Coating stirring and mixing device for constructional engineering

A technology of mixing and construction engineering, which is applied in the direction of mixers, mixer accessories, transportation and packaging, etc., can solve the problems of poor mixing effect, difficulty in popularization and application, and inability to meet the needs of actual use, etc., and achieves significant crushing effect and mixing good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

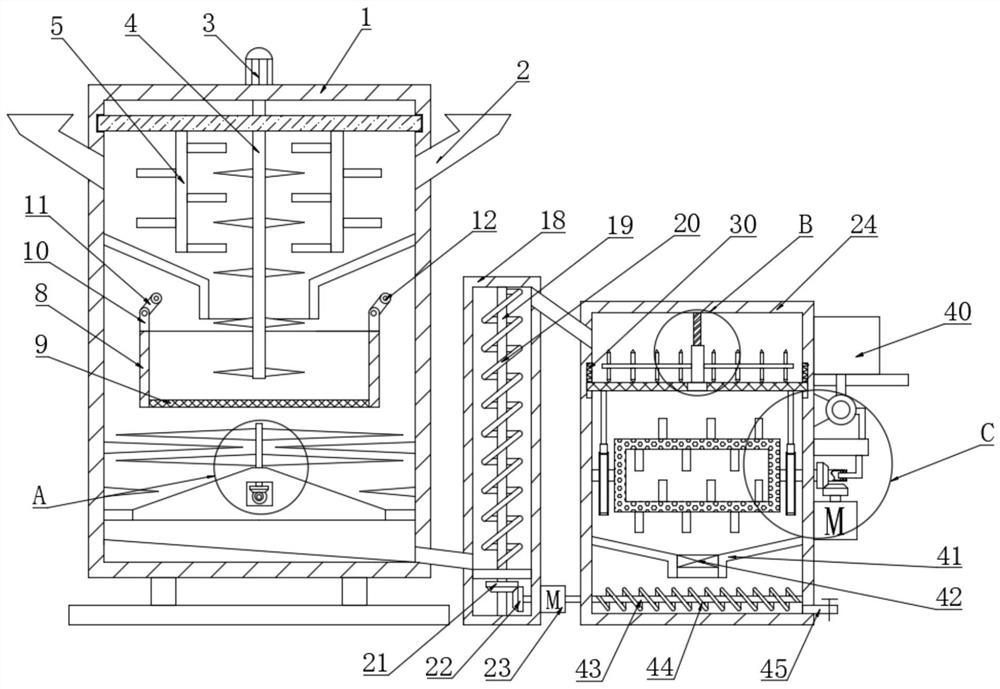

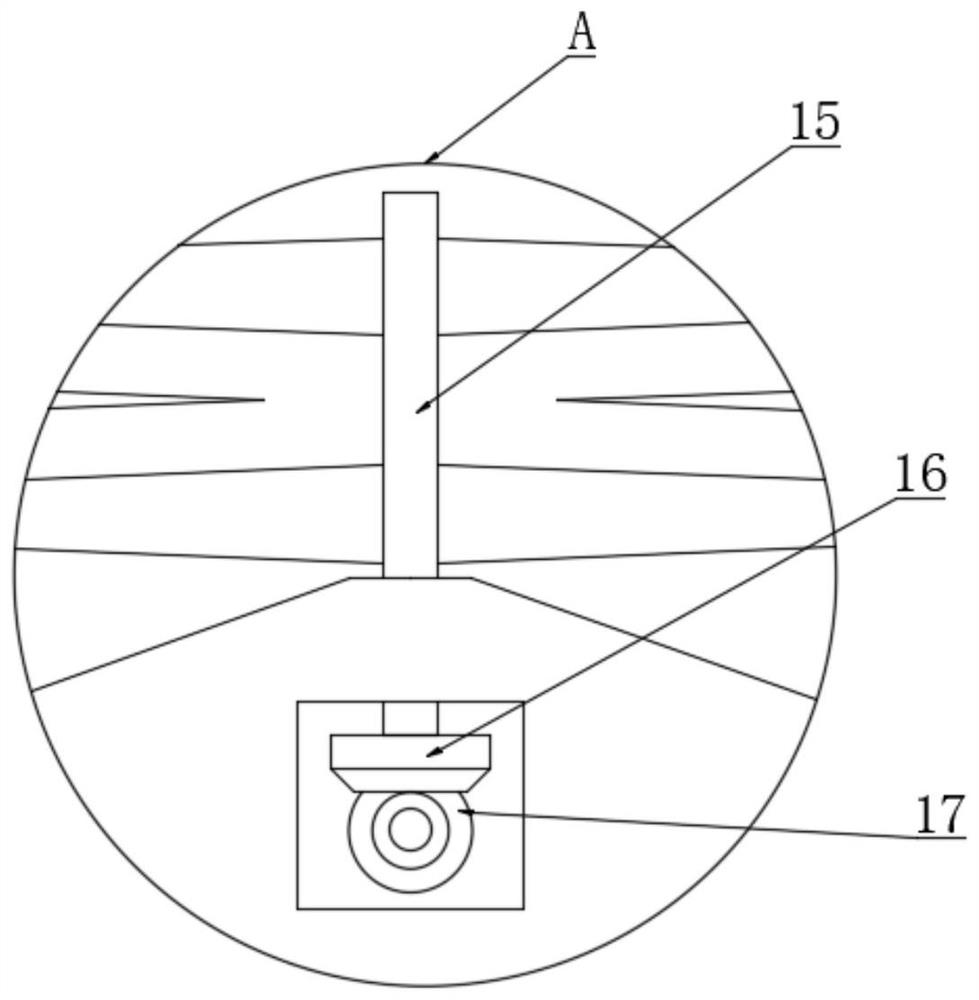

[0030] see Figure 1 to Figure 7, a paint stirring and mixing device for construction engineering, comprising a first box 1, the two ends of the first box 1 are provided with a feed hopper 2 for feeding, and the top of the first box 1 is provided with A first stirring assembly is arranged, and the first stirring assembly comprises a first stirring shaft 4 and a second stirring shaft 5, and several stirring blades are arranged on the first stirring shaft 4 and the second stirring shaft 5, and the first stirring shaft The stirring shaft 4 and the second stirring shaft 5 are connected with a first rotary drive assembly through a first gear 6 and a second gear 7, and the first rotary drive assembly includes a first motor 3, and the bottom of the first stirring assembly is provided with The screen frame 8 and the first screen cloth 9 that are convenient for screening, the screen frame 8 and the first screen cloth 9 are connected with a second rotating drive assembly through a first...

Embodiment 2

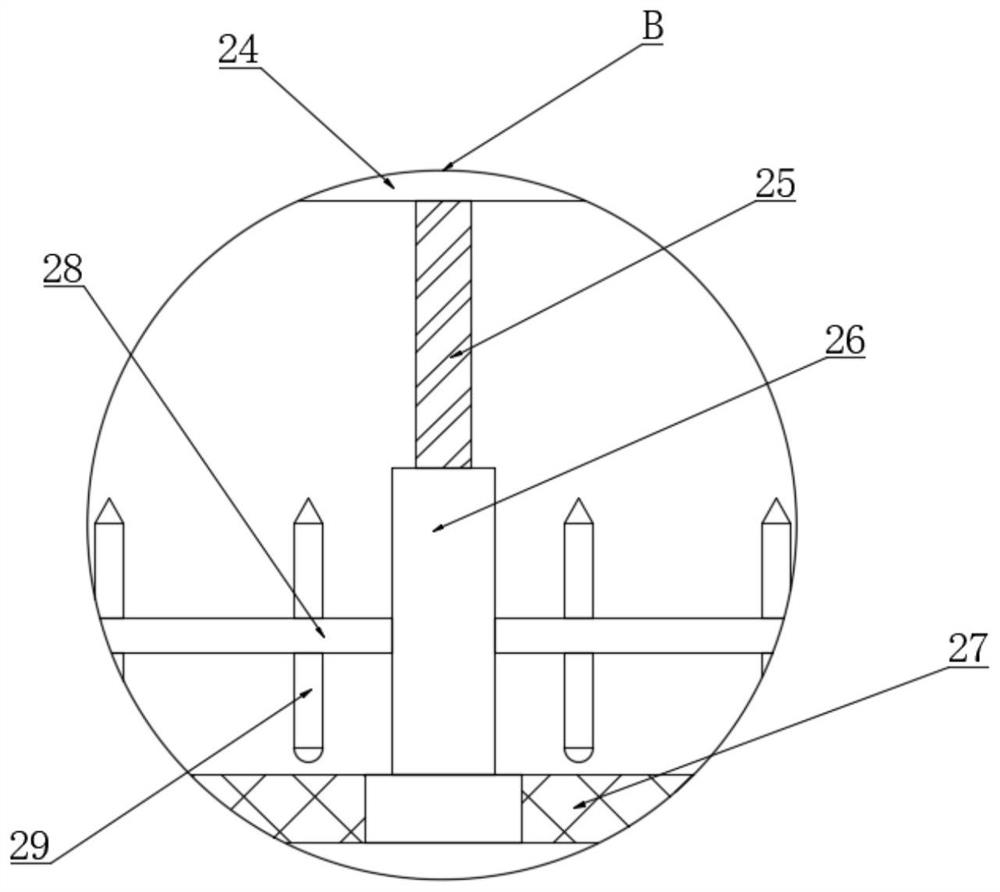

[0038] see Figure 1 to Figure 7 , a paint stirring and mixing device for construction engineering, comprising a first box body 1, a material delivery bin 18 and a second box body 24, the bottom of the first box body 1 is connected with a first material delivery assembly through a pipeline, and the The first feeding assembly includes a feeding bin 18, a first feeding shaft 19 and a first dragon blade 20, the feeding bin 18 communicates with a second box body 24 through a pipeline, and the second box body 24 is provided with Screening and grinding assembly, the screening and grinding assembly includes a second screen 27, a fixed screw 25, a threaded sleeve 26, a grinding rod 29, a spring 30, a fixed rod 31 and a cam 32, and the threaded sleeve 26 is threadedly connected to On the fixed screw rod 25, the threaded sleeve 26 is rotatably connected to the second screen 27 through a bearing, and a stirring frame 33 and a hollow tube 34 for easy stirring are arranged below the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com