Patents

Literature

174results about How to "Meet different processing needs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

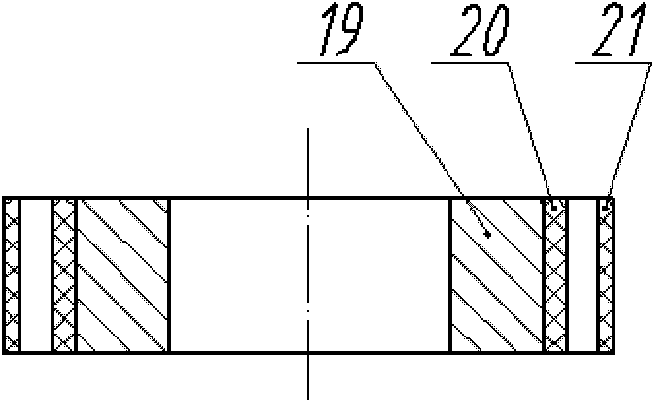

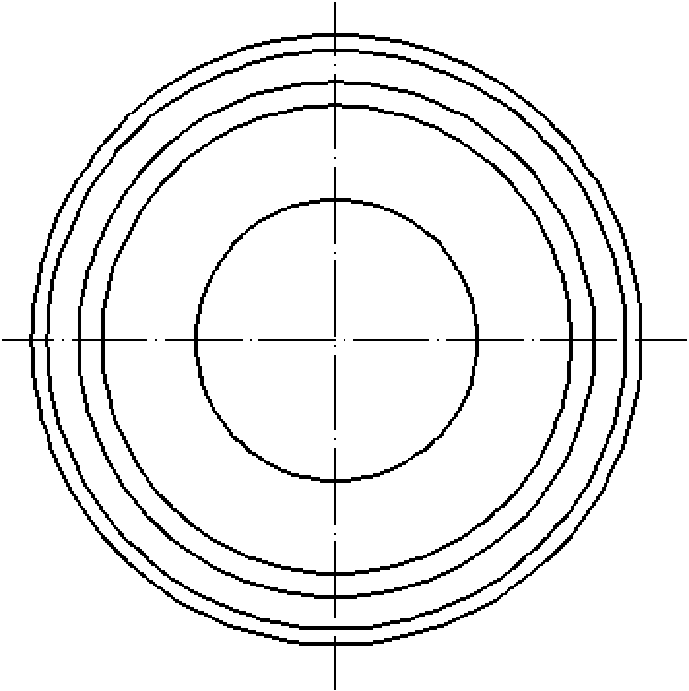

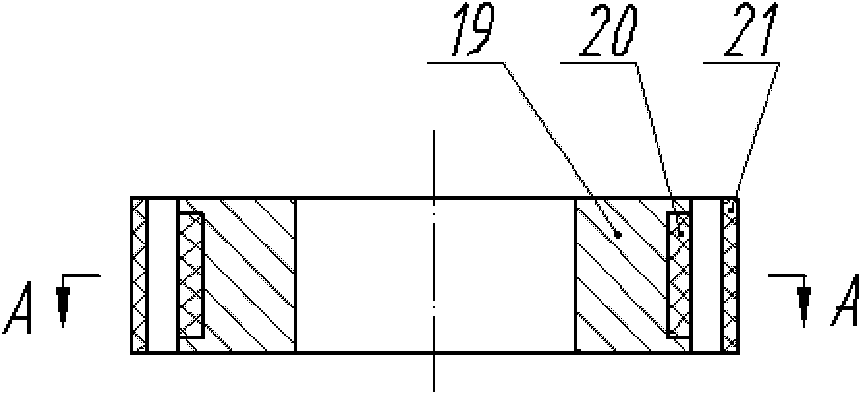

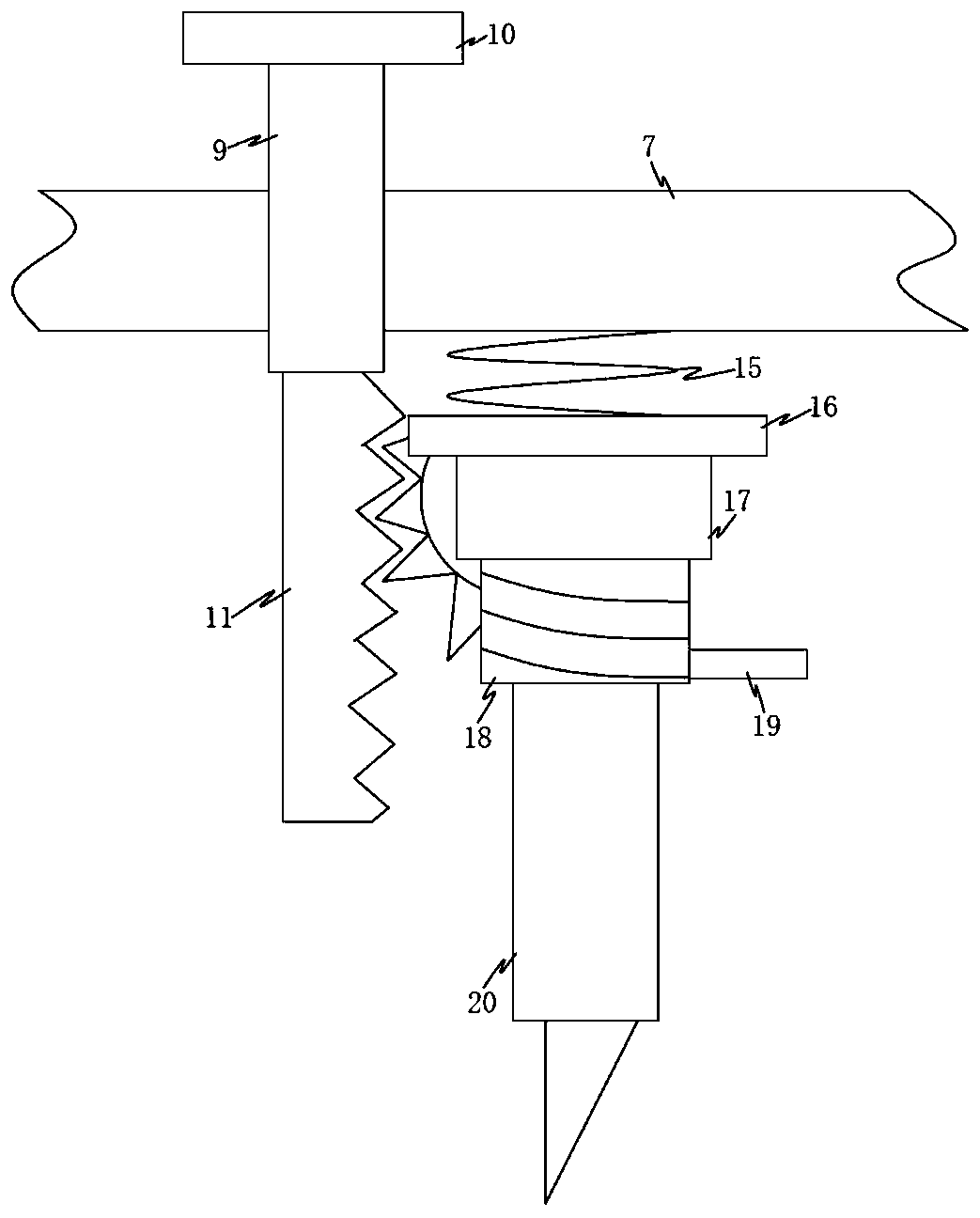

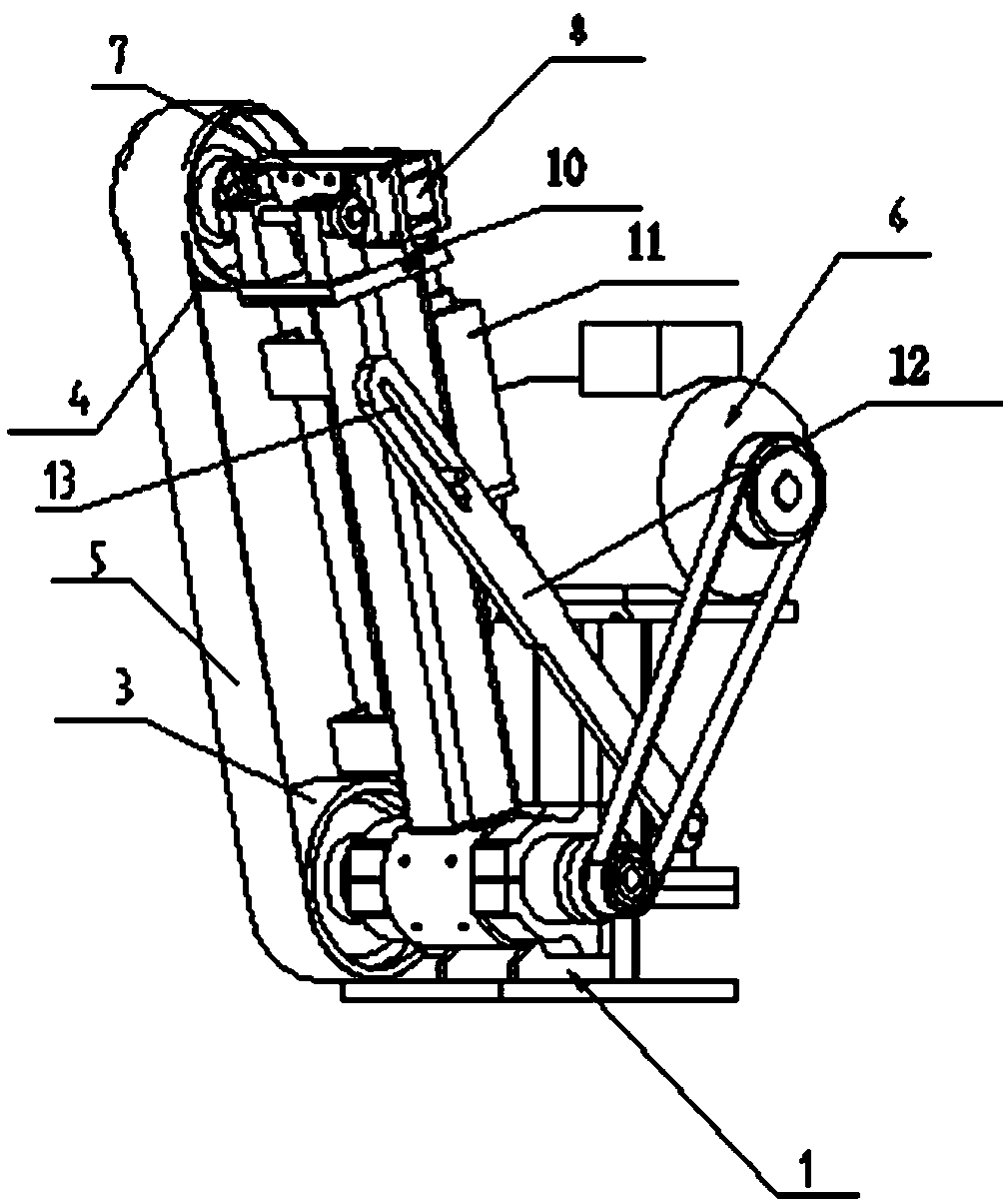

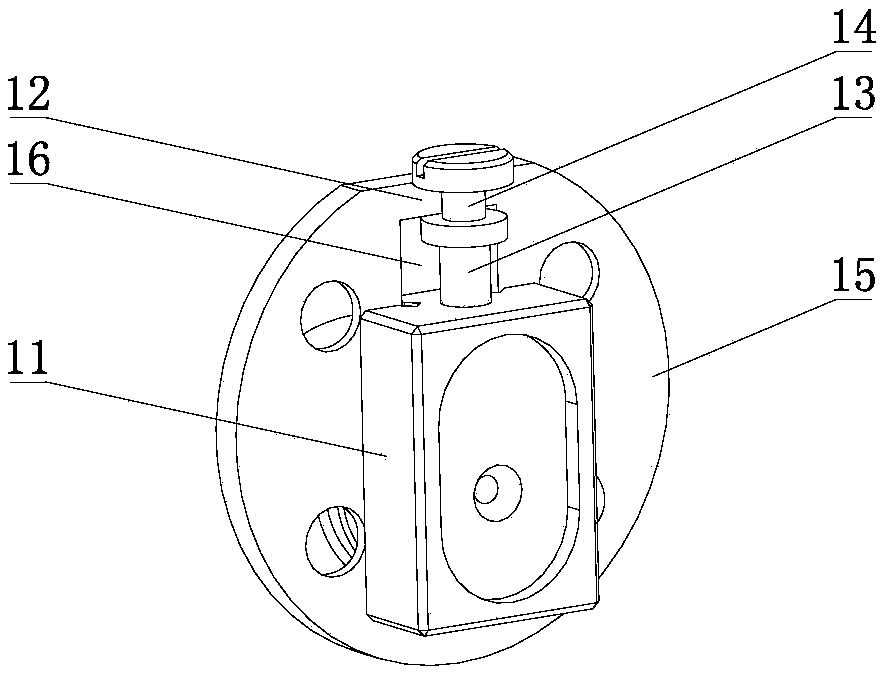

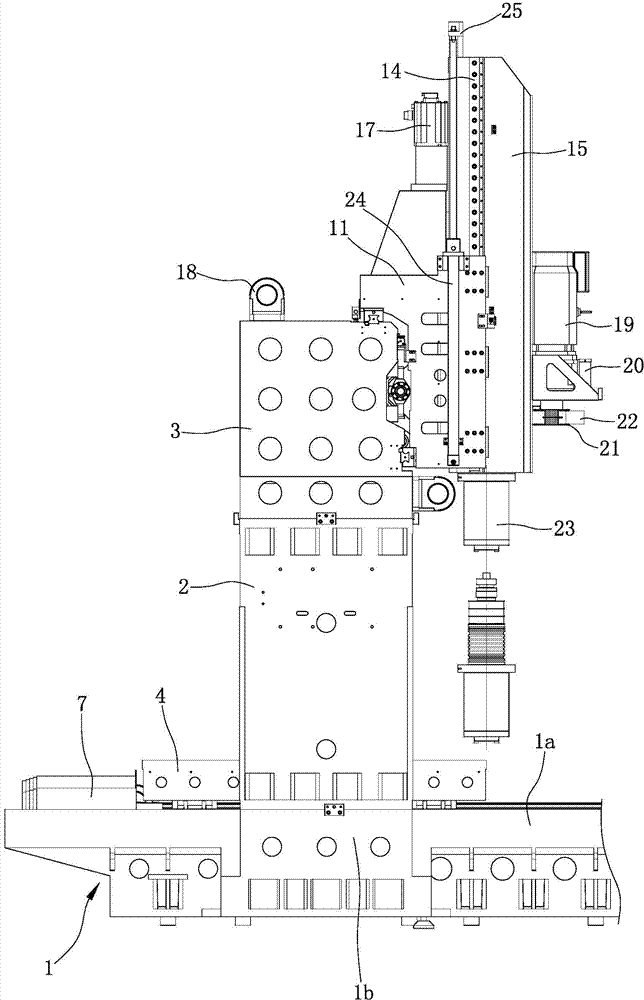

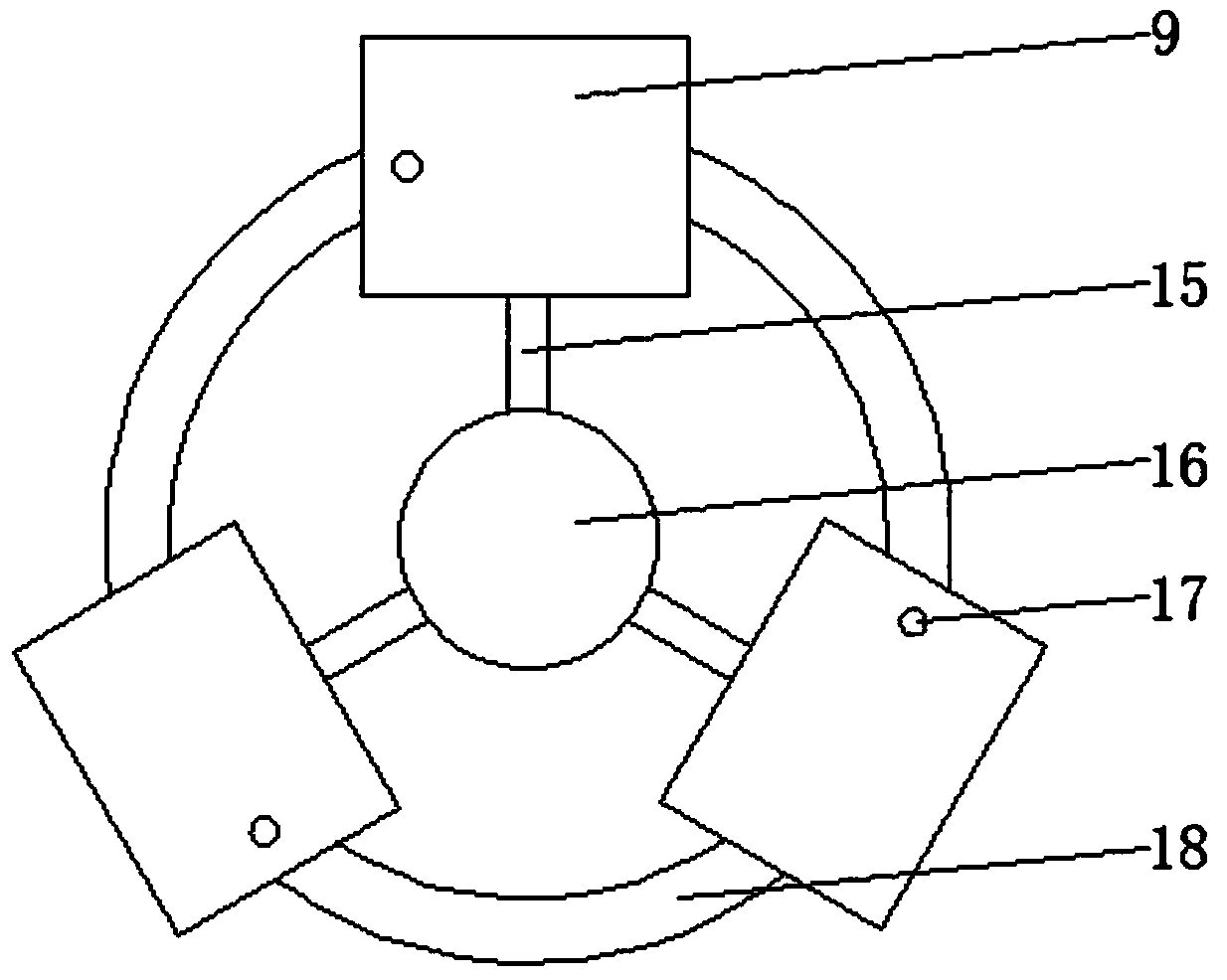

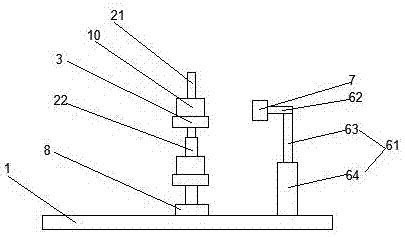

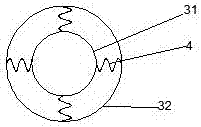

Rotary ultrasonic head based on machine tool attachment

ActiveCN102151867AGood versatility and interchangeabilityImprove induction efficiencyTool holdersUltrasonic machiningEnergy loss

The invention discloses a rotary ultrasonic head based on machine tool attachment. The rotary ultrasonic head comprises an ultrasonic vibration operating device, a non-contact collector ring, a main shaft, a knife handle and a supporting shell, wherein, the knife handle with a standard model is adopted; the ultrasonic vibration operating device is connected with one end of the main shaft; the knife handle is connected with the other end of the main shaft; rotation axes of the ultrasonic vibration operating device, the knife handle and the main shaft are positioned on the same straight line; and the non-contact collector ring is arranged between the main shaft and the supporting shell, and an ultrasonic vibration signal is transmitted to the ultrasonic vibration operating device in a non-contact manner through the non-contact collector ring. The rotary ultrasonic head has the following outstanding advantages: (1) complete machine tool attachment as well as generality and interchangeability of an ultrasonic machining device are realized; and (2) the induction efficiency of a brushless non-contact power supply system of the ultrasonic machining device is improved, the efficient energy transfer is realized, and the energy loss is reduced.

Owner:TIANJIN UNIV

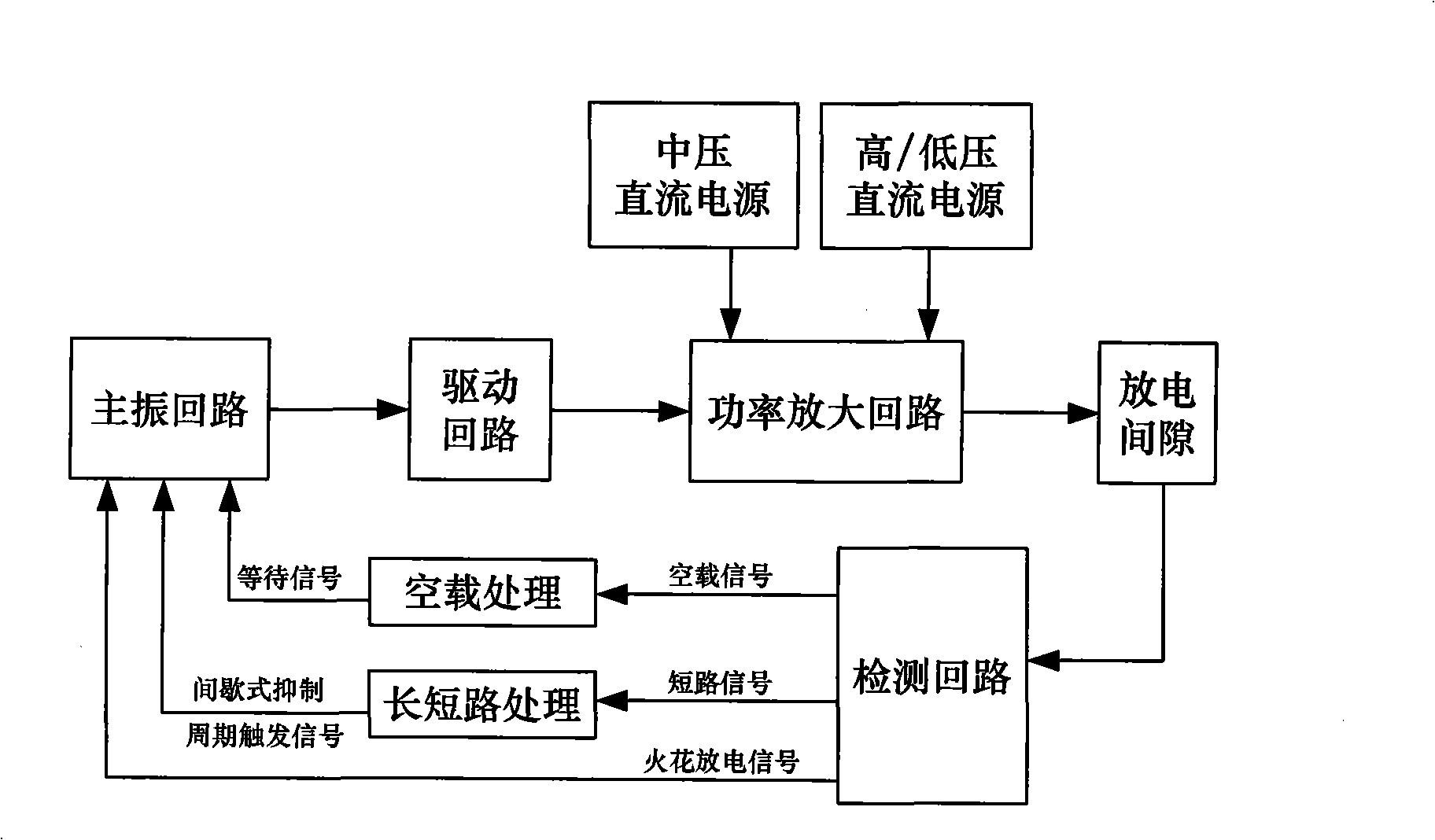

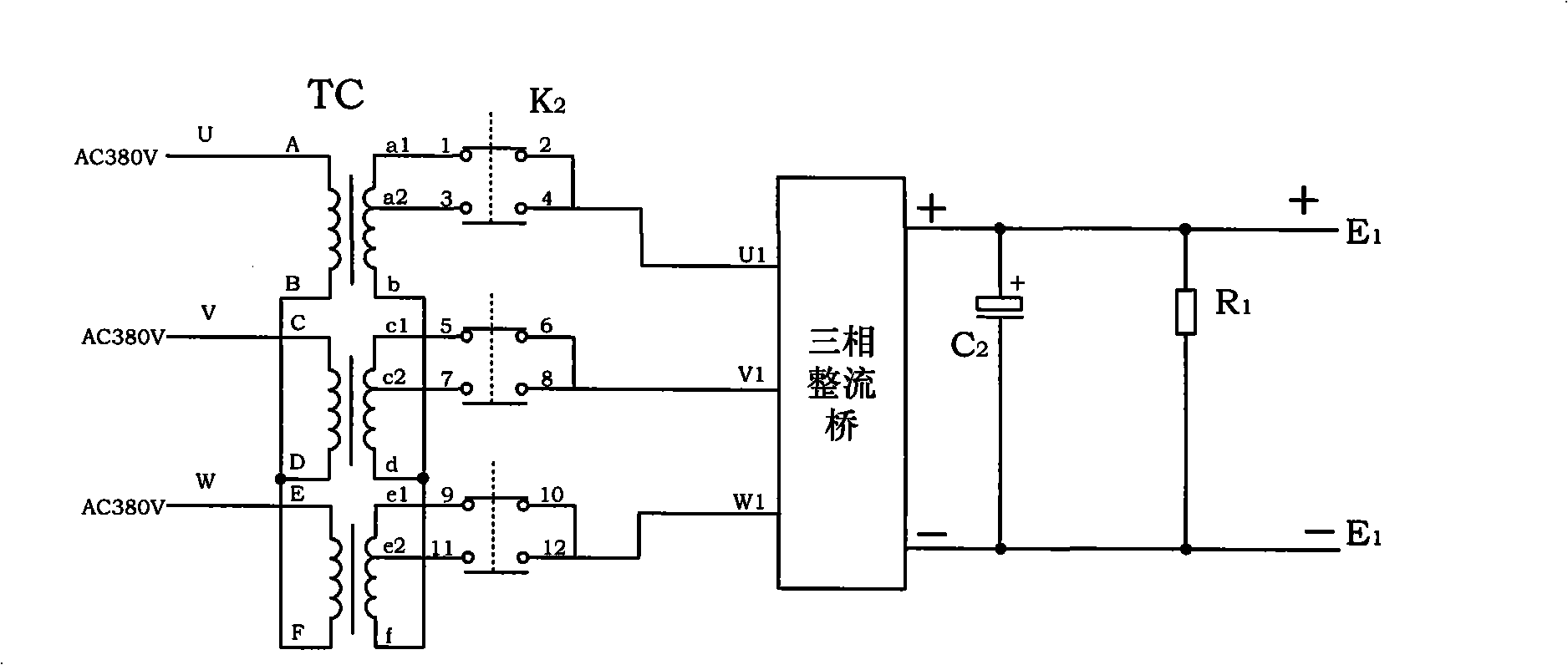

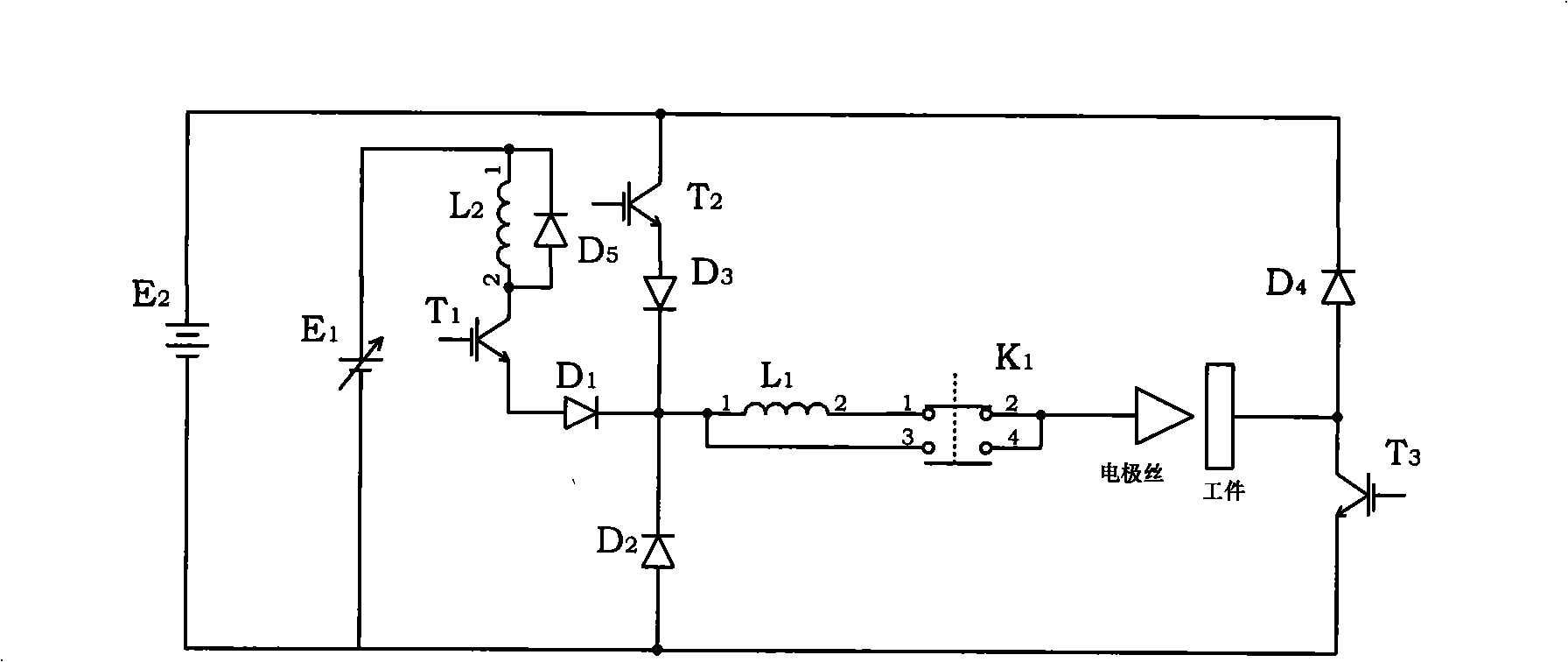

Numerical control double-power mode multifunctional impulsing power source for electrospark wire-electrode cutting processing

InactiveCN101318242ALow calorific valueAvoid burnt wireElectric circuitsNumerical controlLow voltage

The invention discloses multifunctional energy-saving pulse power supply with a dual power mode for the numerical control electrical discharge wire-cutting, which consists of a main vibration circuit, a driving circuit, a detection circuit, a long no-load treatment module, a long and short circuit treatment module, medium-voltage direct current power supply, high / low voltage direct current power supply and a power amplification circuit; wherein, the long no-load treatment module and the long and short circuit treatment module are arranged between the detection circuit and the main vibration circuit. The pulse power supply of the invention can realize the combined processing of high voltage and medium voltage as well as the medium voltage and the low voltage, and the high / low voltage in the combined processing is used for breaking down the discharge gaps and the medium voltage is used in the heavy current spark discharge processing; the signals of the non-normal spark discharge state in the medium-voltage heavy current processing cycle are adopted as the trigger signals of the intermittent inhibitive cycle of the pulse to cut the long-time short circuit, thus avoiding the wire burning; the non-normal spark discharge state in the breakdown cycle is adopted as pulse waiting signal to cause a channel to be completely broken down, thus realizing the equal energy processing and improving the processing efficiency; the function of switching the modes of rough processing and finish processing is provided to meet different processing requirements.

Owner:HARBIN INST OF TECH +1

Simultaneous gas-phase desulfurization and denitration method for smoke gas

ActiveCN103691271ALow investment costLow running costDispersed particle separationAir quality improvementGas phaseKiln

The invention relates to a simultaneous gas-phase desulfurization and denitration method for smoke gas. According to the method, a composite desulfurization and denitration agent is heated and gasified, then is injected into a desulfurization and denitration reaction area, and is in fully mixed reaction with NOx and SO2 in the smoke gas at a certain temperature, so that the aim of simultaneous desulfurization and denitration is achieved, the desulfurization efficiency is greater than 95 percent, and the denitration efficiency is greater than 75 percent. Compared with an existing desulfurization and denitration method, the simultaneous gas-phase desulfurization and denitration method has the advantages that a catalyst is not required; the desulfurization and denitration agent is small in usage; the operation is simple; the operation cost is relatively low; the economic advantages are obvious; the problems of high infrastructure investment, high operation cost, high maintenance cost and complicated operation of an existing simultaneous desulfurization and denitration technology are solved; the method can be applied to treatment on the smoke gas or tail gas of various industrial boilers and industrial kilns.

Owner:SHANDONG UNIV

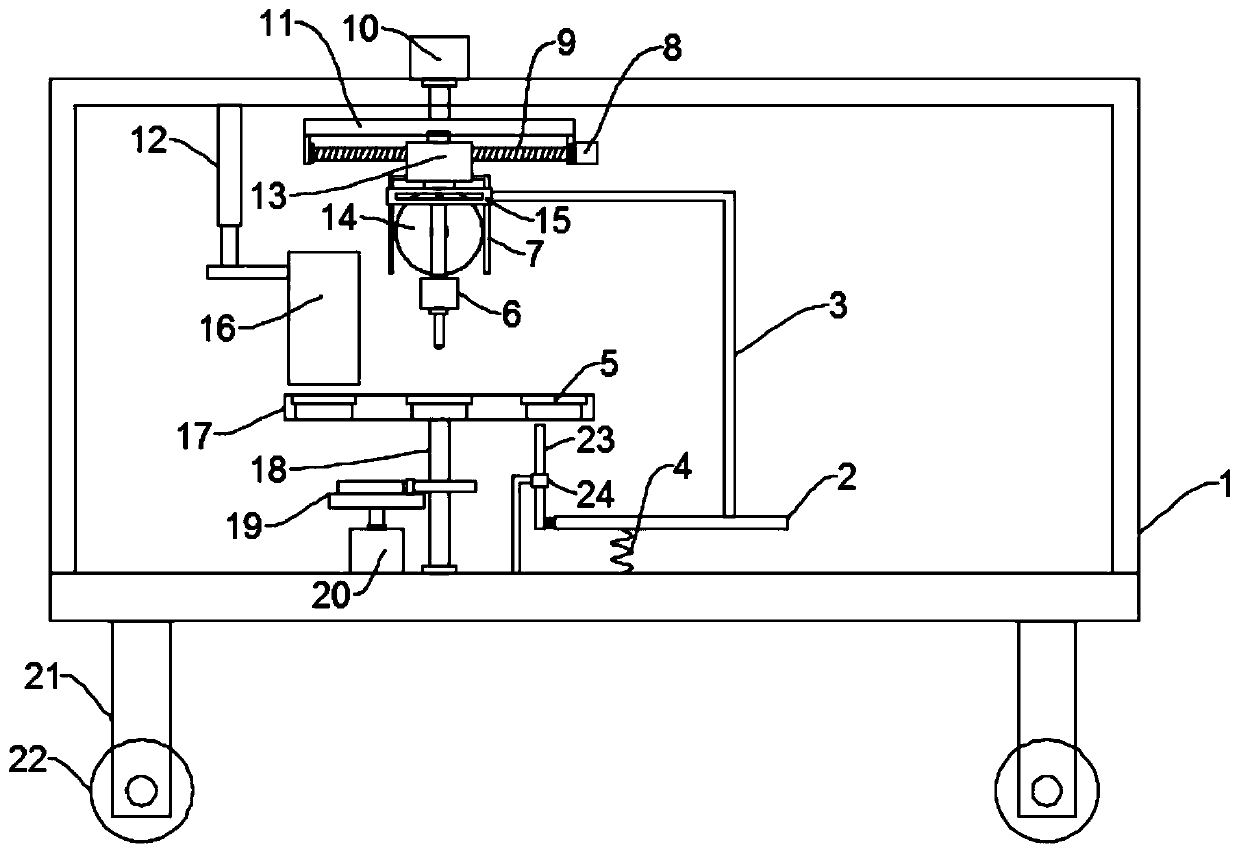

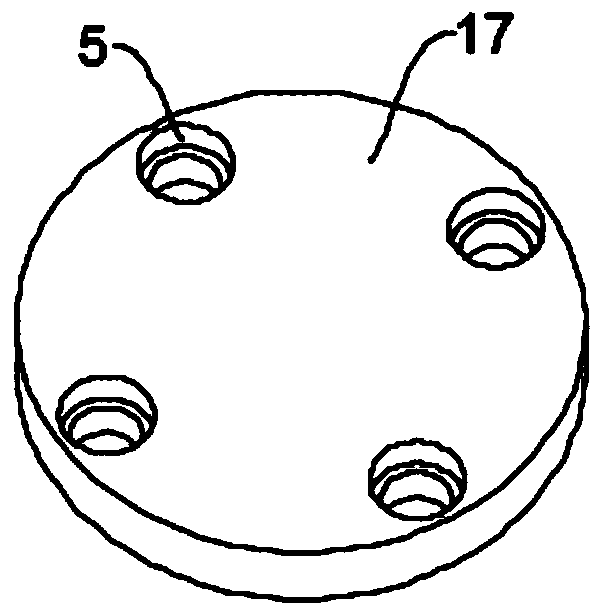

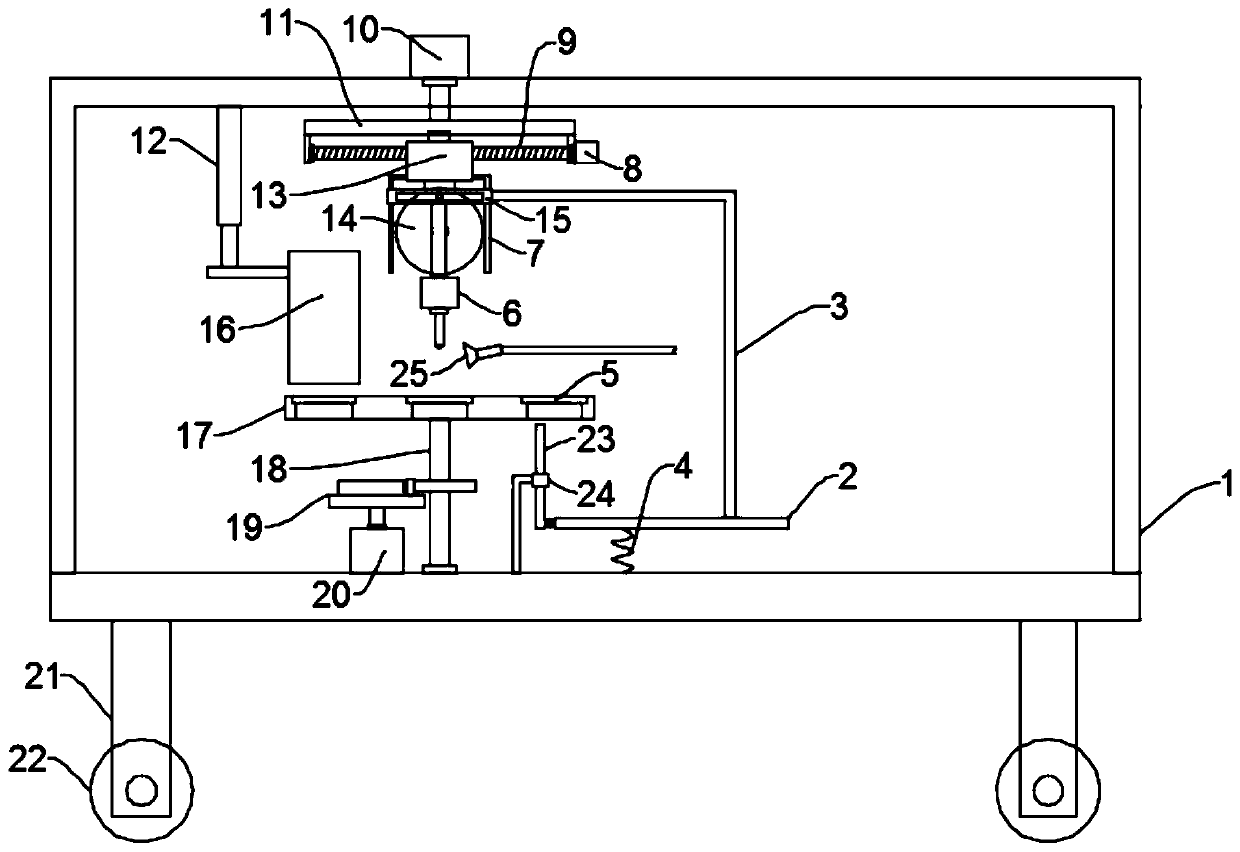

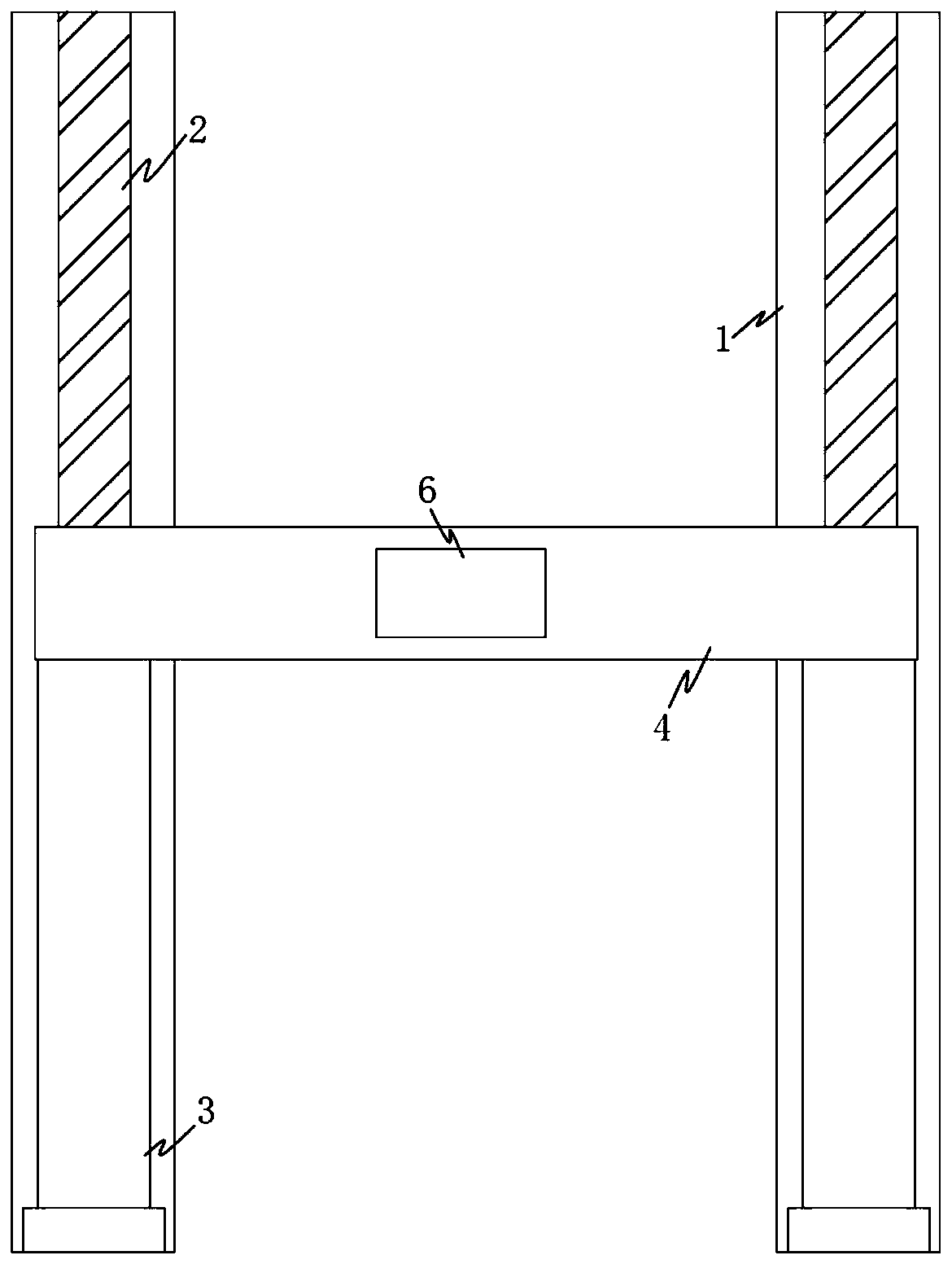

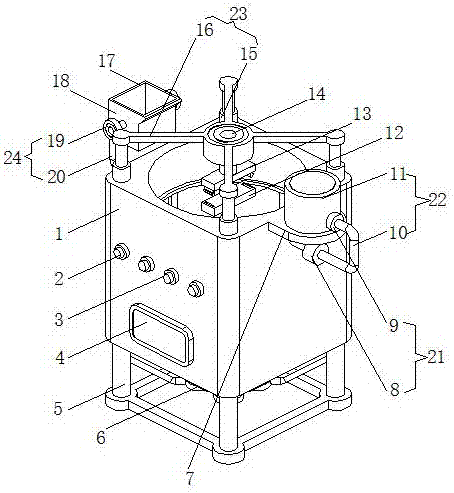

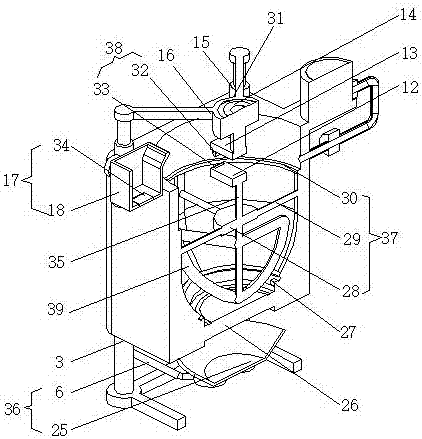

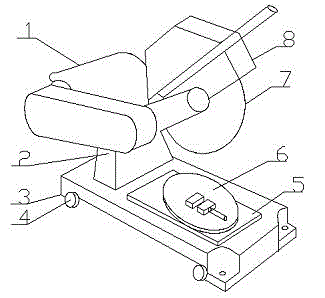

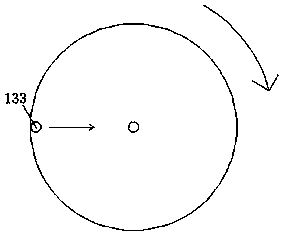

Disc-like workpiece automatic perforating device for machining

InactiveCN110756855AHigh degree of automationImprove work efficiencyFeeding apparatusDriving apparatusElectric machineryDrill hole

The invention discloses a disc-like workpiece automatic perforating device for machining. The disc-like workpiece automatic perforating device comprises a machine frame, a drilling mechanism and a workbench; the machine frame is provided with the workbench; the position, located above the workbench, of the machine frame is provided with the drilling mechanism; the position, located on one side ofa rotary shaft, of the machine frame is provided with a driving mechanism which is used for driving the rotary shaft and the workbench on the machine frame to intermittently rotate; the drilling mechanism comprises a drilling assembly and a power mechanism which is used for driving the drilling assembly to ascend and descend; an ejector rod is arranged at a discharging station located under the workbench; and an adjusting mechanism is connected between the drilling assembly and the machine frame and comprises a stepping motor, an installation plate, a screw rod, a first motor and a moving block. The disc-like workpiece automatic perforating device is provided with the drilling mechanism, the driving mechanism and the ejector rod, feeding, drilling and discharging can be automatically conducted, the automation degree is high, and the working efficiency is improved; and an electric push rod is arranged, the adjusting mechanism is arranged, the drilling position can be adjusted, and different machining requirements are met.

Owner:赣州靖扬科技有限公司

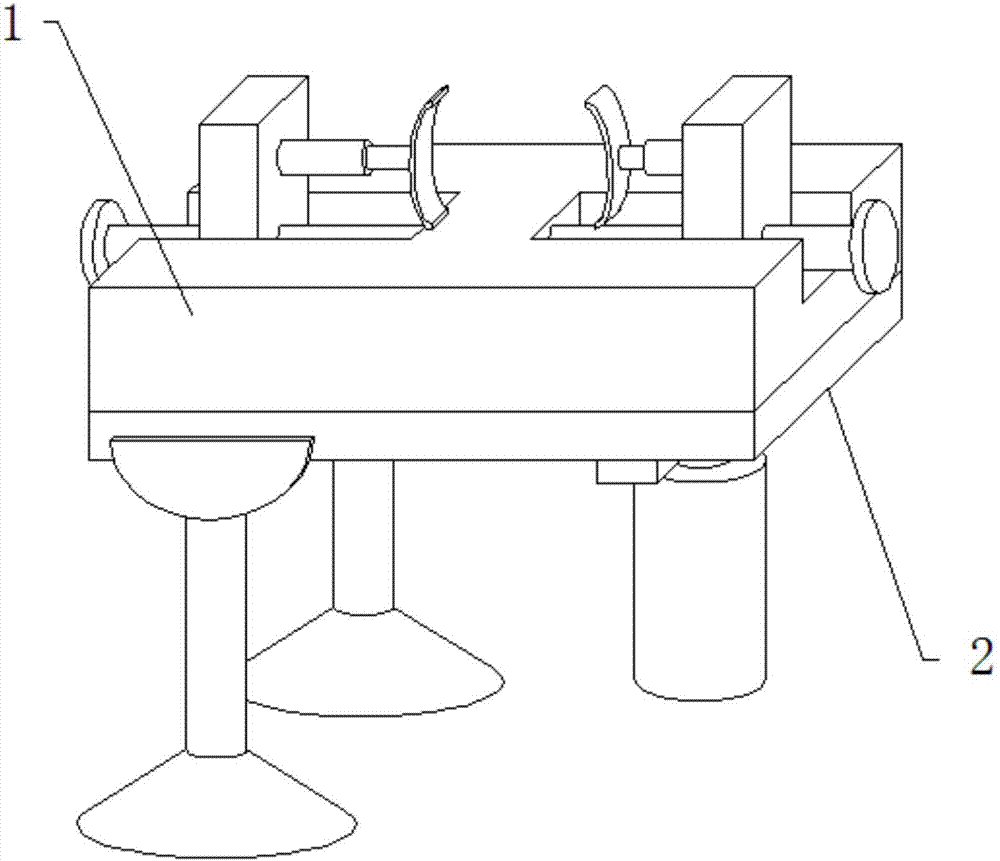

Fixing device for machining

InactiveCN107877428AAdjustable distanceRealize the clamping functionWork holdersPositioning apparatusArchitectural engineeringMachining

The invention provides a fixing device for machining, comprising a base plate, an arc-shaped splint, a two-way screw, a moving seat, an electric telescopic rod, a mounting plate, a support rod, a suction cup and an electric telescopic cylinder. There is an electric telescopic rod, the electric telescopic rod is fixed on the inner end of the moving seat, the moving seat is installed on the two-way screw rod, the two-way screw rod is installed inside the base plate, and the lower end of the moving seat passes through the base plate and the two-way screw rod. The screw rods are connected, the design realizes the clamping function, and the distance between the electric telescopic rods can be adjusted at the same time. For the suction cup, an electric telescopic cylinder is installed on the right side of the support rod, and the design can adjust the angle to meet different processing requirements.

Owner:新昌县羽林街道元洋机械厂

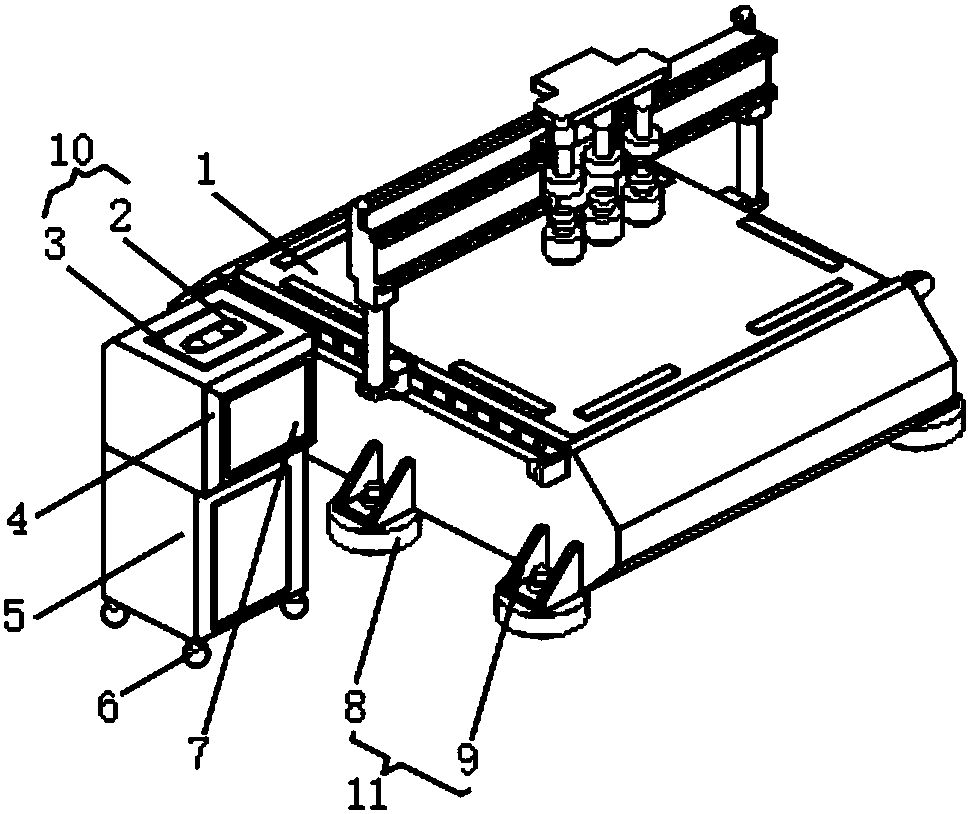

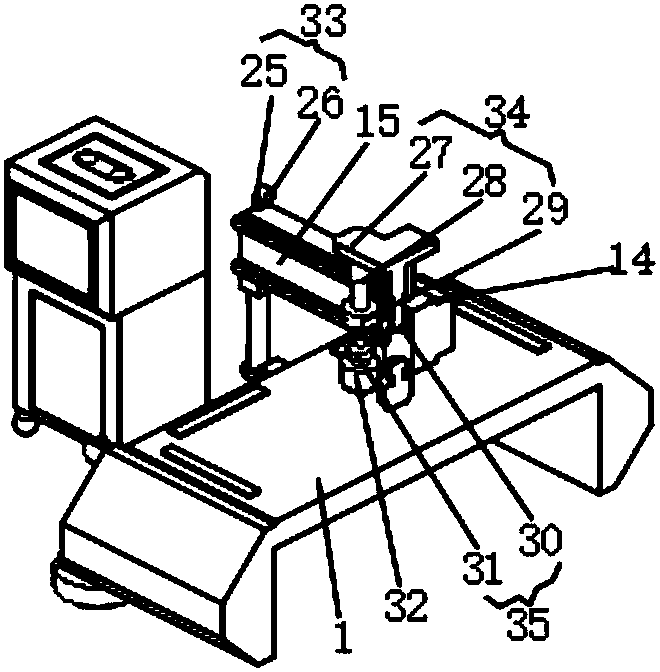

Laser plasma dual-use cutting machine

ActiveCN103157912AQuality improvementImprove dustproof effectWelding/cutting auxillary devicesAuxillary welding devicesNumerical controlTorch

The invention discloses a laser plasma dual-use cutting machine which comprises a beam which is connected with a lathe bed in a transmission mode. A drag plate is connected with the beam in the transmission mode. A working table and a drag chain are fixedly connected with the lathe bed. An yttrium aluminum garnet (YAG) solid laser generator is arranged on the drag plate. The YAG solid laser generator is provided with a light dipping supporting plate. Two sets of lifting mechanisms are connected with the light dipping supporting plate in an installing mode, one set of lifting mechanisms is connected with a double-focal-distance cutting head in the installing mode, and the other set of lifting mechanisms is connected with a plasma cutting torch in the installing mode. The lathe bed is further provided with a rotary cutting pipe chuck and a rotary cutting pipe supporting frame. A laser cutting head and a numerical control plasma cutting head are both arranged on a numerical control cutting machine, and the laser cutting head and the numerical control plasma cutting head are reasonable in structure. Different processing requirements of workpieces can be met by the solid laser generator and the double-focal-distance cutting head, wherein the mirror spacing of the solid laser generator is convenient to adjust, the solid laser generator is good in dust-proof effect, and the double-focal-distance cutting head is capable of changing focal distances rapidly and high in processing precision. The laser plasma dual-use cutting machine particularly conducts cutting on metal tubular products.

Owner:FOSHAN HONGSHI LASER TECH CO LTD

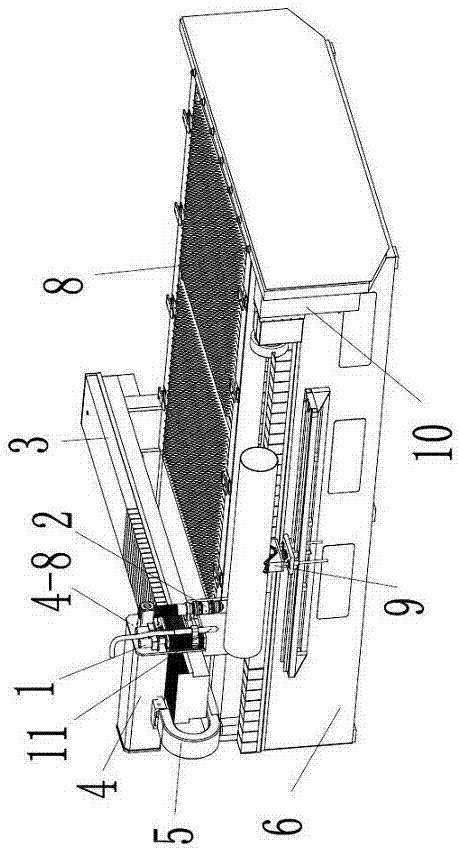

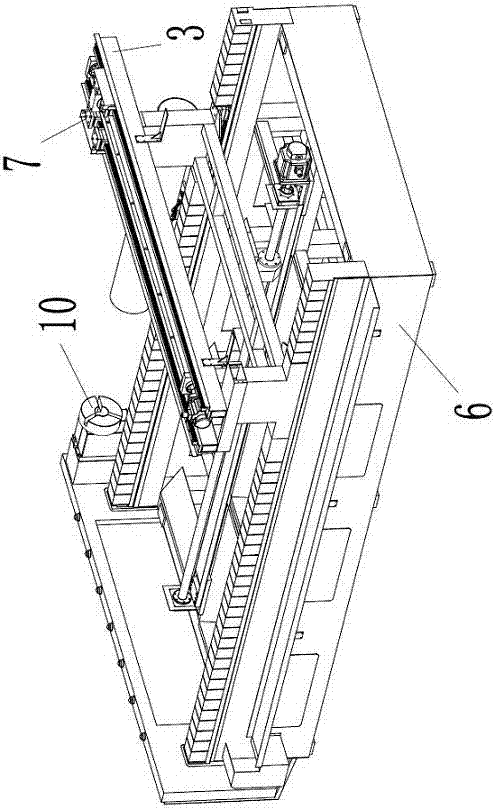

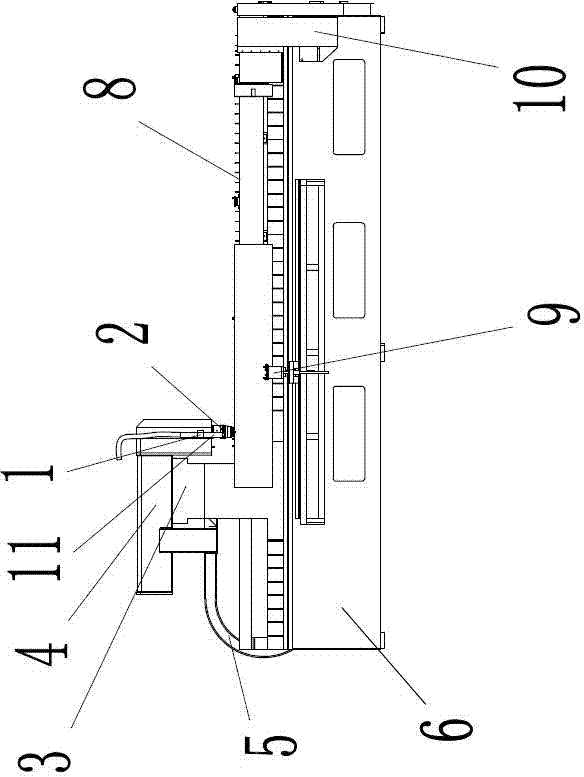

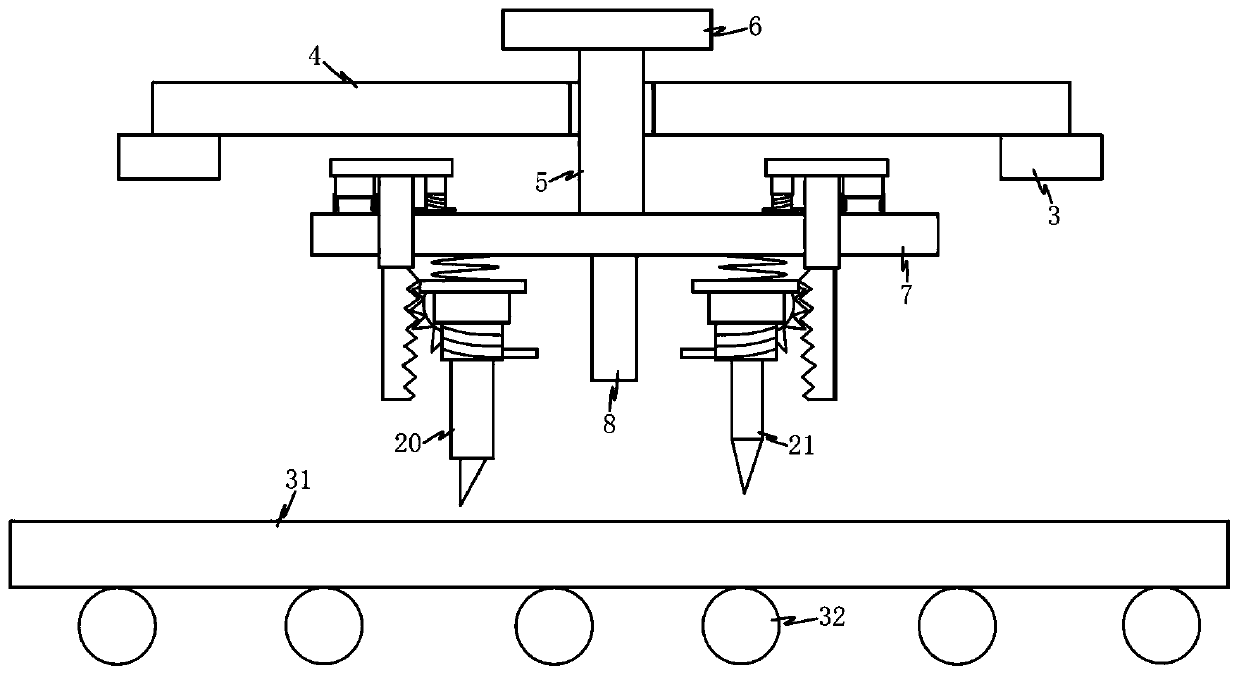

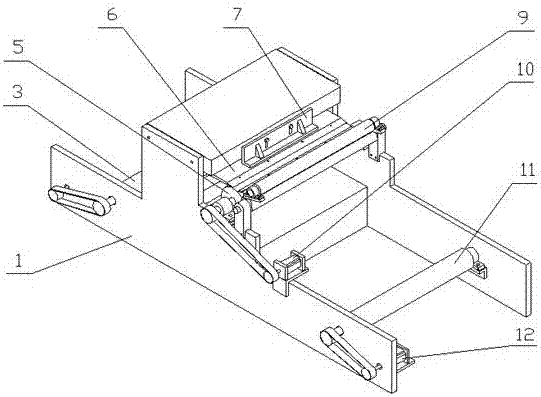

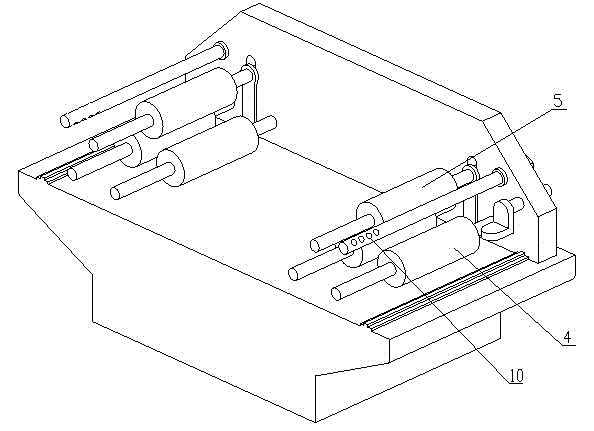

Needle machine for processing carbon fiber products

The invention relates to a needle machine for processing carbon fiber products. The needle machine for processing the carbon fiber products comprises a control system and a mechanical component. The mechanical component comprises a machine base, a feeding mechanism, a height adjusting mechanism, a needle beam and a needle mechanism, wherein the feeding mechanism comprises a linear guide rail, a web supporting plate, a feeding lead screw and a feeding stepper motor. The height adjusting mechanism comprises a height adjusting stepper motor, a height adjusting lead screw and a height adjusting guide pillar. The needle mechanism comprises an asynchronous motor, a horizontal rotating shaft, a needle plate cam mechanism, a needle plate, a needle plate guide pillar, a cotton peeling plate cam mechanism, a cotton peeling plate and a cotton peeling guide pillar. The control system is connected with the feeding stepper motor, the height adjusting stepper motor and the asynchronous motor. The needle machine for processing the carbon fiber products is stable in operation. When carbon fibers are processed by the needle machine, a fiber web is good in uniformity. Besides, needle breakage is avoided to the greatest extent in the processing process, and production requirements for high quality are met.

Owner:常熟万龙机械有限公司

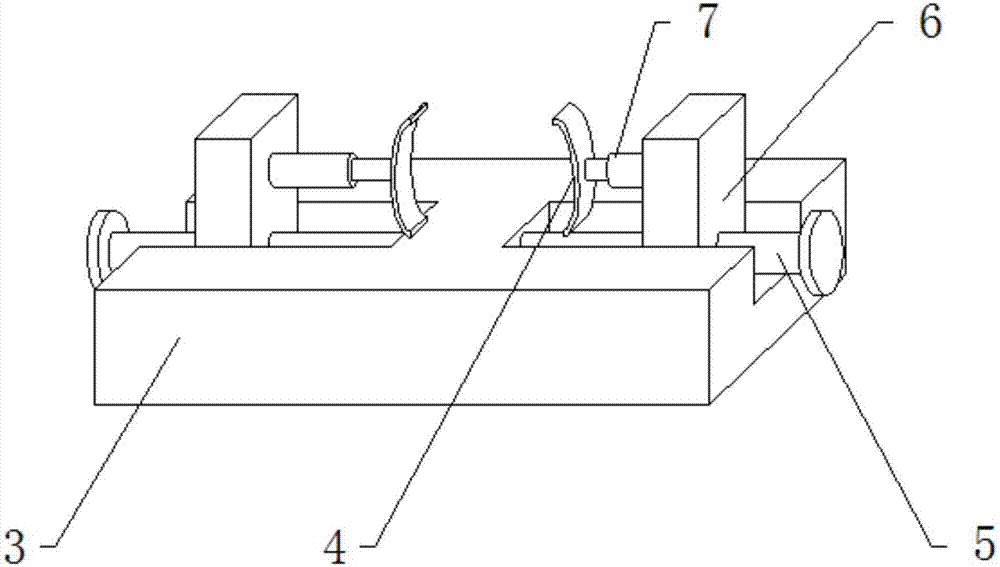

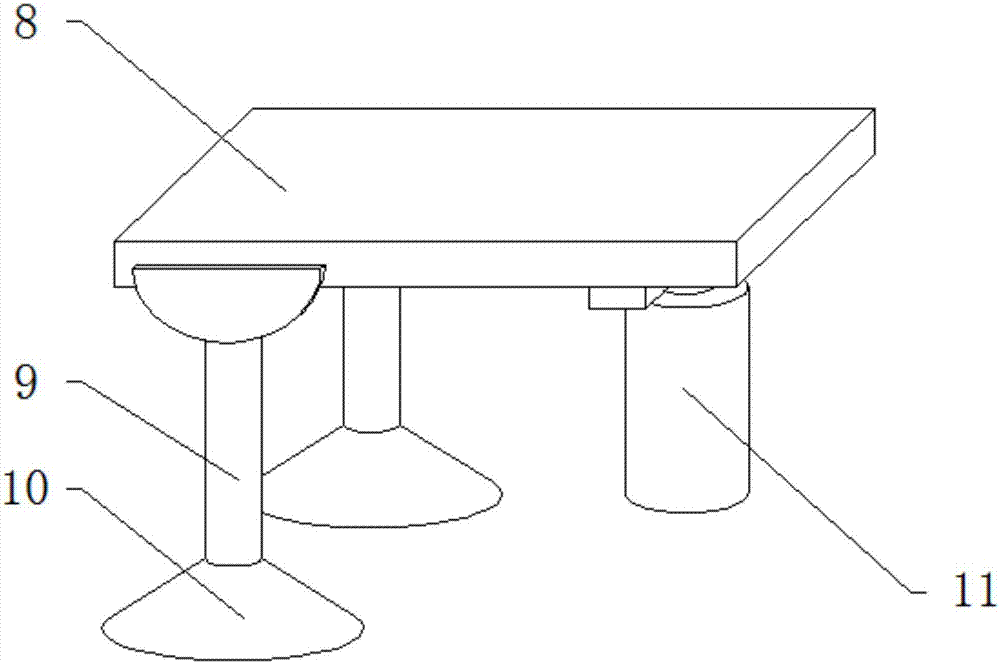

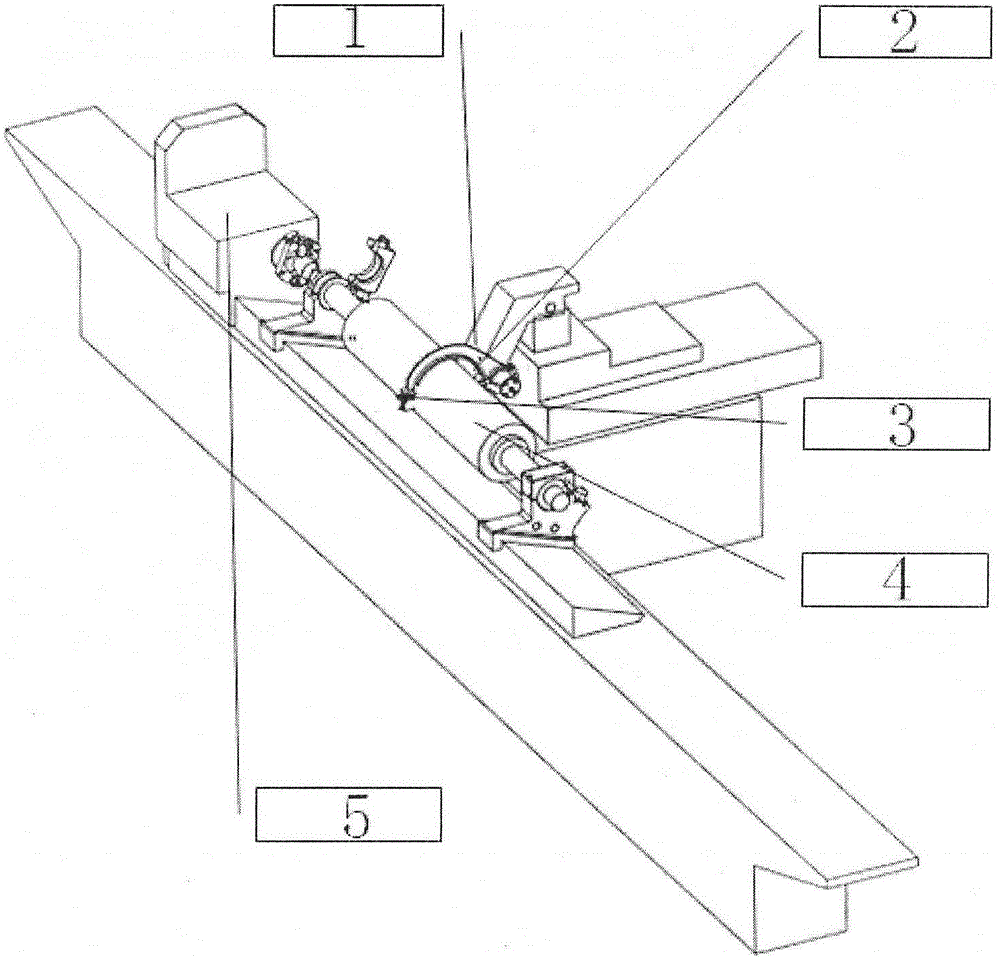

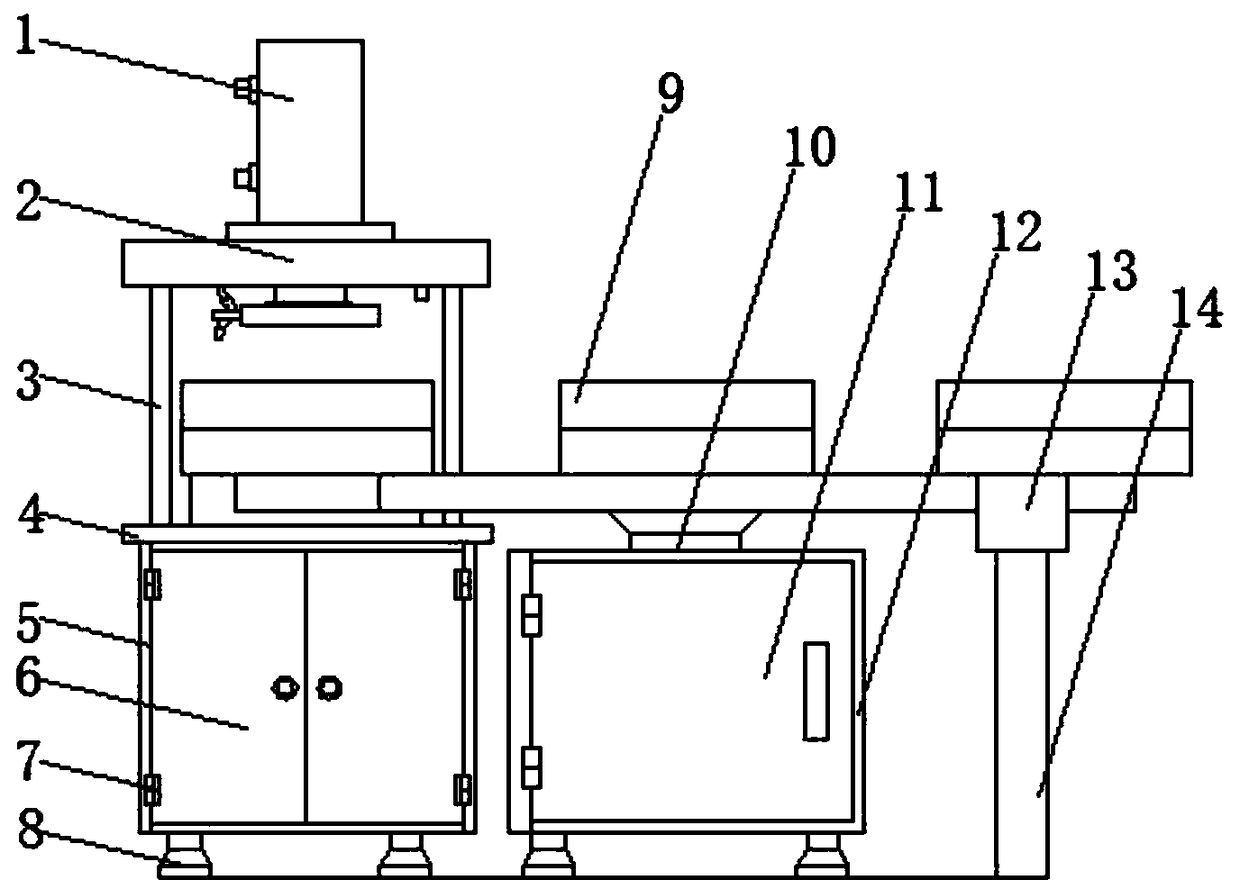

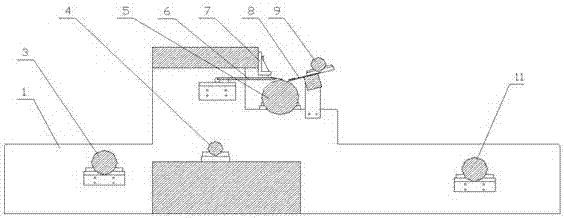

Turning, grinding and polishing all-in-one machine device for rubber roller

InactiveCN105690095AChange contact angleChange contact positionOther manufacturing equipments/toolsDrive wheelEngineering

The invention provides a turning, grinding and polishing all-in-one machine device for a rubber roller. By the adoption of the turning, grinding and polishing all-in-one machine device for the rubber roller, turning, grinding through a grinding wheel and polishing through an abrasive belt can be achieved at the same time. According to the turning, grinding and polishing all-in-one machine device for the rubber roller, a turning machine, a grinding machine and a polishing device for the rubber roller are highly integrated, and new functions are additionally achieved based on the grinding machine special for the rubber roller. A power machine head used for making a workpiece rotate is installed at one end of a machine body, and a machine tail is installed at the other end of the machine body; a spindle is arranged on the machine head; one end of the spindle is connected with a chuck, and the other end of the spindle is connected with a power device; a center used for fixing the workpiece is arranged on the machine tail, and the spindle of the machine head and the center of the machine tail are located on the same center line; a measurement device is installed on the upper surface of the machine body; and an annular abrasive belt driving and tensioning device is installed on a workbench. A whole annular abrasive belt can rotate around the axis of a driving wheel, so that the contact angle between the abrasive belt and the workpiece is changed, and accordingly the position, making contact with the workpiece, of the abrasive belt is changed, and different machining requirements are met.

Owner:SUZHOU HONGSUN ELECTROMECHANICAL TECH CO LTD

Medlar powder preparing method

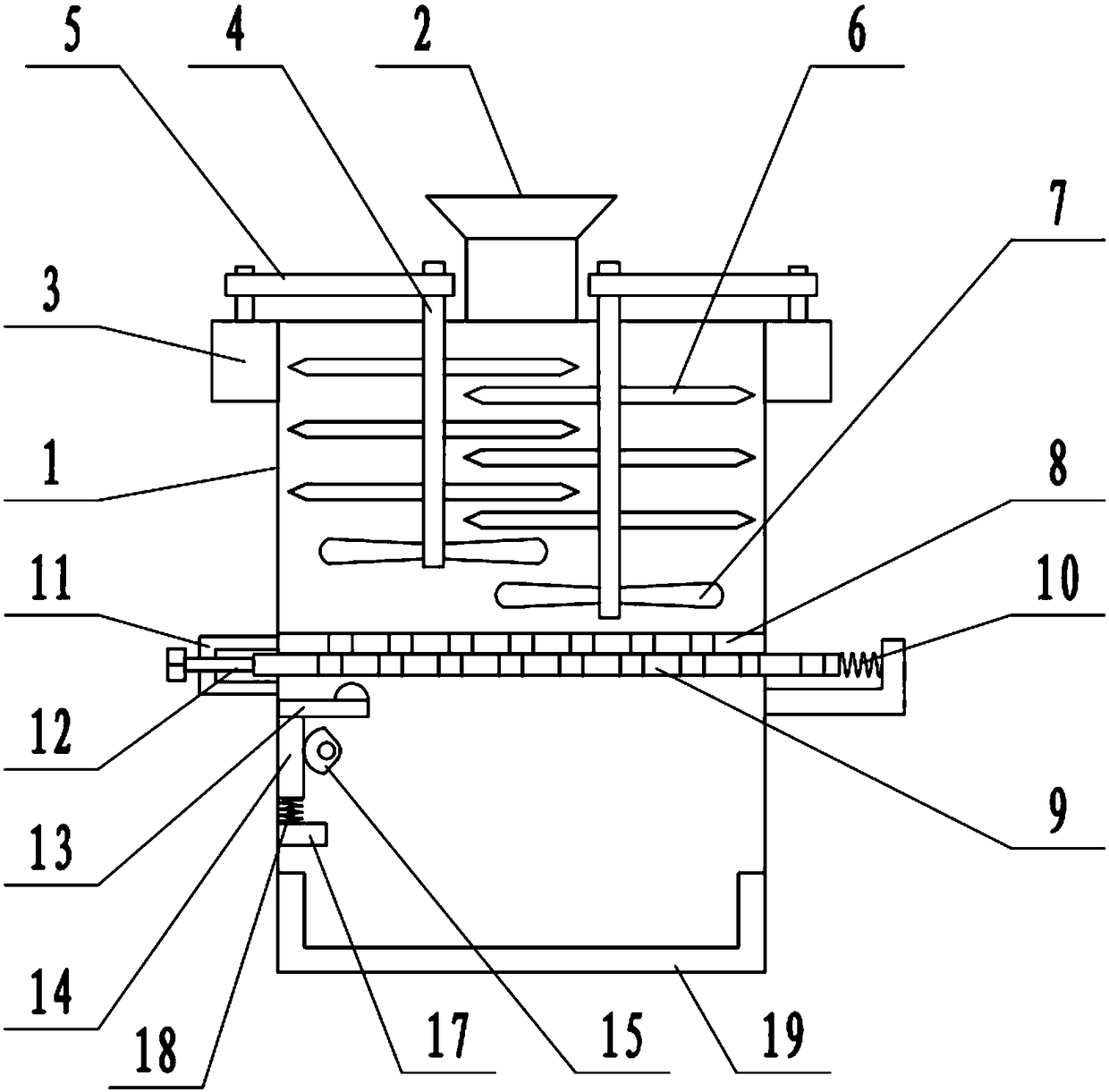

InactiveCN108325648AGood crushing effectImprove crushing efficiencySievingScreeningPulverizerThrough transmission

The invention discloses a medlar powder preparing method. Medlar is taken, a traditional Chinese medicine pulverizing machine for adjusting the particle diameter is used for conducting pulverizing, and the traditional Chinese medicine pulverizing machine for adjusting the particle diameter comprises a shell, a feeding port, pulverizing motors, pulverizing shafts, pulverizing blades and a collecting groove. The pulverizing motors are fixedly connected to the left side and the right side of the shell correspondingly. The pulverizing shafts are arranged on the left side and the right side of thefeeding port correspondingly. The lower ends of the pulverizing shafts penetrate the top of the shell and stretch into the shell. The pulverizing shafts are rotationally connected with the top of theshell. The shaft stretching ends of the pulverizing motors are connected with the pulverizing shafts through transmission mechanisms. An upper sieve plate is arranged below the pulverizing shafts andfixedly connected with the inner wall of the shell. A lower sieve plate is arranged below the upper sieve plate. In the pulverizing process, stirring vanes are used for stirring the medlar, and traditional Chinese medicines are pulverized more evenly; through adjustment of the lower sieve plate, sieve holes in the upper sieve plate and sieve holes in the lower sieve plate are staggered, the size of medlar particles penetrating the upper sieve plate and the lower sieve plate can be conveniently adjusted, and different machining requirements of people are met.

Owner:苏州高新区鼎正精密机电有限公司

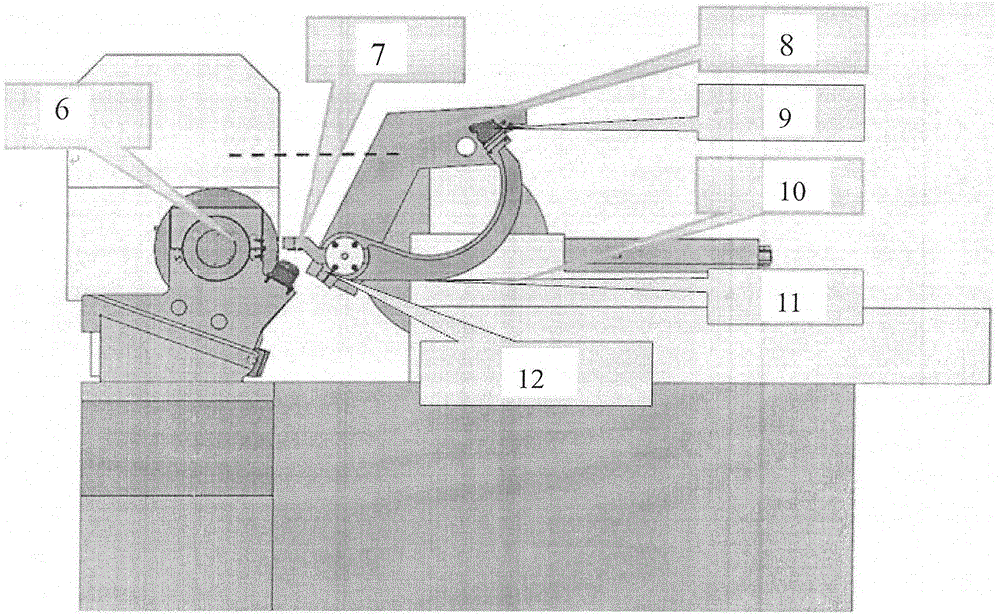

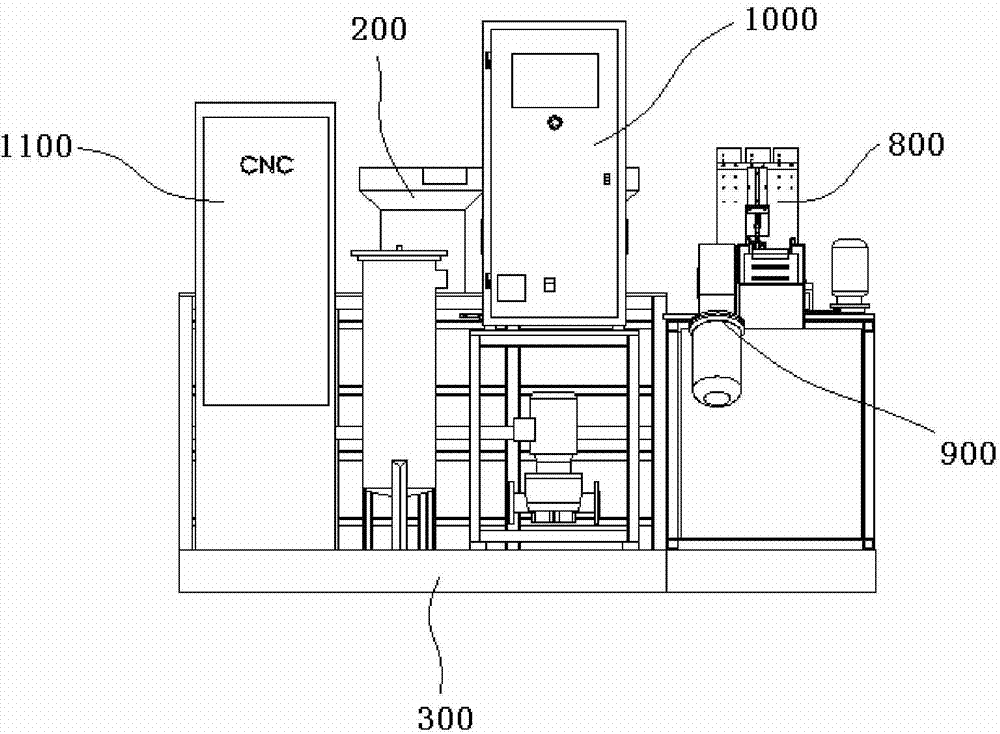

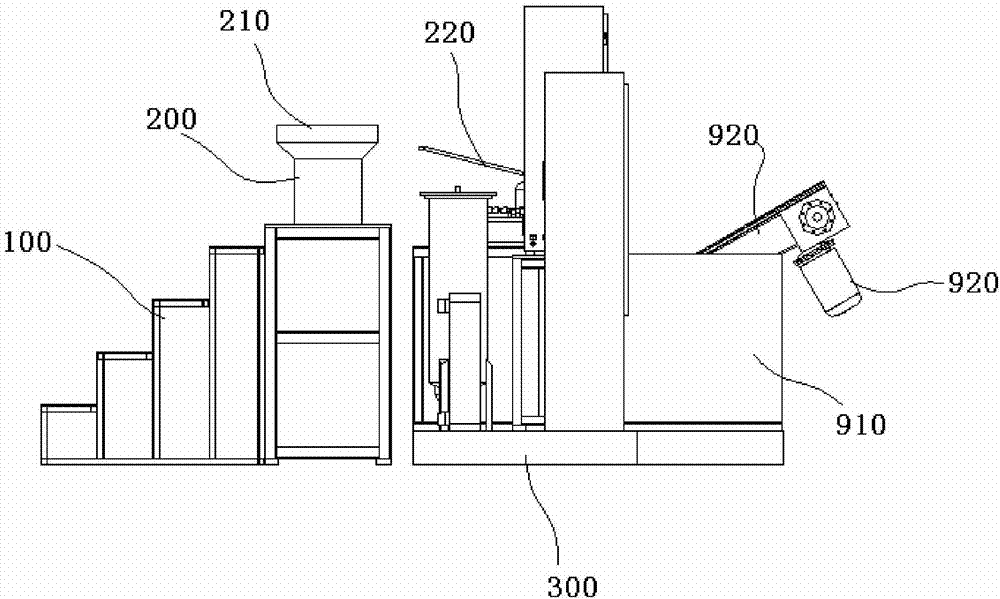

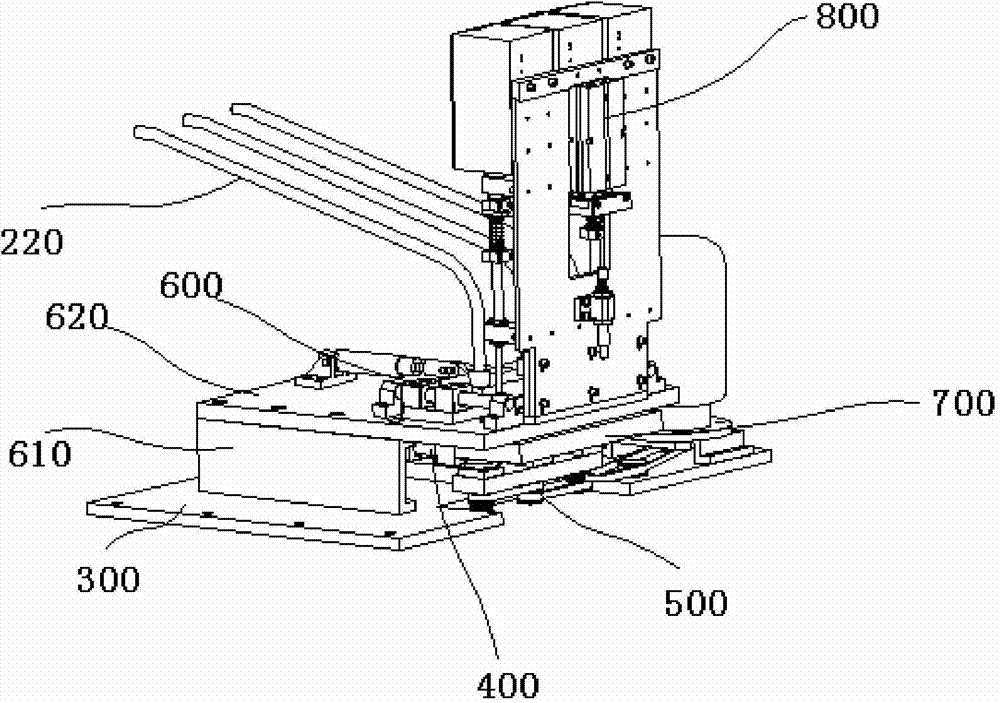

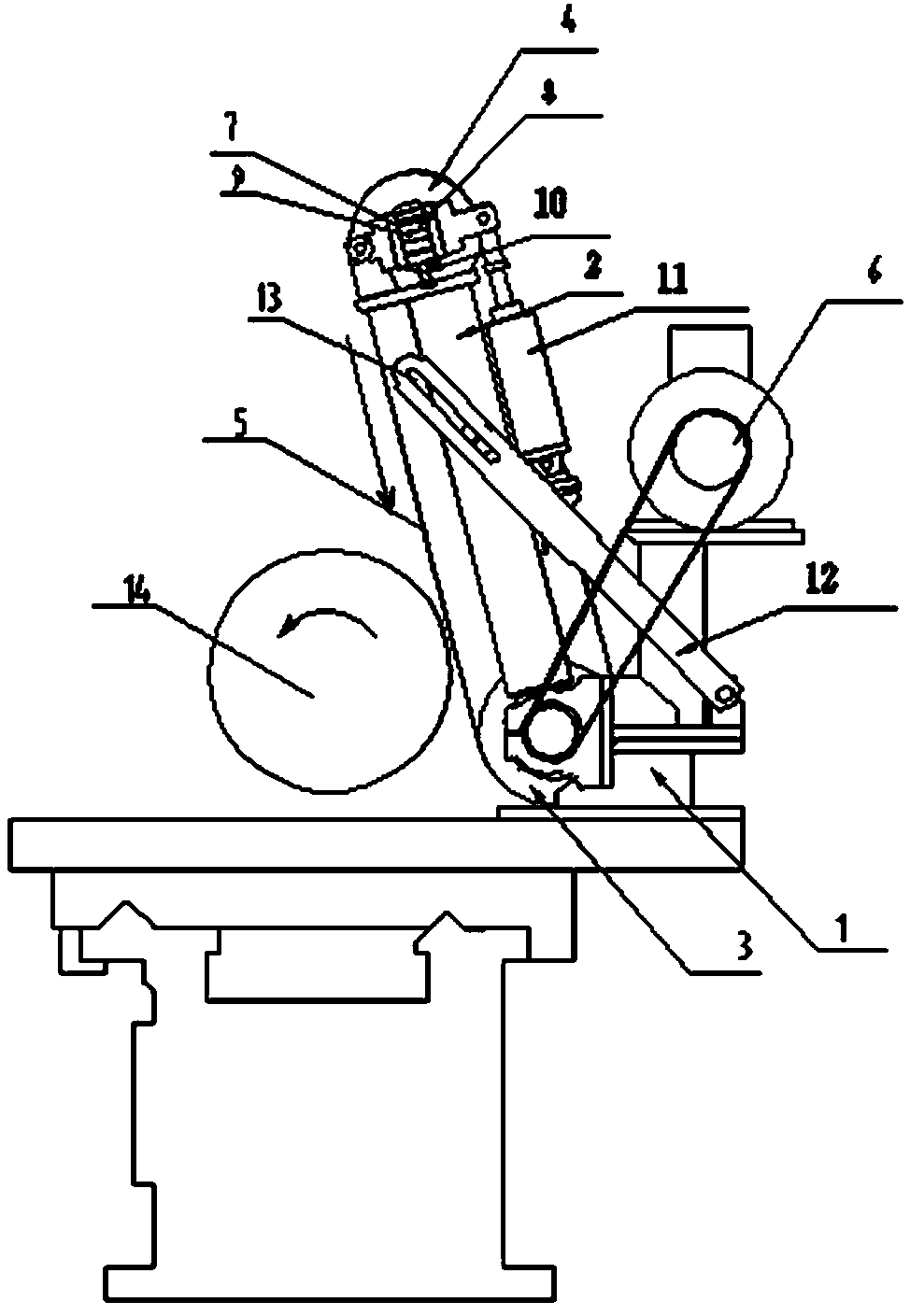

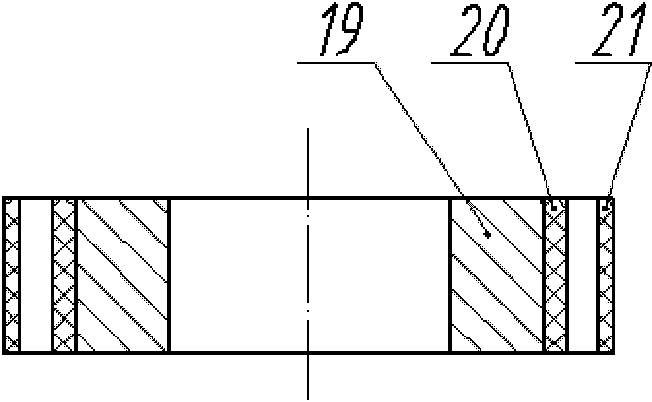

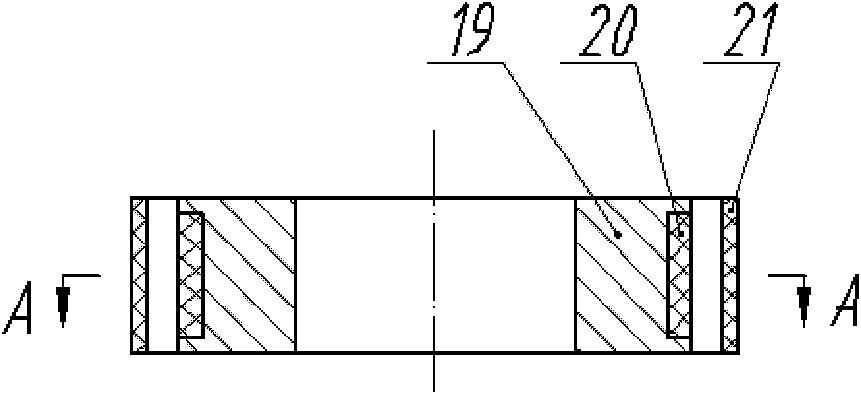

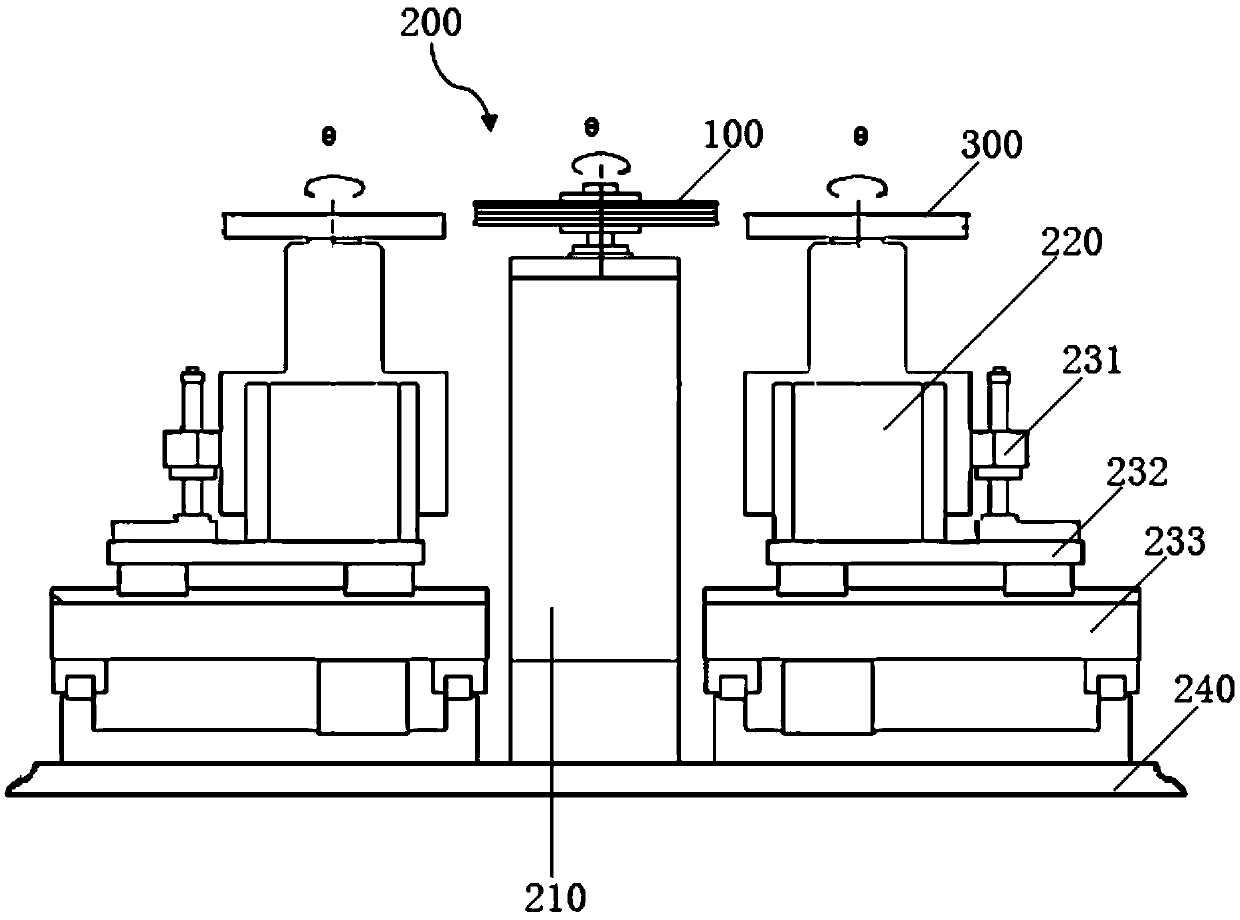

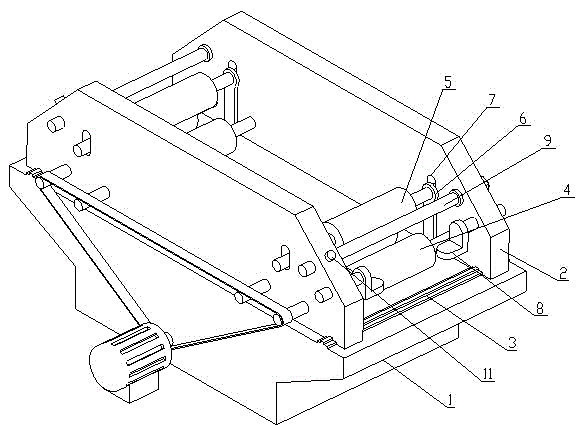

Bearing rolling needle and rolling column quenching machine tool

ActiveCN104726680AImprove processing efficiencyLow costFurnace typesHeat treatment furnacesEngineeringInductor

The invention discloses a bearing rolling needle and rolling column quenching machine tool. The bearing rolling needle and rolling column quenching machine tool comprises a loading mechanism, a quenching mechanism, at least one heating inductor, a photoelectric detection mechanism, a quenching water tank discharging system, a heating and loading system and a machine tool motor numerical control system, wherein the loading mechanism comprises a bed body frame and a vibration loading and guide mechanism arranged on the bed body frame, the quenching mechanism comprises a base, a retreating and blanking mechanism arranged on the base, a workpiece positioning and rotation driving mechanism arranged on the base and a front-and-back loading sliding plate mechanism arranged above the retreating and blanking mechanism, and the vibration loading and guide mechanism is connected with the front-and-back loading sliding plate mechanism through a guide pipe; the heating inductor is arranged on the workpiece positioning and rotation driving mechanism; the photoelectric detection mechanism is arranged above the front-and-back loading sliding plate mechanism, and the photoelectric detection mechanism is responsible for detecting the existence and absence of a workpiece and the height position of the workpiece; and the quenching water tank discharging system, the heating and loading system and the machine tool motor numerical control system are arranged on the base and positioned below the heating inductor. The bearing rolling needle and rolling column quenching machine tool disclosed by the invention can automatically realize loading, unloading, heating and cooling and has no need of artificial participation.

Owner:SHANGHAI HEATKING INDUCTION TECH CORP

Glass cutting and carving all-in-one machine

ActiveCN109773971AReduce manual laborFeature ConcentrationWorking accessoriesStone-like material working toolsEngineeringMachining

The invention discloses a glass cutting and carving all-in-one machine which comprises a guide rod. A guide rail is arranged on the guide rod. Angle and height adjusting devices are symmetrically arranged on the side, away from a through rod, of an operation rod. A cutting tool and a carving tool are fixed to the angle and height adjusting devices correspondingly. Each angle and height adjusting device comprises a push rod, wherein the push rod is provided with a limiting handle, a first adjusting device and a second adjusting device are arranged between the limiting handle and the operation rod, a rack is fixedly connected to the end, away from the limiting handle, of the push rod, the rack is movably provided with a gear, the center of the gear is connected to an inner threaded rod through a connecting rod, and a rotating handle is fixedly arranged on a first outer threaded rod. By means of the glass cutting and carving all-in-one machine, the glass cutting and carving functions areachieved at the same time, the machining efficiency is high, the height distances between the internal cutting tool and carving tool and glass and the machining angle can be subjected to fine adjustment, adaptability is high, and different machining requirements can be met.

Owner:佛山金仕捷玻璃制品有限公司

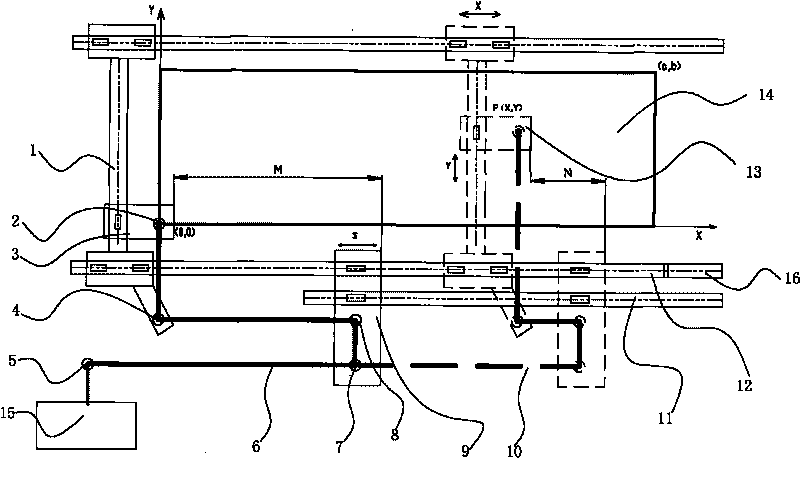

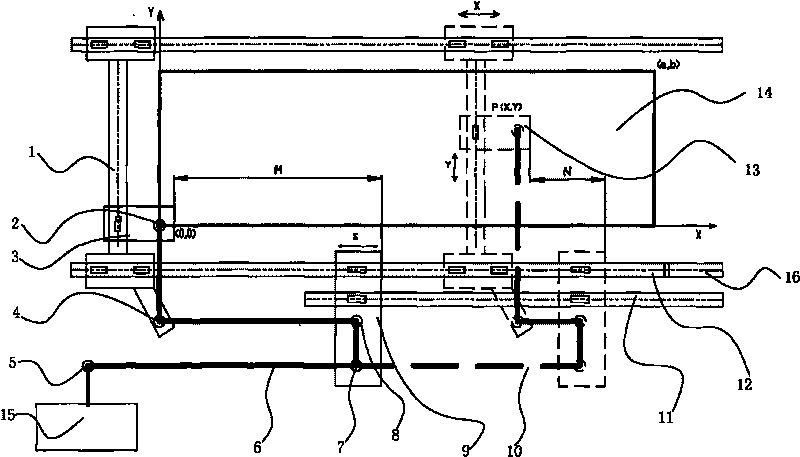

Optical length adjustment device of numerical control laser cutting machine

InactiveCN101722369ASame lengthChange beam diameterMountingsLaser beam welding apparatusNumerical controlEngineering

The invention discloses an optical length adjustment device of a numerical control laser cutting machine, which relates to the numerical control laser cutting machine. The optical length adjustment device comprises a laser generator, a cutting head for forming cutting laser spots on the surface of a work piece by utilizing a lens, a conduction optical path for connecting the laser generator with the cutting head, a beam guide rail and a controller. The optical length adjustment device is characterized by being further provided with an aplanatic device and a length compensation deice of the aplanatic device, wherein the aplanatic device comprises a trolley driven by a servo motor and at least one compensating reflecting mirror arranged on the trolley; the servo motor is connected with the controller; the compensating reflecting mirror is arranged in the conduction optical path in a zigzagging way; an emission reflecting mirror and a receiving reflecting mirror matched with the conduction optical path are arranged in the conduction optical path; and the aplanatic length compensation deice comprises a rail which is arranged on the traveling track of the trolley and has a length greater than that of the beam guide rail. The optical length adjustment device can ensure that the length of the optical path from the laser generator to the cutting head is consistent when the cutting head is at any point between (0, 0) and (a, b).

Owner:江苏扬力数控机床有限公司

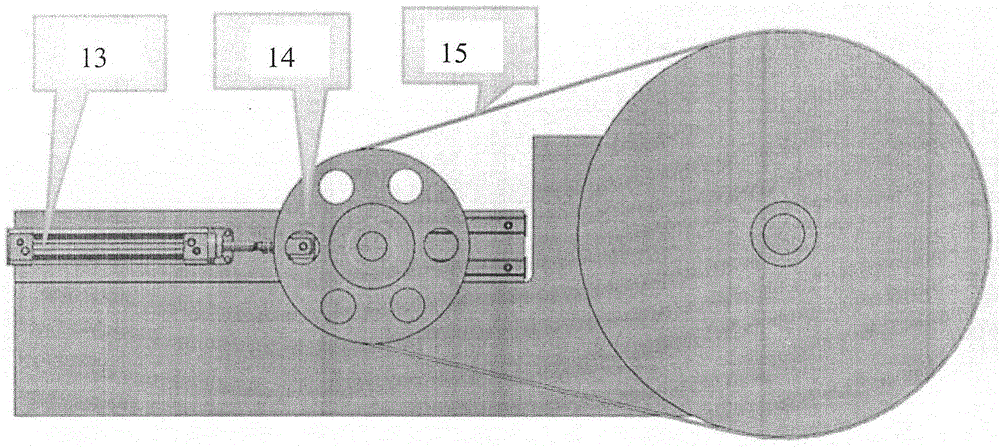

Rubber roller belt sander

The invention discloses a rubber roller belt sander, wherein a long strip-shaped support frame is positioned on a base; a driving wheel can be rotationally positioned at one end of the support frame; a driven wheel can be rotationally positioned at the other end of the support frame; the driving wheel and the driven wheel are arrayed in parallel; a ring-shaped abrasive belt is arranged on the driving wheel and the driven wheel in a sleeving manner; the driving wheel is driven by a motor to rotate; a driven shaft on the driven wheel is inserted in a shaft sleeve at the other end of the support frame; and the driven shaft can be driven by a deviation rectifying adjusting device on the shaft sleeve to rotate around a shaft perpendicular to the axial direction of the driven shaft and the length direction of the ring-shaped abrasive belt. According to the rubber roller belt sander, an adjustment of the axis parallelism of the driving wheel and the driven wheel can be realized, so that the stability of the operation of the abrasive belt can be realized; the tension adjustment of the ring-shaped abrasive belt is convenient, so that the ring-shaped abrasive belt can be adapted to processing of different materials, and the replacement of the ring-shaped abrasive belt is facilitated, the rotation of the whole ring-shaped abrasive belt around an axial line of the driving wheel can be realized, the contact angle of the abrasive belt and a workpiece can be changed, the contact position of the abrasive belt and the workpiece can be changed, and different processing demands can be met.

Owner:昆山诺丹舜蒲胶辊有限公司

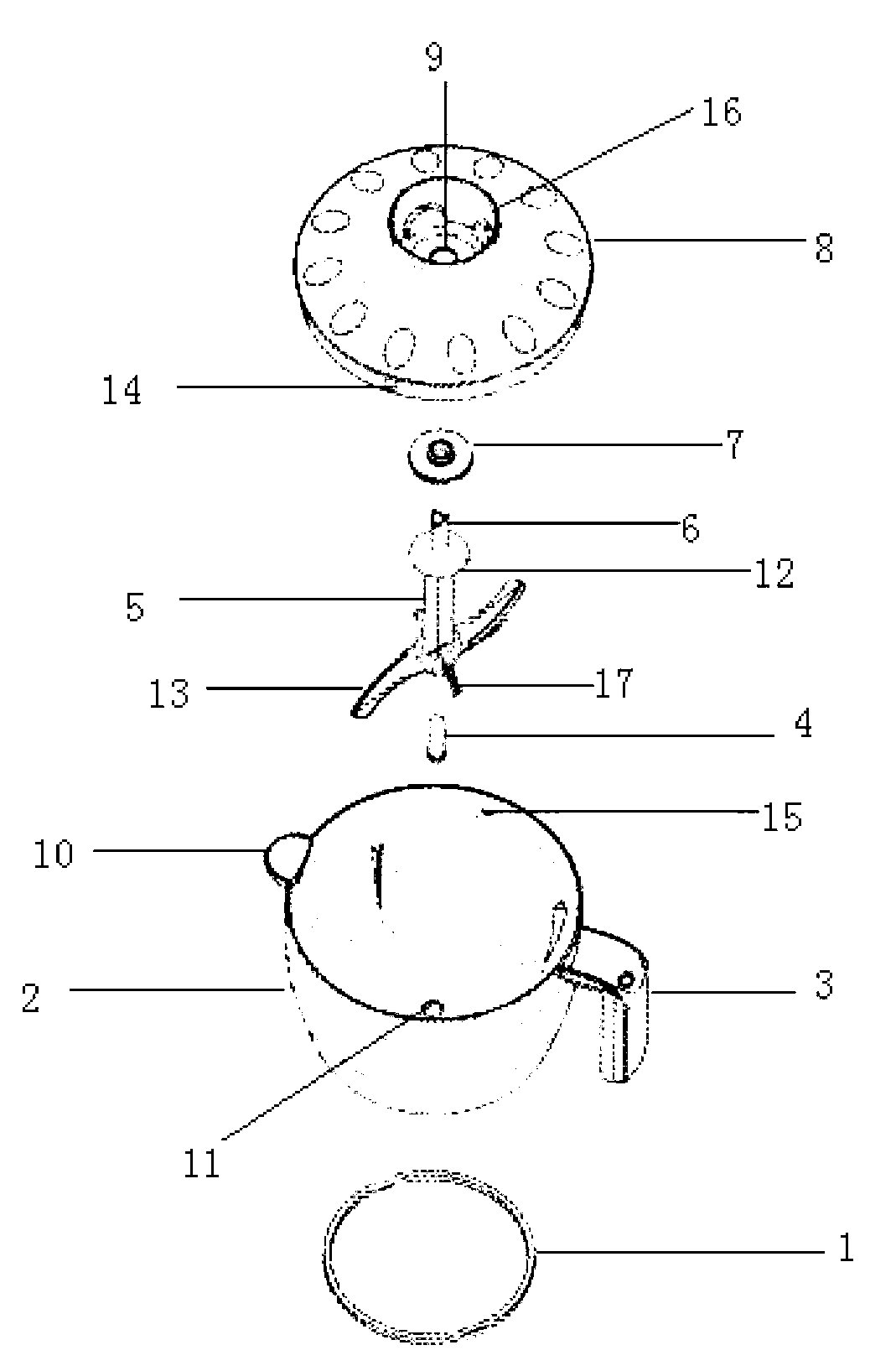

Smashing type food stirring cup

InactiveCN103222810AMeet different processing needsImprove versatilityKitchen equipmentEngineeringShort arms

The invention belongs to the technical field of food processing equipment and relates to a smashing type food stirring cup. The main structure of the smashing type food stirring cup comprises a cup body bottom rubber, a cup body, a handle, an upright post, a smashing knife, a rotating shaft, a bearing, a cup lid, a rotating shaft hole, a discharging spout, a fixing hole, a support plate, a blade, a raised clamp, a clamping groove, a power cavity and a short arm, wherein the upright post is fixedly processed in the center of the bottom end inside the cup body through a fixing hole, the lower end of the smashing knife is in sleeve joint with the upright post in a detachable manner, the annular support plate and the rotating shaft are processed at the upper end of the smashing knife, and the top of the rotating shaft adopts a groove structure so as to be convenient for snap-on butting to external electrodynamic force; and the smashing type food stirring cup is reasonable in structural design, is convenient to operate and use, is fashionable and compact in appearance, conforms to mass aesthetic requirements, is scientific and reliable in principle, is simple and safe to use, is easy to demount, convenient to clean, small in noise, and is multipurpose and environmental-friendly.

Owner:QINGDAO LEKANG ELECTRONICS

Flour processing device with convenient-dismounting stirring shaft

ActiveCN106879658AEasy to disassembleConvenience to workMixing/kneading structural elementsMixing/kneading with vertically-mounted toolsEngineeringMechanical engineering

The invention discloses a flour processing device with a convenient-dismounting stirring shaft. The device comprises a box body, wherein a feeding device is connected to one side of the box body through a swinging mechanism, and a connecting lug is welded to the other side of the box body; a water pouring device which communicates with the inside of the box body is mounted at the top part of the connecting lug; and a quantity control device is mounted on the water pouring device. According to the flour processing device with the convenient-dismounting stirring shaft, the stirring shaft is mounted by clamping through a clamping mechanism, and a lifting mechanism is arranged, so that the stirring shaft can be conveniently dismounted and maintained; residual raw materials on the inner wall of the box body can be swept through a sweeping device, so that the cleanness and the convenience are ensured, and the raw materials can be saved; in addition, the production cost is decreased; the feeding device capable of easily controlling the quantity, the quantity control device and a concentration detecting device are arranged to adjust and control the concentration of paste to meet different processing demands, and thus related workers can work conveniently.

Owner:多麦(福建)食品有限公司

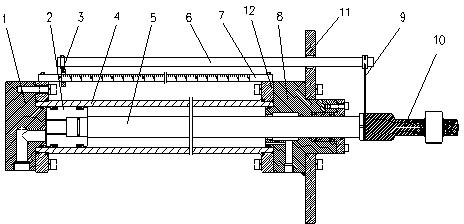

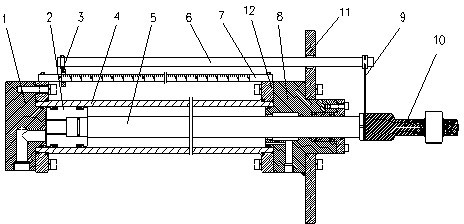

Hydrocylinder provided with measuring scale lever

InactiveCN102678674AAdjustable motion stroke lengthMeet different processing needsFluid-pressure actuatorsCylinder headEngineering

The invention discloses a hydrocylinder provided with a measuring scale lever, which includes a cylinder body, wherein a piston and a piston rod are arranged in the cylinder body; a cylinder head and a cylinder tail are connected with the two ends of the cylinder body respectively; a lifting head is connected with one end of the cylinder head; a slide bar is fixed with one end of the piston rod; a slip ring is fixed at the end part of the slide bar; the measuring scale lever is fixed on one side of the cylinder body; and the slip ring is connected with the measuring scale lever in a sliding manner. According to the invention, the current position of the piston rod can be visually read out on the measuring scale lever, and the hydrocylinder provided with the measuring scale lever can meet different machining requirements through adjusting the moving stroke of the piston rod, has the advantages of simple structure, conveniences for operation and better flexibility, thereby having popularization and application values.

Owner:GLUAL HYDRAULIC SYST CHANGZHOU

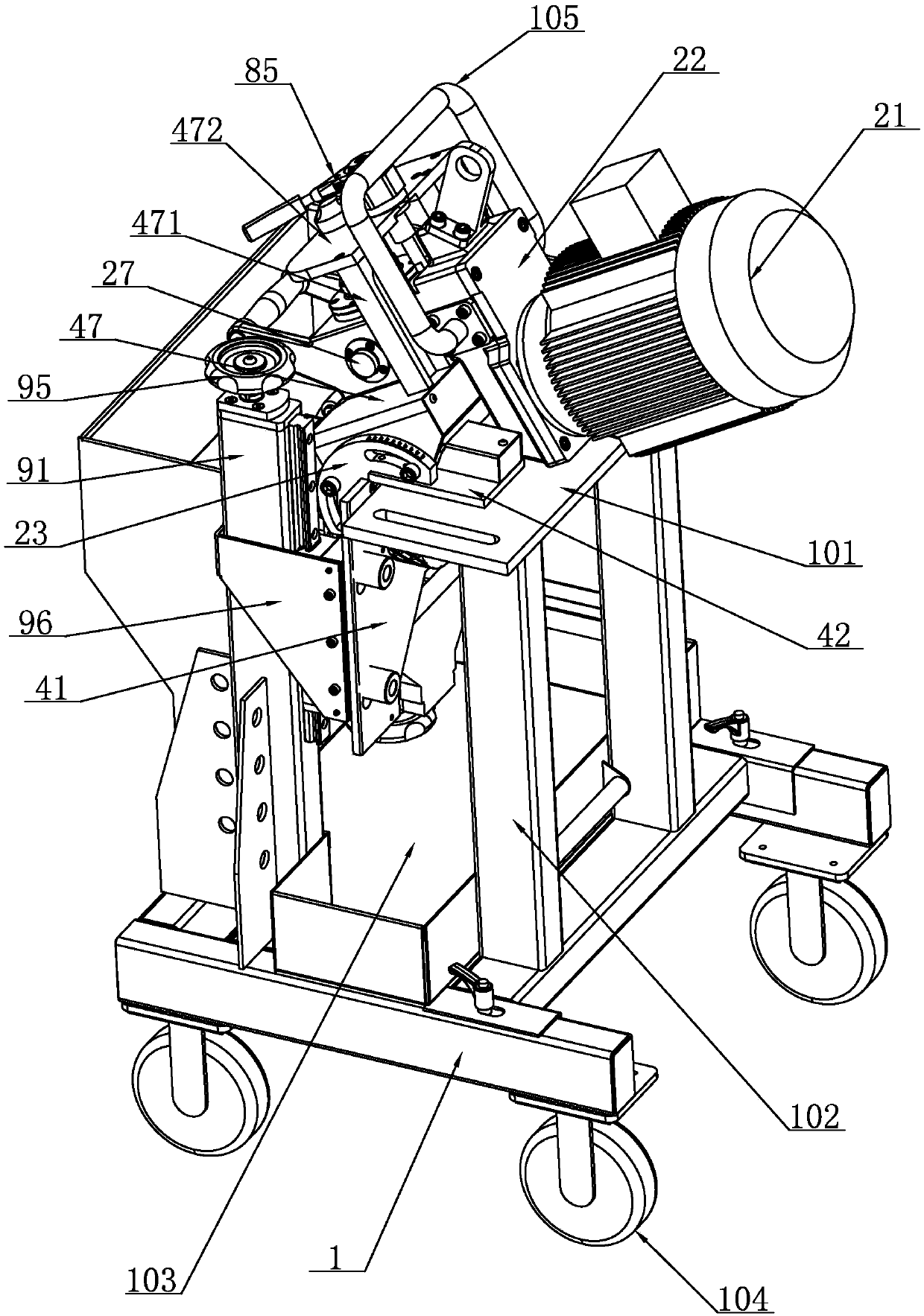

Multi-purpose abrasive wheel cutting machine

InactiveCN104416442AReduce vibrationEasy to moveGrinding machinesGrinding work supportsEngineeringMechanical engineering

The invention discloses a multi-purpose abrasive wheel cutting machine, and relates to the field of industrial machinery. The machine comprises a base, an abrasive wheel, a motor, a bracket and a protective cover; the motor is fixedly arranged on the bracket, wherein the bracket is fixedly arranged on the base; a rotary component clamping device is arranged on the base, and a vibration absorbing device is arranged below the rotary component clamping device; a nanometer silencing layer is arranged at the inner side of the protective cover; the rotary component clamping device is detachably connected with the base and the vibration absorbing device. According to the multi-purpose abrasive wheel cutting machine, a component can be cut in a plurality of directions, so as to meet different processing demands; in addition, the vibration produced by the abrasive wheel cutting machine in running can be effectively reduced, and therefore, the cutting precision of the component is avoided being influenced; the convenience of replacement and maintenance is ensured, and the service life is prolonged.

Owner:SHANGHAI XIWANG ELECTRONICS TECH

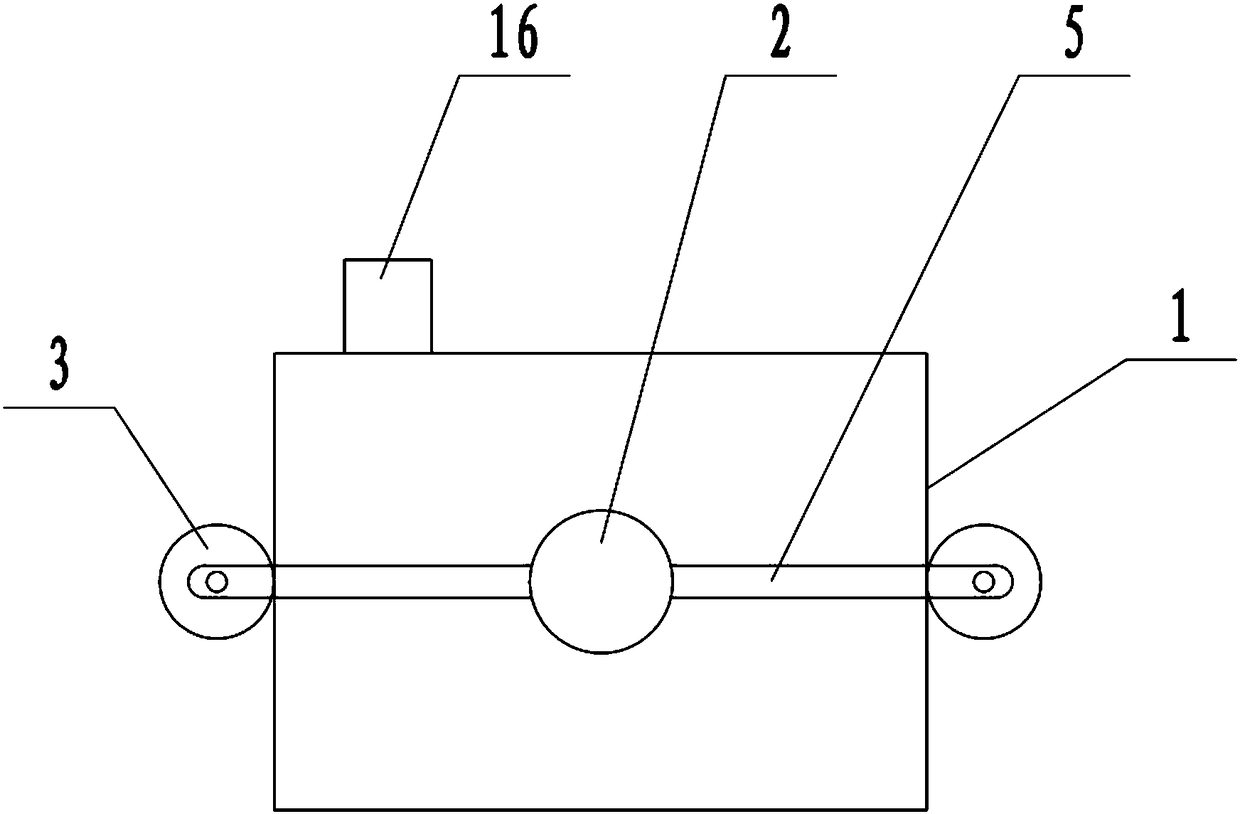

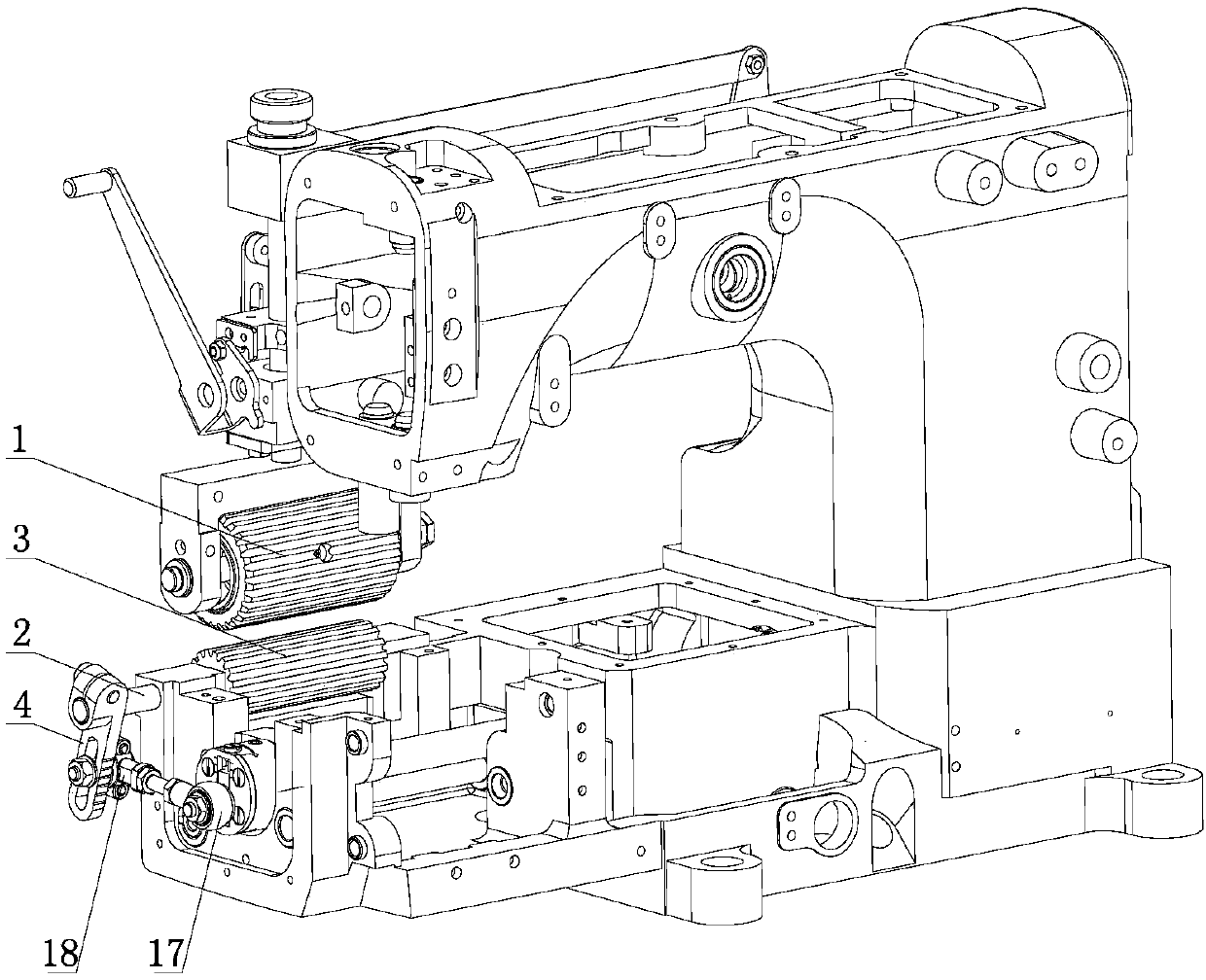

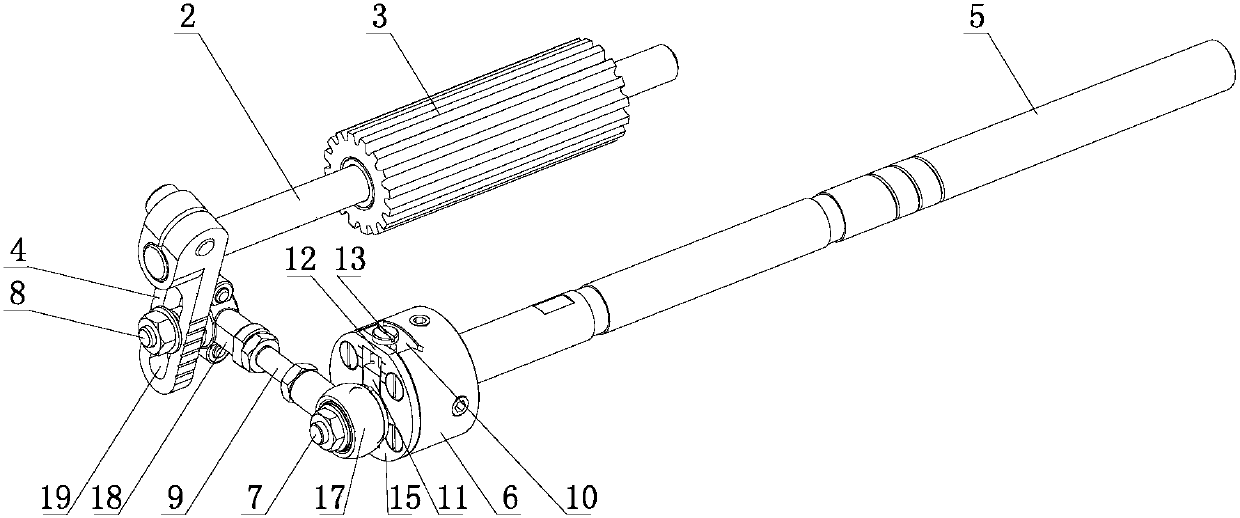

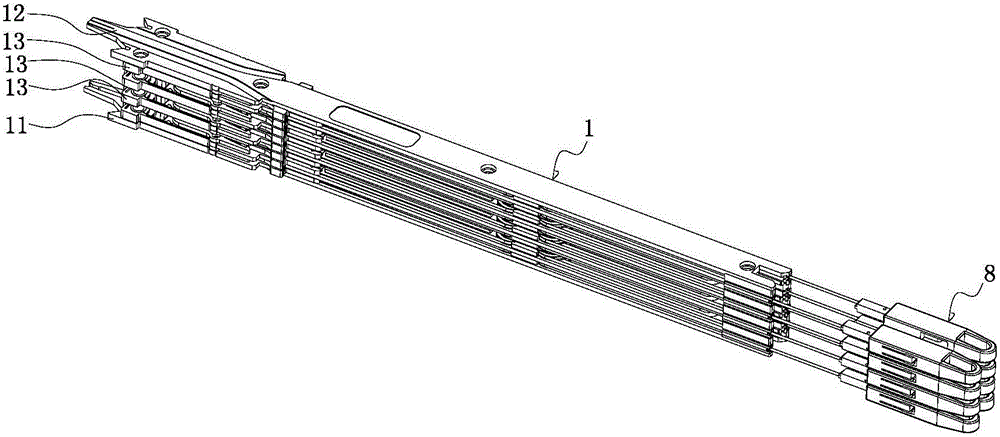

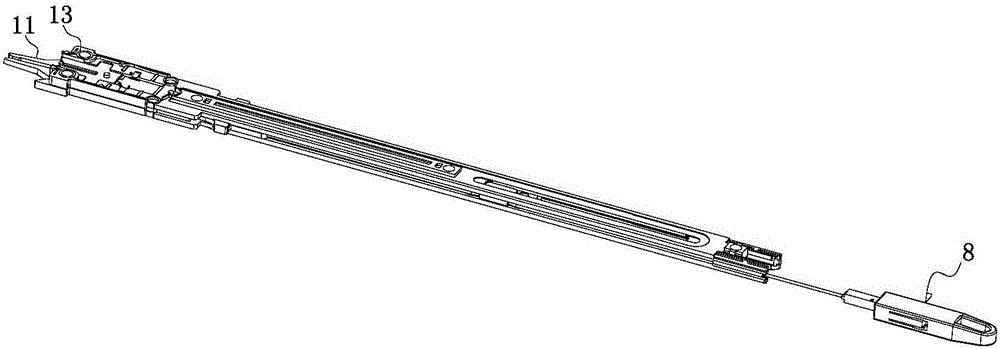

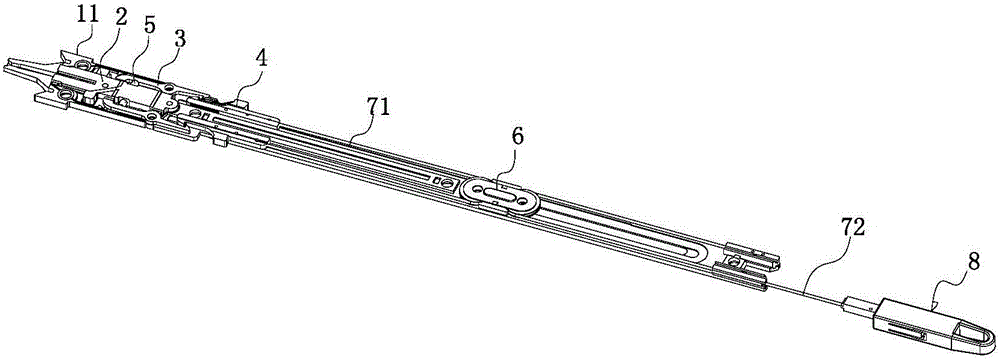

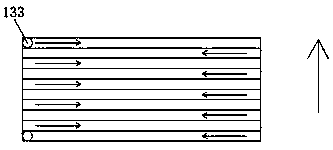

Synchronous feeding structure of lower traction wheel

ActiveCN107805889AAdjustable swing angleNo wrinkleWork-feeding meansSewing-machine control devicesEngineeringMultiple layer

The invention provides a synchronous feeding structure of a lower traction wheel, and belongs to the technical field of sewing machines. The problem that an existing sewing machine only uses upper andrear traction wheels for feeding, and accordingly when multiple layers of sewing materials are conveyed, the upper and lower layers of sewing materials are always staggered. The synchronous feeding structure of the lower traction wheel structurally comprises a rotating shaft and the lower traction wheel, the rotating shaft penetrates through a workbench of the sewing machine and is parallel to the upper traction wheel, the rotating shaft is coaxially sleeved with the lower traction wheel, the lower traction wheel is located under the upper traction wheel and opposite to the upper traction wheel, a swing rod is fixed to the rotating shaft, a transmission assembly used for driving the swing rod to swing when a main shaft rotates is arranged between the swing rod and the main shaft of the sewing machine, and a one-way assembly used for limiting the lower traction wheel to rotate in one direction all the time when the swing rod swings is arranged between the rotating shaft and the lower traction wheel. The synchronous feeding structure has the advantages that the structural design is reasonable, the application range is wide, and the sewing materials are not staggered or wrinkled whenmultiple layers of sewing materials are sewn.

Owner:JACK SEWING MASCH CO LTD

Diamond polishing solution and preparation method thereof

InactiveCN111647356AGood suspensionImprove polishing efficiencyPolishing compositions with abrasivesOxidizing agentSuspending Agents

The invention provides a diamond polishing solution for metallographic polishing and capable of meeting different polishing precision requirements and a preparation method thereof. The diamond polishing solution is prepared from the following raw materials in parts by weight: 70-95 parts of water, 0.1-15 parts of diamond micro powder, 2-5 parts of a suspending agent, 0.01-0.1 part of an antioxidant, 10-20 parts of a lubricant, and 1-5 parts of a dispersant; the preparation method of the diamond polishing solution comprises the following steps: adding the dispersing agent, the lubricating agentand the diamond micro-powder sequentially into stirred water; adding an antioxidant into the water; under the condition that the stirring rotating speed is not lower than 800 rpm, adding a suspendingagent into water for dispersion for 20-30 min. The polishing solution provided by the invention is a water-based polishing solution, and has the characteristics of environmental protection, good suspension property, high polishing efficiency, good smooth finish of a polished surface, low cost and the like.

Owner:特鲁利(苏州)材料科技有限公司

Rotary ultrasonic head based on machine tool attachment

ActiveCN102151867BRealization of complete machine tool accessoriesImprove versatilityTool holdersEnergy transferUltrasonic machining

The invention discloses a rotary ultrasonic head based on machine tool attachment. The rotary ultrasonic head comprises an ultrasonic vibration operating device, a non-contact collector ring, a main shaft, a knife handle and a supporting shell, wherein, the knife handle with a standard model is adopted; the ultrasonic vibration operating device is connected with one end of the main shaft; the knife handle is connected with the other end of the main shaft; rotation axes of the ultrasonic vibration operating device, the knife handle and the main shaft are positioned on the same straight line; and the non-contact collector ring is arranged between the main shaft and the supporting shell, and an ultrasonic vibration signal is transmitted to the ultrasonic vibration operating device in a non-contact manner through the non-contact collector ring. The rotary ultrasonic head has the following outstanding advantages: (1) complete machine tool attachment as well as generality and interchangeability of an ultrasonic machining device are realized; and (2) the induction efficiency of a brushless non-contact power supply system of the ultrasonic machining device is improved, the efficient energy transfer is realized, and the energy loss is reduced.

Owner:TIANJIN UNIV

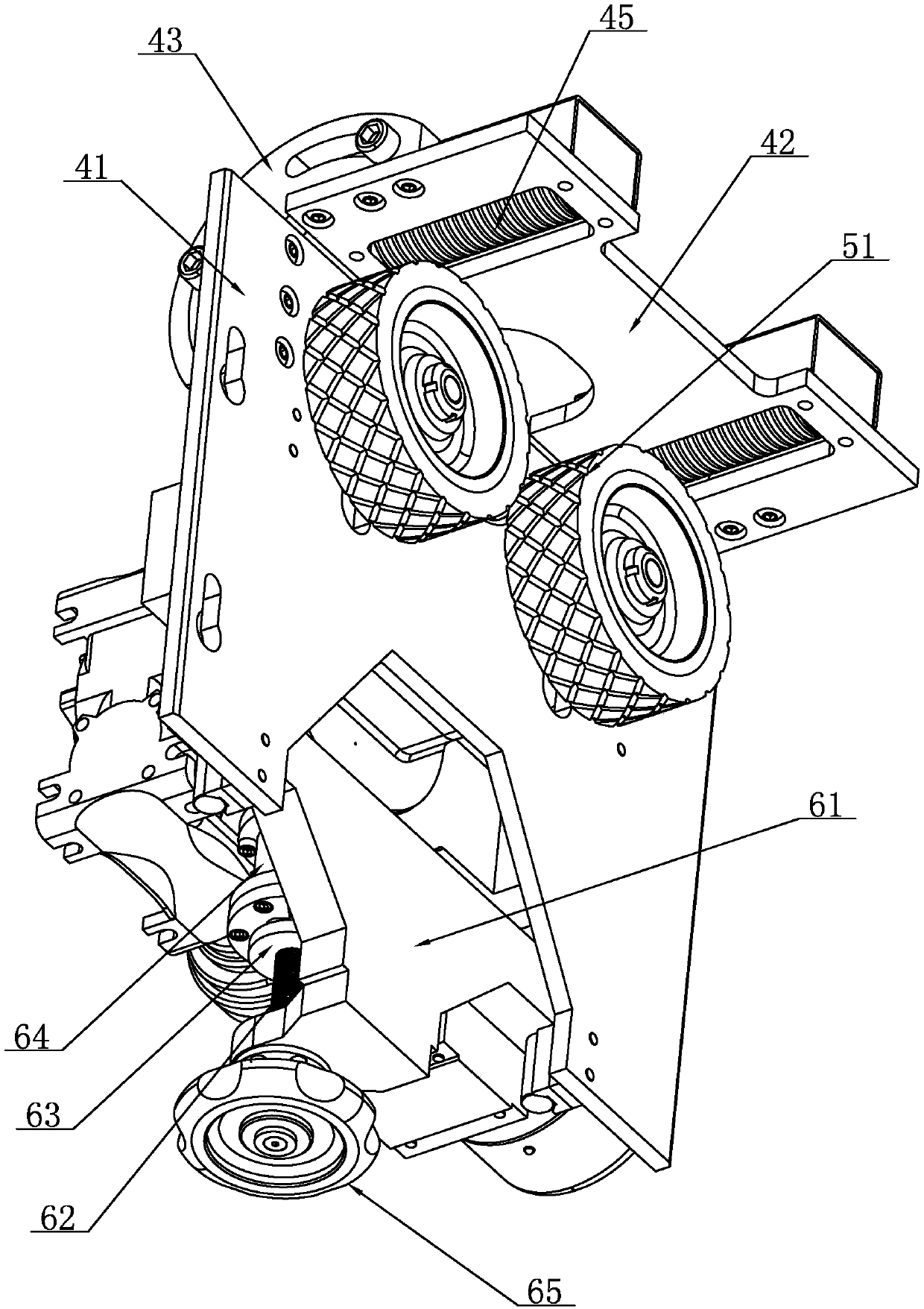

Flat chamfering machine

PendingCN109663988ASimple structureEasy to operateFeeding apparatusDriving apparatusAutomatic transmissionElectric machinery

The invention relates to a flat chamfering machine. The flat chamfering machine comprises a frame, a first motor and a chamfering knife; the first motor is arranged on the frame through a motor mounting seat; a positioning plate and a guiding plate are arranged on the frame; the positioning plate is arranged on the frame; the end of the chamfering knife extends to the middle of the positioning plate and the guiding plate; the positioning plate is provided with a roller assembly, and the roller assembly comprises a first roller and a roller seat; the first roller is arranged on the roller seat;the first roller and the roller seat are correspondingly arranged on two sides of the positioning plate; and the roller seat is provided with a driving assembly capable of driving the first roller torotate; the roller seat is slidably arranged on the positioning plate in the vertical direction; an adjusting assembly is arranged between the roller seat and the positioning plate for adjusting theposition of the roller seat; the adjusting assembly comprises an adjusting bracket; the adjusting bracket is fixedly arranged on the positioning plate; and a spring is arranged between the adjusting bracket and the roller seat for the roller seat to be pressed and moved. The above scheme facilitates automatic transmission of flat plates and the processing precision is higher.

Owner:ZHEJIANG AOTAI MACHINE MFG

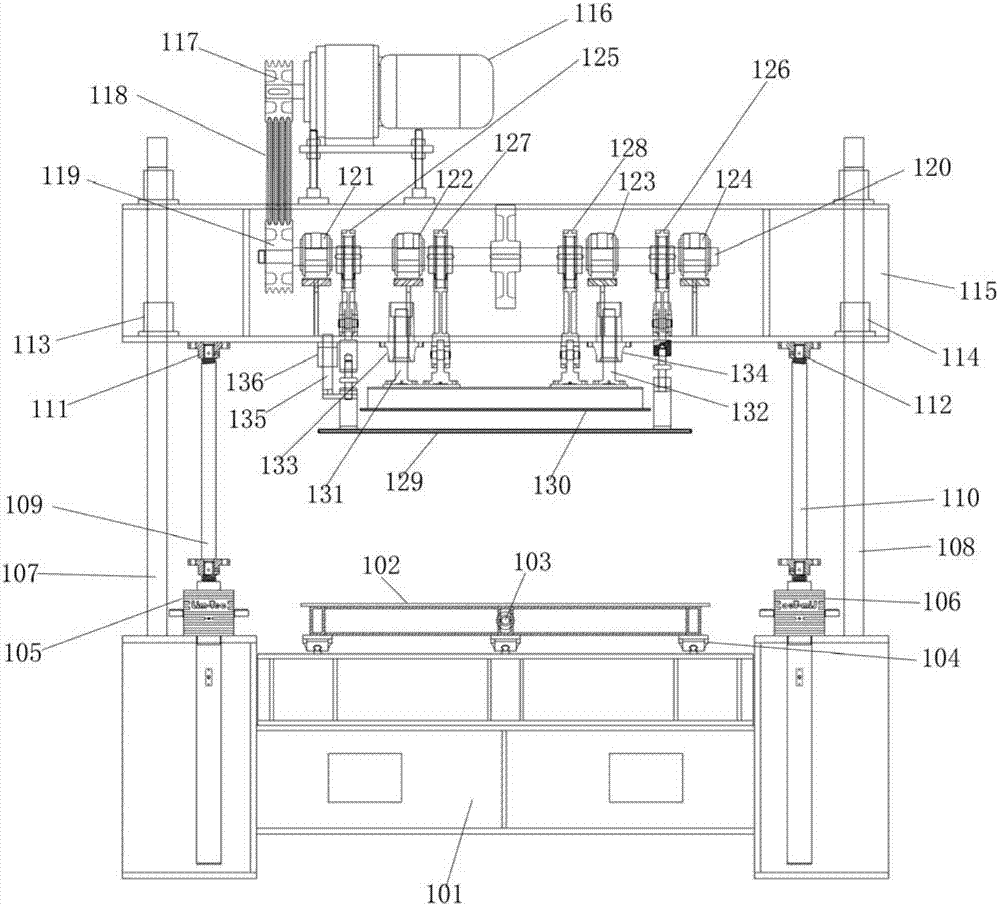

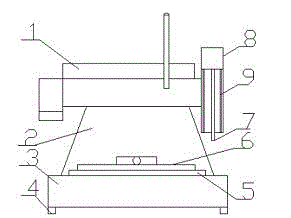

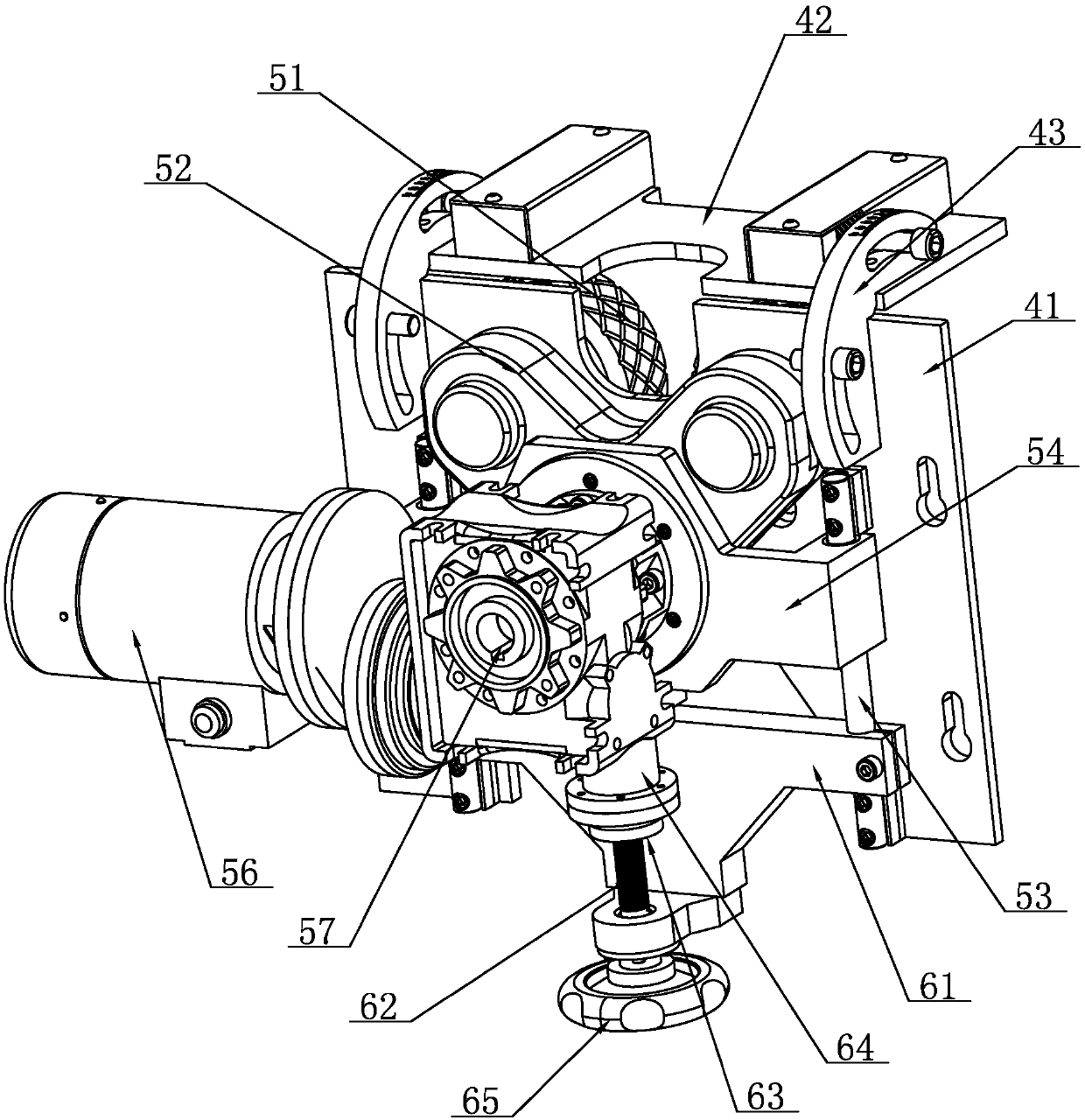

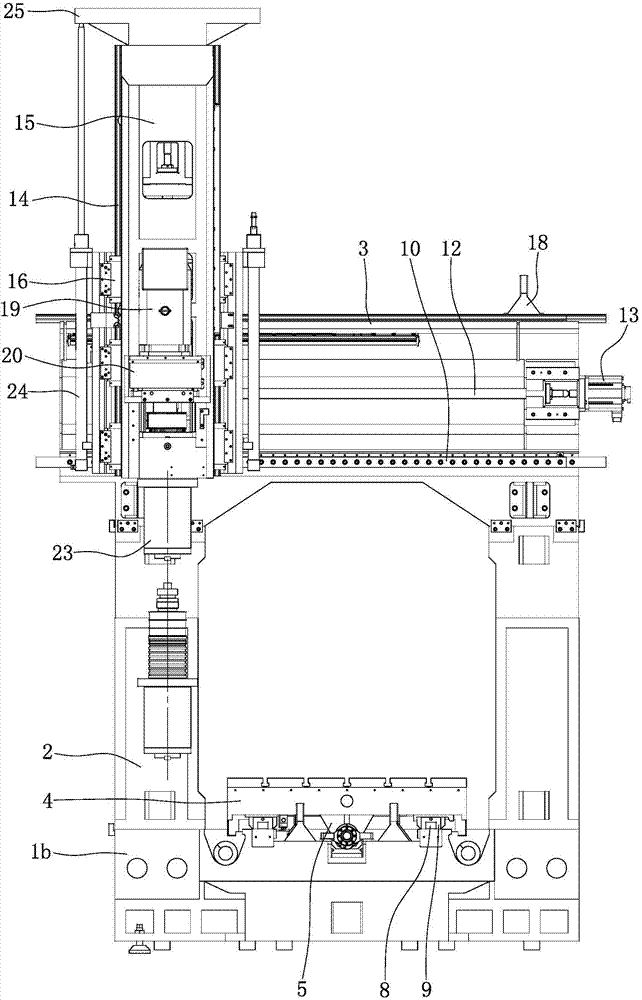

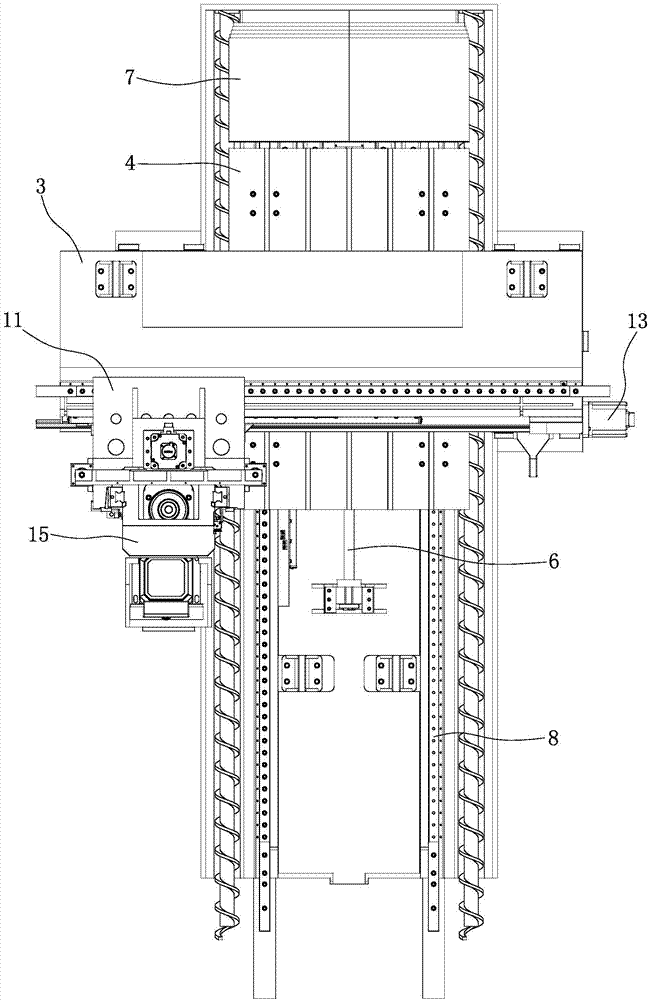

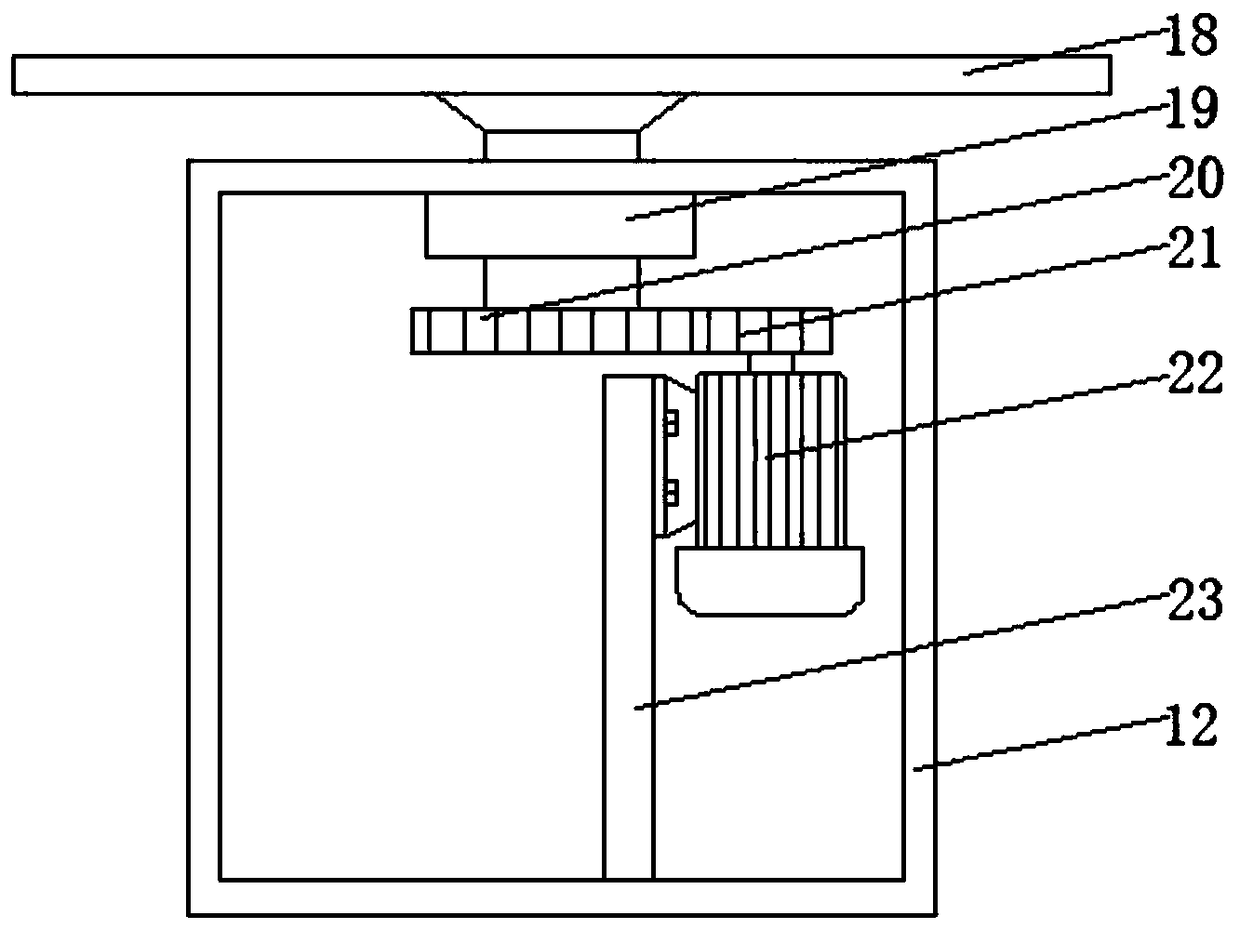

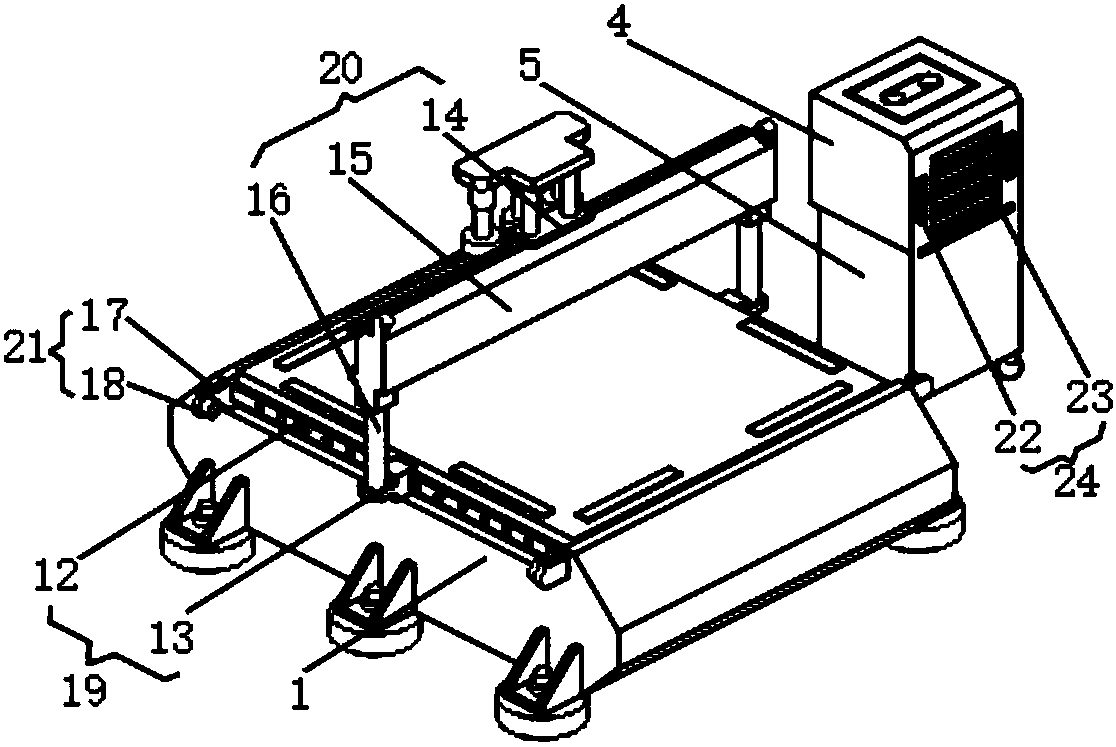

Portal machining center combination for large part machining

InactiveCN104842204AEasy to shapeAuto excludeFeeding apparatusMaintainance and safety accessoriesDrive wheelLow speed

The invention discloses a portal machining center combination for large part machining. A support (1b) is a square frame body. An X-axis nut base (5) at the bottom of a working table (4) is in screw-thread fit with an X-axis lead screw (6). Nitrogen balancing cylinders (24) are symmetrically arranged on the left side and the right side of a Y-axis slide base (11). Cylinder bodies of the nitrogen balancing cylinders (24) are fixed to the Y-axis slide base (11). An output shaft of a main shaft motor (19) is connected with the input end of a gearbox (20). An output shaft of the gearbox (20) is sleeved with a driving wheel (21). The driving wheel (21) is connected with a driven wheel of a main shaft (23) through a belt (22). The movement in each axial direction is achieved through the large-torque motor and a screw-nut pair, complex profiles can be machined, high-speed cutting can be achieved, the low-speed large-torque cutting can be achieved as well, the nitrogen balancing cylinders are used for balancing the gravity of the main shaft box, and the stability of the Z-axis movement is ensured.

Owner:CHONGQING MASITER PRECISION MACHINERY

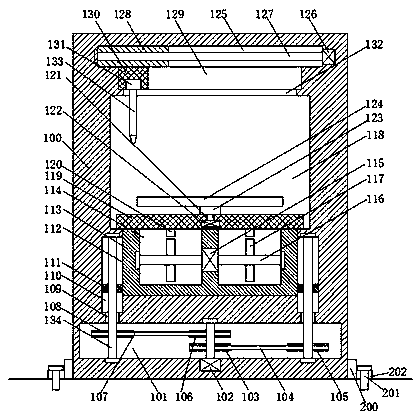

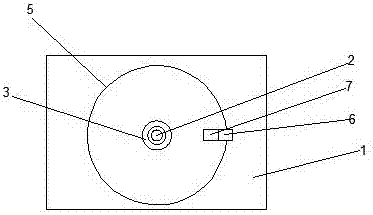

Automatic demolding type injection mold with changeable mold

The invention discloses an automatic demolding type injection mold with a changeable mold. The upper surface of an upper plate body is fixedly connected with the upper surface of a workbench; the workbench is fixed at the top end of a control cabinet; the control cabinet is internally provided with a treatment device and a control panel; the upper surface of the workbench is provided with a mounting seat and a signal transmitter; an output shaft of a motor is provided with a gear disc B; a rotary shaft is fixedly connected with an inner ring of a bearing seat; the top end of the rotary shaft is fixedly connected with a center disc; a frame is provided with a mold body; the right side of a power cabinet is provided with a supporting rod; the cross section of a bracket is in a U shape; a spindle is provided with a rolling shaft; the frame is arranged at the upper end of the rolling shaft. For the automatic demolding type injection mold with the changeable mold, by mounting multiple different mold bodies on the frame and driving the frame under the effect of the motor to rotate, automatic mold body change and one machine with multiple functions are realized, and different processing demands are met.

Owner:周爱忠

Electromagnetic valve module of high-speed jacquard machine

The invention discloses an electromagnetic valve module of a high-speed jacquard machine. The electromagnetic valve module comprises a plate body set, and an electromagnetic valve, moving iron, a vertical hook, a spring assembly, a pulley assembly, a first silk thread and a second silk thread which are installed in the plate body set, wherein the first silk thread is connected between the pulley assembly and the vertical hook, and the second silk thread is connected with the pulley assembly and extends out of the plate body assembly. The end of the second silk thread is provided with a quick coupling. The electromagnetic valve comprises an insulation base, I-iron arranged in the insulation base, a coil wound on the I-iron, a first leaf spring terminal and a second leaf spring terminal, wherein the first leaf spring terminal and the second leaf spring terminal are arranged in the insulation base and electrically connected with the coil. The end of the insulation base is provided with an abutting port. The first leaf spring terminal and the second leaf spring terminal are symmetrically arranged on the inner wall of the abutting port. The electromagnetic valve module is stable in structure, small in thickness and small in size, so that enough electromagnetic valve modules can be installed at the limited installation position of the jacquard machine, large enough jacquard patterns can be woven on textile through the jacquard machine, different processing requirements are met, and market competitiveness is quite high.

Owner:崔如奎

Vibration type wrinkling machine

InactiveCN107009685AGood wrinkle effectIncrease roughnessMechanical working/deformationPattern makingWrinkle skinPiezoelectric actuators

The invention discloses a vibration type wrinkling machine. The vibration type wrinkling machine comprises a machine frame, an unwinding device, a front-end tensioning roller, a conveying device, a material pressing mechanism, a vibrating mechanism, a material lifting mechanism, a rear-end tensioning roller and a winding device, wherein the unwinding device is arranged at the head part of the machine frame, the front-end tensioning roller is arranged on the right side of the unwinding device, the conveying roller is arranged in the middle of the machine frame, the material pressing mechanism, the vibrating mechanism and the material lifting mechanism are sequentially arranged above the conveying roller from left to right, the rear-end tensioning roller is arranged on the right side of the material lifting mechanism, and the winding device is arranged at the tail part of the machine frame. According to the vibration type wrinkling machine, rapid fluctuating pressure is provided for material to be processed through a piezoelectric actuator, compact and complex wrinkles are produced through the caused vibration, the roughness degree of the interior of the material to be processed is improved, the product obtained by processing has stronger adsorbability and ductility, the amplitude and the frequency of the vibration are controlled only by adjusting the input voltage of the piezoelectric actuator, and then the wrinkling effect is controlled. The vibration type wrinkling machine can be used for wrinkling cloth and paper and has a remarkable effect on improving the adsorption performance of the material.

Owner:ZHEJIANG UNIV

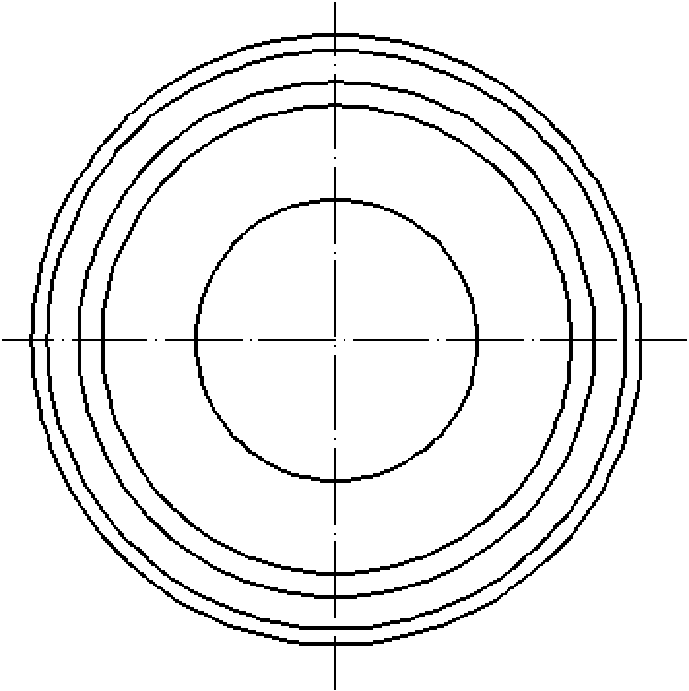

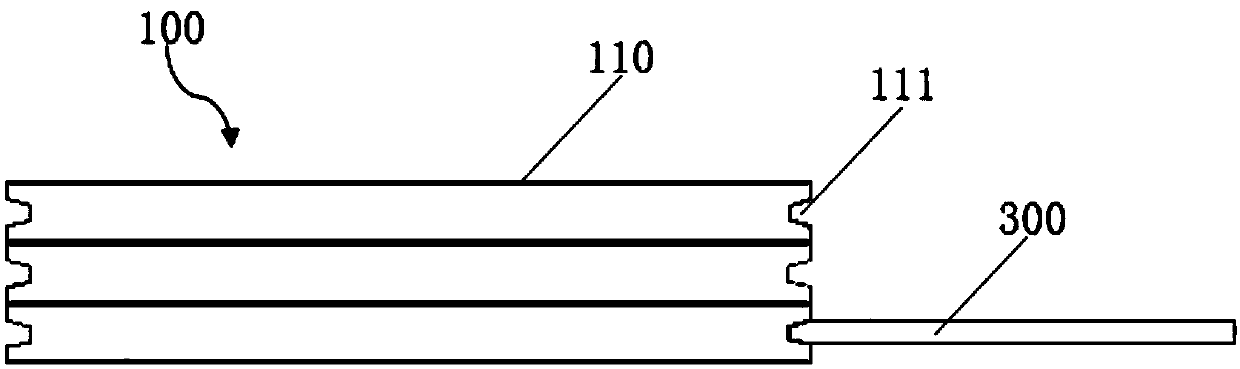

Chamfering grinding wheel, chamfering grinding device and grinding method

InactiveCN109623553AMeet different processing needsIncrease productivityEdge grinding machinesGrinding machine componentsEngineeringGrinding wheel

The invention provides a chamfering grinding wheel, a chamfering grinding device and a grinding method. The chamfering grinding wheel comprises a grinding wheel main body, and at least two grinding grooves peripherally formed in the outer peripheral surface of the grinding wheel main body; and the at least two grinding grooves are distributed on the axis of the grinding wheel main body at intervals. The chamfering grinding wheel can correspondingly machine more than two workpieces, so that the working efficiency is improved.

Owner:XIAN ESWIN SILICON WAFER TECH CO LTD

Precise three-process carpentry engraving machine

InactiveCN108406127AGood flexibilityEasy to adjustLaser beam welding apparatusShip's carpenterWoodworking

Owner:杭州勇冠网络科技有限公司

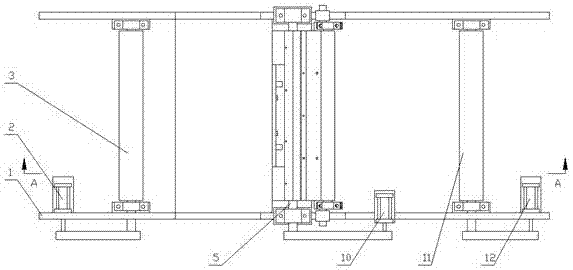

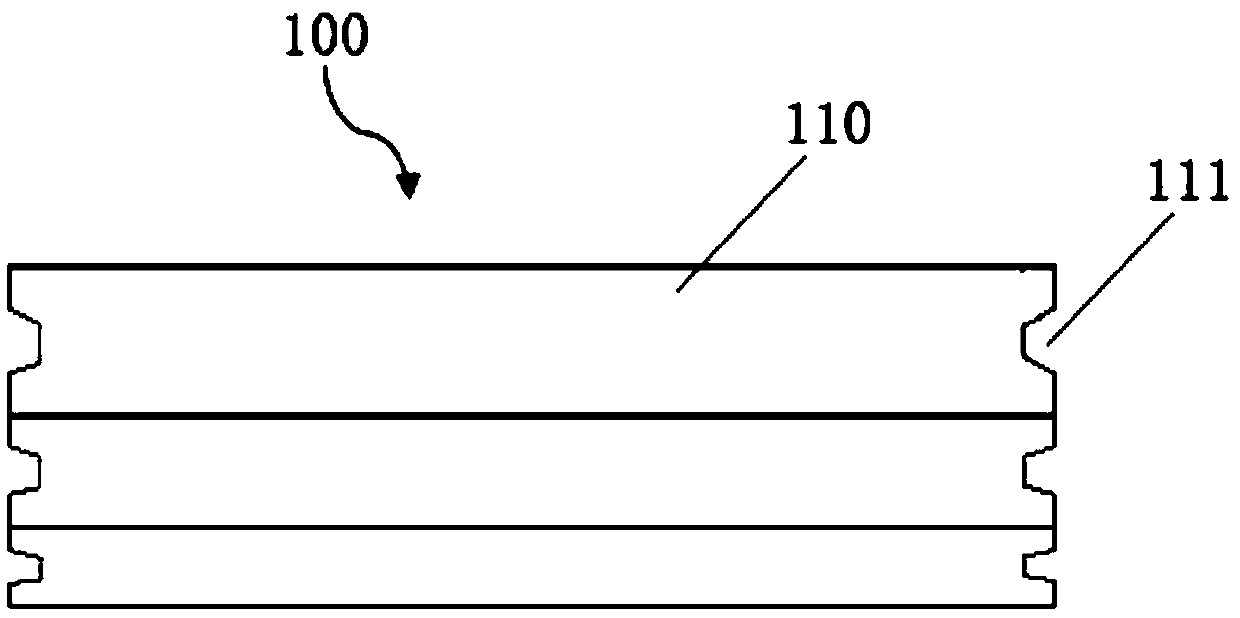

Conveying device used for machining chase mortises of wood floor

The invention discloses a conveying device used for machining chase mortises of a wood floor. The conveying device comprises a base (1), device bodies (2), sliding rails (3), conveying rolls (4), pressing rolls (5), lifting plates (6) and limiting holes (7). The device bodies (2) are arranged on the base (1), the sliding rails (3) are arranged on the base (1), the device bodies (2) are matched with the sliding rails (3), the conveying rolls (4) are arranged on the lower portions of the device bodies (2), the lifting plates (6) are arranged on the base (1), the pressing rolls (5) are arranged on the lifting plates (6), and the limiting holes (7) are formed in the device bodies (2) and matched with the pressing rolls (5). Wood floors of different widths and thicknesses can be conveyed to follow-up chase mortise machining equipment through the conveying device, and the conveying device has the advantages of being high in adaptability, precision and efficiency and low in cost.

Owner:HUZHOU NANXUN SHUANGLIN ZHENSEN WOOD PROCESSING FACTORY

Novel material laser surface modified treatment device

InactiveCN108544084AMeet different processing needsImprove functionalityLaser beam welding apparatusDrive wheelEngineering

The invention discloses a novel material laser surface modified treatment device which comprises a machine body, wherein a transmission cavity is formed in the machine body; a first motor is fixedly arranged in the lower end wall of the transmission cavity; the output shaft of the first motor extends upward in the transmission cavity; the upper end of the output shaft of the first motor and the upper end wall of the transmission cavity are connected in a normal running fit manner; the outer surface of the output shaft of the first motor is in power connection with a first driving wheel; the first driving wheel is connected with a first driven wheel through a first conveyor belt; the outer surface of the output shaft of the first motor is in power connection with a second driving wheel above the first driving wheel; the second driving wheel is connected with a second driven wheel through a second conveyor belt; first threaded rods extending upwards are connected with the interior of thelower end wall of the transmission cavity in bilateral symmetry in a normal running fit manner; and the first driven wheel is fixedly connected with the first threaded rod on the right. The novel material laser surface modified treatment device is simple in structure and convenient to use and adopts integrated design of two working manners to meet the processing requirements of different workpieces.

Owner:张国强

Machining device for casting gear blank part

The invention discloses a processing device for casting a gear blank. The processing device includes a fixing mechanism and a cutting mechanism used in conjunction. The fixing mechanism includes a workbench, a fixed shaft is arranged on the workbench, and an abutment part is arranged on the fixed shaft, and the abutment part can be fixed The abutment part includes an inner ring and an outer ring connected by a spring, the inner ring is made of elastic material, and the fixed shaft includes a first fixed shaft and a second fixed shaft with different inner diameters. The processing device of the present invention is simple in structure and simple in operation, and the abutting portion can adapt to gears of different sizes through the inner ring and the outer ring, thereby satisfying different processing requirements.

Owner:SUZHOU ZHUOCHENG TITANIUM EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com