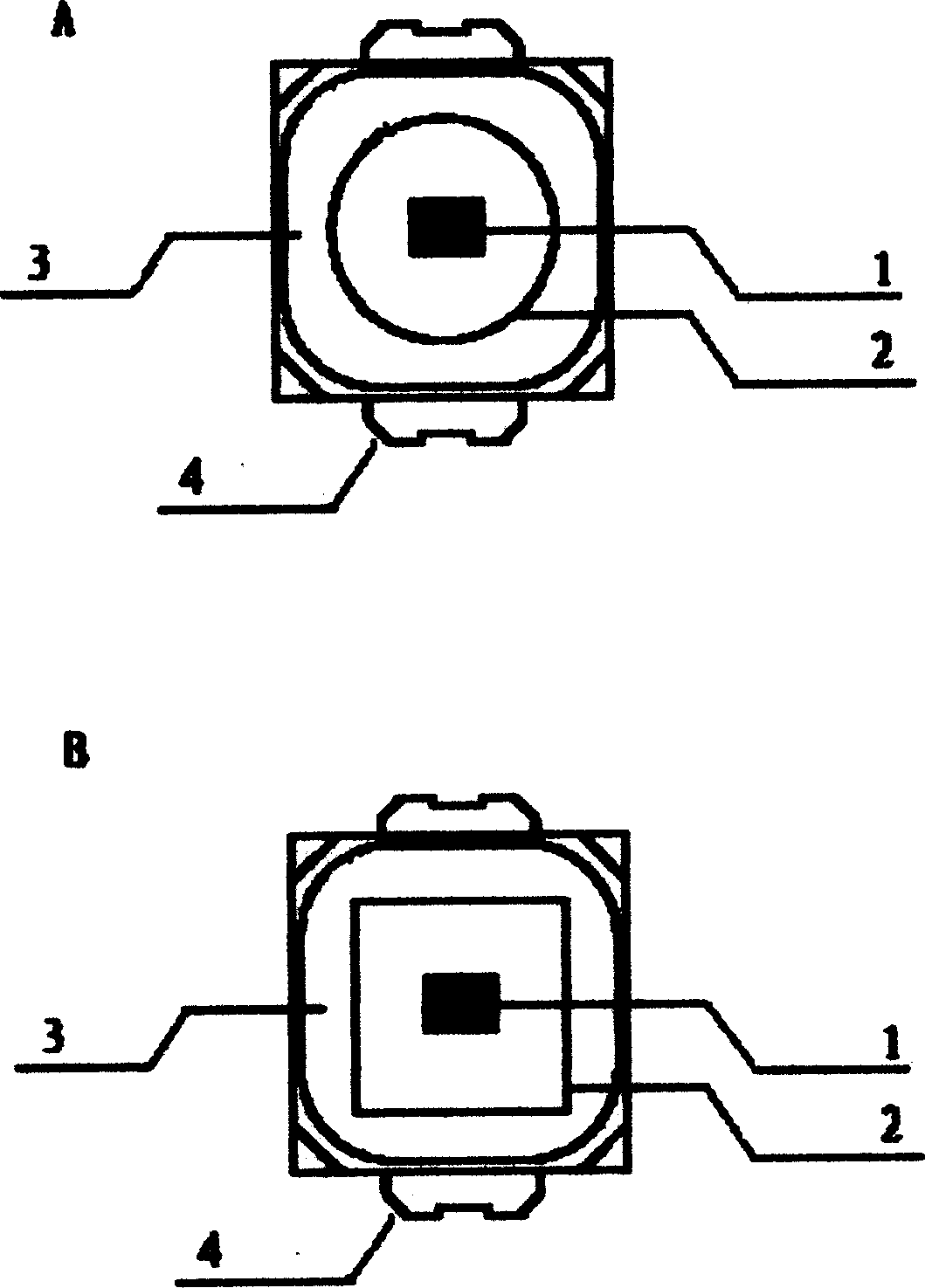

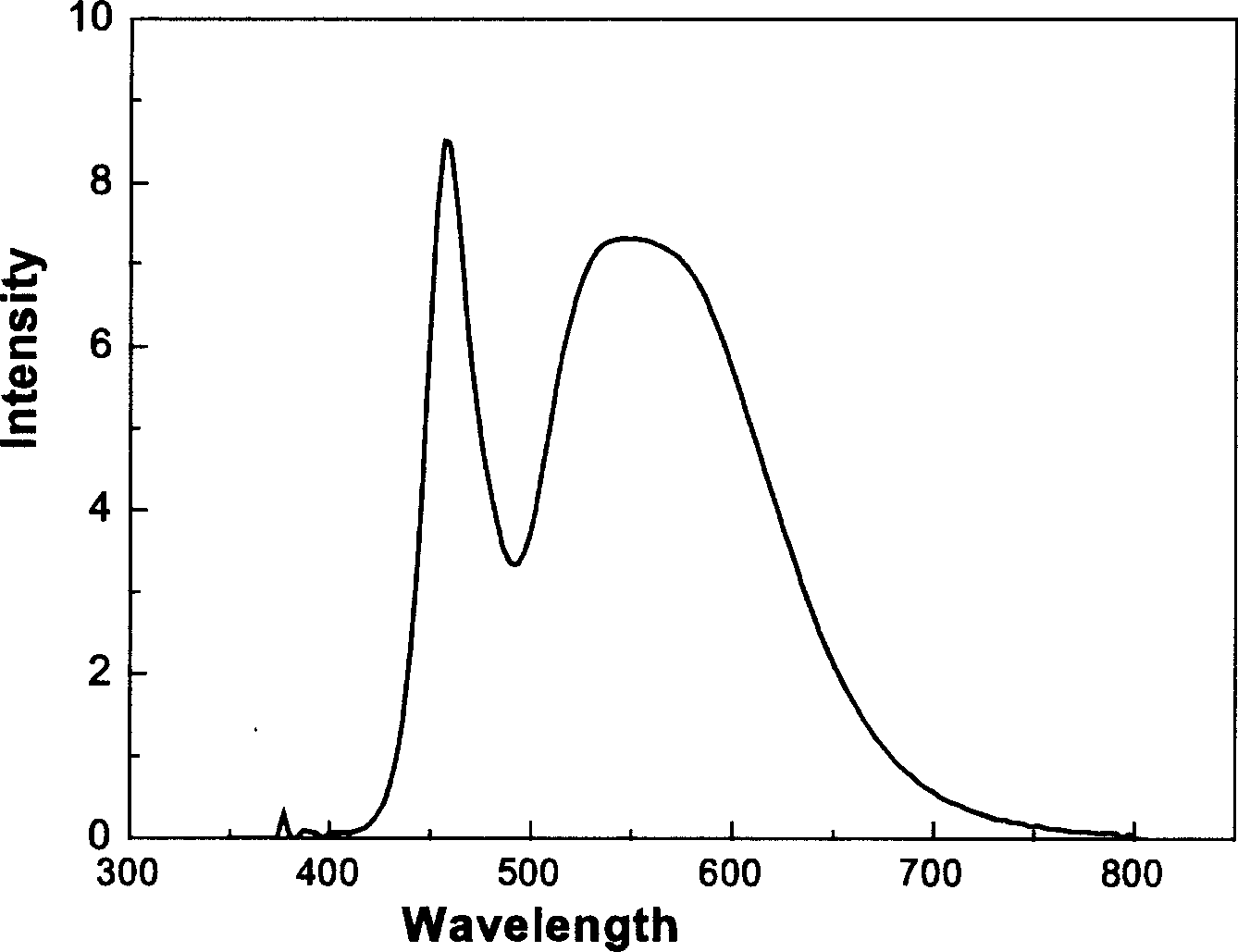

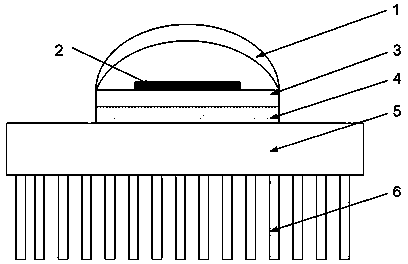

YAG chip-type white-light light-emitting-diode and its packing method

ActiveCN1815765AStable chemical propertiesStable performance at high temperatureSolid-state devicesSemiconductor devicesSingle crystalSealant

Using YAG single crystal body converts part of blue light sent from GaN based semiconductor LED crystal grain to another light in one or more ideal wave bands. Then, not converted remanent blue light sent from LED crystal grain is mixed with the converted light in ideal wave band to generate white light. Through controlling each parameter of fluorophor of single crystal chip, the method adjusts and controls proportion between yellow light converted by the fluorophor of single crystal and not converted blue light. At the same time, using evenness of single crystal chip obtains even white light in high quality. Comparing with traditional technique, the invention solves difficult issue of controlling dispersivity of powder of fluorophor in sealant in silicone greases or resins. After wafer is cut to chips in desired size, packaging operation is full automatic so as to raise degree of mechanization.

Owner:SUN YAT SEN UNIV +2

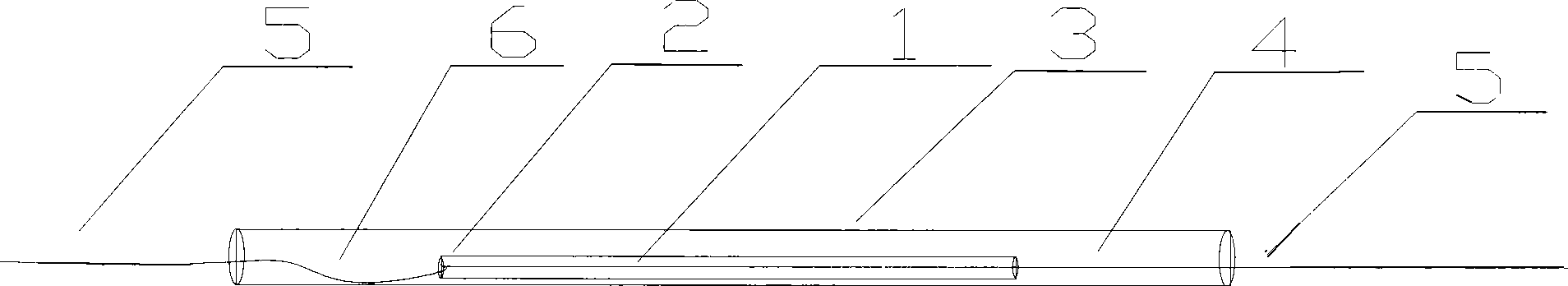

Method for packaging sensitized optical fiber grating temperature sensor

InactiveCN101413831AQuick responseIncrease heat transfer rateThermometers using physical/chemical changesFiberGrating

The invention discloses a packaging method for a sensitivity enhanced optical fiber grating temperature sensor, belongs to the technical field of sensors, and relates to a sensitivity enhanced packaging method of the optical fiber grating temperature sensor. The method is characterized in that the optical fiber grating is packaged into a metal capillary tube by applying prestress to the optical fiber grating and gluing two ends of the optical fiber grating, and the metal capillary tube packaged with the optical fiber grating is put into an outer stainless steel tube the internal diameter of which is greater than the external diameter of the metal capillary tube, then heat conducting silicone grease is filled between the metal capillary tube and the outer stainless steel tube, and finally the two ends of the outer stainless steel tube are connected with an optical fiber jacket or an optical fiber cable; and a fiber pigtail of the optical fiber grating must be ensured to be in a bent state during the packaging process. The beneficial effects of the packaging method is that the sensitivity enhanced optical fiber grating temperature manufactured by the packaging method has the advantages of high temperature sensitivity, rapid response speed, simple structure, reasonable design, high survival rate of the field installation and the like, and can be used for high-precision temperature measurement in such occasions as intense electromagnetic radiation, flammable and explosive occasions and the like.

Owner:DALIAN UNIV OF TECH

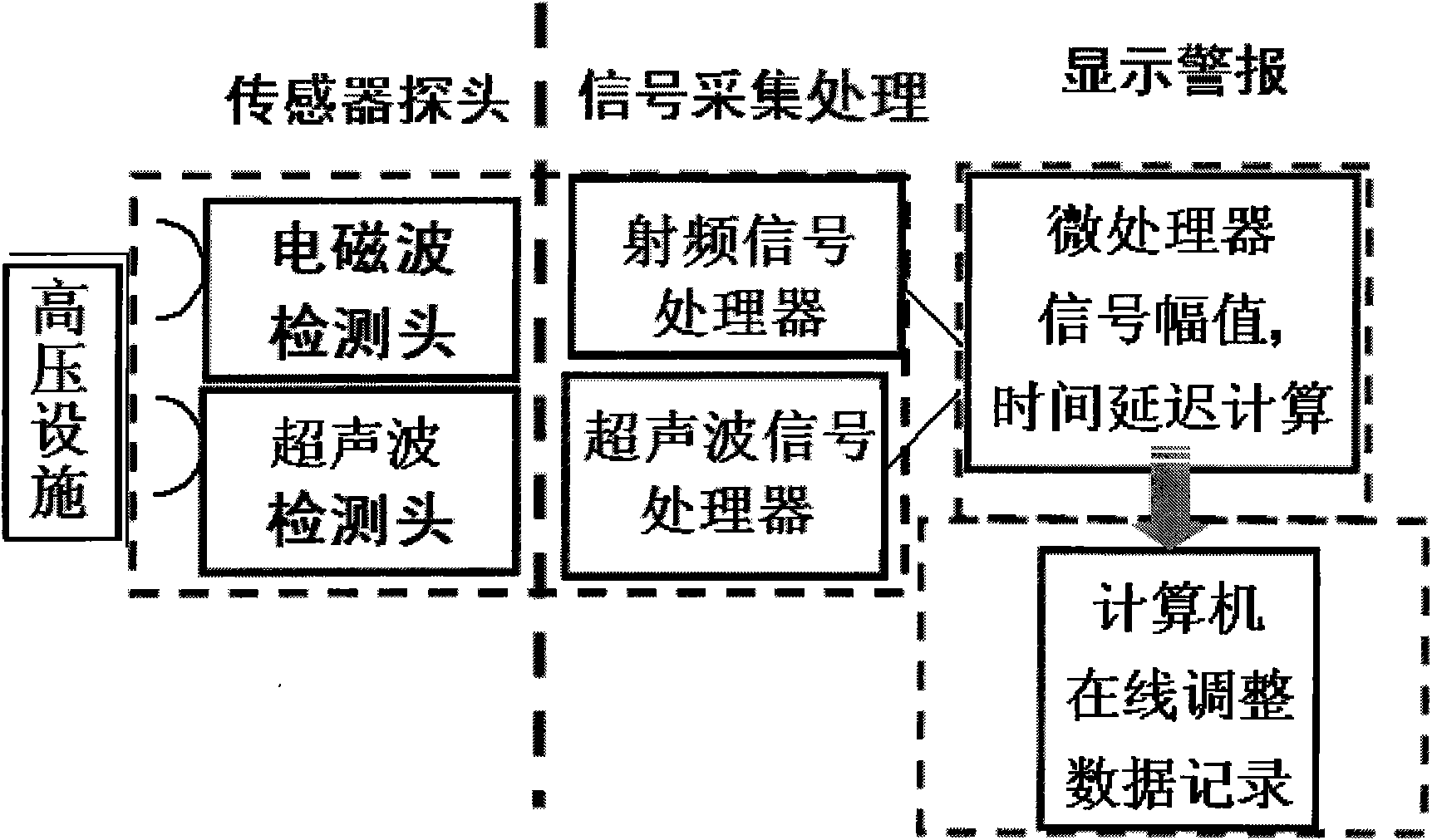

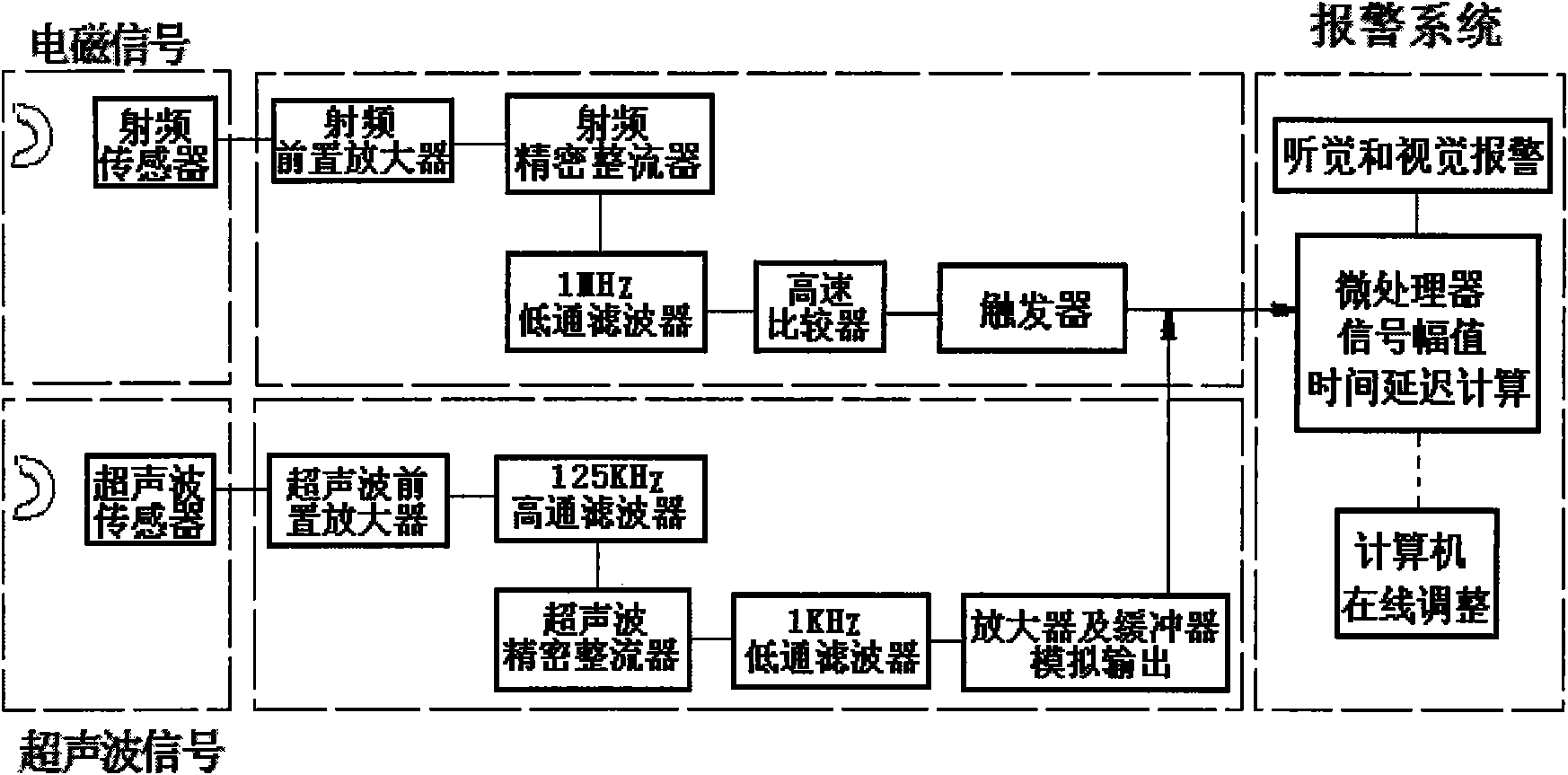

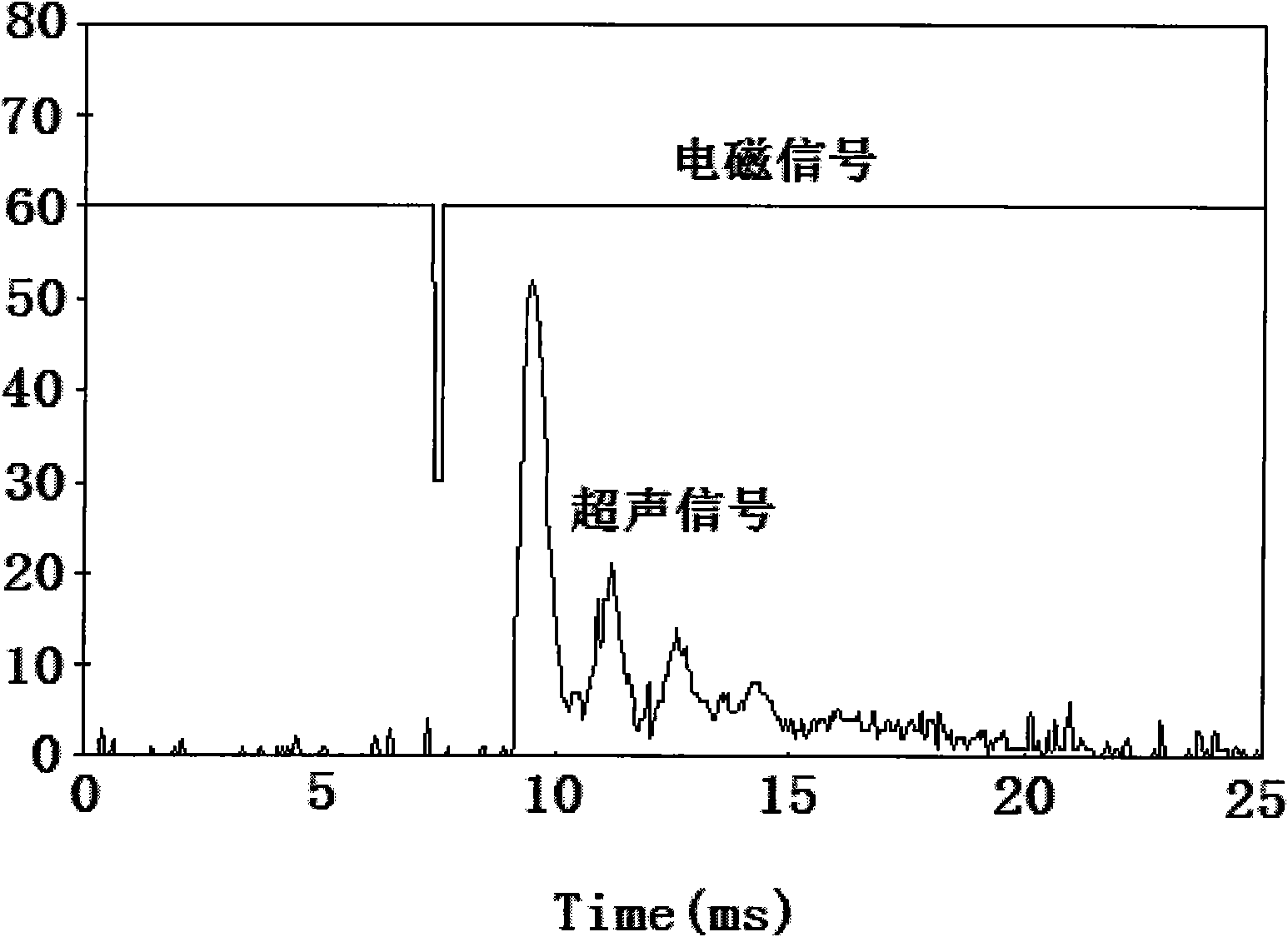

Acoustic-electric detection device for insulation defects of power cable

InactiveCN101666850ARealize detection and alarmHigh sensitivityTesting dielectric strengthElectricityPower cable

The invention relates to an acoustic-electric detection device for the insulation defects of a power cable, characterized by comprising a cable to be detected and a two-channel detection mechanism connected with the cable to be detected. The output end of the two-channel detection mechanism is connected with a receiving device and comprises an electromagnetic wave detecting head and an ultrasonicwave detecting head; the electromagnetic wave detecting head is connected with the cable to be detected; the surface of the ultrasonic wave detecting head is coated by silicone grease; the electromagnetic wave detecting head and the ultrasonic wave detecting head are electrically connected with respective signal acquisition processors and transfer cable insulation defect signals detected by the two-channel detection mechanism to the signal acquisition processors; and the signals processed by the signal acquisition processors are sent to a signal displaying and alarming system to detect and alarm the insulation defects of the cable. Partial defects in the cable are found and positioned as early as possible by the online monitoring or the routing inspection of the partial discharge of the cable. The invention finds the partial defects in the cable as early as possible, grasps the operation conditions of the cable in time and prevents major accidents from occurring.

Owner:YANAN POWER SUPPLY BUREAU

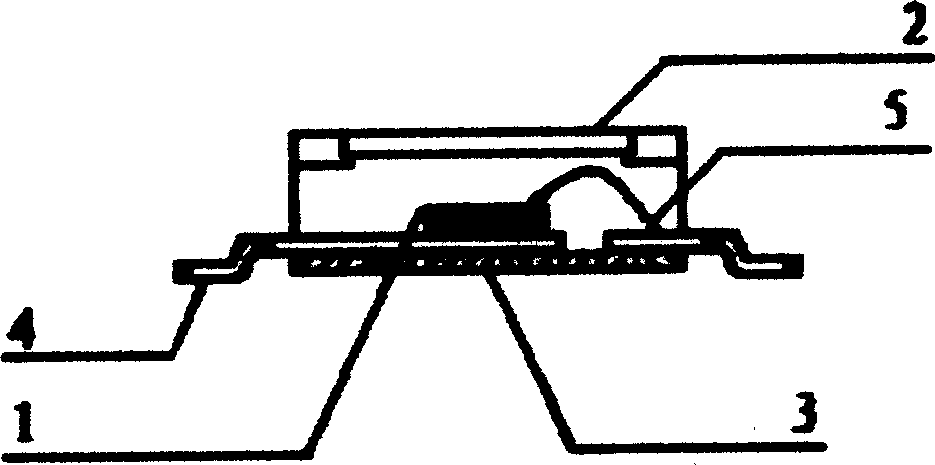

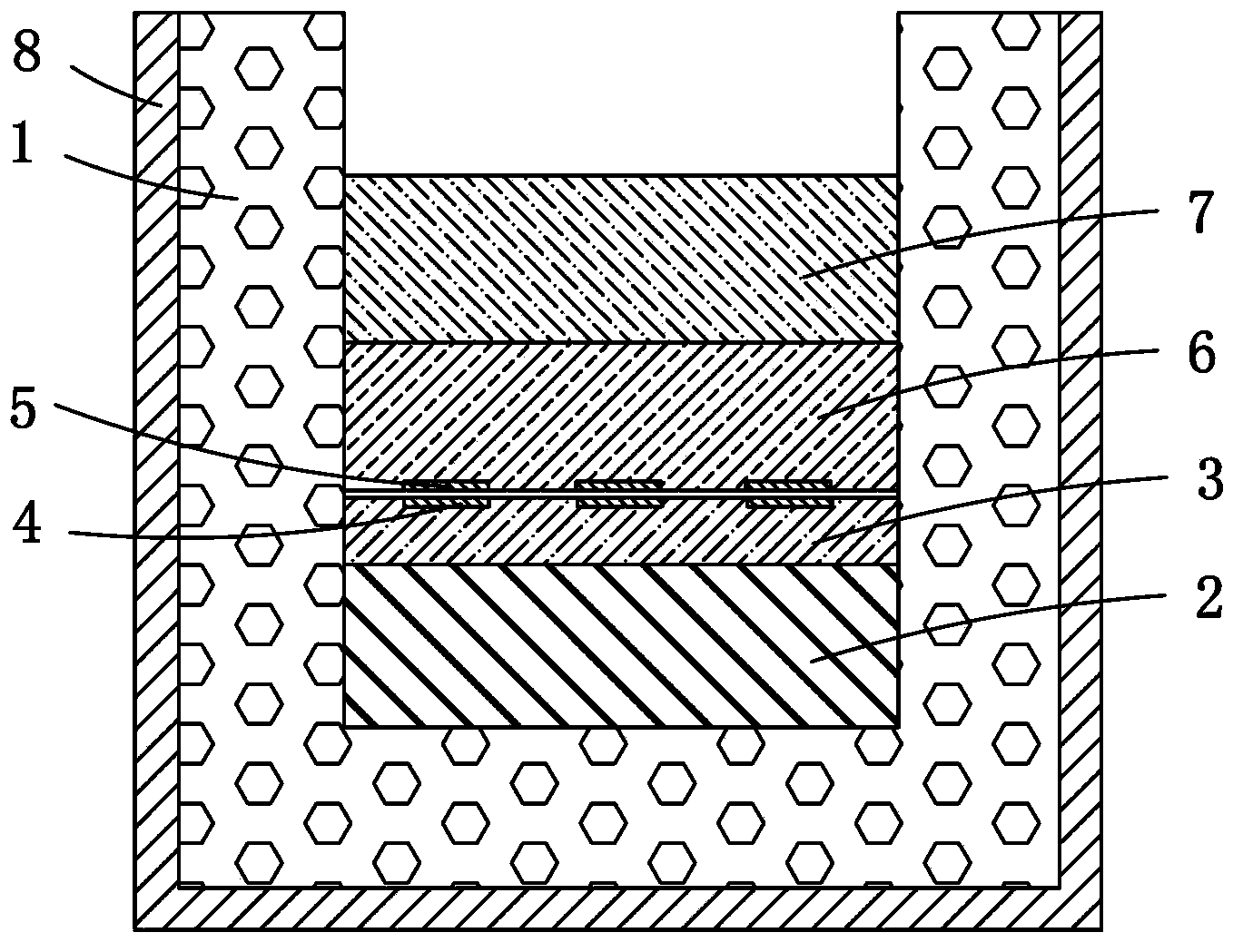

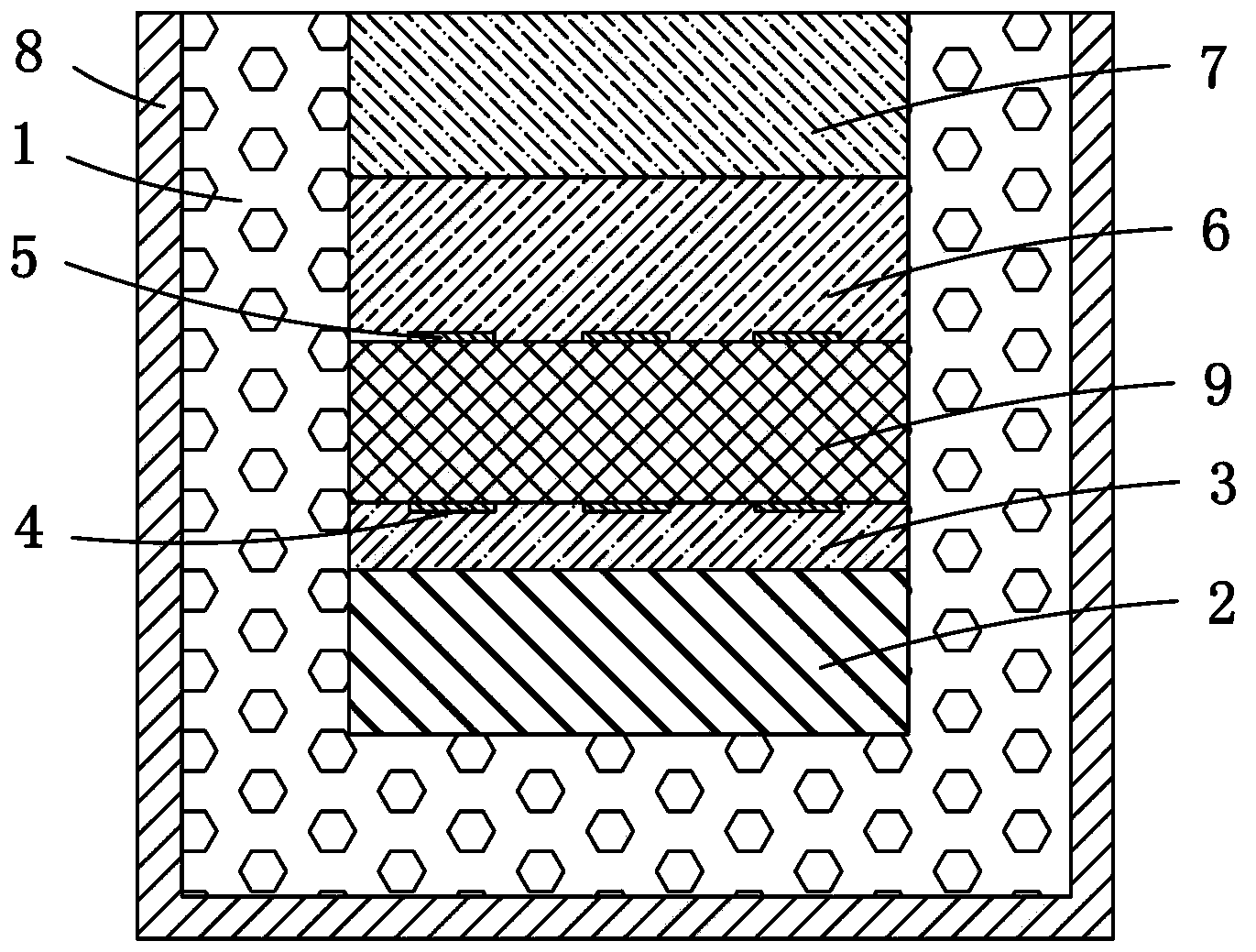

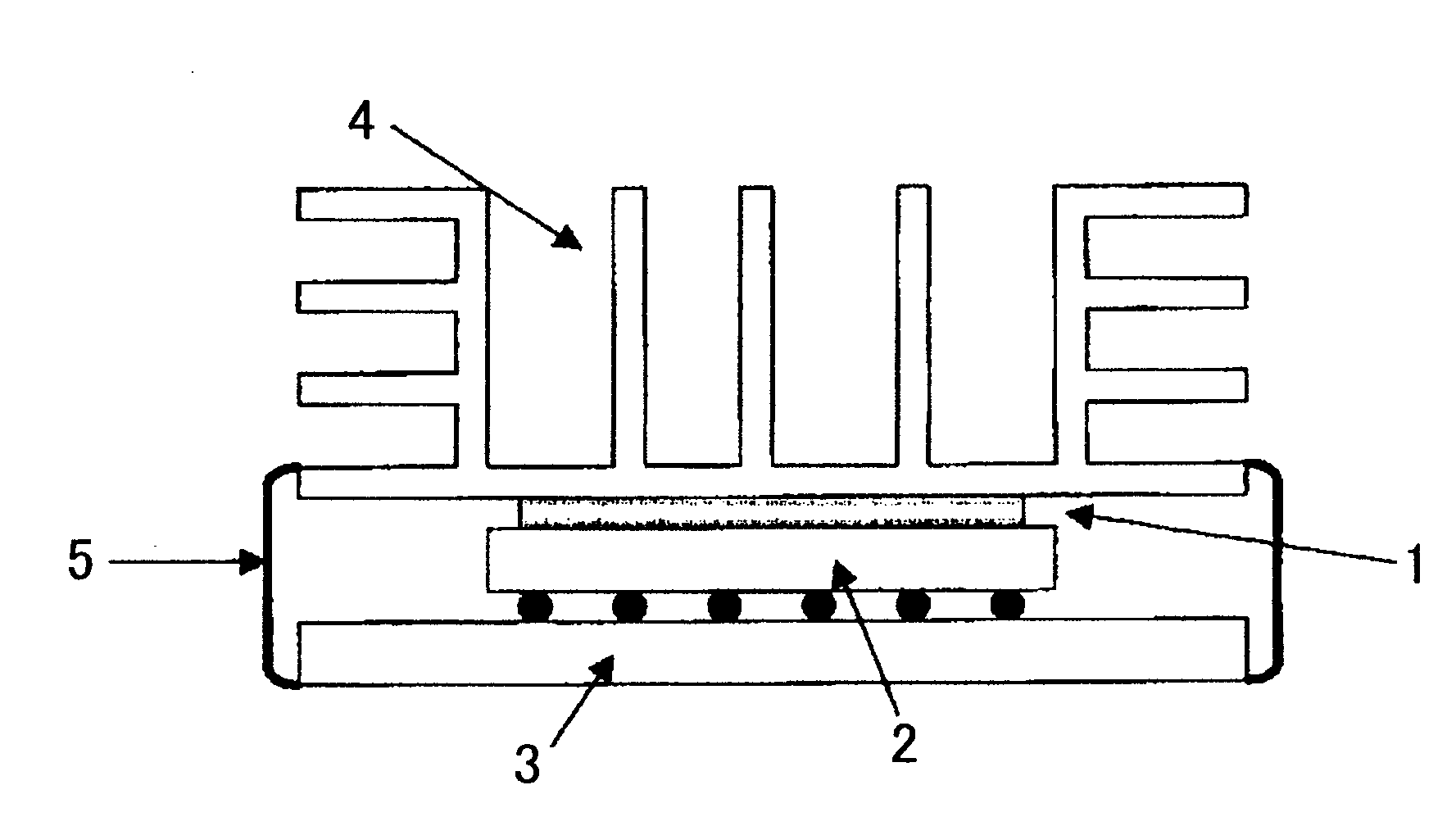

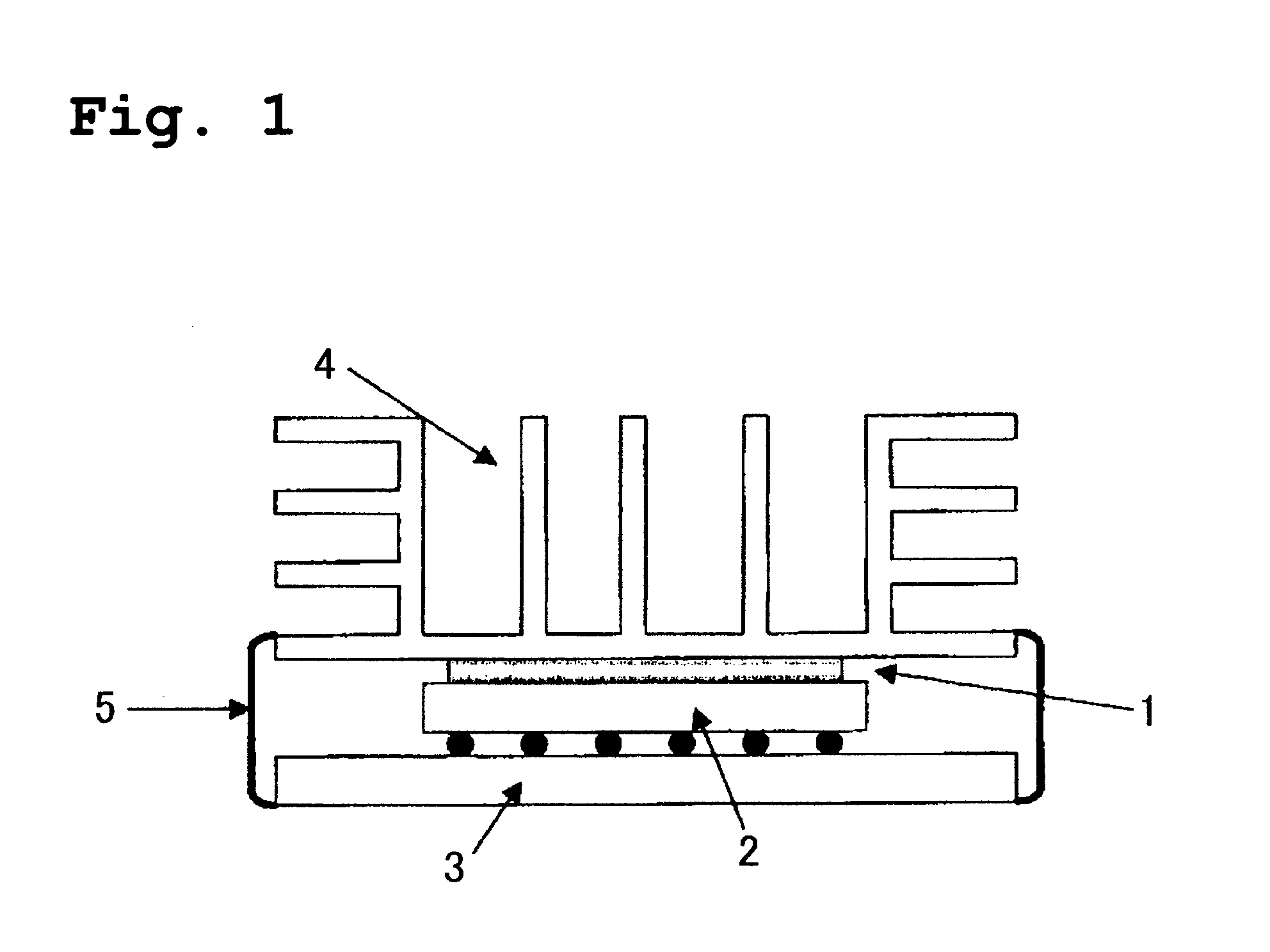

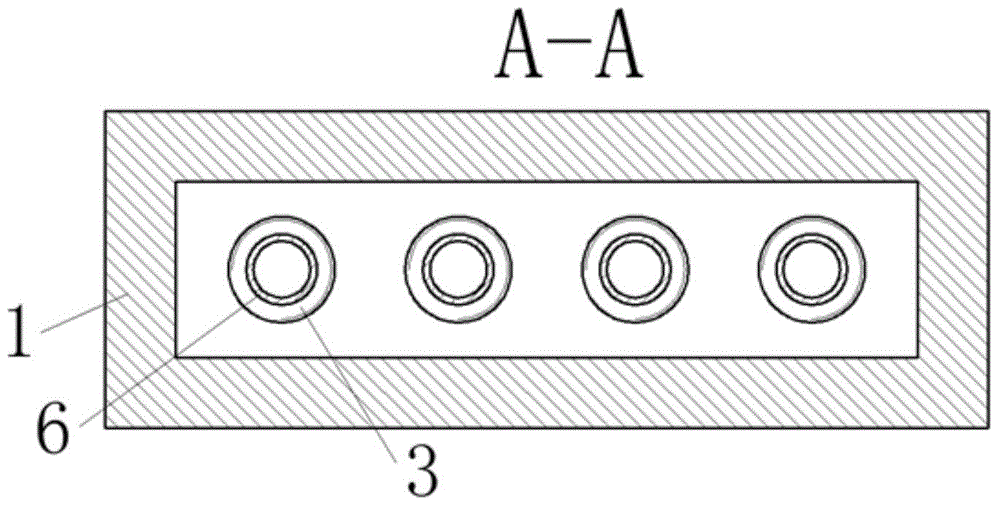

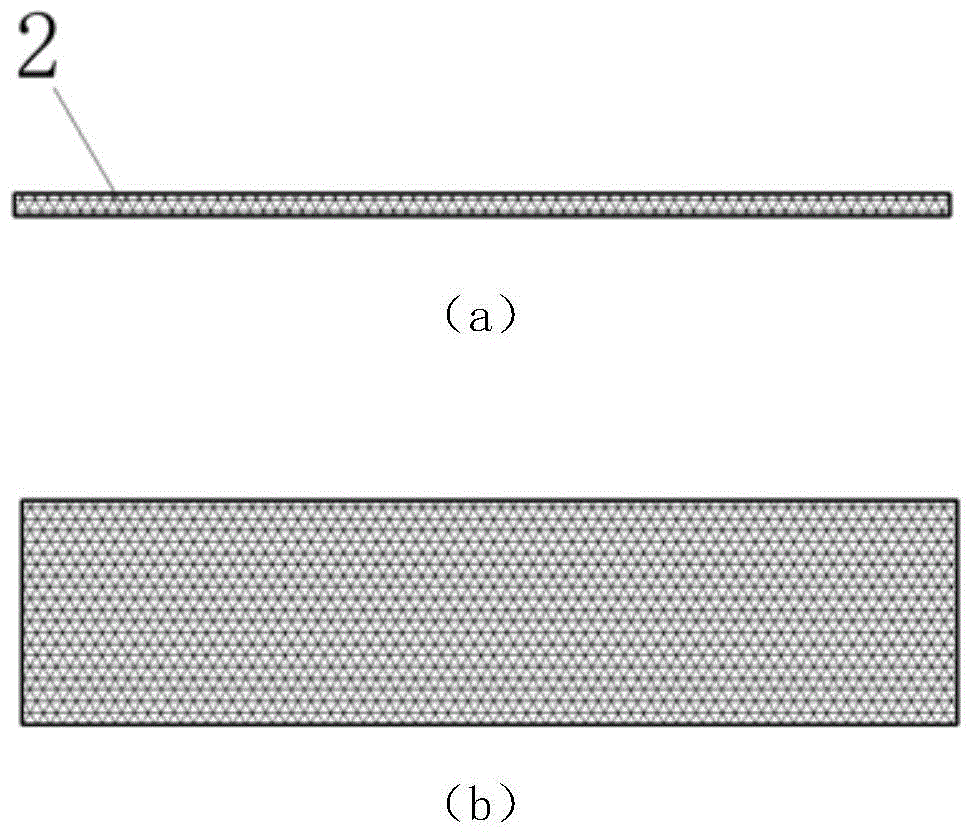

Measuring equipment and measuring method for heat conductivity coefficients of solid materials

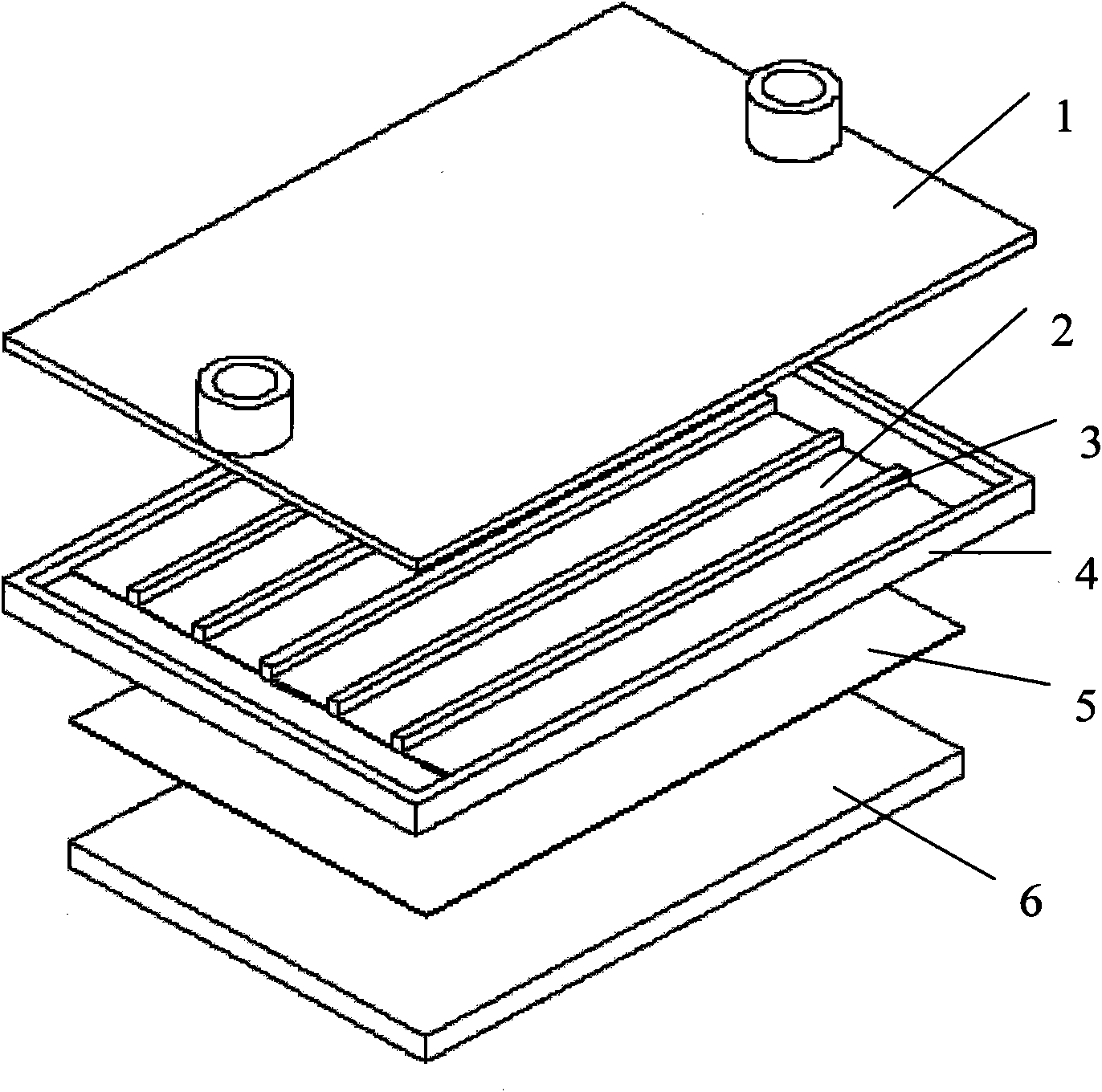

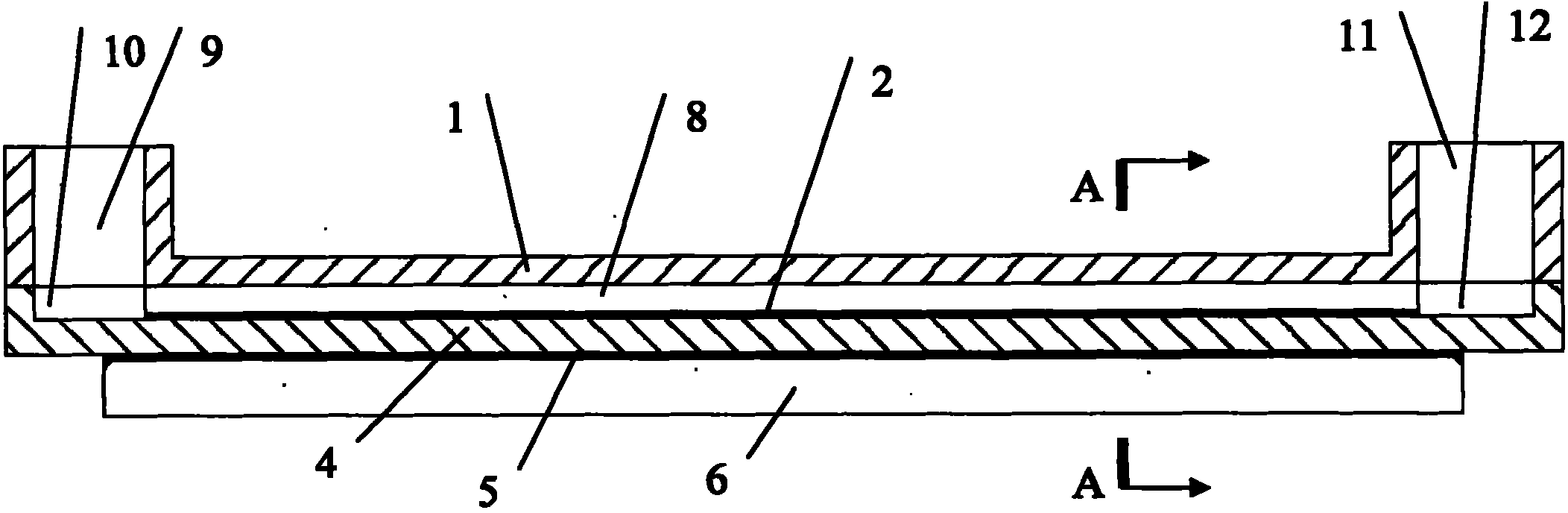

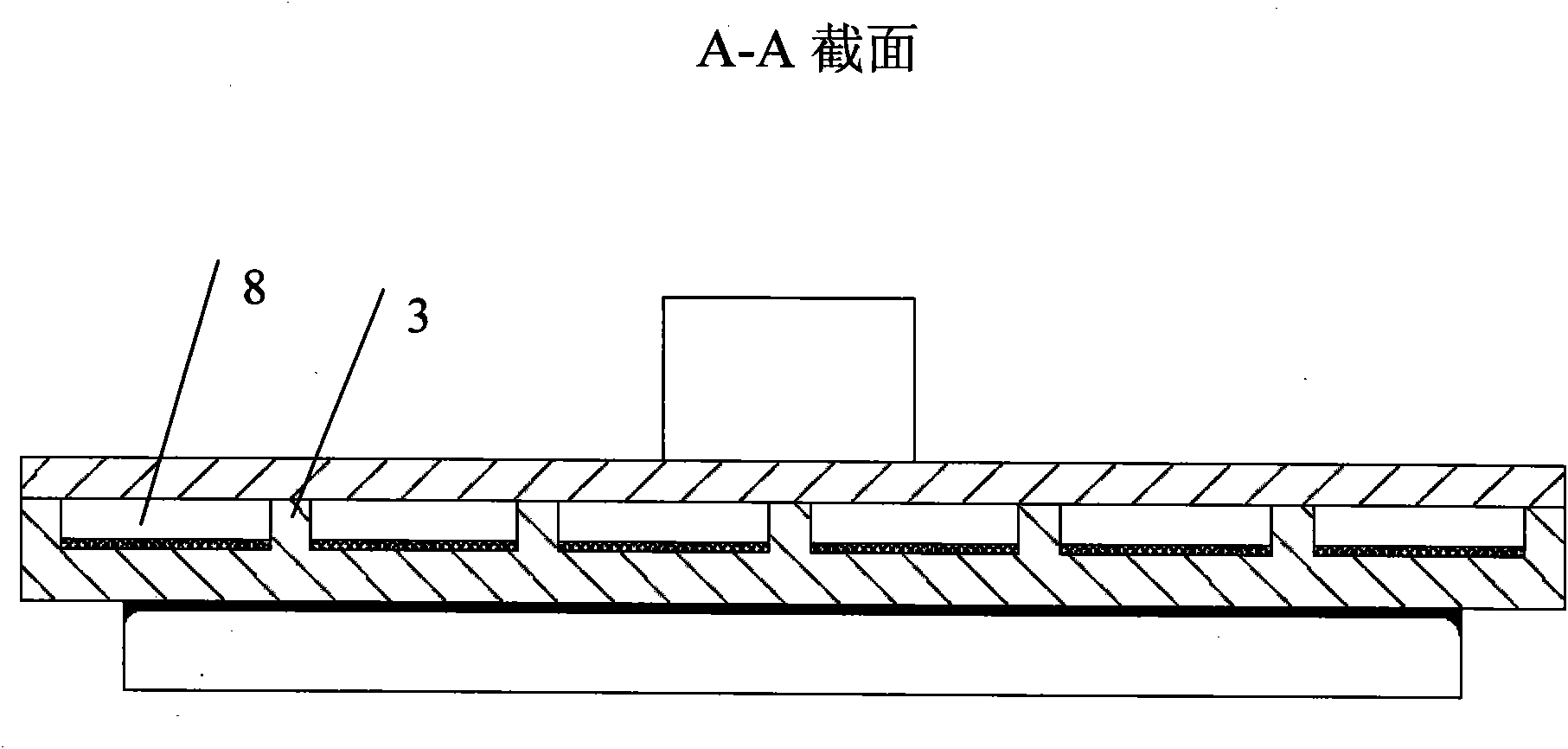

InactiveCN103411996AHigh precisionExtended service lifeMaterial heat developmentThermodynamicsHeat conducting

The invention discloses measuring equipment for heat conductivity coefficients of solid materials. The measuring equipment comprises a thermal insulating layer (1), and a heating plate (2), a soaking plate (3), a temperature sensor group (4), a temperature sensor group (5), a heat dissipation plate (6) and a constant temperature plate (7) which are arranged inside the thermal insulating layer (1) from bottom up in sequence, wherein two wholes are formed by bonding the heating plate (2) with the soaking plate (3), the heat dissipation plate (6) and the constant temperature plate (7) through heat-conducting silicone grease; the temperature sensor group (4) is mounted on the upper surface of the soaking plate (3) and distributed uniformly on the upper surface of the soaking plate (3); the temperature sensor group (5) is mounted on the lower surface of the heat dissipation plate (6) and distributed uniformly on the lower surface of the heat dissipation plate (6); the measuring equipment further comprises fitting function, which relates to the temperature of the lower surface of the heat dissipation plate (6), of temperature gradient of the lower surface of the heat dissipation plate (6). The invention further discloses a measuring method of the measuring equipment. The measuring equipment and the measuring method can rapidly and accurately measure the heat conductivity coefficients of to-be-measured samples.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Silicone defoaming agent for papermaking and pulping and preparation method thereof

InactiveCN101798781ANovel production formulaRaw materials are easy to getDefoamers additionCoatingsEmulsionPapermaking

The invention provides a silicone defomaing agent for papermaking and pulping and a preparation method thereof, which belong to the papermaking chemicals, and mainly comprise silicon grease mixture, silicon oil mixture, emulsifier, thickener and water. In the defoaming agent emulsion, silicon grease mixture and silicon oil mixture account for 70 to 90 percent of the active matter content, wherein total active matter content accounts for 5 to 30 percent of total content of emulsion, and the rest medium is water. The anti-foaming performance is improved through the silicon grease mixture, the defoaming performance is improved through the silicon oil mixture, the viscosity of the silicon grease is reduced by adding the emulsifier, and the emulsion effect is improved. The silicone defoaming agent has novel formula composition and good defoaming and anti-foaming performance, and has excellent performance in the papermaking pulping work procedure and partial water systems.

Owner:XIAN SUNY FINE CHEM

Low-filling-capacity and high-heat-conductivity graphene/silicone grease composite material and preparation method thereof

The invention discloses a low-filling-capacity and high-heat-conductivity graphene / silicone grease composite material and a preparation method thereof. Heat-conductive silicone grease is prepared by filling functional reduction-oxidation graphene sheet with silicone oil. The preparation method of the composite material comprises the following steps: preparing the functional reduction-oxidation graphene sheet as heat-conductive filler; sufficiently mixing the modified heat-conductive filler and dimethicone matrix in a double-roller open mill to uniformly disperse the functional reduction-oxidation graphene sheet in the silicone oil matrix. The heat-conductive silicone grease provided by the invention can be used for effectively avoiding the contacting gap between a high-power electronic component heating element and a heat radiation device, so that the interface contact thermal resistance can be reduced, a high-efficiency heat radiation passage is formed, and heat transfer is accelerated; the silicone grease is beneficial to encapsulation and radiation of the high-power electronic components, can be used for improving the reliability of the electronic component products and prolonging the service life of the products, and is simple in preparation process.

Owner:GUANGDONG UNIV OF TECH

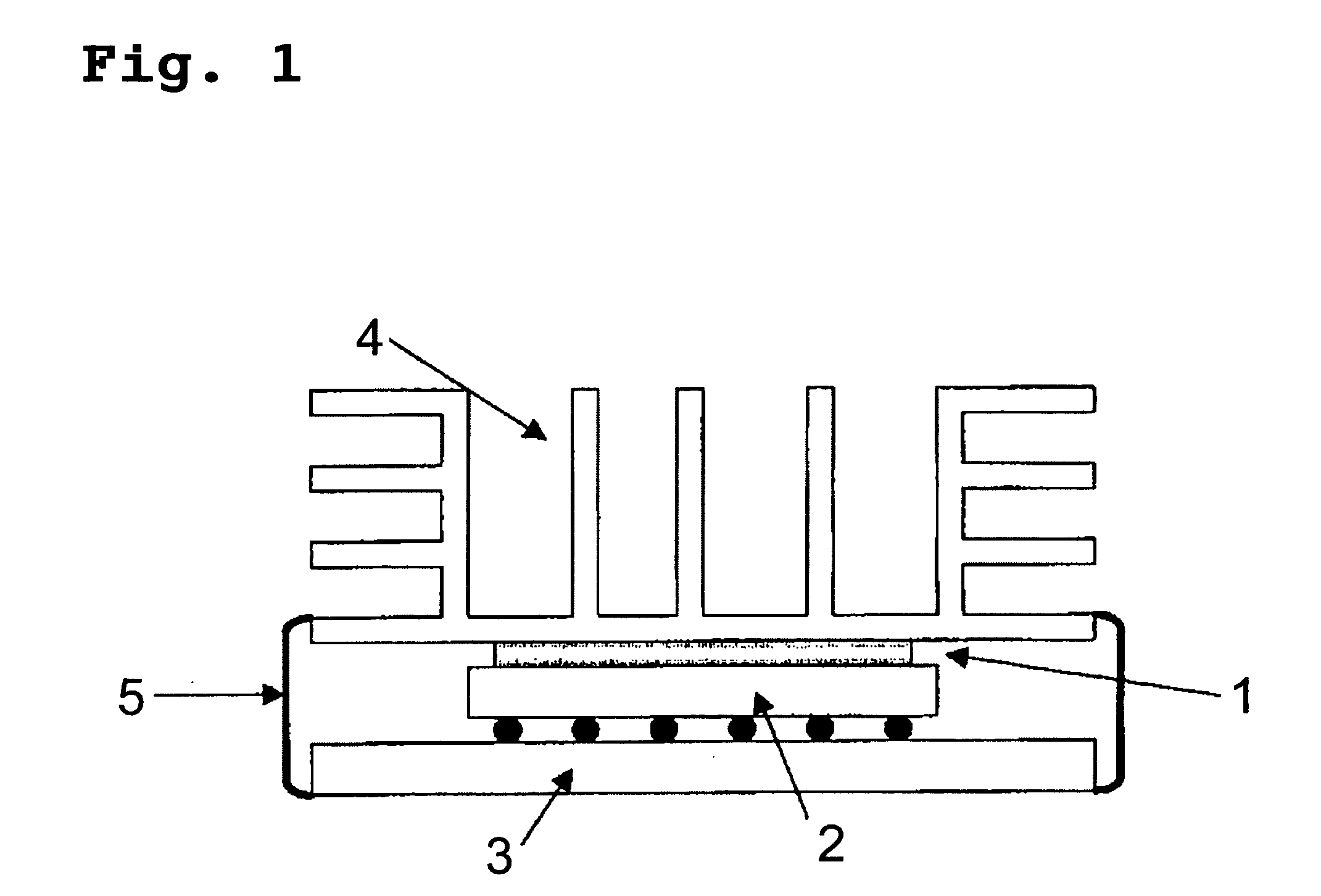

Heat conductive silicone grease composition and cured product thereof

InactiveUS20070042533A1Improve thermal conductivityReduce thermal resistanceLayered productsSemiconductor/solid-state device detailsIndiumPt element

Provided is a heat conductive silicone grease composition including (A) 100 parts by mass of an organopolysiloxane containing 2 or more alkenyl groups bonded to silicon atoms within each molecule, (B) an organohydrogenpolysiloxane containing 2 or more hydrogen atoms bonded to silicon atoms within each molecule, in sufficient quantity to provide from 0.1 to 5.0 hydrogen atoms bonded to silicon atoms within the component (B) for each alkenyl group within the component (A), (C) 100 to 2,200 parts by mass of a heat conductive filler, (D) an effective quantity of a platinum-based catalyst, and (E) an effective quantity of an addition reaction retarder, in which the component (C) includes more than 90% by mass and no more than 100% by mass of an indium powder with an average particle size of 0.1 to 100 μm. Also provided is a heat conductive silicone cured product obtained by curing the above composition by heating at a temperature equal to, or greater than, the melting point of the indium powder. Further provided is an electronic device including an electronic component, a heat radiating member, and a heat conductive member including the above cured product disposed between the electronic component and the heat radiating member. Still further provided is a method of curing the above composition. Even further provided is a method of forming a heat conductive member between an electronic component and a heat radiating member. The above heat conductive silicone grease composition generates a suitably thin cured product with excellent thermal conductivity that prevents problems such as the contamination of components other than the coated component, and the leakage of oily materials from the product if used over extended periods.

Owner:SHIN ETSU CHEM IND CO LTD

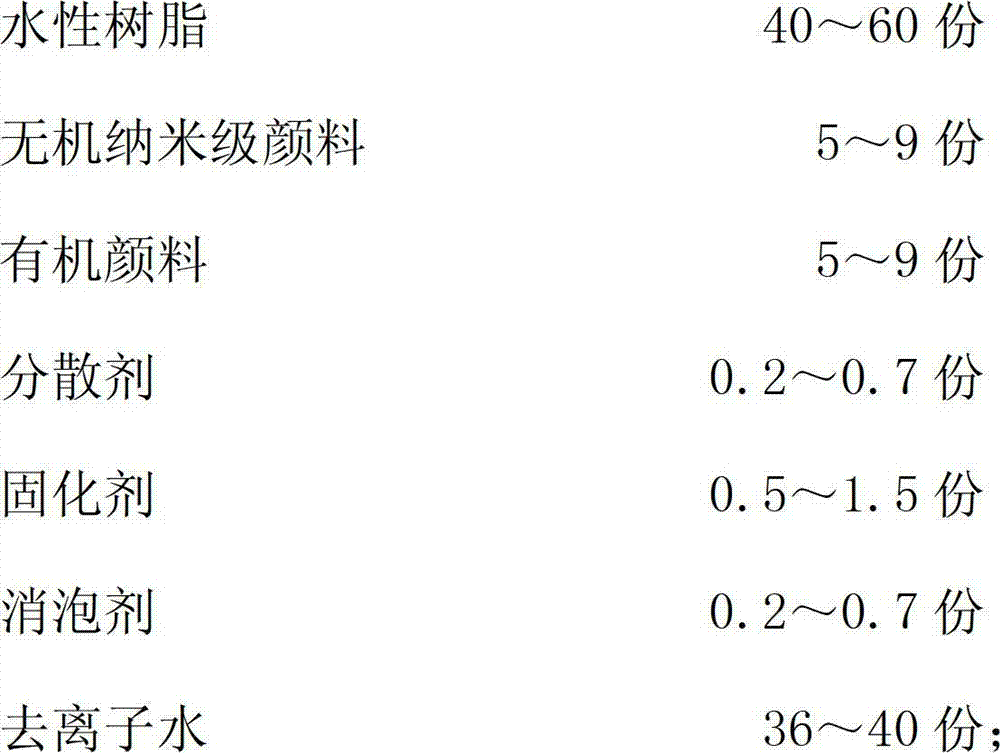

Thermal transfer ribbon and preparation method thereof

InactiveCN102785491AIncrease temperatureImprove heat resistanceInk ribbonsCoatingsWater basedPolyester

The invention discloses a thermal transfer ribbon which comprises an ink layer, a release agent layer, base material and a thermal resistant layer. The ink layer comprises water-dilutable resin, inorganic nanoscale pigment, organic pigment, dispersant, curing agent, deformer and deionized water. The release agent layer comprises organic silicone resin, water-based wax emulsion, talcum powder and deionized water. The base material includes polyester film and thermal-conductive silicone grease. The thermal resistant layer comprises perfluorocarbon, organic silicone resin and deionized water. The invention further discloses a preparation method for the thermal transfer ribbon. The preparation method includes steps of stirring, mixing, drying and the like. The thermal-conductive silicone grease is added to the base material polyester film, using temperature of the thermal transfer ribbon is increased, thermal resistance and adaptability of the thermal transfer ribbon are improved, and printing speed is increased. The thermal resistant layer is added to the thermal transfer ribbon, and accordingly performance of the thermal transfer ribbon is improved. The release layer is added, and accordingly the ink is easier to separate from the base, strippable level is high, printing effect is better, and writing is clearer. The deionized water is used as solvent, and accordingly production cost is reduced, and cost performance of the thermal transfer ribbon is better.

Owner:HUZHOU KAIEN COATING

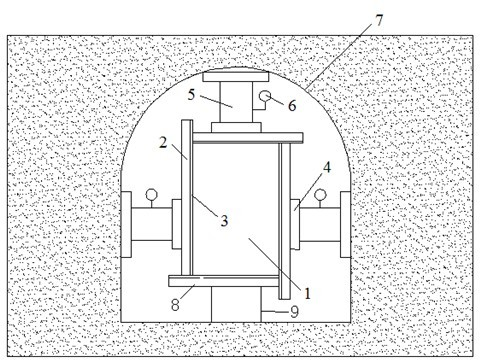

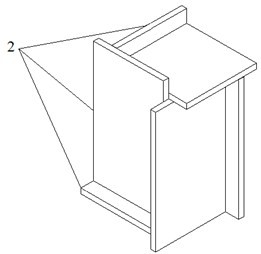

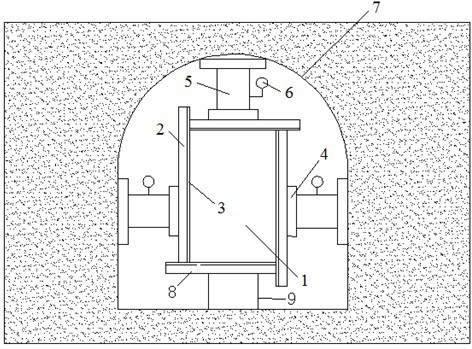

Device for large-scale true tri-axial test of original grading rockfill body and use method of method

ActiveCN102607946AFully reflect the mechanical propertiesReflect mechanical propertiesMaterial strength using tensile/compressive forcesRubber membraneTriaxial shear test

The invention discloses a large-scale true tri-axial test method and a large-scale true tri-axial test device, which can be used for carrying out the true tri-axial test on an original grading rockfill body. The device is arranged in a concrete cave chamber; six faces of a sample are loaded by rigid slabs; three directional main stress is applied by a hydraulic jack controlled by adopting a hydraulic system; two layers of rubber membranes are sleeved at the inner side of a steel plate so as to reduce friction; silicone grease is coated between the rubber membranes; and rigidity compression plates are respectively provided with a displacement sensor or a dialgage used for determining the deformation of the sample in all directions. The device can be used for testing a large-sized original grading sample of the rockfill body, therefore, the size effect can be completely avoided, larger axial strain can be achieved, and a complicated stress-strain path can be simulated.

Owner:WUHAN UNIV

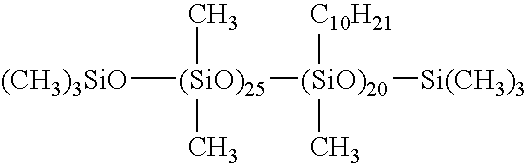

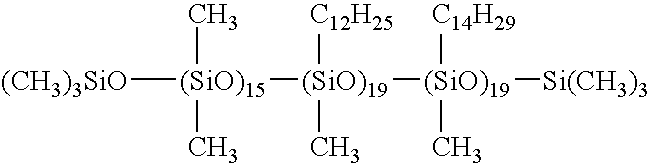

Heat conductive silicone grease composition and cured product thereof

InactiveUS20080213578A1Improve thermal conductivityLower interface thermal resistanceMaterial nanotechnologySemiconductor/solid-state device detailsConductive materialsPolymer chemistry

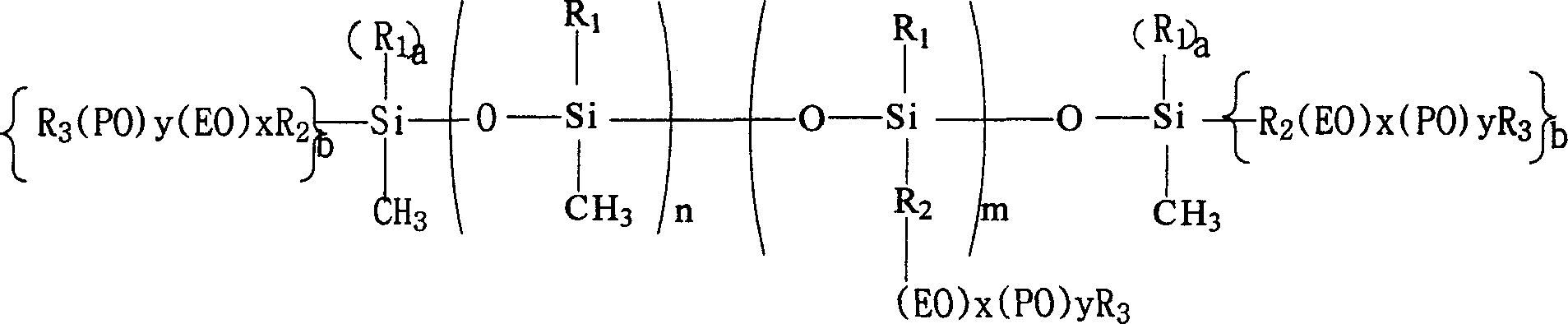

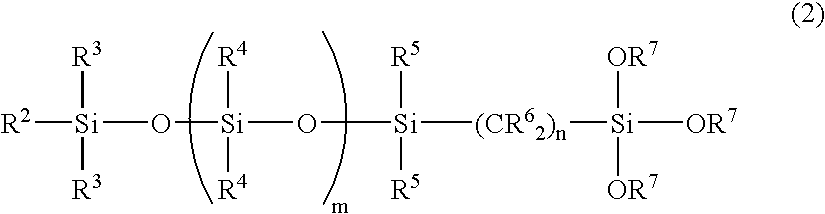

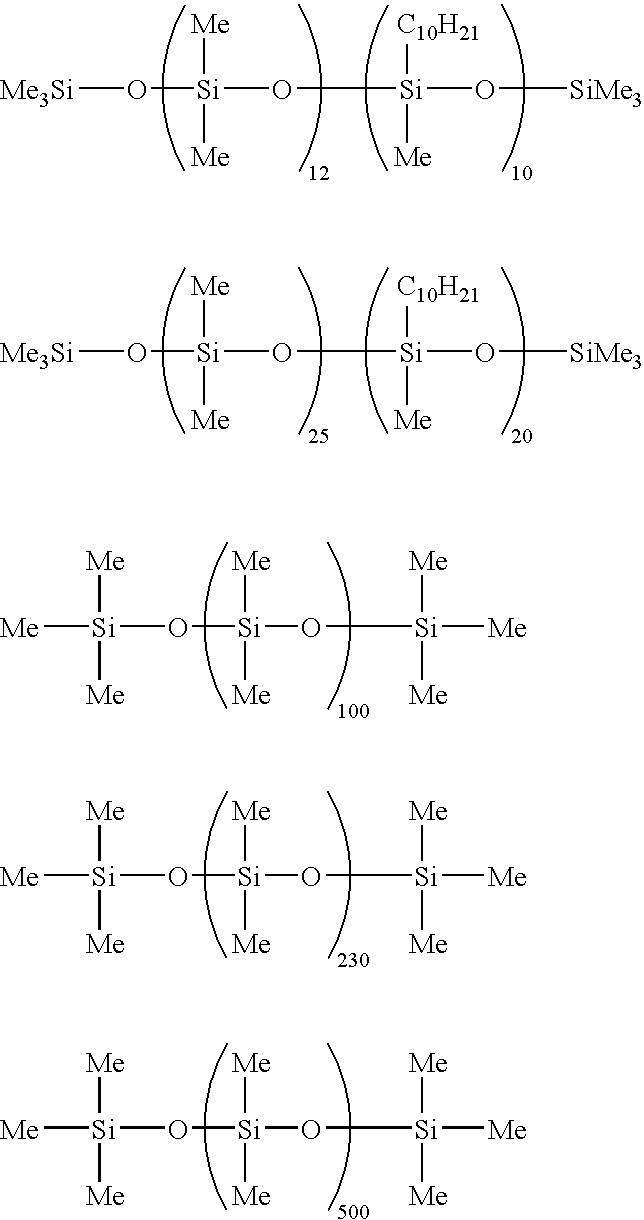

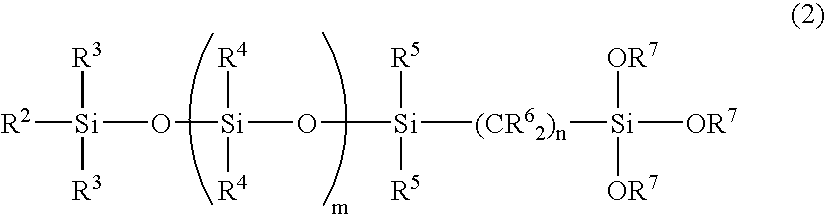

Provided is a heat conductive silicone grease composition, including: an organopolysiloxane containing 2 or more alkenyl groups bonded to silicon atoms within each molecule, an organopolysiloxane with a specific structure and with a kinematic viscosity at 25° C. of 10 to 10,000 mm2 / s, an alkoxysilane containing specific substituent groups, an organohydrogenpolysiloxane containing 2 or more SiH groups within each molecule, a heat conductive filler, a platinum-based catalyst, and an addition reaction retarder. The heat conductive silicone grease composition exhibits high thermal conductivity, has excellent fluidity prior to curing and therefore exhibits favorable workability, is capable of filling fine indentations and therefore reduces contact resistance, and is also able to prevent oil separation and bleeding of the heat conductive material following curing, meaning the composition exhibits excellent heat radiation performance and reliability. Also, the heat conductive silicone grease composition exhibits improved durability under conditions of high temperature and high humidity, and thereby exhibits further improved reliability during actual use.

Owner:SHIN ETSU CHEM IND CO LTD

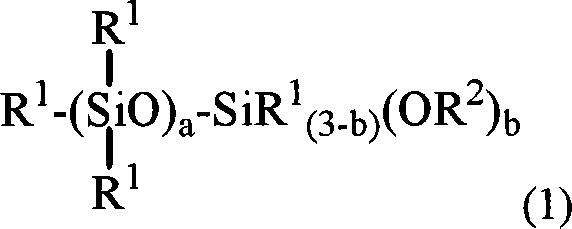

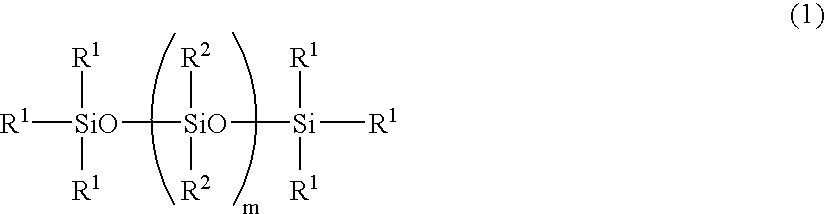

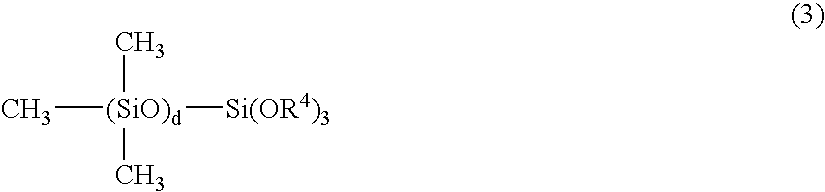

Heat conductive silicone grease composition

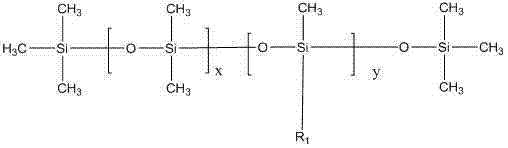

InactiveUS20070293624A1DissipatingImprove thermal conductivitySemiconductor/solid-state device detailsConductive materialThermal radiationSilicone grease

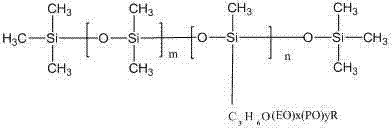

Provided is a heat conductive silicone grease composition, including: (A) 100 parts by volume of an organopolysiloxane of a specific structure with a kinematic viscosity at 25° C. within a range from 10 to 100,000 mm2 / s, (B) 0.1 to 50 parts by volume of an organopolysiloxane that functions as a wetter and contains a triorganooxysilyl group bonded to one terminal via an alkylene group that may be branched, and (C) 100 to 2,500 parts by volume of a heat conductive filler. The composition exhibits high thermal conductivity, displays excellent initial fluidity and is capable of retaining that fluidity over an extended period, and exhibits excellent heat radiation performance. Heat generated by a heat-generating body can be dissipated into a heat-radiating body by sandwiching the composition between the heat-generating body and the heat-radiating body.

Owner:SHIN ETSU CHEM IND CO LTD

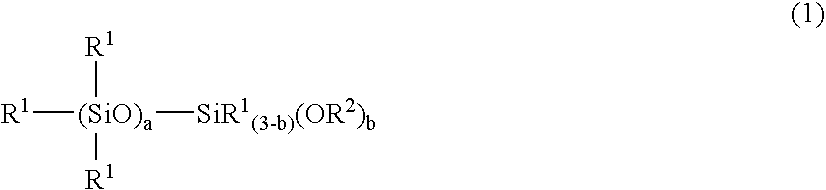

Thermally conductive silicone grease composition

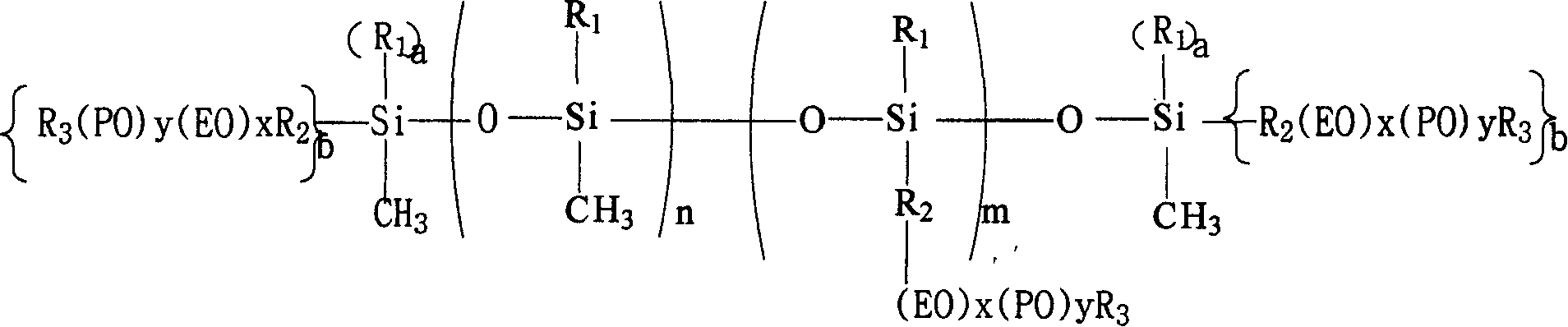

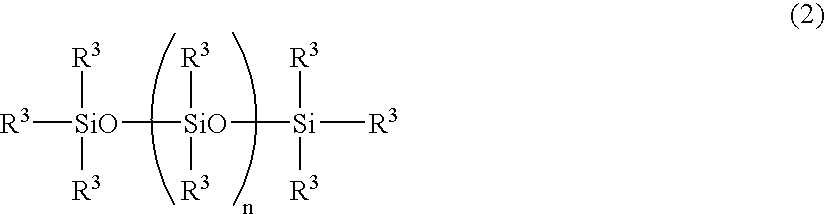

ActiveUS20120119137A1Hardness rise is smallLow elongationSemiconductor/solid-state device detailsHeat-exchange elementsHydrogen atomHydrogen

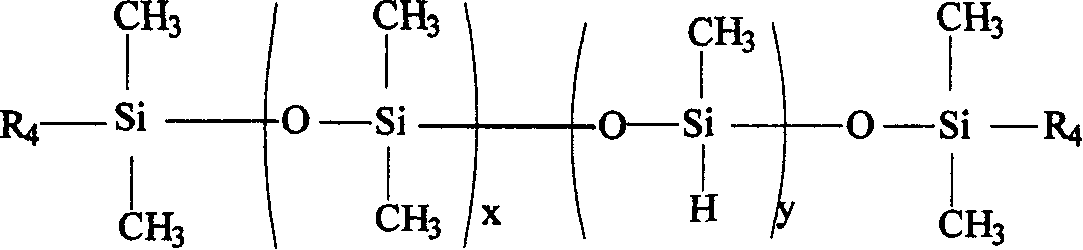

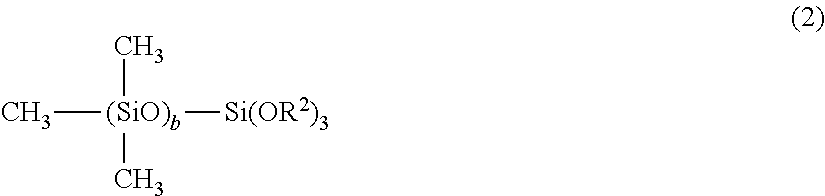

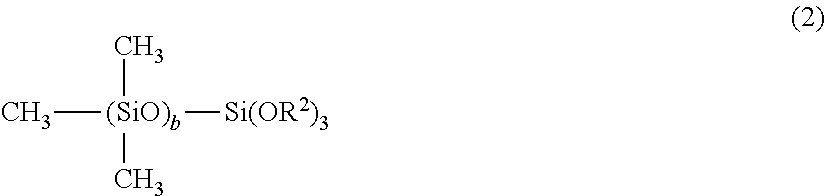

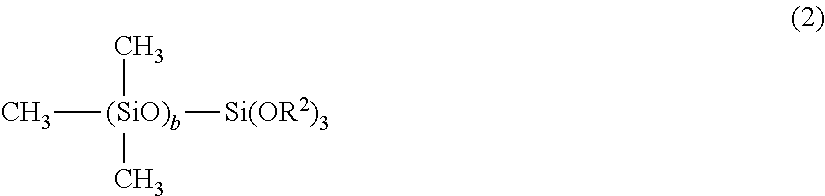

A thermally conductive silicone grease composition comprising:(A) an organopolysiloxane having at least two alkenyl groups in one molecule and having a kinetic viscosity of 5,000 to 100,000 mm2 / s at 25° C.;(B) a hydrolyzable methylpolysiloxane having a trifunctional termination at one end and represented by the following general formula (2):wherein R2 represents an alkyl group having 1 to 6 carbon atoms and b is an integer of 5 to 100;(C) a thermally conductive filler having a thermal conductivity of at least 10 W / m·° C.;(D) an organohydrogenpolysiloxane containing from 2 to 5 hydrogen atoms in one molecule directly bound to silicon atoms (Si—H groups);(E) a bonding aid having a triazine ring and at least one alkenyl group in one molecule; and(F) a catalyst selected from the group consisting of platinum and platinum compounds.

Owner:SHIN ETSU CHEM IND CO LTD

Heat-conducting silica gel and preparation method thereof

The invention discloses a heat-conducting silica gel and a preparation method thereof, wherein the heat-conducting silica gel comprises the following components in parts by weight: 100 parts of a basic polymer, 0.1-10 parts of a crosslinking agent, 500-1800 parts of a filler, and 0.1-15 parts of a silane coupling agent. The technical scheme of the invention can obtain a heat-conducting interface material which has higher heat-conducting stability compared with silicone grease, silicone cream and heat-conducting mud which are generally used on market at present, and solves the problem that the silicone grease, the silicone cream and the heat-conducting mud which are generally used on market at present will become dry when used at a high temperature for a long time, thereby ensuring the heat-conducting efficiency of long-term use of the heat-conducting interface material.

Owner:厦门安耐伟业新材料有限公司

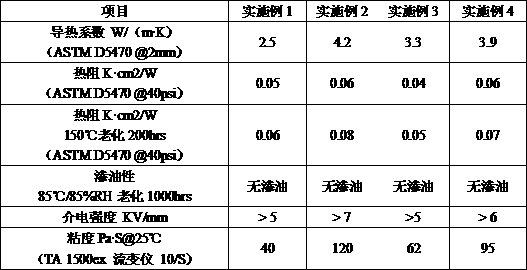

Ultra-low thermal-resistance heat-conducing silicon grease and preparation method thereof

ActiveCN103194067AImprove insulation performanceExcellent dielectric propertiesHeat conductingTemperature resistance

The invention discloses ultra-low thermal-resistance heat-conducing silicon grease. The silicon grease is prepared by the following raw materials according to parts by weight: 100 parts of polydimethylsiloxane, 10-40 parts of polyphenylmethylsiloxane, 1000-2600 parts of aluminum oxide, 20-60 parts of zinc oxide and 1-10 parts of a coupling agent. Furthermore, the invention discloses a preparation method of the ultra-low thermal resistant heat-conducing silicon grease. The heat-conducting silicon grease has the following advantages that the silicon grease has a high heat-conducting coefficient and ultra-low contact thermal resistance, and the contact thermal resistance is lower than 0.06K.cm<2> / W (pressure 40psi); and the silicon grease is stable to store at room temperature, free from oil seepage, good in high-temperature resistance, free from drying after long-time use at high temperature, and excellent in both electric insulating and dielectric performances.

Owner:NICHE TECH KAISER SHANTOU

Solid particle foam inhibitor and preparation method thereof

InactiveCN101721843AGood anti-foam performanceAdd lessFoam dispersion/preventionTextile printerSolid particle

The invention relates to a solid particle foam inhibitor and a preparation method thereof. The foam inhibitor component comprises an organic carrier, a main defoaming substance, an emulsifying agent, a structural agent and deionized water, wherein the organic carrier can be dextrin, starch, and the like; the main defoaming substance is a complex of high-viscosity silicone and low-viscosity silicone; and the structural agent can be acrylic acid and maleic acid copolymer, sodium citrate, and the like. The preparation method of the foam inhibitor comprises the following steps of: fully mixing the main defoaming substance with the emulsifying agent; then adsorbing the mixture on a carrier; adding the structural agent and granulating and drying to form a particle with favorable mobility. The prepared solid particle foam inhibitor is quite applicable to the industrial processes of cleaning, sewage treatment and textile printing and dyeing.

Owner:JIANGSU SIXIN SCI-TECH APPL RES INST CO LTD

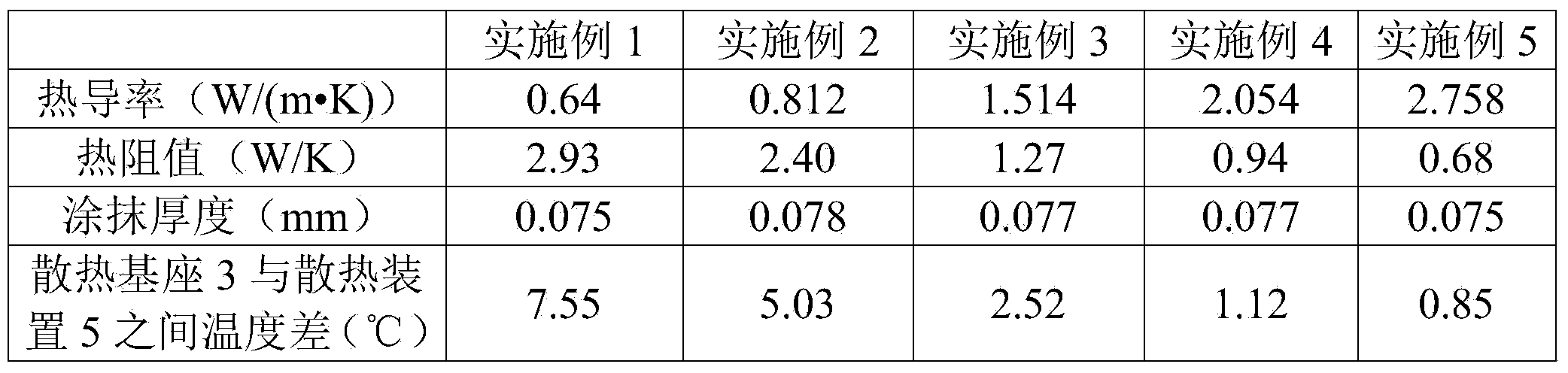

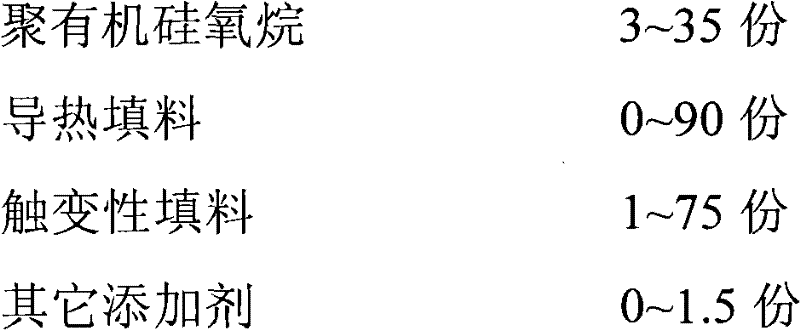

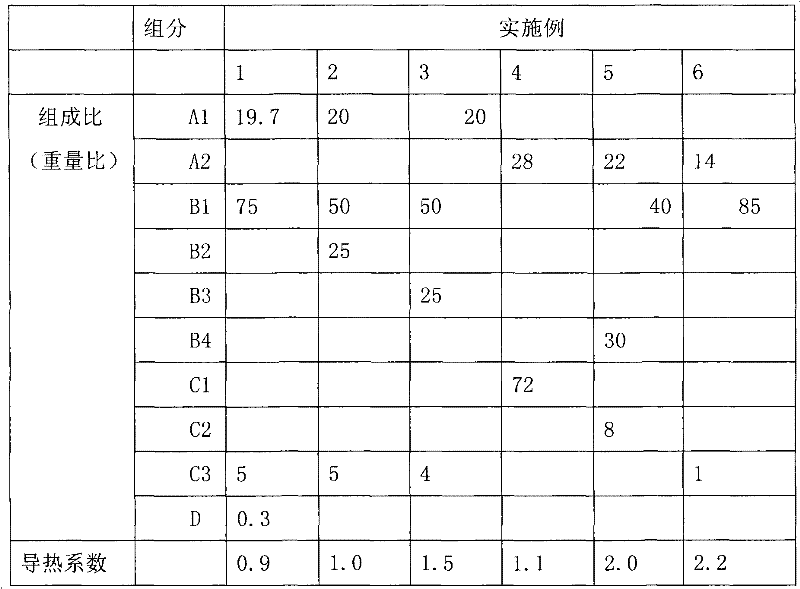

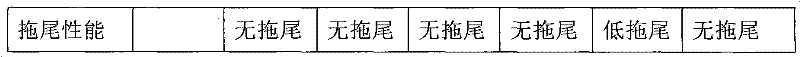

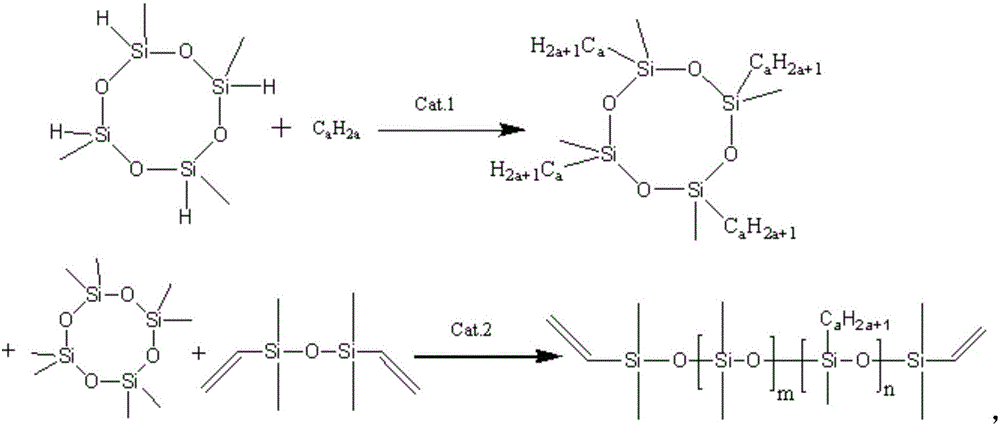

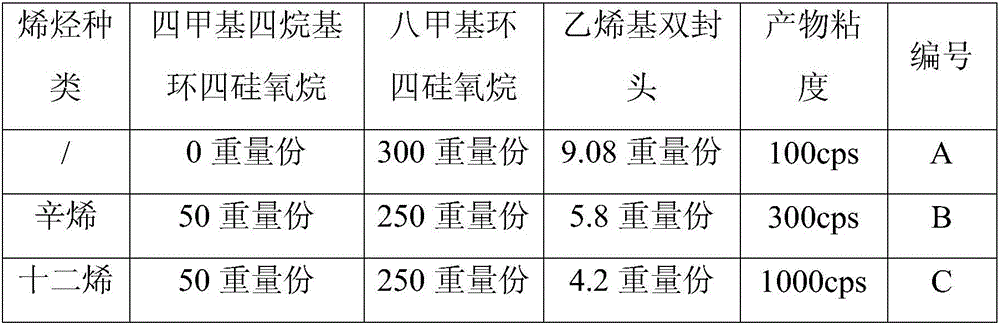

Low-trailing heat conductive silicone grease composition and preparation method thereof

InactiveCN102558867ALow brushed tailNo pollution in the processHeat-exchange elementsSilicone greaseSizing

The invention relates to a low-trailing heat conductive silicone grease composition and a preparation method thereof. The low-trailing heat conductive silicone grease composition consists of the following components in part by weight: 3 to 35 parts of polysiloxane, 0 to 90 parts of heat conductive filler, 1 to 75 parts of thixotropic filler and 0 to 1.5 parts of other additives. The low-trailing heat conductive silicone grease is prepared from the specific type of polysiloxane, the heat conductive filler and the additives in an appropriate formula ratio by a specific process; and the heat conductivity and other properties of the heat conductive silicone grease are the same as those of the universal heat conductive silicone grease in the market, and the heat conductive silicone grease has low wire drawing trailing property, and has the advantages of no pollution and contribution to automatic sizing when used in the process.

Owner:BEIJING HYSTIC NEW MATERIALS

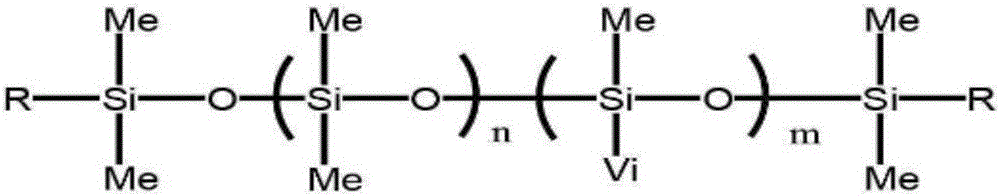

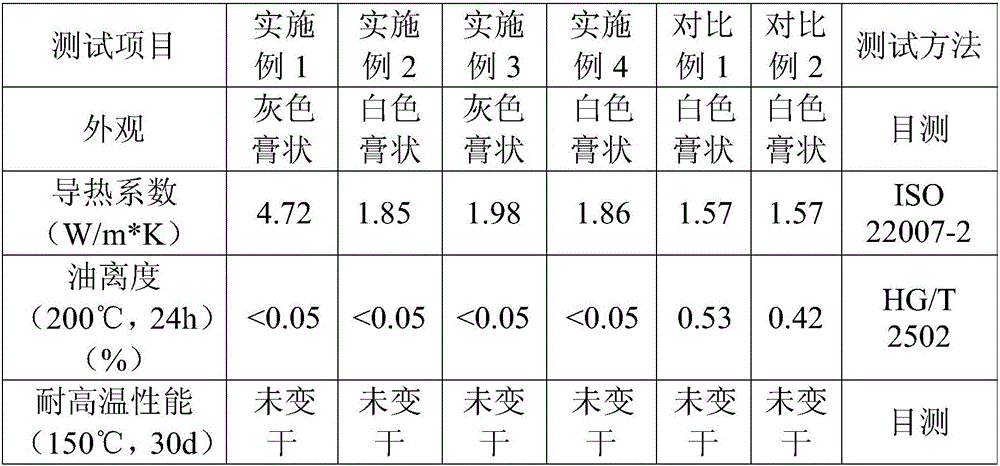

Heat-conducting silicone grease composition with low oil separation degree and preparation method thereof

The invention discloses a heat-conducting silicone grease composition with low oil separation degree and a preparation method thereof. The heat-conducting silicone grease composition with low oil separation degree includes: by weight, 30-40 parts of vinyl silicone oil, 0.1-1.0 part of hydrogen-containing silicone oil, 0.05-0.1 part of an inhibitor, 0.01-0.05 part of platinum-vinyl siloxane complex, and 100-500 parts of heat-conducting filler. The silicone oil in the heat-conducting silicone grease composition with low oil separation degree is difficult to transfer, and the oil separation degree is less than 0.05% (200 DEG C, 24h, HG / T 2502). The composition has secular stable thermolysis when using in the electron component, and has no harmful effect on the electron component because of the transference of the silicone oil.

Owner:CHENGDU GUIBAO SCI & TECH

Method for modification of zeolite molecular sieve outer surface acidity

InactiveCN1927463AEliminate acidityMolecular sieve catalystsOrganic-compounds/hydrides/coordination-complexes catalystsPolymer scienceChemical reaction

The invention relates to a method for using chemical reaction deposit to decorate the outer surface acid of ZSM-5 zeolite. Wherein, said method is characterized in that the silicone grease and the molecule screen are reacted in sealed container at 140-170Deg.C to be cooled and baked; and it uses cyclohexane solution of ethyl orthosilicate at 1-2.0mol / l; therefore, the silicon atom of ethyl orthosilicate can be completely carried by the molecule screen; and then left slag will not contain silicone grease. The invention has high carry efficiency of silicone grease, that only carrying the micrometer ZSM-5 one time while the opposite selectivity of catalyst can reach 90%, and carrying nanometer ZSM-5 two times while the opposite selectivity of catalyst can reach 90%.

Owner:DALIAN UNIV OF TECH

Silicone grease compositions

ActiveUS20050261140A1Improve cooling effectImprove heat transfer performanceAdditivesBase-materialsSilicone greaseMetal powder

A silicone grease composition is provided comprising (A) 2-40% by weight of an organopolysiloxane having a kinematic viscosity of 50-500,000 mm2 / s at 25° C., and (B) 60-98% by weight of at least one heat conductive filler selected from among metal powders, metal oxide powders and ceramic powders having a thermal conductivity of at least 10 W / m° C. and an average particle size of 0.1-15.0 μm. Coarse particles are removed such that a 500-mesh oversize fraction is not more than 50 ppm and a 325-mesh oversize fraction is substantially zero.

Owner:SHIN ETSU CHEM IND CO LTD

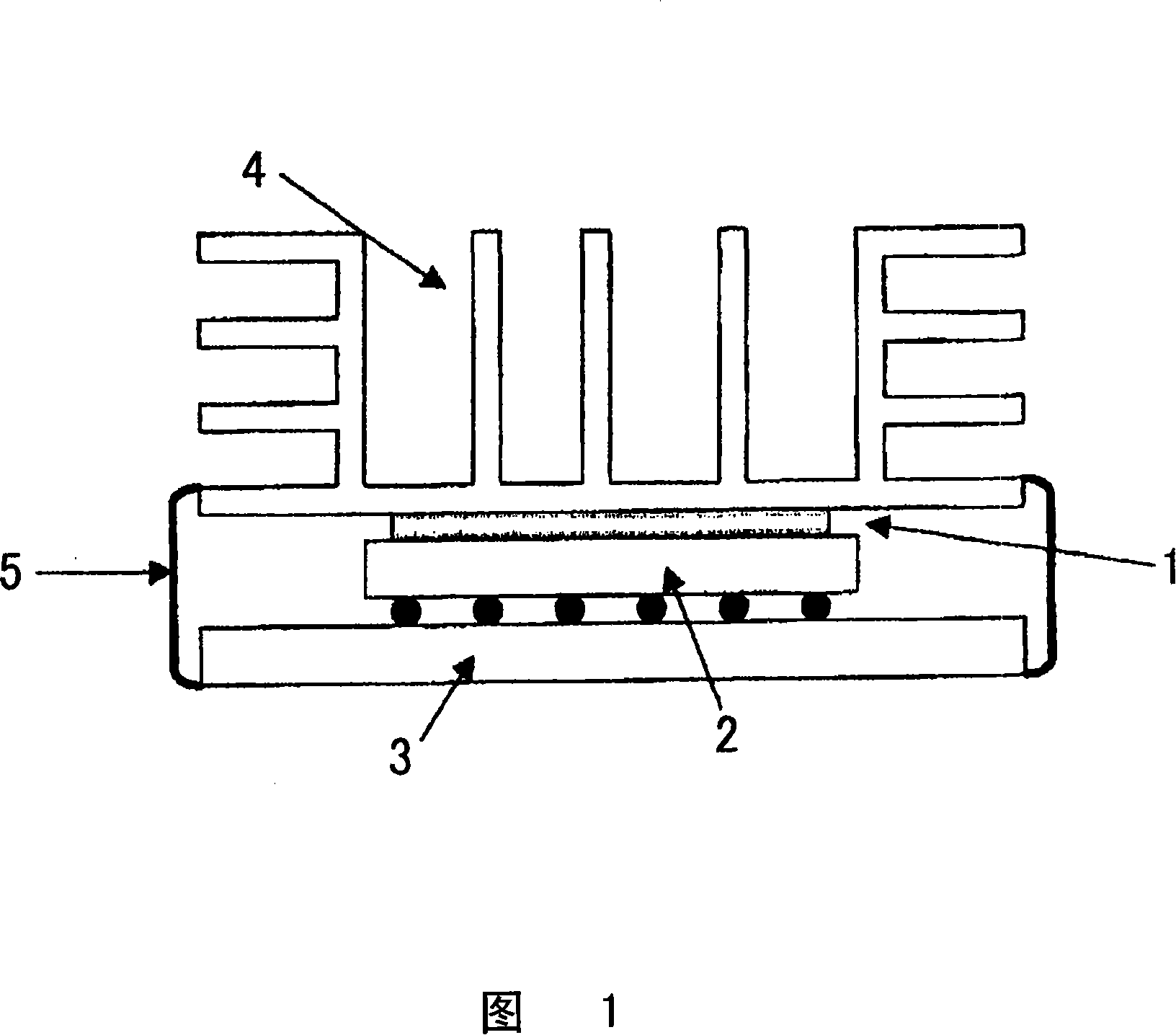

Evaporator for cooling chip and manufacture method thereof

InactiveCN101894812AMeet compactness requirementsImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesHeat transmissionEngineering

The invention relates to an evaporator for cooling a chip and a manufacture method thereof. The evaporator combines a micro-porous surface coat with a plurality of small-scale passageways. An evaporator main body consists of an upper cover plate and a lower base plate. The two ends of the upper cover plate of the evaporator are provided with a cooling liquid inlet and a cooling liquid outlet. The two ends of the lower base plate of the evaporator are respectively provided with an empty cavity; and the lower base plate is machined with a plurality of parallel ribs to form into the plurality of parallel small-scale passageways for flowing cooling liquid. The bottom surface of each small-scale passageway is coated with a layer of micro-porous surface coat for greatly intensifying the boiling phase-change heat transmission of the cooling liquid. The evaporator is glued with a heating electronic chip through a layer of heat-conductive silicone grease, heats up the cooling liquid which flows the passageways therein, absorbs the dissipated power of the electronic chip in the form of flowing boiling heat transmission, has the characteristics of small flow resistance, compact structure and low cost, has strong cooling performance, and is applied to cooling the electronic chip with high dissipated power.

Owner:EAST CHINA UNIV OF SCI & TECH

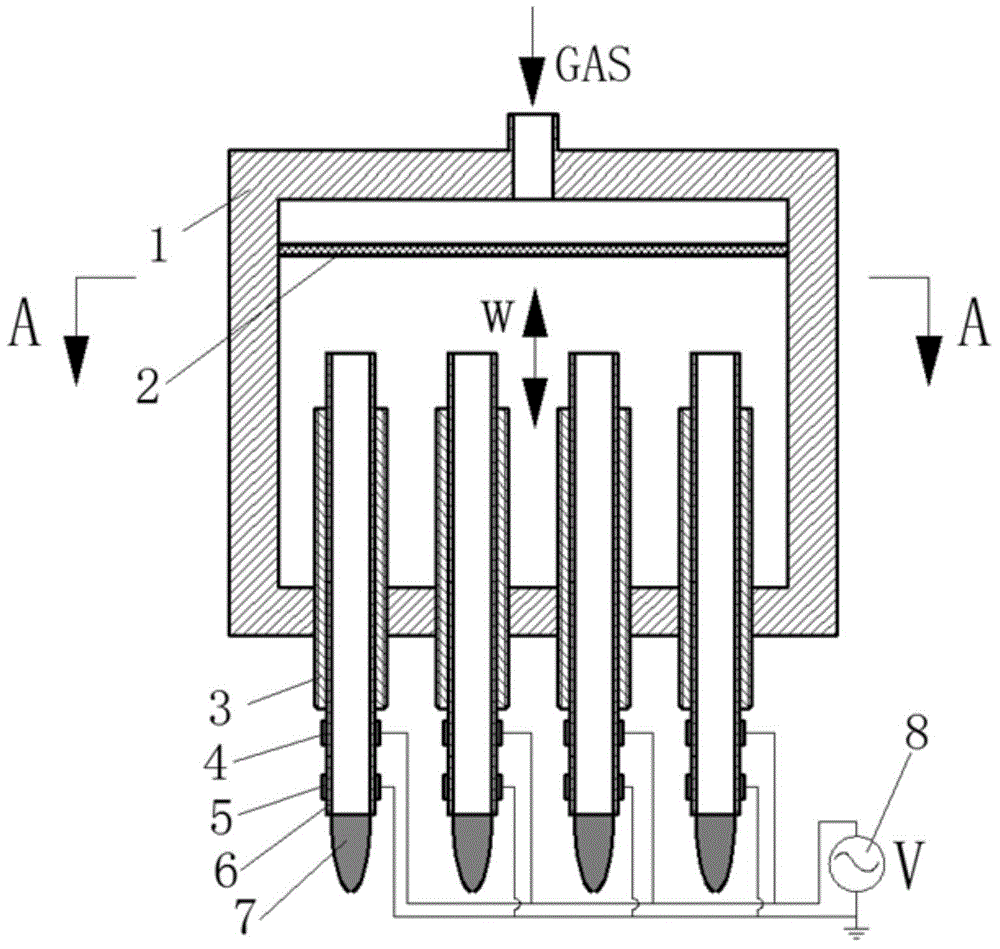

Adjustable device for atmospheric pressure low-temperature plasma jet arrays

ActiveCN104936370AMeet different processing needsImprove application flexibilityPlasma techniquePlasma jetJet flow

The invention provides an adjustable device for atmospheric pressure low-temperature plasma jet arrays. Single plasma generators are fixed with stud sleeves through cementation; the stud sleeves and a box body are in threaded connection, and sealing silicone grease is used for lubricating and sealing at the joints of screws; working gas is introduced into the upper end of the box body, and uniformly flows into the plasma generators through filtering screen meshes; the stud sleeves can be adjusted up and down relative to the position of the box body by screwing the stud sleeves, and thus the plasma generators can be driven to be adjusted up and down; the adjusting distance can be calculated through a screwing number of turns and a screw pitch; various combined adjustments of the plasma jet arrays can be realized by adjusting the up-and-down positions of the single plasma generators, and the adjustable device is suitable for different array forms of existing linear arrays and annular arrays. According to the adjustable device, the up-and-down positions of the plasma generators can be adjusted according to practical requirements, and the application flexibility and processing accuracy of the plasma jet arrays are improved.

Owner:SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com