Grinder for tomato crushing

A technology for crushing and grinding tomatoes, which is applied in the field of tomato crushing and grinding machines, which can solve the problems of tomato waste, tomato pulp residue, and low tomato utilization efficiency, and achieve the effects of improving fineness, good crushing effect, and increasing the area of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

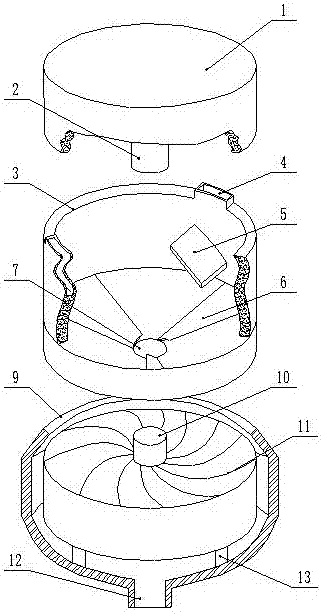

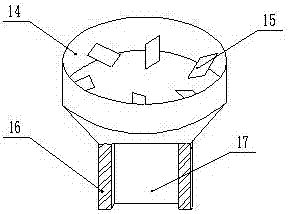

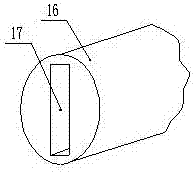

[0017] Description of reference numerals: air supply box 1, first air knife 2, crushing cylinder 3, air inlet 4, second air knife 5, fan plate 6, grinding channel 7, shaft hole 8, collecting box 9, positioning shaft 10. Grinding pattern 11, discharge port 12, connecting column 13, cone 14, blade 15, knife column 16, knife edge 17.

[0018] Such as figure 1 The shown tomato crushing and grinding machine includes an air supply box 1, a crushing cylinder 3, an upper millstone, a lower millstone and a collection box 9. The air supply box 1 is equipped with compressed air with a pressure of 2 to 4Mpa. The bottom surface of the air supply box 1 The first air knife 2 is installed in rotation at the center, such as figure 2 and image 3 As shown, the first air knife 2 is mainly divided into a cone cylinder 14 and a knife column 16. The inner wall of the cone cylinder 14 is welded with 6 blades 15 inclined towards the same direction. The inclination angle of the blades 15 is 30°. H...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com