Numerical control double-power mode multifunctional impulsing power source for electrospark wire-electrode cutting processing

A technology of pulse power supply and cutting processing, which is applied in the direction of electric processing equipment, metal processing equipment, circuits, etc., and can solve problems such as low energy utilization rate, increased cost, and broken wires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings.

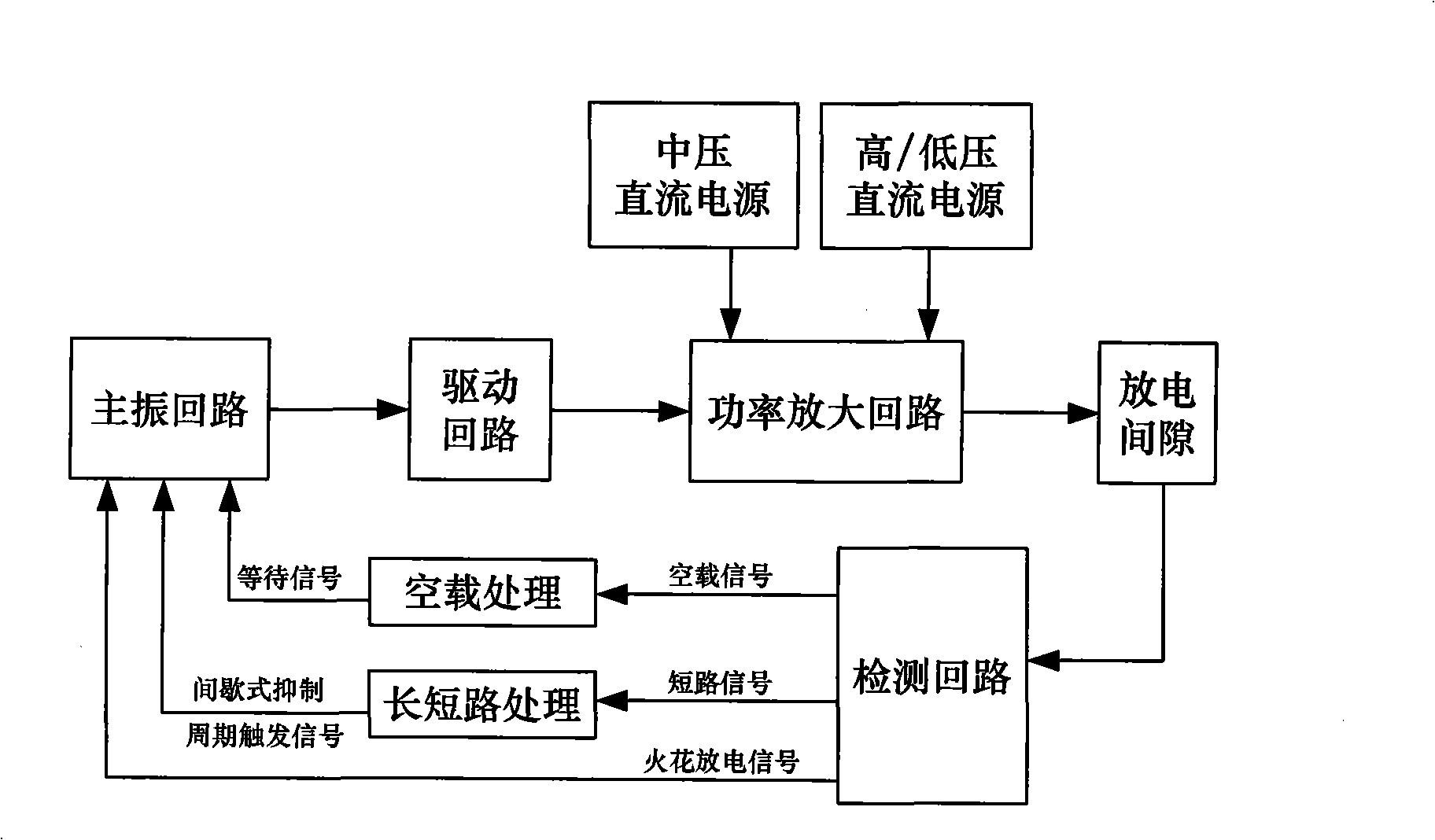

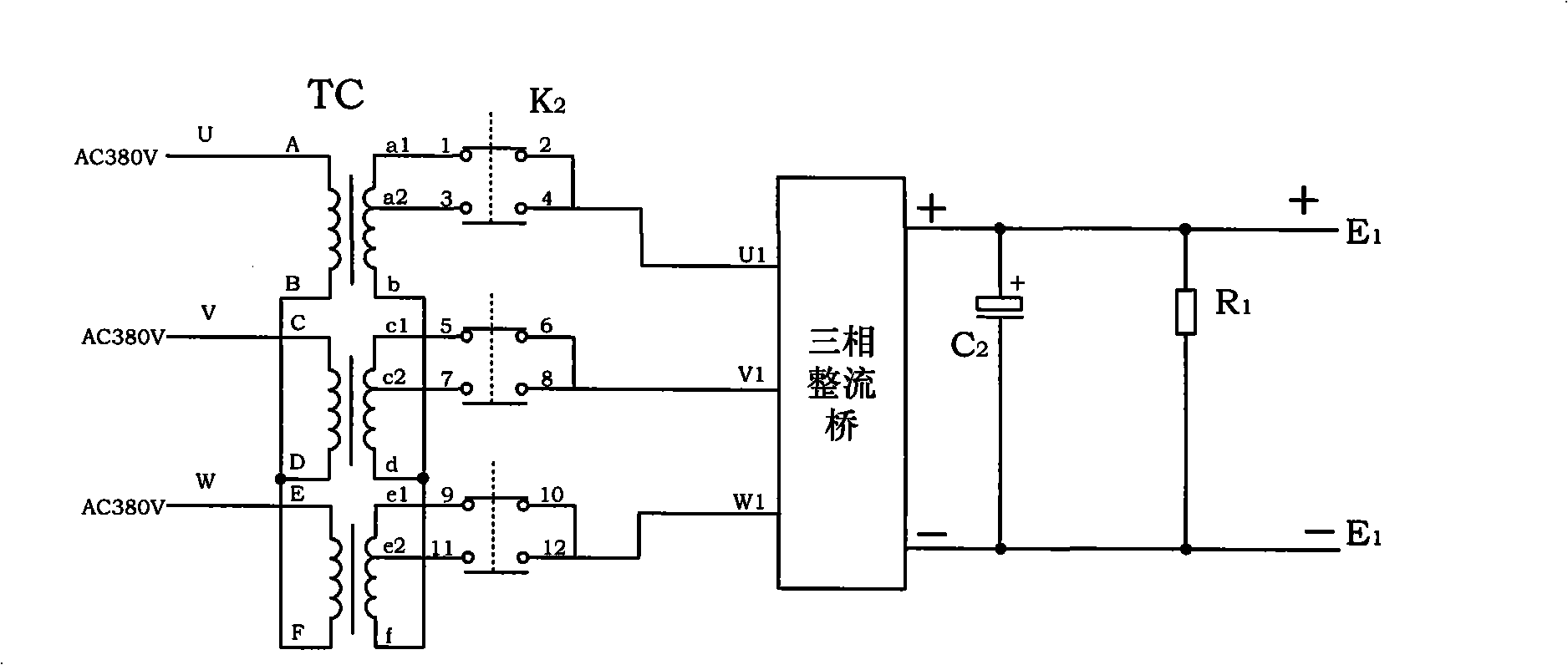

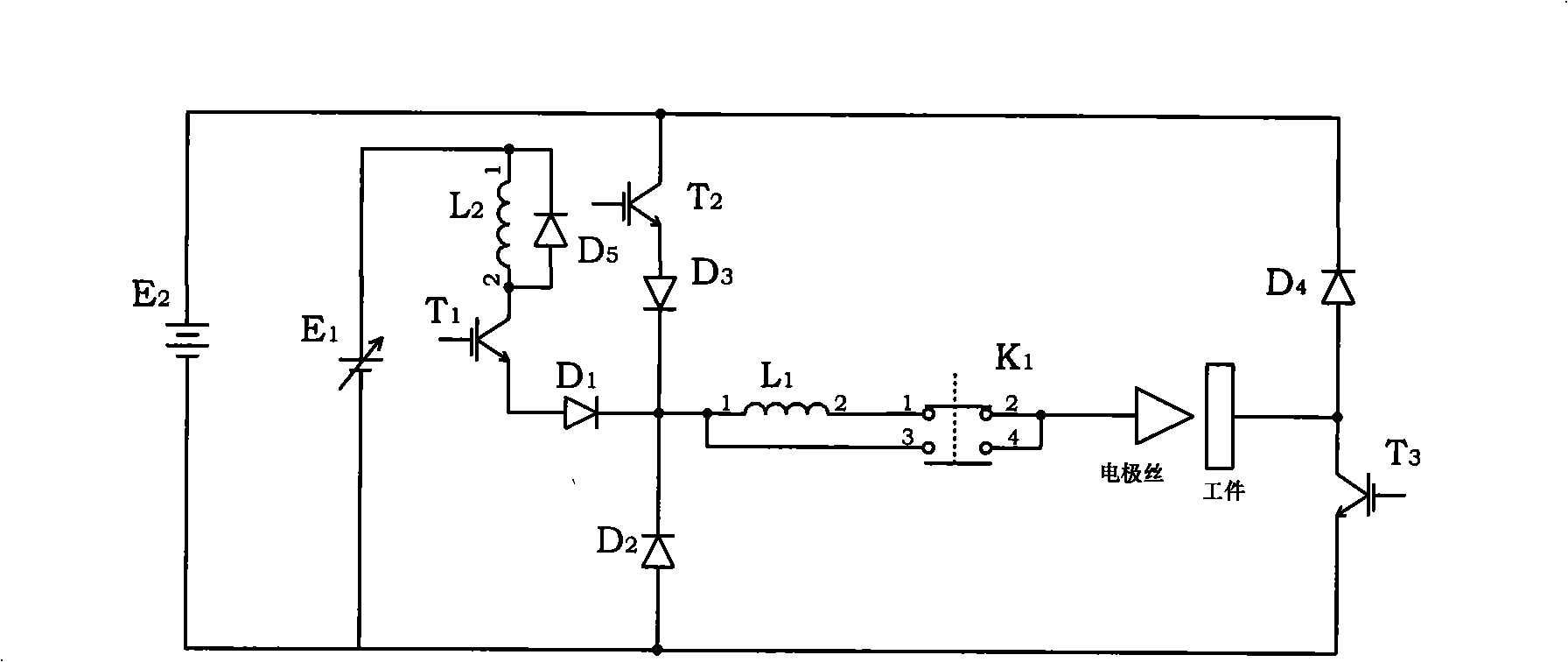

[0023] The present invention is a multi-functional energy-saving pulse power supply with dual power supply mode for numerical control electric discharge wire cutting processing. , high / low voltage DC power supply and power amplification circuit (see figure 1 As shown), the long and no-load processing module and the long and short circuit processing module are arranged between the detection circuit and the main vibration circuit; the main vibration circuit, the drive circuit, and the detection circuit are the conventional circuit structures of the existing CNC wire cutting machine tool.

[0024] The detection circuit is used for real-time online detection of three discharge states of no-load, short circuit and spark in the discharge gap, as well as the no-load duration T d , Short circuit duration T s , spark duration T e ;

[0025] The no-load processing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com