Medlar powder preparing method

A wolfberry and powder technology, which is applied in chemical instruments and methods, solid separation, filtration, etc., can solve the problems of high work intensity, low work efficiency, and the inability to adjust the diameter of wolfberry particles according to needs, and achieve high crushing efficiency and good crushing effect Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

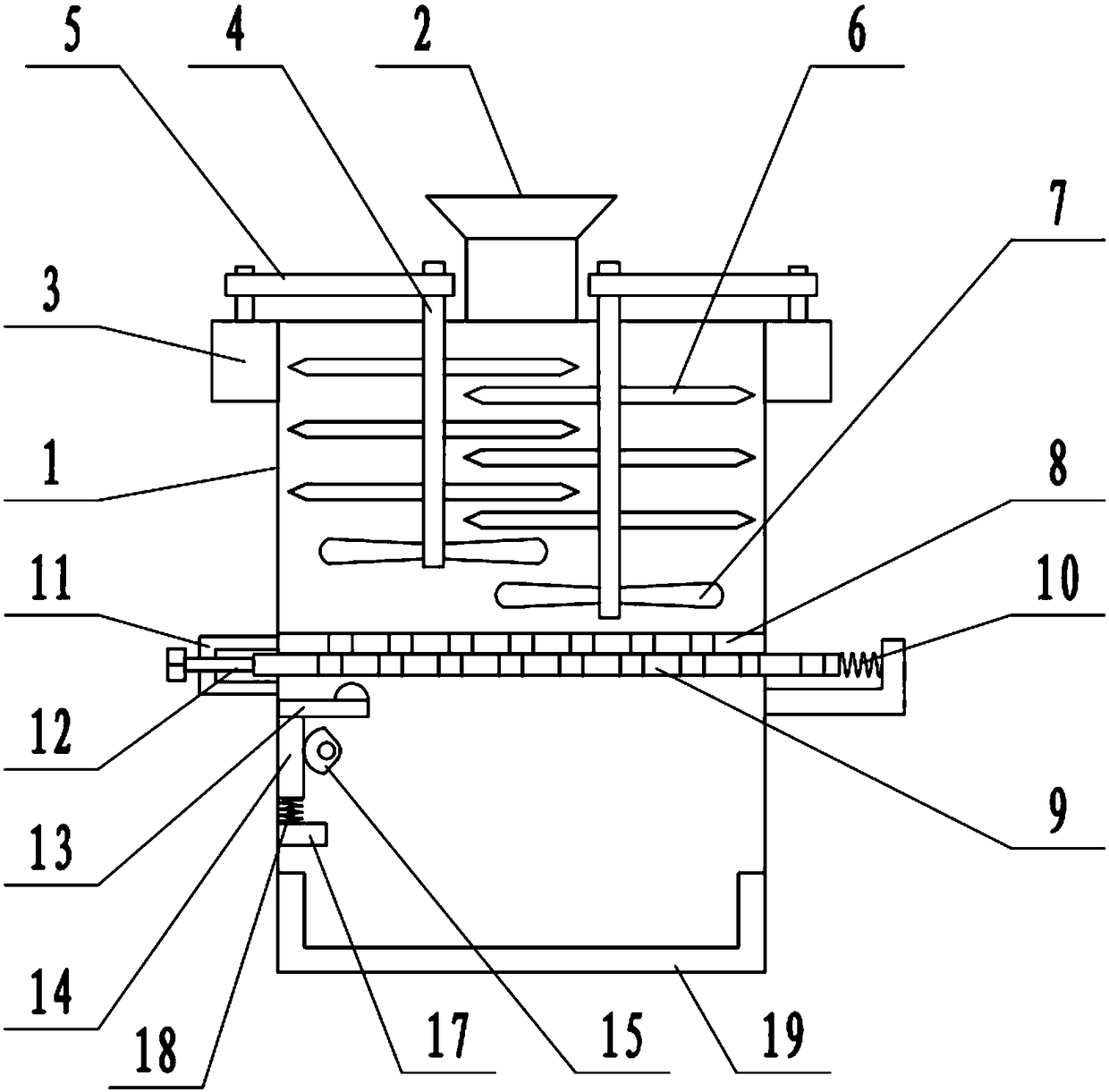

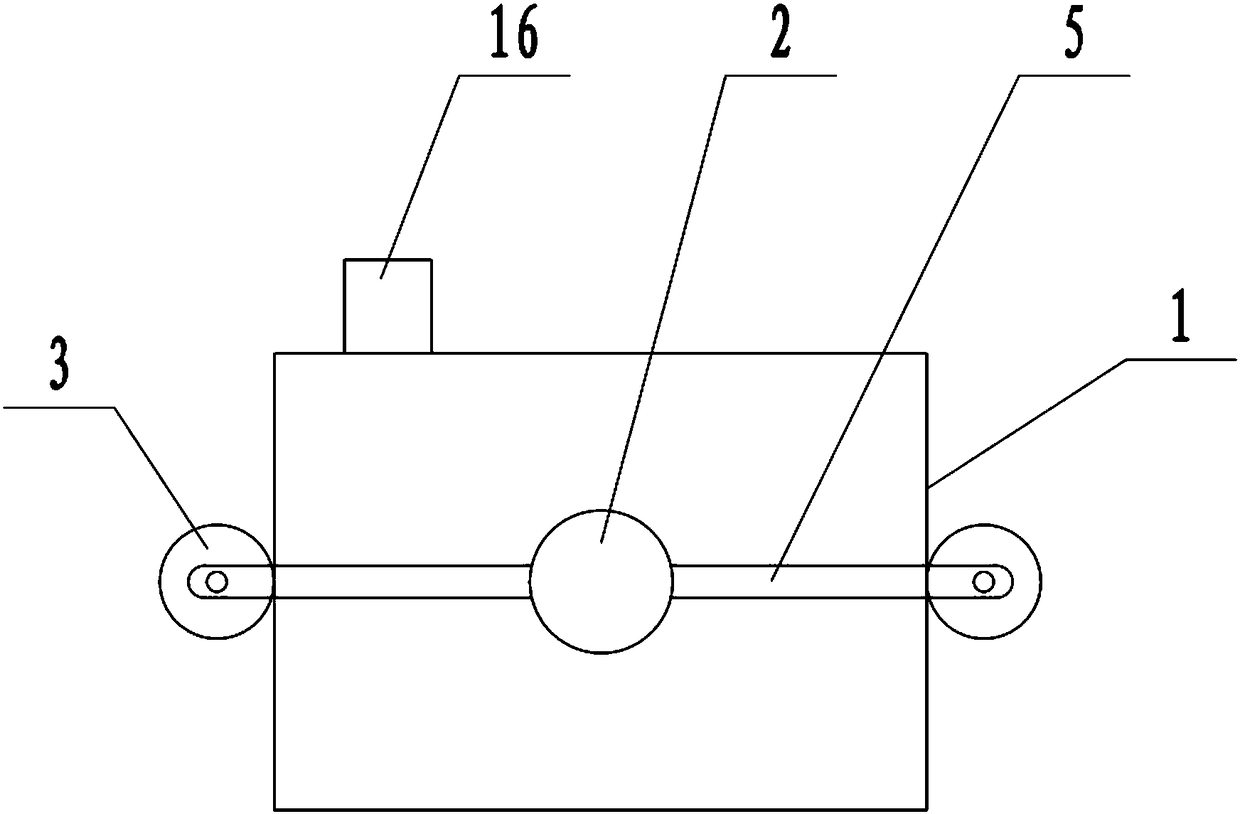

[0016] Example 1: See figure 1 , 2 , a preparation method of wolfberry powder, take wolfberry, use the traditional Chinese medicine pulverizer that regulates particle diameter to pulverize, and the Chinese medicine pulverizer that regulates particle diameter comprises casing 1, feeding port 2, pulverizing motor 3, pulverizing shaft 4, pulverizing blade 6 and The collecting tank 19, the upper surface of the casing 1 is fixedly connected with the feeding port 2, the left and right sides of the casing 1 are respectively fixedly connected with the crushing motor 3, the left and right sides of the feeding port 2 are respectively provided with the crushing shaft 4, and the crushing shaft 4 The lower end passes through the top of the shell 1 and extends into the shell 1. The crushing shaft 4 is rotationally connected with the top of the shell 1. The shaft extension end of the crushing motor 3 is connected with the crushing shaft 4 through the transmission mechanism 5. The transmissio...

Embodiment 2

[0022] Embodiment 2: the impact of different crushing methods on the fineness of wolfberry powder

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com