Patents

Literature

159results about How to "Good crushing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

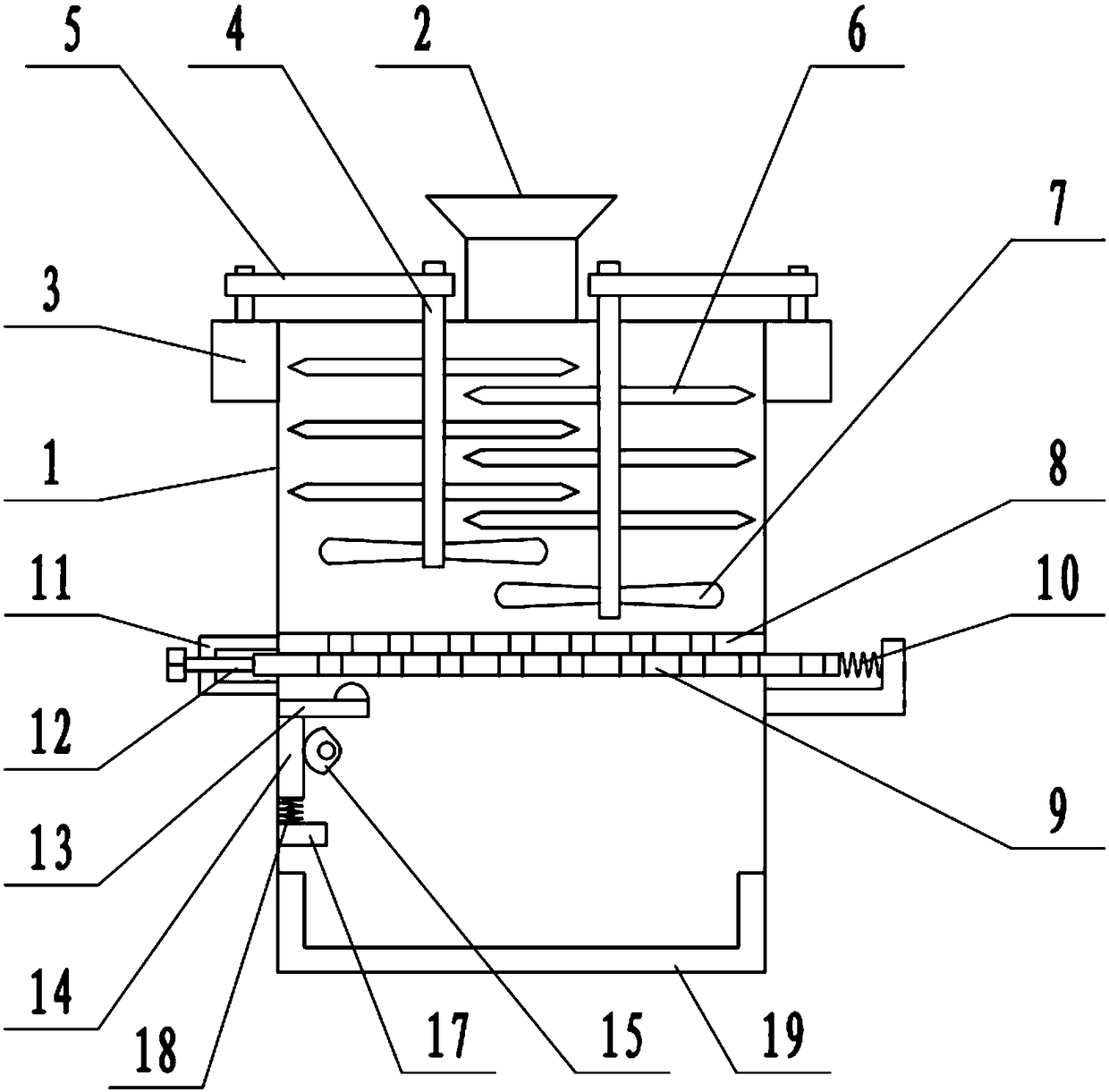

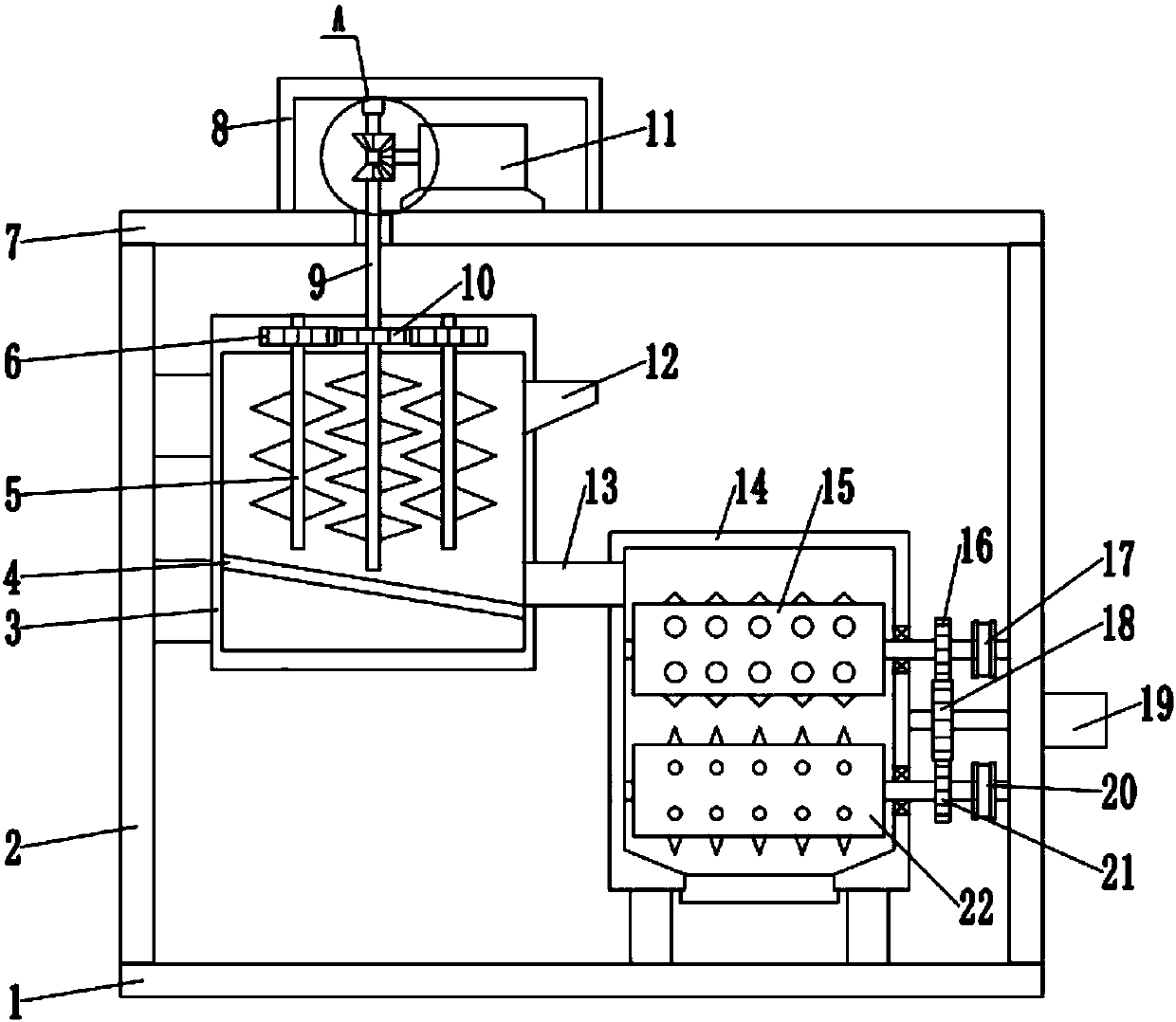

Medical waste garbage treatment equipment with disinfection function

InactiveCN107138255APrevent diseaseGood crushing effectMedical waste disposalGrain treatmentsDisinfectantResistance wire

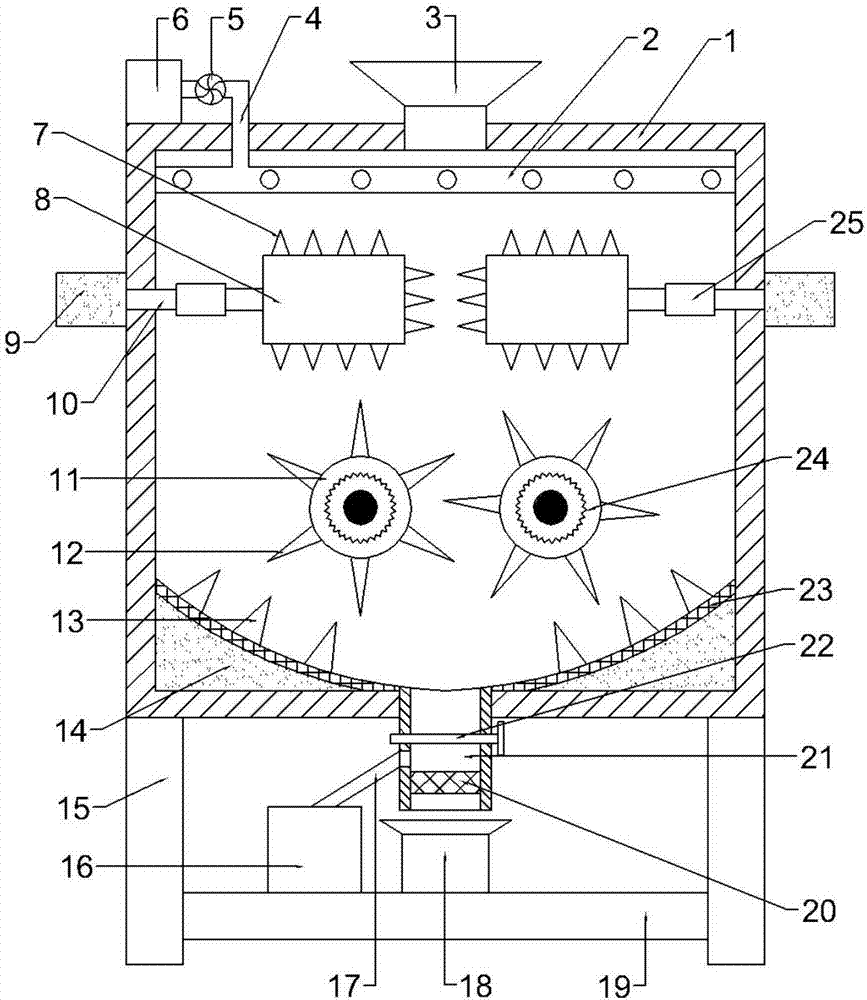

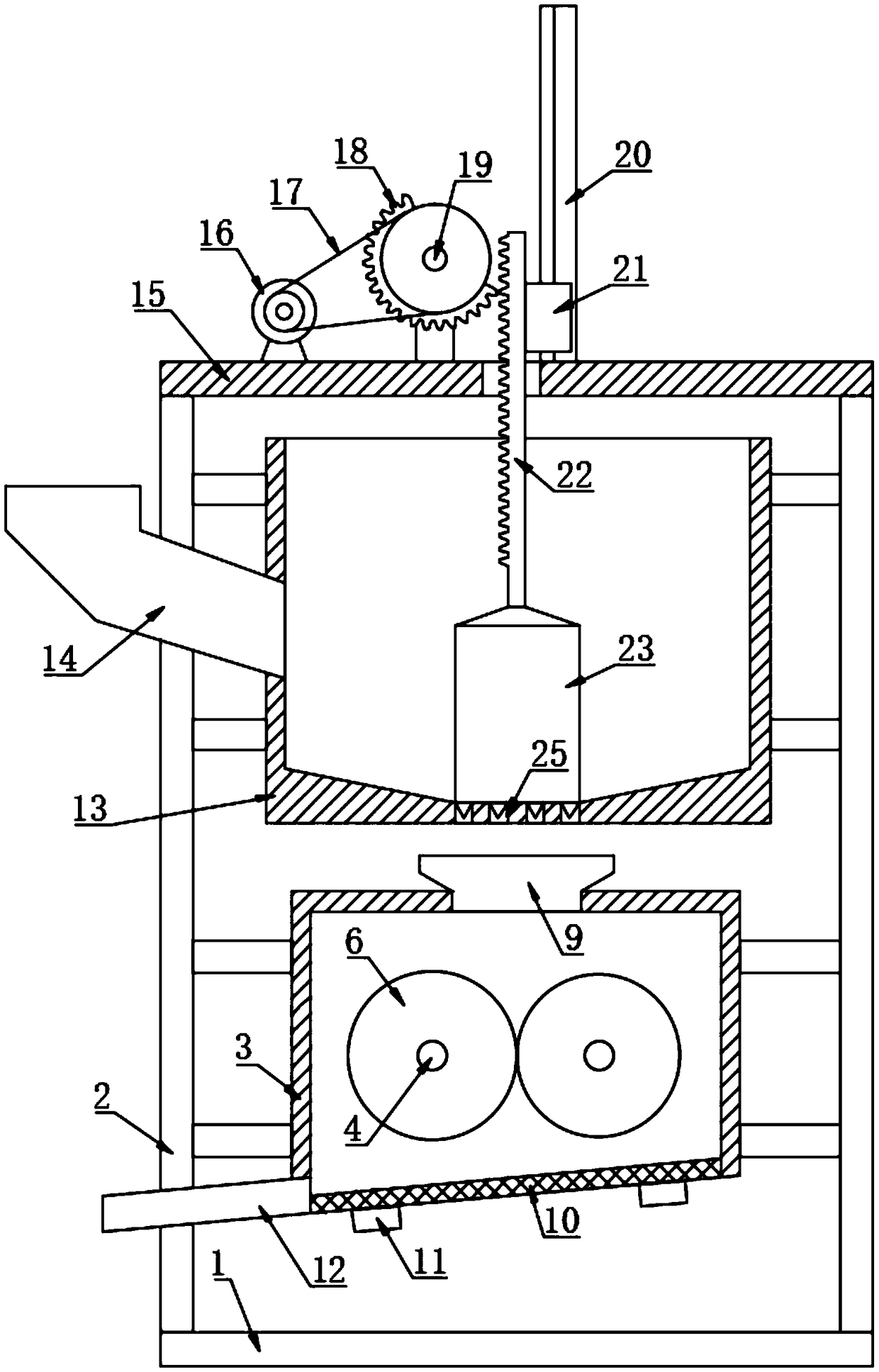

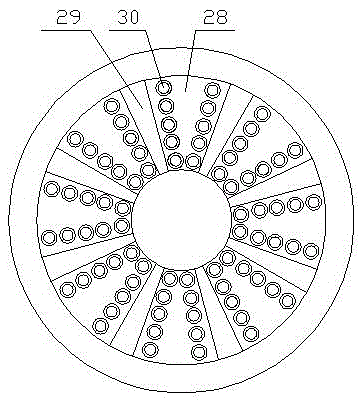

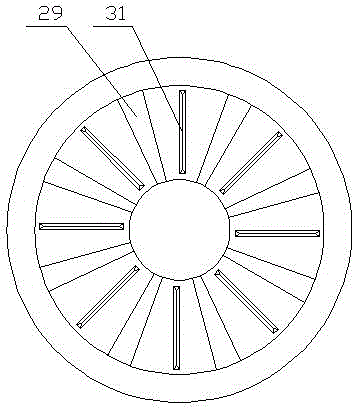

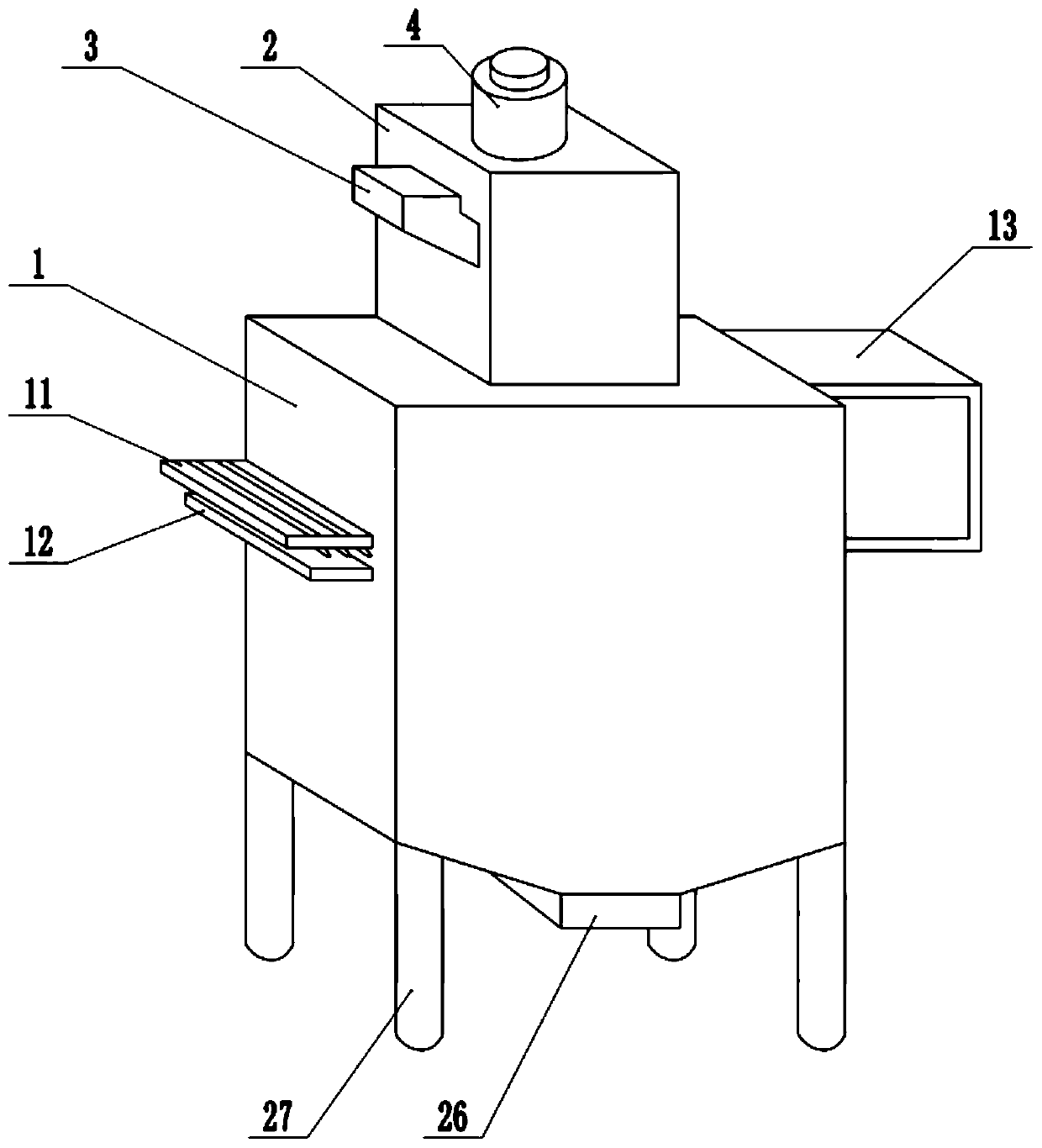

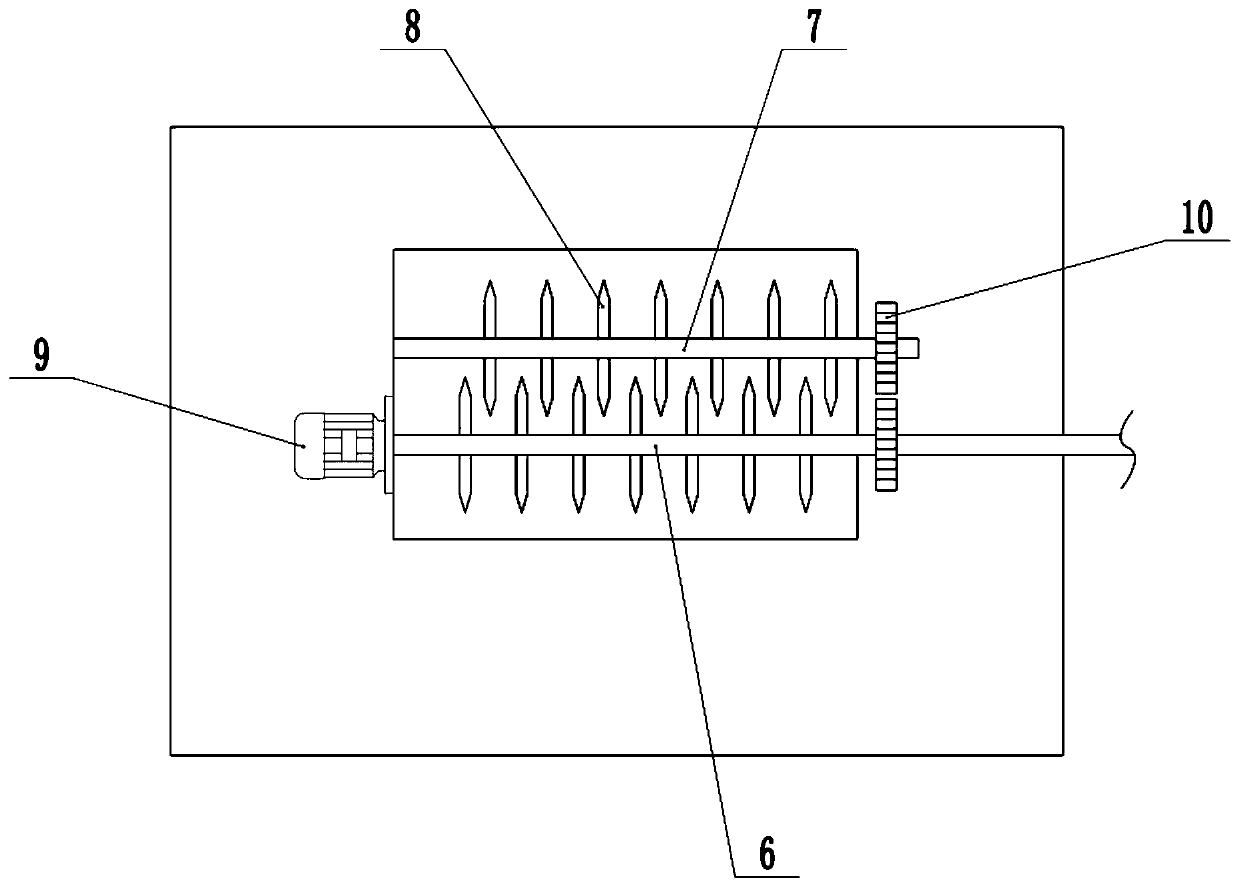

The invention discloses medical waste garbage treatment equipment with a disinfection function. The medical waste garbage treatment equipment comprises a housing, supporting legs arranged at the lower side of the housing and a placing plate arranged between the supporting legs, wherein a disinfectant distributing device is arranged on the top in the housing; the disinfectant distributing device communicates with a disinfectant box positioned above the housing through a liquid inlet tube; two rotary shafts are symmetrically arranged below the disinfectant distributing device; inner ends of the two rotary shafts are fixedly connected with electric pushing rods; rotary rollers are fixedly connected on free ends of the electric pushing rods; a plurality of pulverizing teeth are uniformly distributed on the surfaces of the rotary rollers; two pulverizing rollers are symmetrically arranged below the rotary rollers; a plurality of first pulverizing blades are uniformly distributed on the pulverizing rollers; a plurality of second pulverizing blades are arranged on the inner side wall of the housing and the inner bottom of the housing; and heating resistance wires are distributed in the pulverizing rollers. The medical waste garbage treatment equipment has the advantages of a reasonable structural design, simple and convenient operation, good pulverizing effect and the like, and has certain popularization and application value.

Owner:郑州永泰澳新商贸有限公司

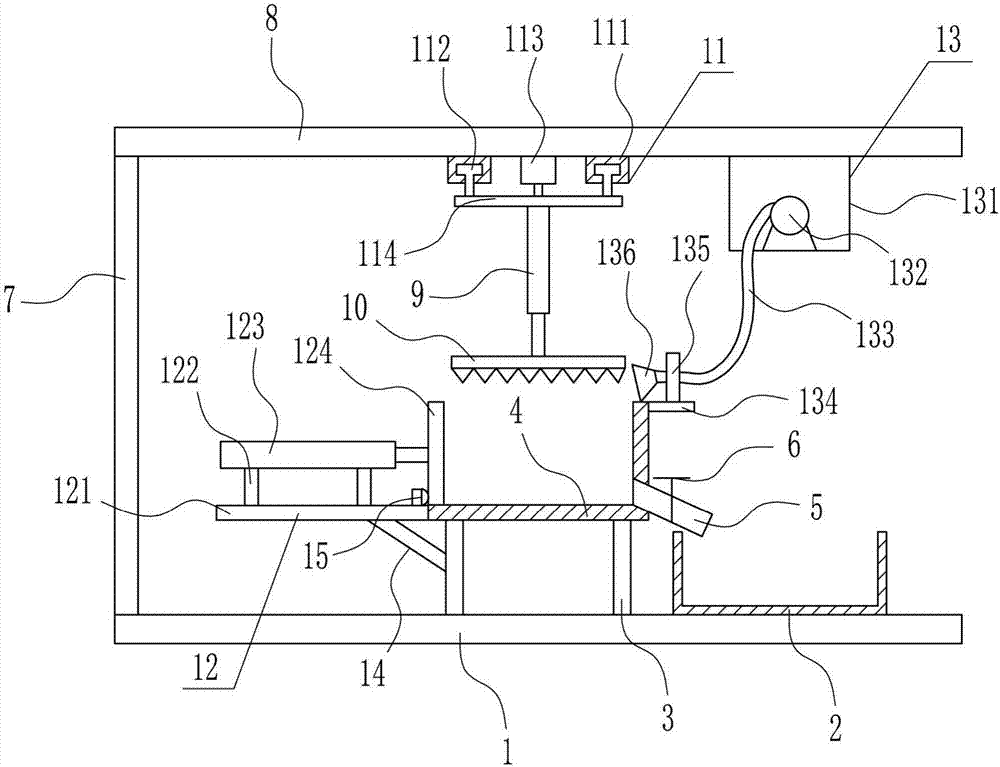

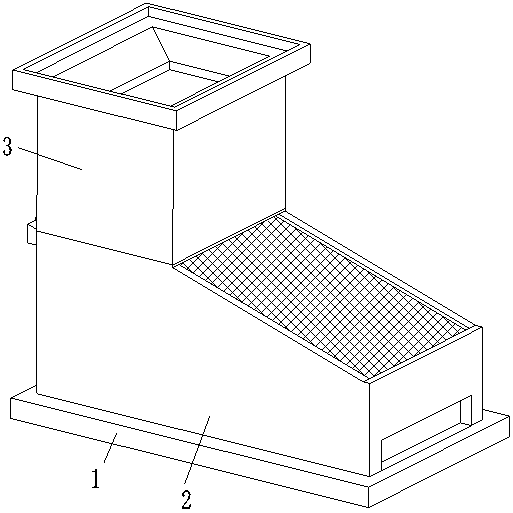

Ore breaking device for smelting

InactiveCN107138211ABroken comprehensiveGood crushing effectDirt cleaningGrain treatmentsEngineeringSmelting

The invention relates to an ore breaking device for smelting, in particular to an ore breaking device for the smelting, so as to achieves the effects that the ore breaking device for the smelting is easy and simple to operate and uniform in breaking, and thus the smelting effect during ore smelting is improved without affecting the quality after the smelting. The ore breaking device for the smelting comprises a bottom plate, a collection frame, support rods, a breaking frame, a discharge pipe, a valve, a support plate, a top plate, a first air cylinder and the like; the support rods are symmetrically arranged in the top middle of the bottom plate in a bolted connection manner; the top ends of the support rods are in bolted connection with the breaking frame; the lower part of the right side of the breaking frame is connected with the discharge pipe; and the discharge pipe communicates with the interior of the breaking frame, and is arranged obliquely. The ore breaking device achieves the effects that the ore breaking device is easy and simple to operate and uniform in breaking, and thus the smelting effect during ore smelting is improved without affecting the quality after the smelting.

Owner:雷海涛

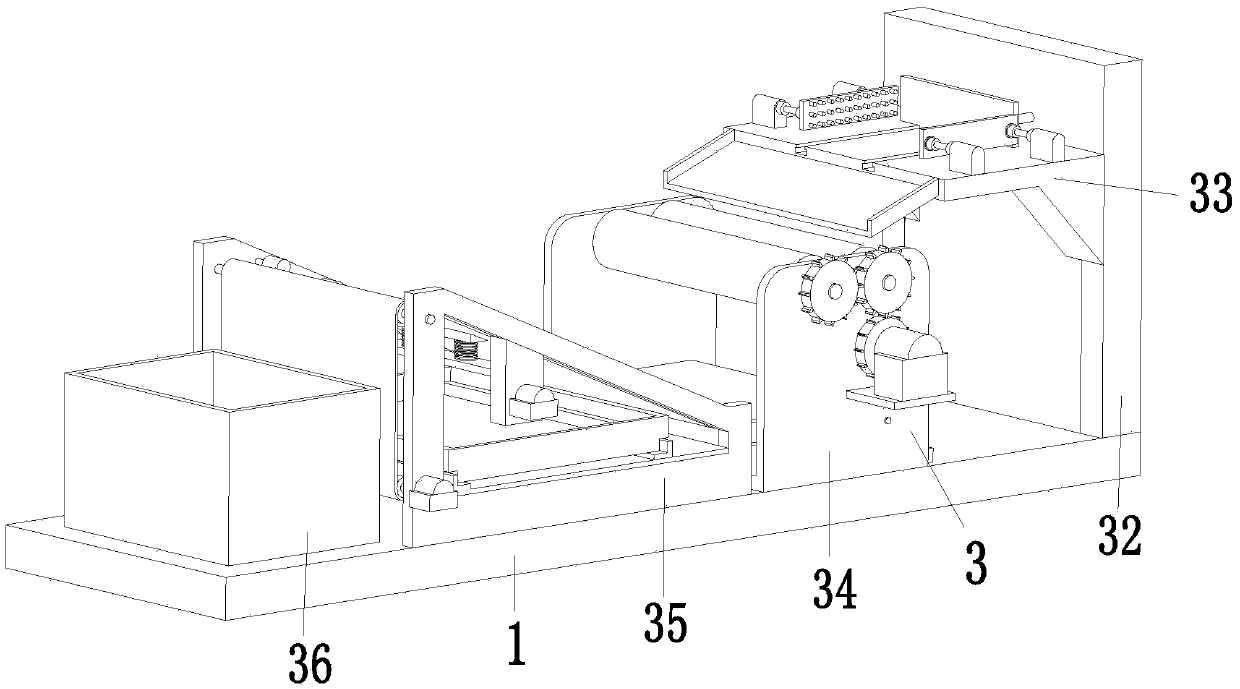

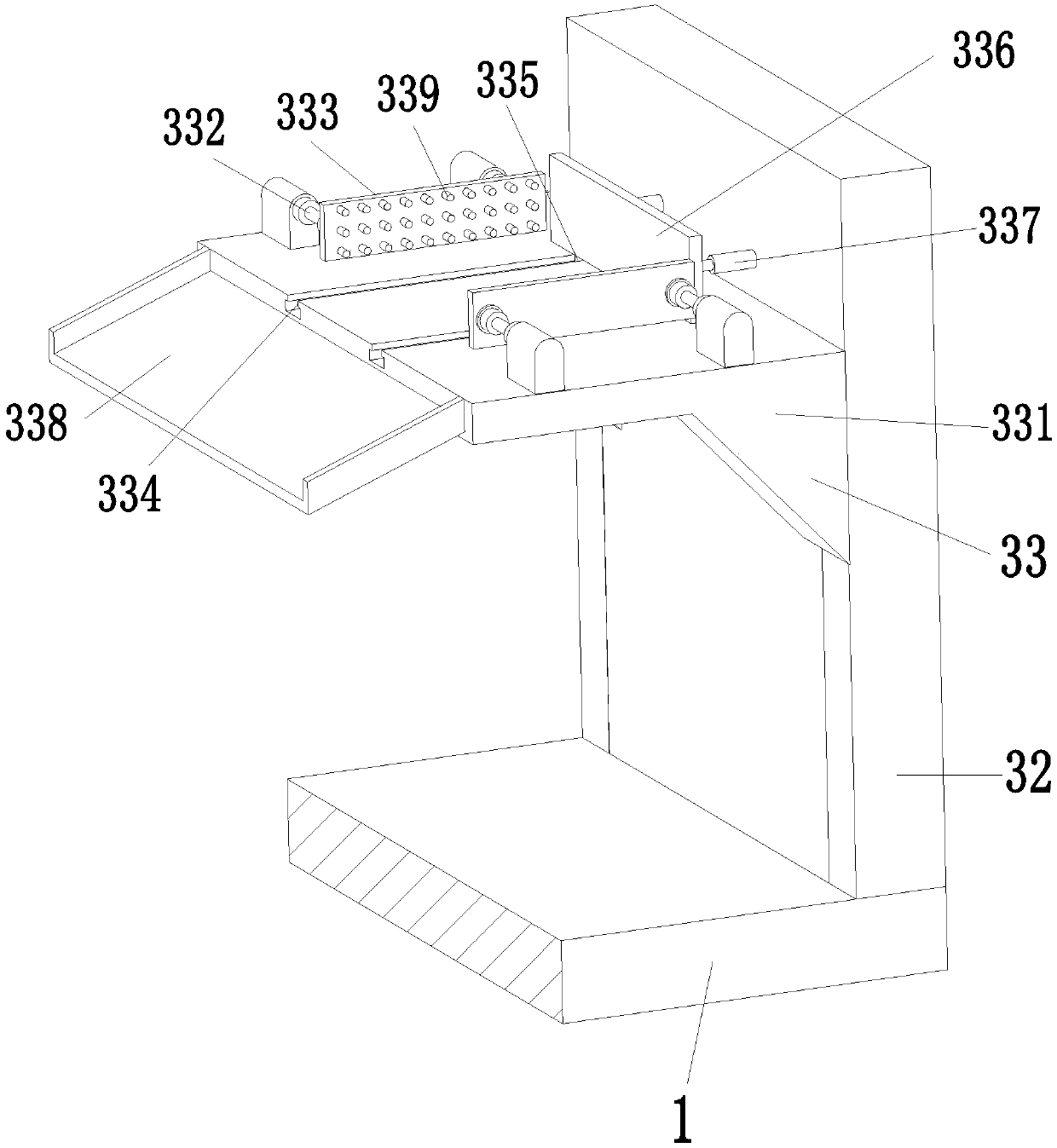

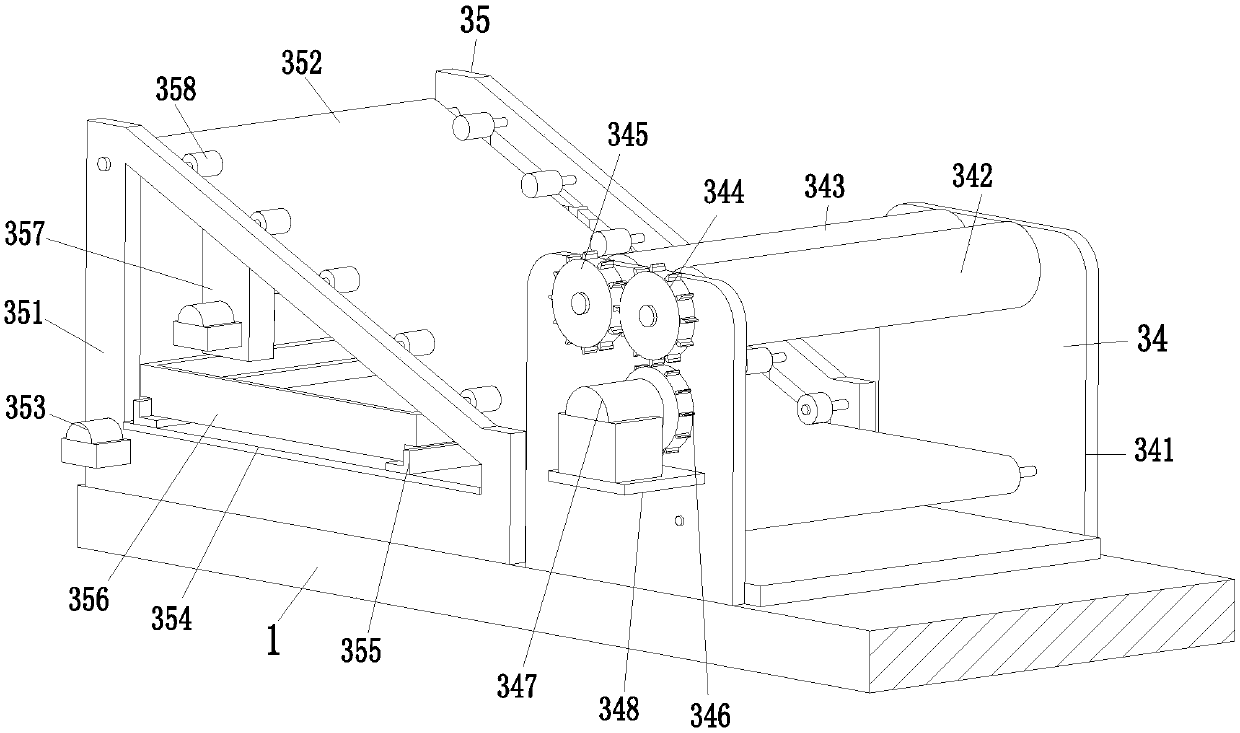

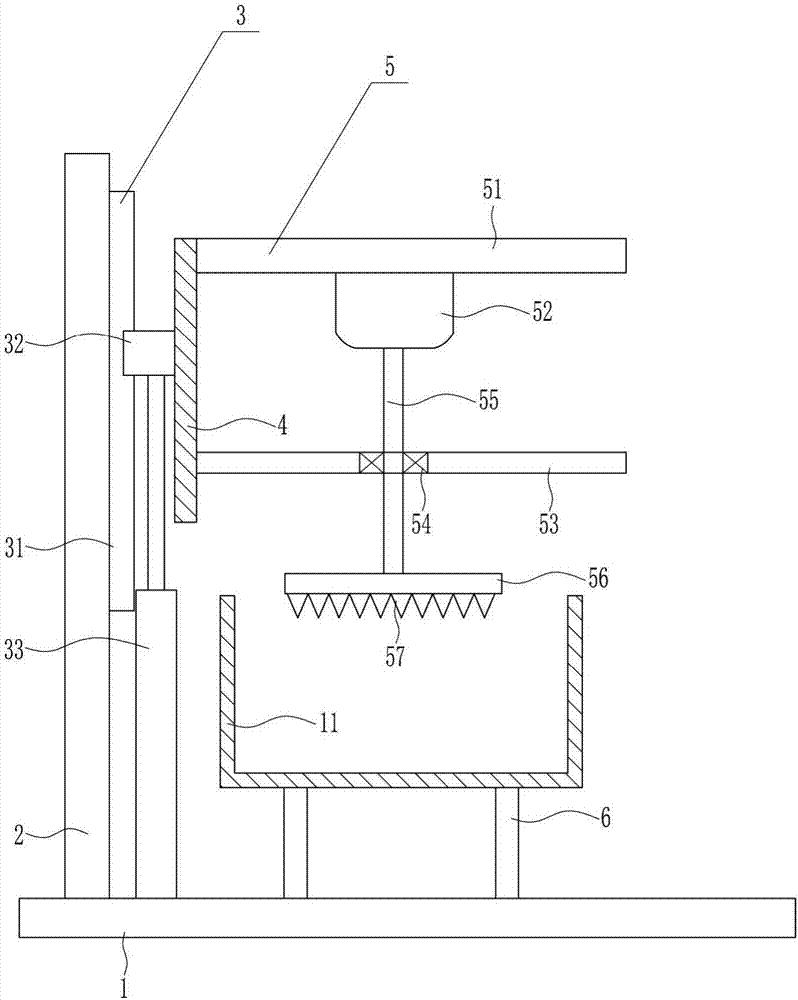

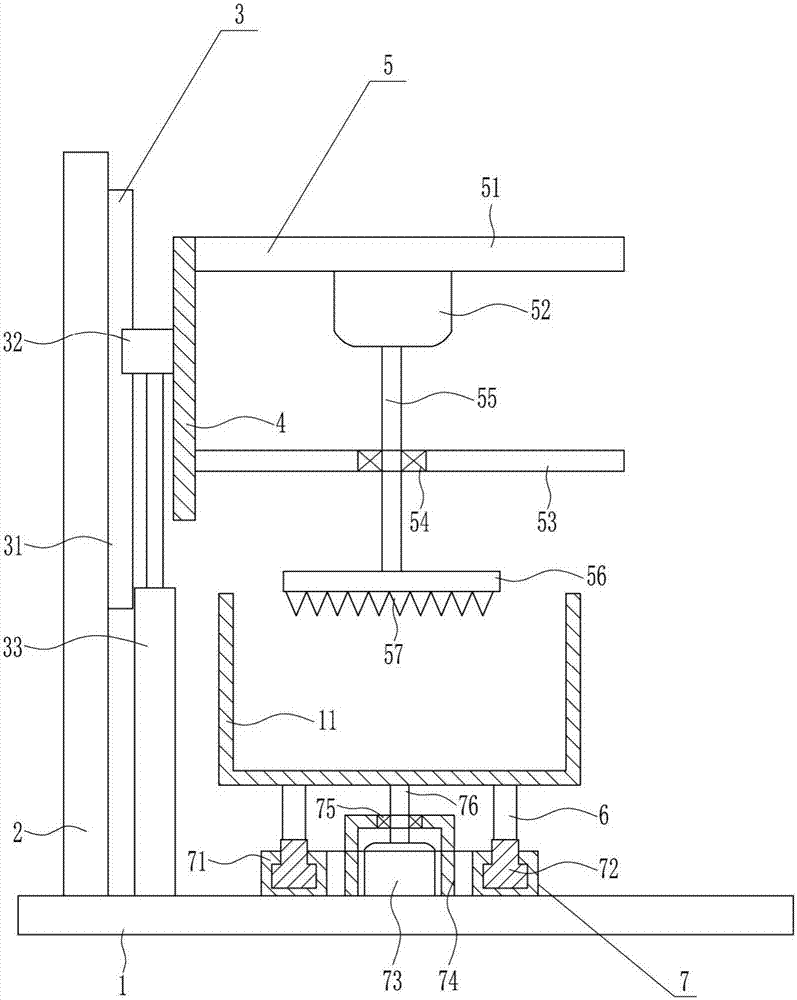

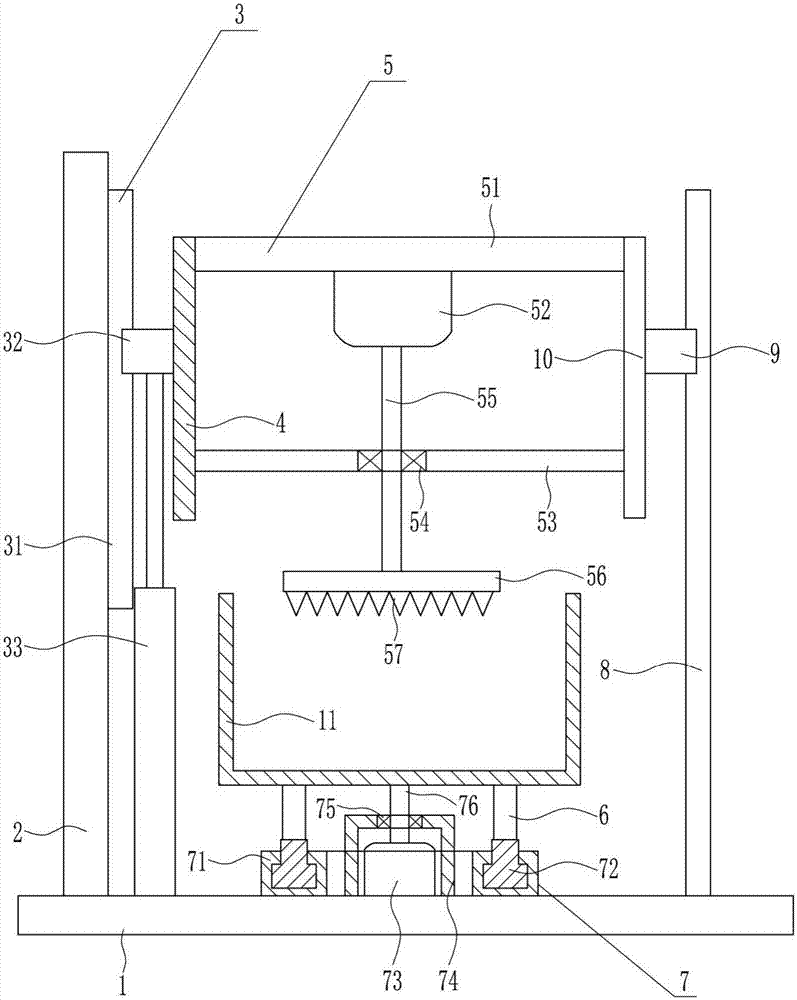

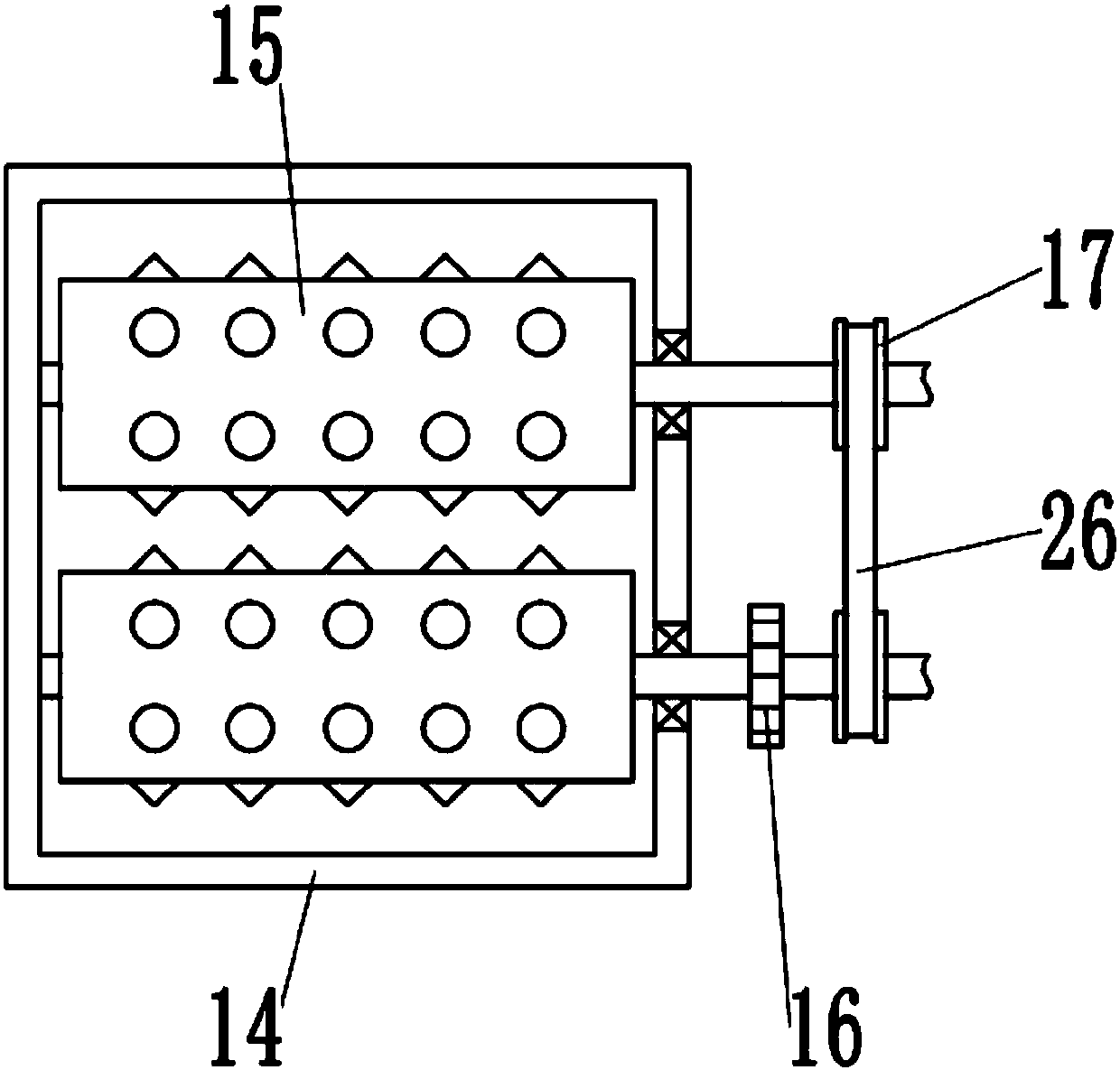

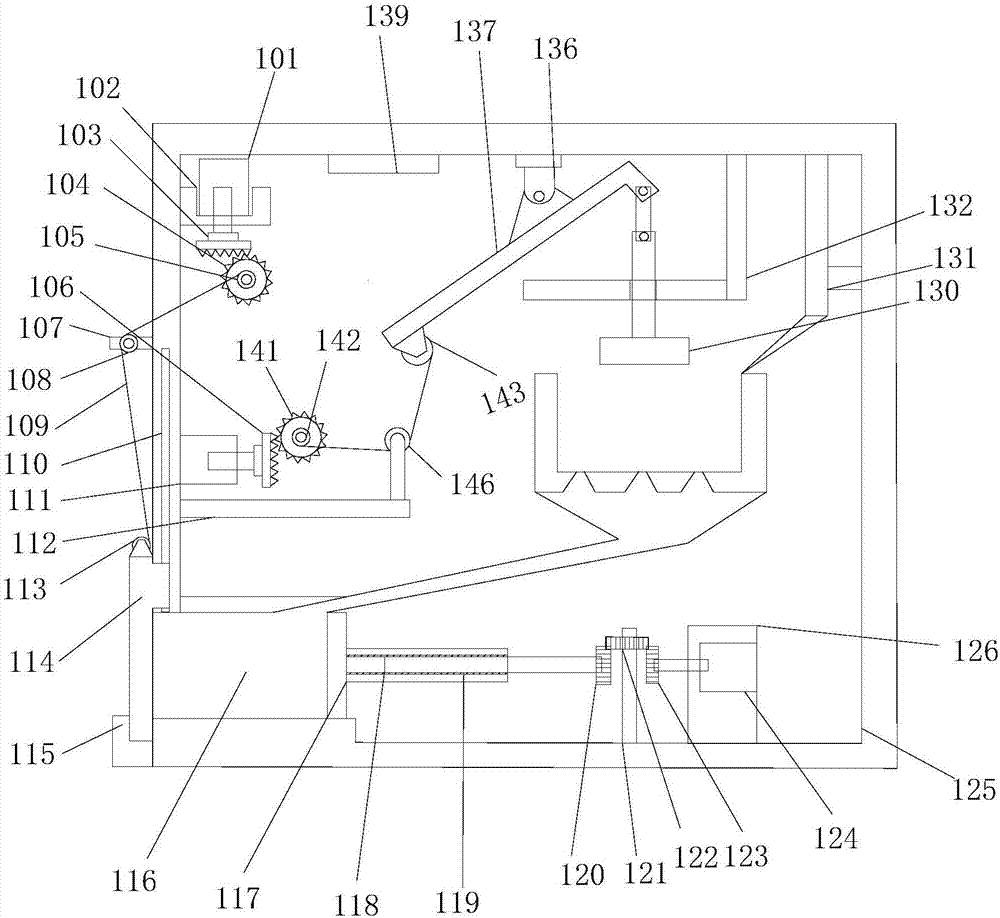

Steel slag breaking sorting reuse system for iron and steel smelting processes

ActiveCN109248728AGood crushing effectReduce manual labor intensitySievingScreeningBuilding materialSmelting process

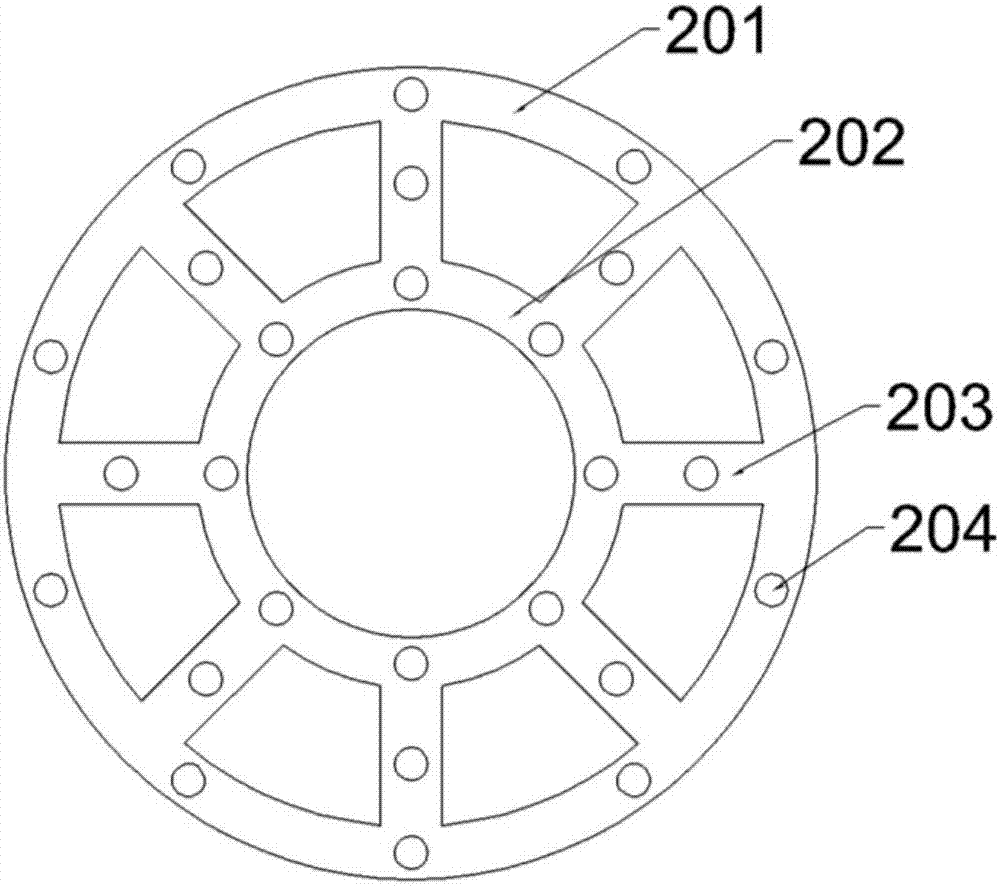

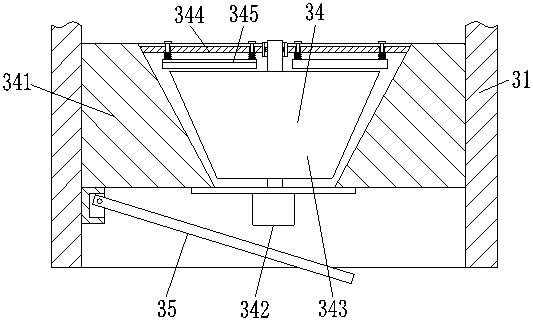

The invention relates to a steel slag breaking sorting reuse system for iron and steel smelting processes. The steel slag breaking sorting reuse system comprises a bottom plate and a breaking device,wherein the upper end of the bottom plate is provided with the breaking device. In the prior art, when the building material is prepared from the existing waste steel slag, the breaking of the existing waste steel slag by the breaking device has disadvantages of poor breaking effect and low efficiency, and the manual screening performed after the breaking has disadvantages of low screening efficiency, high hazard, high labor intensity, complicated operation, low working efficiency and the like. According to the present invention, the steel slag breaking sorting reuse system can solve the problems in the prior art, can automatically break and sort tailings slag, can break steel slag to achieve a uniform particle size, has good breaking effect, can automatically screen steel slag after the breaking so as to reduce the labor intensity and avoid the harm to the worker body, and further has advantages of low labor intensity, simple operation, high work efficiency and the like.

Owner:广西柳钢环保股份有限公司

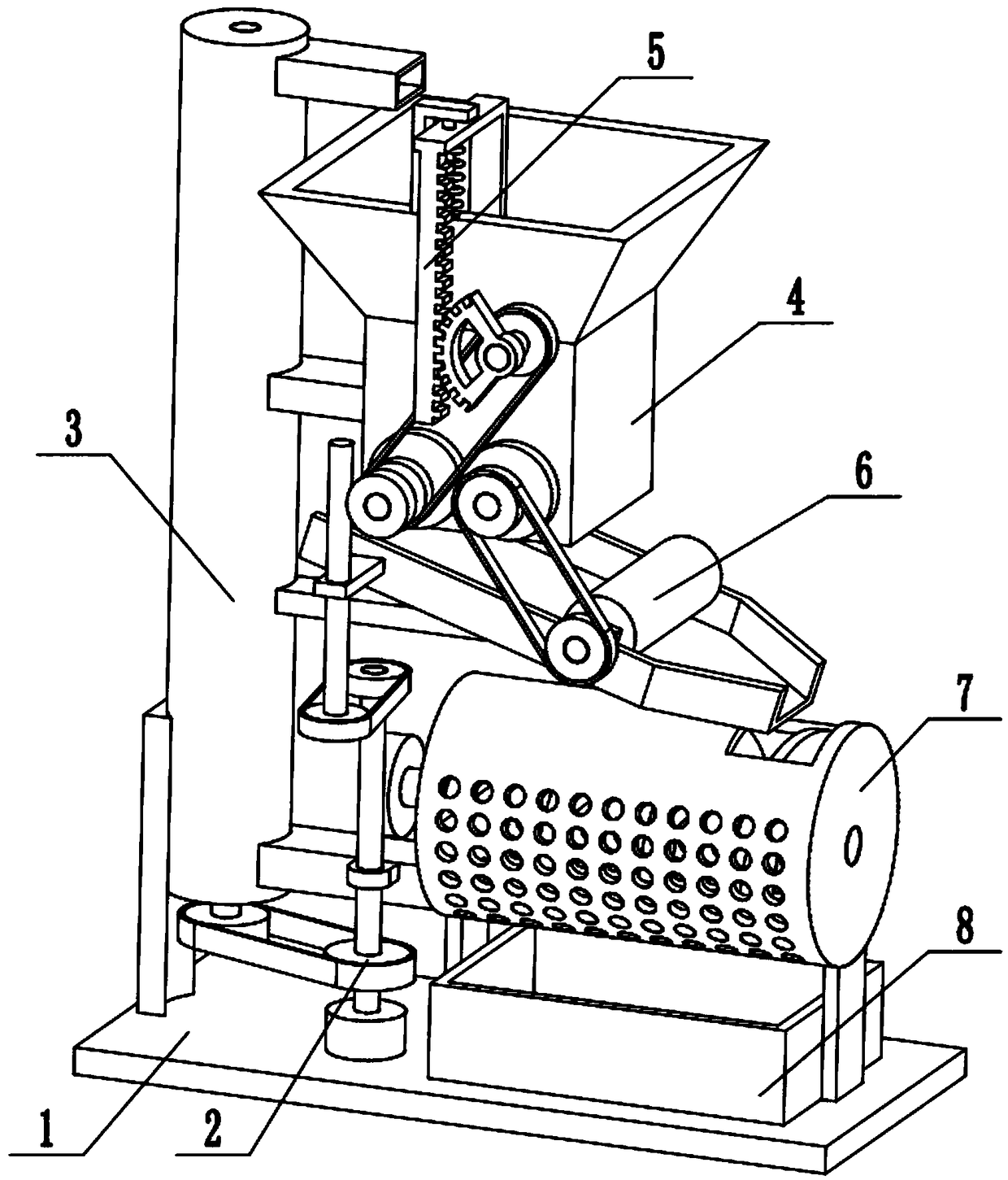

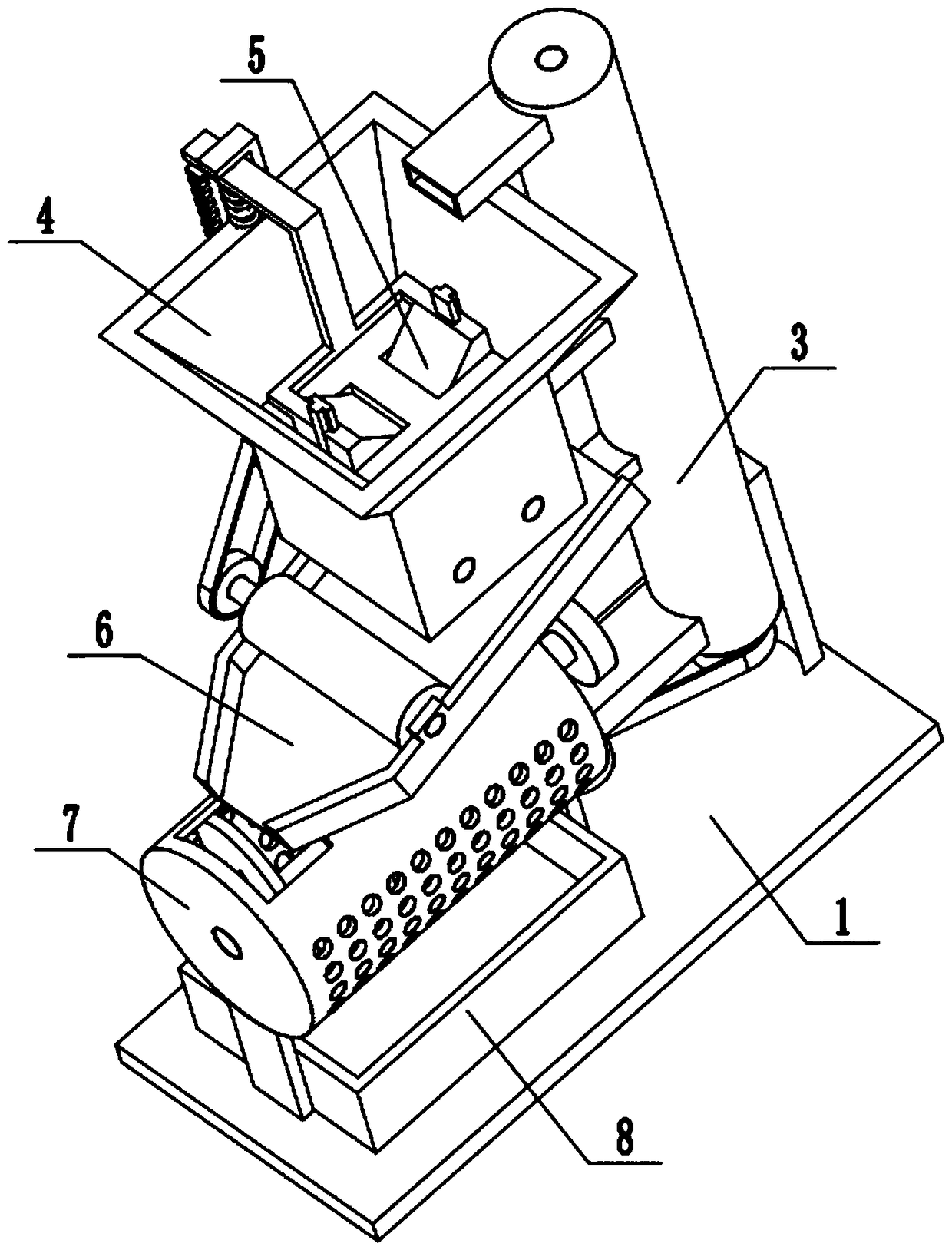

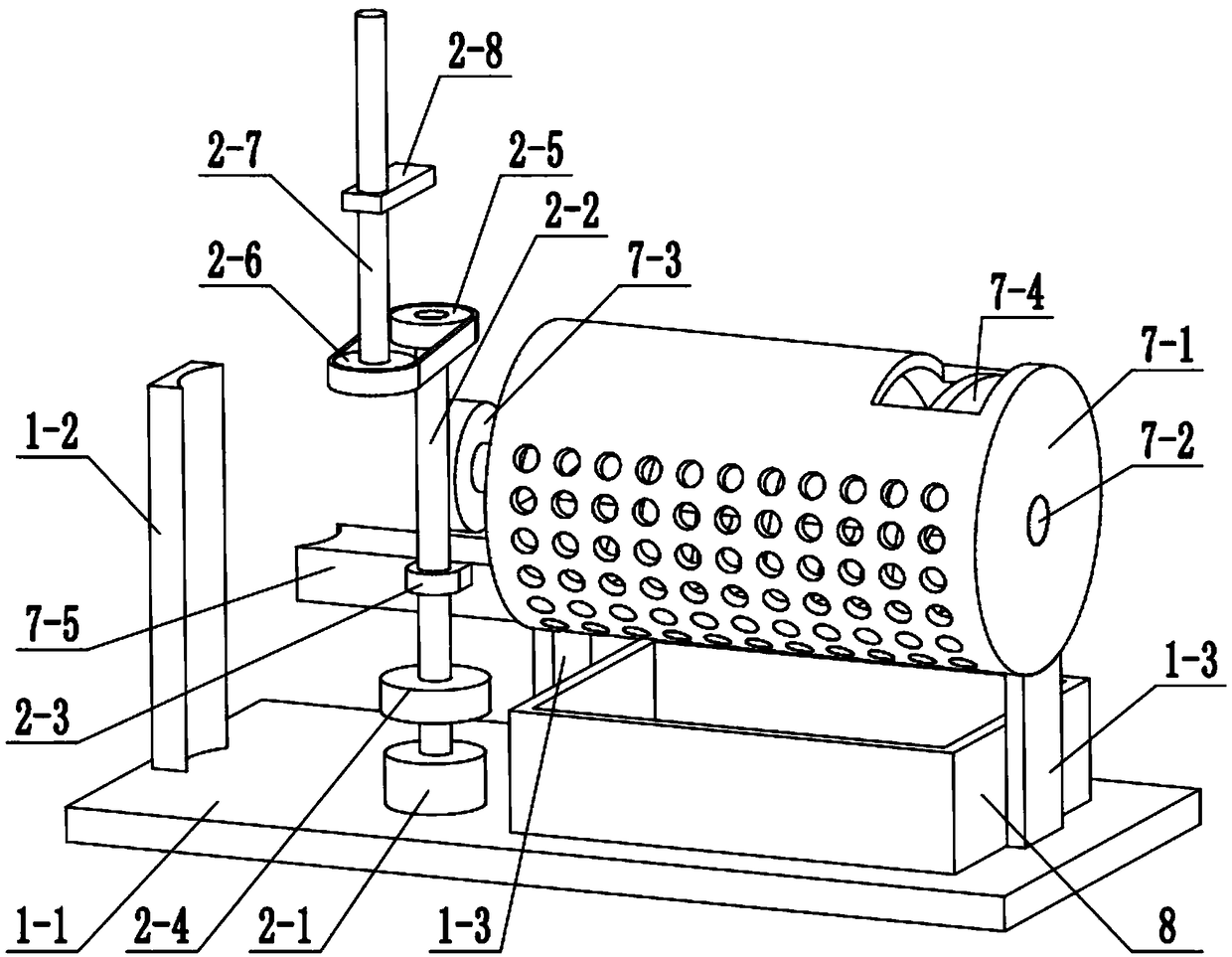

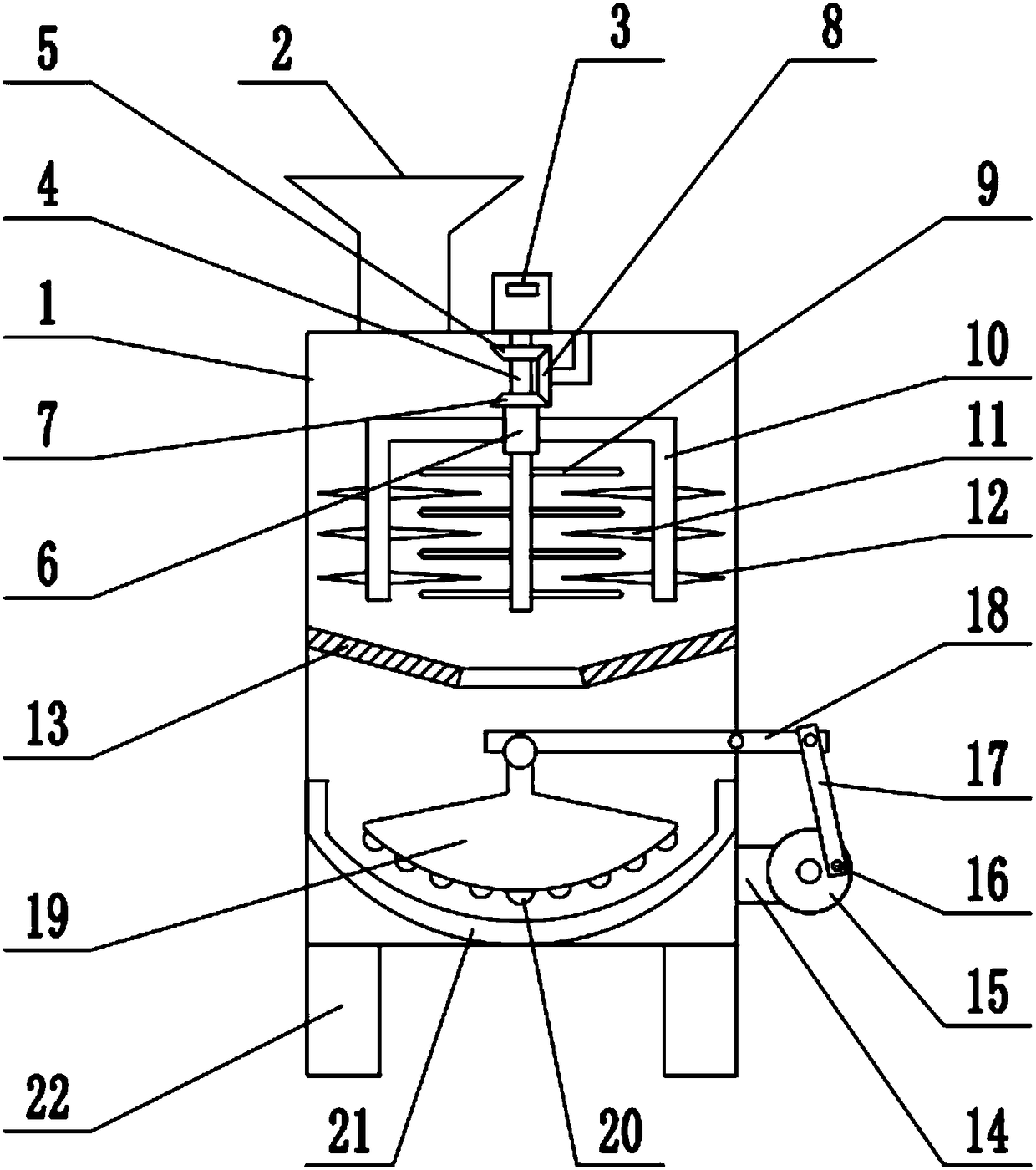

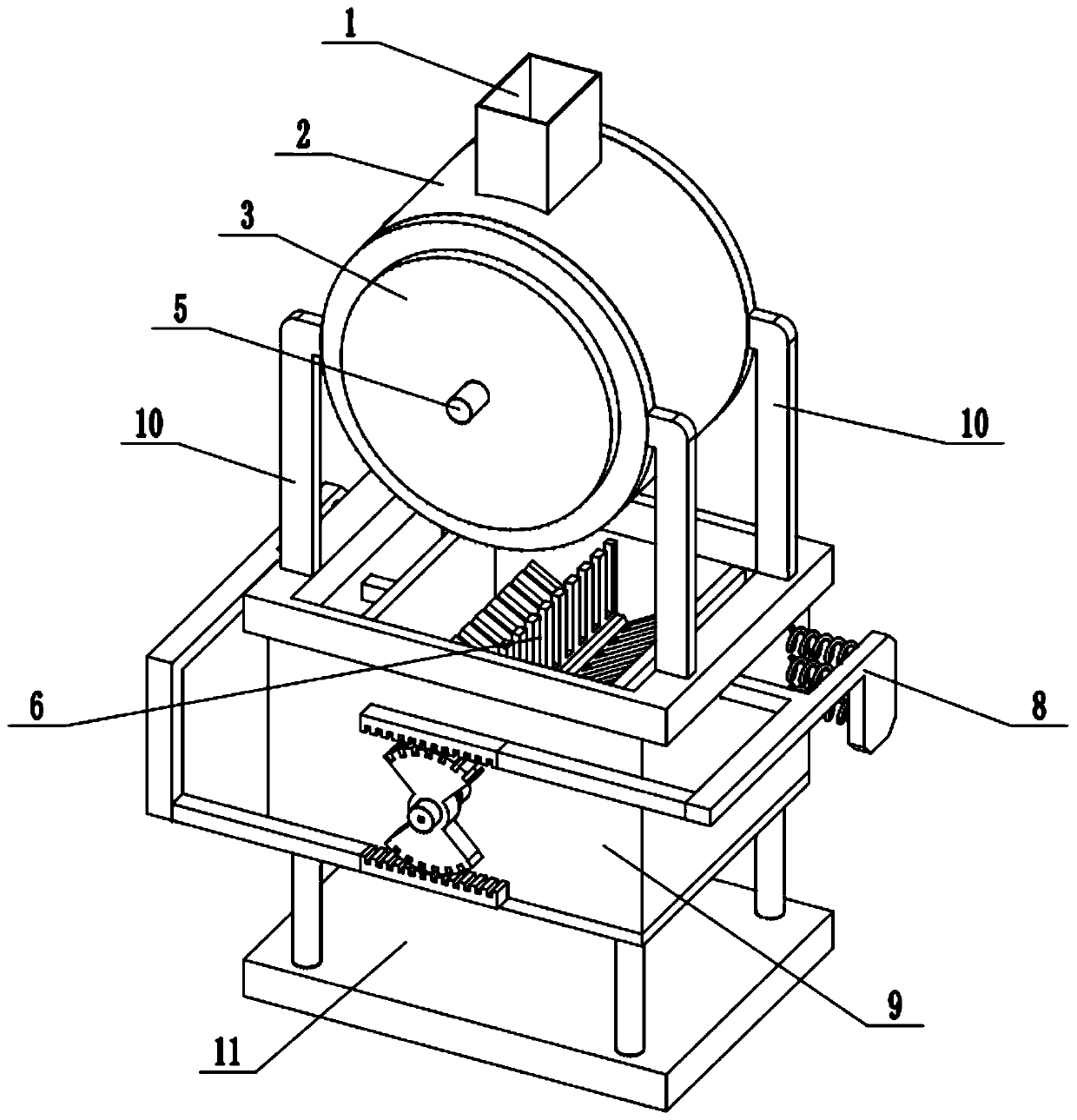

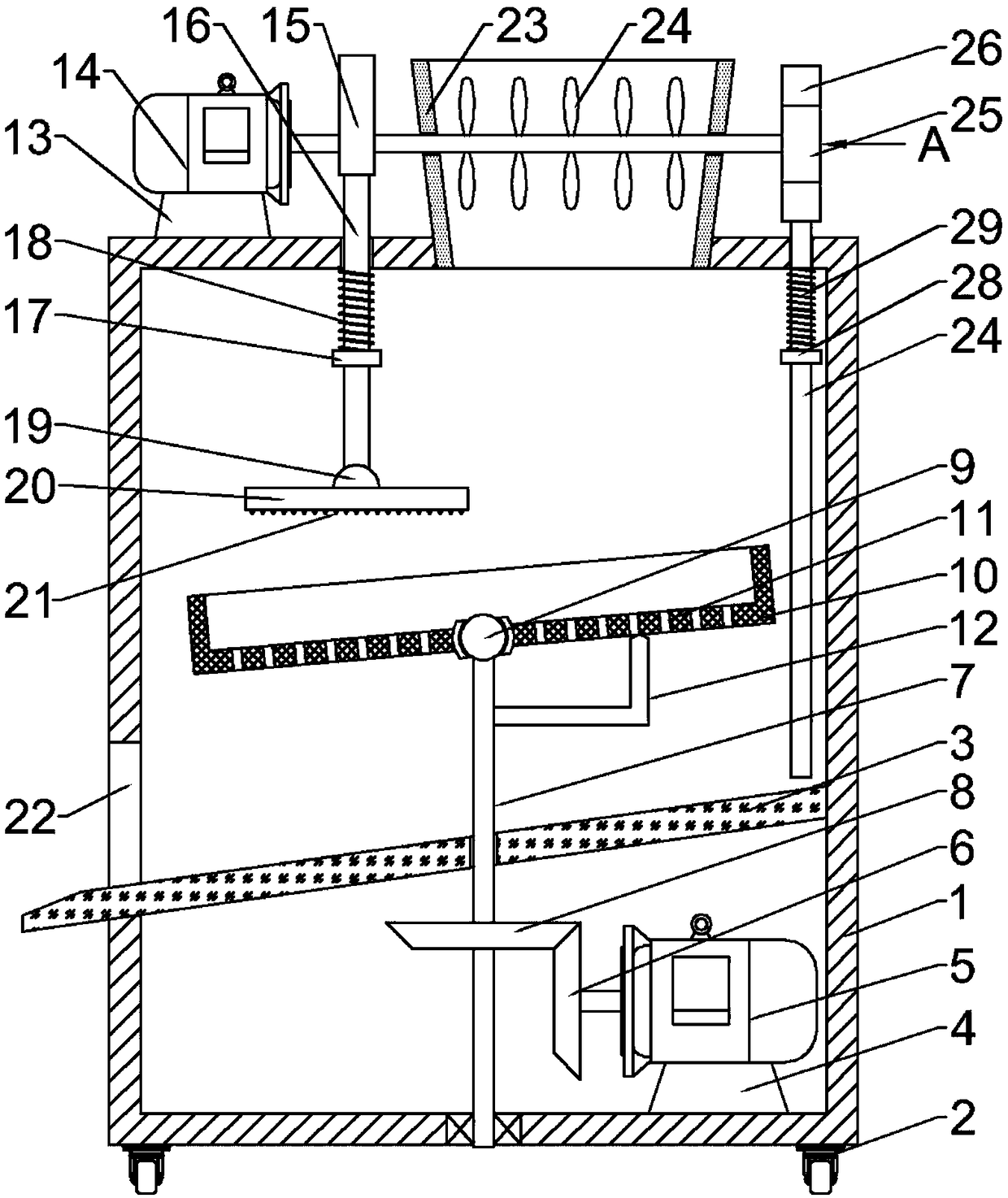

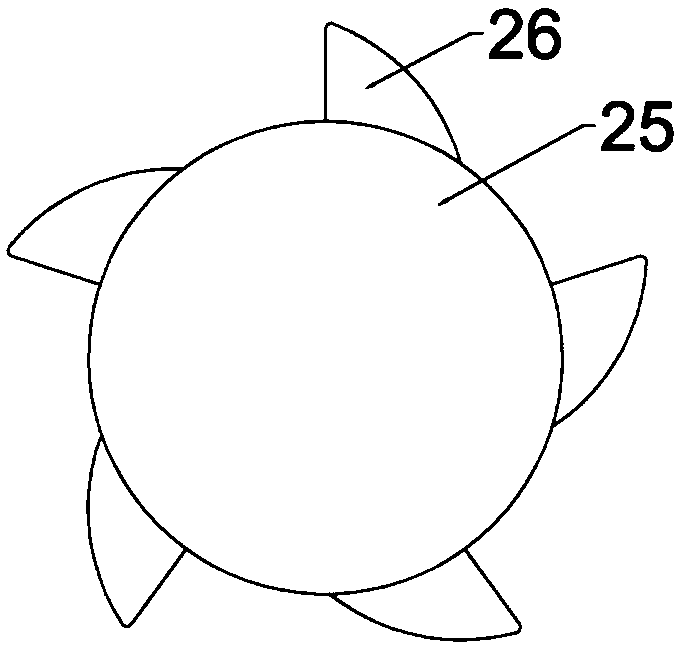

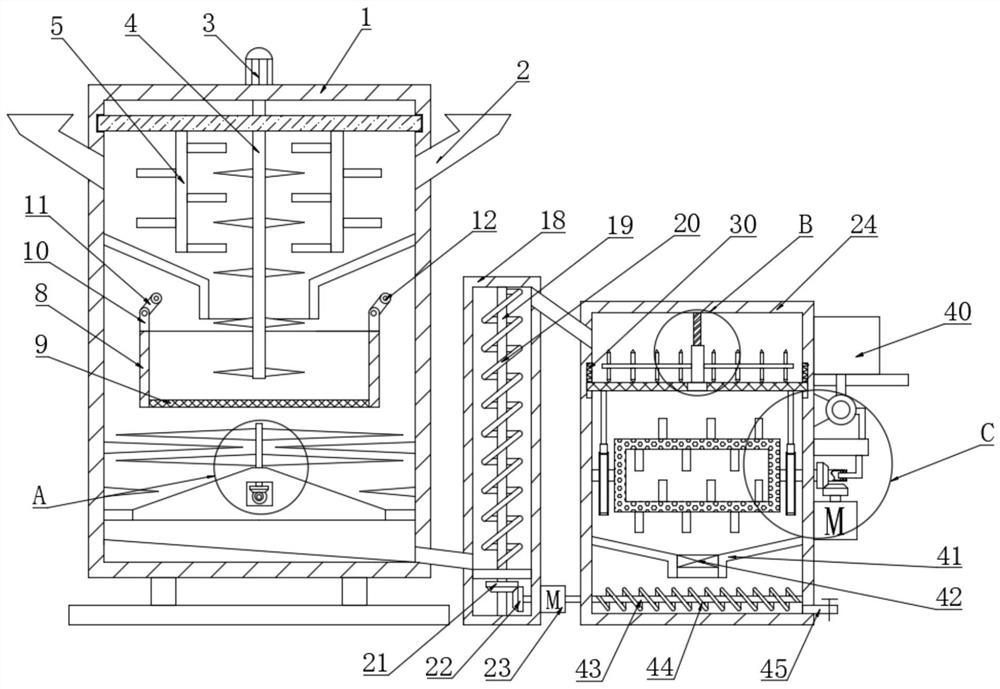

Biomass raw material processing device in field of new energy

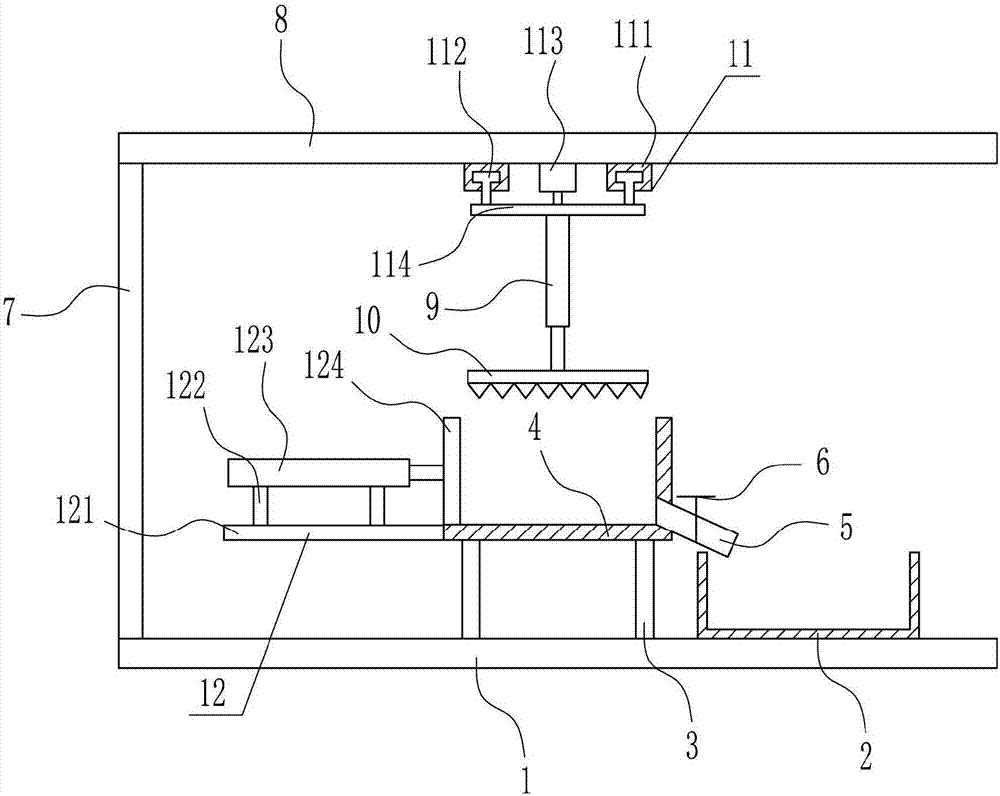

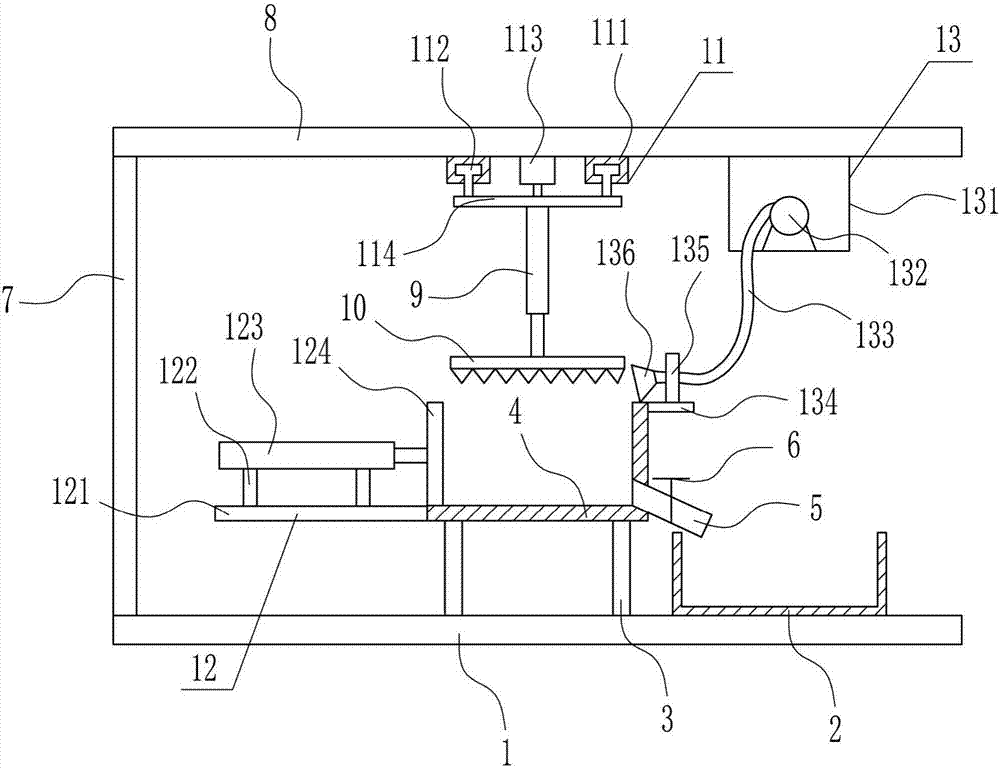

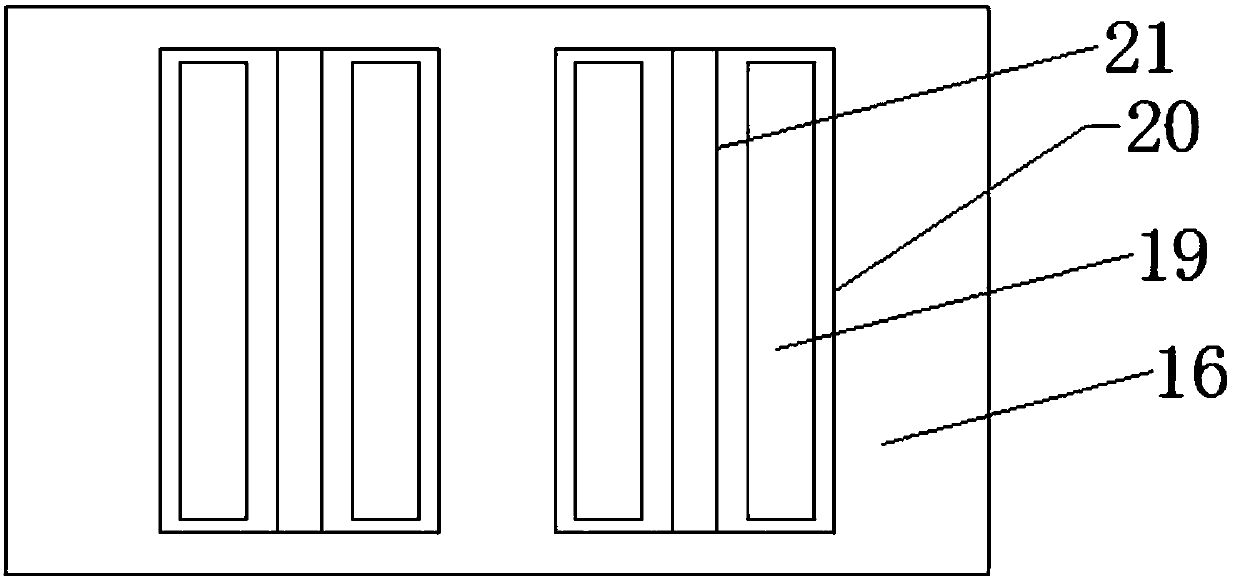

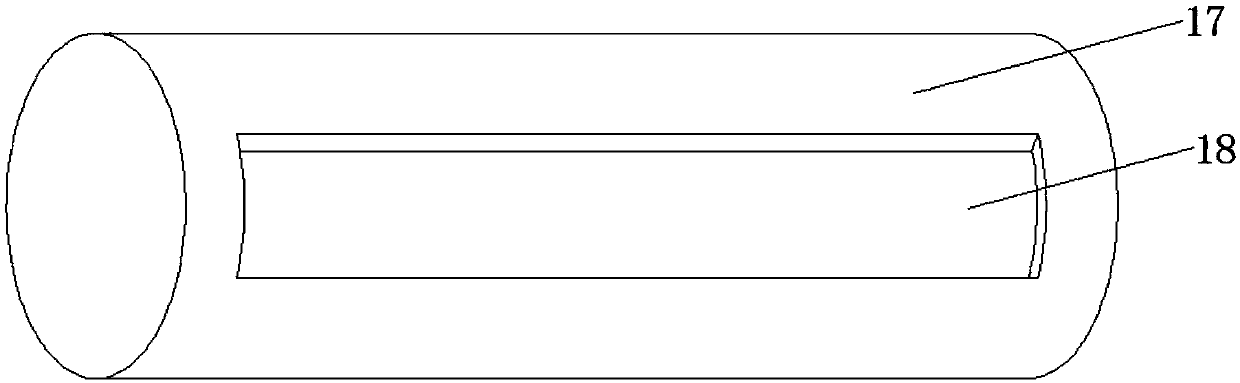

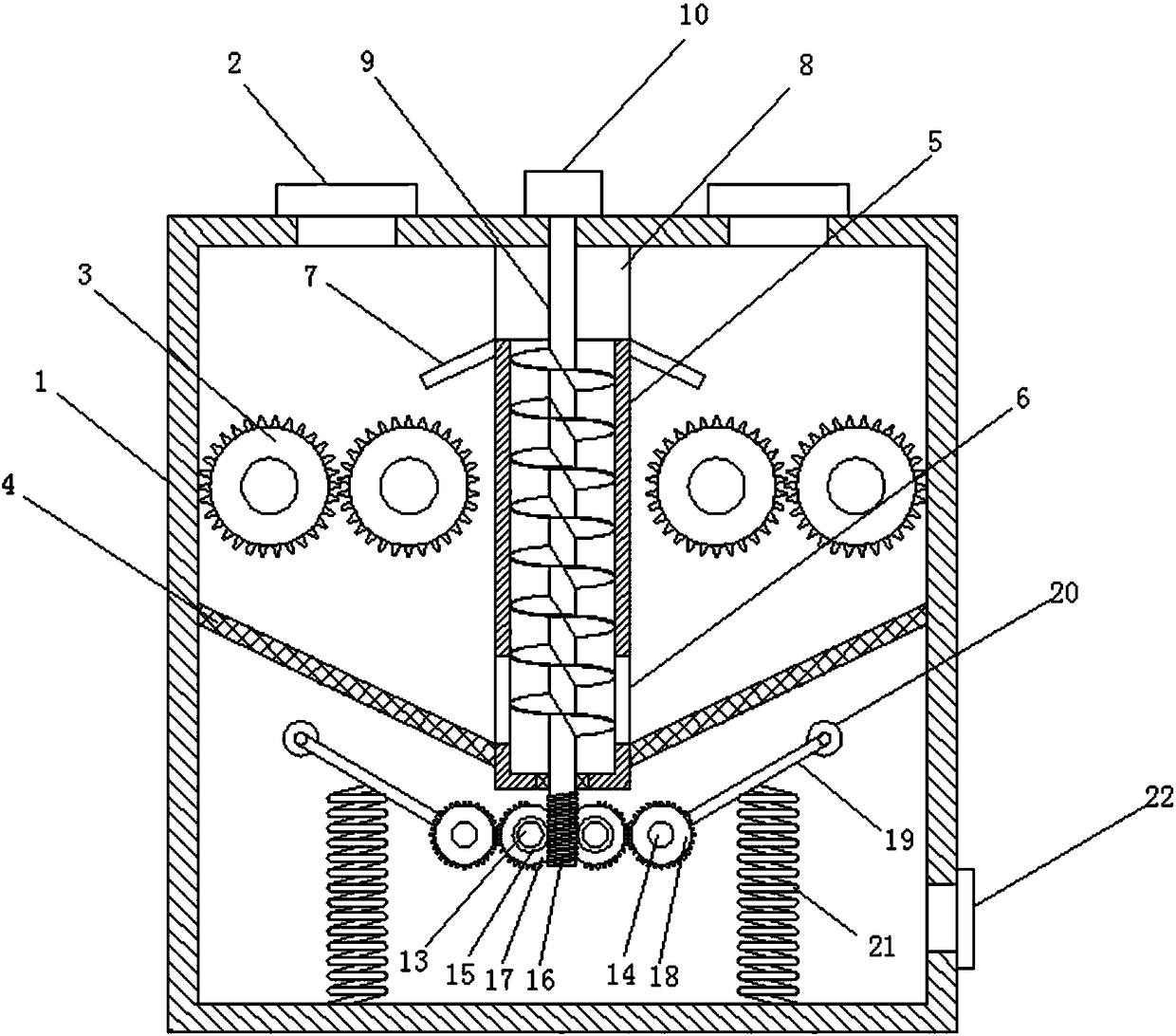

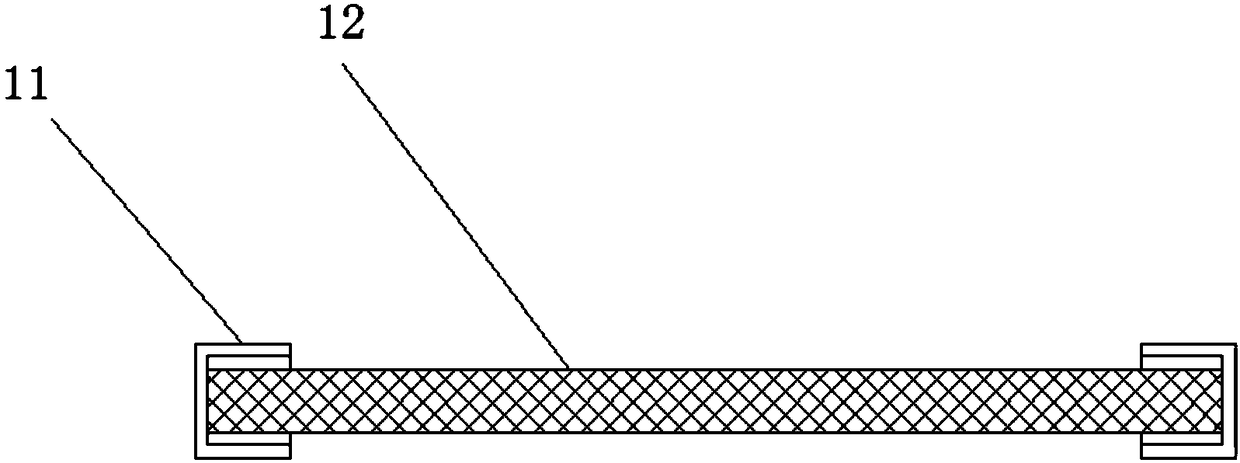

The invention relates to the technical field of new energy, in particular to a biomass raw material processing device in the field of new energy. The biomass raw material processing device is characterized in that a power mechanism is fixedly connected to the middle end of a base, the power mechanism is in transmission connection with a circulating return assembly through a belt, the circulating return assembly is fixedly connected to the left end of the base, a crushing assembly is fixedly connected to the upper end of the circulating return assembly, the power mechanism is in meshed transmission connection with the crushing assembly, an intermittent feeding assembly is slidably connected in the crushing assembly, the intermittent feeding assembly is in meshed transmission connection withthe crushing assembly. According to the biomass raw material processing device, biomass raw materials can be sufficiently crushed, intermittent discharging can be achieved, so that the phenomenon ofblockage is prevented, meanwhile, the biomass raw materials can be continuously pushed to move downwards, so that the crushing efficiency is improved, morever, the crushed biomass raw materials can bescreened so that the biomass raw materials meeting requirements can be screened out, secondary reworking treatment does not need to be performed manually, and it is guaranteed that the crushed biomass raw materials can be fully combusted.

Owner:义乌飞思科技有限公司

Cement hammering and recycling device for building

InactiveCN108607634AGreat hammer forceGood crushing effectGrain treatmentsEngineeringMechanical engineering

The invention discloses a cement hammering and recycling device for a building. The cement hammering and recycling device comprises a base, wherein supporting plates are fixedly arranged on the left side and the right side of the top of the base, a top plate is fixedly arranged at the tops of the supporting plates, and a hammering chamber is fixedly arranged between the left supporting plate and the right supporting plate through a support; and the top of the top plate is fixedly provided with a lifting sliding rail, the left side of the lifting sliding rail is connected with a rack in a sliding mode through a sliding block, the bottom end of the rack is fixedly connected with a heavy hammer, the top of the top plate is rotationally connected with a second rotating shaft through a support,the second rotating shaft is fixedly provided with an incomplete gear, the top of the top plate is further fixedly provided with a second speed reducing motor, and the motor shaft at the front end ofthe second speed reducing motor is connected with the second rotating shaft through a belt transmission mechanism. According to the cement hammering and recycling device, the incomplete gear is meshed with the rack to drive the heavy hammer to move upwards, and when the incomplete gear is disengaged from the rack, the heavy hammer is rapidly descended under the action of gravity, and hammering and crushing are carried out on a cement block in the hammering chamber, and the heavy hammer is large in acting force and good in crushing effect.

Owner:FOSHAN XINLAI ENG TECH CO LTD

Medical glass waste smashing and grinding all-in-one machine

ActiveCN108393173AImprove crushing efficiencyGood crushing effectGrain treatmentsEngineeringWaste product

The invention discloses a medical glass waste smashing and grinding all-in-one machine which comprises a housing, a feeding hole, a first motor, a smashing shaft, a plurality of main smashing blades and a grinding disc, wherein the first motor is fixedly connected with the upper surface of the housing; the smashing shaft is fixedly connected with the shaft stretching end of the first motor; an upper bevel gear is arranged on the smashing shaft in a sleeving manner; a sleeve is arranged below the upper bevel gear; the sleeve is arranged on the smashing shaft in a sleeving manner and is rotatably connected with the smashing shaft; a lower bevel gear is fixedly connected with the top end of the sleeve; a side bevel gear is arranged between the upper bevel gear and the lower bevel gear; and the main smashing blades are distributed on the smashing shaft. The main smashing blades, internal smashing blades and external smashing blades are mutually cooperated to smash glass waste, so that thesmashing efficiency is high and the smashing effect is excellent; smashed glass fragments penetrate through a guide plate to fall into the grinding disc, a grinding hammerhead is utilized to grind theglass fragments in the grinding disc, and the smashing and grinding processes of the glass waste are carried out synchronously, so that the working efficiency is greatly improved.

Owner:黄学玲

Environment-friendly building gravel smashing device

InactiveCN108097436AReasonable device designGood crushing effectCombination devicesDirt cleaningPulmonary diseaseWorking environment

The invention provides an environment-friendly building gravel smashing device and belongs to the field of buildings. The environment-friendly building gravel smashing device comprises a smashing box,smashing rollers, a filtering net, a dust suction pipe, a washing box, wheels, a suction pump, a dust collecting box and a plurality of smashing blades, wherein the wheels are disposed on wheel seatsand can roll in the wheel seats; the smashing box is welded to the upper ends of two supports; the multiple smashing blades are welded to a smashing shaft; the smashing rollers are fixedly disposed on rotary shafts and disposed in a material guiding box; the filtering net is fixedly disposed in the right side of the upper end wall of the smashing box; the dust collecting box is welded to the right side surface of the smashing box; the suction pump is fixedly disposed on a supporting plate; and the washing box is fixedly disposed on the right side of the upper end of the supporting plate. Theenvironment-friendly building gravel smashing device is reasonable in design, a two-level smashing design is adopted, the smashing effect is good, filtering and washing are performed at the same time,dust can be effectively filtered out, the working environment is improved, and the incidence rate of lung disease of workers is lowered.

Owner:ZHENGZHOU AIMOFU INFORMATION TECH CO LTD

High efficiency crushing device for mineral ores

InactiveCN107115924AGood crushing effectNot easy to affect qualityCocoaGrain treatmentsEngineeringExtremely good

The invention relates to an ore crushing device, and particularly to a high efficiency crushing device for mineral ores. In order to solve the technical problem, the invention provides the high efficiency crushing device which is time-saving, labor-saving and excellent in the crushing effect, and does not easily affect the ore quality; in order to solve the technical problem, the high efficiency crushing device for mineral ores provided by the invention comprises a base and the like, wherein a support and support rods are mounted at the top of the base in a bolted connection manner; the support is positioned on the left side of the support rods; a lifting device is arranged on the right side surface of the support; a connecting plate is vertically connected onto a lifting component of the lifting device; a crushing device is arranged on the right side surface of the connecting plate; and a crushing frame is mounted at the tops of the support rods in a bolted connection manner. According to the high efficiency crushing device for mineral ores, the crushing teeth capable of rotating while moving up and down are adopted for crushing ores in the crushing frame, the crushing frame rotates to be matched with the crushing teeth, and the crushing effect is extremely good.

Owner:李翔

Medlar powder preparing method

InactiveCN108325648AGood crushing effectImprove crushing efficiencySievingScreeningPulverizerThrough transmission

The invention discloses a medlar powder preparing method. Medlar is taken, a traditional Chinese medicine pulverizing machine for adjusting the particle diameter is used for conducting pulverizing, and the traditional Chinese medicine pulverizing machine for adjusting the particle diameter comprises a shell, a feeding port, pulverizing motors, pulverizing shafts, pulverizing blades and a collecting groove. The pulverizing motors are fixedly connected to the left side and the right side of the shell correspondingly. The pulverizing shafts are arranged on the left side and the right side of thefeeding port correspondingly. The lower ends of the pulverizing shafts penetrate the top of the shell and stretch into the shell. The pulverizing shafts are rotationally connected with the top of theshell. The shaft stretching ends of the pulverizing motors are connected with the pulverizing shafts through transmission mechanisms. An upper sieve plate is arranged below the pulverizing shafts andfixedly connected with the inner wall of the shell. A lower sieve plate is arranged below the upper sieve plate. In the pulverizing process, stirring vanes are used for stirring the medlar, and traditional Chinese medicines are pulverized more evenly; through adjustment of the lower sieve plate, sieve holes in the upper sieve plate and sieve holes in the lower sieve plate are staggered, the size of medlar particles penetrating the upper sieve plate and the lower sieve plate can be conveniently adjusted, and different machining requirements of people are met.

Owner:苏州高新区鼎正精密机电有限公司

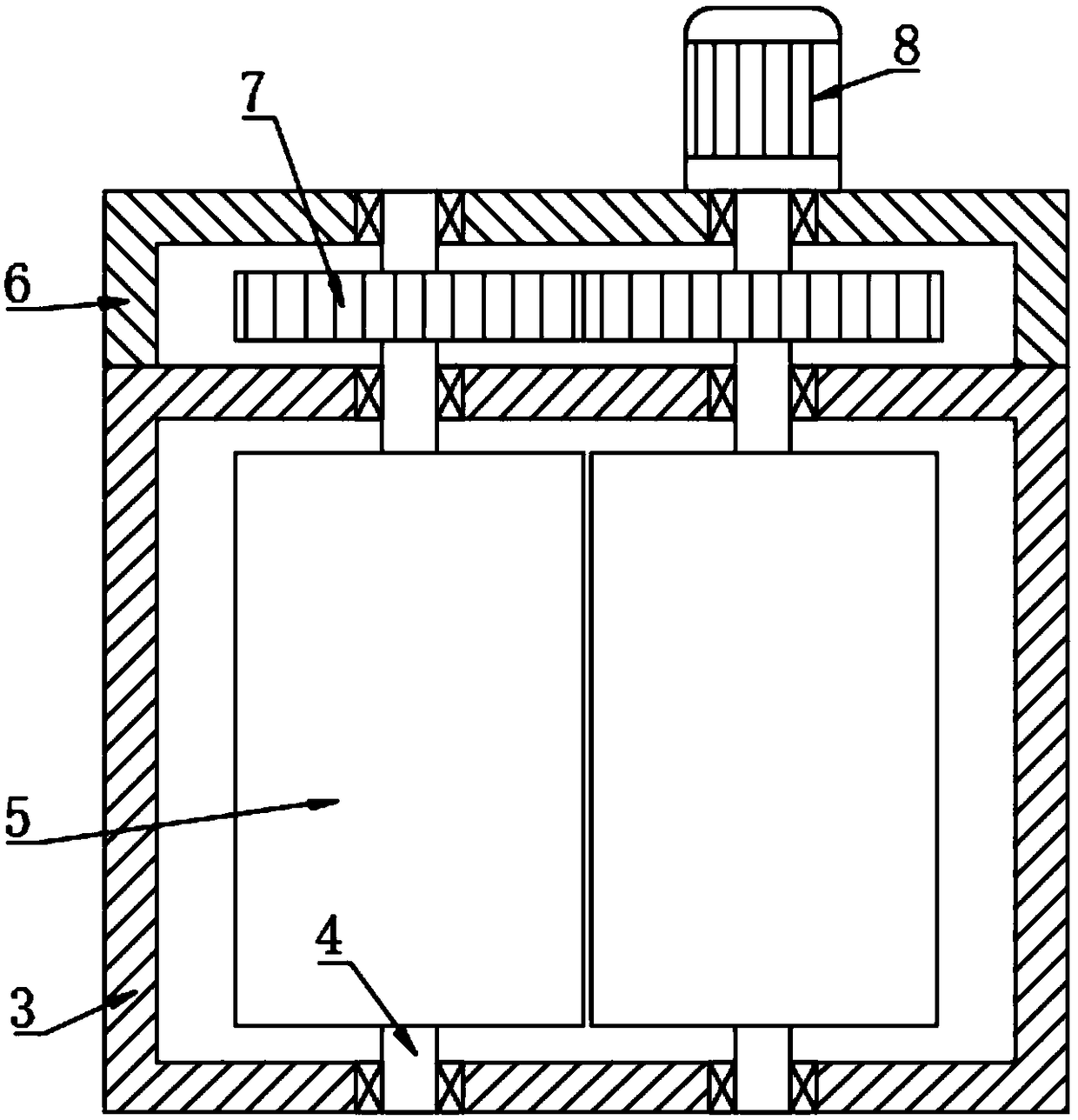

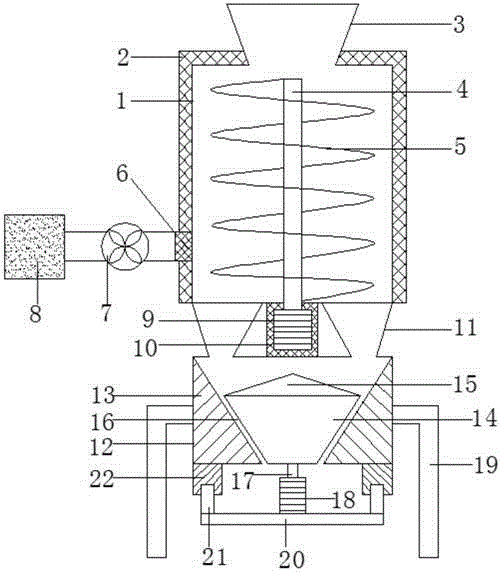

Efficient pulverizer for ceramic production

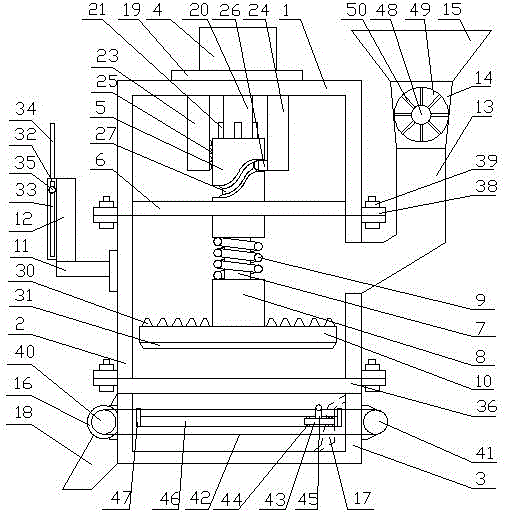

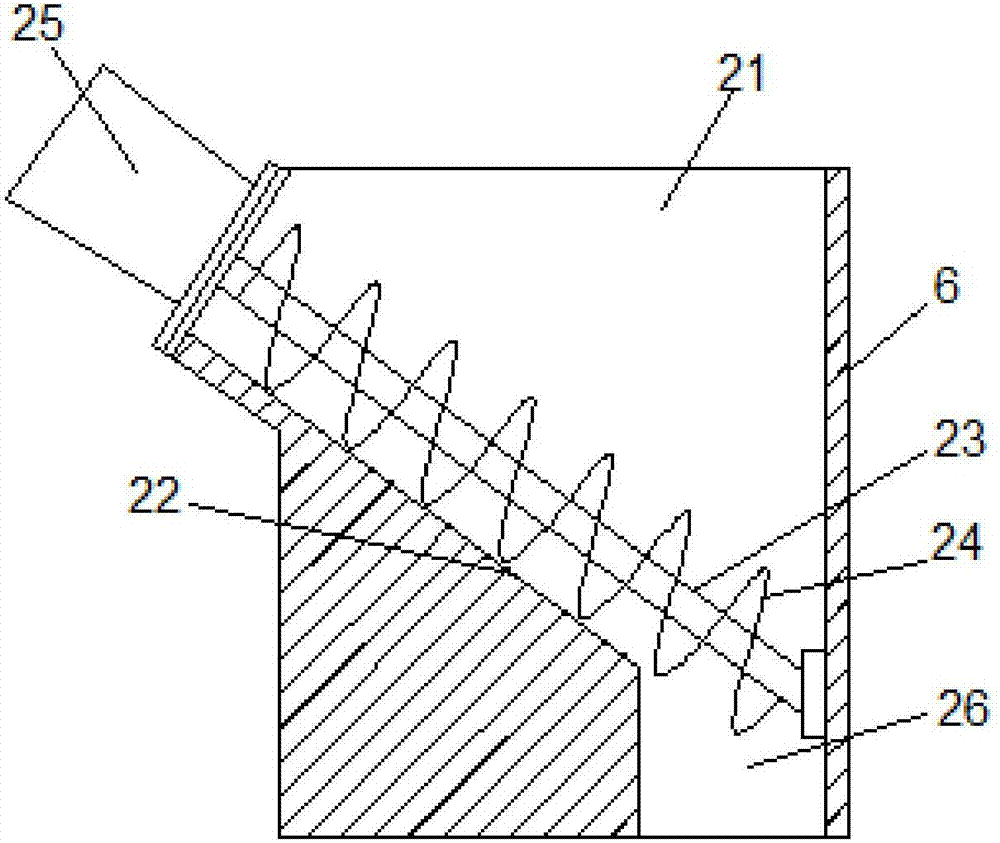

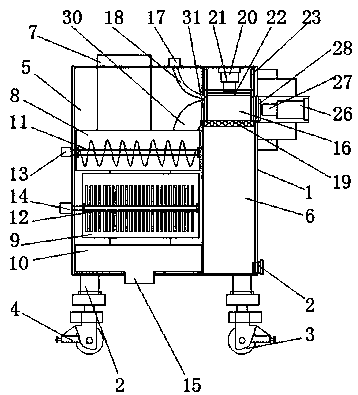

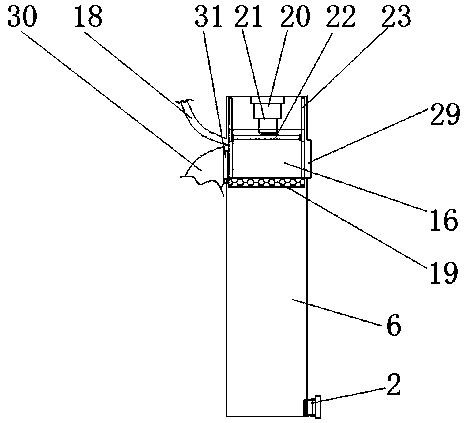

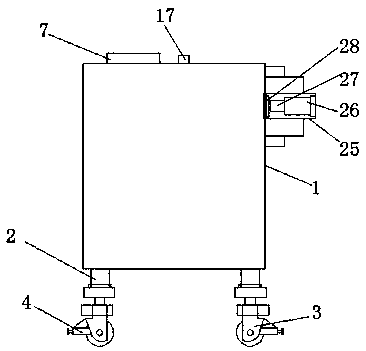

The invention discloses an efficient pulverizer for ceramic production. The efficient pulverizer for ceramic production comprises a first pulverizing cavity, a pulverizing roller and a hydraulic cylinder, wherein the outer wall of the first pulverizing cavity is covered with an electric heating layer, the upper side of the first pulverizing cavity is connected with a feeding funnel, a first rotary shaft is vertically arranged at the axis position of the inside of the first pulverizing cavity, screw blades are evenly arranged on the outer wall of the first rotary shaft, an air outlet pipe is horizontally arranged at the left end of the outer wall of the lower side of the first pulverizing cavity, and the left end of the air outlet pipe is connected with an exhaust fan. The efficient pulverizer for ceramic production integrates material pulverizing and drying functions, ensures the quality of processed finished products and fully pulverizes materials through two pulverizing mechanisms, an oblique pulverizing gap enables pulverizing time to be long and enables pulverizing to be sufficient, the material pulverizing effect is ensured, the size of pulverized material particles can be controlled, practicability is high, dehumidification is performed in the drying process through a drying device, drying efficiency is improved, noise in the working process of the efficient pulverizer is small, and a working environment of an operator is improved.

Owner:陆丽曼

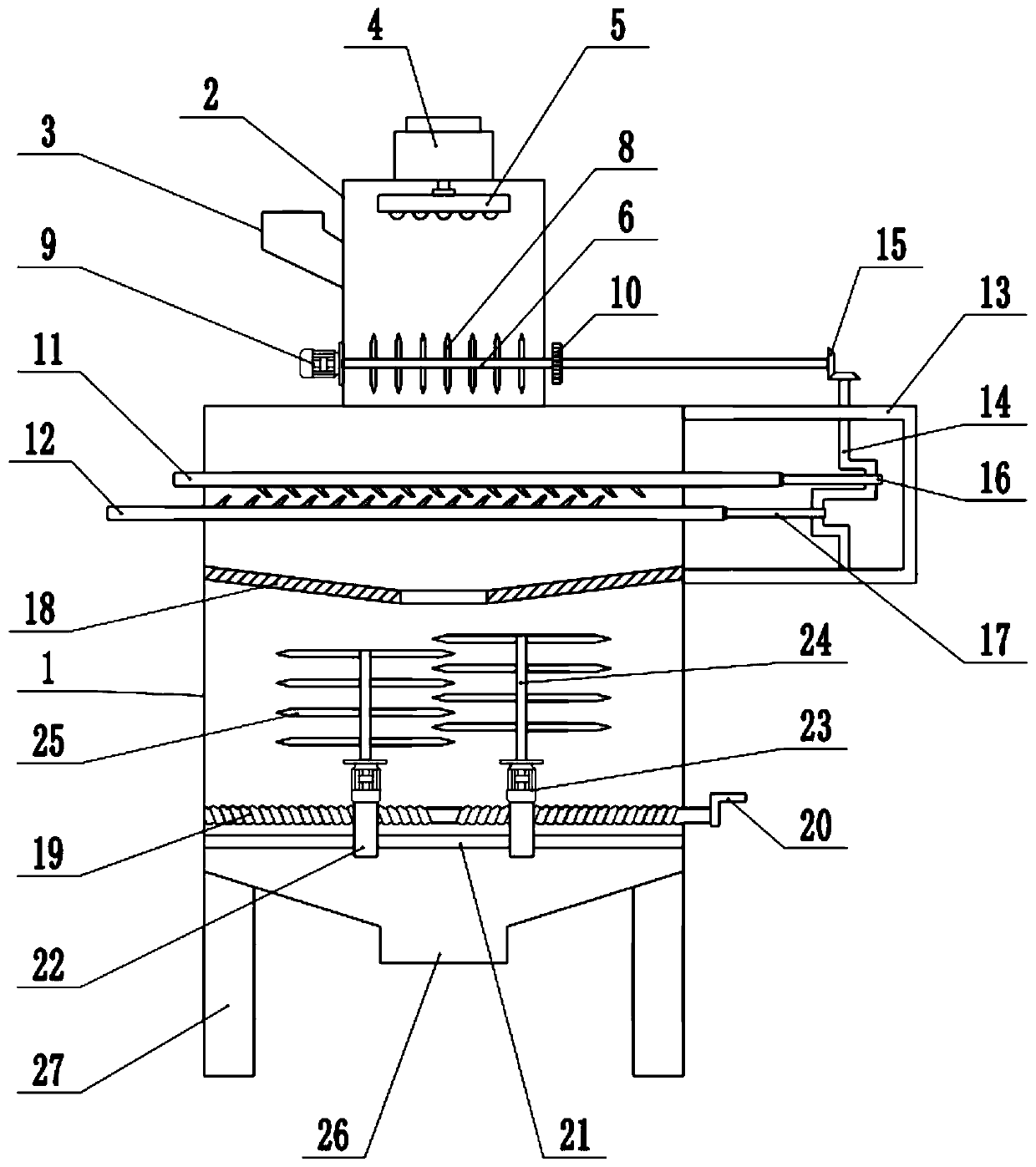

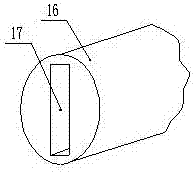

Waterproof coating preparing and processing system

ActiveCN111569995AGood crushing effectEvenly brokenSievingScreeningProcess engineeringManufacturing engineering

The invention relates to a waterproof coating preparing and processing system. A bottom plate, a screening device and a grinding device are included. The screening device is arranged at the upper endof the bottom plate. The left side of the upper end of the screening device is provided with an opening groove provided with the grinding device. The waterproof coating preparing and processing systemcan solve the problems that when existing equipment conducts crushing processing on coating raw materials, the crushing effect is poor, crushing is incomplete, the crushed raw materials cannot be subjected to even grinding processing, the coating preparing effect is influenced, in addition, when the existing equipment screens the coating raw materials, the section area of the raw materials and afilter net is small, consequently, the raw material filter effect is poor, filtering is incomplete, meanwhile, meshes of the filter net are prone to blockage through large-particle impurities, and theraw material screening efficiency is influenced.

Owner:ZHEJIANG YUTONG NEW MATERIAL

Material rubbing and squeezing smashing mechanical device

ActiveCN105618226APrevent material from leaking into the feeding pipelineGood crushing effectGrain treatmentsRubbingShovel

The invention discloses a material rubbing and squeezing smashing mechanical device which comprises an upper device shell, a middle device shell and a lower device shell. A smashing motor is arranged on the upper portion of the upper device shell and matched with a rotating shaft. An ash damper is arranged in the upper device shell. The rotating shaft is matched with a connector through a telescopic rod which is sleeved with a spring. The end of the connector is connected with a rotating pulverizing disc. One side of the middle device shell is connected with a controller through a connecting frame, and the other side of the middle device shell is connected with a feeding pipeline. A feeding device is arranged at the end of the feeding pipeline and communicates with a feeding hopper. One side of the lower device shell is provided with a material clearing motor and a discharge port, and the material clearing motor is matched with a material clearing shovel through a transmission device. When the material rubbing and squeezing smashing mechanical device is used, materials can be smashed under the combined action of downward pressure and rubbing force, the smashing intensity is high, and the smashing effect is good; and in addition, the material clearing device is arranged, so that material clearing is convenient and rapid, and working efficiency is high.

Owner:滁州爱沃富光电科技有限公司

Raw material processing device for making plant wine

ActiveCN110280340AGood crushing effectImprove mixing efficiencyTransportation and packagingMixersFiltrationRaw material

The invention relates to the field of wine making processing equipment, in particular to a raw material processing device for making plant wine. The raw material processing device comprises a feed pipe, a processing barrel, end covers, a material filtration plate, a grinding mechanism, a material mixing mechanism, a driving mechanism, a reciprocating material pushing mechanism, a material mixing box, side supports and a support seat. The feed pipe is fixed to the top end of the processing barrel. The front and rear ends of the processing barrel are each fixedly connected with one end cover. The left and right ends of the processing barrel are fixed to the material mixing box through the two side supports correspondingly. Through the raw material processing device, various raw materials can be ground and smashed, after smashed, raw materials meeting requirements can be sifted out by the material filtration plate and fall into the material mixing box to be stirred, the grinding effect is good, and mixing efficiency is high.

Owner:姜秀花

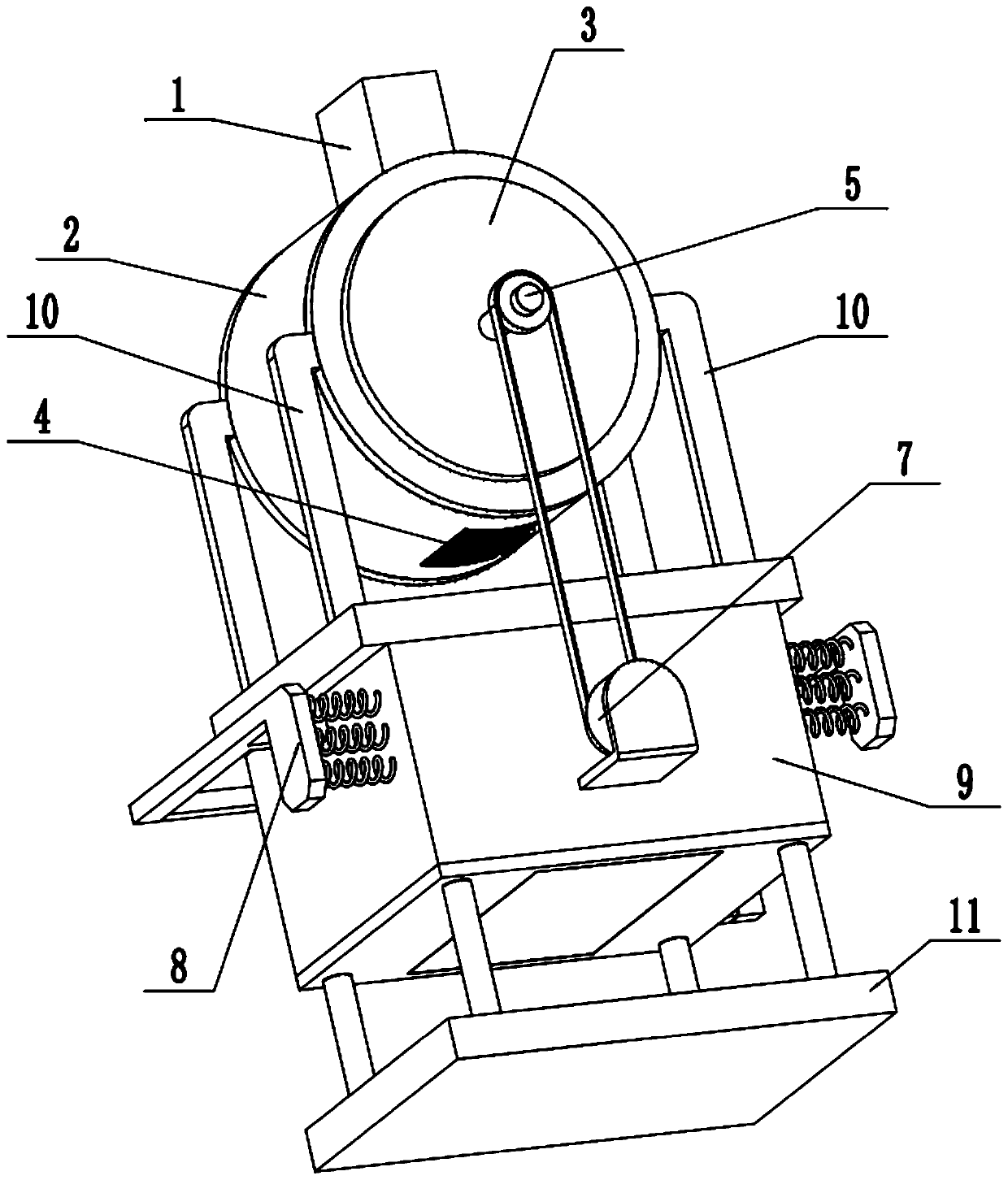

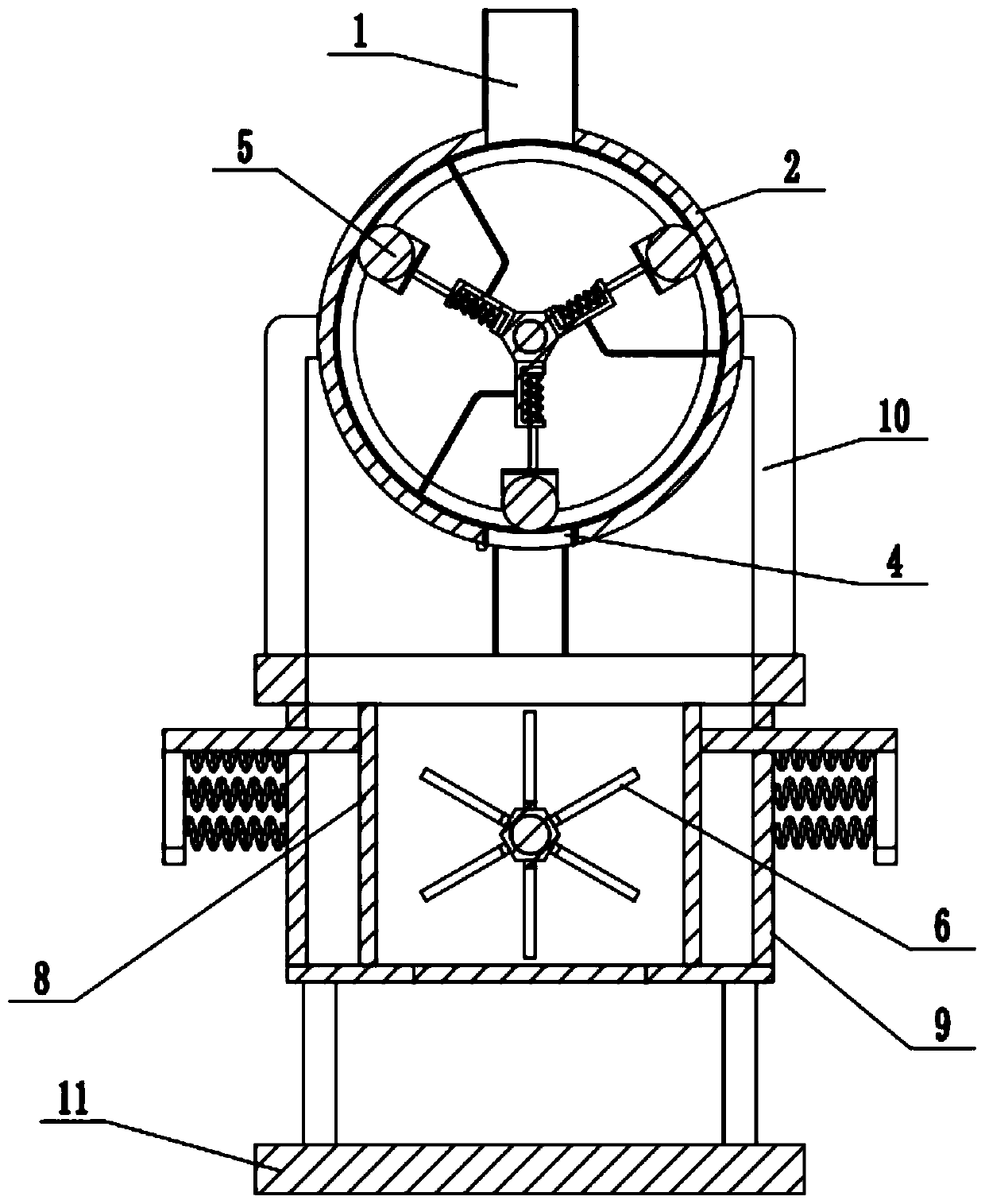

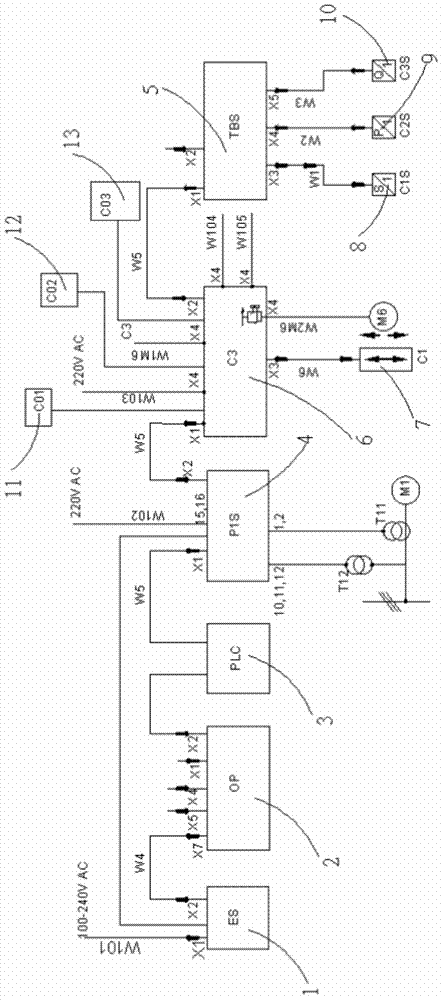

Intelligent control system of hydraulic cone crusher

ActiveCN104511366AIncrease productionGood crushing effectGrain treatmentsAutomatic controlInertial measurement unit

The invention discloses an intelligent control system of a hydraulic cone crusher; the intelligent control system comprises a crusher main machine, a feeding device, a lubricating system, a hydraulic system, and a CIS automatic control system connected with the crusher main machine, the feeding system, the lubricating system and the hydraulic system; the CIS automatic control system comprises a power supply unit, a man-machine interface, a control unit, a power measurement unit, an oil tank measurement unit, a hydraulic drive unit connected with the hydraulic system, and a manual control switch which are interconnected by a CIS bus or an Ethernet bus, and the power supply unit is used for supplying power for the man-machine interface and the power measurement unit; the oil tank measurement unit is connected with a position sensor, a pressure sensor and a temperature sensor; the intelligent control system automatically adjusts the crusher and protects the crusher to prevent overload, reduce the labor intensity of manual operation and improve the work efficiency.

Owner:埃里斯克矿山工程机械有限公司

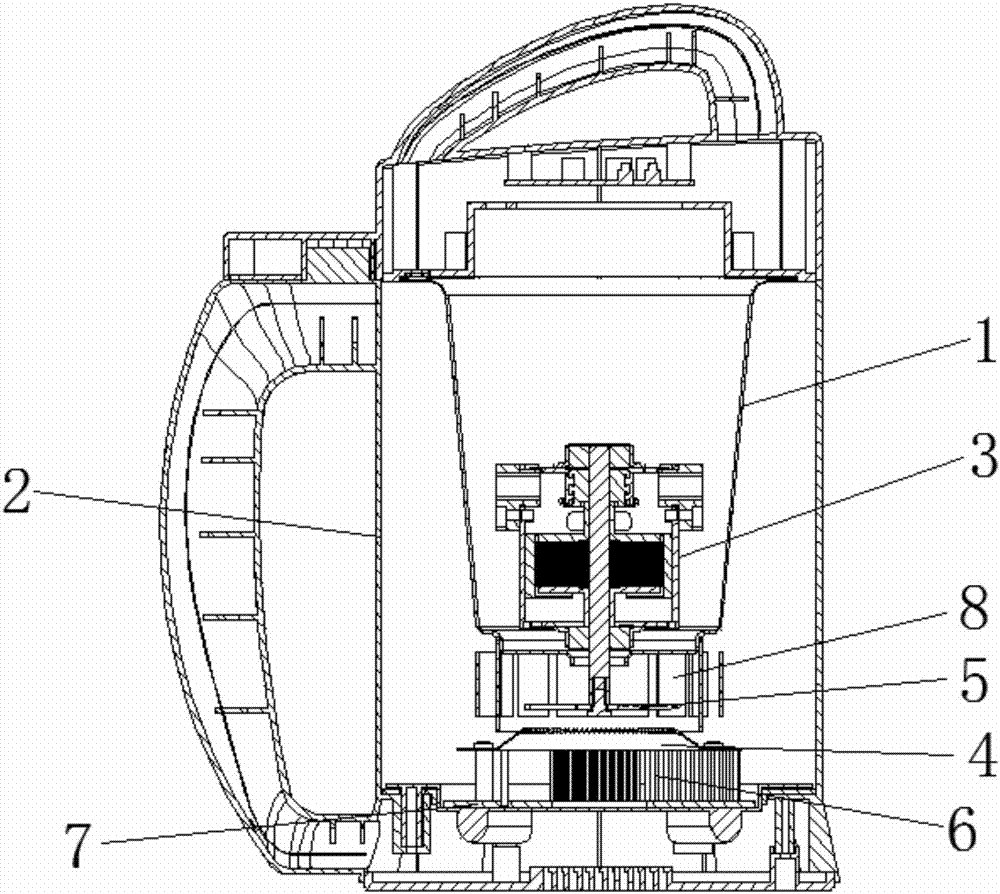

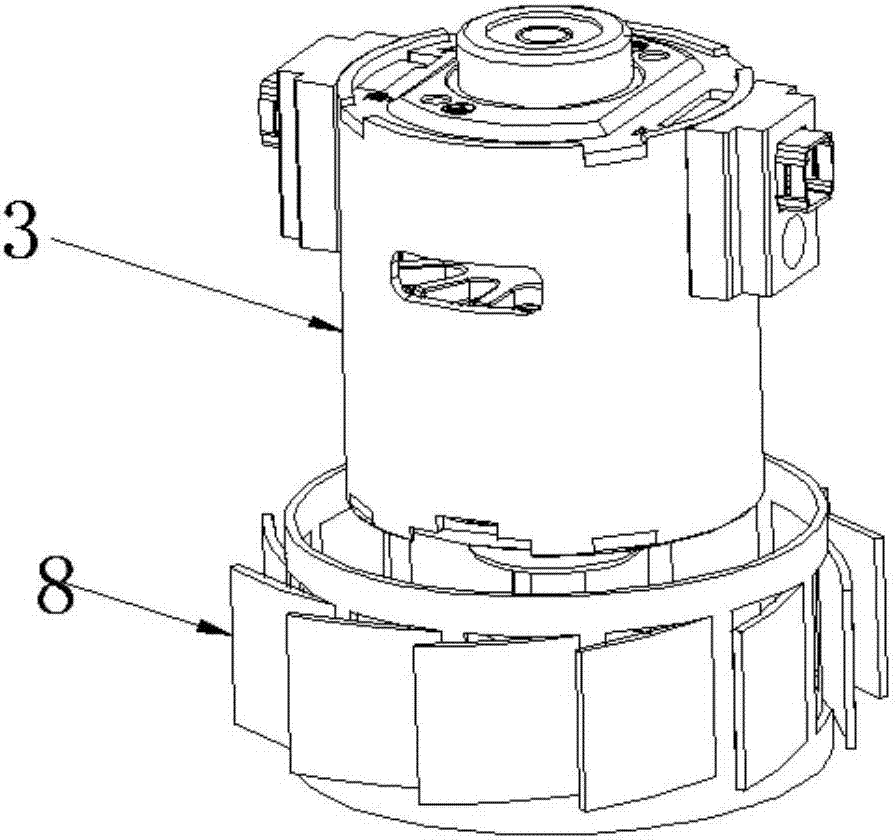

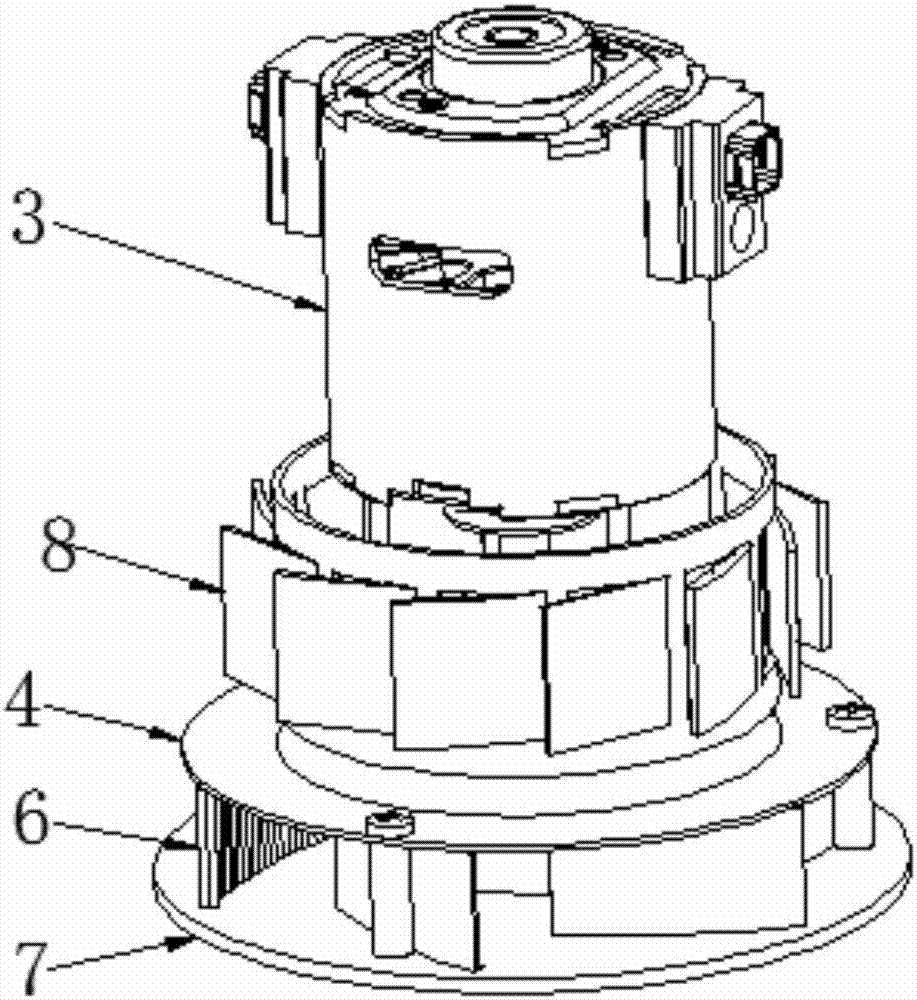

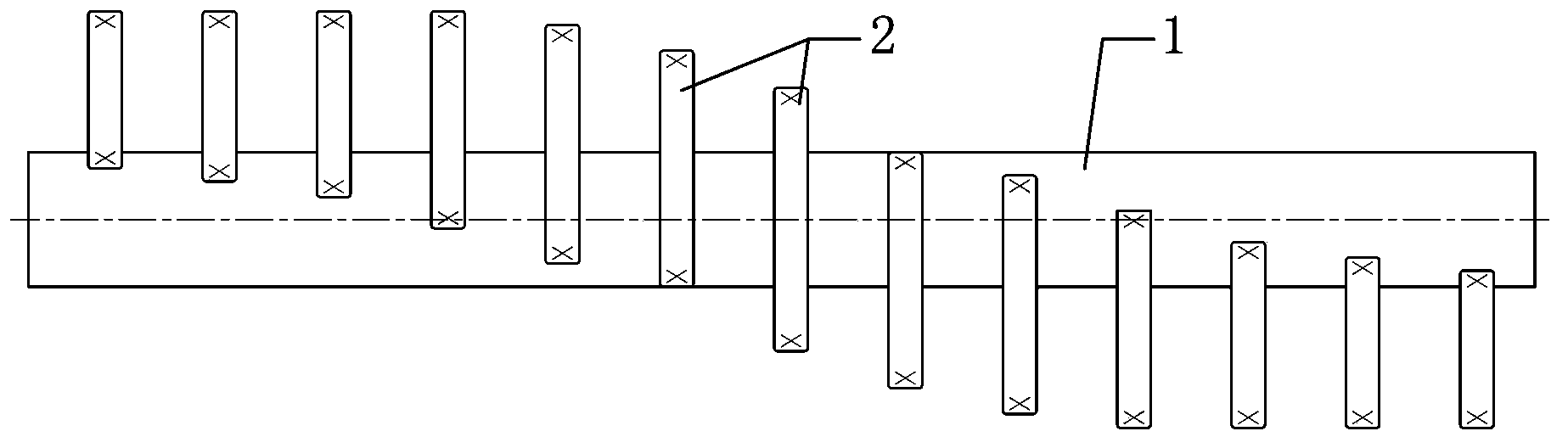

Novel soybean milk machine

PendingCN107019441AImprove crushing efficiencyGood crushing effectBeverage vesselsElectric machineryKnife blades

The invention relates to a novel soybean milk machine. The novel soybean milk machine comprises a machine head, a pulverizing container, a motor, a pulverizing blade and a flow dividing cover; the motor is arranged at the bottom of the machine head; a motor output shaft stretches downwards into an inner cavity of the pulverizing container to be connected with the pulverizing blade; the pulverizing blade is provided with cutting knives arranged circumferentially; flow dividing plates and flow dividing ports which are arranged circumferentially are arranged on the peripheral side of the flow dividing cover; each flow dividing plate extends outwards from the side of the corresponding flow dividing port in an arch shape; the motor drives the pulverizing blade to rotate at high speed to generate a suction force, the suction force sucks food into the flow dividing cover from the lower position of the flow dividing cover, the pulverizing blade rotating at high speed throws out the food to collide to the inner wall of the flow dividing cover, the food flow is discharged from the flow dividing ports by the flow dividing plates in a limited spiral mode, and full circle is repeated until processing is finished. The flow dividing cover has a function of buffering the food to directly flow and impact the inner wall of the pulverizing container, machine vibration is slowed down, the noise is low, the pulverizing efficiency is high, the pulverizing effect is good, the motor burden is small, the load power of a food processor is changed little, and the effect is more excellent than that of a turbulence bone or plate or square cup.

Owner:DONGGUAN ULEGEND SMART APPLIANCES CO LTD

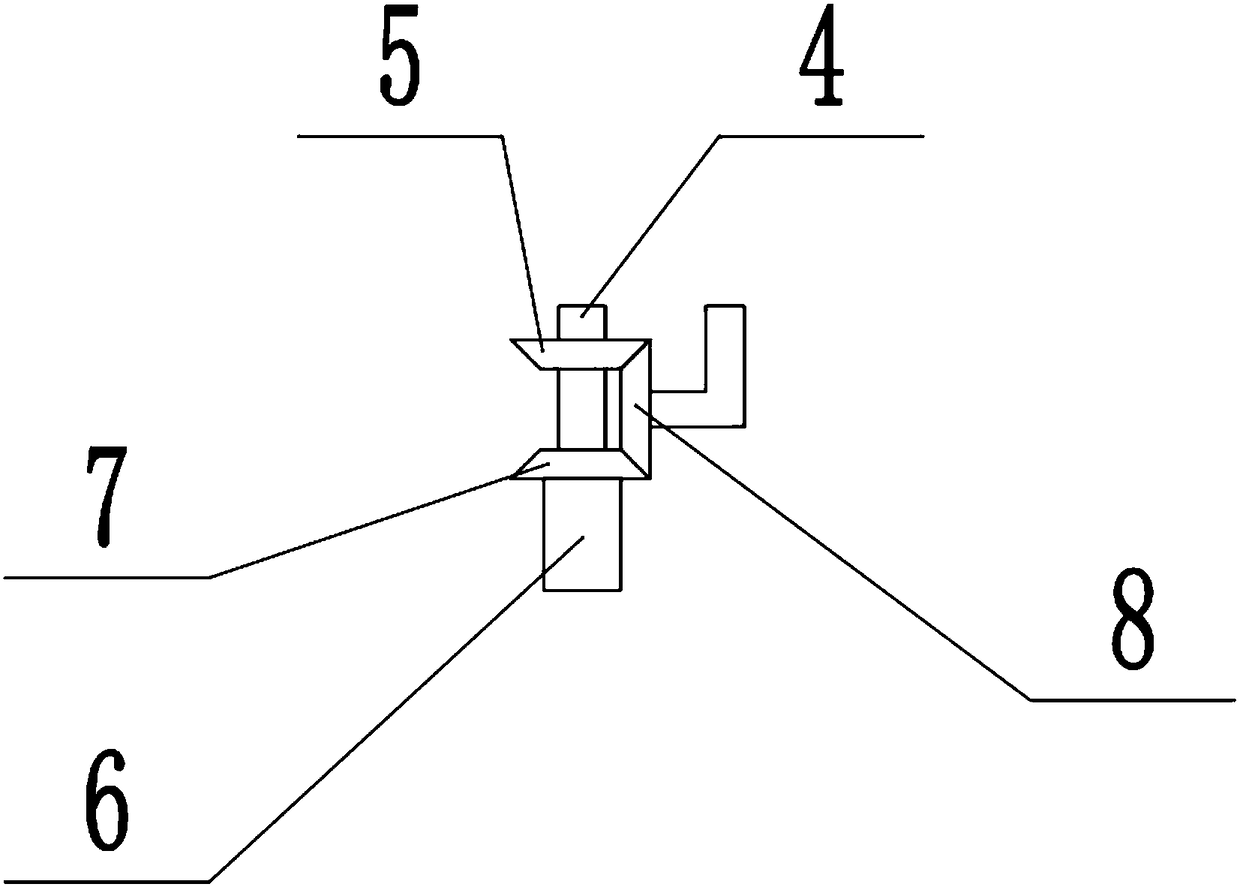

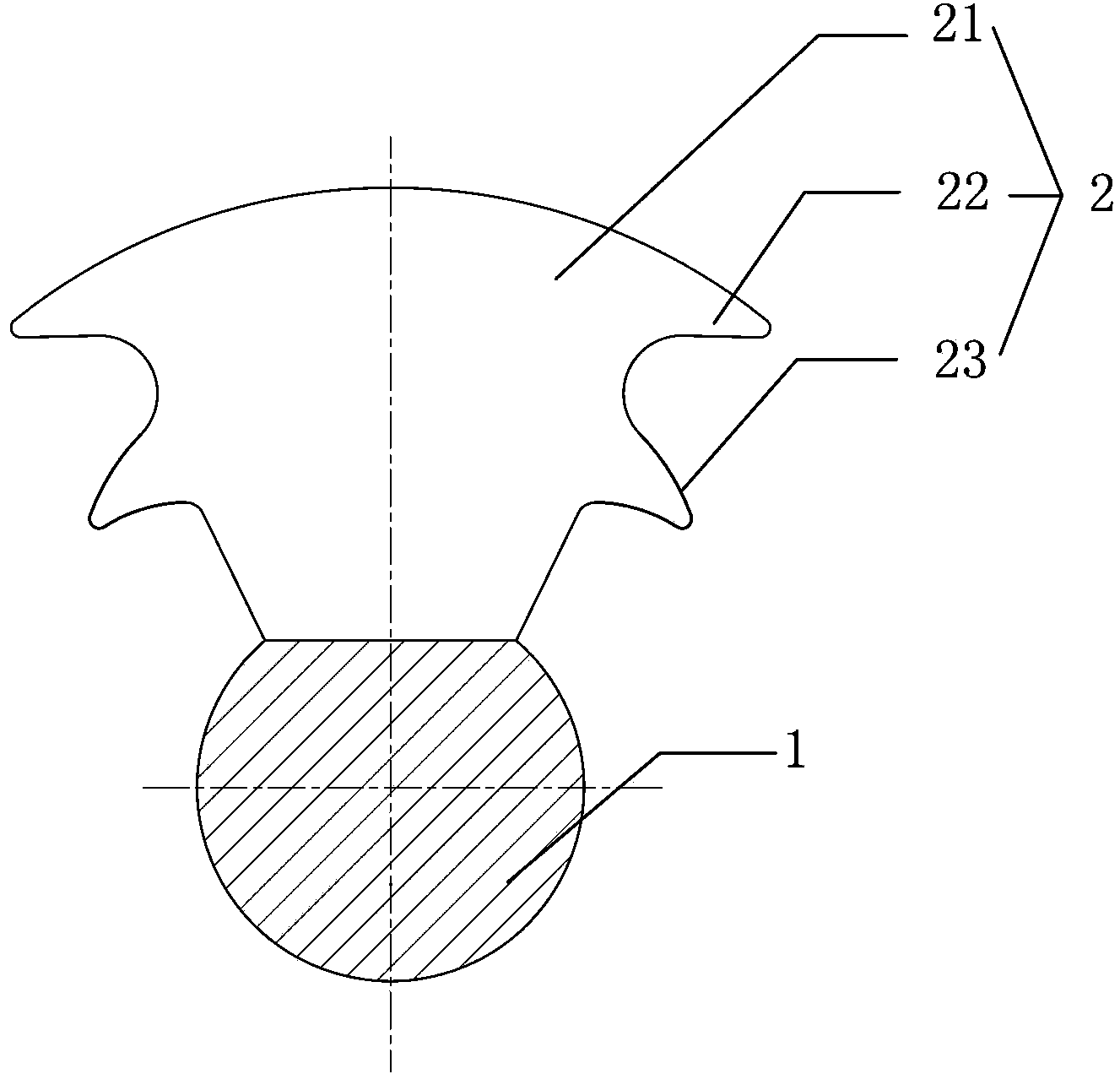

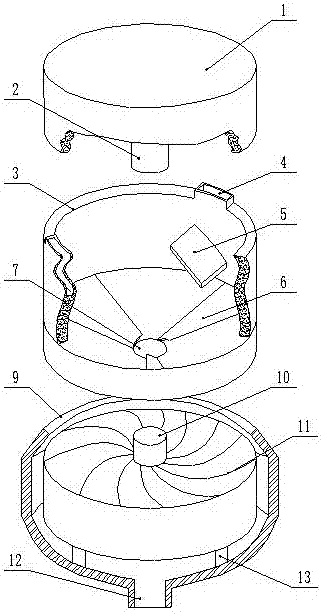

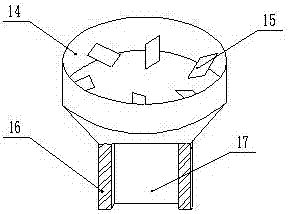

Crushing knife of crusher

The invention provides a crushing knife of a crusher. The crushing knife comprises a rotating shaft and a plurality of blades, wherein the blades are arranged on the rotating shaft; each blade comprises a body, an upper knife body and a lower knife body; the body is connected with the rotating shaft; the upper knife body is arranged on one end, which is far away from the rotating shaft, of the side part of the body; the lower knife body is arranged on the side part of the body and positioned between the rotating shaft and the upper knife body; the connecting position of the upper knife body and the body is in smooth transition, and the connecting position of the lower knife body and the body is in the smooth transition. The crushing knife provided by the invention has the advantages of simple structure, uniformity in crushing and good crushing effect and can be used for crushing garbage and also be used for crushing biomasses.

Owner:ZHEJIANG ZOKSEN ENVIRO ENERGY EQUIP

Environment-friendly smashing device with quantitative discharging function

InactiveCN106423387AGood crushing effectSpeed up the fallUsing liquid separation agentGrain treatmentsEnergy consumptionMechanical engineering

The invention discloses an environment-friendly smashing device with a quantitative discharging function. The environment-friendly smashing device comprises a device body. A silencing layer is arranged on the outer wall of the device body. A feed hopper is arranged on the upper side of the device body. A first rotary shaft is arranged on the upper side of the inside of the device body. A first squeeze roller is arranged on the outer wall of the first rotary shaft. A second rotary shaft is arranged below the first rotary shaft. A second squeeze roller is arranged on the outer wall of the second rotary shaft and arranged parallel to the first squeeze roller. Smashing teeth are arranged on the outer walls of the first squeeze roller and the second squeeze roller. According to the environment-friendly smashing device with the quantitative discharging function, the smashing teeth on the two squeeze rollers arranged vertically are engaged to smash materials, and the smashing effect is good; the two squeeze rollers are driven by one motor, so that the energy consumption is lowered; water mist can be sprayed into the device body through an atomizing device, the water mist fully covers the materials, the materials are humidified while dust is reduced, and the quality of the materials is guaranteed; and in addition, automatic discharging can be achieved, the discharging quantity in the discharging process can be controlled, and quantitative discharging is achieved.

Owner:ZHENGZHOU MOORE ELECTRONICS INFORMATION TECH CO LTD

Building waste smashing device with smashing rollers with grooves

InactiveCN108097359AGood crushing effectReduce the number of repeated crushingNon-rotating vibration suppressionGrain treatmentsExtrusionArchitectural engineering

The invention discloses a building waste smashing device with smashing rollers with grooves. The building waste smashing device comprises a shell, a base, a support plate and a feed hopper. A plurality of support springs and a damping block are fixedly connected between the support plate and the base. Two horizontally side-by-side pre-smashing rollers are arranged in a corresponding pre-smashing cavity under the feed hopper. The parts, corresponding to the lower portions of two movable plates, of a fixed seat are each provided with a downwards-concave smashing groove. The smashing rollers coaxial with the smashing grooves are arranged in the smashing grooves. A plurality of grooves which are concave toward the centers of the smashing rollers are evenly distributed on the side walls of thesmashing rollers. A plurality of protrusions are fixed to the inner walls of the smashing grooves. According to the building waste smashing device, extrusion and smashing are conducted through the twopre-smashing rollers which go close to each other, and the waste is pretreated. The smashing rollers are provided with the grooves, large-size building waste can enter the grooves, larger-size building waste is smashed, the waste achieves mutual extrusion in the smashing grooves, extrusion is enhanced through the protrusions, and the smashing effect is good.

Owner:ZHENGZHOU GUOZHI NETWORK TECH CO LTD

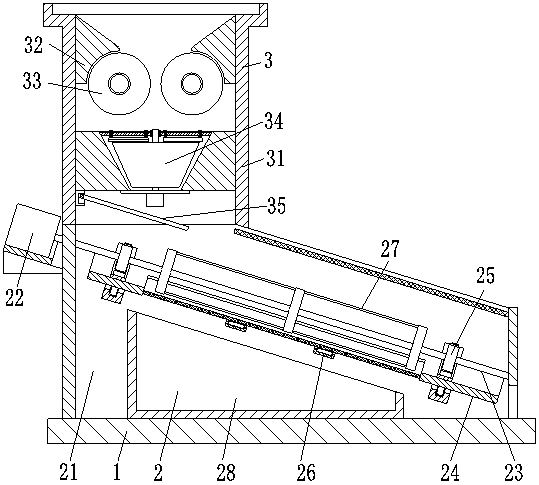

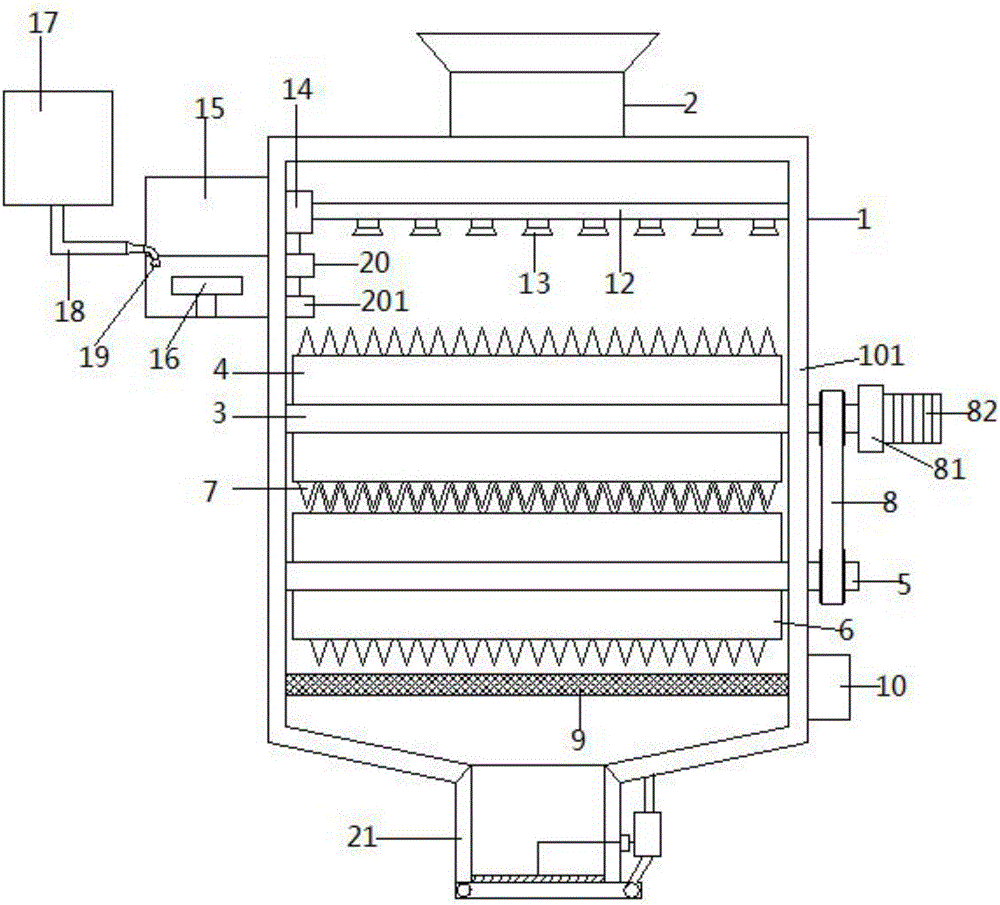

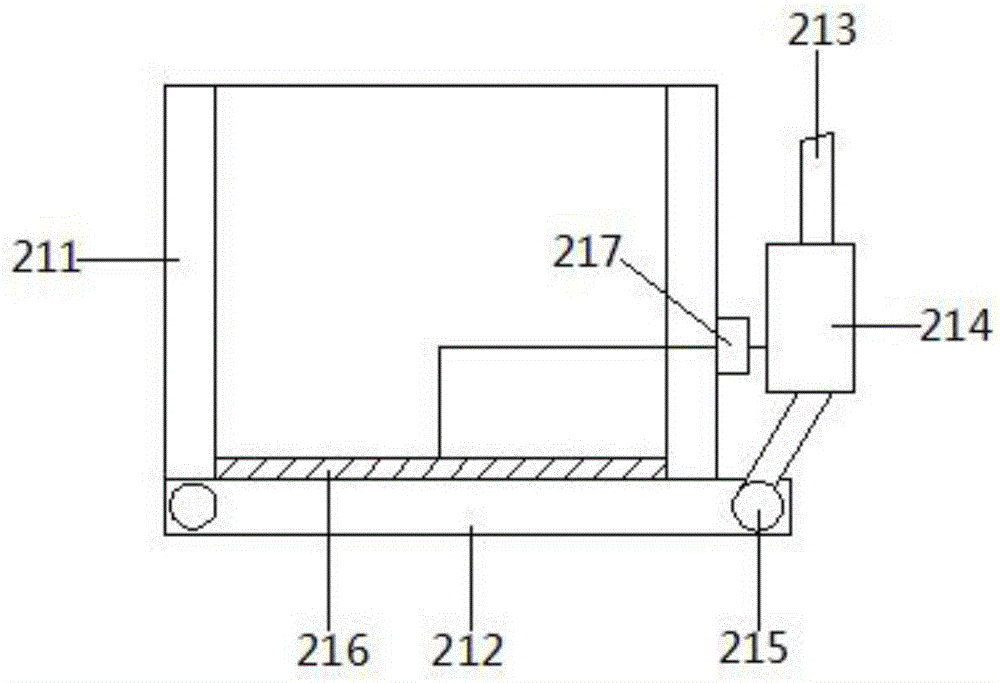

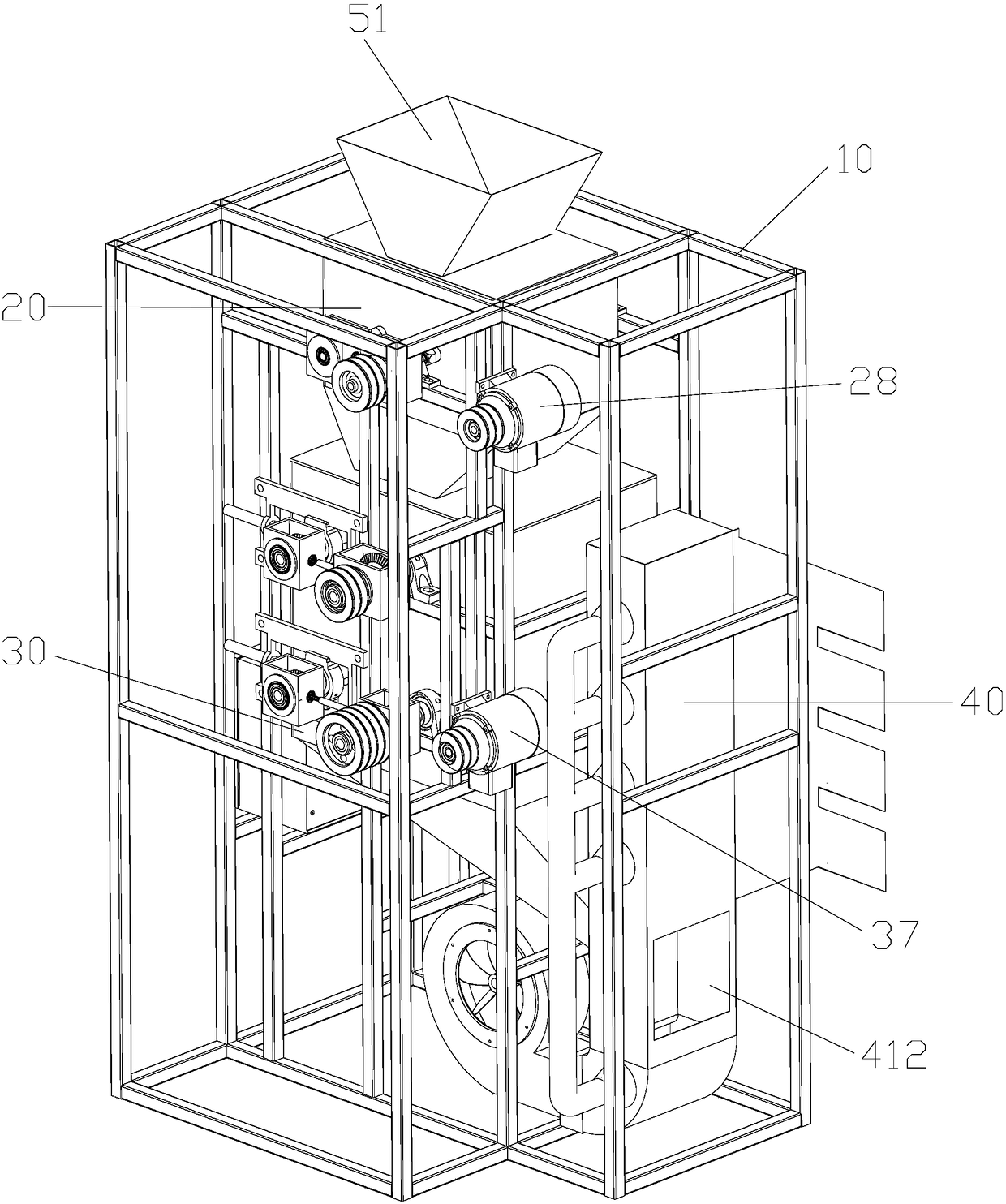

Cyclic type feed particle smashing device

ActiveCN108355754AGood crushing effectAvoid cloggingSievingFeeding-stuffEngineeringMechanical engineering

The invention discloses a cyclic type feed particle smashing device. The cyclic type feed particle smashing device comprises a smashing box body; a feeding port is formed in the top wall of the smashing box body; two first transmission shafts and two second transmission shafts are further arranged in the smashing box body; the two second transmission shafts are located on the two sides of the twofirst transmission shafts correspondingly; a worm segment is arranged at the lower end of a conveying auger; the two sides of the worm segment are engaged with two worm gears correspondingly arrangedon the two first transmission shafts which are each provided with an incomplete gear; the two second transmission shafts are each provided with a transmission gear; the two incomplete gears are correspondingly engaged with the two transmission gears; the two second transmission shafts are further provided with a knocking rod; the lower side end of the knocking rod is connected with the bottom wallof the smashing box body through a reset spring; and a knocking block is further arranged at the outer end of the knocking rod. The cyclic type feed particle smashing device is simple in structure and convenient to operate, avoids blockage of a screening net, meanwhile can perform cyclic smashing, and is good in effect and high in practicability.

Owner:贵阳富源饲料有限公司

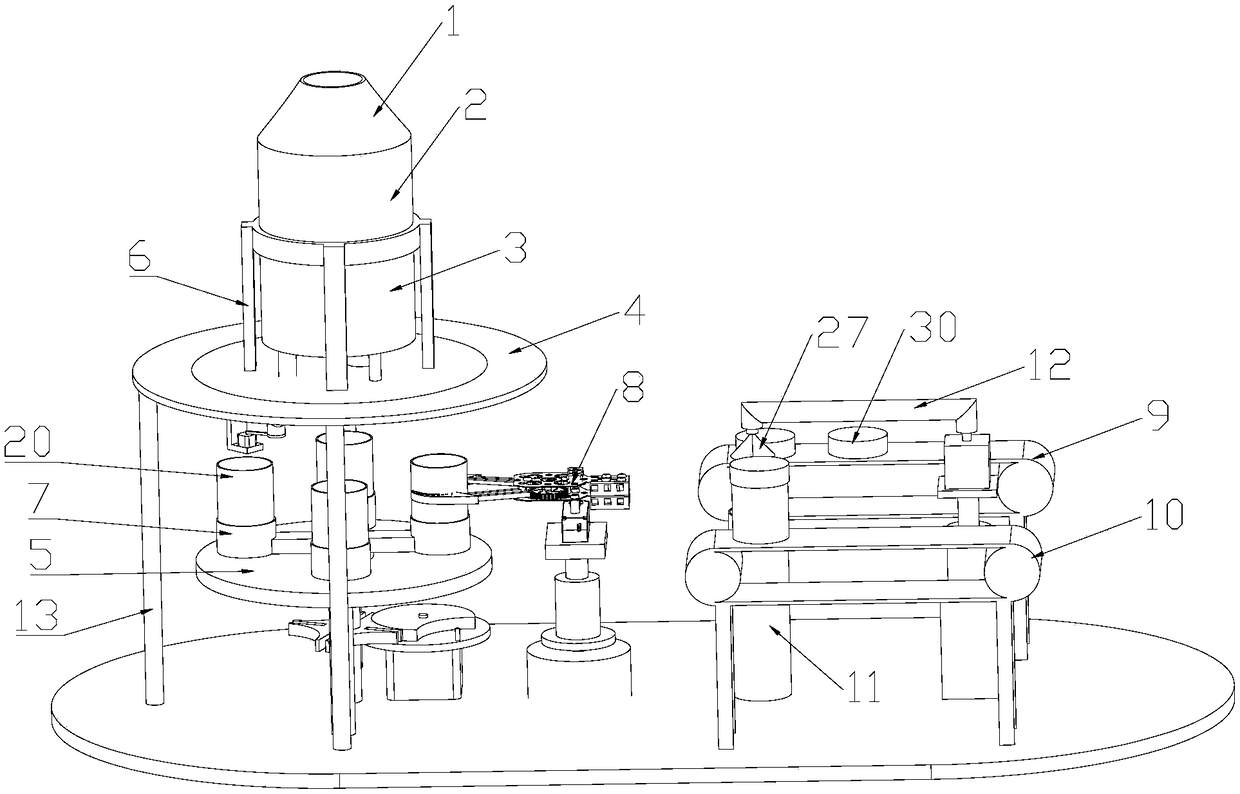

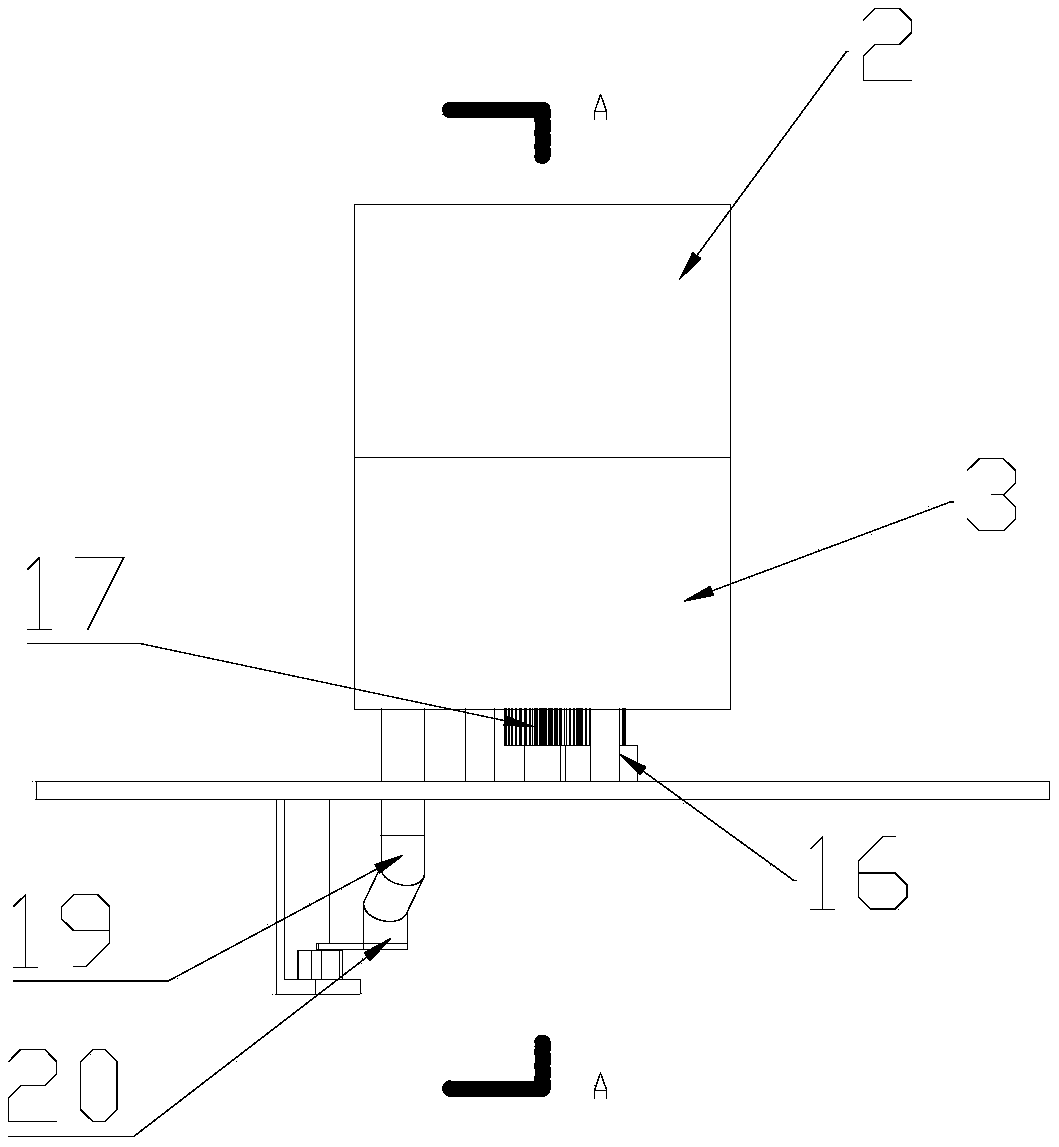

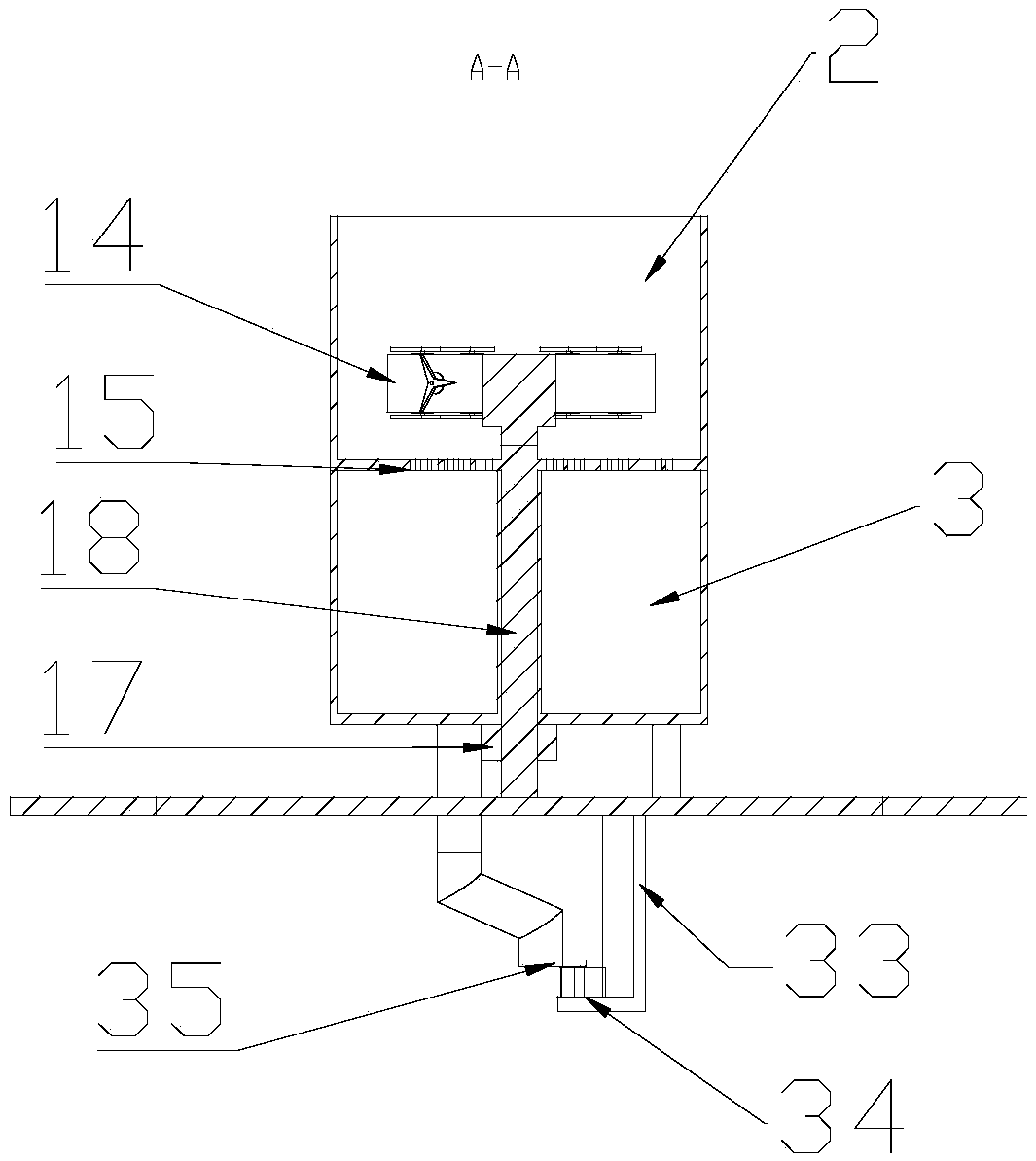

Automated traditional Chinese medicine grinding and filling device

InactiveCN108714462AGood crushing effectHigh degree of automationThreaded caps applicationSolid materialManipulatorEngineering

The invention relates to a medicine machine, in particular to an automated traditional Chinese medicine grinding and filling device. The automated traditional Chinese medicine grinding and filling device is characterized by comprising a rack, a grinding tank, a storage tank, a charging barrel rotary seat, a manipulator, a feeding conveyer belt, a discharging conveyor belt, a transferring table anda cap-tightening mechanism. The automated traditional Chinese medicine grinding and filling device is high in automation degree, manual participation is reduced, and the production efficiency is improved to meet the demands for automatic dispensing and efficient boiling of traditional Chinese medicine.

Owner:杭州显庆科技有限公司

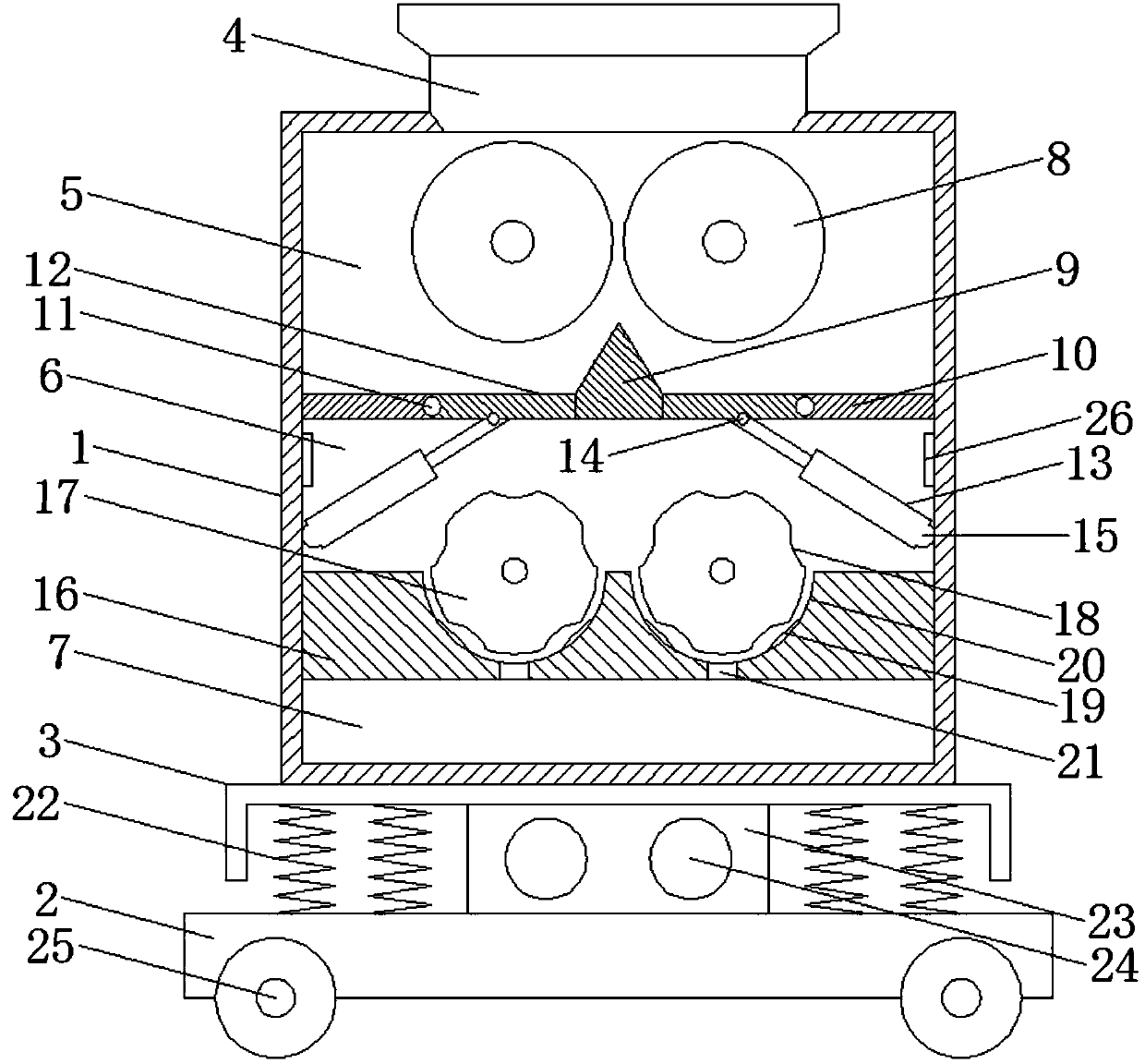

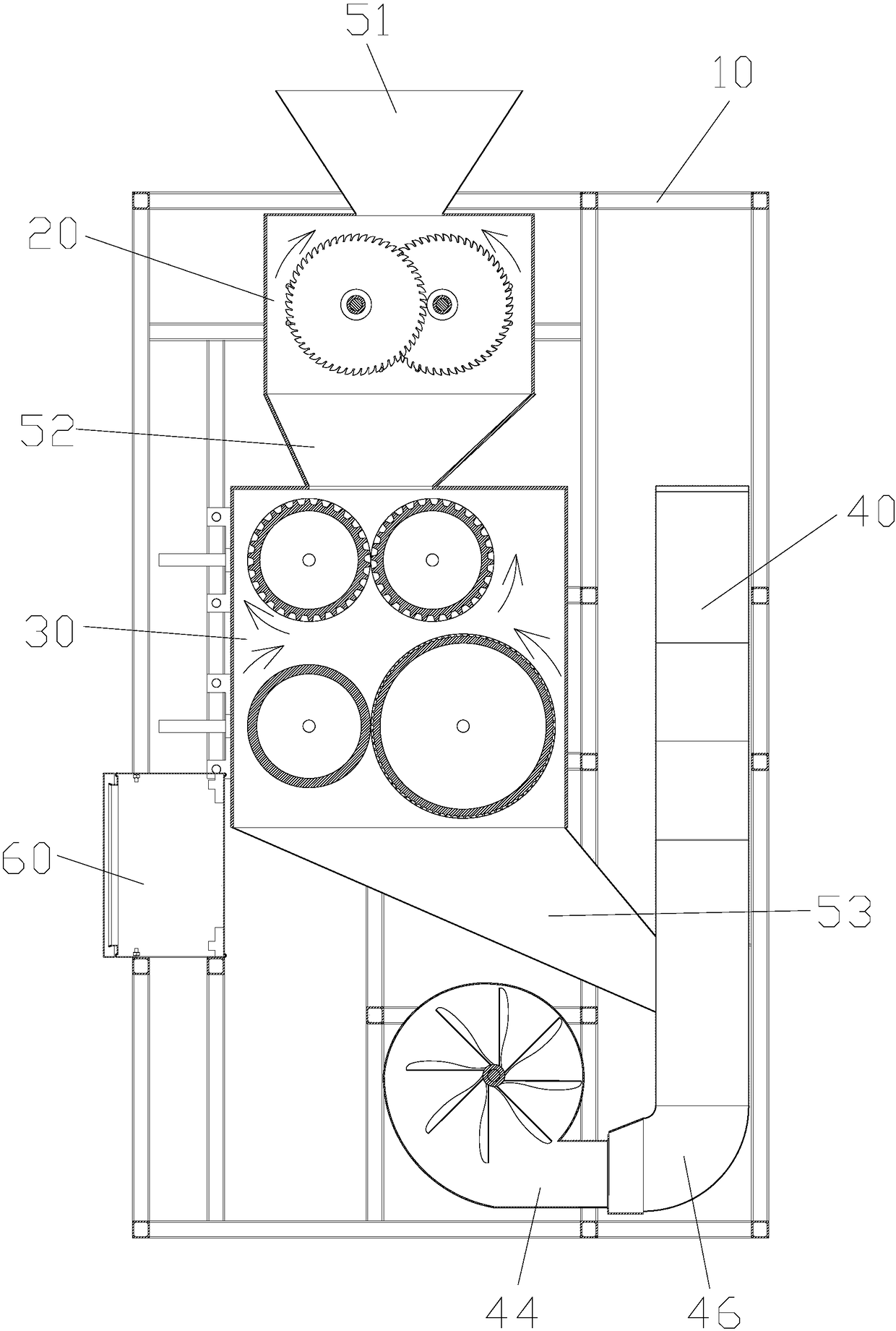

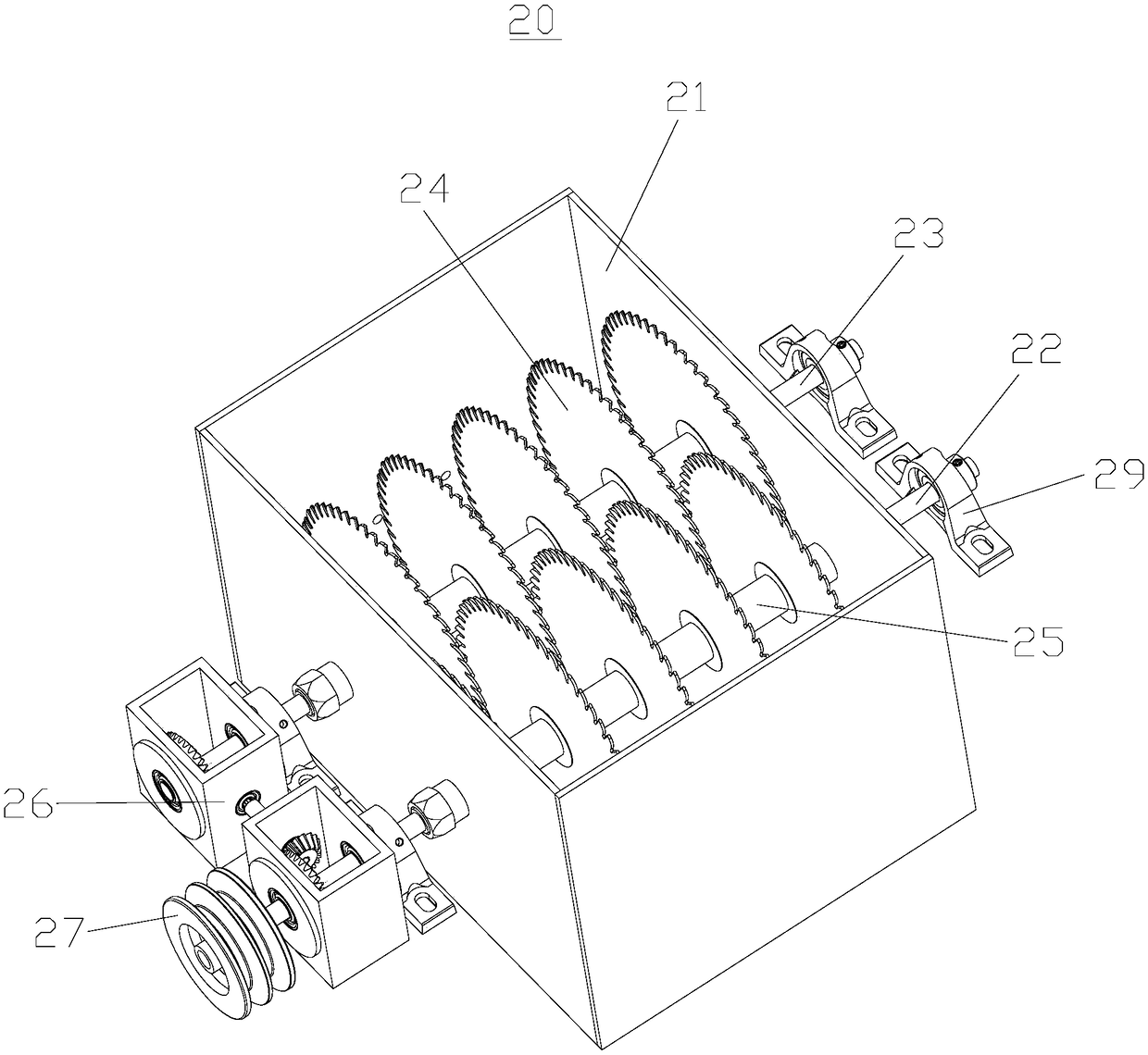

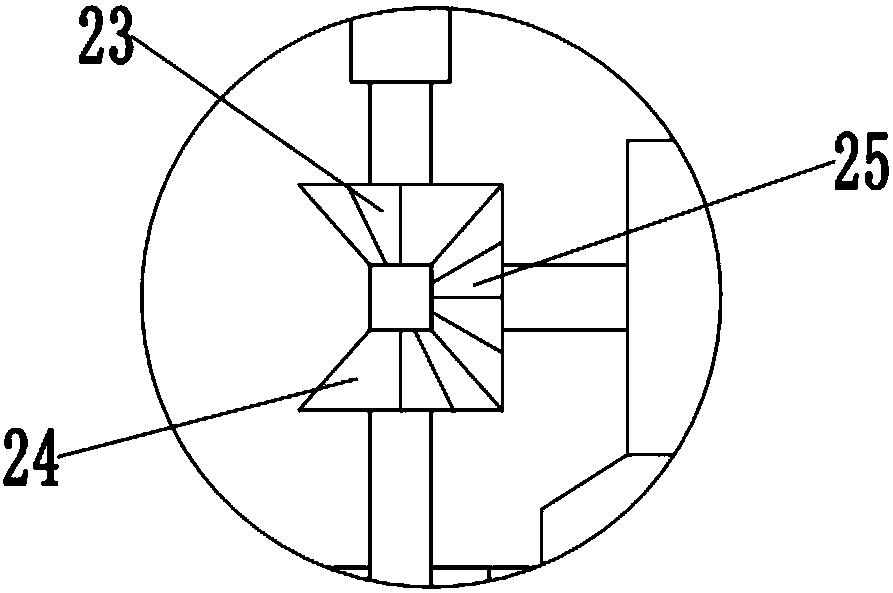

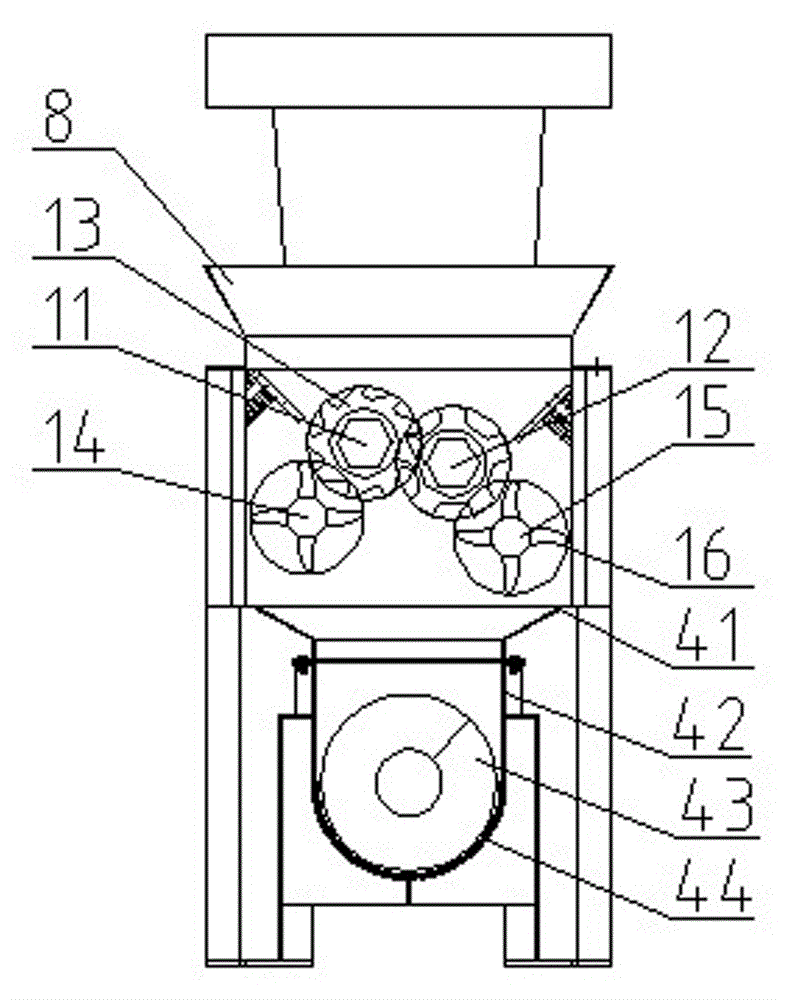

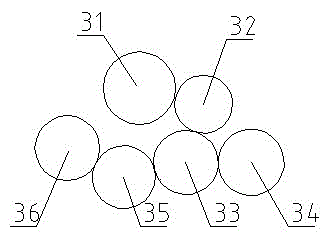

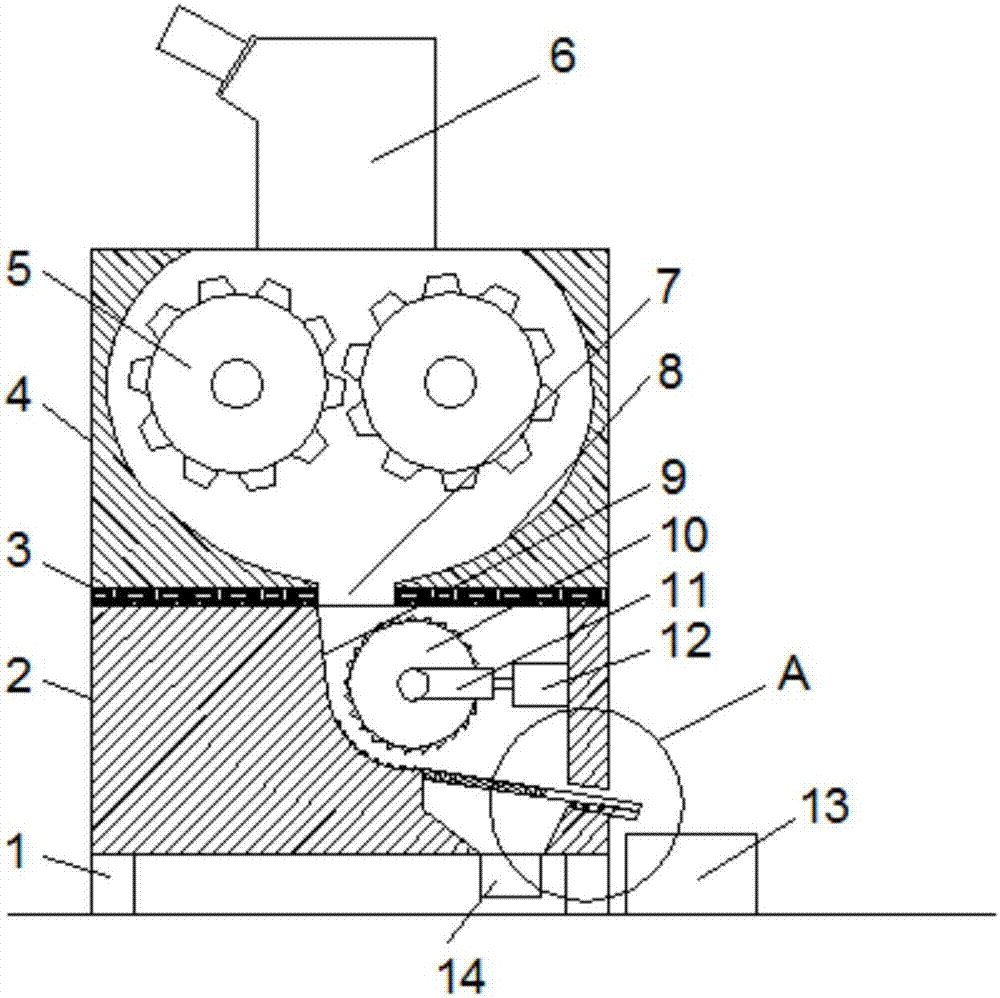

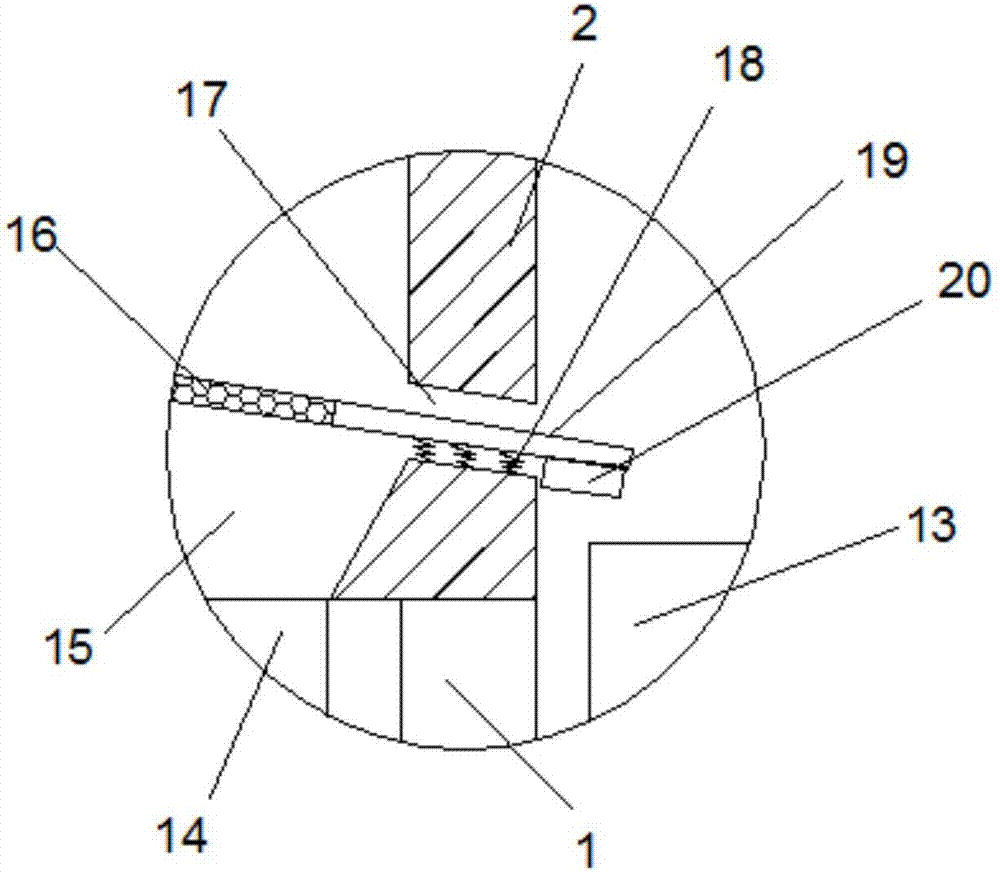

Comprehensive treating device for disassembling old shoes and recycling useful materials in old shoes

InactiveCN108453953AImprove recyclingGood crushing effectGas current separationPlastic recyclingEngineeringResource utilization

The invention relates to a comprehensive treating device for disassembling oil shoes and recycling useful materials in the old shoes. The comprehensive treating device comprises a coarse smashing module, a fine smashing module and a screening and separation module, wherein in the coarse smashing module, a plurality of saw blades are evenly arranged on two shafts and can perform opposite meshed high-speed rotation to coarsely smash the oil shoes; in the fine smashing module, four roller wheels are arranged in a cavity body regularly, two groovy rollers with the same inner diameter can achieve primary fine smashing on the old shoes through opposite meshed differential-speed rotation, two polishing rollers with the different inner diameters and two groovy rollers with the different inner diameters can achieve secondary fine smashing on the old shoes through opposite meshed equal-speed rotation, the screening and separating module can utilize an air blower to blow air to layer different masses of old shoe particles in the cavity body, and then the old shoe particles are classified and recycled. The comprehensive treating device disclosed by the invention can effectively smash waste shoes, the sizes of the smashed particles can be set as an adjustable mode according to need, the smashed materials can be screened and collected according to different masses, a resource utilization rate is improved, and environmental pollution caused by directly incinerating or burying the old shoes and resource waste are reduced.

Owner:WUHAN UNIV OF TECH

Feed multi-stage crushing device for animal husbandry cultivation

PendingCN110152850AGood crushing effectUniform sizeFeeding-stuffGrain treatmentsEngineeringMechanical engineering

The invention discloses a feed multi-stage crushing device for animal husbandry cultivation. The feed multi-stage crushing device comprises a bottom plate, a first crushing box and a second crushing box; a second rotating shaft is rotatably mounted at the middle position in the first crushing box; two first rotating shafts are symmetrically and rotatably mounted at the positions, on the left sideand the right side of the second rotating shaft, in the first crushing box; a plurality of mutually matched crushing blades are uniformly mounted on the first rotating shaft and the second rotating shaft; and the upper side and the lower side in the second crushing box are respectively provided with a coarse crushing roller and a fine crushing roller. According to the feed multi-stage crushing device, the second rotating shaft which continuously changes rotating direction in the first crushing box drives the first rotating shaft to rotate in the opposite direction, so that the feed is cut andcrushed by the crushing blades; and the feed is further crushed by the coarse crushing roller and the fine crushing roller, thus the crushing effect is excellent, the crushed feed particles are uniform in size, the crushing time is short, and the feed is advantageously subjected to subsequent processing.

Owner:连云港励尚信息科技有限公司

Convenient-to-discharge machining equipment for recycling and reusing glass

InactiveCN108714464AGood crushing effectReduce energy consumptionSievingScreeningElectric machineryReproduction

The invention discloses convenient-to-discharge machining equipment for recycling and reusing glass. The equipment comprises a shell; a discharging guide plate which is in an inclined state is fixedlyconnected with the inner lower part of the shell; a first motor base is fixedly connected with the lower right side of the discharging guide plate; a first motor is fixedly connected with the upper side of the first motor base; the output end of the first motor is fixedly connected with a deriving bevel gear; a longitudinal fixed shaft is rotatably connected with the inner bottom of the shell; adriven bevel gear is fixedly connected with the middle part of the longitudinal fixed shaft; the driven bevel gear is meshed with the driving bevel gear; the upper end of a longitudinal rotation shaftpenetrates through the discharging guide plate to be connected with a limiting ball; the outer side of the limiting ball is rotatably connected with a screening box; and a plurality of screening holes are formed in the bottom of the screening box. Compared with the prior art, the equipment has the beneficial effects that used glass is grinded and screened to obtain raw materials for glass machining, and the glass reproduction is carried out, so that the grinding effect and the glass production energy consumption is reduced.

Owner:伍君艺

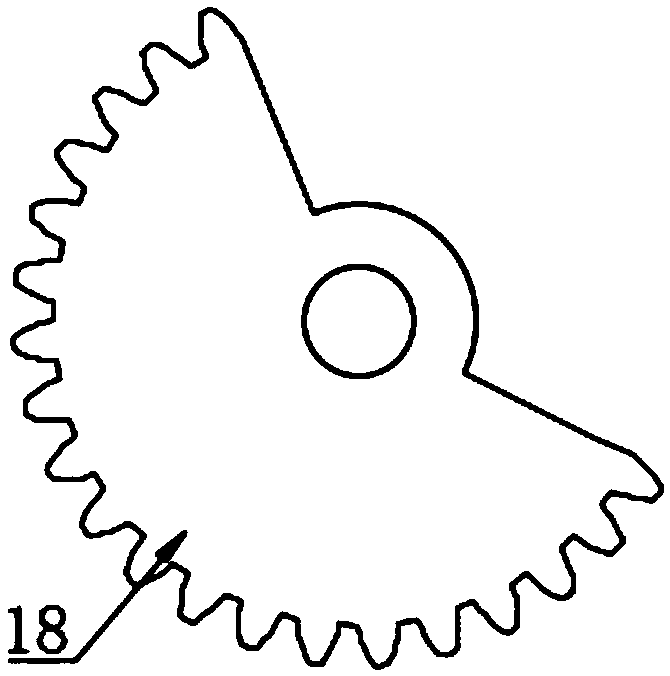

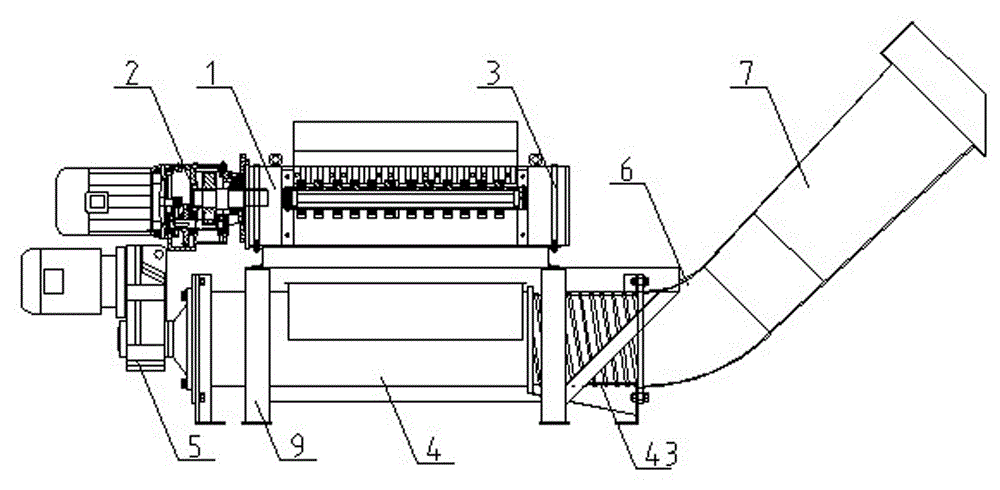

Solid rubbish smashing all-in-one machine

InactiveCN105032905AGood crushing effectSmash thoroughlySolid waste disposalGrain treatmentsPulverizerFunnel shape

The invention relates to a solid rubbish smashing all-in-one machine. The solid rubbish smashing all-in-one machine comprises a smashing machine and a pressing machine. A funnel-shaped feeding opening is formed in the top of the smashing machine. A discharging opening is formed in the bottom of the smashing machine. A double-shaft smashing blade set is arranged in the smashing machine. A shaving tooth assembly matched with the double-shaft smashing blade set is arranged slantly below the double-shaft smashing blade set. A speed reducer and a reduction gearbox are arranged at the left side of the smashing machine. The output end of the speed reducer is connected with the double-shaft smashing blade set. The double-shaft smashing blade set drives the shaving tooth assembly through the reduction gearbox to jointly move. The pressing machine comprises a horizontal cylindrical trough. The trough is installed on an installation support. A conical opening is formed in the top of the trough. A spiral conveying shaft is arranged in the trough. A liner plate is arranged on the inner wall of the trough. A motor is installed at the left side of the trough and connected with the spiral conveying shaft. A compressing pipe is communicated to the right side of the trough. Water draining holes are formed in the bottom of the compressing pipe. The smashing machine is installed on the top face of the trough, and the discharging opening of the smashing machine corresponds to the conical opening in the top of the trough.

Owner:JIANGSU HEHAI WATER SUPPLY & DRAINAGE EQUIP CO LTD

Grass drying and crushing apparatus

InactiveCN110291890AImprove crushing efficiencyGood crushing effectDrying gas arrangementsCuttersCrankshaftMechanical engineering

The invention relates to grass processing equipment, in particular to a grass drying and crushing apparatus, comprising a crushing chamber, a drying chamber, a feeding port, crushing motors and crushing blades. The drying chamber is connected fixedly to the upper surface of the crushing chamber; an upper blade rack and a lower blade rack are mounted inside the crushing chamber; a fixing rack is connected fixedly to the outer wall of the crushing chamber; a crankshaft is mounted inside the fixing rack; an upper connection rod is hinged to the end of the upper blade rack; a lower connection rodis hinged to the end of the lower blade rack; a crushing mechanism is mounted inside the crushing chamber; a segmenting mechanism is mounted inside the drying chamber; grass is dried via an air heaterand is segmented through the crushing blades; the grass is crushed primarily, so that blocking of the grass inside the drying chamber is prevented; the grass is chopped through the upper blade rack and the lower blade rack which can move side to side and can be crushed through the crushing mechanism, a distance between two crushing shafts can be adjusted to adjust grass crushing degree accordingto actual needs.

Owner:田玉琴

Efficient ore crushing device having forced feeding function

The invention discloses a high-efficiency ore crushing device with a forced feeding function, comprising a crushing device and a fine crushing device, the lower end of the fine crushing device is provided with a supporting foot, and the upper end of the fine crushing device is provided with a crushing device; There is a crushing cavity inside the device, and the upper end of the crushing device is provided with a feed hopper communicating with the crushing cavity, and two crushing rollers meshing with each other are arranged in the crushing cavity; the crushing rollers pass through the discharge port and the fine crushing device The fine crushing chamber inside is connected, the fine crushing chamber is provided with a mounting plate, the left end of the mounting plate is provided with a fine crushing roller, and the right end of the mounting plate is connected with the right wall of the fine crushing chamber through a hydraulic cylinder. The invention has reasonable structural design, convenient use, can force feeding, and realizes three-stage crushing, so that the crushing effect is better; realizes crushing of ores in different degrees, and processes ores of different volumes, thereby improving the practicability of the device; Vibration and momentum prolong service life.

Owner:阮霞伟

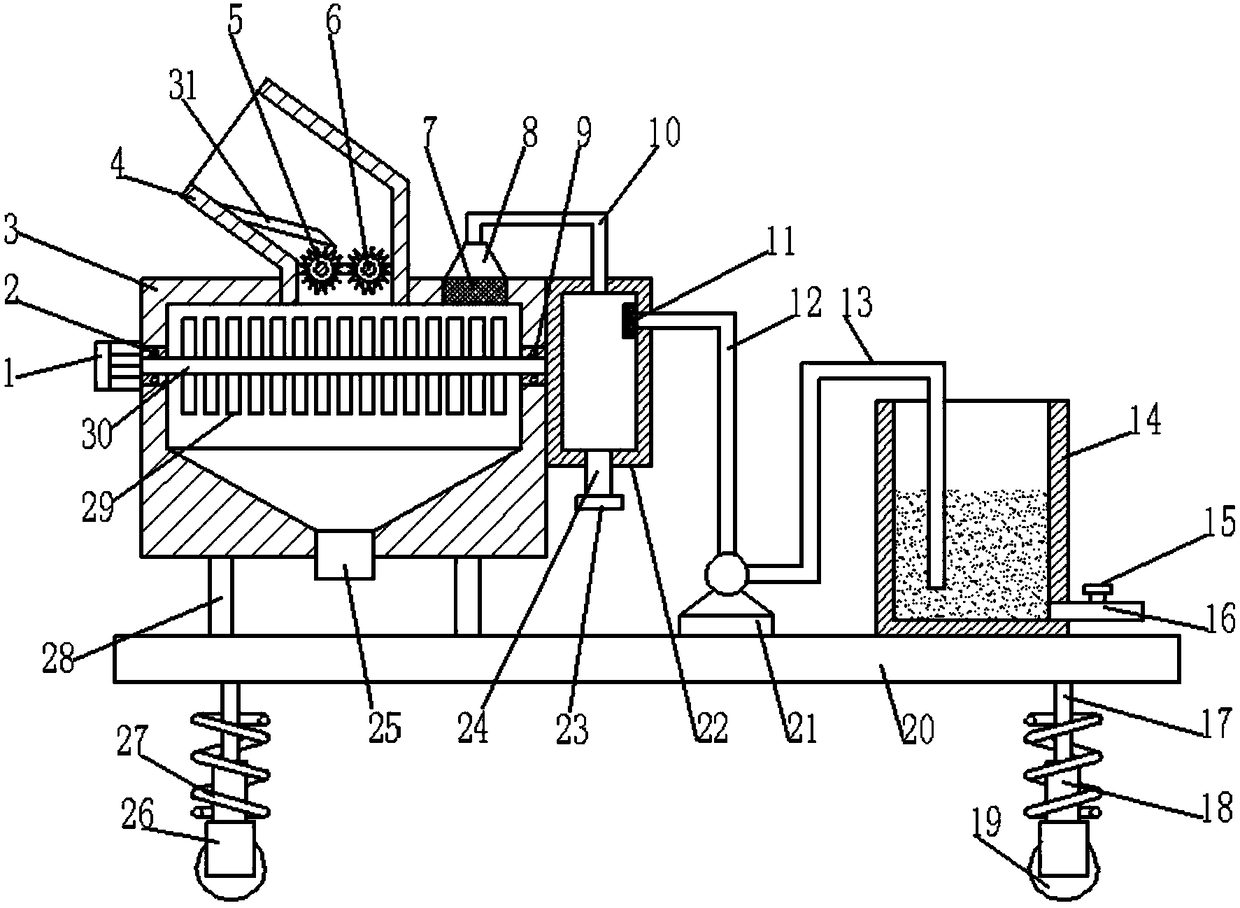

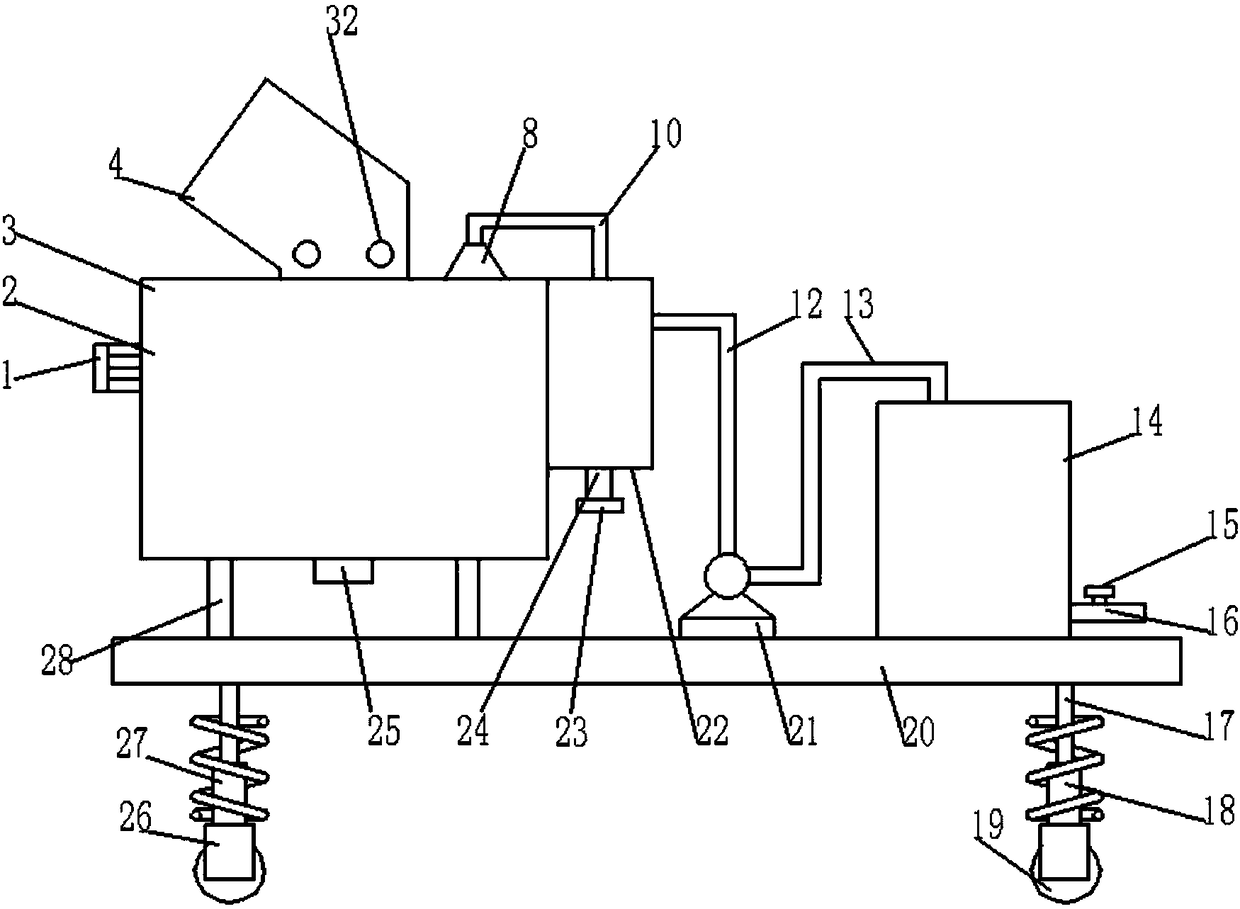

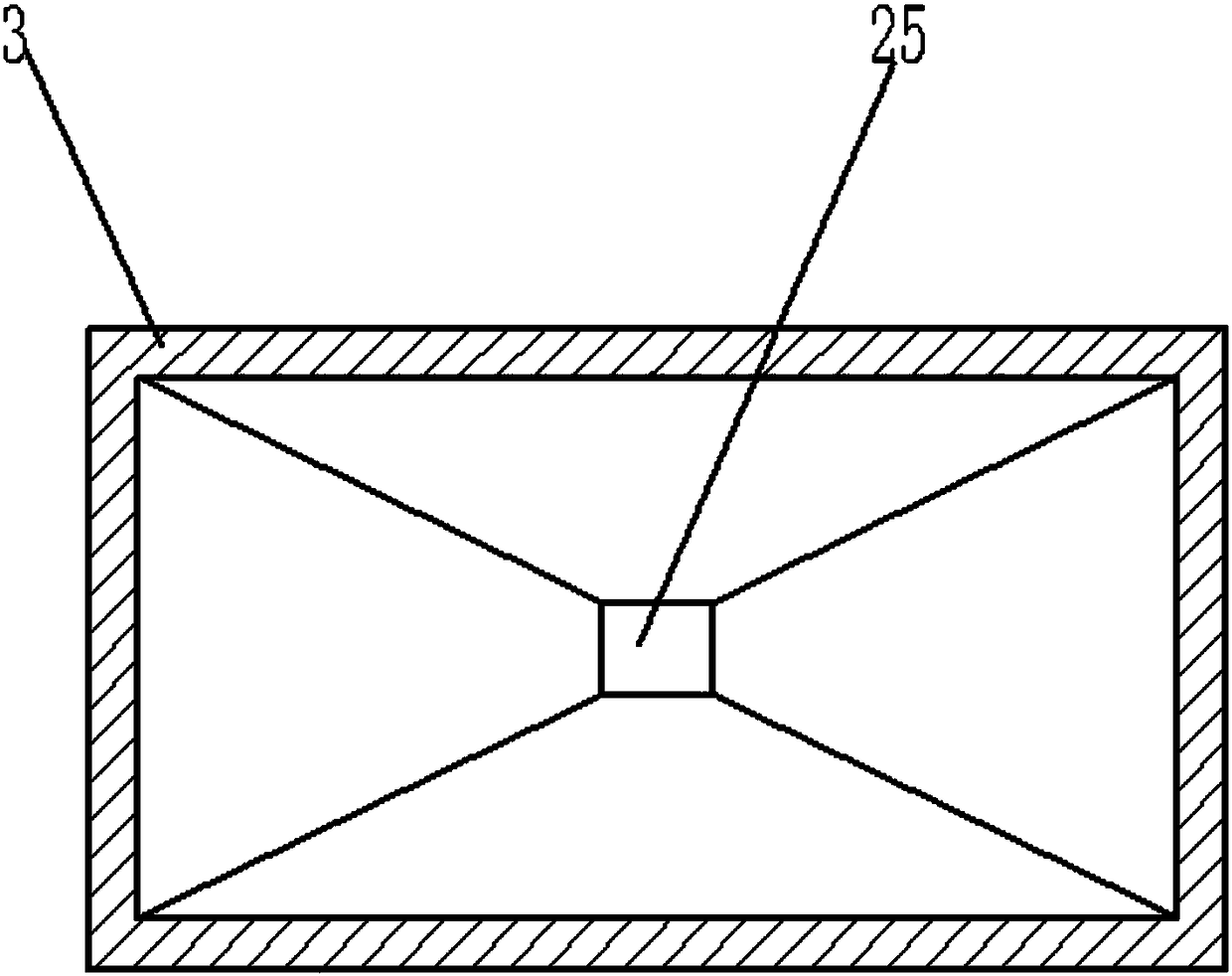

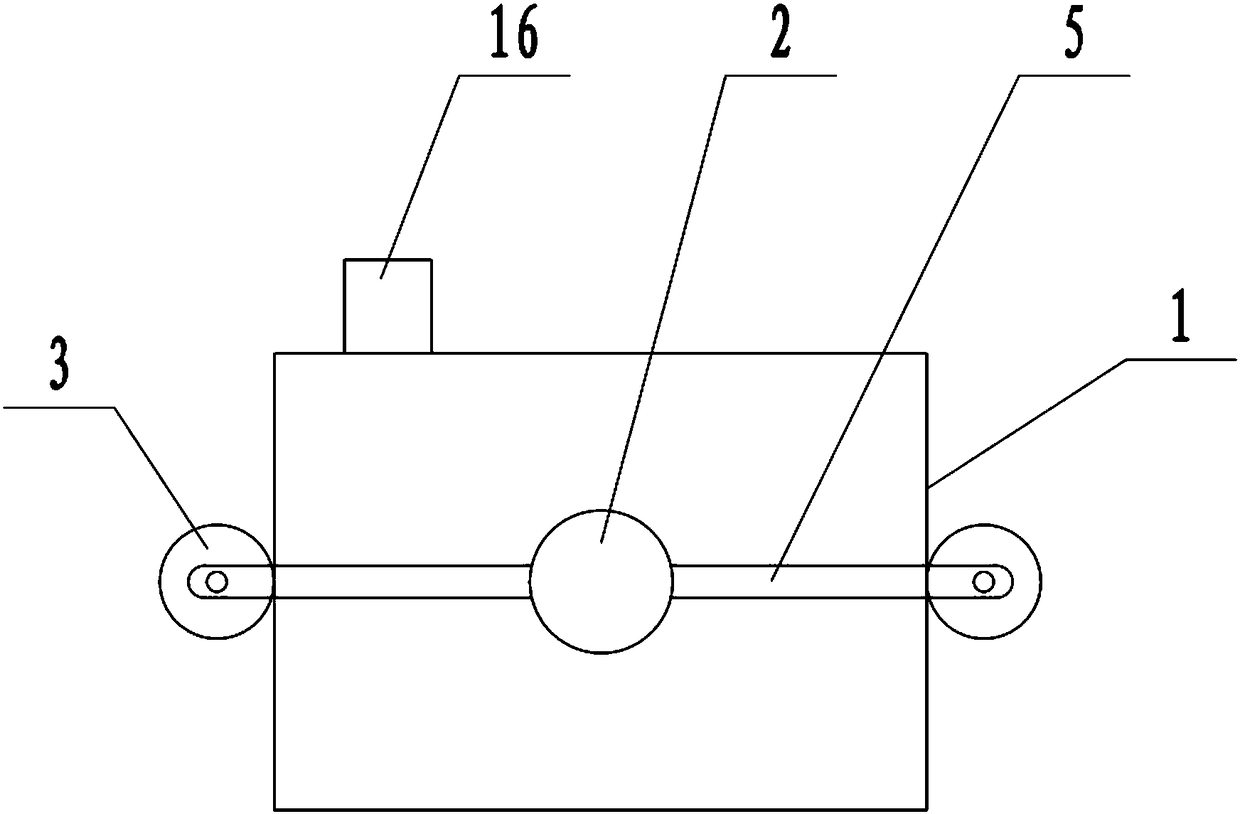

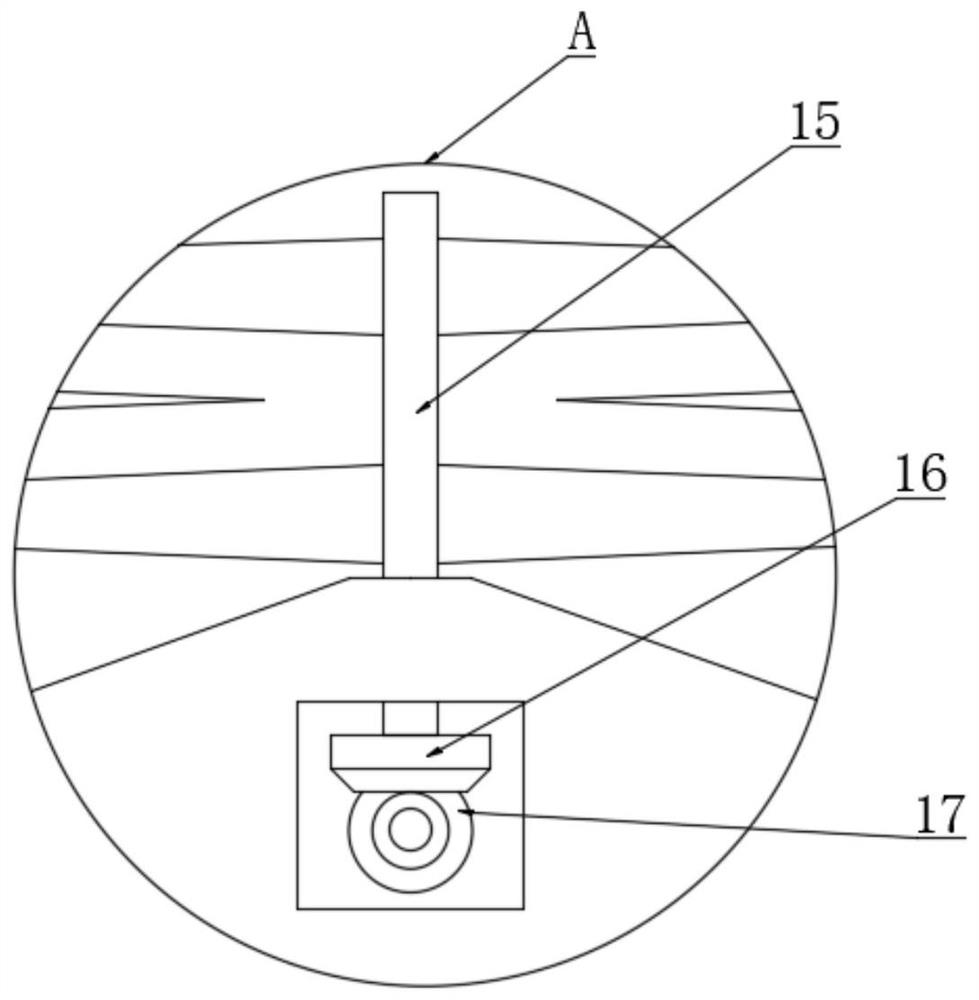

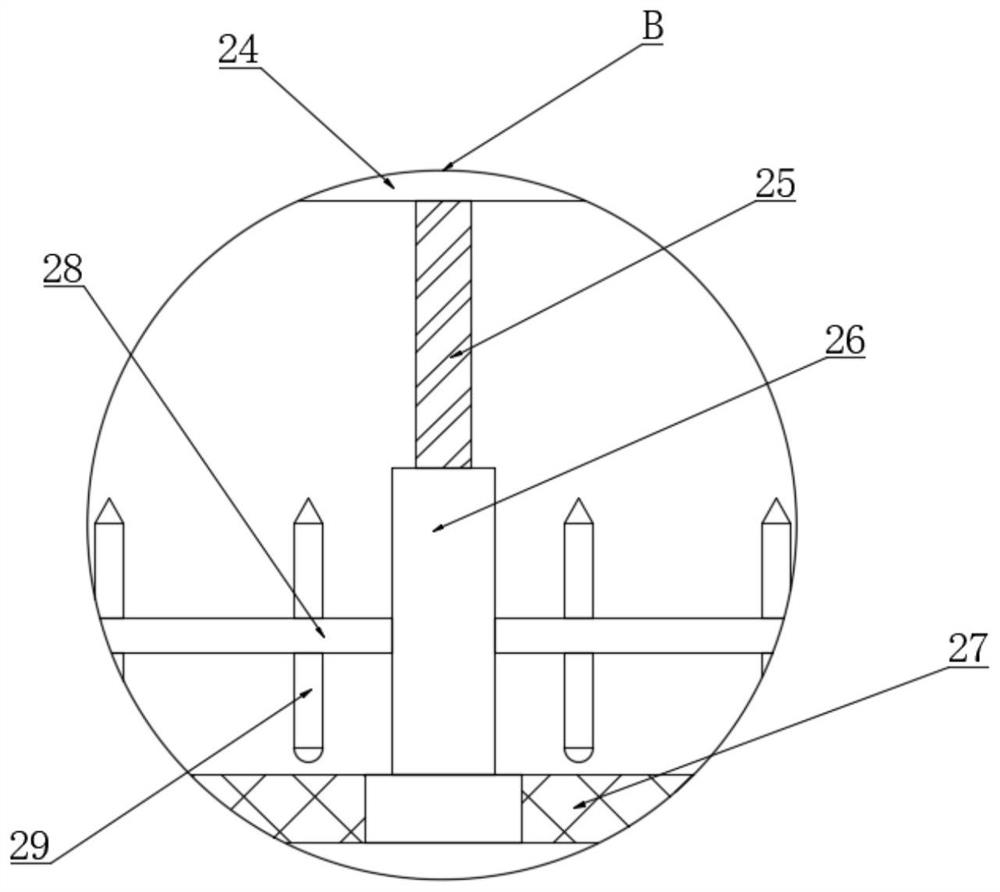

Solid-liquid separation-type garbage processing device

InactiveCN108927402AGood crushing effectEasy to cleanTransportation and packagingSolid waste disposalEngineeringLiquid waste

The invention discloses a solid-liquid separation-type garbage processing device. The solid-liquid separation-type garbage processing device comprises a case body, universal wheels are arranged at thebottom of the casebody, a brake mechanism is arranged at the universal wheels, the case body comprises a crushing bin and a filter bin, the top of the case body is provided with a first feeding portand a second feeding port, a first crushing chamber, a second crushing chamber and a buffer chamber are arranged in the crushing bin, the bottom of the buffer chamber is provided with a feeding opening, a filtering chamber is arranged at the top of the filter bin, a material-feeding channel is arranged at the bottom of the second feeding port, a filter plate is arranged at the bottom of the filtering chamber, a first hydraulic cylinder and a first telescopic rod are arranged on the top of the inner wall of the filter bin, a pressing plate is arranged on the inner side of the filtering chamber,the outer wall of the case body is provided with a second hydraulic cylinder and a second telescopic rod on one side of the filtering chamber, a push plate is arranged on one side of the second telescopic rod, a feeding port is arranged on one side of the outer wall of the filtering chamber, a baffle plate is arranged at the bottom of the inner wall of the feeding port, and a water outlet is arranged at the bottom of the outer wall of the filtering chamber. The processing device can treat the solid waste and the liquid waste separately, and the pulverization effect is good, and the cleaning is convenient.

Owner:李天意

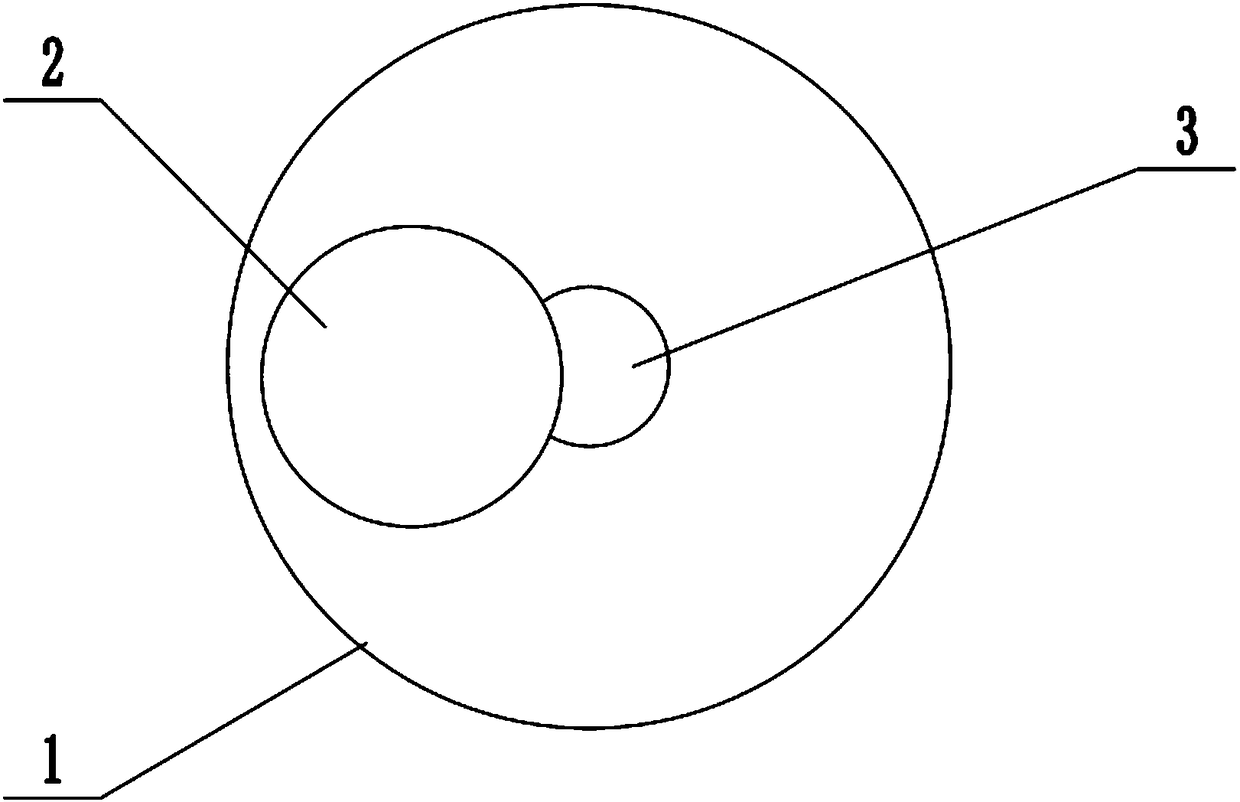

Grinder for tomato crushing

The invention relates to the technical field of crushing or cutting combination, in particular to a grinder for tomato crushing. According to the scheme, high-pressure compressed gas in a gas supply box is pumped in high-pressure cavities of a first gas knife and a second gas knife to form a balanced sheet gas flow in the length directions of the first gas knife and the second gas knife correspondingly after a gas flow passes through a narrow, fine and thin gas outlet, and the generated sheet gas flows are utilized, so that cutting crushing of tomatoes is achieved. The sheet gas flow formed by the second gas knife directly acts on a sector plate on a conical groove after cutting off the side portions of the tomatoes, an grinding disc rotates accordingly, the tomatoes enter a lower grinding disc from a grinding passageway, and thus the thorough grinding crushing effect on the tomatoes is achieved through the grinding effects of the upper grinding disc and the lower grinding disc.

Owner:CHONGQING ZHOUYI FOOD CO LTD

Coating stirring and mixing device for constructional engineering

InactiveCN112892353AGood crushing effectGood mixing effectTransportation and packagingMixer accessoriesPhysicsGrinding

The invention discloses a coating stirring and mixing device for constructional engineering, belongs to the technical field of constructional engineering, and solves the problem of poor stirring and mixing effects of an existing coating stirring and mixing device. The device is technically characterized in that the coating stirring and mixing device comprises a first box body; a powder coating is put into the first box body through a feeding hopper; a first motor is started, and thus stirring blades on a first stirring shaft and a second stirring shaft are driven to alternately rotate for stirring; a screen frame is driven to vibrate up and down for screening; stirring blades on a third stirring shaft are driven to rotate for stirring; a double-shaft motor is started,and thus a first auger blade is driven to place the powder coating into a second box body; a third motor is started, and thus a second screen compression spring performs vibration screening, and a grinding rod rotates constantly to grind; a water pump is started, and thus hot water is sprayed out from through holes in a stirring frame to be mixed, and stirring blades on the stirring frame are used for stirring and mixing; and second auger blades on a second conveying shaft rotate to convey the stirred coating out. The stirring and mixing device has the advantage of being good in stirring and mixing effect.

Owner:王涛

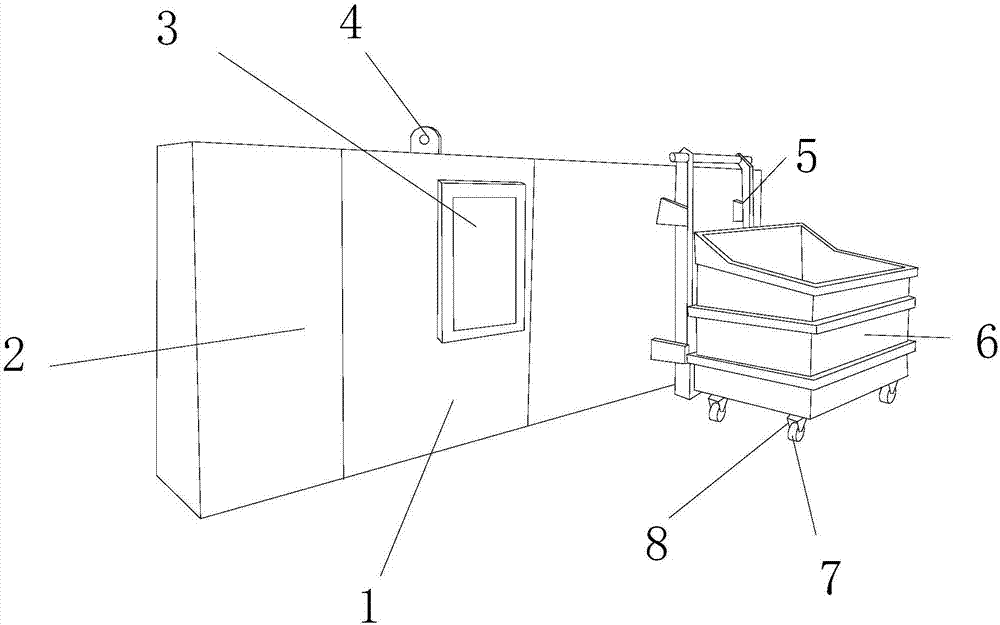

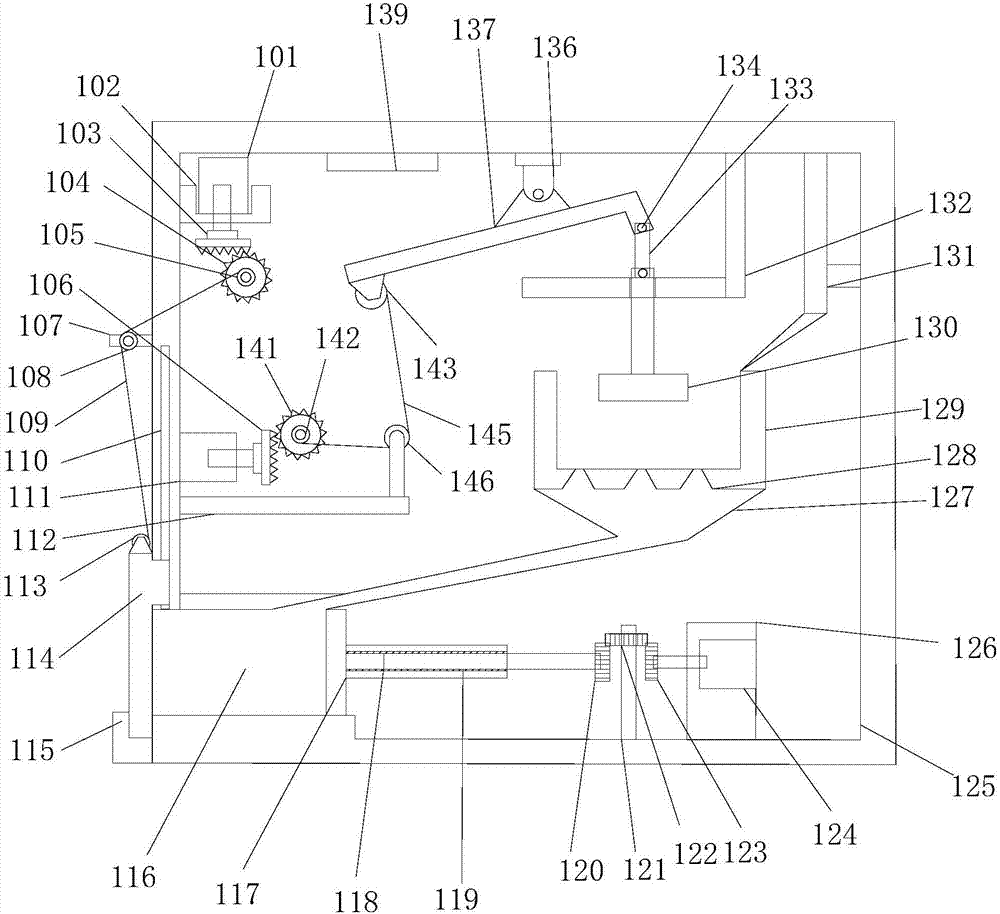

Waste garbage recycling processing equipment for production of solar panel components

InactiveCN107876129AGood crushing effectLow placementWaste accumulators reclaimingGrain treatmentsWaste management

The invention discloses waste garbage recycling processing equipment for production of solar panel components. The waste garbage recycling processing equipment structurally comprises a garbage recycling device, a machine body, a viewing window, a lifting lug, a fixing bracket, a containing frame, connecting blocks and movable wheels. The garbage recycling device is mounted in the machine body. Theside face of the viewing window is embedded into the front surface of the machine body. The top of the machine body is vertically connected with the bottom of the lifting lug. The back of the fixingbracket is fixedly connected with the front side of the right end of the machine body. The connecting blocks are sequentially connected into a rectangular structure and arranged at the bottom of the containing frame. The side faces of the movable wheels are movably connected with the interiors of the corresponding connecting blocks. By the adoption of the garbage recycling device of the waste garbage recycling processing equipment for production of the solar panel components, the garbage smashing processing effect is remarkable, the working efficiency is high, the operation is easy and fast, besides processed garbage can be compacted, the occupied position of the garbage is reduced, placing and transportation are more facilitated, and the practical value of the equipment is increased.

Owner:乐志堡

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com