Mechanical-hydraulic composite energy-saving servo hydraulic machine with toggle rod mechanism

A servo hydraulic press and mechanical hydraulic technology, applied in the field of hydraulic presses, can solve problems that hinder the popularization and development of servo presses, high-power servo motors are expensive, increase design difficulty and cost, and achieve reduced power, low calorific value, and low oil consumption. Small amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

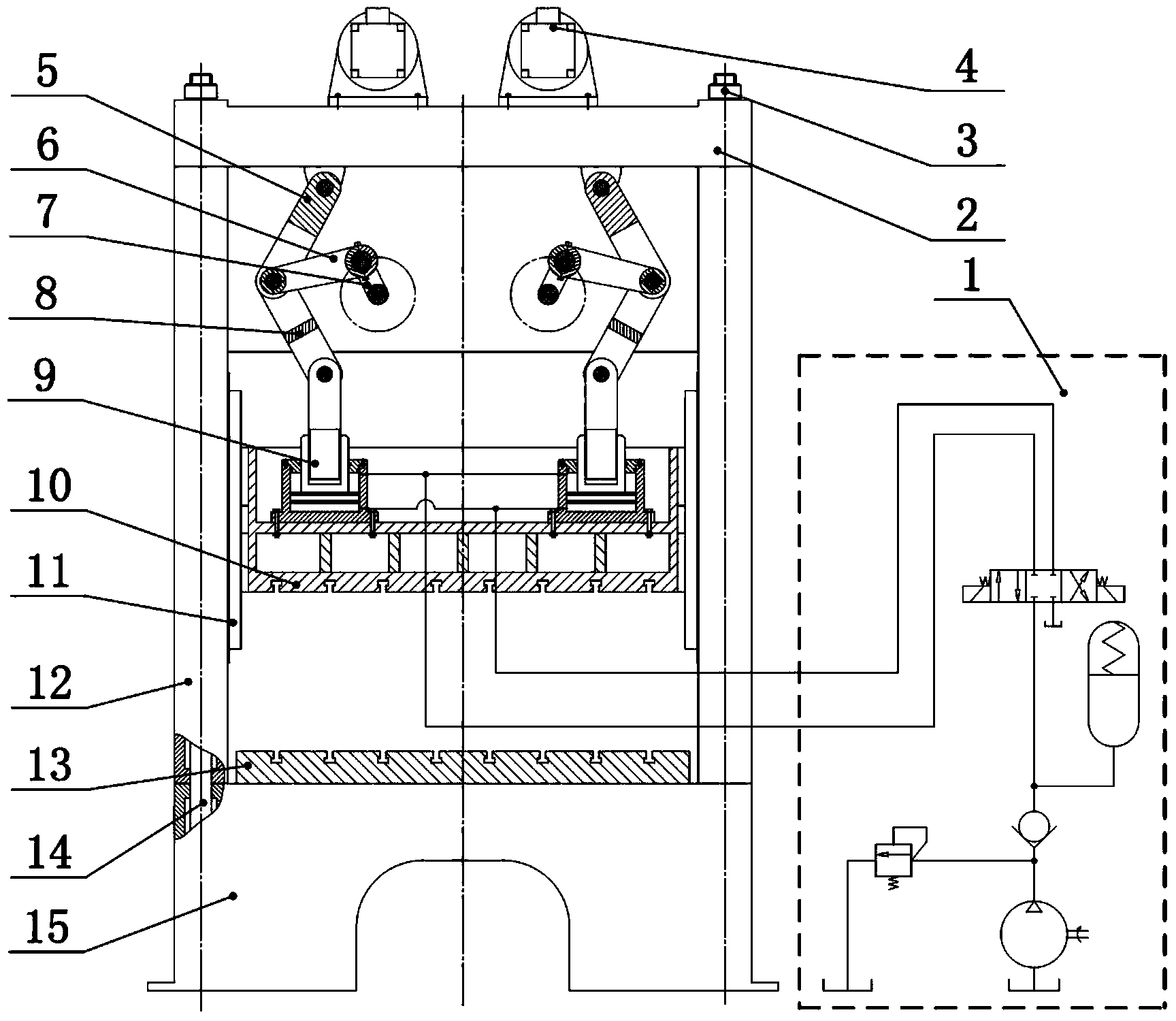

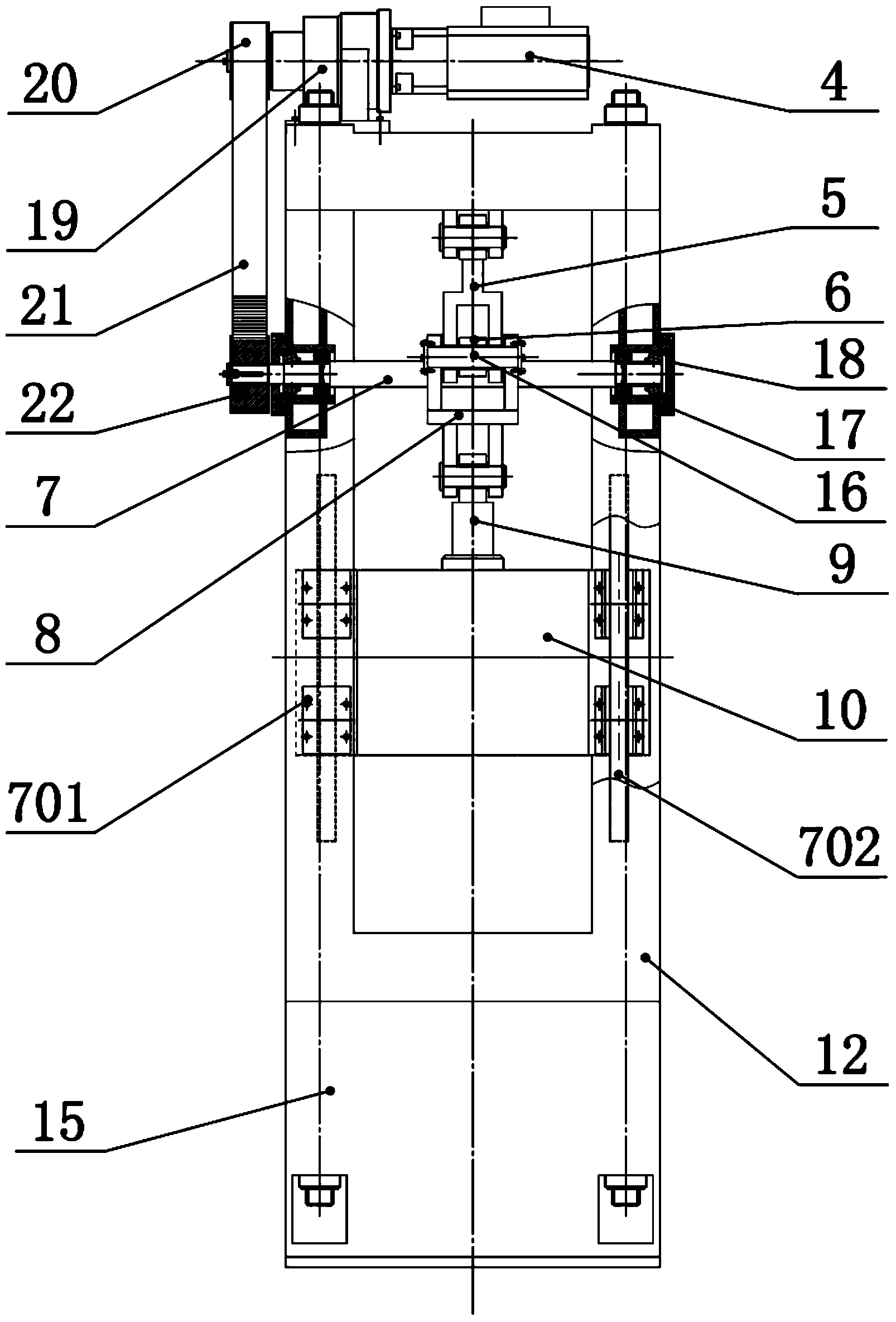

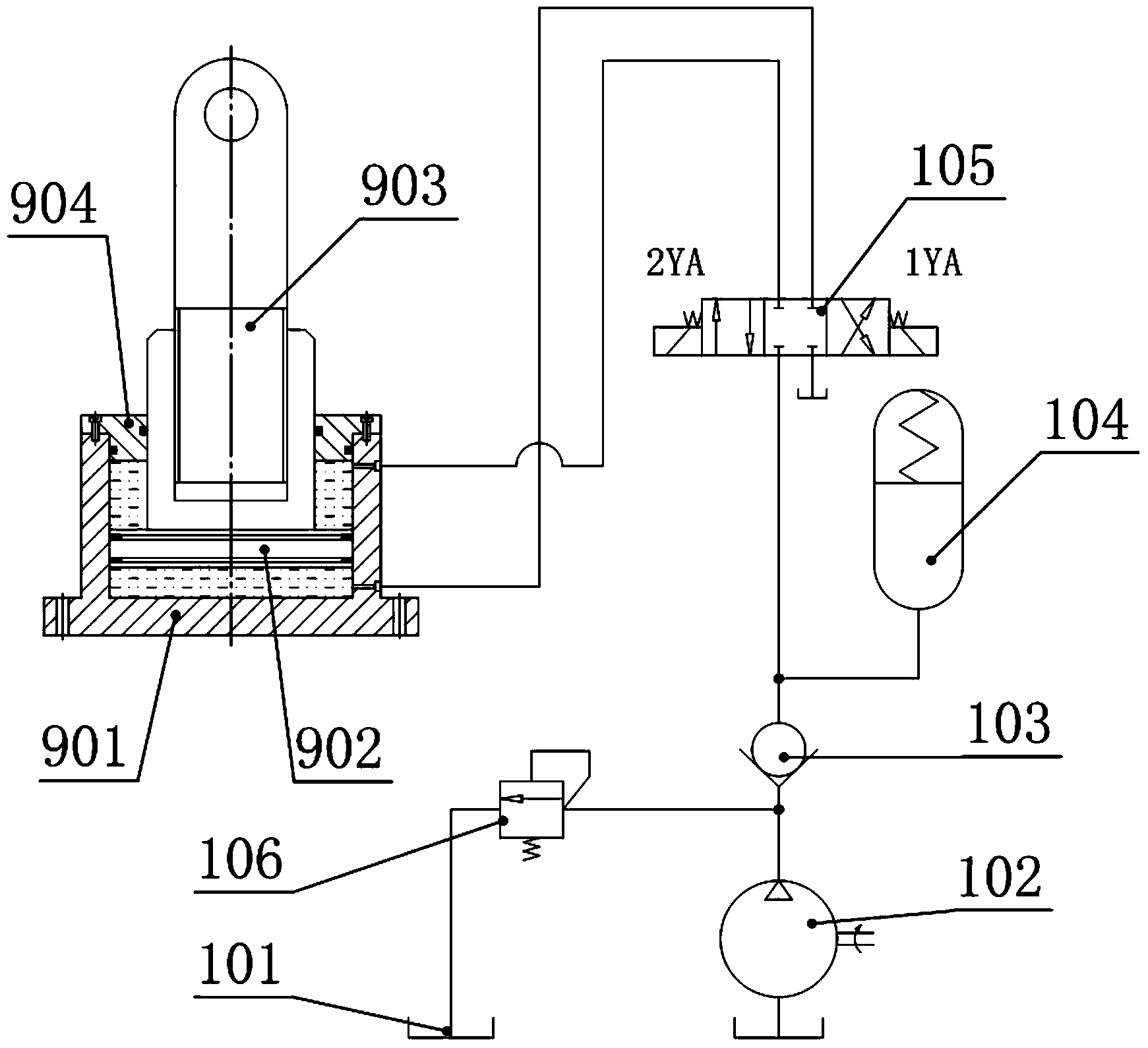

[0020] like figure 1 and figure 2 , a mechanical-hydraulic composite energy-saving servo hydraulic machine with a toggle mechanism, including a worktable 13, the workbench 13 is fixed on the base 15 by bolts, the fuselage structure is in the form of three beams and four columns, and the four columns 12 are hollow, The pull rod 14 passes through the inside of the column 12, the two ends of the pull rod 14 are respectively fixed on the upper beam 2 and the base 15 through the tension nut 3, the column 12 is fixed between the upper beam 2 and the base 15, and the guide rail 11 is fixed on the column 12, The linear guide rail slider 23 is fixed on the outer wall of the press slider 10 by screws, and slides up and down on the guide rail 11; when installing the machine, the pull rod 14 should apply a suitable preload to ensure that the rigidity of the machine body is withi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com