Technology for recovering tellurium from high-tellurium slag

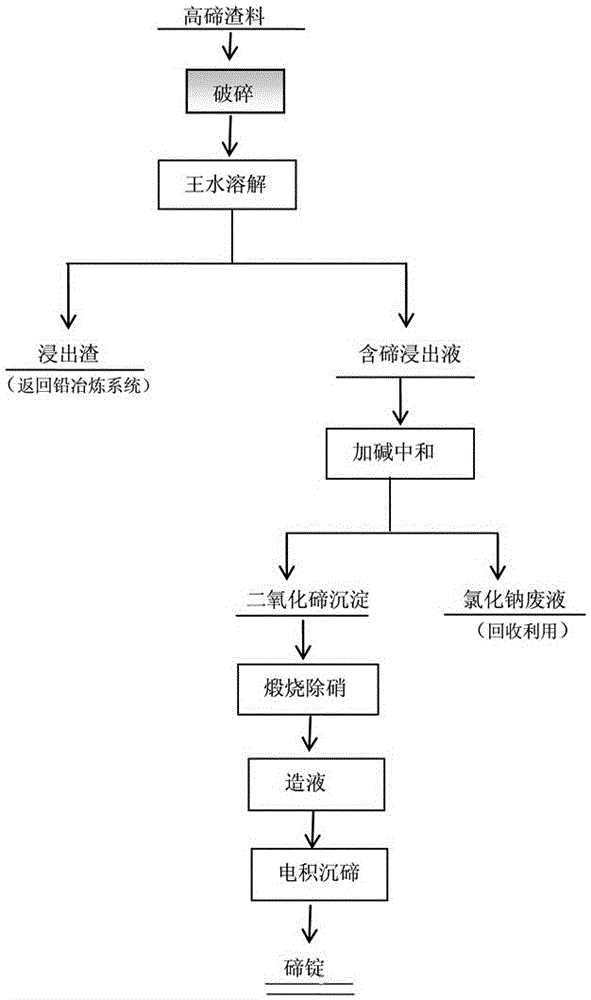

A process and slag technology, applied in the field of non-ferrous metal hydrometallurgy, can solve the problems of difficult oxidation of tellurium metal, unqualified tellurium products, incomplete removal of impurities, etc., and achieve the effects of low production cost, less equipment and significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Example 1: 5000 g of high tellurium slag material (Te73.18%, 3659g; Pb0.64%, 32g; Ag0.055%, 2.75g) was crushed to a particle size ≤ 10mm, and 16L aqua regia solution prepared in advance was slowly added Stir continuously in the reaction tank. After the reaction is complete, liquid-solid separation is carried out to obtain tellurium-containing leaching solution and leaching slag. The leaching slag is tempered and the lead smelting system recovers valuable elements such as Ag and Pb. The leaching solution was neutralized with sodium hydroxide solution until the final pH was 6. Tellurium dioxide precipitate was obtained after liquid-solid separation, and the weight of tellurium dioxide was 4665.85g after denitrification and selenium removal by calcination. The tellurium content was 77.3% (tellurium metal content) by sampling analysis. 3606.7g), the recovery rate of tellurium is as high as 98.57%, the recovery rate of silver is >99.4%, and the recovery rate of lead is >97.6%...

Embodiment 2

[0021] Example 2: 5000 g of high tellurium slag material (Te71.08%, 3554g; Pb0.79%, 39.5g; Ag0.062%, 3.1g) was crushed to a particle size of ≤10mm, and the pre-prepared 12L aqua regia solution was slowly Add it into the reaction tank and keep stirring. After the reaction is complete, liquid-solid separation is carried out to obtain tellurium-containing leaching solution and leaching slag. The leaching slag is tempered and the lead smelting system recovers valuable elements such as Ag and Pb. The leaching solution was neutralized with sodium hydroxide solution until the final pH was 6. Tellurium dioxide precipitate was obtained after liquid-solid separation, and the weight of tellurium dioxide was 4598.7g after denitrification and selenium removal by calcination. The tellurium content was 74.12% (the amount of tellurium metal) analyzed by sampling. 3408.56g), the recovery rate of tellurium is 95.91%, the recovery rate of silver is >99.0%, and the recovery rate of lead is >98.1%....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com