Patents

Literature

138results about How to "Improve recycling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

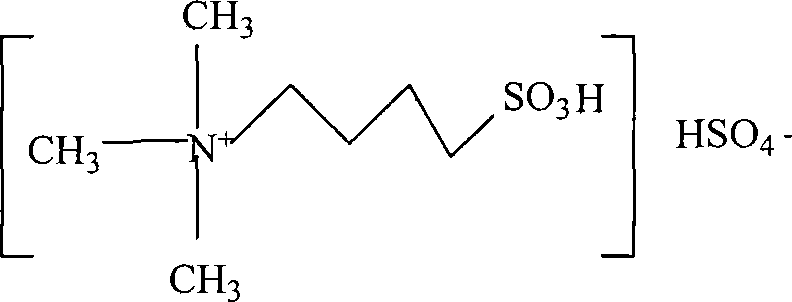

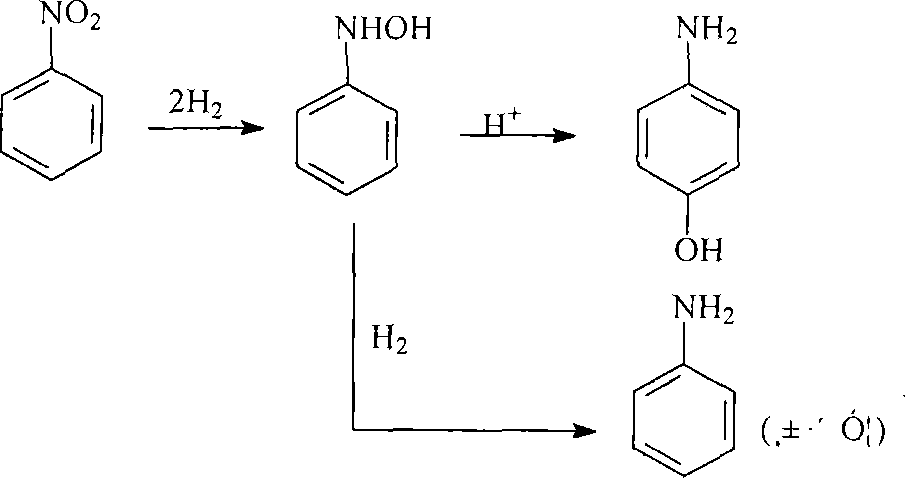

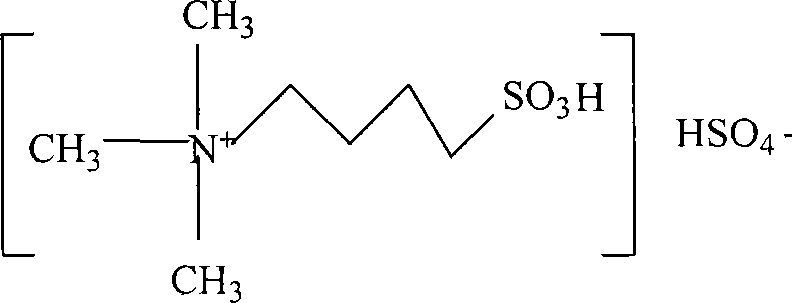

Quaternary ammonium ionic liquid as well as preparation and application method thereof

InactiveCN101182300AUnique physical and chemical propertiesReduce corrosionOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsMolecular compositionHydrogen Sulfate

A quaternary ammonium salt ionic liquid of the present invention and its preparation and application methods belong to quaternary ammonium compounds, and its molecular composition is N, N, N-trimethyl-N-sulfobutyl-ammonium bisulfate, and its molecular formula is [HSO3-b -N(CH3)3]HSO4, the structural formula is as follows: the quaternary ammonium salt ionic liquid of the present invention is non-corrosive equipment and environment-friendly, and the quaternary ammonium salt ionic liquid catalyst of the present invention is used for nitrobenzene catalytic hydrogenation to synthesize p-amino The phenol reaction is a liquid phase method, the reaction temperature is 60-130° C., and the PAP yield reaches 19.5-88%.

Owner:HEBEI UNIV OF TECH

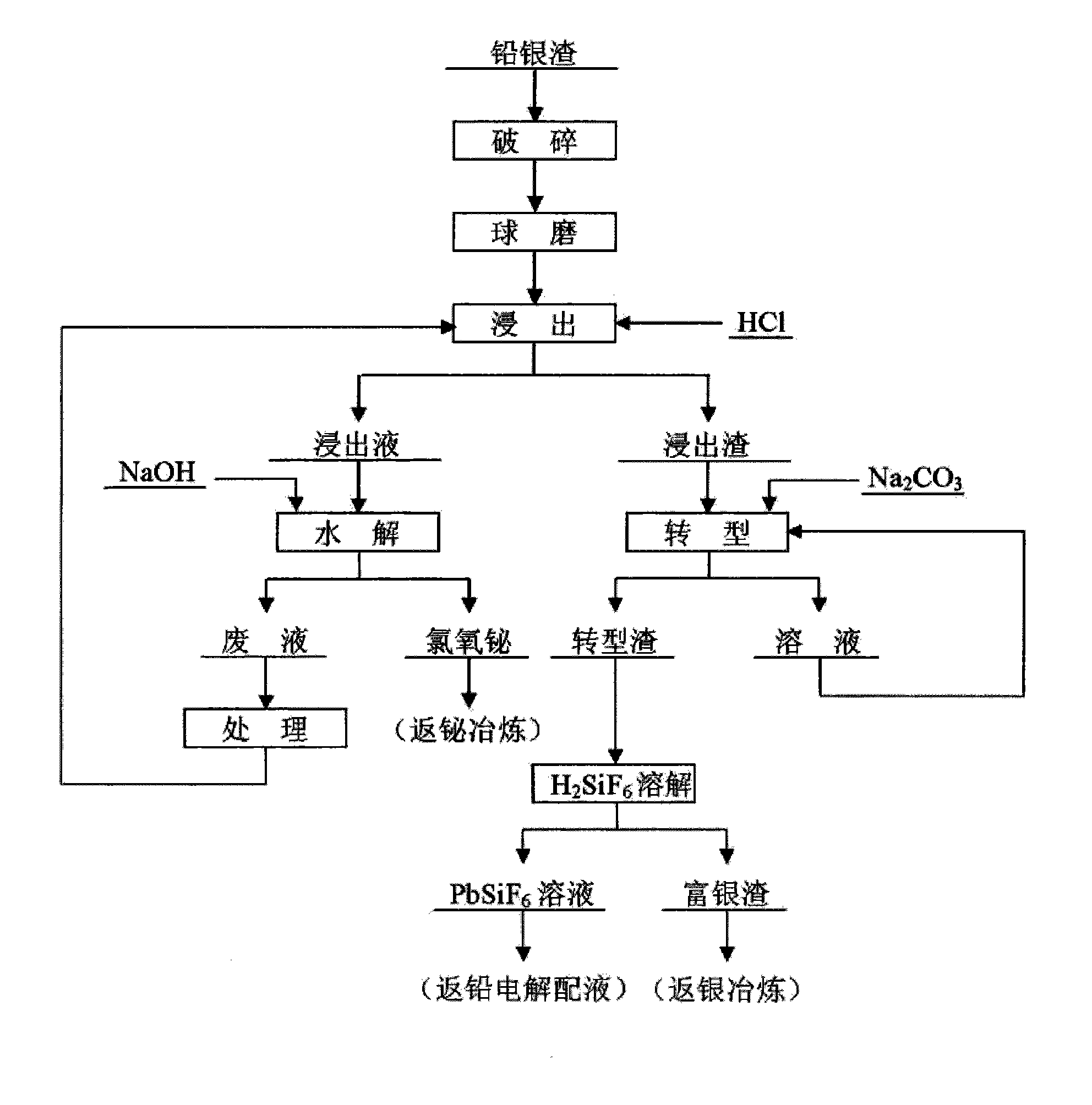

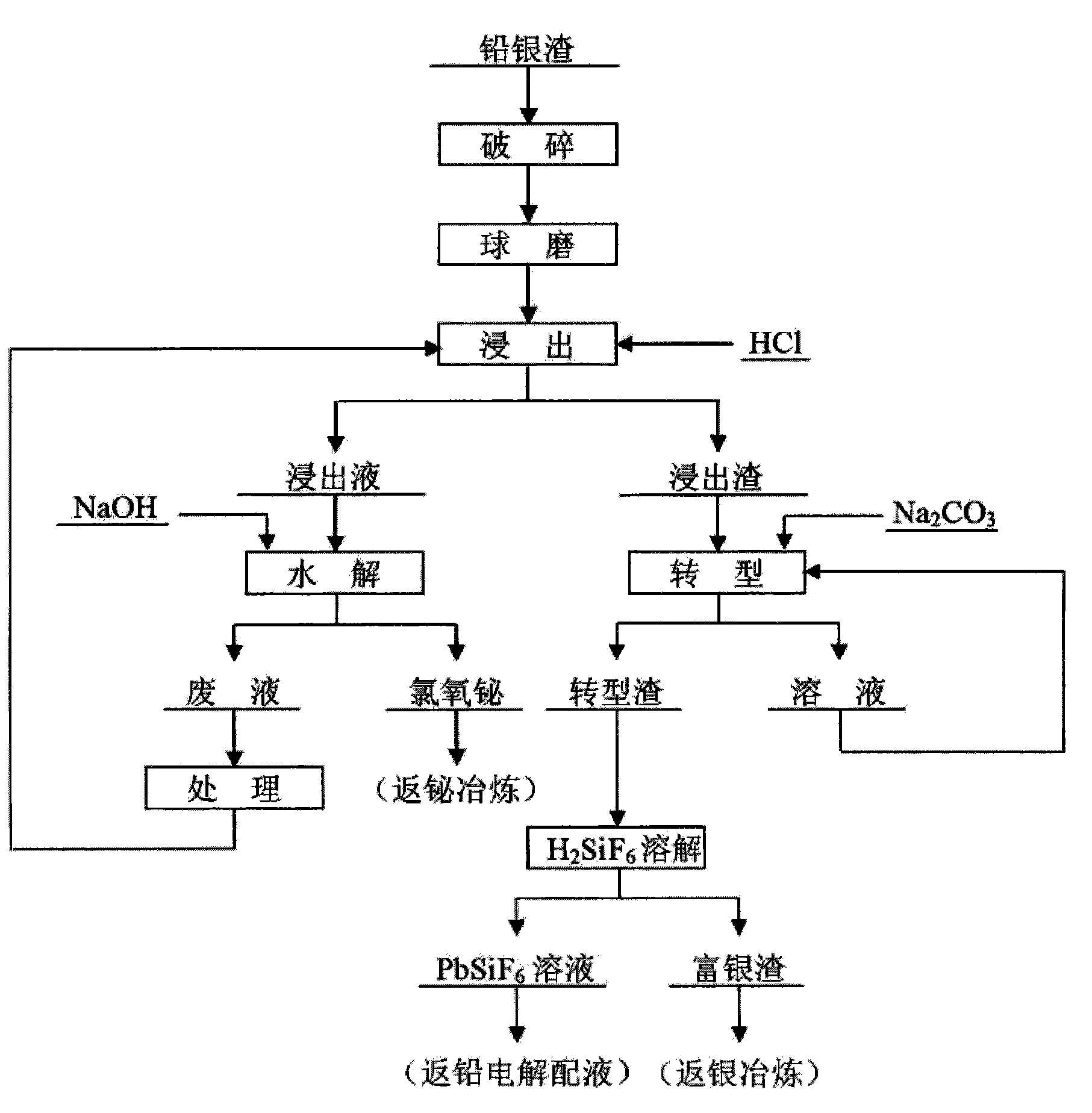

Wet process for lead-silver residues

ActiveCN102031383ANo pollution in the processSimple processProcess efficiency improvementElectrolysisBismuth oxychloride

The invention discloses a wet process for lead-silver residues, which comprises the following major steps: crushing lead-silver residues, carrying out ball milling, leaching with dilute hydrochloric acid, adding sodium hydroxide to the leached solution to hydrolyze so as to generate bismuth oxychloride as a precipitate, transferring the bismuth oxychloride to a bismuth smelting system, and treating the hydrolysis waste solution for cyclic use; and transforming the leached residues with sodium carbonate, then recycling the mother solution, dissolving the transformed residues in silicofluoric acid, filtering the residues to obtain silver-enriched residues, transferring the silver-enriched residues to a silver smelting system, and using the obtained lead silicofluoride solution for preparing a lead electrolyte. The invention has the advantages of simple flow and no environmental pollution; by preparing lead in lead-silver residues into lead silicofluoride used as the electrolyte, the input amount of yellow lead in the lead electrolysis system is reduced; by dissolving lead in silicofluoric acid, silver-enriched residues with a silver content up to more than 60% can be directly obtained, and the direct silver yield is high; the overall system realizes the cyclic use of the solution, and the comprehensive recycling degree is high; and the treatment time is short, and the comprehensive cost is low.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

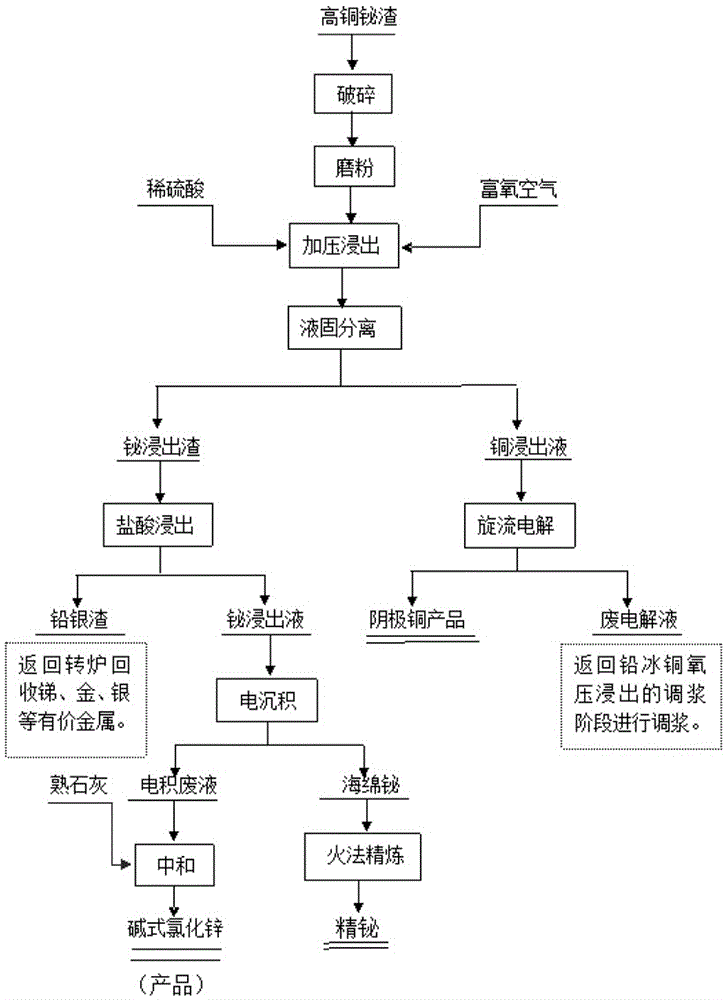

Method used for selective high-efficiency extraction of copper and bismuth from high-copper bismuth slag

InactiveCN106566928AStrong raw material adaptabilityEasy to operateProcess efficiency improvementBismuthPyrometallurgy

The invention discloses a method used for selective high-efficiency extraction of copper and bismuth from high-copper bismuth slag. According to the method, high-copper bismuth slag is taken as a raw material; high-copper bismuth slag powder obtained via smashing, grinding, and sieving and a sulfuric acid solution are subjected to size mixing at a certain ratio, and are delivered into a high-pressure autoclave; rich oxygen is introduced into the high-pressure autoclave, and oxygen pressure in the high-pressure autoclave is controlled for oxidizing leaching, wherein in the oxidizing leaching process, leaching of Cu in the form of Cu2+ is realized, and selective separation of copper with other non-zero valent elements is realized; a copper-containing leachate is subjected to acid adjusting, and is subjected to rotational flow electrolysis directly so as to extract copper in the copper-containing leachate and obtain copper products; a leaching residue is subjected to leaching separation of bismuth with concentrated hydrochloric acid, sponge bismuth is obtained via electro-deposition, and product refined bismuth is obtained via refining of sponge bismuth; and the rest slag is delivered into a lead pyrometallurgy system for comprehensive recycling of non-zero valent elements such as Pb, Ag, and Au. No environment pollution is caused by the method, no three wastes are discharged, and the method is a clean metallurgy technology.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

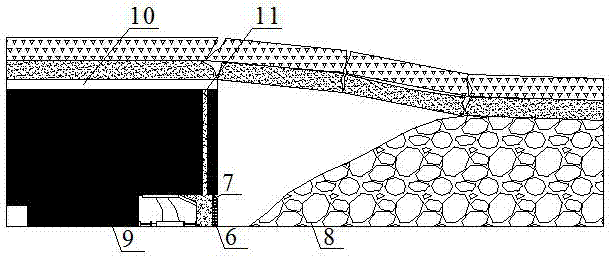

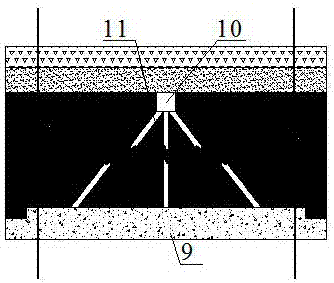

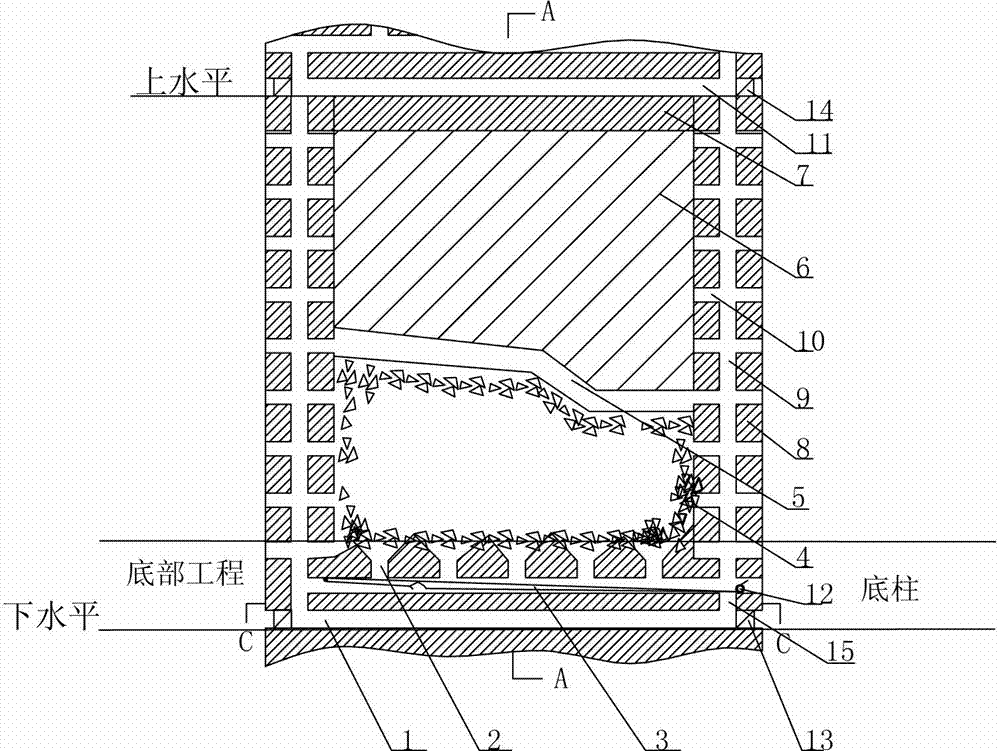

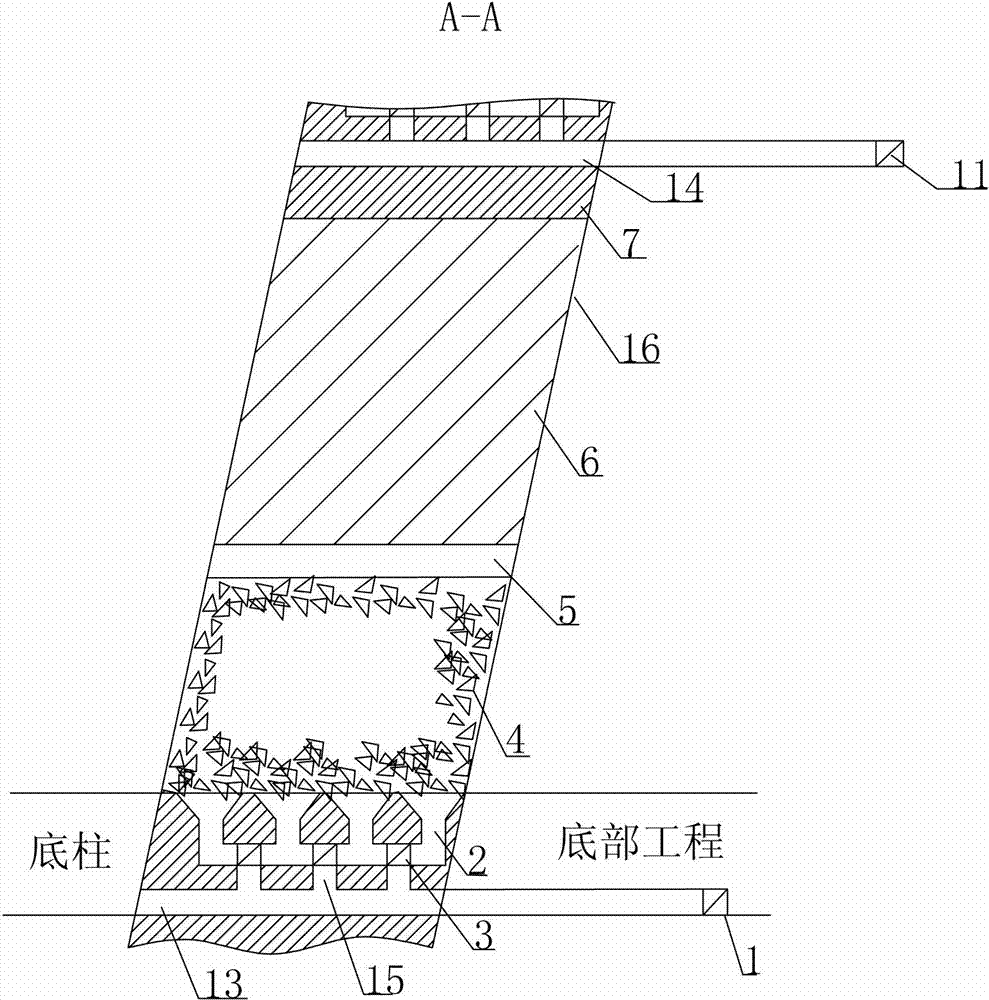

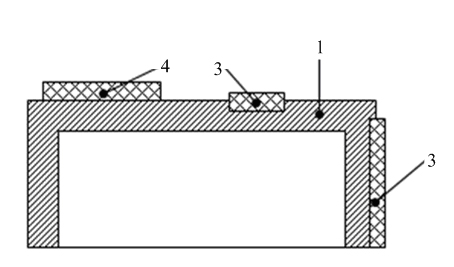

Method for filling and re-mining roadway protection coal pillar in residual mining area of extra-thick coal seam

ActiveCN106930763AImprove recyclingImprove coal recovery rateUnderground miningSurface miningSteel platesCoal pillar

The invention discloses a method for filling and re-mining a roadway protection coal pillar in the residual mining area of an extra-thick coal seam. The method comprises the steps that firstly, a roadway parallel to the working face is formed in the upper portion of the roadway protection coal pillar of the extra-thick coal seam to serve as a grouting roadway, and when the working face is advanced to the roadway protection coal pillar, a thick and solid wall is laid on the side, close to a goaf, outside a working face hydraulic bracket rear scraper conveyer, a metal net is arranged on the upper portion of the wall, the side, close to the goaf, of the working face hydraulic bracket rear scraper conveyer is provided with a groove and a steel plate, the working face is continuously advanced through the method that top coal is not caved, and coal cutting is stopped after the rear scraper conveyer completely enters a straight section; at this time, a closed area is formed in the rear portion of the goaf and filled with paste, and the working face can be continuously advanced after filling slurry sufficiently makes contact with the roof; and the process is repeated, re-mining of the mining stopping line coal pillar of the extra-thick coal seam is completed, the recovery rate of coal resources is increased, and waste of the coal resources is greatly reduced. The method is simple in procedure, construction is convenient, and materials can be used at any time during mining.

Owner:TAIYUAN UNIV OF TECH

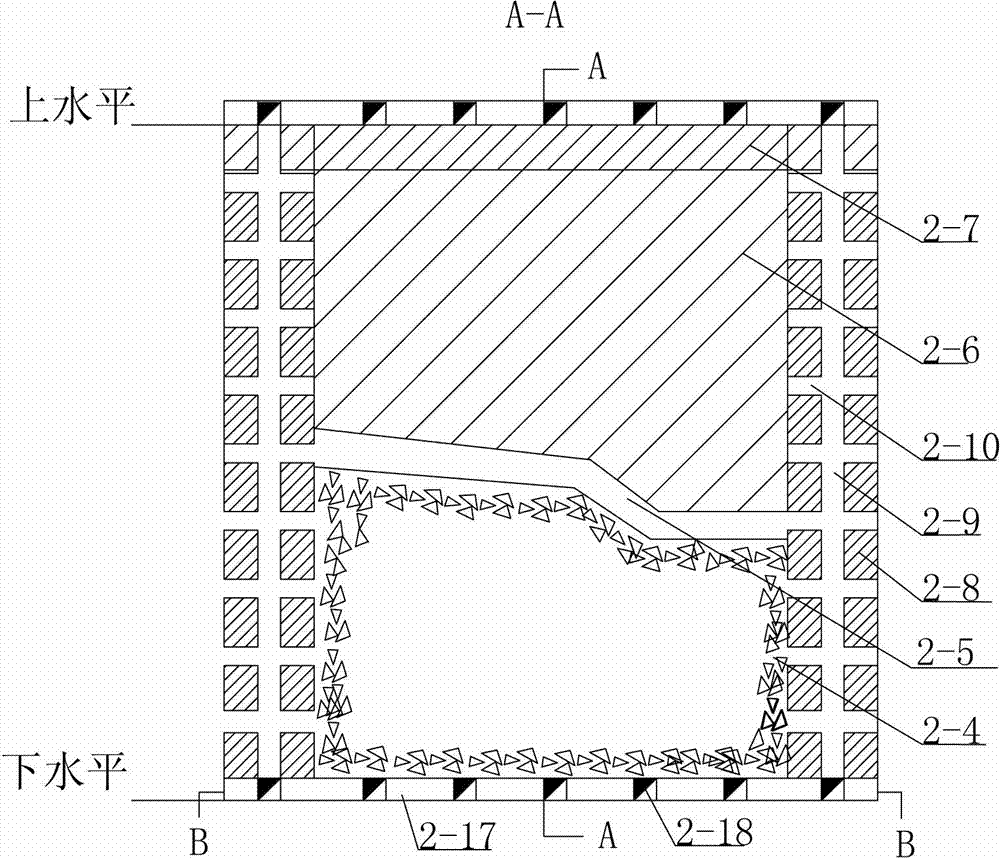

Thin-ore-body shallow hole shrinkage method without sill pillar

InactiveCN103089267AImprove recyclingImprove recovery rateUnderground miningSurface miningEngineeringBoundary line

The invention relates to a thin-ore-body shallow hole shrinkage method without sill pillar. The thin-ore-body shallow hole shrinkage method comprises the engineering of accurate mining, cutting, mining and ore withdrawal. The method is characterized by comprising the following steps of: in the engineering of accurate mining, tunneling a core withdrawal roadway, a communicating channel of a raised shaft, the raised shaft and a communicating channel entering a stope to an ore body after a level haulage roadway is completed; in the engineering of cutting, tunneling a cutting level gallery along the trending direction of the ore body inside the ore body, opening two outer sides of the cutting level gallery to a boundary line of the ore body after the cutting level gallery is completed, and simultaneously carrying out coping treatment on the cutting level gallery so as to form an ore block bottom free surface; in the engineering of mining, drilling a hole with a shadow hole rock drilling machine after the engineering of cutting is completed, carrying out rock drilling blasting mining from bottom to top so as to form a stope working surface, carrying out coyote blasting work on a top pillar after shallow mining is completed, and then carrying out large ore drawing ore removal work and ore removal. The thin-ore-body shallow hole shrinkage method without sill pillar is simple, efficient and safe, and no sill pillar remains. The recycle of ore columns is increased, and the recovery ratio and utilization ratio of resources are improved.

Owner:ANSTEEL GRP MINING CO LTD

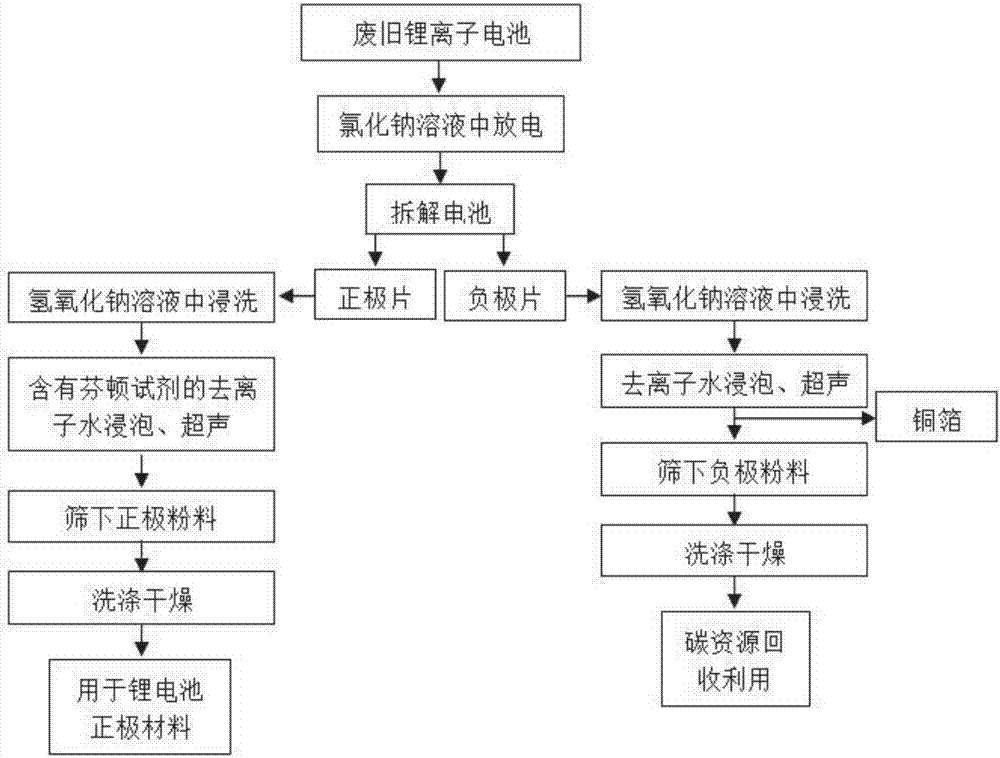

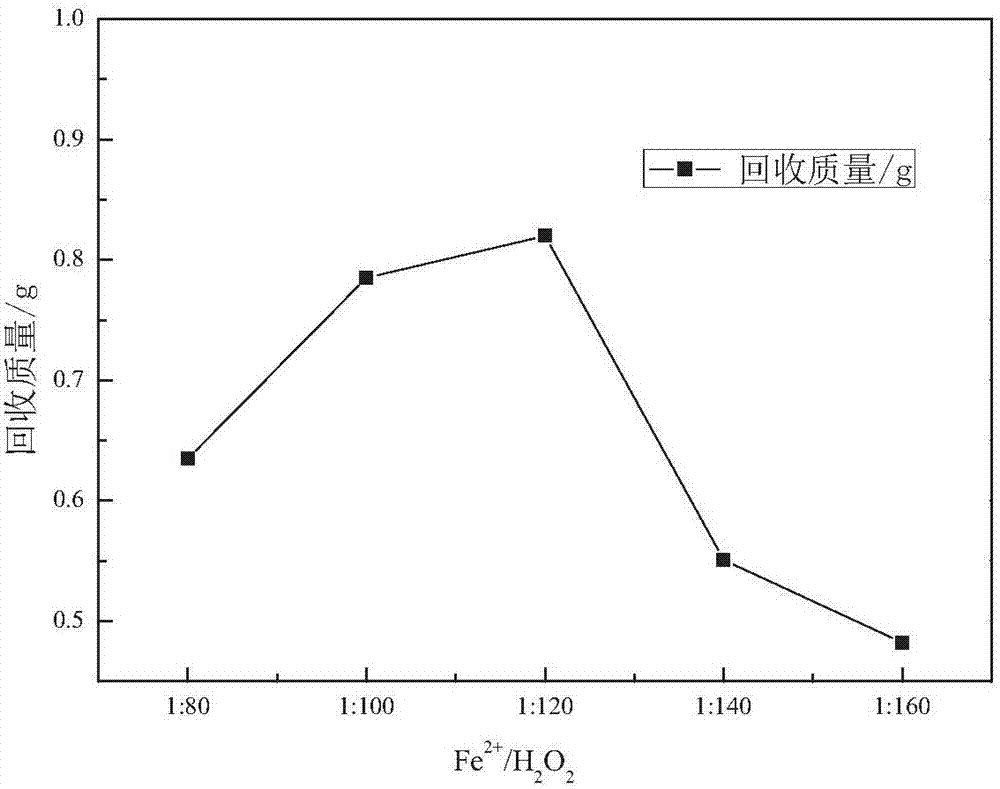

Recovery method of waste lithium battery

InactiveCN107317064AEasy to operateShort processWaste accumulators reclaimingBattery recyclingRecovery methodFenton reagent

The invention provides a recovery method of a waste lithium battery. The recovery method is characterized by comprising the steps of obtaining a positive pole plate and a negative pole plate after short-circuit discharging and disassembly are performed on the waste lithium ion battery; placing the positive pole plate in a water containing a Fenton reagent, and performing immersion under ultrasonic assistant; and performing sieving to obtain an aluminum foil current collector after immersion, and performing solid-liquid separation on a Fenton immersion liquid to obtain a positive electrode active material solid. Moreover, the invention also provides a recovery method of the negative pole plate. The method provided by the invention is simple and is easy to operate, complete copper foil and aluminum foil can be recovered, and relatively-pure positive powder and negative powder also can be obtained; and moreover, smashing and high-temperature roasting are not needed, the production energy consumption is favorably reduced, and no secondary pollution to an environment is prevented.

Owner:CENT SOUTH UNIV

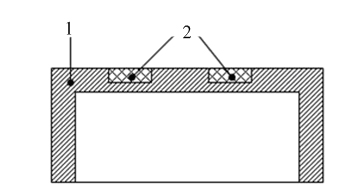

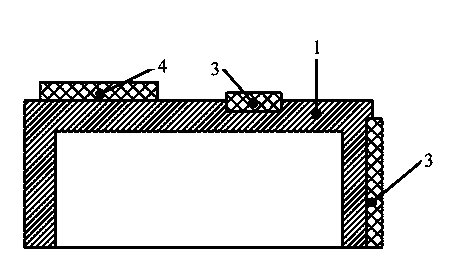

Antenna radiation body made of low-melting-point metal or metal alloy, and manufacturing method

InactiveCN102570024AGood chemical resistanceReduce the impactRadiating elements structural formsMetal alloyInjection moulding

The invention relates to the field of wireless communication technology, in particular to an antenna radiation body made of low-melting-point metal or metal alloy, and a manufacturing method therefor. The manufacturing method for the antenna radiation body made of low-melting-point metal or metal alloy comprises the following steps: (1), a plastic bracket is formed through injection moulding, and a plurality of grooves are formed on the plastic bracket; and (2), molten low-melting-point metal or metal alloy is injected into the grooves of the plastic bracket, and after solidification, the antenna radiation body is made. Compared with the prior art, the manufacture method for the antenna radiation body made of low-melting-point metal or metal alloy material has the advantages that deformation and melting to the plastic bracket can not be caused, and a thinner antenna radiation body can be manufactured; and meanwhile, the electric conductivity is excellent, and the performance of the antenna is improved.

Owner:SHANGHAI AMPHENOL AIRWAVE COMM ELECTRONICS CO LTD

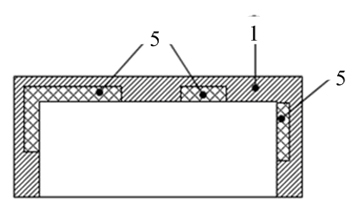

Technology for treating high-arsenic copper material

ActiveCN106555058AEnvironmental pollutionNo pollution to the environmentPhotography auxillary processesProcess efficiency improvementElectrolysisCopper sulfate

The invention discloses a technology for treating a high-arsenic copper material. The technology comprises the steps that the high-arsenic copper material is subjected to crushing, grinding, sodium hydroxide mixing and oxidizing leaching, copper in the high-arsenic copper material is oxidized and left in residues in a residual mode along with lead and noble metal of gold, silver and platinum, arsenic enters a solution in a sodium arsenate mode, leachate is subjected to concentration and crystallization, a sodium arsenate product is obtained, and a concentrated solution returns to be subject to oxygen-pressure alkali leaching; leached residues are subjected to sulfuric-acid atmospheric pressure leaching, copper enters the solution in a copper sulfate mode, acid adjustment is conducted, and vortex electrolysis is directly conducted for extracting copper; electrodeposited waste liquid is recycled; and lead and the noble metal enter lead and silver residues, and valuable elements of Pb, Ag and Au are comprehensively recycled. The technology belongs to a clean metallurgy process, is low in equipment corrosion-resistant requirement, free of pollution to environment, easy to operate and high in comprehensive recycling degree of metal and has the advantages of being higher in practicability and adaptability to raw materials and the like.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

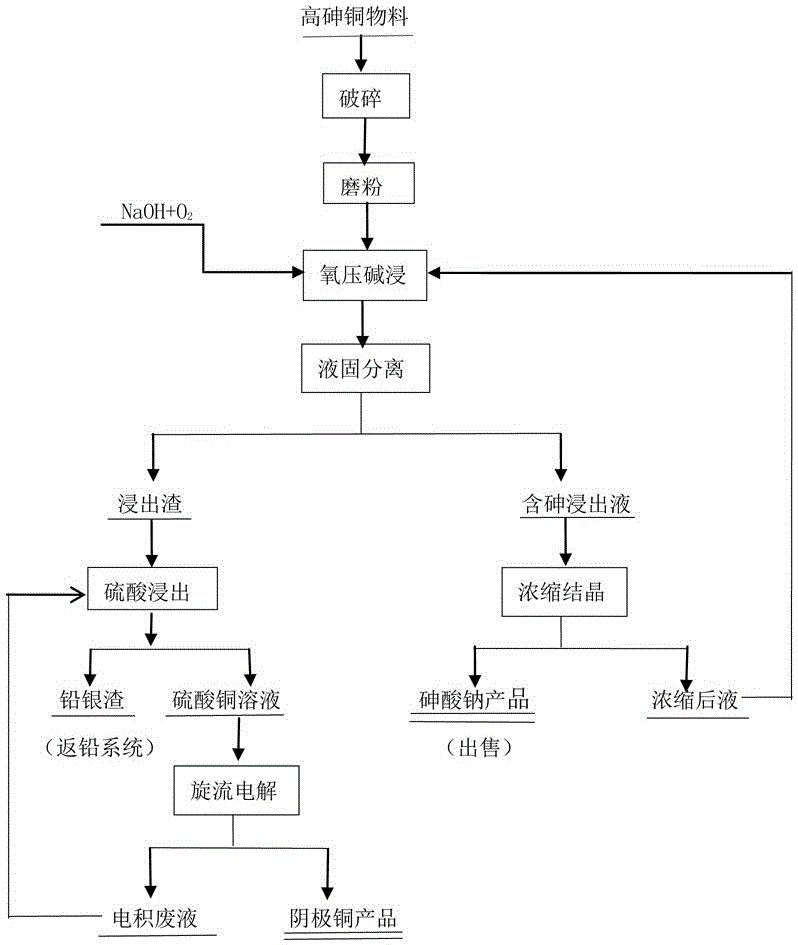

Production method of deinked pulp and environmentally-friendly white cardboard made of deinked pulp

ActiveCN103437227ALow costImprove recyclingPaper recyclingPaper coatingEnvironmentally friendlySecondary stage

The invention discloses a production method of deinked pulp. The production method comprises the following steps of: (1) adding hot water and wastepaper raw materials to a drum pulper, and pulping the wastepaper raw materials; (2) removing material residues, and then enabling pulp to sequentially pass through a first-stage flotation tank, a multiple-disc filtering machine 1, a hot dispersion machine 1, a secondary-stage flotation tank, a multiple-disc filtering machine 2 and a dispersion machine 2 for carrying out impurity removal process so as to remove organic impurities in the pulp; (3) carrying out bleaching treatment on the pulp by using a high-concentration bleaching tower; (4) carrying out third-stage floatation treatment on the pulp; and (5) carrying out reduction bleaching treatment on the pulp by adopting a reduction bleaching tower so as to obtain the deinked pulp. The deinked pulp is used for producing the white cardboards and replacing conventional bleaching chemical pulp for coating and making the white cardboards, so that the cost of the white cardboards is reduced, the cycle use of fibers is improved, and the call of the nation for green and environmentally-friendly paper making is responded.

Owner:DONGGUAN NINE DRAGONS PAPER IND

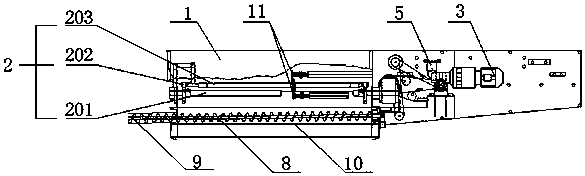

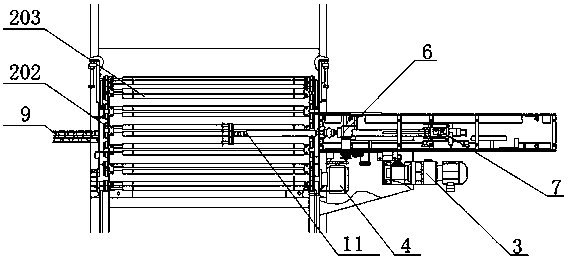

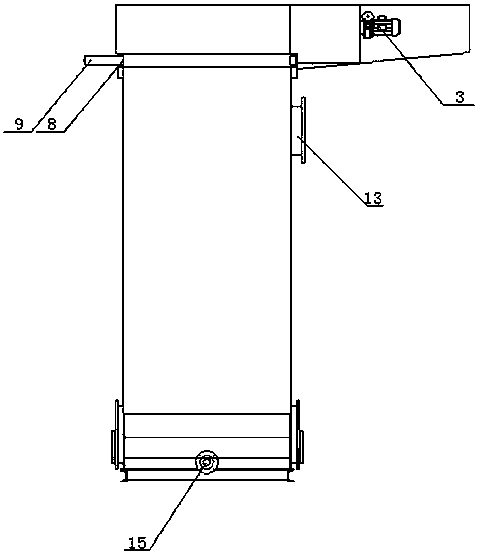

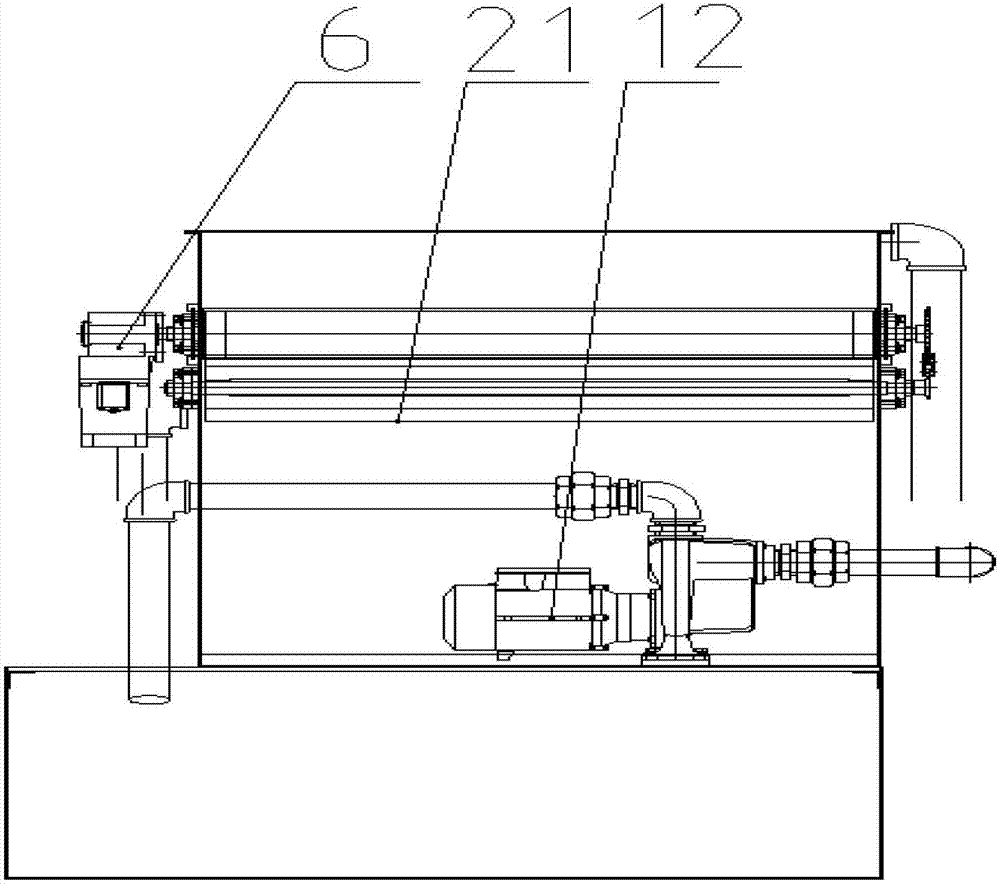

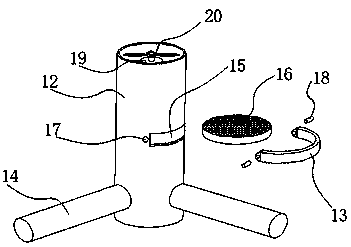

Horizontal magnetic bar filter

The invention discloses a horizontal magnetic bar filter and belongs to the field of filtering equipment. The horizontal magnetic bar filter comprises a filter main body, wherein a transmission deviceis arranged on the filter main body; the transmission device comprises a transmission shaft, a chain and magnetic bars; a variable-frequency speed regulation speed reducer, a chain transmission reduction gearbox, a spring type chain tensioner, a draining transmission reduction gearbox and a magnetic bar dirt scraping opening and closing actuating mechanism are arranged at the outer side of the filter main body; the draining transmission reduction gearbox is connected with a screw rod, and an iron powder sludge outlet is arranged at the outer end of the screw rod; and a groove is arranged below the movement path of a magnetic bar dirt scraping rake, and the magnetic bar dirt scraping opening and closing actuating mechanism is connected with the magnetic bar dirt scraping rake. The horizontal magnetic bar filter has the advantages of long service life, smooth running and low noise, and besides, is large in absorbing area and great in separating effect as a large magnetic field is produced due to the high density of the magnetic bars. Besides, the horizontal magnetic bar filter has a certain dirt floating oil removing function, and at the same time, is convenient to clean and maintain as the transmission system is separate from a box body.

Owner:宁波甬为机电科技有限公司

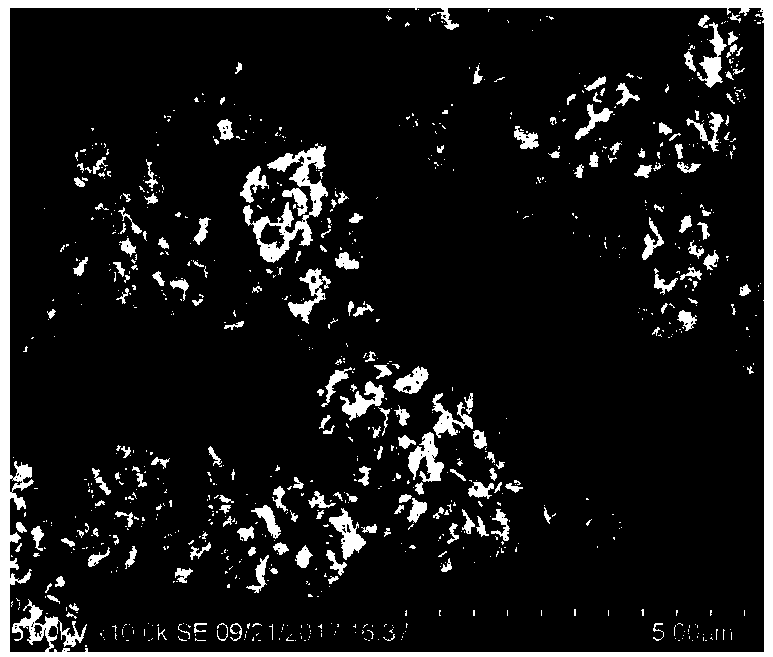

Method for preparing ternary lithium battery cathode material precursor by utilizing spent lithium-ion batteries

ActiveCN109449434AImprove recyclingShort processCell electrodesWaste accumulators reclaimingScrapLithium electrode

The invention provides a method for preparing a ternary lithium battery material precursor by utilizing spent lithium-ion batteries. Main ingredients comprise cathode material waste powder and metal sulfides, ternary lithium battery cathode scraps and nickel sulfide intermediate goods are taken as raw materials, nickel sulfide intermediate goods waste is added into lithium-ion battery cathode material scraps, a right amount of sulfuric acid is added and reaction and leaching are performed under high pressure condition, after pressure relief, a small amount of hydrogen peroxide is added to be taken as a reducing agent for continuously leaching valuable elements such as nickel, cobalt and manganese, impurity removal and matching are performed on leachate, and then metal ion mixed solution after the matching, ammonia water and sodium hydroxide are taken as raw materials for preparing a lithium-ion battery cathode material precursor. The method provided by the invention has high waste leaching rate, short flow, simple process and low cost, not only can treat lithium battery cathode material scraps in a large scale but also can treat abandoned nickel sulfide intermediate goods, so thatrecycling of the lithium-ion battery cathode material scraps and the abandoned nickel sulfide intermediate goods is promoted.

Owner:GUANGDONG JIANA ENERGY TECH CO LTD +1

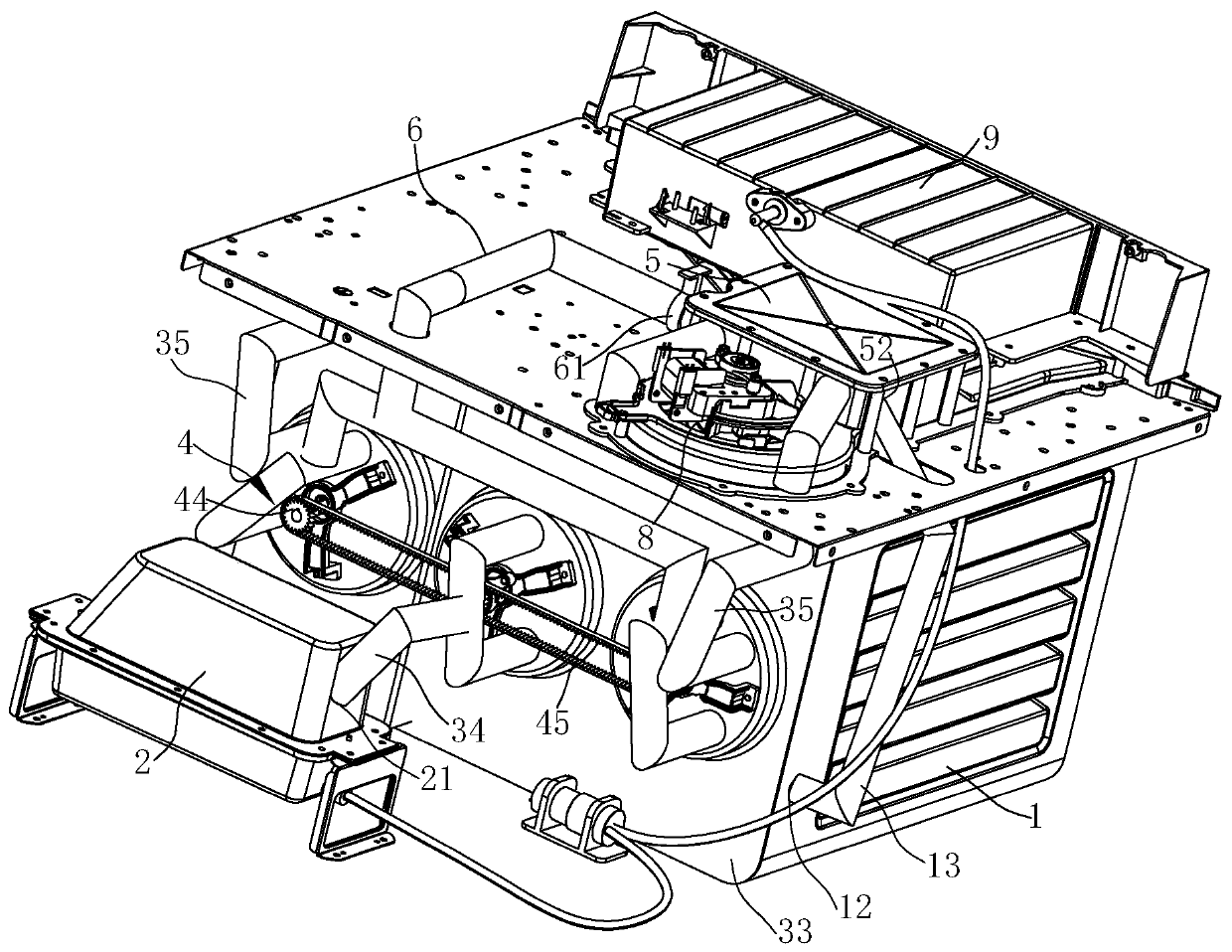

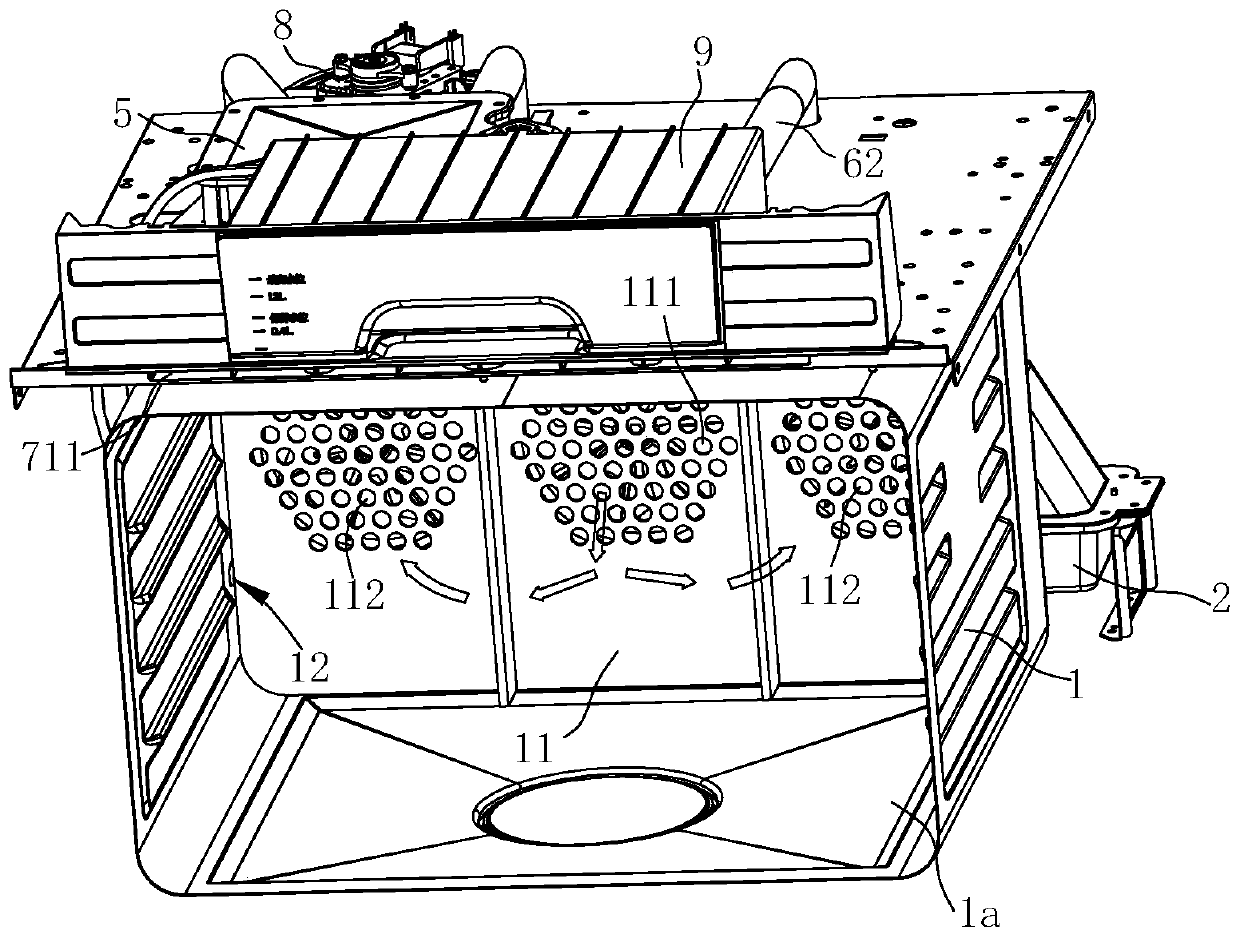

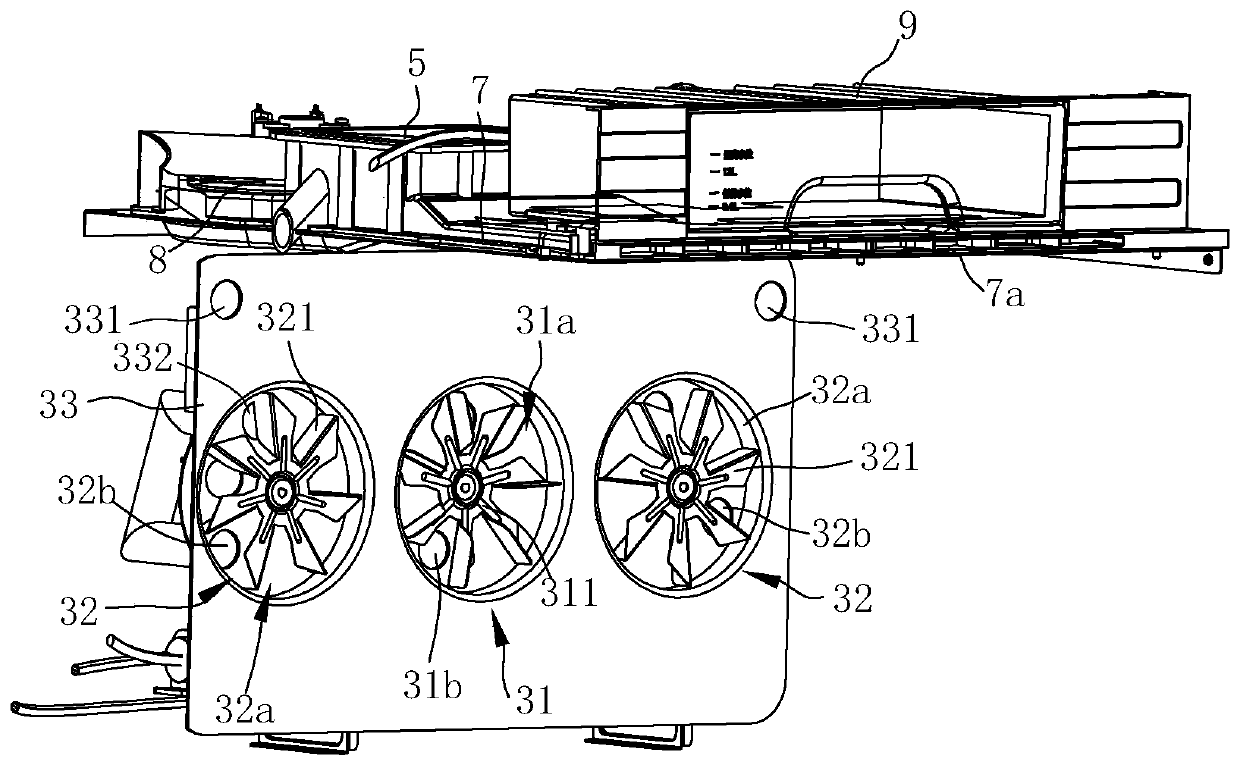

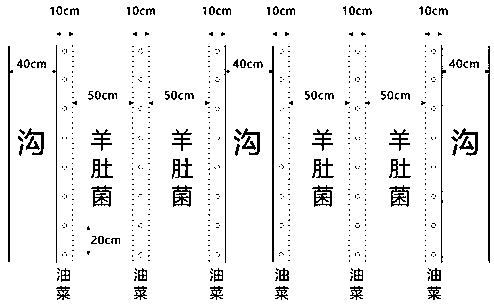

Steaming cooking equipment

ActiveCN110464208ADiffusion fastImprove recyclingSteam cooking vesselsRoasters/grillsSteam cookingEngineering

The invention relates to steaming cooking equipment; the steaming cooking equipment comprises an inner container, a steam generator, a first fluid channel, a second fluid channel, a first fan and a second fan, wherein a containing cavity is formed in the inner container; the steam generator is arranged on the outer side of the inner container and has a steam outlet; the first fluid channel is arranged outside the inner container and is used for communicating the steam outlet of the steam generator with the containing cavity of the inner container; the second fluid channel is arranged outside the inner container and is used for discharging steam in the inner container out of the equipment; the first fan is used for introducing air flow into the inner container from the outside of the innercontainer; the first fan is positioned in the first fluid channel; and the second fan is arranged in the second fluid channel and is used for guiding the airflow from the inner container to the outside of the inner container. According to the steaming cooking equipment, steam in the steam generator is rapidly sucked into the inner container through the first fan, the steam can be rapidly diffusedin the inner container cavity, the second fan sucks steam in the inner container cavity towards the outer side of the inner container, and the flow of the steam in the inner container cavity is accelerated, so that the food in the inner container cavity can be more uniformly contacted with the steam.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

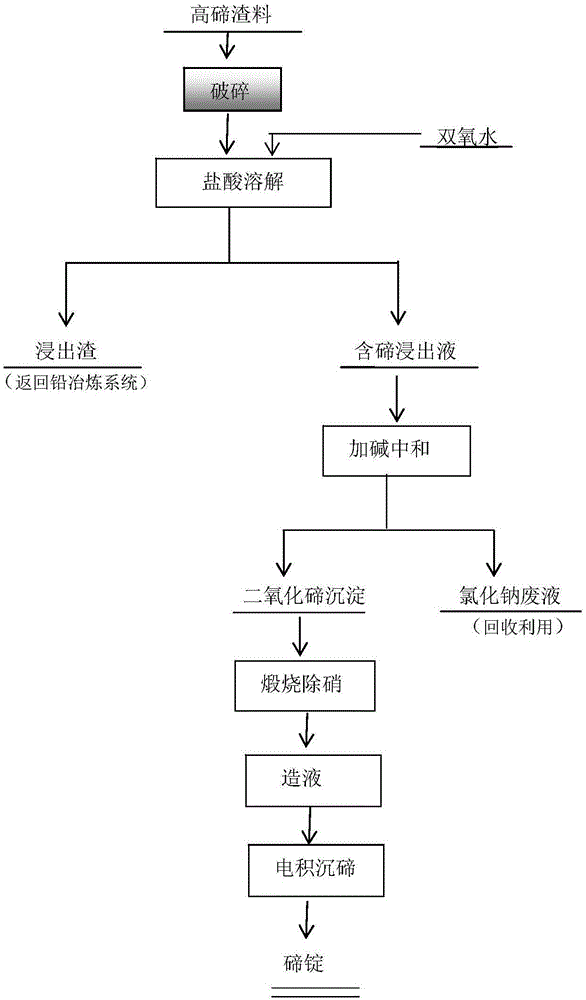

Method for recovering tellurium from high-tellurium residues

ActiveCN106381399AEfficient recyclingReduce consumptionElectrolysis componentsProcess efficiency improvementPregnant leach solutionLead smelting

The invention discloses a method for recovering tellurium from high-tellurium residues in an efficient and environment-friendly mode. The method includes the steps of breaking the high-tellurium residues, slowly adding hydrochloric acid and hydrogen peroxide into the high-tellurium residues, controlling the temperature and continuously stirring to carry out oxidizing leaching; carrying out liquid-solid separation after the residues are completely dissolved, wherein tellurium oxide as the major element enters leaching solutions, valuable metal such as Pb and Ag enters leaching residues in the mode of chloride salt, and lead and silver residues return to a lead smelting system to recover the valuable metal; and adjusting the pH value of the tellurium-containing leaching solutions to be 5.0-6.0 through sodium hydroxide solutions, obtaining TeO2 sediments, carrying out liquid preparation after TeO2 is roasted and nitrate is removed and returning to the electrodeposition process to directly recover the tellurium. According to the method, the high-tellurium residues is directly leached to recover the tellurium through the hydrochloric acid and the hydrogen peroxide, the direct recovery rate of the tellurium can reach above 95%, so that efficient recovery of the tellurium is realized, the recovery rate of silver can reach above 99.0%, and the recovery rate of lead can reach above 97.6%. The method has the advantages that the technological processes are simple, needed equipment is reduced, the production cost is low, the environment friendliness is high and the comprehensive recovery degree is high, thereby having wide application prospects.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

Preparation method of EVA foamed thin film

The invention discloses a preparation method of an EVA foamed thin film. The method includes the steps of preparing a foaming master material, preparing a foaming promoting master material and conducting extruding, blow molding and foaming of the thin film. When the master material is prepared, the foaming master material is prepared through a low-temperature extrusion method so that foaming in the extrusion granulating process can be avoided; by means of the foaming promoting master material, foaming agents can be promoted to decompose as completely as possible in the film blowing process; the two types of master materials and EVA resin are evenly mixed according to the ratio of 1 to 1 to 10 and then added into an extruder to be plasticized and blown to form the film. The master materials are foamed during plasticizing and extruding, and the structure and shape of foams can be adjusted by adjusting the main machine speed and the traction speed. According to the method, the film foaming product can be easily obtained. The film foaming product is suitable for producing rubber feeding bags, low in melting point, easy to tear off, small in density, capable of lowering material consumption, and capable of reducing production cost. Due to the fact that the product is good in mechanical property and tear-off performance, the application range of the product can be further enlarged; when the film is applied to rubber small component packaging bags and the like, resource waste can be greatly reduced, and recycling can be improved.

Owner:XUZHOU COLLEGE OF INDAL TECH

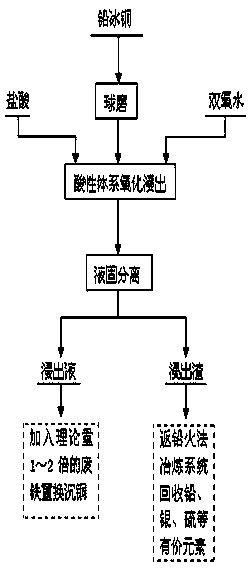

Method for separating copper from lead matte and comprehensively utilizing lead matte

InactiveCN104004907AReduce pollutionLow equipment requirementsProcess efficiency improvementSulfate radicalsRefining (metallurgy)

The invention relates to a method for separating copper from lead matte and comprehensively utilizing lead matte, and belongs to the field of wet metallurgy of non-ferrous metals. The process is characterized by adding hydrogen peroxide under a hydrochloric acid system for oxidization leaching. The method is as follows: ball-milling lead matte blocks until grain size is lower than 100 meshes, and feeding the ball-milled lead matte into a leaching slot for carrying out oxidization leaching, wherein HCl concentration is controlled to 1mol / L-6mol / L, concentration of hydrogen peroxide is controlled to 0.5mol / L-3.5mol / L, a liquid-solid ratio is controlled to (3-10):1, a temperature is controlled to 60-90 DEG C and reaction time is controlled to 1-2 hours. Under a hydrochloric acid condition, hydrogen peroxide is utilized and used as an oxidant for leaching sulfide; in the oxidization leaching process, sulfur in the lead matte is oxidized into elemental sulfur or sulfate radical, copper is oxidized to enter liquor in the form of ion, and lead is left in slag with gold and sliver in the form of lead chloride or lead sulfate. After the leaching process is completed, solid-liquid separation is carried out to realize preliminary separation of copper and lead. Copper-rich leachate can replace deposited copper by adding scrap iron, and leaching residue is returned to a pyrogenic process lead refining system for recycling valuable elements such as lead, sliver, elemental sulfur, and the like.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

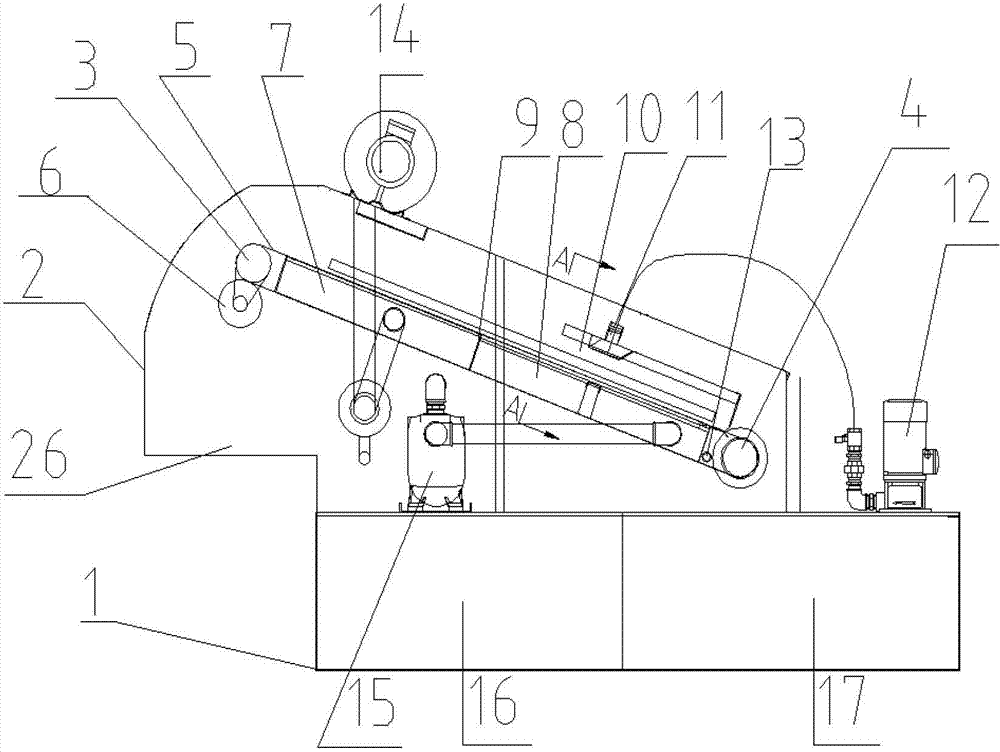

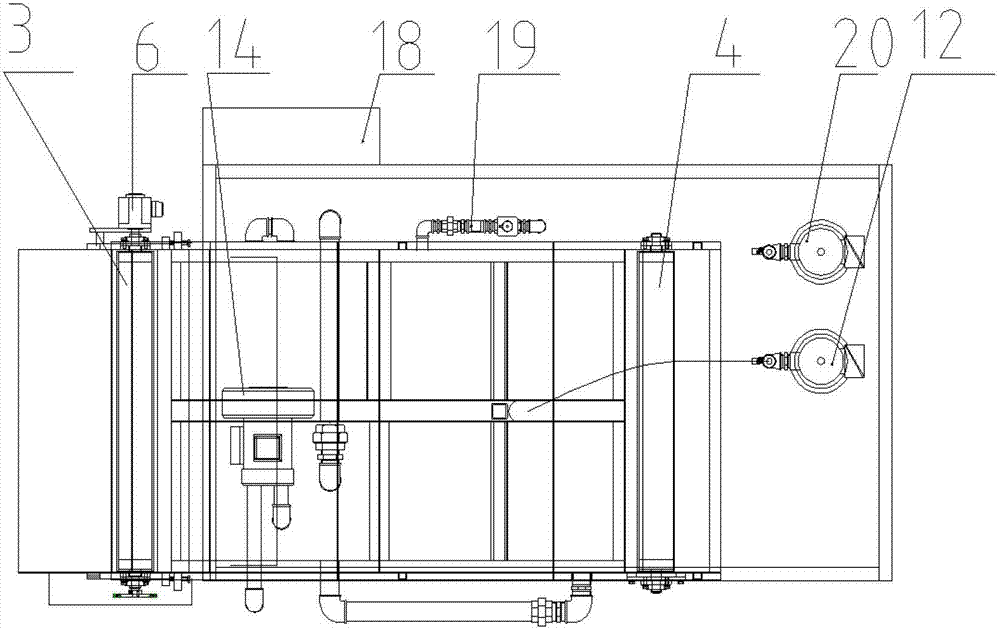

Sucking circulating belt type filtering device

The invention relates to the technical field of cutting liquid filtering equipment, in particular to a sucking circulating belt type filtering device. The device comprises a liquid box and a shell, wherein the shell is fixed on the liquid box; a driving roller is fixed at one end in the shell, and a driven roller is fixed at the other end in the shell; a filtering belt winds the driving roller and the driven roller; a control device and a drive motor are arranged on the side of the shell; the control device is connected with the drive motor, and the drive motor is connected with the driving roller; the upper layer of the filtering belt, the lower layer of the filtering belt and two sides of the shell define a cavity; the cavity is divided into a drying cavity and a sucking cavity by a partition plate; a gap plate is arranged on the lower part of the upper layer of the filtering belt; a filtering cavity is formed on the lower half part of the upper layer of the filtering belt, and a waste liquid inlet is formed in the filtering cavity; and a sucking pump is fixed on the liquid box and connected to a sucking cavity through a pipeline, and a negative pressure message-sending device which is arranged on the side of the shell is connected to the sucking cavity. By the device, the cutting liquid can be effectively filtered, the using cost of a machine tool is reduced, and automatic filtering is realized; and the device is easy to operate and convenient to maintain.

Owner:烟台开发区博森科技发展有限公司

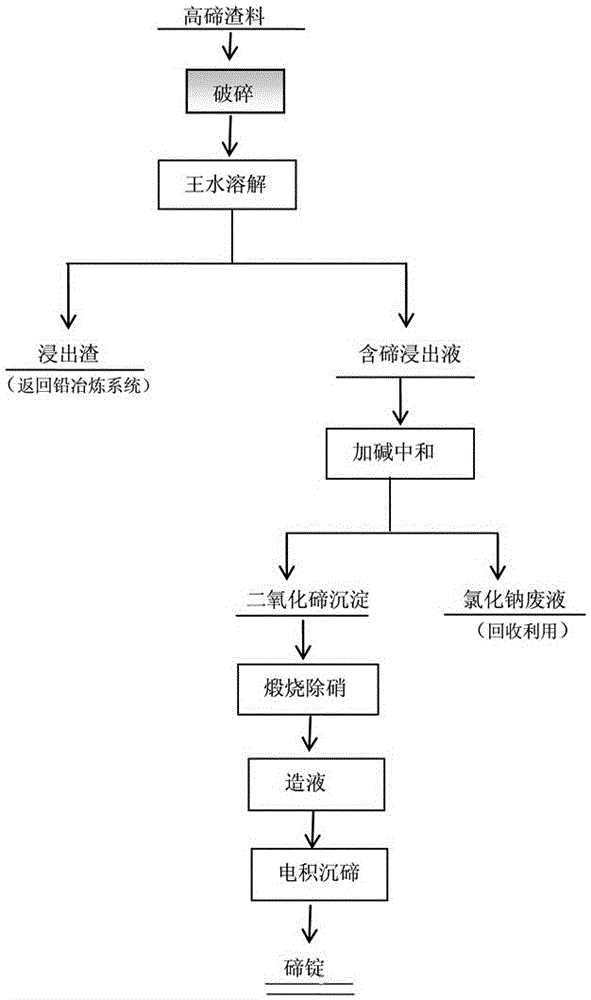

Technology for recovering tellurium from high-tellurium slag

InactiveCN105967153ASolve the problem that the oxidation speed is extremely slow or even not oxidizedAdaptableSelenium/tellurium oxides/hydroxidesBinary selenium/tellurium compoundsPregnant leach solutionGranularity

The invention provides a technology for recovering tellurium from high-tellurium slag. The technology comprises 1, crushing high-tellurium slag until granularity is less than or equal to 10mm, 2, pouring the broken high-tellurium slag into a reactor, slowly adding aqua regia into the high-tellurium slag and carrying out oxidation leaching, 3, after the slag is completely dissolved, carrying out liquid-solid separation so that a main element tellurium enters the leachate and Pb and Ag valuable metals enter slags, returning the Pb and Ag slags to a Pb smelting system and recovering valuable metals, and 4, preparing a solution of caustic soda flakes, slowly adding the solution into the tellurium-containing leachate, adjusting pH to 5.0-6.0, carrying out solid-liquid separation to obtain TeO2 precipitates, carrying out calcining denitration on the TeO2, carrying out liquid preparation, returning the liquid to an electrodeposition process and directly recovering metal Te. The technology has the characteristics of simple processes, less equipment, low production cost and high comprehensive recovery degree and has a certain application prospect.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

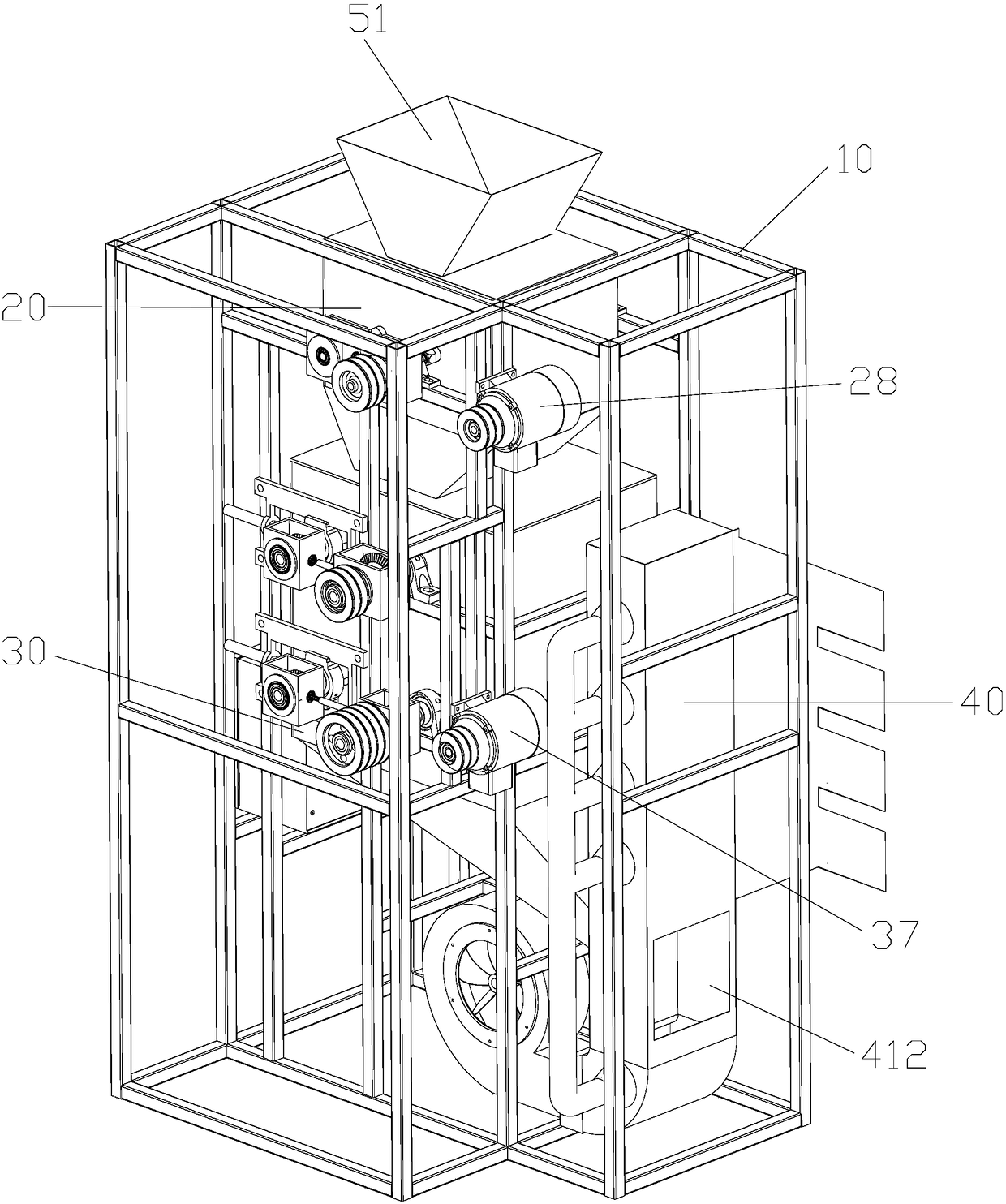

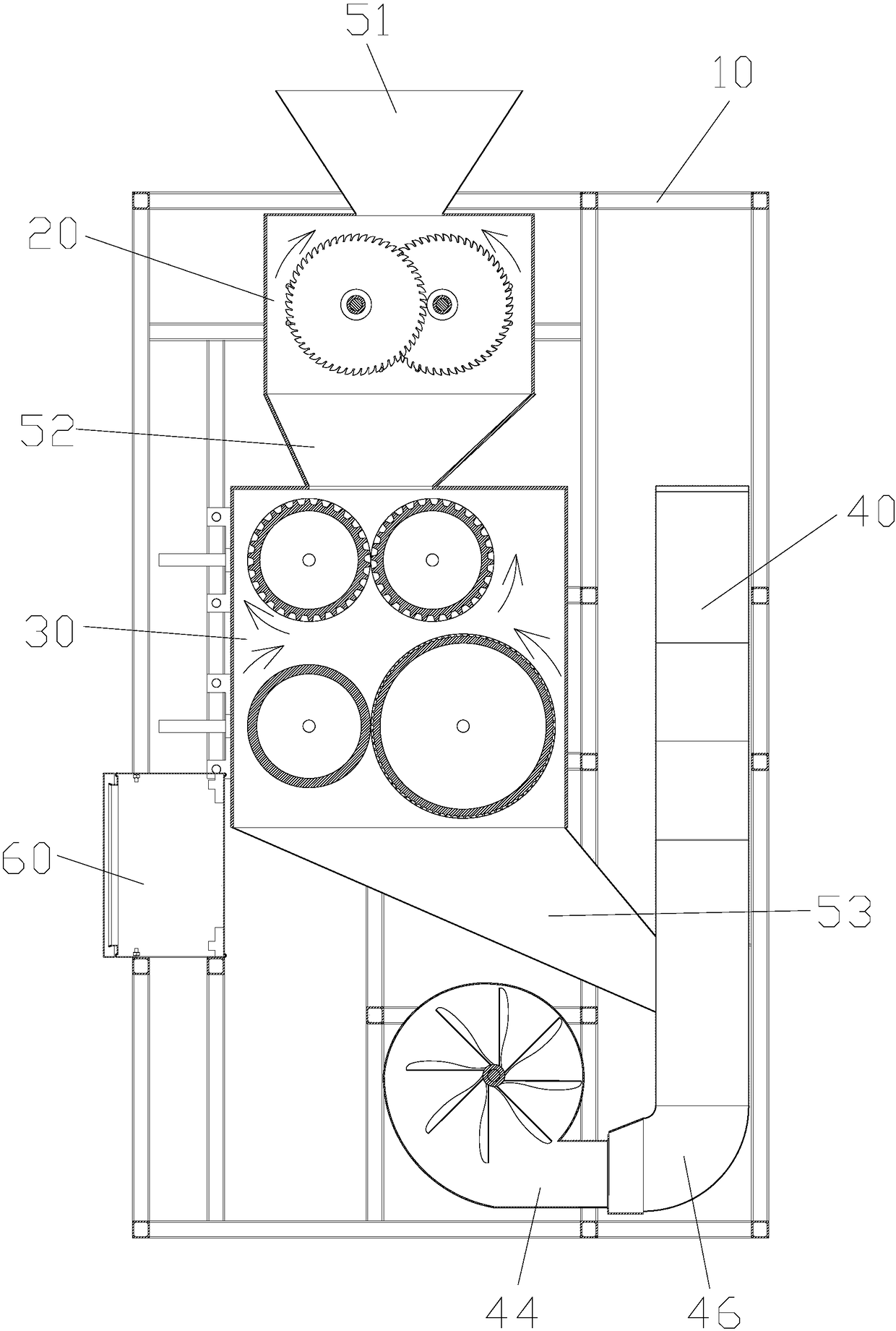

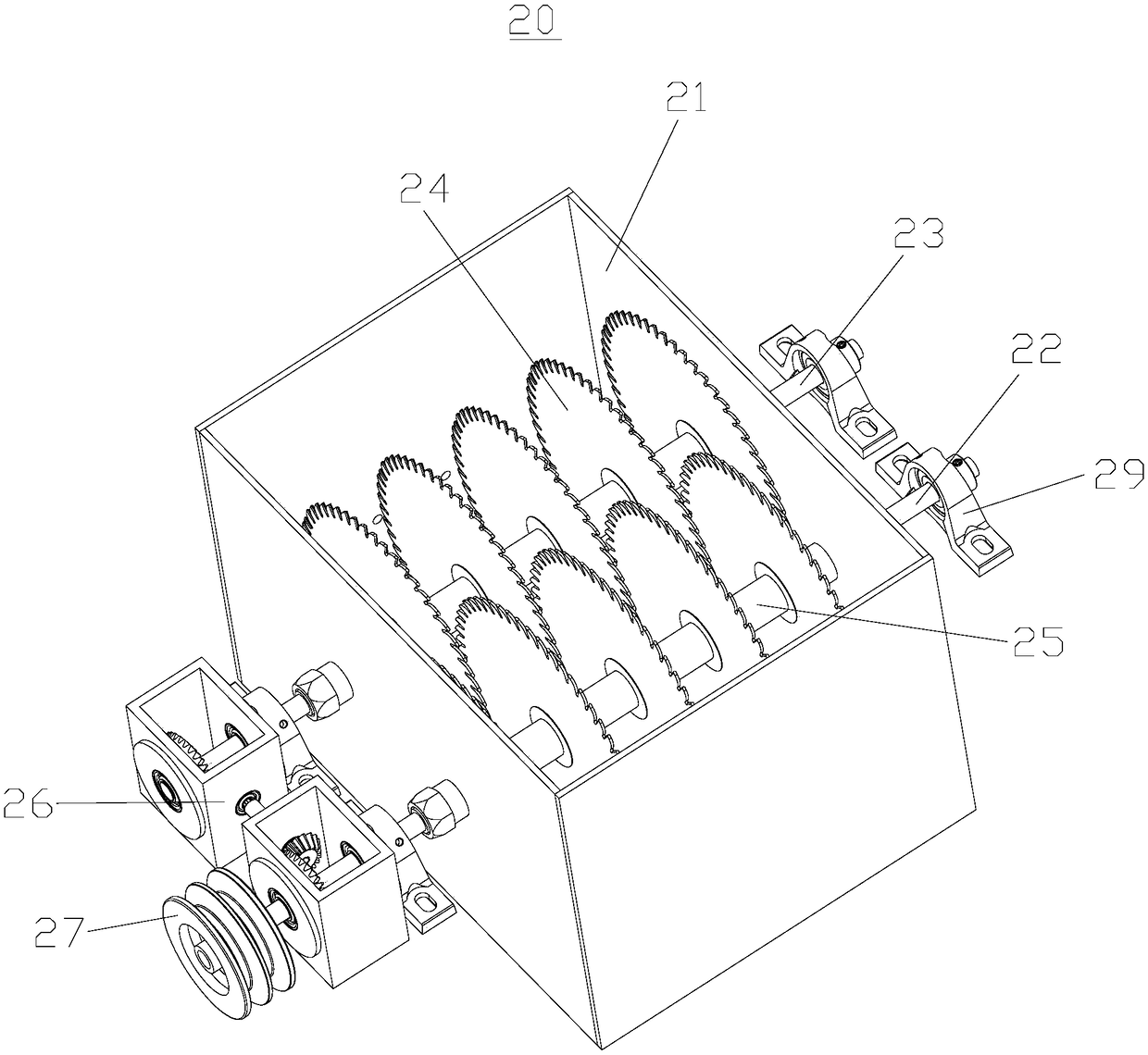

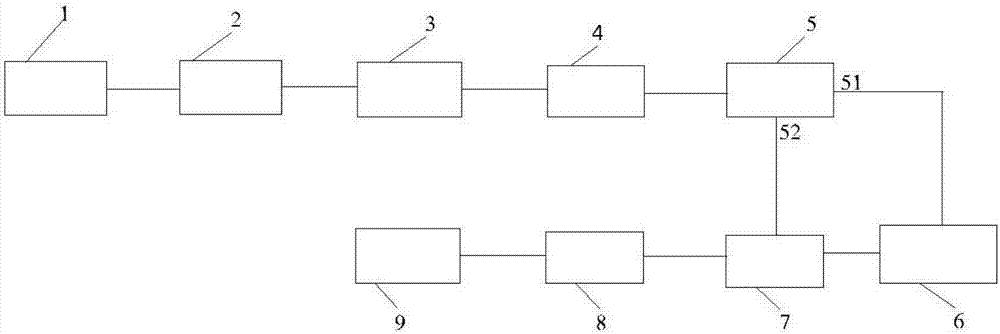

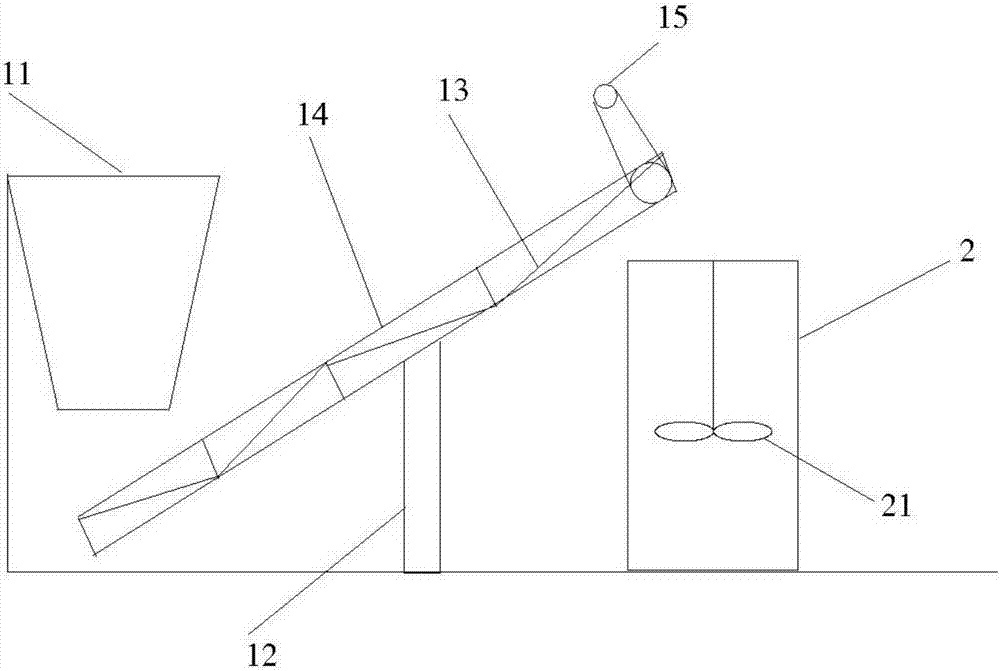

Comprehensive treating device for disassembling old shoes and recycling useful materials in old shoes

InactiveCN108453953AImprove recyclingGood crushing effectGas current separationPlastic recyclingEngineeringResource utilization

The invention relates to a comprehensive treating device for disassembling oil shoes and recycling useful materials in the old shoes. The comprehensive treating device comprises a coarse smashing module, a fine smashing module and a screening and separation module, wherein in the coarse smashing module, a plurality of saw blades are evenly arranged on two shafts and can perform opposite meshed high-speed rotation to coarsely smash the oil shoes; in the fine smashing module, four roller wheels are arranged in a cavity body regularly, two groovy rollers with the same inner diameter can achieve primary fine smashing on the old shoes through opposite meshed differential-speed rotation, two polishing rollers with the different inner diameters and two groovy rollers with the different inner diameters can achieve secondary fine smashing on the old shoes through opposite meshed equal-speed rotation, the screening and separating module can utilize an air blower to blow air to layer different masses of old shoe particles in the cavity body, and then the old shoe particles are classified and recycled. The comprehensive treating device disclosed by the invention can effectively smash waste shoes, the sizes of the smashed particles can be set as an adjustable mode according to need, the smashed materials can be screened and collected according to different masses, a resource utilization rate is improved, and environmental pollution caused by directly incinerating or burying the old shoes and resource waste are reduced.

Owner:WUHAN UNIV OF TECH

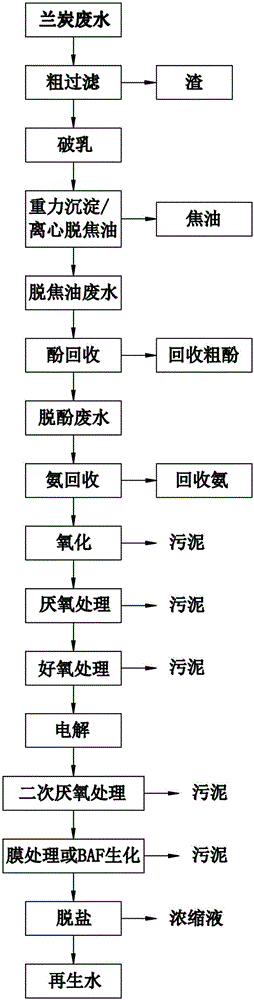

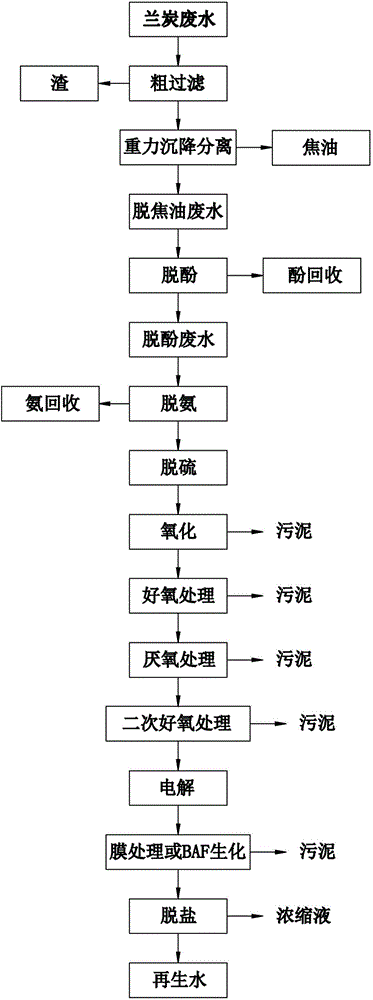

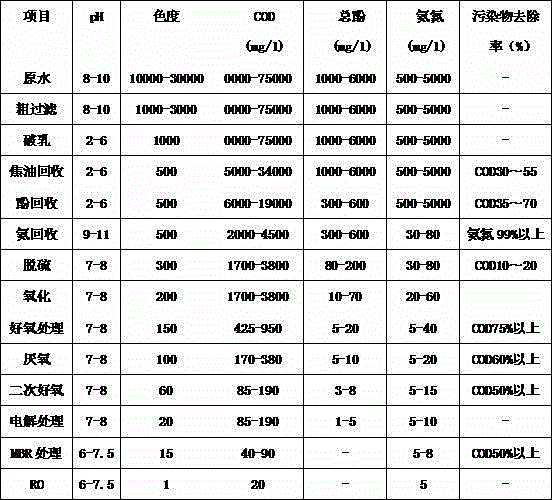

Comprehensive utilization and treatment recycling method for semi-coke wastewater resources

InactiveCN104926028AImprove recyclingAchieve recyclingMultistage water/sewage treatmentFiltrationEngineering

The invention discloses a comprehensive utilization and treatment recycling method for semi-coke wastewater resources. The method comprises the steps of (1) coarse filtration; (2) emulsion breaking; (3) tar recycling; (4) phenol recycling; (5) ammonia recycling; (6) oxidization; (7) anaerobic treatment; (8) aerobic treatment; (9) electrolyzation; (10) secondary anaerobic treatment; (11) membrane treatment with an MBR (membrane bioreactor) or biochemical reaction with a biological aerated filter; (12) desalination. According to the method, semi-coke wastewater is deeply treated by a combined treatment process comprising the processes of emulsion breaking, coal tar recycling, dephenolization, deamination, oxidization, anaerobic treatment, aerobic treatment, electrolyzation and the like, and is finally desalinated to generate recycled water, so that the wastewater is completely treated to eliminate wastewater pollution, and moreover, the wastewater is recycled to realize the recycling of water resources.

Owner:张世文

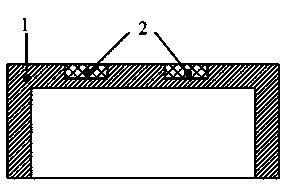

Antenna radiator made of conductive high-molecular material and manufacturing method

InactiveCN103746183AGood chemical resistancePrevent thermal deformationRadiating elements structural formsMolecular materialsMaterials science

The invention discloses an antenna radiator made of a conductive high-molecular material and a manufacturing method. The antenna radiator comprises a nonconductive high-molecular material support and the conductive high-molecular material which is arranged on the nonconductive high-molecular material support. A method for manufacturing the antenna radiator by using the conductive high-molecular material comprises the steps of 1) making the nonconductive high-molecular material support through injection molding and forming a plurality of grooves in the nonconductive high-molecular material support; 2) filling the conductive high-molecular material into the grooves to form the antenna radiator. Compared with the prior art, the method for manufacturing the antenna radiator by using the conductive high-molecular material provided by the invention does not cause the support to be deformed and molten and can be used for manufacturing thinner antenna radiators; the conductivity of the conductive high-molecular material is good and the performance of the antenna is improved.

Owner:SHANGHAI AMPHENOL AIRWAVE COMM ELECTRONICS CO LTD

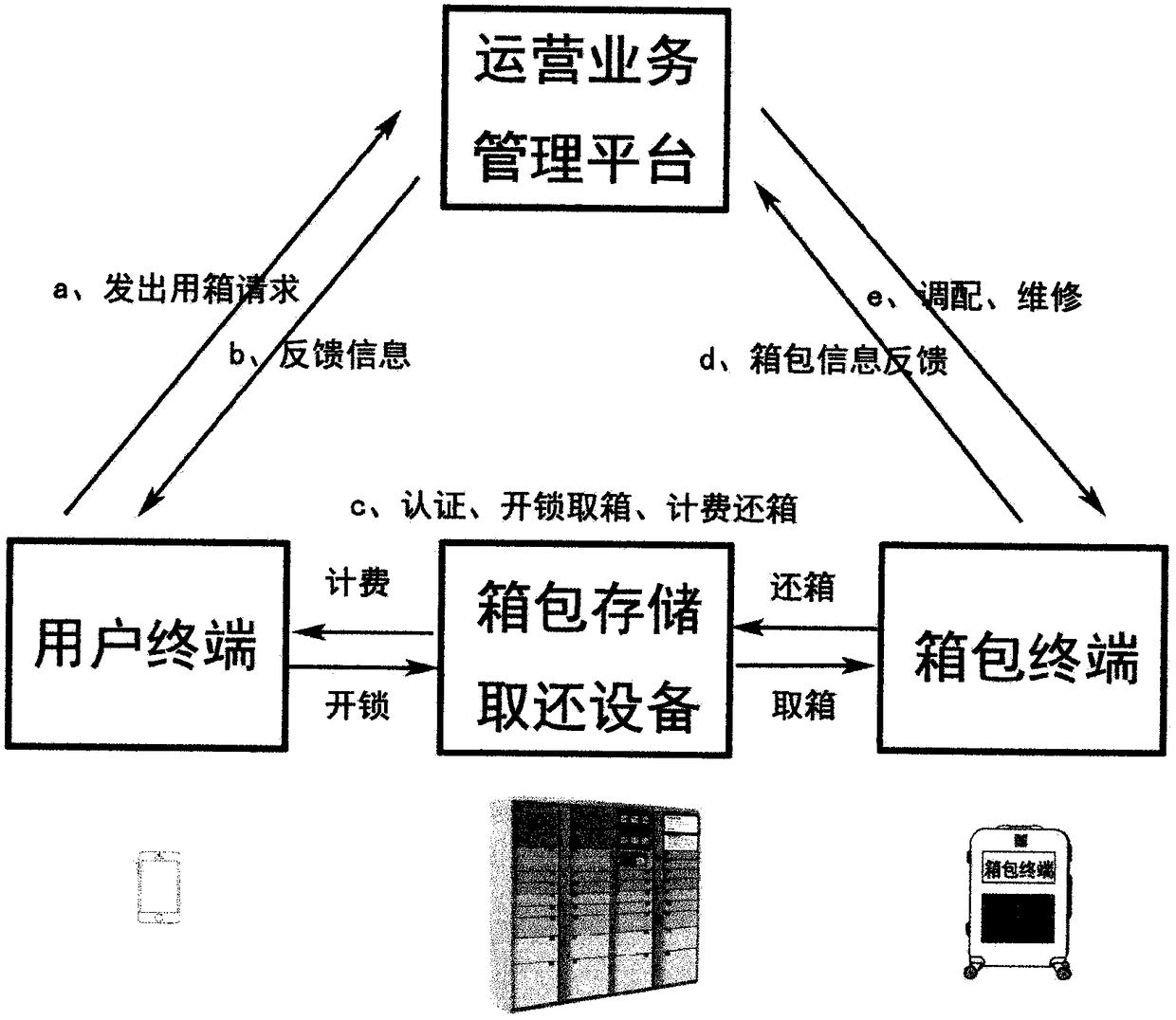

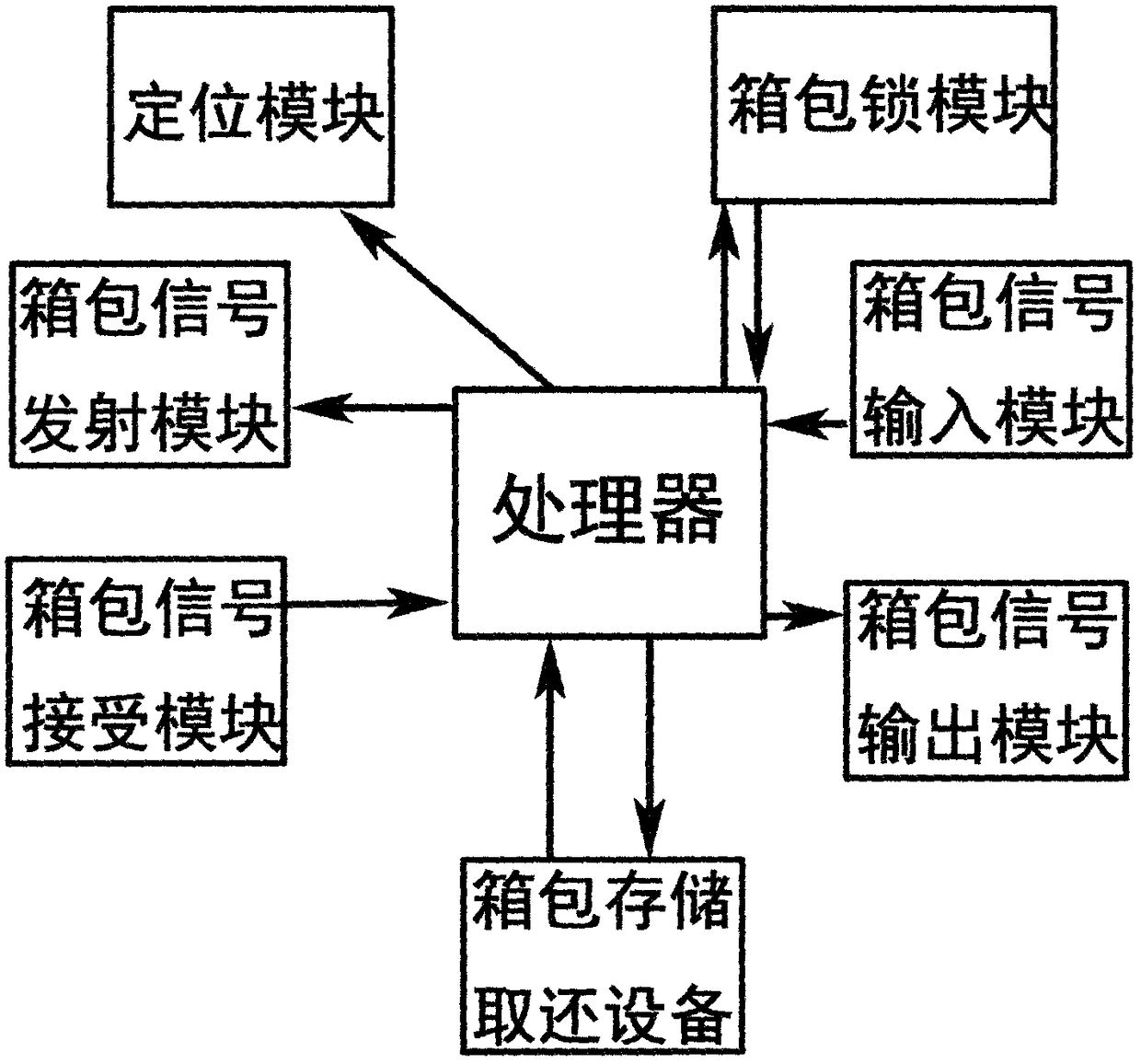

Suitcase leasing operation system and method with fixed borrowing and returning sites

PendingCN108961579AEasy maintenanceImprove recyclingApparatus for meter-controlled dispensingBuying/selling/leasing transactionsOperational costsManagement system

The invention provides a suitcase leasing operation system and method with fixed borrowing and returning sites. The system comprises user terminals, suitcase terminals, suitcase storing, borrowing andreturning devices, an operation service management platform and a suitcase carrying system. The user terminals are terminal devices with a communication function and are used for sending a service request to an operation service management platform and receiving a feedback result. The suitcase terminals are used for positioning suitcases, preventing thievery, receiving platform information, authorizing users and counting the price and getting payment. The suitcase storing, borrowing and returning devices are used for storing the suitcases, and the users can select the suitcases nearby to be borrowed, returned and used on the user terminals. The operation service management platform is used for receiving and responding to a user suitcase using request, and the operation service managementplatform and all the suitcase terminals form a leasing management system. The suitcase carrying system receives an instruction of the operation service management platform and conducts balance distribution management on the density of the suitcases. The suitcase leasing operation system and method have the advantages of being low in operation cost and beneficial for the shared using of the suitcases.

Owner:广东集采电商供应链有限公司

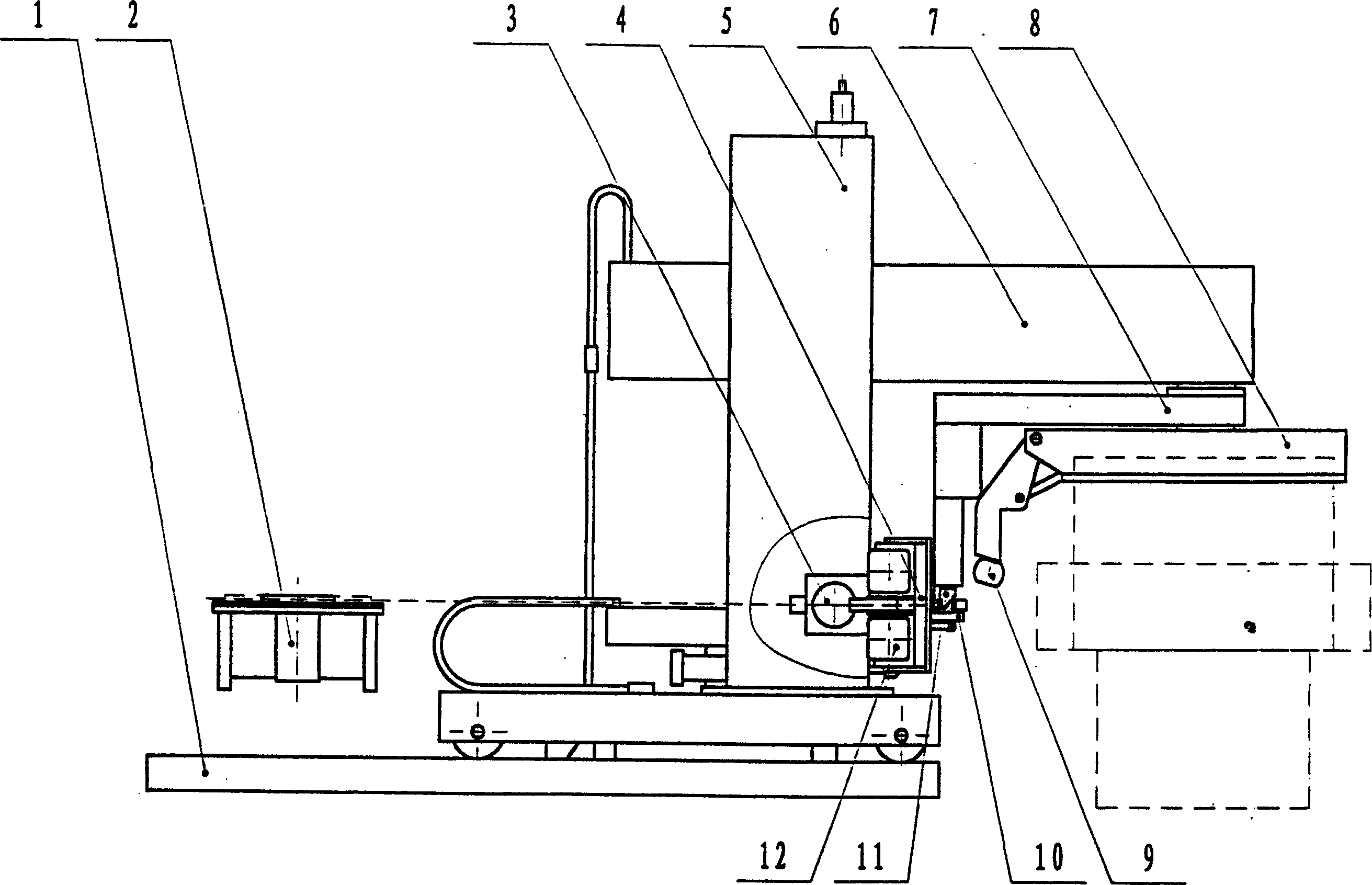

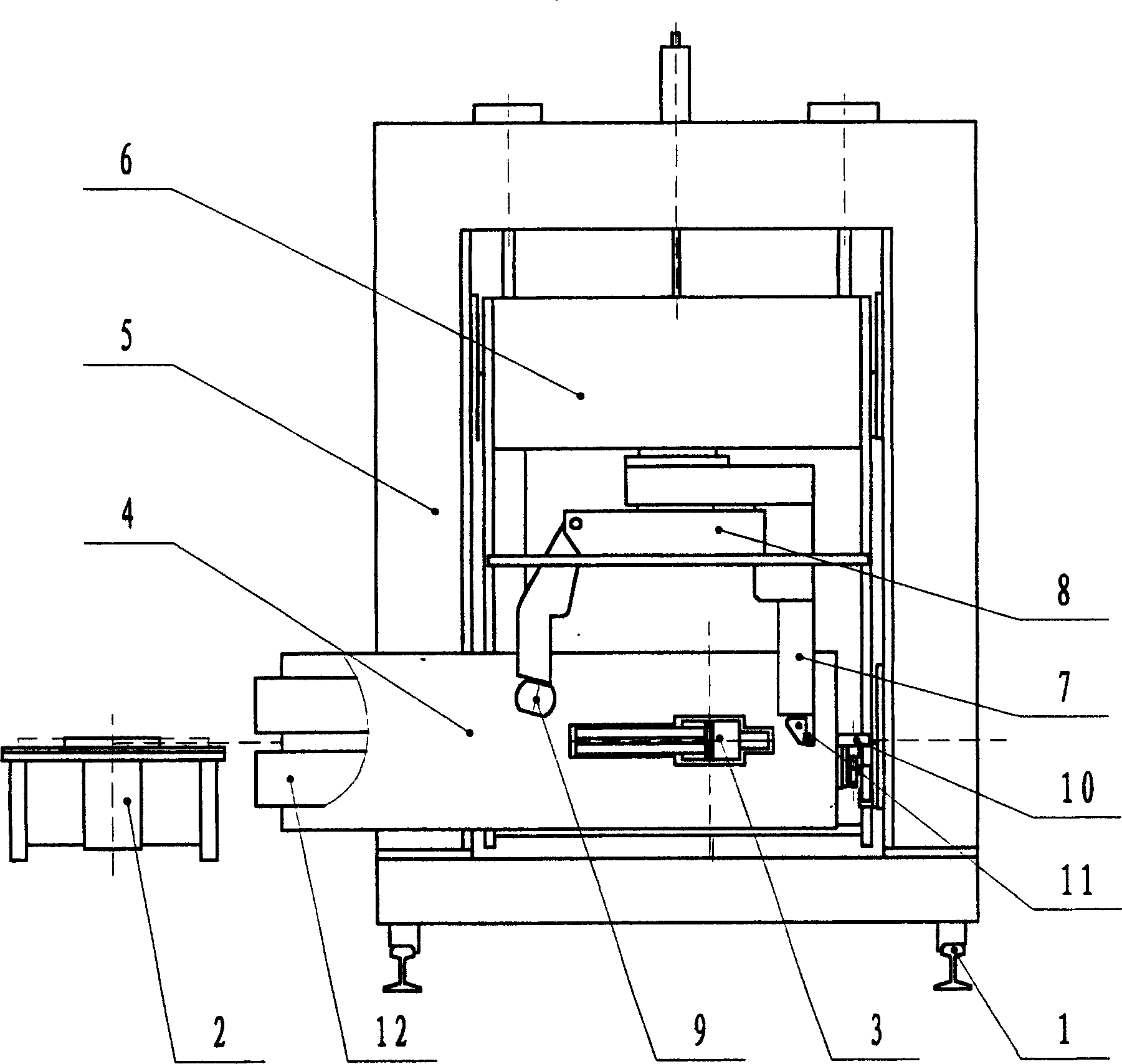

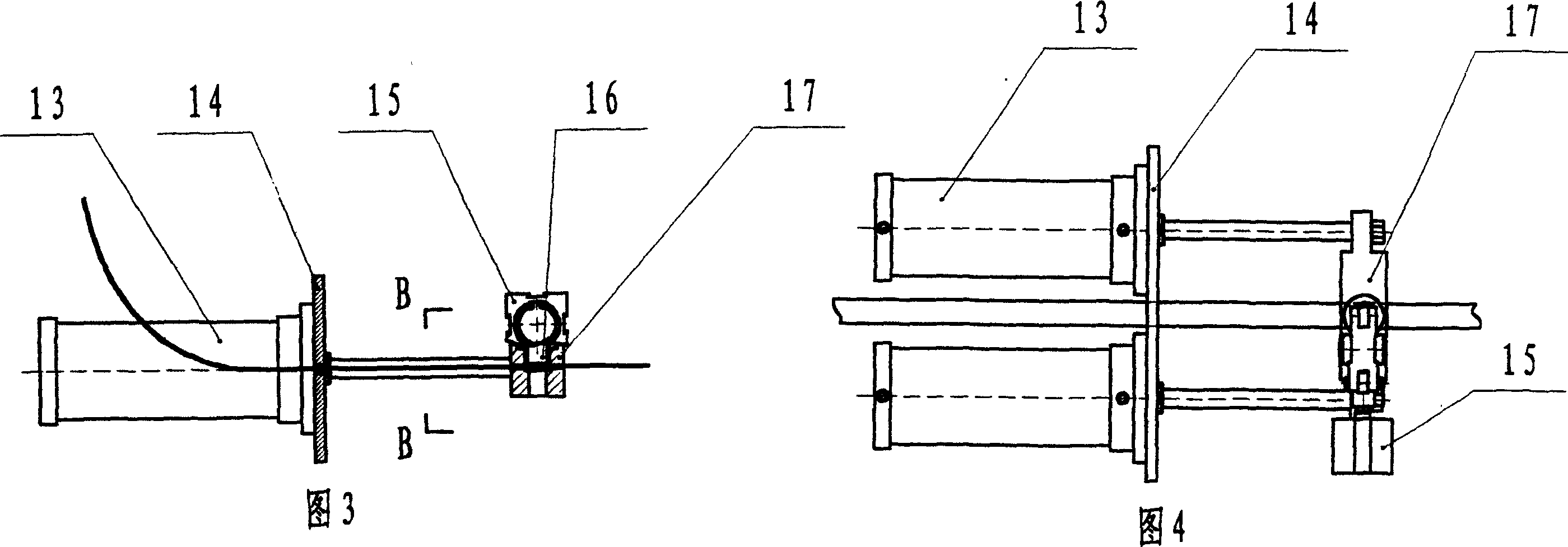

Middle-widthed band automatic bundling method and middle-widthed band automatic bundling machine

InactiveCN1541897AEnsure safety and convenienceIncrease the radius of curvatureBinding material applicationWidebandMechanical engineering

The present invention is automatic wide-tape tying method and automatic wide-tape tying machine. Unlike traditional tying process, the present invention has tying process including grasping the head of the tying tape from the tape feeding mechanism, rotating the tape feeding arm to make the tape encircle coiled steel to be tied, and tightening the tape the tape feeding mechanism holds with the driving mechanism. The automatic wide-tape tying machine of the present invention includes movable frame, driving box assembly with two driving mechanisms to control the tightening arm and the tape feeding arm separately, head frame with head assembly and tape feeding mechanism, and controller.

Owner:许春虎

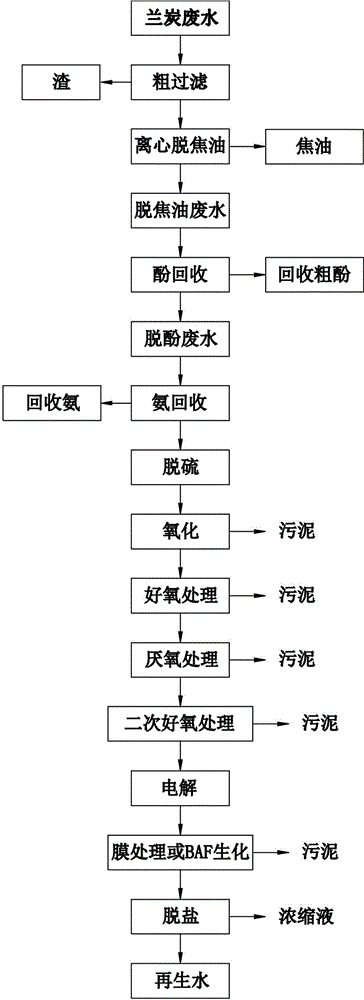

Comprehensive use of coke, phenol and ammonia in semi coke sewage and sewage disposal recycle method

InactiveCN104926029AHigh degree of comprehensive utilizationReduce the amount of alkali usedGeneral water supply conservationMultistage water/sewage treatmentEnvironmental chemistryAnaerobic treatment

A comprehensive use of coke, phenol and ammonia in semi coke sewage and sewage disposal recycle method comprises the following steps: (1) coarse filtering; (2) coal coke recycling; (3) phenol recycling; (4) ammonia recycling; (5) desulfurizing; (6) oxidating; (7) aerobic treatment; (8) anaerobic treatment; (9) secondary aerobic treatment; (10) electrolyzing; (11) membrane disposal or biological aerated filter biochemistry; (12) desalting. Deep disposal of semi coke sewage is performed by a combined disposal process of processes of membrane filtering, coal coke recycling, phenol recycling, ammonia recycling, desulfurizing, oxidating, aerobic treatment, anaerobic treatment, electrolyzing and the like, finally regeneration water is generated by desalting, full disposal of the sewage is realized, sewage pollution is eliminated, and recycle of water resource is realized by sewage regeneration.

Owner:张世文

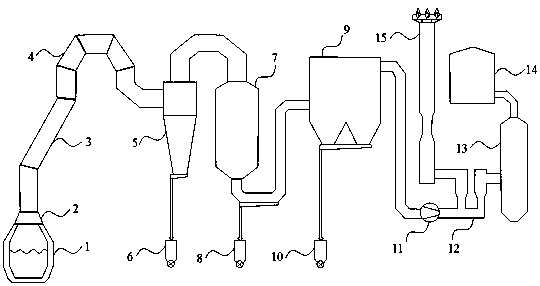

Converter flue gas pure dry purification and waste heat deep recovery system and method

PendingCN109207667AReduce consumptionImprove recyclingManufacturing convertersIncreasing energy efficiencyFlueProcess engineering

The invention provides a converter flue gas pure dry purification and waste heat deep recovery system. The system comprises a gasifying-cooling flue, a water / steam cooling cyclone separator, a waste heat recycling device, a ceramic fiber filter, a fan and a three-way switching valve which are connected in sequence through a pipeline, wherein the other two ends of the three-way switching valve areconnected with a coal gas recycling pipeline and a flue gas difusing pipeline respectively; a flue gas component analyzer is arranged between the fan and the three-way switching valve. By adopting thesystem, converter flue gas can be subjected to dust removal under a whole-dry condition, so that the consumption of water and vapor is lowered; meanwhile, waste heat in a low-medium-temperature segment of the converter flue gas is recycled on a large scale, so that the recycling amount of the waste heat resource is improved, and a remarkable energy saving effect is achieved.

Owner:WISDRI ENG & RES INC LTD

Recovery device for recovery of heavy metal in scraps of neodymium iron boron by utilizing saponification and extraction

InactiveCN107236863AImprove recyclingReduce governance costsProcess efficiency improvementFiltrationDecomposition

The invention of the creation relates to the technical field of metallurgy, in particular to a recovery device for recovery of heavy metal in scraps of neodymium iron boron by utilizing saponification and extraction. Hydrochloric-acid optimum solubilizing treatment is conducted on the scraps of the neodymium iron boron by utilizing an acid-decomposition device, so that rare earth chloride feed liquid is obtained, and extraction separation is conducted on the rare earth chloride feed liquid by an extraction separating device by utilizing a P507 phosphate extraction agent to obtain rare earth difficult-to-extract components and heavy metal ions; the rare earth difficult-to-extract components enter a second extraction tank, and the aqueous phases of the heavy metal ions enter the second extraction tank of a saponification device; and thus replacement is conducted on the aqueous phases of the heavy metal ions and the rare earth difficult-to-extract components in the second extraction tank, so that heavy metal aqueous phases are obtained, the heavy metal aqueous phases are subjected to treatment by a settling device and a vacuum filtration tank, and heavy metal carbonate solid bodies are obtained. According to the recovery device for recovery of the heavy metal in the scraps of the neodymium iron boron by utilizing saponification and extraction, compared with a traditional resource recovery technology of the scraps of the neodymium iron boron, recovery and using of the heavy metal are increased, so that wasting of resources can be effectively reduced, and the use ratio of resources is improved.

Owner:XUNWU HENGYUAN TECH DEV CO LTD

Figured island fiber and preparation method of imitated leather

InactiveCN104389048AImprove recyclingReduce manufacturing costConjugated synthetic polymer artificial filamentsArtifical filament manufactureChemistryMicrofiber

The invention belongs to the technical field of superfine fiber synthetic leather and imitated leather, and in particular relates to figured island fiber and a preparation method of the imitated leather. Island composite components of the figured island fiber provided by the invention contain protein. The method for preparing the imitated leather from the figured island fiber, provided by the invention, comprises the following steps of 1, preparing the figured island fiber; 2, preparing non-woven cloth; 3, preparing synthetic leather; 4, preparing the imitated leather. The figured island fiber and synthetic leather base cloth prepared from the figured island fiber have protein components by adding animal protein into the island composite components, grease can be effectively kneaded and filled by using a processing technology during the after-treatment of the base cloth, and highly-imitated leather which is full, oily and pendulous can be prepared.

Owner:朱奕凝

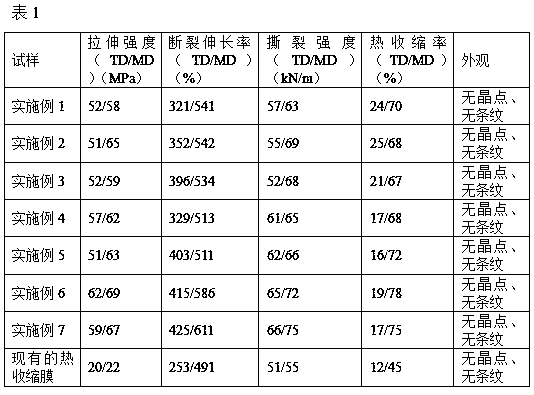

PEF heat shrinkable film and preparation method thereof

ActiveCN111267449AImprove recyclingApparently stableLamination ancillary operationsSynthetic resin layered productsAntioxidantThermal shrinkage

The invention is applicable to the technical field of materials, and provides a PEF heat shrinkable film. The PEF heat shrinkable film comprises an outer film layer, a middle film layer and an inner film layer, wherein each of the outer film layer and the inner film layer is prepared from, by weight, 40-55 parts of high-pressure low-density polyethylene, 15-25 parts of high-density polyethylene, 10-15 parts of an ethylene-vinyl acetate copolymer, 5-10 parts of polyurethane acrylate, 5-10 parts of modified argil, 4-6 parts of oleamide and 2-5 parts of an antioxidant; and the middle film layer is prepared from, by weight, 25-35 parts of high-pressure low-density polyethylene, 20-30 parts of high-density polyethylene, 10-15 parts of the ethylene-vinyl acetate copolymer, 2-6 parts of modifiedgas silicon, 4-6 parts of oleamide and 1-3 parts of the antioxidant. The PEF heat shrinkable film formed by compounding the raw materials which are nontoxic and wide in source is stable in appearance,has good physical and mechanical properties such as the heat shrinkage rate, the tensile property and the tearing strength, is suitable for package and transportation of articles including but not limited to foods, electronic products and the like, and has good development prospects.

Owner:汕头市明佳热收缩膜有限公司

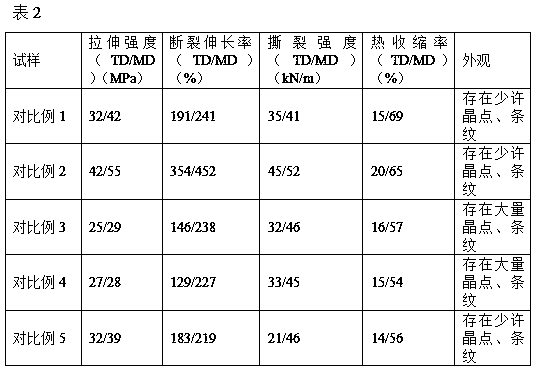

Morchella esculenta (L.) Pers nutrient bag, preparation method thereof and morchella esculenta (L.) Pers interplanting culture method thereof

PendingCN110249910AImprove recyclingIncrease productionLeaf crop cultivationCultivating equipmentsNutrientGypsum

The invention relates to a morchella esculenta (L.) Pers nutrient bag, a preparation method thereof and a morchella esculenta (L.) Pers interplanting culture method. The morchella esculenta (L.) Pers nutrient bag comprises, by weight, 28-32% of wheat grains, 35-38% of rape pods, 28-32% of saw dust, 1-2% of quicklime and 1-2% of gypsum. The invention further provides the preparation method of the morchella esculenta (L.) Pers nutrient bag and the morchella esculenta (L.) Pers interplanting culture method. The invention provides a nutrient bag culture formula capable of increasing the yield of morchella esculenta (L.) Pers. According to the morchella esculenta (L.) Pers nutrient bag, by using the rape pods, in cooperation with other raw materials, new resources for planting of the morchella esculenta (L.) Pers are developed, and recycling of rape crops is improved. The external nutrient bag can be removed locally, rich nutrients are provided for the rape crops, the yield is increased, application of a chemical fertilizer is reduced, and the cost is lowered.

Owner:湖南迪为农业科技有限公司

Method for preparing 2-ethylhexyl acrylate by catalysis of acidic caprolactam ionic liquid

InactiveCN105130803AEasy to separateActivity unchangedOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsIsooctyl acrylateIsooctyl alcohol

The invention provides a method for preparing 2-ethylhexyl acrylate by catalysis of acidic caprolactam ionic liquid, and the method comprises the steps: taking acrylic acid and isooctyl alcohol as raw materials, a cyclohexane as a dehydrator and acidic caprolactam ionic liquid as catalyst in presence of a polymerization inhibitor for azeotropy dehydration condensation under 80-120 DEG C, processing a reaction liquid after the reaction is finished to obtain 2-ethylhexyl acrylate. The method has the characteristics of simple preparation of the catalyst, easiness in separation, simple operation, good product quality, capability of repeatedly using the catalyst and the like. According to the method, cycle use of the catalyst is improved, product recovery is improved and product purity is improved.

Owner:JIANGSU GUOJIAO CHEM TECH

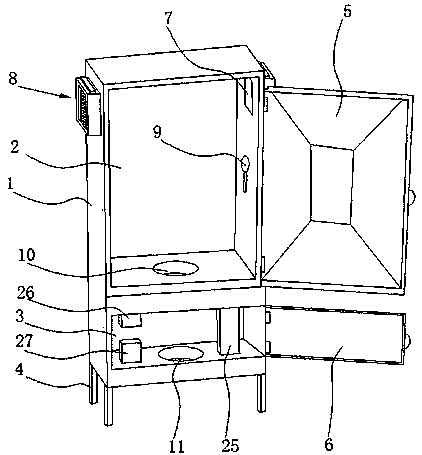

High-protection-level power distribution cabinet for building electrical engineering

InactiveCN110137817AAvoid wasting electricitySave electricitySubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsTemperature controlArchitectural engineering

The invention discloses a high-protection-level power distribution cabinet for building electrical engineering. The power distribution cabinet comprises a power distribution cabinet housing. The upperportion of the power distribution cabinet housing is provided with an electrical component chamber; and the lower portion of the power distribution cabinet housing is provided with an accessory chamber. The bottom surface of the accessory chamber is equipped with an air inlet cylinder. The air inlet cylinder is connected with air inlet branch pipes. Each air inlet branch pipe is internally and fixedly provided with a first arc dust collector plate and a second arc dust collector plate, which are symmetrically arranged. An electrode bar is fixedly arranged between the first arc dust collectorplate and the second arc dust collector plate. One side wall of the air inlet cylinder is provided with a second limit hole. The second limit hole is internally equipped with a circular dust filter mesh. The upper inner portion of the air inlet cylinder is fixedly provided with a motor. The output end of the motor is coaxially and fixedly connected with an air blower oar. The opposite side walls of the upper portion of the electrical component chamber are respectively provided with a square through hole; and each square through hole is equipped with a dust filter device. The technical effectsare that the power distribution cabinet has a cooling and protection effect, a constant-temperature control effect, an efficient dust reduction and dust removing protection effect and convenient use and operation.

Owner:HEBEI CONSTR GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com