Patents

Literature

82results about "Selenium/tellurium oxides/hydroxides" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Novel high-impurity copper anode mud treatment technology

InactiveCN105969989AReduce pollutionEasy to operatePhotography auxillary processesProcess efficiency improvementElectrolysisIntermediate frequency

The invention discloses a novel high-impurity copper anode mud treatment technology. The novel high-impurity copper anode mud treatment technology includes the following steps that firstly, copper anode mud is subjected to sulphating roasting and selenium removing, and copper is leached and removed; secondly, a side-blown converter is used for reduction smelting, wherein a slagging agent and a reducing agent are added to the copper anode mud obtained after sulphating roasting and selenium removing and copper removing, even mixing is conducted, a mixed material is obtained and subjected to melting, slagging and a reduction reaction, and smoke, dross on the upper layer and melt-shaped noble lead on the lower layer are formed; thirdly, vacuum distillation is conducted; and fourthly, gold and silver electrolysis and lead and bismuth recovery are conducted, wherein a Dore alloy is put into an intermediate-frequency furnace to be cast into a silver anode plate for silver electrolysis, and lead electrolysis is conducted after a lead and bismuth alloy is cast into a lead plate. The novel high-impurity copper anode mud treatment technology has the beneficial effects that reaction smelting and vacuum distillation are conducted through the side-blown converter, precious metal and valuable metal are recovered to the maximum degree, and the amount of precious metal left in the technology is reduced to the minimum.

Owner:TONGLING NONFERROUS METALS GRP TONGGUAN NEW TECH

Method for recycling metal bismuth from anode slime

ActiveCN105821215ASimple methodEasy to operateProcess efficiency improvementSelenium/tellurium oxides/hydroxidesLiquid temperatureSulfite salt

A method for recycling metal bismuth from anode slime includes the following steps that a, sintering is performed; b, copper separation is performed so that a sulfate solution and copper separation slag can be obtained; c, gold separation is performed so that gold separation mother liquor can be obtained, wherein the concentration of sulfuric acid is 100 g / L to 120 g / L, the concentration of hydrochloric acid is 10 g / L to 15 g / L, the concentration of chloride ions is 25 g / L to 35 g / L, temperature is raised to 75 DEG C to 85 DEG C, excessive sodium chlorate is added, after a reaction, gold metal, platinum metal, palladium metal, tellurium metal and bismuth metal are dissolved in the gold separation mother liquor, then sodium sulfite is added in the gold separation mother liquor to separate gold so that gold separation liquid can be obtained; d, sodium chloride and sodium sulfite are added in the gold separation liquid obtained in the step c, the concentration of sodium chloride is controlled to be 250 g / L to 300 g / L, liquid temperature is controlled to be 75 DEG C to 85 DEG C, precious metal, tellurium and selenium in the liquid are reduced into suspended matter, and after filtration, bismuth separation liquid is obtained; and e, sodium hydroxide is added into the bismuth separation liquid obtained in the step d, PH is adjusted to be 10 to 11, bismuth in the liquid is hydrolyzed, bismuth slag is obtained after filtration, and metal bismuth is obtained after reduction. The method has the following beneficial effects that the method is simple, operation is convenient, and the bismuth recycling rate and the bismuth recycling purity are high.

Owner:ZHEJIANG YADONG IND CO LTD

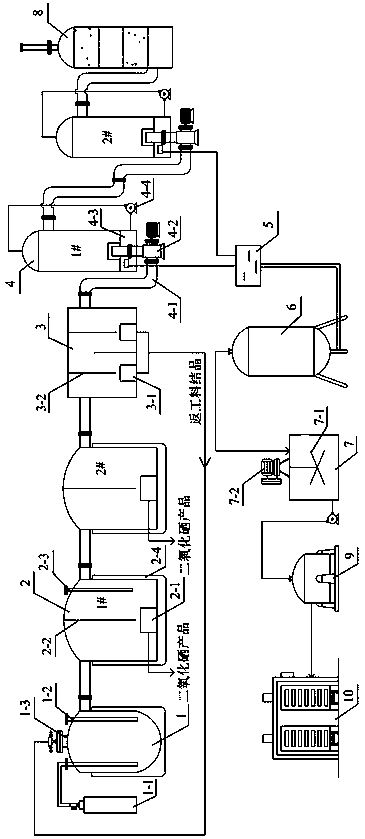

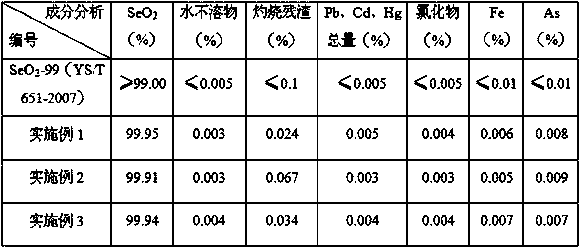

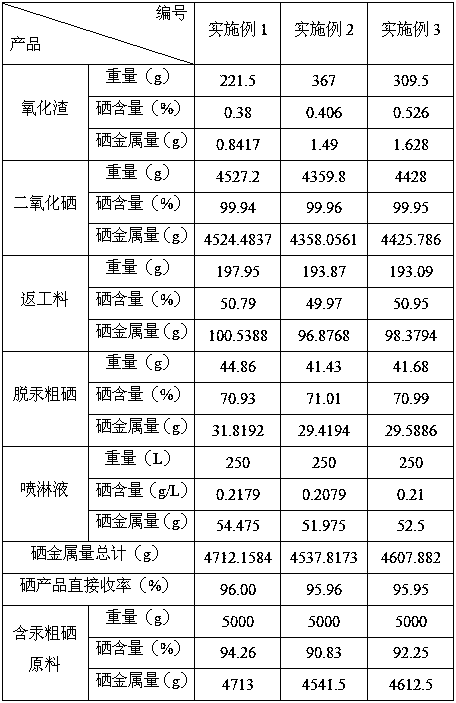

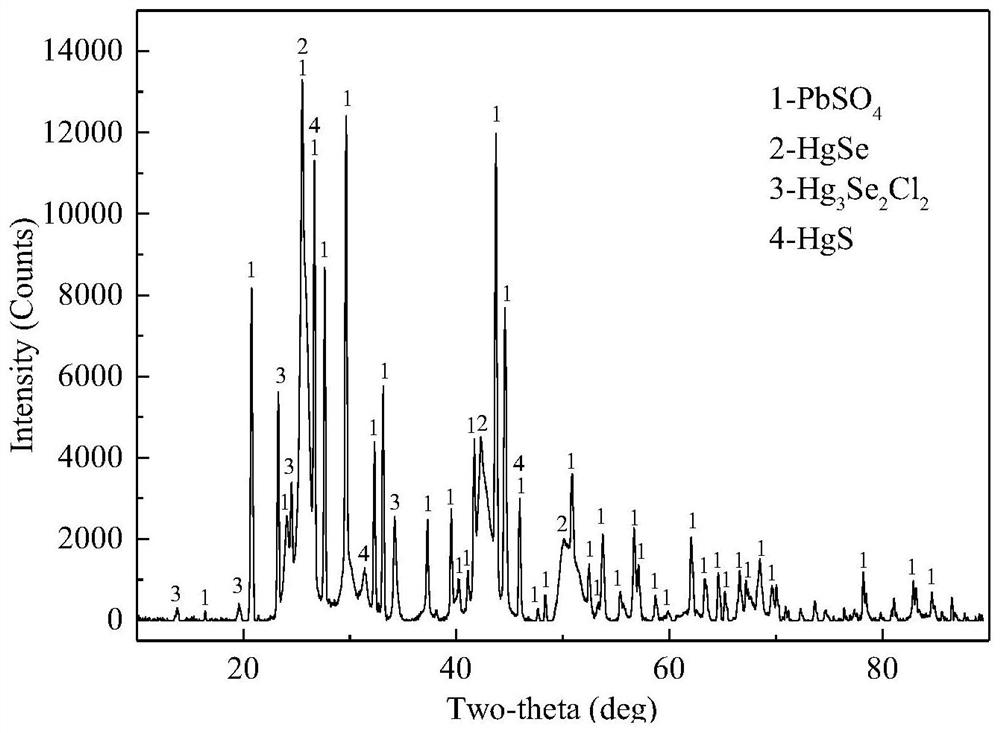

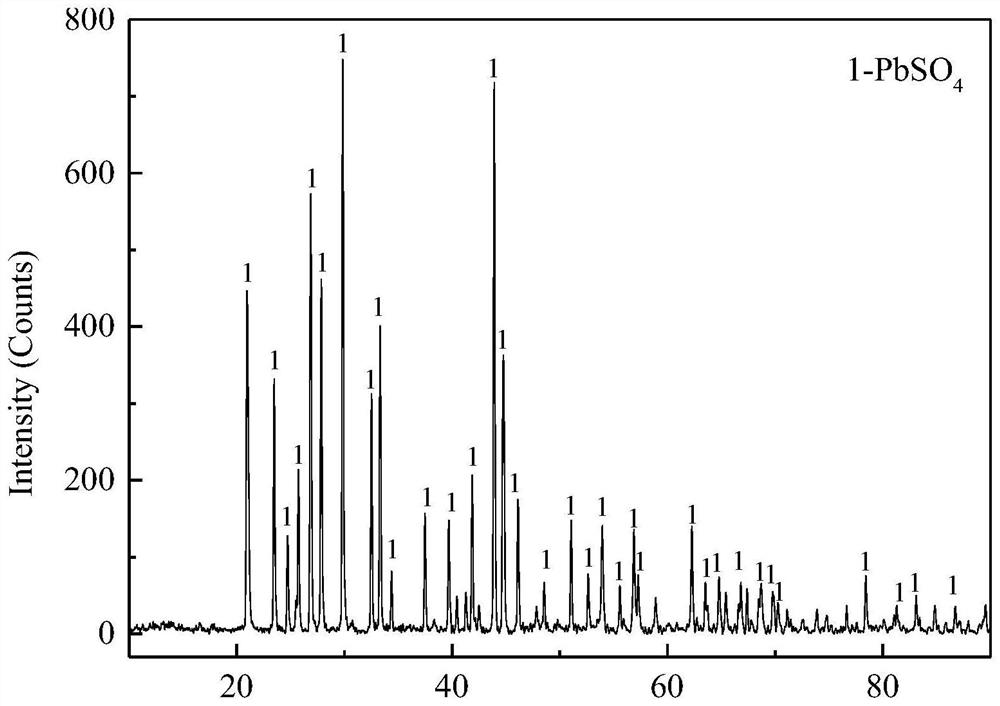

Device and method for removing impurities in mercury-containing crude selenium

ActiveCN108975290AEasy to separateSimple structureSelenium/tellurium preparationSelenium/tellurium oxides/hydroxidesIon exchangeSpray tower

The invention relates to a device and a method for removing impurities in mercury-containing crude selenium. The device comprises an oxidizing furnace, a crystallizer, a separator, a spraying tower, afilter, an ion exchange column and a reduction tank, wherein an oxygen gas conveying device and a temperature measuring device are arranged at the top part of the oxidizing furnace; an air outlet atthe upper part of the oxidizing furnace is connected with an air inlet at the upper part of the crystallizer; an air outlet at the upper part of the crystallizer is connected with an air inlet at theupper part of the separator; the lower part of the crystallizer is provided with a material outlet; an air outlet of the separator is connected with an air inlet at the lower part of the spraying tower through a water sealing device and an induced draft fan; a water tank at the bottom part of the spraying tower is connected with the top part of the spraying tower through a spraying pump; a water outlet of the water tank is connected with the filter; the filter is connected with an inlet at the lower part of the ion exchange column; an outlet at the upper part of the ion exchange column is connected with the reduction tank. The invention also discloses the method for removing the impurities in the mercury-containing crude selenium. The device and the method have the advantages that the device and the method are simple, the selenium separating effect is good, the cost is low, and the device and the method are suitable for industrialized production.

Owner:映泽新材料(深圳)有限公司

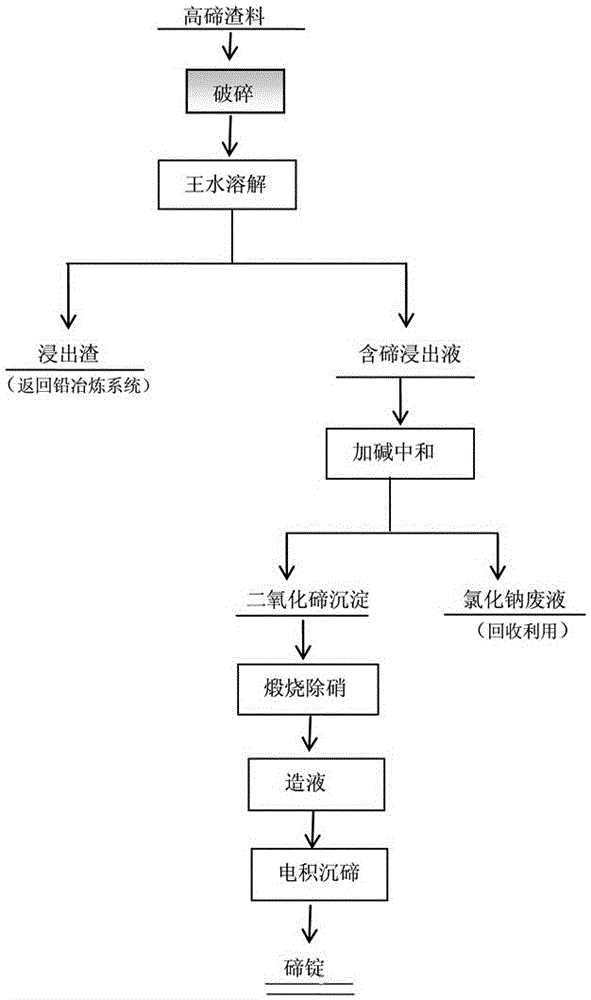

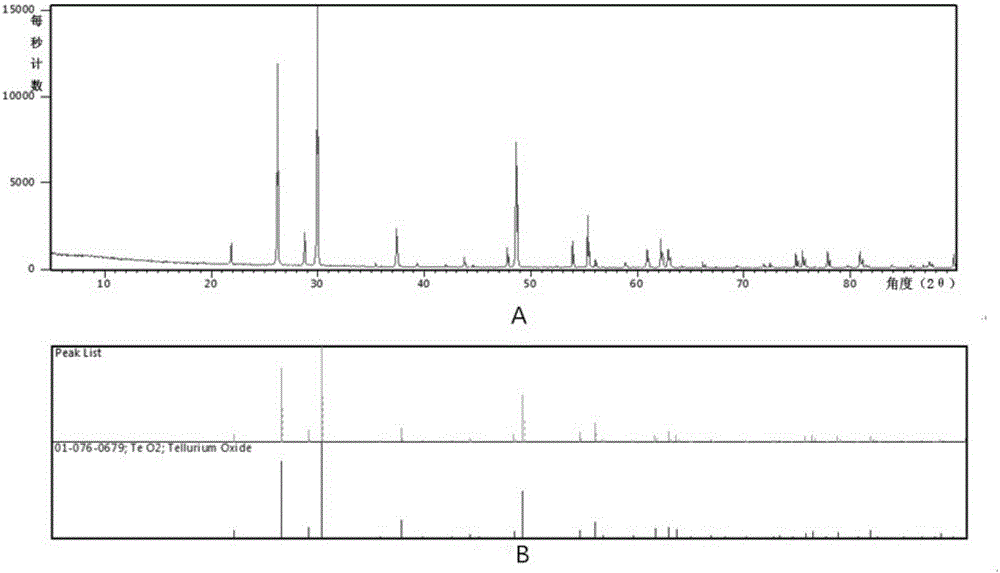

Technology for recovering tellurium from high-tellurium slag

InactiveCN105967153ASolve the problem that the oxidation speed is extremely slow or even not oxidizedAdaptableSelenium/tellurium oxides/hydroxidesBinary selenium/tellurium compoundsPregnant leach solutionGranularity

The invention provides a technology for recovering tellurium from high-tellurium slag. The technology comprises 1, crushing high-tellurium slag until granularity is less than or equal to 10mm, 2, pouring the broken high-tellurium slag into a reactor, slowly adding aqua regia into the high-tellurium slag and carrying out oxidation leaching, 3, after the slag is completely dissolved, carrying out liquid-solid separation so that a main element tellurium enters the leachate and Pb and Ag valuable metals enter slags, returning the Pb and Ag slags to a Pb smelting system and recovering valuable metals, and 4, preparing a solution of caustic soda flakes, slowly adding the solution into the tellurium-containing leachate, adjusting pH to 5.0-6.0, carrying out solid-liquid separation to obtain TeO2 precipitates, carrying out calcining denitration on the TeO2, carrying out liquid preparation, returning the liquid to an electrodeposition process and directly recovering metal Te. The technology has the characteristics of simple processes, less equipment, low production cost and high comprehensive recovery degree and has a certain application prospect.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

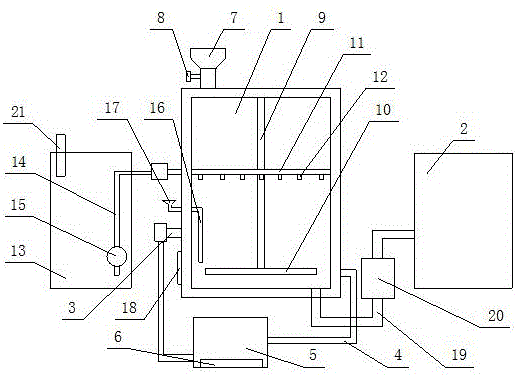

High-purity tellurium dioxide preparation method and device

ActiveCN106365129AAccurately control the dosagePrecise control of concentrationSelenium/tellurium oxides/hydroxidesBinary selenium/tellurium compoundsTe elementTellurium dioxide

The invention discloses a high-purity tellurium dioxide preparation method and device. The method includes the steps: a, oxidizing reaction: oxidizing 4N tellurium powder by hydrogen peroxide, accurately controlling the adding quantity and the adding rate of the hydrogen peroxide by a flow pump and controlling the concentration of the hydrogen peroxide to range from 10% to 25%; b, purification: adding 2g / L of purifying agents into solution obtained after oxidizing reaction, stirring the solution and then standing for 20-30 minutes; c, concentration and crystallization: distilling and crystallizing the purified and settled solution at high temperature; d, high-temperature cracking: cracking crystals at high temperature to obtain high-purity tellurium dioxide. The usage and the concentration of the hydrogen peroxide are accurately controlled, so that peroxidation is avoided, the purity of products is ensured, and production efficiency and product yield are effectively improved.

Owner:石棉阔山新材料科技有限公司

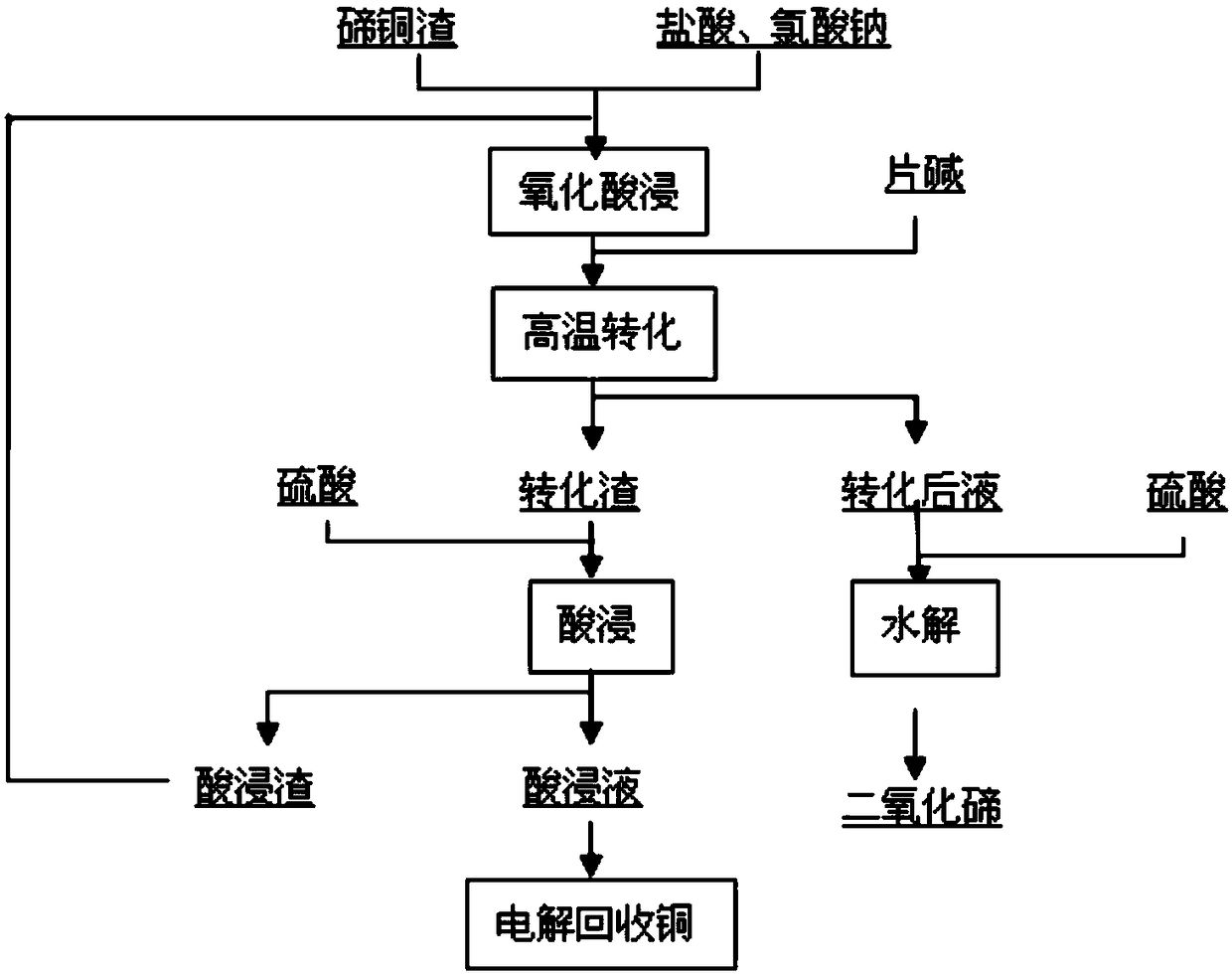

Tellurium copper slag treatment method

InactiveCN108559853AThe separation effect is thoroughHigh recovery rateCopper oxides/halidesProcess efficiency improvementTe elementHydrometallurgy

The invention provides a tellurium copper slag treatment method which includes the steps of S1, subjecting tellurium copper slag to acidic oxidation and leaching through acid solution and oxidizing agent to obtain acid leachate; S2, subjecting the acid leachate to solid-liquid separation to obtain liquid phase, regulating pH value of the liquid phase to be 12-14 with sodium hydroxide, raising temperature until the liquid is boiled to complete reaction to obtain alkaline transfer solution; S3, subjecting the alkaline transfer solution to acidic hydrolysis to obtain a tellurium dioxide product.The acid solution refers to hydrochloric acid solution or sulfuric acid solution. According to the technical scheme, copper, selenium and tellurium are separated by steps, excellent separation effectis achieved, and recovery rate of valuable elements such as tellurium is high. The whole treatment process is simple, stable and reliable, is adaptable to large-scale industrial application, and achieves good economic benefit. Besides, general hydrometallurgical equipment can be utilized as production equipment, and acidic oxidation and leaching and alkaline transfer can be completed through the equipment only, and thus, equipment investment can be saved.

Owner:YANGGU XIANGGUANG COPPER

Method for recovering tellurium and cadmium from cadmium telluride wastes

InactiveCN106277037ARealize separation and recoverySimple processCadmium sulfidesSelenium/tellurium oxides/hydroxidesFiltrationSulfite salt

The invention relates to a method for recovering tellurium and cadmium from cadmium telluride wastes. The method comprises the following steps: S1: breaking the cadmium telluride wastes, sieving the broken cadmium telluride wastes and then mixing the powder with water uniformly, thus forming first mixed liquor; S2: adding acid to the first mixed liquor to react for a period of time and then adding an oxidant to form second mixed liquor; S3: filtering the second mixed liquor, thus obtaining a first solution and a tellurium dioxide precipitate; S4: adding Cl<-> to the first solution, then adding sodium sulfite for reduction purification and carrying out filtration, thus obtaining a crude tellurium precipitate and a second solution; S5: then adding sulfides to the second solution and carrying out filtration, thus obtaining a cadmium sulfide precipitate. The method has the beneficial effects that separation and recovery of tellurium and cadmium are achieved by controlling the oxidation potential in the cadmium telluride waste leaching process; the purity of finally obtained tellurium dioxide and cadmium sulfide can reach 2-3N; the method is simple in process, is safe to operate and is low in cost and high in recovery rate.

Owner:FIRST RARE MATERIALS CO LTD

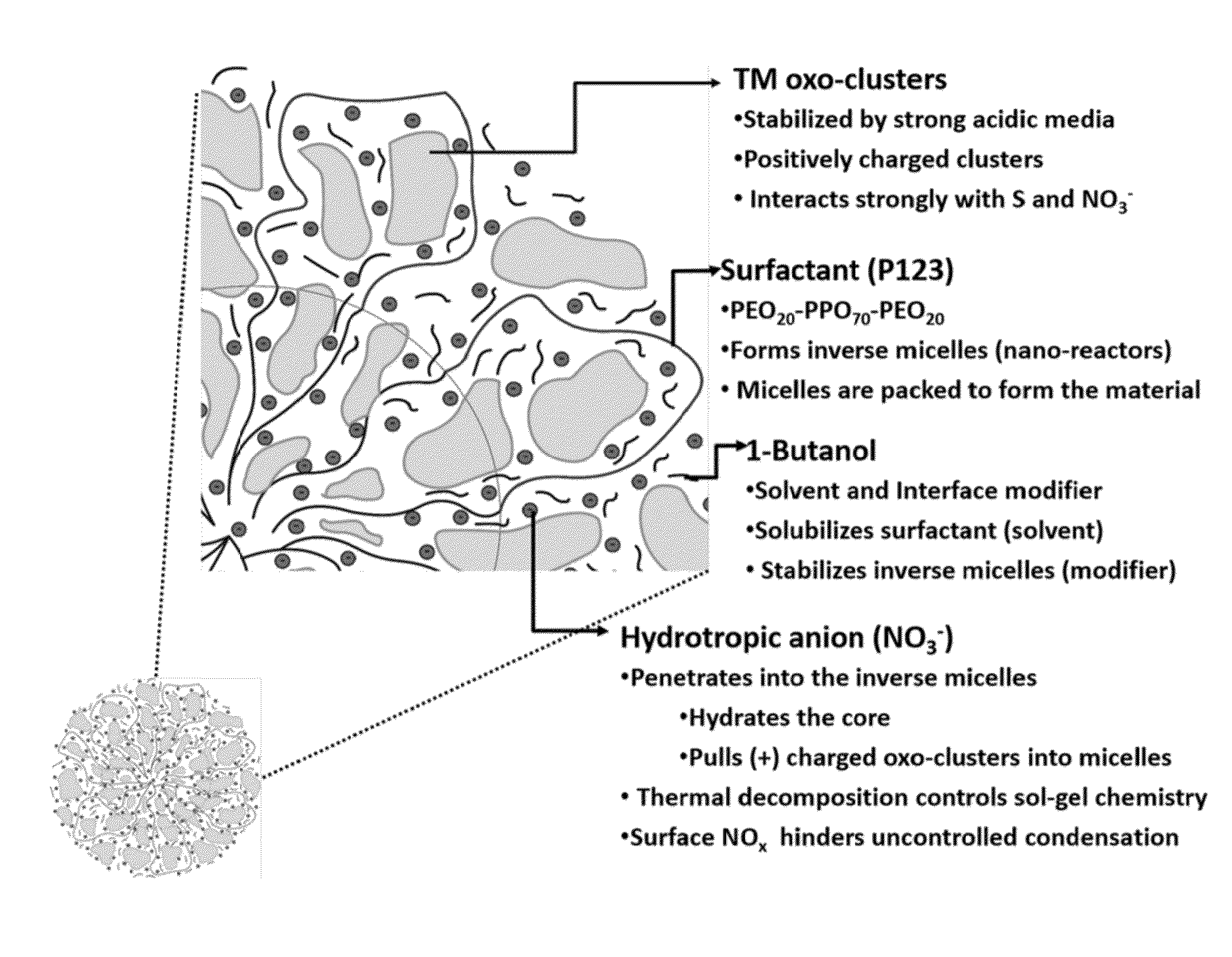

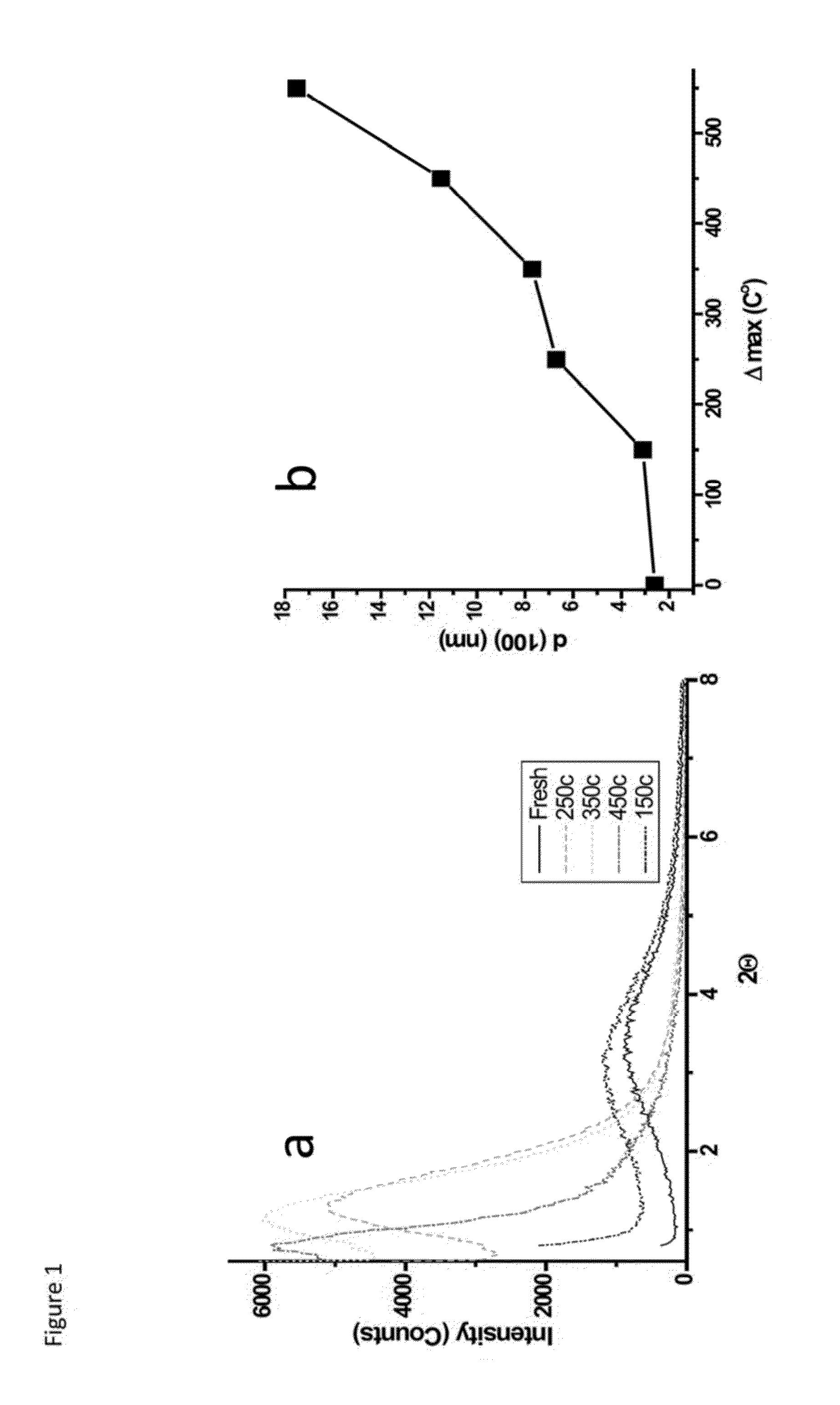

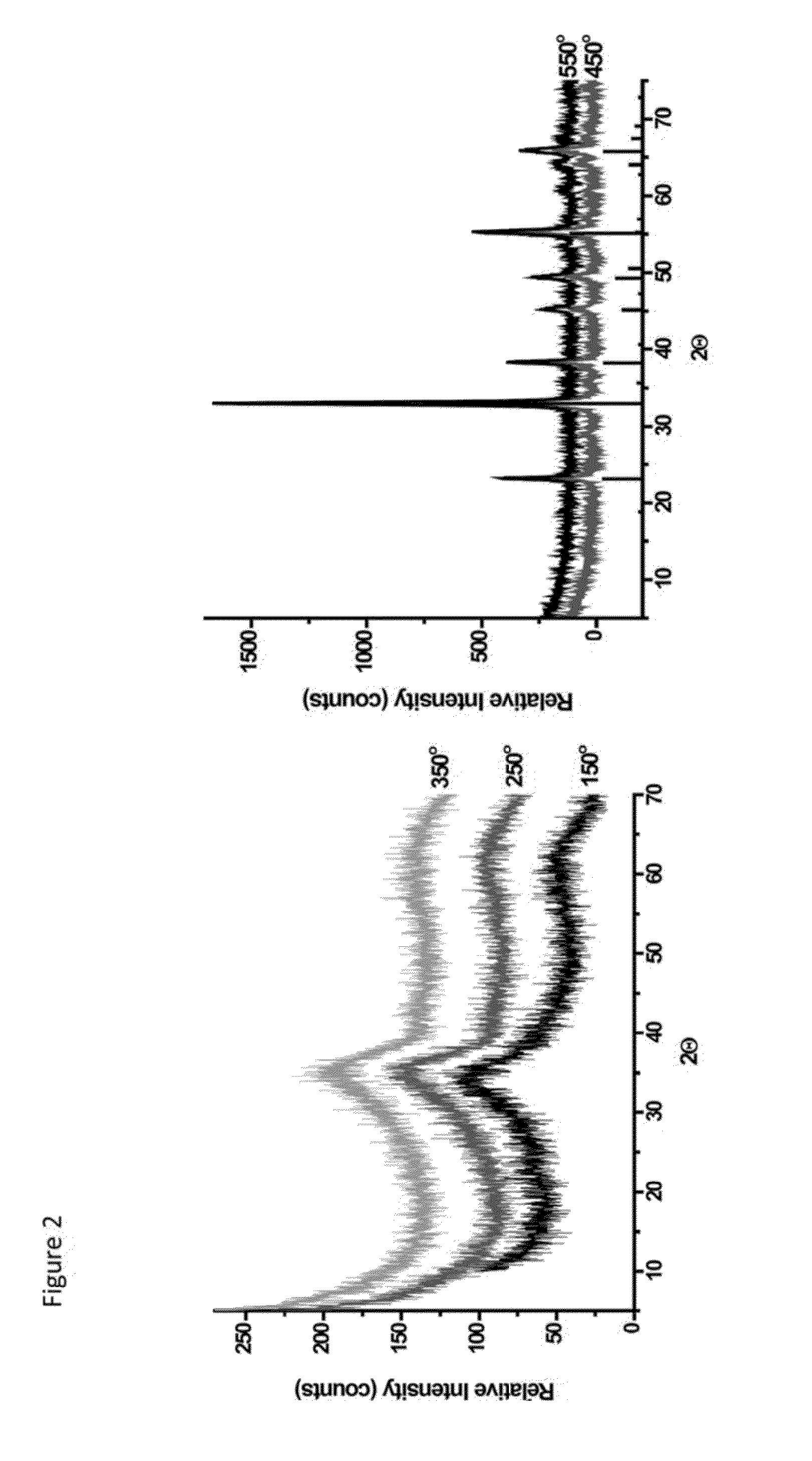

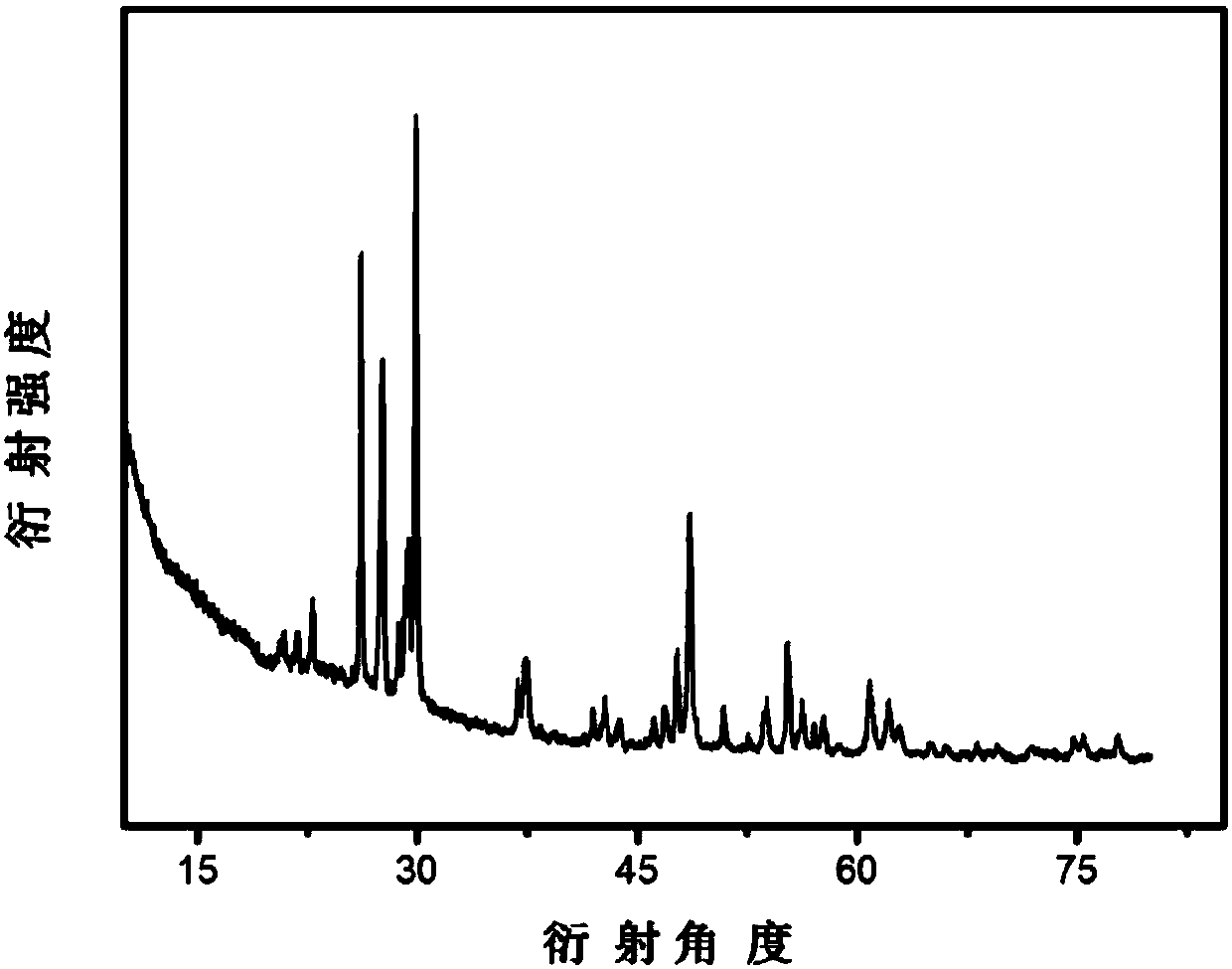

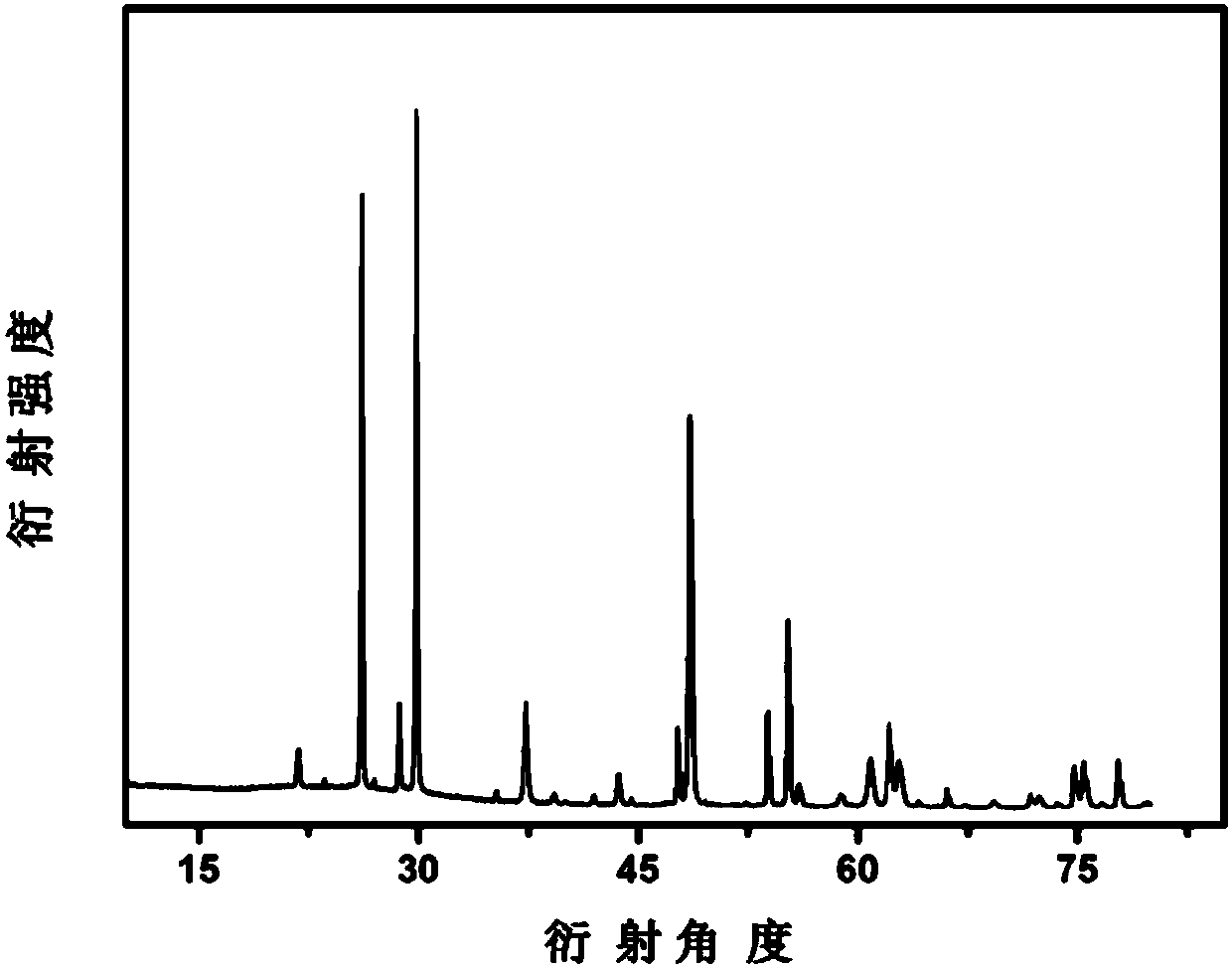

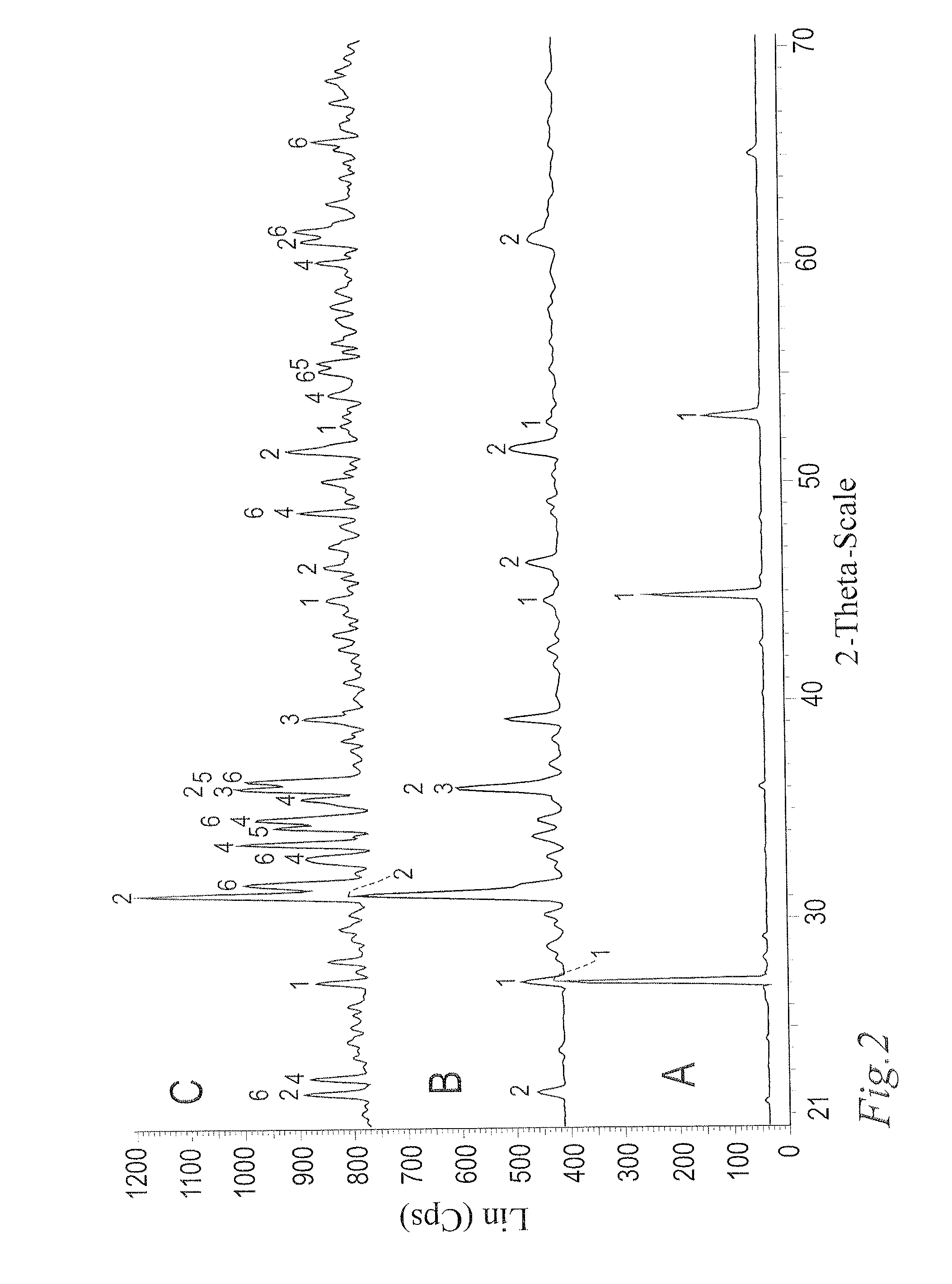

Mesoporous metal oxides and processes for preparation thereof

ActiveUS9452933B2Simple heat treatment processDifferent porous structureMaterial nanotechnologySilicaLanthanideCrystallinity

A process for preparing a mesoporous metal oxide, i.e., transition metal oxide, Lanthanide metal oxide, a post-transition metal oxide and metalloid oxide. The process comprises providing a micellar solution comprising a metal precursor, an interface modifier, a hydrotropic ion precursor, and a surfactant; and heating the micellar solution at a temperature and for a period of time sufficient to form the mesoporous metal oxide. A mesoporous metal oxide prepared by the above process. A method of controlling nano-sized wall crystallinity and mesoporosity in mesoporous metal oxides. The method comprises providing a micellar solution comprising a metal precursor, an interface modifier, a hydrotropic ion precursor, and a surfactant; and heating the micellar solution at a temperature and for a period of time sufficient to control nano-sized wall crystallinity and mesoporosity in the mesoporous metal oxides. Mesoporous metal oxides and a method of tuning structural properties of mesoporous metal oxides.

Owner:UNIV OF CONNECTICUT

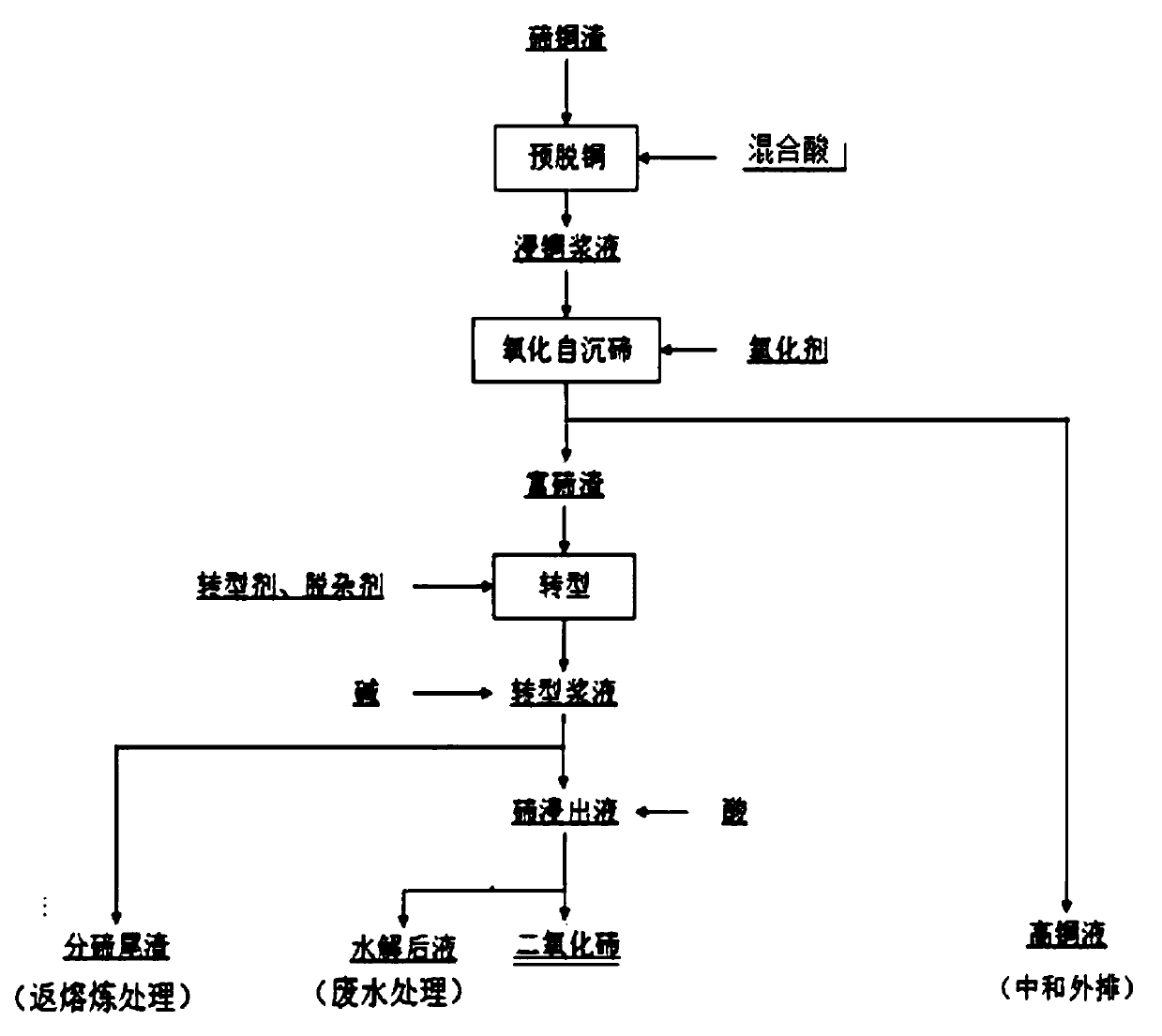

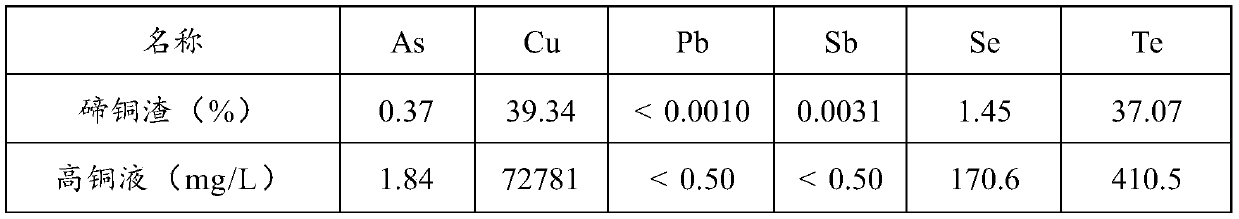

Process for preparing tellurium dioxide

ActiveCN110255509AHigh recovery rateEffective leachingSelenium/tellurium oxides/hydroxidesBinary selenium/tellurium compoundsPregnant leach solutionTe element

The invention provides a process for preparing tellurium dioxide. The process comprises the following steps: (A) enabling tellurium copper slag to be pulpified and then adding mixed acid to react to obtain pre-leaching slurry; (B) enabling the pre-leaching slurry to react with an oxidizing agent and then adjusting the pH value to 2-4 to obtain high-copper liquid and tellurium-rich slag; (C) enabling the tellurium-rich slag to be pulpified and then react with a transformation agent and an impurity-removing agent to obtain transformation slurry; and enabling the transformation slurry to react with alkali to obtain tellurium-separated tailings and tellurium leach liquor; and (D) hydrolyzing the tellurium leach liquor to obtain the tellurium dioxide. The invention firstly provides the steps of pre-leaching to remove copper through controlling a weak acid environment, then oxidizing self-precipitated tellurium, separating the tellurium from the copper effectively and then removing impurities and transformed high-valence tellurium through adding the transformation agent and the impurity-removal agent before alkali leaching, the steps of the process realize multiple functions in a short condition and are easy to control, so that the leaching rate is high, the impurity-removing effect is good, and the recovery rate of the copper and the tellurium is high.

Owner:YANGGU XIANGGUANG COPPER

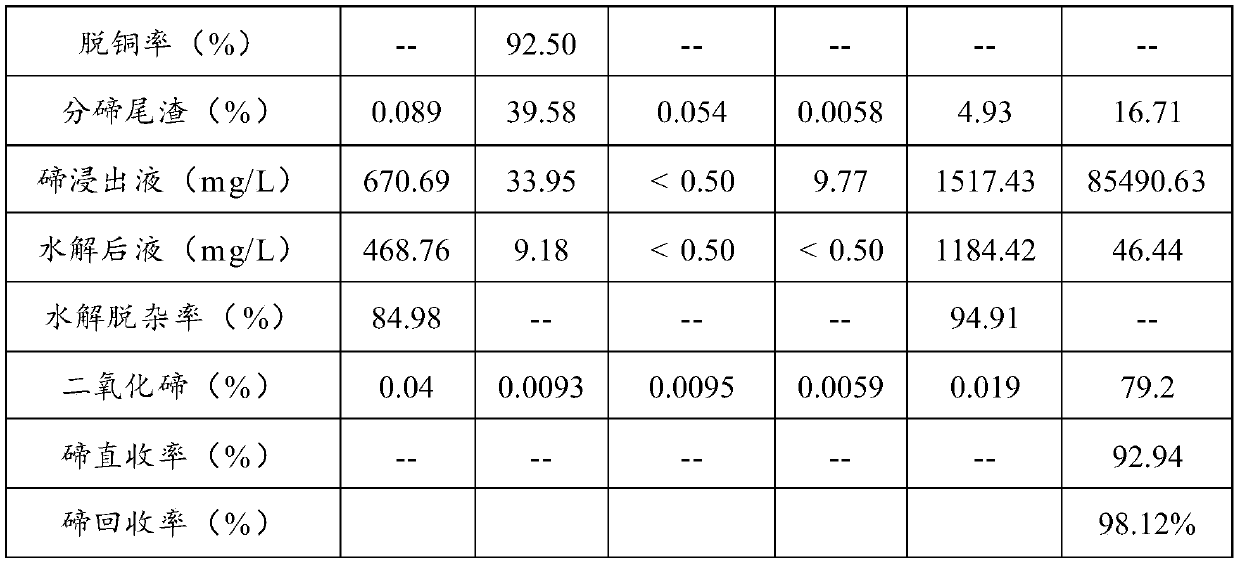

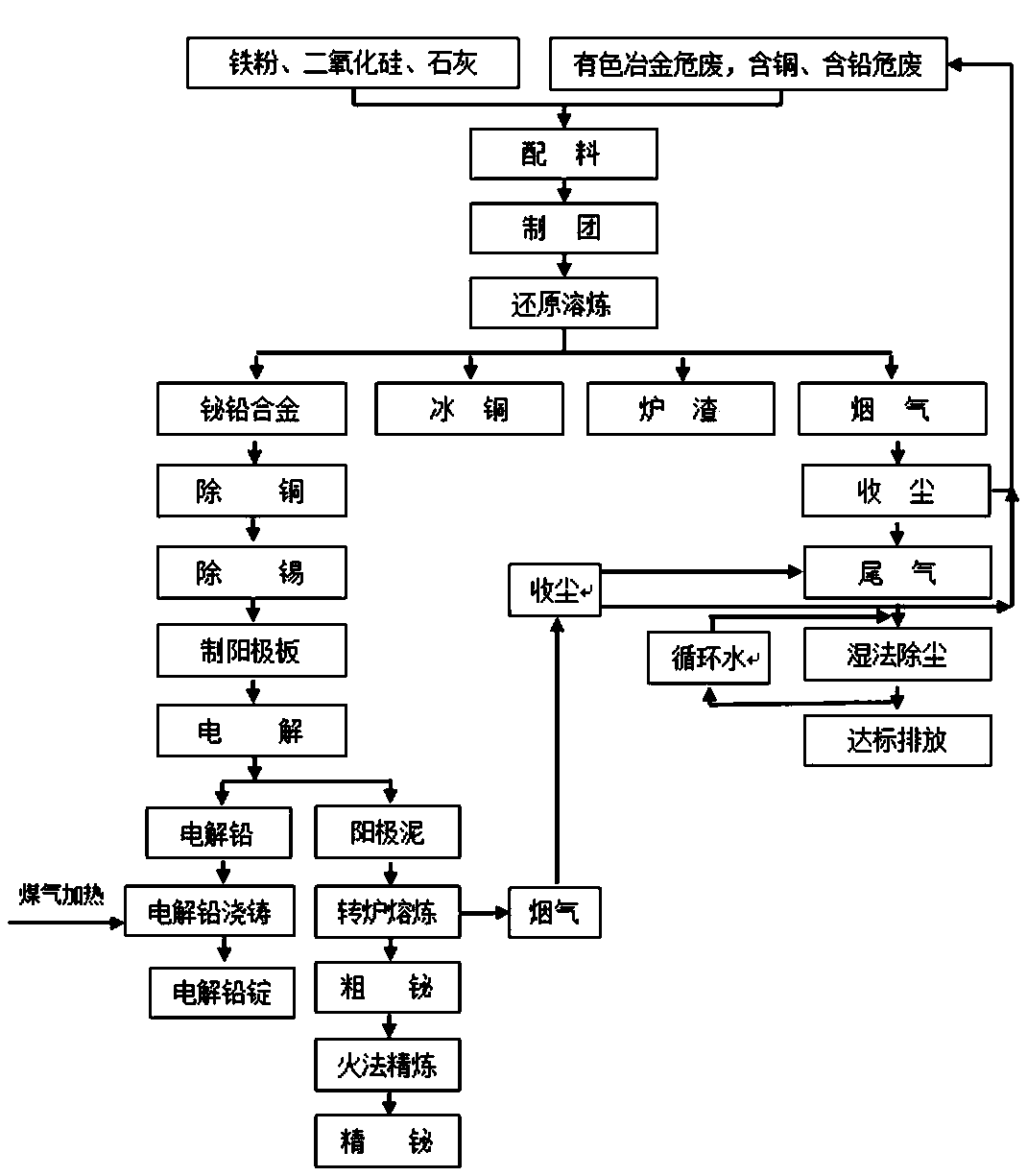

Comprehensive utilization method for recycling industrial hazardous wastes

InactiveCN110004298ARealize resource utilizationReduce usagePhotography auxillary processesProcess efficiency improvementElectrolysisShaft furnace

The invention relates to a comprehensive utilization method for recycling industrial hazardous wastes. The method is characterized in that copper-containing hazardous wastes, lead-containing hazardouswastes and nonferrous metallurgical hazardous wastes are mixed and prepared into furnace charge, the furnace charge is added with additives such as iron, silicon, and calcium to be subjected to briquetting, and then copper matte and a lead-bismuth alloy are prepared through reduction smelting in a shaft furnace; electrolytic lead is prepared through copper removal and tin removal of the lead-bismuth alloy through electrolysis, and coarse bismuth is prepared by smelting electrolytic anode mud through a converter, specifically, in the process of preparing refined bismuth by pyrorefining, gold,silver, antimony and tellurium are recovered in the form of slag and smoke dust; and the electrolytic lead obtained by electrolysis is smelted by a pyrometallurgical method to obtain an electrolytic lead ingot. According to the method, comprehensive utilization of valuable metals in the copper-containing hazardous wastes, the lead-containing hazardous wastes and the nonferrous metallurgical hazardous wastes, wastewater zero discharge in the process and standard discharge of tail gas in the smelting process are achieved, and the method is a novel environment-friendly resource-oriented process.

Owner:福建铭祥金属材料有限公司

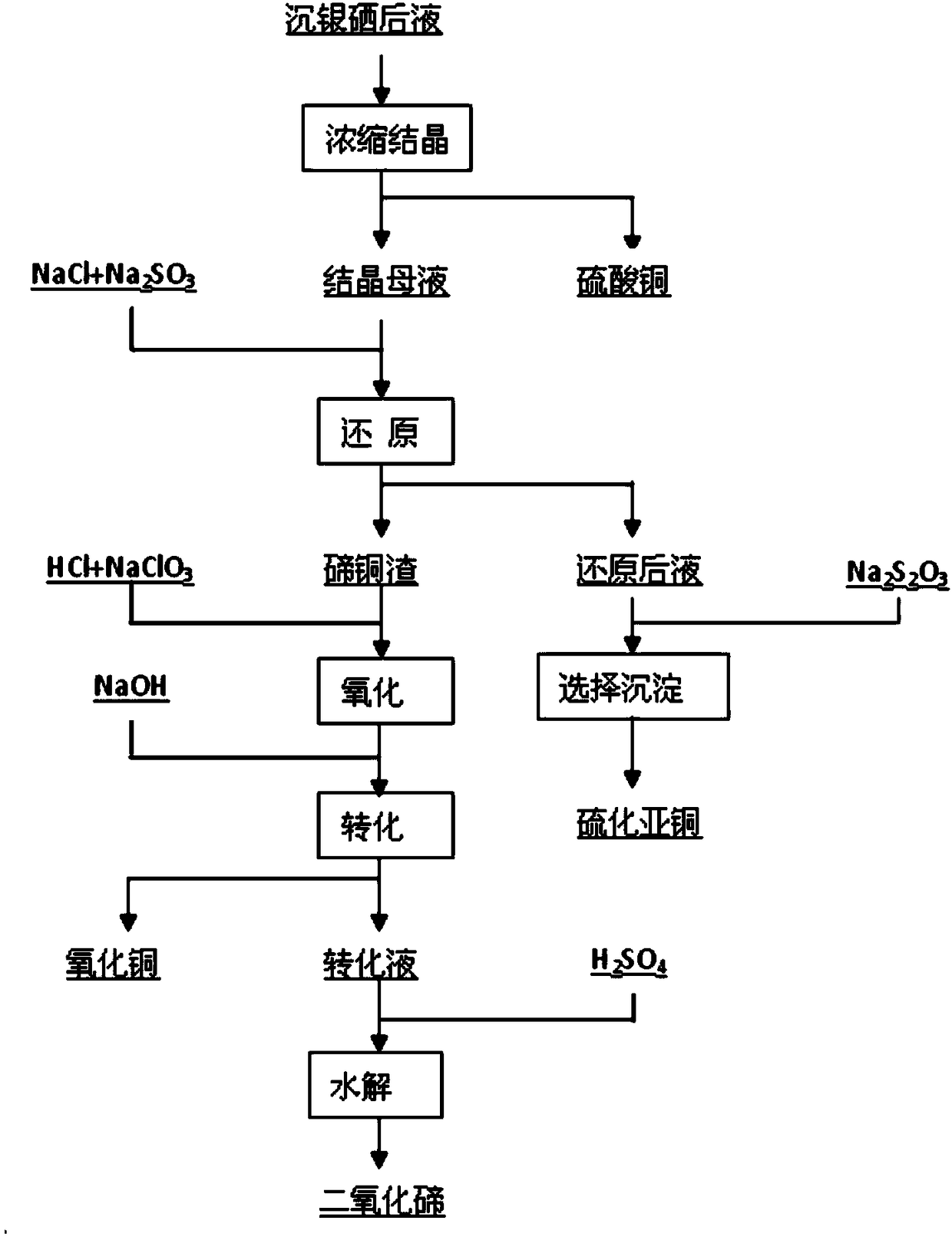

Method for treating tellurium-containing waste liquor

ActiveCN108545706ARealize step-by-step recyclingEasy to separateCopper oxides/halidesCopper sulfidesLiquid wasteHydrolysis

The invention provides a method for treating tellurium-containing waste liquor. The method comprises the following steps: S1, the tellurium-containing waste liquor is concentrated and crystallized forobtaining copper sulfate and crystallization mother liquor respectively, and the tellurium-containing waste liquor contains elements of tellurium and copper and sulfuric acid; S2, the crystallizationmother liquor is reduced with a reducing agent, and tellurium-copper slag and reduced liquor are obtained respectively; S3, an acid solution and an oxidant are adopted for acid oxidation leaching onthe tellurium-copper slag, an acid leaching solution is obtained, and the acid solution is a hydrochloric acid solution or a sulfuric acid solution; S4, the acid leaching solution is subjected to solid-liquid separation, a liquid phase is taken, pH is adjusted with sodium hydroxide to 12-14, heating is performed to a boiling state for reaction, and an alkaline conversion solution is obtained; S5,the alkaline conversion solution is subjected to acidic hydrolysis, and a tellurium dioxide product is obtained. Copper and tellurium are recovered step by step by the technical scheme, the separationeffect of copper and tellurium is good, the comprehensive recovery rate of copper and tellurium is high, the cost is low, and the economic benefit is increased.

Owner:YANGGU XIANGGUANG COPPER

Method for extracting tellurium dioxide from anode slime produced through tellurium electro-deposition

ActiveCN105399062AImprove conversion rateLess residual tellurium in slagSelenium/tellurium oxides/hydroxidesBinary selenium/tellurium compoundsIron powderTe element

The invention discloses a method for extracting tellurium dioxide from anode slime produced through tellurium electro-deposition. The method comprises the following steps that 1, the anode slime is put into a reaction kettle, water and sodium hydroxide are added, heating and mixing are performed for two hours, and filter pressing is performed to obtain filter residues, namely the tellurium dioxide; 2, the filter residues are put into the reaction kettle, water is added, a PH value is regulated to be 1.0-1.5 by using sulfuric acid, heating is performed to reach 85 DEG C, stirring is performed for two hours, and filter pressing is performed to obtain filtrate; 3, the filtrate is added into the reaction kettle, and iron powder is added and stirred for three hours; 4, sodium hydroxide is added after the solution is clarified and transparent, the PH value is regulated to be 7.0, then sodium hydroxide with the tellurium metal content 70% is added and stirred for an hour, filter pressing is performed to obtain a sodium tellurite solution, the PH value is regulated to be 5-5.5 by using sulfuric acid, and filter pressing is performed to obtain tellurium dioxide. In the step 3, the amount of the iron powder is determined according to the tellurium content in the filtrate and meets the requirements of a reaction equation: Te<6+> + Fe<0>= Te<4+> + Fe<2+>.

Owner:湖南省金润碲业有限公司

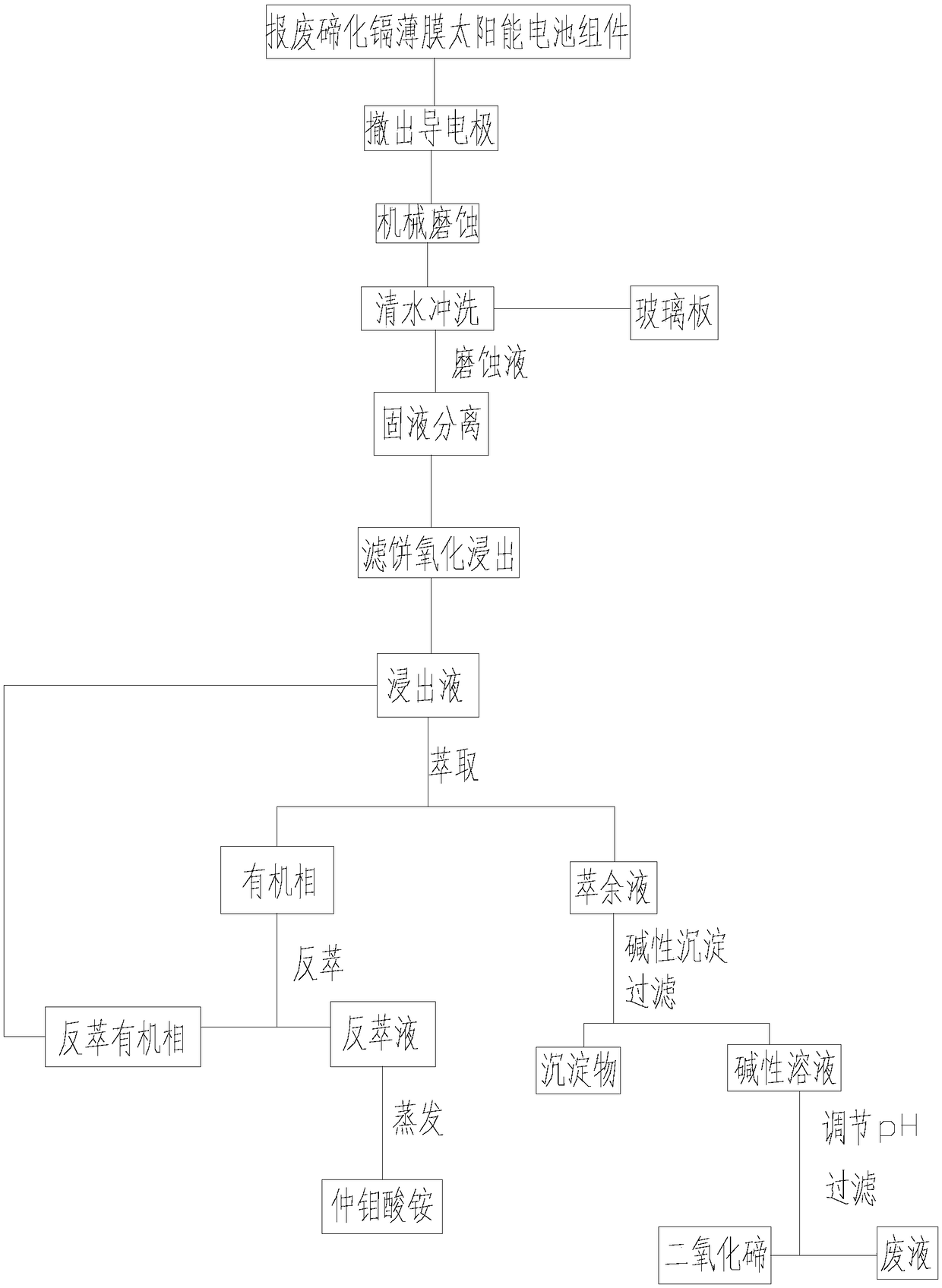

Mechanical grinding recovery method for cadmium telluride film solar cells

InactiveCN109082527AHigh recovery rateImprove working environmentProcess efficiency improvementSelenium/tellurium oxides/hydroxidesRecovery methodFiltration

The invention discloses a mechanical grinding recovery method for cadmium telluride film solar cells. The method comprises two steps of stripping of photovoltaic film layers and dissolving recovery ofvaluable metal, wherein the step of stripping of the photovoltaic film layers comprises the following substeps: back plate glass and conductive poles of wasted cadmium telluride film solar cell modules are removed to obtain glass substrates with photovoltaic film layers; then, the photovoltaic film layers are mechanically grinded; the glass substrates are flushed by clear water after mechanical grinding; the flushing waste water is gathered for filtration to obtain filter slag; and the valuable metal is recovered from the filter slag. The method is high in recovery rate of the valuable metaland excellent in working environment, can recycle the back plate and substrate glass to achieve high comprehensive utilization rate, improves the material recovery rate and recovery effect of the cadmium telluride film solar cells, improves the resource utilization rate, and guarantees environmental protection in the whole process of a product chain.

Owner:CNBM CHENGDU OPTOELECTRONICS MATERIAL

Preparation method of high-purity tellurium dioxide powder

InactiveCN106348259AIncrease contact areaReduce decreaseClosures to prevent refillingSelenium/tellurium oxides/hydroxidesHigh energyTe element

The invention discloses a preparation method of high-purity tellurium dioxide powder. The method comprises the following steps: carrying out fine grinding on the raw material tellurium powder until the particle size is less than or equal to 150 mu m; nitric acid oxidization: adding 66-67% concentrated nitric acid into a reaction kettle, heating to 55-65 DEG C, adding the tellurium powder in the step (1), and stirring at the constant temperature of 70-80 DEG C for 2-3 hours until the reaction is complete; pH value regulation: after the temperature drops to at most 50 DEG C, adding aqua ammonia to accelerate precipitation, separating the supernate and the material precipitate, and washing the material with deionized water until the pH value of the washing solution is 7; and dewatering and calcination: drying for 2-3 hours while controlling the material temperature at 200 DEG C, and calcining for 3-3.5 hours while controlling the material temperature at 600-650 DEG C, thereby obtaining the high-purity tellurium dioxide powder. By performing the grinding and screening, the method solves the problems of complex steps, high consumption of chemical reagents, high energy consumption and lower efficiency in the prior art.

Owner:乐山凯亚达光电科技有限公司

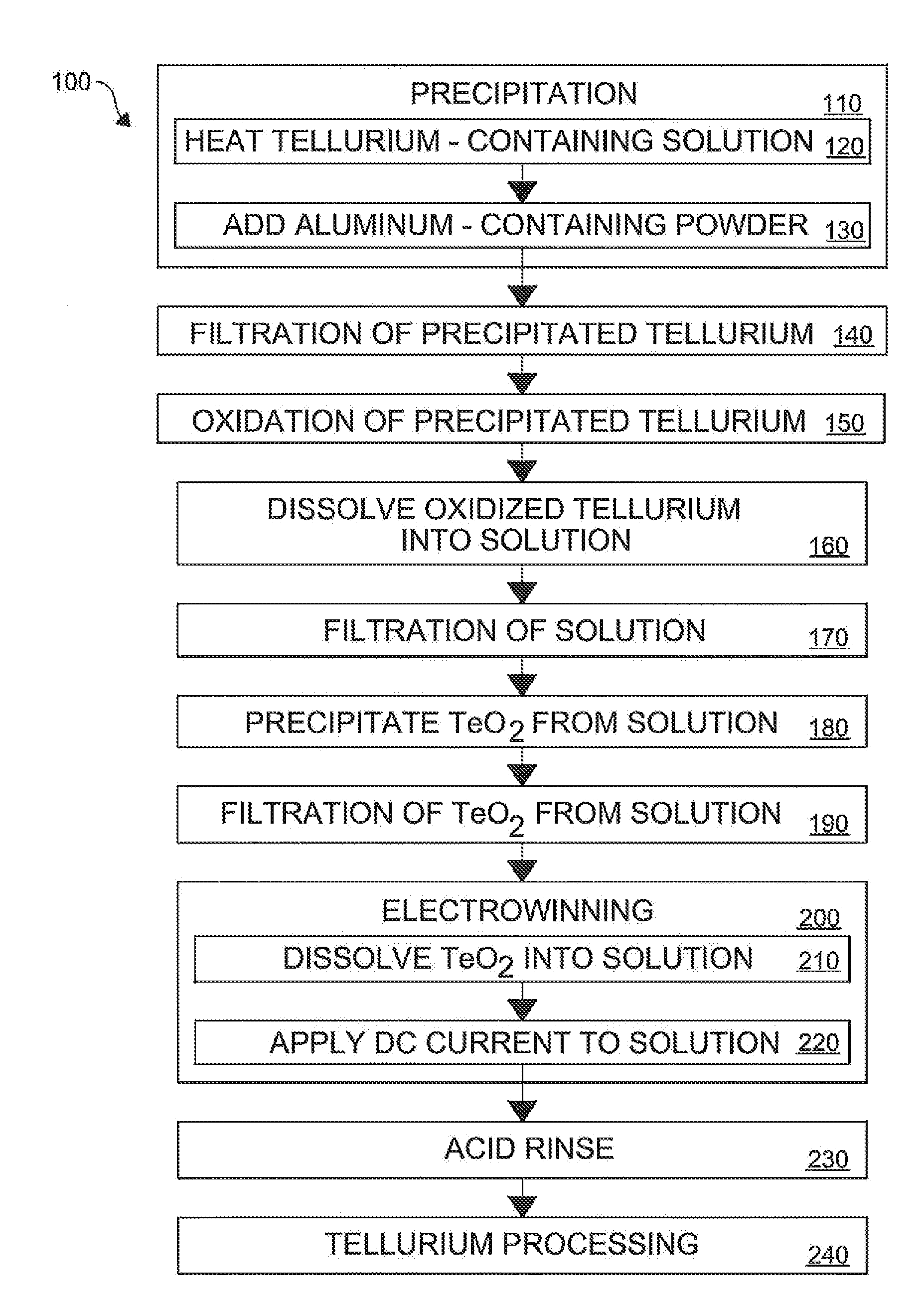

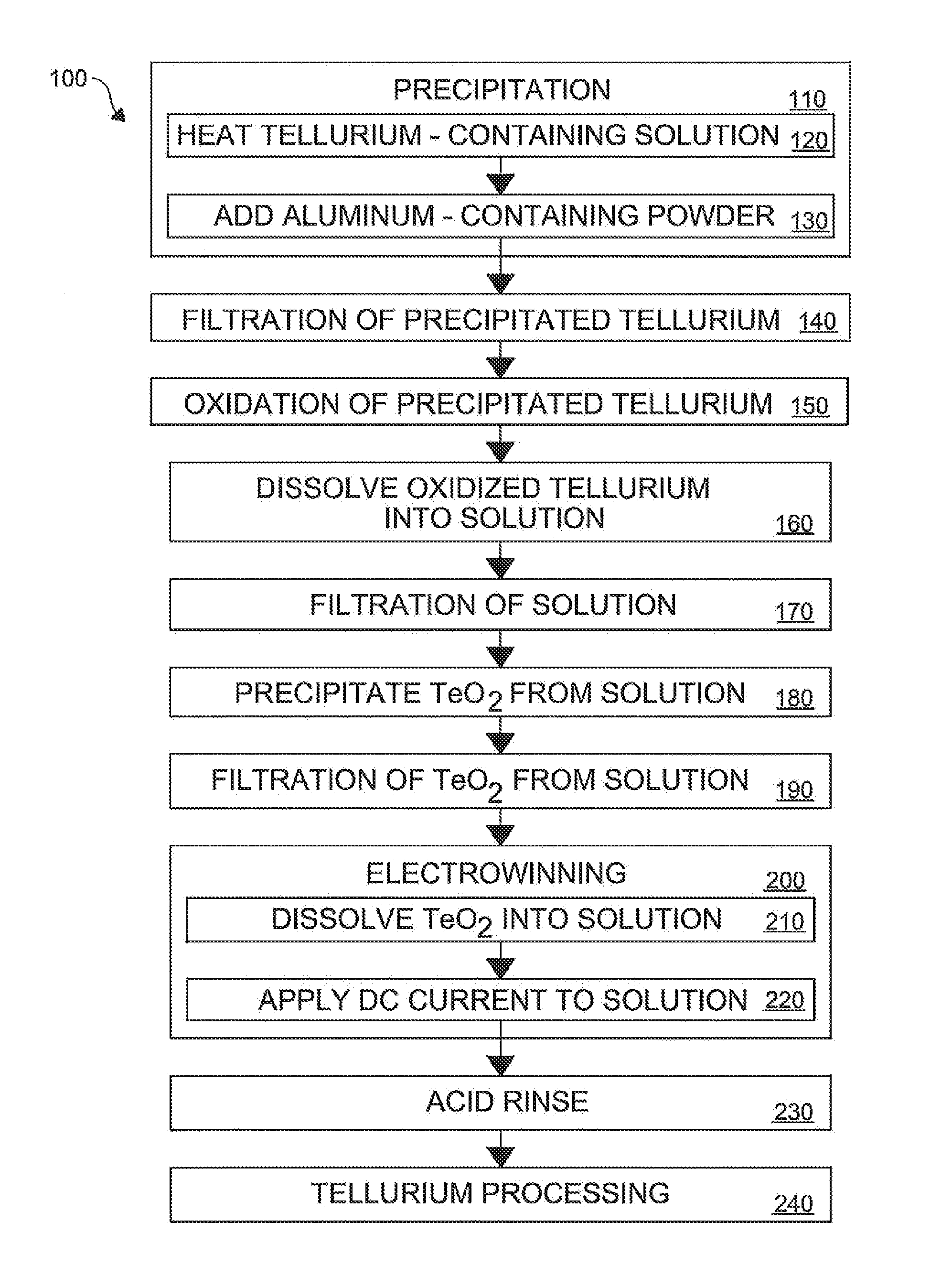

Method of recovering a metal from a solution

InactiveUS20140251820A1Efficient methodPhotography auxillary processesElectrolysis componentsPhysical chemistryMetal

A method for recovering a metal from either an acidic or a basic solution using an aluminum cementation process is disclosed. The method involves adding an aluminum-containing powder to a tellurium-containing solution to precipitate tellurium from the tellurium-containing solution and then removing the precipitated tellurium therefrom.

Owner:FIRST SOLAR INC (US)

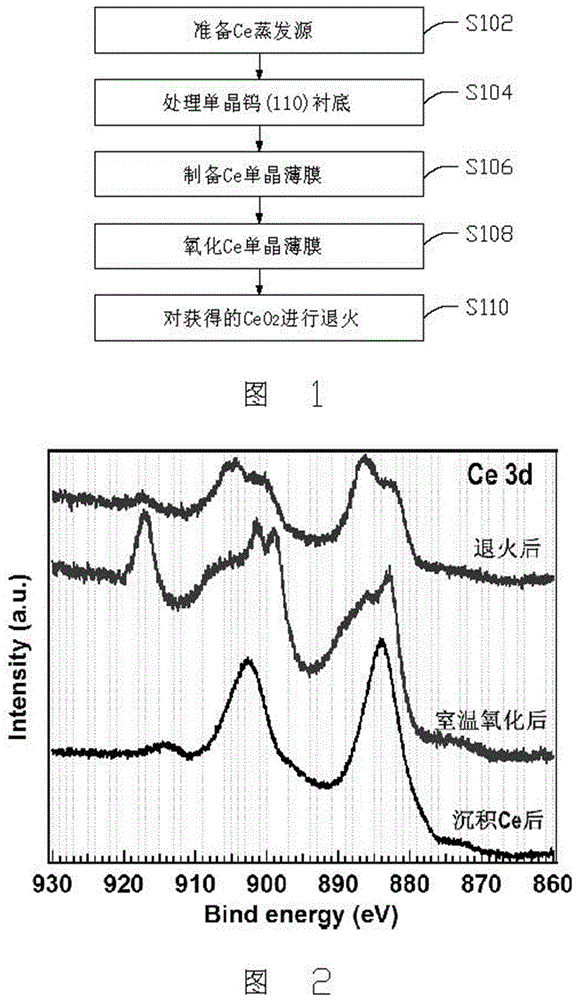

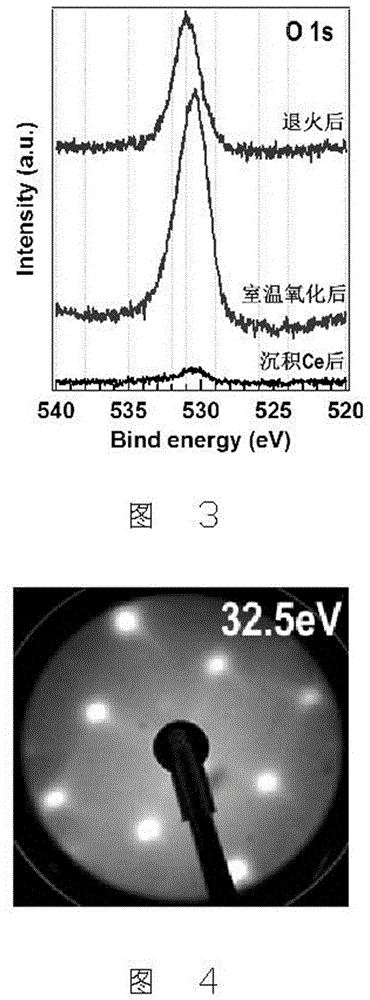

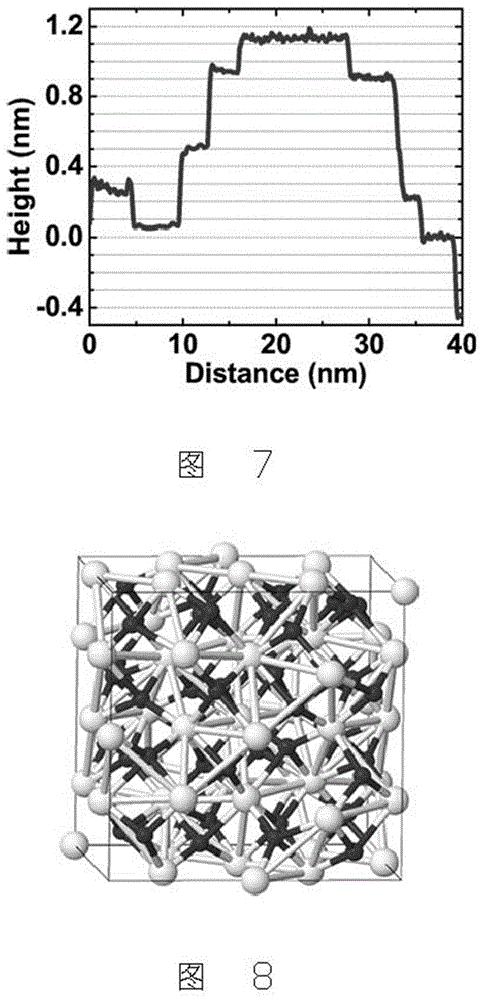

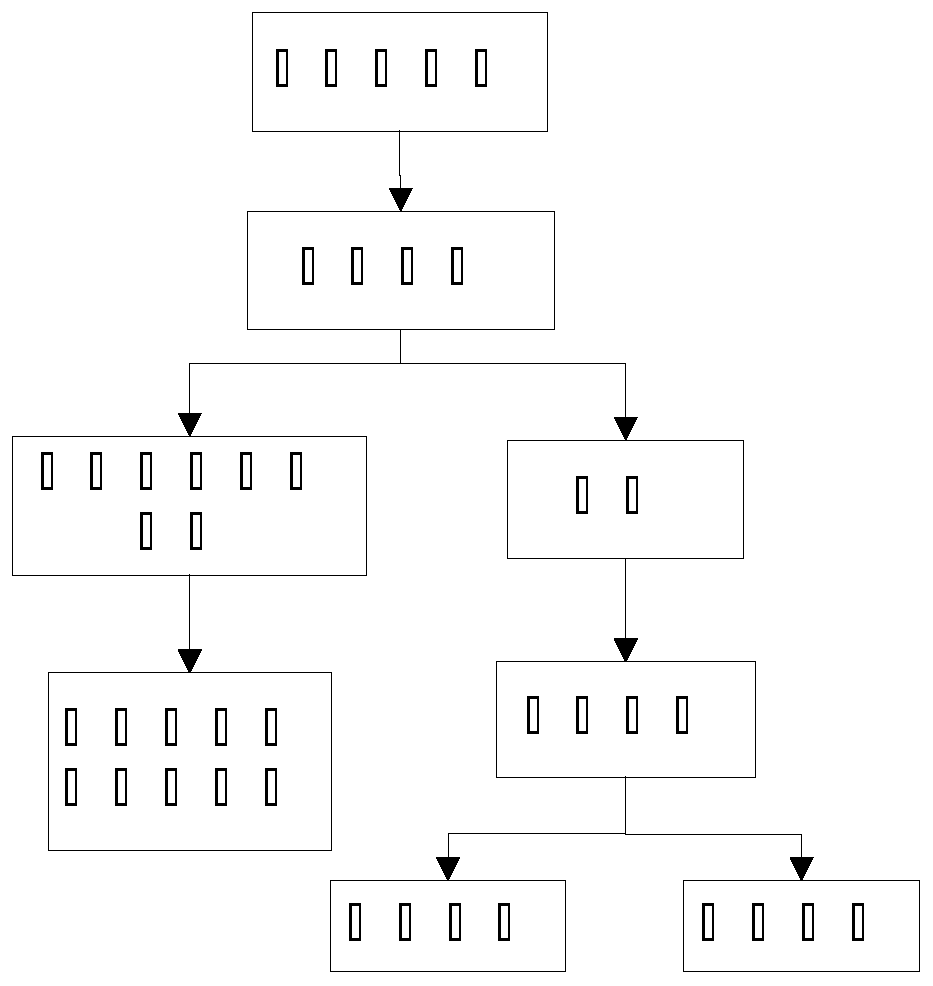

Preparation method for cubic-phase dicerium trioxide single-crystal thin film

The invention belongs to the field of preparation of thin films, and discloses a preparation method for a cubic-phase dicerium trioxide single-crystal thin film. According to the invention, dicerium trioxide has a structure of (Mn0.5Fe0.5)2O3, and a space group of 206. The method comprises the following steps: taking a single-crystal tungsten (110) substrate, and subjecting the surface of the single-crystal tungsten (110) substrate to cleaning treatment so as to obtain an atomic-scale flat surface; taking a cerium (Ce) evaporation source, and depositing cerium (Ce) on the surface of the treated single-crystal tungsten (110) substrate so as to obtain a cerium (Ce) single-crystal thin film with a thickness of 2 to 5 nanometers on the surface of the treated single-crystal tungsten (110) substrate; oxidizing the cerium (Ce) single-crystal thin film at a room temperature so as to obtain cerium dioxide (CeO2); and subjecting cerium dioxide (CeO2) to annealing treatment in a vacuum environment with an annealing temperature of 900 DEGC and an annealing time of 15 to 30 minutes so as to obtain the dicerium trioxide (Ce2O3) single-crystal thin film of a (001) plane. The cubic-phase dicerium trioxide (Ce2O3) single-crystal thin film of the (001) plane obtained by using the method provided by the invention is a supplement to a conventional catalytic model system.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

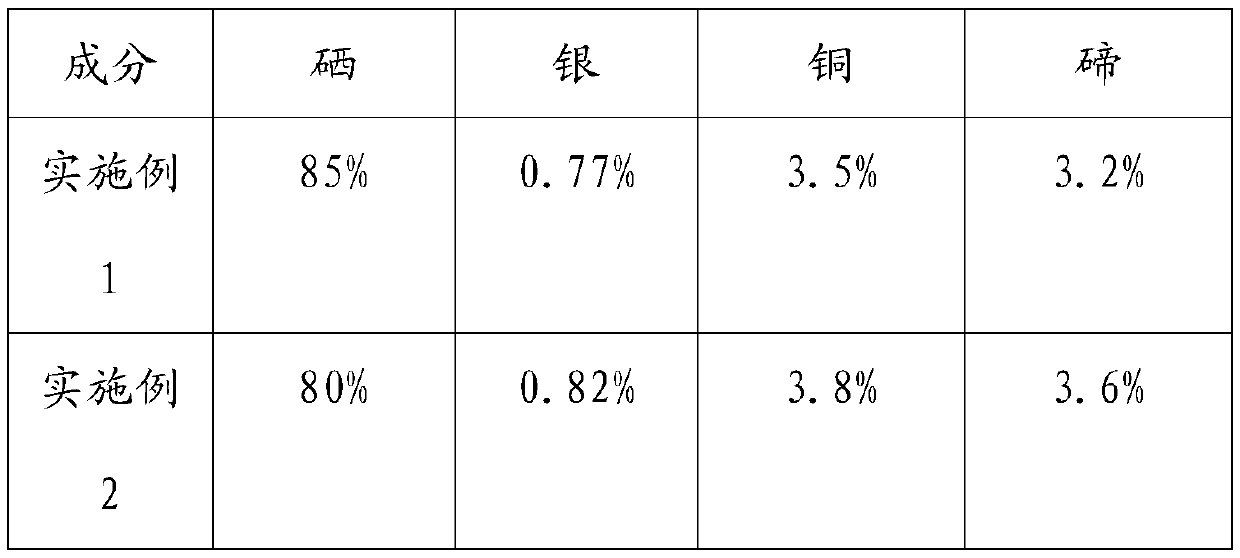

Method for recovering selenium from high tellurium, silver and selenium slag through short process

InactiveCN110042246ASolve the separation problemOptimizing Process ParametersChemical industryProcess efficiency improvementSlagCopper

The invention discloses a method for recovering selenium from high tellurium, silver and selenium slag through a short process. The method comprises the following steps that S1, the high tellurium, silver and selenium slag is placed in a vacuum distillation furnace, vacuum distillation is carried out under the conditions of 20 Pa-100 Pa and 300 DEG C-350 DEG C for 2 h-3 h, and coarse selenium andbottom slag containing silver, copper and selenium are produced; and S2, the coarse selenium obtained in the step S1 is placed in a selenium oxidizing furnace, a reaction is made under the conditionsthat the oxygen flow rate is 6 m<3> / h-10 m<3> / h and the temperature is 500 DEG C-570 DEG C for 3 h, and selenium dioxide and bottom slag containing tellurium are obtained. Through a vacuum distillation method, the selenium is separated from the silver, the tellurium and the copper simply, quickly and efficiently in an energy-saving manner, the selenium can be purified, and the selenium dioxide isfinally obtained.

Owner:ZIJIN MINING GROUP +1

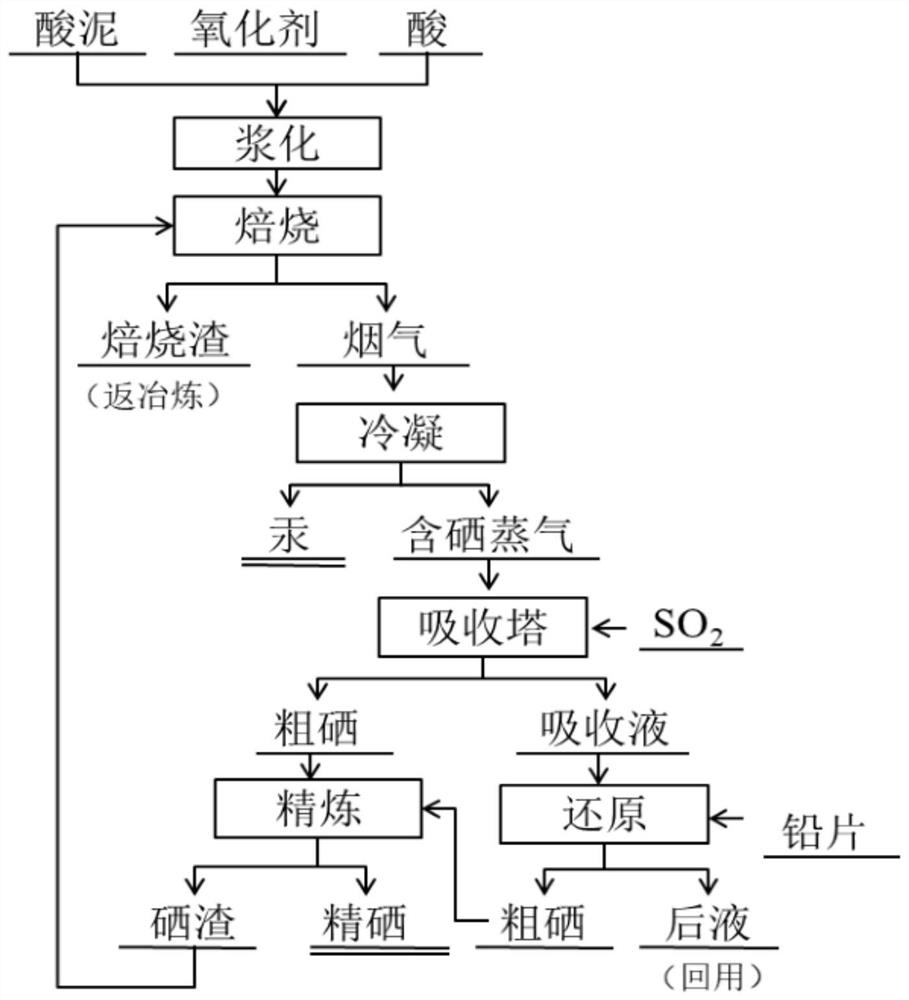

Method for separating and recovering selenium and mercury in acid mud through one-step method

ActiveCN113528836AImprove separation efficiencyShort separation processProcess efficiency improvementSelenium/tellurium oxides/hydroxidesFlue gasSlag

The invention relates to a method for separating and recovering selenium and mercury in acid mud through a one-step method, and belongs to the technical field of acid mud treatment. The method comprises the following steps: mixing and slurrying are carried out on acid mud and slurrying liquid for 30-120 minutes to obtain slurry; wherein the slurrying liquid contains acid liquid and an oxidizing agent; the slurry is subjected to microwave roasting for 20-120 min at the temperature of 400-800 DEG C, mixed steam of Hg and SeO2 and roasting slag are obtained, and valuable metal recycling is conducted on the roasting slag; the mixed steam of the Hg and the SeO2 is condensed to separate out crude SeO2 steam and an Hg elementary substance; and the crude SeO2 steam is introduced into an absorption tower for hydrolysis to obtain H2SeO3, SO2 flue gas is introduced for reduction of H2SeO3 to obtain crude selenium, and the crude selenium is dried and refined to obtain refined selenium. According to the method, selenium and mercury phases in the acid mud are directly roasted into SeO2 and mercury, mercury is condensed and recycled, selenium dioxide is reduced and recycled, refining is carried out, mercury-containing residues and selenium-containing residues generated in the process are refined again, and therefore efficient and simple treatment of harmful acid mud is achieved.

Owner:KUNMING UNIV OF SCI & TECH

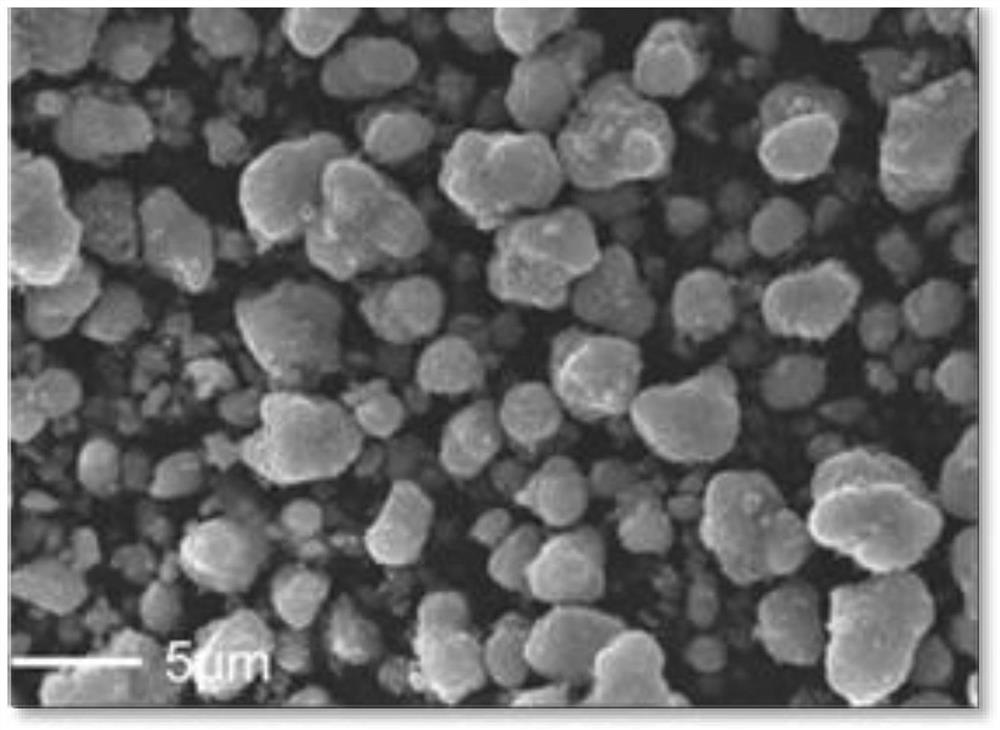

Method for preparing nanometer TeO2 from aerosol through microwave assistance

InactiveCN107934922AAvoid breakingShorten the production cycleNanotechnologySelenium/tellurium oxides/hydroxidesMass ratioSolvent

The invention discloses a method for preparing nanometer TeO2 from aerosol through microwave assistance. The method comprises the following steps of A, dispersing precursors into a polar solvent to form a colloidal solution or true solution, i.e., a precursor solution, wherein the mass ratio of the precursors to the polar solvent is (0.01 to 10):(90 to 99.9); B, atomizing the precursor solution prepared in the step A to form aerosol liquid drips; C, dripping the aerosol liquid prepared in the step B into a microwave generator to perform microwave radiation; then, performing drying roasting toform nanometer powder particles. The preparation method of the spherical powder has the advantages that the production period is short; the operation is simple and convenient; no pollution is caused;the microcosmic structures of the obtained spherical powder cannot be easily damaged; the amplification can be easily realized; the method is suitable for being popularized and applied. A product canbe widely used in the fields of corrosion resistance, bacterium resistance, electronic component materials, emission spectrum analysis and the like.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

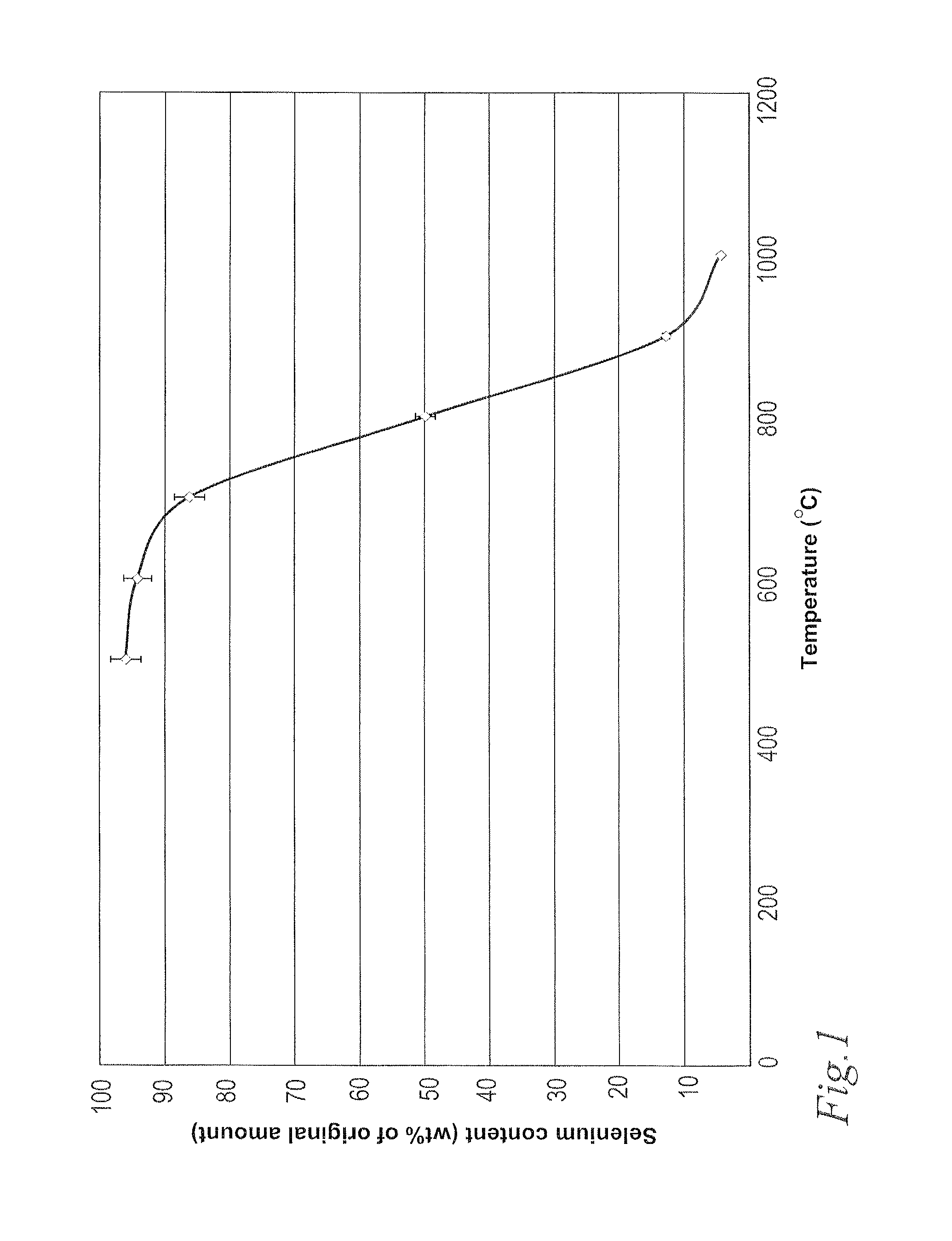

Recycling of copper indium gallium diselenide

InactiveUS20140341799A1Overcome disadvantagesReduce disadvantagesWaste processingGlass recyclingIndiumCopper

There is provided a method for providing selenium dioxide and a copper indium gallium residue from a material comprising a compound of formula (I) CuInxGa(1-x)Se2 (I), wherein x has a value from 0.01 to 0.99, said method comprises the steps of: a) heating the material comprising the compound of formula (I) to at least 500° C., b) contacting the material with a gas flow comprising oxygen, and d) collecting the formed products. The method may be used in recycling in the field of solar cell technology.

Owner:MIDSUMMER

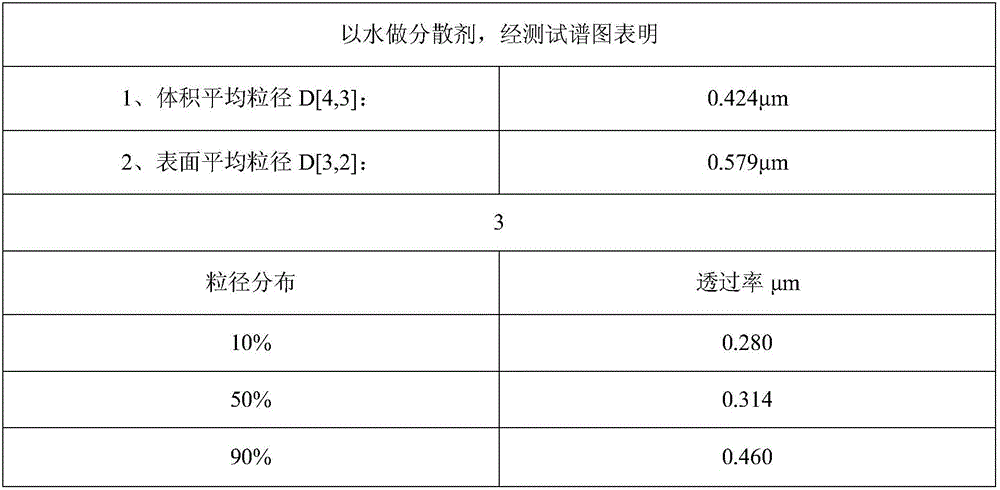

Preparation method and application of ultrathin 4N tellurium dioxide powder

InactiveCN106542508AHydrophilicGood dispersionPolycrystalline material growthNanotechnologyMicrowaveTe element

The invention discloses a preparation method and an application of ultrathin 4N tellurium dioxide powder. The method is characterized by comprising the steps of grinding a tellurium raw material; performing leaching by adopting a hydrochloric acid and nitric acid mixed solution at the normal temperature; performing filtering; performing neutralization by volatile alkali under the action of a dispersant; and performing thermal washing by de-ionized water, microwave drying and microwave roasting to obtain the ultrathin 4N tellurium dioxide powder. The particle size of the obtained ultrathin 4N tellurium dioxide powder is smaller than 0.5 microns. According to the ultrathin 4N tellurium dioxide powder, few preparation steps are used, the energy consumption is reduced, and the product quality is stable, so that the productivity is increased; and the technological process is simplified, and equipment is simple, so that industrial production is facilitated.

Owner:四川中蓝基业新材料科技有限公司

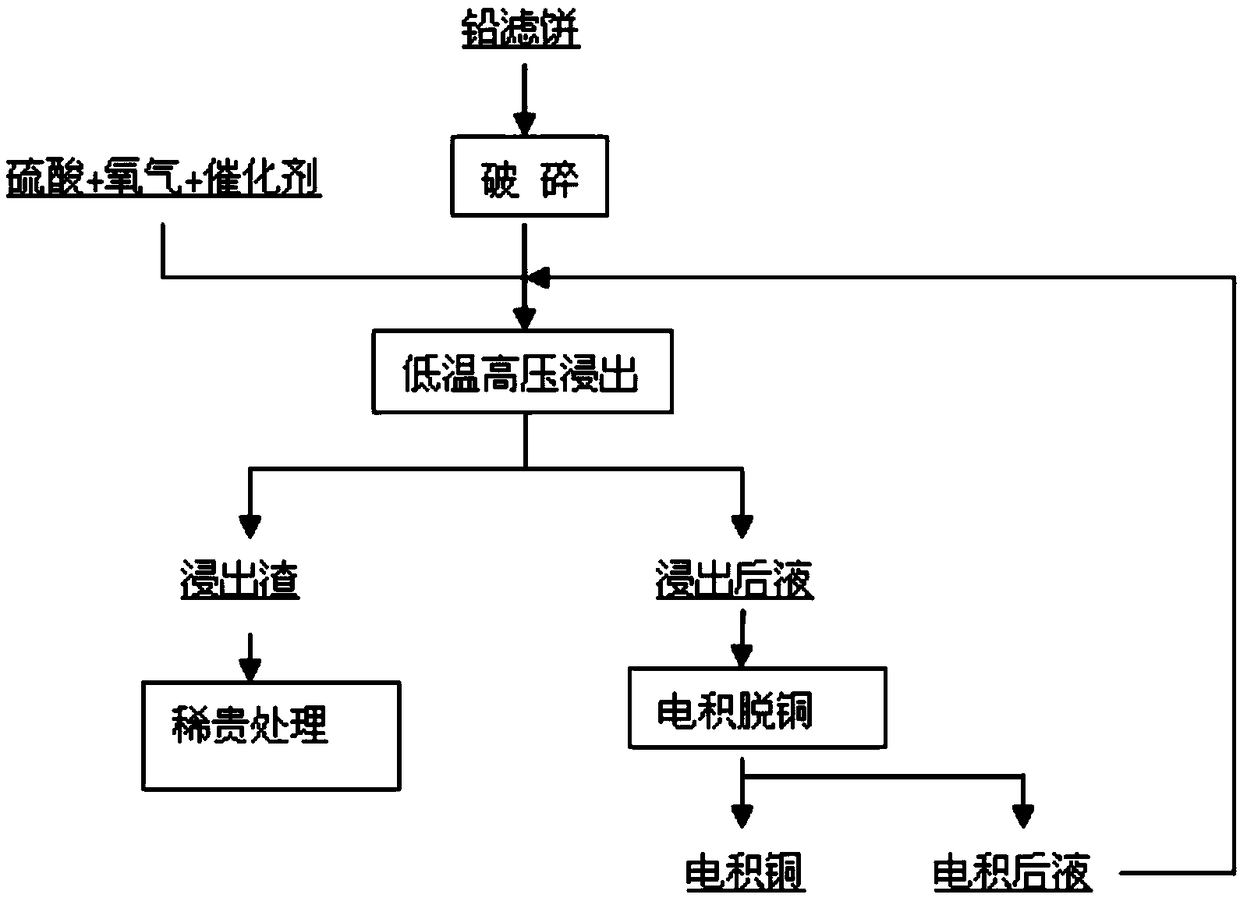

Copper removal treatment method for waste material containing copper and selenium

ActiveCN109055762AHigh recovery rateThe separation effect is thoroughPhotography auxillary processesProcess efficiency improvementSlagHigh pressure

The invention provides a copper removal treatment method for a waste material containing copper and selenium. The copper removal treatment method includes the following steps that S1, presoaking liquid is obtained by mixing the waste material containing the copper and the selenium, an iron-containing catalyst and dilute sulfuric acid; and S2, the presoaking liquid is subjected to high pressure leaching by using an oxidizing agent under the low temperature condition below 90 DEG C, then separation is carried out, and leaching slag containing silver and the selenium and leaching liquid containing the copper are obtained. According to the copper removal treatment method for the waste material containing the copper and the selenium, copper removal treatment is carried out on an industrial waste material, that is, a lead filter cake with the high copper and selenium content; according to the copper removal treatment method, the separation effect of precious metal such as the copper and theselenium is thorough, the cooper leaching effect is good, and the copper leaching rate is 96% or above; in addition, the selenium and other precious metal are all concentrated in the slag, the selenium, lead, gold and the silver can be recovered by entering a rare and expensive system, and the recovery rate of the precious metal is increased advantageously; and the overall process is stable and reliable, the copper removal treatment method for the waste material containing the copper and the selenium is suitable for large-scale industrial application, and the economic benefit is good.

Owner:YANGGU XIANGGUANG COPPER

Cobalt-free positive electrode material, preparation method and application thereof

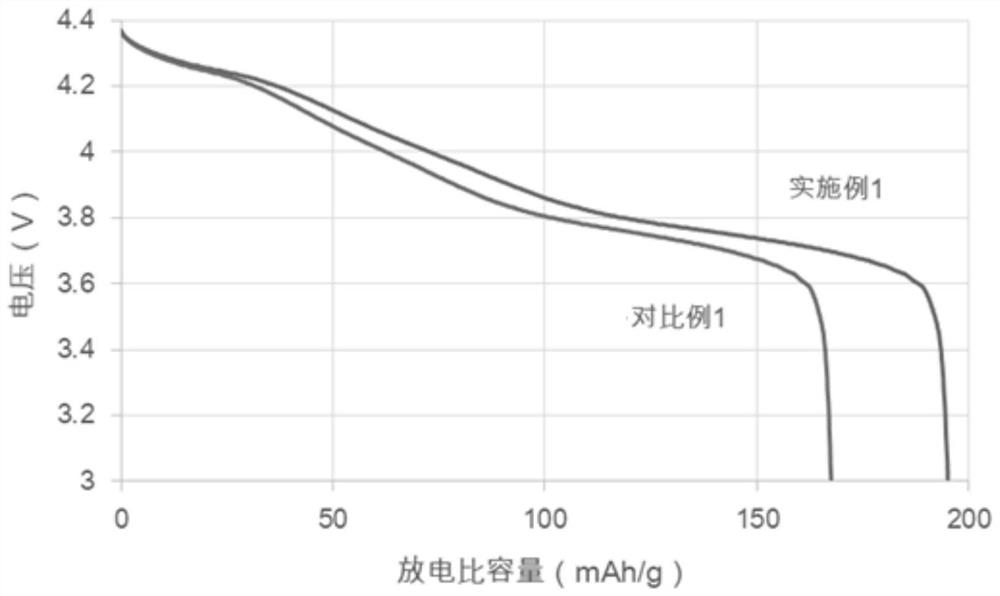

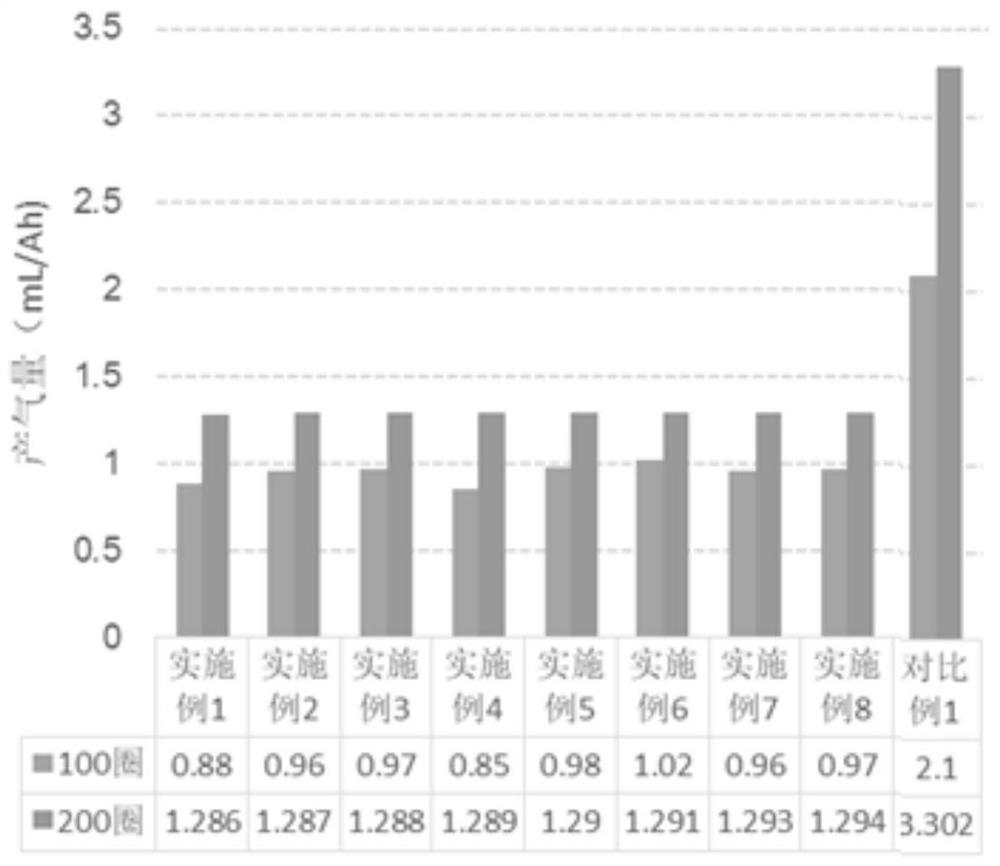

PendingCN113666433AImprove electrical performanceHigh gas productionPositive electrodesSecondary cell gas removalElectrolytic agentLithium

The invention provides a cobalt-free positive electrode material, a preparation method and application thereof. The cobalt-free positive electrode material comprises a cobalt-free base material and a coating layer located on the surface of the cobalt-free base material, wherein the coating layer is a TeO2 coating layer, the mass of the TeO2 coating layer accounts for 0.1-0.8% of the mass of the base material, According to the invention, the TeO2 material is adopted to coat the cobalt-free high-nickel material, so that lithium ions can be embedded and emigrated in the material in the charging and discharging process, and the capacity and the first efficiency of the material are improved; and the coating layer reduces the contact area between the material and an electrolytic solution, and slows down the side reaction between the material and the electrolyte, so that the cycle performance of the material is improved, the oxygen loss of the material is slowed down, and the gas production is reduced so as to improve the high-temperature cycle performance and safety of the material.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

Preparation method of hollow bowl-shaped carbon-based metal/selenium/oxygen co-doped composite material and lithium ion battery

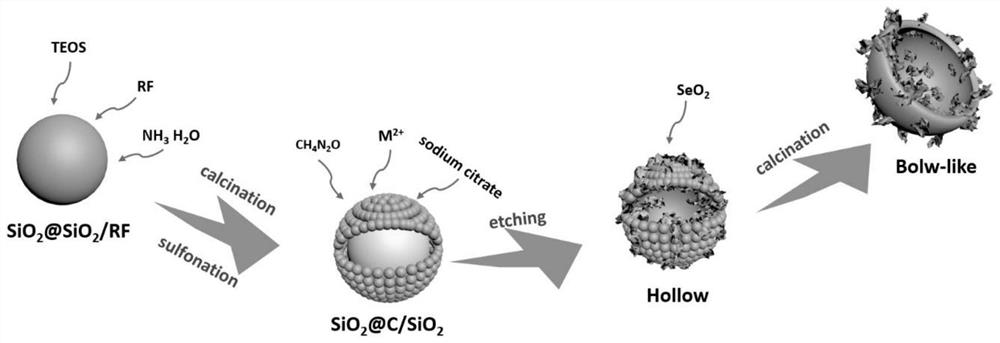

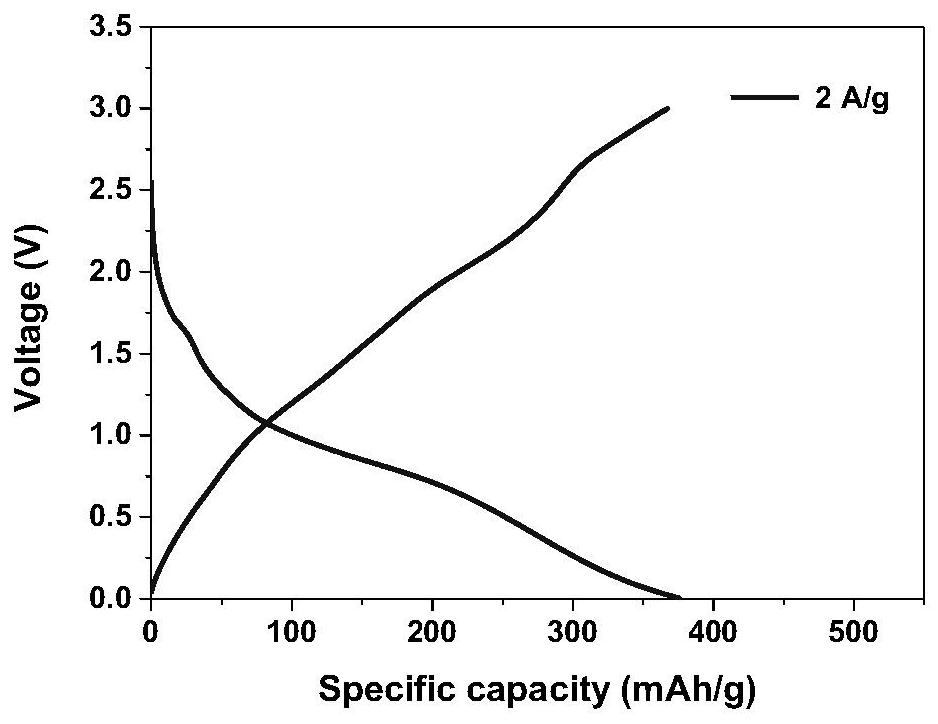

ActiveCN112563500AGood lookingGood process repeatabilityIron oxides/hydroxidesCell electrodesElectrical batterySelenium Oxide

The invention provides a preparation method of a hollow bowl-shaped carbon-based metal / selenium / oxygen co-doped composite material. The method comprises the following steps: A), carbonizing a SiO2@phenolic resin / SiO2 composite material, and performing sulfonating to obtain a sulfonated carbon material; B), mixing the sulfonated carbon material, metal salt, an amine compound and sodium citrate, andperforming reacting to obtain a composite material; C), etching silicon dioxide in the composite material to obtain a hollow carbon-doped metal oxide material; and D), mixing the hollow carbon-dopedmetal oxide material with selenium oxide, and performing sintering to obtain the hollow bowl-shaped carbon-based metal / selenium / oxygen co-doped composite material. The preparation process of the composite material is simple and convenient to operate, process parameters are easy to control, and the obtained bowl-shaped morphology has the advantages of low density, large specific surface area and the like of a hollow spherical structure, the material is more excellent in that the close packing density of the bowl-shaped morphology is higher than that of the hollow spherical structure, and is expected to be applied to the field of lithium ion battery negative electrode materials.

Owner:GUANGDONG UNIV OF TECH

Method of recovering tellurium from cadmium telluride waste materials

ActiveCN107128885ARealize separation and recoverySimple processCadmium sulfidesSelenium/tellurium oxides/hydroxidesTe elementCadmium Cation

Owner:广东先导稀贵金属材料有限公司

Method for preparing high-purity tellurium dioxide by using crude carp as raw material

ActiveCN109019531AHigh purityOptimizing the Reaction TemperatureSelenium/tellurium oxides/hydroxidesReaction rateCarp

The invention provides a method for preparing high-purity tellurium dioxide from crude tellurium as a raw material, the method effectively solves the problems of failure preparation or low purity of the high-purity tellurium dioxide due to reaction passivation and fast reaction rate reaction rate and the like in the prior art when a nitric acid method is used for preparing the high-purity tellurium dioxide from the crude tellurium as the raw material, and a high-purity tellurium dioxide product (>=5N) is prepared.

Owner:中船重工黄冈贵金属有限公司

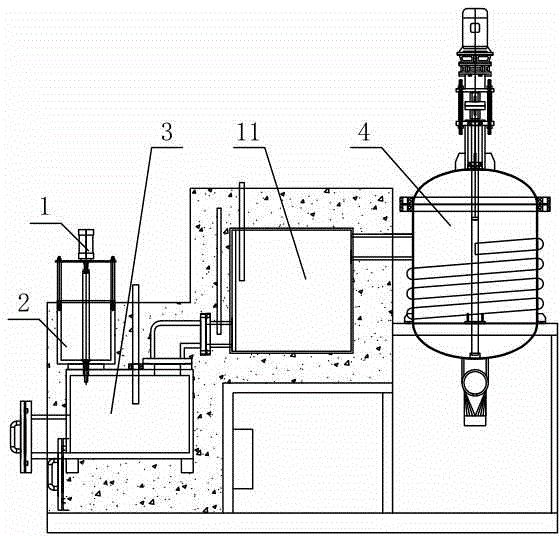

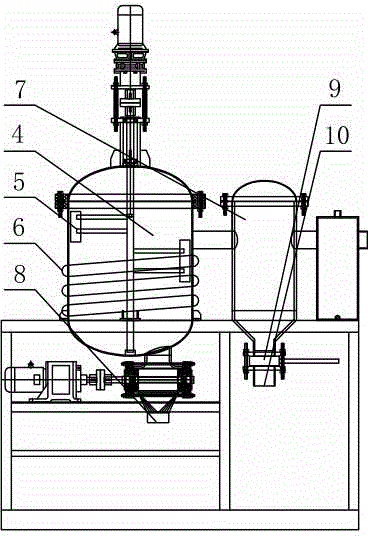

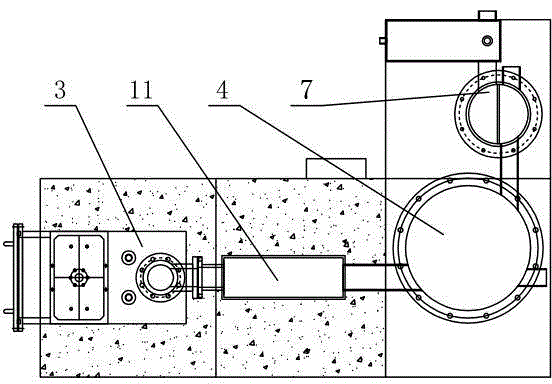

Selenium oxidation production device

ActiveCN104477860AAvoid corrosionIncrease productivitySelenium/tellurium oxides/hydroxidesBinary selenium/tellurium compoundsEngineeringRaw material

The invention relates to a selenium oxidation production device. The selenium oxidation production device comprises a forehearth generator, an oxidation furnace and a collecting box. The forehearth generator comprises a reaction cavity A, a feeding device is connected to the reaction cavity, and a heating assembly A for heating raw materials is arranged in the forehearth generator; the reaction cavity is communicated with the oxidation furnace through a connecting pipe A, a reaction cavity B is formed in the oxidation furnace, and a heating assembly B is arranged in the reaction cavity B; the collecting box is connected with the oxidation furnace through a connecting pipe B and comprises a collecting cavity, a cooling assembly is arranged on the outer wall of the collecting cavity, the collecting box further comprises a collecting assembly, a discharging device is connected to the bottom of the collecting box and comprises a discharging pipe, and a grinding device is arranged in the middle of the discharging pipe; a settling box used for settling dust is further connected to the collecting box, a settling discharging opening is formed in the bottom of the settling box, and a valve is arranged on the settling discharging opening.

Owner:江苏科强电器有限公司

Comprehensive utilization method of ammonia synthesis catalyst waste material

InactiveCN104627969ASimple processHigh recovery rateZinc halidesSelenium/tellurium oxides/hydroxidesMicrometerEvaporation

The invention discloses a comprehensive utilization method of an ammonia synthesis catalyst waste material. The comprehensive utilization method comprises following steps: the ammonia synthesis catalyst waste material is smashed into powder with a diameter of 100 to 300 micrometers; the powder is subjected to hydrochloric acid immersing, and filtering; filter residue is removed, excess zinc powder is added into an obtained filtrate, and an obtained mixture is stirred continuously; excess hydrochloric acid is added into the mixture, an obtained mixed material is subjected to filtering so as to obtain filter residue pure copper; and an obtained filtrate product is subjected to evaporation so as to obtain crystal substance zinc chloride. Recovery of copper and zinc after ammonia synthesis is realized via the comprehensive utilization method. The comprehensive utilization method is capable of realizing individual separation of valuable elements in ammonia synthesis such as copper and zinc, realizing further utilization of resources, and obtaining a large amount of signal valuable elements.

Owner:孔龙

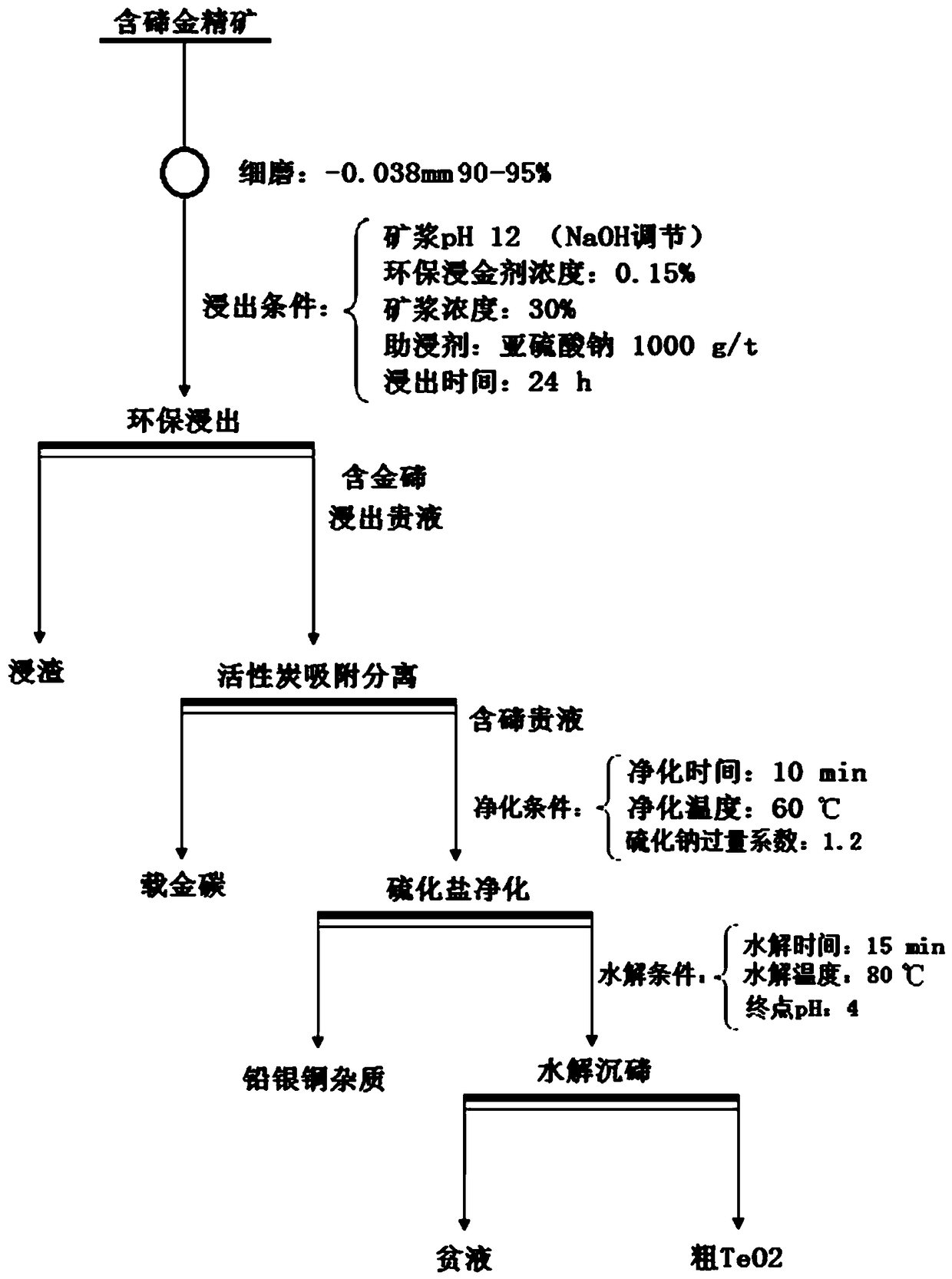

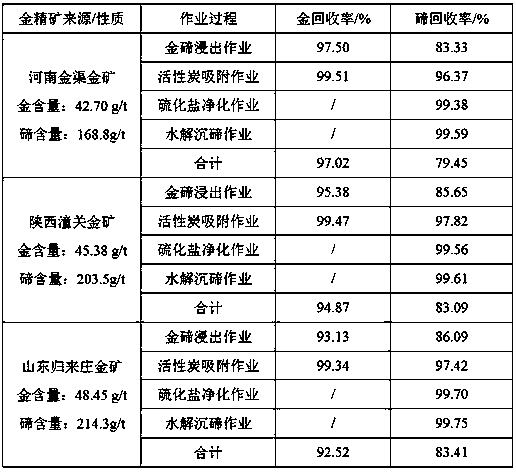

Novel gold-tellurium separation and extraction technology for tellurium-containing gold concentrates

InactiveCN108411109AEffective separation and extractionProcess environmental protectionProcess efficiency improvementSelenium/tellurium oxides/hydroxidesActivated carbonAlkalinity

The invention discloses a novel gold-tellurium separation and extraction technology for tellurium-containing gold concentrates. The novel gold-tellurium separation and extraction technology comprisesthe steps that firstly, the tellurium-containing gold concentrates are subjected to fine grinding, so that gold and tellurium are exposed from wrapping of sulfide ores; then, the concentration and alkalinity of ore pulp are adjusted in a stirring leaching tank through water and NaOH, an environment-friendly gold leaching agent is added, and gold and tellurium are leached simultaneously; by utilizing the characteristic that activated carbon adsorbs gold selectively but does not adsorb tellurium, gold is adsorbed and separated in a leaching pregnant solution, and gold-bearing carbon is formed; and after being subjected to impurity removing through sulphurizing salt, the tellurium-containing pregnant solution is subjected to neutralizing hydrolysis through sulfuric acid, so that tellurium isprecipitated from the solution, a rough TeO2 product is formed, and effective separation and extraction of gold and tellium are achieved. The technological method is simple in process, environmentallyfriendly and free of pollution, and the recovery rates of gold and tellurium are high.

Owner:ZHENGZHOU UNIV +1

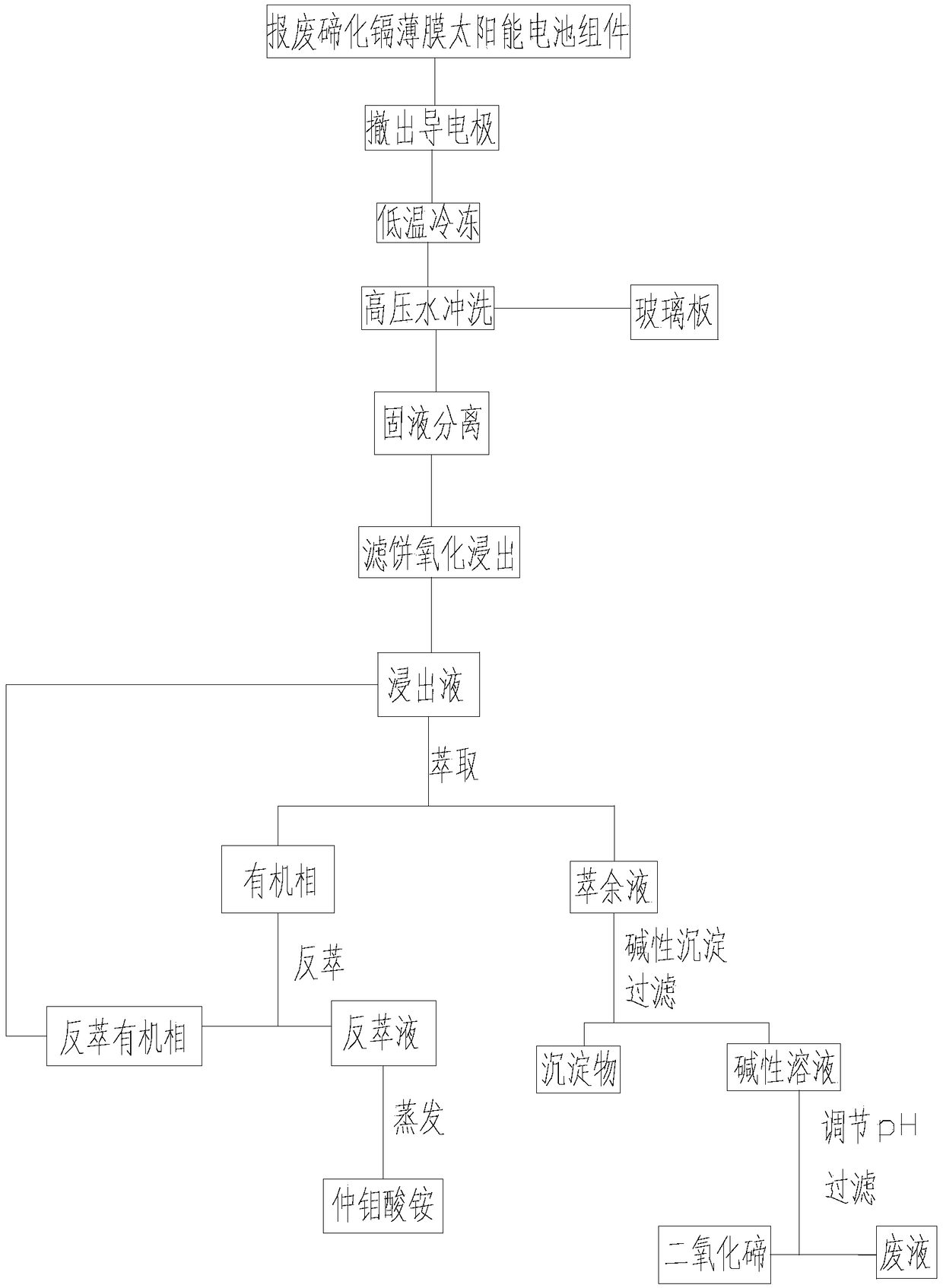

Low-temperature-freezing recycling treatment method for cadmium telluride thin-film solar cell

InactiveCN108913903AHigh recovery rateImprove working environmentProcess efficiency improvementSelenium/tellurium oxides/hydroxidesResource utilizationHigh pressure water

The invention discloses a low-temperature-freezing recycling treatment method for a cadmium telluride thin-film solar cell. The method includes two major steps of stripping a photovoltaic film layer and dissolving and recycling valuable metal, and specifically includes the steps of removing backboard glass and electroconductive poles of a scrapped cadmium telluride thin-film solar cell to obtain aglass substrate with a photovoltaic film layer, freezing the glass substrate with the photovoltaic film layer at the lower temperature of minus 10 DEC G for more than 200s, washing the frozen glass substrate through high-pressure water jetting after taking out the same, allowing the photovoltaic film layer to be gradually separated from the glass substrate, gathering the washing water together, performing filtration to obtain a photovoltaic film layer filter cake, and recycling the valuable metal from the filter cake. The method has the advantages that the recovery rate of the valuable metalis high, the working environment is good, backboard and substrate glass can be recycled, the comprehensive utilization rate is high, the material recovery rate and the recovery effect of the cadmium telluride thin-film solar cell are improved, the resource utilization rate is increased, and environmental friendliness of a product chain is guaranteed throughout the process.

Owner:CNBM CHENGDU OPTOELECTRONICS MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com